Patents

Literature

860results about How to "Improve product qualification rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

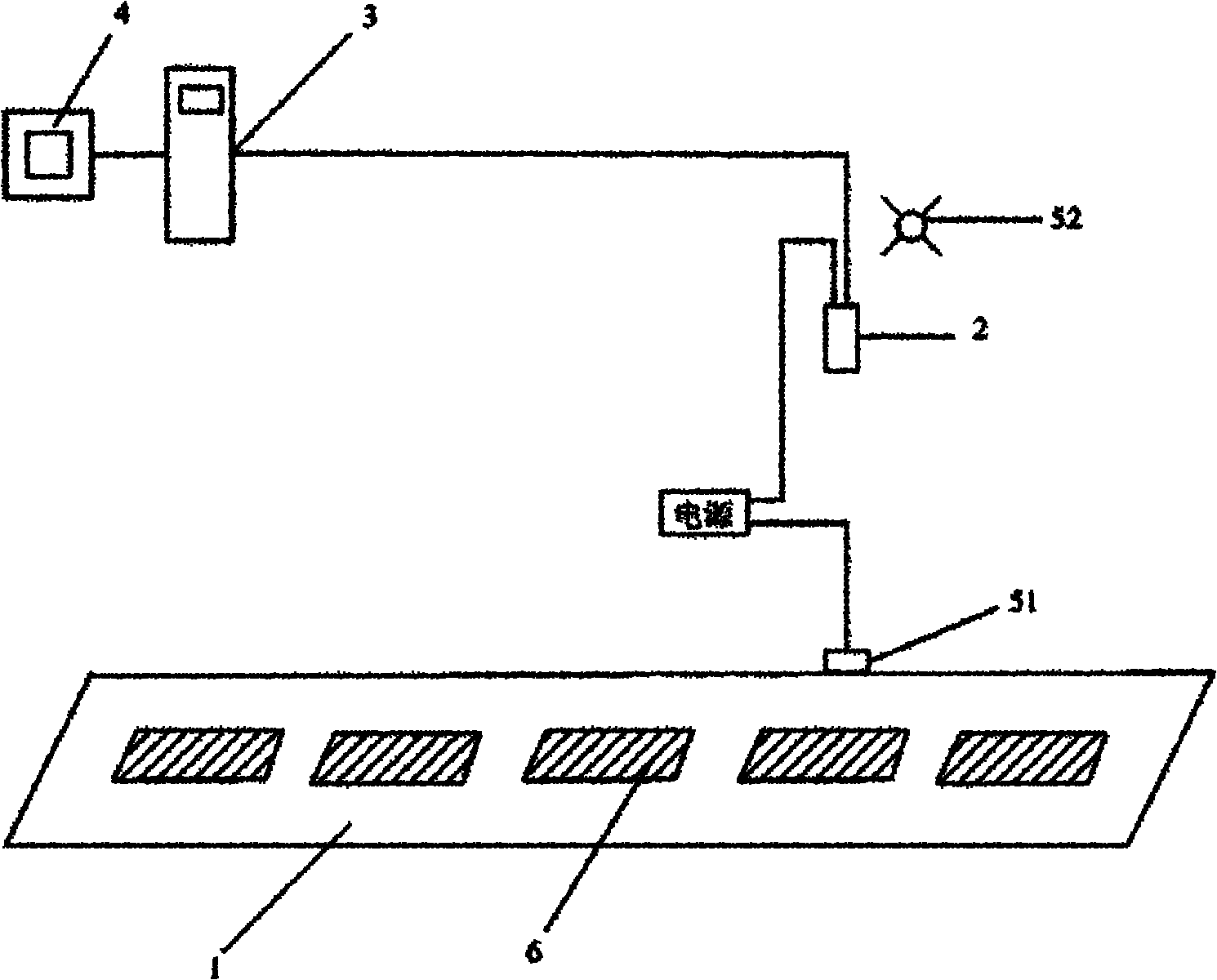

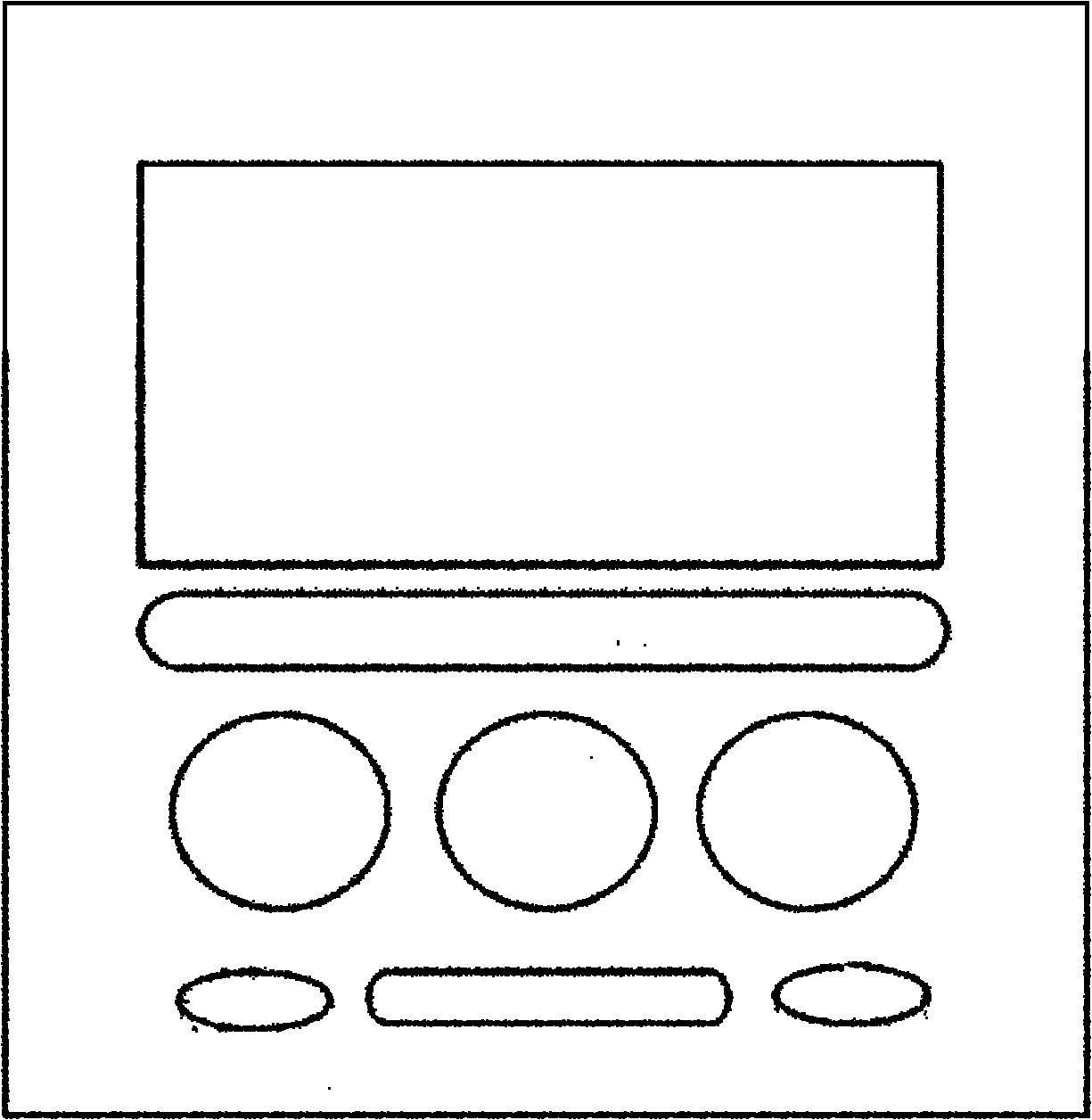

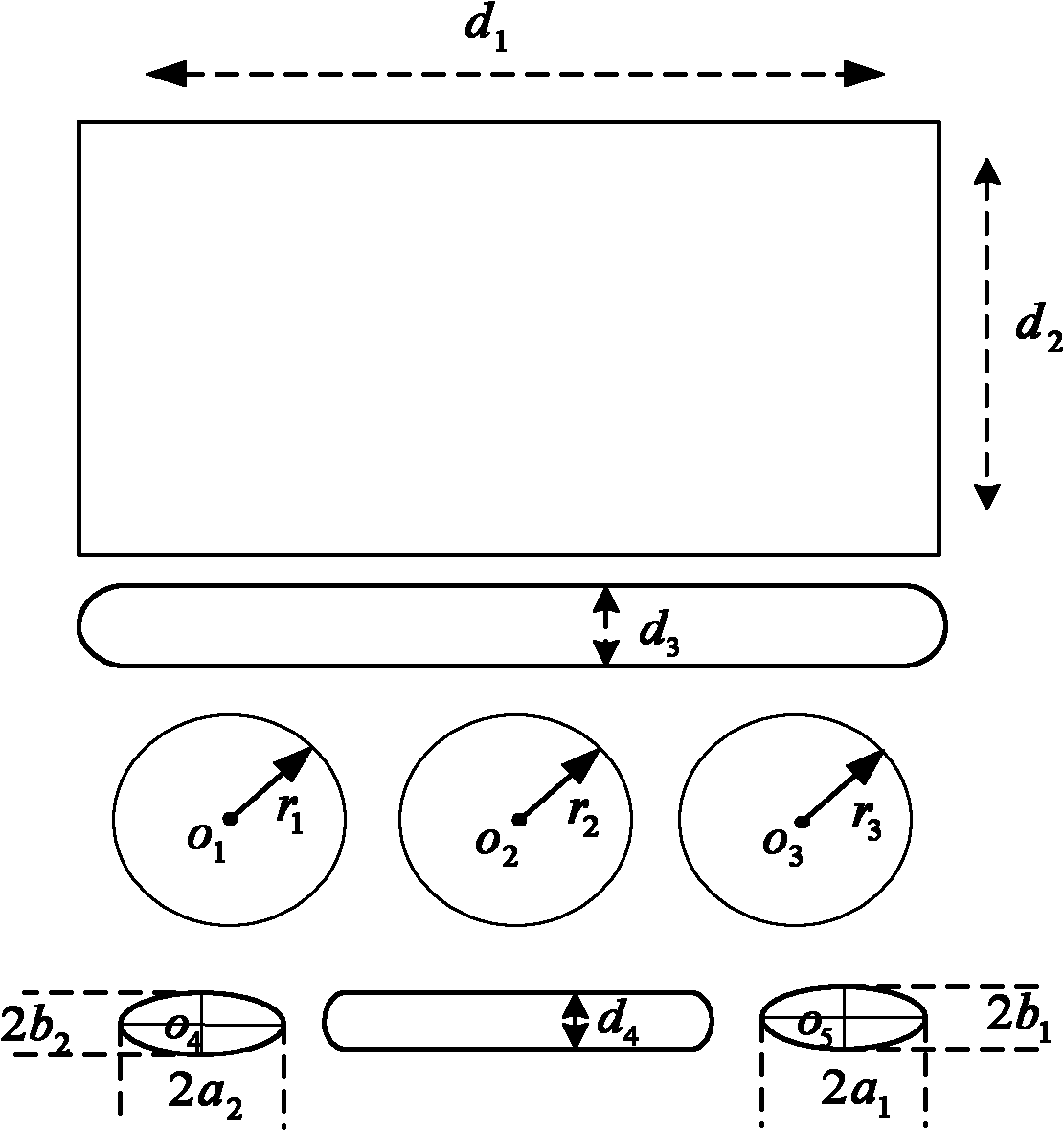

Automatic on-line detection method and device for size of automobile parts based on machine vision

InactiveCN102116610AReduce testing labor intensityHigh precisionBiological modelsUsing optical meansProduction lineImaging processing

The invention relates to the on-line detection technical field by utilizing machine vision and an image processing technology, in particular to an automatic on-line detection method and a device for size of automobile parts based on machine vision, aiming at solving the problems that the labor intensity is high and the detection quality is poor by adopting an artificial on-line detection method for size of automobile parts. An industrial camera is utilized for shooting a clear, complete and flaw-free standard image for the automobile part running in an automatic production line, the image is utilized as a standard image template and is stored in a computer, the precision range of detection parameters for the automobile part is set according to user requirements, the image of the on-line running automobile part, which is shot in real time by the industrial camera, is transmitted to the computer and is compared with the standard image template and is processed, the size of the automobile part can be computed, and if the precision of the part is lower than the setting requirements, the computer starts and gives an alarm, so as to prompt operational staff to treat inferior-quality products. The method and the device have high detection precision to the automobile parts and have rapid speed, so as to greatly reduce the labor intensity for artificial detection.

Owner:CHANGZHOU SITEEN AUTOMOTIVE TRIM SYST +1

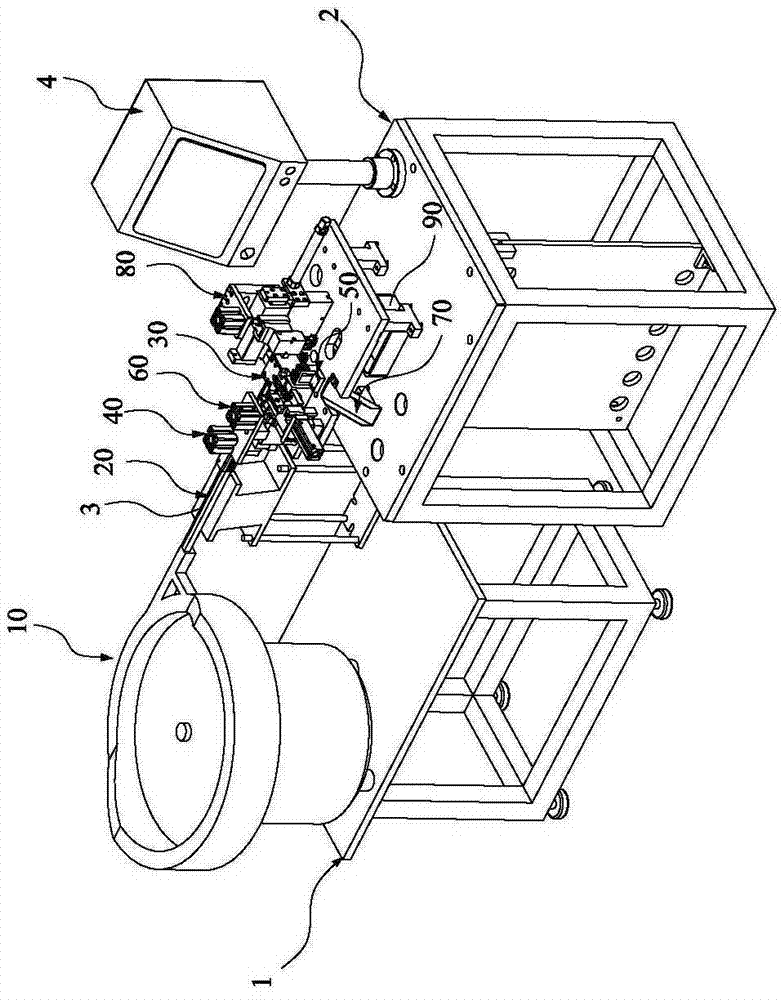

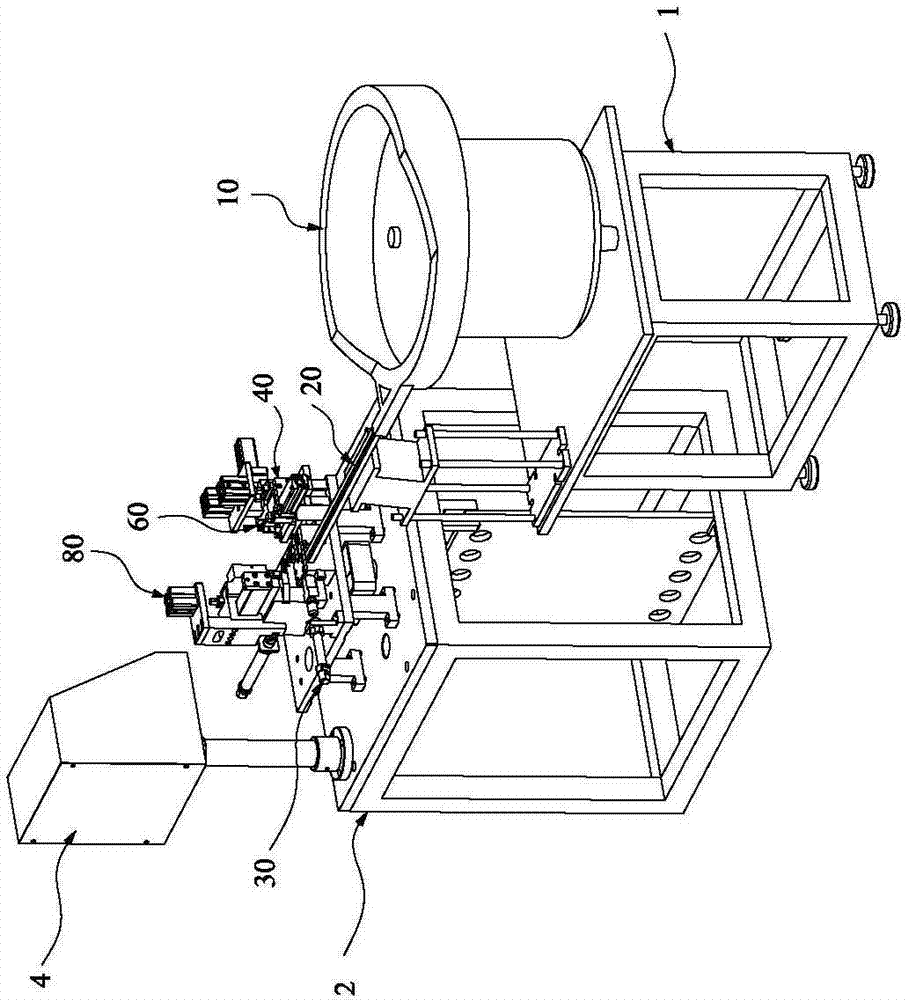

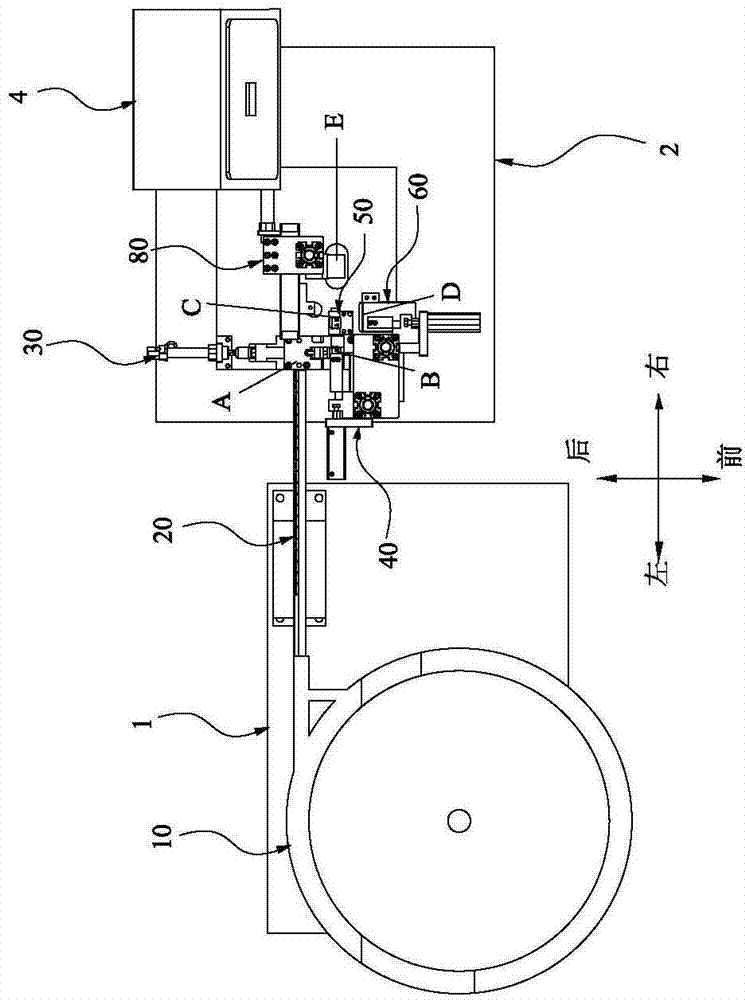

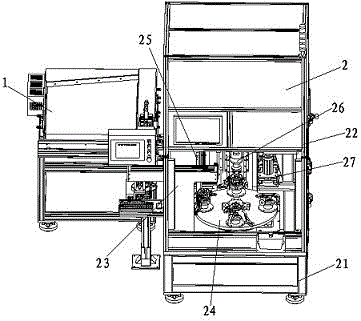

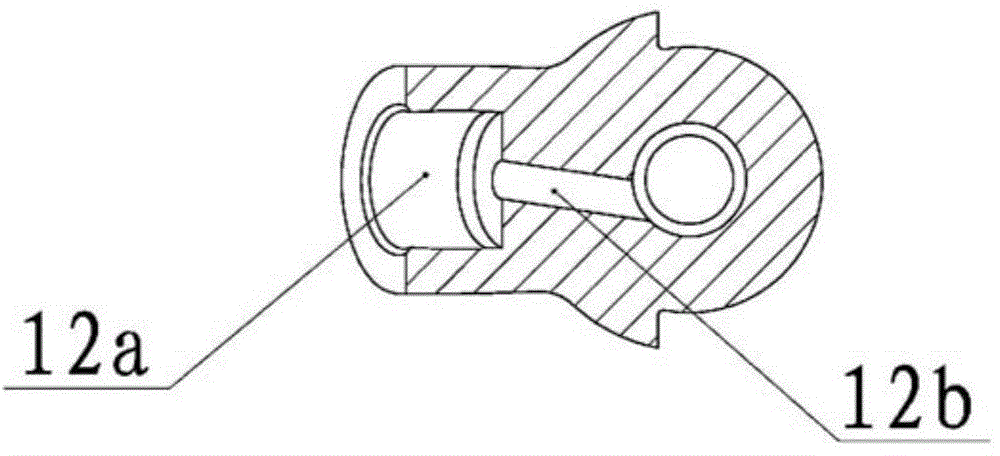

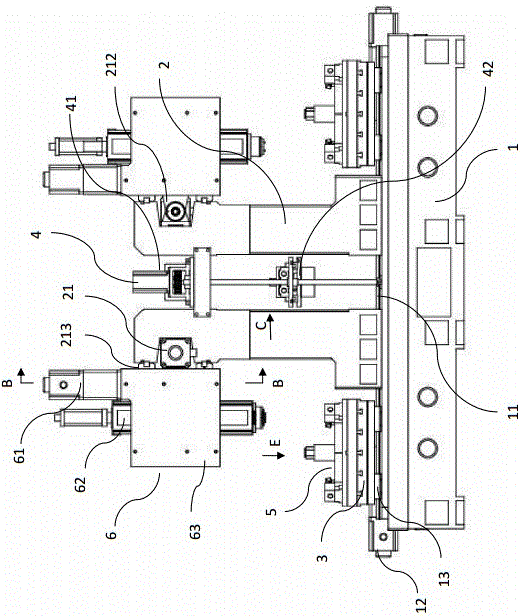

Automatic deformation screening machine for pins of connector housings

InactiveCN103041995AThe detection process is fastAvoid many deficiencies of human judgmentSortingEngineeringManipulator

The invention discloses an automatic deformation screening machine for pins of connector housings. The automatic deformation screening machine comprises a vibrating disk mounting rack, a vibrating disk, a vibrating feeding channel, a test bench, a pushing mechanism, a feeding manipulator, a detecting mechanism, a first delivery manipulator, a qualified product delivery channel, a second delivery manipulator and an unqualified product collecting tank. When the pins of the connector housings are detected, the vibrating disk regularly conveys the connector housings to a feeding station A at the tail end of the vibrating feeding channel in a shaking process; the pushing mechanism conveys the connector housings to an appointed sucking and feeding station B; the feeding manipulator conveys the connector housings to a detecting station C; the pins of the connector housings are detected by the detecting mechanism; when the pins are good in quality and do not deform, the first delivery manipulator is used for adsorbing the pins to a first unloading station D, and the qualified product delivery channel discharges the pins; and the second delivery manipulator is used for clamping the pins to a second unloading station E and putting the pins into the unqualified product collecting tank when the pins of the connector housings deforms.

Owner:DONGGUAN KECHENDA ELECTRONICS TECH

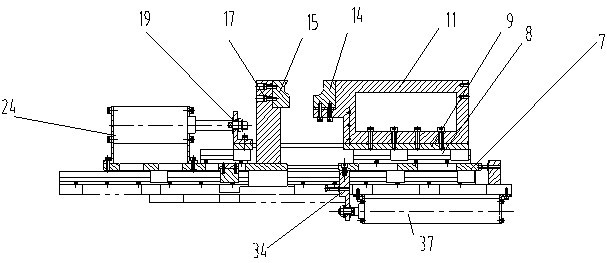

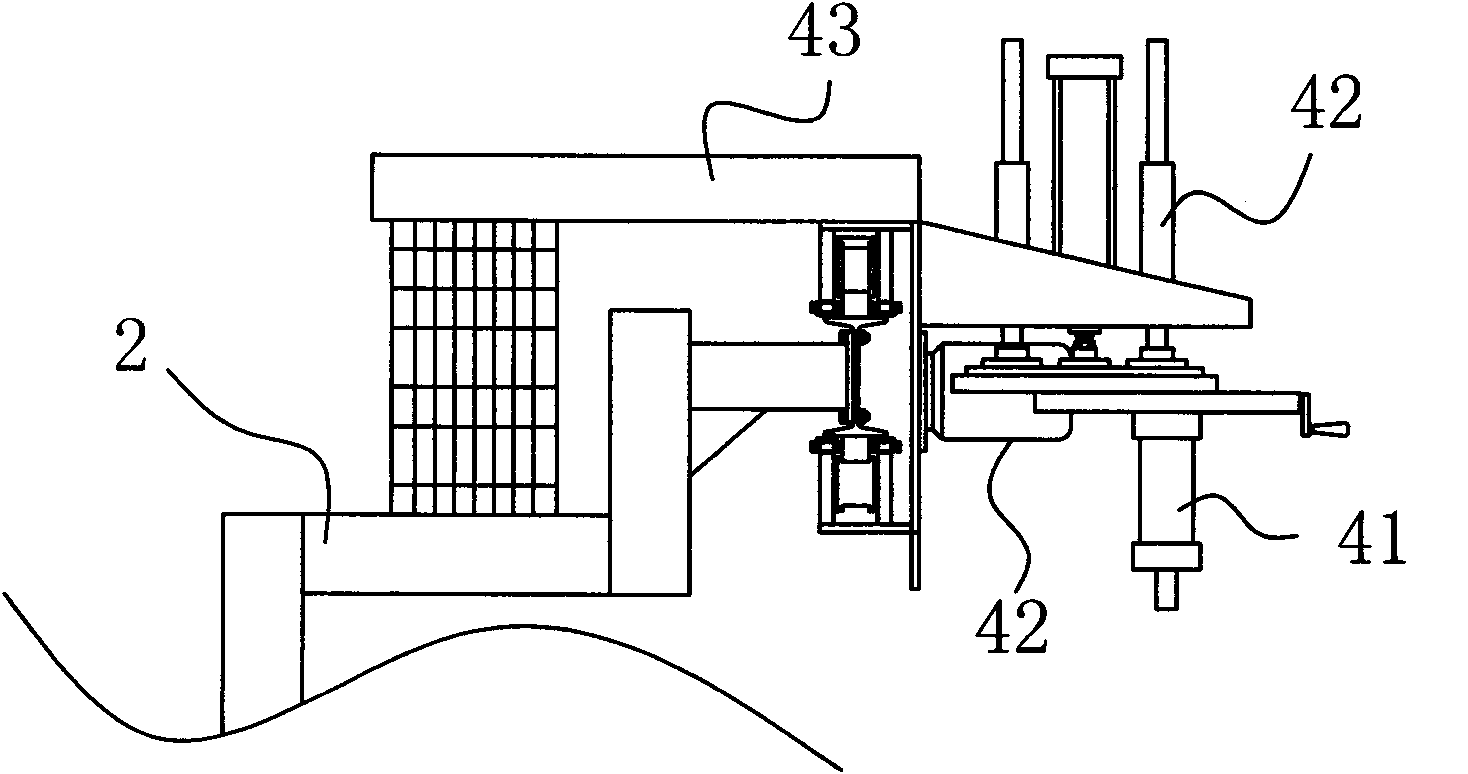

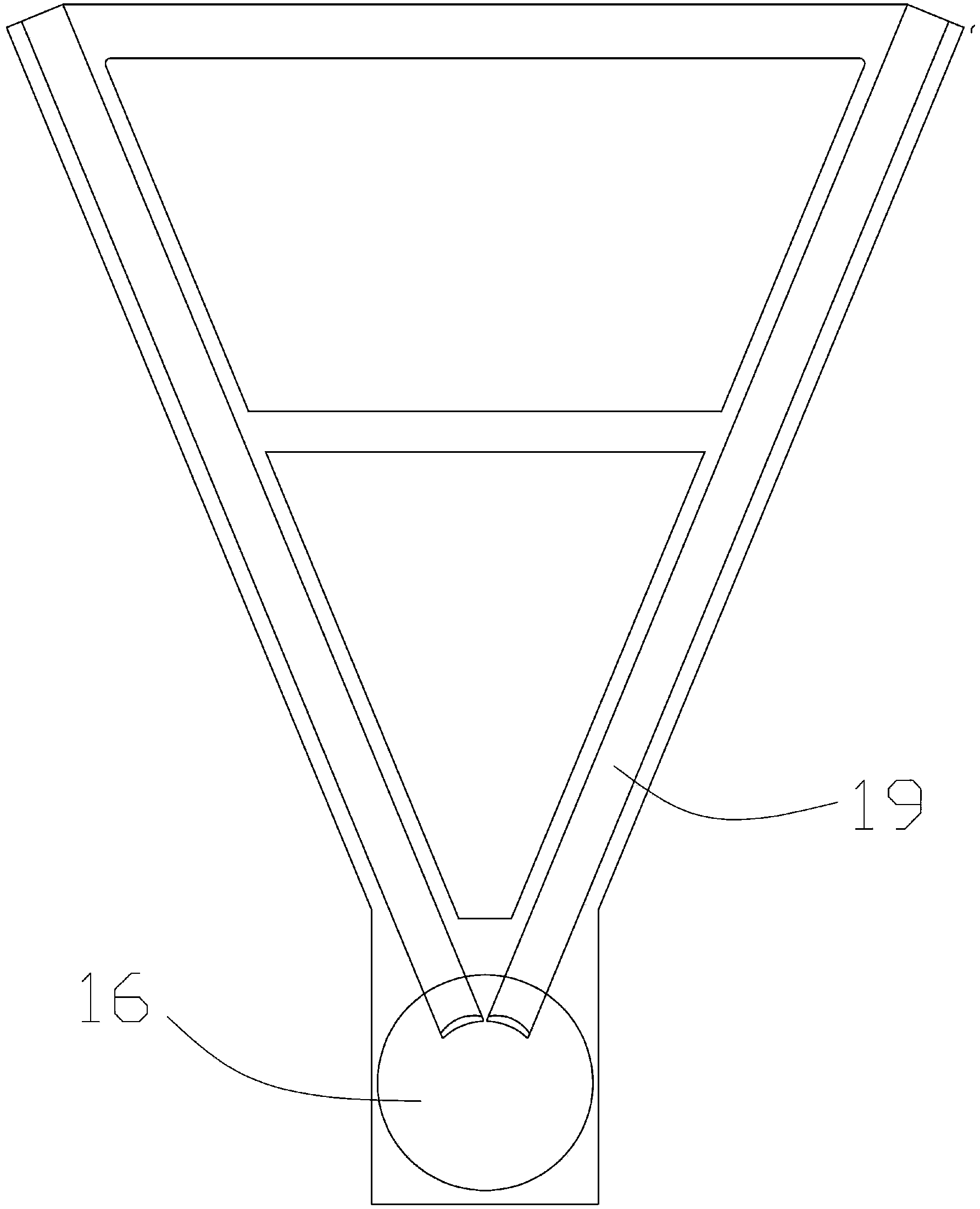

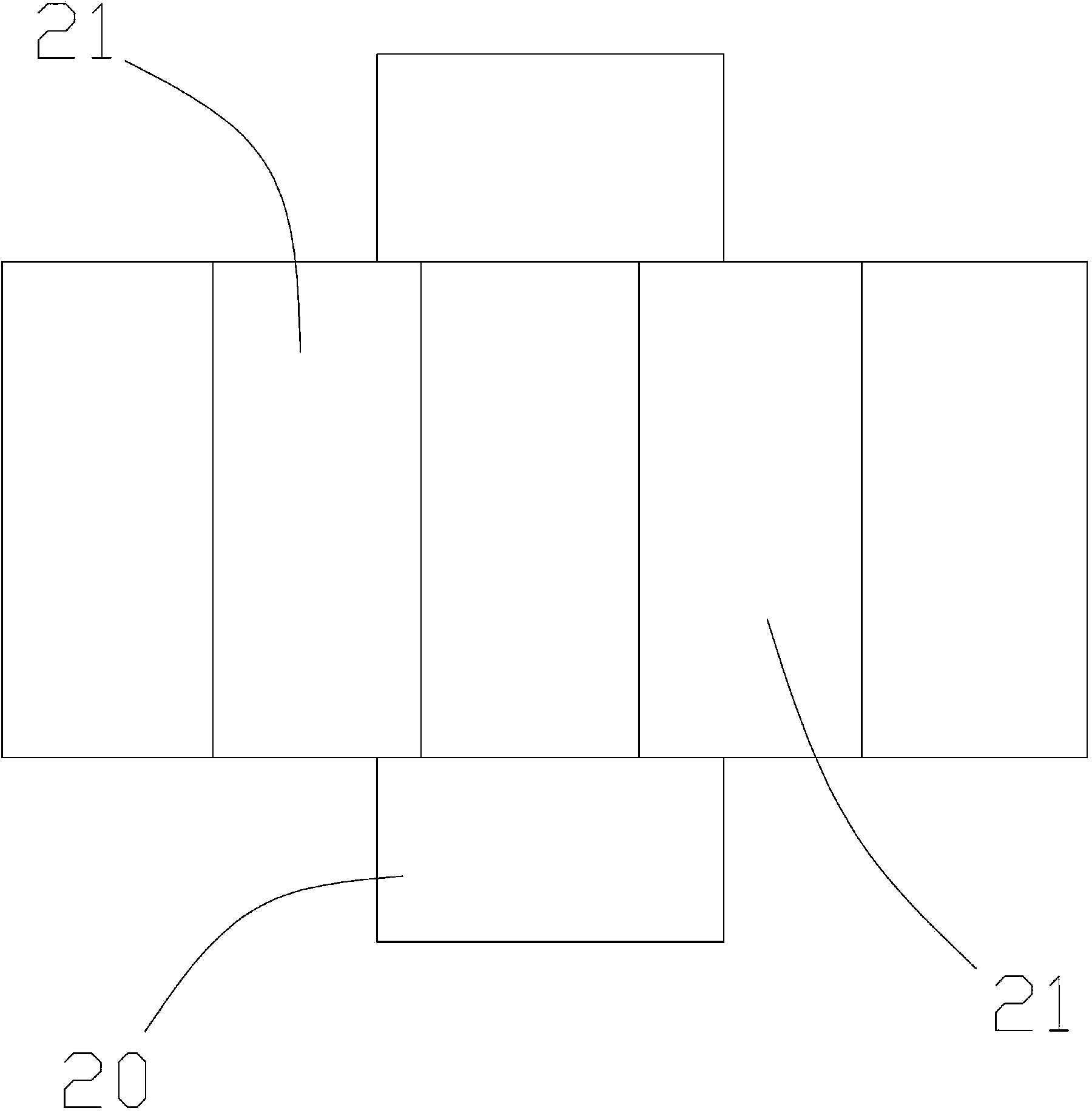

Automatic drilling and tapping machine tool for valves

InactiveCN102528458ALow costIncrease productivityFeeding apparatusOther manufacturing equipments/toolsEngineeringMachine tool

The invention provides an automatic drilling and tapping machine tool for valves, which comprises a blanking mechanism, a workpiece locating mechanism, an automatic drilling mechanism, an automatic tapping mechanism, a workpiece clamping mechanism, a main clamping cylinder, a tapping mechanism feed cylinder, a drilling mechanism transmission lead screw, a workbench feed cylinder and a drilling mechanism feed servo motor. The blanking mechanism is perpendicularly disposed on a machine tool base, and the workpiece clamping mechanism is arranged at the bottom of the blanking mechanism and connected with the main clamping cylinder and the workbench feed cylinder. The automatic drilling mechanism comprises a pair of automatic drilling power heads which are coaxially and oppositely arranged. The automatic tapping mechanism is parallel to the automatic drilling mechanism in position and comprises a pair of automatic tapping power heads which are coaxially and oppositely arranged. The automatic drilling power heads are connected with the servo motor through the drilling mechanism transmission lead screw, and the automatic tapping power heads are connected with the cylinders. The automatic drilling and tapping machine tool for valves performs processing of four-station automatic drilling and tapping, processing of different parts can be achieved in one process, and production efficiency and product percent of pass are improved.

Owner:RES INST OF ZHEJIANG UNIV TAIZHOU

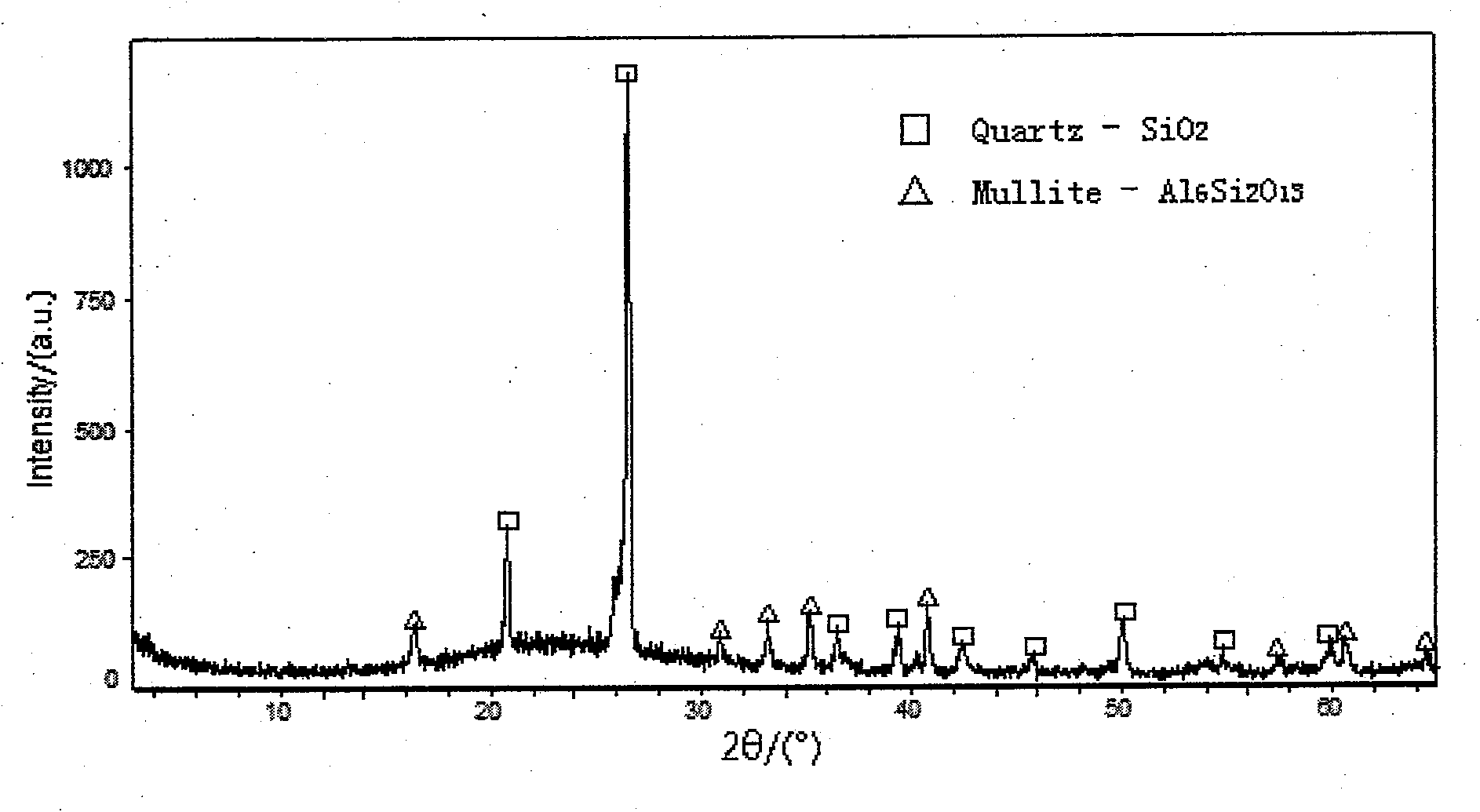

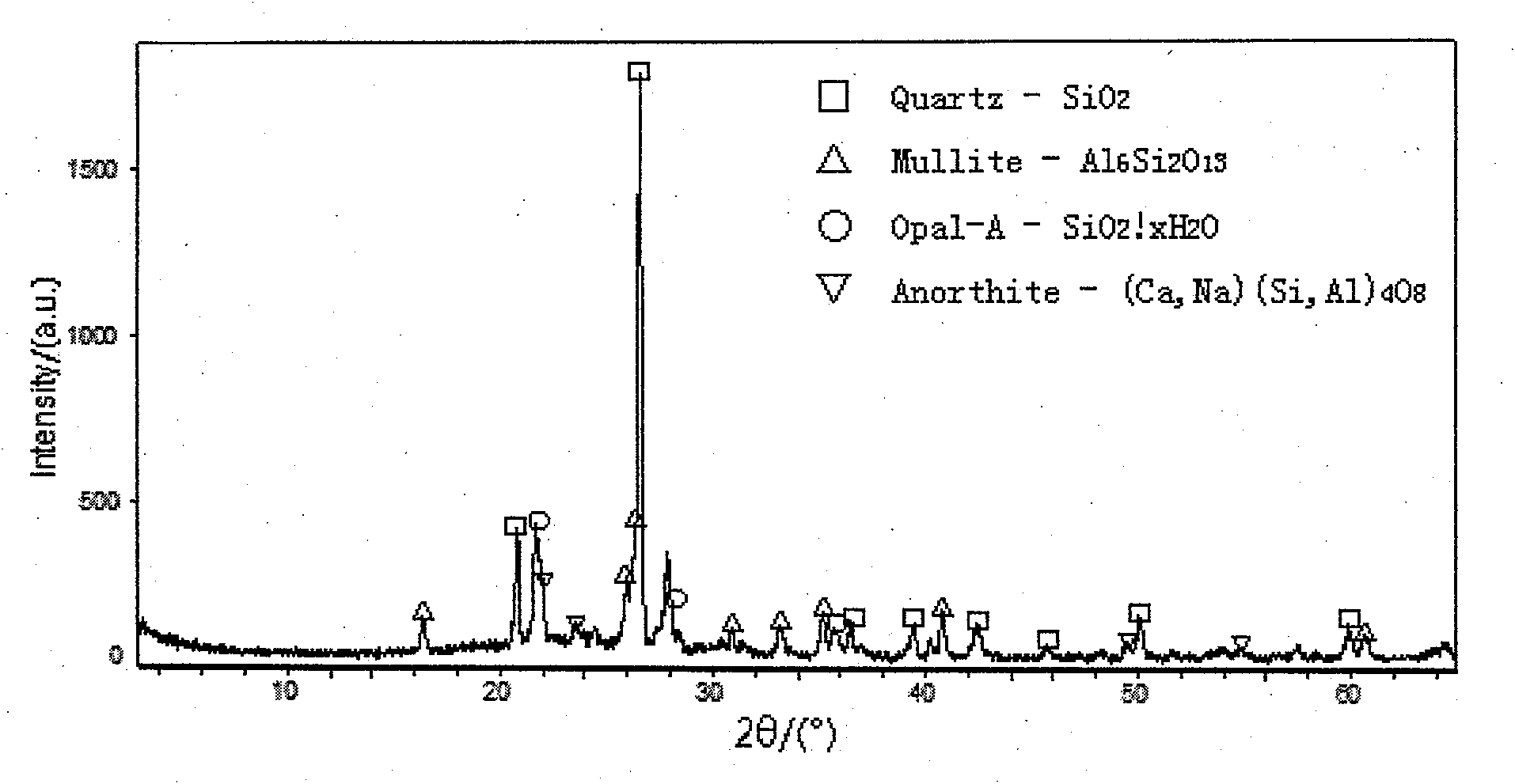

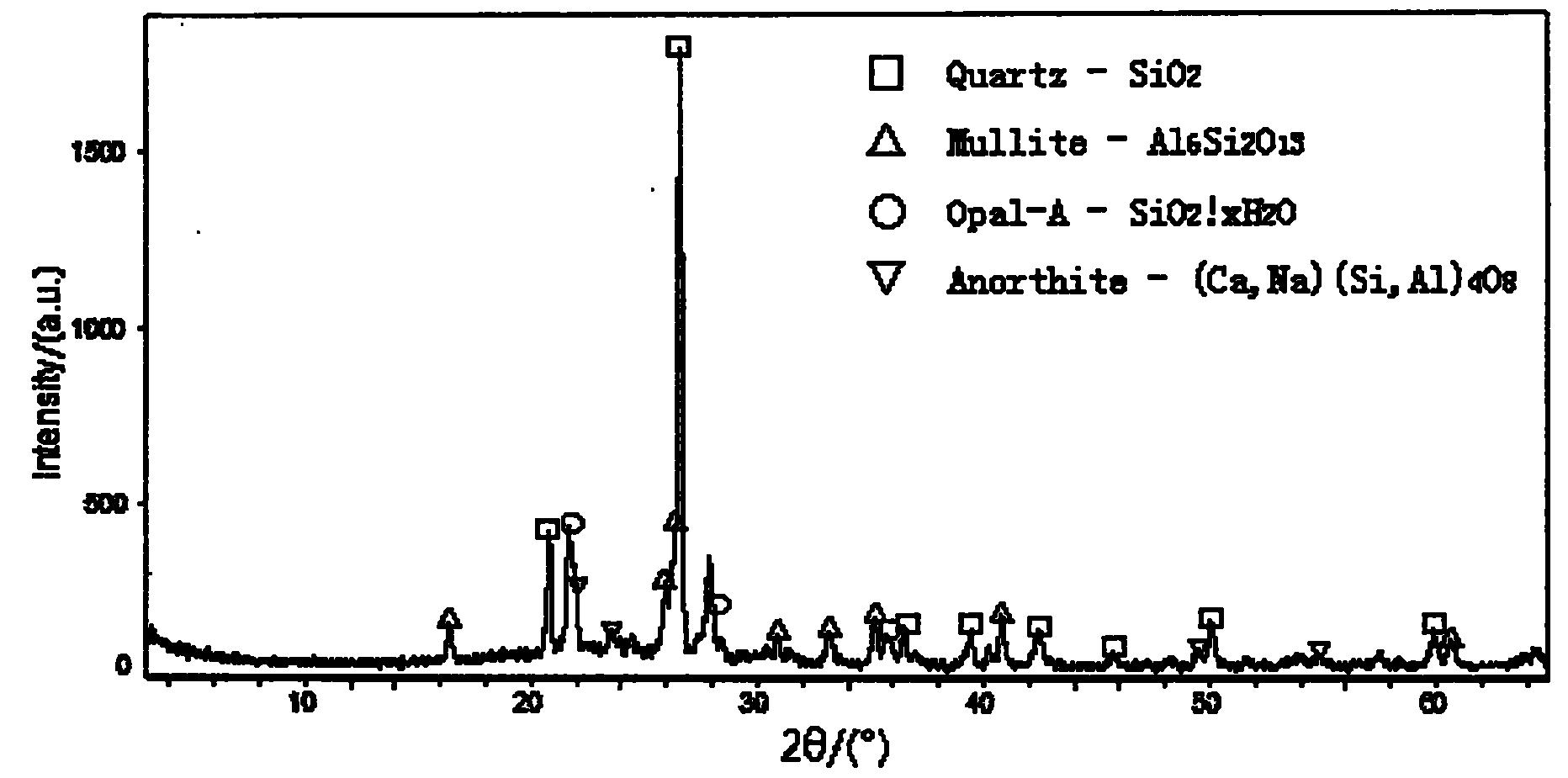

Fine-pottery sanitary ceramic body and manufacturing method thereof

ActiveCN101811858AReduce hygroscopic swellingHigh coefficient of thermal expansionClaywaresGranularityMullite

The invention relates to a fine-pottery sanitary ceramic body and a manufacturing method thereof and belongs to the technical field of ceramic products, which is used for reducing the deformation of a sanitary ceramic product and improving the quality of glaze. The fine-pottery sanitary ceramic body is characterized in that a body raw material comprises the following components in part by mass: 10 to 30 parts of ball clay, 30 to 60 parts of kaoline, 5 to 15 parts of porcelain clay, 5 to 15 parts of quartz and 5 to 15 parts of wollastonite, wherein the kaoline comprises 10 to 25 calcined kaoline. In the manufacturing method, the raw materials and the adding proportion of the fine-pottery body are preferably selected, the crystal phase content of mullite, quartz and the like is controlled, and the glass phase content and the high-temperature plastic deformation are reduced so as to fulfill the aim of reducing the deformation of fine-pottery sanitary ceramics; while reducing the hygroscopic expansion of the body, the manufacturing method improve thermal expansion coefficient of the body at the temperature of 200 DEG C to make the glaze bear high compressive stress, thereby improving the anti-cracking performance of products and ensuring enough long service life. Through the refinement of slurry granularity, the method remarkably reduces the occurrence of disadvantage of glaze pinholes, does not need to reduce the pinholes by using engobe, simplifies a production process, and improves the production efficiency and the qualification rate of the products.

Owner:HUIDA SANITARY WARE

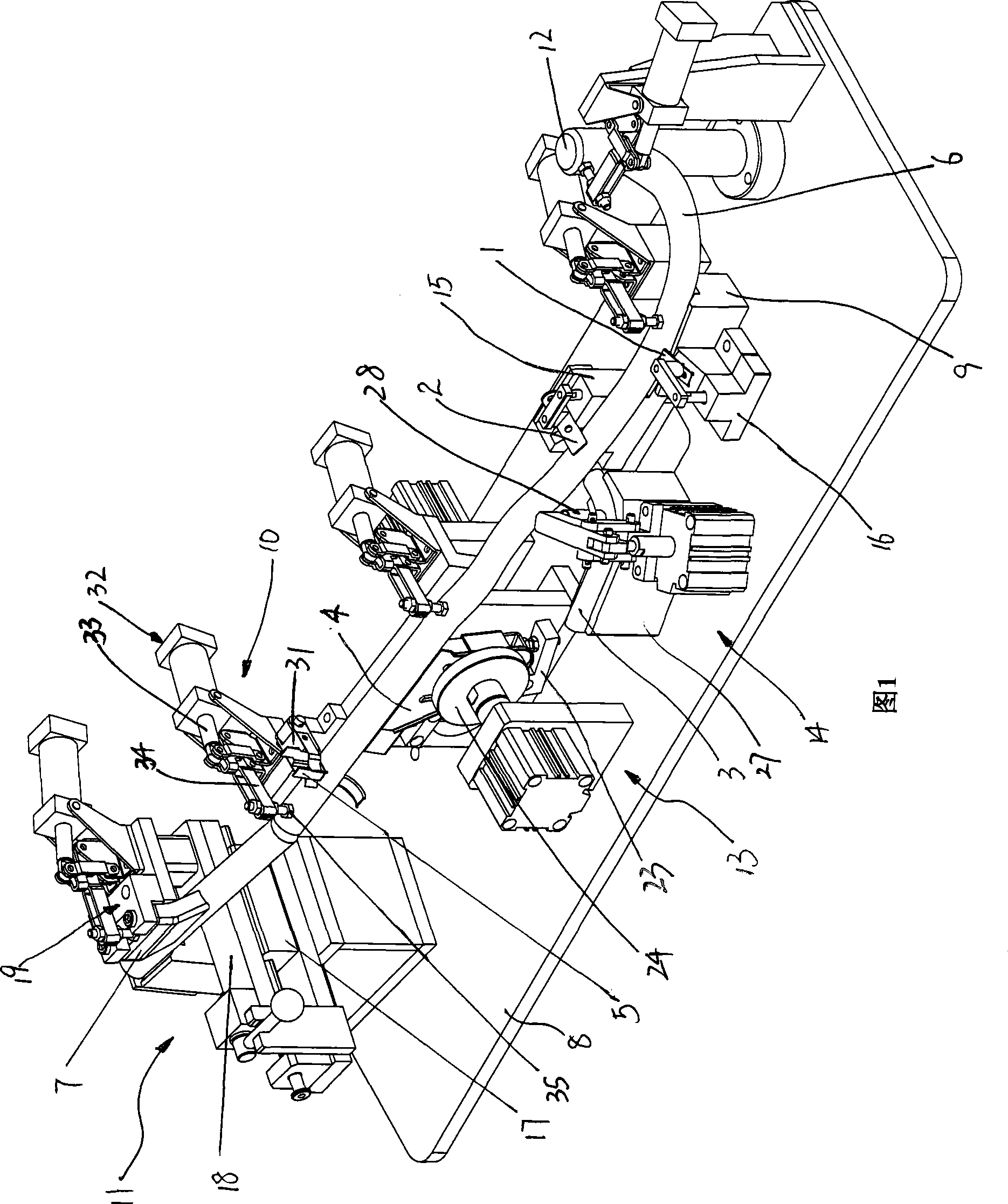

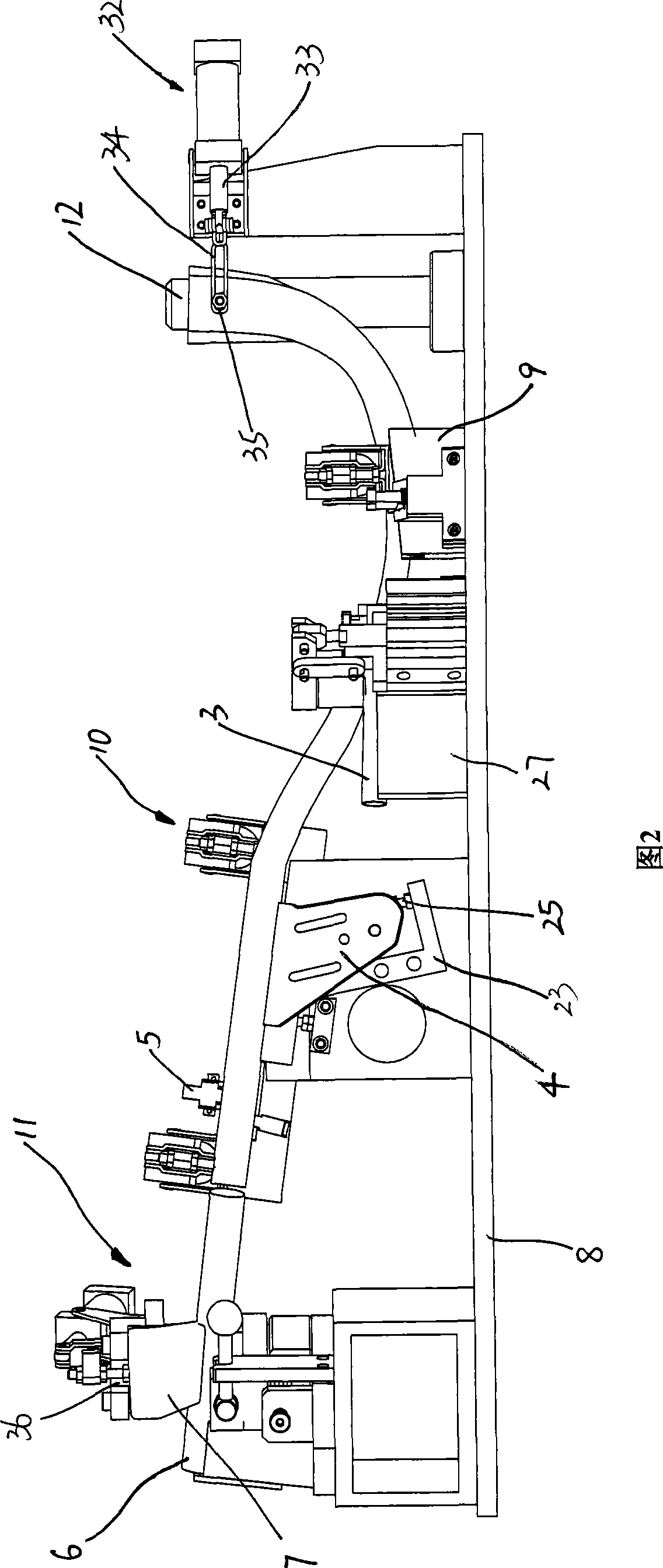

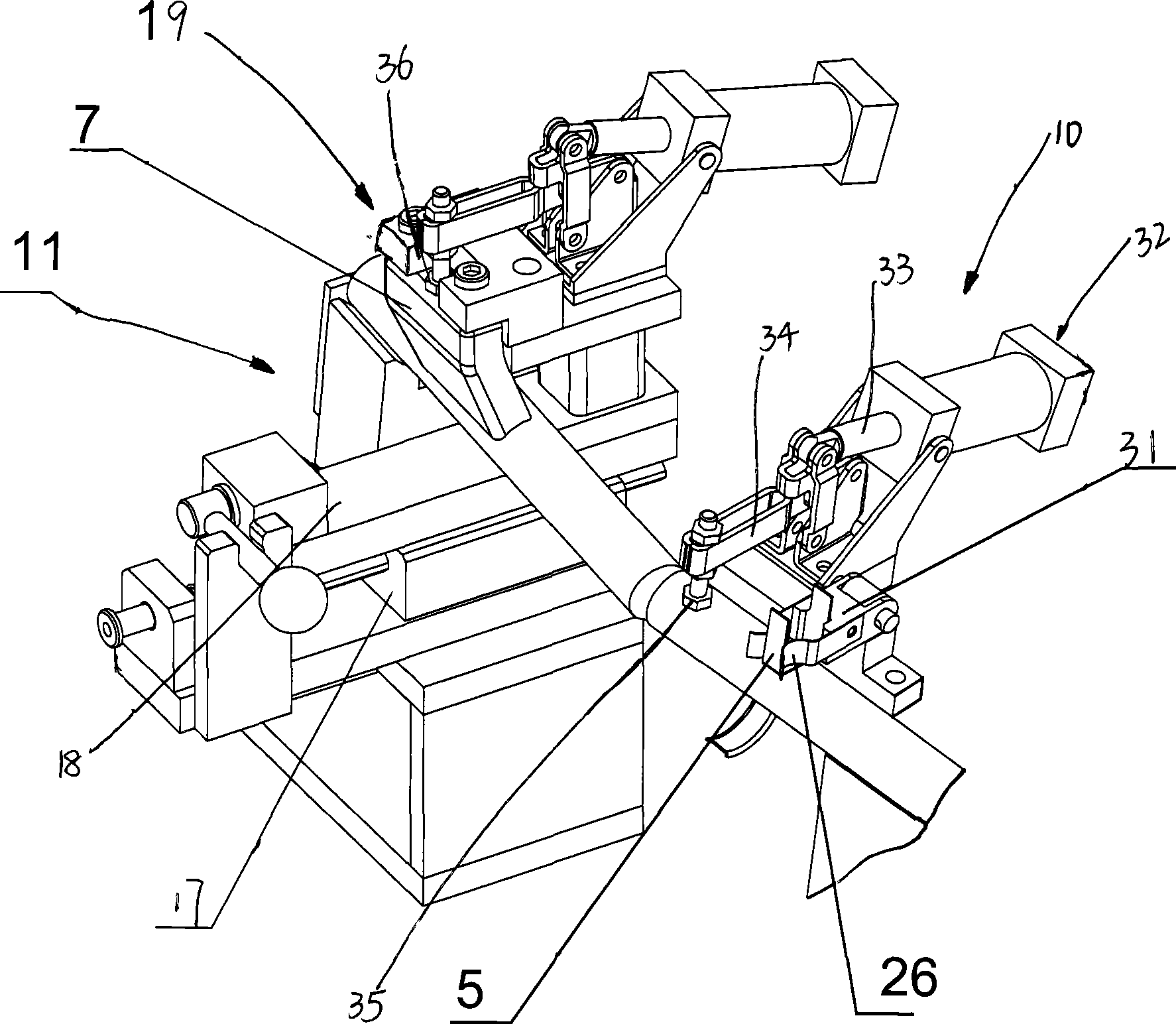

Welding clamp of winding pipe assembly

InactiveCN101376201AAccurate locationQuick positioning clampingWelding/cutting auxillary devicesAuxillary welding devicesFuel tankEngineering

The invention relates to a welding fixture of bent pipe components, which comprises a pedestal, a supporting module fixedly arranged on the pedestal and used for supporting workpieces to be welded, and a plurality of clamping devices with the parts clamped on the surfaces of the workpieces to be welded used for fixing the workpieces to be welded. A cylindrical positioning block is fixedly arranged at the front part of the pedestal, and an oil tank pressure plate fixing seat is arranged at the rear part of the pedestal; a power hanging frame fixing seat is also fixedly arranged between the oil tank pressure plate fixing seat and the positioning block; and a branch pipe fixing seat is also fixedly arranged on the pedestal in front of the power hanging frame fixing seat. The welding fixture can rapidly position and clamp components to be welded, thereby avoiding the complex preparatory work before welding, so as to allows the multi-step welding during the one-time process of clamping, and improve work efficiency; meanwhile, the invention can ensure accurate positions among the components when welding, and improve processing precision and qualified rate of the product.

Owner:庄添财

Method for performing neutral electronickelling following magnesium alloy chemical nickeling

InactiveCN101560662AImprove bindingHarm reductionLiquid/solution decomposition chemical coatingSuperimposed coating processBiological activationFluoride

The invention discloses a method for performing neutral electronickelling following magnesium alloy chemical nickeling, which comprises the technical steps as follows: (1) surface treatment of magnesium alloy material: performing surface treatment to the magnesium alloy material by adopting the prior art; (2) acid membrane removal: removing the membrane by using fluoride-containing acid solution; (3) alkaline erosion: performing surface erosion by using fluoride-excluding alkaline solution; (4) activation: performing surface activation by using fluoride-containing solution; (5) chemical nickeling; (6) thermal treatment; (7) subsequent neutral nickeling; and (8) regular nickeling. According to the method, neutral electronickelling is performed following magnesium alloy chemical nickeling so that double-layer nickel is covered on the magnesium alloy base material. The method has the advantages of high bonding force, good uniformity and dense property, strong wearing resistance and corrosion resistance, and simple technical process and convenient operation. In the whole process, alkaline-copper electroplating and chromium are not needed, thus reducing harm to environment and human.

Owner:李远发

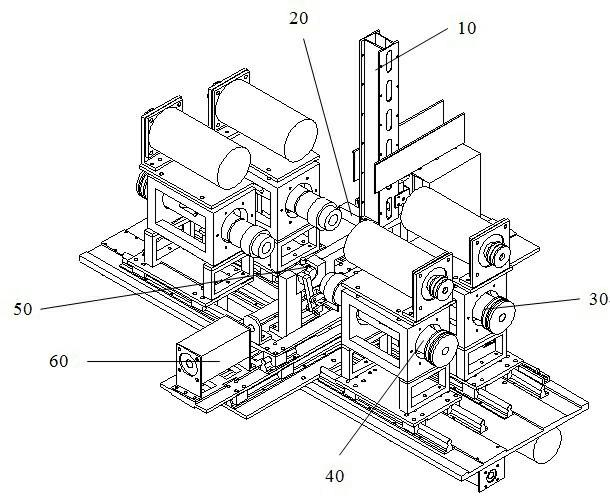

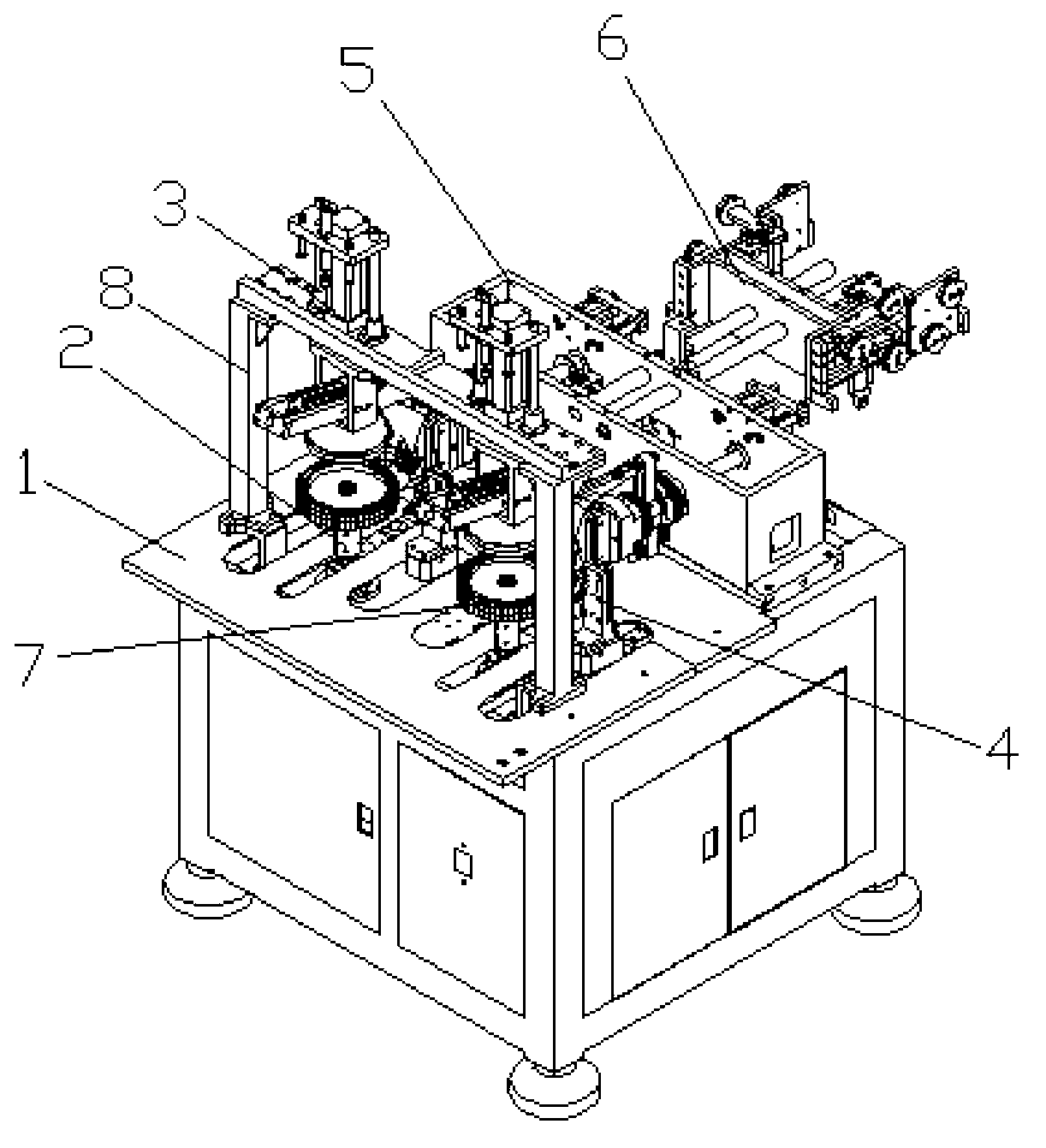

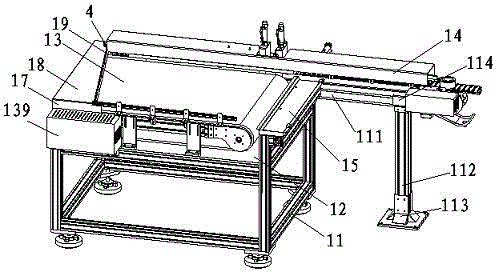

Automatic wire winding machine of motor stator of electric car

InactiveCN103312097AEasy to operateImprove product qualification rateElectric machinesManufacturing dynamo-electric machinesWire frameWinding machine

The invention provides an automatic wire winding machine of a motor stator of an electric car and belongs to the technical field of machinery. The automatic wire winding machine comprises a worktable, wherein an indexing mechanism, a wire clamping and shearing mechanism and a protection plate reshaping mechanism are arranged at the front part of the worktable; a main shaft box flying fork wire winding and arranging mechanism is arranged in the middle part of the worktable; a wire frame tension mechanism is arranged at the rear part of the worktable; the wire clamping and shearing mechanism is arranged above the indexing mechanism through a large bracket; the protection plate reshaping mechanism is arranged at one side of the indexing mechanism; the wire frame tension mechanism is connected with the main shaft box flying fork wire winding and arranging mechanism; and the main shaft box flying fork wire winding and arranging mechanism is connected with the indexing mechanism. The automatic wire winding machine disclosed by the invention is simple and convenient to operate and high in product yield; sizes are convenient to replace; a high-groove full product can be wound; and when a plurality of wires are wound in parallel, equipment is basically not vibrated, and the stability is good.

Owner:TAIZHOU BOYA AUTOMATION EQUIP TECH

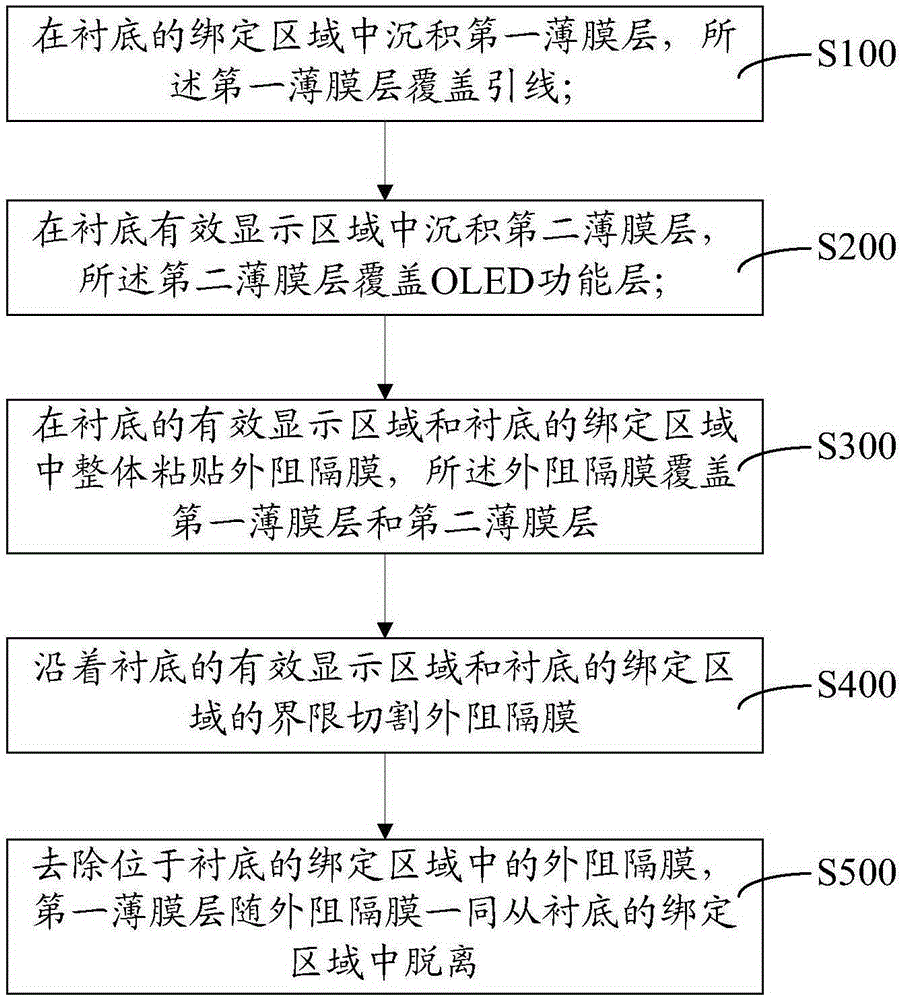

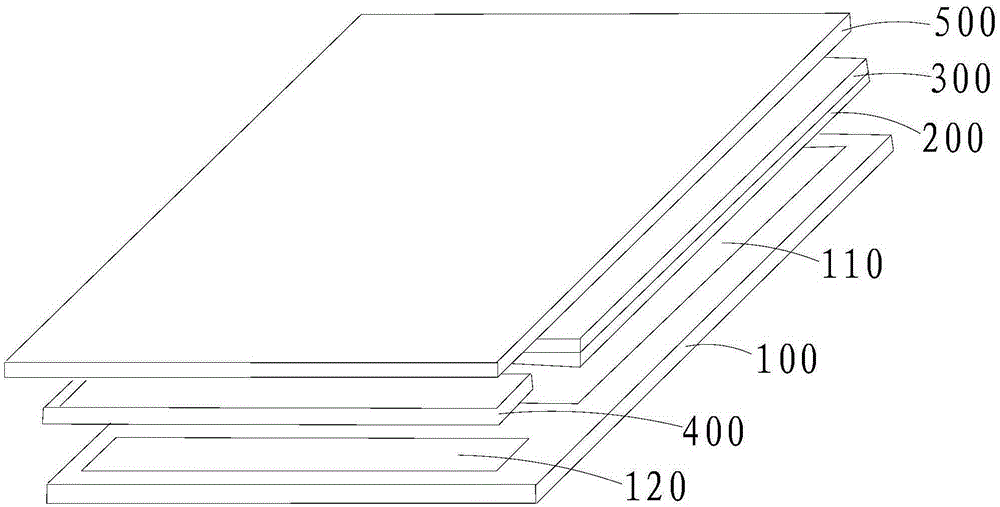

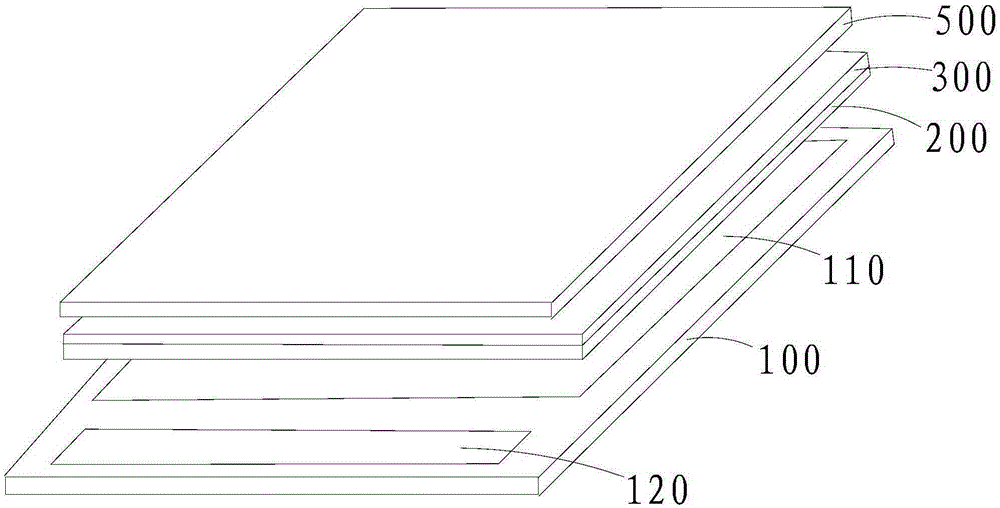

Packaging method of OLED (organic light emitting diode) display panel

ActiveCN105322104AImprove production efficiencyExtend your lifeSolid-state devicesSemiconductor/solid-state device manufacturingLight-emitting diodeSeparation process

The invention discloses a packaging method of an OLED (organic light emitting diode) display panel. The method comprises the following steps: depositing a first film layer in a binding area of a substrate, wherein the first film layer covers a lead; depositing a second film layer in an effective display area of the substrate, wherein the second film layer covers an OLED functional layer; integrally adhering an outer obstruction film in the effective display area of the substrate and the binding area of the substrate, wherein the outer obstruction film covers the first film layer and the second film layer; cutting the outer obstruction film along a boundary of the effective display area and the binding area of the substrate; and removing the outer obstruction film in the binding area of the substrate, wherein the first film layer is separated from the effectively display area along with the obstruction film. The outer obstruction film is adhered in an integral pasting manner, so that the adhesion efficiency and adhesion precision of the outer obstruction film are effectively improved, damage on the lead in the binding area during the separation process of the outer obstruction film is avoided, the service life of the OLED display panel is prolonged, and the application safety is improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

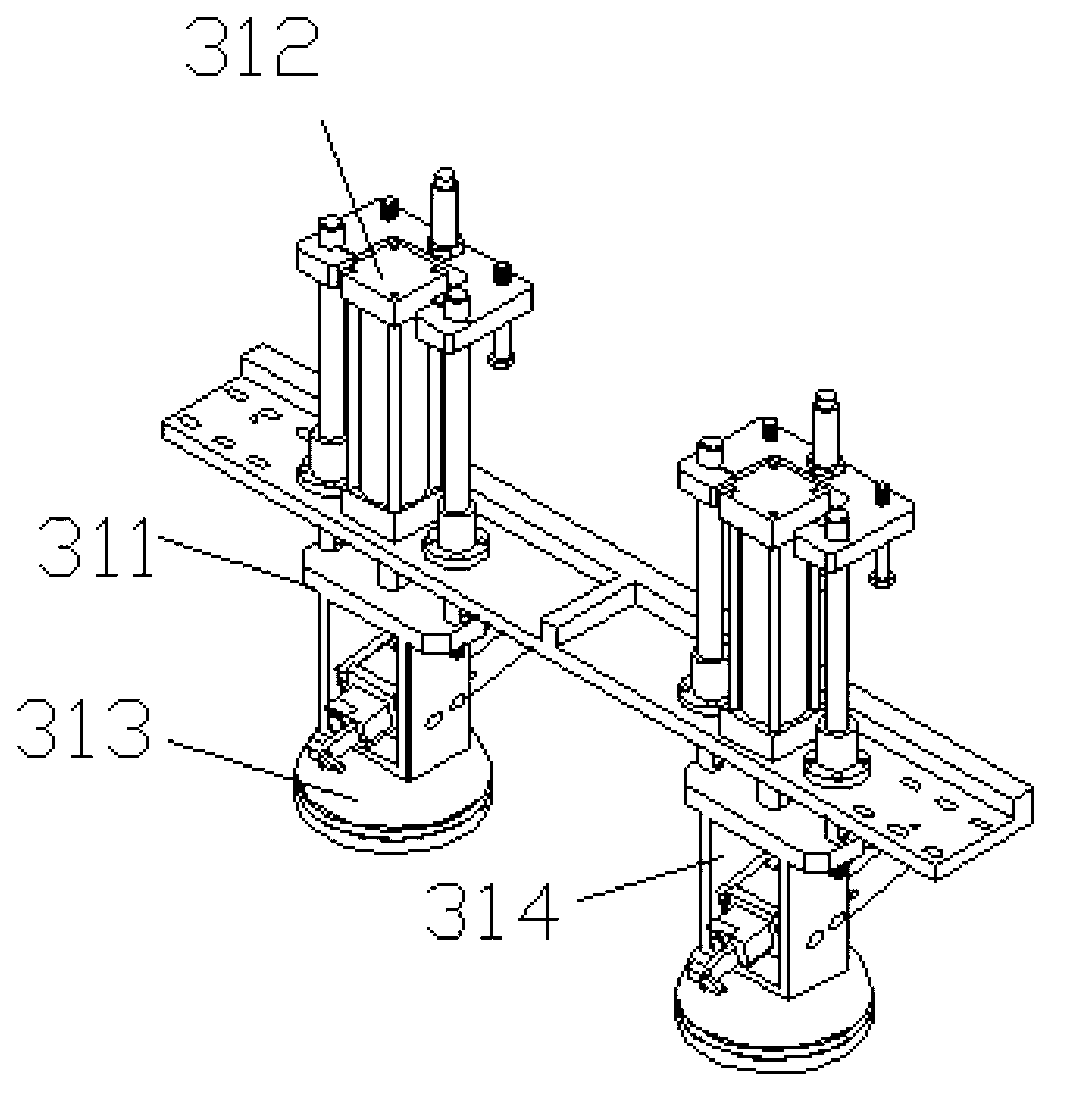

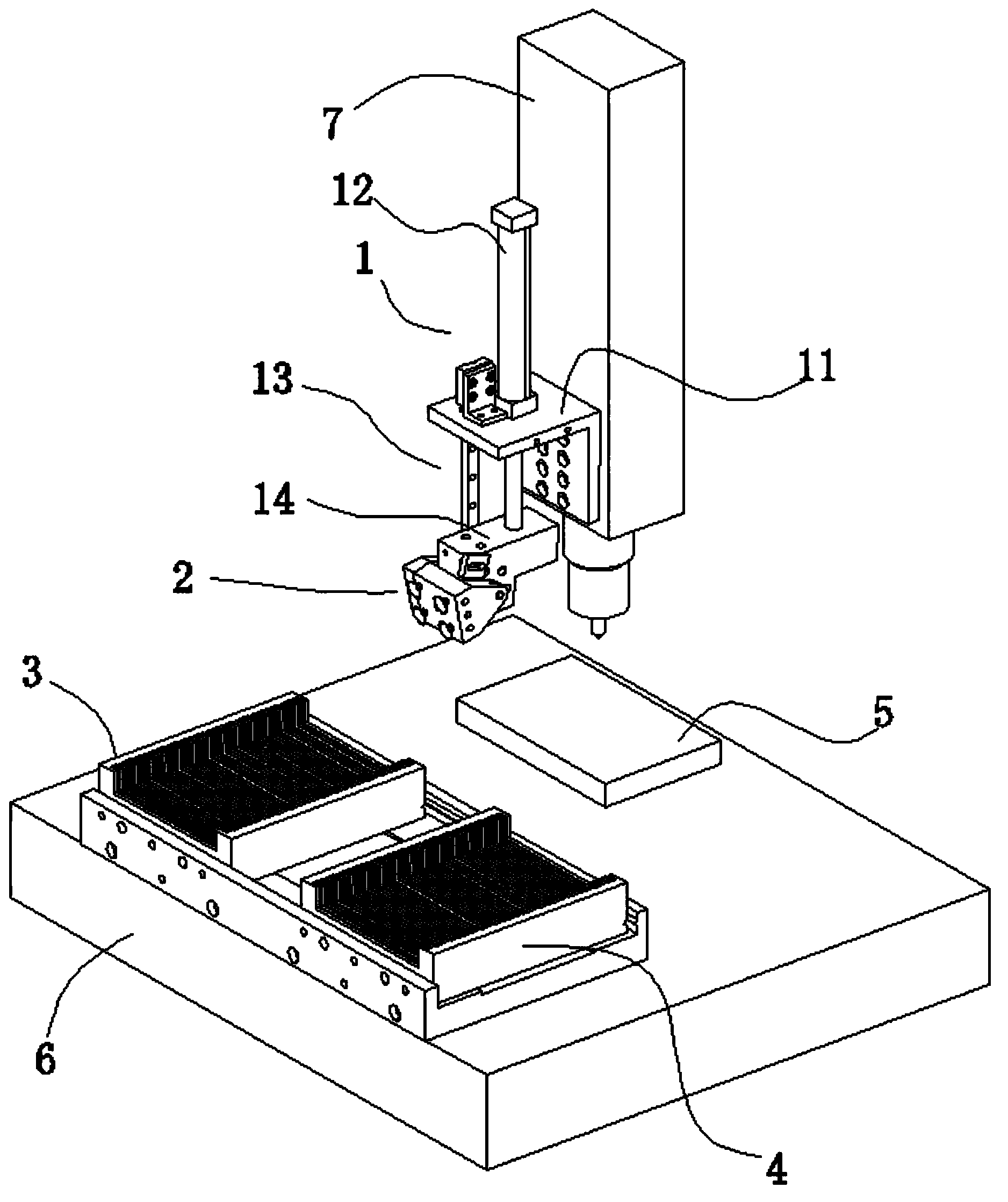

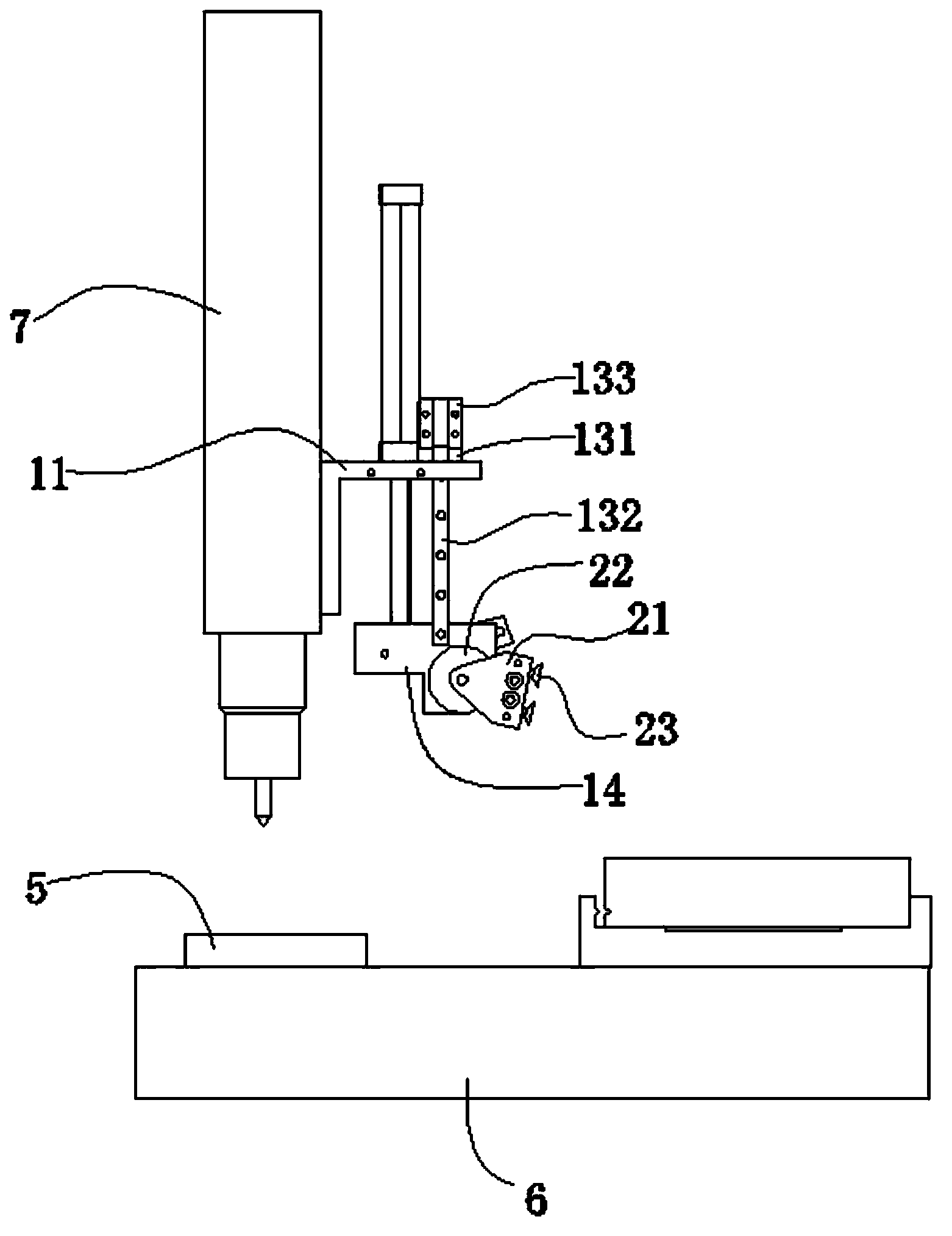

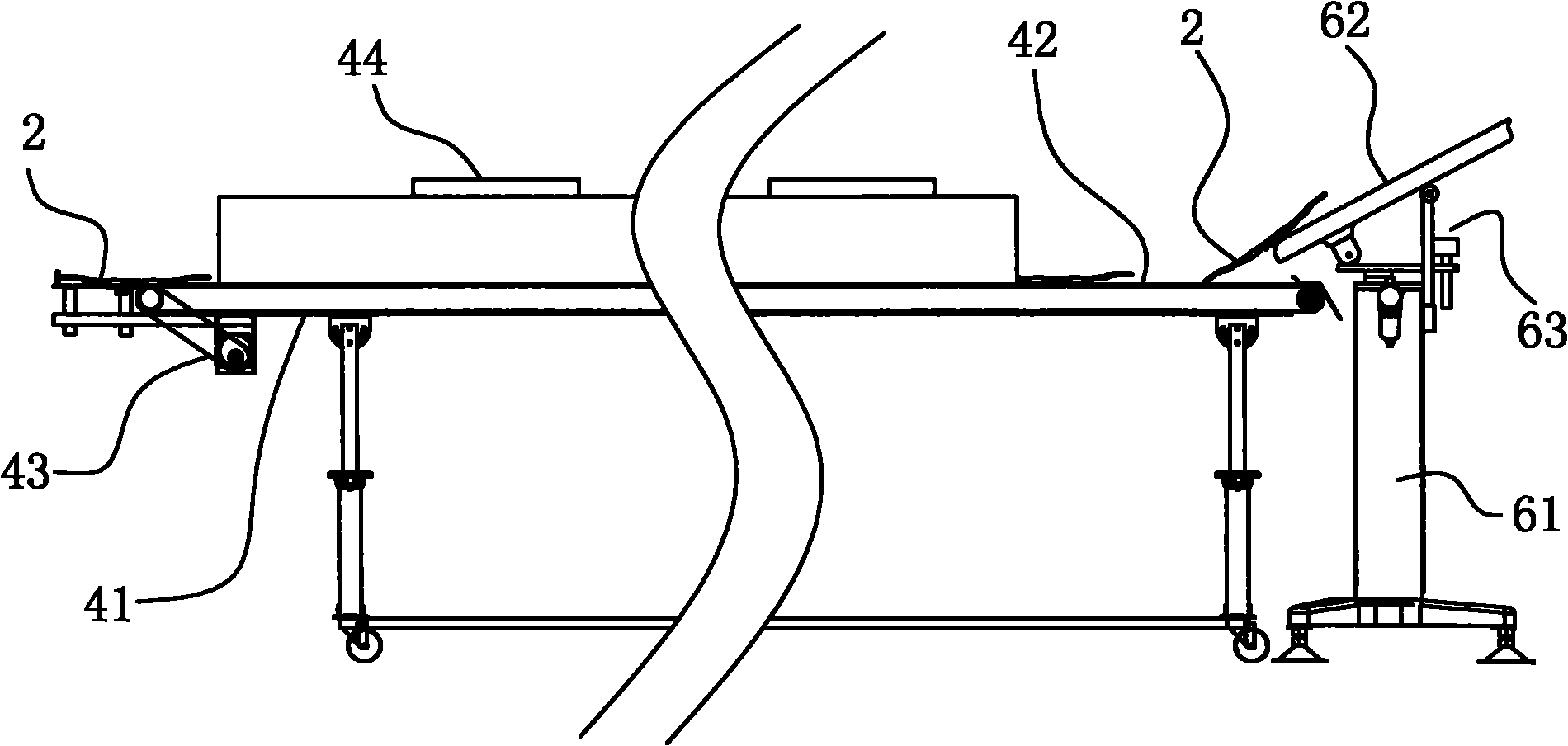

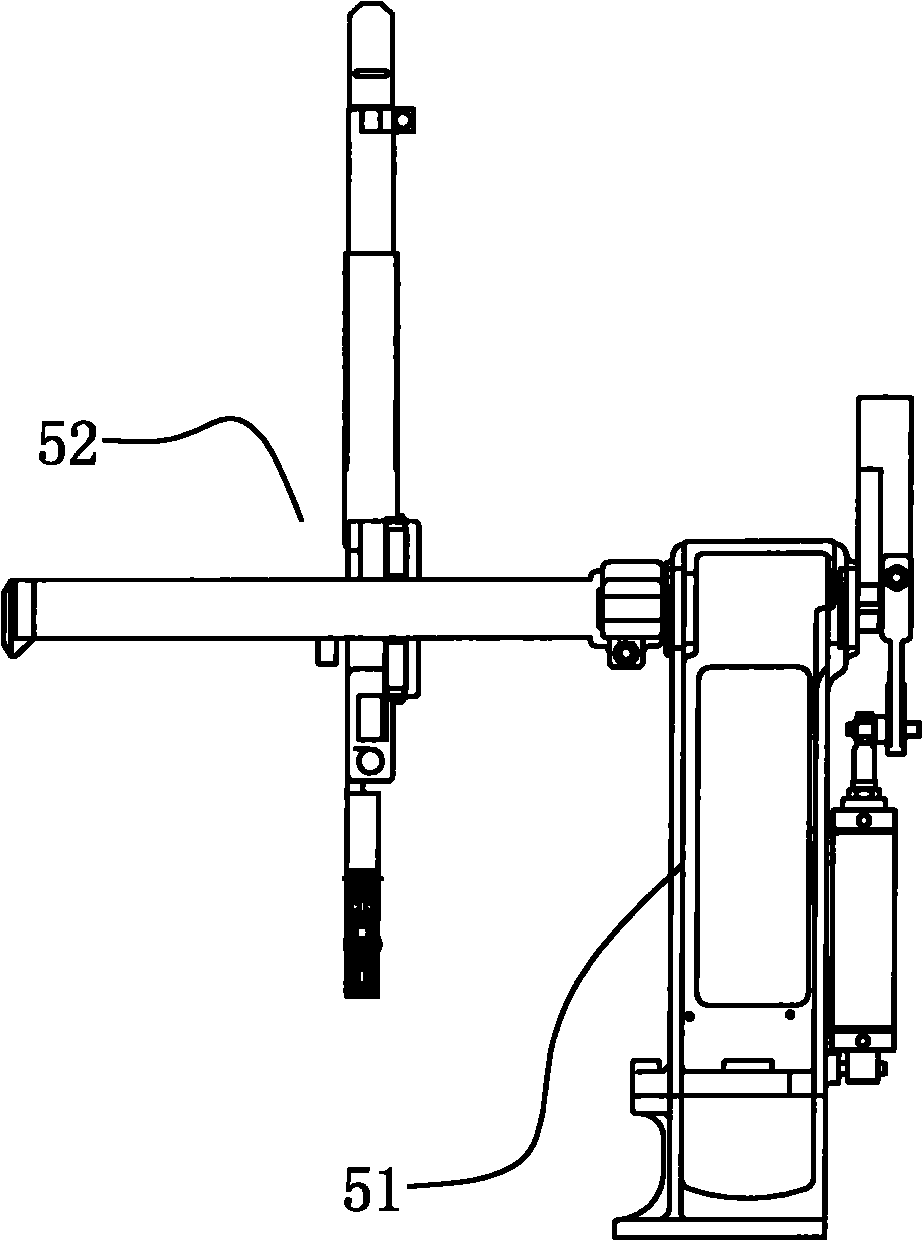

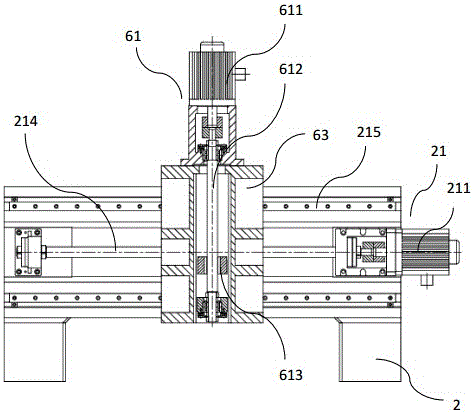

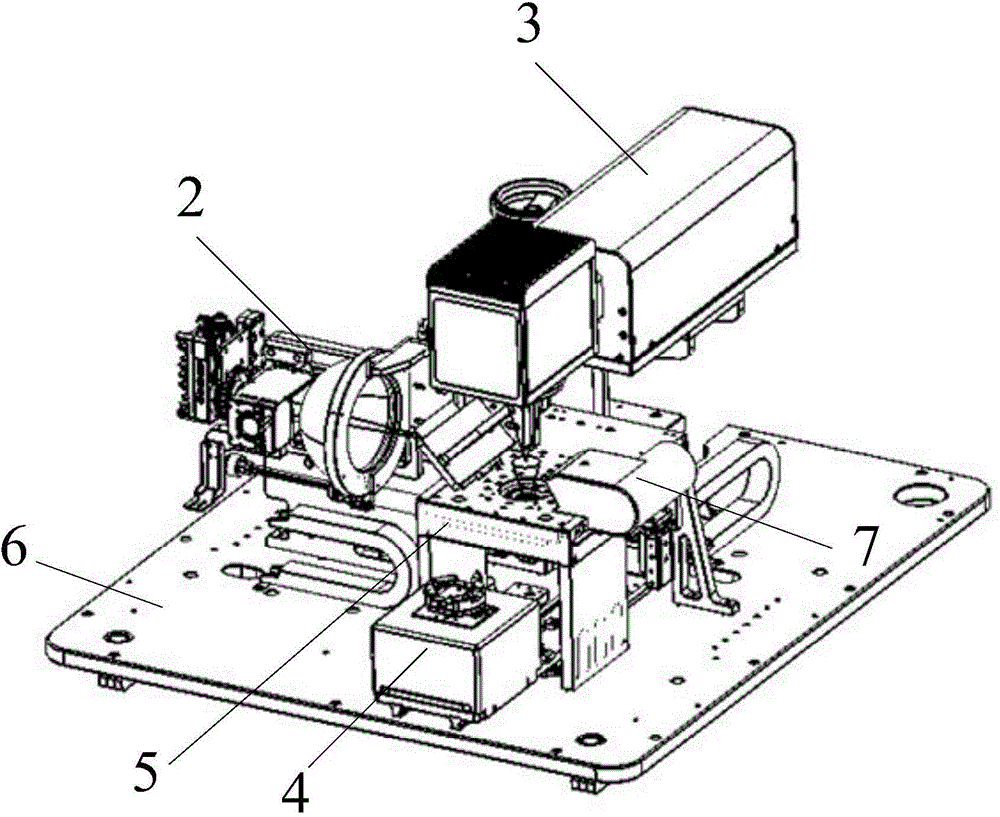

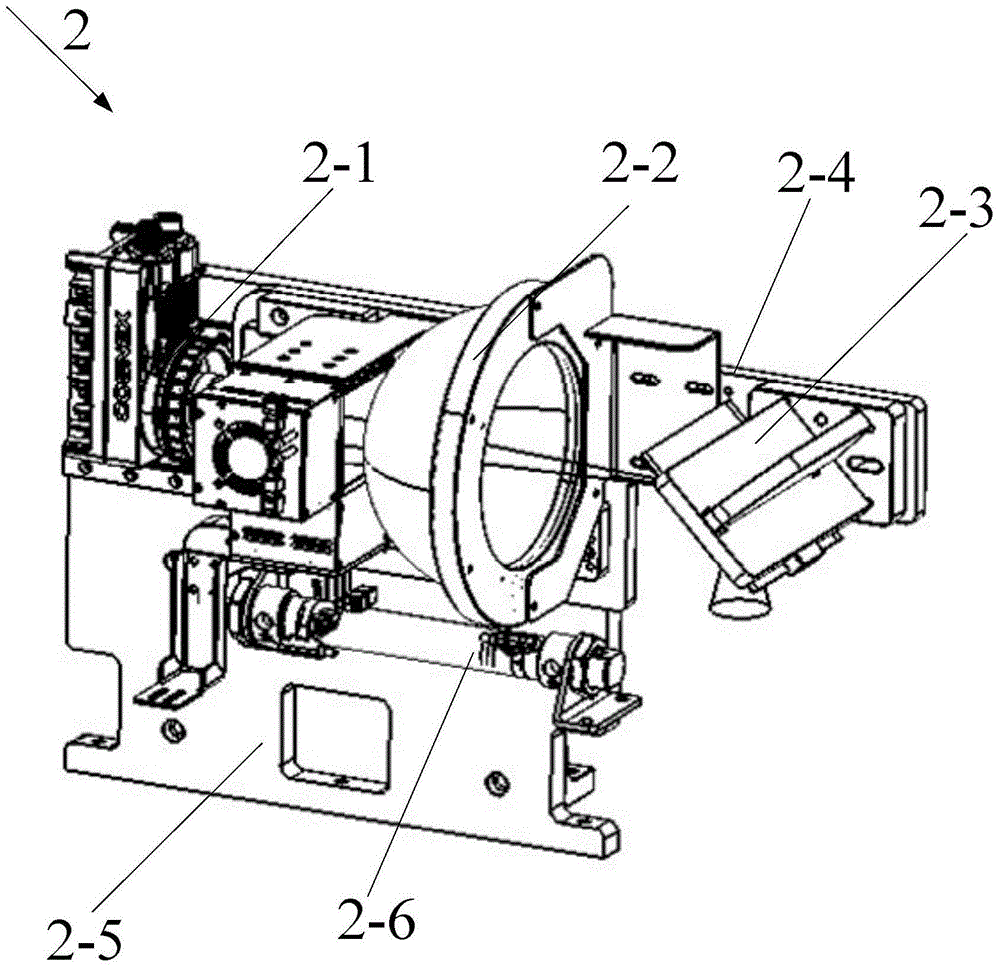

Automatic feeding and blanking mechanism for lens grinder

InactiveCN103846762AEnsure safetyReasonable structural designOptical surface grinding machinesGrinding feedersPass rateLens plate

The invention discloses an automatic feeding and blanking mechanism for a lens grinder. The automatic feeding and blanking mechanism comprises a lifting module, an overturning module, a feeding frame, a blanking frame, a processing platform and a moving working table. The lifting module comprises a fixed seat, an up-down cylinder, a guide support and a fixed block. The guide support is vertically arranged on the fixed block, the fixed block is fixed at the lower end of the guide support, a cylinder body of the up-down cylinder is fixed on the fixed seat, and a piston rod of the up-down cylinder is connected to the fixed block. The automatic feeding and blanking mechanism is reasonable in structural design, automatic feeding and blanking motions can be achieved rapidly through the matching between the lifting module, the overturning module and the moving working table, an automatic mode is adopted to replace a manual mode, and the automatic feeding and blanking mechanism has motion flexibility, is convenient to operate, easy to control, high in efficiency and quick in speed and greatly improves production efficiency and product pass rate.

Owner:陈哲雄

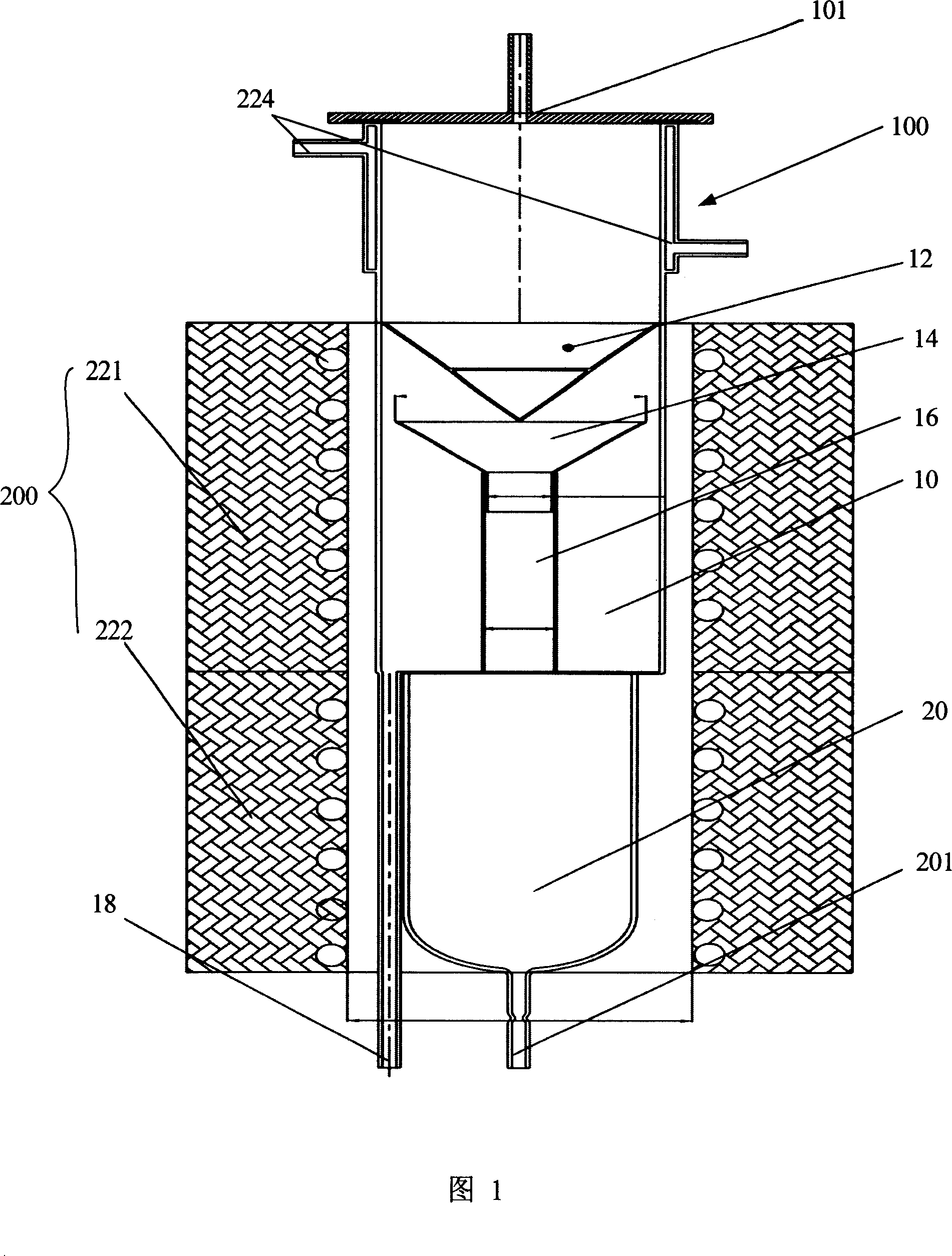

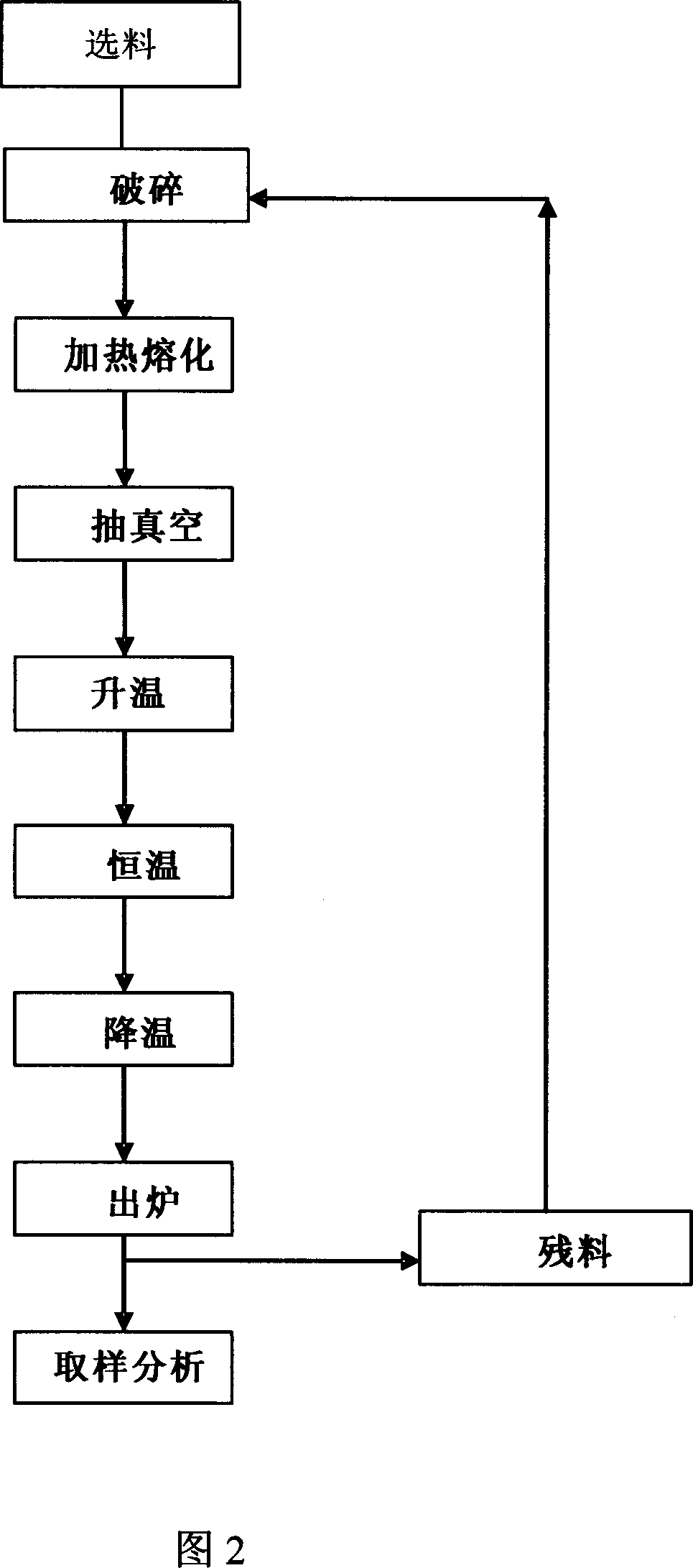

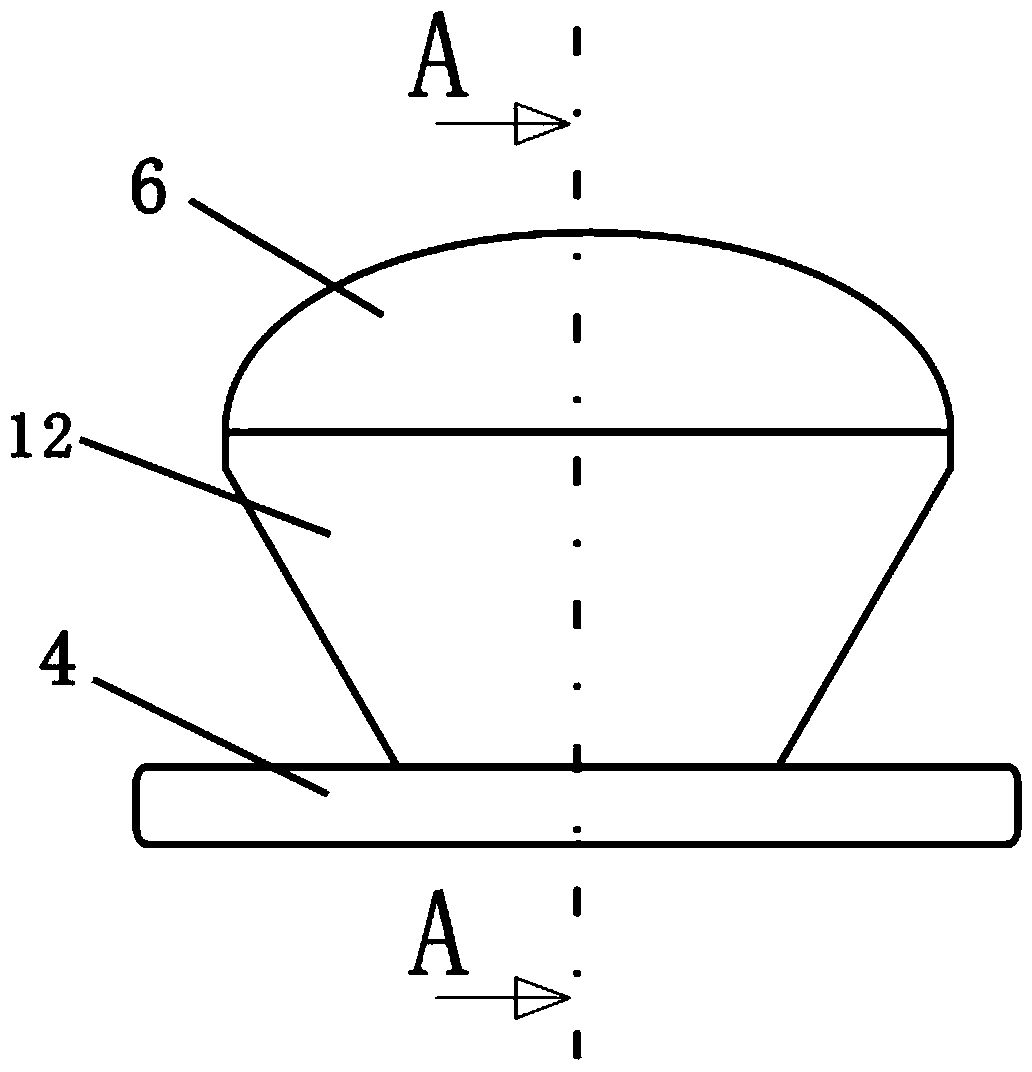

Producing device of high-purity selenium and producing process

ActiveCN1927701AEasy to collectHelp to separateElemental selenium/telluriumTemperature controlBoiling point

High purity selenium producing apparatus and process are disclosed. The producing apparatus includes one rectifying unit coated with heat insulating layer, one temperature controlling system and one vacuum system comprising one mechanical pump and one diffusion pump. The rectifying unit with vacuum gland in the upper part is divided into one material layer and one product layer communicated mutually. The material layer includes one conical condenser, one umbrella shaped material accepter and one connecting pipe vertically distributed successively; and the product layer is provided with one product kettle connected through the connecting pipe to the material accepter. The rectifying unit in inside multilayer structure is favorable to the separation of selenium from other impurity elements, and has high yield and high product purity.

Owner:广东先导稀贵金属材料有限公司

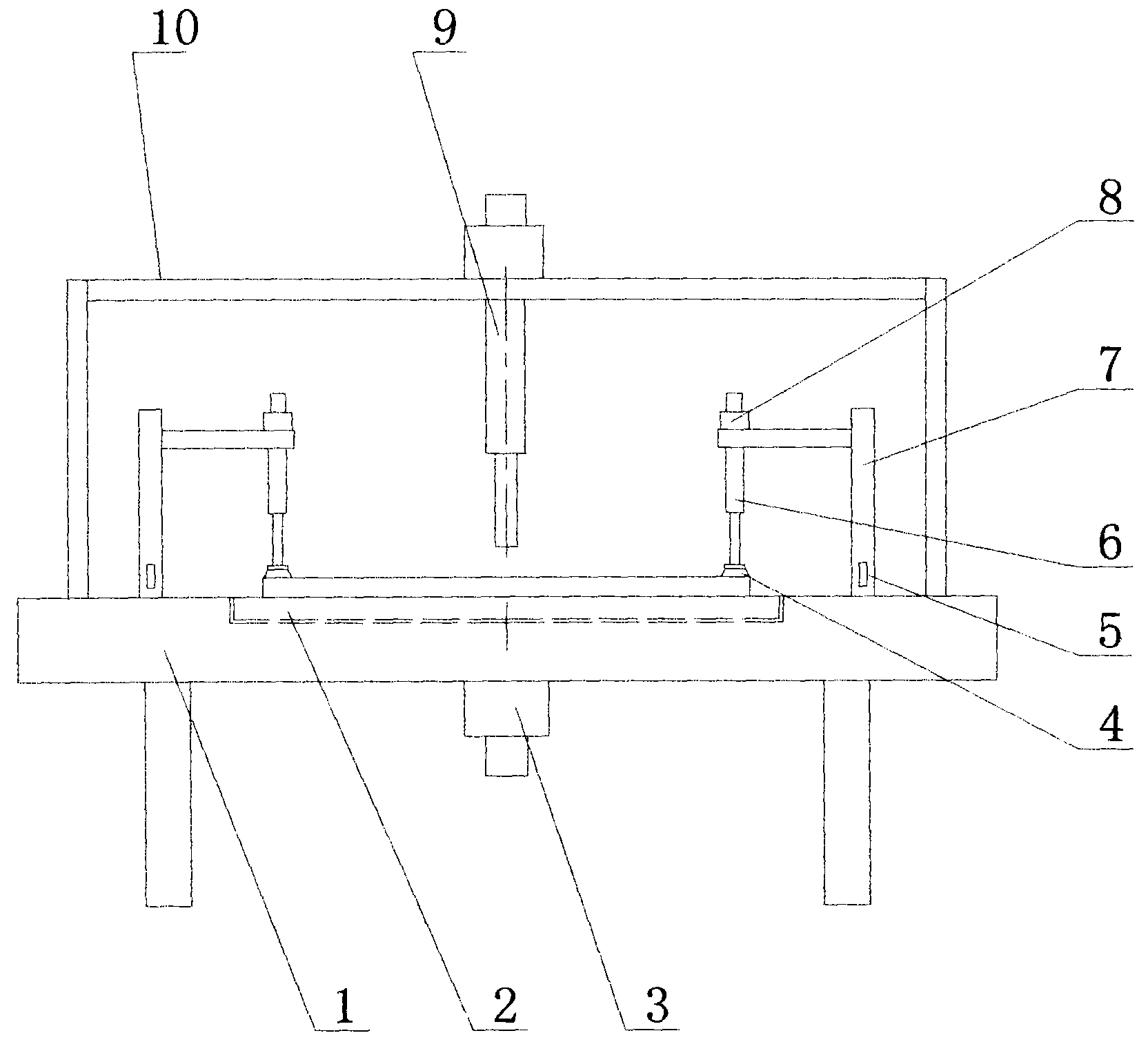

Automatic multi-station boring machine

InactiveCN102091800AReduce labor intensityImprove processing efficiencyPositioning apparatusBoring/drilling componentsThrough transmissionDrill bit

The invention discloses an automatic multi-station boring machine, which comprises a rack, wherein a workbench is arranged on the rack; first and second boring mechanisms are arranged on the workbench; motors are arranged on the first and second boring mechanisms, and the motors drive drill bits positioned on the lower parts of the boring mechanisms through transmission parts; and the workbench is provided with left, middle and right clamping mechanisms and first and second positioning mechanisms opposite to the middle clamping mechanism, wherein the directions of the left and right clamping mechanisms are opposite. The structure is adopted in the automatic multi-station boring machine, a hub to be processed is placed in the left, middle and right clamping mechanisms and the first and second positioning mechanisms, the left, middle and right clamping mechanisms clamp the hub, and the first and second boring mechanisms bores the hub according to the preset operation, so manual processing of workers is replaced, the labor intensity of the workers is reduced, and the processing efficiency, the processing precision and the qualification rate of products are improved.

Owner:KAIPING SHUIKOU SIHAI HARDWARE MFG

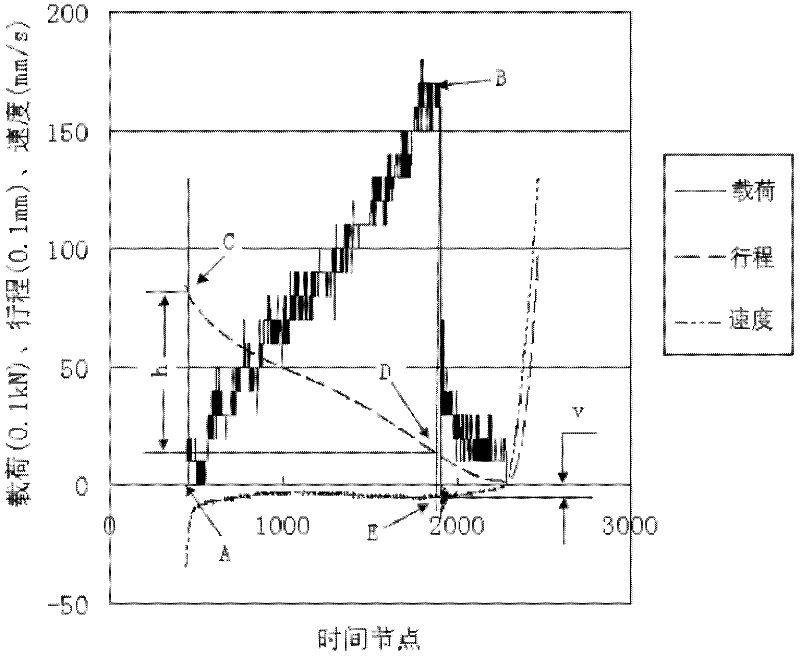

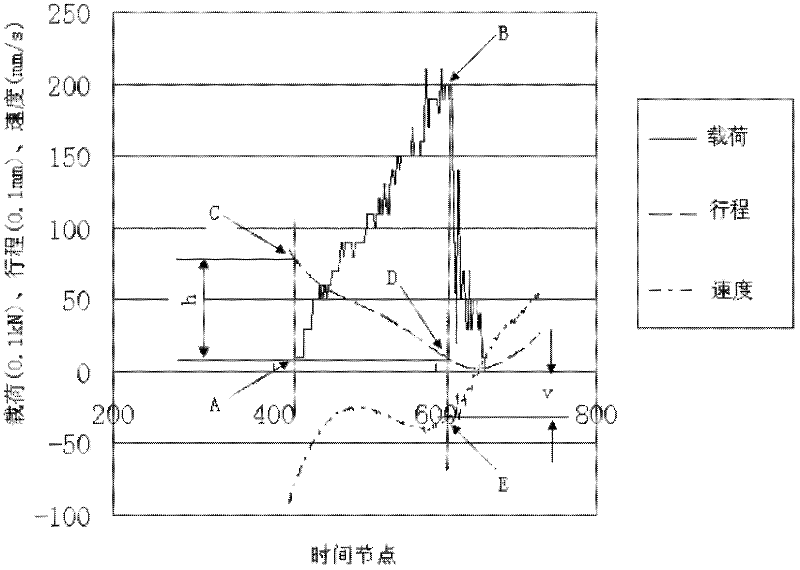

Metal sheet cupping test method related to strain rate

InactiveCN102507344AImproved forming process performanceImprove product qualification rateShaping toolsInvestigating material ductilityMachine pressMulti material

The invention relates to a metal sheet cupping test method related to a strain rate. The measured cupping test value is related to the strain rate in the test, a test die is mounted on a servo press, and a strain rate variable cupping test is performed according to that the rate of the servo press is variable on the basis of the sine rule; a pressure sensor and a linear position sensor both installed on the test die accept, compute and process pressure and position signals through a monitoring system, and the cupping test value and a corresponding rate rule curve of a sample can be directly displayed on a displayer; and the value of difference between positions of a male die at a cupping point and the rate of the male die at a corresponding penetrated fracture point are read to be used as the cupping test value together. The invention provides a set of conception and method for testing the cupping performance of the strain rate related metal stamping sheet, the experiments on various materials show that the method of the invention can be used for testing the expansion character index of the metal sheet under the condition of variable rate.

Owner:SHANGHAI UNIV OF ENG SCI

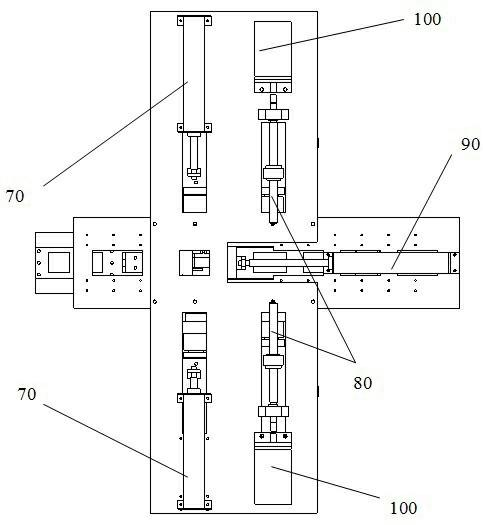

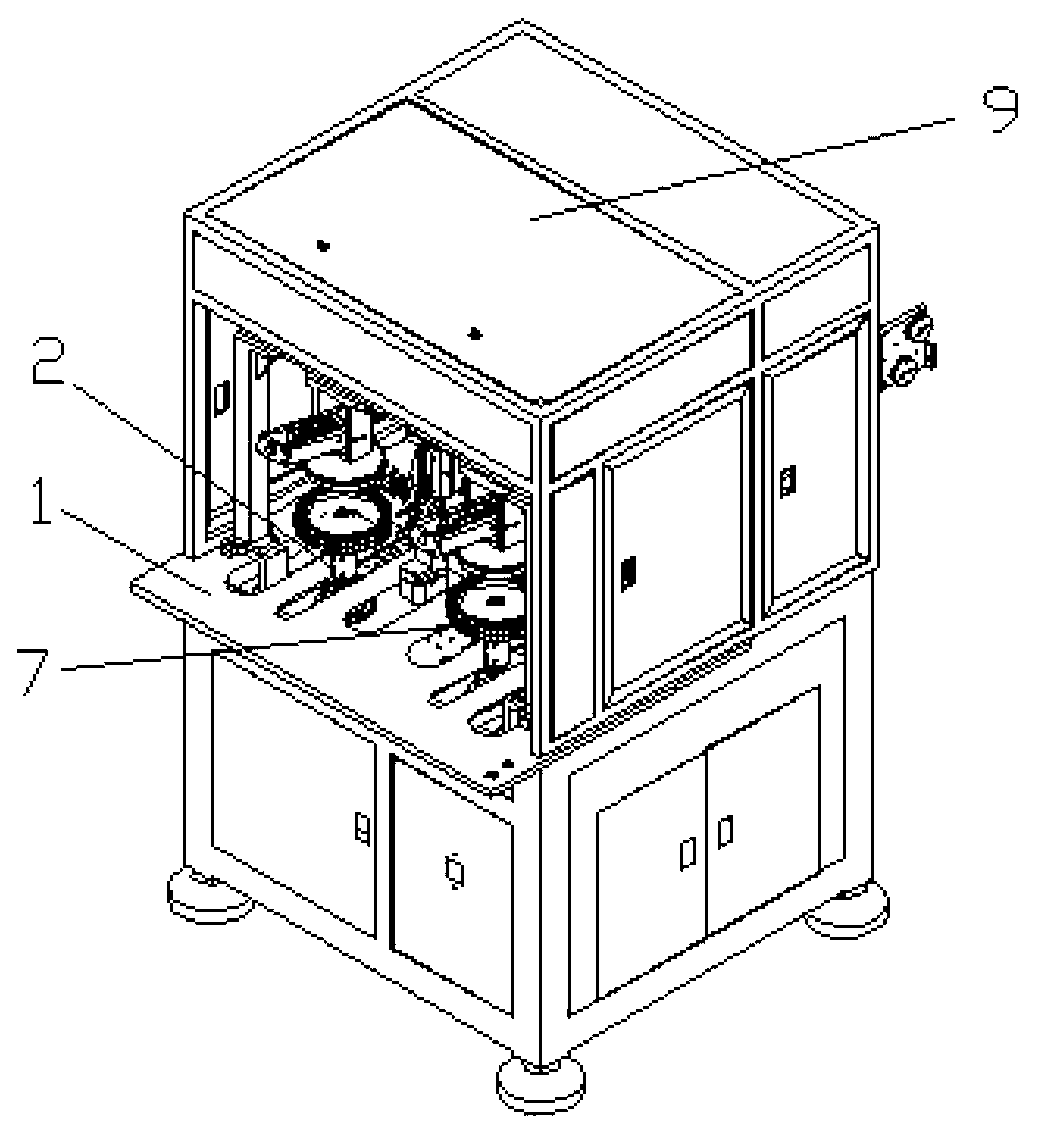

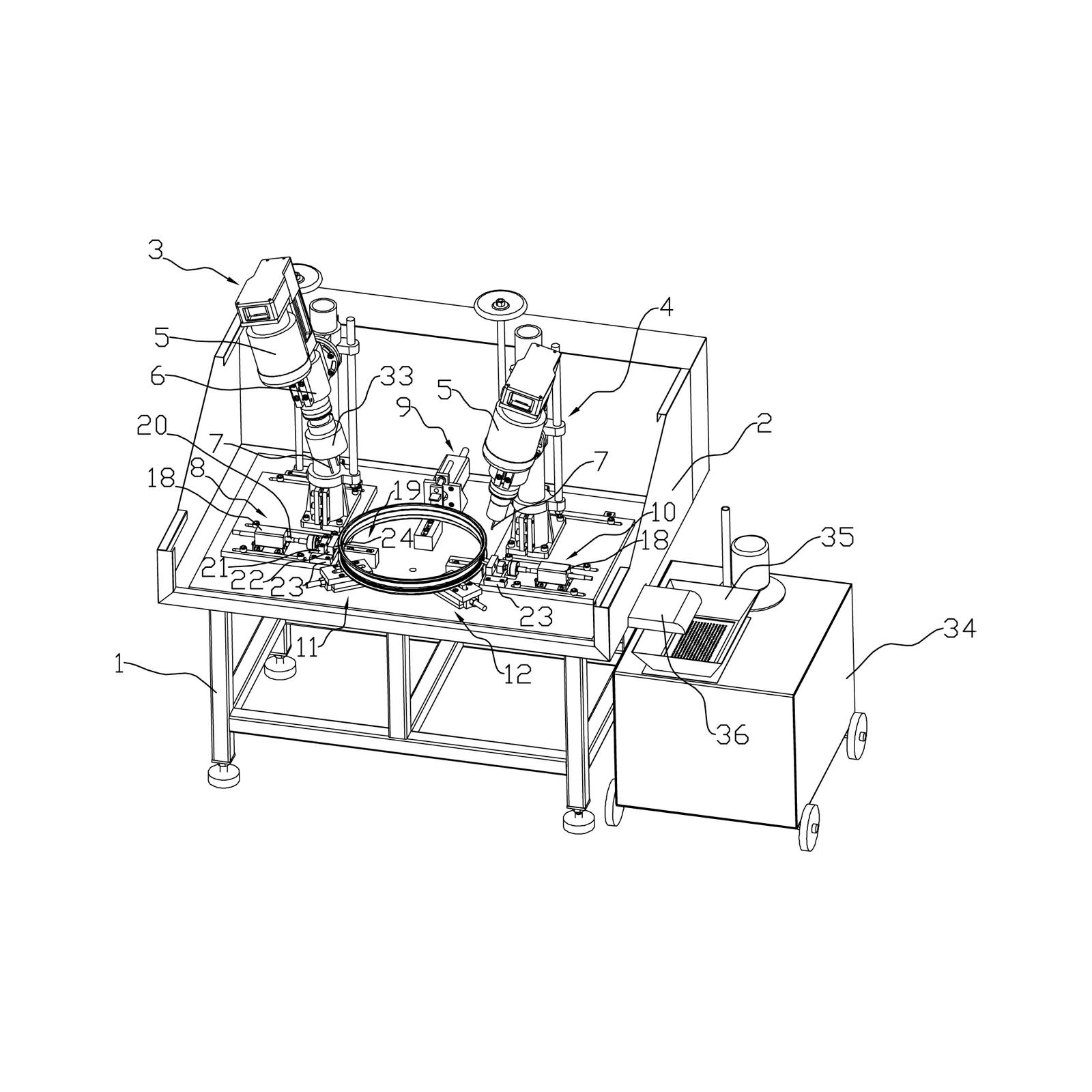

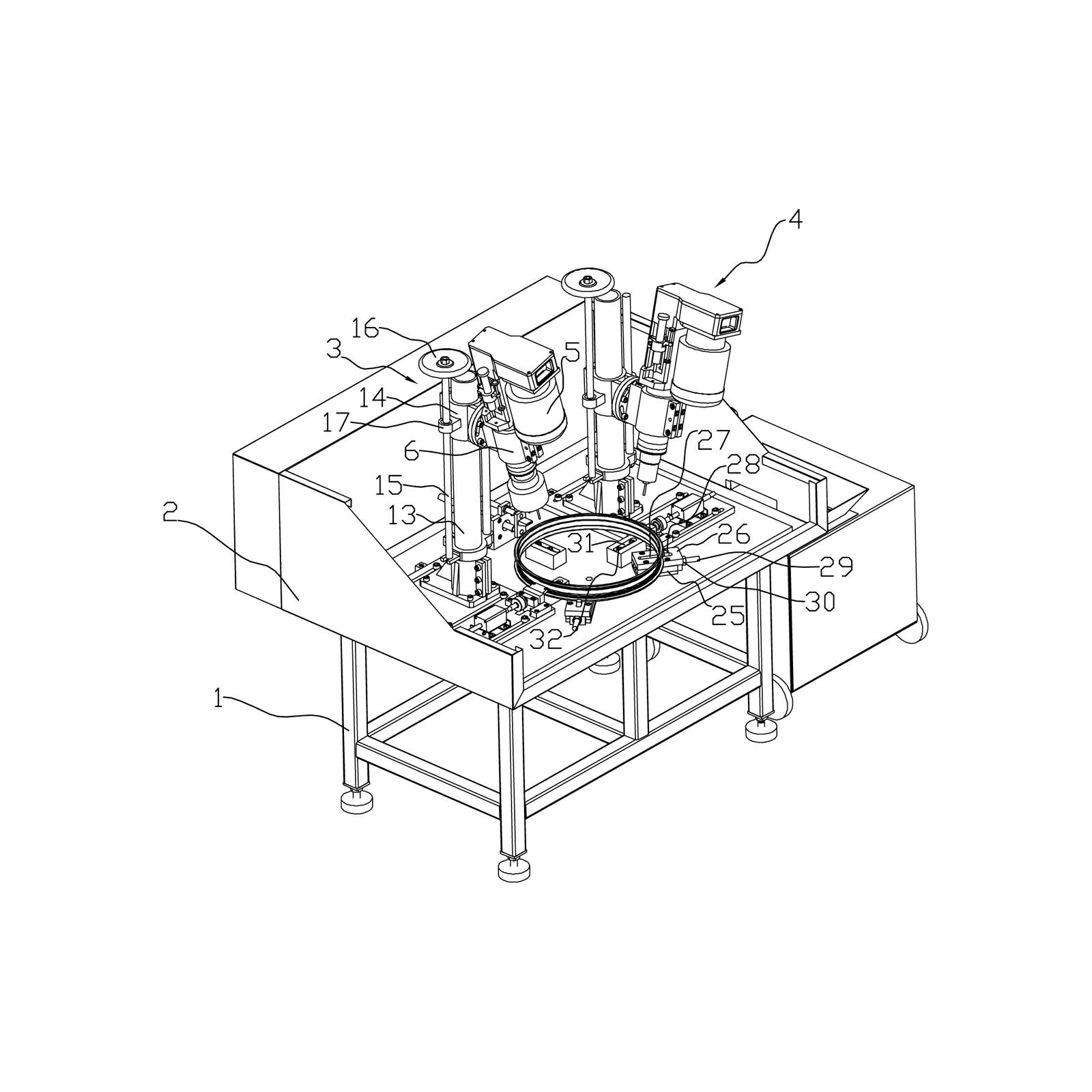

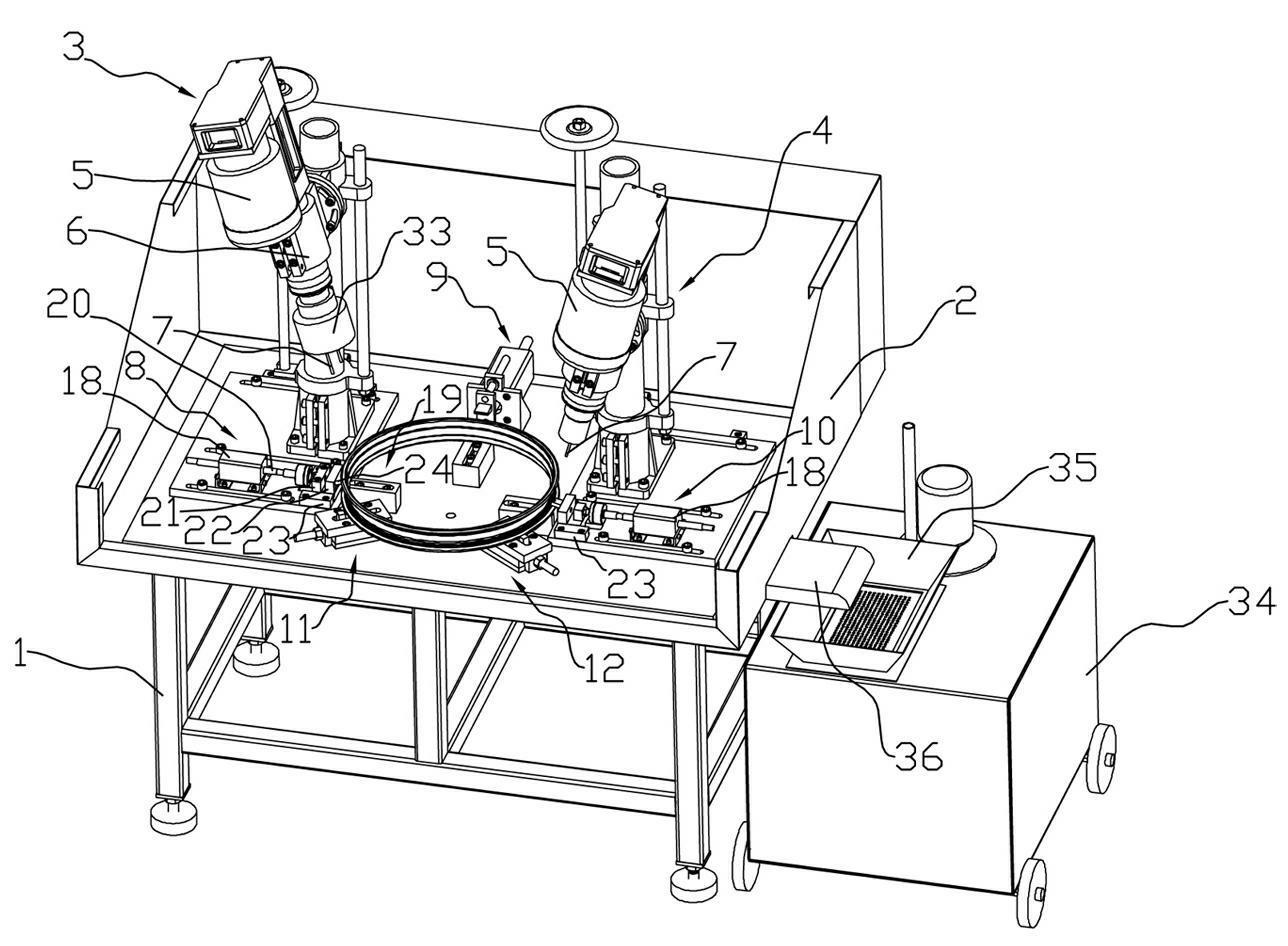

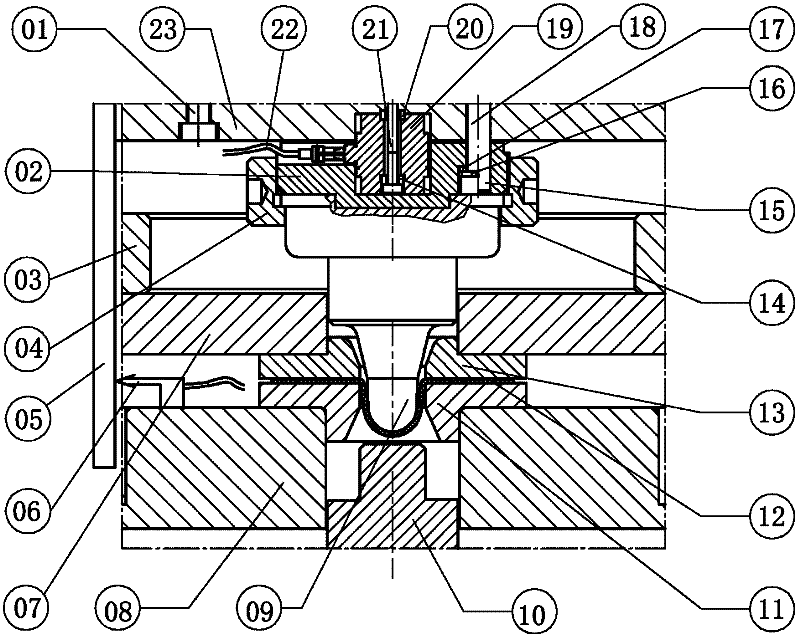

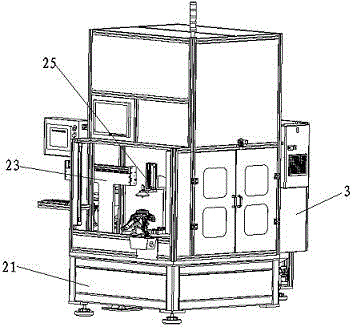

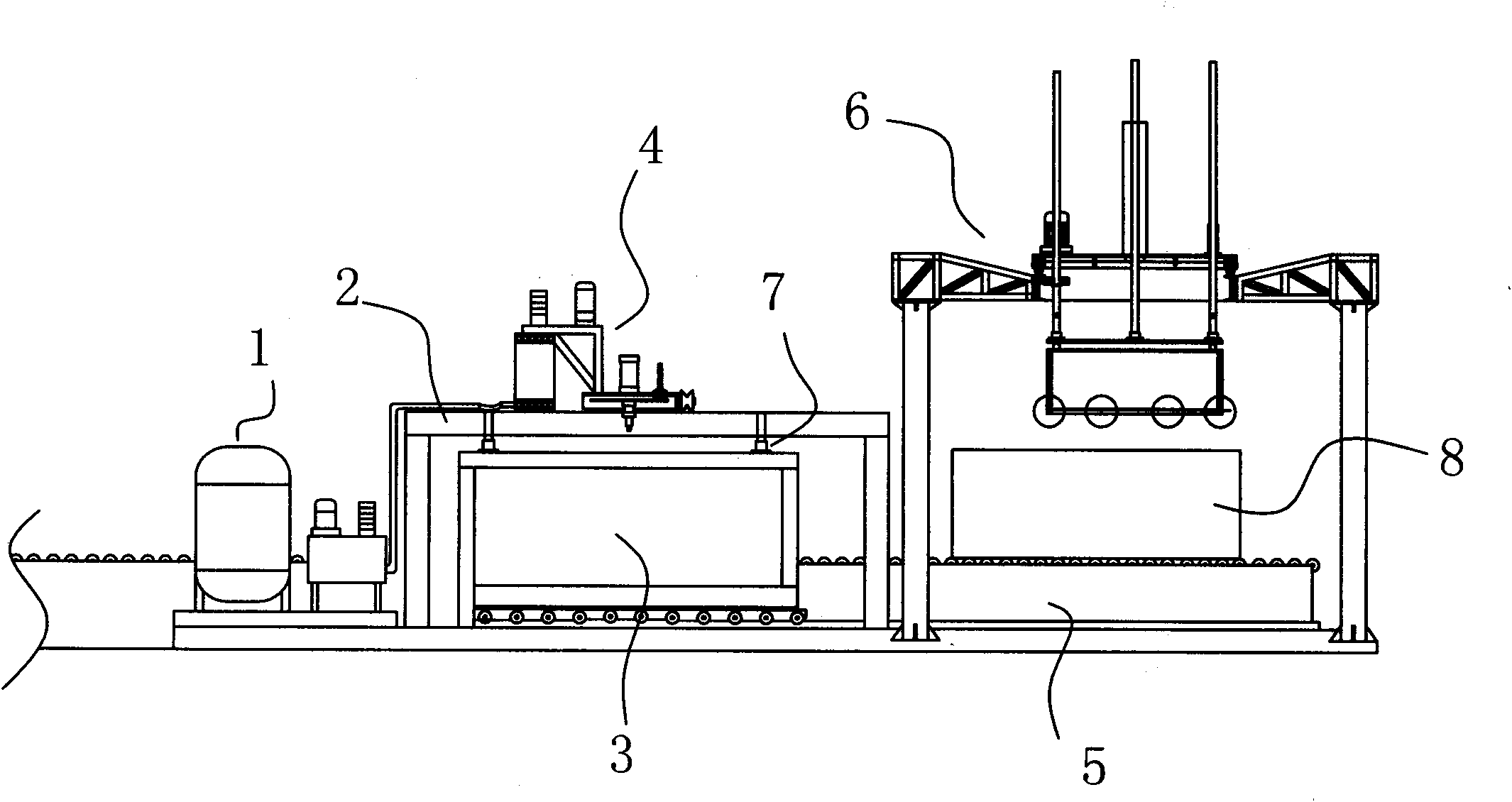

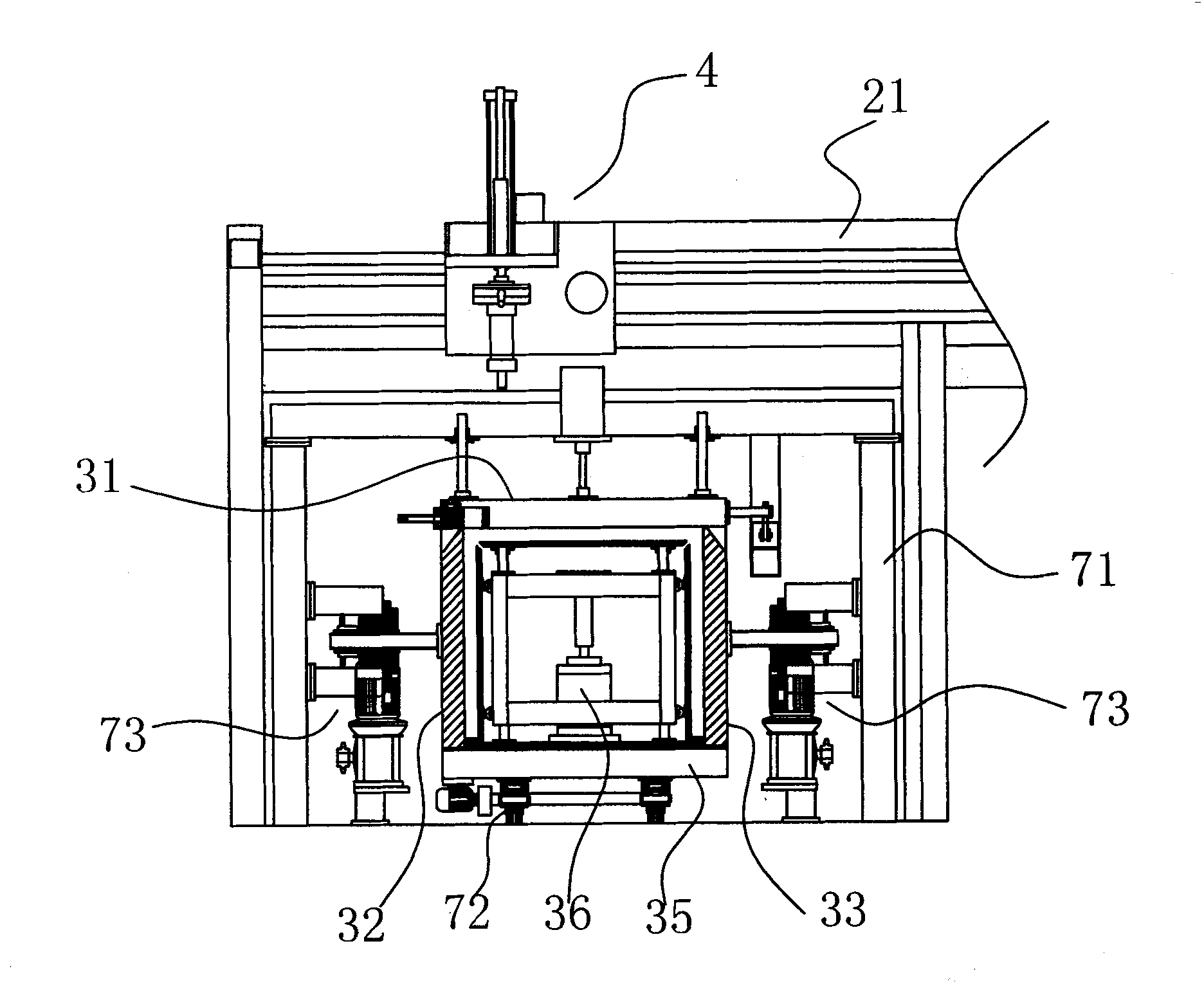

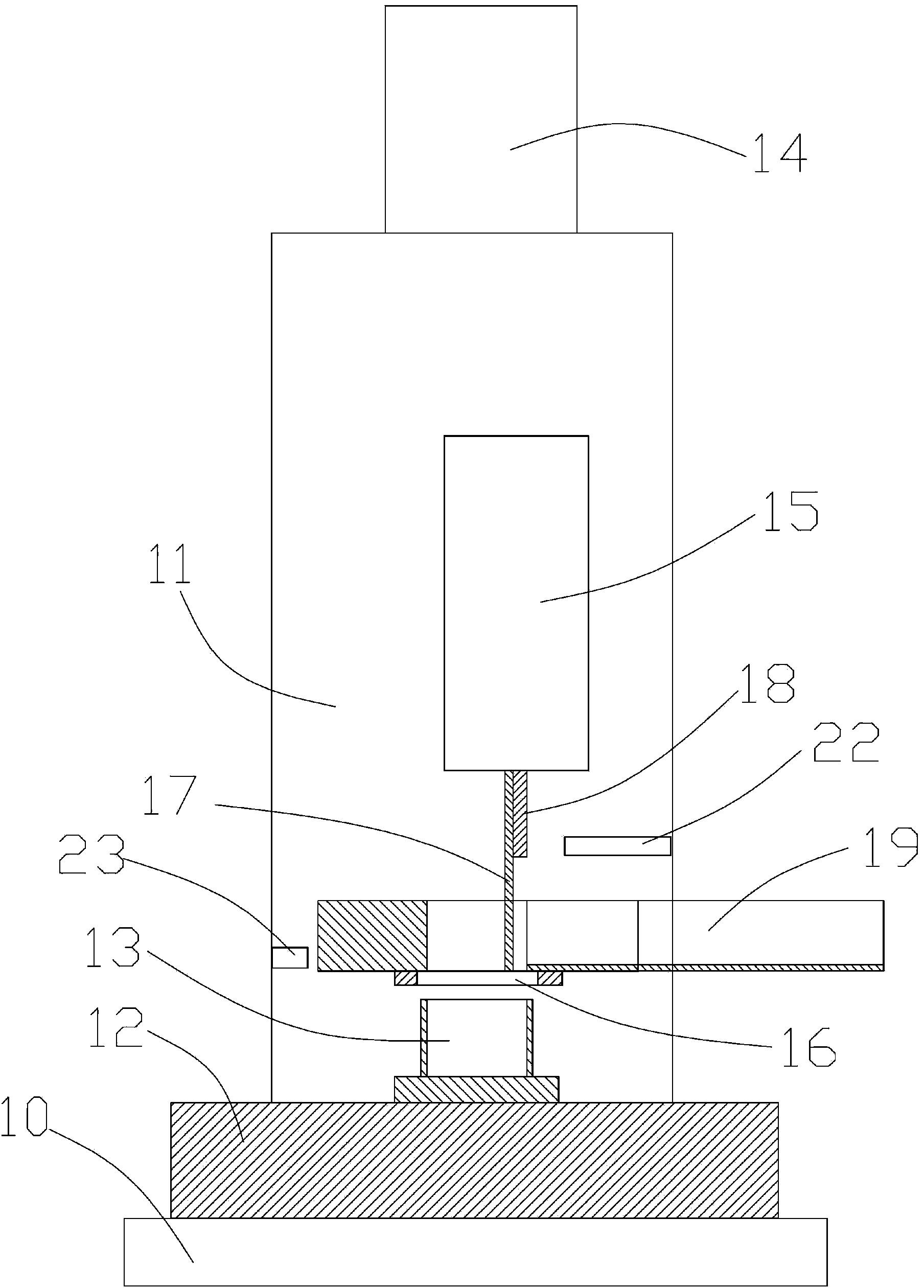

Forward-rotating guide-in automatic pressing machine

ActiveCN106041479AImprove product qualification rateIncrease productivityMetal working apparatusManipulatorPhotoelectric sensor

The invention discloses a forward-rotating guide-in automatic pressing machine. The forward-rotating guide-in automatic pressing machine comprises a bearing feeding mechanism, a pressing mechanism, an electric cabinet and a reflecting type photoelectric sensor; the electric cabinet is fixed behind the pressing mechanism; the bearing feeding mechanism is connected with the electric cabinet and located on the left side of the pressing mechanism and the electric cabinet; the pressing mechanism comprises an assembling machine base fixed to the ground; an upper hood frame is fixed to the assembling machine base; a bearing material grabbing manipulator is fixed to the left end of the assembling machine base; a rotating disk device is fixed to the center of the assembling machine base; clamps are arrayed on a rotating disk of the rotating disk device around the circle center of the rotating disk in a quartering manner; and an oil injecting device, a bearing pressing device and a snap spring pressing device are correspondingly arranged at three peripheries, corresponding to the clamps, of the assembling machine base.

Owner:滦州吉宏包装有限公司

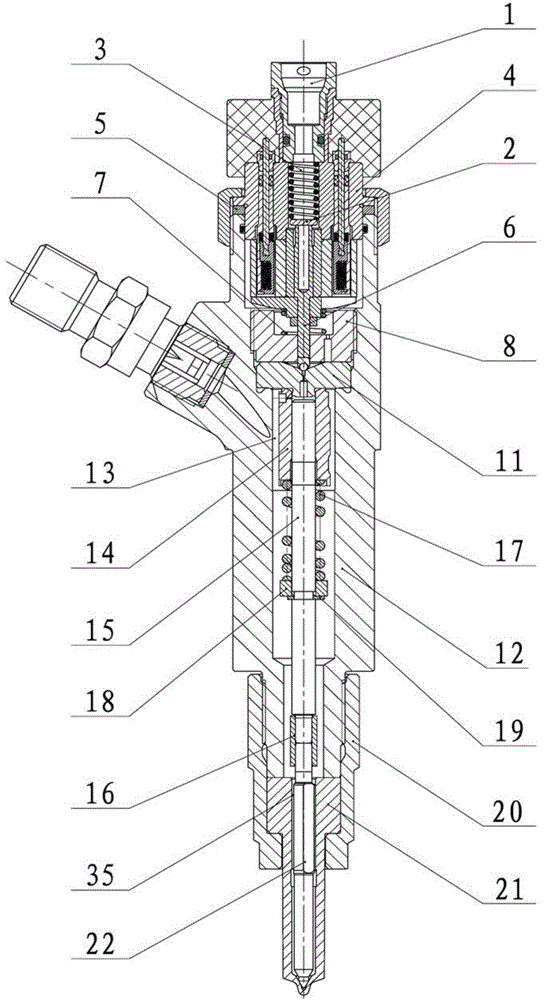

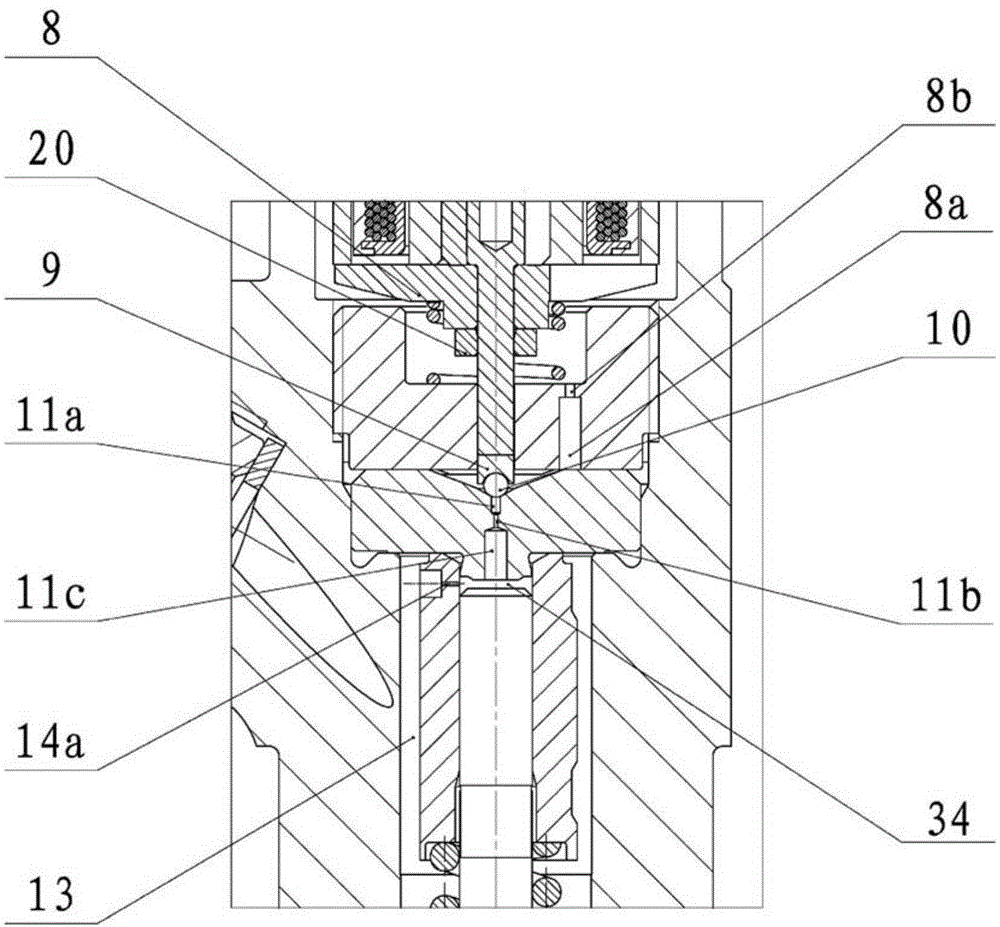

Middle hole pressure storage static leakage-free oil sprayer

ActiveCN104314725ASimple structureImprove sealingFuel injection apparatusMachines/enginesSolenoid valvePlunger

The invention discloses a middle hole pressure storage static leakage-free oil sprayer, comprising a high speed solenoid valve, a locking screw sleeve, a tapered surface ball valve type switch valve, a control plunger and barrel assembly, an oil sprayer spring, a spring seat, an opening check ring, an oil sprayer body, an oil sprayer assembly and an oil nozzle locking cap; the tapered surface ball valve type switch valve is arranged in a concave cavity in the upper end of the oil sprayer body; the upper end of the oil sprayer body is connected with the high speed solenoid valve by a locking nut; the lower end of the oil sprayer body is connected with the oil nozzle assembly by the oil nozzle locking cap; the control pole plunger and barrel assembly is arranged in a central hole formed along the axis of the oil sprayer body; the central hole of the oil sprayer body and the control pole plunger and barrel assembly form a middle hole pressure storage cavity. The oil sprayer is simple in structure, low in machining cost and convenient to mount, so the production efficiency and product percent of pass are improved.

Owner:钧风电控科技(大连)有限责任公司

Full-automatic production method of multi-station mobile fixed foaming freezer body and system thereof

InactiveCN101913223AFlexible adjustment of specificationsReduce investmentDomestic articlesAutomatic controlRobot hand

The invention discloses a full-automatic production method of a multi-station mobile fixed foaming freezer body, comprising the following steps of: (1) setting foaming equipment and an automatic foaming control system capable of controlling the work state of the foaming equipment; (2) setting a foaming mould frame with a slide at the top; (3) arranging multiple fixed foaming moulds below the slide juxtaposedly; and (4) setting a pouring manipulator which is controlled by the automatic foaming control system. The invention also discloses a system for implementing the method. The invention employs a mobile fixed foaming technology and an automatic control technology and has simple production process and automated process, thereby effectively decreasing the supervisor, making the operation convenient, greatly reducing the labour intensity, saving the manpower and material resources, and reducing the production cost; furthermore, a multi-station batch production technology with rapid production speed, short period and guaranteed product quality is added, thereby greatly improving the production efficiency and the product qualification rate and strengthening the enterprise competitiveness.

Owner:东莞市百利电器有限公司 +1

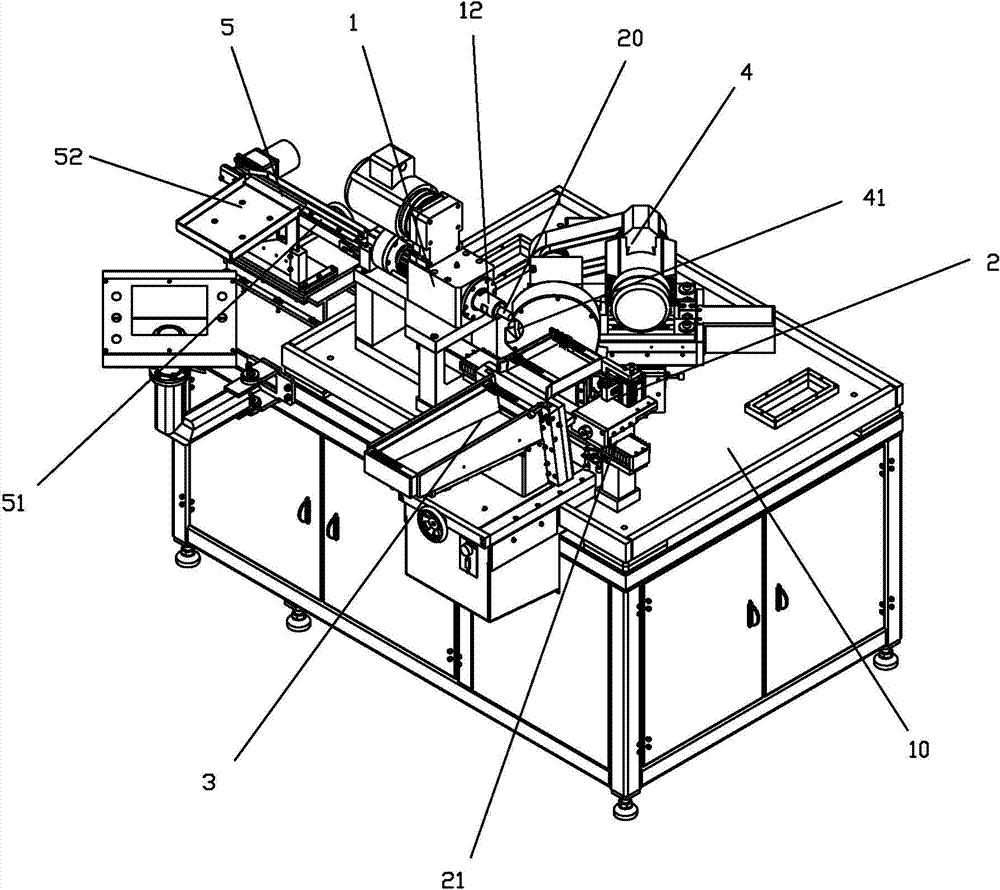

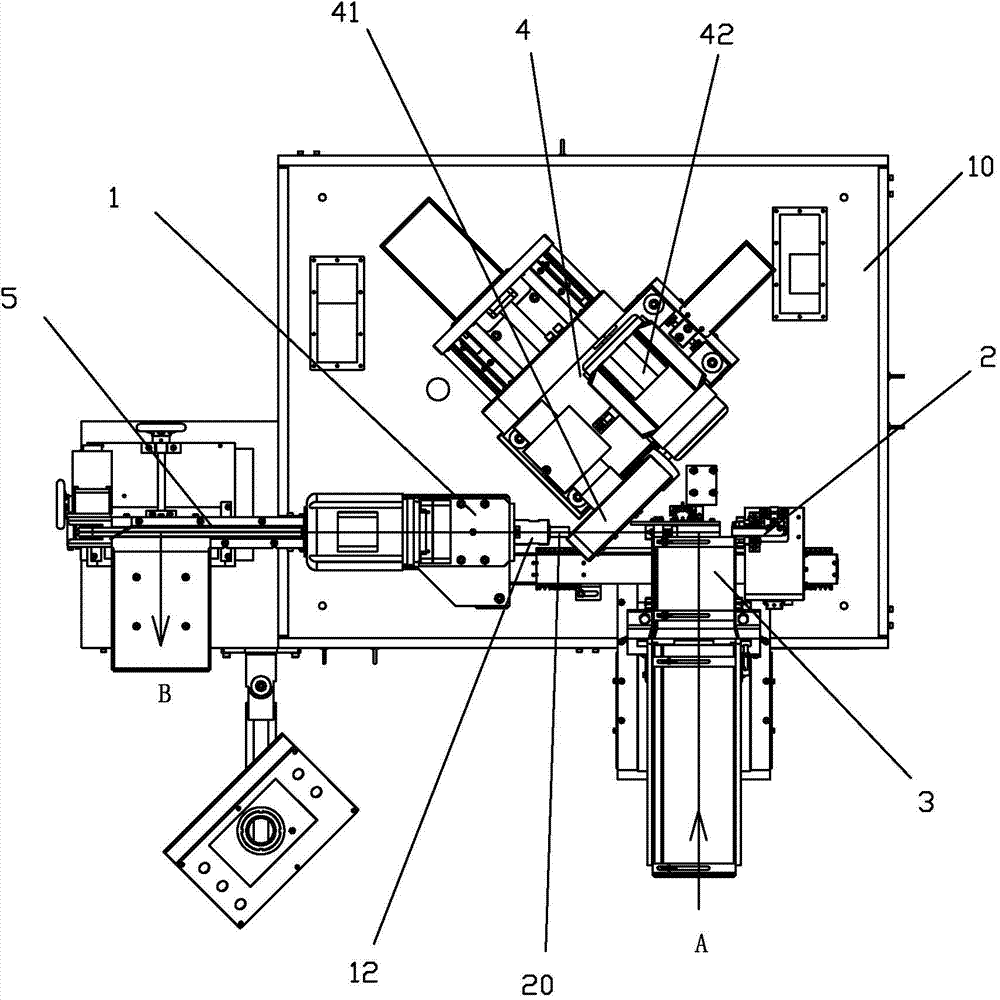

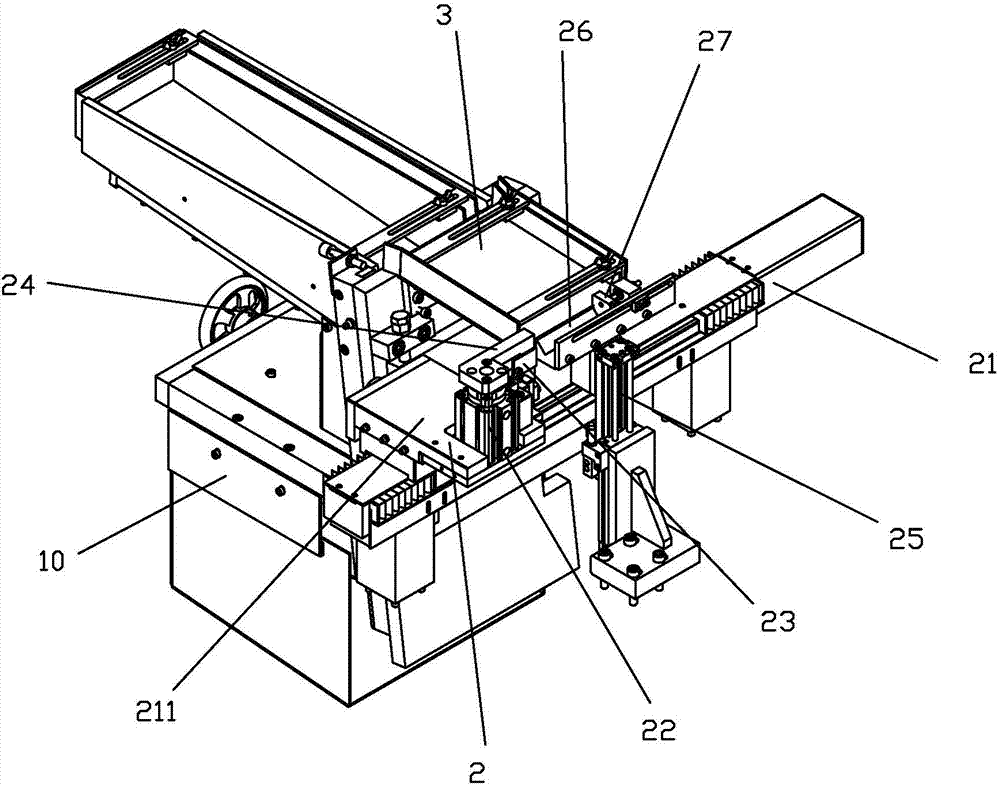

Automation equipment for installing motor rotor magnetic steel sheets

ActiveCN103944325AStrong coherenceAutomate installationManufacturing stator/rotor bodiesMagnetic polesEngineering

The invention particularly relates to automation equipment for installing motor rotor magnetic steel sheets, and belongs to the technical field of motor accessory machining equipment. The automation equipment comprises a base, a dividing device and a guide rail are arranged on the base, a sheet inserting mechanism and a power device I for driving the sheet inserting mechanism to slide along the guide rail are arranged on the guide rail, the sheet inserting mechanism comprises a power device II and a butting base, a feeding assembly is arranged on the power device II, a feeding groove for storing the magnetic steel sheets is formed in the butting base, and the butting base is located between the dividing device and the power device II. The automation equipment achieves automated installation, saves manpower, reduces workload, is high in magnetic steel sheet separation and insertion continuity, simplifies installation steps, is stable, achieves insertion of a plurality of magnetic steel sheets, is distinct in magnetic pole, increases the production efficiency and the product percent of pass, and is simple in structure, convenient to operate and low in manufacturing cost.

Owner:台州市速普机电有限公司

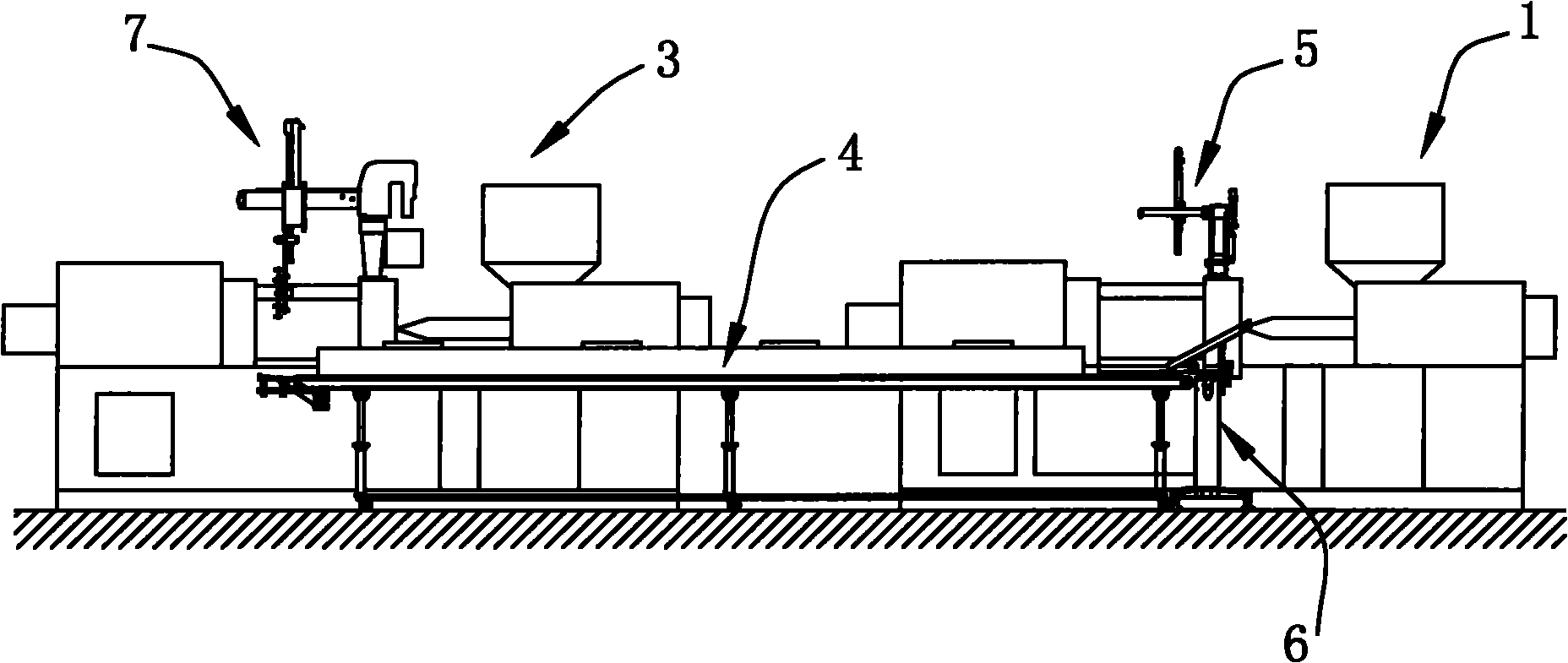

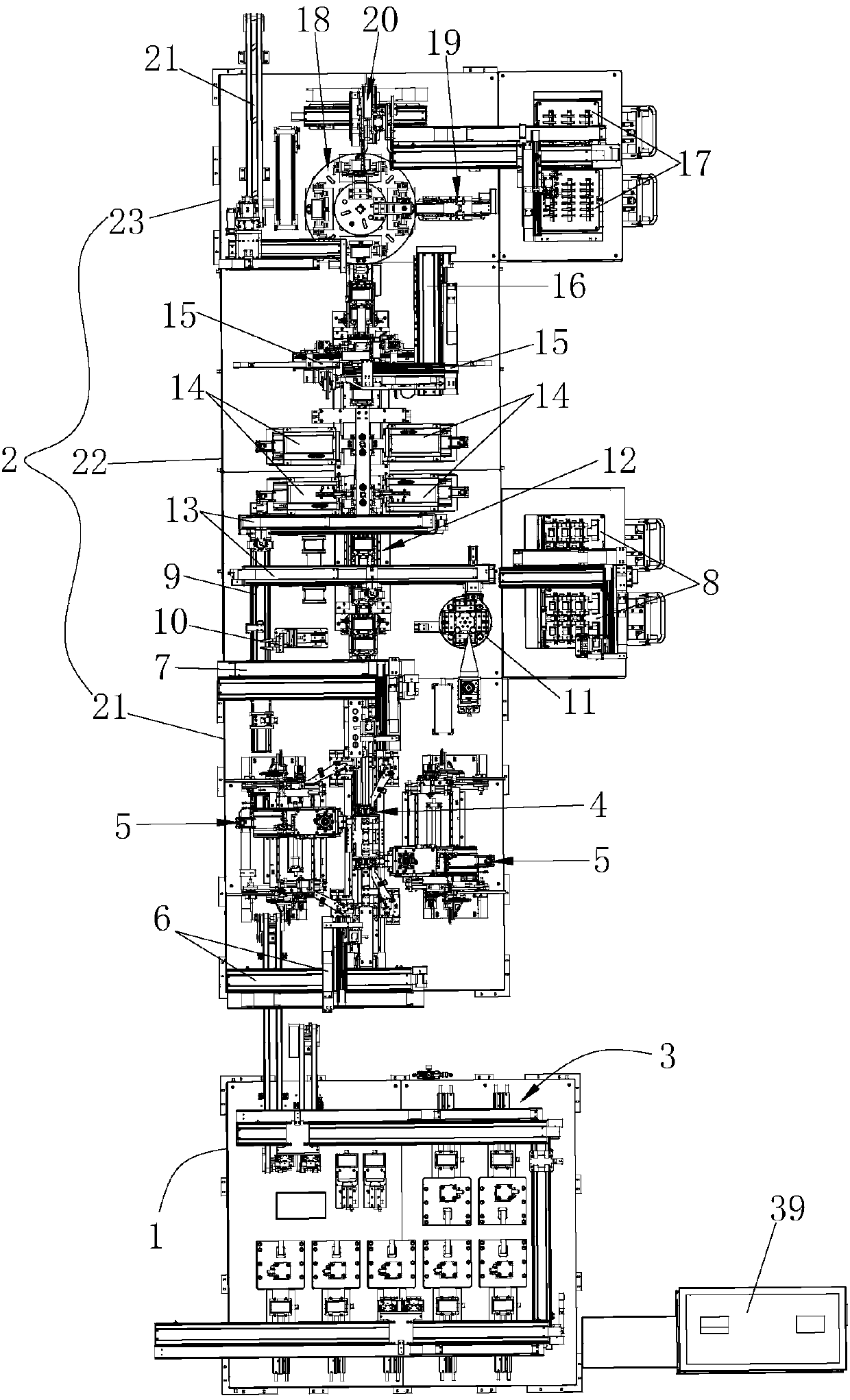

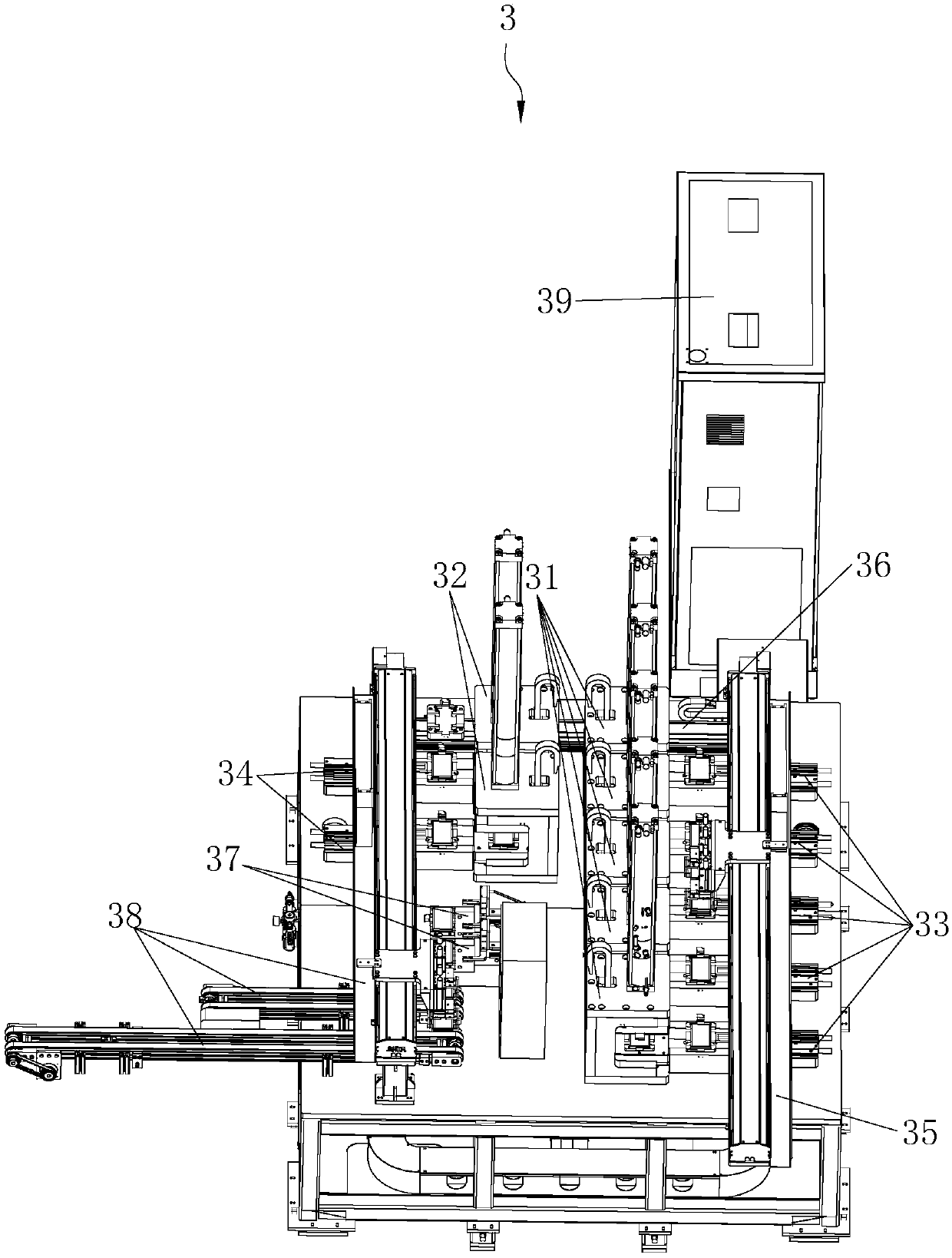

Secondary injection molding method for toothbrush handles and system for implementing same

InactiveCN102166807AReduce manufacturing costGood product qualityDomestic articlesEngineeringInjection moulding

The invention discloses a secondary injection molding method for toothbrush handles, comprising the following steps of: (1) arranging a molding injection machine for performing injection molding of a toothbrush body; (2) arranging an encapsulating injection machine for performing secondary encapsulating injection on the toothbrush body to obtain the finished product; and (3) arranging a control system which is respectively connected with the molding injection machine and the encapsulating injection machine for controlling the operating modes thereof. The invention also discloses a system for implementing the method. The method provided by the invention can realize secondary injection molding on the basis of not changing the existing structure of the mold, so that the production cost is effectively reduced and the product quality is good. The system provided by the invention has a simple and reasonable structure, combines the molding injection machine and the encapsulating injection machine, realizes secondary injection molding, has high efficiency and quick speed, greatly improves the production efficiency and the product percent of pass, has high degree of automation, and greatly reduces the labor intensity.

Owner:东莞艾尔发自动化机械有限公司

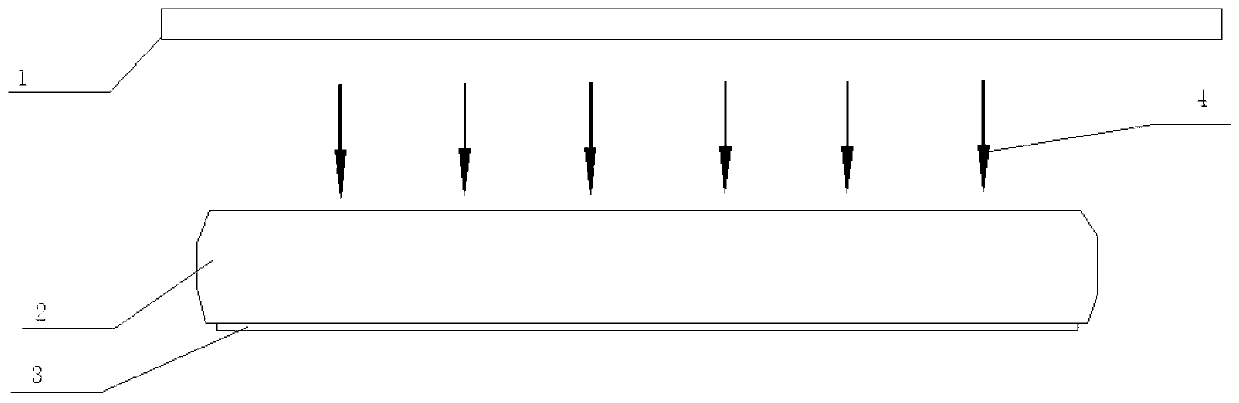

Large-sized paper-surface gypsum board production process with annual yield of 60,000,000 square meters and production line thereof

ActiveCN103862565AReduce pollutionReduce labor intensityCeramic shaping plantsSurface layering apparatusAutomatic controlEngineering

The invention discloses a large-sized paper-surface gypsum board production process with the annual yield of 60,000,000 square meters and a production line thereof. The process is simple; equipment and all automatic control systems of the production line are improved, so that the requirements on continuously increasing production volume are met, the annual yield reaches over 60,000,000 square meters, the speed reaches over 120 meters, and the technical blockades of similar foreign production lines are broken through; the aspects, such as heat energy utilization, flue gas emission treatment and waste scrap collection, are improved, so that energy saving and emission reducing are realized, and the pollution to the environment is reduced; the whole production line adopts the automatic control systems, so that the labor intensity of staff is reduced, the manual work is reduced, the production cost of enterprises is reduced, and the production efficiency and the rate of qualified products are increased.

Owner:TAISHAN GYPSUM CO LTD

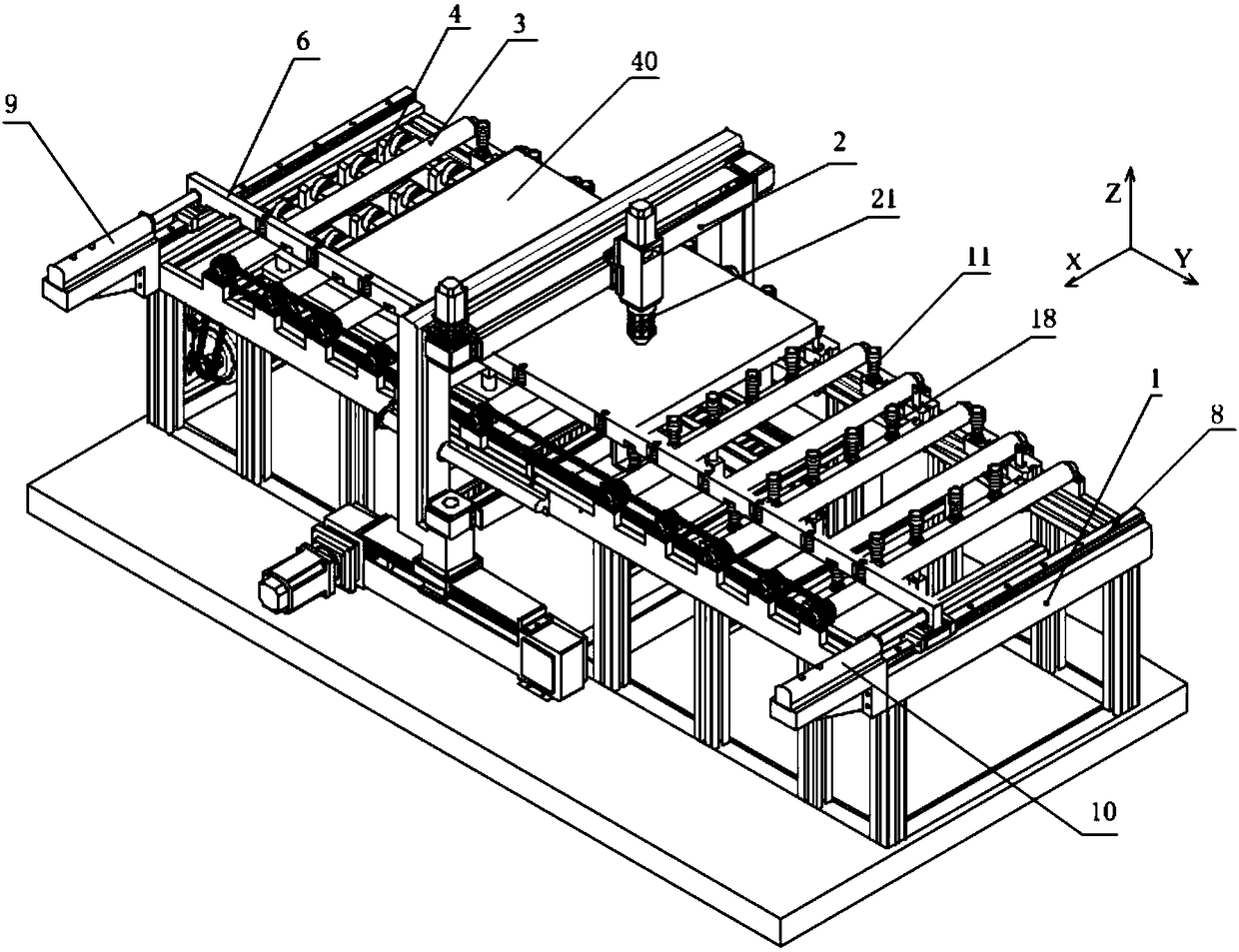

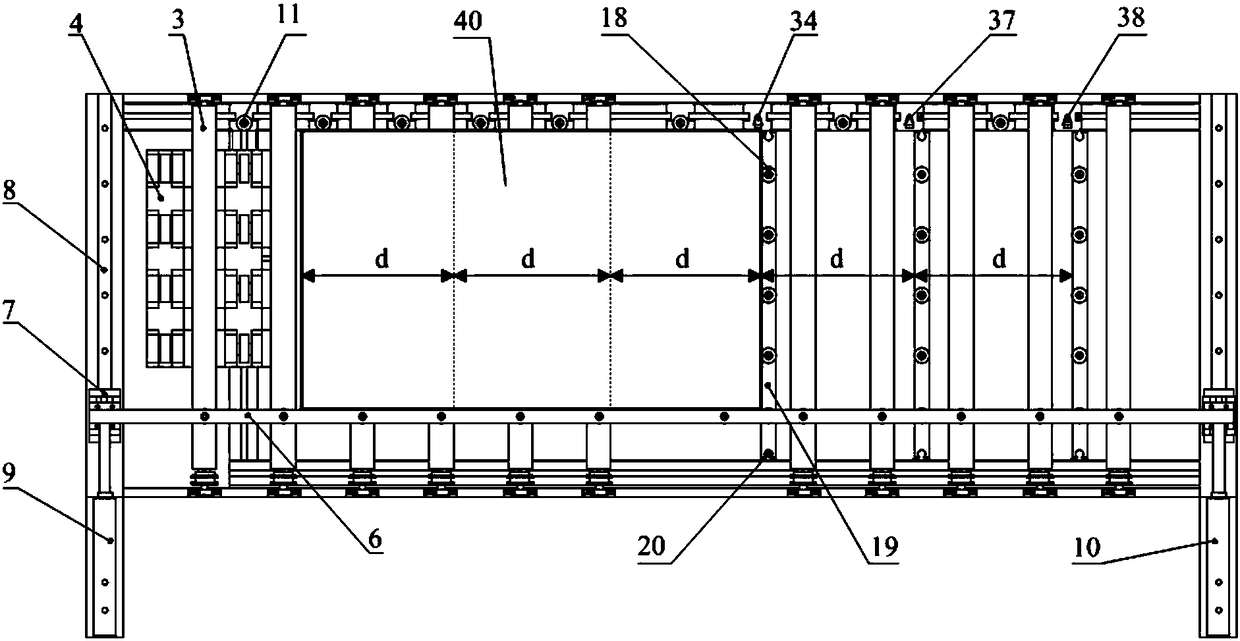

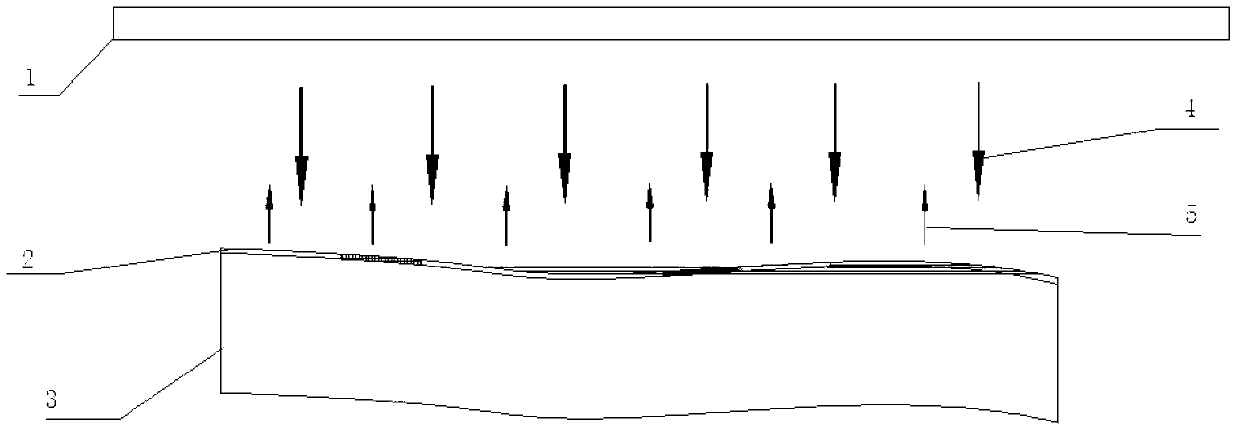

Device and method for realizing automatic thickness ratio detection of composite plate

ActiveCN108489434AComprehensive and accurate detectionImprove product qualification rateUsing subsonic/sonic/ultrasonic vibration meansUsing optical meansLaser rangingSpeed of sound

The invention relates to a device capable of realizing automatic thickness ratio detection of the whole surface of a composite plate. The device comprises a composite plate conveying machine tool anda three-coordinate detecting device. The three-coordinate detecting device is connected with the composite plate conveying machine tool through a sliding bearing. The composite plate conveying machinetool is provided with an automatic plate positioning device which comprises X-axis and Y-axis direction positioning devices and a positioning auxiliary device. The three-coordinate detecting device comprises a three-coordinate meter, a laser-ultrasonic integrated probe and laser ranging. The method capable of realizing automatic thickness ratio detection of the whole surface of the composite plate comprises the steps that the laser-ultrasonic integrated probe of the three-coordinate meter is lowered to press against the surface of the composite plate; the ultrasonic and reflection waves of the interface of the base layer and the stratified layer of the composite plate is detected; and according to the detecting time of the reflection waves and the propagation sound velocity of the ultrasonic wave in the stratified layer material, the thickness of the stratified layer and the base layer is calculated. The device and the method have the advantages of comprehensive and accurate detection, high degree of automation, improved production efficiency and reduced cost.

Owner:BEIJING XINGHANG MECHANICAL ELECTRICAL EQUIP

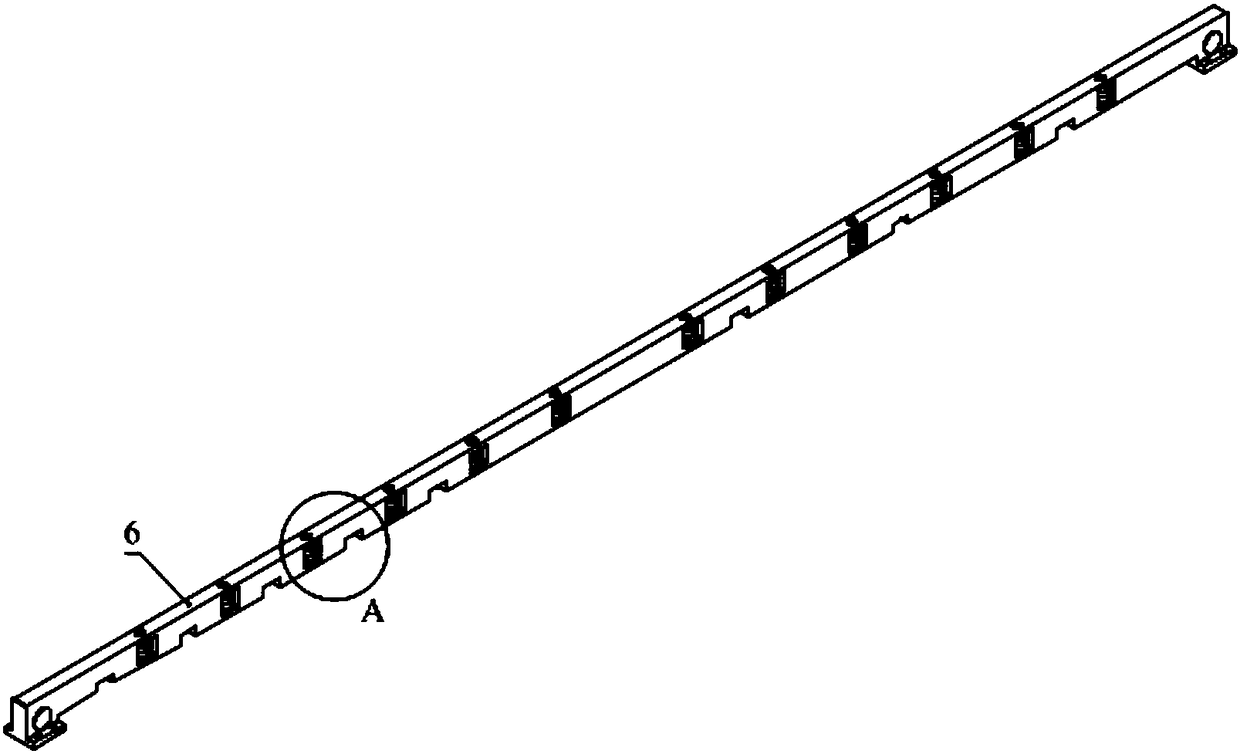

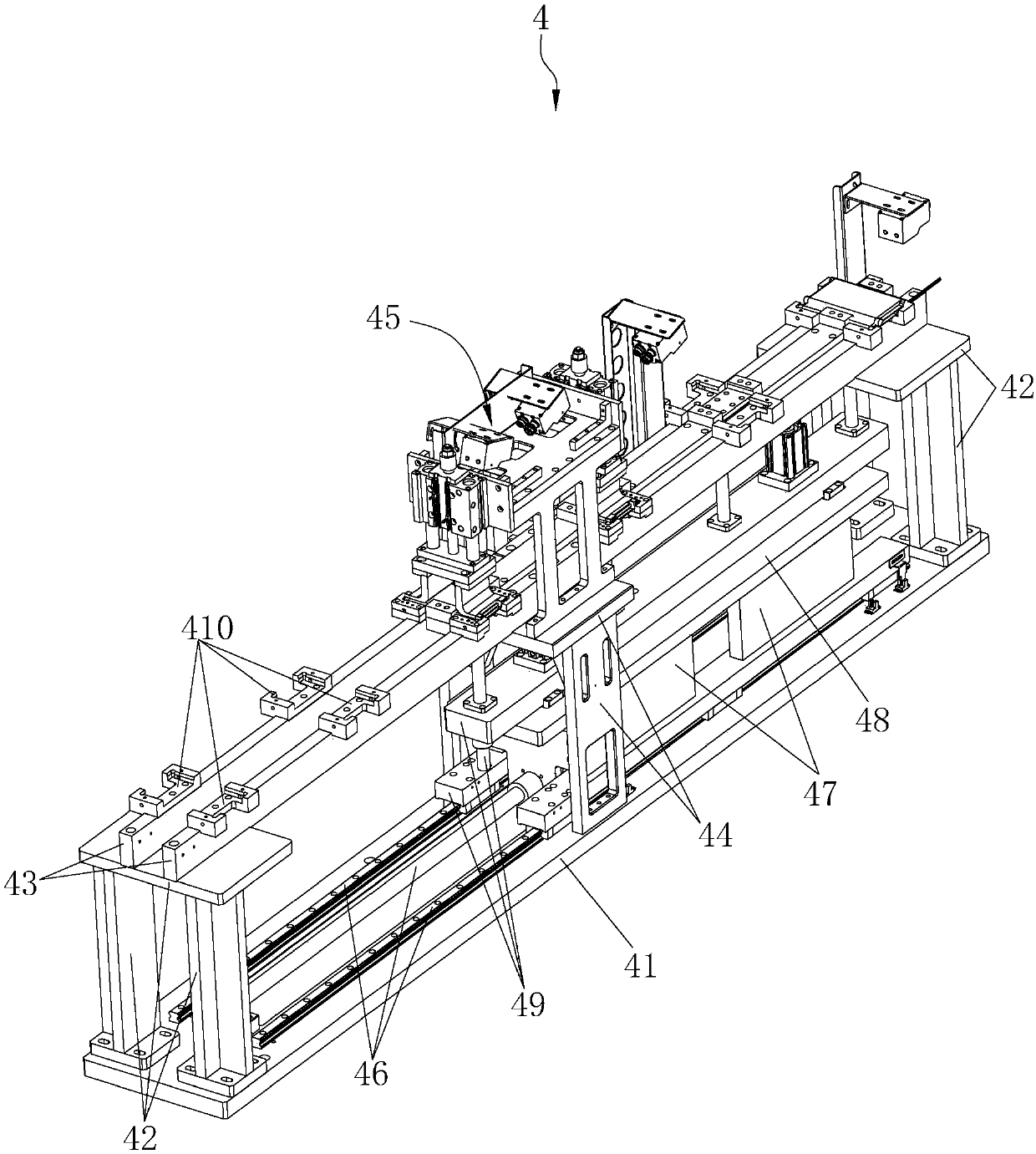

Linear feeding and discharging mechanism of full-automatic bar chamfering machine

ActiveCN103769970AAvoid wasted man-hoursCompact structureEdge grinding machinesGrinding feedersEngineeringMechanical engineering

The invention discloses a linear feeding and discharging mechanism of a full-automatic bar chamfering machine. The linear feeding and discharging mechanism of the full-automatic bar chamfering machine comprises a work head mechanism, a feeding mechanism and a receiving mechanism. The work head mechanism comprises a clamping head used for clamping bars and a spindle used for driving the clamping head to rotate. A hollow inner cavity is formed in the spindle, and the bars at the front end of the spindle can be conveyed out toward the rear end of the spindle along the hollow inner cavity. The feeding mechanism comprises a linear feeding precision linear module which can make linear reciprocating movement, and the linear feeding precision linear module is arranged at the position where linear reciprocating movement can be made in the axis direction of the spindle of the work head mechanism to enable the bars of the work head mechanism to be pushed in the hollow inner cavity of the spindle along a straight line. The receiving mechanism is arranged to enable the bars discharged by the hollow inner cavity of the work head mechanism to be conveyed to a receiving position in a linear mode. According to the linear feeding and discharging mechanism, the feeding mode is changed into a front positioning mode from a rear positioning mode, the feeding mode of front feeding and front discharging is changed into a work head inside linear discharging mode, so that the entire structure of the mechanism is compact, and the production efficiency and the product percent of pass are improved while the requirement for precision can be met.

Owner:XIAMEN TUNGSTEN

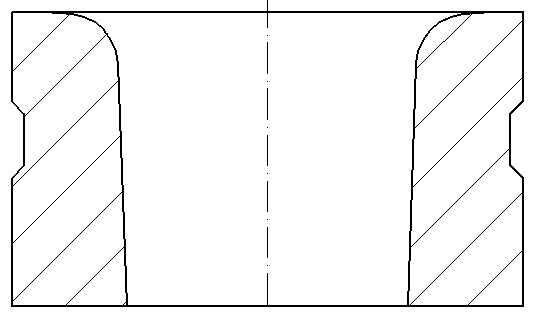

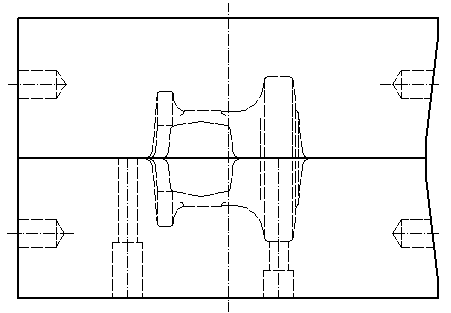

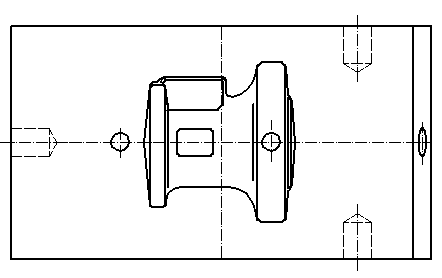

Flange ball valve body forging technology

InactiveCN103264137AImprove product qualification rateGood product quality controlValve arrangementsBall valveEngineering

The invention discloses a flange ball valve body forging technology, and relates to a forging technology and production of valve parts. The flange ball valve body forging technology is characterized in that a flange ball valve body is produced by a forging method; a flange and a valve body are integrally forged; the ball valve body is subjected to one-time hot die forging; round steel is subjected to upsetting forming and performing; and after finish forging, the flange ball valve body is trimmed to meet the requirement of the product on the dimension. A special preforming method is adopted, a round rod is preformed, a forge piece can be well filled in a cavity in the forming process, and defects that a material is not filled in the cavity, and the like are effectively avoided, so that the yield of the product is obviously improved; and the product has an excellent forging flow line, the product quality is well controlled, the inside metallographic structure is uniform and compact, and the product almost meets the requirements by 100 percent through ultrasonic flaw detection, and has an attractive appearance.

Owner:DALIAN DAGAO VALVE

Novel seasoned flour product and preparation method thereof

The invention relates to a novel seasoned flour product and a preparation method thereof. The novel seasoned flour product is prepared from 25 parts of flour, 2-2.25 parts of edible salt, 0.1 part of an emulsifying agent, 0.0170-0.0196 part of a sweetening agent, 0.0152-0.0171 part of a preservative, 7.1-7.4 parts of softened water, 0.1 part of a compound water-retaining agent, 6.86-8.58 parts of edible oil, 0.102-0.103 part of a compound preservative, 0.0022 part of an antioxidant, 0.114 part of essence, 0.39 part of monosodium glutamate powder, 0.52 part of white granulated sugar, 0.248 part of natural flavor and 0.41 part of chili. The proportion of the edible salt in the novel seasoned flour product is reduced by 10-30%, so that the novel seasoned flour product is more healthy; furthermore, the proportion of the sweetening agent is reduced by 5-10%, so that the raw material consumption is reduced; the water retention and corrosion prevention functions of the novel seasoned flour product are also reduced due to the reduction of the proportion of the edible salt, so that the compound water-retaining agent is added into the novel seasoned flour product for improving the water retention function, and the compound preservative is added into the novel seasoned flour product for improving the corrosion prevention function; therefore, the total shelf life and best taste period of the product provided by the invention are prolonged.

Owner:漯河市平平食品有限责任公司

Processing method for rapidly tempering low-e glass

InactiveCN103274585AImprove product qualification rateSave electricityGlass tempering apparatusGlass productionHeating furnaceElectric energy

The invention provides a processing method for rapidly tempering low-e glass. The processing method comprises the following steps of: 1, cutting the glass; 2, edging the glass; 3. downwards placing a low-e film in a heating furnace; 4, preheating and heating the glass; and 5, air cooling the glass. The processing method has the beneficial effects that the low-e film of the glass faces downwards, the problems of low temperature raising speed, non-uniformity in heating, damage to equipment and service life of the glass during heating are solved; electric energy is saved, the cost is further saved; the production efficiency is improved; and the quality of the glass is improved and the yield of the glass is increased.

Owner:天津南玻节能玻璃有限公司 +2

Full-electrode-lug cell automatic assembly line

PendingCN107658505AReduce labor intensityReduce manufacturing costAssembling battery machinesFinal product manufactureAssembly linePhysical health

The invention discloses a full-electrode-lug cell automatic assembly line which comprises a first rack group and a second rack group. A hot-cold pressing mechanism is arranged on the first rack group,a first cell clamp conveying mechanism, a pre-welding mechanism, a cell incoming component and a front-section cell unloading component are arranged on a front-section rack, a cover plate feeding component is arranged beside a middle-section rack, a cell storing component, a cell turning component, a labeling component, a second cell clamp conveying mechanism, a grabbing module, a welding mechanism, a first rubberizing component and a middle-section cell unloading component are arranged on the middle-section rack, a heat-insulating ring feeding component is arranged beside a rear-section rack, and a turnplate mechanism, a spacer bush entering mechanism, a second rubberizing component and a rear-section cell unloading component are arranged on the rear-section rack. The technical problemsthat existing cell assembly production processes are troublesome and low in production efficiency and automation level, and use laser welding machines for welding, thereby being prone to generating dust and having impact on physical health of operation personnel are solved.

Owner:UNITED WINNERS LASER CO LTD

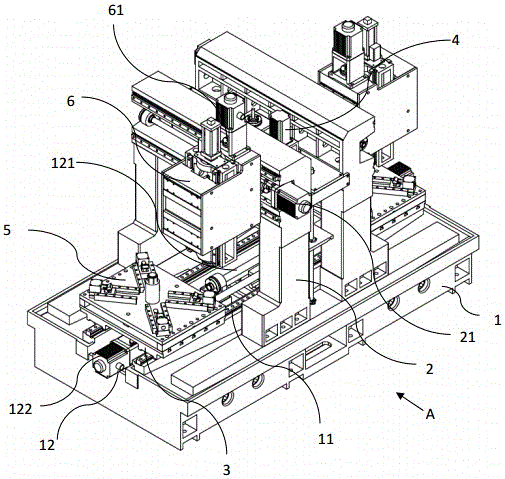

Gantry type double-head computer numerical control (CNC) milling machine for hub machining

ActiveCN106624084AHigh degree of automationSmall footprintMilling machinesLarge fixed membersNumerical controlSmall footprint

The invention provides a gantry type double-head computer numerical control (CNC) milling machine for hub machining, comprising a bedplate and characterized in that two symmetrical gantry racks are arranged on the bedplate; vertical milling head devices are installed at the reverse positions of the two gantry racks, and longitudinal guide rails are arranged on the bedplate, and run through the two gantry racks; two workbenches are installed on the longitudinal guide rails movably, and fixtures able to clamp workpiece are arranged on the workbenches; a workpiece delivery device is arranged between the two gantry racks, and comprises a clamping device and a lifting device able to drive the clamping device to move upward or downward; the workpiece on the left workbench can be delivered to the right workbench through transition of the workpiece delivery device. The CNC milling machine provided by the invention is mainly used for the hub machining, and the workpiece can be clamped automatically by the fixtures. The workpiece roughly machined is delivered to the right workbench through the workpiece delivery device for fine machining. The CNC milling machine provided by the invention has the advantages of high level of automation and small occupied area.

Owner:NINGBO DEMA INTELLIGENT MACHINERY CO LTD

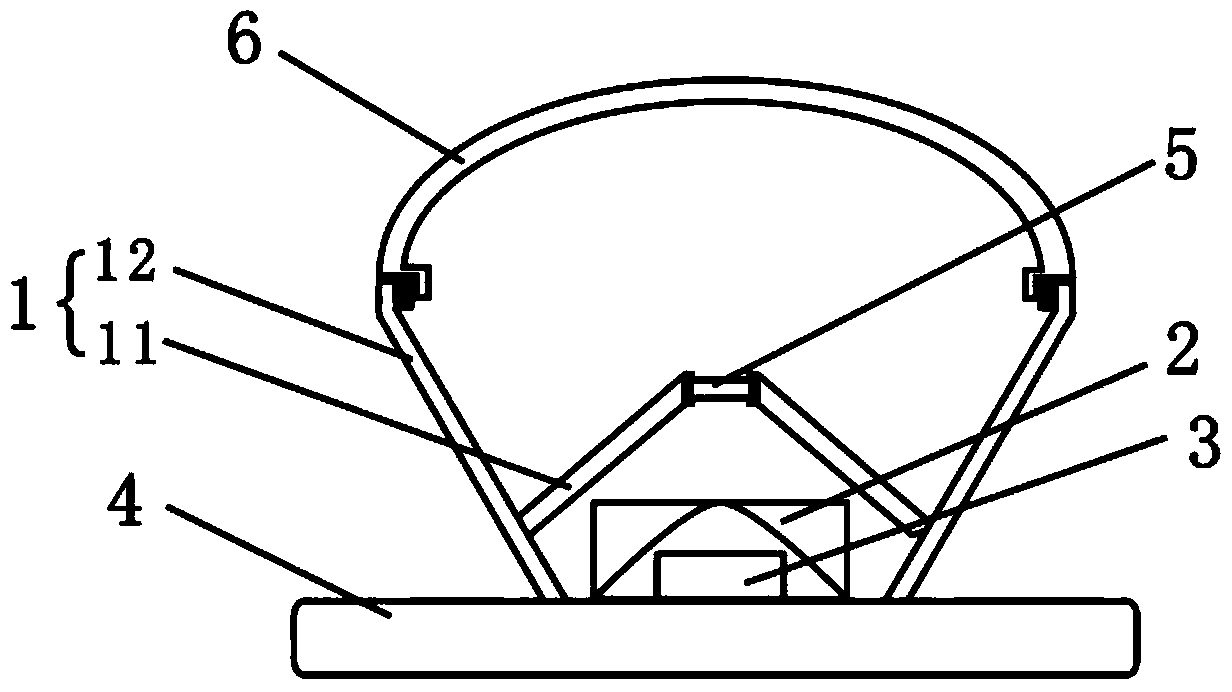

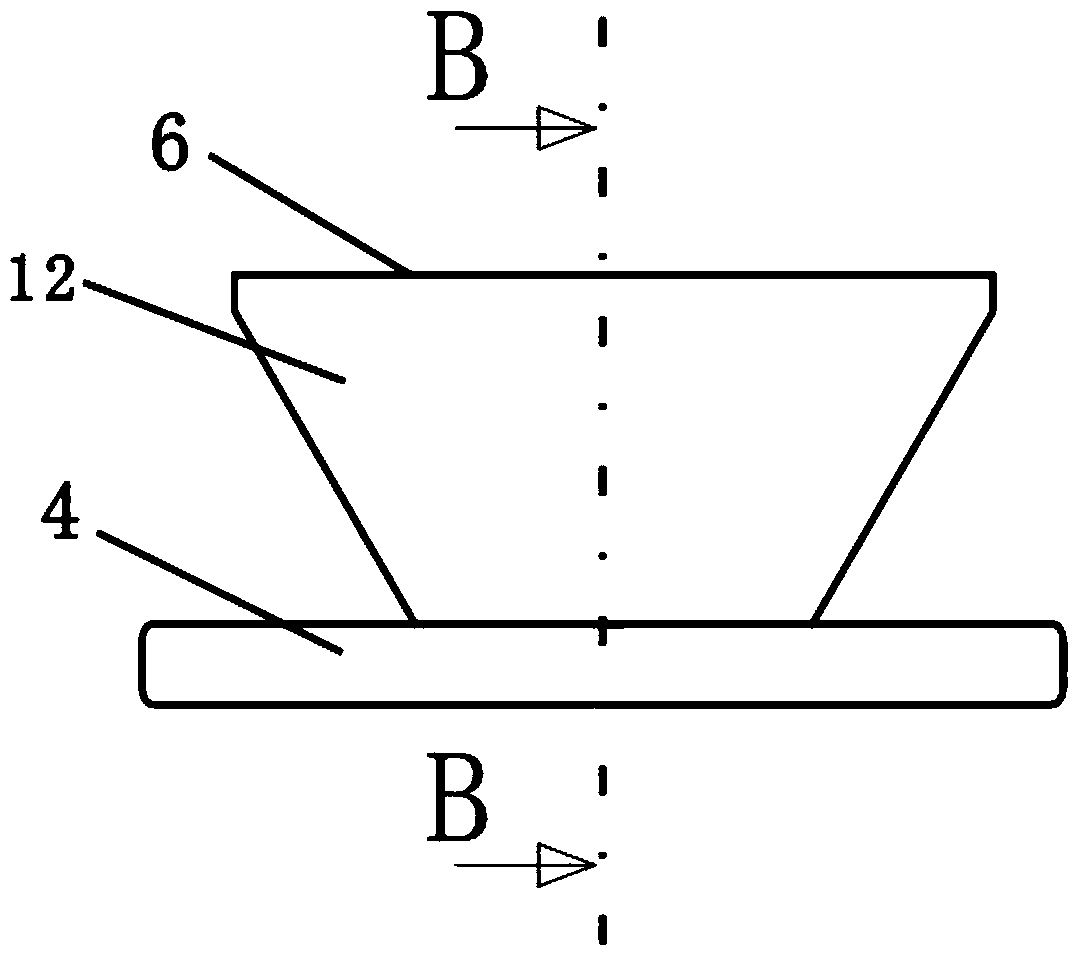

Remote fluorescent LED (Light Emitting Diode) device

InactiveCN103557453AAvoid attenuationExtended service lifePoint-like light sourceElectric lightingRare earthEngineering

The invention discloses a remote fluorescent LED (Light Emitting Diode) device which comprises a light diffusion lampshade, a rare-earth fluorescent resin sheet, an LED condensing lens, an LED chip and a combined reflection cup, wherein the combined reflection cup comprises an outer reflection cup and an inner reflection cup; the inner reflection cup is upside-down and is combined with the outer reflection cup; a first sealed space is formed after the opening of the bottom of the inner reflection cup is combined with the rare-earth fluorescent resin sheet; the LED condensing lens and the LED chip are located in the first sealed space; the LED chip is located below the LED condensing lens and above the outer reflection cup; the outer reflection cup and the light diffusion lampshade are tightly connected to form a second sealed space; the first sealed space is located in the second sealed space. Fluorescent powder is separated from the LED chip to be conductive to heat radiation of the chip and keep use stability of the fluorescent powder; a light conversion range is limited in a small region, so that use amount of the fluorescent resin sheet is reduced, and cost is lowered; the light diffusion lampshade protects the inner part, so that the lights are soft and the appearance is beautiful.

Owner:SOUTH CHINA NORMAL UNIVERSITY

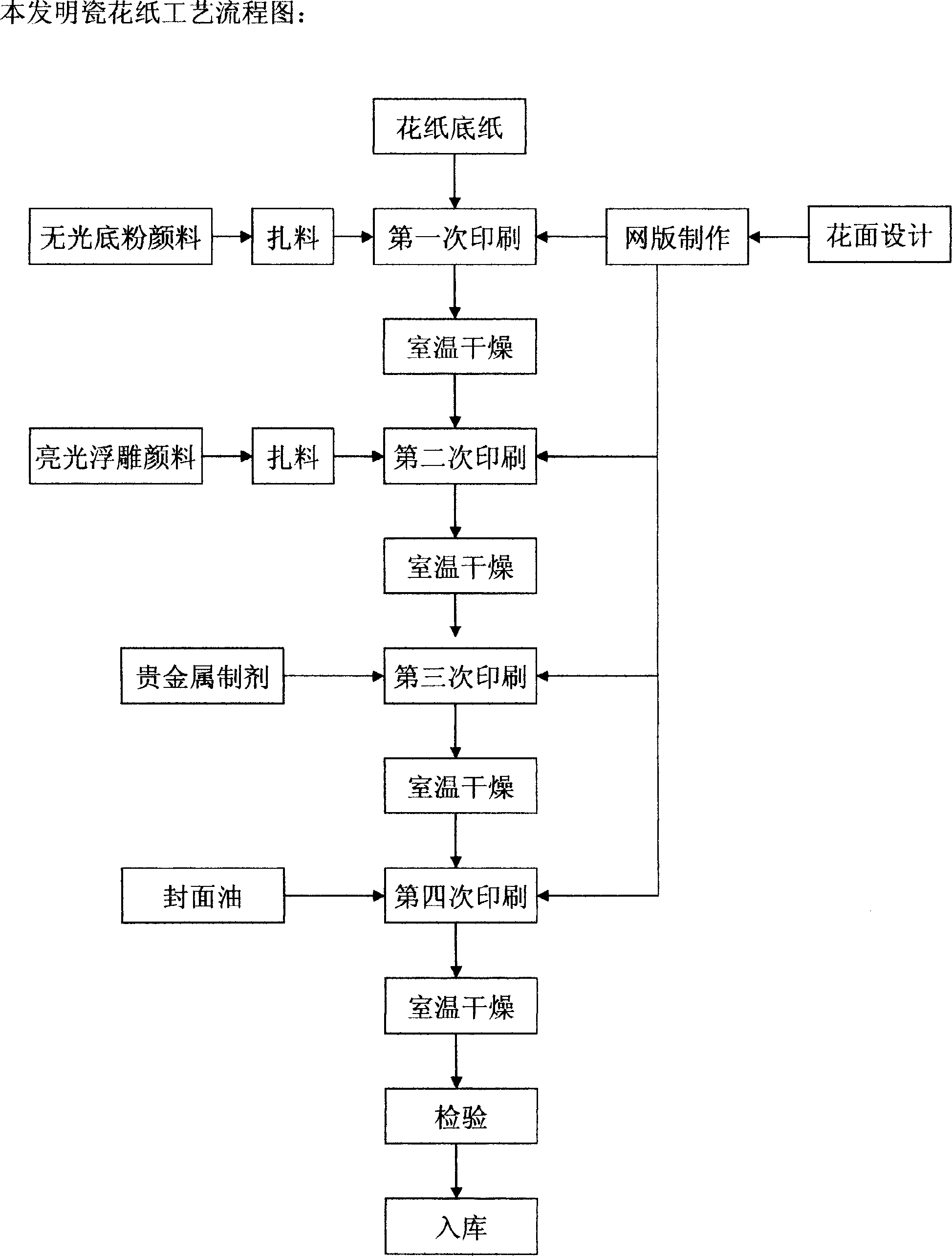

Method for making paper for used in embossed and patterned gold porcelain

InactiveCN1865591AStrong three-dimensional senseIncrease productivityScreen printersInksCeramicMaterials science

The invention discloses a manufacturing method of cameo gold-covering plaque paper, which comprises the following steps: preparing non-optical bottom-powder pigment; making gloss cameo pigment; preparing ink oil and screen; proceeding fourth print. The plaque paper can be sintered by traditional ceramics pigment and valued metal agent once, which saves artificial painting procedure.

Owner:CHAOZHOU XIHU CERAMIC DECAL

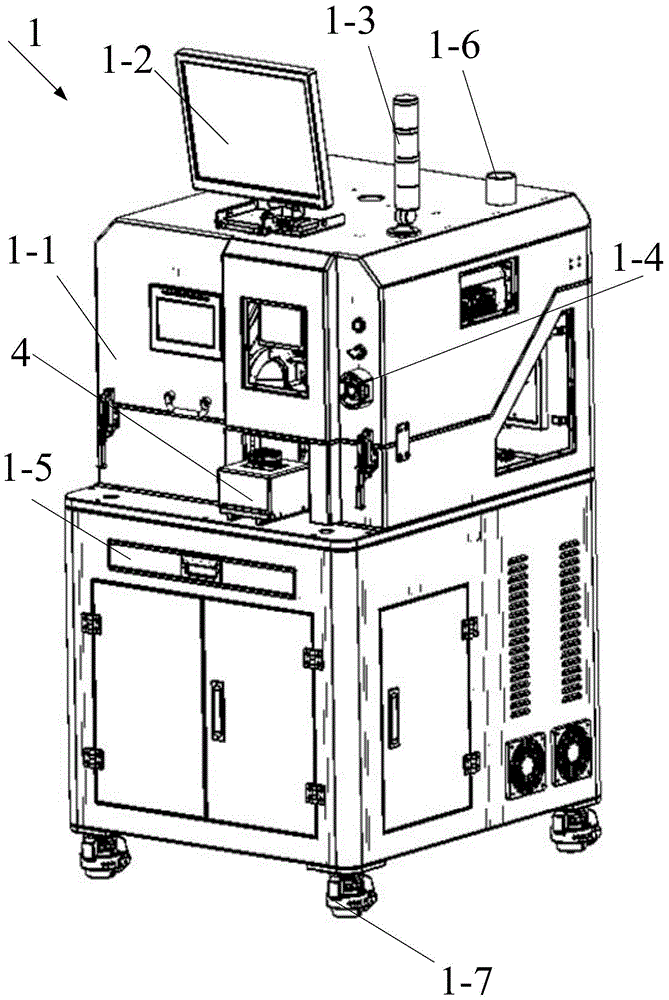

Laser engraving machine and operating method thereof

ActiveCN104889572AHigh precisionIncrease profitLaser beam welding apparatusControl systemLaser engraving

The invention discloses a laser engraving machine which comprises a box body, an alternating-current voltage stabilizer, a visual positioning system, a laser engraving machine system, a pre-positioning module, a correction module, a safety system, a supporting table, an exhaust system and a control system. The visual positioning system is in sliding connection with a visual positioning system motion guide rail on the supporting table, and the visual positioning system does X-direction motion along the visual positioning system motion guide rail on the supporting table. The correction module is fixed to the position, below the laser engraving machine system, of the supporting table. The pre-positioning module is arranged below the correction module, and is in sliding connection with a pre-positioning module motion guide rail on the supporting table. The pre-positioning module does Y-direction motion along the pre-positioning module motion guide rail. The invention further discloses an operating method of the laser engraving machine. The pre-positioning module and the correction module of the laser engraving machine can be replaced with different pre-positioning modules and correction modules, laser engraving on different parts is achieved, the utilization rate of the laser engraving machine is improved, the cost of factories is saved, and the application range is wide.

Owner:JIANGSU CHUANGYUAN ELECTRON CO LTD

Stone cutting machine with fixing and limiting device

InactiveCN103753711AGuaranteed not to moveSimple structureWorking accessoriesStone-like material working toolsRotary stageSTONE CUTTER

The invention relates to the field of stone cutting equipment, in particular to a stone cutting machine with a fixing and limiting device. The stone cutting machine comprises an operation table provided with a lower frame, a sawing device is arranged on the lower frame, an inverted L-shaped support is arranged in the middle of each of the left side and the right side in the lower frame on the upper surface of the operation table, a telescopic cylinder is disposed at the outer end of a horizontal cross rod of each inverted L-shaped support, a servo motor is connected to the upper end of each telescopic cylinder, and a sucker is connected to a telescopic cylinder end at the lower end of each telescopic cylinder. A movable rotation table is embedded in the middle of the surface of the operation table 1, and a bottom motor which drives the movable rotation table to rotate is disposed in the middle of the bottom face of the operation table. The stone cutting machine with the fixing and limiting device is simple in structure and convenient to operate, a stone block can be fixed by the suckers on two sides of the operation table and is guaranteed against moving, and consequently operating efficiency and product yield are improved.

Owner:刘彪

Alloy material and application thereof

The invention provides an alloy material, a plate for an inner liner of a refrigeration device, an inner container for the inner liner of the refrigeration device and the refrigeration device, and the refrigeration device. The alloy material is a polyethylene / polystyrene alloy or a polypropylene / polystyrene alloy. According to the alloy material of the embodiment of the invention, the alloy material simultaneously has great toughness on the basis of keeping relatively high strength; the alloy material further has great capability of resistance to corrosion of a single foaming agent, a polynary mixed foaming agent, edible oil and the like; in addition, as the toughness and strength of the alloy material can achieve great balance by formula adjustment, the thickness of the plate can be thinned by 10%-50% on the basis of keeping the technical standard of the existing plate for the refrigeration device, and then the production cost can be reduced.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com