Precast concrete short-limb shear wall provided with door windows and manufacturing method thereof

A technology of precast concrete and production method, applied in the direction of walls, building components, buildings, etc., can solve the problems of difficult to guarantee the quality of structural construction, complicated on-site construction procedures and management, unfavorable construction methods for the environment and energy saving, etc., to achieve easy construction quality. Guarantee, improvement of construction environment and conditions, effect of reducing construction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

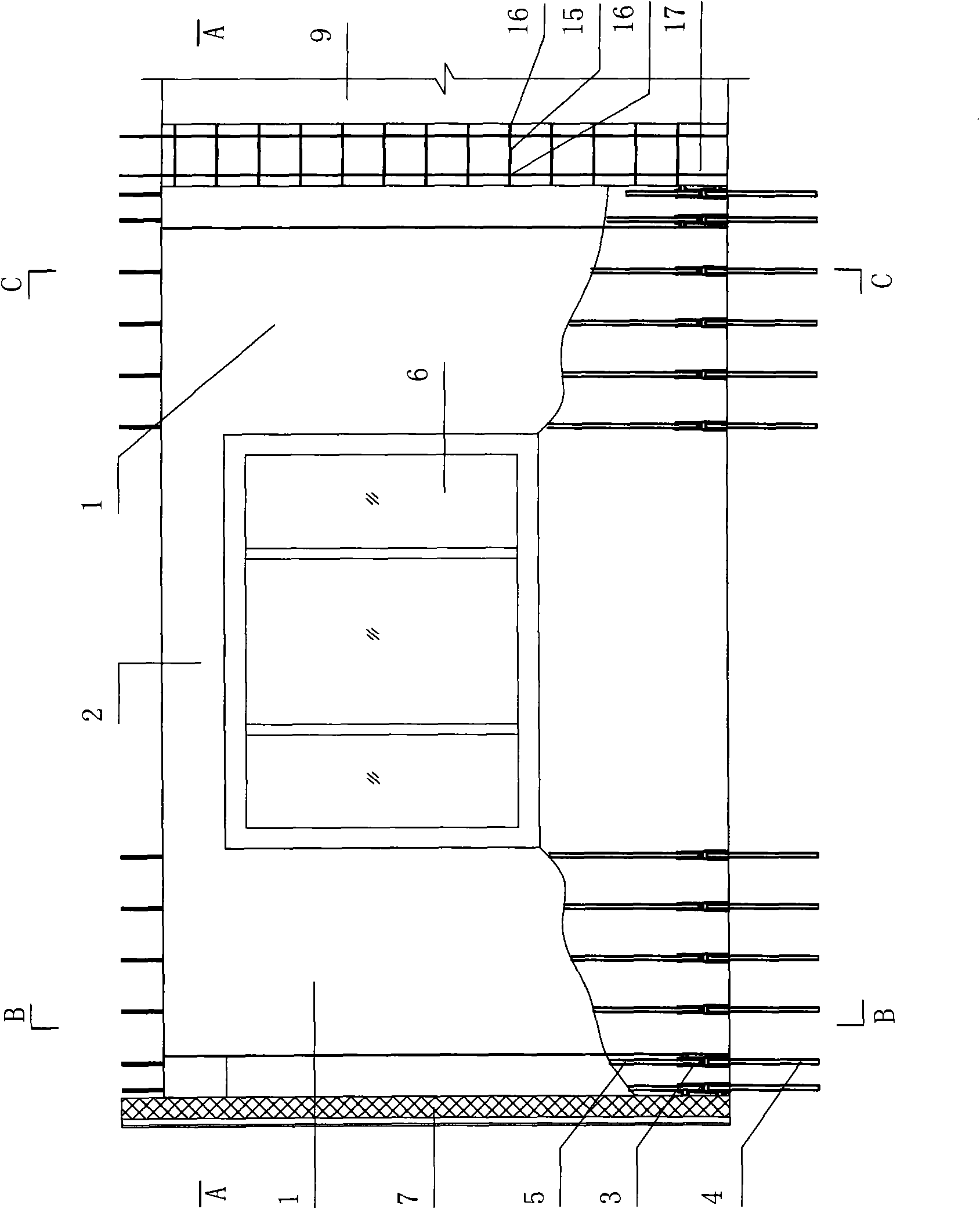

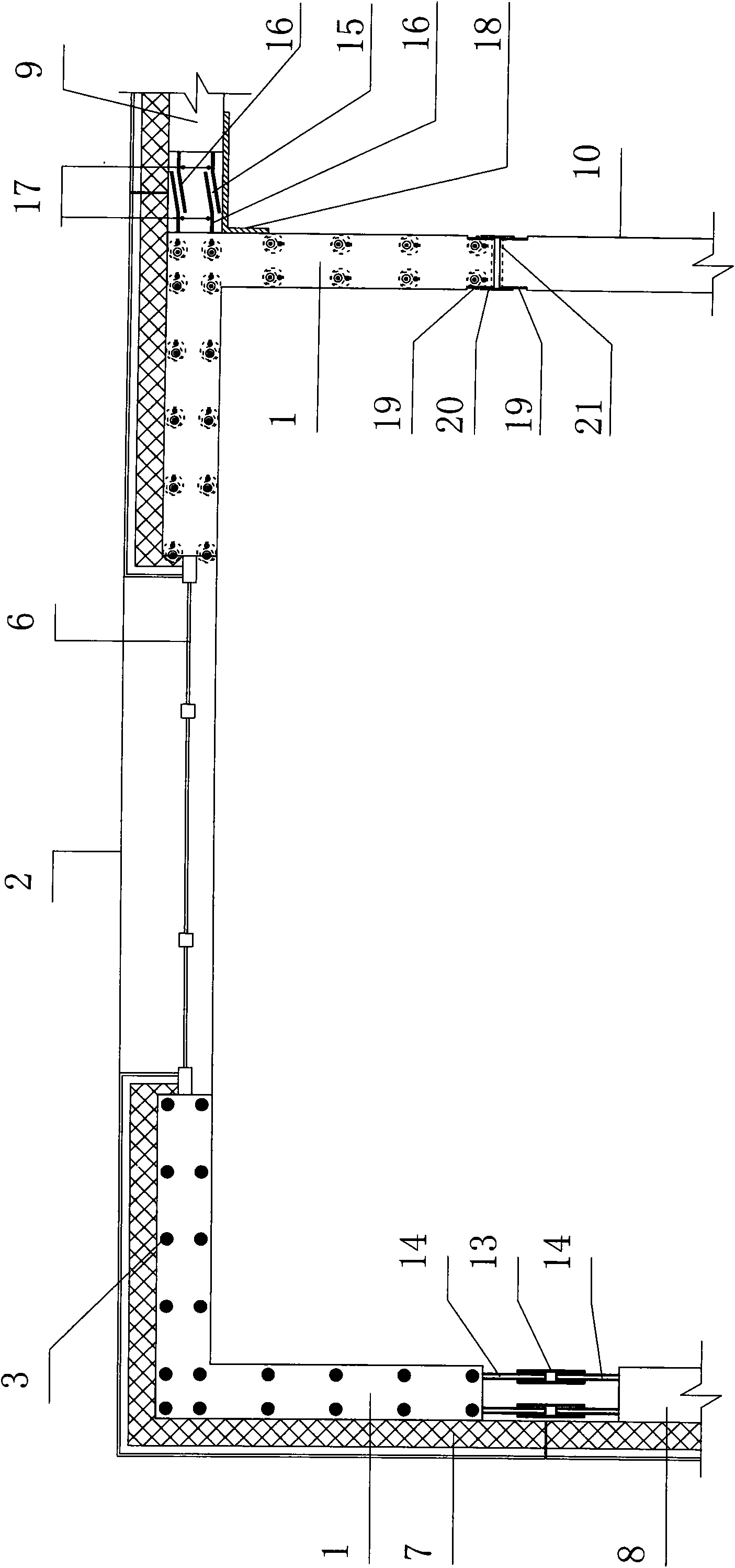

[0020] The prefabricated concrete short-leg shear wall with doors and windows comprises: a prefabricated concrete wall body, the wall body is connected with a connecting beam, the wall body has doors and windows, and the wall body is thermally insulated from the outer wall The layer and the decorative surface layer are connected, and the connection between the wall piers is connected by fabricated steel bars.

[0021] That is, the prefabricated concrete short limb shear wall structural parts are composed of wall limbs 1 and connecting beams 2, on which there are doors and windows 6, external wall thermal insulation layer and decorative surface layer 7. The ratio of the section height to thickness of the wall pier is 5 to 8, and the section shape of the wall pier can be in the shape of a "one". As an example, there are multiple connection methods listed in the drawings, and one or a combination of them may be used in actual design and construction as required.

Embodiment 2

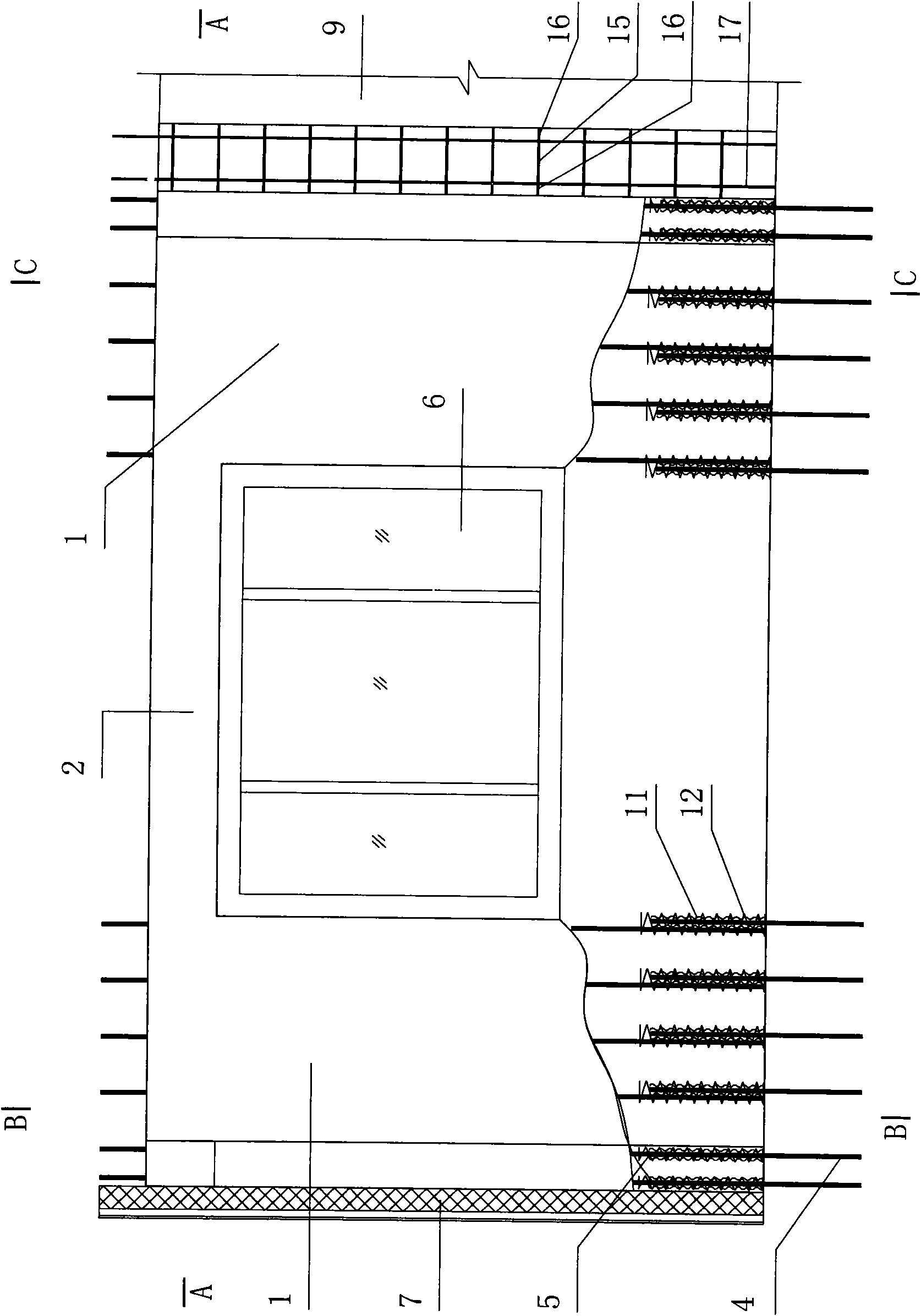

[0023] The above-mentioned precast concrete short-leg shear wall with doors and windows, the structural parts of the precast concrete short-leg shear wall are composed of wall piers 1 and connecting beams 2, which include doors and windows 6, external wall thermal insulation layers and decorative surface layers 7 . The ratio of the section height to thickness of the wall pier is 5 to 8, and the section shape of the wall pier can be "T" shape. As an example, there are multiple connection methods listed in the drawings, and one or a combination of them may be used in actual design and construction as required.

Embodiment 3

[0025] The above-mentioned precast concrete short-leg shear wall with doors and windows, the structural parts of the precast concrete short-leg shear wall are composed of wall piers 1 and connecting beams 2, which include doors and windows 6, external wall thermal insulation layers and decorative surface layers 7 . The ratio of the section height to thickness of the wall pier is 5-8, and the section shape of the wall pier can be "L" shape. As an example, there are multiple connection methods listed in the drawings, and one or a combination of them may be used in actual design and construction as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com