Heat sink

A technology of a heat sink and a heat sink, which is applied in the directions of heat sinks, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of small contact area, inability to achieve breakthrough improvement in heat dissipation performance, and inability to quickly transfer heat from heat pipes to heat sinks. , to achieve the effect of increasing the contact area and high heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

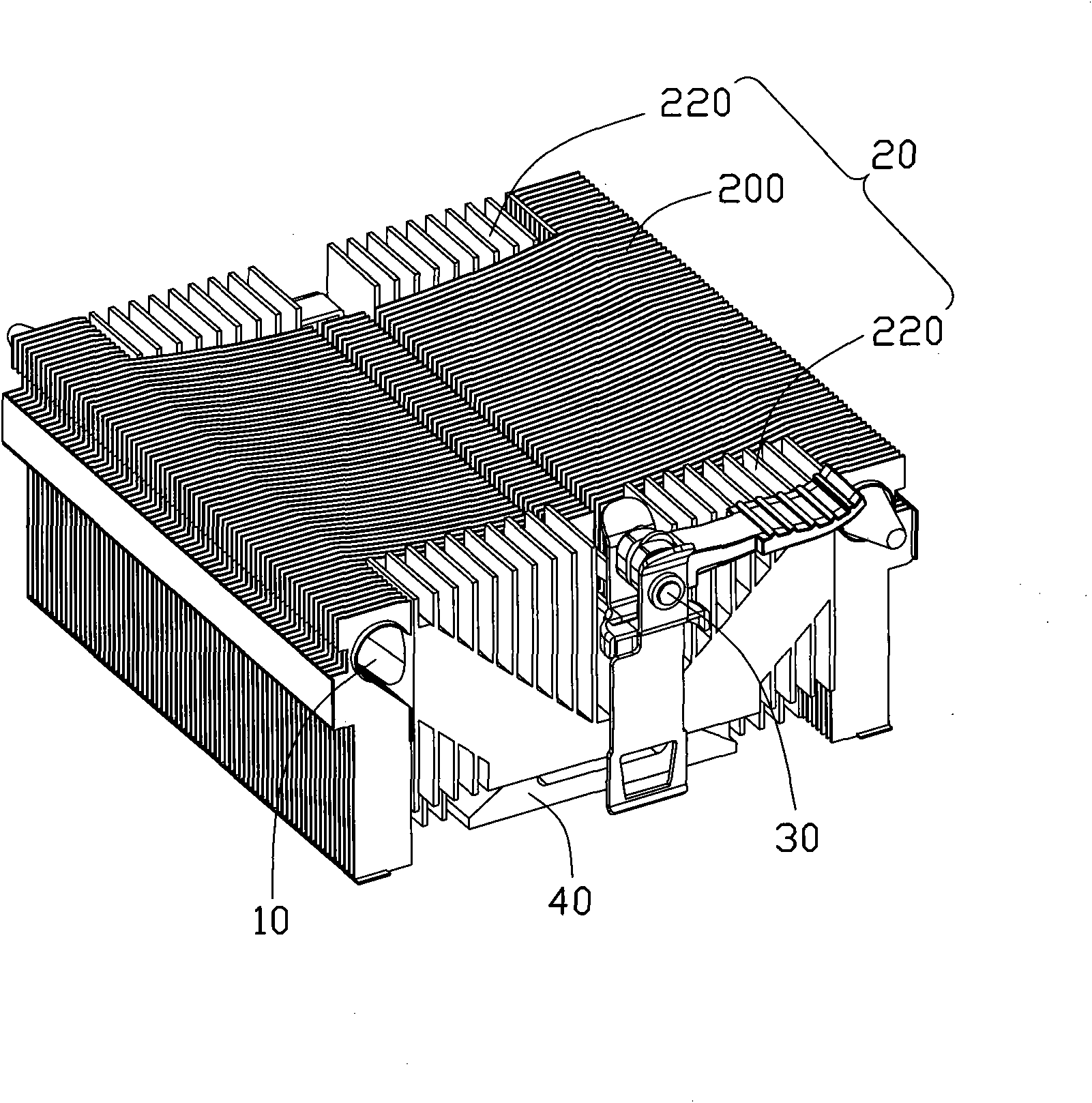

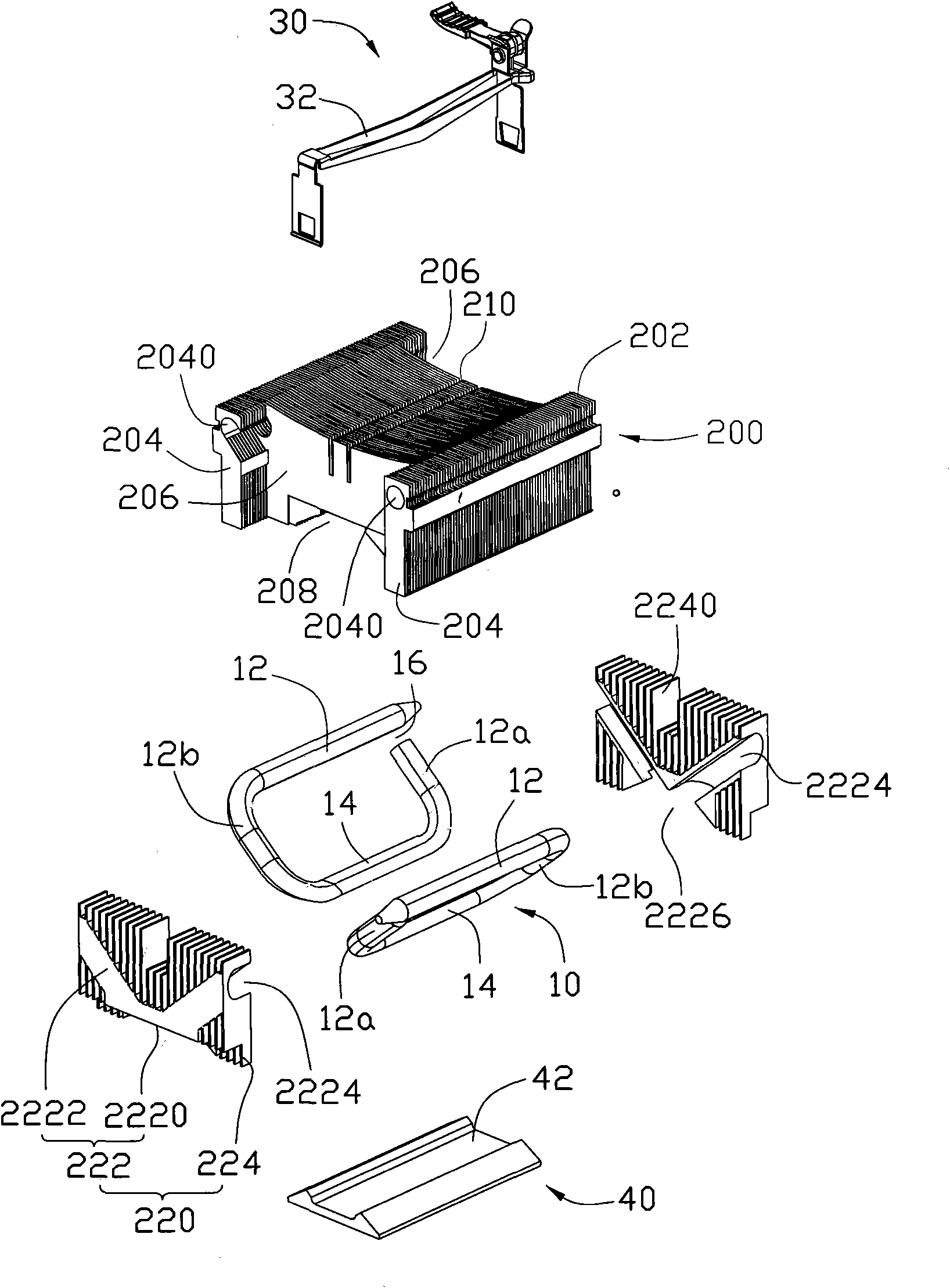

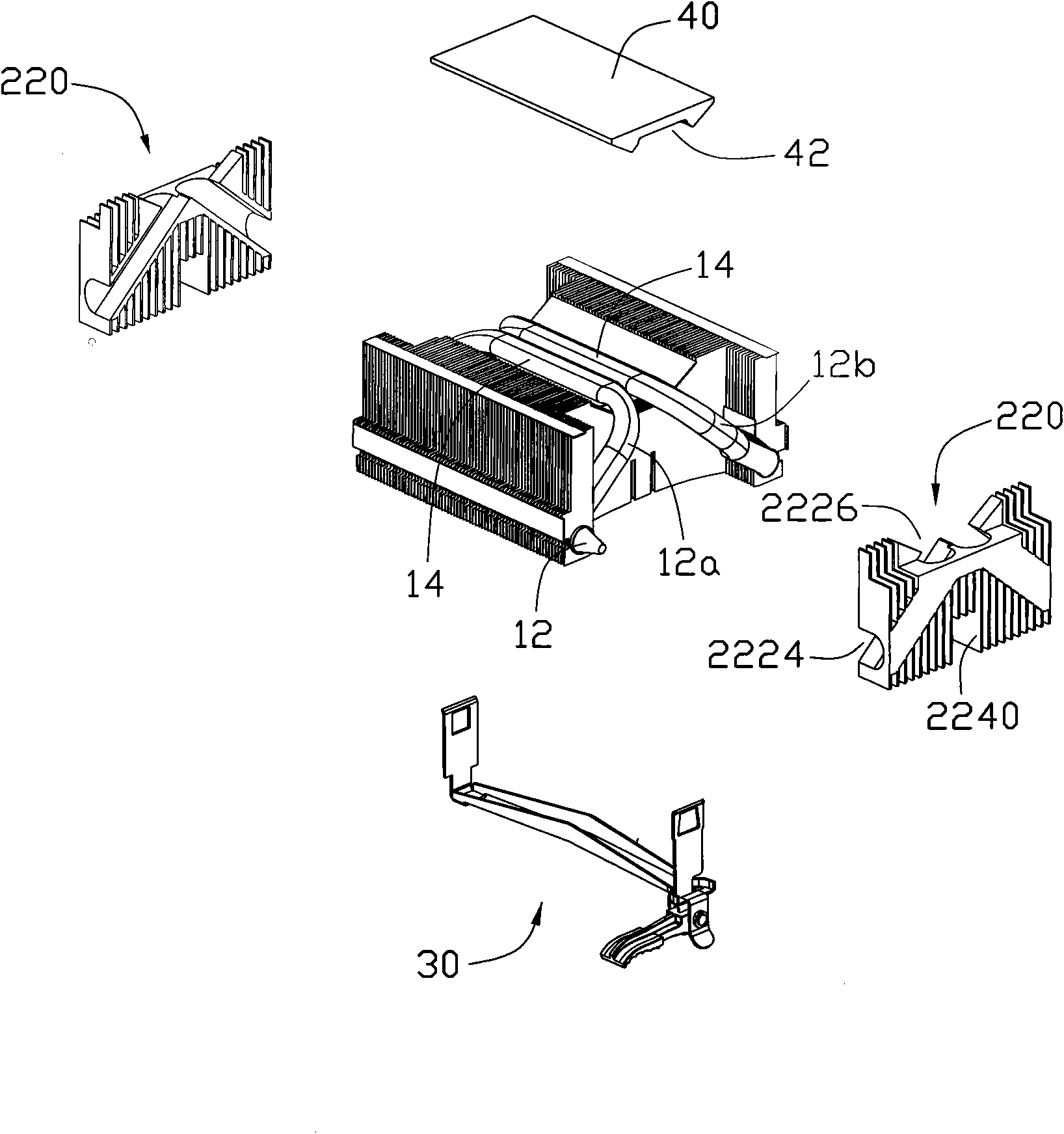

[0012] The heat dissipation device of the present invention will be further described below with reference to the accompanying drawings.

[0013] figure 1 and figure 2 Shown is a three-dimensional assembly and exploded view of a preferred embodiment of the heat dissipation device of the present invention. The heat dissipation device includes two heat pipes 10, a heat sink 20 and a fastener 30. The heat dissipation device cooperates with the fixing seat (not shown) on the circuit board (not shown) through the fastener 30 to make the heat dissipation The bottom end of the device 20 is in contact with a heat-generating electronic component (not shown) on the circuit board through a heat-absorbing plate 40, and absorbs its heat.

[0014] The two heat pipes 10 are disposed opposite to each other on the heat sink 20 . The heat pipes 10 are circular heat pipes bent and extended to form an open square frame structure. The sections where the two free ends of the heat pipe 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com