Preparation method of copper clad plate

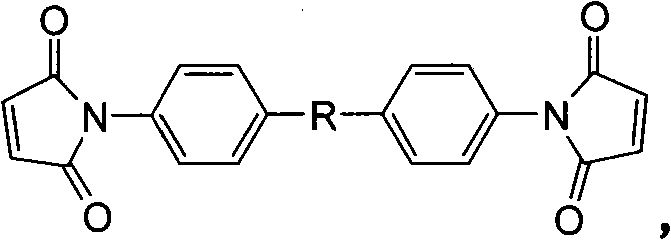

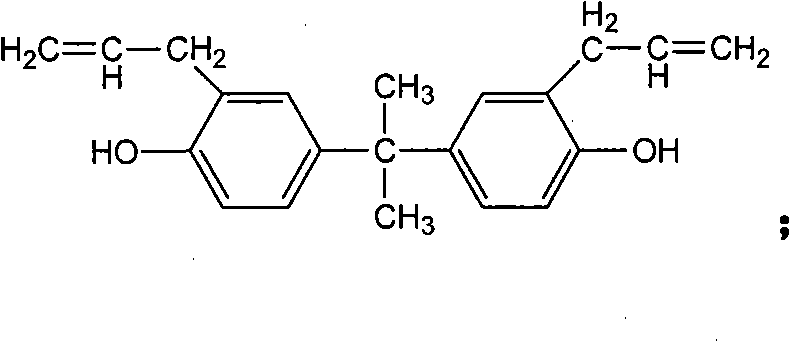

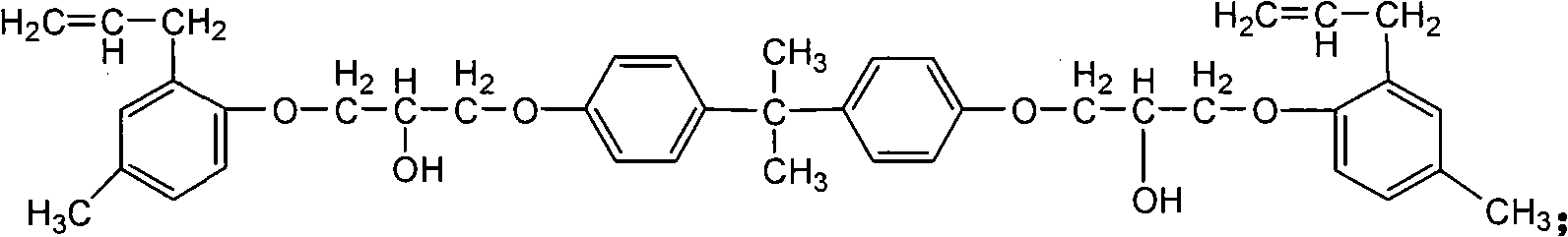

A copper-clad laminate and resin technology, which is applied in chemical instruments and methods, printed circuit manufacturing, lamination, etc., can solve the compatibility problem of improper ratio of bismaleimide resin and affect the high performance of bismaleimide resin. Heat resistance, unable to meet the problems of high-performance copper clad laminates, etc., to achieve good flame retardant effect, low dielectric loss, and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Take 100g of 4,4'-diphenylmethane bismaleimide and 50g of allyl bisphenol A, put them into a 500ml beaker, react at 130-150°C for 50min to obtain a modified bismaleimide resin, add an appropriate amount of acetone after cooling dissolve. After the modified double horse resin is completely dissolved, add 40g of phosphorus-containing epoxy resin (the selected phosphorus-containing epoxy resin is: KDP555MC80 (KUKDO) or SEN-250MC80 (SHIN-ATδC)), 10g of bisphenol A phenolic resin (hydroxyl Equivalent 120g / mol), 25g of phosphorus-containing phenolic resin (the grade of selected phosphorus-containing phenolic resin is XZ92741), 0.05g of 2-methyl-4-ethylimidazole, stir and mix evenly to obtain glue. Select a 300×300cm, flat and smooth E-glass fiber cloth, evenly coat the above glue, and bake it in an oven at 165°C for 10 minutes to make an adhesive sheet. Superimpose 5 adhesive sheets with burrs cut off, attach 35μ copper foil up and down, place them in a vacuum hot press and ...

Embodiment 2

[0051] Take 100g of 4,4'-diphenyl ether bismaleimide and 70g of allyl phenoxy resin (AE), put them into a 500ml beaker, and react at 130-150°C for 65min to obtain modified bismaleimide resin, after cooling Add appropriate amount of acetone to dissolve. After the modified double horse resin is completely dissolved, add 100g of phosphorus-containing epoxy resin (the grade of the selected phosphorus-containing epoxy resin is one of KDP550MC65 (KUKDO) or SEN-290MC65 (SHIN-ATδC)), 15g of bisphenol Type A benzoxazine resin (hydroxyl equivalent 120g / mol), 15g phosphorus-containing phenolic resin (the grade of selected phosphorus-containing phenolic resin is XQ82976), 0.10g 2-methyl-4-ethylimidazole, stir and mix evenly to obtain glue liquid. Select a 300×300cm, flat and smooth E-glass fiber cloth, evenly coat the above glue, and bake it in an oven at 165°C for 10 minutes to make an adhesive sheet. Superimpose 5 adhesive sheets with burrs cut off, attach 35μ copper foil up and down,...

Embodiment 3

[0053] Take 100g of 4,4-diphenylisopropyl bismaleimide and 40g of allylphenolic resin (AF), put them into a 500ml beaker, and react at 130-150°C for 42min to obtain modified bismaleimide resin, after cooling Add appropriate amount of acetone to dissolve. After the modified double horse resin is completely dissolved, add 55g phosphorus-containing epoxy resin (the grade of the selected phosphorus-containing epoxy resin is selected from: one of KEG-H5138 (KOREA KOLON) or BEP400A70 (Taiwan Changchun)), 40g Phenolic biphenylene type resin (hydroxyl equivalent 260g / mol), 20g phosphorus-containing phenolic resin (the grade of selected phosphorus-containing phenolic resin is XZ92741), 0.10g 2-methyl-4-ethylimidazole, stir and mix evenly to obtain glue liquid. Select a 300×300cm, flat and smooth E-glass fiber cloth, evenly coat the above glue, and bake it in an oven at 165°C for 10 minutes to make an adhesive sheet. Superimpose 5 adhesive sheets with burrs cut off, attach 35μ copper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com