Patents

Literature

3177results about How to "Good stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

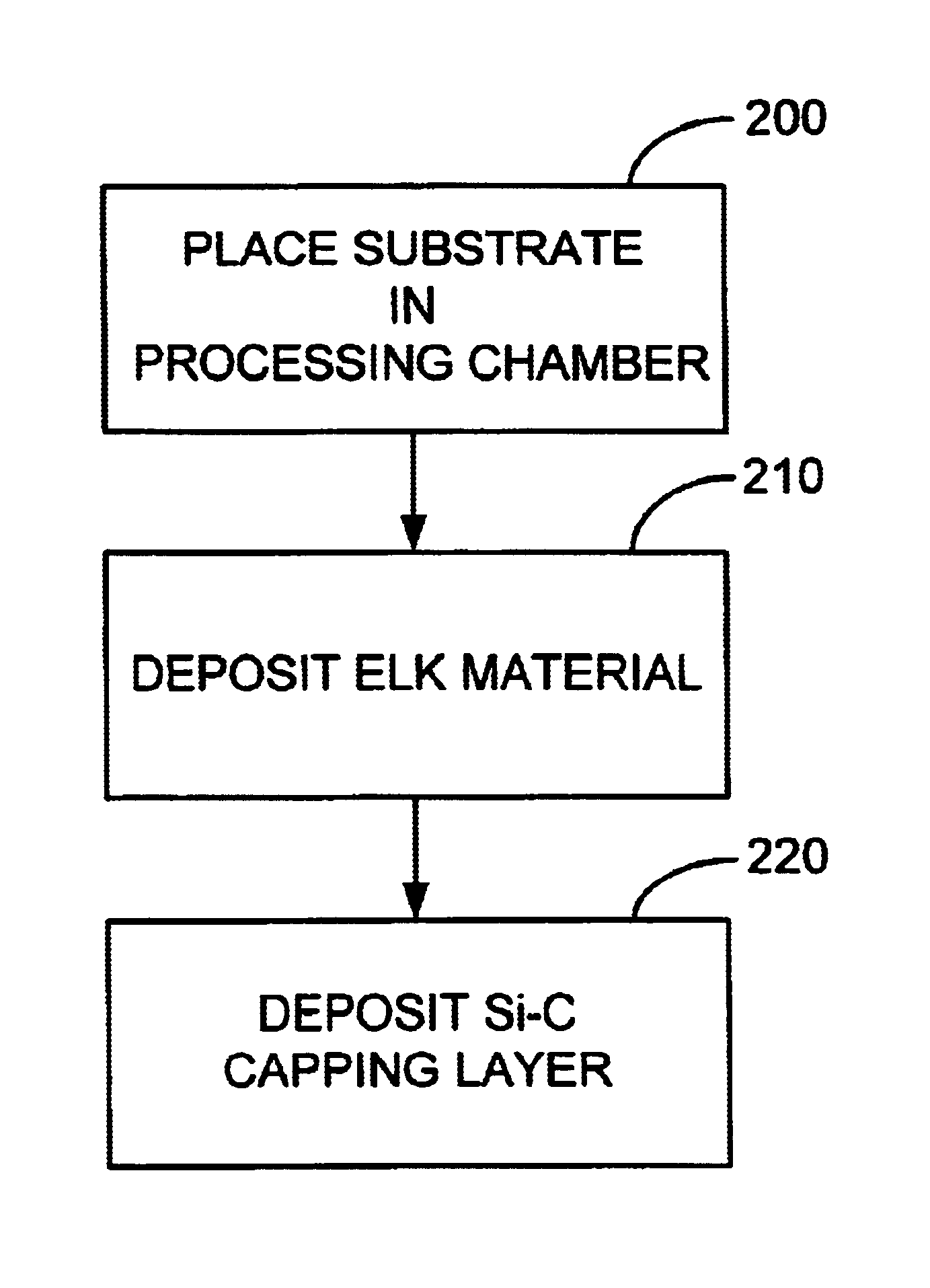

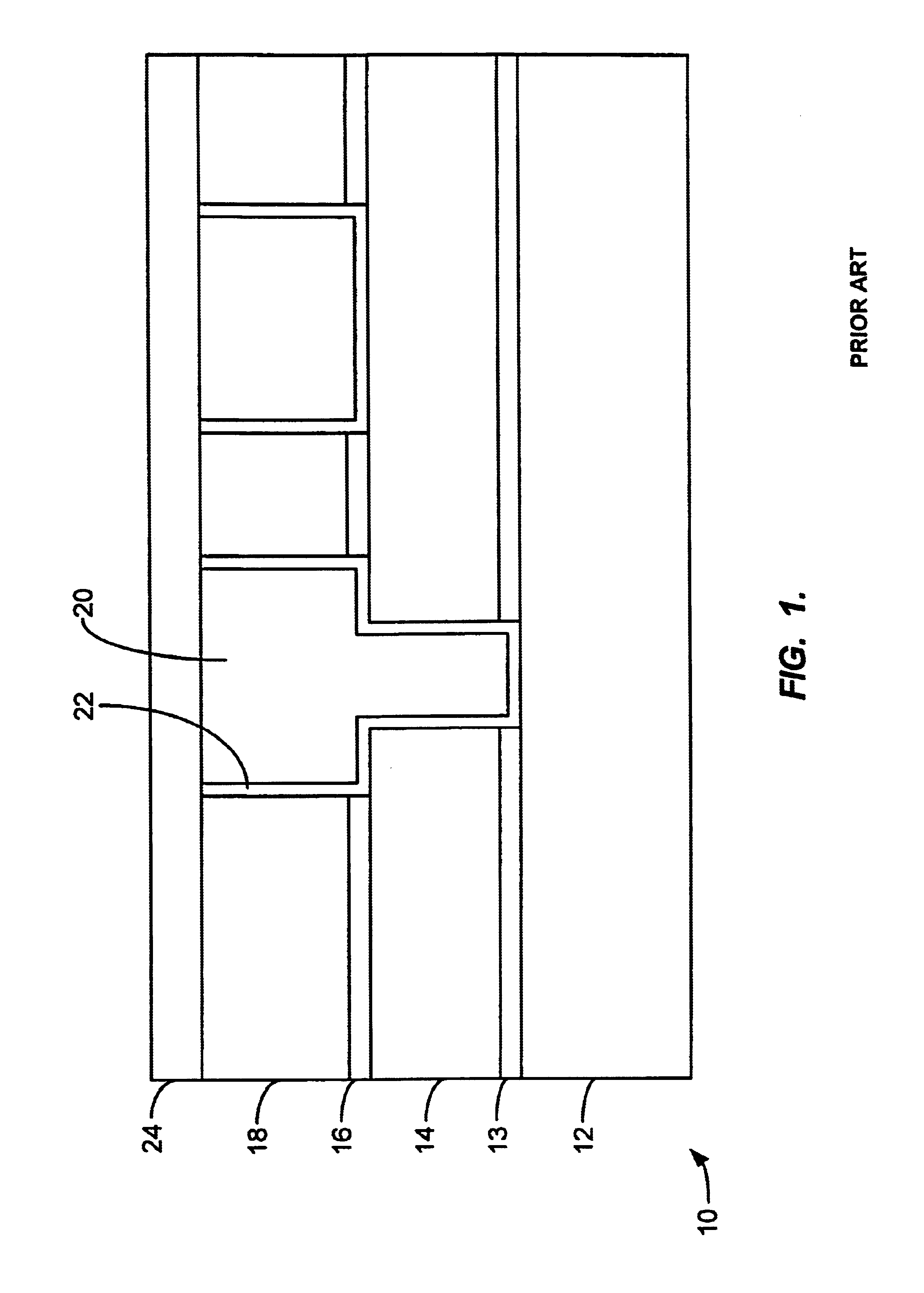

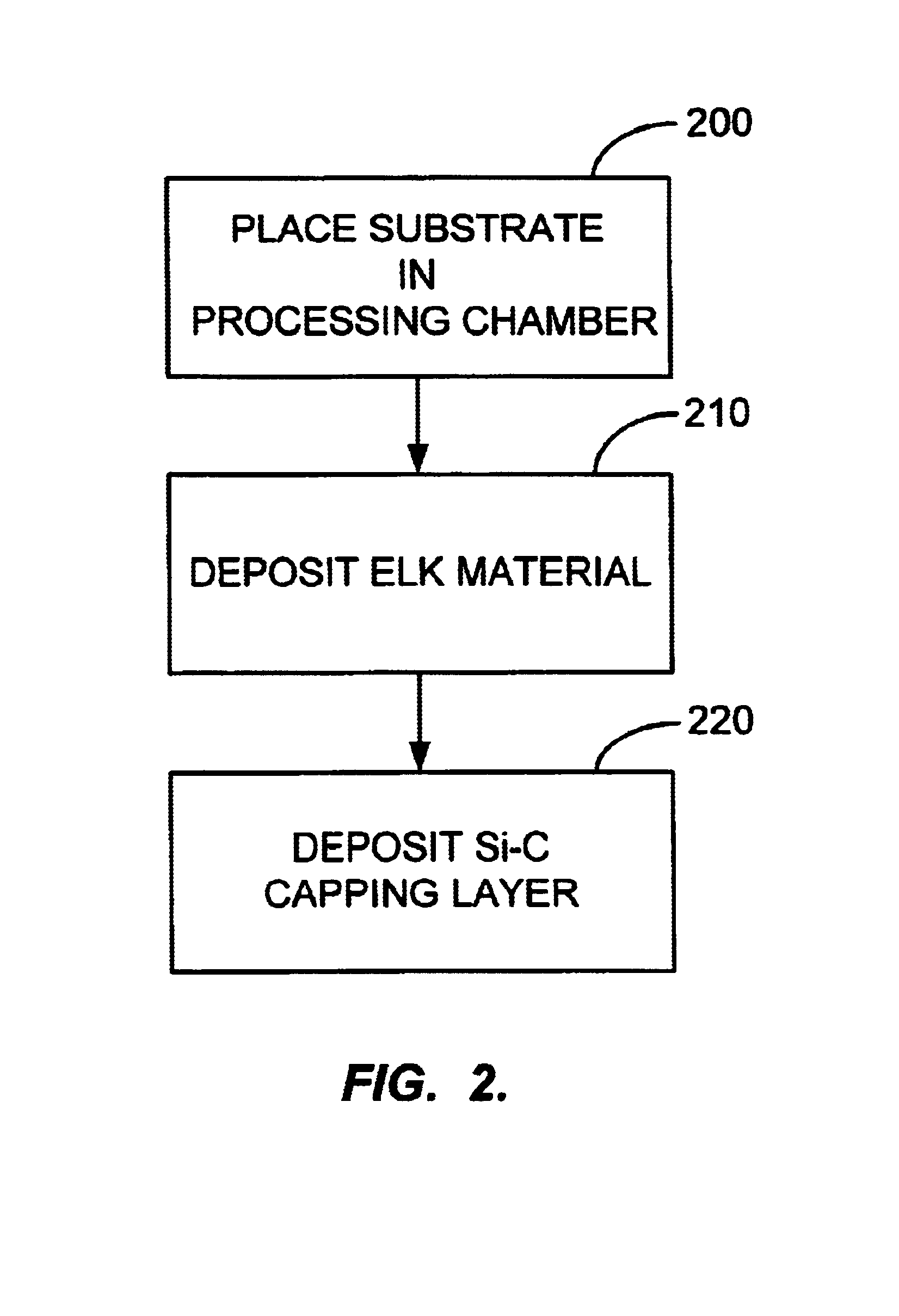

Capping layer for extreme low dielectric constant films

InactiveUS6875687B1Superior adhesion characteristicGood stabilitySemiconductor/solid-state device detailsSolid-state devicesCarbon dopedLow-k dielectric

Specific embodiments of the invention provide a silicon-carbide-type or silicon oxycarbide (also often called carbon-doped-oxide [CDO] or organosilicate glass) capping material and method for depositing this capping material on ELK films which are used as a dielectric material in integrated circuits. The ELK film may include any ELK film including but not limited to inorganic, organic and hybrid dielectric materials and their respective porous versions. The silicon-carbide-type material may be an amorphous silicon carbide type material such as the commercially available BLOk™ material, or a carbon-doped oxide material such as the commercially available Black Diamond™ both of which are developed by Applied Materials of Santa Clara, Calif. The amorphous silicon carbide (a-SiC) material is deposited using a plasma process in a non-oxidizing environment and the CDO-type material is deposited using an oxygen-starved plasma process. The non-oxidative or oxygen-starved plasma processes do not significantly degrade the underlying film's chemical and electrical properties. The CDO material offers the advantageous property of having a lower dielectric constant value of less than 3.5 as opposed to the a-SiC material which has a dielectric constant of approximately 4.5. The CDO material besides, having a lower dielectric constant also has a superior adhesion characteristics to the underlying ELK material. However, experiments have indicated that despite its higher dielectric constant, the a-SiC-type material (e.g. BLOk™) may be used to generate capped ELK films with similar or even reduced dielectric constants relative to lower k capped films, and may provide composite (i.e. ELK+cap) structures exhibiting superior k stability.

Owner:APPLIED MATERIALS INC

Method for preparing Nano silver piece

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

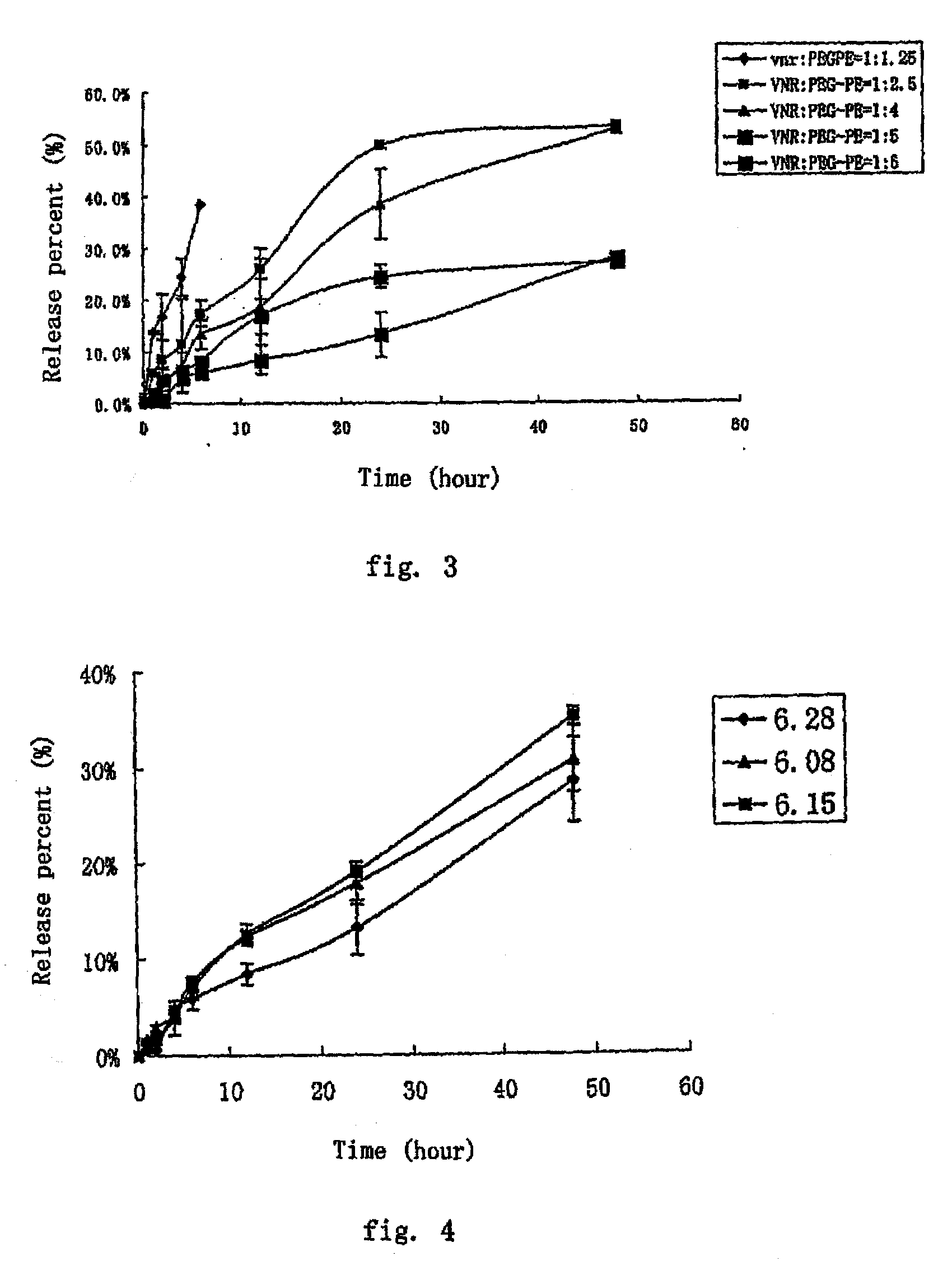

Nano Anticancer Micelles of Vinca Alkaloids Entrapped in Polyethylene Glycolylated Phospholipids

ActiveUS20090053293A1Good stabilityImprove drug distributionBiocidePharmaceutical non-active ingredientsVinorelbineAdjuvant

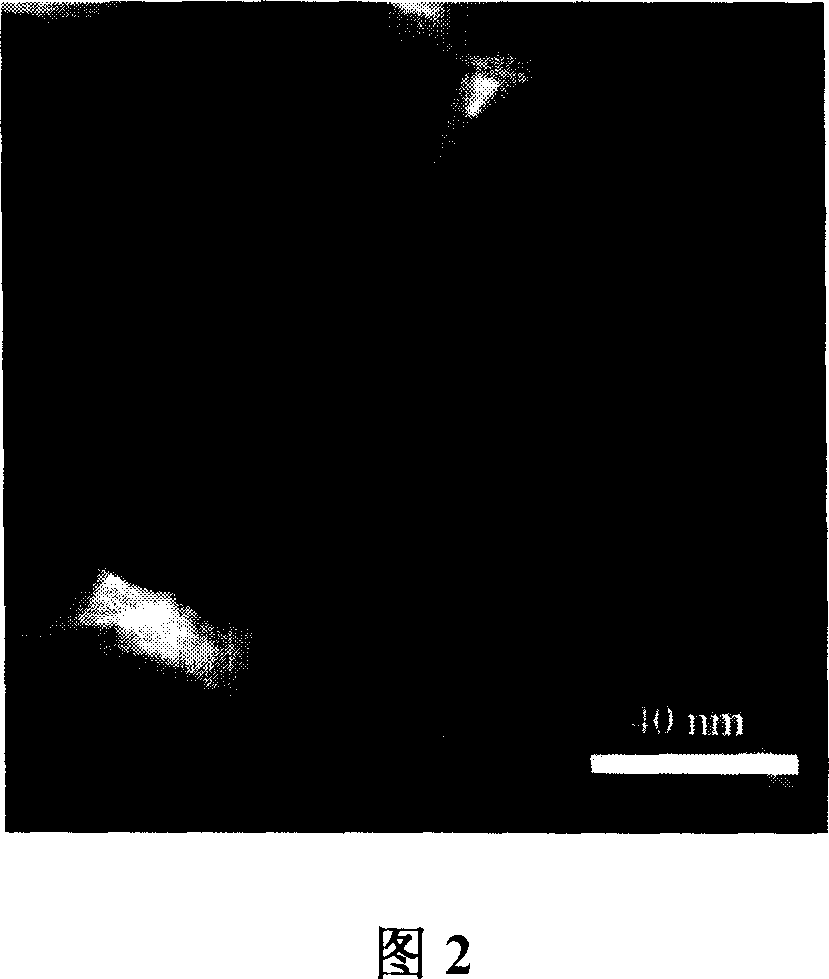

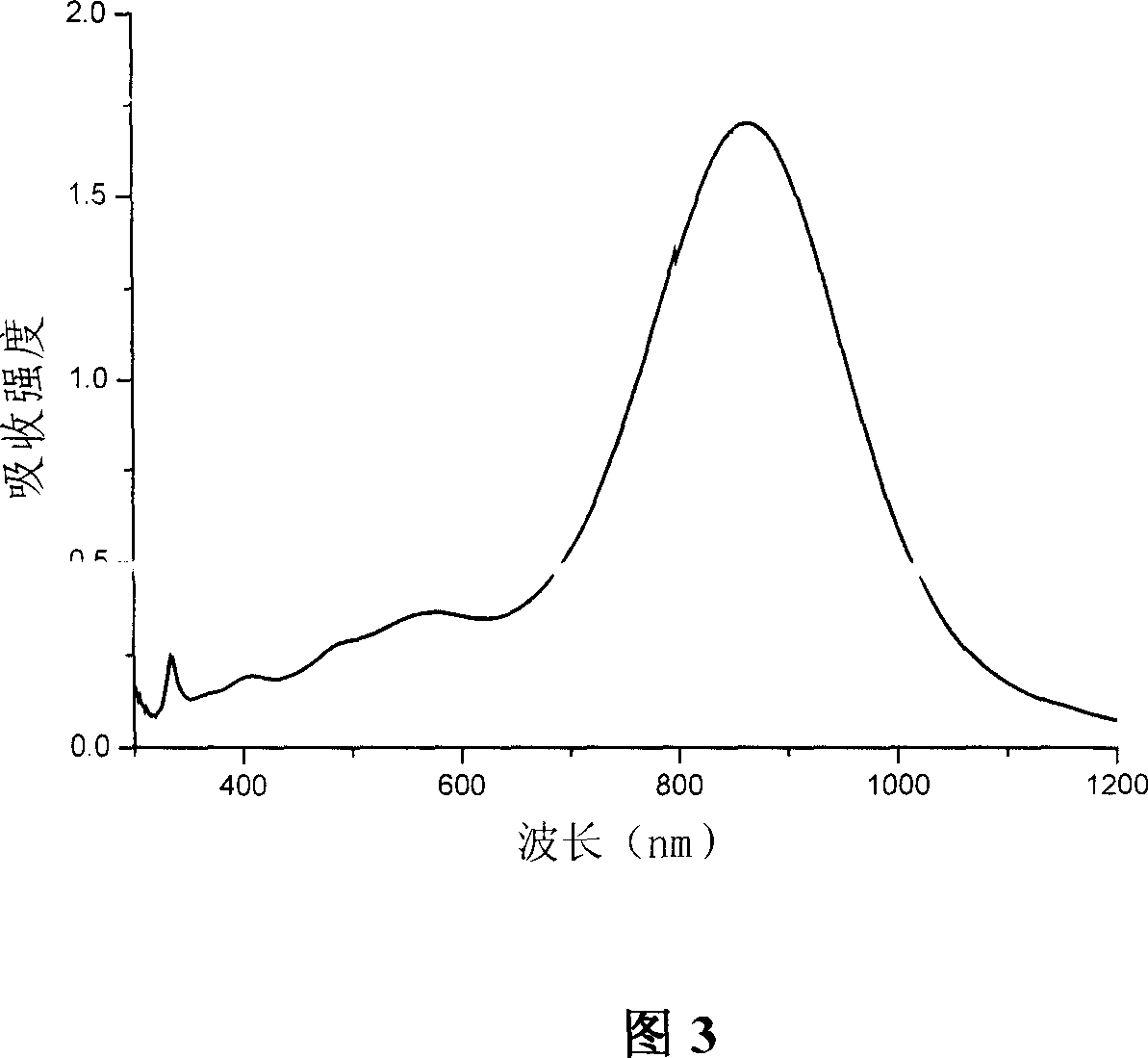

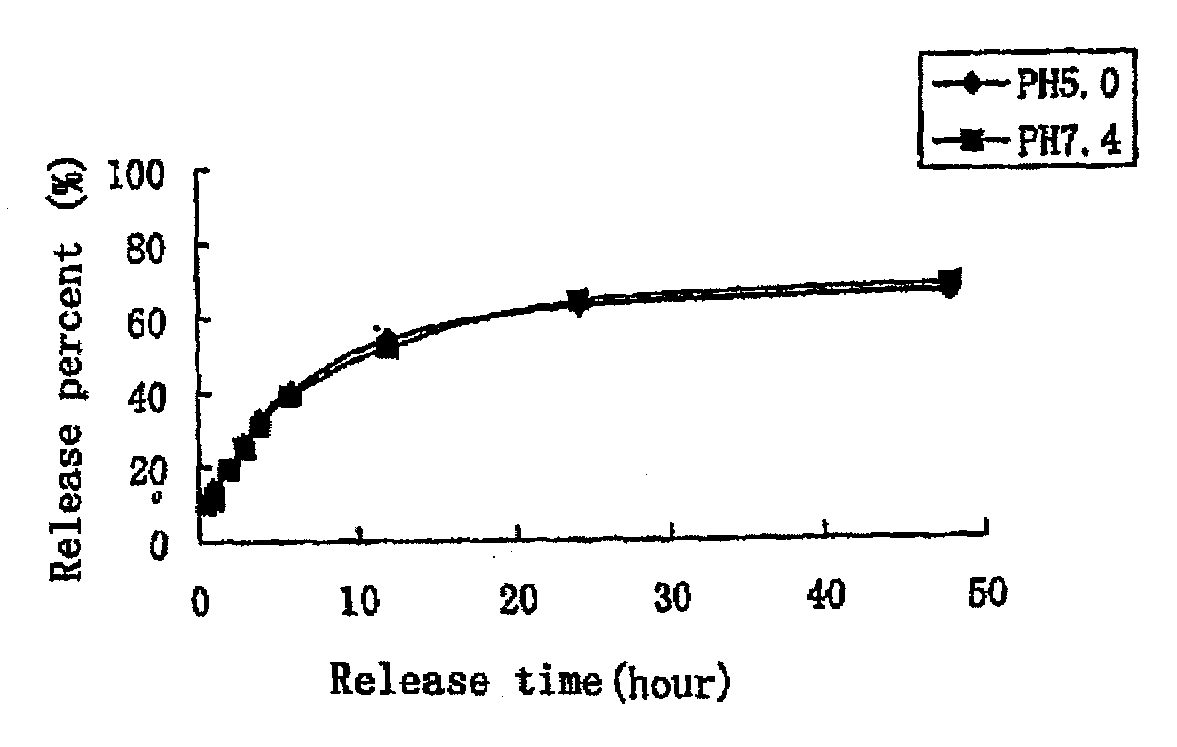

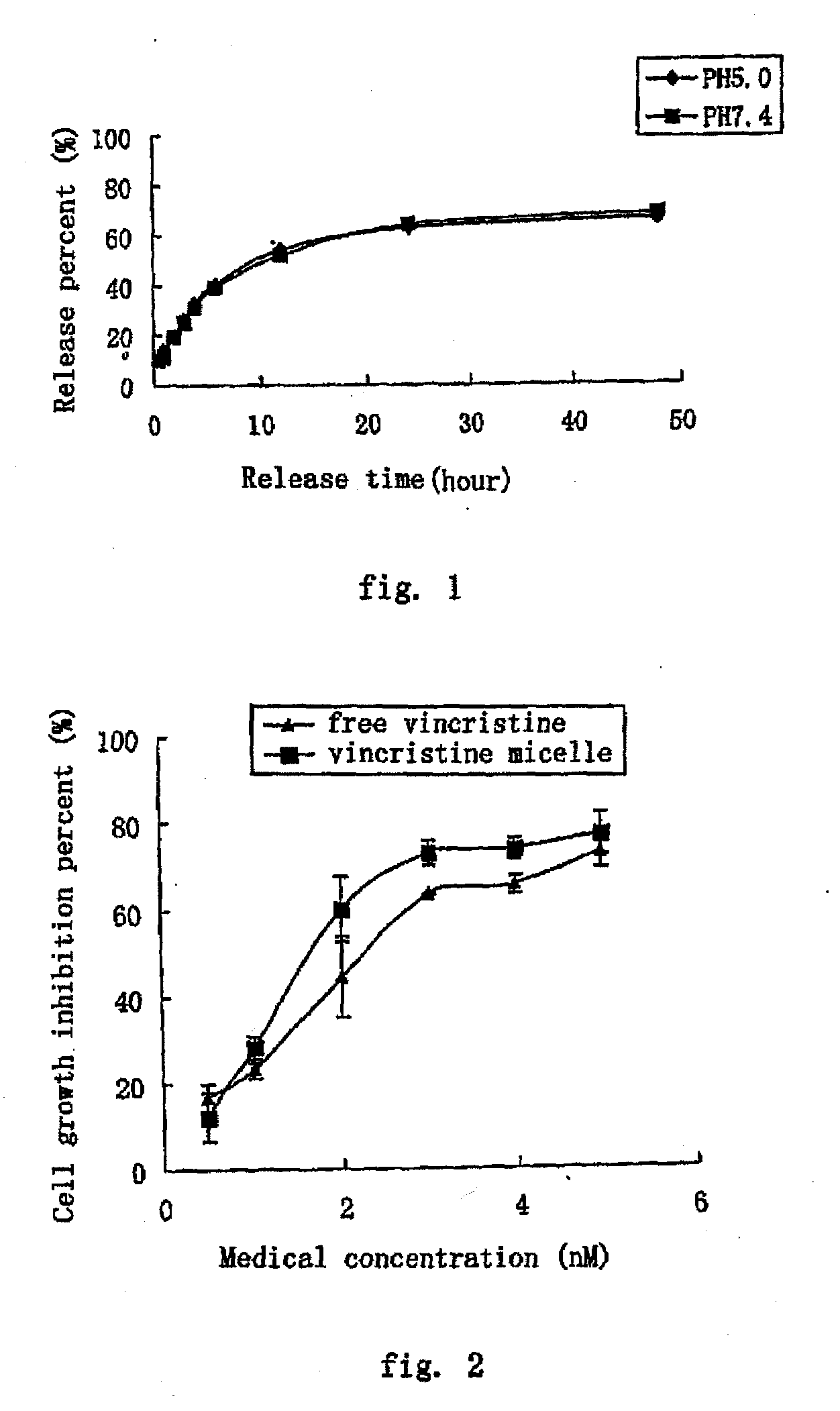

The present invention provides a nano-micellar preparation containing vinca alkaloids antitumor agent for intravenous injection, which cincludes a therapeutically effective amount of vinca alkaloids antitumor agent (vinblastine, vincristine, vindesine and vinorelbine), a phosphatide derivatized with polyethylene glycol, together with pharmaceutically acceptable adjuvants. The preparation is prepared by encapsulating the medicament with a nano-micelle to obtain the nano-micellar preparation containing vinca alkaloids antitumor agent for injection. The vinca alkaloids antitumor agent and the phosphatide derivatized with polyethylene glycol form a nano-micelle with a highly uniform particle size. In the micelle, the hydrophobic core of encapsulated medicament is surrounded by polyethylene glycol molecules to form a hydrophilic protective layer, so that the medicament is prevented from contacting with the enzymes and other protein molecules in blood and being recognized and phagocytozed by reticuloendothelial system in body, and the circulation time in vivo of the micelle is prolonged.

Owner:BEIJING DIACRID MEDICAL TECH

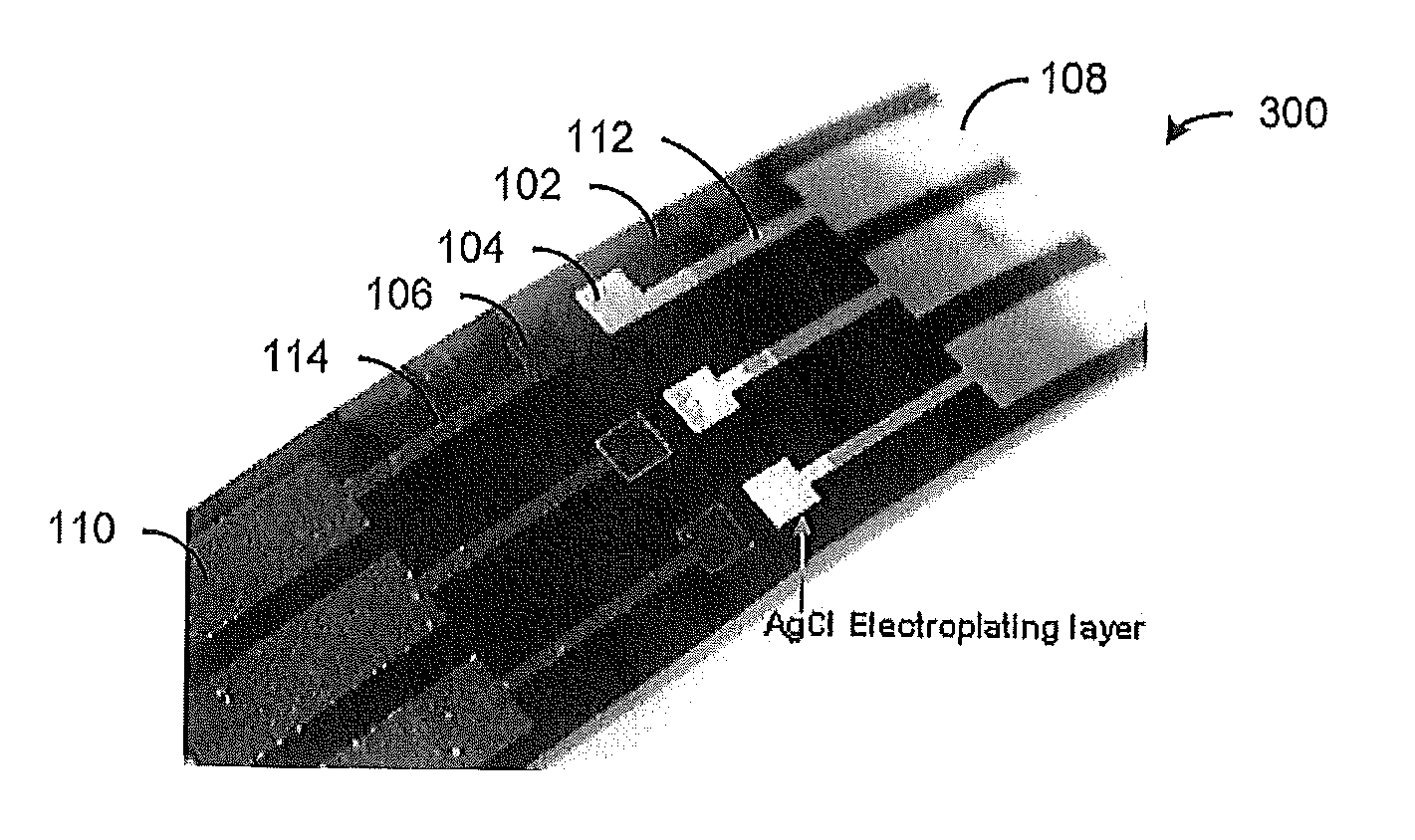

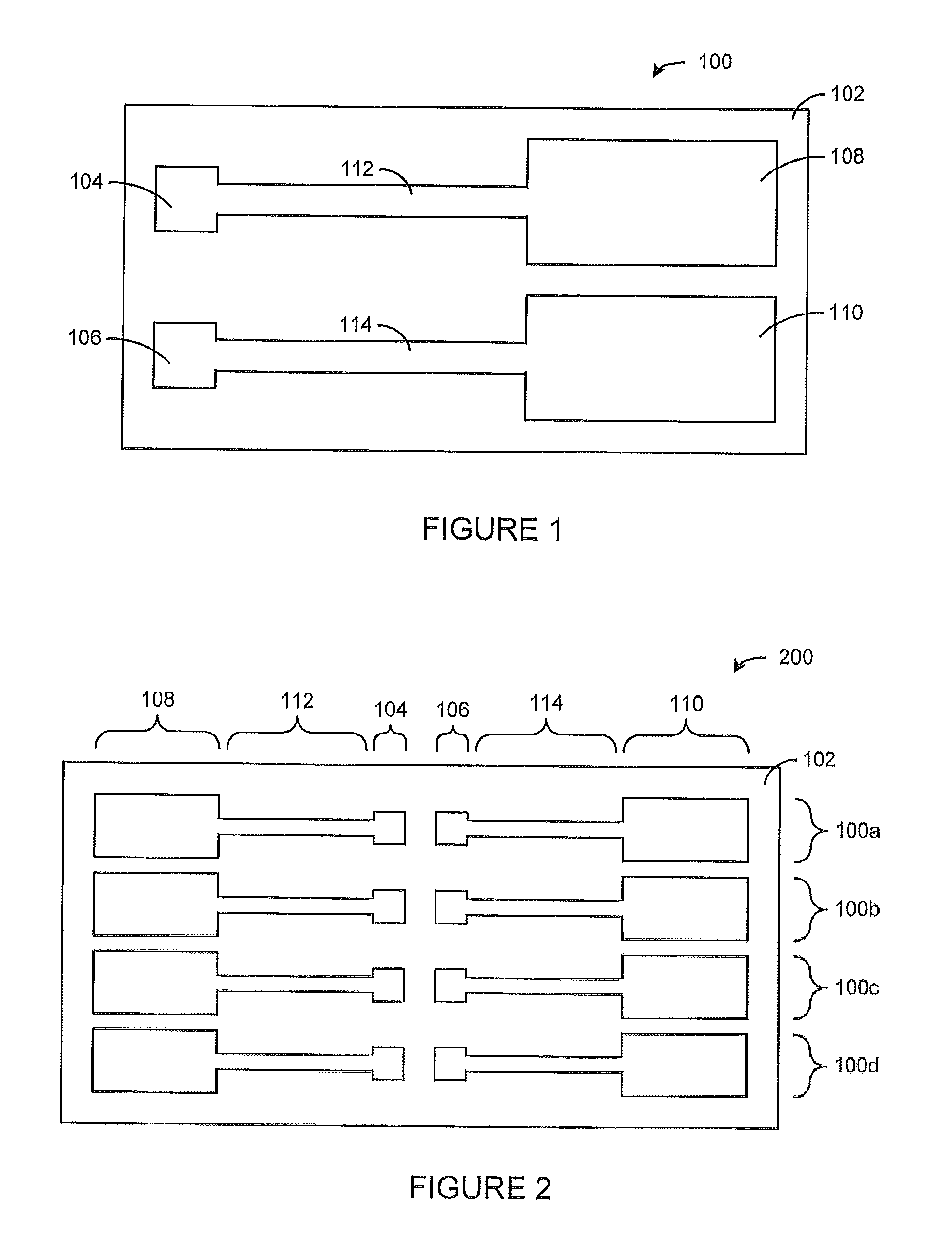

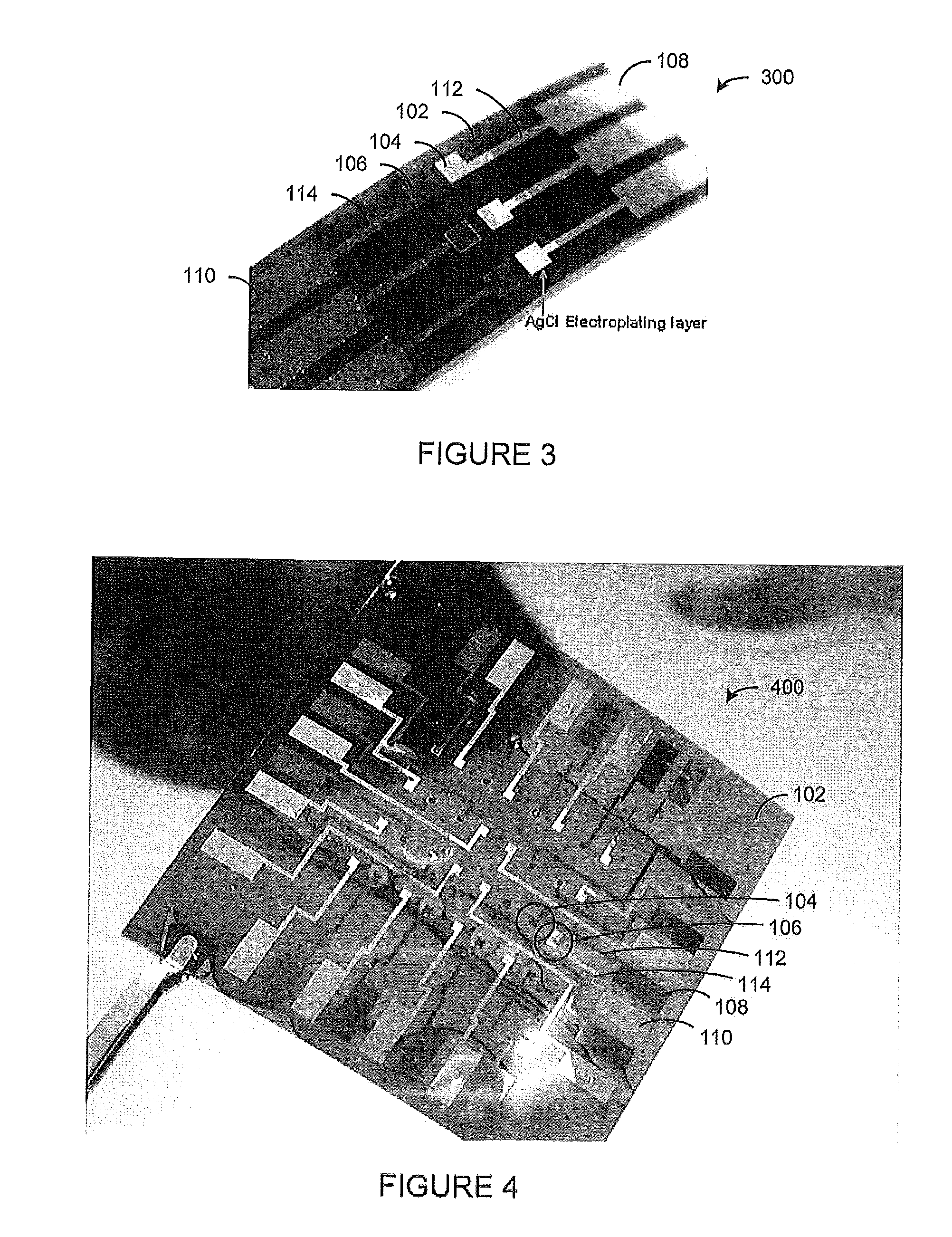

Amorphous irox film ph sensor

ActiveUS20110140703A1Good stabilityLess driftMaterial analysis by electric/magnetic meansSuperimposed coating processPhysicsPolymer substrate

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

UWB-based vehicle positioning system and method

ActiveCN106205136AHigh positioning accuracyGood stabilityTicket-issuing apparatusRoad vehicles traffic controlEngineeringBase station

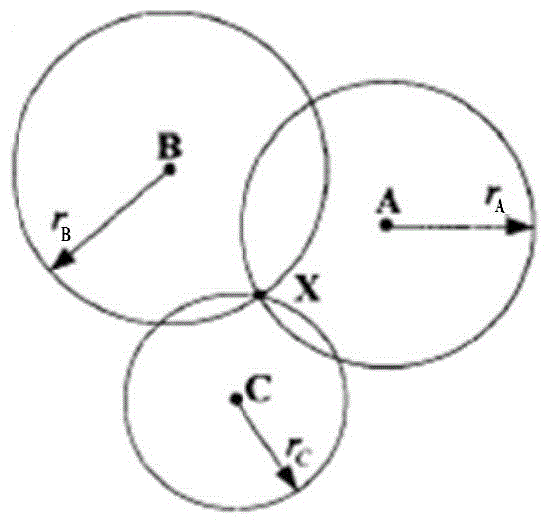

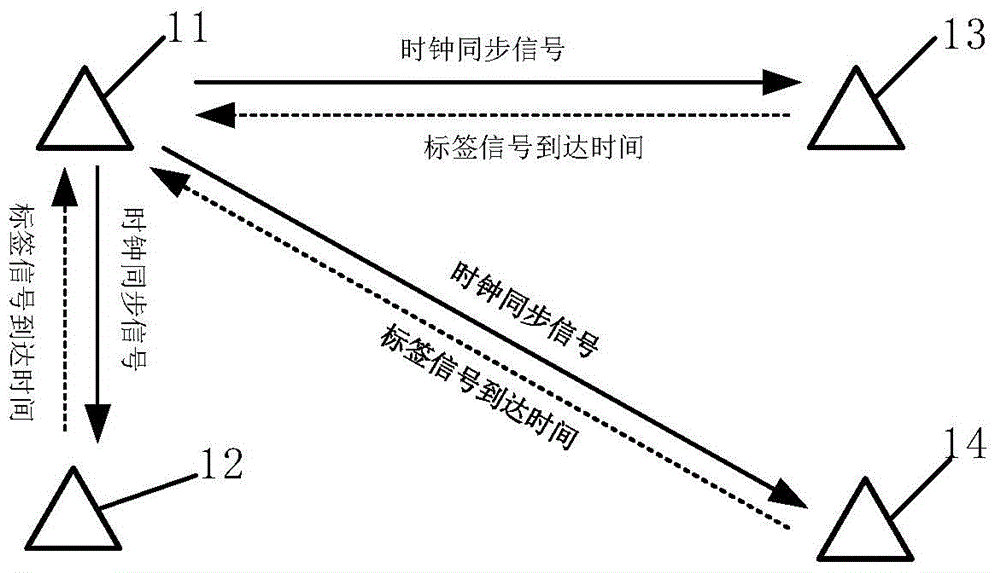

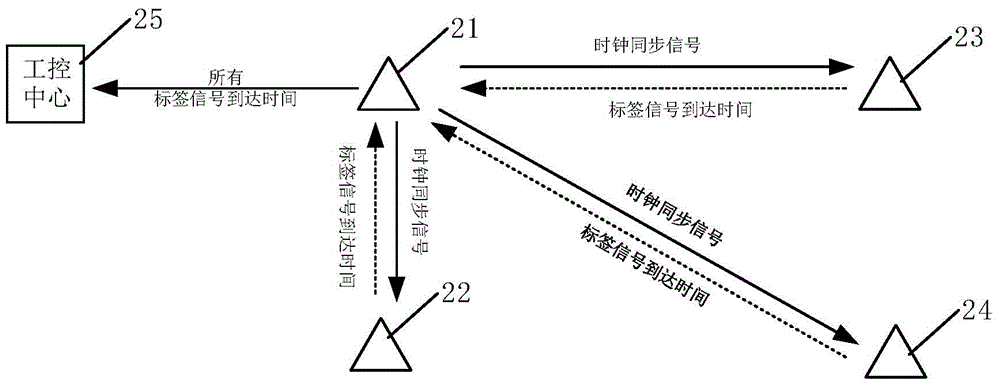

The invention provides a UWB-based vehicle positioning system and method. The positioning system comprises a UWB electronic label arranged on a vehicle; a plurality of UWB base stations arranged in a parking area at intervals; and a processing apparatus used for determining position information of the vehicle according to parameter values from at least three UWB base stations. The positioning method comprises the following steps: receiving clock synchronization signals emitted by a synchronization signal emission device, and synchronizing a synchronization clock in real time; receiving wireless positioning signals emitted by the UWB electronic label carried by the vehicle entering the parking area; and after the wireless positioning signals are received, according to the synchronization clock, generating receiving time, sending the receiving time to the processing apparatus so as to enable the processing apparatus to calculate the position of the vehicle according to the receiving time of the same wireless positioning signals respectively received by the at least three UWB base stations. The system and method have the advantages of high positioning precision, good stability and the like.

Owner:SHENZHEN GENVICT TECH

Catalyst used for synthesizing middle distillate from synthetic gas, its preparation method and application

InactiveCN1785515AHigh thermal and hydrothermal stabilityGood stabilityLiquid hydrocarbon mixture recoveryCatalyst activation/preparationCOBALTOUS NITRATENon noble metal

A catalyst for synthesizing the intermediate oil from synthetic gas by Fischer-Tropsch reaction contains Co (5-35 Wt%), mesoporous ZrO2 as carrier (53-93), noble metal (0-2) and oxide of non-noble metal. Its preparing process includes such steps as impregnating said carrier in the aqueous solution of nitrate containing the oxide of non-noble metal or the alcohol solution of organic alkydester, and impregnating it in the equeous solution of cobalt nitrate and the nitrate (or chloride) or noble metal. It has high activity, stability, selectivity and mechanical performance.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Fabric finishing liquor for expelling and killing mosquitoes, method of use and products thereof

ActiveCN1664227AGood stabilityModerate viscosity of the systemBiocideBiochemical fibre treatmentEngineeringTextile

This invention refers to a fabric liquidate liquid used of killing mosquito and method of application and produce. The quality pencent direction of fabric liquidate liquid include pesticide and / or repellent 0.05-40.00%, bond 5.00-40.00%, crosslinking agent 0.025-1.50% and the rest is watetr, the sum of each elements is 100%. The pesticide and repellent is aqua repellent of effective content 1%-50%, the bond is aqua repellent of effective solid content 40%-50%. The use method of fabric liquidate liquid adopt printing liquidate fabric. After use the fabric liquidate liquid and dipping, adjust the roller press, enter in the drying machine with control contained liquid rate 30-150% and the drying temperature is 60-250oC.The textile which make use of fabric liquidate liquid or liquidate method is fiber fabric produce.

Owner:沧州永阔隆化工有限公司

Graphene conductive slurry as well as preparation method and application method of graphene conductive slurry

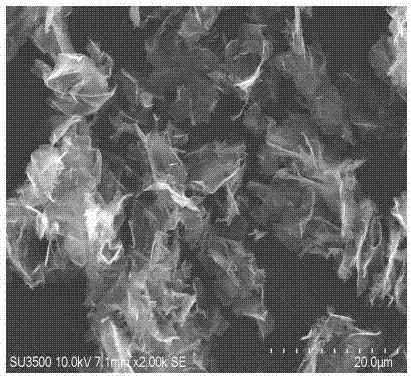

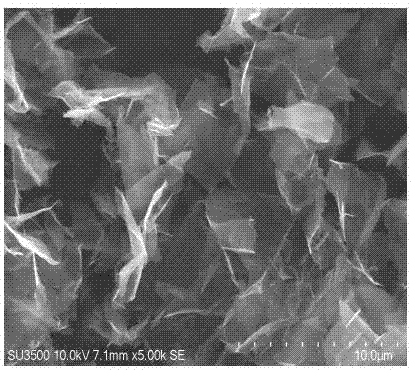

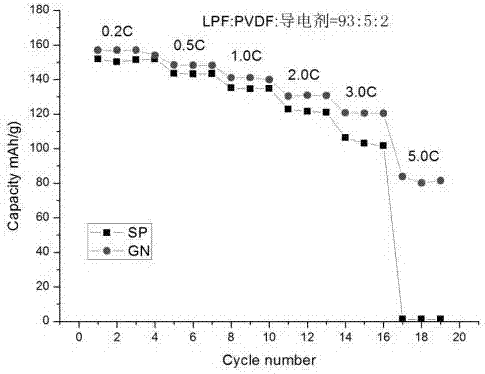

InactiveCN107298924AGood stabilityImprove stabilityNon-conductive material with dispersed conductive materialCarbon-silicon compound conductorsSolventCvd graphene

The invention belongs to the technical field of graphene materials. Graphene conductive slurry is prepared from the following raw materials in parts by weight: 0.5 to 15.0 weight percent of oligegraphene, 0.1 to 0.5 weight percent of a dispersant, 80 to 99.4 weight percent of a diluent and 10 to 40 weight percent of organic resin. According to the graphene conductive slurry disclosed by the invention, by screening the dispersant in the early stage, the graphene can be more easily dispersed in the diluent during a mixing process of graphene powder and the diluent, and an obtained dispersion solution is good in stability; by adding the selected dispersant and using a technology adopted by the invention, stripping of the graphene in the diluent can be promoted; in the graphene conductive slurry, a part of solvent is replaced with a part of resin, so that the solid content of the graphene conductive slurry is increased, the stability of the graphene conductive slurry is increased, re-overlaying of the graphene is prevented, and very good compatibility is also provided for application in the late. The graphene conductive slurry which is good in performance and high in stability can be prepared, the cost is low, the technology is feasible, and the graphene conductive slurry is suitable for industrial production.

Owner:SHENZHEN GUOCHUANG JIAWEI GRAPHENE TECH CO LTD

Process for preparing alumina carrier

ActiveCN101450327AGood mechanical strengthGood stabilityCatalyst carriersPelletizingMolecular dimensions

The invention belongs to the technical field of catalysis and relates to a method for preparing an alumina carrier. The carrier is prepared by mixing alumina (or pseudobochmite) with an adhesive and a pore-forming material and performing granulation, drying, tabletting and forming and roasting. The carrier prepared by the method has high mechanical strength, has the radial crushing resistant force reaching more than 300 N / cm, can be used as a carrier of a hydrogenation catalyst, and is particularly suitable to be used as a carrier of a hydrogenation catalyst containing compounds with larger molecular dimension such as benzene or compounds containing benzene rings.

Owner:SINOPEC NANJING RES INST OF CHEM IND CO LTD

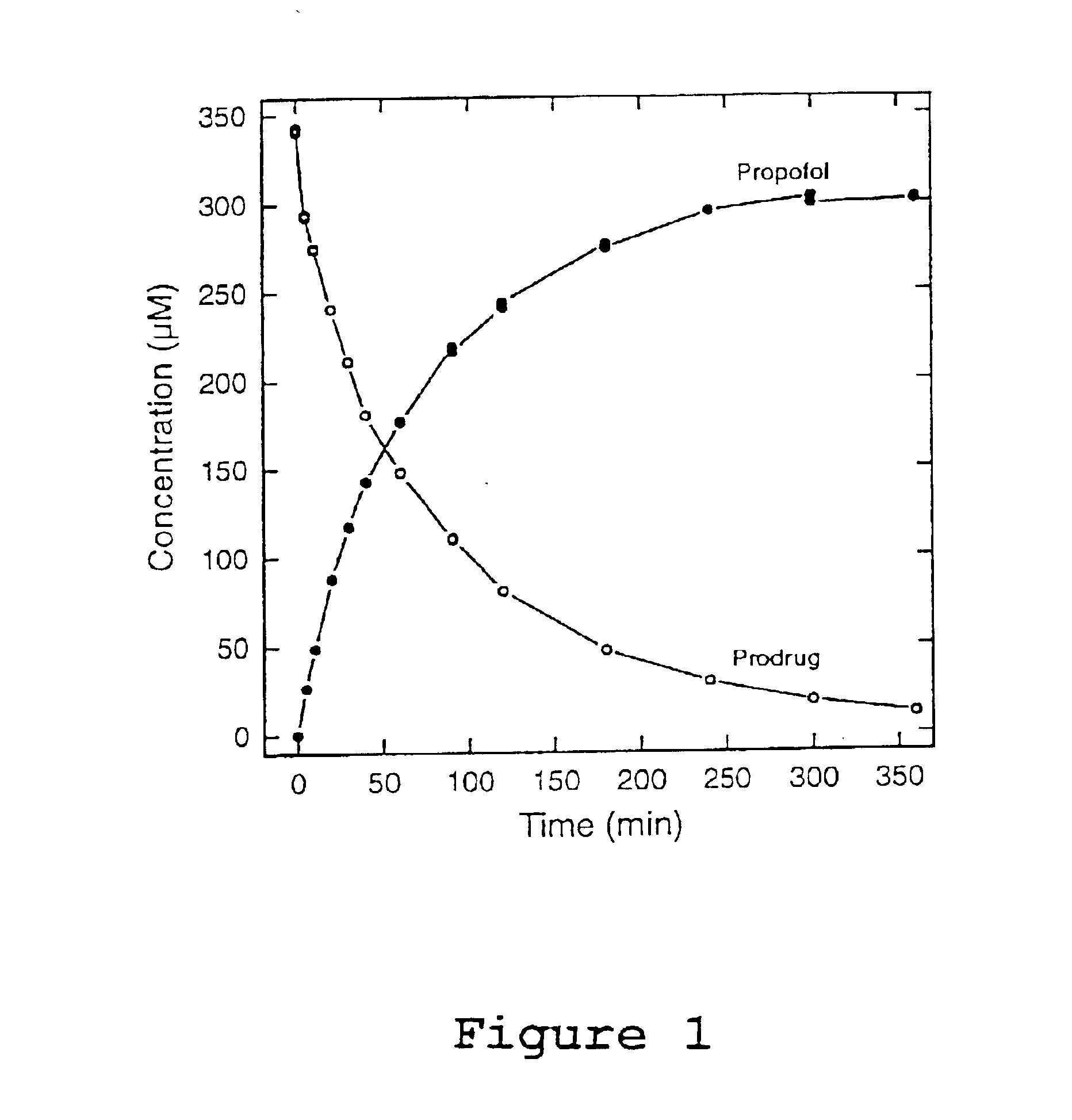

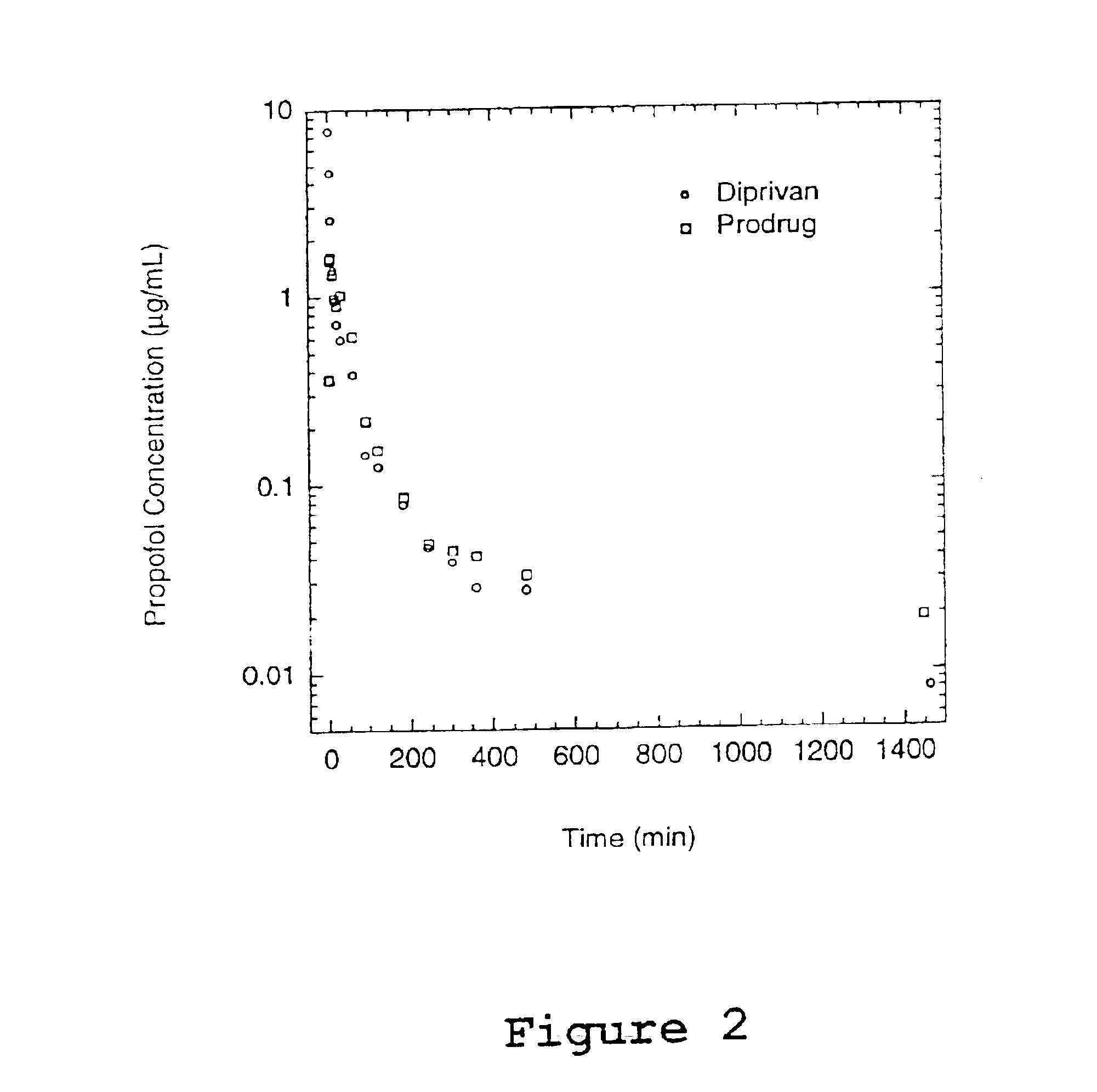

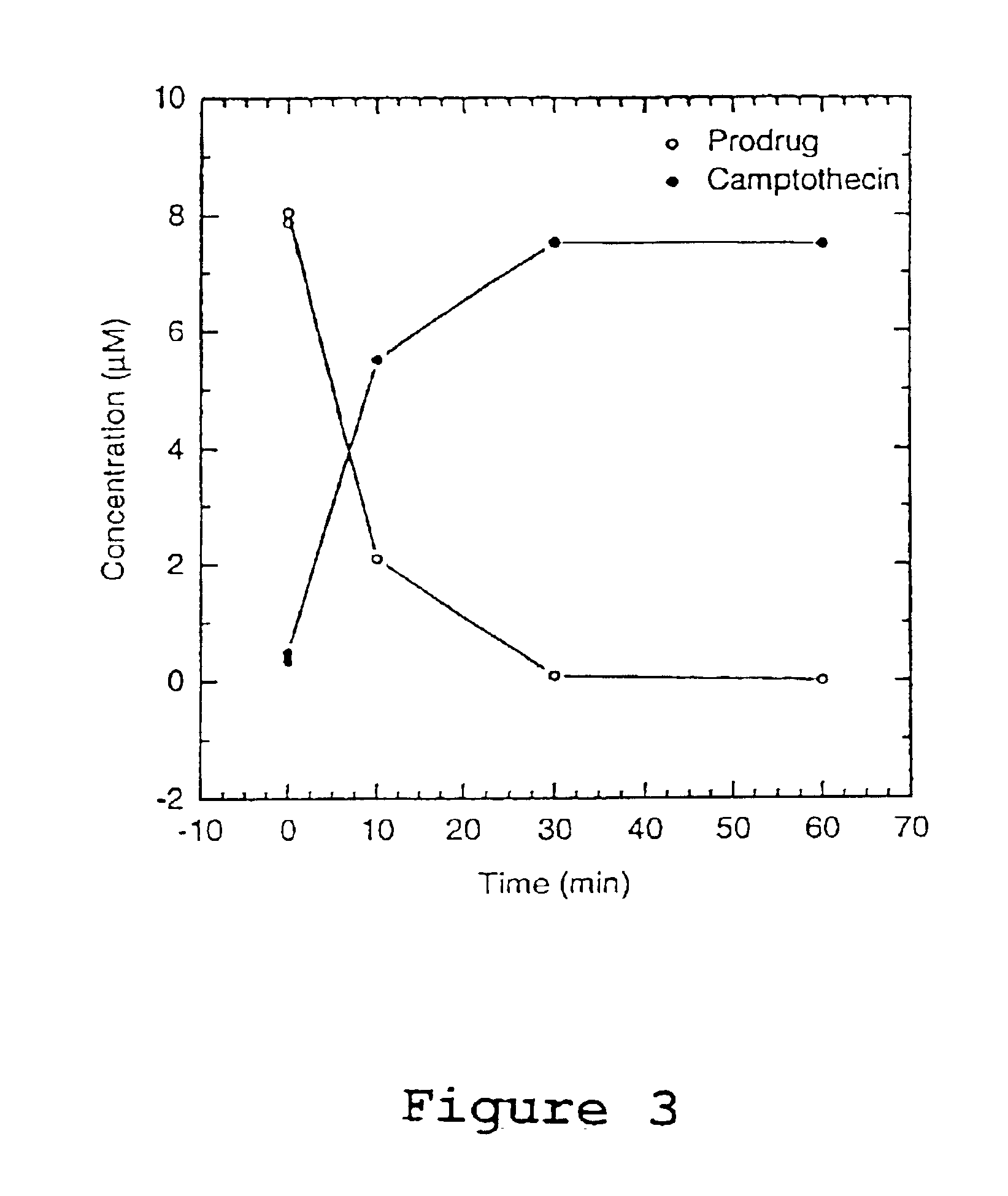

Water soluble prodrugs of hindered alcohols

InactiveUS6872838B2Good stabilityImprove stabilityBiocideNervous disorderWater soluble prodrugWater soluble

Owner:UNIVERSITY OF KANSAS

Controlled released stably coating material capable of purifying air and preparation method thereof

InactiveCN1687268AGood stabilityStrong persistencePolyurea/polyurethane coatingsPolyester coatingsIonLong acting

The present invention adopts special dispersion technological process and nano treatment process to make the material capable of releasing negative ions into a nano negative ion powder pulp, then adds the nano negative ion powder pulp to paint so as to obtain a long-acting stable air-purifying paint. Said paint can effectively decompose harmful gases in the air, such as formaldehyde, benzene, dimethylbenzene and nitrogen oxide, etc, and the harmful gas removing rate can be up to above 90%, and can automatically release negative ions for a long period. Its paint solid content is 20-70 wt%, and negative ion powder content is 1-10 wt%.

Owner:FUDAN UNIV

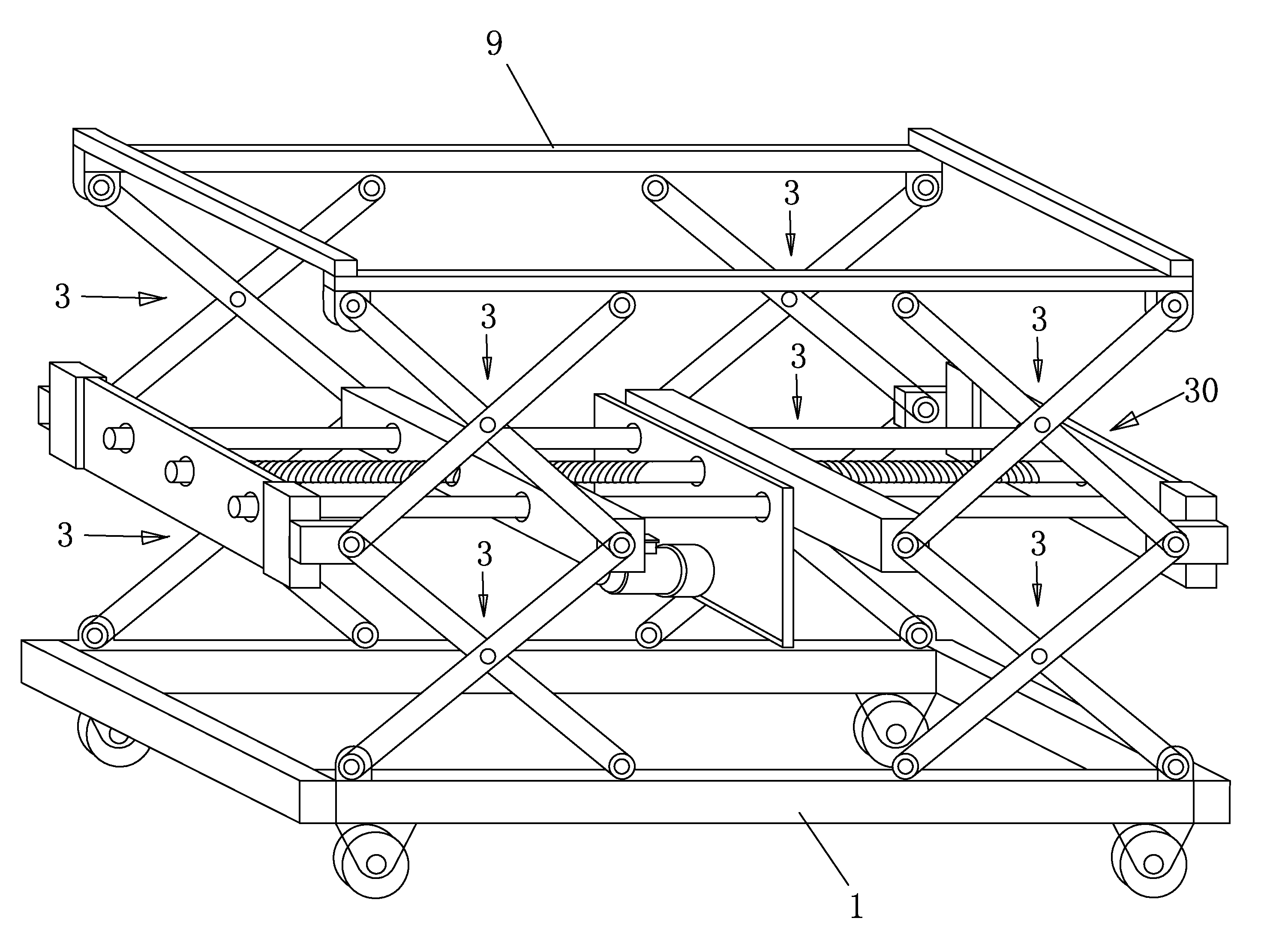

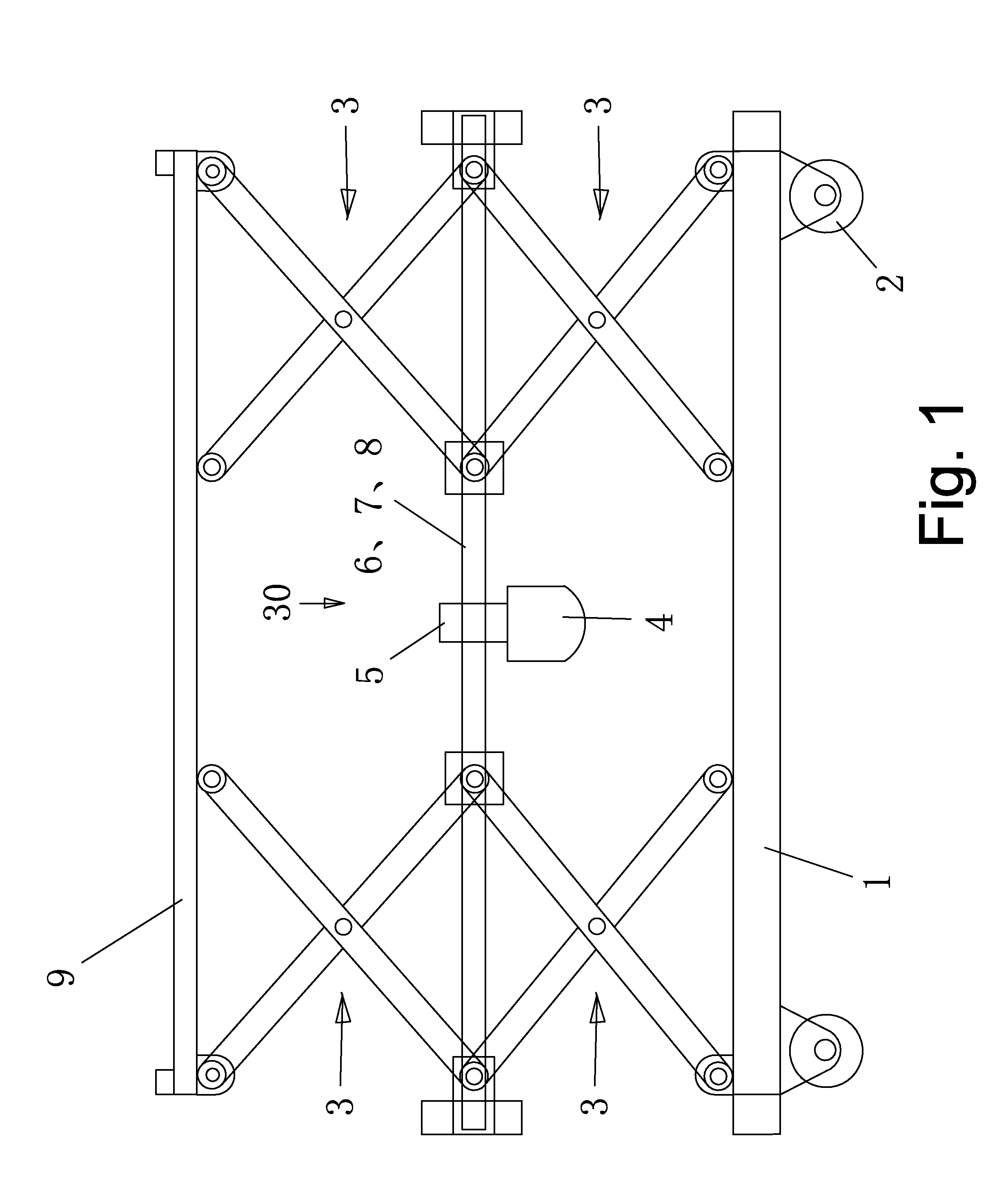

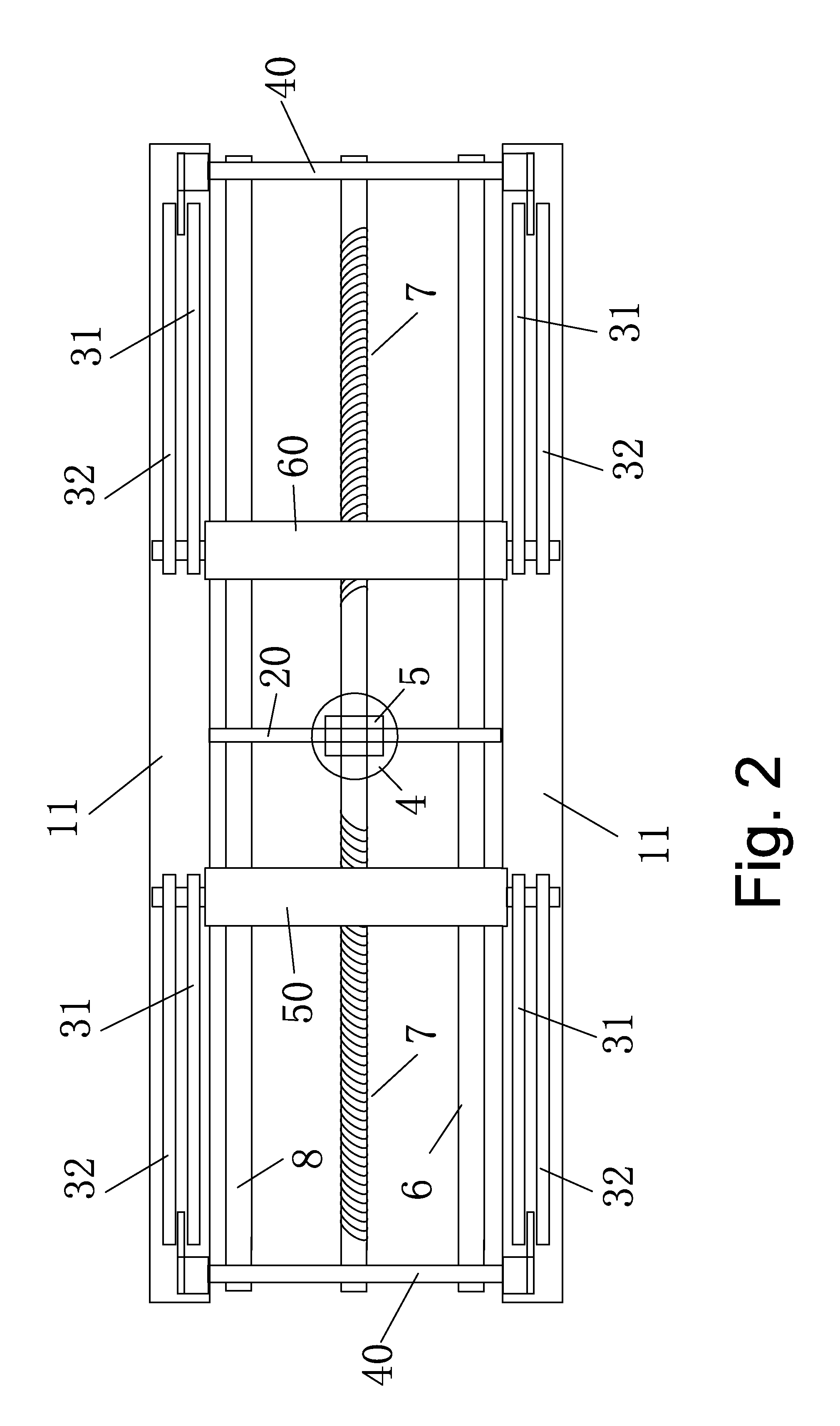

Screw-driven lifting platform

InactiveUS20140374680A1Simple structureGood stabilitySupporting partsLifting framesEngineeringThreaded rod

A screw-driven lifting platform, includes a lifting portion and a transmitting portion, which is characterized in comprising a base, a left-and-right screw thread rod, a left and a right group (two group in total) of X-shaped connecting rods and a horizontal lifting platform, wherein two groups (a left group and a right group) of the X-shaped connecting rods are respectively provided on left and right end portions between the base and the horizontal lifting platform, fixed ends of the X-shaped connecting rod are respectively hinged on the base and the horizontal lifting platform, movable ends of the X-shaped connecting rod are connected with the left-and-right screw thread rod, when the left-and-right screw thread rod rotates, the movable ends of the left and right groups of the X-shaped connecting rod are driven to move, so as to realize lifting and lowering the horizontal lifting platform.

Owner:TSANG LINGCHU

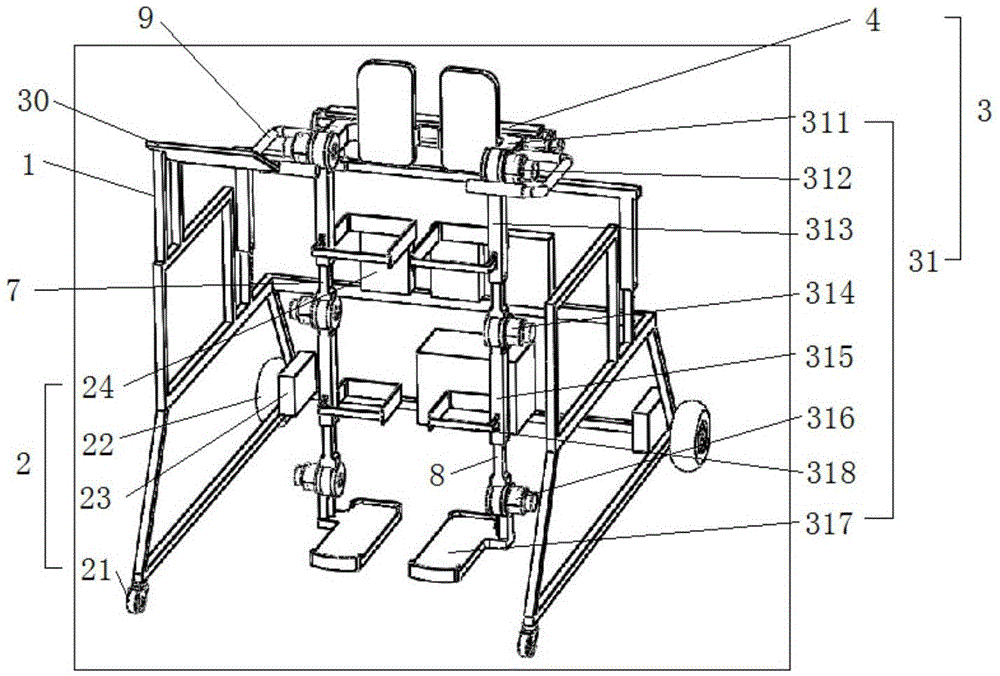

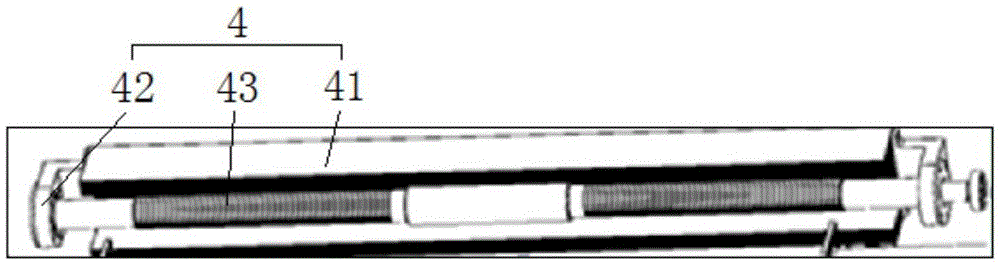

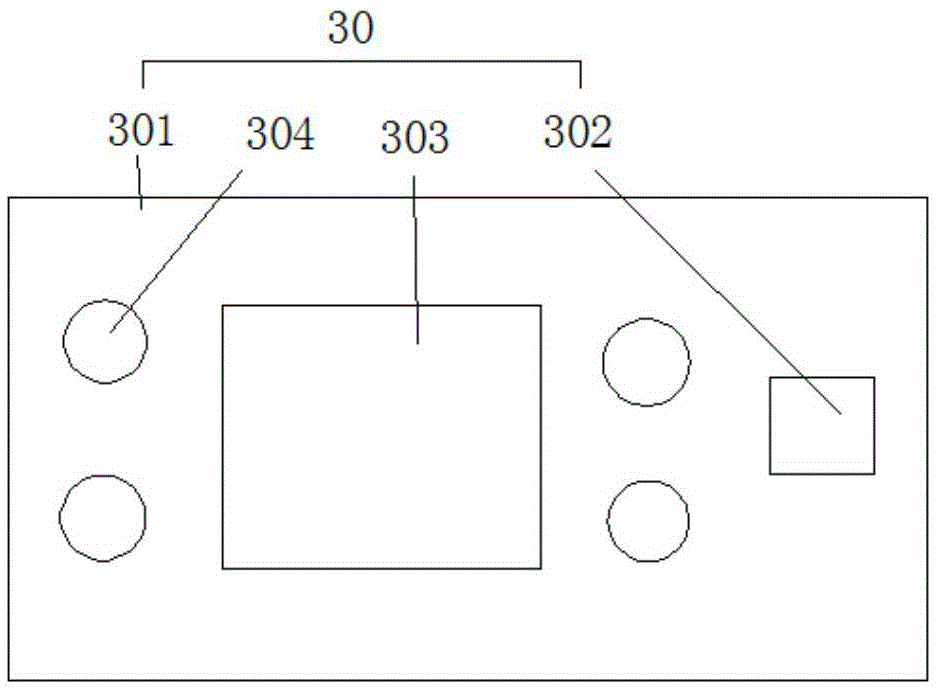

Exoskeleton type moving and walking rehabilitation training device and method

ActiveCN105456004ACompact structureGood stabilityProgramme-controlled manipulatorGymnastic exercisingEngineeringExoskeleton

The invention relates to an exoskeleton type moving and walking rehabilitation training device and method which can be used for walking rehabilitation training of the lower limbs of the human body. The device comprises an embedded upper computer, a moving motion control unit, a walking motion control unit, a gait measuring unit and a man-machine interaction unit. Under coordination control of all the units, the lower limbs of the human body can be driven by exoskeleton mechanical legs to conduct walking rehabilitation training in a movable platform. According to the main power of the lower limbs of the human body, the walking training modes can be divided into an active training mode and a passive training mode. The device can provide lower limb standing walking training in different lower limb rehabilitation stages for people with lower limb disabilities.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

Alumina supporter and preparation method thereof

ActiveCN101322949AHigh activityGood stabilityCatalyst carriersPreparation by hydrogenationAluminium saltsCarbon black

The invention provides an aluminum oxide carrier and a preparation method thereof. The aluminum oxide carrier takes a mixture prepared by mixing pseudo-boehmite powder prepared by the carbonization method and pseudo-boehmite powder prepared by the aluminum sulfate method according to a weight proportion of 1:0.1 to 5 as a precursor and a complex acid as a peptizing agent; substances such as zirconium, titanium, silicon, alkali metals, alkaline-earth metals, rare-earth metals, carbon black, and the like, are added during kneading process; then the aluminum oxide carrier is obtained after forming, drying and roasting. The physical properties of the carrier are as follows: pore volume is 0.4 to 1.2ml / g; specific surface area is 180 to 370m<2> / g; pores with the diameter being more than 100nm accounts for more than 90 percent of total pore volume; the amount of B acid is 0.1 to 0.3mmol / g; the amount of L acid is 0.2 to 0.5mmol / g. The carrier is especially applicable to the preparation of 1, 4-butanediol catalysts in the two-stage hydrogenation catalytic synthesis of 1, 4-butynediol.

Owner:SHANXI UNIV

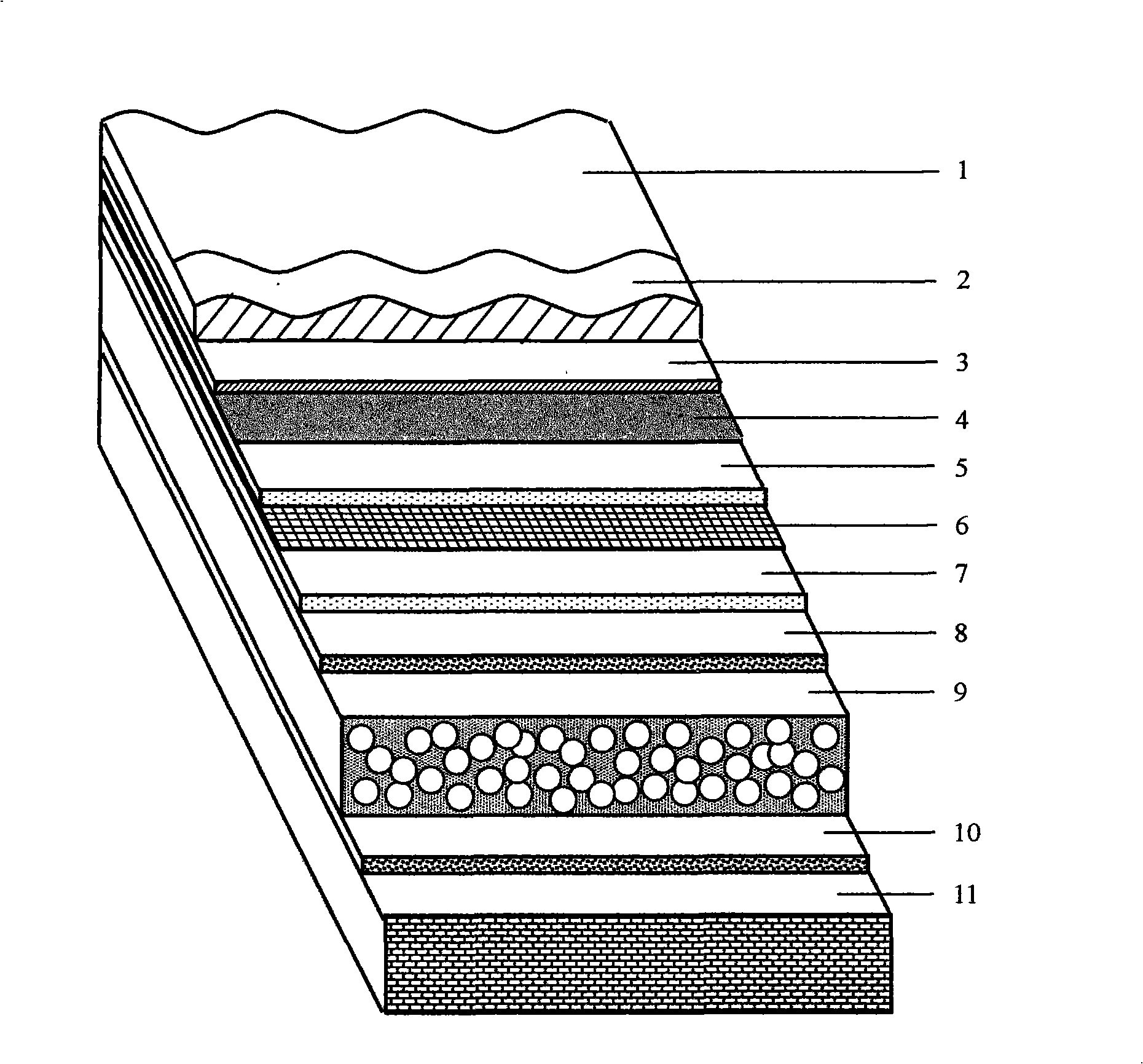

Thermal insulation and water proof integrated system of roof covering and construction method thereof

ActiveCN101311456AGood matching and bonding performanceGood stabilityBuild-up roofsThermal insulationIntegrated systems

The invention provides an integral system integrated with roof heat preservation and water resistance and a construction method thereof. The construction method is as follows: cleaning the substrate, and having slope-making or leveling treatment for needed roof; preparing polymer cement waterproof mortar scraped on the roof substrate as a first waterproof layer with the thickness of 2 to 5 mm; preparing rubber powder poly-phenyl granule cement mortar scraped on the first waterproof layer as an insulating layer with the thickness of 20 to 50 mm; preparing polymer cement waterproof mortar scraped on the insulating layer as a second waterproof layer with the thickness of 2 to 5 mm; preparing polymer cement anti-crack mortar scraped on the second waterproof layer, paving alkali-proof glass fiber gridding cloth, and then scraping the polymer cement anti-crack mortar once as a protective layer, and the thickness of each polymer cement anti-crack mortar is 1 to 2 mm. The roof substrate, the polymer cement waterproof mortar and the polymer cement anti-crack mortar are taken as cement base materials, and materials of cement, sand, and the like are also contained in rubber powder poly-phenyl granule insulating mortar, so the base material, the waterproof layer, the insulating layer and the protective layer have fine matching and bonding performances and perfect system stability.

Owner:SHENZHEN JIADA HIGH TECH IND DEV

Modified dimaleimide resin and its preparation method and application in cladding copper plate

A modified bimaleimid resin is prepared from bimaleimide resin, allyl compound, epoxy resin, solidifying agent, and promoter. It can be used to prepare the substrate of copper coated board, which has high resistance to high temp (15-280 deg.C), low loss, high fire retarding performance and thermal and wet stability, and excellent mechanical performance. It can be used for computer, satellite communication equipment, mobile telephone, etc.

Owner:梁国正 +1

Catalyzed hydrogenation de-chlorine method of chlorinated aromatic hydrocarbons

InactiveCN101037374AHigh reactivityGood stabilityPhysical/chemical process catalystsHydrocarbon from halogen organic compoundsChemistryActive carbon

The invention relates to a method for chloro arene catalyzing hydrogenation and dechlorination. The processing is as follows: filling load nickel phosphide catalyst in the fixing bed reactor; airing the hydrogen gas into the reactor with an airspeed of 10-10000 h-1 and airing chlorobenzene, dichlorobenzene or trichlorobenzene with an airspeed of 0.01-10 h-1 at normal atmosphere and in 200-400 DEG C for catalyzing hydrogenation and dechlorination. Said load nickel phosphide catalyst has silicon dioxide, alumina, HY molecule screen, zirconia, titanic anhydride or active carbon as carrier. The active component nickel exists in a phase of Ni2P, Ni12P5 or Ni2P. The nickel mass content in the catalyst is 5-25%. The advantages of the invention are that the catalyst has a good reacting activity and stability of hydrogenation and dechlorination and it achieves continuous application.

Owner:TIANJIN UNIV

Preparation method of styrene-acrylate copolymer emulsion used in antirust paint

InactiveCN102199240AGood stabilityEmulsion particle size is smallAnti-corrosive paintsFunctional monomerIon

The invention relates to a novel method for preparing a styrene-acrylate copolymer emulsion used in antirust primer paint. The method comprises steps that: (1) phosphate ester functional monomers are subject to a polymerization reaction; two hydroxyl groups of each phosphate ester group are subject to a chelation reaction on the metal surface, such that a dense phosphate ester (salt) protective film is formed on the metal surface, and water molecules and other salt ions are prevented from contacting the metal; the introduced phosphate ester group assists in improving the adhesion of painted coatings on metal surfaces, and in improving the antirust capacity of the painted coatings; (2) diacetone acrylamide (DAAM) and adipic dihydrazide (ADH) form a cross-linking system of the antirust emulsion; hydrazine groups in hydrazino-(NH2-NH2) and ketone groups in the DAAM (C=O) are subject to a dehydration condensation reaction, wherein the ketone groups are copolymerized on the copolymer; through outer cross-linking, a emulsion film with a three-dimensional reticular structure is obtained; (3) an emulsifying system is formed by combining a reactive anion emulsifier and a non-ion emulsifier, such that problems of emulsion deposition and gelling are solved. With the method provided by the invention, an aqueous emulsion with a high solid content is prepared, and water resistance and weathering resistance of the antirust paint is improved.

Owner:BEIJING UNIV OF CHEM TECH

Digital inkjet thermal transfer printing water-based ink for textiles and preparation method of ink

The invention discloses digital inkjet thermal transfer printing water-based ink for textiles and preparation method of the ink. The ink comprises the following raw materials in mass ratio: 5-15 parts of disperse dye, 5-10 parts of a dispersing agent, 0.1-0.5 part of a wetting agent, 5-25 parts of a cosolvent, 0.02-0.05 part of a preservative, 0.1-0.3 part of an antifoaming agent and 50-70 parts of deionized water. The digital inkjet thermal transfer printing water-based ink is prepared by using a method of effectively dispersing the disperse dye via a dispersing system and carrying out combined dispersion via a mechanical sand grinder and an ultrahigh-pressure homogenizer, and is suitable for the thermal transfer printing of textiles and the thermal transfer printing of plate materials such as aluminum plates coated with polyester; and the prepared water-based ink has the advantages of small particle size, uniformity in distribution, good stability, no nozzle blocking, rapidness in drying, bright color, clear patterns, high transfer rate, low cost and the like.

Owner:HANGZHOU HIWETECH CHEM TECH CO LTD

Aerated products with reduced creaming

InactiveUS20070116848A1Good stabilityExcellent stabilityMilk preparationFrozen sweetsHydrophobinOrganic chemistry

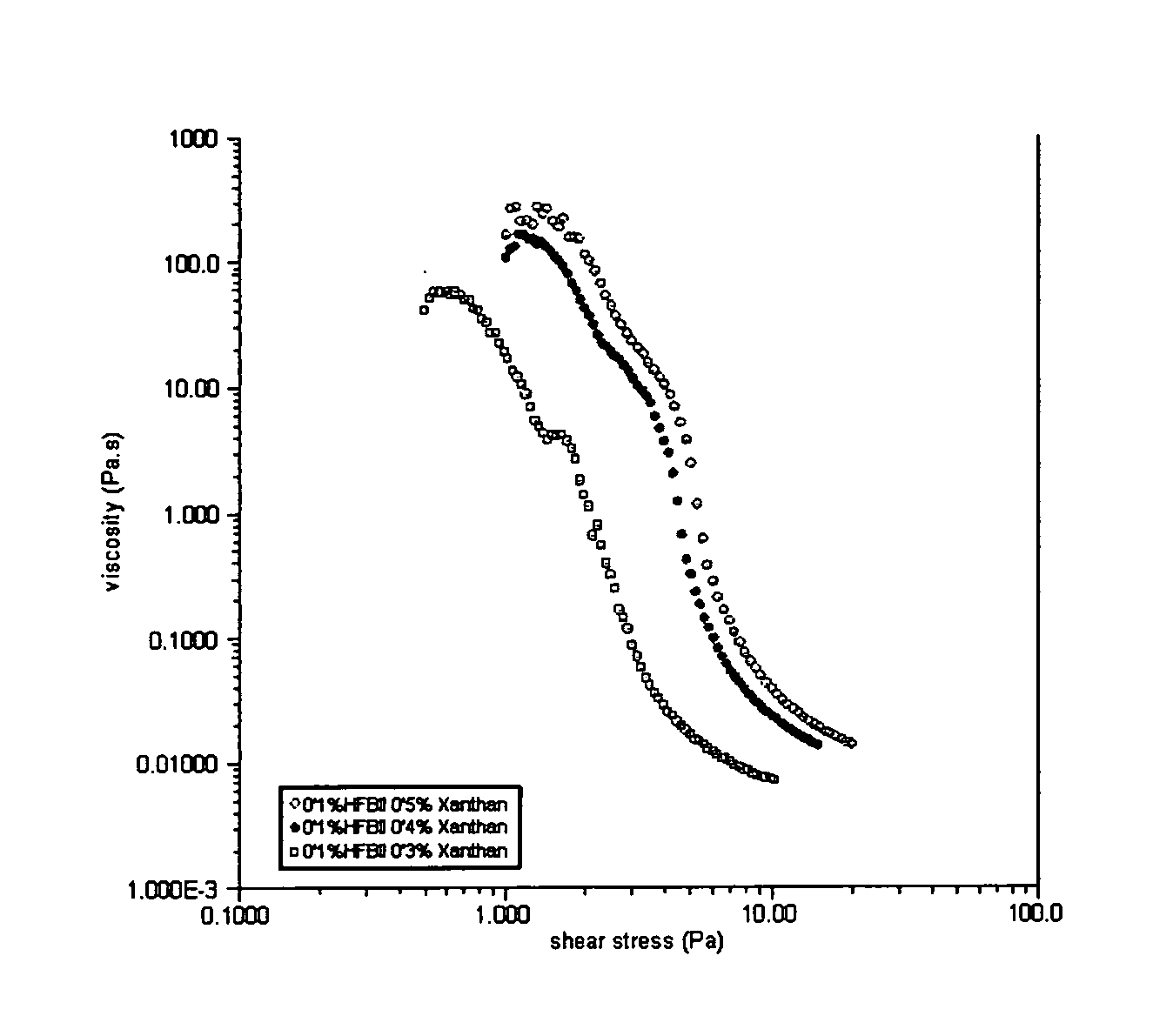

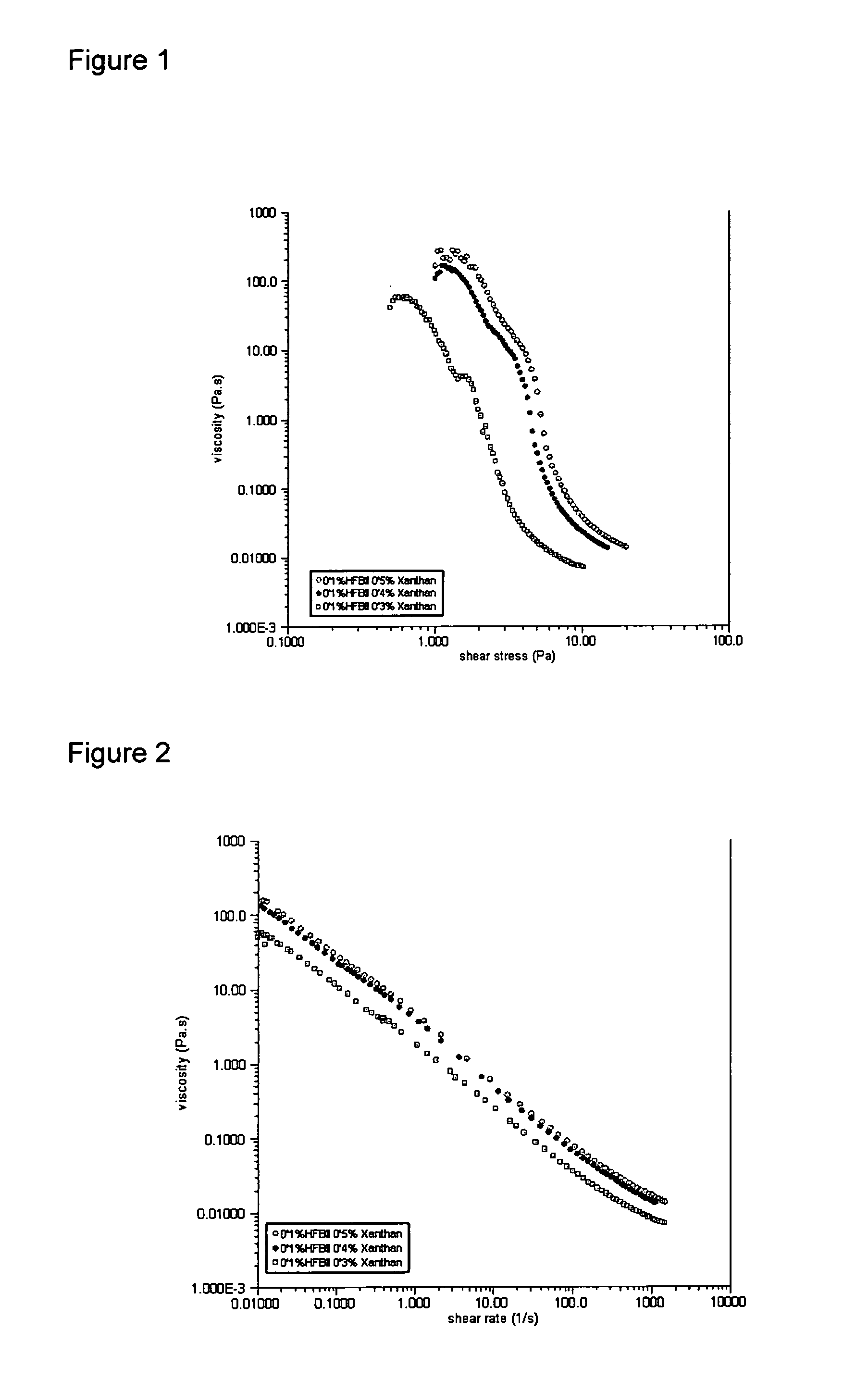

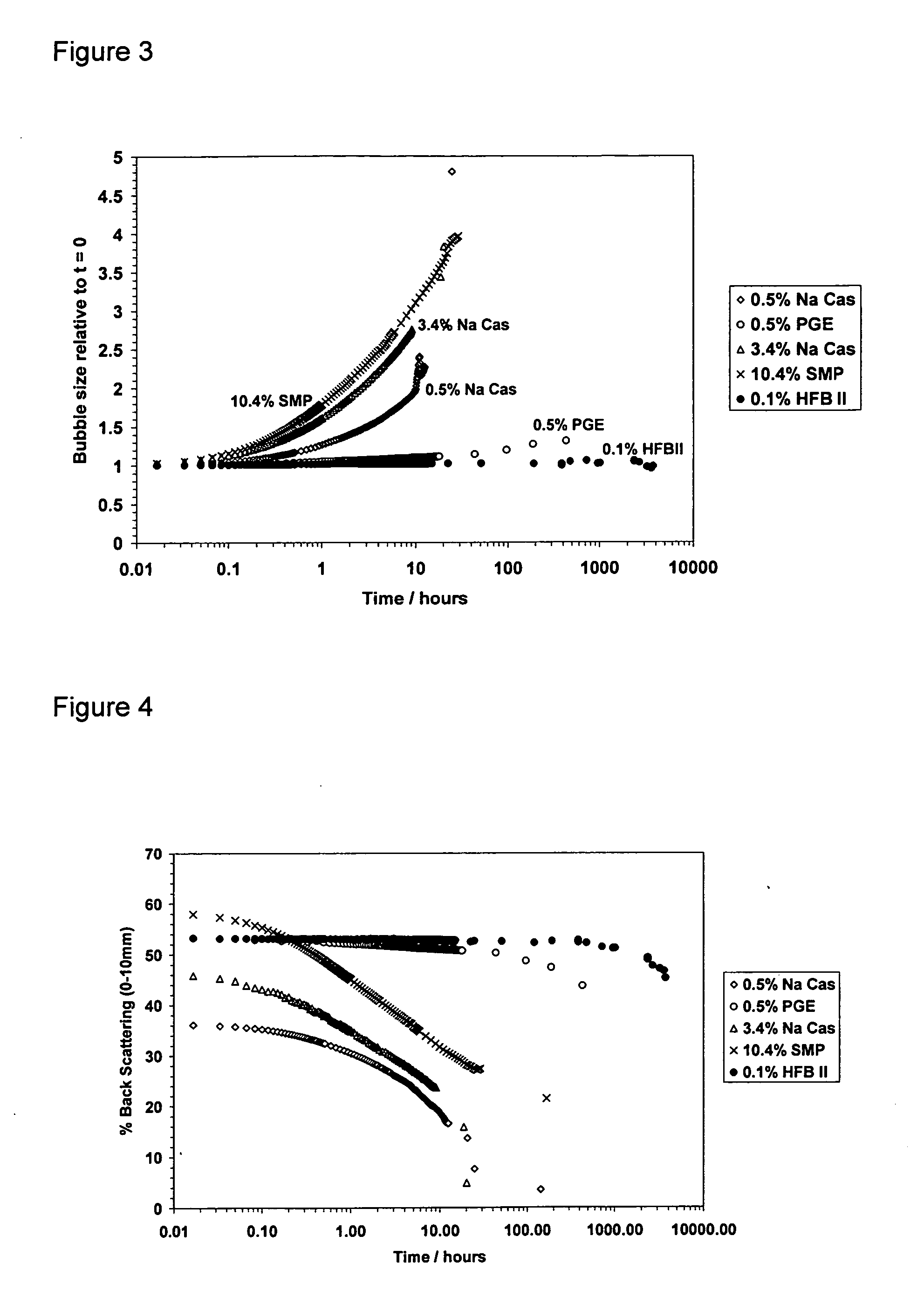

A flowable aerated composition is provided which comprises hydrophobin and a yield stress agent, the composition having a continuous phase viscosity, measured at a shear rate of 10 s−1, of from 0.01 to 2000 Pa s, and a continuous phase apparent yield stress of at least 4 Pa.

Owner:CONOPCO INC D B A UNILEVER

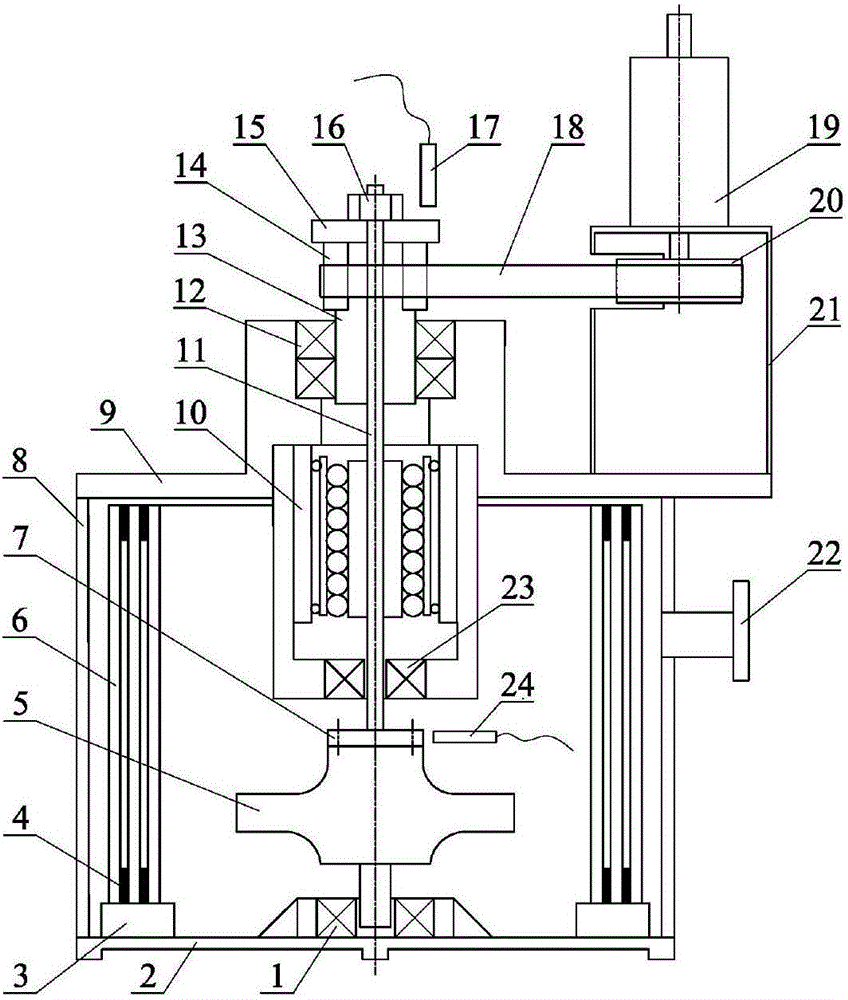

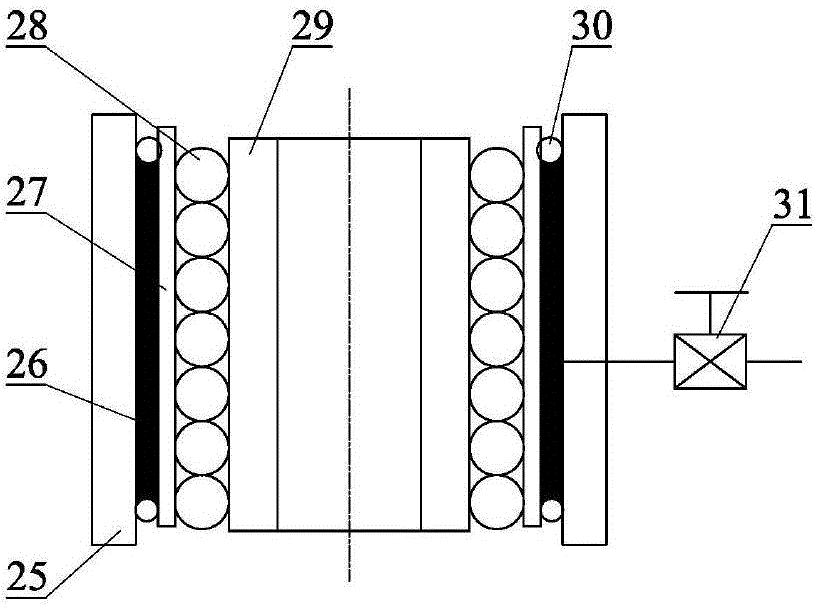

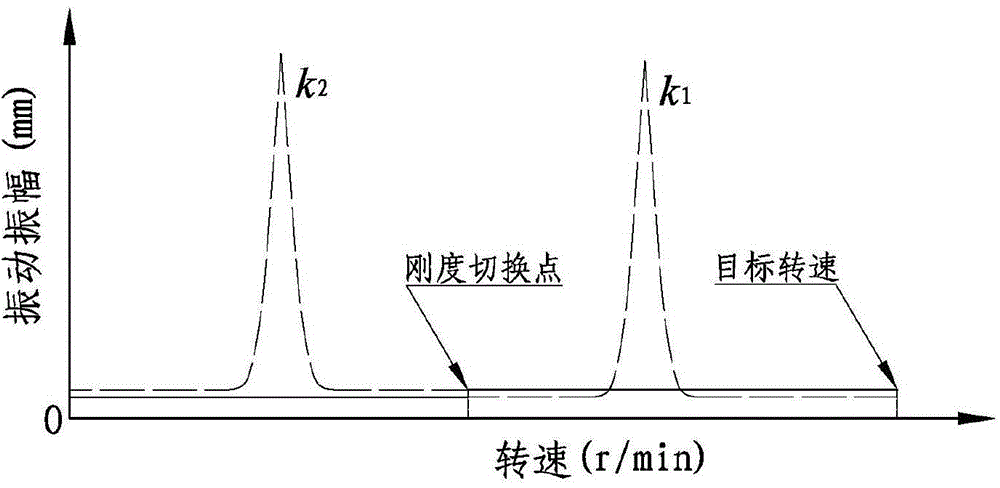

High-speed rotation testing machine and method for testing high-speed rotation strength performance of rotor

InactiveCN103604587ALarge single bearing capacityGood stabilityMachine part testingTest objectDrive motor

The invention discloses a high-speed rotation testing machine and a method for testing the high-speed rotation strength performance of a rotor. The high-speed rotation testing machine comprises a test cavity, a rotor system which is accommodated in the test cavity and used for testing the test rotor, a driving system that drives the rotor system and a rotating speed control system that controls the rotating speed of the rotor system, wherein the driving system includes a driving motor and a speeder which is connected with the driving motor and drives the rotor system to rotate at a high speed, the rotor system includes a test rotor fixed part, a main shaft connected with the test rotor fixed part and driven to rotate by the speeder, and a damper which is sleeved outside the main shaft and supports the main shaft, the test cavity is equipped with a vacuumizing opening, a plurality of layers of containing rings is arranged in the test cavity and surround the rotor system, and the containing rings are connected through spacing blocks arranged at tail ends of the containing rings. The high-speed rotation testing machine uses a high-speed rotating rotor as a test object, the rotor is speeded up through the speeder system, the working condition of the rotor in high-speed rotation is simulated, and the performance requirement of high speed centrifugal load effect resistance of the rotor is tested.

Owner:HANGZHOU HAILUOMA SCI & TECH

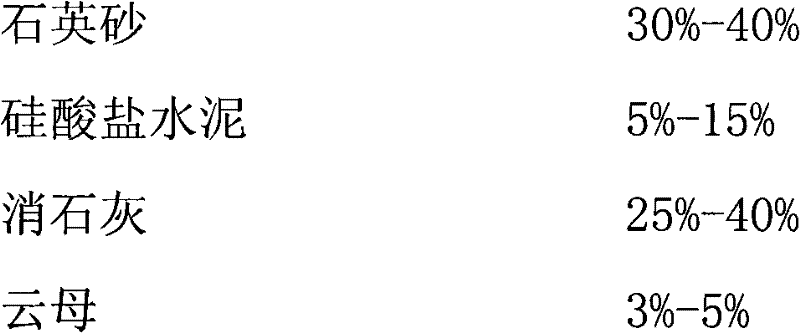

Novel thermal insulation fireproof wall calcium silicate board and preparation method thereof

InactiveCN102515675AGood stabilityStrong elasticity and toughnessCeramic shaping apparatusThermal insulationMica

The invention discloses a novel thermal insulation fireproof wall calcium silicate board and a preparation method thereof. The novel thermal insulation fireproof wall calcium silicate board comprises the following components in percentage by mass: 30-40% of quartz sand, 5-15% of portland cement, 25-40% of slaked lime, 3-5% of mica, 8-13% of vermiculite and 7-8% of wood pulp fiber. The preparation method comprises the following steps of: preparing raw materials by using all the components in percentage by mass; shredding paper; pulping; discharging pulp; forming; carrying out three-working-position operation; demoulding; autoclave curing; drying; and sanding to obtain the novel thermal insulation fireproof wall calcium silicate board. The novel thermal insulation fireproof wall calcium silicate board remains the favorable universality of a calcium silicate board and has an extremely low coefficient of heat conduction. The coefficient of heat conduction of the novel thermal insulation fireproof wall calcium silicate board provided by the invention is (31+273)K, 0.154W / mk; (100.5+273)K, 0.164W / mk.

Owner:宁波易和绿色板业有限公司

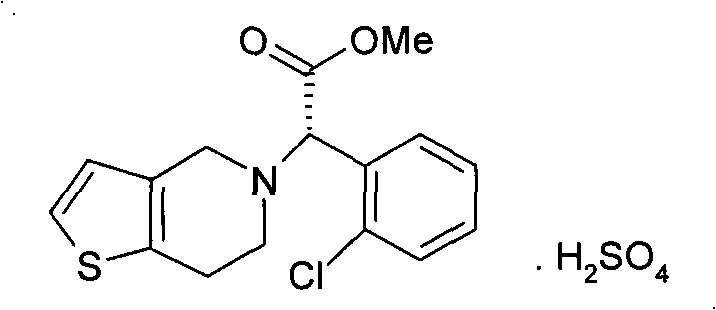

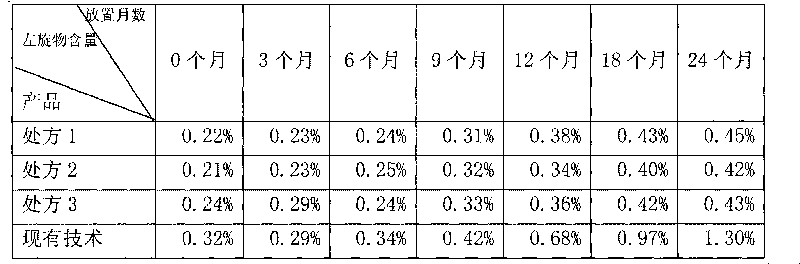

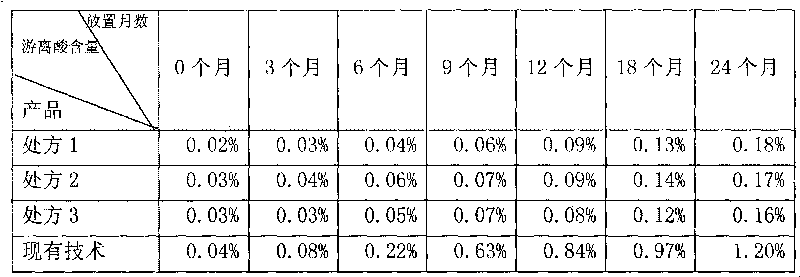

Bisulfate clopidogrel solid preparation, particles and preparation method thereof

InactiveCN101690719AGood stabilityImprove stabilityPowder deliveryOrganic active ingredientsCross-linked polyethylenePharmaceutical preservatives

The invention relates to a bisulfate clopidogrel solid preparation, particles and a preparation method thereof. Particles contained by the solid preparation are solid mixture formed from bisulfate clopidogrel, cellulose excipients and molten adhesive with the melting point between 50 and 86 DEG, and an additionally added excipient of the particles contains weak alkaline lubricants and crosslinked polyvinylpyrrolidone. The solid preparation and the particles thereof are prepared by a melting-granulating method. The solid preparation has the advantages of solving sticking-picking problems existing in the preparation process, effectively reducing the degradation of clopidogrel during storage, reducing the incidence of transforming clopidogrel dextroisomer into clopidogrel levisomer and increasing the stability and security of the solid preparation.

Owner:SHENZHEN SALUBRIS PHARMA

Preparation method of graphene compound silver paste and graphene compound silver paste

ActiveCN103811130AGood electrical performanceGood stabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureCvd grapheneSilver paste

The invention relates to a solar cell technology, aims to solve the problem of poor electrical performance and stability of conductive silver paste in the conventional solar cell, and provides a preparation method of graphene compound silver paste and the graphene compound silver paste. According to the technical scheme, the preparation method of the graphene compound silver paste comprises the following steps: preparing a silver / graphene compound, and preparing silver-coated glass powder; preparing an organic carrier; mixing the obtained silver / graphene compound, the silver-coated glass powder, the organic carrier and an inorganic additive as required, dispersing fully, measuring the viscosity, and adjusting the viscosity to obtain uniform graphene compound silver paste. The graphene compound silver paste has the beneficial effects of higher electrical performance and higher stability, and is suitable for conductive silver paste.

Owner:成都中金黎阳新材料科技有限公司

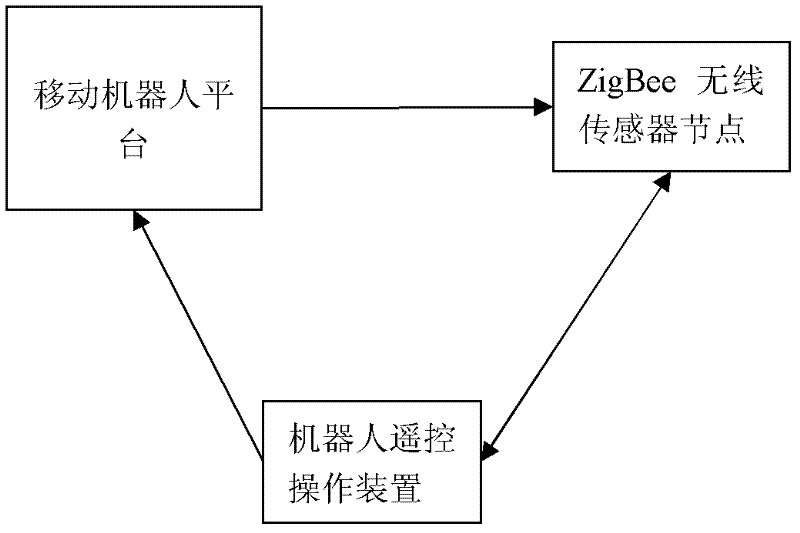

Wireless-sensor-network-based remote control rescue robot system and control method

InactiveCN102340894AMove fastGood stabilityTransmission systemsNetwork topologiesRobotic systemsElectric machinery

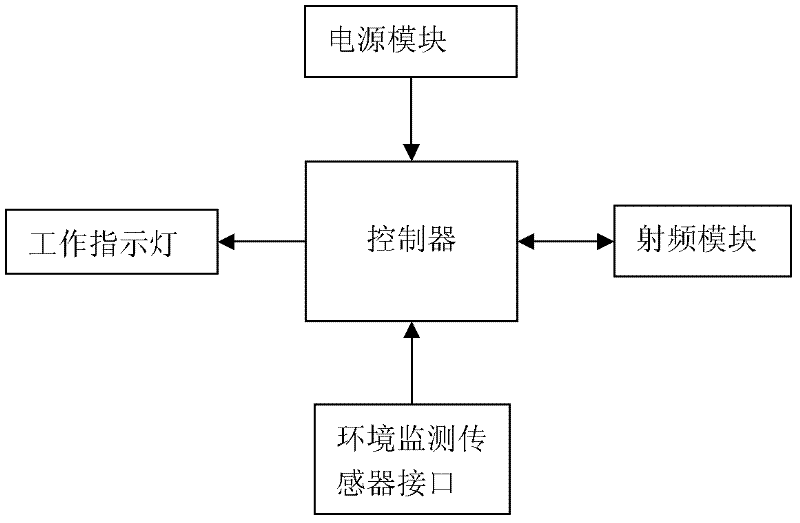

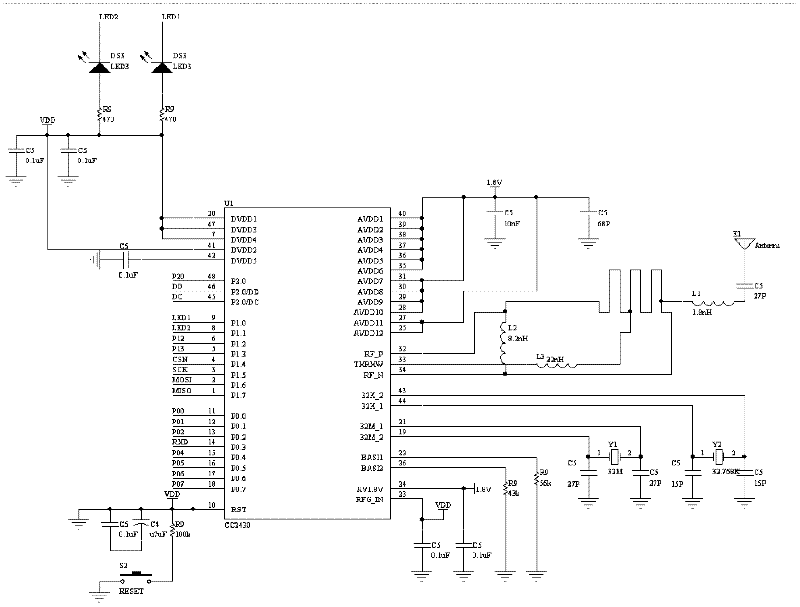

The invention discloses a wireless-sensor-network-based remote control rescue robot system, which comprises a ZigBee wireless sensor node, a mobile robot platform and a robot remote control operation device. The ZigBee wireless sensor node comprises a controller, an environment monitoring sensor interface, a working indicator lamp, a radio frequency module and a power module. The mobile robot platform comprises a controller, a six-wheel mobile base plate, a camera module, a wireless audio and video transmission module, a node releasing module, a wireless communication module, a high-power motor driving module and a power module. The robot remote control operation device comprises a controller, a rocker handle module, a video management module, a wireless communication module and a power module. The system adopts the six-wheel robot base plate so as to move fast, is adapted to various complex terrains and has a damping device. A robot is relatively lower, and can fully utilize a space with relatively higher visibility in the vicinity of the ground. Wireless communication is performed by utilizing a ZigBee protocol, so the system is reliable in communication, wide in range and low in energy consumption.

Owner:NORTHEASTERN UNIV

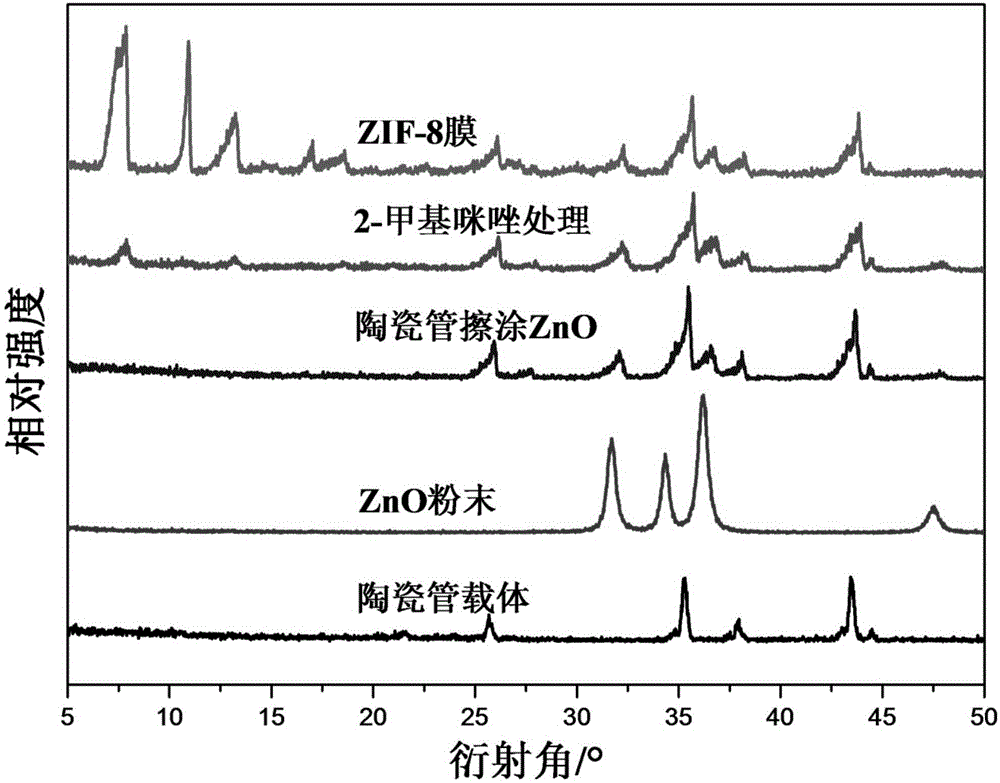

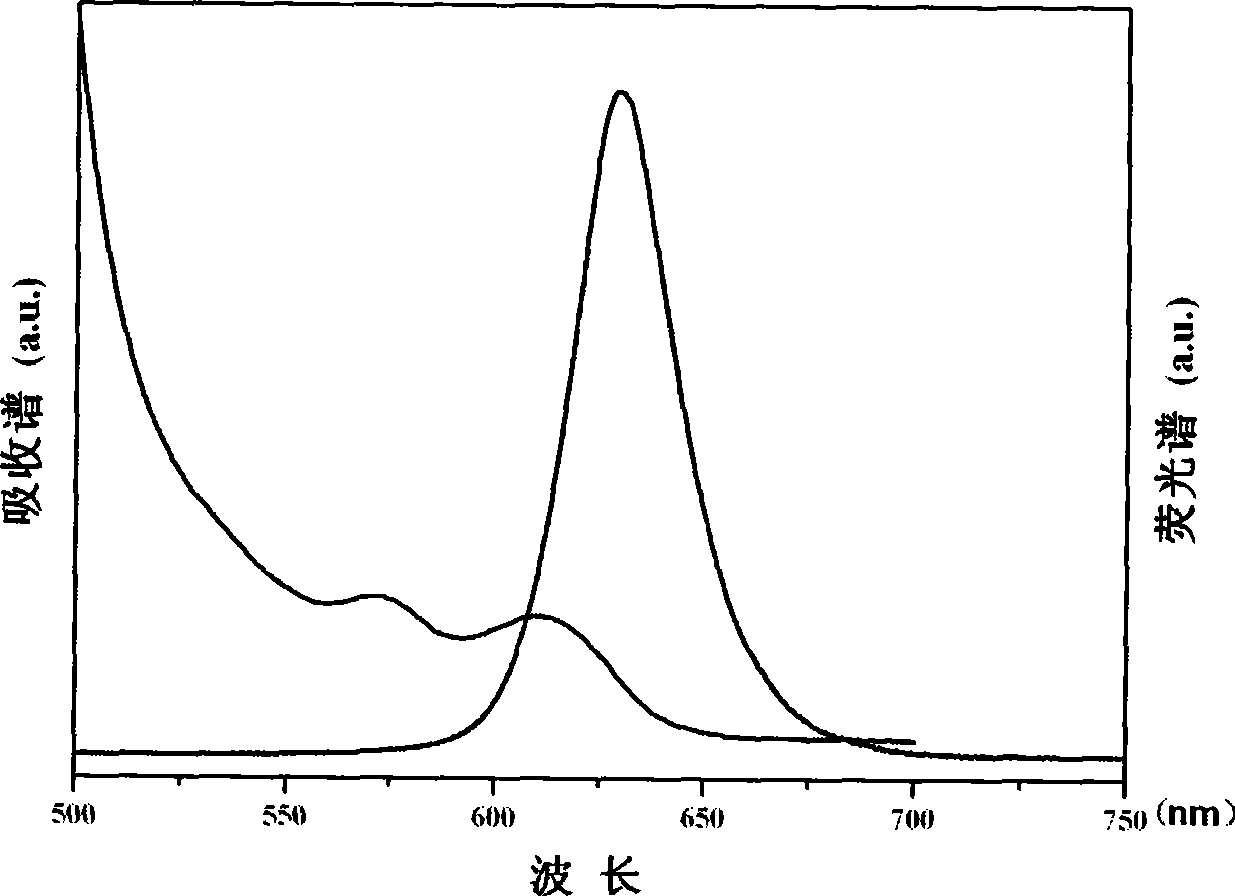

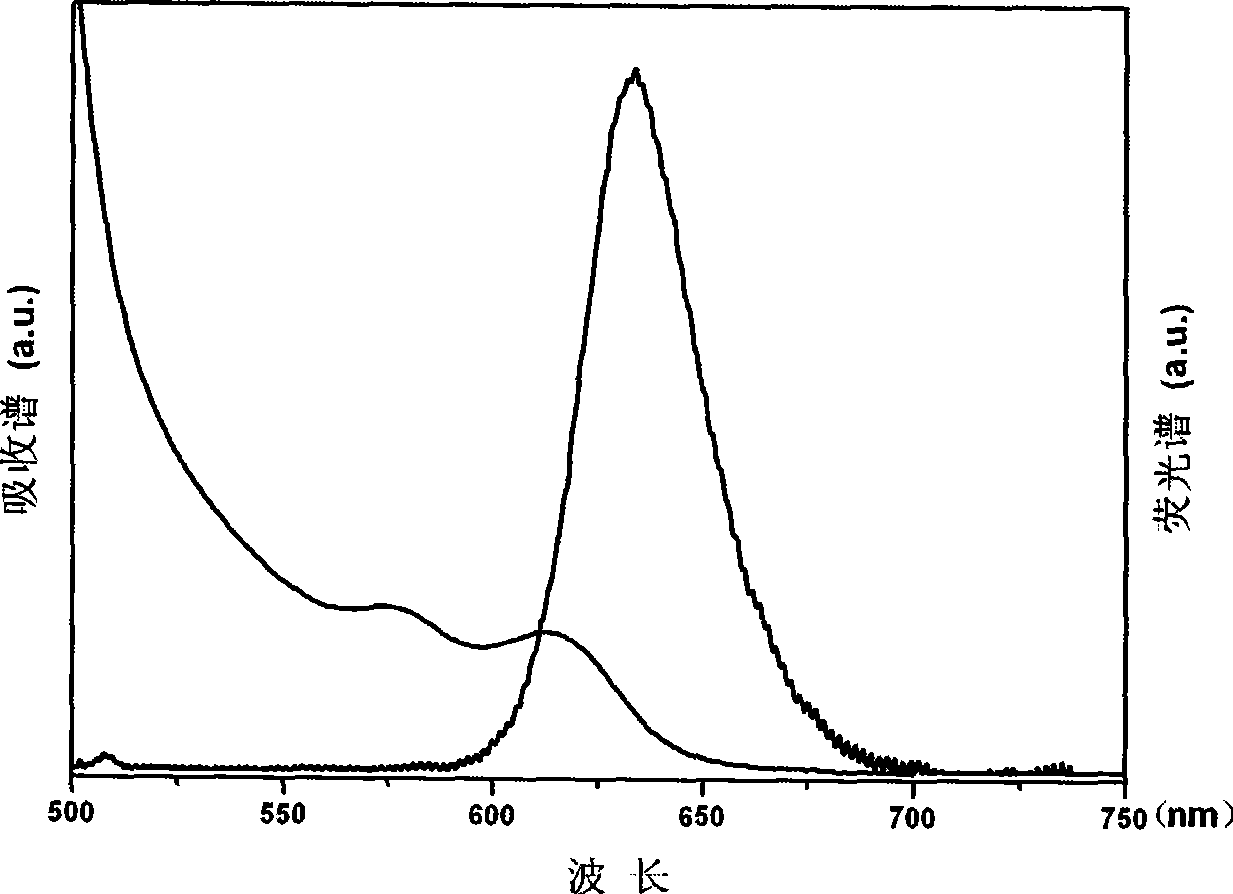

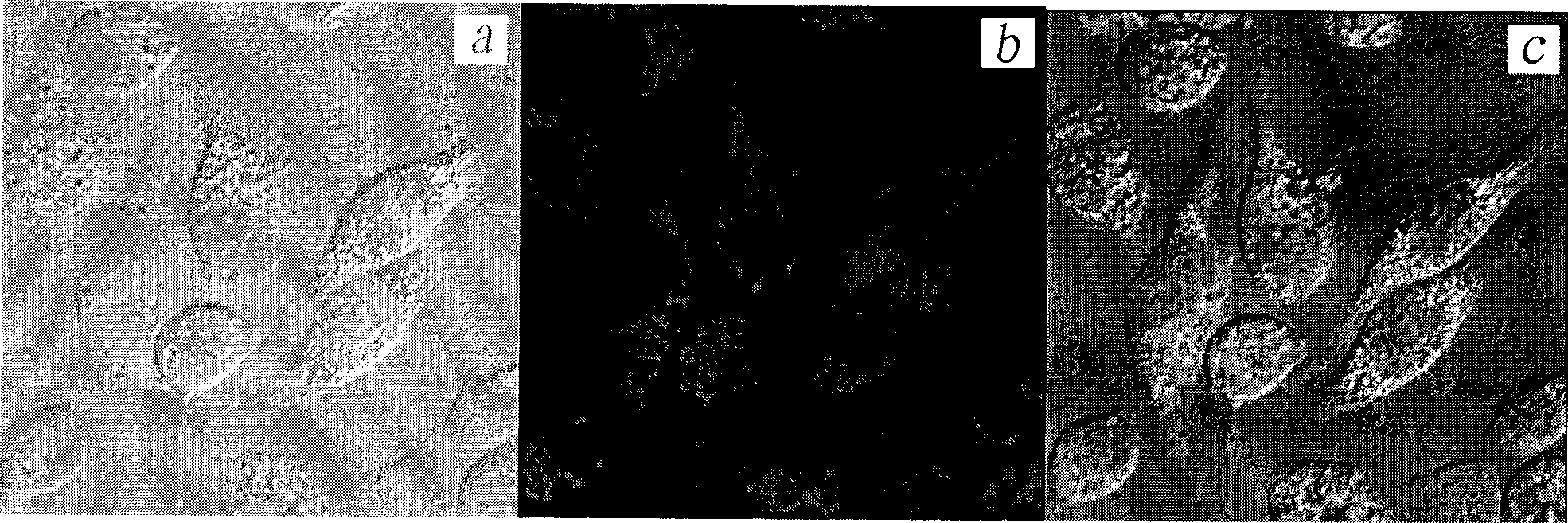

Method for performing induced synthesis on MOFs (metal-organic frameworks) membrane by implanting homologous metal oxide particles into surface of macroporous carrier by virtue of swabbing process

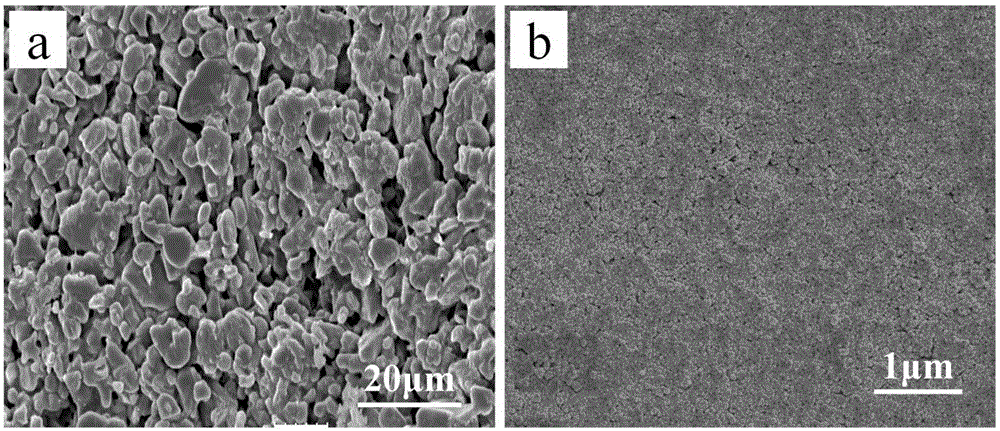

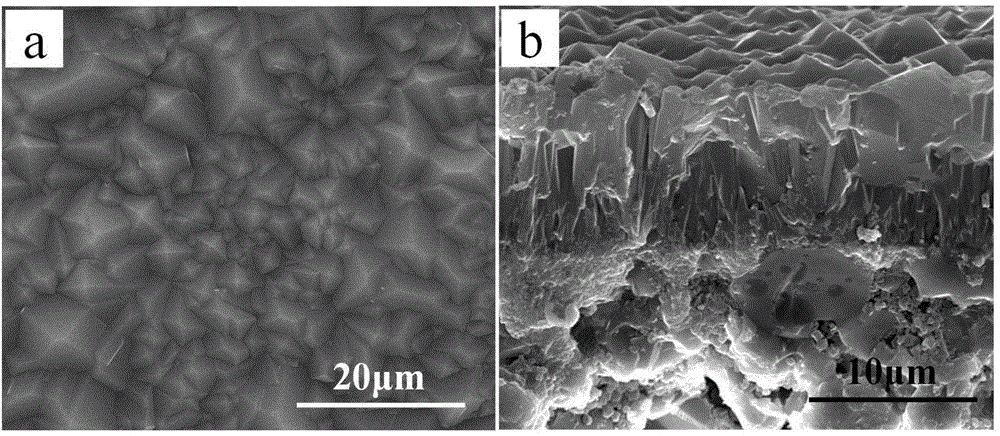

The invention provides a method for performing induced synthesis on a stable MOFs (metal-organic frameworks) membrane by implanting homologous metal oxide particles into the surface of a macroporous carrier by virtue of a simple swabbing process, belonging to the field of new materials, and relating to a method for preparing the corresponding stable MOFs membrane by swabbing homologous metal oxide powder, introducing a growth crystal seed and a fixed connecting point for synthesizing the MOFs membrane on the surface of the macroporous carrier, and then performing induced growth. The method is characterized by comprising the following steps: introducing the homologous metal oxide powder into the surface of a macroporous plate-type or tubular carrier in advance by using the simple swabbing process, and then performing solvothermal growth to prepare continuous and dense MOFs membranes. The method provided by the invention has the effects and advantages that a universal method for preparing the MOFs membrane by using the macroporous carrier is provided, and the method is simple to operate in a preparation process, is high in repeatability and good in membrane stability, is suitable for amplified large-scale application, and has important industrial application values.

Owner:DALIAN UNIV OF TECH

Preparation method of biocompatible aqueous phase quantum point

InactiveCN101381600AHigh fluorescence efficiencyGood stabilityLuminescent compositionsBiological macromoleculeOrganic molecules

The invention discloses a method for preparing a biocompatible aqueous quantum dot. The method comprises the following steps: a high-quality quantum dot and a nucleocapsid structure thereof are prepared; a surface modification technology is combined; the nucleocapsid structure is utilized to improve the stability of the quantum dot; through mutual action of intermolecular force, an organic molecular chain on the surface of the quantum dot is changed; an organic molecule of a long chain on the surface of an oil-phase quantum dot is changed into a small molecule which contains sulfhydryl and carboxyl or amidocyanogen and has biocompatibility and is water-soluble or a derivative of a large biological molecule; and finally, the biocompatible aqueous quantum dot which can be directly dissolved in phosphate buffer and the like is obtained. The method has the advantages: the preparation and surface modification method of the quantum dot are simple and easy to control the quality, the dimension and the surface property of the quantum dot; the obtained aqueous quantum dot has the advantages of higher fluorescent efficiency, even distribution of particle diameter, strong stability and the like; and the aqueous quantum dot prepared by the method can be used for biological detection, medical diagnosis, energy transferring and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

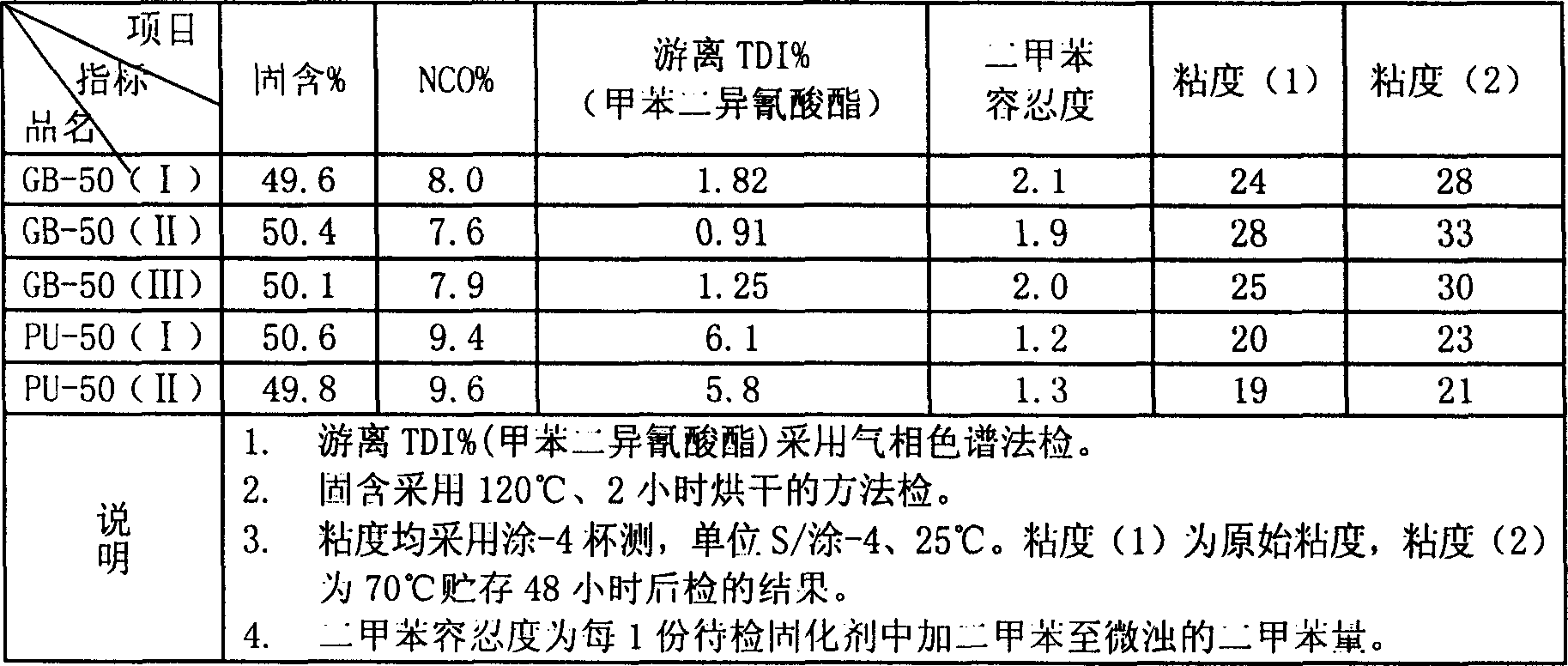

Preparation of polyurethane curing agent with low free toluene diisocyanate

A low-free toluene diisocyanate as the solidifying agent of polyurethane is prepared from toluene diisocyanate, ester-type solvent, trihydroxymethyl propane, aliphatic compound, trimerizing catalyst of isocyanate, and trimerizing inhibitor of isocyanate through two-step reaction including addition reaction to obtain TDI / TMP. Its advantages are low viscosity and high stability.

Owner:SHENZHEN FEIYANG IND CO LTD

Water-soluble (Ultra Violet) curing ink and preparation method thereof

The invention relates to a water-soluble (Ultra Violet) curing ink and a preparation method thereof, and belongs to the technical field of environmental protection ink. The water-soluble UV curing ink comprises the following components by mass percent: 60 to 85% of silica sol modified water-soluble urethane acrylate prepolymer, 1 to 10% of photoinitiator, 5 to 15% of pigment, 5 to 20% of solvent and 0 to 1% of assistant. The water-soluble UV curing ink is environment-friendly, nontoxic, fast in curing rate, high in stability, excellent in ageing resistance and solvent resistance, outstanding in adhesive force and wear resistance and suitable for a plurality of printing modes, meets the production requirement, and can be widely applied to the surfaces of printing materials such as paper materials, wood materials, plastics, metals and glass.

Owner:WUHAN UNIV

Method for preparing tungsten phosphide catalyst

InactiveCN102921441AGood stabilityImprove hydrodesulfurization activityPhysical/chemical process catalystsRefining to eliminate hetero atomsChemistryTungsten

The invention discloses a method for preparing a tungsten phosphide catalyst, and relates to a method for preparing the catalyst. The method for preparing the tungsten phosphide catalyst comprises the following steps of: smashing amorphous phosphotungstate at room temperature, uniformly mixing the amorphous phosphotungstate and gamma-Al2O3, pressing, screening, reducing particles of a certain mesh number in 923K hydrogen flow for 4 hours, and carrying out passivating in nitrogen flow with 0.5 percent of O2 at the room temperature for 2 hours. The tungsten phosphide catalyst is relatively high in stability; the hydrodesulfurization activity is extremely high; and the hydrodesulfurization rate of thiophene is reduced.

Owner:SHAANXI HI TECH ENERGY DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com