Patents

Literature

2478results about How to "Fast production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

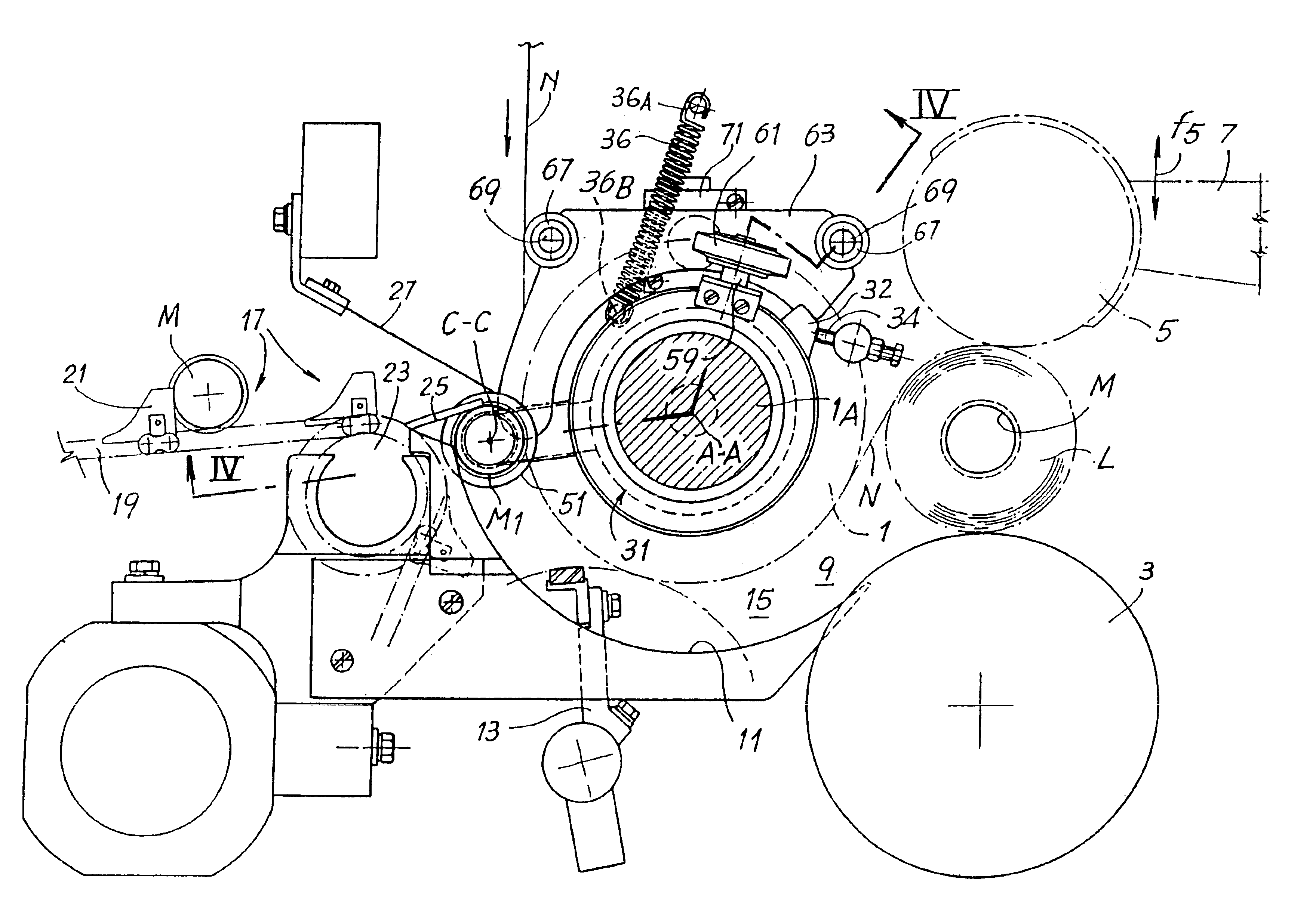

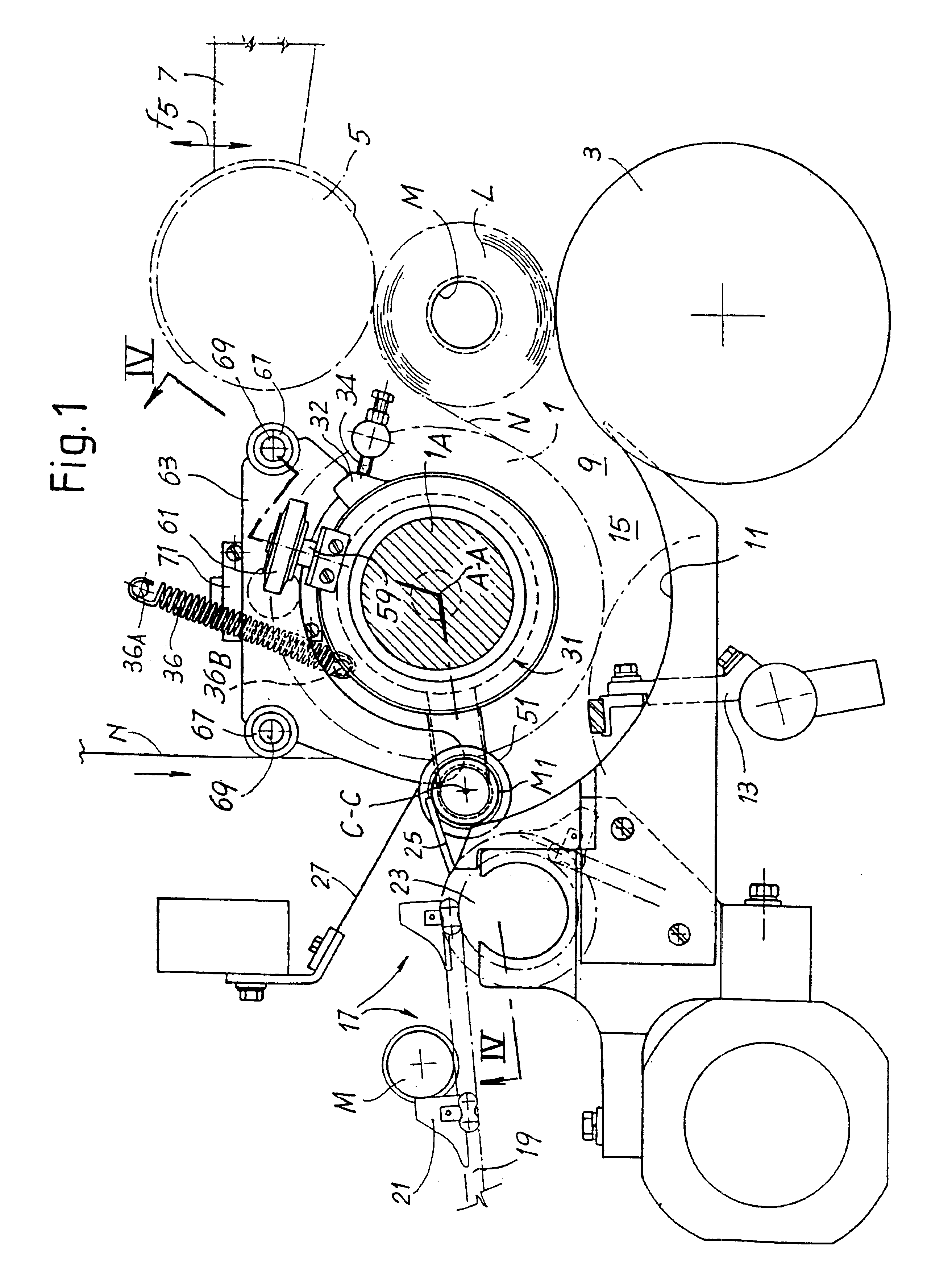

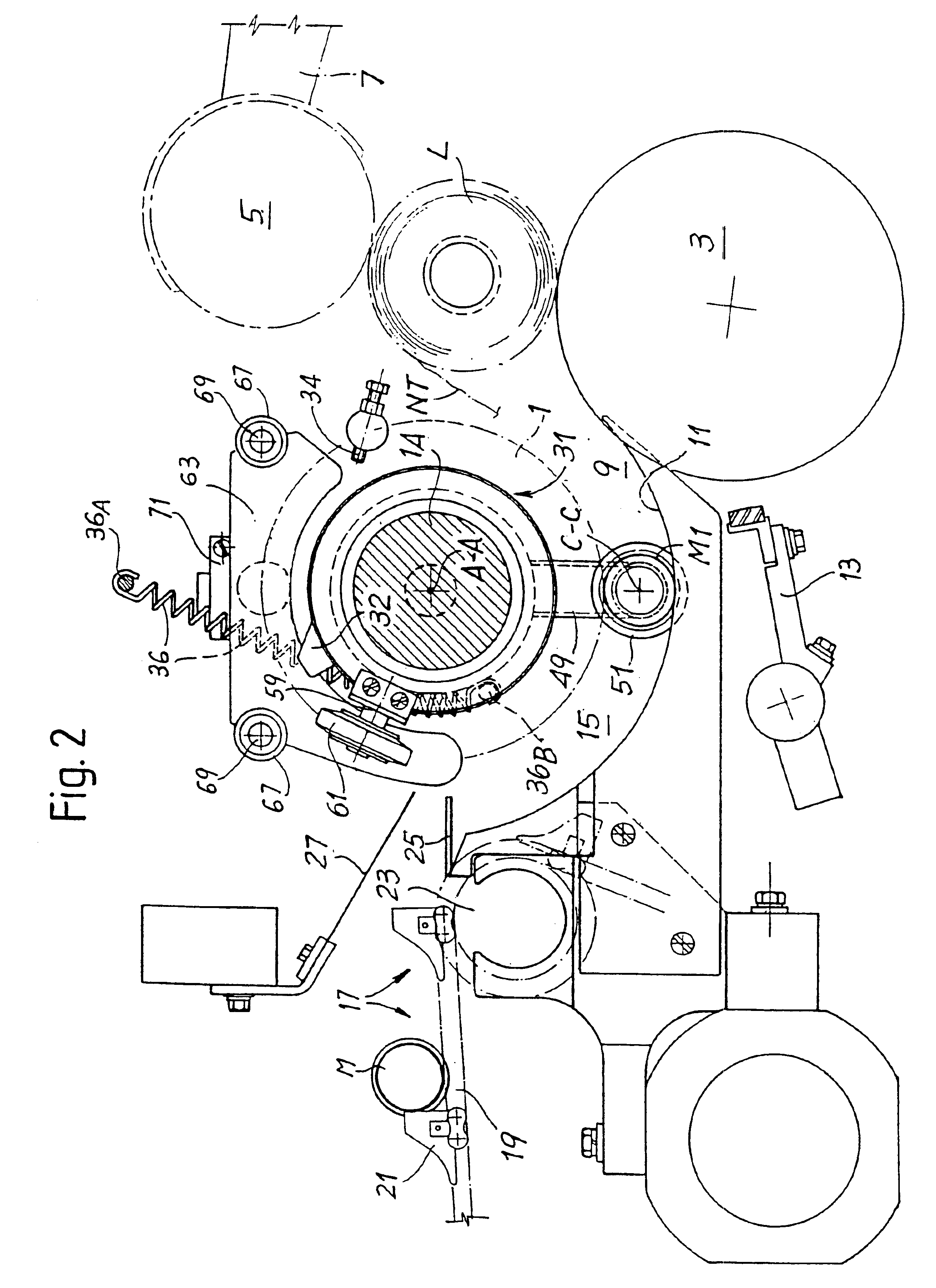

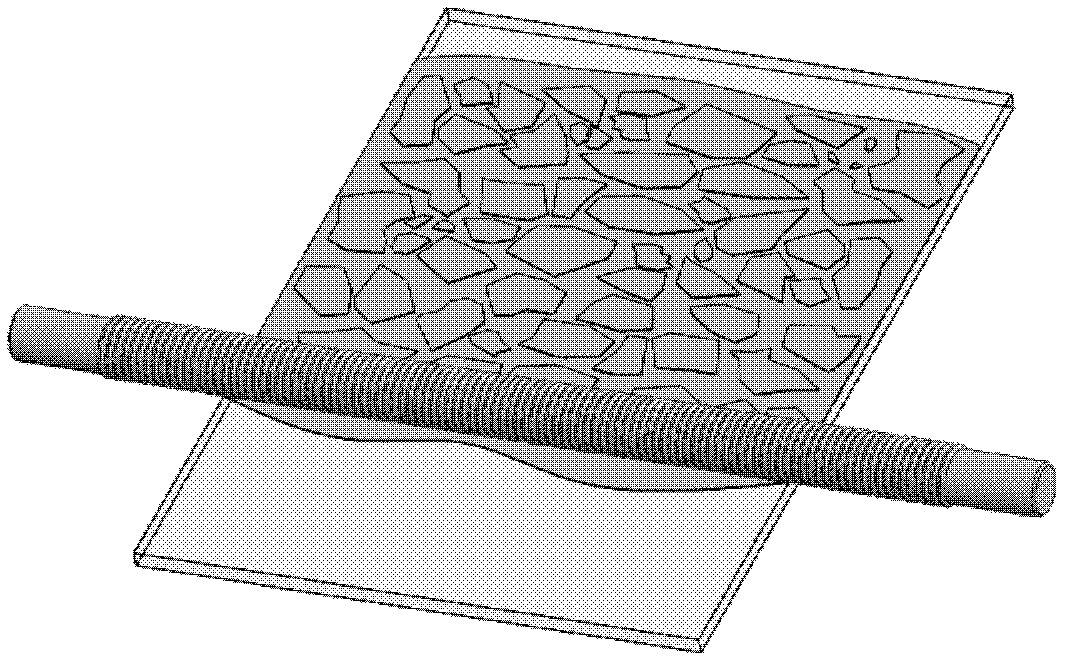

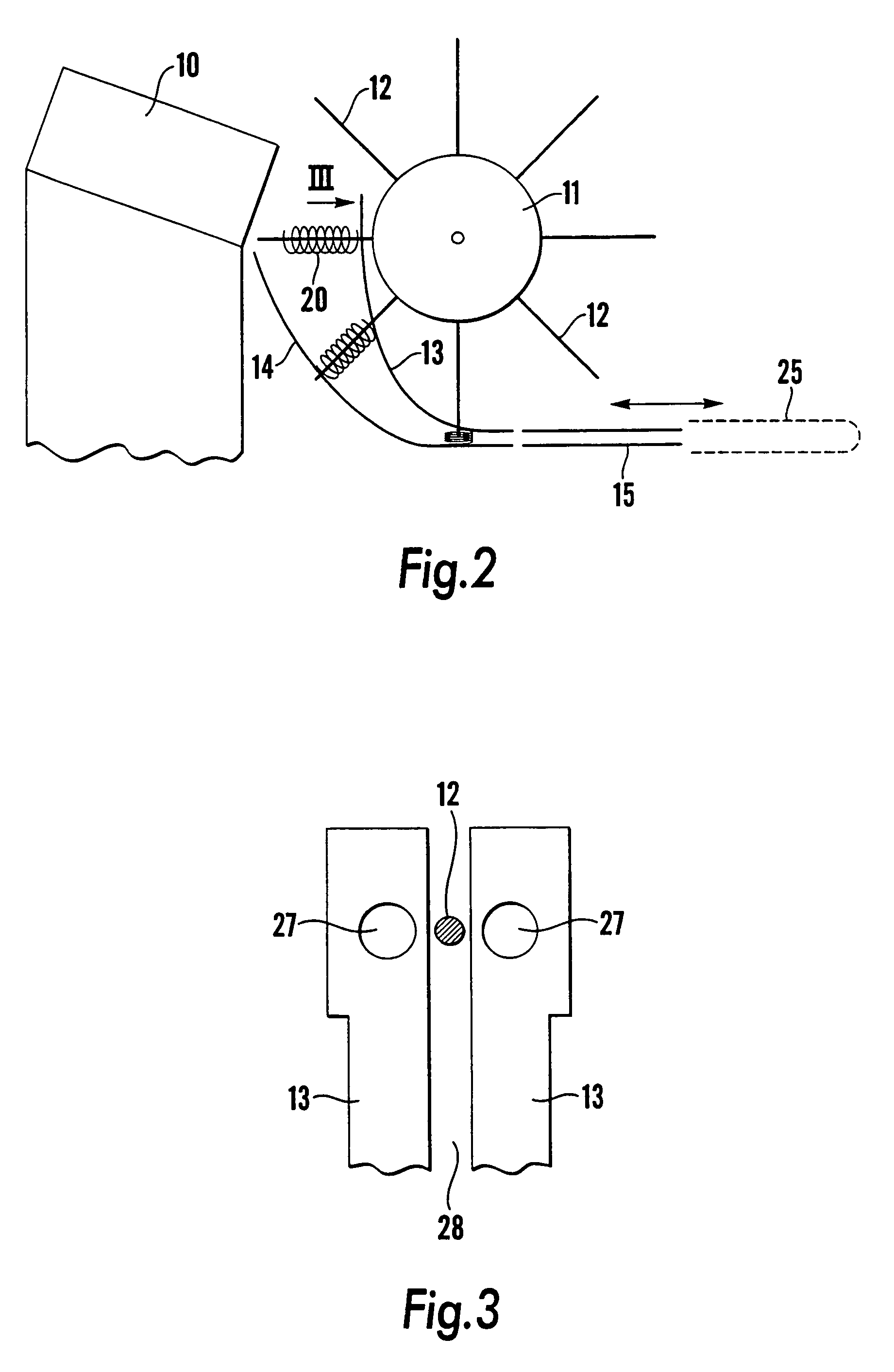

Method and device for the production of rolls of web material without a winding core

InactiveUS6595458B1Suitable for high production speedEfficient and fast and reliableFilament handlingWebs handlingEngineeringInsertion device

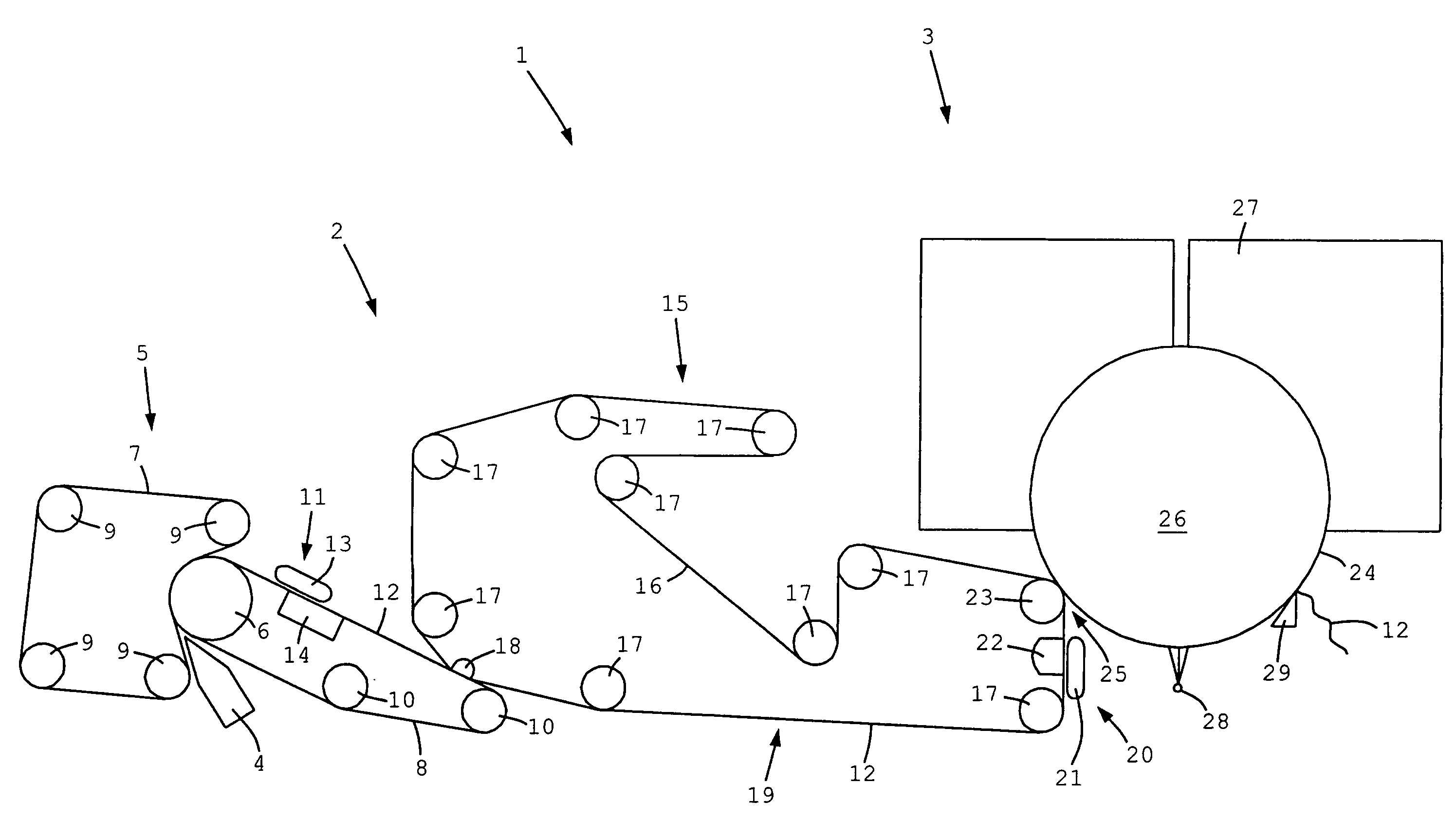

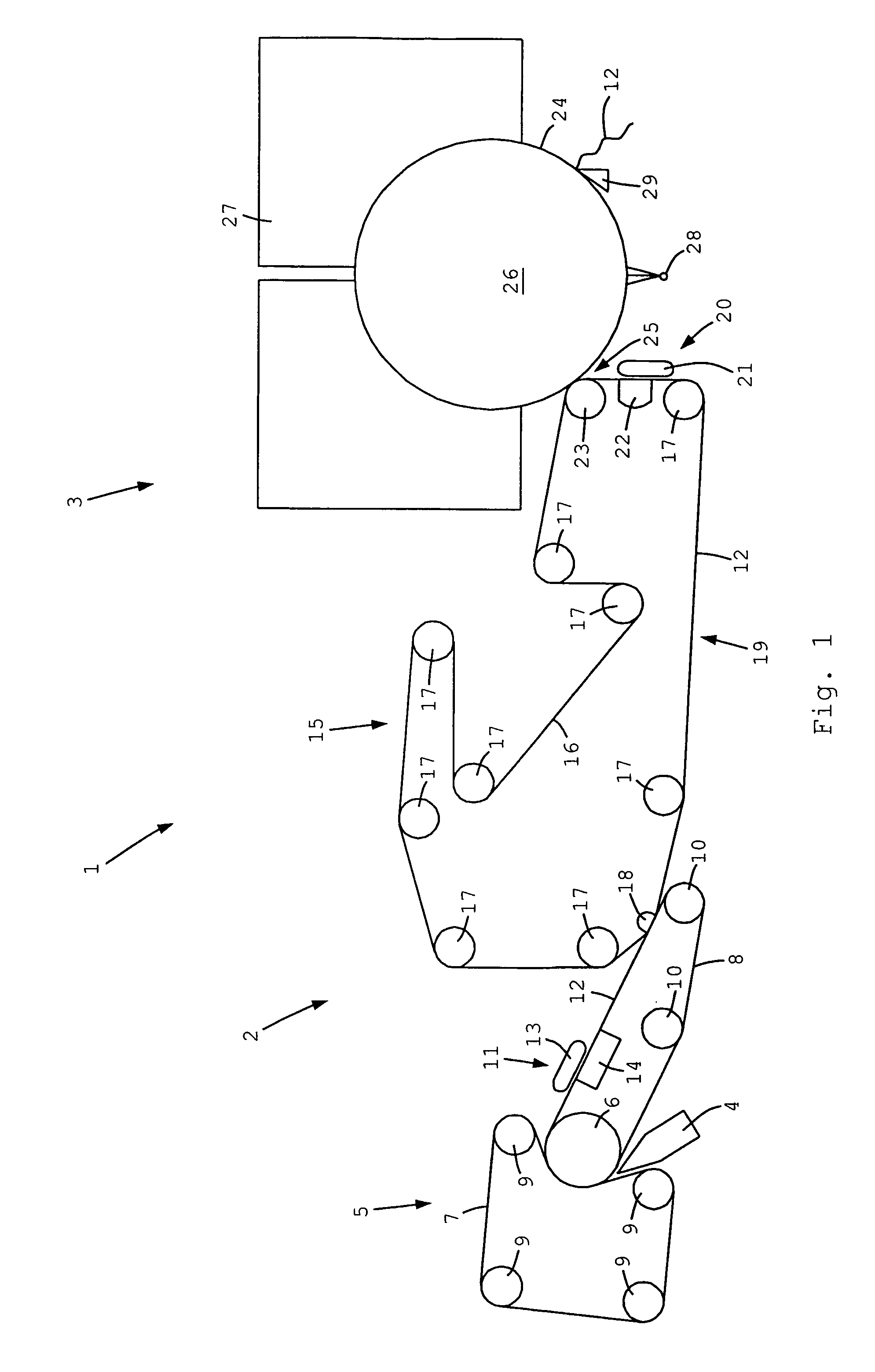

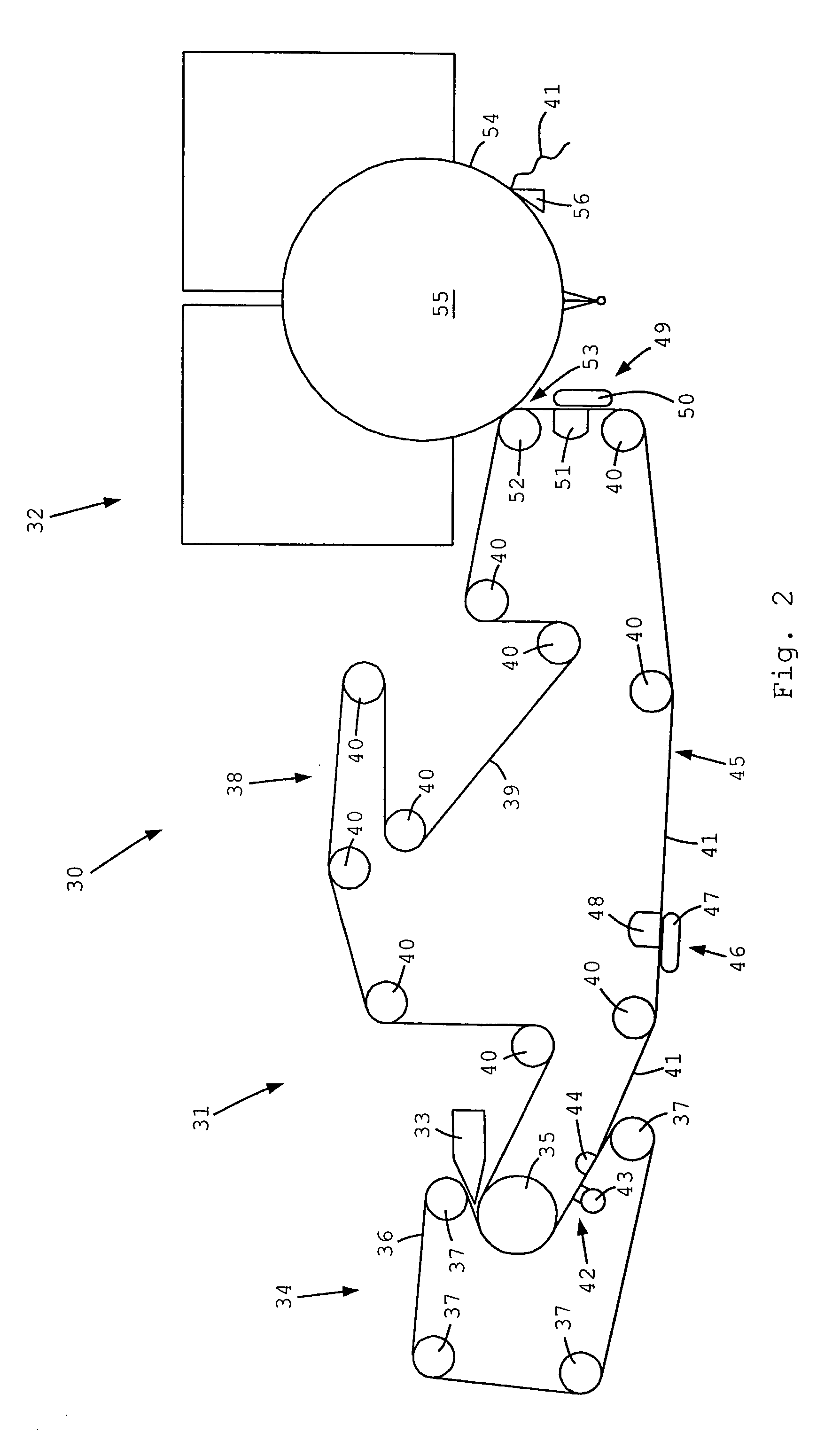

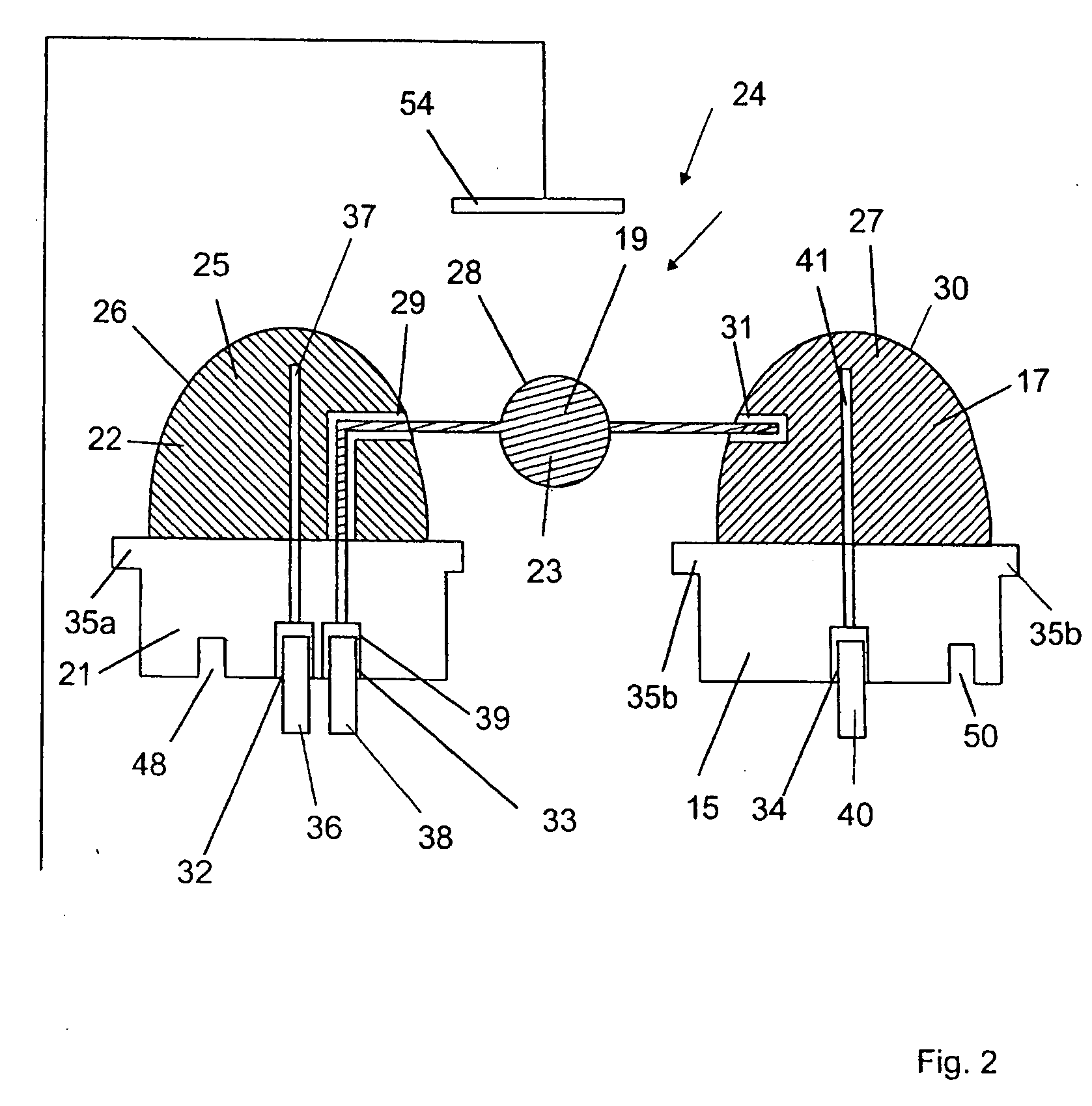

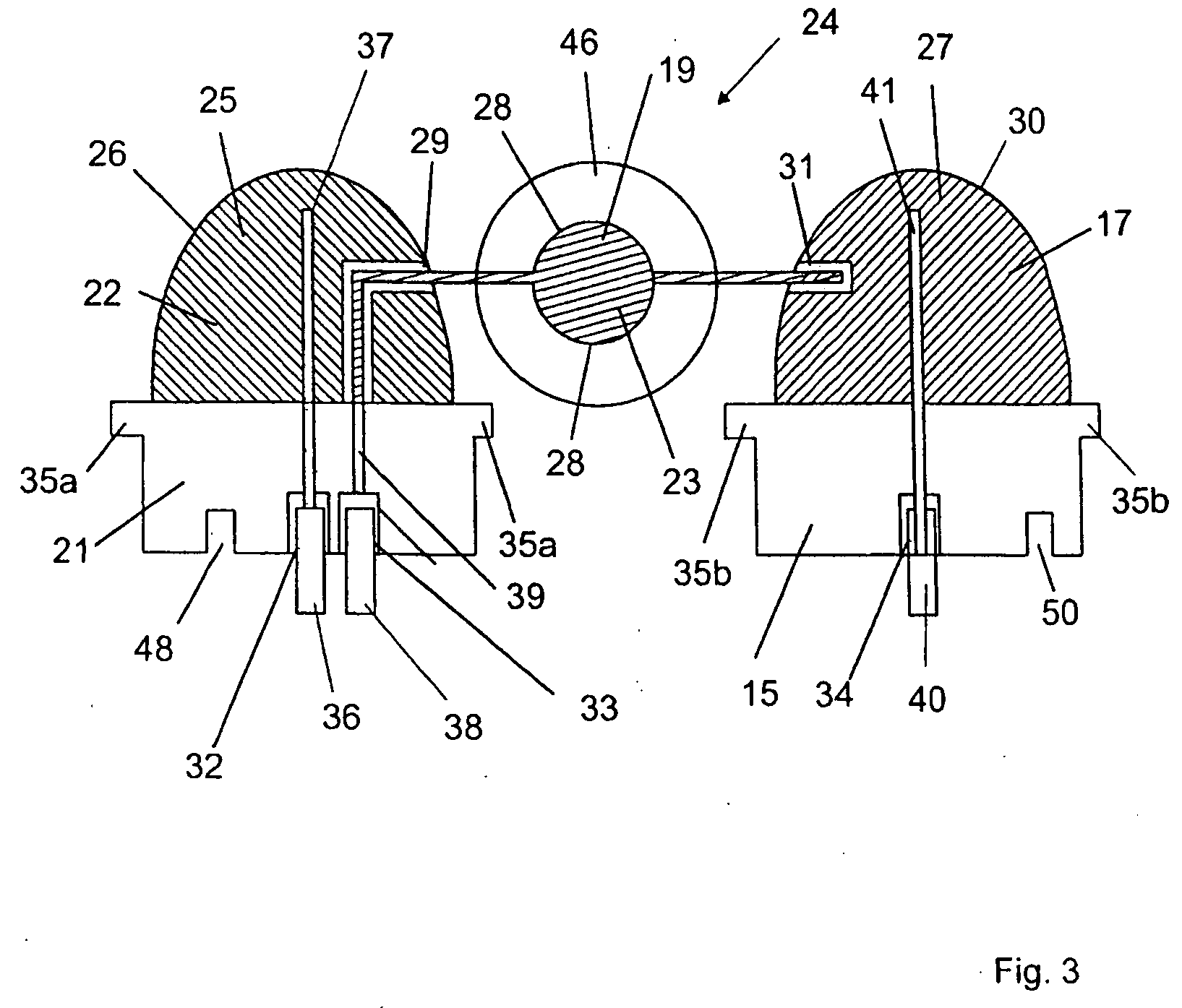

A surface rewinding machine for the production of rolls of wound web material is described. The machine comprises: a winding cradle (1, 3, 5) for winding the web material and sequentially forming rolls (R) of wound web material; an insertion device (25) for inserting sequentially, into said winding cradle, winding spindles (M1; M) on which the rolls are formed; an insertion path for the spindles inside the winding cradle. A suction system (51) which follows the spindles along at least one portion of the insertion path so as to produce a vacuum inside the spindles is also envisaged.

Owner:FABIO PERINI SPA

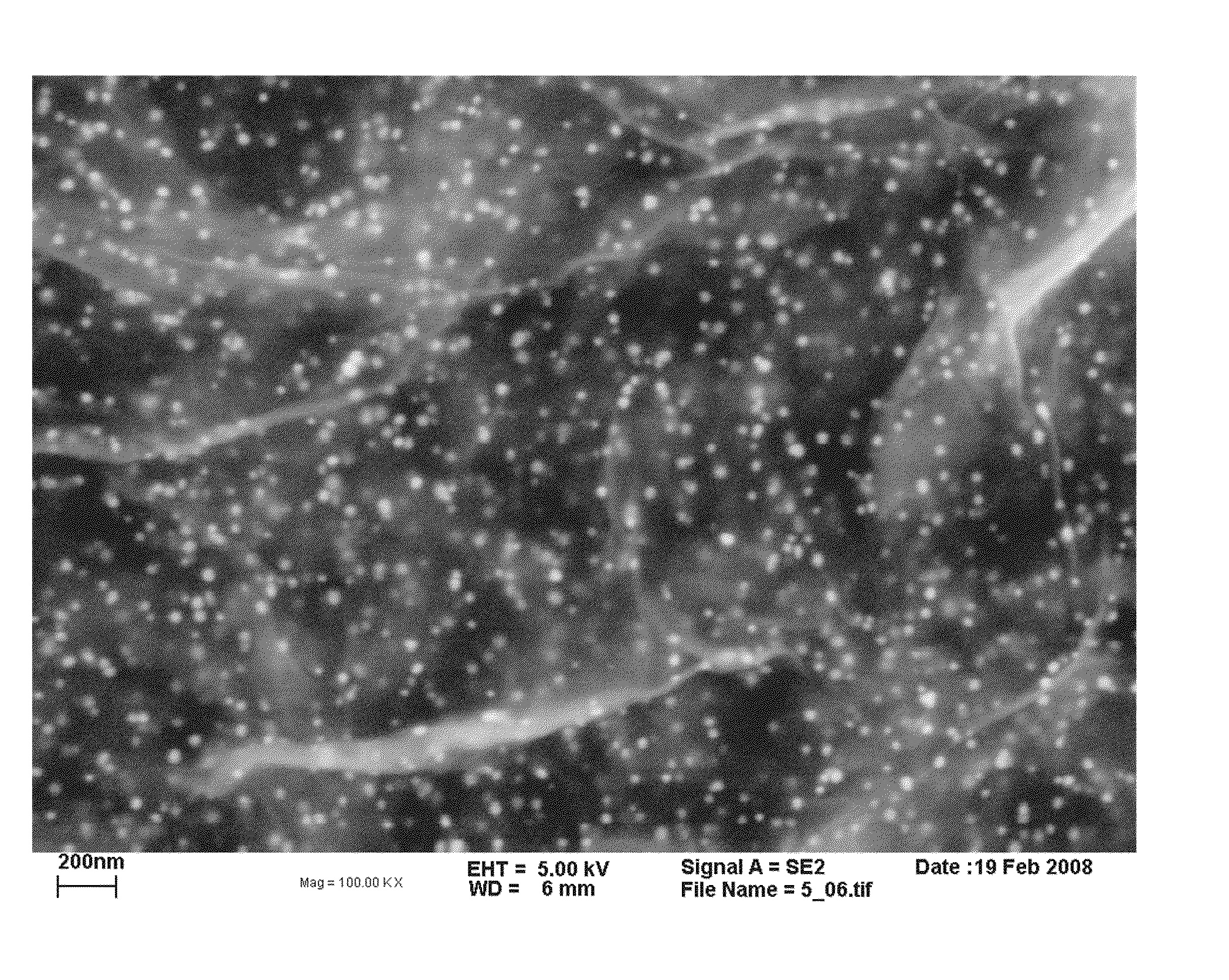

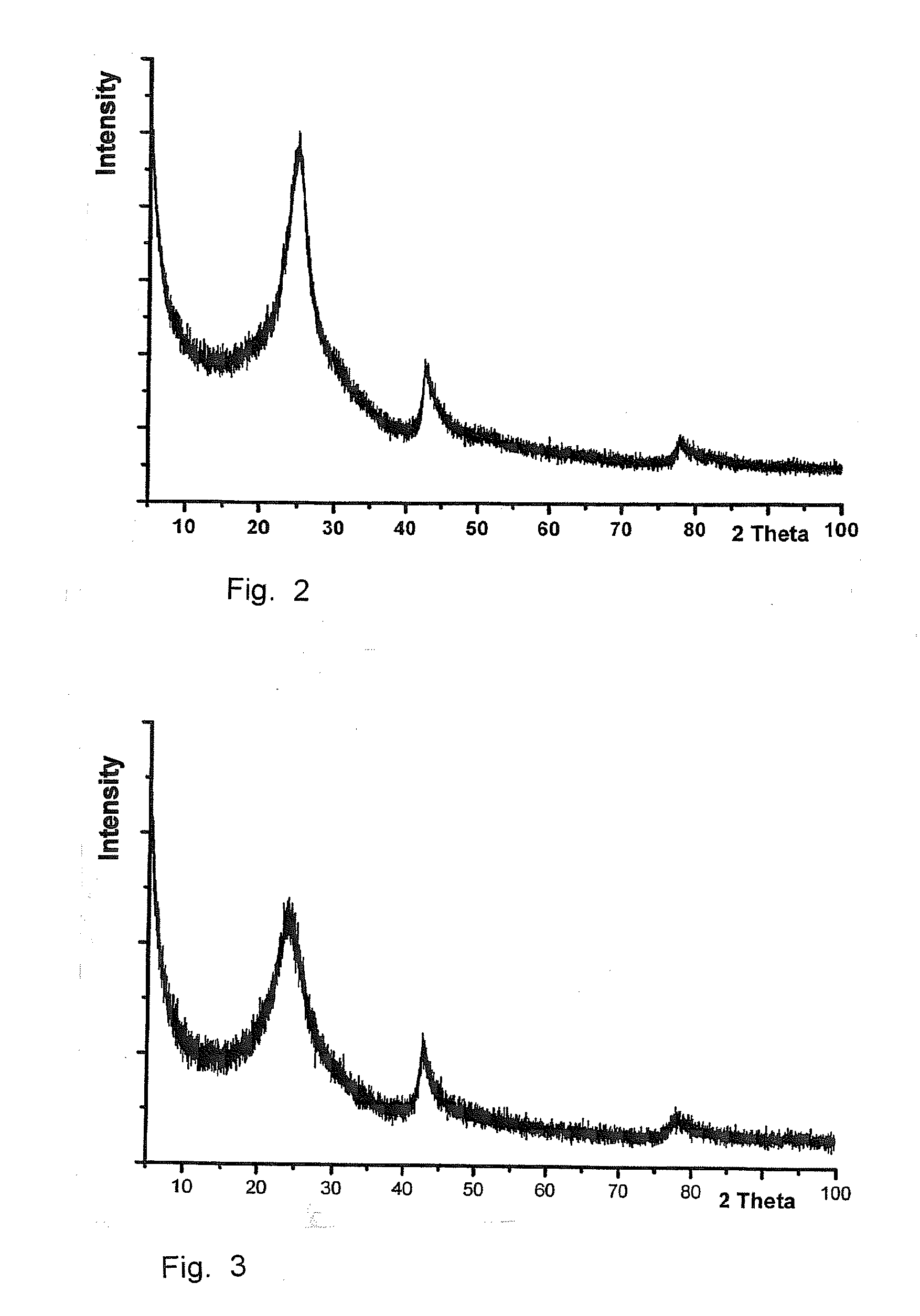

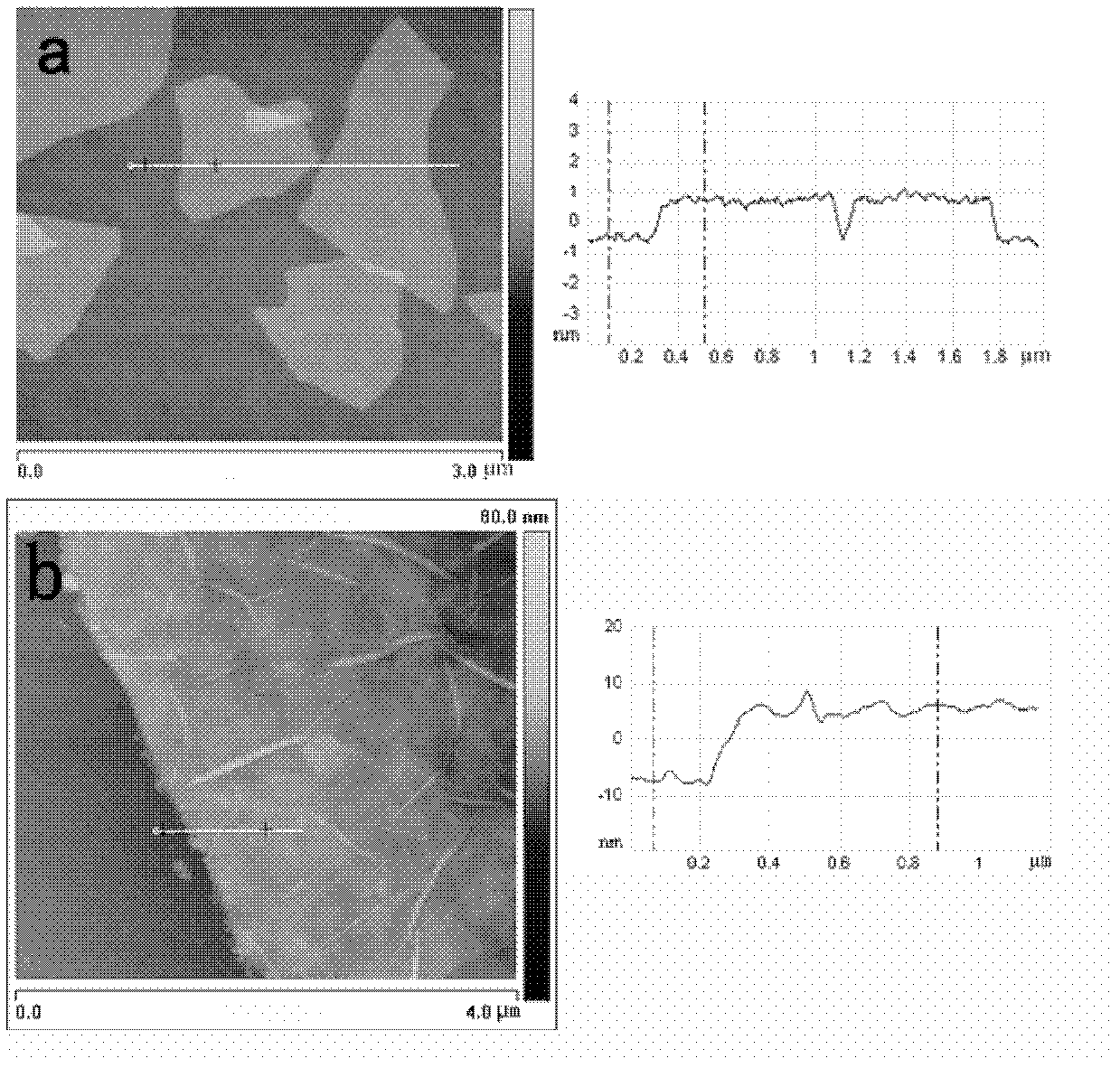

Stable dispersions of single and multiple graphene layers in solution

ActiveUS20100301279A1Improved propertyInhibition formationMaterial nanotechnologyCell electrodesColloidCvd graphene

Disclosed is a method for producing colloidal graphene dispersions comprising the steps of(i) dispersing graphite oxide in a dispersion medium to form a colloidal graphene oxide or multi-graphene oxide dispersion(ii) thermally reducing the graphene oxide or multi-graphene oxide in dispersion.Dependent on the method used for the preparation of the starting dispersion a graphene or a multi-graphene dispersion is obtained that can be further processed to multi-graphene with larger inter-planar distances than graphite. Such dispersions and multi-graphenes are for example suitable materials in the manufacturing of rechargeable lithium ion batteries.

Owner:BELENOS CLEAN POWER HLDG

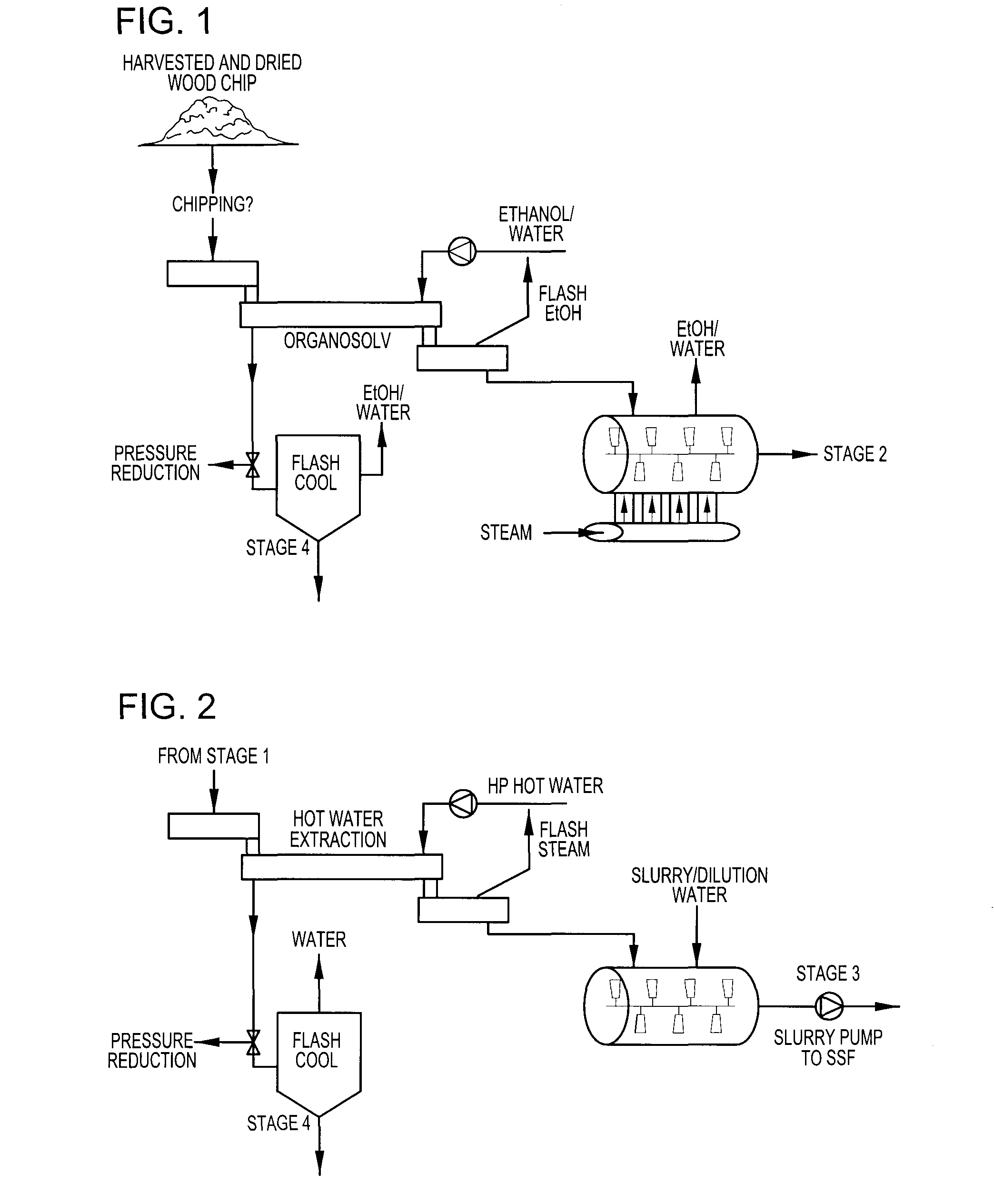

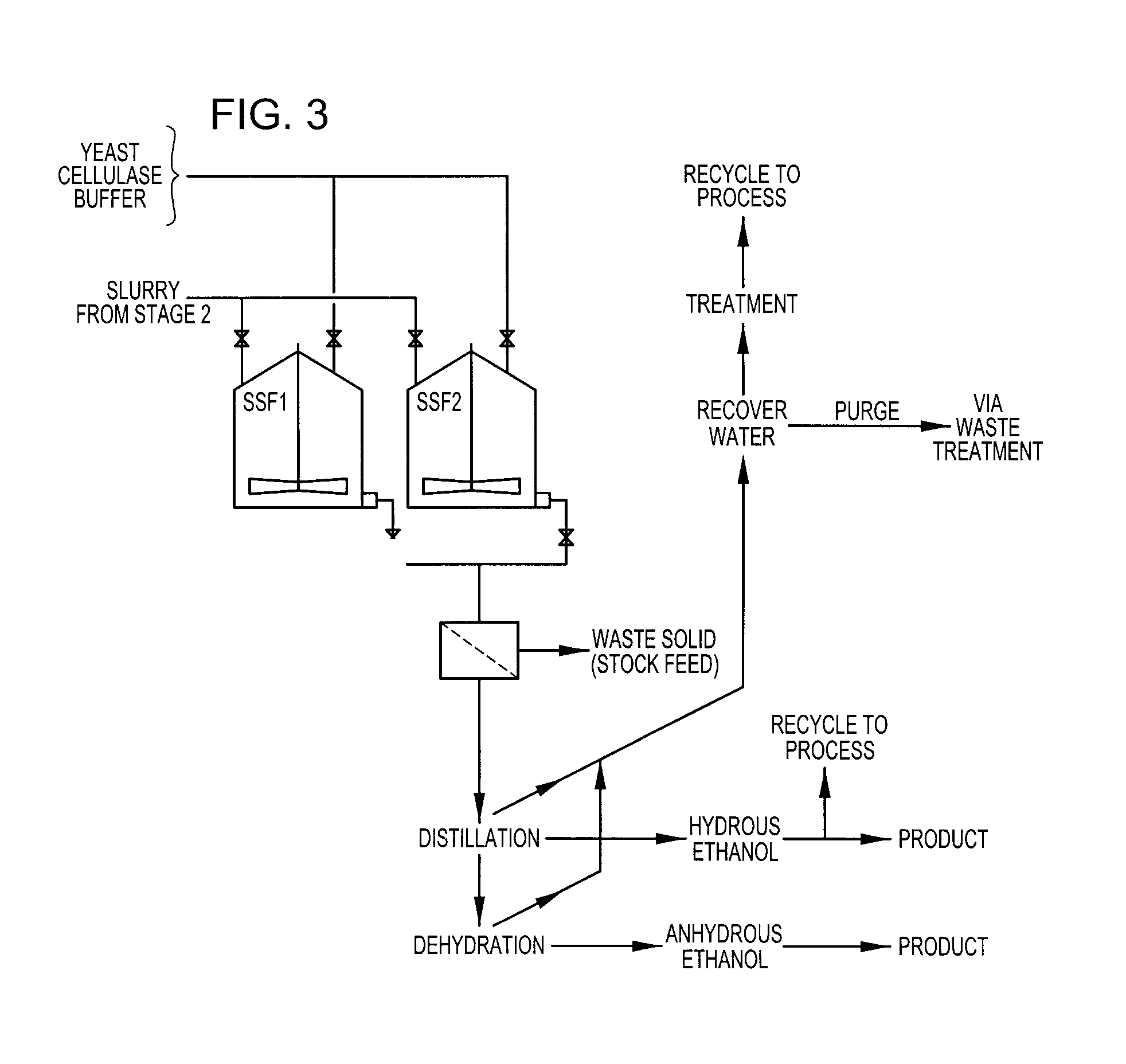

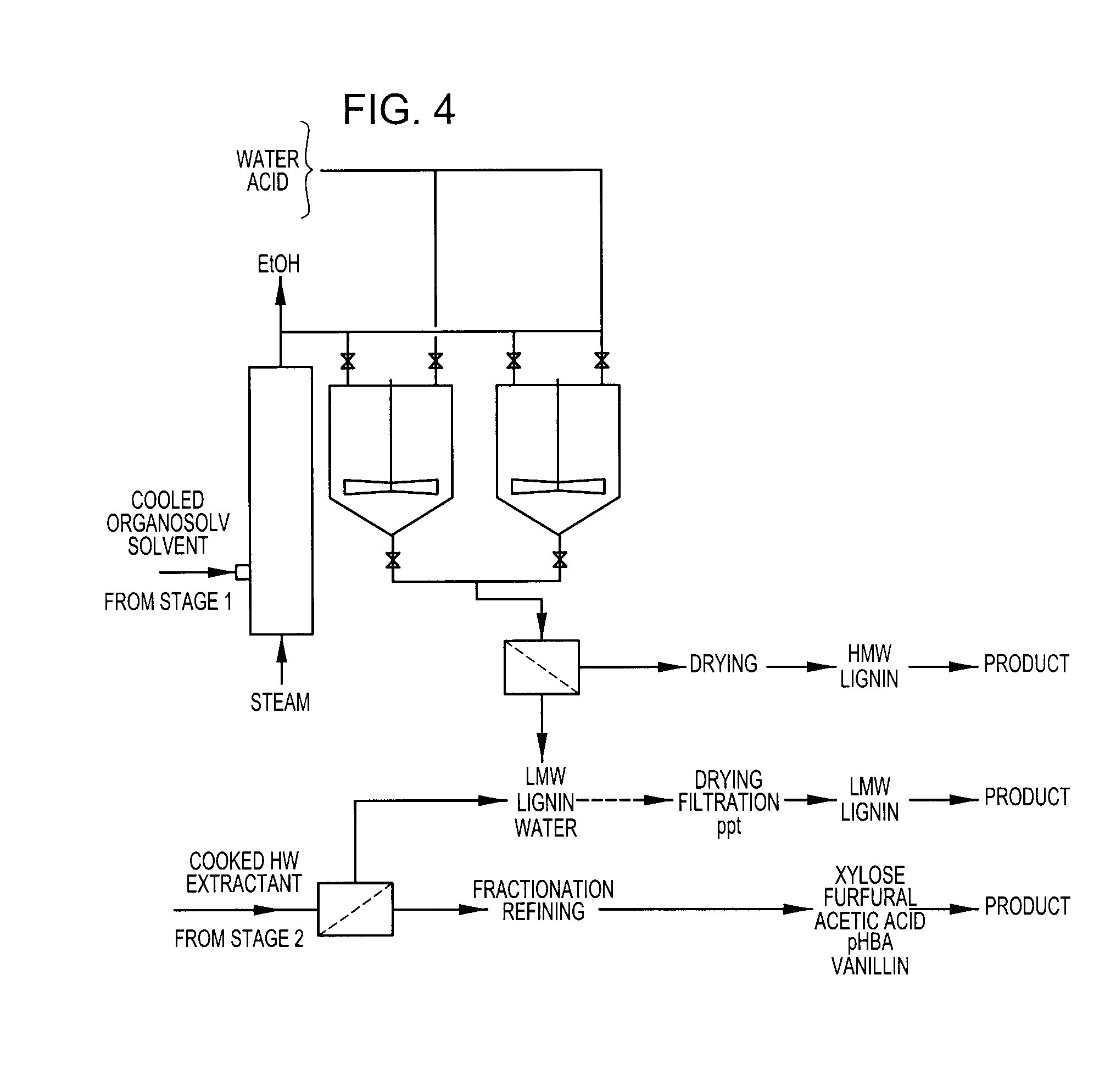

Integrated processing of plant biomass

InactiveUS7649086B2Rapid productionEfficient and cost-effective useBiofuelsLignin derivativesCelluloseWoody plant

An integrated process for the production of ethanol from woody plant material is provided, the process comprising: contacting a continuous flow of the plant material with a counter-current continuous flow of an aqueous ethanol solution at elevated temperature and pressure to provide plant material depleted of lignin; removing ethanol from the lignin-depleted plant material; contacting a continuous flow of the lignin-depleted plant material with water at elevated temperature and pressure to solubilize xylose within the plant material; and hydrolyzing cellulose present in the plant material to form glucose, which in turn is fermented to produce ethanol.

Owner:VERTICHEM CORP

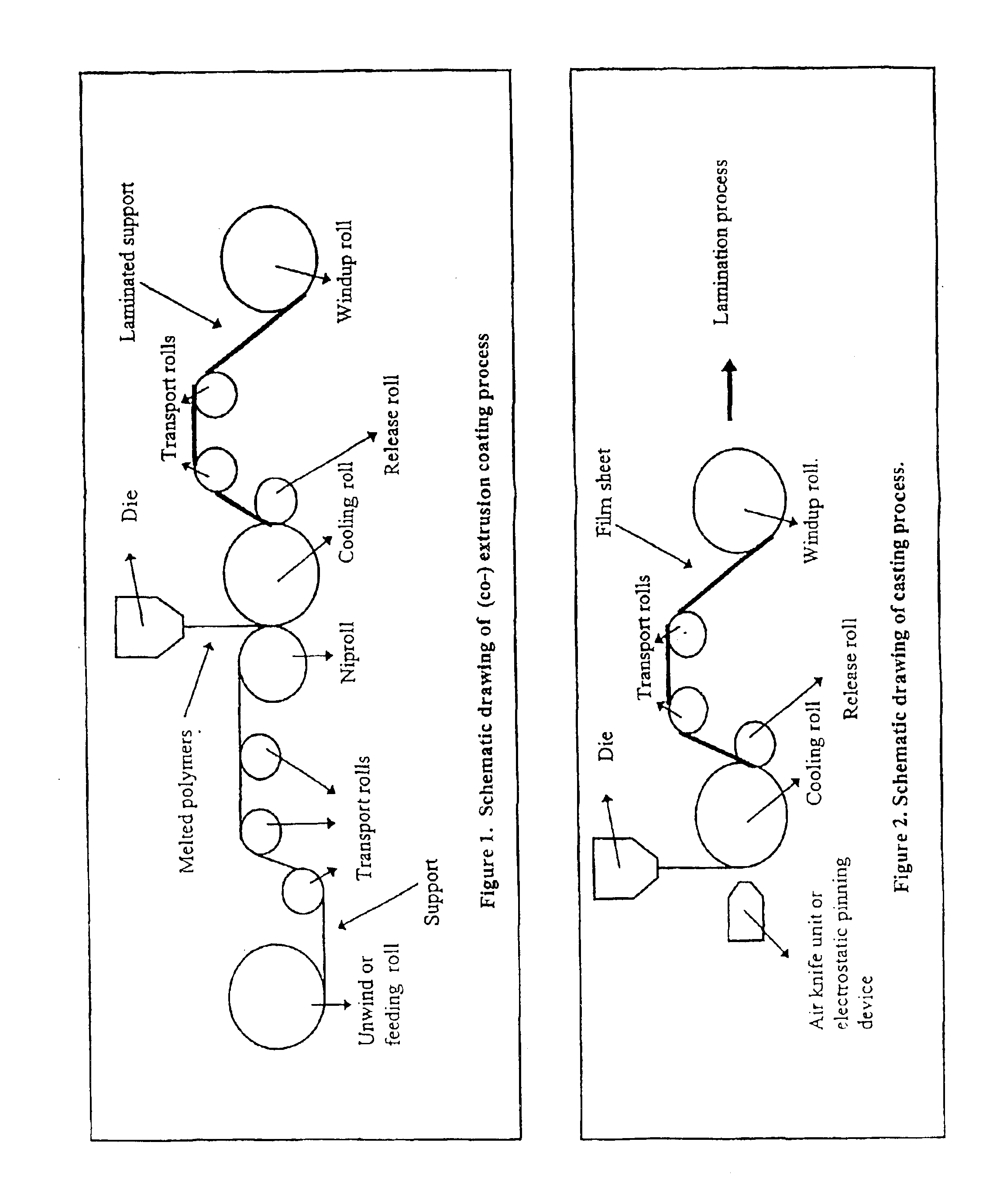

Photocatalytic sheet or film and its manufacturing process

InactiveUS6890645B2Fast productionDrying processSynthetic resin layered productsCellulosic plastic layered productsExtrusion coatingSheet material

The invention is directed to a photocatalytic sheet comprising a support, a photocalalytic layer comprising photocatalyst materials and binder, and at least one functional layer wherein said functional layer is in between said support and said photocatalytic layer, wherein said photocatalytic layer and said functional layer are brought on the support using extrusion coating technology or casting technology, as well as to a photocatalytic film sheet comprising: a photocatalytic layer comprising photocatalyst materials and binder, and at least one functional layer, wherein said film is formed by applying casting technology.

Owner:FUJIFILM MFG EURO

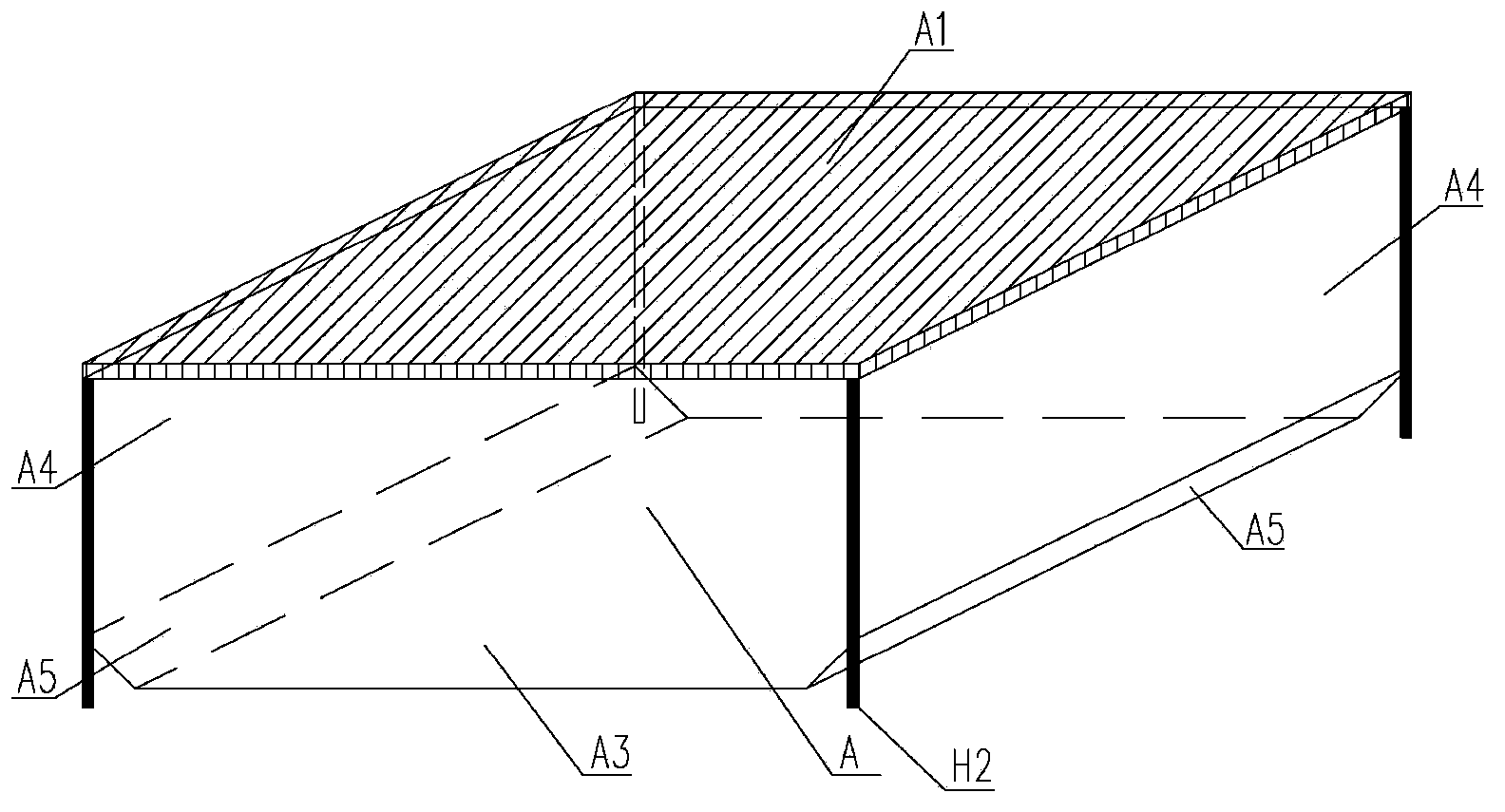

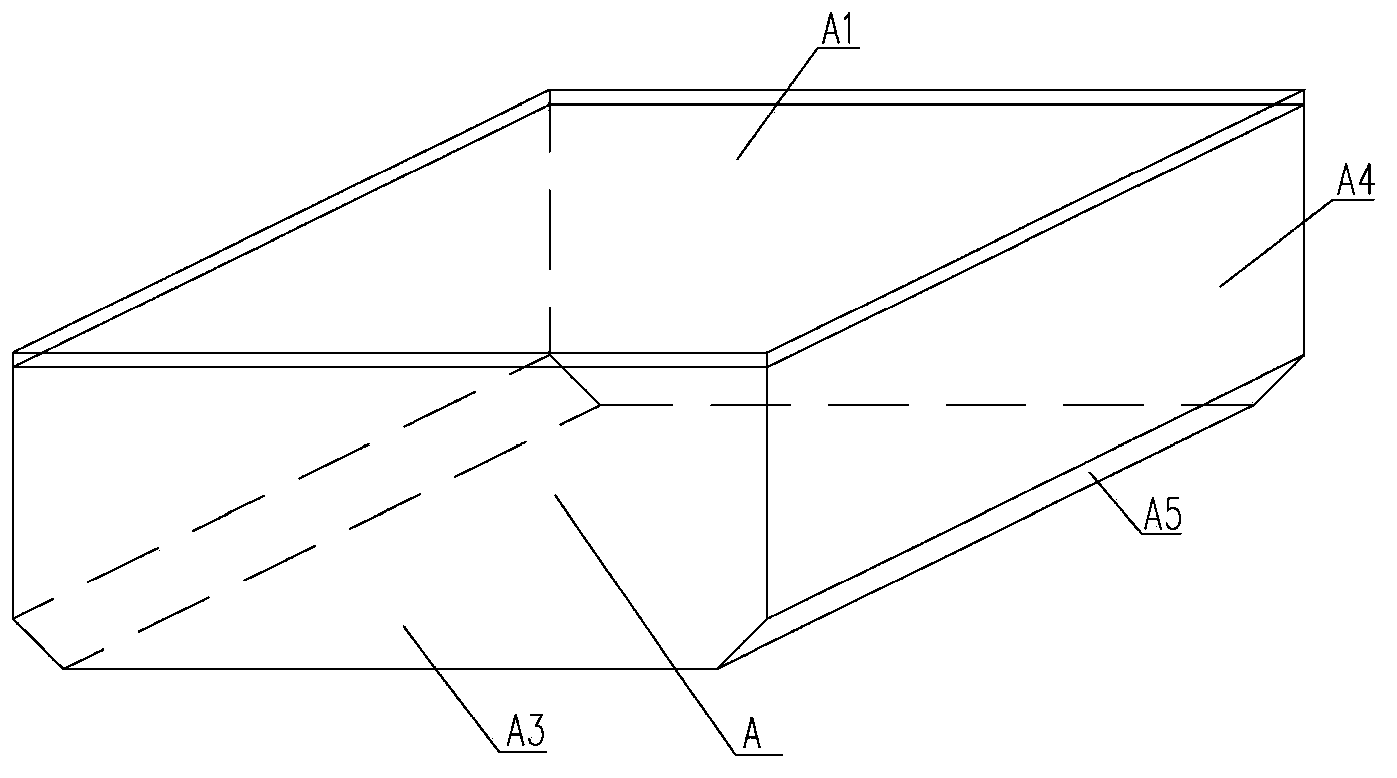

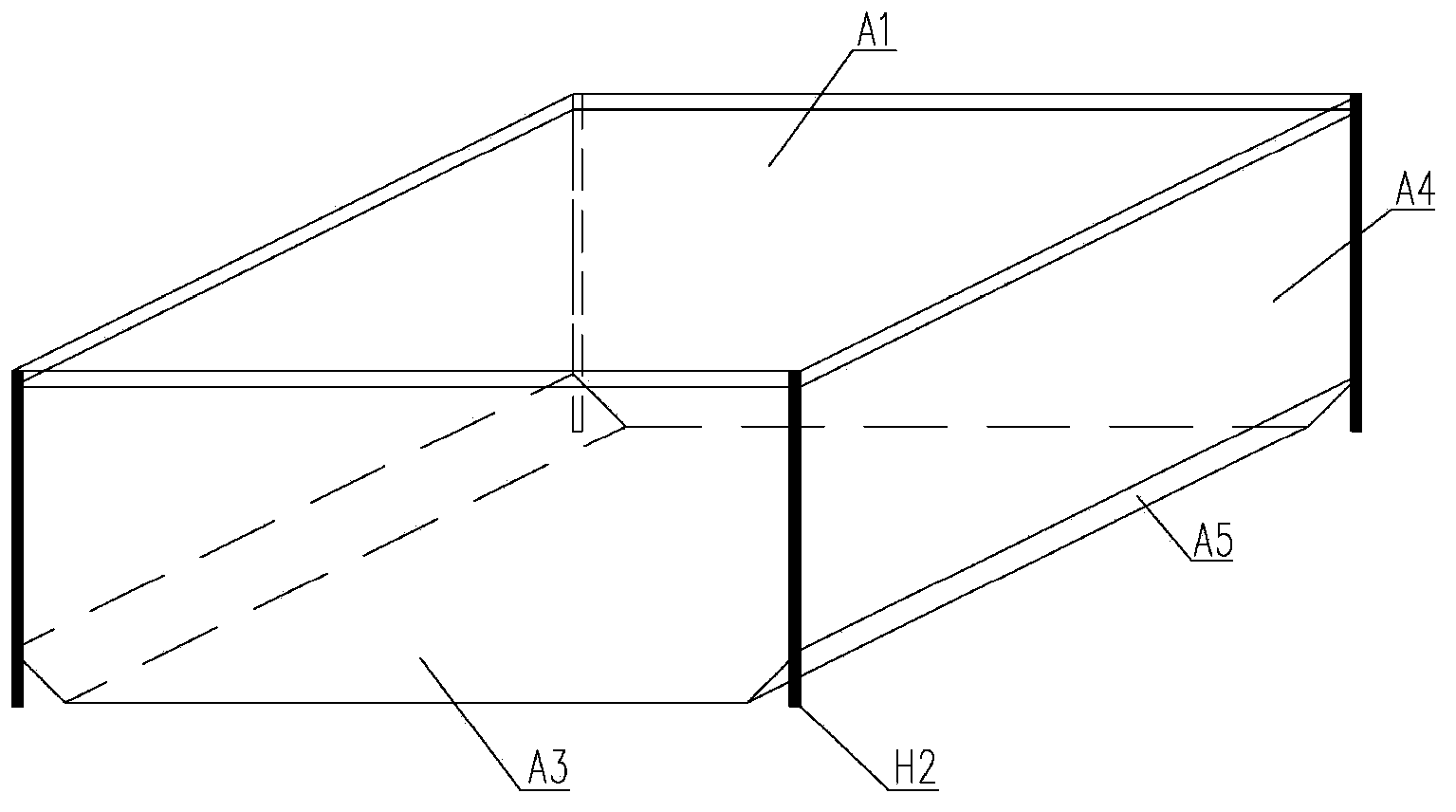

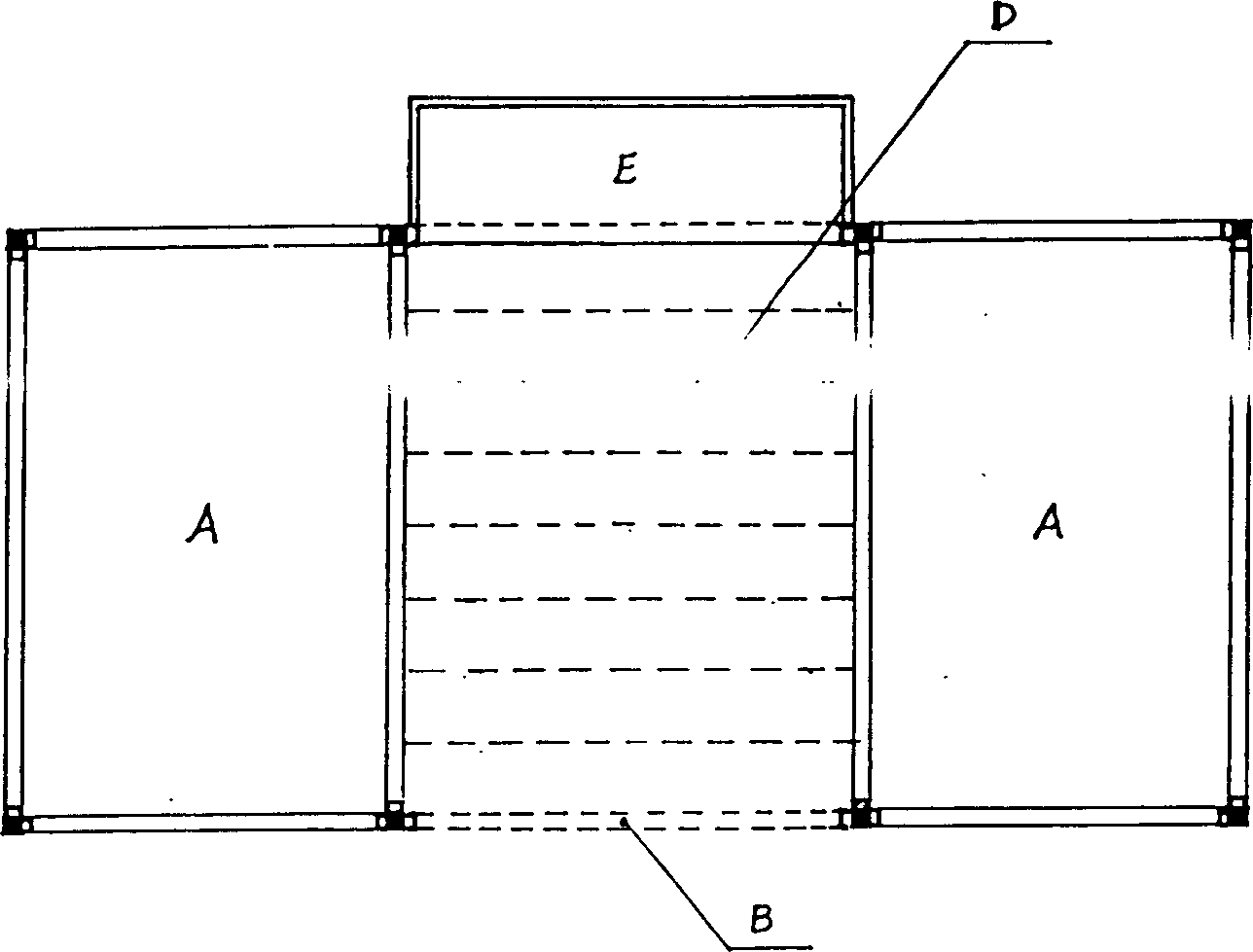

Netlike box-shaped component for forming holes in cast-in-situ hollow floor

The invention provides a netlike box-shaped component for forming holes in a cast-in-situ hollow floor. The netlike box-shaped component is formed by combining a box roof, a box body (side wall) and a box bottom; the box roof is compounded with cement mortar or styrofoam or a board; the box body and the box bottom are manufactured by netlike bodies; each netlike body comprises a netlike board, reinforcing ribs and connecting nets; the netlike board, the reinforcing ribs and the connecting nets form an interacting integral structure; the area of a grid in the netlike board is smaller than 120 mm<2>; the reinforcing ribs are V-shaped; the reinforcing ribs are higher than 3mm; the space between the reinforcing ribs in each netlike body is larger than 30mm; the netlike box-shaped component is formed by combining at least two netlike bodies; at least two structural inclined planes are arranged at corners of the box bottom and the box body of the netlike box-shaped component; the netlike bodies of the netlike box-shaped component are made of steel or plastic. The unsealed netlike box-shaped component replaces a fully-sealed hollow filling body and a solid filling body as a hole forming technology of the conventional cast-in-situ hollow floor, so that technical defects of the existing hollow floor are effectively solved.

Owner:王本淼 +1

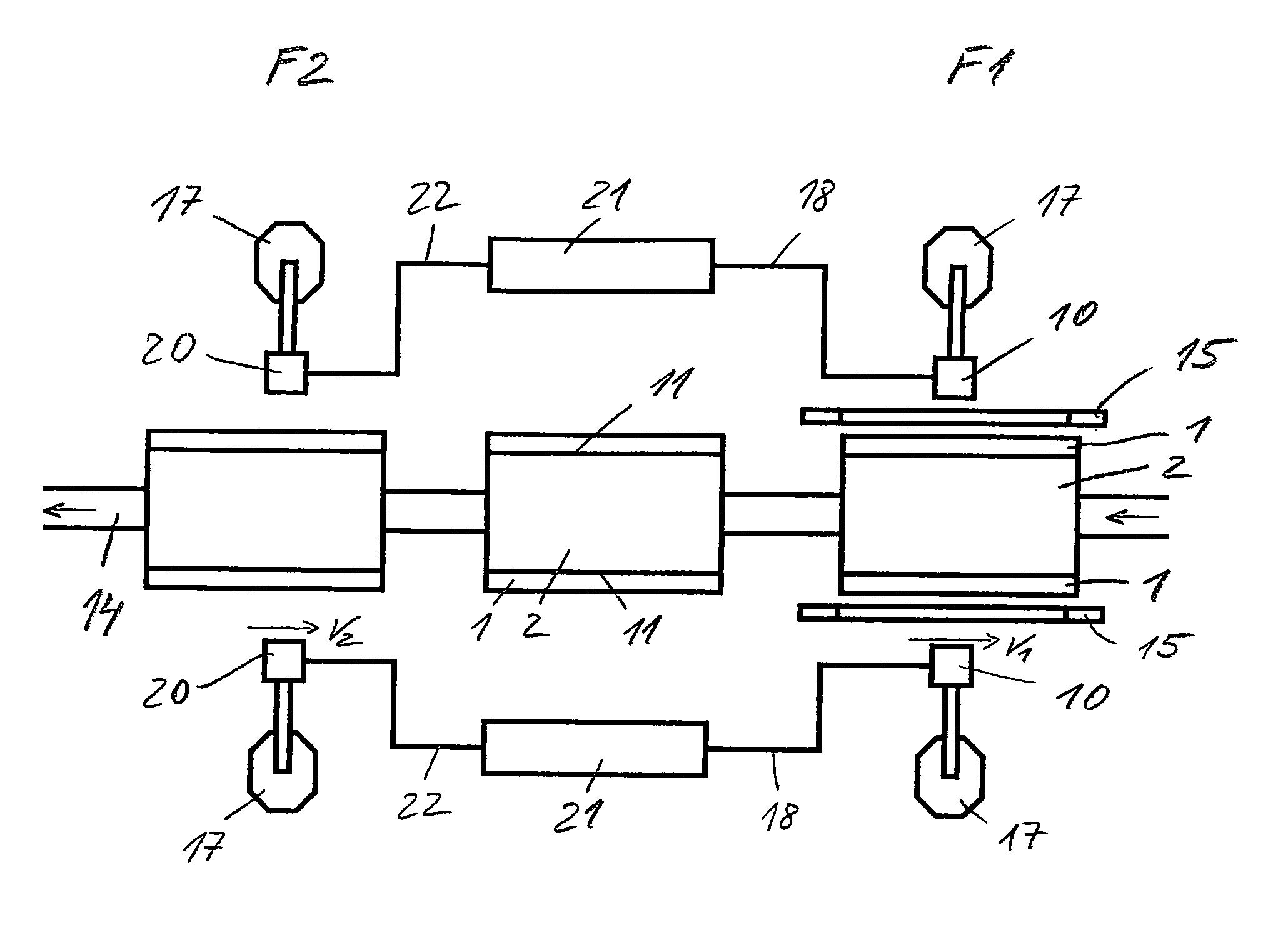

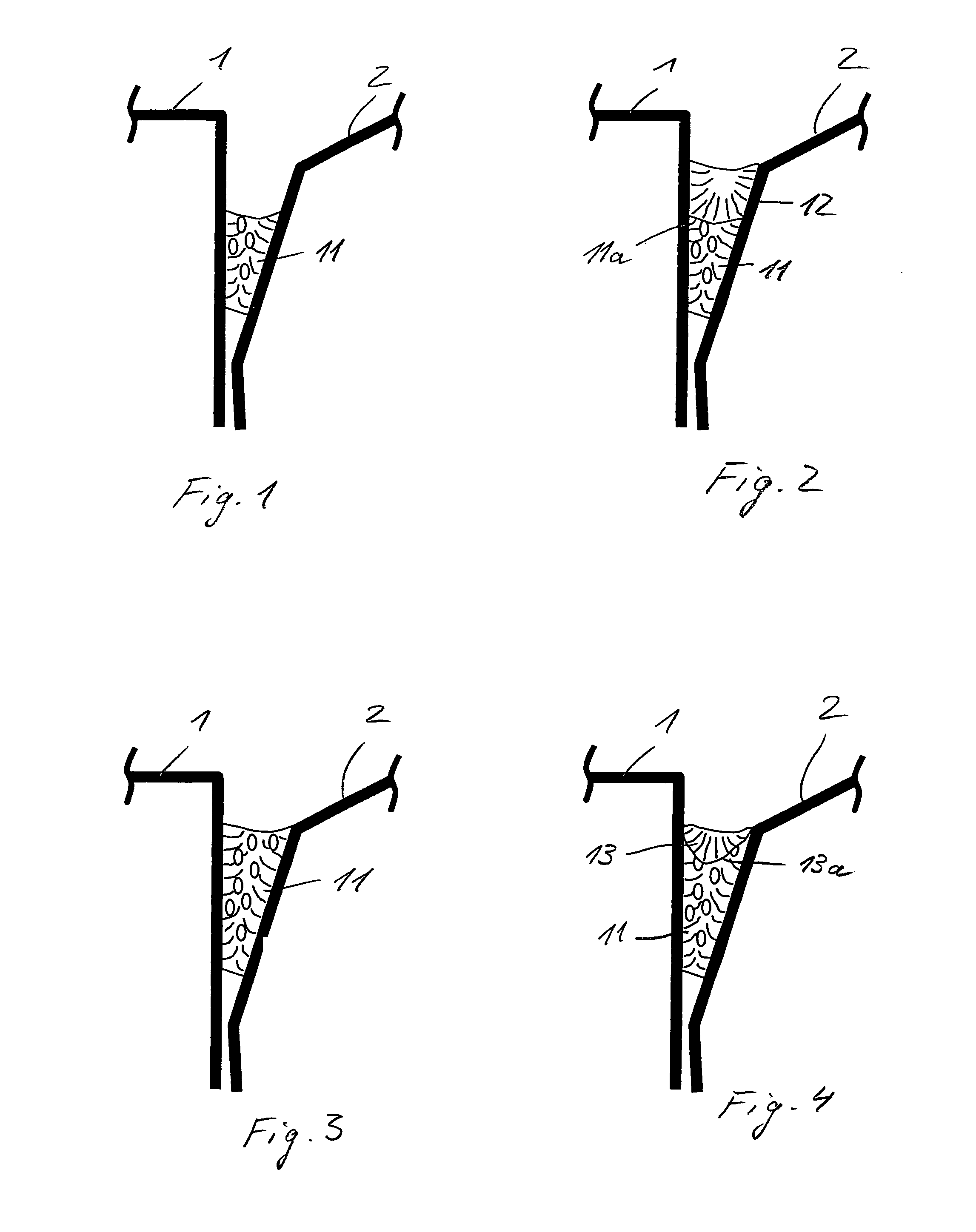

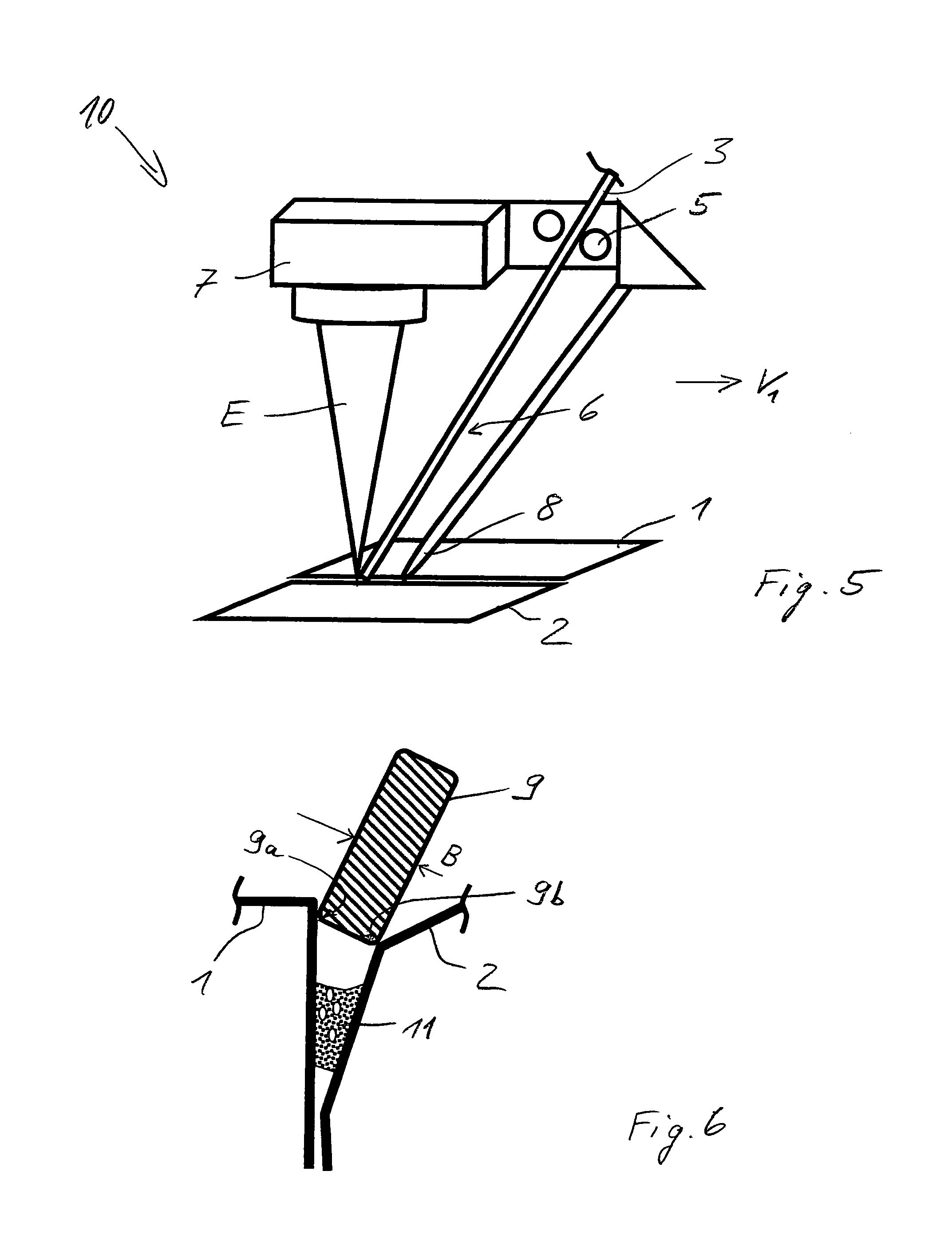

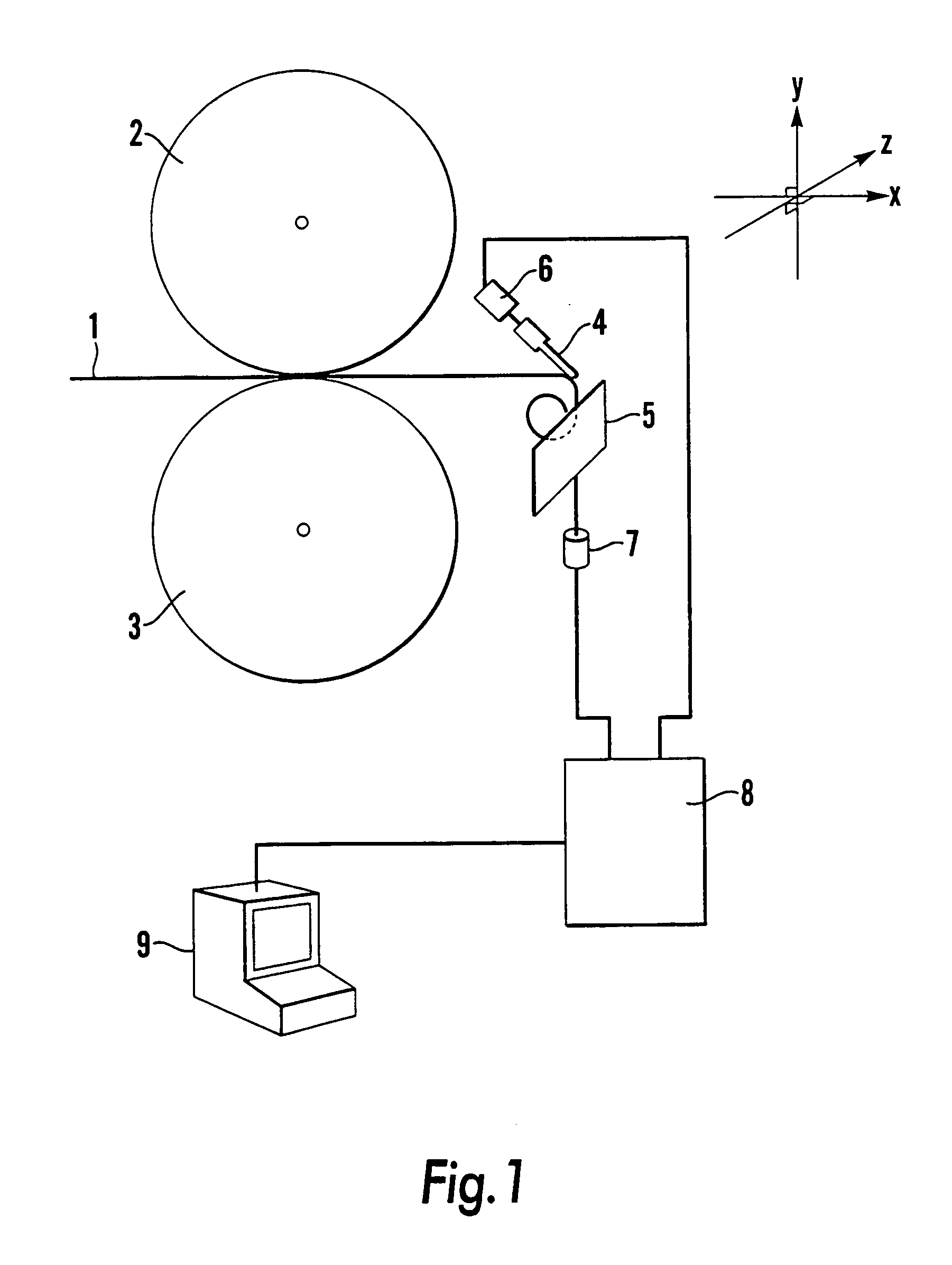

Method of soldering or welding components

ActiveUS8686314B2Increase speedIncrease production speedWelding/cutting auxillary devicesVehicle componentsEngineeringSoldering

Owner:FFT PRODIONSSYST

Film containing graphene and/or graphene oxide, and preparation method thereof

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

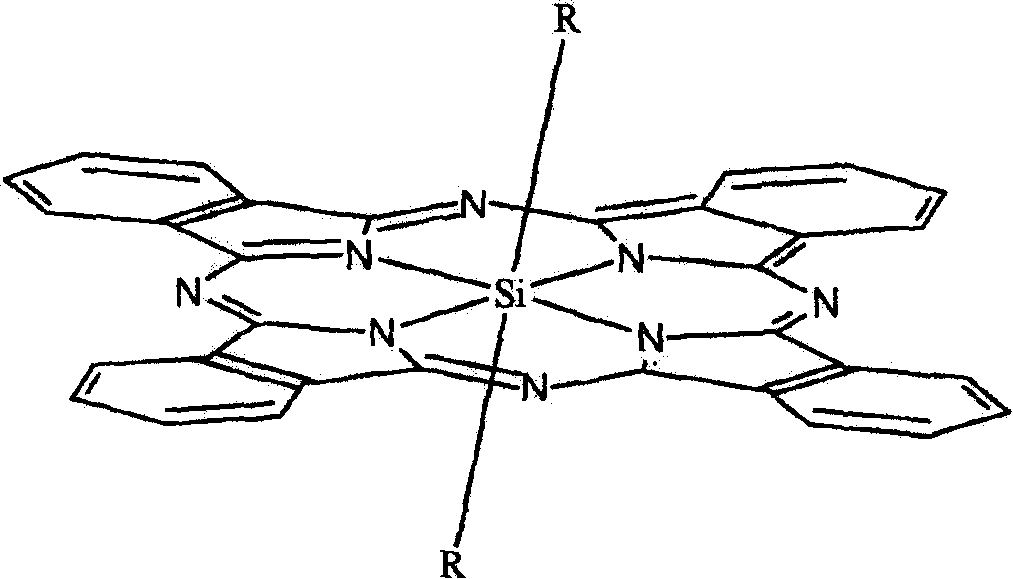

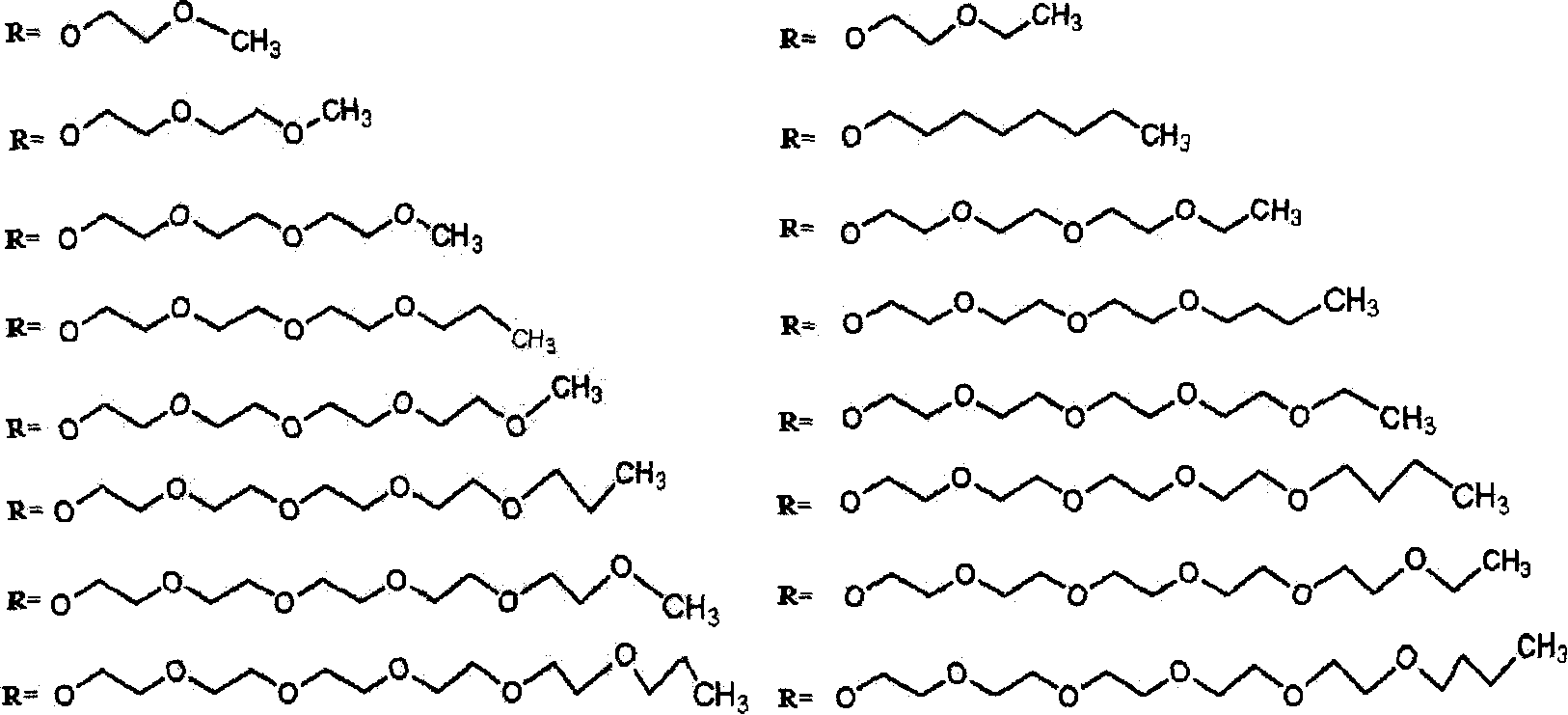

Silicon phthalocyanine compound and composite, their preparation and application thereof

ActiveCN1861603AStrong photosensitivityClear structureSilicon organic compoundsSilicon compound active ingredientsCompound sDisease

An axially substituted silicon-phthalocyanin match and its composition are disclosed, which have high optical spectrum characteristics and can be used as the photosensitizer used for photodynamic therapy to tumor and the diseases other than cancer, photodynamic diagnosis and photodynamic disinfecting.

Owner:FUZHOU UNIVERSITY

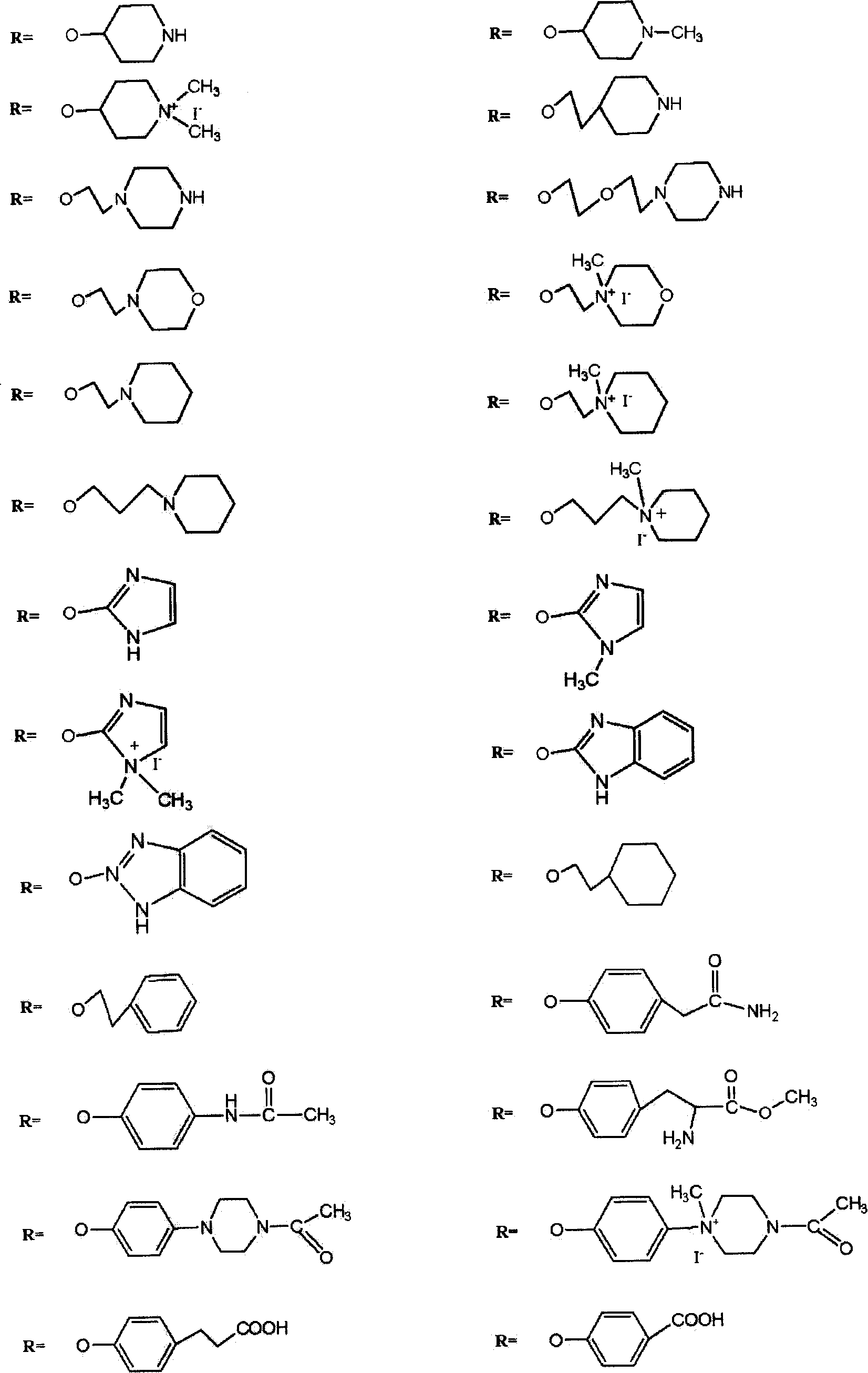

Halogen-free flame-retardant electric wire and cable sheath polymer material and uses thereof

ActiveCN101205324ASolve the problem of unsatisfactory flame resistanceNormal channel workInsulated cablesInsulated conductorsMolecular materialsElectrical polarity

The invention relates to a high molecular material of the halogen-free fire retardant sheath for wire cable and the application thereof. The invention solves the problem of bad fire retardant performance of the existing flame-retardant wire cable. The high molecular material of the invention is characterized in that the material comprises the following components by weight: a) 8-50 per cent of halogen-free expansive flame retardant pretreated by coupling agent occupying 0.1-3 wt per cent of the halogen-free expansive flame retardant; b) 0.5-10 per cent of graft polymer of the polar compound; c) 5-30 per cent of inorganic padding pretreated by coupling agent occupying 0.1-3 wt per cent of the inorganic padding; and d) at least one organic polymer for the rest.

Owner:HANGZHOU JLS FLAME RETARDANTS CHEM

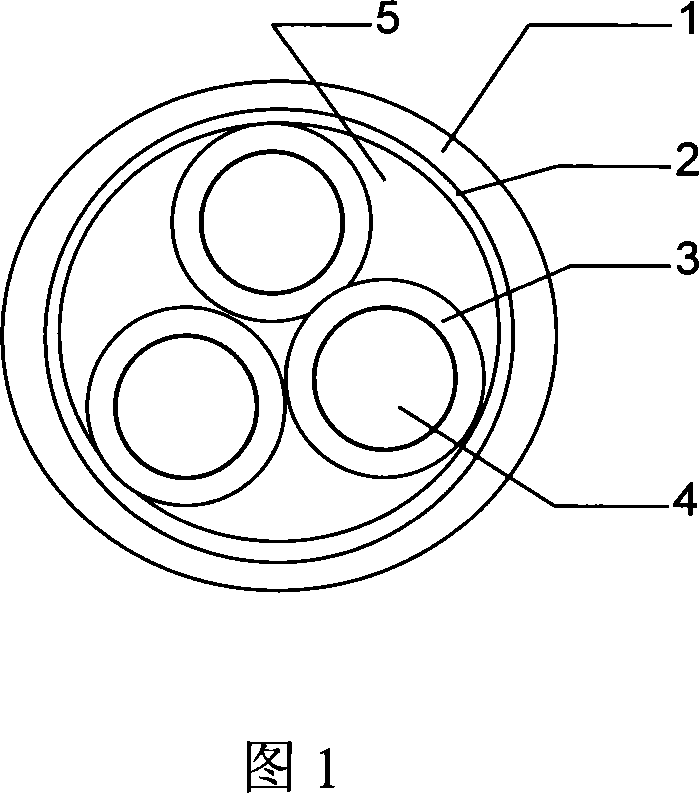

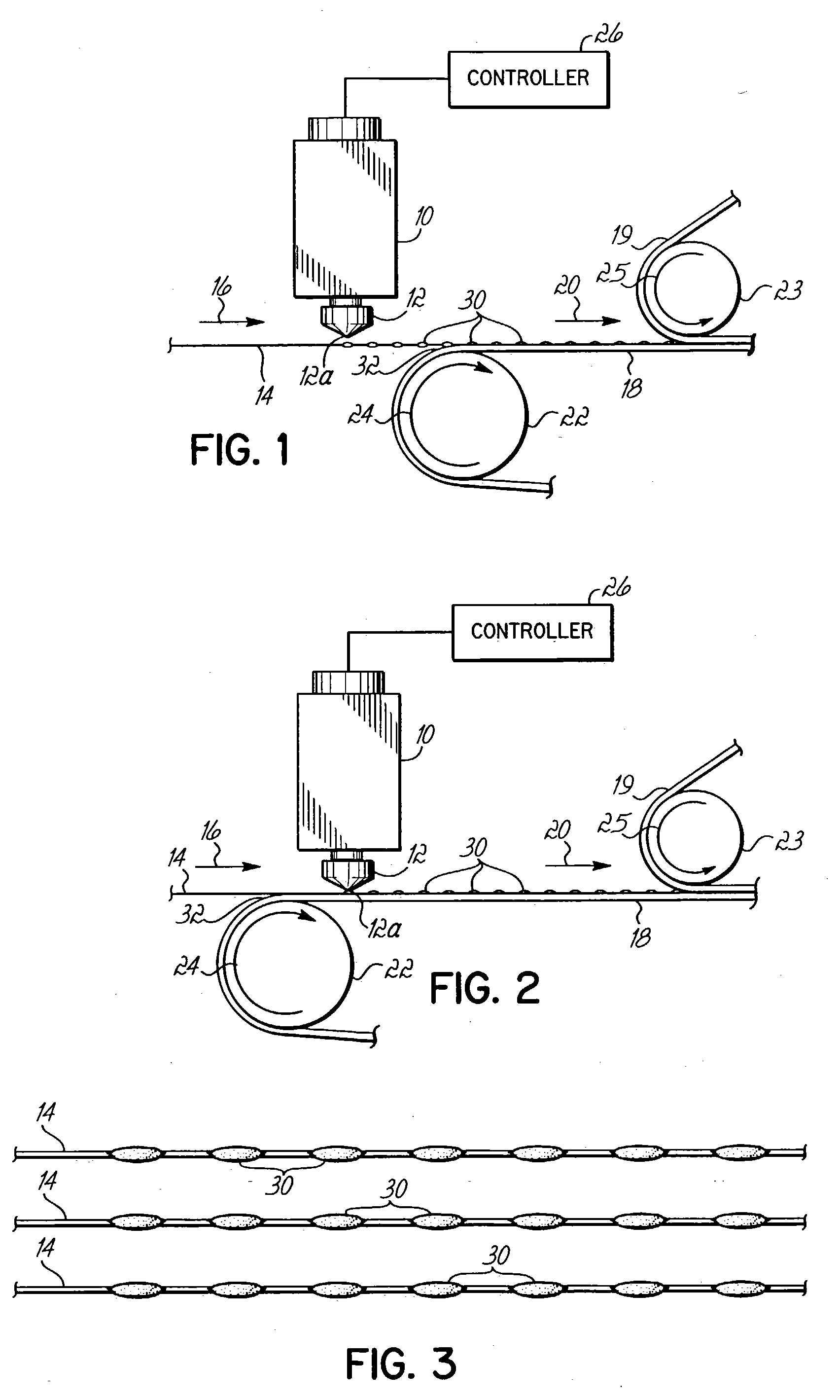

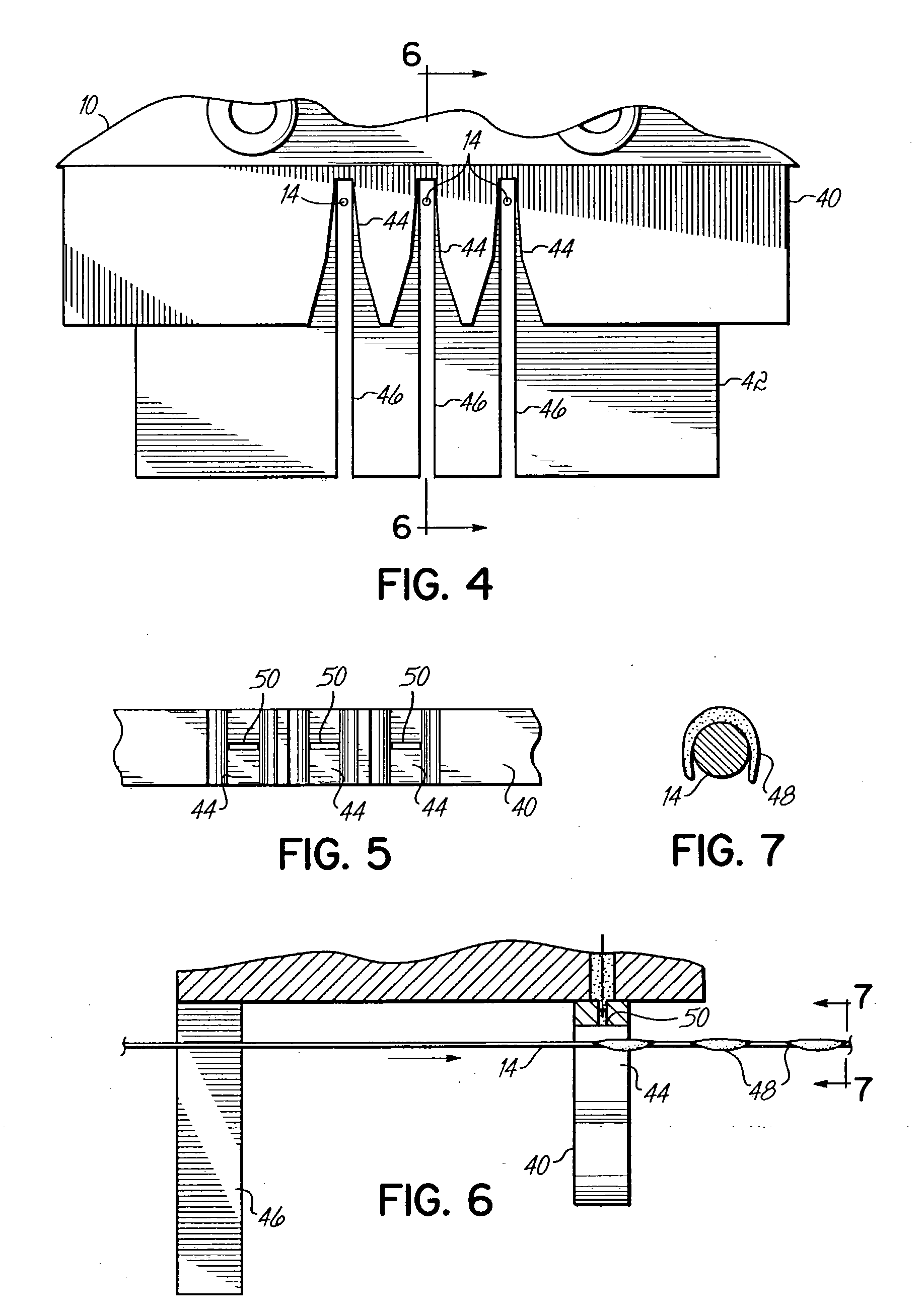

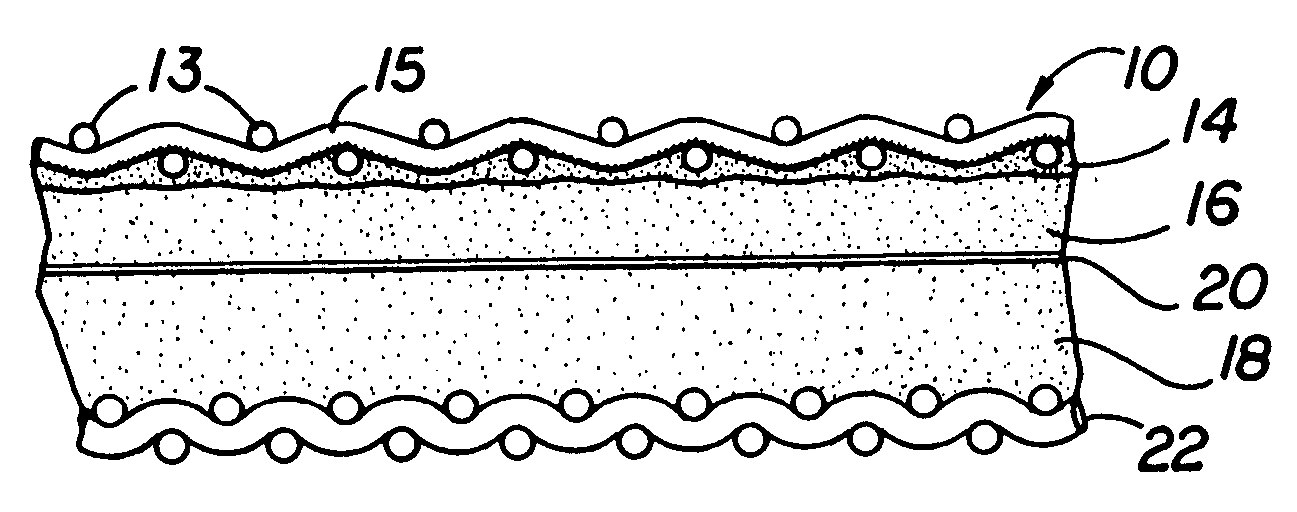

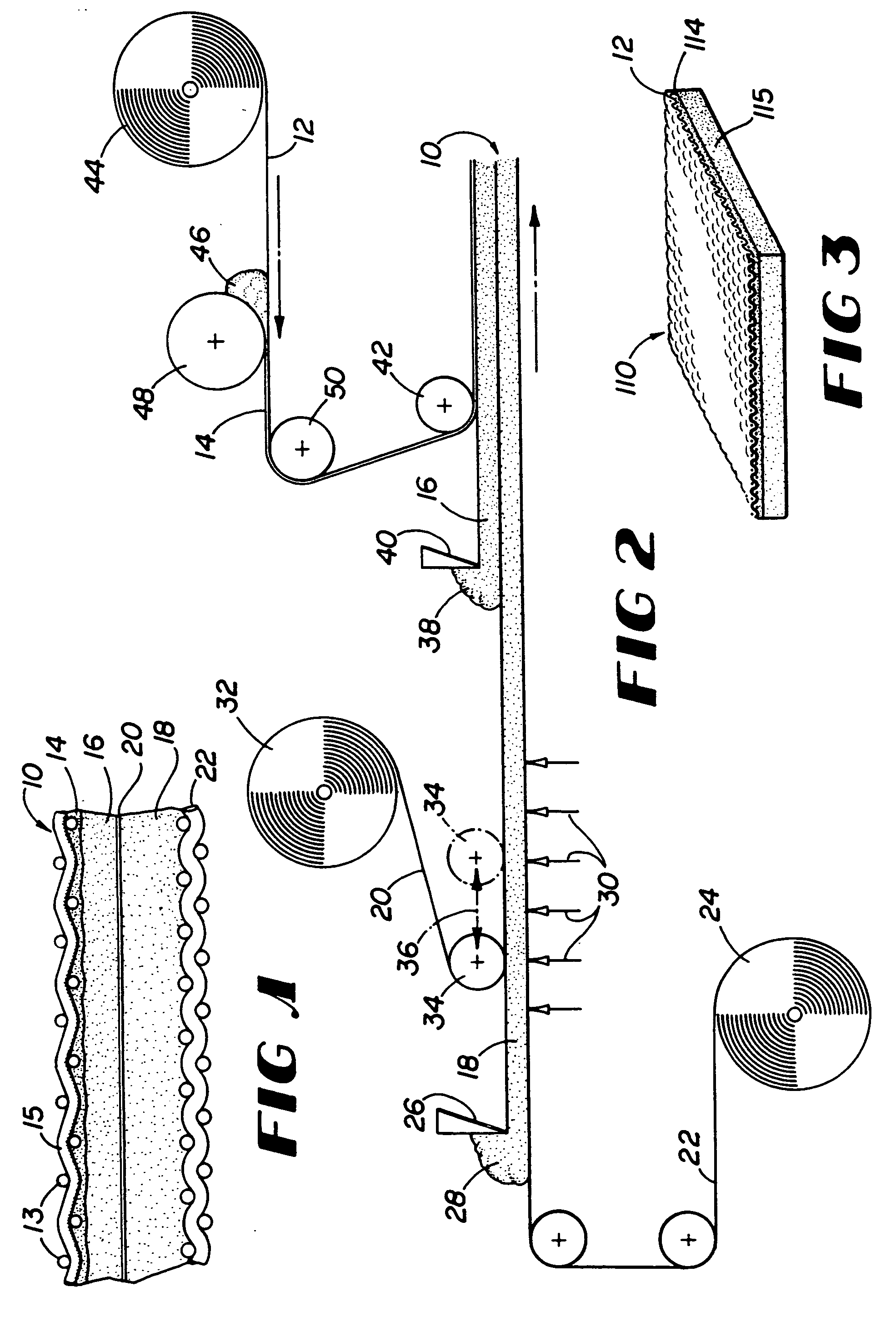

Method of securing elastic strands to flat substrates and products produced by the method

PendingUS20050013975A1Cost reductionIncrease creep resistanceLiquid surface applicatorsPersonal careEngineeringAdhesive

A method of securing an elastic strand to a sheet of material includes moving the elastic strand and the sheet in a converging manner from a position in which the elastic strand is spaced from the sheet to another position in which the elastic strand contacts one surface of the sheet. Discrete elongate segments of adhesive are intermittently applied to the strand. The elongate segments of adhesive secure the strand to the sheet. Various articles of manufacture may be formed using the method, including hygienic articles such as diapers.

Owner:NORDSON CORP

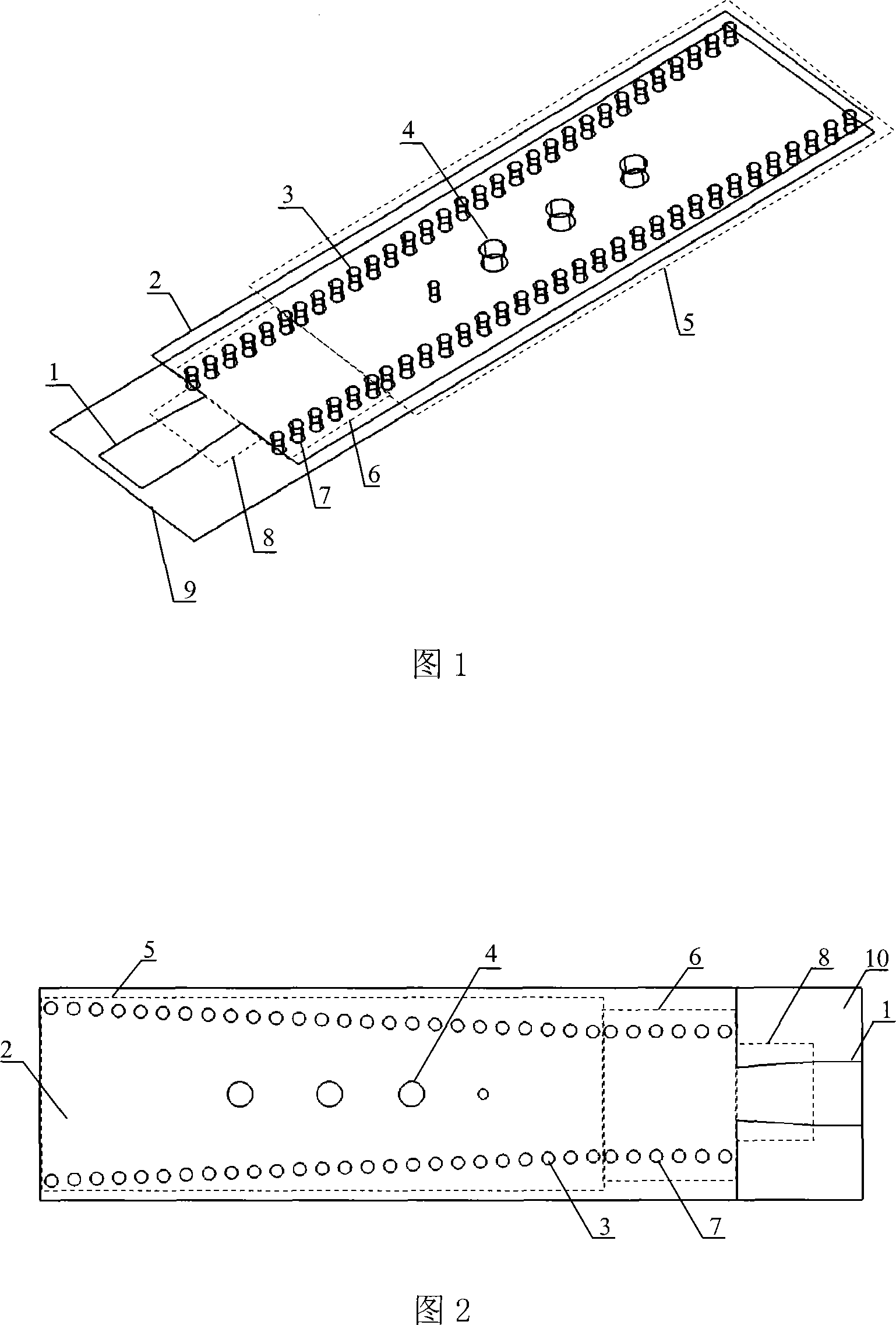

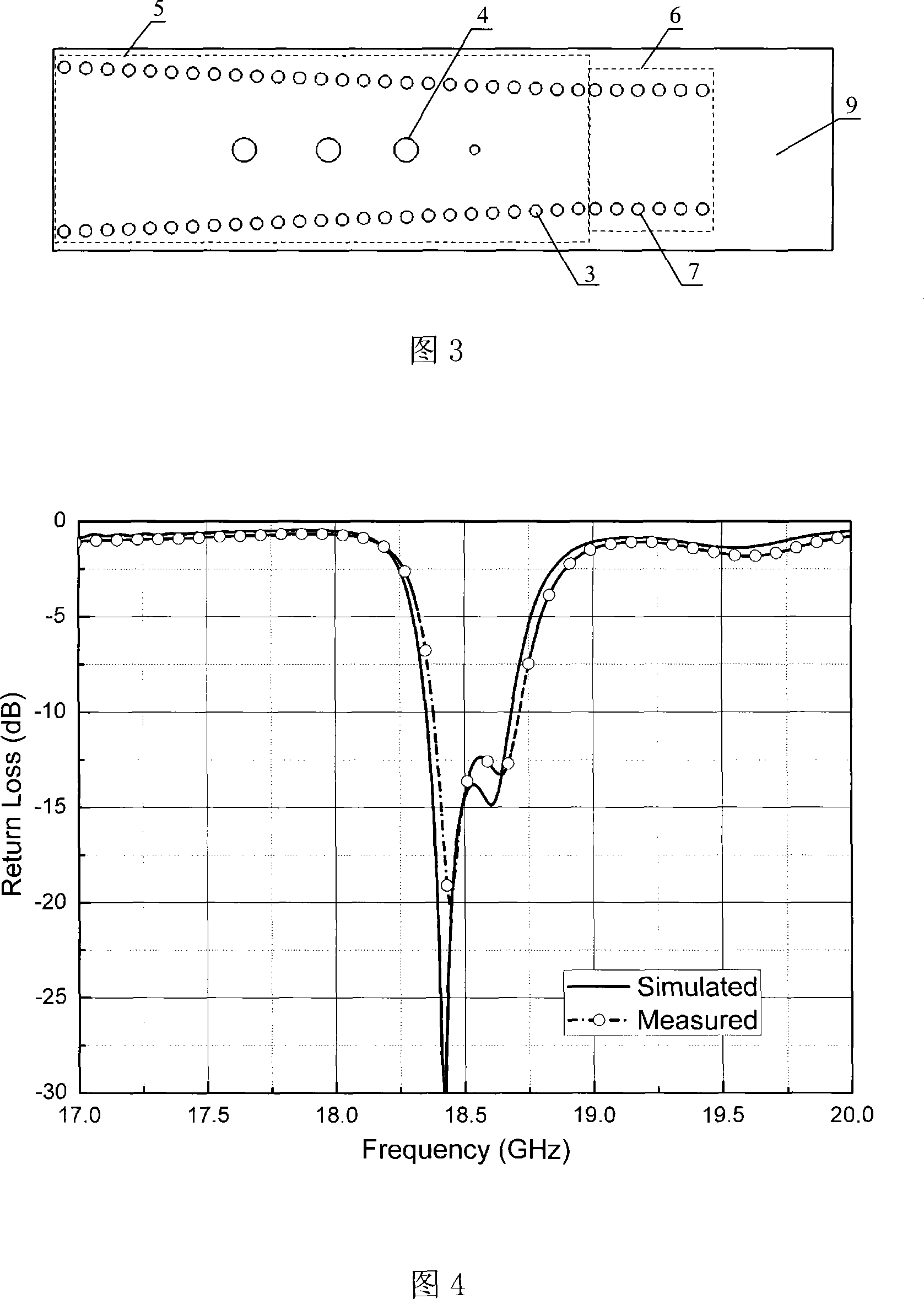

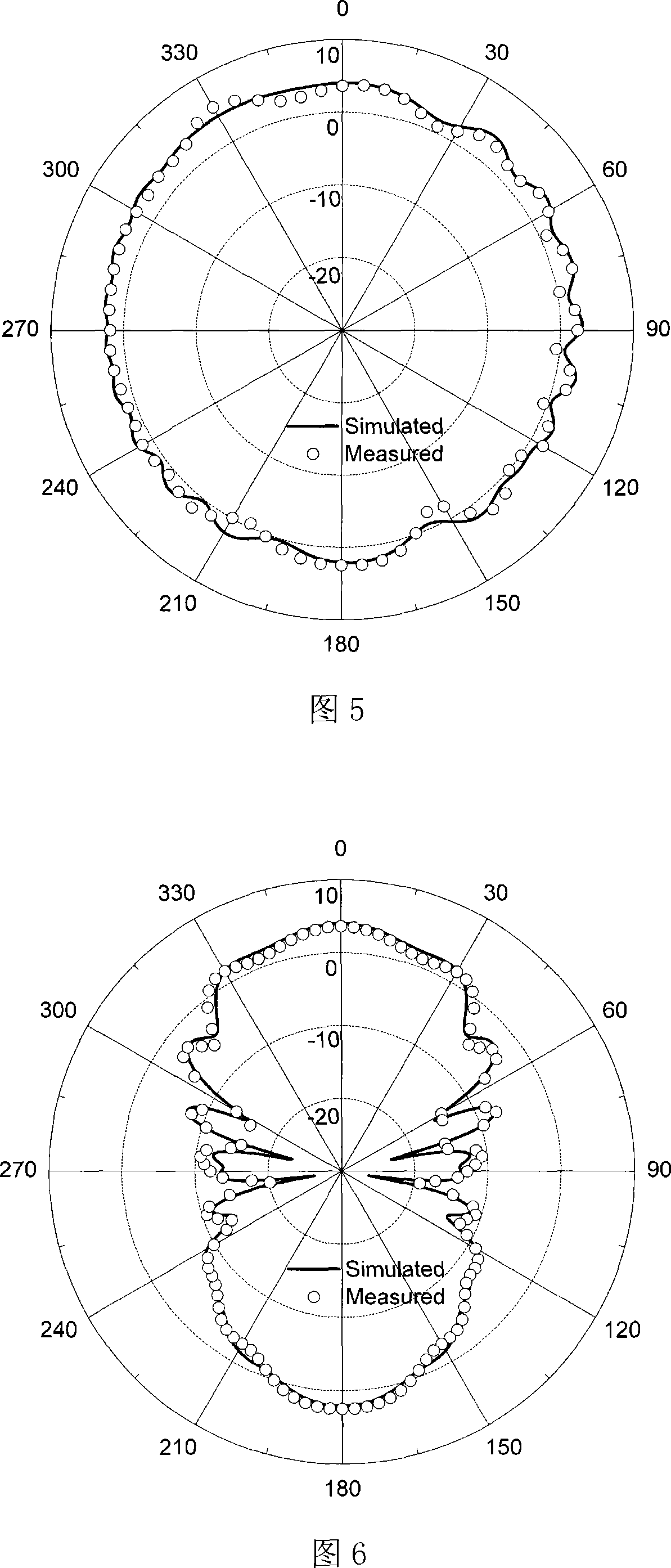

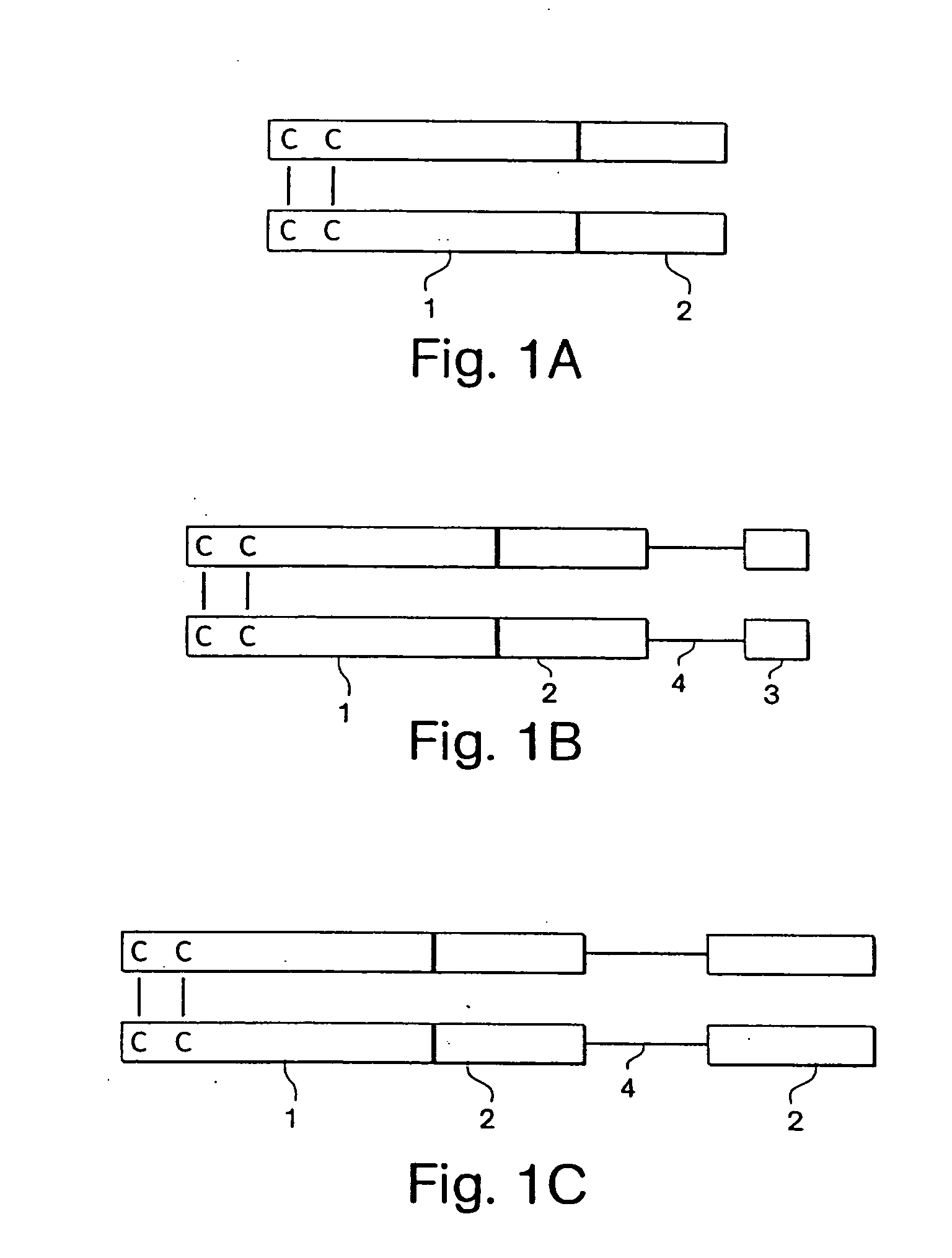

H face sectoral horn antenna including filter function

InactiveCN101179155AReduce volumeReduce manufacturing costWaveguide hornsWaveguide type devicesHorn antennaPhysics

The invention relates to an H-plane fan-shaped horn antenna including a filter function. The existing horn antenna has a large volume, cannot be integrated in a plane, and has high processing costs. In the invention, a metal layer is plated on both sides of a dielectric substrate, and the upper metal layer is etched for a microstrip line and a microstrip converter for power feeding. Through the upper metal layer, the dielectric substrate and the lower metal layer, a plurality of metallized through holes arranged in a circle are opened to form a substrate integrated waveguide and an H-plane fan-shaped horn. Four perturbation metallization through holes are opened on the central axis of the fan-shaped horn opening area of the H surface through the entire substrate, and are used for adjusting impedance matching and forming filtering functions. The new structure uses substrate-integrated waveguide technology to realize the function equivalent to the traditional metal H-plane fan-shaped horn antenna on a common dielectric substrate, and successfully integrates the filtering function of the traditional inductive metal pillar waveguide filter. The dual-function integrated module has a very compact volume, and the entire structure can be manufactured by a low-cost PCB process, and can be seamlessly integrated with the system.

Owner:HANGZHOU DIANZI UNIV

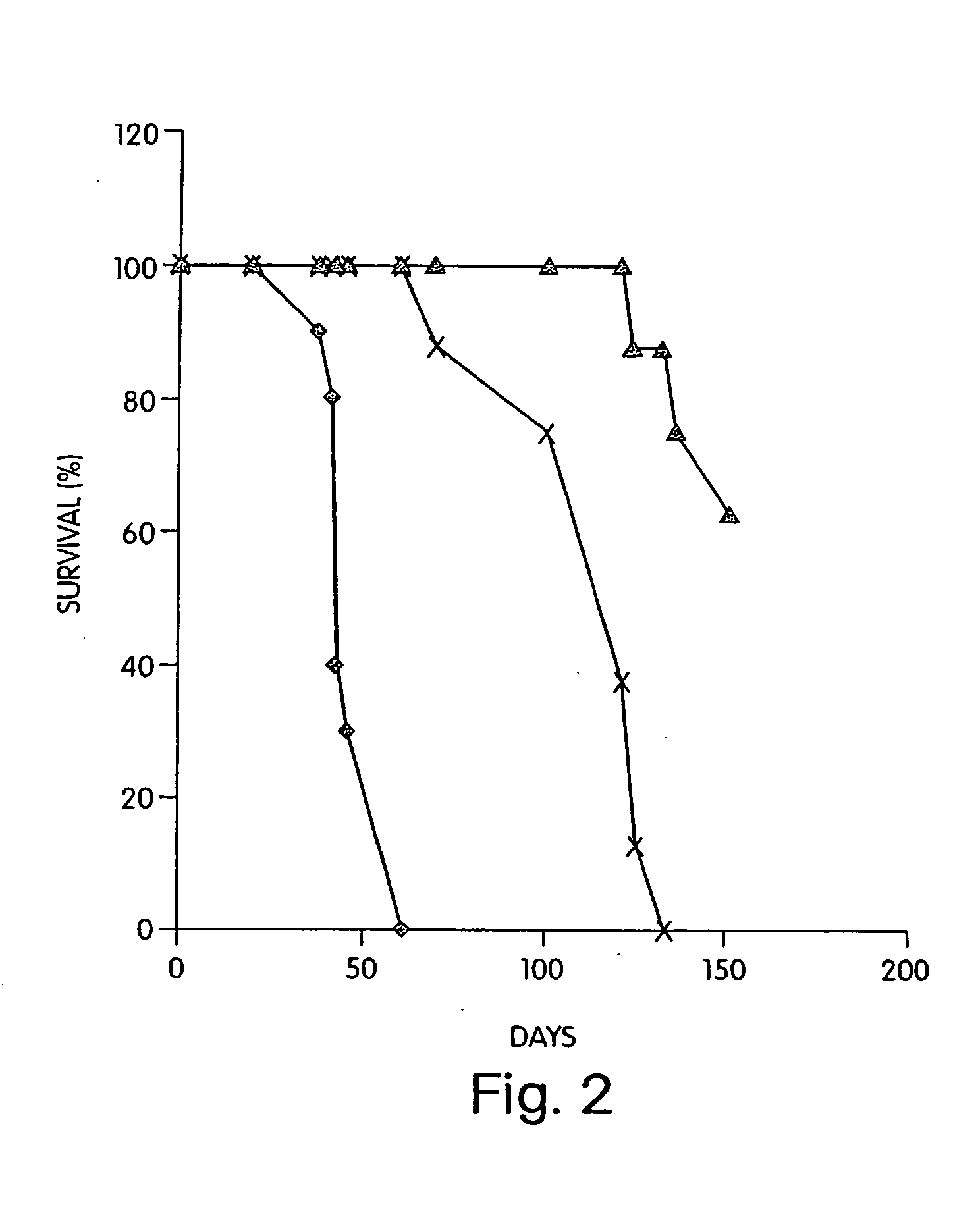

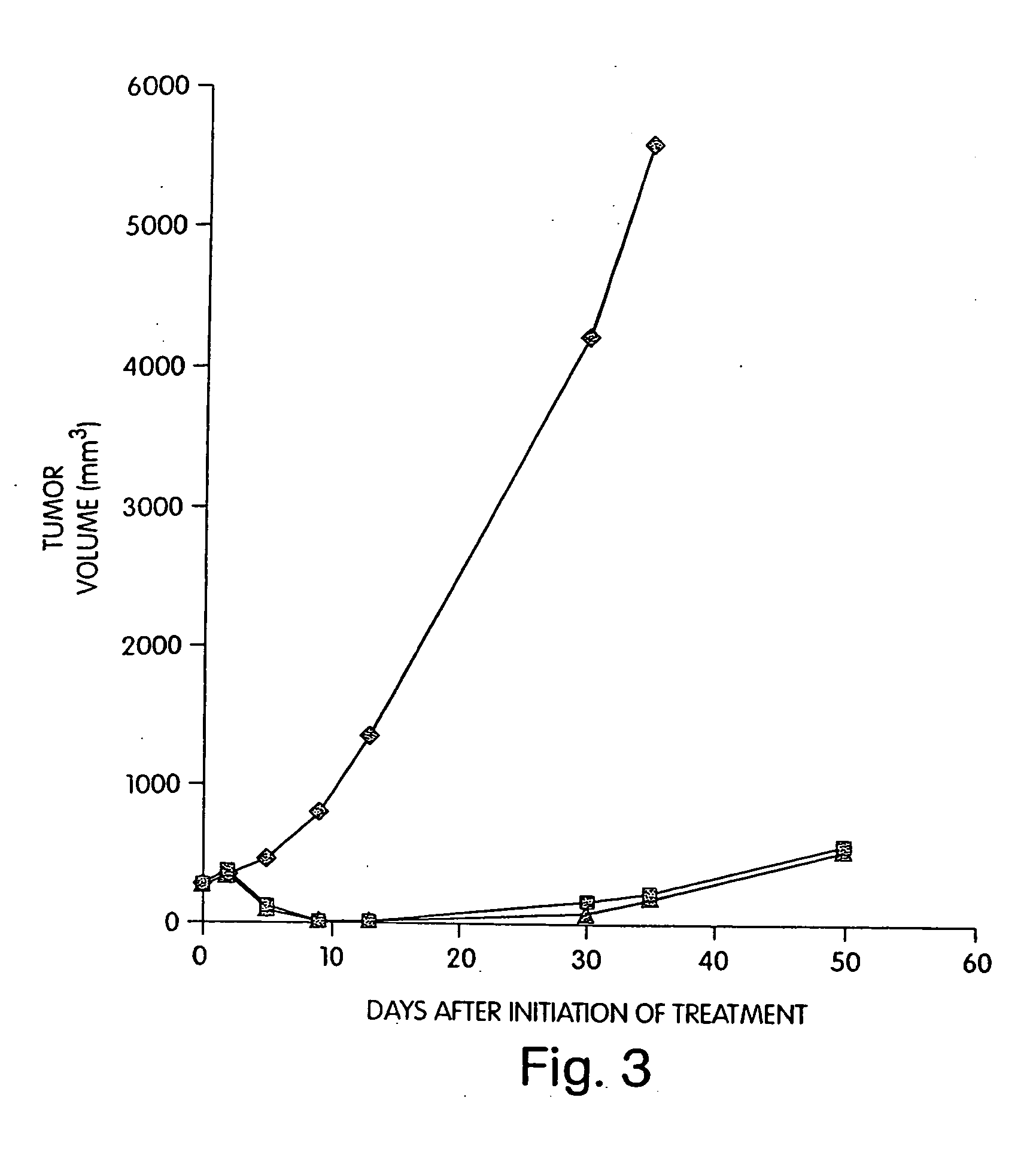

Expression and export of interferon-alpha proteins as Fc fusion proteins

InactiveUS20050042729A1Promote productionEfficient productionPeptide/protein ingredientsAntibody mimetics/scaffoldsRNA SequenceHepatitis

Disclosed are nucleic acid sequences, for example, DNA or RNA sequences, which encode an immunoglobulin Fc-Interferon-alpha fusion protein. The nucleic acid sequences can be inserted into a suitable expression vector and expressed in mammalian cells. Also disclosed is a family of immunoglobulin Fc-Interferon-alpha fusion proteins that can be produced by expression of such nucleic acid sequences. Also disclosed are methods of using such nucleic acid sequences and / or fusion proteins for treating conditions, for example, hepatitis, which are alleviated by the administration of interferon-alpha.

Owner:EMD LEXIGEN RES CENT CORP

Paper machine and method for manufacturing paper

InactiveUS7887673B2Fast productionNon-fibrous pulp additionNatural cellulose pulp/paperFiberPaper sheet

Paper machine for manufacturing a fiber web of paper without through air drying (TAD) or pressing, comprising: a wet end, having a wire section with at least one forming wire, a clothing, being air and water permeable, and a dewatering unit for dewatering the fiber web; and a drying section, comprising a drying surface for the fiber web; and also a transfer roll for transferring the fiber web to the drying section, wherein the fiber web is supported by said clothing from the wire section all the way to and over the transfer roll. The clothing has a three dimensional structure for structuring the fiber web.

Owner:VALMET AB

Hot melt adhesive

InactiveCN102653665ASuitable for production process requirementsReasonable formula designMacromolecular adhesive additivesEpoxyPolyolefin

The invention discloses a hot melt adhesive which comprises the following components in parts by mass: 5-10 parts of EVA (ethylene-co-vinyl acetate), 2-6 parts of tackifier, 5-10 parts of diluent, 0.5-1.5 parts of antioxidant and 0.5-1.5 parts of plasticizer. The tackifier is one of rosin resin, petroleum resin, terpene resin, phenolic resin and epoxy resin; the diluent includes one or both of wax and low-molecular polyolefin; the antioxidant is phenolic antioxidant; and the plasticizer is DCHP (Dicyclohexyl phthalate). The EVA contains 20-30% of vinyl acetate monomer; and the wax is microcrystalline wax with molecular weight of 3,000-4,000 and melting point of 65-85 DEG C.

Owner:成都鑫三洋科技发展有限公司

Process for the production of a dental model, a dental model with a ceramic layer deposited thereon and a dental moulding, dental model,,and use of 3D printer and a kit

InactiveUS20060131770A1Fast productionIncrease contactAdditive manufacturing apparatusFastening prosthesisElectrically conductiveMaterials science

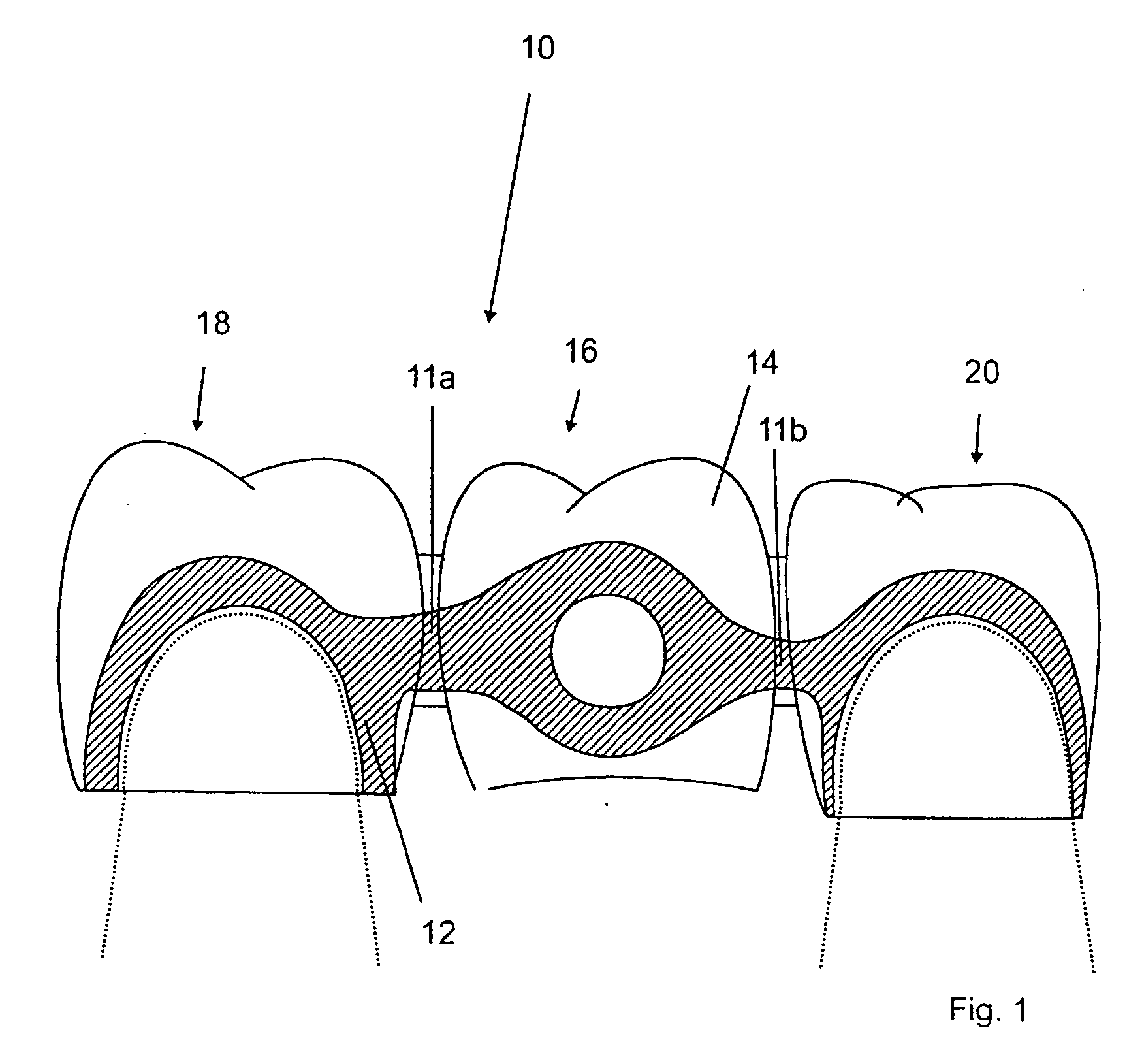

The invention relates to a process for the production of a dental model (24). The invention furthermore relates to a dental model which can be produced in this way, optionally with a ceramic layer deposited thereon, a process for the production of a dental moulding, the use of a 3D printer and the use of a kit. According to the invention, the following steps are proposed for the process: (a) provision of one or more fluid, solidifiable materials and one or more electrically conductive substances and (b) production of the dental model (24) by rapid prototyping using the fluid, solidifiable material or materials and the one or more electrically conductive substances, so that the dental model produced is electrically conductive in one or more areas (26, 28, 30) of its surface.

Owner:BEGO BREMER GOLDSCHLAGEREI WILH HERBST

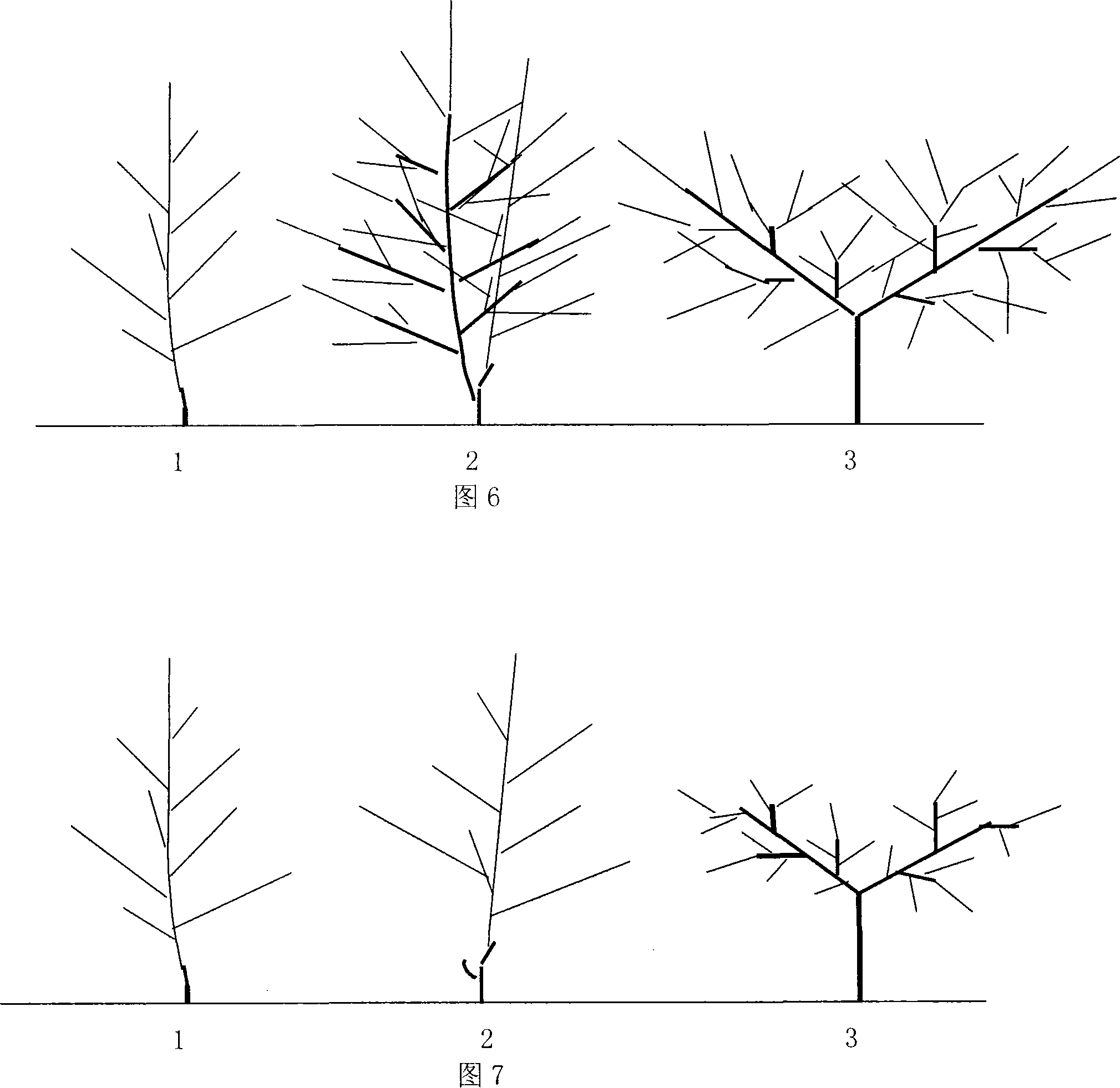

A peach shape for high-density planting and tree body controlling means

InactiveCN101156540ASmall footprintUncontrollable sizeCultivating equipmentsHorticultureHigh densityPeach orchard

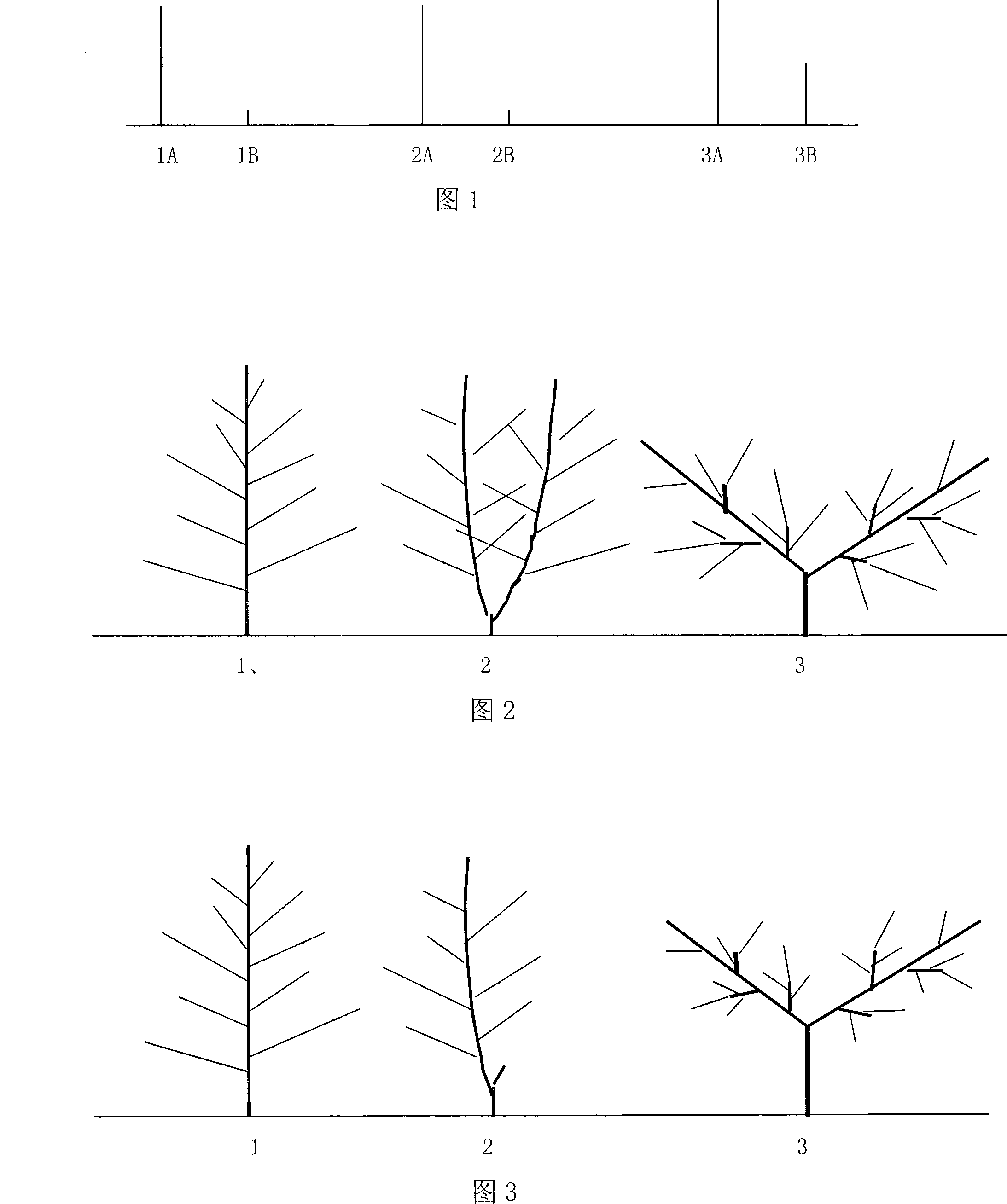

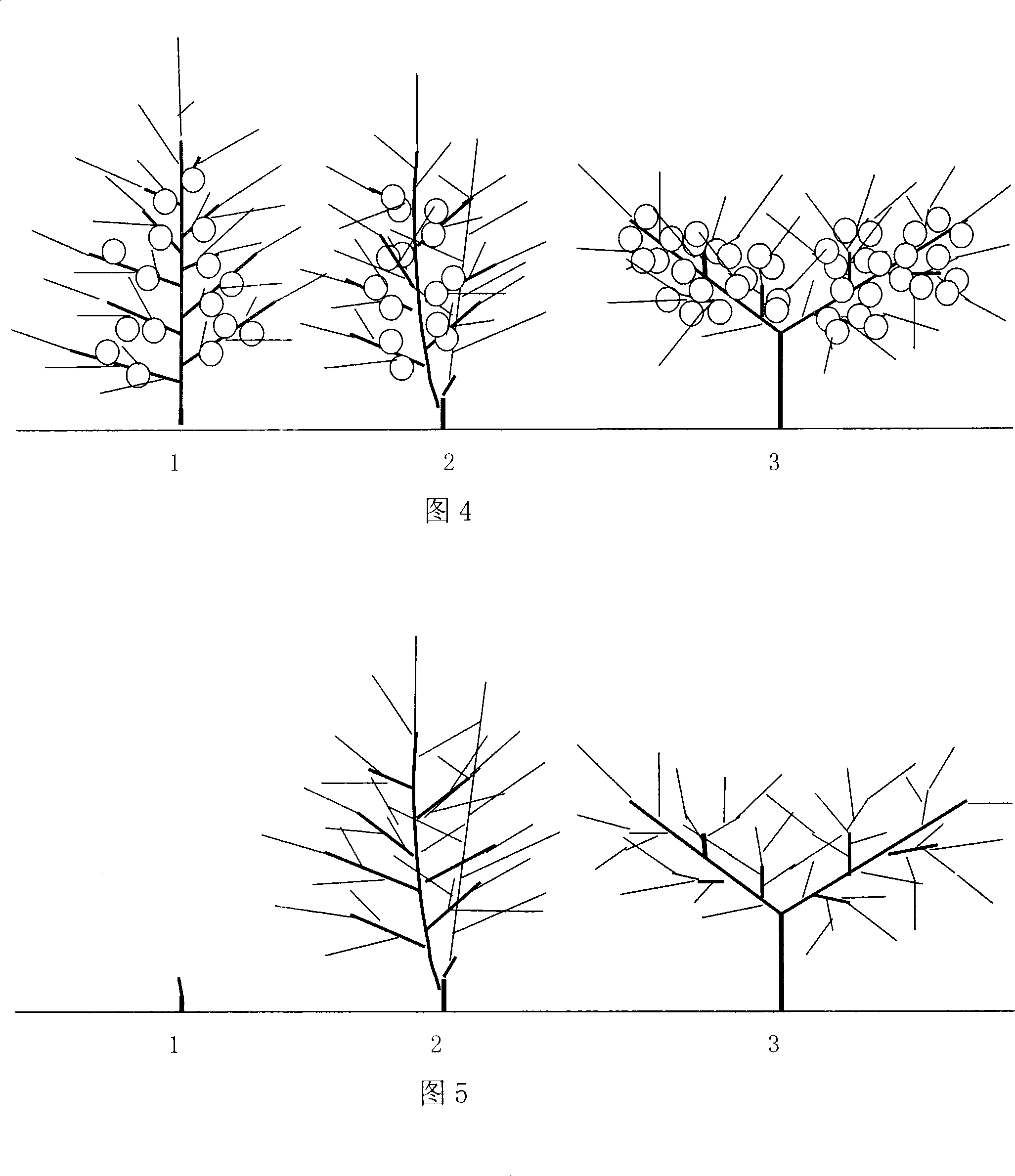

The invention discloses a peach tree shape applicable for high-density planting. The peach tree shape of the invention is Y-shaped, and consists of a trunk and two large branch groups. Two large fruit branch groups can be produced on the upside of the trunk, and are arrayed oppositely in a line, and respectively extend into the two side rows; the extension direction is perpendicular to the row direction, as well as has a 45-55 degrees angle with the vertical direction. Fruit branches and small sized fruit branch groups are produced on the large fruit branch groups. The peach tree shape of the invention is applicable for high density planting, the structure of the tree is simple, the pruning is simple, the forming is quick, and the cost is low. The method of the invention is easy to be learned, the operation is simple. Standard management can be conducted for the invention to ensure that the peach orchard realize early rich and high-quality yield, high yield and stable yield.

Owner:CHINA AGRI UNIV

High-efficiency imitative wild cultivation method for Tetrastigma hemsleyanum Diels et Gilg

InactiveCN102919013AIncrease productionFast productionClimate change adaptationHorticultureCottus marginatusStellaria alsine

The invention relates to a high-efficiency imitative wild cultivation method for Tetrastigma hemsleyanum Diels et Gilg (stellaria alsine Grimm.), which comprises the following steps of: 1) selecting a fertile land or northward terrace land in a mountain area, clearing weeding in fields, and performing fertilizer application; 2) dividing the land subjected to deep tillage into planting belts, forming irrigation ditches between the planting belts, digging drain ditches and operation ditches at the edges of the planting belts, and laying trickle irrigation equipment; 3) performing grass mulching and film mulching on the planting belts; 4) establishing Tetrastigma hemsleyanum Diels et Gilg germchits; 5) in the second year, when the vines of the Tetrastigma hemsleyanum Diels et Gilg grow to 30-50 centimeters long, guiding the vines of the Tetrastigma hemsleyanum Diels et Gilg onto a trellis, and starting three-dimensional planting; 6) in the second year, erecting a steel-structured greenhouse 1.5 meters beyond the planting belts, and covering a shading mesh on the top; and 7) in the fourth or fifth year, harvesting. According to the invention, the artificial field planting of the Tetrastigma hemsleyanum Diels et Gilg is realized; and the advantages of quick putting into production, high yield of underground tubers and overground leaves and vines for medical use, high profit, low planting cost, simple operation process and the like can be achieved.

Owner:浙江汉邦生物科技有限公司

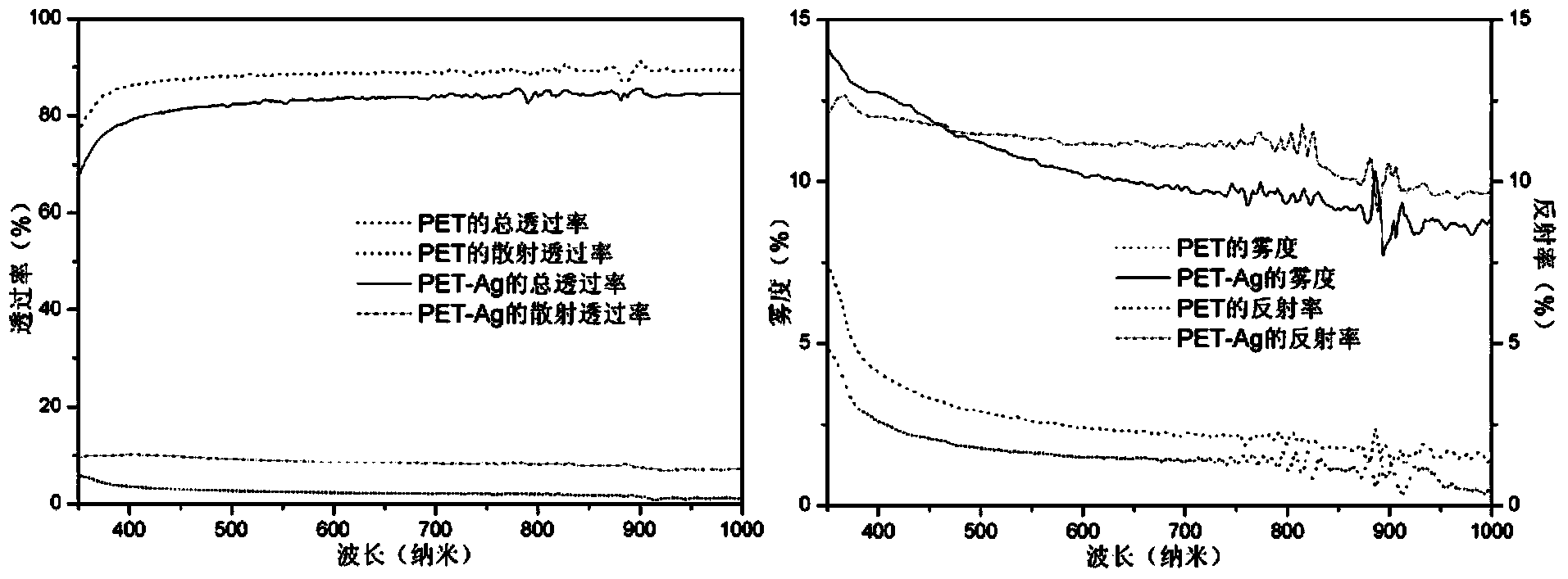

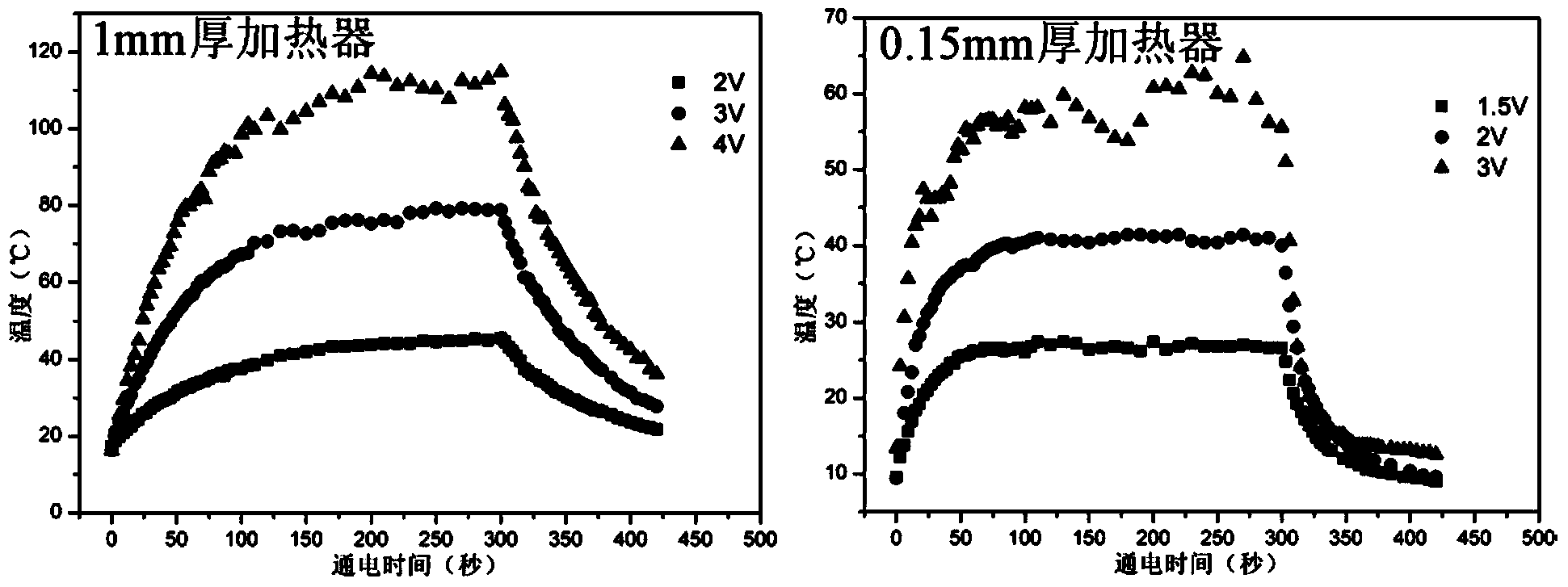

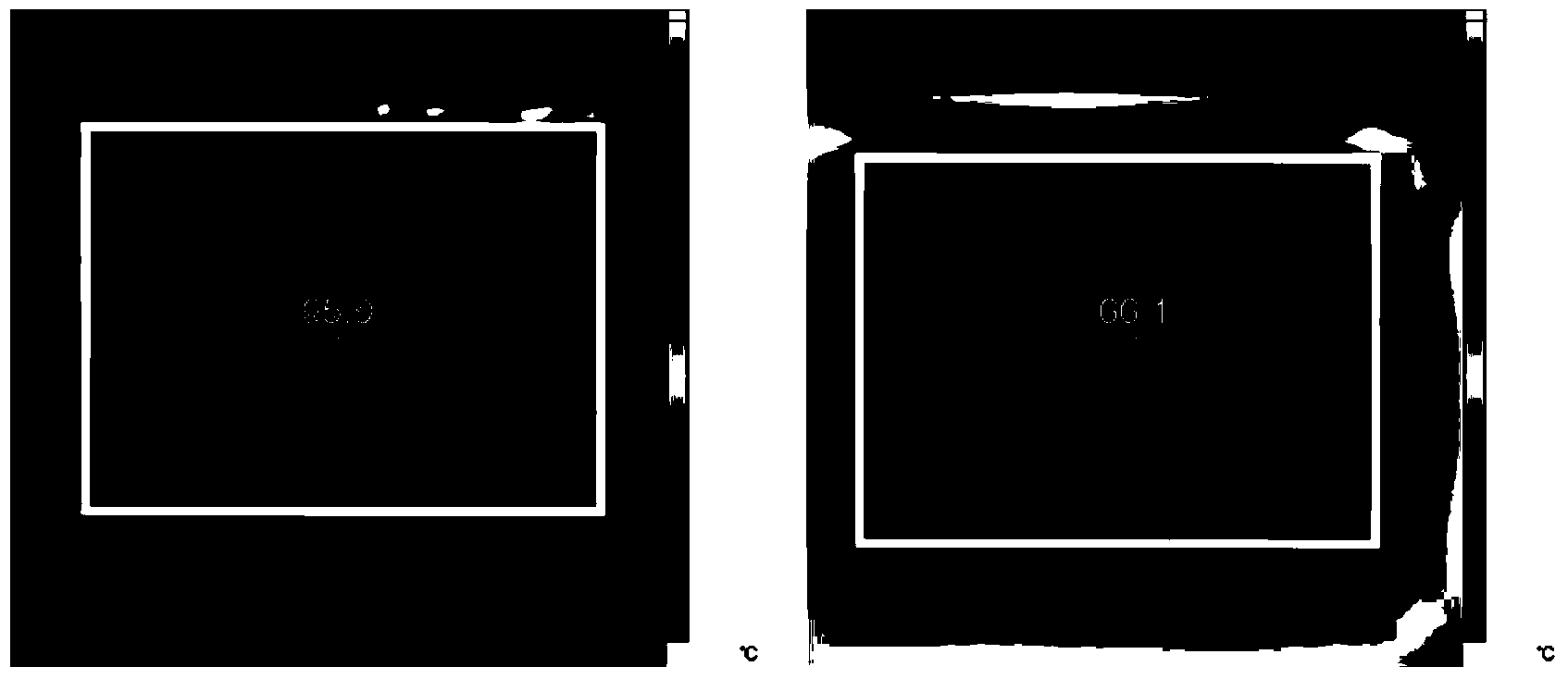

Heater based on transparent silver nanowire conducting thin film and preparation method thereof

ActiveCN104053256ALow costExpand application spaceTransparent/reflecting heating arrangementsHeating element materialsHydrophilizationConductive polymer

The invention discloses a heater based on a transparent silver nanowire conducting thin film and a preparation method of the heater. The heater is simple in structure, uniform in heating and resistant to corrosion. The heater comprises a transparent substrate, the transparent conducting thin film, a conducting electrode and a protective layer. The heater is applied to defogging glass, a thermochromic substrate, a sensor substrate and the like. The preparation method of the heater comprises the steps of hydrophilization processing of the substrate, preparation of the transparent conducting thin film, preparation of the conducting electrode and preparation of the protective layer. According to the heater, silver nanowires synthesized through a low-temperature liquid phase method are used as raw materials, the transparent substrate is coated with the transparent conducting thin film through a non-vacuum non-high-temperature filming technology, the heating uniformity of the thin film is improved through technically mature and commercial conducting polymers, and the thin-layer protective film is obtained by means of liquid phase coating of cheap organic polymers. The heater is simple in structure, the raw materials are cheap, the requirement for preparation technological conditions is low, and large-scale production is facilitated.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

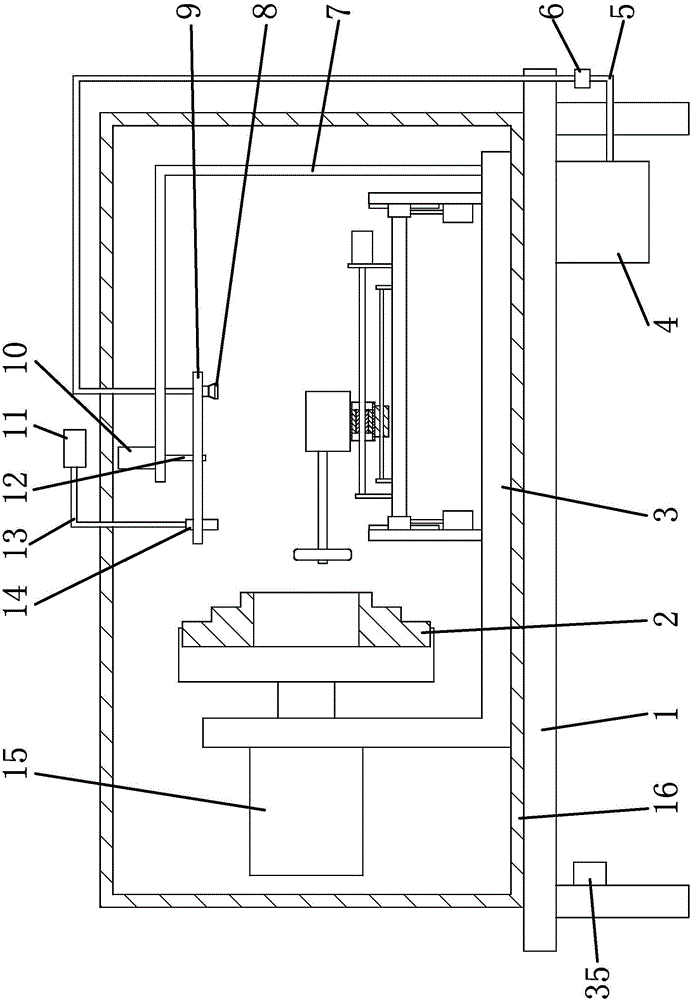

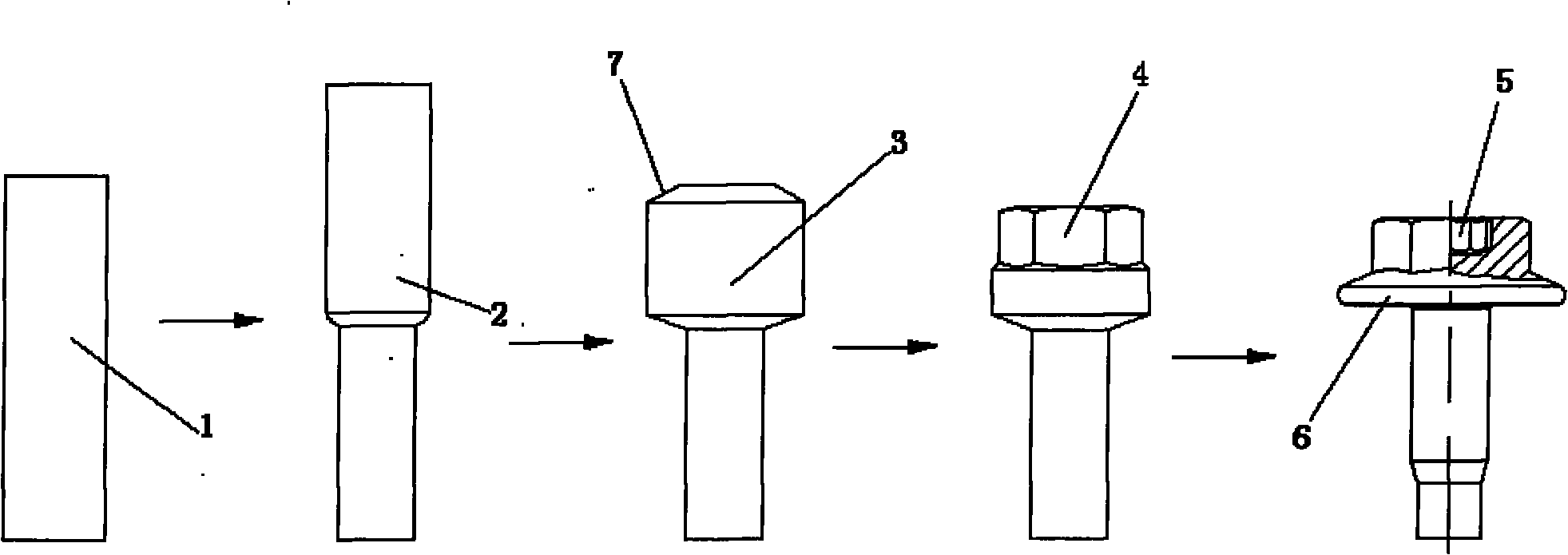

Production system of hub bearing

ActiveCN106050920ANo need for manual operationFast productionLiquid surface applicatorsGrinding carriagesThrust bearingEngineering

The invention provides a production system of a hub bearing, in order to solve the technical problems that the hub bearing is to be carried manually and the production speed is low because the structure of the conventional processing device is too simple. The production system of the hub bearing comprises a workbench, wherein an outer ring grinding device for grinding an outer ring of the hub bearing, an inner ring grinding device for grinding an inner ring of the hub bearing, a cleaning device for cleaning the hub bearing, a spraying device for spraying the hub bearing, and a detection device for detecting the hub bearing are sequentially arranged on the workbench. The production system has the advantage of high production speed.

Owner:嘉兴福可吉精密机械有限公司

Floor covering with woven face

InactiveUS20040198120A1Increase rate of changeReduce the chance of changeSynthetic resin layered productsFloor coveringsYarnPolyester

Flooring that utilizes sophisticated, self-stabilizing, woven face fabric using relatively heavy "carpet weight" nylon, polyester, PTT or other yarns on modern Jacquard computer controlled looms to produce flat-weave fabrics that are bonded to engineered backing structures. Urethane modified bitumen may be used as a backing layer, and an optional latex precoat may be used on the fabric layer, together with an optional antimicrobial in the precoat.

Owner:SCOTT GRAHAM +2

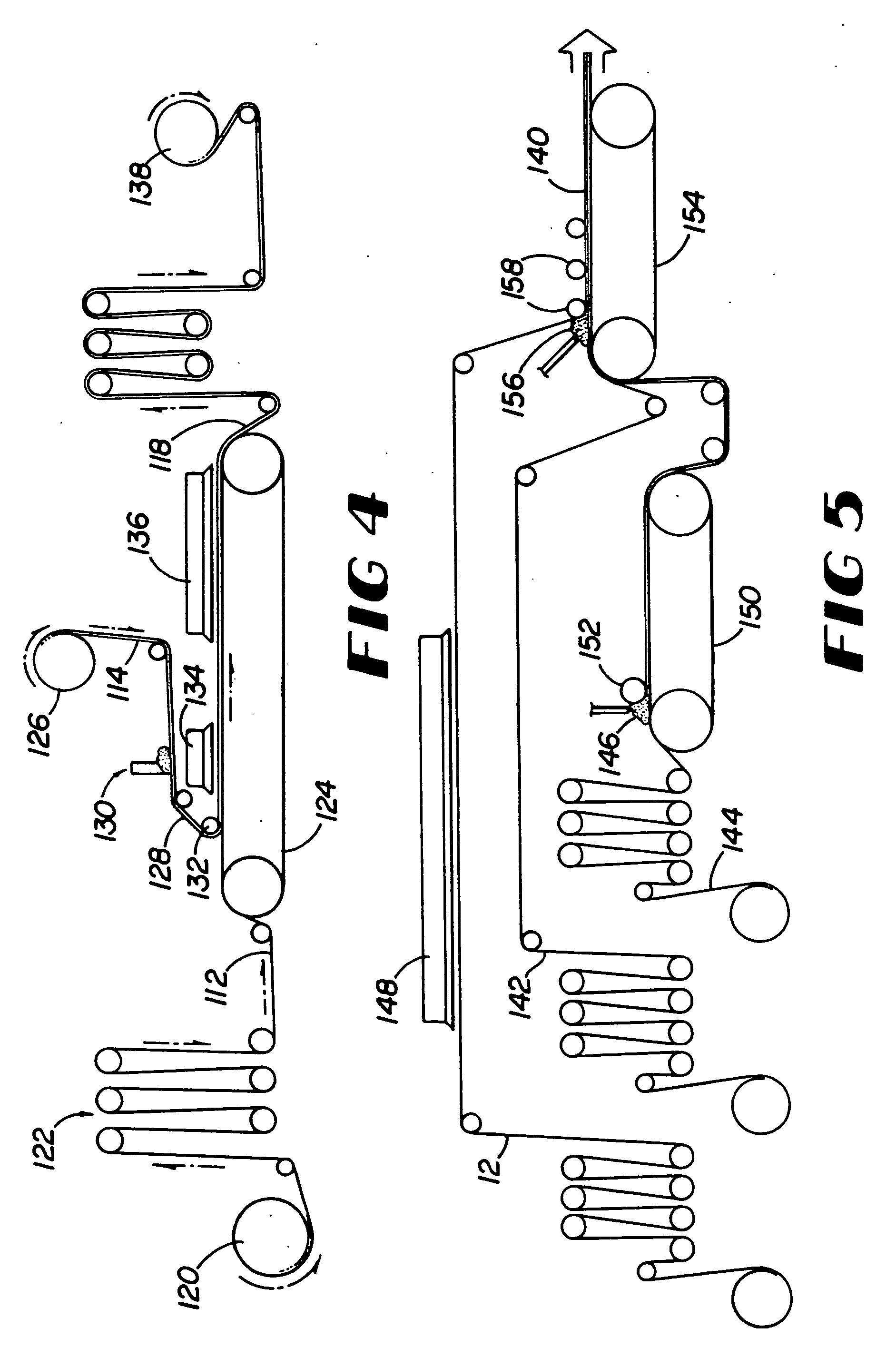

Polyurethane-urea elastomers

The present invention is directed to polyurethane-urea materials and to a process for their production. These polyurethane-ureas are preferably optically clear and comprise the reaction product of a (cyclo)aliphatic polyisocyanate or prepolymer thereof, with an isocyanate-reactive component that comprises one or more aromatic diamines which contains two primary amine groups, and one or more compounds containing two secondary amine groups which may be linked to aliphatic and / or aromatic moieties. This isocyanate-reactive component may additionally comprise one or more hydroxyl-functional compounds. The present invention offers a relatively fast “Green-Cure Time” of solid polyurethane-ureas which enables these to be demolded in a relatively short time period, followed by subsequent post-curing outside the mold.

Owner:COVESTRO LLC

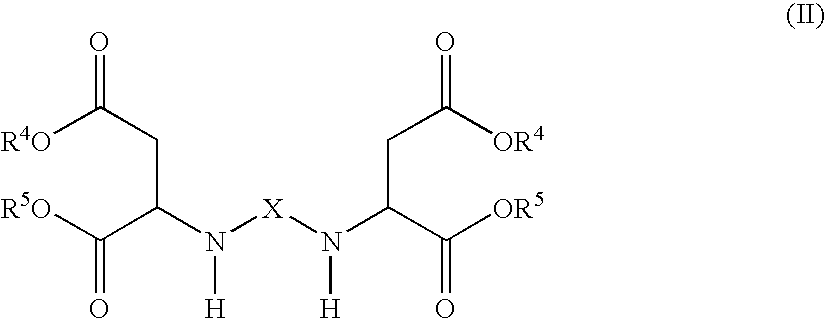

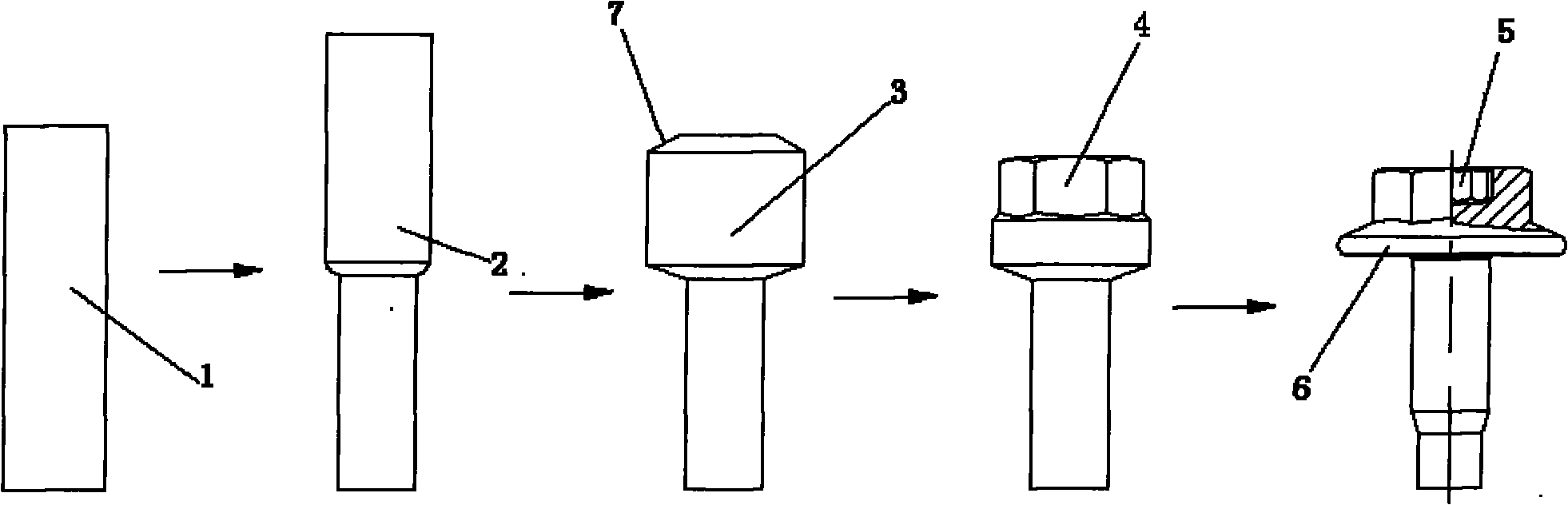

Method for manufacturing high-intensity internal multi-tooth hexagonal-head flange-face bolt

The invention discloses a method for manufacturing a high-intensity internal multi-tooth hexagonal-head flange-face bolt. The method comprises the following steps of: firstly, performing phosphate surface treatment on a round plate material of the high-intensity internal multi-tooth hexagonal-head flange-face bolt; then performing spheroidizing annealing, phosphate epithelium treatment, and definite extraction and sizing on a roughly extracted blank material of the high-intensity internal multi-tooth hexagonal-head flange-face bolt; and finally performing a cold heading and forming treatment working procedure. By the adoption of a cold header for forming at one time, the raw material during processing has no loss, so the raw material is saved, the cost is reduced, the quality of the high-intensity internal multi-tooth hexagonal-head flange-face bolt is enhanced, and the production efficiency is improved.

Owner:宁波拓隆精密模具有限公司

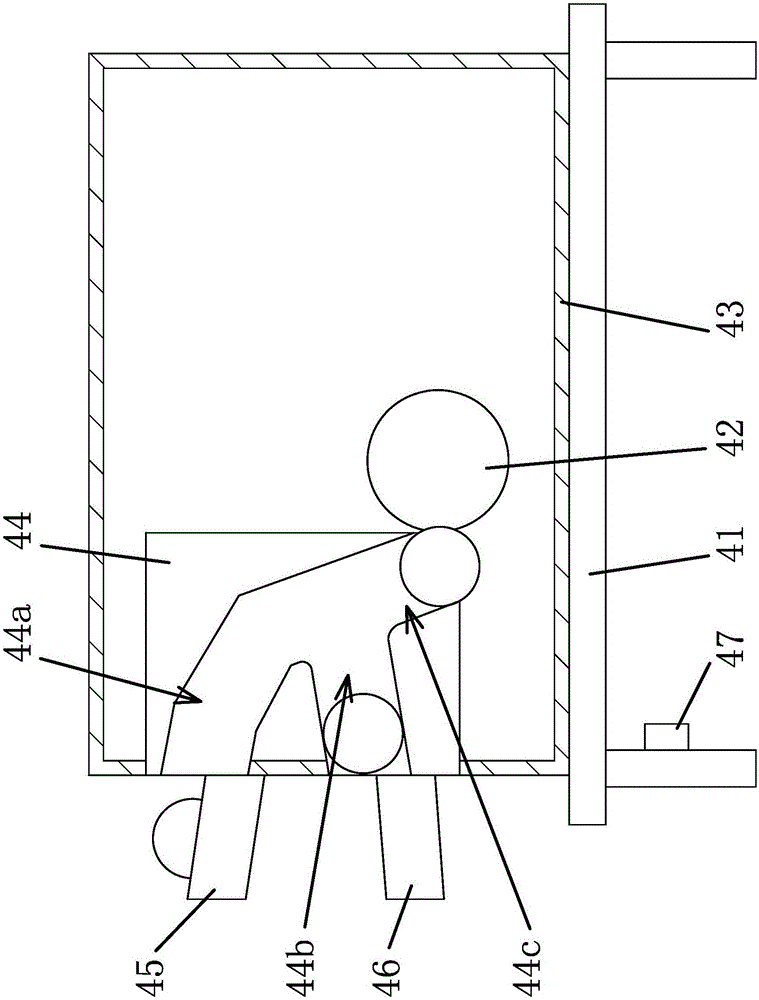

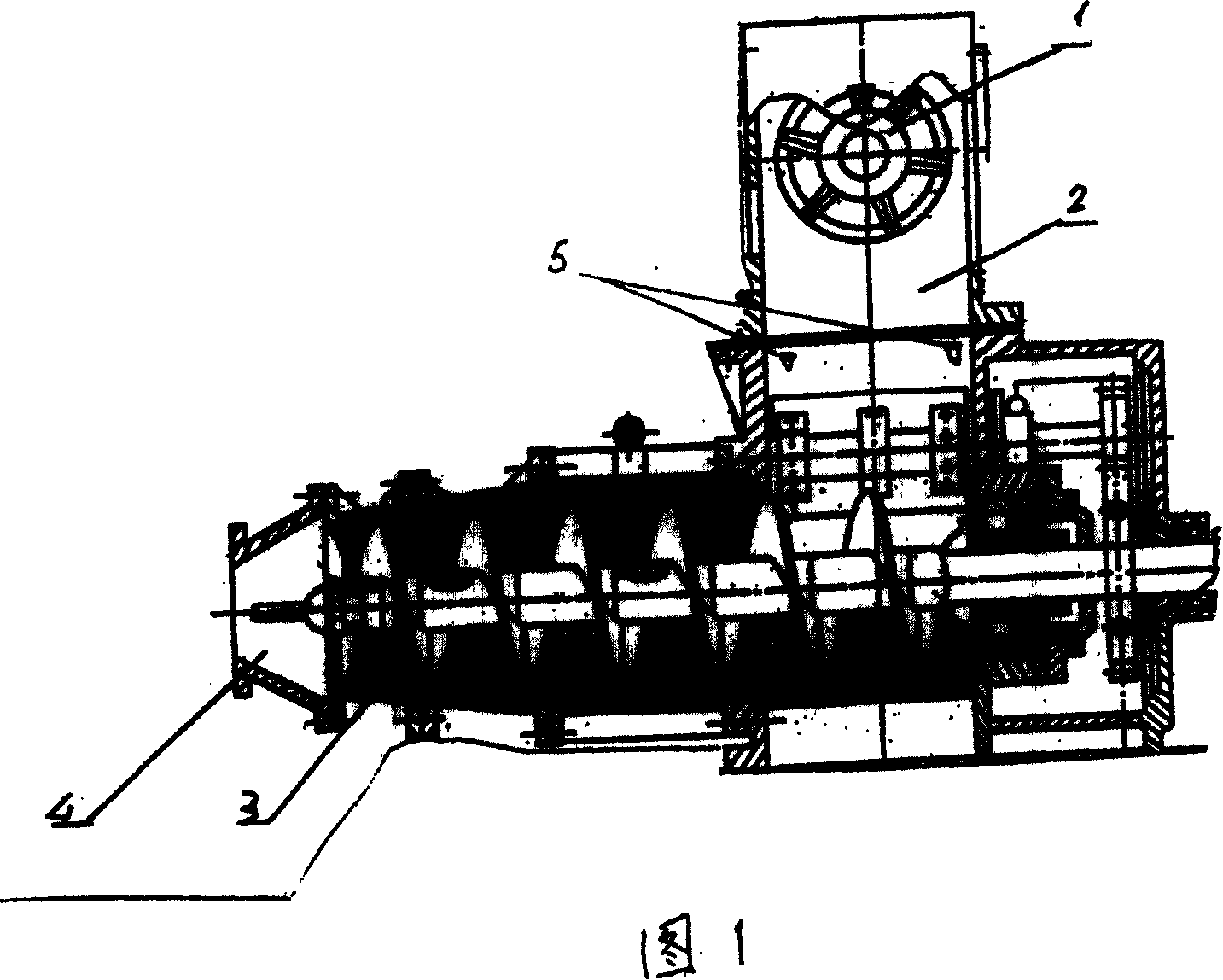

Method for producing gypsum building products by using expressing technique

InactiveCN101138863AReduce production energy consumptionFast productionSolid waste managementCeramic shaping plantsBuilding productPresent method

The present invention provides a process method for producing a gypsum building product, namely an extruding method which is energy-saving and time-saving and which can rapidly produce a gypsum building product with excellent quality. The process method mainly consists of three major parts: the preparation of a gypsum extrusion material, an extruder group and a production process procedure. The structure of the extruder consists of four parts: a mixing segment 1, a buffer segment 2, an extruding segment 3 and a forming machine head 4. The extruding method produces a gypsum building product mainly through the following procedures: a material, which is mainly gypsum and to which a small amount of mixing water added, is extruded and formed by the extruder group, smeared into a specified size by a cutting machine head and becomes a finished product after a finishing processing. The gypsum building product of the present process method has the following advantages: (1) that the product substrate with a compressive strength one to two times as strong as that of the ordinary product by a pouring method is compact and has strong strength, (2) that the product without too much free moisture and does not need a heat drying or drying process, thus greatly reducing production energy consumption, (3) and that the present method with a rapid production speed and a short production cycle is a quick process for producing gypsum building products.

Owner:方承仕

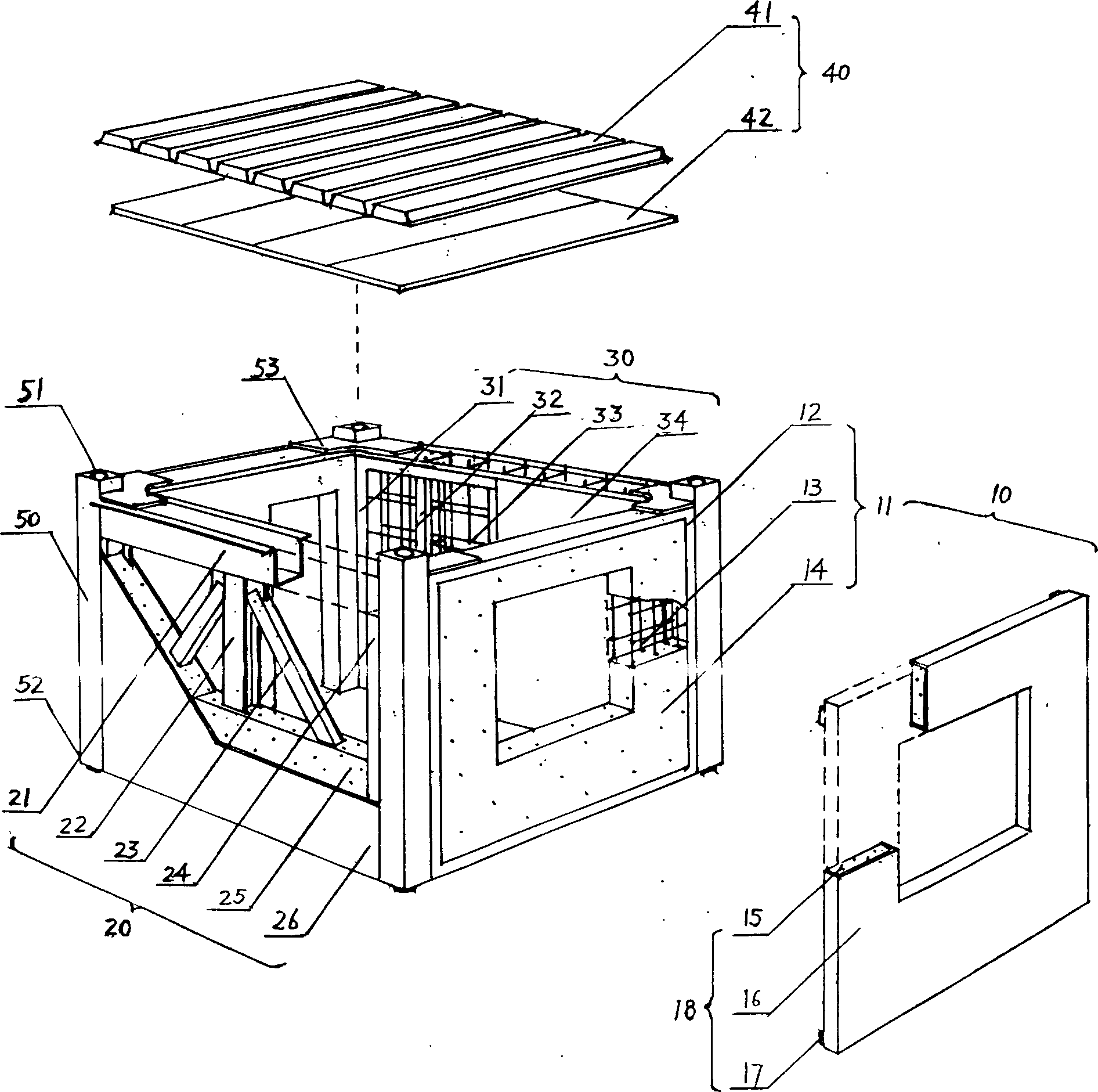

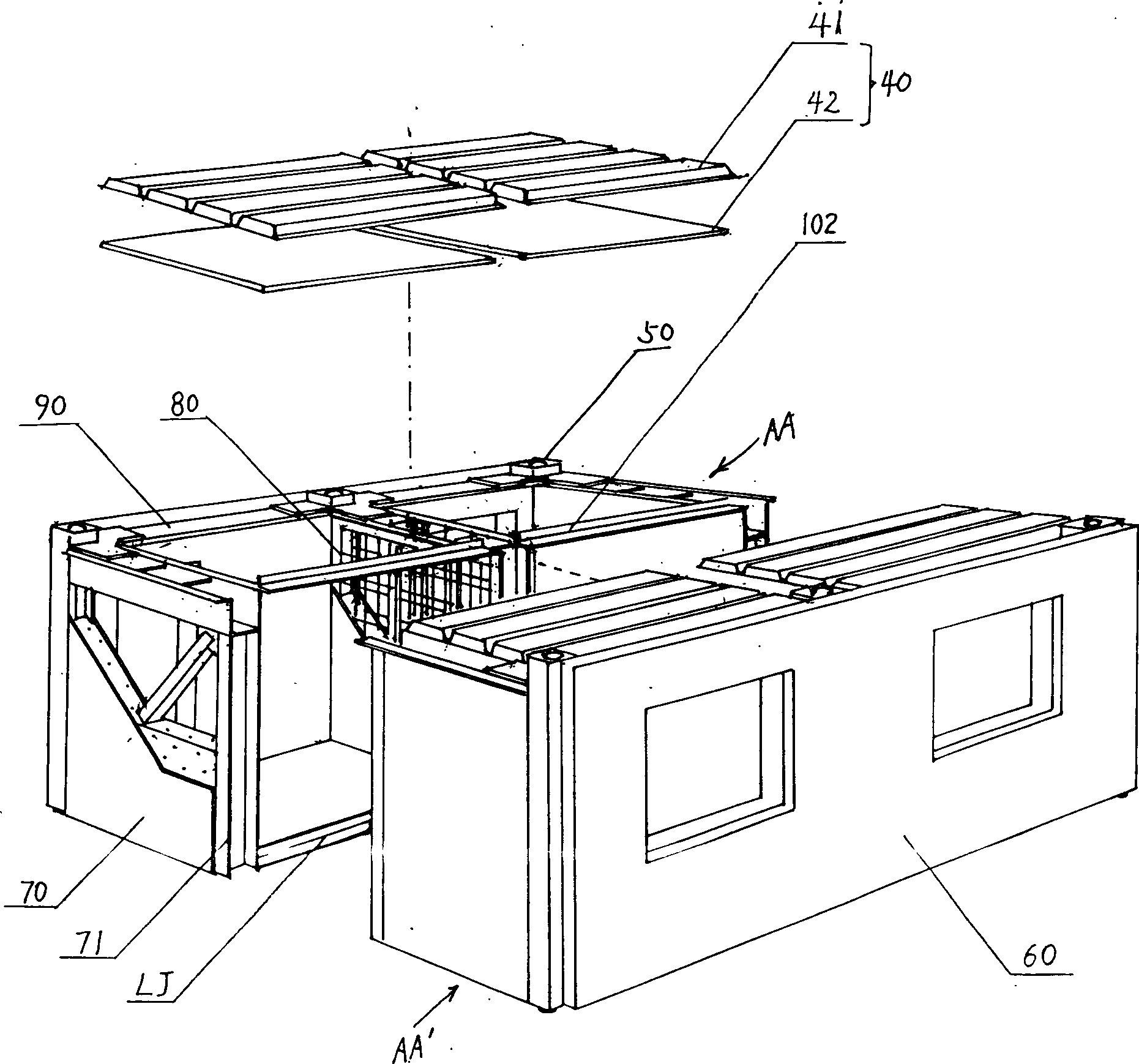

Box shaped house model of construction and fabricating method

A box type of house mould used on building consists of outer wall formed by steel frame, steel screen frame and aero ¿C concrete plate; inner wall formed by hollow wall plate and composite frame wall plate; top plate mould formed by pressed steel bearing plate and light thin plate and steel tube. It is featured as enclosing box type of house mould by one outer wall and three inner walls and furthermore forming stereo structure house mould with five surfaces by welding said box type of house mould with top plate mould.

Owner:张东川

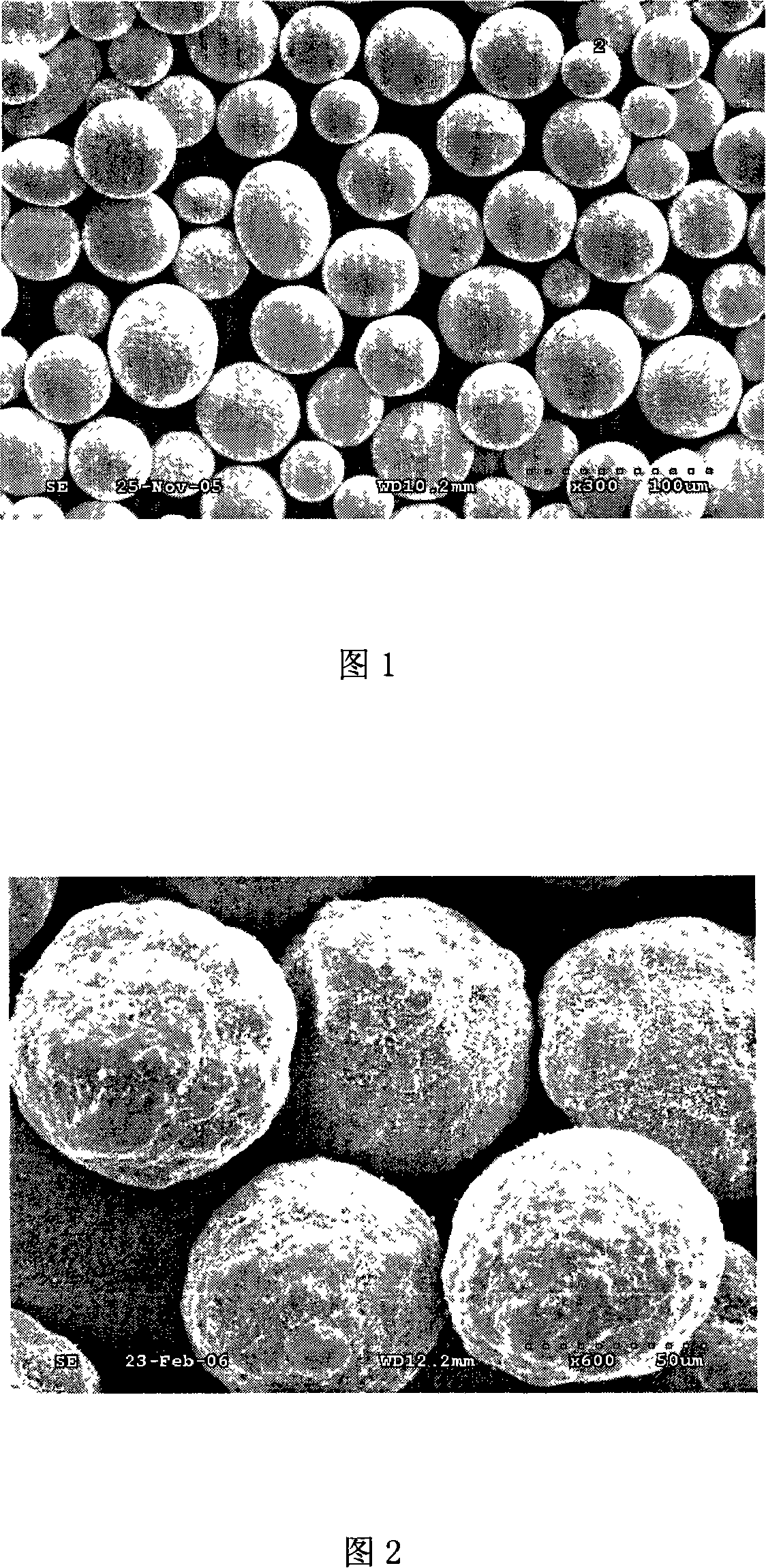

Hot spraying WC/Co powder and coat preparation

The present invention discloses one kind of hot sprayed WC / Co powder and its coating and their preparation. The hot sprayed WC / Co powder consists of Co 5-25 wt%, C 5-6 wt%, and W for the rest, and is in spherical granular structure of size below 150 micron. The powder is prepared through the following steps: 1. sieving, washing and stoving W powder; 2. spheroidizing W powder; 3. carbonizing spheroidized W powder; and 4. coating with Co to form the WC / Co powder. The hot sprayed WC / Co coating is prepared through spraying the WC / Co powder with ultrasonic flame. The WC / Co powder is compact, high in flowability and homogeneous in components; and the hot sprayed WC / Co coating is compact and homogeneous, and has close combination with the base, micro hardness up to 894HV0.2 and wide application.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

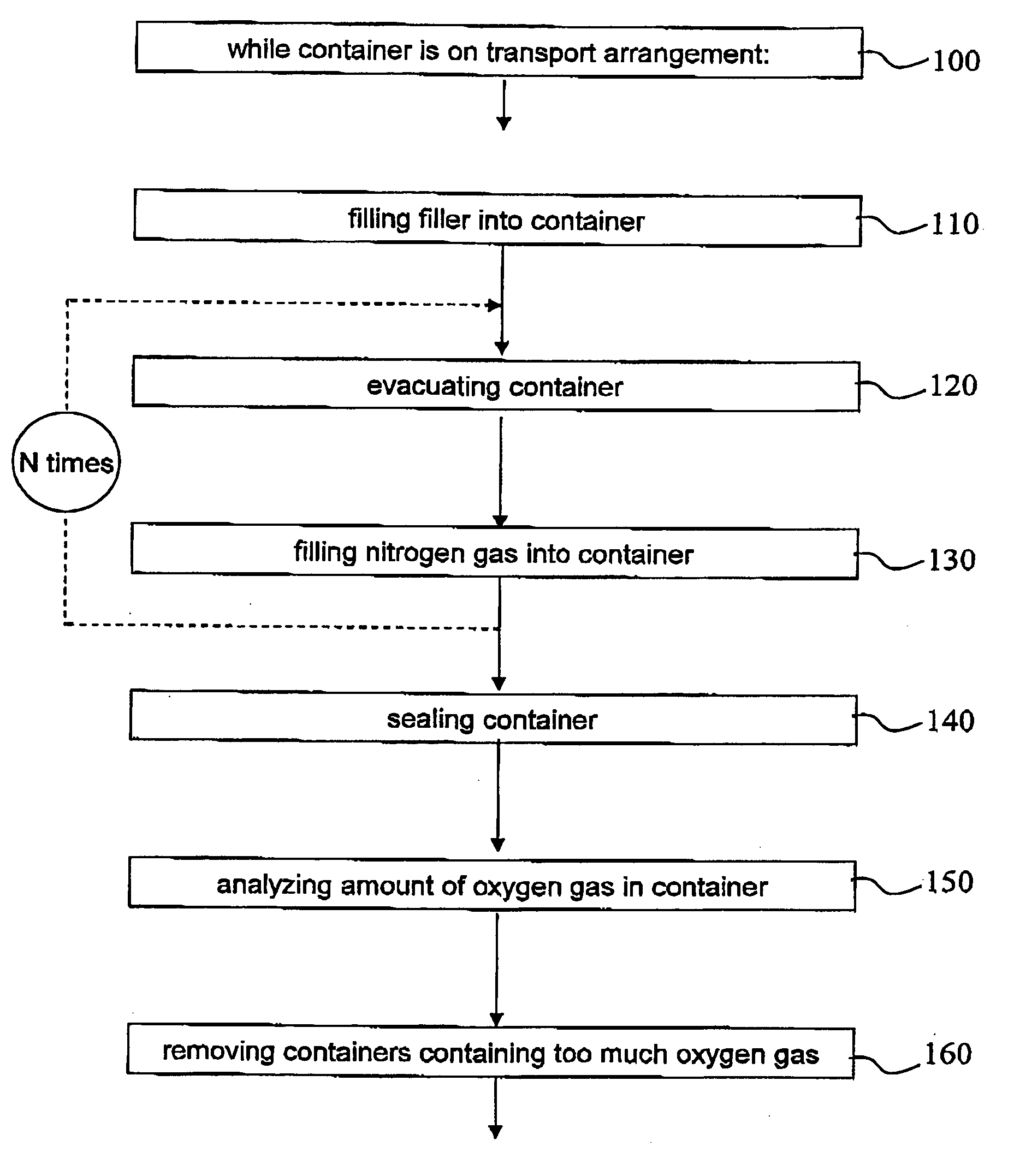

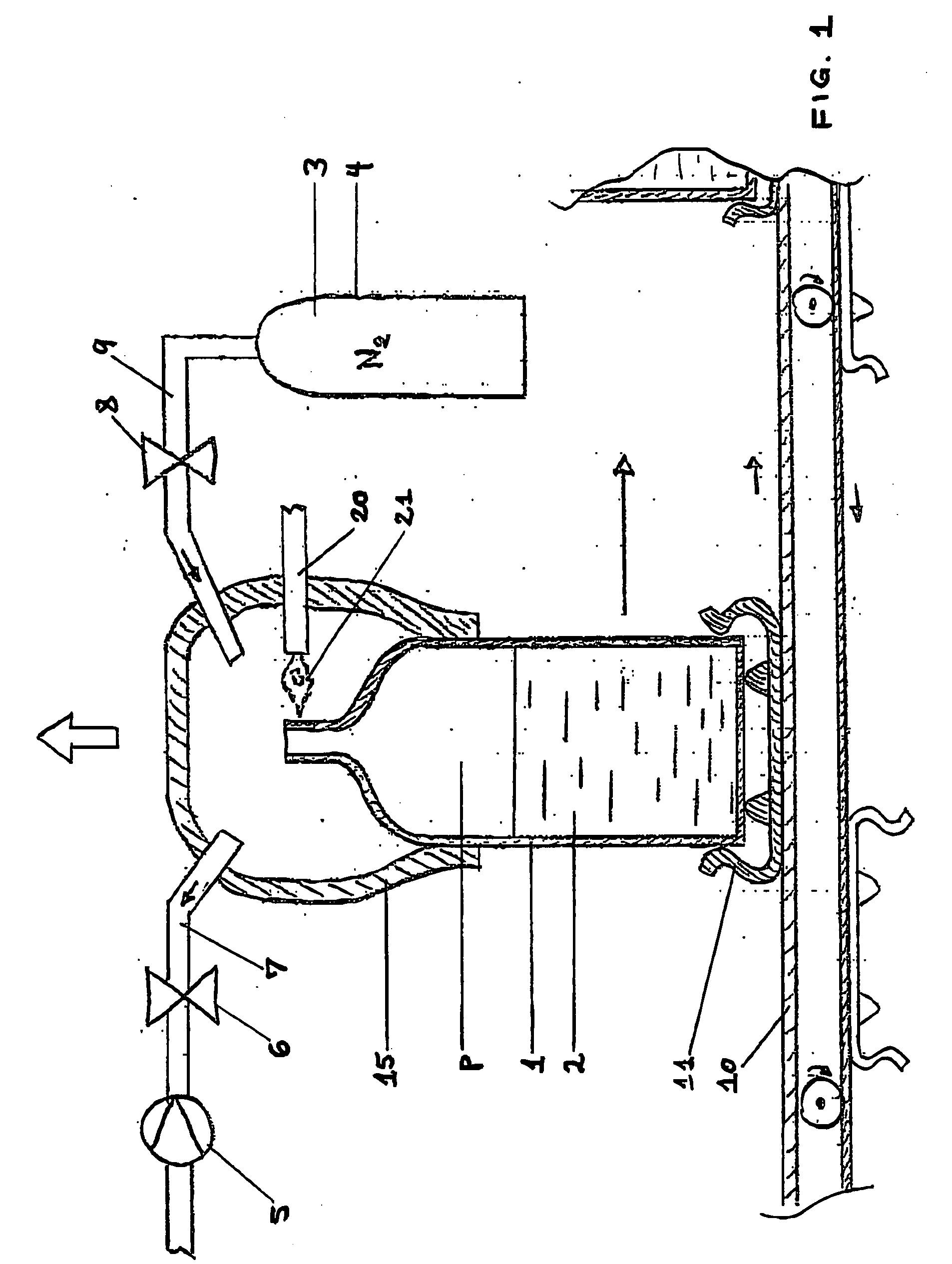

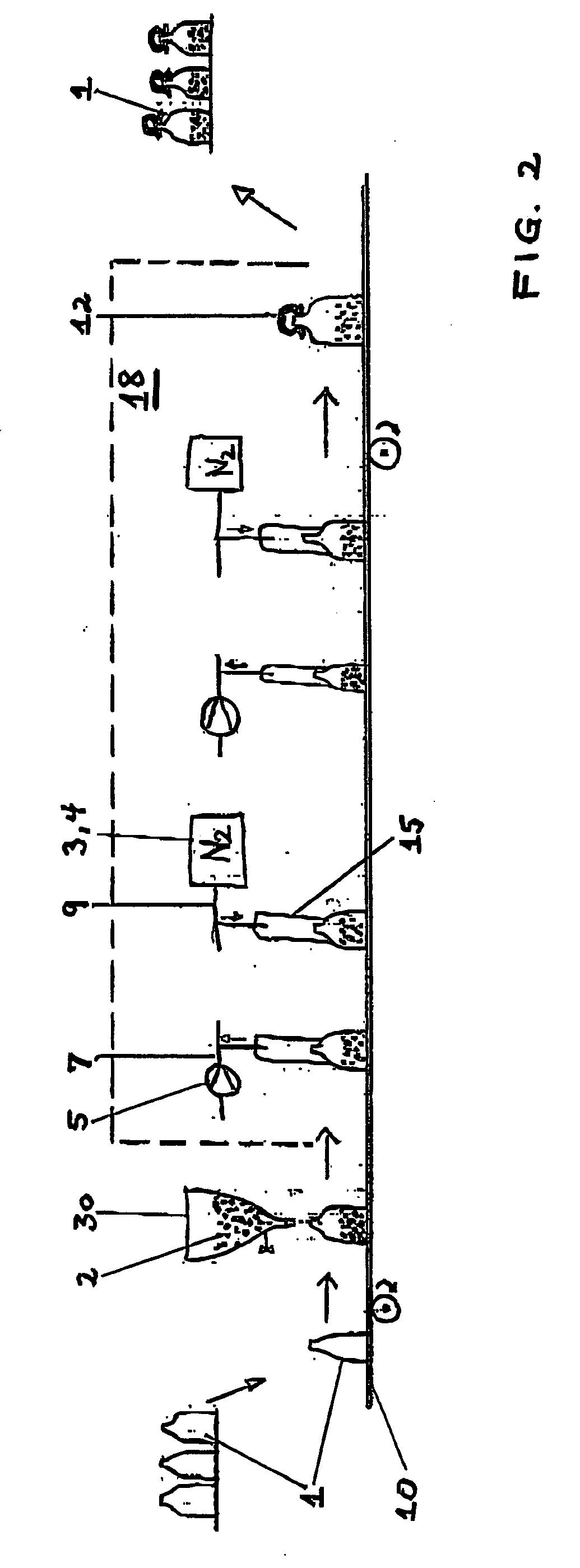

Method and apparatus for cleaning containers to be sealed and containing a filler from oxygen gas

InactiveUS20070062162A1Rapid productionFast productionPackaging by pressurising/gasifyingPackaging under vacuum/special atmosphereNitrogen gasProcess control

The method of manufacturing a sealed container for containing a non-gaseous filler, which filler is to be protected from Oxygen gas, comprises the following steps in the indicated sequence: 1.) filling said filler into said container; 2.) evacuating said container substantially without evaporating parts of said filler; 3.) filling Nitrogen gas into said container; 4.) sealing the container. The method can be used in-line. The apparatus for cleaning filled containers containing a non-gaseous filler, comprises at least one holder for holding said containers; at least one pump adapted for evacuating said containers; a Nitrogen reservoir for supplying Nitrogen gas to be filled into said containers; a process control unit adapted to allowing for an evacuation of said containers by means of said at least one pump and subsequentially filling said Nitrogen gas into said containers.

Owner:LEHMANN MARTIN

Manufacturing method of hot bent 3D (Three Dimensional) glass white sheet

InactiveCN106746525AEliminate internal stressFlat surfaceEdge grinding machinesPolishing machinesNumerical controlHeating time

The invention relates to a manufacturing method of a hot bent 3D (Three Dimensional) glass white sheet. The manufacturing method comprises the following steps: (1) cutting a material: cutting a glass white sheet material into a plurality of small glass white sheets with proper sizes; (2) finely engraving: putting the small glass white sheets into a CNC (Computer Numerical Control) fine engraving machine, and punching and grinding edges; (3) cleaning: carrying out cleaning treatment on the glass white sheet by utilizing a glass cleaning machine; (4) carrying out ultrasonic treatment: washing surface residual waste dreg on the surface of the glass white sheet by utilizing an ultrasonic washing machine; (5) hot bending: putting the glass white sheet into a hot bending mold and hotly bending, machining and molding the glass white sheet into a 3D curve surface; (6) tempering: putting the hotly bent glass white sheet into a tempering frame; conveying the tempering frame into a tempering furnace and raising the temperature to 380 DEG C-420 DEG C, wherein the heating time is 4h-8h and the hardness reaches 7H; (7) carrying out plasma spraying: putting the glass white sheet into a fingerprint oil spraying machine and spraying fingerprint oil on a surface through plasmas; baking at a temperature of 140 DEG C-160 DEG C for 25-30 minutes until the fingerprint oil is dried; (8) fitting: fitting release films on upper and lower surfaces of the glass white sheet; and (9) packaging.

Owner:DONGGUAN YUANMEI PRECISION ELECTRONICS CO LTD

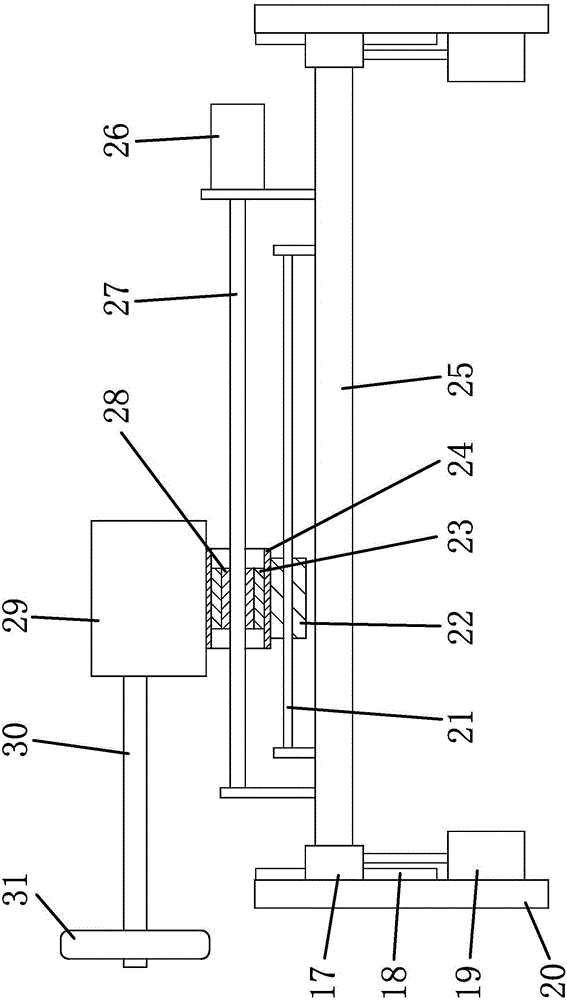

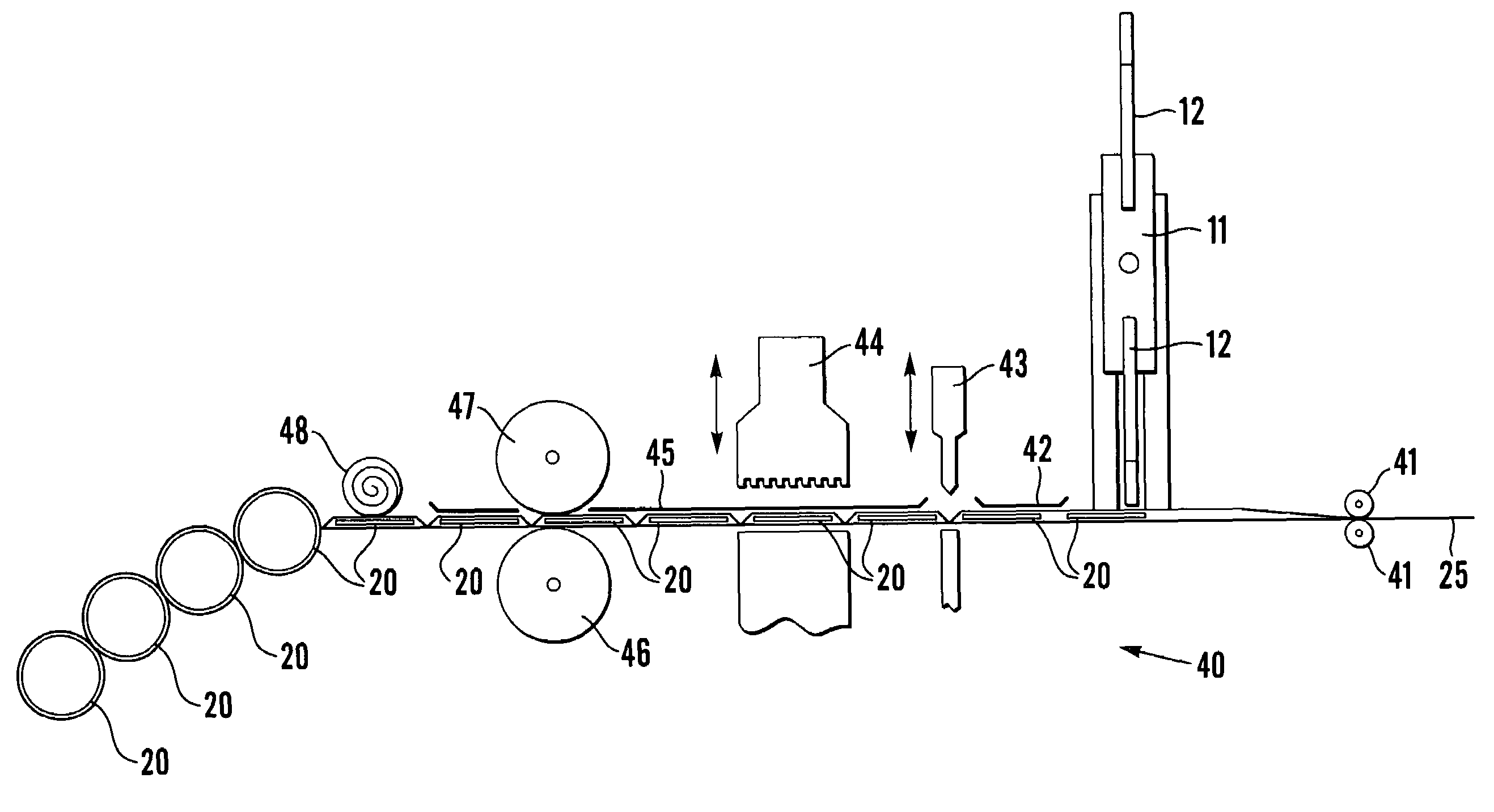

Apparatus for the production of pocketed coil springs

InactiveUS6922895B1Easy to createEasy to modifyStuffed mattressesSpring mattressesCoil springEngineering

Owner:SPRINGFORM TECH

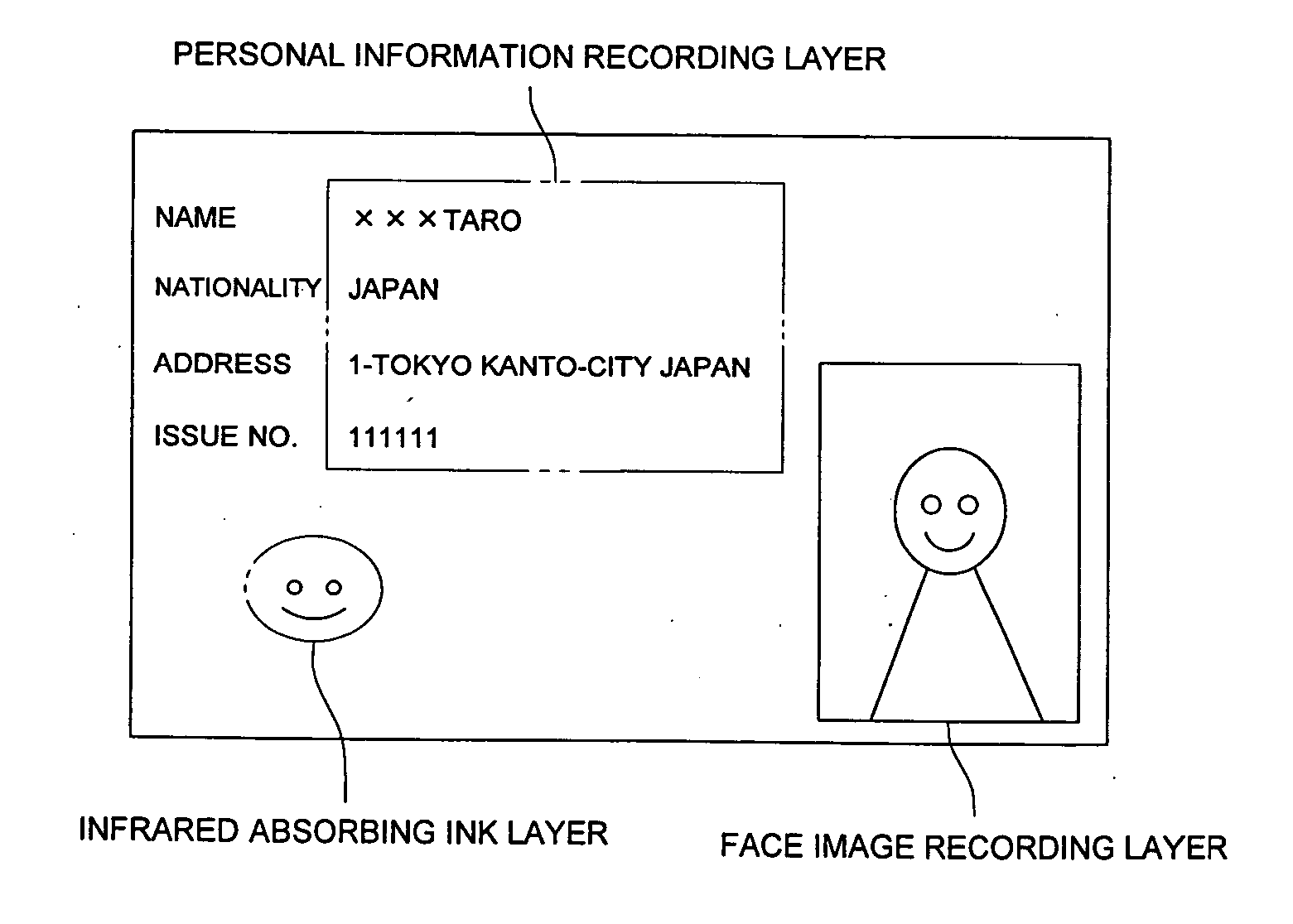

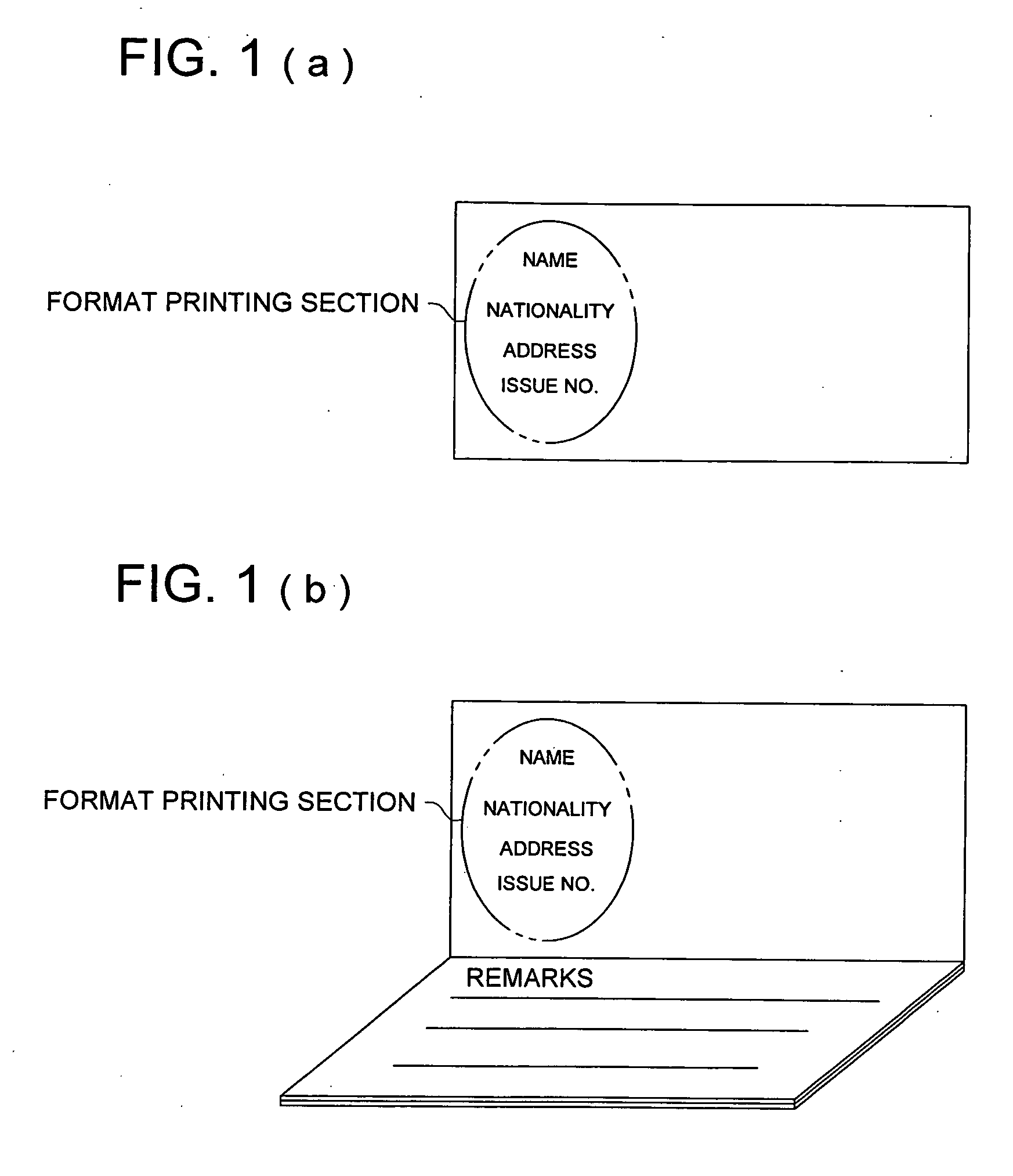

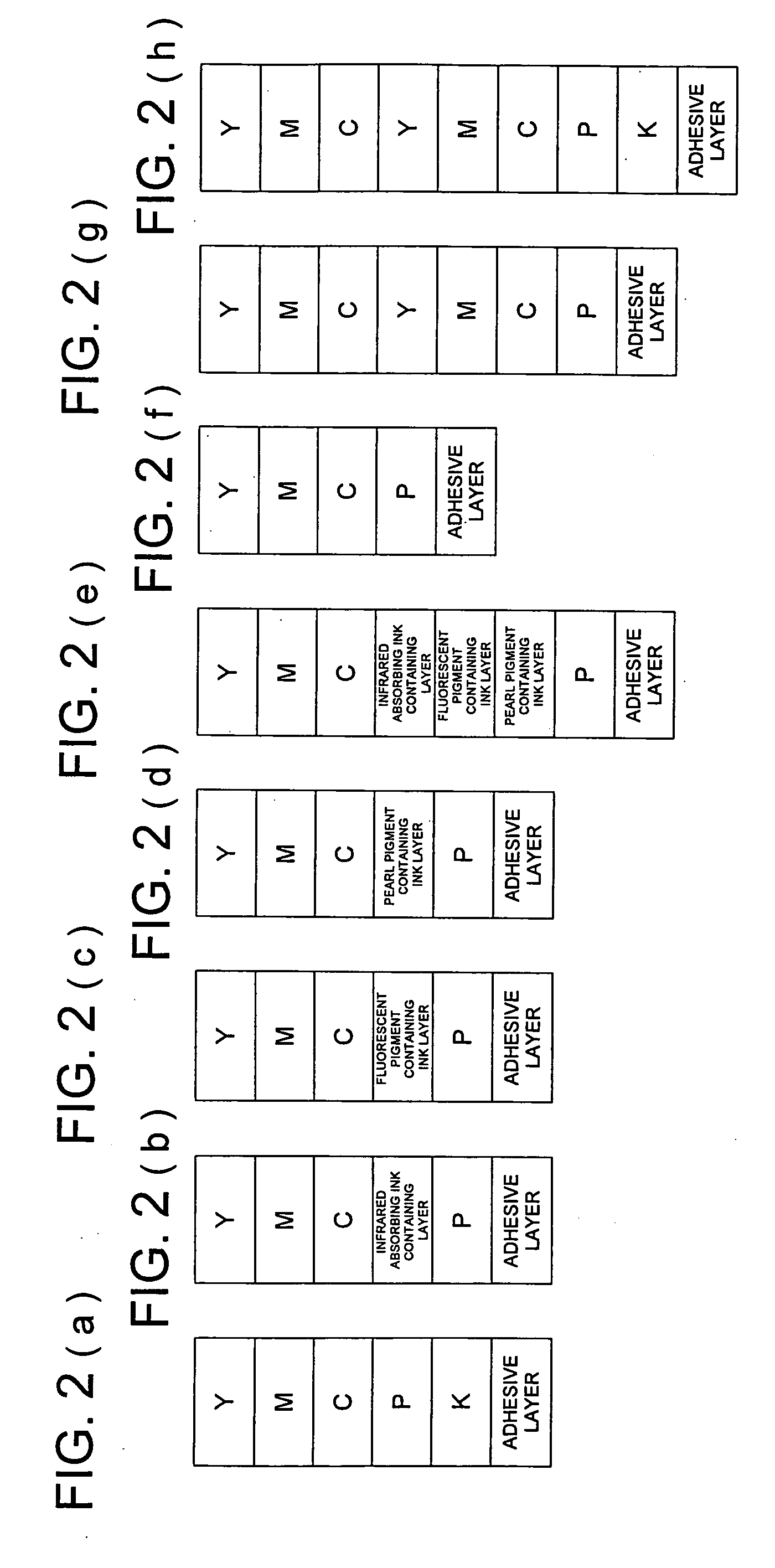

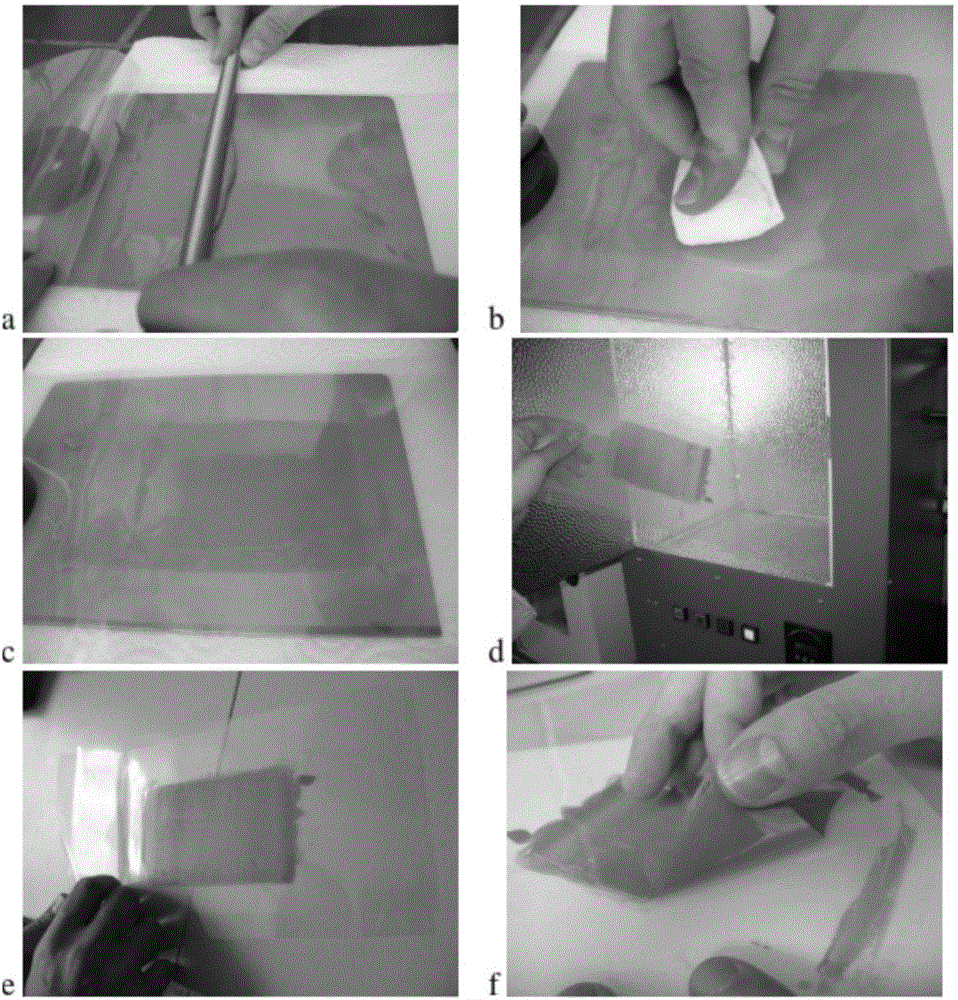

Authentication recording medium and medium and authentication recording medium producting method

InactiveUS20060262367A1Good lookingSatisfactory adhesionOther printing matterPaper-money testing devicesMaterials scienceAuthentication

An authentication recording-medium, comprising a substrate for the authentication recording-medium having a center line average roughness (Ra) of 0.5 to 80.0 μm: a substrate light scattering preventing layer provide on the substrate; and a hologram provided on the substrate light scattering preventing layer. With the above structure, it can be possible to provide an authentication recording-medium in which an adhesion capability with a hologram can be made well without spoiling an appearance of a hologram and falsification and modification can be made difficult.

Owner:KONICA MINOLTA PHOTO IMAGING

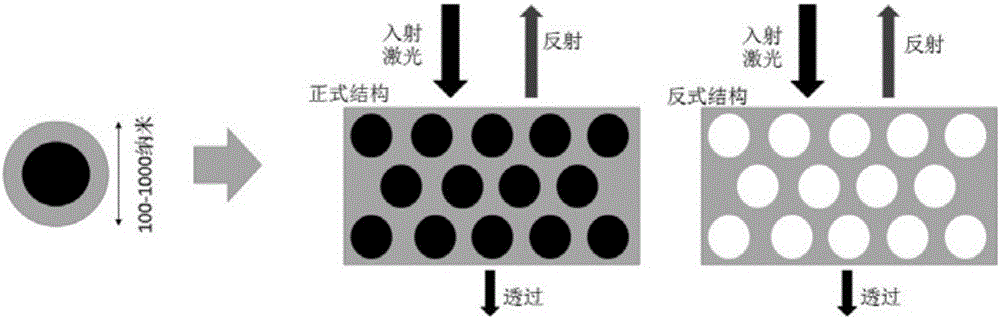

Nanoparticle, surface optical material and preparation method of surface optical material

ActiveCN105949379AImprove brittlenessEasy to controlCoatingsMicroballoon preparationElastomerNanoparticle

The invention relates to a nanoparticle, a surface optical material and a preparation method of the surface optical material. The nanoparticle adopts a core-shell structure and is characterized in that a core material of the nanoparticle comprises an organic or inorganic material, a shell material of the nanoparticle comprises an elastomer polymer material, and the nanoparticle has the size ranging from 100 nanometers to 1,000 nanometers. The material adopts entirely different preparation technologies and nanoparticle structures, the excellent strain discoloration function and monochromaticity are guaranteed, the production speed of the material is greatly increased, the yield in unit time is increased by ten times or above, and meanwhile, production of thinner optical films is facilitated.

Owner:PHOMERA METAMATERIALS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com