Patents

Literature

453 results about "UL 94" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

UL 94, the Standard for Safety of Flammability of Plastic Materials for Parts in Devices and Appliances testing, is a plastics flammability standard released by Underwriters Laboratories of the United States. The standard determines the material’s tendency to either extinguish or spread the flame once the specimen has been ignited. UL-94 is now harmonized with IEC 60707, 60695-11-10 and 60695-11-20 and ISO 9772 and 9773.

Thermoplastic resin composition, molding material, and molded article thereof

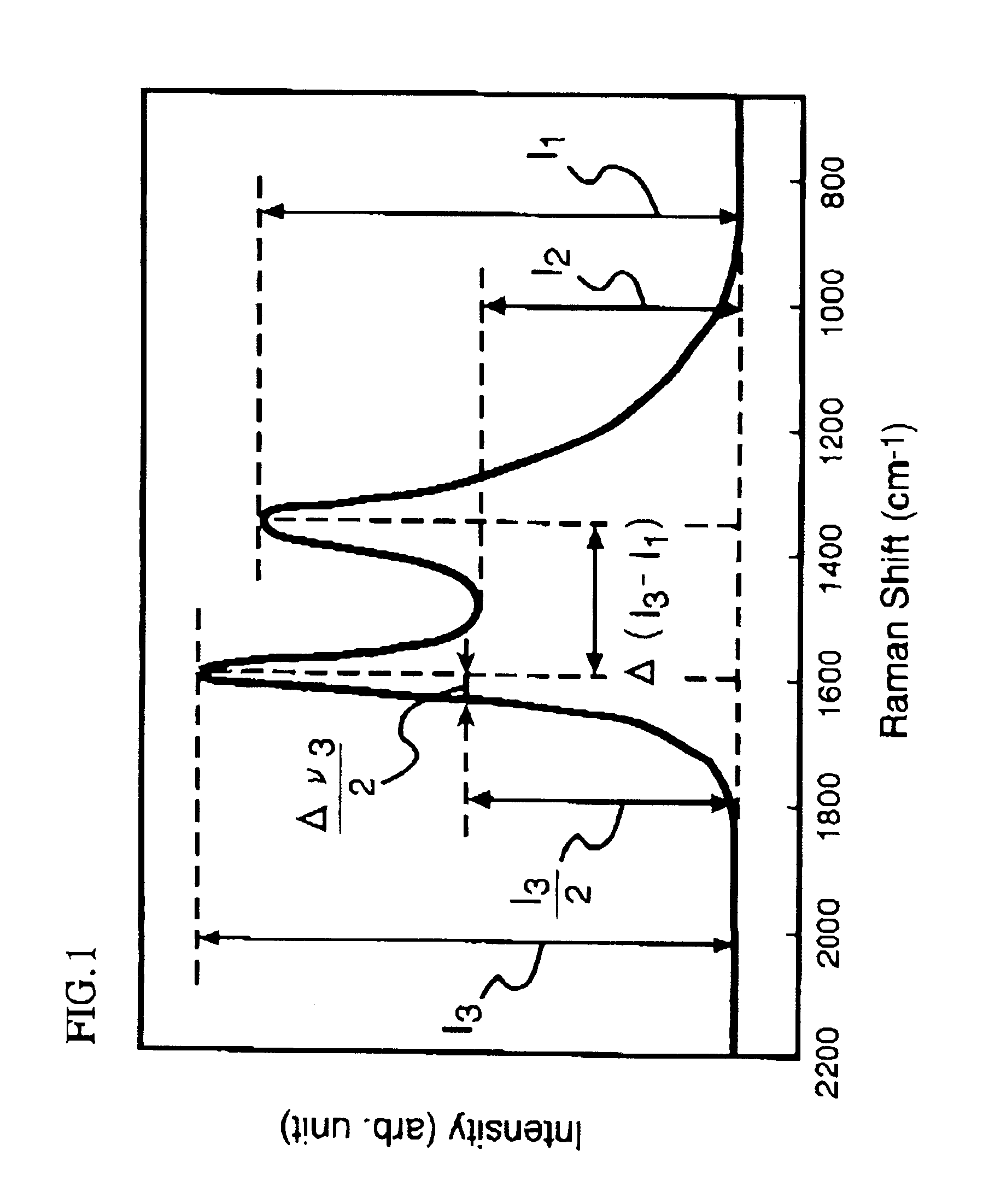

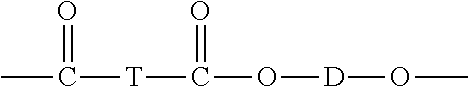

A thermoplastic resin composition capable of providing a thin walled molded article whose flame retardancy with a thickness of 1.6 mm ({fraction (1 / 16)} inch) in accordance with an UL 94 standard is V-0 or better, and which comprises the following components [A], [B] and [C], wherein the component [B] satisfies the following conditions (B1) and / or (B2):[A]: an electrically conductive fiber;[B]: a carbon powder;[C]: a thermoplastic resin;(B1): Raman scattering intensity ratio I2 / I1 is 0.55-0.8;(B2): Raman scattering intensity ratio I2 / I3 is 0.54-0.8; whereI1: local maximum value of Raman scattering intensity appearing near a Raman shift of 1360 cm-1;I2: local minimum value of the Raman scattering intensity appearing near a Raman shift of 1480 cm-1;I3: local maximum value of the Raman scattering intensity appearing neat a Raman shift of 1600 cm-1.

Owner:TORAY IND INC

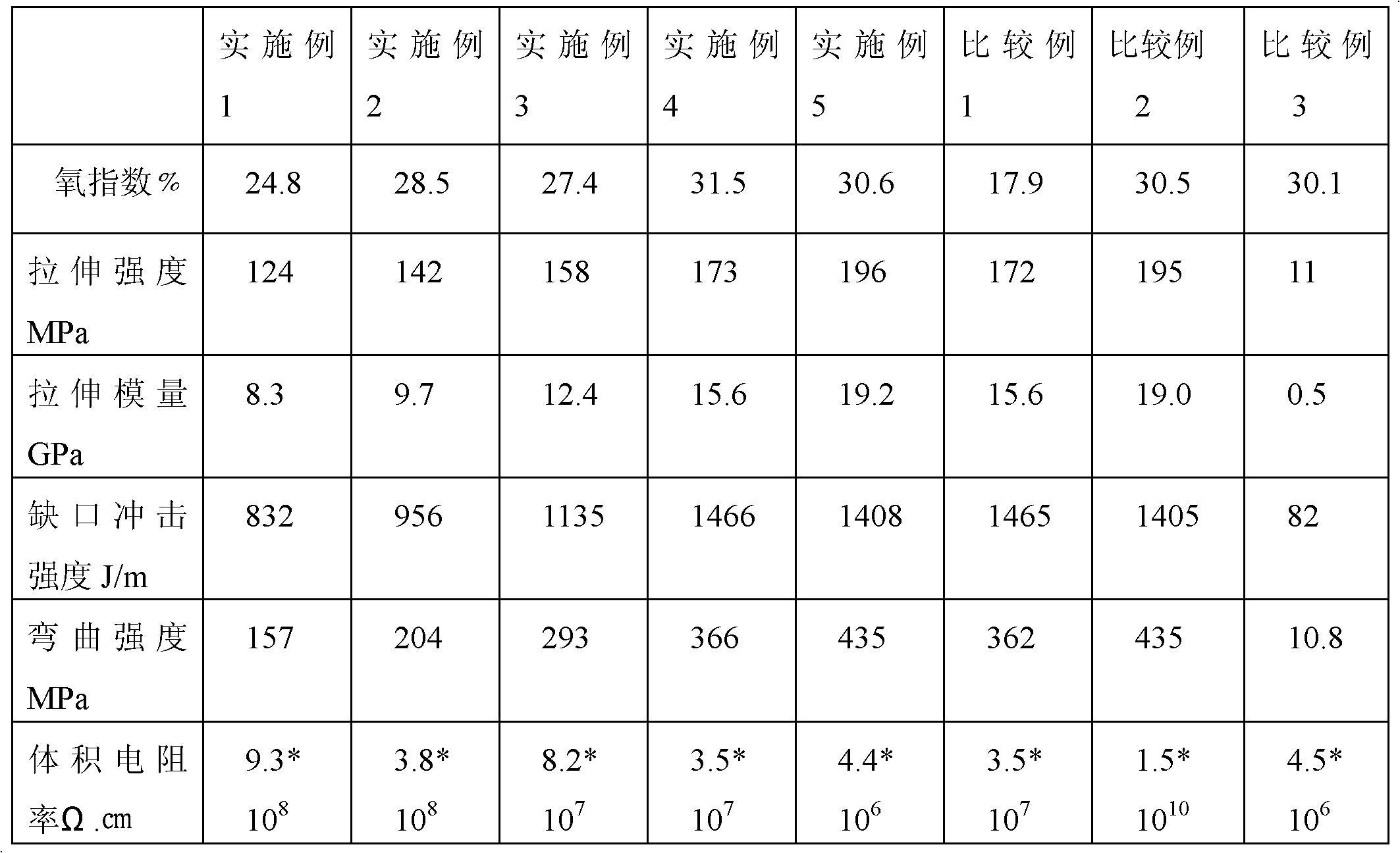

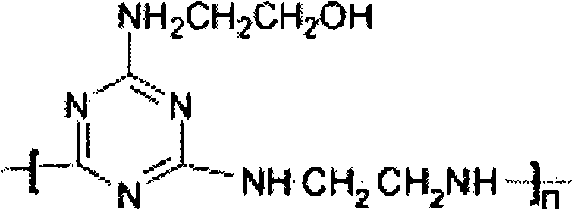

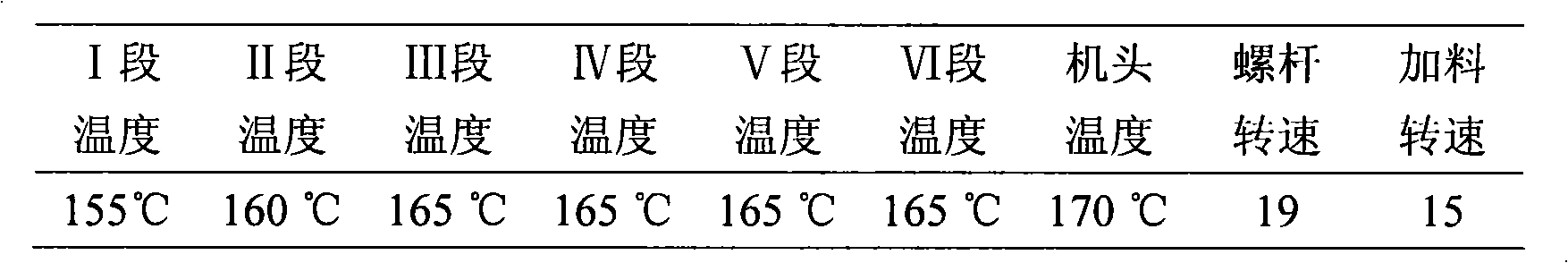

Flame-retardant antistatic high-strength thermoplastic composite material and its preparation method

The invention belongs to polymer modification technical field and processing technology field, and discloses a flame-retardant antistatic high-strength thermoplastic composite material and its preparation method. The material comprises (by weight share) 80-100 thermoplastic resin, 50-120 reinforcing fiber, 8-18 flame retardant, 0-5 flame retardant synergistic agent, 0.5-1.8 antistatic agent, 15-30 compatibilizer, 4-10 composite antioxidants, and 0-80 other additives. The invention also discloses the thermoplastic composite material preparation method. The inventive lame-retardant antistatic high-strength thermoplastic composite material has high tension and bending strength, high impact resistance property at low and high temperature, obvious antistatic property, high flame-retardant and fire proof performance. It can reach UL-94 V-O level standard.

Owner:杭州电力设备制造有限公司建德冠源成套电气制造分公司

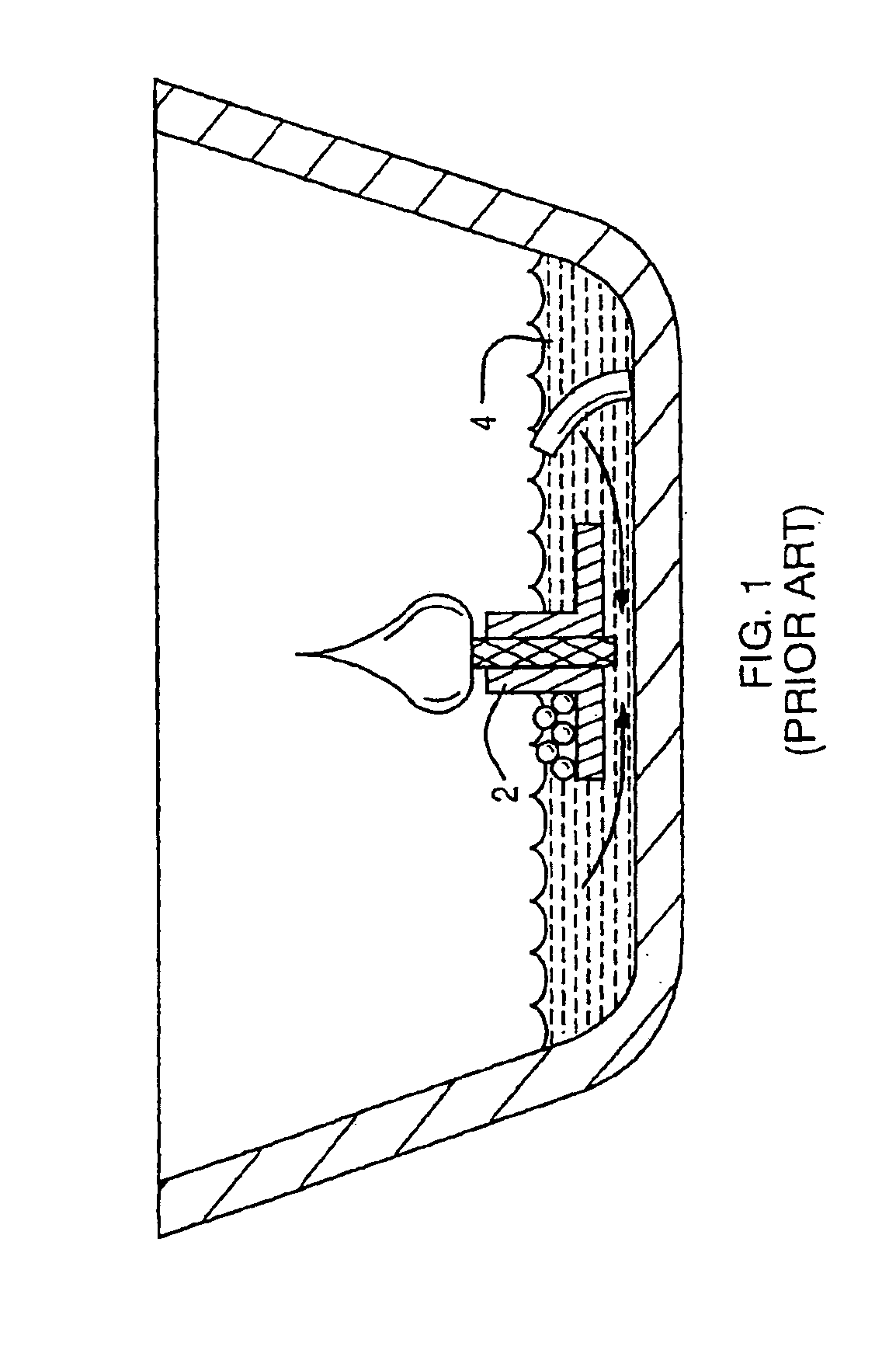

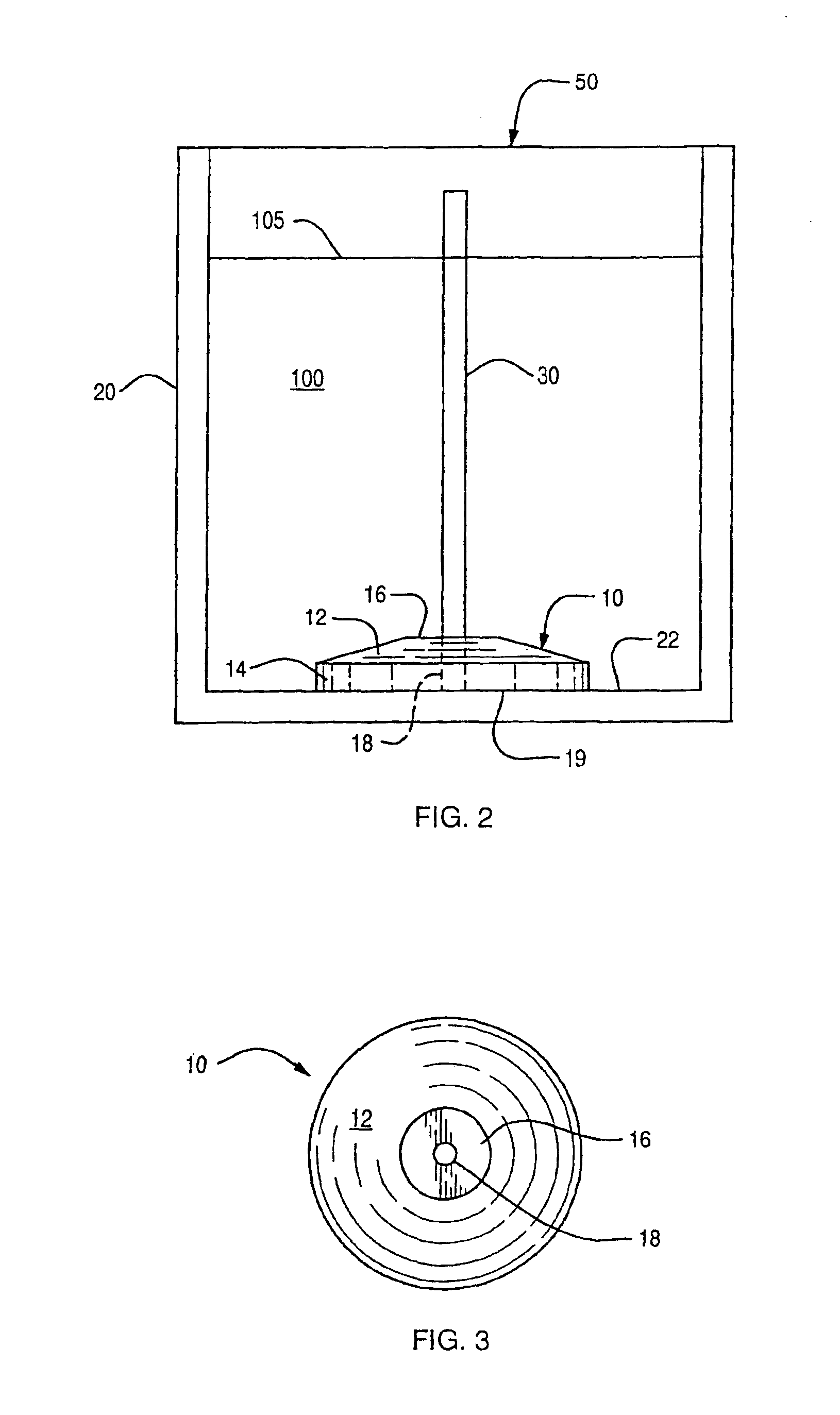

Flame-resistant wick holder for candle

InactiveUS6923639B2Eliminate flashoverEasily incorporated into candleCandle holdersCapillary burnersCandleCeramic

Owner:BEAUTYAVENUES

Ultraviolet crosslinked expansion type flame-retardant polyolefin cable insulation sheath material and preparation thereof

ActiveCN101481475AAdd lessHigh flame retardant efficiencyPlastic/resin/waxes insulatorsInsulated cablesPolyolefinProcedure Agents

The invention discloses an insulating and sheathing material of ultraviolet light crosslinking expanding type phosphorus nitrogen flaming resistance polyolefine cables and a preparation method thereof. The invention is characterized in that polyethylene / PEMA and / or ethylene vinyl acetate or maleic anhydride grafted ethylene vinyl acetate or acid amide grafted ethylene vinyl acetate copolymer are taken as base, added with expanding type phosphorus nitrogen halogen-free flame retardants, light trigger, polyfunctional group cross linker and chemical inhibitor and matched with flaming retardant synergistic agent, antismoke agent and processing aid, and then squeezed out and pelleted into photo-crosslinking flame retardant cable materials; and then the flame retardant cable materials are melted and extruded on a cable conductor wire core and clad into an insulating layer and a sheathing layer; hereupon the ultraviolet light irradiation crosslinking is carried on the insulating layer or the sheathing layer. Via detecting, the oxygen index of the insulating layer or the sheathing layer is larger than 30%, the vertical flaming experiment passes through UL-94 V0 level, the tensile strength is larger than 12Mpa, the elongation at break is larger than 350%, and the electric volume resistivity is larger than 8*10 omega.cm.

Owner:HONGLONGJIANG ORIENT SCI & TECH +1

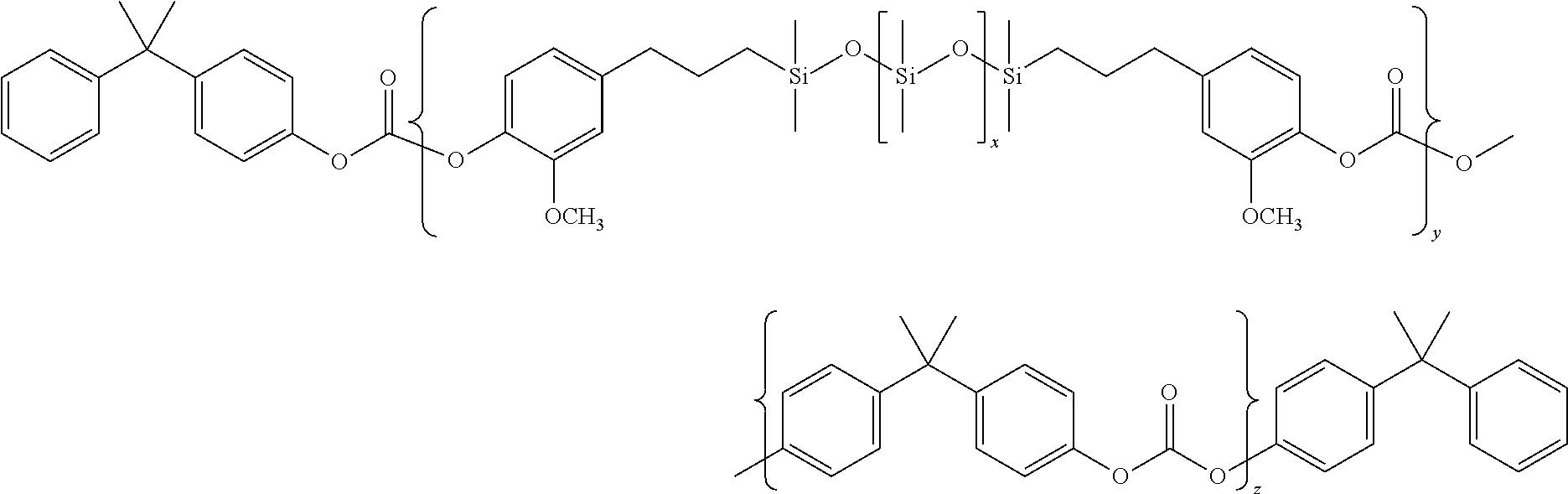

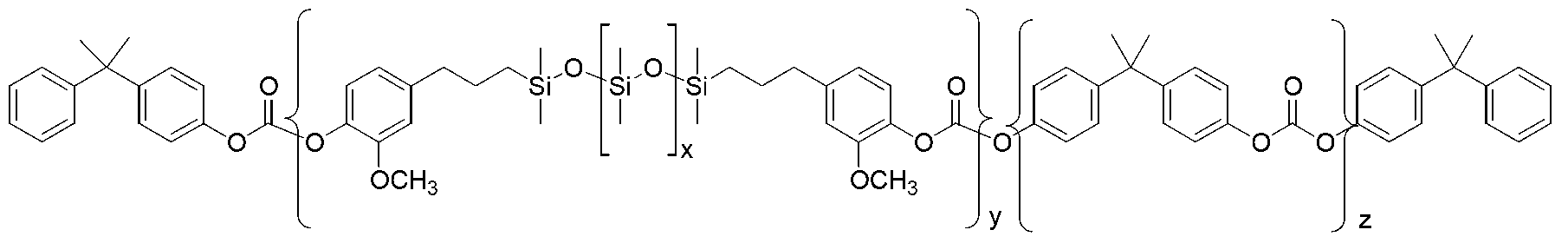

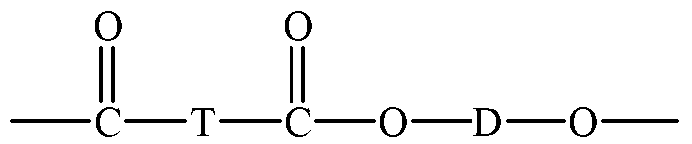

Flame-resistant polyester-polycarbonate compositions, methods of manufacture, and articles thereof

A composition comprising a polyester, polycarbonate, organopolysiloxane-polycarbonate block copolymer, organophosphorus flame retardant, fluorinated polyolefin, and one or more additives. In one embodiment, the composition has an improved balance of properties, including one or more of a melt volume rate, Vicat softening temperature, notched Izod impact strength and a UL 94 flammability rating.

Owner:SABIC GLOBAL TECH BV

Efficient halogen-free flame retardant rubber system as well as preparation method thereof

ActiveCN104558716AReduce the temperatureImprove flame retardant performancePolymer scienceUltimate tensile strength

The invention provides an efficient halogen-free flame retardant rubber system which comprises the following components in parts by weight: 100 parts of rubber, 30-50 parts of a fortifier, 0-10 parts of a structural controller, 0.5-2 parts of a vulcanizing agent, 0.1-2 parts of an accelerant, 1-20 parts of a flame retardant and 1-20 parts of a synergist. The tensile strength of the rubber system is 5.4-33.8MPa, LOI is 28.9-45.5% and UL-94 is V-1 to V-0. The invention further provides a preparation method of the system. According to the rubber system provided by the invention, as the flame retardant and the flame retardant synergist which are matched with the rubber system, since the addition is a little, mechanical property is hardly affected and a good flame retardant effect can be further realized.

Owner:SICHUAN UNIV

Halogen-free flame-proof phenolic plastic

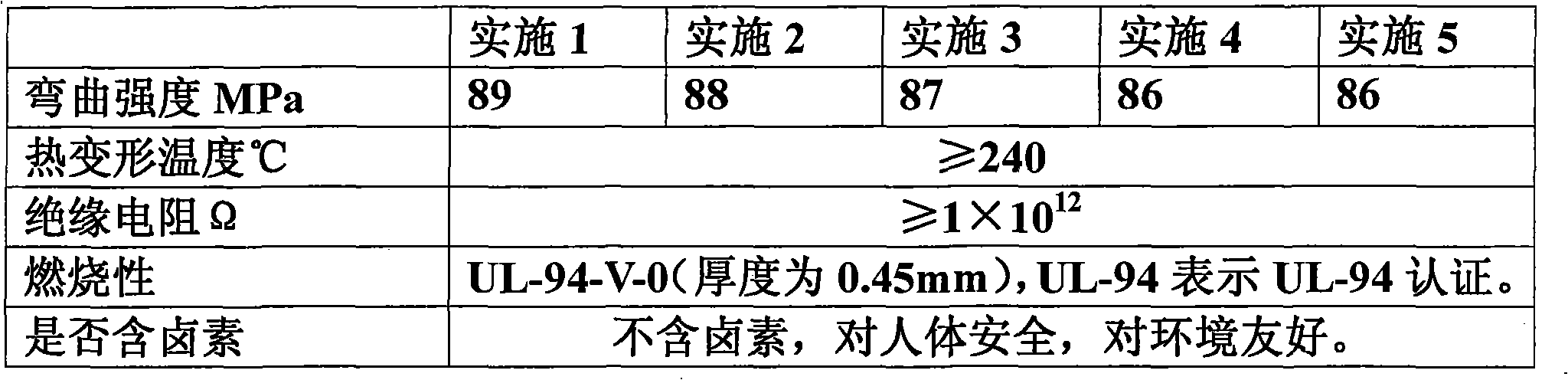

The invention relates to non-halogen flame-resistant phenolic molding compound. According to the weight parts, the raw material of the non-halogen flame-resistant phenolic molding compound comprises 40 parts to 45 parts of phenolic resin, 4 parts to 9 parts of curing agent, 1.1 parts to 2.3 parts of curing accelerator, 1.5 parts to 3 parts of mould releasing agent, 4.8 parts to 6.3 parts of phosphate, 1.5 parts to 2.8 parts of metal oxide, 45 parts to 50 parts of mineral filler and 20 parts to 25 parts of reinforcing fiber. The non-halogen flame-resistant phenolic molding compound has the advantages that because halogen is not contained in the formulation, when being burnt, noxious gas and corrosive gas can not be generated, thus the physical safety and the environmental protection can be ensured; the flame-resistant performance can reach grade UL-94-V-0 (0.45 mm), the insulation resistance is greater than or equal to 1X10<12> Omega; the bending strength is more than (MPa) 85; the thermal deformation temperature is higher than or equal to 240 DEG C.

Owner:常熟东南塑料有限公司

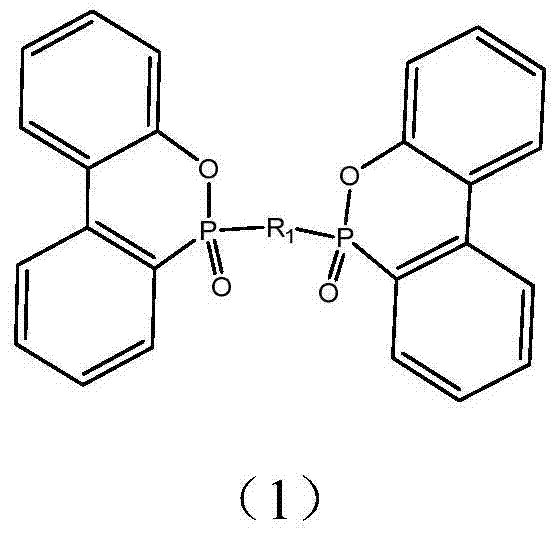

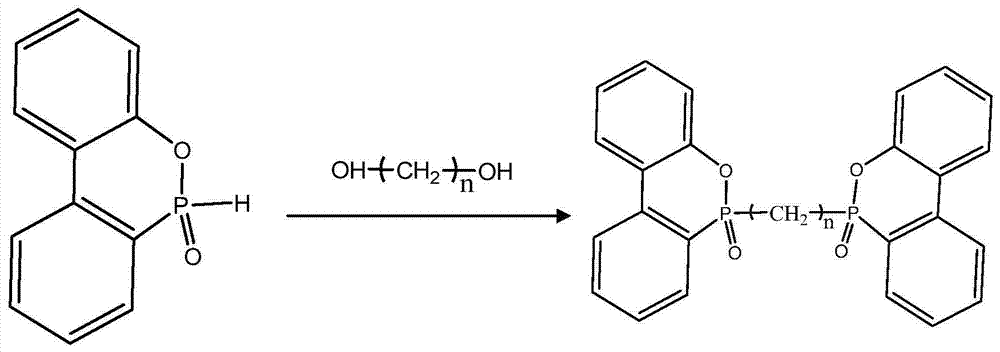

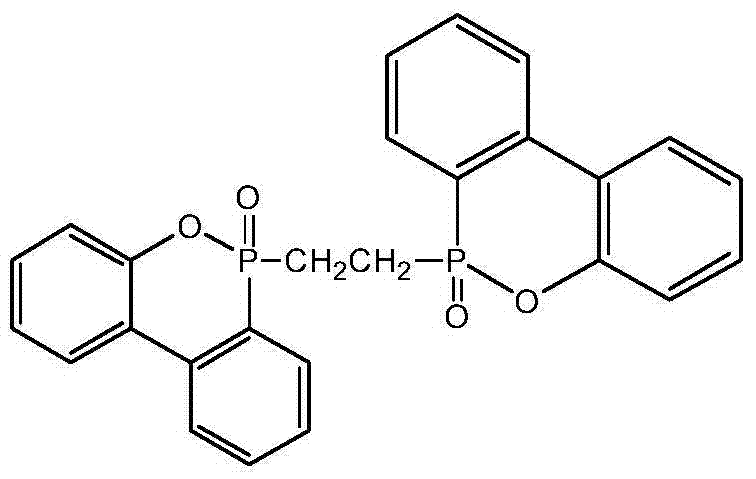

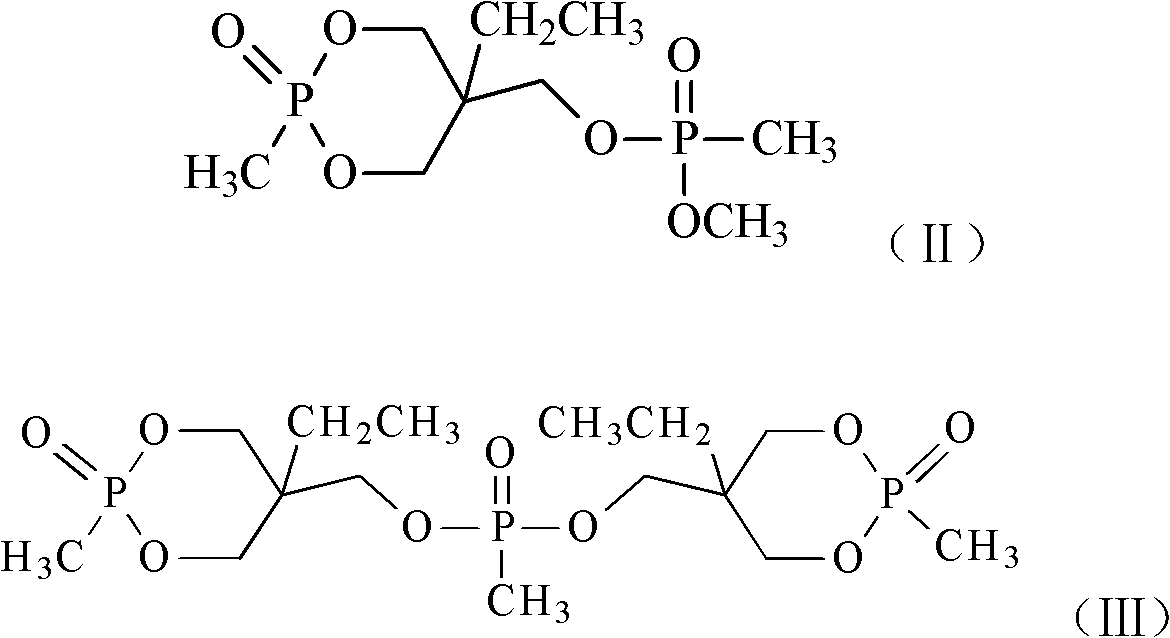

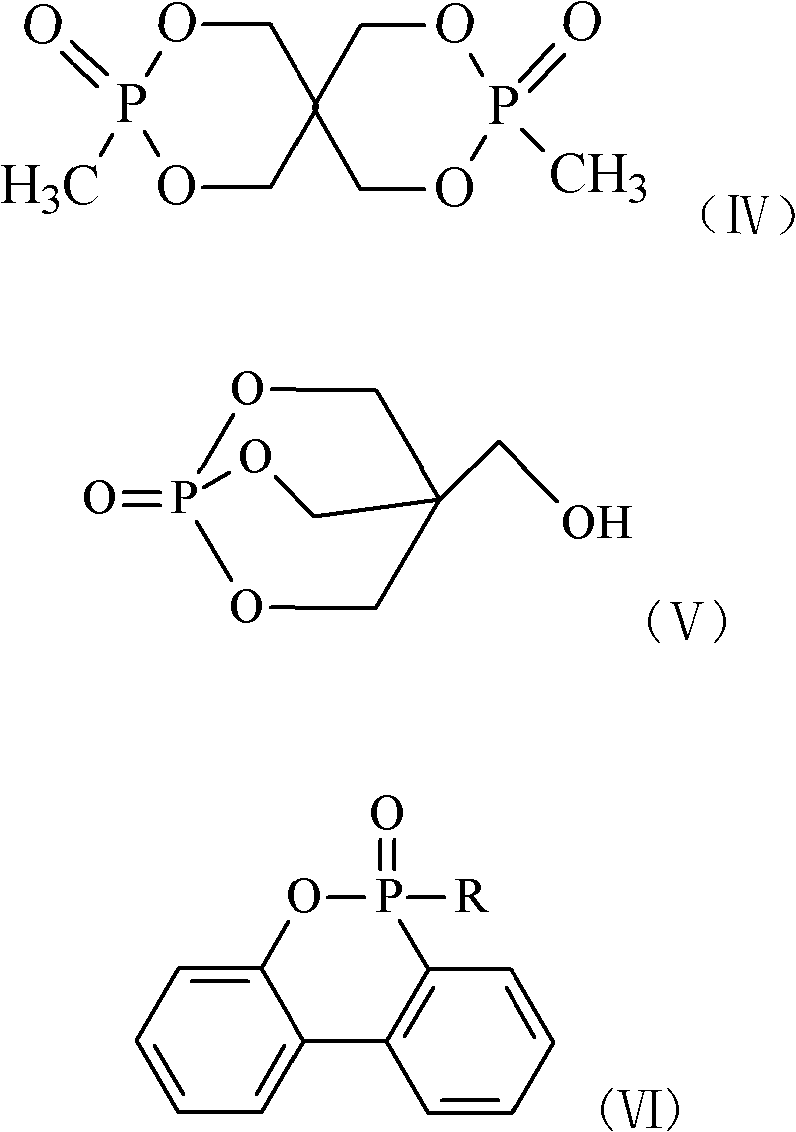

Phosphorus-containing flame retardant composition, and phosphorus-containing polyphenyl ether resin composition, prepreg and laminated board using the same

ActiveCN104774476AExcellent dielectric propertiesImprove heat resistanceSynthetic resin layered productsCircuit susbtrate materialsDielectricHalogen

The invention provides a phosphorus-containing flame retardant composition, including: a hypophosphite compound, a DOPO derivative and a polyphosphazene compound. The composition as a flame retardant can play a synergistic effect of several phosphorus-containing compounds, realizes halogen-free flame retardance under small addition amount and reaches level V-0. The invention also provides a contains a polyphenyl ether resin composition containing the above phosphorus-containing flame retardant compositions and a prepreg and a copper clad laminated board prepared from the same. After curing, the polyphenyl ether resin composition achieves flame retardance of V-0 grade under the condition to which the halogen flame retardant does not apply and keeps good dielectric property and heat resistance of polyphenyl ether resin; the prepreg and copper clad laminated board made from the composition have good dielectric property and heat resistance, and realize halogen-free flame retardance to UL 94-V0 grade while ensuring excellent heat resistance and dielectric property; and the composition is applicable to the field of high speed and high frequency printed circuit board, and is in line with the future requirements of green and environmental protection.

Owner:GUANGDONG SHENGYI SCI TECH

Halon-free intumescent fire-retardant epoxy resin compound

A halogen-free expansion flame-retardant epoxy resin combination mainly includes the following components (in terms of weight portion) 45 to 85 portions of epoxy resin, 4 to 40 portions of ammonium polyphosphate, 2 to 30 portions of melamine or the derivatives, 1 to 20 portions of phosphonate ester, 1 to 13 portions of solidified agent, 0.1 to 8 portions of diluting agent and 0.1 to 4 portions of filling agent. The combination with no halogen, strong moisture resistance and good flame retardance can reach V-0 standard in UL-94; therefore, the combination is used as the substrate of manufacturing spare parts and fittings in the electronic and electric field.

Owner:SHANGHAI RES INST OF CHEM IND

Flame-protected, partially aromatic polyamide molding compounds

ActiveUS20120083558A1Reduce the amount requiredGroup 5/15 element organic compoundsSynthetic resin layered productsThermoplasticPolyamide

The invention relates to a flame-retardant polyamide molding composition based on semicrystalline polyamides. This polyamide molding composition is based on(A) from 30 to 92% by weight of at least one aliphatic or semiaromatic, semicrystalline polyamide with melting point (Tm) in the range from 240° C. to 340° C.;(B) from 0 to 50% by weight of at least one filler and reinforcing agent;(C) from 8 to 18% by weight of at least one halogen-free flame retardant;(D) from 0 to 2.0% by weight of at least one barium carboxylate;(E) from 0 to 5% by weight of at least one additive;wherein the percentages by weight of components (A) to (E) give a total of 100%, and with the proviso that if the proportion of component (D) is in the range from 0 to 0.1% by weight the halogen-free flame retardant of component (C) is based on a barium phosphinate. The invention further relates to the use of barium carboxylate in a polyamide molding composition using a halogen-free flame retardant for inhibiting corrosive action during processing. The molding compositions comply with fire-protection class UL 94 V-0, and have no, or only slight, corrosive action with respect to the machine components used in thermoplastic processing, and exhibit good mechanical properties. They are suitable for producing, in particular, thin-walled moldings for the electrical and electronics industry, examples being housings, housing components, and connectors.

Owner:EMS PATENT AG

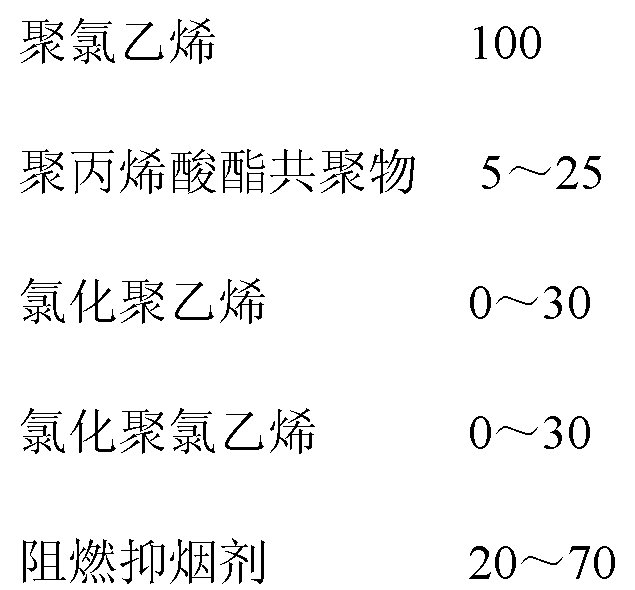

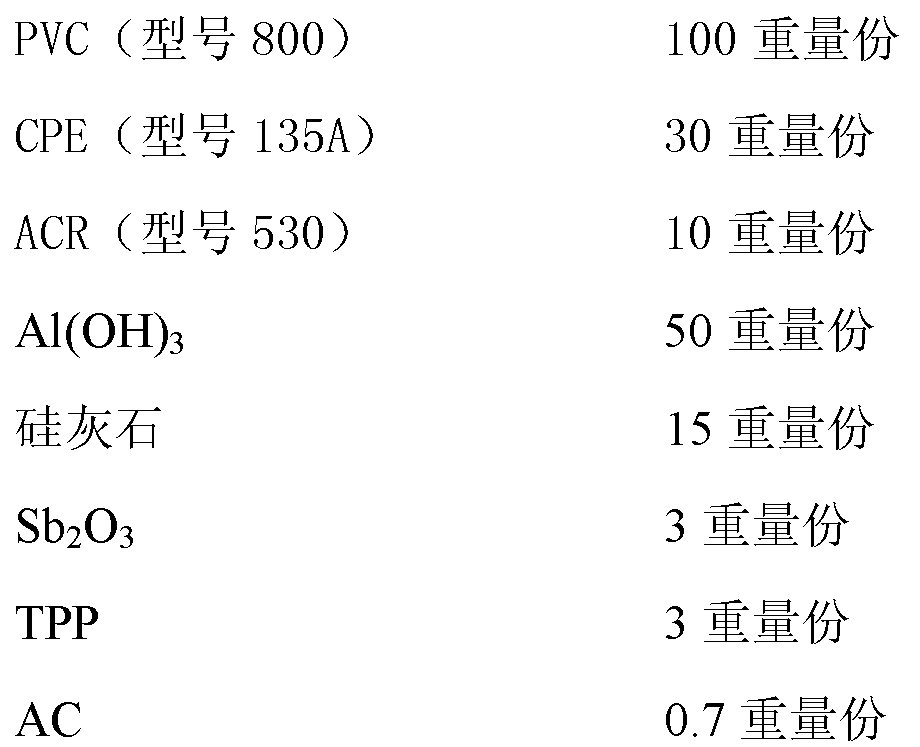

Composition for flame-retardant polyvinyl chloride (PVC) plastic foam board, product prepared from same, and preparation method thereof

The invention relates to a composition for a flame-retardant polyvinyl chloride (PVC) plastic foam board, and the flame-retardant PVC plastic foam board produced by a double screw extrusion method. The composition comprises the following components in part by weight: 100 parts of polyvinyl chloride, 5 to 25 parts of polyacrylate copolymer, 0 to 30 parts of chlorinated polyethylene, 0 to 30 parts of chlorinated polyvinyl chloride, 20 to 70 parts of flame retardant and smoke suppression agent, and 0 to 5 part of plasticizer, and also comprises a resin melt reinforcing agent and additives such as a foaming agent, a lubricating agent and a stabilizing agent and the like. After the produced flame-retardant PVC plastic foam board is detected by Shanghai Building Material and Component Quality Surveillance Office and State Laboratory of Fire Science (University of Science and Technology of China, Hefei), the oxygen index is more than or equal to 32, the smoke density grade is less than or equal to 75, the average combustion time is less than or equal to 30 seconds, the heat release rate is less than 250W / g, the heat conductivity is 0.047W / m.K, and the flame-retardant PVC plastic foam board meets the B1 requirement of GB / T8624-1997, and meets the V-0 standard of UL-94.

Owner:SHANGHAI YUANQI ENERGY TECH DEV

A kind of halogen-free flame-retardant thermoplastic polyurethane elastomer sheath material and its preparation and application

InactiveCN102295835ANo need to investWide extrusion processing temperatureInsulated cablesInsulated conductorsHalogenThermoplastic polyurethane

The invention discloses a zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material and a preparation method thereof. The zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material is prepared from the following raw material components in parts by weight: 50-80 parts of polyurethane, 10-30 parts of zero-halogen flame retardant, 10-20 parts of zero-halogen smoke suppressant, 5-20 parts of processing modifier, 0.2+ / -0.05 part of processing auxiliary agent, 0.2+ / -0.05 part of antioxidant and 0.2+ / -0.05 part of ultraviolet resistant. Compared with the prior art, the zero-halogen flame-retardant thermoplastic polyurethane elastomer sheath material prepared by the invention has the advantages of wider processing temperature range, ultrahigh physical and mechanical properties and flame retardant property of UL-94 and V-0 level.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

PBT and ABS flame-proof material

The invention relates to a PBT and ABS flame- proof material. The component and their weight proportion are follows: PBT 30-70%, ABS 10-50%, AS 1-20%, AS-GMA 1-20%, montmorillonite 1-20%, flame- proof agent 1-20%, and anti-oxidant 0.1-1%. The PBT and ABS flame- proof material possesses high flame- proof performance, the flame- proof grade can reach V0 class of UL 94 standard, and it aslo improves material performance, especially the rigidity and thermal resistance, and the size stability is good. It is suited to inject and shape electrical apparatus that requires environmental protectio and flame proof.

Owner:SHANGHAI KUMHO SUNNY PLASTICS

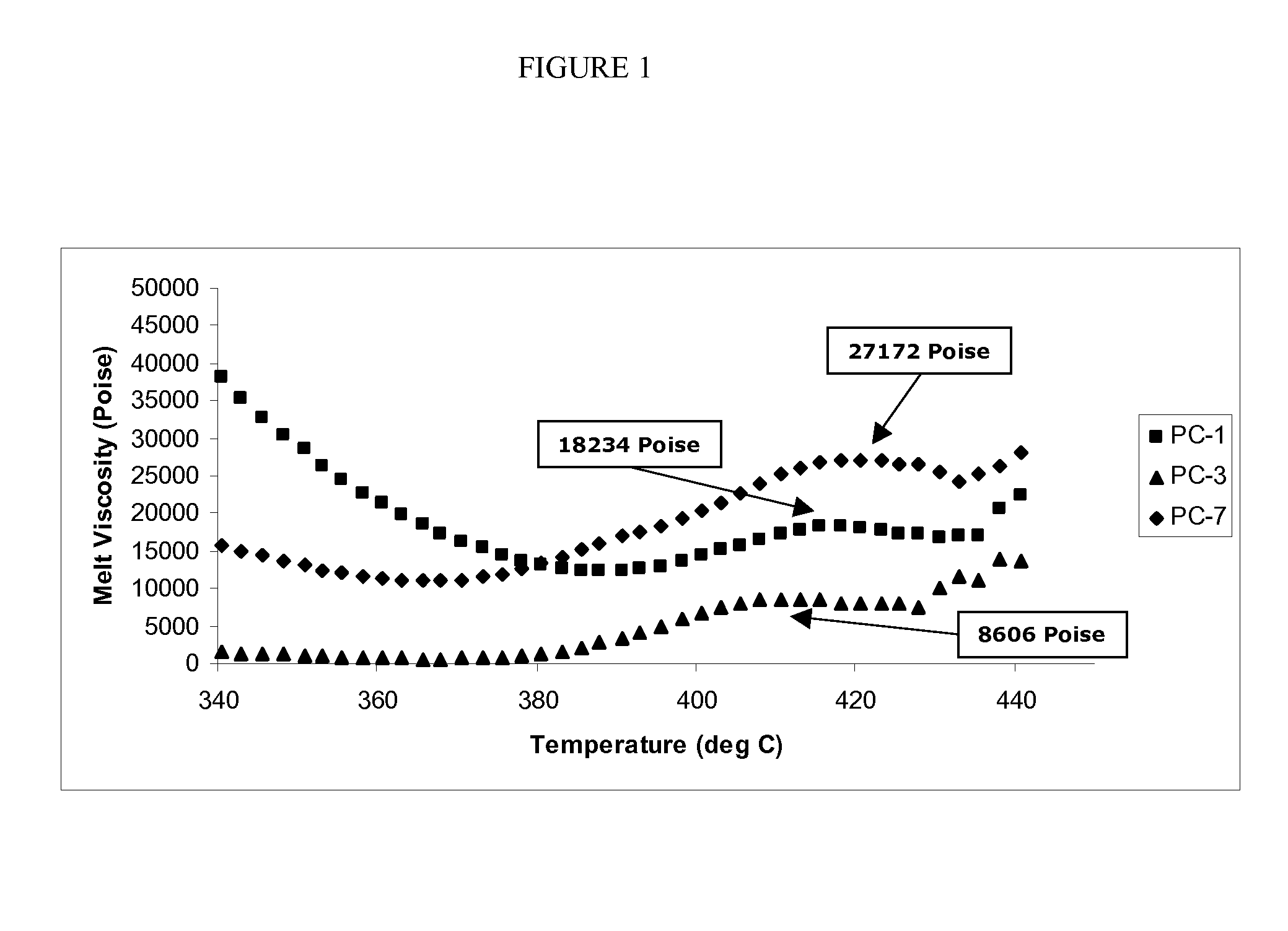

Compositions and articles of manufacture containing branched polycarbonate

A polycarbonate containing composition comprising a peak melt viscosity of at least 8,000 poise when measured using a parallel plate melt rheology test at a heating rate of 10° C. / min at a temperature of between about 350° C. to about 450° C., and wherein a molded article of the composition has a UL 94 VO rating at a thickness of 1.0 mm, 1.5 mm, 2.0 mm, or between 1.0 mm and 2.0 mm is disclosed.

Owner:SABIC GLOBAL TECH BV

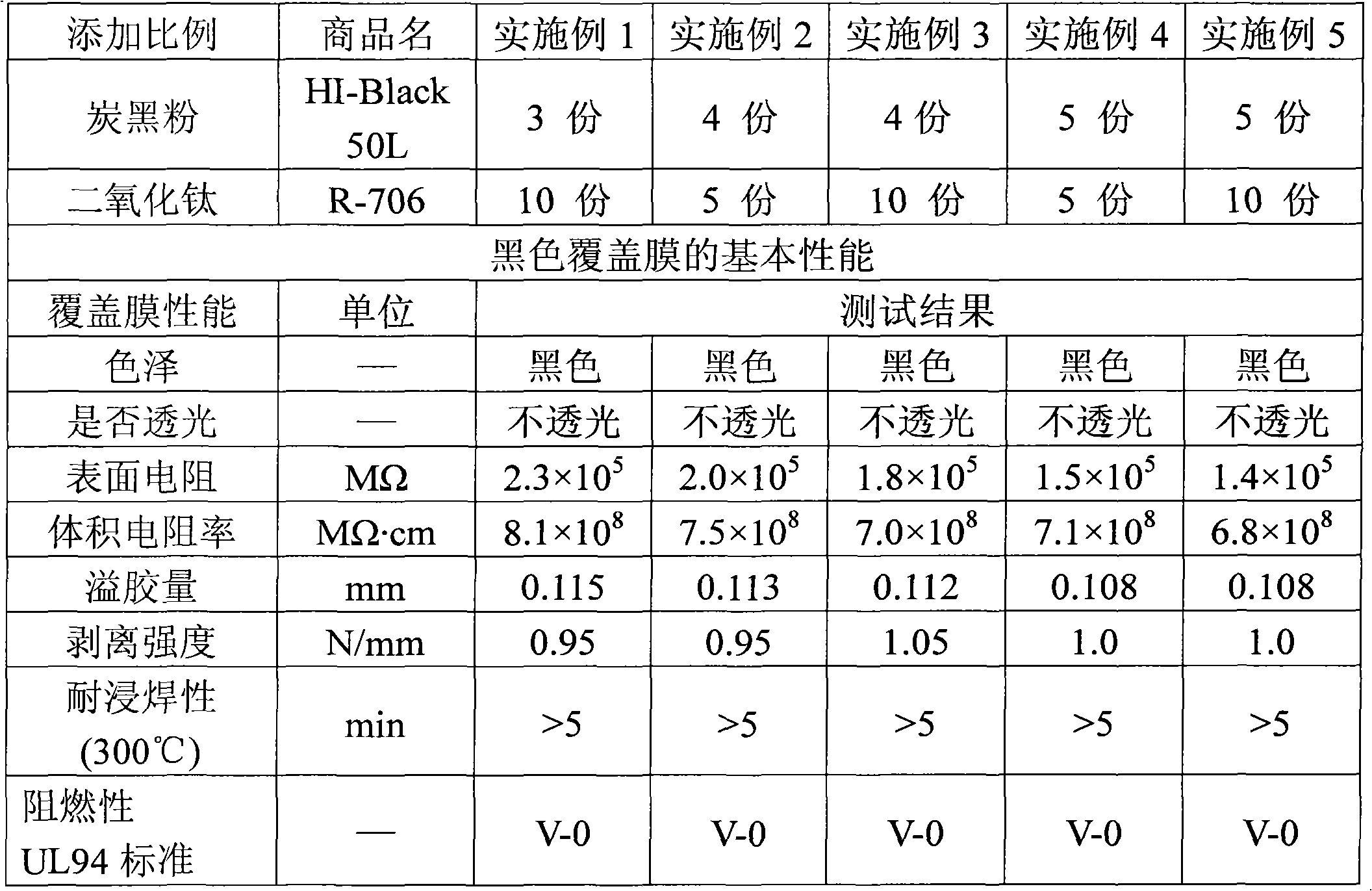

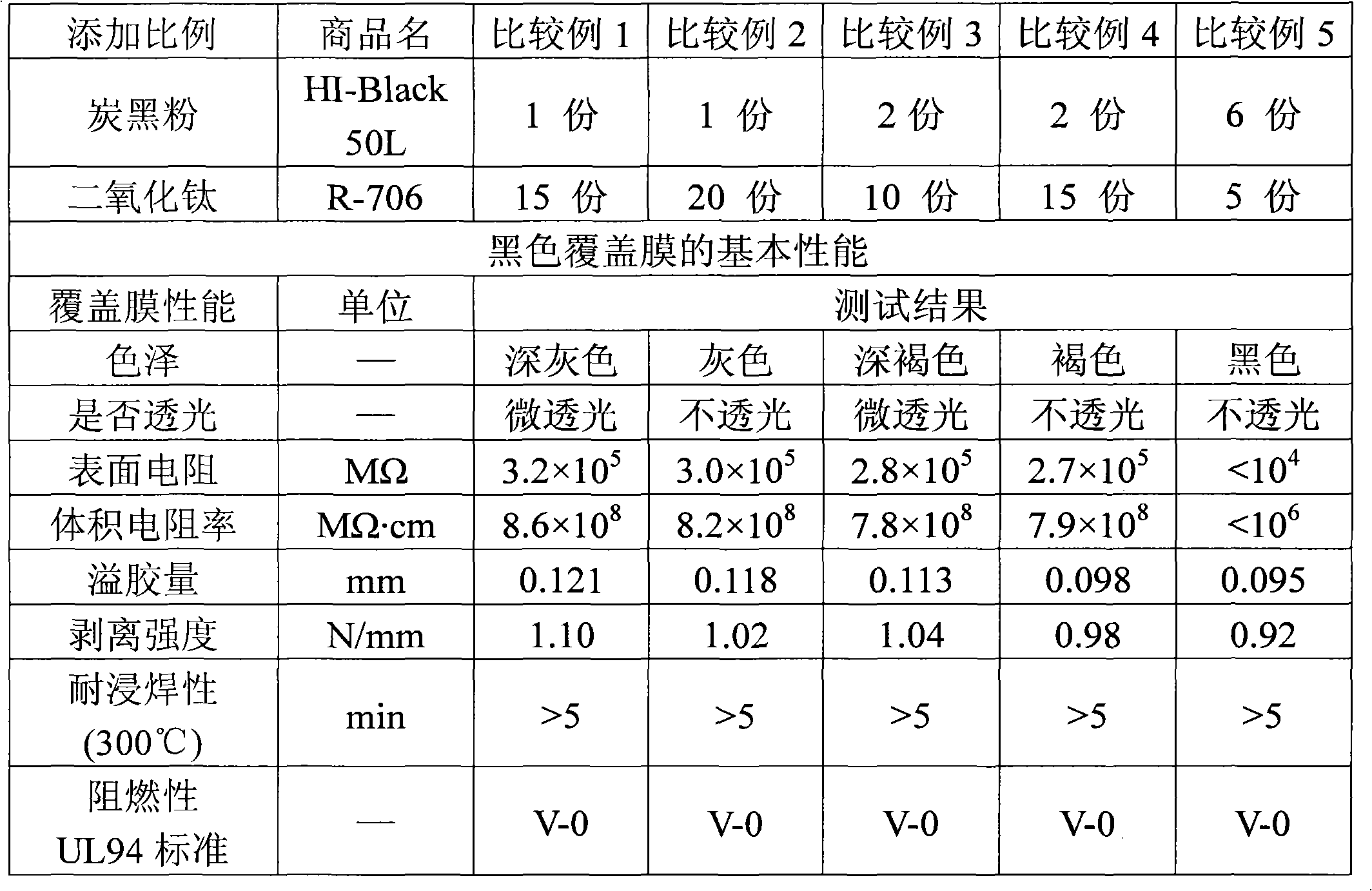

Black halogen-free epoxy resin composition and covering film prepared from same

InactiveCN101851390AImprove mechanical propertiesHigh peel strengthSynthetic resin layered productsEpoxyChemistry

The invention relates to a black halogen-free epoxy resin composition and a covering film prepared from the same. The black halogen-free epoxy resin composition comprises epoxy resin, CTBR (Carboxyl Terminated Butadiene Rubber), acrylic ester modified epoxy resin, a curing agent, a curing accelerator, carbon black powder, titanium dioxide, a phosphorus flame retardant, inorganic fillers and an organic solvent. The covering film prepared from the composition comprises a polyimide insulated film, a black halogen-free epoxy resin composition coating coated on the polyimide insulated film and release paper covered on the black halogen-free epoxy resin composition coating. The resin composition does not contain halogens, is black by adopting less carbon black powder to play the shading effect and adopts titanium dioxide to enhance the shading effect. Meanwhile, the acrylic ester modified epoxy resin is used so that a resin system reaches fire retardance and keeps favorable mechanical performance. The covering film prepared from the composition reaches the standards of surface resistance and volume resistivity, reaches a flame retardance level of UL 94 V-0 and has high peeling strength and excellent size stability, flexibility and processing performance.

Owner:GUANGDONG SHENGYI SCI TECH

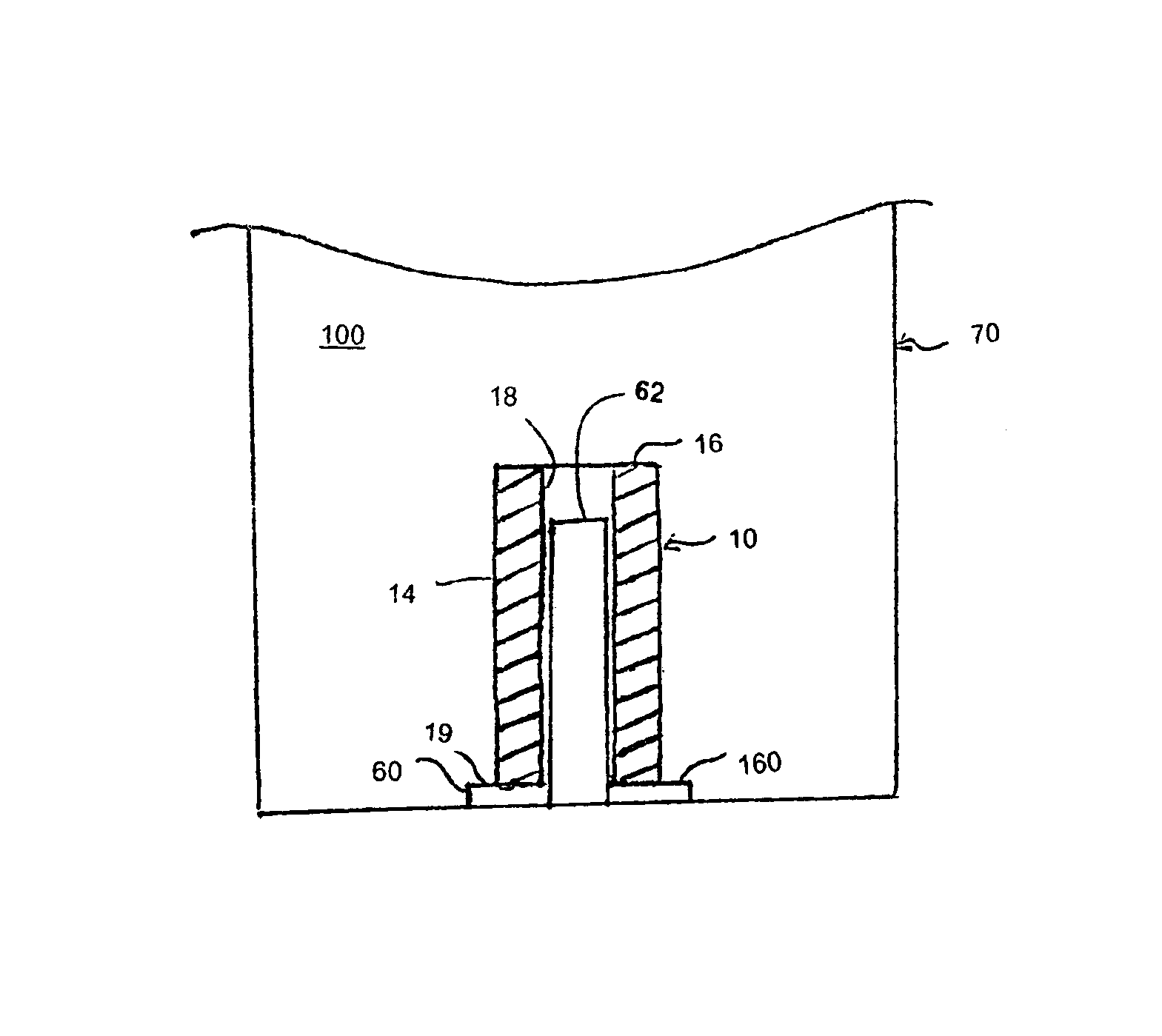

Thermally conductive flame retardant polymer compositions and uses thereof

InactiveUS20140171567A1Semiconductor/solid-state device detailsSolid-state devicesThermoplasticThermosetting polymer

Disclosed herein is a thermally conductive composition, comprising 20 to 80 wt % of a thermoplastic or thermosetting polymer; 10 to 70 wt % of a metal hydroxide; 0.5 to 40 wt % of a silicone char-forming agent, and 0.05 to 5 wt % of an anti-flame dripping agent; wherein the thermally conductive composition has a thermal conductivity of at least 0.5 W / mK for through plane thermal conductivity; and a flame retardancy of at least V-0 performance at a thickness of 1.2 mm or less when tested as per a UL-94 testing standard.

Owner:SABIC GLOBAL TECH BV

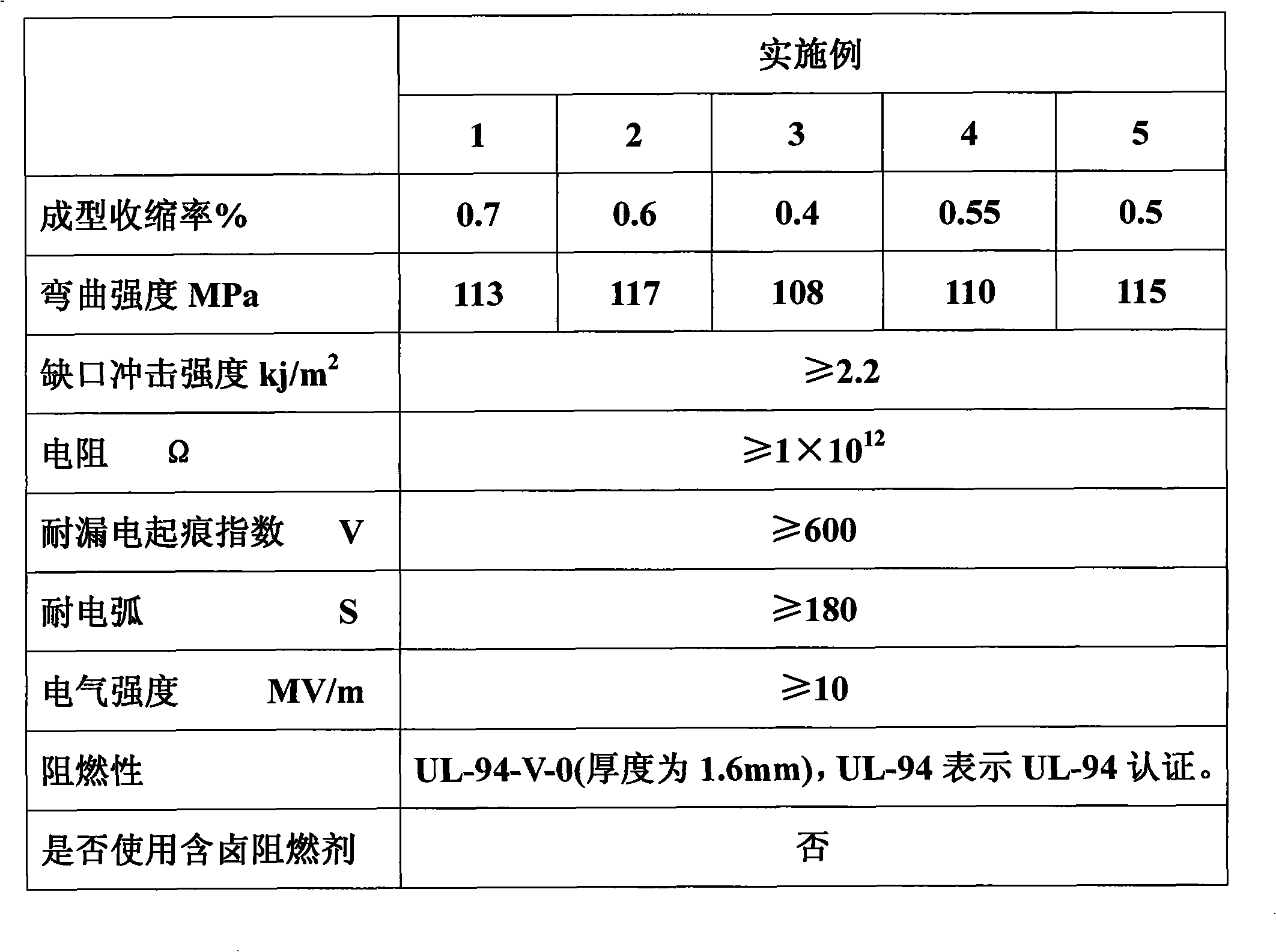

Halogen-free flame-proof glass fiber reinforcement epoxy molding compound

The invention relates to non-halogen flame-resistant glass fiber reinforced epoxy molding compound. According to the weight parts, the material of the non-halogen flame-resistant glass fiber reinforced epoxy molding compound comprises 20 parts to 25 parts of epoxy resin, 7 parts to 9 parts of phenolic resin, 1.4 parts to 3.4 parts of curing agent, 60 parts to 75 parts of mineral filler, 4 parts to 7.5 parts of phosphate, 0.8 parts to 2 parts of metal oxide, 1.8 parts to 2.5 parts of mould releasing agent and 15 parts to 20 parts of reinforced fiber. The non-halogen flame-resistant glass fiber reinforced epoxy molding compound has advantages that because halogen is not contained in the formulation, when being burnt, noxious gas and harmful gas can not be generated, and the physical safety and the environmental protection can be ensured; the shrinkage ratio is 0.4 percent to 0.7 percent, the bending strength is 105 to 120 MPa, the notched impact strength is greater than 2.2 KJ per m<2>, the resistance is 1X10<12> Omega, the proof tracking index is greater than 600 V, the arc resistance is greater than 180 s, the electrical strength is greater than 10 MV per m, the flame-resistant performance reaches grade UL-94-V-0 (1.6 mm), and the non-halogen flame-resistant glass fiber reinforced epoxy molding compound can be suitable for the sealing material for manufacturing automobile commutators and electronic products.

Owner:常熟东南塑料有限公司

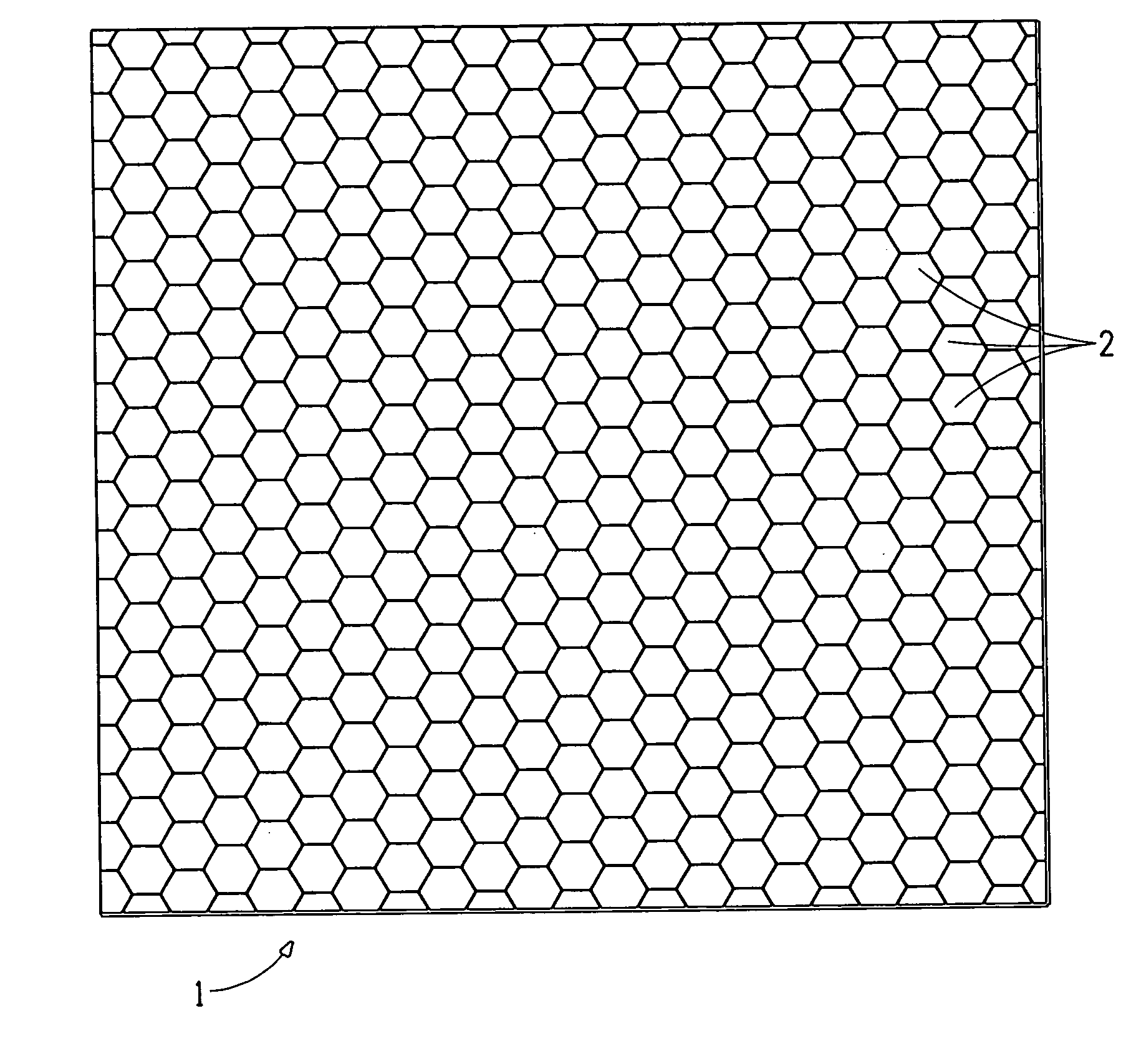

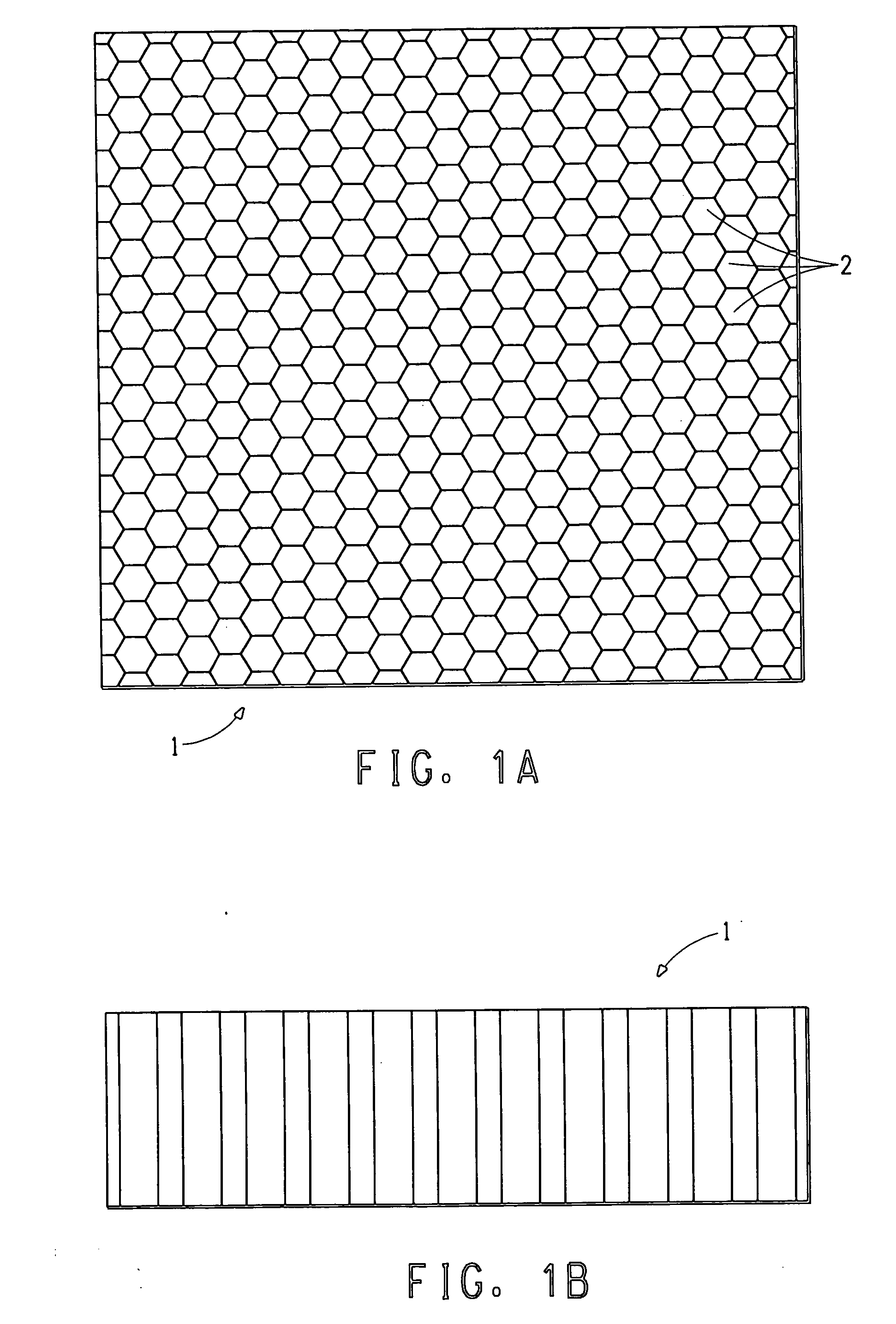

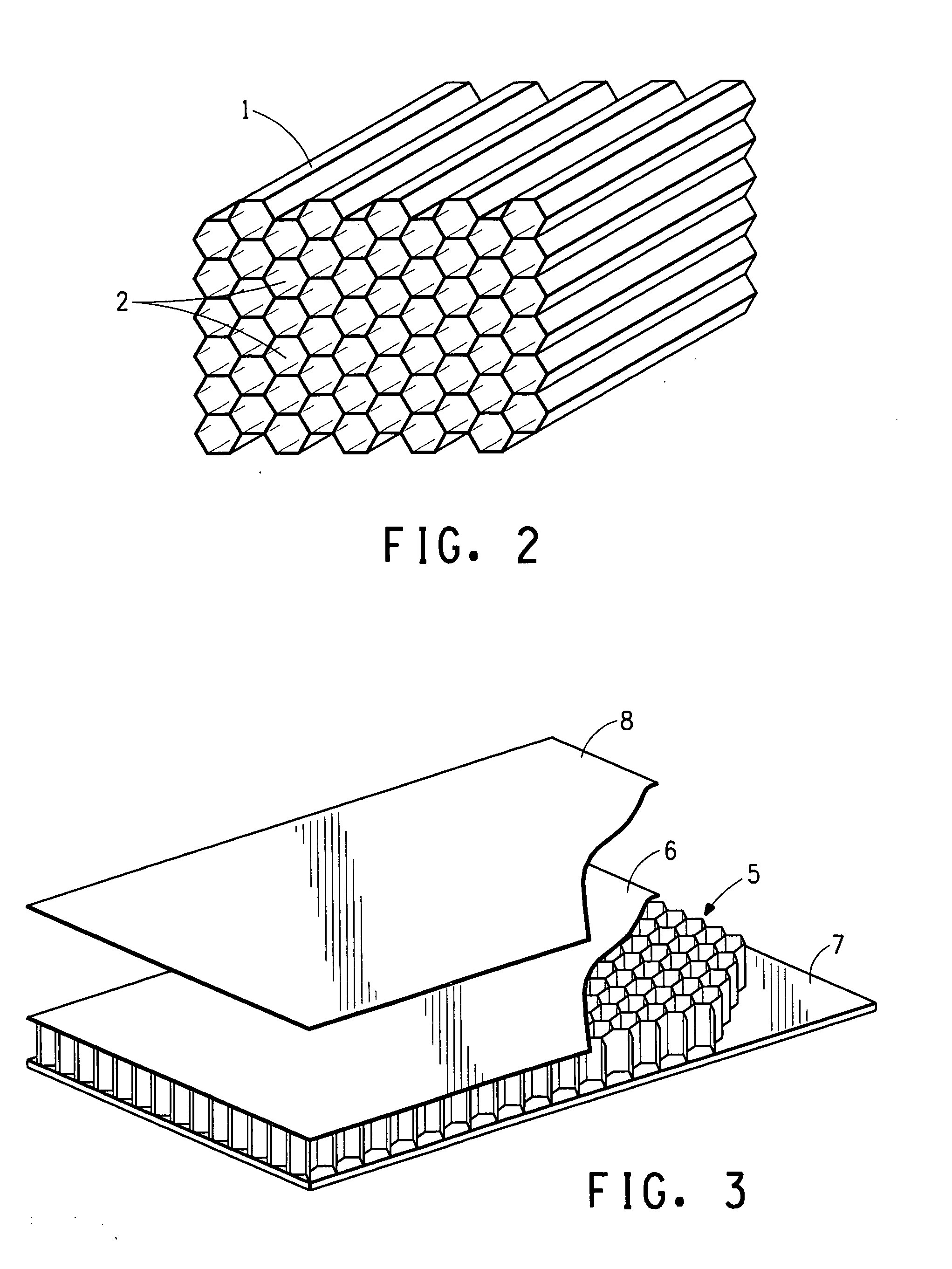

Honeycomb from paper having flame retardant thermoplastic binder

This invention relates to an improved flame retardant honeycomb comprising high modulus fiber and a flame retardant thermoplastic binder having a melt point of from 120° C. to 350° C. and a limiting oxygen index of 26 or greater, methods for making the honeycomb, and articles comprising the honeycomb. In a preferred embodiment the paper in the honeycomb has a flame classification of UL-94 V-0.

Owner:DUPONT SAFETY & CONSTR INC

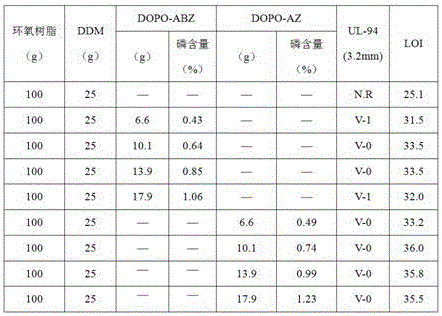

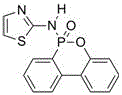

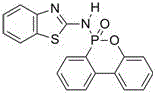

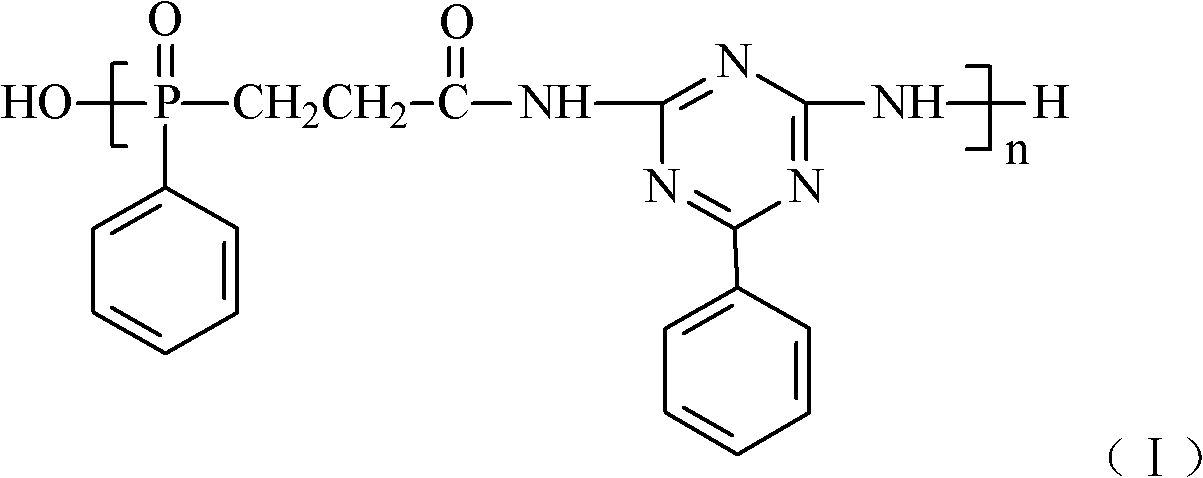

Flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and preparation method of flame retardant

InactiveCN106009040AThe synthesis process is simpleShort cycleGroup 5/15 element organic compoundsEpoxySulfur

The invention discloses a flame retardant containing phosphorus, nitrogen and sulfur and used for epoxy resin and a preparation method of the flame retardant. Firstly, DOPO and aminothiazole are taken as reaction raw materials and subjected to an Atherton-Todd reaction for preparation of the flame retardant containing phosphorus, nitrogen and sulfur. The process steps of the method are simple, the yield and the purity of the flame retardant are high, and the post-treatment process is simple and convenient. The flame retardant containing phosphorus, nitrogen and sulfur and prepared with the method is used for modifying cured epoxy resin and has good compatibility with epoxy resin, and the obtained cured flame-retardant epoxy resin has excellent flame retardancy; when the phosphorus content of the epoxy curing system reaches 0.43wt%-1.23wt%, the vertical burning grade can pass UL-94 V-0 level, and the limit oxygen index is as high as 36%.

Owner:FUJIAN NORMAL UNIV

Flame-resistant polyester-olycarbonate compositions, methods of manufacture, and articles thereof

Owner:SHPP GLOBAL TECH BV

Halogen-free high-efficiency flame retardant composition and preparation method thereof

InactiveCN102337034AImprove thermal stabilityImprove liquidityFibre treatmentPolyolefinPolymer science

The invention discloses a halogen-free high-efficiency flame retardant composition and a preparation method thereof. The halogen-free high-efficiency flame retardant composition is prepared from the following components in percentage by mass: 10-80% of phenyl melamine carboxyethyl phenyl phosphinic acid condensation compound, 15-70% of melamine and / or derivative thereof and 5-20% of organic phosphate. The halogen-free flame retardant composition can be used for flame retarding of various polyolefin, nylon, polyurethane, polyester and other synthetic materials and textiles, and is particularly suitable for polyester and nylon engineering plastic; and by the addition of 12wt% of the flame retardant composition to polybutylene terephthalate (PBT) resin, the flame-retarding level can reach UL 94 V-0 (1.6 mm). The flame retardant composition has the characteristics of high flame retarding efficiency, good fluidity, no precipitation and the like, and can meet the use requirements of flame-retardant resin for electric appliance shells and supports, electronic and electric device connectors and the like.

Owner:DONGHUA UNIV

Non-halogen flame-retardant resin composition

InactiveUS20070135538A1Excels in moldabilityExcels in safetySolid electrolyte fuel cellsGreenhouse cultivationSimple Organic CompoundsHalogen

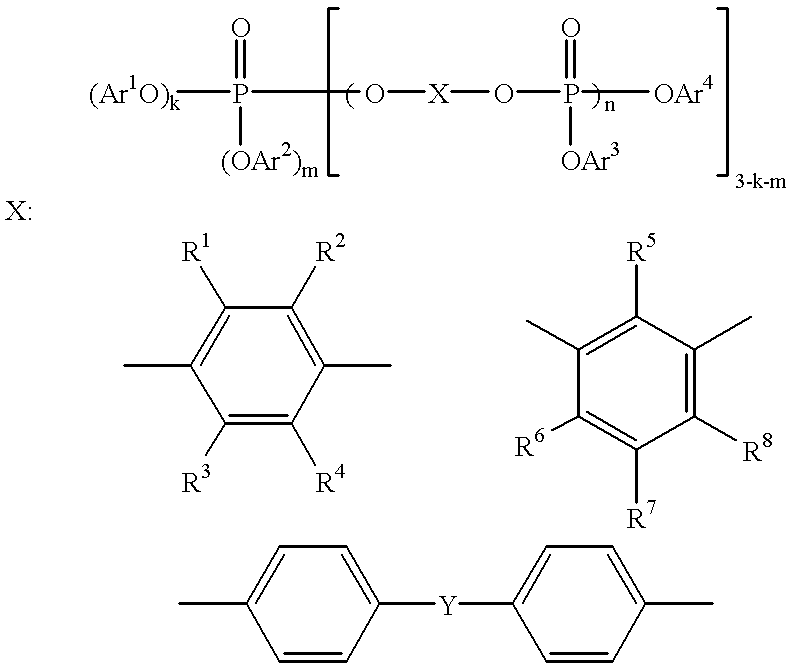

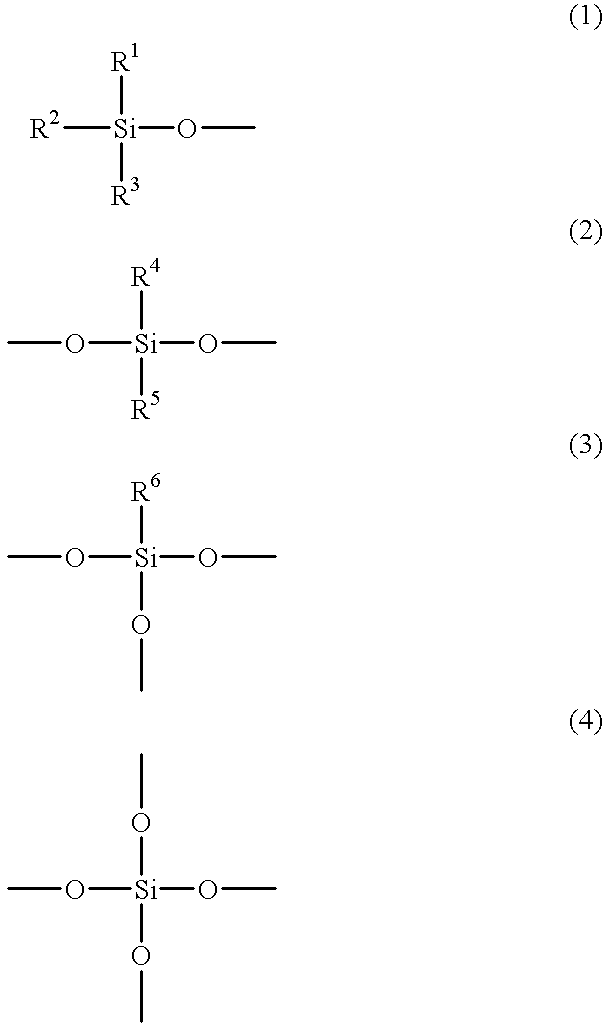

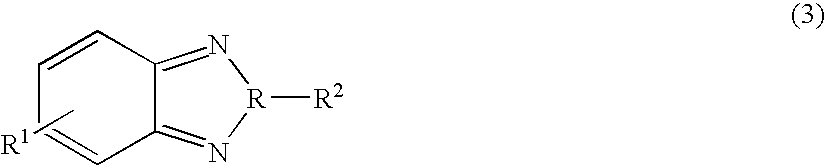

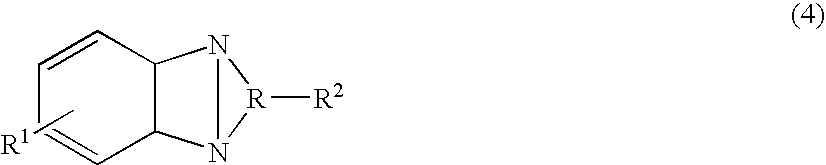

Provided by the invention is a non-halogen flame-retardant thermoplastic resin composition not requiring crosslinking with a peroxide, having excellent in moldability, and moreover, having high flame-retardancy to pass the test for V-0 grade of the UL-94. standards The non-halogen flame-retardant thermoplastic resin composition comprises, as a uniform blend: (A) 100 parts by mass of a thermoplastic resin other than polycarbonate and polyphenylene ether resins, (B) 10 to 300 parts by mass of an inorganic powder, (C) 1 to 50 parts by mass of an organopolysiloxane having a specified structure, and (D) 0.01 to 10 parts by mass of an organic compound having a specified structure.

Owner:SHIN ETSU CHEM IND CO LTD

Preparation of halogen-free flame-proof nylon 66 having high-mechanical property and composite material

The invention discloses a preparation method for high-mechanical performance halogen-free flame-retardant nylon 66 composite materials, comprising the following steps: (1) weighing; (2) mixing; (3) blending and extruding. The invention also discloses a composite material prepared with the method; the composite material has the following components: nylon 66, short glass fibers, main antioxidant, auxiliary antioxidant, compound flame retardant and lubricant. The method of the invention has the advantages that the composite material has the fire-retardant performance up to UL 94 V-0 (0.8mm) level, and has more prominent mechanical properties than the existing halogen-free flame retardant system, with equivalent mechanical properties with the halogen-containing flame retardant system; therefore, the composite material of the invention can completely replace the existing halogen-containing flame-retardant products and halogen-free flame-retardant products, with easy preparation method and easy operation. The high-mechanical performance halogen-free flame-retardant nylon composite material can be widely used in home appliances, electronics parts, auto parts, and so on.

Owner:刘成志

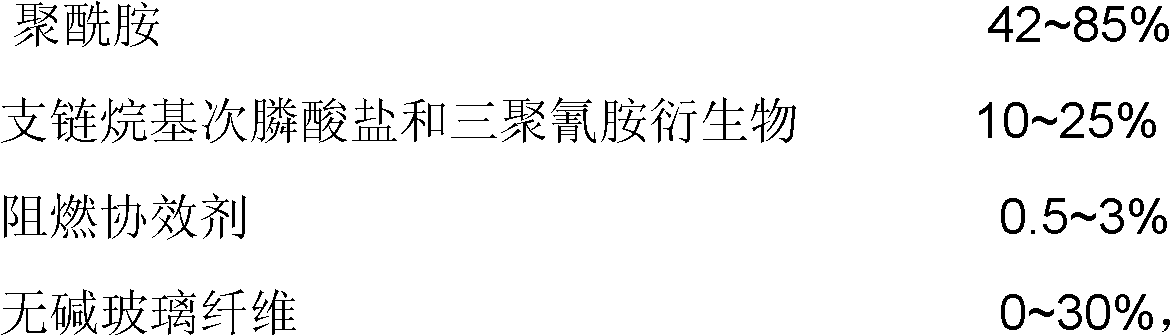

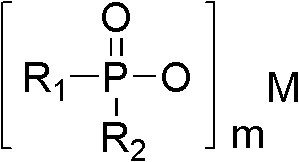

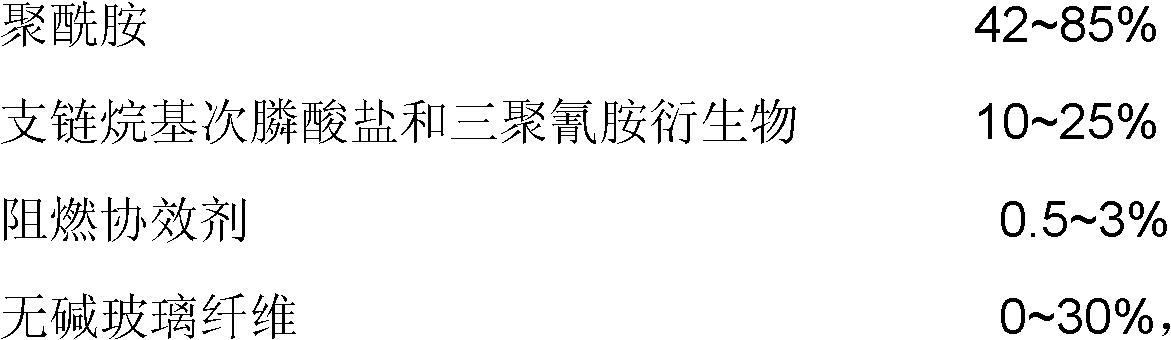

High-retardant polyamide

The invention discloses high-retardant polyamide which is prepared from the following components in percentage by weight through cross blending fusion: 42-85% of polyamide, 10-25% of branched chain alkyl phosphinic acid and melamine derivatives, 0.5-3% of fire-retardant synergist, and 0-30% of alkali-free glass fiber, wherein the mass ratio in percentage of branched chain alkyl phosphinic acid tothe melamine derivatives is (2:1)-(4:1), or the mass percentage of the melamine derivatives is 0, the oxygen index of the high-retardant polyamide is 27.3-32.2%, and the vertical flame UL-94 of a test sample with the thickness of 1.6mm is V-1, and the vertical flame UL-94 of a test sample with the thickness of 0.8mm is NR-(V-0). The high-retardant polyamide provided by the invention is obtained through adding a retardant system of a novel branched chain alkyl phosphinic acid fire retardant, a nitrogen or phosphorous compound and the formulation of the synergist, not only has an excellent fireretardant effect, but also can be used for lowering the cost through reducing the additive amount of the fire retardant.

Owner:SICHUAN UNIV

Flame retardant radiation curable compositions

InactiveUS20050209357A1Improve mechanical propertiesImprove propertiesAdditive manufacturing apparatus3-dimensional image productionFire retardantRapid prototyping

The invention relates to a radiation curable composition comprising radiation curable components wherein the composition comprises at least two flame retardants and wherein the flame retardants belong to different classes of compounds, to a process for making three dimensional flame retardant articles and to a three dimensional article, made by rapid prototyping means, that passes the flame retardancy UL-94-V0 test.

Owner:DSM IP ASSETS BV

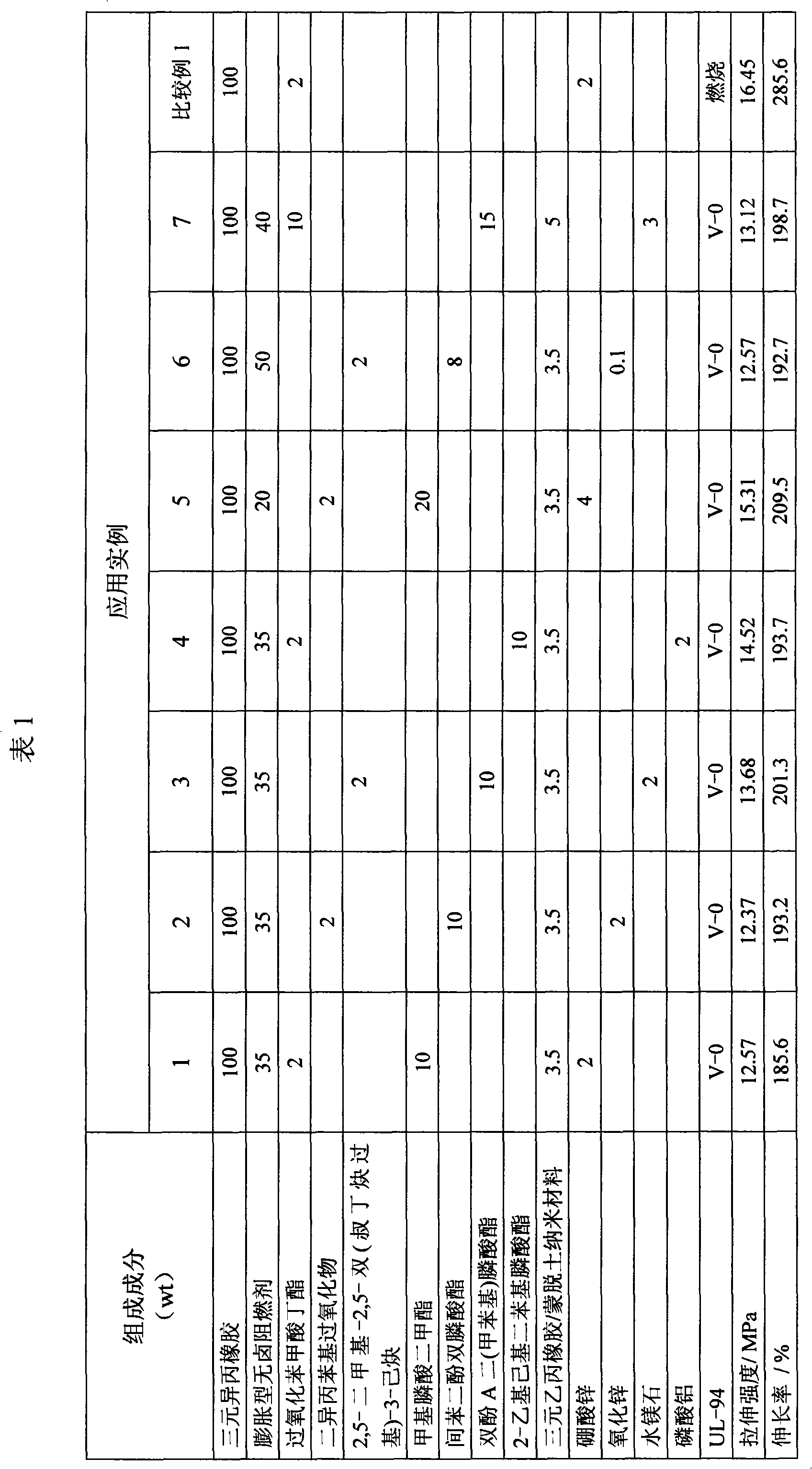

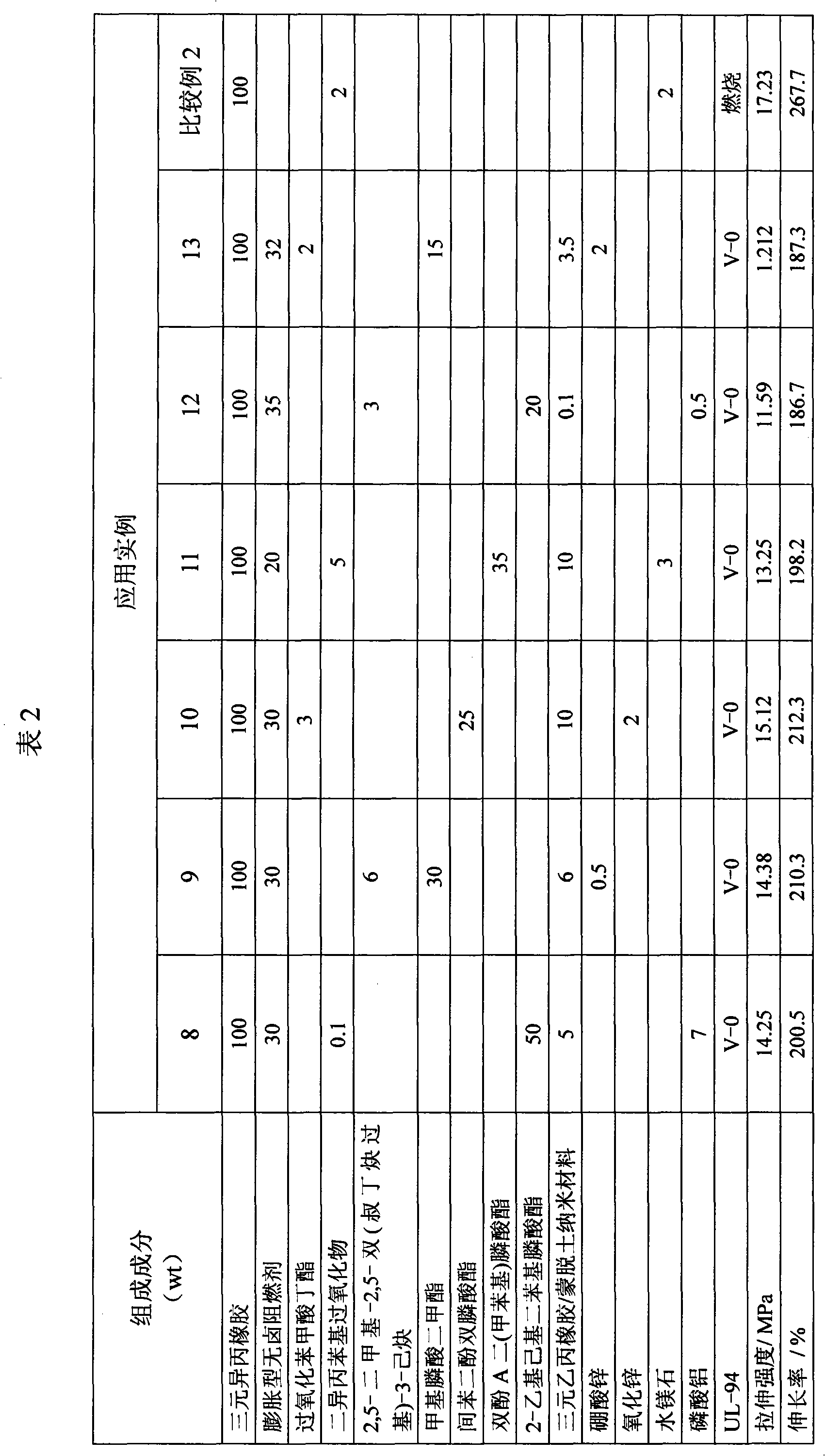

Halogen-free flame retardant ethylene propylene diene monomer (EPDM) material and preparation method thereof

ActiveCN101928431AImprove flame retardant performanceSmall mechanical propertiesPolymer scienceEthylene-propylene-diene-monomer

The invention discloses a halogen-free flame retardant ethylene propylene diene monomer (EPDM) material and a preparation method thereof. The halogen-free flame retardant EPDM material comprises the following components in parts by mass: 100 parts of EPDM, 20-50 parts of intumescent halogen-free retardant agent, 0.1-10 parts of cross linking agent, 8-50 parts of phosphonate, 0.1-10 parts of EPDM / montmorillonite nanocomposite and 0.1-7 parts of filler. Because the material adopts intumescen halogen-free retardant agent and EPDM / montmorillonite nanocomposite in the combination, the EPDM material has favourable fire retardance and obtains the standard of UL-94 V-0 level.

Owner:SHANGHAI RES INST OF CHEM IND

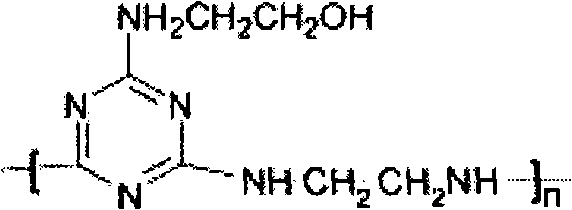

Halogen-free expansion-type flame retardant for polyethylene and preparation method thereof

ActiveCN101928409AOvercome environmental problemsOvercome the disadvantages of harmAntioxidantTriazine derivative

The invention relates to a halogen-free expansion-type flame retardant for polyethylene and a preparation method thereof. The flame retardant comprises the following components in percentage by mass: 30 to 60 percent of coated ammonium polyphosphate, 5 to 40 percent of macromolecular triazine derivative, 5 to 30 percent of melamine and derivative thereof, 0.1 to 15 percent of polymer / inorganic nano composite material, 0.05 to 8 percent of synergetic flame retardant, 0.05 to 5 percent of coupling agent and 0.01 to 3 percent of antioxidant. Compared with the prior art, the halogen-free expansion-type fire retardant radically avoids the harm of a halogenated fire retardant for the polyethylene to environment and human body, and ensures that the polyethylene material has the flame retardancy reaching a UL-94 V-0 level.

Owner:SHANGHAI RES INST OF CHEM IND

Halogen-free polyvinyl composite for manufacturing pipes and manufacturing method thereof

InactiveCN101469089AImprove flame retardant performanceImprove antistatic performanceHalogenAntistatic agent

The invention relates to a halogen free polyethylene composition for preparing pipes and a preparation method thereof. The composition comprises the following components by weight portion: 11 to 45 portions of halogen free fire retardant, 0.1 to 8 portions of antistatic agent, and 45 to 85 portions of polyethylene,, wherein the halogen free fire retardant is compounded by an expansion type fire retardant and a phosphonate ester fire retardant. The composition is characterized by no halogen content, environmental friendliness and good fire retardation. The composition can reach the V-0 level standards of UL-94 and have excellent antistatic property and good mechanical property. Therefore, the composition is the plastic combined material for preparing the pipes applied to hazardous operations such as coal mine, underground mining, water supply and drainage, gas transmission, and the like.

Owner:SHANGHAI RES INST OF CHEM IND

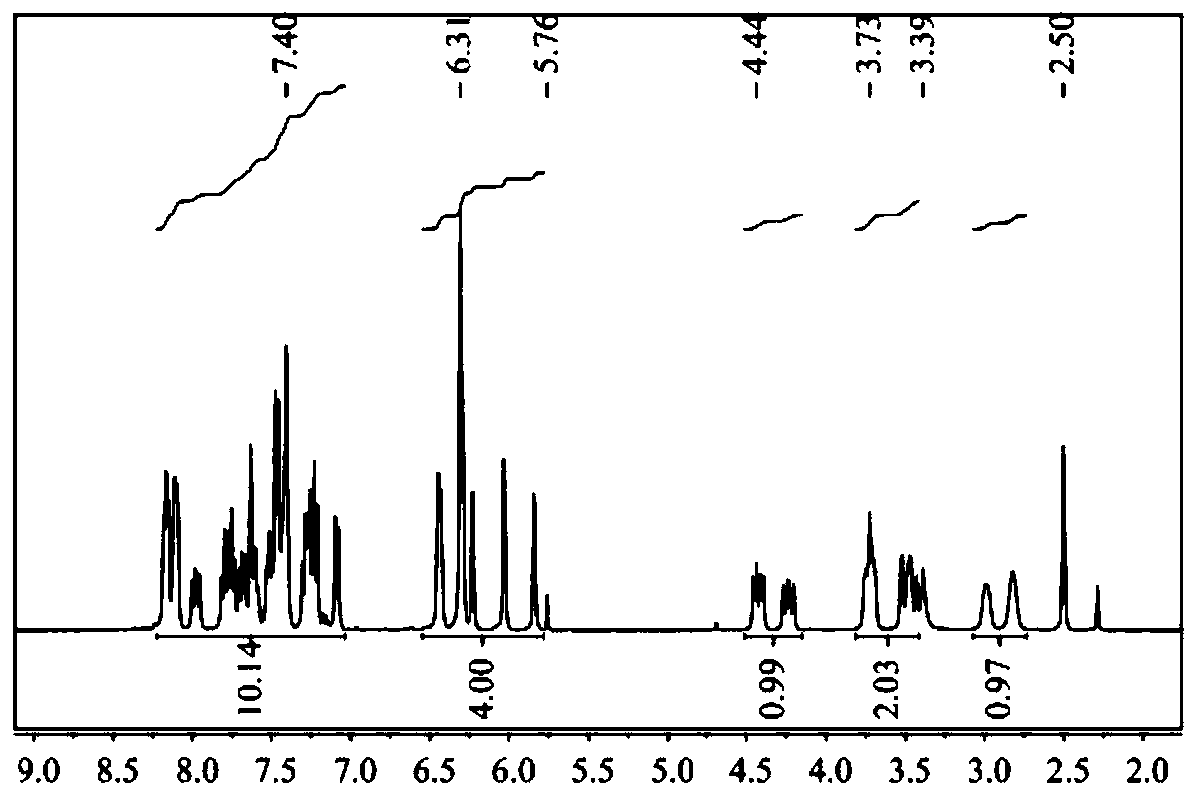

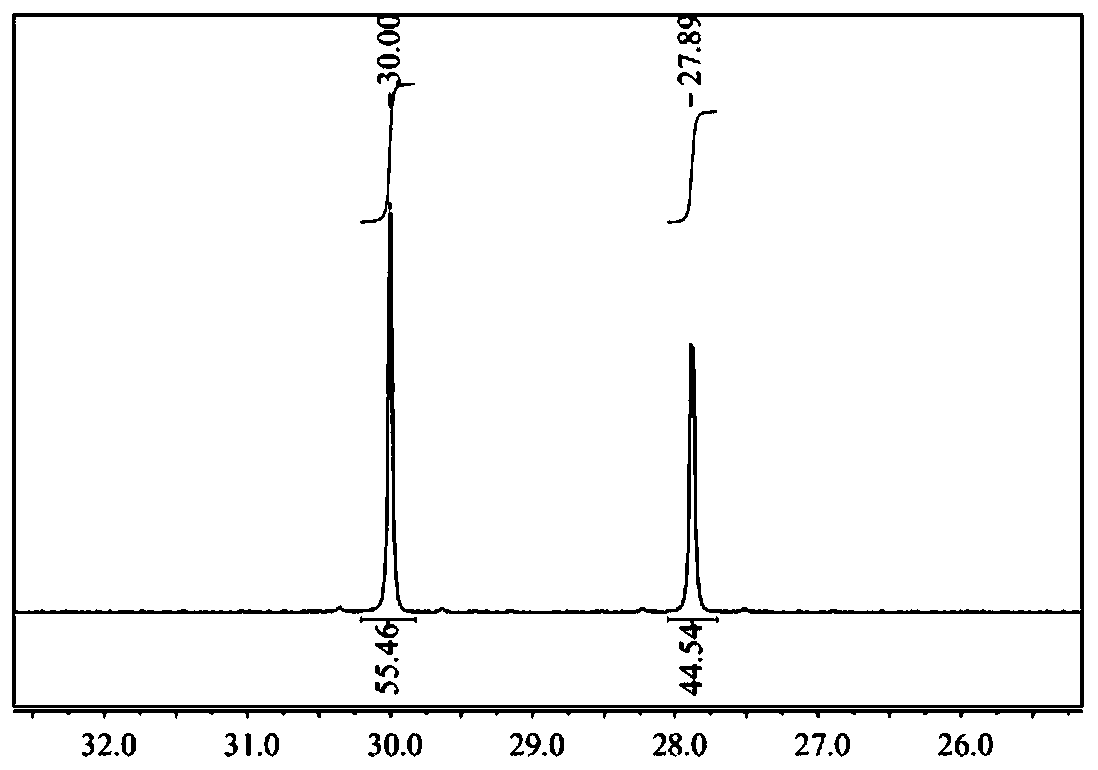

Phosphorus-nitrogen system biology based flame retardant as well as synthesis method and application thereof

ActiveCN109912650ASynthetic process is simple and low toxicityHigh yieldGroup 5/15 element organic compoundsEpoxyPolyester

The invention discloses a phosphorus-nitrogen system biology based flame retardant as well as a synthesis method and application thereof. The method comprises the following steps: completely dissolving a raw material 1 into an organic solvent at room temperature, adding a raw material 2 into the mixture, uniformly stirring through magnetic force, rising the temperature to 25 to 100 DEG C, and reacting for 2 to 12h; keeping the current reaction temperature, adding a phosphorus-containing material 3 into a reaction flask, ensuring that reaction is continued for 4 to 12 at 25 to 80 DEG C after the phosphorus-containing material 3 is completely dissolved. The flame retardant is simple in synthesis technology, small in pollution, low in toxicity, simple in aftertreatment, and very high in yieldand degree of purity, belongs to a melting point compound, has excellent processing property and excellent flame retardant efficiency, can not only obtain excellent flame retardant effect in epoxy resin, but also be properly applied to polyester compounds (polylactic acid), can obviously improve the UL-94 degree and oxygen index of the polylactic acid, and has little influence on the heat stability and mechanical property of flame retardant composite materials.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

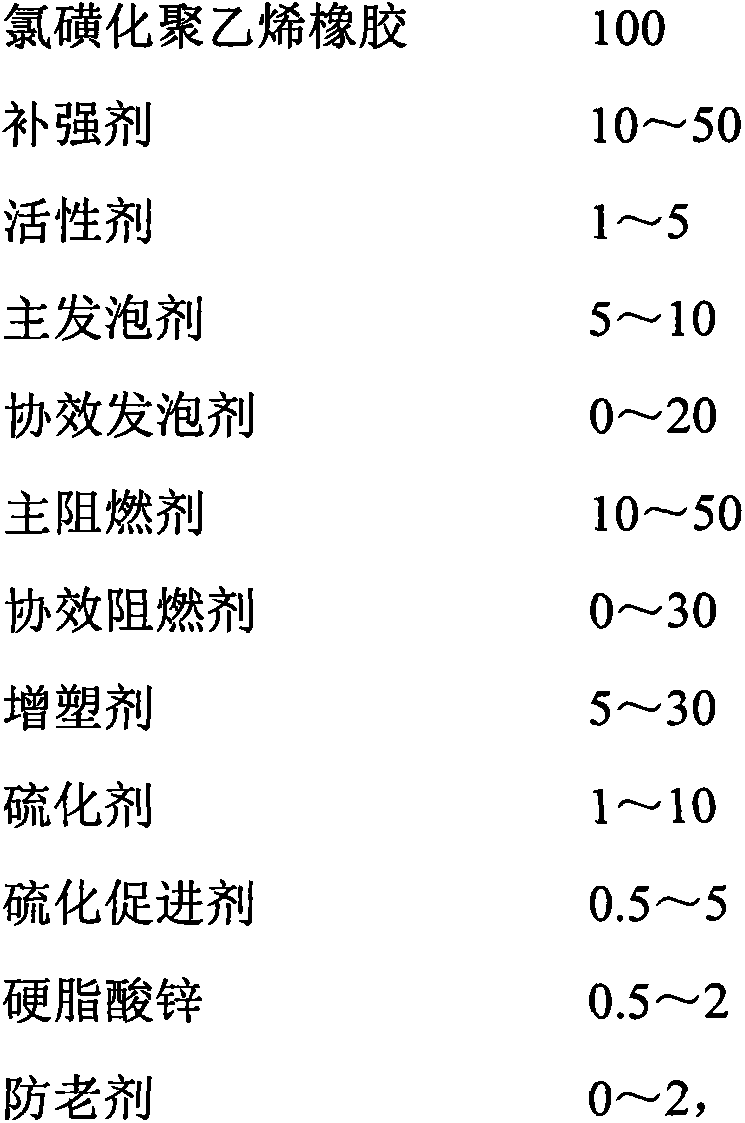

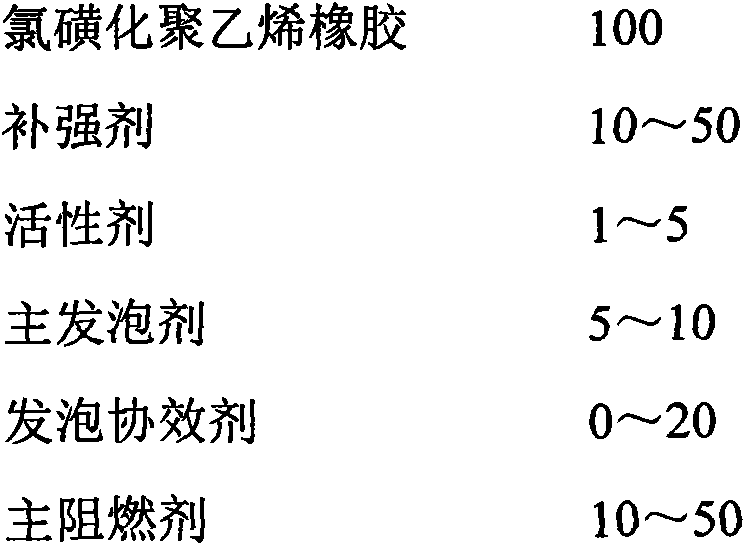

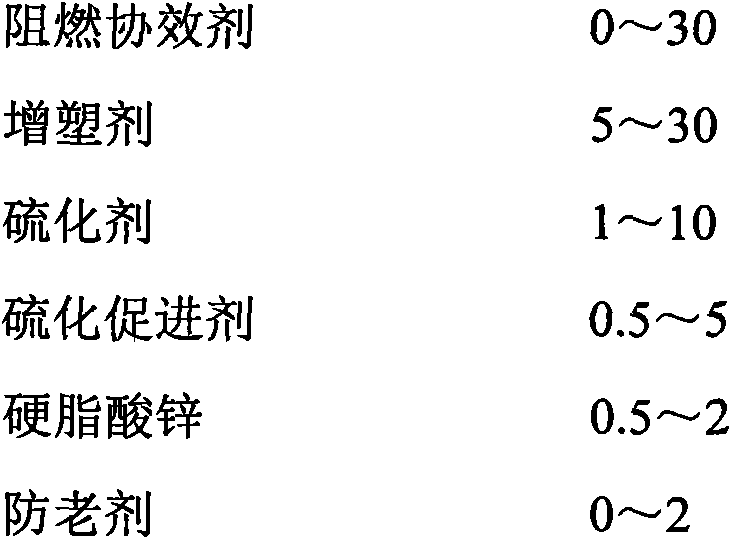

Environmentally-friendly ultralight flame-retardant rubber sole material and manufacturing method thereof

The invention relates to an environmentally-friendly ultralight flame-retardant rubber sole material and a manufacturing method thereof, and particularly relates to a manufacturing method of footwear product soles with high requirements on light weight and flame retardant property. The environmentally-friendly ultralight flame-retardant rubber sole material comprises chlorosulfonated polyethylene rubbers, a reinforcing agent, an active agent, a plasticizer, a foaming agent, a synergistic foaming agent, a flame retardant, a synergistic flame retardant, a vulcanizing agent and a vulcanization accelerator. According to the invention, through the screening and optimization of a series of formulas of the reinforcing agent, the plasticizer, the vulcanizing agent, the foaming agent, the synergistic foaming agent and the synergistic flame retardant, an ultralight flame-retardant sole material with a relative density of 0.3-0.5 g / cm3 is prepared, wherein in a flame retardant property test, the limit oxygen index of the sole material is greater than or equal to 34.5%, and the UL-94 reaches level V-a. The material has the following advantages: soles are lighter in weight and excellent in flame retardant property, and abandoned soles do not release toxic nitrosamine, polybrominated dibenzo-p-dioxins (PBDD) and polybrominated diphenyl furans (PBDF) in the process of burning.

Owner:CHINA LEATHER & FOOTWEAR IND RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com