Patents

Literature

682results about How to "Improve the construction environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Premixing mortar with high moisture retention and production method thereof

The invention discloses pre-stirring mortar with high moisture retention and a production method thereof. The premixing mortar comprises the following components by weight ratio: 100 parts of cement with the high moisture retention, 1 to 900 parts of fine aggregate and 30 to 200 parts of water, wherein the cement with the high moisture retention contains a cellulose ether component and has the moisture retention above 90 percent; and the fine aggregate is natural sand or artificial sand obtain through screen sizing or removing harmful components, and has the maximum grain diameter of 1.18 mm to 2.36 mm. The production method comprises the following steps: arranging a mortar stirring machine on a construction site or nearby; adopting the cement with the high moisture retention and the fine aggregate to automatically meter and stir, enable mortar to be usable while stirring, and the like to ensure the mortar quality; and adopting a closed stirring mode, a dust-collecting mode and the like to reduce dust raise. The pre-stirring mortar can effectively improve and ensure the qualities of the mortar buildings, obviously improves the construction environment, greatly decreases the production cost of the pre-stirring mortar and solves the difficult problems that the prior pre-stirring mortar has over-high cost and are difficult to popularize and apply.

Owner:SOUTH CHINA UNIV OF TECH

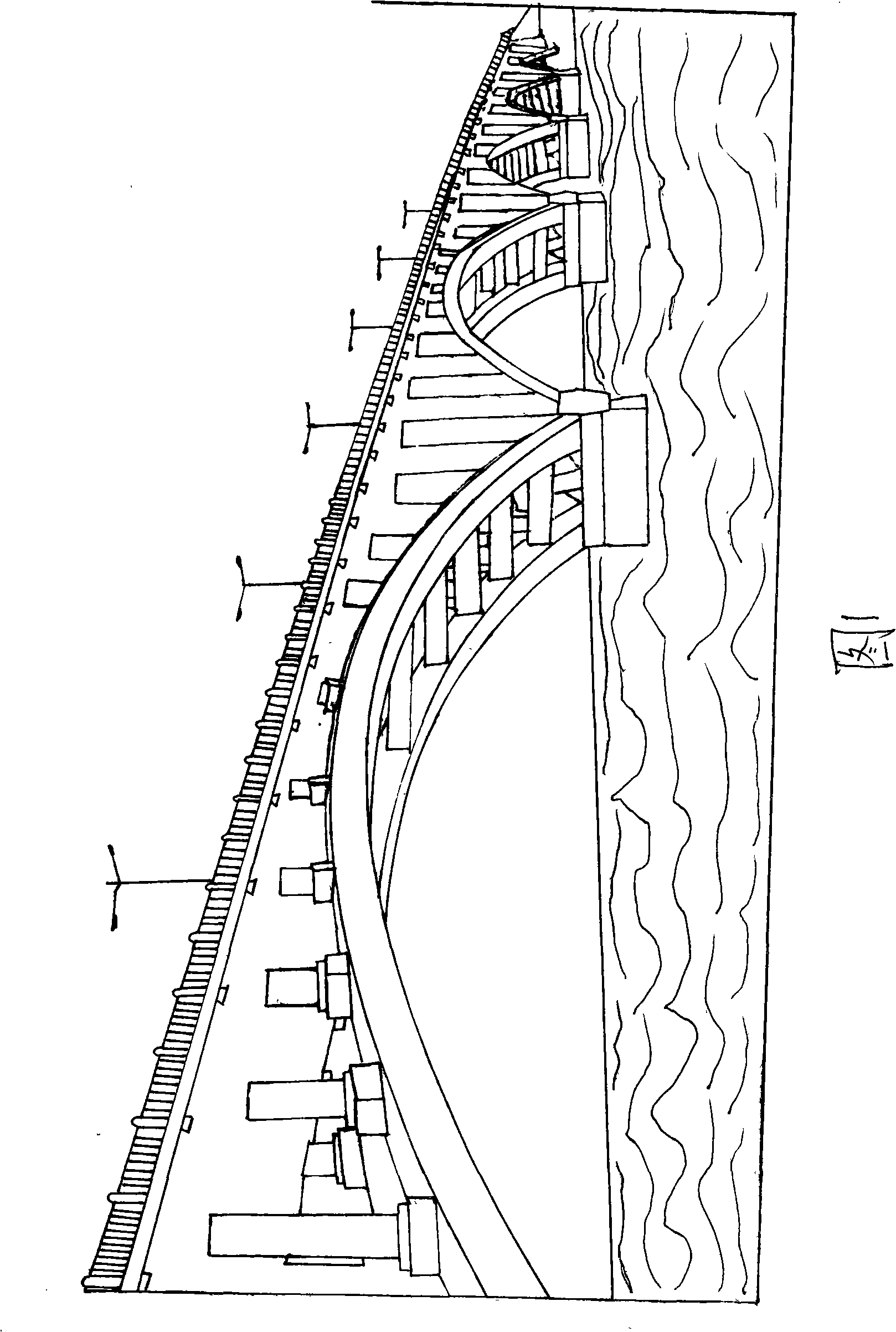

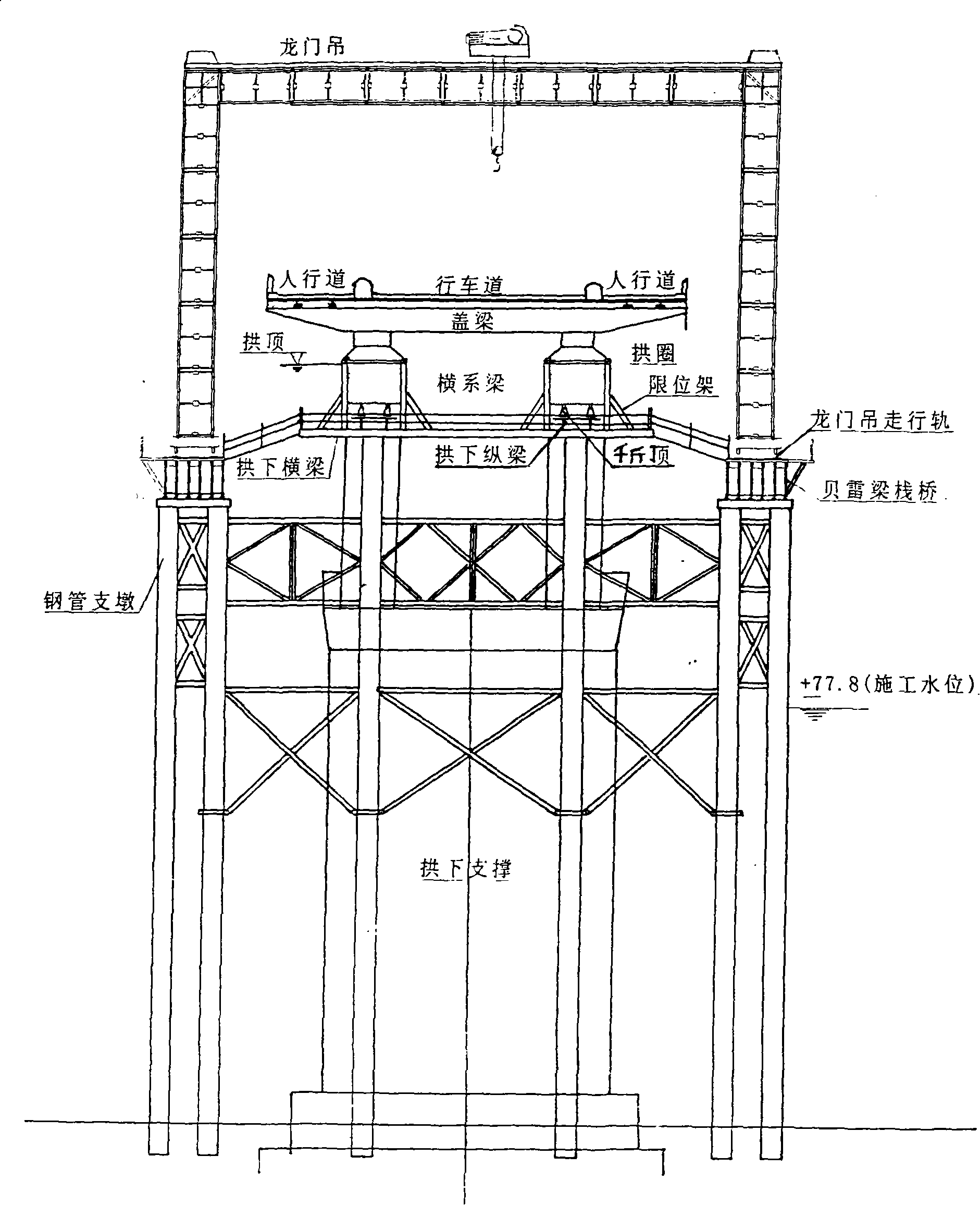

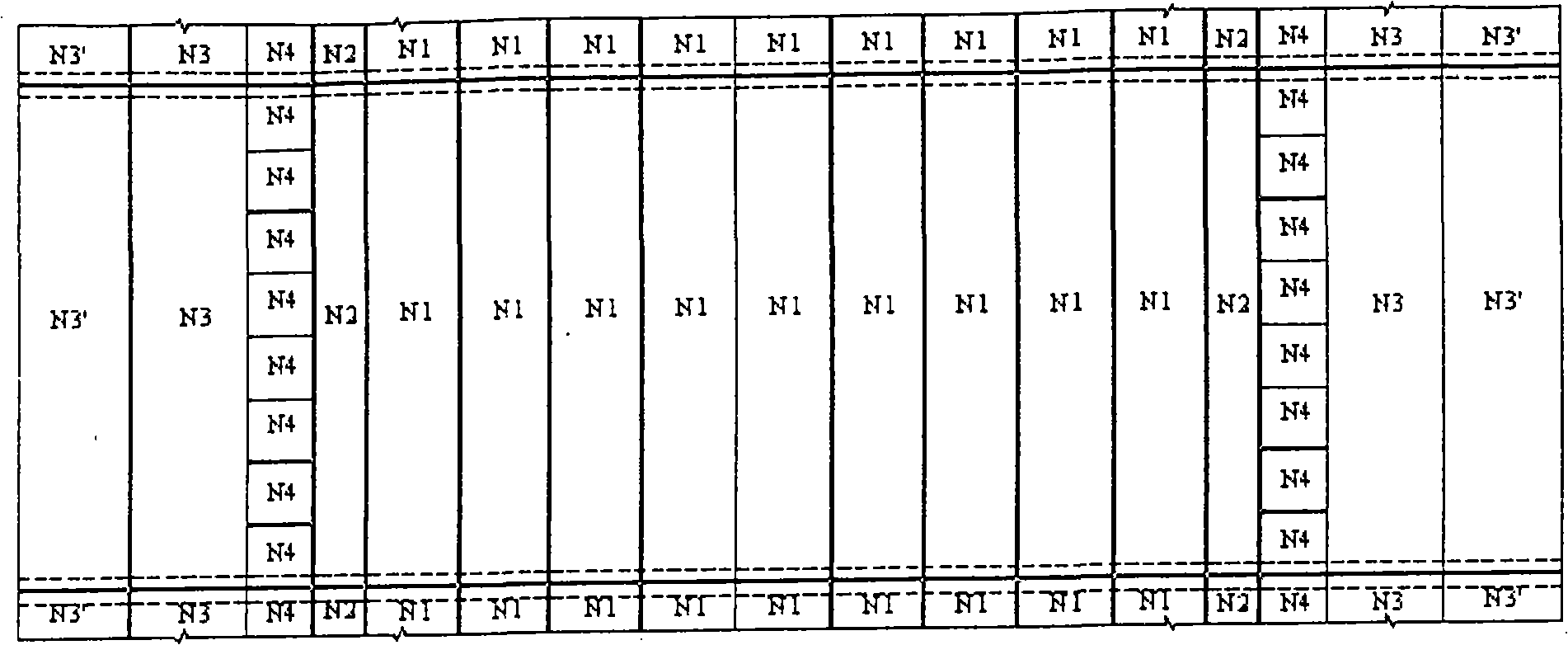

Method for dismantling arch bridge for protection

InactiveCN101265690AShort construction periodEnsure construction safetyBuilding repairsSocial benefitsReverse order

The invention provides a protective method for removing an arch bridge, which belongs to the technology field of bridge removal. The method aims to provide a protective bridge removal method with safety, high efficiency and no pollution. The technical points include: building up a new trestle, erecting a gantry crane, carrying out the bridge removal in a reverse order of the bridge building including bridge decking, coping, column, beam, arch rib and arch support in sequence. The removal stage of the arch rib especially includes removing by adopting methods of top-supporting under the arch, arch box transverse stop and horizontal restraining rope, which better solves the difficult problem of the protective bridge removal with safety, high efficiency and no pollution in a complex construction environment of guaranteeing under-arch navigation, high security level, short construction period and various unpredictable elements, manages to meet the design requirements of the removal safety factor in the protective bridge removal process and the limit control under various removal working conditions and guarantees the removal quality and the construction safety. The removal method has low cost and remarkable social benefit reflected in the direct economic analysis, which is a protective removal method of large-span bridges with safety, high efficiency and practicability.

Owner:CHINA TIESIJU CIVIL ENG GRP CO LTD +1

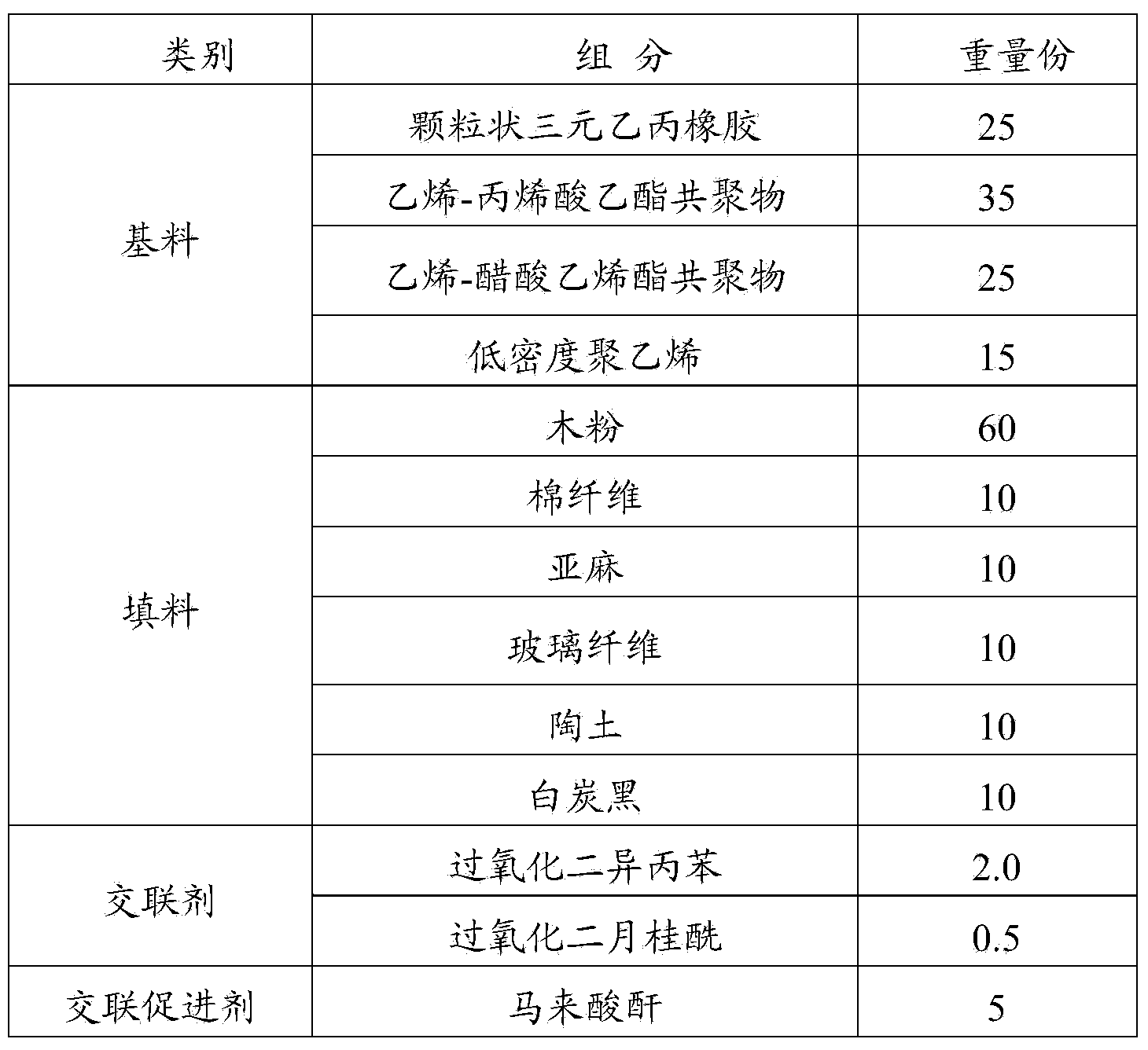

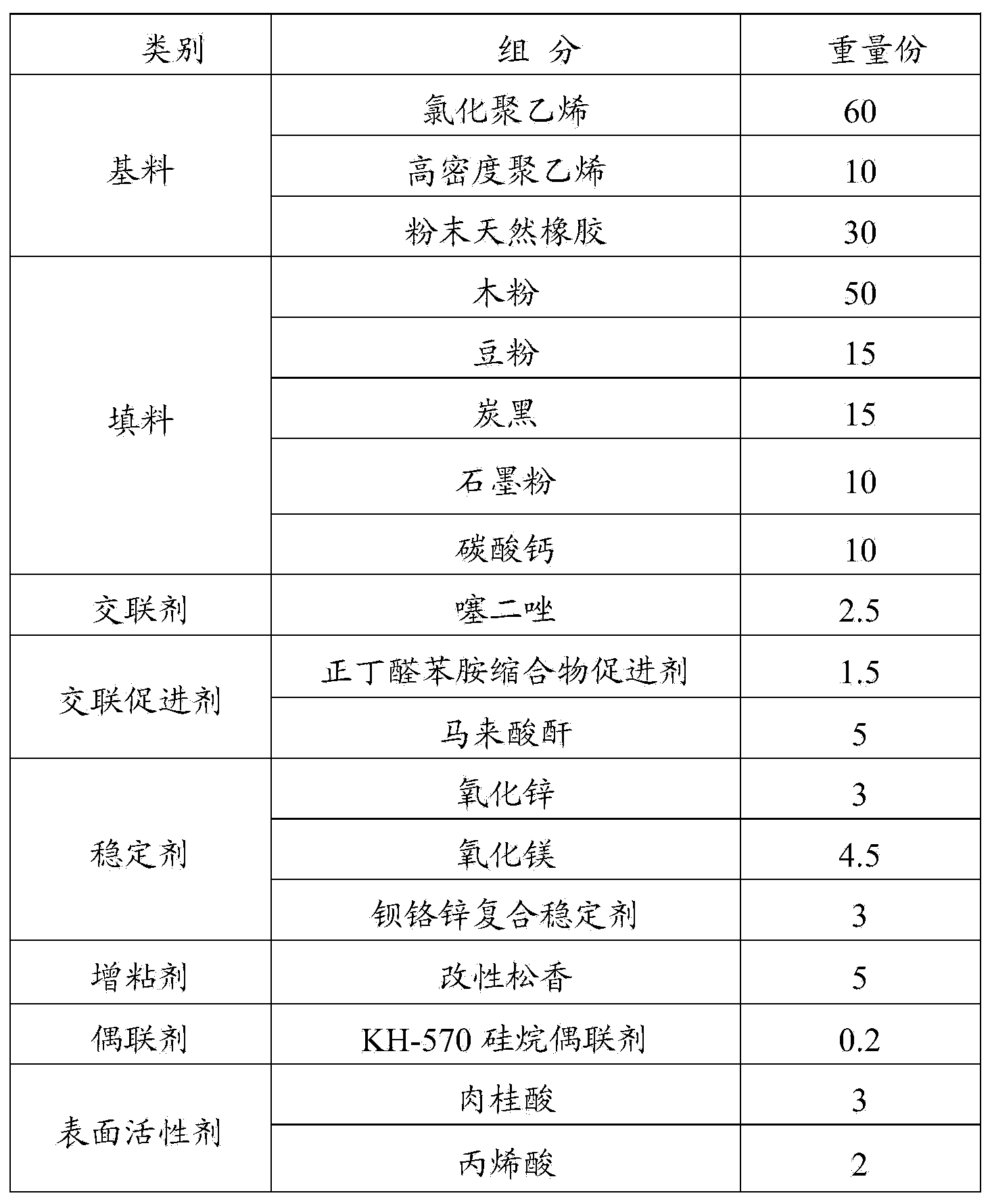

Formaldehyde-free wood adhesive film

InactiveCN103965796AGood value for moneyImprove the construction environmentNatural rubber adhesivesNon-macromolecular adhesive additivesChemistryHuman health

A formaldehyde-free wood adhesive film comprises the following components in parts by weight: 100 parts of basic material, 1 to 300 parts of filler, 0.1 to 10 parts of a cross-linking agent, 0.01 to 10 parts of a cross-linking accelerator, 1 to 15 parts of a stabilizer, 1 to 20 parts of a tackifier, 0 to 10 parts of a coupling agent, 1 to 30 parts of a surfactant and 0.5 to 10 parts of a lubricant, wherein the basic material is at least two of chloride high polymer, chlorosulfonated high polymer, ethylene vinyl acetate copolymer, ethylene-ethyl acrylate copolymer, polyolefin and rubber; and the filler is at least one of organic filler, inorganic filler, compound filler and synthetic filler. The formaldehyde-free wood adhesive film contains no formaldehyde or organic volatile matter so as not to affect and harm the environment and the human health, and is excellent in environmental performance, convenient to use, transport and store and long in shelf life. The formaldehyde-free wood adhesive film is blended, modified and extruded into shape by a plastic extruding film technique.

Owner:杨学荣

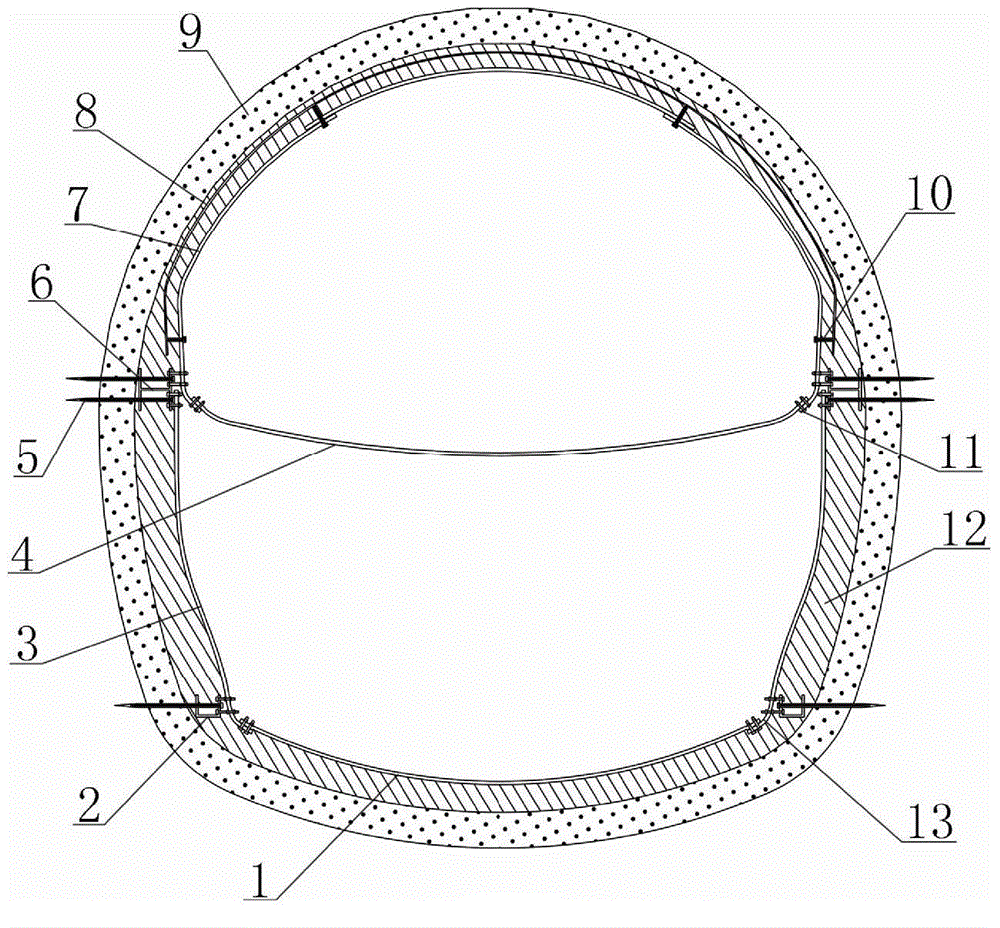

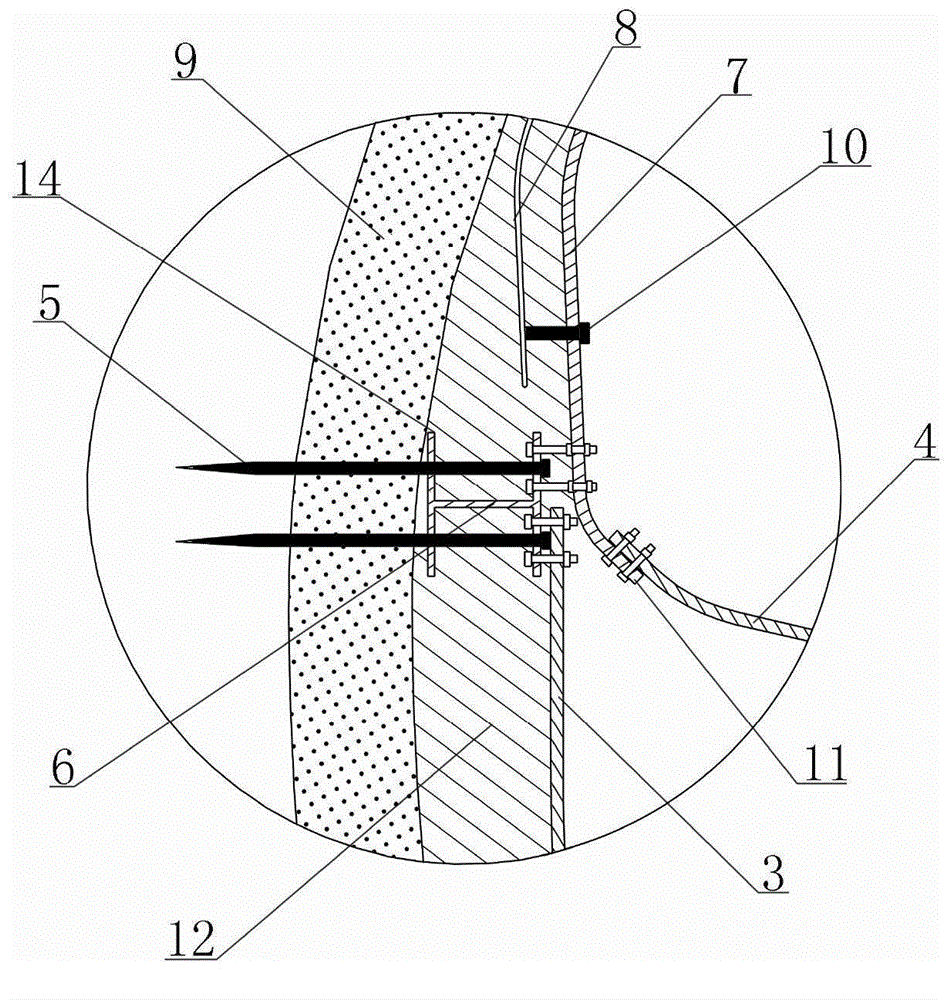

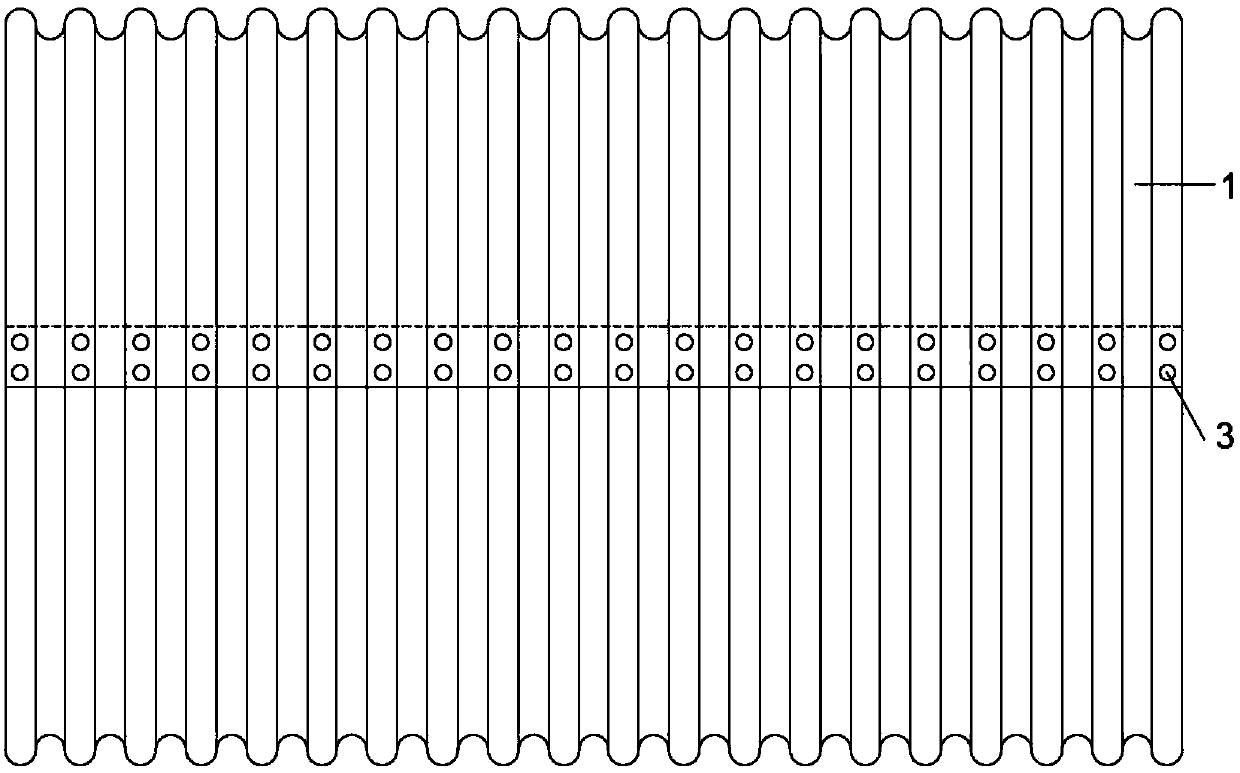

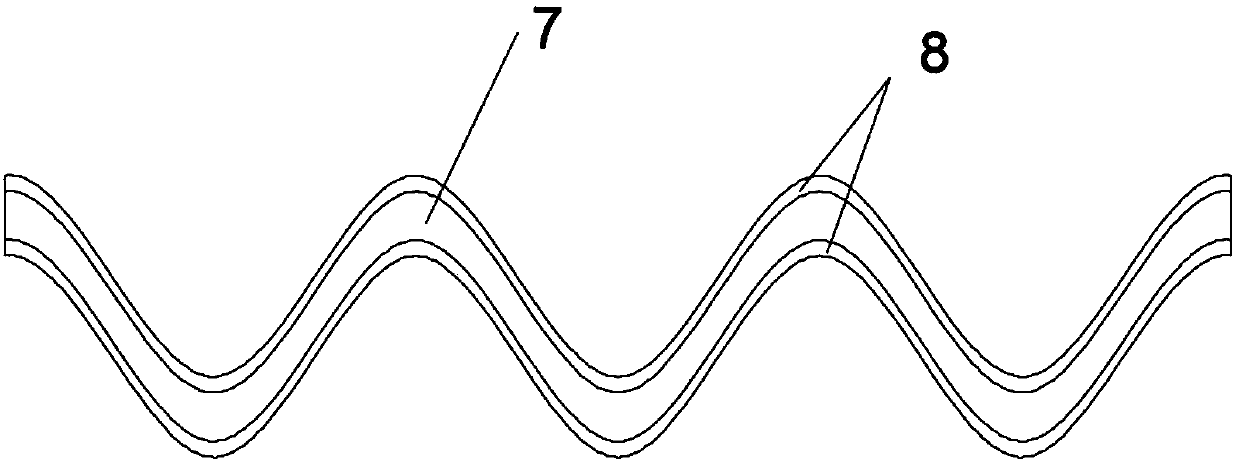

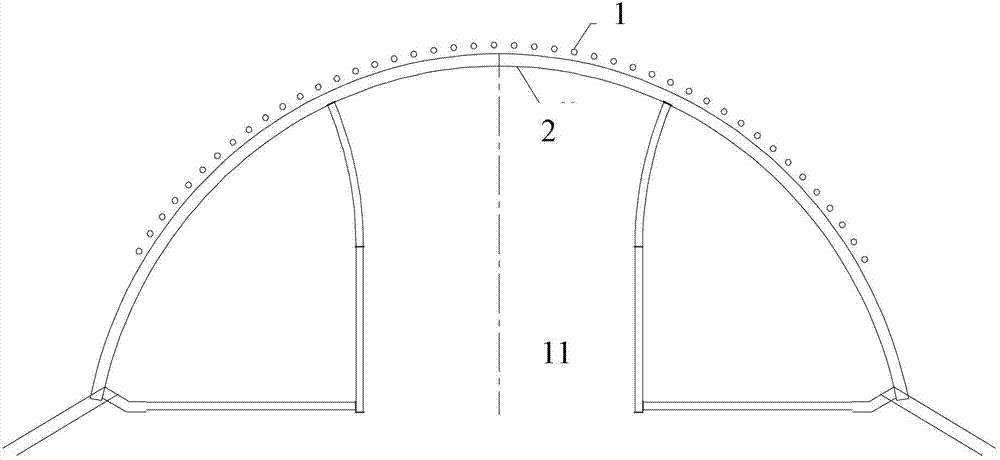

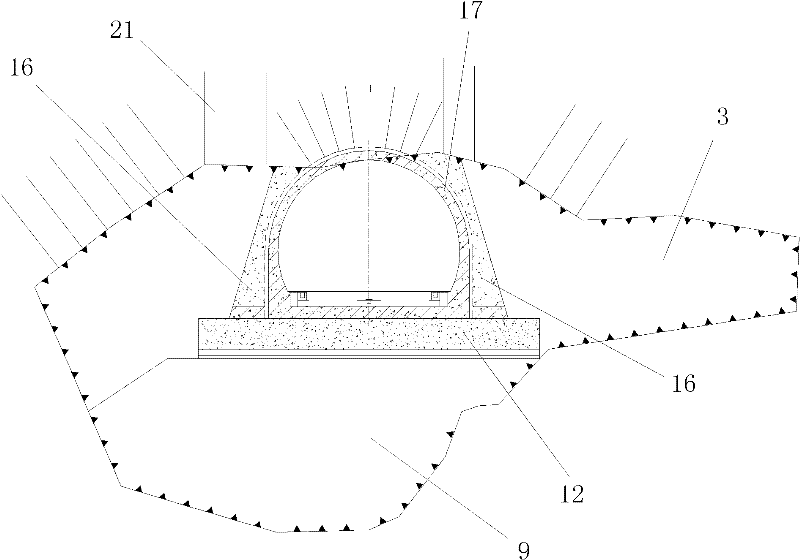

Method for primary support with corrugated steel plate and concrete combined structure taking place of steel grating

InactiveCN104863614AImprove the force characteristicsReduce disturbanceUnderground chambersTunnel liningSheet steelGrating

The invention discloses a method for primary support with a corrugated steel plate and concrete combined structure taking the place of a steel grating. The corrugated steel plate and concrete combined structure is formed by assembling and connecting an upper supporting corrugated plate, a side wall corrugated plate and an inverted arch corrugated plate into a ring; two arch feet of an upper step of a cavern are fixedly provided with two pieces of H-section steel, and the upper end of the upper supporting corrugated plate and the upper end of the side wall corrugated plate are supported and fixed through the H-section steel; two arch feet of a lower step are fixedly provided with two pieces of channel steel, the lower end of the side wall corrugated plate is supported and fixed through the channel steel, and an inverted arch lap joint is reserved on the lower end of the side wall corrugated plate; the upper supporting corrugated plate, the side wall corrugated plate and the inverted arch corrugated plate are sequentially connected through flanges in the longitudinal direction; concrete is poured among the upper supporting corrugated plate, the side wall corrugated plate, the inverted arch corrugated plate and surrounding rock. The structure is manufactured through the structure mixing a corrugated steel plate and the concrete, stress is balanced through the structure and the surrounding rock, strength of the primary support is guaranteed, and the structure has the advantages that construction is facilitated, the period is short, efficiency is high, stability is high, and cost is low.

Owner:HEBEI TENGSHIDA METAL STRUCTURE +1

Nanometer acrylic acid microemulsion, water-thinned heat reflecting and isolating paint and their production process

InactiveCN1361186AWill not polluteImprove densification performanceFireproof paintsOrganic solventEmulsion

The present invention is one kind of nano acrylic acid microemulsion, water-thinned heart reflecting and isolating paint with the nano acrylic acid microemulsion and their prodcution process. The present invention aims at solving the technological problems of available paint, which contains great amount of organic solvent to pollute environment and has poor heat reflecting and isoalting performance. The water-thinned heat reflecting and isolating paint consists of nano acrlic acid microemulsion, conventional acrylic acid emulsion, pigment, filler, infrared ray reflector, assistant, pH regulator, densifier and softened water. The paint contains no organic solvent and has excellent heat reflecting and isolating performance.

Owner:耿世斋

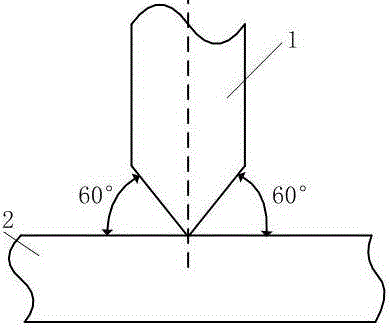

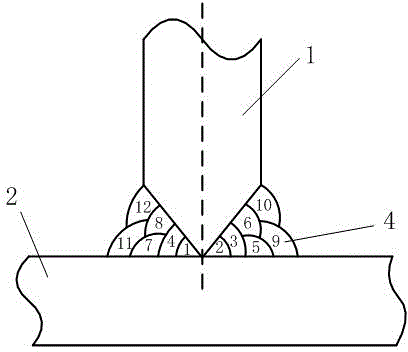

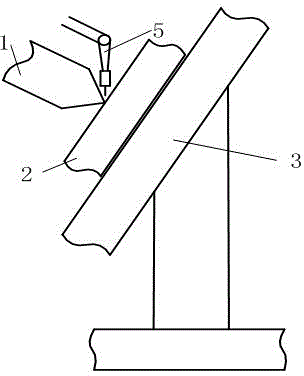

Fillet weld welding structure for K-type grooves of moderately-thick plate without back chipping and welding technology of fillet weld welding structure

InactiveCN105081595AFull penetration ensuresImprove the construction environmentArc welding apparatusWelding/soldering/cutting articlesFillet weldThick plate

The invention relates to a fillet weld welding structure for K-type grooves of a moderately-thick plate without back chipping and a welding technology of the fillet weld welding structure. The fillet weld welding structure is characterized in that symmetric grooves are formed in the two sides of a web plate, the web plate and a bottom plate are tightly attached when assembled in welding, and no gap is reserved when the web plate and the bottom plate are assembled; the grooves of the web plate are machined through a milling machine, no truncated edge is reserved, and the length parts between the two ends in the grooves are fixed at equal diversion points and polished; a welding robot is used for stably welding a welding bead at the position of ship-type welding, welding is carried out alternatively on the two sides in a multi-layer and multi-run manner, back chipping is not carried out on the back face, and slag is not removed in the bead; and the backward deformation theory is utilized in the assembling process, and double-face alternating welding is adopted in the welding process to restrain deformation. By means of the technology, full penetration of the fillet weld below the K-type grooves of the moderately-thick plate is ensured, and the welding quality is improved; and meanwhile, the welding automation degree and the production efficiency are obviously improved, and the welding construction environment is improved.

Owner:SHANGHAI SHIPBUILDING TECH RES INST

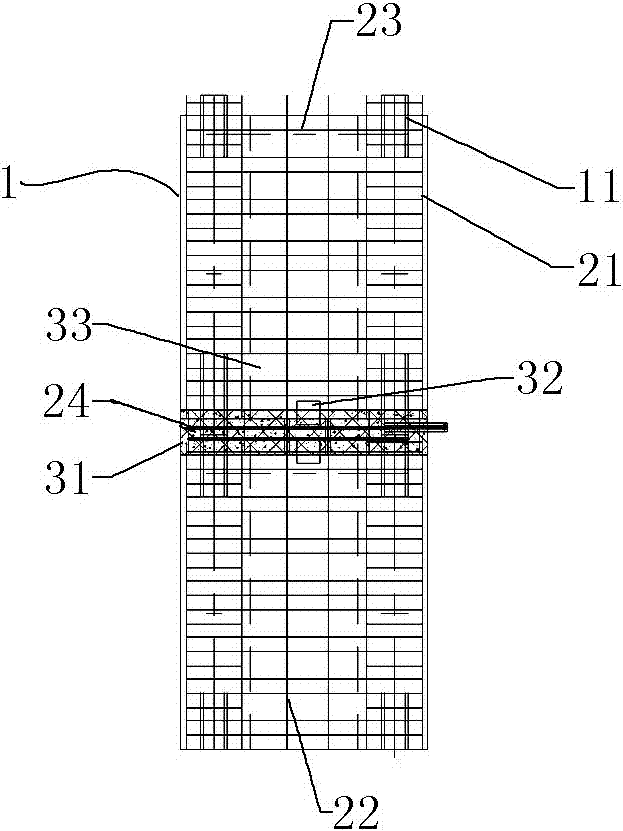

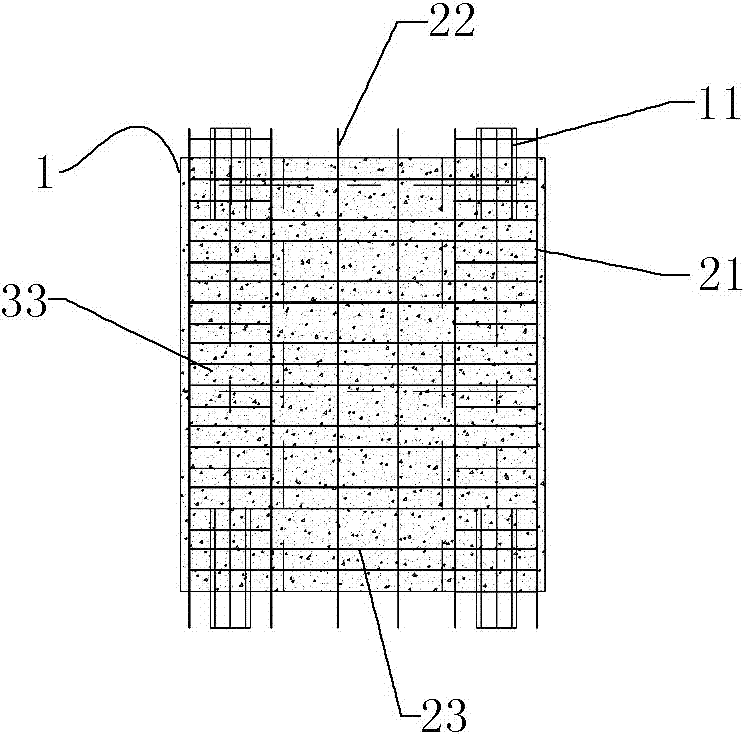

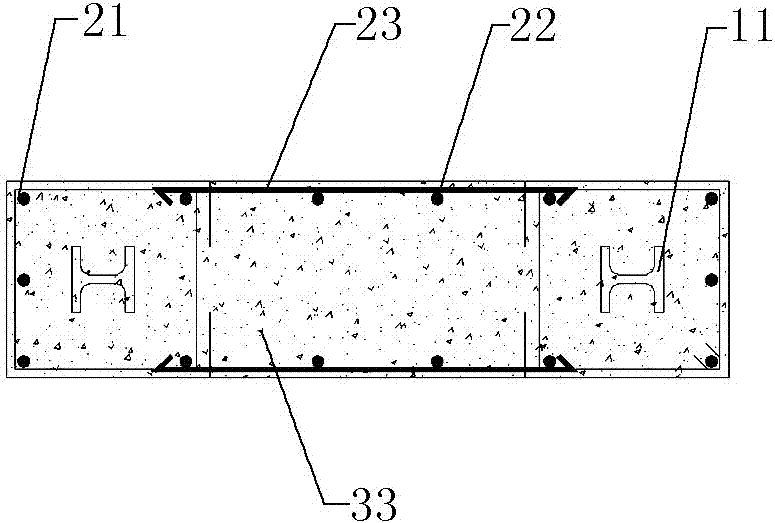

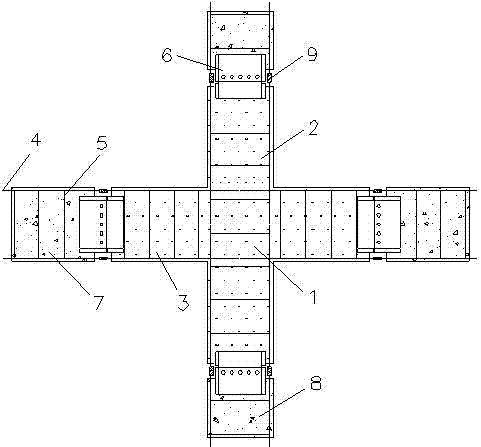

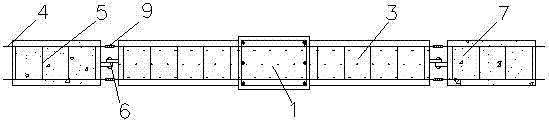

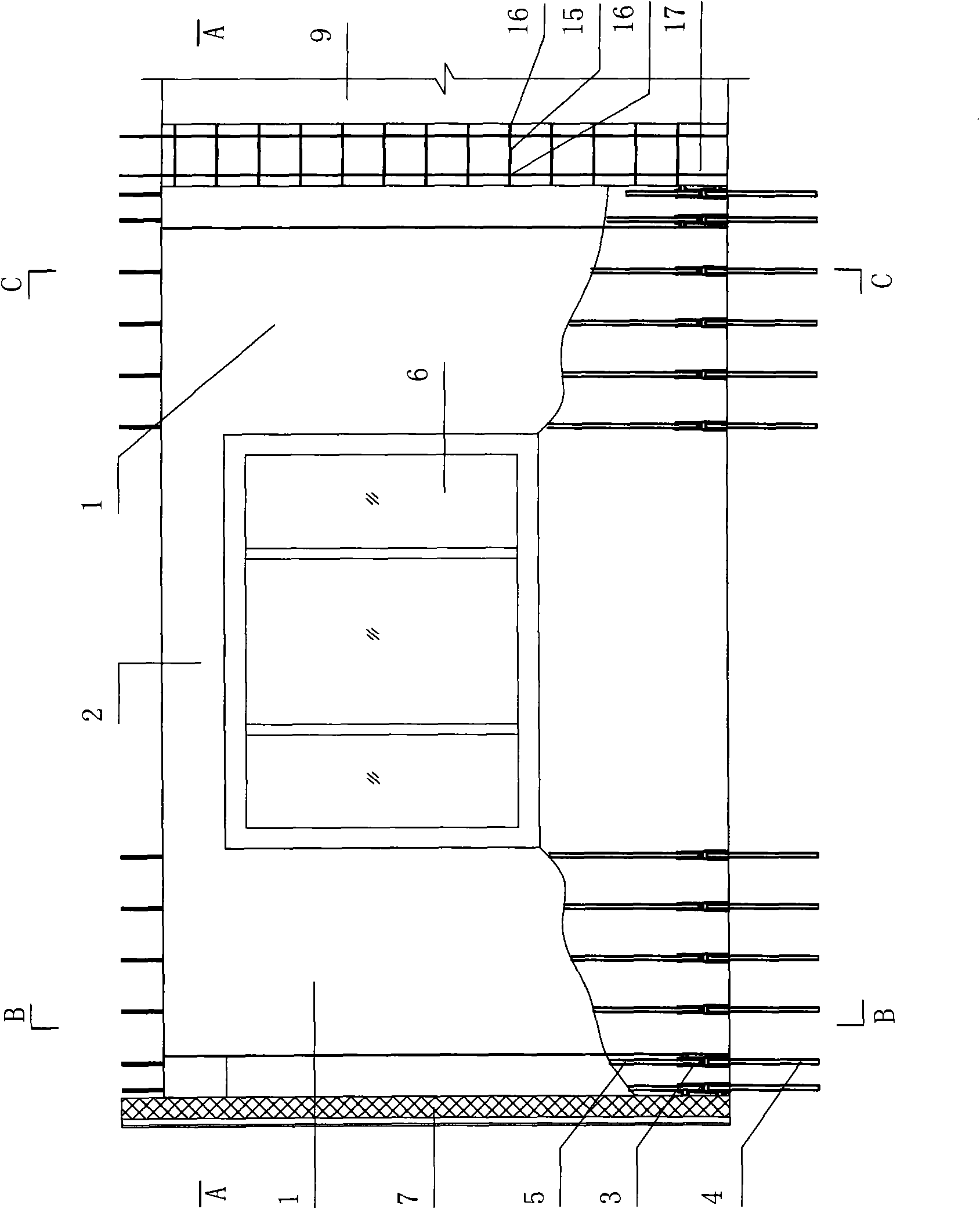

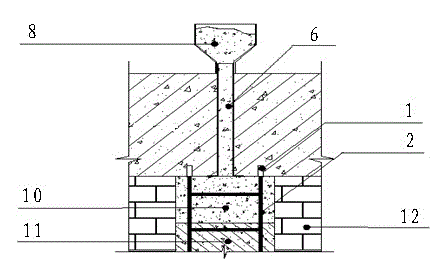

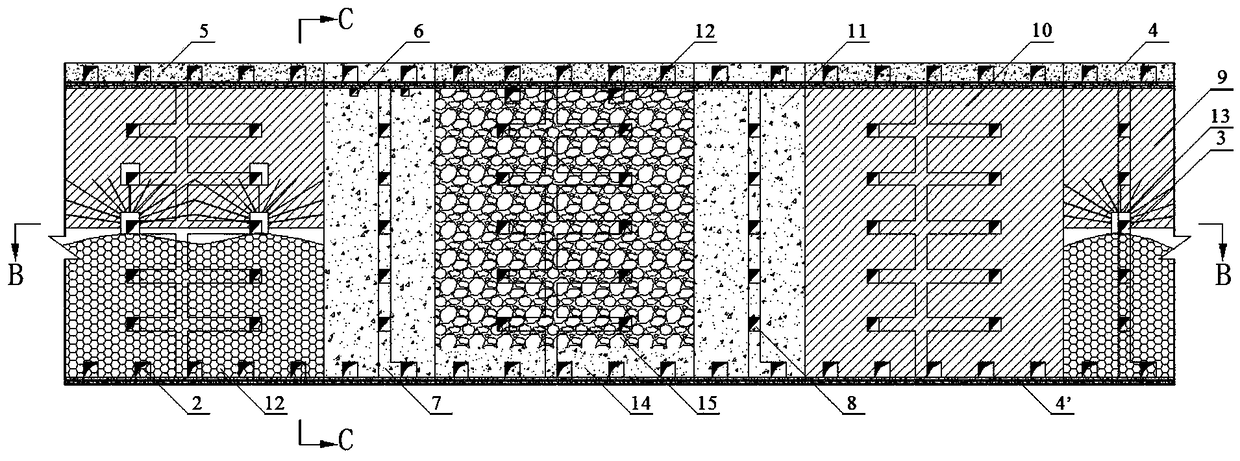

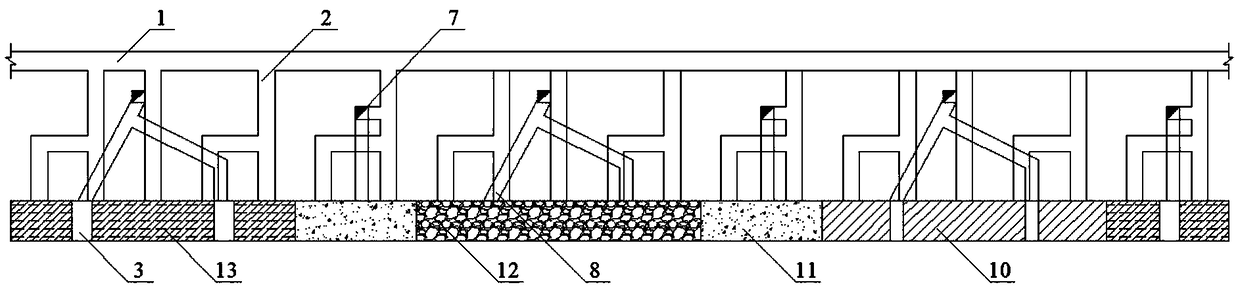

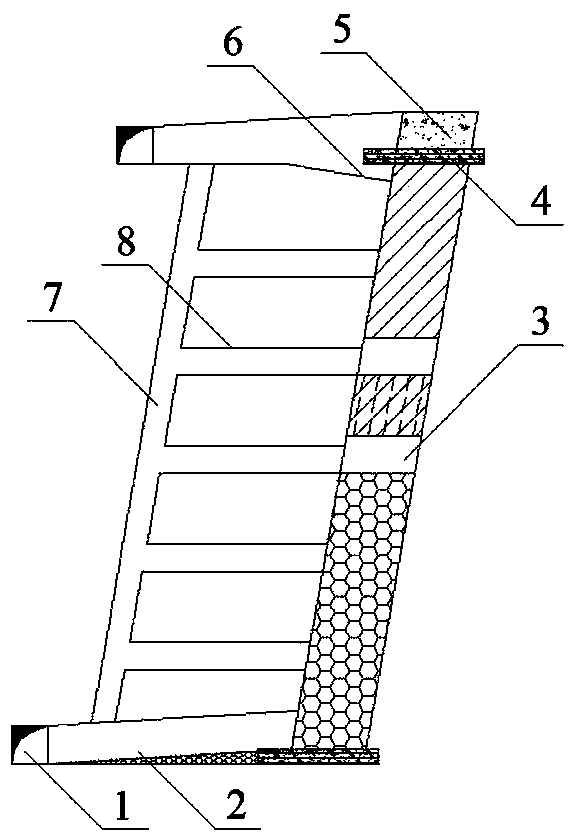

Reinforced type prefabricated steel bar concrete shear wall, structural system and construction method thereof

PendingCN107090925AIncreased shear strengthImprove the bending capacityWallsBrickReinforced concrete

The invention relates to the technical field of structural systems of shear walls, and discloses a reinforced type prefabricated steel bar concrete shear wall, a structural system and a construction method thereof. The reinforced type prefabricated steel bar concrete shear wall is composed of a prefabricated wallboard connected from up to down, and comprises reinforced vertical steel bones, steel bars and poured concrete wall bodies, wherein the reinforced vertical steel bricks and steel bars are located in the edge area of the prefabricated wallboards. The vertical steel bones are arranged discontinuously and are arranged at the connection nodes of the upper and lower ends of the prefabricated wallboards; edge longitudinal bars are fixed by horizontal hooped reinforcements or tie bars and arranged outside the reinforced vertical steel bones in a sleeved mode. The outer sides of the reinforced vertical steel bones are connected with the edge longitudinal bars in a lapped, anchored or welded mode, one end extends out of the concrete walls; the height of the concrete walls is not higher than the height of the edge longitudinal reinforcements and wall body vertical steel bars; the upper and lower adjacent prefabricated wallboards are connected by the corresponding reinforced vertical reinforcements, edge longitudinal reinforcements and walls body vertical steel bars, and connecting gaps are poured at the connection nodes. The reinforced type prefabricated steel bar concrete shear wall, the structural system and the construction method thereof have the advantages of being low in cost and convenient in construction; having excellent shear strength at the connections; being convenient to control the construction quality.

Owner:姚攀峰

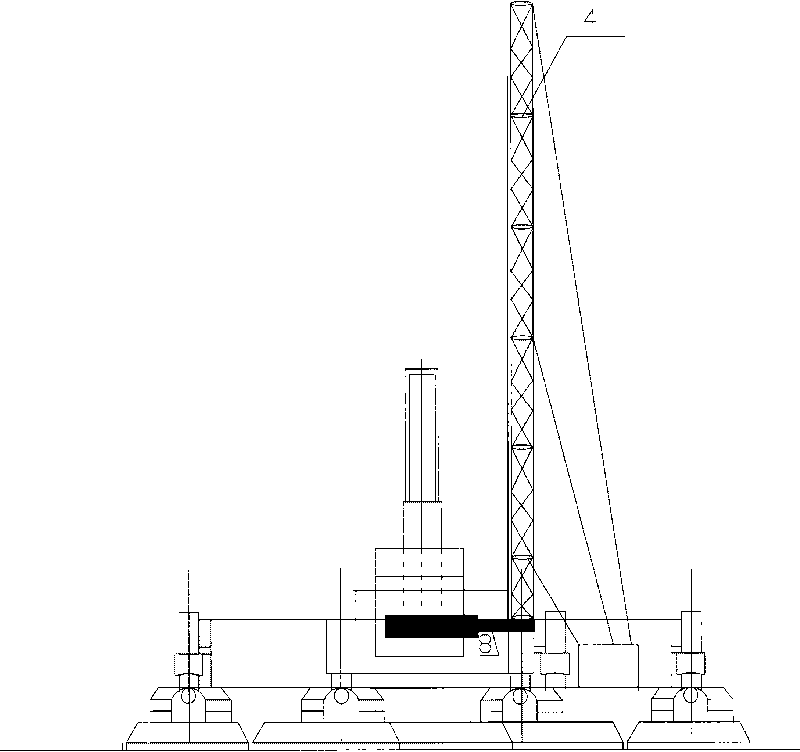

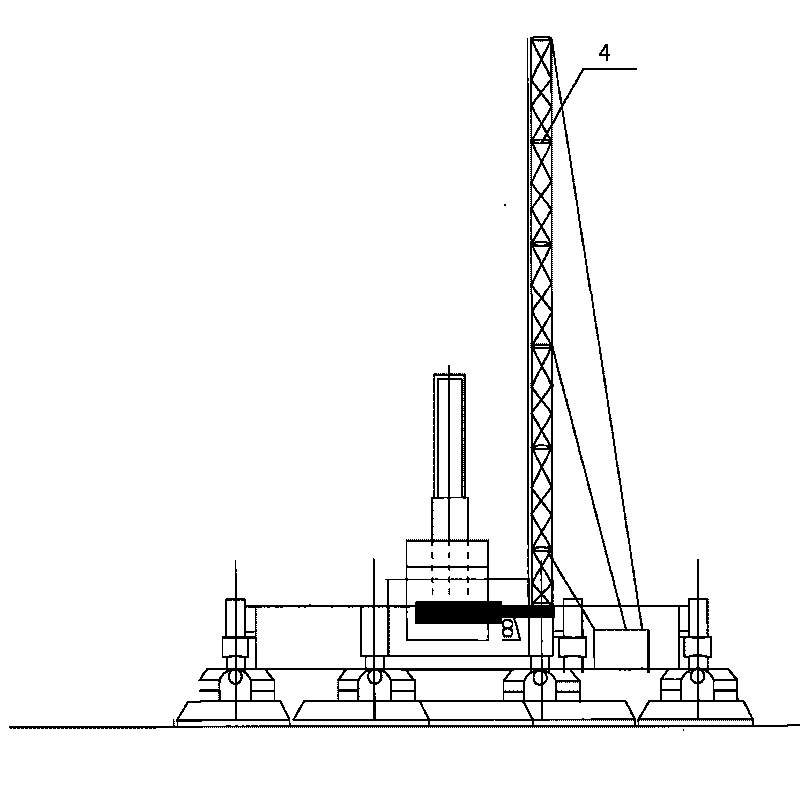

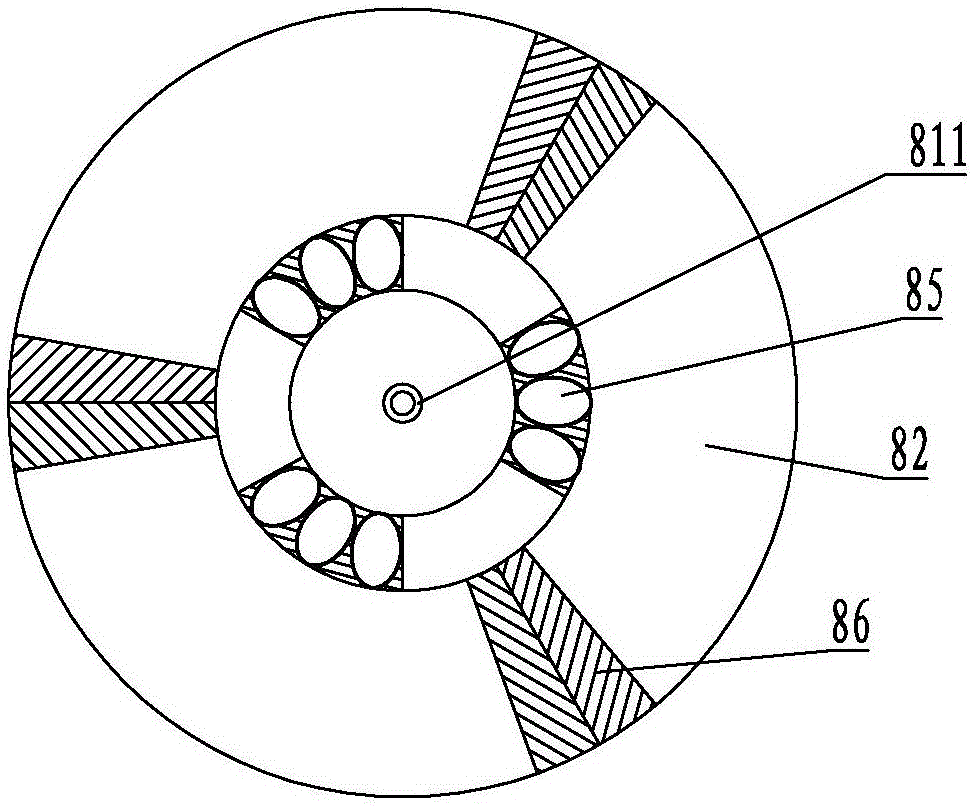

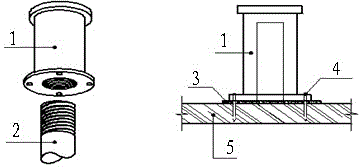

Static sunken pile construction technique for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe

InactiveCN101725146ADoes not affect bearing capacityDoes not cause tiltBulkheads/pilesMaximum pressureDrill pipe

The invention relates to an automatically leading hole and statically sinking pile method for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe, and further relates to a PHC pipe pile static pile sinking device. The automatically leading hole and statically sinking pile method for alternatively, sectionally and gradually spirally leading hole and statically sinking pile in pipe comprises: leading hole to a foundation 7 by a drilling rod 6 in a hollow hole 3 in the PHC pipe pile 2 when the PHC pipe pile 2 cannot be sunken at the maximum pressure by a static pile pressing machine 1; then statically sinking the PHC pipe pile 2; and repeatedly and alternatively operating until the PHC pipe pile 2 is sunken to part with level as designed. Making use of the method, the obvious problem that the geology hard layer cannot be penetrated in the way of static pressing PHC pipe pile can be solved, specifically the difficult problem that thick and deep grit layer cannot be penetrated; other subordinate contamination can be prevented in construction process of the method; excellent construction condition can be kept; the hole will not fall off when leading hole, and the leading hole failure phenomenon can be prevented.

Owner:江守慈

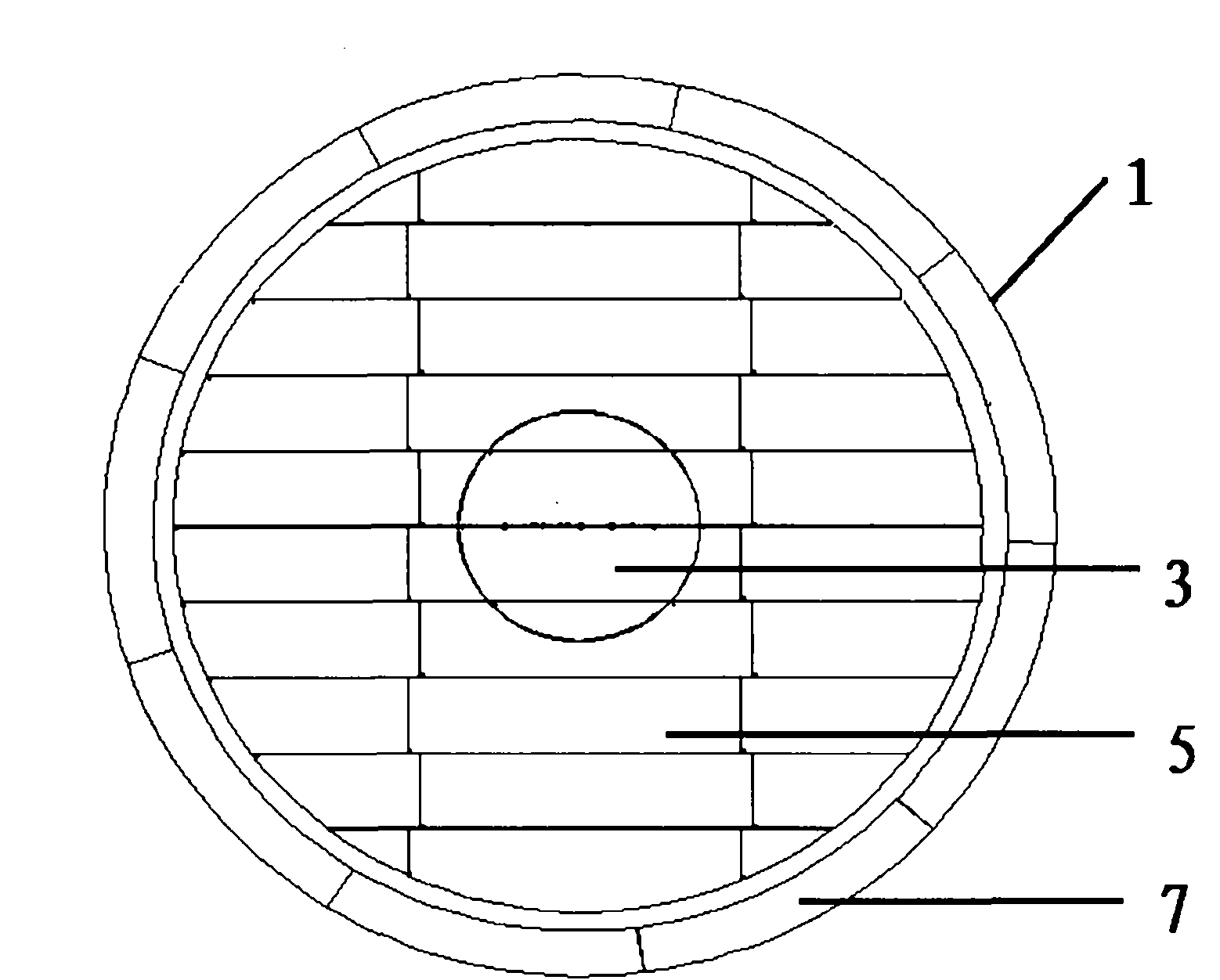

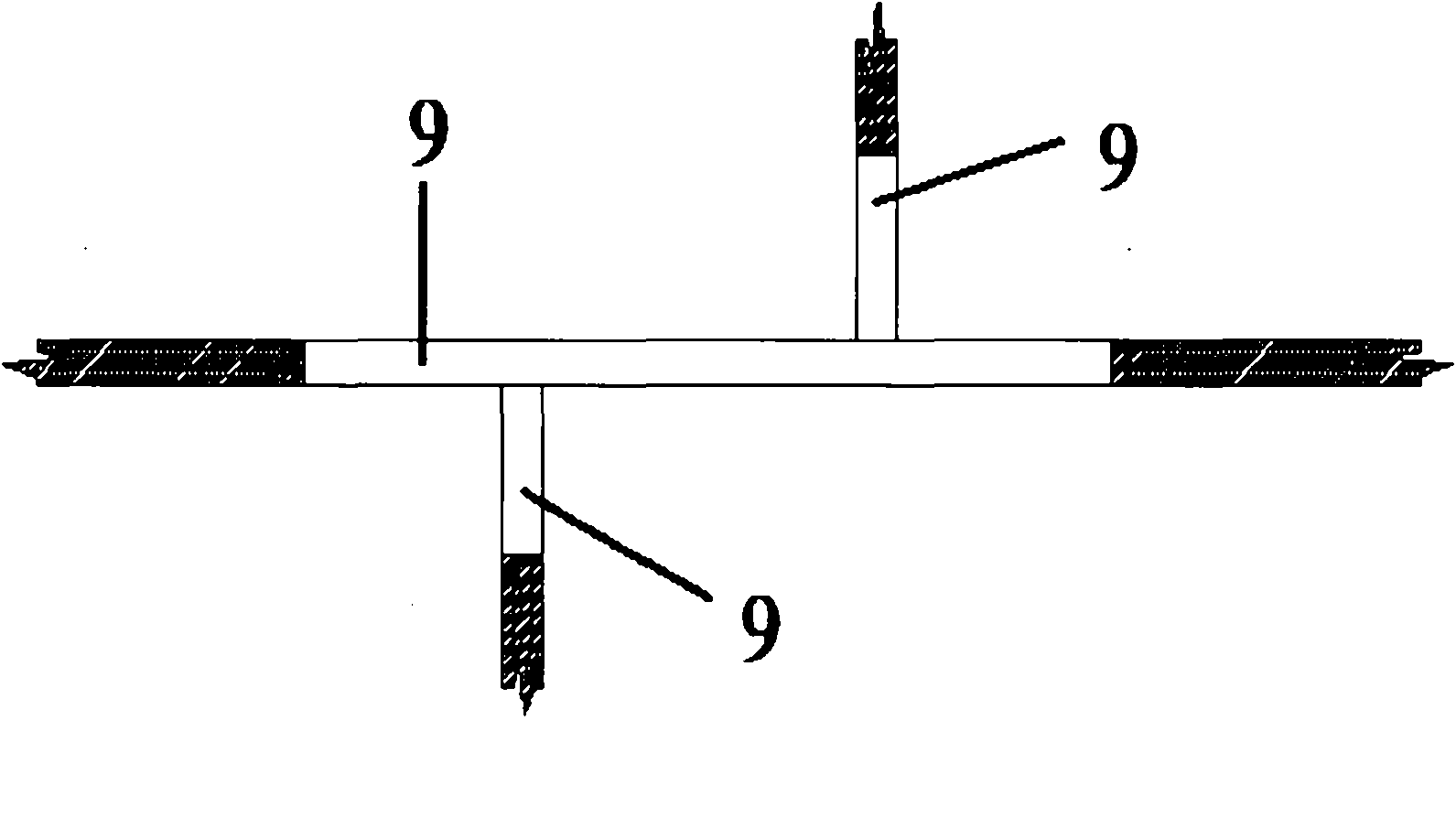

Method for mounting bottom plates and cylinder of steel lining of nuclear power plant

ActiveCN102061788AShort construction periodShorten the construction periodCovering/liningsArc welding apparatusSupporting systemArchitectural engineering

The invention provides a method for mounting bottom plates and a cylinder of a steel lining of a nuclear power plant. The bottom plates are basically circular, and are divided into circular center bosses, annular intermediate annular plates and annular edge plates which consist of a plurality of precast slabs from inside to outside; the cylinder comprises frustums and cylinder wall plates which are formed by splicing the plurality of precast slabs; and the cylinder wall plates are divided into a plurality of layers. The mounting method sequentially comprises the following steps of: mounting a bottom plate support system; putting the bottom plates on the bottom plate support system; putting the frustums; welding the bottom plates and the frustums in pairs; and mounting each layer of cylinder wall plates from bottom to top respectively. By rationally setting a welding process and a construction assembly process, a mounting construction period of the steel lining is effectively shortened, and the sealability of welding seams of the steel lining is ensured.

Owner:CHINA NUCLEAR IND HUAXING CONSTR

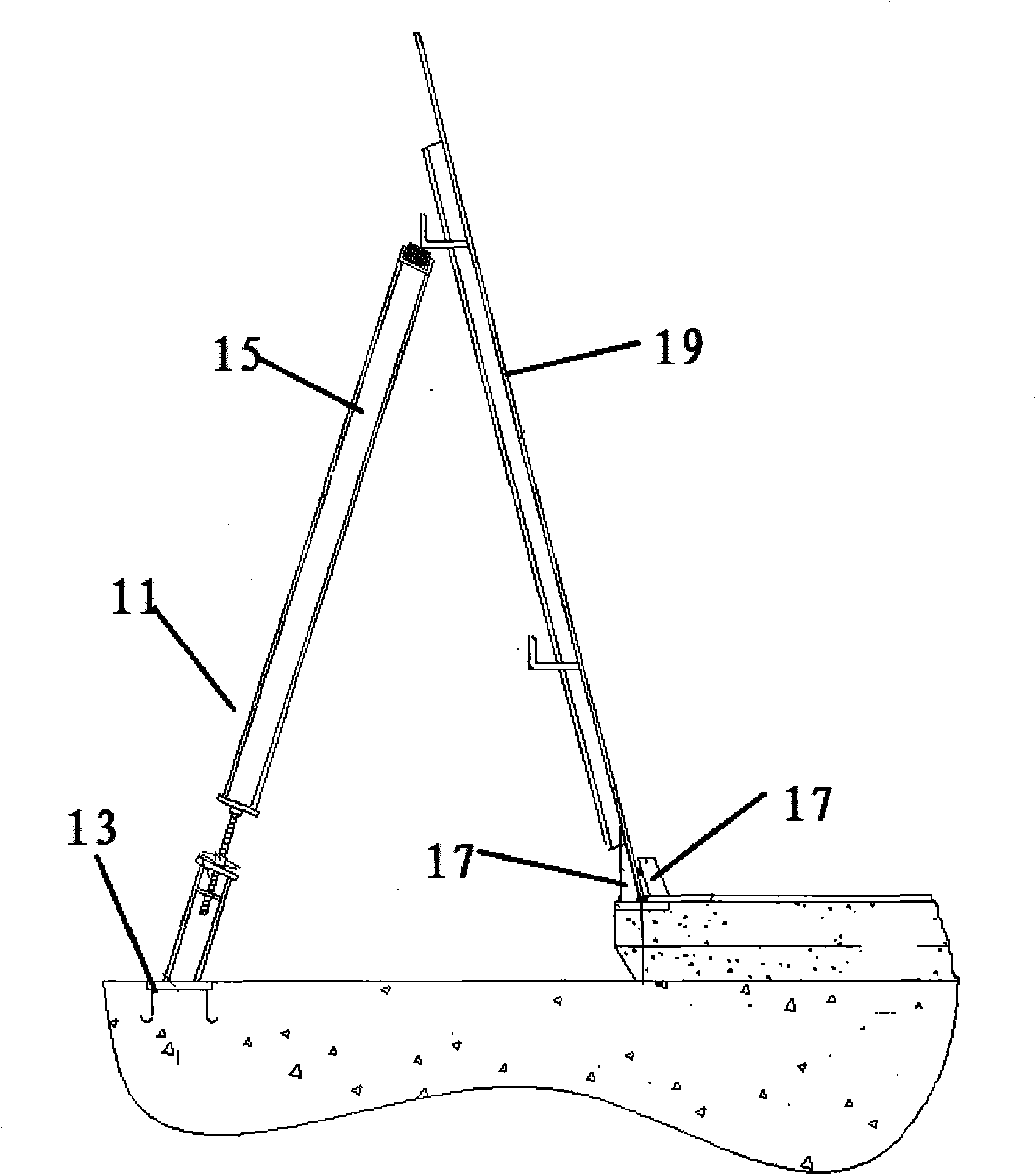

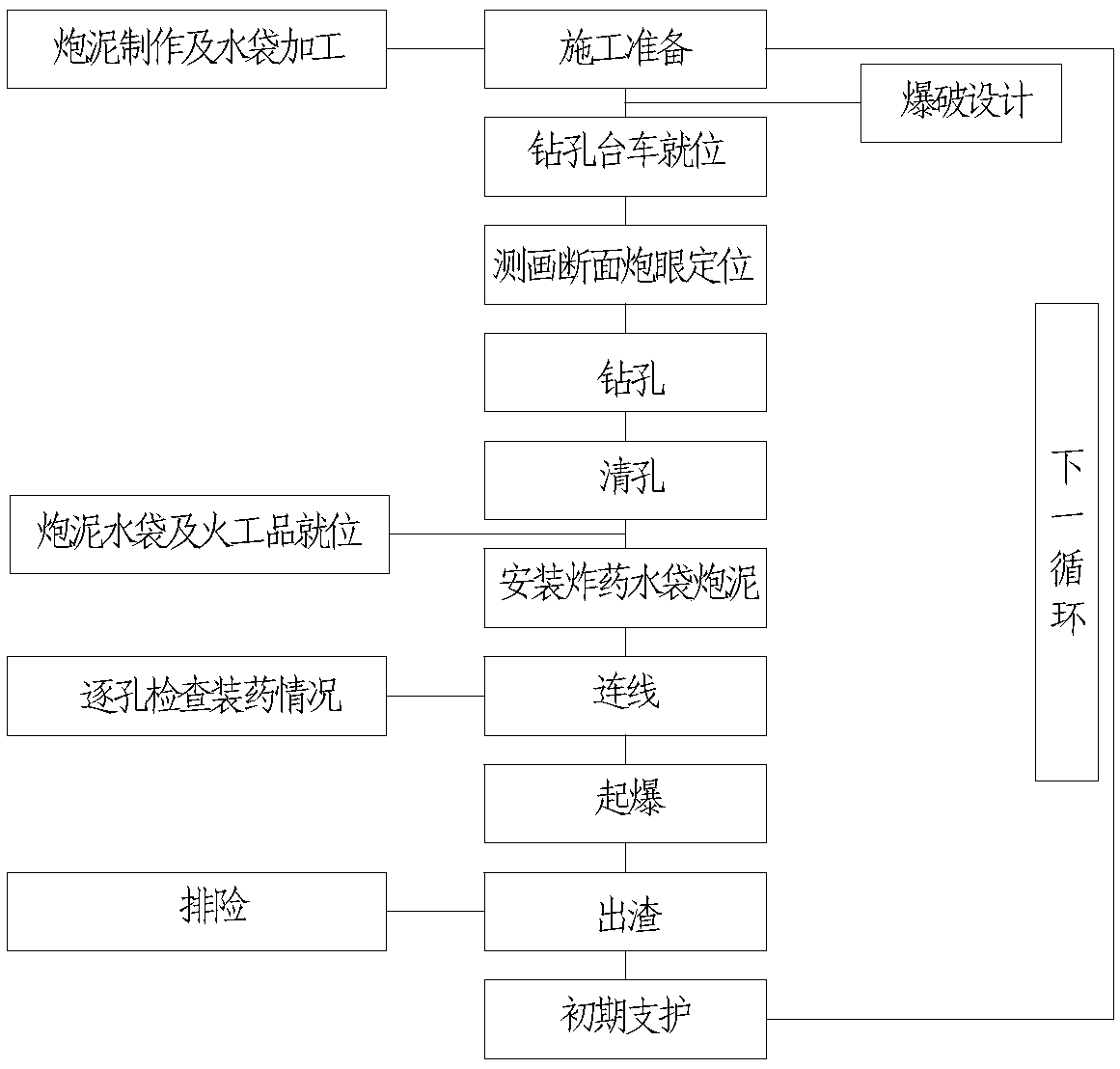

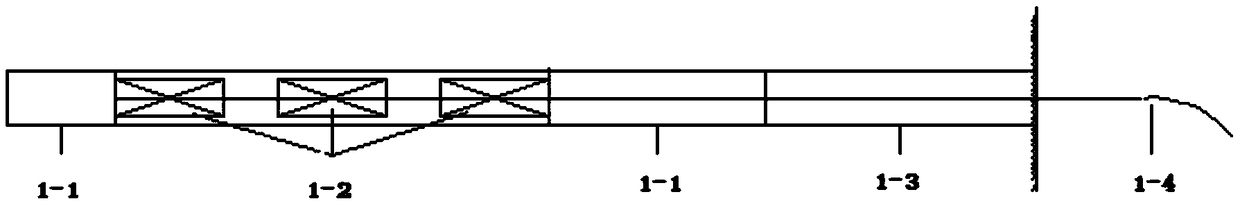

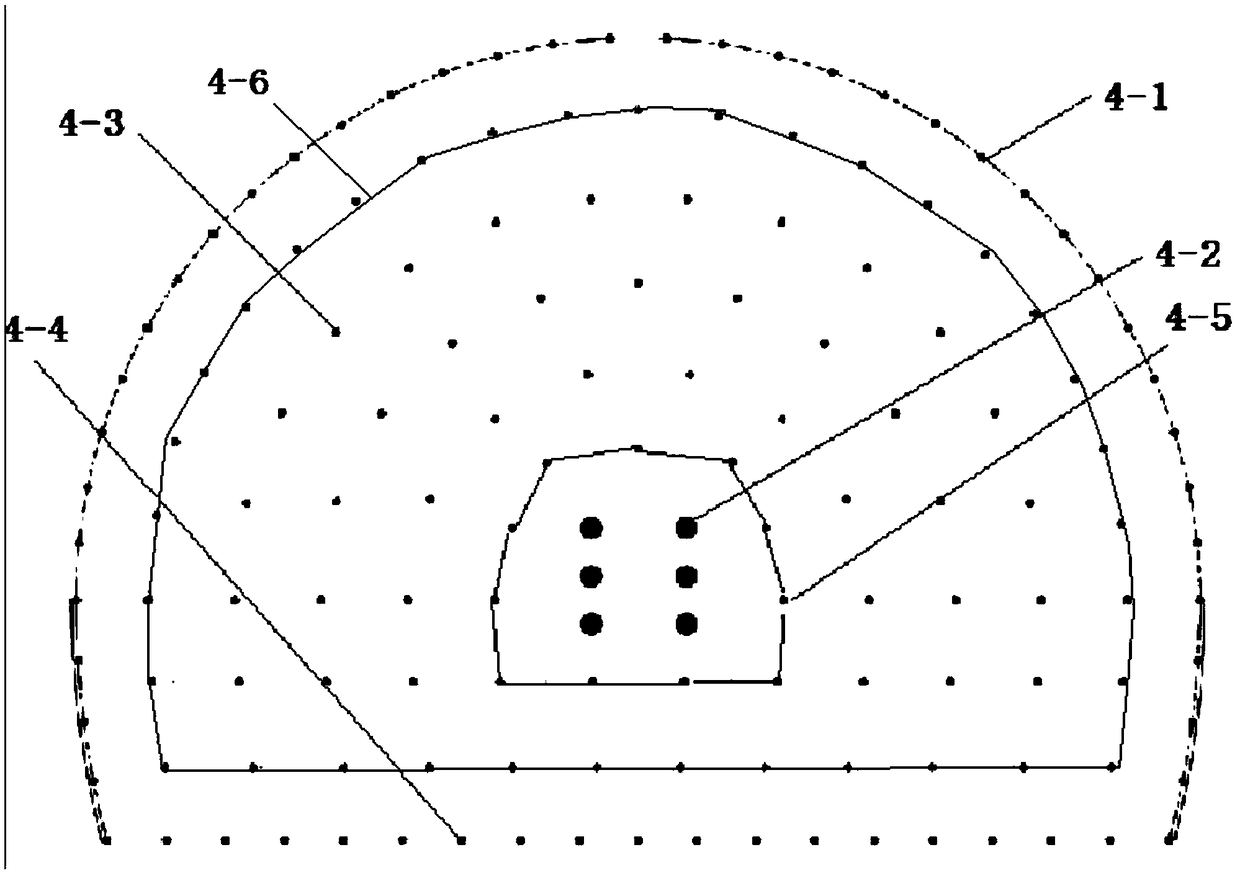

Tunnel excavation water pressure blasting construction method

InactiveCN109373840AImprove the construction environmentIncrease profitBlastingTunnelsGeomorphologyDetonation

The invention discloses a tunnel excavation water pressure blasting construction method. The tunnel excavation water pressure blasting construction method comprises the following steps of (1) arranging a trolley in place and conducting danger elimination; (2) measuring, distributing and drilling holes; (3) installing explosives, water bags and stemming, wherein the peripheral holes are excavated on the arc edge of the tunnel face of a tunnel, and the explosives, the water bags and stemming are installed in the following manners of air spacing, decoupling charge and the explosive quantity at hole bottoms more than that of other parts; cut holes are drilled in an inclined mode, and the included angle between the cut holes and the excavation face is 65 degrees-75 degrees; the continuous coupling charge method is adopted for loosening holes, relief holes, inner ring holes and bottom plate holes, blasting caps are buried into hole bottom cartridges, and energy gathering holes face orifices;the water bags are arranged at the hole bottoms of shot holes, and the water bags are arranged again after completion of explosive charging, and the holes are blocked through the stemming; (4) detonating a detonating network; (5) conducting after-detonation check and misfire processing; and (6) withdrawing the explosives to the warehouse. Through the tunnel excavation water pressure blasting construction method, the energy of explosives can be made full use of, environmental pollution can be reduced, and the cost can be saved.

Owner:GUANGXI ROAD & BRIDGE ENG GRP CO LTD

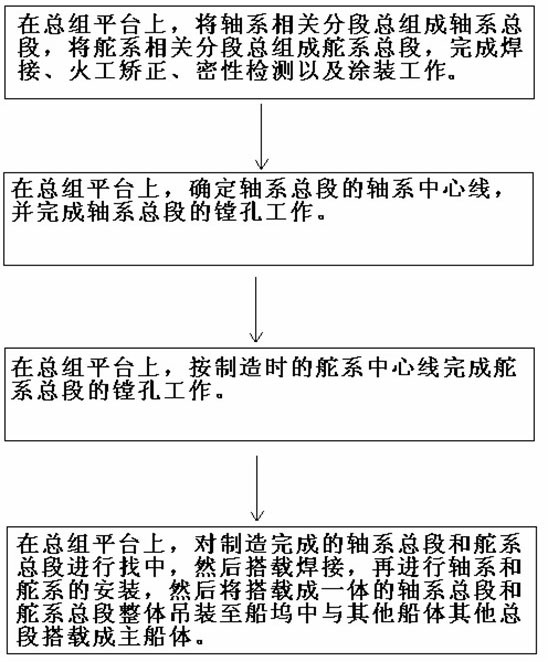

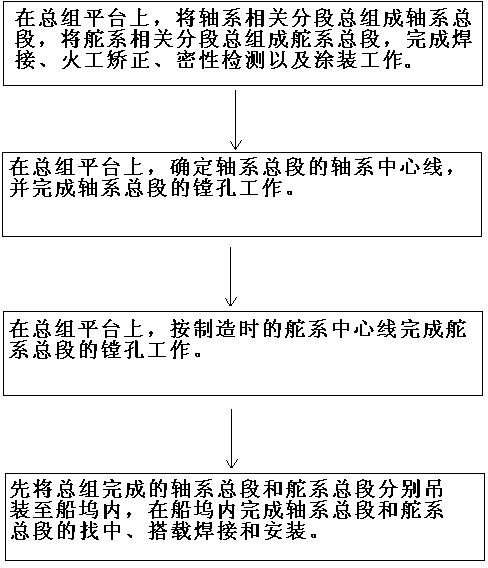

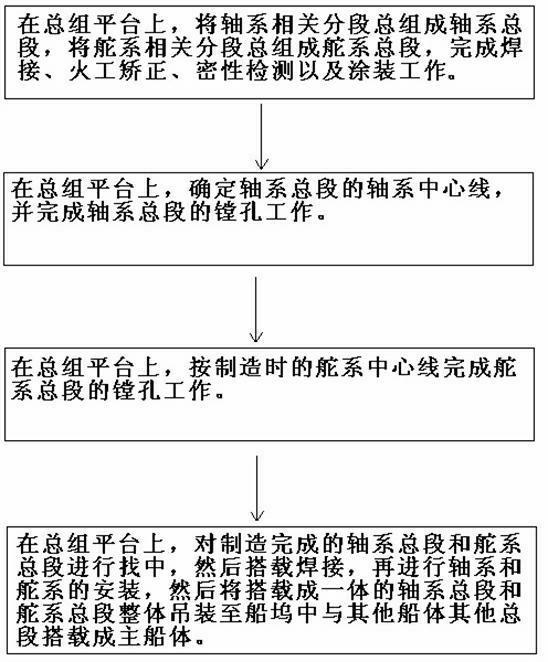

Final assembly method of ship shafting and rudder system

ActiveCN102627139AReduce build timeShorten the construction periodVessel partsRudderBuilding construction

The invention relates to a final assembly method of a ship shafting and a rudder system. The final assembly method comprises first performing expansion and final assembly to relative subsections of the shafting of the ship on a final assembly platform so that the relative subsections of the shafting become a shafting block, performing expansion and final assembly to relative subsections of the rudder system so that the relative subsections of the rudder system become a rudder system block, inspecting the manufactured shafting block and the rudder system block until the shafting block and the rudder system block fully meet the construction requirements, performing hole boring to the shafting and the rudder system respectively according to the shafting center line of the shafting block and the rudder system center line of the rudder system block, performing alignment and lap welding to the manufactured shafting block and the rudder system block on the final assembly platform, installing the shafting and the rudder system, and finally integrally lifting the shafting block and the rudder system block which are integrated by lapping into a dock so that the shafting block and the rudder system block and other blocks are lapped into a main ship body. The method improves manufacturing precision and quality of the shafting block and the rudder system block of the ship, deformation of the shafting block and the rudder system block of the ship in the lapping process is effectively controlled, and degree and progress of final assembly shipbuilding are improved.

Owner:SHANGHAI JIANGNAN CHANGXING SHIPBUILDING +1

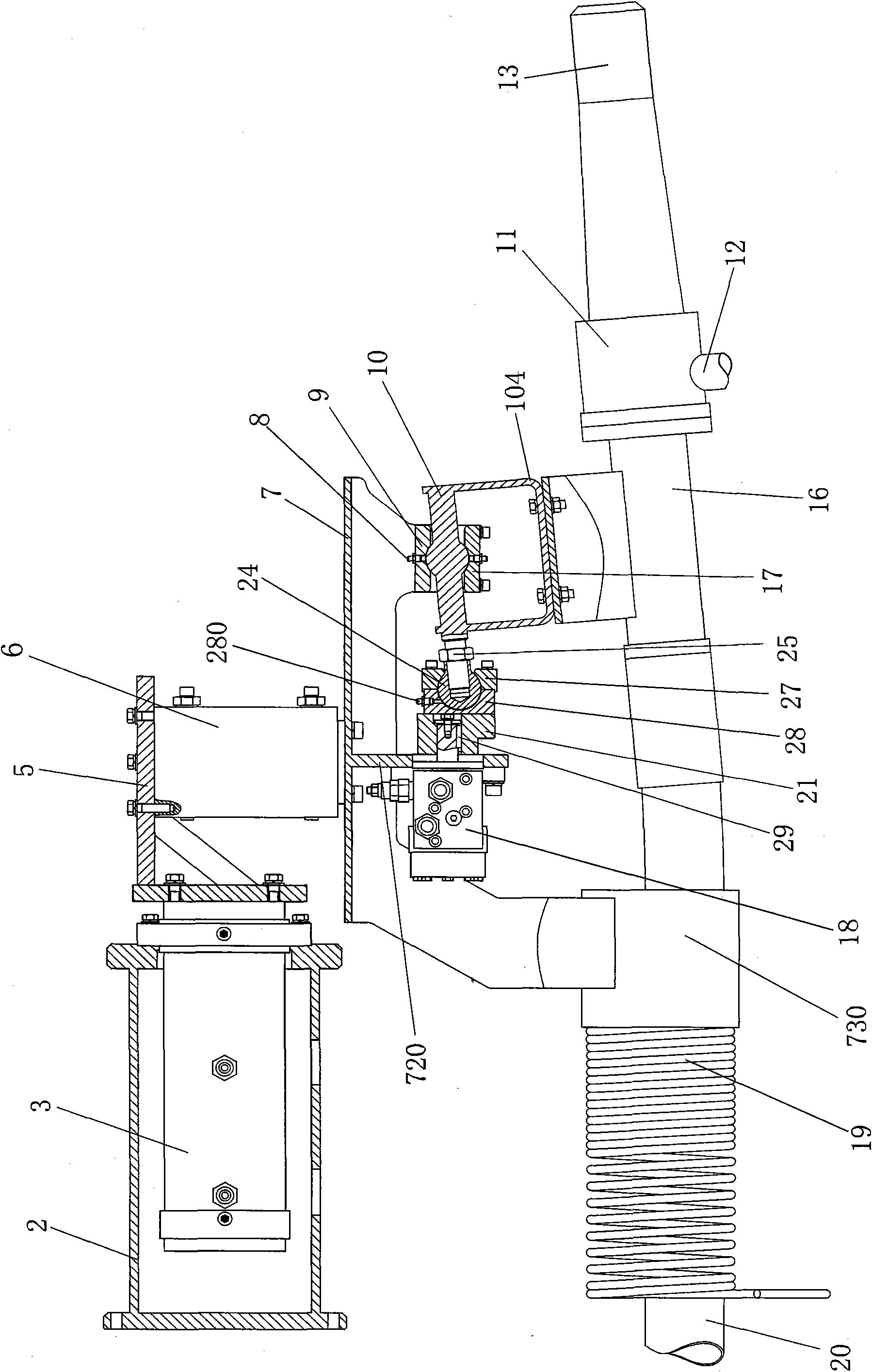

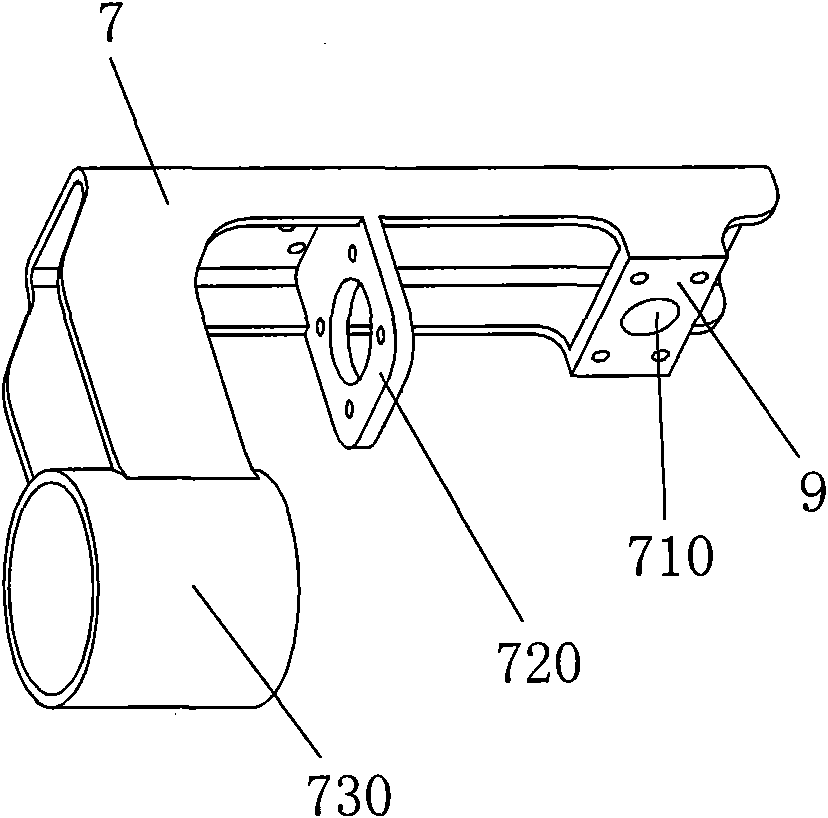

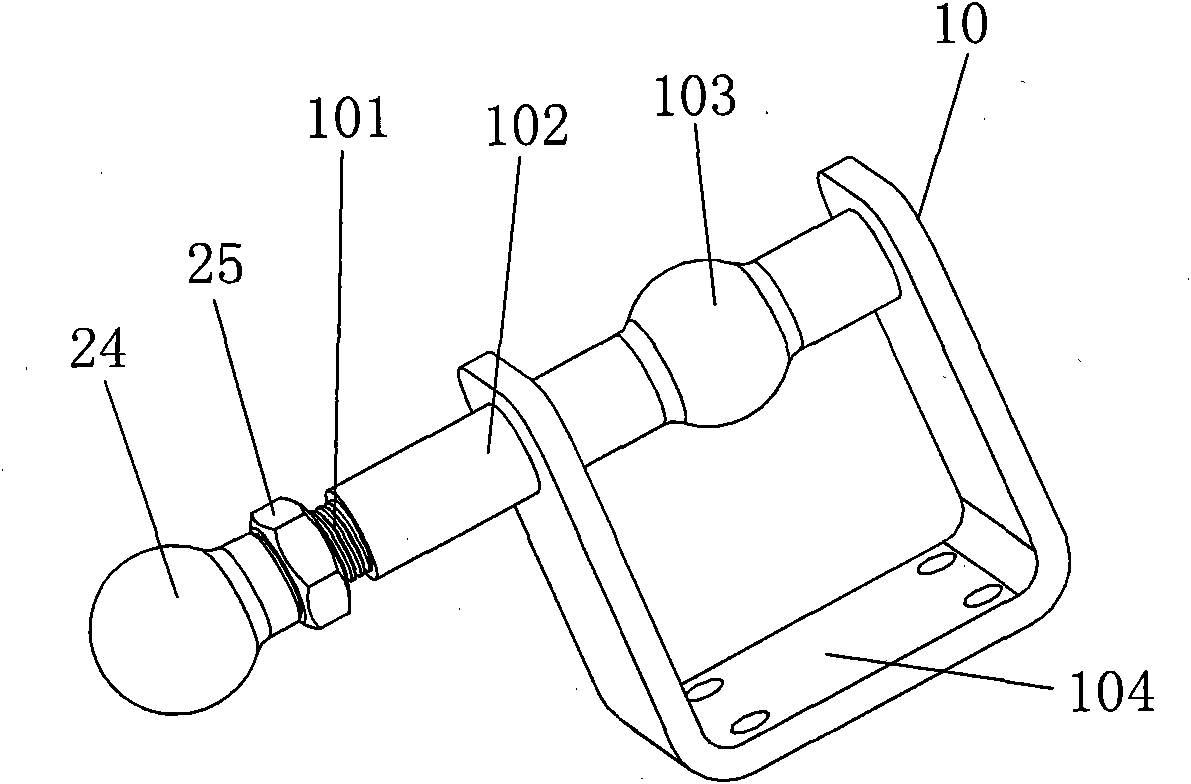

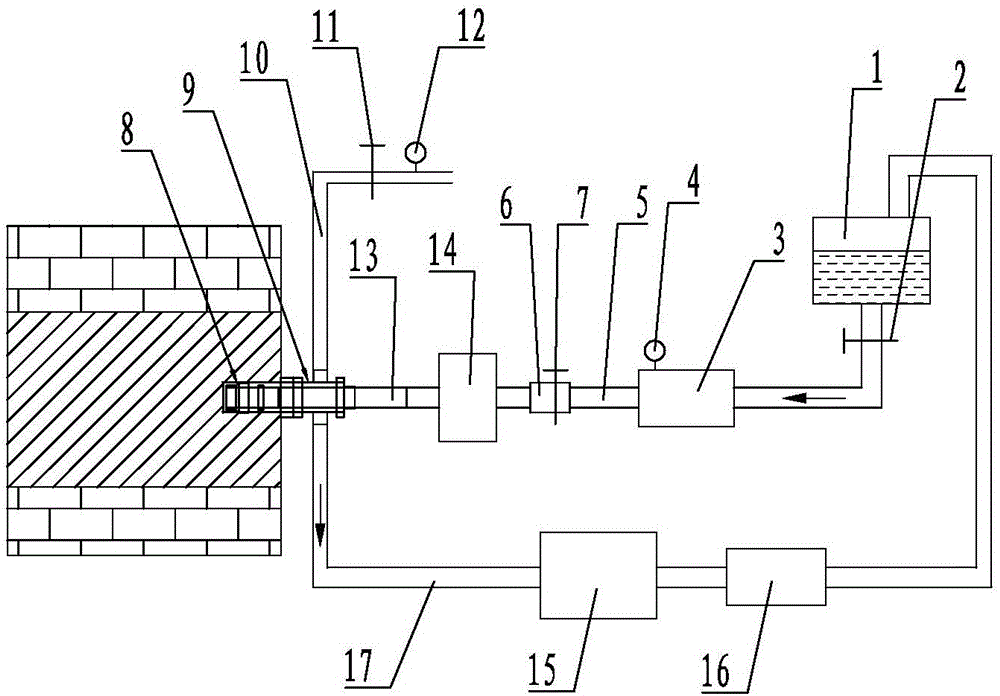

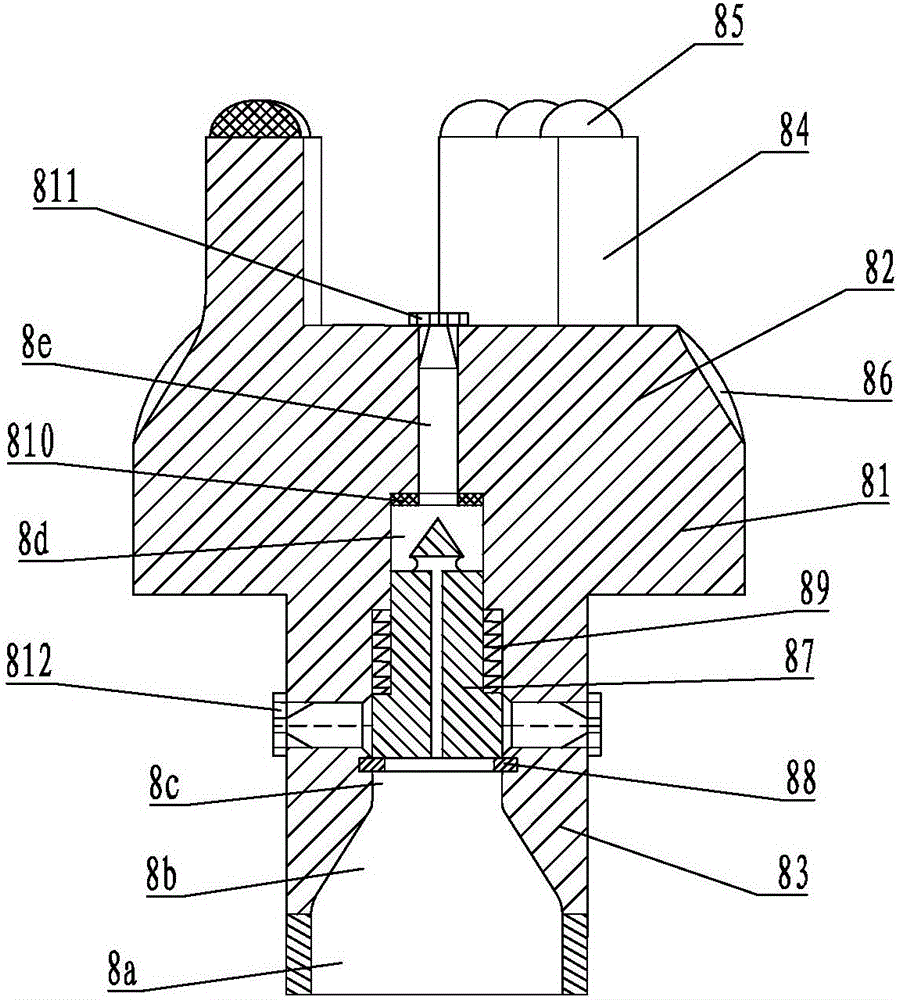

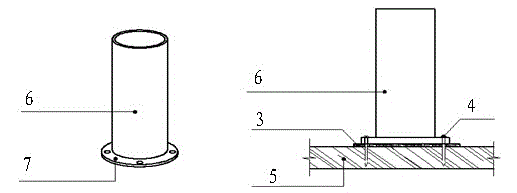

Brush-type spraying device for concrete sprayers

InactiveCN101806221AWide range of working directionsReduce rebound rateUnderground chambersLiquid spraying apparatusHydraulic motorSprayer

The invention relates to a brush-type spraying device for concrete sprayers. The brush-type spraying device comprises a hollow cylindrical spraying device mounting seat 2, a first hydraulic motor 3, a second hydraulic motor 6 and a third hydraulic motor 18, wherein the first hydraulic motor 3 is installed in the cavity of the spraying device mounting seat 2; the first hydraulic motor 3 is connected with the second hydraulic motor 6 through a right-angled mounting rack 5, and the second hydraulic motor 6 is connected with a spraying nozzle mounting rack 7; the spraying nozzle mounting rack 7 is provided with a third motor seat 720 and a brush rack hinged support 9; the protruding end of a swing axle 102 is connected with the output shaft of the third hydraulic motor 18 through an eccentric disc 21 and a knuckle bearing, and the swing axle 102 is connected with the brush rack hinged support 9 through a ball joint structure; and a concrete delivery hard pipe 16 is fixed on a brush rack 10. The invention has the advantages of reducing the resiliency and the slump of concrete spraying, increasing the utilization ratio of the concrete, improving the tunnel construction environment, enhancing the concrete spraying quality and the like.

Owner:上海鸿得利重工有限公司

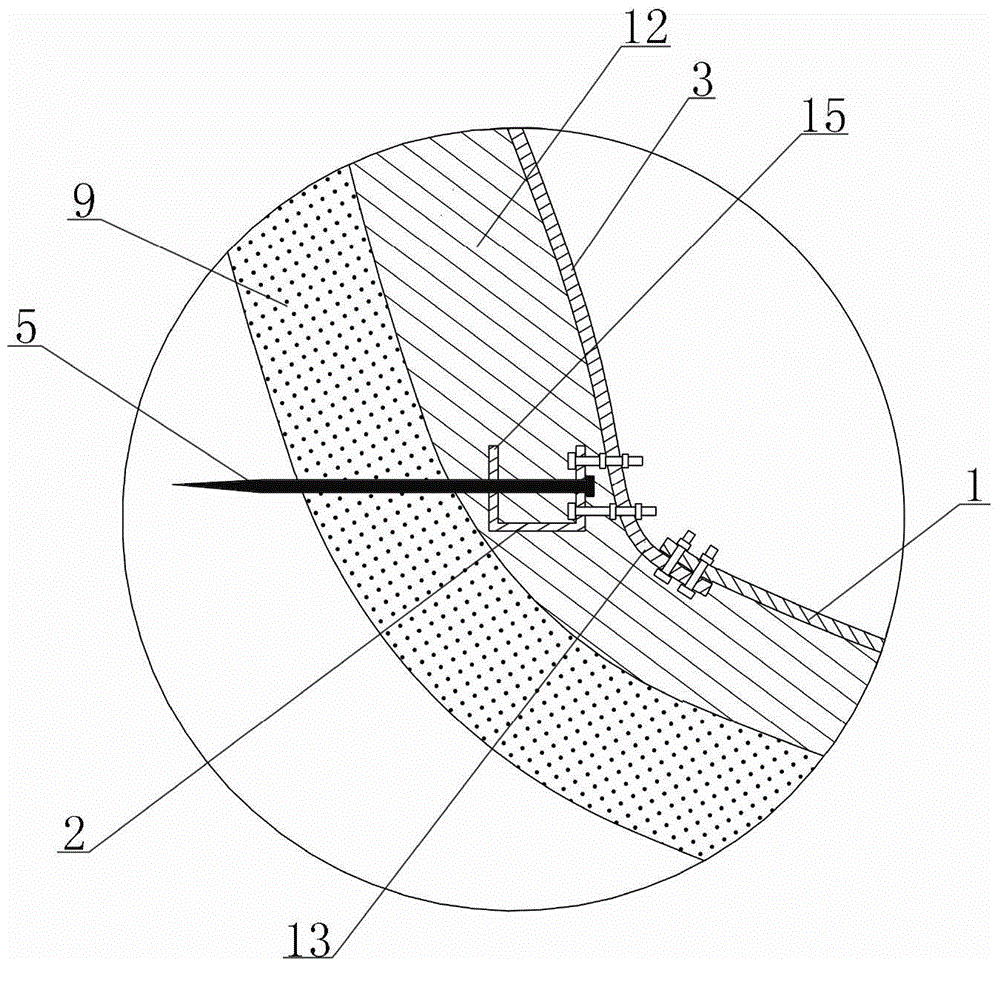

High-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, and related method

ActiveCN106320985AHigh strengthExtended service lifeDrill bitsConstructionsPunchingHigh pressure water

The invention discloses a high-pressure water jet punching-drilling-expanding-cutting integrated antireflection device for coal seam, which comprises a drilling machine, a drilling rod and a drill bit. The drill bit comprises a cylindrical body, wherein the front end of the body extends forward to form a cone-like reaming portion. A reaming cutter is fixed on the conical surface of the reaming cutter. The end face of the small head end of reaming portion extends forward to form a drilling cutter. The rear end of the body is extended backward to form a slitting portion, and the rear end of the slitting portion is fixedly connected with the drilling rod. Pore passages allowing liquid to pass through are provided in the reaming portion, the body and the slitting portion. The rear end of the pore passages is connected with the center hole of drilling rod. The front hole of the pore passages is provided with a punched hole nozzle. A horizontal slit nozzle is provided within the slitting portion, and the pore passages are also provided with a valve core. Therefore, the invention provides a punching-drilling-expanding-cutting integrated antireflection device for the coal seam, and also provides a method for the antireflection of the coal seam by using this punching-drilling-expanding-cutting integrated antireflection device, in order to effectively avoid the borehole deviation, improve the construction environment, reduce water waste and gas waste, and improve work efficiency.

Owner:CHONGQING UNIV

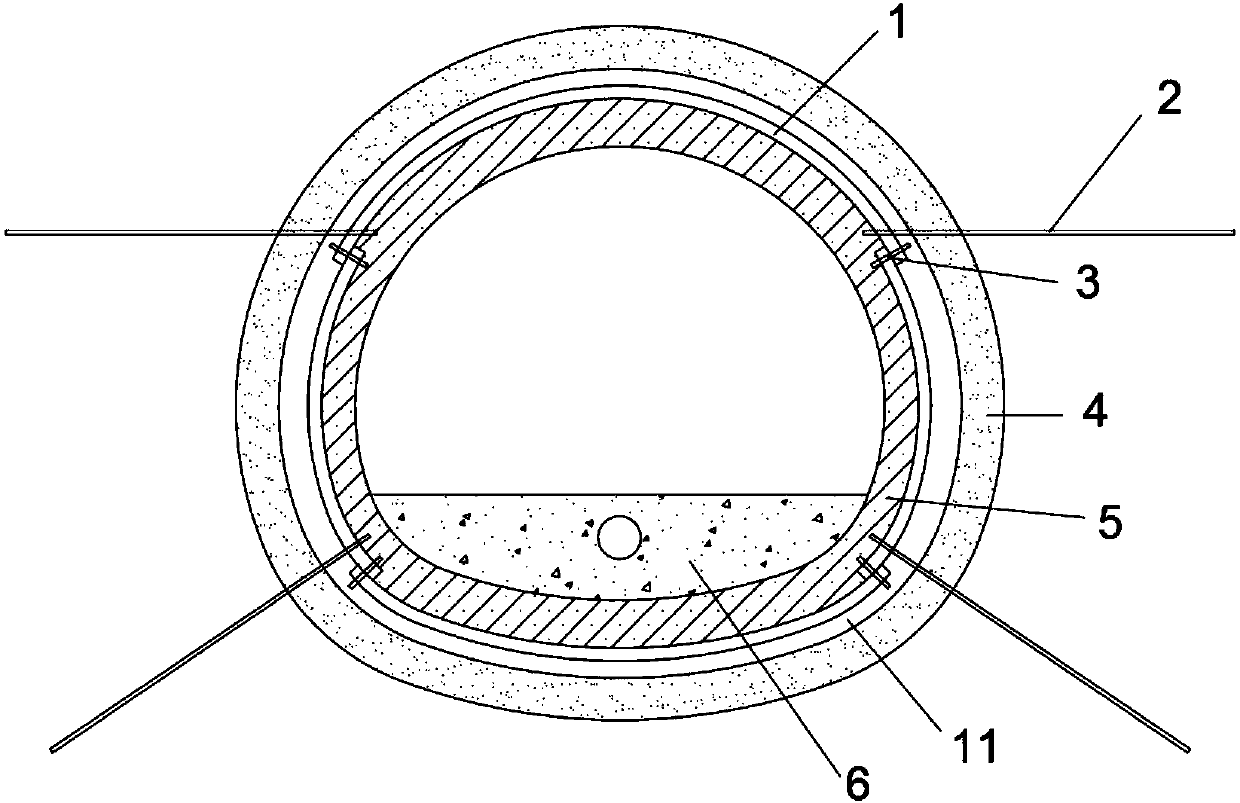

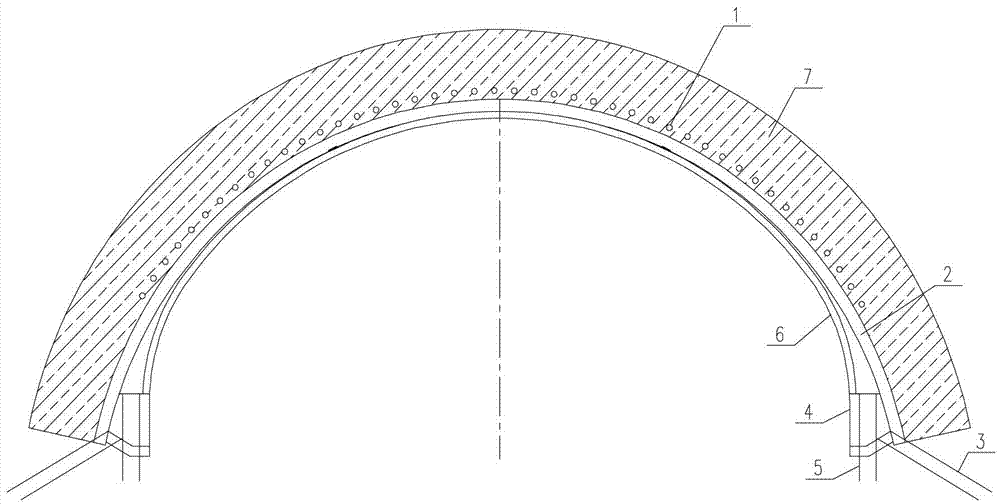

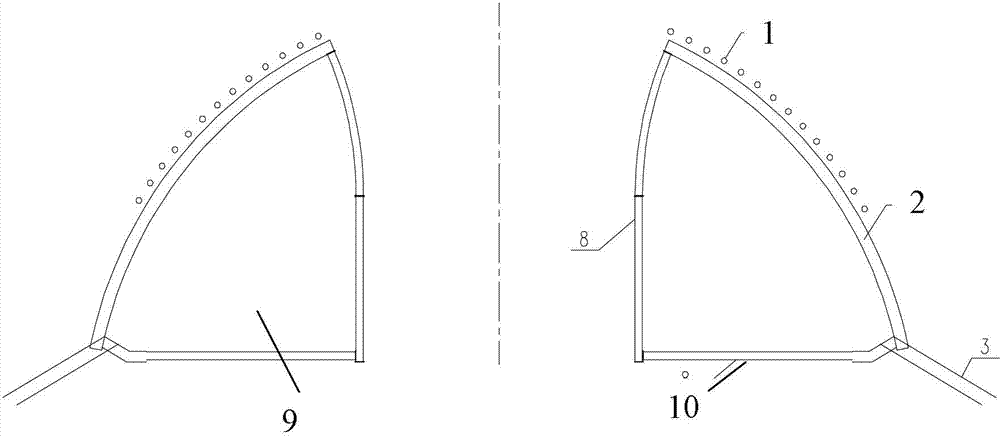

Steel-FRP (fiber reinforced plastic) composite corrugated plate tunnel supporting method

The invention discloses a steel-FRP (fiber reinforced plastic) composite corrugated plate tunnel supporting method and belongs to the technical field of research and development of composites and novel structures in the tunnel engineering field. The method comprises procedures as follows: prefabrication of a corrugated plate, reinforcement of surrounding rock by driving advanced small pipes, excavation of upper steps, mounting of a top corrugated plate, excavation of lower steps, mounting of side wall corrugated plates, excavation of an inverted arch, fixation of a corrugated plate at the inverted arch, setting of a waterproofing and drainage system and secondary lining construction. After the steps are implemented, construction of preliminary tunnel supporting, the waterproofing and drainage system and a secondary lining structure is completed, and the whole tunnel supporting structure can be completed through repeated implementation of the steps with advancing of the tunnel during specific construction. According to the method, performance of an FRP material and a steel material are sufficiently played, advantages of the corrugated plate are combined, and the method has the advantages that the corrosion resistance is good, the bearing capability is high, the hoop rigidity is high, the construction speed is high, the operation environment is excellent, the excavation range issmall and the like.

Owner:BEIJING UNIV OF TECH

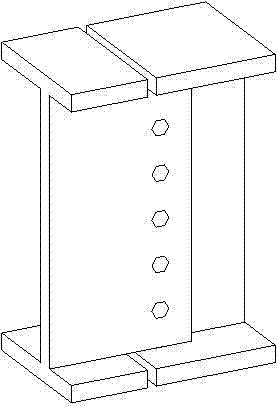

Prefabricated ECC-RC combination beam column joint component

InactiveCN103774754AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention provides a prefabricated ECC-RC combination beam column joint component, wherein ECC refers to engineered cementitious composites, and RC refers to reinforced concrete. The prefabricated ECC-RC combination beam column joint component comprises a joint, an outward-extending column and an outward-extending beam, wherein the joint, the outward-extending beam and the outward-extending column are respectively composed of an ECC material, longitudinal bars and stirrups, the outward-extending length of the outward-extending column is about 1-2 times of the height of the column section, the outward-extending length of the outward-extending beam is about 1-2 times of the height of the beam section, H-shaped steel is embedded in the end of the outward-extending beam and the end of the outward-extending column, the embedded depth ranges from 10 cm to 20 cm, the H-shaped steel and the longitudinal bars extend out of the ends for 10-20 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of a prefabricated RC beam, the embedded H-shaped steel of a prefabricated RC column and the embedded H-shaped steel of the prefabricated ECC joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prefabricated ECC-RC combination beam column joint component, the prefabricated beam column joint component formed by pouring the steel bar reinforced ECC material is applied to an assembly type frame structure, compared with a general reinforced concrete joint component, the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; besides, the high tenacity of the ECC material can reduce residual deformation of the structure after an earthquake, and therefore post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

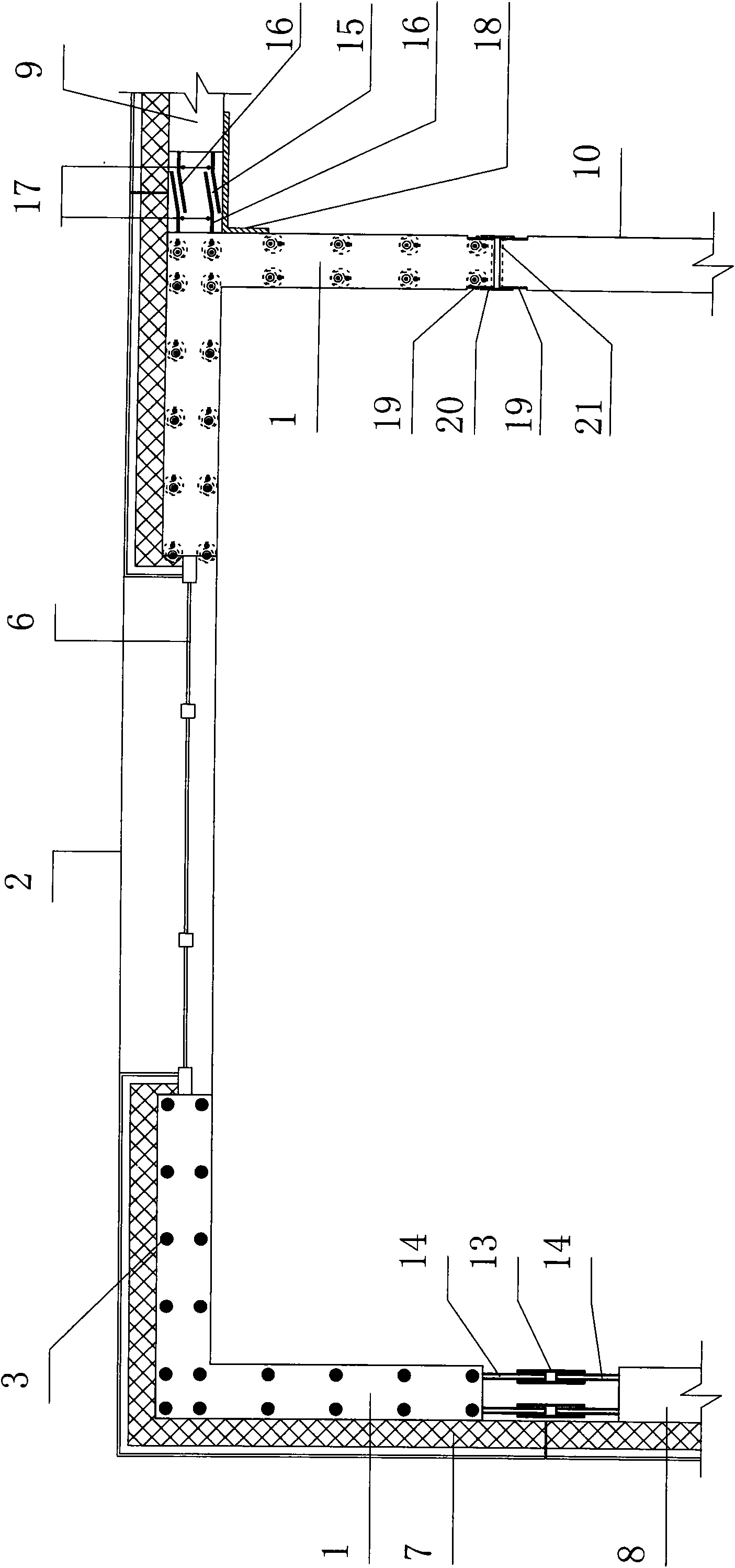

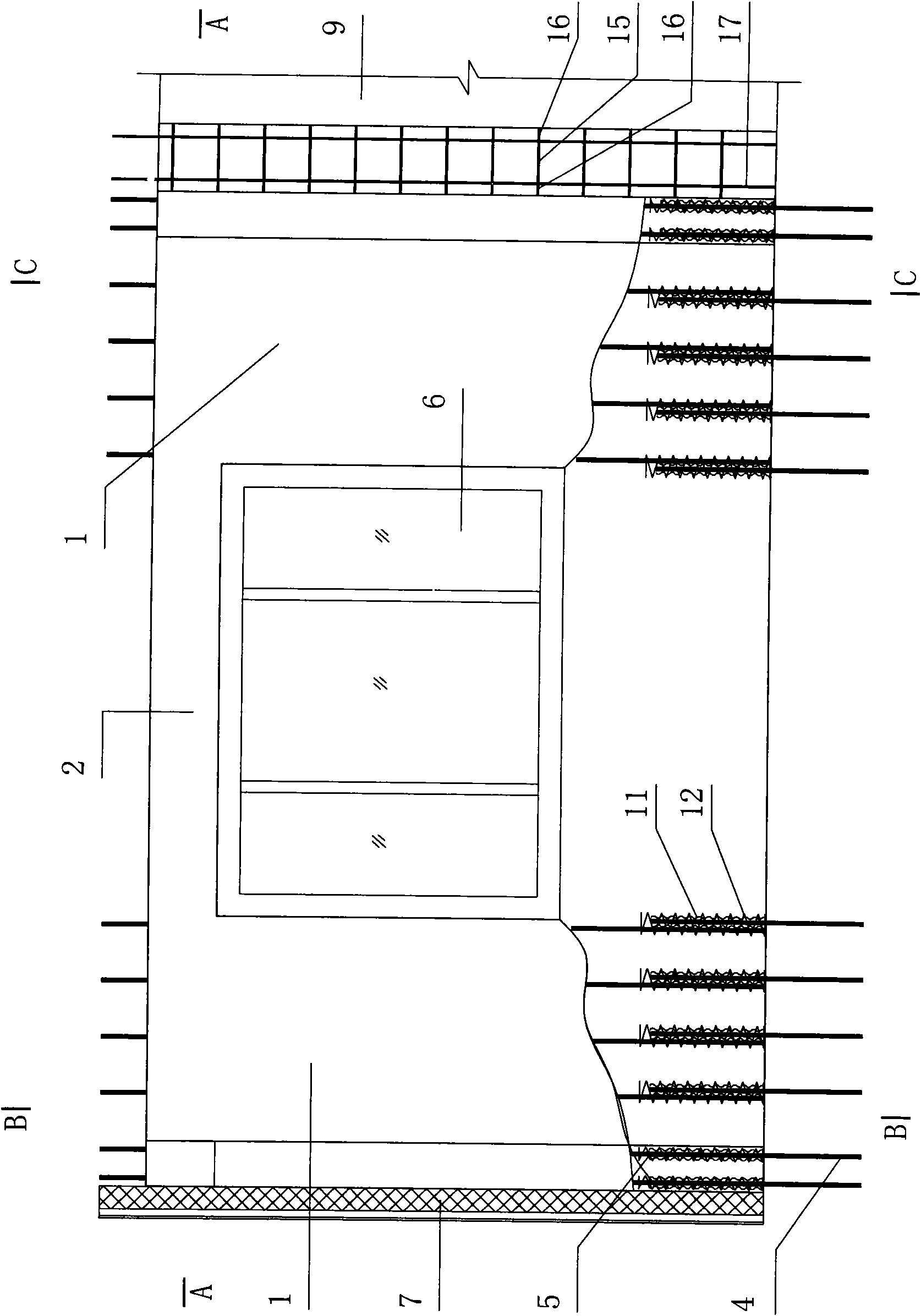

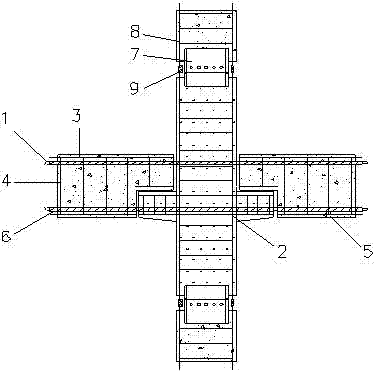

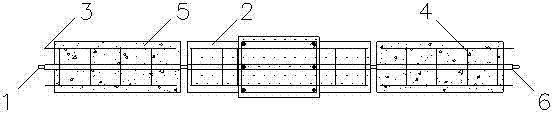

Precast concrete short-limb shear wall provided with door windows and manufacturing method thereof

The invention relates to a precast concrete short-limb shear wall provided with door windows and a manufacturing method thereof. The concrete short-limb shear wall refers to a shock-resistant wall of which the ratio of the wall limb cross section height to the thickness is between 5 and 8, and according to the active code requirement in China, the cross section thickness of a wall body is not less than 200 millimeters, and the stress performance of the structure of the concrete short-limb shear wall is between a specially-shaped column and a common shear wall structure. Because of the good performances in various aspects of construction, structure, construction cost, energy conservation and environmental protection and the like, the structural system becomes the structural form which is most suitable for residential constructions. The precast concrete short-limb shear wall comprises precast concrete wall limbs (1), wherein the wall limbs (1) are connected with connecting beams (2), are provided with door windows (6), and are connected with an external wall heat insulation layer and an architectural surface (7), and the wall limbs are connected with each other by assembling steel bars. The precast concrete short-limb shear wall is applied to industrialized fully-assembled shear walls for residential buildings.

Owner:HEILONGJIANG YUHUI NEW BUILDING MATERIAL

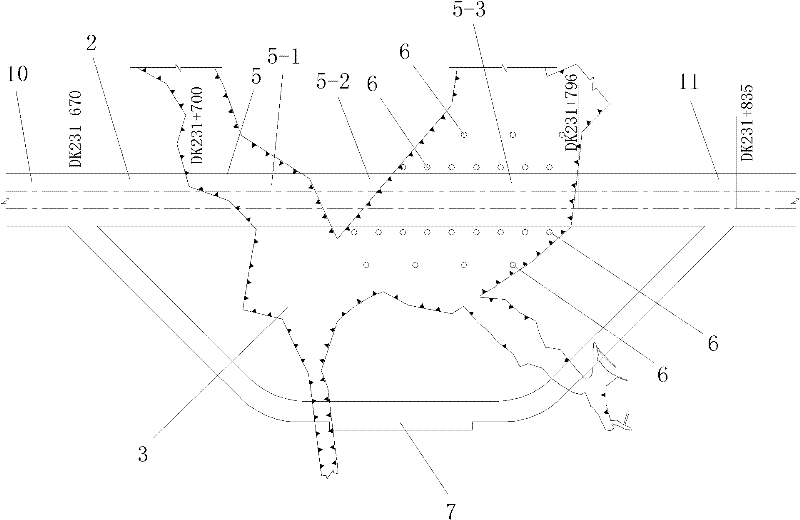

Long-span tunnel overlapping carrying arch structure for upper-soft and lower-hard stratum and construction method thereof

InactiveCN102758642ASimple structureImprove mechanical performanceUnderground chambersCarrying capacityLong span

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

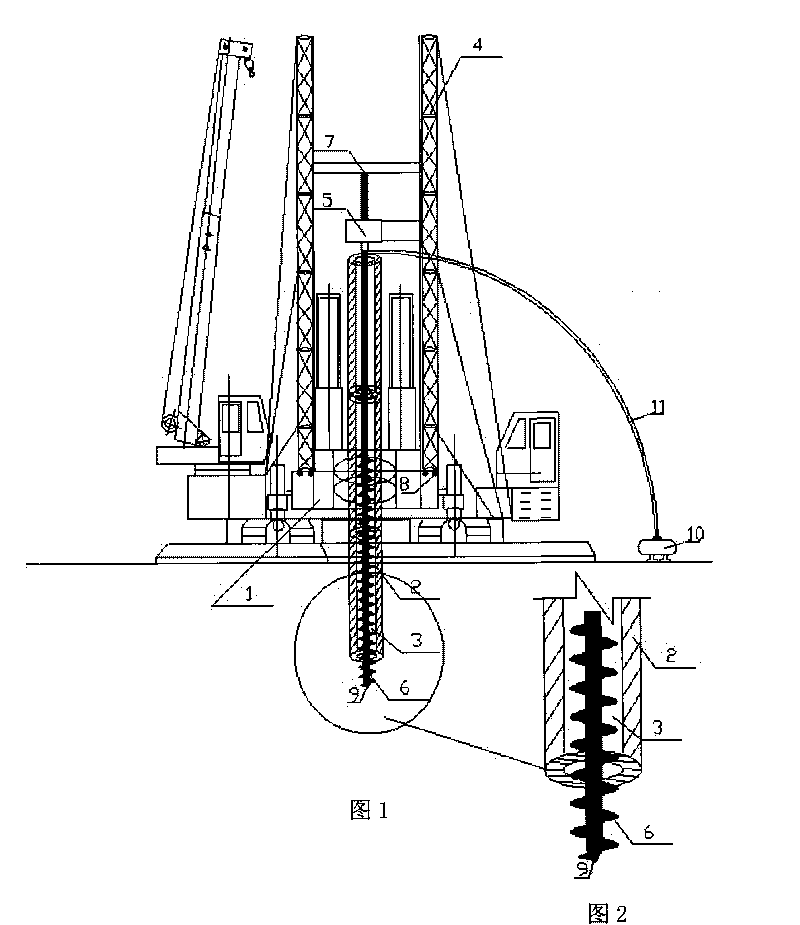

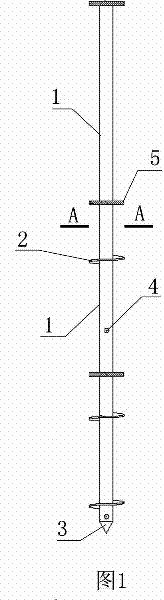

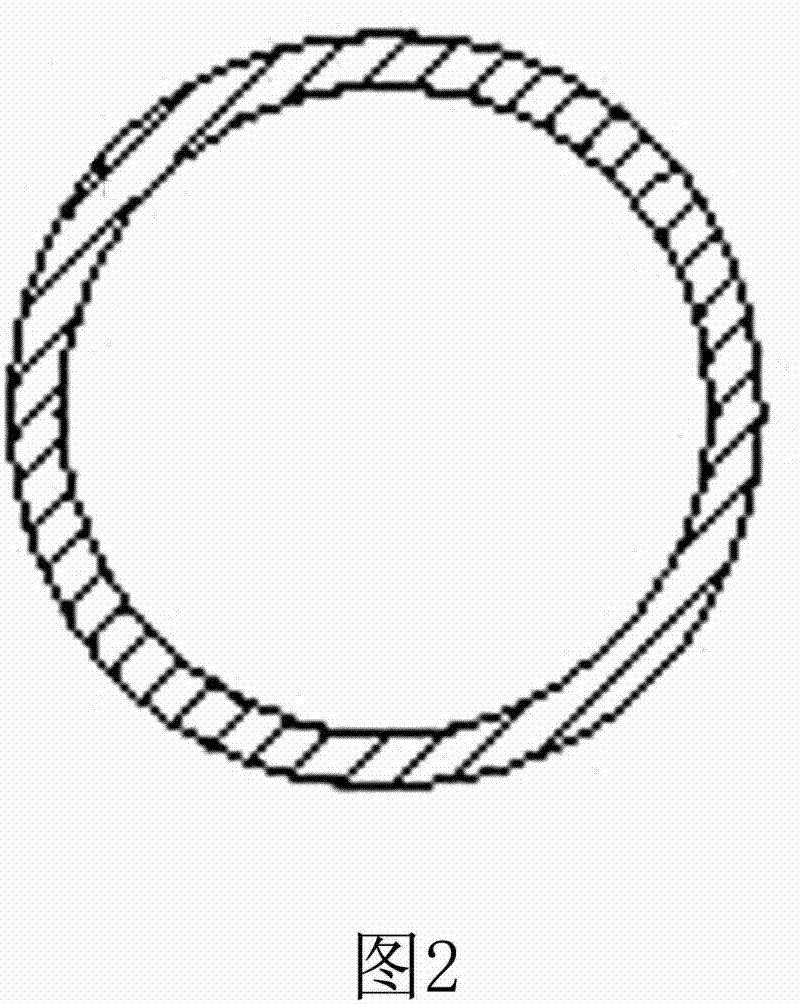

Prefabricated rotary drilling compound pile and construction method thereof

ActiveCN102312426AImprove carrying capacityIncrease the speed of precessionBulkheads/pilesAcute angleSlurry

The invention relates to a prefabricated rotary drilling compound pile and a construction method thereof and belongs to the technical field of a construction foundation component. The prefabricated rotary drilling compound pile comprises a pile body and a pile tip, wherein the pile tip is taper-shaped; a blade, which forms an acute angle together with a horizontal cross section of the pile body, is arranged on the outer surface of the pile body; the number of the blade is at least one; the blade is spiral, fan-blade-shaped or coulter-shaped; the blade is continuously or discontinuously distributed on the outer surface of the pile body along the axial direction of the pile body; spiral plates are arranged on the outer surface of the pile body at intervals; and the spiral plates are continuously or discontinuously arranged in a 360-degree range on the outer surface of the pile body. The spiral plates are arranged on the outer surface of the pile body, outer packing slurry is poured outside the pile body and inner core slurry is poured in the pile body, thereby forming the expanded head type prefabricated compound pile, further greatly increasing bearing capacity of a pile and expanding the application range of the prefabricated pile. The prefabricated rotary drilling compound pile has the advantages of strong applicability, high construction efficiency, environmental protection,and the like, and can be applied to foundations of engineering fields, such as industrial and civil architectures, municipal architectures, bridges and roads, railways, water conservancy projects, mines, ports, and the like.

Owner:苗启松 +1

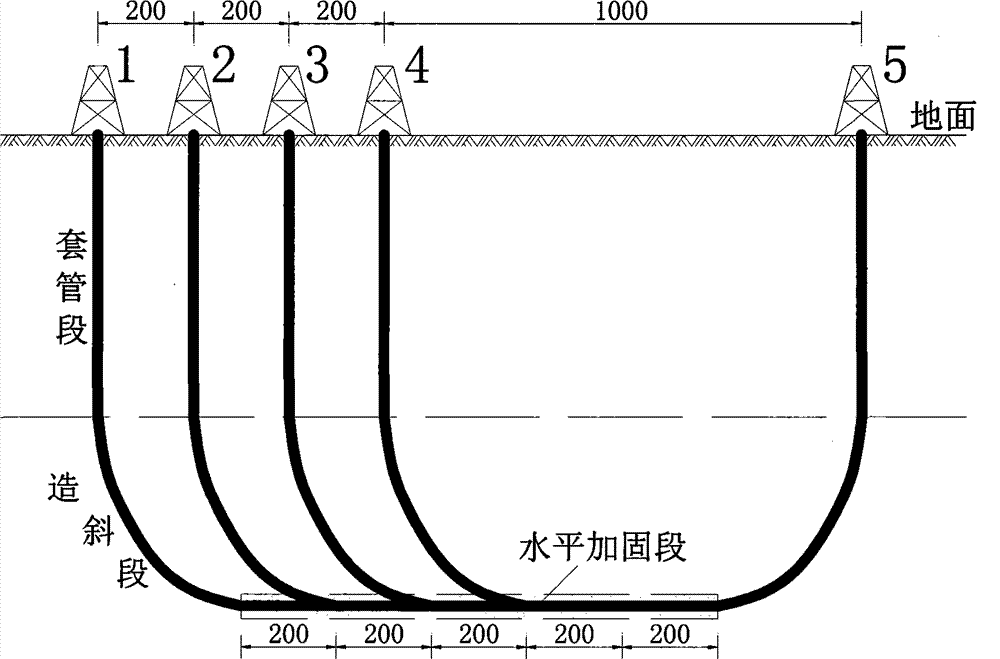

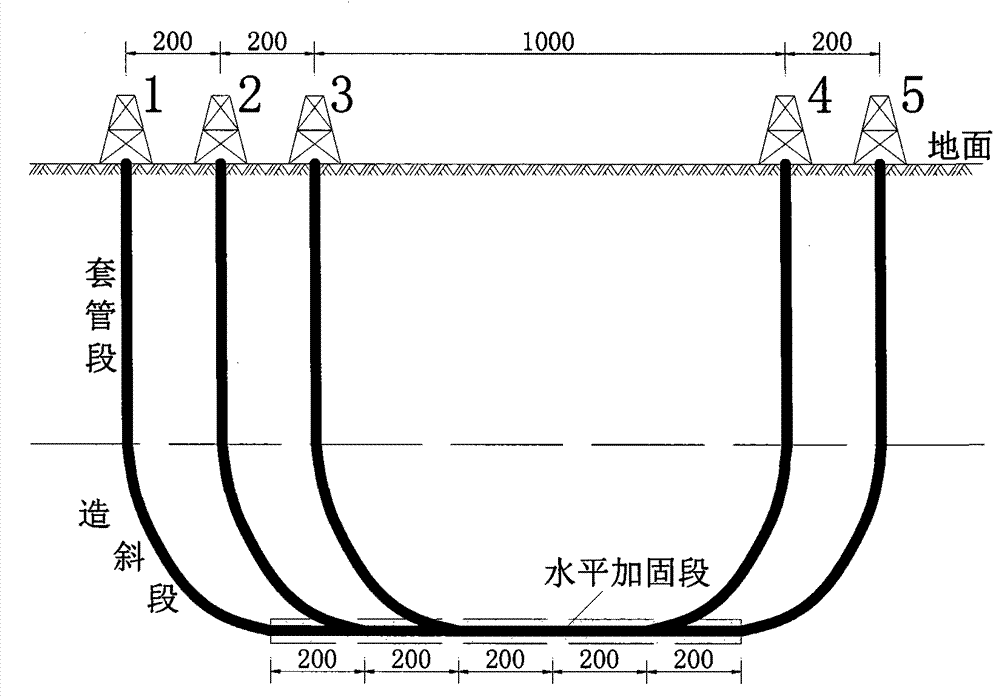

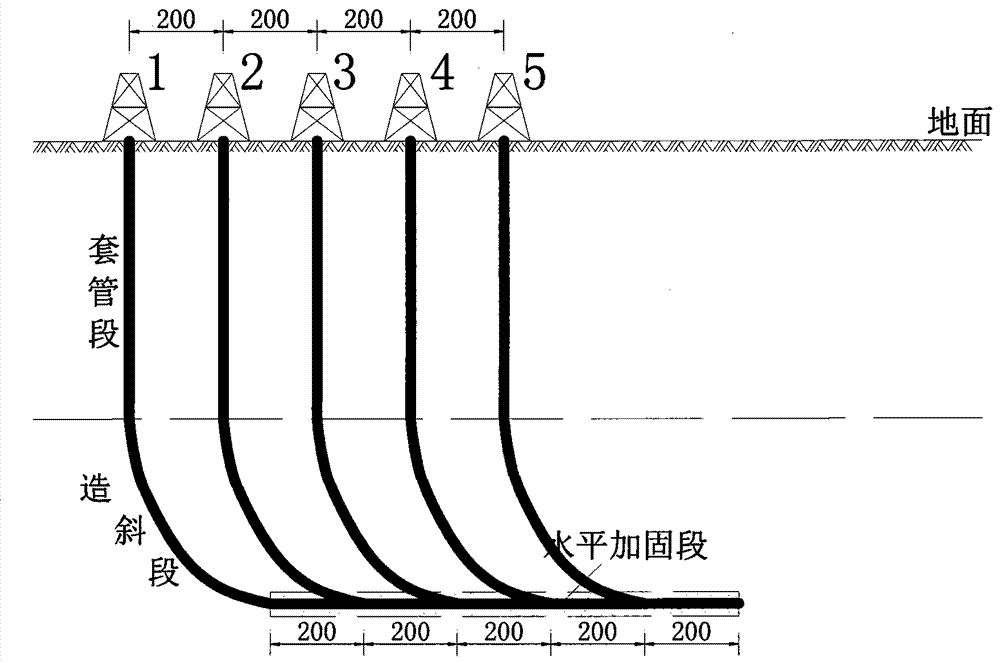

Ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock

ActiveCN103835729AImprove liquidityControllable clotting timeUnderground chambersTunnel liningSlurryLarge range

The invention discloses a ground pre-grouting construction technology suitable for strengthening deep long-distance roadway surrounding rock, and particularly relates to a ground pre-grouting strengthening technology for deep long-distance roadway surrounding rock. The ground pre-grouting strengthening technology for the deep long-distance roadway surrounding rock includes the following steps that firstly, a ground grouting drill hole is formed in the ground through a drilling machine, the ground grouting drill hole comprises a casing pipe segment, a deflecting segment and a horizontal strengthening segment, a casing pipe segment drill hole is internally provided with a casing pipe, the deflecting segment and the horizontal strengthening segment are provided with rock open holes, and ground inlets of the ground grouting drill hole are formed in the walking direction of a roadway; secondly, grout is injected into a stratum rock body where the horizontal strengthening segment exists through a grouting pump located on the ground, and beforehand strengthening government of the roadway surrounding rock is achieved. According to the ground pre-grouting construction technology for strengthening the deep long-distance roadway surrounding rock, strengthening and grouting of the whole roadway surrounding rock can be achieved, and the ground pre-grouting construction technology is suitable for active strengthening of the coal mine large-range roadway surrounding rock and is high in safety and adaptability.

Owner:BEIJING CHINA COAL MINE ENG CO LTD

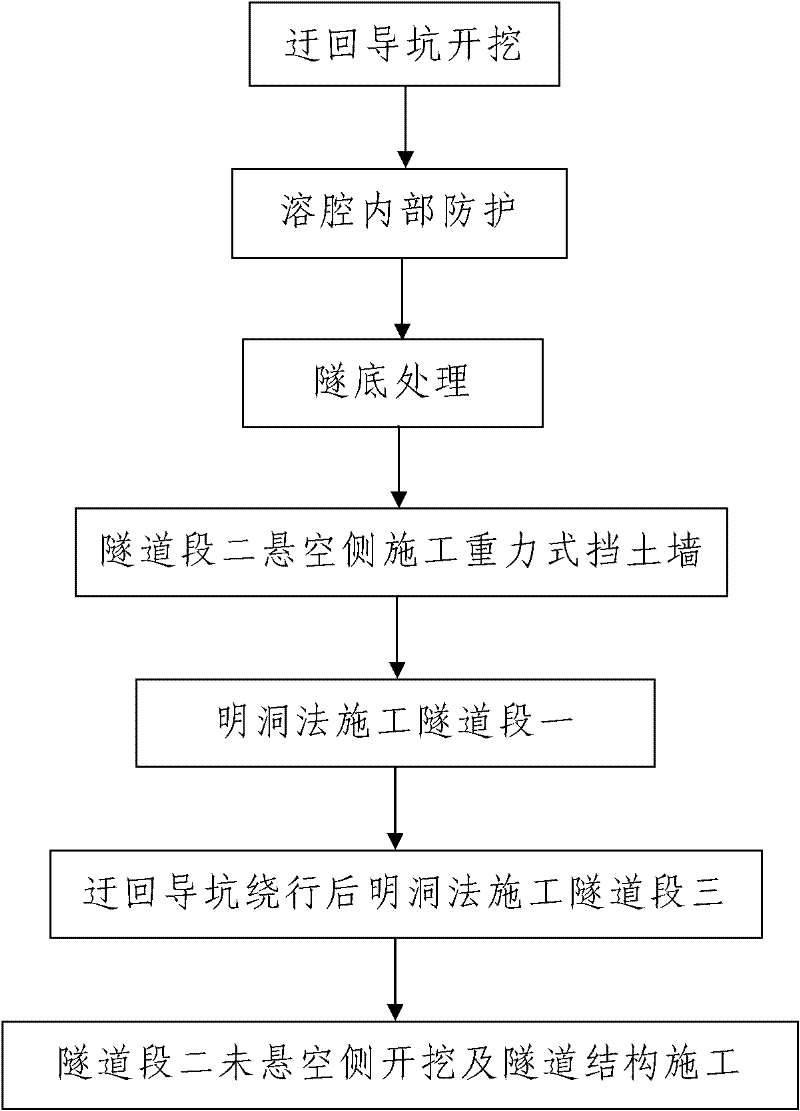

A large-scale solution cavity treatment method for karst tunnels

ActiveCN102296961AReasonable designSimplify construction stepsUnderground chambersTunnel liningLarge distanceKarst tunnel

The invention discloses a karst tunnel large-scale cavern processing method. A cavern traversing tunnel section penetrating through a cavern comprises a tunnel section I, a tunnel section II and a tunnel section III according to the distribution positions, wherein two sides of the tunnel section I are suspended in midair and the top of the tunnel section I is at a smaller distance away from a cavern top plate, one side of the tunnel section II is suspended in midair, and two sides of the tunnel section III are suspended in midair and the top of the tunnel section III is at a larger distance away from the cavern top plate. The processing method comprises the steps of: 1, excavating a bypass pilot tunnel; 2, protecting inside of the cavern; 3, processing the bottom of the tunnel: filling the cavern below the tunnel section I with rock residues and grouting for reinforcing, and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section III with concrete and then distributing an armoured concrete slab girder, filling the cavern below the tunnel section II with hard fillers; 4, constructing a gravity retaining wall at the suspending side of the tunnel section II; 5, constructing the tunnel section I with an open cut tunnel process; 6, constructing the tunnel section III with the open cut tunnel process after the bypass pilot tunnel bypasses; and 7, constructing the tunnel section II. The karst tunnel large-scale cavern processing method has the advantages of reasonable design, convenience for construction, safe and reliable construction process and short construction period, good processing effect on the large-scale cavern.

Owner:CHINA RAILWAY 20 BUREAU GRP

Infilled wall constructional column construction method

InactiveCN103938864AImprove compactnessImprove seismic performanceBuilding material handlingArchitectural engineeringRebar

The invention relates to a construction method, in particular to an infilled wall constructional column construction method, and belongs to the building field. The infilled wall constructional column construction method comprises the steps of construction preparation, measurement and positioning layout, reinforced connecting sleeve model selection and installation, pouring vibration hole pre-buried steel pipe manufacturing and installation, root rebar pre-burying and fixation, rebar connection and binding, template manufacturing and installation, concrete pouring and construction joint retention, and secondary pouring of expansive concrete. Constructional column longitudinal carrying bars are connected with a main structure, and due to the adoption of the rebar mechanical splicing technology, working efficiency is improved by five times and construction cost is reduced by 30 percent. A constructional column template is fixed through a split bolt, a fixing point is arranged inside a constructional column, reservation of holes in a wall is avoided, and damage to an infilled wall during template fixation is reduced.

Owner:宿迁明远建设有限公司

Artificial roof room-and-pillar shrinkage subsequent filling mining method

ActiveCN108661646AImprove securityAvoid constructionUnderground miningSurface miningRoom and pillar miningBlock structure

The invention provides an artificial roof room-and-pillar shrinkage subsequent filling mining method. The method comprises the steps that mine block structures are divided, specifically, an ore body is divided into multiple stages, ore chambers and ore pillars are divided in the stages in an ore body trend, and the ore chambers and the ore pillars are divided into multiple subsections; mining preparation and out seam mining preparation are conducted, specifically, a stage transportation haulage, a stage ore removal crosscut, a service ventilating raise, a subsection connection roadway, a filling inclined roadway and a drilling chamber are arranged; cutting is conducted; exploding is conducted, specifically, sector-shaped blast holes are drilled in the stage drilling chamber to cave down ores; stopping and ore removal are conducted, specifically, exploding is conducted from bottom to top in each stage, after each time of exploding, part of ores are transported from the stage ore removalcrosscut, remaining ores are shoveled out collectively on the stage ore removal crosscut after the ores are circulated to the topmost subsection ores are exploded and caved down, if the way of working to the dip is adopted during the stages, before upper stage stoping, an artificial roof is constructed on the top of the upper stage, and an artificial bottom is constructed on the bottom of the upper stage, and the artificial bottom of the upper stage is the stoping artificial roof of the next stage; and if the way of working from bottom up is adopted, the artificial roof of the next stage serves as the stoping artificial bottom of the upper stage.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

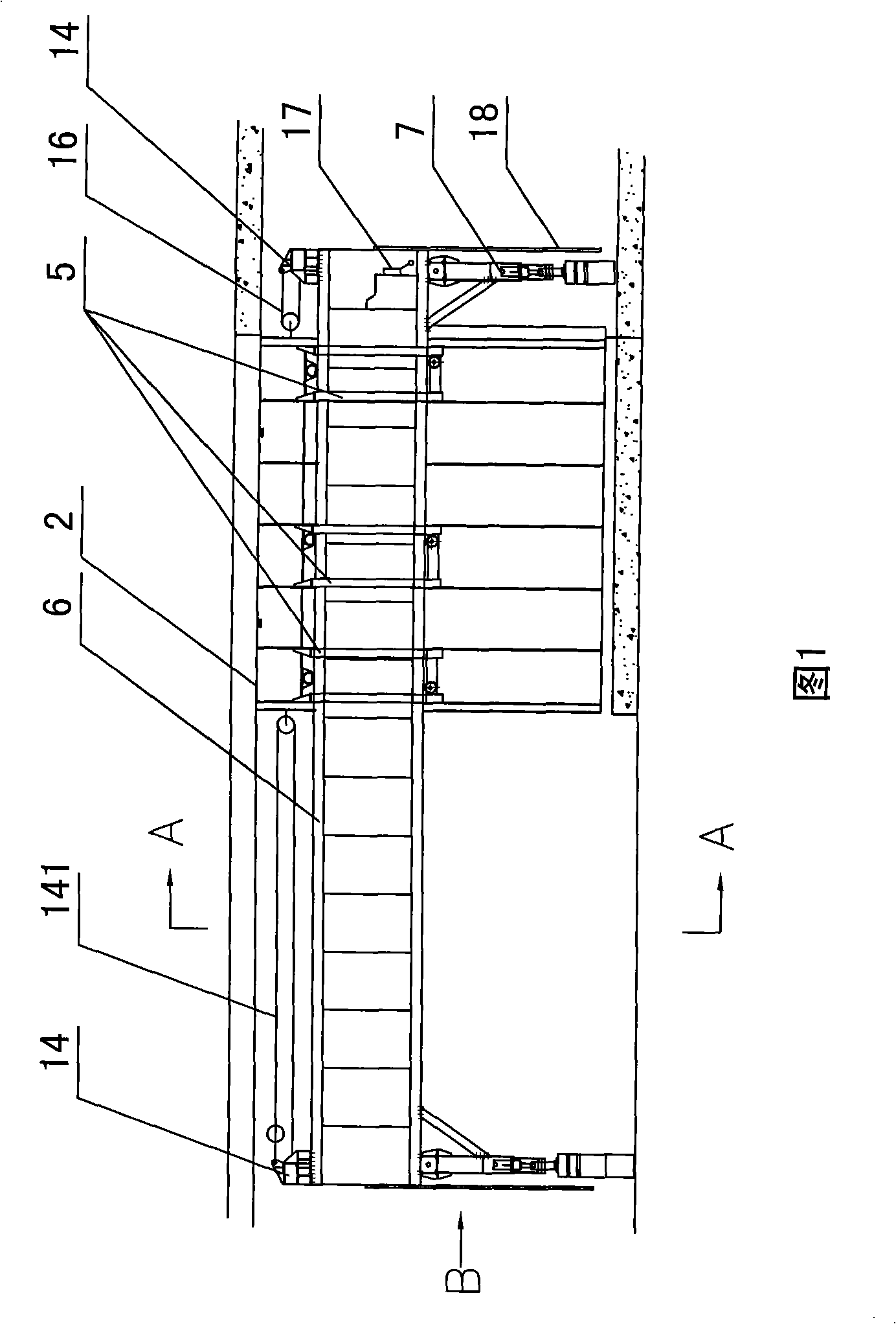

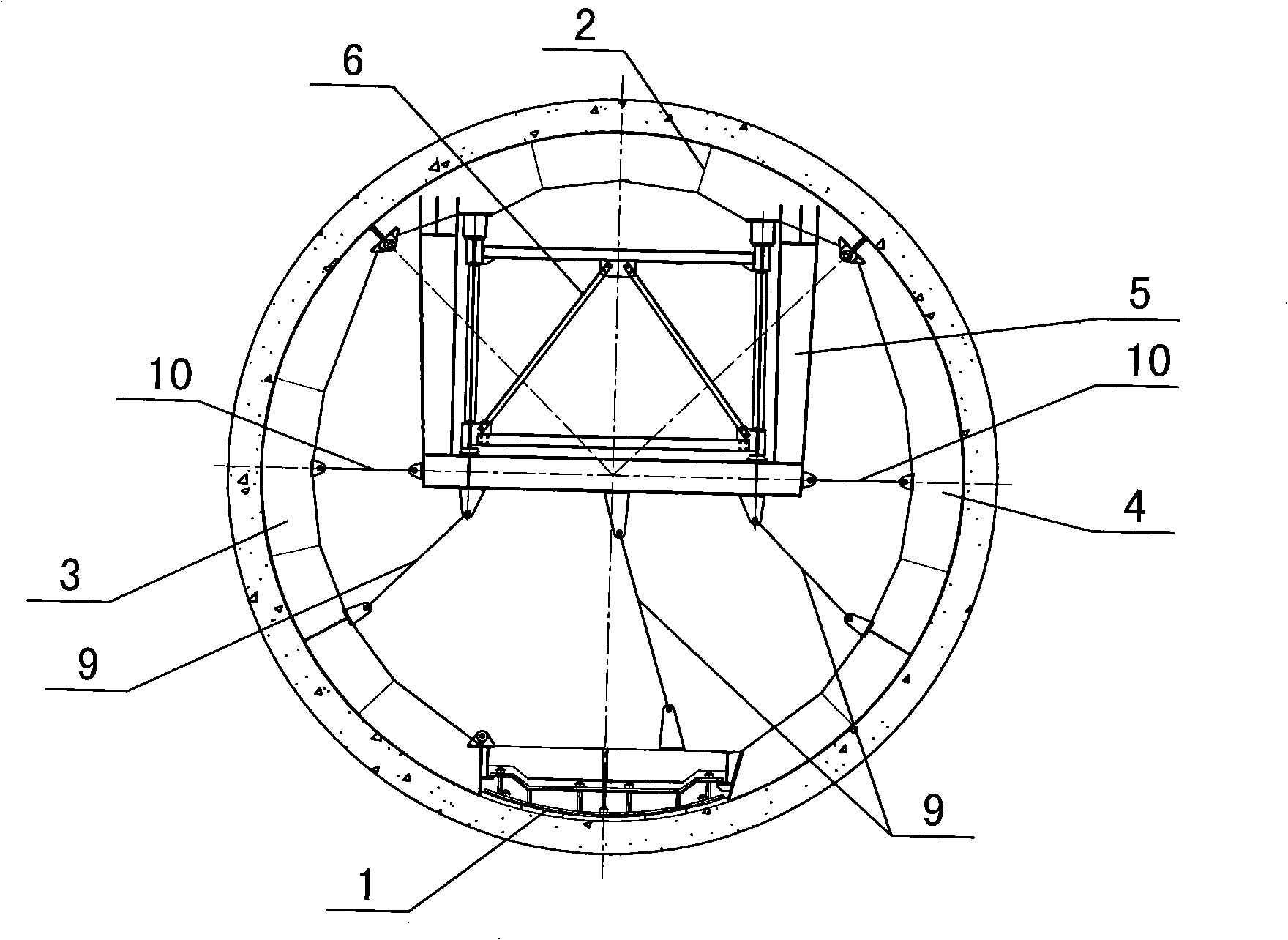

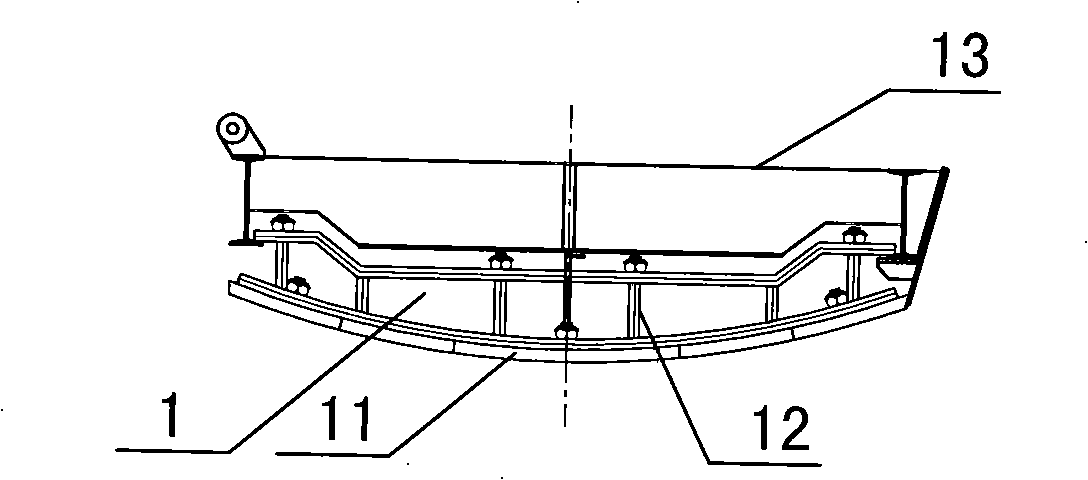

Tunnel concrete lining formwork apparatus

InactiveCN101298839AGood tunnel forming qualityImprove pouring qualityUnderground chambersTunnel liningEngineeringSliding contact

The present invention discloses a tunnel concrete lining template device comprising a template system and needle beam system for bearing; the template system comprises template assembly and template pylon; the template assembly comprises arced left die, right die, top die and bottom die; the left die, right die, top die and bottom die are correspondingly connected to form template assembly with round section; the template pylon is hung on the top die; and bottom of the template pylon is respectively installed with left die, right die and telescopic standing demoulding device connected by the bottom die; the needle beam system comprises bearing needle beam placed in the upper part of the tunnel and pre and post supporting leg device for supporting the bearing needle beam; upper end face of the bearing needle beam is in slide contact with the top die and the needle beam is placed on the template pylon; and the bottom die is in the detachable structure; the bottom die in the detachable structure is installed with opening part which is able to execute trowel-finishing on the surface of the tunnel bottom arch concrete after detaching or turning over when the concrete is initially set. The template device effectively removes the problem of foam of the traditional whole section template bottom arc foam and improves the internal appearance molding quality of the bottom arc concrete.

Owner:SINOHYDRO BUREAU 14 CO LTD

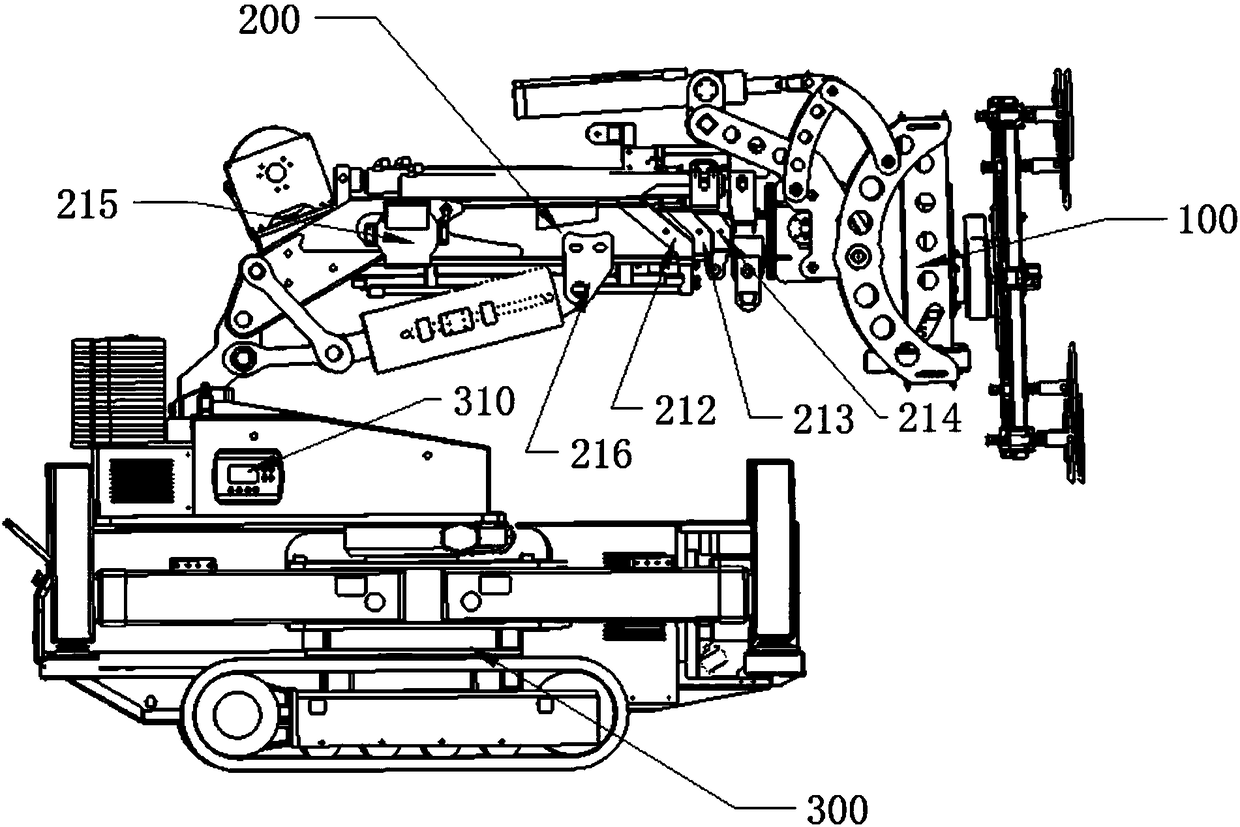

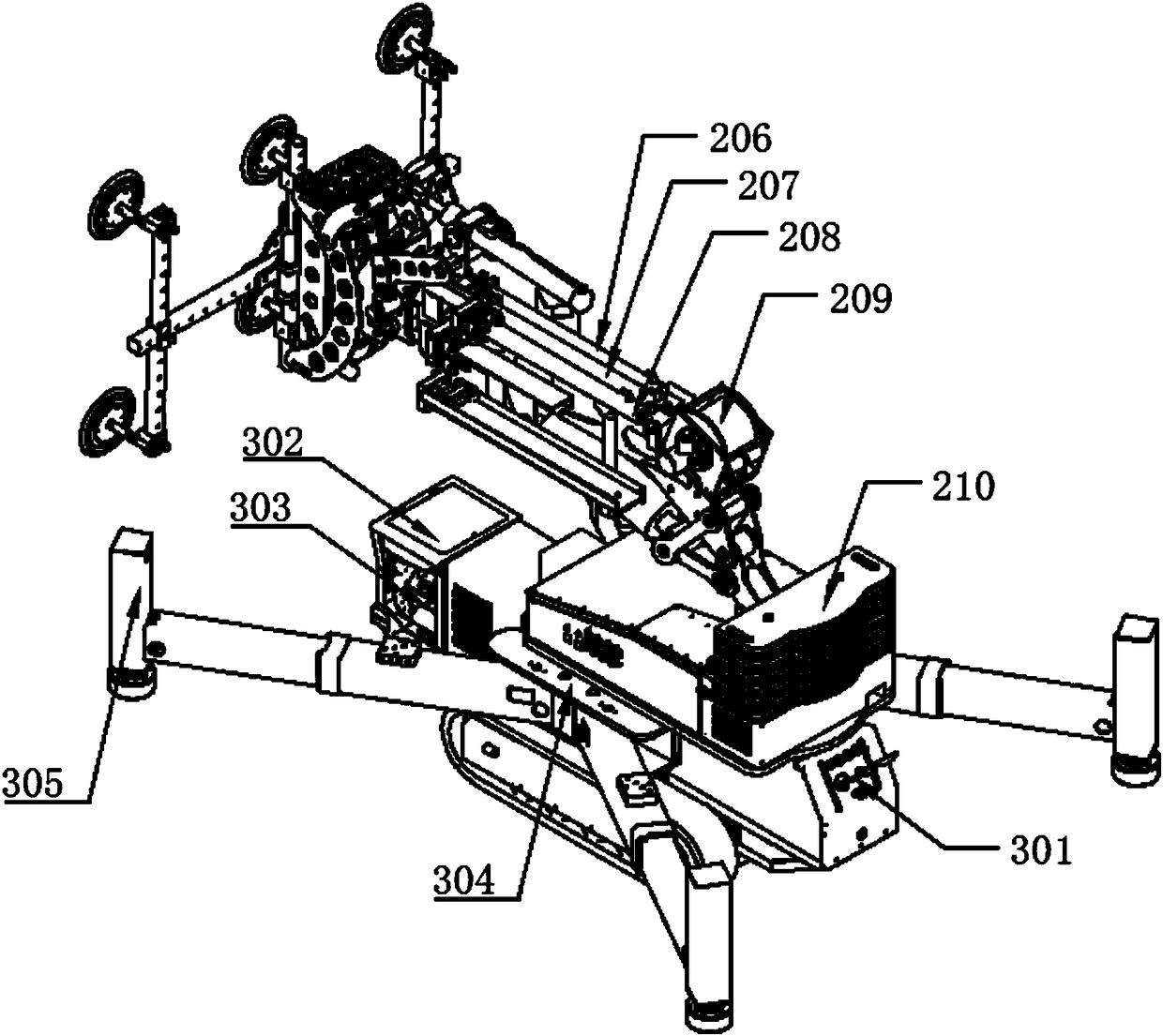

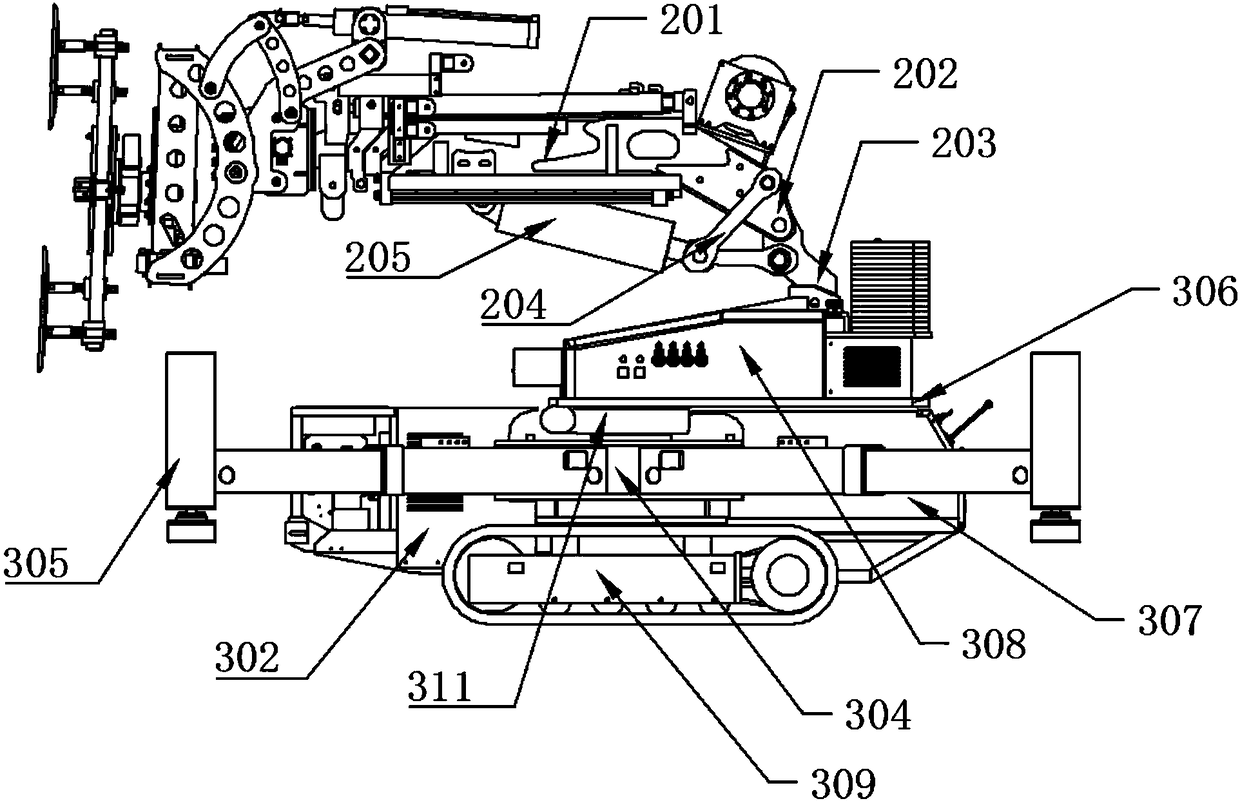

Multi-dimensional glass mounting robot

PendingCN108453697AIncrease productivityImprove production efficiencyProgramme-controlled manipulatorGripping headsEngineeringMulti dimensional

The invention discloses a multi-dimensional glass mounting robot which comprises a multi-dimensional mounting head, a telescopic mechanical arm and a rotary walking chassis, wherein the multi-dimensional mounting head is mounted on the telescopic mechanical arm; the telescopic mechanical arm is mounted on the rotary walking chassis; the multi-dimensional mounting head comprises an up-down slidingunit, a left-right rotating unit, an overturning unit, a rotary unit and a translation unit. The multi-dimensional glass mounting robot is scientific and reasonable in design and compact in structure,at least can achieve movement in eight directions, solves the problems of multi-dimensional and multi-angle mounting and carrying, and achieves the effects of efficiently and flexibly mounting and carrying by coarse and fine adjustment. The multi-dimensional glass mounting robot disclosed by the invention achieves mechanical and auxiliary automatic operations of grabbing, carrying and mounting large glass panels, so that the large panel mounting quality, the production efficiency and the benefit are improved, a lot of labor forces are saved, the labor intensity is reduced, and the construction cost is lowered.

Owner:GUANGZHOU COWEST MACHINERY EQUIP CO LTD

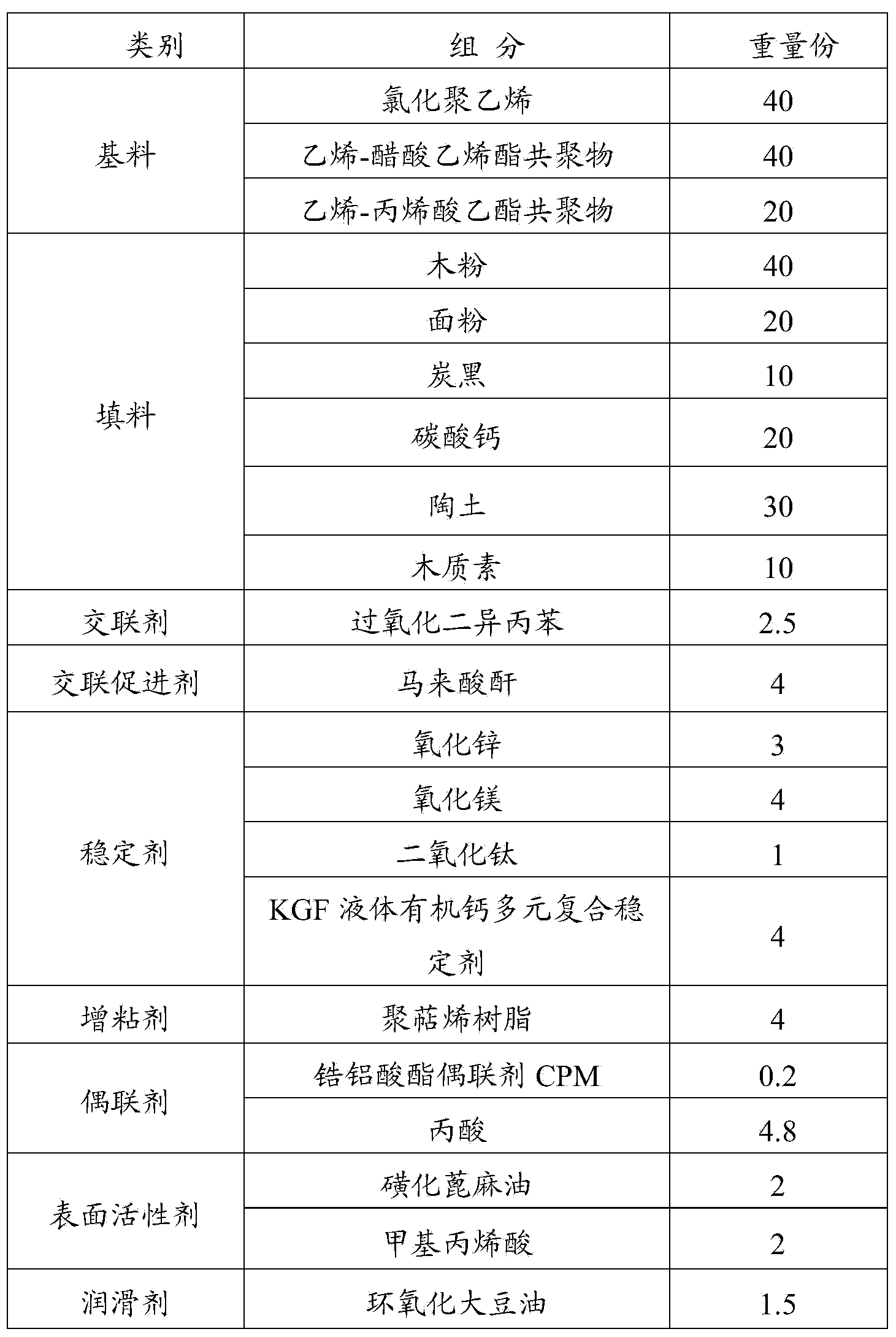

Formaldehyde-free wood adhesive film

The invention provides a formaldehyde-free wood adhesive film which comprises the following components in parts by weight: 100 parts of base material, 10-100 parts of filler, 5-15 parts of tackifier, 0.1-5 parts of crosslinking agent, 2-4 parts of stabilizer, 3-10 parts of maleic anhydride, 0-10 parts of cinnamic acid, 3-15 parts of atactic polypropylene or polyethylene wax, 0-3 parts of coupling agent, 1-5 parts of zinc oxide and 0.5-2.0 parts of stearic acid. The base material is a mixture of at least two of chloride high polymer, chlorosulfonate high polymer, ethylene-vinyl acetate copolymer, ethylene-ethyl acrylate copolymer and polyolefin; and the filler is at least one of shell powder, bark powder, wood meal, flour, short fiber, argil and graphite powder. The wood adhesive film is free of formaldehyde and organic volatile matters, can not influence and jeopardize the environment and human health, has the advantages of excellent environmental protection property and long shelf life, and is convenient for use, transportation and storage.

Owner:杨学荣

Prestressed prefabricated ECC-RC combination beam column joint component

InactiveCN103774755AReduce construction difficultyReduce labor costsClimate change adaptationBuilding constructionsJoint componentResidual deformation

The invention relates to a prestressed prefabricated ECC-RC combination beam column joint component which comprises a prestressed rib and a joint with a bracket. The joint with the bracket is composed of an ECC material, longitudinal bars and stirrups. The joint with the bracket comprises an outward-extending column, wherein the length of the outward-extending column is about 1-2 times of the height of the column section. A hole channel is required to be reserved between the joint and a prefabricated RC beam connected with the joint. The prefabricated ECC joint is connected with the prefabricated RC beam through the post-tensioned prestressed rib which penetrates through the hole channel. H-shaped steel is embedded in the end of the outward-extending column and the end of a prefabricated RC column, wherein the embedded depth and the outward-extending length both range from 10 cm to 15 cm, the longitudinal bars at the end of the outward-extending column and the end of the prefabricated RC column respectively extend outwards by 10-15 cm, the embedded part of the H-shaped steel is welded to the longitudinal bars, the embedded H-shaped steel of the prefabricated RC column and the embedded H-shaped steel of the prefabricated joint are connected through high-strength bolts, and the longitudinal bars are connected through a straight thread sleeve. According to the prestressed prefabricated ECC-RC combination beam column joint component, the prestressed prefabricated joint component formed by pouring of the steel bar reinforced ECC material is applied to an assembly type frame structure, so that the ductility and the anti-seismic property of the structure are improved remarkably, the number of joint stirrups in use is reduced substantially, pouring is facilitated, and construction is convenient; since prestress is used as an assembly means, residual deformation of the structure after an earthquake can be reduced, the restorable function is achieved, and post-earthquake repair expenses are reduced.

Owner:TONGJI UNIV

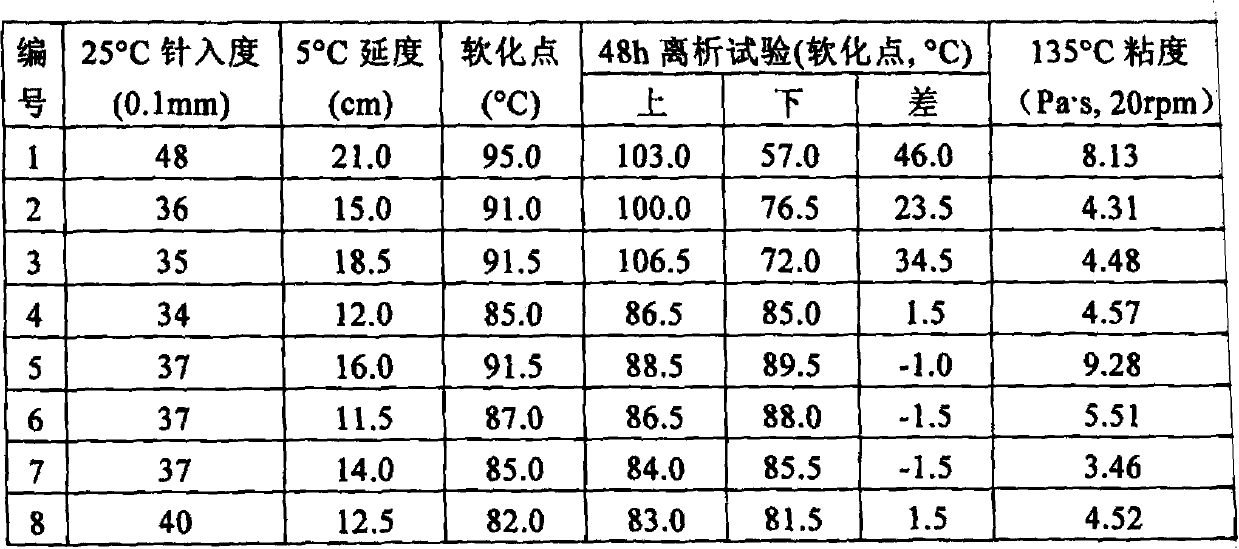

Composite high-viscosity modified asphalt and preparation method thereof

InactiveCN103819918AGood high and low temperature performanceImprove thermal storage stabilityBuilding insulationsEnvironmental effectEconomic benefits

The invention relates to composite high-viscosity modified asphalt and a preparation method thereof. The raw material comprises the following components by weight percent: 84-88% of heavy duty bitumen and 12-16% of modified compounds. The method comprises the following steps: mixing SBS, desulfurized colloidal particles and a compatilizer containing an epoxy group to prepare a modified compound; preparing modified particles after mechanically pelletizing; adding the modified particles to asphalt at 170-190 DEG C; melting and refining compound particles after shearing at a high speed for 30-60 minutes on a high-speed mixing emulsifier; transferring the sheared asphalt to a high-speed disperser, and agitating to obtain the composite high-viscosity modified asphalt. The composite high-viscosity modified asphalt prepared by using the method has the characteristics of stable heat storage, and excellent high and low temperature properties, has good economic benefits and environmental effects because of use of waste rubber, and is free of sulphur as a stabilizer, the construction viscosity can be reduced, the construction environment can be improved, and the problem that incompatible asphalt is difficult to stabilize is solved.

Owner:SHANGHAI JIAO TONG UNIV

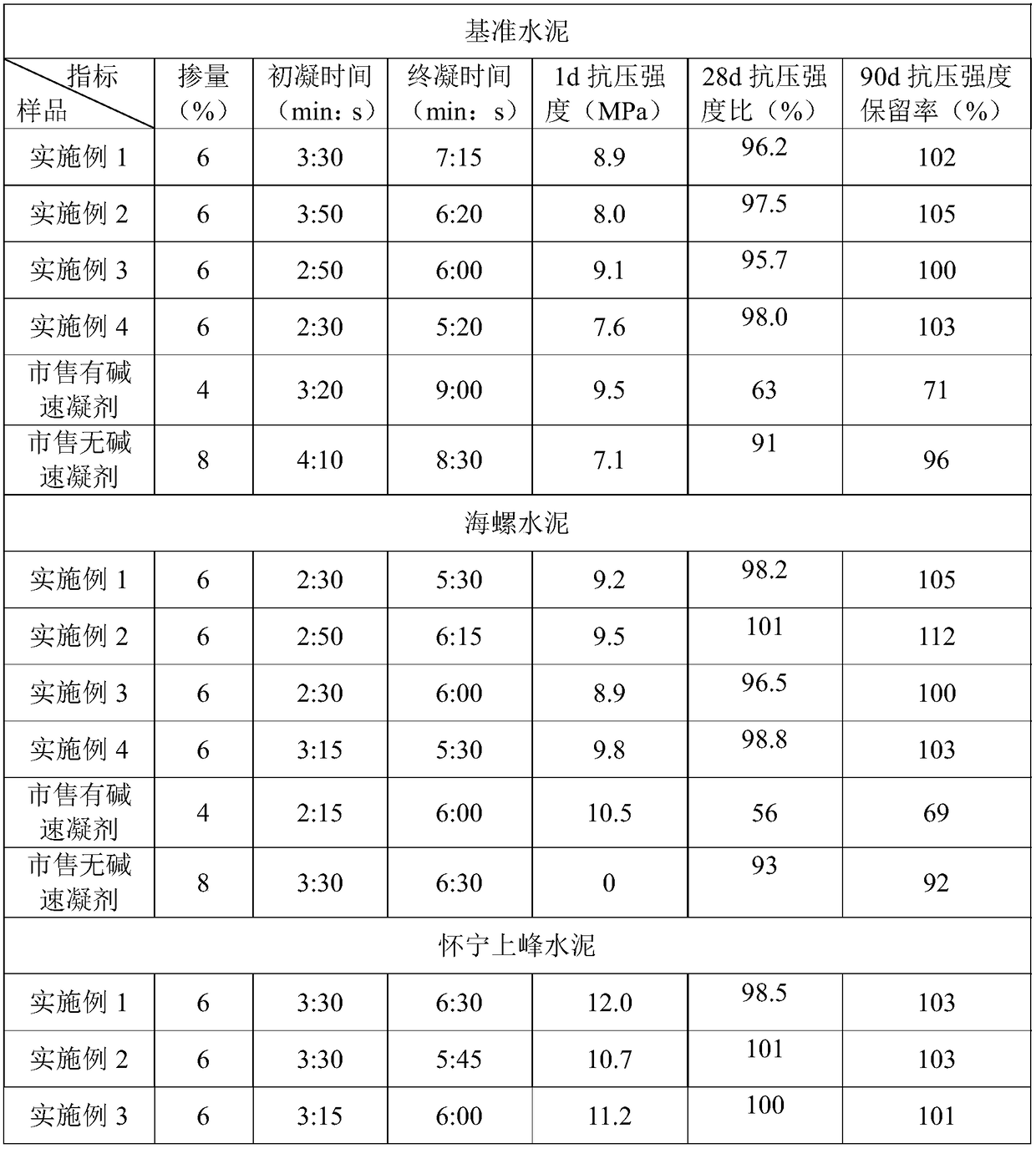

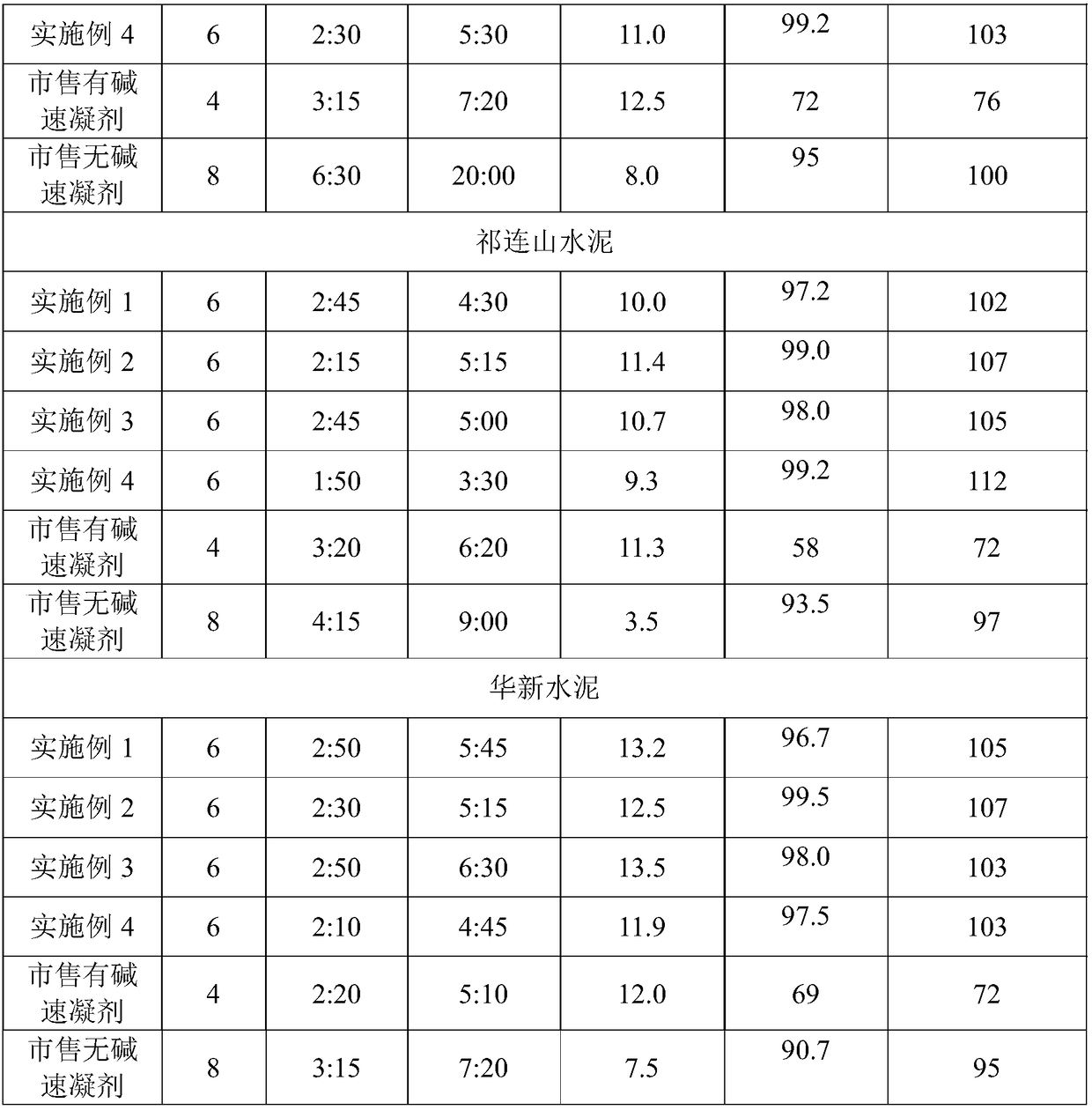

Liquid alkali-free setting accelerator widely applicable to various types of cement

The invention provides a liquid alkali-free setting accelerator widely applicable to various types of cement, wherein the liquid alkali-free setting accelerator includes 35-60 parts by weight of water, 40-50 parts by weight of polyaluminum sulfate or aluminum sulfate, 0-5 parts by weight of iron sulfate, 0-3 parts by weight of a complexing agent, 2-5 parts by weight of organic amine, 2-5 parts byweight of an early strength agent, 0-2 parts by weight of a pH regulator, 0.5-1 part by weight of a slag activator, 0.1-0.3 part by weight of a defoamer, and 2-8 part by weight of aluminum fluoride. The invention also provides a preparation and application of the liquid alkali-free setting accelerator. The liquid alkali-free setting accelerator provided by the invention is especially suitable forshotcrete, has wide adaptability to various kinds of cement, can improve the applicability of the alkali-free setting accelerator to cement, improves the strength of the shotcrete, and is more widelyapplied in various projects.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

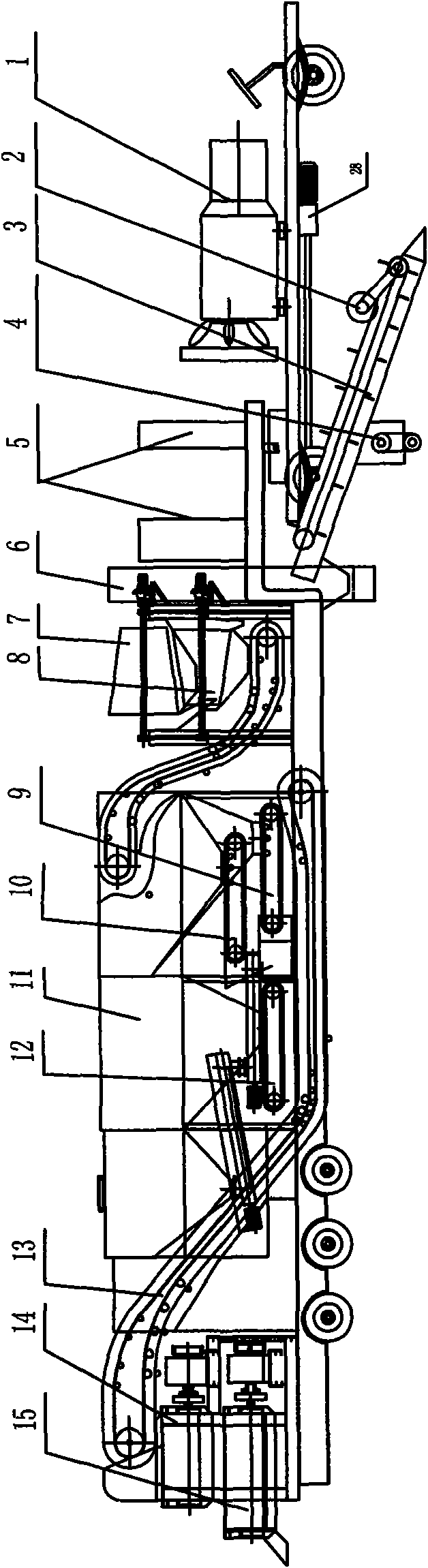

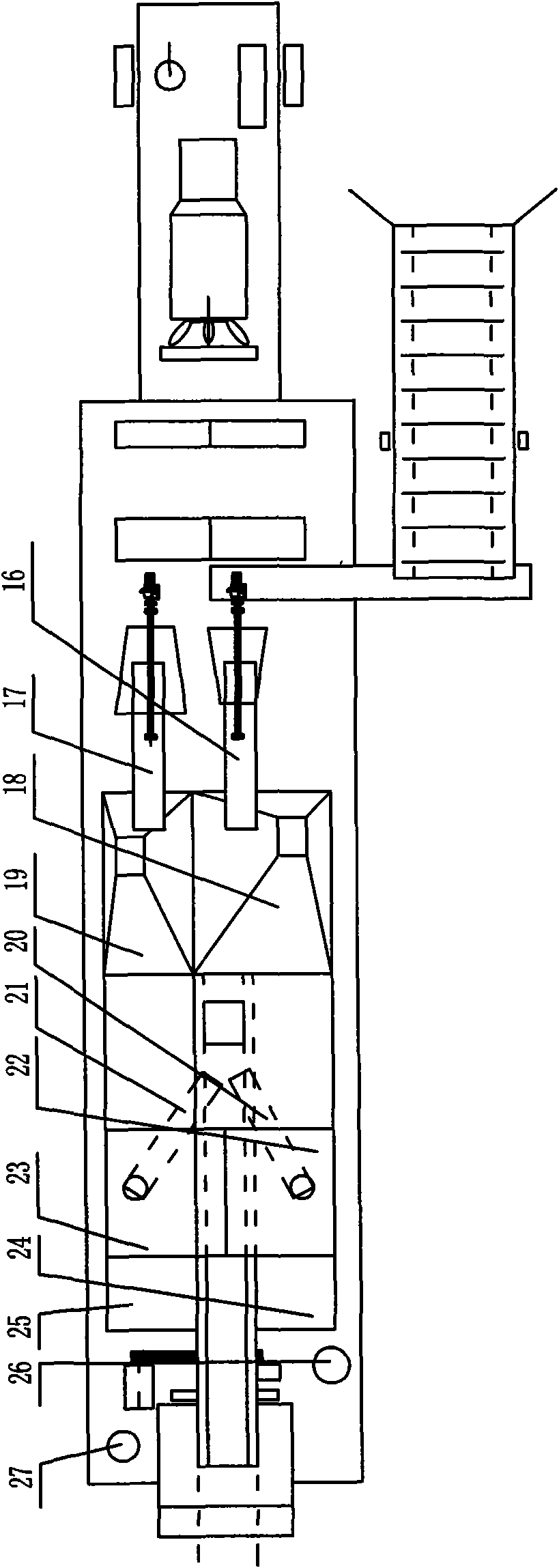

Asphalt cool recycled cement gravel mixed in place train and method for construction

The invention discloses an asphalt cool recycled cement gravel mixed in-place train and a method for construction. The train comprises a scraper feeder, and also comprises a generating unit, a power control cabinet, a water tank, a metering pump, an emulsion asphalt tank, an emulsion asphalt pump, a powder shifter, a mixer, a lateral charging belt conveyor and a main conveying belt which are arranged on the train body, wherein the train body is also provided with a cement tank, a mineral powder tank, an aggregate recycle bin and a new aggregate bin; cement and mineral powder metering spiral conveyors which are used for weight graduation and have discharge ports jointed with the main conveying belt, a recycled aggregate electronic feeder and a new aggregate electronic feeder are respectively arranged under discharge ports of each vessel; and the power control cabinet is in electrical connection with a running conversion motor on the scraper feeder, and is in electrical connection with the metering pump, the emulsion asphalt pump, the recycled aggregate and the new aggregate electronic feeders, and the cement and mineral powder metering spiral conveyers. The recycling technology does not require removing, crushing and heating scraps, shortens construction time, and saves materials and transportation cost.

Owner:HENAN TONGHE HIGHWAY MAINTENANCE PROJECT +1

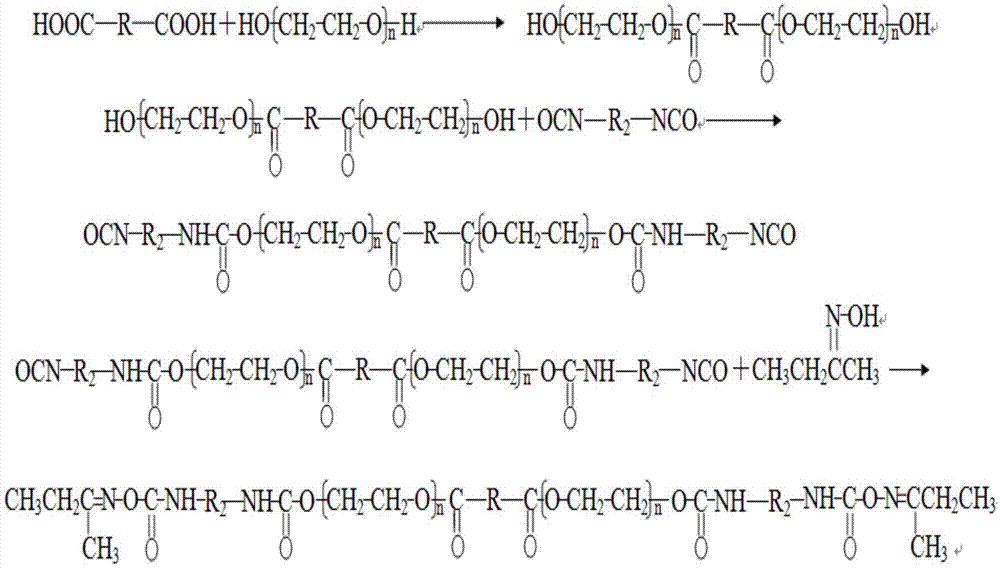

Water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and preparation method thereof

The invention relates to a water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and a preparation method thereof. The cold-recycling agent is prepared from the following components in parts by mass: 100 parts of emulsified asphalt and 10-20 parts of water-borne epoxy composite, wherein the water-borne epoxy composite comprises a component A and a component B, the component A is prepared from the following ingredients in parts by mass: 100 parts of water-borne epoxy emulsion, 10-25 parts of waterborne blocked polyurethane, 0.5-2 parts of associated thickener and 0.5-2 parts of coupler, and the component B is prepared from the following ingredients in parts by mass: 100 parts of an amine water-borne epoxy curing agent and 10-20 parts of accelerant. Compared with the prior art, the water-borne epoxy composite-containing emulsified asphalt cold-recycling agent belongs to a homogeneous system, has an excellent low-temperature flexibility, high-temperature stability, excellent water stability, good abrasion resistance and high early strength while the strength is improved, and the mixed material has excellent pavement performances and can be directly applied to the surface layer of pavement.

Owner:SHANXI PROVINCIAL RES INST OF COMM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com