Ceramic circuit board

A technology of circuit boards and ceramics, which is applied in the direction of circuit substrate materials, printed circuit components, etc., can solve the problems of reducing the thermal conductivity of ceramic circuit boards, not easy to cut and punch holes, and high manufacturing costs, so as to achieve easy cutting and punching and high pass rate , to avoid the effect of brittle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

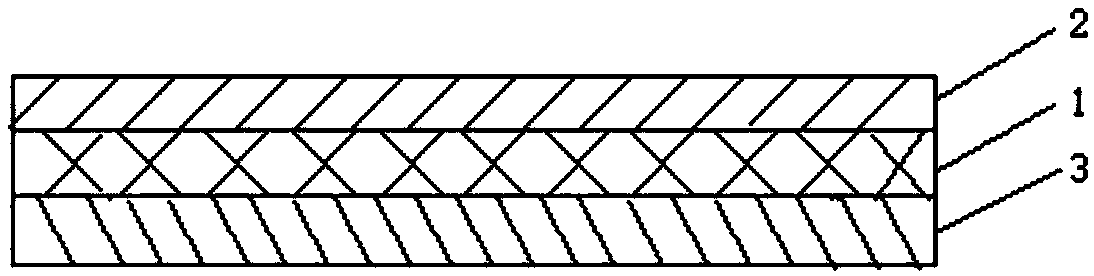

[0017] A ceramic circuit board, comprising a metal substrate layer 1, a ceramic insulating and heat-conducting layer 2 and a graphene heat-dissipating coating 3, the ceramic insulating and heat-conducting layer 2 covering the upper surface of the metal substrate layer 1, and the graphene heat-dissipating coating 3 covering the metal substrate layer 1 the lower surface, the ceramic insulating and heat-conducting layer 2 the upper surface is fixed with a circuit board.

[0018] Wherein, the metal substrate layer 1 is made of high thermal conductivity alloy material, and the thickness of the metal substrate layer 1 is any value within the range of 0.05-2 mm. Preferably, the metal substrate layer 1 is selected from one of copper substrate layers, aluminum alloy substrate layers or iron alloy substrate layers.

[0019] Working principle: After the circuit board is laid and packaged on the ceramic insulating and heat-conducting layer 2, the heat generated by the operation of the cir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com