Patents

Literature

943results about "Natural rubber adhesives" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

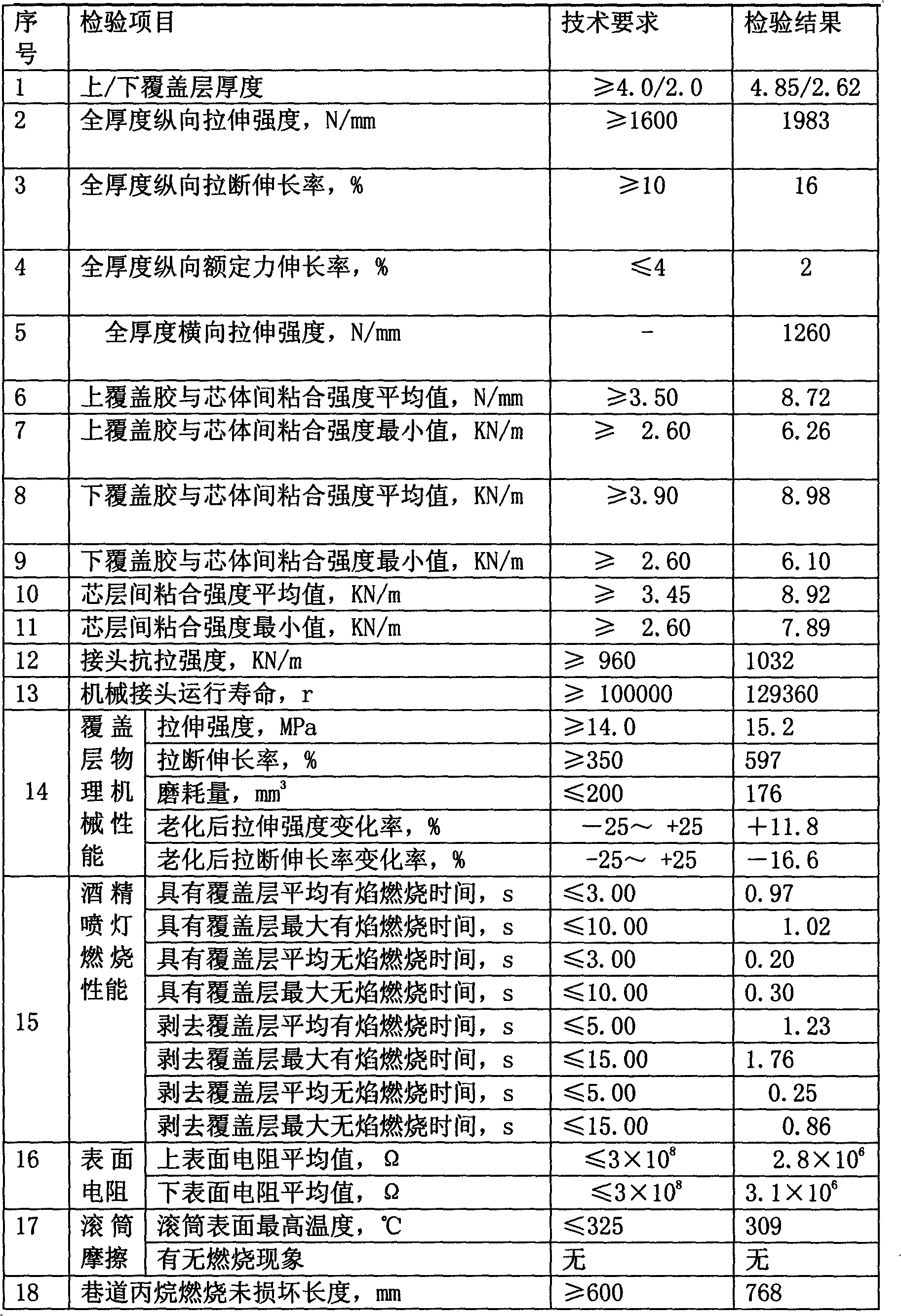

Energy-saving high strength aramid fiber conveyer belt and preparation method thereof

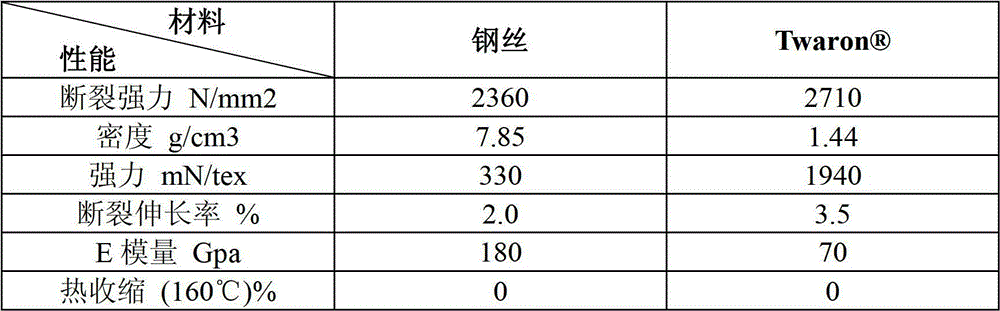

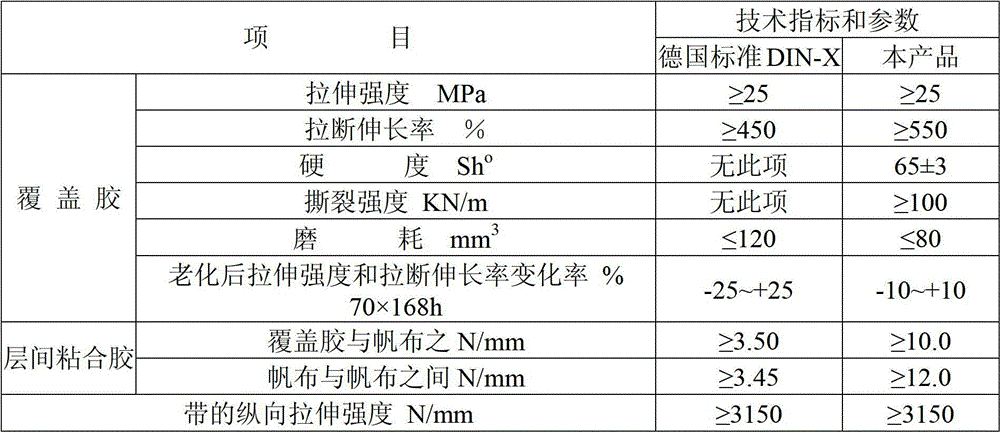

The invention relates to an energy-saving high strength aramid fiber conveyer belt and a preparation method thereof. The conveyer belt is composed of a skeleton layer, adhesive glue and an upper-lower cover adhesive laminated structure. Firstly, the skeleton layer employs aramid fiber canvas after dipping treatment to replace a conventional steel wire rope, so that the problems of large weight of the steel wire rope which brings much inconvenience for processes of shaping, installing, maintaining and the like is solved. Secondly, the aramid fiber canvas has structure in broadwise direction, has excellent anti-tear and anti-impact performances, so that phenomena of longitudinal tear and the like of the steel wire rope conveyer belt cab be prevented. Compared with a conventional steel wire rope high strength conveyer belt, the energy-saving high strength aramid fiber conveyer belt has high strength, good corrosion resistance, wear resistance and impact and fatigue resistance, and greatly reduce the weight and thickness of the conveyor belt, so that conveying power energy consumption is saved. The energy-saving high strength aramid fiber conveyer belt is expected to have longer service life and better energy-saving and environment-friendly properties, and is particularly suitable for long-distance material conveyance in industries such as coal mine, metallurgy, mine, etc.

Owner:WUXI BOTON TECH CO LTD +1

Optically clear and antistatic pressure sensitive adhesives

InactiveUS20070141329A1Natural rubber adhesivesNon-macromolecular adhesive additivesAntistatic agentPolymer chemistry

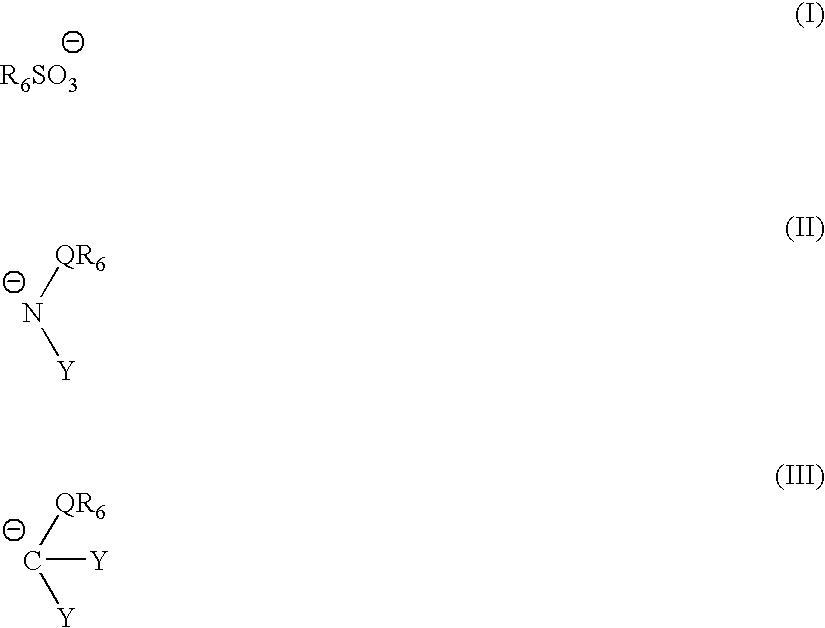

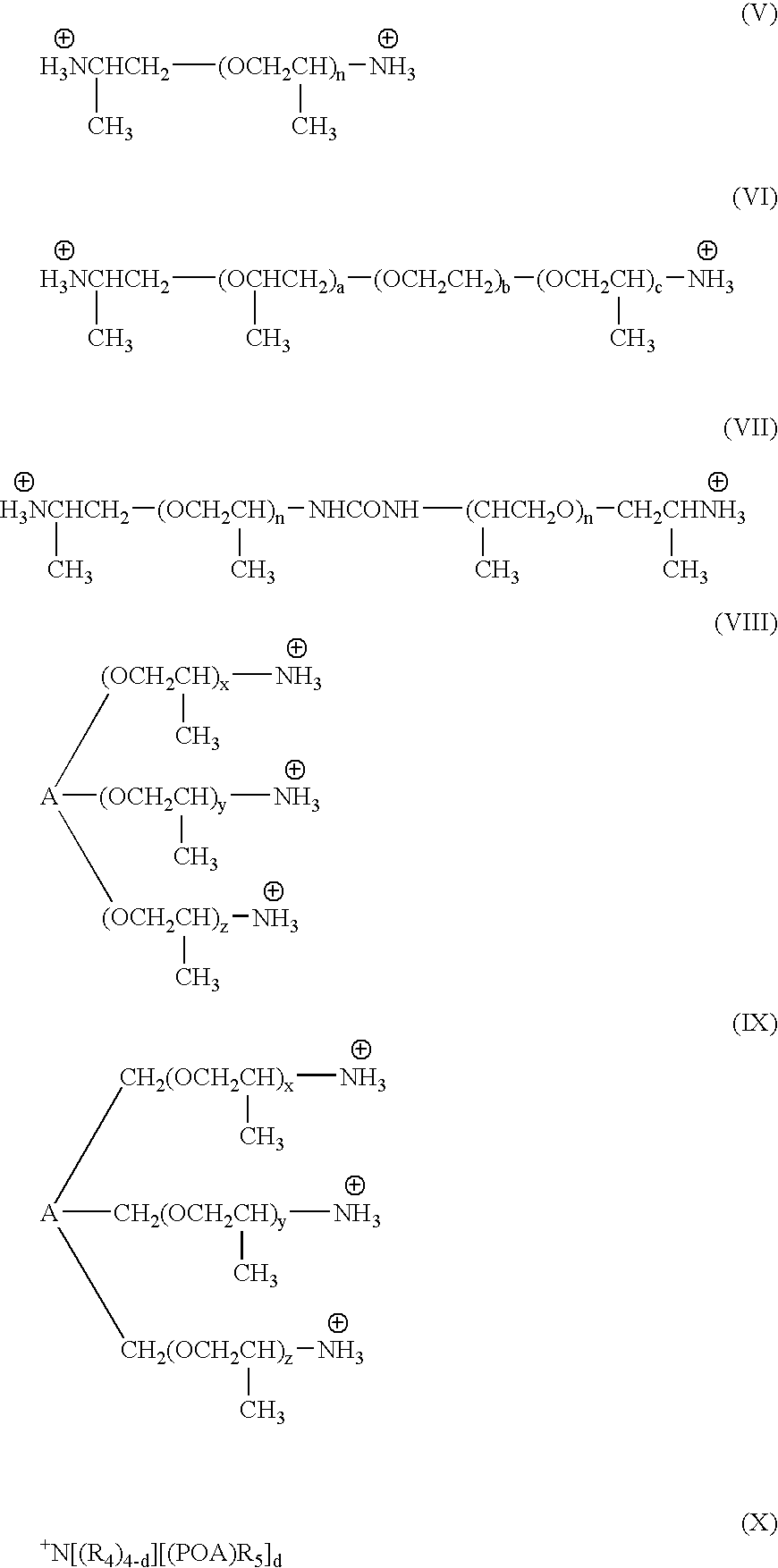

The present invention is directed to an antistatic pressure sensitive adhesive. The antistatic pressure sensitive adhesive comprises a pressure sensitive adhesive, and an antistatic agent comprising at least one organic salt. Certain embodiments of the antistatic pressure sensitive adhesive also have a luminous transmission of greater than about 89% according to ASTM D 1003-95. Additional embodiments of the antistatic pressure sensitive adhesive have a haze of less than about 5% according to ASTM D 1003-95, and in specific embodiments the haze is less than about 2% according to ASTM D 1003-95.

Owner:3M INNOVATIVE PROPERTIES CO

Adhesive tape

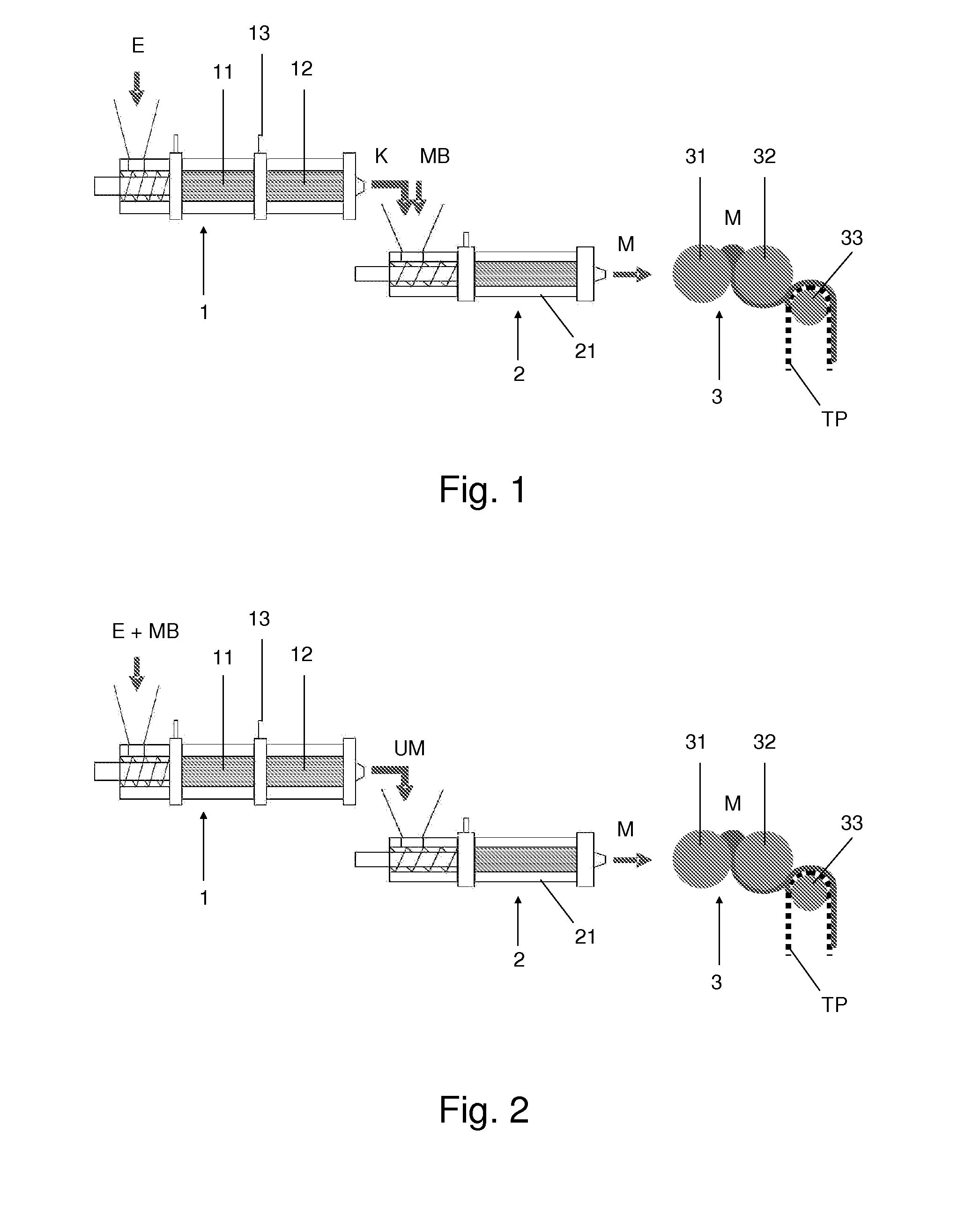

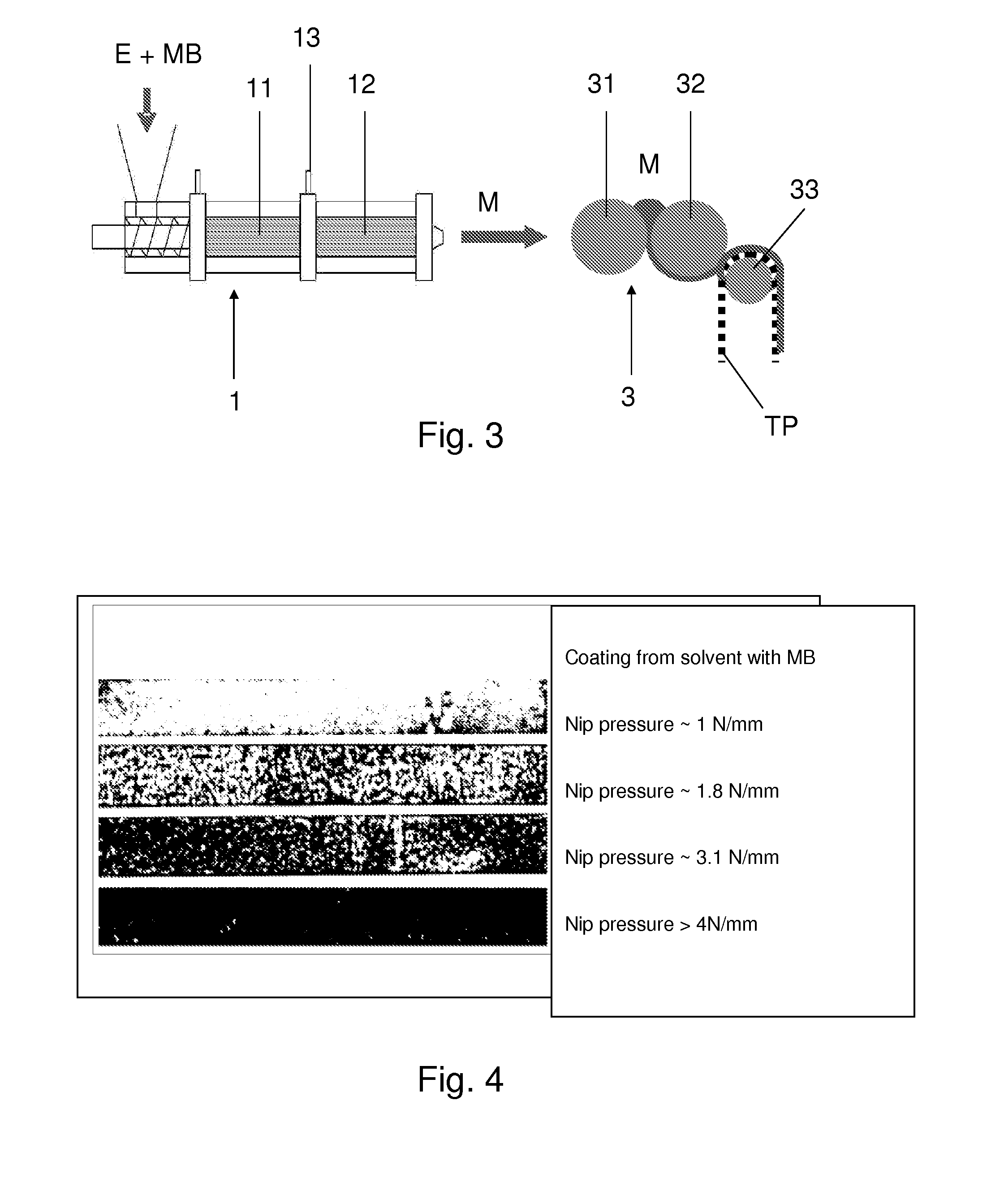

An adhesive tape which comprises: (1) a backing film, wherein the backing film has at least two intermeshed coextruded layers of different composition, whose interface has a nonlinear course in cross section, which continues laminarly in the machine direction and has been oriented in the machine direction, and has plane-parallel outer faces; and (2) at least one adhesive layer which is attached to the backing film.

Owner:TESA SE

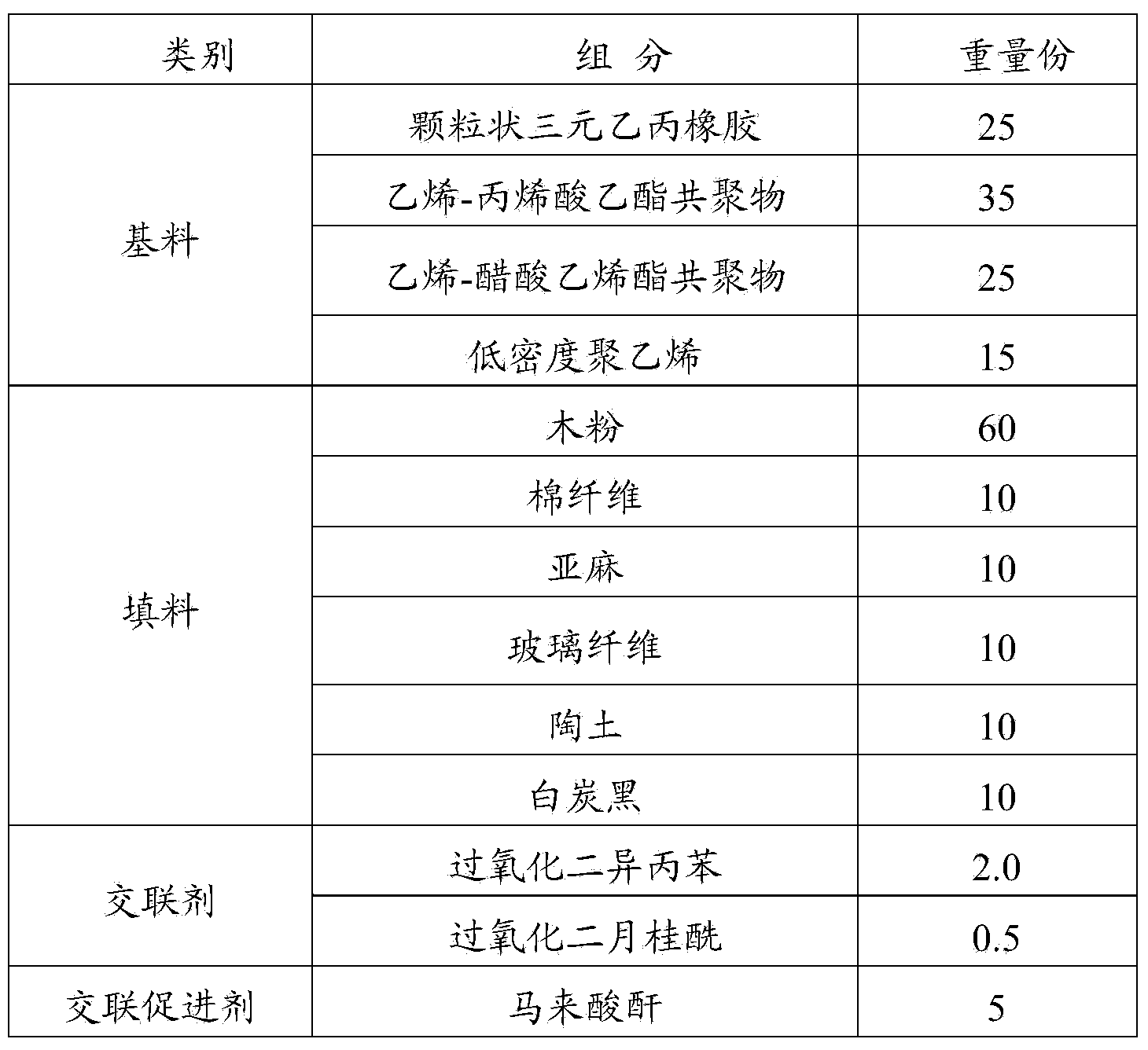

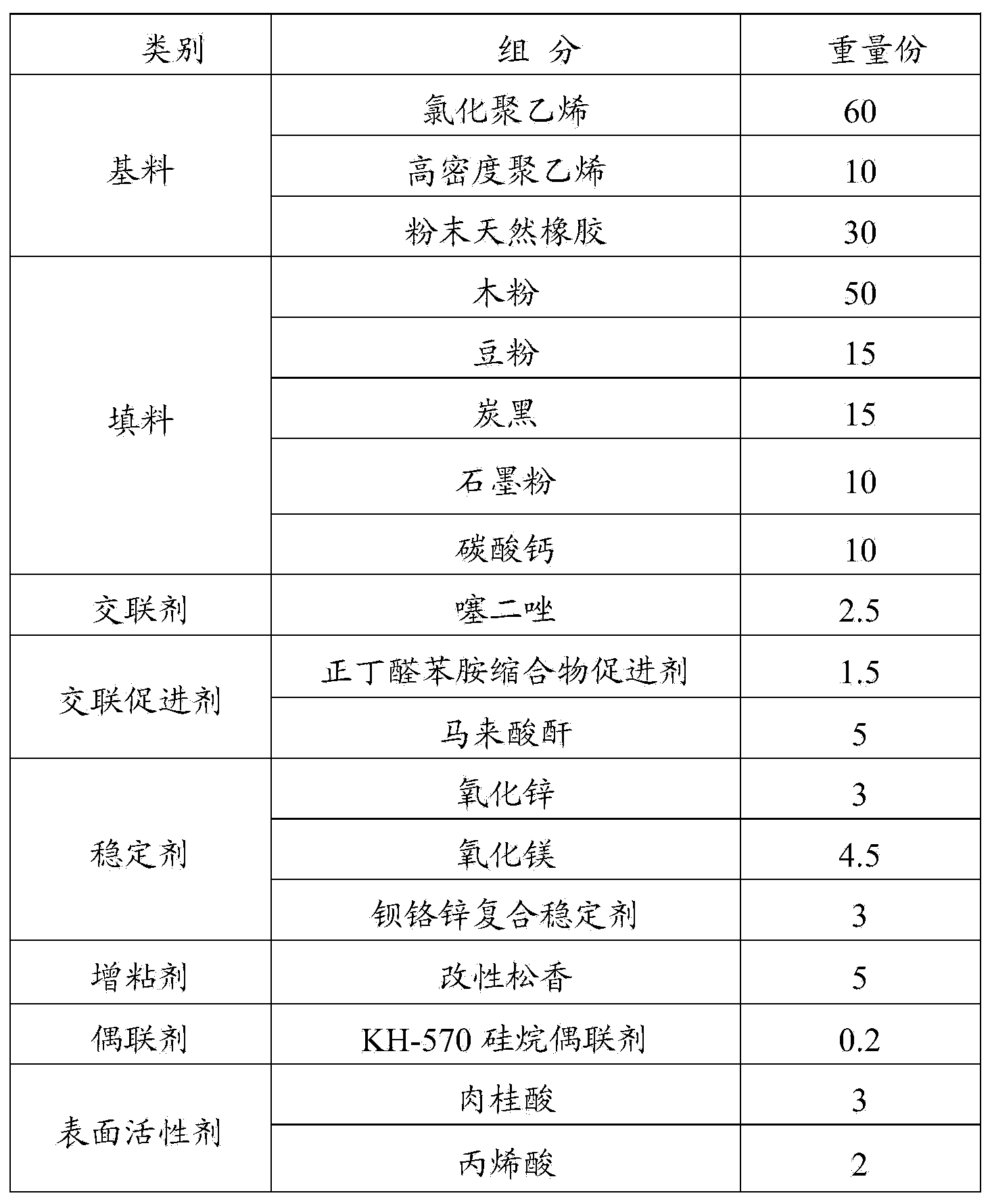

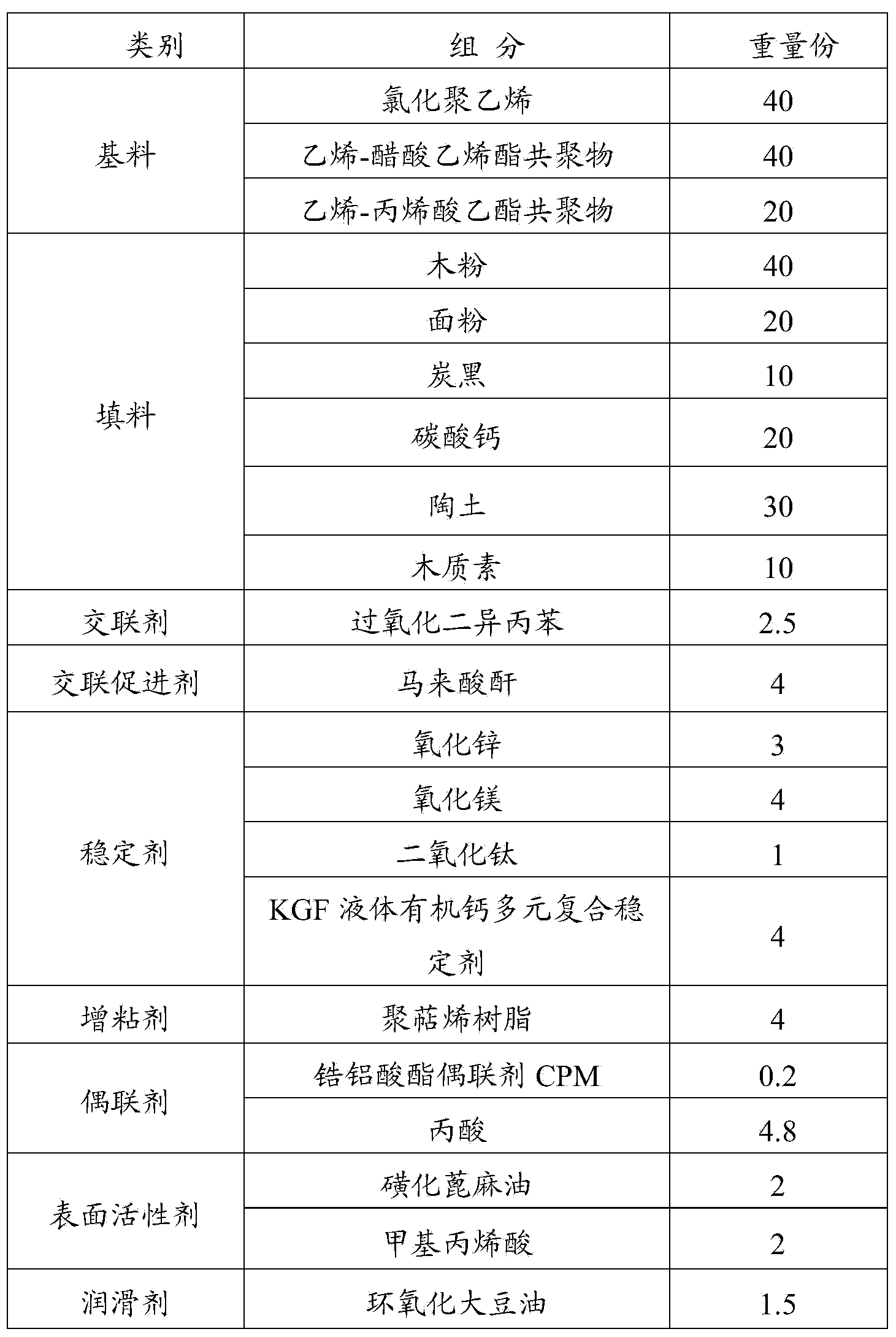

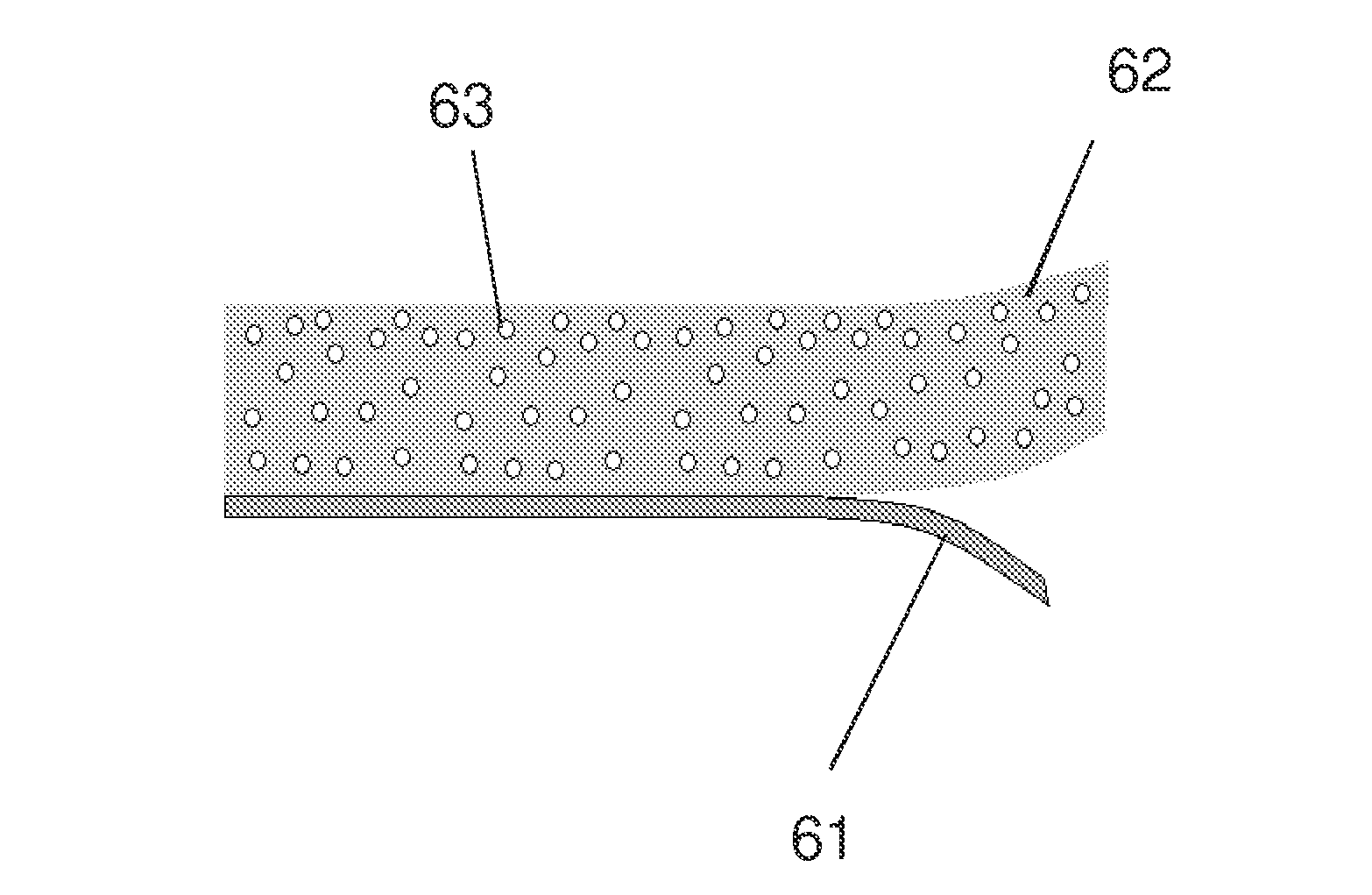

Formaldehyde-free wood adhesive film

InactiveCN103965796AGood value for moneyImprove the construction environmentNatural rubber adhesivesNon-macromolecular adhesive additivesChemistryHuman health

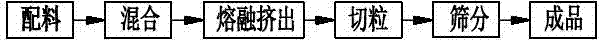

A formaldehyde-free wood adhesive film comprises the following components in parts by weight: 100 parts of basic material, 1 to 300 parts of filler, 0.1 to 10 parts of a cross-linking agent, 0.01 to 10 parts of a cross-linking accelerator, 1 to 15 parts of a stabilizer, 1 to 20 parts of a tackifier, 0 to 10 parts of a coupling agent, 1 to 30 parts of a surfactant and 0.5 to 10 parts of a lubricant, wherein the basic material is at least two of chloride high polymer, chlorosulfonated high polymer, ethylene vinyl acetate copolymer, ethylene-ethyl acrylate copolymer, polyolefin and rubber; and the filler is at least one of organic filler, inorganic filler, compound filler and synthetic filler. The formaldehyde-free wood adhesive film contains no formaldehyde or organic volatile matter so as not to affect and harm the environment and the human health, and is excellent in environmental performance, convenient to use, transport and store and long in shelf life. The formaldehyde-free wood adhesive film is blended, modified and extruded into shape by a plastic extruding film technique.

Owner:杨学荣

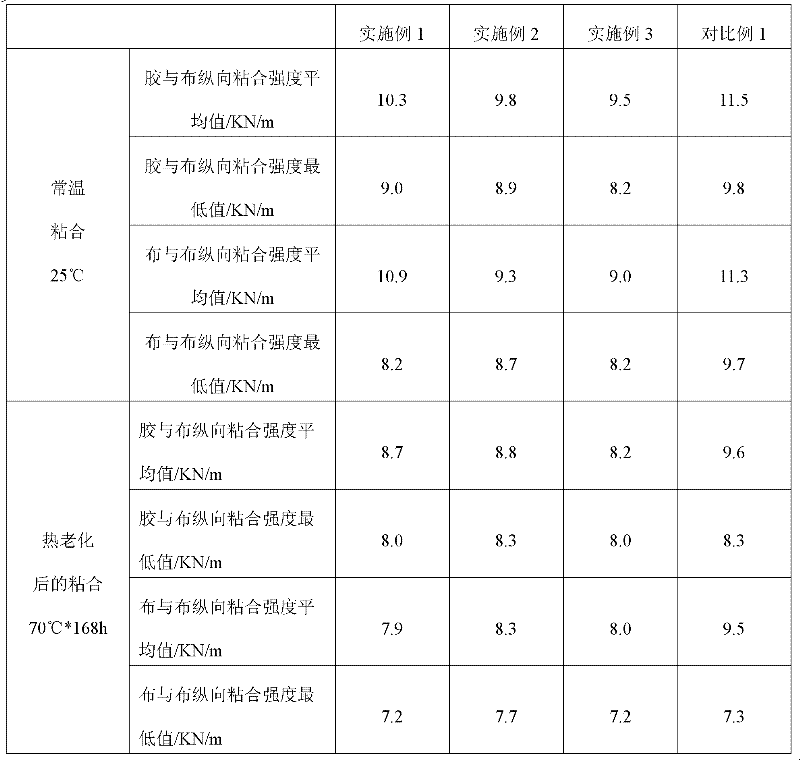

Foamed adhesive, more particularly pressure-sensitive adhesive, process for the production and also the use thereof

InactiveUS20090181250A1Natural rubber adhesivesMacromolecular adhesive additivesPolymer scienceMicrosphere

Adhesive, more particularly pressure-sensitive adhesive, which comprises expanded microballoons, the bond strength of the adhesive comprising the expanded microballoons being reduced by not more than 30%, preferably not more than 20%, more preferably 10%, in comparison to the bond strength of an adhesive of identical coatweight and formula which has been defoamed by the destruction of the voids produced by the expanded microballoons.

Owner:TESA SE

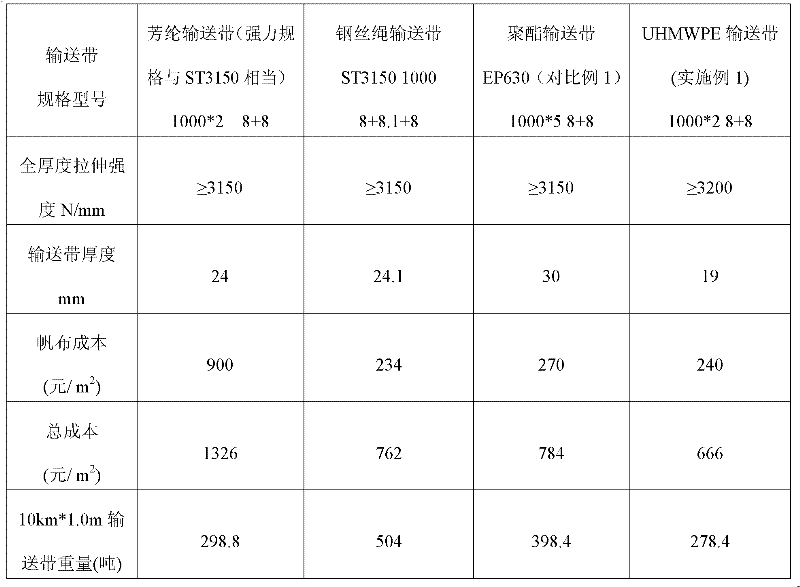

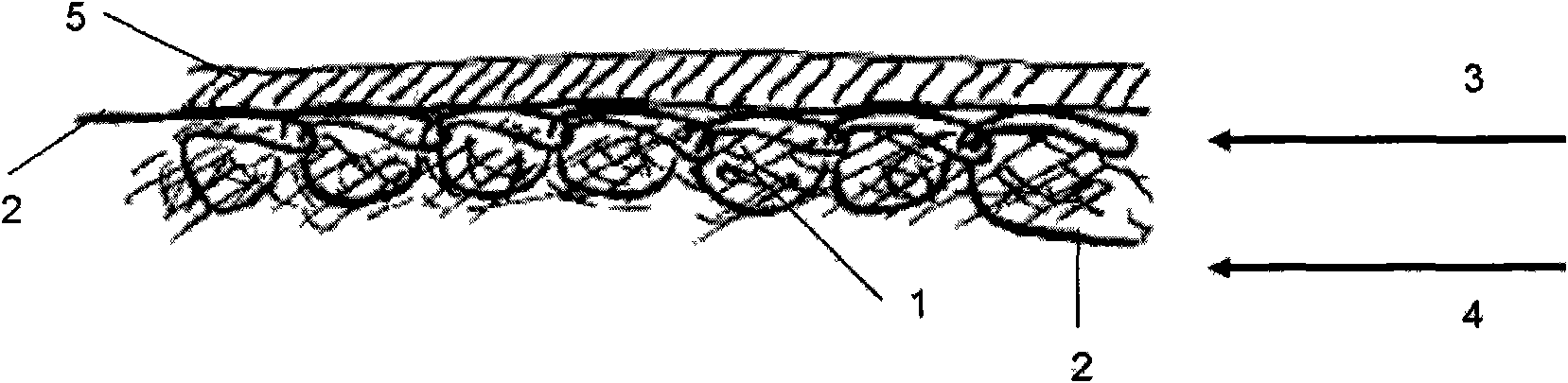

Light and high-strength rubber conveyor belt and preparation method thereof

The invention relates to a light and high-strength rubber conveyor belt and a preparation method tof the conveyor belt. The conveyor belt comprises a framework layer, an adhesive glue, and upper and lower cover rubber laminated structures; the framework layer adopts mixed woven canvas of ultra-high molecular weight polyethylene fibers and polyester fibers which are treated by plasma, simultaneously adopts low-temperature vulcanization technology to be subjected to covulcanization with the adhesive glue and a cover rubber at a low temperature, and solves the problem of the bonding of ultra-high molecular weight polyethylene fiber cloth and rubber. Compared with the conventional high-strength conveyor belt of wire rope core, the light and high-strength rubber conveyor belt in the invention not only has high strength, and good corrosion resistance, wear resistance, shock resistance and fatigue resistance, but also greatly reduces the weight and thickness, thereby reducing the conveying power energy consumption, which is expected to have long service life and good energy saving and environment friendly performances. Therefore the light and high-strength rubber conveyor belt disclosed in the invention is particularly suitable for the long-distance material conveying in the industries of coal mine, metallurgy, mine and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

High temperature resistant conveyor belt

ActiveCN102275712AImprove adhesionGood burning resistanceConveyorsNatural rubber adhesivesEthylene-propylene-diene-monomerMetallic materials

The invention provides a high-temperature resistant conveyer belt which comprises a framework layer and a covering glue layer which covers the surface of the framework layer, wherein the framework layer is made of a metal material; the covering glue layer is mainly made of ethylene propylene diene monomer rubber and chloroprene rubber and is added with a fire retardant agent, trichloroethyl phosphate, a binding agent and a binding improver apart from a main cross-linking agent, an auxiliary cross-linking agent, an activating agent, an anti-aging agent, a reinforcing agent, a dispersing agent and a softening agent, wherein the binding agent comprises phenolic resin and hexakis(methoxymethyl)melamine; and the binding improver comprises maleic anhydride complexing butadiene and liquid natural rubber. The high-temperature resistant conveyer belt provided by the invention can be used at a temperature of 300 DEG C and has good firing bonding performance and firing resistant performance.

Owner:YANKUANG GRP CO LTD +1

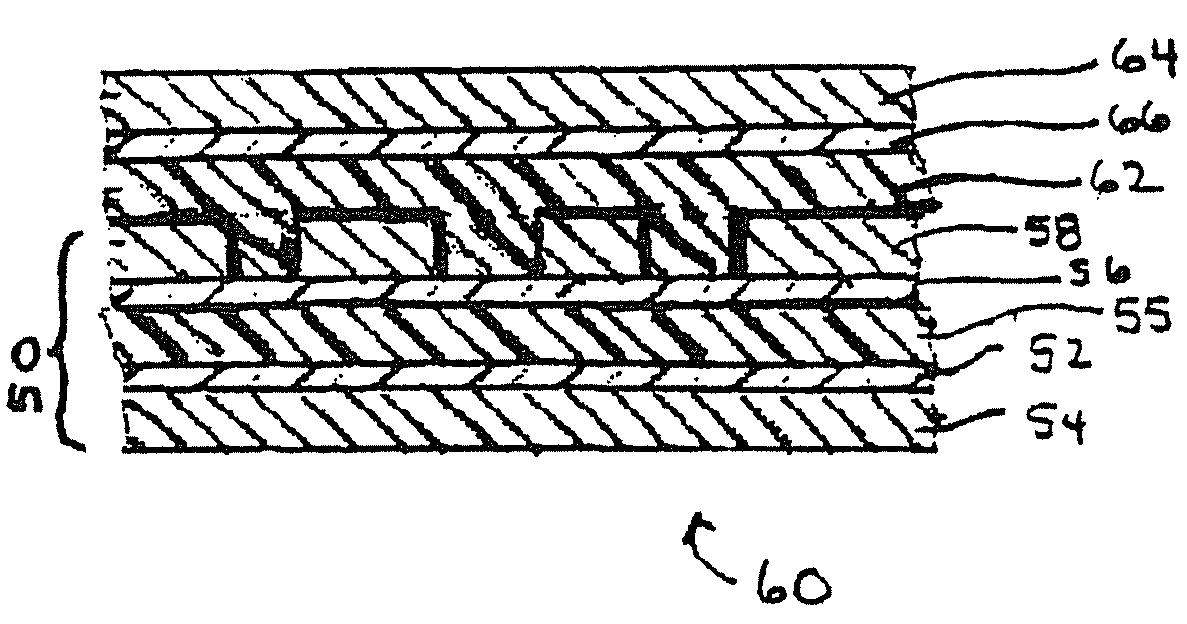

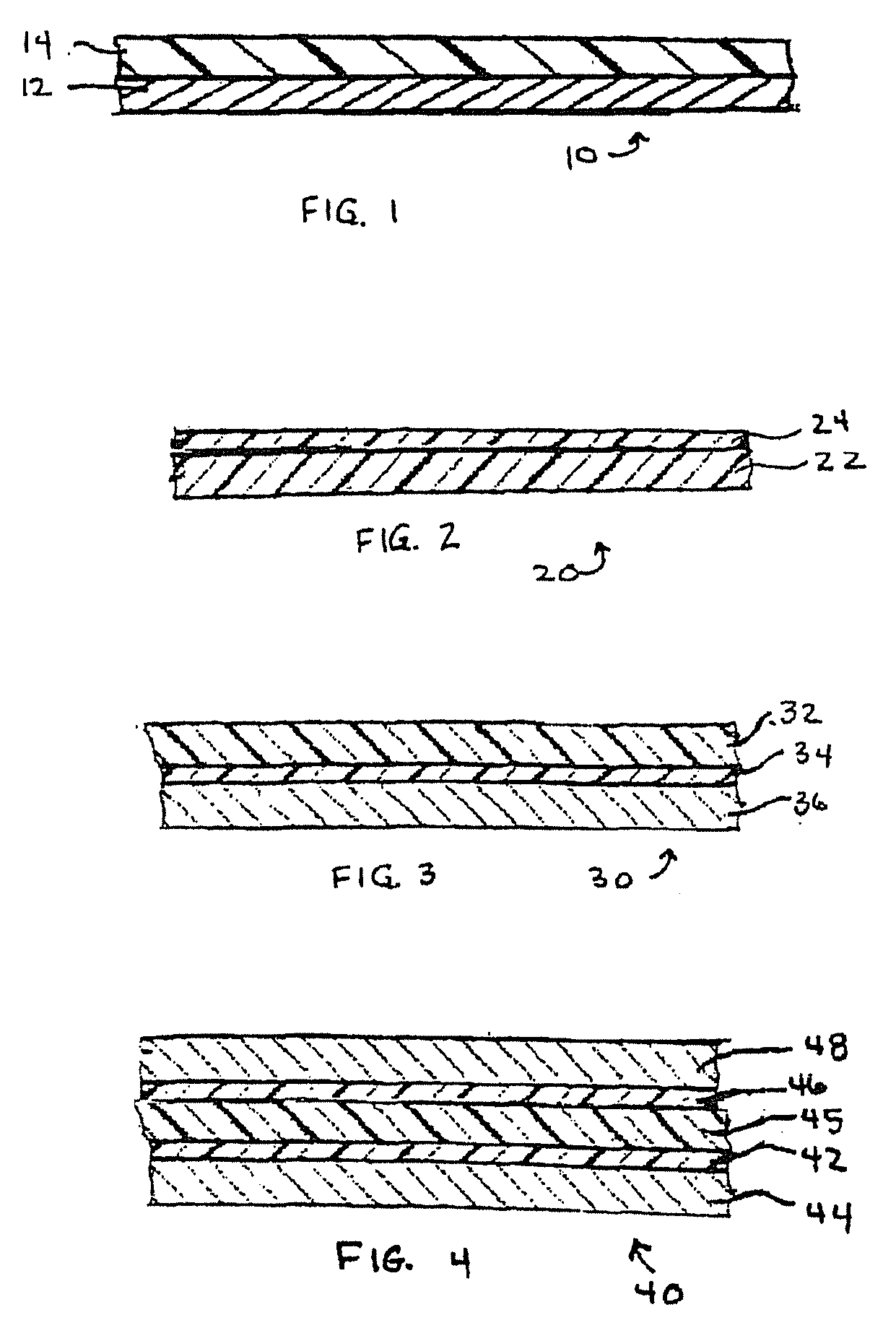

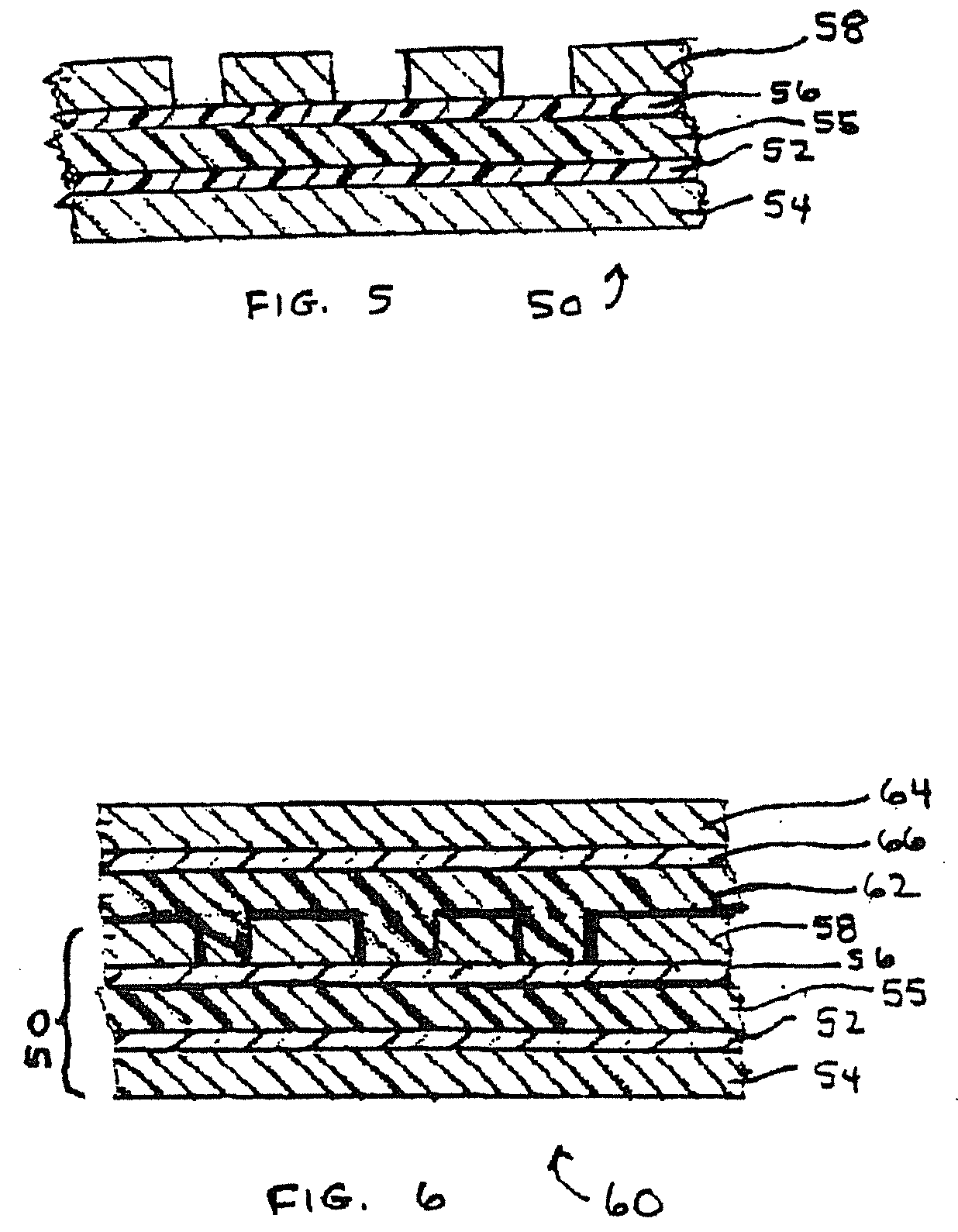

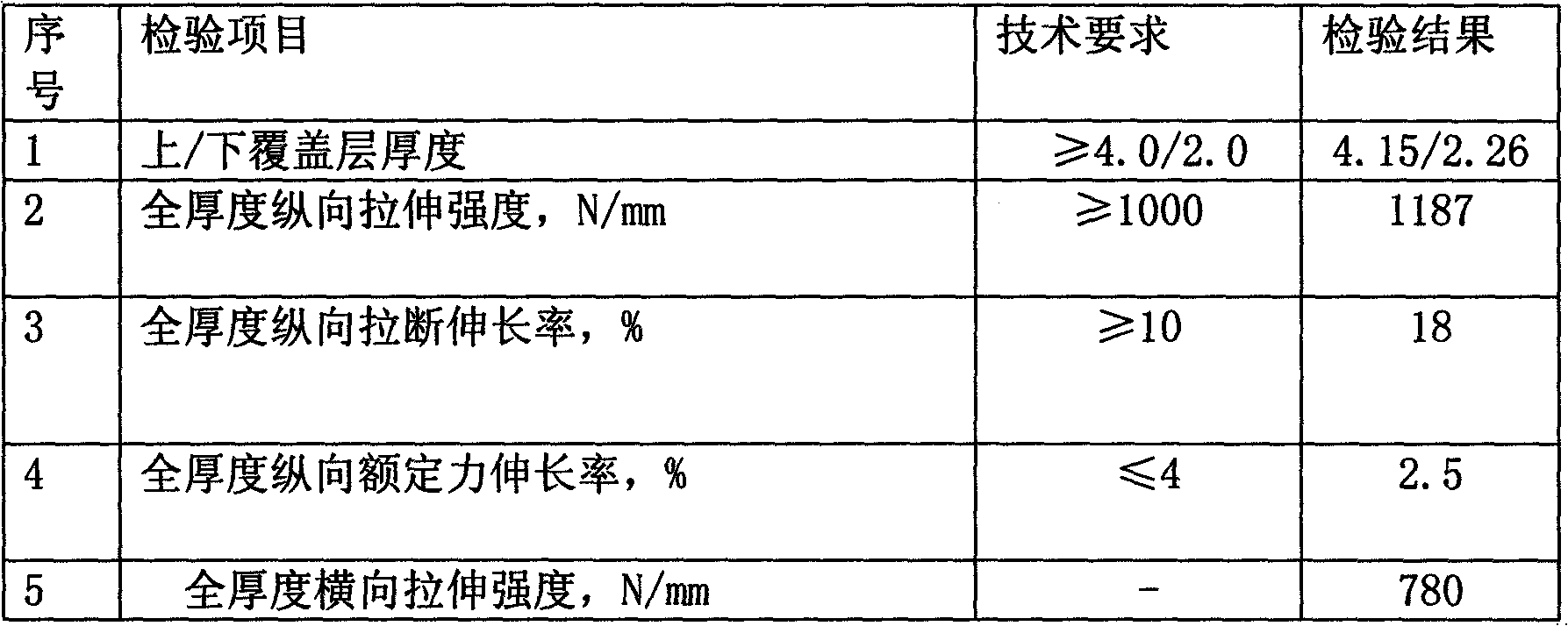

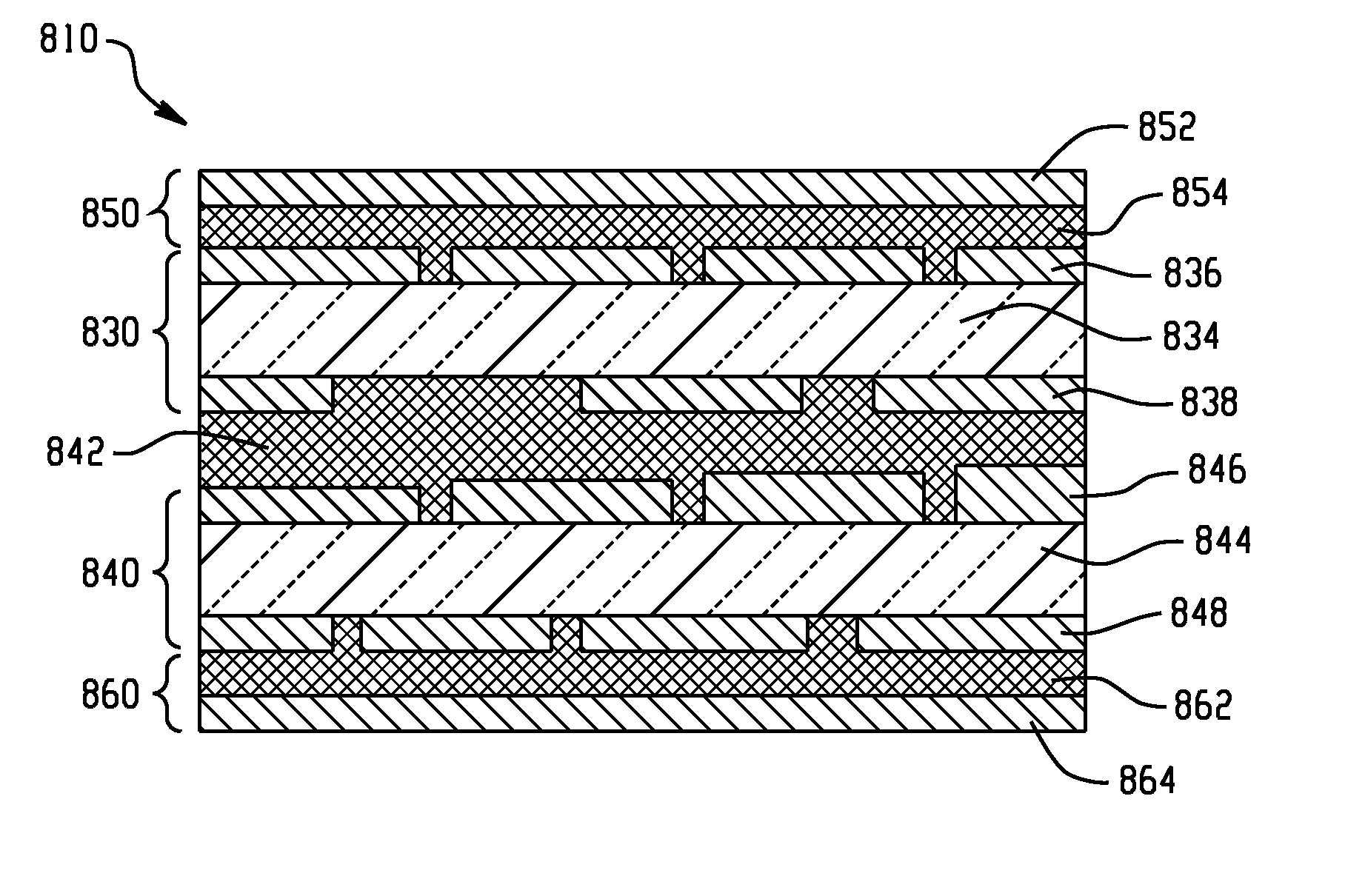

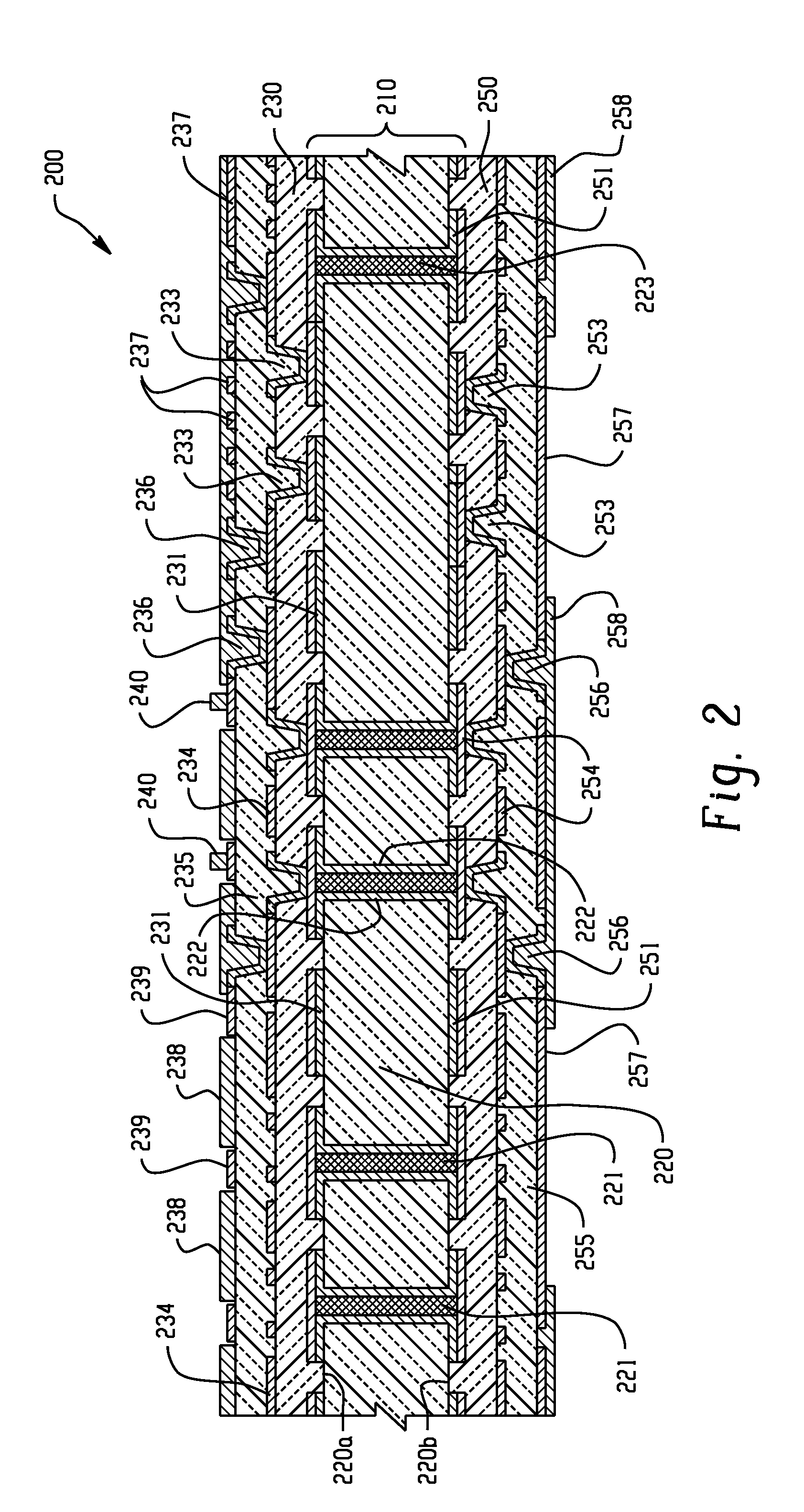

Circuit materials with improved bond, method of manufacture thereof, and articles formed therefrom

A circuit material, comprising a conductive metal layer or a dielectric circuit substrate layer and an adhesive layer disposed on the conductive metal layer or the dielectric substrate layer, wherein the adhesive comprises a poly(arylene ether) and a polybutadiene or polyisoprene polymer.

Owner:WORLD PROPERTIES

Tube-shaped flame retardant conveying belt with fabric laminations for coal mine

InactiveCN102642693AOptimizing process designReduce dosageNatural rubber adhesivesConveyorsEngineeringFire retardant

The invention discloses a tube-shaped flame retardant conveying belt with fabric laminations for a coal mine, which solves the problem that exiting products are not suitable for usage for underground conveying belts with laminations for coal mines. The conveying belt is characterized by comprising an upper flame retardant covering adhesive layer, a lower flame retardant covering adhesive layer, a side adhesive, skeleton layers, a flame retardant bonding layer and a buffering layer. A flame retardant bonding adhesive is used for bonding among the skeleton layers, among the skeleton layers and buffering layer and between the buffering layer and the upper flame retardant covering adhesive layer to form a whole, and formulas of the flame retardant bonding adhesive and a flame retardant covering adhesive are designed. Flame retardant epoxide resin (EP) canvas which is subjected to flame retardant impregnation processing serves as a skeleton, produced conveying belts have high pipe forming capability, conveying belt bodies have suitable softness, and produced conveying belts can meet turning requirements of tube-shaped conveying belts at different levels and requirements of tube-shaped conveying machines on physical mechanical properties of tube-shaped conveying belts; a flame retardant bonding adhesive material has high infiltration capacity on skeleton materials, after sulfuration, the bonding force of the flame retardant bonding adhesive material is large, dynamic heat is small, and the flame retardant bonding adhesive material has repeated bending fatigue resistance; and abrasion resistant and yielding resistant performance of the flame retardant bonding adhesive material is improved, and the flame retardant performance meets underground flame retardant requirements for coal mines.

Owner:胡世献

Dielectric materials, methods of forming subassemblies therefrom, and the subassemblies formed therewith

A circuit subassembly, comprising a dielectric layer formed from a dielectric composition comprising, based on the total volume of the composition: about 15 to about 65 volume percent of a dielectric filler; and about 35 to about 85 volume percent of a thermosetting composition comprising: a poly(arylene ether), and a carboxy-functionalized polybutadiene or polyisoprene polymer.

Owner:ROGERS CORP

Preparation method for basalt fiber conveying belt

ActiveCN104692027AReduce weightReduce energy consumptionNatural rubber adhesivesConveyorsPolymer scienceAdhesive

The invention relates to a preparation method for a basalt fiber conveying belt, and belongs to the technical field of rubber products. The preparation method comprises the following steps: performing hydrochloric acid treatment, coupling agent treatment and plasma grafting and impregnation treatment on basalt fiber cloth; mixing natural rubber, synthesized rubber, an activating agent, an anti-aging agent, a reinforcement agent and a plasticizer to obtain a first section of mixed rubber; adding a promoter and a vulcanizer for mixing to obtain a second section of mixed rubber, and extruding the second section of mixed rubber to obtain a coverage rubber sheet; mixing the natural rubber, the synthesized rubber, the activating agent, the anti-aging agent, an adhesive, the reinforcement agent and the plasticizer to obtain a first section of mixed rubber; then adding the promoter, the vulcanizer and an adhesive RA for mixing to obtain a second section of mixed rubber, freshening after the second section of mixed rubber is stewed, and attaching the second section of mixed rubber and the basalt fiber cloth to obtain rubberized canvas; attaching the basalt fiber rubberized canvas layer by layer to obtain a framework, attaching the coverage rubber sheets to the upper surface and the lower surface of the framework to obtain a belt blank, and vulcanizing the belt blank to obtain the basalt fiber conveying belt. The conveying belt prepared by the preparation method is low in cost, light in mass, high in intensity, fatigue-resistant and long in service life; the conveying energy consumption can be greatly reduced.

Owner:WUXI BOTON CONVEYOR SOLUTION CO LTD

Multifunctional aqueous adhesive and preparation method thereof

ActiveCN101058704AAvoid poisoningAvoid the chance of occupational diseasesMonocarboxylic acid ester polymer adhesivesNatural rubber adhesivesPolymer scienceAdjuvant

The invention discloses a multipurpose aqueous adhesive, which comprises the following parts: 10-35% thermoplastic rubber or emulsion, 0. 5-35% solvent, 28-45% emulsion, 20-80% viscosifying resin or its emulsion, 0. 5-5% functional adjuvant and 1-20% water. The making method comprises the following steps: putting the solvent into autoclave; stirring at middle speed and adding thermoplastic rubber and its modifying product until dissolving completely; or putting into copolymerized rubber emulsion directly; stirring to add the viscosifying resin or the viscosifying resin in the invention; blending evenly; adding emulsion; fetching the sample to test the viscosity; adding fitful quantity of water and corresponding functional adjuvant according to the purpose and viscosity; dispersing at high speed until even condition; cooling; filtering; packing; obtaining the product for shoe-making, hand pocket and decorative aspect with low cost.

Owner:林润强

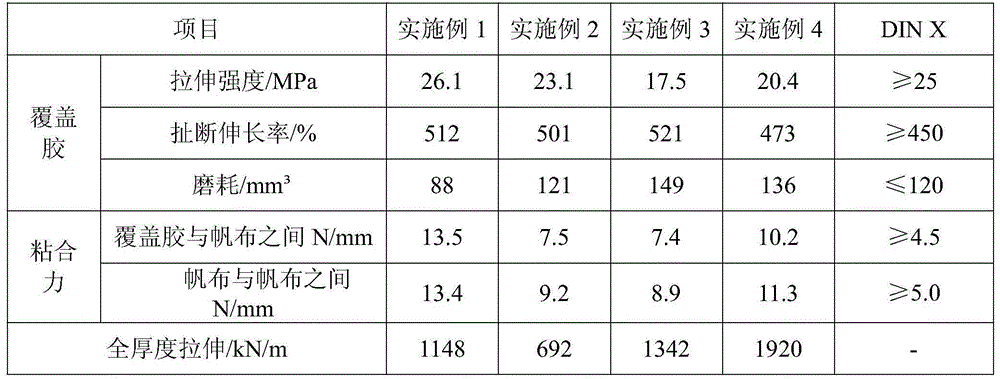

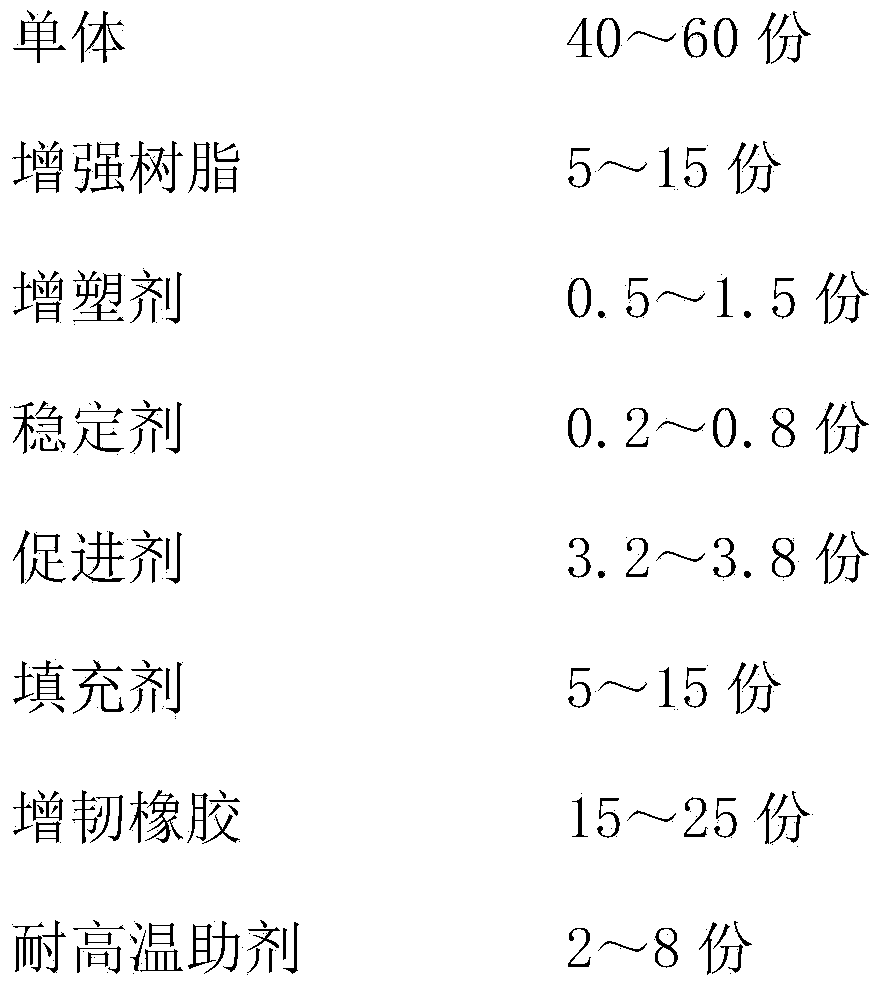

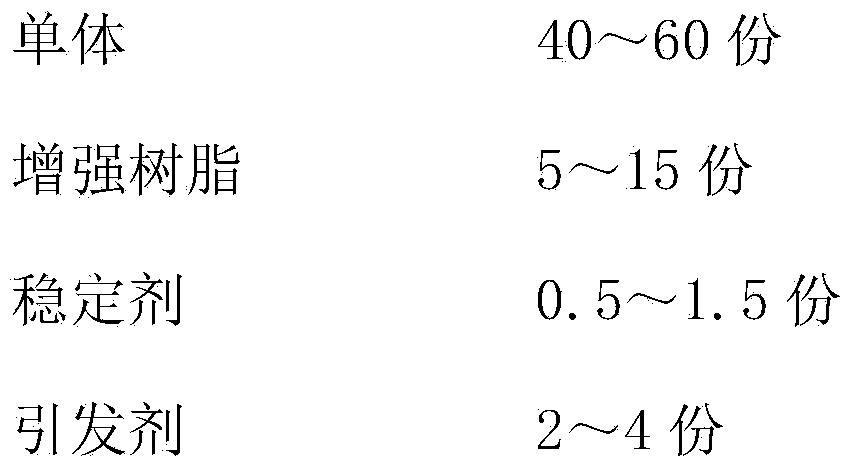

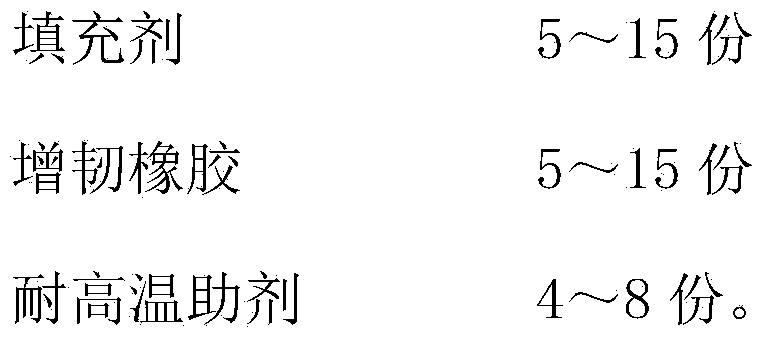

Two-component high-temperature-resisting adhesive for assembling loudspeaker and preparation method thereof

ActiveCN103725206AImprove high temperature resistanceSolve high temperature resistanceNatural rubber adhesivesNon-macromolecular adhesive additivesAdhesivePlasticizer

The invention discloses a two-component high-temperature-resisting adhesive for assembling a loudspeaker. The two-component high-temperature-resisting adhesive comprises a main agent and a curing agent, wherein the main agent comprises the following ingredients in parts by weight: 40 to 60 parts of monomer, 5 to 15 parts of reinforcing resin, 0.5 to 1.5 parts of plasticizer, 0.2 to 0.8 part of stabilizer, 3.2 to 3.8 parts of promoter, 5 to 15 parts of filler, 15 to 25 parts of toughening rubber and 2 to 8 parts of high-temperature-resisting additive; the curing agent comprises the following ingredients in parts by weight: 40 to 60 parts of monomer, 5 to 15 parts of reinforcing resin, 0.5 to 1.5 parts of stabilizer, 2 to 4 parts of initiator, 5 to 15 parts of filler, 5 to 15 parts of toughening rubber and 4 to 8 parts of high-temperature-resisting additive. The adhesive can be cured at normal temperature, and the high-temperature-resisting effect is good.

Owner:江苏东禾电声配件有限公司

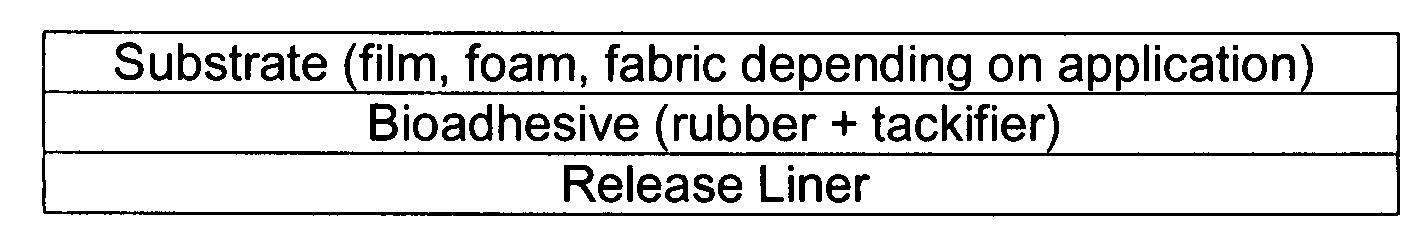

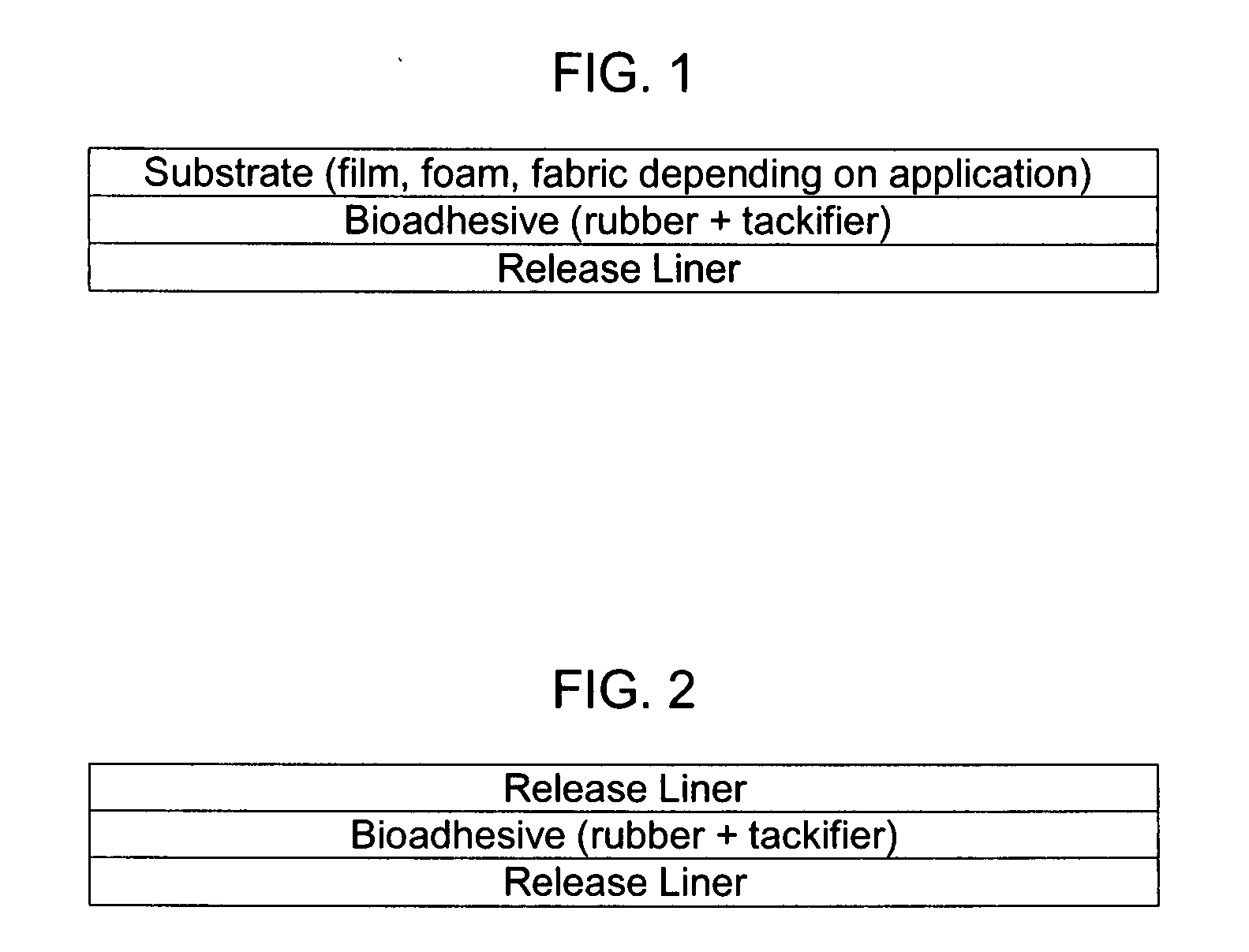

Guayule rubber and resin wet-stick bioadhesives

A bioadhesive for bonding to wet skin is disclosed, including a novel non-Hevea-based resin, which serves as a tackifier for the rubber, possessing strong wet adhesion to human skin and the remarkable property of bonding to it underwater, and a novel non-Hevea rubber that provides cohesive strength to the adhesive. Pressure-sensitive adhesive tapes are used in many applications where there is a need to adhere to skin, for example, medical tapes, wound or surgical dressings, athletic tapes, surgical drapes, or tapes or tabs used in adhering medical devices such as sensors, electrodes, ostomy appliances, and so on.

Owner:YULEX CORP

Hot-melt adhesive for steel-plastic composite pipe

ActiveCN102190984AImprove performanceExtended service lifeNatural rubber adhesivesNon-macromolecular adhesive additivesPolyolefinRare earth

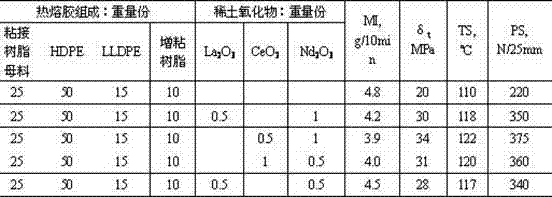

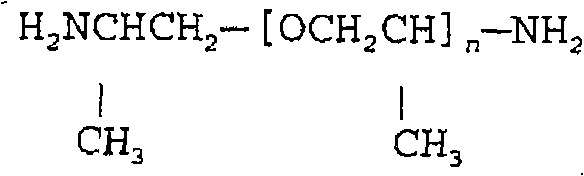

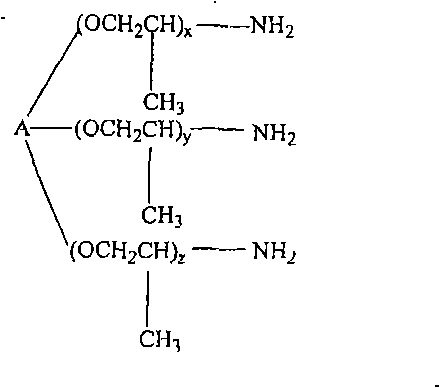

The invention discloses a hot-melt adhesive for a steel-plastic composite pipe, which is prepared by blending and extruding the following components in percentage by weight by a parallel double screw extruder: 5-40% of binding resin master batch, 50-80% of polyolefin resin, 5-25% of tackifying resin and 0.02-5% of inorganic rare-earth oxide, wherein the binding resin is prepared by carrying out graft modification on polyethylene and / or ethylene copolymer, which is / are used as the matrix resin, and initiator (accounting for 0.01-0.2 wt% of the binding resin master batch) and unsaturated polar monomer (accounting for 0.1-5 wt% of the binding resin master batch); the polyolefin resin is used for adjusting the consumption of the binding resin master batch and the comprehensive properties of the hot-melt adhesive; and the tackifying resin is one or combination of SBS (styrene-butadiene-styrene), SEBS (styrene-ethylene-butadiene-styrene), SIS (styrene-isoprene-styrene), cis-1,4-polybutadiene rubber, nitrile-butadiene rubber and natural rubber. Since the rare-earth oxide is added, the grafting ratio of the binding resin master batch in the hot-melt adhesive is increased, thereby obviously enhancing the initial viscosity, enduring viscosity, binding strength and other properties.

Owner:河北金天塑胶新材料有限公司

High-performance tyre curtain glue stock containing resorcinol-formaldehyde adhesion system

InactiveCN101191040AImprove dynamic performanceHigh bonding strengthNatural rubber adhesivesPneumatic tyre reinforcementsAdhesiveEngineering

The invention relates to a high performance tire fabric rubber compound with a resorcinol-formaldehyde adhesion system, and comprises outer layer cord fabric rubber compound and cushion rubber compound. The key points are that: the invention is made by a plurality of raw materials, wherein, the adhesion system thereof adopts the resorcinol-formaldehyde adhesion system. The raw materials of the outer layer cord fabric rubber compound are natural rubber, rosin extended styrene-butadiene rubber, butadiene rubber, carbon black N330 / N660, zinc oxide, stearic acid, age inhibitor 4010NA / RD / BLE, oil-extended butadiene sulphur powder (S), aromatic oil, accelerant CZ / TMTD, RF-90 resin and adhesive RA-65. The raw materials of cushion the rubber compound are natural rubber, rosin extended styrene-butadiene rubber, carbon black N330 / N660, zinc oxide, stearic acid, age inhibitor 4020 / RD, oil-extended butadiene sulphur powder (S), aromatic oil, accelerant CZ / TMTD / DM, vulcanized agent DTDM, RF-90 resin and adhesive RA-65. The invention is essentially used for the outer layer cord fabric rubber compound and the cushion rubber compound in a bias tire. H pullout force can be obviously enhanced by using the rubber compound of the invention; the problem of cord fabric delaminating in practical use can be reduced by using the bias tire made from the rubber compound of the invention.

Owner:SICHUAN TYRE & RUBBER CO LTD

Curable epoxy resin-based adhesive compositions

ActiveCN101517029AImprove energy absorptionNatural rubber adhesivesNon-macromolecular adhesive additivesEpoxyAdhesive

Owner:HENKEL KGAA

Leak-blocking adhesive and preparation method thereof

ActiveCN102329585AImprove general performanceGood plugging effectMineral oil hydrocarbon copolymer adhesivesProductsPolymer scienceFoaming agent

The invention relates to a leak-blocking adhesive and a preparation method thereof. The adhesive consists of the following components in part by weight: 15 to 25 parts of synthetic resin, 15 to 30 parts of lubricating grease, 10 to 15 parts of foaming agent, 20 to 35 parts of fibrous filler, 30 to 50 parts of heat-resistant filler and 5 to 10 parts of coloring agent; the synthetic resin, the foaming agent, the heat-resistant filler and the coloring agent are uniformly dispersed and then are added with the lubricating grease and the fibrous filler, the uniformly mixed materials are added into an extruder and are extruded to form a stick shape, and after being cooled to the room temperature, the stick-shaped adhesive is cut. Compared with the prior art, the leak-blocking adhesive can tolerate most of chemical media, is highly universal, can be automatically filled into a neighboring gap when being heated, enhances the leak-blocking effect, prevents the phenomena of adhesive leakage and adhesive spouting, has excellent flowing property before being solidified, is convenient and easy to operate, and has a wide resisted temperature range.

Owner:上海海鹰粘接科技有限公司

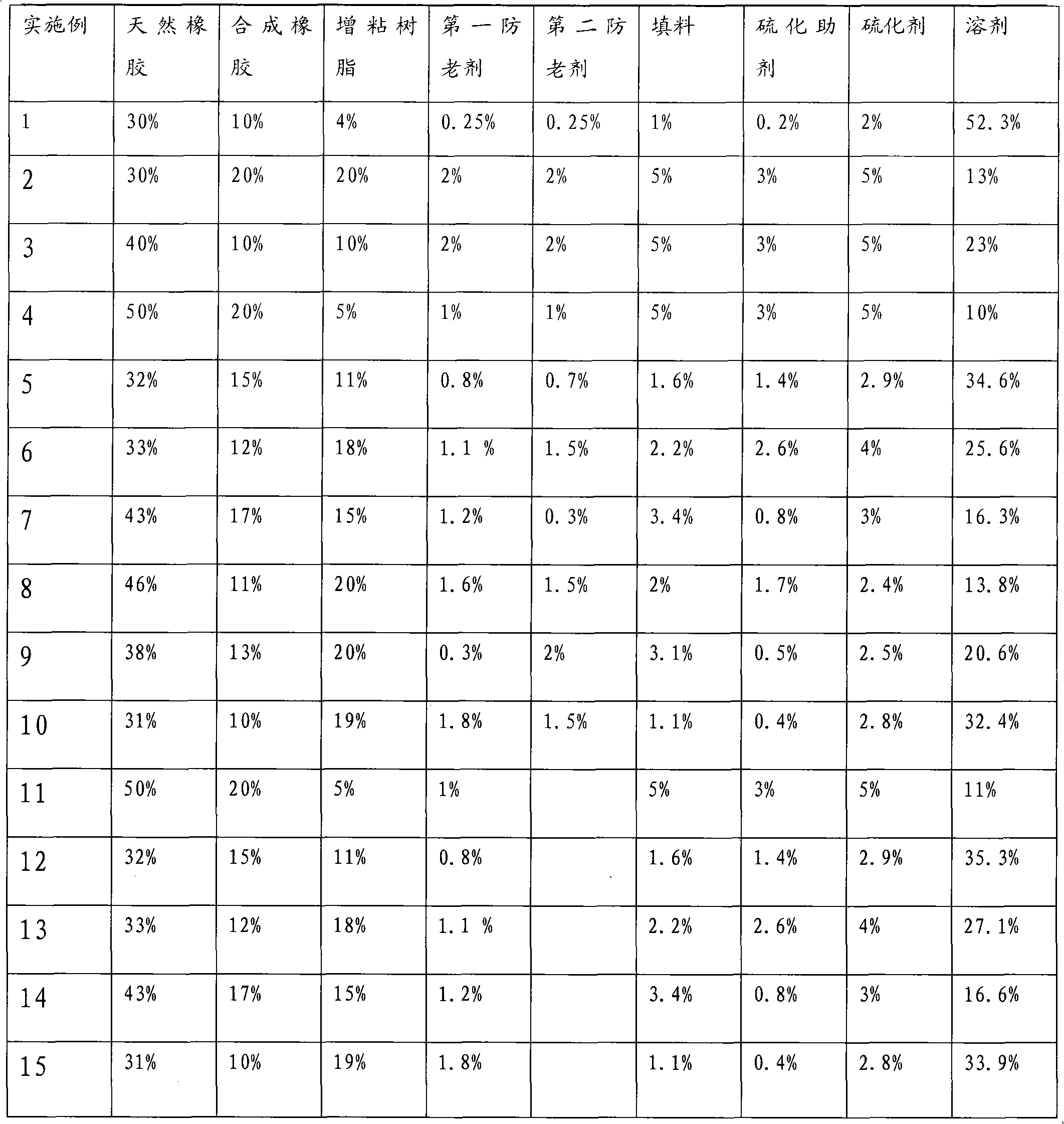

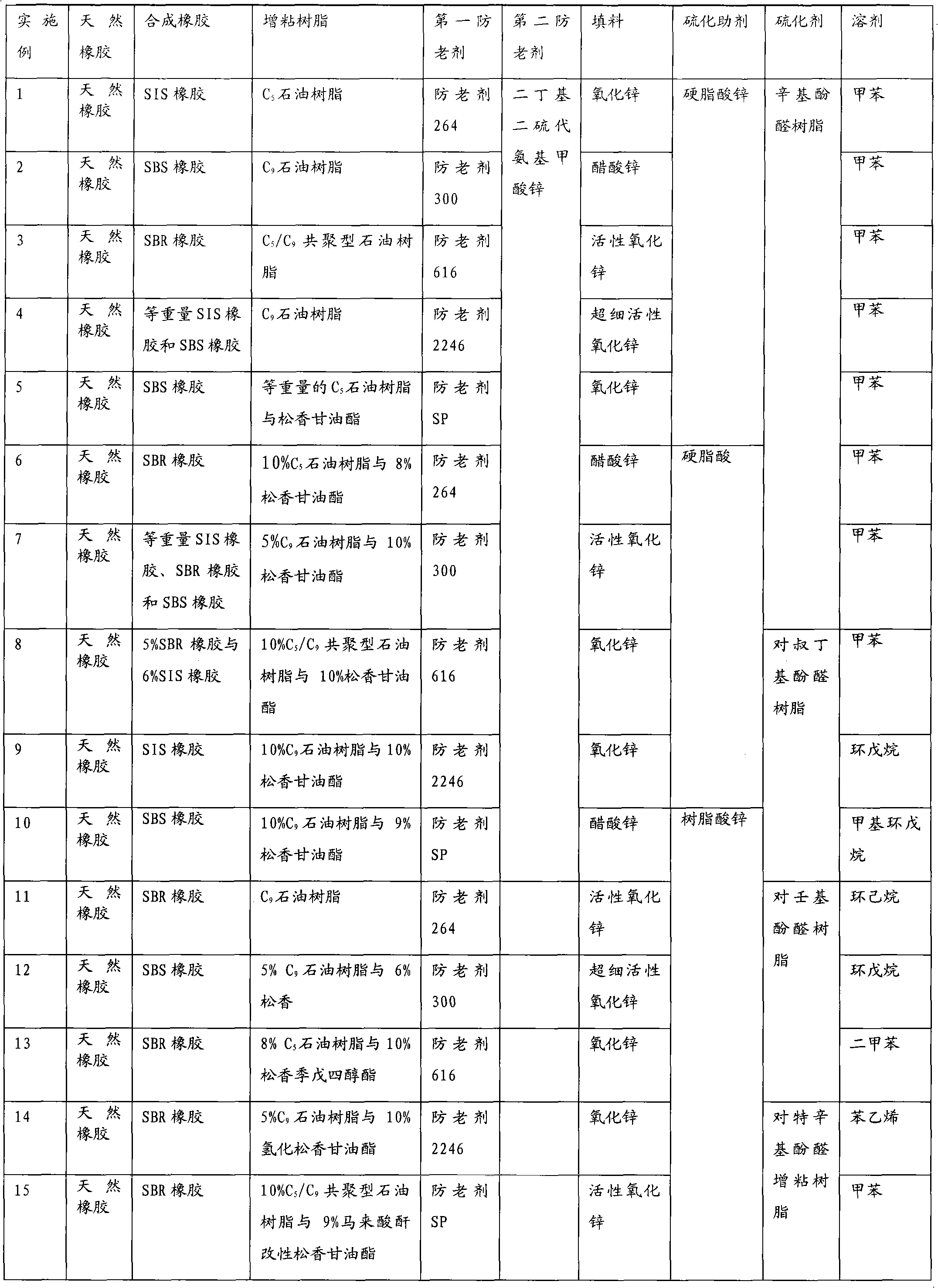

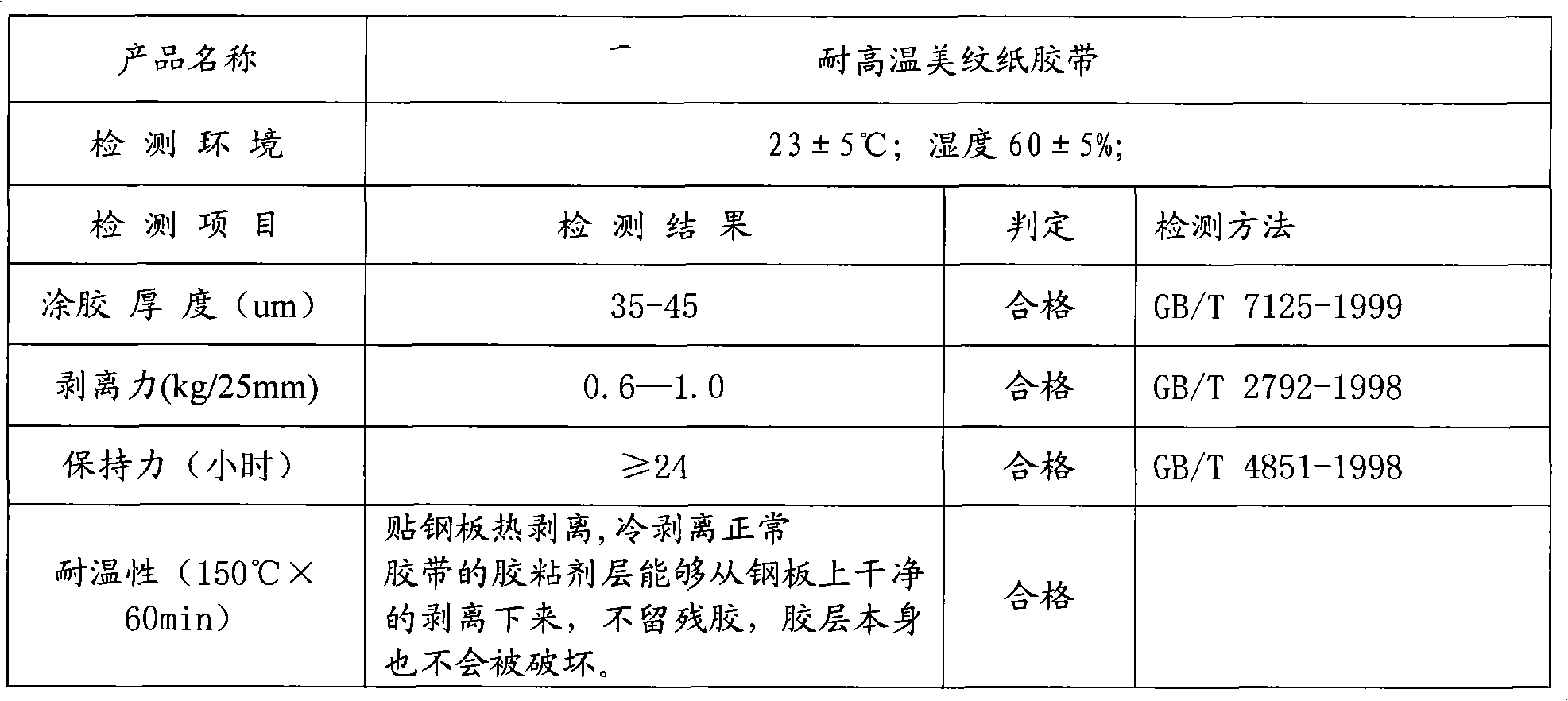

Adhesive for high-temperature-resistant masking tape and high-temperature-resistant masking tape

ActiveCN102120922AThermal peeling is normalCold peeling index is normalMineral oil hydrocarbon copolymer adhesivesNatural rubber adhesivesVulcanizationMasking tape

The invention discloses an adhesive for a high-temperature-resistant masking tape. The adhesive for the high-temperature-resistant masking tape is characterized by comprising the following components in percentage by weight: 30 to 50 percent of natural rubber, 10 to 20 percent of synthetic rubber, 4 to 20 percent of viscous resin, 0.5 to 4 percent of anti-aging agent, 1 to 5 percent of filler, 0.2 to 3 percent of vulcanization auxiliary agent, 2 to 5 percent of vulcanizing agent and the balance of solvent. The adhesive for the high-temperature-resistant masking tape has high temperature resistance and normal hot stripping and cold stripping indexes after being used continuously at the temperature of 150 DEG C for 60 minutes. The adhesive is applied to adhesion at the temperature of 150 DEG C without degumming and cracking and is particularly applied to high-temperature environments such as automobile baking varnish, an electronic circuit board and the like.

Owner:SHANGHAI SMITH ADHESIVE NEW MATERIAL

Adhesive tape with textile holder for cable bandaging

ActiveCN101586008AGood cross tearEffective knotNatural rubber adhesivesFilm/foil adhesivesYarnEngineering

The invention relates to an adhesive tape with textile holder for cable bandaging. The invention relates to an adhesive tape intended preferably for wrapping elongate material, such as lines or cable looms more particularly, having a textile carrier and having a pressure-sensitive adhesive coating applied at least to one side of the carrier. Adhesive tape for jacketing elongate material having a nonwoven-based carrier provided at least on one side with an adhesive coating, the carrier having a basis weight of 30 to 120 g / m2, and the carrier being composed of at least one ply of a preconsolidated nonwoven webfiber, specifically a spinning sticking webfiber, fusing spraying webfiber or mechanically reinforced short fibre webfiber that is overstitched with a multiplicity of threads, and has a thread density of less than 22 threads per 25 mm width of the carrier, preferably between 9-20 threads per 25 mm.

Owner:TESA SE

Production process for bamboo fiber double-dot lining fabric

The invention discloses a production process for a bamboo fiber double-dot lining fabric, which includes the steps of base fabric weaving, overflow slack pretreatment, shaping and cropping, feeding, dispensing, baking, after-finishing, rolling, final inspection and packaging. The product adopts 40S bamboo fibers and terylene interlaced yarns as materials, and is differentially woven by a air jet loom, and thereby the bulkiness of the lining fabric is greatly improved; the lining fabric has the characteristics of the bamboo fibers, i.e. moisture absorbability, moisture releasability, bacteria inhibition and bacteria resistance; the handle of the lining fabric is soft; the lining fabric is highly woolly, moreover, in the processes of pretreatment and after-finishing, the base fabric is treated by softening agent in bath, so that ultrathin 'protective films' can be formed on the fibers, consequently, the smoothness, softness and elasticity of the fabric in treatment bath are at appropriate levels in order to reduce fabric entanglement and decrease the coefficient of wet friction between the fabric and mechanical metal parts, as a result, defects, such as creases and scratches, can be prevented from being produced on the surface of the fabric, the quality of the product is guaranteed, and the overall properties of the lining fabric are excellent.

Owner:ZHEJIANG KINGSAFE INTERLINING

Method for manufacturing environment-friendly pressure sensitive adhesive material

InactiveCN102153962AImprove propertiesAvoid pollutionNatural rubber adhesivesNon-macromolecular adhesive additivesEvaporationSolvent

The invention discloses a method for manufacturing an environment-friendly pressure sensitive adhesive material. The method mainly comprises the following steps of: 1, in a closed environment, heating solvent type pressure sensitive adhesive to the temperature of between 60 and 200 DEG C so that the solvent contained in the solvent type pressure sensitive adhesive is evaporated and 50 to 99.9 mass percent of pressure sensitive adhesive is obtained; 2, adding a curing agent into the pressure sensitive adhesive obtained in the step 1, and mixing the curing agent and the pressure sensitive adhesive uniformly by using a vibrating bar or a screw extruder; 3, coating; and 4, rolling. The evaporation time of the solvent during coating the pressure sensitive adhesive can be reduced, so that the coating production efficiency is greatly improved.

Owner:SUZHOU SIDIKE NEW MATERIALS SCI & TECH

Thermal-activated adhesive film and method of producing the same

InactiveCN101402831ALow curing temperatureFast curingNatural rubber adhesivesFilm/foil adhesivesCross linkerBiological activation

The invention discloses a thermal activating glue film. The thermal activating glue film is characterized by consisting of resin, rubbers, fillings, a cross linker, a perduren compound and a promoter which are melted and mixed by a mixing mill and then calendered into a film. The thermal activation glue film is a thermal activating glue film which has the advantages of fast solidifying speed, excellent storage stability and high solidifying intensity, temperature resistance, environment protection and low cost.

Owner:YANTAI DARBOND TECH

Method for preparing hydrated adhesive

InactiveCN101654602AHigh sticky surface cleanlinessEasy to storeNatural rubber adhesivesAlginic acid adhesivesAdhesiveWater soluble

The invention provides a method for preparing hydrated adhesive, which solves the problems of disposable usage, difficultly-controlled pasting position, difficult removal and the like in the traditional tackifier fundamentally. The technical key points of the invention are as follows: the hydrated adhesive is prepared by mixedly stirring the following raw materials by weight percent at normal temperature and pressure: 10%-35% of sodium alga acid (C6H7O8Na), 5%-30% of competed hydrate, 20%-50% of water-soluble adhesive and 5%-65% of water. The hydrated adhesive in the invention has the advantages of controllable viscosity, stable physicochemical property, environment protection, capability of repeated use, no residual and the like, and is suitable for caking of solid materials such as various paper, plastic and the like.

Owner:梁跃飞

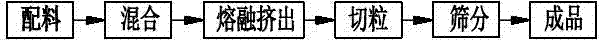

Hot melt adhesive film for adhering rubber/foamed EVA (ethylene-vinyl acetate copolymer) composite sole and preparation method thereof

InactiveCN104559843AFit evenlyAchieve fitNatural rubber adhesivesSolesAdhesion strengthUltimate tensile strength

The invention discloses a hot melt adhesive film for adhering a rubber / foamed EVA (ethylene-vinyl acetate copolymer) composite sole and a preparation method thereof. The hot melt adhesive film for adhering the rubber / foamed EVA composite sole comprises a hot melt adhesive film and a release film, wherein the hot melt adhesive film comprises the following raw materials in part by weight: 60 to 95 parts of polyethylene-lipin polymer, 5 to 40 parts of rubber and 0.1 to 8 parts of an assistant; the hot melt adhesive film is prepared by carrying out extrusion pelletization in an extruder at the temperature of 80-200 DEG C to obtain hot melt adhesive particles and then carrying out tape casting by a tape-casting machine or carrying out scrape coating by a coating machine. The hot melt adhesive film disclosed by the invention is uniformly adhered; the hot melt adhesive film is adhered to the surface of a rubber outsole to be vulcanized together with the outsole and then the rubber outsole with an adhesive is compounded with an EVA midsole, so that complete adhesion between the hot melt adhesive film and the outsole as well as the midsole can be realized; in the vulcanizing process, bubbles are avoided, so that adhesion strength of the hot melt adhesive film is enhanced, the adhesive failure and cracking of the sole are prevented and the service life of the sole is prolonged.

Owner:GUANGZHOU LUSHAN NEW MATERIALS

Formula of adhesive agent for aircraft tire renewing

ActiveCN101200625AHigh adhesion retentionMeet performance requirementsNatural rubber adhesivesSulfurGasoline

The present invention discloses a prescription of an adhesive used for an aircraft tire retreading. The adhesive considers caoutchouc as the main material and also contains the main auxiliary materials of styrene butadiene rubber, adhesion promoter, adhesive, high abrasion furnace black, high dispersion white carbon black, ketoamine age inhibitor, indiscerptible sulfur and sulfenamide accelerant. The main material and the main auxiliary materials are made into gross rubber according to certain weight portion ratio, and the gross rubber is mixed with gasoline by certain proportion to be made into the adhesive. The adhesive of the prescription has the advantage that the adhesive solves the problem of sticking an old tire body with a retreading component when the aircraft tire is retreaded, which ensures that the aircraft tire does not have the problem of the delamination of the glue material between the old tire body and the retreading component, bulging and other quality problems during the use course, and the tire is safe for using.

Owner:中国化工集团曙光橡胶工业研究设计院有限公司

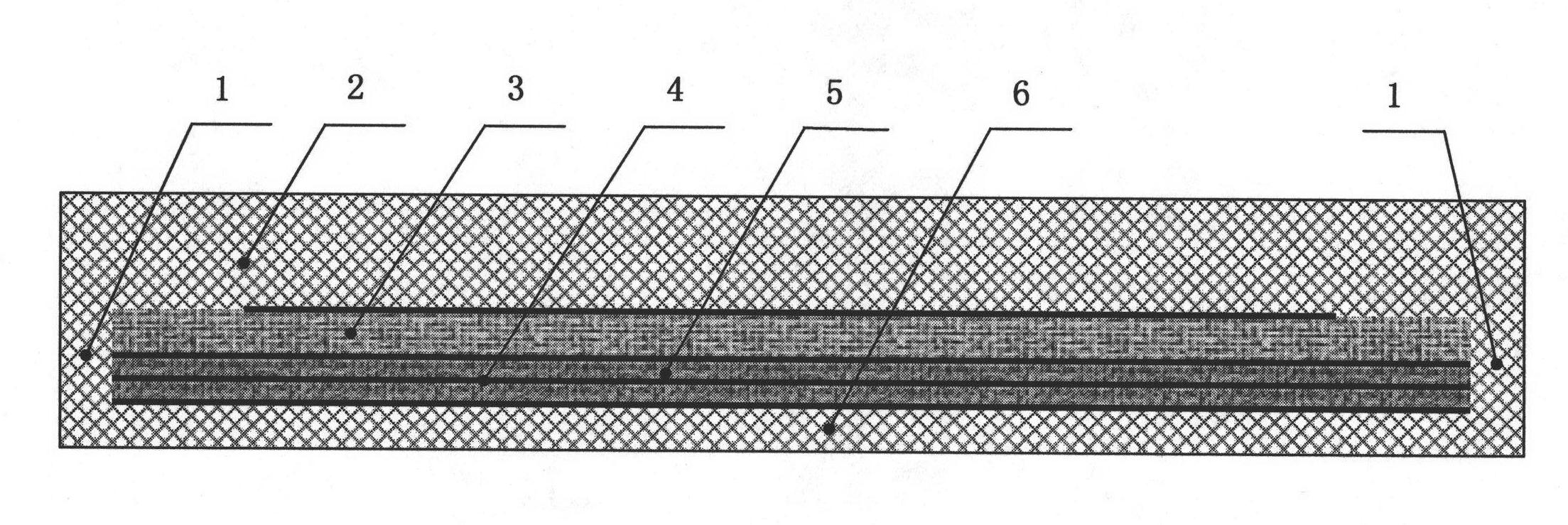

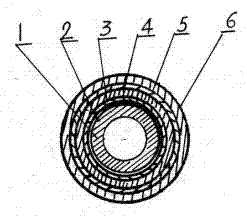

Corrosion-resistant high-pressure hose and production method thereof

ActiveCN102865420ATightly bondedImprove impact resistanceNatural rubber adhesivesFlexible pipesHigh pressureButyl rubber

The invention discloses a corrosion-resistant high-pressure hose and a production method thereof. The corrosion-resistant high-pressure hose comprises an inner pipe layer (1), a steel wire enhancing layer (3), a middle glue layer (4) and an outer glue layer (6). The hose is characterized in that the inner pipe layer is made from hydrogenated butyl rubber and is coated with an aramid fabric layer (2), the steel wire enhancing layer is wound or woven outside the aramid fabric layer, the middle glue layer, namely a middle glue bonding layer, is arranged outside the steel wire enhancing layer, a second steel wire enhancing layer (5) is wound or woven outside the middle glue bonding layer, the middle glue bonding layer and the wound or woven steel wire enhancing layer are fused together, and the outermost layer of the hose is the outer glue layer which is a protective layer. The production method is implemented through carrying out processes such as banburying and extrusion on materials of the inner pipe layer made from the hydrogenated butyl rubber, the middle glue bonding layer and the outer glue protective layer, and winding the steel wire enhancing layer and coating the aramid fabric layer respectively. The corrosion-resistant high-pressure hose disclosed by the invention is good in stability, strong in corrosion resistance and H2S prevention, and wear-resisting especially; and the impact resistance of the hose is improved, the strength and flexibility of the hose are enhanced, and the service life of the hose is effectively prolonged by more than 50%.

Owner:HEBEI JINGBO PETROLEUM MACHINERY

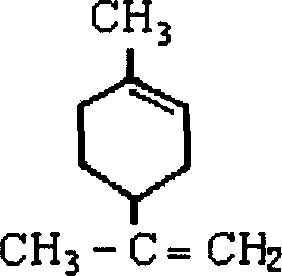

Binder in use for jointing covering rubber on table tennis bat

InactiveCN101003711AImprove solubilityShort manufacturing timeNatural rubber adhesivesConjugated diene hydrocarbon adhesivesPolymer scienceTennis racket

This invention discloses a pressure-sensitive adhesive for rubber layer on table tennis racket. The adhesive is composed of: solvent 60-90 wt. %, rubber 8-20 wt. %, and thickening resin 2-20 wt. %. The solvent is 1, 8-terpadiene, or a mixture of 1, 8-terpadiene and one or two of ethyl acetate, methanol and ethanol. The rubber is one or two of nonpolar rubbers such as natural rubber, and polar rubbers such as polychlorobutadiene, or rubber compound. 1, 8-terpadiene used as the solvent has high solvency for rubber layer on table tennis racket, and is harmless and environmentally friendly. The adhesive, when used on rubber layer on table tennis racket, has such advantages as rapid swelling, long elasticity-enhancing effect, and simple process.

Owner:徐昊为

Process for preparing a pressure-sensitive self-adhesive composition wherein tackifiers in dispersed, melted or solid form are mixed with natural rubber latex

Process for preparing a pressure-sensitive adhesive composition, characterized in that tackifiers in dispersed, melted or solid form are mixed with natural rubber latex, the water content being not more than 45% by weight.

Owner:TESA SE

Pressure Sensitive Adhesive Composition and Pressure Sensitive Adhesive Tape

InactiveUS20110306677A1Improve balanceHigh bonding strengthBiocideHydroxy compound active ingredientsPolymer sciencePlasticizer

A pressure sensitive adhesive composition comprising, as a rubber component solid at ordinary temperature, from 10% by mass or more to less than 50% by mass of polyisoprene, from more than 50% by mass to 90% by mass or less of a styrene-isoprene-styrene block copolymer and 0 to 30% by mass of polyisobutylene, and further comprising, per 100 parts by mass of the solid rubber component, 1 to 30 parts by mass of polyisobutylene liquid at ordinary temperature, 50 to 120 parts by mass of a tackifier, and 1 to 40 parts by mass of a plasticizer liquid at ordinary temperature; and a pressure sensitive adhesive tape comprising a base material and the above-described pressure sensitive adhesive composition provided on the base material.

Owner:NICHIBAN CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com