Patents

Literature

81results about How to "No need for manual operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

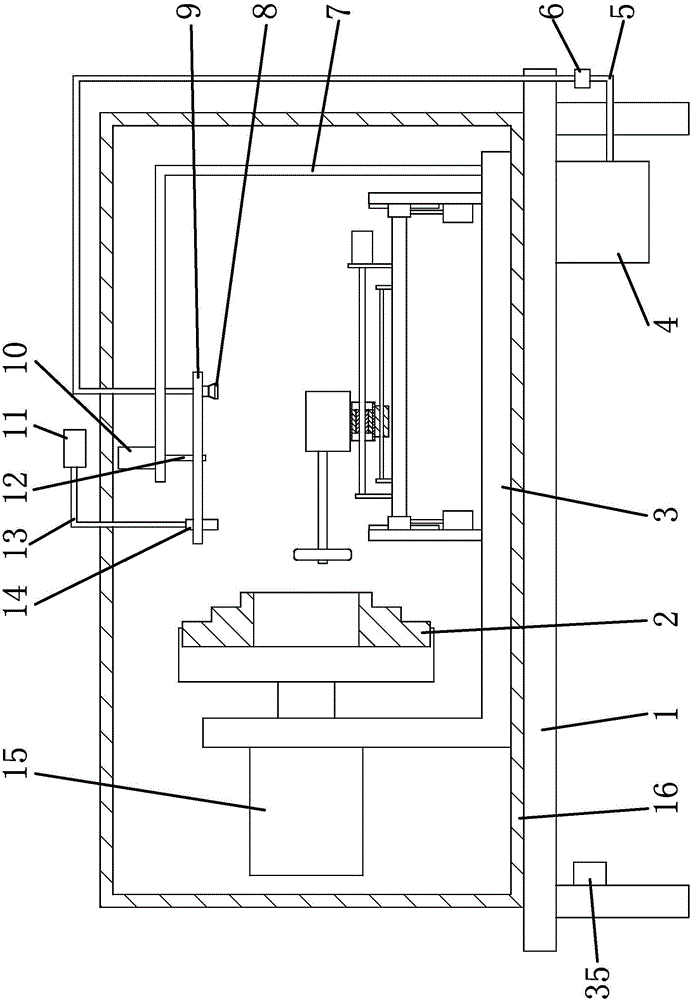

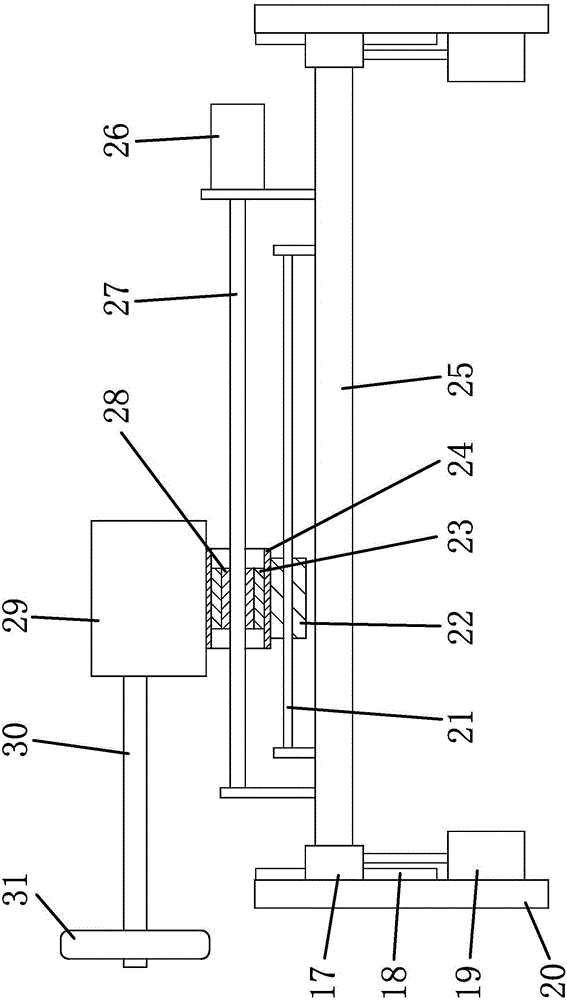

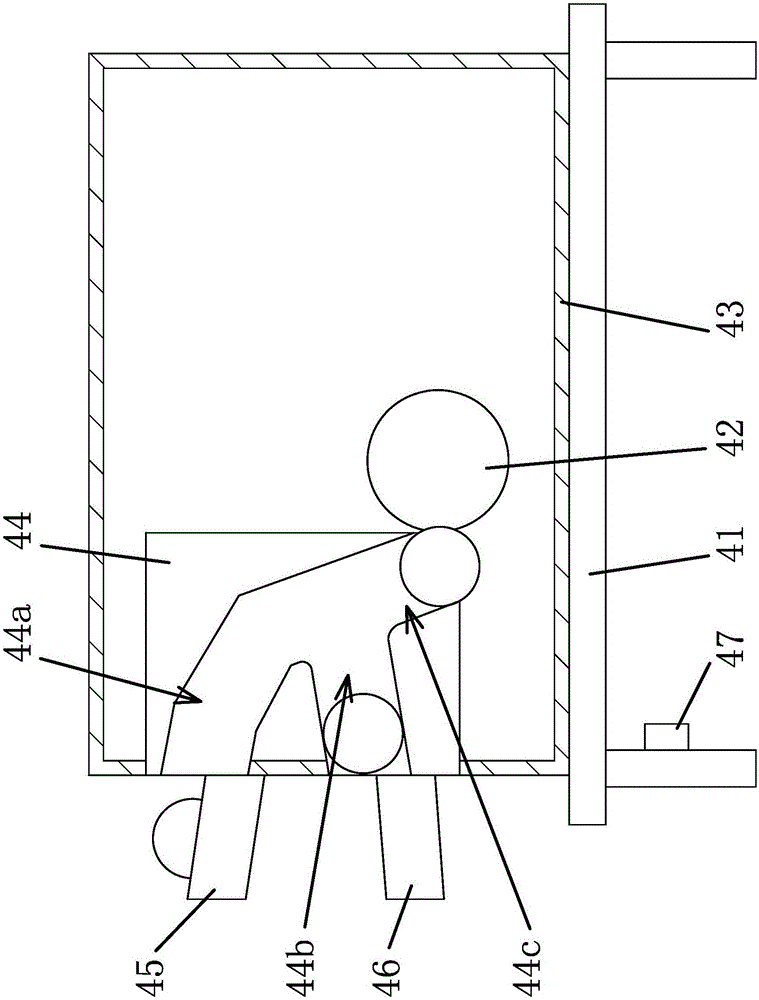

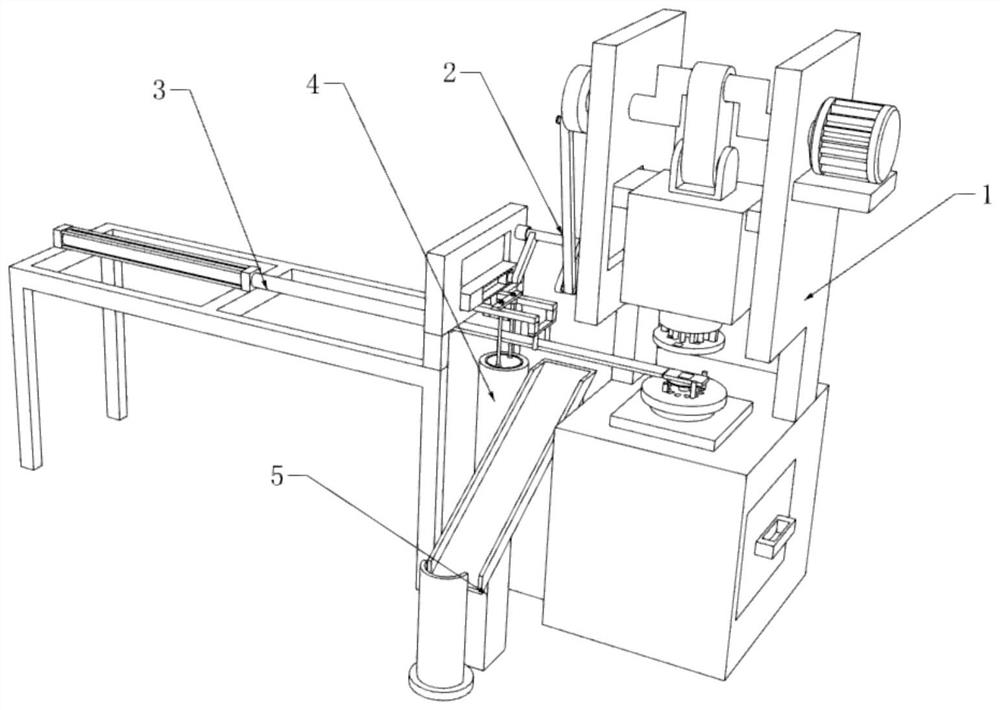

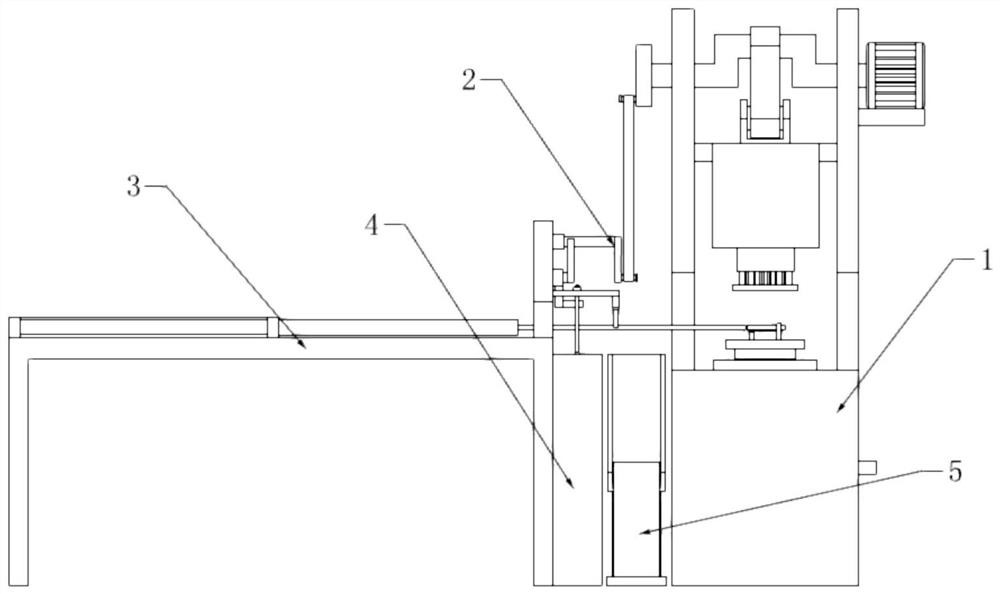

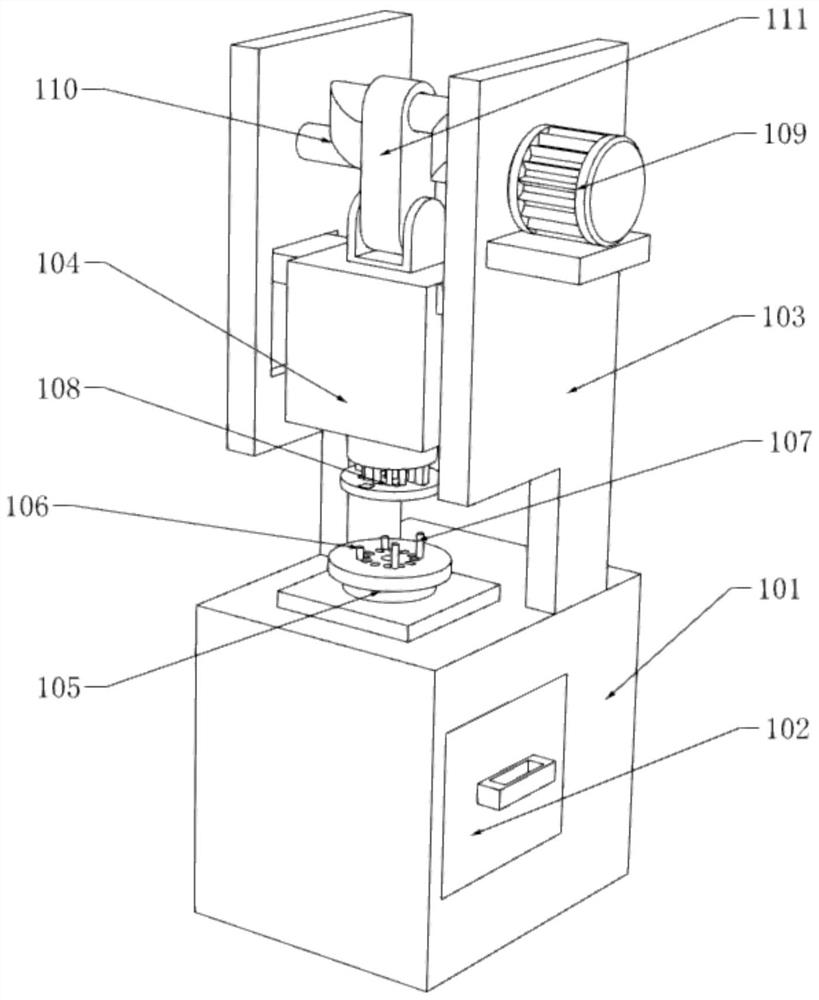

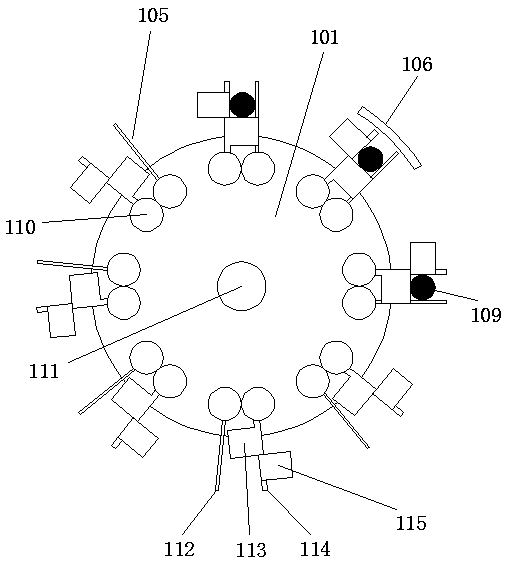

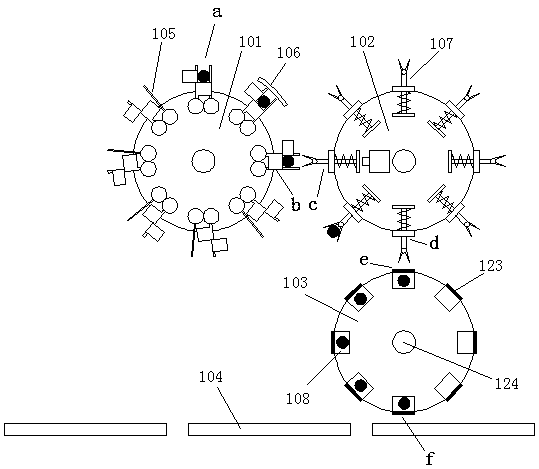

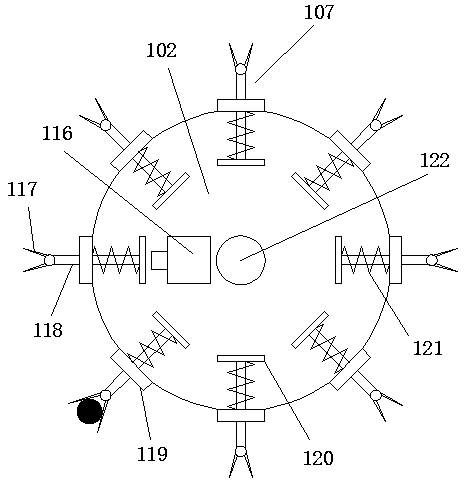

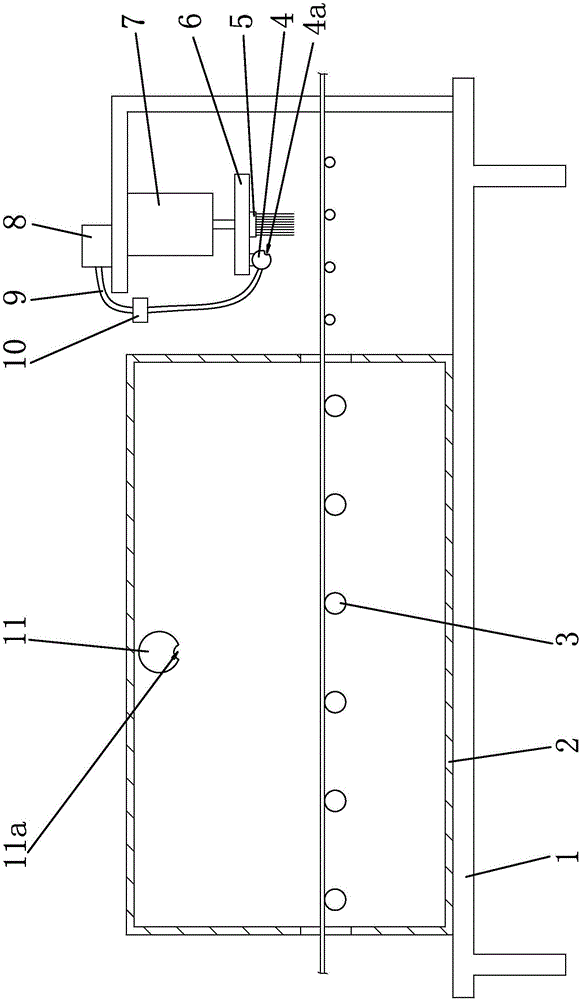

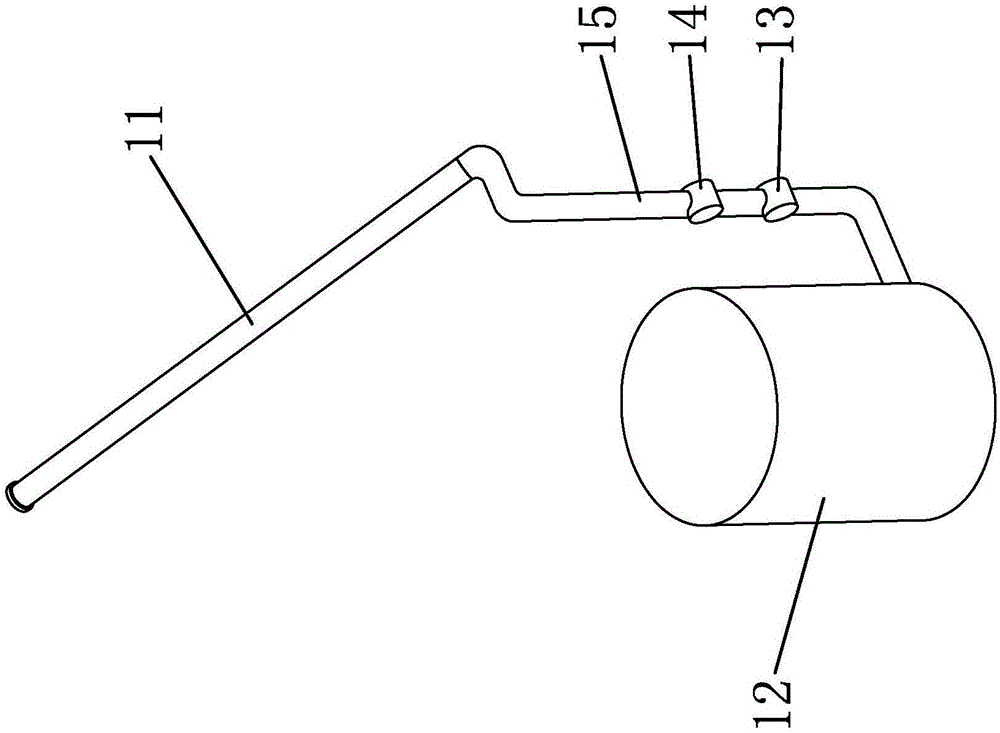

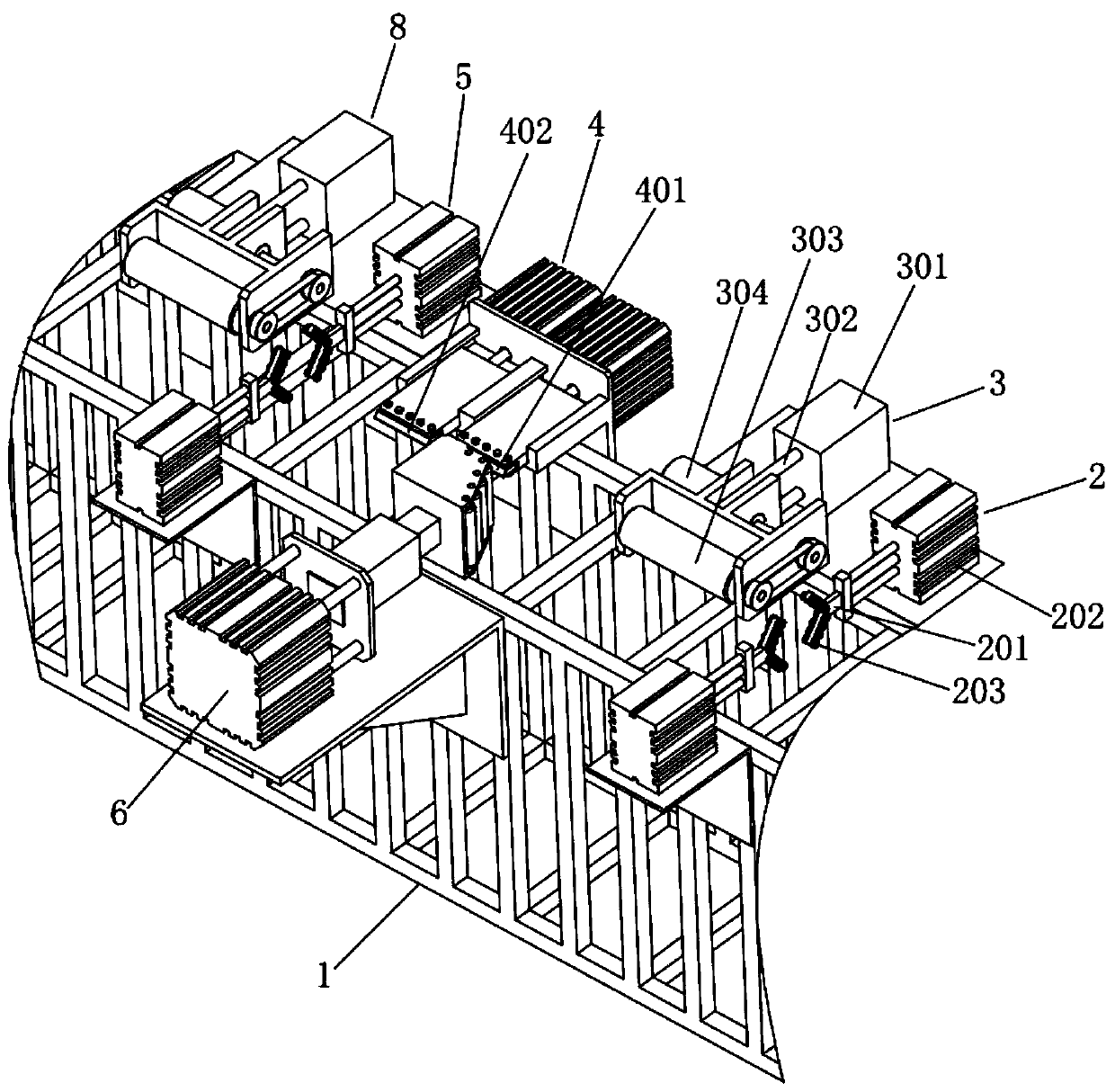

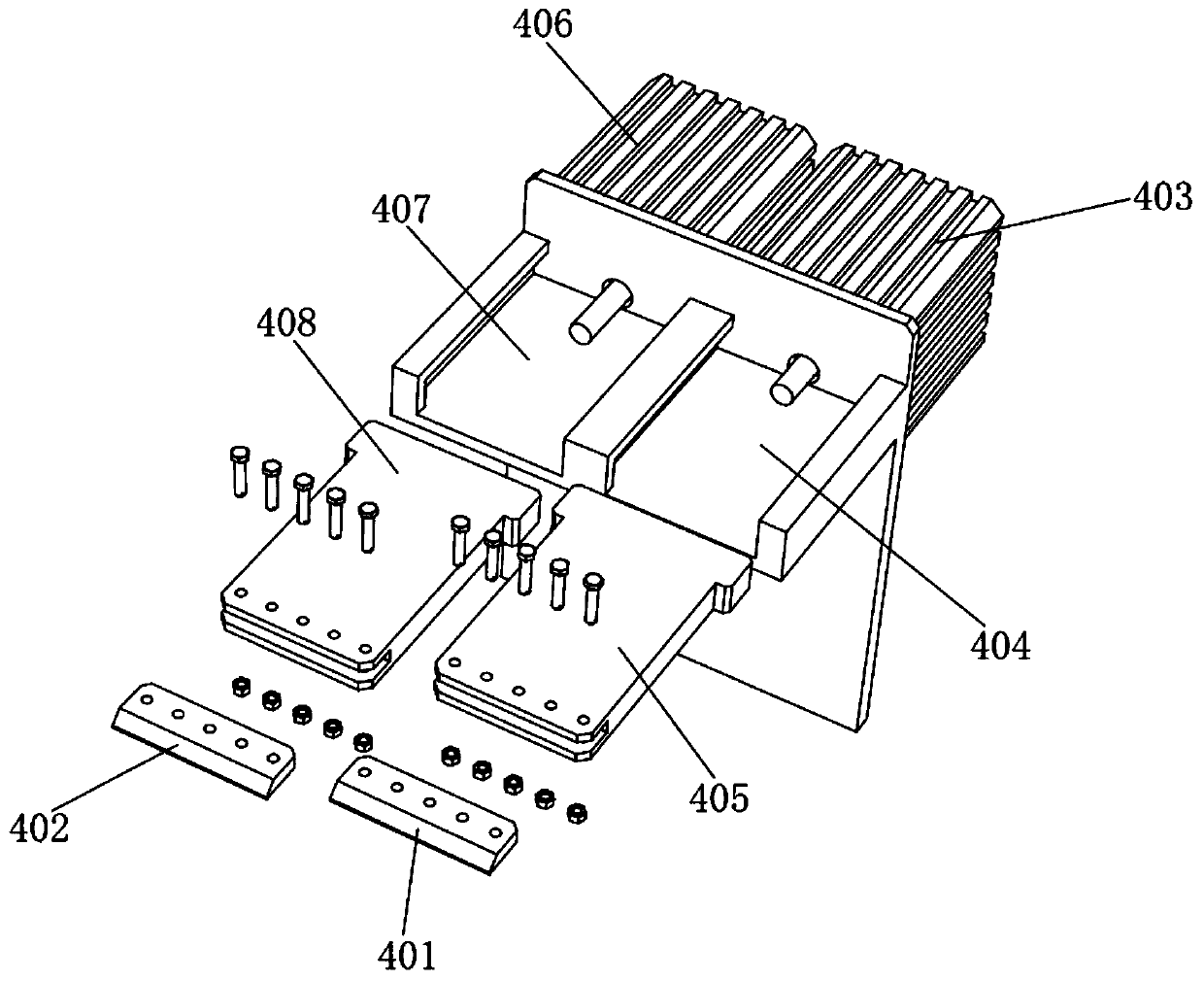

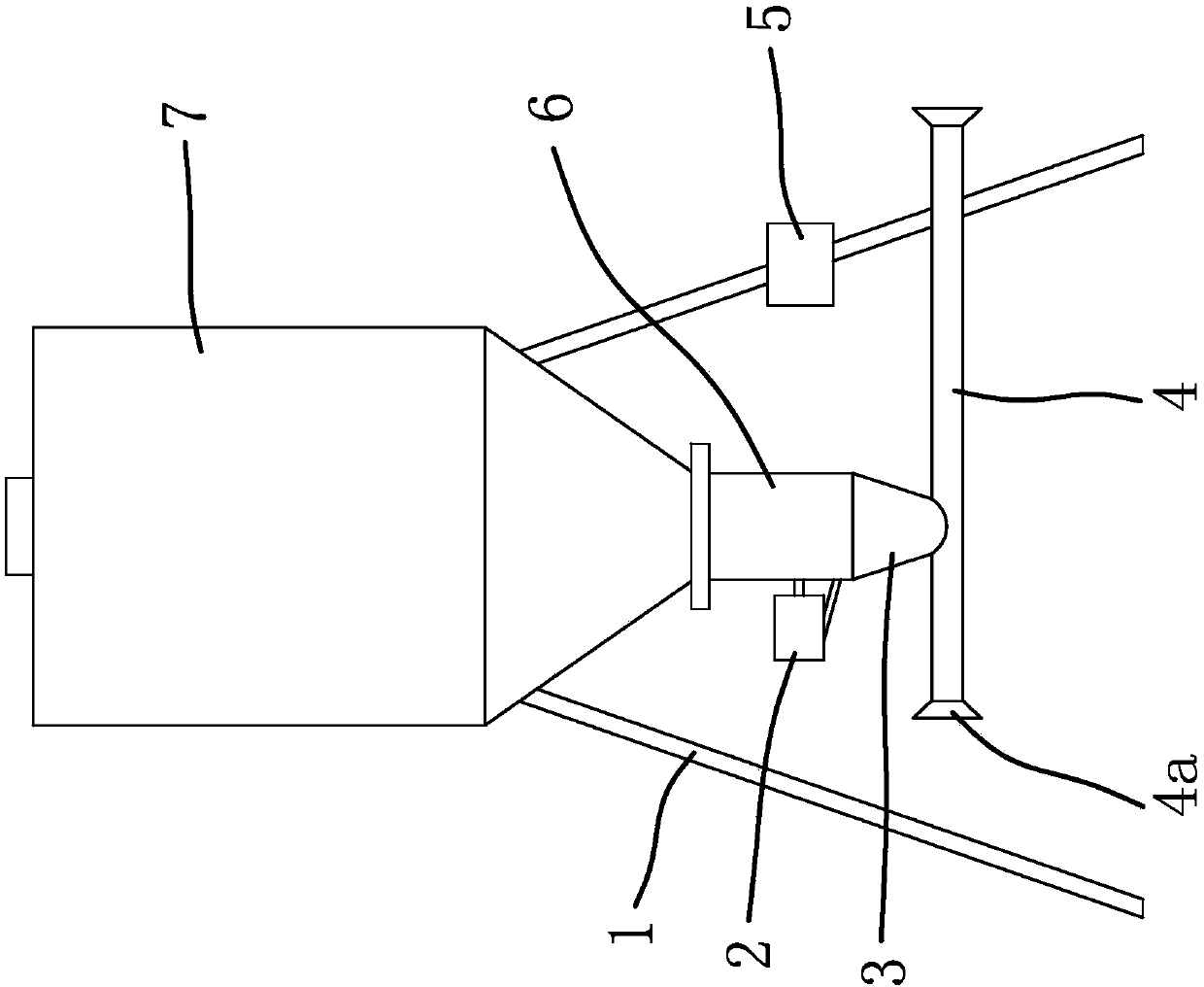

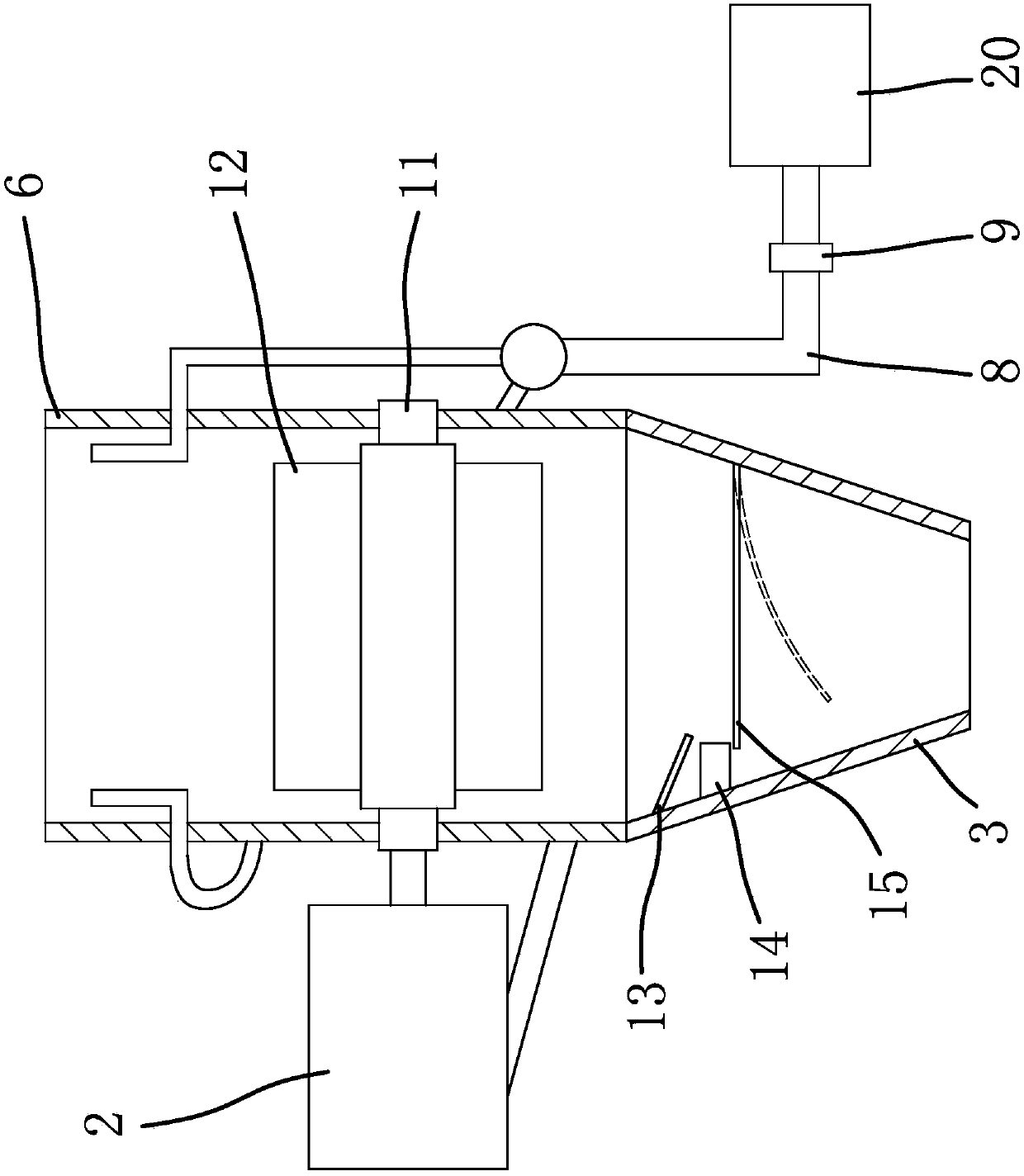

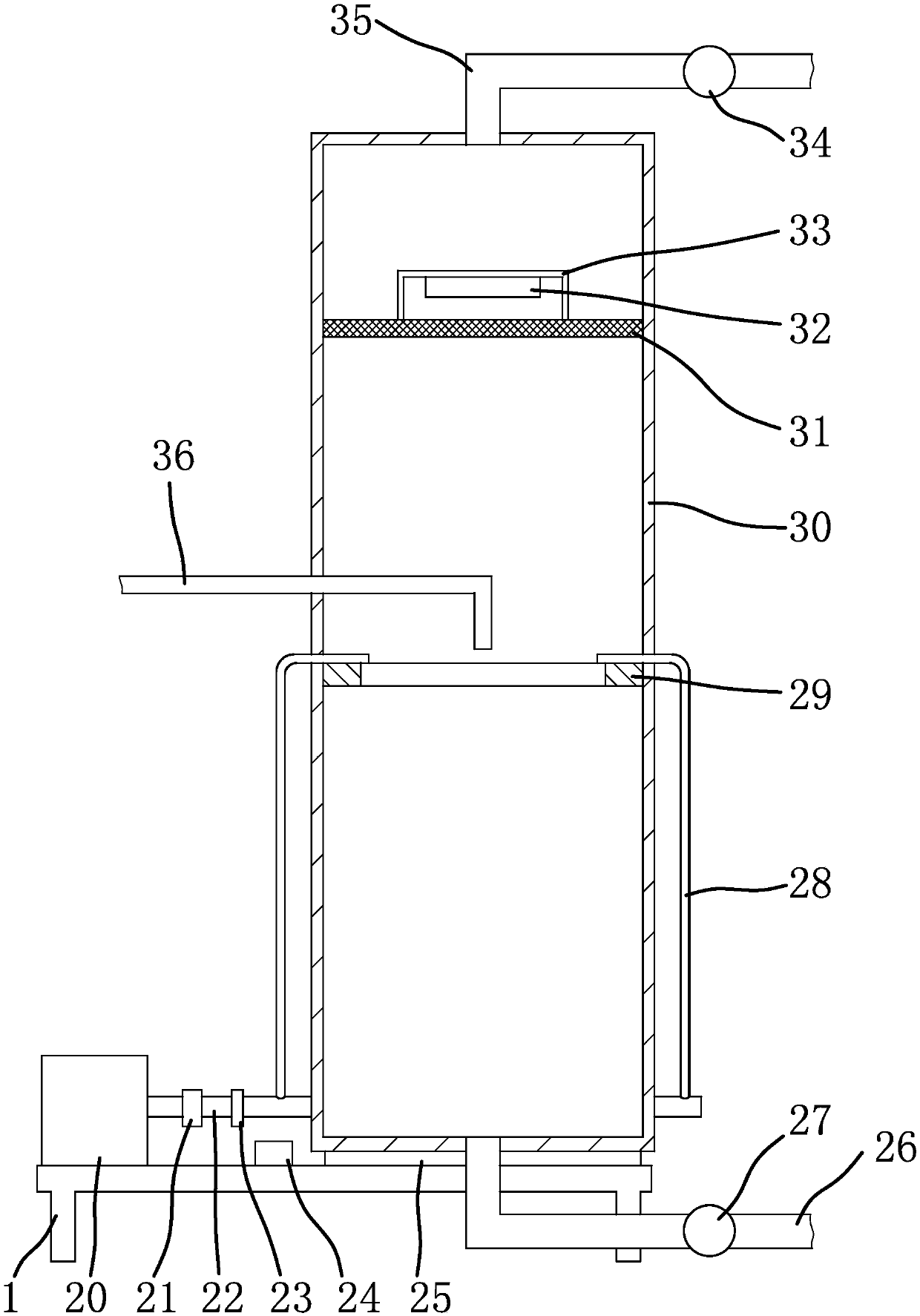

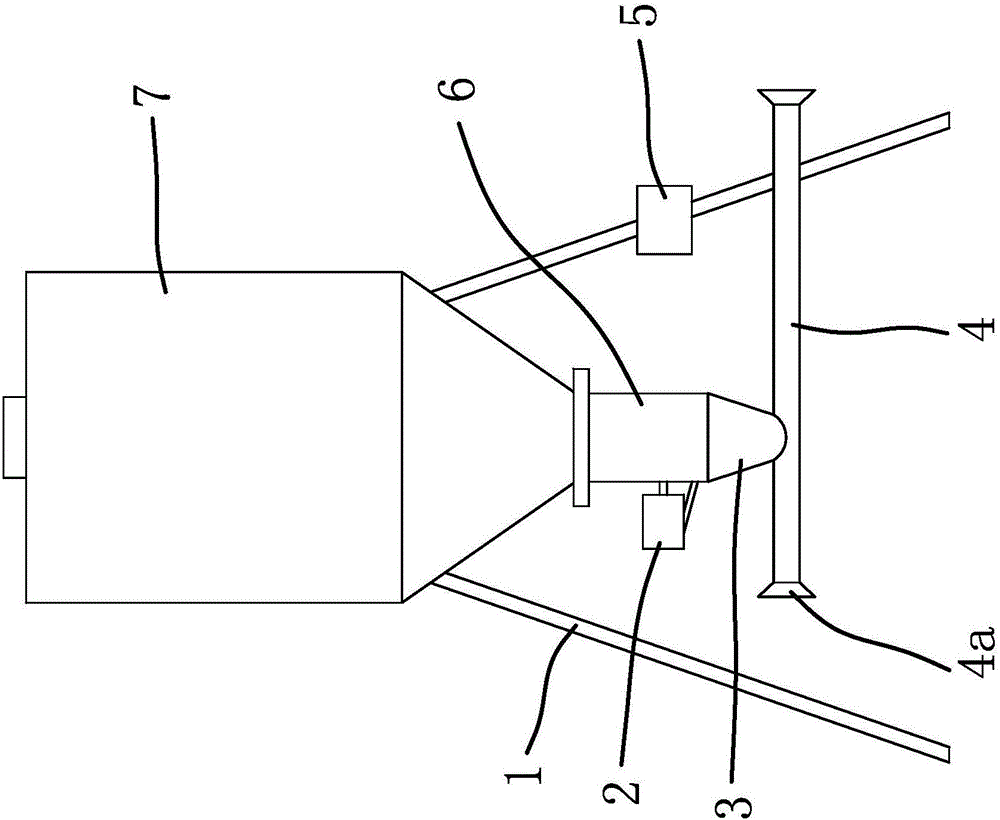

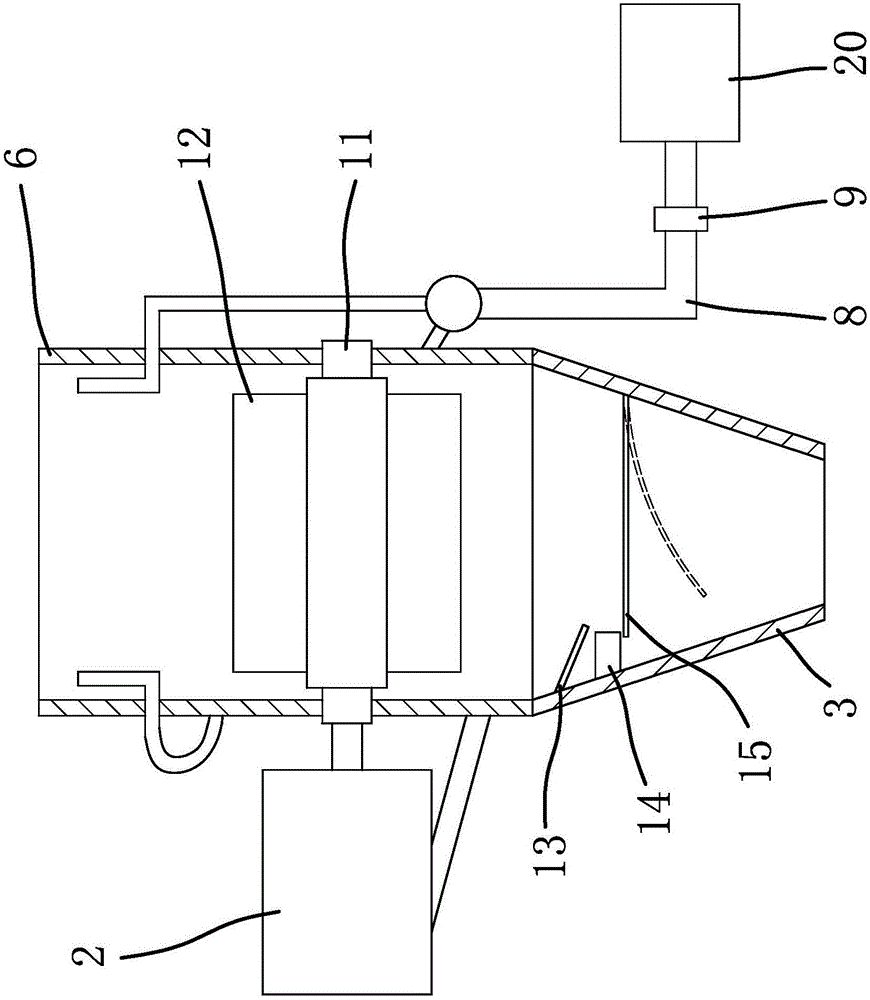

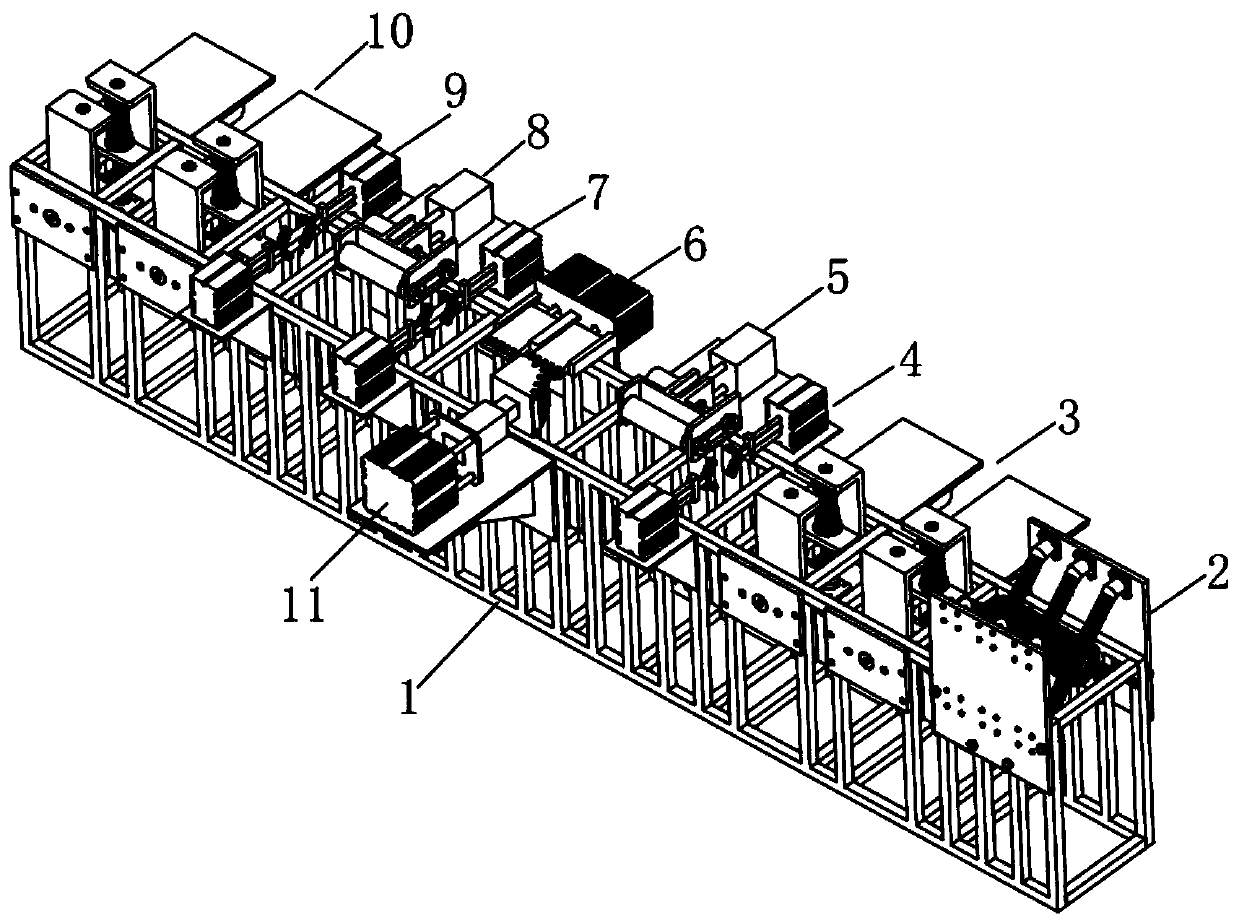

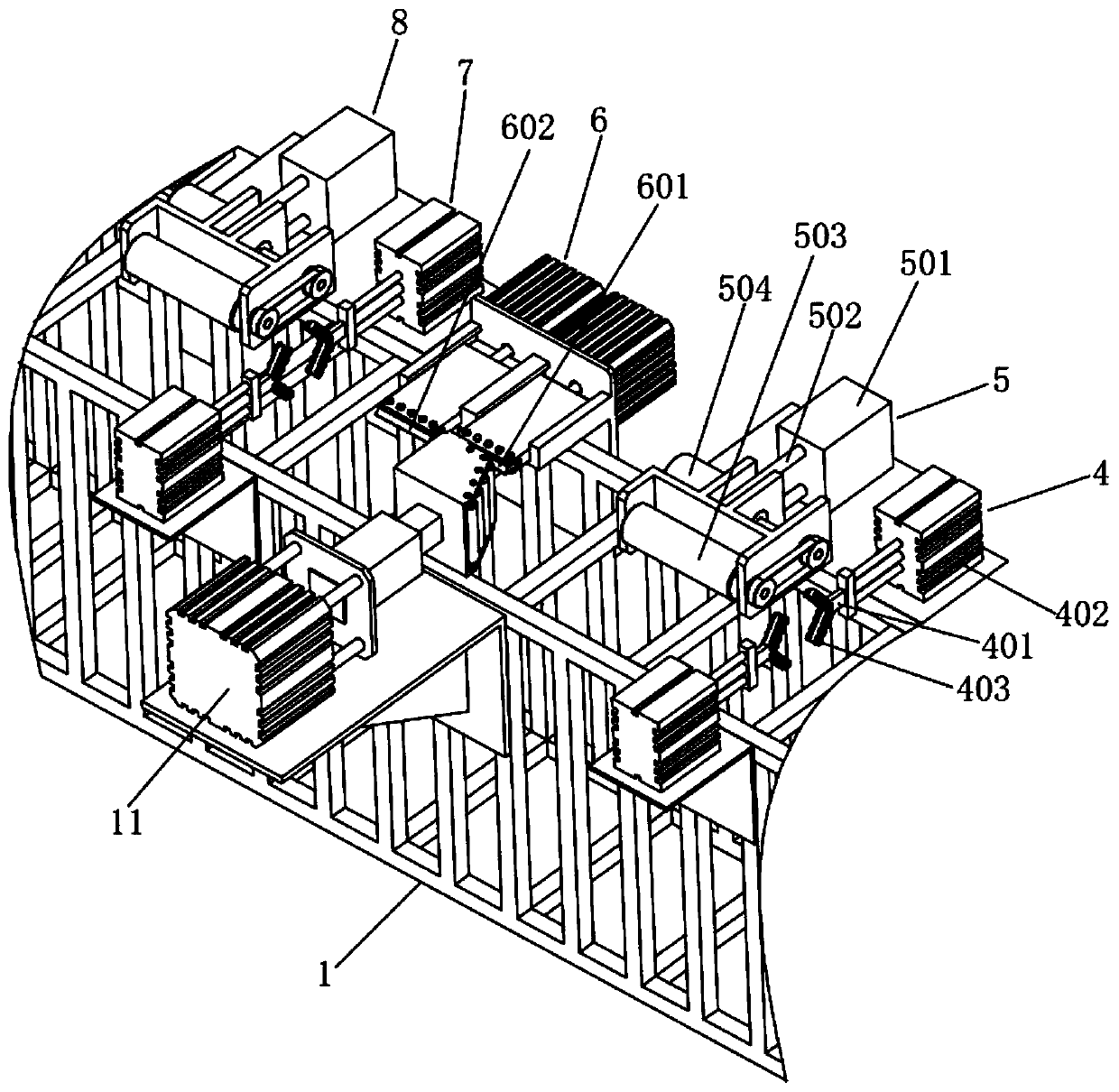

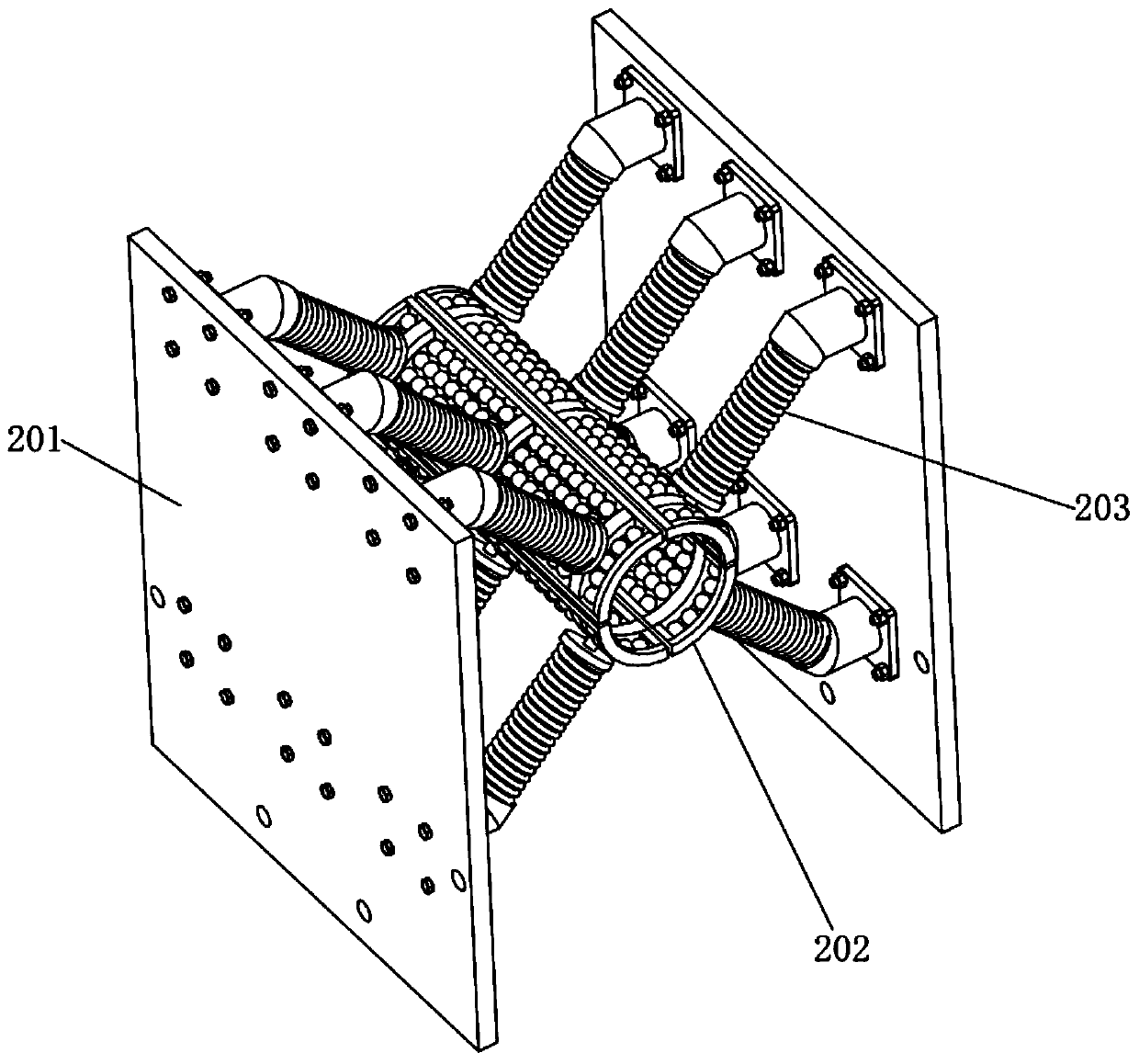

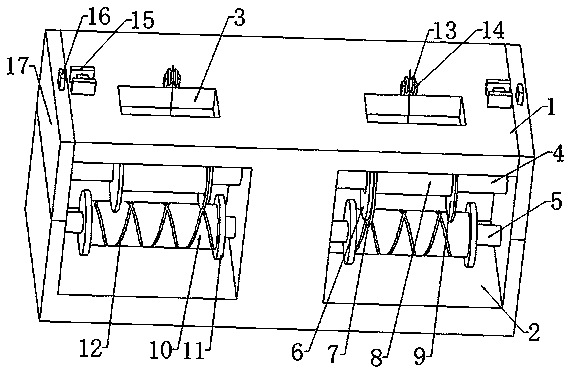

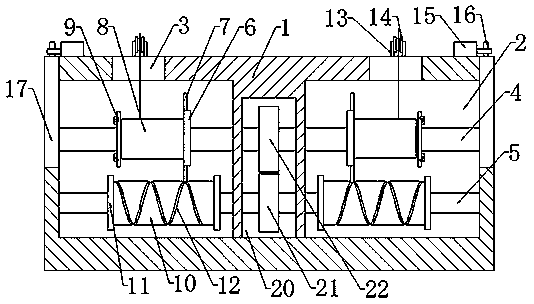

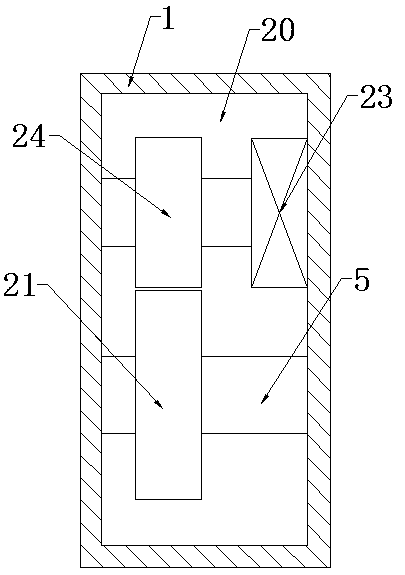

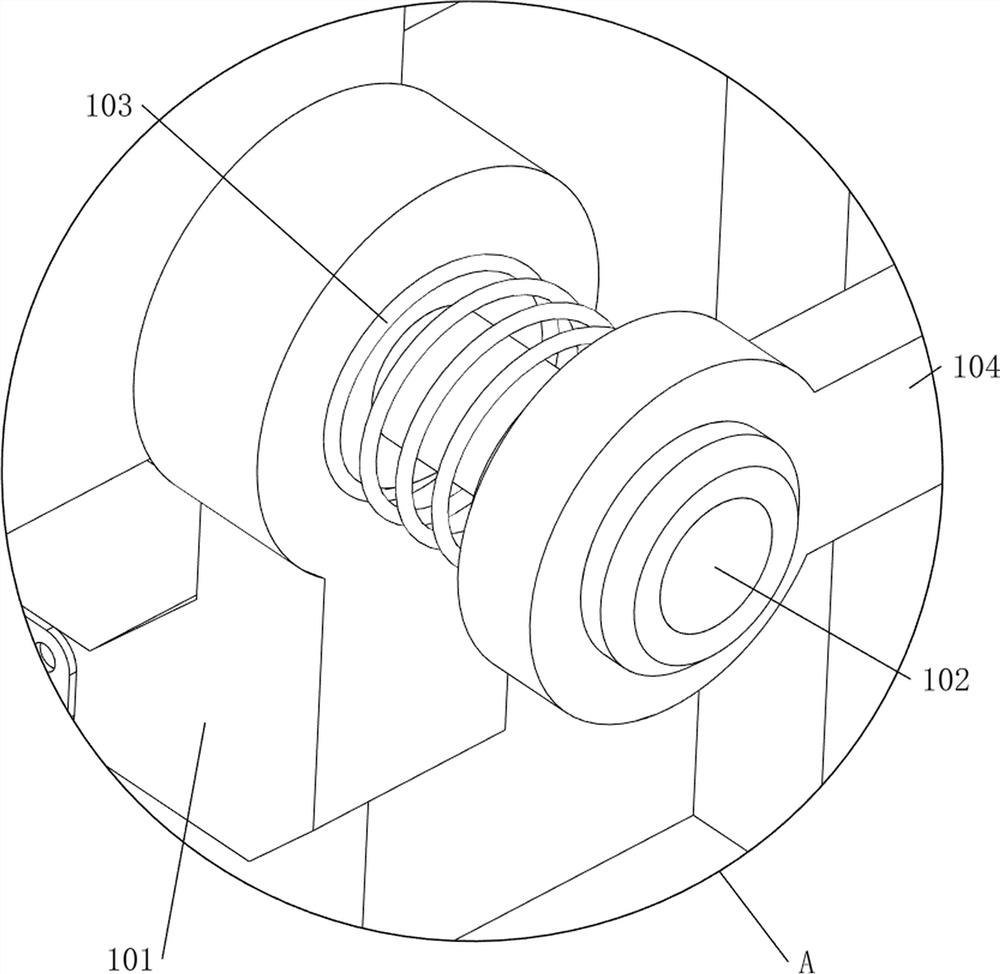

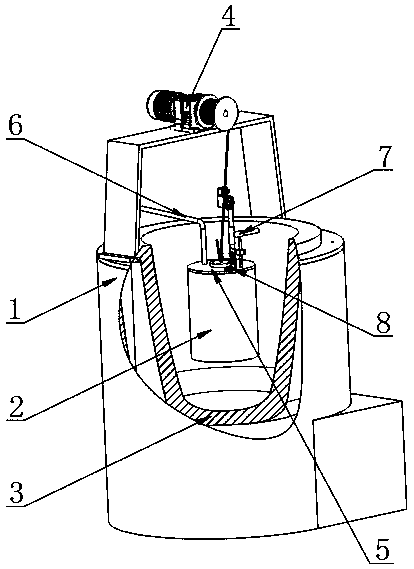

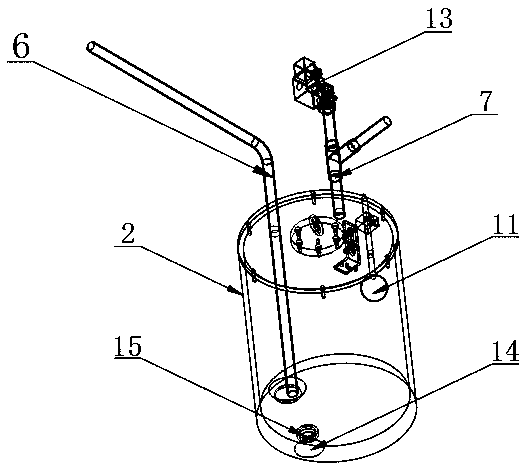

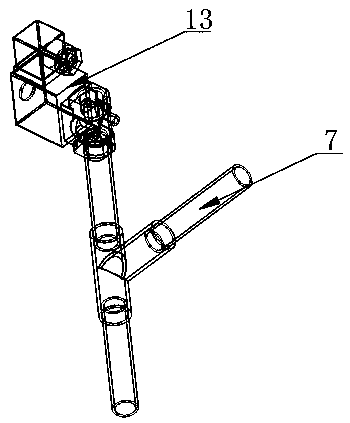

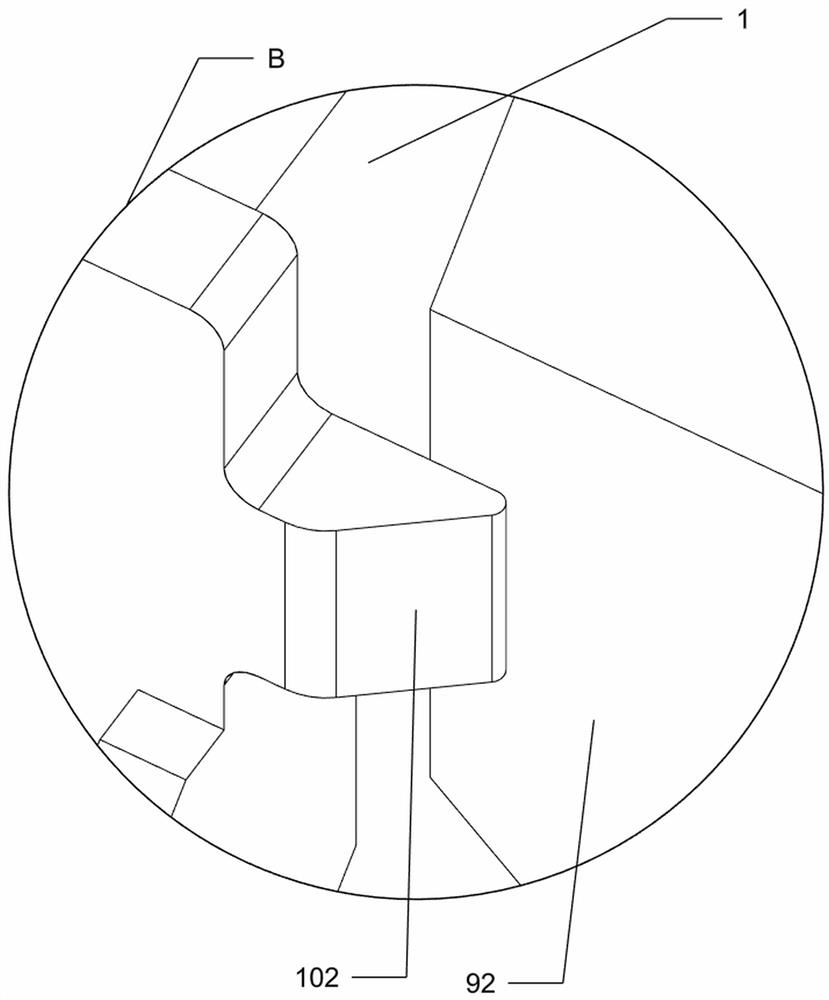

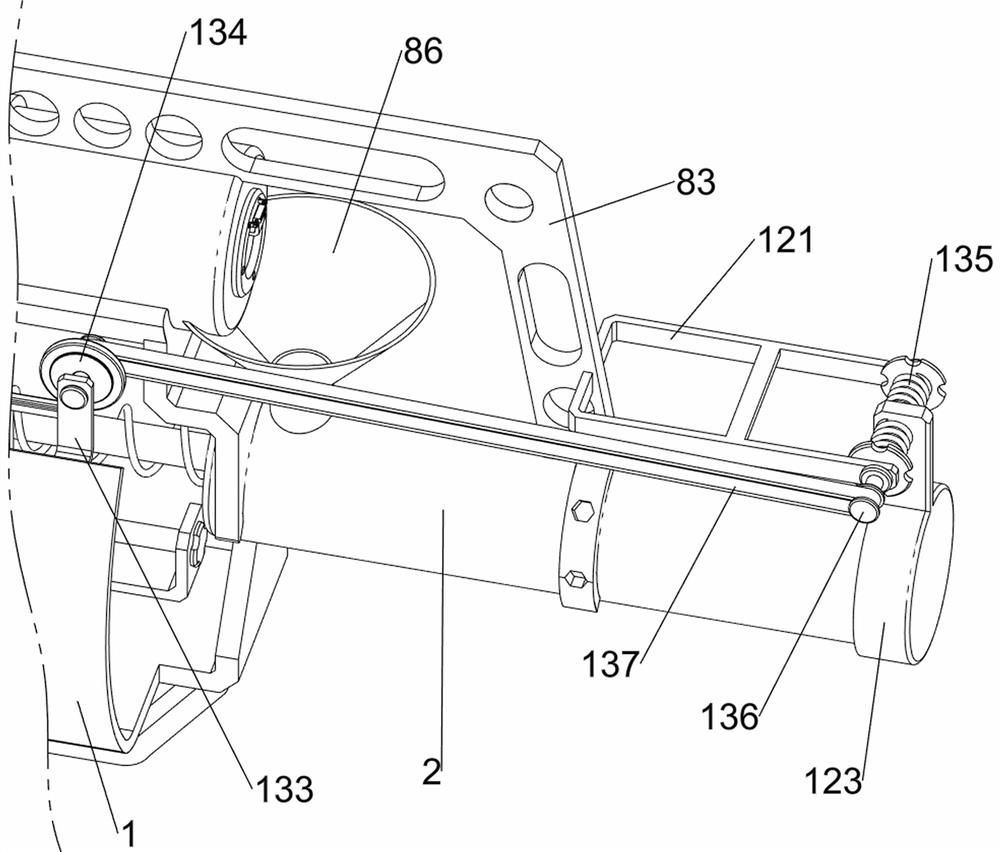

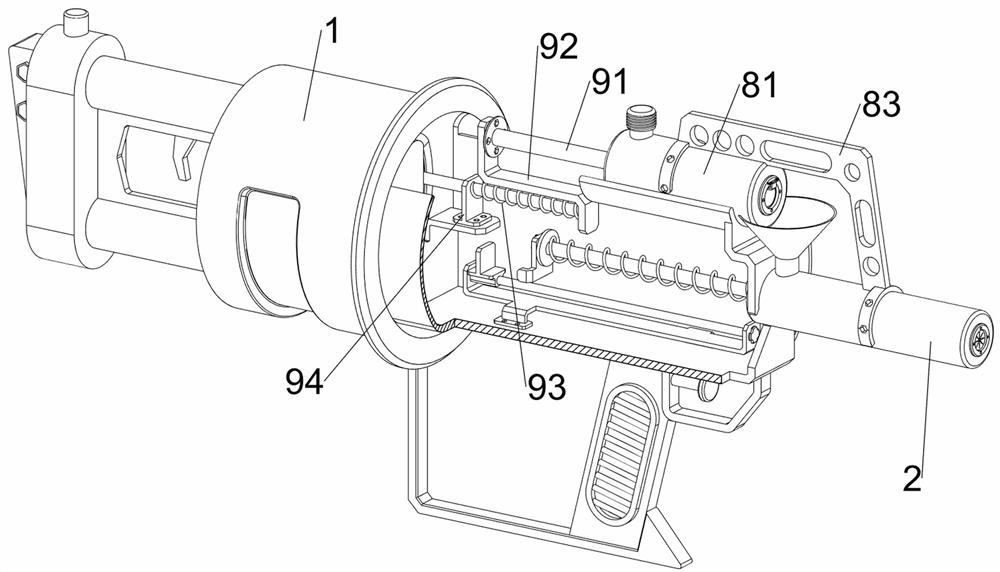

Production system of hub bearing

ActiveCN106050920ANo need for manual operationFast productionLiquid surface applicatorsGrinding carriagesThrust bearingEngineering

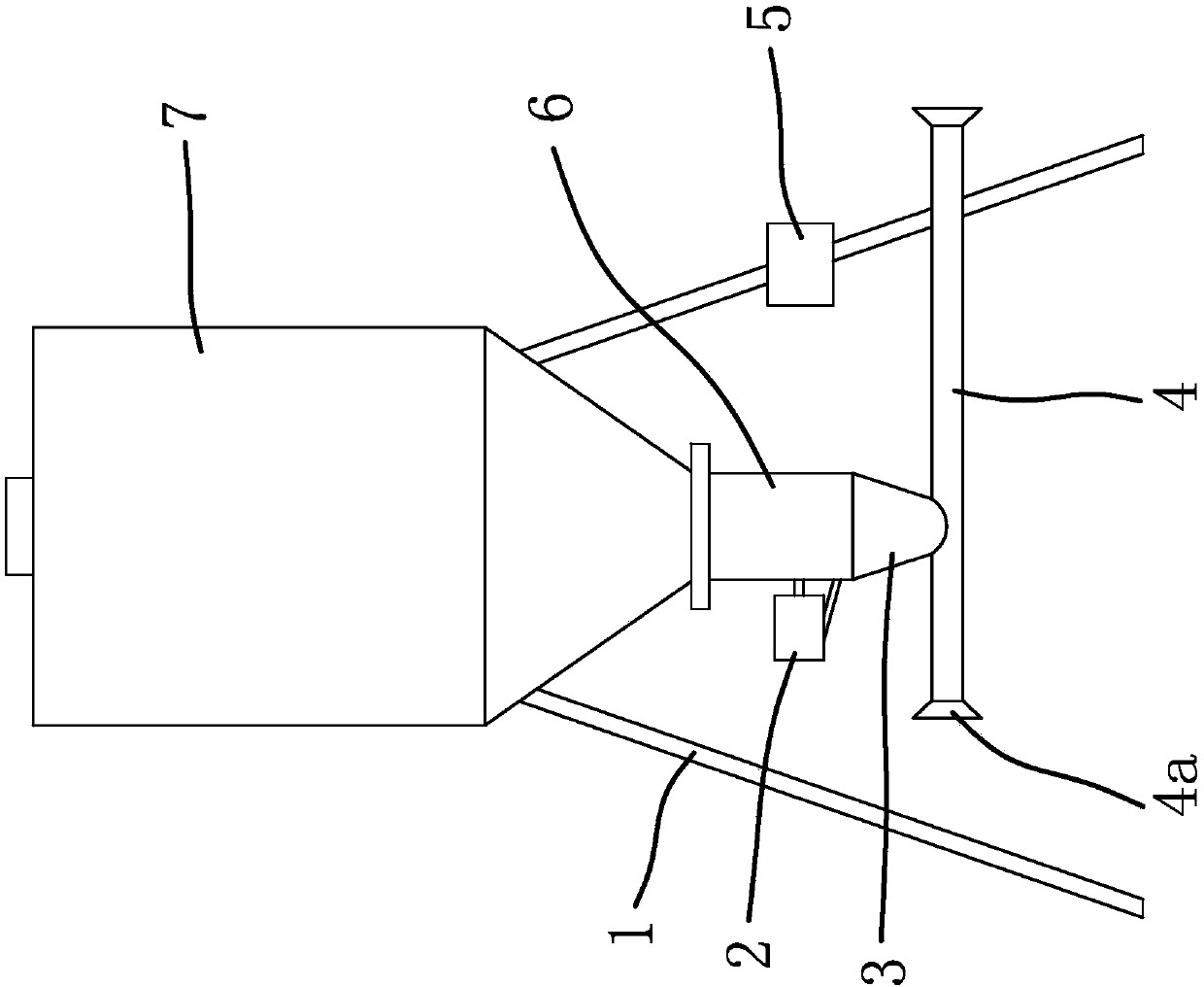

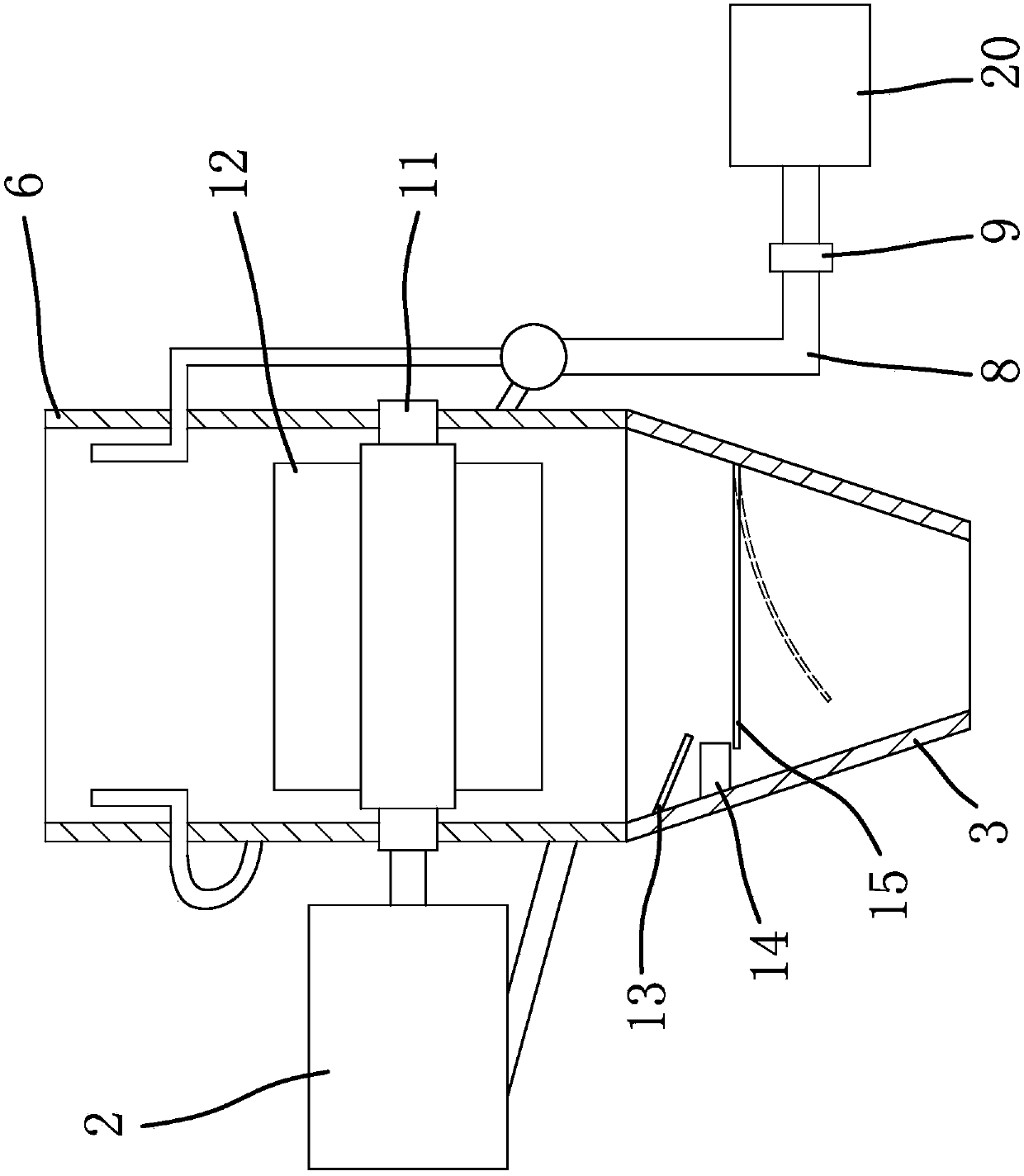

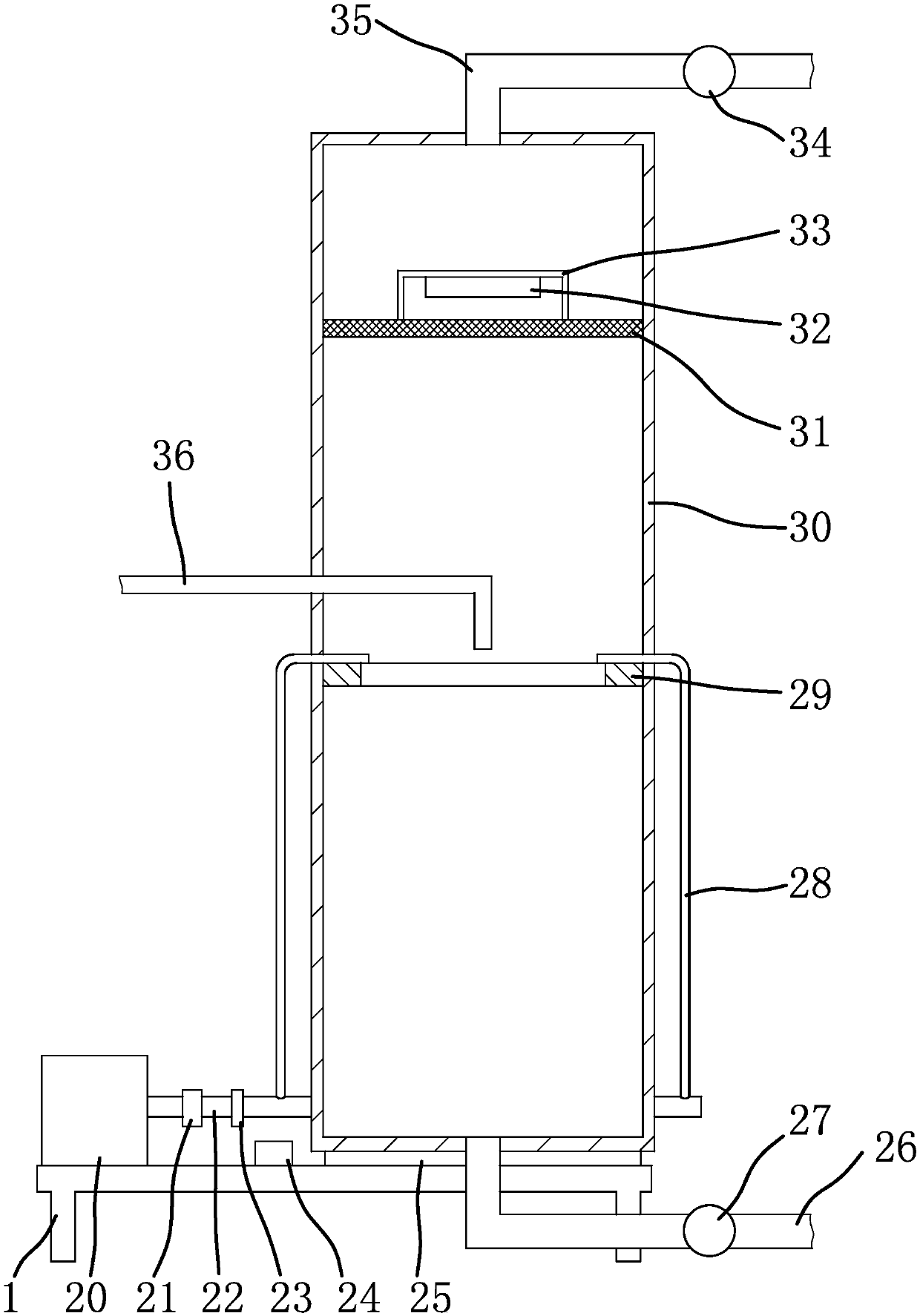

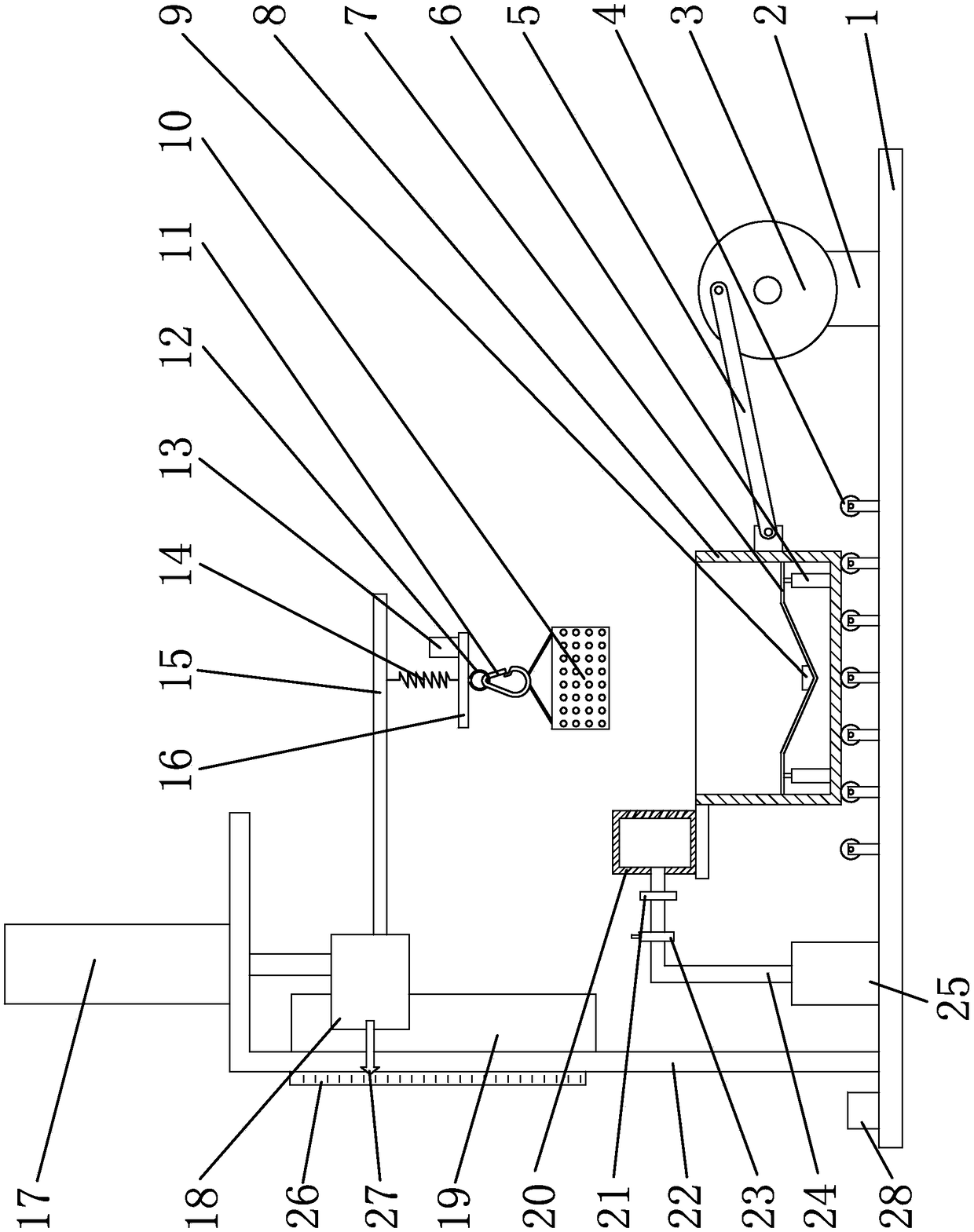

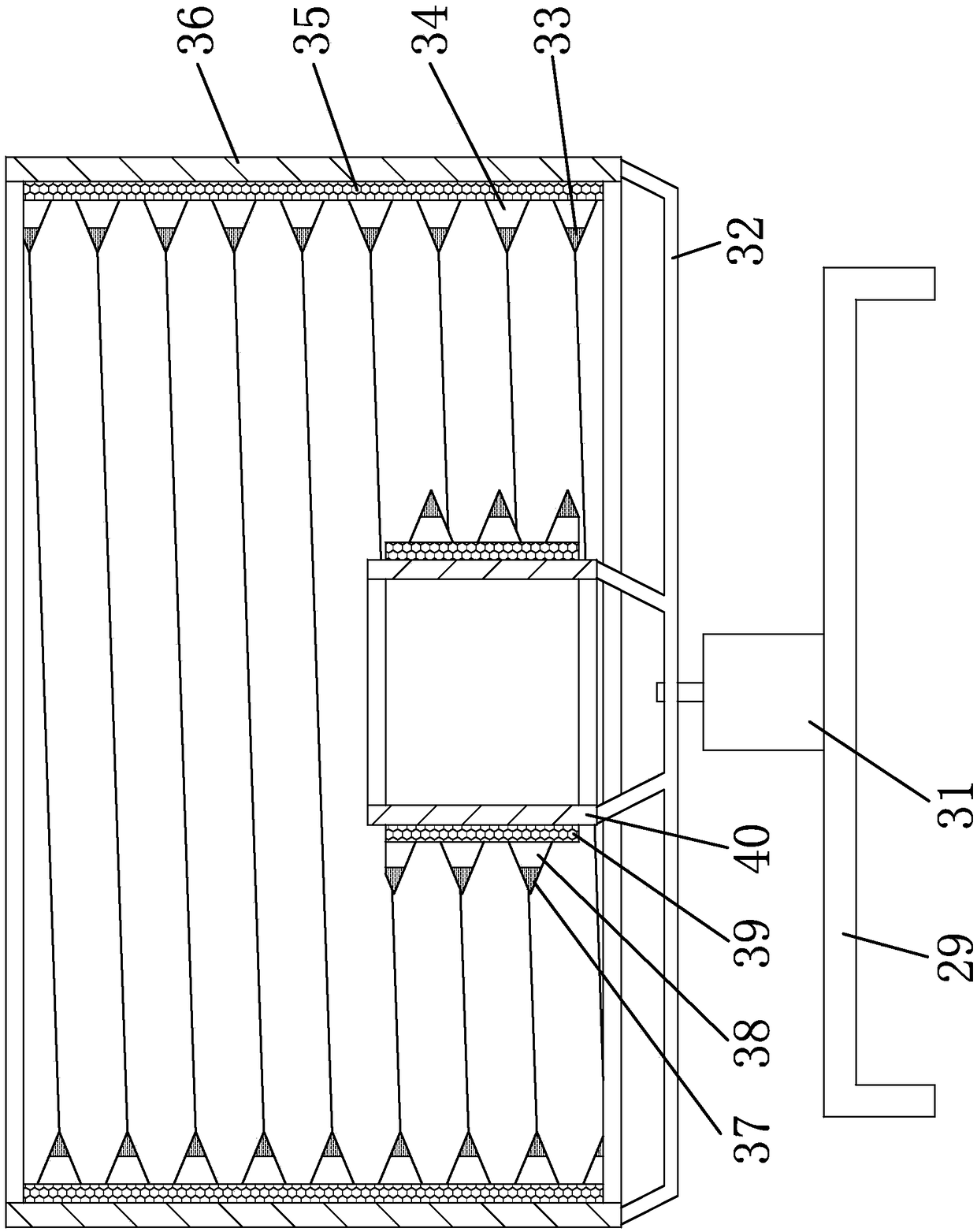

The invention provides a production system of a hub bearing, in order to solve the technical problems that the hub bearing is to be carried manually and the production speed is low because the structure of the conventional processing device is too simple. The production system of the hub bearing comprises a workbench, wherein an outer ring grinding device for grinding an outer ring of the hub bearing, an inner ring grinding device for grinding an inner ring of the hub bearing, a cleaning device for cleaning the hub bearing, a spraying device for spraying the hub bearing, and a detection device for detecting the hub bearing are sequentially arranged on the workbench. The production system has the advantage of high production speed.

Owner:嘉兴福可吉精密机械有限公司

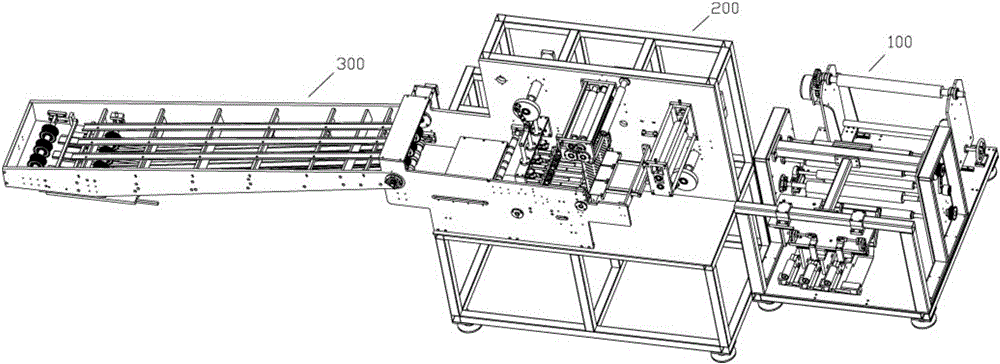

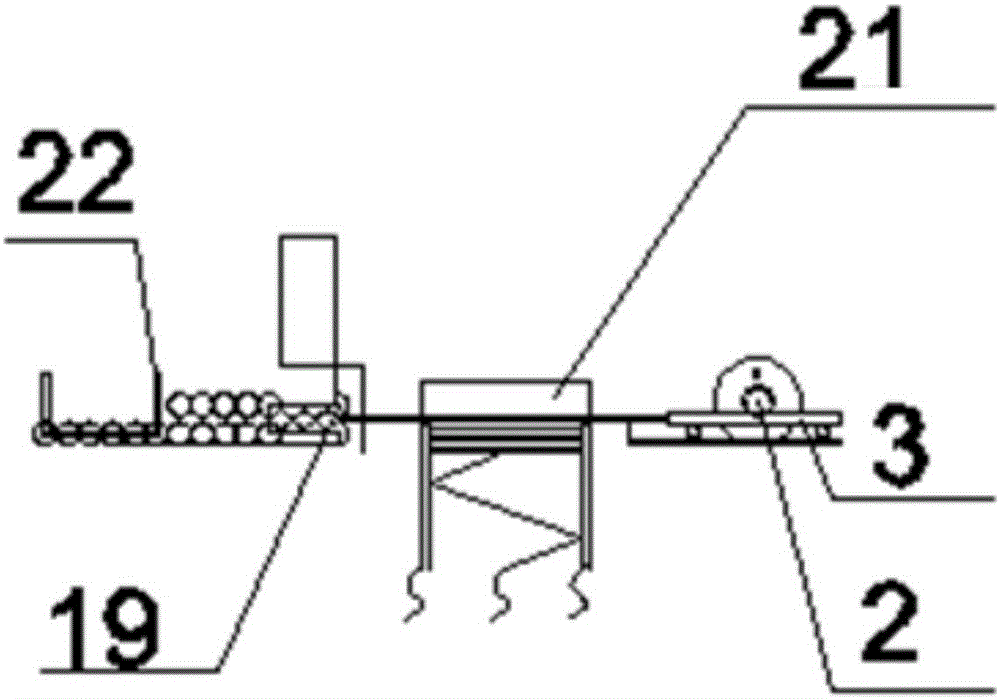

Non-woven fabric slitting, folding and conveying device

ActiveCN104986501AImprove efficiencyNo need for manual operationConveyorsSevering textilesEngineeringNonwoven fabric

The invention discloses a non-woven fabric slitting, folding and conveying device which comprises a slitting mechanism, a folding mechanism and a conveying mechanism. The slitting mechanism comprises a slitting machine frame. Two loading plates are arranged above the rear portion of the slitting machine frame. The two ends of a feeding roller are hinged to the two loading plates. One end of the feeding roller is fixedly provided with a transmission gear. A driving servo motor is fixedly arranged on one loading plate. A driving gear is fixedly arranged on an output shaft of the driving servo motor and meshed with the transmission gear. Two slitting middle supporting plates are fixedly arranged in the middle of the slitting mechanism. A plurality of transmission rollers are hinged to the two slitting middle supporting plates. A servo motor is fixedly arranged on one slitting middle supporting plate. A slitting driving wheel is fixedly arranged on an output shaft of the servo motor. The non-woven fabric slitting, folding and conveying device can slit non-woven fabric, then fold and cut off the non-woven fabric repeatedly and convey the non-woven fabric to packaging equipment and is high in efficiency, safe and reliable, no manual operation is needed, and the labor cost is lowered.

Owner:ZHENDE MEDICAL CO LTD

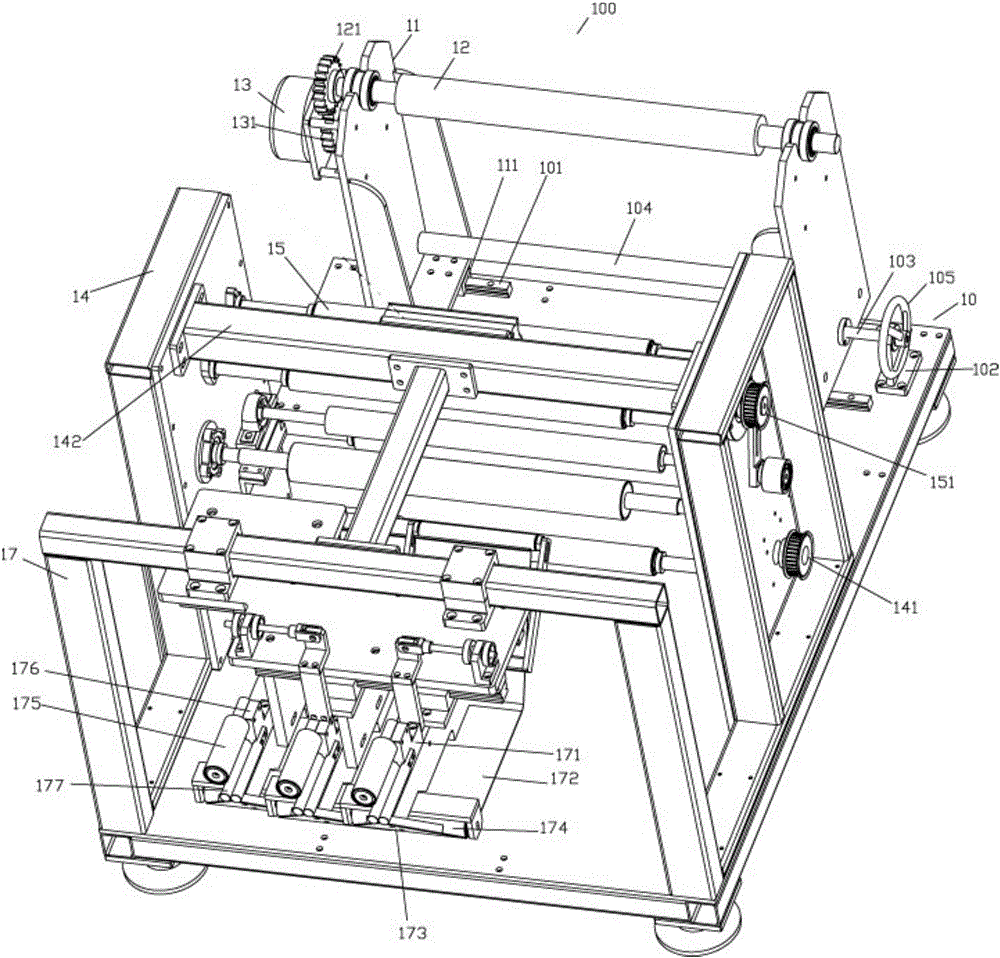

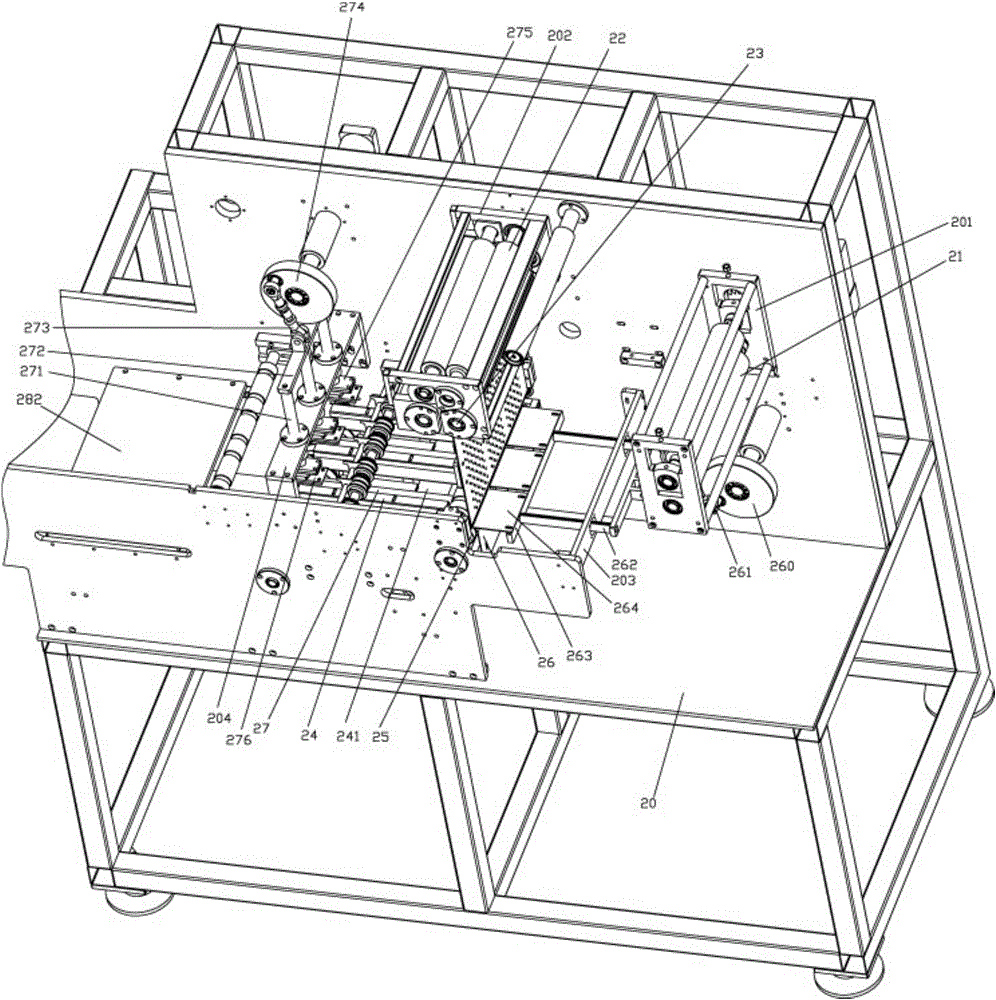

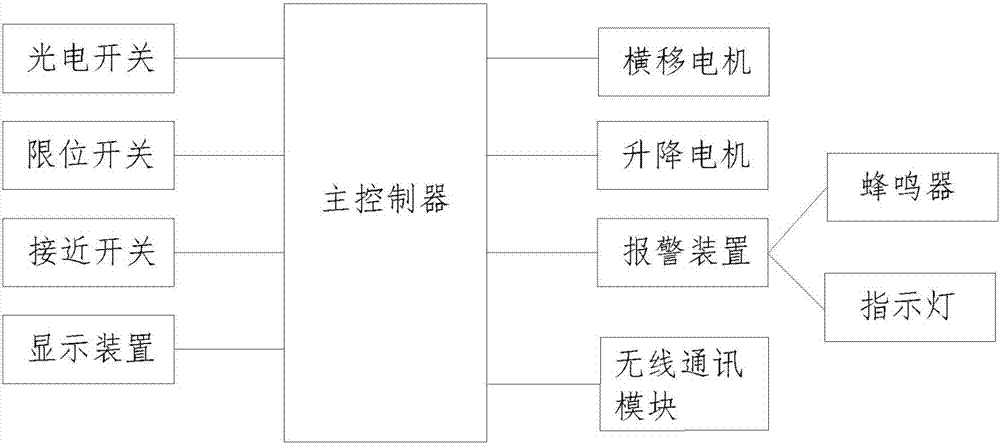

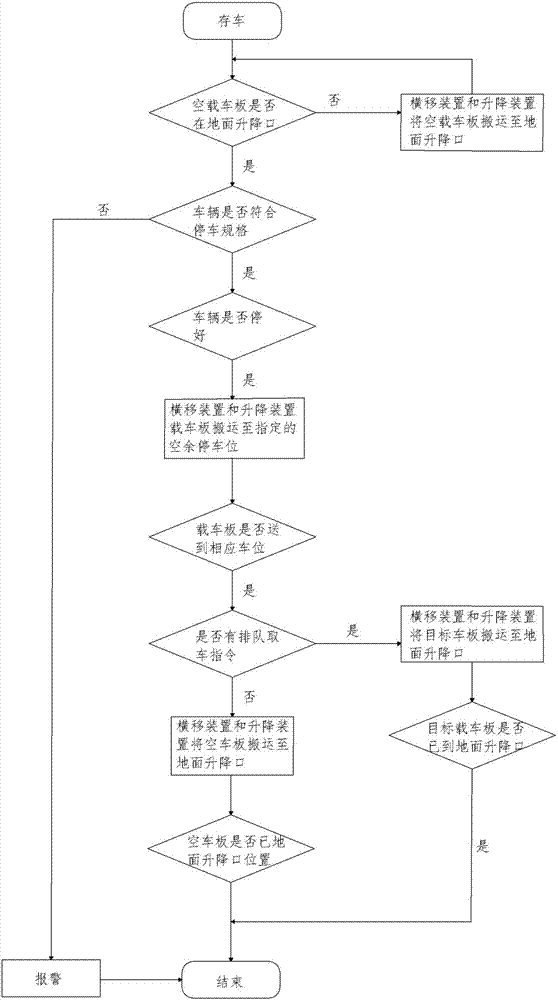

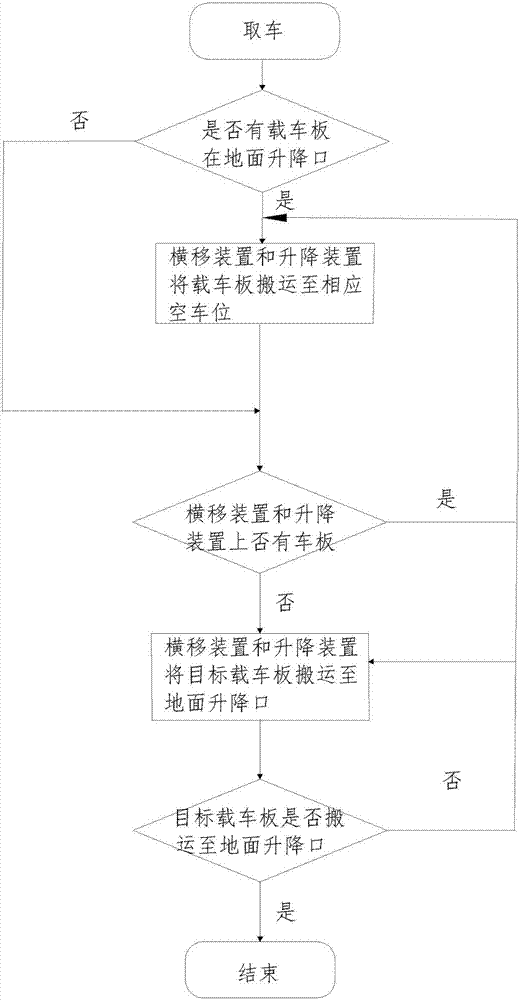

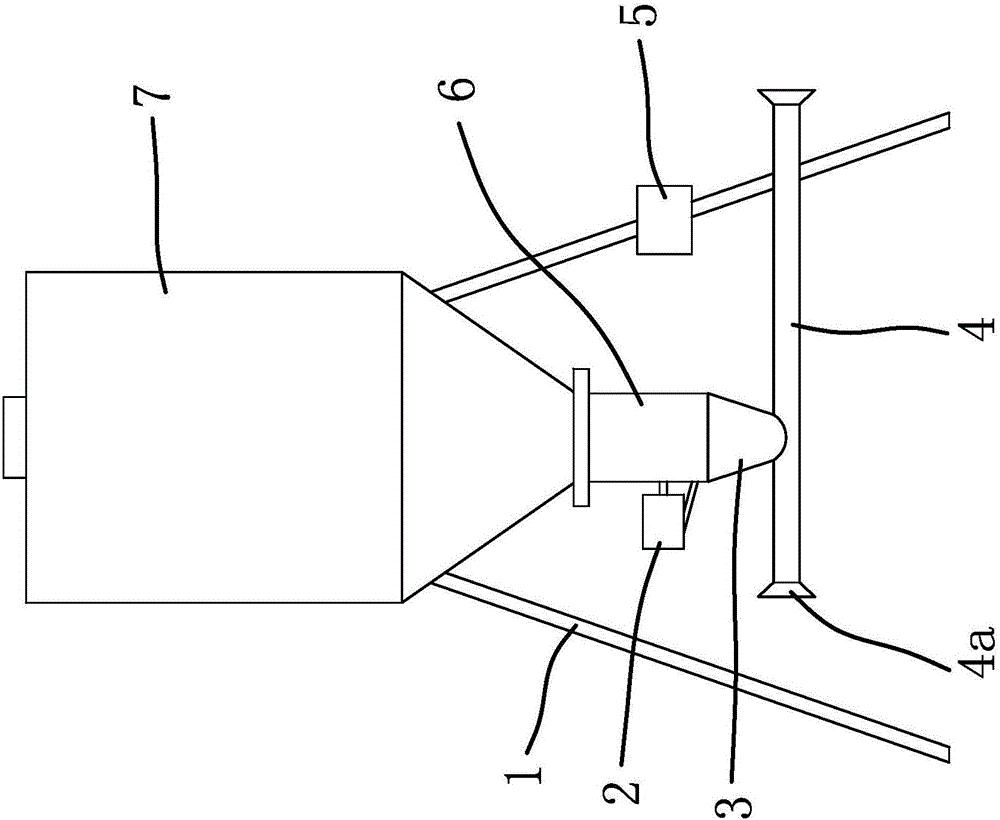

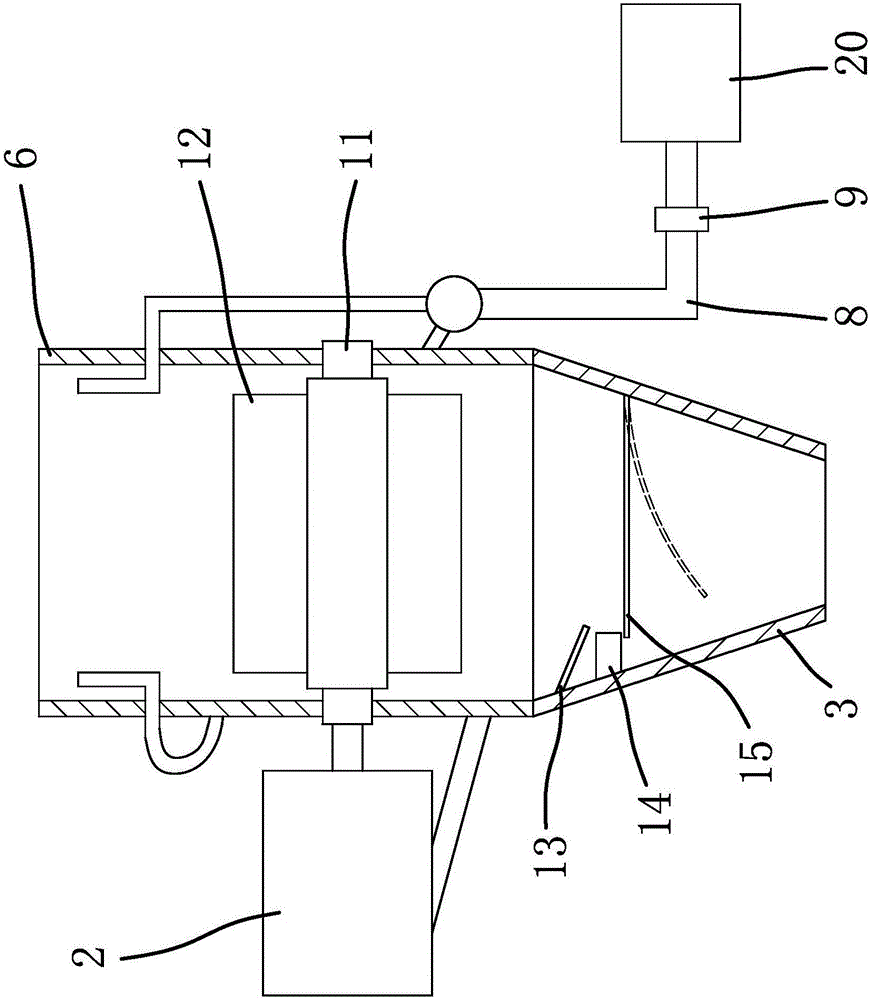

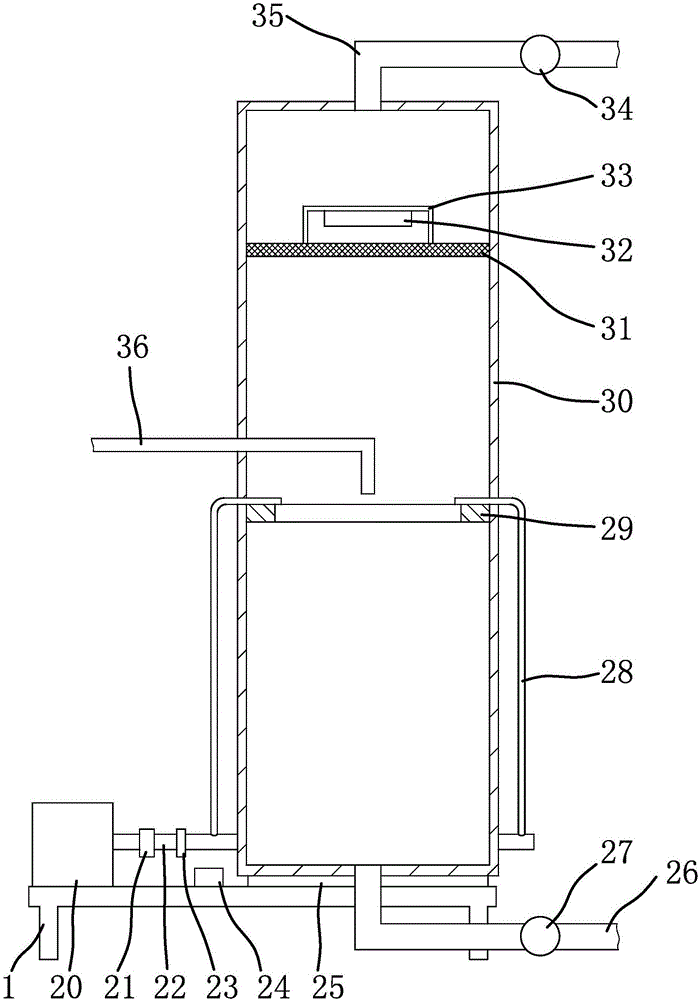

Control system and control method for automatic vehicle access of stereo garage

PendingCN107246169ANeatly parkedNot easy to dropProgramme control in sequence/logic controllersParkingsControl systemControl engineering

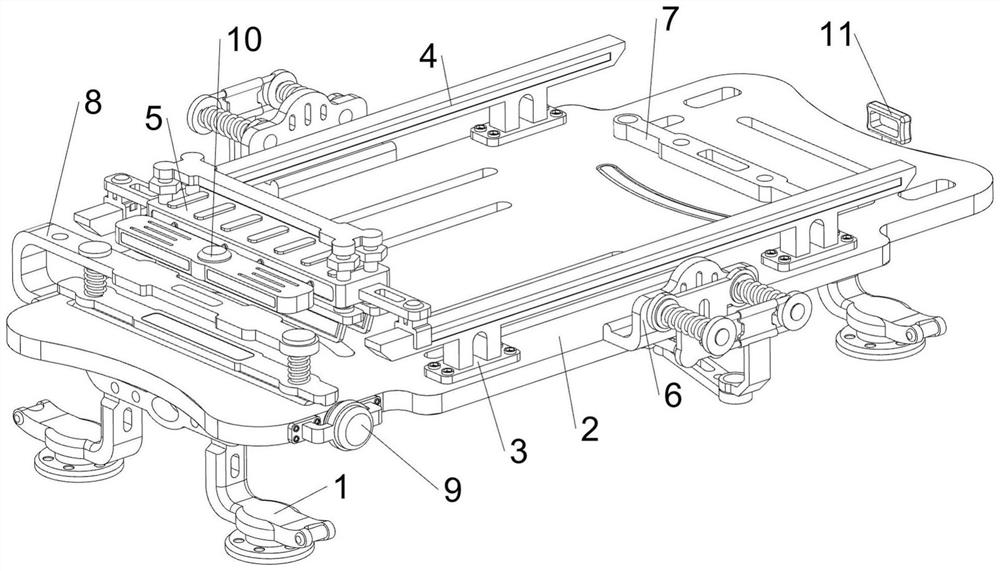

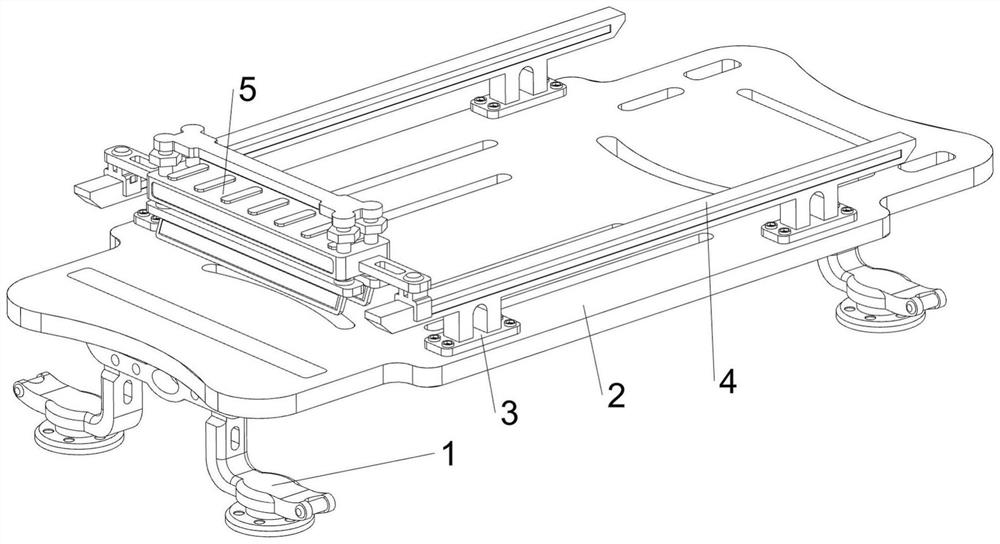

The invention discloses a control system and a control method for automatic vehicle access of a stereo garage. A stereo garage is provided with transverse shifting devices, lifting devices, positioning detection devices, and alarm devices to realize automatic parking and automatic vehicle taking. Through the positioning detection devices, whether the position of a vehicle in a vehicle carrying board meets requirement is determined, and the position of the vehicle entering the vehicle carrying board is stipulated, so vehicle parking is in order, and vehicles stop in normative positions and are safer. When the vehicles move transversely or lift, the vehicles do not easily drop, the whole process complete automatically, manual command and operation is not needed, manpower cost is greatly saved, and vehicle storage and taking processes are more convenient and faster.

Owner:GUANGDONG MINGHE INTELLIGENT EQUIP CO LTD

Preparation method for diatom ooze

The invention provides a preparation method for diatom ooze. The technical problems that an existing preparation method is complex in step and low in production speed, and manual operation is required are solved. Diatomite is adopted as the raw material. The preparation method for diatom ooze includes the following steps of a, airflow crushing; b, screening; c, premixing of additives; and d, anion stirring. The preparation method has the advantage of being high in production speed.

Owner:广东莫尼安家居科技有限公司

Round pipe welding clamping device

InactiveCN112427845AEffective distributionEasy to circulate refrigeration needsWelding/cutting auxillary devicesAuxillary welding devicesCold airEngineering

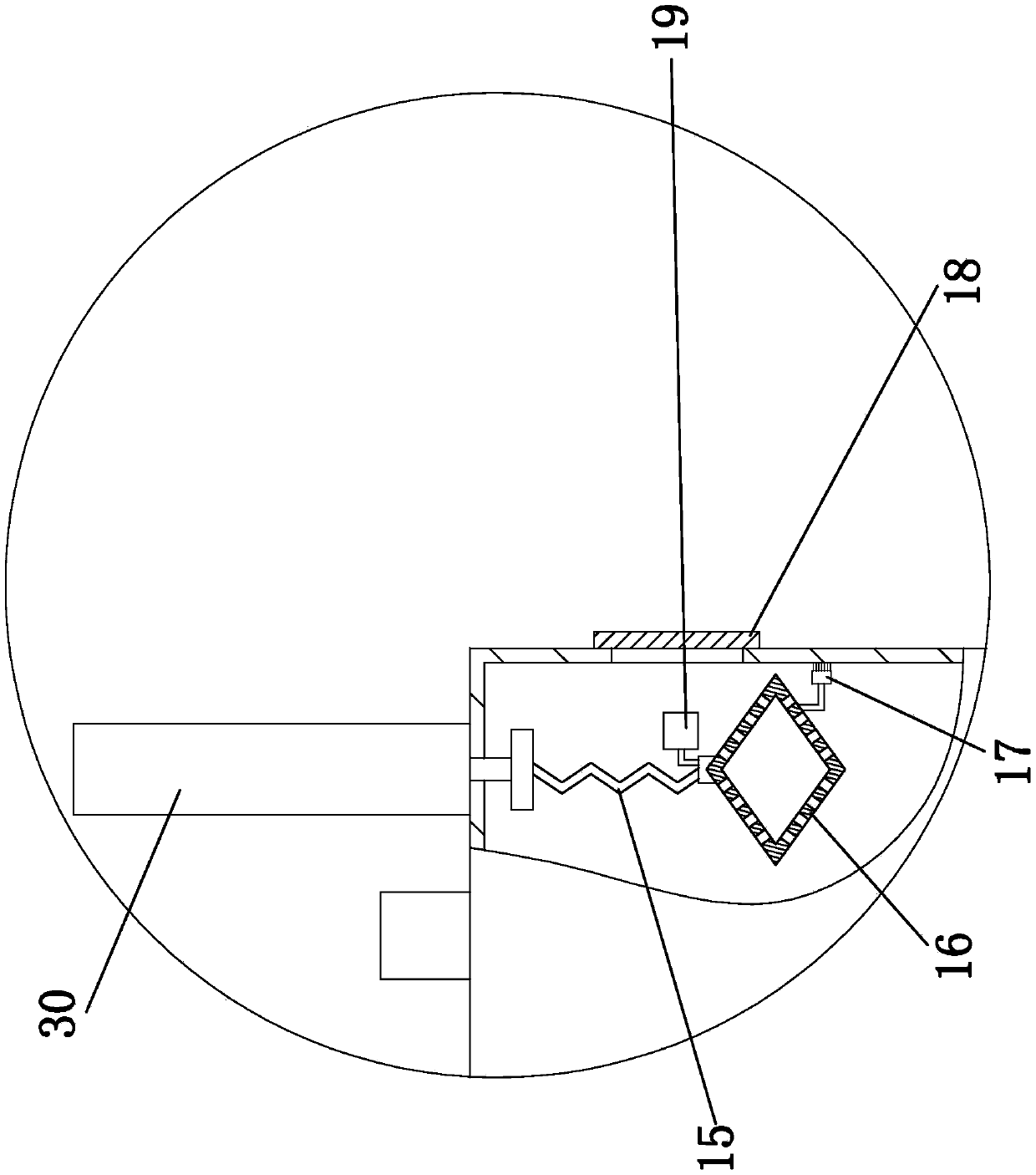

The invention discloses a round pipe welding clamping device, and belongs to the technical field of round pipe welding assistance. A round pipe is arranged between a pair of hollow annular jackets, apneumatic suction mechanism is matched with a semiconductor refrigeration box to supply air into the hollow annular jackets, cold air overflows into a hollow cavity and continuously presses a plurality of annularly arranged piston driving mechanisms to push heat conduction arc-shaped clamping pieces to move towards the outer side so as to clamp and fix the round pipe, and cold air guided into thehollow cavity is matched with the heat conduction arc-shaped clamping pieces, so that heat generated by welding of the circular pipe is effectively dissipated outwards for cooling and heat dissipation; and meanwhile, after welding, the interior of the hollow cavity is in a negative pressure state through back suction operation of the pneumatic suction mechanism, on one hand, the multiple heat conduction arc-shaped clamping pieces are effectively moved towards the inner ends of the hollow annular jackets and separated from the outer wall of the circular pipe, and on the other hand, heated air in the hollow cavity is led out to be replaced, so that the requirement for next circulation refrigeration is met.

Owner:广西天正钢结构有限公司

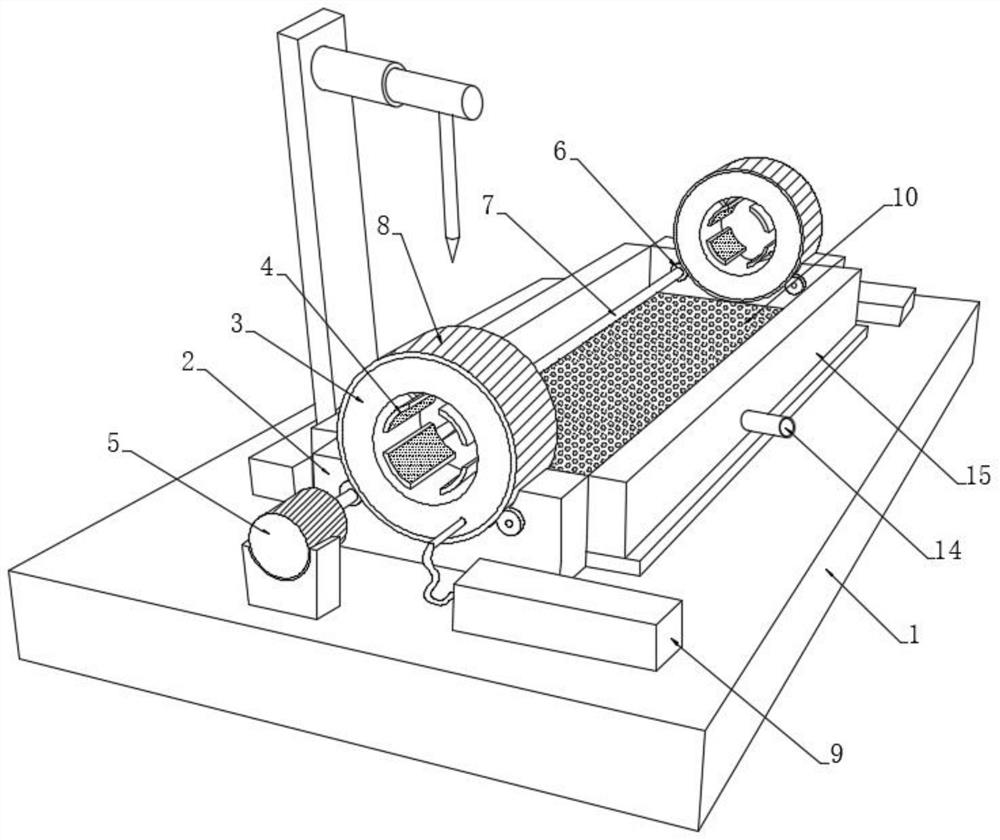

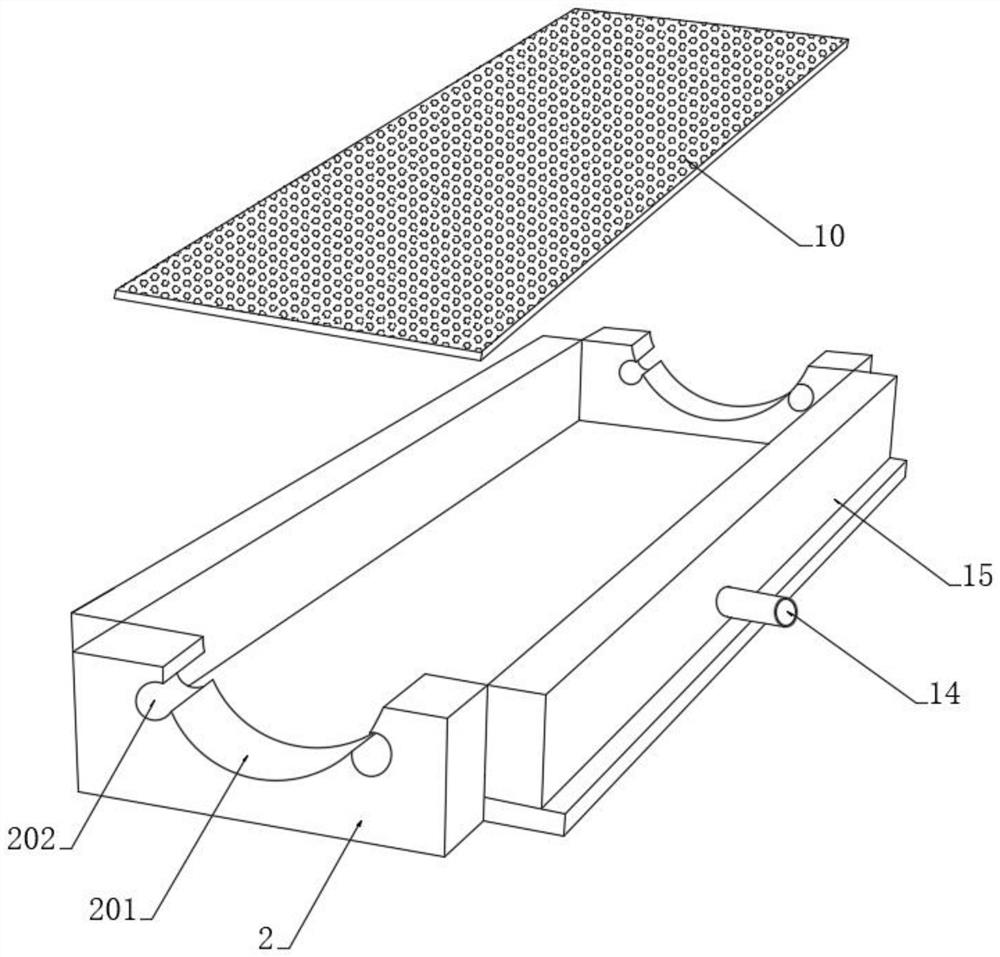

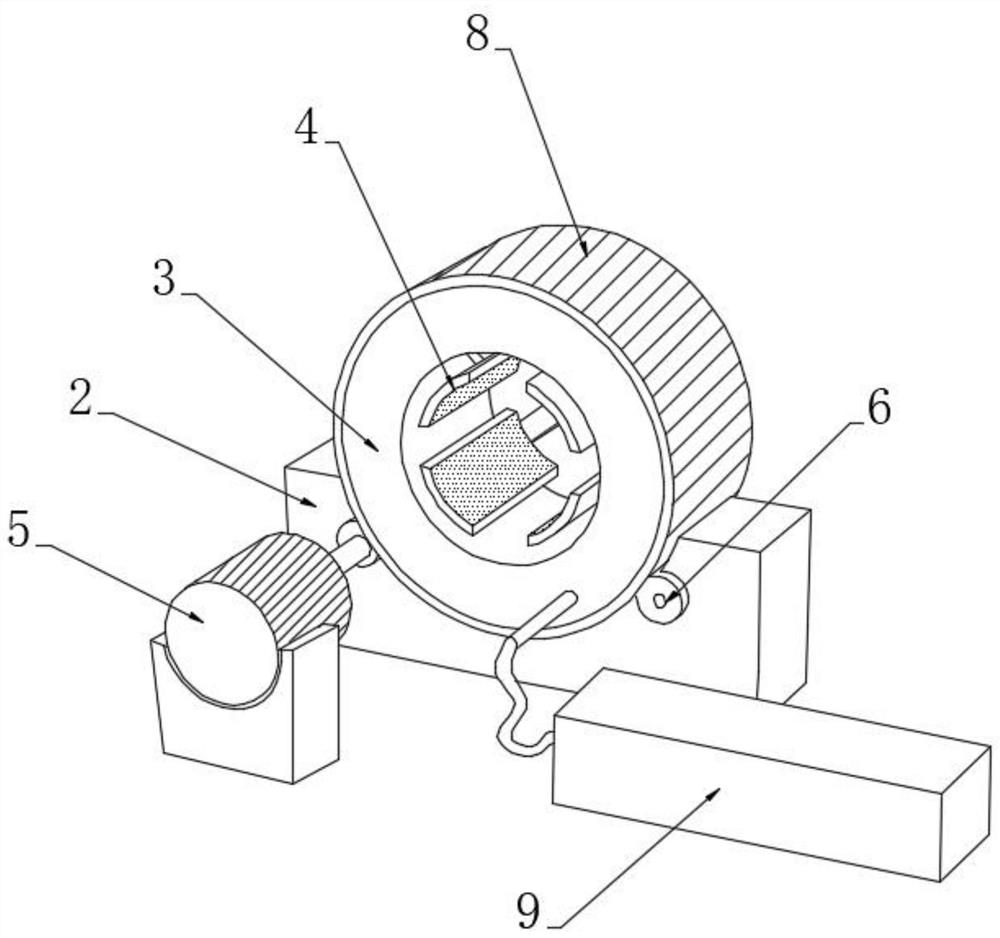

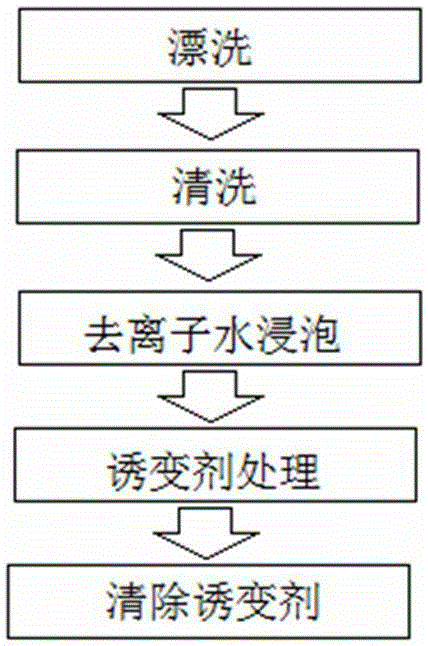

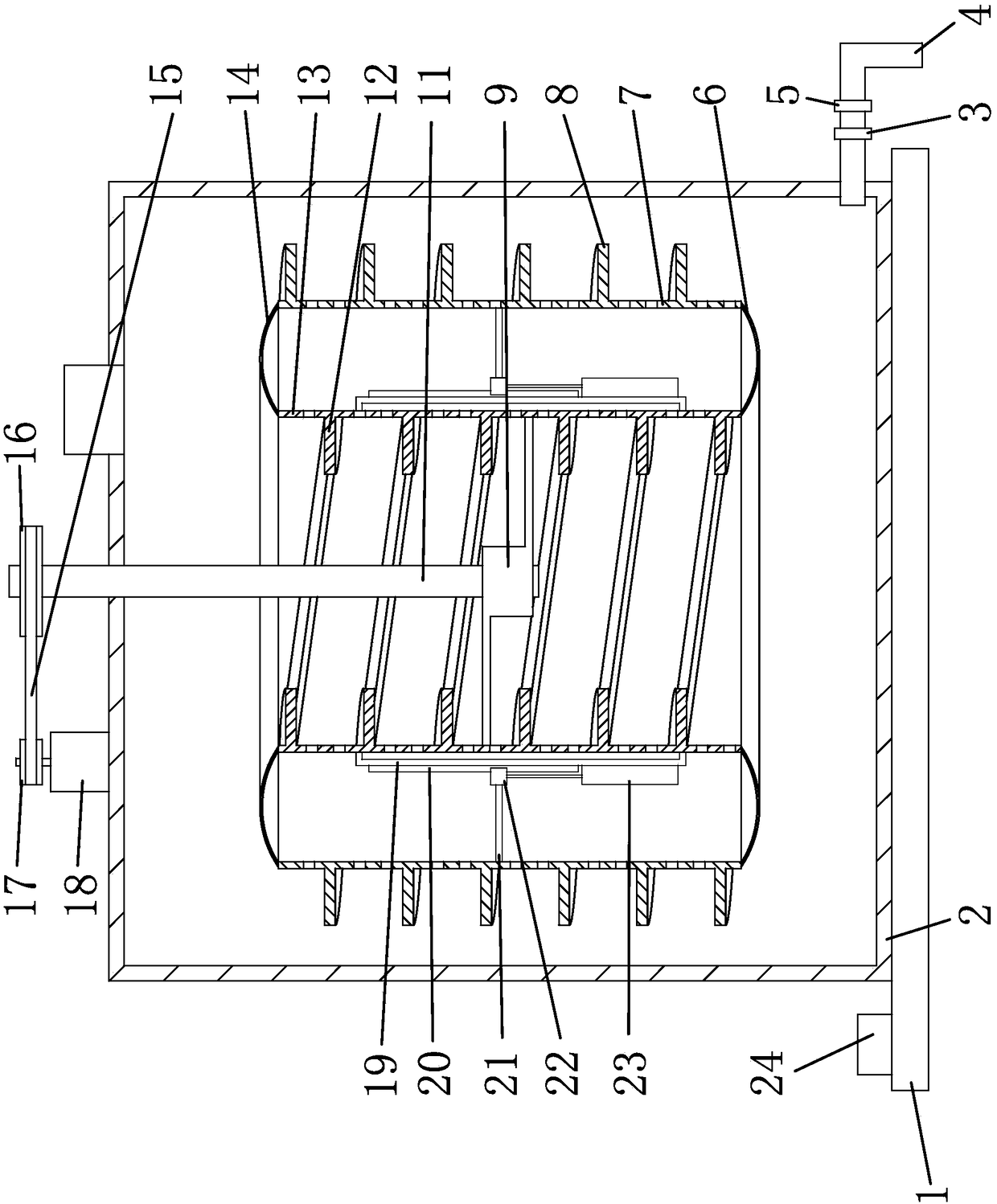

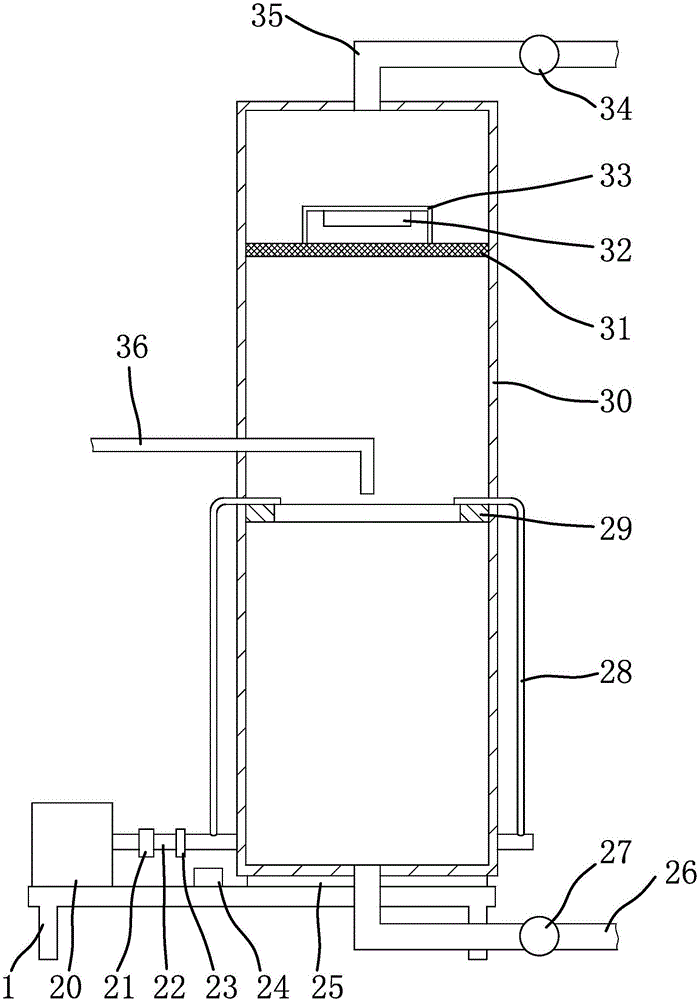

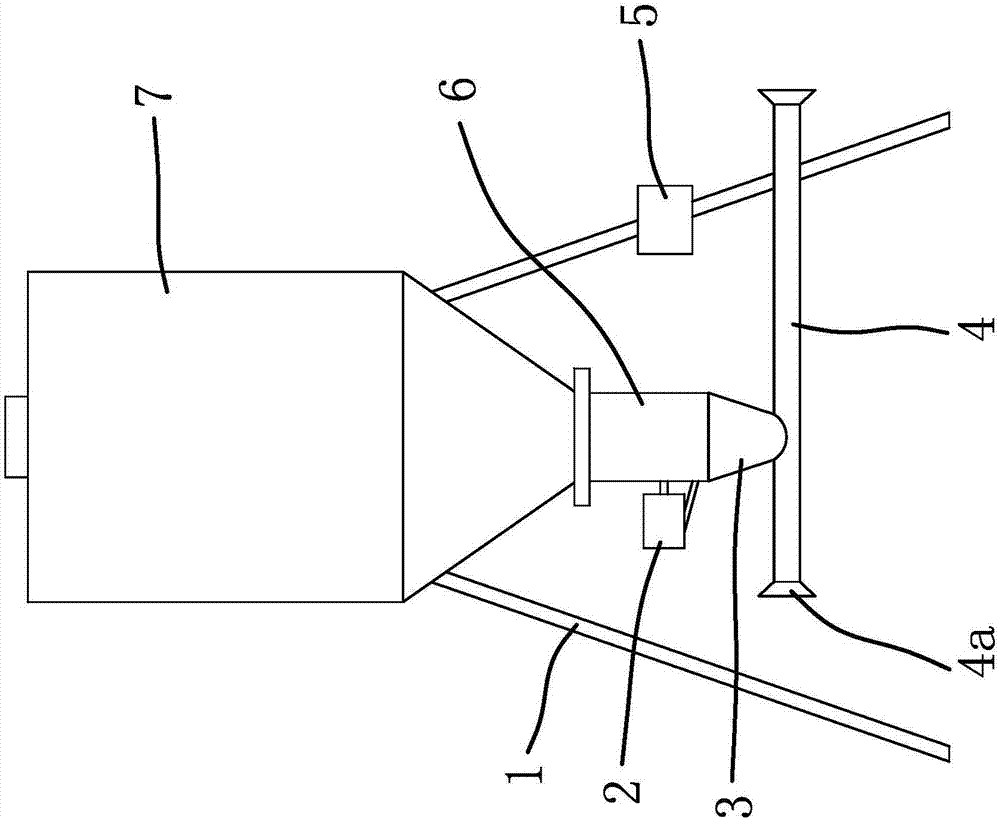

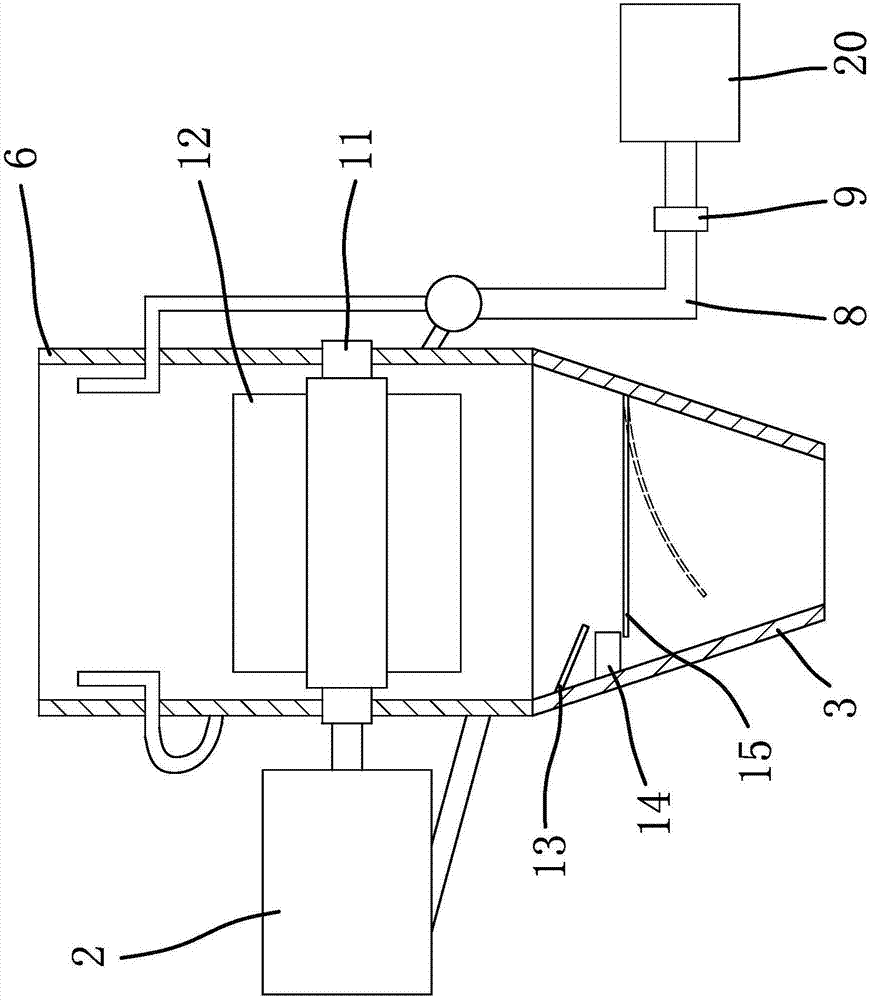

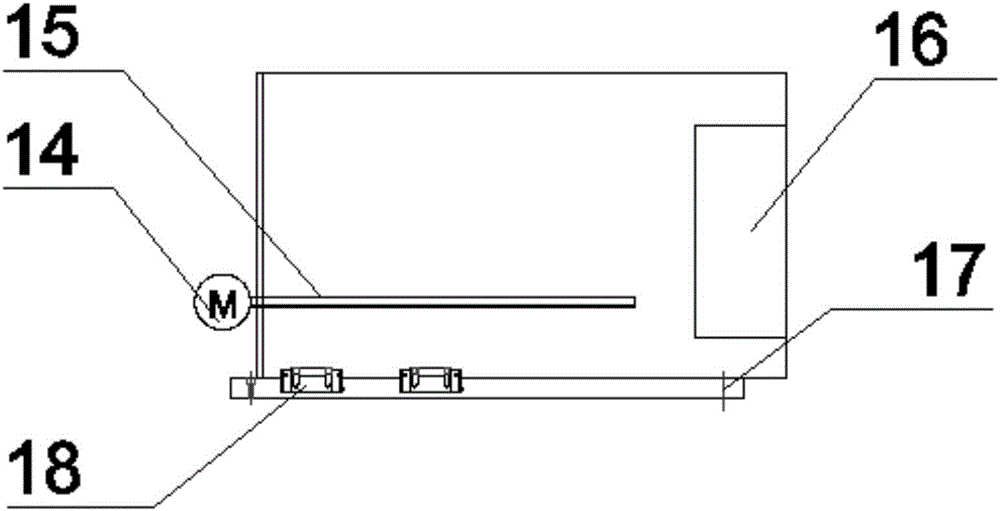

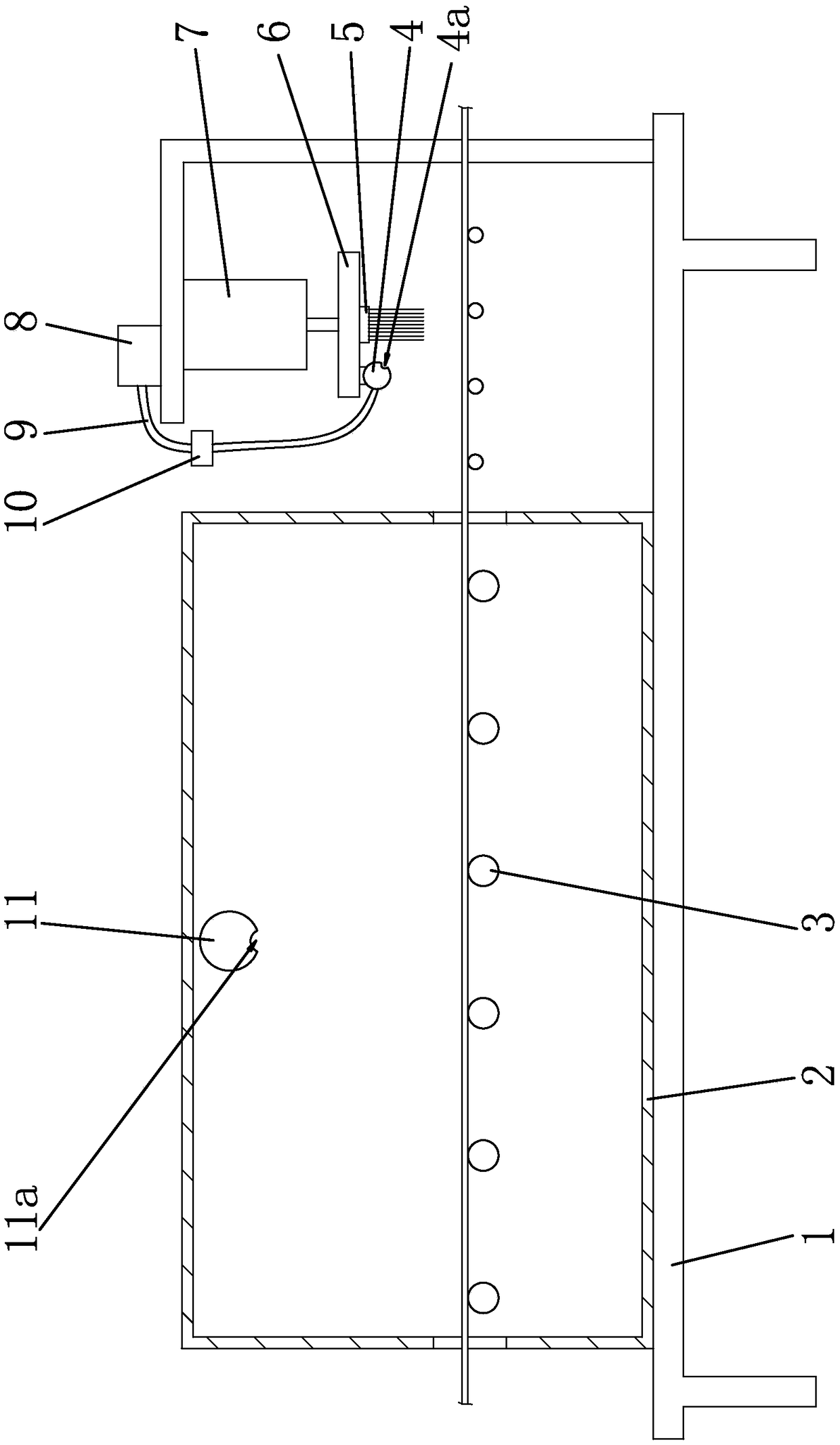

Plant seed mutagenesis method and device

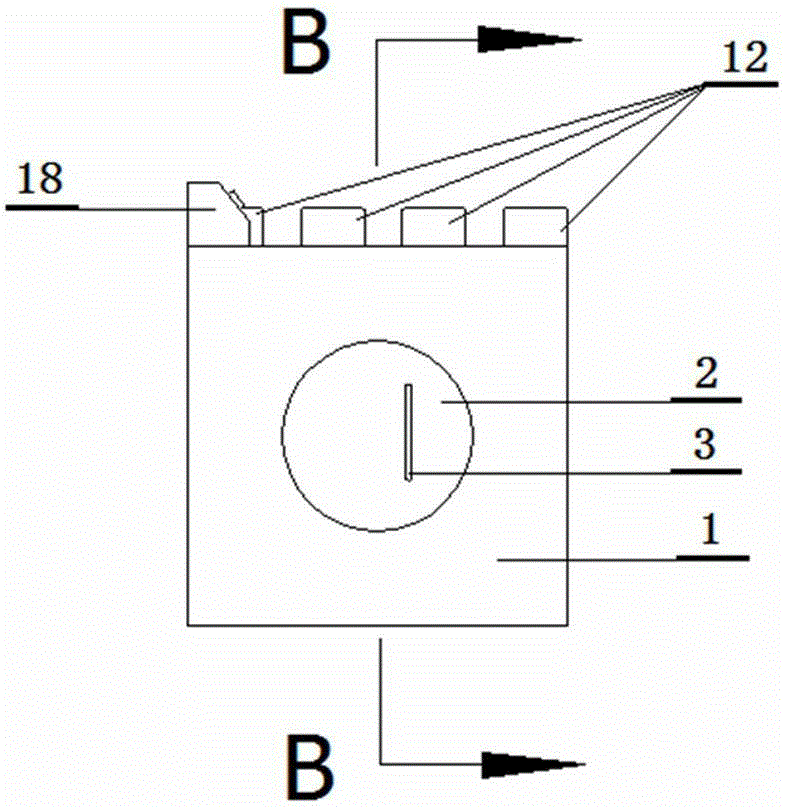

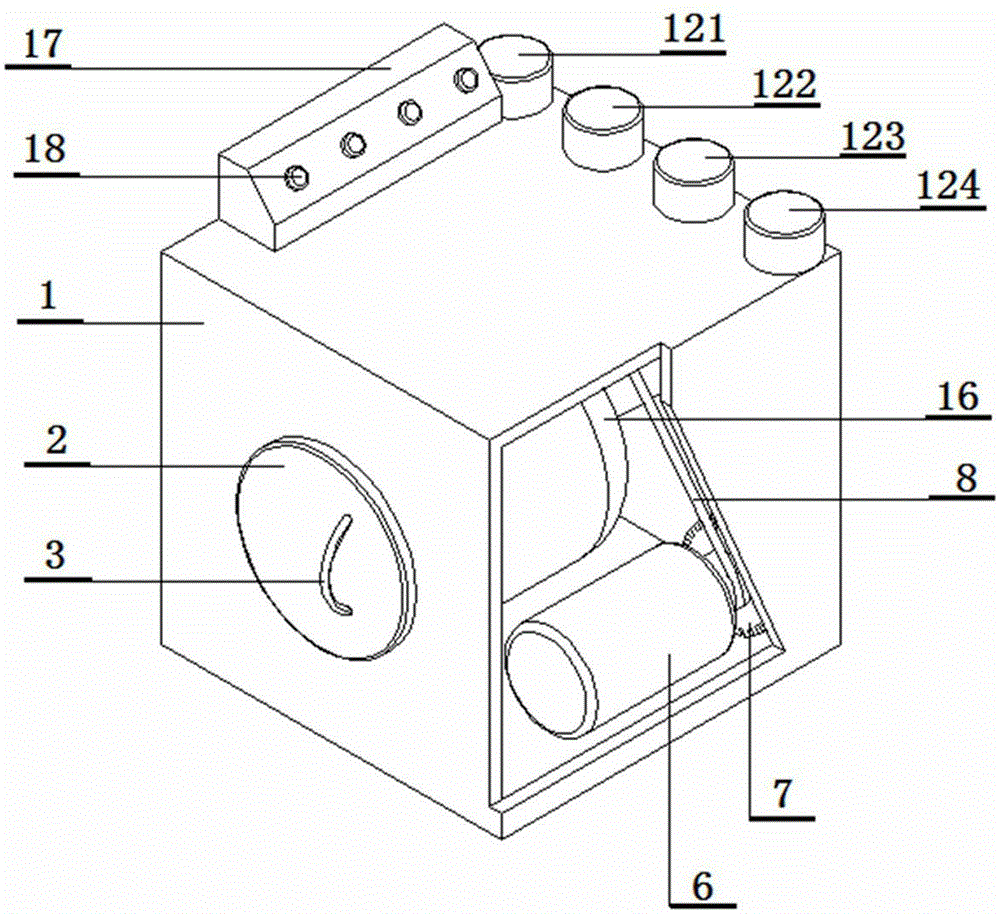

ActiveCN105210862APromote germinationEliminate mutagen completelyPlant genotype modificationElectric machineryDrive motor

The invention discloses a plant seed mutagenesis method and device. The method provided by the invention includes the steps of: rinsing; cleaning; soaking in deionized water; mutagen treatment; and mutagen removal. The device provided by the invention includes: a box, a roller and a driving motor. The box is provided with the roller, the roller is connected to the driving motor, the roller is in connection with a water supply pipe and a water outlet pipe, the water supply pipe is provided with a treatment agent pipe that is communicated with a treatment agent box, and the treatment agent pipe is equipped with a feeding gate valve, which is connected to an automatic controller. According to the invention, the driving motor drives the roller, the roller rotates to stir a seed treatment liquid so as to conduct mutagenesis on seeds. The water supply pipe communicated with the roller is connected to the treatment agent pipe, the treatment agent pipe is provided with the feeding gate valve, and the automatic controller controls the feeding gate valve, the roller and other components so as to adapt to each step of seed mutagenesis and realize full automation of the seed mutagenesis treatment process. Without the need of long-term artificial operation, the method and the device reduce the labor intensity, and guarantee that the technical staff can avoid mutagen damage.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

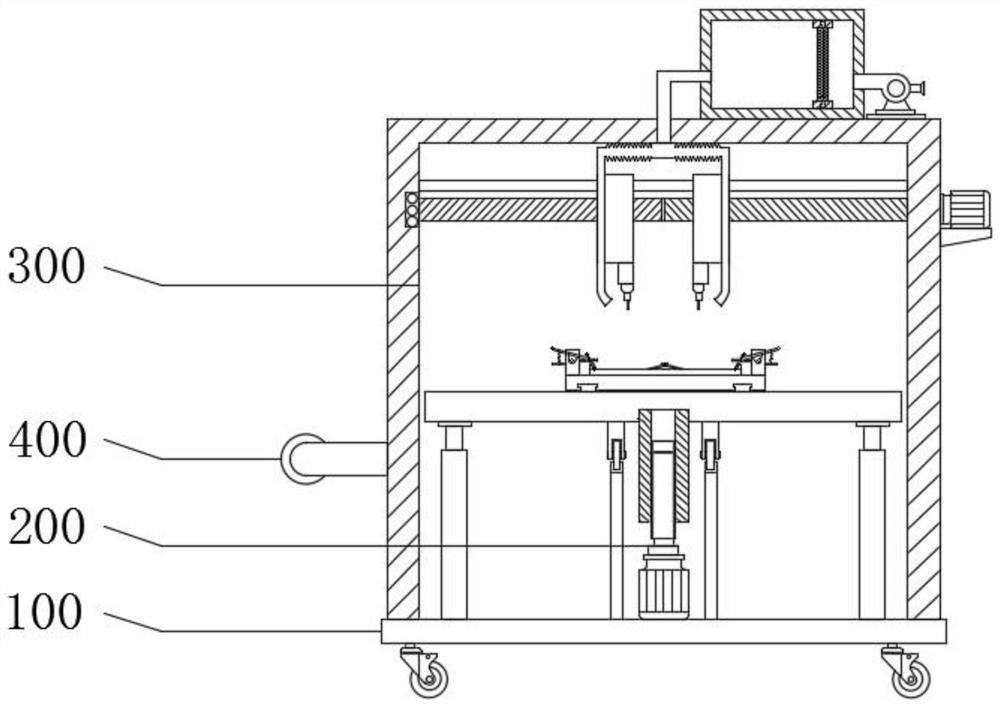

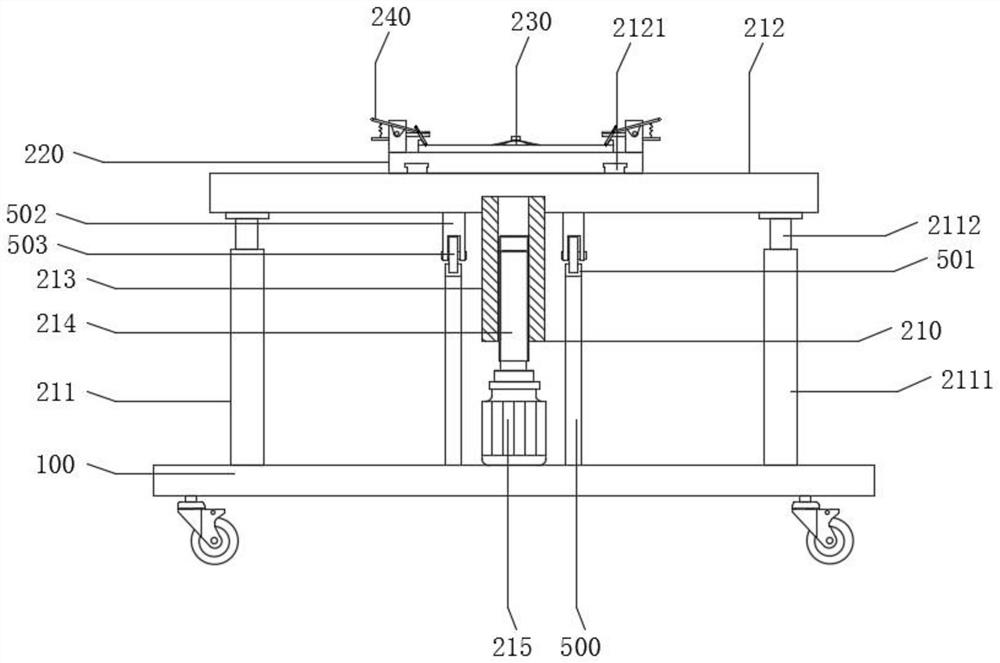

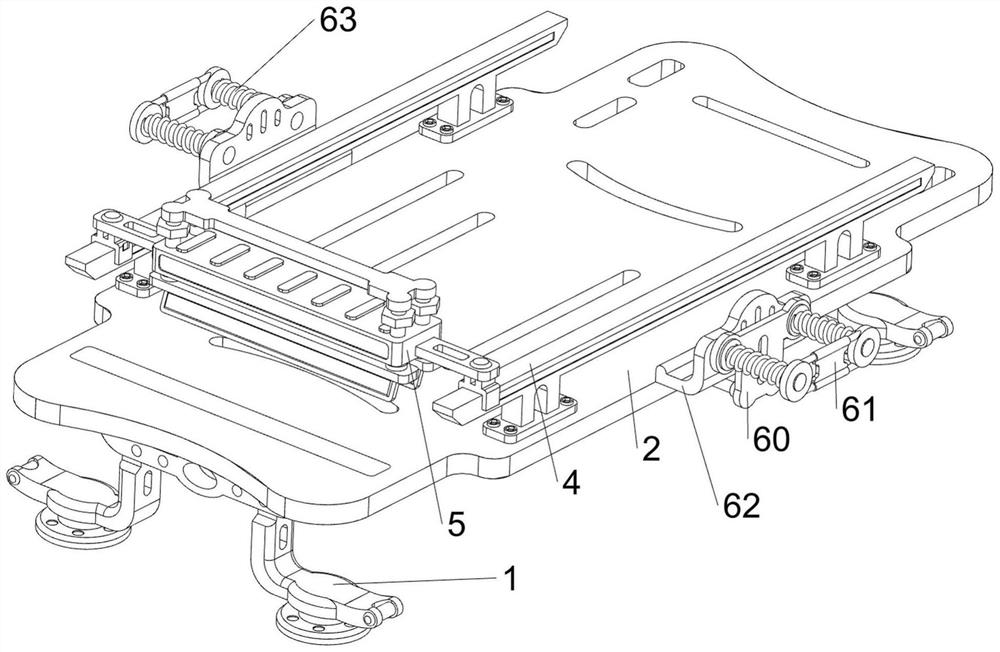

Automatic stripping and laser drilling equipment for LCP flexible circuit board

InactiveCN113385841AStripping to achieveNo need for manual operationDispersed particle filtrationWelding/cutting auxillary devicesFlexible circuitsStructural engineering

The invention provides automatic stripping and laser drilling equipment for an LCP flexible circuit board, and belongs to the technical field of circuit board machining. The laser drilling equipment for the LCP flexible circuit board comprises a base, a fixing assembly and a laser drilling assembly. The fixing assembly comprises a lifting piece, a sliding table, an electric push rod and a clamping piece. The sliding table is driven by the lifting piece to descend, in the descending process, a jacking column moves along with the sliding table, when a supporting roller at the lower end of the jacking column makes contact with a supporting guide rail at the upper part of a supporting column, the supporting guide rail generates supporting force on the supporting roller and the jacking column, and along with downward movement of the sliding table, the jacking column jacks a stripping plate upwards, the drilled LCP flexible circuit board on the sliding table is ejected through the stripping plate, stripping of the LCP flexible circuit board is achieved, manual stripping is not needed, and the production efficiency is greatly improved.

Owner:聂三磊

Environment friendly oil pipeline processing equipment

PendingCN108453578ALight in massReduce volumeGrinding machine componentsRevolution surface grinding machinesGear wheelPetroleum engineering

The invention discloses environment friendly oil pipeline processing equipment which comprises an oil pipeline inner wall chamfer and burr removing device. The device comprises a positioning fixing barrel, a first rotating shaft is fixedly installed at the center position of the surface of a fixing plate at the middle portion of the inner surface of the side wall of the positioning fixing barrel,a tooth sleeve base is fixedly installed at the top end of the first rotating shaft, and a driving bevel gear is fixedly installed at the bottom end; and meanwhile, a second rotating shaft is fixedlyinstalled at the position, on the outer surface of the side wall of the lower portion of the fixing plate, of the positioning fixing barrel in an equal-angle manner, one end of the second rotating shaft is fixedly connected with a first bevel gear meshed with the driving bevel gear, the other end of the second rotating shaft is fixedly connected with a limiting screw through a bearing, and the limiting screw is provided with a limiting chamfer removing mechanism. According to the environment friendly oil pipeline processing equipment, during oil pipeline molding monitoring, chamfers and burrson the inner wall of the oil pipeline can be polished, the mass is small, the size is small, monitoring can be achieved in real time, polishing at any time can be achieved, the oil pipeline does not need to be moved additionally for polishing, one person can complete the operation, manpower and material cost is saved, and the working efficiency can be improved.

Owner:陈智彬

Machining device and machining process of motor stator punching sheet

PendingCN113976714ACompact structureReduce complexityMetal-working feeding devicesStripping-off devicesPunchingElectric machine

The invention discloses a machining device and a machining process of a motor stator punching sheet, relates to the field of motor stators, and aims to solve the problems that an existing machining device is complex in structure, large in size, high in operation difficulty, large in number of electric control devices, high in heat energy loss caused by long-term operation, high in energy consumption, and high in use cost. Due to the complex structure, in order to solve the problems of high later maintenance difficulty and high cost caused by many electric control devices, the invention provides the following scheme: the machining device comprises a punching machine table, a feeding mechanism, a linkage mechanism and a storage mechanism, and the punching machine table is in transmission connection with the feeding mechanism through the linkage mechanism; and the feeding mechanism is used for feeding the punching raw material in the storage mechanism to the punching machine table for punching to form a stator punching sheet. The device is compact in structure and small in occupied area, the number of structural parts of the device is reduced, energy consumption is reduced, all functional parts act synchronously, the actions of feeding, returning and collecting can be completed within extreme time, and the working efficiency of the device is greatly improved.

Owner:台州市华熠冲件有限公司

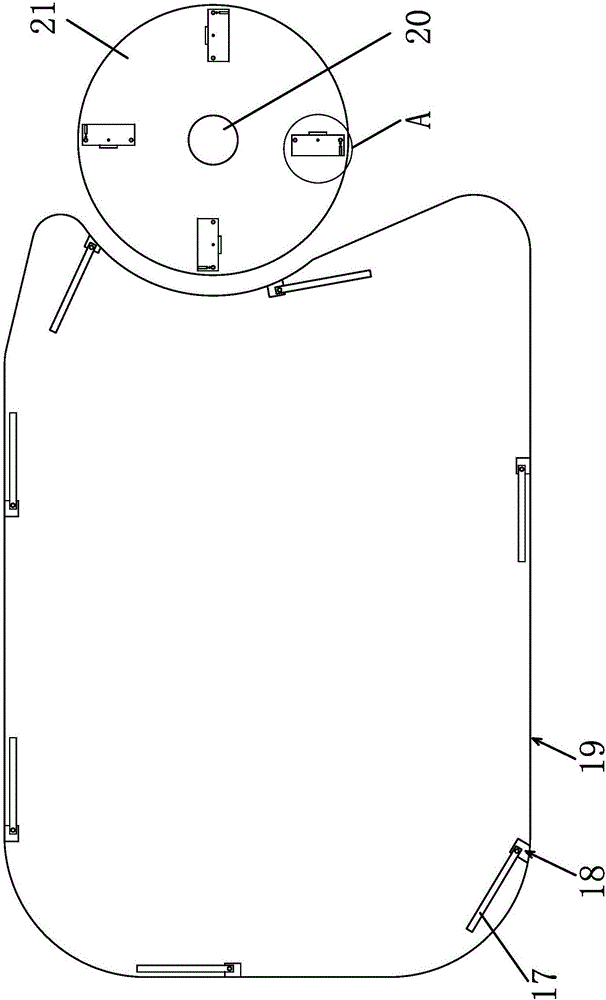

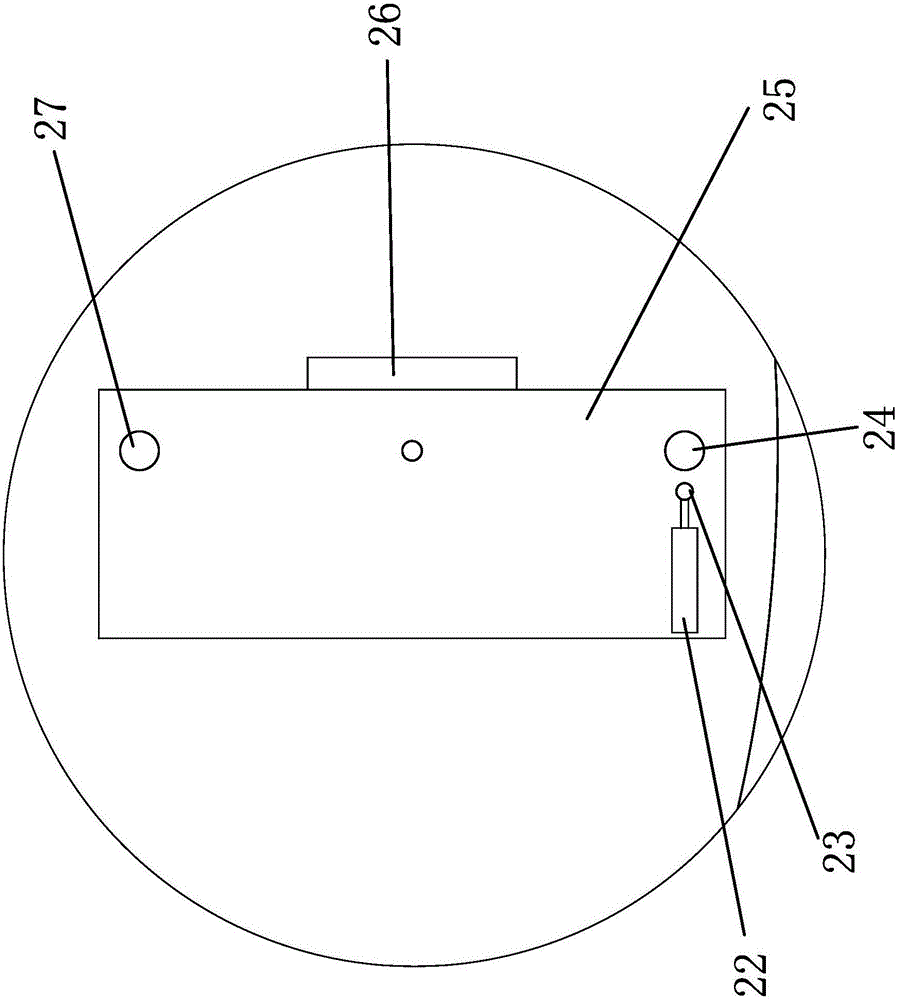

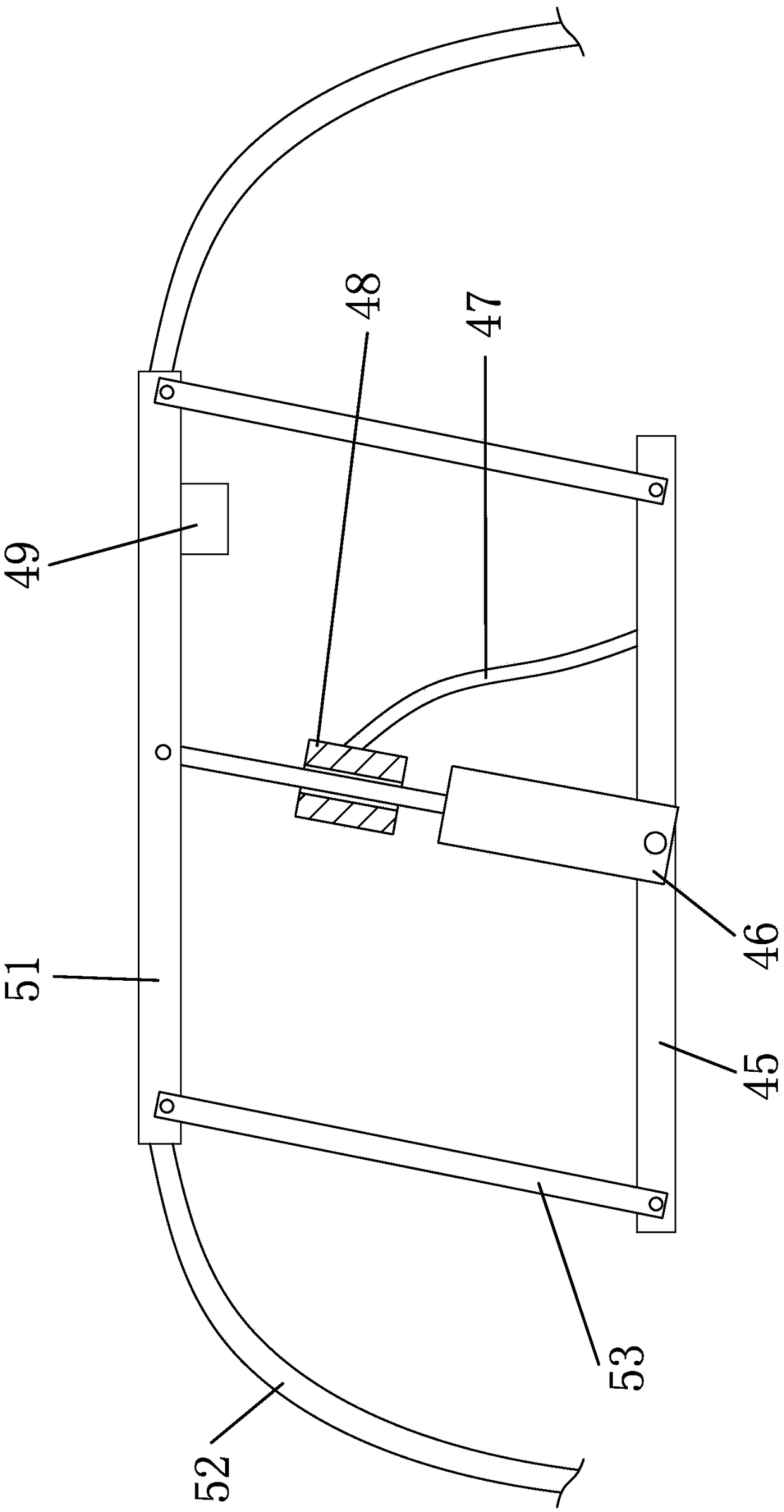

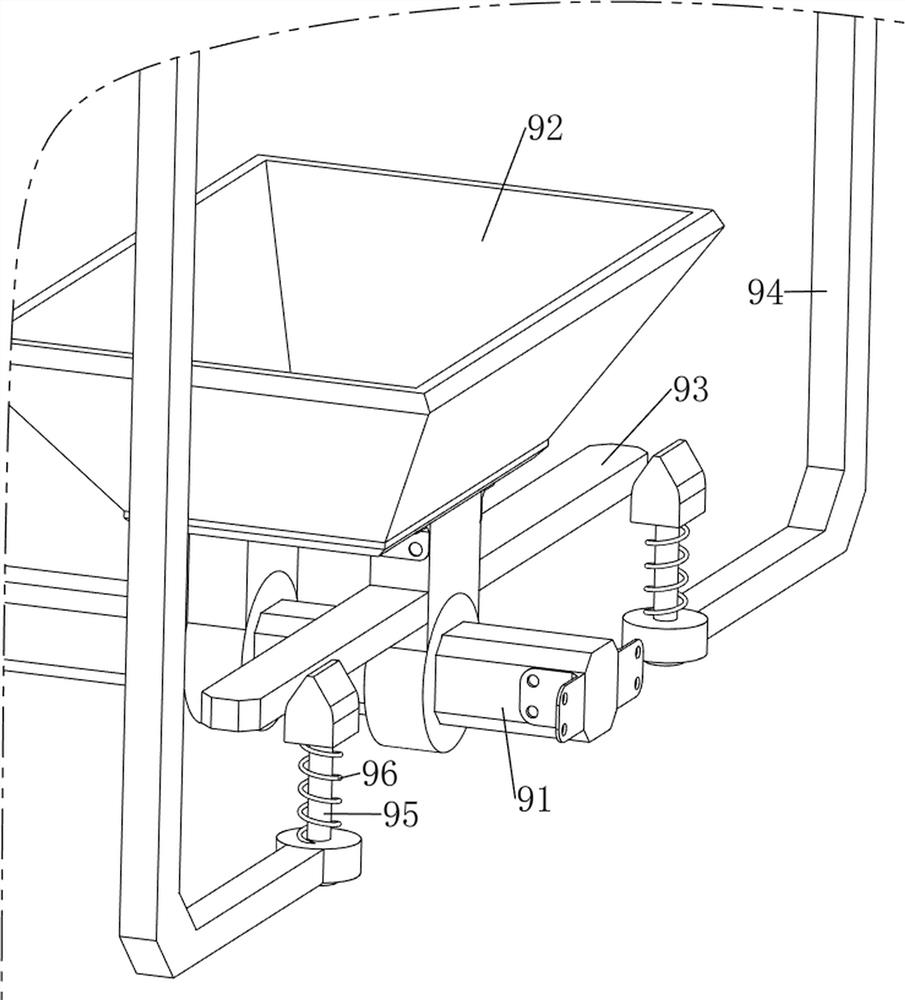

Ingot-shaped wonton forming device

ActiveCN107821507ARealize automated productionImprove production efficiencyDough processingIngotEngineering

The invention relates to the technical field of food machinery, specifically to an ingot-shaped wonton forming device. The device of the invention comprises a forming die capable of moving along a fixed track. A block is arranged right above the moving track of the forming die, and the distance between the block and the moving track of the forming die is greater than the distance between the top of the forming die and the moving track. Through cooperation between the forming die and the block, forming of ingot-shaped wonton is completed, automatic production of ingot-shaped wonton is completely achieved, manual operation is not required, and making efficiency of ingot-shaped wonton is greatly raised. The device of the invention is suitable for large-scale batch production of ingot-shaped wonton, and size and shape of ingot-shaped wonton produced by large-scale industrial production are very consistent.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

Automobile interior shell fabric and preparation method thereof

ActiveCN106835685AGood for healthImprove anti-agingFibre treatmentLiquid/gas/vapor removalSodium laurateEngineering

The invention provides an automobile interior shell fabric and a preparation method thereof and aims at solving the technical problems that an existing automobile interior shell fabric is too simple in structure and has no health function, practicability is poor and no preparation method is provided. The automobile interior shell fabric comprises a base cloth layer and an adhesive layer, wherein the adhesive layer is composed of the following components in parts by weight: 24-30 parts of nano tourmaline powder, 3-5 parts of sodium laurate, 1-2 parts of an antioxidant, 4-8 parts of a dispersing agent, 2-7 parts of a coupling agent and 70-90 parts of deionized water. The automobile interior shell fabric provided by the invention has the advantage of strong practicability.

Owner:ZHEJIANG LVLONG NEW MATERIAL CO LTD

Bamboo green and bamboo joint removal device and method

ActiveCN111571743AAutomatic removalConsistent flatnessCane mechanical workingIrregularity removal devicesAgricultural engineeringStructural engineering

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Production method of antistatic filter bag

ActiveCN106268079AFast preparationFast AntistaticDispersed particle filtrationLiquid repellent fibresAcupuncturePulp and paper industry

The invention provides a production method of an antistatic filter bag. The invention aims at solving the technical problems that an existing preparation method is too complex, manual operation is required and production efficiency is low. The production method of the antistatic filter bag comprises the following steps: a, opening aramid fiber, mixing, carding, lapping, carrying out grid connection, then adding base cloth, and carrying out acupuncture, so that a filter material plain felt is obtained; b, preparing a treatment agent; c, pouring the treatment agent into a material slot of a padding machine, and enabling the treatment agent to be uniformly permeated into the interior of the filter material plain felt by virtue of the padding machine; d, pre-drying and baking the filter material plain felt dipped with the treatment agent by virtue of a drying oven, so that redundant moisture on the surface and in the interior of the filter material plain felt is dried; e, cutting and sewing the filter material to form a filter bag; and f, packaging the filter bag by virtue of a packaging system. The production method of the antistatic filter bag has the advantages of high production speed.

Owner:ZHEJIANG YUBANG FILTER MATERIAL TECH CO LTD

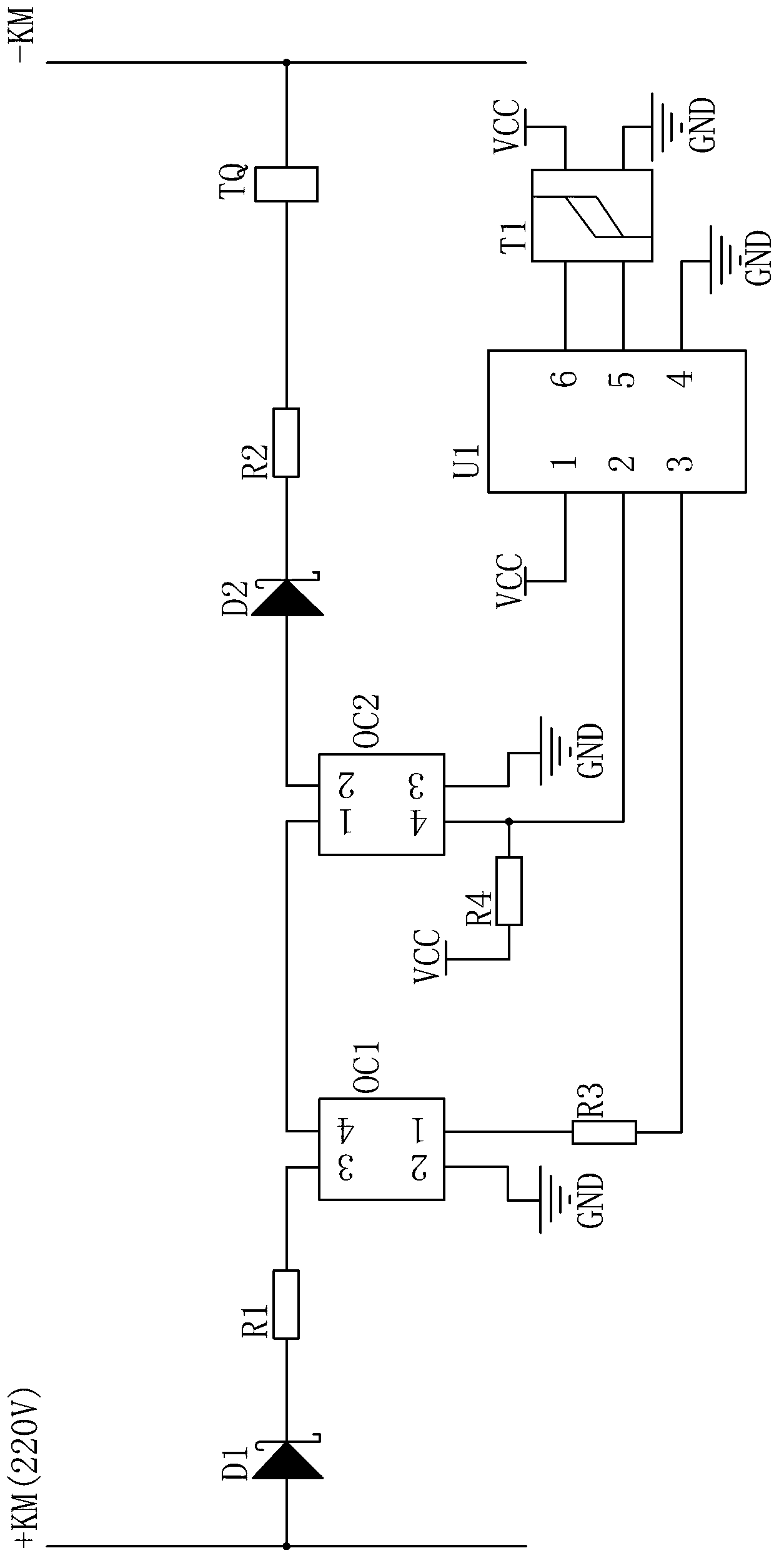

Detection circuit of open circuit of operating mechanism opening coil and detection method thereof

The invention relates to a detection circuit of the open circuit of an operating mechanism opening coil and a detection method thereof. The detection circuit comprises a breaker opening coil TQ, an operating circuit positive power supply +KM, an operating circuit negative power supply -KM, an optoelectronic isolator OC1 and an optoelectronic isolator OC2. The detection method is characterized in that the input pin 2 of the optoelectronic isolator OC1 is grounded, and the other input pin 1 of the optoelectronic isolator OC1 is connected with the output pin 3 of a singlechip; the output pin 3 of the optoelectronic isolator OC1 is connected with the operating circuit positive power supply +KM, and the other output pin 4 of the optoelectronic isolator OC1 is connected with the input pin 1 of the optoelectronic isolator OC2; the input pin 2 of the optoelectronic isolator OC2 is sequentially connected with the breaker opening coil TQ and the operating circuit negative power supply -KM; the output pin 3 of the optoelectronic isolator OC2 is grounded; the output pin 4 of the optoelectronic isolator OC2 is branched into two ways to be respectively connected with a power supply VCC (Voltage To Current Converter) and the detection pin 2 of the singlechip; and the singlechip is connected with an alarm circuit. The detection circuit disclosed by the invention has the advantages of simpler structure, more convenience for implementation and operation and suitability for the detection of the open circuit of the operating mechanism opening coil or the improvement of similar methods.

Owner:宁波舜利高压开关科技有限公司

Improved preparation method of diatom ooze

The invention provides an improved preparation method of diatom ooze, and solves the technical problems that the steps of the conventional preparation method are complicated, manual operation is required in the conventional preparation method, and the production speed is low. The improved preparation method of the diatom ooze takes kieselguhr as a raw material, and comprises the following steps: a, air jet pulverization; b, screening; c, premixing of an additive; d, anion agitation. The improved preparation method has the advantage of high production speed.

Owner:海宁永欣科技咨询有限公司

Preparation method of biodegradable mulching film

The invention provides a preparation method of a biodegradable mulching film. Technical problems that a conventional preparation method is too complex in step, high in requirement on preparation environment parameters and tedious in preparation are solved. The preparation method of the biodegradable mulching film comprises the following steps: a, preparing materials; b, pelletizing; c, performingfilm blowing; d, opening holes; e, packaging. The preparation method of the biodegradable mulching film has the advantage of convenience in preparation.

Owner:卢巧巧

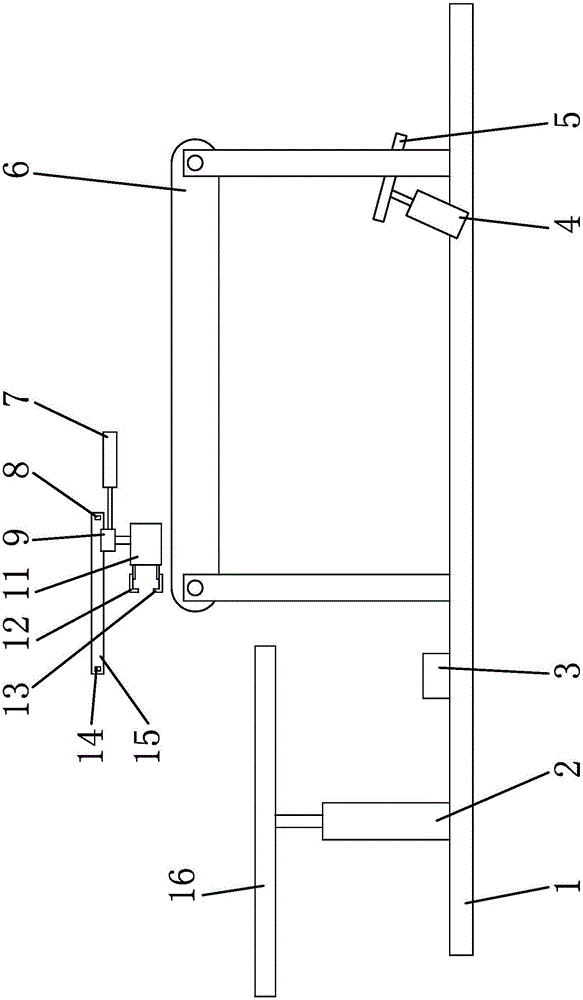

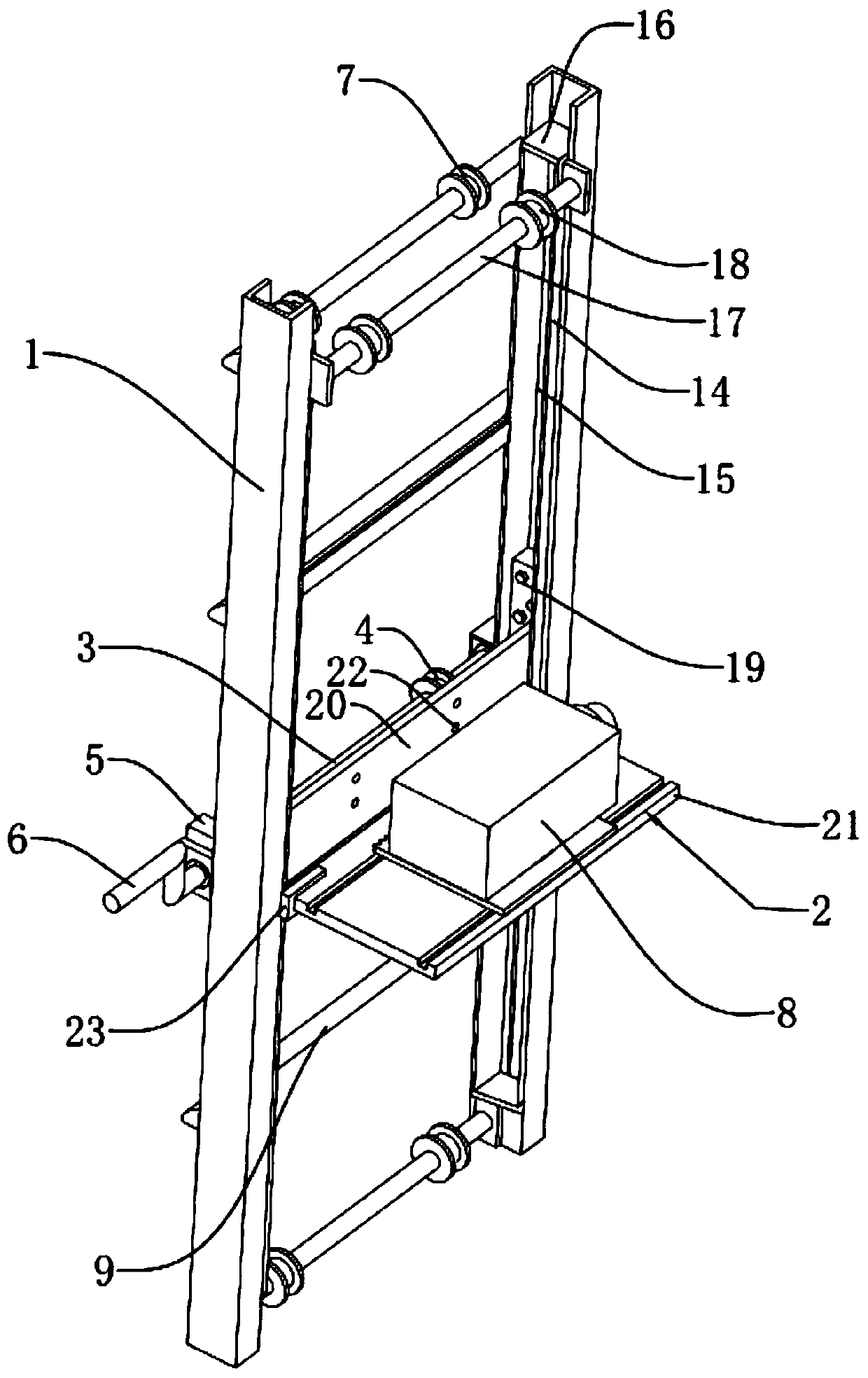

Portal for wall face slotting and punching device

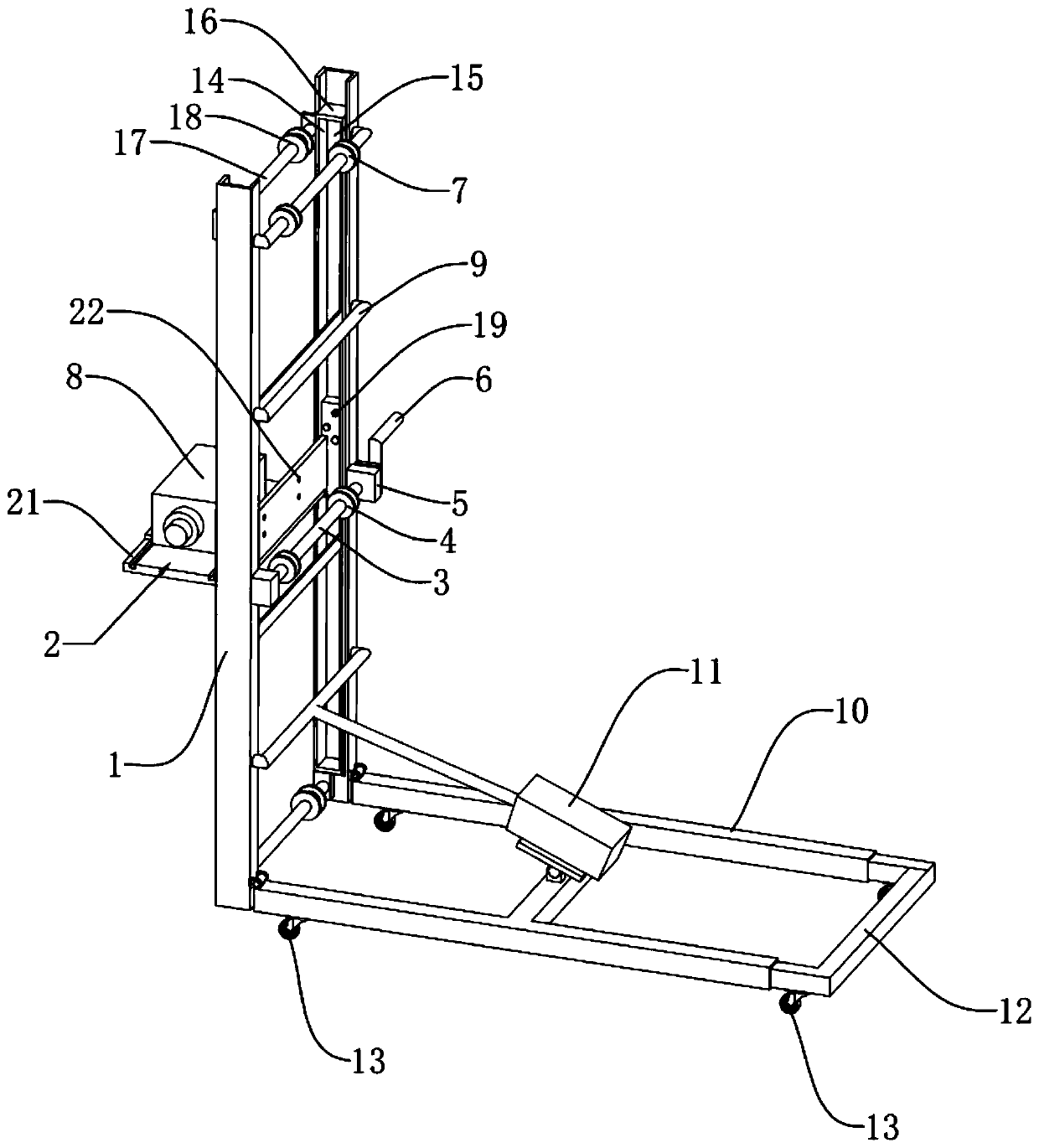

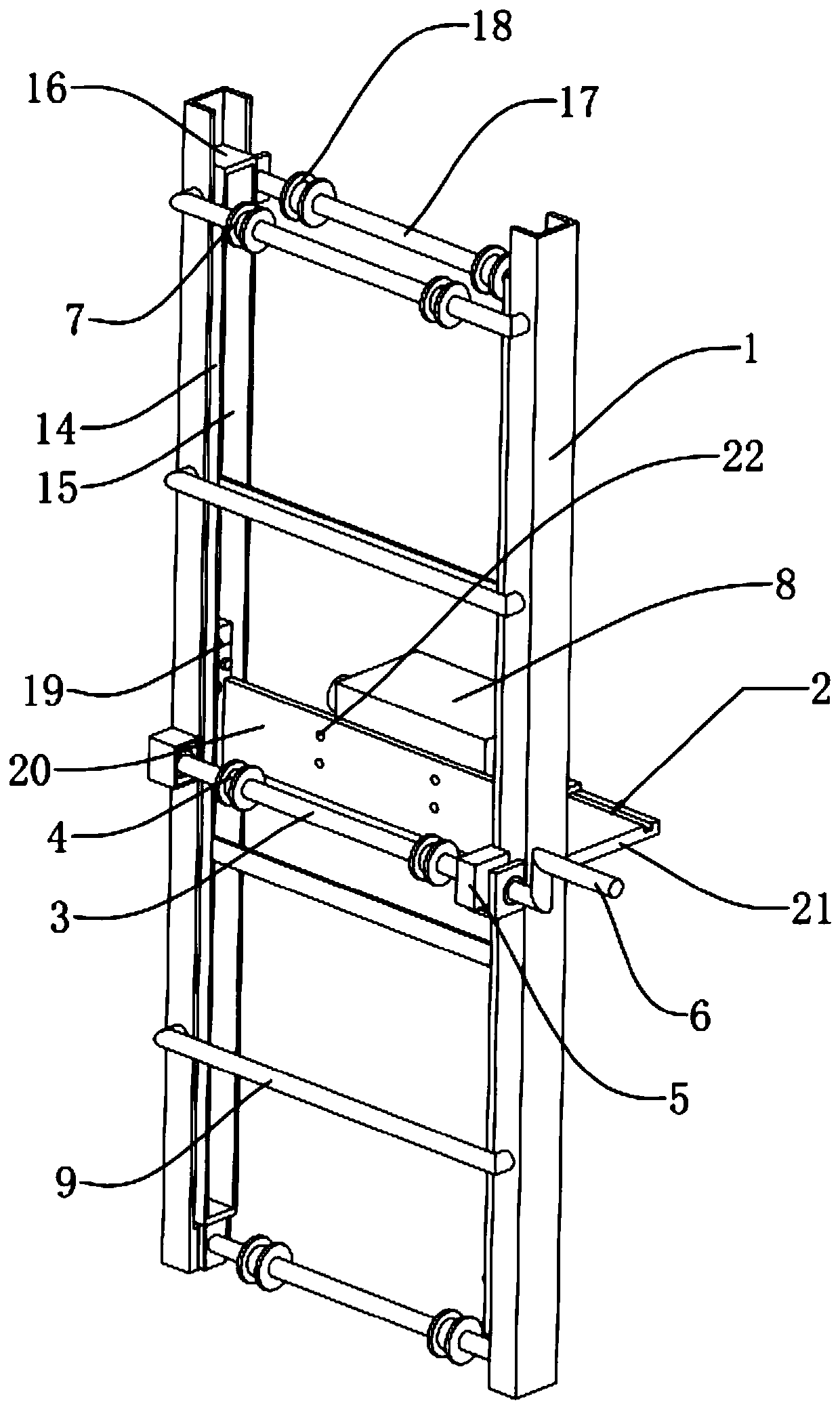

PendingCN109822769AProtection securityGuaranteed working accuracyWorking accessoriesStone-like material working toolsEngineeringSelf locking

The invention discloses a portal for a wall face slotting and punching device. The portal comprises two mutually-independent outer frames, a working table for installing the slotting and punching device is in sliding connection between the two outer frames, one main shaft is rotationally connected to one sides of the two outer frames, the main shaft is provided with a bidirectional self-locking mechanism, one end of the main shaft is provided with a driving member for driving the main shaft to rotate, and the tops of the outer frames are provided with a sliding wheel, a steel cable is connected to the main shaft, and the free end of the steel cable is wound around the sliding wheel to hoist the working table. The portal has the following beneficial effects that the gantry can control the slotting and punching device to perform operation, the labor intensity is reduced, the work efficiency is improved, safety of construction workers is further protected, and meanwhile, the slotting andpunching precision can be improved.

Owner:王根平

Improved blended fabric processing method

InactiveCN108729239ARealize processingNo need for manual operationLiquid surface applicatorsShaking/oscillating/vibrating mixersFiberEpoxy

The invention relates to an improved blended fabric processing method and aims to solve the technical problems that a conventional processing method is too complex in step, takes a great deal of time,is low in processing speed, and the like. The improved blended fabric processing method comprises the following steps: a, taking a blended fabric of a sea-island fiber and a polyamide fabric; b, weighing 25 parts of polyvinyl chloride, 18 parts of an epoxy resin, 2 parts of titanium dioxide, 4 parts of nano copper oxide, 1.2 parts of an anti-mold agent, 2 parts of a cross-linking agent, 0.2 partof a defoaming agent and 30 parts of a solvent; c, stirring the polyvinyl chloride, the epoxy resin, the titanium dioxide, the nano copper oxide, the anti-mold agent, the cross-linking agent, the defoaming agent and the solvent in a preparation device so as to obtain a coating liquid; d, uniformly coating the surface of the blended fabric with the coating liquid; and e, drying the coated blended fabric in a drying oven, thereby obtaining a finished product. The method has the advantage of being high in processing speed.

Owner:HAINING WENSHUO TECH CONSULTING CO LTD

Improved production method of nanometer lithium iron phosphate cathode material

ActiveCN107834069AEnsure consistencyImprove product qualityMaterial nanotechnologyCell electrodesNitrogen gasChemical measurement

The invention provides an improved production method of nanometer lithium iron phosphate cathode material. The improved production method is capable of solving technical problems in the prior art thatthe steps are too simple, product quality is impossible to be ensured, and product quality is poor. The improved production method comprises following steps: a, a lithium source compound, a ferric iron source compound, and a phosphor source compound are mixed with water at a certain stoichiometric ratio, a doped metal ion oxide and a primary carbon source are added, and an obtained mixture is mixed to be uniform, and is subjected to spray drying so as to obtain a dried powder; b, the dried powder is subjected to pretreatment for 3 to 8h at 350 to 550 DEG C, a secondary carbon source and waterare added after cooling, and spray drying is carried out so as to obtain a spherical powder; c, the spherical powder obtained in step b is delivered through a fluid energy milling system for crushing, is subjected to treatment for 8 to 24h at 600 to 650 DEG C in nitrogen, high temperature treatment for 8 to 16h at 700 to 960 DEG C, and cooling so as to obtain the nanometer lithium iron phosphatecathode material. The nanometer lithium iron phosphate cathode material is high in product quality.

Owner:湖南鹏博新材料有限公司

Method for producing nanometer light conducting particles

ActiveCN106318015AGuaranteed to proceed normallyImprove job stabilitySievingScreeningAlcoholPhysical chemistry

The invention provides a method for producing nanometer light conducting particles. The technical problems that an existing preparing method is excessively complex in step, manual operation is required, and the preparing efficiency is low are solved. The method for producing nanometer light conducting particles includes the following steps that a, under the ultrasonic stirring effect, 6%-12% by mass of absolute ethyl alcohol, 3%-8% by mass of terpilenol, 4%-7% by mass of stearic acid, 6%-12% by mass of a coupling agent, 3%-5% by mass of fluorescent powder and 50%-76% by mass of nanometer liquid conducting powder are weighed and subjected to surface treatment for 10 min to 24 min; b, 3%-11% by mass of a scratch-resistant assistant continues to be added into the nanometer liquid conducting powder treated in the step a, the mixture continues to be stirred, and the nanometer liquid conducting powder and the scratch-resistant assistant are mixed to be even; c, the mixture is sprayed, dried and pulverized through an airflow pulverizing system, and nanometer light conducting particles are prepared. The method has the advantages of being high in production efficiency.

Owner:南京金升华包装材料有限公司

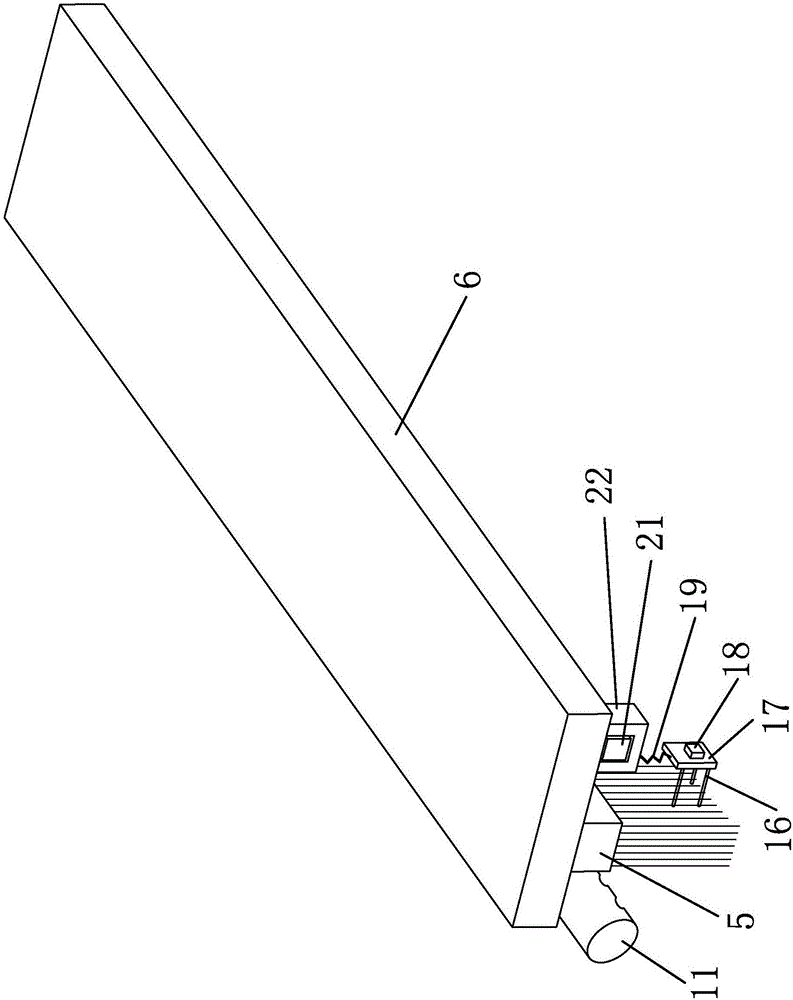

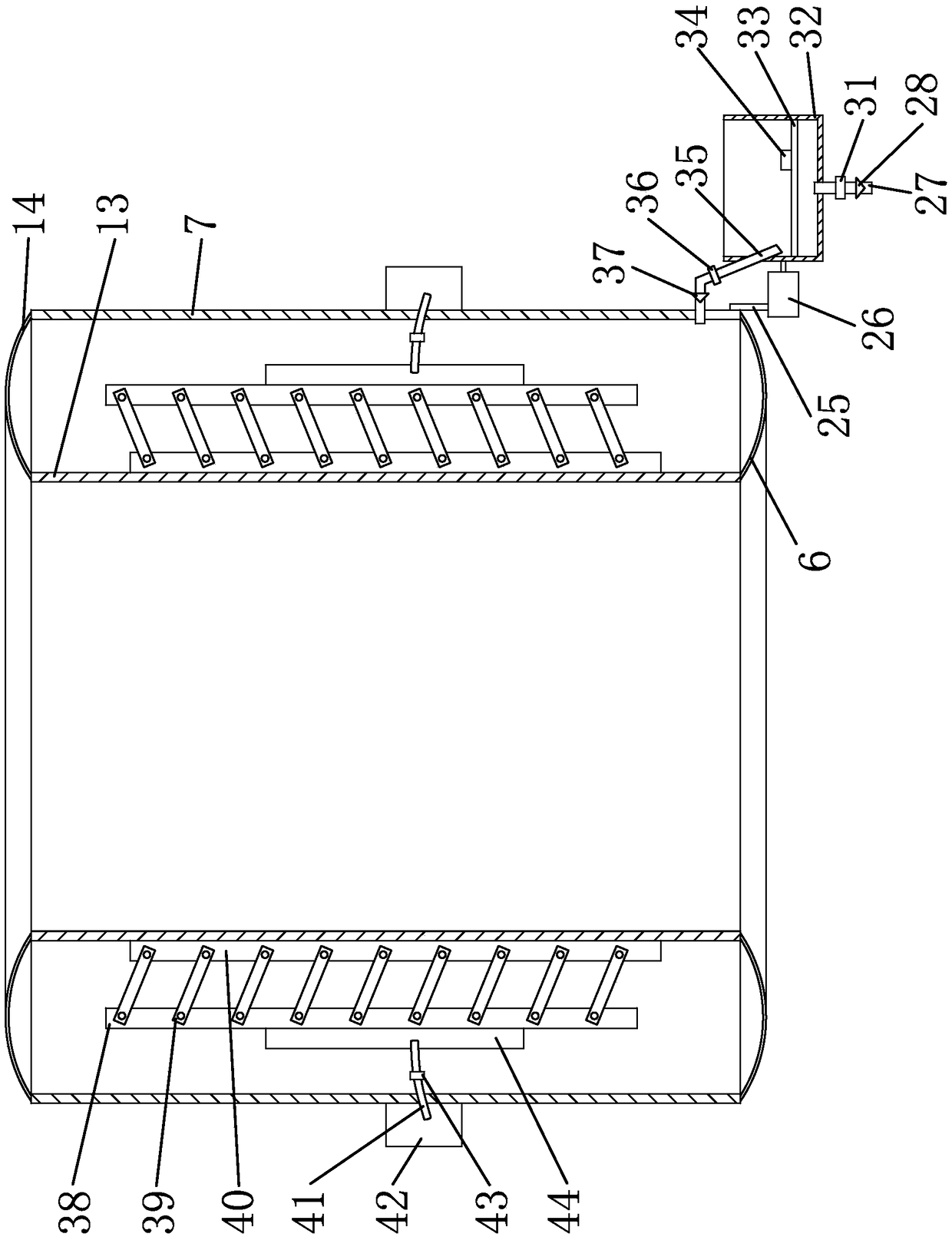

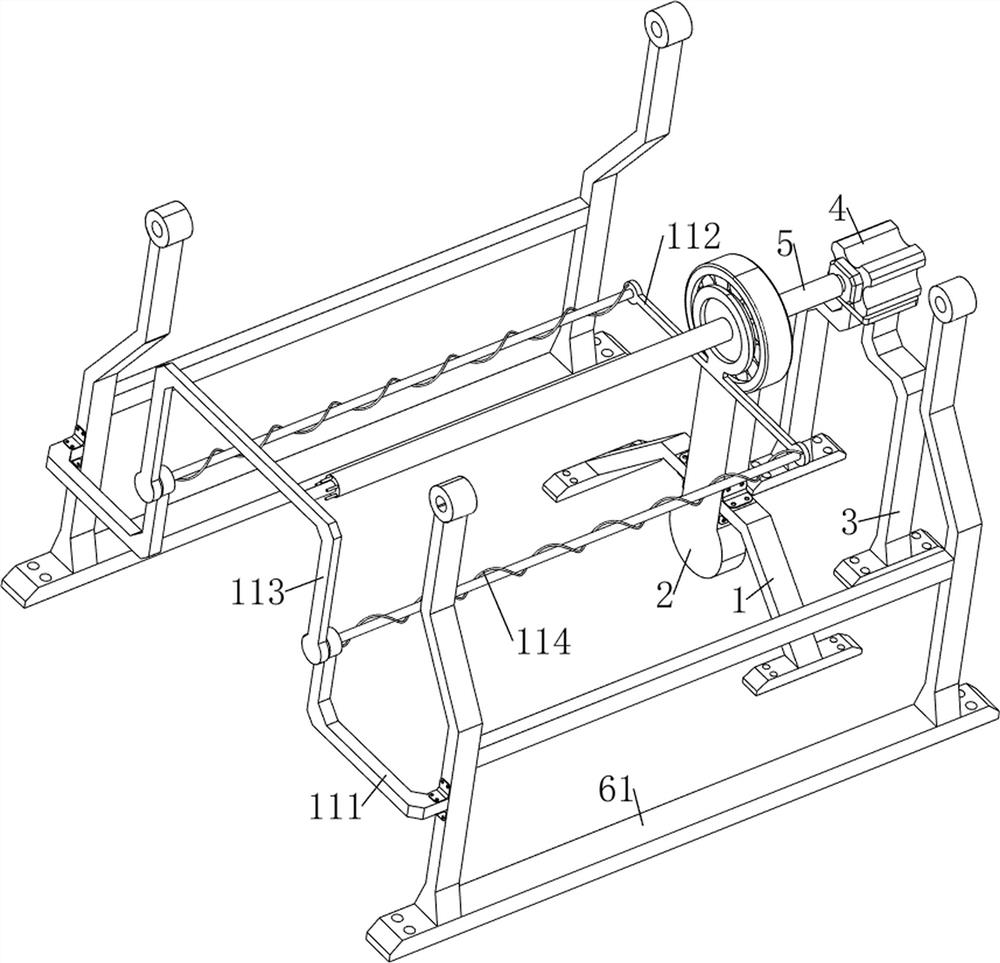

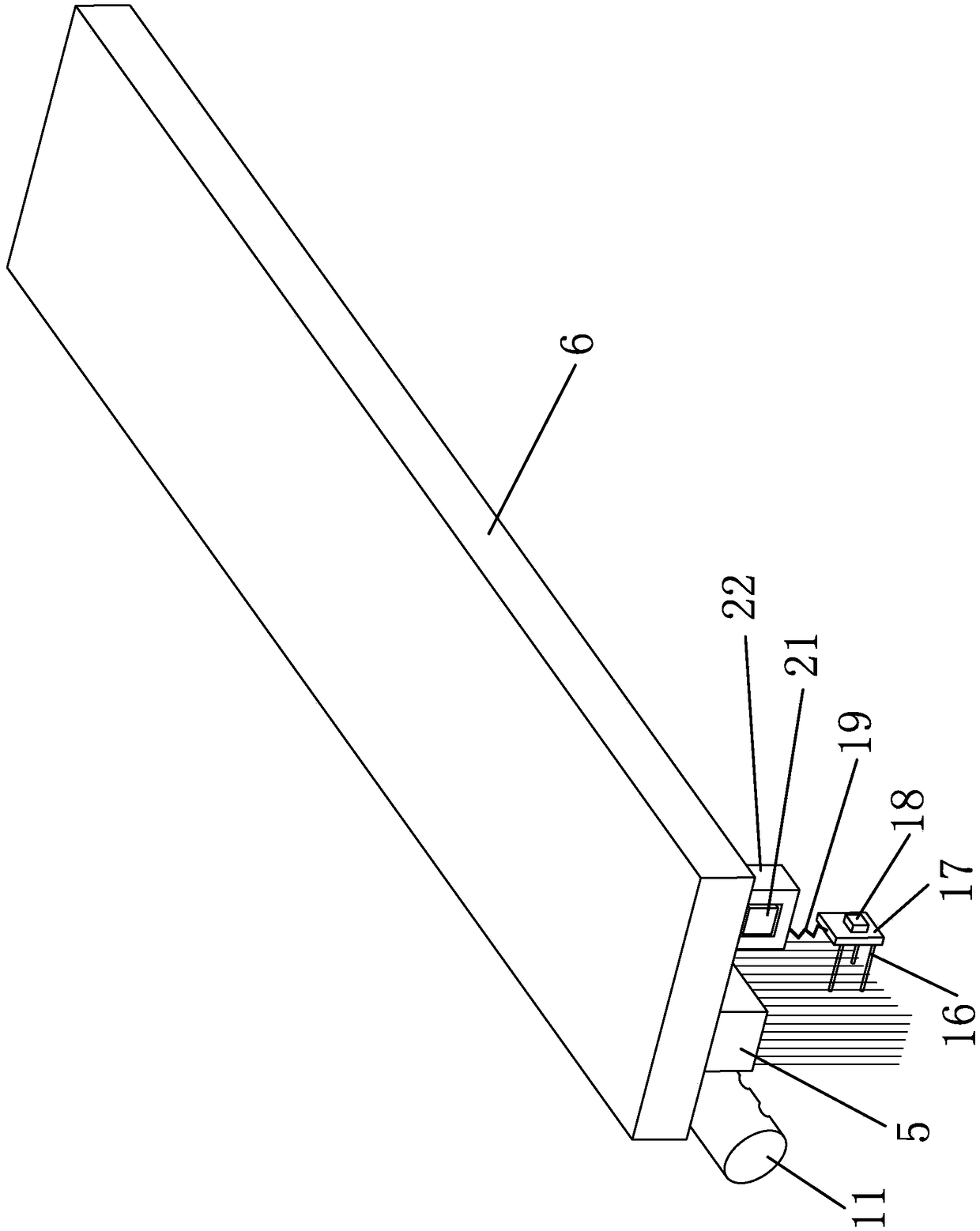

Device for automatically removing bamboo outer skin and bamboo joints

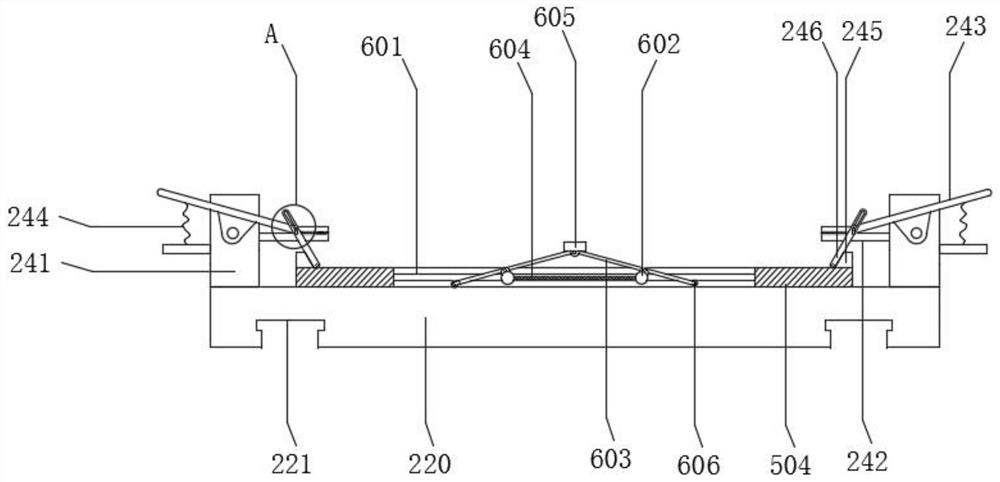

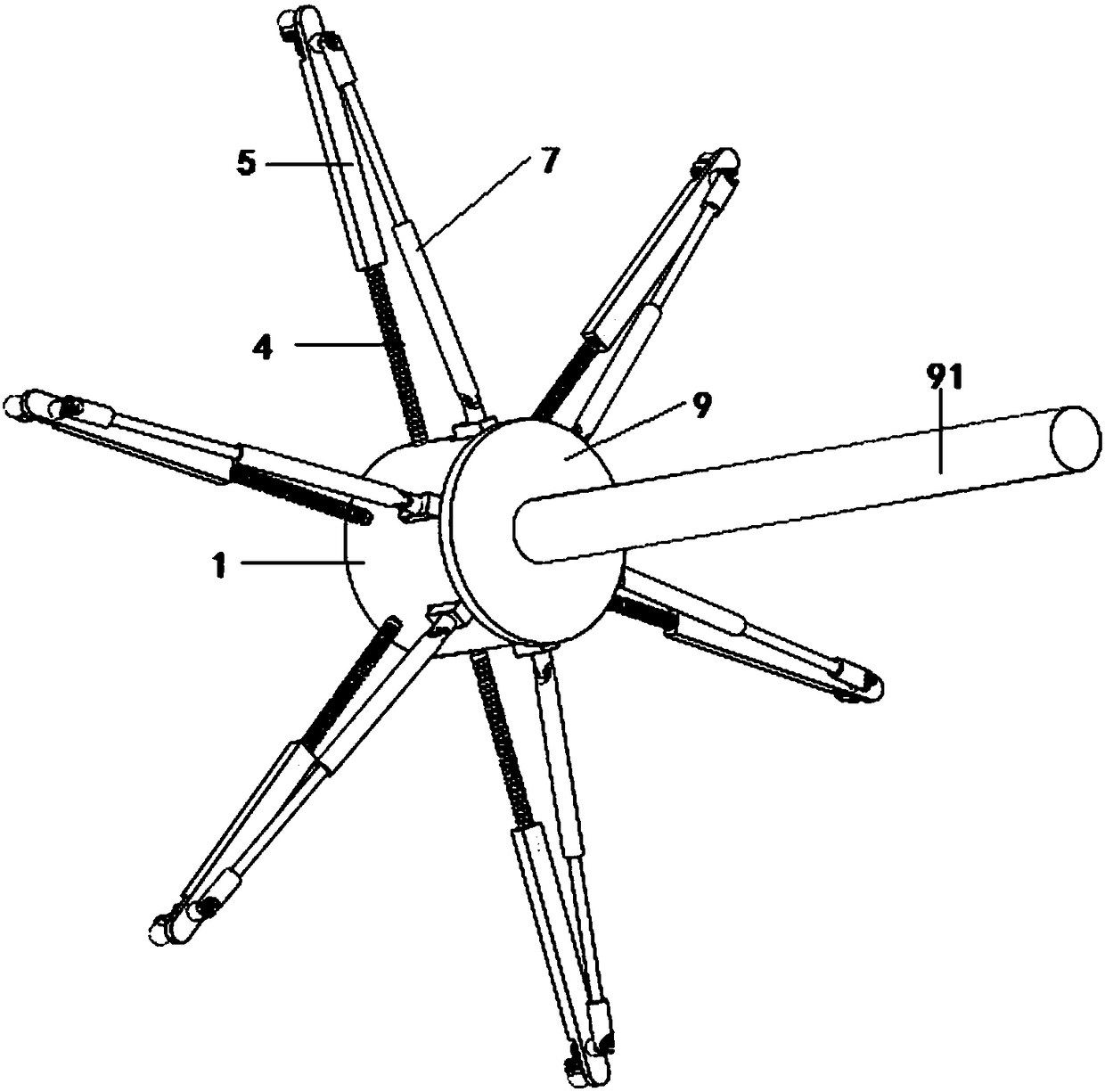

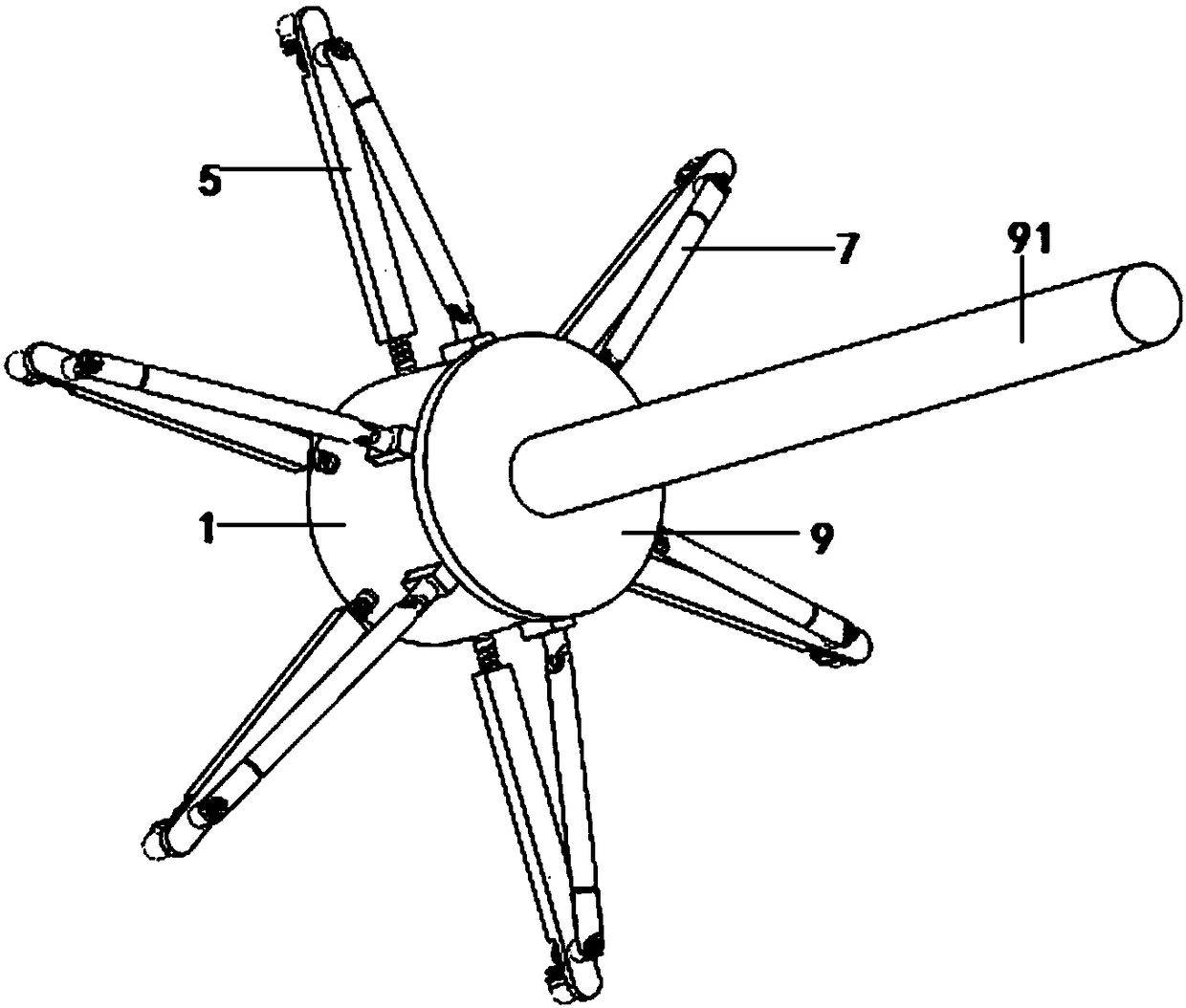

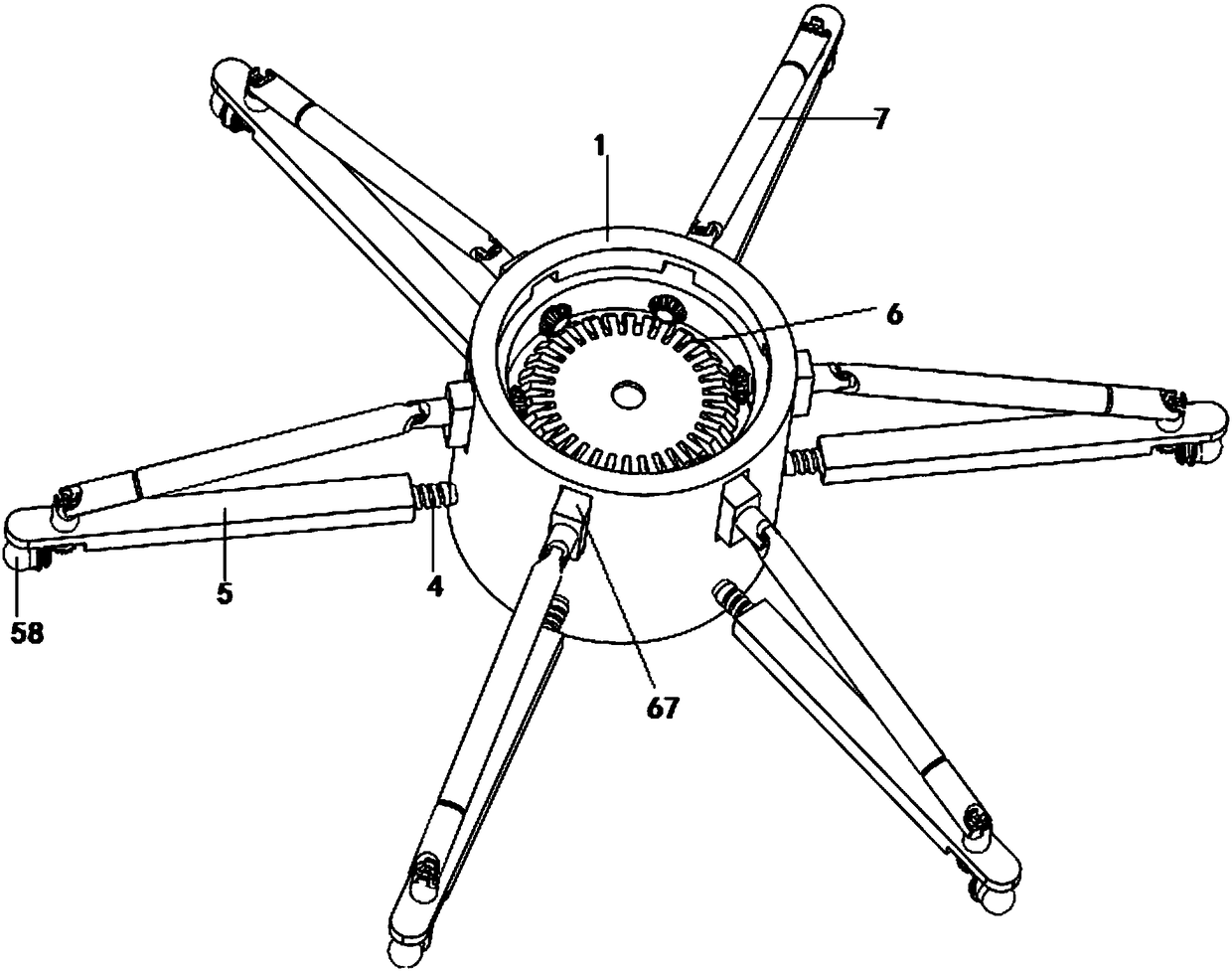

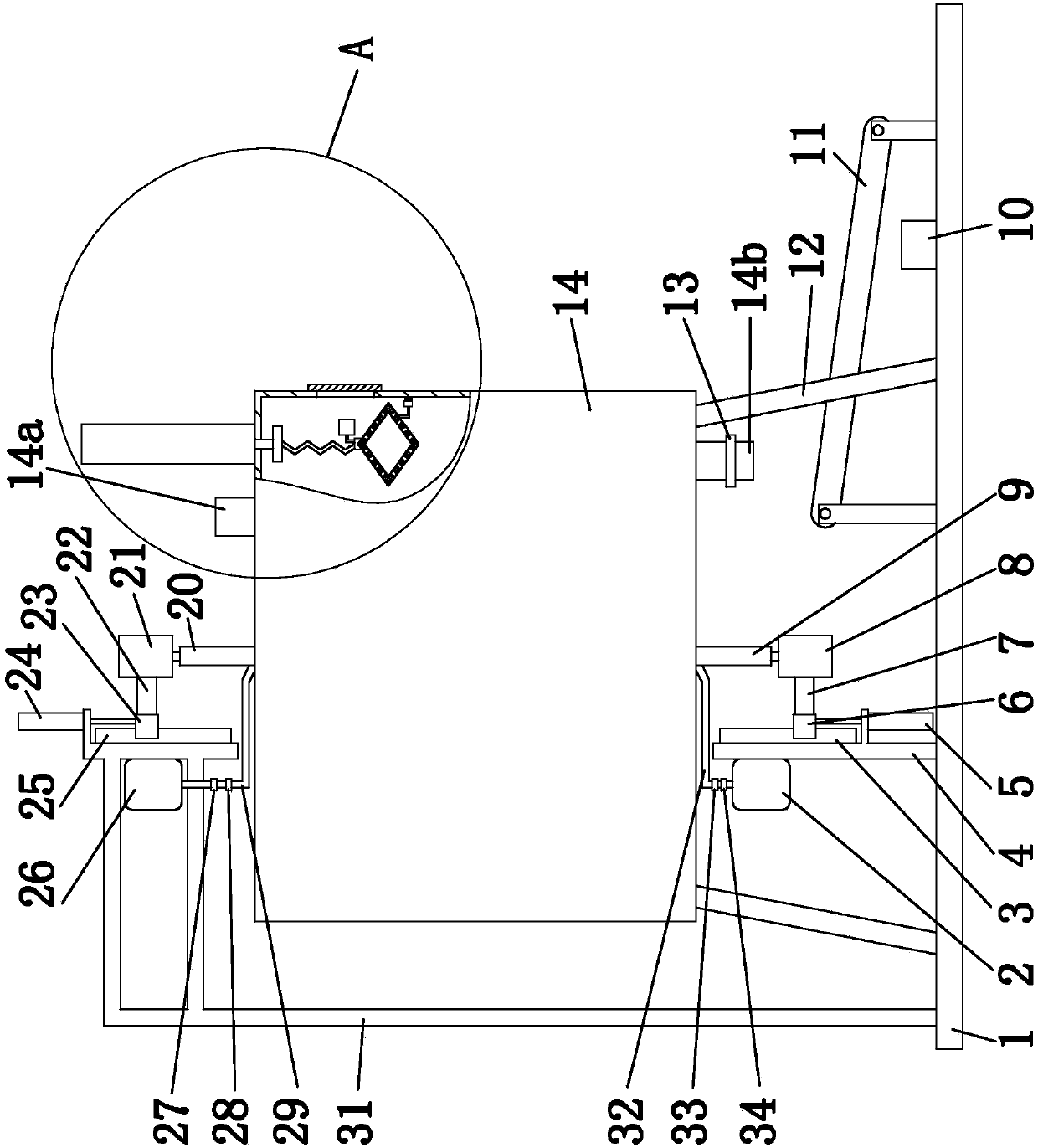

ActiveCN111571742AControl positionAutomatic removalMechanical diameter measurementsCane mechanical workingStructural engineeringMechanical engineering

The invention discloses a device for removing bamboo outer skin and bamboo joints. The device comprises a frame, wherein the frame is sequentially provided with a guide mechanism, a first conveying mechanism, a first supporting mechanism, a first bamboo rod driving mechanism, a bamboo outer skin and bamboo joint removing mechanism, a second supporting mechanism, a second bamboo rod driving mechanism, a third supporting mechanism and a second conveying mechanism from front to back; the first conveying mechanism and the second conveying mechanism are used for conveying a bamboo rod from the front side of the frame to the rear side of the frame; the guide mechanism is used for guiding the directions for the bamboo rod; the first supporting mechanism, the second supporting mechanism and the third supporting mechanism are used for supporting the bamboo rod; the first bamboo rod driving mechanism and the second bamboo rod driving mechanism are used for driving the bamboo rod to rotate; and the frame is further provided with a bamboo joint detection mechanism for detecting the positions of bamboo joints on the bamboo rod. The device for removing the bamboo outer skin and the bamboo jointscan automatically remove the outer skin and the joints of the whole bamboo rod without manual cutting, both time and effort are saved, and the working efficiency is greatly improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Improved production method of nanometer light guide particles

InactiveCN107880639ARealize continuous and uninterrupted productionIncrease productivitySievingScreeningAlcoholLight guide

The invention provides an improved production method of nanometer light guide particles. The method solves the technical problems that the steps of the existing preparation method are too complicated;the manual operation is needed; the preparation efficiency is low, and the like. The improved production method of the nanometer light guide particles comprises the following steps of a, under the ultrasonic agitation effect, 10 percent of absolute ethyl alcohol, 5 percent of terpilenol, 6 percent of stearic acid, 8 percent of coupling agents, 4 percent of fluorescent powder and 58 percent of nanometer light guide powder are weighed through being metered in percentage by mass to subject to surface treatment for 16min; b, 9 percent of scratch-resistant auxiliary agents are continuously added into the nanometer light guide powder treated in the step a and keep stirring, so that the nanometer light guide powder and the scratch-resistant auxiliary agents are uniformly mixed; c, the mixture issubjected to spray drying; crushing is performed through an air flow crushing system; the nanometer light guide particles are prepared. The improved production method has the advantage of high production efficiency.

Owner:海宁永欣科技咨询有限公司

Automatic packaging equipment special for polyester silk

The invention discloses automatic packaging equipment special for polyester silk, and belongs to the technical field of polyester silk packaging. The automatic packaging equipment special for the polyester silk comprises a box body, a through groove is formed in the top of the box body, two first symmetrical grooves are formed in the box body, and first rotary shafts and second rotary shafts are rotatably connected to the inner walls of the two first grooves correspondingly. First rotary disks are slidably connected to the outer walls of the first rotary shafts correspondingly, and second rotary disks are fixedly connected to the outer walls of the first rotary disks in a sleeving mode. Rollers are fixedly connected between two fixed disks, two groups of first sliding grooves staggered mutually are formed in the rollers, and the second rotary disks are matched with the first sliding grooves. The automatic packaging equipment special for the polyester silk is simple in structure and convenient to operate, manual matching operation is not required, the manual labor intensity is reduced, the occurrence of potential safety hazards is avoided, meanwhile, packaging barrels can rotate andmove, the aesthetics of the packaging is increased, the situation that the polyester silk is wound intricately on the packaging barrels is avoided, and the using is convenient.

Owner:HUAXIANG (CHINA) HIGH FIBER CO LTD

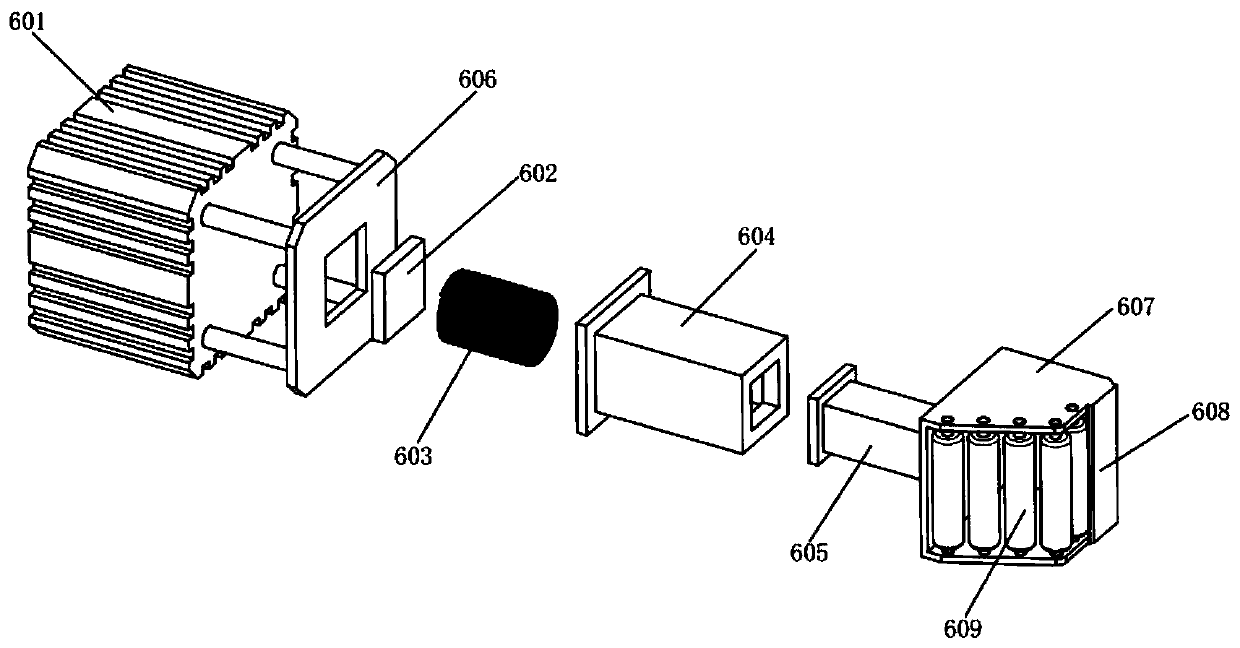

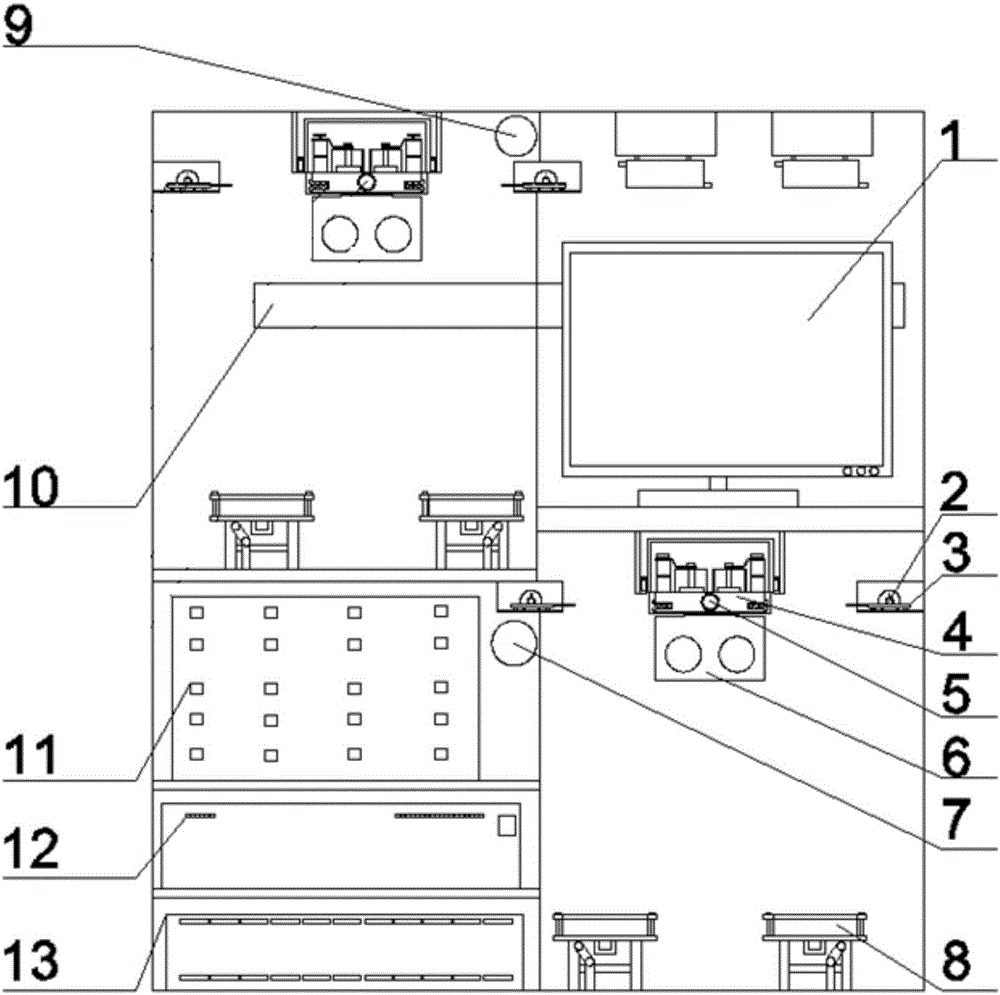

Expressway intelligent toll collecting and card fetching system

InactiveCN106709533AReduce weightImprove reliabilityTicket-issuing apparatusConveying record carriersInfraredLED display

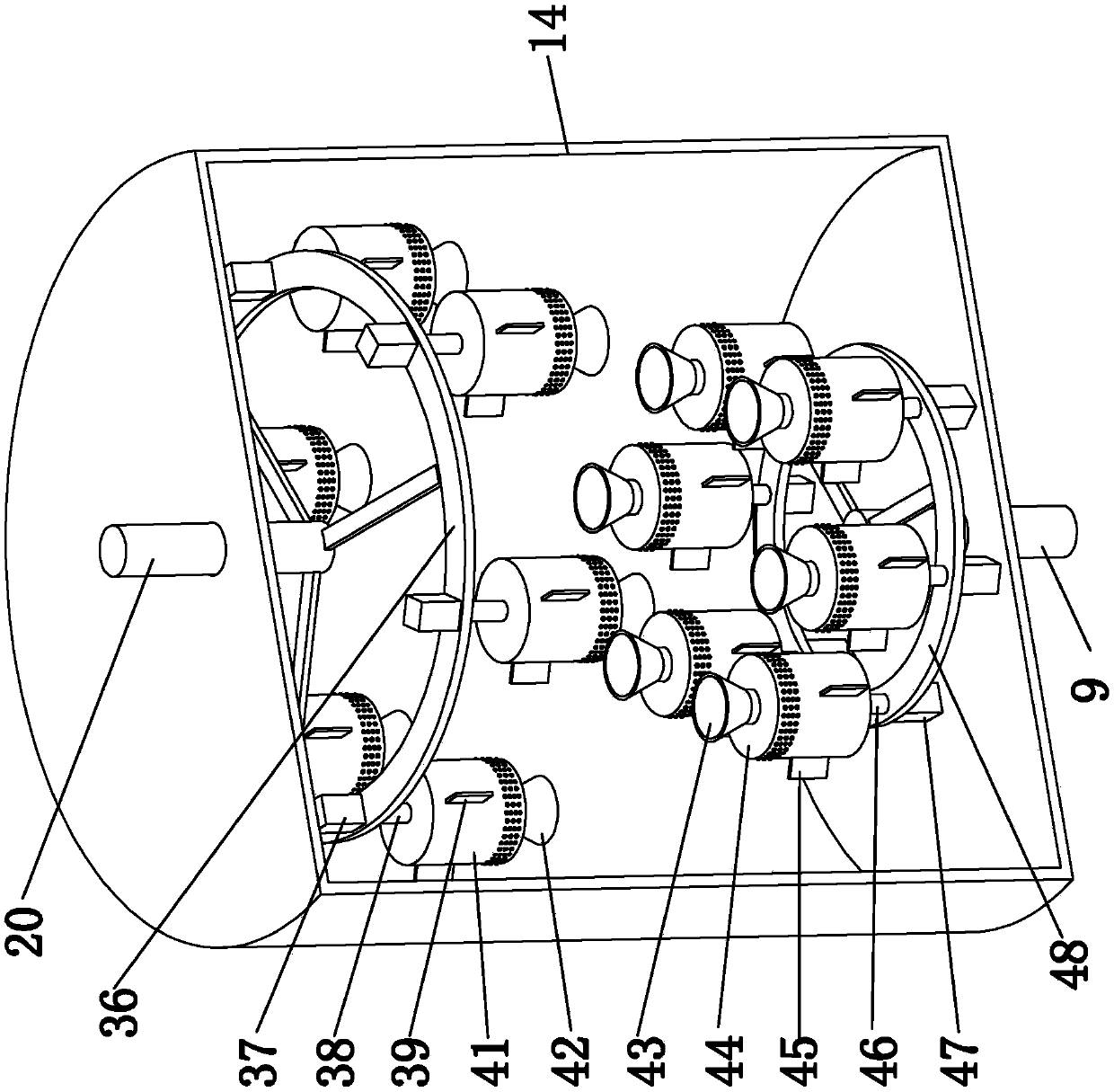

The invention discloses an expressway intelligent toll collecting and card fetching system, which comprises a machine frame, a power distribution unit, and an industrial control computer display, an acoustic ranging device, an infrared ray sensing device, an LED display screen, a lane controller, an upper card issuing mechanism, a lower card issuing mechanism and a gravity sensor which are connected with an industrial control computer, wherein the upper card issuing mechanism is arranged on the upper part of the machine frame, the infrared ray sensing device is arranged beside the upper card issuing mechanism, the lower card issuing mechanism is arranged on the lower part of the machine frame, the acoustic ranging device is arranged beside the lower card issuing mechanism, and the power distribution unit provides operating voltage for the whole system. Since the two sets of card issuing mechanisms operate simultaneously and independently, the expressway intelligent toll collecting and card fetching system can realize hot-swapping card supplementing function and zero-delay magnetic card supplementation, can realize all-weather unattended operation, reduces potential safety hazards of the old expressway card fetching machine, and has high popularization value.

Owner:ZHEJIANG UNIV

Steel pipe derusting and paint spraying device for building

ActiveCN114392856ANo need for manual operationReduce the hassle of manual operationRevolution surface grinding machinesGrinding drivesElectric machineClassical mechanics

The invention relates to a derusting and paint spraying device, in particular to a derusting and paint spraying device for a steel pipe for a building. The derusting and spraying device for the steel pipe for the building is high in efficiency and does not need excessive manual operation, and extra paint cannot be sprayed and left around at will. A steel pipe derusting and paint spraying device for a building comprises supporting frames, a first connecting rod, a first fixing frame, a motor, a rotating rod, a moving mechanism and the like, the motor is arranged at the top of the first fixing frame, the rotating rod is arranged on an output shaft of the motor, the supporting frames are symmetrically placed on the left side of the first fixing frame front and back, and the first connecting rod is connected between the two supporting frames; the rotating rod is rotationally connected with the first connecting rod, and a moving mechanism is placed on the outer sides of the two supporting frames. The rotating rod is sleeved with the steel pipe, the motor works to drive the rotating rod and the steel pipe to rotate, paint is evenly sprayed to the outer wall of the steel pipe, operation can be automatically conducted, and excessive manual operation is not needed.

Owner:佛山绿水清源管业科技有限公司

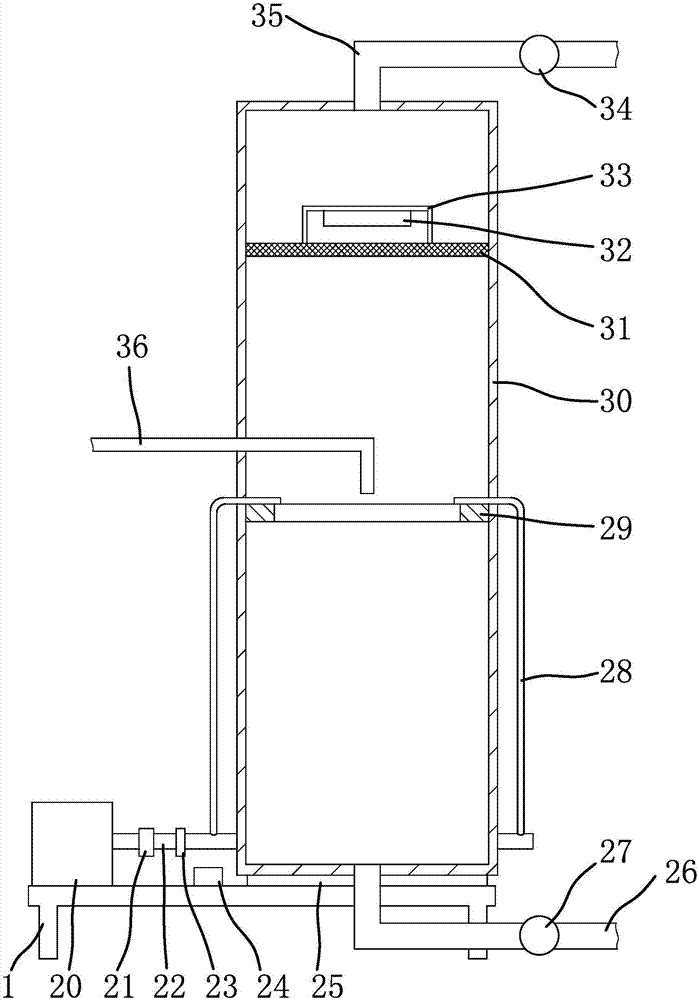

Die-casting quantitative feeding system

The invention relates to the technical field of quantitative feeding systems, and discloses a die-casting quantitative feeding system which includes a boiler and a material drawing box. The inner wallof the boiler is fixedly connected with a crucible, a motor dragging system is fixedly connected to one side of the top of the boiler, and the top of the material drawing box is fixedly connected with a material drawing box cover; and a discharge pipe is fixedly connected to one side of the top of the material drawing box cover, the bottom end of the discharge pipe penetrates through the materialdrawing box cover and extends to the lower part of the inner part of the material drawing box. According to the die-casting quantitative feeding system, descending of the material drawing box is controlled by the motor dragging system, so that the liquid surface pressure difference is generated, melt in the crucible is poured back into the material drawing box, then air intake supercharging is carried out by an air intake pipe to enable air pressure difference to be generated between the material drawing box and the outside world, the melt in the material drawing box is pressed out, by cooperating with a sliding column, a stainless steel float, an induction block and an induction switch control system, a new cycle is started after the melt is pressed out of the quantitative value, the purpose of quantitative feeding as set is achieved, and quantitative feeding in the process of die casting is realized.

Owner:东莞市蒂安斯实业有限公司

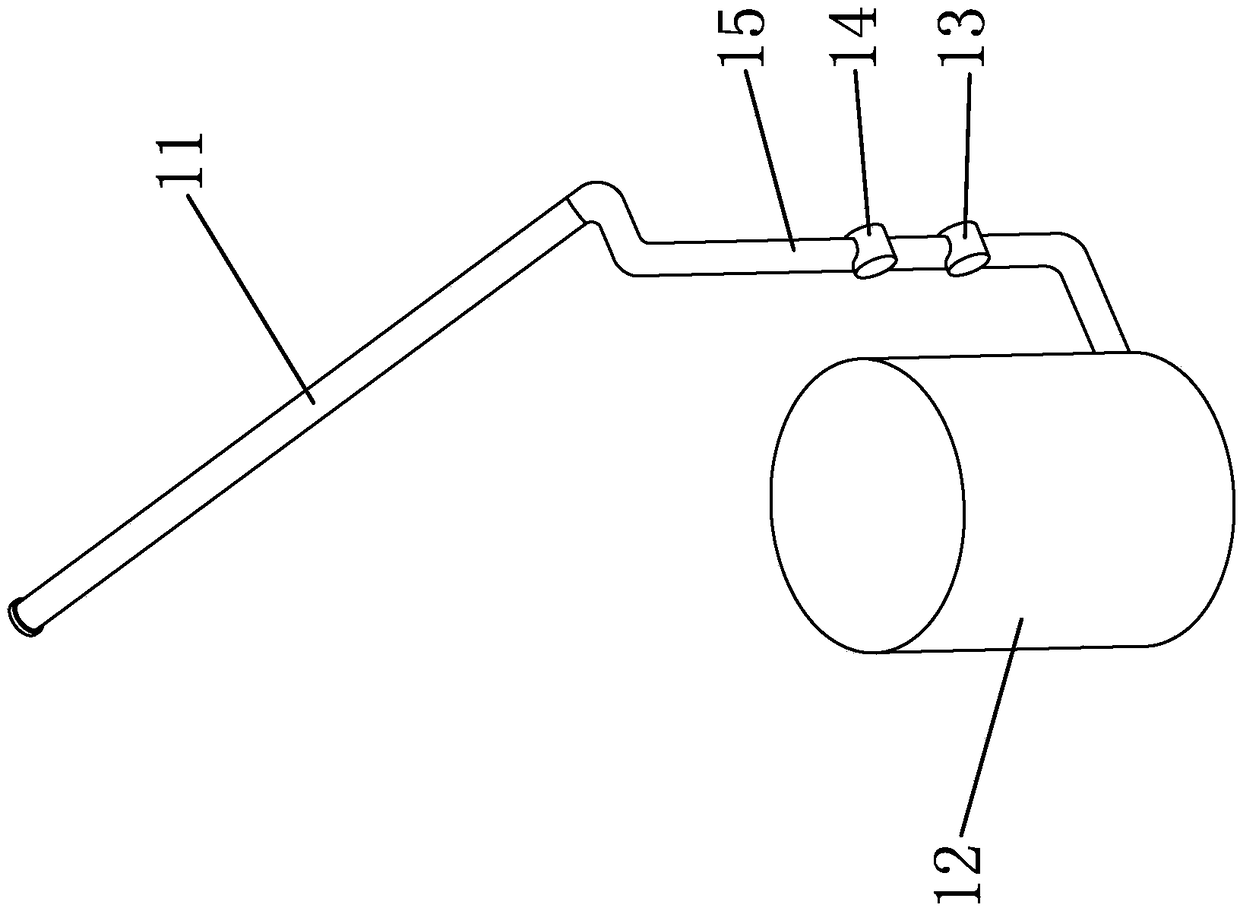

Pediatric liquid medicine atomization device

PendingCN113975555AGood treatment effectReduce troubleFouling preventionDentistryBiomedical engineeringPediatric Medicine

The invention relates to an atomization device, in particular to a pediatric liquid medicine atomization device. The invention provides a pediatric medicine liquid atomization device which can atomize medicine liquid in an equal amount, continuously spray the medicine liquid into the oral cavity for multiple times and enable the atomized medicine liquid to be fully fused into the oral cavity. The pediatric liquid medicine atomization device comprises a rack, a first storage pipe, a first piston rod and the like, the first storage pipe is arranged on the right side of the rack, liquid medicine flows into the first storage pipe, the first piston rod is arranged on the first storage pipe in a sliding mode, and the first piston rod can push the liquid medicine in the first storage pipe into the oral cavity of an infant. A second piston rod moves rightwards to push liquid medicine into a first storage tube for atomization drug administration, meanwhile, the second piston rod can push the liquid medicine equivalently and repeatedly under the action of five sliding blocks, the liquid medicine cannot be pushed out too much at a time, meanwhile, the liquid medicine can be more fully blended into the oral cavity of the infant through repeated pushing, and the treatment effect is better.

Owner:林振源

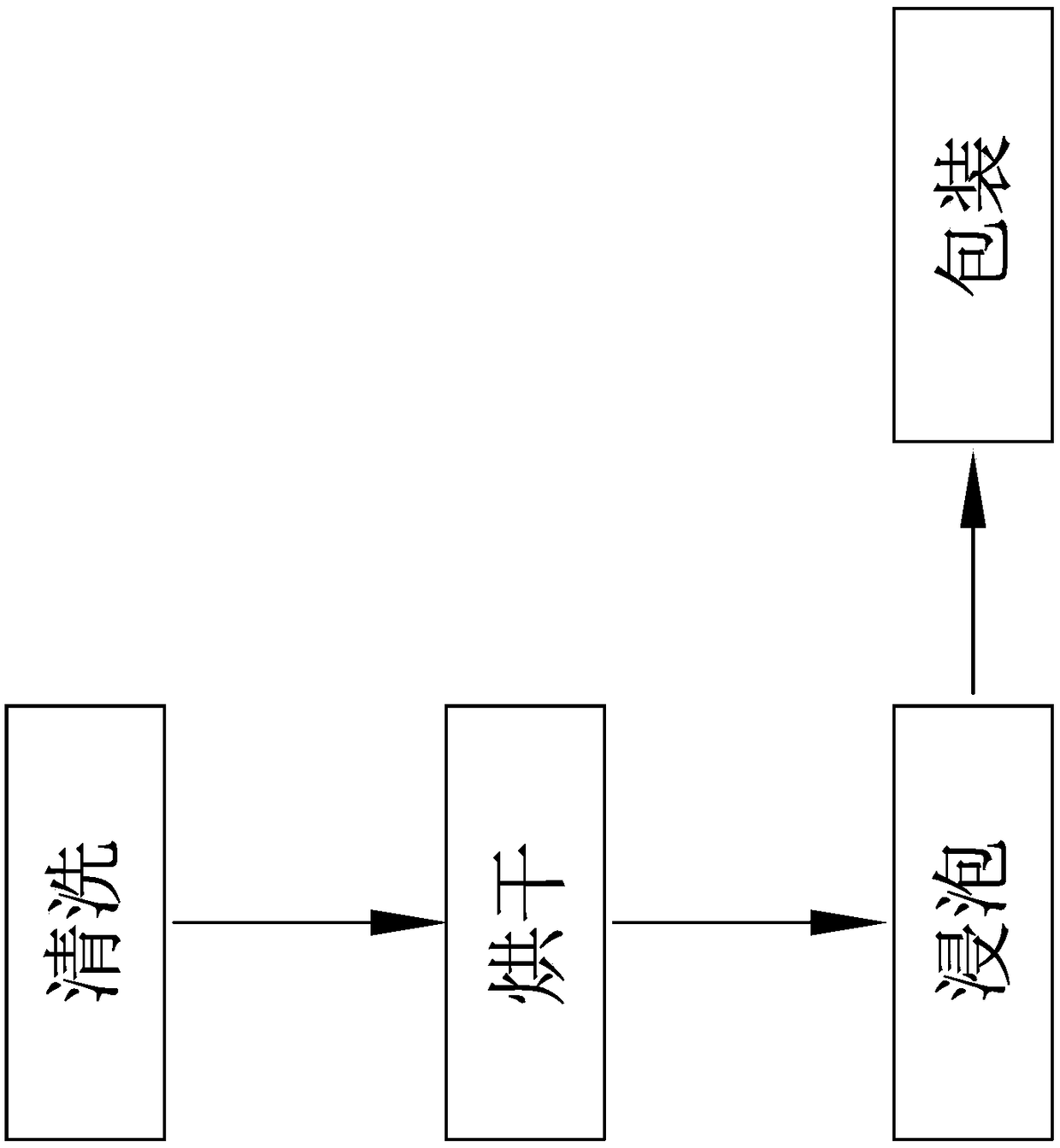

Rust-proof treatment method for bolt

InactiveCN108237064AReliable handlingEasy to adjustLiquid surface applicatorsCleaning using toolsTreatment effectMedicine

The invention provides a rust-proof treatment method for a bolt, and solves the technical problems of poor treatment effect and the like caused by that treatment is carried out only by virtue of the experience of workers due to the lack of a treatment method for a bolt in the prior art. The rust-proof treatment method for the bolt comprises the following steps: a. cleaning; b. drying; c. soaking;and d. packaging. The rust-proof treatment method for the bolt has the advantage of being reliable in treatment.

Owner:海宁迪万沃浦建材科技有限公司

Coloring device for processing touch screen function piece

ActiveCN114100963AAvoid affecting the coloring workUniform colorLiquid surface applicatorsCoatingsEngineeringTouchscreen

The invention relates to a coloring device, in particular to a coloring device for processing a touch screen functional sheet. The invention provides the coloring device for processing the touch screen function piece, which not only can automatically color the function piece, but also can clamp and fix the function piece. A coloring device for touch screen function piece processing comprises supporting frames, a supporting plate, supporting blocks, electric sliding rails and the like, the supporting frames are arranged on the left side and the right side of the bottom of the supporting plate, the supporting blocks are arranged on the front side and the rear side of the top of the supporting plate in a bilateral symmetry mode, and the electric sliding rails are connected between the tops of the two supporting blocks corresponding left and right. People push the functional piece to the right side, a rubber plate drives a sliding block to move to the right side, a clamping block is driven by a first connecting rod to move to the inner side to clamp the functional piece, the situation that coloring work is affected by pushing the functional piece when coloring equipment makes contact with the functional piece can be prevented, and meanwhile the functional piece can be located in the middle of a supporting plate through the clamping block; the coloring is more uniform.

Owner:江西视显高科技有限公司

Automobile interior fabric and preparation method thereof

ActiveCN106835685BGood for healthImprove anti-agingFibre treatmentLiquid/gas/vapor removalEngineeringSodium

The invention provides an automobile interior trim fabric and a preparation method thereof. It solves the technical problems that the structure of the existing automotive interior fabric is too simple, there is no health care function, the practicability is poor, and there is no preparation method. The automobile interior fabric comprises a base cloth layer and an adhesion layer, and the adhesion layer is composed of the following components in parts by weight: 24-30 parts of nano tourmaline powder, 3-5 parts of sodium laurate, and 1-2 parts of antioxidant , 4-8 parts of dispersant, 2-7 parts of coupling agent and 70-90 parts of deionized water. The invention has the advantage of strong practicability.

Owner:ZHEJIANG LVLONG NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com