Filled filter plate of a disc filter

A disc filter and filling technology, which is applied in the direction of fixed filter element filter, mobile filter element filter, filter separation, etc., can solve the problem of poor design of internal channel structure, inconvenient replacement of filter cloth, steel mesh plate Over-thickness and other problems, to achieve the effect of light weight, high rigidity, and full cake unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The invention can be explained in detail by the following examples, disclosing the objectives of the invention to protect all techniques in the scope of the invention.

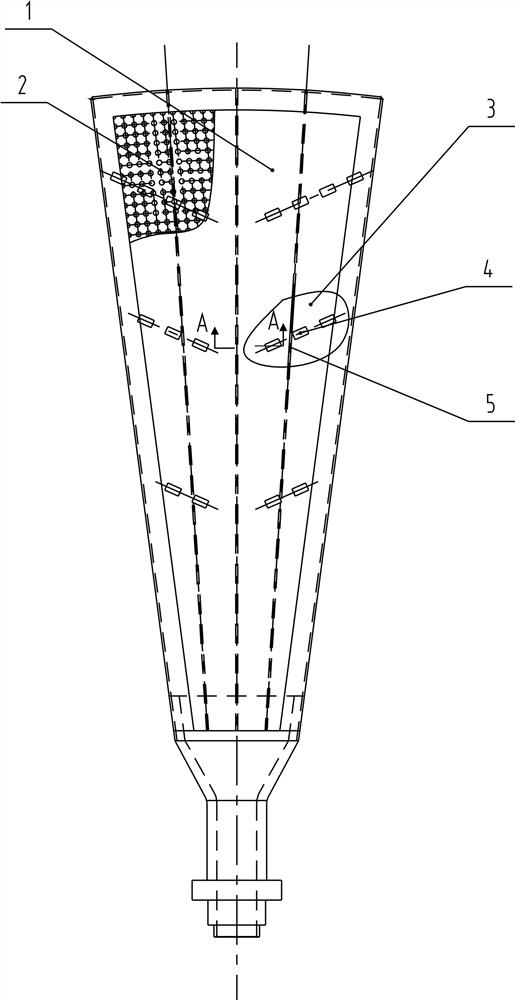

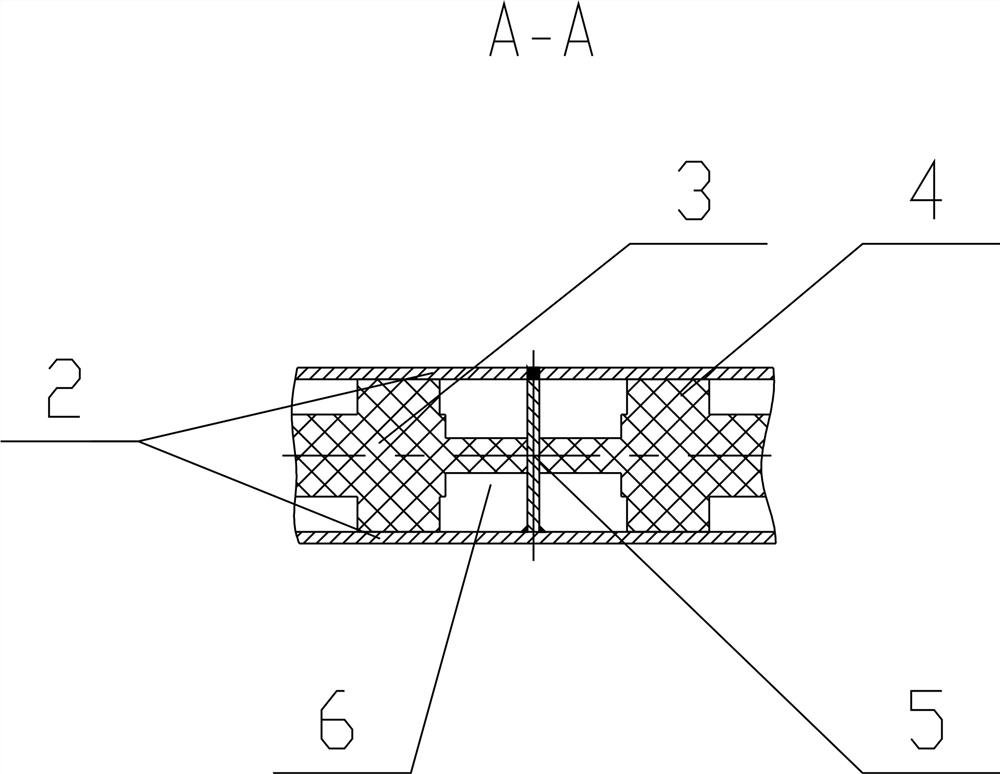

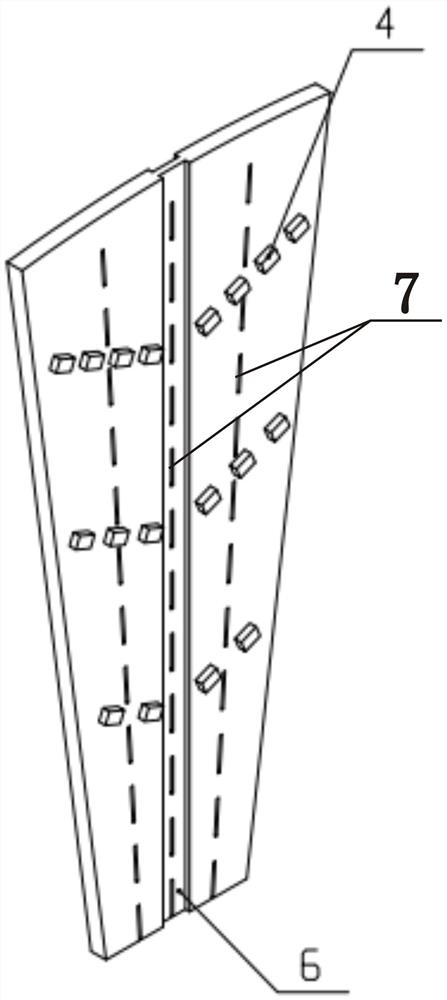

[0019] Join Figure 1-3 The filler plate of the disc filter includes the outer casing 1 of the filter plate, and the inner core 3 is provided inside the outer casing 1 of the filter plate. At least one vertical groove 6 is provided on the upper and lower surface of the inner core 3, and there is a plurality of through holes 7 between the upper and lower surfaces of the inner core 3 and the upper and lower surfaces of the groove 6, On the upper and lower surface of the core 3, and the center line of the core 3 is configured with a plurality of sets of bumps, each set of bumps groups include a plurality of inclined projections 4, up and lower end faces of the projection 4 The inner surface of the upper and lower mesh plates 2 is in contact with the inner portion of the plurality of through holes 7, and the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com