Patents

Literature

3643results about "Dough processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

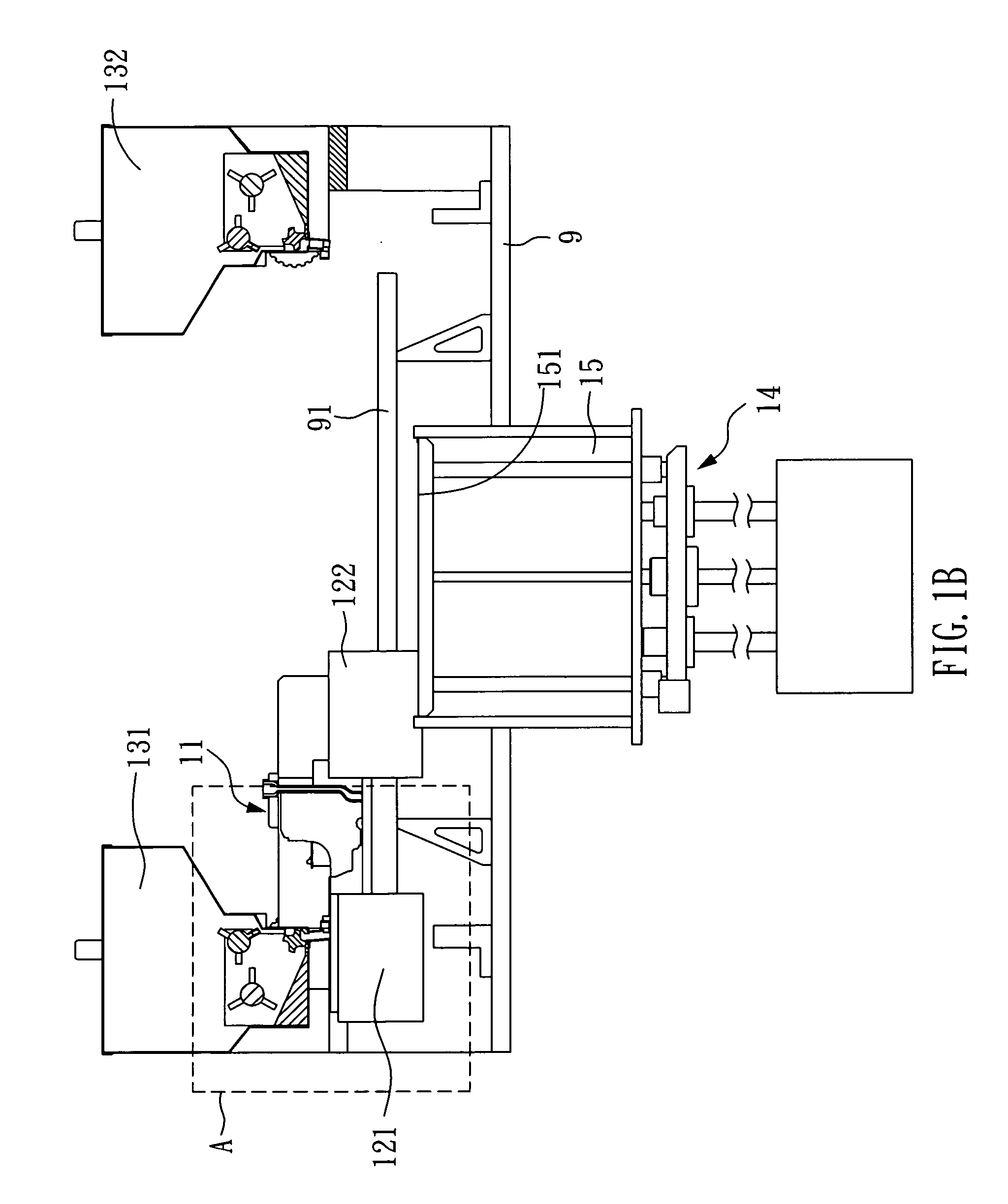

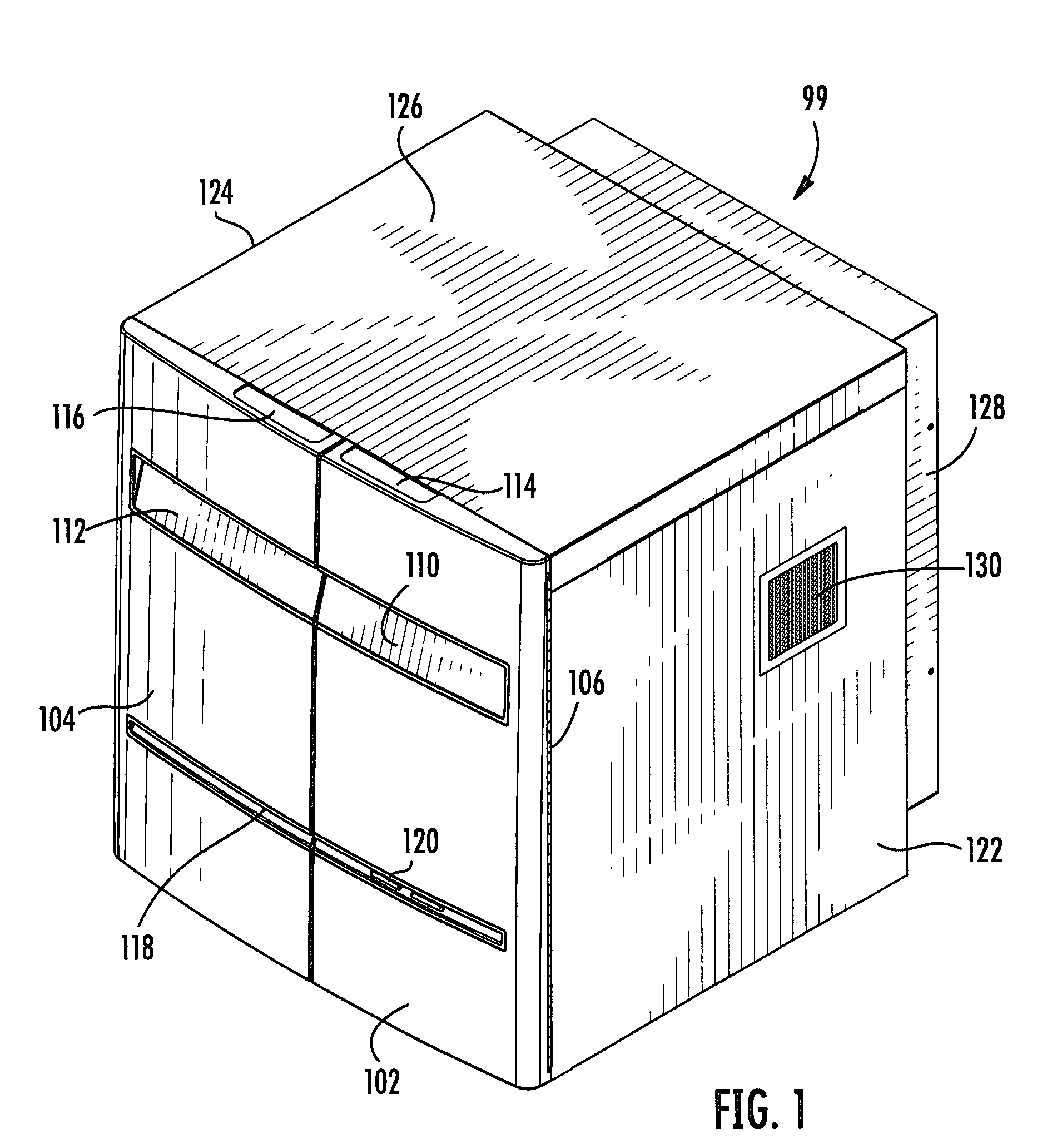

Beverage forming device with opening/closing mechanism for a beverage cartridge receiver

ActiveUS7513192B2Convenient ArrangementEasy to manufactureBeverage vesselsFood shapingEngineeringActuator

Owner:KEURIG GREEN MOUNTAIN INC

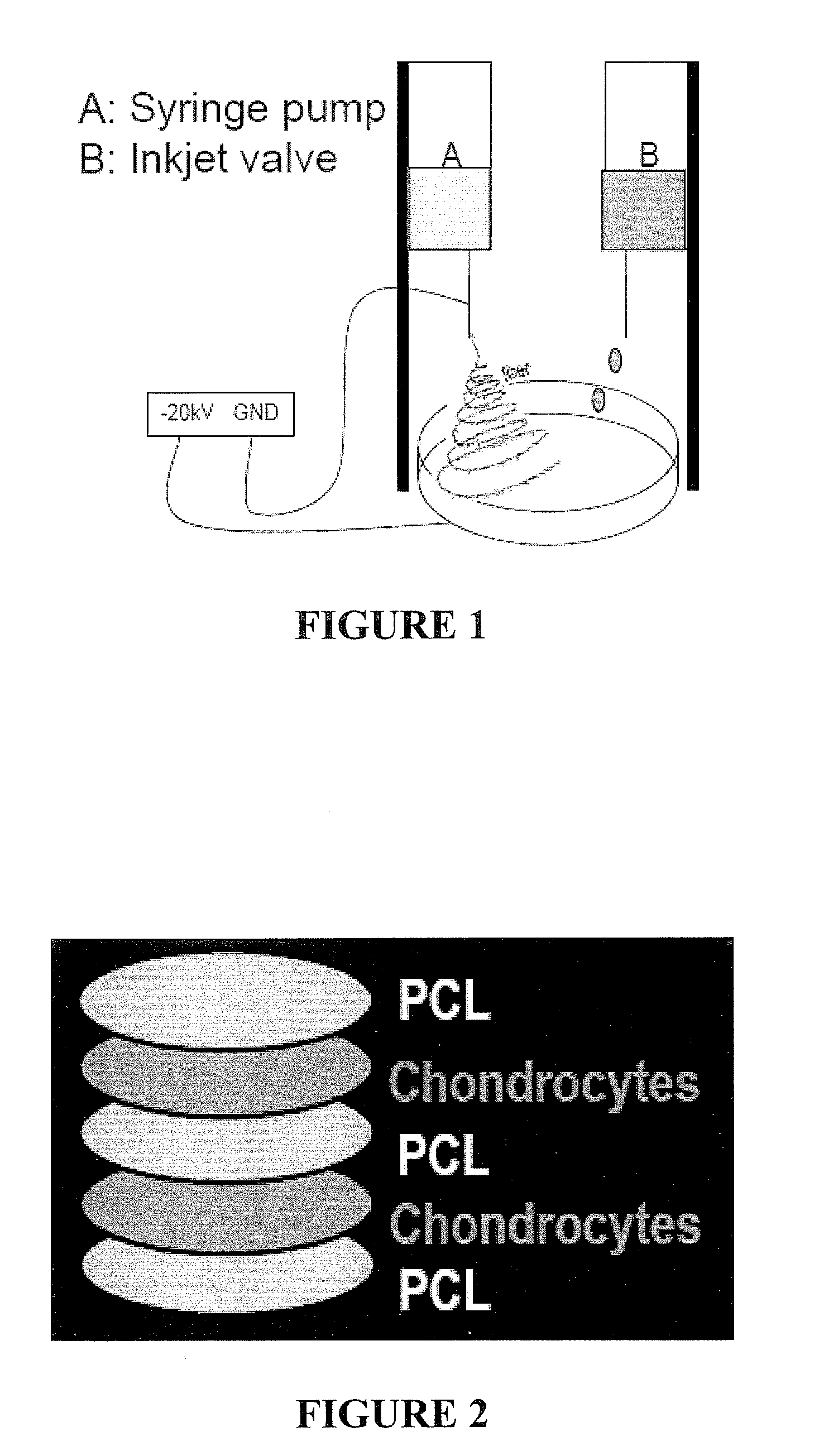

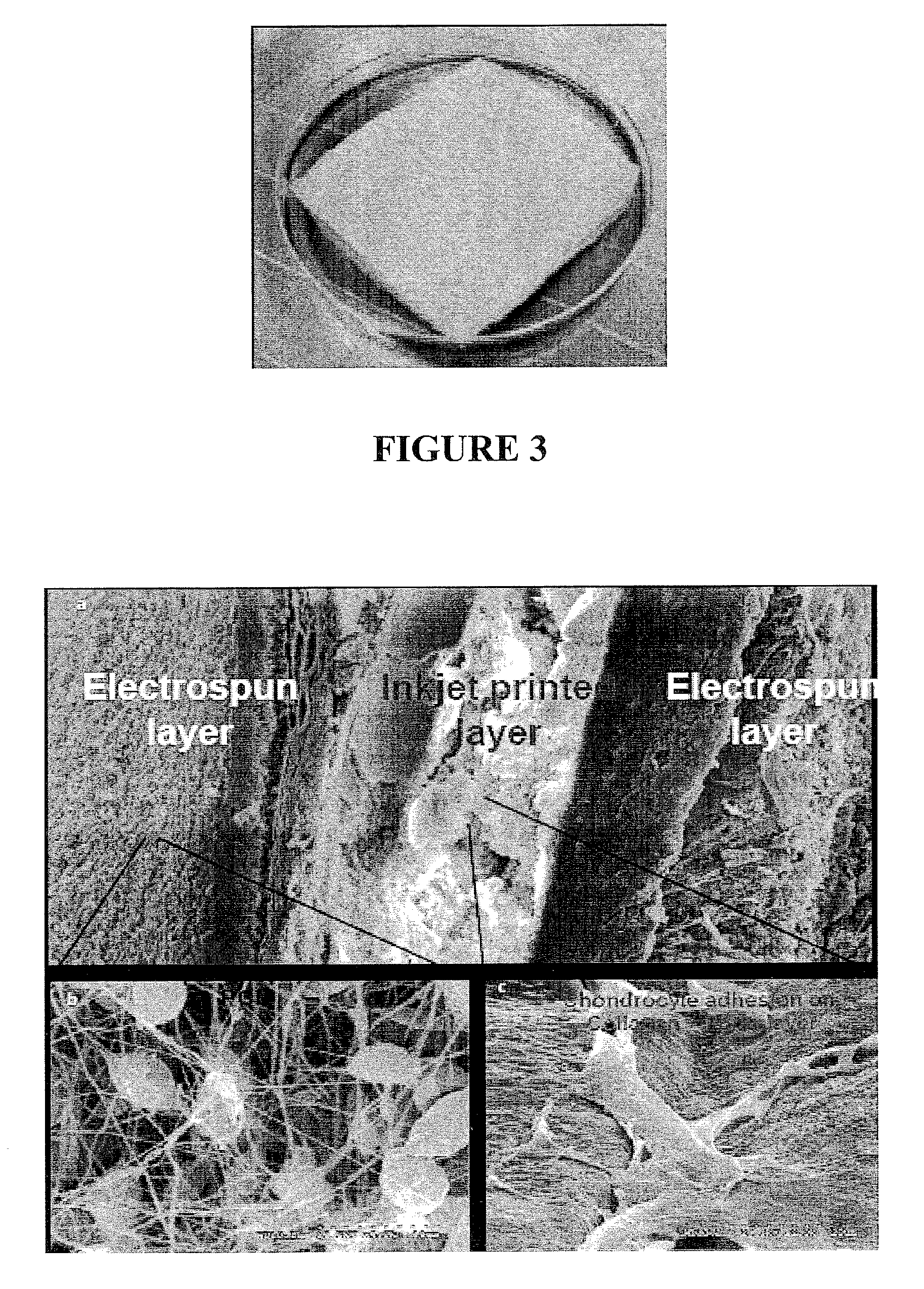

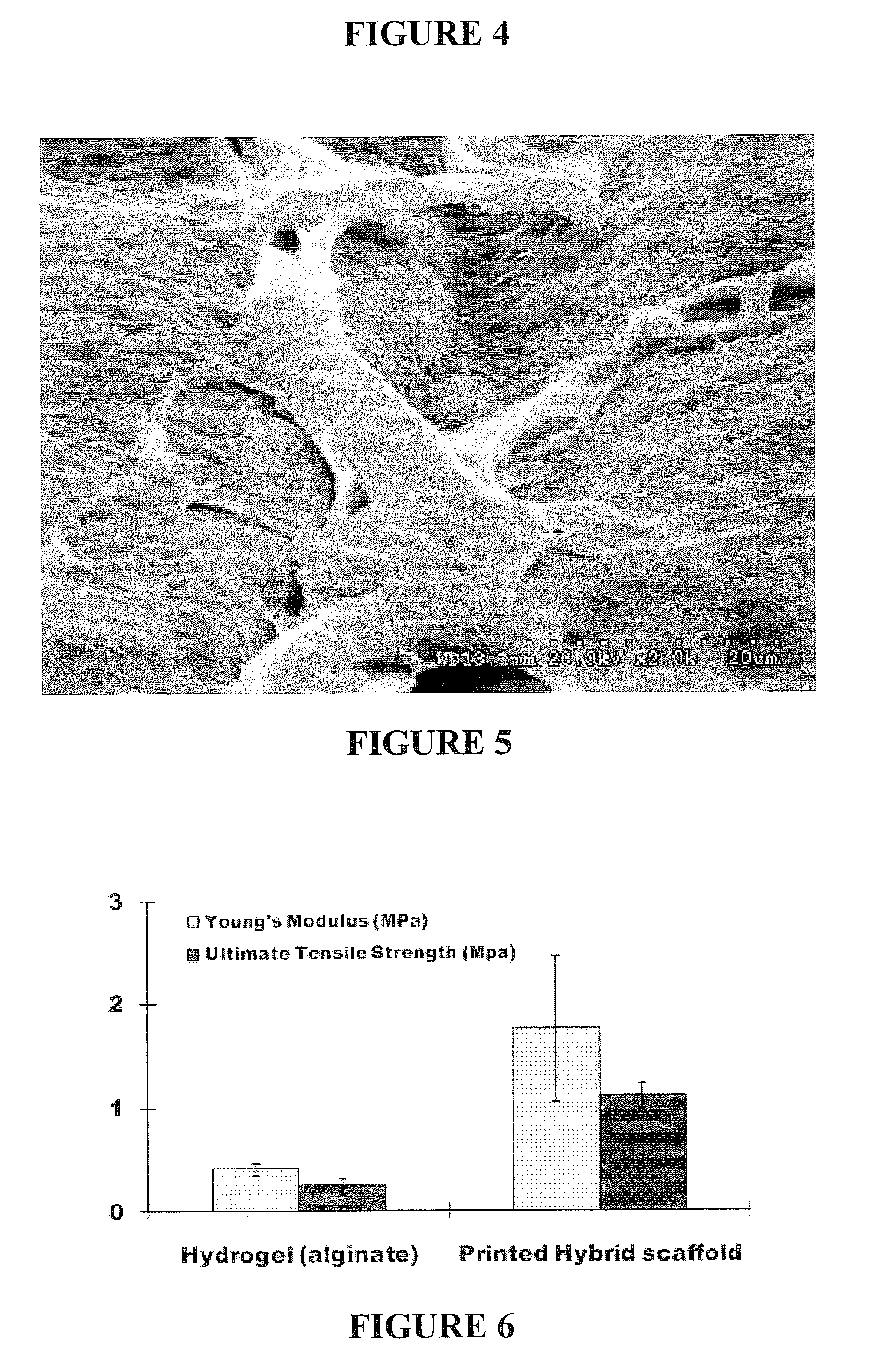

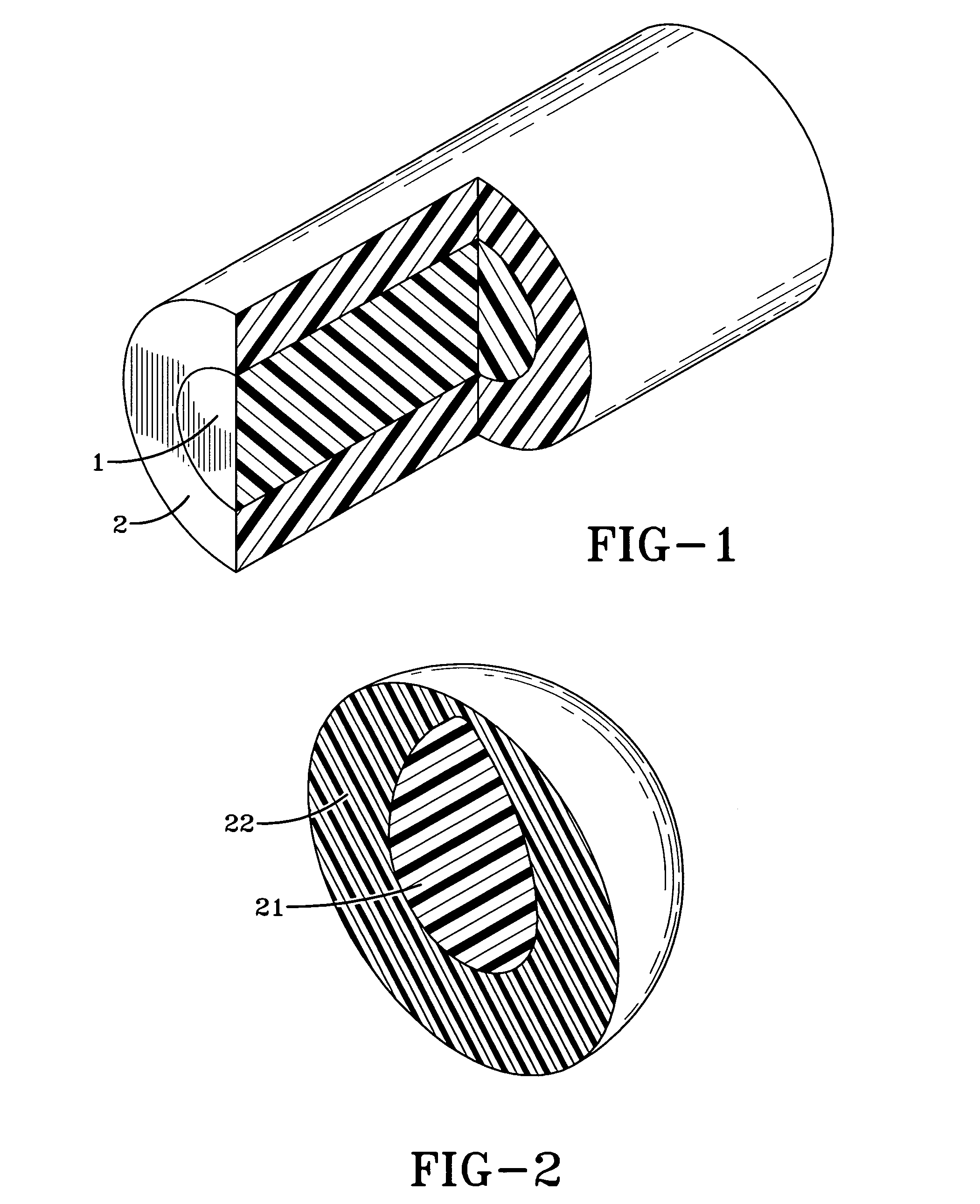

Inkjet Printing of Tissues and Cells

Provided herein is an apparatus for printing cells which includes an electrospinning device and an inkjet printing device operatively associated therewith. Methods of making a biodegradable scaffold having cells seeded therein are also provided. Methods of forming microparticles containing one or more cells encapsulated by a substrate are also provided, as are methods of forming an array of said microparticles.

Owner:WAKE FOREST UNIV HEALTH SCI INC

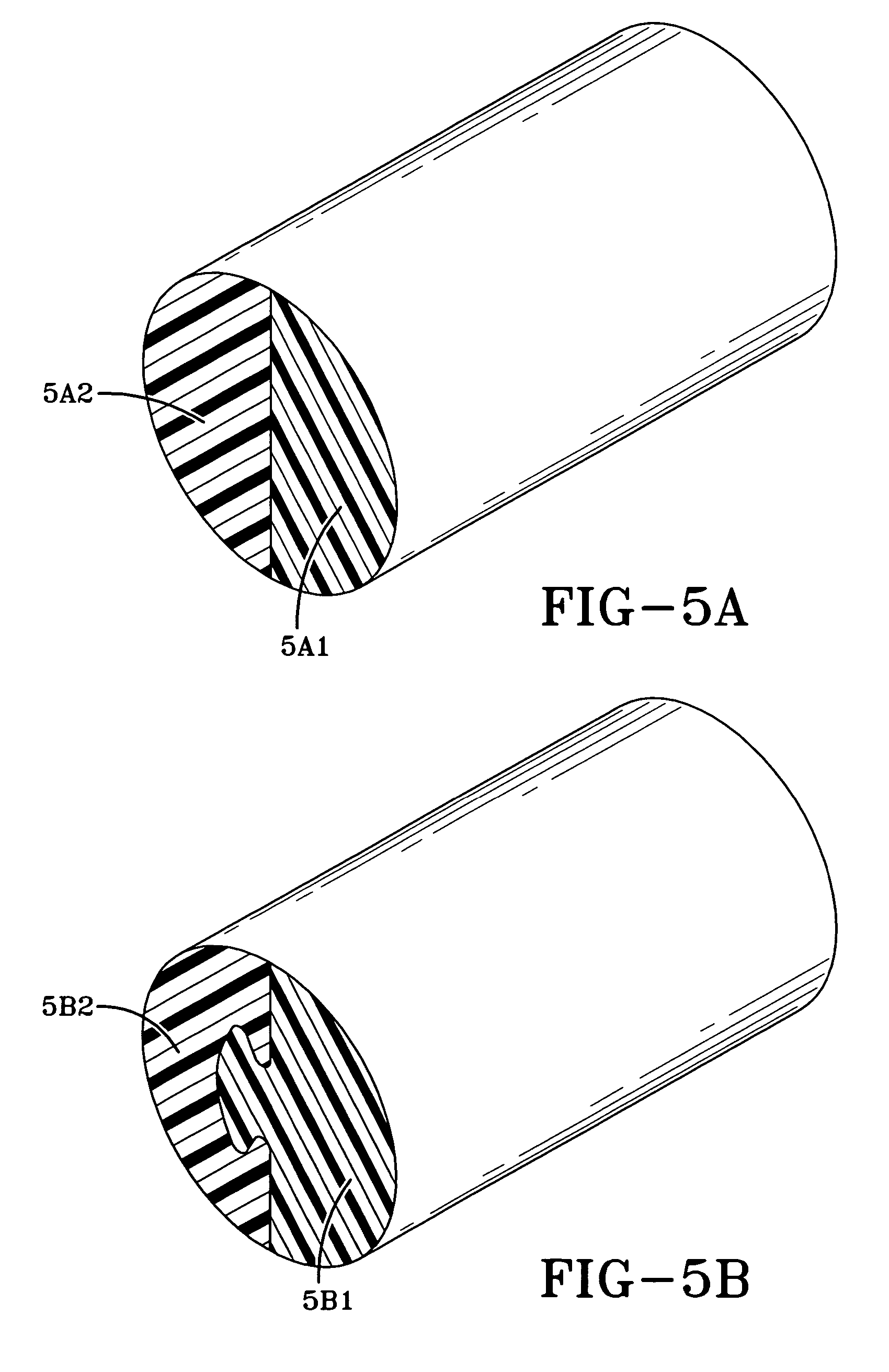

Compartmentalized resin pellets for oxygen scavenging

Owner:M&G POLIMERI ITALIA SPA +1

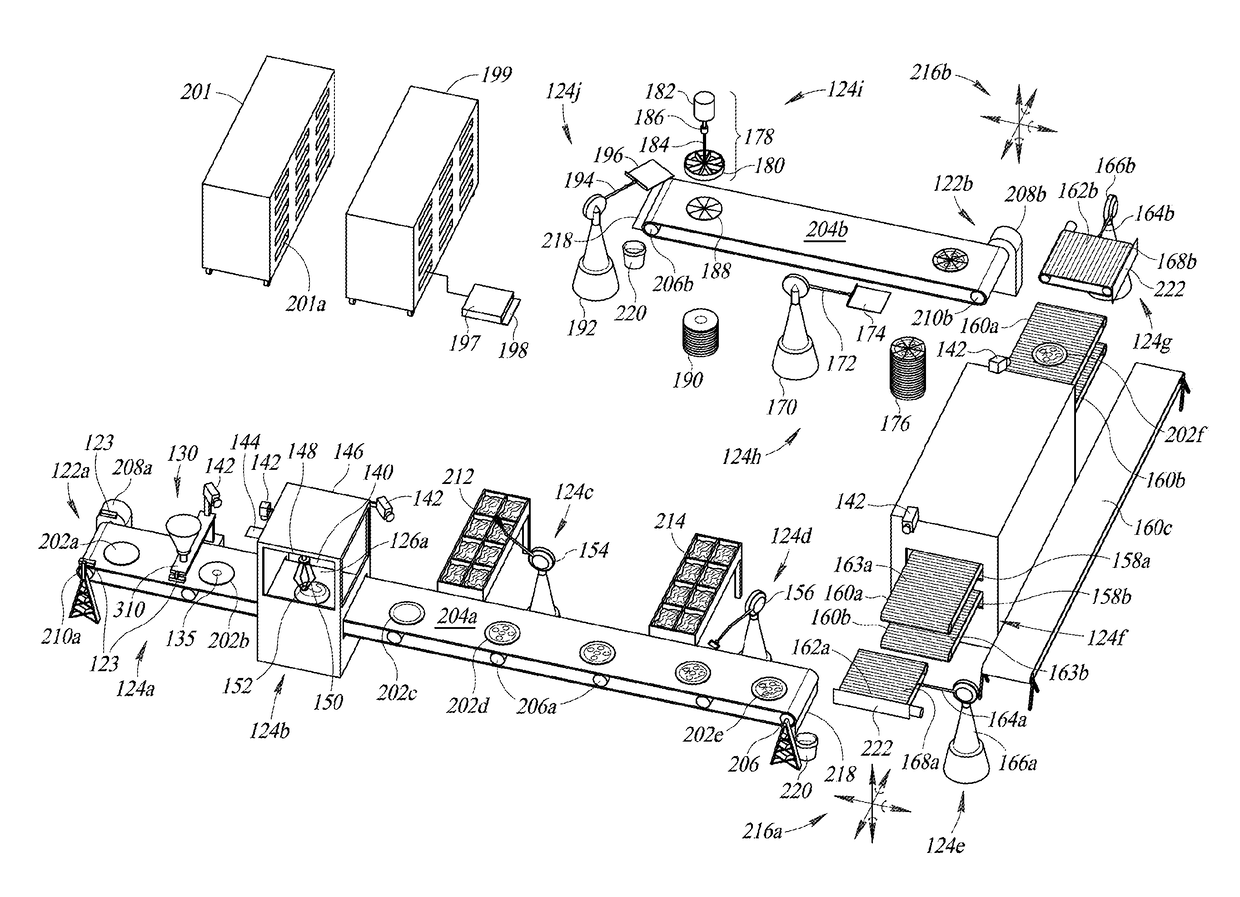

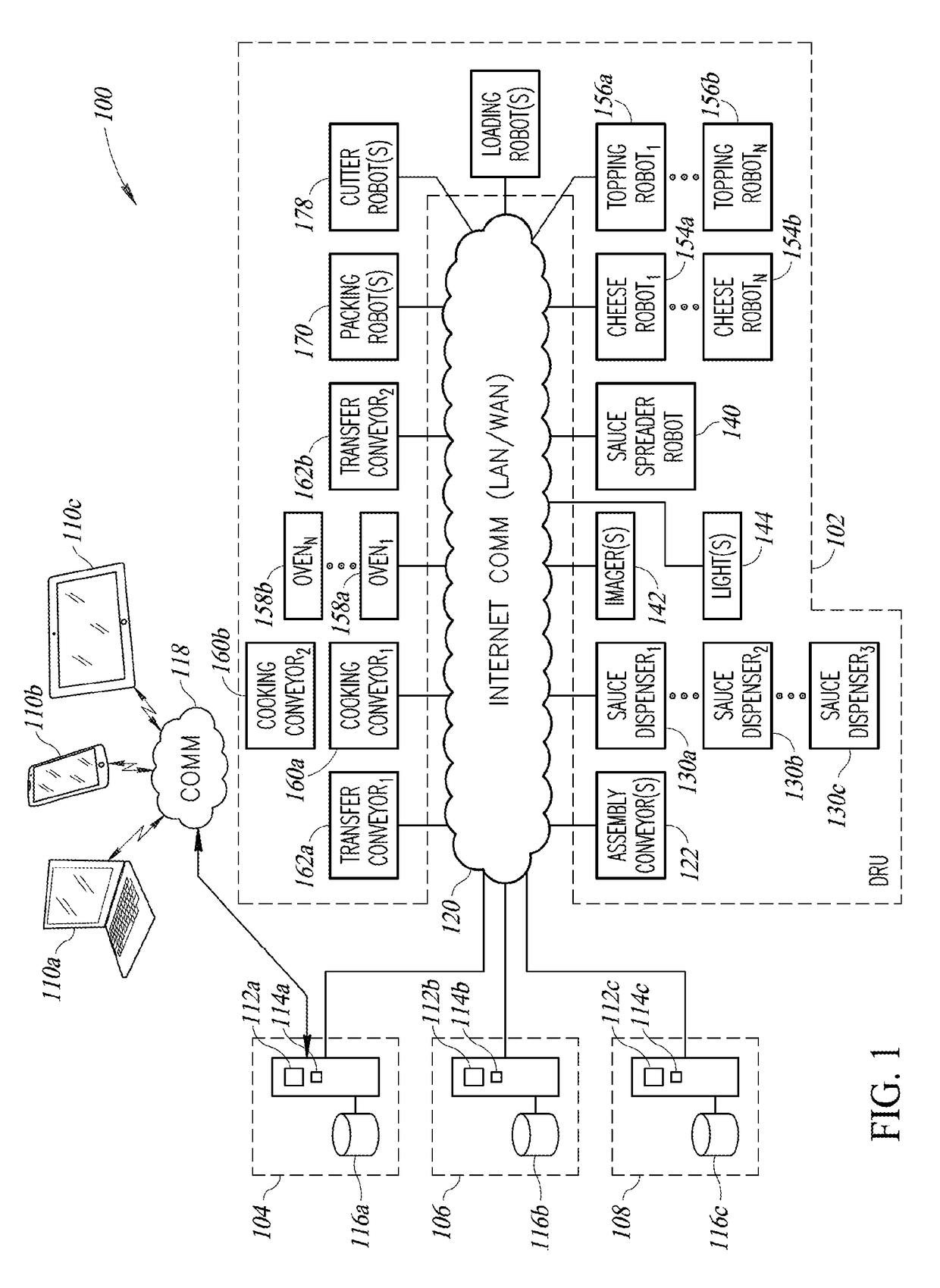

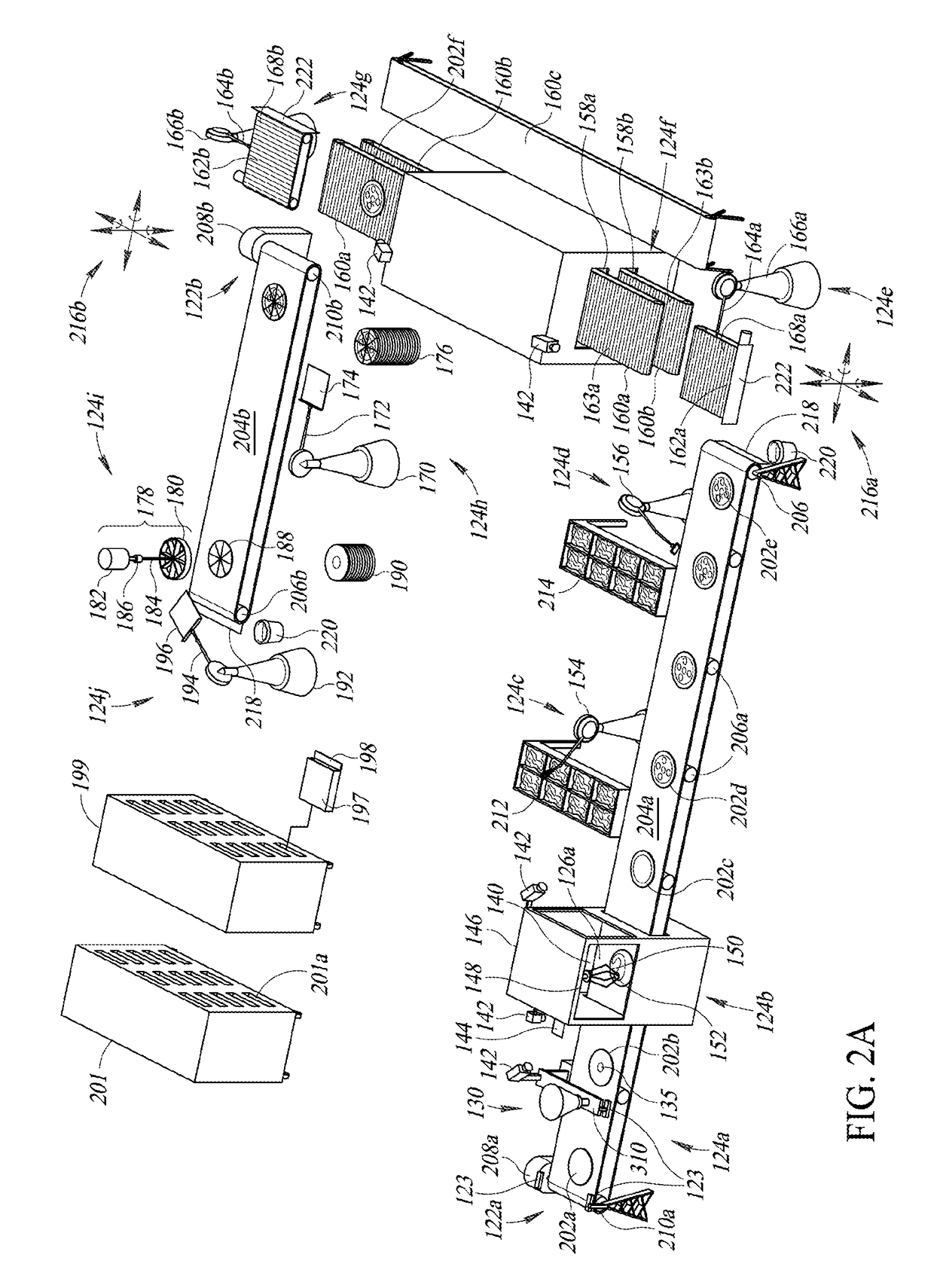

On-demand robotic food assembly and related systems, devices and methods

An on-demand robotic food assembly line can include one or more conveyors and one or more robots, operable to assemble food items in response to received orders for food items, and one or more ovens operable to, for example, partially cook assembled food items. The on-demand robotic food assembly line can optionally package the assembled and partially cooked food items in packaging, and optionally load the packaged partially cooked food items into portable cooking units (e.g., ovens) that are optionally loaded into racks that are, in turn, optionally loaded into delivery vehicles, where the food items are individually cooked under controlled conditions while en route to consumer destinations, such the cooking of each food item is completed just prior to arrival at the consumer destination location. A dynamic fulfillment queue for control of assembly is maintained based at least in part on estimated transit time for orders.

Owner:ZUME INC

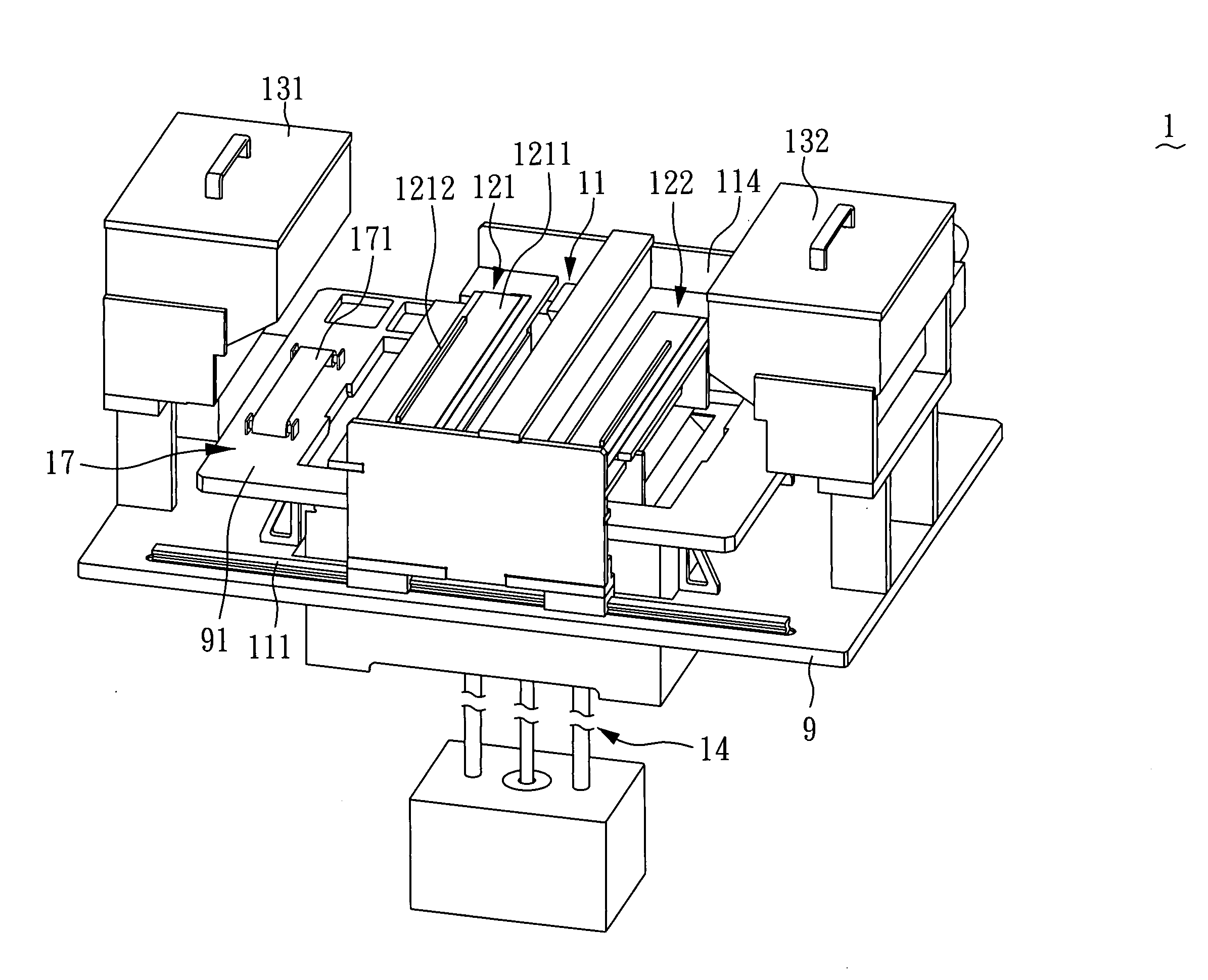

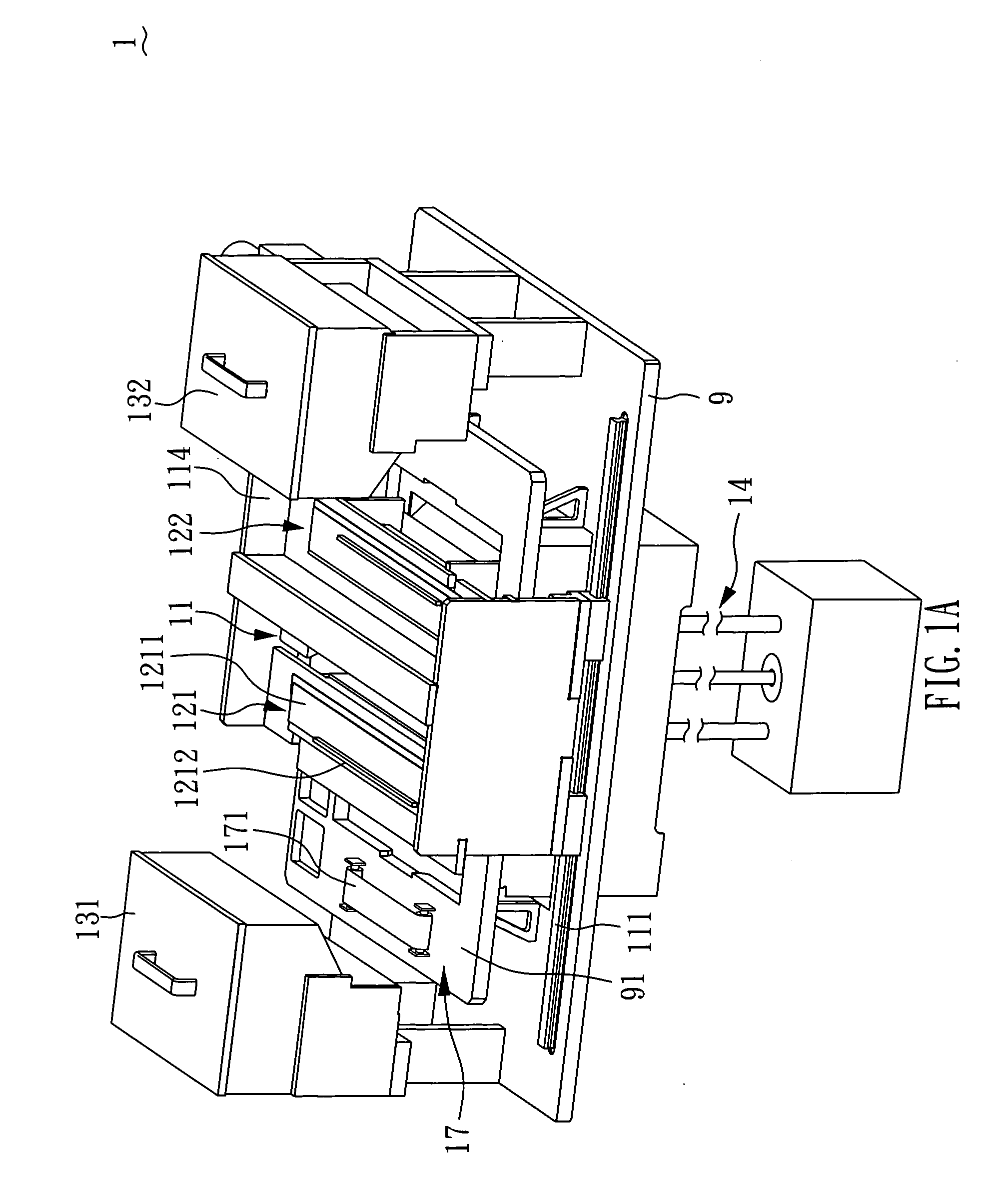

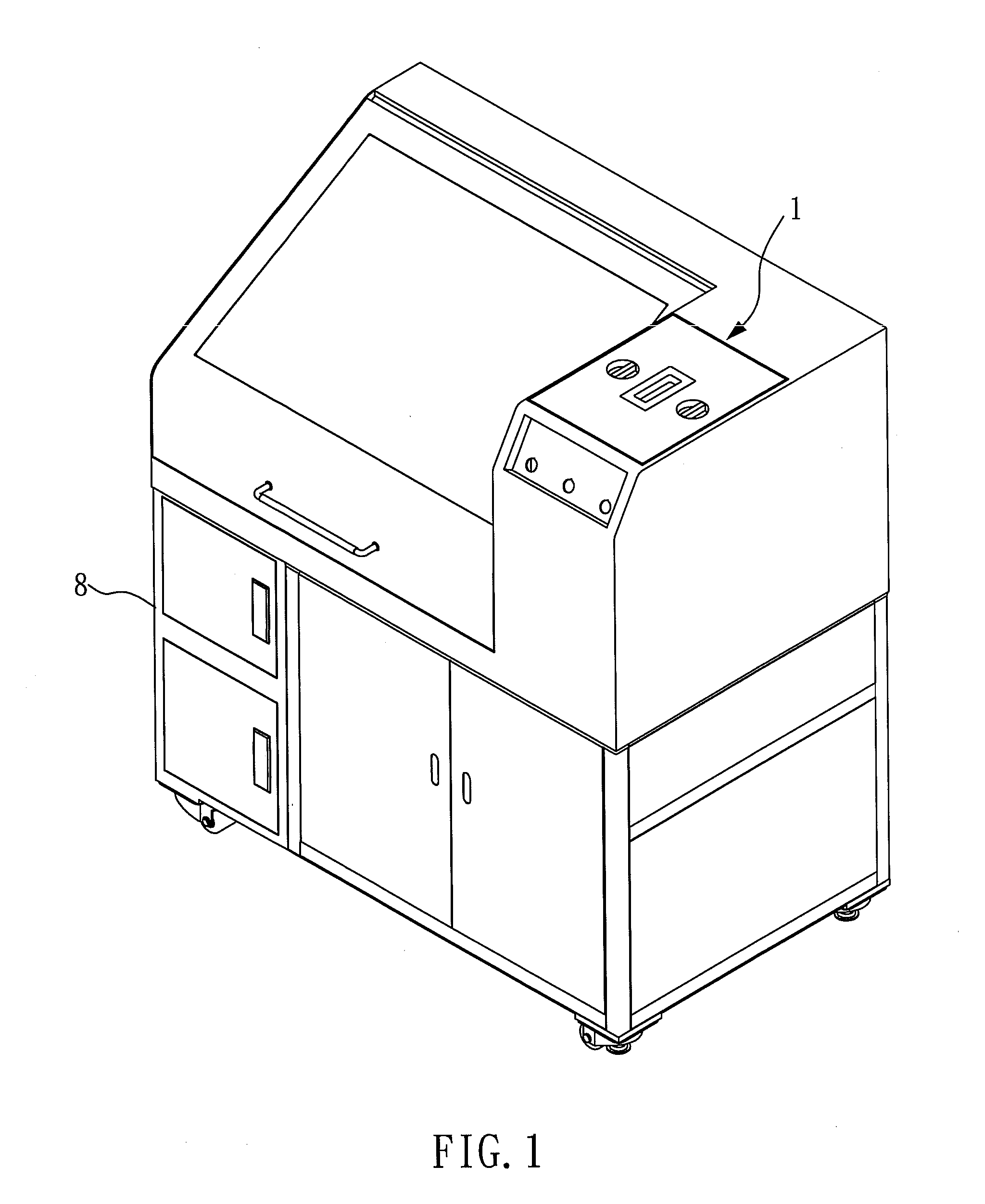

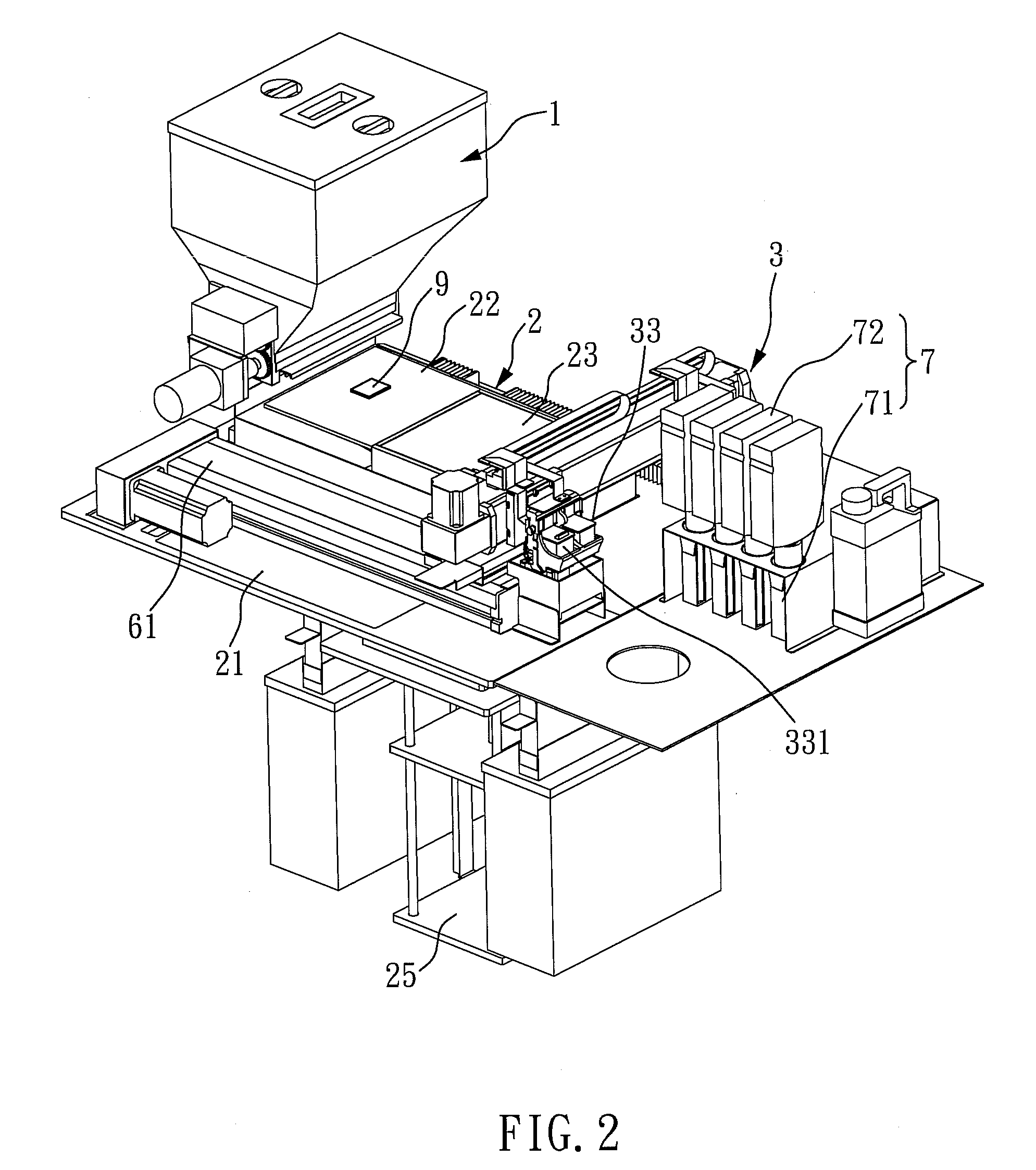

Three-dimensional object forming apparatus and method for forming three-dimensional object

InactiveUS20100247742A1Avoid pollutionLiquid surface applicatorsConfectioneryComputer moduleEngineering

Owner:MICROJET TECH

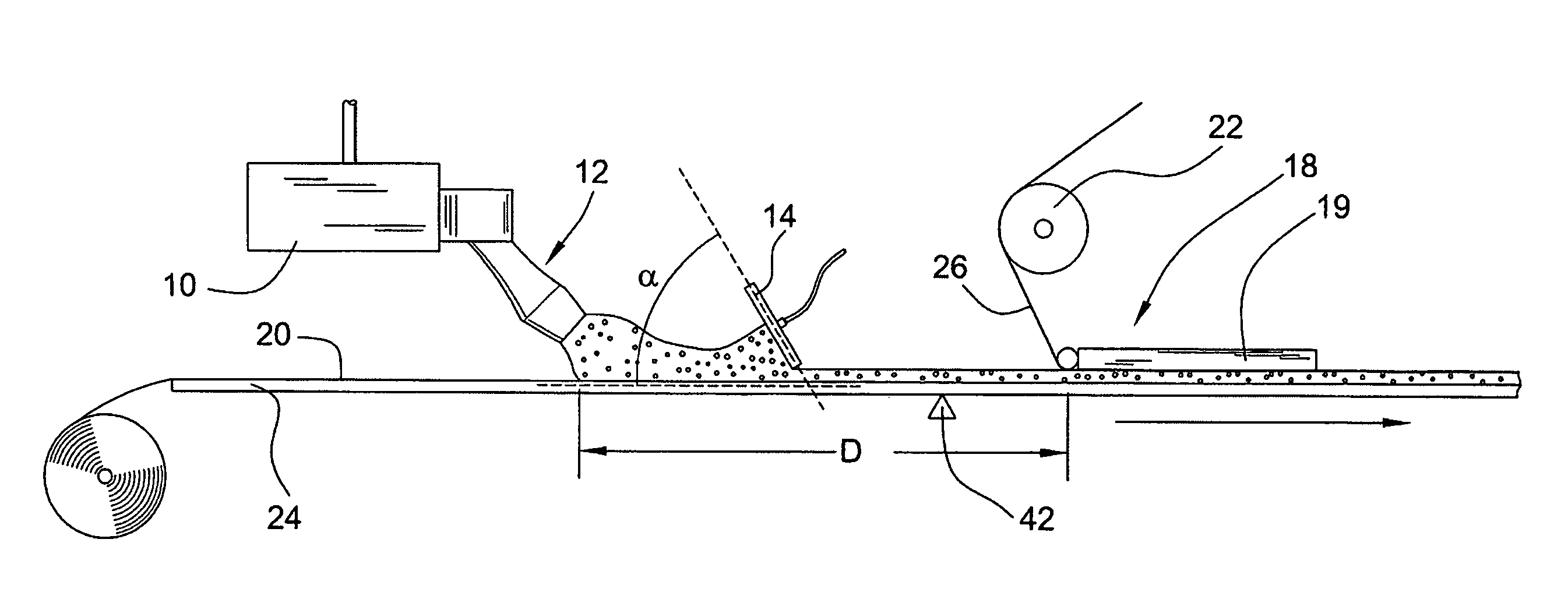

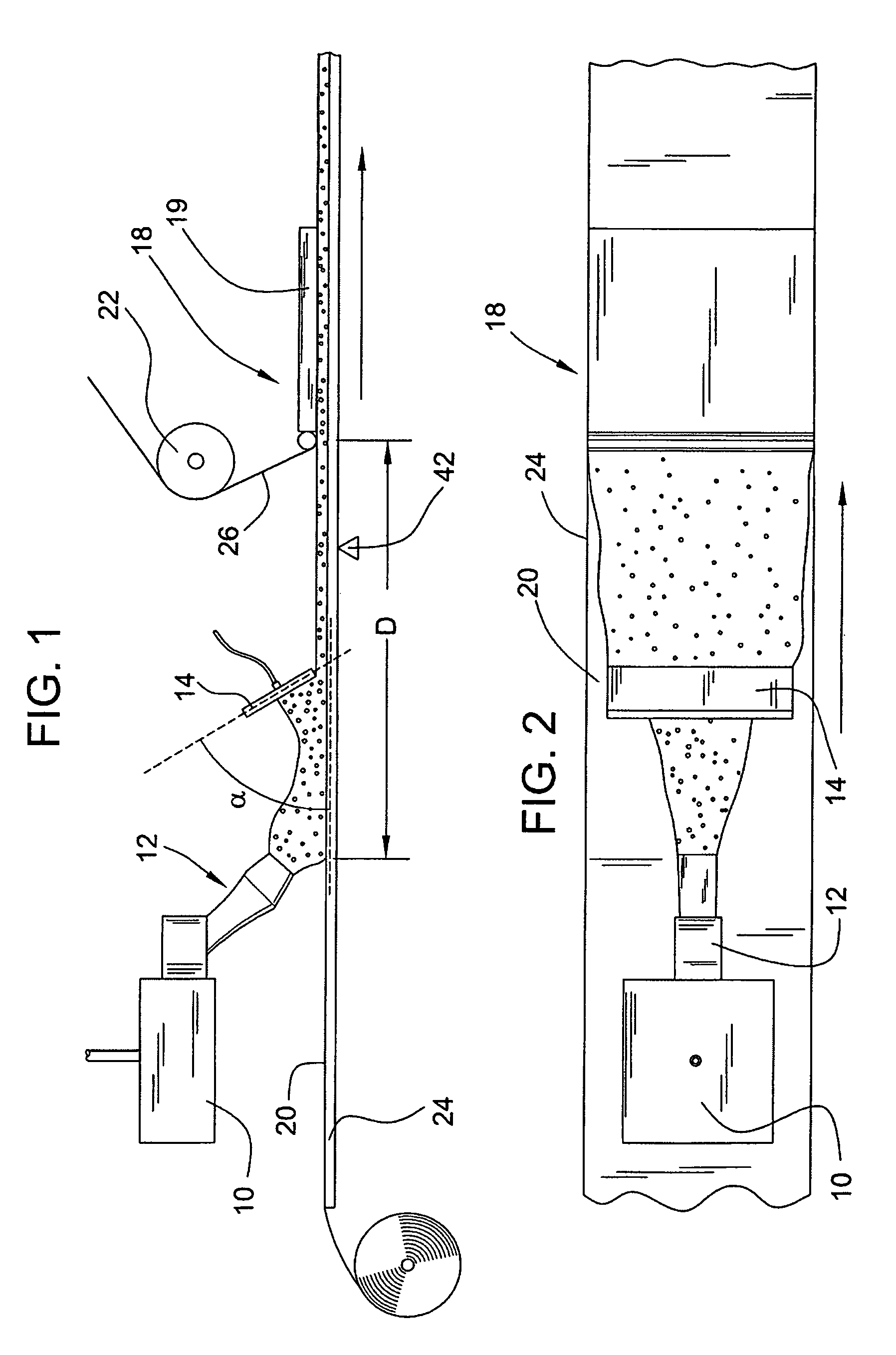

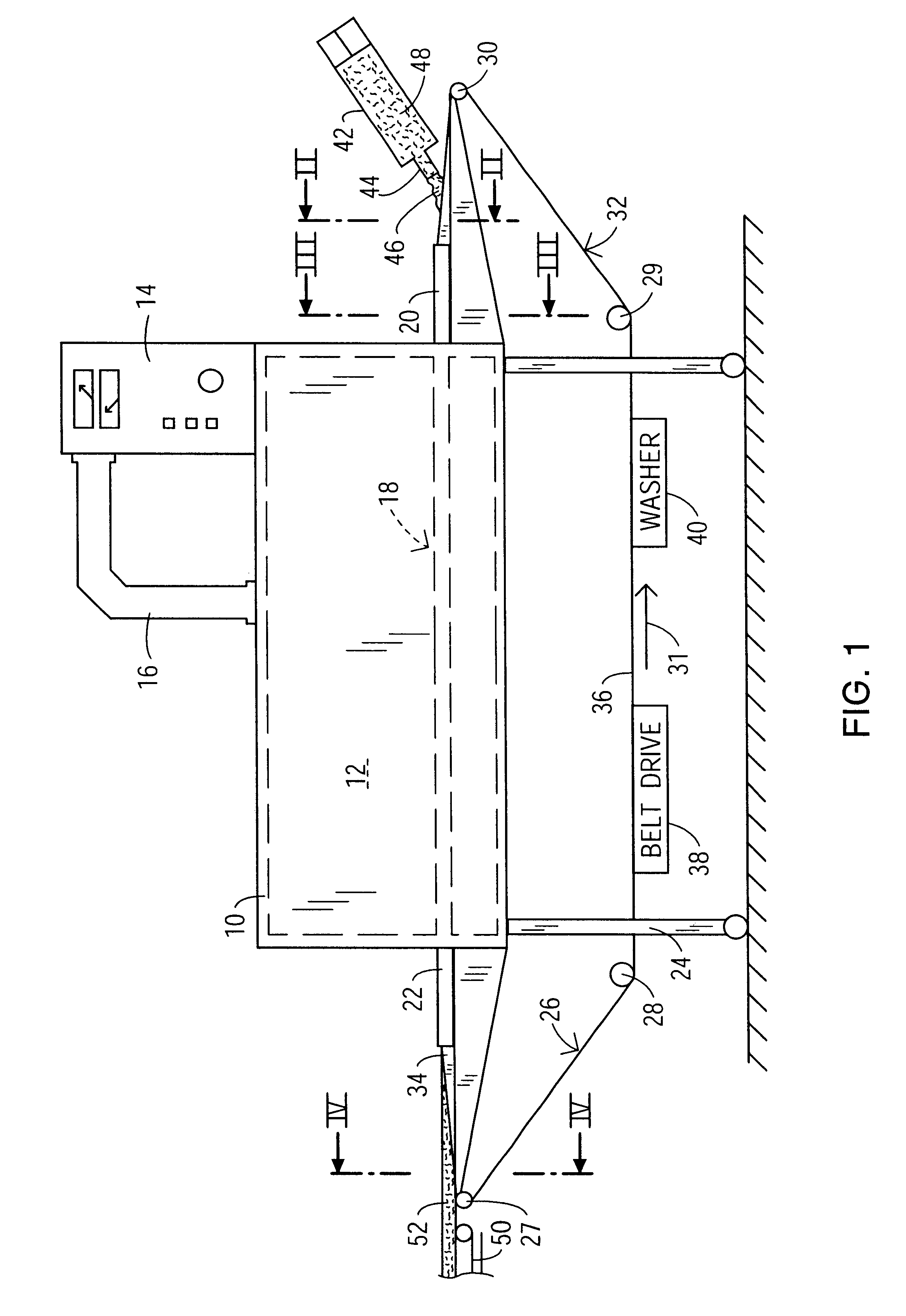

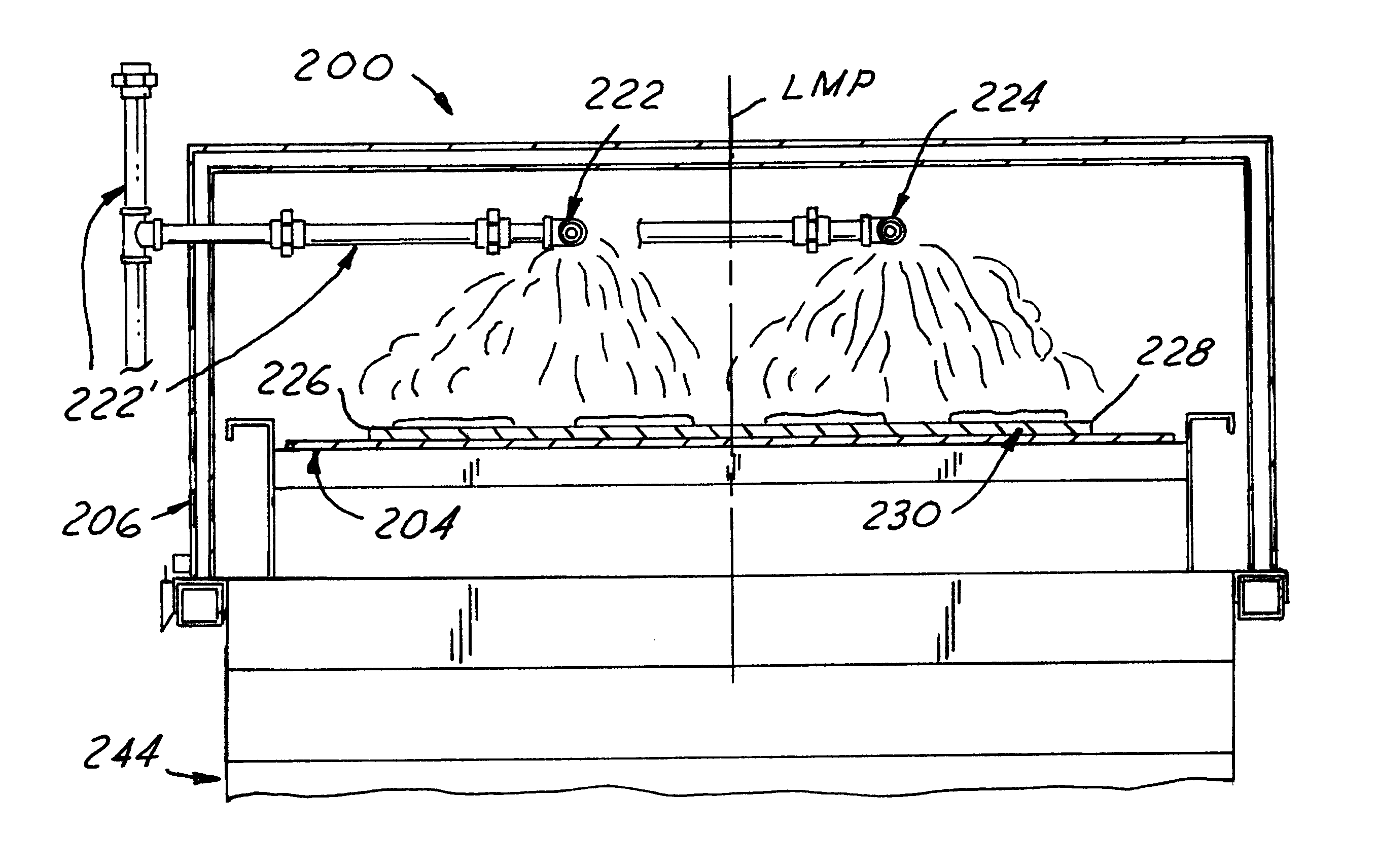

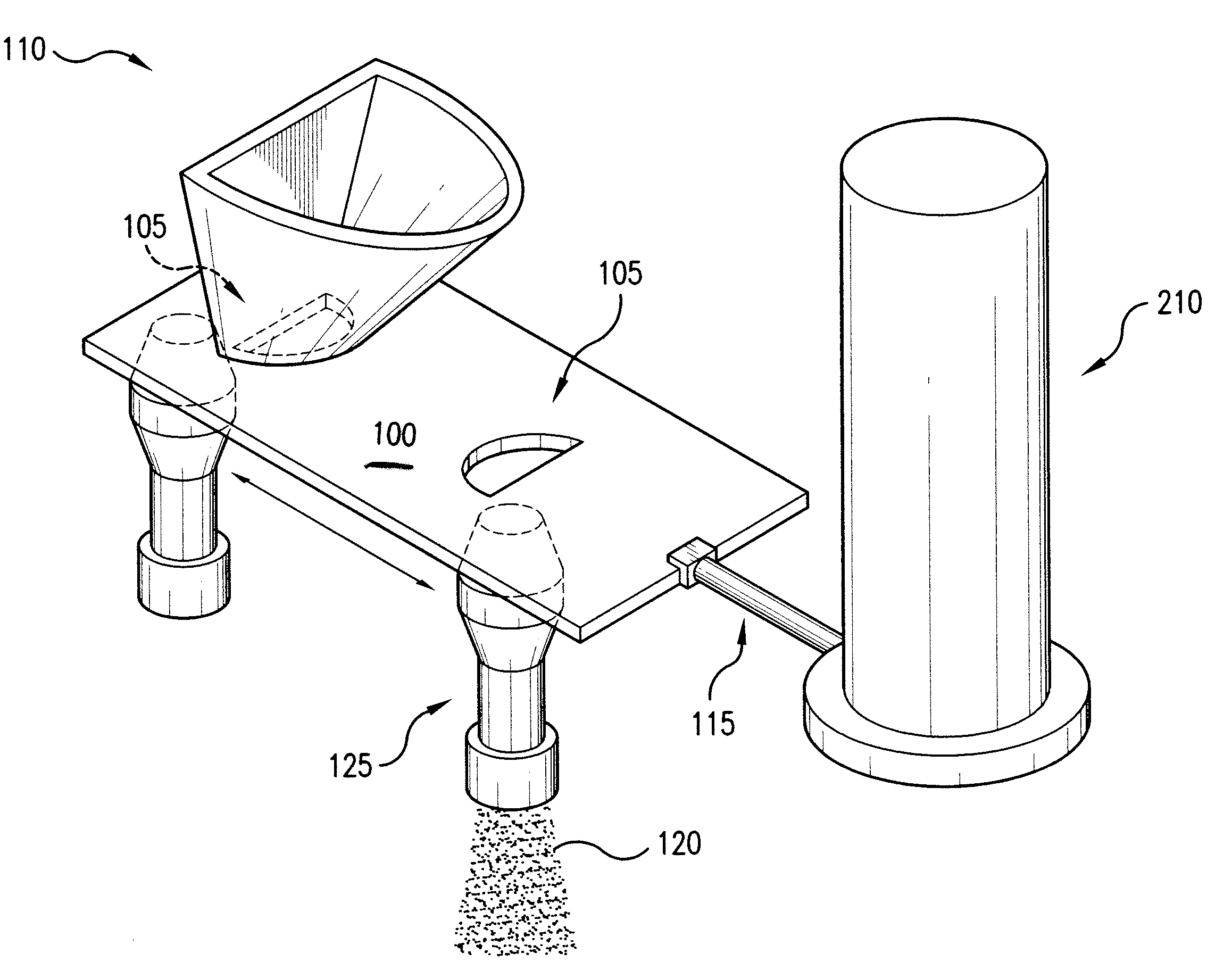

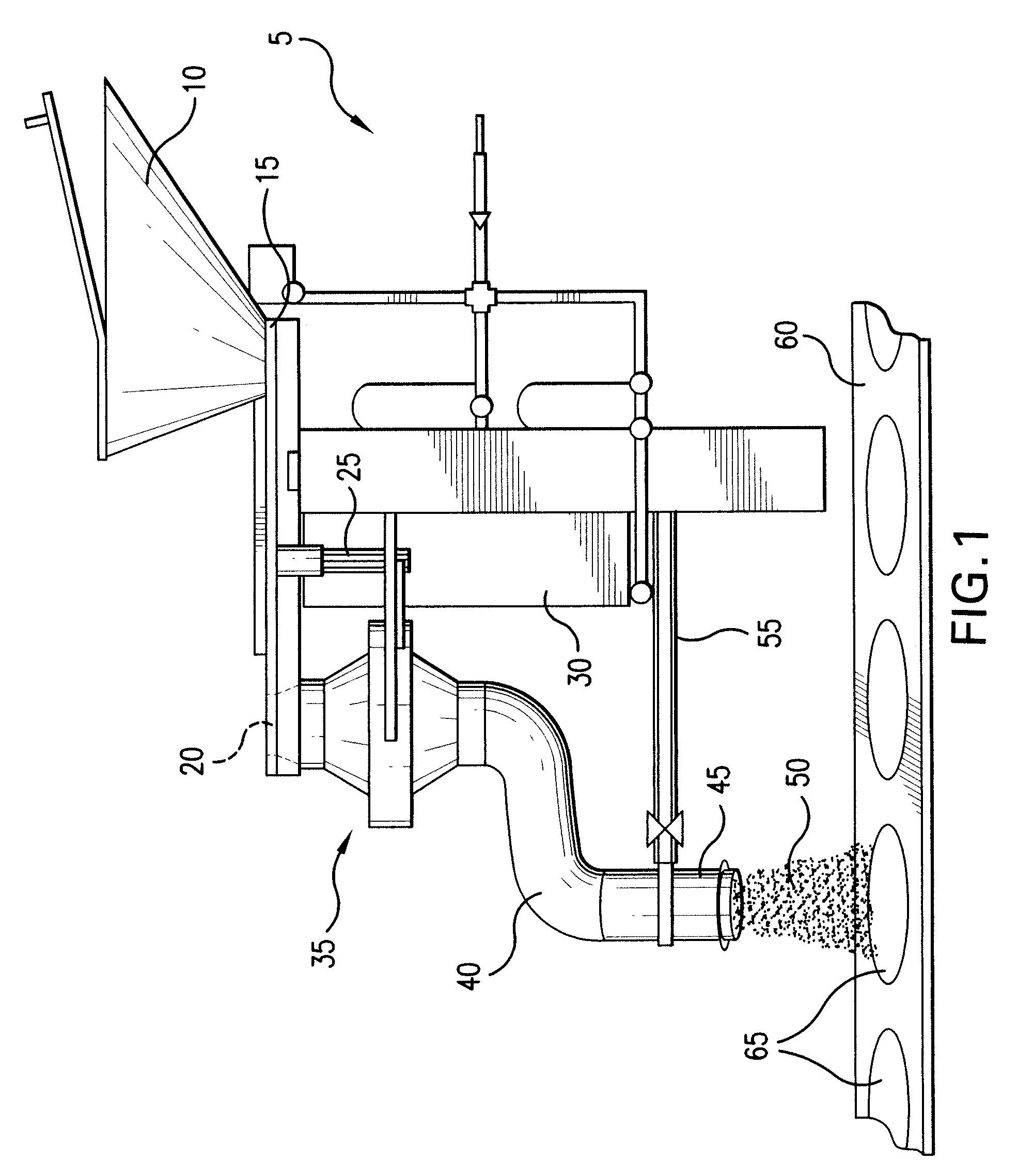

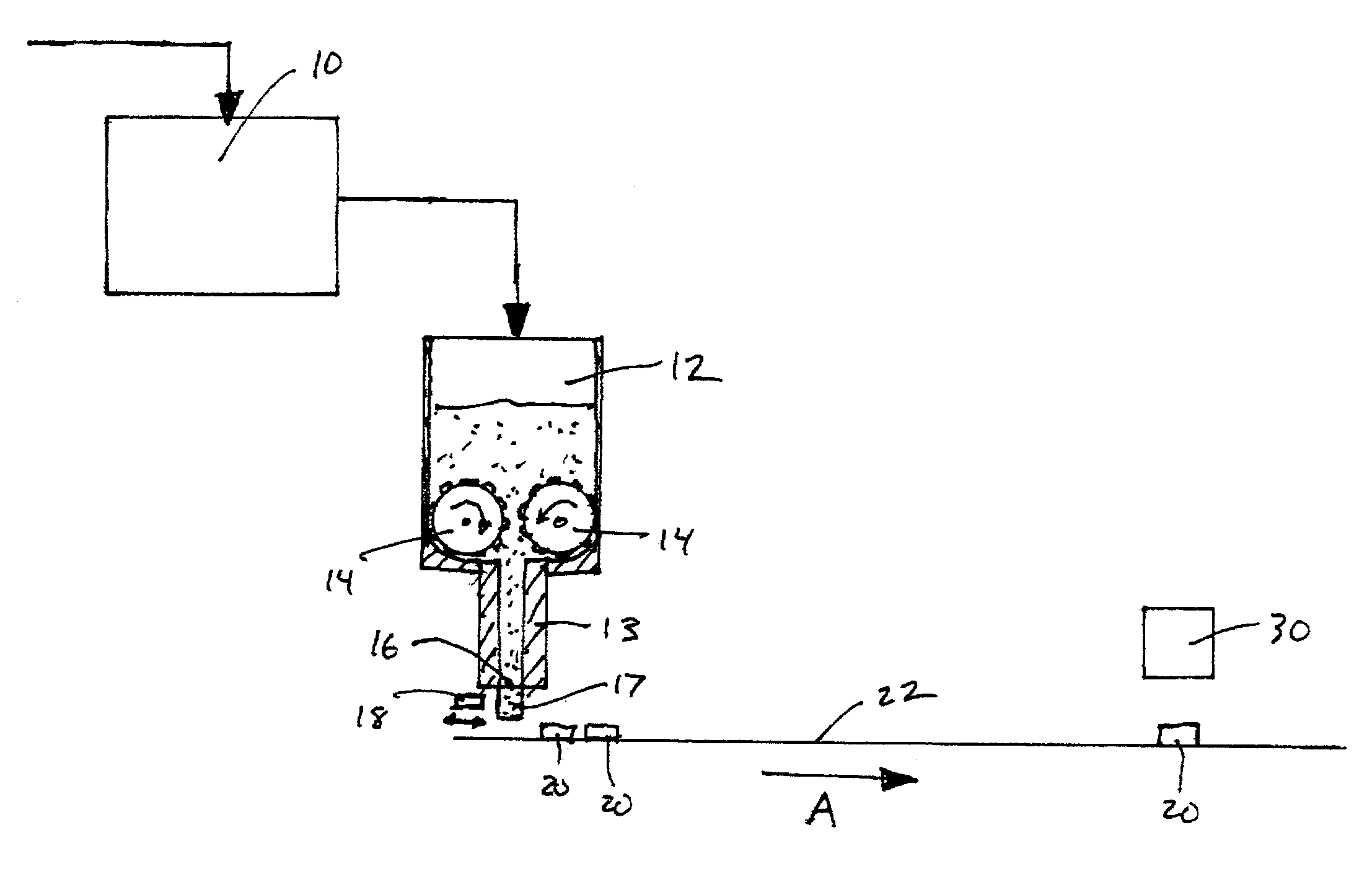

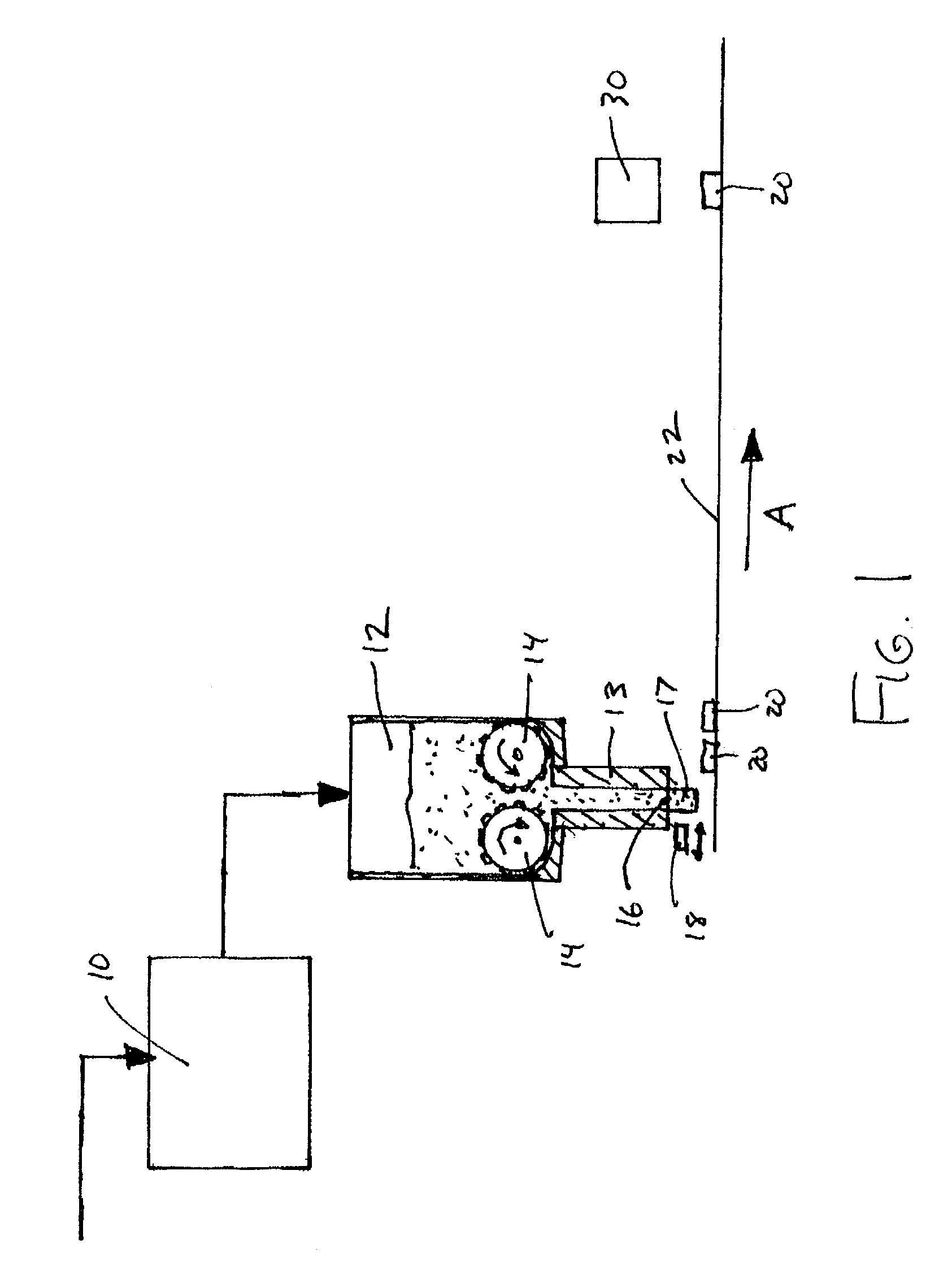

Slurry spreader for cementitious board production

InactiveUS7364676B2Increase productionSubstantial eliminationConfectioneryPress rollersCement boardEngineering

The invention provides a board forming system comprising a forming table comprising a belt with a surface for conveying a backing layer; a mixer fitted with a mechanism capable of depositing cementitious slurry material over a top surface of the backing layer; and a slurry spreader positioned downstream of the mixer, wherein a portion of the slurry spreader comprises a plurality of apertures which are connected to a source of pressurized fluid. The slurry spreader is configured such that the pressurized fluid flows out of the slurry spreader through the apertures so as to provide a continuous film of fluid across an outer surface of the slurry spreader. The slurry spreader is positioned such that it can contact at least a portion of the cementitious slurry after the slurry exits the discharge and before the slurry is spread across the width of the backing layer such that the thickness of the slurry is approximately equal to the desired slurry thickness for board formation. The invention further provides methods for forming cementitious board comprising the use of the slurry spreader.

Owner:UNITED STATES GYPSUM CO

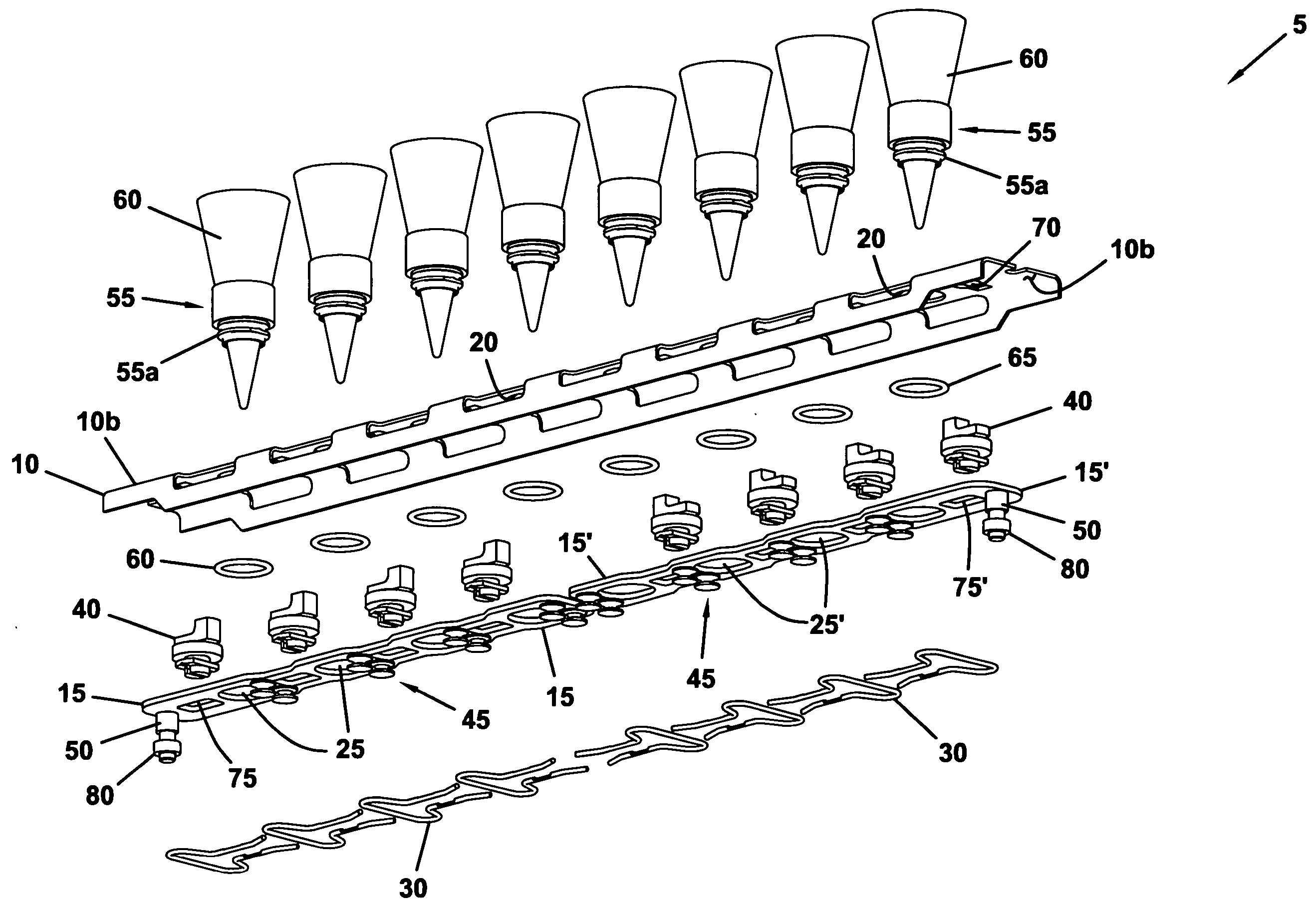

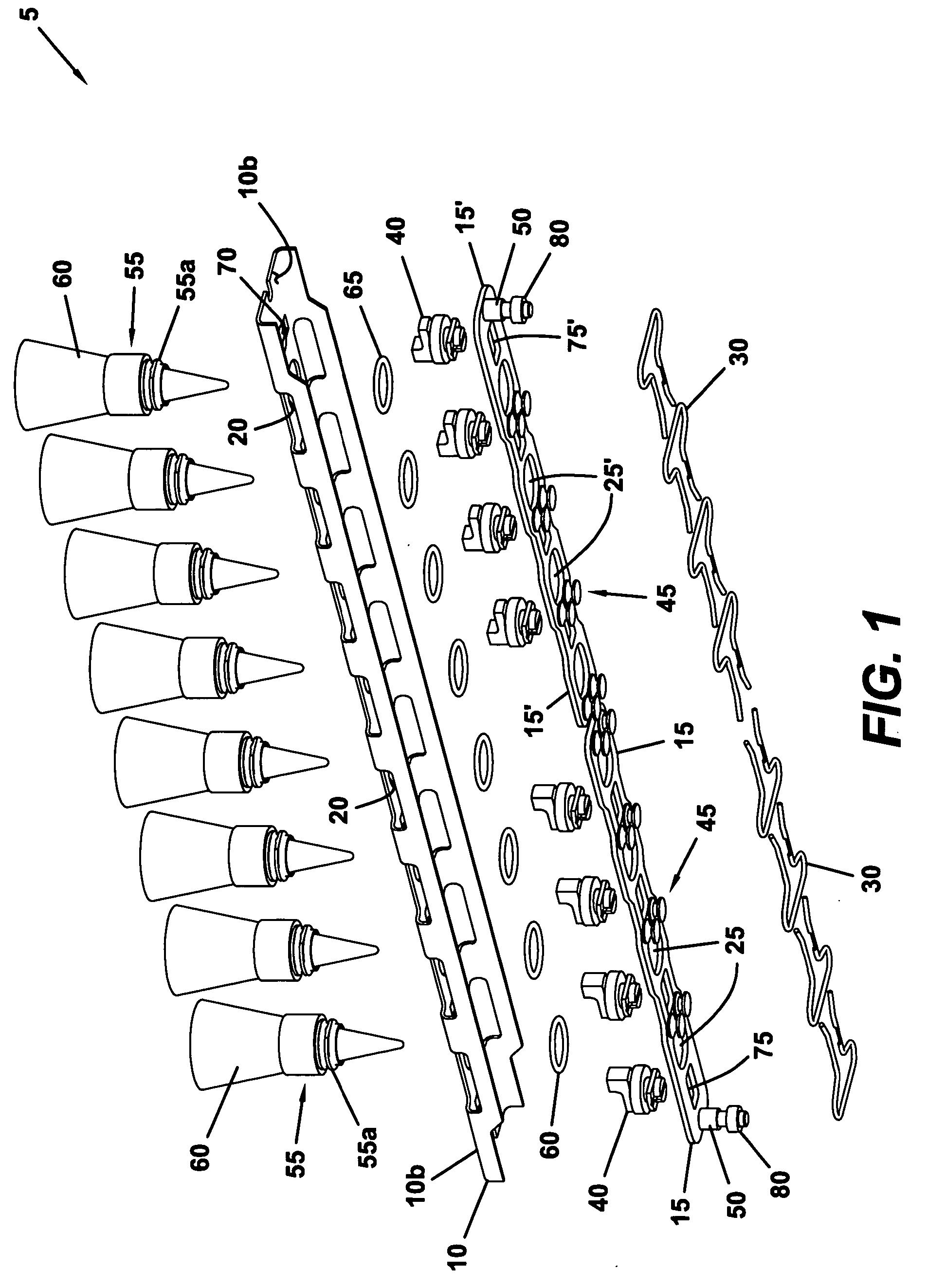

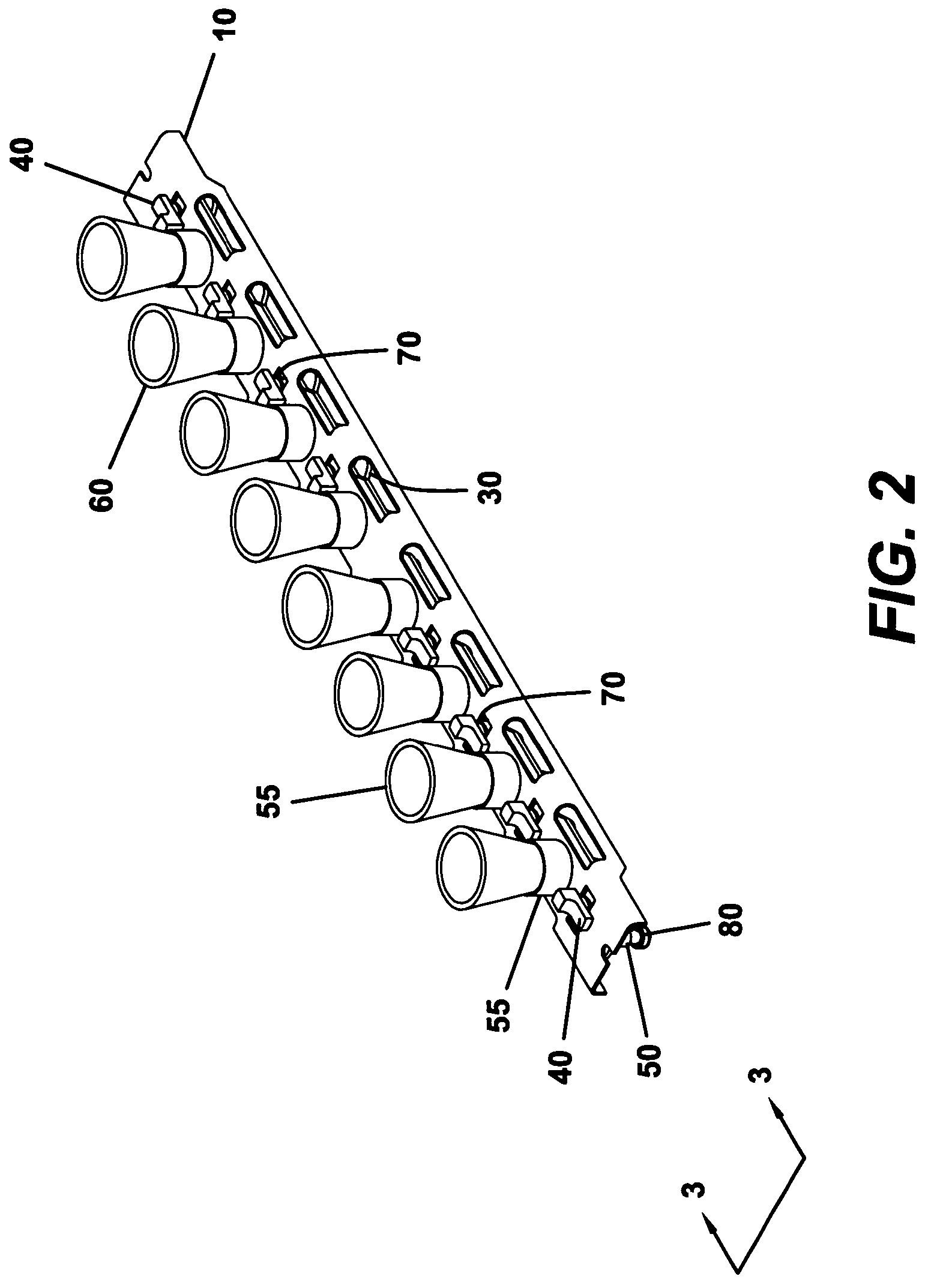

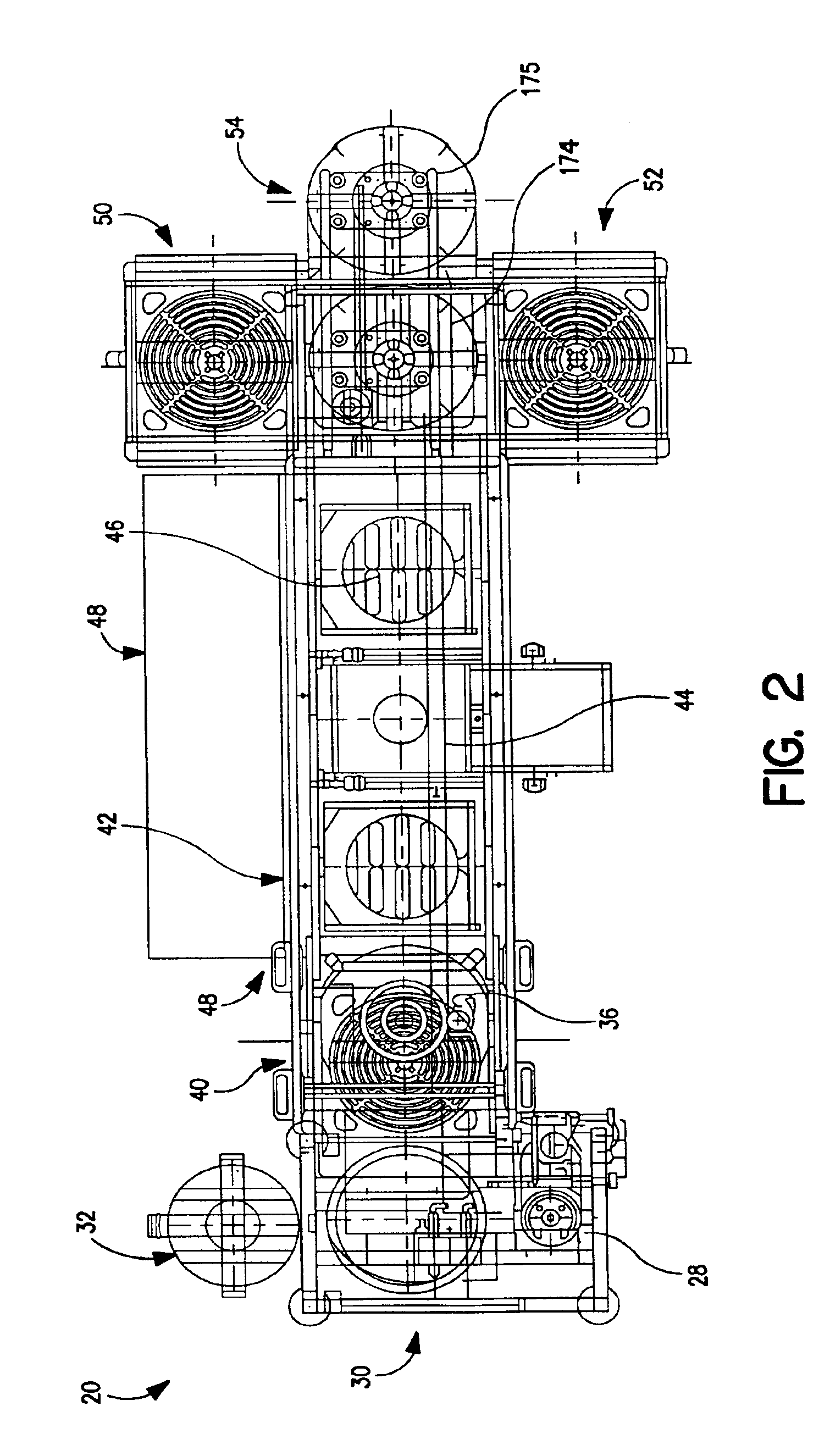

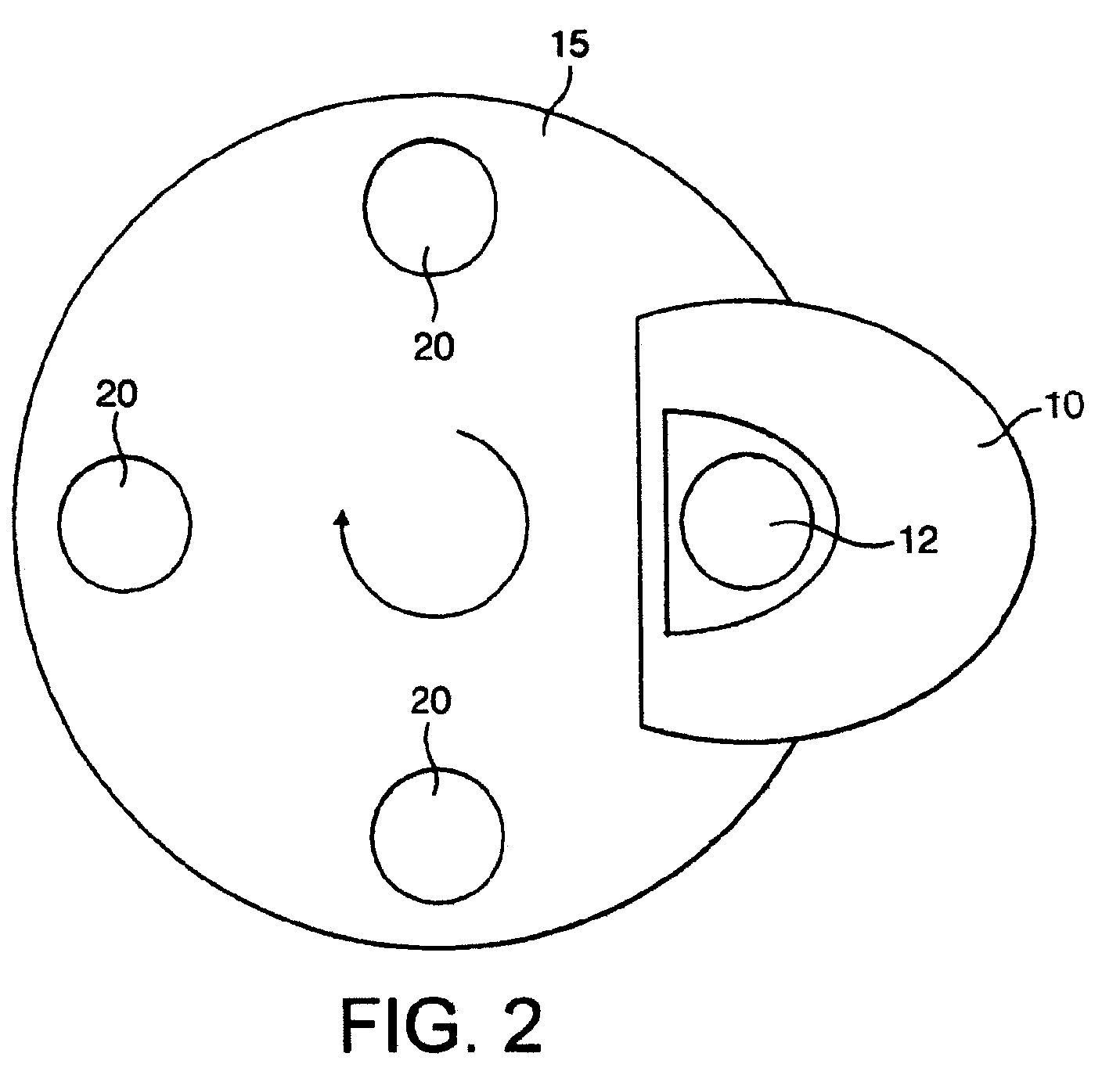

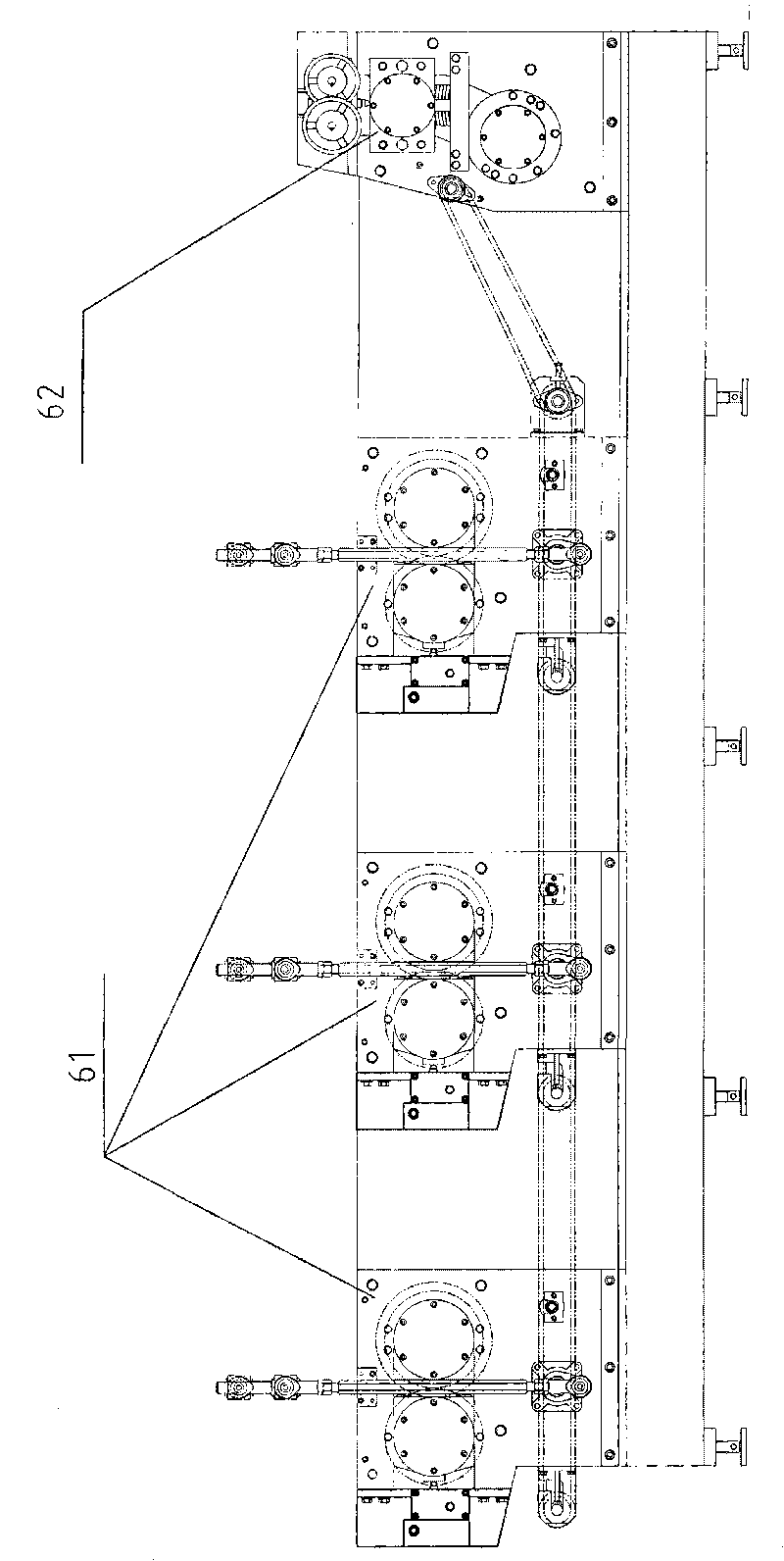

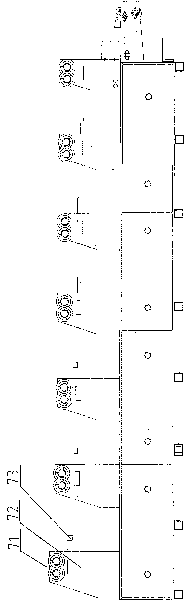

Modular and reconfigurable frozen cone confection manufacturing system and method

InactiveUS20050086961A1Overall design flexibilityEasy to produceLiquid surface applicatorsAir-treating devicesEngineeringReconfigurable Manufacturing System

The present invention relates to an apparatus and method for grasping, retaining, inverting, coating and transporting a plurality of frangible conical confection shells. The present invention also relates to a modular and reconfigurable manufacturing system for producing frozen cone confections and the like.

Owner:NORSE DAIRY SYST

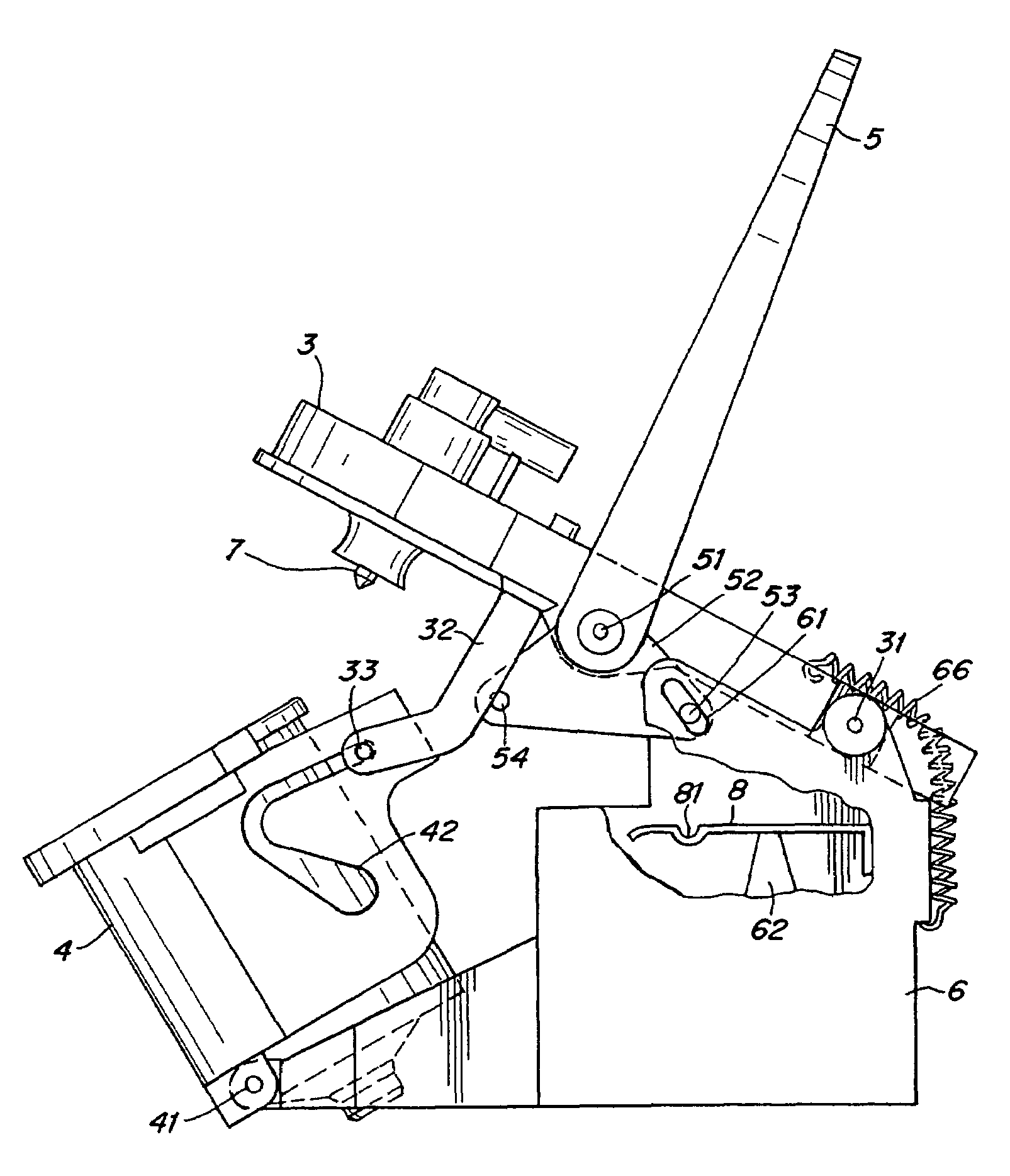

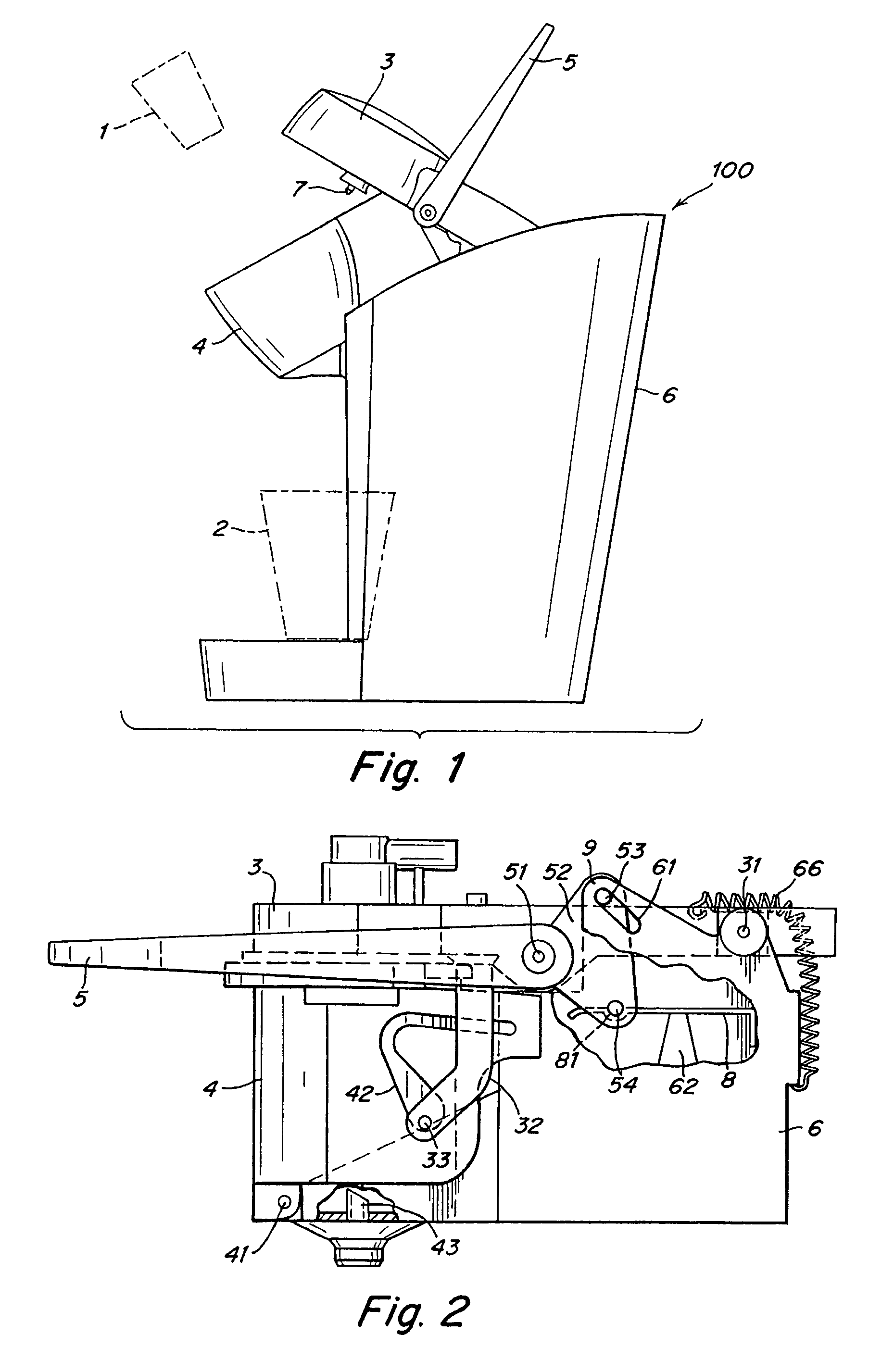

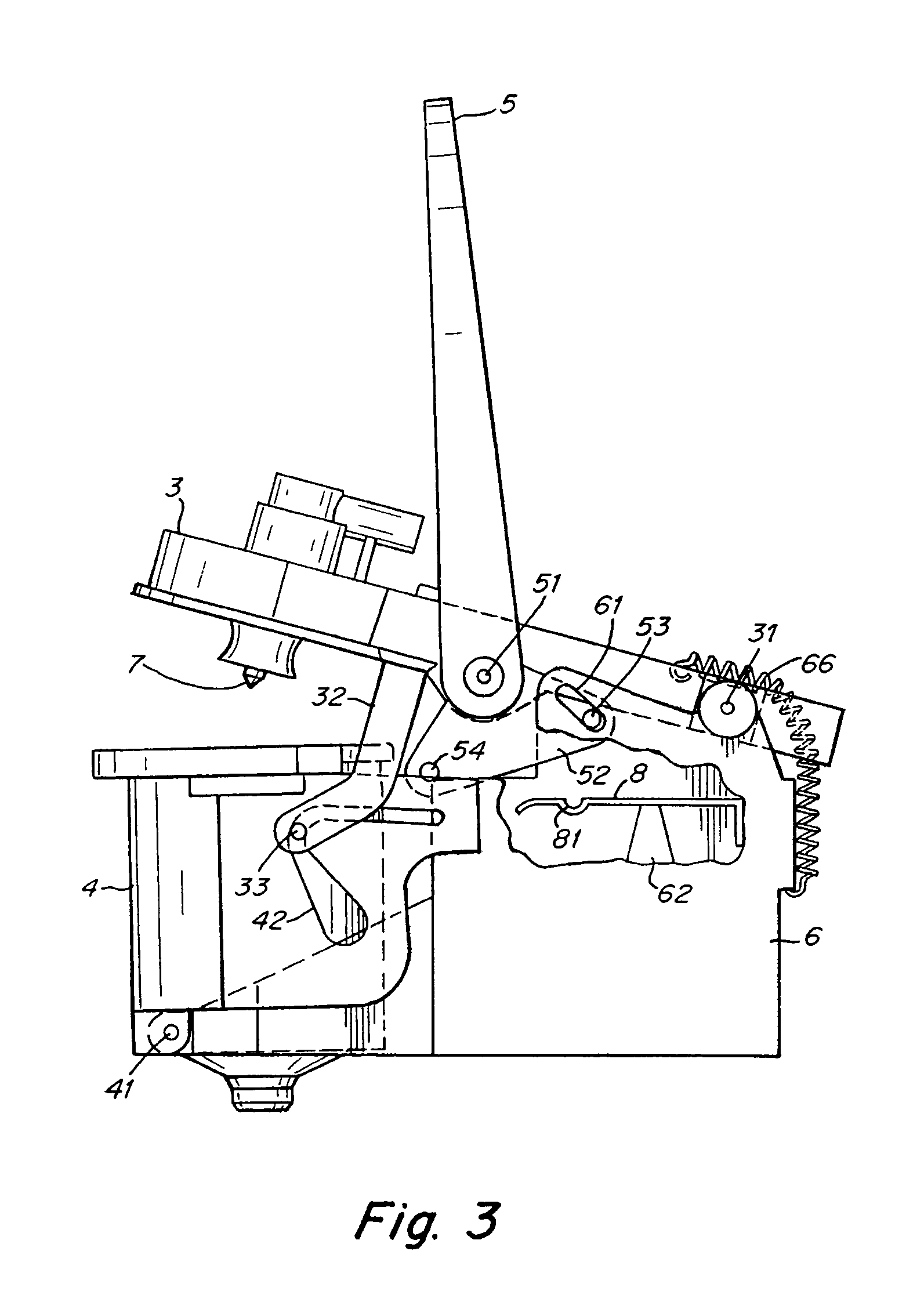

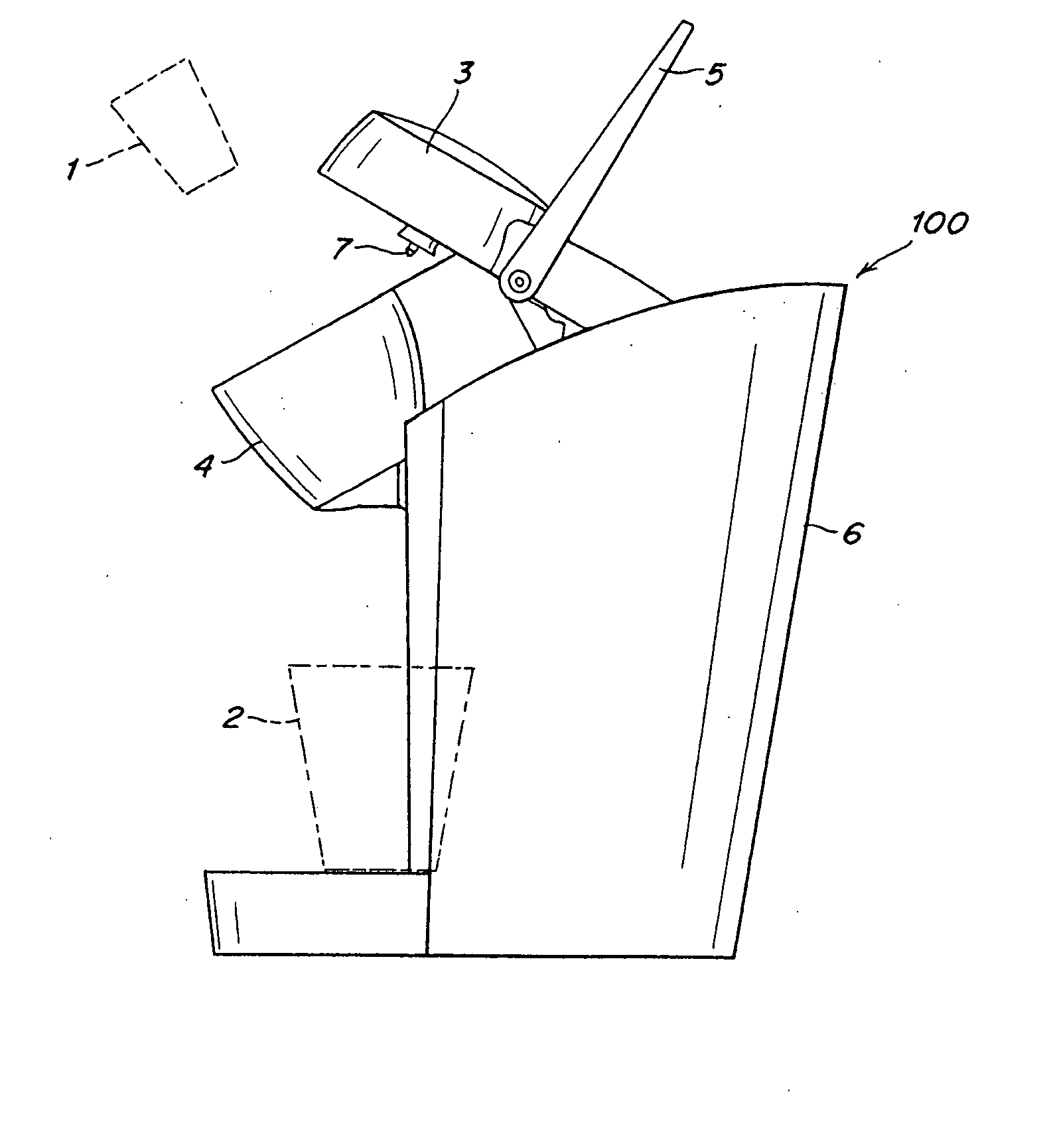

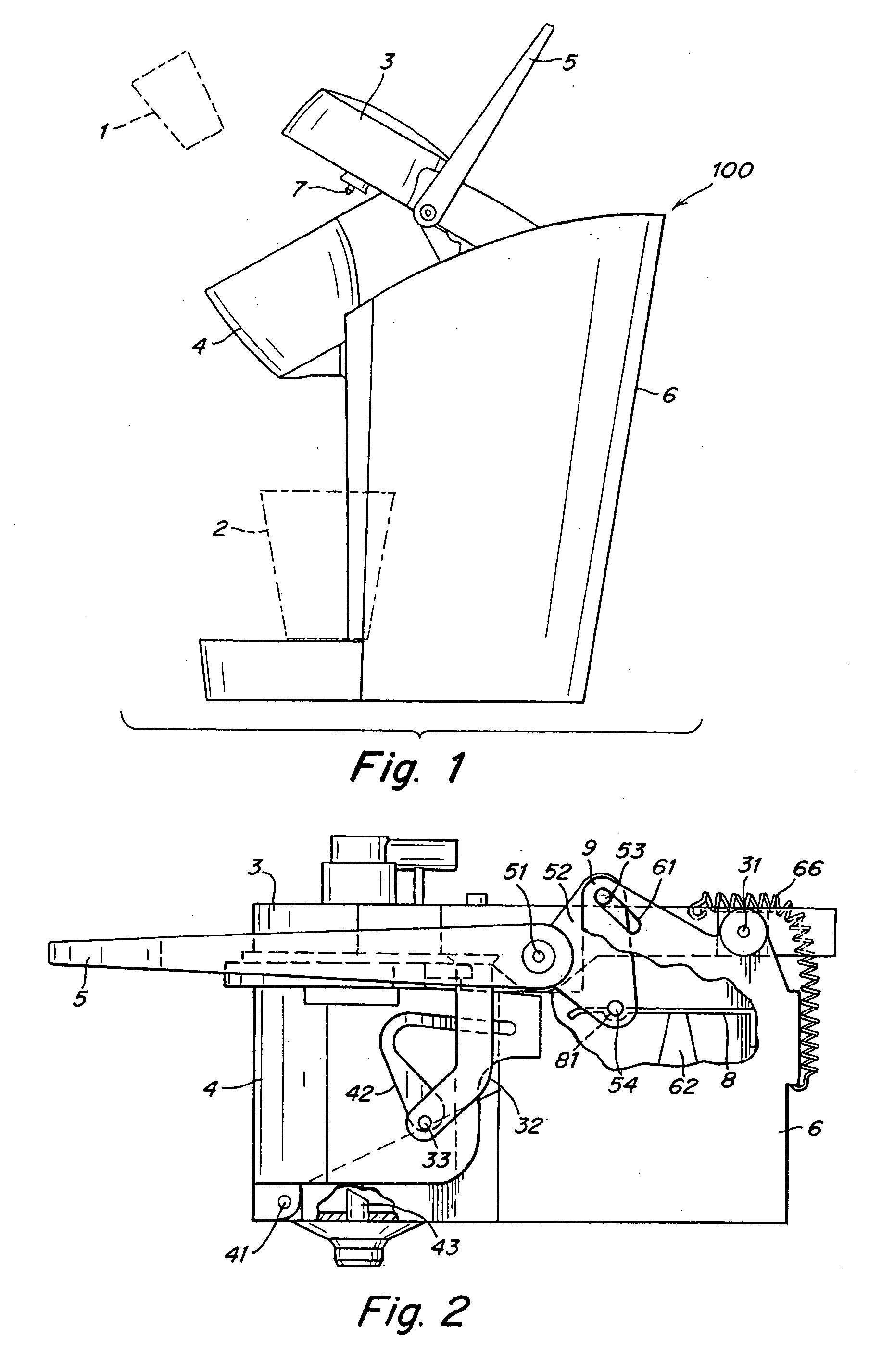

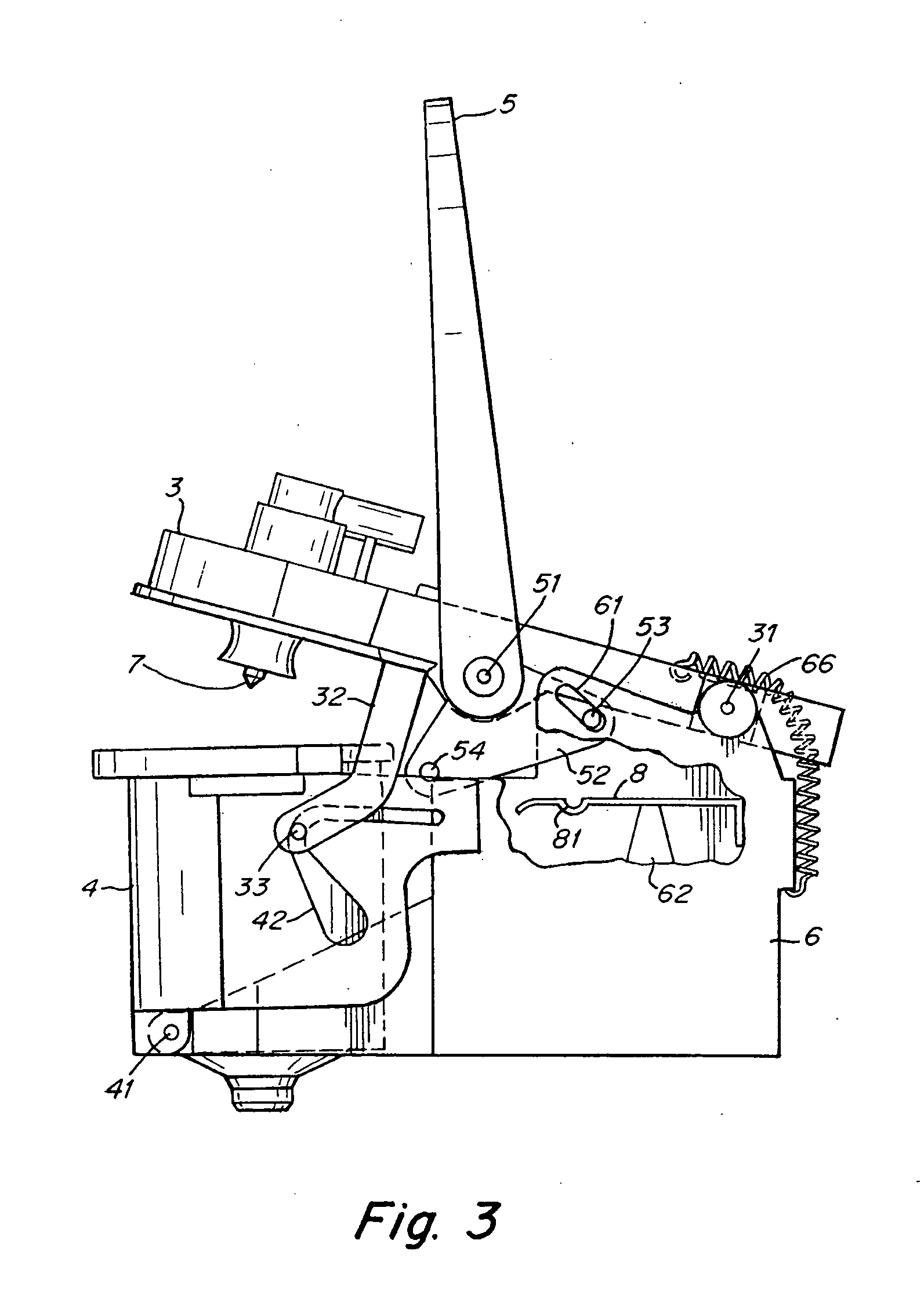

Beverage forming device with opening/closing mechanism for a beverage cartridge receiver

ActiveUS20070221066A1Convenient ArrangementEasy to manufactureBeverage vesselsFood shapingEngineeringActuator

A beverage forming system includes an actuator and first and second portions that are movable relative to each other between open and closed positions. The first and second portions include a cartridge receiving portion to accept a cartridge for forming a beverage, e.g., a disposable single serve cartridge. A first linkage member may be fixed to the actuator and physically contact a second linkage member that may be fixed to the first or second portion (or to a frame that supports the first and second portions). Movement of the actuator may cause movement of the first and second linkage members relative to each other, thereby causing relative movement of the first and second portions between open and closed positions.

Owner:KEURIG GREEN MOUNTAIN INC

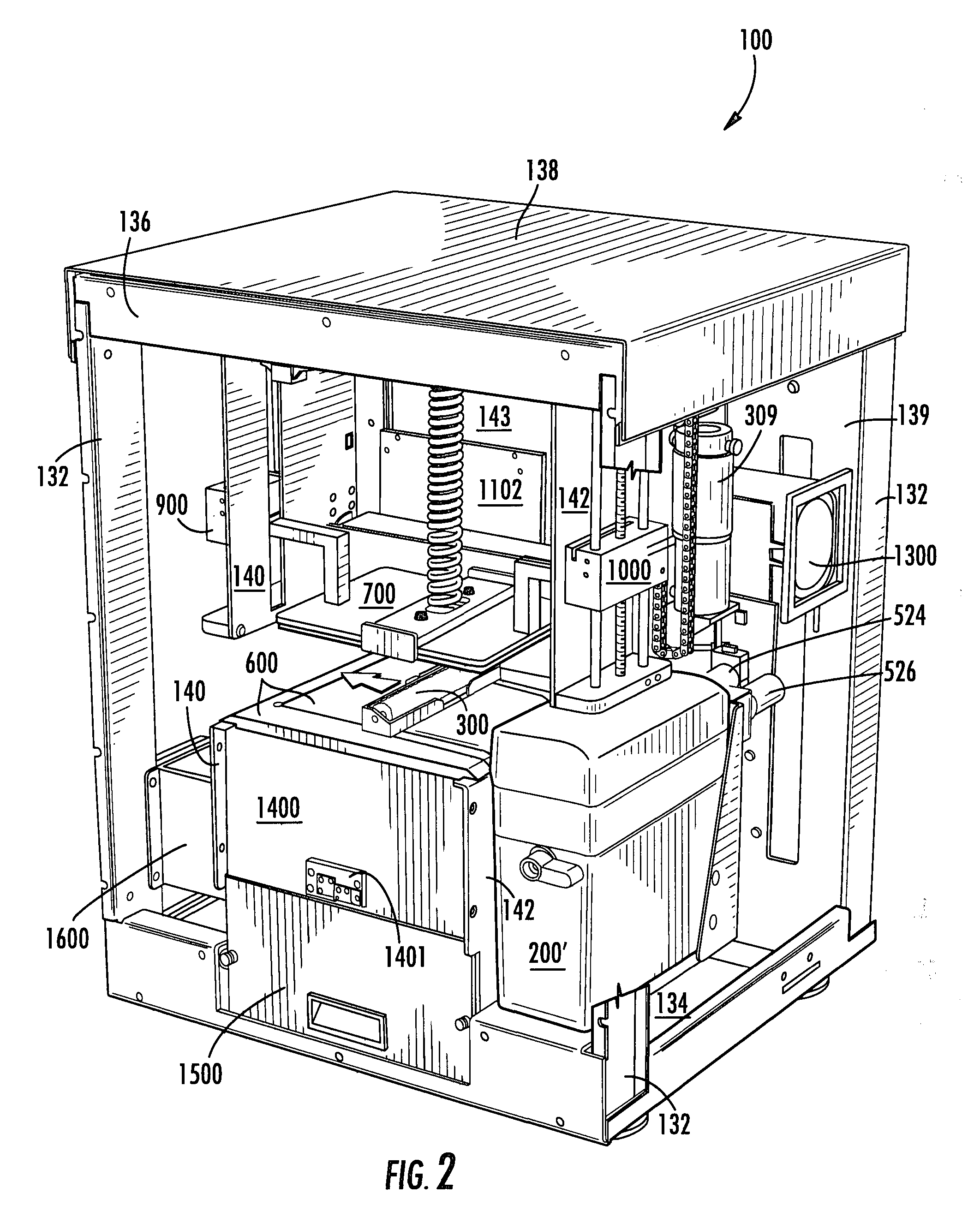

Automated pizza preparation apparatus

InactiveUS20120185086A1Facilitate pizza-making processDough treatmentDough dividingAdditive ingredientEngineering

Automated apparatus for preparing pizza, and method of operating same. A customer selects a type of pizza, such as toppings or crust style. The apparatus slices and defrosts dough, applies cheese, slices and applies toppings, and cooks the pizza to order. The cooked pizza is packaged for delivery to the customer and may include a separate cutting apparatus. Proper temperature of hot and cold sections is maintained while ingredients are stored and as the pizza is cooked. The process is monitored and controlled by one or more processors.

Owner:K & G ENTERPRISES

Brush assembly for removal of excess uncured build material

InactiveUS20080181977A1Less post-build cleaningLess curingFrozen sweetsConfectioneryAir entrainmentHigh intensity

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

Various grains nutritious vermicelli produced with dual-extrusion pressing and compound steam combined method

InactiveCN101366479AImprove qualityGreat tasteDough extruding machinesFood preparationCombined methodThermal stability

The invention relates to flour food, in particular to a minor cereal nutrient dried noodle produced by a double extrusion and secondary steaming combination method and a preparation method thereof. The invention is characterized in that the minor cereal nutrient dried noodle is prepared through the following steps: five cereals are taken as main raw materials, cucurbits, vegetables and potatoes are added or are not added, an auxiliary material capable of improving and enhancing the quality of a product and a complex quality improvement liquid are added, and processes such as raw material pretreatment, mixing and stirring, noodle-making molding by the double extrusion and secondary steaming combination method, drying, cutting, packing and so on, are performed. The reasonable formula design and the noodle-making molding process by the double extrusion and secondary steaming combination method, namely a process of steaming and cooking once again after two-stage extrusion molding, assure the balanced nutrition and the strong health care function of the product, and the minor cereal nutrient dried noodle has the advantages of long storage period, steady quality, no turbid soup during the cooking, boiling fastness, good thermal stability, smooth appearance, and chewy taste, and can be eaten as staple food like ordinary dried noodles.

Owner:奥生平 +1

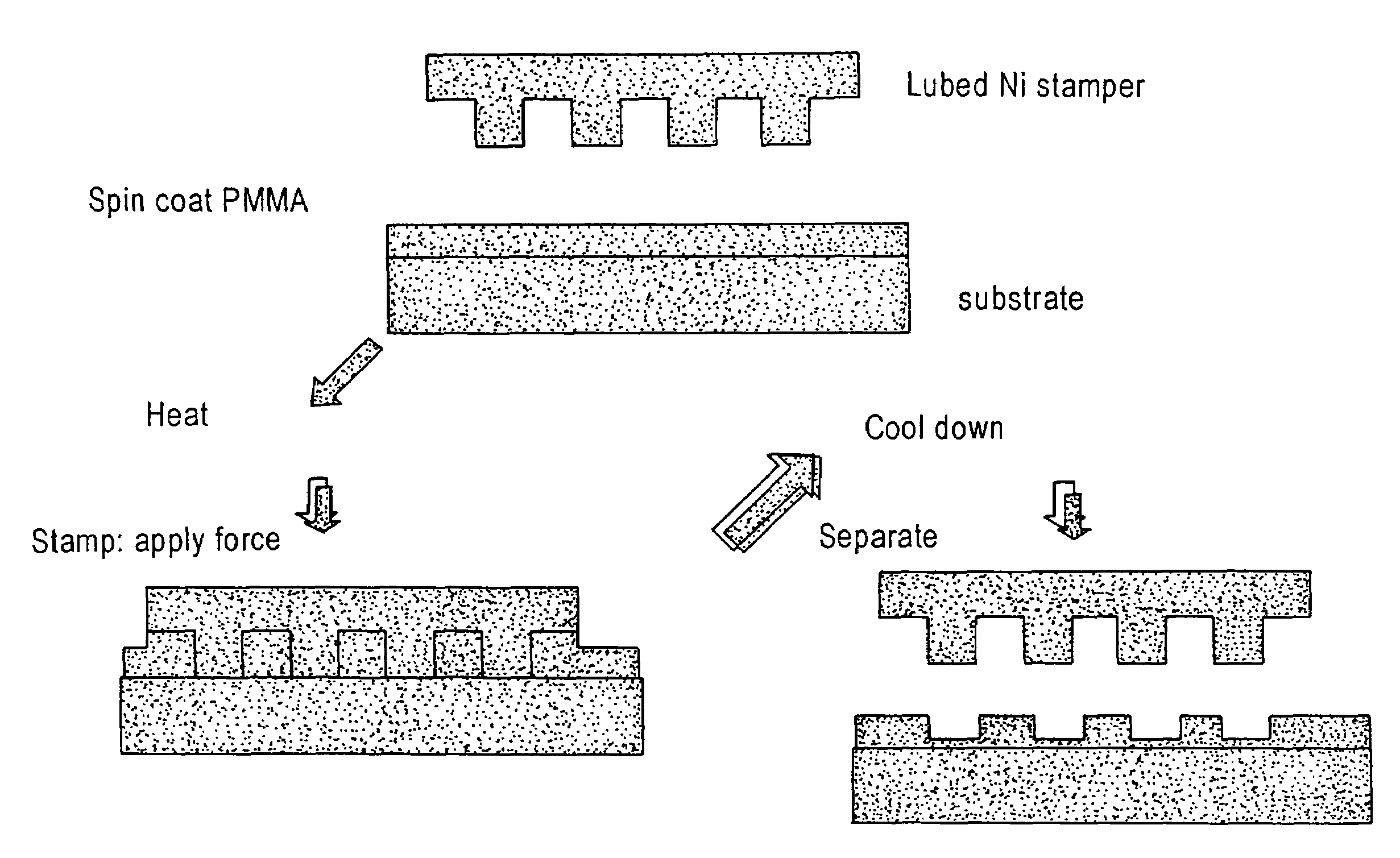

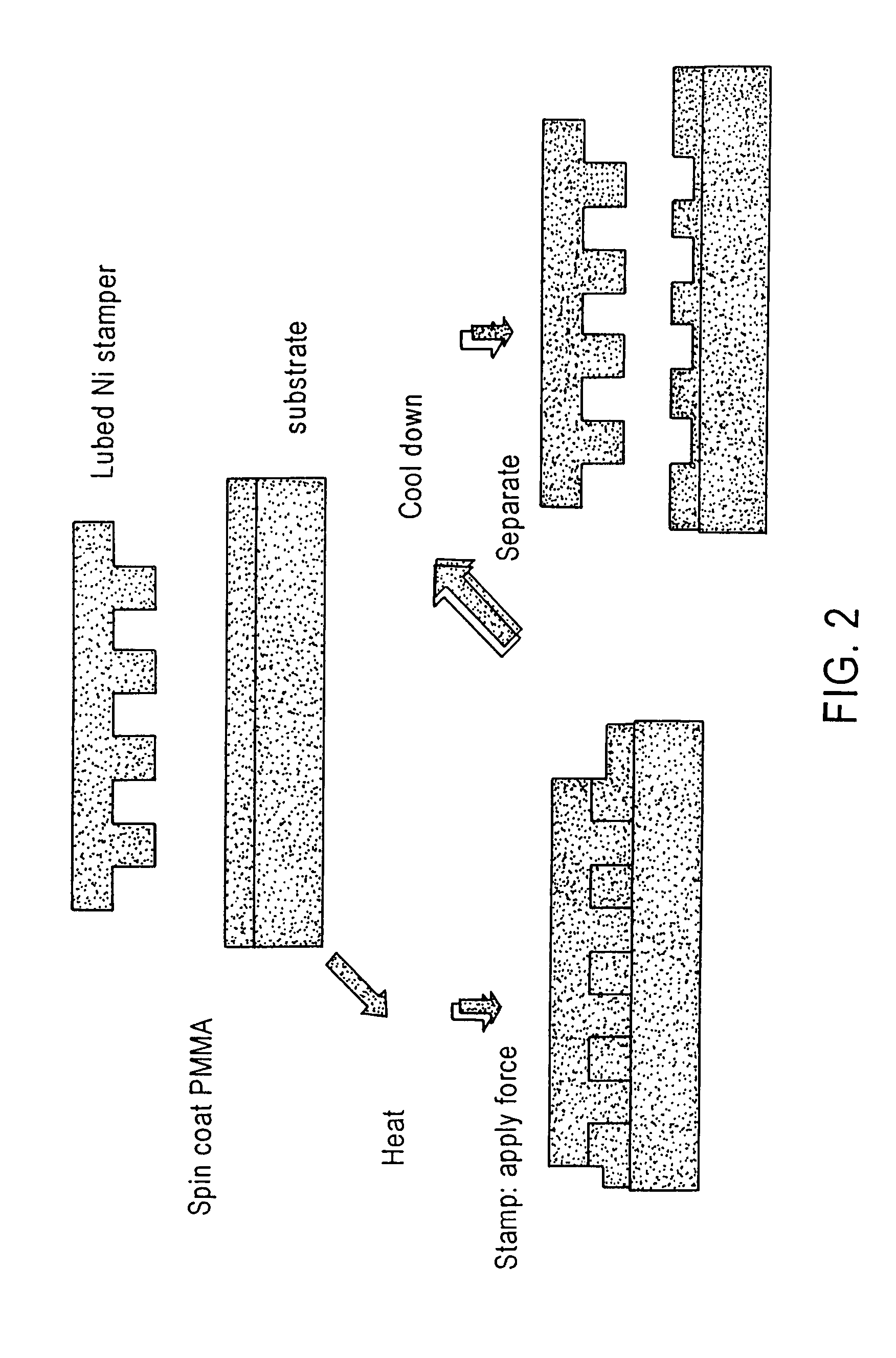

Surface modified stamper for imprint lithography

InactiveUS7294294B1Good release effectMinimize peelingRecord carriersNanoinformaticsLithographic artistEngineering

A method of performing imprint lithography of a surface substrate includes a stamper having a thin lubricant coating thereon to facilitate release of the stamper from the imprinted surface to reduce degradation of image replication. Embodiments of the invention include stampers suitable for use in patterning servo information on magnetic recording media having a lubricant coating of from about 1 nm to about 20 nm.

Owner:SEAGATE TECH LLC

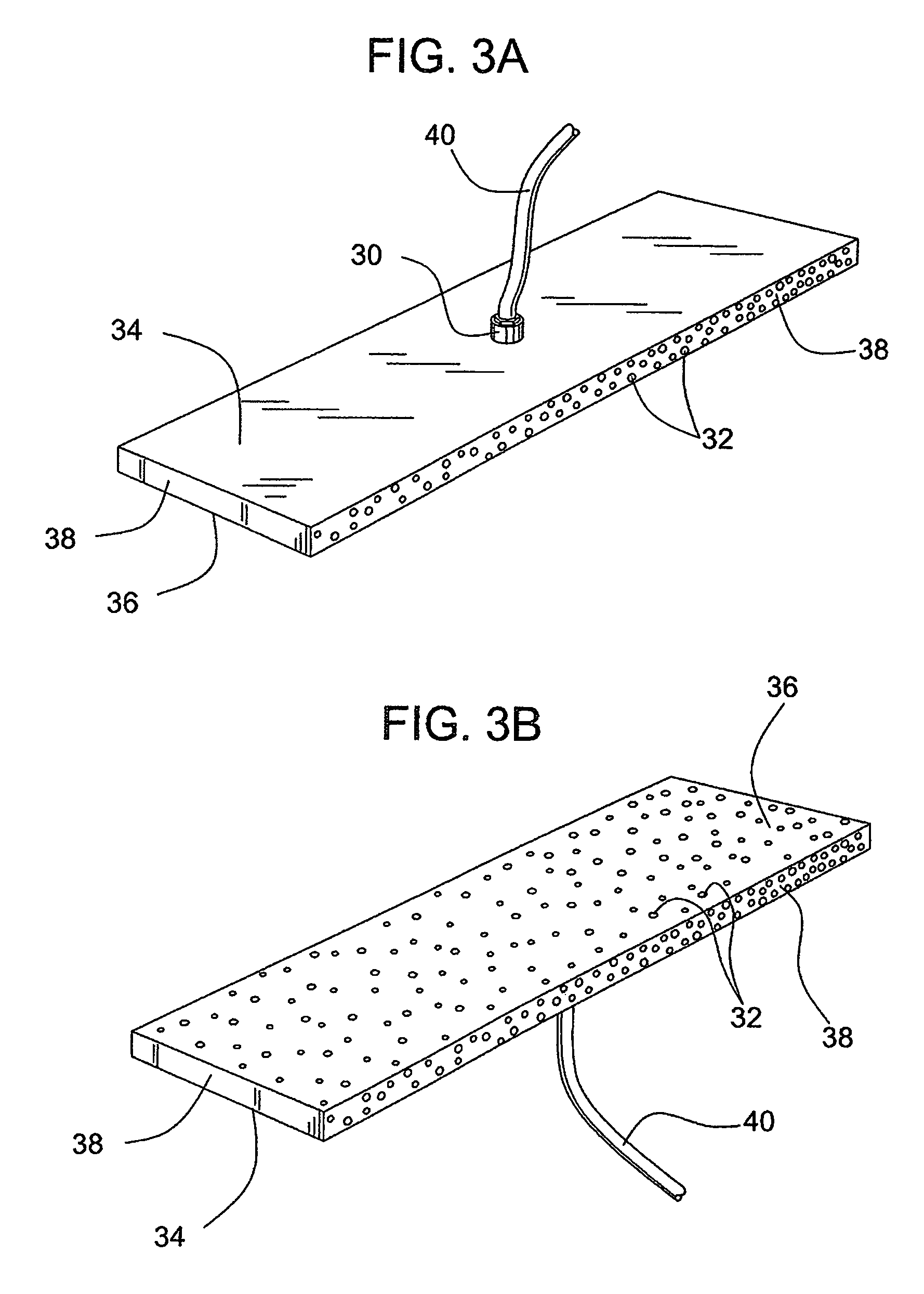

Gypsum board forming device

A gypsum board forming device having a gypsum forming station including two laterally disposed edger shoes, and at least one laterally disposed edger bar clamping element on the edger bar. In one embodiment a laterally extending forming plate extends over the top surface of the formed gypsum board, the forming plate including a plurality of micropore conduits through which pressurized water is supplied to provide a film of smoothing water over the top surface of the gypsum board. In another embodiment the edger shoes have a flapper mechanism for retaining unset slurry skimmed off the surface of the gypsum board by the edger bar.

Owner:BPB LTD

Skinless sausage or frankfurter manufacturing method and apparatus utilizing reusable deformable support

InactiveUS6326039B1Reduce manufacturing costLow costDough treatmentConfectioneryEngineeringConveyor belt

In a method for the manufacture of frankfurters, hot dogs and other skinless sausage products, a meat emulsion is extruded onto a flexible conveyor belt which is then conveyed through a tube whose internal diameter is equal to the desired diameter of the sausage product plus twice the thickness of the conveyor belt. In a camming type process, the conveyor belt is caused, upon its entry into the tube, to temporarily form a cylinder containing the meat emulsion. The temporary belt cylinder together with the surrounded meat emulsion extrudate is then conveyed through an ultrasonic waveform generator to cook an outer layer of the meat emulsion. The outer layer may be part of the meat emulsion or a thermoset gelling material deposited on the extruded meat emulsion. At the exit end of the tube, the conveyor belt naturally opens under internal stresses from its cylindrical shape to a flattened belt. The at least partially cooked sausage is then removed from the belt for further processing or packaging. The conveyor belt acts as a temporary skin to hold the meat emulsion during its ultrasonic processing.

Owner:MISONIX INC

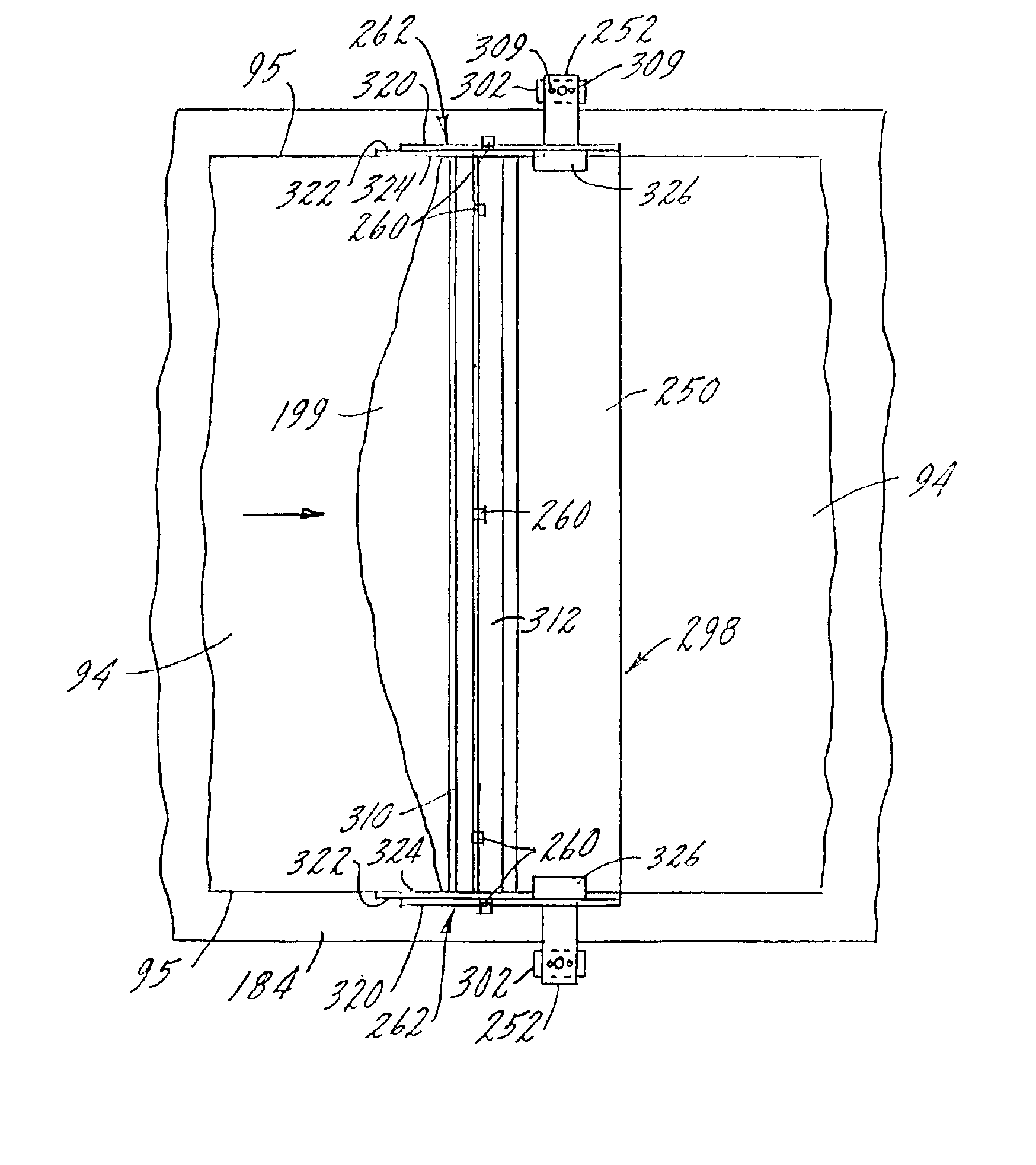

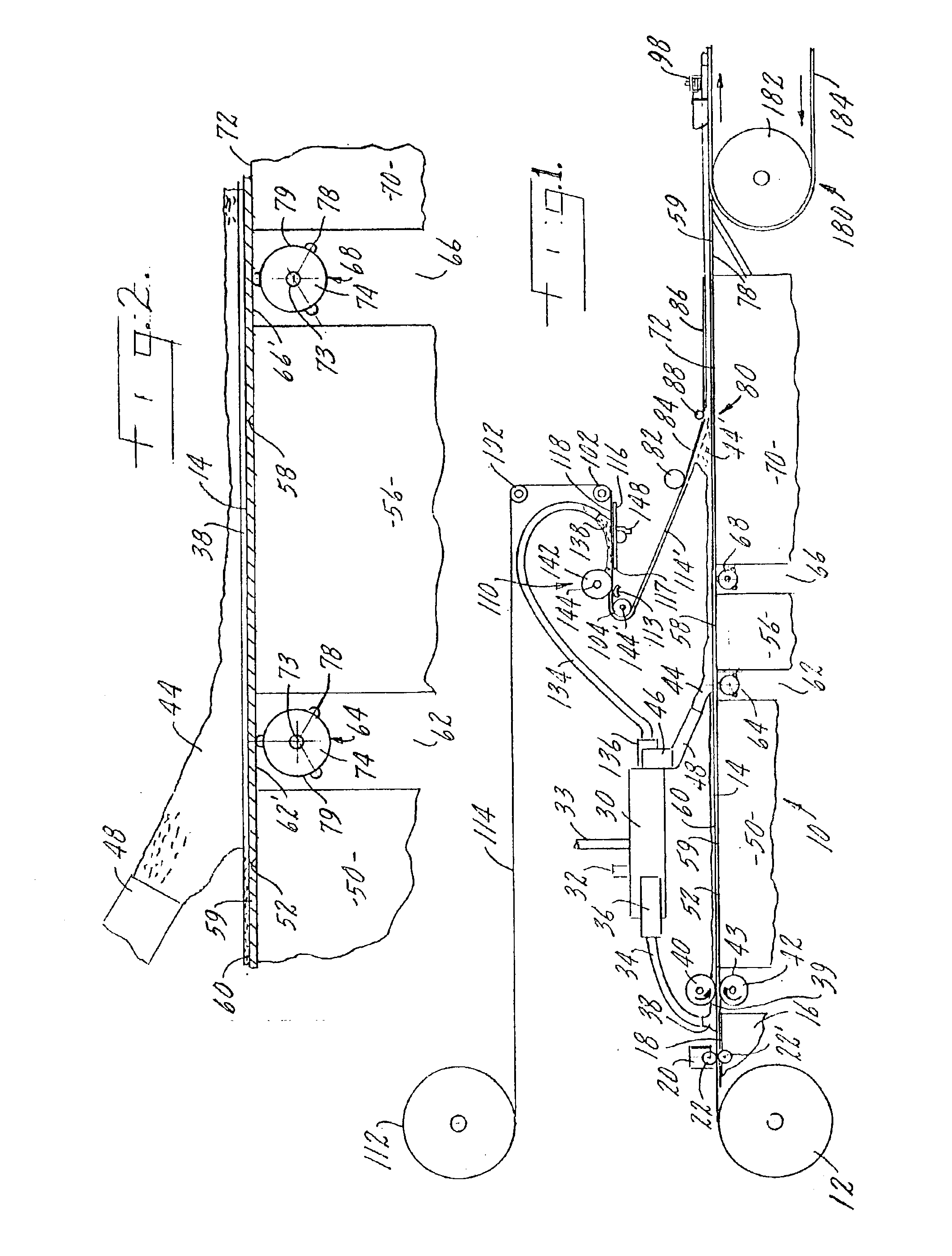

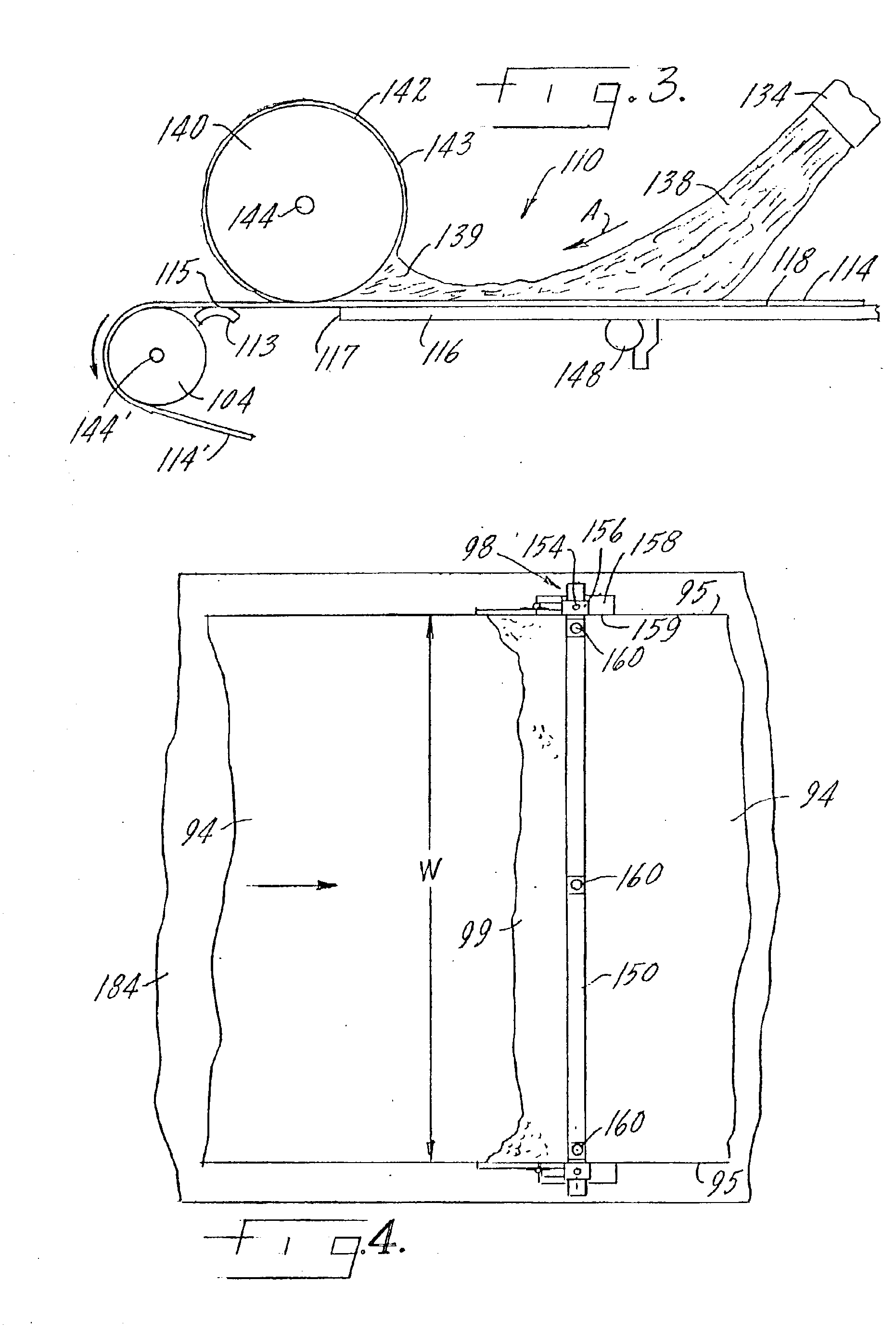

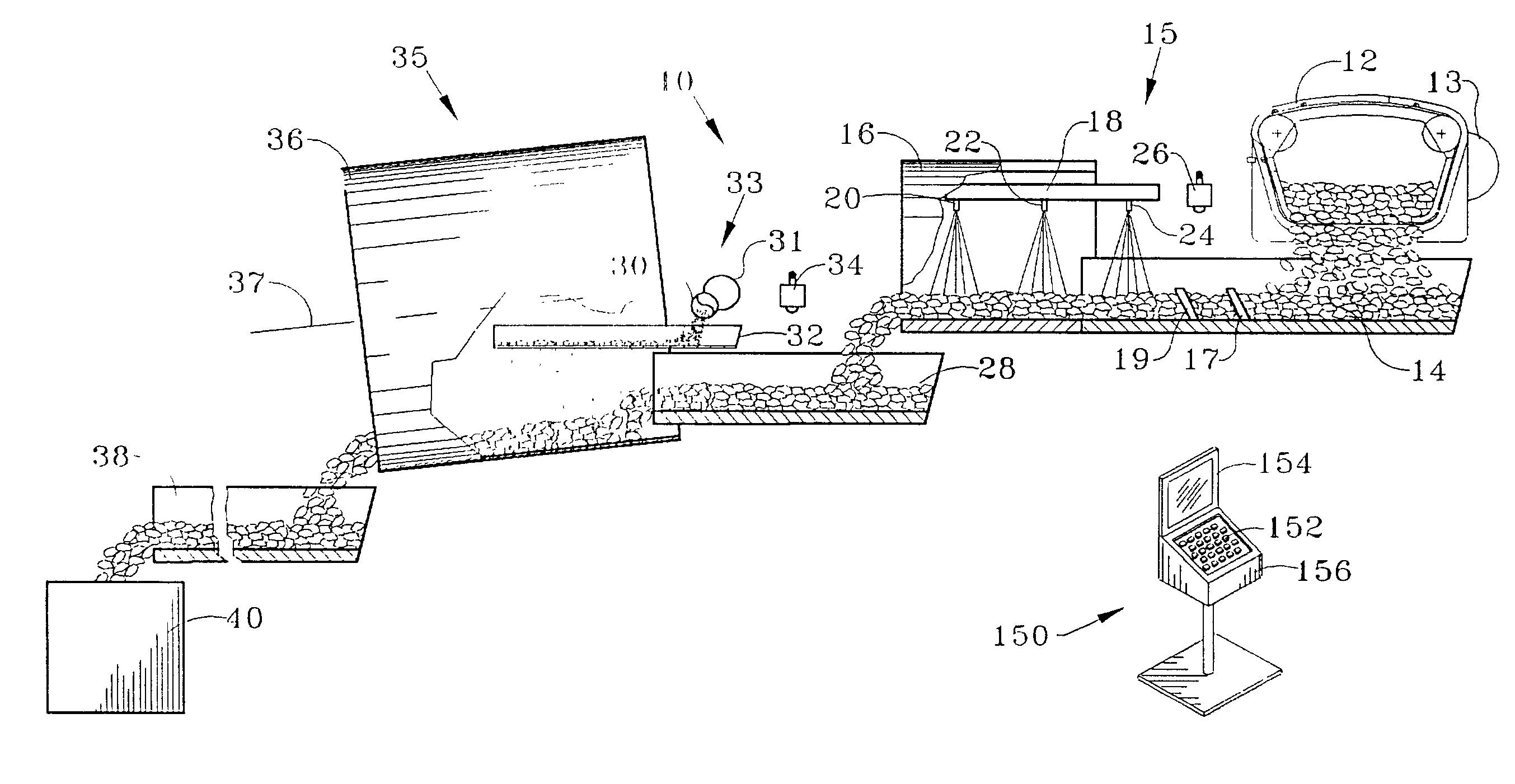

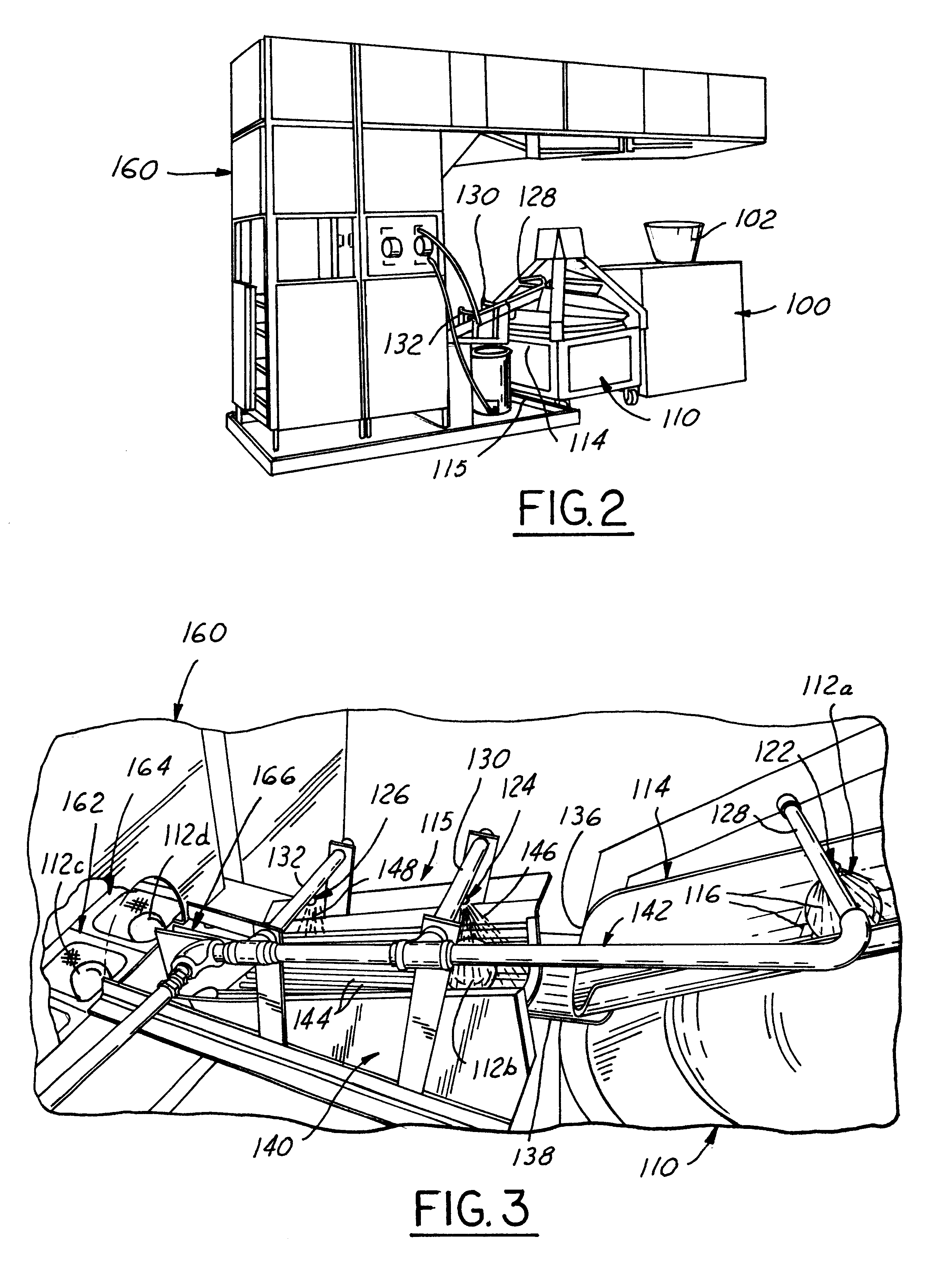

Seasoning system and method

InactiveUS7153533B2Reliably dispersedEasy to cleanLiquid surface applicatorsConfectioneryEngineeringMechanical engineering

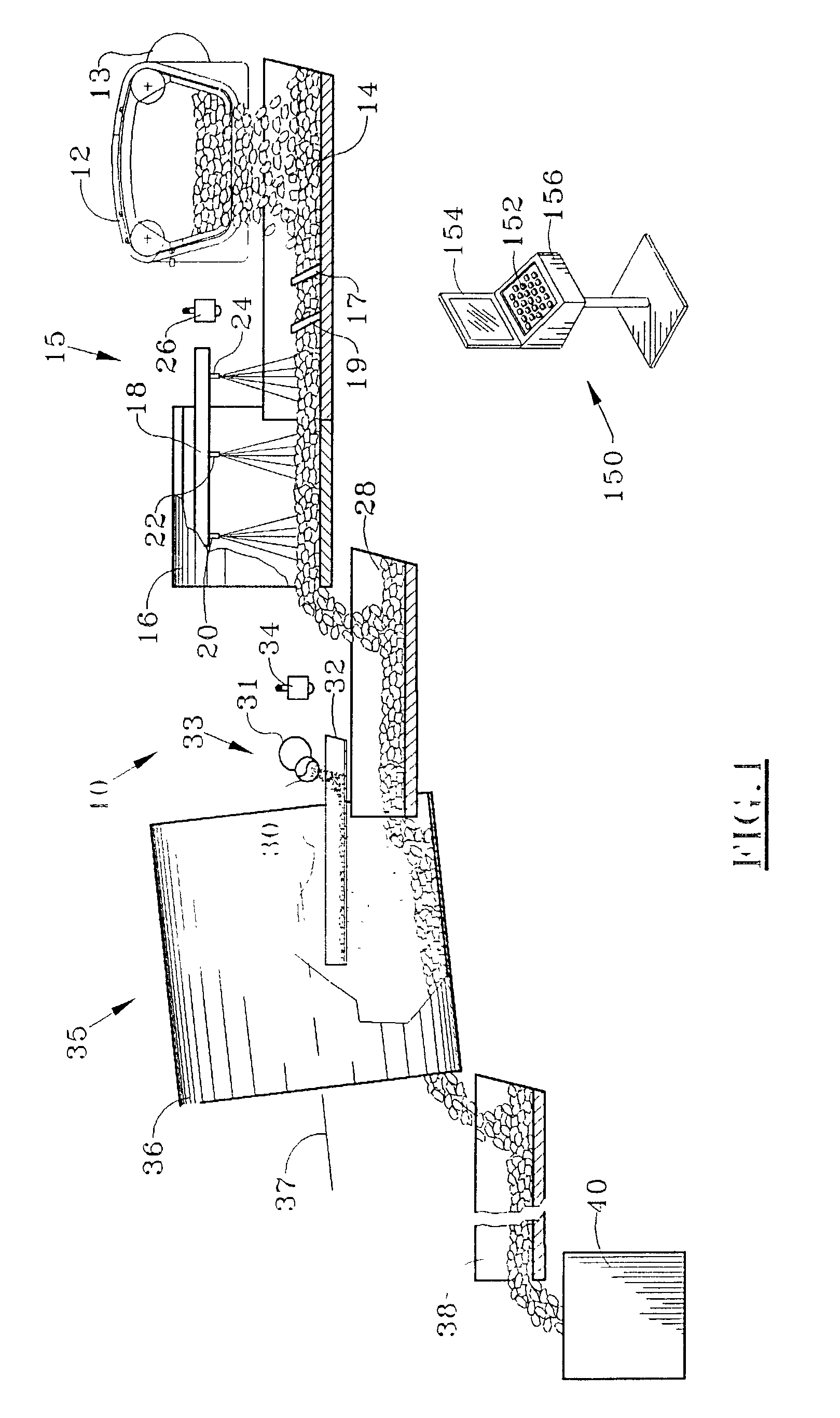

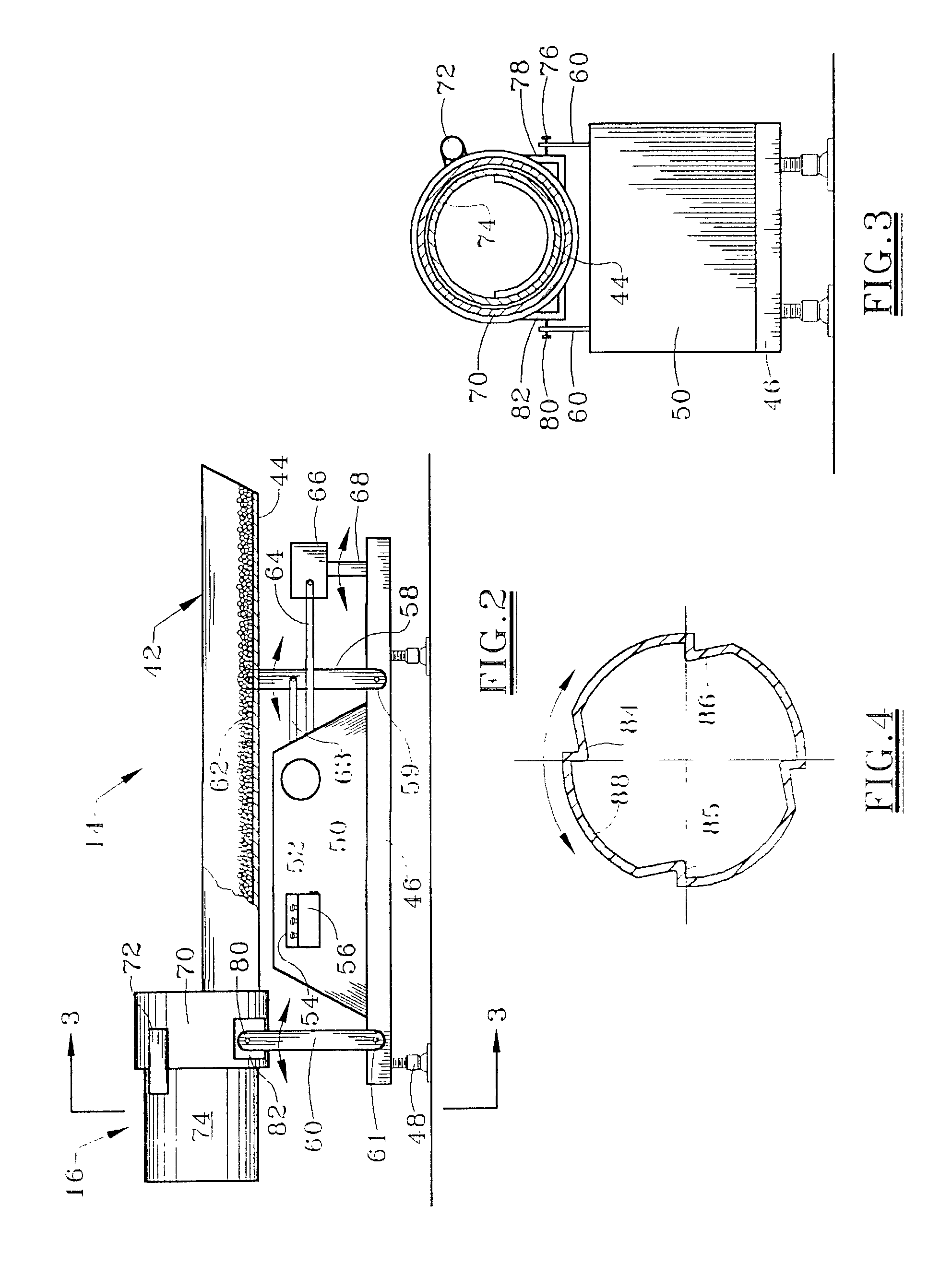

An improved seasoning system 10, 11, 13 uniformly coats a food product with the desired amount of seasoning, with the seasoning rate preferably being controlled as a function of the product volume signals from the sensors 26, 34, 108 and 110. The seasoning system preferably utilizes linear motion conveyors and either a rotating drum 36 or a deflector 98 and a second seasoning unit 112, 114 between linear conveyors 94, 96. Oil may be sprayed onto food products and tumbled in a drum 16 which both rotates and moves in a reciprocating manner with the conveyor tray 14. An improved seasoning tray 123, 144, 148 has a planar floor 122, 138, 162 with an angled discharge edge 124, 137, 182 for uniformly distributing seasoning on the product. The seasoning system minimizes damage to the food product and uniformly coats the product with a desired amount of seasoning.

Owner:KAREN SUE SVEJKOVSKY TRUSTEE OF THE PAUL A SVEJKOVSKY +1

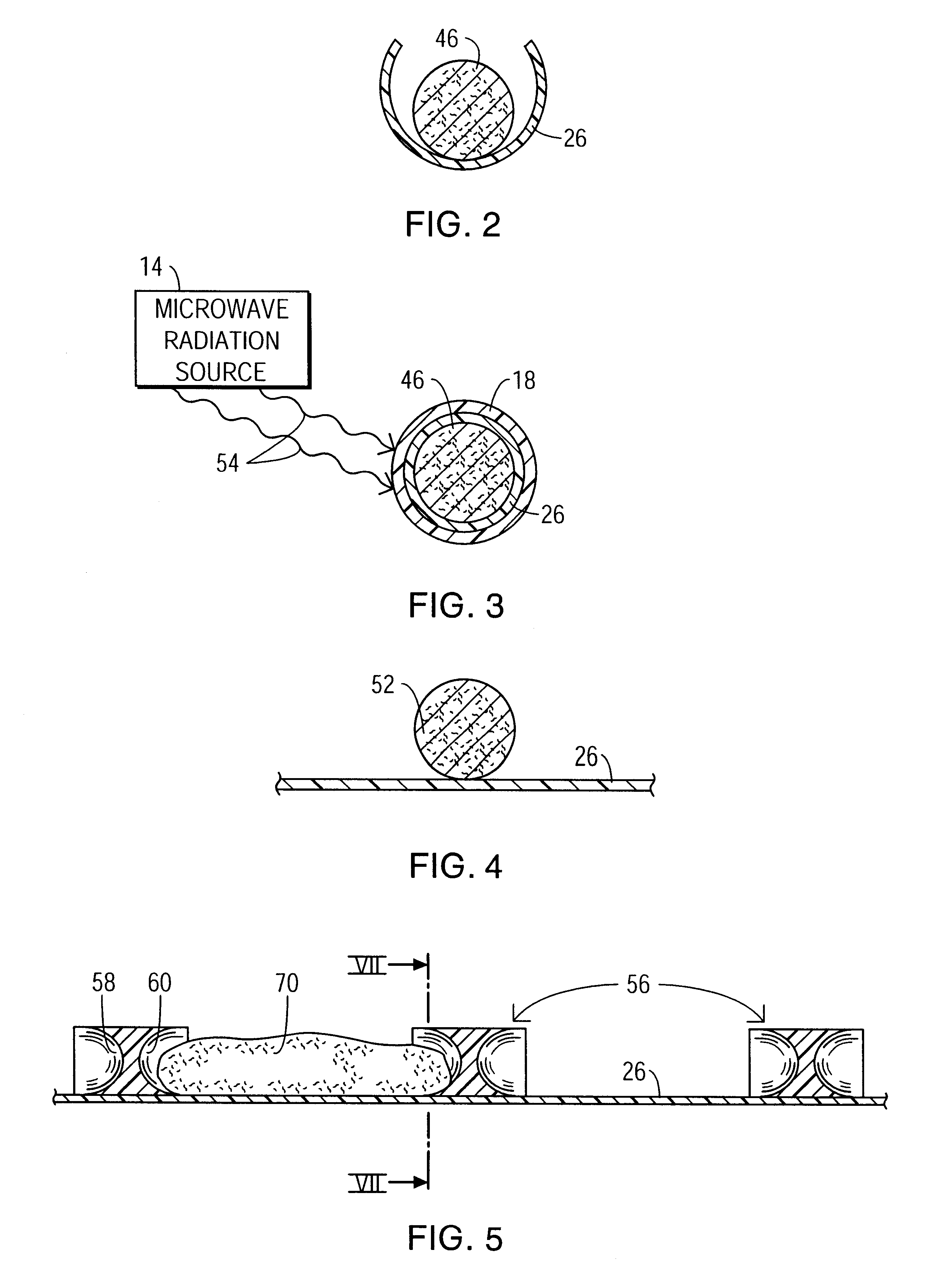

Pizza crust and process and apparatus for making same

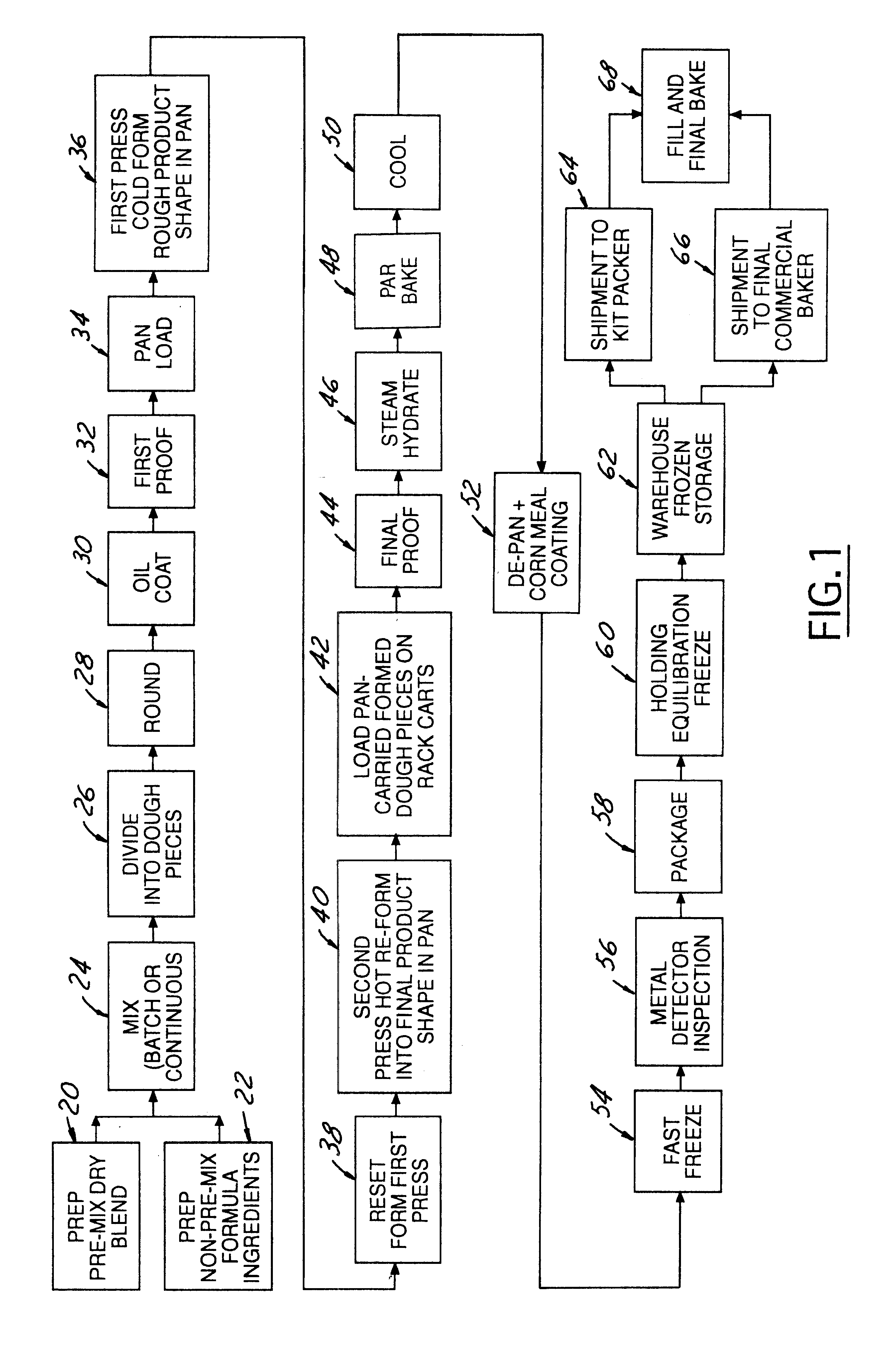

InactiveUS6629493B1Speed up the processEasy to adjustAir-treating devicesBakery productsStarch gelatinizationMoisture absorption

Apparatus for preparing parbaked food products, such as pizza crust shells, and dough formulation used therein, and the product produced thereby and / or therefrom. The apparatus operates on a starting material dough including flour, sugar and water, and preferably also a leavening agent such as instant yeast. The dough is rounded, first proofed, panned, pressed and second proofed in the apparatus. The prepared dough piece is then steam hydrated in the apparatus under conditions sufficient to cause moisture absorption and a resultant increase in moisture content throughout the dough. Then the hydrated dough piece is immediately sequentially parbaked until gelatinization of the starch is complete. At least one parbaking condition of the apparatus is adjusted as selected from the group consisting of initial dough temperature, oven temperature, parbaking time, dough absorption and dough thickness and coordinated with the moisture content condition of the dough upon completion of the steam hydration for thereby delaying external browning of the dough until the starch gelatinization is complete, and for thereby discontinuing the parbaking before substantial caramelization of the sugar in the crust takes place.

Owner:M & M HLDG

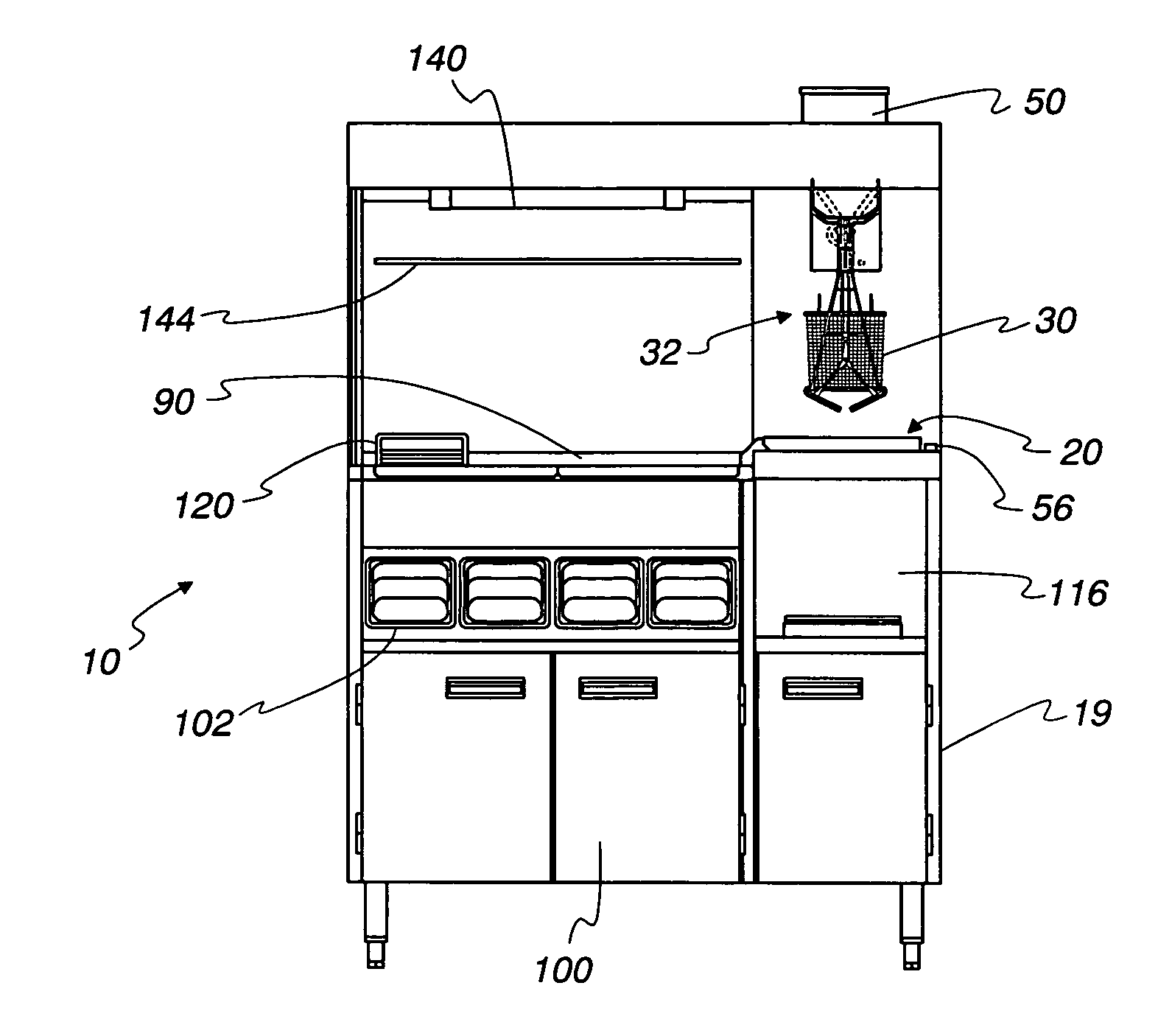

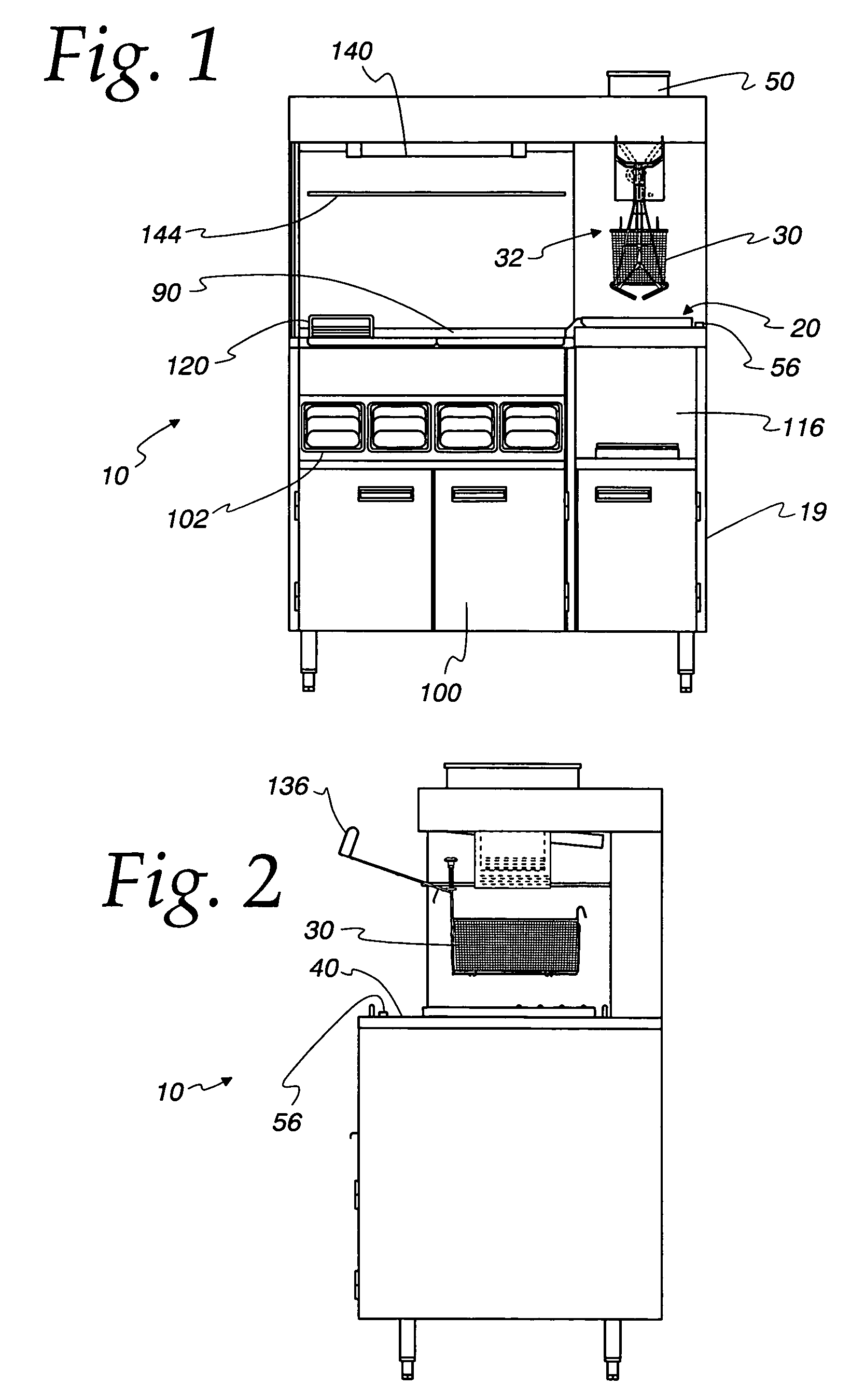

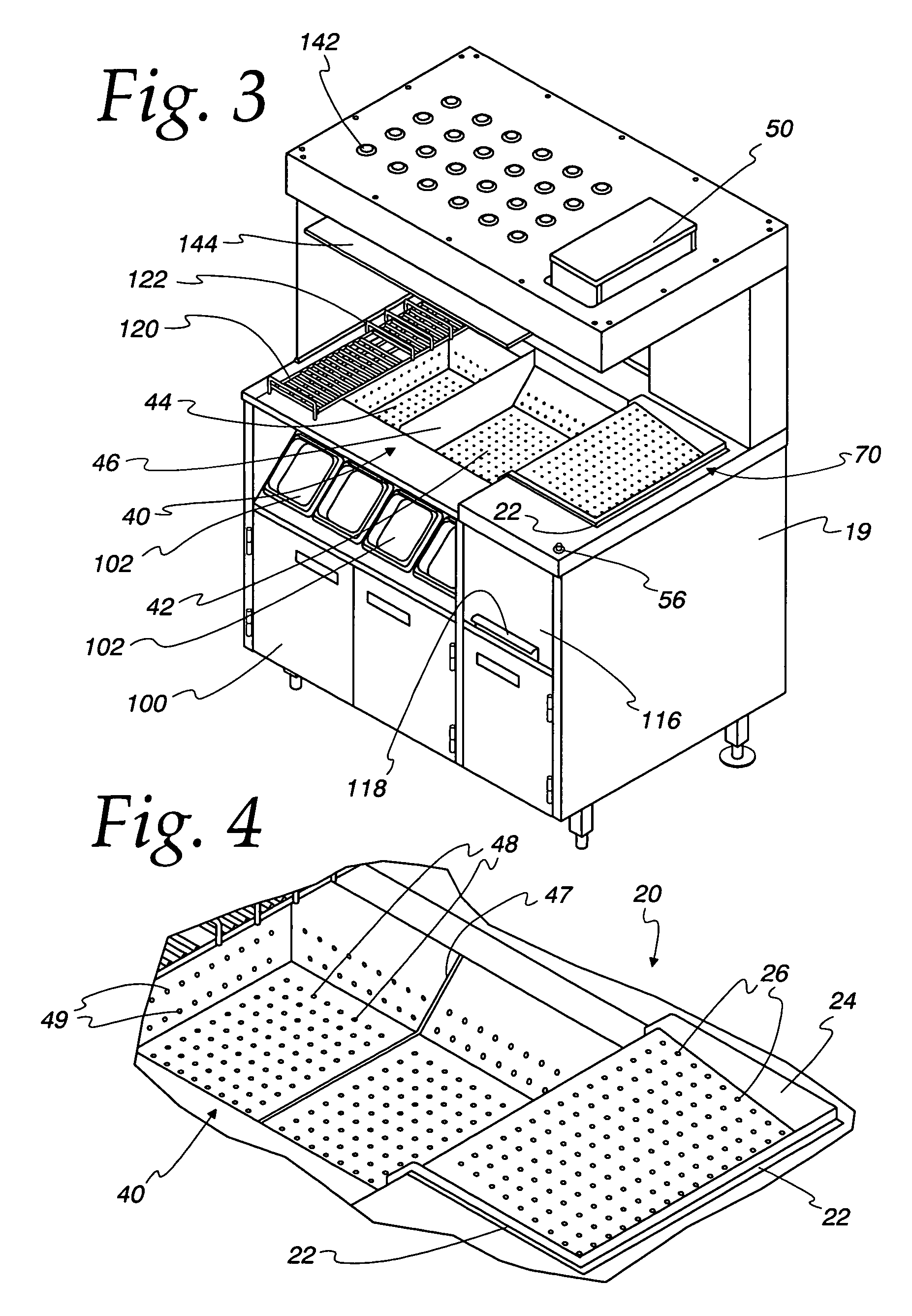

Storage and packaging of bulk food items and method

InactiveUS20070251397A1Seasoning adhesionSalted so quicklyLiquid surface applicatorsConfectioneryEngineeringLength wave

A semi-automated food processing station, system and method is provided that allows food to be dispensed, stored and packaged in a suitable container, which may be an individual portion-sized container for serving to a customer. In one embodiment, the system includes an automated salting device, and may include a pivotable food receiving tray that automatically transfers the food items to one or more storage bins, where an infrared heater maintains the temperature of the food items by directing infrared radiation thereon. In a preferred embodiment, the infrared radiation passes through a filter that filters out the wavelengths of infrared radiation that may be irritating to an operator.

Owner:RESTAURANT TECH

Method and apparatus for dispensing frozen confectionary

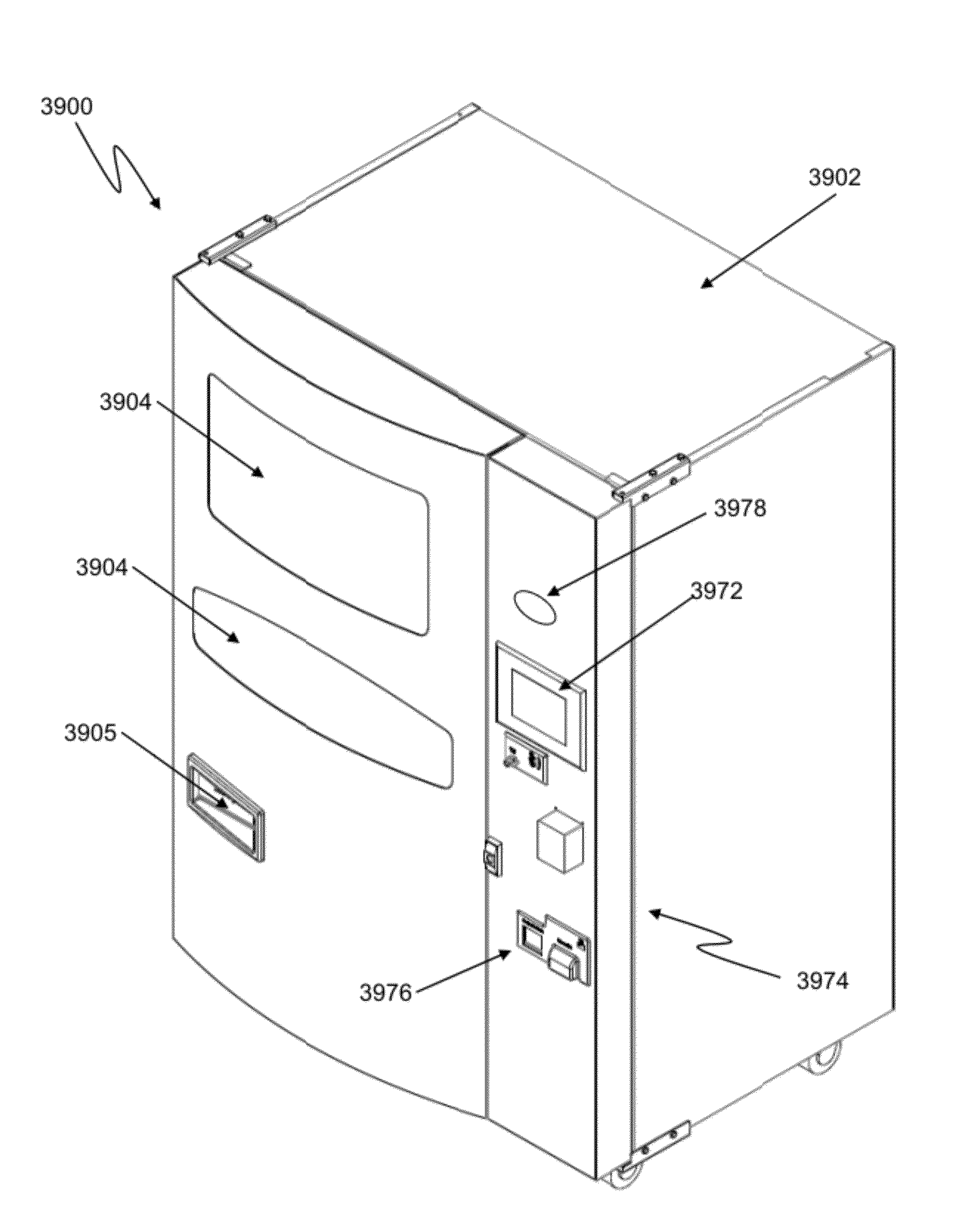

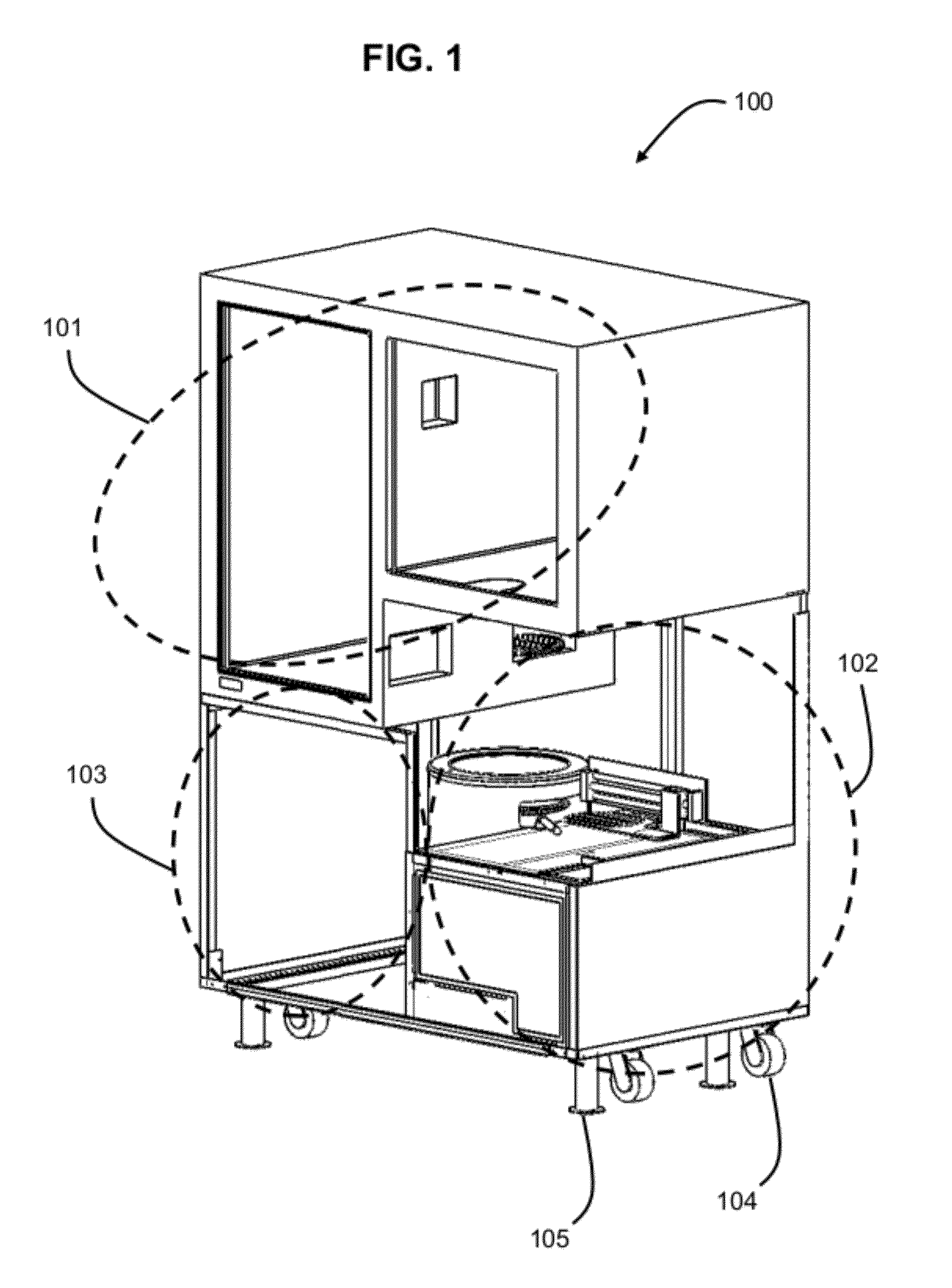

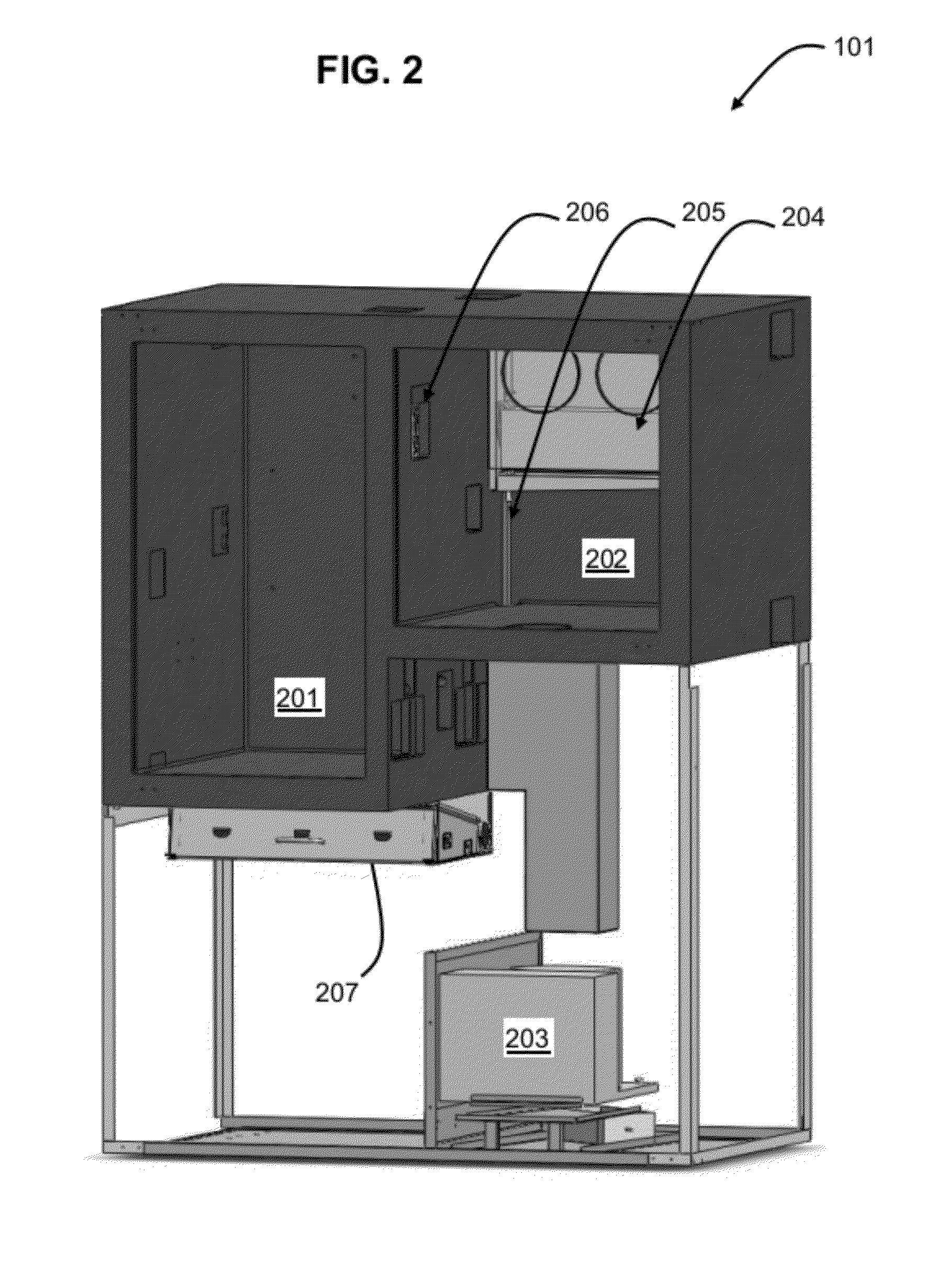

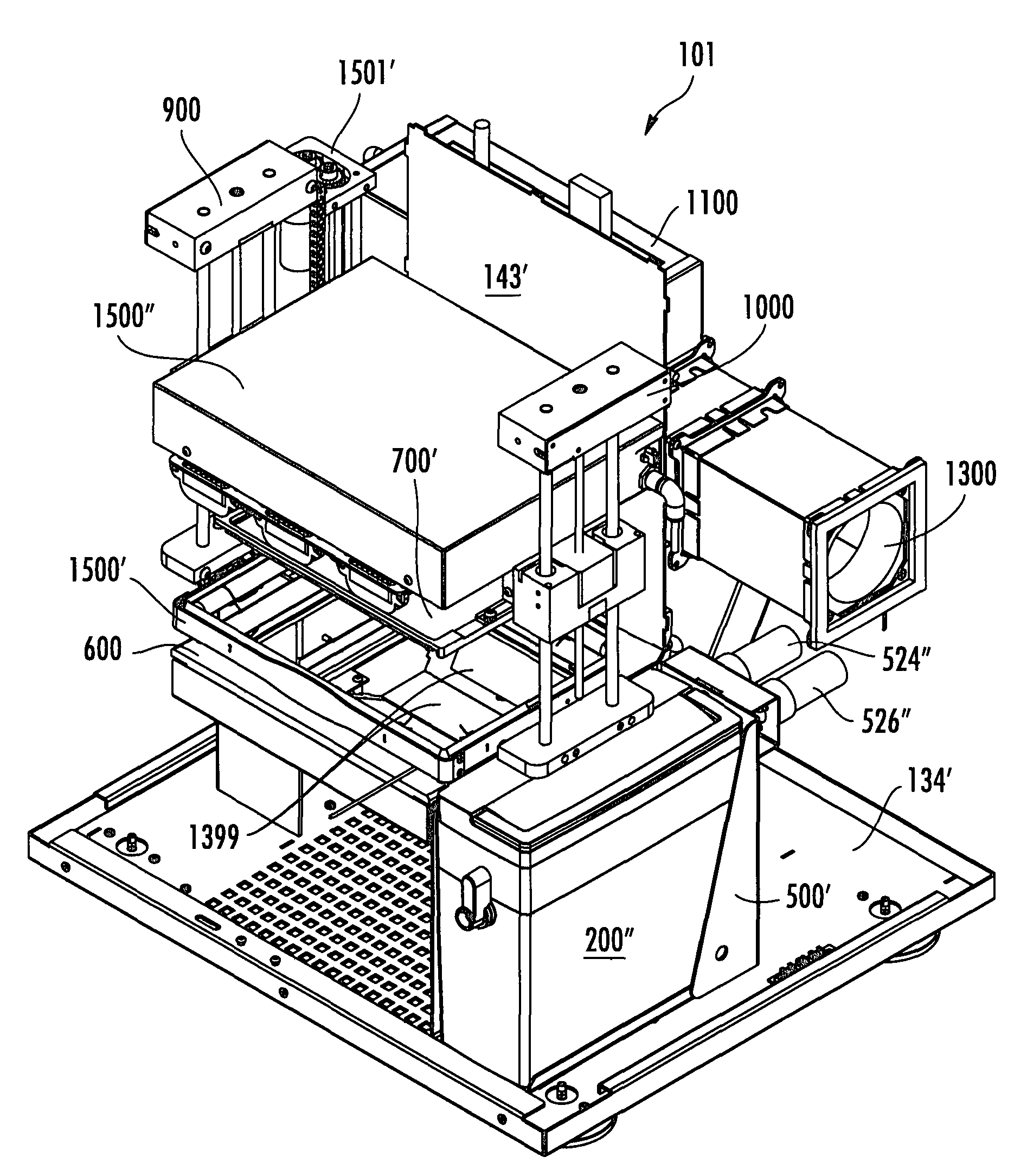

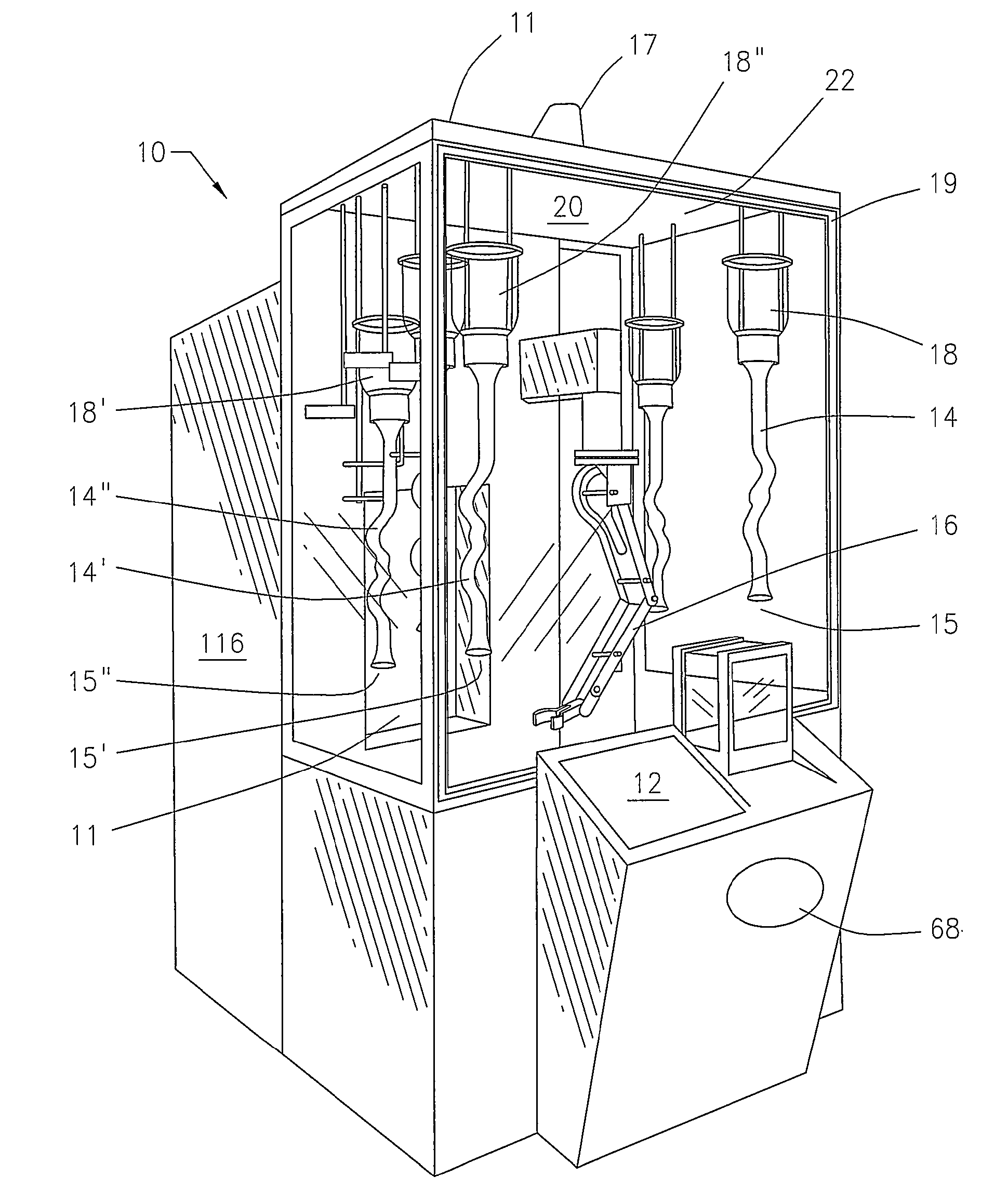

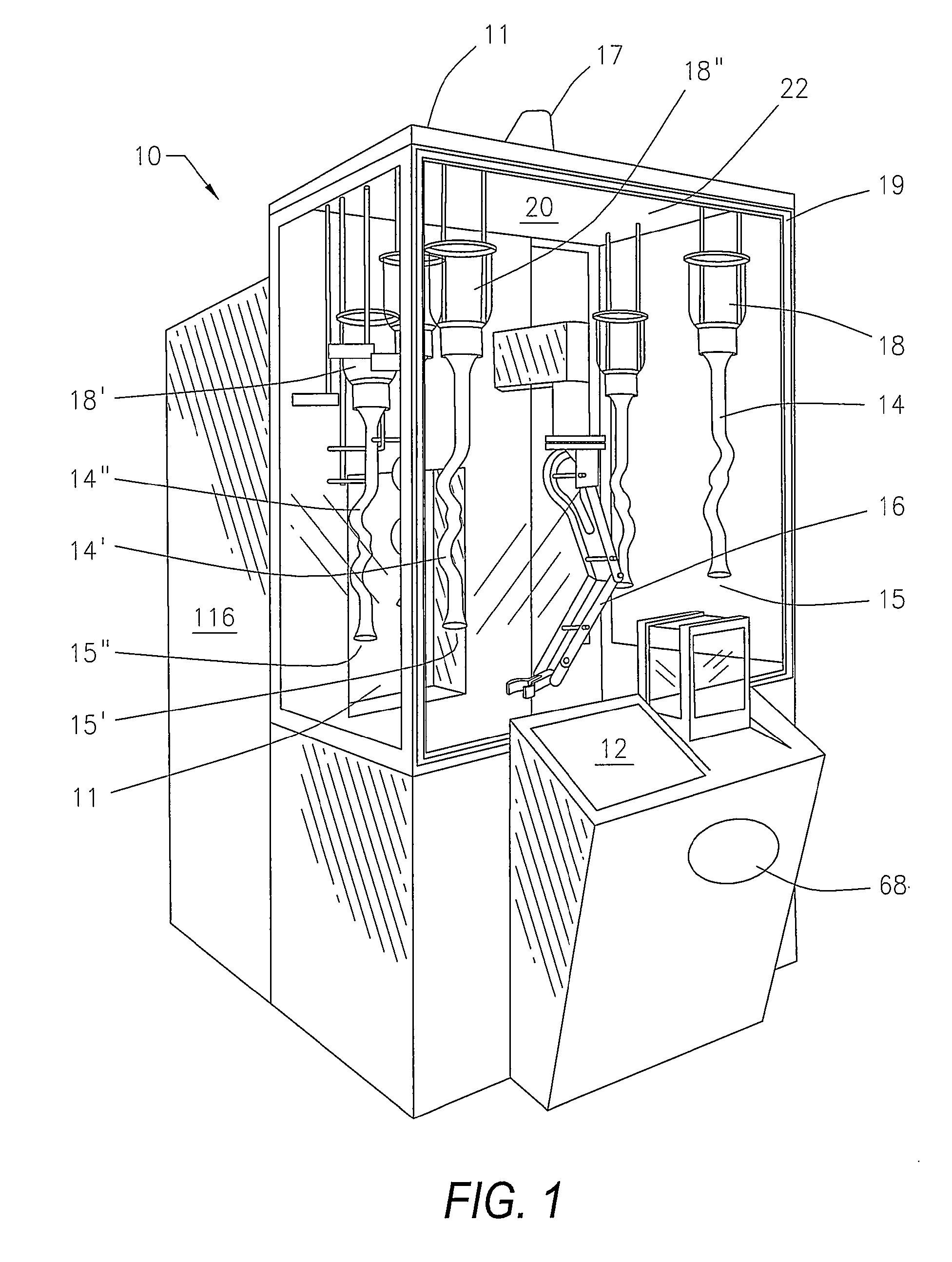

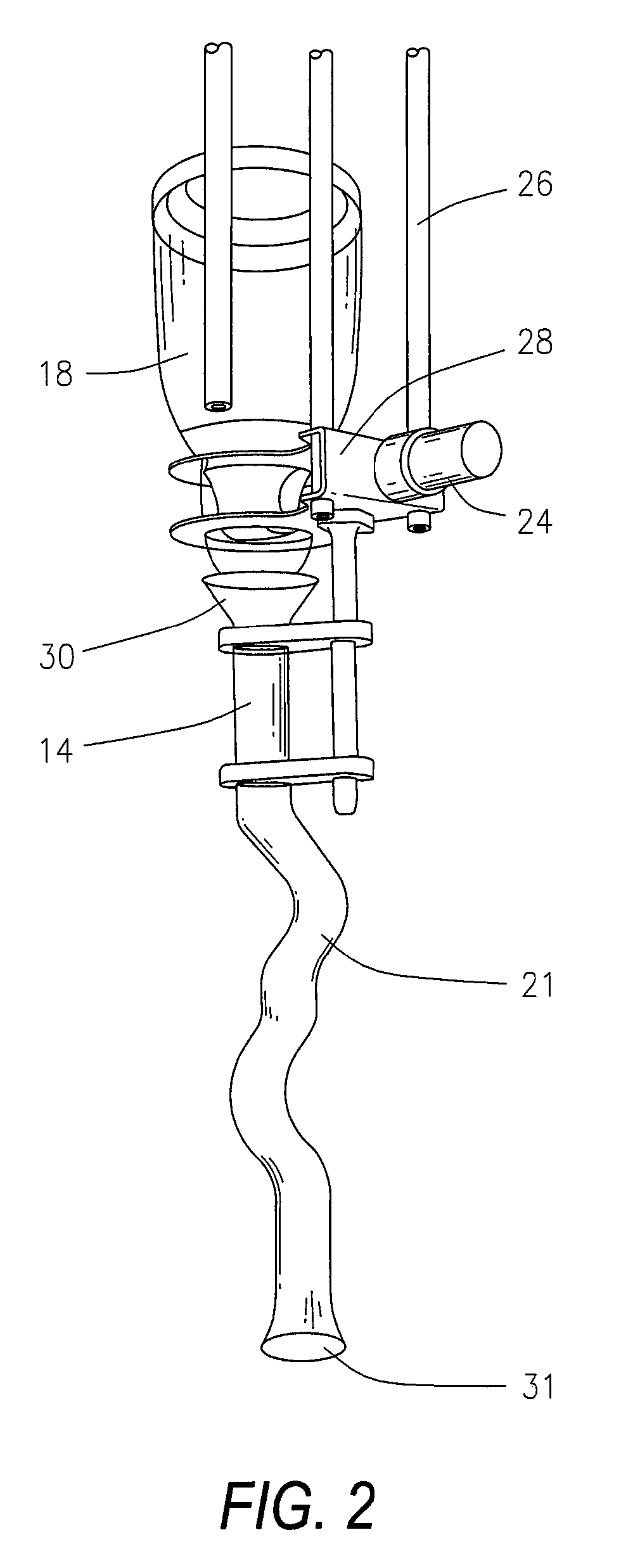

InactiveUS20070267087A1High degreeImprove viewing experienceLiquid fillingLighting and heating apparatusRobotic armFuture of robotics

A frozen confectionary vending machine employs robotics and other features to provide a customized frozen confectionary product, with or without toppings, in an entertaining environment. At least portions of the vending machine interior are visible to customers as the machine assemblies a frozen confectionary product according to specifications selected by the customer. A robotic arm moves a product receptacle between various dispensing stations that dispense measured amounts of a frozen confectionary and one or more optional toppings into the receptacle. After assembly, the product is moved by the robotic arm to a product delivery port that provides customer assess to the product in a sanitary manner.

Owner:GENERATION NEXT FRANCHISE BRANDS INC

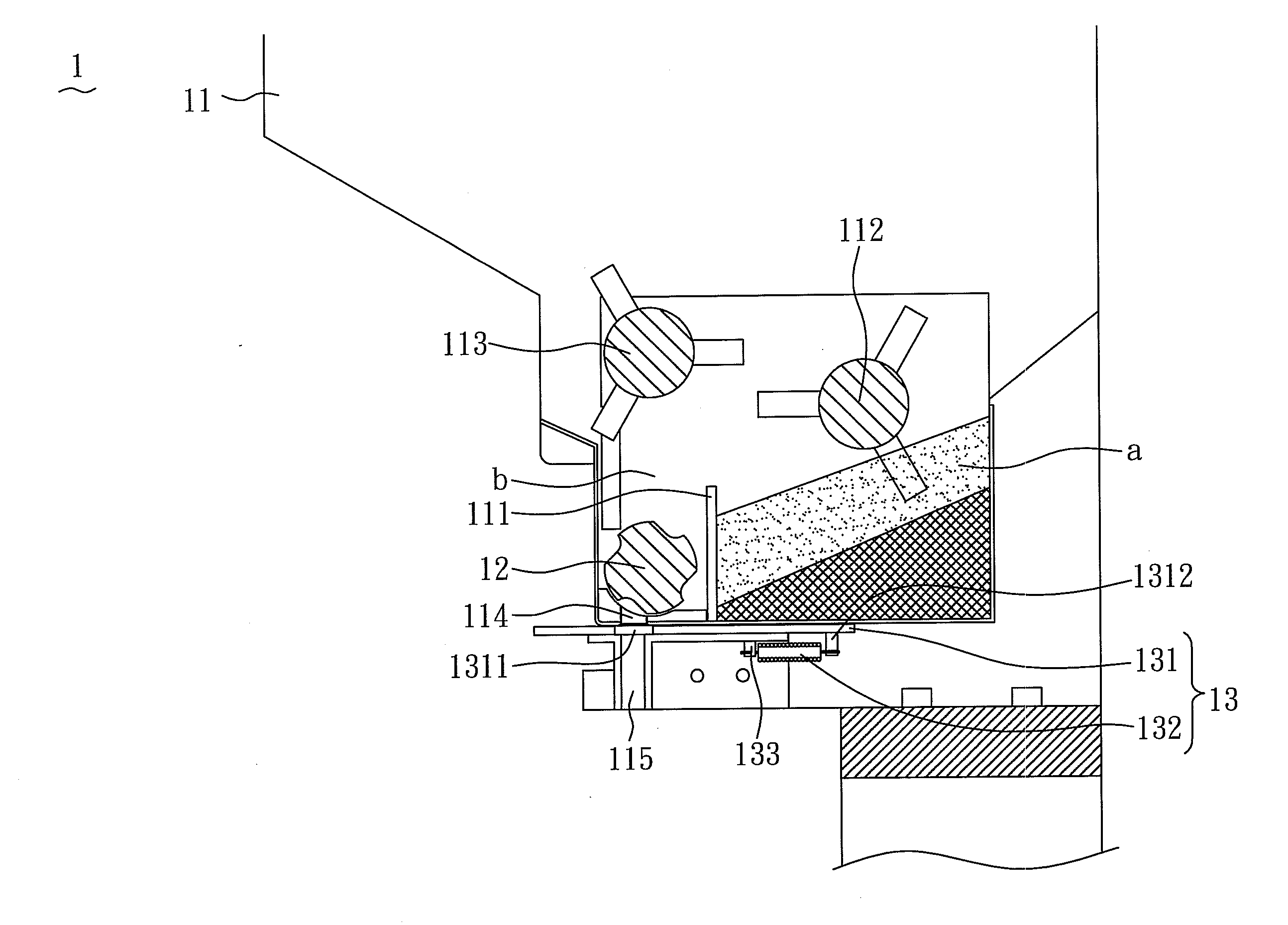

Three-dimensional object-forming apparatus

ActiveUS20110300248A1Avoid wastingLow production costManufacturing enclosuresConfectioneryEngineeringHeating system

A three-dimensional object-forming apparatus is disclosed, which includes an in-batches powder-rationing tank system, a construction tank system, a printing powder-applying system, a rapid drying heating system, a printing maintenance device, a dust-proof device, a successive liquid-supplying device, a powder auto-filtrating and recycling device, and a print quality detection device.

Owner:MICROJET TECH

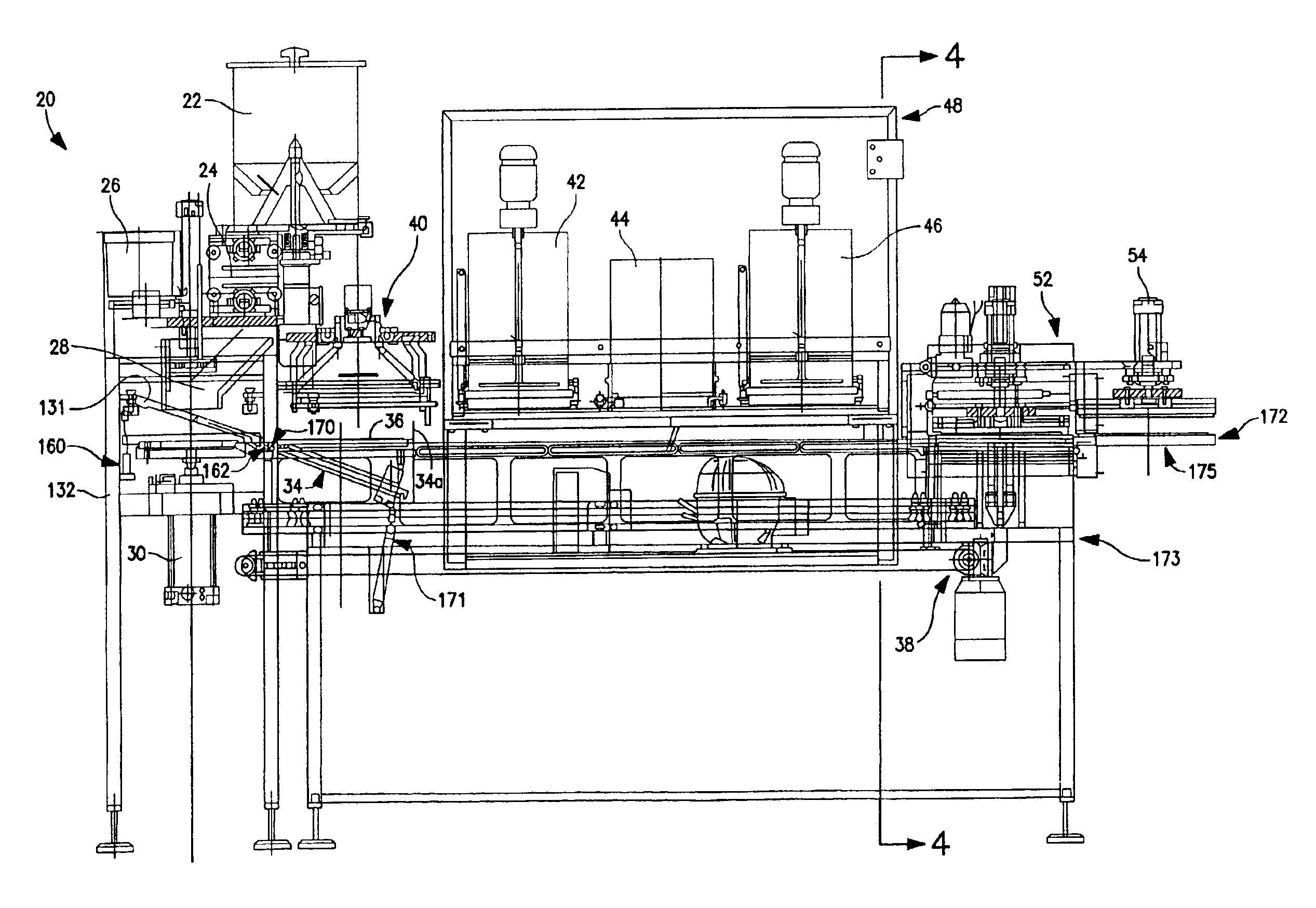

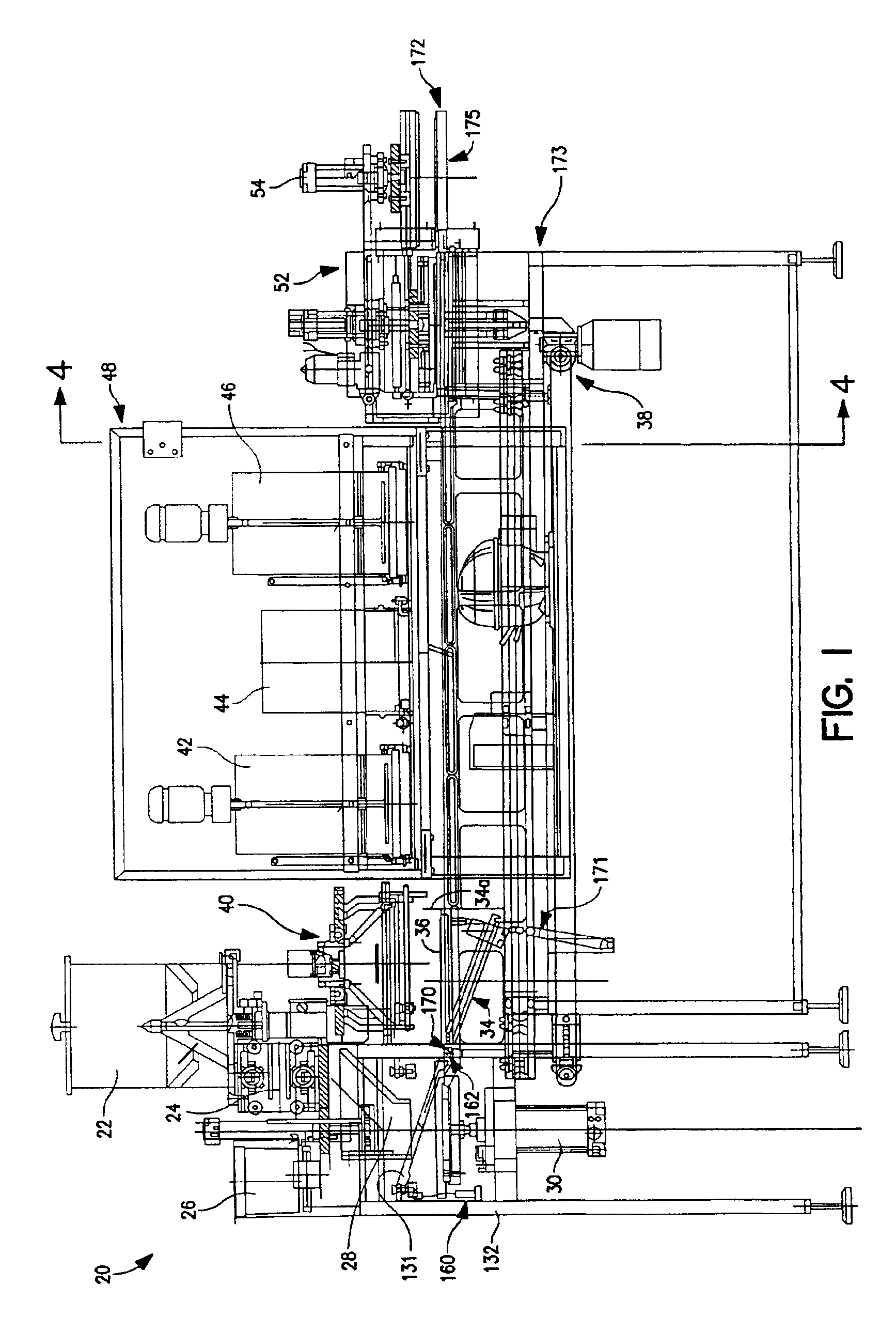

Pizza making method and system

InactiveUS6915734B2Simple and compact designMeet actual needsTransportation and packagingRotary stirring mixersCooking & bakingAdditive ingredient

The invention provides an automated method and apparatus for pizza production which is initiated by individual order placement and uses only fresh ingredients (no ingredients are frozen, pre-prepared or pre-cooked). Each dough portion is individually and mechanically prepared from flour and other fresh, pre-proportioned ingredients. The dough portion passes through a series of shaping and pre-heating processing stations to prepare a flattened and partially baked pizza base. Using a preheated or continuously heated conveying tray, the pizza base passes under a number of metering and distribution devices for selected application of tomato sauce and / or various other toppings according to the order. Baking occurs in one of multiple ovens to complete pizza preparation. Multiple ovens are provided to facilitate the automated preparation of multiple pizzas at any given time. A tray conveying system transports one or more trays through the various processing stations to accommodate multiple orders at the same time.

Owner:SITOS

Seasoning Bag

A bag for applying seasoning to a food item is provided. The bag comprises a mouth, an interior surface, and a seasoning. The mouth receives the food item, and the seasoning is adhered to at least a portion of the interior surface such that the food item may be seasoned if placed through the mouth into the bag. In another embodiment, the bag may comprise a compartment for holding a seasoning. The compartment may have a releasable seal to release the seasoning on the food item. The bag may be provided to the consumer in a container such that the consumer may remove the bag from the container and place a food item in the bag to season the food item.

Owner:LEE ROGER V +2

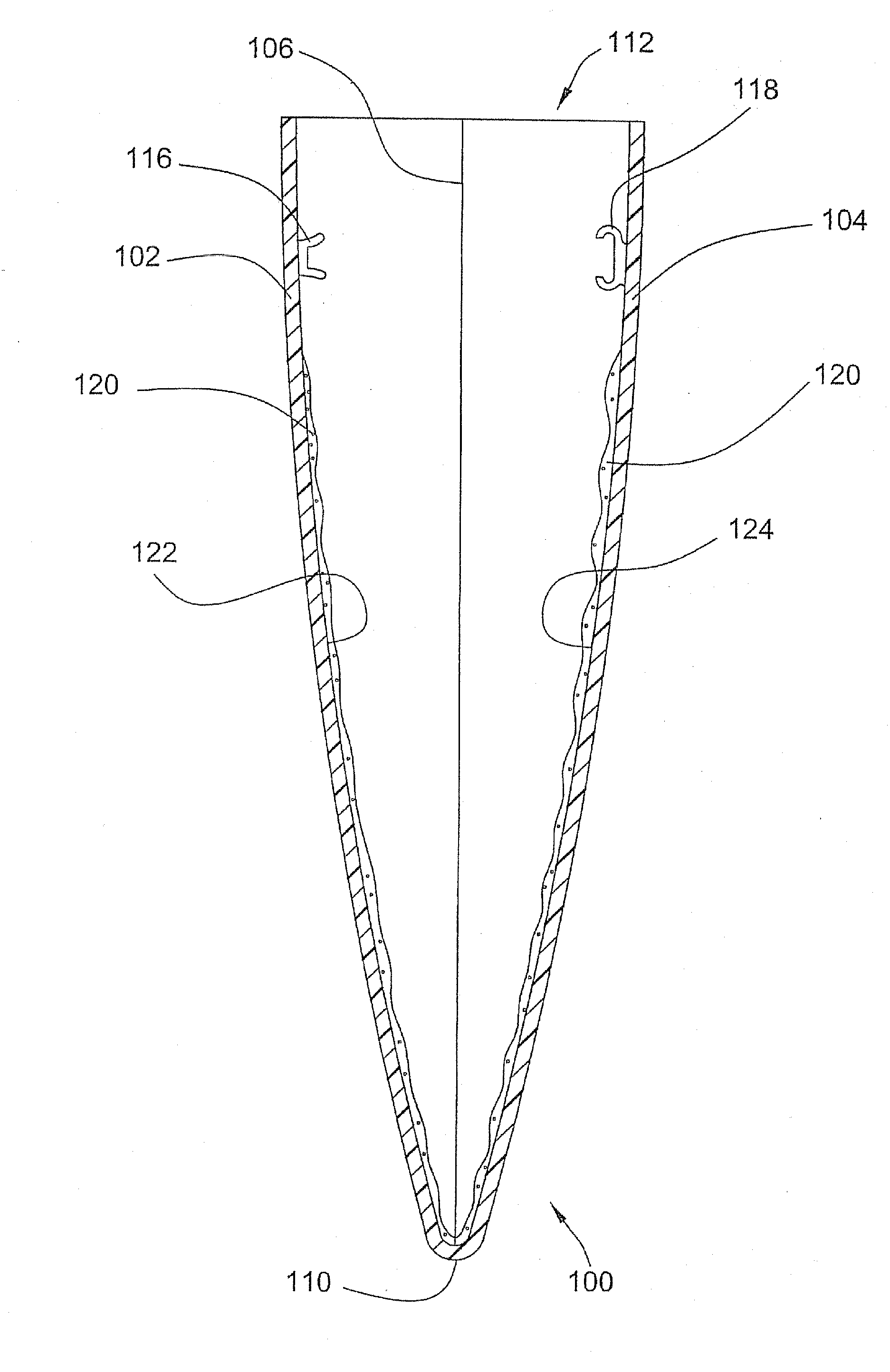

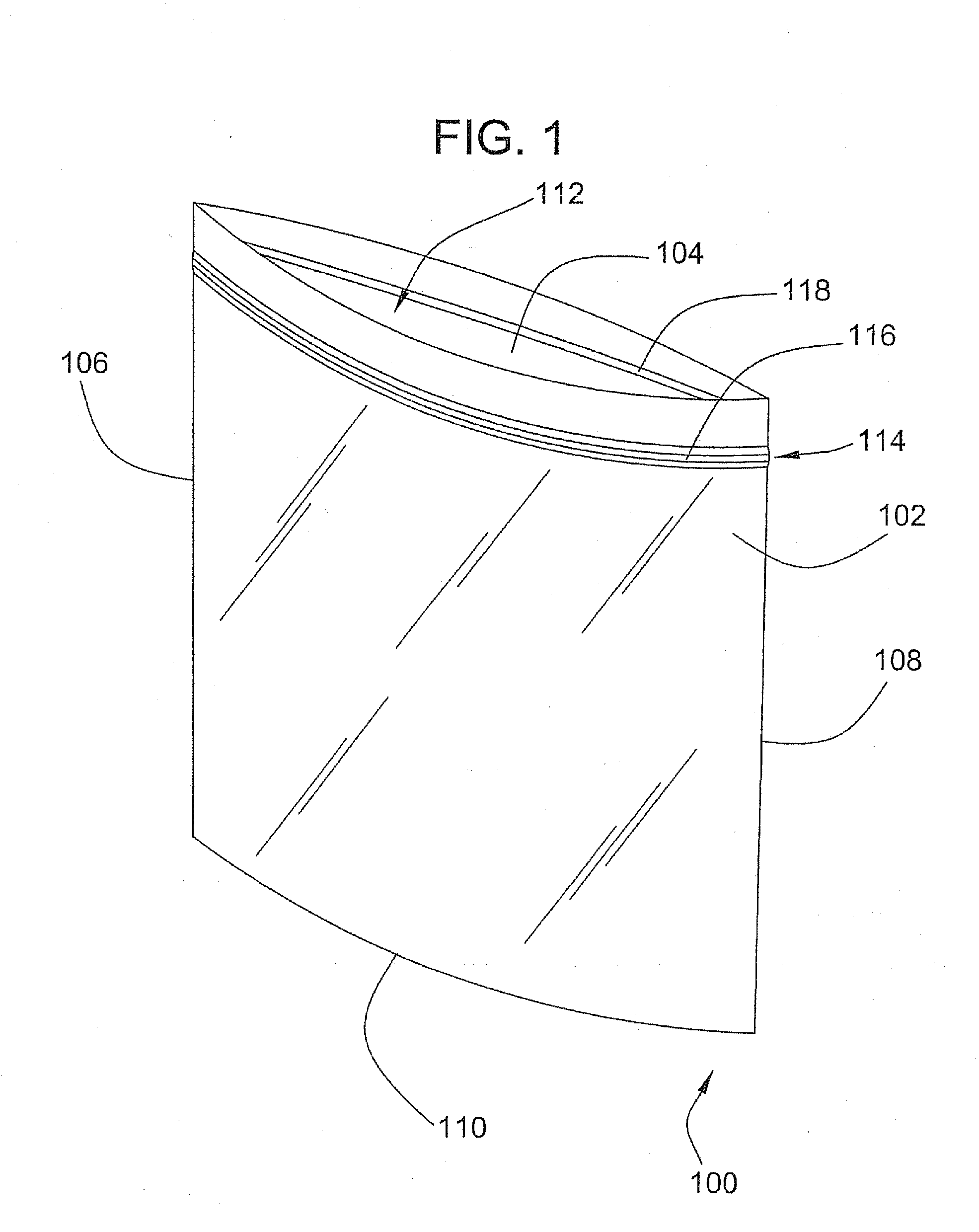

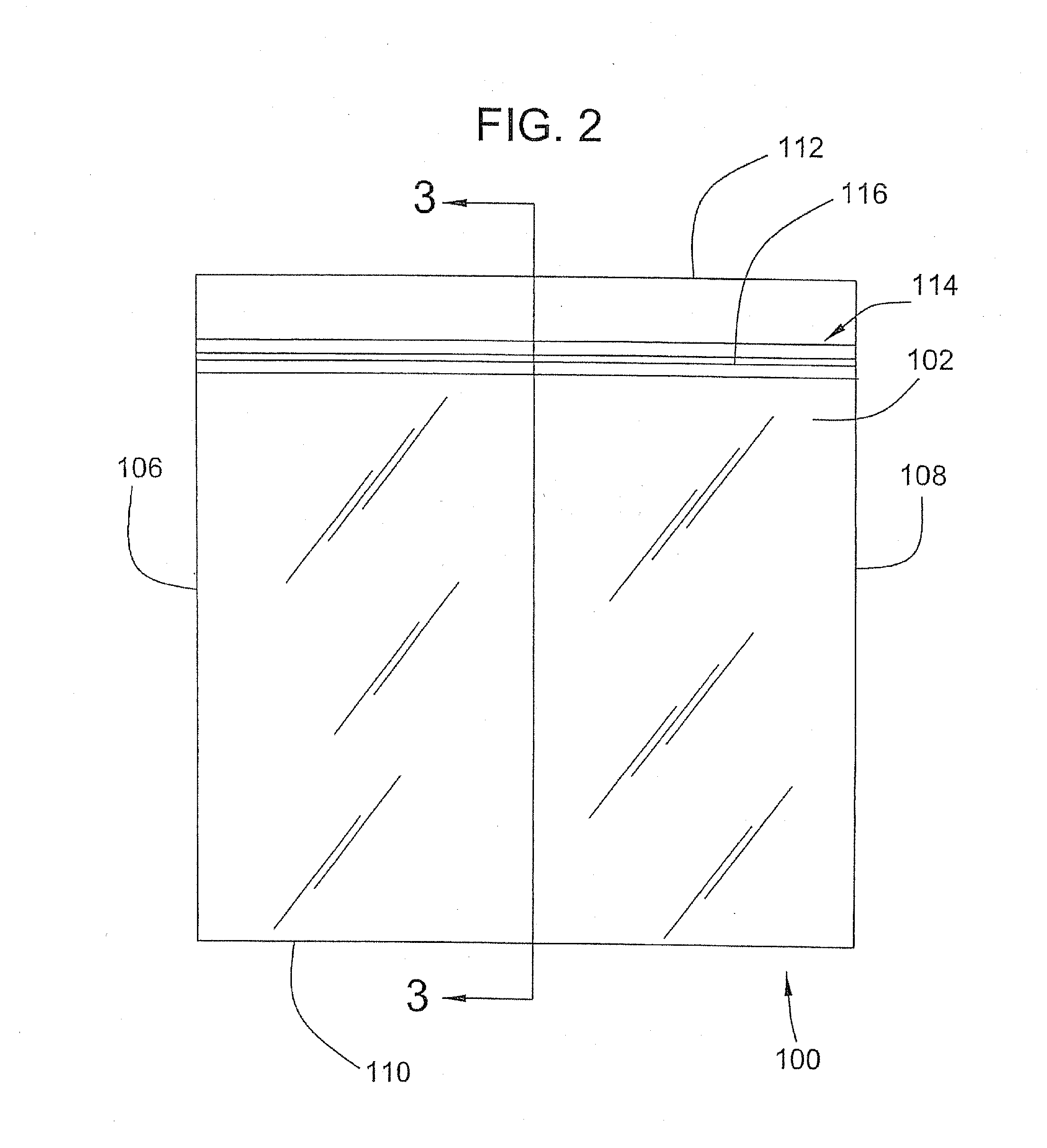

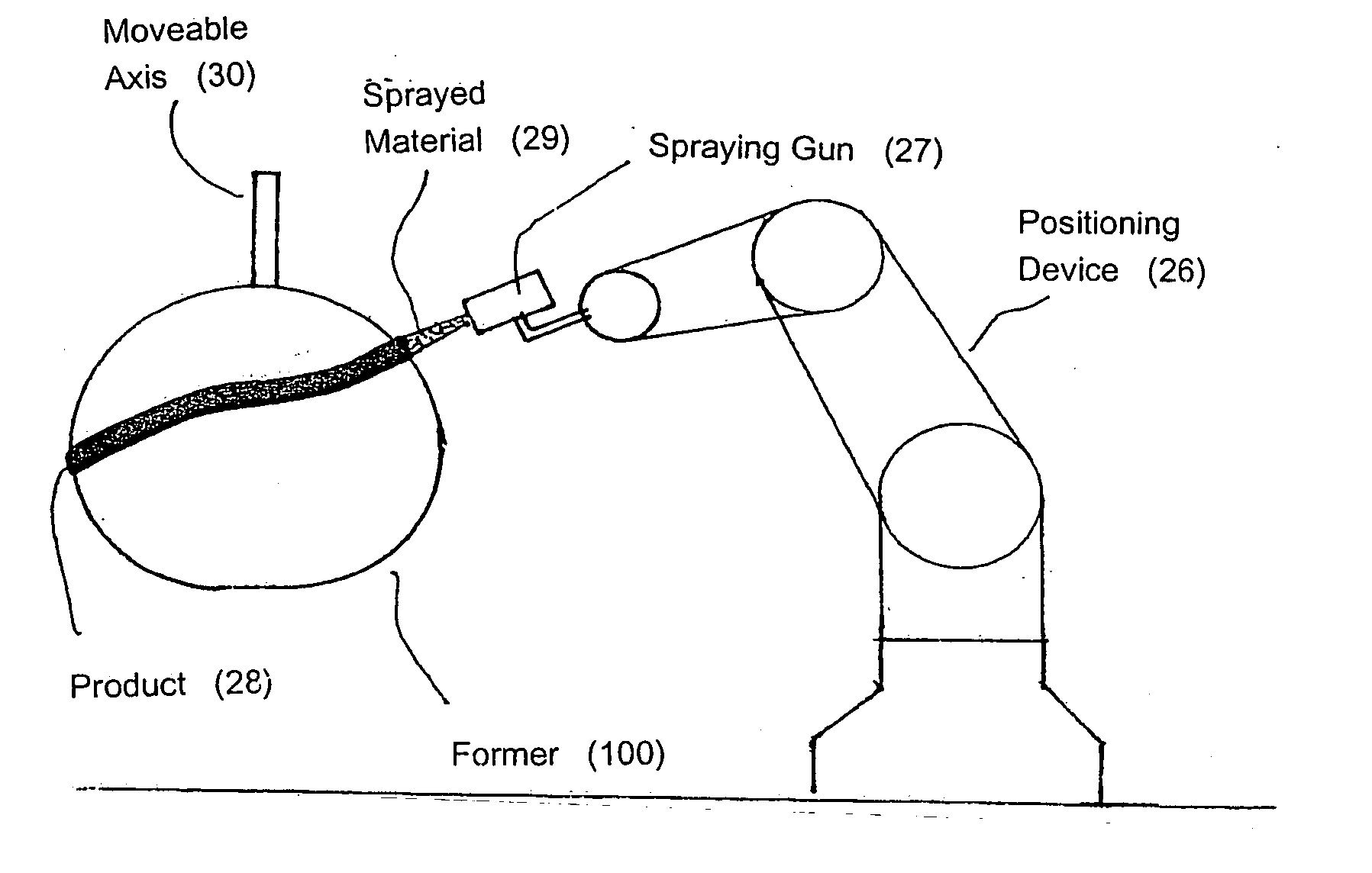

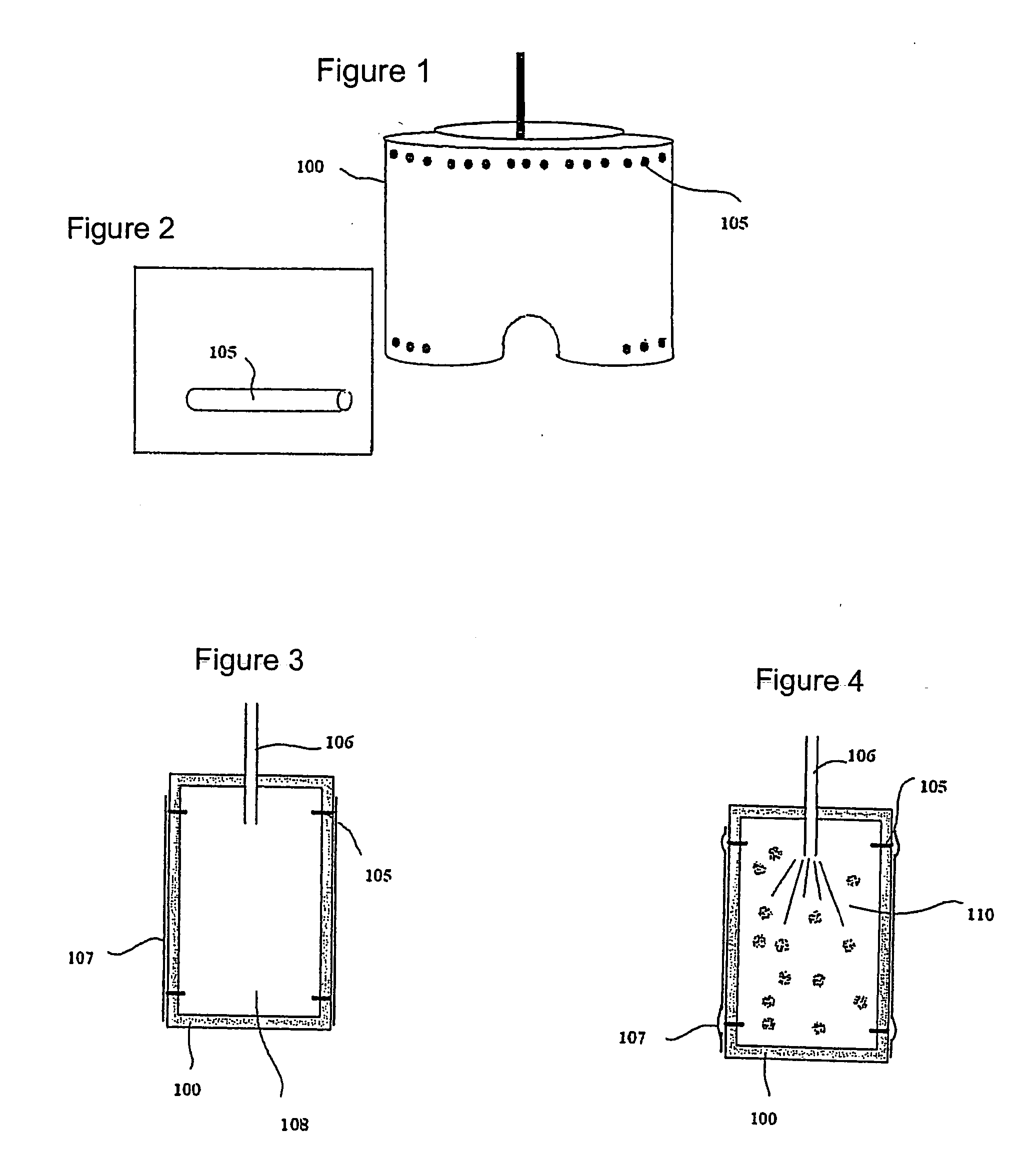

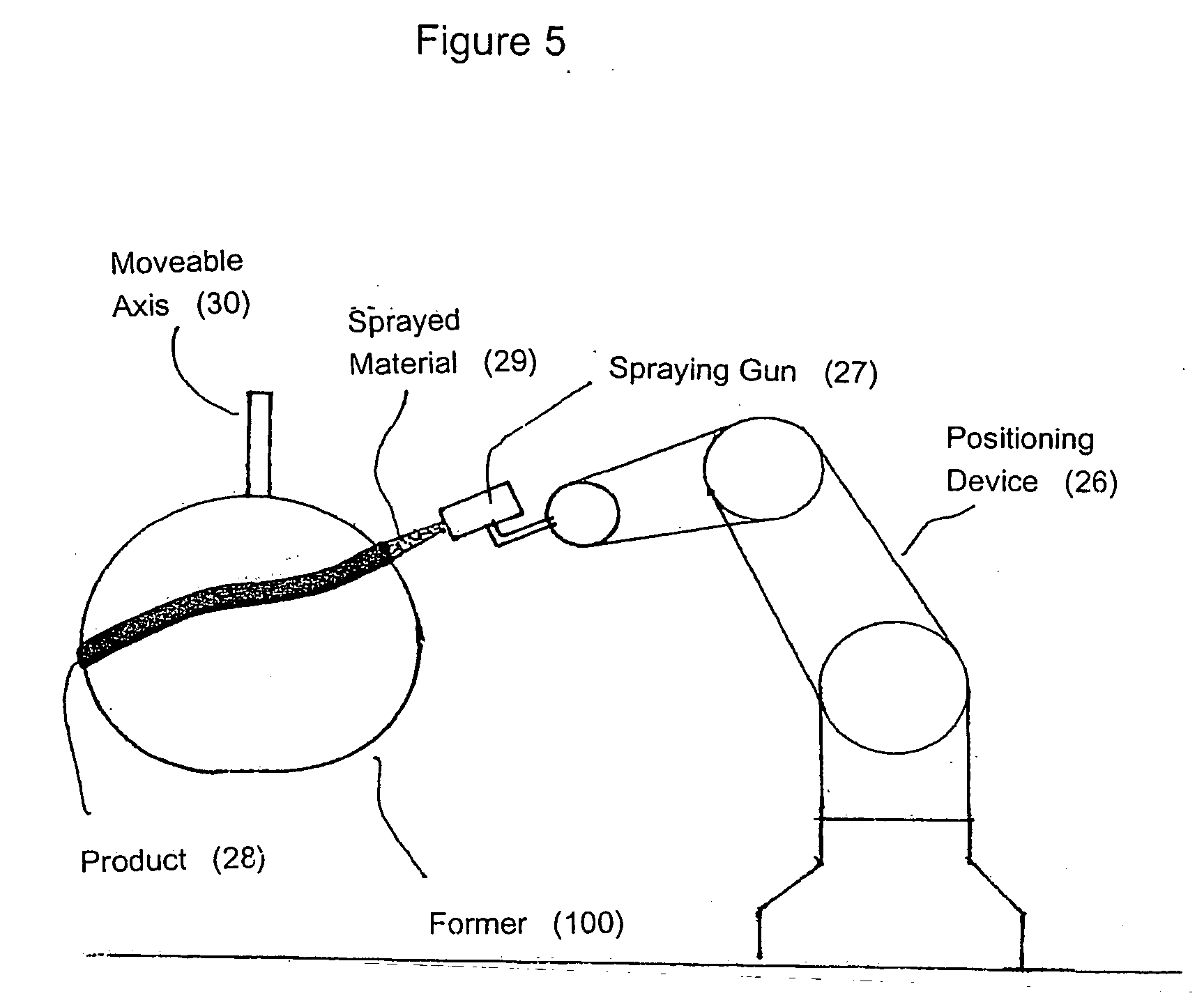

Method and apparatus to produce stretchable products

ActiveUS20060113714A1Facilitate temporary adherenceEasy to disassembleButtonsMouldsElastomerFibre coating

The invention provides methods and apparatus for producing flexible, stretchable, and / or elastic products comprised principally of material such as natural elastomers and other synthetic polymers. The method and apparatus for producing stretchable products by spraying product material over a workpiece former, and method and apparatus for creating perforated products by spraying product material over a perforated surface or partly breathable surface, The invention also provides methods and apparatus for making double sided fibre coating of the product and, or to at least coating the product surface on the side facing the wall without the need for removing the product from the wall. The method and apparatus also enable easy removal of the product from the former. Workpiece formers are also provided.

Owner:TAMICARE LTD

Method for applying solid edible particulates to an edible substrate

Owner:SOC DES PROD NESTLE SA

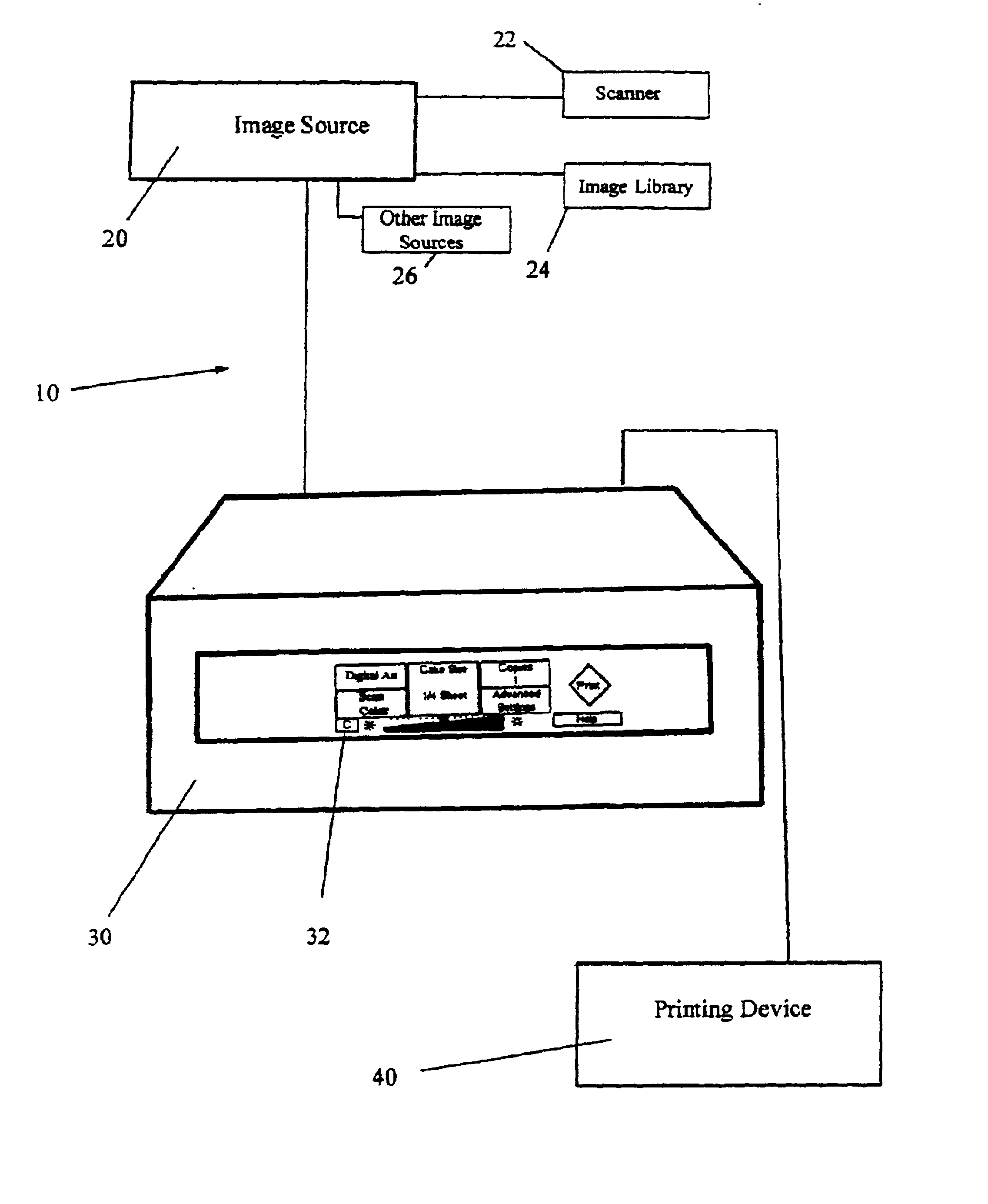

Decorating system for edible items

InactiveUS6903841B2Easy to transportEasy to useDigitally marking record carriersMeasurement apparatus componentsGraphicsControl signal

A system for creating a decorative edible item from a selected image. The system includes at least one image source, such as a scanner and / or a library of stored images, a controller unit and a printer. An edible media is inserted into the printer. The user then selects the image source, such as the scanner for scanning in a photograph reminiscence of a person or event being honored. The size of the printed image is then selected as well as the number of copies to be printed from the image. The print sequence is then activated. The controller unit applies color correction to the digital image and converts the digital image into printer control signals to operate the printer. The printer then prints a rendition of the image with edible inks as the edible media travels through the printer. A high-quality pictorial rendition of the image is thus created. The printed edible media can then be applied onto a product, shipped to a separate location or eaten as is.

Owner:DECOPAC INC

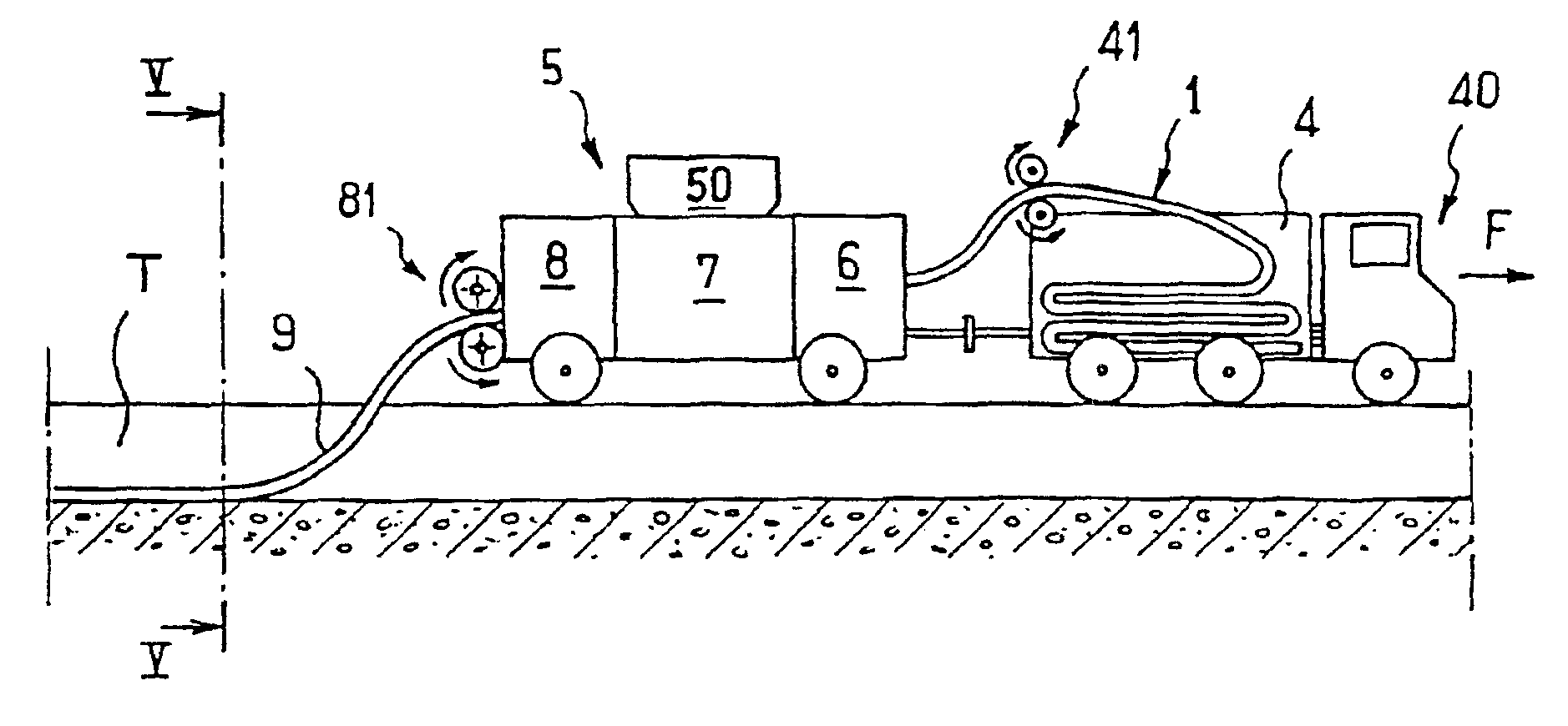

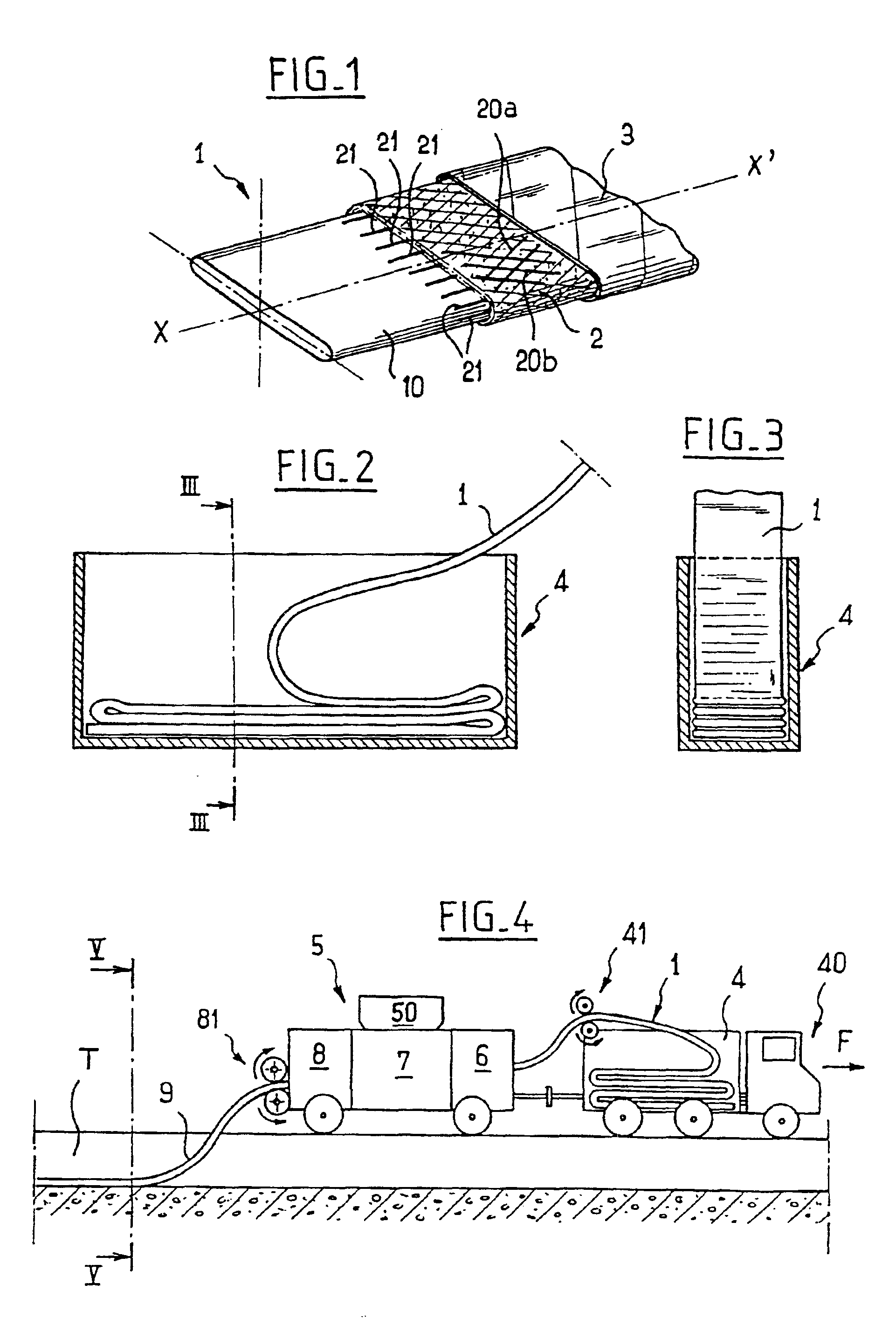

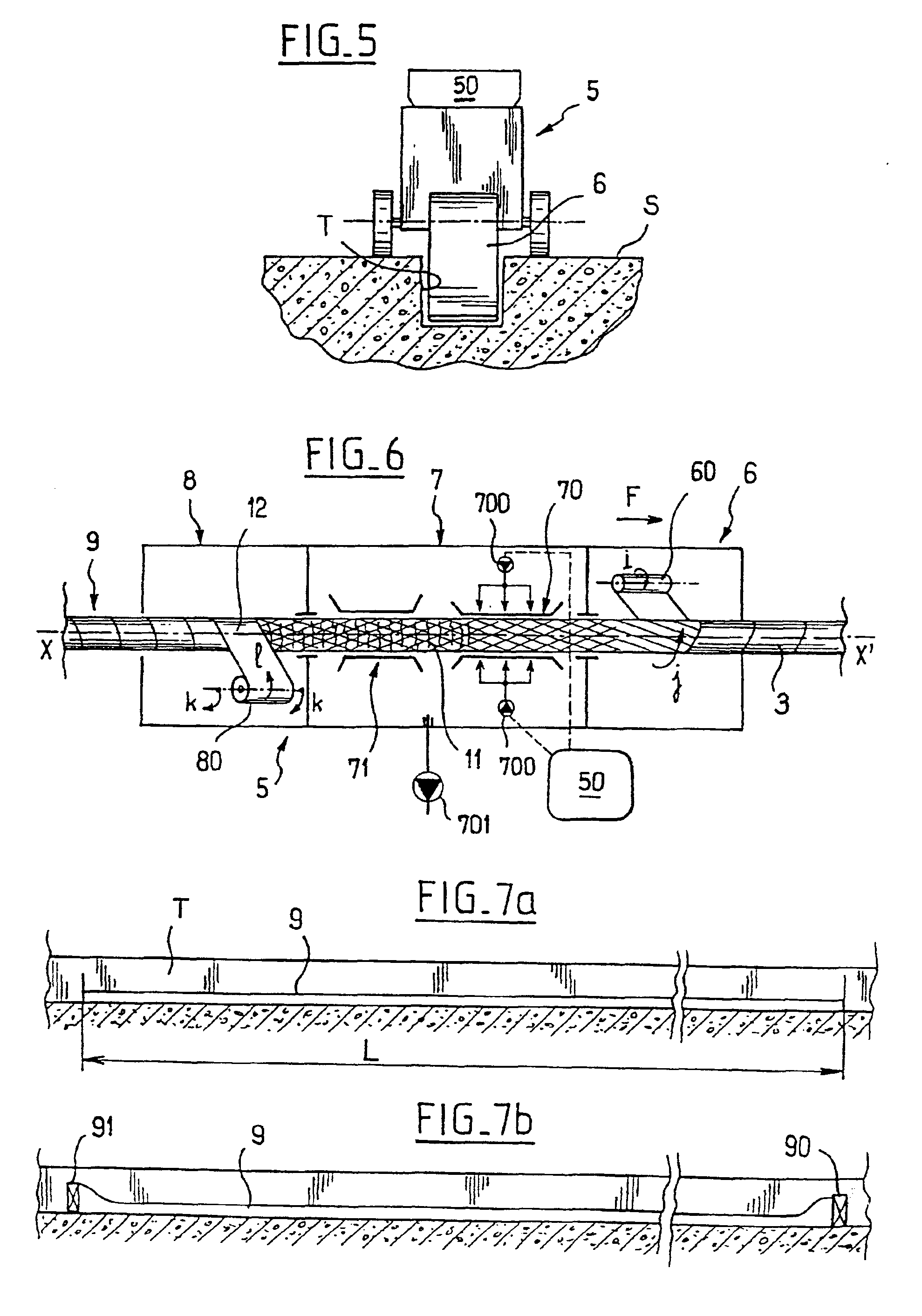

Method and installation for laying a cylindrical pipe on a support

InactiveUS6899842B1Simple and inexpensive implementationAvoid radial expansionUnderground chambersButter manufactureWaste managementStructural engineering

Owner:SERVICES PETROLIERS SCHLUMBERGER SA

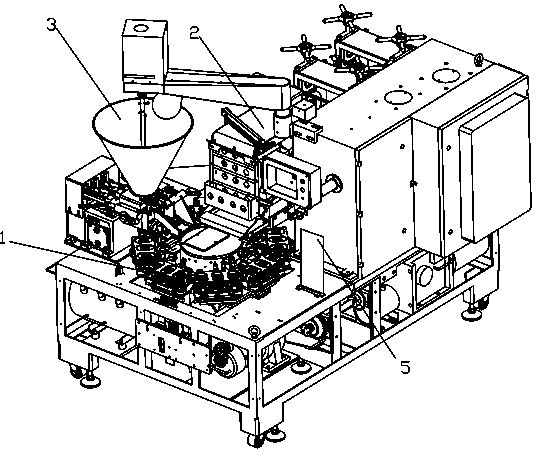

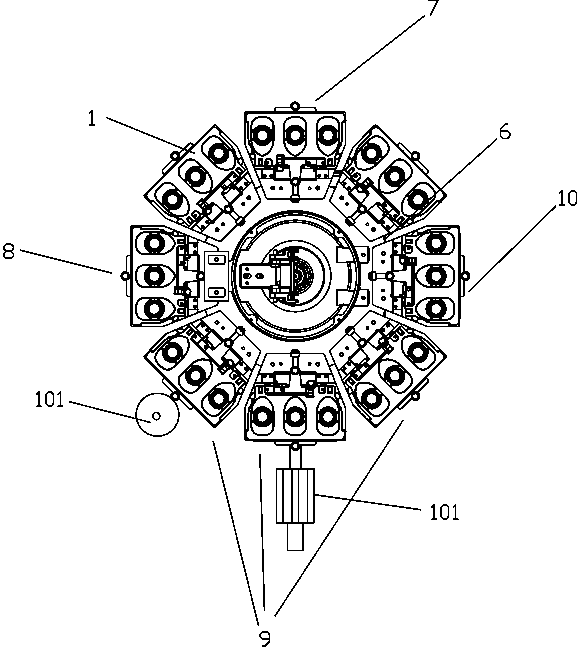

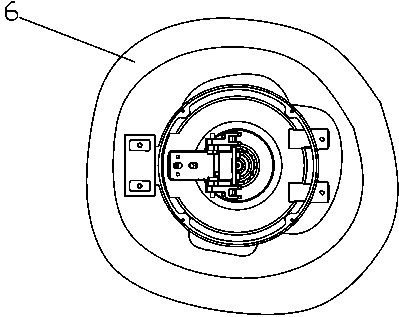

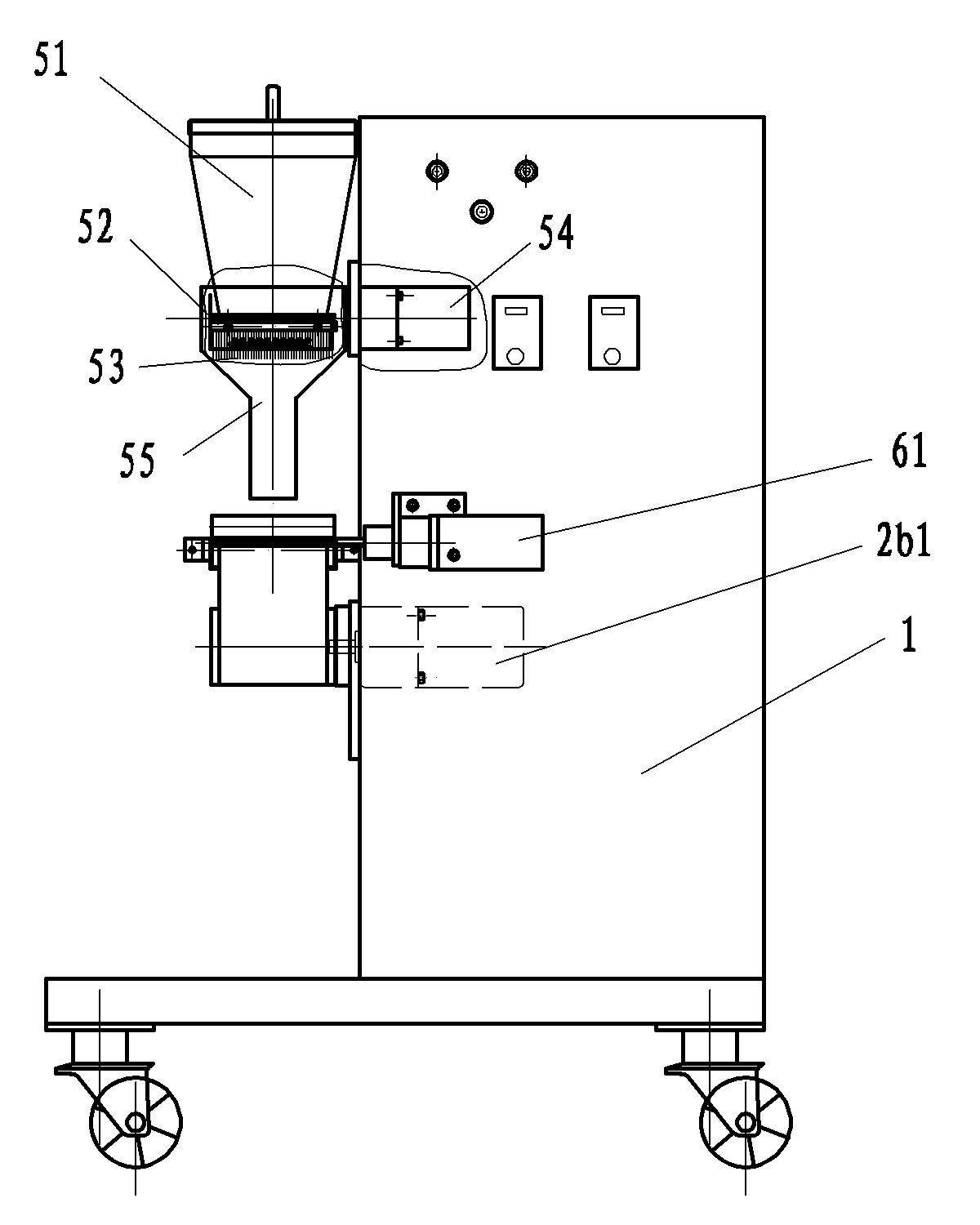

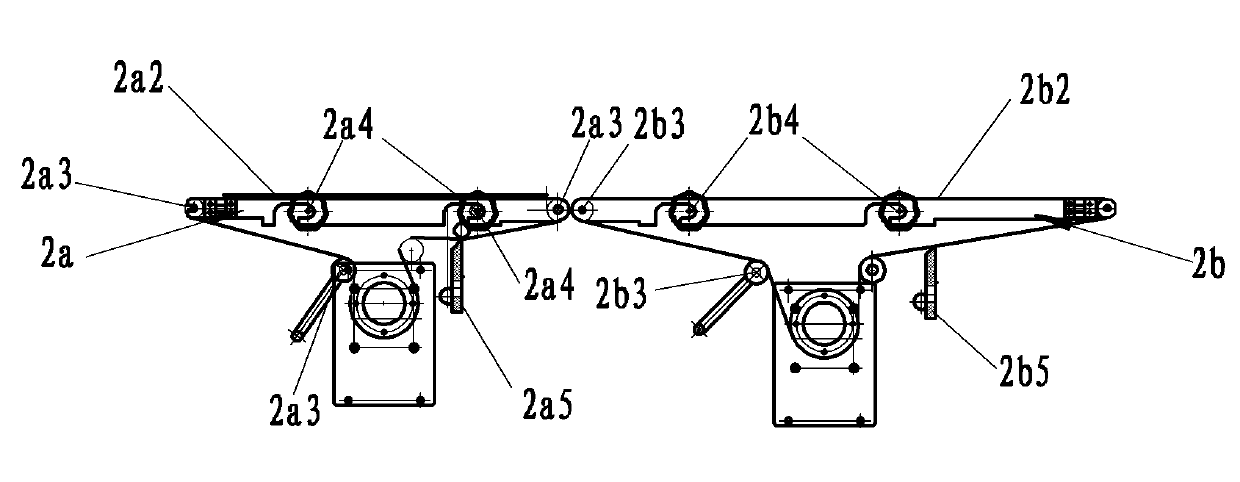

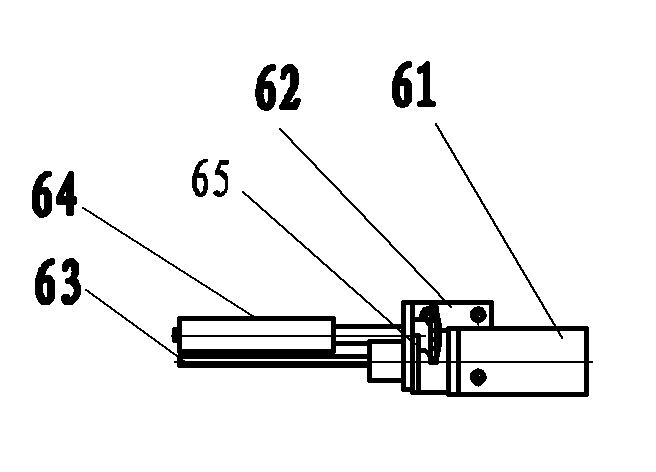

Farci food forming machine

The invention belongs to the technical field of food processing, and particularly relates to a farci food forming machine. The farci food forming machine comprises a stander and a flour wrapper transporting device, a stuffing feeding device, a flour wrapper receiving plate, a withdrawing device and an annular track arranged on the stander, wherein the flour wrapper transporting device, the stuffing feeding device and the withdrawing device are respectively and fixedly arranged on the flour receiving station, the stuffing injecting station and the withdrawing station of the annular track, the flour wrapper receiving plate capable of moving around the annular track is arranged on the annular track, a die assembly device is arranged under the flour wrapper receiving plate, the die assembly device of the farci food forming machine can provide a persistent press force when the farci food is processed, so that the compactness of the fit part of the flour wrapper of the farci food can be guaranteed, and the flour wrapper can not be opened after being pressed for a long time, so that the yield of the farci food can be guaranteed.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

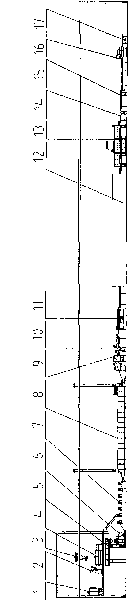

Oil spraying instant noodle production line and production technology thereof

InactiveCN101720890AFragrant and delicious tasteReduce oil contentFood preparationDough processingAlkaline waterHigh volume manufacturing

The invention relates to oil spraying instant noodle production line and production technology thereof. The production line is sequentially provided with an alkaline water bucket, a quantitative water adding bucket, a vibrating screen, a double shaft flour-mixing machine, a curing feeder, a composite tablet machine, a continuous tablet machine, a three-layer vaporizer, a cutting folder, a spraying flavouring machine, an oil spraying noodle frying machine, a microwave drying machine, an air cooling machine and an output packaging device. The equipment is full automatic, production efficiency is high, thus being applicable to mass production; in the production equipment, oil spraying device is adopted to carry out oil spraying treatment on noodle block, the noodle block has the flavour of common instant noodles while the oil content thereof is only about 5%, thus the noodle block is a good low oil content healthy food.

Owner:BUHLER GUANGZHOU FOOD MACHINERY

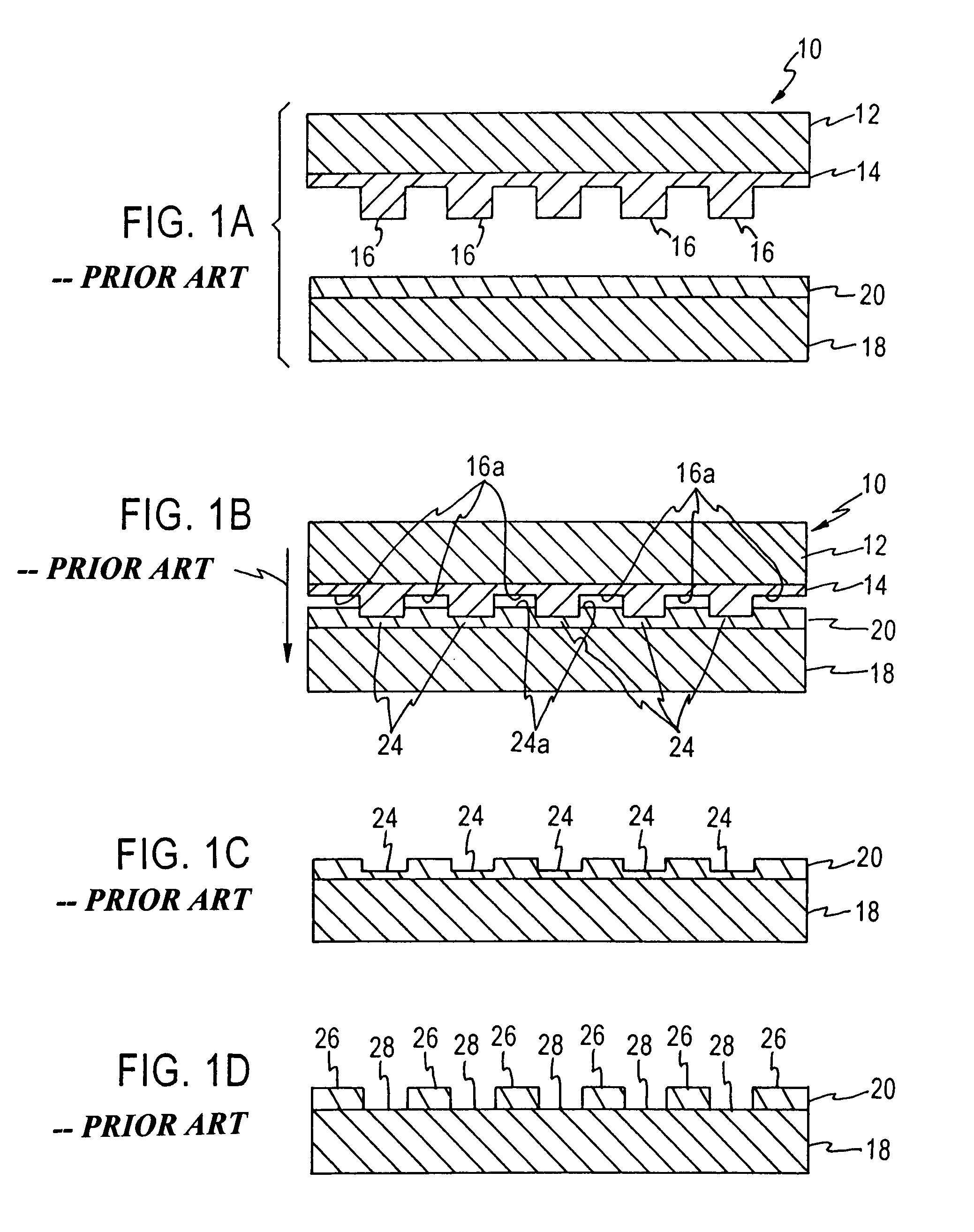

Method for making sweet cookie dough having an imprinted surface

ActiveUS7067167B2Rapid and efficient and systematic processConfectioneryCeramic shaping apparatusWire cuttingEngineering

Rapid, efficient, and systematic processes and apparatuses for making repeatable imprints on multiple, individual sweet dough pieces are provided. An advantage of the process is the ease of making uniform imprints that are aligned with the individual dough pieces as formed and deposited. Such provides the ability to create a three-dimensional pattern on the surface of a sweet dough piece, particularly a soft cookie dough piece. The methods can be accomplished by high-speed wire cutting production methods as well as other dough piece depositing apparatuses, such as roller-type depositors.

Owner:GENERAL MILLS INC

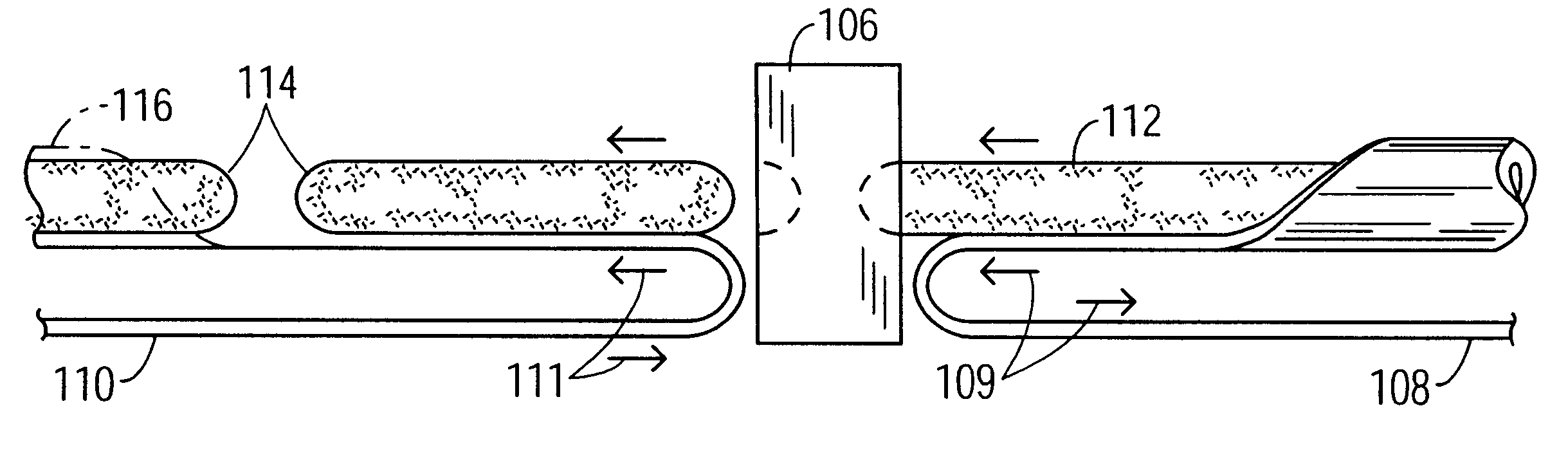

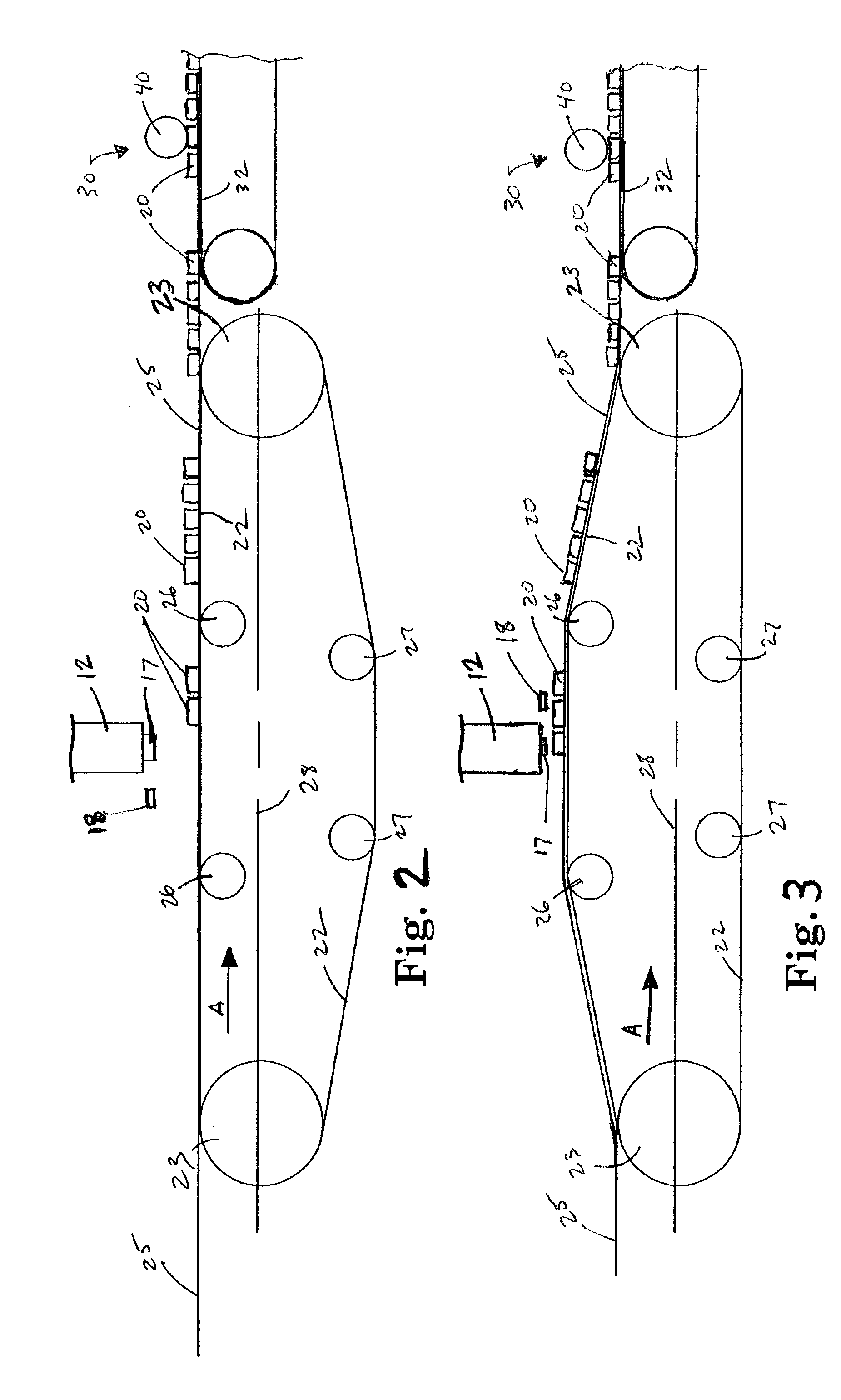

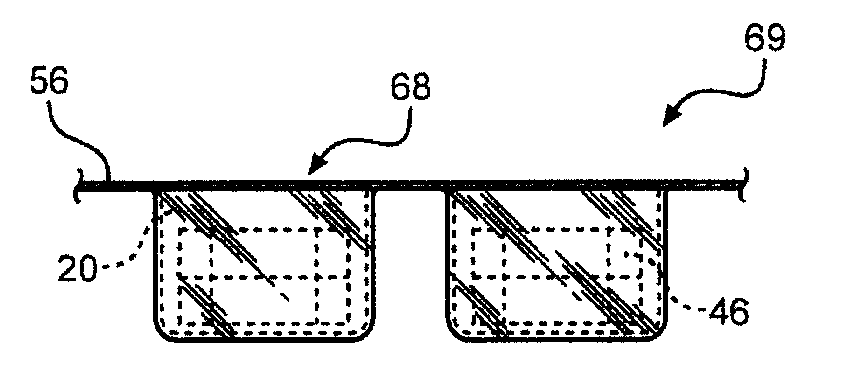

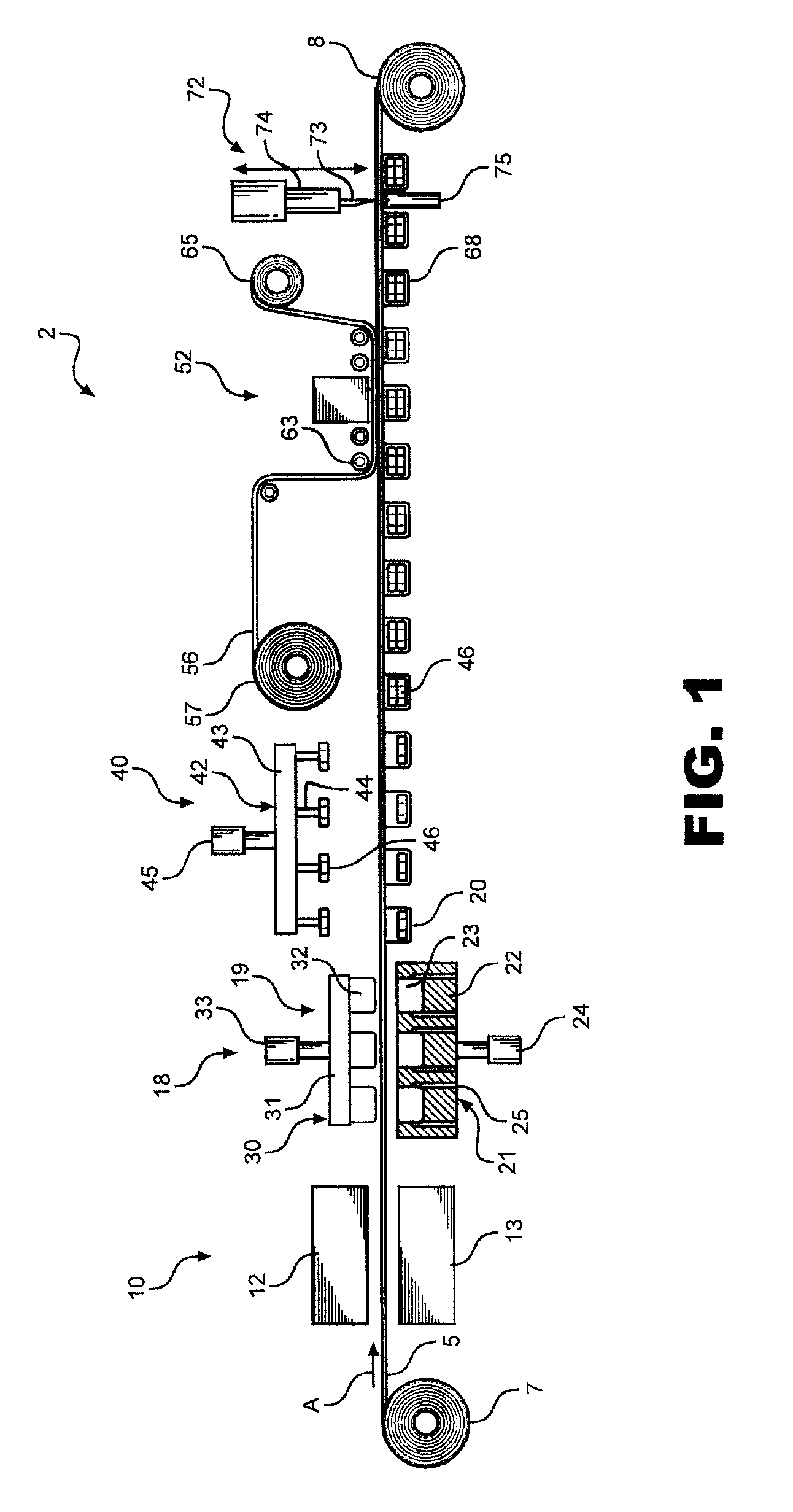

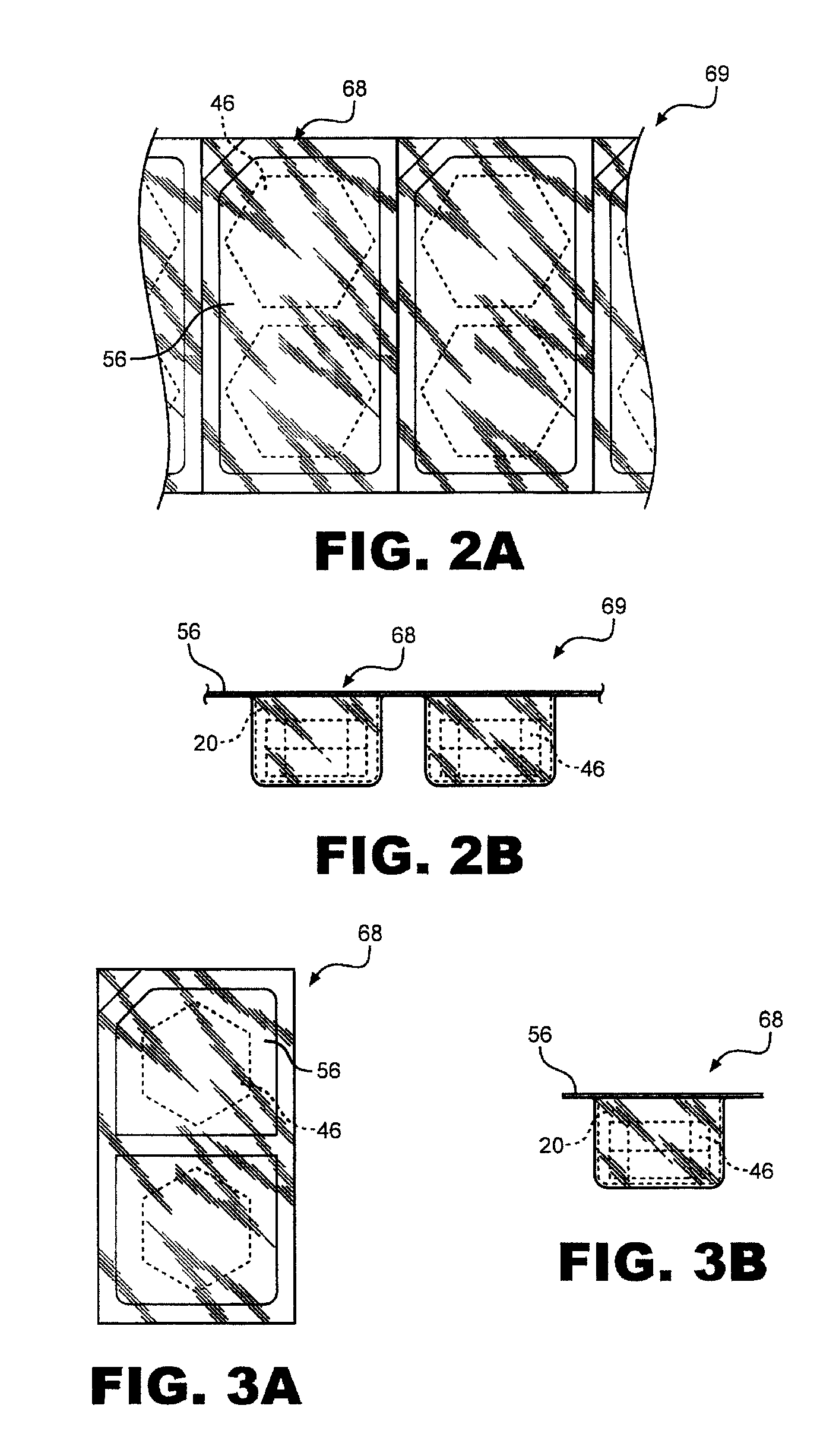

Hffs packaging method and apparatus for refrigerated dough

A method for packaging products utilizes a horizontal form, fill and seal (HFFS) system in combination with a vertical loading system. The packaging method includes creating product receiving cavities in a lower film, directly vertically stacking products in the product receiving cavities and then sealing the vertically stacked products in the cavities with an upper film to form product pouches. In one embodiment of the invention, a product fill station of the HFFS system is advantageously defined by a shaped packer including a stamping unit for directly vertically stacking the products. In another embodiment, a vertical lift and feed mechanism is employed to vertically stack the products in the receiving cavities.

Owner:GENERAL MILLS INC

Cake surface sesame scattering machine

The invention relates to a sesame scattering machine. The sesame scattering machine comprises a machine body, a cake introduction conveying mechanism, a cake surface syrup spraying mechanism, a syrup mist suction-removal mechanism and a cake surface sesame scattering mechanism, wherein the cake introduction conveying mechanism is formed by motors, conveyor belts, tension rollers and transmission rollers; the cake surface syrup spraying mechanism is formed by a syrup storage tank, a syrup conveying tube and a nozzle; the syrup mist suction-removal mechanism is formed by a syrup mist suction tube, a filter and a vacuum pump; and the cake surface sesame scattering mechanism is composed of a sesame storage bucket, a sesame distributor, a hairbrush and a sesame catching bucket. The syrup is sprayed on the surfaces of cakes in a pressurization mode, and the granule distributor with the surface fully distributed with pits is used for scattering sesames, so the syrup spray distribution and the sesame distribution are fast and uniform; the syrup mist suction-removal mechanism is arranged, so the splash of the sprayed syrup and the suffusion of the syrup in air are controlled; the cake introduction conveying mechanism is provided with conveyor cleaning scrapers, so it is benefit for cleaning, and material recovery can be realized; a cake passing and pressing apparatus is arranged at the stroke tail end, so the granules are firmly viscous after the rolling, and blocking and clamping phenomena at the junctions of the conveyor belts to where the cakes are transmitted are eliminated. The sesame scattering machine has the characteristics of reliable operation, automation and fastness, less material loss, environment cleaning, and suitableness for line production.

Owner:江苏裕铭铜业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com