Patents

Literature

247 results about "Allyl compound" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Substance that consists of two or more chemical elements in union and containing the univalent organic group, -CH2 or allyl.

Metal complexes useful in metathesis and other reactions

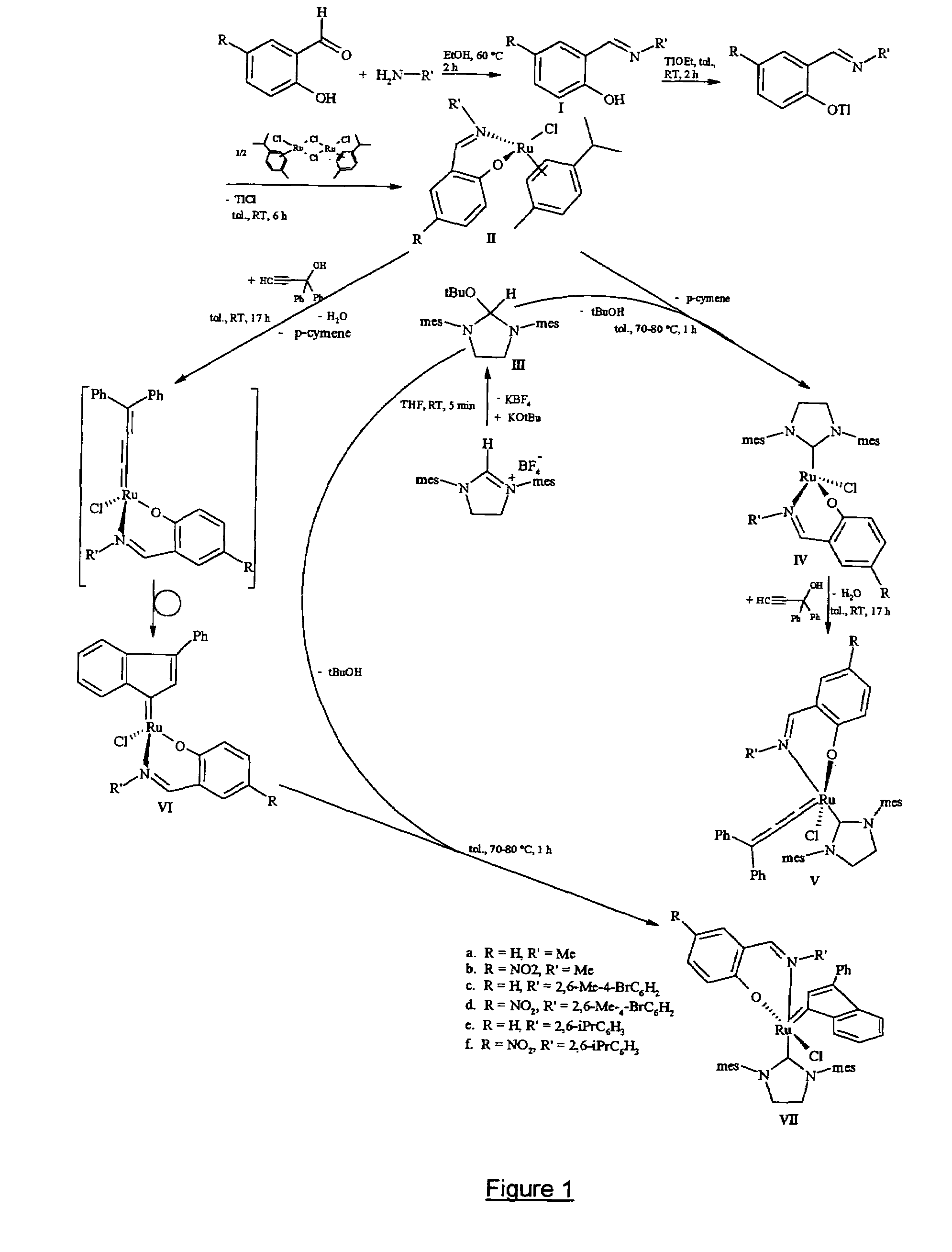

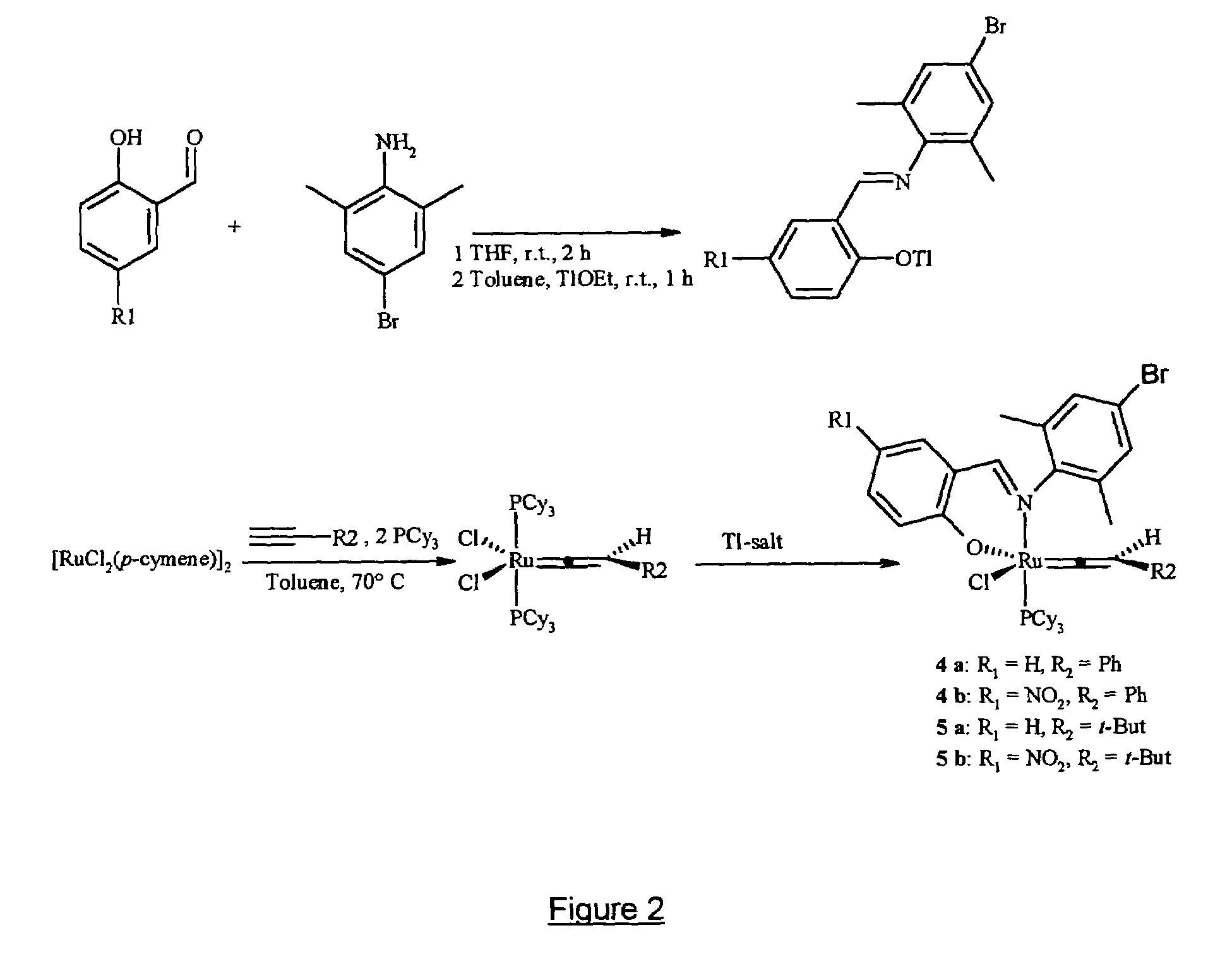

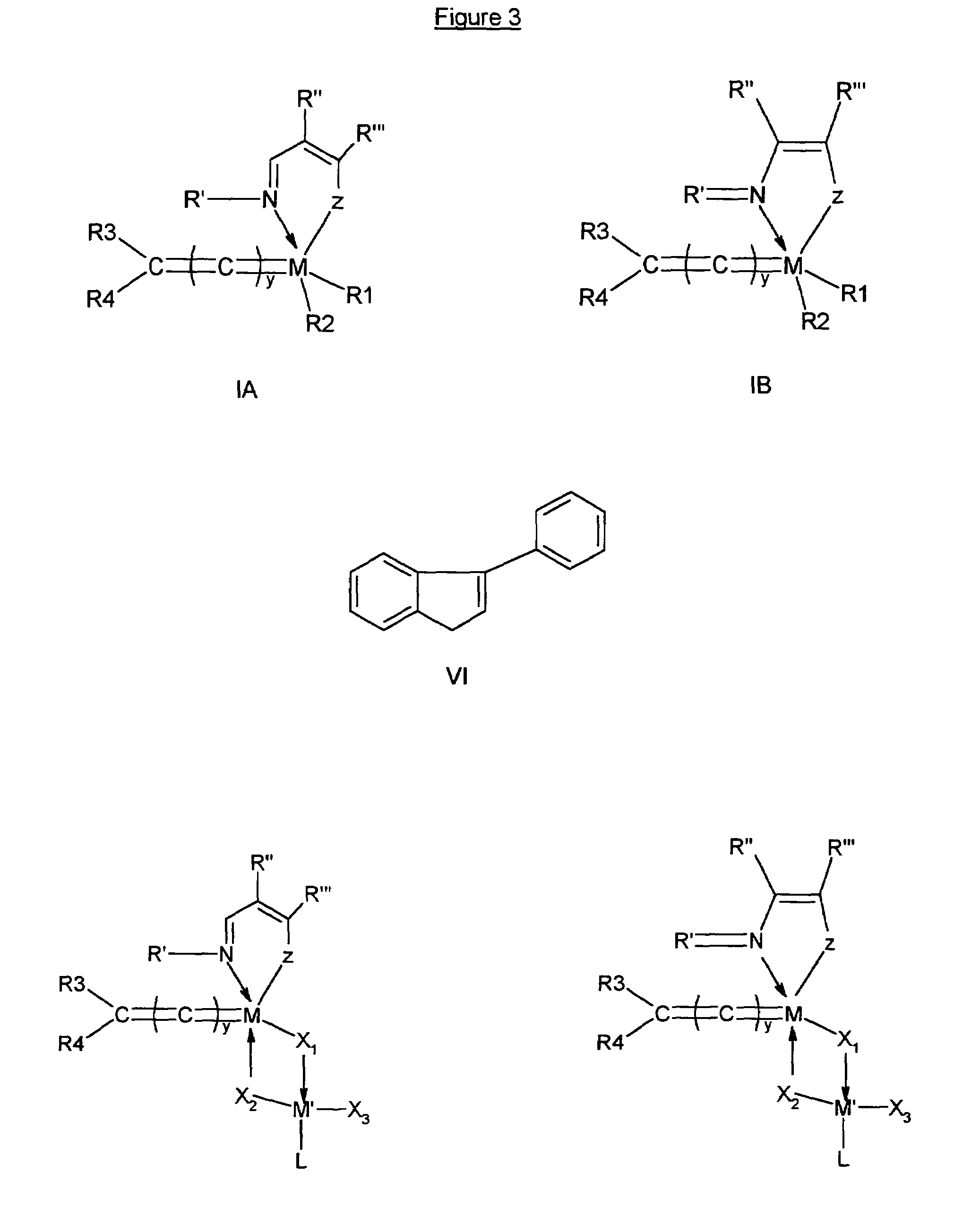

This invention provides metal complexes being useful as catalyst components in metathesis reactions and in reactions involving the transfer of an atom or group to an ethylenically or acetylenically unsaturated compound or another reactive substrate and, with respect to a sub-class thereof, for the polymerisation of α-olefins and optionally conjugated dienes, with high activity at moderate tempera-tures. It also provides methods for obtaining polymers with very narrow molecular weight distribution by means of a living reaction. It also provides methods for making said metal complexes and novel intermediates involved in such methods. It further provides derivatives of said metal complexes which are suitable for covalent bonding to a carrier, the product of such covalent bonding being useful as a supported catalyst for heterogeneous catalytic reactions. It also provides a direct one-step synthesis of pyrrole, furan and thiophene compounds from diallyl compounds.

Owner:RIMTEC CORP

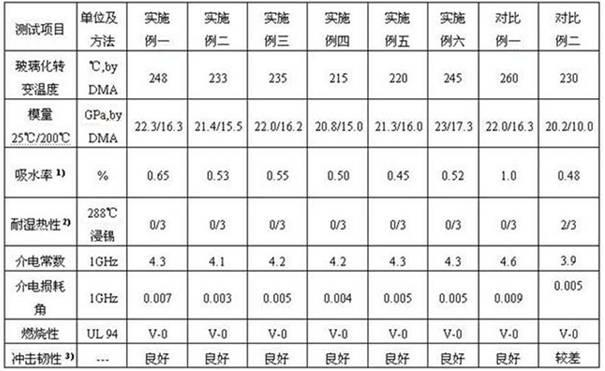

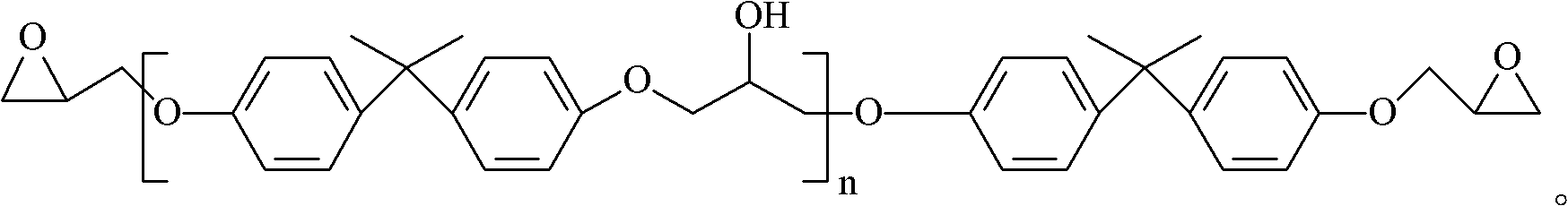

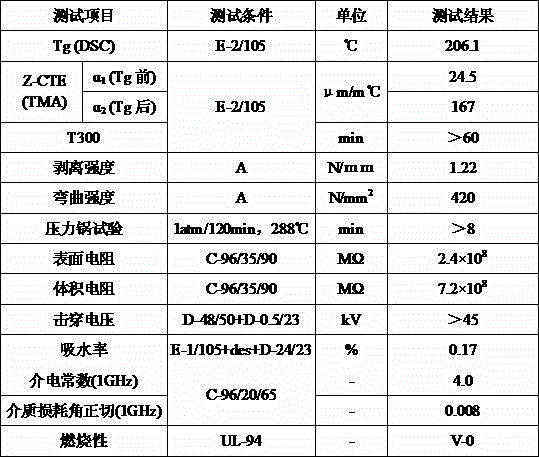

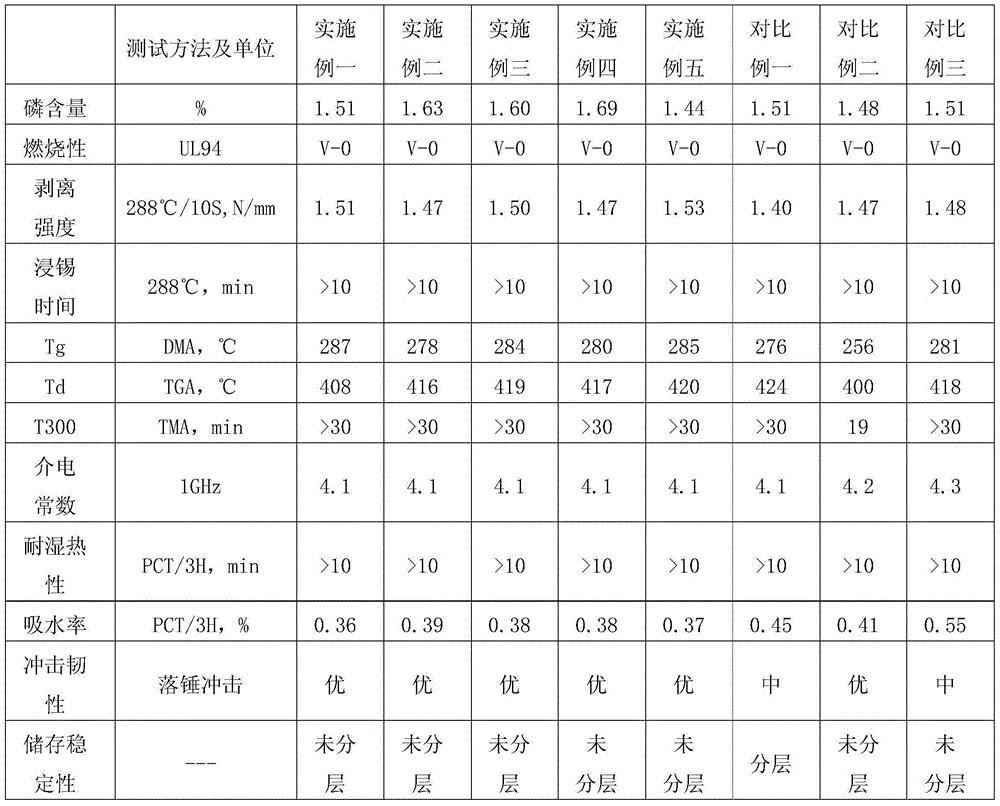

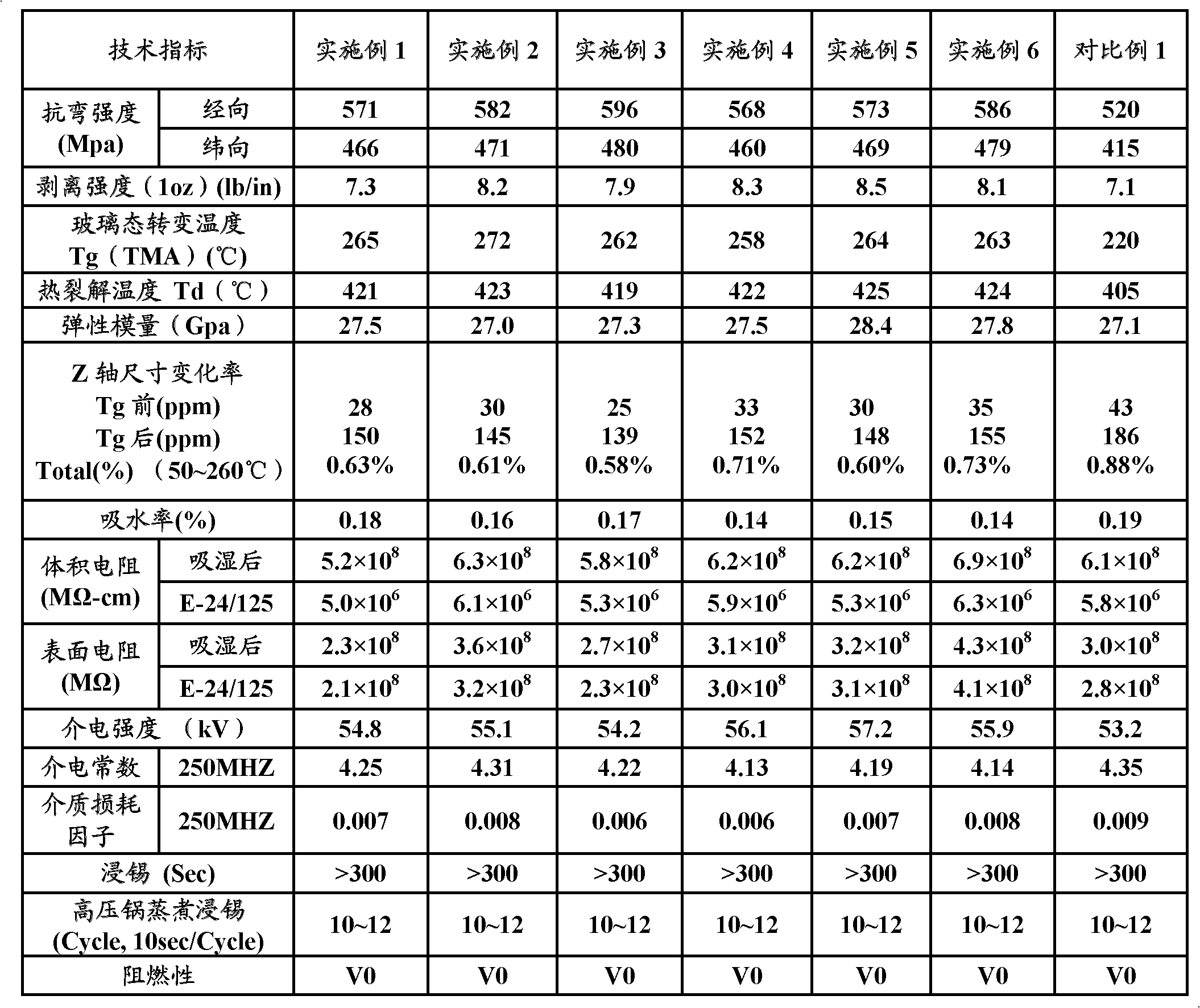

High weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby

InactiveCN101735456AImprove heat resistanceSmall coefficient of thermal expansionFibre treatmentPaper coatingEpoxyManufacturing technology

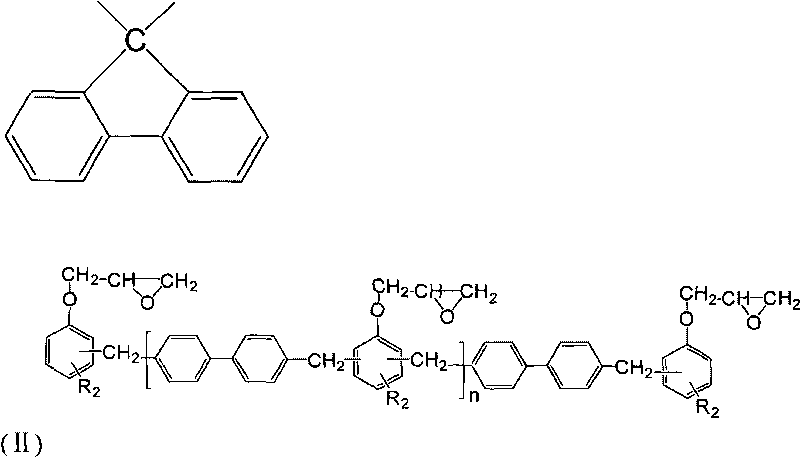

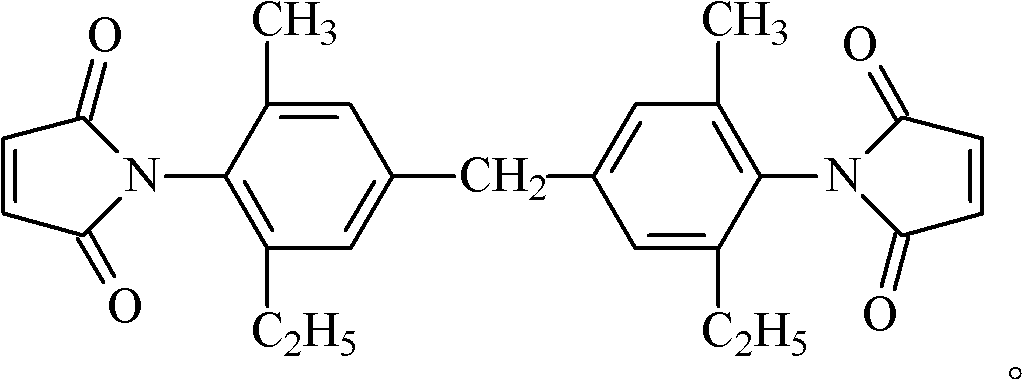

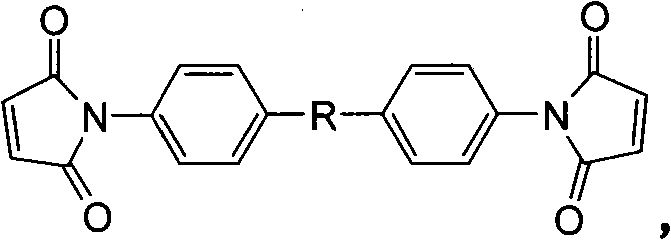

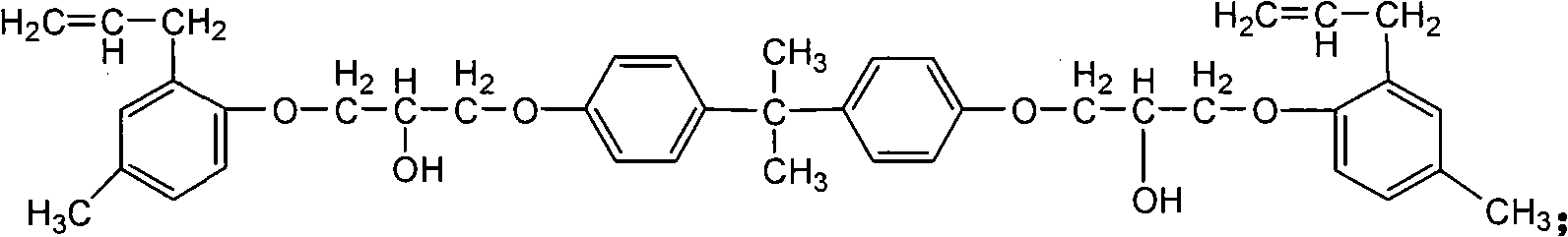

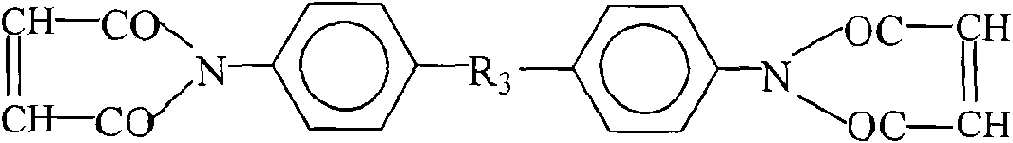

The invention relates to a high weather-proof thermosetting resin composite and prepreg and copper-clad laminate prepared thereby. The high weather-proof thermosetting resin composite comprises the following components in parts by weight: 10-40 parts of allyl compound, 8-80 parts of bismaleimide compound, 0-30 parts of epoxy resin and 0.05-5 parts of catalyst, wherein the molar ratio of allyl compound to bismaleimide compound is 1:2-4. The high weather-proof thermosetting resin composite provided by the invention has higher heat resistance, and the coefficient of thermal expansion (CTE) can be lowered to be below 2.0% to satisfy the requirements of manufacturing high multi-layer PCB. The prepreg prepared by the high weather-proof thermosetting resin composite has simple manufacture, better heat-resistant effect and high heat conductivity. The copper-clad laminate of the invention can be applied to heat-resisting and high multi-layer circuits and has simple manufacturing technology and low cost.

Owner:GUANGDONG SHENGYI SCI TECH

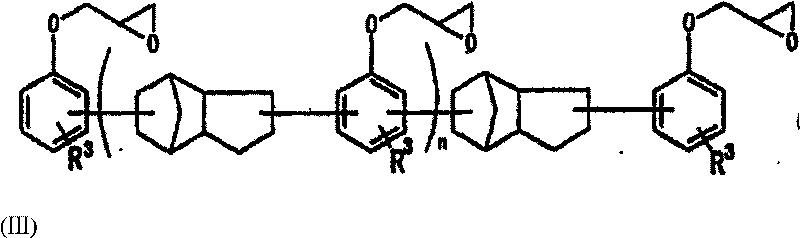

Thermosetting resin composition, prepreg and laminated board

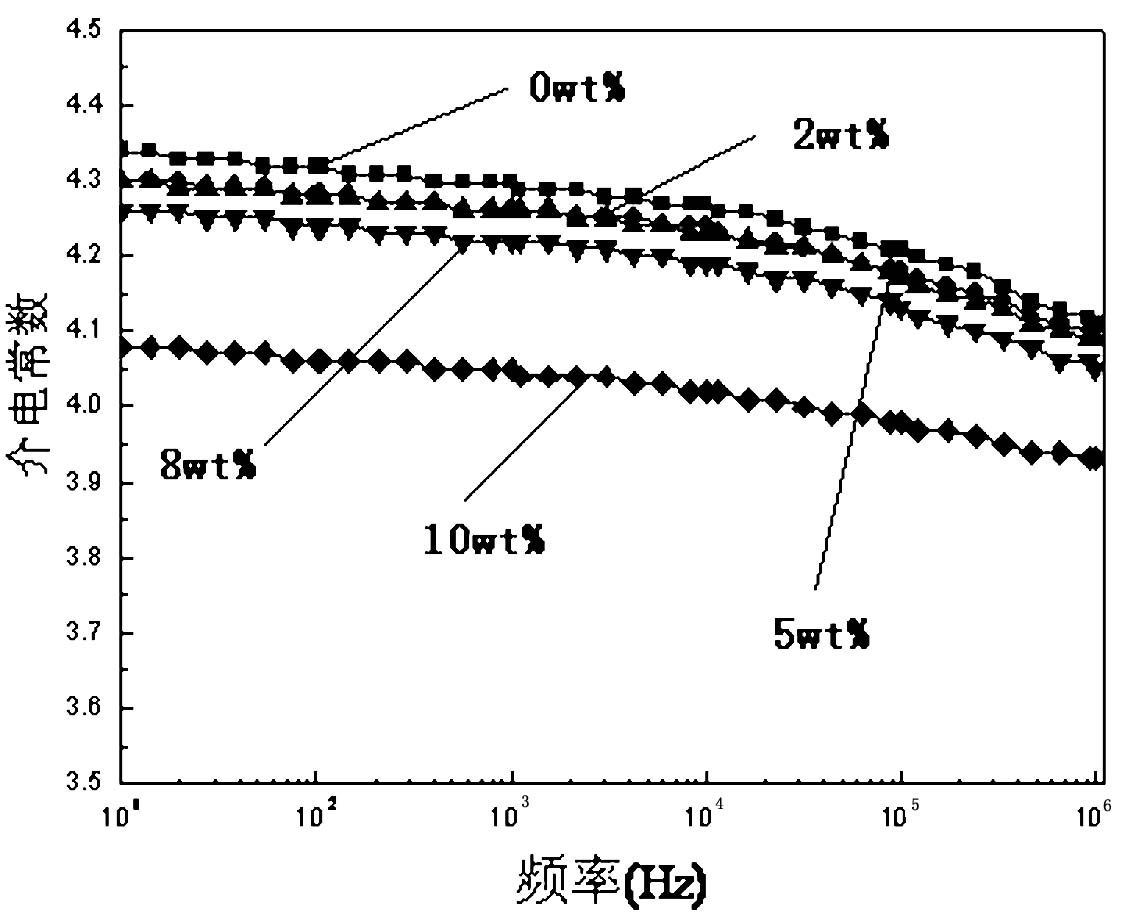

ActiveCN102115600AExcellent heat and humidity resistanceImprove heat resistanceGlass/slag layered productsMetal layered productsEpoxyDielectric loss

The invention discloses a thermosetting resin composition, which is characterized by comprising the following components in part by weight: 8 to 80 parts of allyl modified bismaleimide resin prepolymer, 15 to 60 parts of cyanate resin and 5 to 40 parts of halogen-free epoxy resin, wherein the allyl modified bismaleimide resin prepolymer is prepared by reacting bismaleimide resin with an allylcompound at the temperature of between 110 and 160DEG C for 20 to 100 minutes, and a weight ratio of the bismaleimide resin to the allylcompound is 100:(30-120). The composition can be used for preparing a prepreg and a laminated board. The composition and the laminated board have excellent humidity resistance, high heat resistance, low water absorption rate, high modulus, lower dielectric constant and dielectric loss, and good processing toughness, and can realize halogen-free flame retardancy.

Owner:SHENGYI TECH SUZHOU

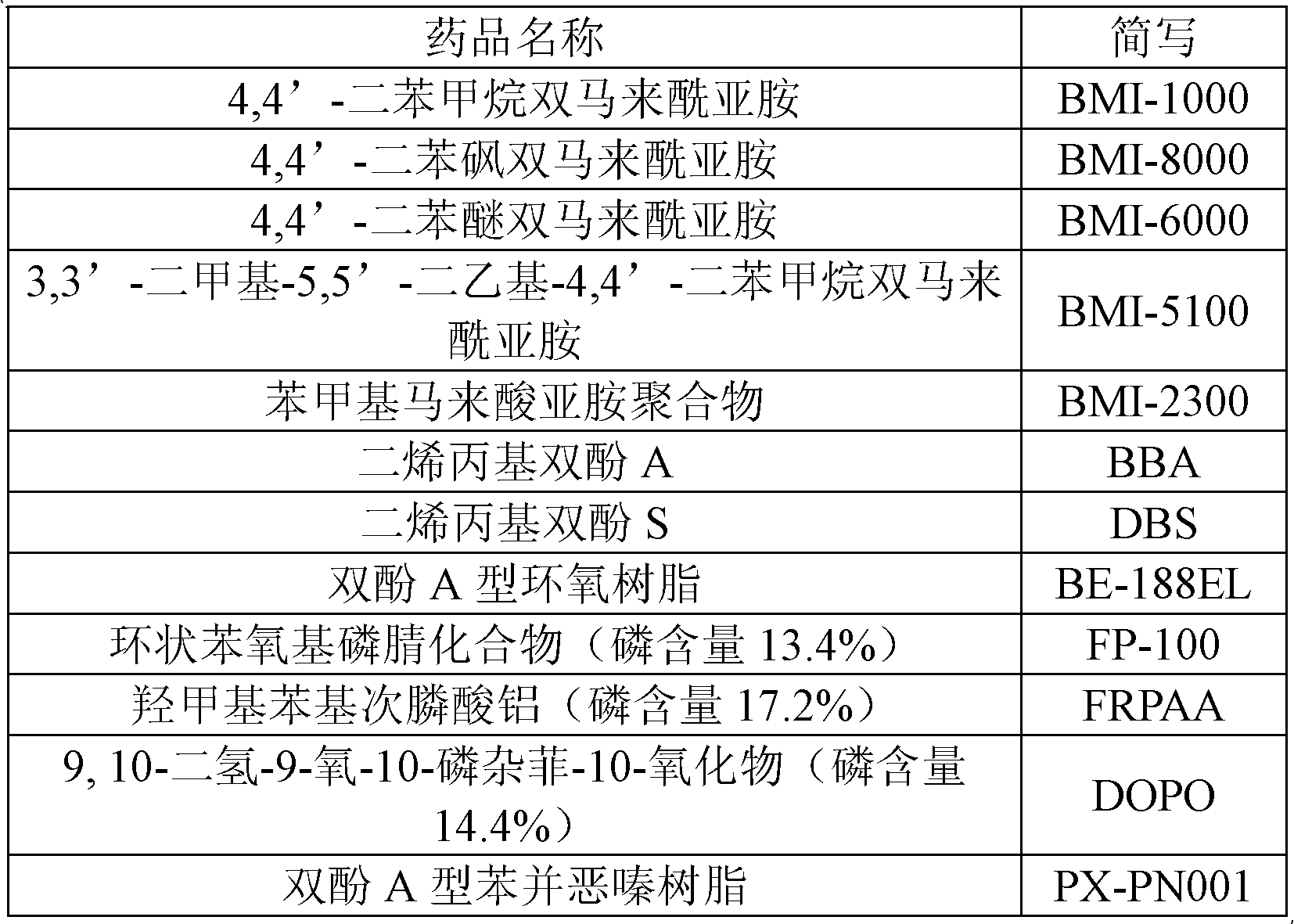

Halogen-free phosphorus-containing flame-retardant polyimide resin composition and preparation method thereof

ActiveCN102276837AImprove flame retardant performanceImprove toughnessGlass/slag layered productsMetal layered productsHalogenCopper

The invention relates to a halogen-free phosphorus-containing flame retardant polyimide resin composite, which is characterized by comprising the following components in part by weight: 150 to 180 parts of bismaleimide, 90 to 110 parts of allyl compound, 10 to 20 parts of bisphenol A epoxy resin and 10 to 50 parts of phosphorus-containing compound. The invention also relates to a preparation method for the halogen-free phosphorus-containing flame retardant polyimide resin composite. The method comprises the following steps of: adding the bismaleimide, the allyl compound, the bisphenol A epoxyresin and the phosphorus-containing compound into a reaction kettle, and reacting at the temperature of between 120 and 140 DEG C for 3 to 5 hours to obtain the halogen-free phosphorus-containing flame retardant polyimide resin composite. The halogen-free phosphorus-containing flame retardant polyimide resin composite is synthesized in one step and does not contain halogens and has high flame retardant performance; according to UL94 V0 flame retardant grade tests, the toughness of the cured composite is improved; and the moist heat resistant performance of the composite is high, and the composite meets the requirements of flame retardance and processing in the process of processing copper-clad plates and has high the storage stability.

Owner:INNOTEK TECH CHINA

Thermosetting resin composition, prepreg and laminated board

ActiveCN102199351AGood workmanshipExcellent heat and humidity resistanceSynthetic resin layered productsLaminationEpoxyThermal expansion

The invention discloses a thermosetting resin composition which is characterized by comprising the following components in parts by weight: 10-65 parts of alkyl modified bismaleimide resin prepolymer, 5-60 parts of composite cyanate resin and 5-65 parts of halogen-free epoxy resin, wherein the total weight of the resins is 100 parts; the alkyl modified bismaleimide resin prepolymer is obtained byreacting a bismaleimide resin with a diallyl compound for 20-120 minutes at the temperature of 110-160 DEG C and then cooling; and the weight ratio of bismaleimide resin to diallyl compound is 100: (15-120). A prepreg and a laminated board can be prepared by using the composition. The composition, the prepreg and the laminated board have the characteristics of good manufacturability, halogen-free inflaming retardance, excellent humidity resistance and heat resistance, low thermal expansion coefficient and low dielectric constant and dielectric loss, and are suitable for the fields of integrated circuit package, high-frequency, high-speed and high-density interconnection and the like.

Owner:SHENGYI TECH SUZHOU

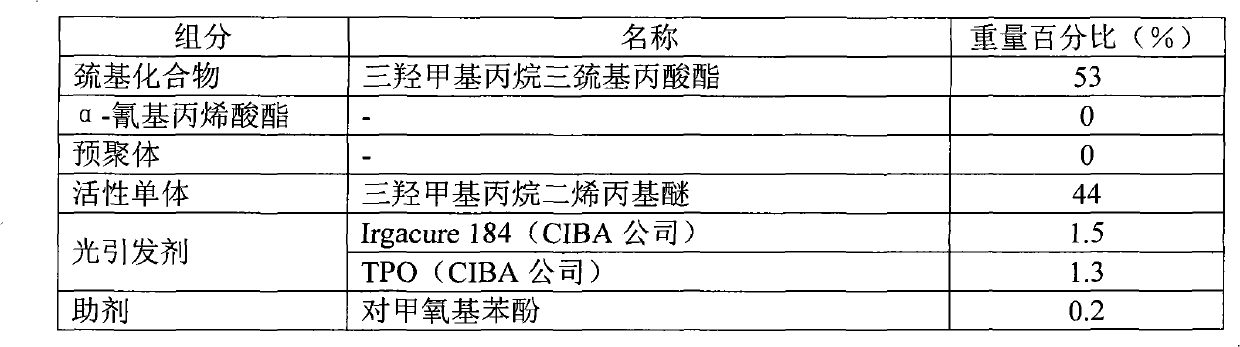

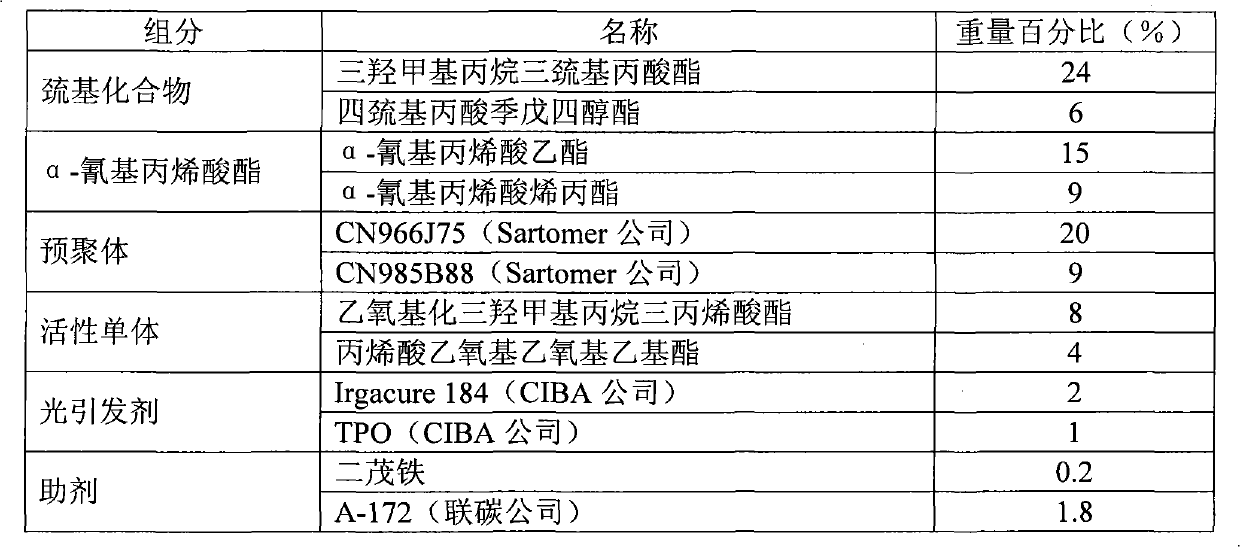

UV curable adhesive

ActiveCN101928541AHigh bonding strengthSuitable for continuous productionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPhotochemistry

The invention discloses a sulfydryl / cyano acrylic ester UV curable adhesive composition, which comprises: 5 to 60 percent of sulfydryl compound which is selected from a sulfydryl alkyl acid ester and alkyl hydrosulfide; 5 to 60 percent of alpha-cyanoacrylate of a formula below; 0 to 60 percent of a prepolymer selected from polyester acrylate prepolymers, epoxy acrylate prepolymers and urethane acrylate prepolymers; 0 to 50 percent of active monomer which is selected from acrylic esters having a mono-functional group, double functional groups and multiple functional groups, allyl compounds and ethenyl compounds; 1 to 10 percent of photoinitiator; and 0 to 10 percent of assistant. The UV curable adhesive composition has a quick curing capability, high adhesive strength and low internal stress; and the obtained cured layer is flexible and can be widely to bond metal, metal oxides, plastics, rubber, glass, polyester and other substrate materials.

Owner:JIANGSU HECHENG ADVANCED MATERIALS

Light-curing edge sealing adhesive

ActiveCN103865470ASuitable for adhesionSuitable stabilityPolyureas/polyurethane adhesivesModified epoxy resin adhesivesAdhesive cementHydrofluoric acid

The invention discloses a light-curing adhesive and in particular relates to an ultraviolet-curing adhesive. The light-curing adhesive comprises the following components in percentage by mass: 10%-75% of matrix resin, 5%-50% of auxiliary resin, 10%-70% of activated monomer of acrylate, allyl compound or vinyl compound, 5%-15% of adhesion accelerator, 1%-10% of photoinitiator and 0.5-10% of auxiliary agent. The light-curing adhesive provided by the invention has fast curing capability, high bonding strength and low internal stress; an obtained cured layer is soft and has excellent hydrofluoric acid resistance.

Owner:惠晶显示科技(苏州)有限公司

Preparation method of copper clad plate

ActiveCN101652026AGuaranteed performanceGuaranteed flame retardant performanceLaminationLamination apparatusEpoxyCopper foil

The invention discloses a preparation method of copper clad plate and the method comprises the following steps: (1) adopting bismaleimide resin and allyl compound in a weight ratio of 100:40-100 to react at 110-160 DEG C for 10-120min and obtain prepolymer, cooling to room temperature after finishing the reaction, using acetone to prepare prepolymer solution; (2) adding 15-150 parts of epoxy resinwith phosphorous, 10-100 parts of compound curing agent and 0-5 parts of curing accelerator in the solution obtained in the step 1, stirring evenly to obtain a glue solution, selecting a flat E-glassfibic cloth, coating the glue solution evenly on the glassfibic cloth, then roasting to prepare B-stage prepreg; (3) cutting the B-stage prepreg to proper size according to the size of a pressing machine, overlying five prepregs while placing two high impact copper foils with the same size separately on the top and bottom of the prepregs, placing the prepregs with copper foils in a vacuum hot pressing machine to press and obtaining the copper clad plate. The obtained copper clad plate can meet the demand for halogen-free and flame resistance, the heat resistance and humidity resistance are excellent, and the low dielectric loss and pressing toughness are good.

Owner:SHENGYI TECH SUZHOU

Resin composition and prepreg laminated board manufactured by employing same

InactiveCN104830059AImprove performanceGood thermal expansion performanceSynthetic resin layered productsMetal layered productsThermal expansionSilorane Resins

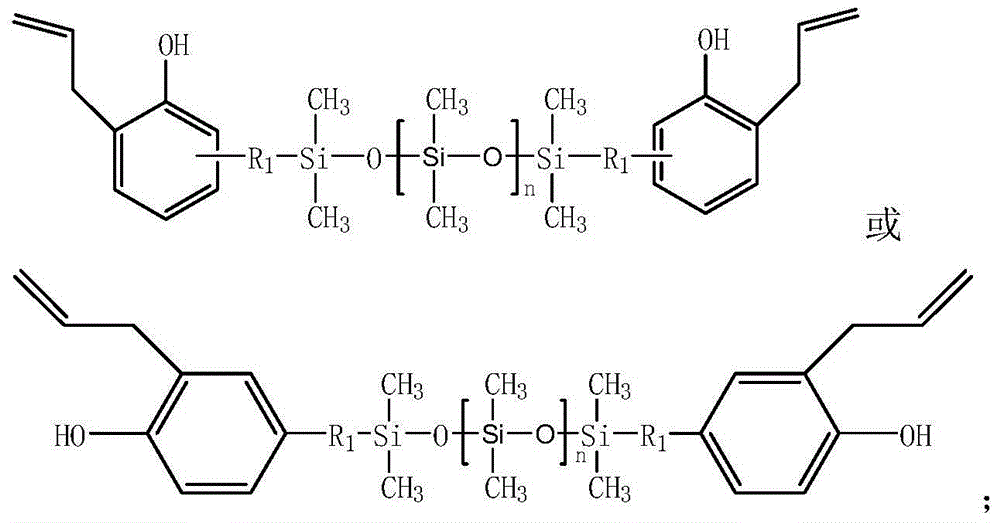

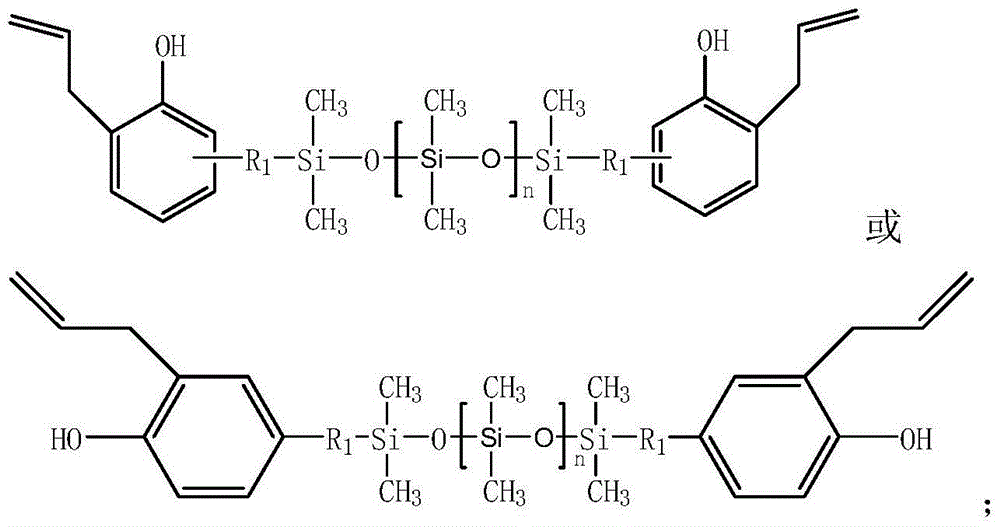

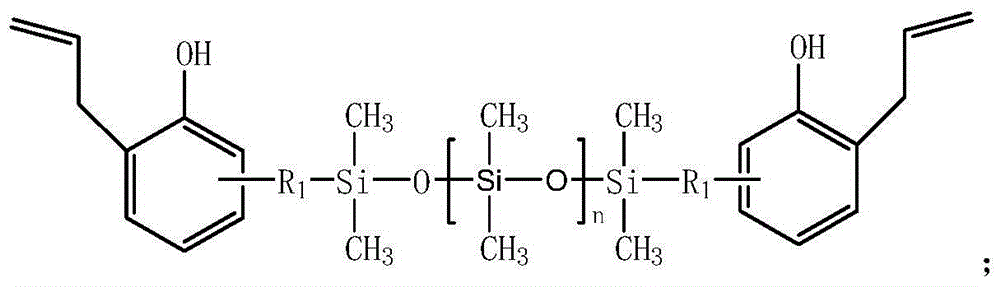

The invention discloses a resin composition which comprises the following solids by weight: (a) 100 parts of a bismaleimide resin prepolymer, (b) 5-80 parts of cyanate ester, (c) 0-50 parts of a flame retardant and (d) 0-65 parts of inorganic filler, wherein the bismaleimide resin prepolymer is obtained by carrying out reaction on an allyl compound and bismaleimide resin and the ratio of bismaleimide resin and allyl compound by weight is 100: (10-120). According to the resin composition disclosed by the invention, by adopting siloxane containing allyl at the tail end as a modifier of bismaleimide resin and limiting the content of siloxane in the modifier, unreacted siloxane resin is not generated in reaction, so that the advantages and characteristics of siloxane resin can be fully exerted and the interlaminar adhesive force at the high temperature is greatly improved. Moreover, the thermal expansion properties of the solids are optimized, so that the resin composition satisfies the requirements on high precision electronic substrate materials.

Owner:SHENGYI TECH SUZHOU

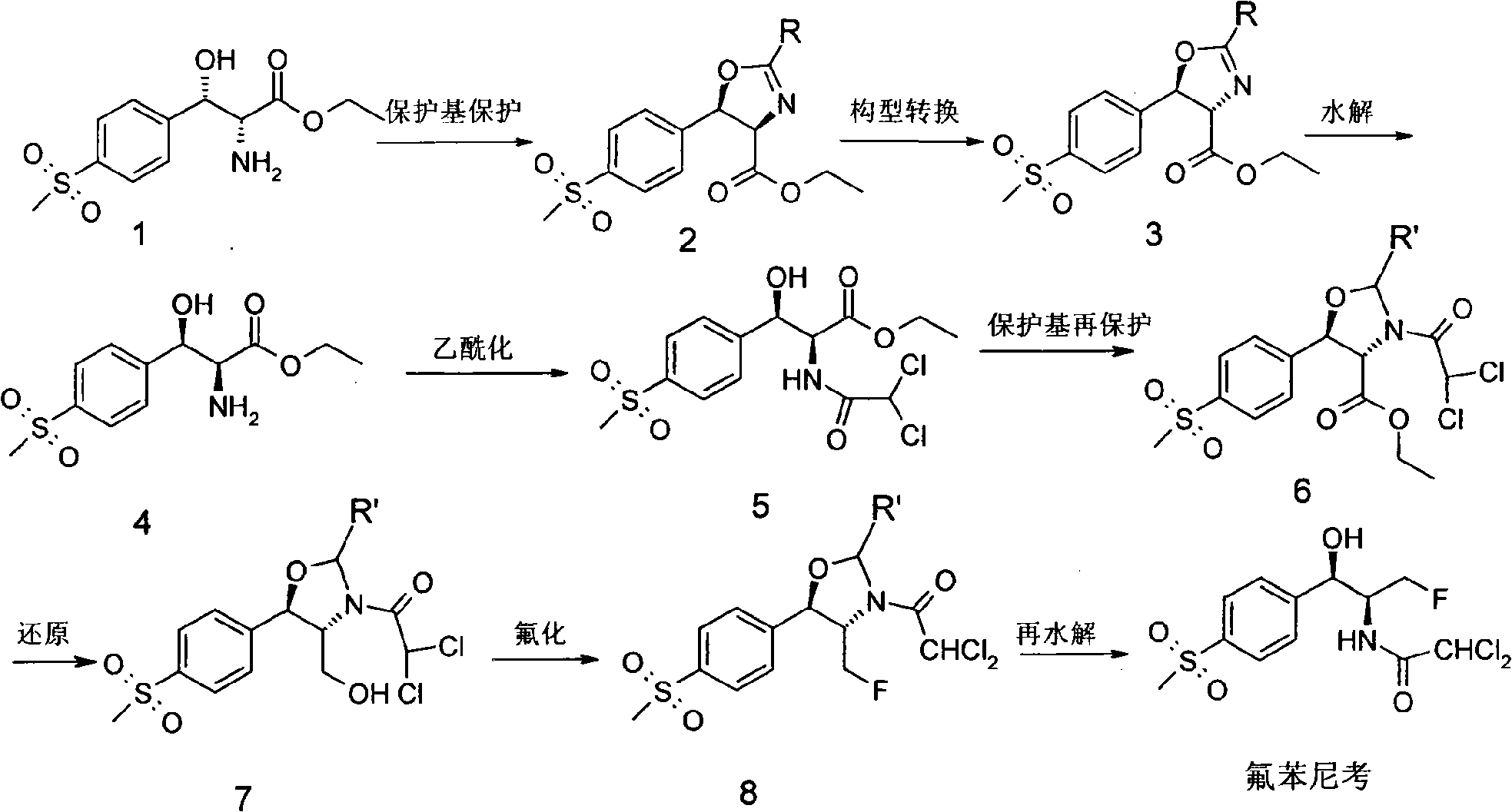

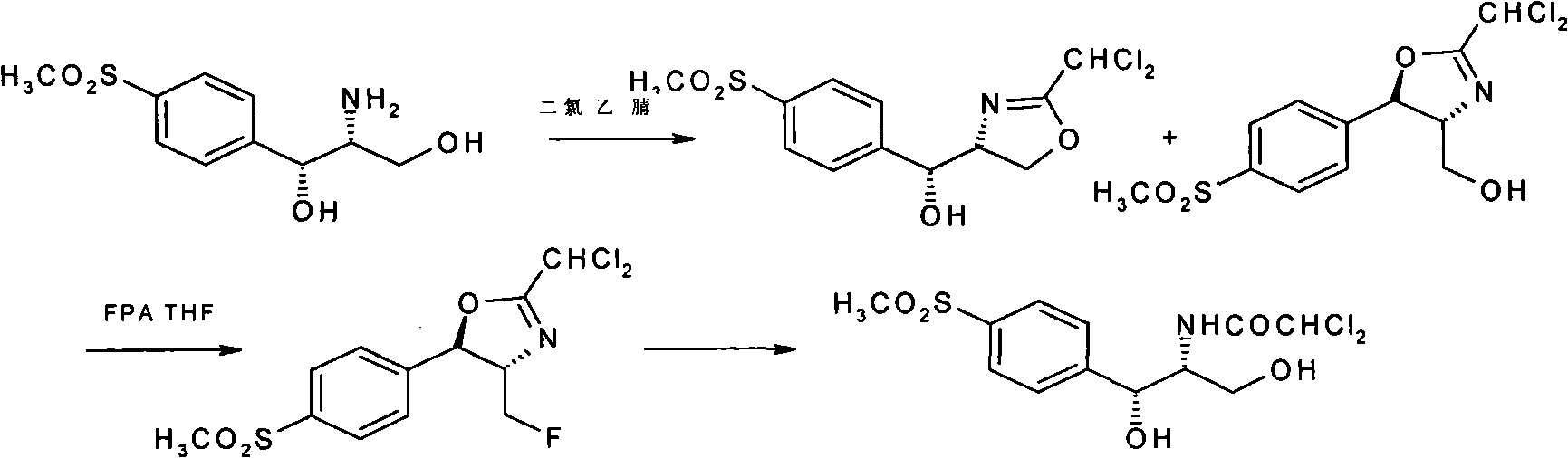

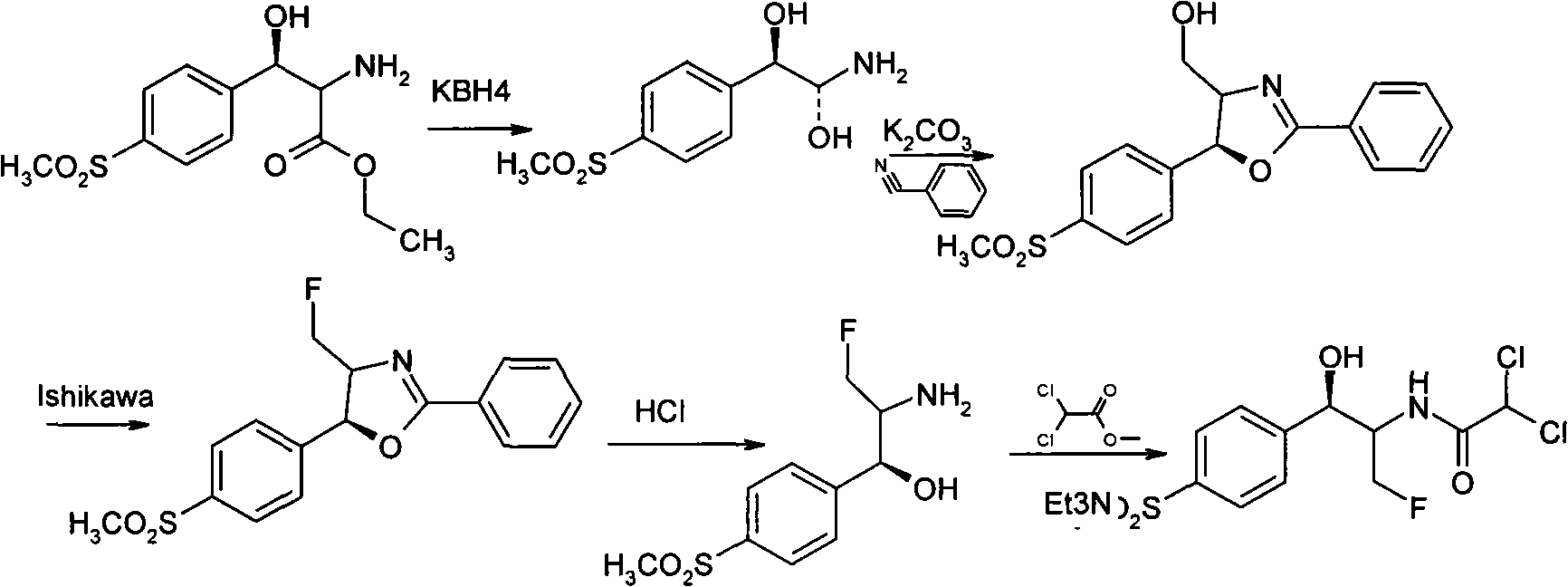

Method for synthesizing florfenicol

InactiveCN101265220AEasy marketEasy to operateAntibacterial agentsOrganic chemistrySodium methoxideSynthesis methods

The invention discloses a synthesis method of synthesizing florfenicol. The synthesis method comprises the following steps: L-threo-(p-(methylsylfonyl) phenyl) serine ethyl ester which is used as raw material is processed by the protection by a protecting group, configurational transition, hydrolyzation, acetylation, re-protection, deoxidation, fluorination, and pre-hydrolyzation, so that the florfenicol is obtained, wherein, the protecting group R is one of benzoyl chloride, phthalic anhydride, cyanophenyl, and allyl compounds; the configurational transition is performed when sodium alcoholate or sodium methoxide exists. The raw material which is used in the method is a byproduct which is generated during the process of preparing thiamphenicol, is easy to get in the market, and is inexpensive; the technological operation is simple, the cost is low, the yield rate is high, and the synthesis method has industrialized value.

Owner:SHANGHAI RECORD PHARM CO LTD

Resin composition and preparation method thereof

ActiveCN102719096AImprove solubilityImprove toughnessSemiconductor/solid-state device detailsSynthetic resin layered productsThermal expansionSolvent

A resin composition is made of, by weight, 100 parts of bismaleimide, 1-50 parts of allyl compound, 100-300 parts of cyanate ester, 0.01-0.4 part of catalysts, 2-12 parts of unit phenol, 70-150 parts of halogen-free epoxy resin, 15-20 parts of flame retardant, 120-300 parts of inorganic filler, 0.5-4 parts of coupling agent and 200-450 parts of solvent. Bismaleimide is modified by the allyl compound, the halogen-free epoxy resin and the cyanate ester, the modified bismaleimide is fine in dissolubility, the resin composition is low in viscosity, and solidified products of the resin composition have fine toughness and thermal stability. The vitrification transformation temperature of copper-clad plates made of the resin composition can reach 190-220 DEG C, Z-axial thermal expansion coefficient satisfies that a1 is equal to or smaller than 30ppm / DEG C and a2 is equal to or smaller than 160ppm / DEG C, and the requirements of IC (integrated circuit) packaging carrier plate substrates can be met.

Owner:汕头超声覆铜板科技有限公司

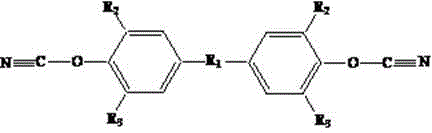

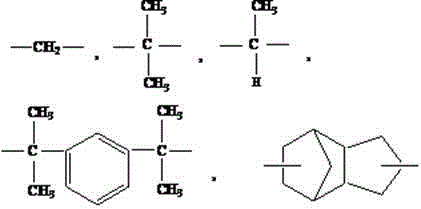

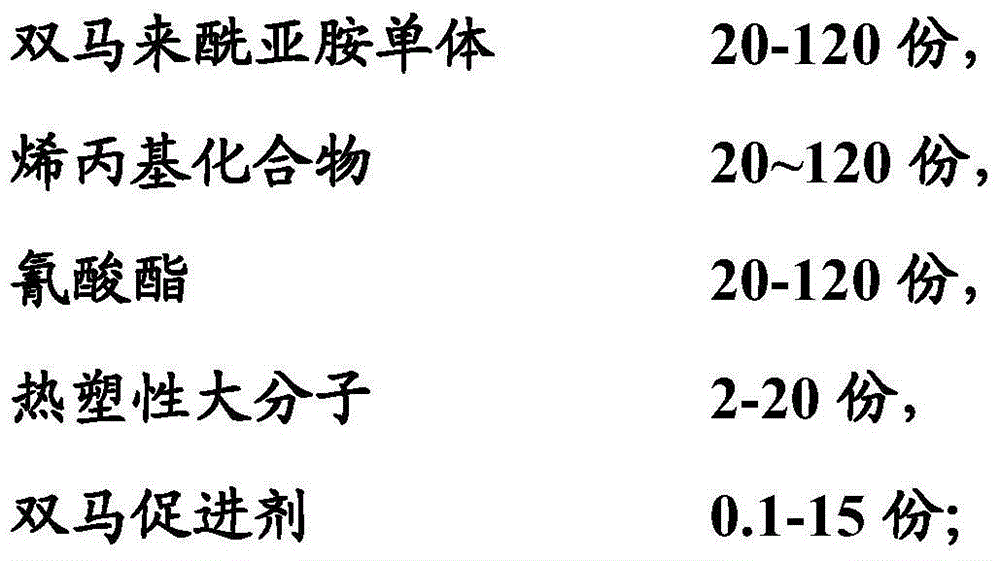

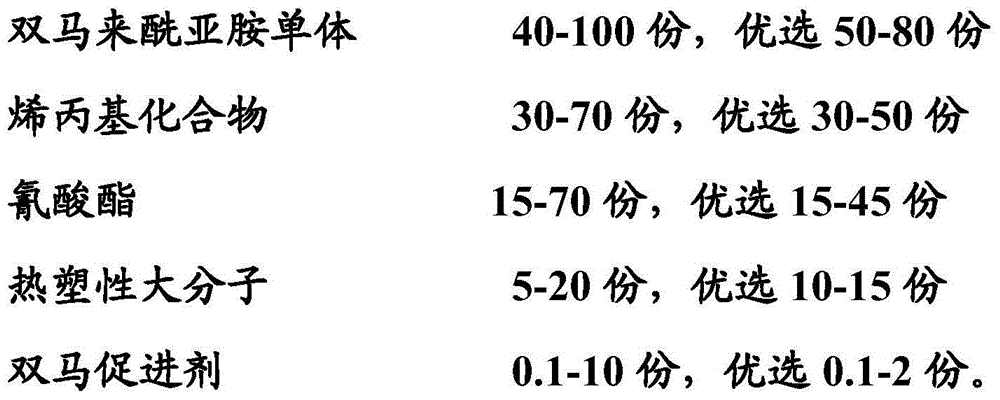

Fluorine-containing low-dielectric-loss bismaleimide resin, and preparation method and application thereof

ActiveCN104479130AImprove heat resistanceImprove mechanical propertiesDielectric lossChemical compound

The invention discloses a fluorine-containing low-dielectric-loss bismaleimide resin and a cured resin thereof, and a preparation method and application thereof. The resin is prepared by carrying out blend reaction on the following composition, wherein the composition comprises the following components in parts by weight: 20-120 parts of bismaleimide monomer, 20-120 parts of allyl compound, 20-120 parts of cyanate, 2-20 parts of thermoplastic high molecule and 0.1-1.5 parts of bismaleimide accelerator. At least one of the bismaleimide monomer and allyl compound contains fluorine. The bismaleimide resin disclosed by the invention has excellent heat stability, dielectric properties and mechanical properties, can be used as a high-performance composite material resin matrix, and has application value in the fields of copper clad plates, electronic packaging, aerospace and the like.

Owner:INST OF CHEM CHINESE ACAD OF SCI

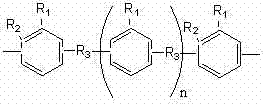

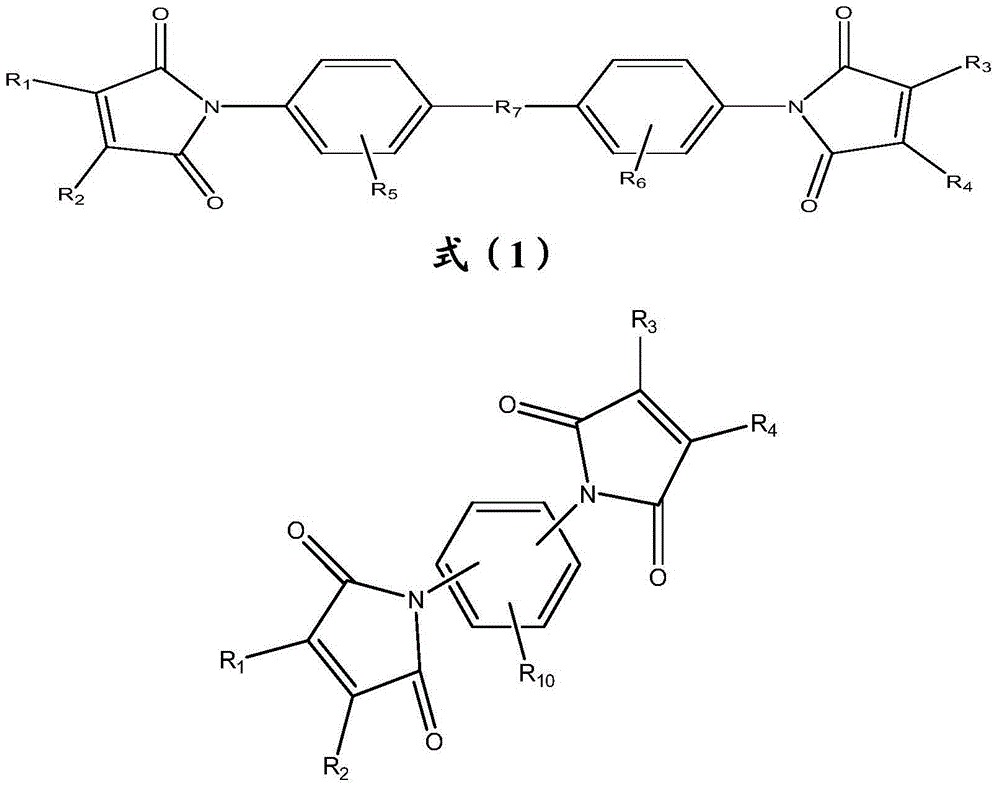

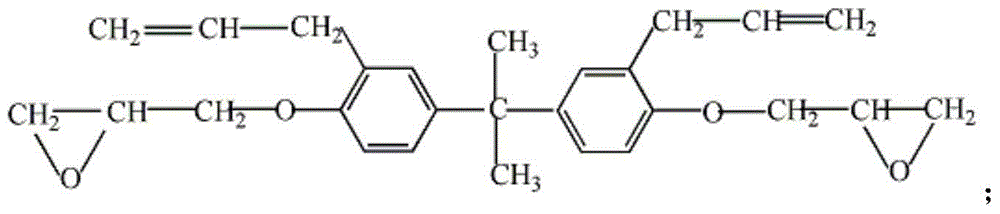

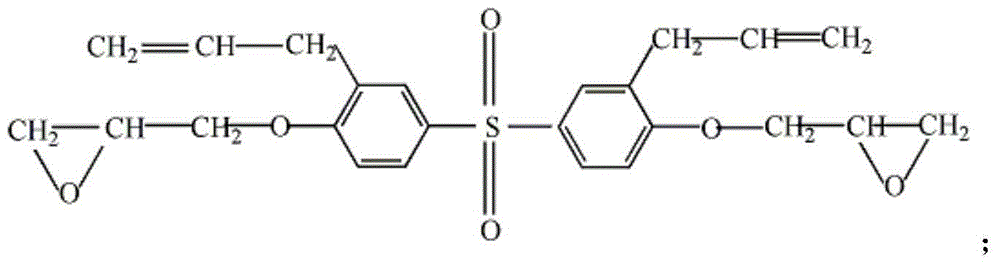

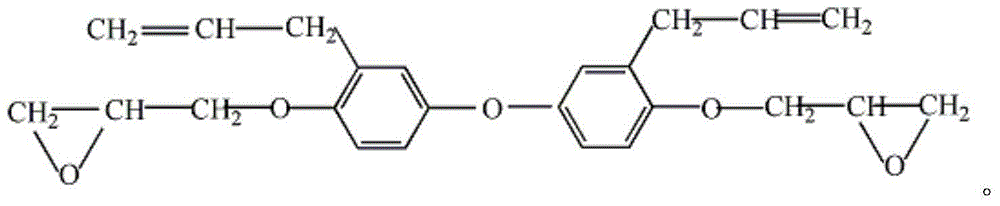

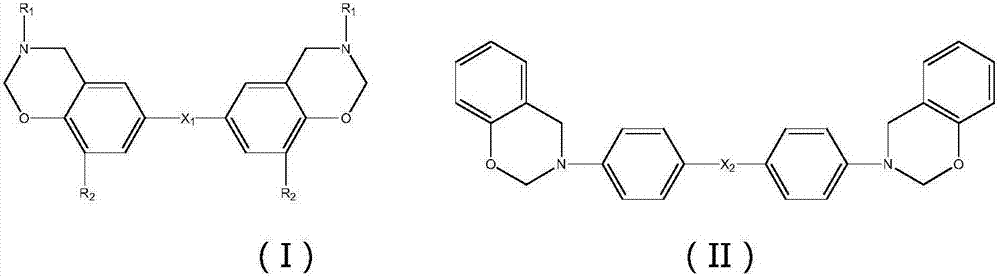

Thermosetting resin composition, and prepreg and laminated board made from thermosetting resin composition

ActiveCN104861652AImprove toughnessHigh peel strengthSynthetic resin layered productsLaminationBottleFire retardant

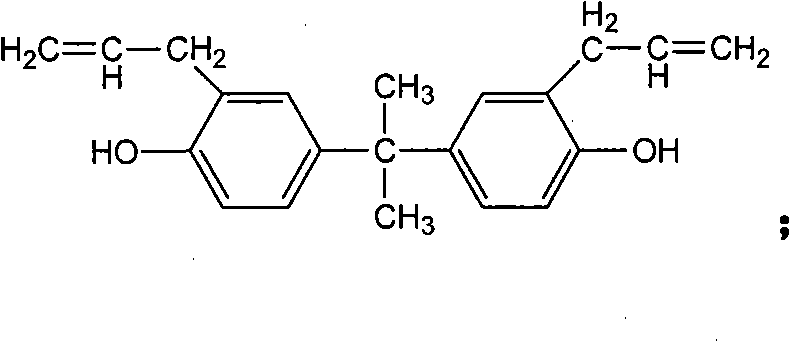

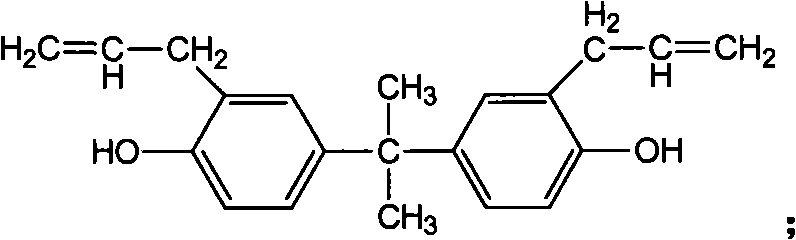

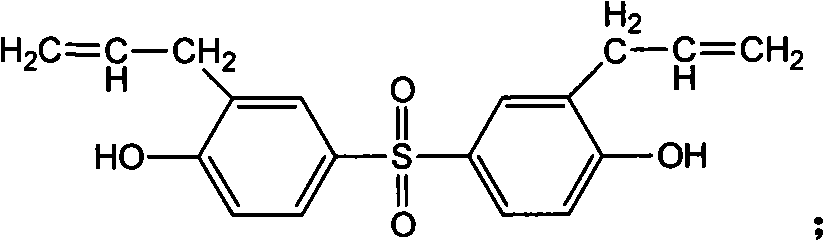

The invention discloses a thermosetting resin composition. The thermosetting resin composition comprises the following solids by weight: (a) a modified bismaleimide prepolymer, (b) a curing accelerator, (c) a fire retardant, and (d) inorganic fillers. A preparation method of the modified bismaleimide prepolymer comprises the following step: heating bismaleimide and a composite allyl compound in a reaction bottle, wherein the composite allyl compound is composed of a first-class allyl compound and a second-class allyl compound, the first-class allyl compound is selected from one or more of diallyl bisphenol A, diallyl bisphenol S, allyl phenoxy resin and diallyl diphenyl ether, and the second-class allyl compound is selected from one or more of diallyl bisphenol A diglycidyl ether, diallyl bisphenol S diglycidyl ether and diallyl diphenyl ether diglycidyl ether. A laminated board integrates high heat resistance, high toughness, low water absorption, excellent dielectric property and good fire resistance.

Owner:SHENGYI TECH SUZHOU

Flame-retardant bismaleimide resin and preparation method thereof

The invention discloses flame-retardant bismaleimide resin and a preparation method thereof. The flame-retardant bismaleimide resin is prepared by uniformly mixing 100 weight parts of bismaleimide resin, 0 to 200 weight parts of allyl compound and 1 to 100 weight parts of amino functional group-containing polysiloxane at the temperature of between 90 and 200 DEG C. The resin has high flame retardance, toughness, heat resistance and dielectric property, can be used as a high-performance resin matrix, an adhesive, an insulating varnish and the like, has great application prospect in the highly technical fields of aerospace, electronic and electrical appliances, transportation and the like; and the preparation method of the resin has the characteristics of high applicability, environmental friendliness, simple operation process and the like.

Owner:苏州亚傲鑫企业管理咨询有限公司

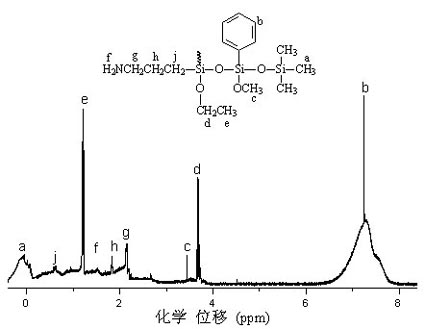

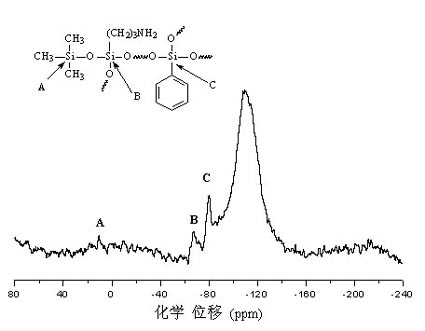

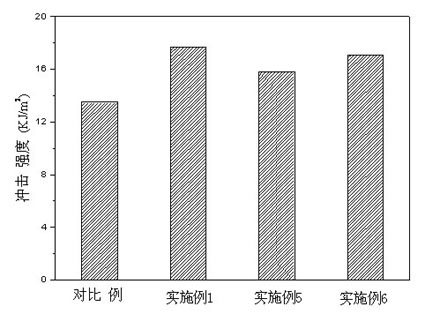

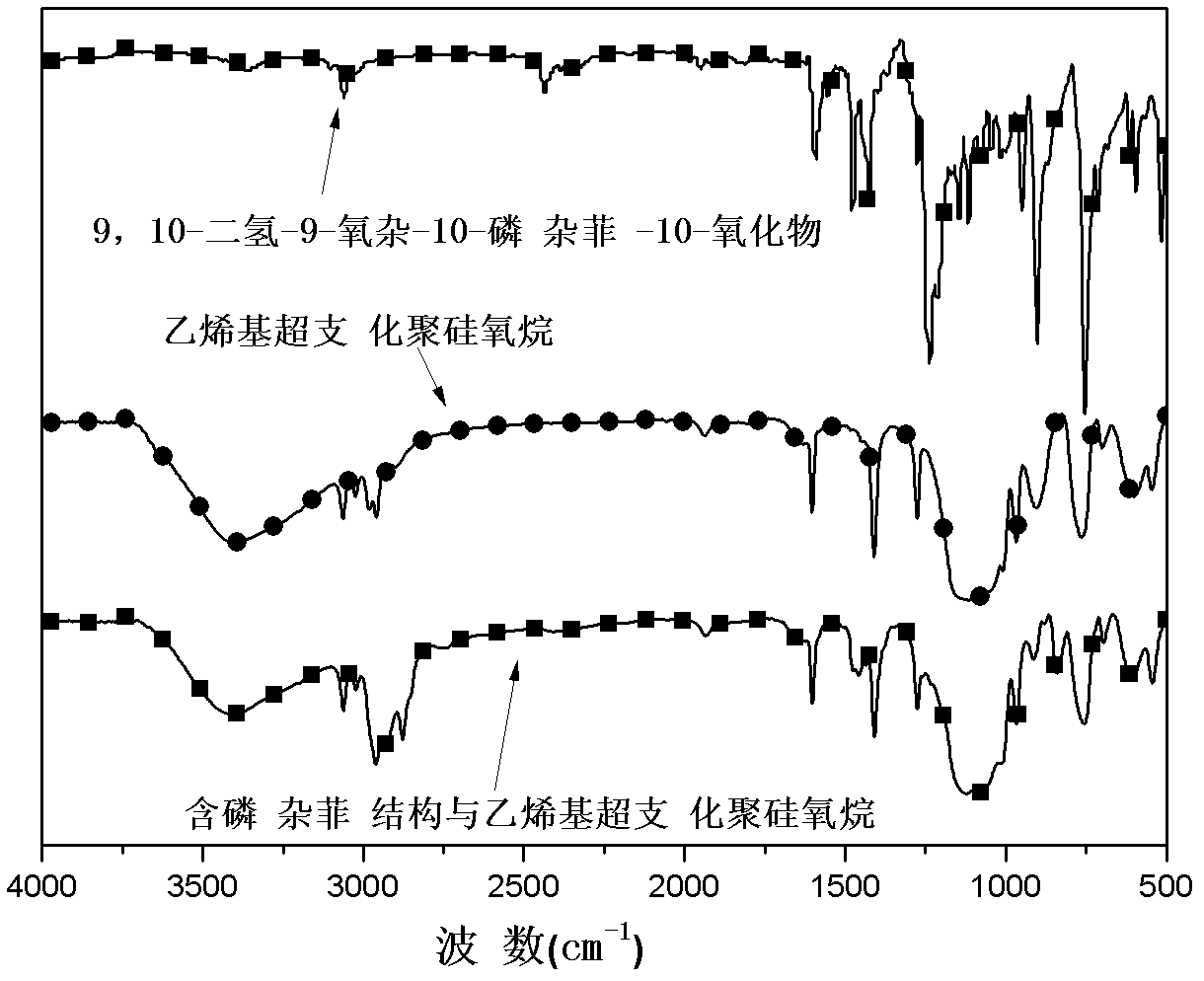

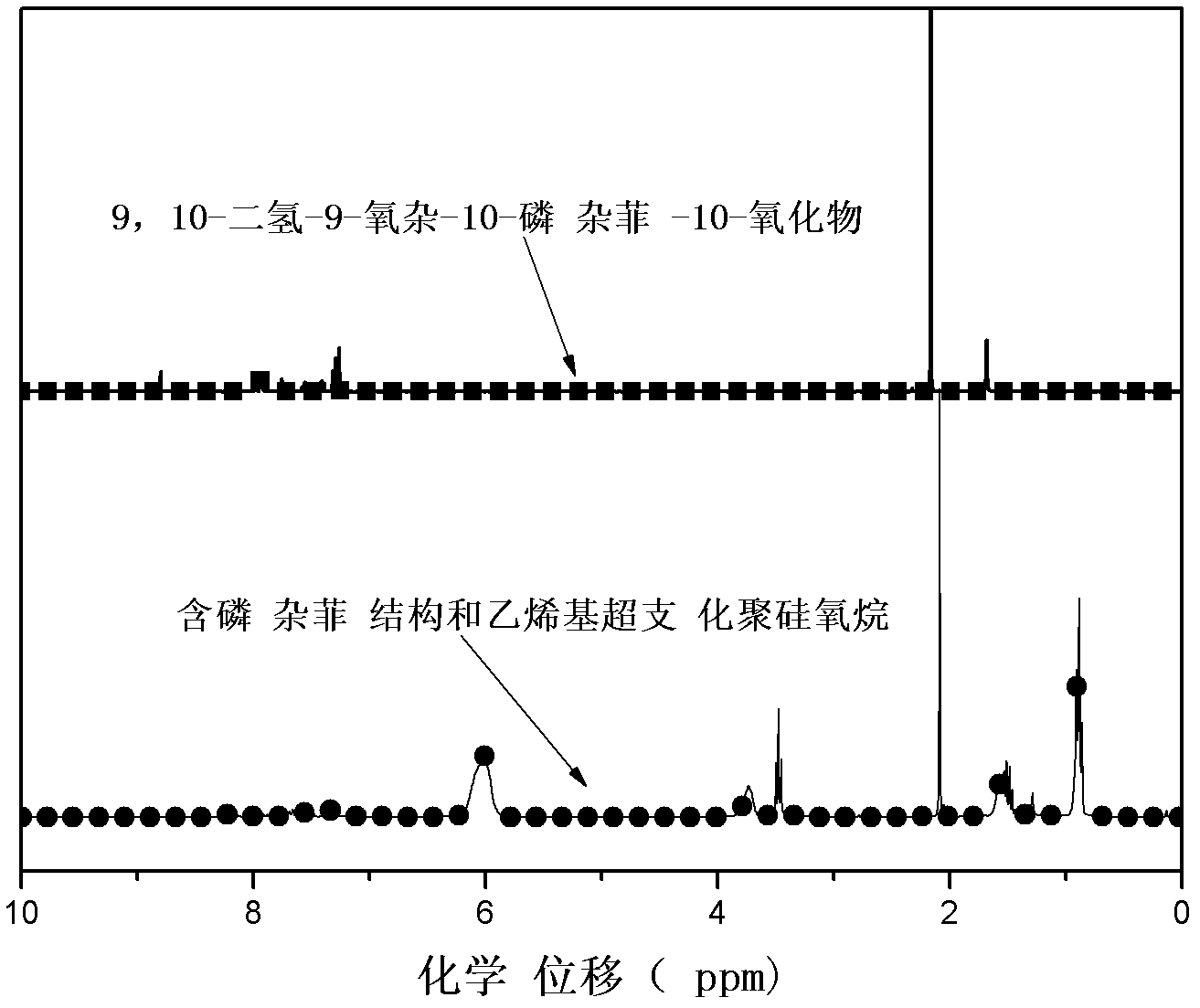

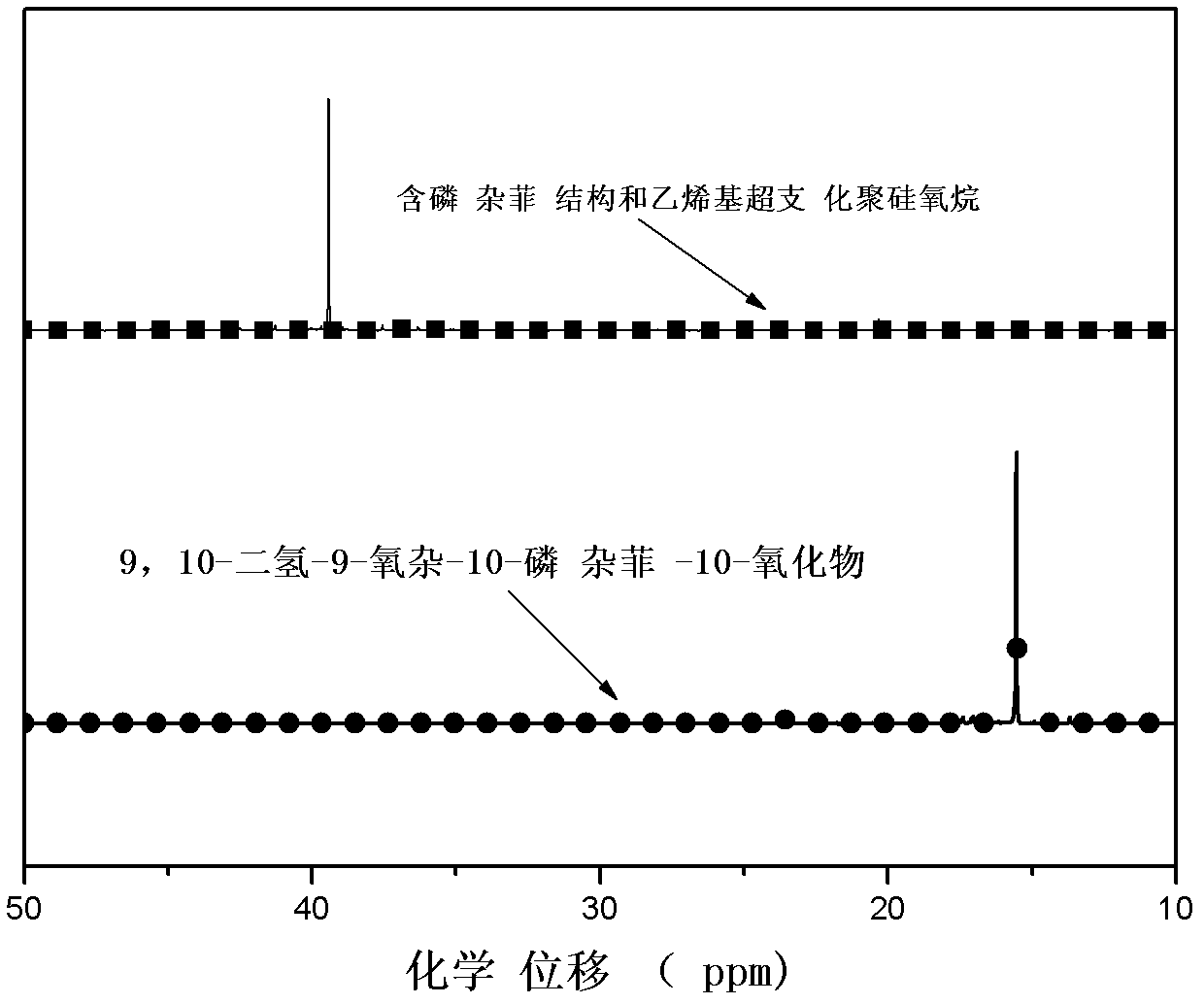

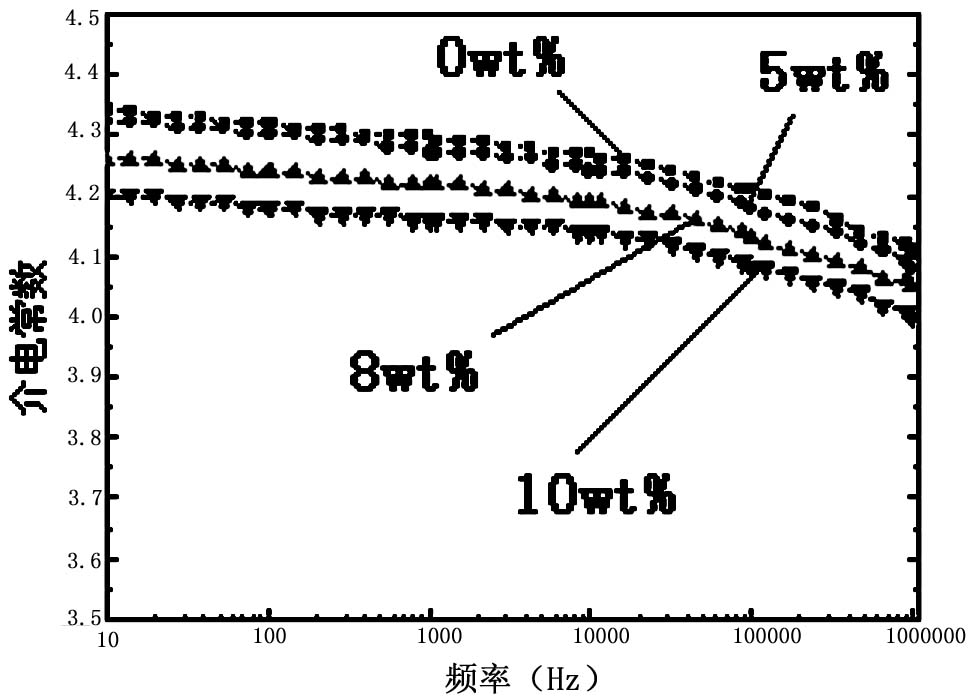

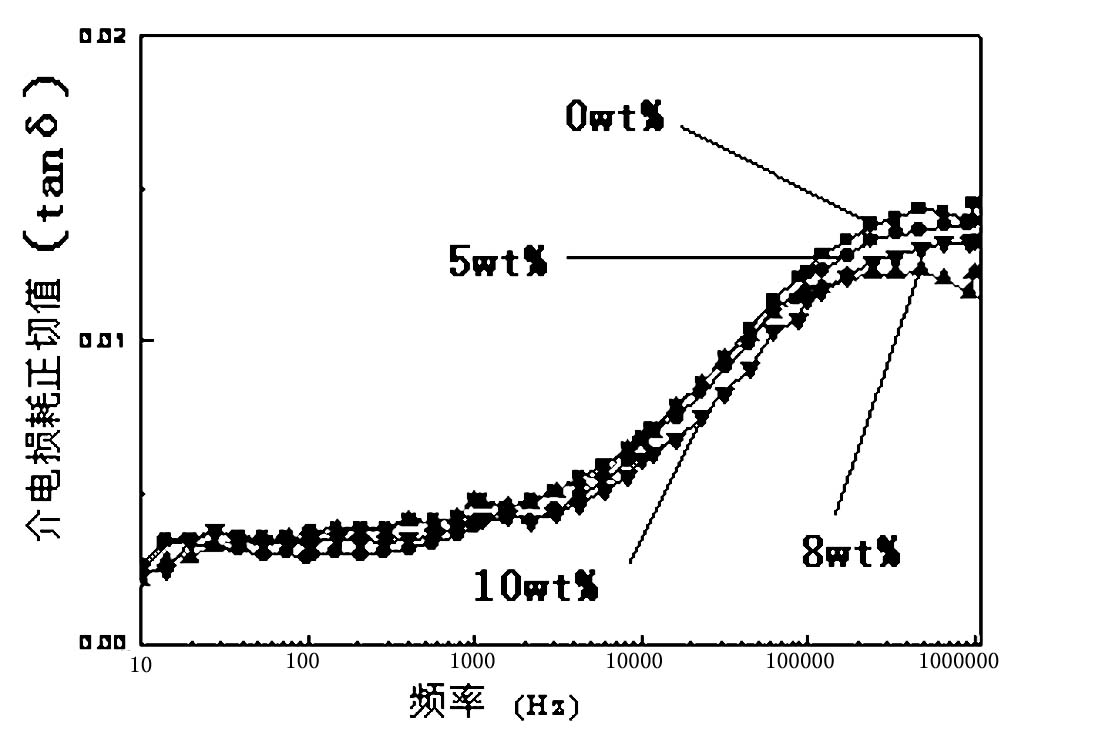

A kind of flame-retardant bismaleimide resin and preparation method thereof

The invention discloses a flame retardant bimaleimide resin and a preparation method thereof. 100 weight parts of bimaleimide resin, 0-200 weight parts of allyl compound and 1-100 weight parts of hyper branched polysiloxane containing a phosphaphenanthrene structure and vinyl are uniformly mixed at 90-200 DEG C to obtain a flame retardant bimaleimide resin. The resin has high fire resistance, high toughness, excellent heat resistance and manufacturability. In addition, the preparation technology has characteristics of wide raw material sources and easy operation, etc. The resin has promising application prospects to be used as a high performance resin matrix, an adhesive and an insulating varnish in hi-tech fields of aviation, spaceflight, electron, electric appliance and transportation, etc.

Owner:SUZHOU UNIV +1

Bismaleimide resin system and preparation method thereof

The invention discloses a bismaleimide resin system and a preparation method thereof. In the method, a polyphenyl ether coated epoxy resin microcapsule is filled into allyl compound modified BMI (Bismaleimide) to obtain a novel BMI resin system. Compared with the BMI resin system in which the microcapsule is not added, the novel resin system has low dielectric constant, and glass-transition temperature is improved. The novel resin system can be used for the frontier field of national defense and civil industry, such as the production of aerospace materials, electron components and the like.

Owner:SUZHOU UNIV

Preparation of polyimide thermosetting resin and application thereof in two-layer method flexibility coat copper plate

ActiveCN101148509AImprove solubilityImprove stabilityLiquid surface applicatorsCoatingsPolyamideThermal expansion

Owner:华烁电子材料(武汉)有限公司

Halogen-free flam retardant prepolymer, preparation method thereof and application of halogen-free flam retardant prepolymer in copper clad laminate (CCL)

ActiveCN101974156AGuaranteed performanceImprove flame retardant performanceLaminationLamination apparatusCopper foilChemistry

The invention particularly relates to a halogen-free flame retardant prepolymer, and an application thereof in the manufacture of the copper clad laminate (CCL). The manufacture of the CCL comprises the following steps: taking and reacting the bismaleimides, allyl compound and phosphorus-containing compound for 10 to 120 minutes at the temperature of 80 to 160 DEG C to obtain the halogen-free flame retardant prepolymer; preparing the prepolymer into solution, stirring uniformly the solution to obtain a glue solution, coating the glue solution uniformly on an E-glass fiber cloth with smooth surface, and then baking the E-glass fiber cloth to prepare a B-rank prepreg; and cutting the B-rank prepreg into proper size according to the size of a pressing machine, overlapping a certain amount of prepregs, and pressing the prepregs with a copper foil with the same size on the top and a copper foil with the same size at the bottom in a hot pressing machine to obtain the CCL. The CCL has good flame retardant effect, no release of harmful gases during the burning, and the product after the solidification of the CCL has the advantages of good toughness, higher thermal decomposition temperature and lower dielectric loss.

Owner:SHENGYI TECH SUZHOU

Ultraviolet cured paint, preparation method and application thereof

The invention provides ultra violet curing coating, and a preparation method and an application thereof; the coating contains light trigger, compound with mercapto, monofunctional extractant or polyfunctional group allyl compound and aliphatic diisocyanate, contains or does not contain monofunctional extractant or polyfunctional group acrylic ester; the preparation method comprises the following steps: the substances are evenly mixed under normal temperature or heating condition, and then placed stationarily, to obtain the required ultra violet curing coating. The coating is simple to be prepared, has high transparency, high gloss and adjustable refraction index, can be applied to polymer optical fiber and optical devices, and can be used as ultra violet curing agent to be applied in polymer dispersion liquid crystal.

Owner:TAICANG JIA RUI PRECISION MOLD CO LTD

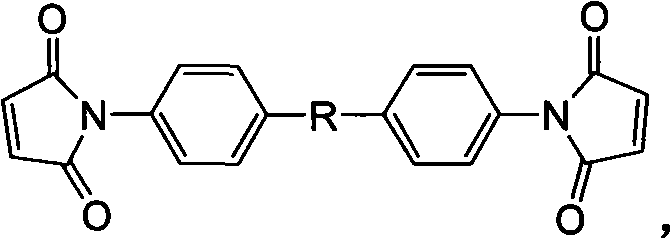

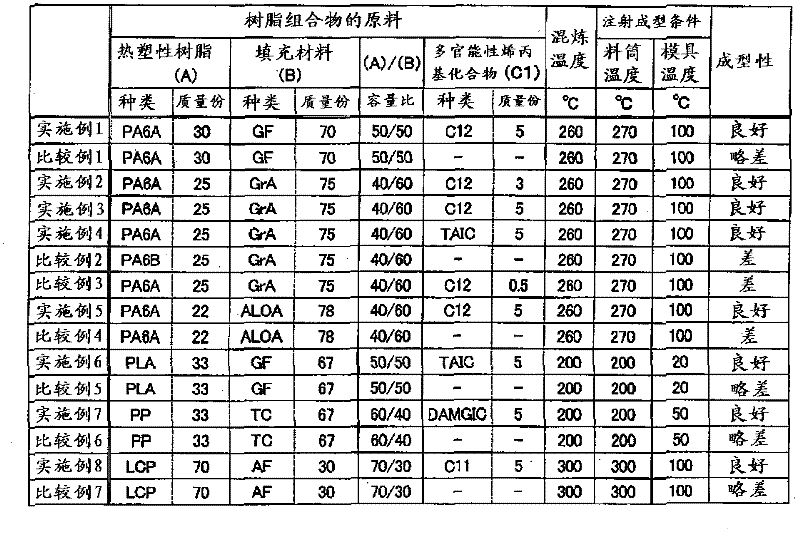

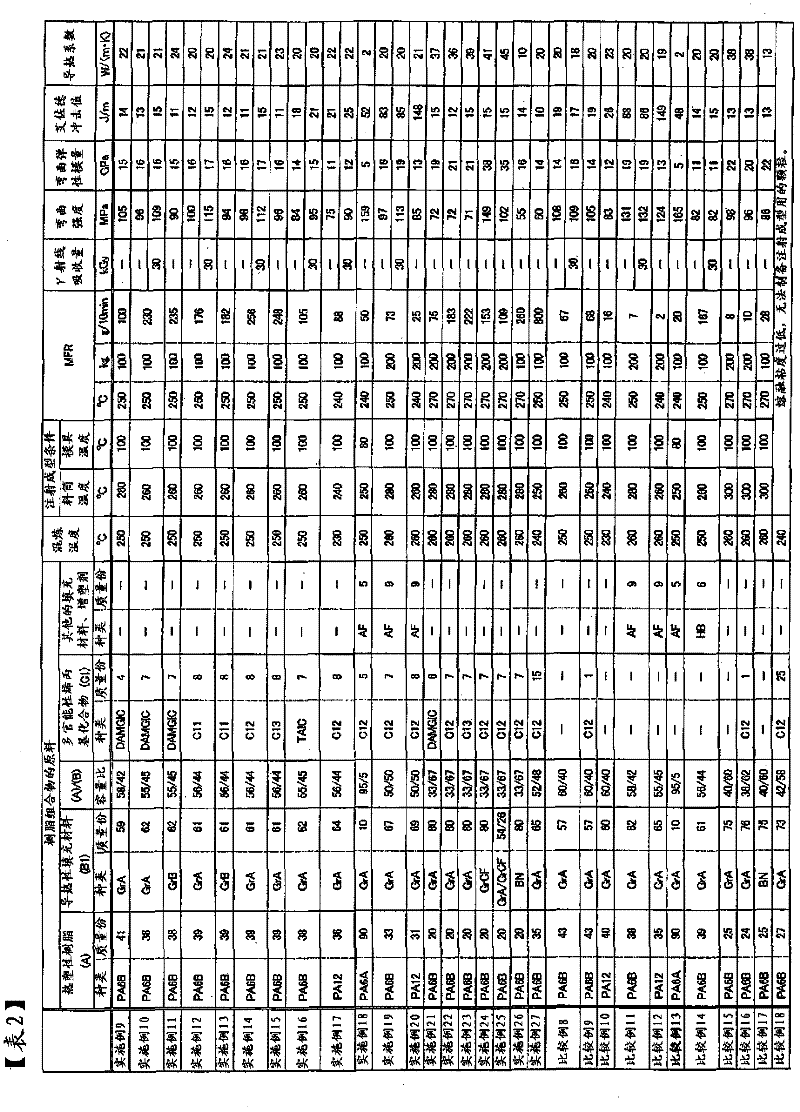

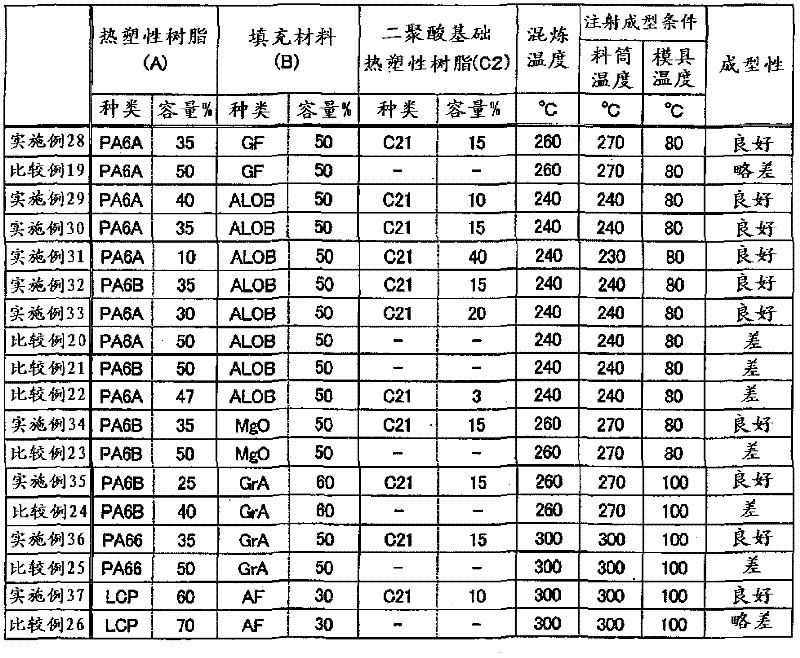

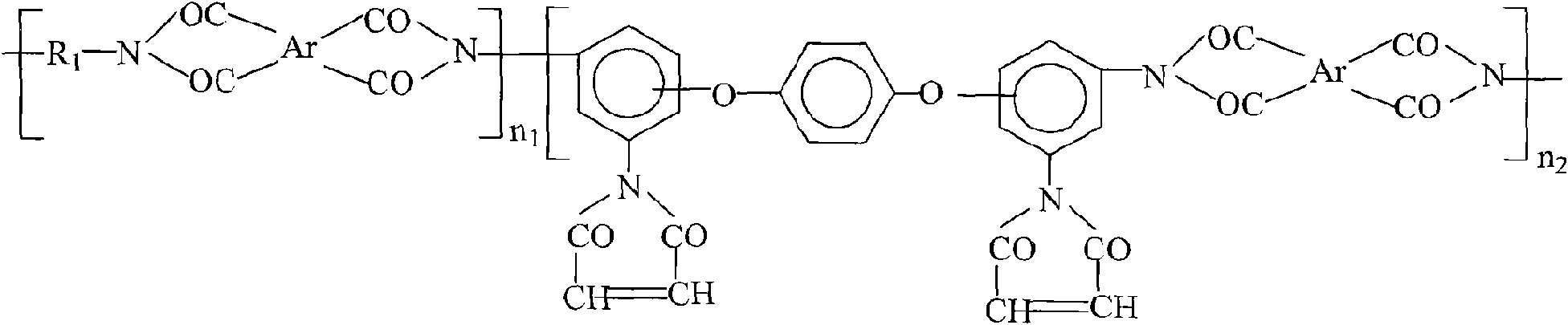

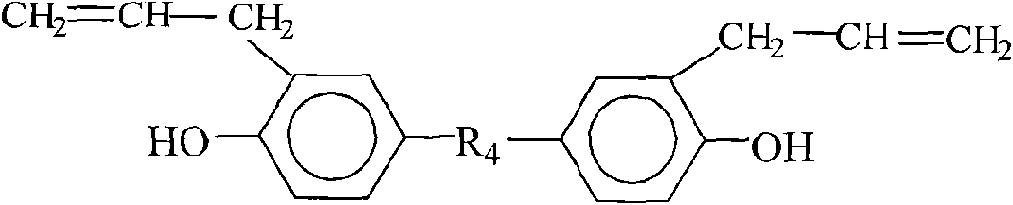

Resin composition and molded article comprising the same

Provided is a resin composition comprising a thermoplastic resin (A), a filler (B), and a predetermined amount of a melt viscosity reducing agent (C). The melt viscosity reducing agent (C) used in a predetermined amount is either the following (a) or (b): (a) The melt viscosity reducing agent (C) is a polyfunctional allyl compound (C1), and the content of polyfunctional allyl compound (C1) with respect to a total of 100 parts by mass of the thermoplastic resin (A) and filler (B) is 3 to 20 parts by mass, or (b) the melt viscosity reducing agent (C) is a dimer acid-based thermoplastic resin (C2), and the content of the dimer acid-based thermoplastic resin (C2) with respect to a total of 100 parts by volume of the thermoplastic resin (A) and filler (B) is 10 to 45 parts by volume.

Owner:UNITIKA LTD

High temperature resistant composite matrix resin and preparation method thereof

The invention relates to a high temperature resistant composite matrix resin and a preparation method thereof. The high temperature resistant composite matrix resin comprises the following components: maleimide-based polyimide powder, diallyl compounds and bismaleimide resin powder. The preparation method of the high temperature resistant composite matrix resin comprises the following steps: mixing 1,4-bis(2,4-diaminophenoxy) benzene with strong polar aprotic organic solvent and adding raw materials such as maleic anhydride, and the like to prepare a resin solution; then adding a dehydrant, a catalyst and a precipitation agent and stirring the mixture to carry out reaction to separate solid powder; and placing the maleimide-based polyimide powder, the diallyl compounds and the bismaleimide resin powder into a reaction kettle to carry out melt polymerization reaction and dissolving the mixture in the organic solvent. The high temperature resistant composite matrix resin can be applied to glass-fiber reinforced composite materials and high-performance fiber-reinforced advanced composite materials such as carbon fiber, aramid fiber, and the like, and has simple process, low cost and no environment pollution, and can be prepared in general equipment, thereby being suitable for industrial production.

Owner:DONGHUA UNIV

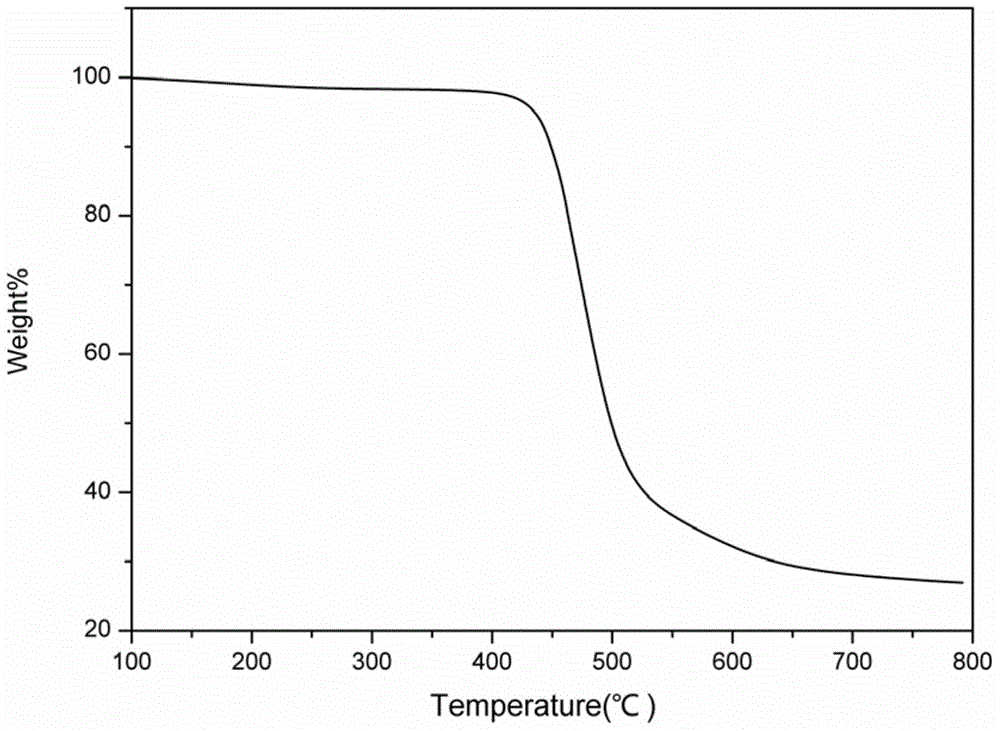

Flame-retardant bismaleimide resin

The invention discloses a flame-retardant bismaleimide resin. The resin is prepared by uniformly mixing bismaleimide, an allyl compound and phosphaphenanthrene-group-containing bismaleimide according to a mass ratio of 100: (1-100): (1-50) and then carrying out curing. The flame-retardant bismaleimide resin provided by the invention is prepared by blending and curing phosphaphenanthrene-group-containing bismaleimide, bismaleimide and the allyl compound, and has the advantages of heat resistance, electric insulation performance, weather resistance and excellent flame retardant property. The flame-retardant bismaleimide resin in the invention has a thermal weight loss temperature of greater than 410 DEG C and a limit oxygen index (LOI) of 32% to 40% and reaches the fire rating of UL94V-0.

Owner:XIAN ORIGIN CHEM TECH

Halogen-free flame-retardant polyimide resin composition and prepreg and laminate made with same

ActiveCN104877134AImprove solubilityGood storage stabilityMetal layered productsHigh resistanceDiphenyl ether

The invention discloses a halogen-free flame-retardant polyimide resin composition, comprising, by weight, bismaleimide a, composite allyl compound b, and phosphorous compound c. A preparing method of the halogen-free flame-retardant polyimide resin composition includes: heating the bismaleimide, the composite allyl compound and the phosphorous compound in a reaction flask for reaction, with the composite allyl compound being composed of first allyl compound and second allyl compound. The first allyl compound is made from one or any of diallyl bisphenol A, diallyl bisphenol S, allyl phenoxy resin, and diallyl diphenyl ether. The second allyl compound is made from one or any of diallyl bisphenol A diglycidyl ether, diallyl bisphenol S diglycidyl ether, diallyl diphenyl ether diglycidyl ether. A laminate made from the halogen-free flame-retardant polyimide resin composition has the advantages of high resistance, high toughness, low water absorption rate, and excellent dielectric property and flame retardance.

Owner:SHENGYI TECH SUZHOU

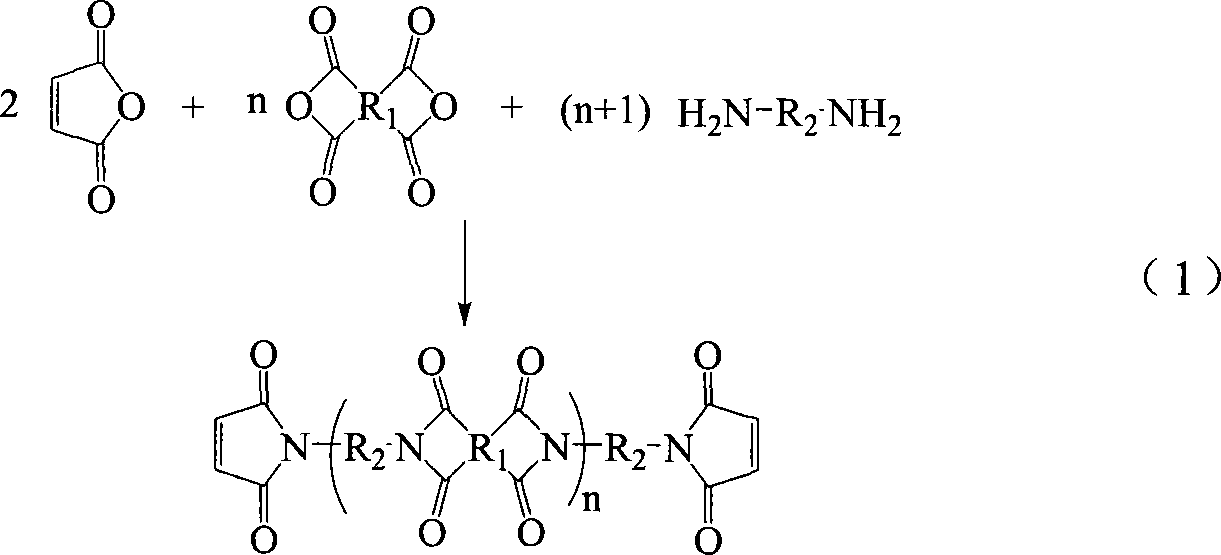

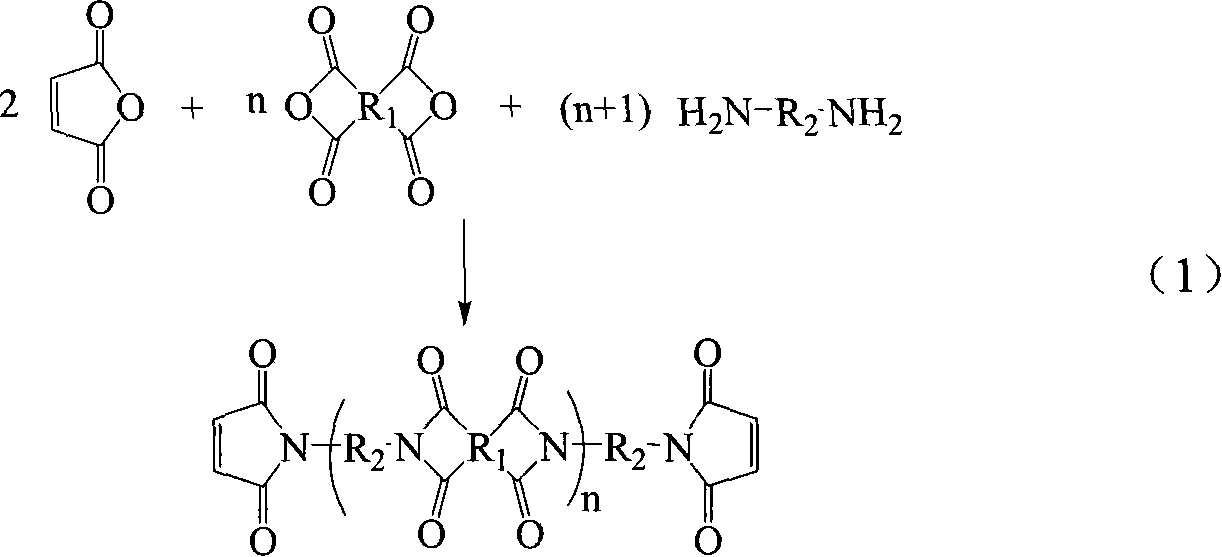

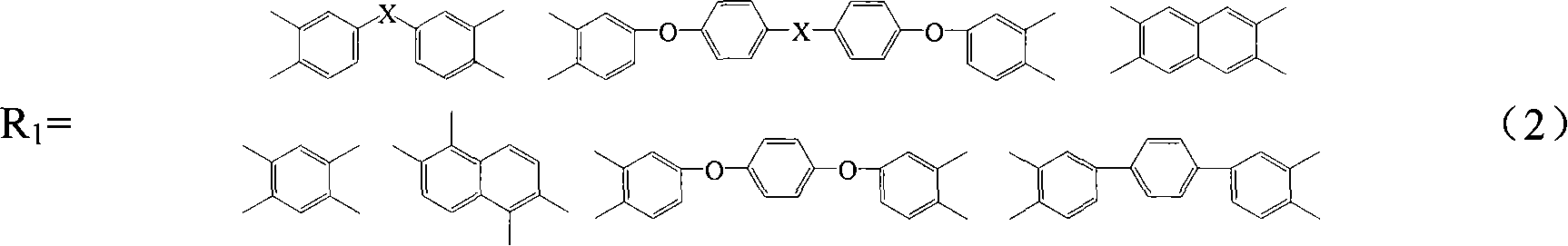

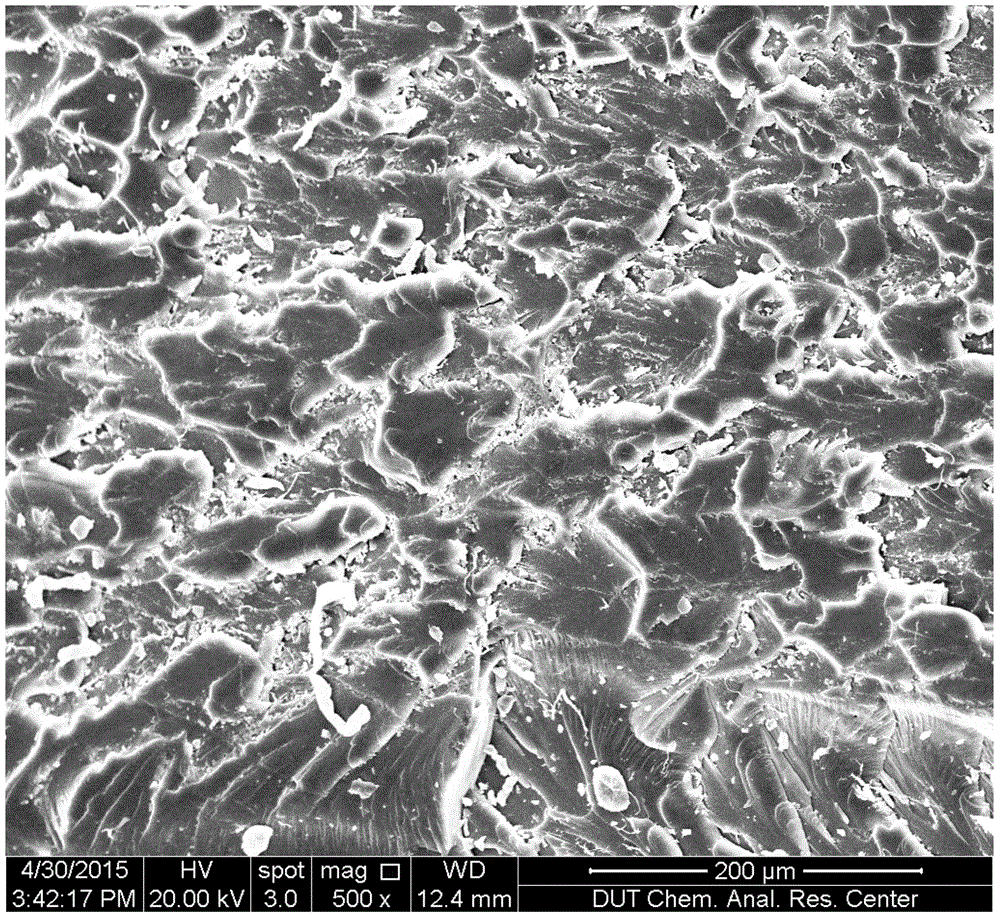

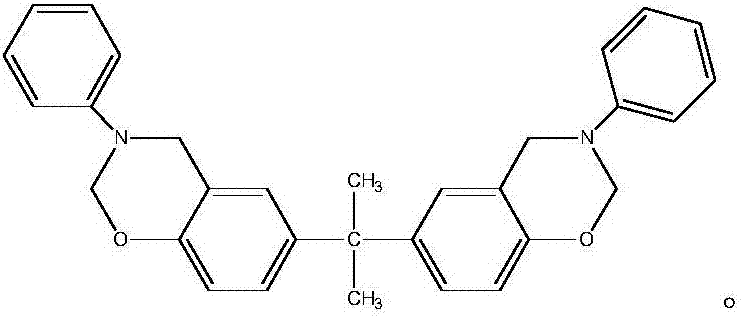

Preparation method of liquid-crystal allyl-compound-modified bismaleimide resin

The invention relates to a liquid-crystal allyl-compound-modified bismaleimide resin and a preparation method thereof. The liquid-crystal allyl-compound-modified bismaleimide resin comprises a phenyl 1,4-di(4-allyloxybenzoate) liquid-crystal allyl compound, 2,2'-diallyl bisphenol A, a bismaleimide monomer and the like. The preparation method comprises the following steps: melting the phenyl 1,4-di(4-allyloxybenzoate) liquid-crystal allyl compound by heating; adding the 2,2'-diallyl bisphenol A, and uniformly mixing; controlling the temperature at 130-160 DEG C, adding the bismaleimide monomer while stirring to perform prepolymerization until the system becomes a uniform transparent red brown liquid; and cooling to room temperature to obtain the red brown transparent solid resin. The modified bismaleimide resin is soluble in acetone, chloroform and other conventional low-boiling solvents, and has favorable curability. The cured product has excellent heat resistance and toughness. Thus, the modified bismaleimide resin is a matrix resin of advanced polymer-base composite materials required by the fields of aerospace, electronics and electricity.

Owner:DALIAN UNIV OF TECH

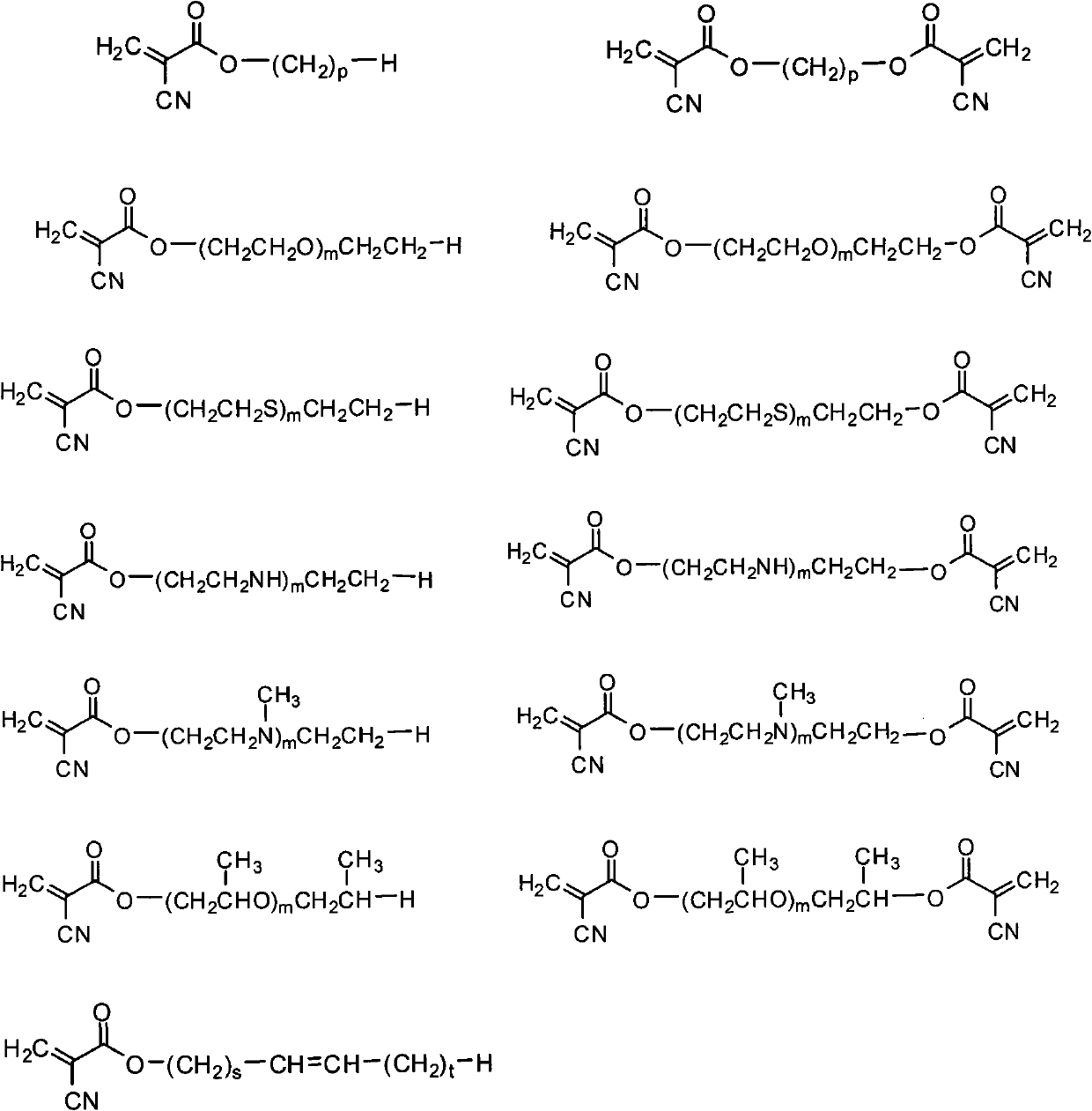

Production method of copolymer of allyl monomer containing polar group

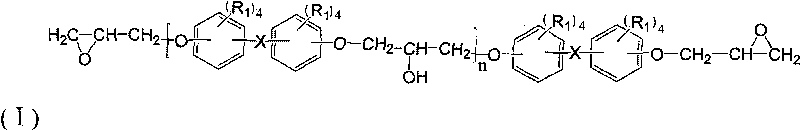

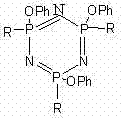

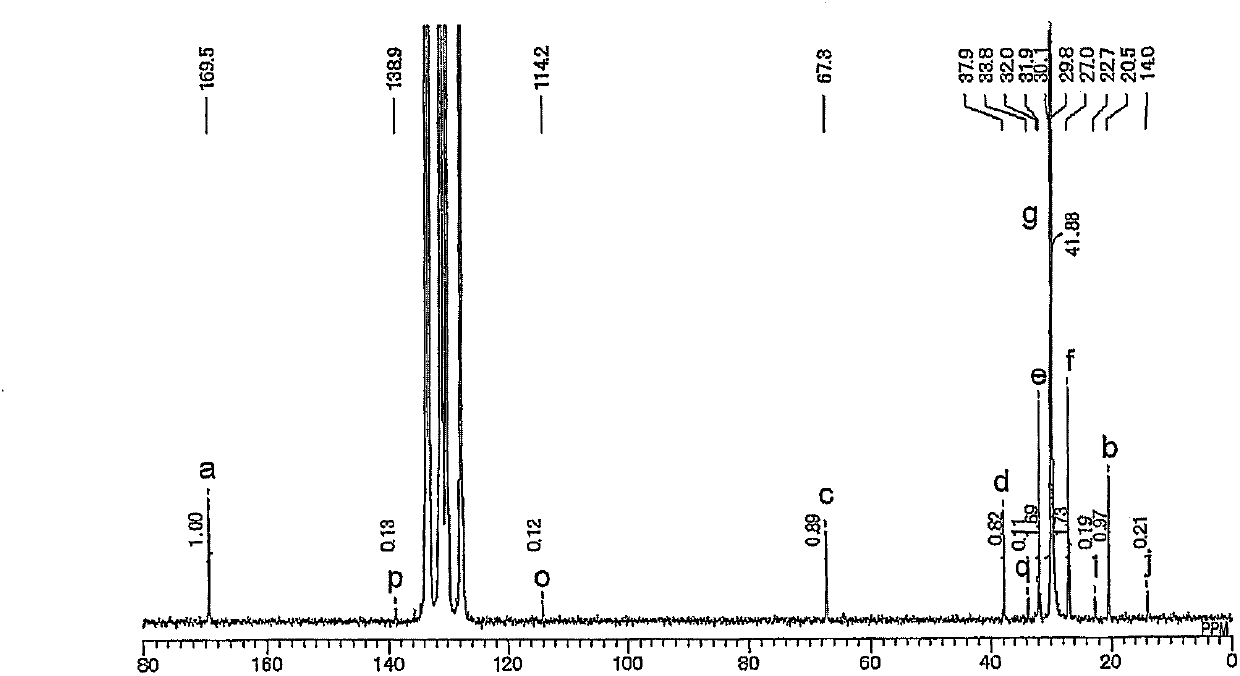

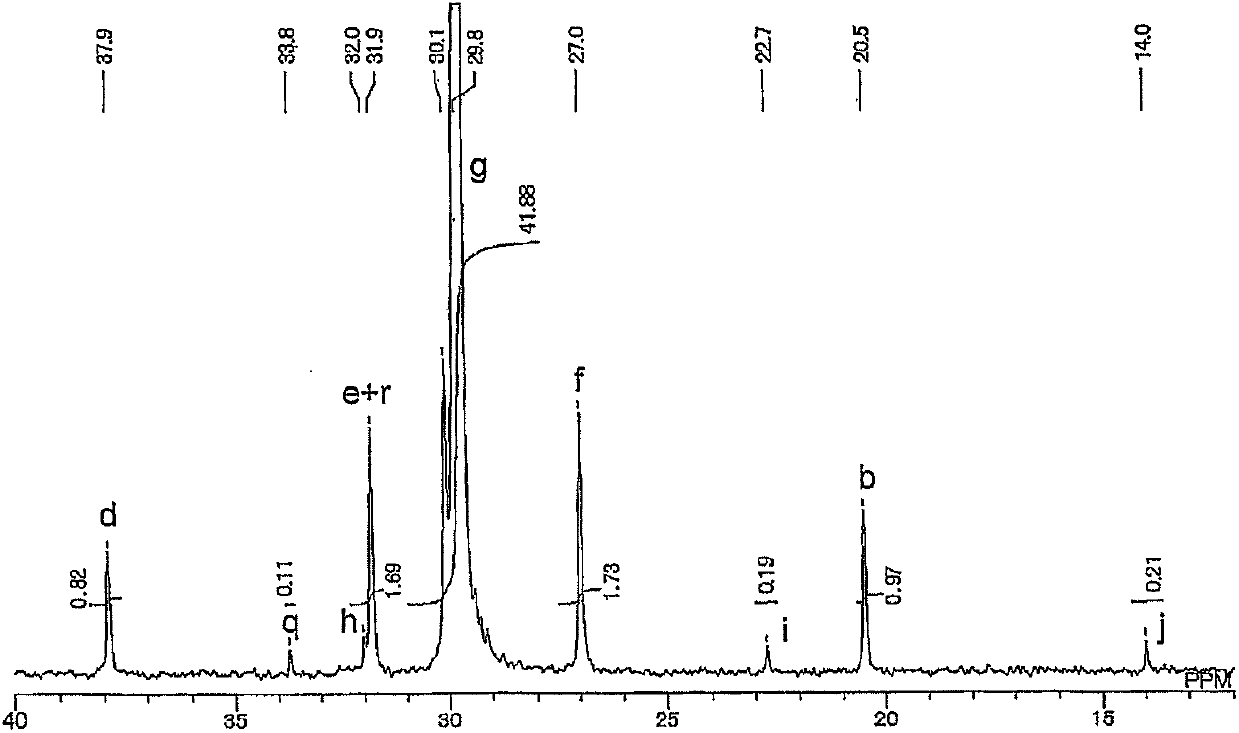

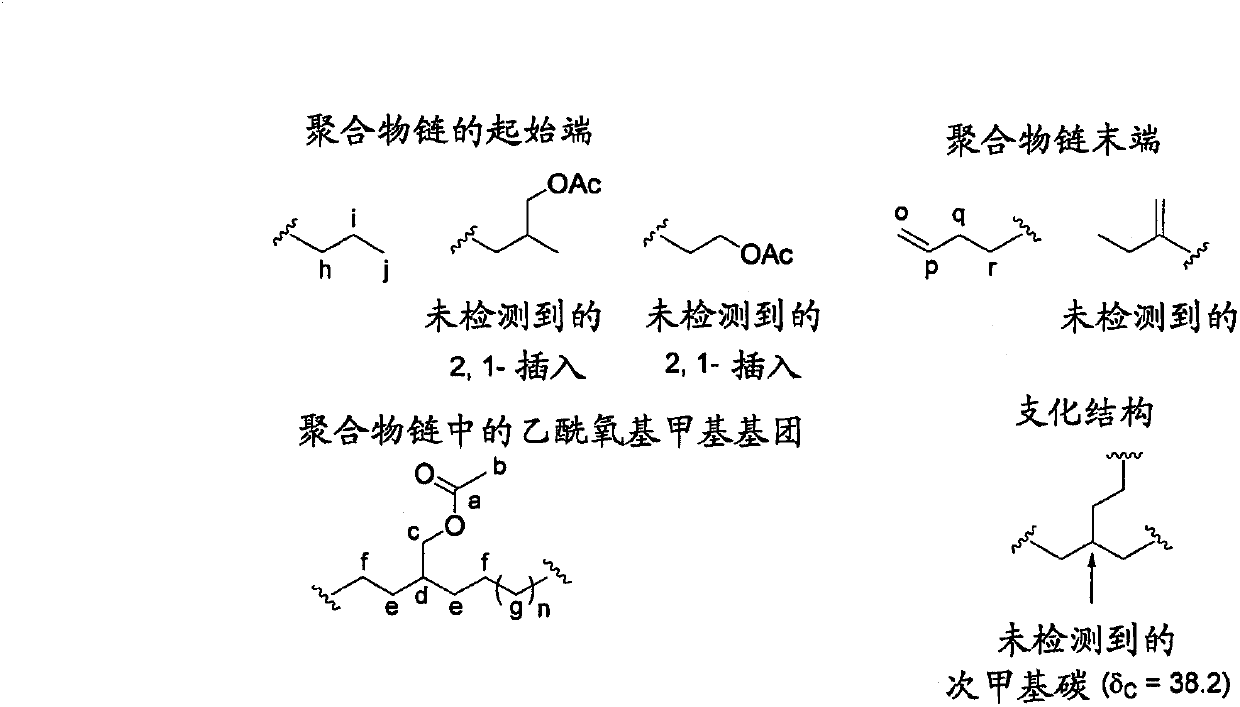

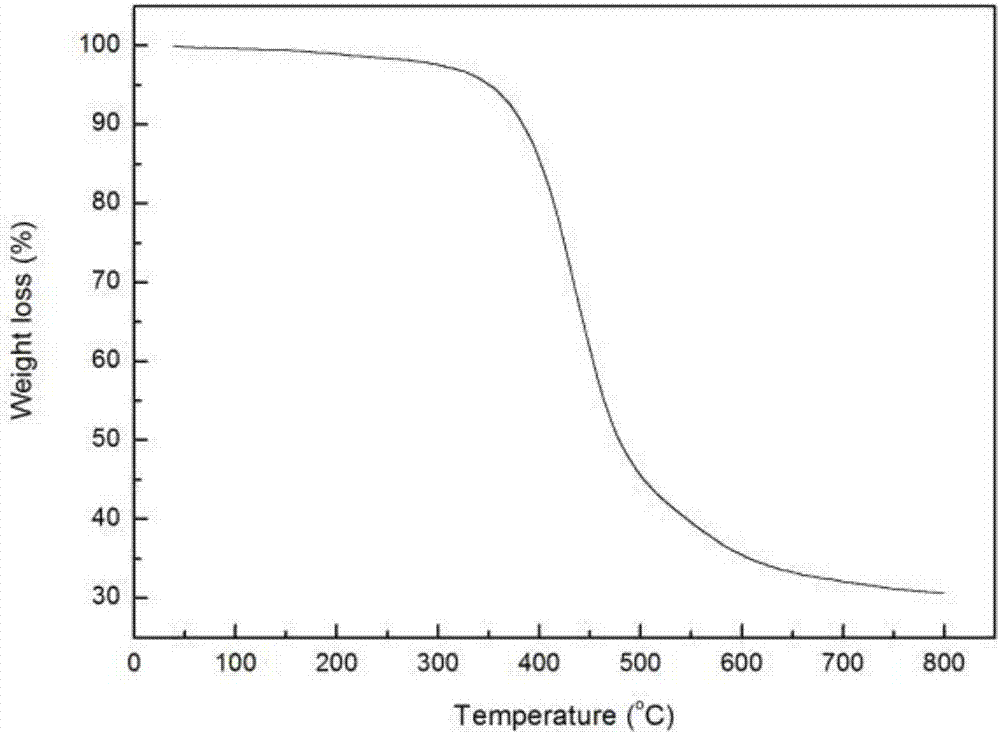

The present invention relates to a method for producing a high-molecular-weight copolymer of polar group- containing allyl monomers comprising monomer units represented by formulae (3) and (4) (in the formulae, R1 represents a hydrogen atom (H) or hydrocarbon group having 1 to 6 carbon atoms; R2 represents -OH, -OCOR3 (R3 represents hydrocarbon group having 1 to 5 carbon atoms), -N(R4)2 (R4 represents a hydrogen atom or hydrocarbon group having 1 to 5 carbon atoms); and n and m are a value representing the molar ratio of each of the monomer units), which has few branches and unsaturated group at the molecular end, by copolymerizing olefin and an allyl compound using a metal complex of group 10 elements in the periodic system represented by a specific formula as a catalyst.

Owner:THE UNIV OF TOKYO +1

Modified bismaleimide resin prepolymer and preparation method thereof

The invention provides a modified bismaleimide resin prepolymer. Bismaleimide is subjected to copolymerization, chain extension and toughening modification by a melting polymerization process and by using an allyl compound, aminophenylacetylene and benzoxazine; the obtained modified bismaleimide resin prepolymer has excellent processing property while maintaining high heat resistance of the bismaleimide, and can greatly improve the mechanical property; furthermore, the prepolymer is moderate in melt viscosity, low in volatile component, high in paving and covering property, long in storage period and low in cost, and is an ideal adhesive film material for prepreg; and the modified bismaleimide resin prepolymer can serve as matrix resin of a composite material, a high-temperature-resistant adhesive, an electronic appliance copper-clad plate insulating material and the like, and is applicable in the technical fields of aerospace, electronic appliances, traffic and transportation and the like.

Owner:WUHAN UNIV OF TECH

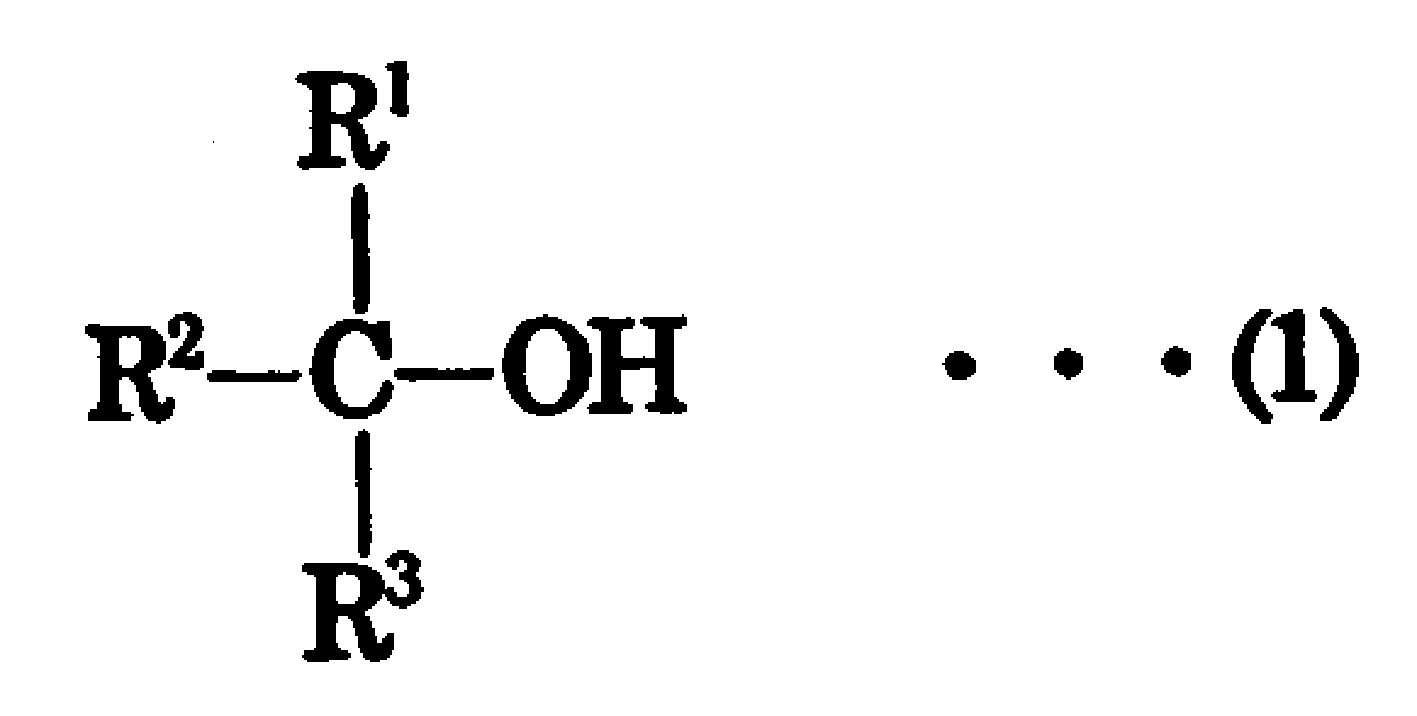

Composition for optical material, optical material, process for producing the same, and lens

An optical material which is reduced in coloration due to an ultraviolet absorber, is highly colorless and transparent, and has an excellent balance among material properties required of optical materials; a process for producing the optical material; a lens; and a composition to be used as a raw material for these optical materials. The composition comprises one or more monomers including a diallyl compound and additives including an ultraviolet absorber and an alcohol compound (1) represented by the formula (1): (1) wherein R<1>; is phenyl or substituted phenyl; and R<2> and R<3> each represents C1-3 alkyl or hydrogen.

Owner:NOF CORP

Halogen-free flame-retardant prepolymer, and prepreg and laminated board made from same

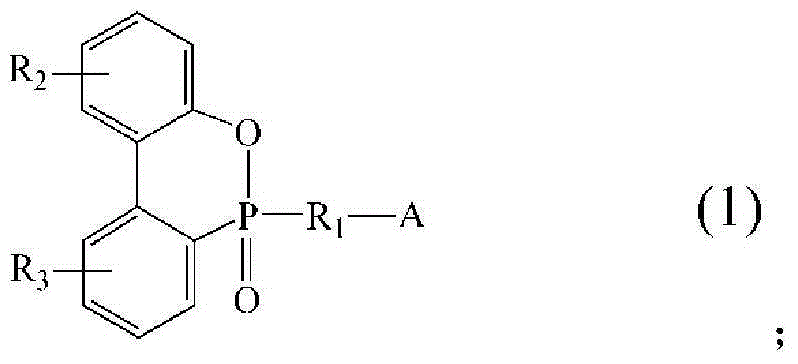

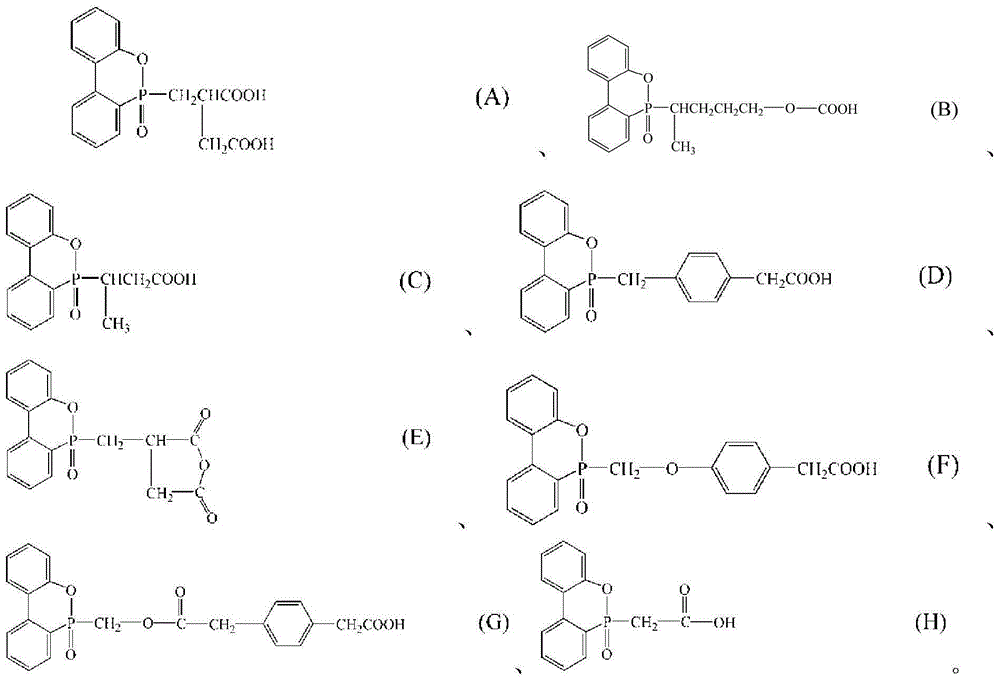

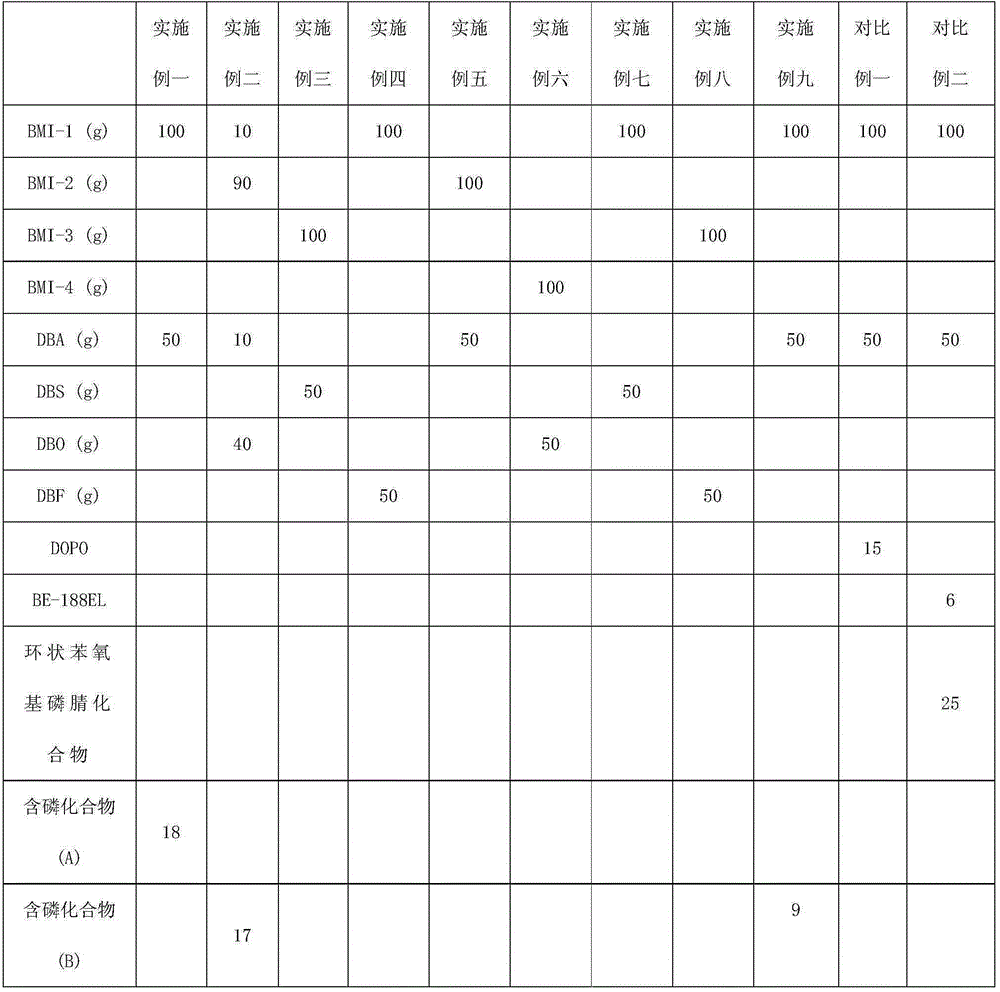

ActiveCN105037723ASolve the mechanical propertiesAddressing Dielectric PropertiesMetal layered productsStructural formulaPrinted circuit board

The invention discloses a halogen-free flame-retardant prepolymer. The halogen-free flame-retardant prepolymer is prepared through the following methods: heating a phosphorous compound, bismaleimide and an allyl compound in a reaction flask according to a mass ratio of m (phosphorous compound) to m (bismaleimide) to m (allyl compound) to obtain the halogen-free flame-retardant prepolymer, wherein the mass ratio of m (phosphorous compound) to m (bismaleimide) to m (allyl compound) is (1-20):(50-80):(15-50), the total mass of the phosphorous compound, the bismaleimide and the allyl compound is 100 parts, and a structural formula of the phosphorous compound contains a phosphaphenanthrene structure and at least one carboxyl group. A prepreg and a laminated board made from the halogen-free flame-retardant prepolymer have integrated functions of excellent flame retardancy, dielectric property, mechanical property, high heat resistance and Tg, meet requirements on the development of a high-performance printed circuit board material, and can be applied to the fields of integrated circuit packaging, high-frequency high-speed and high-density interconnection and the like.

Owner:SHENGYI TECH SUZHOU

Method for synthesizing high-ceramic-yield polycarbosilane

The invention discloses a method for synthesizing high-ceramic-yield polycarbosilane. The method comprises the following steps: mixing polycarbosilane of which the molecular weight is 500-1,500 with an allyl compound according to the proportion 100:(12-4); dissolving the mixture into dimethylbenzene; putting into a reaction vessel; adding an organic lithium reagent; heating under the protection of protection gas for reacting; controlling the highest reaction temperature at 100-150 DEG C; preserving heat for reacting for 2-8 hours; after finishing the reaction, filtering insoluble substances; removing a solvent by evaporating to obtain the high-ceramic-yield polycarbosilane. The method has the characteristics of easiness in controlling of the reaction conditions, simple and convenient steps, self-crosslinking performance of a product, and adjustable Si-H and allyl content. The method can be used for preparing liquid-state or solid-state high-ceramic-yield polycarbosilane conveniently.

Owner:NAT UNIV OF DEFENSE TECH

Glue solution for copper-clad substrate, and preparation method thereof

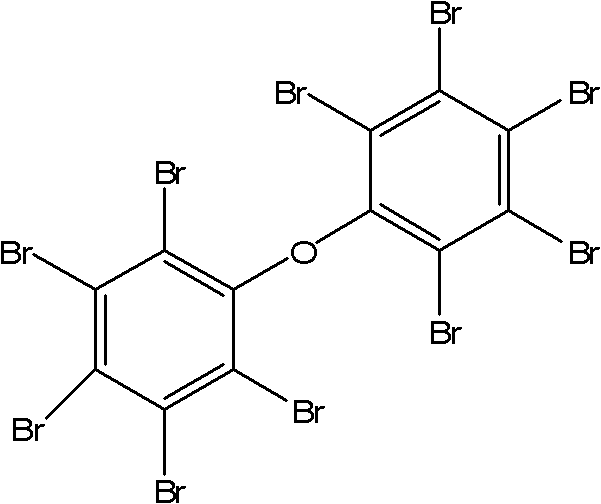

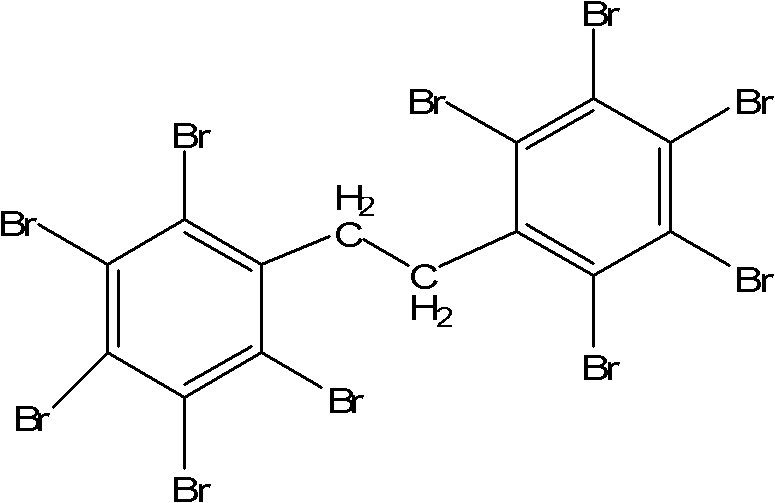

ActiveCN102304343ALow heat resistanceLow costNon-macromolecular adhesive additivesHeat resistanceDecabromodiphenyl oxide

The invention relates to a glue solution for copper-clad substrate, and a preparation method thereof. A raw material formula of the glue solution comprises, by weight, 100 parts of bismaleimide resin, 30-100 parts of an allyl compound, 5-100 parts of decabromodiphenyl oxide or decabromodiphenylethane or a composition comprising the decabromodiphenyl oxide and the decabromodiphenylethane, 0-6 parts of a curing accelerator, 0-30 parts of an inorganic filler and 10-60 parts of a solvent. The preparation method for the glue solution comprises: weighing the bismaleimide resin and the allyl compound according to the formula; carrying out the reaction for 10-150 min at a temperature of 110-180 DEG C; cooling to the room temperature after the reaction is completed; adding the partial solvent to dissolve all the resin; adding the flame retardant, the curing accelerator, the inorganic filler and the residual solvent according to the use amount in the formula; uniformly stirring to obtain the glue solution. With adopting the glue solution provided by the present invention, the copper-clad substrate has the combination of excellent heat resistance, excellent electrical property and excellentflame retardance, is applicable for preparing the multi-layer printed circuit board, and is easy to be subjected to PCB processing.

Owner:VENTEC ELECTRONICS SUZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com