Patents

Literature

413results about How to "Guaranteed heat resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

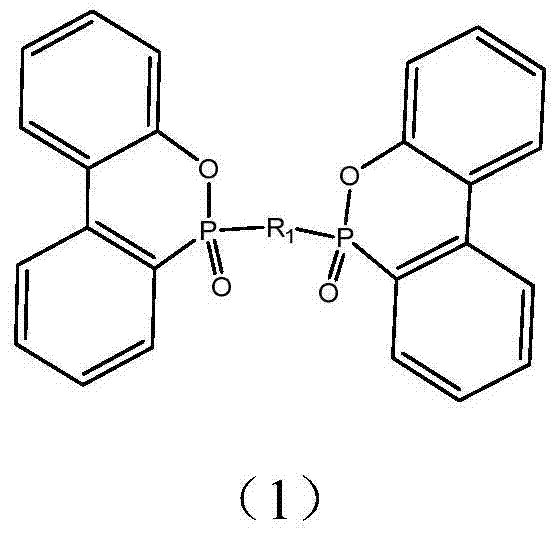

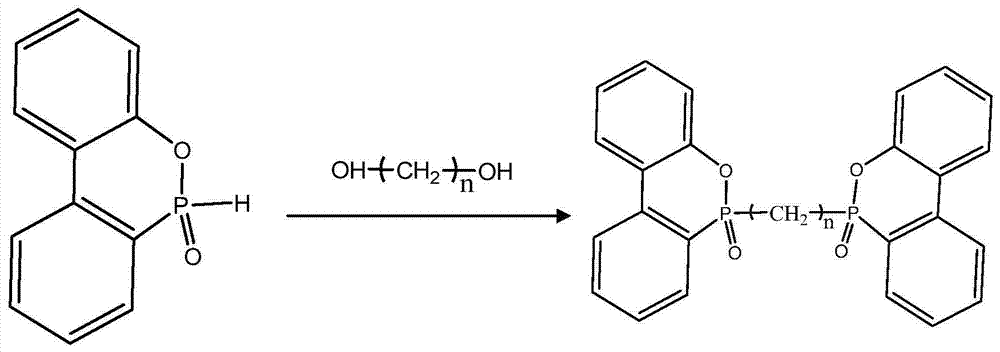

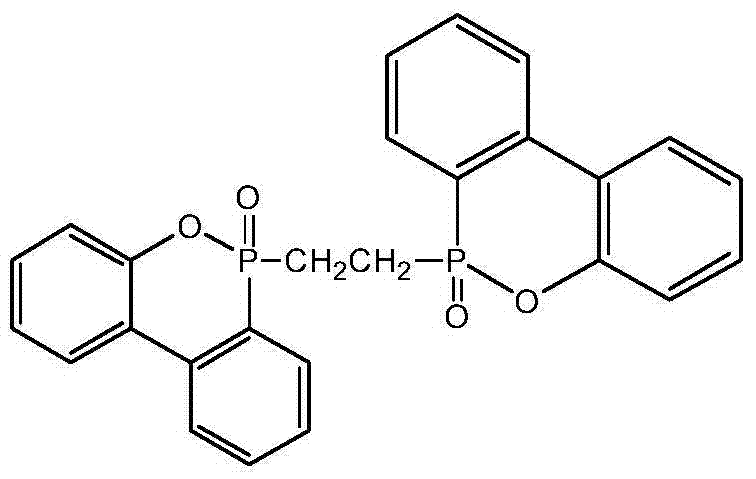

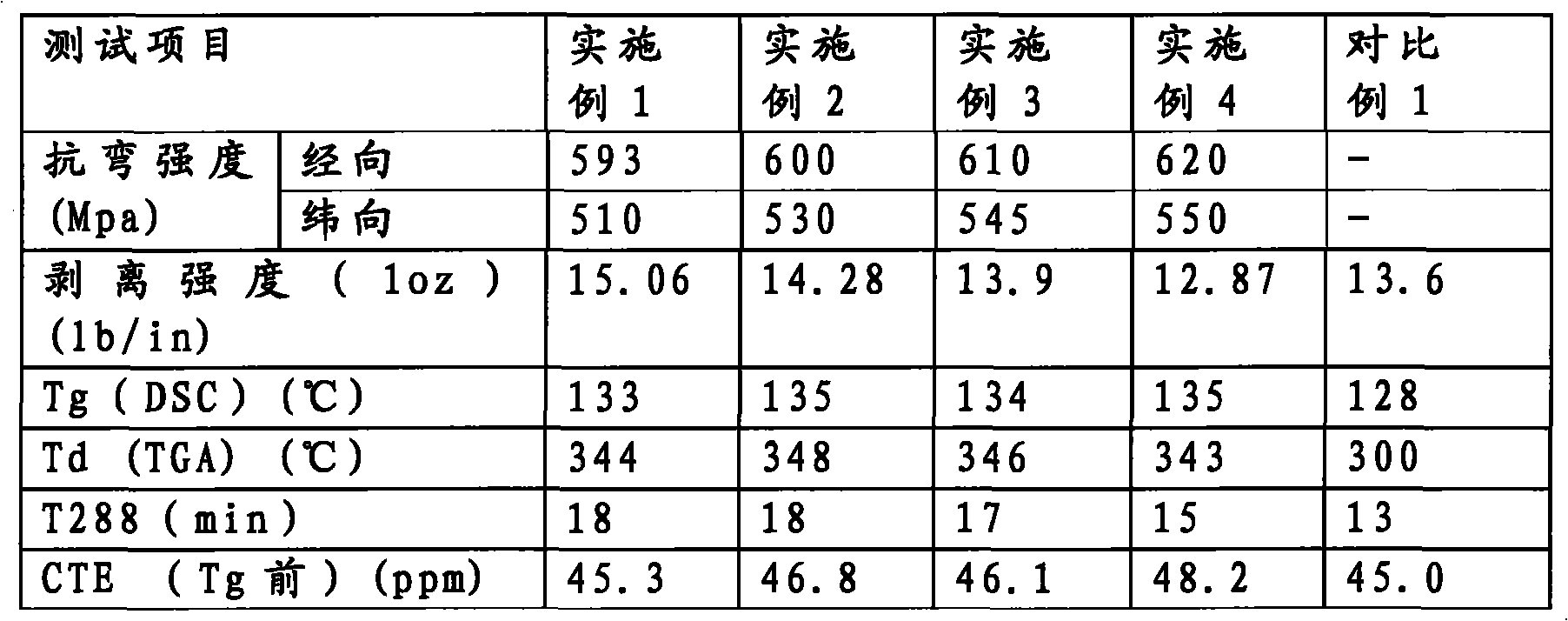

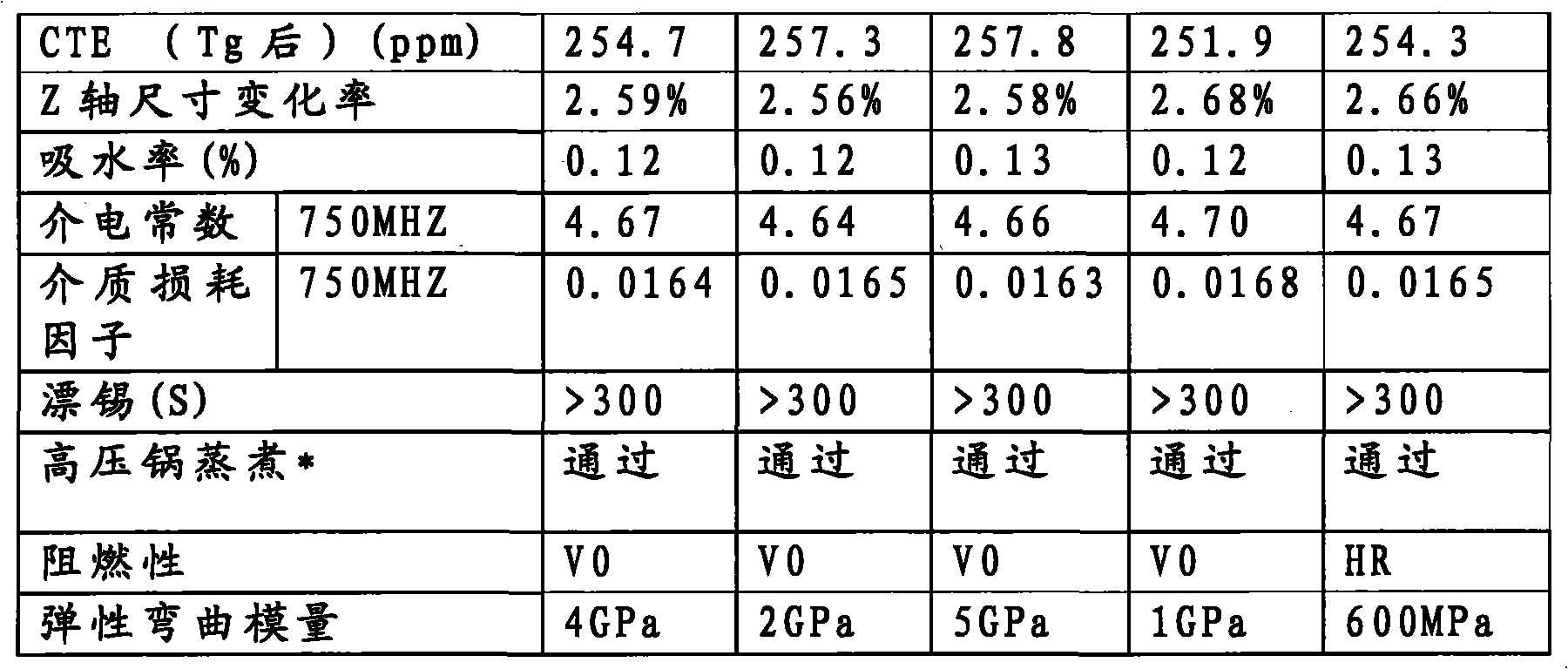

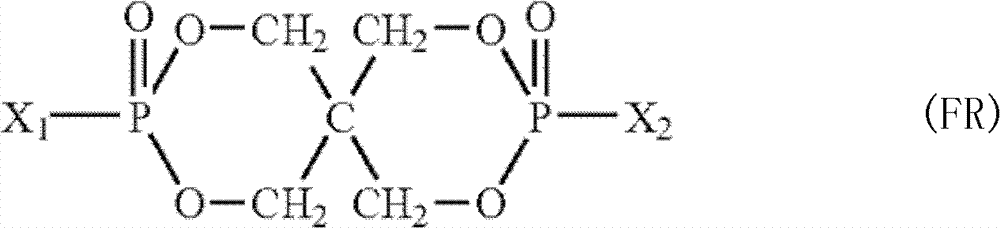

Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

ActiveCN104774476AExcellent dielectric propertiesImprove heat resistanceSynthetic resin layered productsCircuit susbtrate materialsDielectricHalogen

The invention provides a phosphorus-containing flame retardant composition, including: a hypophosphite compound, a DOPO derivative and a polyphosphazene compound. The composition as a flame retardant can play a synergistic effect of several phosphorus-containing compounds, realizes halogen-free flame retardance under small addition amount and reaches level V-0. The invention also provides a contains a polyphenyl ether resin composition containing the above phosphorus-containing flame retardant compositions and a prepreg and a copper clad laminated board prepared from the same. After curing, the polyphenyl ether resin composition achieves flame retardance of V-0 grade under the condition to which the halogen flame retardant does not apply and keeps good dielectric property and heat resistance of polyphenyl ether resin; the prepreg and copper clad laminated board made from the composition have good dielectric property and heat resistance, and realize halogen-free flame retardance to UL 94-V0 grade while ensuring excellent heat resistance and dielectric property; and the composition is applicable to the field of high speed and high frequency printed circuit board, and is in line with the future requirements of green and environmental protection.

Owner:GUANGDONG SHENGYI SCI TECH

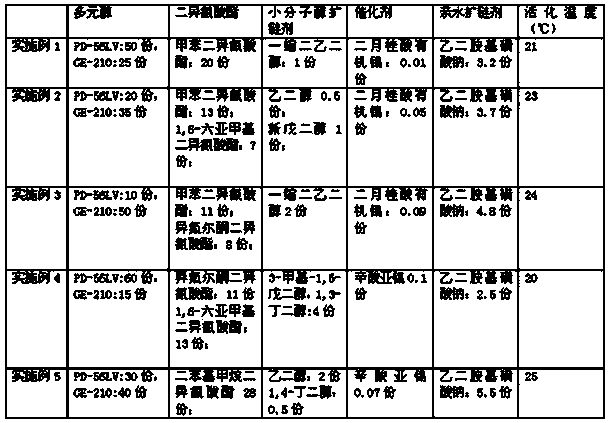

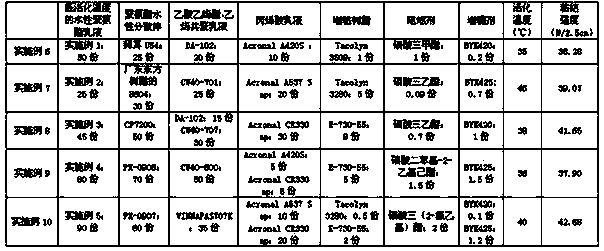

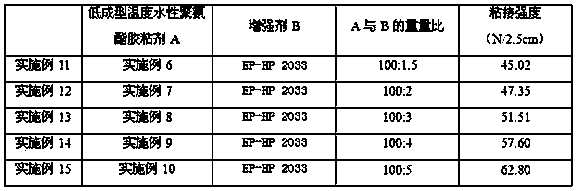

Low-molding-temperature waterborne polyurethane adhesive and preparation method thereof

ActiveCN104031596AImproved sag performanceReduce lossNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolymer sciencePolyurethane adhesive

The invention discloses a low-molding-temperature waterborne polyurethane adhesive and a preparation method thereof. The low-molding-temperature waterborne polyurethane adhesive is prepared by matching a waterborne polyurethane dispersion, ethylene-vinyl acetate (EVA) emulsion, acrylic emulsion and the like based on low-activation-temperature waterborne polyurethane emulsion, wherein the low-activation-temperature waterborne polyurethane emulsion mainly consists of polyhydric alcohols, diisocyanate, a small molecule alcohol chain extender, a catalyst and a hydrophilic chain extender and has the activation temperature of less than 25 DEG C; the low-molding-temperature waterborne polyurethane adhesive prepared based on the low-activation-temperature waterborne polyurethane emulsion has the activation temperature of 30-60 DEG C, is high in bonding strength, is water-based emulsion, does not contain organic solvents or volatile organic compounds, is green and environment-friendly and can well meet the service requirements of adhesives for automobile roofs. The low-molding-temperature waterborne polyurethane adhesive also can be matched with a certain amount of enhancers, the bonding strength of colloid at the later stage is effectively improved, and the heat resistance of the roof at the later molding stage is guaranteed.

Owner:重庆中科力泰高分子材料有限公司

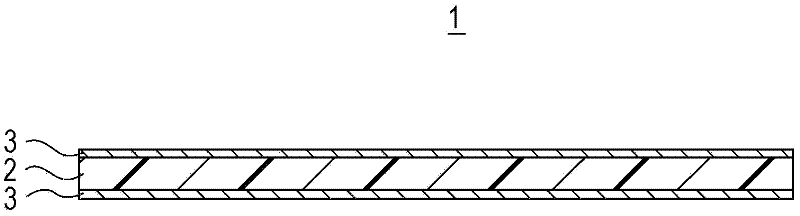

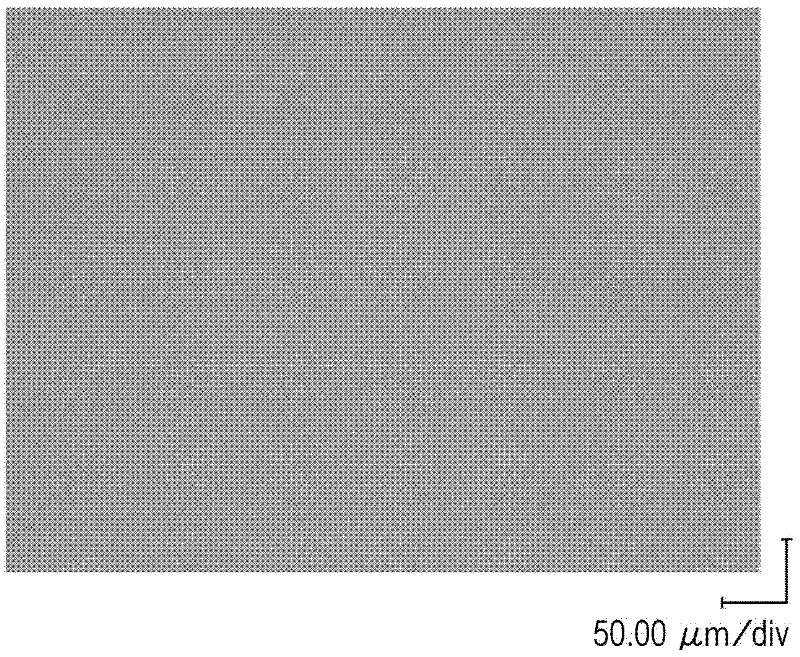

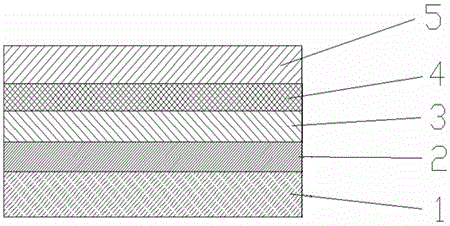

Heat resisting micro pore film and battery diaphragm

ActiveCN102468466AIncrease the number ofReduce the number of protrusionsCell seperators/membranes/diaphragms/spacersLi-accumulatorsSurface layerPorous membrane

The invention relates to a heat resisting micro pore film and a battery diaphragm. The heat resisting micro pore film and the battery diaphragm respectively include substrates formed by utilizing porous membranes and heat resisting layers including heat resisting resin and heat resisting particles formed on at least one surfaces of the substrates. Less than 60 projections per 0.0418 mm2 are formed on the surface of the heat resisting layer. The projections are perpendicular to the heat resisting layer and have an area of less than 500 micro mm2 per 0.0418 mm2. The projections are formed by the gathering of the heat resisting particles and are a highly average face relatively to the heat resisting layer. The projections have a height of at least double of the average particle diameter of the heat resisting diameter. The invention provides the heat resisting micro pore film and the battery diaphragm. In the invention, without increasing the thickness of the surface layer, the heat retraction can be inhibited.

Owner:MURATA MFG CO LTD

A water tree-resistant polyolefin cable material and a preparation method thereof

ActiveCN103289162AShorten the lengthExcellent water tree resistancePlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a water tree-resistant polyolefin cable material and a preparation method thereof. The water tree-resistant polyolefin cable material comprises, by mass, 70 to 95 parts of low density polyethylene, 5 to 30 parts of water tree resistant masterbatch, 1 to 2 parts of a crosslinking agent, 0.3 to 0.5 parts of a crosslinking coagent, 1 to 2 parts of an antioxidant, and 0.1 to 0.5 parts of a rheology modifier. Porous particles in the prepared water tree-resistant polyolefin cable material have adsorption characteristics, so that a more uniform distribution of water is obtained, water will not gather to be droplets, the probability of water tree growth is reduced by 50% or more than that of a conventional cross-linked polyethylene cable material, and the water tree-resistant polyolefin cable material of the invention has excellent water tree resistance; an elastic modulus ratio increases by 30% than that of a conventional cross-linked polyethylene cable material, so the water tree-resistant polyolefin cable material of the invention has excellent mechanical strength and toughness; and the water tree-resistant polyolefin cable material of the invention meet electrical performance standards of chemically cross-linked polyethylene insulation materials used for medium / low-voltage cable, etc., and has good processability.

Owner:XI AN JIAOTONG UNIV

Preparation method of copper clad plate

ActiveCN101652026AGuaranteed performanceGuaranteed flame retardant performanceLaminationLamination apparatusEpoxyCopper foil

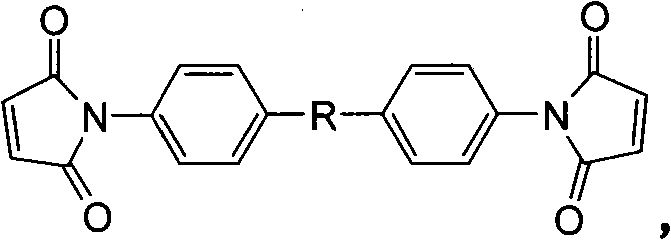

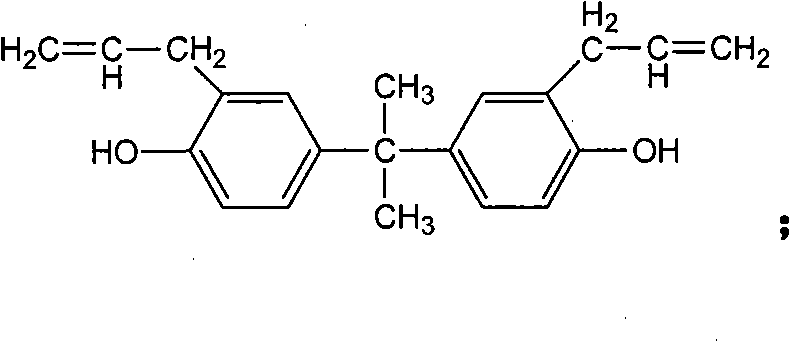

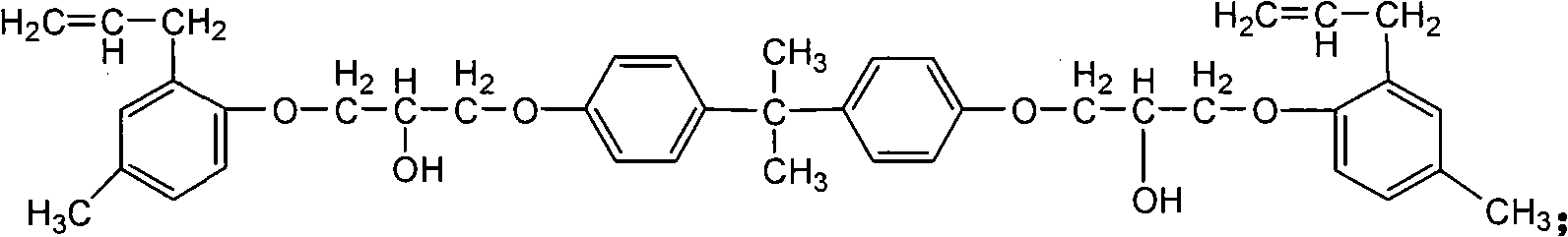

The invention discloses a preparation method of copper clad plate and the method comprises the following steps: (1) adopting bismaleimide resin and allyl compound in a weight ratio of 100:40-100 to react at 110-160 DEG C for 10-120min and obtain prepolymer, cooling to room temperature after finishing the reaction, using acetone to prepare prepolymer solution; (2) adding 15-150 parts of epoxy resinwith phosphorous, 10-100 parts of compound curing agent and 0-5 parts of curing accelerator in the solution obtained in the step 1, stirring evenly to obtain a glue solution, selecting a flat E-glassfibic cloth, coating the glue solution evenly on the glassfibic cloth, then roasting to prepare B-stage prepreg; (3) cutting the B-stage prepreg to proper size according to the size of a pressing machine, overlying five prepregs while placing two high impact copper foils with the same size separately on the top and bottom of the prepregs, placing the prepregs with copper foils in a vacuum hot pressing machine to press and obtaining the copper clad plate. The obtained copper clad plate can meet the demand for halogen-free and flame resistance, the heat resistance and humidity resistance are excellent, and the low dielectric loss and pressing toughness are good.

Owner:SHENGYI TECH SUZHOU

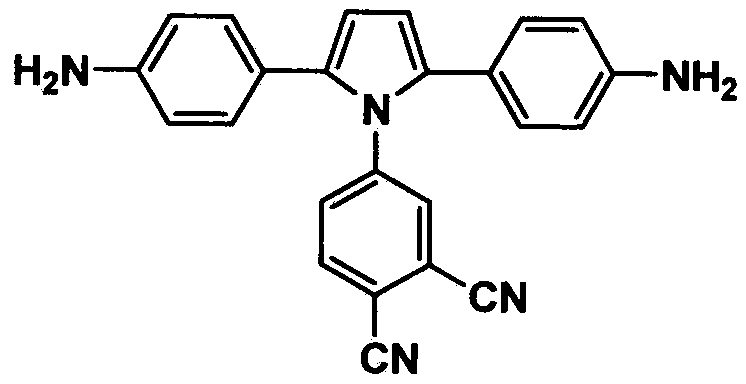

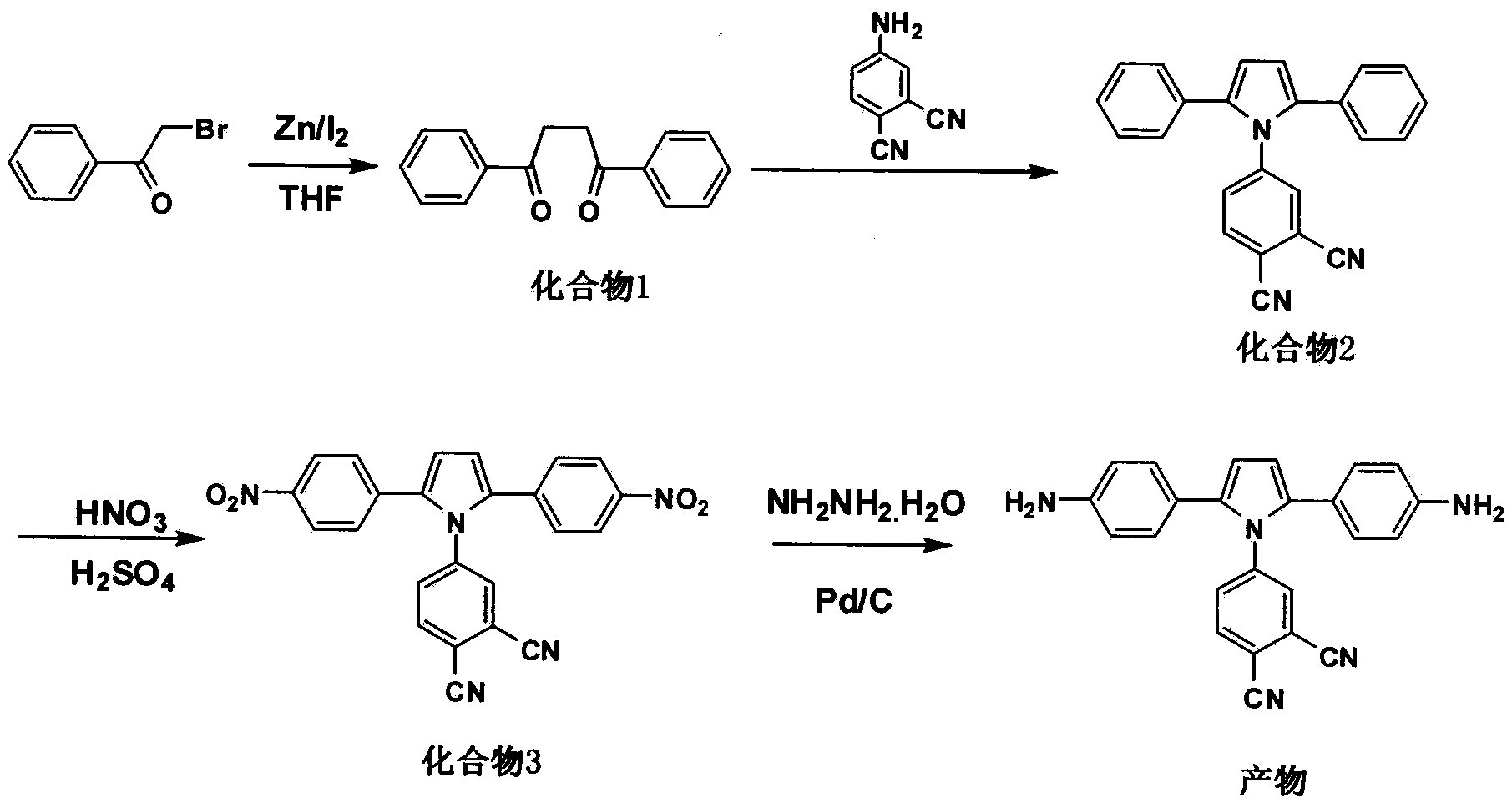

Pyrrole aromatic diamine containing phthalic nitrile structure as well as preparation method and application thereof

The invention discloses a pyrrole aromatic diamine containing a phthalic nitrile structure and a preparation method thereof. 2-bromoacetophenone is taken as a raw material to prepare 4-(2,5-bi(4-aminophenyl)-pyrryl) phthalonitrile by reaction of four steps, namely condensation, closed loop, nitration and reduction. The aromatic diamine disclosed by the invention is high in purity, and stable at room temperature, and is an important monomer component for preparing a plurality of polyimides, and an application of the polyimides in the fields such as a high-performance fiber, organic luminescent materials, a functional coating, a special adhesive and the like is expanded.

Owner:四川启科新材料有限责任公司

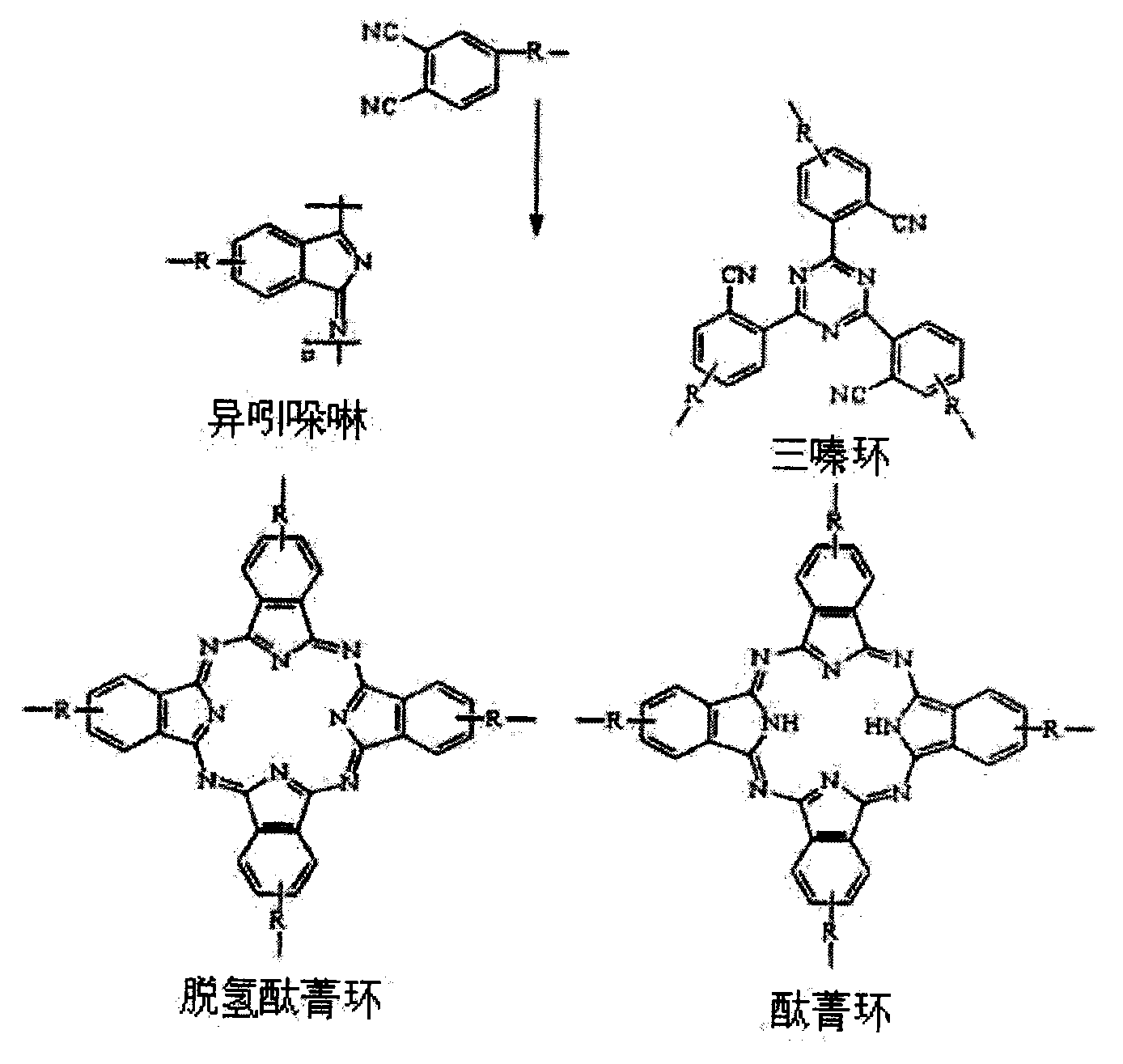

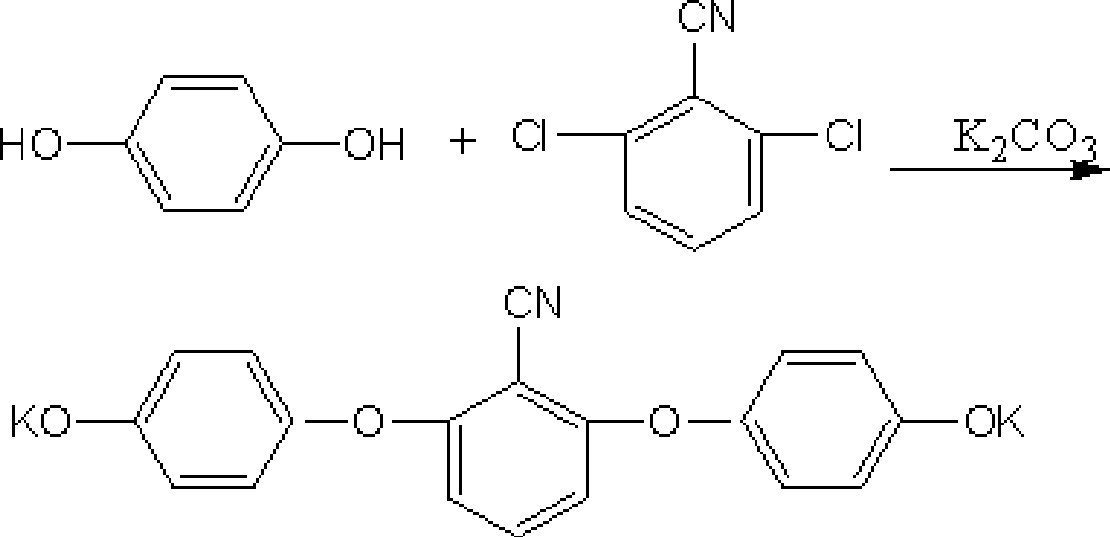

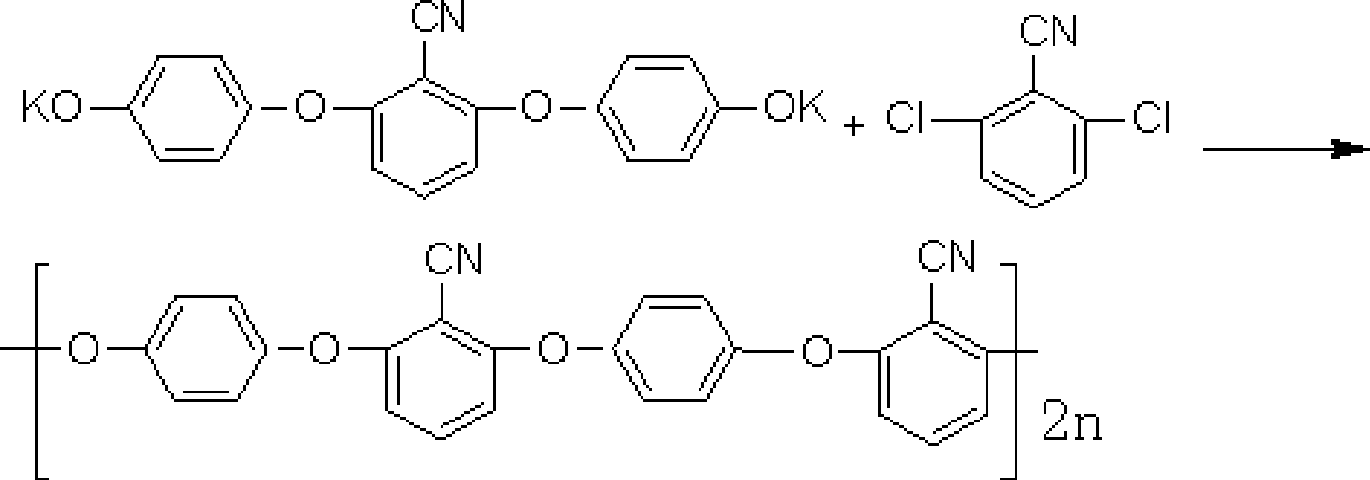

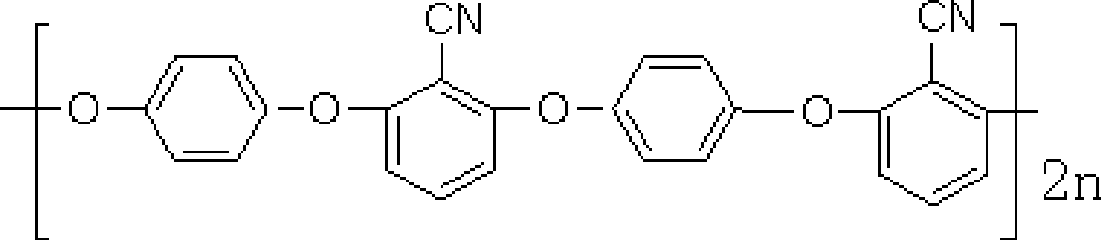

Polyarylether carbonitrile industrial production method

The industrial process of polyarylethernitrile, this invention relates to the Synthesis of polyarylethernitrile. Adding 2, 6-dichlorocyanobenzene, polyhydric phenol, anhydrous potassium carbonate, solvent NMPA, toluene in autoclave, heating-up the autoclave to 100-200 deg C in the condition of 2. 0-2. 5MPa in autoclave, heating-up the autoclave to 150-300deg C after 2-6h heat preservation, taking out the fixed object of autoclave after 1-6h heat preservation, getting the polyarylethernitrile after washing by boiling-water, desiccation and granulation. The production condition of this invention is easy to realize, the industrial process is easy to control, and the produced polyarylethernitrile is low in cost and suit to use of multirealm.

Owner:YANGZHOU TIANCHEN FINE CHEM

POSS (Polysilsesquioxane)-containing antireflective film coating liquid and preparation method and application thereof

The invention discloses a POSS (Polysilsesquioxane)-containing antireflective film coating liquid and a preparation method and application thereof, and belongs to the field of film coating liquids. The preparation method of the POSS-containing antireflective film coating liquid comprises the following steps of: adding the following raw materials in percentage by weight: 0.01%-20% of POSS derivatives, 0-10% of nanometer silicon dioxide granules, 0%-10% of hollow silicon dioxide, 0%-5% of non-silicon nanometer oxide granules, 0%-10% of organic silicon compounds, 0%-50% of deionized water and 0%-2% of catalysts into a solvent; and reacting at 20-150 DEG C for 0-45 hours to obtain the POSS-containing antireflective film coating liquid. The POSS-containing antireflective film coating liquid disclosed by the invention can be applied to photovoltaic glass, display screen base plate glass, building glass and automobile glass; and the obtained antireflective film has the advantages of good film layer uniformity, high adhesive force and rigidity and good weather resistance.

Owner:武汉绿凯科技有限公司

Industrial production method of semi-crystalline poly aryl ether nitrile

The invention relates to an industrial production method for semi-crystal poly(aromatic ether nitrile), which belongs to the field of polymer material. The method comprises the following steps: 2, 6-dichloro benzonitrile and hydroquinone are taken as raw materials; anhydrous potassium carbonate is taken as a catalyst; in the presence of a solvent and a dehydrating agent, the raw materials and the catalyst react under atmospheric pressure to obtain the poly(aromatic ether nitrile) homopolymer with low molecular weight and regular chain segments; and then the molecular weight of polymer is increased through pressurization, so as to obtain the semi-crystal poly(aromatic ether nitrile) polymer with high molecular weight. Due to the increase of crystallinity and molecular weight, the mechanical properties and heat resistance of the semi-crystal poly(aromatic ether nitrile) polymer are obviously improved.

Owner:SICHUAN FEIYA NEW MATERIAL

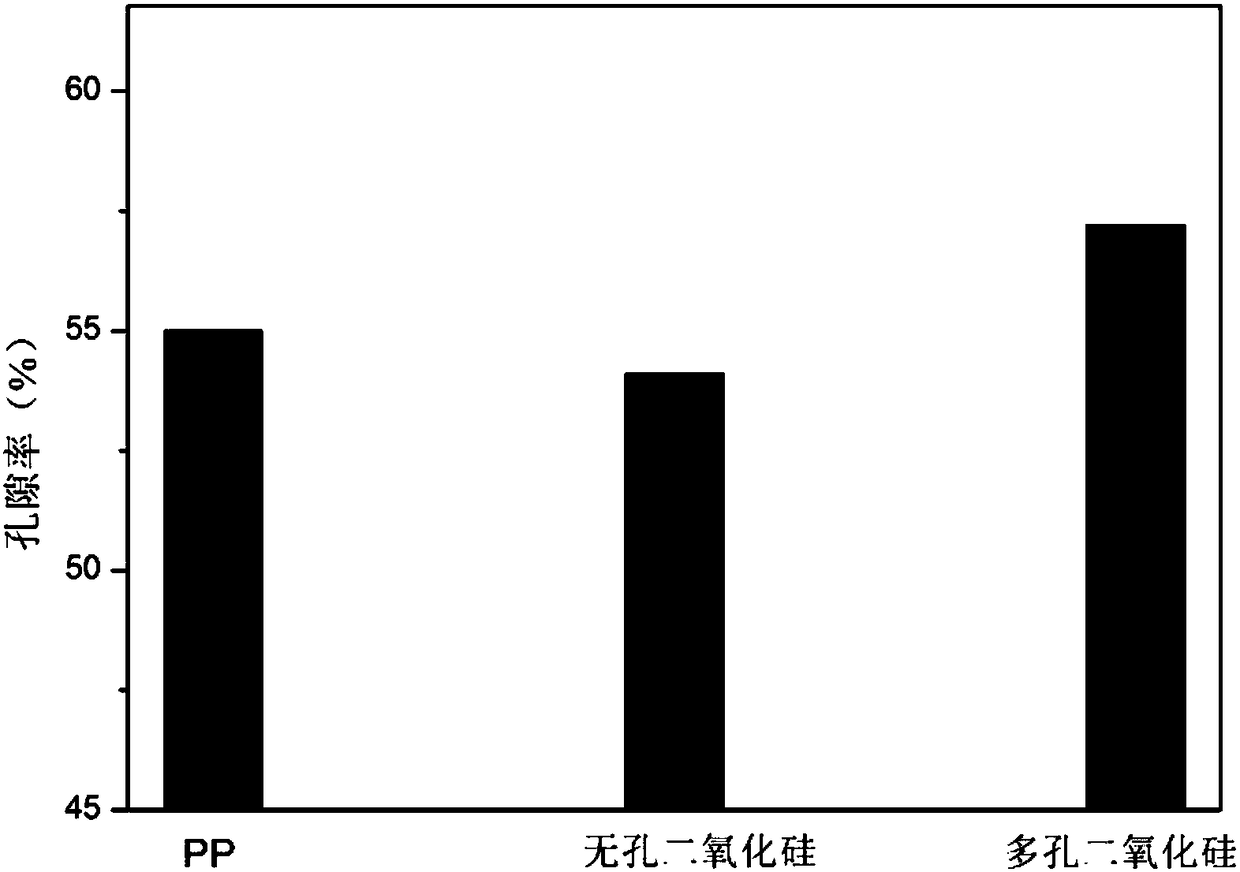

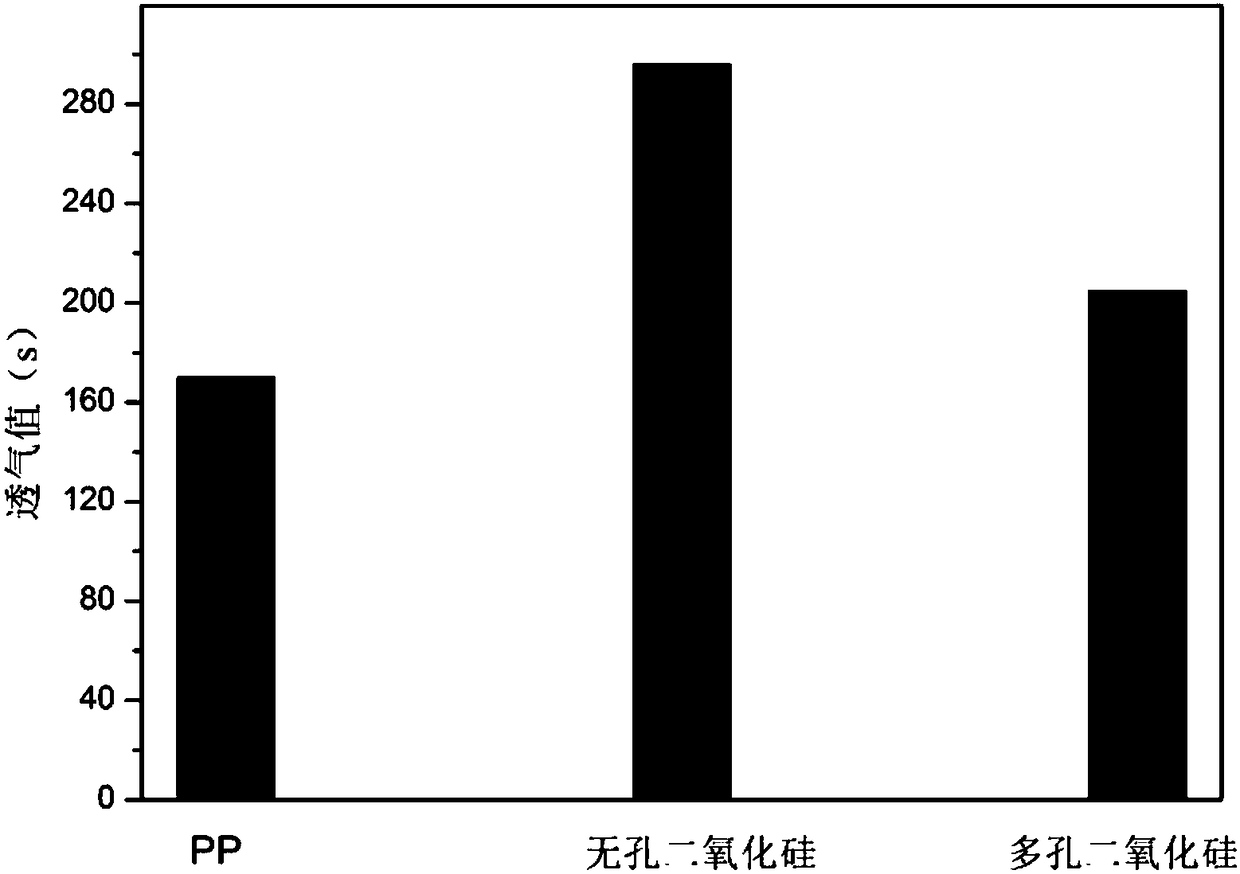

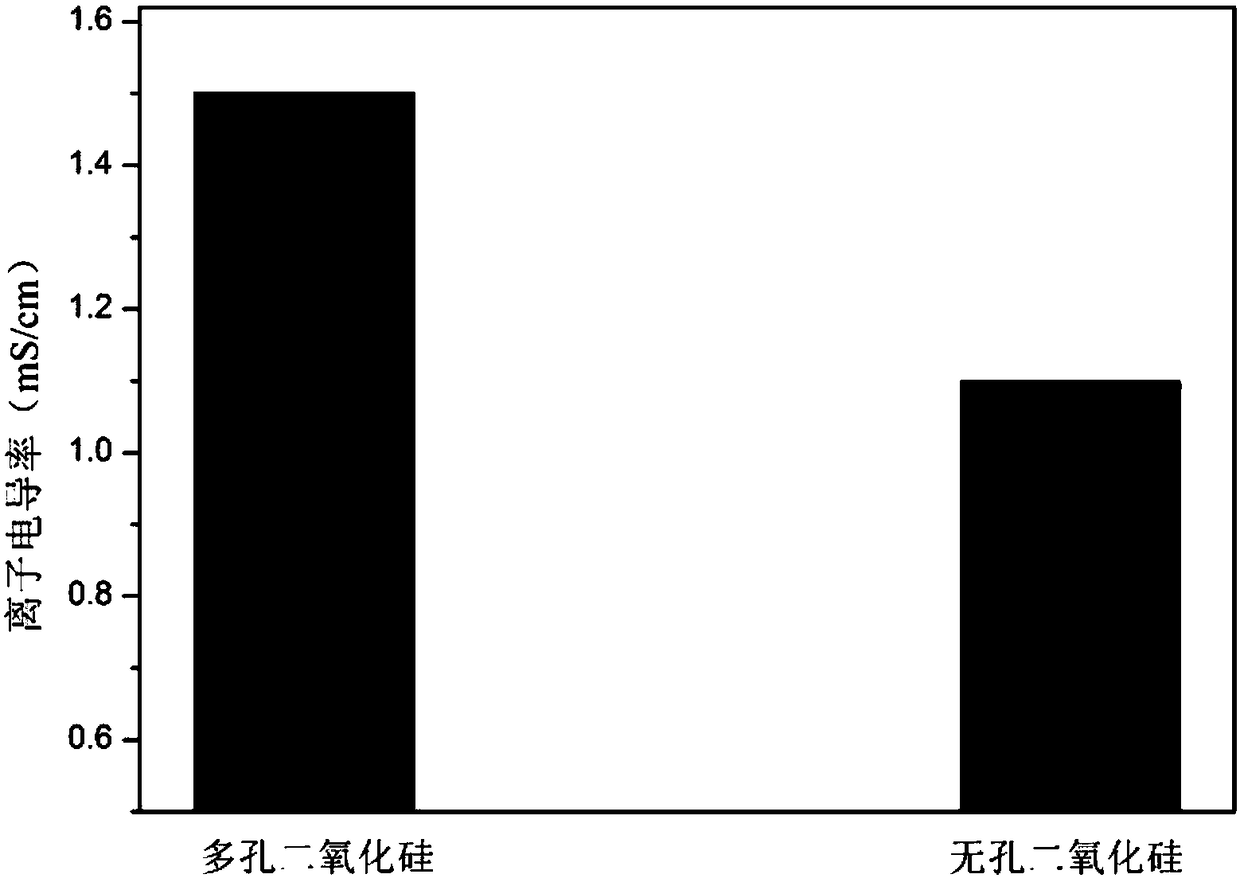

Nanoparticle coated lithium ion battery diaphragm and preparation method thereof

InactiveCN108336279AGuaranteed ion mobility performanceFacilitate deliveryCell component detailsHigh rateFree diffusion

The application discloses a nanoparticle coated lithium ion battery diaphragm and a preparation method thereof. The nanoparticle coated lithium ion battery diaphragm comprises a basal membrane and nanoparticles coated on at least one surface of the basal membrane, wherein the nanoparticles have porous structures, and at least a part of channels penetrate the surface of the nanoparticles. The nanoparticle coated lithium ion battery diaphragm employs the nanoparticles with the porous structures to prepare a coating, the nanoparticles with the porous structures have developed channel structures,lithium ions can diffuse in gaps between nanoparticles, and lithium ions can freely diffuse in the internal channels in the porous structures of the nanoparticles, in order to improve porosity of thediaphragm with the nanoparticle coating, and improve wettability of diaphragm electrolyte. The nanoparticle coated lithium ion battery diaphragm keeps heat resistance of the traditional diaphragms with nanoparticle coatings, and at the same time improves conductivity of lithium ions, so that batteries have high rate performance and long circulation performance.

Owner:武汉中兴创新材料技术有限公司

High-toughness, anti-impact and high-flexibility epoxy pouring sealant and preparation method thereof

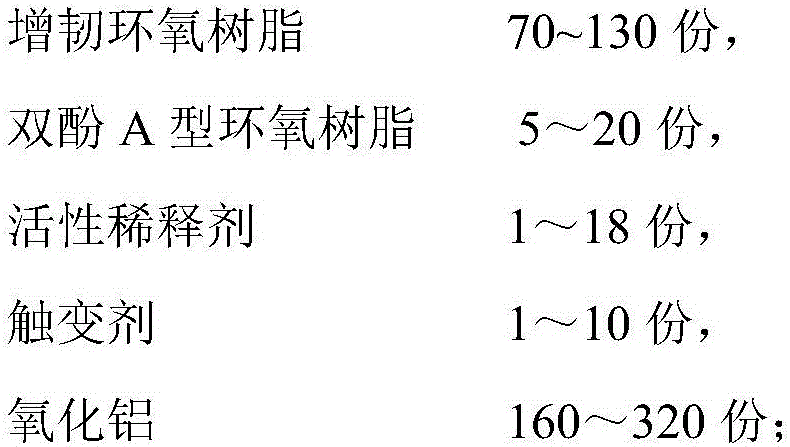

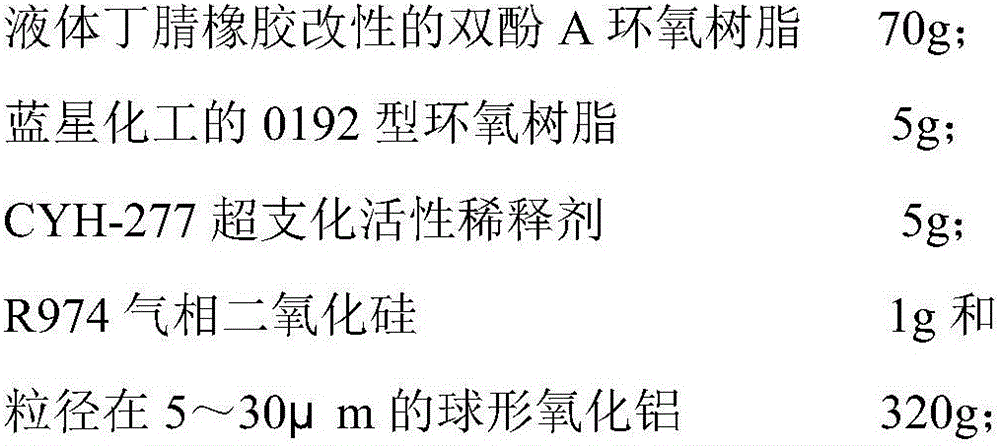

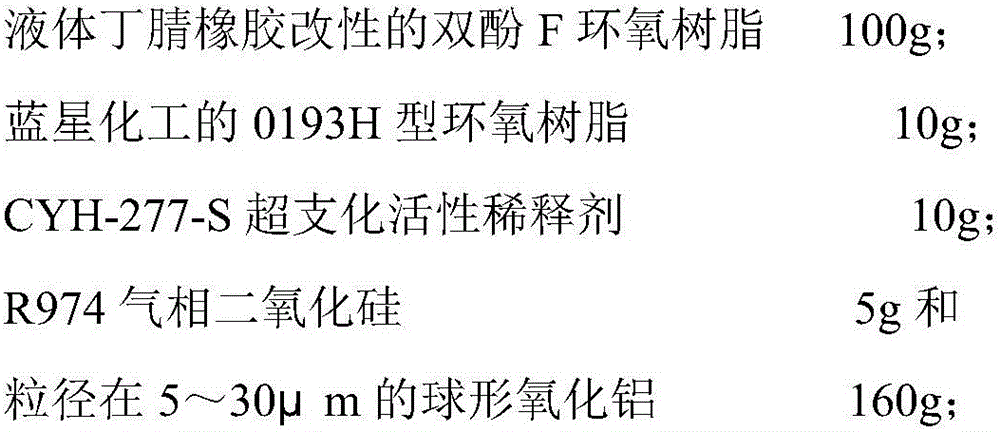

ActiveCN106281174AGuaranteed crosslink densityGuaranteed heat resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesTO-18Diluent

The invention discloses a high-toughness, anti-impact and high-flexibility epoxy pouring sealant. The high-toughness, anti-impact and high-flexibility epoxy pouring sealant is composed of a component A and a component B, wherein the component A is prepared from the following raw materials in parts by weight: 0 to 130 parts of toughening epoxy resin, 5 to 20 parts of bisphenol A type epoxy resin, 1 to 18 parts of an active diluent, 1 to 10 parts of a thixotropic agent and 160 to 320 parts of aluminum oxide; the component B is prepared from the following raw materials in parts by weight: 20 to 50 parts of a flexible curing agent, 25 to 50 parts of a hyperbranched curing agent and 1 to 5 parts of an accelerant; the mass ratio of the component A to the component B ranges from (10 to 1) to (20 to 1). According to a preparation method provided by the invention, the materials are prepared and mixed according to formulas of the component A and the component B respectively. The epoxy resin provided by the invention not only has rubber flexibility, but also has excellent heat-resisting performance and rigidity.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

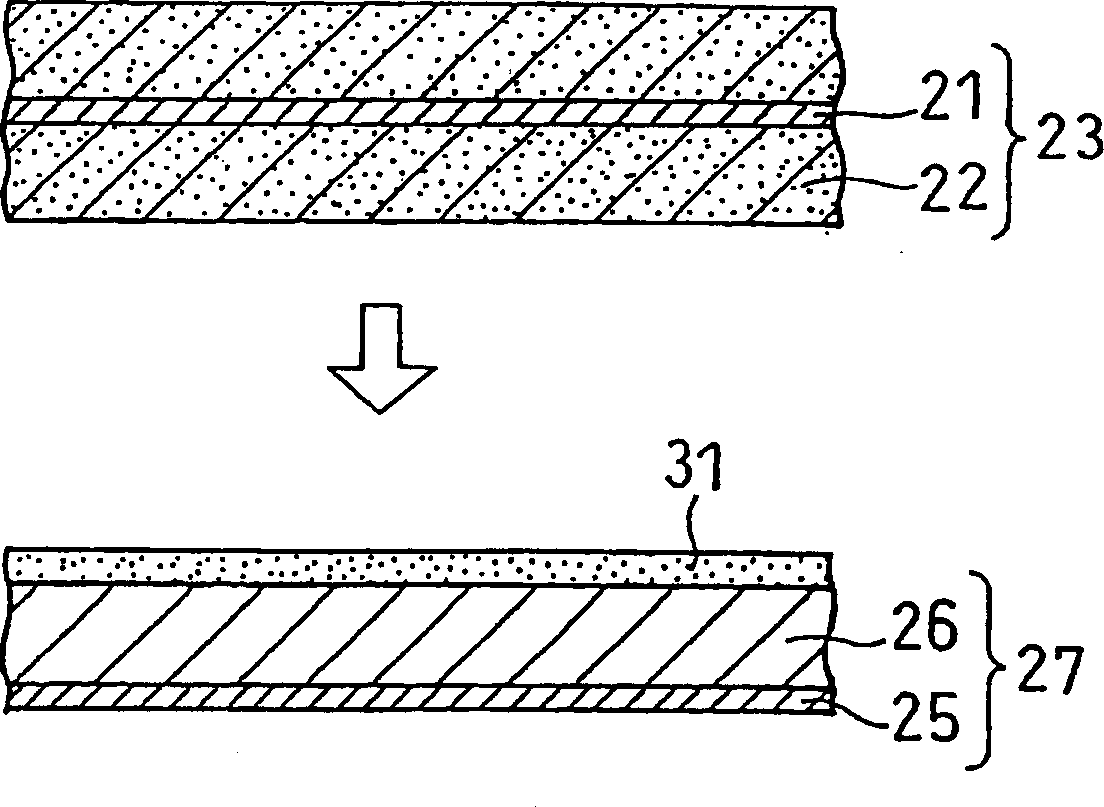

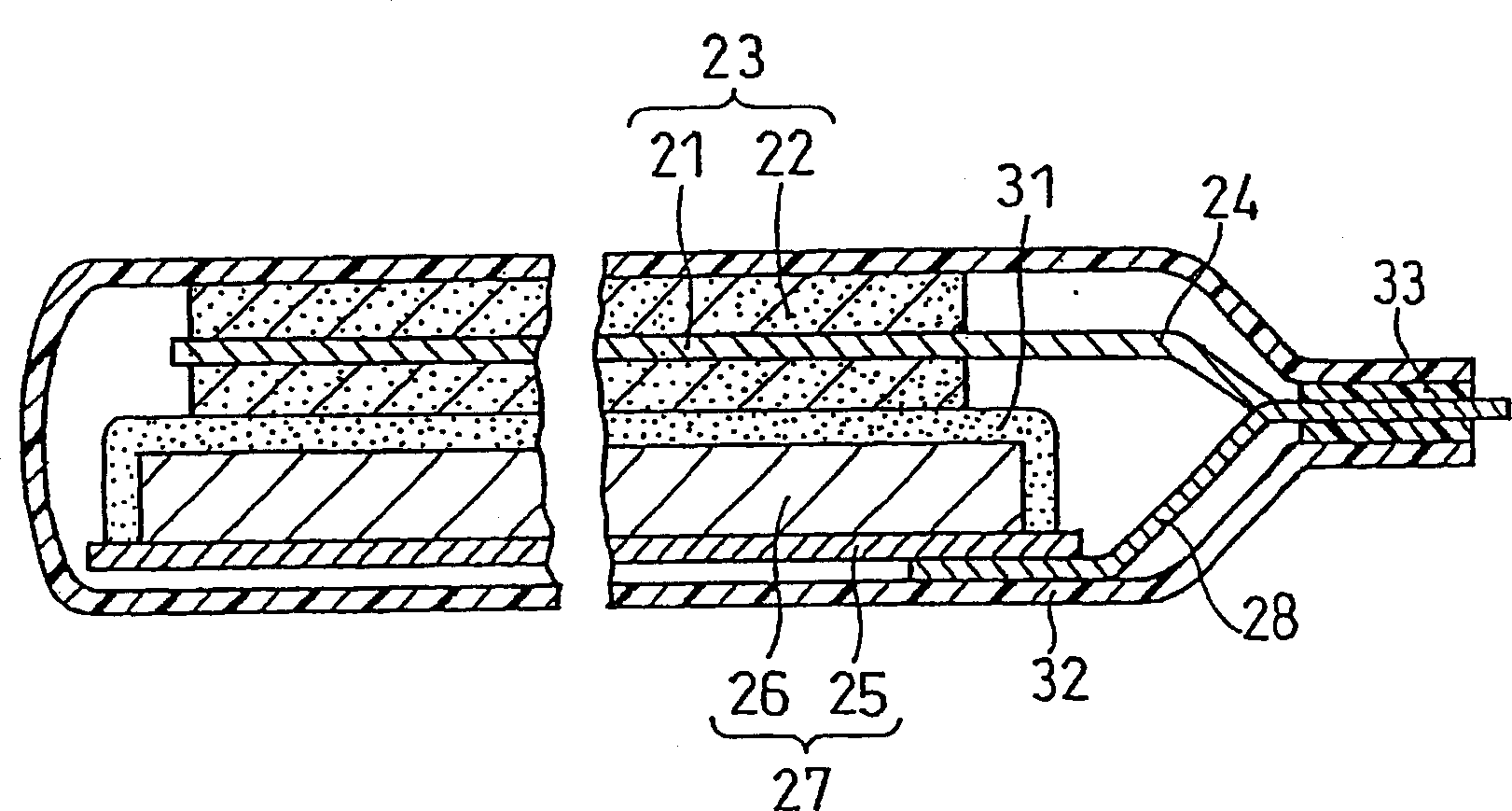

Adhesive polyimide resin and adhesive laminate

InactiveCN1406262AImprove liquidityImprove heat resistanceSemiconductor/solid-state device detailsSynthetic resin layered productsVitrificationElectrical conductor

An adhesive polyimide resin which comprises a siloxane polyimide resin obtained from (A) an aromatic tetracarboxylic dianhydride and (B) a diamine ingredient comprising (B1) a diamine having a phenolic hydroxyl group, carboxyl group, or vinyl group as a crosslinkable reactive group and (B2) a siloxanediamine and has a glass transition temperature of 50 to 25 DEG C and a Young's modulus (storage modulus) at 25 DEG C of 10<5> Pa or higher; and a laminate which comprises a substrate comprising a conductor layer and an insulating supporting layer having at least one polyimide resin layer and, disposed on a surface of the substrate, an adhesive layer comprising a layer of the adhesive polyimide resin. The adhesive polyimide resin and the laminate have satisfactory adhesion strength even after exposure to a high temperature of up to 27 DEG C and further have excellent heat resistance in reflow ovens. They are hence suitable for use in the bonding of electronic parts.

Owner:NIPPON STEEL CHEMICAL CO LTD

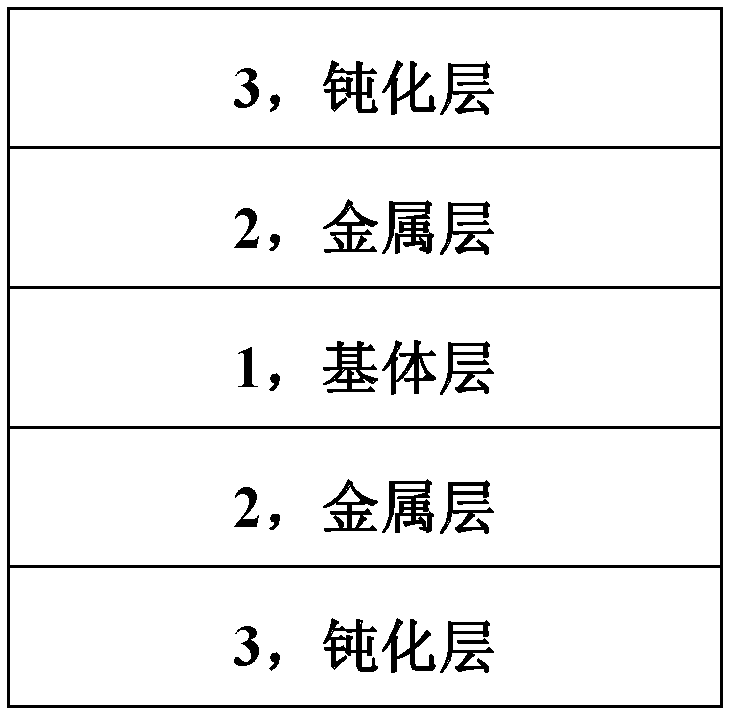

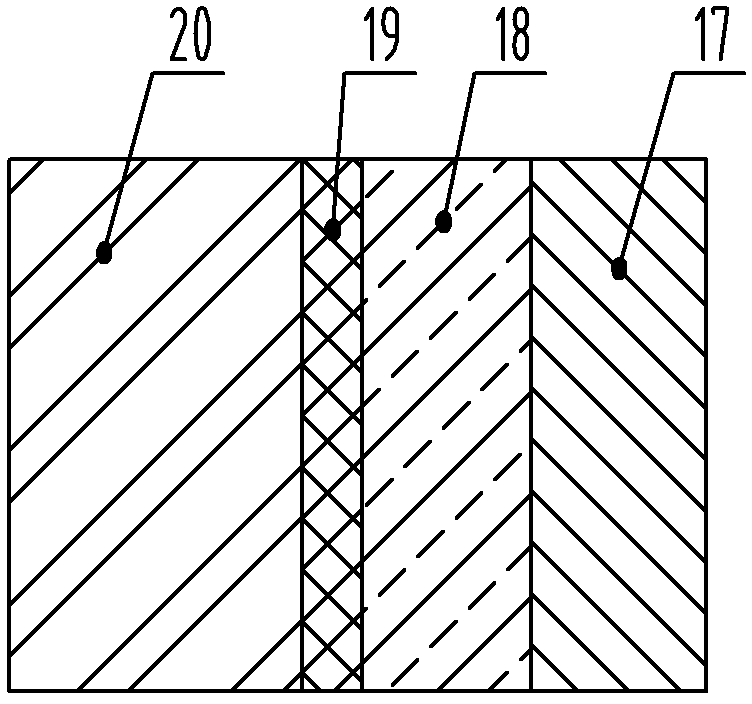

Soft board base material without glue and preparation method thereof

ActiveCN103167731AHigh composite strengthImprove reliabilityPrinted circuit manufactureCircuit susbtrate materialsHeat resistanceHigh intensity

A functional soft board base material without glue is composed of a metal layer, a basal layer and a metal passivation layer which are superimposed. The manufacturing method includes that (1), polyimide is used to make a basal body, and surface treatment is performed for two faces (or one face) of the basal body; (2), a physical vapor deposition (PVD) method is adopted to deposit and form a metal membrane layer on a product improve (PI) face of a treated face; and (3), passivation treatment is performed for the metal membrane layer. The soft board base material without the glue has high-strength tensile performance, excellent chemical resistance, heat resistance, dimensional stability, peel strength, compactness, uniform consistency, and mechanical machining performance, is strong in shielding function, and can be used for manufacturing printed circuit boards (PCB), flexible printed circuits (FPC), soft and hard combination plate, special function (shielding function) material and the like, the PVD method is adopted to deposit the metal layer, the thickness of the metal layer is enabled to be adjustable, achievement of superfine precision circuit is enabled to be possible, and the soft board base material without glue is low in cost, environment-friendly, good in bending performance and easy for technical processing.

Owner:英德宏庆电子有限公司

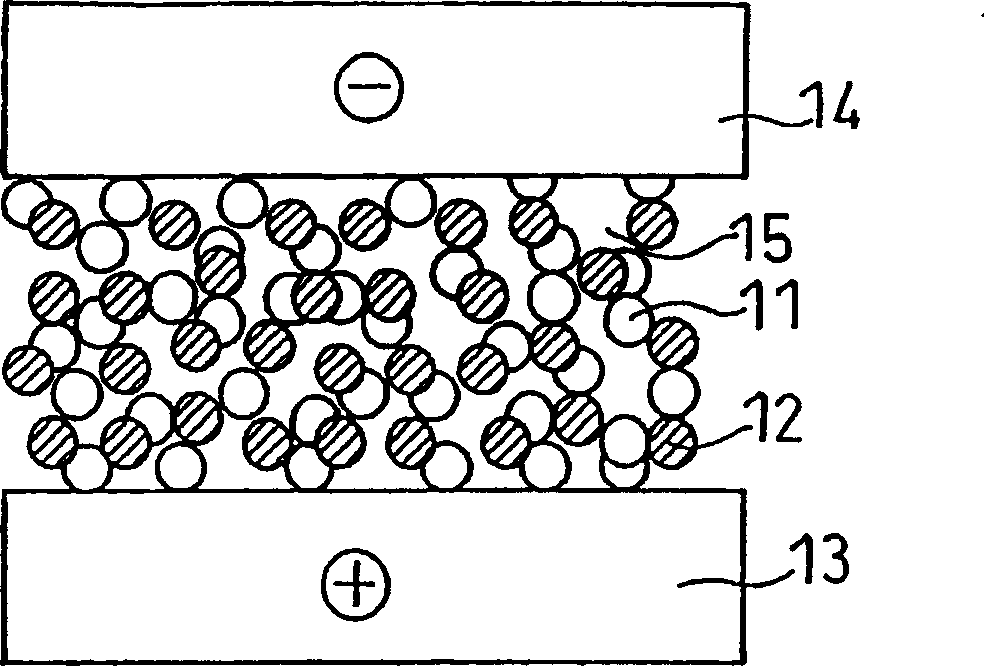

Lithium ion secondary battery

ActiveCN1795578AGuaranteed heat resistanceTake security into considerationCell seperators/membranes/diaphragms/spacersFinal product manufactureMethacrylateMaterials science

A lithium ion secondary battery includes a positive electrode capable of absorbing and desorbing lithium ion, a negative electrode capable of absorbing and desorbing lithium ion, a porous film interposed between the positive electrode and the negative electrode, and a non-aqueous electrolyte: the porous film being adhered to a surface of at least one of the positive electrode and the negative electrode; the porous film including a filler and a resin binder; the resin binder content in the porous film being 1.5 to 8 parts by weight per 100 parts by weight of the filler; and the resin binder including an acrylonitrile unit, an acrylate unit, or a methacrylate unit.

Owner:PANASONIC CORP

Thermoplastic electromagnetic wave shielding film used for rapid processing

ActiveCN105120643AFast processingAdapt to the requirements of rapid processingMagnetic/electric field screeningSynthetic resin layered productsHybrid typeThermoplastic

The invention discloses a thermoplastic electromagnetic wave shielding film used for rapid processing. The electromagnetic wave shielding film comprises a base material, a release layer, an insulation protection layer, a metal layer and a thermoplastic conductive resin layer. The thermoplastic conductive resin layer is composed of a hybrid-type thermoplastic polyamide imide, thermoplastic hydroxyl polyurethane, thermoplastic acrylic resin, gas-phase silicon dioxide, conductive metal powder and anti-oxidants. The provided shielding film has the following advantages: the conductive resin layer has thermoplasticity, cold storage is not needed, and the shielding film can be processed on a flexible connection circuit rapidly and has excellent adhesion fastness, grounding filling ability and step filling ability.

Owner:BAODING LUCKY INNOVATIVE MATERIALS

High-tear strength silicone rubber and preparation method thereof

The invention discloses high-tear strength silicone rubber which comprises the following raw materials: 100 parts of methylvinyl crude rubber, 30-60 parts of white carbon black, 4-6 parts of vinyl silicone oil, 0.5-2 parts of hydroxyl silicone oil, 0.5-1 part of vinyltrimethoxy silane and 0.1-0.4 part of demoulding auxiliary. The invention also discloses a preparation method of the high-strength silicone rubber, which comprises the following steps: (1) putting the methylvinyl crude rubber, hydroxyl silicone oil, vinyltrimethoxy silane and a demoulding auxiliary into a kneading machine for kneading; (2) adding the white carbon black in 3-5 batches, mixing into agglomerate, heating and vacuumizing; and (3) cooling to 60-80 DEG C, adding the vinyl silicone oil in 3-5 batches, mixing into agglomerate and discharging and packaging to obtain the high-strength silicone rubber. In the invention, by adding the vinyl silicone oil into the raw materials of the high-strength silicone rubber, the tear strength of silicone rubber is remarkably improved while guaranteeing the hardness, elasticity, heat resistance and tensile strength of the silicone rubber; and the preparation method is simple in process, and the production efficiency is high.

Owner:QINGDAO HUILU SILICONE CO LTD

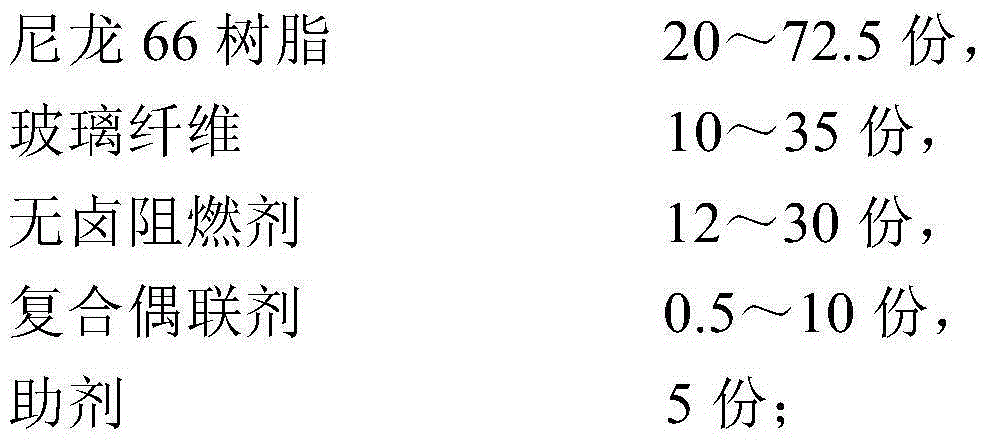

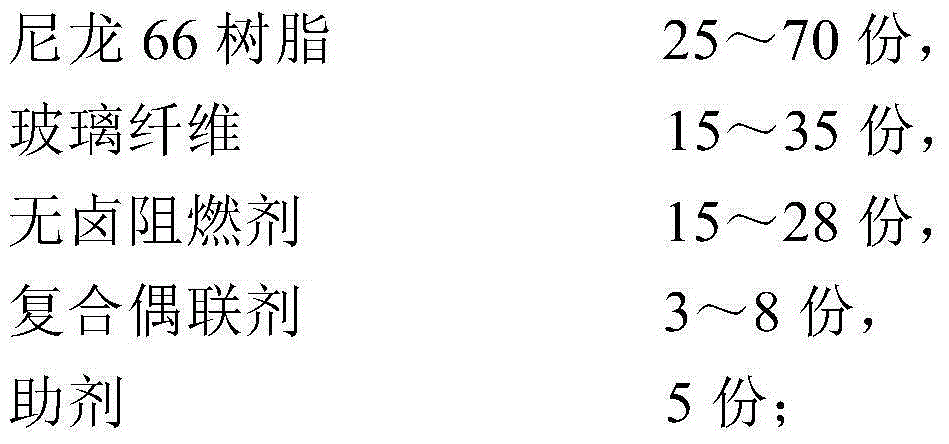

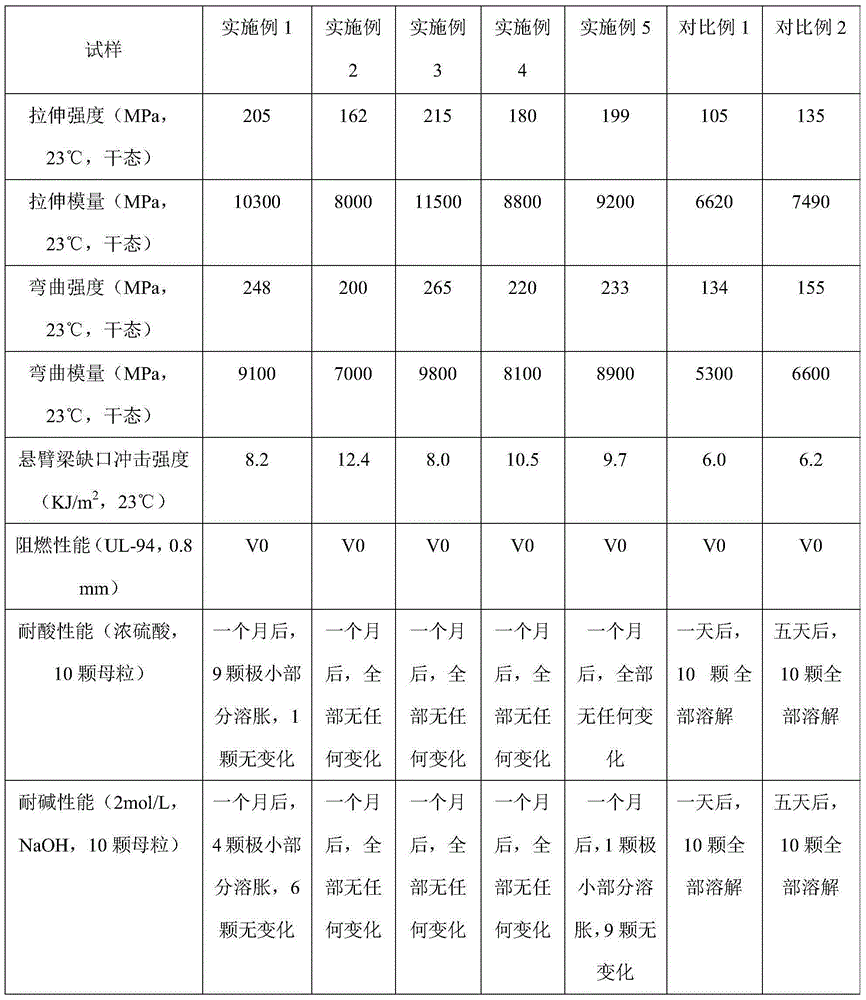

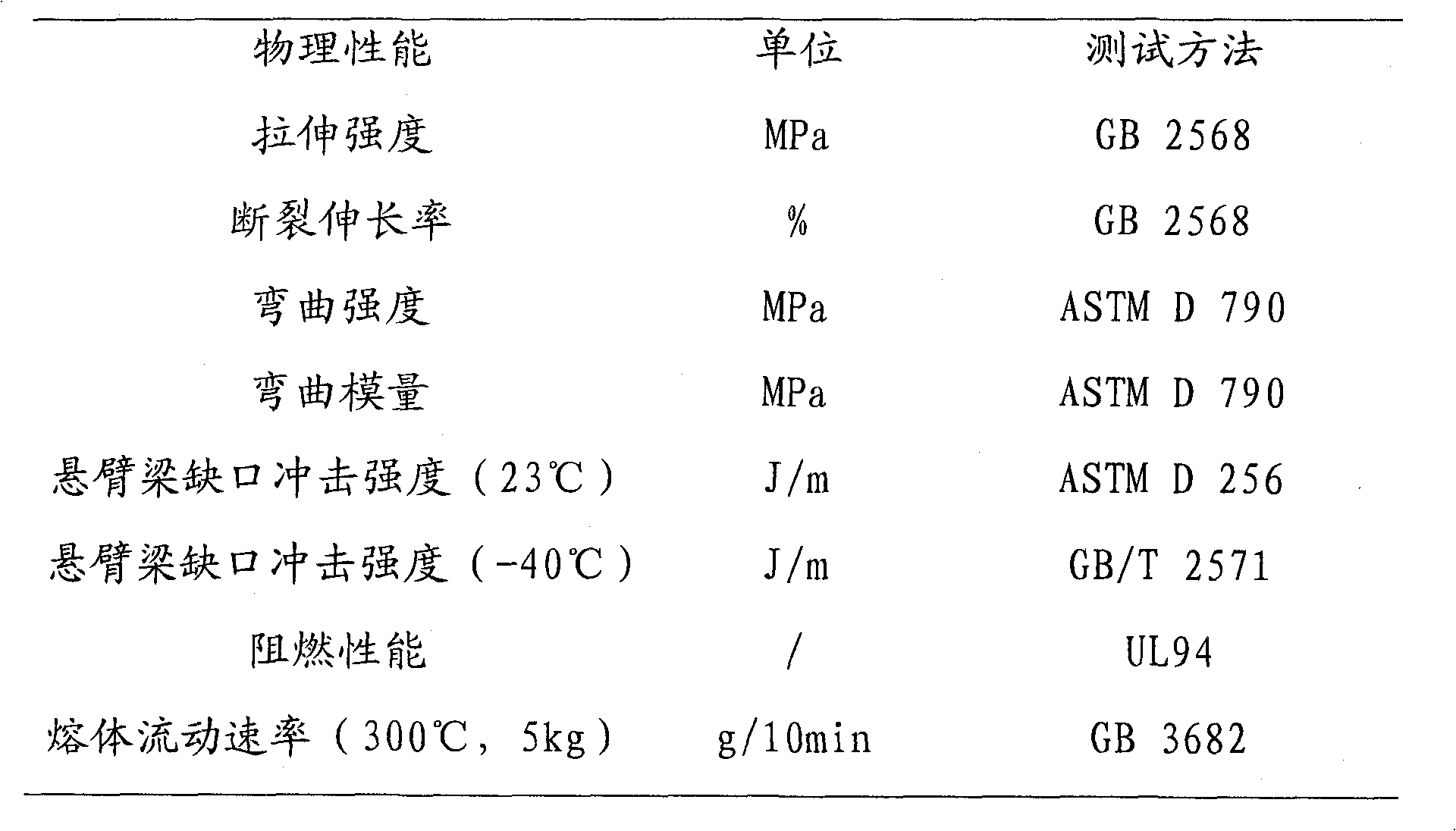

Halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance and preparation method of PA66 composite material

InactiveCN105062050AGood acid and alkali resistanceStrong acid and alkali resistanceEpoxyGlass fiber

The invention discloses a halogen-free flame retardant and glass fiber reinforced PA (polyamide) 66 composite material with acid and alkali resistance. The PA66 composite material comprises raw materials in parts by weight as follows: 20-72.5 parts of PA66 resin, 10-35 parts of glass fiber, 12-30 parts of a halogen-free flame retardant, 0.5-10 parts of a composite coupling agent and 5 parts of an auxiliary, wherein the composite coupling agent is selected from a mixture formed by mixing gamma-aminopropyl triethoxysilane with gamma-epoxy propoxy propyl trimethoxysilane or epoxy resin in the weight ratio being 1: (1-50). The composite material has higher acid and alkali resistance, good processing fluidity as well as excellent mechanical properties, heat resistance and flame retardation, the problem of insufficient acid and alkali resistance of PA products in the prior art is particularly solved, the acid and alkali resistance is improved remarkably, and the composite material has broad market prospects.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

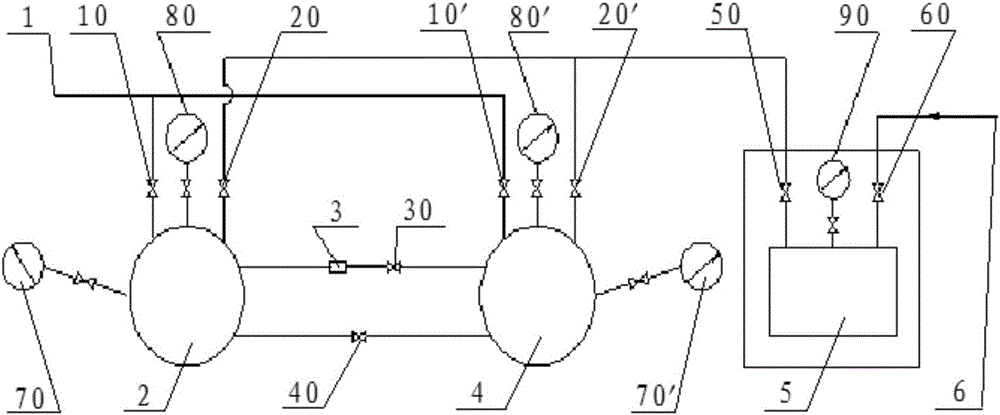

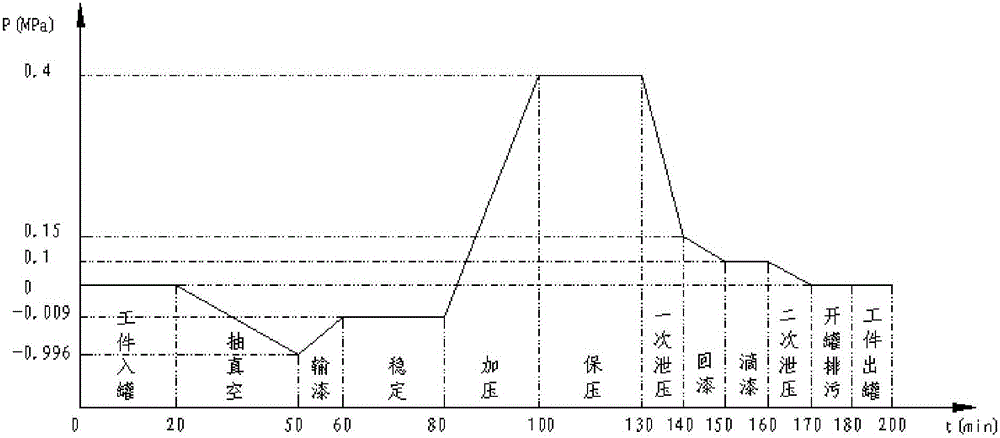

Vacuum pressure paint-soaking process for dry-type transformer coil

ActiveCN105097272AImprove insulation performanceEnsure moisture resistancePretreated surfacesCoatingsLiquid viscosityVacuum pressure

The invention discloses a vacuum pressure paint-soaking process for a dry-type transformer coil. The vacuum pressure paint-soaking process sequentially comprises the following procedures: a paint liquid viscosity adjusting procedure, a drying procedure before paint soaking, a first paint-soaking procedure, a drying procedure, a second paint-soaking procedure and a curing procedure; and the first paint-soaking procedure adopts a pressure paint-soaking mode, and sequentially comprises the following steps: a vacuum supply step, a paint transfer step, a pressurized paint-soaking step and a paint dripping step. According to the vacuum pressure paint-soaking process for the dry-type transformer coil disclosed by the invention, second paint-soaking is adopted; the pressure paint-soaking mode is adopted by the first paint-soaking procedure; and an atmospheric pressure paint-soaking mode or the pressure paint-soaking mode is adopted by the second paint-soaking procedure, so that the condition that the transformer coil is covered with an insulating paint in an omnibearing manner can be ensured; the insulating effect of the transformer is further improved; and the anti-moisture performance, the heat resistance, the conductivity, the magnetic conductivity and the mechanical property are ensured.

Owner:ZHONGBIAN GRP SHANGHAI TRANSFORMER CO LTD

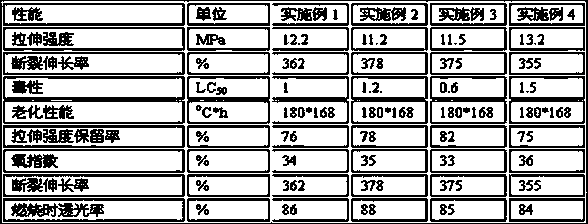

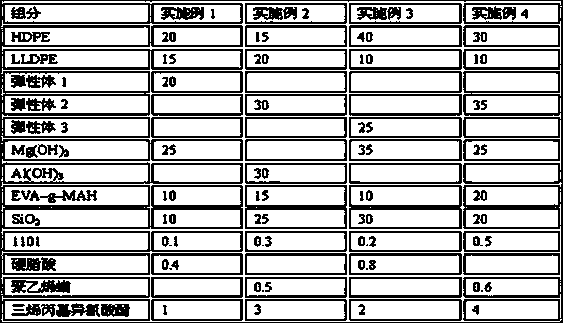

Low-smoke halogen-free flame retardant high-elongation-rate polyolefin cable material for bullet train and preparation method of polyolefin cable material

ActiveCN104231394ASmall mechanical propertiesLow elongation at breakPlastic/resin/waxes insulatorsLow-density polyethyleneElastomer

The invention discloses a low-smoke halogen-free flame retardant high-elongation-rate polyolefin cable material for a bullet train. The polyolefin cable material is prepared from the following raw materials in parts by weight: high-density polyethylene, linear low-density polyethylene, a flame retardant, silicon dioxide, ethylene-vinyl acetate graft maleic anhydride copolymer, an elastomer, an antioxidant and a lubricant. The invention further discloses a preparation method of the polyolefin cable material. The preparation method comprises the following steps: adding prepared polyolefin and an assistant into a high-speed mixer, mixing at the speed of 1,000-1,500r / min for 5-10 minutes, and mixing and granulating by virtue of a double-screw extruder at 150-170 DEG C to obtain the polyolefin cable material. The polyolefin cable material has the advantages of high elongation rate, low smoke, no halogen, flame retardancy, no toxics and the like, and specifically can be used for manufacturing wires and cables for the bullet train with the speed of 350km / h.

Owner:ANHUI HUALING CABLE GRP

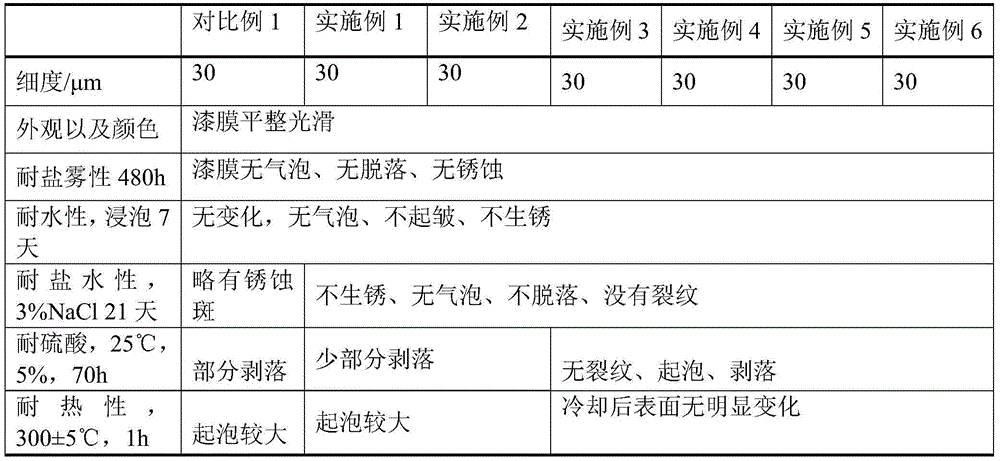

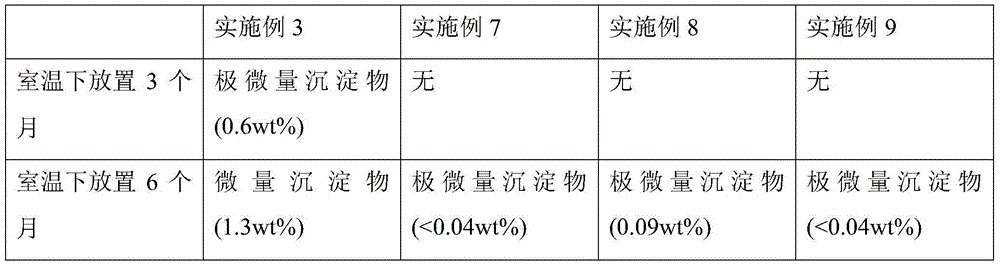

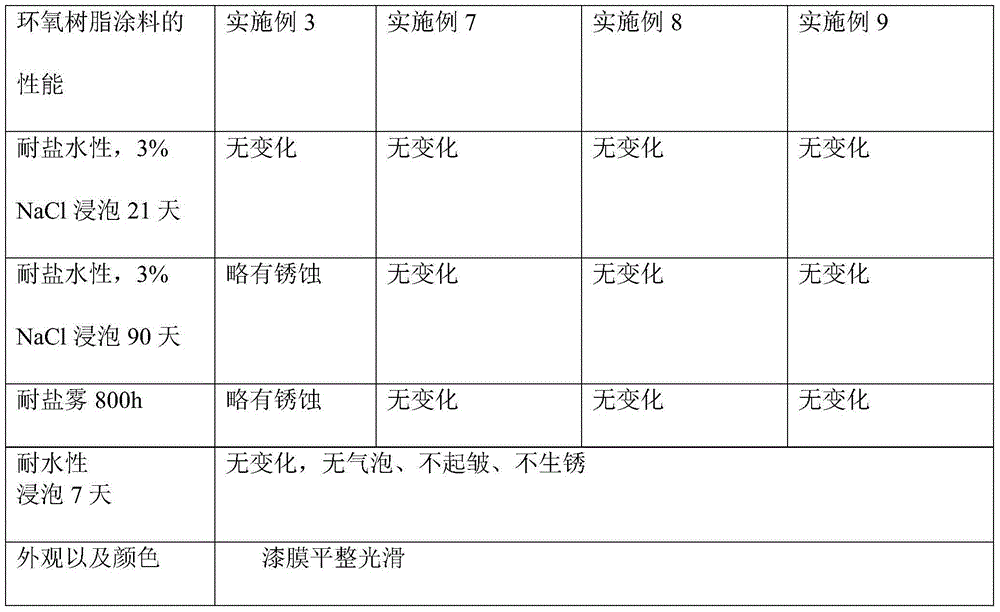

Anticorrosive paint composition comprising modified ceramic waste and preparation method thereof

InactiveCN104946059AImprove high temperature resistanceExtended service lifeAnti-corrosive paintsPolyurea/polyurethane coatingsHeat resistanceGas phase

The invention discloses a ceramic waste anticorrosive paint with favorable brine / salt mist corrosion resistance and favorable heat resistance and a preparation method thereof. The ceramic waste anticorrosive paint is prepared by adding a filler, an assistant and porous carbon powder on the basis of a film forming matter, a ceramic waste antirust pigment and aminosilane-modified vapor-phase-process silica. The ceramic waste anticorrosive paint comprehensively utilizes and converts solid waste resources into the high-value high-performance antirust pigment suitable for the paint, and implements harmless and recycling treatment on the ceramic waste. The anticorrosive paint has the characteristics of excellent properties, high cost performance, environment friendliness, no toxicity and the like.

Owner:HUNAN RUISHI SCI & TECH DEV

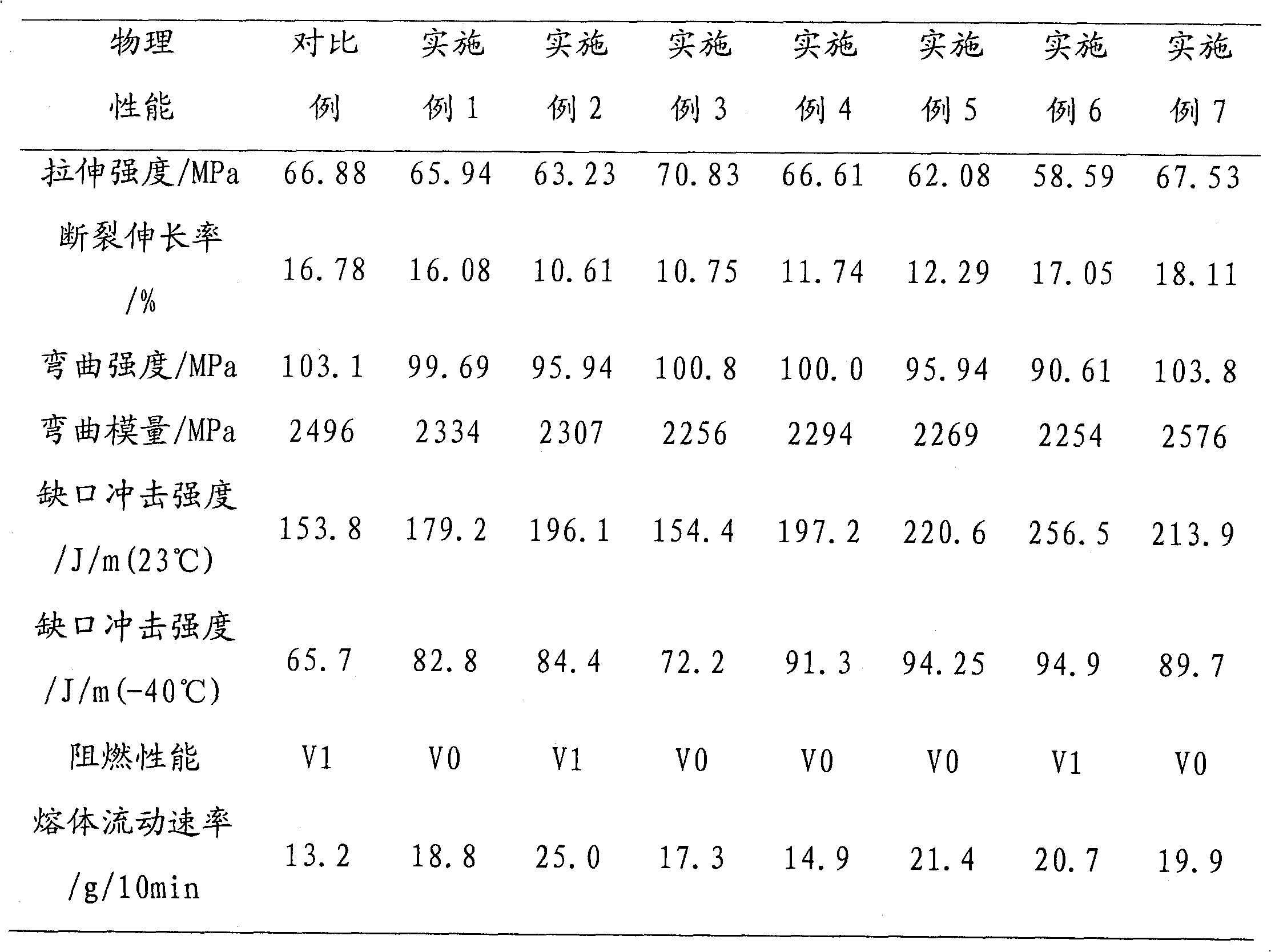

Halogen-free fire-retardant polyphenyl ether composition capable of improving low-temperature toughness and preparation method thereof

The invention discloses a halogen-free fire-retardant polyphenyl ether composition capable of improving low-temperature toughness and a preparation method thereof. The composition comprises the following components in parts by weight: 70 to 90 parts of polyphenyl ether resin, 10 to 30 parts of high impact polystyrene resin, 3 to 8 parts of elastic body, 5 to 10 parts of main fire retardant, 2 to 5 parts of assistant fire retardant, 0.1 to 1 part of antioxidant, and 0.05 to 0.5 part of anti-dripping agent. The polyphenyl ether composition is prepared after the components are subjected to pre-mixing, double-screw extruder plasticization and mixing. The polyphenyl ether composition has the advantages of fire retardance, high mechanical performance, good low-temperature toughness, high heat resistance, high flowability, outstanding weather resistance and the like, and is applicable in the fields of electronic appliance, office equipment, vehicles and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Porous ceramic diaphragm slurry and preparation method thereof, battery diaphragm and battery

PendingCN109742298AGuaranteed heat resistanceGreat suctionCell component detailsHydrofluoric acidOrganic solvent

The invention relates to porous ceramic diaphragm slurry and a preparation method and application thereof. The preparation method comprises the following steps: corroding ceramic powder by using hydrofluoric acid to obtain porous ceramic powder, wherein the ceramic powder is made of at least two ceramic materials; mixing the porous ceramic powder and hydrochloric acid or nitric acid to perform activation so as to obtain activated porous ceramic powder; cladding a surface of the activated porous ceramic powder by using silane coupling agent to obtain sensitive porous ceramic powder; mixing thesensitive porous ceramic powder with adhesive and organic solvent, uniformly stirring to obtain the porous ceramic diaphragm slurry. The ceramic powder prepared from a plurality of ceramic materials is corroded through the hydrofluoric acid, the porous ceramic powder which is the porous structure is manufactured by utilizing the corrosion speed difference on different types of ceramic materials byutilizing the hydrofluoric acid, the porous ceramic powder obtains the porous ceramic diaphragm slurry through activation, sensitization and like treatment; the porous ceramic diaphragm slurry can obviously improve the electric performance of the battery.

Owner:SOUNDON NEW ENERGY TECH CO LTD

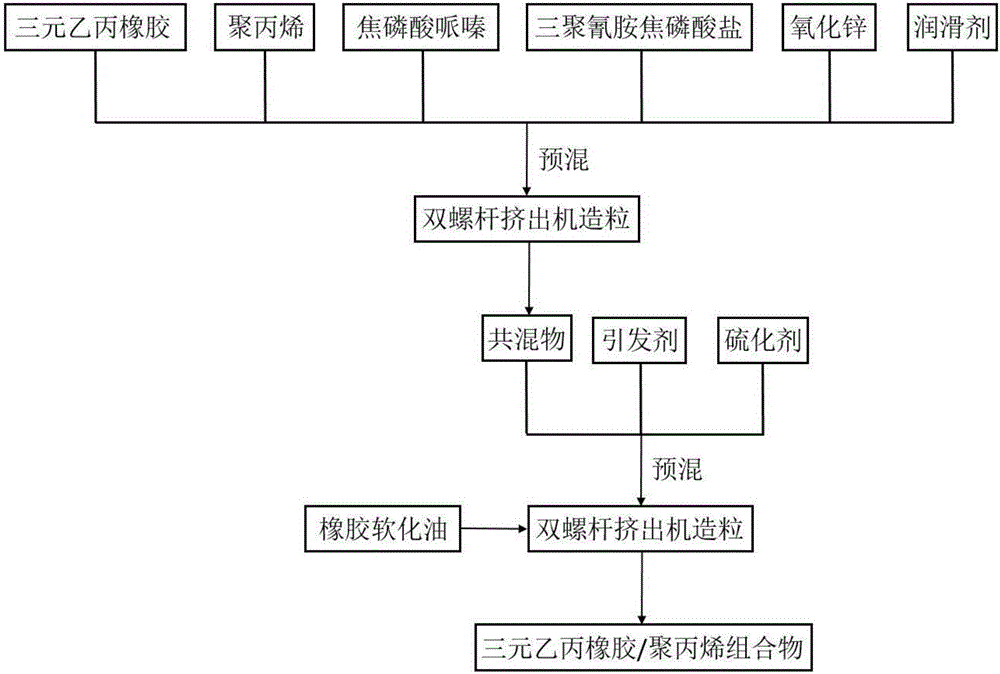

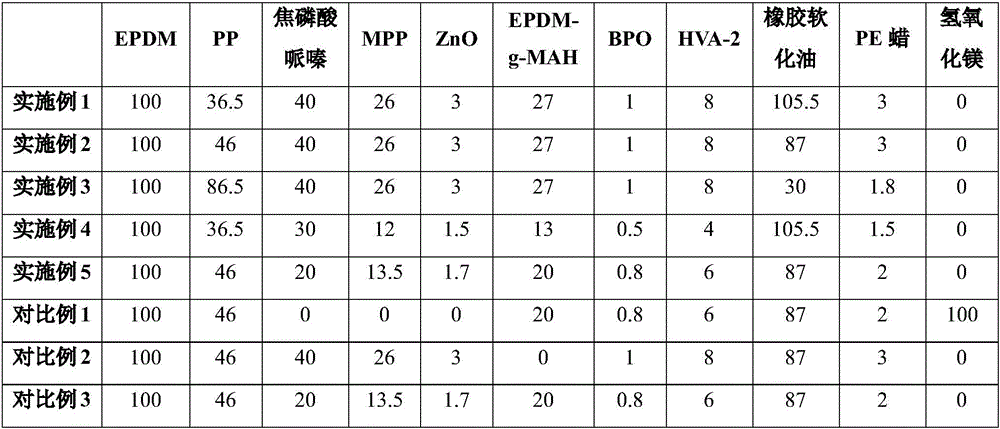

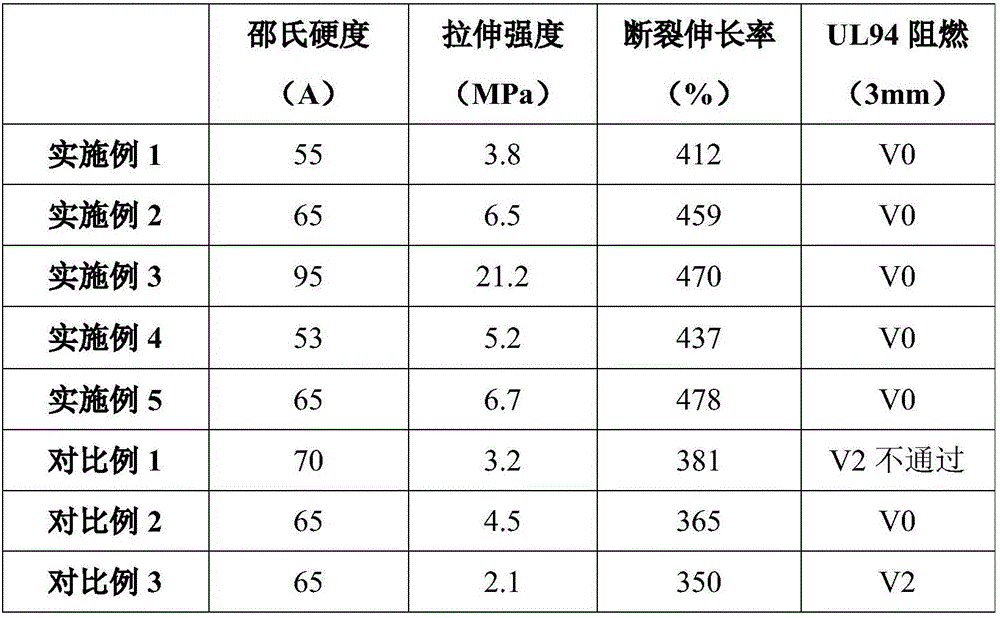

Halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber/polypropylene composition and preparation method thereof

The invention discloses a halogen-free flame-retardation thermoplastic dynamic sulfurated ethylene-propylene-diene monomer rubber / polypropylene composition and a preparation method thereof. The ethylene-propylene-diene monomer rubber / polypropylene composition is prepared by ethylene-propylene-diene monomer rubber, polypropylene, coked piperazine phosphate, melamine pyrophosphate, zinc oxide, ethylene-propylene-diene-grafted maleic anhydride, an initiator, a vulcanizing agent, rubber softening oil and a lubricant. The preparation method comprises the following steps: 1) mixing EPDM, PP, coked piperazine phosphate, MPP, ZnO, EPDM-g-MAH and the lubricant, and dispersing the materials; 2) performing melt extrusion on a premix obtained in the step 1) and performing granulation on the premix; and 3) mixing the premix, the initiator, the vulcanizing agent and the rubber softening oil, extruding a mixture, and granulating the mixture. The ethylene-propylene-diene monomer rubber / polypropylene composition has the advantages of heat resistance, aging resistance, excellent mechanical property and flame resistance performance, enables thermoplastic processing, has a production process, and can be widely used for wire and cable compounds with high flame-resistance requirements.

Owner:广东省石油化工研究院

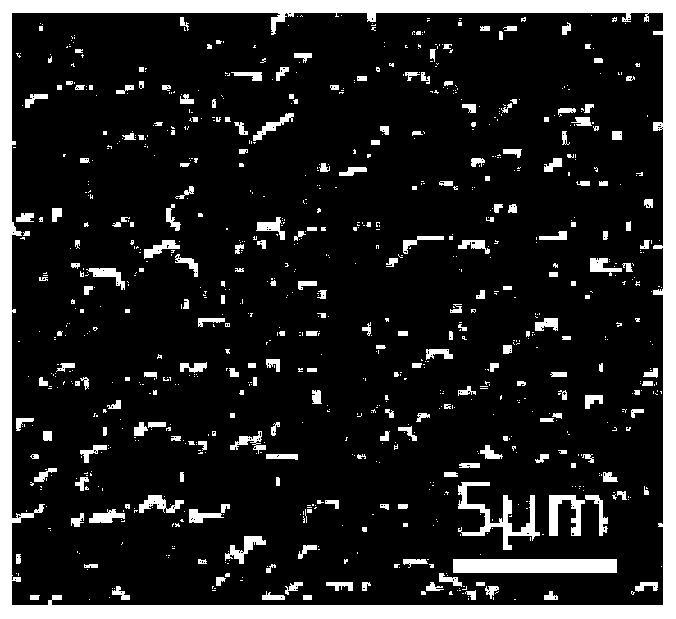

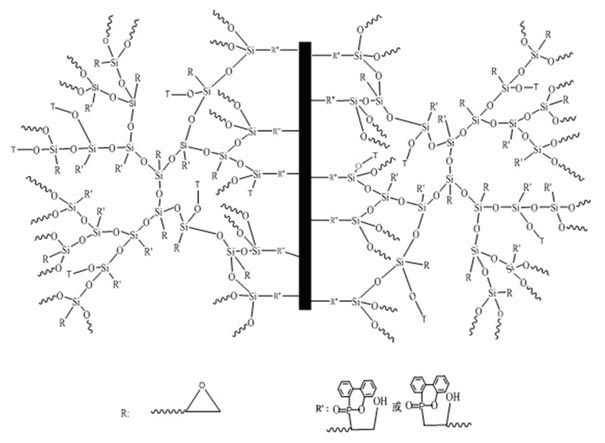

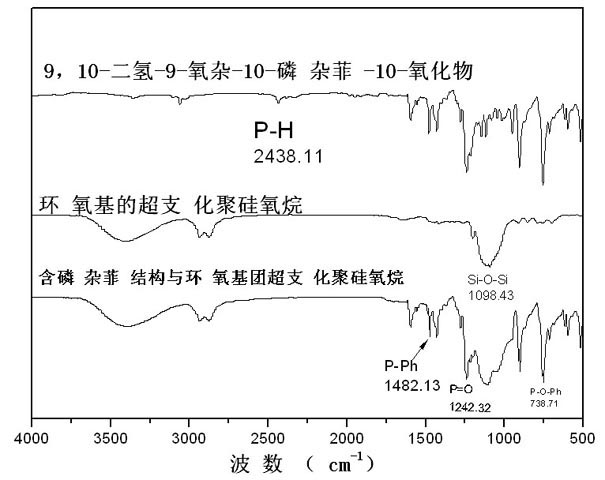

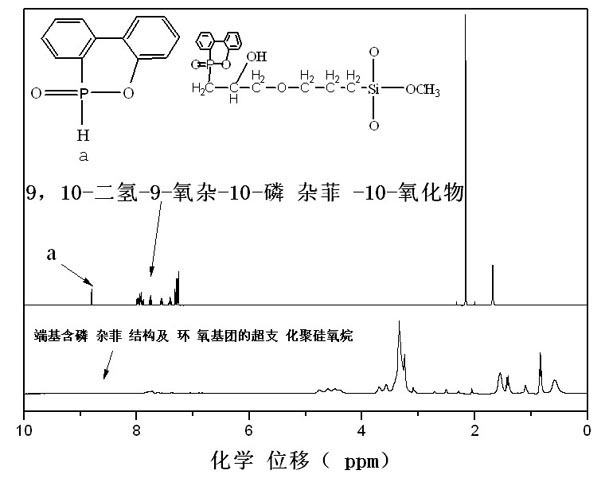

Surface modified carbon nanotube and preparation method thereof

InactiveCN102442660AImprove stabilityTo achieve the "amplification" effectMaterial nanotechnologyCarbon compoundsPolymer sciencePolymer modified

The invention relates to a surface modified carbon nanotube, the surface of which is grafted with hyperbranched polysiloxane containing a phosphaphenanthrene structure and epoxide groups through chemical bonding. A preparation method for the surface modified carbon nanotube comprises the following steps: mixing prepared hyperbranched polysiloxane containing a phosphaphenanthrene structure and epoxide groups with a functionalized carbon nanotube, adding the catalyst triphenylphosphine, adding an obtained mixture into a solvent, carrying out ultrasonic treatment, and removing the solvent after a reaction is finished so as to obtain the surface modified carbon nanotube. The surface modified carbon nanotube provided in the invention contains active reactive groups, can well disperse in thermosetting resin and endows the thermosetting resin with good flame resistance and toughness on the basis of maintaining heat resistance and rigidity of the thermosetting resin; therefore, the surface modified carbon nanotube has immense application potential in the fields of research and development of novel high-molecular materials, modification, high performance development and multi-functionalization of polymers, etc.

Owner:SUZHOU UNIV +1

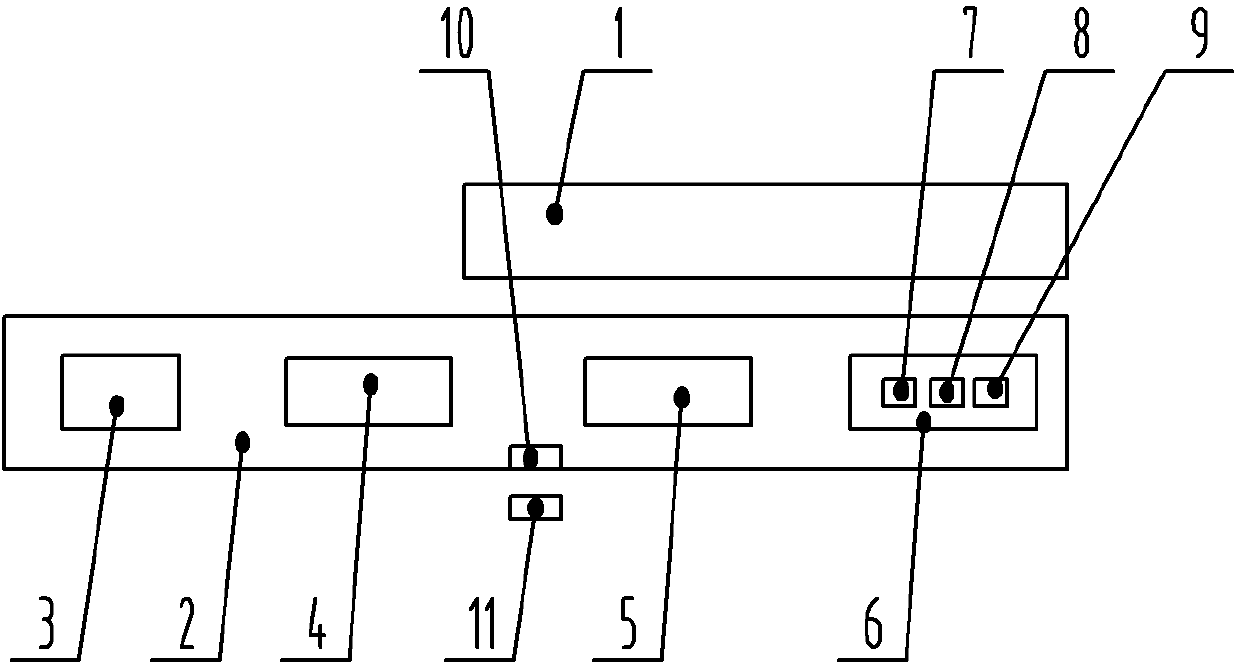

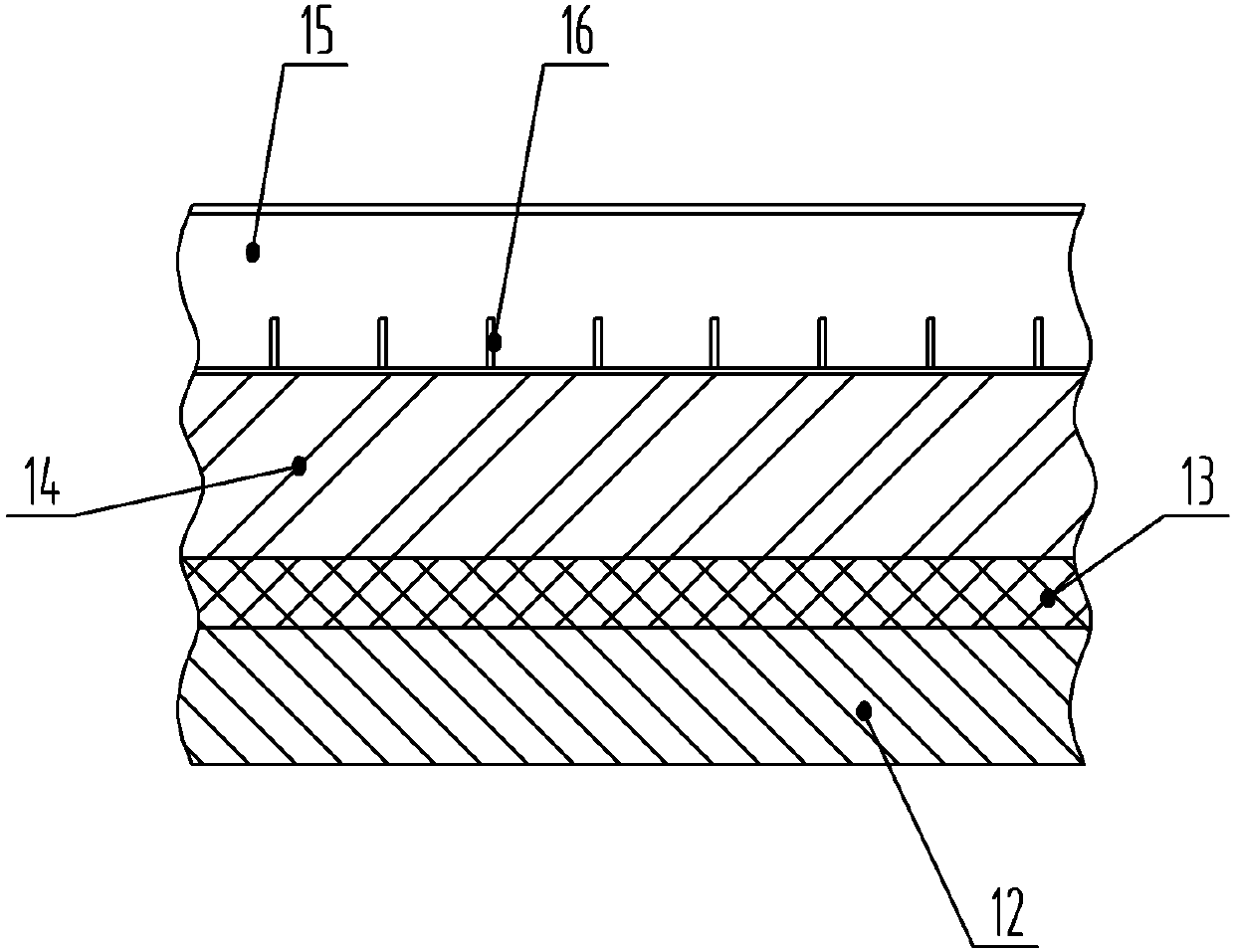

Energy-saving tunnel kiln used for gangue sintered brick production

InactiveCN103423992AReduce lossesFast roastingFurnace typesCeramic materials productionTunnel kilnAutomatic control

The invention belongs to the technical field of gangue sintered brick production, in particular to an energy-saving tunnel kiln used for gangue sintered brick production. The energy-saving tunnel kiln comprises a drying kiln and a calcining kiln, wherein the calcining kiln comprises a kiln body extending along the horizontal direction, and a light kiln car, the kiln body comprises a kiln top, a kiln wall and a working passage, the working passage comprises a preheating section, a calcining section, a holding section and a cooling section in sequence along the extending direction, the cooling section at a kiln tail is provided with a cooling system, an under-kiln balance cooling system and a bootstrap system, a kiln temperature and kiln pressure monitoring and controlling system is also arranged on the kiln body, and the kiln temperature and kiln pressure monitoring and controlling system is provided with a computer automatic control system in a connected way. The energy-saving tunnel kiln has the beneficial effects that above-thermal calcining and fast calcining are realized, the calcining period is shortened, the calcining energy consumption is reduced, and the heat utilization rate is improved, so that the goal of energy saving is achieved.

Owner:郑州鹏泰高新建材制品有限公司

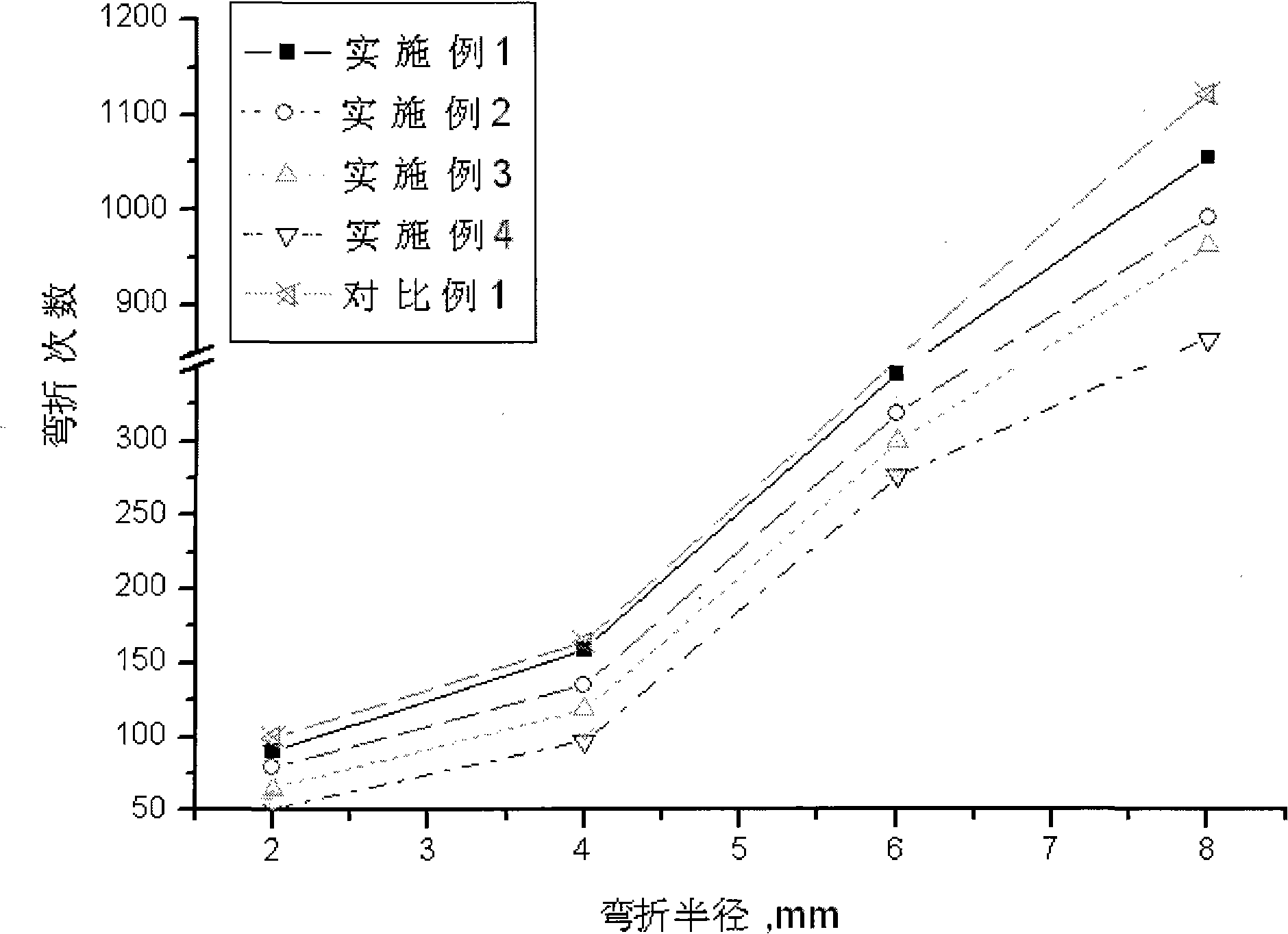

Manufacturing method of copper-clad plate and glue solution for copper-clad plate

ActiveCN101808466AFlexibleReduce manufacturing costPrinted circuit manufactureEpoxy resin adhesivesEpoxyGlass fiber

The invention relates to a manufacturing method of a copper-clad plate and glue solution for the copper-clad plate. The manufacturing method takes glass cloth as base cloth and successively comprises the steps of preparing glue solution, sizing base cloth and hot forming. The glue solution comprises 100 parts of epoxy resin, 10-40 parts of organic fire retardant, 1-30 parts of curing agent, 0.005-0.05 part of curing accelerator and 10-50 parts of dissolvent, wherein the epoxy resin is composed of 25-75 wt% of nitrile rubber modified epoxy resin and 25-75 wt% of bromination epoxy resin, and the content of nitrile rubber in the nitrile rubber epoxy resin is 30-60%. The invention provides a 'semi-soft plate' with medium elasticity bending modulus. The semi-soft plate has certain flexibility, has the supporting performance provided by a rigid copper-clad plate, is especially suitable for electronic connection devices without very high flexibility requirements and has the advantages of low manufacturing cost and convenient installation and connection.

Owner:VENTEC ELECTRONICS SUZHOU

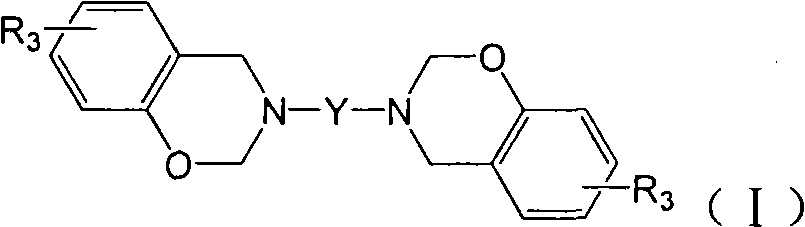

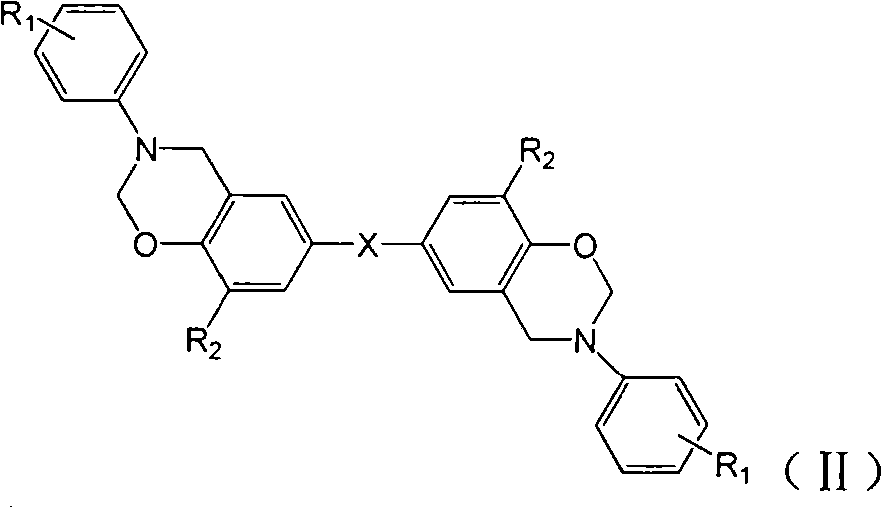

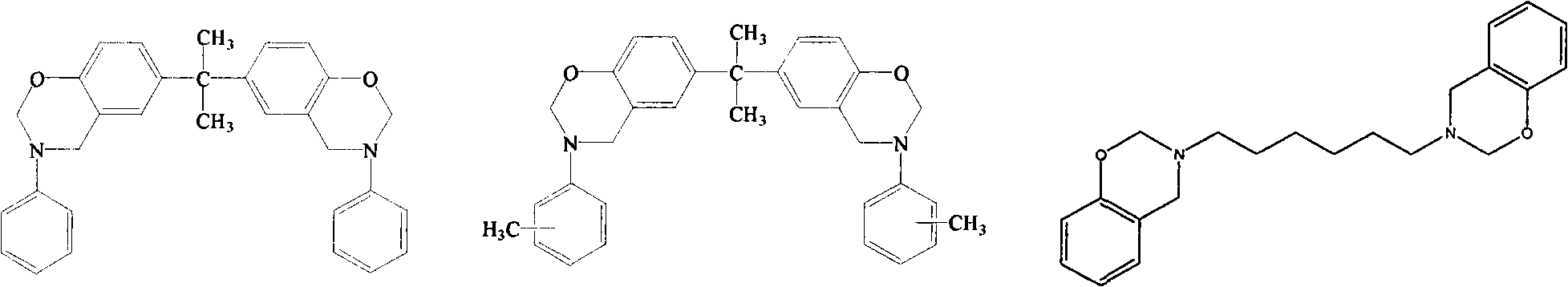

Thermoset polybenzoxazine-polyimide resin composite/mesoporous molecular sieve hybrid material and preparation method thereof

The invention belongs to the field of organic / inorganic hybrid materials, and discloses a thermoset polybenzoxazine-polyimide resin composite / mesoporous molecular sieve hybrid material, which consists of a thermoset polybenzoxazine-polyimide resin composite and a mesoporous molecular sieve, wherein the mesoporous molecular sieve mass content of the hybrid material is 0.5 to 15 percent. Through a preparation method of the invention, the polybenzoxazine-polyimide resin composite / mesoporous molecular sieve hybrid material with a good interface structure and high comprehensive performance can be obtained. Compared with resin composites, the hybrid material not only maintains the heat resistance of substrate resin materials, but also has higher room-temperature storage modulus and lower dielectric constant so as to broaden the application prospect of the polybenzoxazine-polyimide resin composite in the fields of electrical engineering, electronics, information, military, aviation, aerospace and the like.

Owner:TORAY FIBER RES INST(CHINA) CO LTD

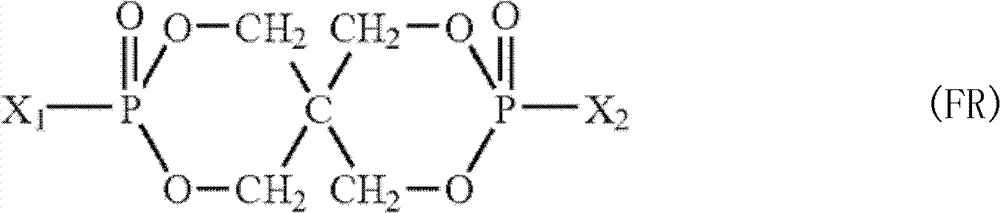

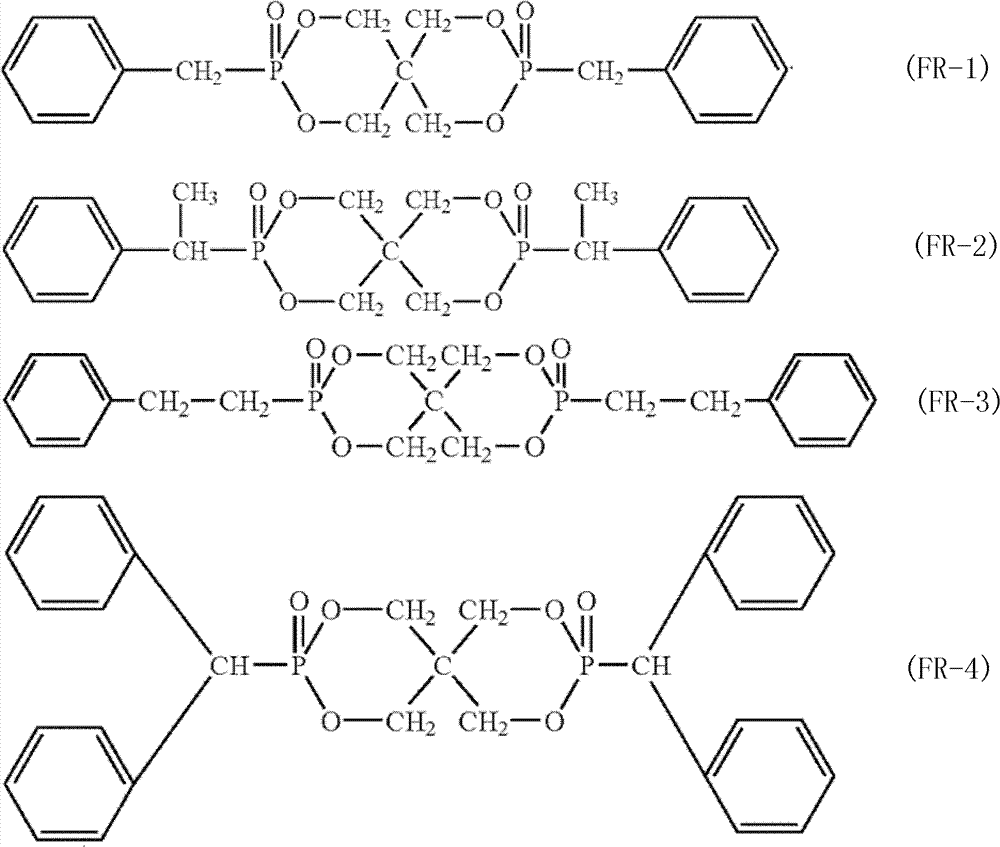

Polylactic resin composition

InactiveCN102775749AImprove flame retardant performanceGuaranteed heat resistanceState of artHalogen

The invention provides a polylactic resin composition which mainly comprises the following components expressed in mass parts: 100 parts of a polylactic resin, 1 to 40 parts of a novel phosphorus flame retardant, 0 to 0.8 part of a trickling-down resisting agent, 0 to 40 parts of thermoplastic elastomers, 0.1 to 30 parts of an inorganic filler and 0 to 20 parts of a high-molecular compatibilizer. Compared with the prior art, the polylactic resin composition provided by the invention has the following advantages: (1) flame resistance of a material is improved, the grade of flame resistance of the material is above Grade UL94V-2, and heat resistance of the material is maintained as well; (2) the novel phosphorus flame retardant is employed in the invention to improve flame resistance the material, and no halogen flame retardant is used, which accords with the environmental protection concept of sustained development; and (3) the polylactic resin composition has the characteristic of capacity of rapid crystallization, so the composition can be easily used in manufacturing procedures of common plastic products, processing performance and production efficiency of the products are improved, and production cost is reduced.

Owner:MITAC PRECISION TECH(KUNSHAN) CORP

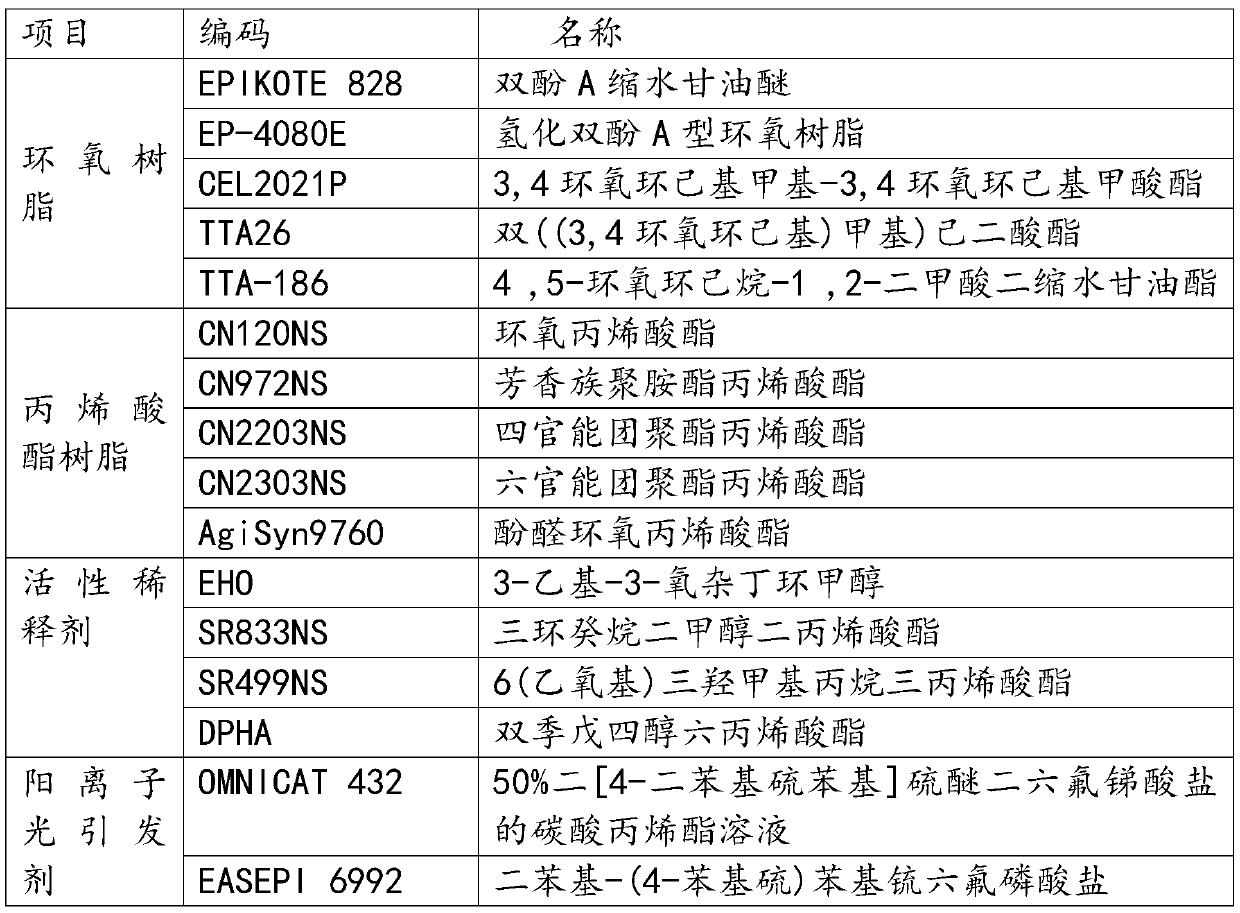

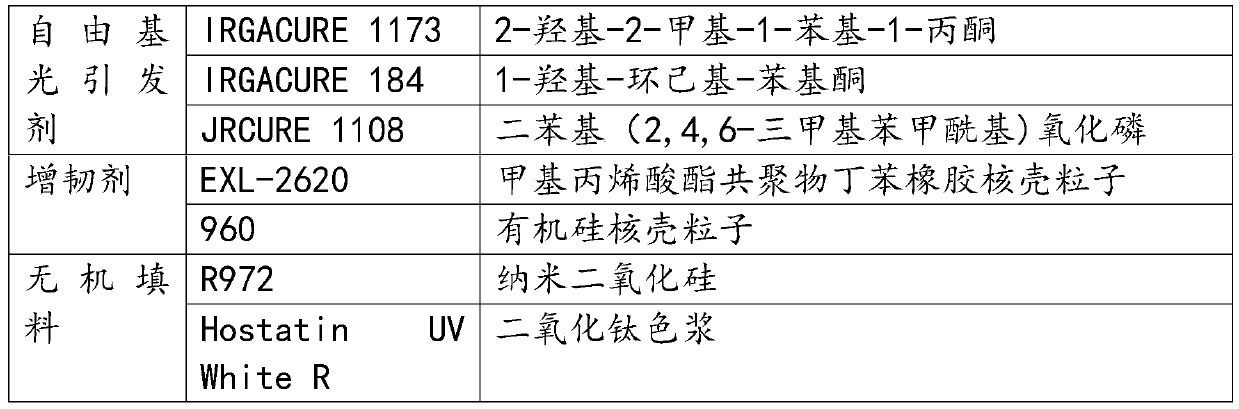

High-temperature-resistant light-cured resin and preparation method thereof

InactiveCN110724236APlay a synergistic roleLight curing reaction speed is fastAdditive manufacturing apparatusEpoxyPolymer science

The invention provides high-temperature-resistant light-cured resin and a preparation method thereof. The light-cured resin comprises the following components in percentage by mass: 40%-70% of epoxy resin, 5%-20% of acrylic resin, 10%-20% of an active diluent, 3%-6% of a cationic photoinitiator, 1%-3% of a free-radical photoinitiator, 5%-20% of a flexibilizer and 0.1%-3% of an inorganic filler. The high-temperature-resistant light-cured resin is high in curing reaction rate and has both toughness and strength.

Owner:威斯坦(厦门)实业有限公司

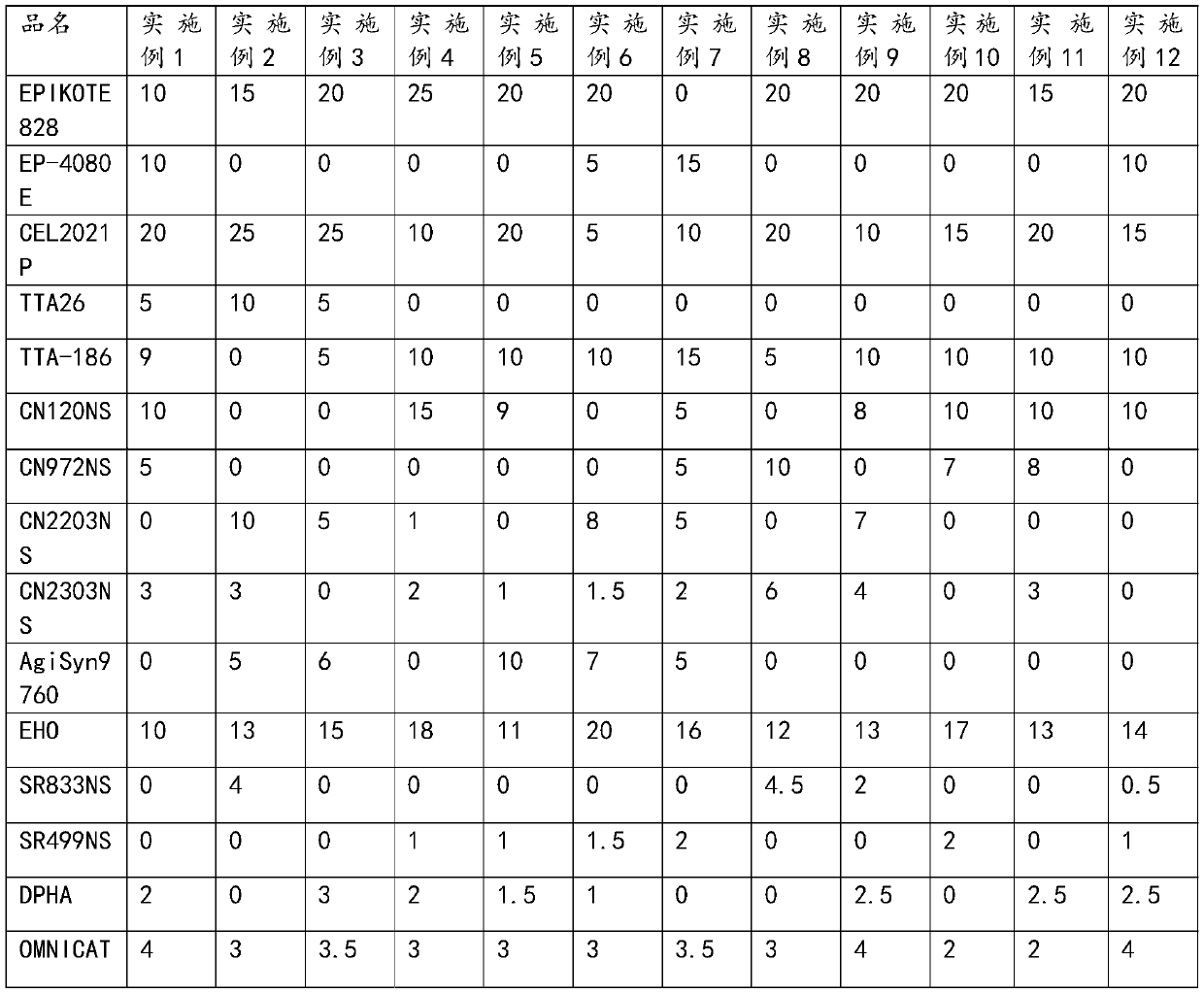

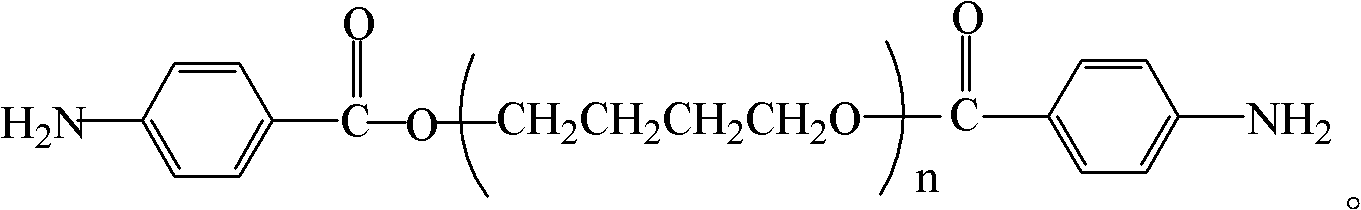

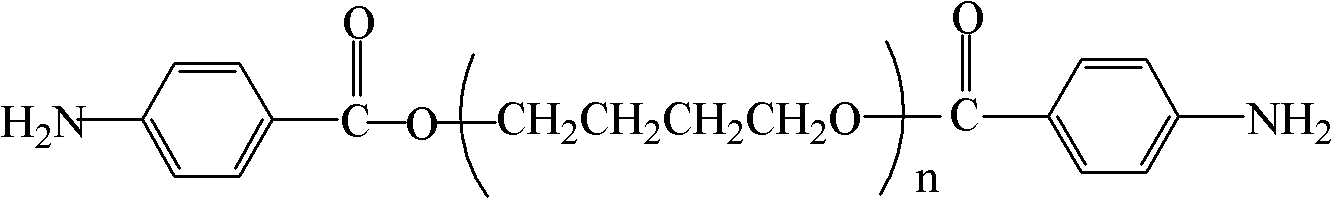

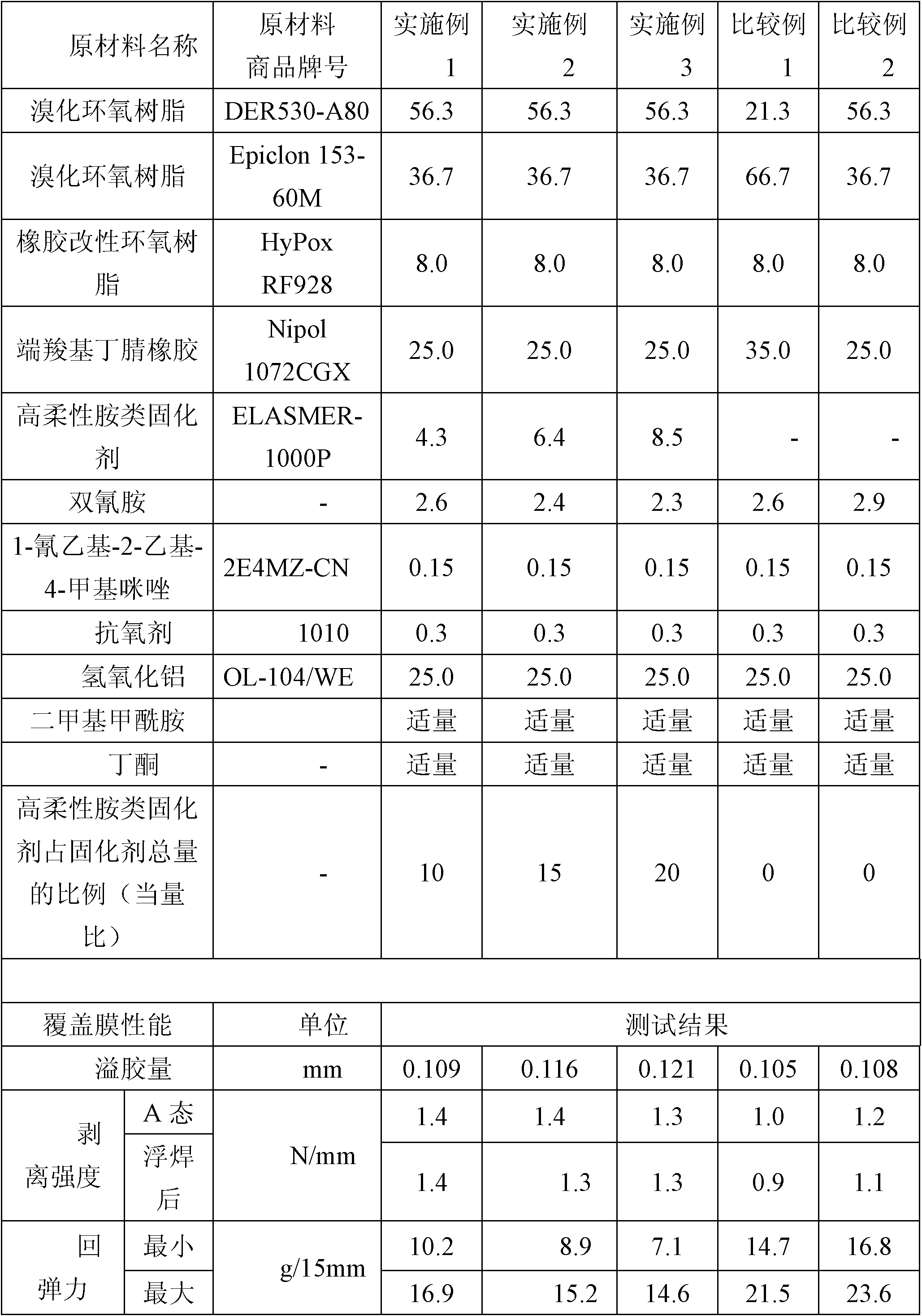

Epoxy resin composite and covering film prepared from same

ActiveCN102093667AGuaranteed storage periodGuaranteed heat resistancePrinted circuit detailsFilm/foil adhesivesEpoxyOrganic solvent

The invention provides an epoxy resin composite and a covering film prepared from the same. The epoxy resin composite comprises brominated epoxy resin, rubber modified epoxy resin, chemigum, a high-flexibility amine curing agent, a latency amine curing agent, a curing promoter, an antioxidant, an inorganic padding and an organic solvent. The covering film prepared from the epoxy resin composite comprises a polymide film, an epoxy resin composite layer coated on the polymide film and release paper coated on the epoxy resin composite layer. In the epoxy resin composite, the high-flexibility amine curing agent and the latency amine curing agent are used as a compound curing system; and the flexibility of the composite is effectively improved while the storage life and the heat resistance are ensured, thus the dosage of the chemigum and the content of the bromine in the composite can be reduced, thus the peel strength, heat resistance and the like of the covering film are improved. The covering film prepared by the epoxy resin composite has the advantages of excellent heat resistance, flexibility, peel strength, longer storage life and suitability for flexibility printed circuits.

Owner:东莞海丽化学材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com