Patents

Literature

99results about How to "Slightly high" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

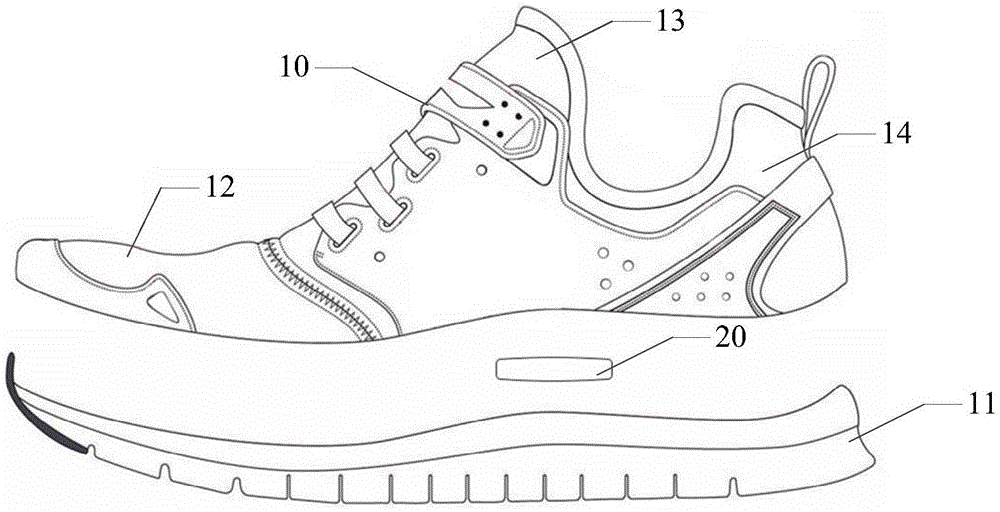

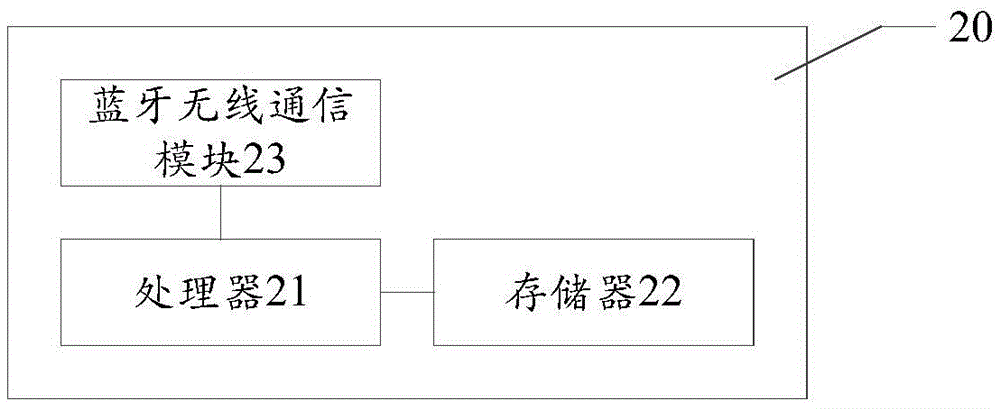

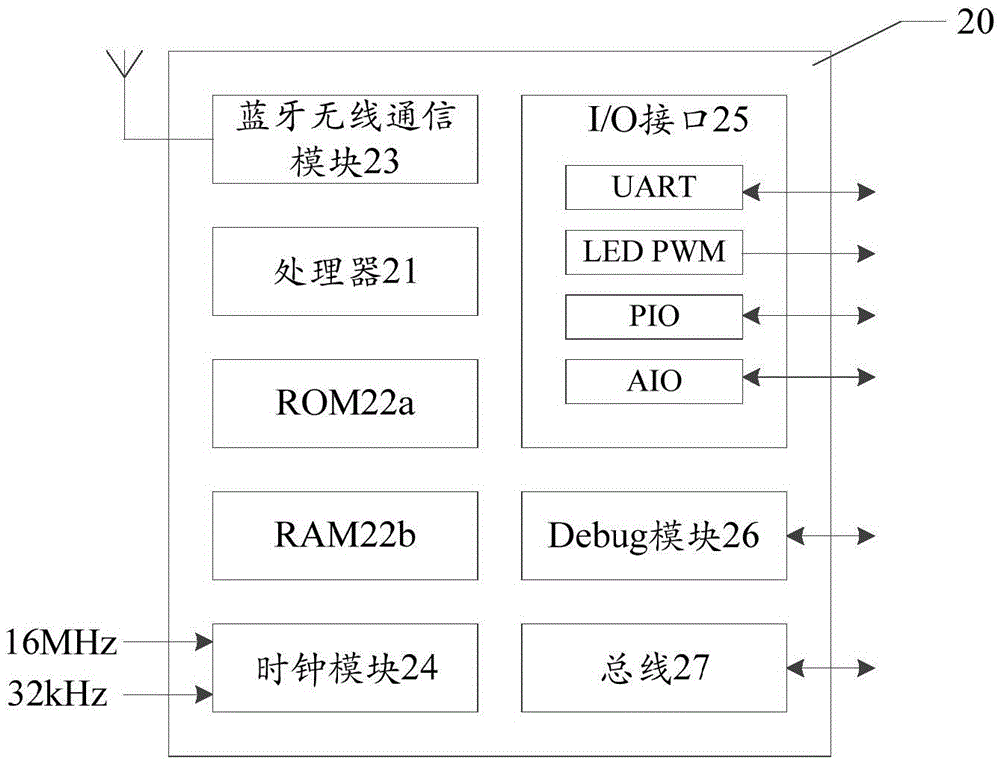

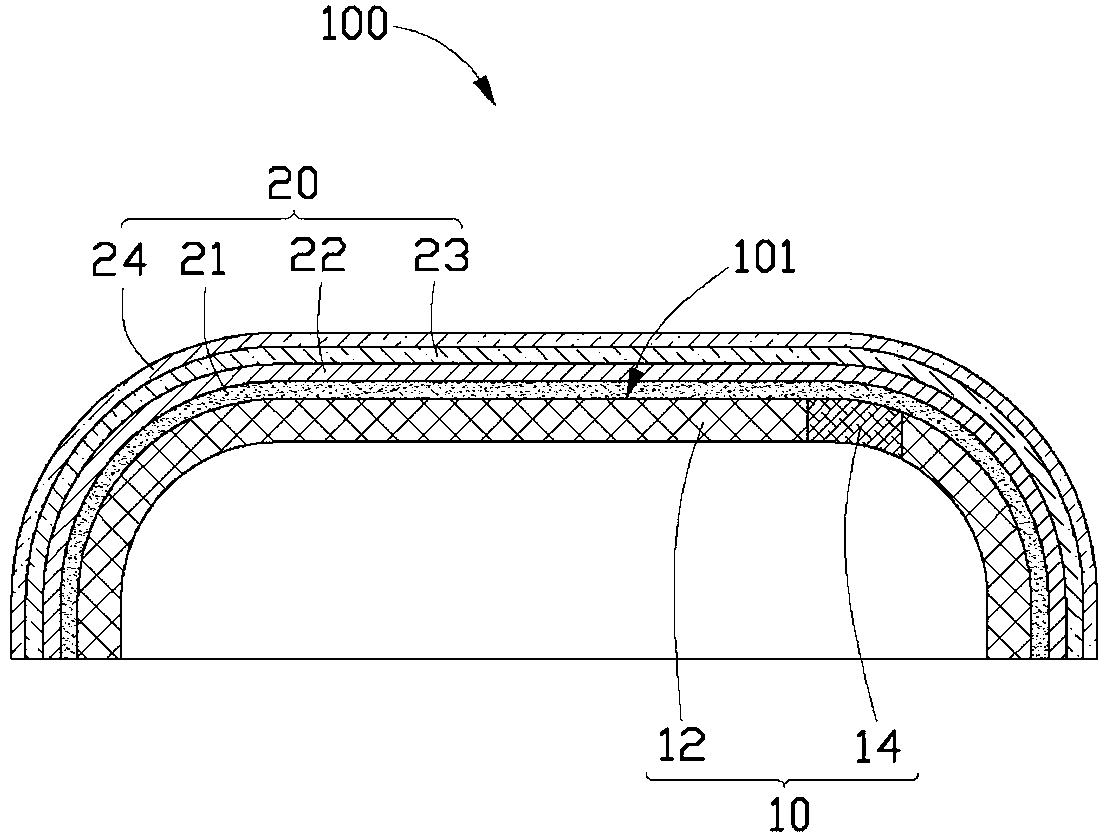

Intelligent shoe and positioning system based on same

The invention discloses an intelligent shoe and a positioning system based on the same, and belongs to the technical field of wearable equipment. The intelligent shoe comprises a shoe body, a Bluetooth chip arranged in the shoe body and used for realizing a positioning function, and a power supply battery for the Bluetooth chip; the Bluetooth chip comprises a processor, and a memory and a Bluetooth wireless communication module which are electrically connected with the processor; and the processor is used for controlling the Bluetooth wireless communication module to send a Bluetooth broadcast message to the outside, wherein the Bluetooth broadcast message includes an identifier of the Bluetooth chip. The Bluetooth chip is arranged in the shoe body of the intelligent shoe and realizes a positioning function. On the one hand, compared with a GPS (Global Positioning System) positioning module, the Bluetooth chip is smaller and is beneficial to improving the portability and the comfort of the intelligent shoe on the premise of realizing the positioning function; and on the other hand, compared with the GPS positioning module, the Bluetooth chip is lower in power consumption and electricity consumption.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Shell, electronic device using the same and manufacturing method thereof

InactiveCN103037642AReduce weightHigh strengthMagnetic/electric field screeningLaminationGlass fiberFiber

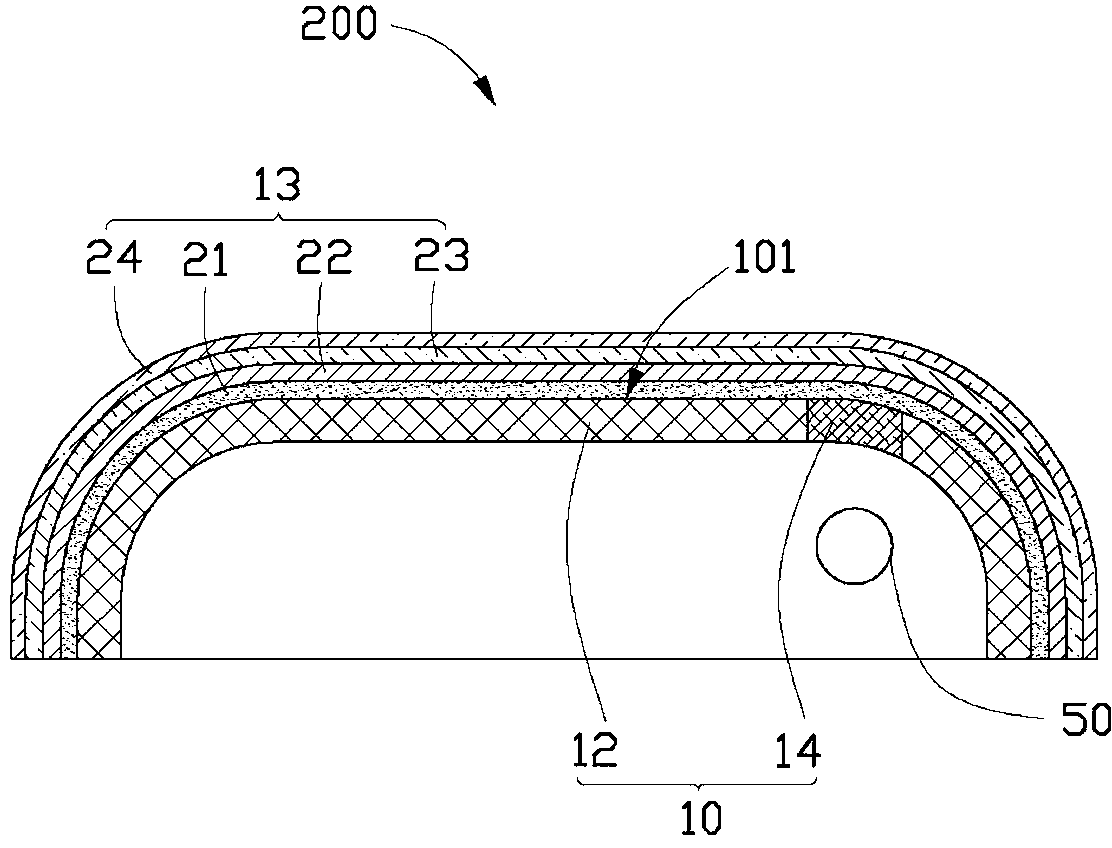

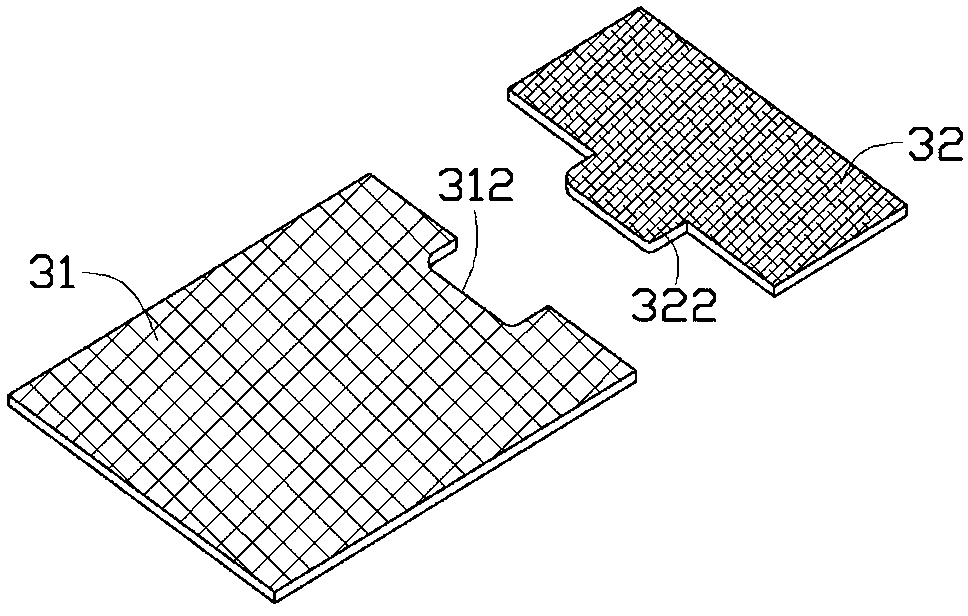

The invention provides a shell which comprises a base body and a decorative layer formed on the base body. The base body comprises a first part and a second part which is connected with the first part, the first part and the second part together forms the outer surface of the base body, the first part and the second part are all formed by woven fiber layers macerated with resin, the resin is formed on the surface of and inside the woven fiber layers, the woven fiber layers of the first part are formed by carbon fiber, the woven fiber layers of the second part are formed by glass fiber, and the decorative layer is formed on the outer surface. The invention further provides an electronic device using the shell and a manufacturing method of the shell.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD

Zinc alloy for manufacturing die

Owner:ZHUZHOU SMELTER GRP

Foamed water glass expanded perlite thermal insulating board

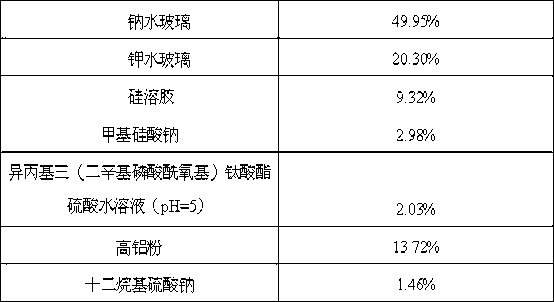

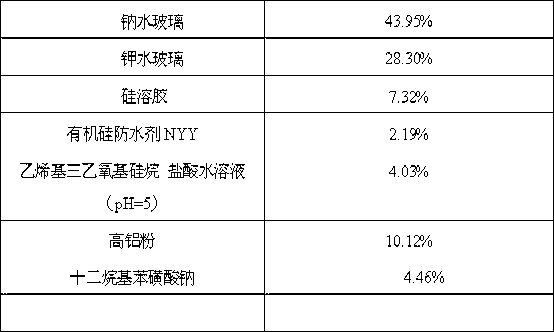

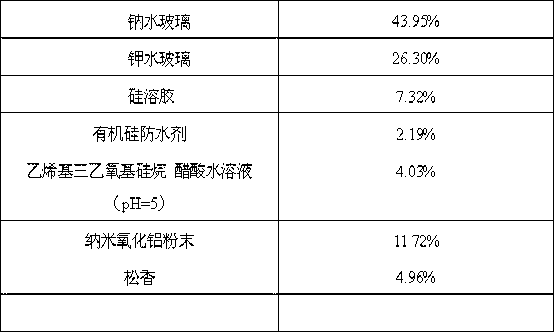

The invention provides a foamed water glass expanded perlite thermal insulating board, which is formed by pressing and drying modified foamed water glass as an adhesive and expanded perlite as an aggregate, wherein the water glass adhesive comprises the following components: sodium water glass, potash water glass, silica sol, an additive, a waterproofing agent, a stabilizer and a foaming agent. The prepared thermal insulating board has the advantages of low price, wide application range, low density, good water resistance, high strength, good thermal insulating performance and the like. In addition, the prepared thermal insulating board is foamed, so that the material consumption is saved, i.e. the cost is lowered.

Owner:NANJING TECH UNIV

Fumigating traction bed

ActiveCN106691819APlay the role of waist physiotherapyGood massageBathing devicesRoller massageMassageEngineering

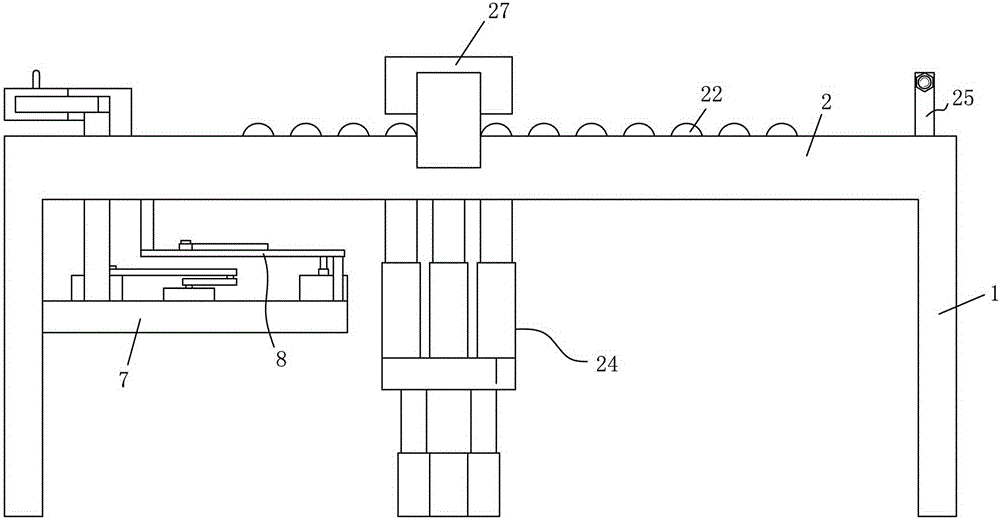

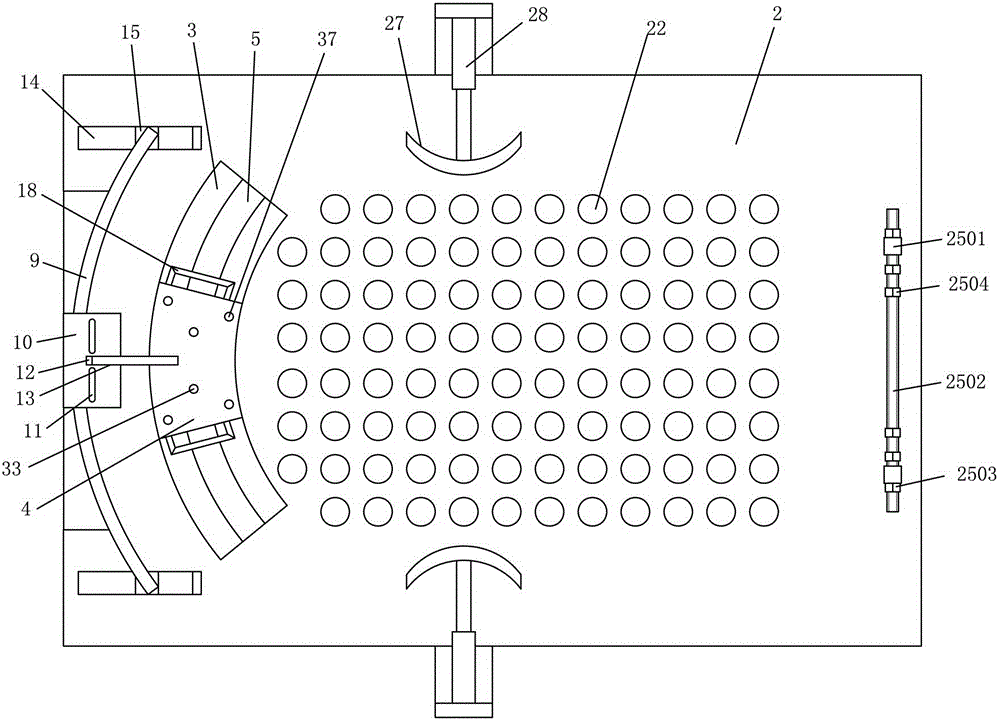

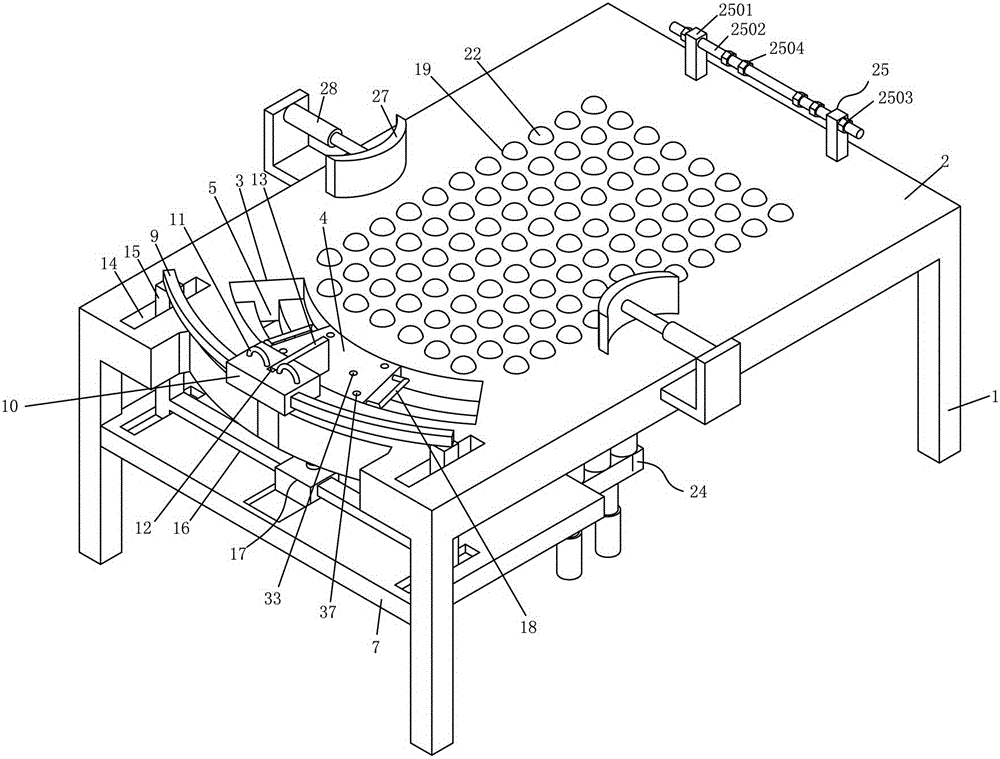

The invention provides a fumigating traction bed; the fumigating traction bed can perform multiple modes of physiotherapies on a human body, and carry out multiple modes of fused physiotherapies; the fumigating traction bed is high in selectivity, good in physiotherapy effect, has rolling contact with body, and massage function and waist supporting function; the bed can perform the fumigating treatment on every part of the human body conveniently. The fumigating traction bed comprises a bed board of which lower part is provided with supporting legs, wherein the upper end face of the tail part of the bed board is provided with an arc chute faced to the head opening of the bed board; a foot rest glidingly placed in the arc chute is arranged on the bed board; the bottom face of the arc chute at the lower end of the foot rest is provided with an arc hole which is concentric with the arc chute; the bottom part of the foot rest is downwards extended with a swaying rod crossing through the end part of the arc hole and placed at the lower part of the bed board; the swaying rod is swayed through a crank and rocker mechanism along the arc hole; multiple through holes are arranged on the bed board between the arc chute and the head part of the bed board; a circular placing groove is arranged on the upper end of the through hole; a column body is penetrated in the through hole; the upper end of the column body is provided with a roll bead in a rolling manner; the fumigating traction bed comprises a fumigating machine.

Owner:XINXIANG HUAXI MEDICAL SANITARY MATERIALS

A kind of preparation method of vacuum insulation panel

ActiveCN105970742BEasy to prepareImprove insulation performanceFibreboardSynthetic cellulose/non-cellulose material pulp/paperFiberGlass fiber

The invention relates to a preparing method for a vacuum heat insulation board. The preparing method comprises the following steps that firstly, glass beads, glass fibers, active carbon fibers and the like are mixed at a proportion; secondly, the mixture obtained in the first step and a methylcellulose saturated solution are fully stirred and mixed into a flocculent state; thirdly, the mixture obtained in the second step is uniformly poured onto a stainless steel screen according to the thickness requirement, and a vacuum heat insulation board core is obtained after airing, drying and cutting; fourthly, the vacuum heat insulation board core is put into an isolation packaging bag, vacuum pumping encapsulation is carried out, and the vacuum heat insulation board is obtained. In the first step, the glass beads account for 30-50%, the glass fibers account for 49-69%, and the active carbon fibers account for 1-6%. The mesh number of the screen is 60-90. The glass beads are hollow. The preparing method for the vacuum heat insulation board is easy and convenient to implement, the heat insulation effect of the vacuum heat insulation board is greatly improved, and meanwhile the vacuum heat insulation board is light, good in flexibility and capable of being bent by around 10%. Meanwhile, the problem of bulging is effectively solved through the screen airing and drying mode.

Owner:NANJING CENGO ENERGY SAVING MATERIAL

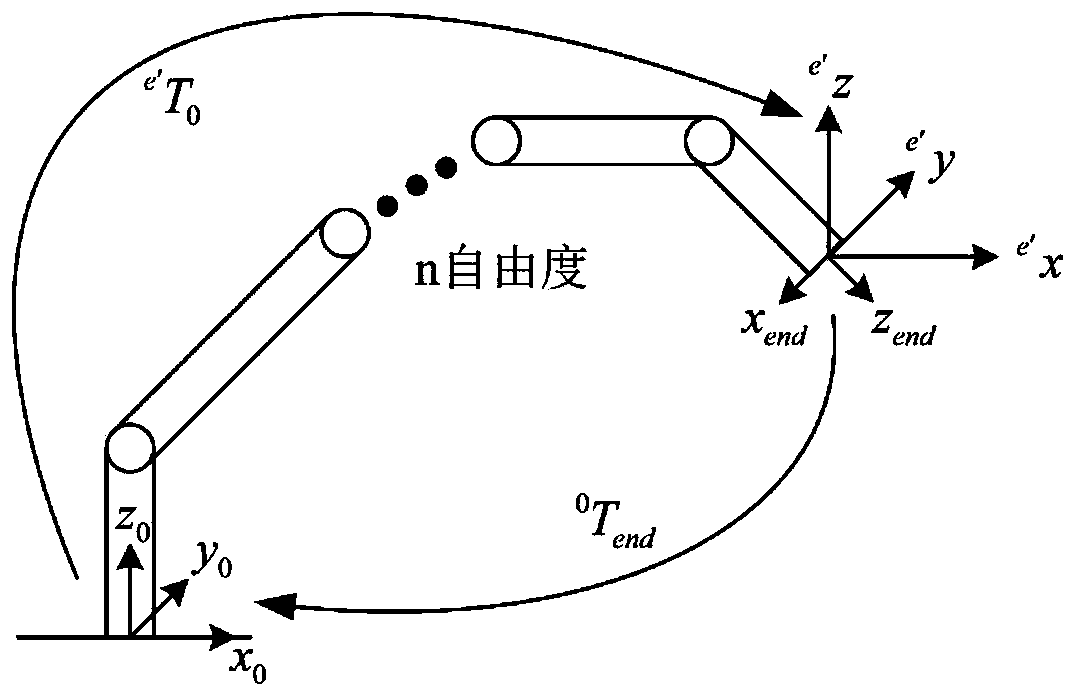

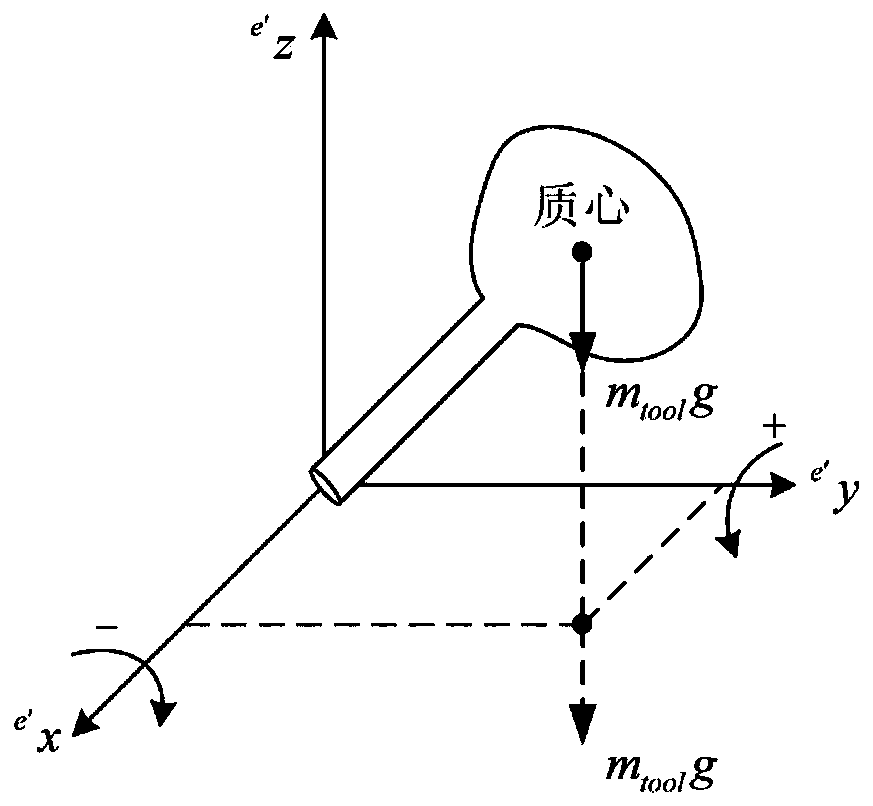

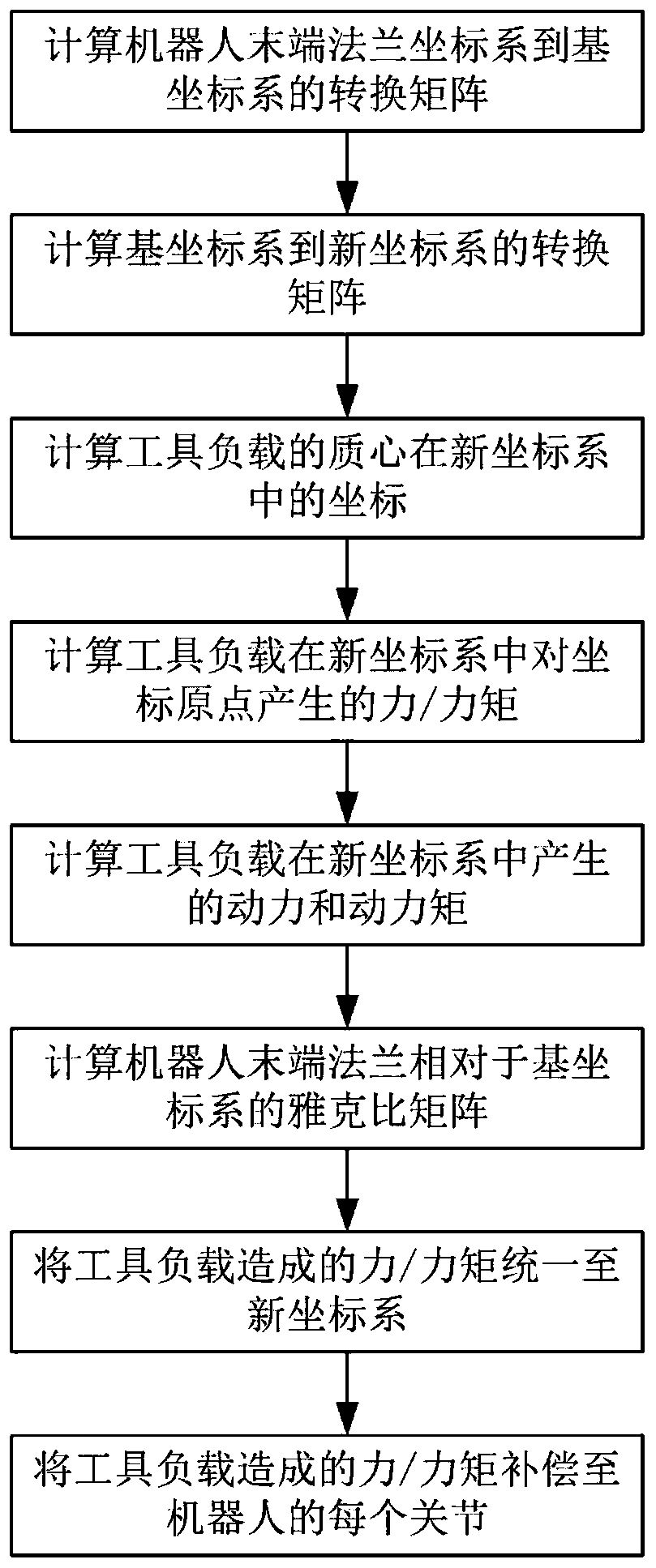

Tail-end load compensating method dragged by multi-degree-of-freedom cooperation robot

ActiveCN110666794AEasy to dragEasy load draggingProgramme-controlled manipulatorClassical mechanicsControl theory

The invention discloses a tail-end load compensating method dragged by a multi-degree-of-freedom cooperation robot. The method comprises the steps of 1, building a robot tail-end flange stress and torque mathematic model; 2, building a joint coordinate system, a base coordinate system, a tail end flange coordinate system of the robot and calculating transition matrixes for transition among the coordinate systems; 3, measuring load mass center parameters; 4, building a new coordinate system and calculating static force and static torque generated by a tool loaded at the original point of the new system; 5, calculating dynamic force and dynamic torque generated by the tool loaded at the original point of the new system; 6, calculating a Jacobian matrix of the robot tail-end coordinate systemrelative to the base coordinate system; 7, compensating for torque and force caused by the load of the tool to each joint of the robot. By compensating for force and torque generated by the load, therobot with the load is dragged more portably, and no extra force or torque sensor needs to be added.

Owner:TIANJIN UNIV

Low basis weight damp-proof coated white board and preparation method thereof

InactiveCN106436477AHigh strengthSlightly highFlexible coversCoatings with pigmentsWhiteboardPolymer science

The invention discloses a low basis weight damp-proof coated white board which comprises a coated base paper board and a damp-proof coating layer. By adding of a moisture proof agent into surface pulp and prime pulp of the base paper board and coating of the surface with the damp-proof coating layer, the damp-proofing function can be cooperatively realized. The invention further discloses a preparation method of the damp-proof white board. The preparation method comprises the following steps: (1) slurry preparation, (2) dehydration and forming, (3) squeezing, (4) pre-drying, (5) coating, (6) after-drying, and (7) splitting. The white board prepared based on the preparation method is high in printing surface intensity and physical intensity and high in damp-proofing property; a user product is light in weight, and the packaging cost of a user is reduced; the production cost and the transportation cost of an enterprise are reduced; the market competitiveness is enhanced.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

Diamond/Si (Al) composite preparation technological method by vacuum infiltration method

InactiveCN108257880AImprove thermal conductivityReduce bloatSemiconductor/solid-state device manufacturingOrganic solventElectronic packaging

The invention discloses a diamond / Si (Al) composite preparation technological method by a vacuum infiltration method, which belongs to the field of electronic packaging materials. The method is characterized by comprising steps: the vacuum infiltration method is adopted to mix silicon powder, aluminum powder and an organic binder according to a proper proportion, and being wetted to a paste by using an organic solvent is carried out; then, diamond particles are added, uniform stirring is carried out, uniform mixing by using a mixer is carried out, and a porous prefabricated billet with a regular shape is pressed; degreasing treatment is then carried out and the organic binder is decomposed completely; the porous billet is then put in a vacuum infiltration furnace and is buried by the silicon powder, sealing and vacuuming are carried out, the temperature rises above the melting point of silicon, liquid infiltration is carried out, compactness of the porous billet is realized, and a diamond / Si / Al composite with a regular shape, high compactness and excellent thermal physical properties can be prepared. The composite is a potential matrix material for electronic packaging, and has theadvantages of high thermal conductivity, low expansion, low density, high lightness, easy preparation, and little later processing difficulty.

Owner:UNIV OF SCI & TECH BEIJING

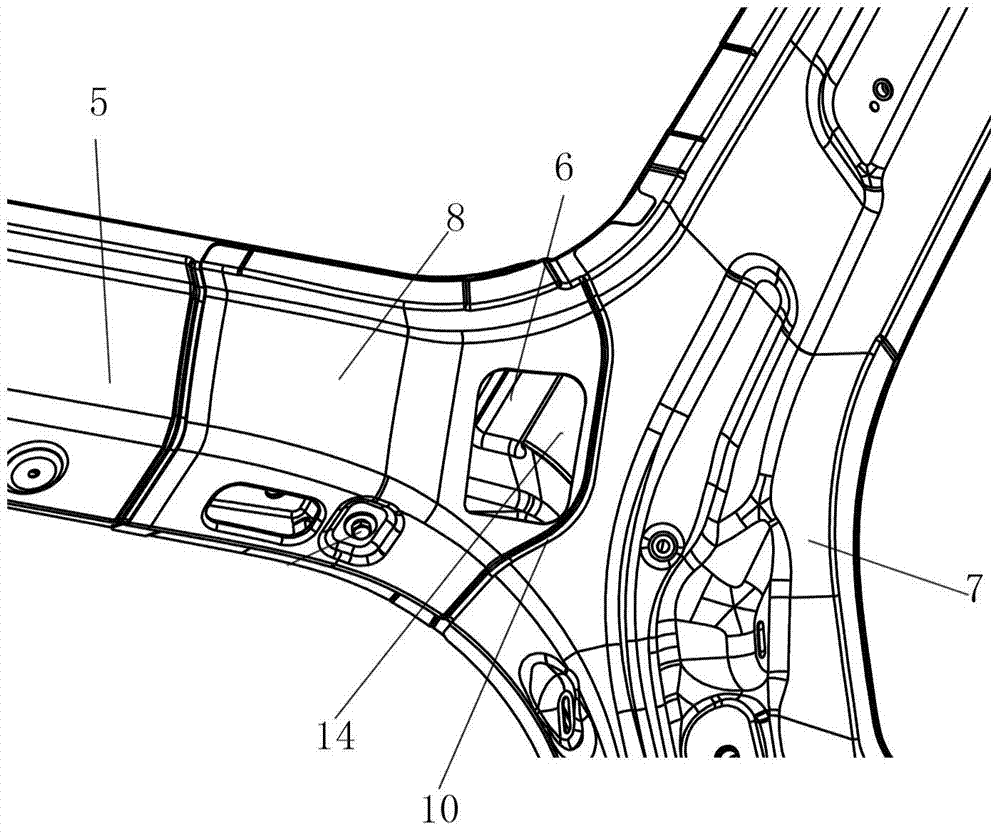

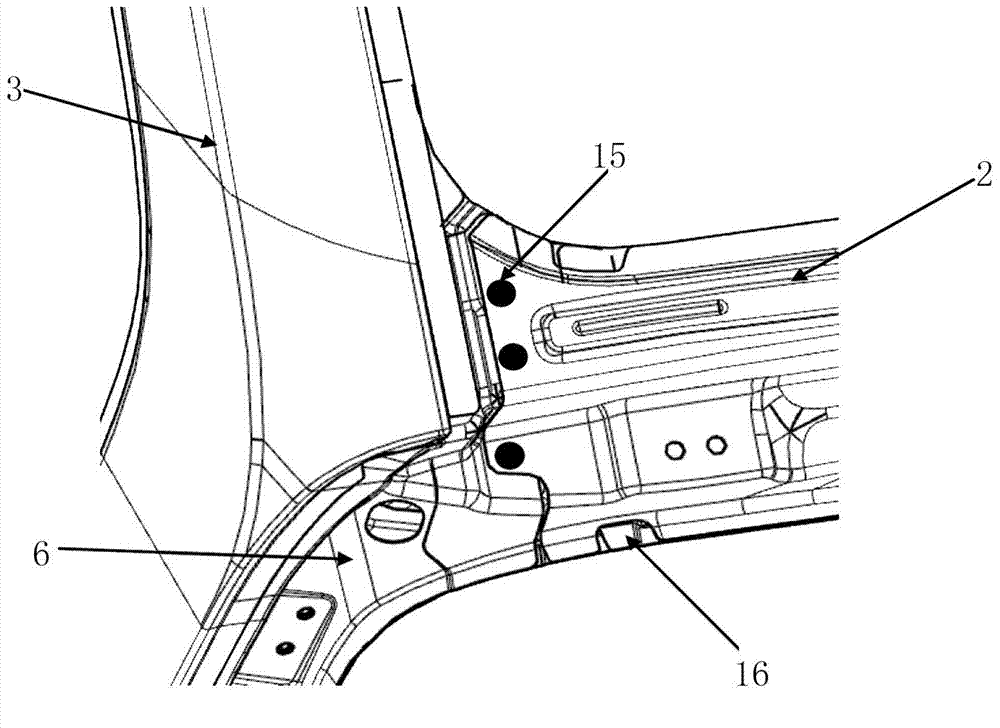

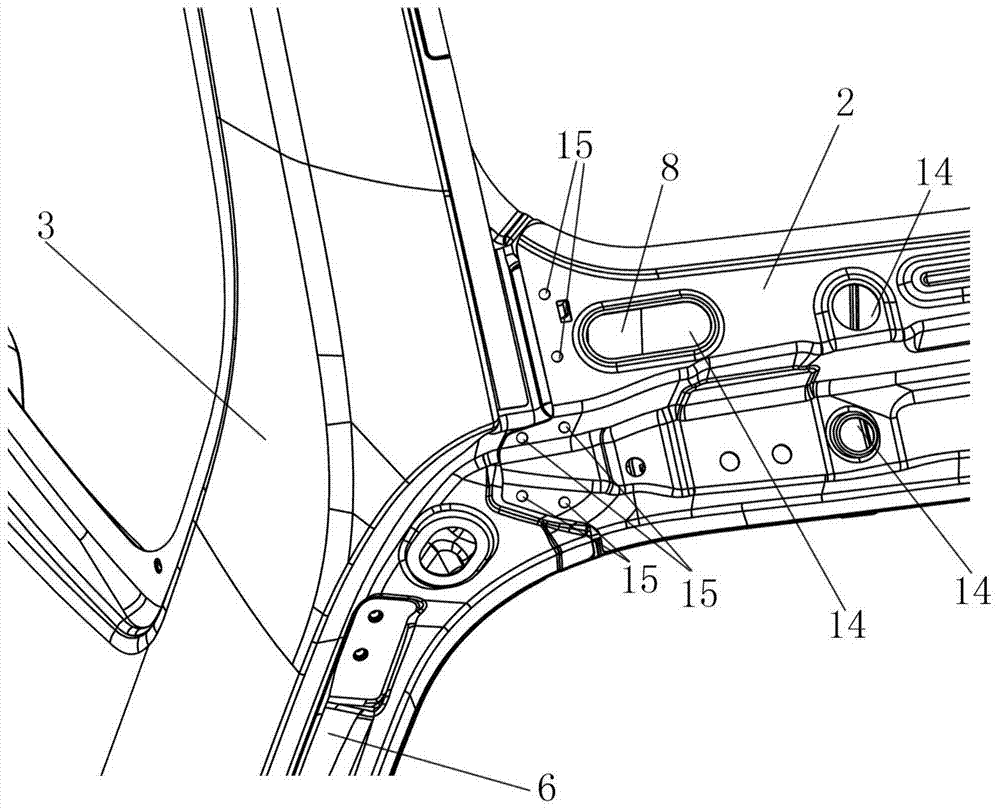

D-column upper end joint structure

ActiveCN103661618AEasy to fixReduce the draw depthSuperstructure subunitsStress concentrationDiagnostic Radiology Modality

The invention discloses a D-column upper end joint structure which comprises a top cover, a rear beam outer board, a rear beam inner board, an Upper D-column reinforcing board, a rear surrounding outer board, an Upper D-column outer board and a rear surrounding inner board. The rear surrounding outer board is welded and fixed to the Upper D-column outer board. The cut edge of the Upper D-column reinforcing board and the cut edge of the rear surrounding inner board are arranged in a staggered mode. The Upper D-column reinforcing board is of an L shape, an arc transitional section is arranged in the middle of the Upper D-column reinforcing board, and the upper portion of the Upper D-column reinforcing board extends to one side so that an extending portion can be formed. An inward-recessed arc elbow is arranged at the top of the rear surrounding inner board. The root portion of the extending portion is welded to the arc elbow of the rear surrounding inner board. The Upper D-column reinforcing board and the rear beam outer board are detachably and fixedly connected. The Upper D-column outer board is welded and fixed to the rear beam outer board. The Upper D-column outer board, the rear beam outer board and the top cover are welded and fixed. According to the D-column upper end joint structure, the structure is simple, stress concentration is effectively reduced, the phenomenon that stress concentration is generated due to the arrangement of a notch is avoided, the part forming efficiency and the material use rate are improved, and the modality of a body in white is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Preparation method of flame-retardant regenerated paperboard

InactiveCN105862495AGood flexibilitySlightly highNon-fibrous pulp additionMechanical working/deformationCardboardPhosphate

The invention discloses a method for preparing flame-retardant recycled cardboard, which comprises the following steps: a method for manufacturing a recycled corrugated paper core: mixing regenerated pulp and plant fiber pulp that have undergone impurity removal and filtration treatment, and then blending, adding Alginate is used to produce recycled raw material paper, and the recycled raw material paper is pressed and cut into corrugated cores; the production method of flame-retardant panel paper: flame-retardant polylactic acid polymer, phosphated starch-polyurethane and calcium carbonate are used as raw materials to make flame-retardant Burn the raw material paper, cut the flame retardant raw material paper into panel paper; cardboard composite: glue the upper and lower sides of the corrugated paper core and the panel paper with adhesive, and the product is ready. The method for preparing flame-retardant recycled cardboard provided by the invention has good flexibility and strength, and excellent flame-retardant properties, and is suitable for use as carton packaging materials.

Owner:JURONG DINGSHENG CARTON PACKING

Electric safety fence

Owner:GUODIAN UNITED POWER TECH

Briquette binder using potato starch as raw material, and preparation and application thereof

InactiveCN102766421AImprove adhesionSlightly highNon-macromolecular adhesive additivesSolid fuelsPotato starchPreservative

The invention provides a briquette binder using potato starch as a raw material. The briquette binder is prepared from raw materials comprising potato starch, a stabilizer, an oxidizing agent, a preservative and a complexing agent in a certain proportion. The briquette binder with strong cohesiveness prepared by the invention can be used for preparation of coke and has small additive amount; and the prepared coke has high strength. Besides, the preparation technology is simple, uses cheap and easily available raw materials, and has low cost and good application prospect in preparation of briquette.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Biomass-based colour glaze tile and production process thereof

The invention belongs to the field of energy-saving and environmental-friendly new materials, and particularly relates to a production process of a biomass-based colour glaze tile. The biomass-based colour glaze tile is produced according to the following steps: (1) using a pulverizer to crush plant straw to obtain plant straw powder; (2) mixing stones, quartz sand and fragments of bricks according to an arbitrary proportion to obtain a mixture, and smashing the mixture to obtain mountain flour; (3) mixing the mountain flour, the plant straw and an additive; (4) conducting layered laying of the mixed raw materials; (5) compressing the raw materials with a roller press; (6) cutting the raw materials, and using a die to conduct the pressure maintaining after cutting to obtain the composite colour glaze tile. The biomass-based colour glaze tile is high in strength, is lighter in quality when being compared with that of a colour steel plate, has good freezing resistance, sun protection performance, cold and hot shock resistance and anti-aging performance, and is more energy-saving and environmental-friendly.

Owner:ANHUI ZHONGZHENG AGRI TECH DEV CO LTD

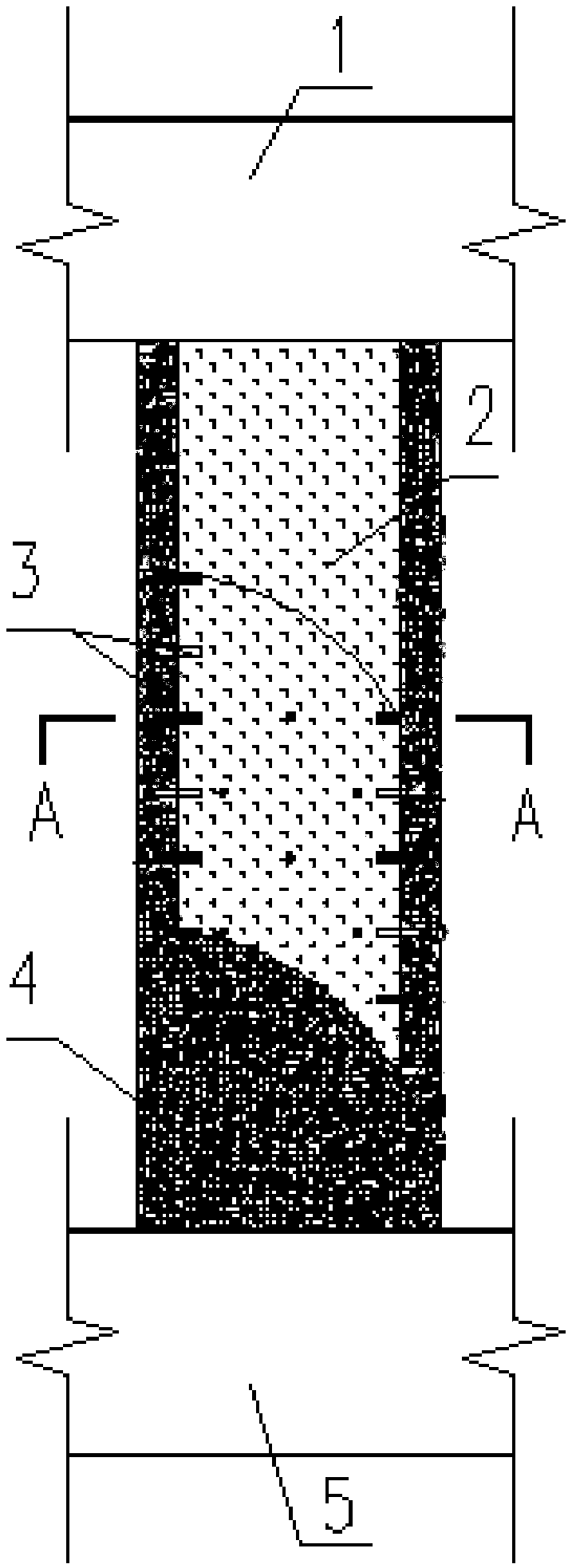

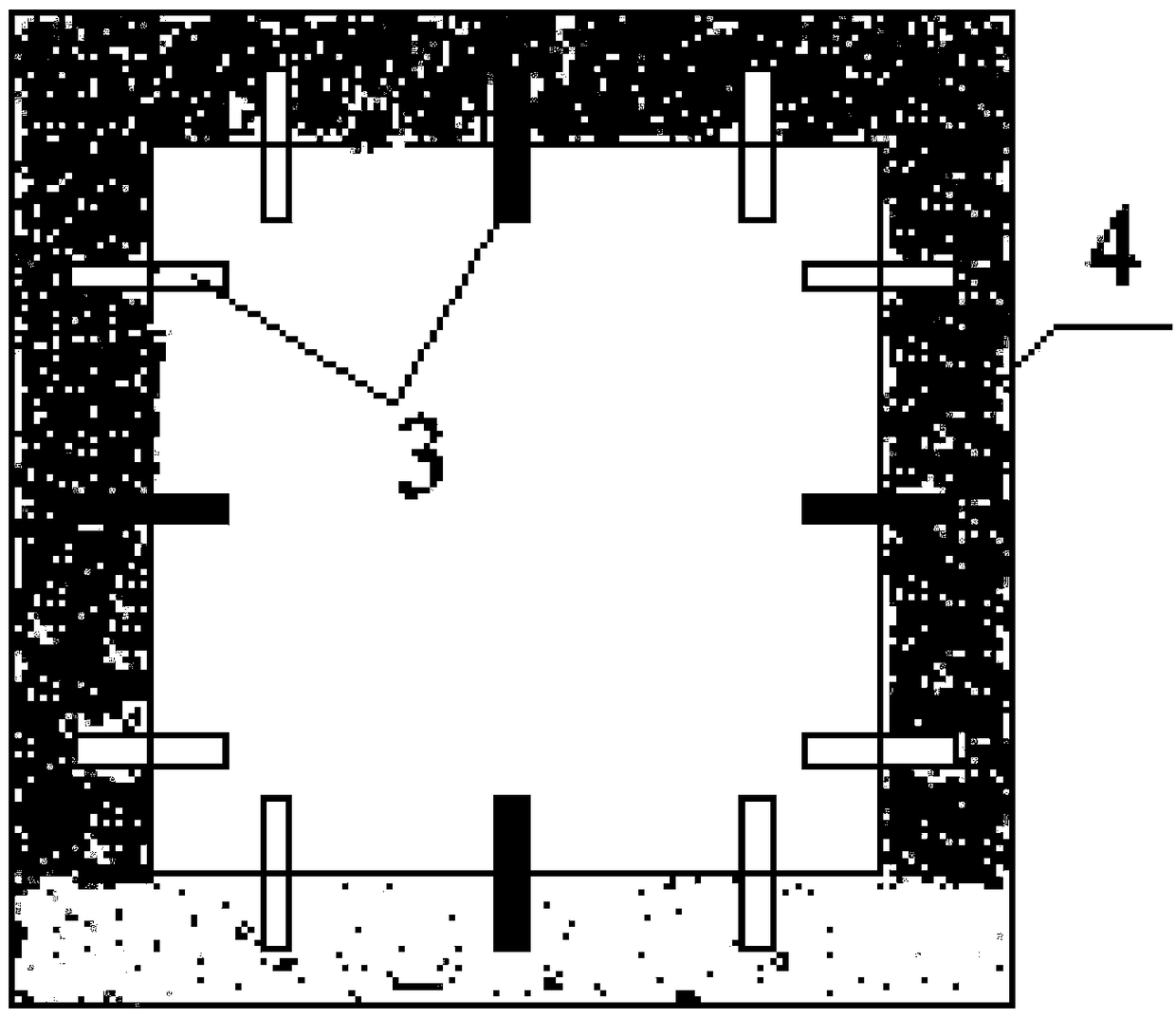

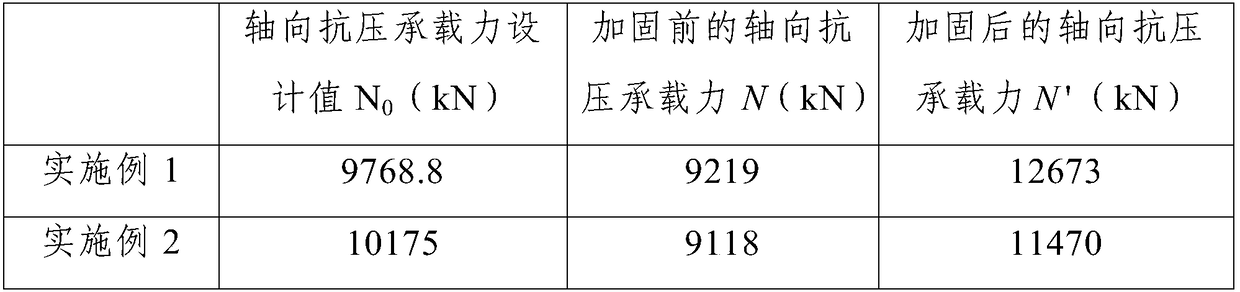

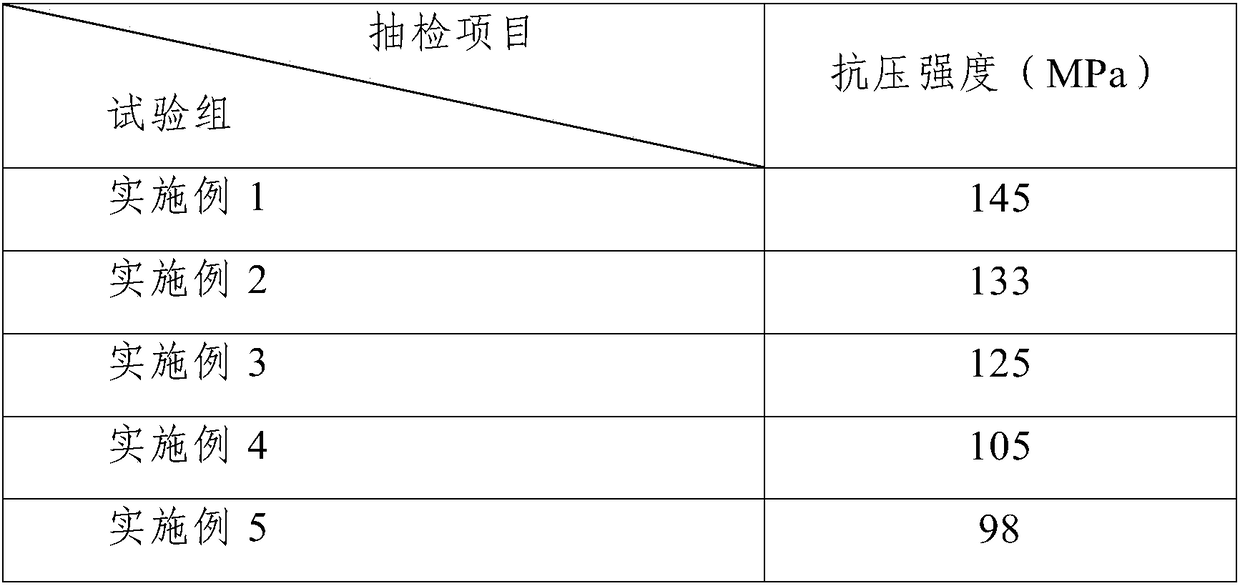

Method for reinforcing concrete columns by adopting UHPC

The invention discloses a method for reinforcing concrete columns by adopting UHPC. The method comprises the steps that 1, rough chiseling treatment is conducted on the surfaces of concrete columns; 2, multiple shear-resistant steel bars are implanted into the surfaces, undergoing rough chiseling treatment, of concrete columns, and parts of shear-resistant steel bars extend out of the surfaces ofthe concrete columns; 3, the surfaces of the concrete columns with implanted shear-resistant steel bars are coated with the UHPC until the UHPC completely wraps the parts, extending out of the surfaces of the concrete columns, of the concrete columns and the shear-resistant steel bars, and UHPC layers are formed. According to the method, the UHPC containing silica fume, sand and steel fiber is directly applied to the surfaces of the concrete columns with implanted shear-resistant steel bars to form the UHPC layers, the UHPC layers are bonded with original concrete to form a whole after reinforcement, the overall structure performance of the concrete columns is improved, the plastic deformation capability of the concrete columns is ensured, timber formworks are not needed in the reinforcement process, the reinforcement cost is reduced, the reinforcement speed is improved, and the use area of a building is not affected.

Owner:陕西建研结构工程股份有限公司

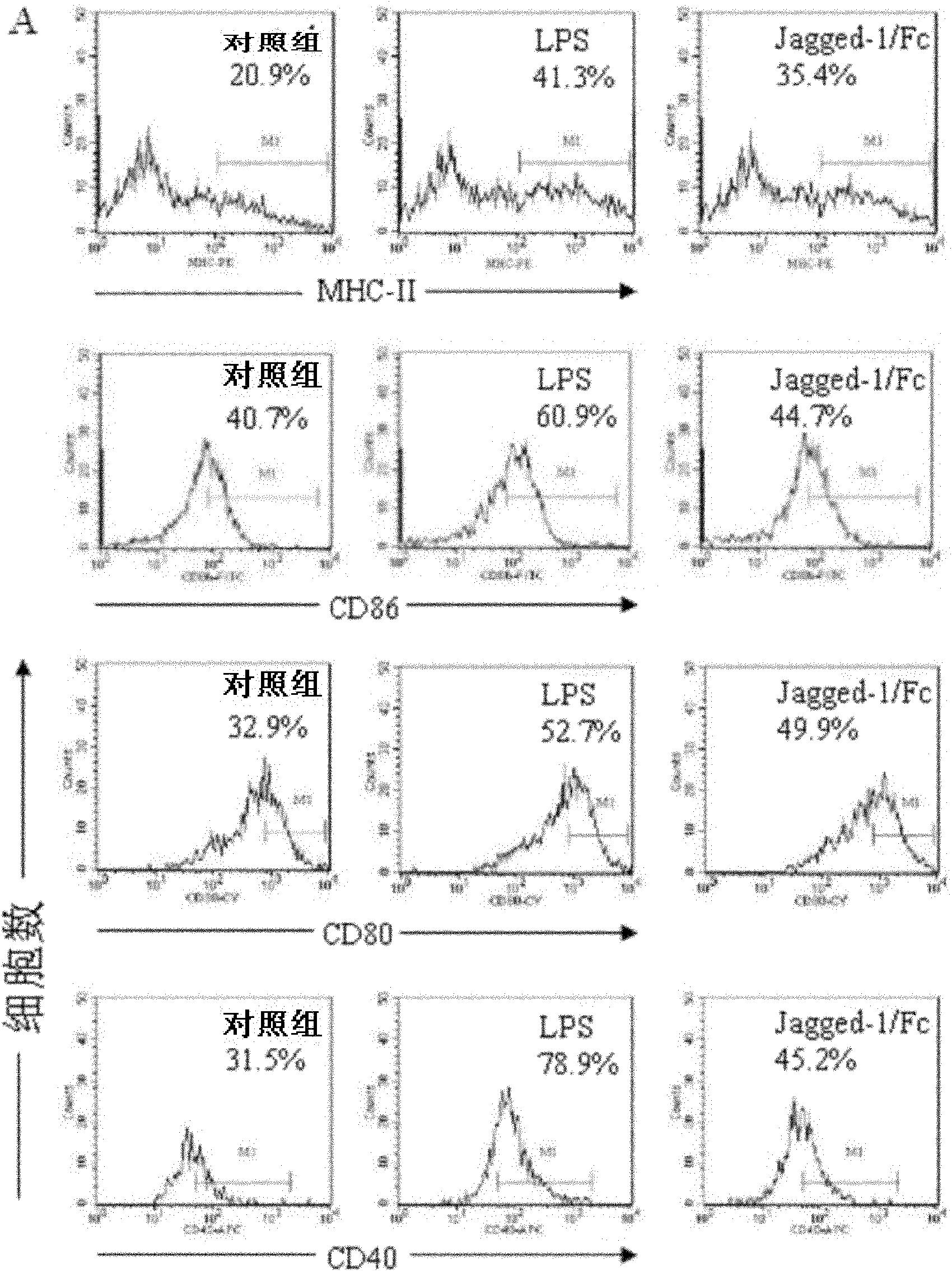

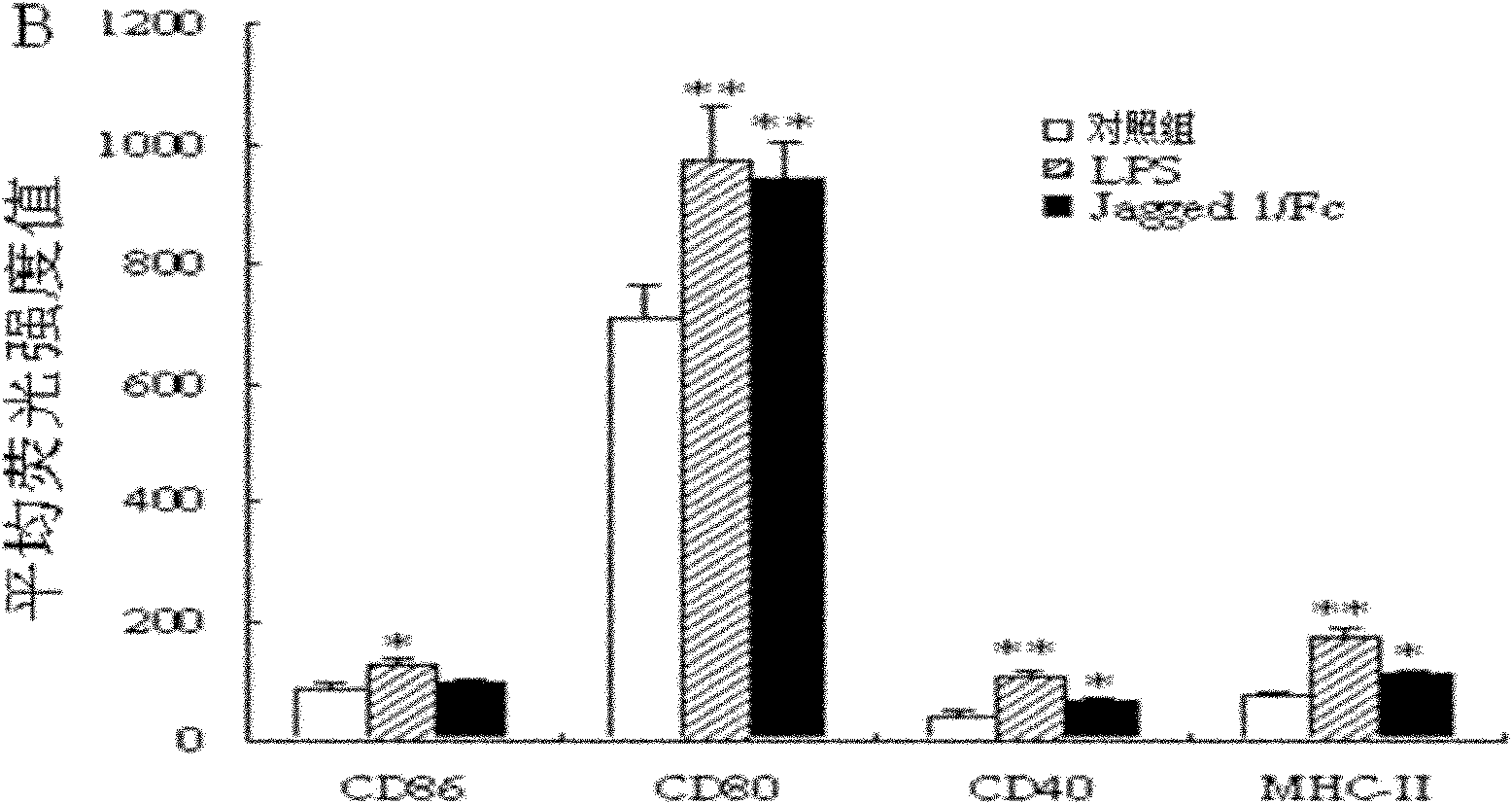

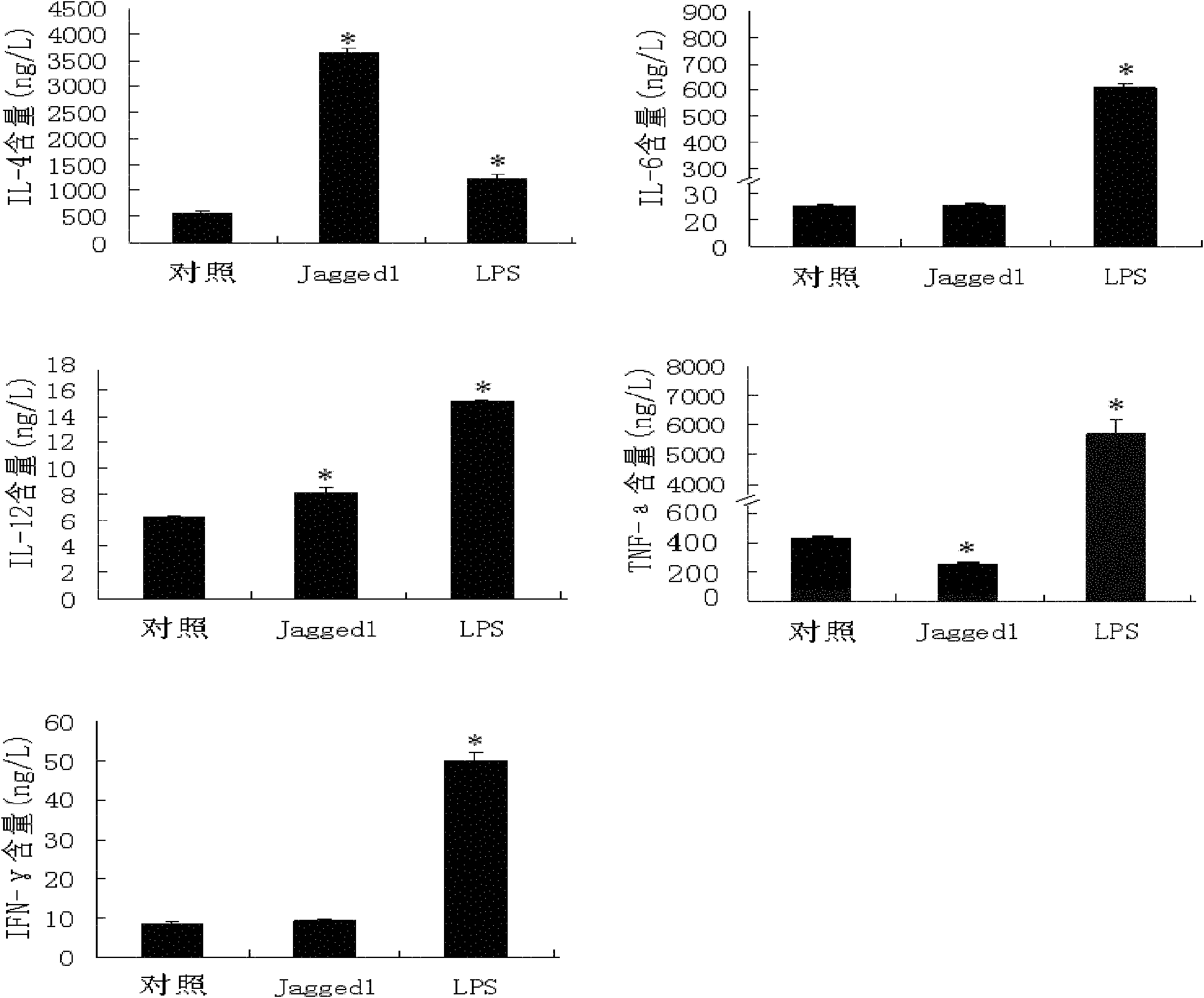

Method for in-vitro preparation of semimature dendritic cells

InactiveCN102154199AInduction of immune toleranceLower levelSkeletal/connective tissue cellsBlood/immune system cellsInterleukin 4Granulocyte macrophage colony-stimulating factor

The invention discloses a method for in-vitro preparation of semi-mature dendritic cells, which comprises: collecting suspension of mouse bone marrow cells, centrifuging, lysing, suspending cells in a Roswell Park Memorial Institute (RPMI) 1610 complete culture medium, adding recombinant murine granulocyte macrophage colony stimulating factor (rmGM-CSF) at a concentration of 10 to 20 mu g / L, recombinant murine interleukin 4 (rmIL-4) at a concentration of 2.5 to 10 mu g / L and Jagged-1 / Fc at a concentration of 1 to 5mg / L, incubating, collecting loose anchorage-dependent cells, resuspending cells in a complete culture medium, adding the rmGM-CSF, rmIL-4 and Jagged-1 / Fc in the same amount, collecting loose anchorage-dependent cells, adding the rmGM-CSF and rmIL-4 in half amount and Jagged-1 / Fc in the same amount in the 6th to 8th day, and collecting loose anchorage-dependent cells, namely semi-mature DCsJagged-1. The cells are only treated by Jagged-1 / Fc, and can reduce the immune response capability of allogeneic lymphocytes and help to induce immune tolerance.

Owner:JINAN UNIVERSITY

Ultra-high-performance fiber concrete and production method thereof

ActiveCN108409235ASlightly highImprove compactnessSolid waste managementSuperplasticizerWell cementing

The invention discloses ultra-high-performance fiber concrete, comprising cement, silica fume, sand, steel fiber, polypropylene fiber, a polycarboxylate superplasticizer, an organosilicon defoaming agent and water. The silica fume in the fiber concrete improves compactness and homogeneity for the concrete; the sand has filling and framework functions; stress can be effectively transmitted, and load can be effectively supported; contraction and cracking of the concrete are inhibited; the steel fiber inhibits and restrains the occurrence and development of microcracks in the concrete, so that the concrete has improved toughness and ductility. The invention also discloses a preparation method of the concrete, comprising: stirring well cement, silica fume, polypropylene fiber and sand, addingthe polycarboxylate superplasticizer, organosilicon defoaming agent and 90% by total mass of water, adding steel fiber, stirring well, adding the rest 10% of water, and stirring well. The production method has reasonable process and good simplicity as well as high efficiency.

Owner:陕西建研结构工程股份有限公司

Water-based board adhesive and preparation method thereof

InactiveCN106634694ASuitable for mass production for personal useSimple processNatural rubber adhesivesNon-macromolecular adhesive additivesWater basedSulfite salt

The invention discloses a water-based board adhesive and a preparation method thereof. The water-based board adhesive is composed of the following components in parts by mass: 8-10 parts of asbestos powder, 10-12 parts of natural latex, 1-2 parts of formaldehyde, 2-4 parts of polyorganosiloxane, 2-4 parts of sodium sulfite, 3-4 parts of urea, 2-3 parts of sodium hydroxide, 1-2 parts of dicyandiamide, 5-7 parts of polyvinyl alcohol, 2-4 parts of formic acid, 3-5 parts of complexing agent and 1-2 parts of anti-aging agent. The technique is simple, is suitable for mass production and self use for companies, and is low in cost. The water-based board adhesive can effectively resist water, has the advantages of environment friendliness and low formaldehyde release amount, and achieves the CARB2 standard. The adhesive can enhance the lightness and strength of the plywoods when being used for greater-curvature plywoods and light-weight plywoods.

Owner:浦北县建业胶合板有限责任公司

Ultrahigh-strength thermal insulation material and preparation method thereof

The invention provides an ultrahigh-strength thermal insulation material and a preparation method thereof, and belongs to the field of new high-strength thermal insulation materials. The preparation method comprises the following steps: impregnating quartz chopped reinforced fiber felt with phenolic resin to obtain a prepreg; solidifying the prepreg in an oxygen-enriched environment to obtain thethermal insulation material; performing thermal insulation on the thermal insulation material in oxygen-enriched environment at 320-380 DEG C for 2-6 h to obtain the ultrahigh-strength thermal insulation material. The thermal insulation material prepared with the method meets the requirement that the tensile strength of the vertical surface of the national building exterior wall composite materialis higher than 150 Kpa proposed by JG149-2003, and the tensile strength of the vertical surface of the material can reach 4 Mpa or higher.

Owner:BEIJING SATELLITE MFG FACTORY

electric safety fence

Owner:GUODIAN UNITED POWER TECH

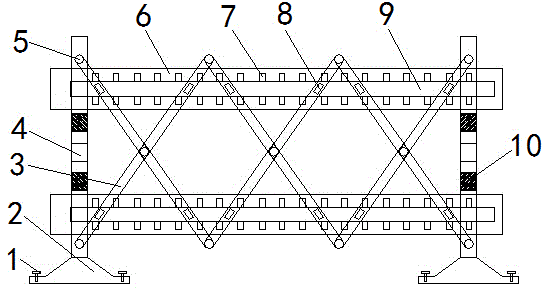

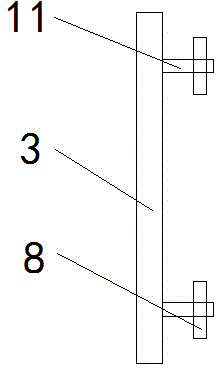

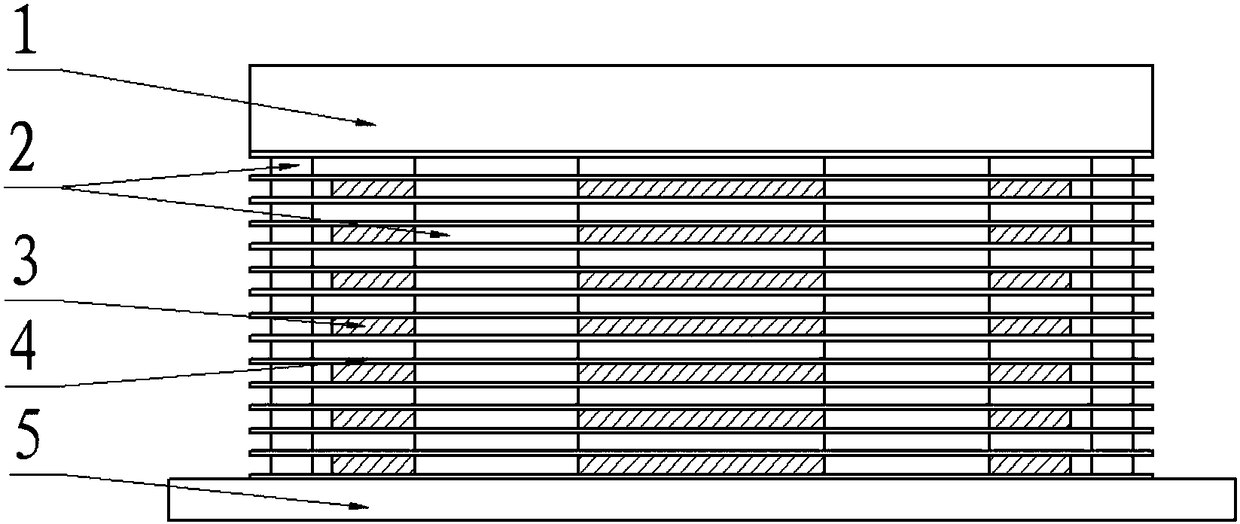

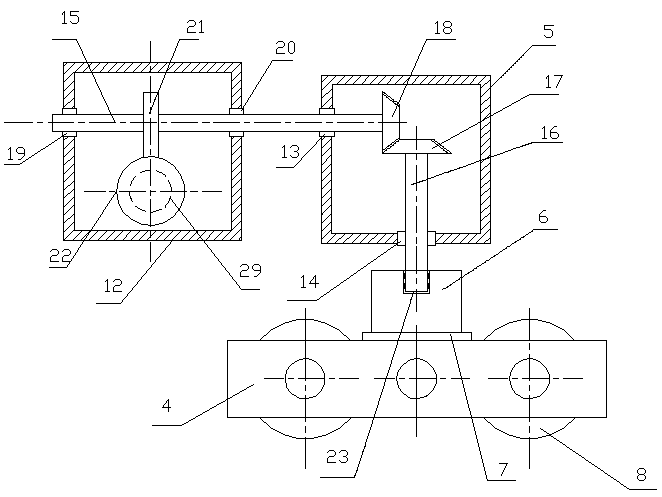

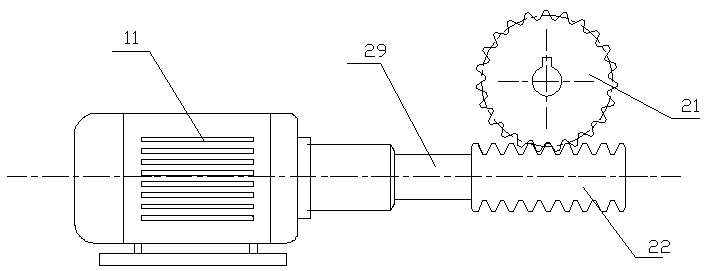

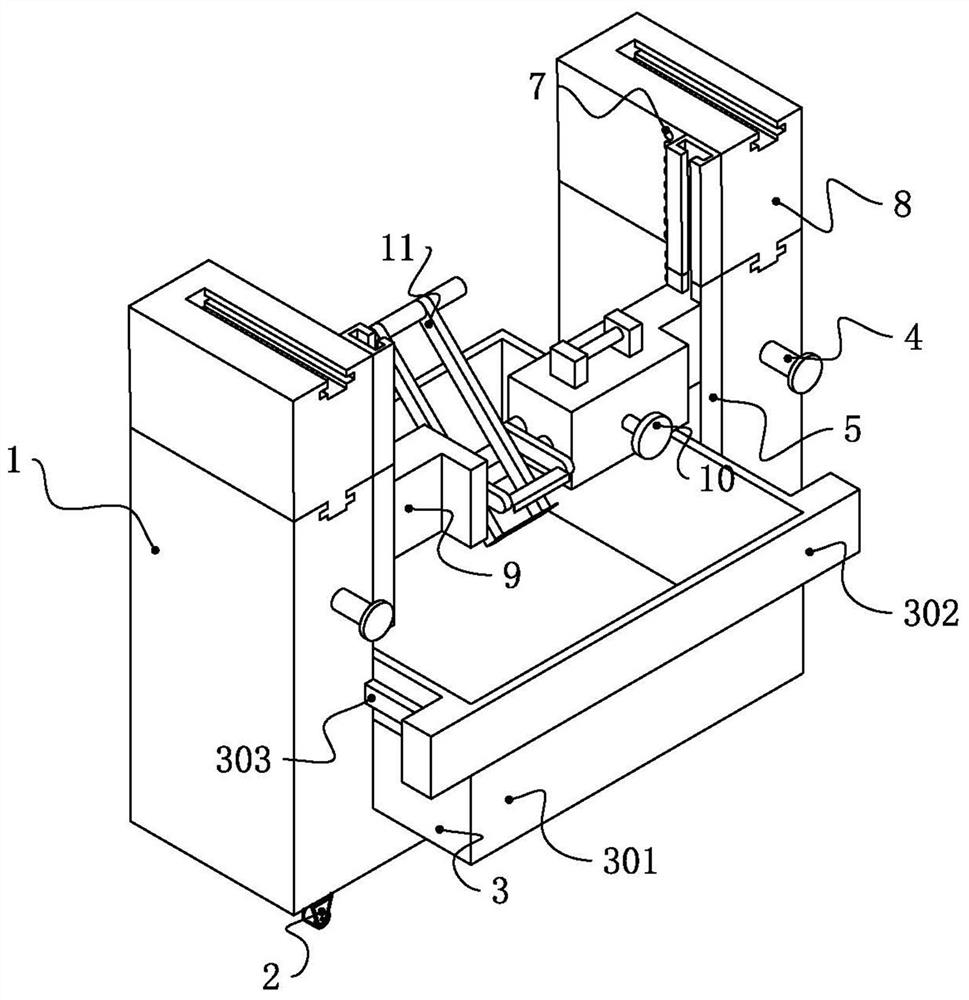

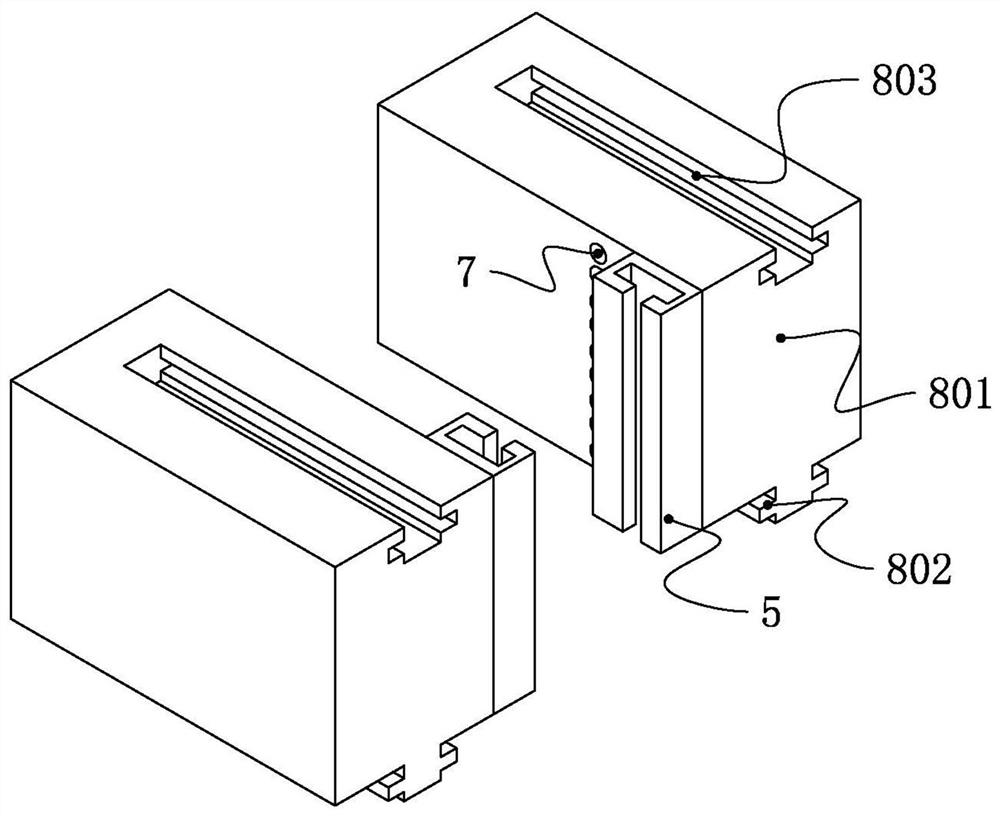

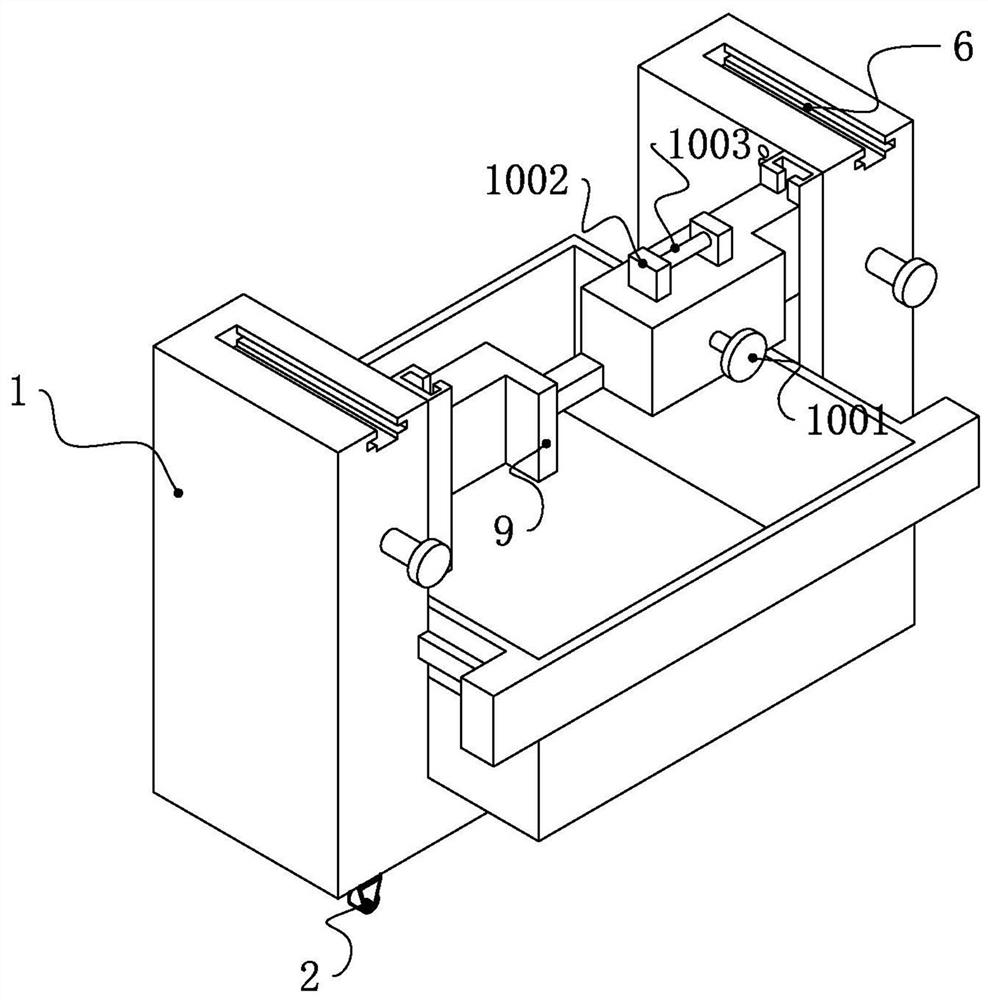

Automatic moving trolley with vertical and horizontal direction steering function and steering method

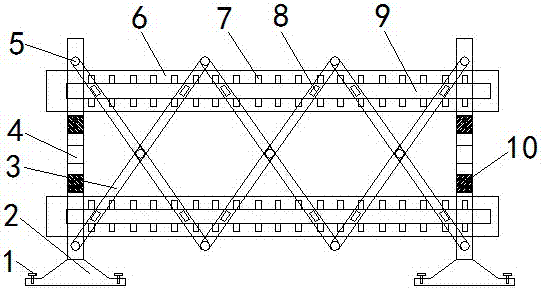

PendingCN108442944ATranslation implementationSolve the defect that the template cannot be moved horizontally due to complexityUnderground chambersTunnel liningBogieSteel frame

The invention discloses an automatic moving trolley with a vertical and horizontal direction steering function and a steering method. A tunnel lining trolley is special equipment which is necessary for second lining during tunnel construction, and is used for lining the inner wall of a tunnel. The automatic moving trolley with the vertical and horizontal direction steering function comprises vertical support steel frames (1), a horizontal support steel frame A (2), a horizontal support steel frame B (3) and limit wheel connecting plates (4). Gear boxes A (5) is installed at the bottoms of thetwo vertical support steel frames (1), gear boxes A are connected with steering frames (6), the bottoms of the steering frames are welded to a horizontal fixing frame (7), the bottom of the horizontalfixing frame (7) is welded to the upper parts of the two limit wheel connecting plates, a limit wheel (8) is installed between the two limit wheel connecting plates, the limit wheel is arranged abovea slide (9), an installation frame (10) is welded to the vertical support steel frames, and an asynchronous motor (11) is installed on the installation frame through a bolt assembly. The automatic moving trolley with the vertical and horizontal direction steering function and the steering method are applied to the automatic moving trolley with the vertical and horizontal direction steering function.

Owner:HEILONGJIANG LONGJIAN ROAD & BRIDGE OF THIRD BRANCH

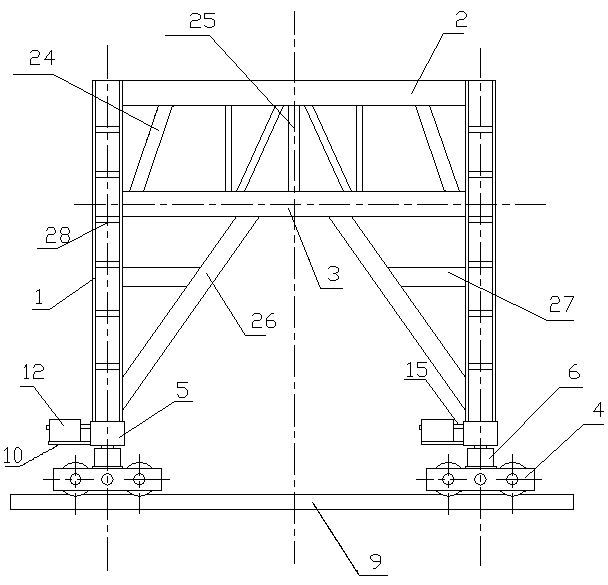

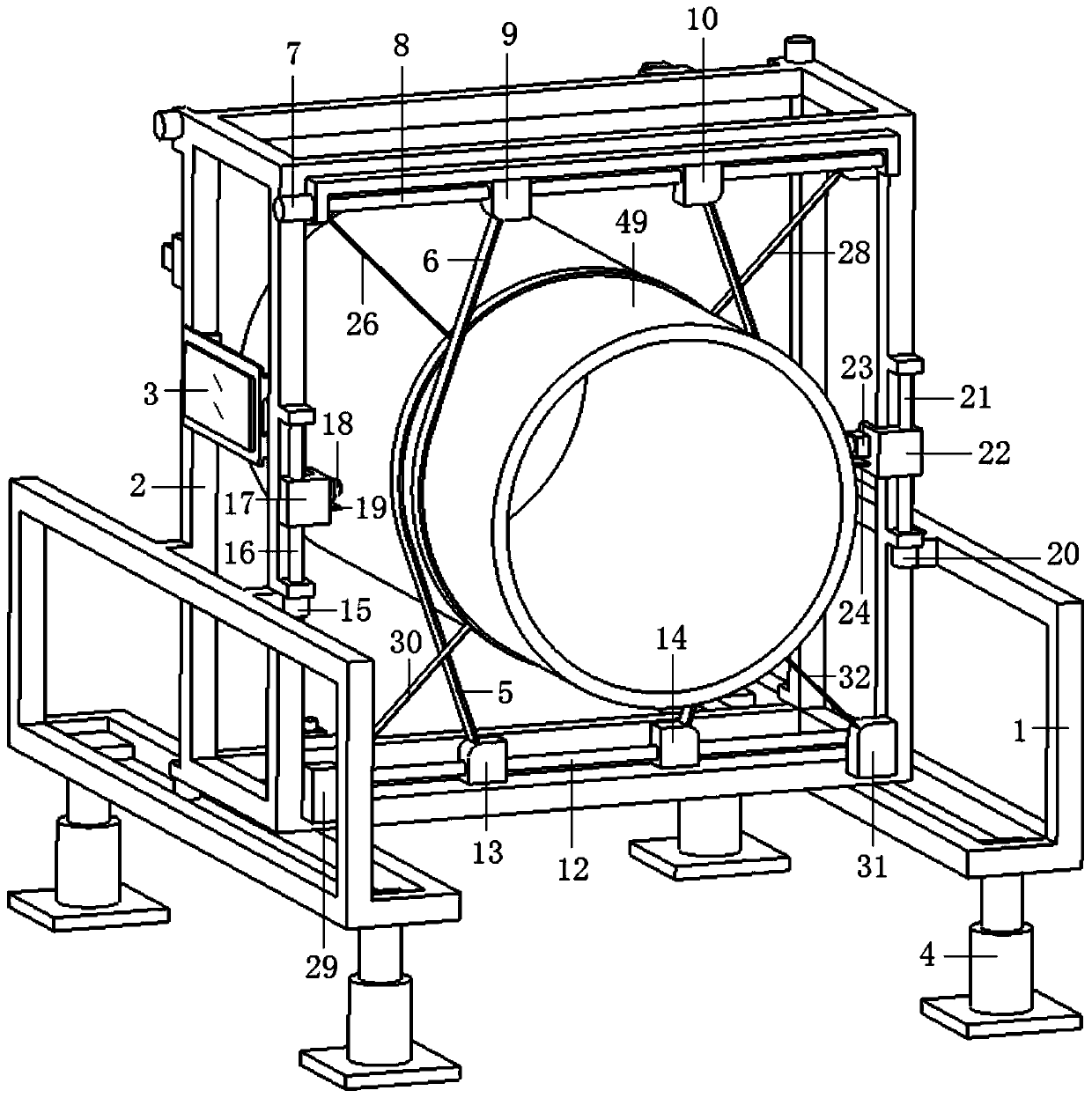

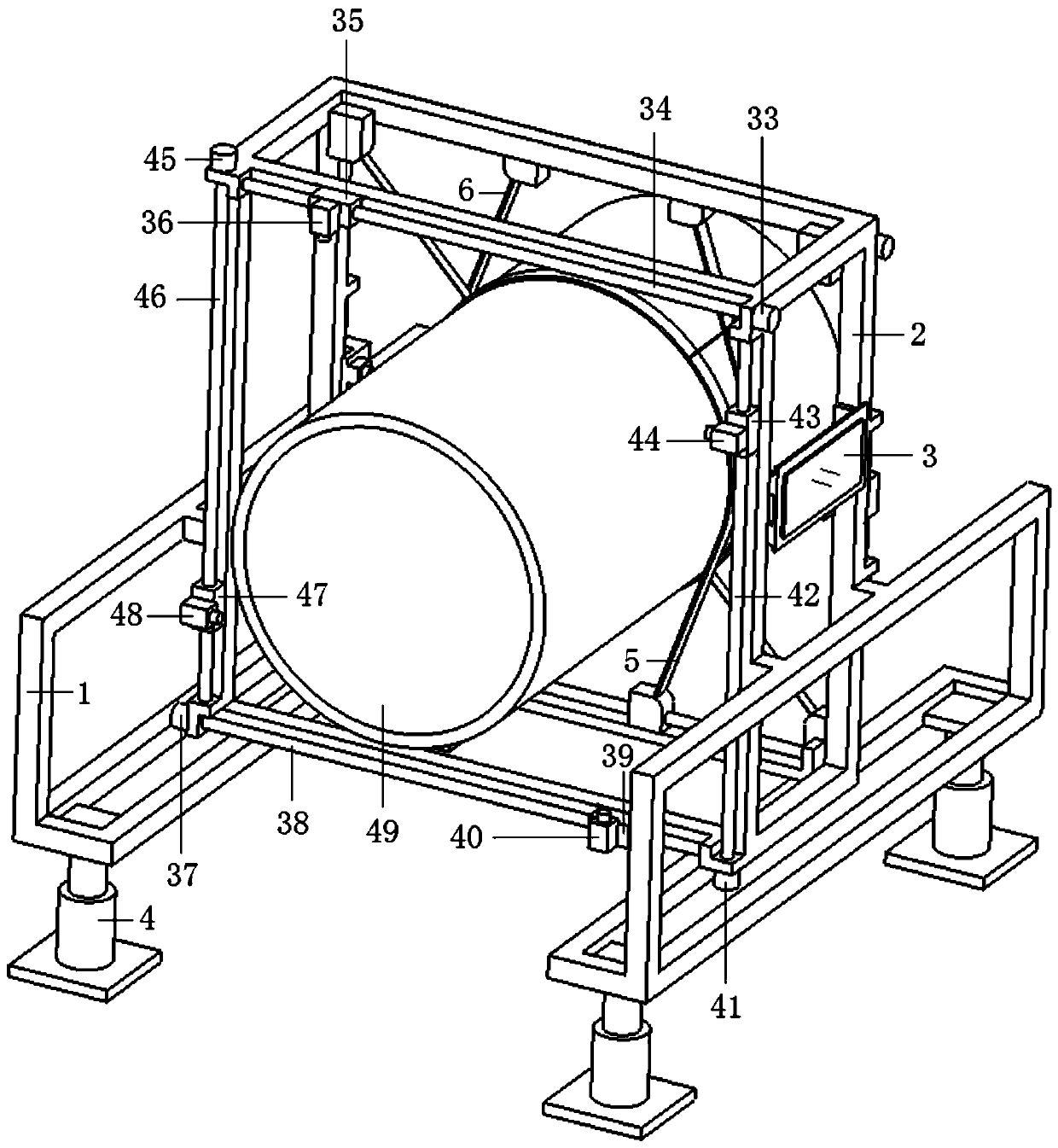

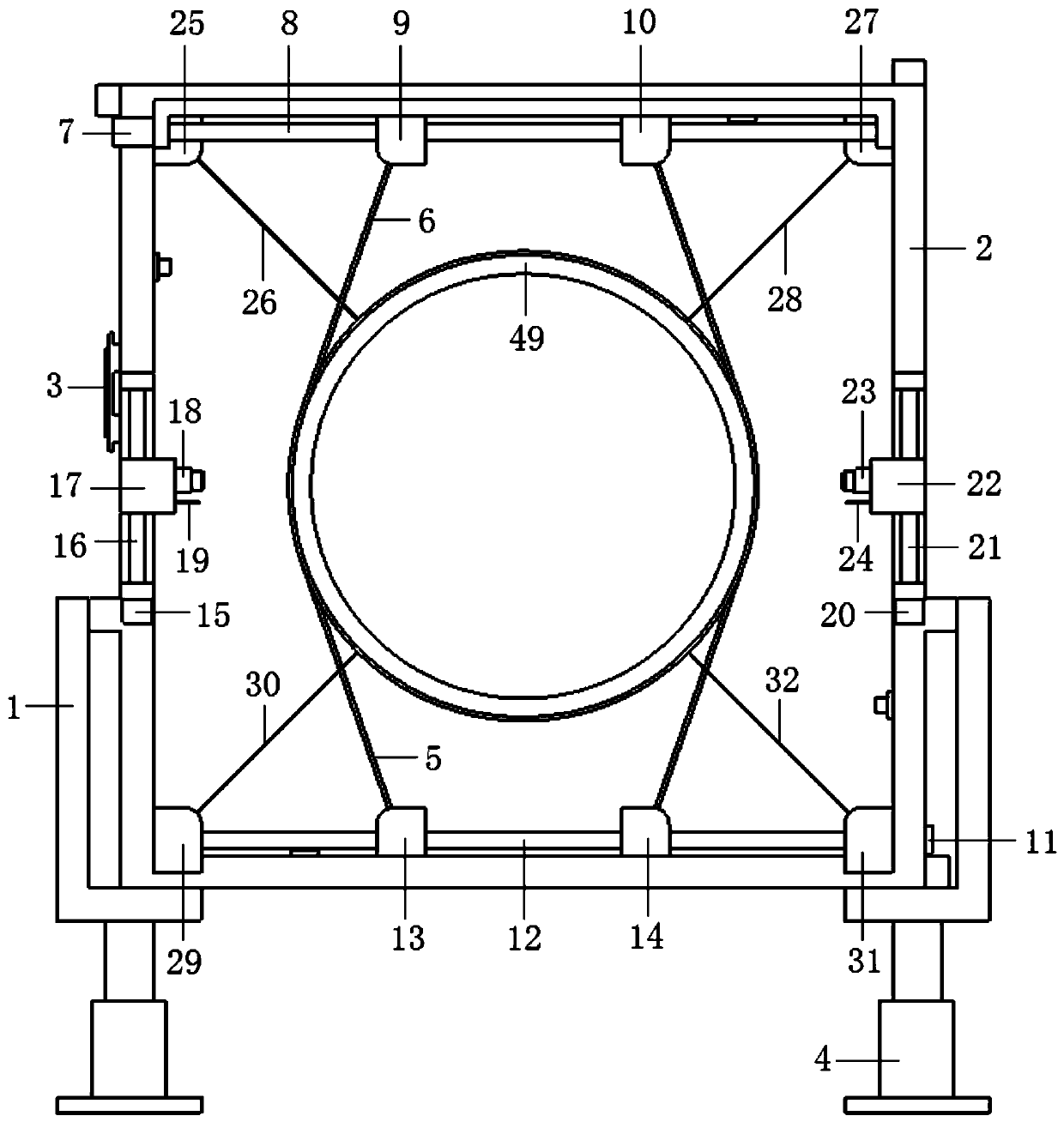

On-line monitoring device for diameter and roundness of expanded pipeline

PendingCN111336936AReduce labor intensityReduce the impactMechanical counters/curvatures measurementsMechanical diameter measurementsLaser rangingInteraction interface

The invention relates to an on-line monitoring device for the diameter and roundness of an expanded pipeline. The device comprises a base, a base frame, a computer, a pipeline diameter measuring assembly and a pipeline roundness measuring assembly. A plurality of lifting stand columns are evenly distributed at the bottom of the base, and the height of the base is adjusted through stretching of thelifting stand columns. The base frame employs a rectangular frame type structure and is vertically and fixedly installed on the base. The computer, the pipeline diameter measuring assembly and the pipeline roundness measuring assembly are all installed on the base frame. The computer is provided with a touch panel, and a human-computer interaction interface is displayed on the touch panel. The pipeline diameter measuring assembly comprises two flexible rulers, two flexible ruler tightening mechanisms and two fixed-length photographing mechanisms. The pipeline roundness measuring assembly comprises four sets of laser ranging mechanisms. The online measuring device can meet online measurement of the diameter and roundness of the pipeline at the same time, has the advantages of being high inmeasuring precision, high in measuring speed and high in measuring efficiency, can adapt to pipelines with different diameter ranges, is slightly affected by the production environment, and has highportability on the whole.

Owner:广东省珠海市质量计量监督检测所 +1

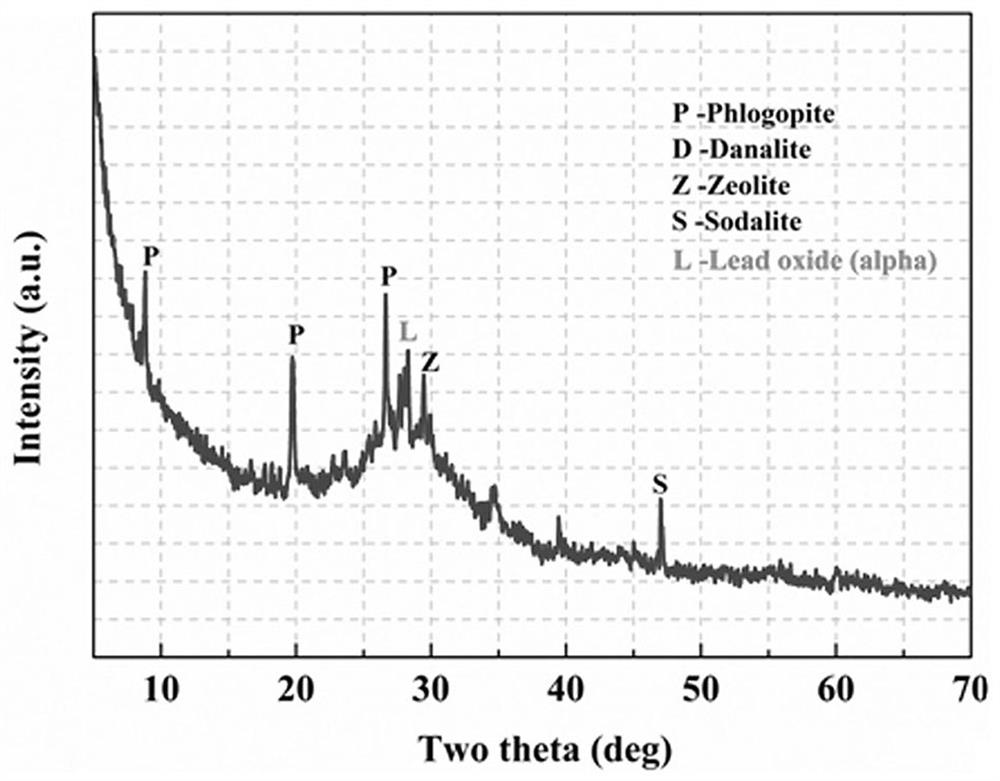

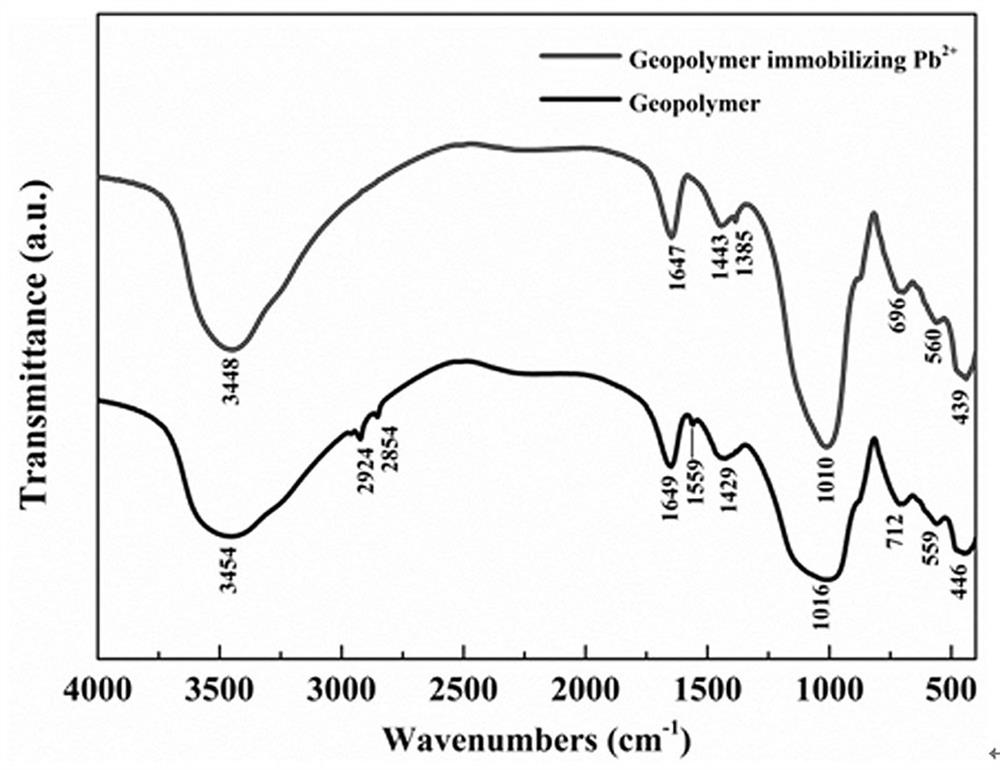

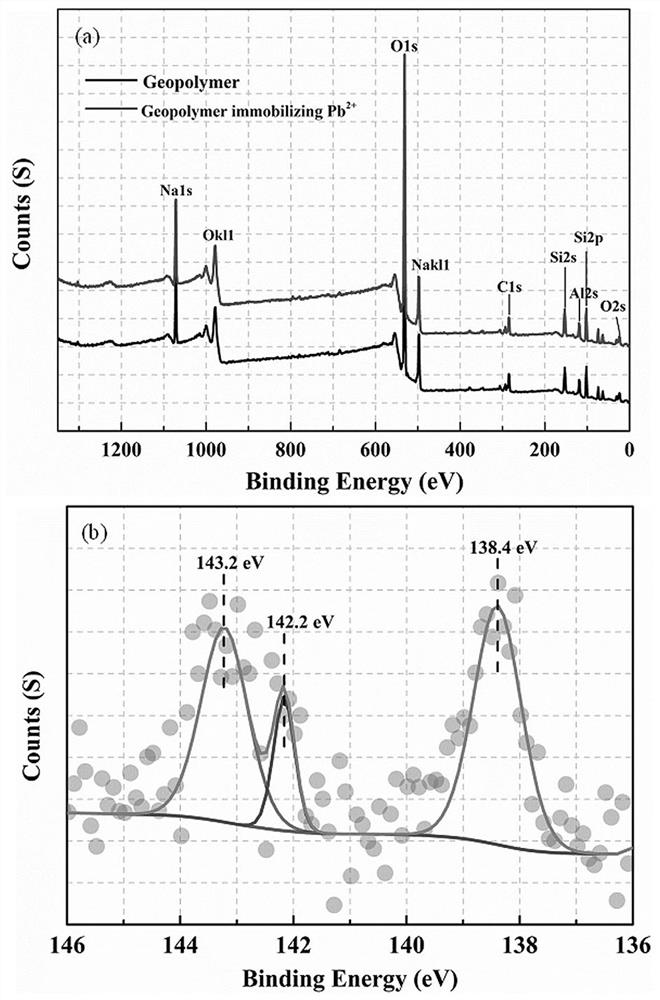

Method for preparing geopolymer finished product by using typical rare earth tailings in western Sichuan

ActiveCN111018417BHigh strengthSlightly highSolid waste managementCement productionGeopolymerKaolin clay

The present invention is a method for preparing geopolymer finished products using typical rare earth tailings in western Sichuan, and solves the problem of low strength of rare earth tailings for preparing geopolymer finished products. Silica fume 5-50, NaOH 28-40, water 60-138, heavy metal source (lead salt Pb(NO 3 ) 2 ) 0.1-5. The preparation method is as follows: roast kaolin at 800 °C for 6 h to obtain metakaolin of the same quality, dissolve NaOH in water, add silica fume and stir until the silica fume dissolves, and simultaneously add Pb(NO 3 ) 2 , when the temperature drops to 30°C~80°C, add metakaolin and rare earth tailings and stir together, pour the mixed slurry into a mold to form, and the 7d compressive strength of the prepared geopolymer can reach 36MPa. Pb in leach solution 2+ The concentrations are all lower than the limit value of the national standard: total Pb<5 mg / L.

Owner:四川省地质矿产勘查开发局成都综合岩矿测试中心

Formula and production process of STC ultrahigh-toughness concrete

The invention discloses formula and a production process of STC ultrahigh-toughness concrete, wherein the STC ultrahigh-toughness concrete comprises the following raw materials: 60-70 parts of cement,10-15 parts of a mineral admixture, 40-60 parts of coarse aggregate, 20-30 parts of fine aggregate, 25-30 parts of red mud powder, 14-24 parts of an anti-cracking toughening agent, 10-15 parts of steel fiber, 20-25 parts of glass fiber, 20-30 parts of stainless steel fiber, 15-20 parts of polyvinyl alcohol fiber, 32-42 parts of spider silk imitation fiber, 7-9 parts of a high-performance water reducing agent, 18-22 parts of a PH sensitive hydrogel, and 30-40 parts of water. According to the invention, by adding the anti-cracking toughening agent, the steel fibers, the glass fibers, the stainless steel fibers, the polyvinyl alcohol fibers and the spider silk imitation fibers, the added fibers and the added anti-cracking toughening agent are high-strength and high-toughness materials, so that the lightness and the toughness of the concrete are greatly improved, the working performance of the concrete can be well improved, the self-compacting strength is improved, and the shrinkage performance is improved.

Owner:宁夏润宇泽节能环保有限公司

Shearing device of shear wall pulling piece and using method

InactiveCN113070689AQuick cutAchieve preliminary collectionEdge grinding machinesForms/shuttering/falseworksPolishingEngineering

The invention discloses a shearing device of a shear wall pulling piece and a using method. The shearing device comprises a U-shaped main body; universal wheels are fixedly installed at the four corners of the bottom end of the U-shaped main body; a collecting mechanism is installed at the bottom end of a U-shaped opening of the U-shaped main body in a clamped mode; two pressing columns are fixedly installed on the front face of the U-shaped main body; vertical sliding grooves are fixedly formed in the edge sides of the inner wall of the U-shaped main body; a sliding mechanism is connected between the vertical sliding grooves in a clamped mode; and a polishing mechanism and a cutting mechanism are arranged on the sliding mechanism. According to the shearing device, through the cutting mechanism on the sliding mechanism, the rapid cutting of the pulling piece on the surface of a wall is achieved, and the problem that in the prior art, a hammer or other tools need to be used for smashing a pulling piece to be flat or smashing the pulling piece out, and the process is strenuous is solved; and through the polishing mechanism on the sliding mechanism, the cut pulling piece is polished, and the problem that in the prior art, the follow-up construction is affected due to the fact that the end opening treatment of the pulling piece is not good enough is solved.

Owner:中建新疆建工集团第五建筑工程有限公司

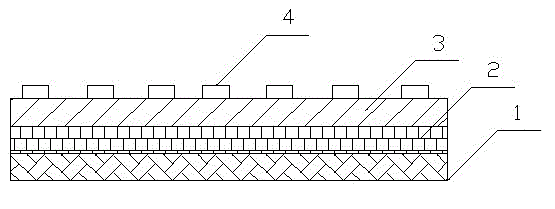

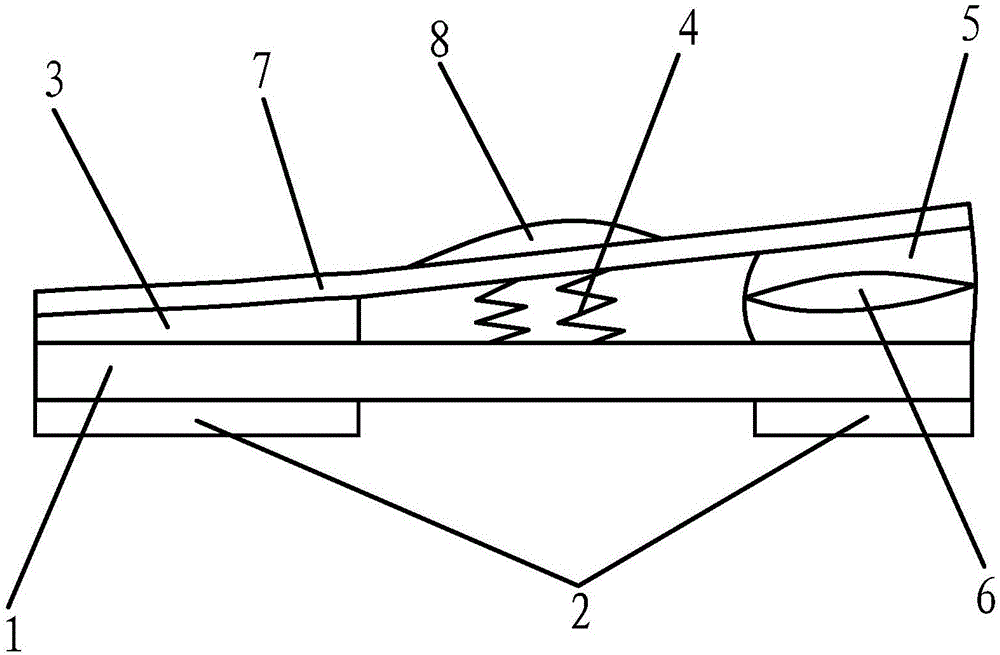

Radiation-resistant reflective antifouling artificial leather

InactiveCN104420282APlay the role of radiation protectionImprove wear resistanceFibre typesClothingsPolyesterYarn

The invention relates to a radiation-resistant reflective antifouling artificial leather. The artificial leather comprises a substrate (1) and a surface layer (2) which are bonded to each other, the surface of the surface layer (2) is provided with a metal fiber layer (3), the metal fiber layer (3) is provided with a plurality of reflective strips (4), the substrate is made of a fabric, the fabric comprises a fabric body, the fabric body is formed by interweaving warps and wefts, the upper surface and the lower surface of the fabric body are respectively provided with an antifouling coating, the yarns are 16S polyester yarns, and the antifouling coating is a polytetrafluoroethylene coating. The artificial leather has a light reflecting function, and also has radiation resistance. The artificial leather has an antifouling effect.

Owner:JIANGYIN LICHEN IND

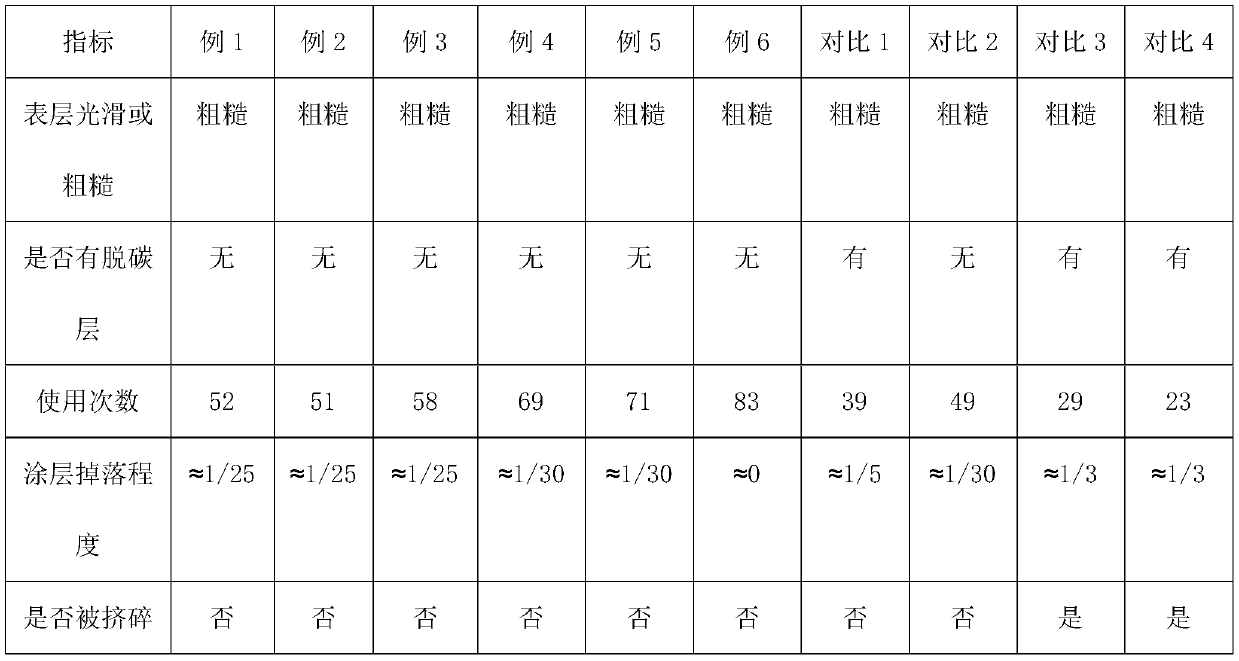

Composite ultralight anti-yellowing shoe sole and manufacturing method thereof

The invention provides a composite ultralight anti-yellowing shoe sole and a manufacturing method thereof. The composite ultralight anti-yellowing shoe sole sequentially comprises an anti-yellowing layer, a buffer layer and a surface layer from bottom to top, wherein the anti-yellowing layer, the buffer layer and the surface layer are attached. The buffer layer comprises a sole cushion located on the front portion, an arch supporting rib located in the middle, and a heel air cushion located on the rear portion. The bottom face of the sole cushion adheres to the top face of an anti-abrasion layer through a glue layer, and the sole cushion is gradually thickened from the front end to the rear end. The arch supporting rib comprises at least one bent elastic strip, bent top angles of the elastic strips are forward, and bent openings of the elastic strips are backward. The heel air cushion comprises an air bag, a supporting cotton body is arranged in the air bag, and the air bag is gradually thickened from the front end to the rear end. The bottom face of the surface layer adheres to the top face of the sole cushion and the top face of the heel air cushion through glue layers, the middle of the surface layer is provided with an elastic part protruding upwards, and the arch supporting rib is located below the elastic part and abuts against the elastic part. Multiple layers of structures are attached to achieve integration of multiple functions of resisting yellowing, being light and the like.

Owner:嘉兴宜泰鞋业有限公司

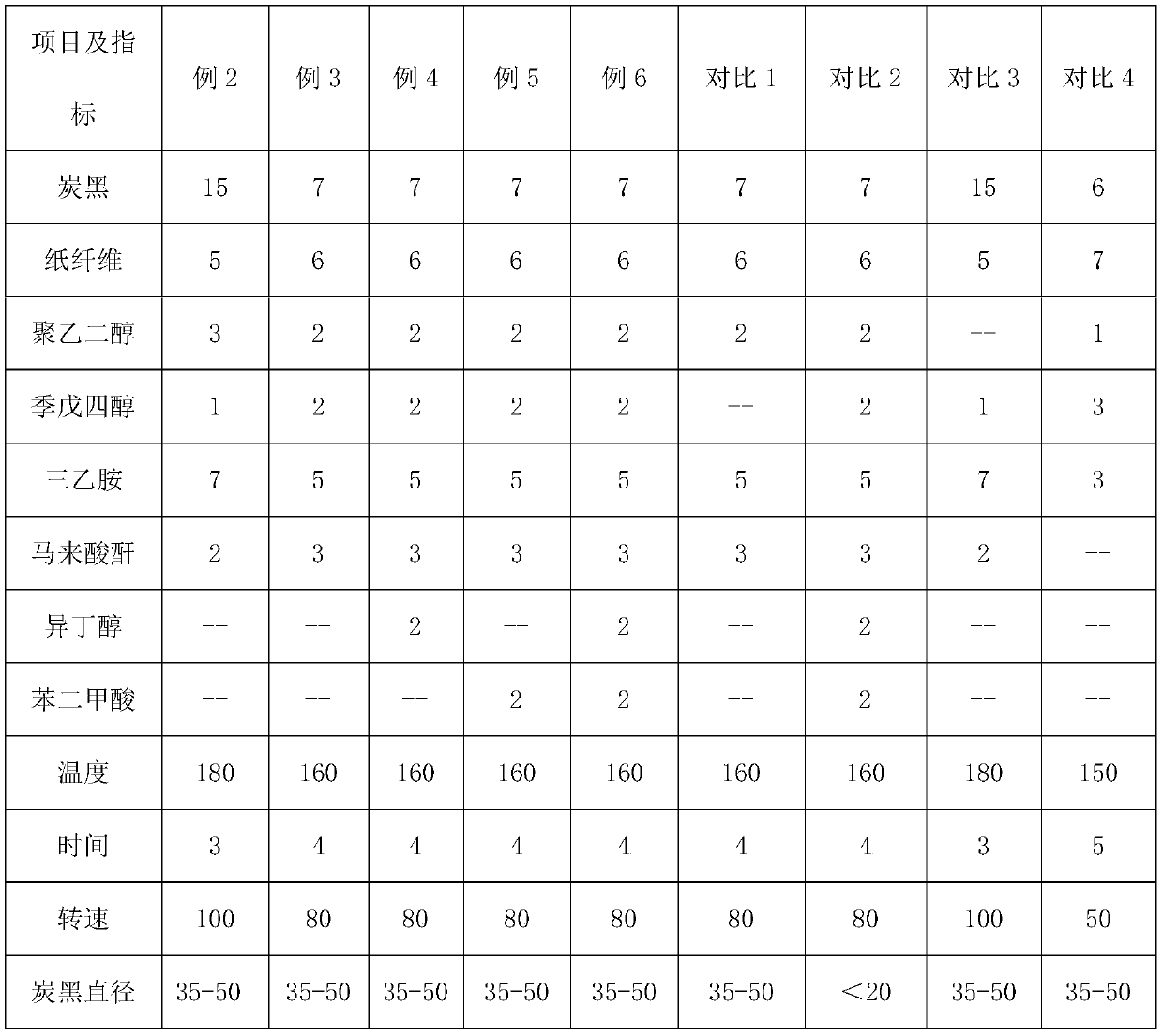

Coating paint for magnesia carbon bricks

ActiveCN111378364APrevent oxidationHigh strengthPolyether coatingsLignin material coatingsFiberBrick

The invention discloses a coating paint for magnesia carbon bricks, which belongs to the technical field of materials and comprises the following components: carbon black, paper fiber, polyethylene glycol, pentaerythritol, triethylamine, maleic anhydride and water. The coating paint disclosed by the invention can prevent the magnesia carbon brick from being oxidized at high temperature, and can absorb expansion of the magnesia carbon brick when a converter is started, so that the strength of the magnesia carbon brick is enhanced, and the service life of the magnesia carbon brick is prolonged;the coating paint also has the advantages of being low in cost, simple in preparation method and convenient to use.

Owner:秦皇岛首钢黑崎耐火材料有限公司

Preparation method of recycled cardboard

InactiveCN105926345AReduce use of plant resourcesIncreased long fiber contentNon-fibrous pulp additionMechanical working/deformationCardboardVegetable fibre

The invention discloses a preparation method of a recycled cardboard. The preparation method comprises mixing recycled paper pulp subjected to impurity removal and filtration and plant fiber paper pulp, carrying out blending, wherein in blending, an alginate is added into the pulp, carrying out paper making, vacuum squeezing dewatering, low temperature drying and paper cutting to obtain a recycled raw material paper, pressing the recycled raw material paper, cutting the recycled raw material paper to obtain a corrugated paper core, cutting the recycled raw material paper to obtain panel papers, and bonding the panel papers to the upper and lower surfaces of the corrugated paper core by glue. The recycled cardboard has good toughness, strength and fire resistance and is suitable as a carton packaging material.

Owner:JURONG DINGSHENG CARTON PACKING

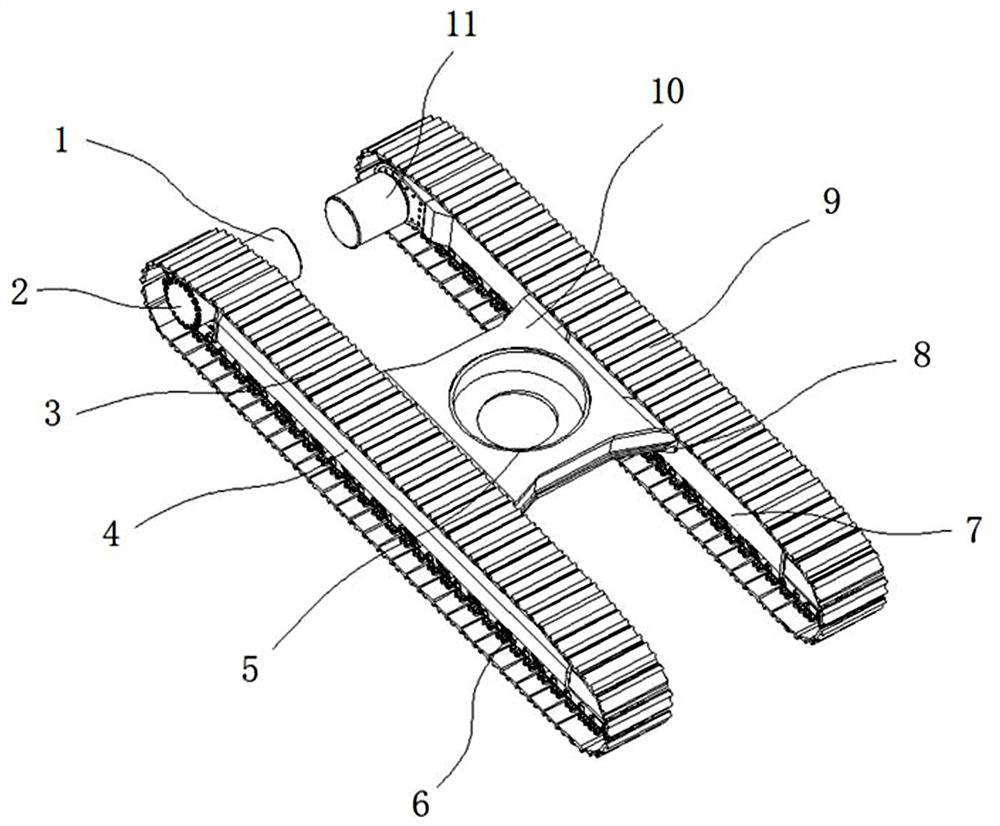

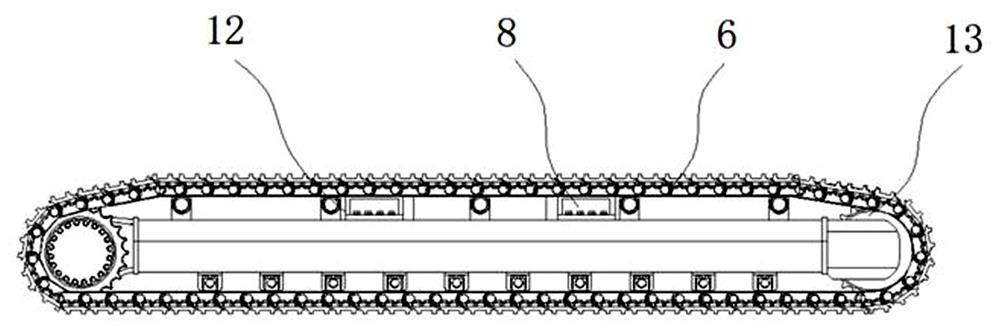

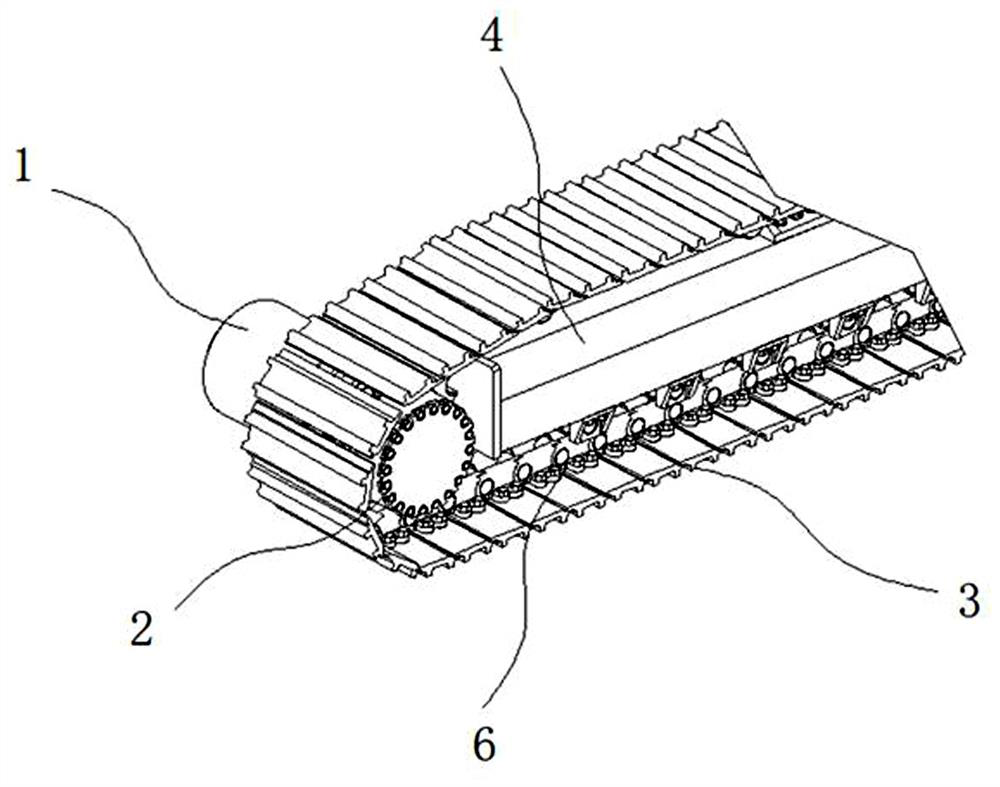

Double-electric-drive type crawler chassis

PendingCN113276972ALightweight structureIncreased load-bearing capacityElectric propulsion mountingMotor depositionElectric machinerySprocket

The invention provides a double-electric-drive type crawler chassis which comprises a first crawler belt and a second crawler belt, the second crawler belt is arranged at one end of the first crawler belt, a first steel beam is arranged in the first crawler belt, a second steel beam is arranged in the second crawler belt, driving chain wheels are movably connected with one side of the first steel beam and one side of the second steel beam correspondingly, center shafts of the driving chain wheels are fixedly connected with a first driving motor and a second driving motor respectively. According to the double-electric-drive type crawler chassis, the first driving motor, the driving chain wheels and the second driving motor are arranged, the first driving motor and the second driving motor rotate oppositely after being powered on, the speed can be adjusted through a built-in frequency converter, flexible steering is achieved, and operation is easy; the first driving motor and the second driving motor are directly connected with the center shafts of the driving chain wheels to directly drive the driving chain wheels, power loss is small, power is strong, the chassis is small and flexible, and the problem of insufficient moving flexibility is solved.

Owner:南阳市海创科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com