Halogen-free polyvinyl composite for manufacturing pipes and manufacturing method thereof

A polyethylene and composition technology, applied in the preparation of halogen-free polyethylene composition for pipes and its preparation field, can solve the problems of incomplete flame retardant regulations, etc., and achieve excellent mechanical and mechanical properties, excellent antistatic properties, and environmental friendliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~10 and comparative example 1~2

[0040] This group of examples aims to demonstrate the halogen-free polyethylene composition for preparing pipes and the preparation method thereof according to the present invention. The polyethylene described in the embodiment is high density polyethylene.

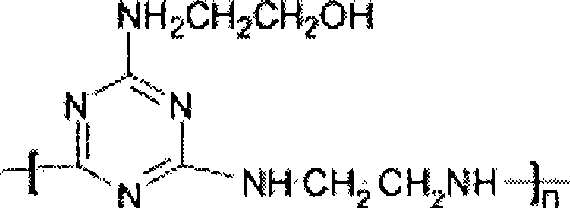

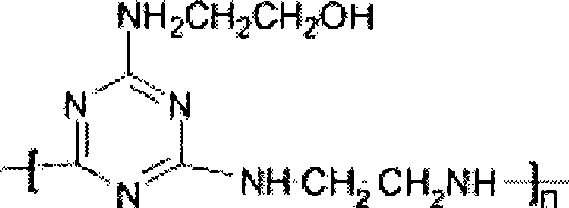

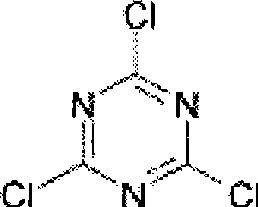

[0041] According to the data listed in Table 1, the coated ammonium polyphosphate, melamine and its derivatives, and the halogen-free macromolecular carbon-forming flame retardant CAR were pulverized in a jet mill, and then mixed in a high-speed mixer to obtain a halogen-free expansion type flame retardant. Then the halogen-free intumescent flame retardant, phosphonate flame retardant, antistatic agent, high-density polyethylene, flow modifier, and dispersant obtained above are mixed in proportion, mixed in a high-speed mixer, and extruded to produce Granules, sample preparation by injection molding, test performance, the results are also shown in Table 1.

Embodiment 11~20 and comparative example 3~4

[0043] The polyethylene in this group of examples is a blend of ultra-high molecular weight polyethylene and high-density polyethylene, and the weight ratio of the two blends is 1: (1-5). The matrix viscosity-average molecular weight of ultra-high molecular weight polyethylene is 2 to 3.5 million.

[0044] According to the data listed in Table 2, the coated ammonium polyphosphate, melamine and its derivatives, and the halogen-free macromolecular carbon-forming flame retardant are pulverized in a jet mill, and then mixed in a high-speed mixer to obtain a halogen-free expansion type flame retardant. Then mix the obtained halogen-free intumescent flame retardant, phosphonate flame retardant, antistatic agent, polyethylene, flow modifier, and dispersant in proportion, mix in a high-speed mixer, extrude and granulate, and inject Sample preparation, test performance, the results are also shown in Table 2.

Embodiment 21~30 and comparative example 5~6

[0046] The polyethylene used in this group of examples is a blend of ultra-high molecular weight polyethylene, high-density polyethylene and low-density polyethylene. The weight ratio of the blending of the three is: 1:1-7:0.4-3. The matrix viscosity-average molecular weight of ultra-high molecular weight polyethylene is 4 to 6 million.

[0047] According to the data listed in Table 3, the coated ammonium polyphosphate, melamine and its derivatives, and the halogen-free macromolecular carbon-forming flame retardant are pulverized in a jet mill, and then mixed in a high-speed mixer to obtain a halogen-free expansion type flame retardant. Then mix the obtained halogen-free intumescent flame retardant, phosphonate flame retardant, antistatic agent, polyethylene, flow modifier, and dispersant in proportion, mix in a high-speed mixer, extrude and granulate, and inject Sample preparation, test performance, the results are also shown in Table 3.

[0048]

[0049]

[0050]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com