Patents

Literature

31results about How to "Fast even distribution" patented technology

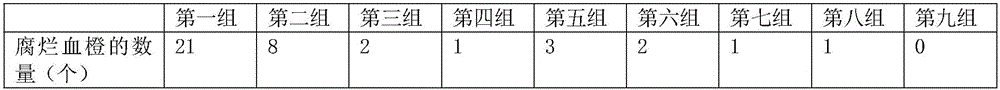

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

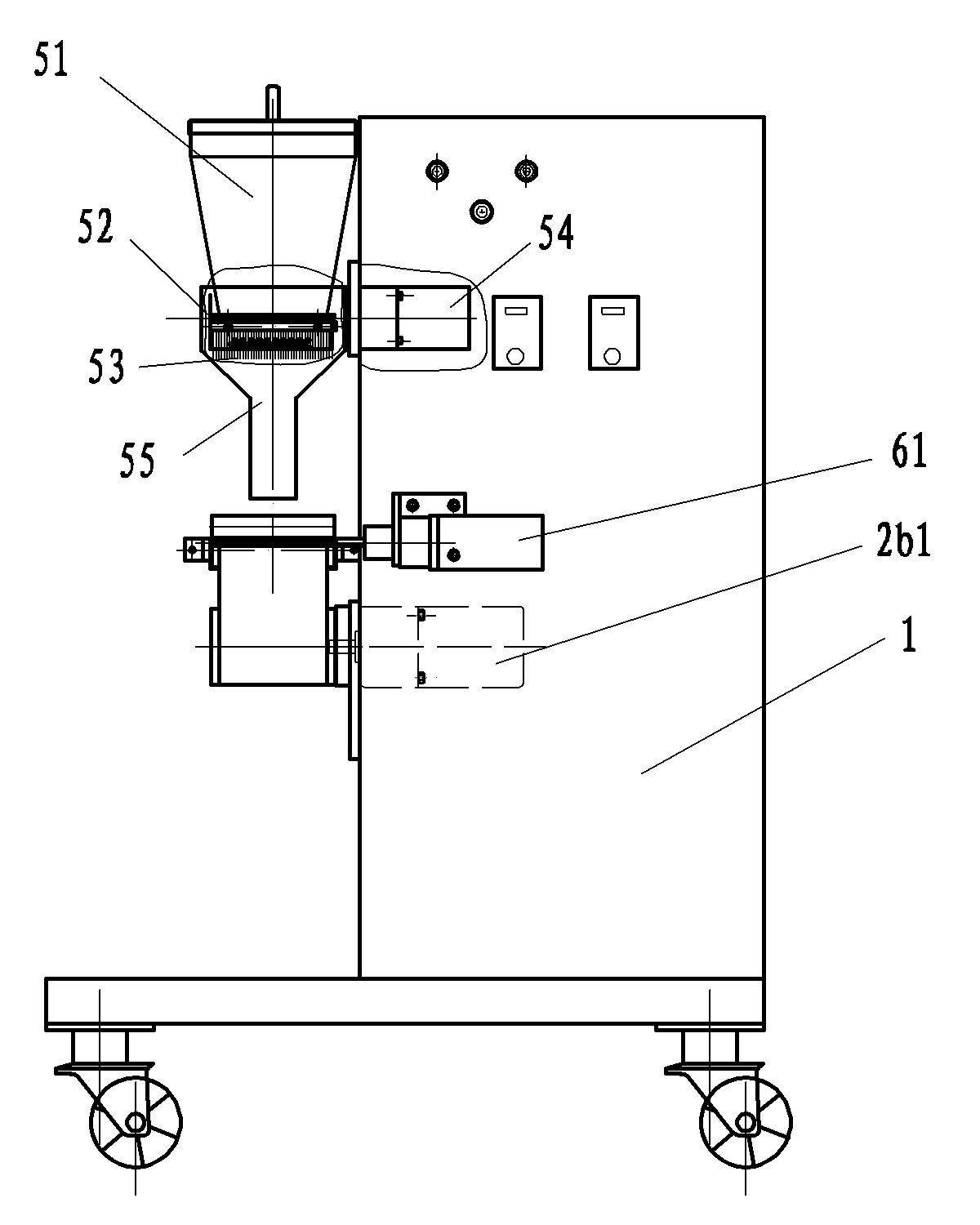

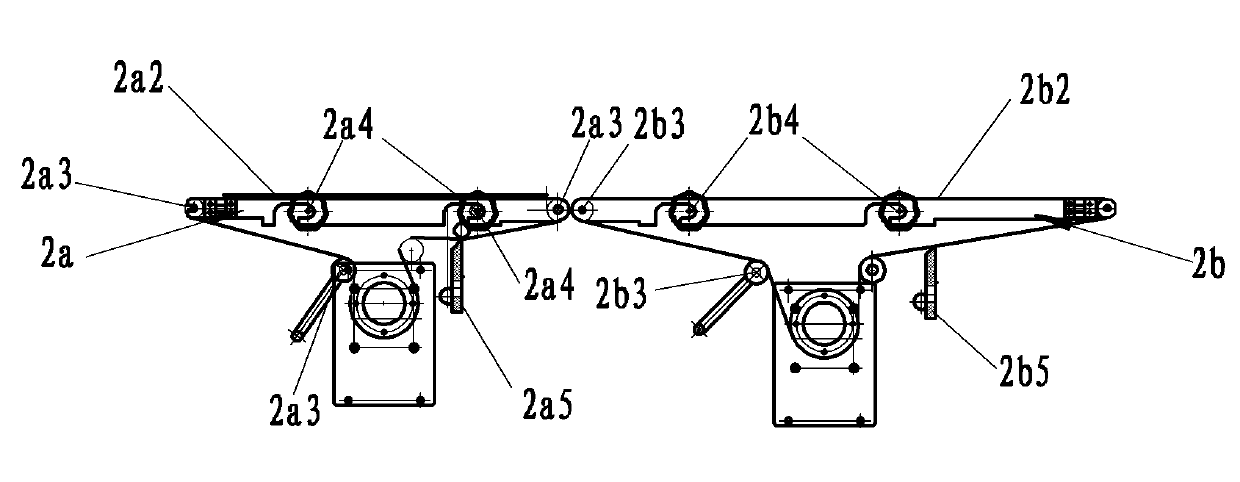

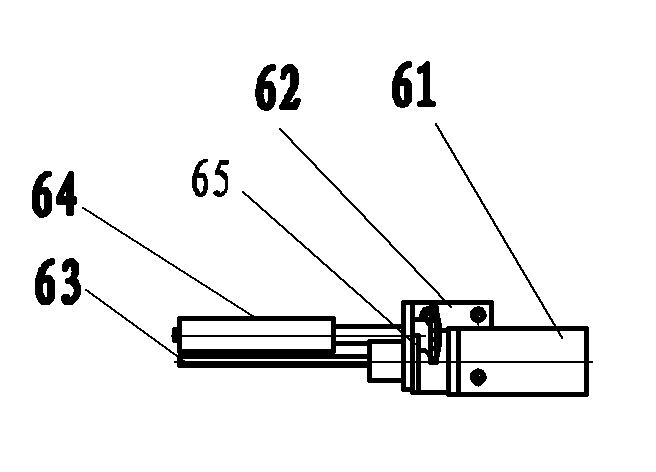

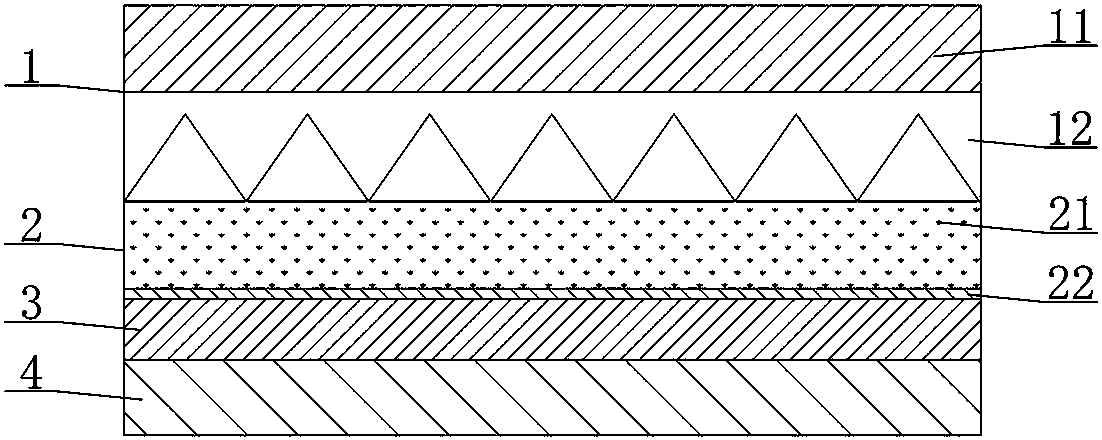

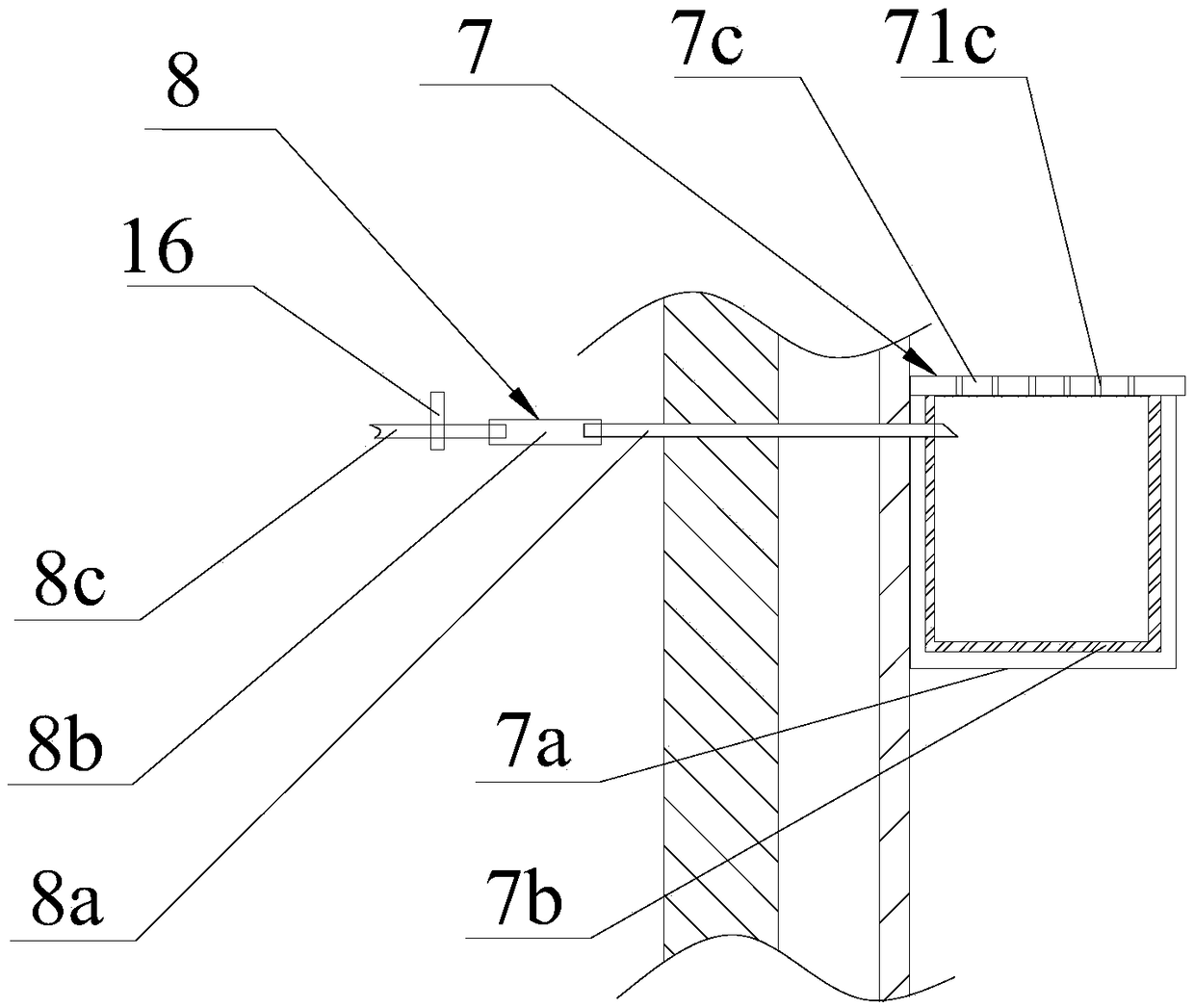

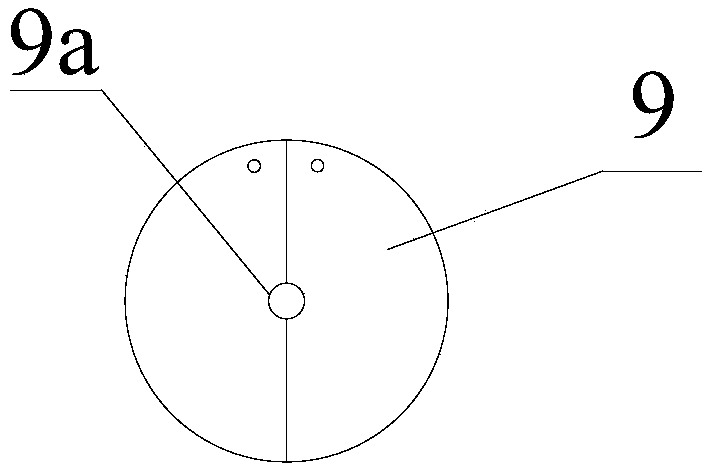

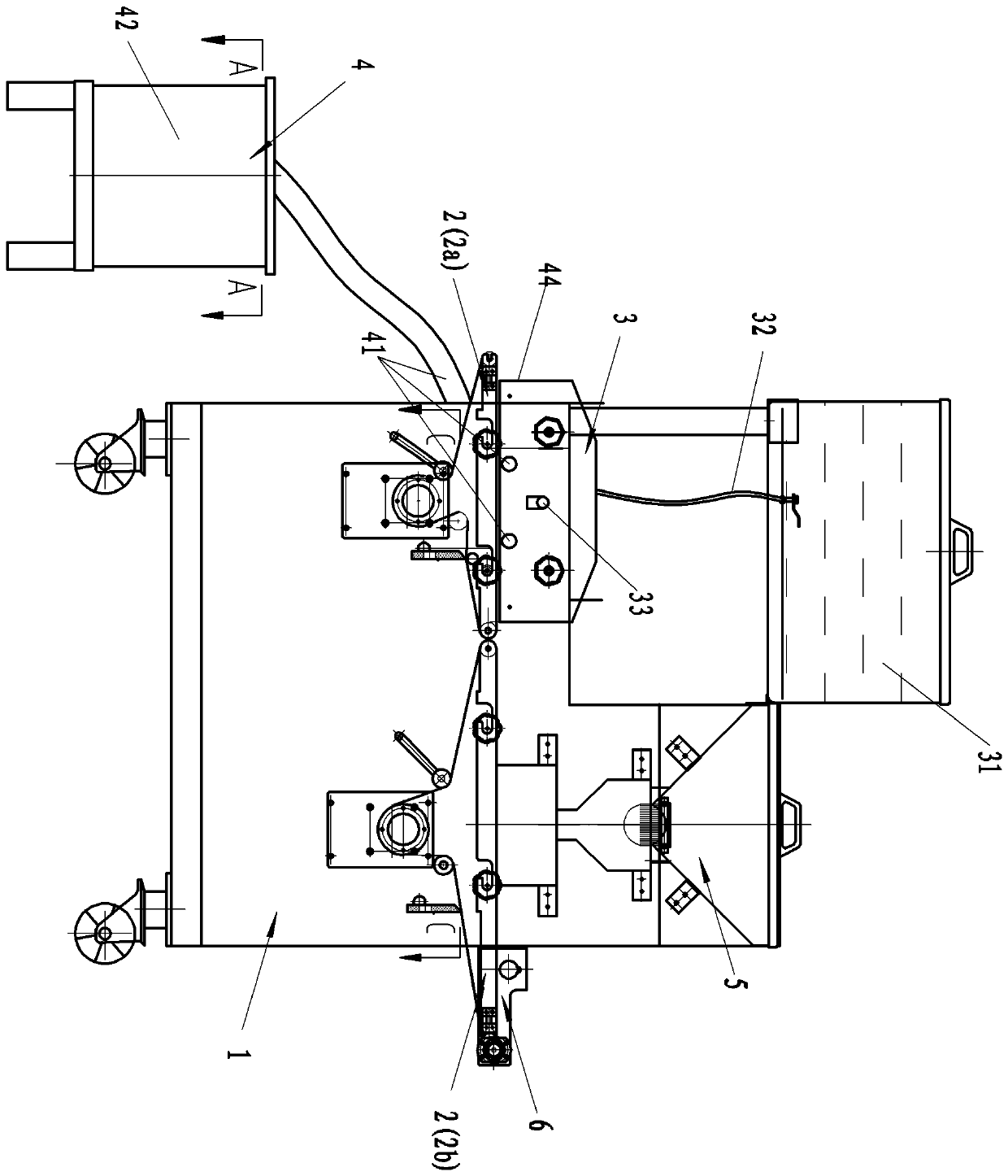

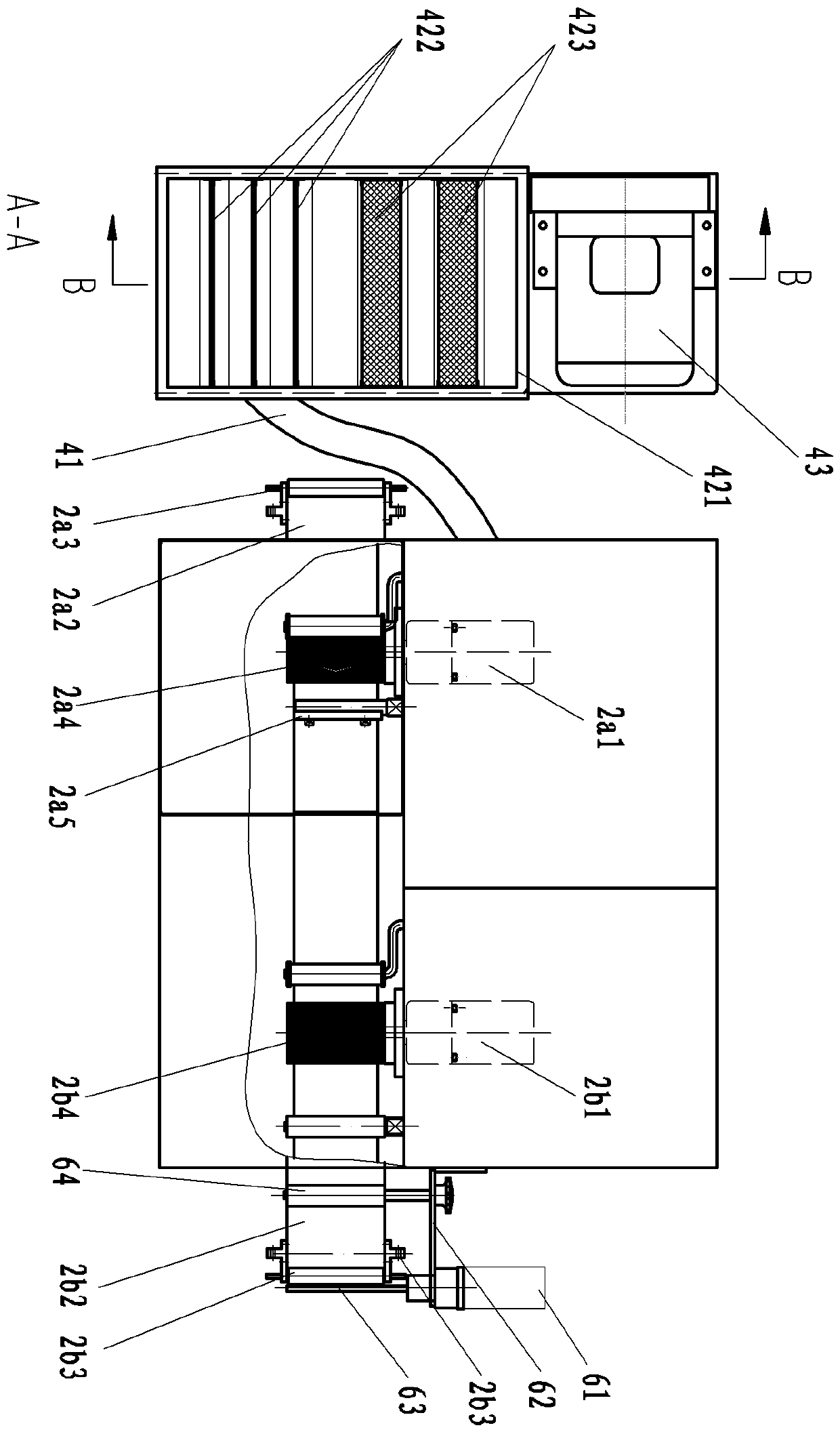

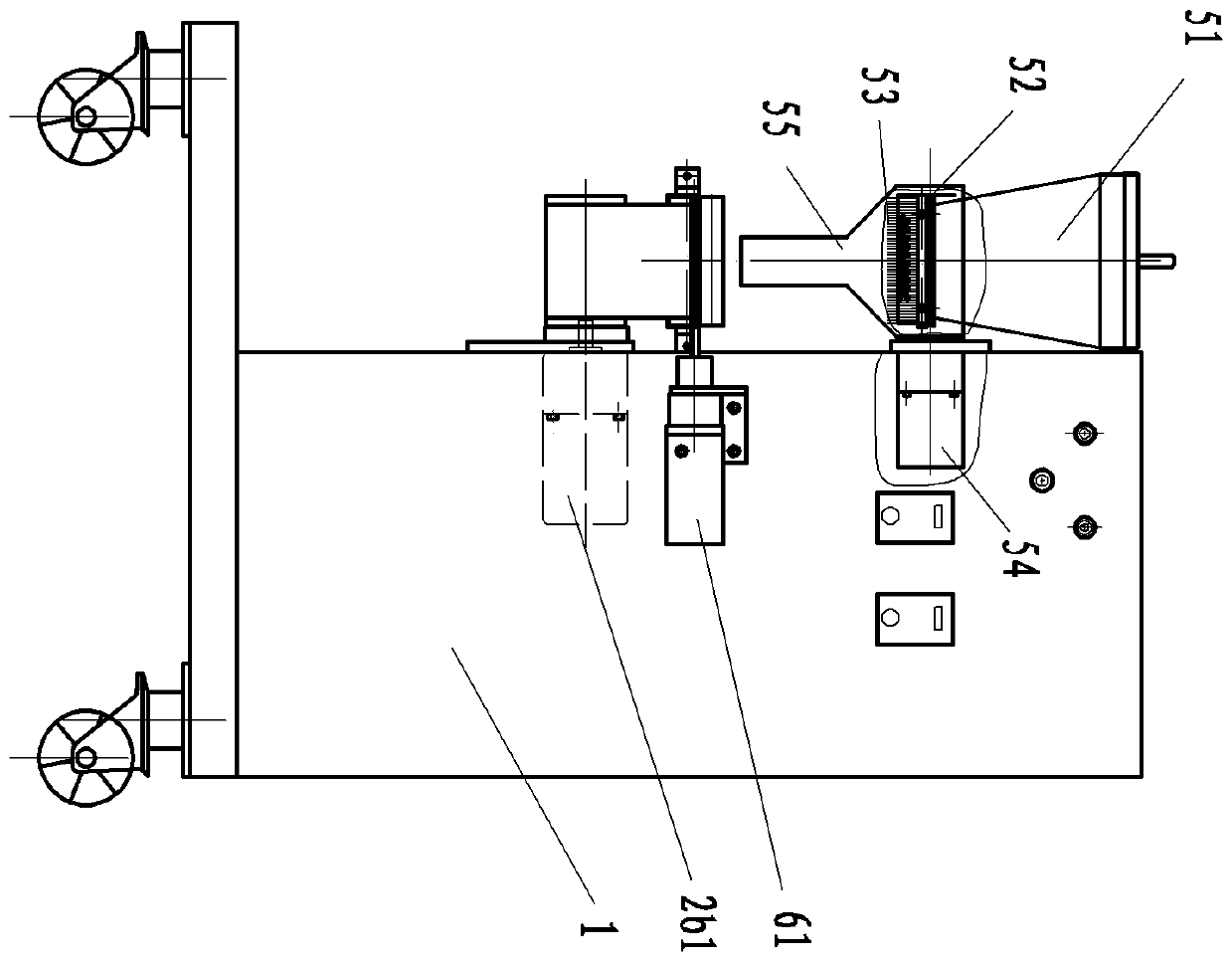

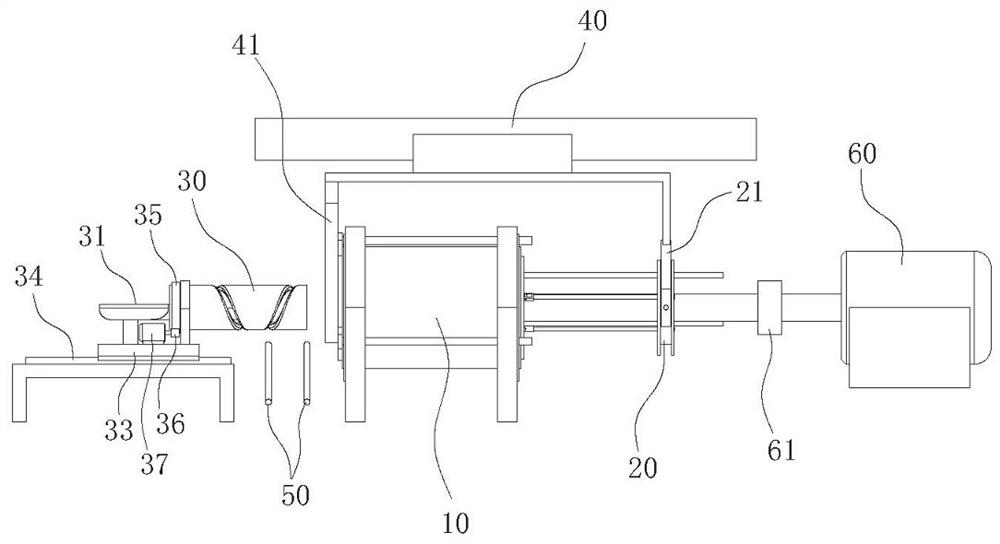

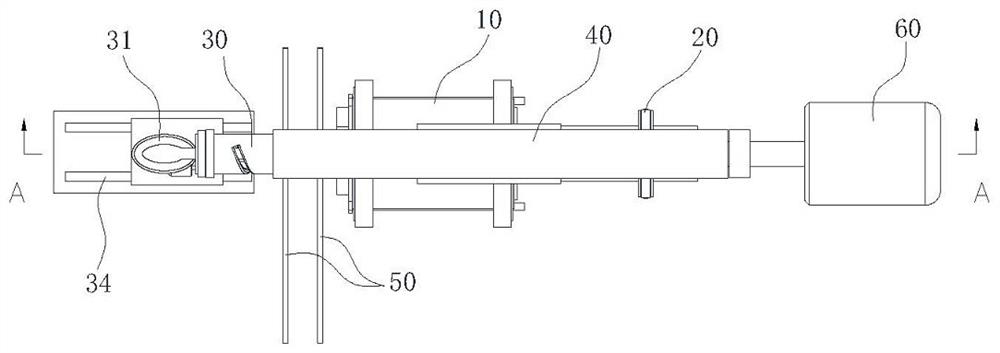

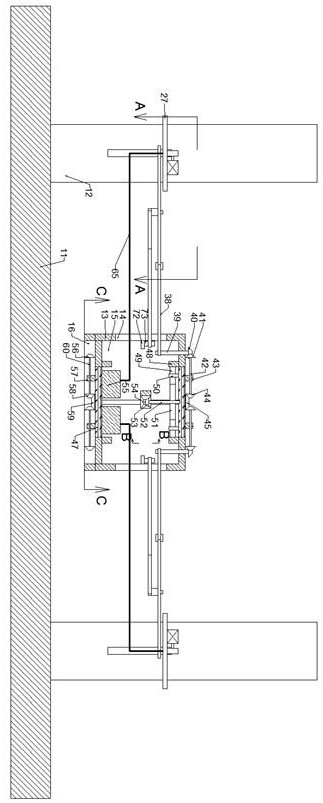

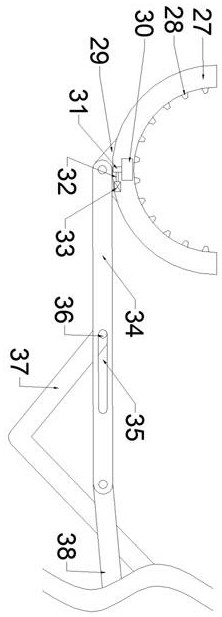

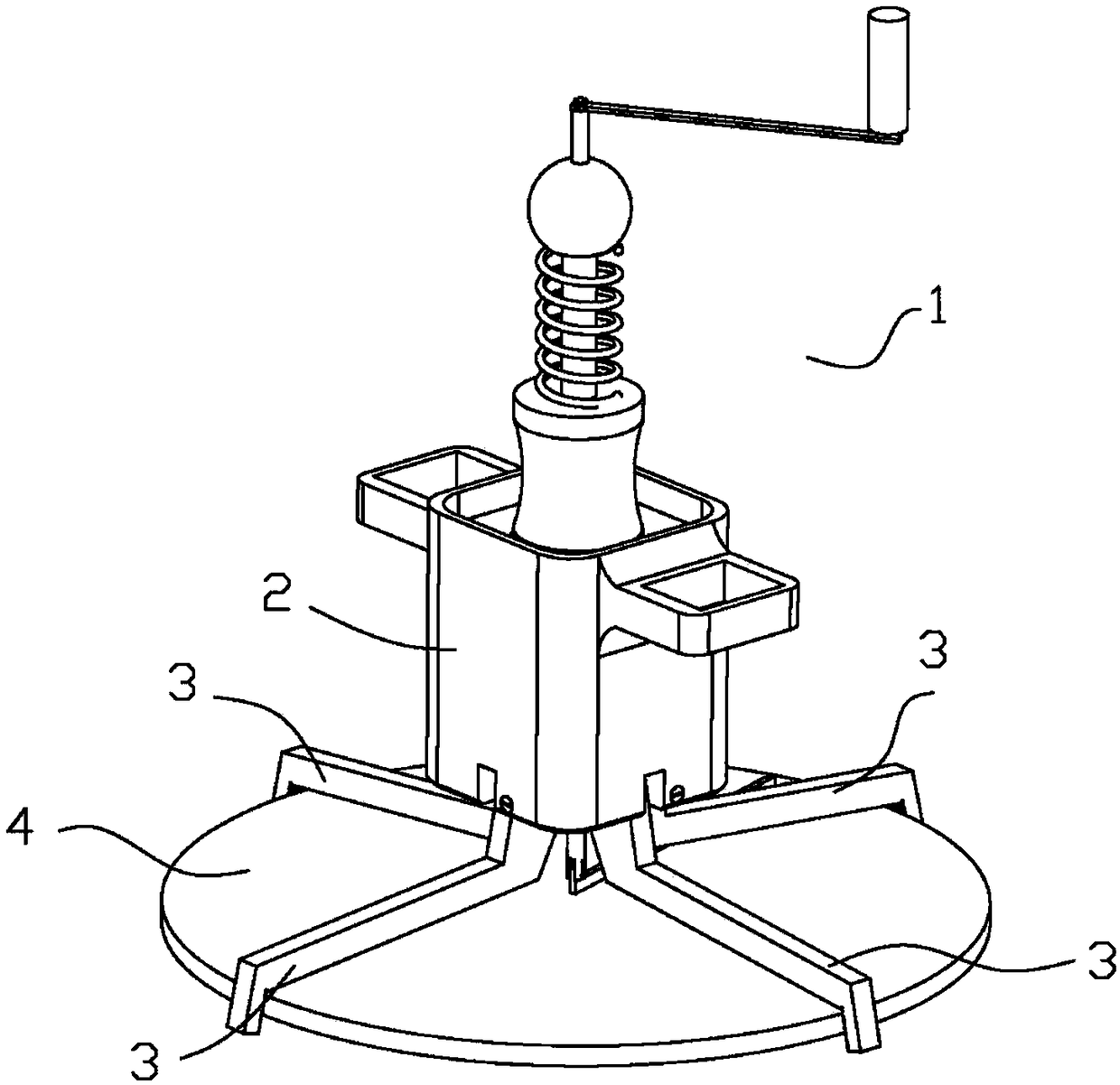

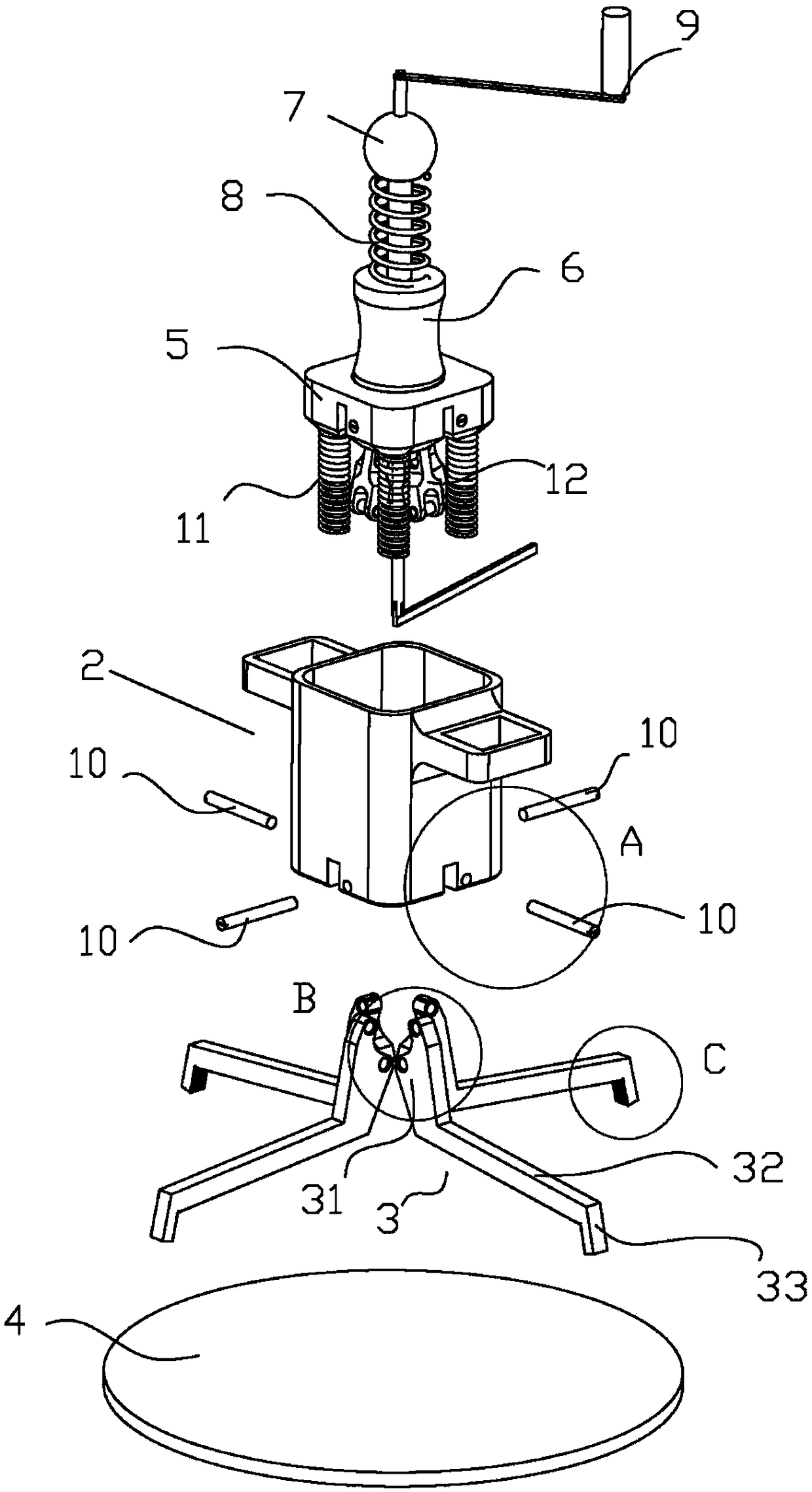

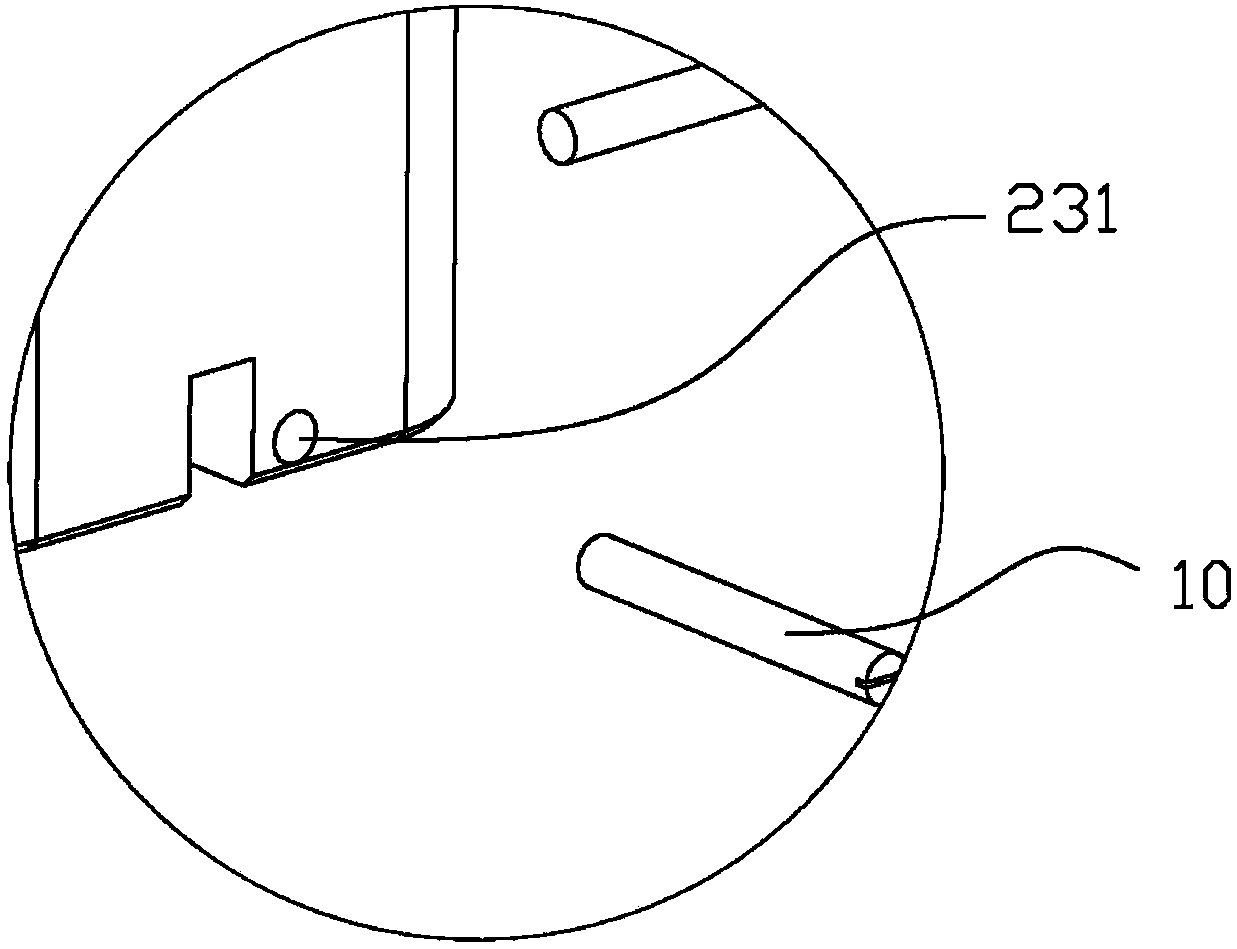

Cake surface sesame scattering machine

The invention relates to a sesame scattering machine. The sesame scattering machine comprises a machine body, a cake introduction conveying mechanism, a cake surface syrup spraying mechanism, a syrup mist suction-removal mechanism and a cake surface sesame scattering mechanism, wherein the cake introduction conveying mechanism is formed by motors, conveyor belts, tension rollers and transmission rollers; the cake surface syrup spraying mechanism is formed by a syrup storage tank, a syrup conveying tube and a nozzle; the syrup mist suction-removal mechanism is formed by a syrup mist suction tube, a filter and a vacuum pump; and the cake surface sesame scattering mechanism is composed of a sesame storage bucket, a sesame distributor, a hairbrush and a sesame catching bucket. The syrup is sprayed on the surfaces of cakes in a pressurization mode, and the granule distributor with the surface fully distributed with pits is used for scattering sesames, so the syrup spray distribution and the sesame distribution are fast and uniform; the syrup mist suction-removal mechanism is arranged, so the splash of the sprayed syrup and the suffusion of the syrup in air are controlled; the cake introduction conveying mechanism is provided with conveyor cleaning scrapers, so it is benefit for cleaning, and material recovery can be realized; a cake passing and pressing apparatus is arranged at the stroke tail end, so the granules are firmly viscous after the rolling, and blocking and clamping phenomena at the junctions of the conveyor belts to where the cakes are transmitted are eliminated. The sesame scattering machine has the characteristics of reliable operation, automation and fastness, less material loss, environment cleaning, and suitableness for line production.

Owner:江苏裕铭铜业有限公司

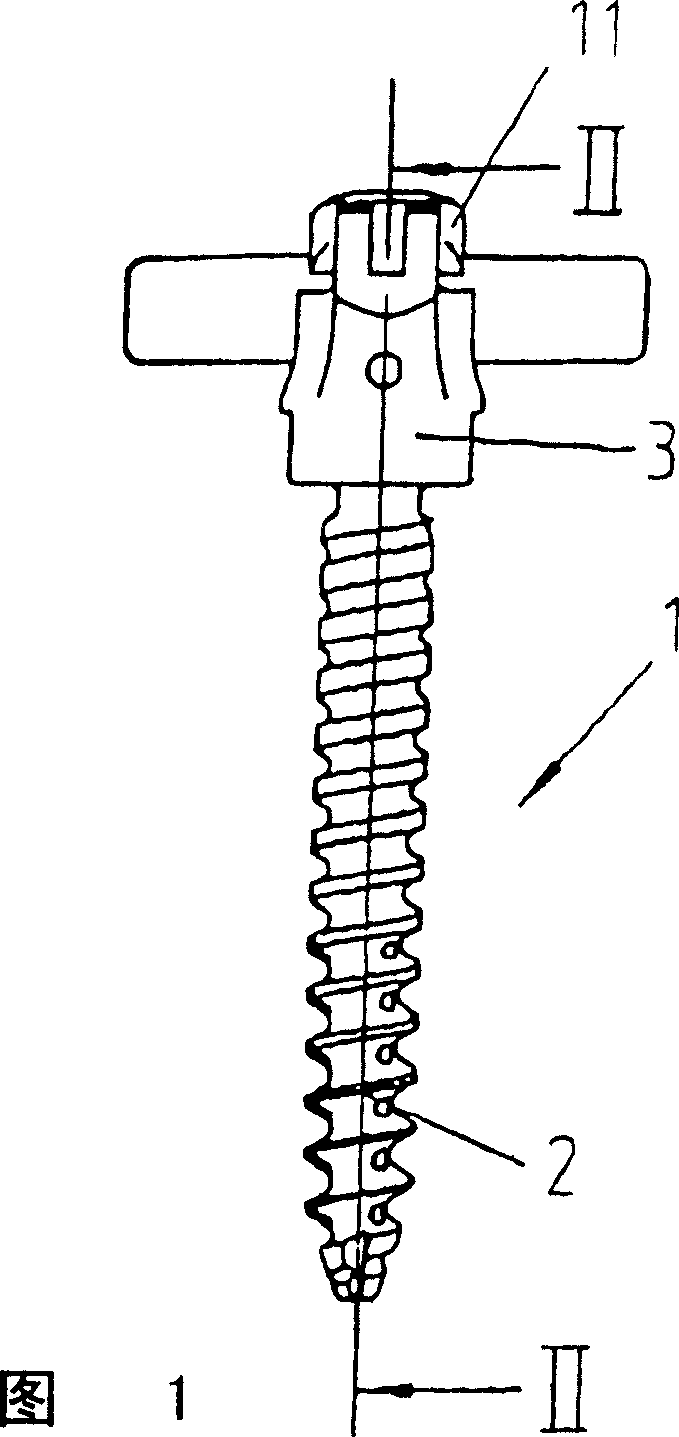

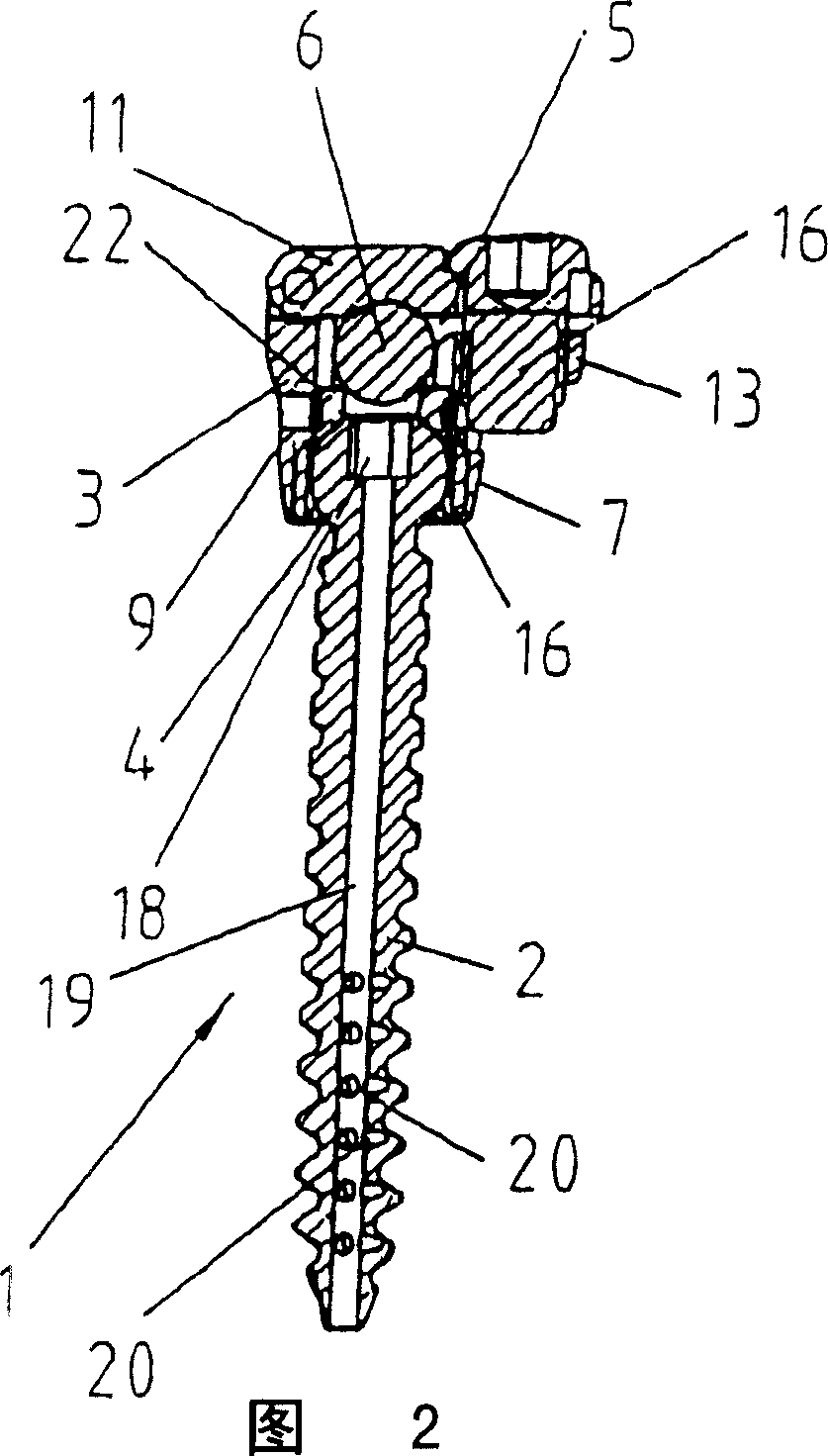

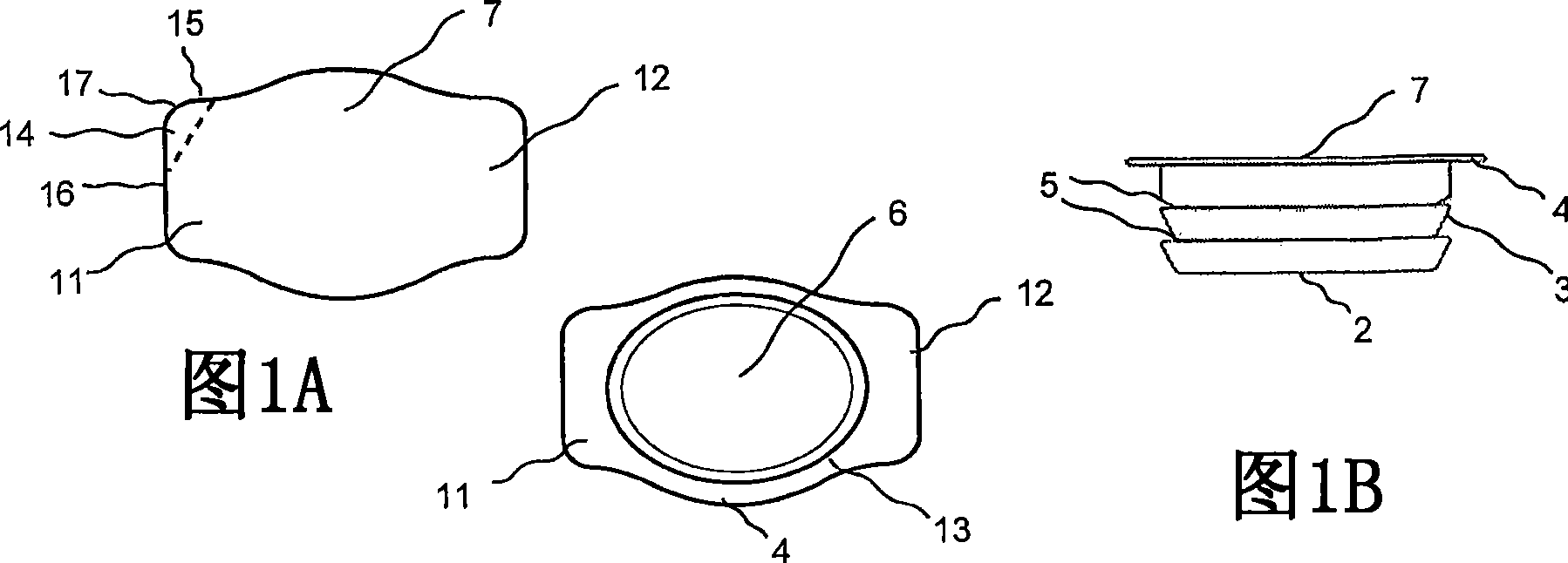

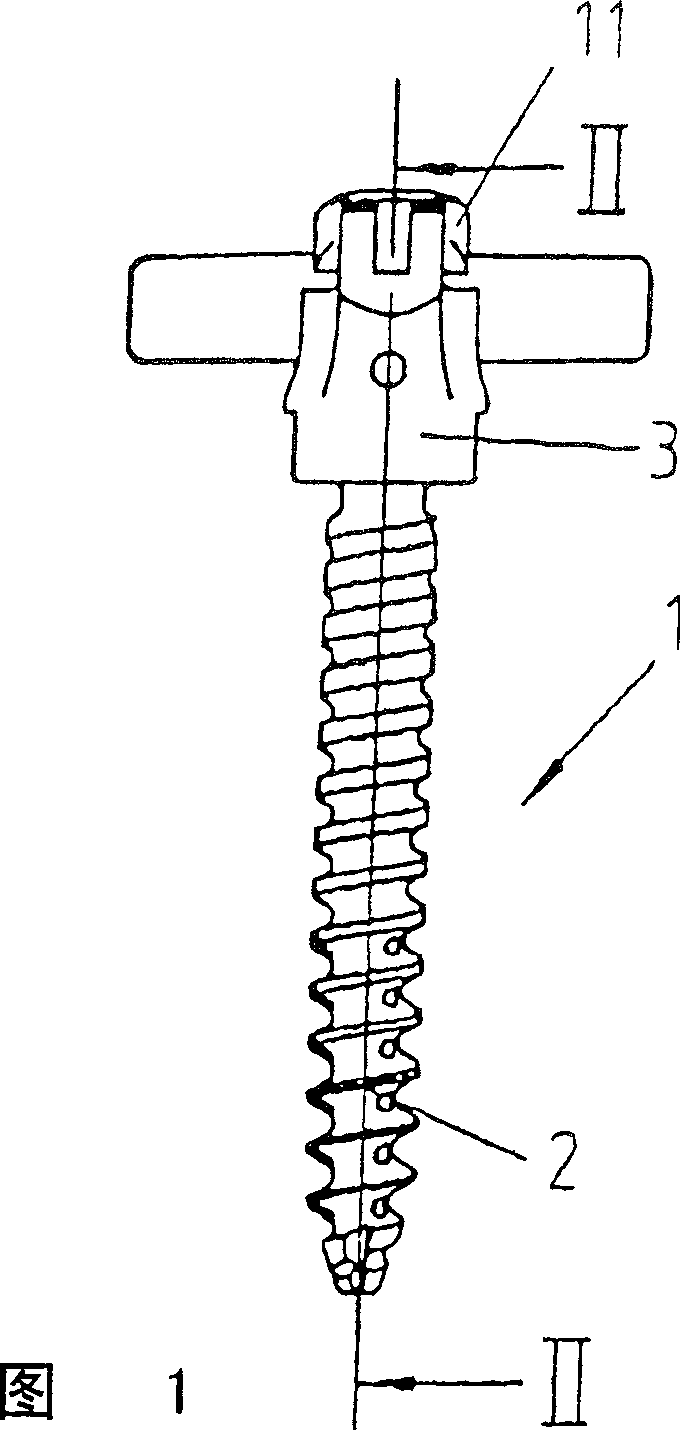

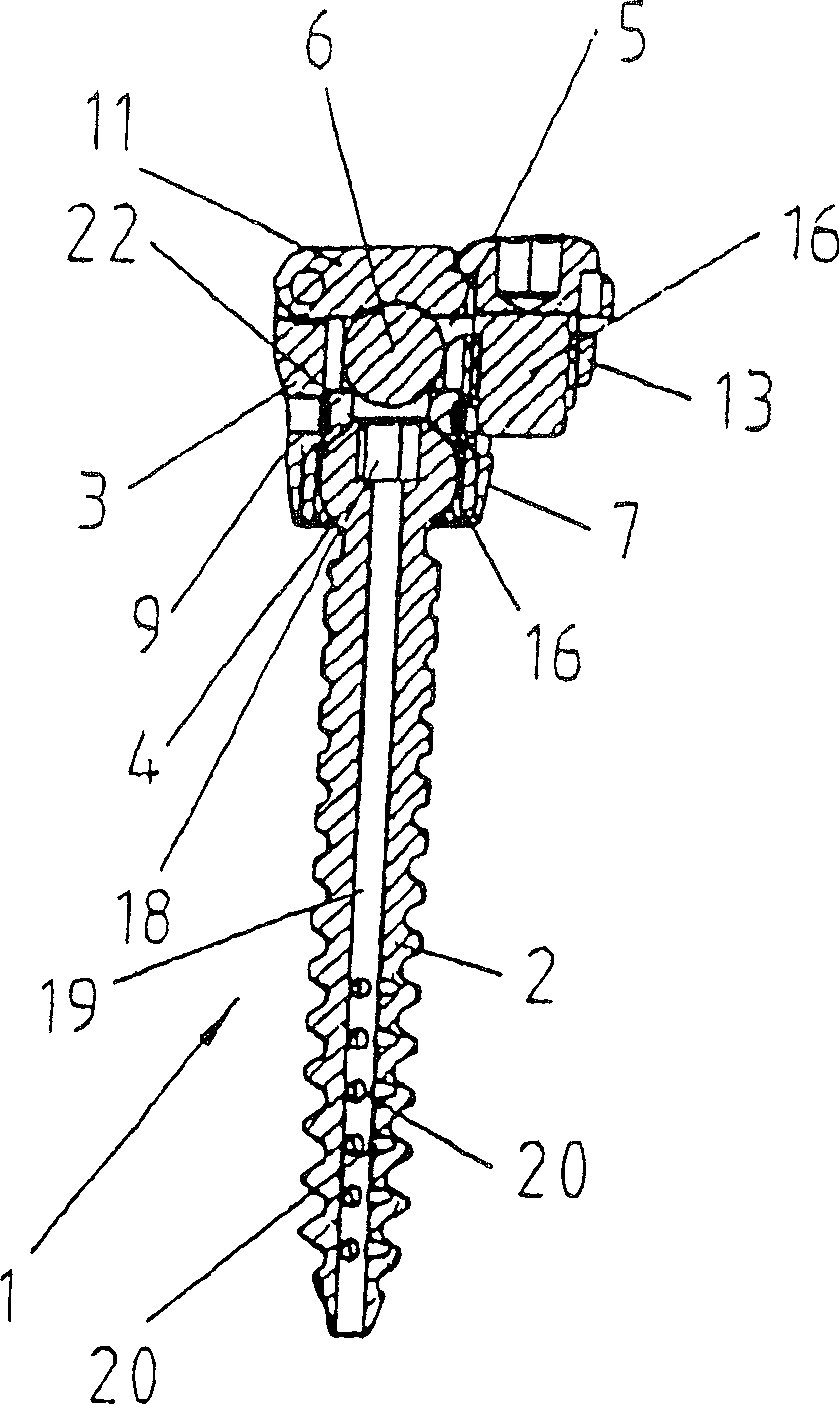

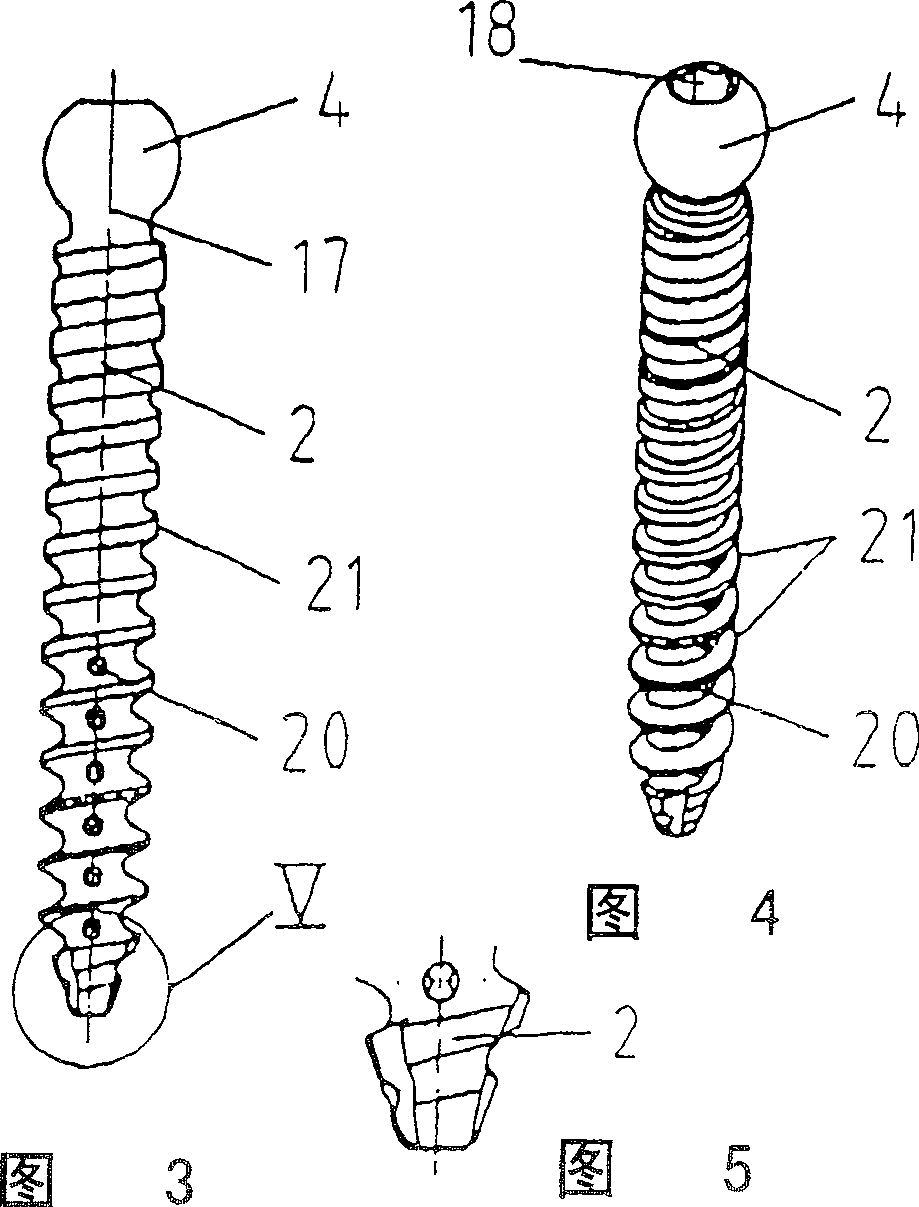

Pedicle screw

InactiveCN1946349AWill not adversely affect the use ofAffectInternal osteosythesisFastenersSpinal columnScrew thread

The invention relates to a pedicle screw for implants for the correction and stabilisation of the spinal column, comprising a head piece (4), on one axial end of a threaded shaft (2) to which a clamp piece (3) may be connected, comprising a clamp housing (5) for a bar (6) which may be fixed to the head piece (4). A threaded drilling (8) is embodied in the clamp piece (3) for housing a thread provided on the head piece (4).

Owner:ULRIKH GMBKH & KO KG

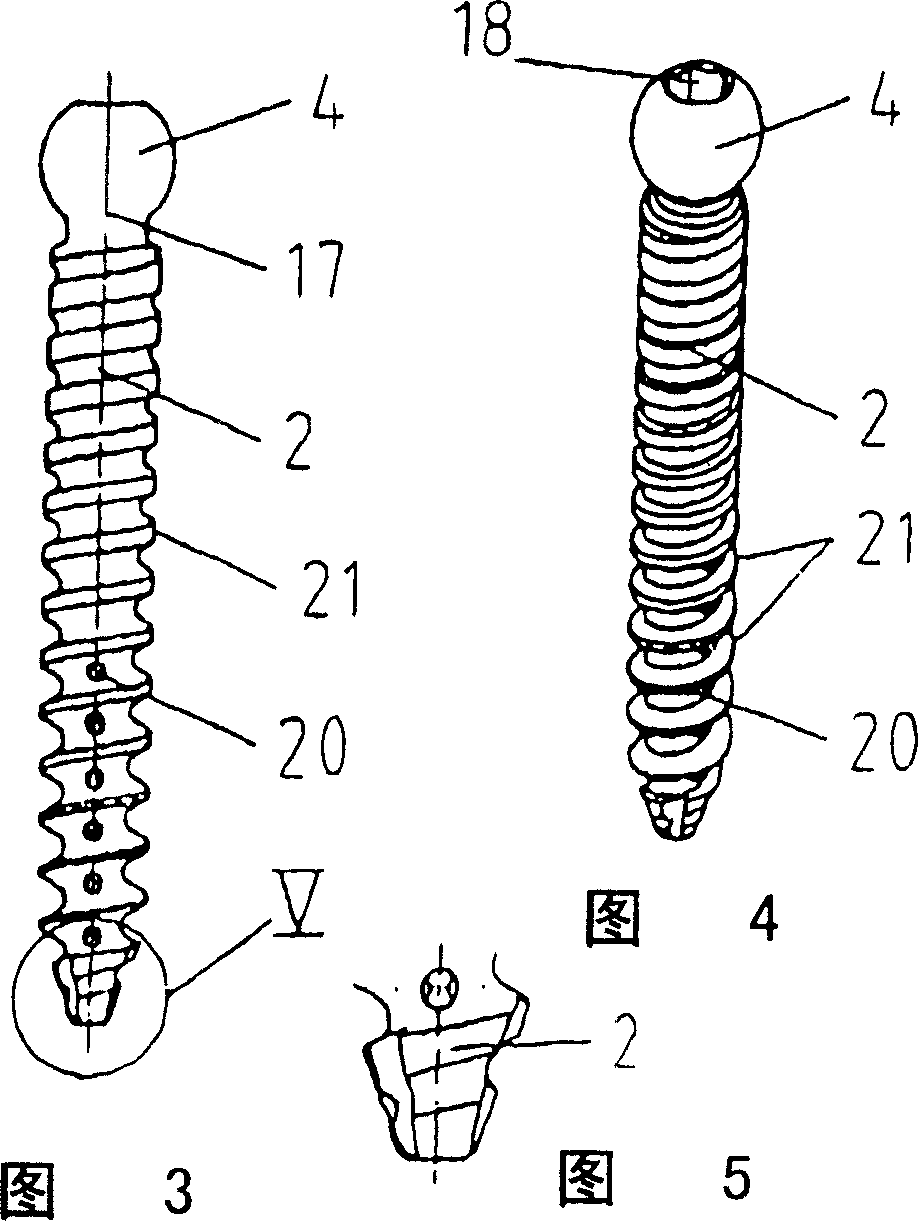

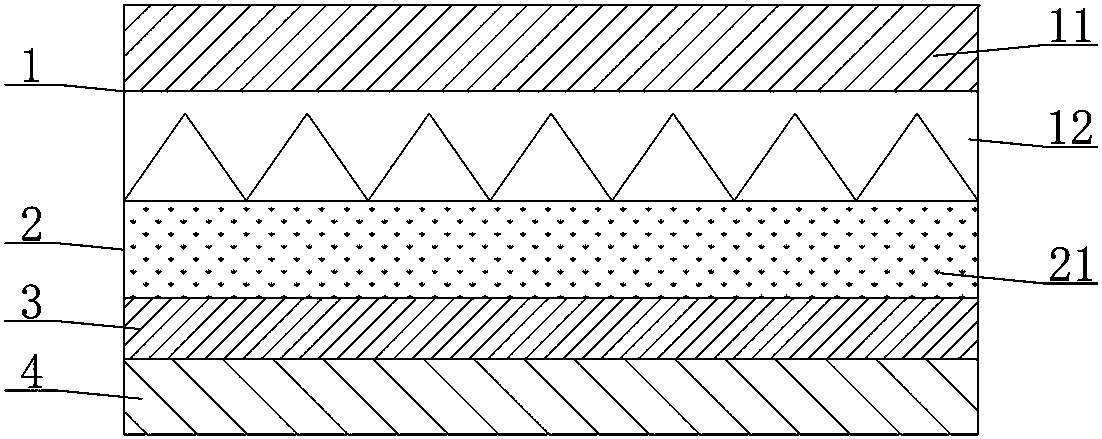

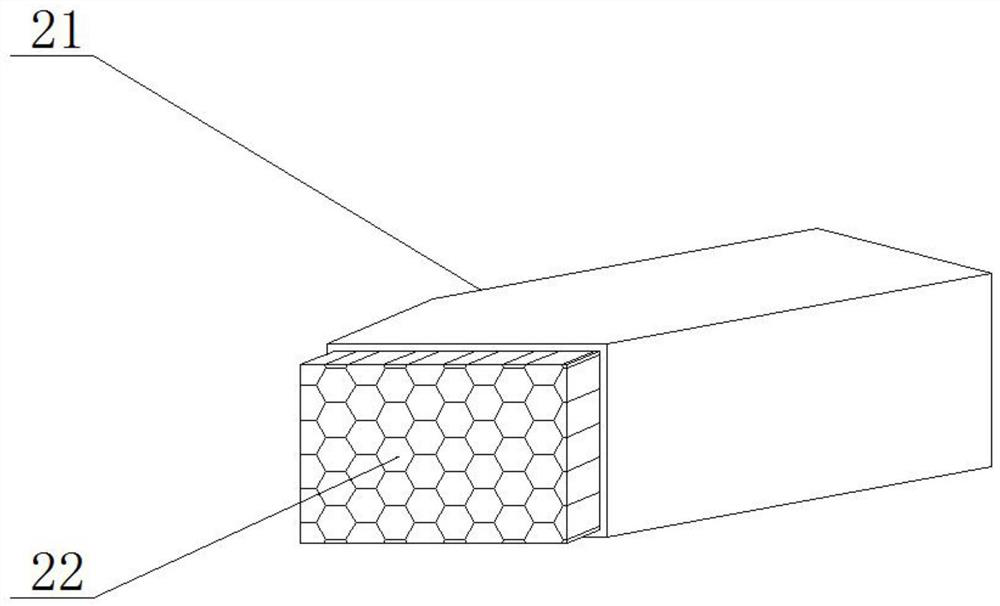

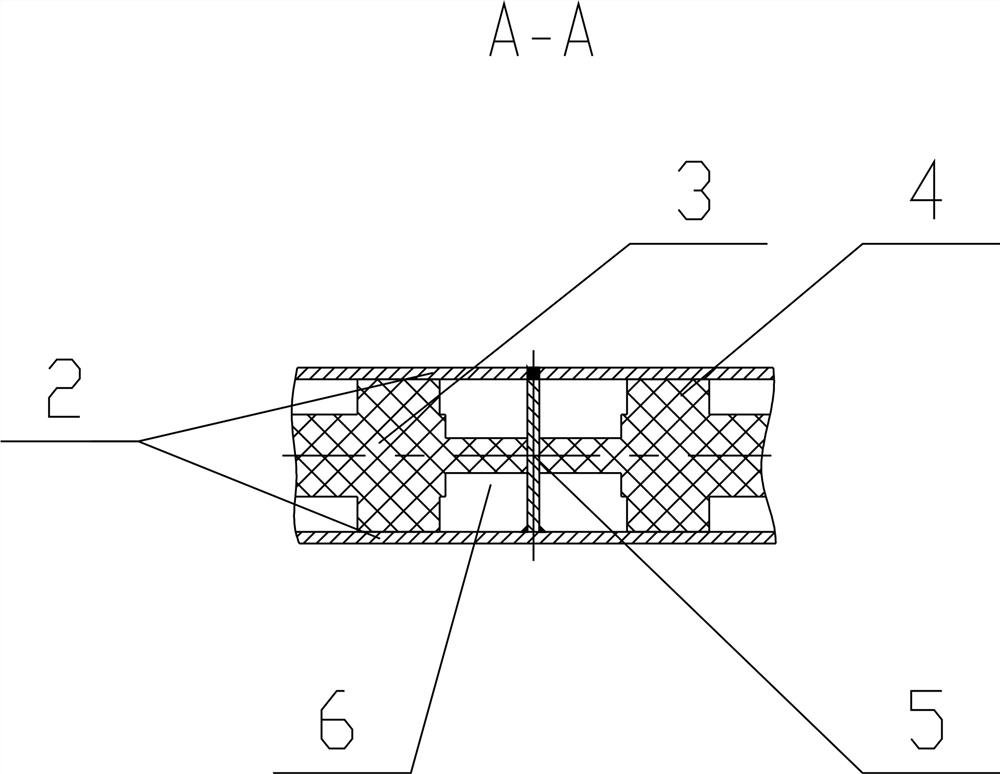

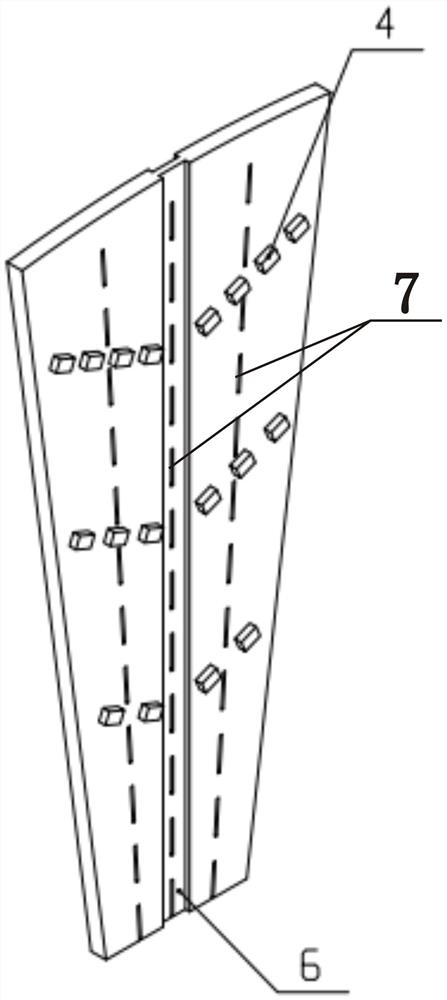

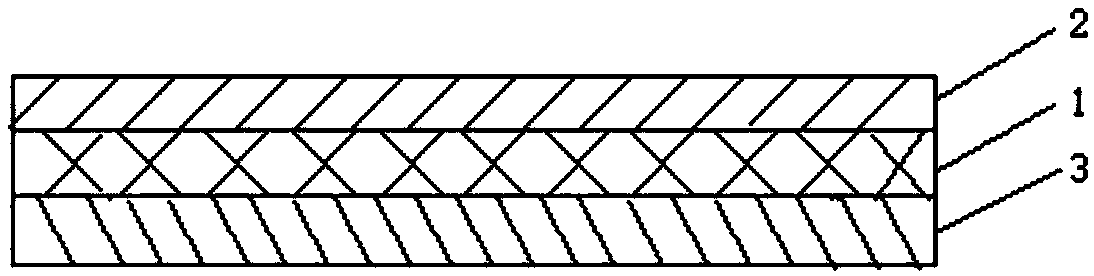

Enhanced heat-insulation composite film spaced by metal wire grating and application thereof

The invention relates to an enhanced heat-insulation composite film spaced by a metal wire grating and application thereof. The enhanced heat-insulation composite film consists of 3-20 layers of sandwich metal-plated high-polymer composite films which are spaced by parallel or orthorhombic metal wire gratings on fiber meshes. The enhanced heat-insulation composite film is characterized in that one side of the enhanced heat-insulation composite film can bear the effect of high temperature and low temperature within negative 250DEG C to 250DEG C, the other side of the enhanced heat-insulation composite film is kept to be at 5-40DEG C normal temperature, the enhanced heat-insulation composite film is a multilayer composite material which can realize rapid and even heat distribution, heat insulation and warmth keeping, the natural thickness is 4-20mm, the actual compact thickness is 1-8mm, the weight per square meter is 40-800g / m<2>, and the enhanced heat-insulation composite film is a fully-closed bonded or sewn heat-insulation, warmth-keeping soft enhanced heat-insulation composite film. The enhanced heat-insulation composite film can be solely used or can be combined with other materials and be used for human body protection and environmental heat insulation of high-temperature and low-temperature occasions such as firefighting, military, exploration and industry.

Owner:DONGHUA UNIV

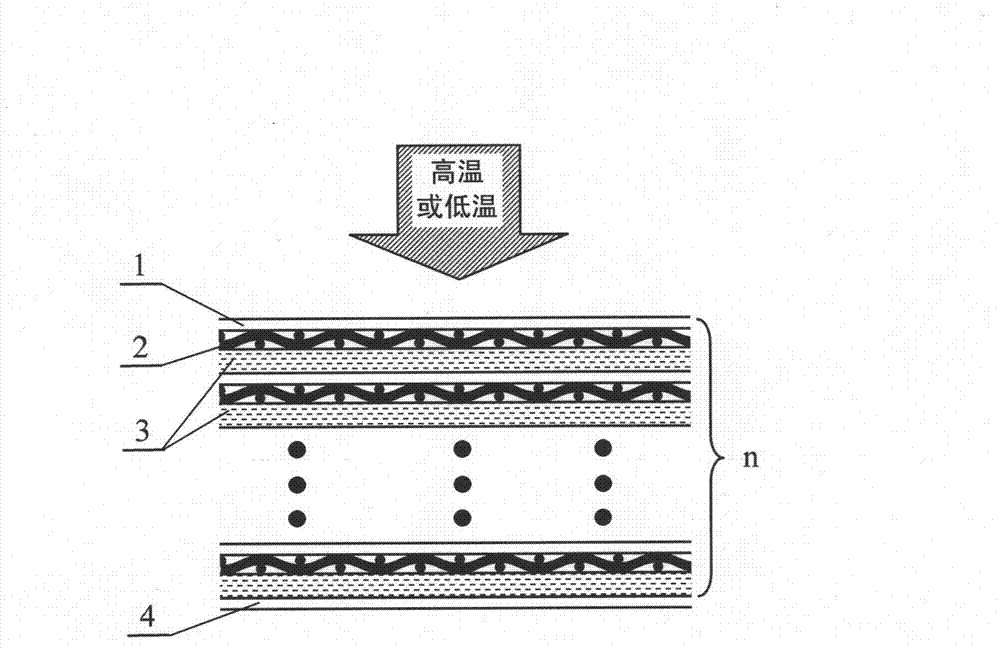

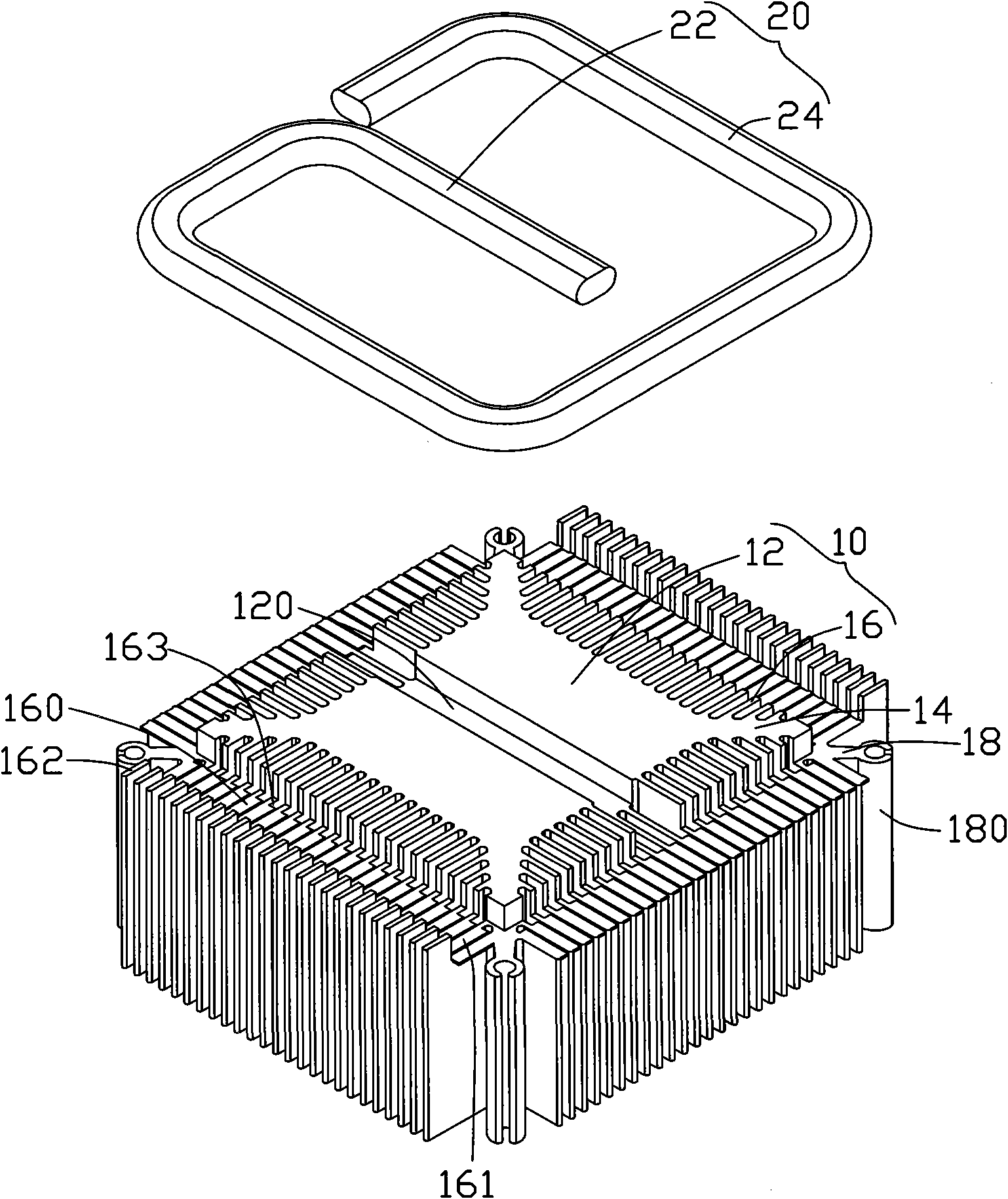

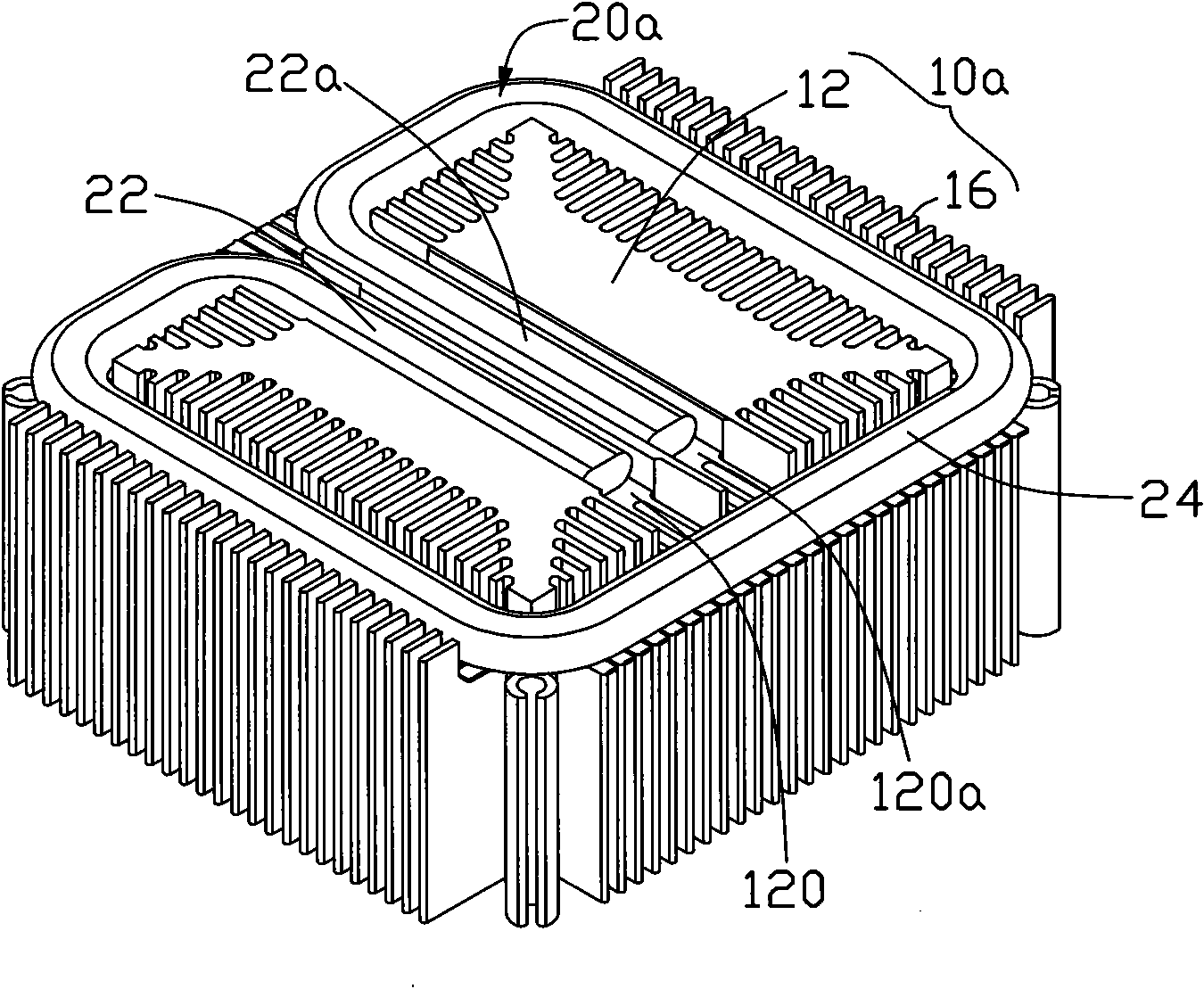

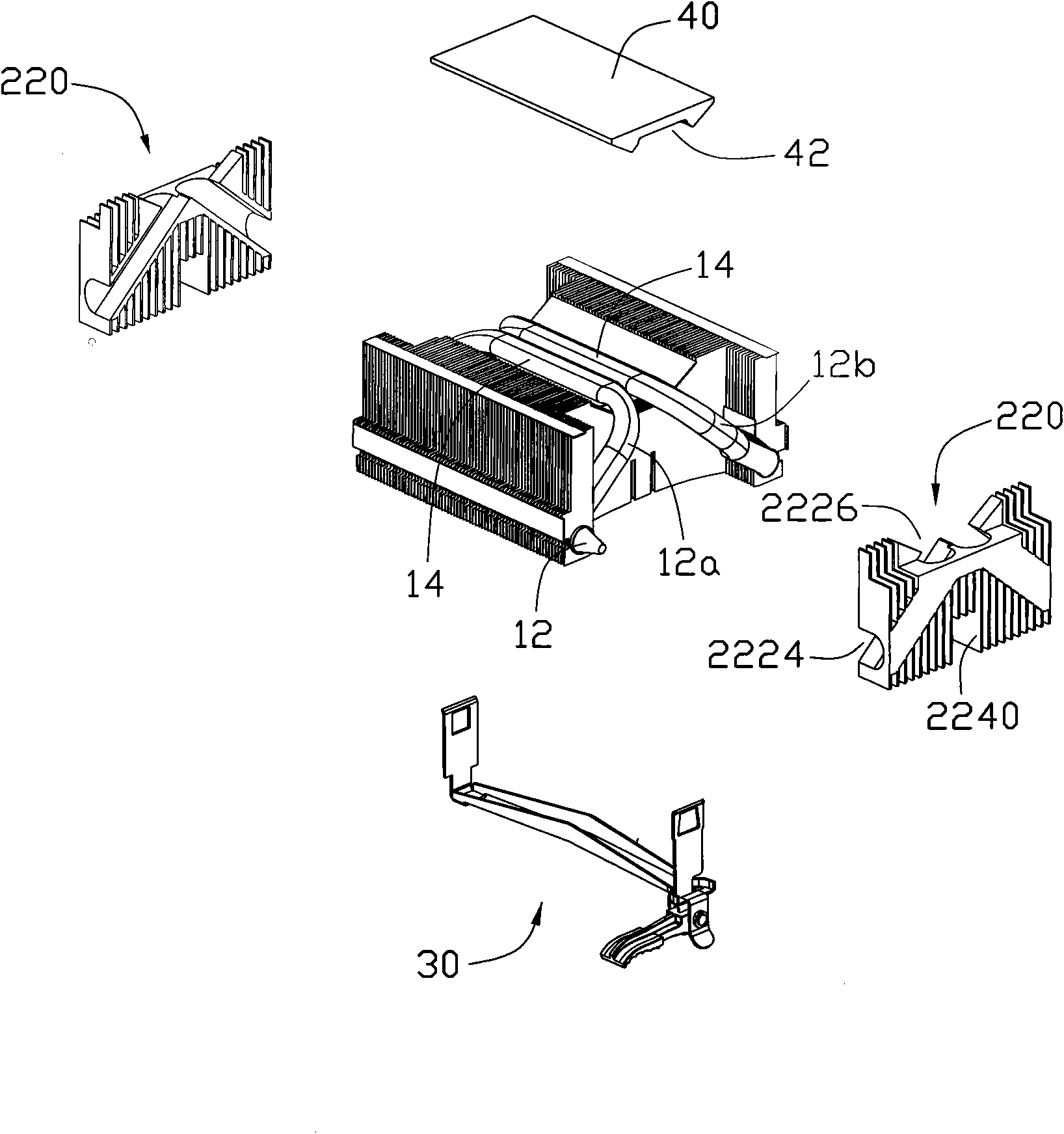

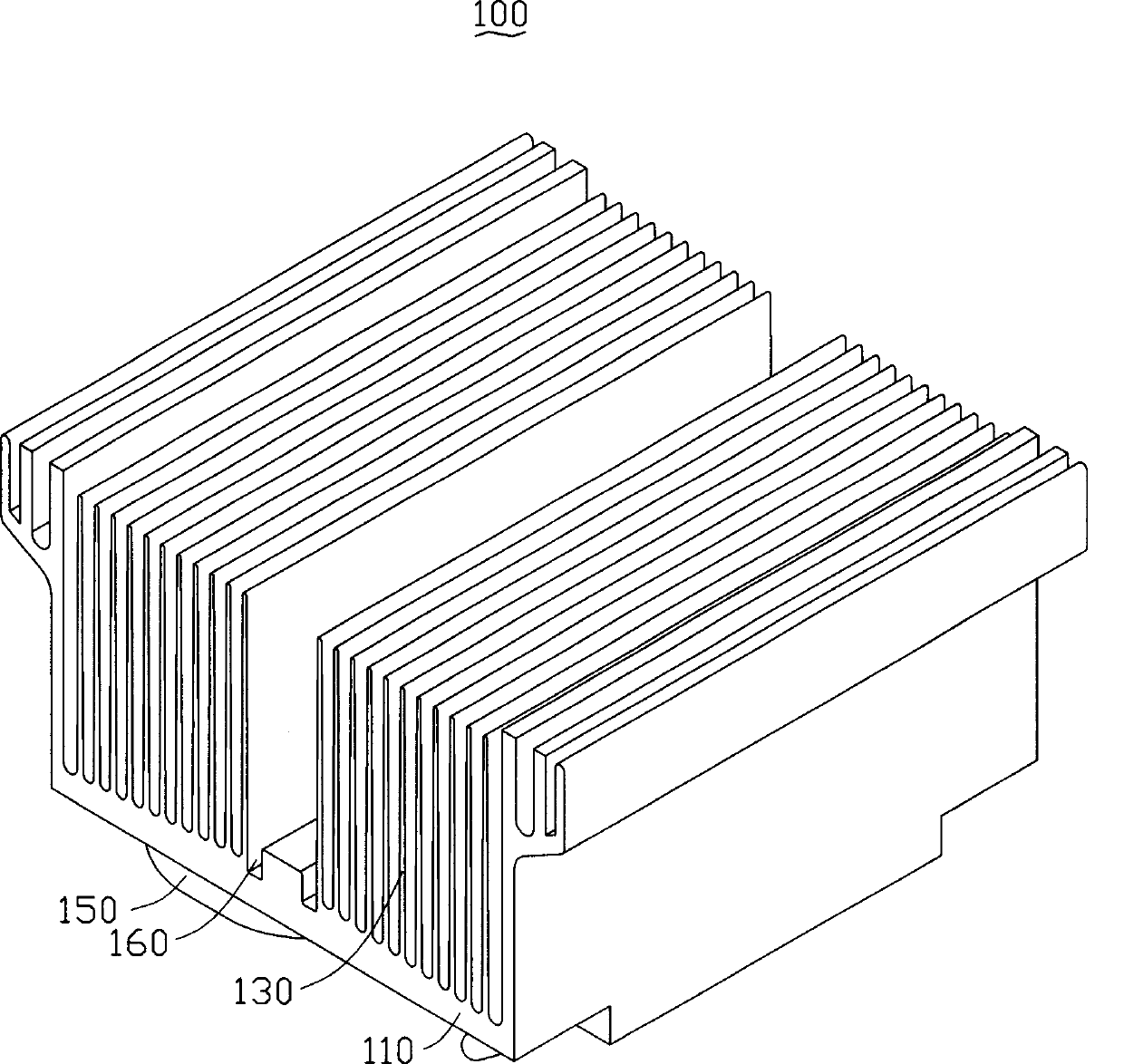

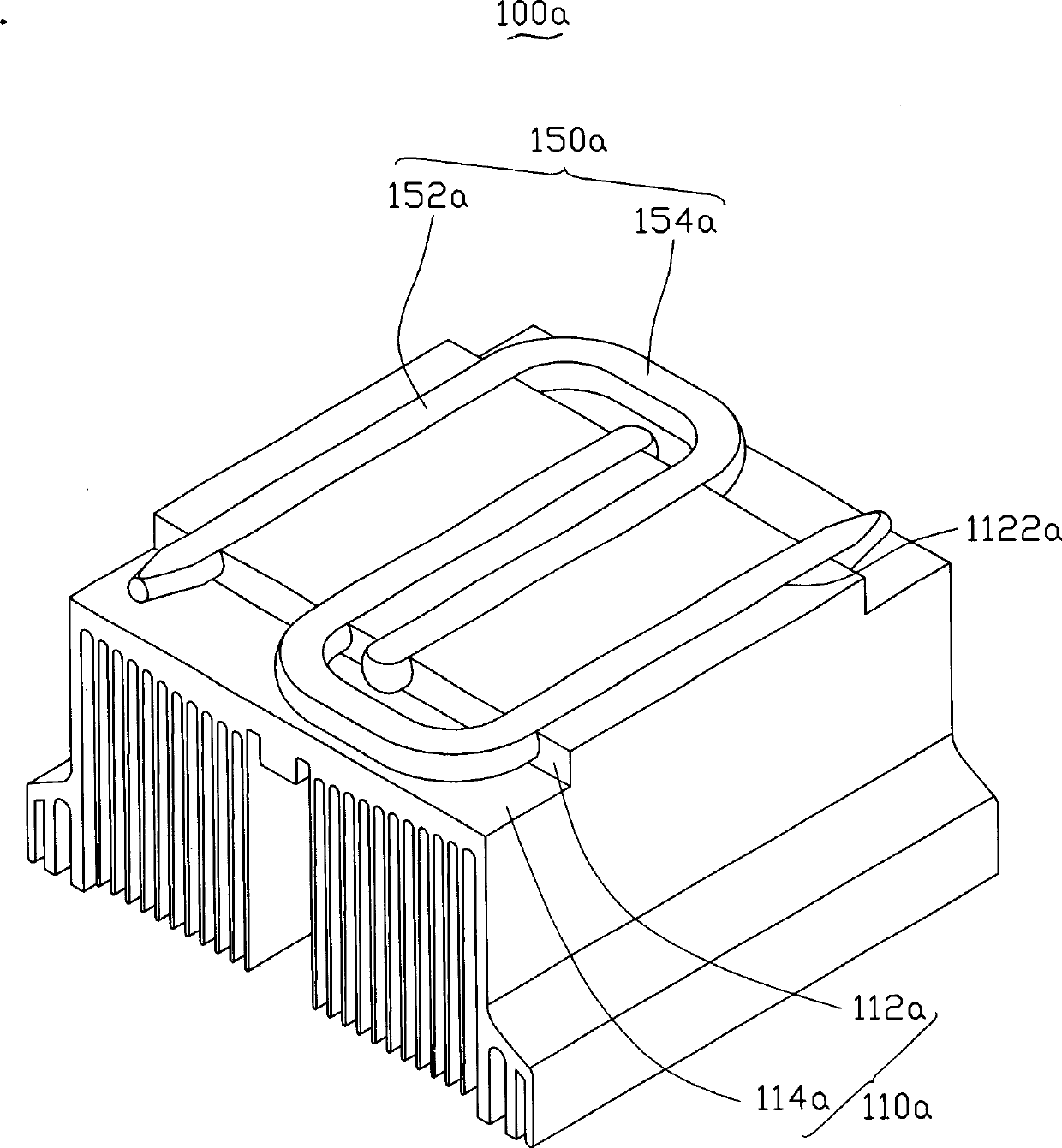

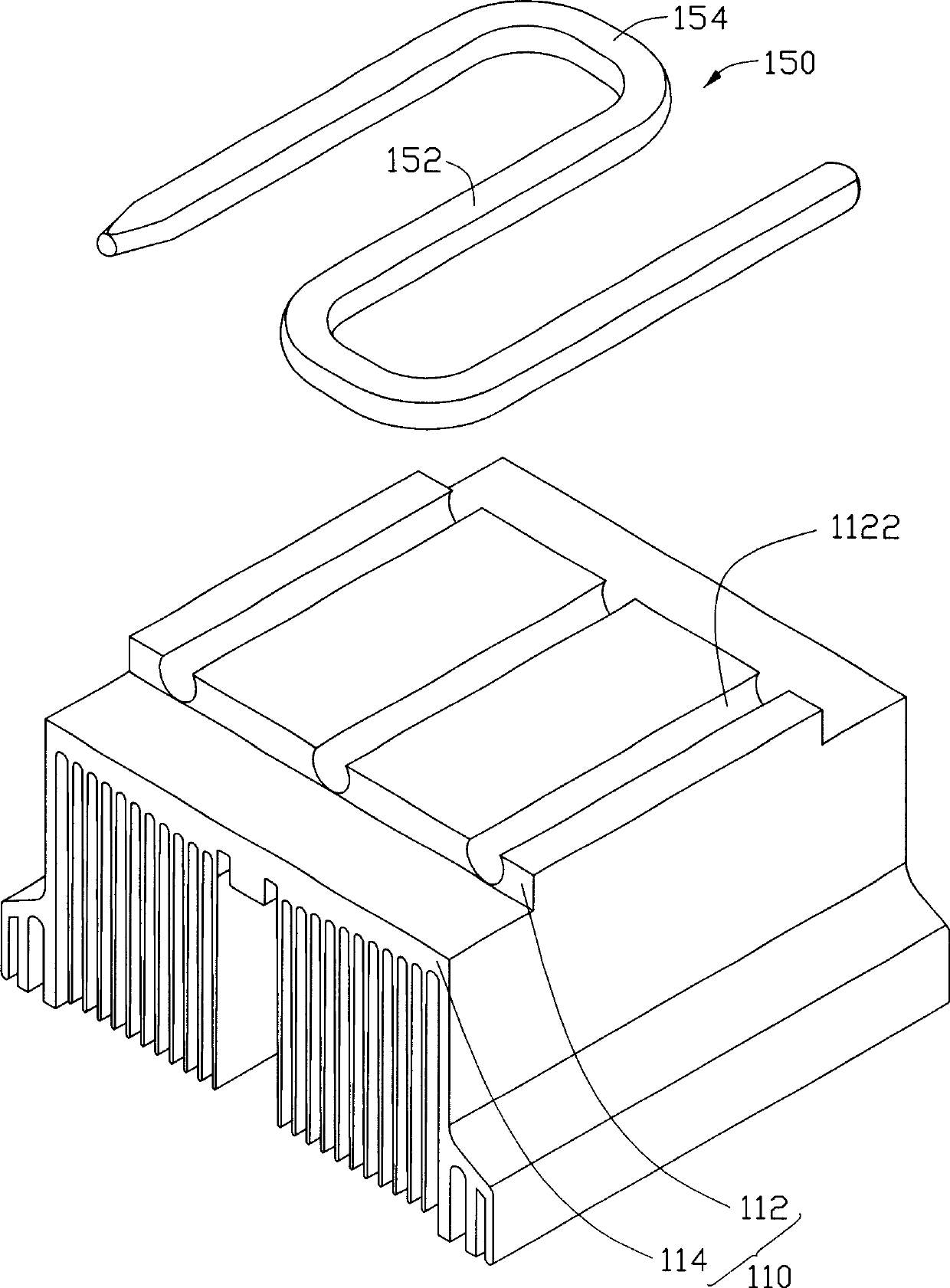

Heat radiating device and manufacturing method thereof

InactiveCN101594764AIncrease contact areaFast even distributionSemiconductor/solid-state device detailsSolid-state devicesEngineeringBearing surface

The invention relates to a heat radiating device which comprises a heat radiator and a heat pipe, wherein the heat radiator comprises a body and a plurality of heat radiating fins which are formed by radially extending from the body; the top surface of the heat radiator is provided with a groove and a bearing surface; the bearing surface is arranged around the groove and is communicated with the groove; and the heat pipe is extended and arranged on the groove and the bearing surface. Because the groove and the bearing surface are formed on the heat radiating device and the heat pipe is arranged in the heat radiating device, heat can be quickly and evenly distributed to the whole heat radiating device and radiated.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

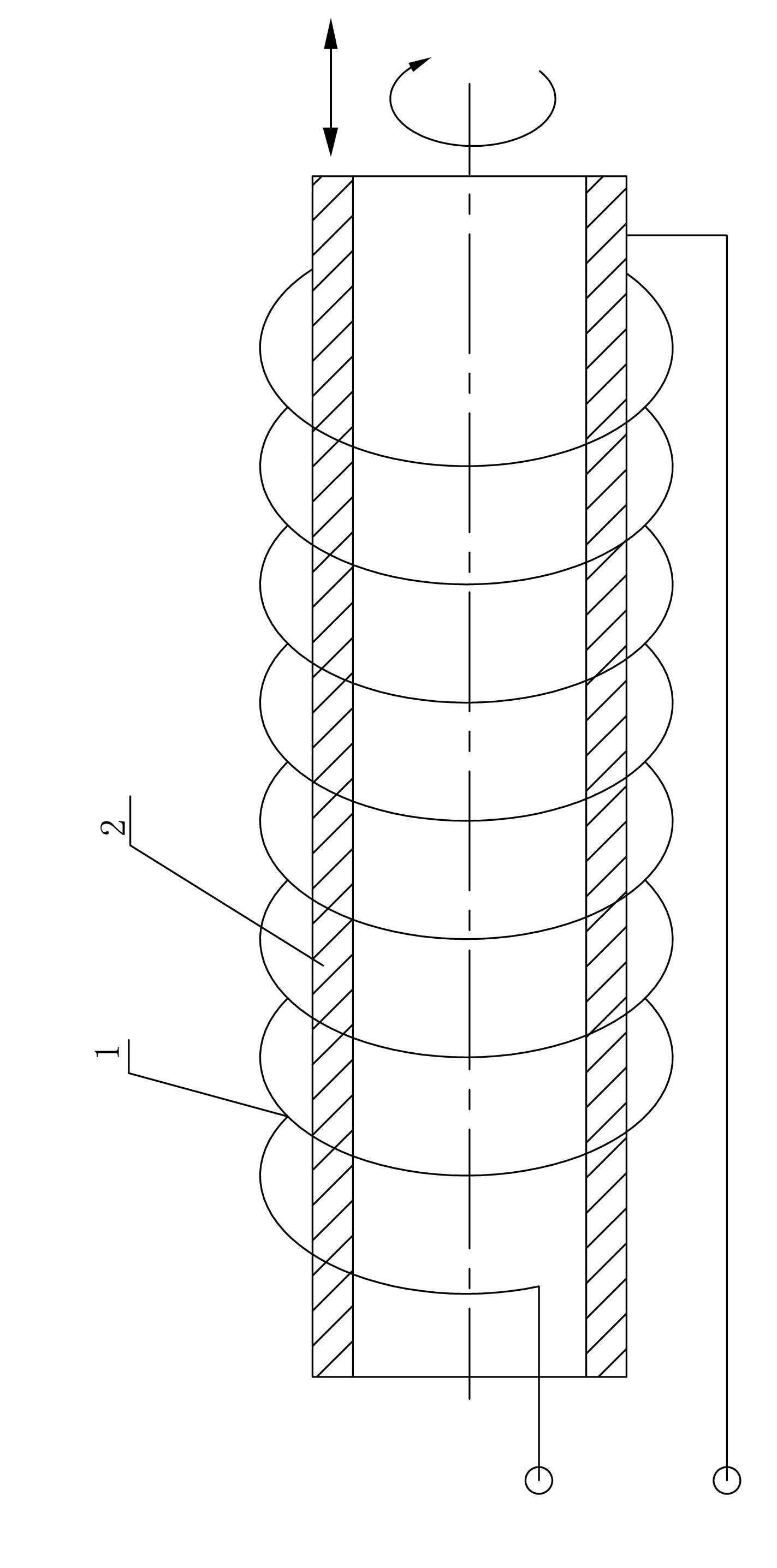

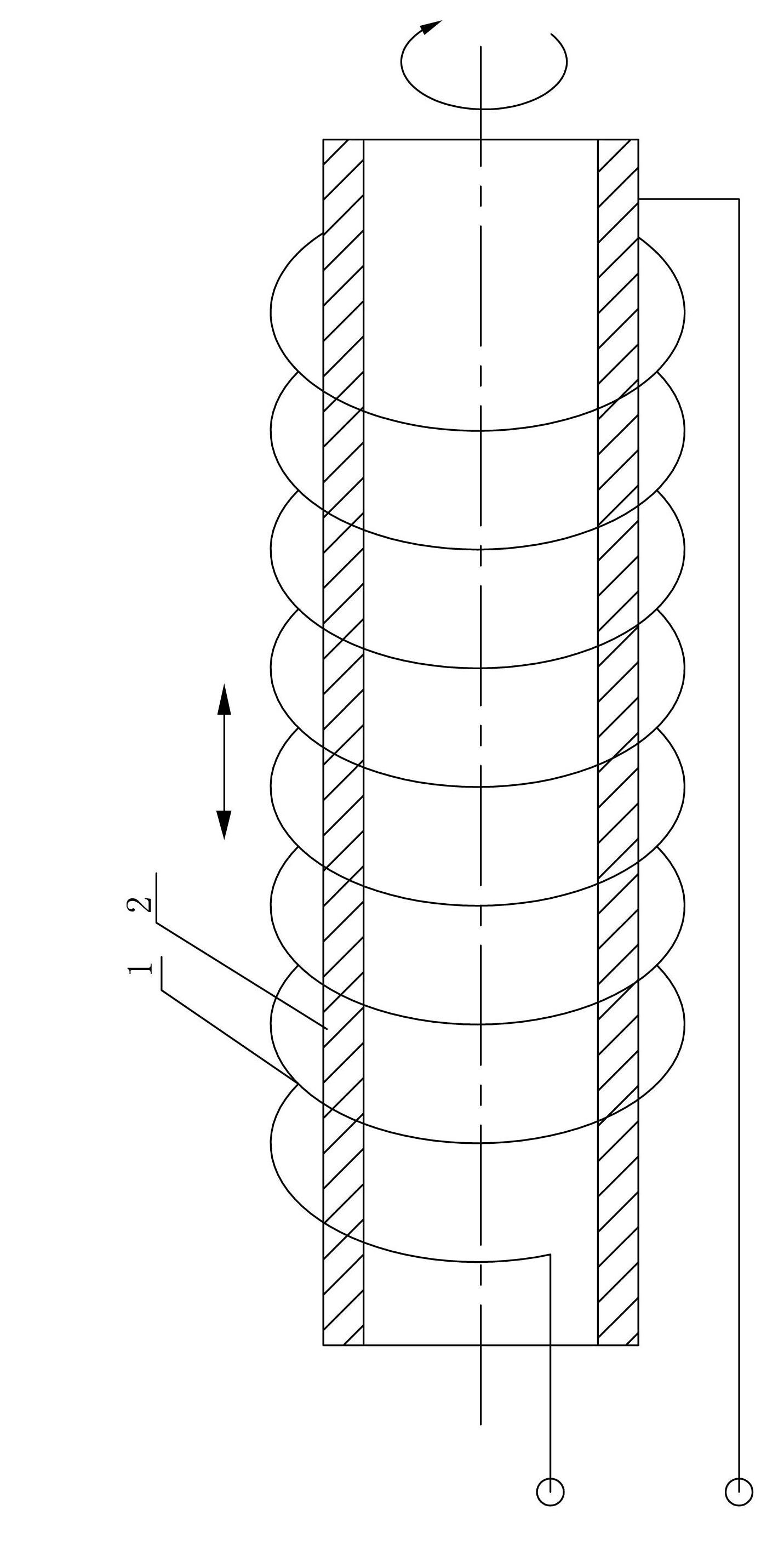

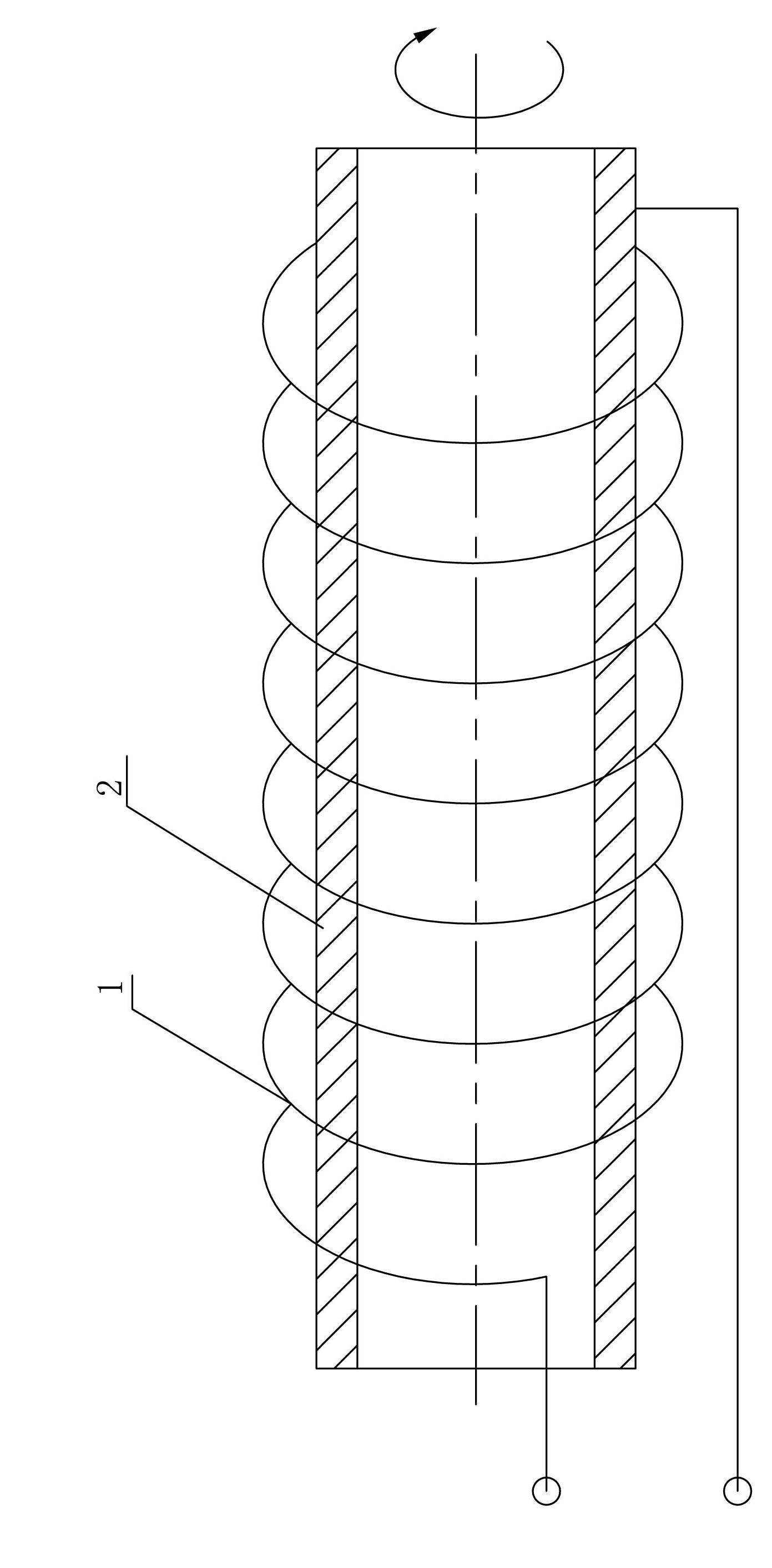

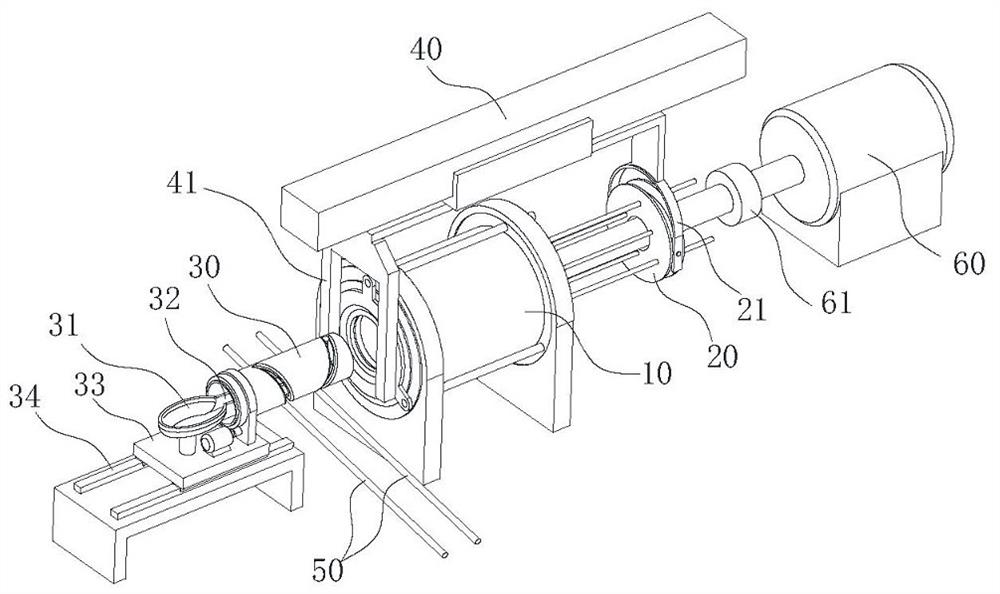

Rapid uniform heating method for metal tube

The invention relates to a heating method for a metal tube, in particular to a rapid uniform heating method for the metal tube. The heating method comprises the steps that firstly, the metal tube to be heated is placed into an induction heating coil; secondly, the induction heating coil is energized, and the metal tube is heated; thirdly, the metal tube and the induction heating coil are moved relatively when the metal tube is heated; and fourthly, the heating is stopped when the heated temperature of the metal tube reaches 300 DEG C to 1100 DEG C, and the metal tube is taken out of the induction heating coil. The rapid uniform heating method is applicable to heating metal tubes and capable of solving the problems that the circumference temperature and the axial temperature of metal tubes are unevenly distributed and the forming of the metal tubes are influenced by the uneven distributed temperatures in prior induction heating methods of the metal tubes.

Owner:HARBIN INST OF TECH

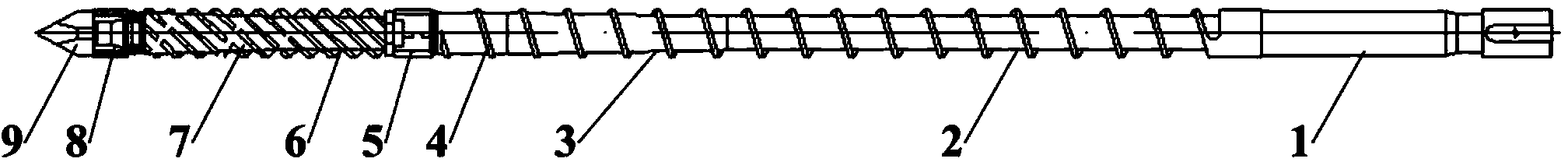

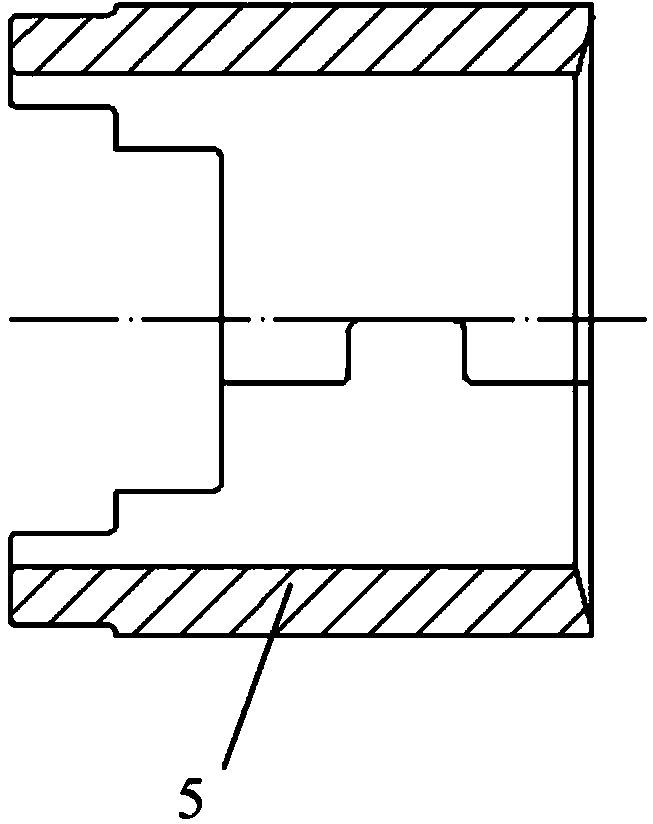

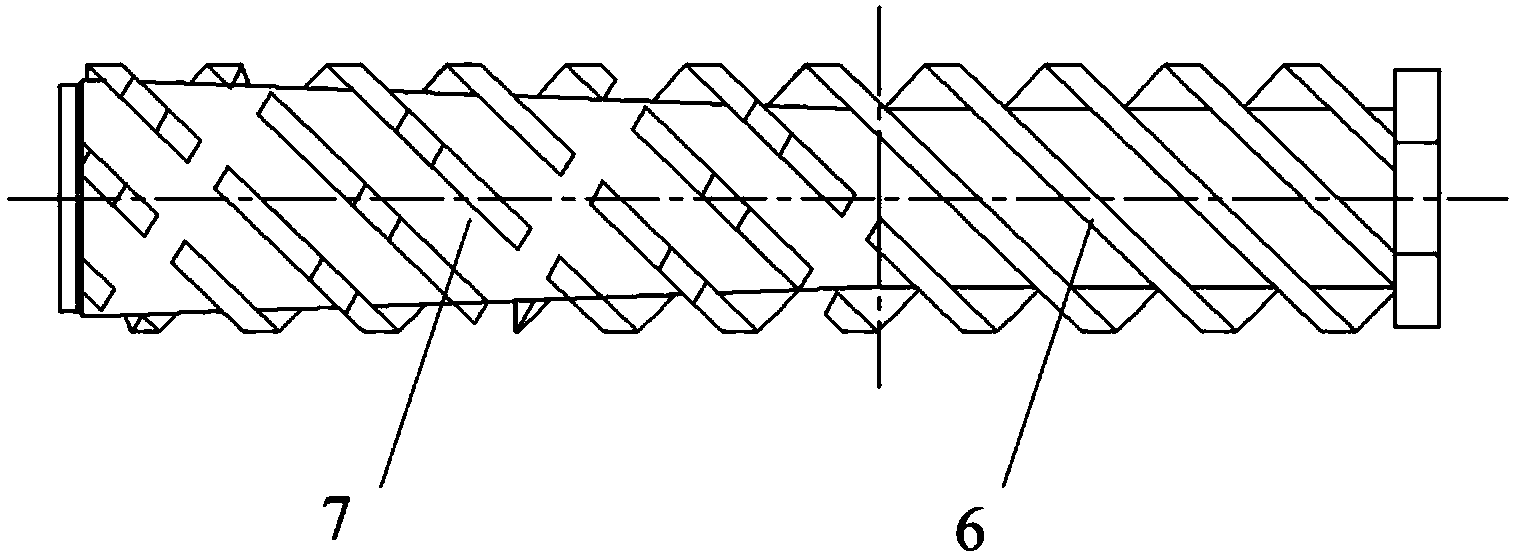

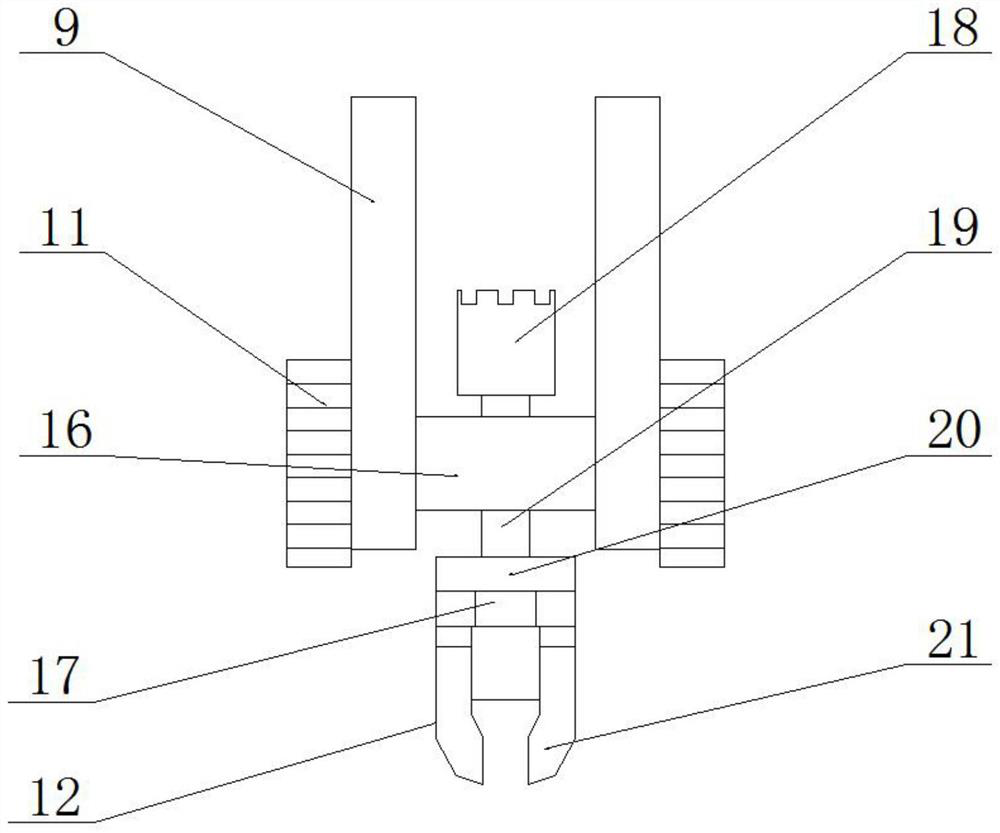

Threaded rod for polymer microcellular foaming injection molding

The invention discloses a threaded rod for polymer microcellular foaming injection molding. A threaded rod feeding section, a threaded rod compression section and a threaded rod metering section are arranged in front of the polish rod part of the threaded rod in sequence, and the length of the threaded rod metering section is 1-2 D; a middle non-return valve is arranged in front of the threaded rod metering section, the manner of two semirings disconnected in a ladder shape is adopted, and the two semirings are arranged on the ladder shaft of the threaded rod in a sleeving mode after being aligned; a shearing section and a mixing section are arranged in front of the middle non-return valve in sequence, and the shearing section and the mixing section adopt multiple threads; a reversed multi-thread screw groove is formed in the mixing section; a front non-return valve and a threaded rod head are arranged in front of the mixing section, the front non-return valve is arranged on the ladder shaft of the threaded rod head in a sleeving mode, and the threaded rod head is connected to the front end of the threaded rod through threads. The middle non-return valve is additionally arranged on the threaded rod disclosed by the invention, and the semirings disconnected in the ladder shape are arranged on the integrally designed and processed ladder shaft of the threaded rod in the sleeving mode, so that an injected supercritical fluid foaming agent is prevented from escaping backwards.

Owner:SHANDONG UNIV

Diaphragm with dual-effects of reflecting and transmission and manufacturing method thereof

PendingCN109254339ASolve the defect of short service lifeIncrease reflected light intensityMirrorsDual effectEffect light

The invention discloses a diaphragm with dual-effects of reflecting and transmission and a manufacturing method thereof. The diaphragm comprises a reflecting layer, a pressure-sensitive adhesive layerand a release layer, and the pressure-sensitive adhesive layer is adhered with the release layer; the diaphragm further comprises a transmission layer adhered with the reflecting layer and adhered with the pressure-sensitive adhesive layer, and fine particles are arranged in the transmission layer. The transmission layer is arranged at a lower surface of the reflecting layer, the light intensityattenuation when irradiation light ray of an external lighting source irradiating from an upper surface of the reflecting layer penetrates the transmission layer arranged at the upper surface of the reflecting layer in the prior art is fundamentally solved, and the defect that the product is short in service life since the transmission layer on the upper surface of the reflecting layer quickly ages after being influenced by the light, the moisture, the temperature change and like external environment factors in the prior art is effectively solved; the reflected light intensity of the product is greatly improved, the service life of the product is effectively prolonged when the reflecting performance, the caution and identification effects of the product are effectively improved.

Owner:ZHEJIANG DAOMING OPTOELECTRONICS TECH

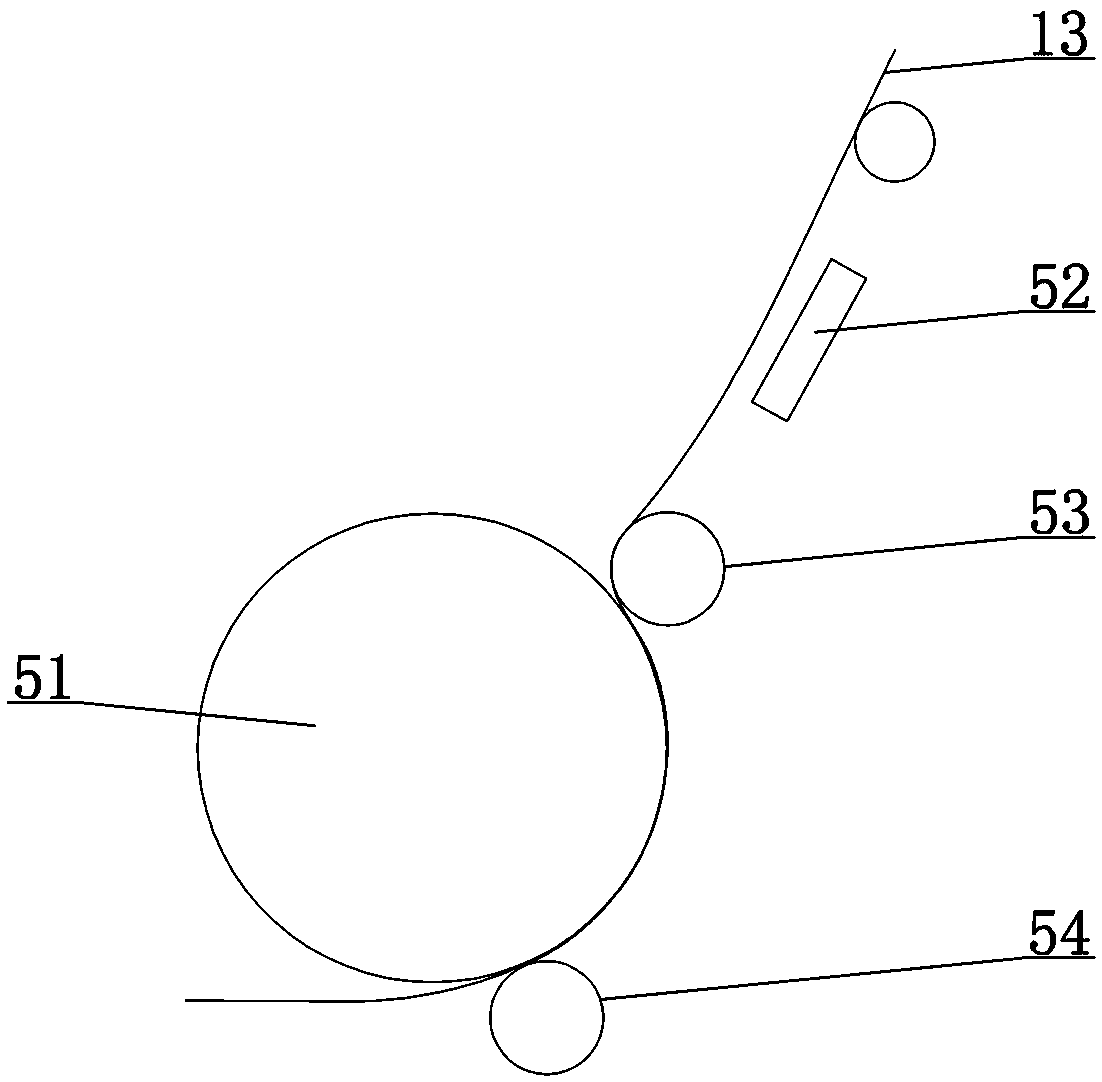

Special smelting furnace

The invention discloses a special smelting furnace. The special smelting furnace comprises a shell, a heating assembly, a crucible, a driving assembly, a stirring blade, a furnace cover, an evaporatorand a water inlet pipe. A transmission shaft of the driving assembly penetrates through the furnace cover, and the stirring blade is located in the crucible and mounted on the transmission shaft of the driving assembly. The evaporator comprises an evaporator shell, an evaporator copper crucible and an evaporator cover body, the evaporator copper crucible is arranged in the evaporator shell in a sleeving mode, the evaporator shell is fixed to the inner wall of the crucible, water vapor through holes are formed in the evaporator cover body, and the evaporator cover body is mounted on the evaporator shell. The water inlet pipe comprises a ceramic pipe, a flexible pipe and a metal water pipe. Aluminum alloy finished products prepared by the special smelting furnace are rich in a plurality oftiny holes, the tiny holes enable the aluminum alloy finished products to be provided with ventilated, oil-through and permeable functions, pollution to the environment is not caused in the preparation process, and the aluminum alloy finished products can be produced on a large scale.

Owner:岳阳联创热能设备有限公司

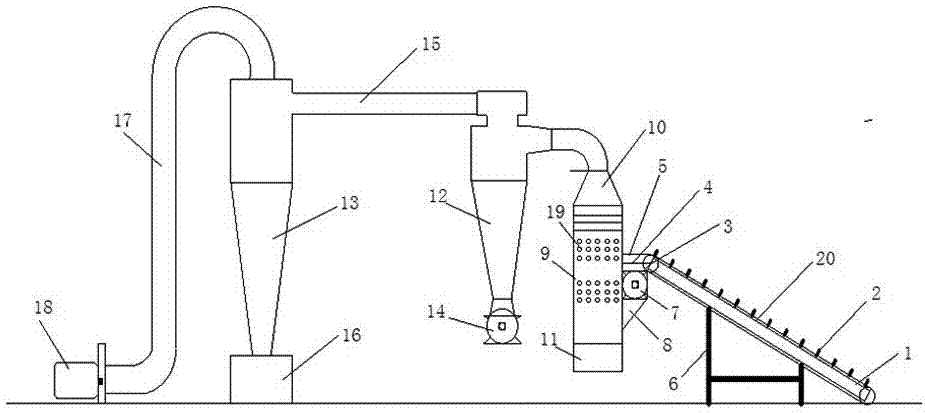

Bipolar sedimentation chilli cleaning equipment

PendingCN107362978ASimple structureEasy to operateSolid separationEnvironmental engineeringWind power

The invention discloses bipolar sedimentation chilli cleaning equipment comprising a feed device, a supply device and a cleaning device. The supply device is arranged between the feed device and the cleaning device. The cleaning device comprises a first-level cyclone unloader and a second-level cyclone dust remover which communicate with each other through a wind pipe. The cleaning device communicates with a fan. The bipolar sedimentation chilli cleaning equipment disclosed by the invention is simple in structure, convenient to operate, safe and reliable. The impurity removing effect is achieved by means of wind power, specificity is high, the impurity removing rate is high, the chilli quality is improved, subsequent deep processing operation is facilitated, environmental pollution is prevented effectively, and environmental protection is facilitated.

Owner:XINJIANG LONGPING HONGAN BIOTECH CO LTD

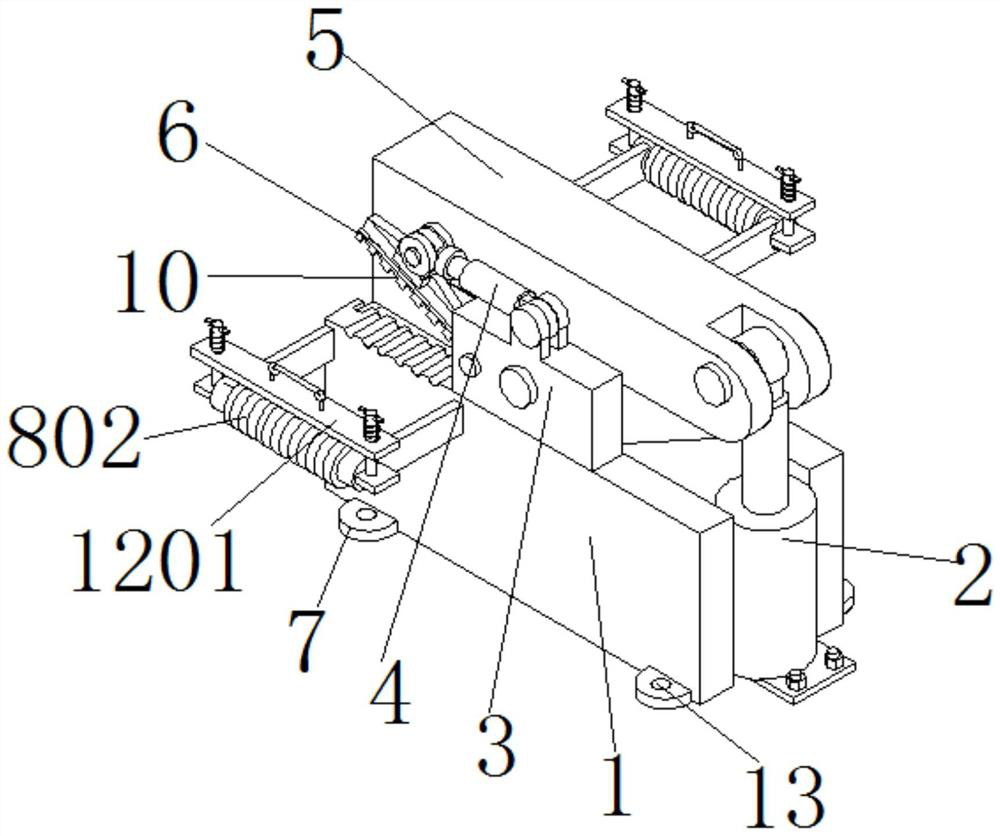

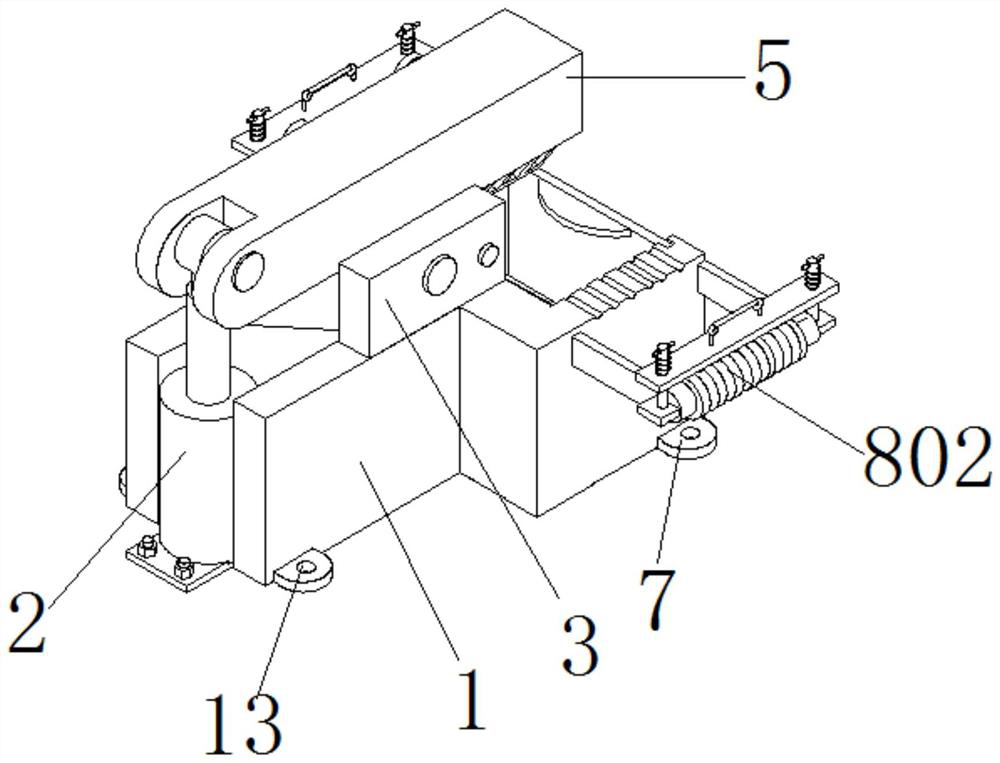

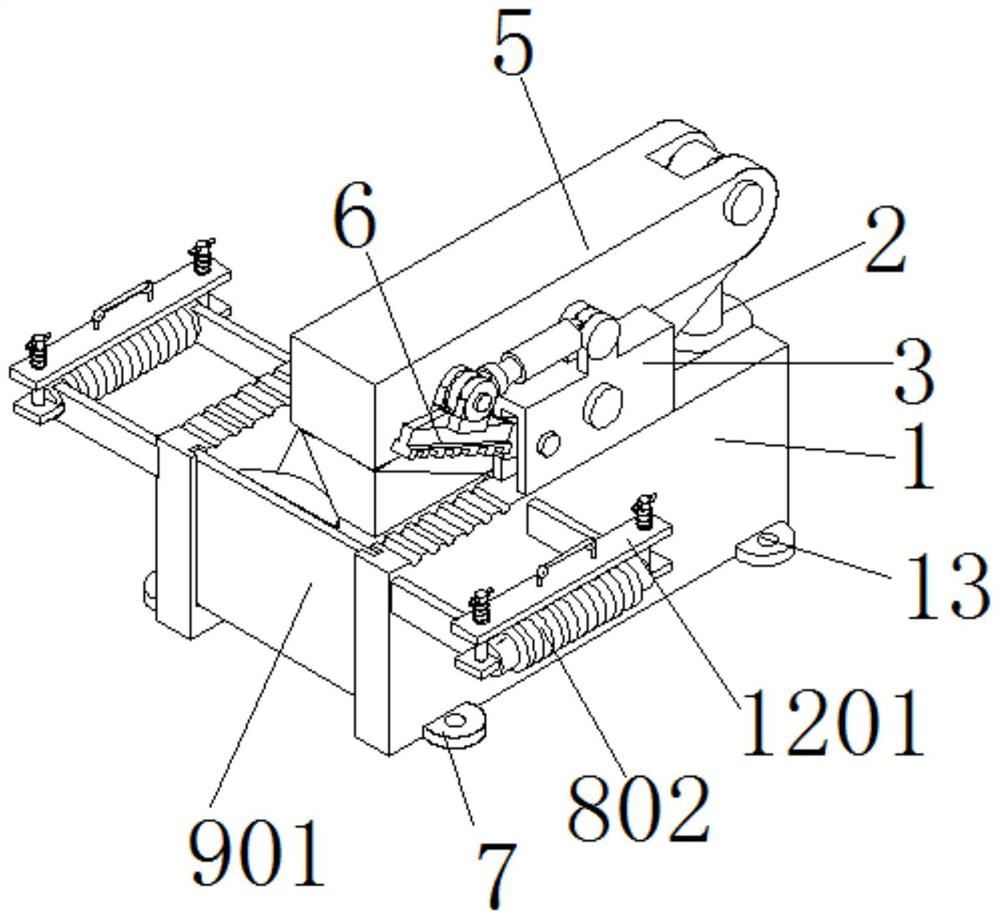

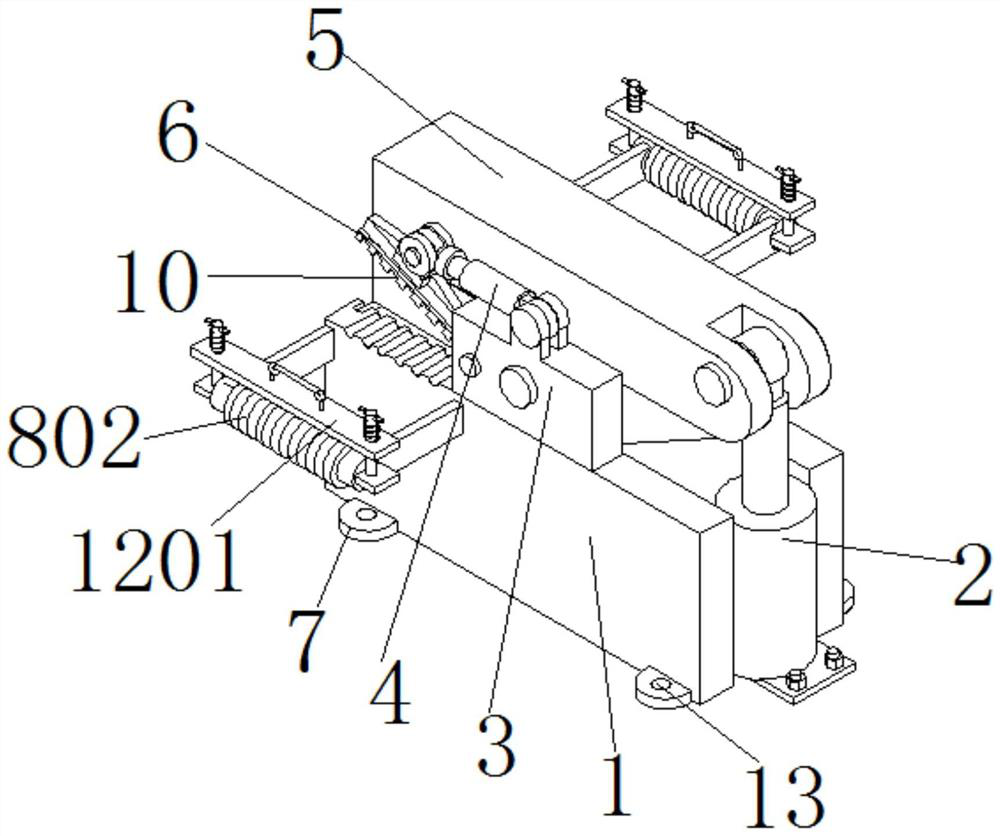

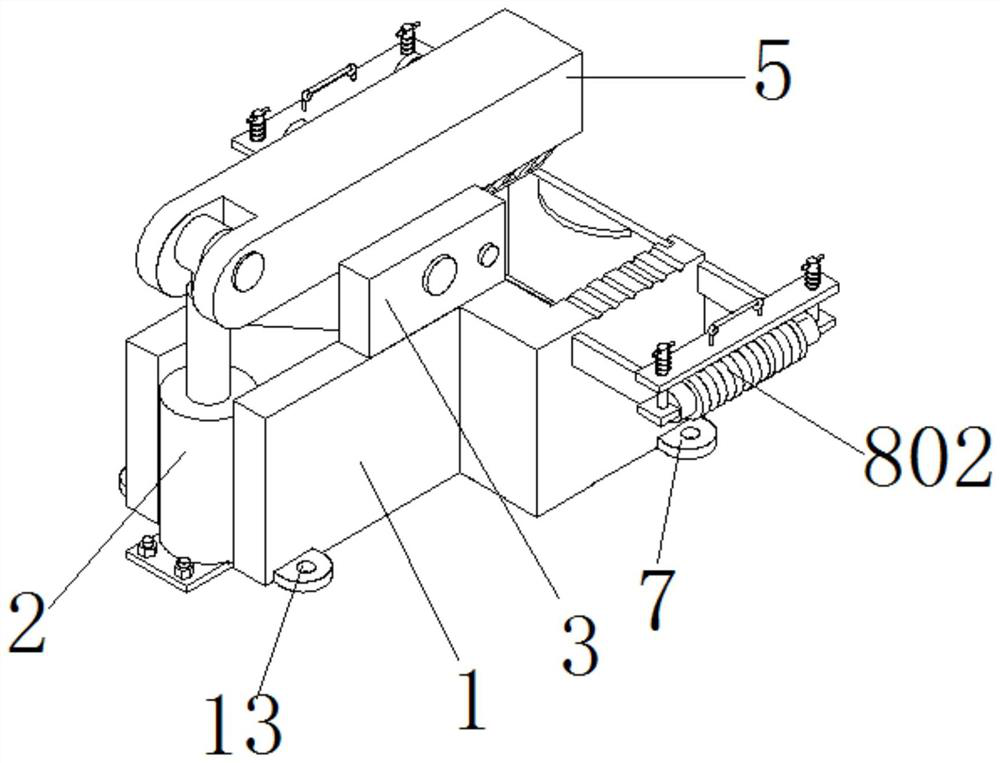

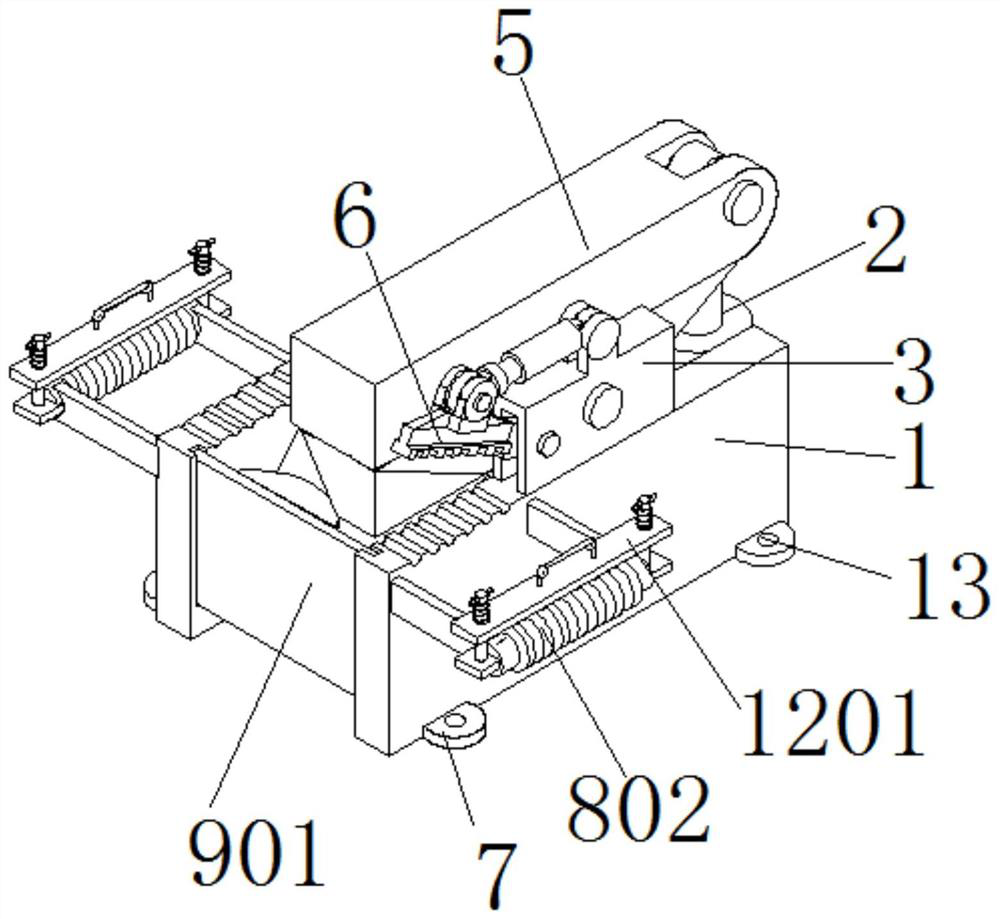

Cold shearing device and process for finish-rolled deformed steel bars

ActiveCN112643124AImprove support stabilityFast even distributionShearing machinesShearing machine accessoriesStructural engineeringWaste material

The invention provides a cold shearing device and process for finish-rolled deformed steel bars, and relates to the technical field of deformed steel bars. The cold shearing device comprises a base, a first electric telescopic rod, a supporting seat, a second electric telescopic rod, a shearing knife, a fixing arm, fixing feet, an auxiliary supporting assembly and a deformed steel bar storage assembly. According to the cold shearing device and process for the finish-rolled deformed steel bars, a first limiting groove is formed in the base, and the arrangement time of the deformed steel bars can be shortened; a lifting rod and a supporting roller are fixedly connected to the outer side of the base, the deformed steel bars entering a shearing area can be supported, and a sheared standby deformed steel bar section can be supported, so that the deformed steel bars are always kept in a horizontal state in the shearing process, manual supporting is not needed, and smooth feeding is ensured; and a limiting plate is arranged, so that the deformed steel bars can be prevented from falling off from the supporting roller. According to the cold shearing device and process for the finish-rolled deformed steel bars, a material collecting inclined plate and a baffle are arranged, so that cut deformed steel bar waste can be collected, the baffle is in sliding connection with the base, and the baffle can be conveniently disassembled.

Owner:JIANGSU BINXIN STEEL GRP

PE drain pipe and production process thereof

ActiveCN111533985AHigh thermal conductivityGuaranteed stabilityGeneral water supply conservationPhysical chemistryFire retardant

The invention belongs to the technical field of plastic products. The invention discloses a PE drain pipe and a production process thereof. The PE drain pipe is prepared from, by weight, 80-100 partsof PE, 3-5 parts of nano MgO, 0-5 parts of nano MnS, 5-15 parts of ground calcium carbonate, 2-5 parts of a coupling agent, 0-3 parts of EVA, 3-5 parts of a flame retardant, 3-10 parts of a tougheningagent, 1-5 parts of a heat stabilizer and 0-2 parts of a processing aid. Beneficial effects of the PE drain pipe and the process are that the nano MgO can enhance the heat-conducting property of a PEproduct and avoid the cold welding phenomenon in a PE pipe welding process; the nano MnS can keep the stability of a polyethylene molecular chain in the welding process, and thermal oxidation of polyethylene when the welding temperature is too high is avoided; the ground calcium carbonate, the nano MgO and the nano MnS have a synergistic effect, so that the stability of a welding part can be improved, and the firmness of the welding part is improved; by adding the nano MgO, the nano MnS and the ground calcium carbonate, the temperature range of the PE pipe during welding can be widened, and the welding stability of the PE pipe is improved.

Owner:宜昌宜硕塑业有限公司

A special melting furnace

Owner:岳阳联创热能设备有限公司

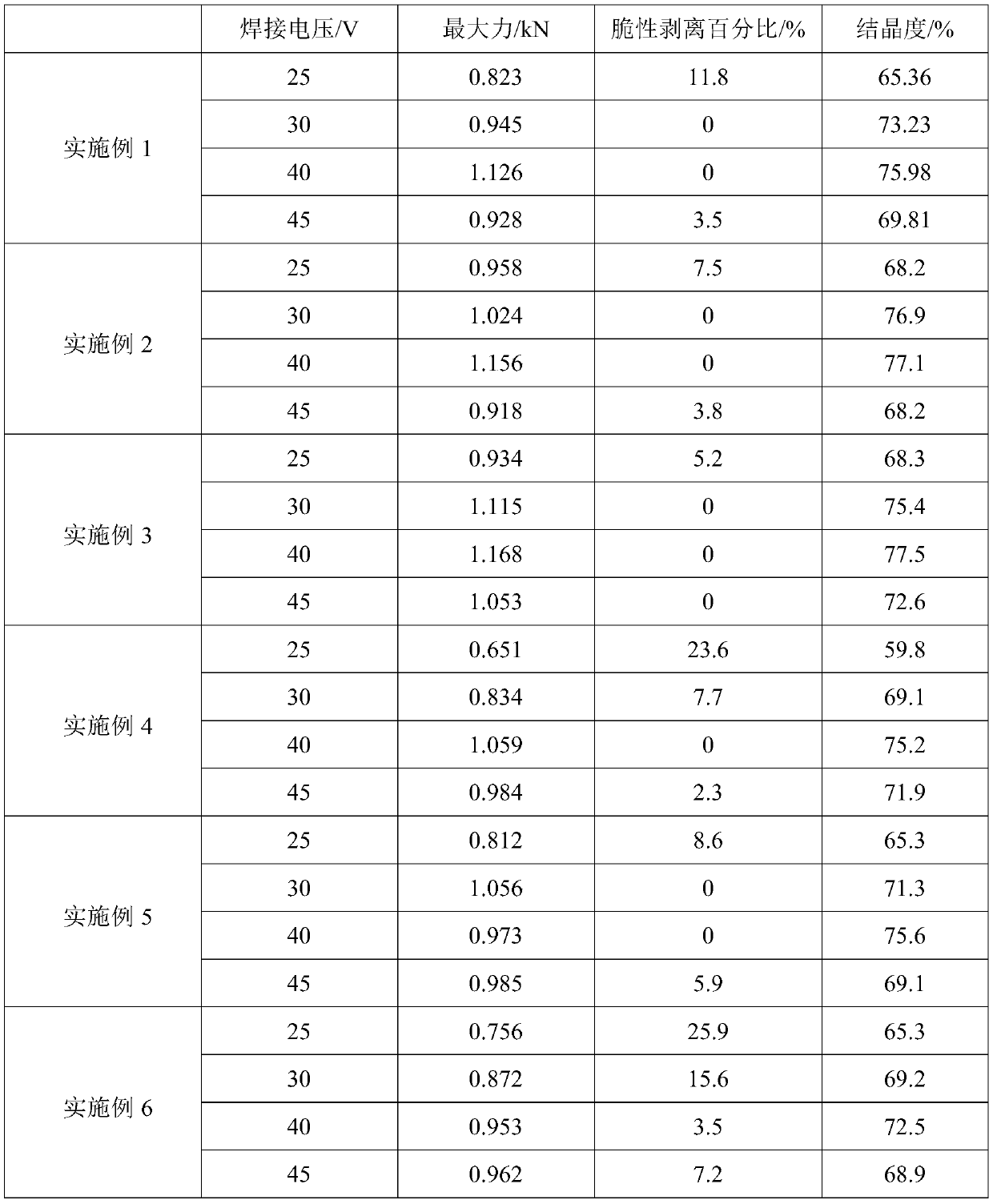

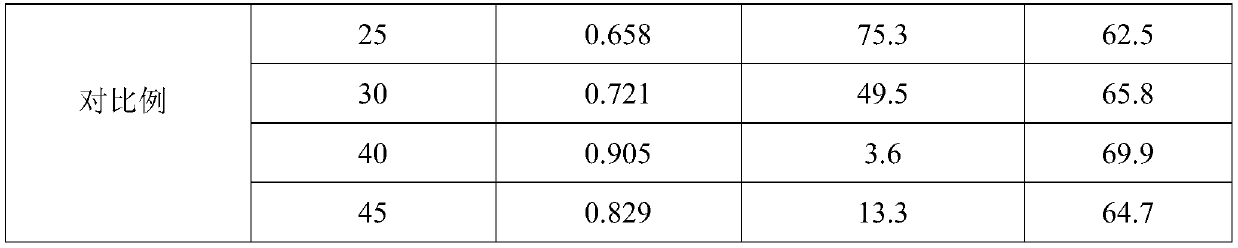

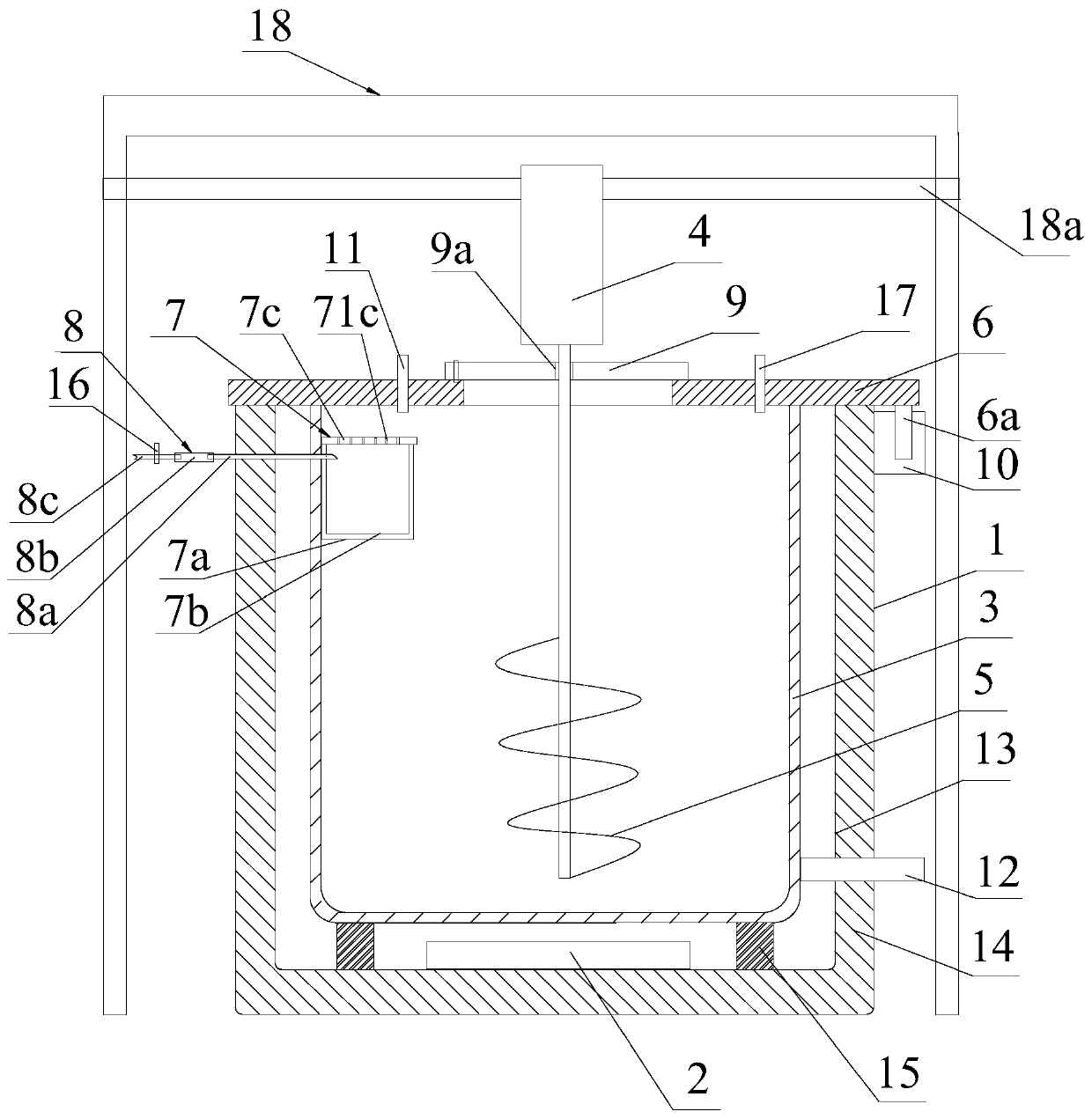

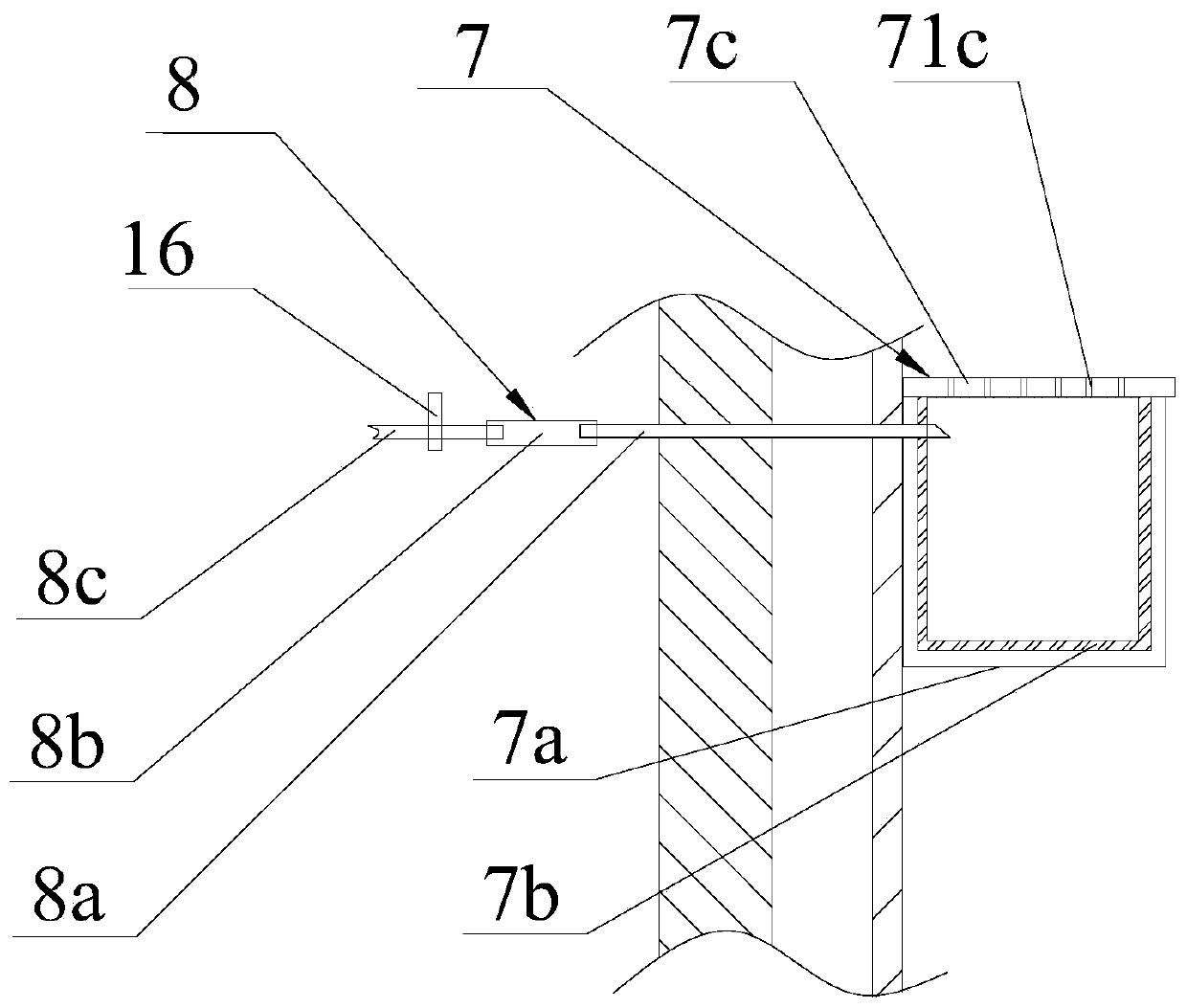

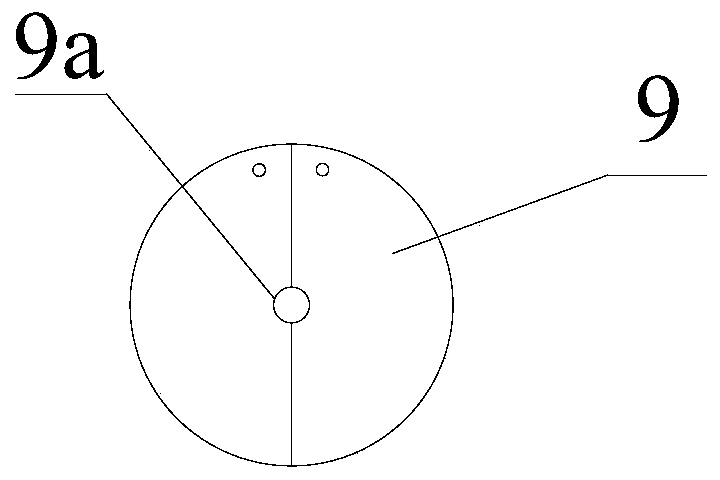

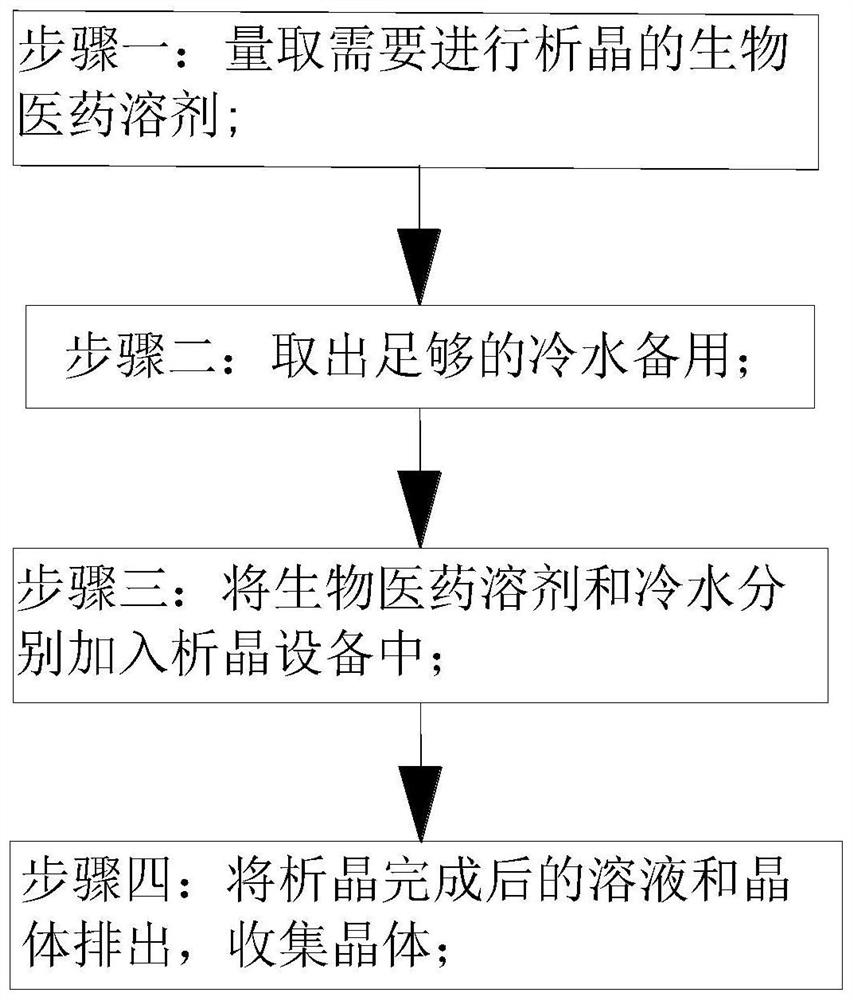

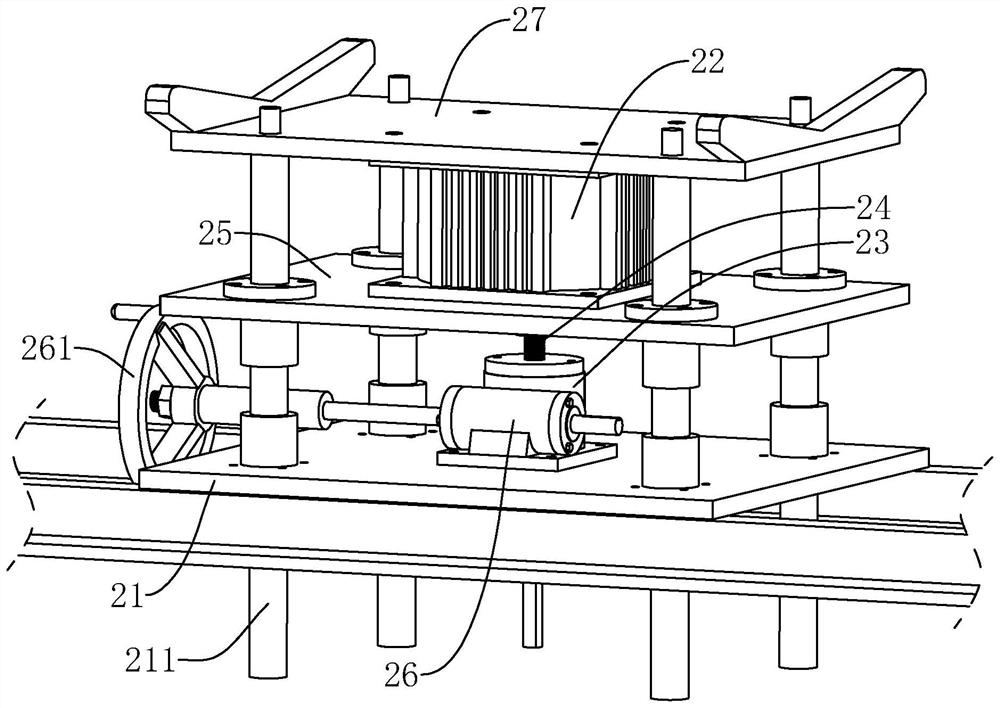

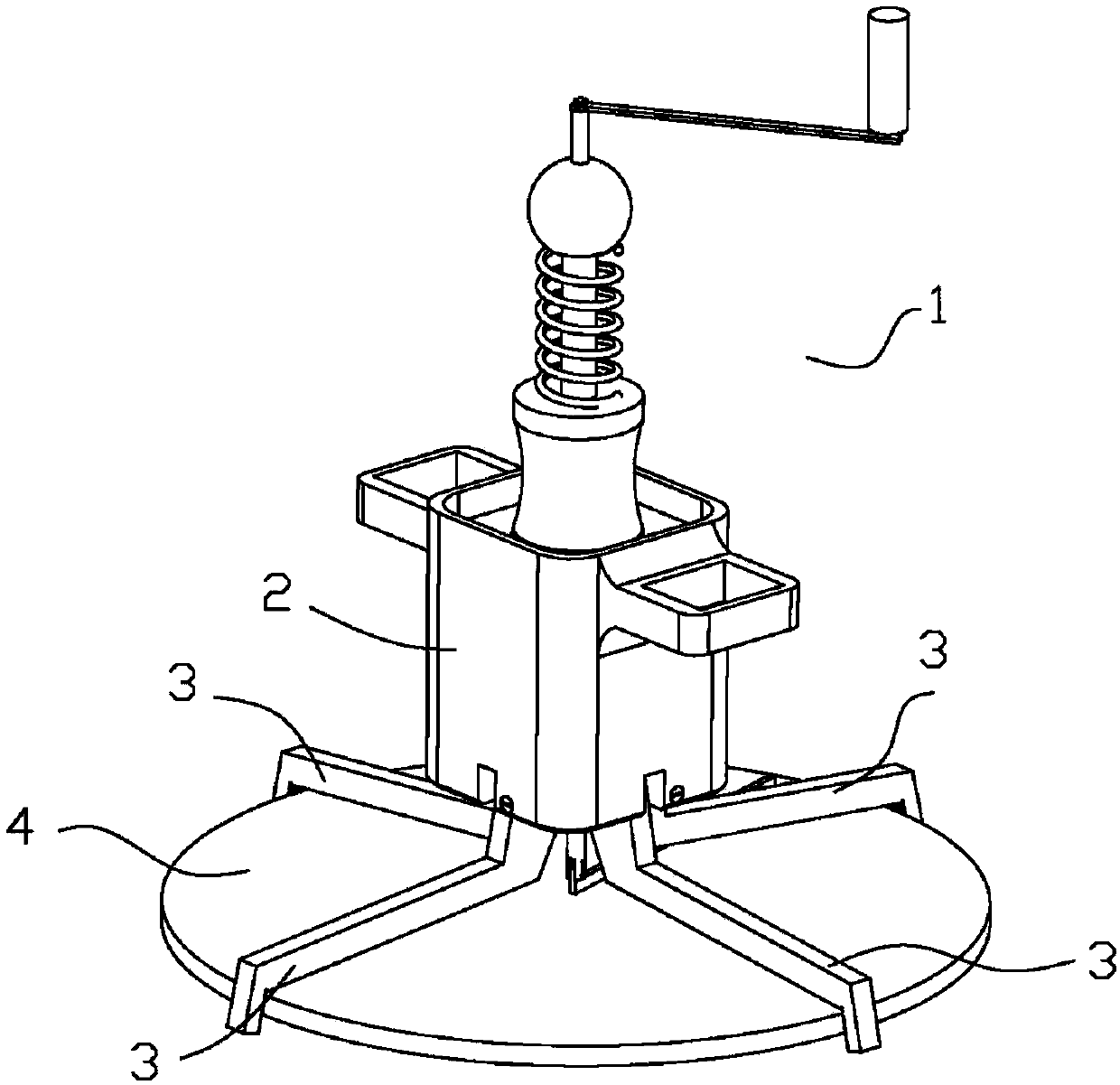

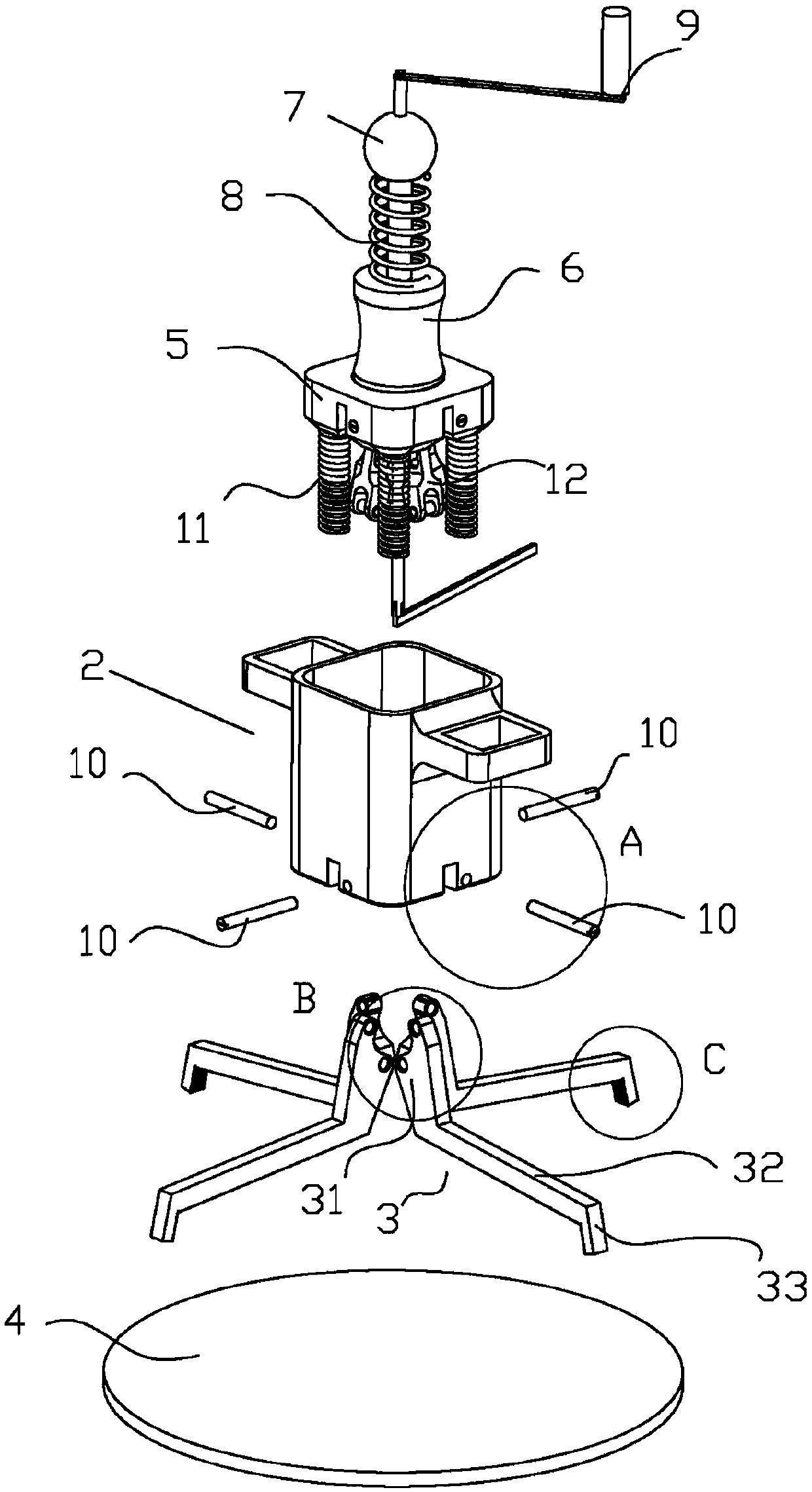

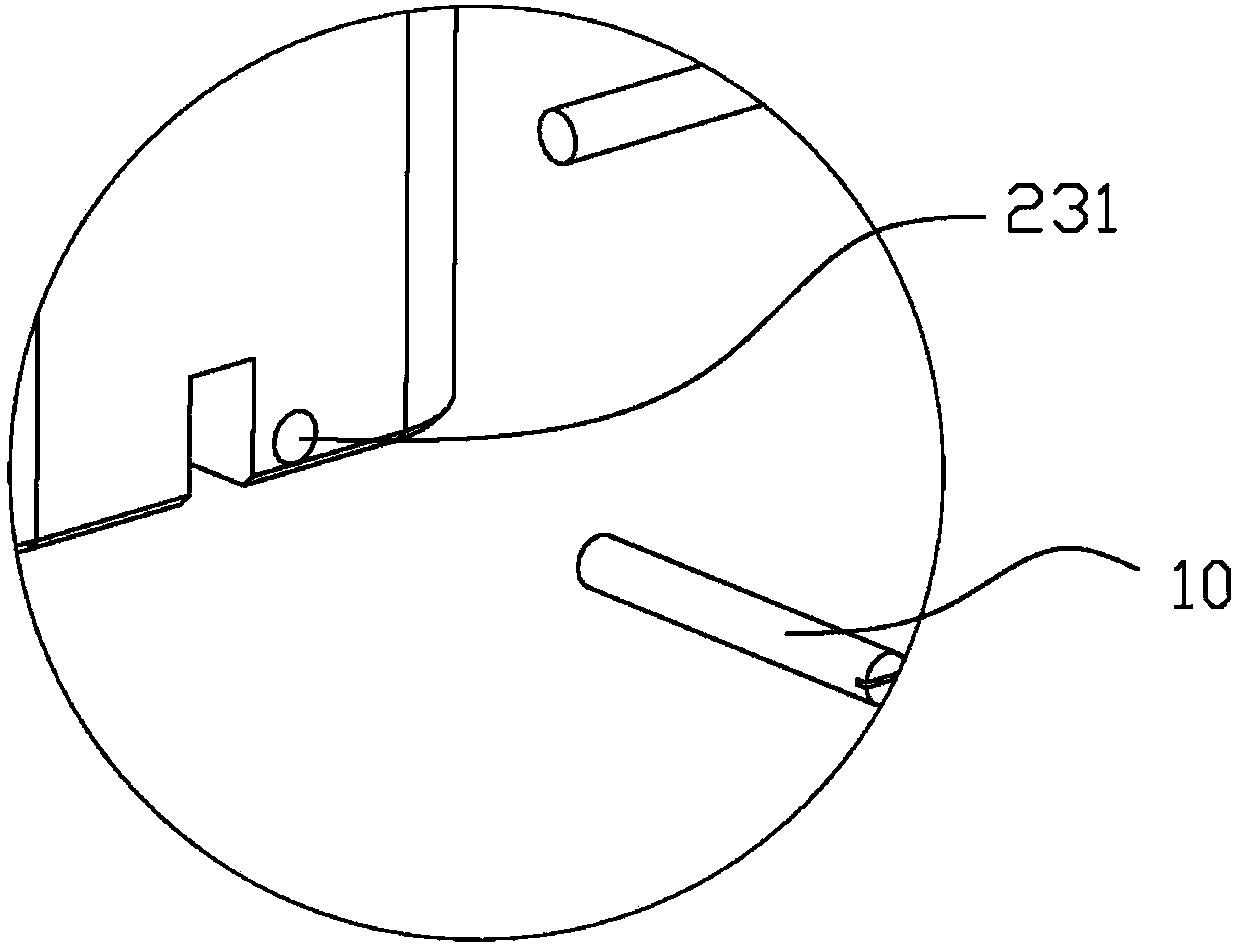

Crystallization method for biological medicine preparation

ActiveCN113617053AFast even distributionRapid and uniform precipitationTransportation and packagingRotary stirring mixersPharmaceutical drugBiomedical engineering

The invention discloses a crystallization method for biological medicine preparation in the technical field of crystallization methods for biological medicine preparation. The method comprises the following specific steps: step 1, measuring a biological medicine solvent needing to be crystallized; 2, taking out enough cold water for later use; 3, adding a biological medicine solvent and cold water into crystallization equipment for biological medicine preparation; and 4, discharging the crystallized solution and crystals, and collecting the crystals. The crystallization equipment for biological medicine preparation is used for medicine crystallization, so that a solvent in the crystallization cylinder can be quickly and uniformly separated out, and the crystallization efficiency is improved.

Owner:河北赛谱睿思医药科技有限公司

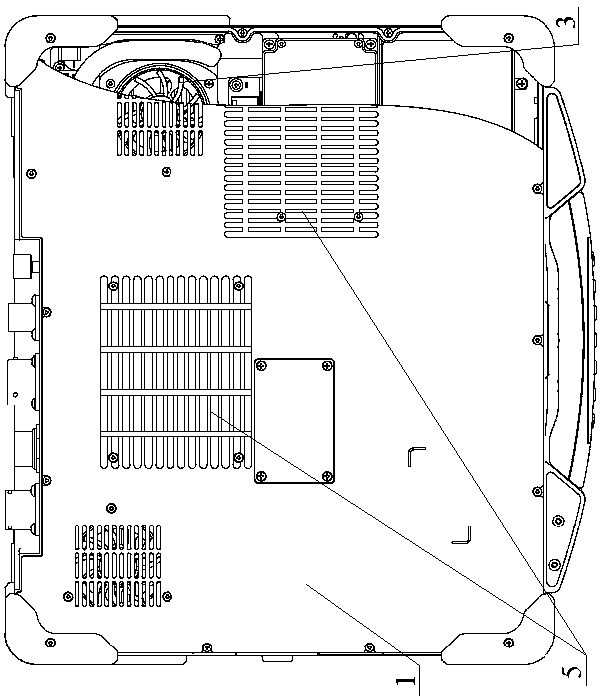

A heat dissipation device and a heat dissipation method of a power supply isolation module

InactiveCN109068533AImprove liquidityImprove cooling effectMetal casingsModifications by conduction heat transferEngineeringChassis

The invention discloses a heat dissipation device and a heat dissipation method of a power supply isolation module, belonging to the technical field of heat dissipation of an electric function module.The heat dissipation device of the power supply isolation module of the invention comprises a chassis, a power supply isolation module, a plurality of heat dissipation tubes and a fan. The power supply isolation module and the fan are arranged on the bottom shell of the chassis, and the heat dissipation tubes are arranged on the bottom shell and are in contact with the power supply isolation module. The heat dissipation device of the power supply isolation module of the invention can uniformly dissipate heat, and has good popularization and application value.

Owner:SHANDONG CHAOYUE DATA CONTROL ELECTRONICS CO LTD

Sesame sprinkler on the surface of the cake

The invention relates to a sesame scattering machine. The sesame scattering machine comprises a machine body, a cake introduction conveying mechanism, a cake surface syrup spraying mechanism, a syrup mist suction-removal mechanism and a cake surface sesame scattering mechanism, wherein the cake introduction conveying mechanism is formed by motors, conveyor belts, tension rollers and transmission rollers; the cake surface syrup spraying mechanism is formed by a syrup storage tank, a syrup conveying tube and a nozzle; the syrup mist suction-removal mechanism is formed by a syrup mist suction tube, a filter and a vacuum pump; and the cake surface sesame scattering mechanism is composed of a sesame storage bucket, a sesame distributor, a hairbrush and a sesame catching bucket. The syrup is sprayed on the surfaces of cakes in a pressurization mode, and the granule distributor with the surface fully distributed with pits is used for scattering sesames, so the syrup spray distribution and the sesame distribution are fast and uniform; the syrup mist suction-removal mechanism is arranged, so the splash of the sprayed syrup and the suffusion of the syrup in air are controlled; the cake introduction conveying mechanism is provided with conveyor cleaning scrapers, so it is benefit for cleaning, and material recovery can be realized; a cake passing and pressing apparatus is arranged at the stroke tail end, so the granules are firmly viscous after the rolling, and blocking and clamping phenomena at the junctions of the conveyor belts to where the cakes are transmitted are eliminated. The sesame scattering machine has the characteristics of reliable operation, automation and fastness, less material loss, environment cleaning, and suitableness for line production.

Owner:江苏裕铭铜业有限公司

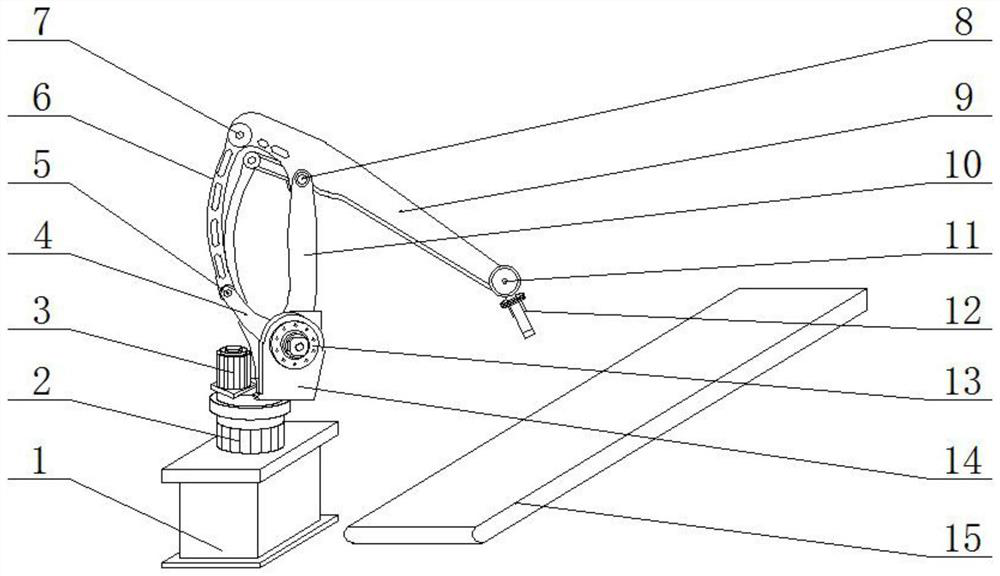

Overturning device for aluminum alloy profile machining

The invention discloses an overturning device for aluminum alloy profile machining. The overturning device comprises a base, a first rotating wheel is fixedly installed at the upper end of the base, amotor is fixedly installed at the left side of the upper end of the first rotating wheel, a fixing base is fixedly installed at the right side of the motor, and a second rotating wheel is fixedly installed at the front end of the fixing base; and a mechanical arm is fixedly installed above the fixing base, and a grabbing structure is fixedly installed at the lower right portion of the mechanicalarm. According to the overturning device, a plurality of sets of movable blocks capable of moving at will are adopted in the grabbing structure, each set of movable block can stretch out and draw backindependently, and therefore a mechanical clamp can be completely attached to profiles needing to be grabbed; clamping can be firmer, and the mechanical clamp of the overturning device can adapt to clamping of the various profiles of different sizes; and in addition, a connecting shaft and a sealing bearing which are convenient to disassemble are arranged, so that the overturning device is convenient to disassemble and stable and smooth in operation, and few faults occur.

Owner:杨富松

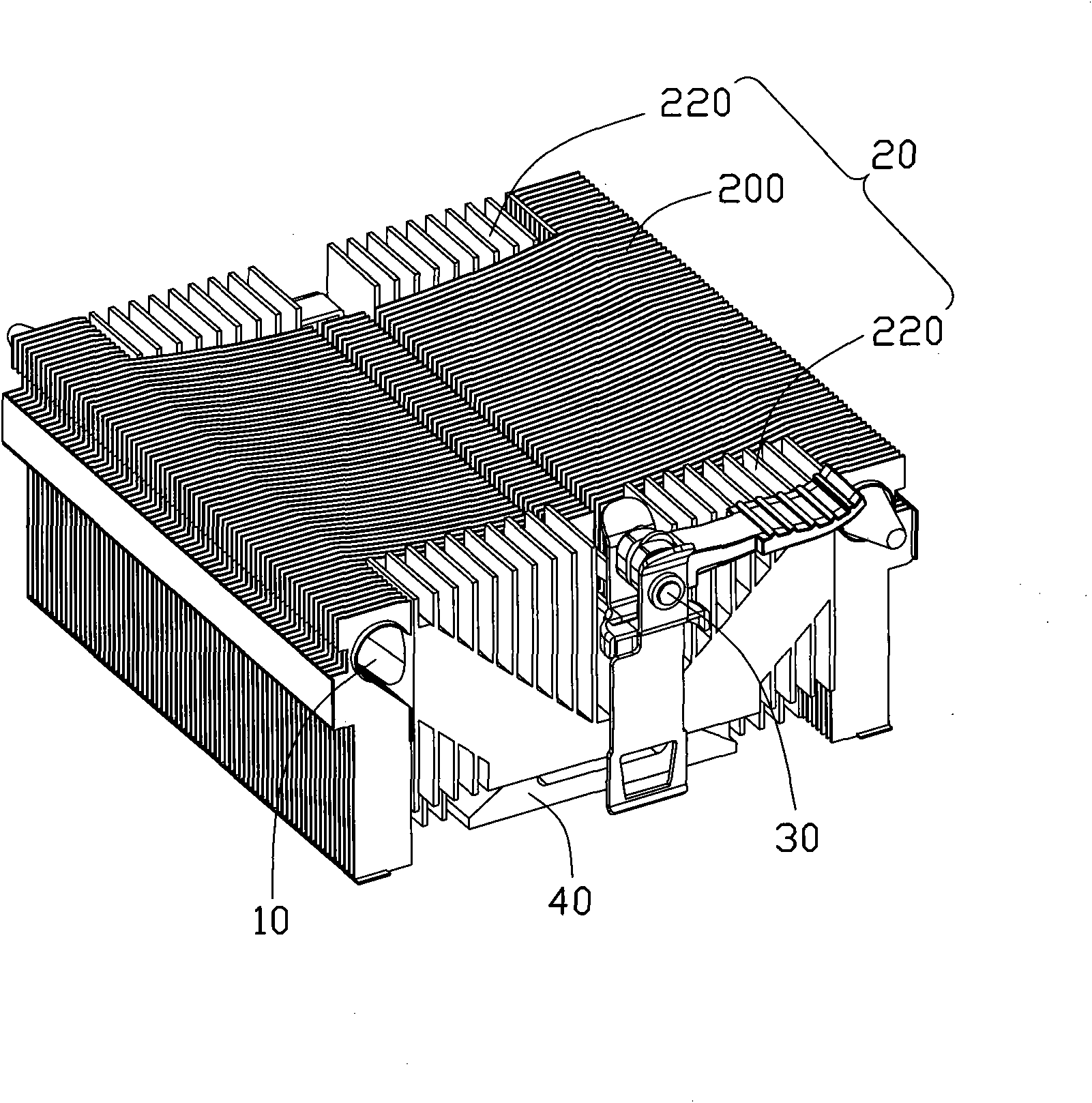

Heat sink

InactiveCN101616567AIncrease contact areaFast even distributionSemiconductor/solid-state device detailsSolid-state devicesEngineeringBearing surface

The invention discloses a heat sink, which comprises a radiator and a heat pipe, wherein the radiator comprises a body part and a plurality of radiating fins formed by extending in a radial form from the body part; the top face of the radiator is provided with a groove and a bearing face; the bearing surface surrounds the groove and is communicated with the groove; and the heat pipe is arranged on the groove and the bearing face in an extending mode. The heat sink forms the groove and the bearing face, and arranges the heat pipe in the groove and the bearing face, so that the heat can be more quickly and evenly distributed to the whole heat sink and emitted.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

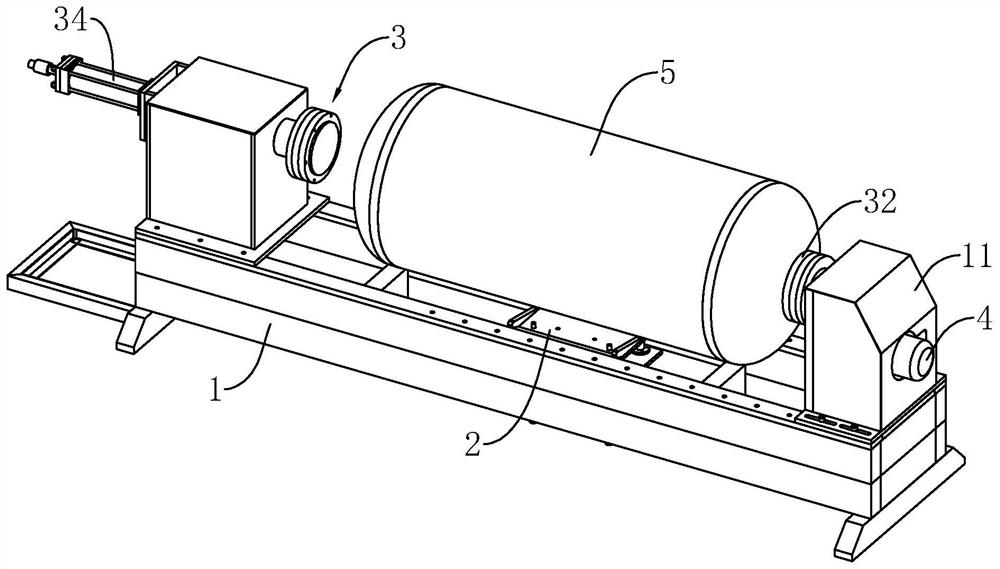

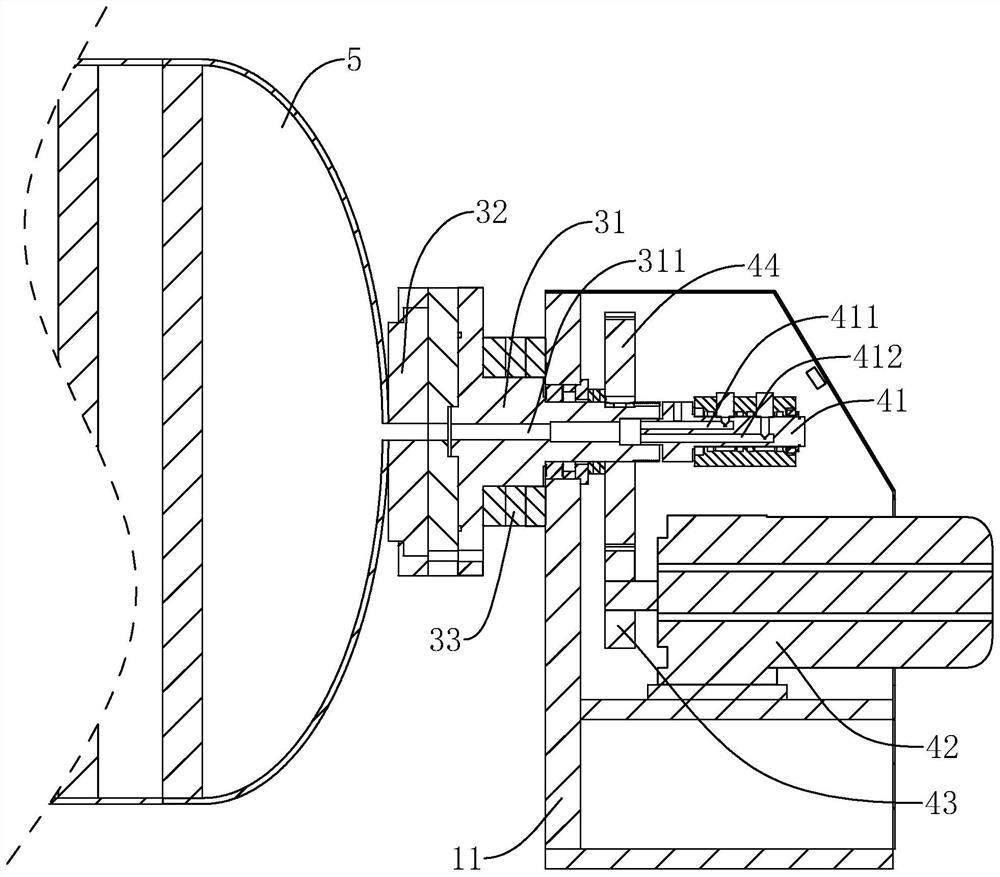

Pipeline filter pressure testing machine

PendingCN114659771AEasy to passPromote shakingMachine part testingMeasurement of fluid loss/gain rateEngineeringFiltration technique

The invention relates to a pipeline filter pressure testing machine, and relates to the technical field of gas filtration, and the pipeline filter pressure testing machine comprises a pedestal, a pipeline filter rotatably arranged on the pedestal, abutting members abutting against two ends of the pipeline filter are arranged on the pedestal, and rotating shafts driving the abutting members to rotate are rotatably arranged at two ends of the pedestal. The rotating shaft slides on the base in the direction of the rotating axis of the rotating shaft, a clamping air cylinder for driving the rotating shaft to slide and driving the abutting piece to clamp the pipeline filter is arranged on the base, a rotating assembly for driving the rotating shaft away from the air cylinder to rotate is further arranged on the base, and the rotating assembly is further used for filling gas into the pipeline filter. According to the pipeline filter, the rotating shaft is arranged, so that the pipeline filter rotates, internal air can be quickly and uniformly distributed, powder filtered matter shakes, powder is loose, gaps are generated among the powder, air can pass through the pipeline filter conveniently, the detection effect is improved, and the pipeline filter has the advantage of improving the detection accuracy.

Owner:台州重友焊接科技有限公司

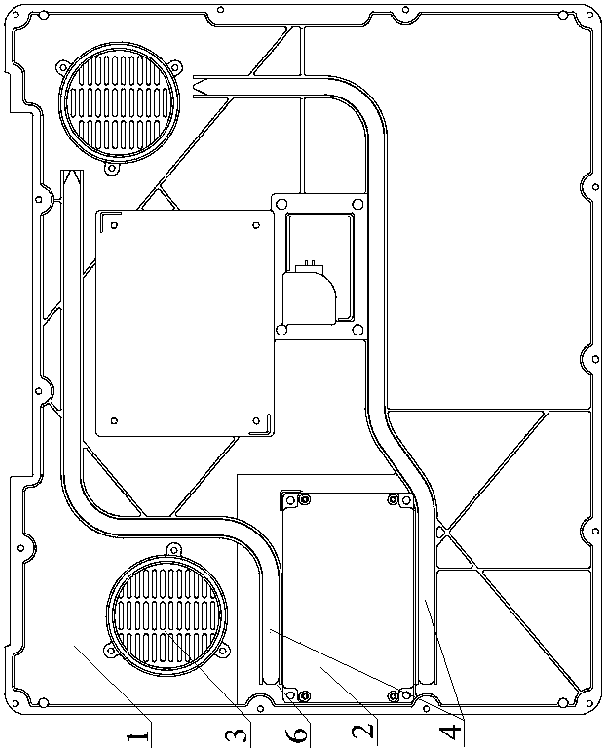

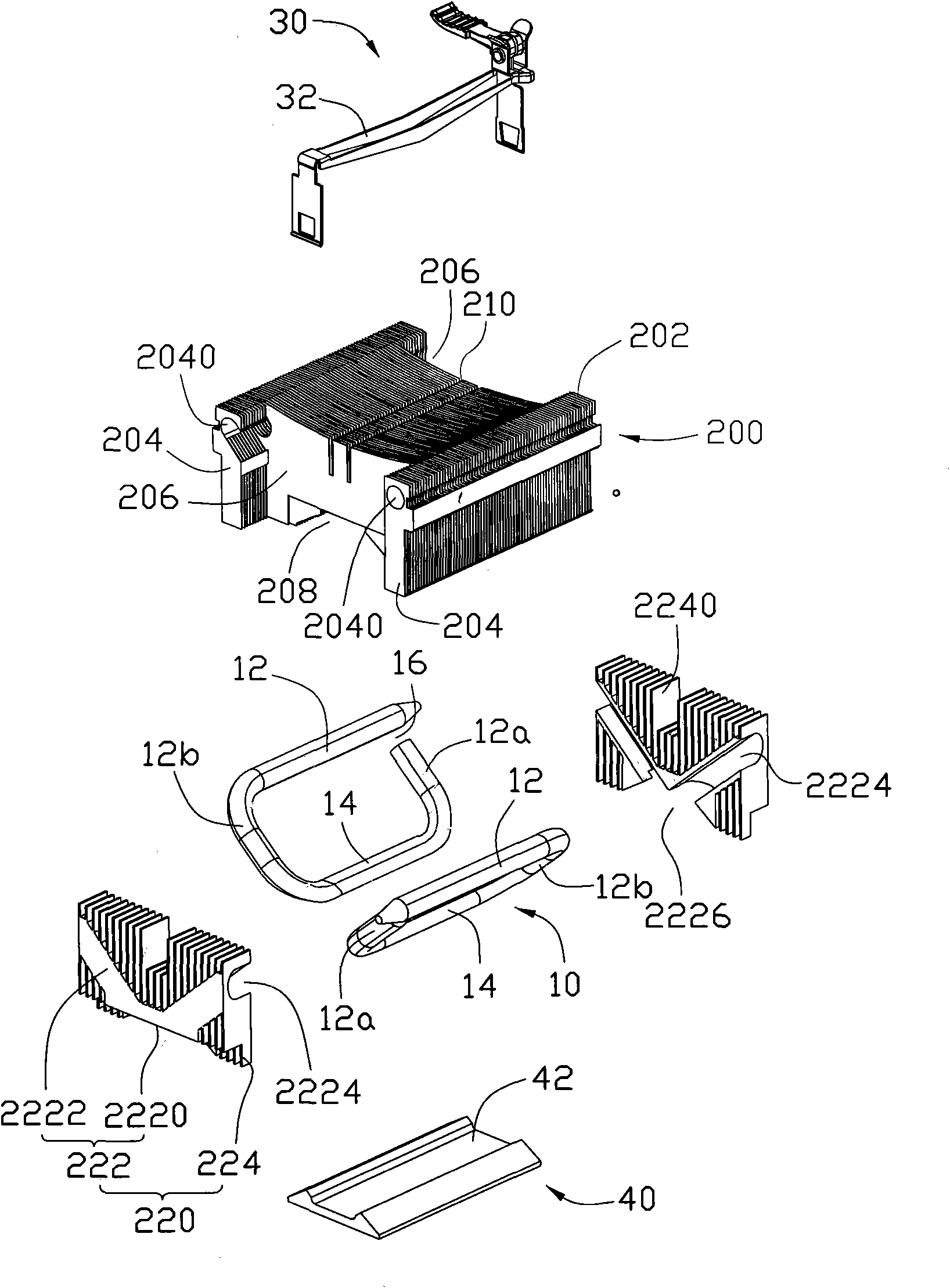

Heat radiating device

InactiveCN101141865BFast even distributionImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat sink

The present invention relates to a heat radiating device, which comprises a base seat and a plurality of heat radiating fins arranged on the base seat, the base seat comprises a first heat sink board, the heat radiating fin is arranged on the one side surface of the first heat sink board, Wherein, the base seat also comprises a second heat sink board arranged on the other side surface of the first heat sink board, the width of the second heat sink board is less than the width of the first heat sink board, the heat radiating device also comprises a heat pipe that is inserted on the bottom surface of the second heat sink board and extended out the side direction of the second heat sink board, and extended to the first heat sink board. The heat pipe is inserted on the bottom surface of the second heat sink board in the heat radiating device described in the present invention, the heat pipe not only can be directly touched with an electronic component, the heat quantity generated by the electronic component also can be distributed on the whole base seat uniformly, therefore, compared with the other traditional heat radiating device, the cooling performance of the heat radiating deviceof the present invention is improved greatly.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

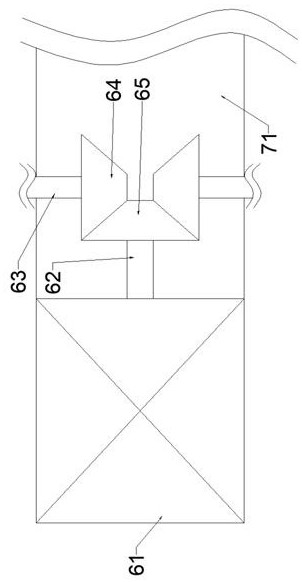

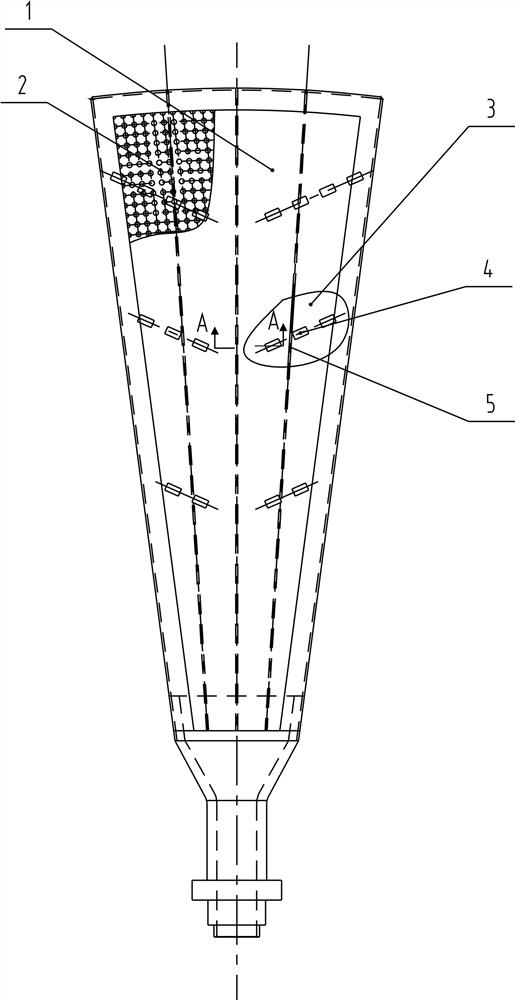

Centrifugal casting runner and centrifugal casting system

The invention belongs to the technical field of casting and processing of auto parts, and specifically relates to a centrifugal casting sprue, which includes a bowl-shaped material receiving trough and a fixed flow channel connected to the bowl-shaped material receiving trough, and a rotating body is sleeved on the fixed flow channel , the rotating body is arranged to rotate along a rotating shaft parallel to the length direction of the fixed flow channel, and a movable flow channel is opened on the rotating body, and the movable flow channel penetrates from the inner ring surface of the rotating body to the outer ring surface of the rotating body, The movable channels are arranged in a spiral shape. The movable runner of the invention can make the drop point of the casting liquid in the mold change linearly along the axial direction of the mold, ensure rapid and uniform distribution of the casting liquid, shorten the casting time, and avoid local accumulation of the casting liquid to affect the quality of the casting.

Owner:ANHUI PROVINCE YUEXI CYLINDER

Limewater spraying device for forests

InactiveCN111974591AFast even distributionImprove efficiencySpraying apparatusPlant protectionAgricultural engineeringEnvironmental geology

The invention discloses a limewater spraying device for forests. A land is involved, a plurality of rows of trees are planted on the land at equal intervals, two rear wheels and a front wheel abut against the upper side face of the land, rear wheel shafts are fixedly connected in the rear wheels, rear wheel stress blocks are fixedly connected to the right sides of the rear wheel shafts, and a chassis is rotationally connected to the two rear wheel shafts. A hydraulic space is formed in the upper side of the chassis, a transmission space is formed in the front side of the hydraulic space, a hydraulic wheel device is arranged in the hydraulic space, and a smearing transmission device is arranged in the transmission space. An execution transmission device is provided with smearing devices which are symmetrically distributed about a vertical center line of the transmission space, limewater can be smeared on two rows of trees at the same time and can be rapidly and evenly distributed in a smeared area by spraying, the efficiency is improved, and automation can be achieved.

Owner:台州池泽科技有限公司

Multipurpose electric pancake maker

InactiveCN108042010ASpeed up preparationIncreasing the thicknessFrying pansElectric driveEngineering

The invention discloses a multipurpose electric pancake maker. The multipurpose electric pancake maker comprises a cylinder base, a fixing pawl array, a pancake making plate, a slide seat, a transmission fork bar array, a slide column, a guide device and a rotating component, wherein the fixing pawl array is formed by fixing pawls; the transmission fork bar array is formed by transmission fork bars which are rotatably arranged at the bottom of the slide seat; the slide column is detachably arranged on the slide seat; the guide device comprises a hollow long guide tube, and a plurality of oblique paste guiding screw holes are arranged in the periphery of the bottom of the long guide tube; the rotating component comprises a long rotating rod, a rotating handle, a spreading support, an electric drive box and a plurality of feeding devices; each feeding device comprises a tubular feeding tube and a feeding spiral rod. Due to the fact that the multiple feeding devices are used, rice paste can be fast and evenly distributed on the pancake making plate, pancake making is accelerated, and uniform pancake thickness is achieved.

Owner:吴振明

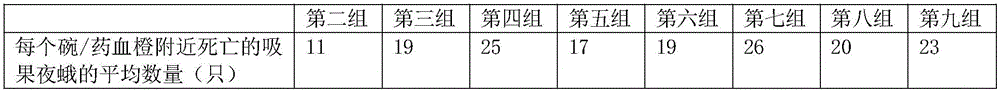

Composition for killing blood orange fruit-piercing moth

The invention belongs to the field of plant disease prevention and control, and specifically discloses a composition for killing blood orange fruit-piercing moth, wherein the composition comprises 7-10 parts of toad, 4-6 parts of nerium indicum mill, and 2-4 parts of branchy euporbia root. According to the present invention, the composition can kill fruit-piercing moth, and no drug residue exists in the normal blood orange; and with the applications of the method to apply the composition, the good trapping effect is provided in bad weathers such as wind blowing and raining.

Owner:重庆全合农业发展有限公司

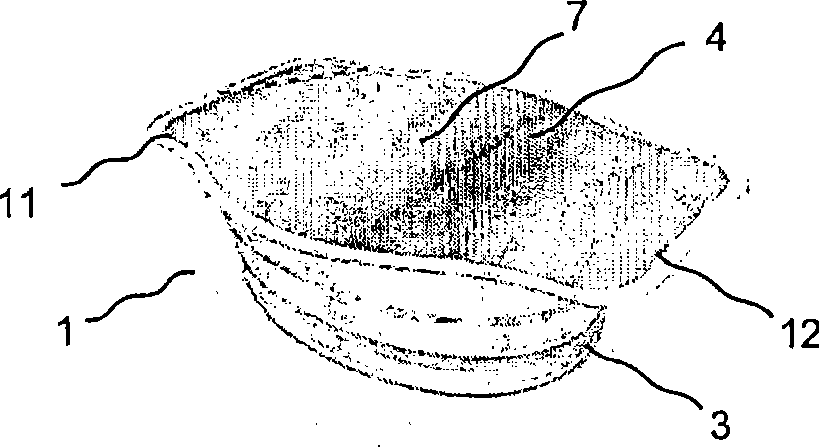

Portion package and semi-fluid product

InactiveCN101432198BLow costSimply empty the packVariable capacity containersEngineeringLateral extension

Owner:WEASY PACK INT

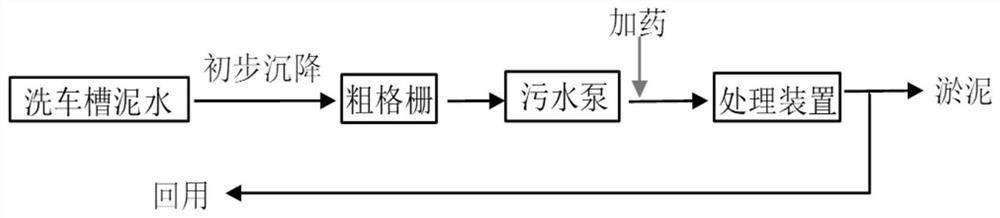

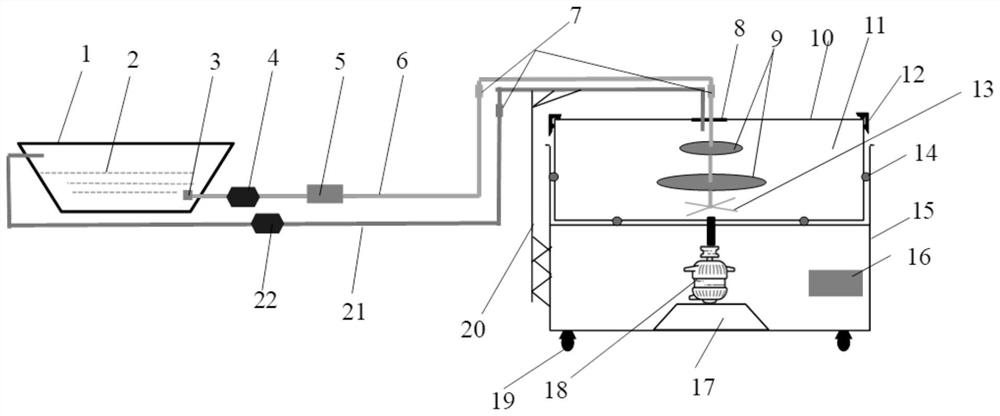

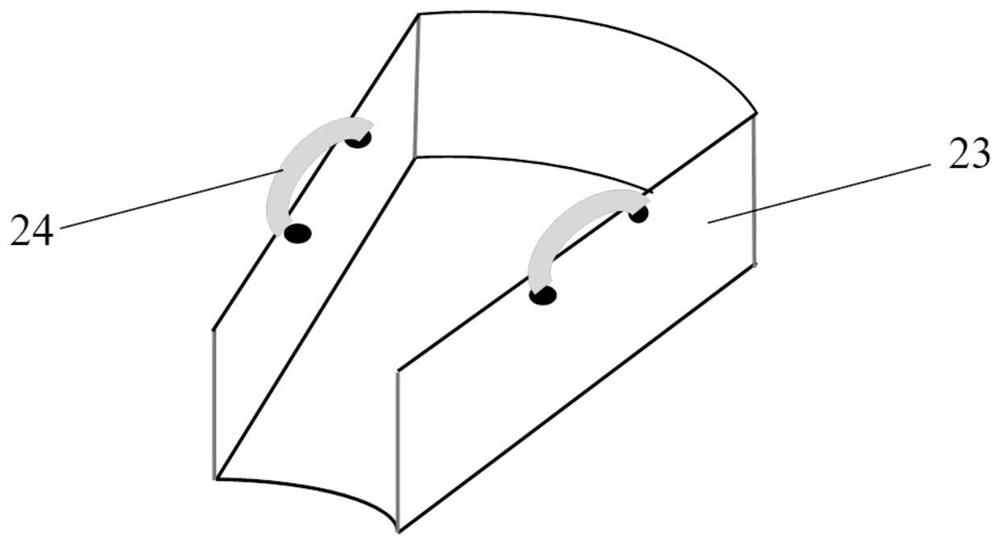

Method and device for quickly treating and recycling sewage of car washing tank

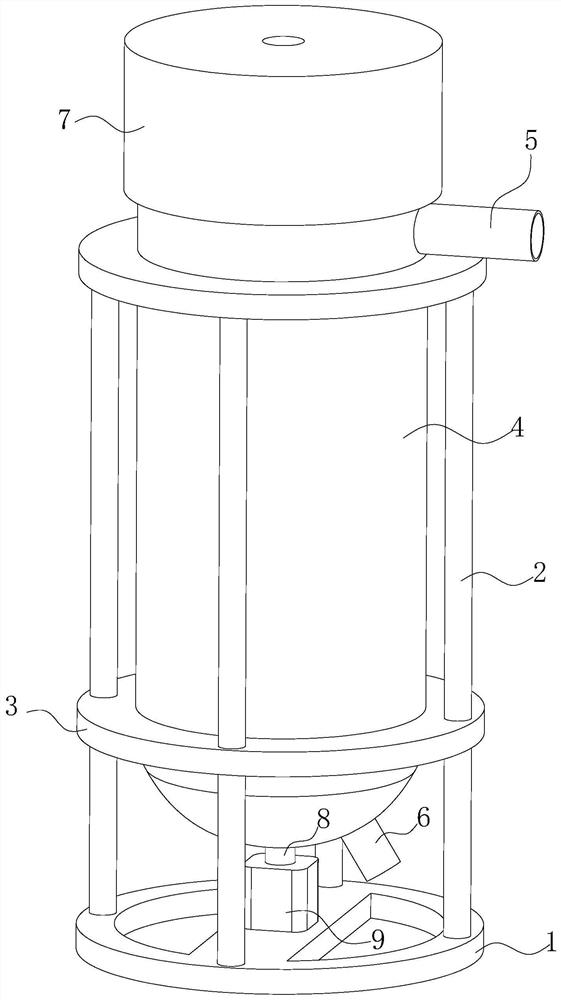

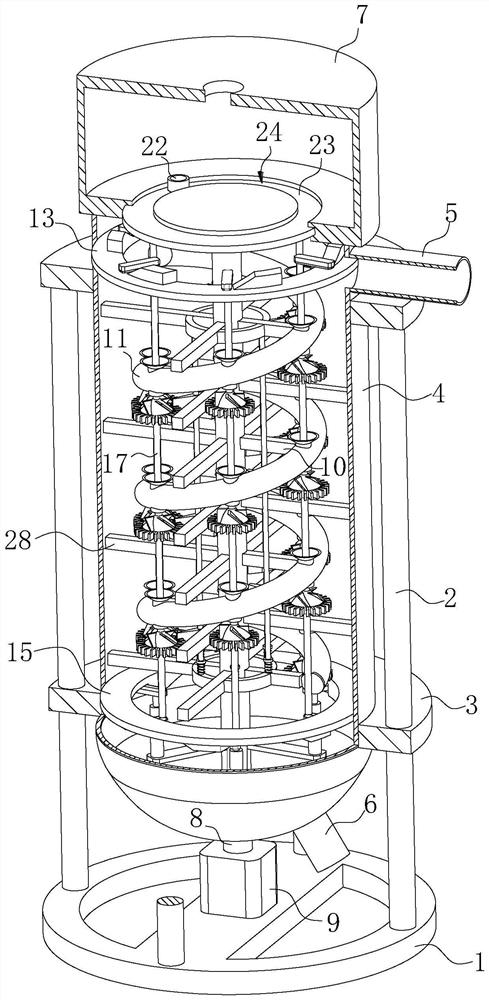

PendingCN113336384ASolve the problem of poor natural settlement performanceFast even distributionWater/sewage treatment by centrifugal separationTreatment involving filtrationSludgeSewage

The invention discloses a method and a device for quickly treating and recycling sewage in a car washing tank. Sewage in the car washing tank is pumped by a sewage pump to enter a centrifugal drum through a grid and a doser, whether a flocculating agent is added or not is selected by the doser as required before the sewage enters the centrifugal drum, and the sewage flows to the periphery of the bottom through a water distributor after entering the centrifugal drum; after full filling, the sewage pump is stopped, the centrifugal drum is started, sewage is subjected to mud-water separation through density difference under the centrifugal effect, impurities including mud and sand are gradually enriched on the inner wall, clear water is left in the center, and after stable operation, the sewage pump and the drainage pump synchronously work at equal flow; and newly injected sewage is squeezed in and is kept at the lower part of the center under the action of self sedimentation and a flow baffle, the same amount of squeezed clean water is discharged back to the car washing tank from the upper part of the center by the drainage pump, mud-water separation and water circulation are stopped after water in the car washing tank is qualified, and impurities and a small amount of residual water in the centrifugal drum are cleaned. The device is good in sludge-water separation effect, high in treatment efficiency, simple in structure, easy to operate and high in practicability.

Owner:中冶南方城市建设工程技术有限公司 +1

Pancake device for rapidly processing pancake

The invention discloses a pancake device for rapidly processing a pancake. The pancake comprises a cylinder seat, a fixed pawl array, a pancake disc, a sliding seat, a transmission fork strip array, asliding column, a guider and a rotating assembly. The fixed pawl array is composed of fixed pawls rotatably arranged at the bottom of the cylinder seat; the transmission fork strip array is composedof transmission fork strips; the rotating assembly is rotatably arranged in the cylinder seat and comprises a long-rod-shaped rotating long rod, a rotating handle, a flat-spreading support and a plurality of feeders; and each feeder comprises a tubular feeding tube and a feeding spiral bar, and the feeding spiral bars are rotatably and separably arranged in the feeding tubes. The multiple feedersare adopted, thus rice milk can be distributed on the pancake disc rapidly and evenly, the pancake manufacturing process is accelerated, and the thickness of the pancake is also more even.

Owner:吴振明

Filled filter plate of a disc filter

ActiveCN109011774BImprove filtering effectImprove hydrophobicityStationary filtering element filtersMoving filtering element filtersEngineeringFilter effect

A filled filter plate of a disc filter, relating to a filled filter plate, comprising an outer frame of the filter plate, an inner core is arranged inside the outer frame of the filter plate, and upper and lower inner surfaces of the outer frame of the filter plate Both are equipped with screen plates, and at least one vertical groove is arranged on the upper and lower sides of the inner core, and a plurality of through holes are arranged at intervals between the upper and lower sides of the inner core and the upper and lower sides of the groove. On the upper and lower sides of the core, and along the center line of the inner core, there are multiple groups of bump groups symmetrically arranged left and right. Each group of bump groups includes a plurality of obliquely arranged protrusions. The inner surface of the stencil is in contact with each other, and reinforcing ribs are arranged at intervals in a plurality of through holes. The inner surface of each screen plate is fixedly connected; the present invention has good filtering effect and light overall weight, and is provided with protrusion groups, so that the compressed air distribution is more uniform and fast during reverse blowing, and the cake is fully unloaded.

Owner:CITIC HEAVY INDUSTRIES CO LTD

Embedded screw

InactiveCN100479774CWill not adversely affect the use ofAffectInternal osteosythesisFastenersSpinal columnScrew thread

Owner:ULRIKH GMBKH & KO KG

A cold-shear shearing device and shearing process for finish-rolled rebar

ActiveCN112643124BImprove support stabilityFast even distributionShearing machinesShearing machine accessoriesClassical mechanicsEngineering

The invention provides a cold-shear shearing device and shearing process for fine-rolled threaded steel, which relate to the technical field of threaded steel bars, including a base, an electric telescopic rod one, a support seat, an electric telescopic rod two, shear knives, a fixed arm, and a fixed foot , auxiliary support assembly and rebar storage assembly; the present invention can reduce the arranging time of rebar by offering a limited slot 1 on the base; by being fixedly connected with a lifting rod and a support roller on the outside of the base, it can not only prevent the entering shear The rebar in the cutting area is supported, and it can also support the cut rebar section, so that the rebar is always in a horizontal state during the cutting process, without manual support, ensuring smooth feeding; by setting the limit plate , can prevent the threaded steel from falling off from the support roller, the present invention can collect the cut threaded steel waste by setting the collecting sloping plate and the baffle plate, and the baffle plate and the base are connected by sliding to facilitate the disassembly of the baffle plate.

Owner:JIANGSU BINXIN STEEL GRP

Ceramic circuit board

InactiveCN109788637AImprove breakdown voltageImprove pass rateCircuit susbtrate materialsAdhesiveFilling materials

The invention discloses a ceramic circuit board, comprising a metal substrate layer, a ceramic insulation heat conduction layer and a graphene heat dissipation coating; the ceramic insulation heat conduction layer covers the upper surface of the metal substrate layer, the graphene heat dissipation coating covers the lower surface of the metal substrate layer, and a circuit board is fixed on the upper surface of the ceramic insulation heat conduction layer, wherein the metal substrate layer is made of a high-thermal-conductivity alloy material, and the ceramic insulation heat conduction layer is composed of an adhesive and a ceramic inorganic filling material. The ceramic circuit board in the invention has excellent heat conductivity, the defect that the existing ceramic circuit board is brittle and hard is overcome, the ceramic circuit board is easy to cut and punch, the manufacturing cost is low, and the percent of pass is high.

Owner:江西增孚新材料科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com