Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

A flame retardant composition, polyphenylene ether resin technology, applied in the directions of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems of high melting point, reduced heat resistance, and strong plasticity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

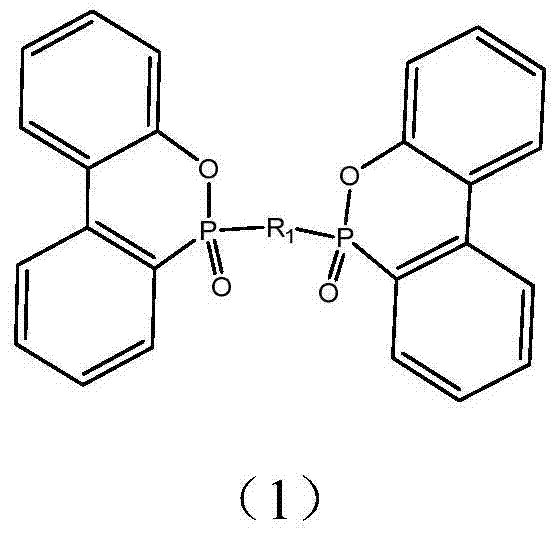

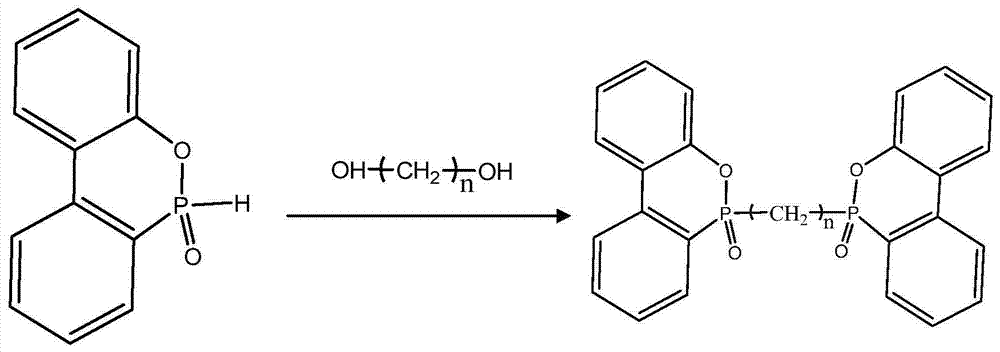

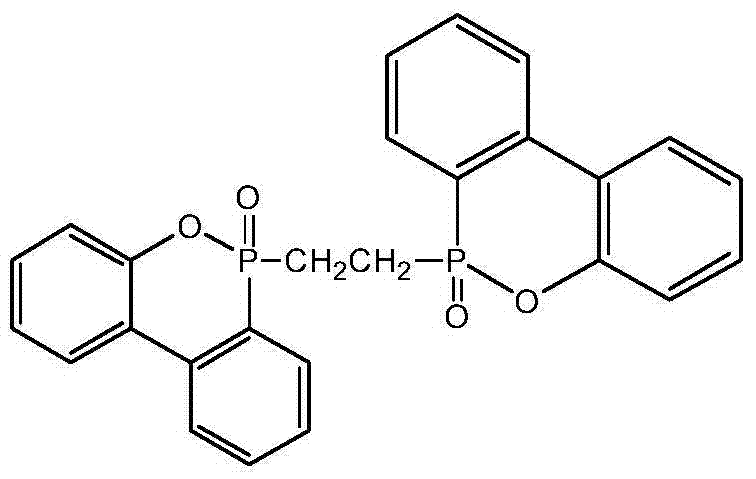

[0096] Synthesis Example 1: Preparation of DOPO Derivatives

[0097] Add potassium tert-butoxide 230g in the four-neck reactor equipped with addition funnel, thermocouple, mechanical stirrer and nitrogen flow, solvent anhydrous DMSO1.5L. The mixture was stirred at room temperature until it became a homogeneous solution. The solution was cooled to 10°C, and DOPO 42.3g was added in 10 small portions to keep the reaction temperature below 30°C. Slowly add 92 g of dichloroethane in the addition funnel to the above solution within 1 hour. Heated to 50°C for 1 hour. Cool to 10°C to react and add 3 L of water. The slurry was filtered and the wet cake was washed with water, acetone ethyl acetate to give 532 g of crude wet material which was refluxed in MeCN / ethanol / water 5320 ml and cooled slowly to 5°C. Filter the white solid through a funnel, and dry it in a vacuum oven at 80°C for 8 to 10 hours to obtain 260 g of a dry white powder, which is DOPO derivative 1 of formula (1), wh...

Synthetic example 2

[0099] The synthetic method is with reference to Synthetic Example 1, and dichloromethane is replaced with dichloro-p-xylene, obtains the DOPO derivative 2 of formula (1), wherein R 1 For phenyl.

[0100] Mixing example 1: Preparation of phosphorus-containing flame retardant composition (P15.4%)

[0101] 35 parts by weight of the hypophosphite compound, 100 parts by weight of the DOPO derivative of Synthesis Example 1 and 18 parts by weight of the polyphosphazene compound were mixed to obtain a phosphorus-containing composition;

[0102] Described hypophosphite compound is:

[0103]

[0104] The polyphosphazene compound has the following structure:

[0105] Wherein R is a methyl group, and wherein n is an integer of 3-100.

[0106] Mixing example 2: Preparation of phosphorus-containing composition (P16%)

[0107] The hypophosphite compound of 50 parts by weight, the DOPO derivative of Synthetic Example 1 of 100 parts by weight and the polyphosphazene compound of 25 pa...

Embodiment 1

[0128] Mix 100g of methyl methacrylate-modified polyphenylene ether SA9000 with toluene as a solvent, dissolve completely to obtain an end-group functionalized polyphenylene ether resin solution, and then add 45g of styrene-butadiene copolymer R100 as a crosslinker agent, add 2g dicumyl peroxide as initiator, 45g mixing example 1 phosphorus composition as flame retardant, 0.8g epoxy silane coupling agent and 80g silicon dioxide (SC-2050SQ) as filler, The above mixture was mixed in toluene, stirred and dissolved to obtain a uniform resin composition, ie glue.

[0129] Impregnate the above-prepared glue into the E-glass fiber cloth, heat and dry at 155°C for 3-10 minutes, and completely evaporate the solvent to obtain a prepreg. Copper foils with a thickness of 35 μm were attached to both sides of the 8-ply prepreg prepared above, and hot-pressed at a temperature of 200 ° C and a pressure of 3.0 MPa for 90 minutes to obtain a double-sided copper-clad laminate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com