Polyester having excellent fire-retardancy and preparation method thereof

A technology of flame retardant performance and polyester, applied in the field of polyester and production, can solve the problems of secondary fire of polyester, non-lasting flame retardant effect, toxic smoke, etc., and achieve the effect of excellent flame retardant performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

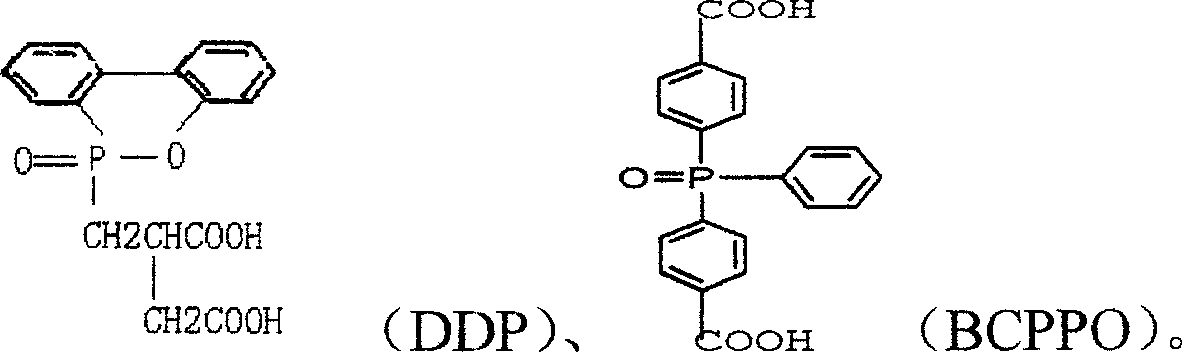

Image

Examples

Embodiment 1

[0026] Add 1.5 parts of diphenylsilanediol, 12.32 parts of terephthalic acid, and 5.63 parts of ethylene glycol into a series of reactors with evaporators and vacuum devices, and heat them to about 250 degrees for esterification reaction. When the chemical reaction is carried out to more than 90%, add 0.98 parts of ethylene glycol solution with a concentration of 60% PHP, 0.006 parts of catalyst antimony trioxide, and 0.053 parts of titanium dioxide in the reaction system, and gradually reduce the pressure to below 200 Pascals, and the temperature is 290 The polycondensation reaction is carried out under high temperature conditions, and the reaction is about three hours. After the reaction is completed, the flame-retardant chips are obtained, and conventional melt spinning is carried out, or the next step is processed to obtain fibers.

Embodiment 2

[0028] The addition of raw materials is as follows: 2.25 parts of hydroxy silicone oil (hydroxyl content 8%), 12.75 parts of terephthalic acid, 5.83 parts of ethylene glycol, 0.053 parts of titanium dioxide, 0.006 parts of catalyst antimony trioxide, the concentration is 70% 3 parts of DDP in ethylene glycol solution. All the other are with embodiment 1.

Embodiment 3

[0030] The device is the same as in Example 1, and the amount of raw materials added is as follows: 1.5 parts of diphenylsilanediol, 15 parts of dimethyl terephthalate, 9.79 parts of ethylene glycol, 0.004 parts of cobalt acetate as a transesterification catalyst, 0.053 parts 1 part of titanium dioxide, 0.006 part of 65% BCPPO in ethylene glycol solution of 0.006 part of catalyst antimony trioxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com