Ultrahigh-strength thermal insulation material and preparation method thereof

A thermal insulation material and ultra-high-strength technology, applied in the field of high-strength thermal insulation new materials, it can solve the problems of low strength and easy peeling, and achieve the effect of high strength, avoiding oxidative decomposition, and avoiding excessively low internal temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] An embodiment of the present invention provides a method for preparing an ultra-high-strength thermal insulation material, comprising the following steps:

[0027] Step 1, using phenolic resin to impregnate the quartz-type chopped reinforcing fiber mat to obtain a prepreg;

[0028] Specifically, in the embodiment of the present invention, the quartz-based chopped reinforcing fiber mat is preferably one or a combination of chopped glass fiber mat or chopped quartz fiber mat, more preferably a chopped fiber mat with a fiber diameter of 6-9 mm. Glass fiber, to ensure that the insulation material obtained has higher strength; the density of the quartz-like chopped reinforcing fiber mat is preferably 120-180kg / m3, to ensure that the fiber mat has good impregnation performance and ensure that the resin matrix is evenly distributed; The resin mass content is preferably 20%-70%, more preferably 23%-30%;

[0029] Step 2, curing the prepreg in an oxygen-enriched environment to...

Embodiment 1

[0037] Step 1. Preparation of prepreg:

[0038] According to the proportion of resin mass content being 25%, adopting phenolic resin to impregnate chopped non-alkali glass fiber mat with fiber diameter of 6-9mm, the density of said chopped non-alkali glass fiber mat is 150kg / m 3 ;

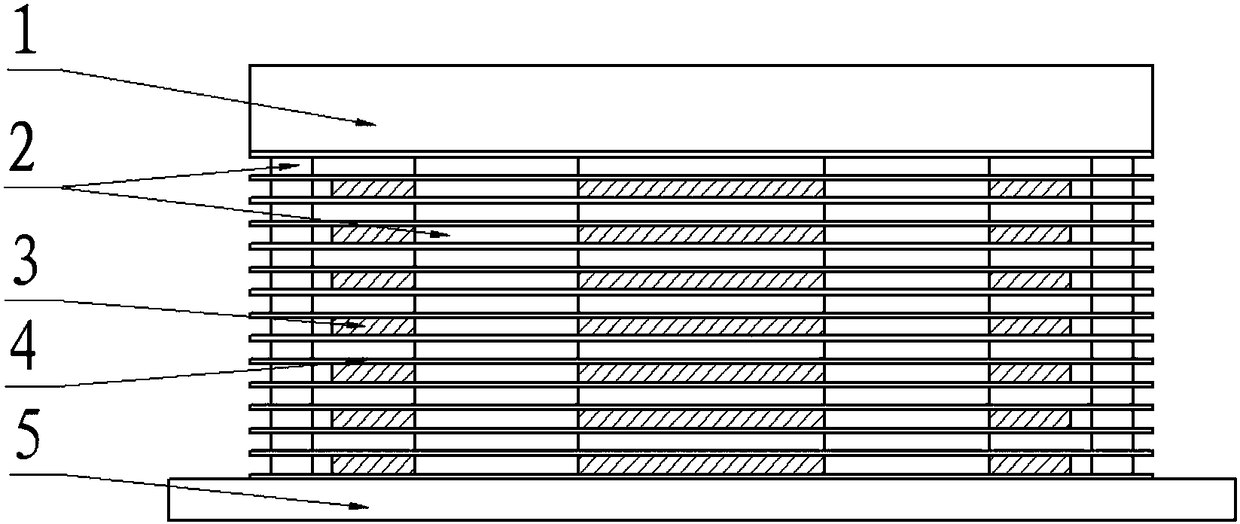

[0039] Step 2, see figure 1 , each of the multiple prepregs 3 prepared in step 1 is supported by a porous partition 4 (porous plate), and stacked in layers. When stacked, the partitions 4 are overhead through the limit block 2 placed on the platform 5 Position limit, press block 1 on the uppermost partition 4 to form a component to be cured, put the component to be cured into a heating furnace, and raise the temperature to 185°C at a heating rate of 5-6°C / min, Keep warm for 3 hours to obtain the insulation material;

[0040] Step 3. Raise the temperature to 350° C. at a heating rate of 10° C. / min, keep it warm for 2 hours, and cool down to obtain an ultra-high-strength thermal insulation materia...

Embodiment 2

[0043] Step 1. Preparation of prepreg:

[0044] According to the proportion that the resin mass content is 70%, adopt phenolic resin to impregnate the chopped non-alkali glass fiber mat with fiber diameter of 6-9mm, the density of the chopped non-alkali glass fiber mat is 150kg / m 3 ;

[0045] Step 2, see figure 1 , each of the multiple prepregs 3 prepared in step 1 is supported by a porous partition 4 (porous plate), and stacked in layers. When stacked, the partitions 4 are overhead through the limit block 2 placed on the platform 5 Position limit, press block 1 on the uppermost partition 4 to form a component to be cured, put the component to be cured into a heating furnace, and raise the temperature to 185°C at a heating rate of 5-6°C / min, Keep warm for 3 hours to obtain the insulation material;

[0046] Step 3. Raise the temperature to 350° C. at a heating rate of 10° C. / min, keep the temperature for 2 hours, and cool down to obtain an ultra-high-strength thermal insulat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com