Patents

Literature

6643 results about "Low-density polyethylene" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-density polyethylene (LDPE) is a thermoplastic made from the monomer ethylene. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerization. Its manufacture employs the same method today. The EPA estimates 5.7% of LDPE (recycling number 4) is recycled. Despite competition from more modern polymers, LDPE continues to be an important plastic grade. In 2013 the worldwide LDPE market reached a volume of about US$33 billion.

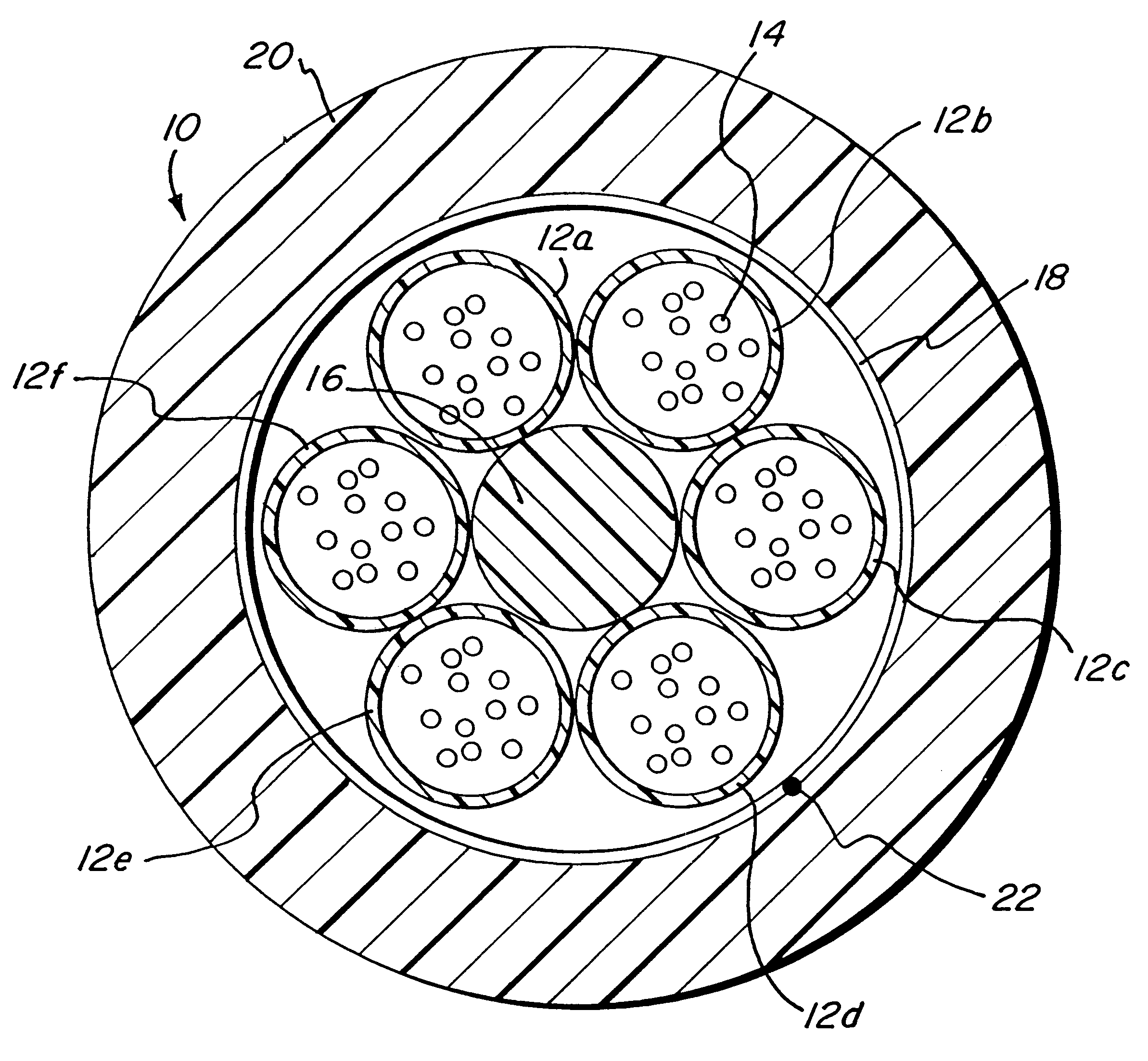

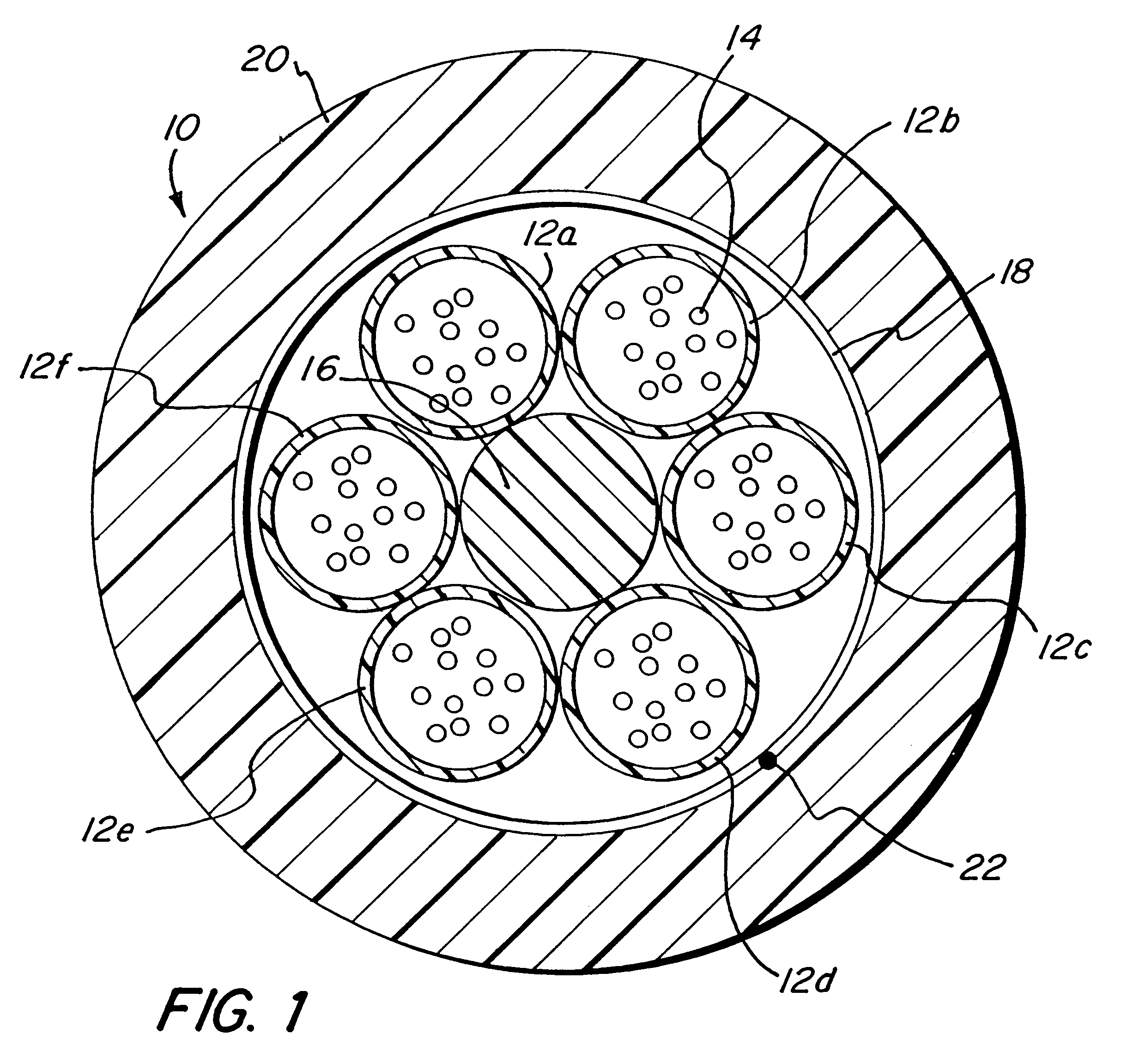

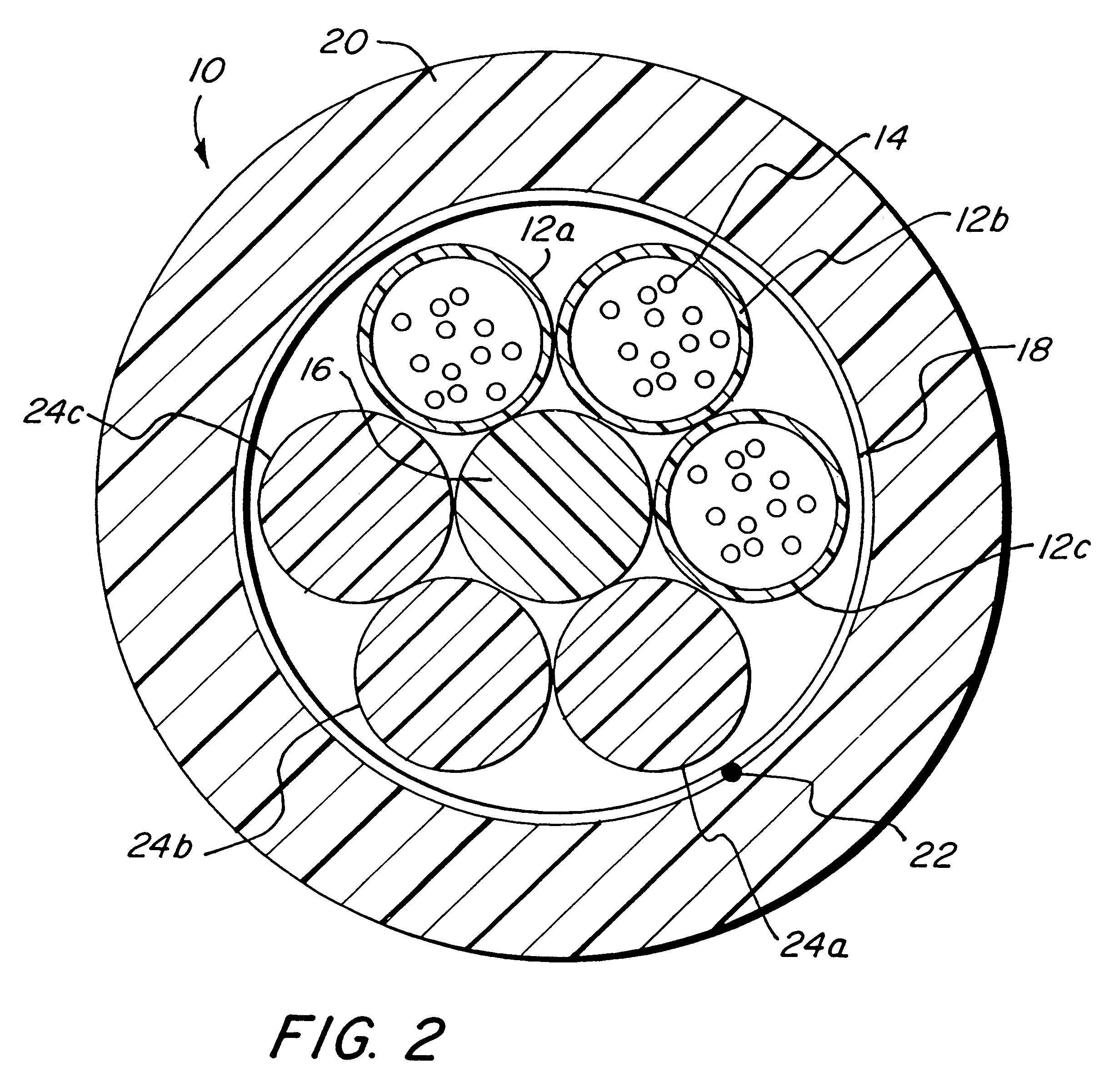

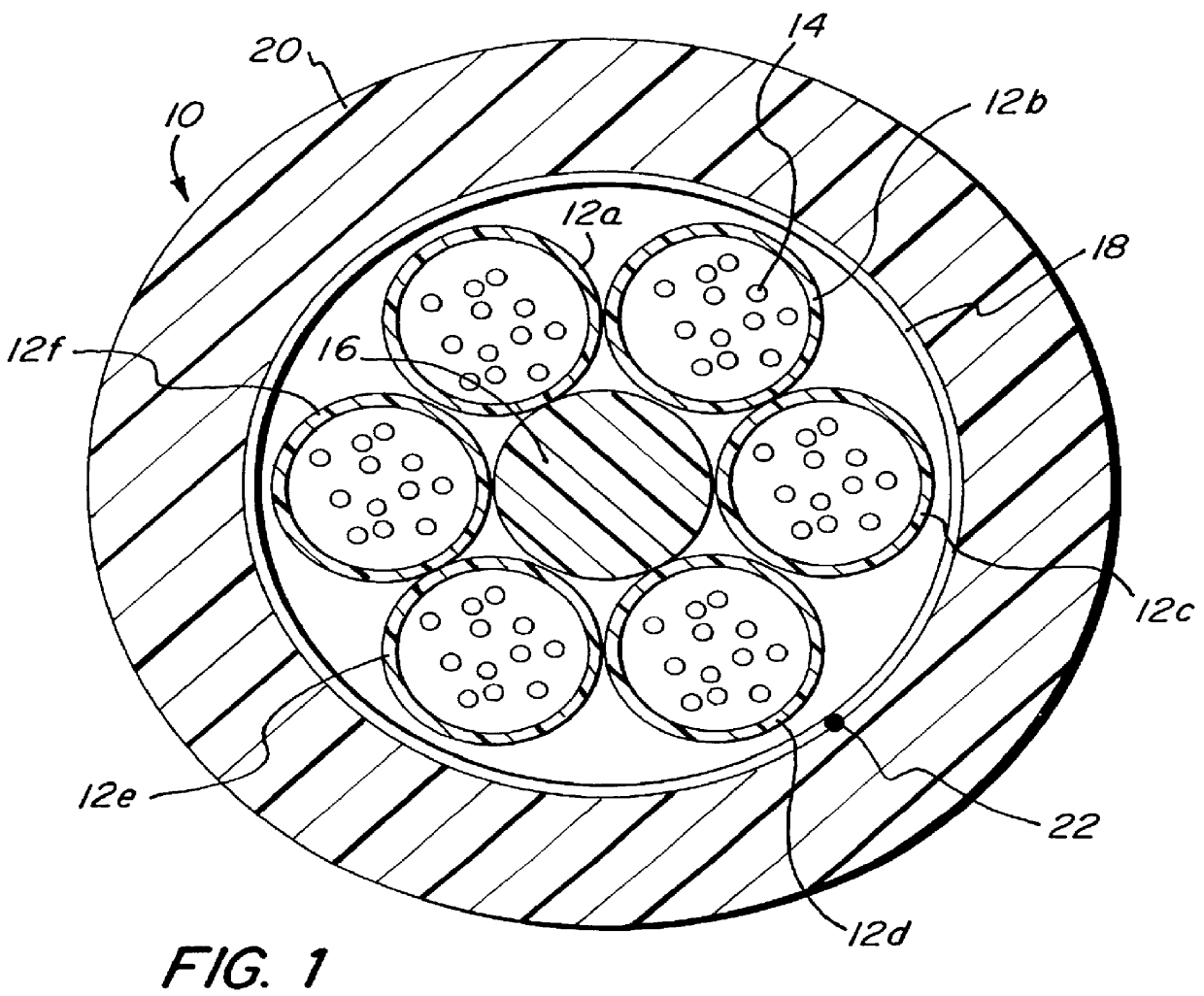

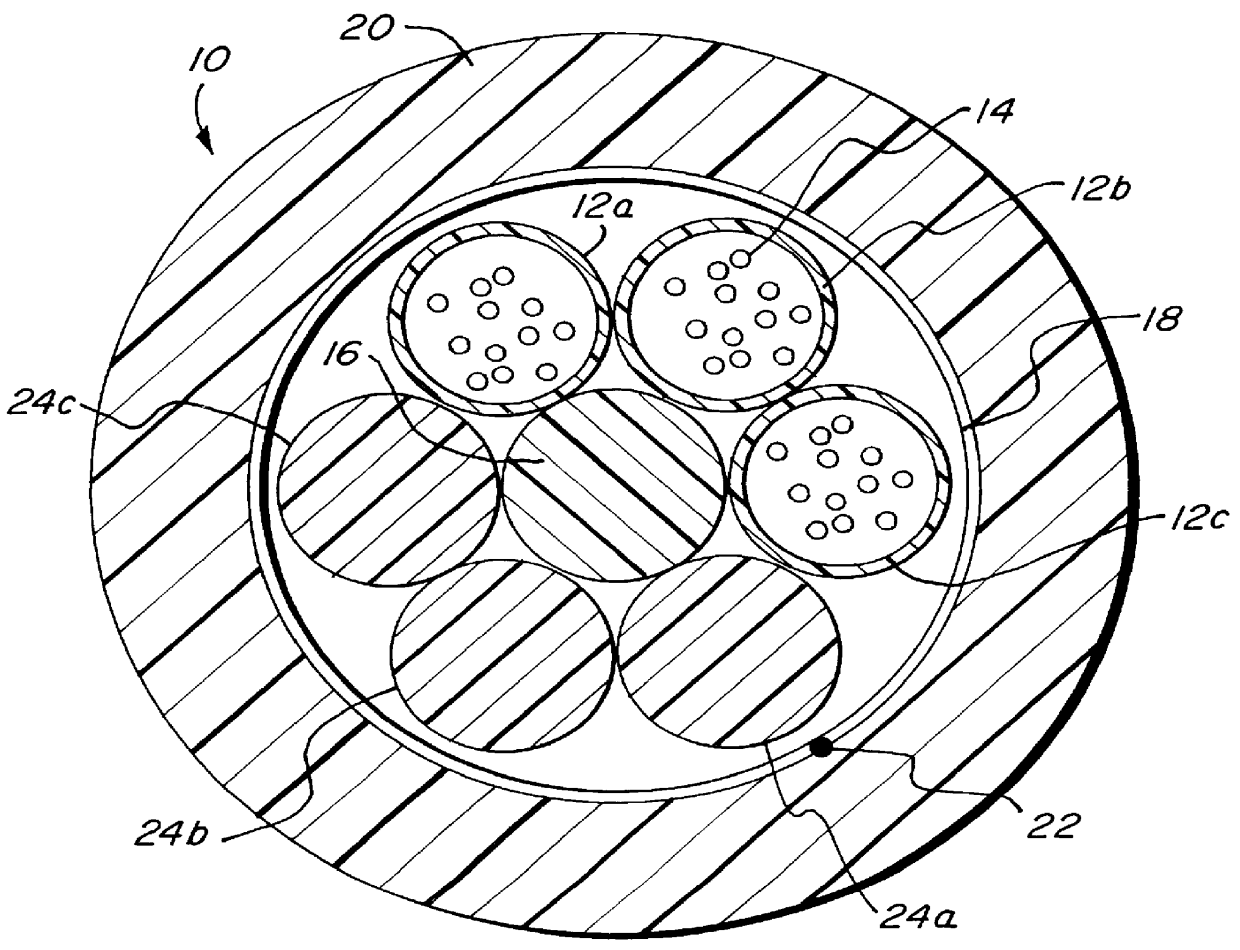

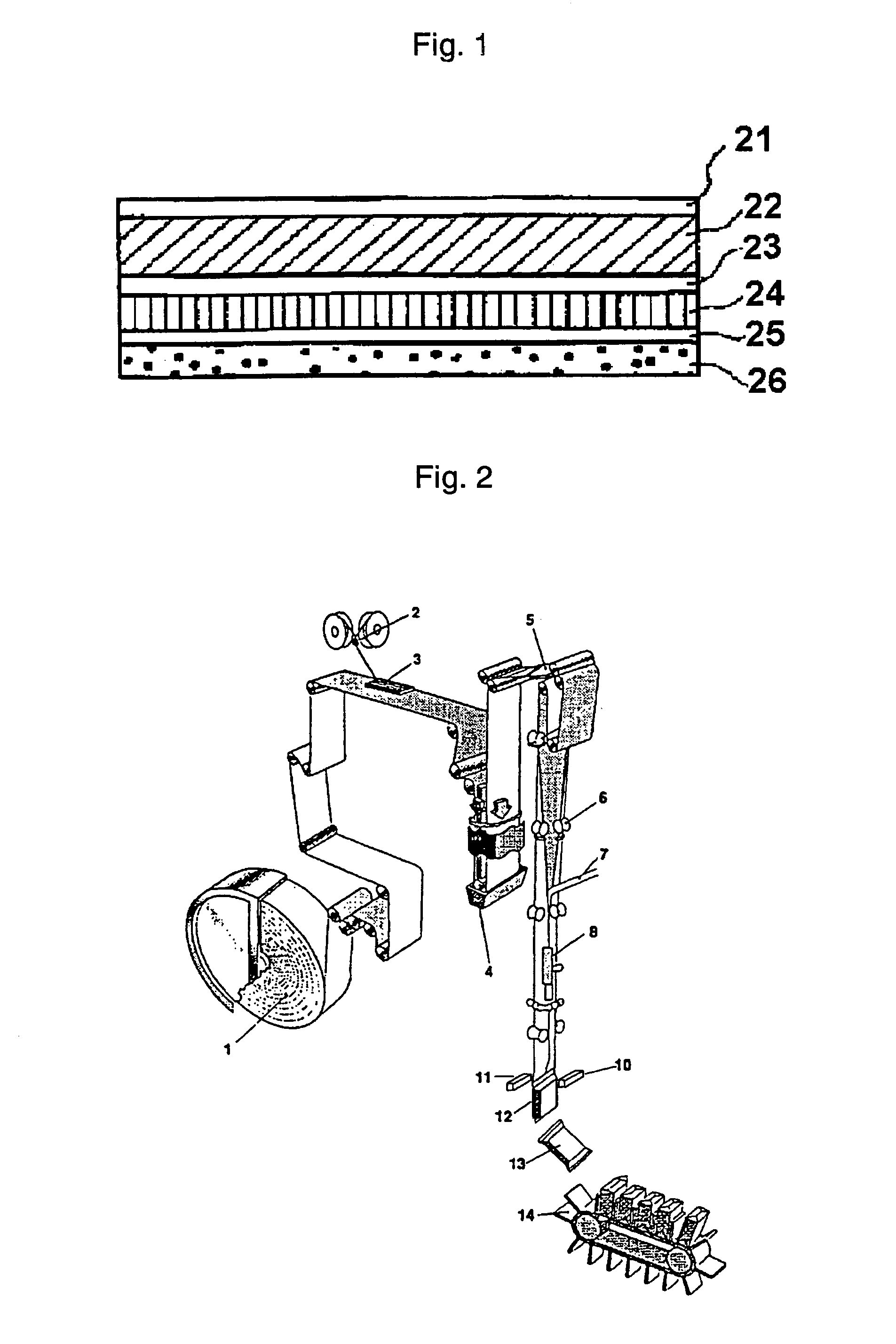

Polypropylene filler rods for optical fiber communications cables

InactiveUS6210802B1Synthetic resin layered productsFibre mechanical structuresLow-density polyethyleneEngineering

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

Linear low density polymer blends and articles made therefrom

ActiveUS20070260016A1Synthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

This invention relates to blends of linear low density polyethylene copolymers with other linear low density polyethylenes or very low density, low density, medium density, high density, and differentiated polyethylenes. The invention also includes articles produced from the linear low density polyethylene and polyethylene blends described.

Owner:EXXONMOBIL CHEM PAT INC

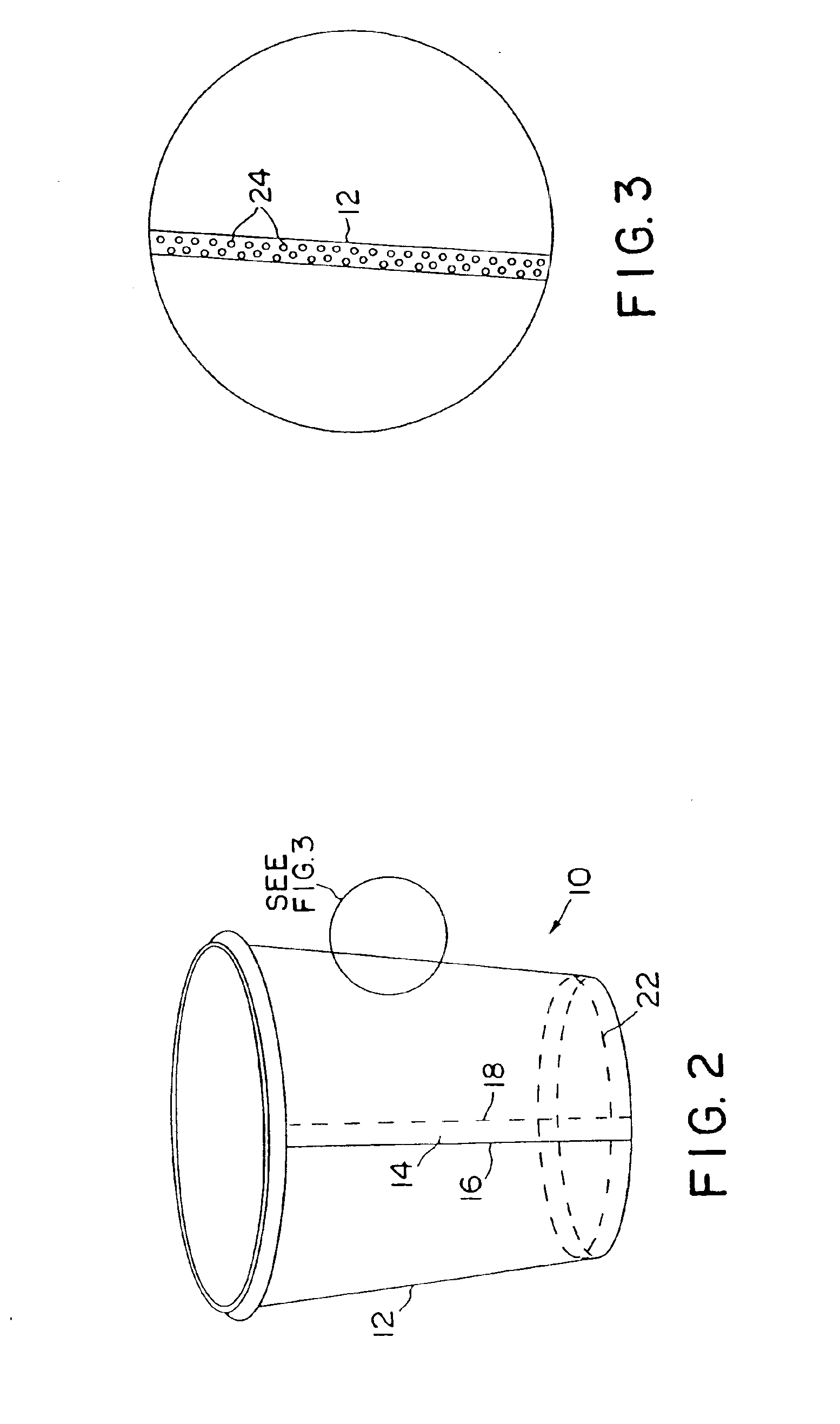

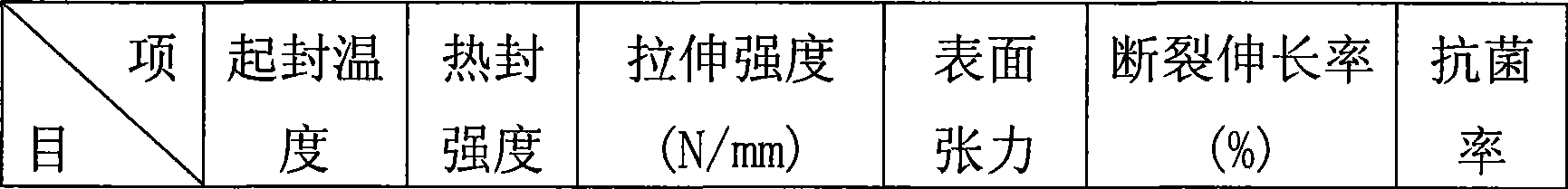

Polypropylene filler rods for optical fiber communications cables

InactiveUS6066397ACladded optical fibreFibre mechanical structuresLow-density polyethyleneEngineering

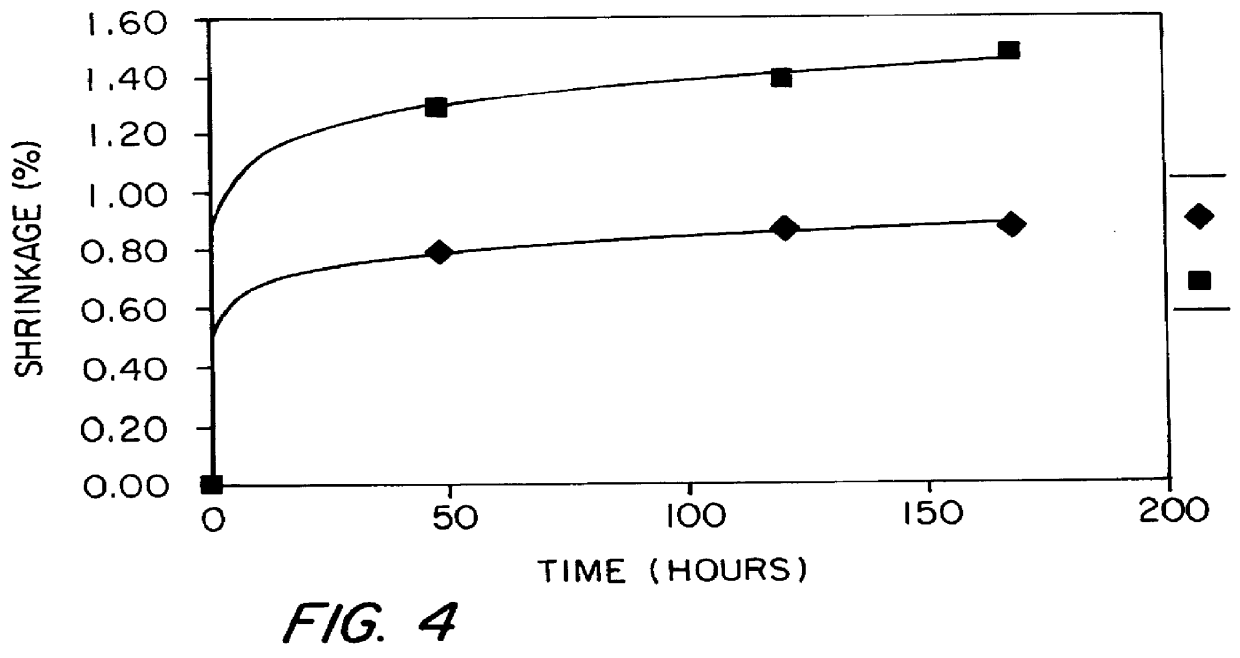

A filler rod for occupying space in a stranded optical fiber communications cable having at least one buffer tube containing at least one optical fiber is disclosed. The filler rod comprises an elongated rod extruded from a polypropylene homopolymer, a polypropylene-polyethylene copolymer (i-PP) resin material, or preferably, from a polypropylene-polyethylene copolymer having a nucleating agent disbursed therein. The resin material is foamed during extrusion so as to have a plurality of void spaces therein and a relative density which is less than 1 relative to the unfoamed resin material. As compared to rods made from high density polyethylene, the i-PP filler rods show a greater foaming efficiency, more efficient use of material, an improved combination of mechanical properties and density, reduced post-extrusion shrinkage and a substantial reduction in the sticking of the filler rods to the outer jacket that is experienced with high density polyethylene filler rods.

Owner:DRAKA COMTEQ BV

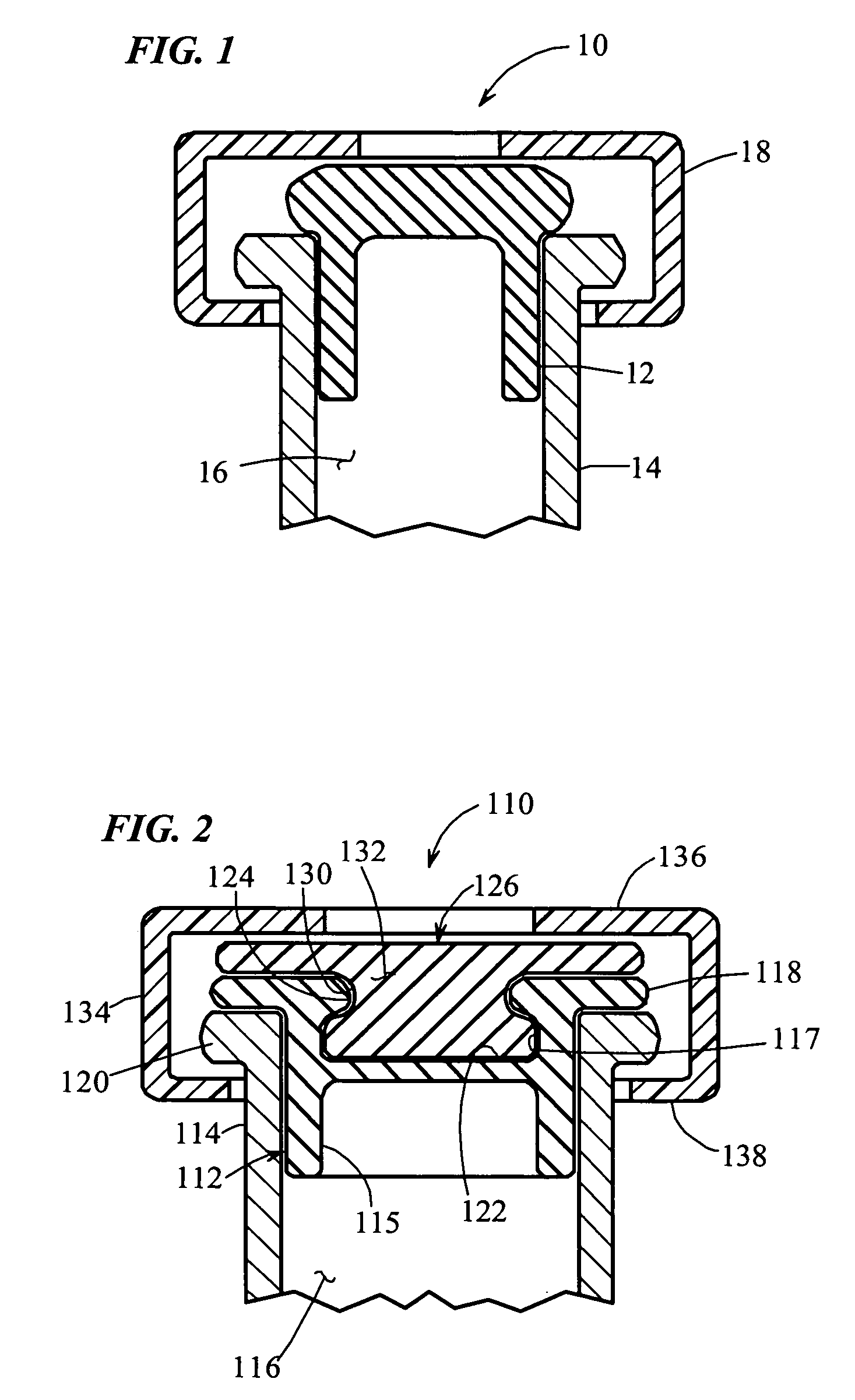

Surgical device with tack-free gel and method of manufacture

InactiveUS20050033246A1Significant drag forceImprove complianceCannulasSurgical needlesMolten stateLow-density polyethylene

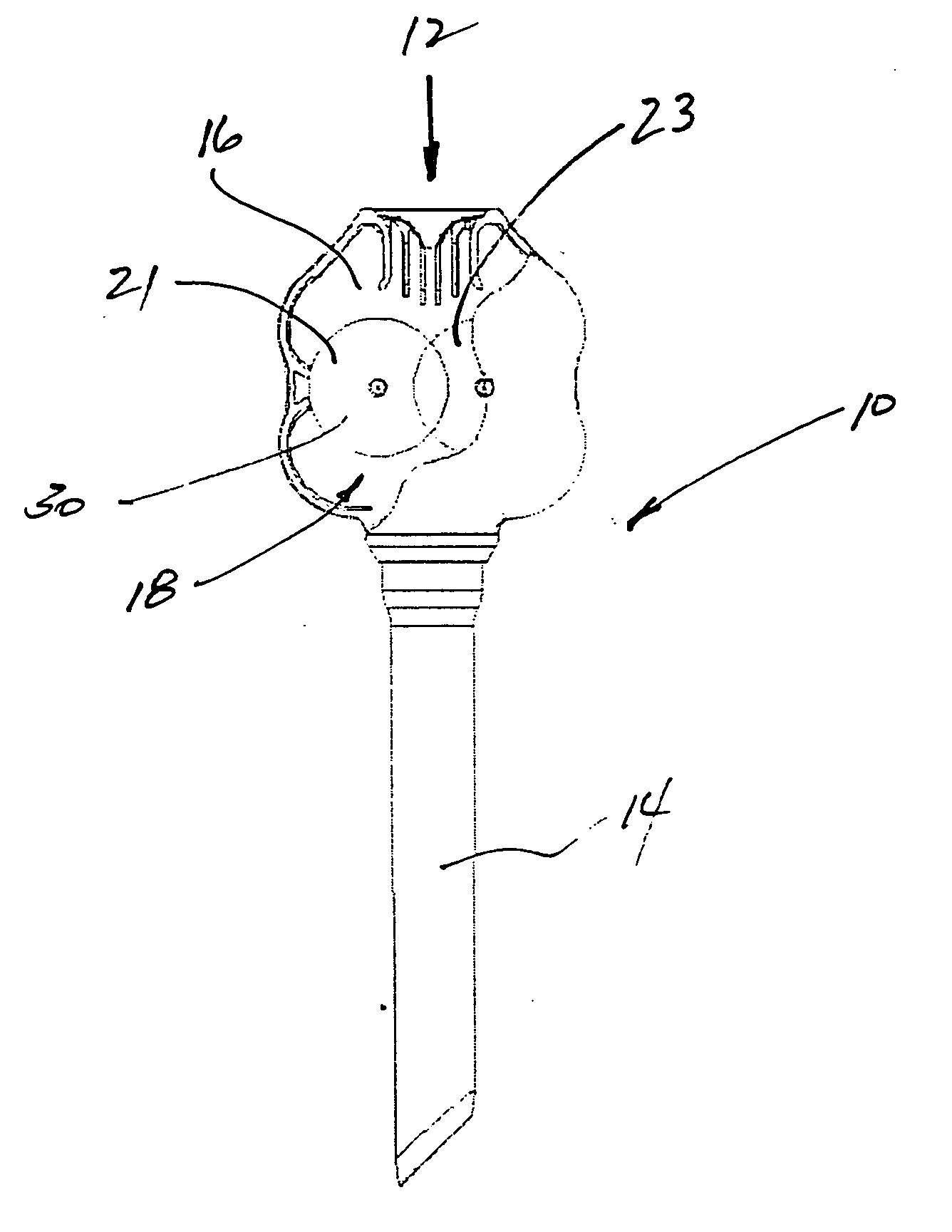

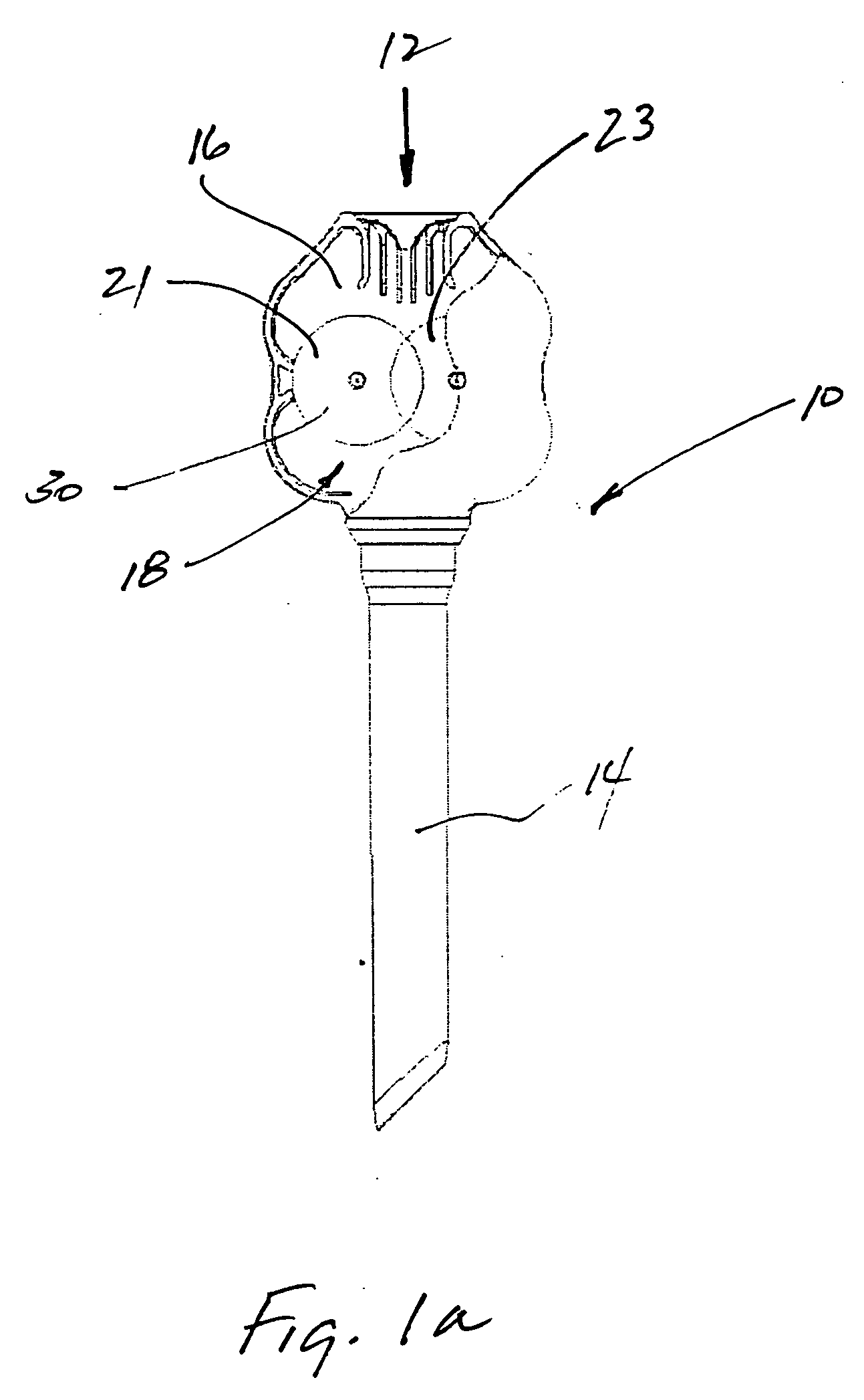

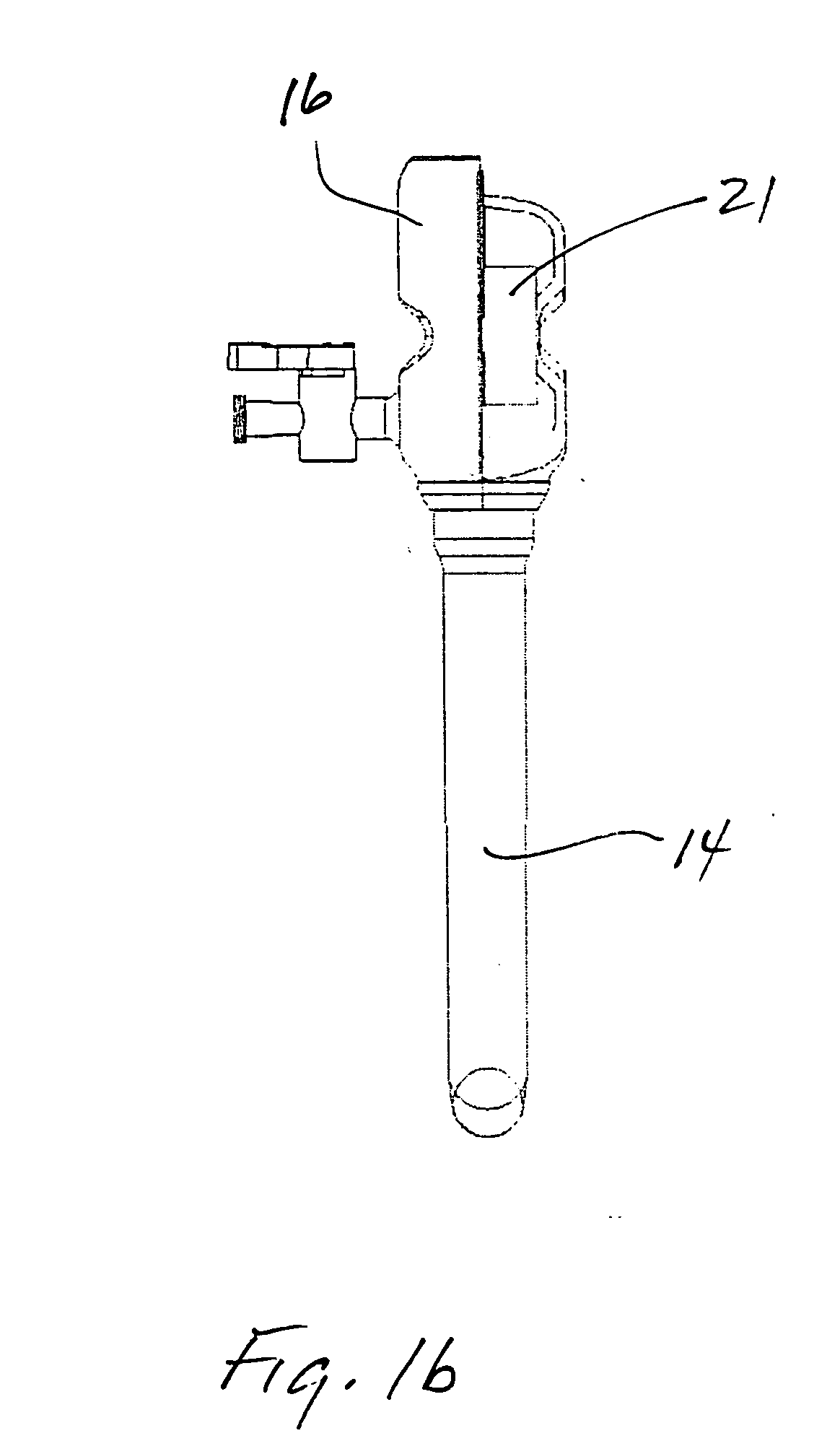

A process of making a tack-free gel is disclosed comprising the steps of providing a mold defining a mold cavity, the mold cavity comprising a plastic material; pouring or injecting a molten gel having a high molding temperature into the mold cavity; and forming the tack-free gel as a thin layer of plastic of the mold cavity is melted over the gel. The forming step further comprises cooling the gel from the molten state to a solidified state. The melting temperature of the plastic material is lower than the molding temperature of the gel; and the higher the temperature differential, the greater the melting of the plastic material and the thicker the layer of the plastic material on the surface of the gel. The mold may be formed of low-density polyethylene (LDPE). With the process of the invention, the heat of the molten gel at its molding temperature is transferred to the surface of the LDPE mold so as to melt a thin layer of the LDPE. The mold may comprise a mold base having a plurality of mold holes forming a plurality of mold cavities, each of the mold holes comprising an axial pin to mold an axial hole through a center of the gel, an LDPE cylinder providing a predetermined inside diameter for the mold, and an LDPE disc mounted on the axial pin and disposed at the bottom of each mold cavity in the mold base. The process may further comprise the step of dabbing the gel in a low-friction powder such as polytetrafluoroethylene (PTFE) and a lubricant. The mold may further comprise a mold top disposed axially of the mold base and comprises a plurality of holes forming a plurality of cavities, each of the mold top holes is adapted to receive the LDPE cylinder, and a second LDPE disc disposed at the top of each mold cavity of the mold top.

Owner:APPL MEDICAL RESOURCES CORP

Linear low density polymer blends and articles made therefrom

ActiveUS7951873B2Synthetic resin layered productsDomestic containersLow-density polyethyleneLinear low-density polyethylene

This invention relates to blends of linear low density polyethylene copolymers with other linear low density polyethylenes or very low density, low density, medium density, high density, and differentiated polyethylenes. The invention also includes articles produced from the linear low density polyethylene and polyethylene blends described.

Owner:EXXONMOBIL CHEM PAT INC

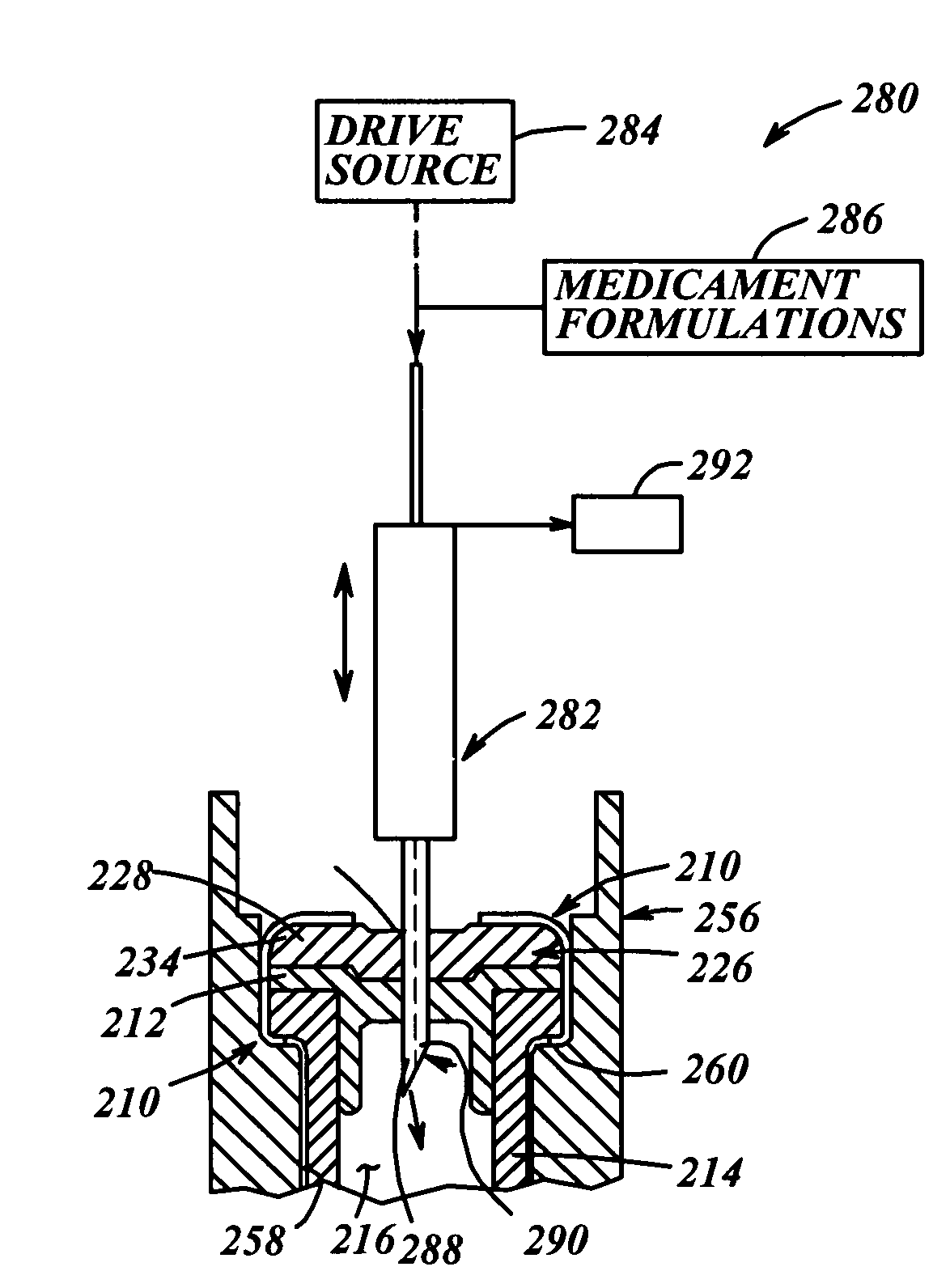

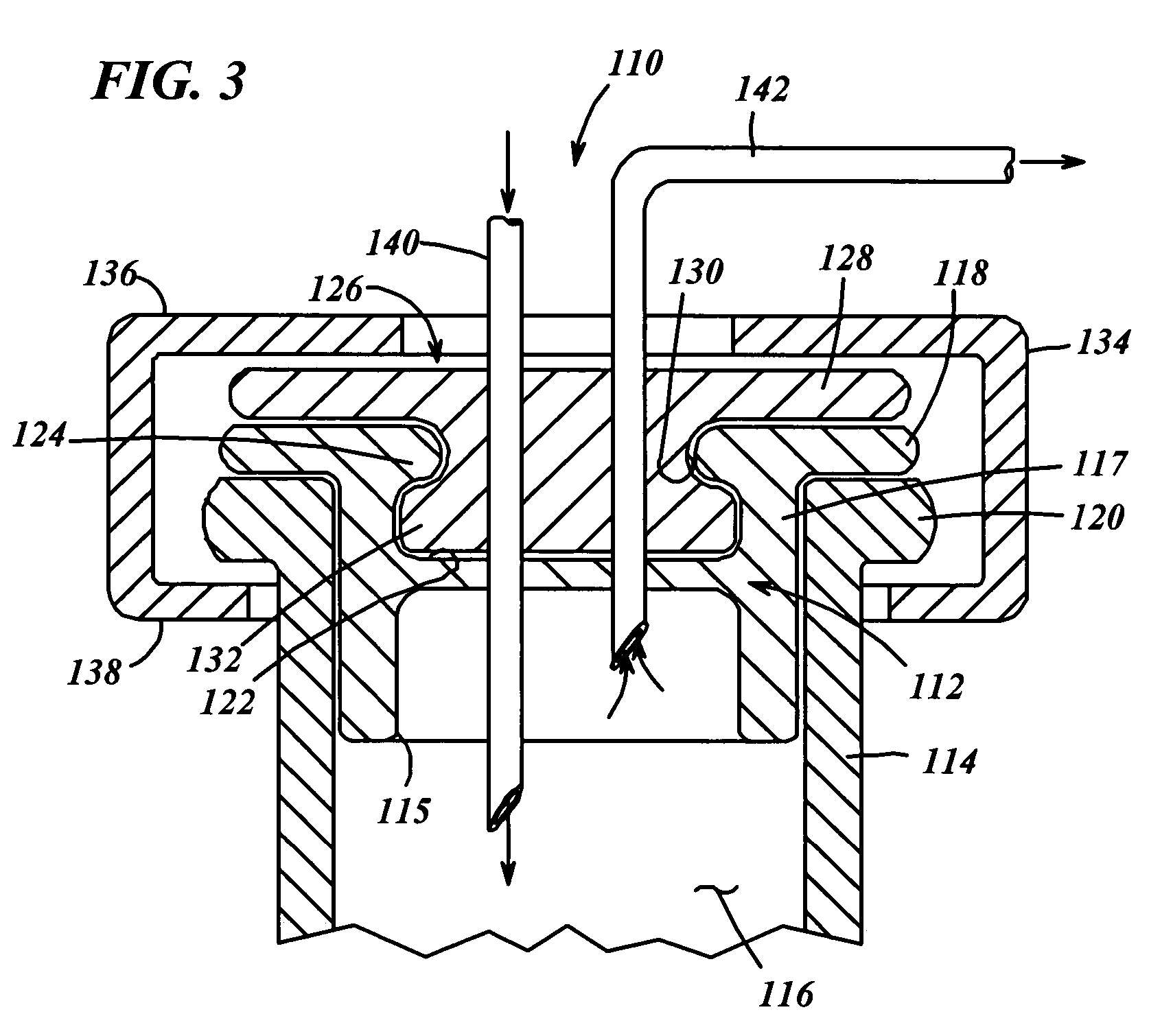

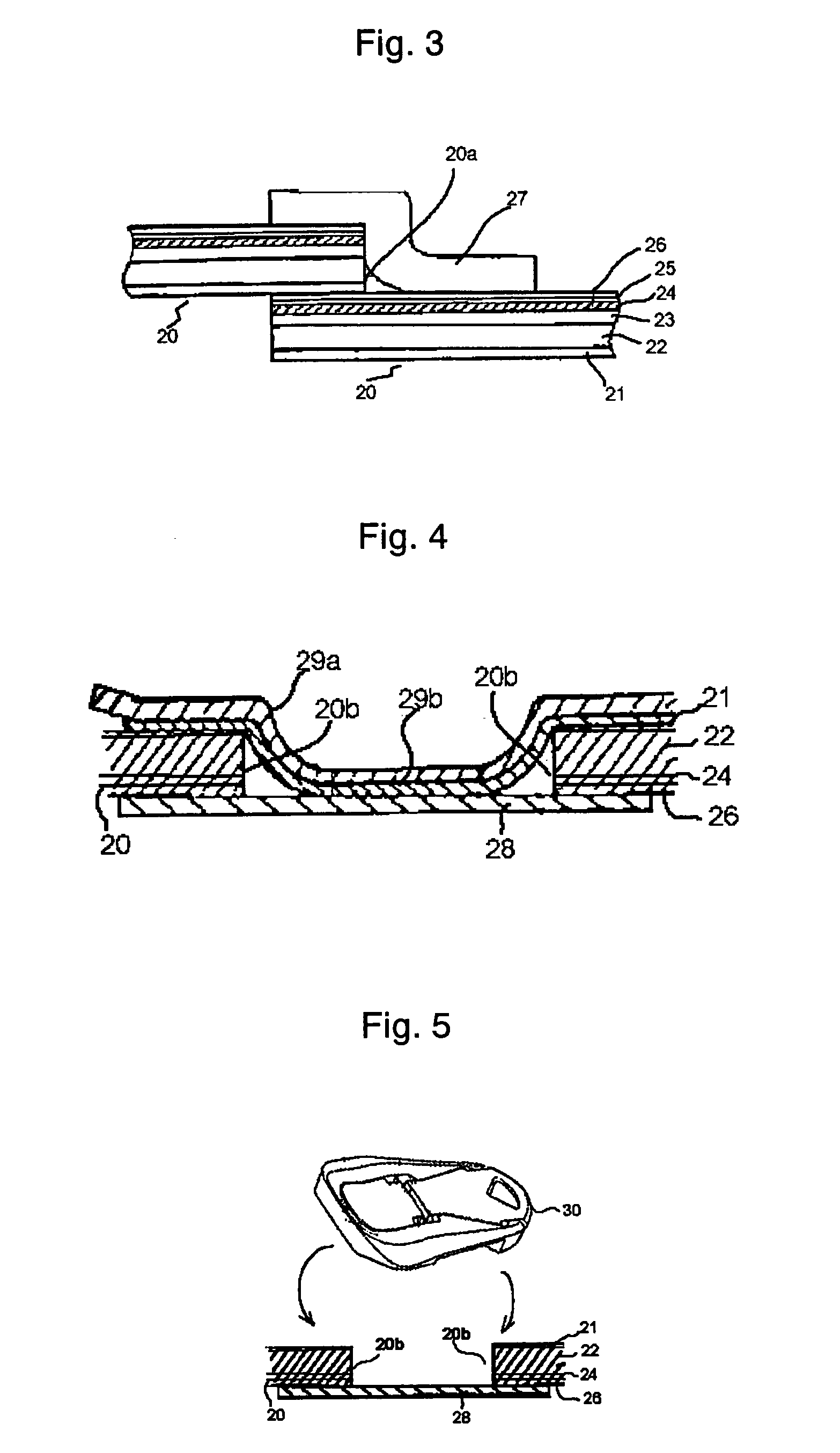

Medicament vial having a heat-sealable cap, and apparatus and method for filling the vial

InactiveUS7032631B2Stable environmentReduce frictionCapsCap application using vaccuumVialLow-density polyethylene

A resealable cap (110, 210) for a medicament vial (114, 214) has a base portion (112, 212) formed of vulcanized rubber or like material known for providing a stable environment for the medicament contained within the vial, and a resealable portion (126, 226) overlying the base portion. The resealable portion (126, 226) is made of low-density polyethylene or like material, and can be punctured by a needle or like injection member (140, 282) for dispensing medicament into the vial (114, 214). Prior to filling, the cap (110, 210) is assembled to the vial (114, 214) and the cap / vial assembly is sterilized. Then, a needle (140, 282) is inserted through the cap (110, 210) and medicament is introduced through the needle and into the vial. Upon withdrawal of the needle (140, 282), the penetrated region of the cap (248) is fused by laser (276) or direct heat sealing (264) to hermetically seal the needle hole (294) in the cap.

Owner:MEDINSTILL DEV

Flame retardant composition

Owner:NIPPON YUNIKAA

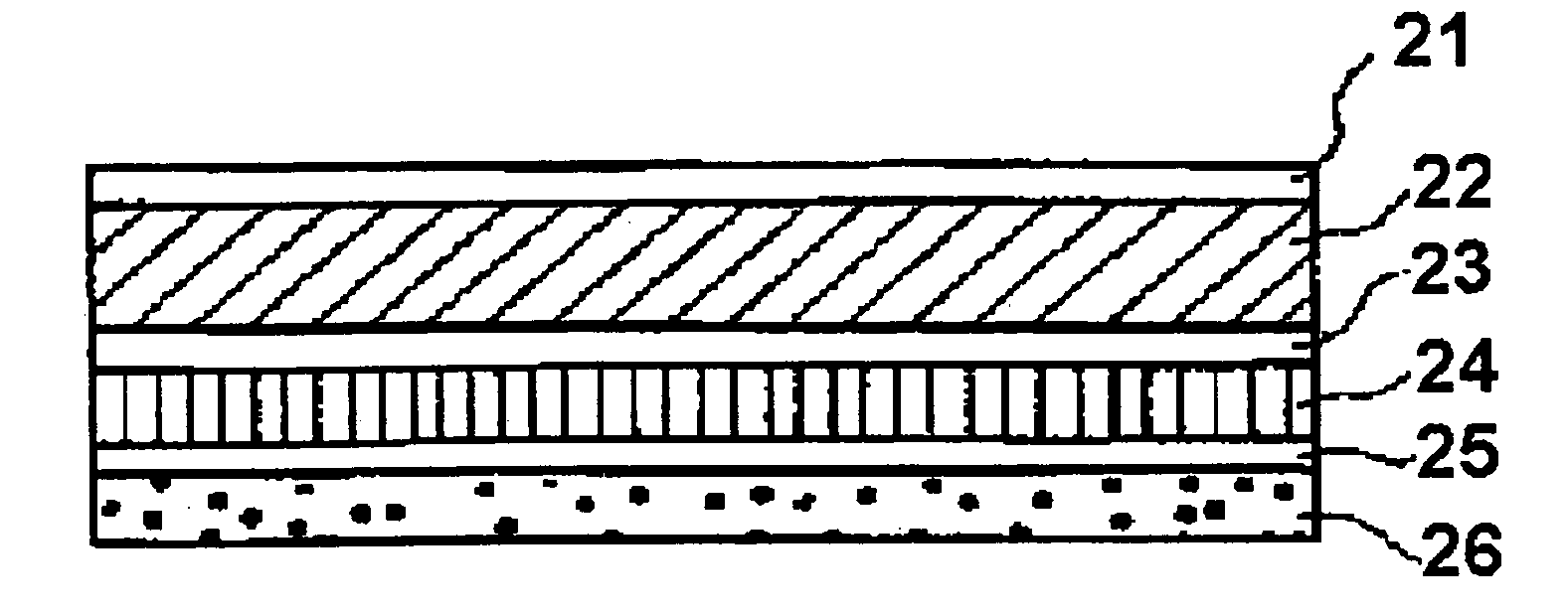

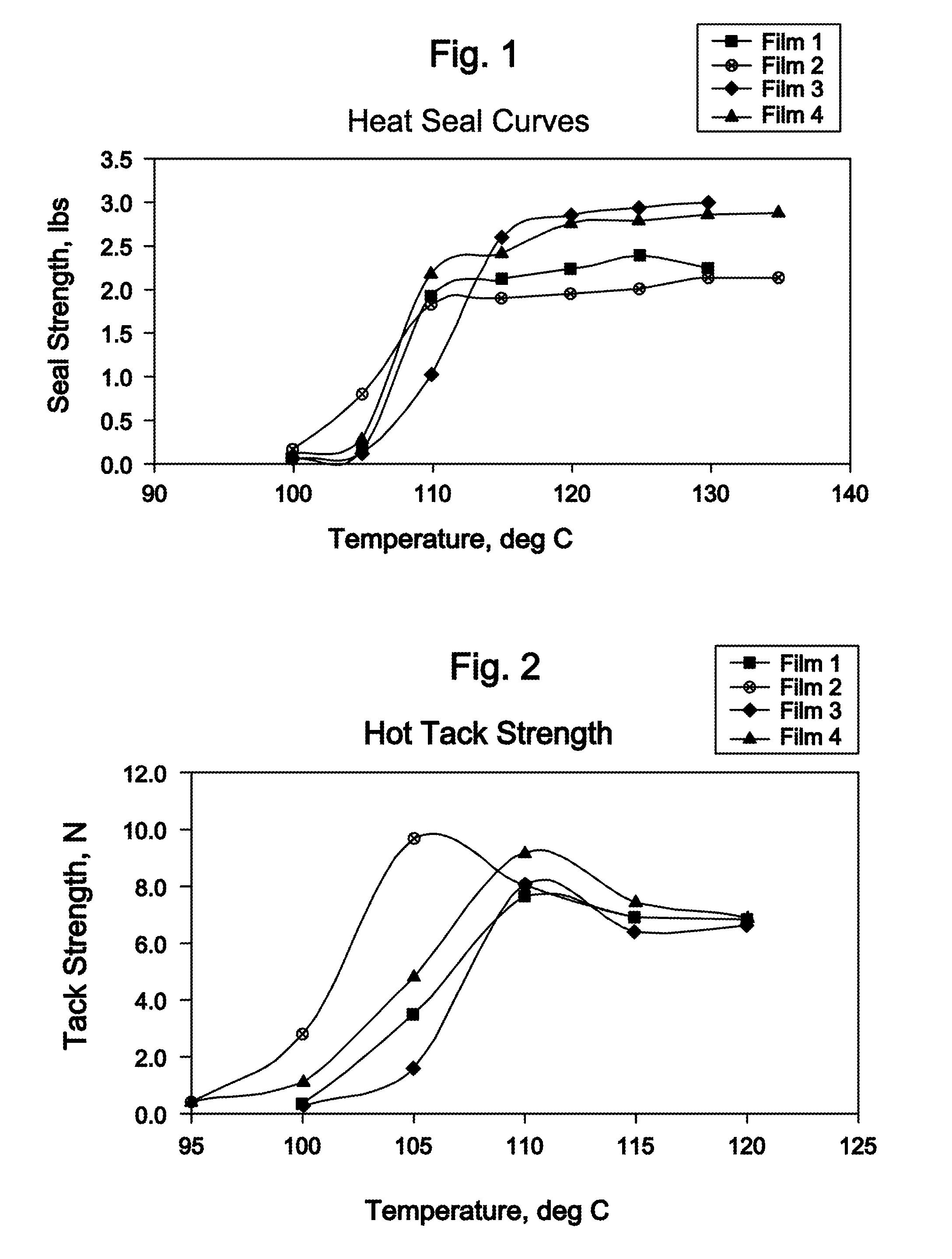

Laminated packaging material for paper container

InactiveUS6974612B1Easy to manufactureQuick heat sealEnvelopes/bags making machineryFlexible coversLow-density polyethyleneLinear low-density polyethylene

A paper packaging container is formed from the packaging material comprising constitution layers of at least an outside thermoplastic material layer, a paper substrate layer, and an inside thermoplastic material layer, wherein the inside thermoplastic material layer contains at least a linear low density polyethylene, and has properties parameters of an average density of 0.900–0.930, a predetermined peak melting point, a melt flow index of 5–15, and a swelling ratio of 1.3–1.8. The use of the packaging material allows easy filling and packaging to the packaging container and quick heat sealing, and results in more toughly and strongly sealed container, and the material can be used for achieved good sealing independently of the temperature of food contents and thus maintaining the non-scalping and quality preservability of the content product.

Owner:TETRA LAVAL HLDG & FINANCE SA

Processes for producing polymer blends and polymer blend pellets

InactiveUS7803876B2Beneficial performance characteristicBeneficial storage and handling characteristicCeramic shaping apparatusChemical/physical/physico-chemical stationary reactorsLow-density polyethylenePolyester

Owner:EXXONMOBIL CHEM PAT INC

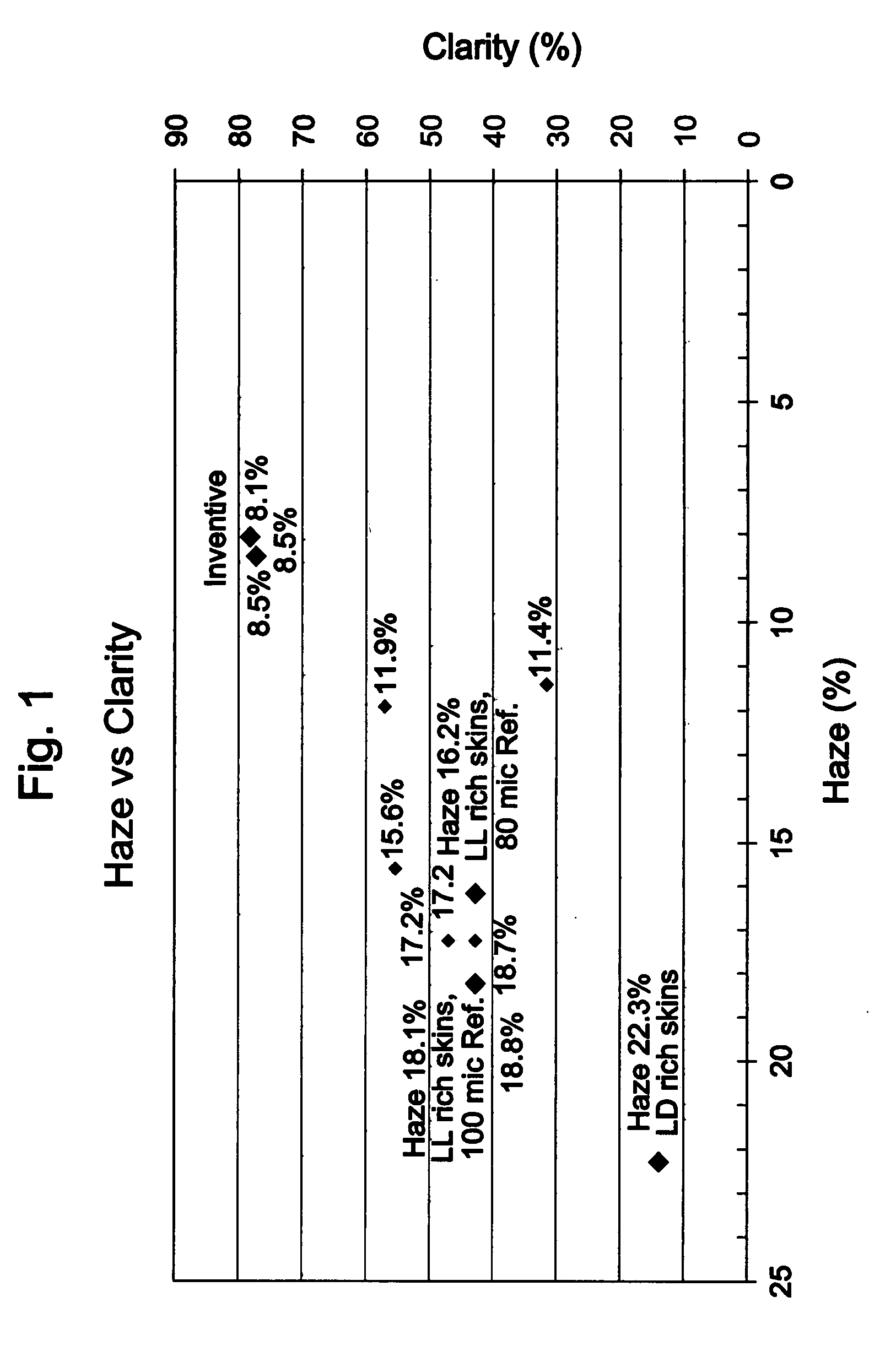

Ethylene-Based Polymers And Articles Made Therefrom

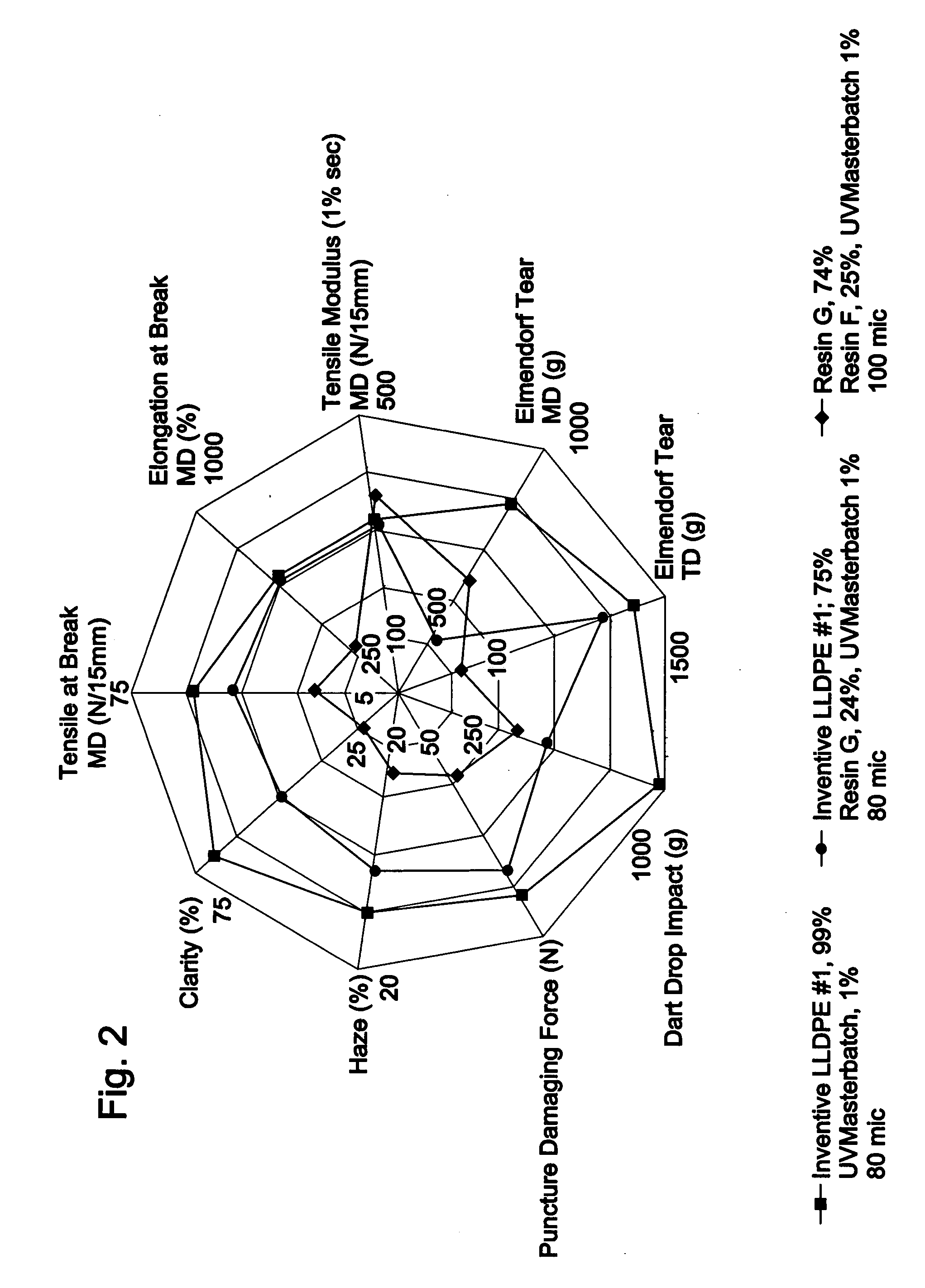

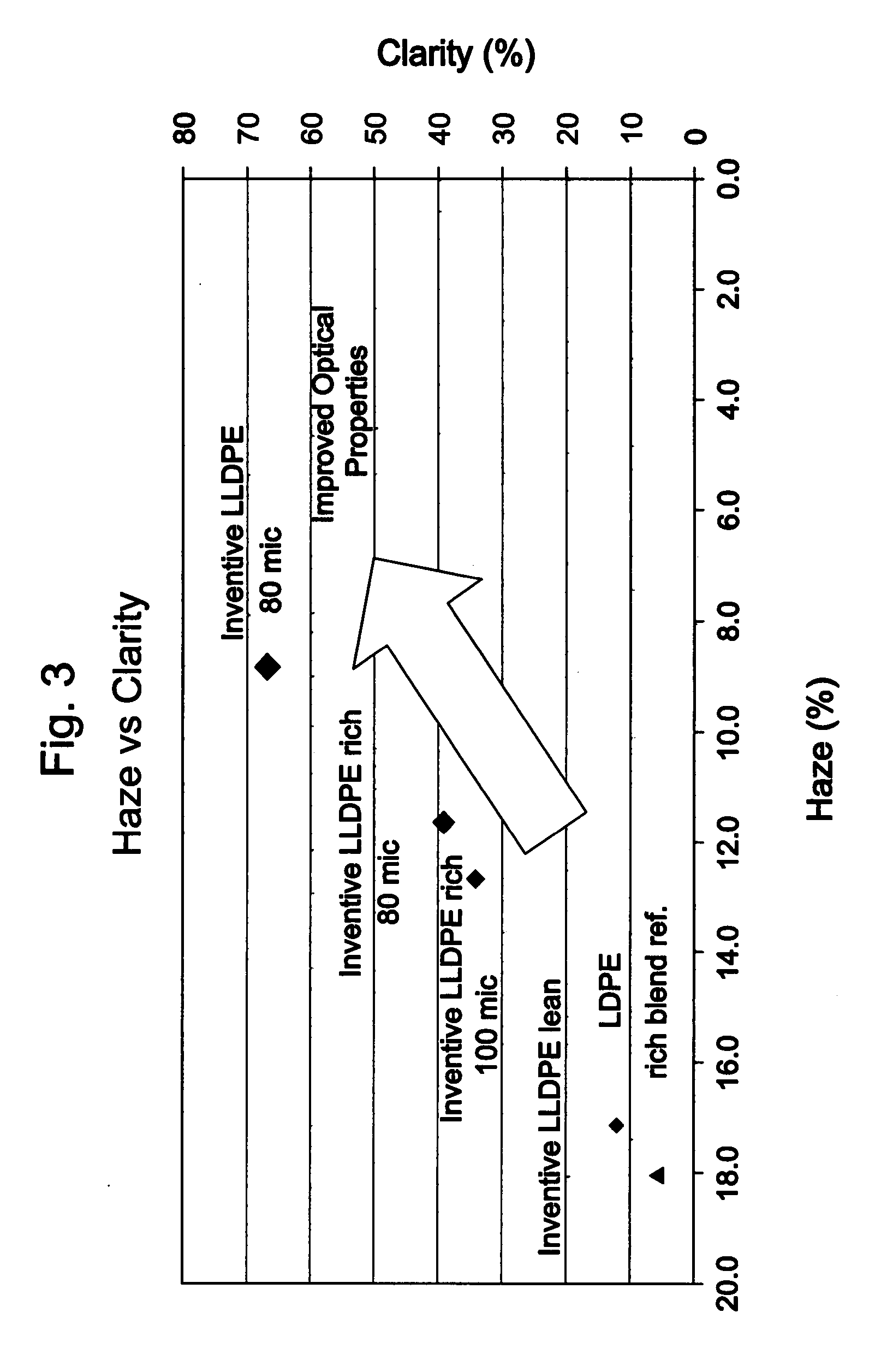

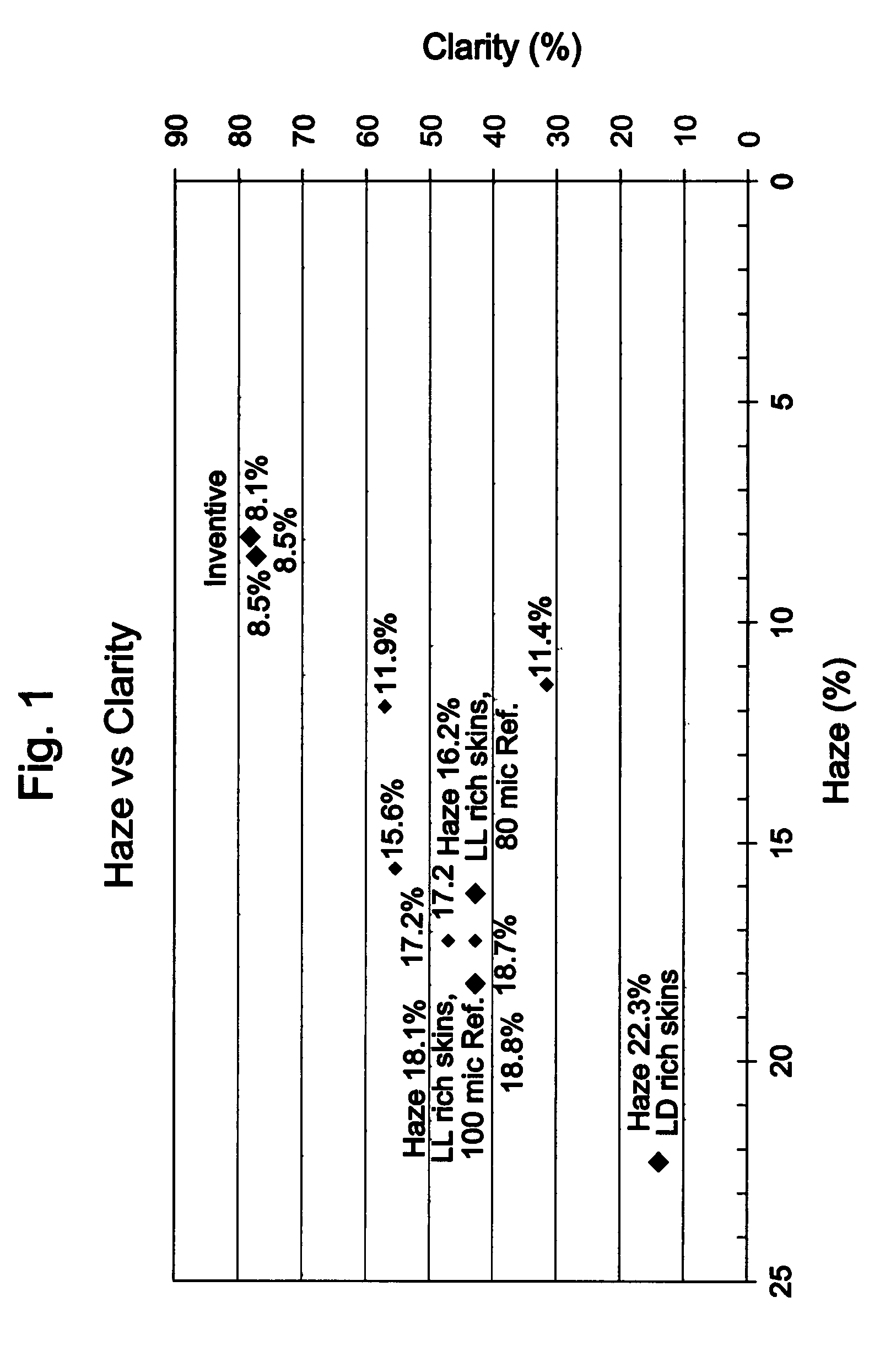

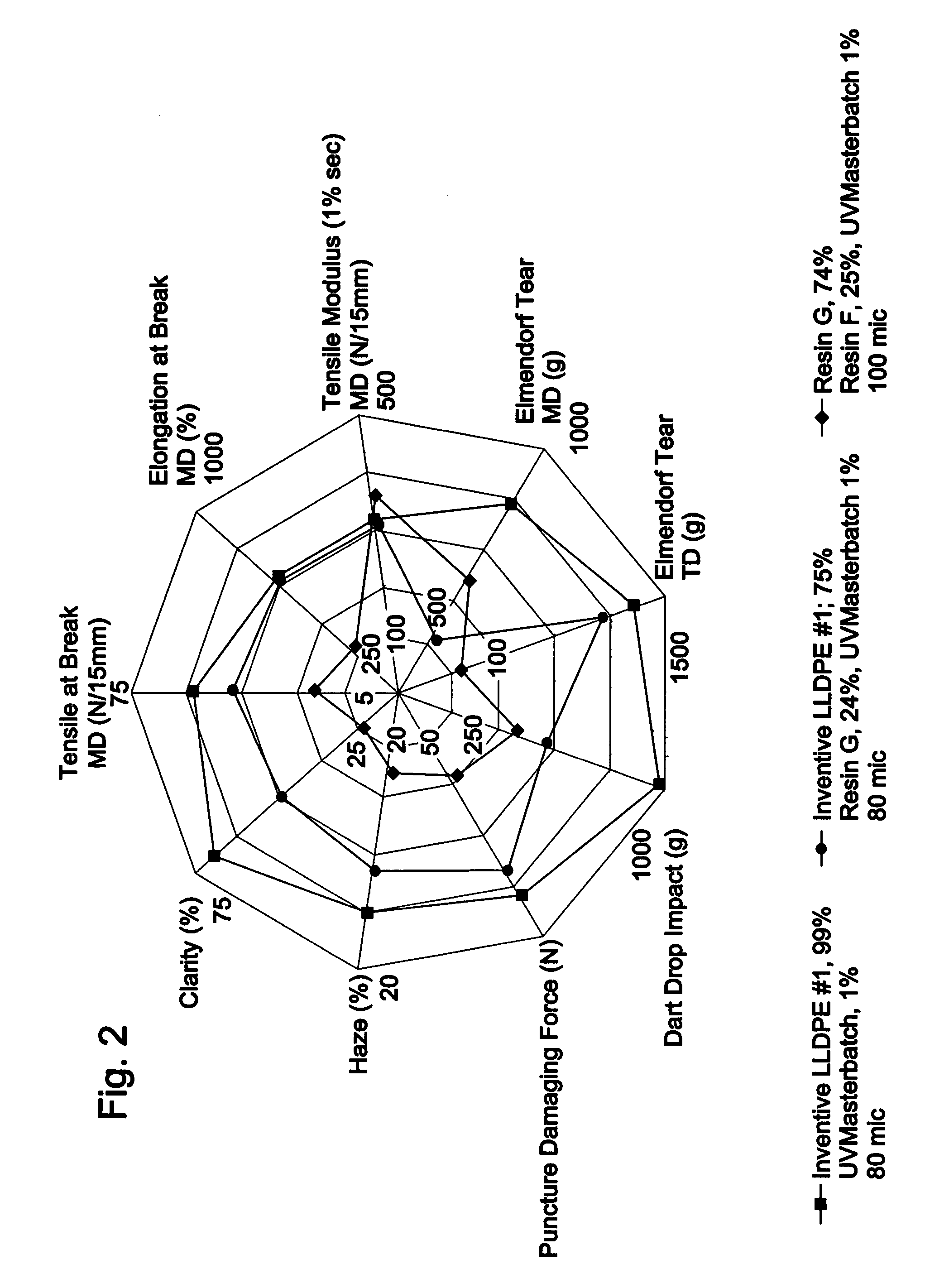

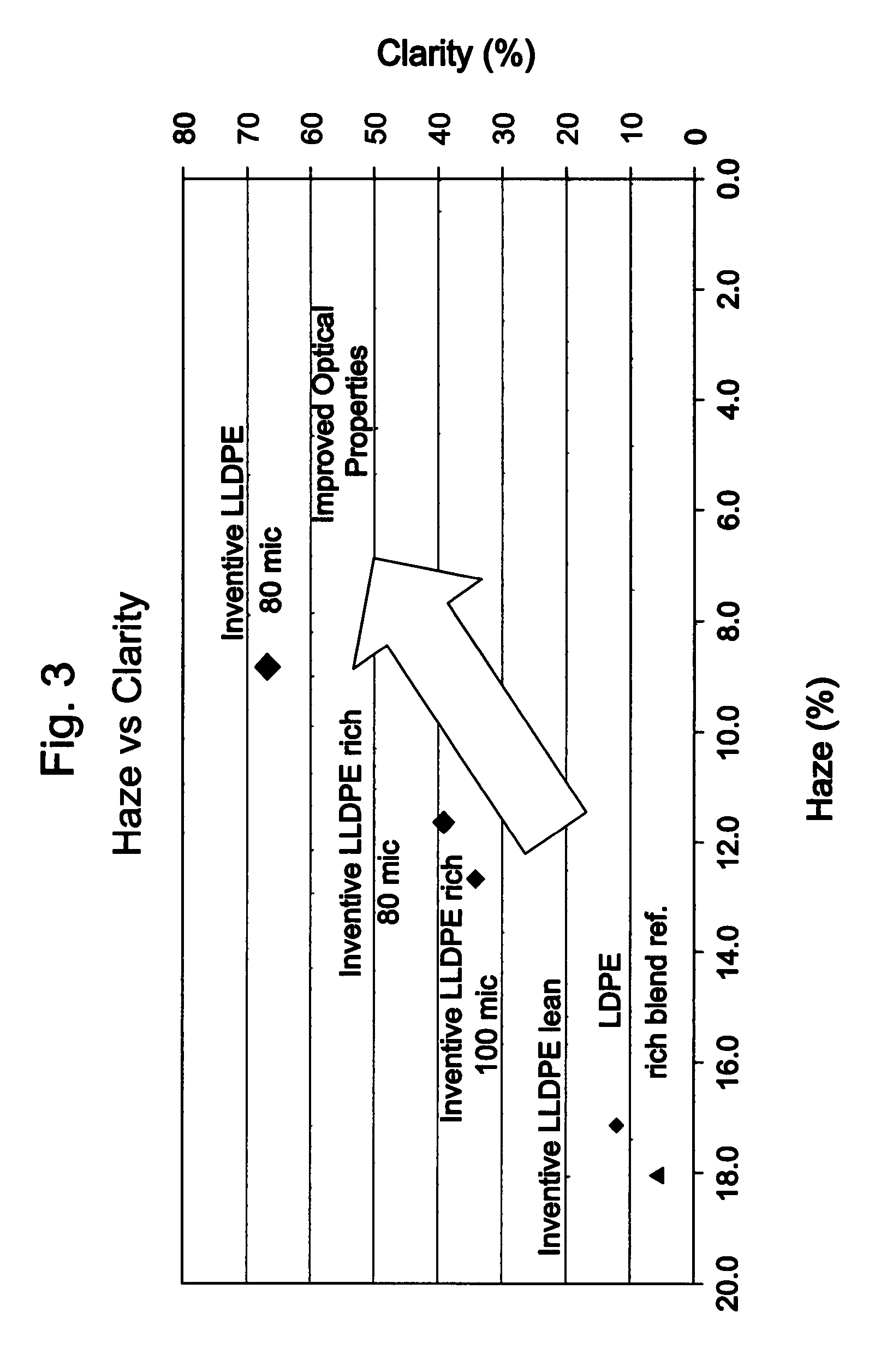

ActiveUS20090192270A1Good physical propertiesDrop clarityPersonal careSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

Provided are ethylene-based polymer compositions, articles made therefrom, and methods of making the same. Ethylene-based polymer compositions include blends of a linear low density polyethylene prepared with metallocene catalyst and a low density polyethylene. The linear low density polyethylene may optionally have about five mole percent or less of monomer units derived from an alpha-olefin comonomer. Articles composed of such ethylene-based polymer compositions, such as blown films, exhibit favorable physical properties, including excellent optical properties and retained strength i.e., mitigation of expected decline in physical strength due to LDPE addition.

Owner:EXXONMOBIL CHEM PAT INC

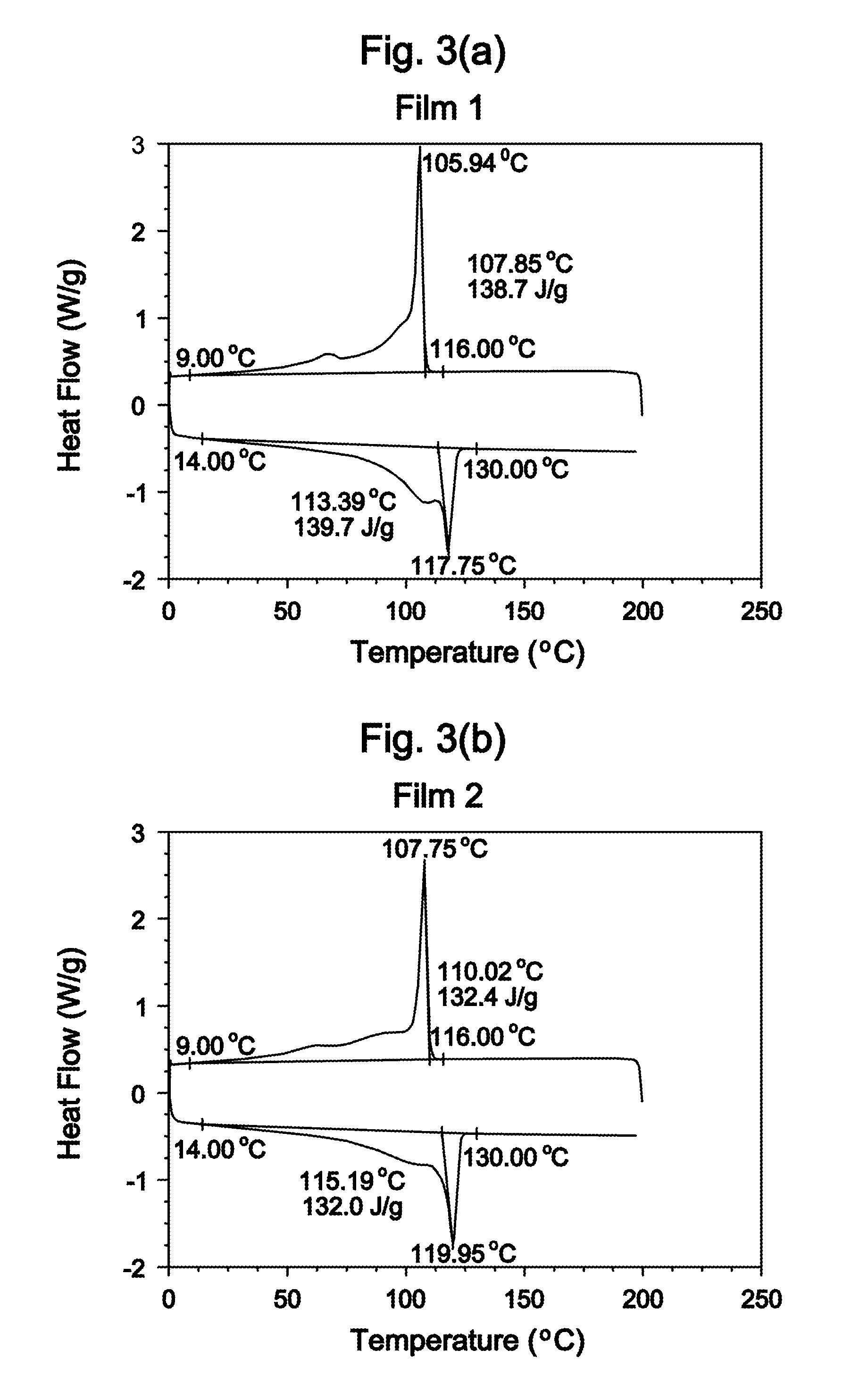

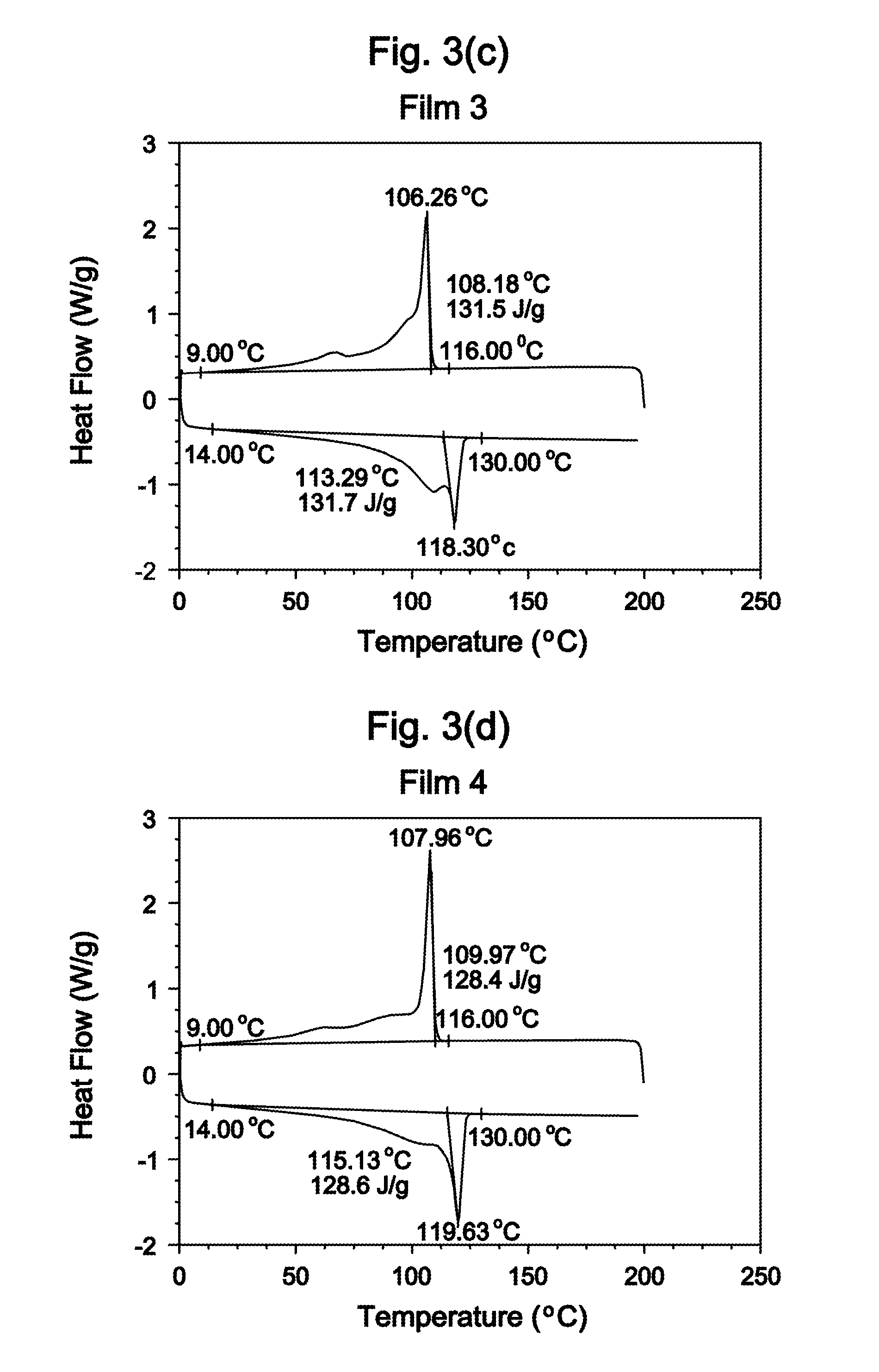

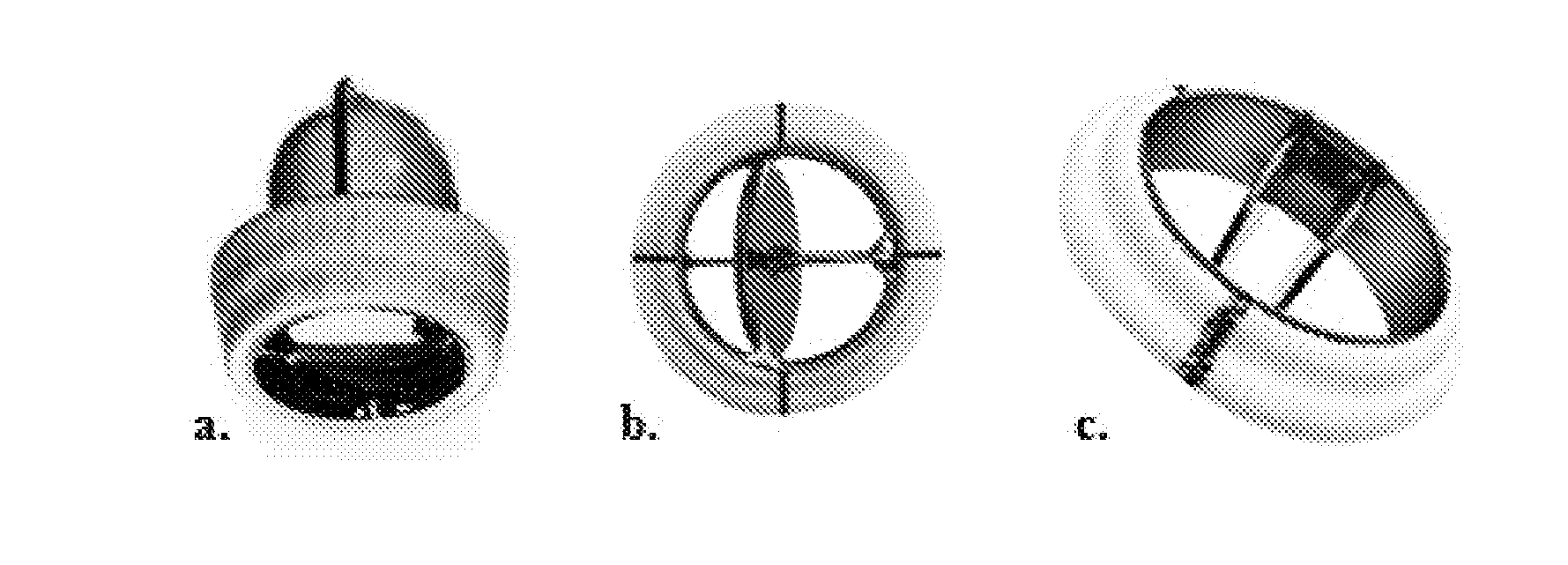

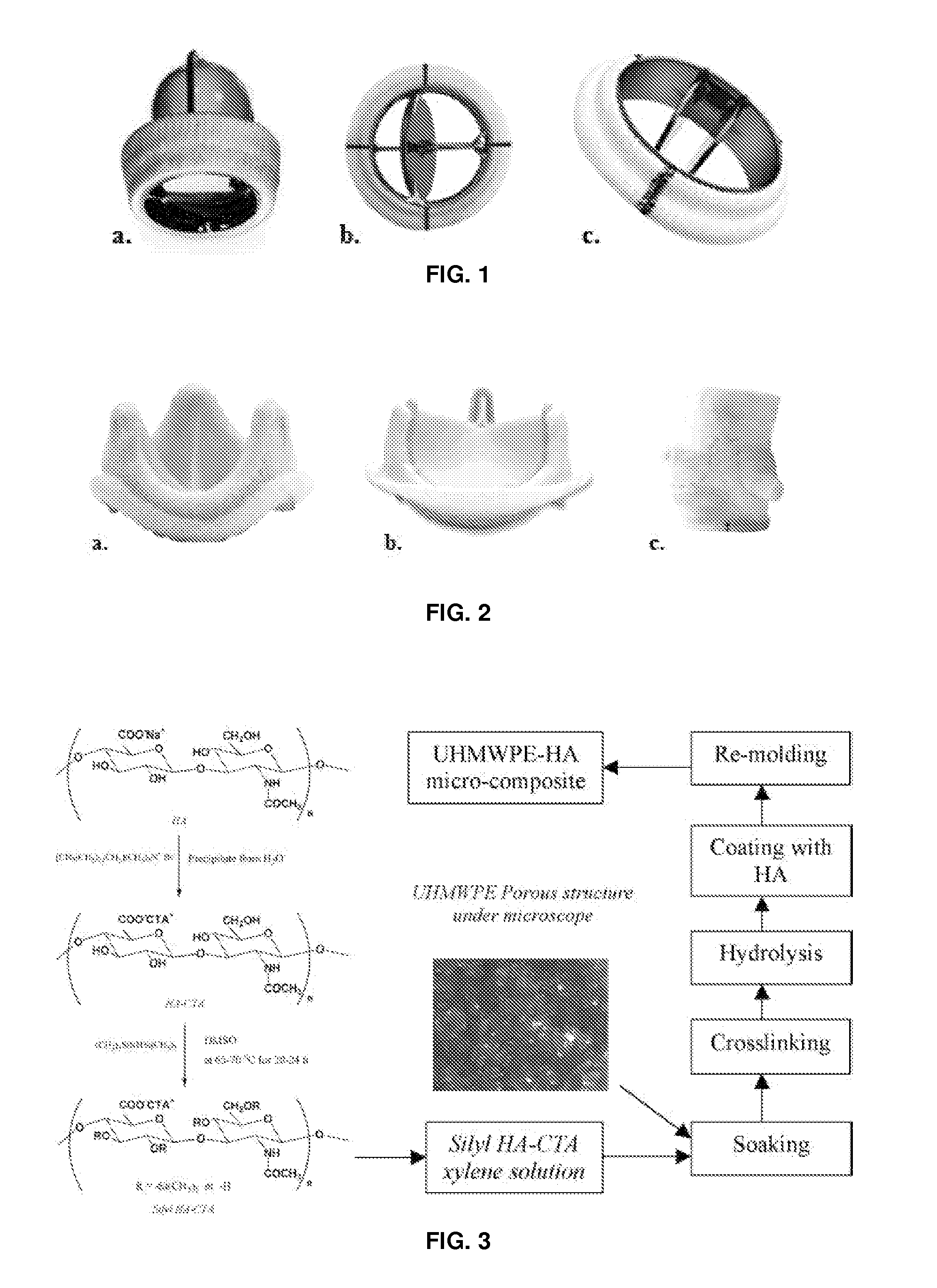

Glycosaminoglycan and Synthetic Polymer Material for Blood-Contacting Applications

ActiveUS20150196688A1Improve surface chemistryFeasible at commercial productionSuture equipmentsOrganic active ingredientsLow-density polyethyleneLinear low-density polyethylene

Provided herein is a composite, comprising: a polymer host selected from the group consisting of low-density polyethylene (LDPE), linear low-density polyethylene (LLDPE), polyethylene terephthalate (PET), polytetrafluoroethylene (PTFE), and polypropylene (PP), polyurethane, polycaprolactone (PCL), polydimethylsiloxane (PDMS), polymethylmethacrylate (PMMA), and polyoxymethylene (POM); and a guest molecule comprising hyaluronic acid; wherein the guest molecule is disposed within the polymer host, and wherein the guest molecule is covalently bonded to at least one other guest molecule. Also provided herein are methods for forming the composite, and blood-contracting devices made from the composite, such as heart valves and vascular grafts.

Owner:COLORADO STATE UNIVERSITY

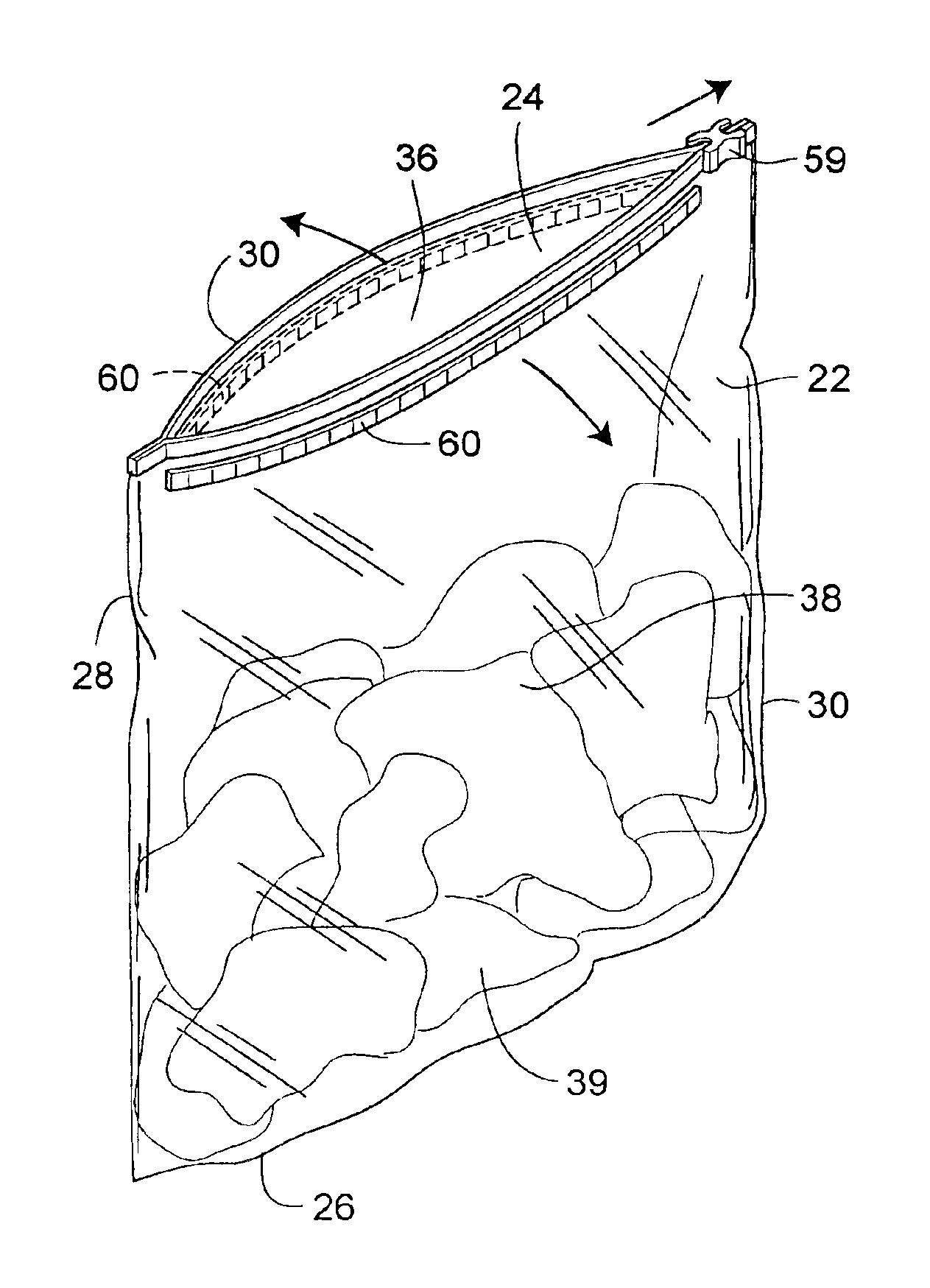

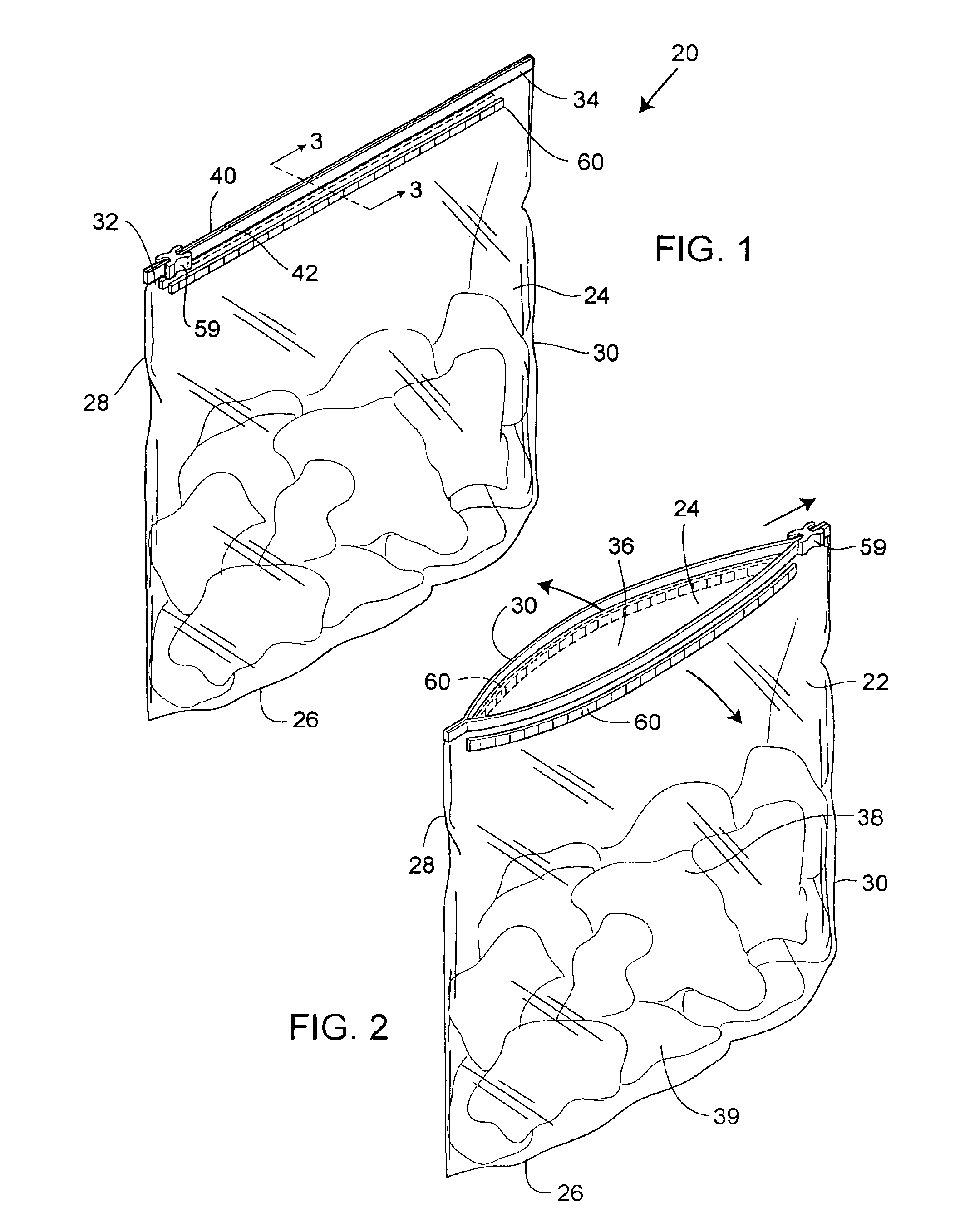

Storage bag with openly biased mouth

A storage bag having a recloseable mouth, which is biased into an open configuration, is disclosed. The bag, typically manufactured from thermoplastic material such as low-density polyethylene, includes first and second adjacent layers joined or folded along bottom and side edges. The top edges are not folded or permanently joined, but are provided with closure members such as mating male and female zipper strips. The bag is further provided with structure to bias the top edges apart from one another thus biasing the mouth of the bag into an open configuration. The closure members are sufficiently strong to overcome the force of the biasing structure and thereby hold the bag closed when the closure members are engaged. However, upon disengagement of the closure members the biasing structure forces the bag top edges apart to thereby place the bag into an open mouth configuration.

Owner:SC JOHNSON & SON INC

Synergistic flame-retardant low-smoke halogen-free polyolefin cable material and preparation method thereof

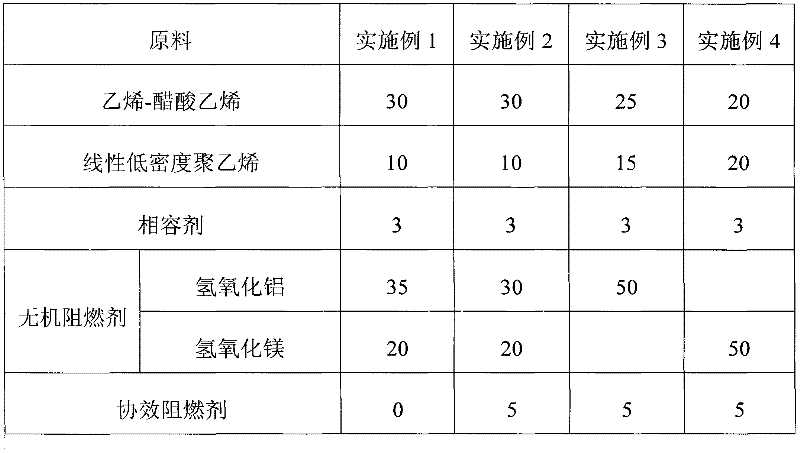

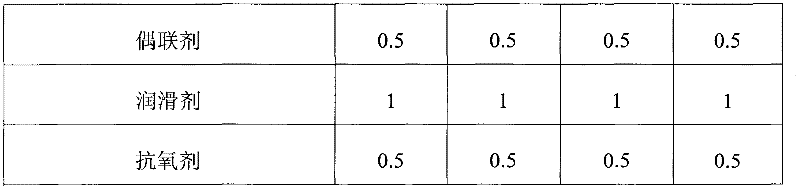

ActiveCN102250409AImprove flame retardant performanceImprove uniformityPlastic/resin/waxes insulatorsLow-density polyethylenePolymer science

The invention discloses a low-smoke halogen-free flame-retardant polyolefin cable material and a preparation method thereof. The formula of the cable material comprises the following raw materials in percentage by weight: 20-30% of ethylene-vinyl acetate copolymer, 10-20% of linear low-density polyethylene, 3-6% of compatilizer, 50-60% of inorganic flame retardant, 2-5% of synergistic flame retardant, 0.5-1% of coupling agent, 0.2-0.5% of lubricant and 0.2-0.5% of antioxidant. The preparation method of the cable material comprises surface treatment of the inorganic flame retardant, burdening,mixing, milling, extrusion and granulation and other process steps. Compared with the prior art, the cable material disclosed by the invention has the advantages of superior flame retardancy, low smoke, low toxicity, no droplets, good processing performance, good dispersion of the inorganic flame retardant, and better uniformity and surface finish degree.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

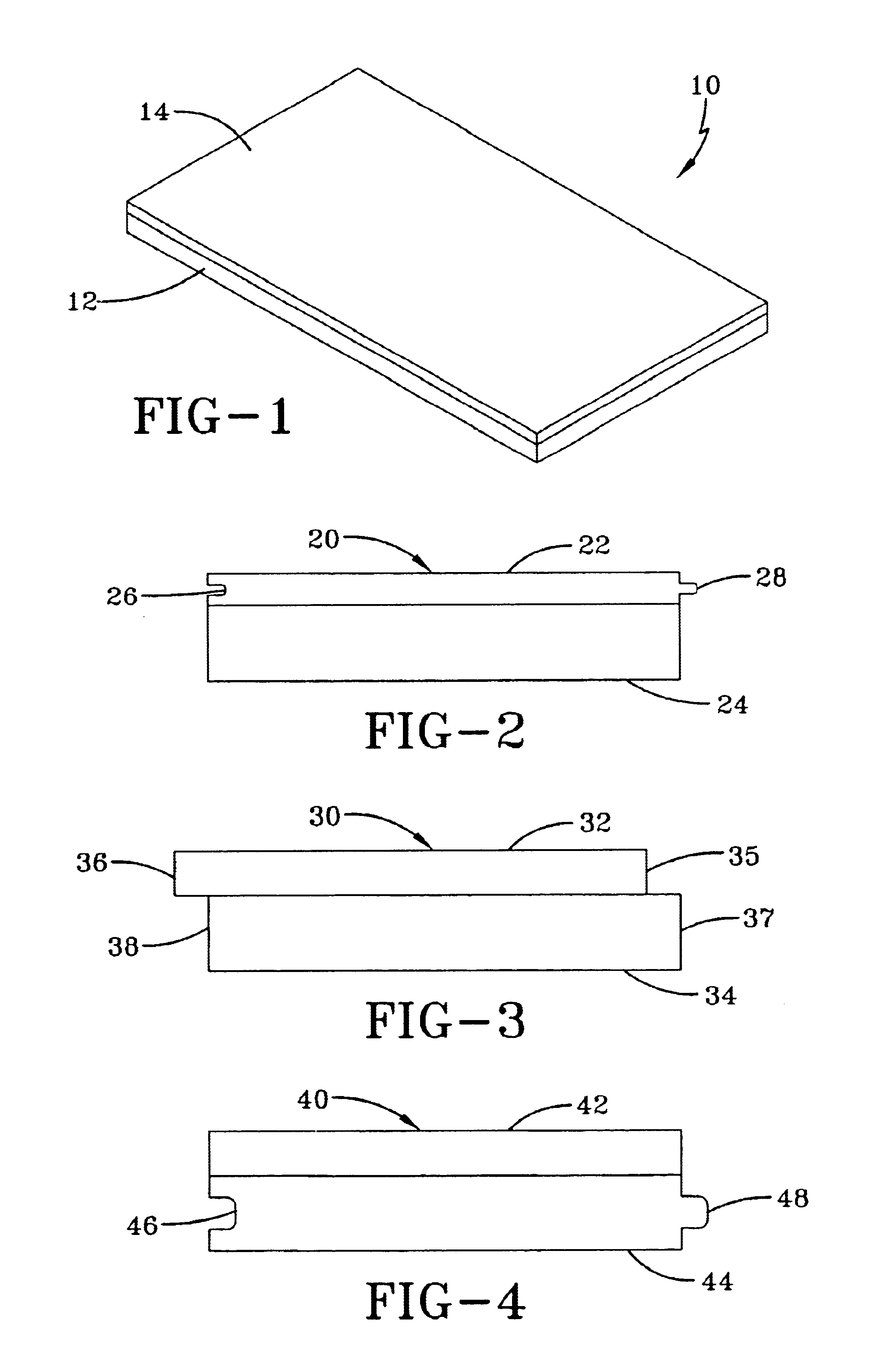

Synthetic wood component having a foamed polymer backing

InactiveUS6863972B2Superior resistance to wear and tearImprove the immunityHair accessoriesDead plant preservationLow-density polyethyleneLinear low-density polyethylene

The present invention is a component having a synthetic wood layer that is secured to a foamed polymer layer. The foamed polymer layer is comprised of a polymer selected from the group consisting of high density polyethylene, polypropylene, polyvinyl chloride, low density polyethylene, chlorinated polyvinyl chloride, acrylonitrile butadiene styrene, ethyl-vinyl acetate, and polystyrene. The component can be used for a variety of different purposes such as fencing, furniture, cabinets, storage devices, lawn edging, flower boxes, flooring, roofing, wall covering, building siding, basement flooring, basement wall covering, interior and exterior decorative house moldings, crown moldings, chair rails, picture frames, porch decks, deck railings, window moldings, window components, door components, door moldings, various other lawn and garden uses, various other below grade uses, and various other indoor and outdoor uses.

Owner:CRANE BUILDING PRODS

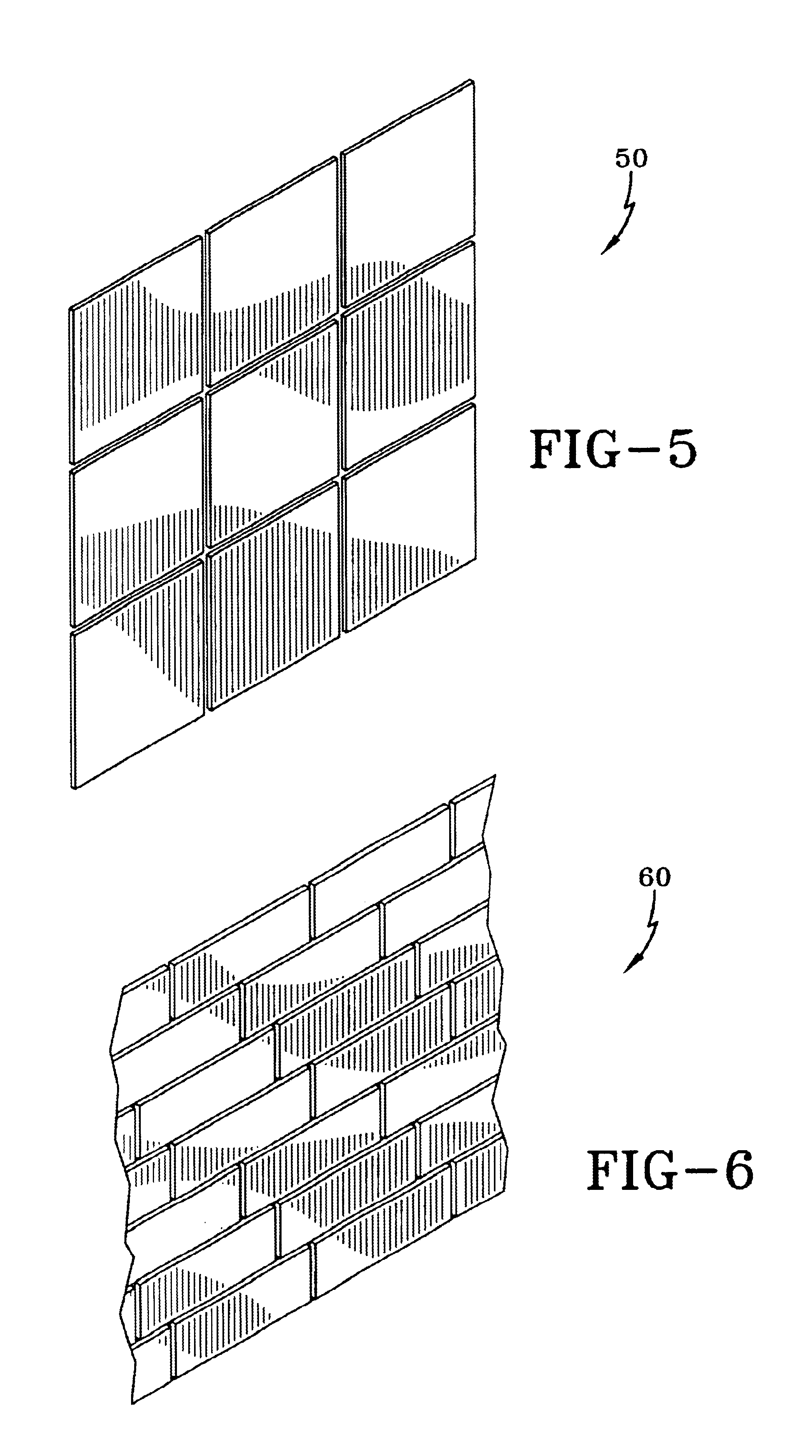

Low density paperboard articles

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

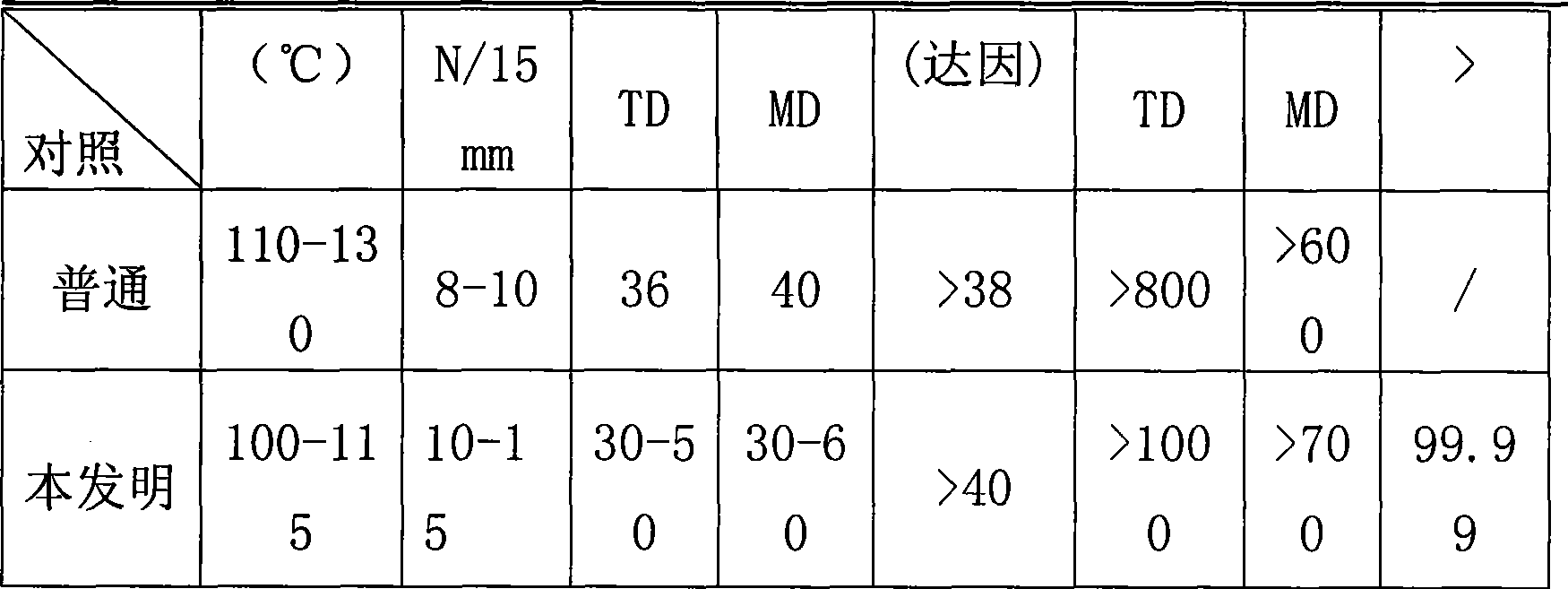

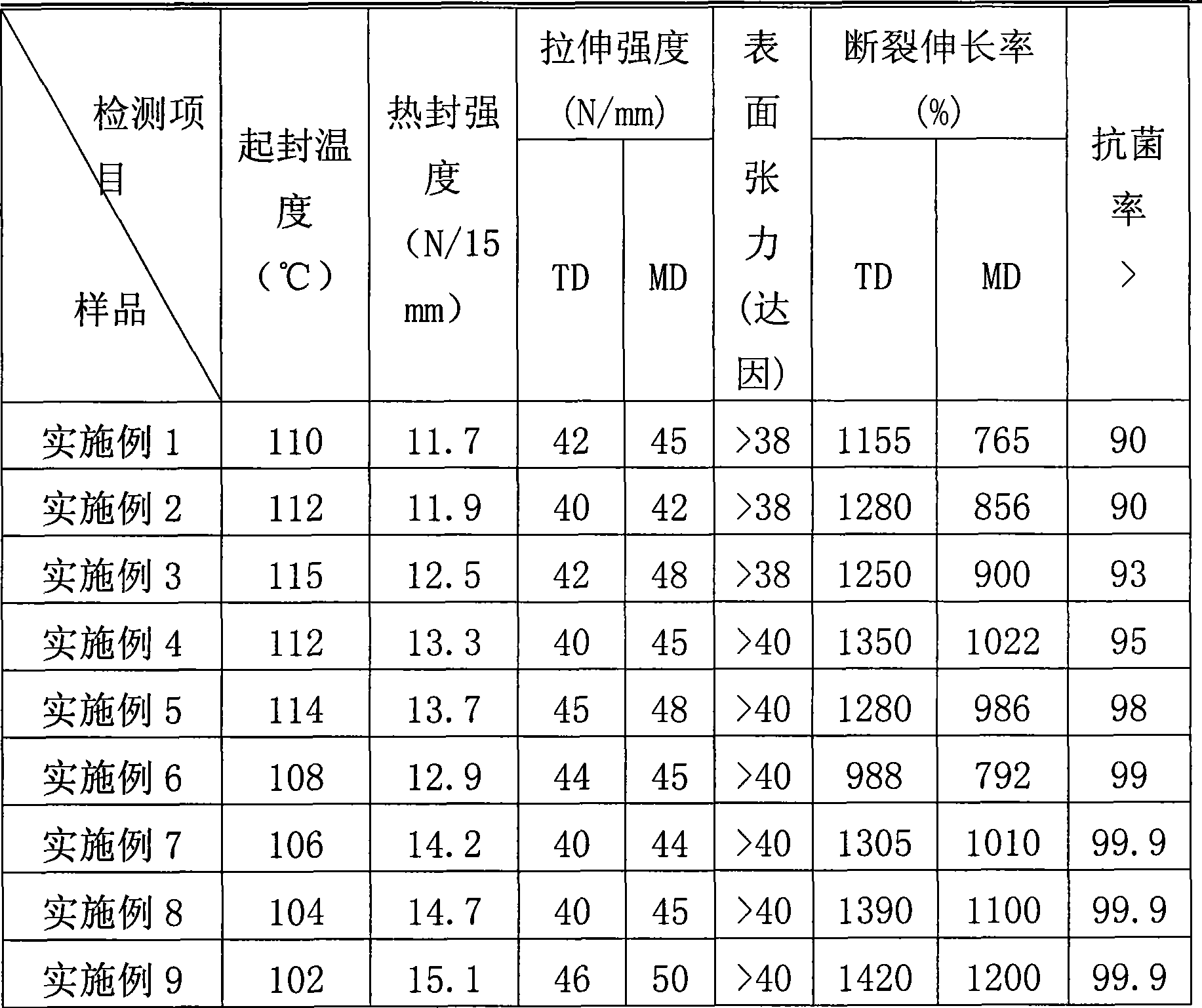

Antimicrobial polyethylene film and preparing technique thereof

ActiveCN101367283APlay a protective effectImprove antibacterial propertiesFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses an antibacterial polyethylene film and a method for preparing the same. The film consists of an outer layer, a middle layer and an inner layer; the outer layer consists of low-density polyethylene and linear low-density polyethylene; the middle layer consists of low-density polyethylene and linear low-density polyethylene; and the inner layer comprises low-density polyethylene, linear low-density polyethylene, metallocene linear low-density polyethylene, a slipping agent and an antibacterial agent. Compared with the prior art, the antibacterial polyethylene film has the characteristics of broad-spectrum sterilization, lasting antibacterial effect, good safety, no toxicity, no side effects and uneasy discoloration, thereby really achieving the protective function on packaged foods.

Owner:HUANGSHAN NOVEL

Production technology of embossing laminating release paper

ActiveCN101597874AWon't happenUnity of depthPaper coatingLaminationLow-density polyethylenePulp and paper industry

The invention discloses a production technology of embossing laminating release paper, the production technology is characterized by comprising the following steps: 1) preparing laminating paint, adding the high-density polyethylene and the low-density polyethylene into a stirring vessel to mix and stir for 5-10 minutes to mix evenly, the weight ratio of the high-density polyethylene and the low-density polyethylene is 1:1.5-2, and then heating, bridging, heating and melting, pressing and extruding the mixture. 2) preparing the embossing laminating release paper, laminating the extruded polyethylene mixture to the surface of the paper by a composite wheel, pressing and compositing the mixture by the composite wheel, and cooling the temperature at 30-40 DGE C after compositing, continually moving the paper after laminating driven by a roller and cooling the paper at the temperature of 12-20 DGE C, and side cutting, rolling, packaging for the paper, finally, coating silicon oil on the surface of the laminating paper to prepare the finished product of the embossing laminating release paper. The invention has convenient production technology; the embossing laminating release paper prepared by the production technology has the advantages of beautiful shape and good use effect, can be widely used in the technology of manufacturing the embossing laminating release paper.

Owner:FOSHAN NANHAI DISTRICT XINYONGTAI ADHESIVE PROD CO LTD

Halogen-free flame-retardant thermal-shrinkage sleeve materials and sleeve prepared thereby

ActiveCN1629216AWon't happenRaw materials are readily availableTubular articlesLow-density polyethyleneLinear low-density polyethylene

The invention provides a bittern-free flame-proof thermal contraction sleeve which comprises (by weight ratio), (1) 100 parts of one or more selected from ethane-vinyl acetate copolymer (EVA), ethene-ethyl acrylate copolymer (EEA), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), (2) 5-50 parts of one or more selected from ethylene-propylene terpolymerisate rubber (EPDM), ethylene propylene rubber (EPM), dimethyl silicone rubber (MQ), methylvinyl silicone rubber (VMQ), methylsilicone rubber with phenyl and vinyl Group (PVMQ), thermoplastic elastomer styrene - butadiene - styrene blocked copolymer (SBS), styrene-isoprene blocked copolymer (SIS), (3) 50-100 parts of bittern-free flame retardant, and (4) 0.5-6 parts of coupling agent.

Owner:深圳市沃尔热缩有限公司

Polyethylene pipes

A pipe composition comprising, in one embodiment, from 80 to 99 wt % of a high density polyethylene by weight of the composition and from 1 to 20 wt % of a filler by weight of the composition; the polyethylene having a density of from 0.940 to 0.980 g / cm3, and an 121 of from 2 to 18 dg / min; characterized in that the pipe composition extrudes at an advantageously low melt temperature and at an advantageously high specific throughput. Also provided is a method of forming a pipe comprising in embodiment providing a filler composition comprising from 5 to 50 wt % of a filler and from 95 to 50 wt % of a low density polyethylene and from 0 to 3 wt % of one or more stabilizers; then melt blending the filler composition and a high density polyethylene having a density of from 0.940 to 0.980 g / cm3, and an I21 of from 2 to 18 dg / min to a target drop temperature of from 16° C. to 185° C. to form a pipe composition, melt blending such that the pipe composition comprises from 1 to 20 wt % of the filler by weight of the pipe composition; and extruding the pipe composition to form a pipe.

Owner:UNIVATION TECH LLC

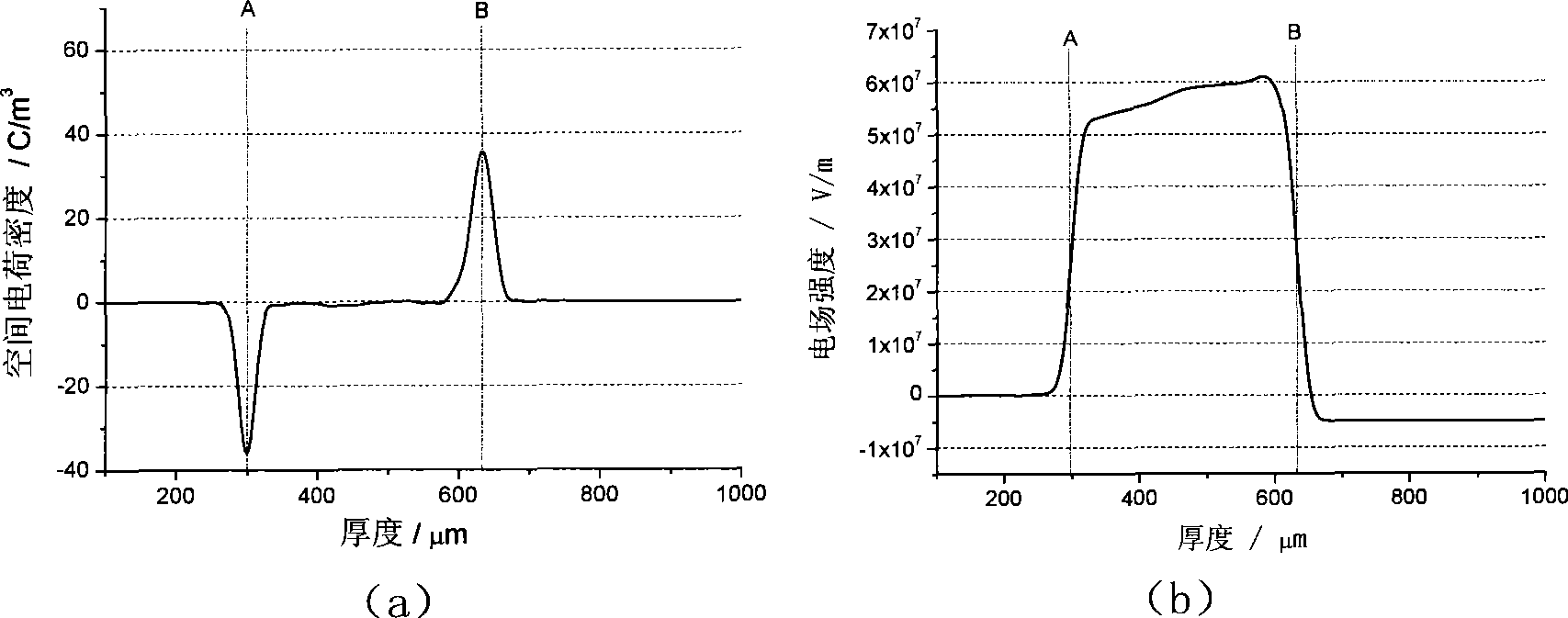

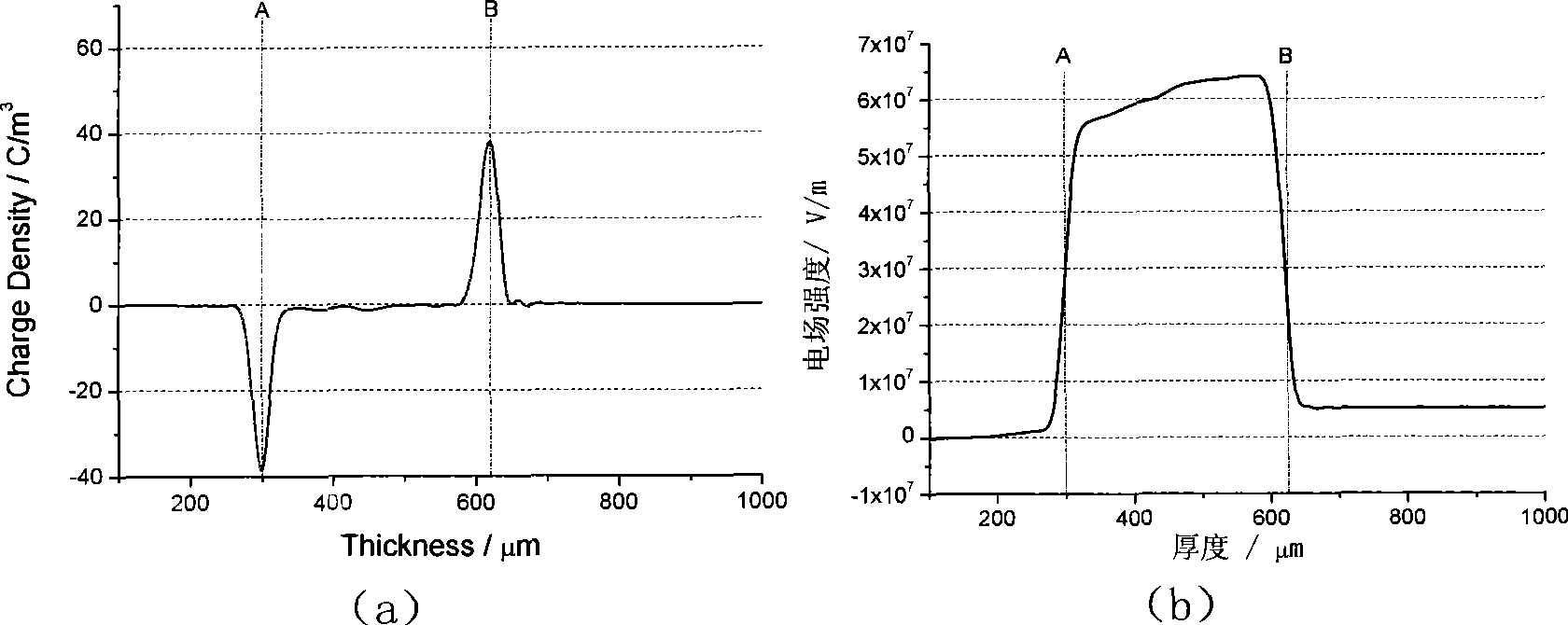

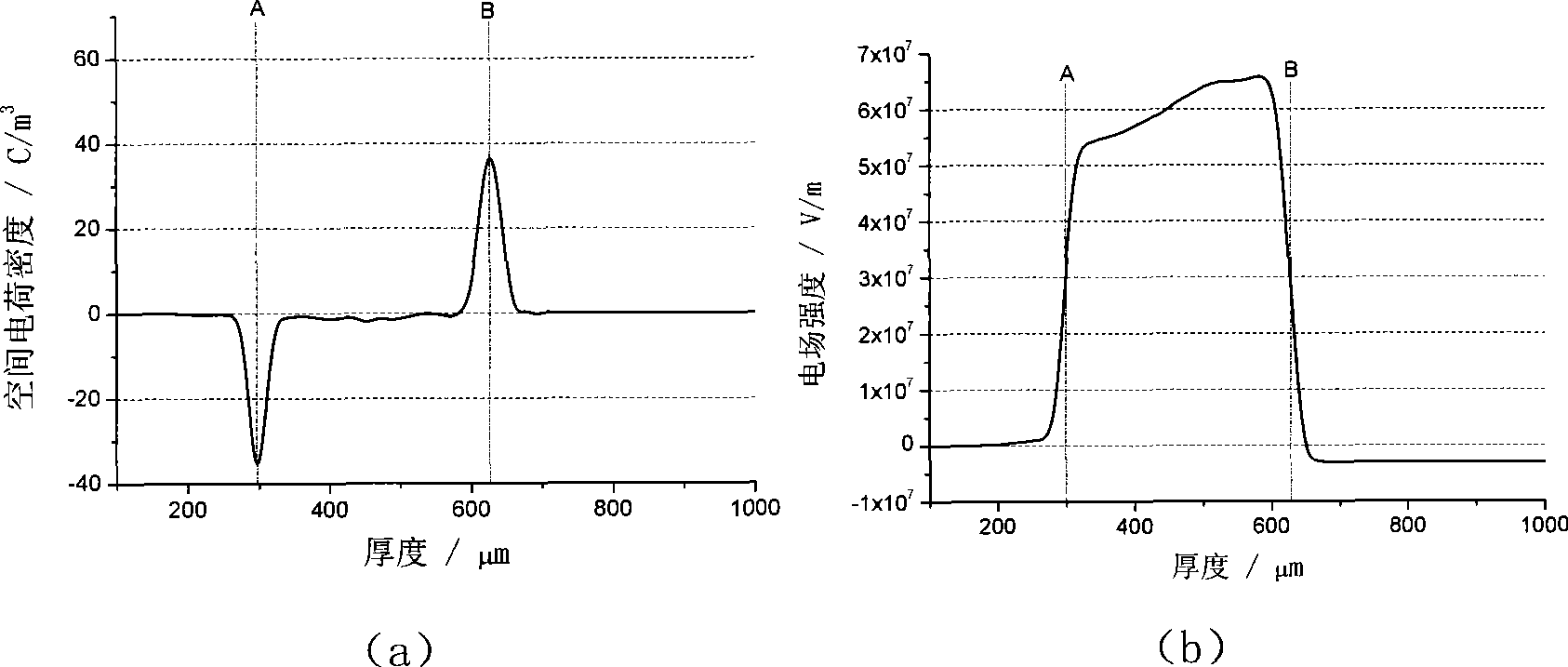

High-voltage DC cable insulating material and a preparation method thereof

InactiveCN101445627AAvoid accumulationApparent space charge phenomenonPlastic/resin/waxes insulatorsLow-density polyethyleneHigh-voltage direct current

The invention relates to high-voltage DC cable insulating material and a preparation method thereof in the technical field of the insulating material. The preparation method is that: 100 weight portions of low-density polyethylene, 0.1-1 weight portion of anti-oxidizer, 0.5-5 weight portions of nano inorganic powder and 0.2-5 weight portions of maleic anhydride are placed into and mixed and compounded in a banbury mixer; the temperature of mixing and compounding is 373K to 378K and the mixing and compounding time is 10 to 15 minutes; 0.1-5 weight portions of cross-linking agent is added into the mixture and is mixed and compounded under the temperature of 373K to 378K for 10 to 15 minutes; then, the high-voltage DC cable insulating material is obtained; wherein, the density of the low-density polyethylene is less than 0.9g / cm<3>. The insulating material of the preparation method can effectively improve the mechanical and electric properties of the high-voltage DC cable, thus avoiding the disadvantage that the environment is polluted and damaged by an oilpaper insulating cable due to the leakage of the insulating oil.

Owner:SHANGHAI JIAO TONG UNIV

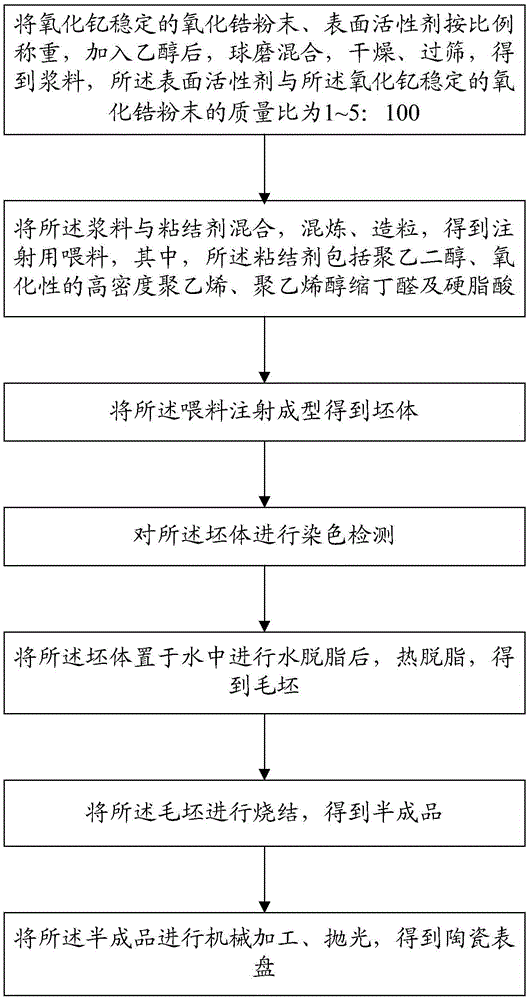

Preparation method of mobile telephone shell

ActiveCN105541324AHigh strengthAvoid breakingTelephone set constructionsLow-density polyethylenePolyethylene glycol

The invention discloses a preparation method of a mobile telephone shell. The preparation method comprises weighing yttrium oxide-stabilized zirconia powder and a surfactant according to a mass ratio of the surfactant to yttrium oxide-stabilized zirconia powder of 1-5: 100, adding ethanol into the weighed materials, carrying out ball milling mixing, carrying out drying and sieving to obtain slurry, mixing the slurry and a binder, carrying out mixing and granulation to obtain feed for injection, wherein the binder comprises polyethylene glycol, oxidizing high density polyethylene, polyvinyl butyral and stearic acid, carrying out injection molding on the feed to obtain a green body, carrying out staining detection on the green body, putting the green body into water, carrying out water debinding, carrying out thermal debinding to obtain a blank, sintering the blank to obtain a semifinished product, and carrying out machining and polishing on the semifinished product to obtain the mobile telephone shell. The mobile telephone shell has high strength, is not easily broken and has high density and uniform apertures. The preparation method has simple processes, operation easiness and high production efficiency.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

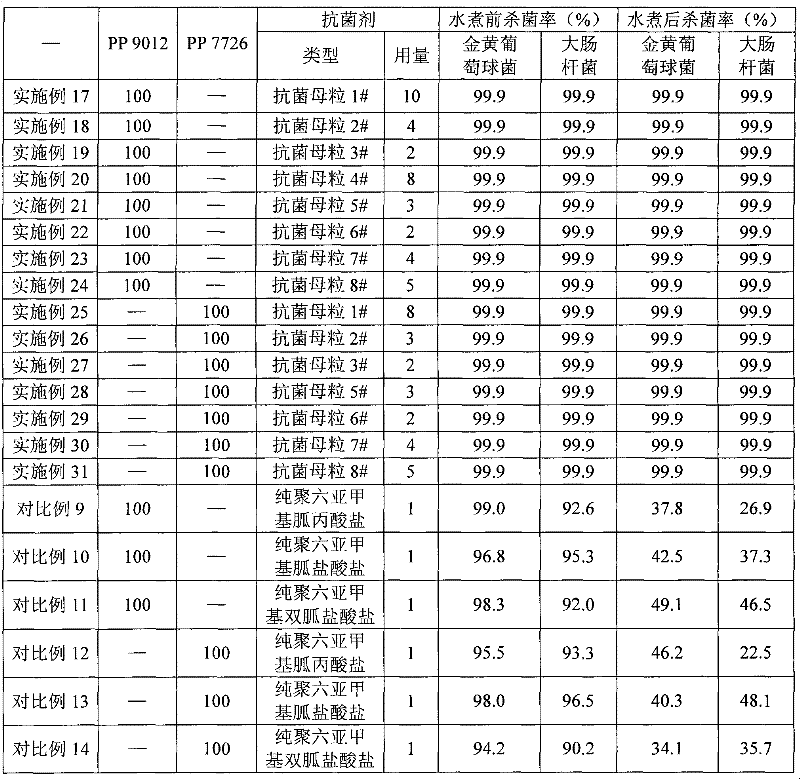

Antibacterial master batch based on guanidinium polymer and preparation method thereof

ActiveCN102453273ANot easy to change colorHigh antibacterial efficiencyLow-density polyethyleneOrganic acid

The invention provides an antibacterial master batch based on a guanidinium polymer and a preparation method thereof. The antibacterial master batch comprises the following blended components: a matrix resin, a composite antibacterial agent and a dispersant, wherein, on the basis of 100 parts by weight of the matrix resin, the composite antibacterial agent is 10 to 30 parts by weight, the dispersant is 2 to 10 parts by weight, the matrix resin is at least one selected from the group consisting of low-density polyethylene and high-melt index polypropylene, and the composite antibacterial agentis a polyguanidine / polysilicate composite antibacterial agent and is prepared by mixing an aqueous solution of water-soluble polyguanidine inorganic acid salt or organic acid salt with an aqueous solution of water-soluble silicate and adding an aqueous solution of water-soluble metal salt. The antibacterial master batch is used for antimicrobial modification of polypropylene, and addition amount of the antibacterial master batch is 2 to 10 wt % of the matrix material polypropylene; prepared modified polypropylene has the advantages of high antibacterial efficiency, a white color, good washingfastness, etc.

Owner:CHINA PETROLEUM & CHEM CORP +1

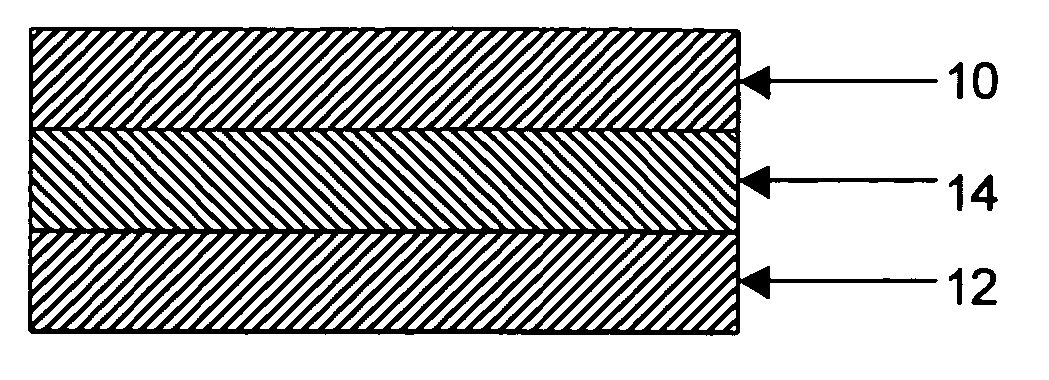

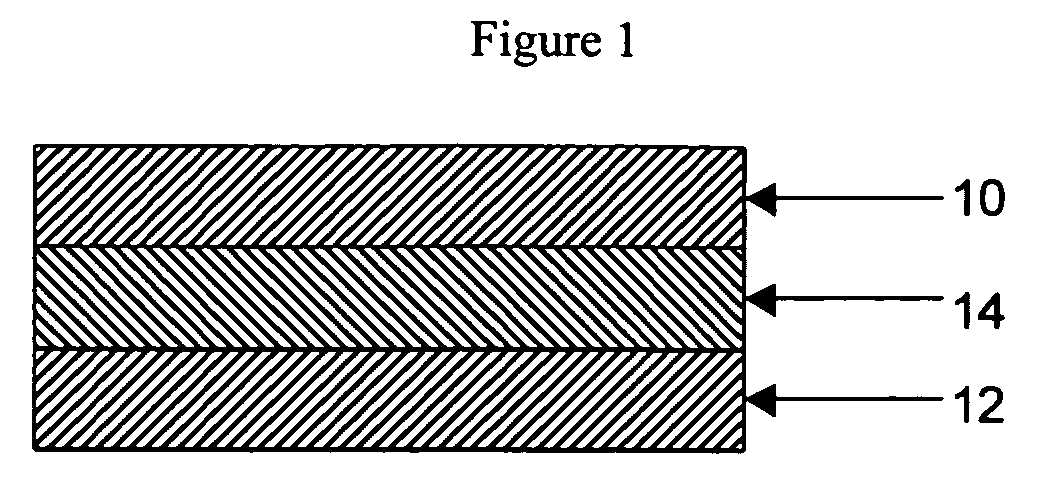

Multilayer high clarity shrink film comprising monovinylarene-conjugated diene copolymer

InactiveUS20050166551A1Wrappers shrinkageSynthetic resin layered productsLow-density polyethyleneLinear low-density polyethylene

We disclose a shrink film comprising a first layer comprising a monovinylarene-conjugated diene copolymer; a second layer comprising low density polyethylene (LDPE) and linear low density polyethylene (LLDPE); and a third layer comprising a monovinylarene-conjugated diene copolymer; wherein the second layer is disposed between the first layer and the third layer. We also disclose methods of using the shrink film to prepare bundled or fully enclosed groups of objects.

Owner:CHEVRON PHILLIPS CHEMICAL CO LP +1

Polyester full-biodegradable mulch film

ActiveCN103627151AHigh transparencyGood flexibilityPlant protective coveringsLow-density polyethylenePolyester

The invention relates to a mulch film, in particular to a polyester full-biodegradable mulch film. The polyester full-biodegradable mulch film is prepared from the following raw materials in percentage by mass: 40%-80% of flexible degradable polyester, 10%-55% of rigid degradable polyester, 0.5%-1.5% of a reactive compatibilizing agent, 1%-2% of a heat preservation agent, 1%-2% of a moisturizing agent, 0.5%-1.5% of an ageing-resistant agent, 0.5%-1% of a smooth agent and 0.5%-3% of an anti-block agent. The polyester full-biodegradable mulch film does not contain any non-biodegradable general plastic and starch; the film blowing operation can be performed on a general LDPE (low-density polyethylene) film blowing machine; equipment does not need to be modified; the polyester full-biodegradable mulch film is good in transparency, flexibility and heat preservation property, high in strength, low in water vapor penetration rate and favorable for preserving moisture.

Owner:新疆纳爱斯环保科技有限公司

Expandable polypropylene beading, preparation method thereof, and its foaming beading and foaming molding products

The invention provides an expandable polypropylene bead and a preparation method of the expandable polypropylene beads, and also provides foaming beads and foaming molding products of the expandable polypropylene beads, which relates to the resin expandable beads technical field. Random copolymerized polypropylene is used as basic resin, so that melting intensity can reach to an ideal range when in foaming with high melting intensity polypropylene and low density polyethylene resin being added. Expandable beads are prepared in a closed reactor without external pressure with pentane being used as foaming agent. The expandable beads contain 1 to 15 parts by weight of the high melting intensity polypropylene, 1 to 10 parts by weight of the low density polyethylene, 1.0 to 3.8 parts by weight of the foaming agent and 0.1 to 10 parts by weight of nucleating agent on the basis of 100 parts by weight of the random copolymerized polypropylene. The expandable polypropylene beads are easy to foam, whose foaming rate can reach to 16 times with uniform cells and whose foam volume weight is about 0.05 to 0.12g / cm3. The invention adopts a low-pressure method to produce the polypropylene foaming products in different shapes according to the requirement with low equipment requirement and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-smoke halogen-free inflaming-retarding cable material and preparation method thereof

InactiveCN101597395AHigh strengthHigh elongationRubber insulatorsPlastic/resin/waxes insulatorsLow-density polyethyleneLinear low-density polyethylene

The invention provides a low-smoke halogen-free inflaming-retarding cable material and preparation method thereof. The cable material comprises 5 to 15 parts (part by weight) of compatilizer that comprises maleic anhydride functional group grafted ethylene-vinyl acetate copolymer and maleic anhydride functional group grafted ethylene propylene terpolymer; 85 to 95 parts of base material formed by blending two or more than two of linear low-density polyethylene, ethylene-vinyl acetate copolymer and ethylene propylene terpolymer granular materials; 2 to 6 parts of composite antioxidant composed of the following antioxidants in terms of weight ratio: hindered phenol antioxidants : thiol ester antioxidants = 1 : (2 to 6); 20 to 40 parts of ammonium polyphosphate; 10 to 20 parts of pentaerythritol; 8 to 15 parts of melamine; 50 to 100 parts of composite inorganic fire retardant composed of the following fire retardants: magnesium hydroxide : zinc borate = (2 to 4) : 1; 2 to 6 parts of lubricant; 0 to 0.5 parts of metal passivator; 0 to 3 parts of crosslinking assistant agent; and 0 to 5 parts of halogen-free master batch. The invention has provided a harmless halogen-free inflaming-retarding cable material having high temperature tolerance, high tension, high elongation and high fire resistance.

Owner:ORIGIANL DOW ADVANCED COMPOUNDS SHANGHAI +2

Self-opening bag stack and method of producing same

InactiveUS6142302AReduce the temperatureEnvelopes/bags making machineryBag making operationsLow-density polyethyleneStructural engineering

A bag stack made of low density polyethylene material is disclosed. The bag stack comprises a plurality of bags where consecutive bags are adhesively connected together and where the back walls of the bags in the stack are hot welded together near the tops of the back walls of the bags. When a bag is removed from the stack, the front wall of the following bag is pulled open to permit easy removal of the next bag. A method is disclosed for forming a bag stack in accordance with the present invention.

Owner:BETTER BAGS

Ethylene-based polymers and processes to make the same

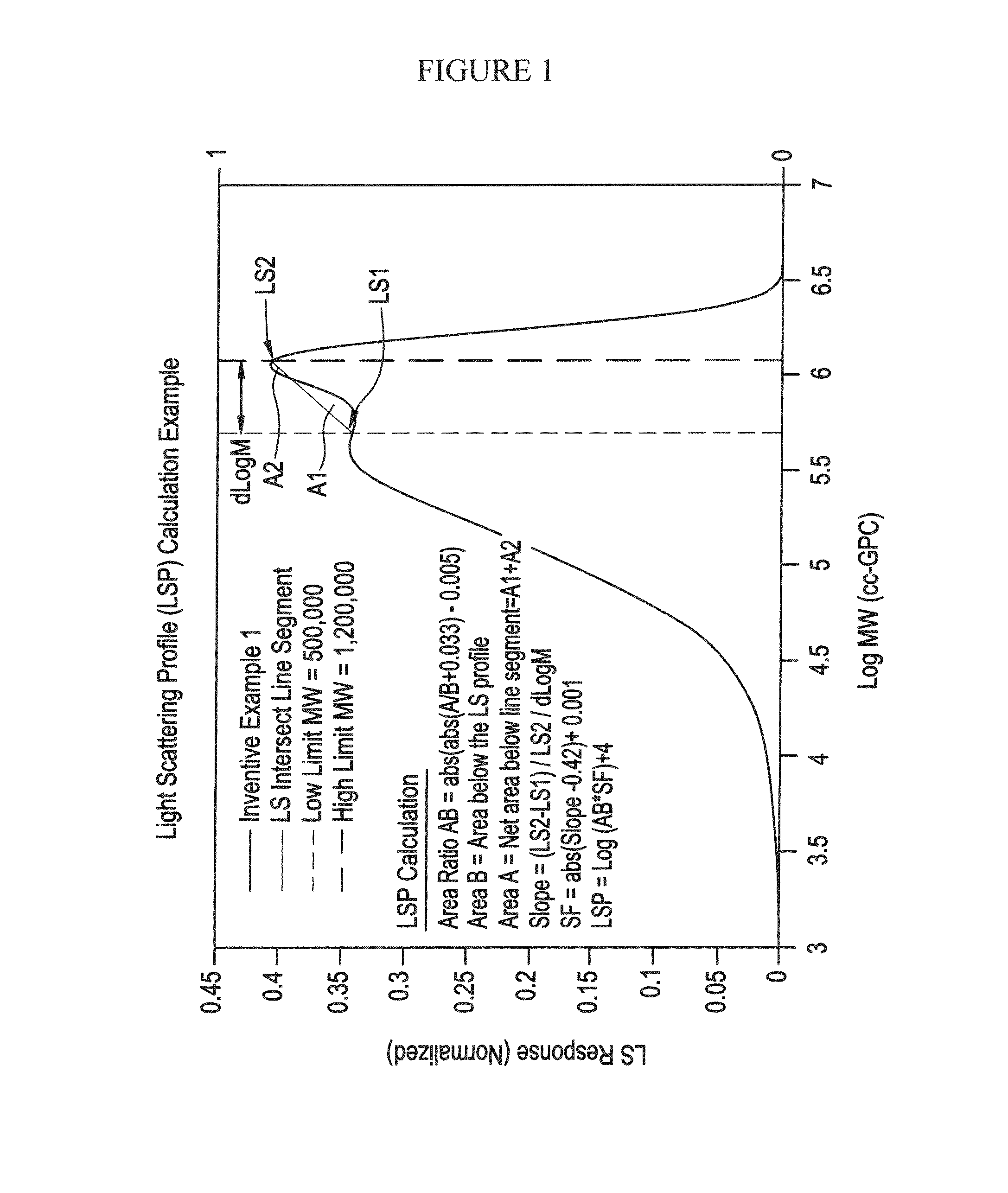

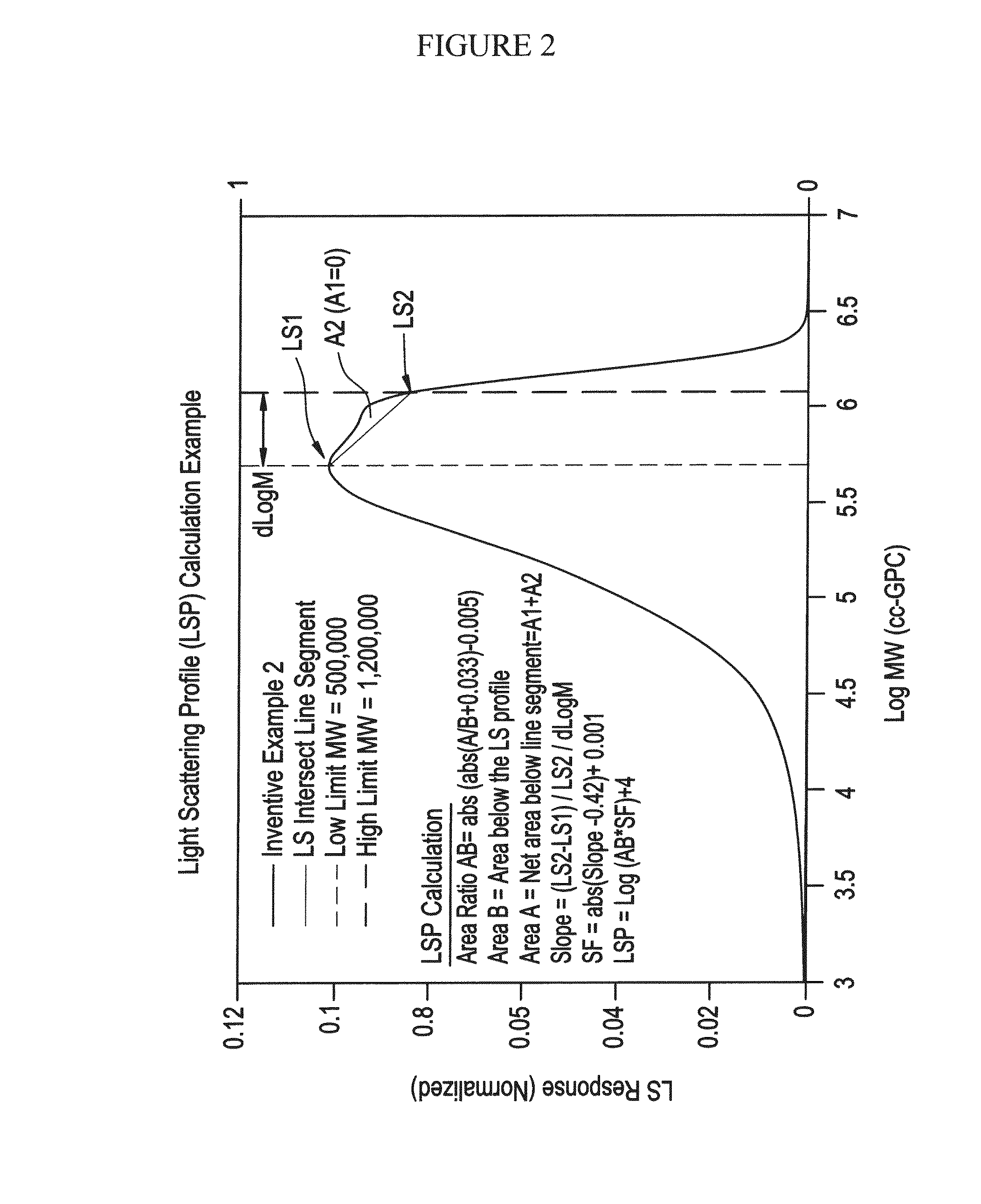

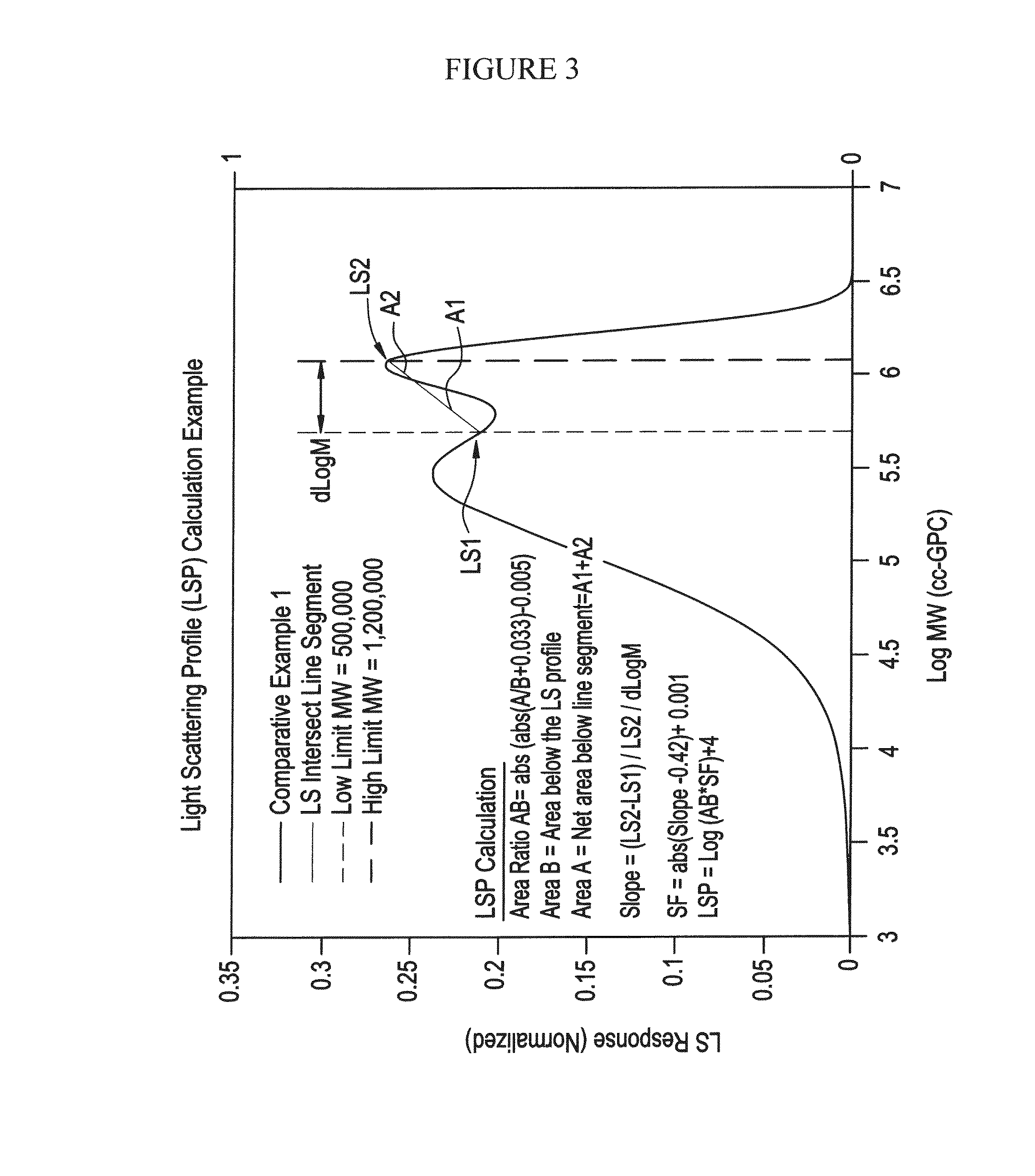

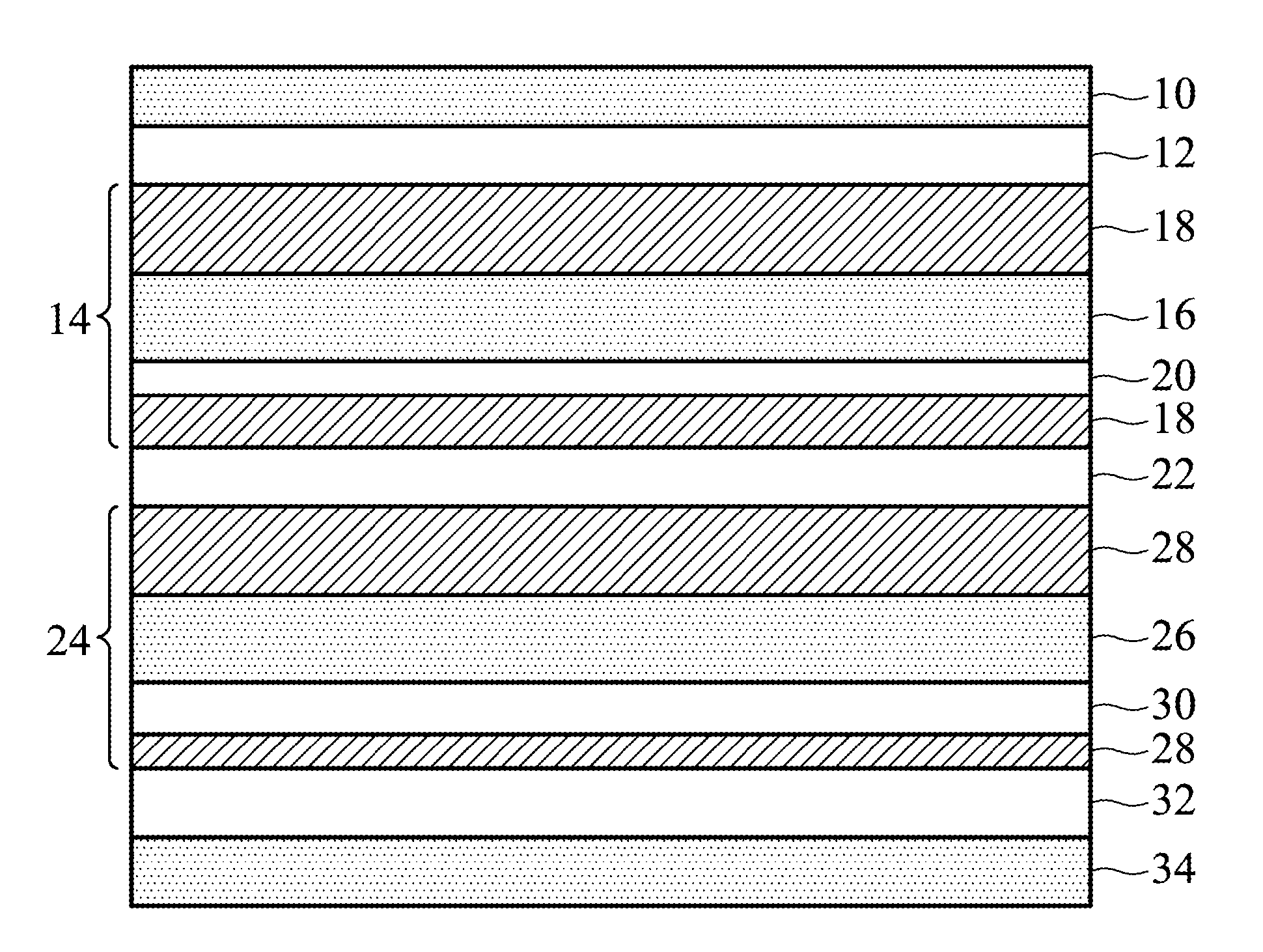

An ethylene-based polymer, which is a low density polyethylene (LDPE), obtained by free radical polymerization of ethylene, and wherein the LDPE has a GPC parameter “LSP” less than 1.60.An ethylene-based polymer that comprises the following features:a) at least 0.1 amyl groups per 1000 total carbon atoms;b) a melt index of 0.01 to 0.3;c) a z-average molecular weight of Mz (conv.) of greater than 350,000 g / mol and less than 425,000 g / mol;d) a gpcBR value from 1.50 to 2.05, ande) a MWD(conv) [Mw(conv) / Mn(conv)] from 6 to 9.An ethylene-based polymer that comprises the following features:a) at least 0.1 amyl groups per 1000 total carbon atoms;b) a melt viscosity ratio (V0.1 / V100), at 190° C., greater than, or equal to, 58;c) a melt viscosity at 0.1 rad / s, 190° C., greater than, or equal to, 40,000 Pa·s, andd) a gpcBR value from 1.50 to 2.25.

Owner:DOW GLOBAL TECH LLC

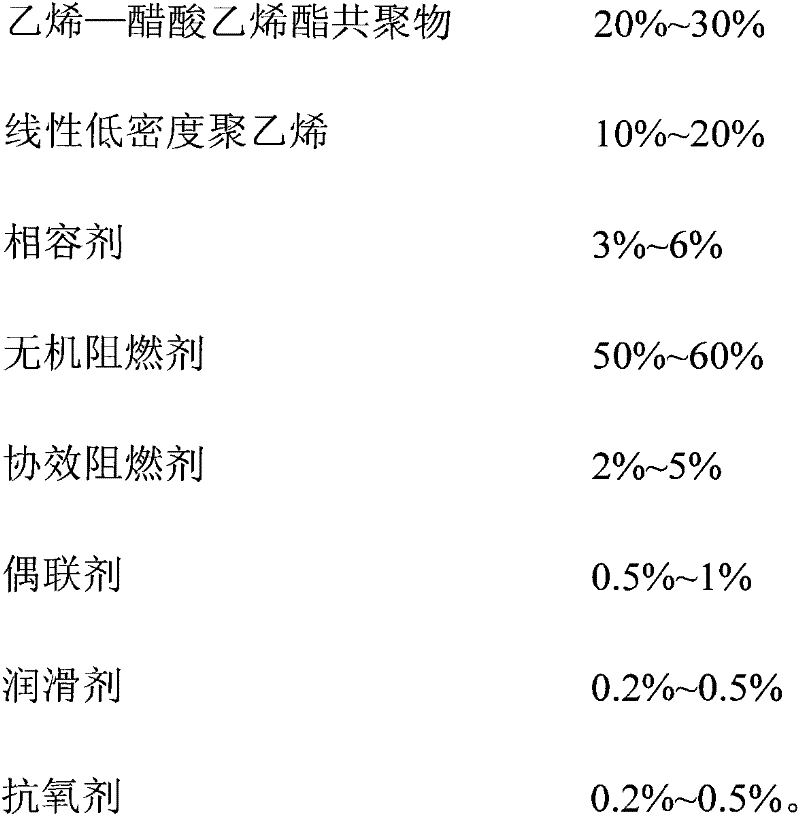

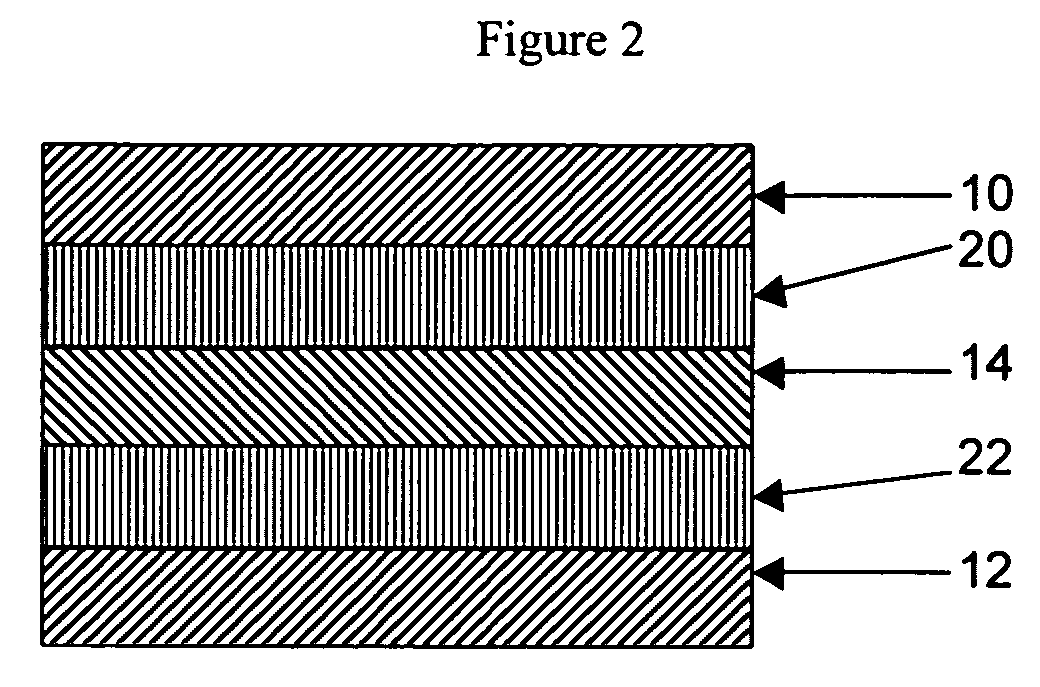

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

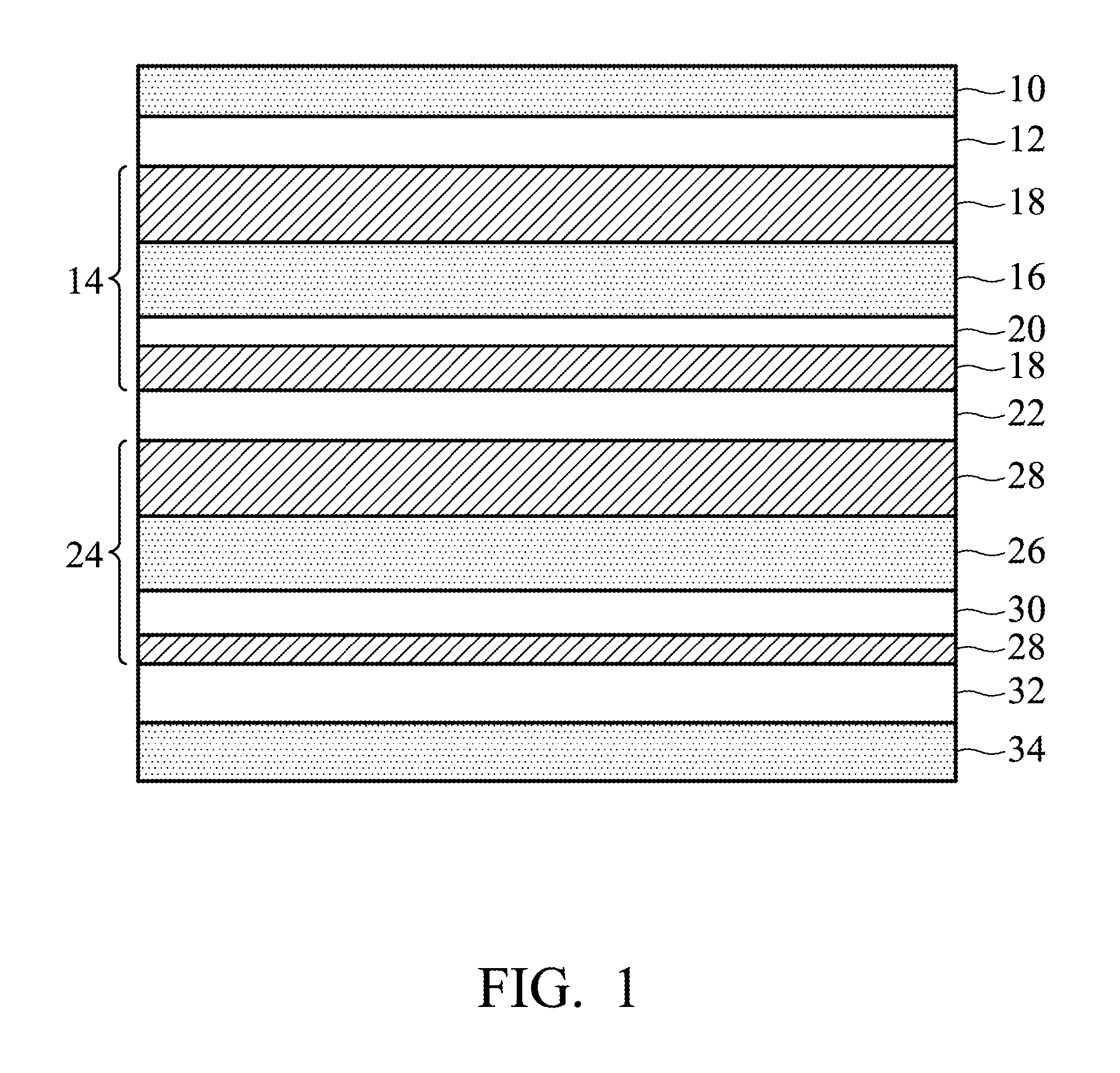

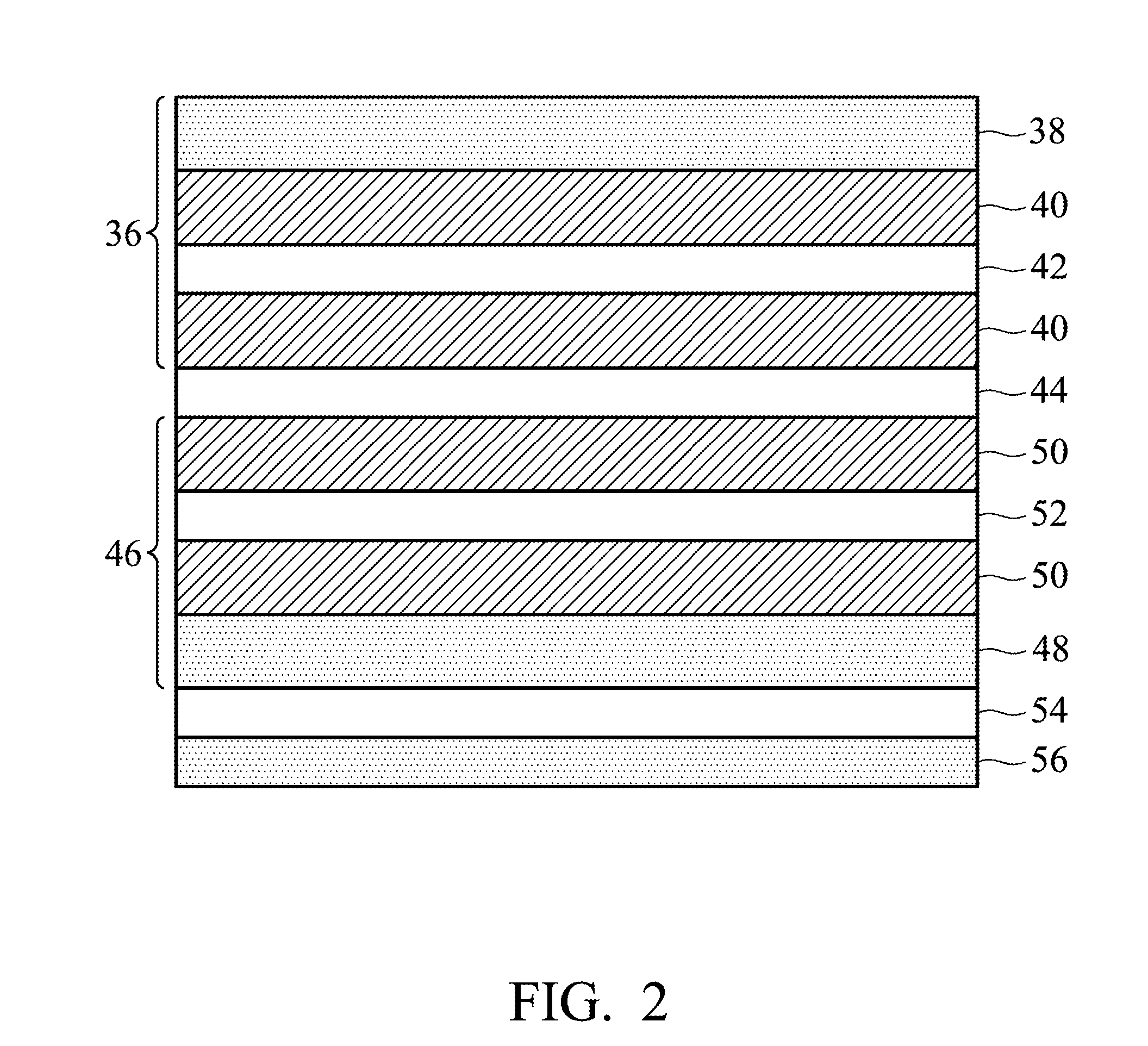

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

Thermoplastic oil-resistant halogen-free low-smoke flame-retardant polyolefin cable material and preparation method thereof

ActiveCN102731891AMitigates melt fractureHigh elongation at breakPlastic/resin/waxes insulatorsInsulated cablesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a thermoplastic oil-resistant halogen-free low-smoke flame-retardant polyolefin cable material. The material is characterized in that: the material is prepared from raw materials of: substrate resin, a fire retardant, a lubricating agent, and an anti-oxidant. The substrate resin is composed of metallocene linear low-density polyethylene (MLLDPE), an ethylene-vinyl acetate polymer, and an interface compatibilizing agent. The preparation method comprises the steps that: the raw materials are well mixed in a high-speed mixing machine; the mixture is subjected to mixed extrusion under a processing temperature of 125-145 DEG C on a same-direction double-screw extruder; and the material is subjected to hot-cut granulation, such that a finished product is obtained. Compared with a traditional thermoplastic halogen-free low-smoke flame-retardant polyolefin cable material, the cable material provided by the invention has good oil resistance. When the cable material is soaked in mineral oil, the change rates in tensile strength and breaking elongation are low.

Owner:中广核三角洲(江苏)塑化有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com