Automatic wire winding machine of motor stator of electric car

An automatic winding machine and motor stator technology, applied in the field of machinery, can solve the problems of low product qualification rate, backward production technology, poor stability, etc., and achieve the effect of high product qualification rate, convenient model replacement and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings and examples. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

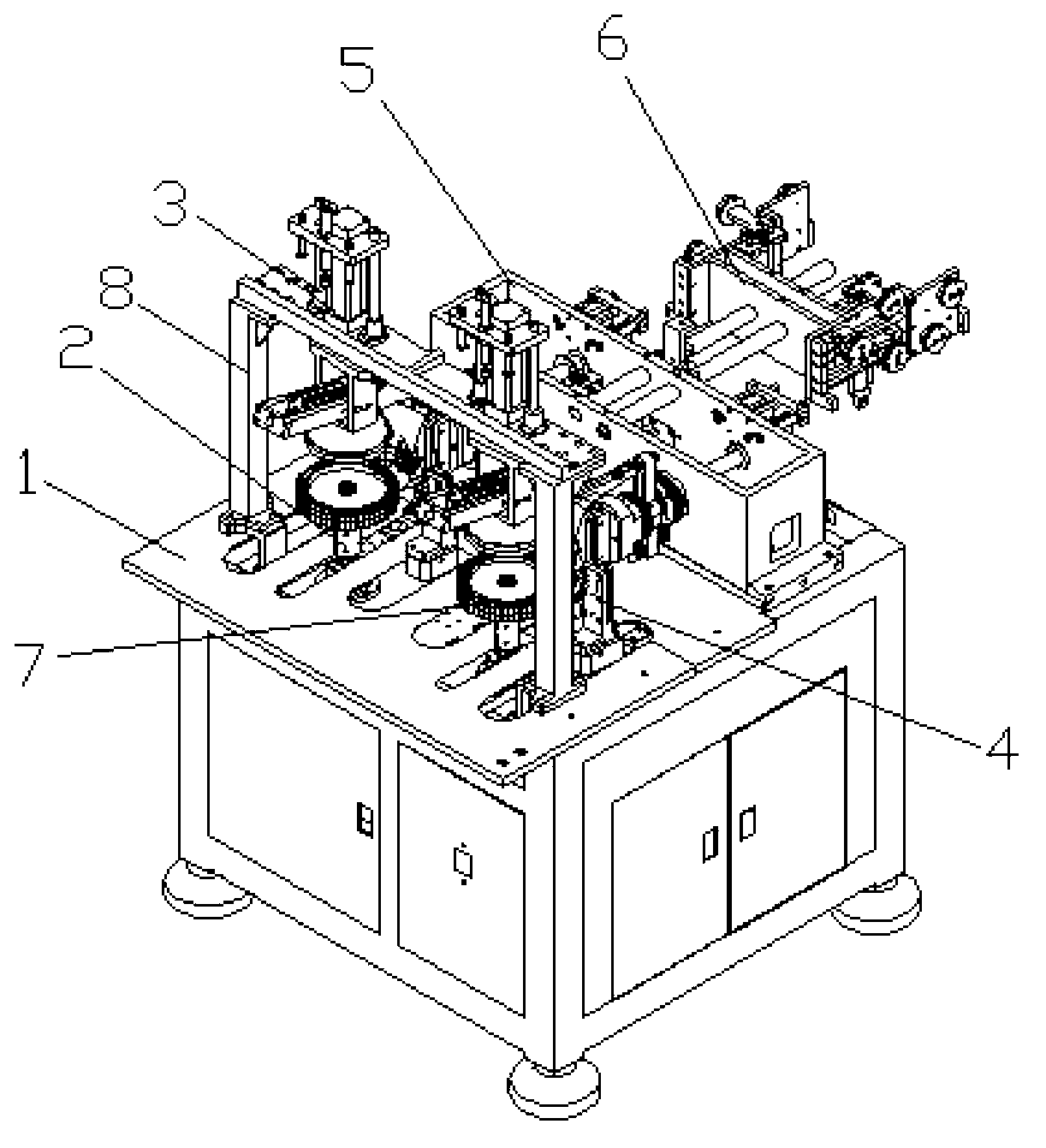

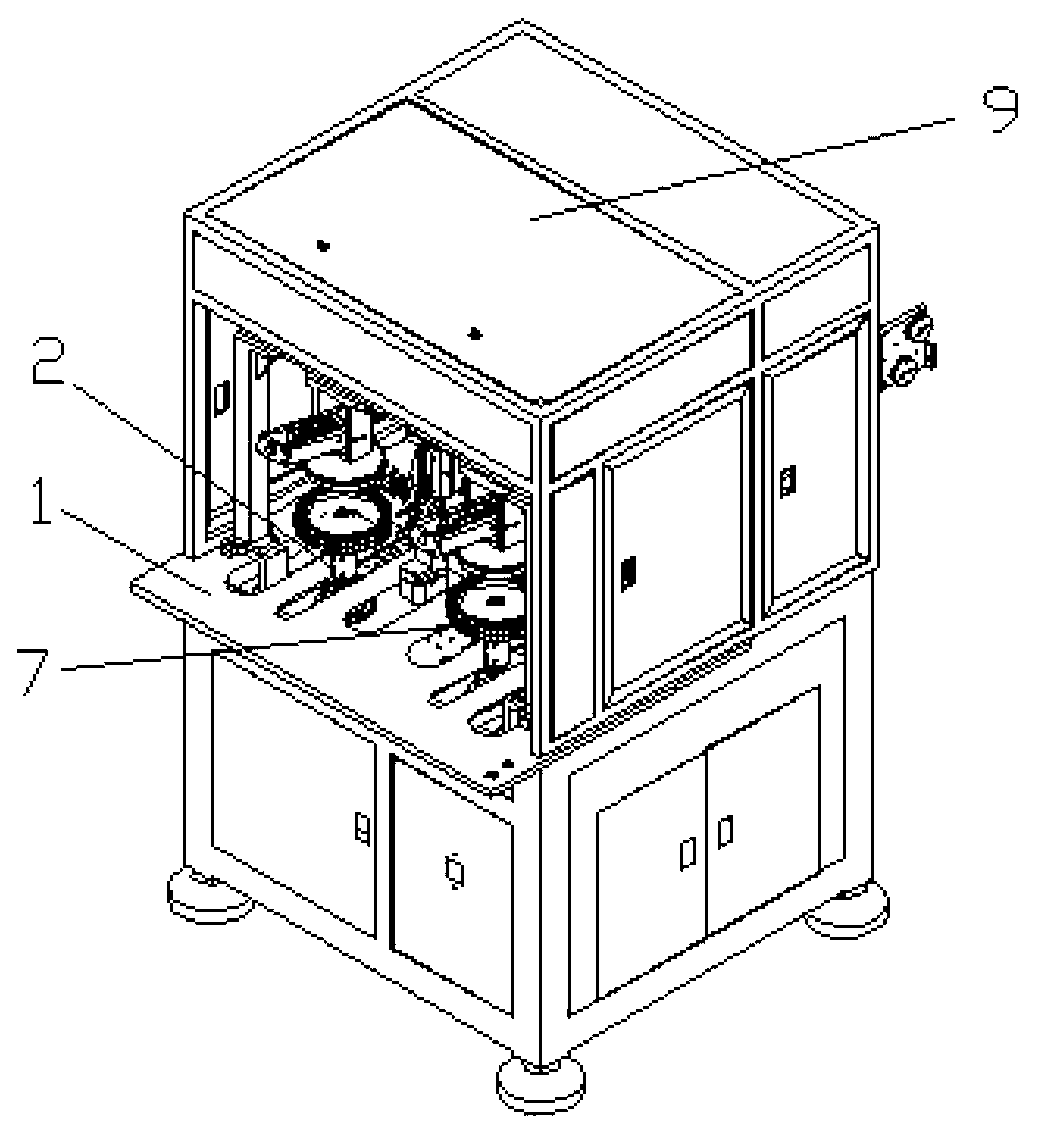

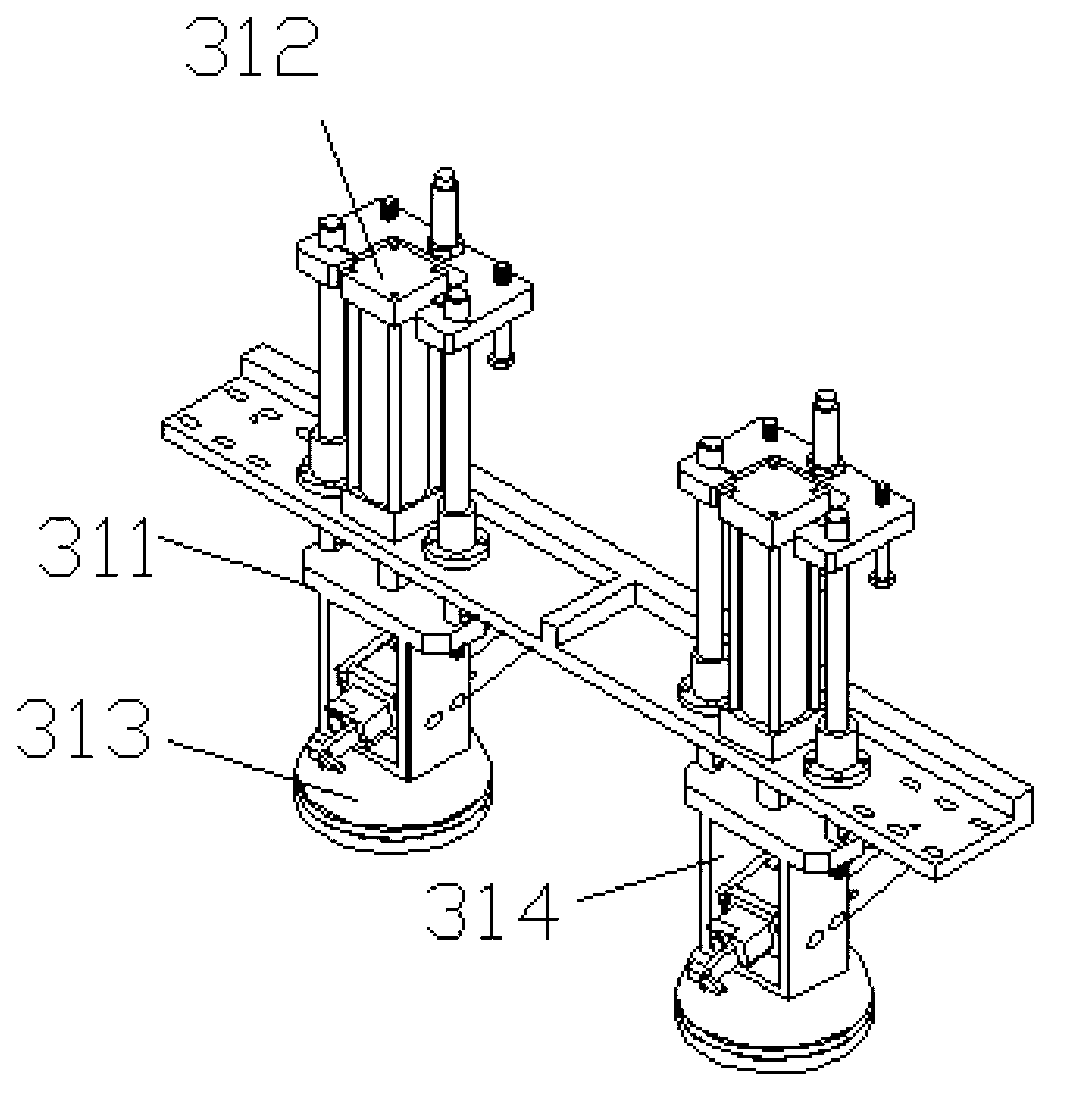

[0025] Such as Figure 1-9 As shown, the electric vehicle motor stator automatic winding machine includes a workbench 1, an indexing mechanism 2, a wire clipping mechanism 3 and a guard plate shaping mechanism 4 are arranged at the front of the workbench 1, and the middle part of the workbench 1 is arranged There is a spindle box flying fork winding and arranging mechanism 5, and a wire rack tension mechanism 6 is arranged at the rear of the workbench 1; the clamping and cutting mechanism 3 is arranged above the indexing mechanism 2 through a large bracket 8, and the guard plate is shaped The mechanism 4 is arranged on one side of the indexing mechanism 2; the wire stand tension mechanism 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com