Automatic iron mold sand lined production line

An automatic assembly line and iron mold sand coating technology, which is applied in the field of assembly line, can solve the problems of easy breakage of cylinder rods, large equipment area, slow turning speed, etc. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

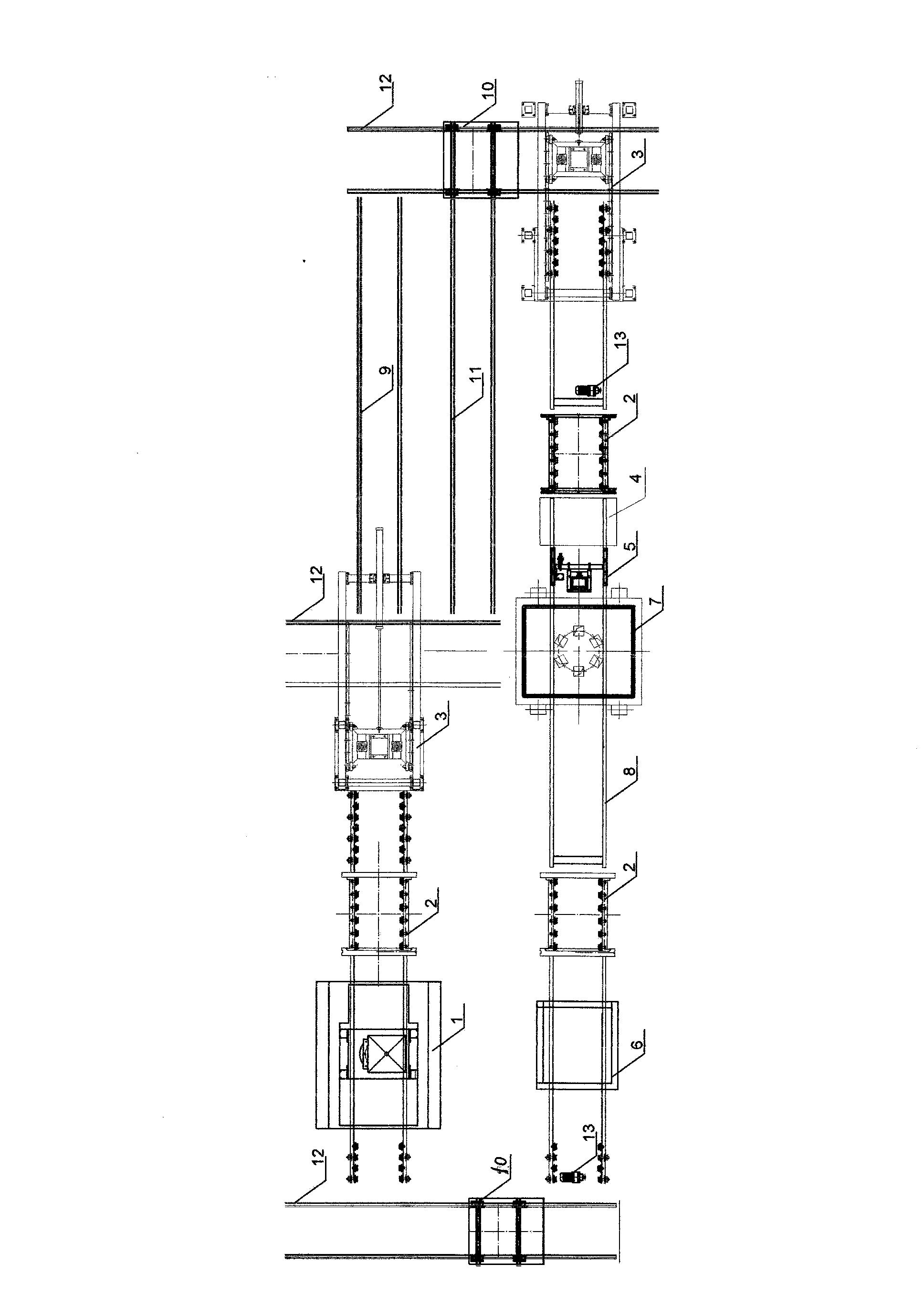

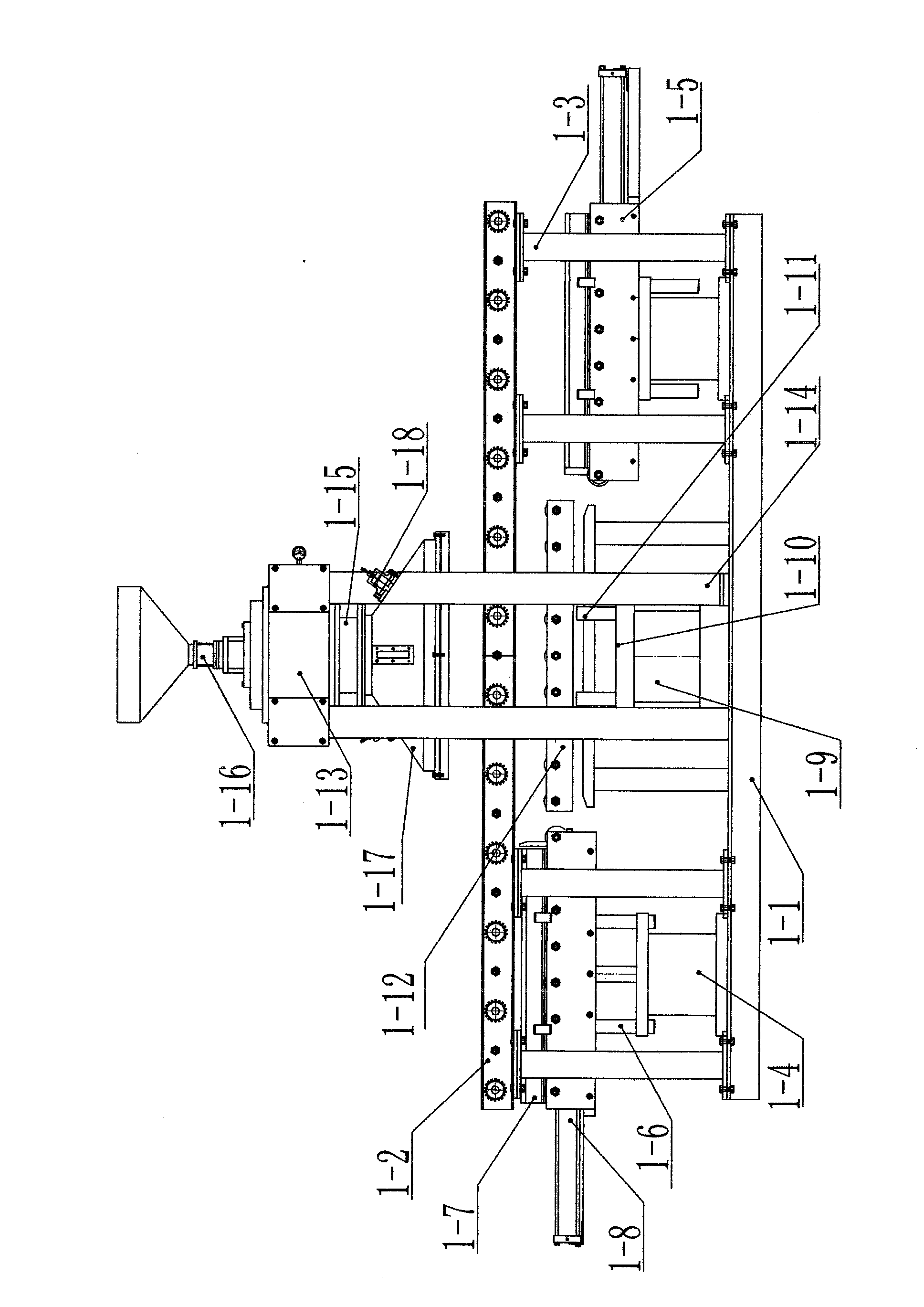

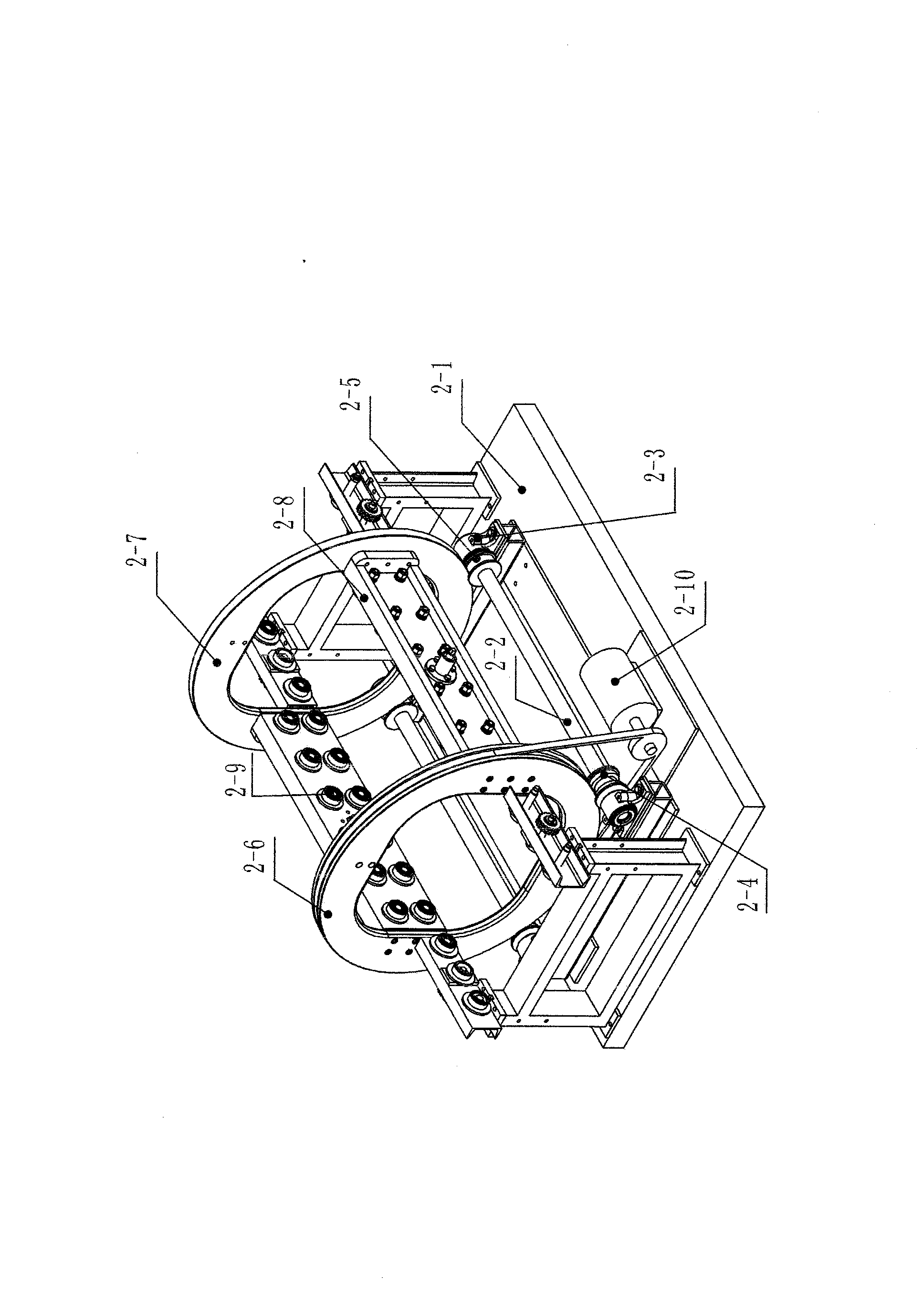

[0023] refer to figure 1 , which includes a double-station sand shooting machine 1, three box turning machines 2, two box opening and closing machines 3, a punching sand shakeout machine 4, a box pulling machine 5, a female mold cooling device 6, and a Vibrating shakeout machine 7; also includes several sections of track 8, casting line rail 9 and three sections of trailer rail 12, each section of track is fixed on the track support, and each section of track is provided with several driving wheels and several slaves The driving wheel is connected with a chain between the driving wheels, and the driving wheel and the driven wheel are arranged at intervals. Several motors 13 are fixed on the track support, and the driving wheel is connected with the sprocket on the motor power output shaft by a chain;

[0024]The head end of the female mold support of the double-station sand shooting machine 1 is connected to the first section of the track, the tail end of the female mold suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com