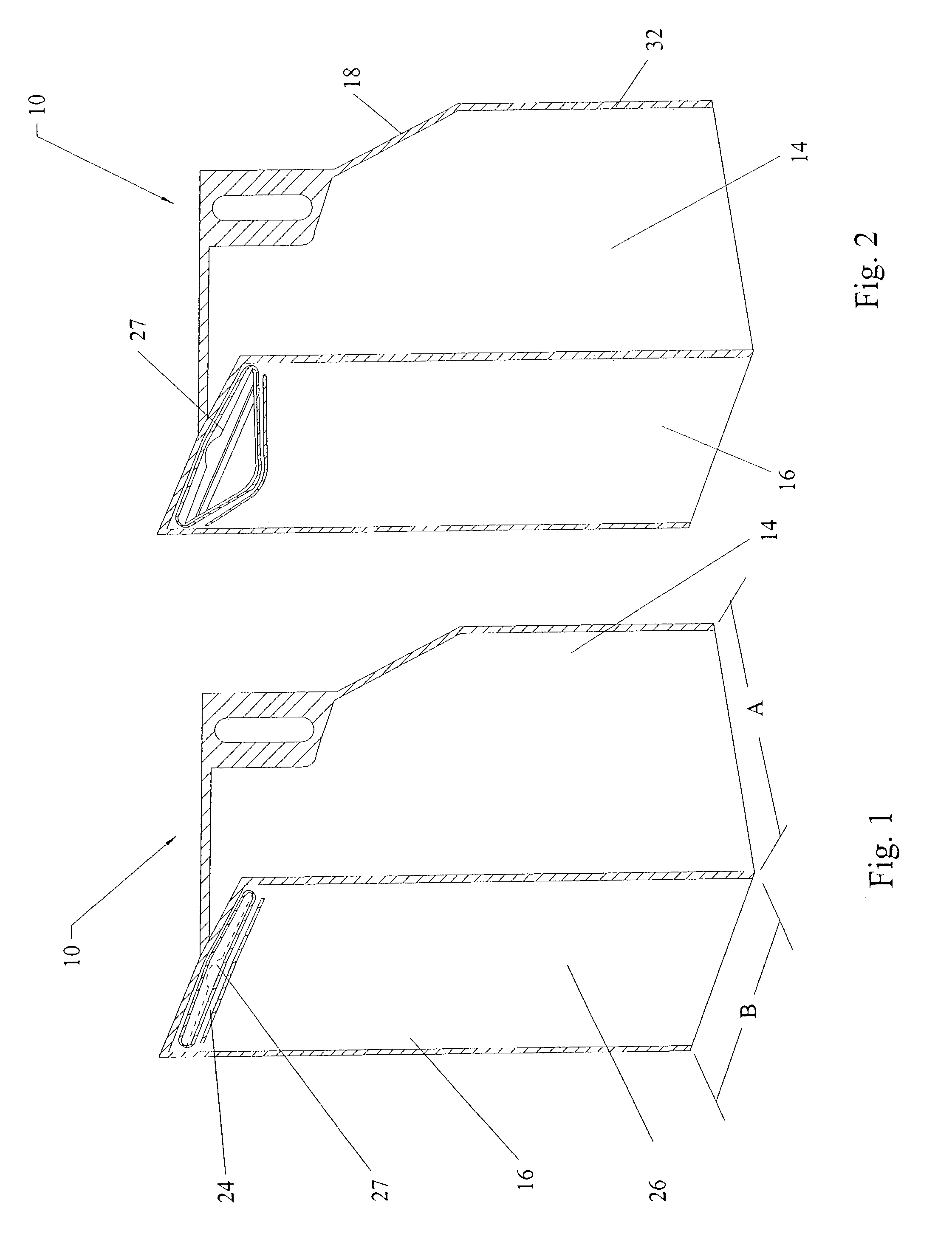

Patents

Literature

4483results about "Bag making operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

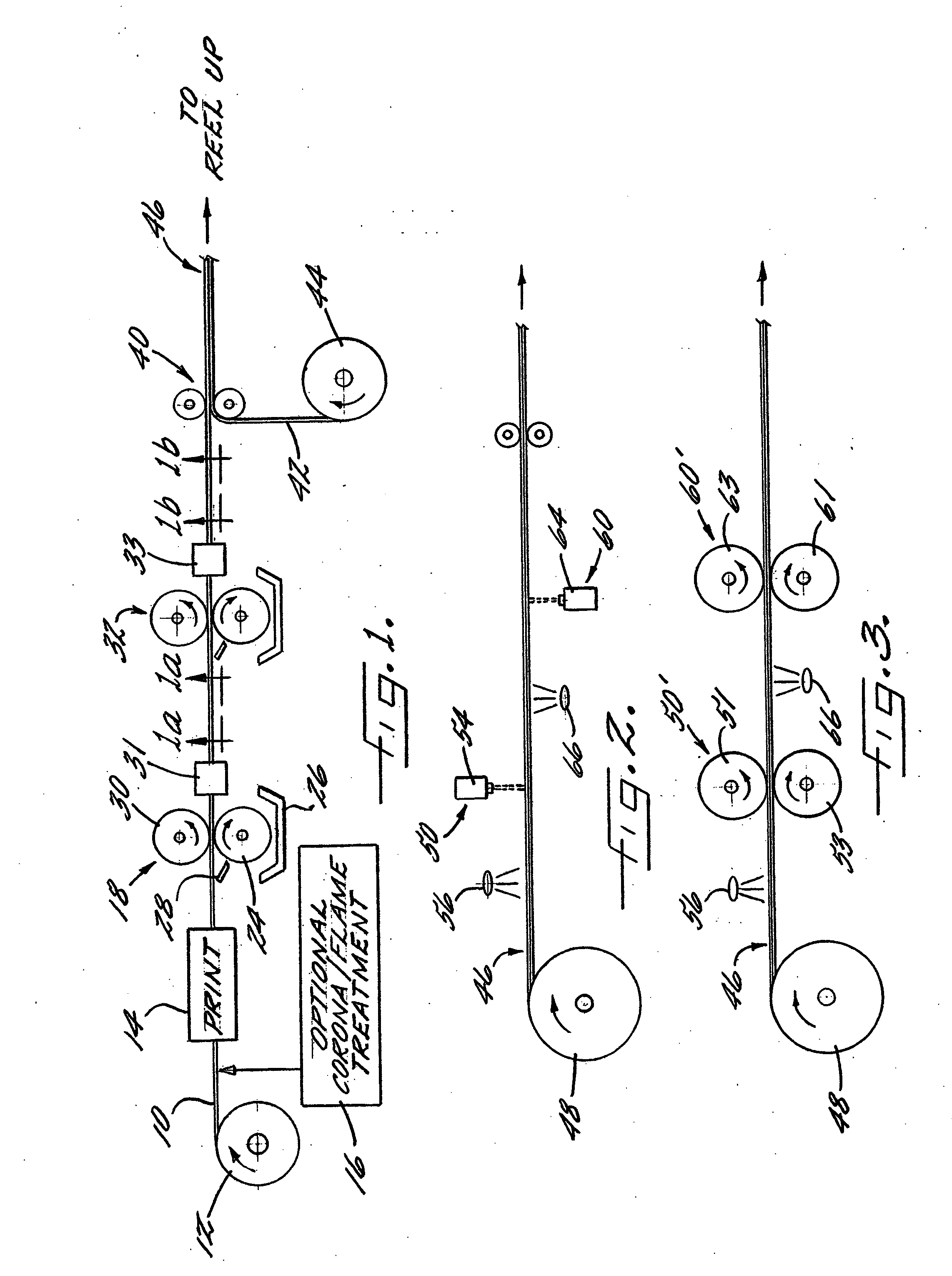

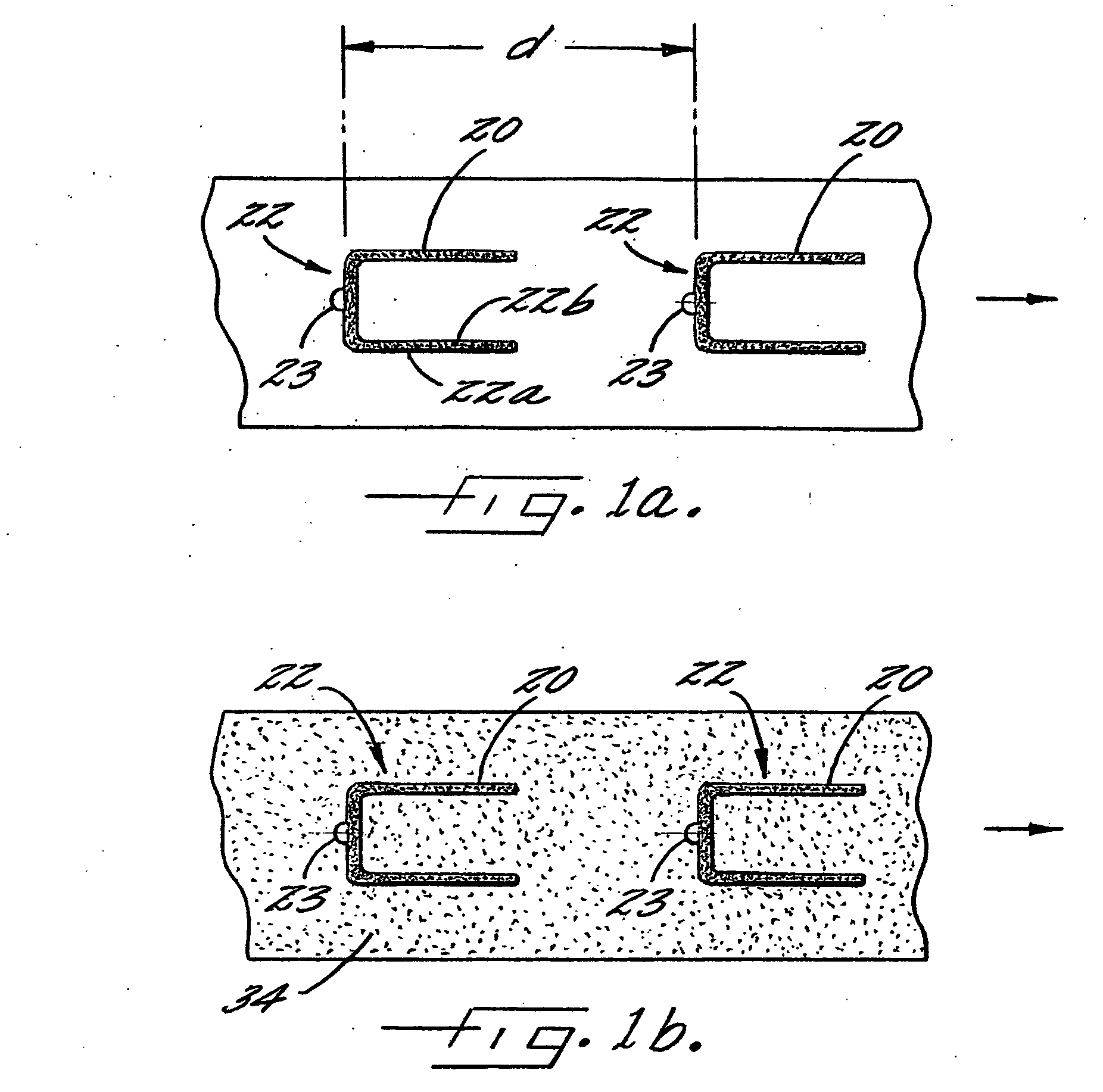

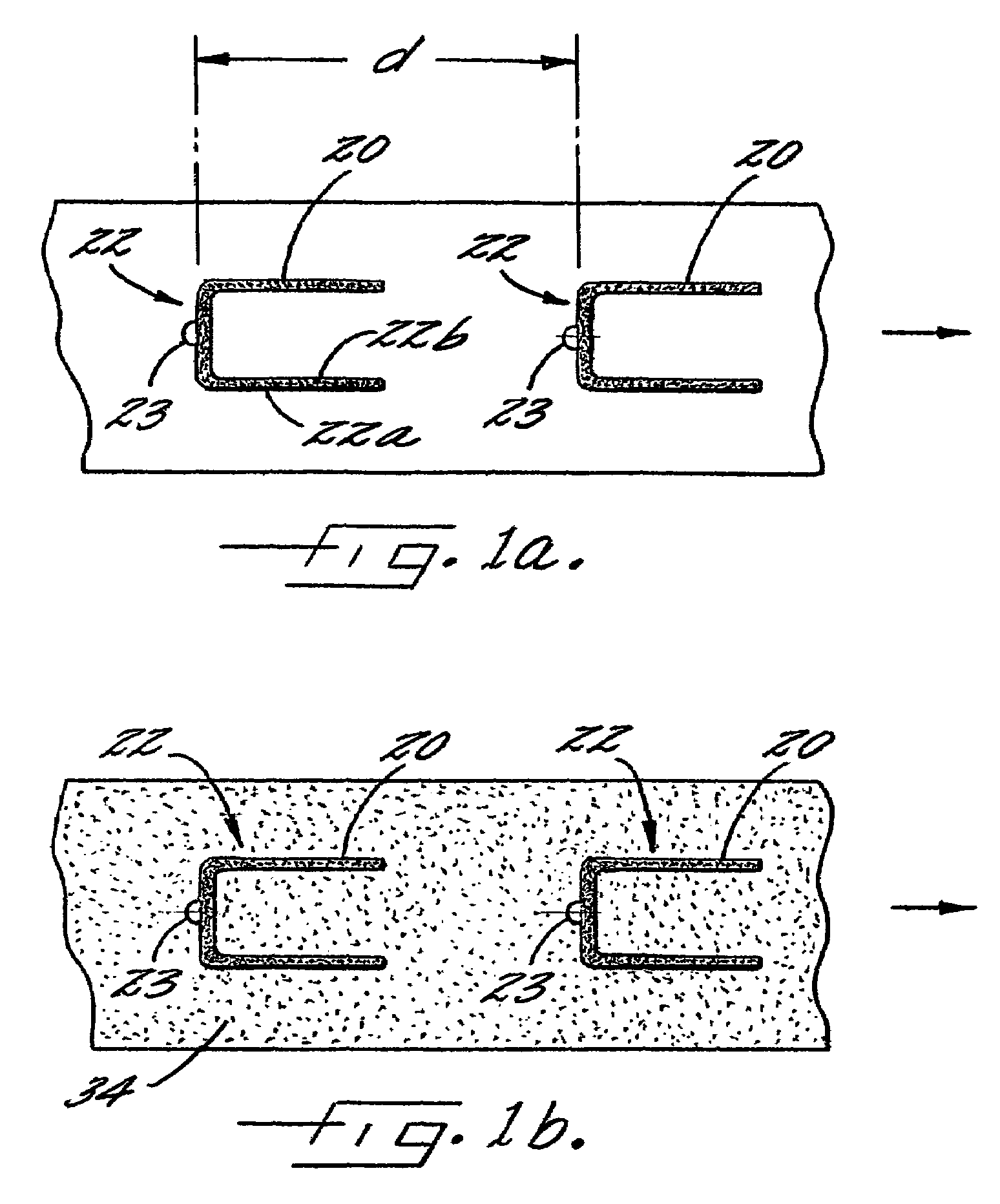

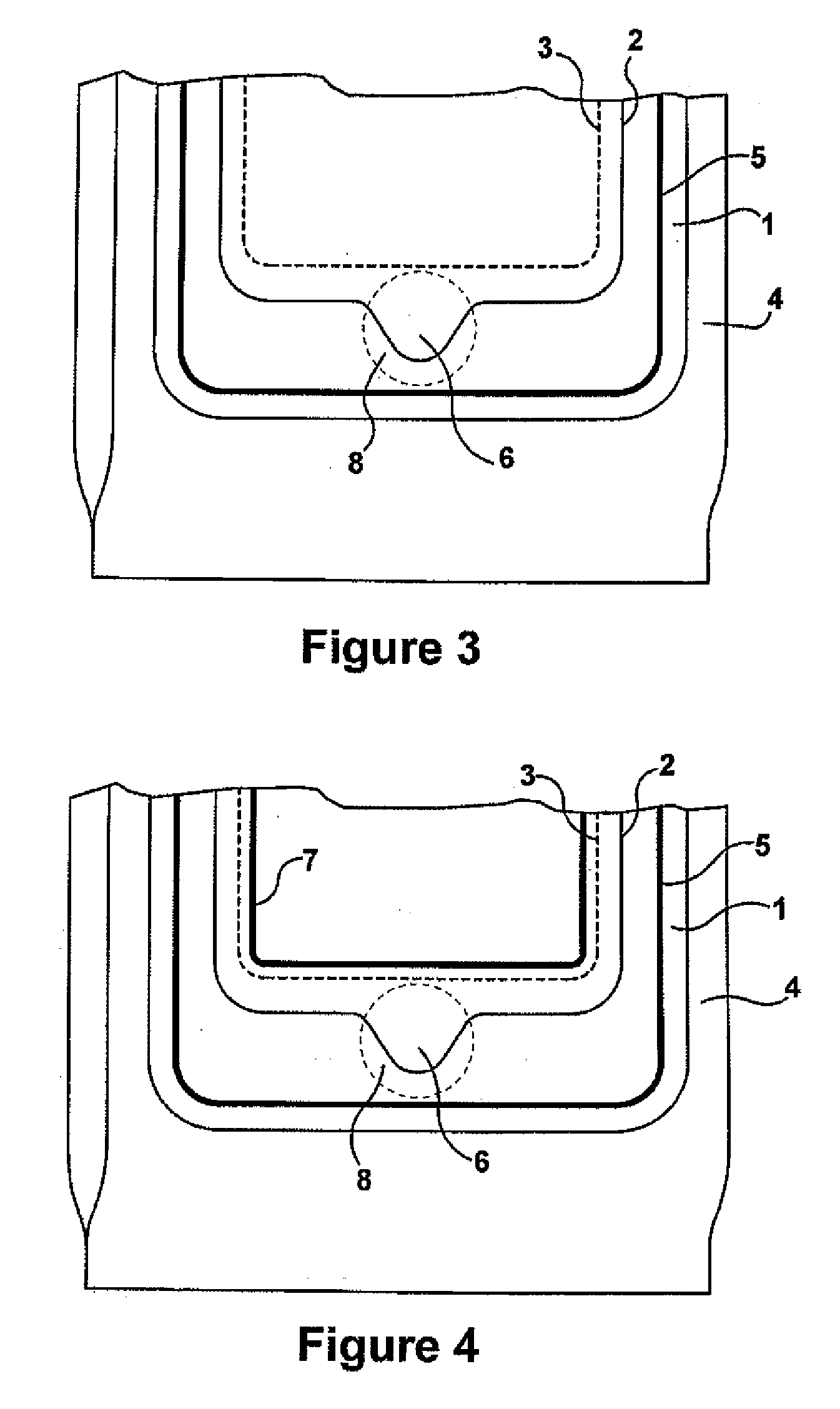

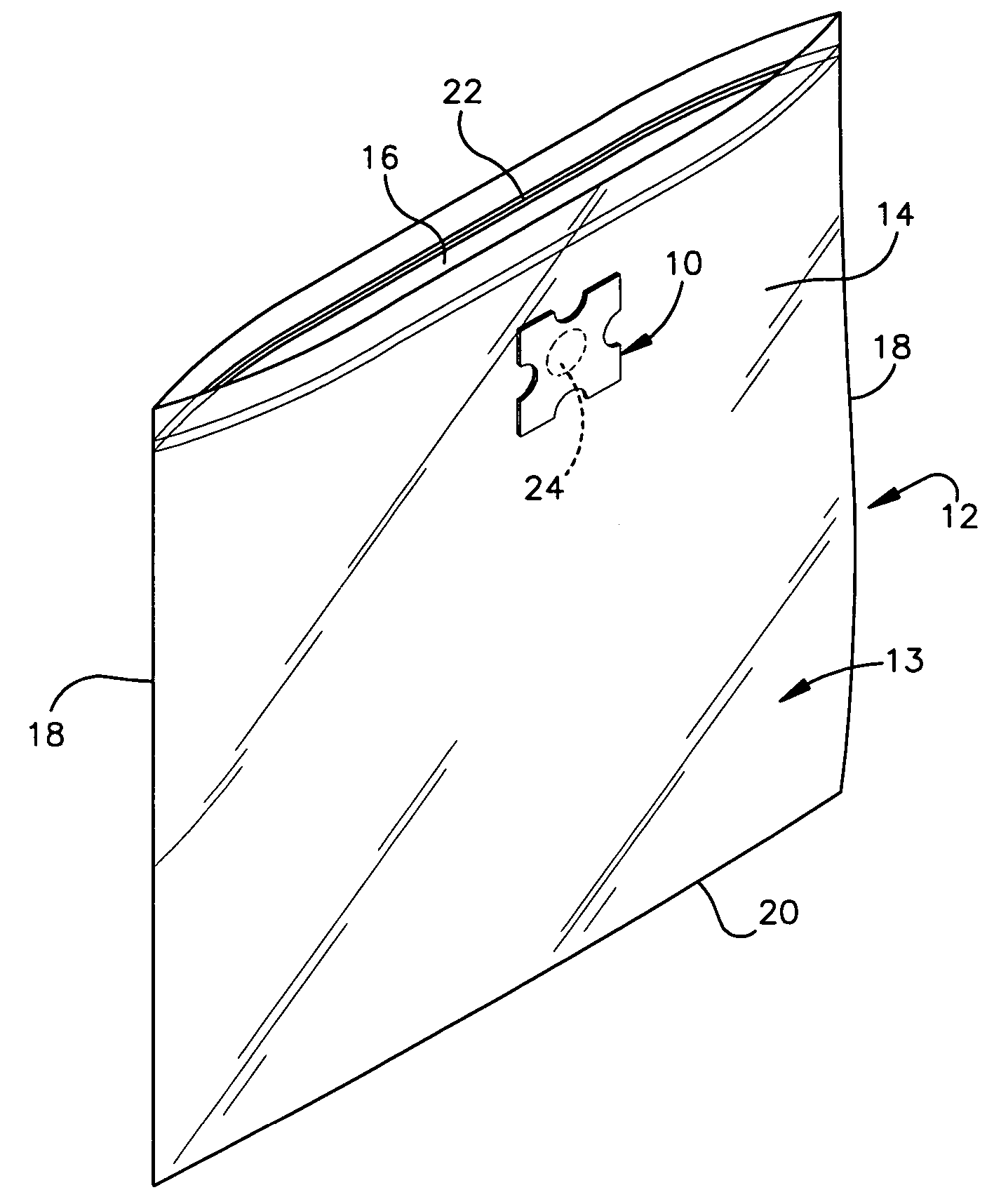

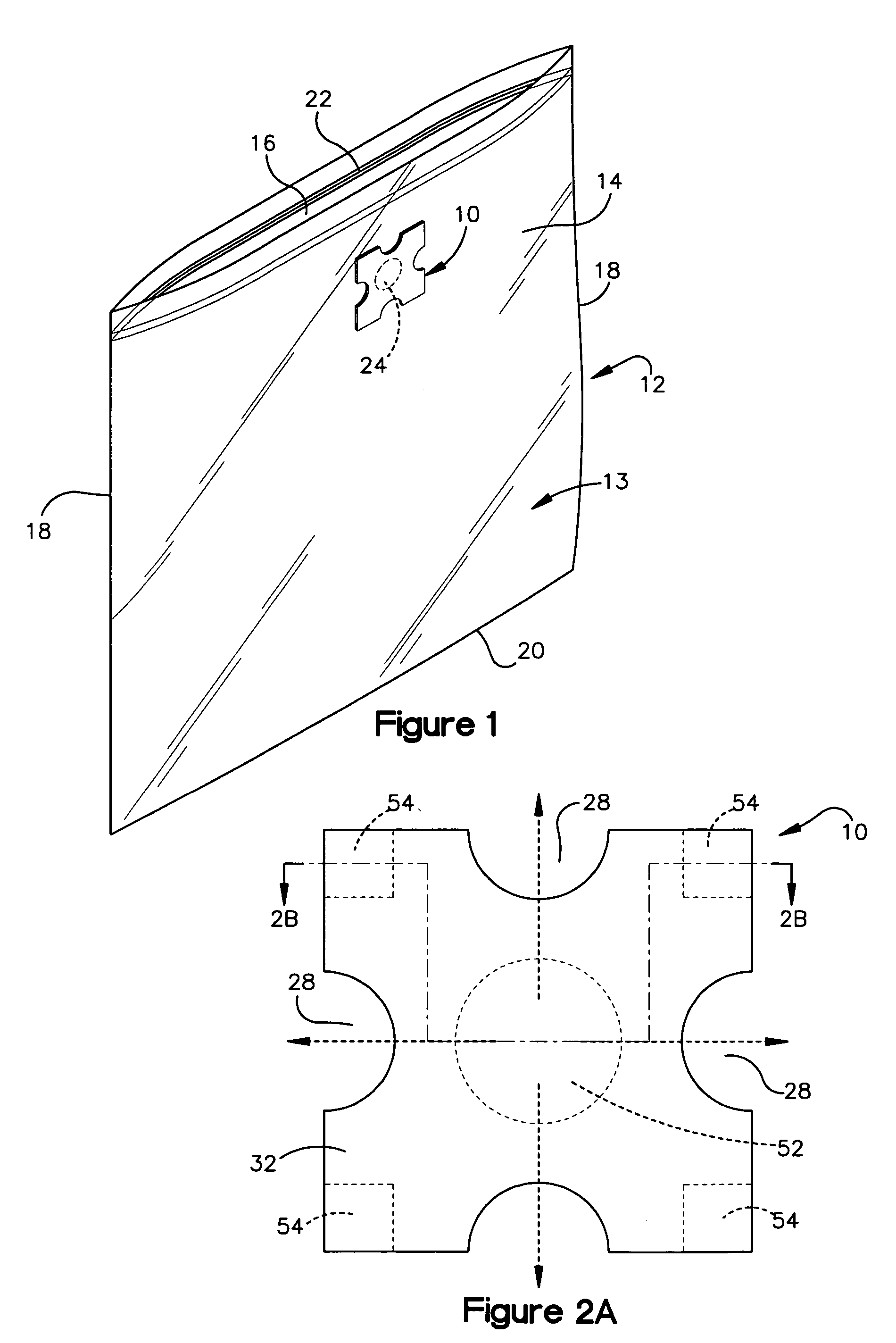

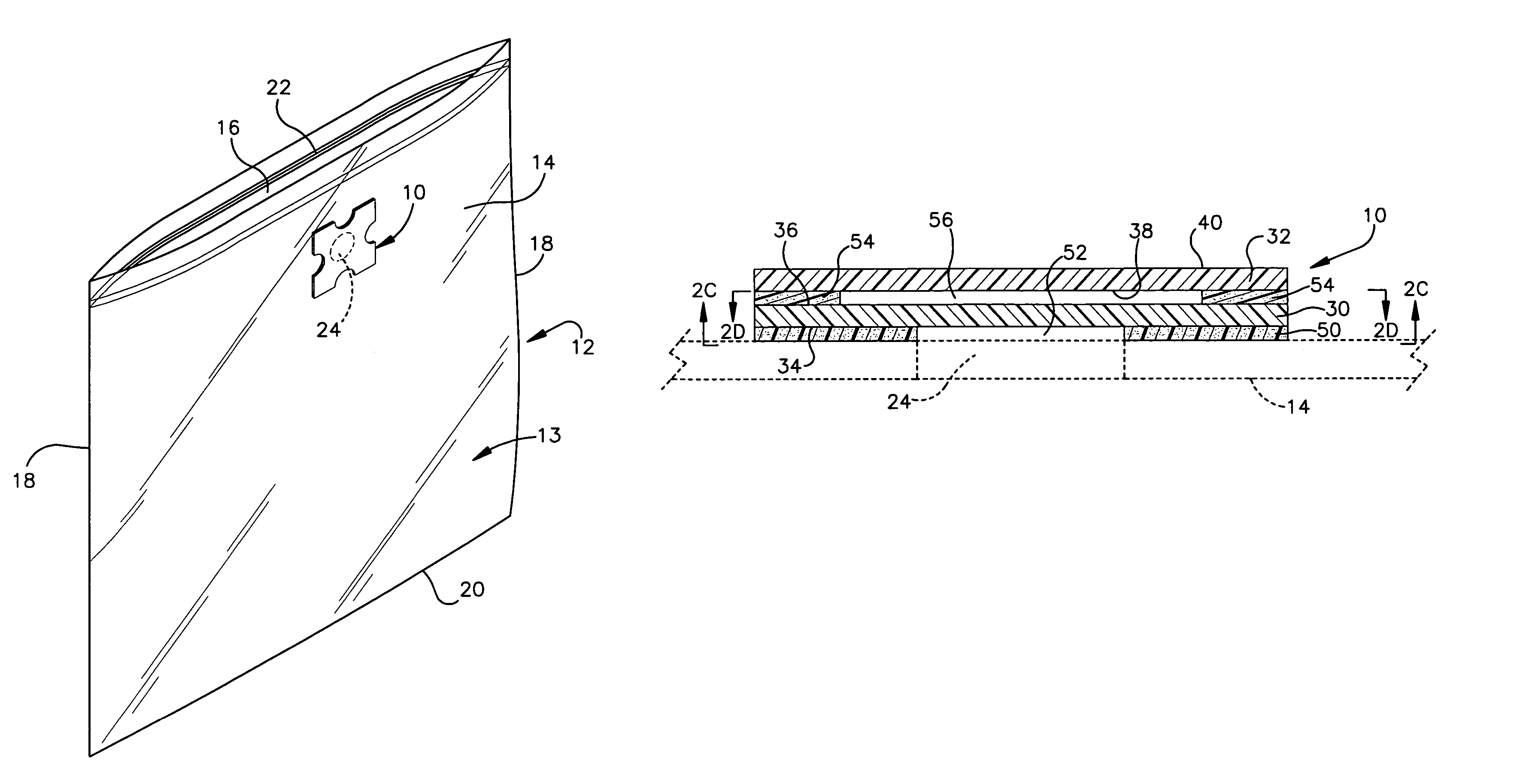

Flexible packaging structure with a built-in opening and reclose feature, and method for making same

ActiveUS20050276525A1Envelopes/bags making machineryWrappersMechanical engineeringPressure sensitive

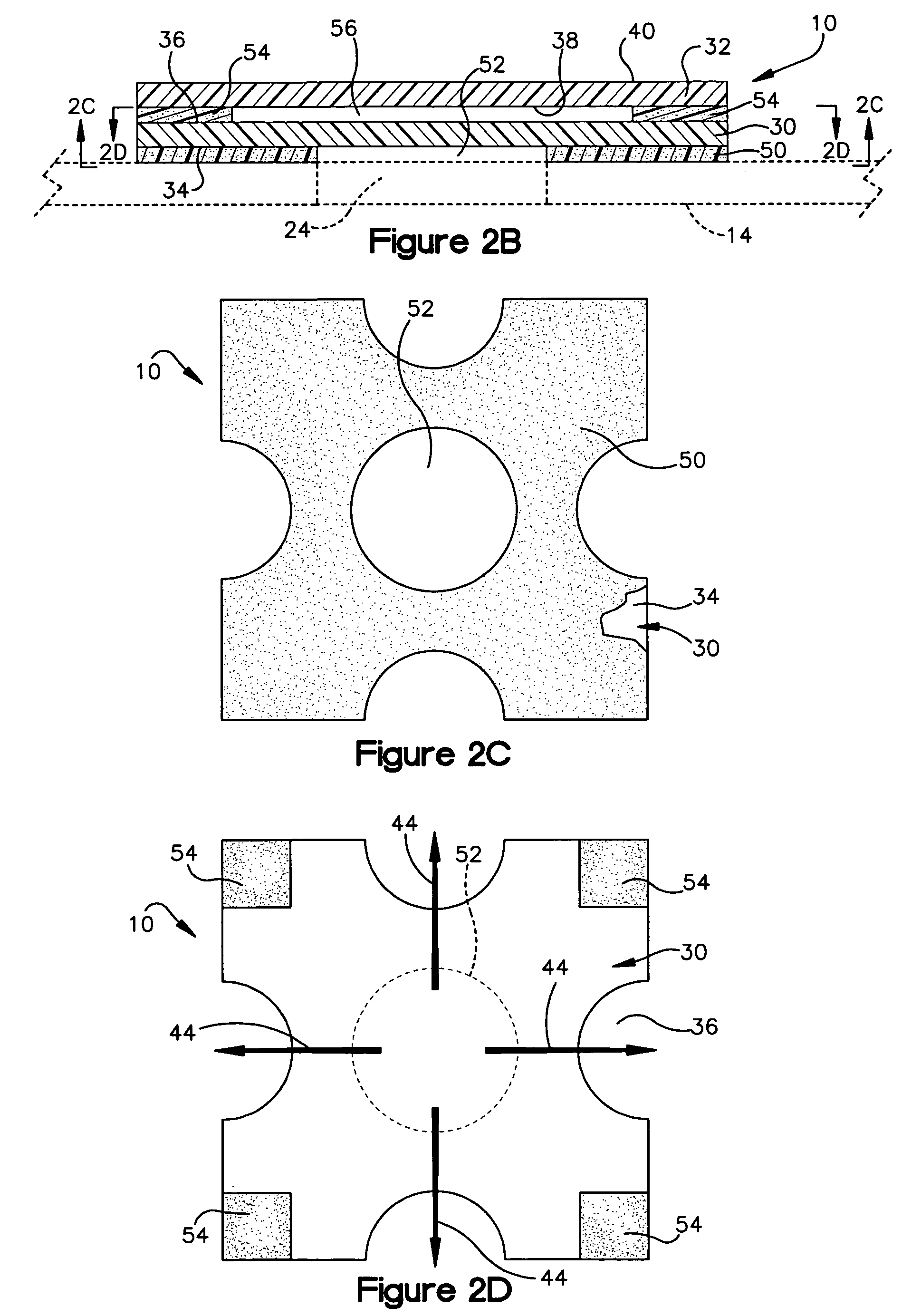

A flexible packaging laminate is formed to have a built-in opening and reclose feature by forming the laminate as a two-part structure having an outer structure joined in face-to-face relation with an inner structure. Score lines are formed in both structures to enable an opening to be formed through the laminate by lifting an opening portion (e.g., a flap or the like) of the two structures out of the plane of the laminate. The score line through the outer structure defines a larger opening than the score line through the inner structure, such that a marginal region of the outer structure extends beyond the edge of the opening portion of the inner structure. A pressure-sensitive adhesive is used to re-adhere the marginal region to an underlying surface of the inner structure adjacent the opening through the laminate.

Owner:SONOCO DEV INC

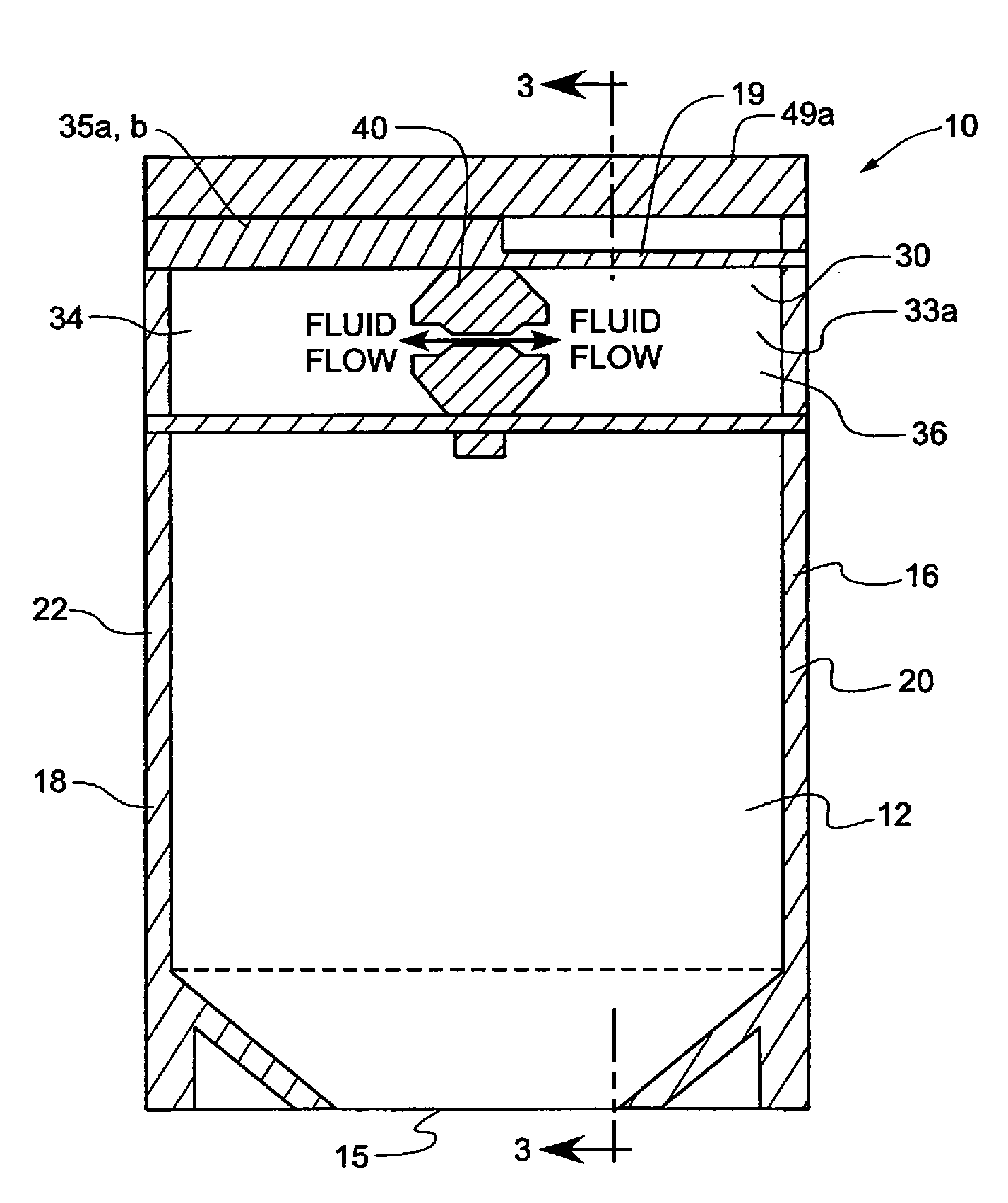

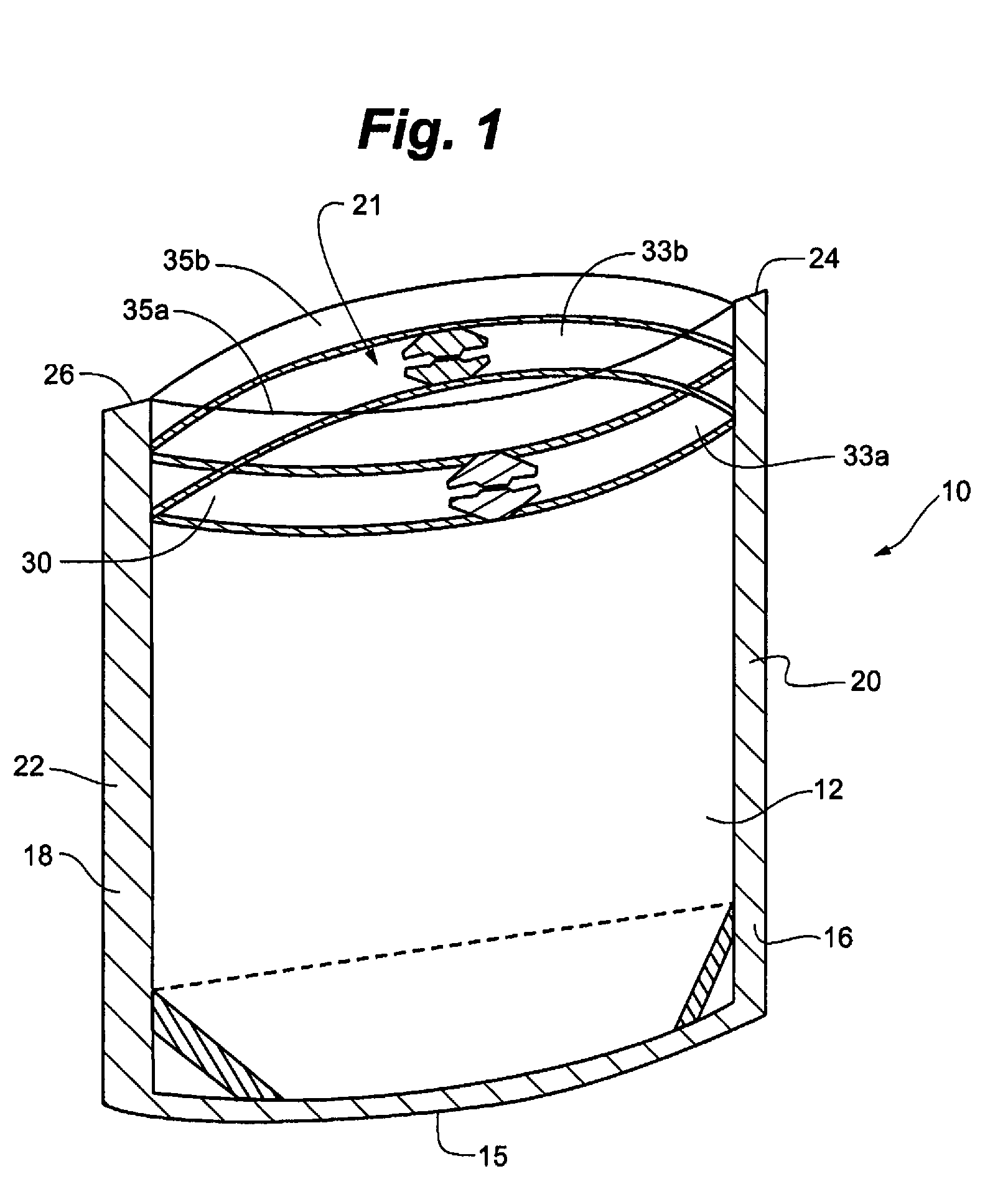

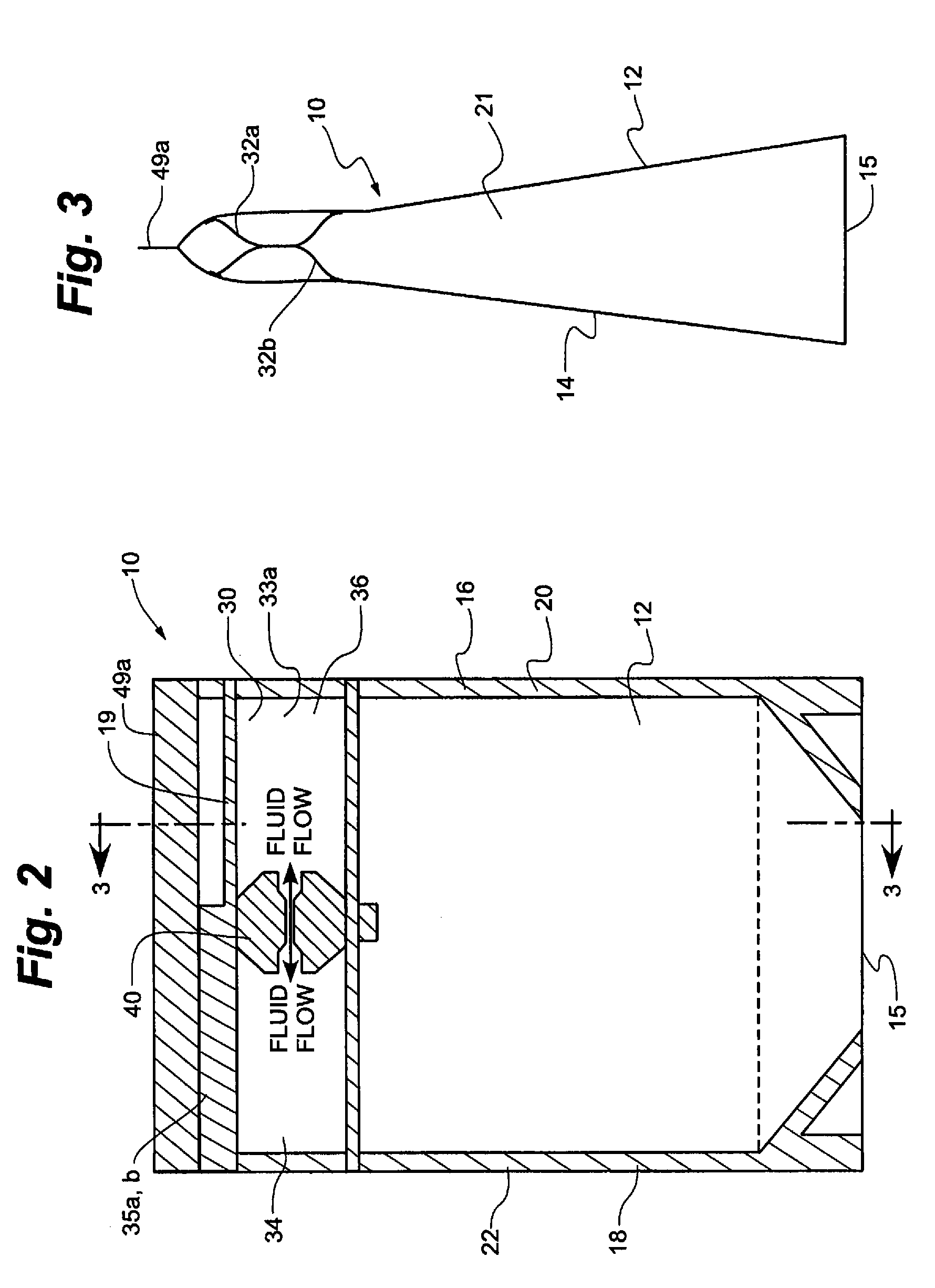

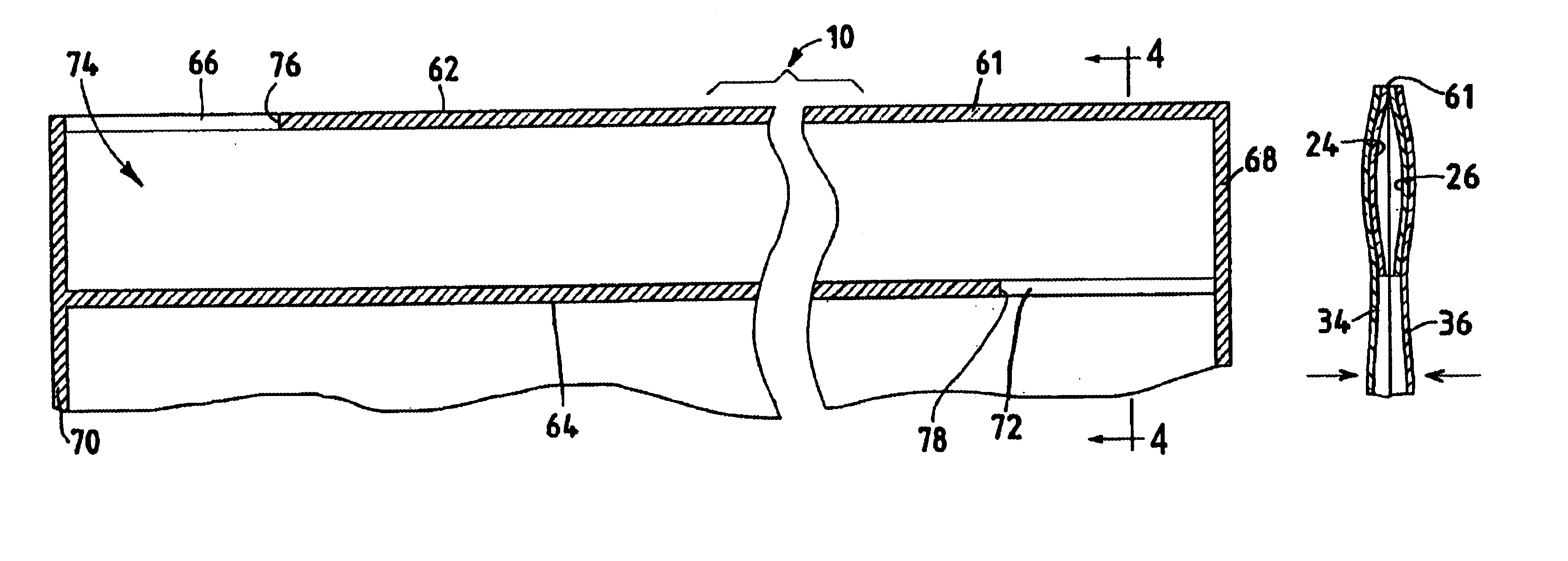

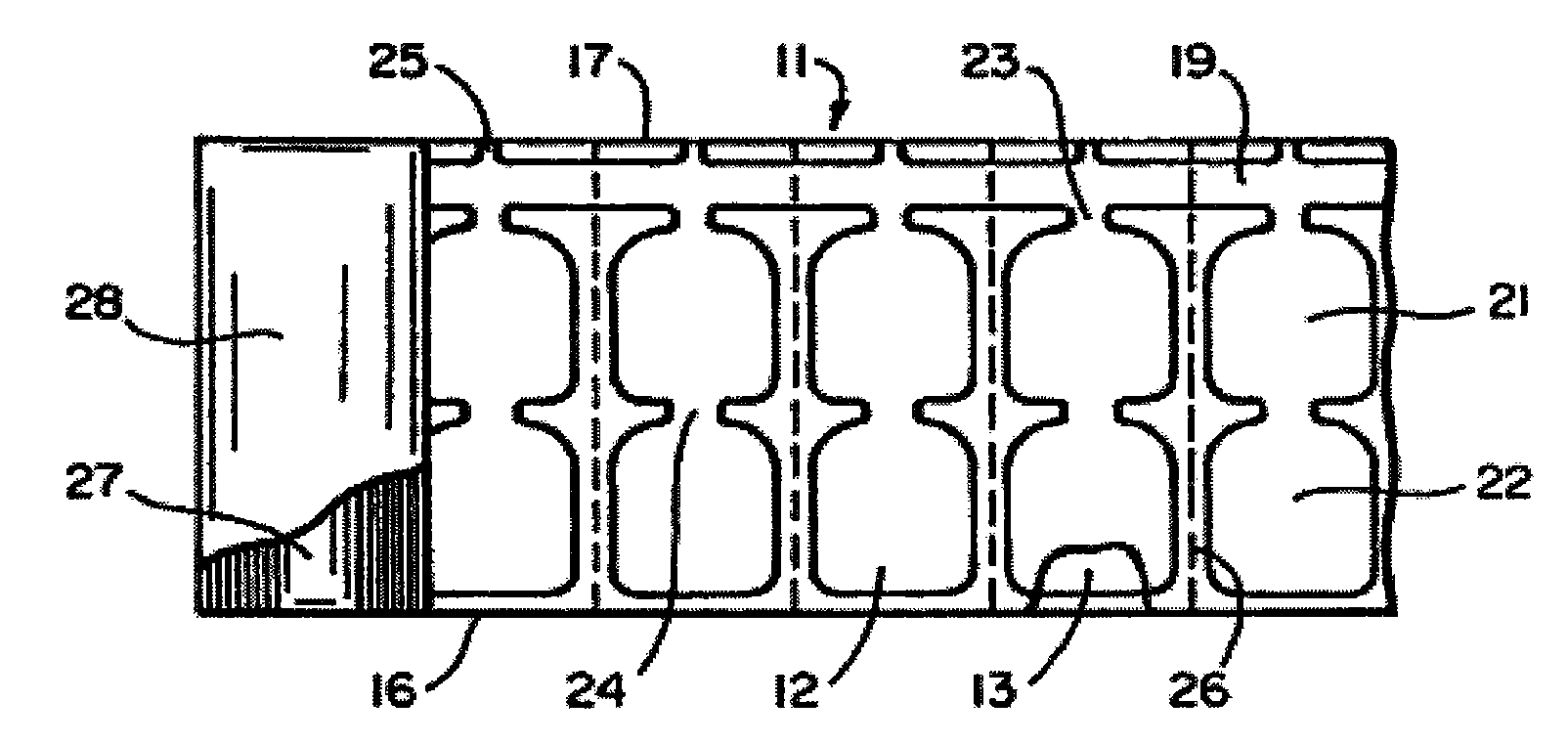

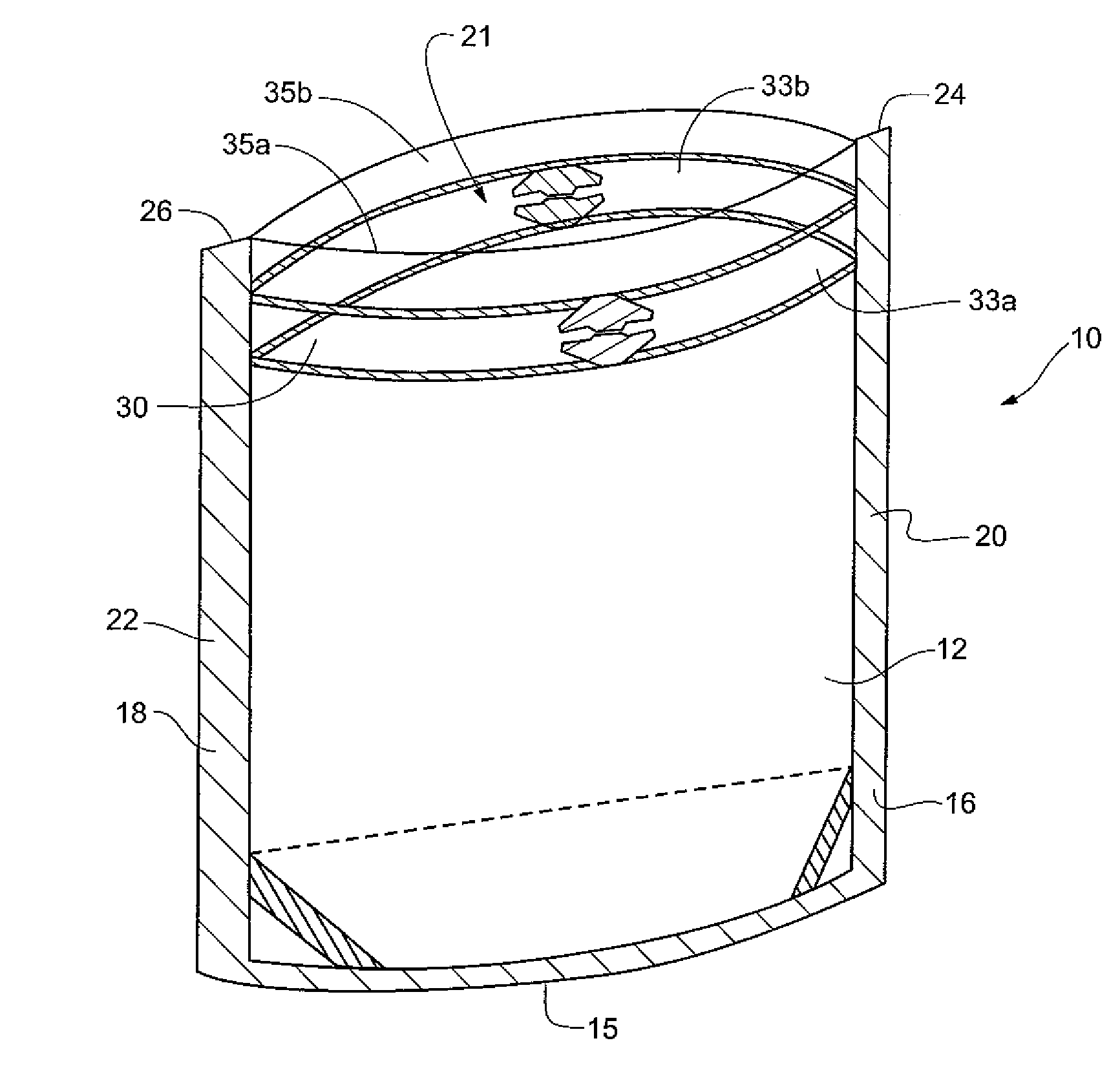

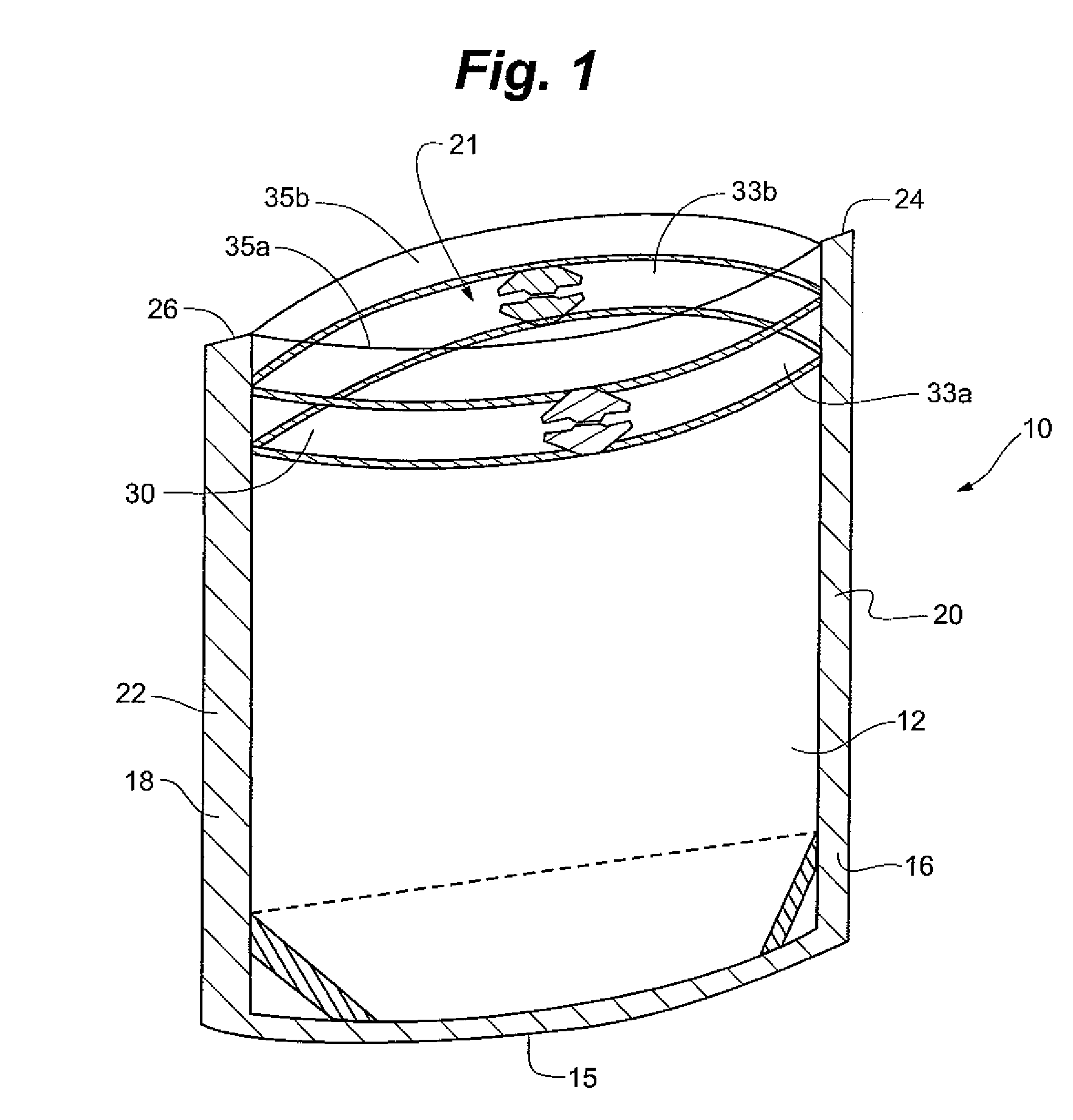

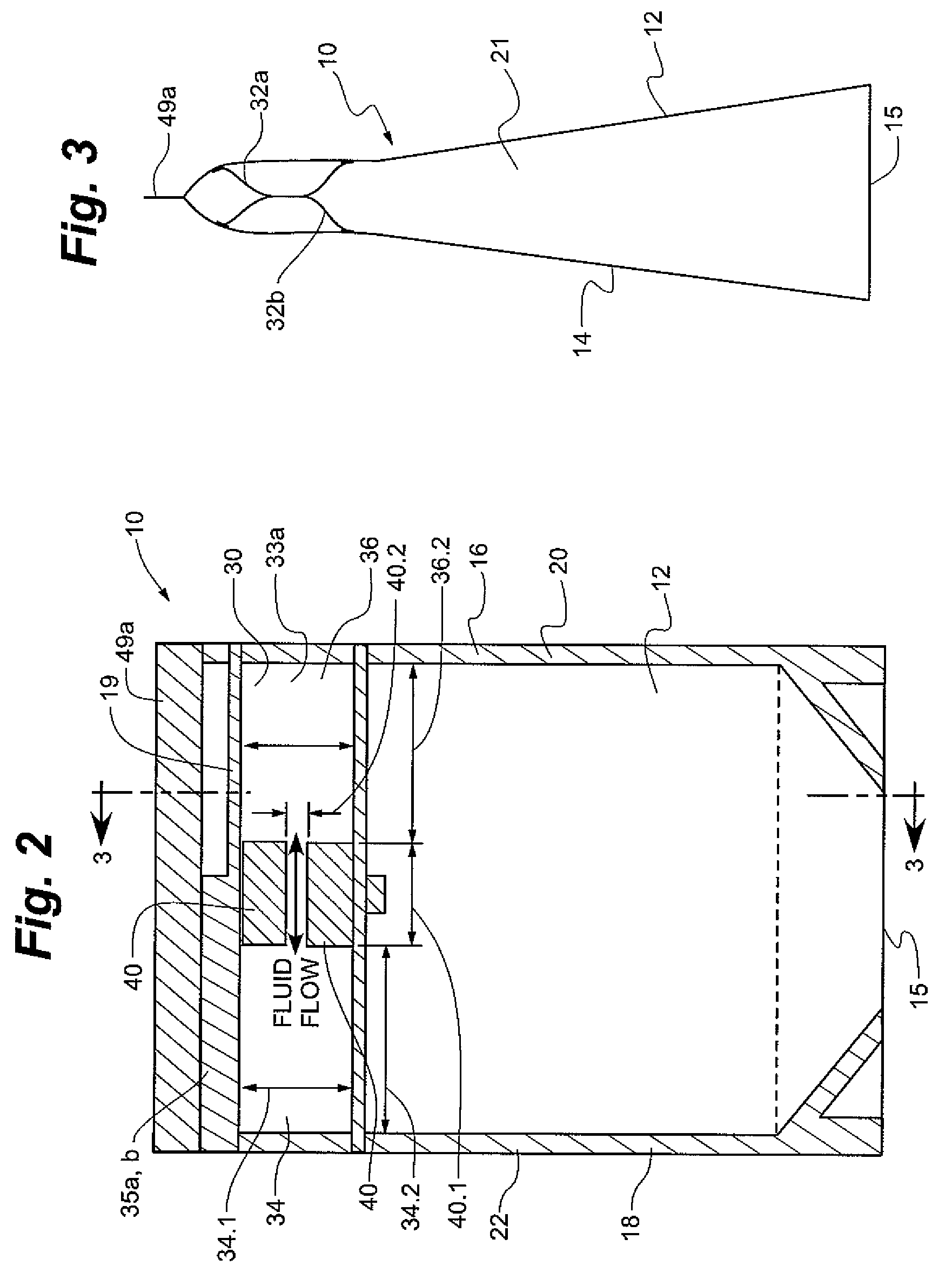

Package having a fluid actuated closure

ActiveUS7207717B2Solve the real problemEnvelopes/bags making machineryBag making operationsMechanical engineering

The package generally includes at least one front and back panel joined at least partially together to define an interior accessible through an access opening. The interior is capable of storing and dispensing product and other objects or materials. Further, at least one web member can be joined to each of the front and back panel portions respectively to form at least two generally parallel chambers and / or channels that extend generally along at least a portion of the access opening. In one embodiment, each of the chambers includes a reservoir or storage portion and a closure portion in fluid communication such that either the reservoir portion or the closure portion are generally inflated or expanded to correspondingly close or open the access opening.

Owner:STEELE MARK

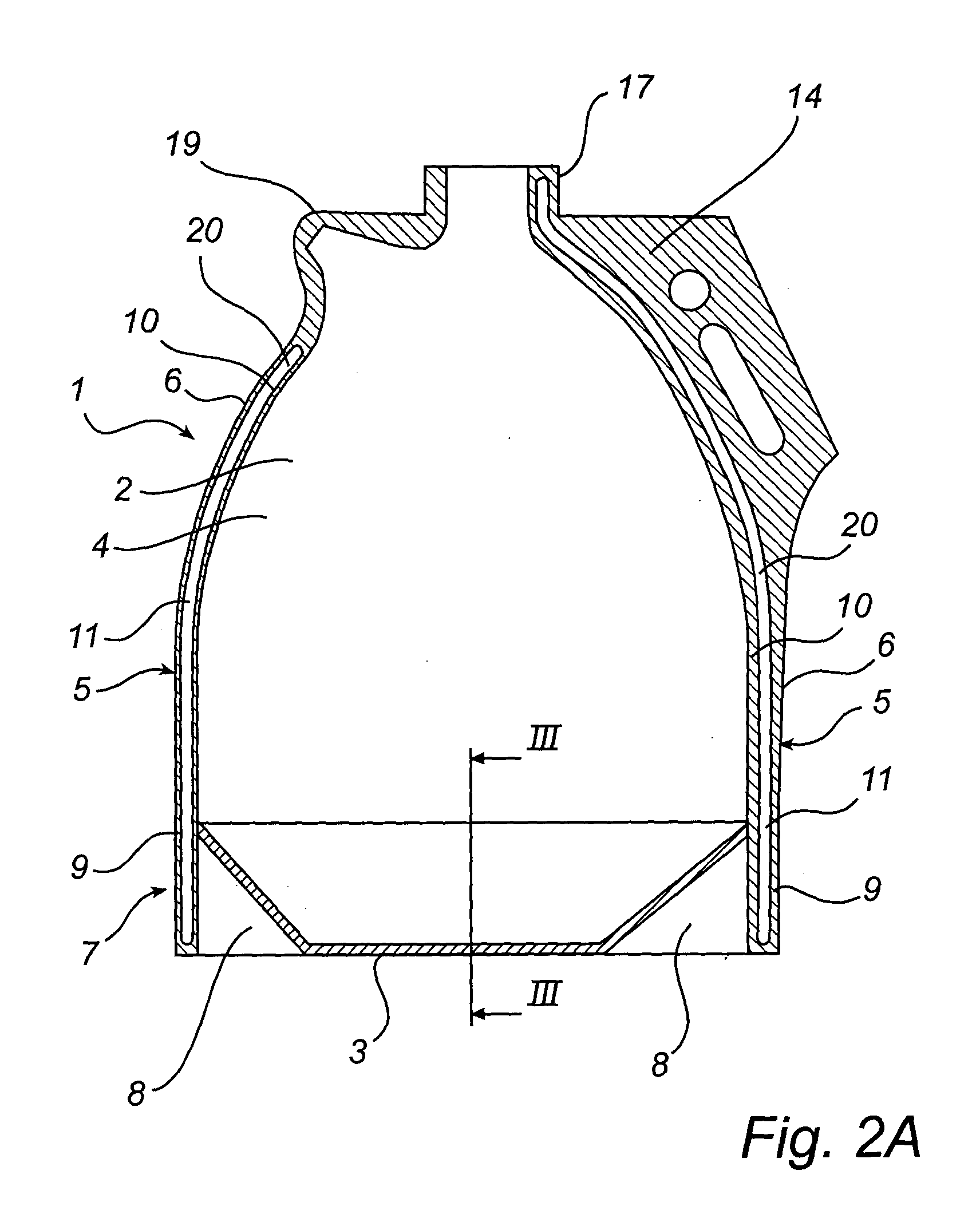

Container

InactiveUS20040035865A1Envelopes/bags making machineryBag making operationsEngineeringMechanical engineering

Owner:ECOLEAN RES & DEV AS

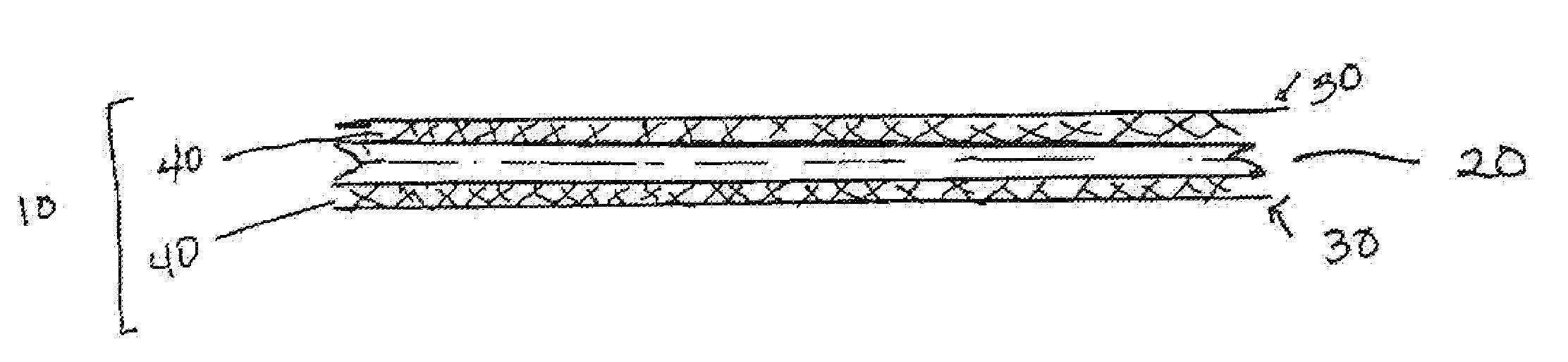

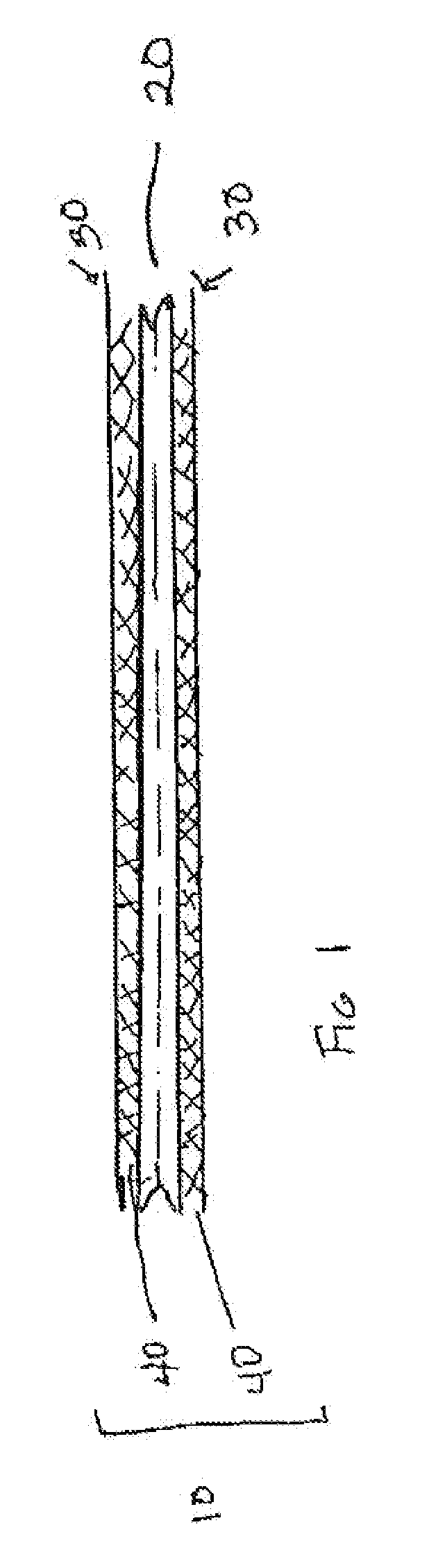

Flexible packaging structure with a built-in opening and reclose feature, and method for making same

A flexible packaging laminate is formed to have a built-in opening and reclose feature by forming the laminate as a two-part structure having an outer structure joined in face-to-face relation with an inner structure. Score lines are formed in both structures to enable an opening to be formed through the laminate by lifting an opening portion (e.g., a flap or the like) of the two structures out of the plane of the laminate. The score line through the outer structure defines a larger opening than the score line through the inner structure, such that a marginal region of the outer structure extends beyond the edge of the opening portion of the inner structure. A pressure-sensitive adhesive is used to re-adhere the marginal region to an underlying surface of the inner structure adjacent the opening through the laminate.

Owner:SONOCO DEV INC

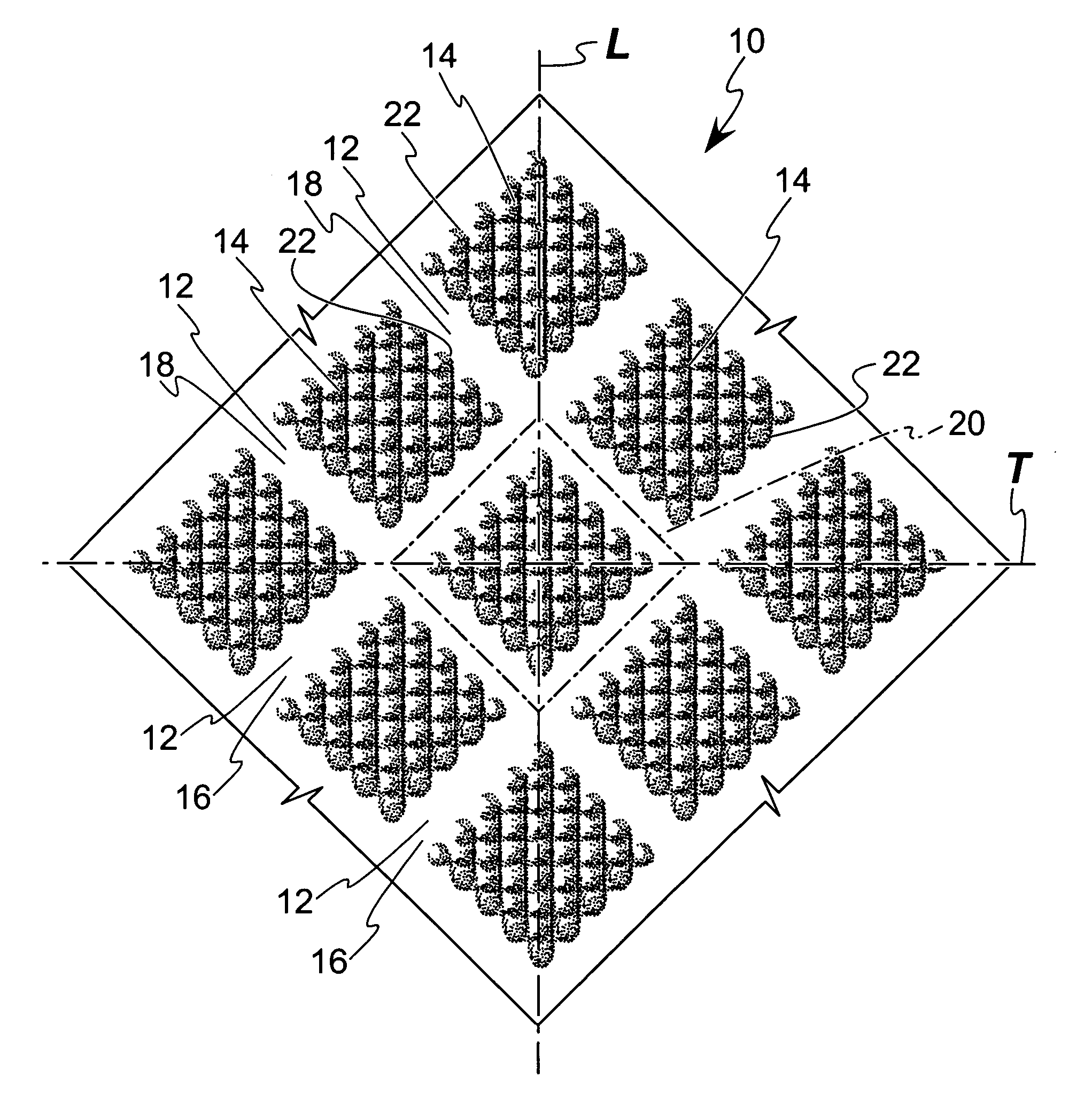

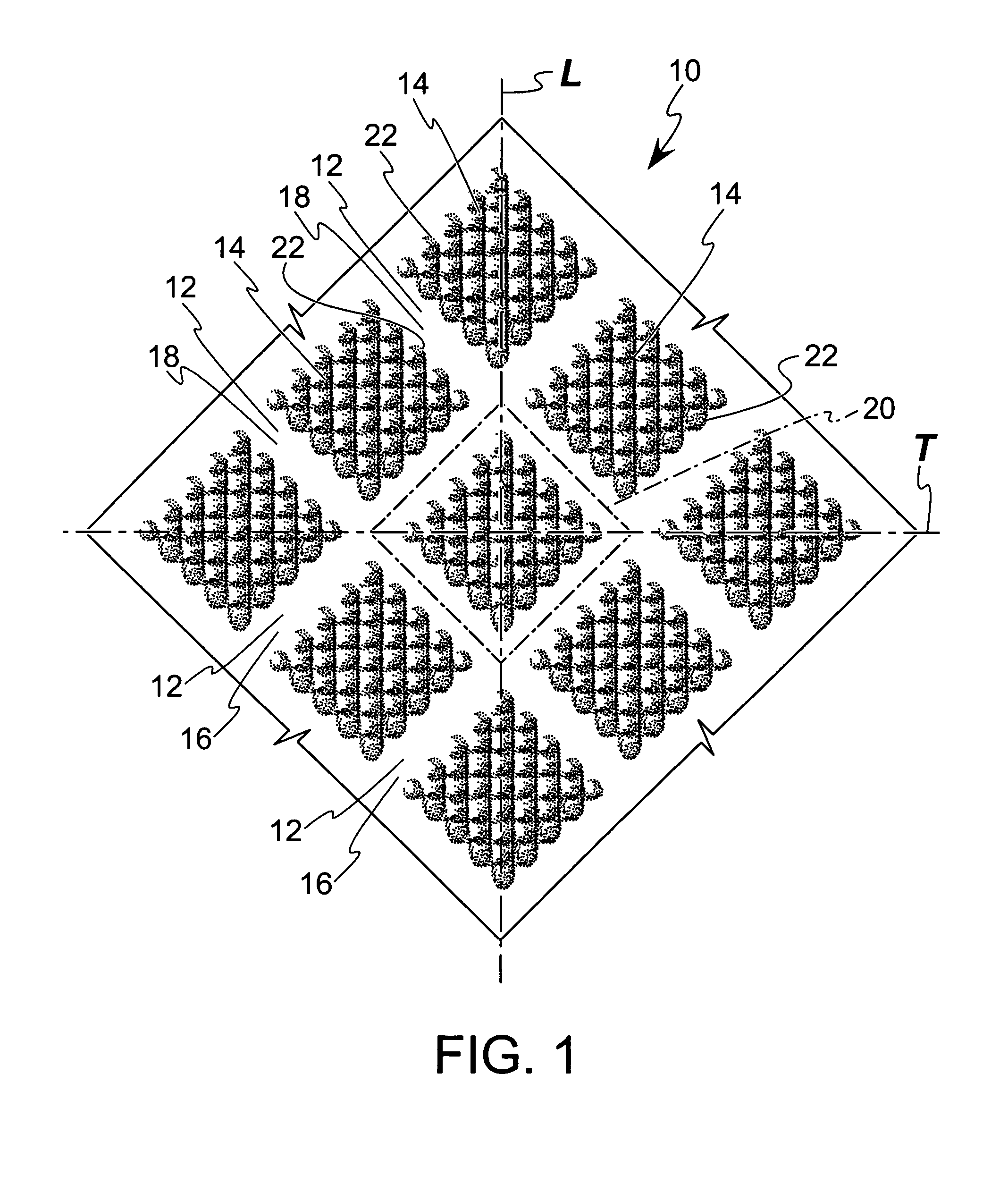

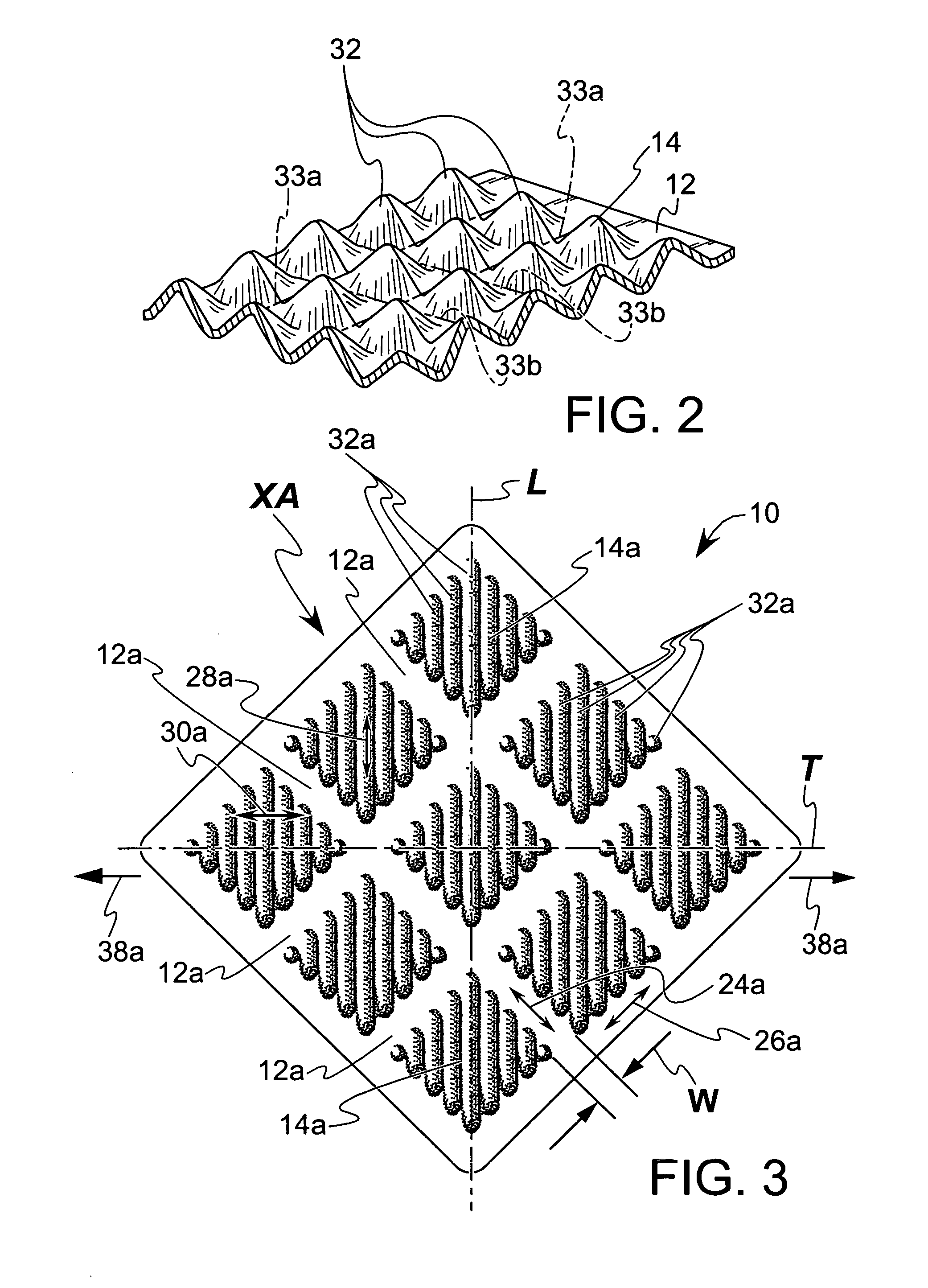

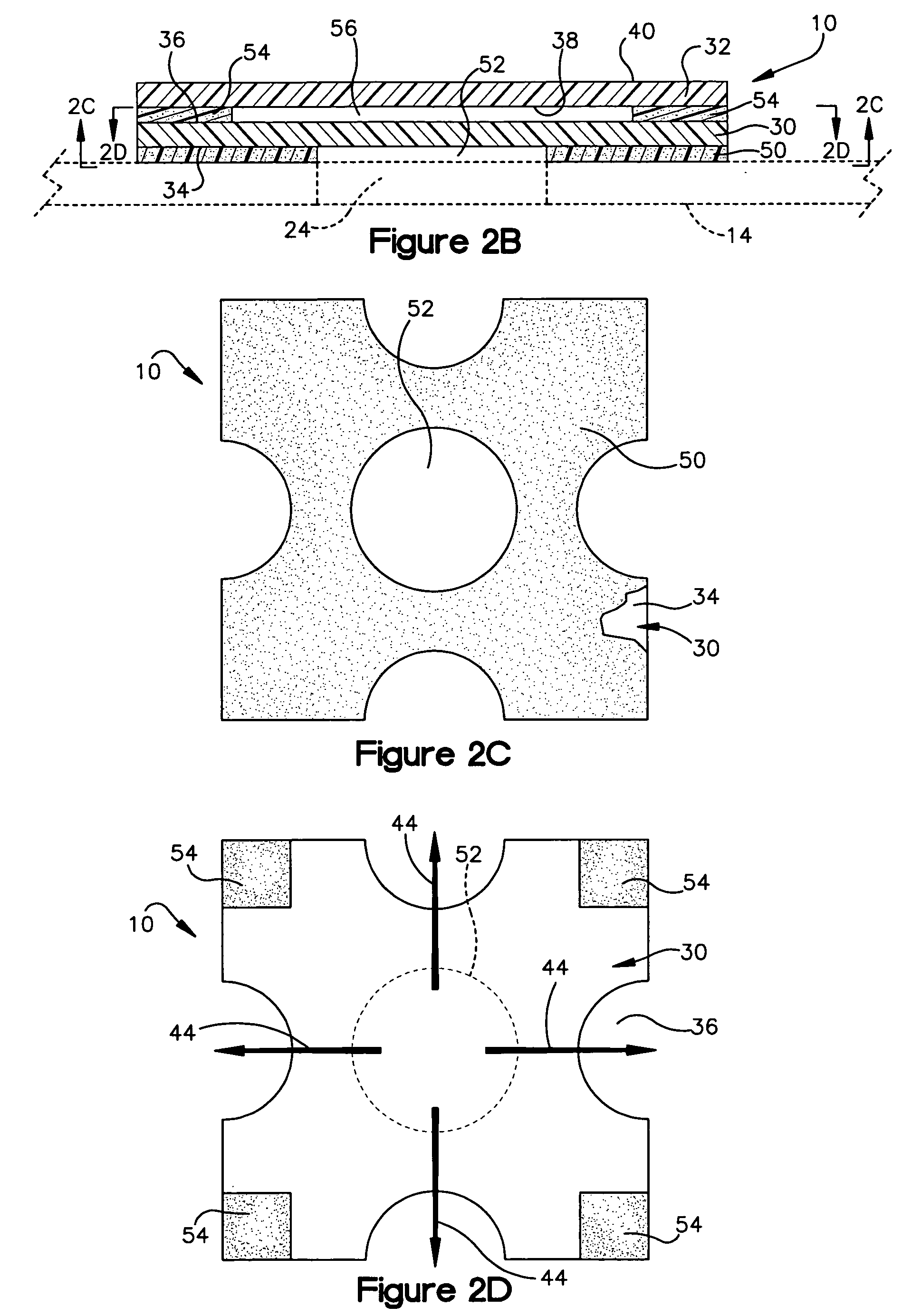

Multi-directional elastic-like material

InactiveUS20060093766A1Envelopes/bags making machineryMechanical working/deformationEngineeringMulti directional

A sheet material including a strainable network formed in the surface of the sheet material. The strainable network includes first network areas and second network areas, the first network areas substantially surrounding the second network areas. The second network areas include geometrically deformable elements, and the first network areas define substantially unformed portions of the sheet material surrounding the second network areas. The deformable elements are geometrically deformable in plural directions generally parallel to the plane of the sheet material to provide the sheet material with a stretchable elastic-like characteristic in response to elongation forces applied to the sheet material in plural directions.

Owner:THE PROCTER & GAMBLE COMPANY

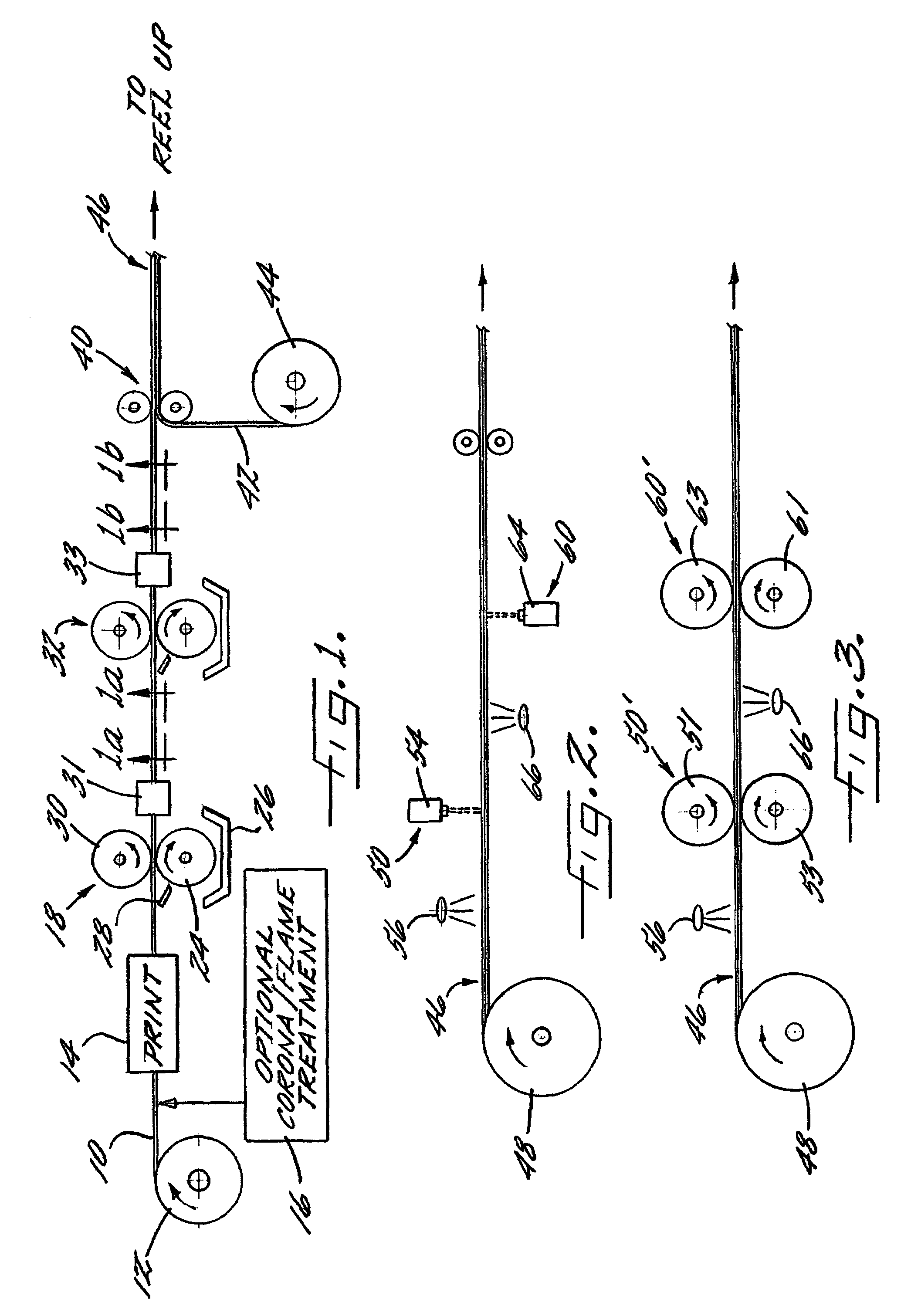

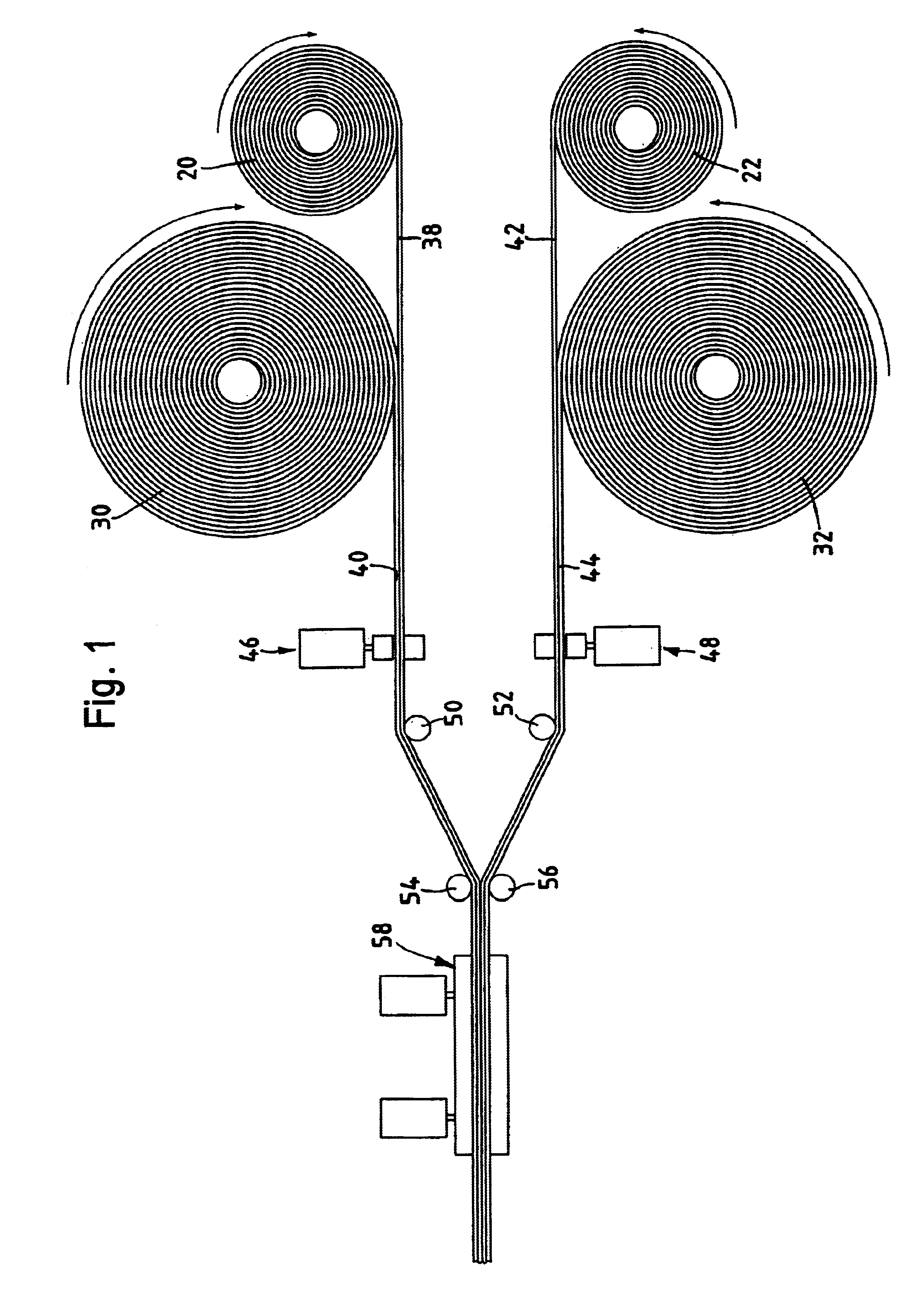

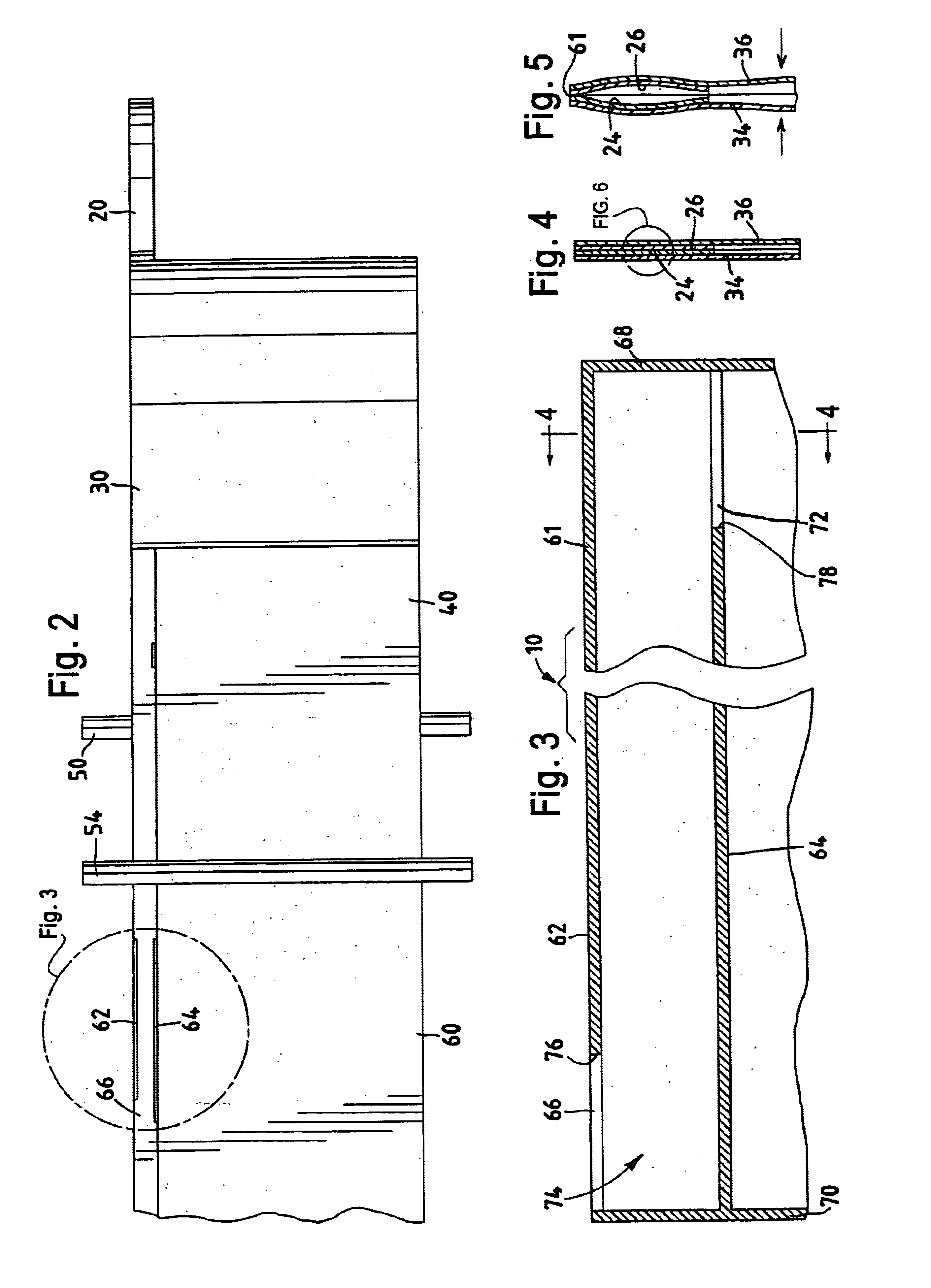

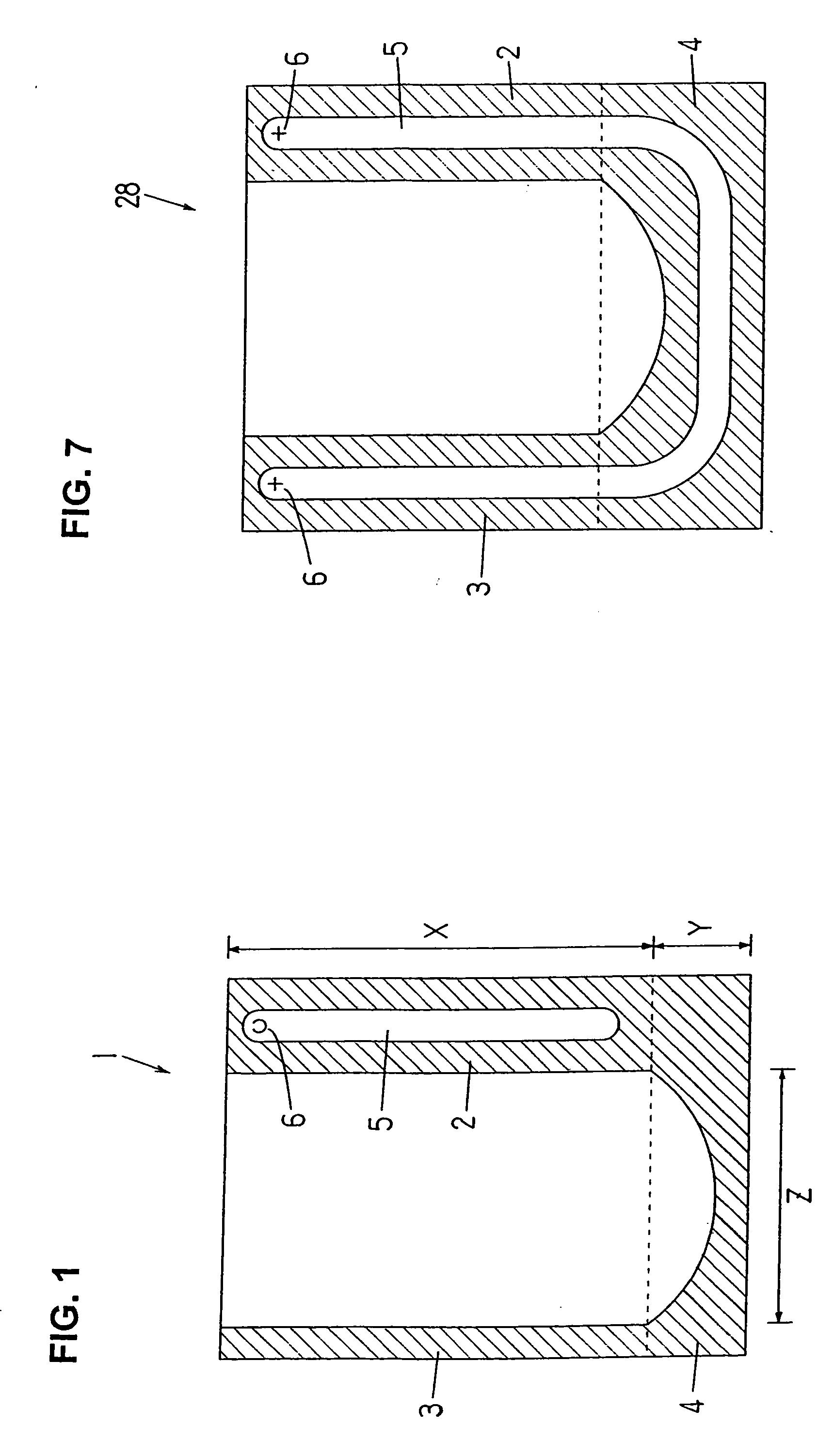

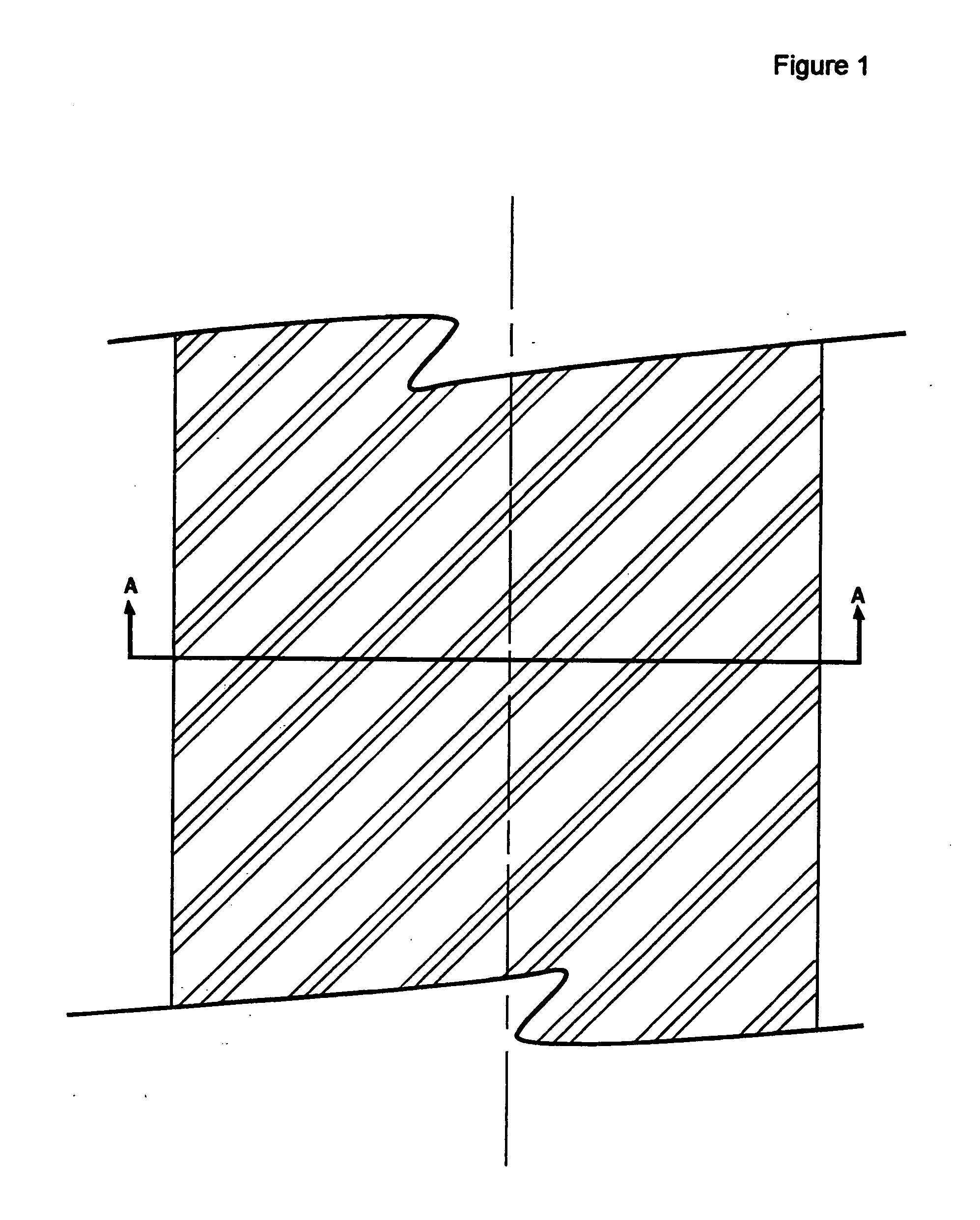

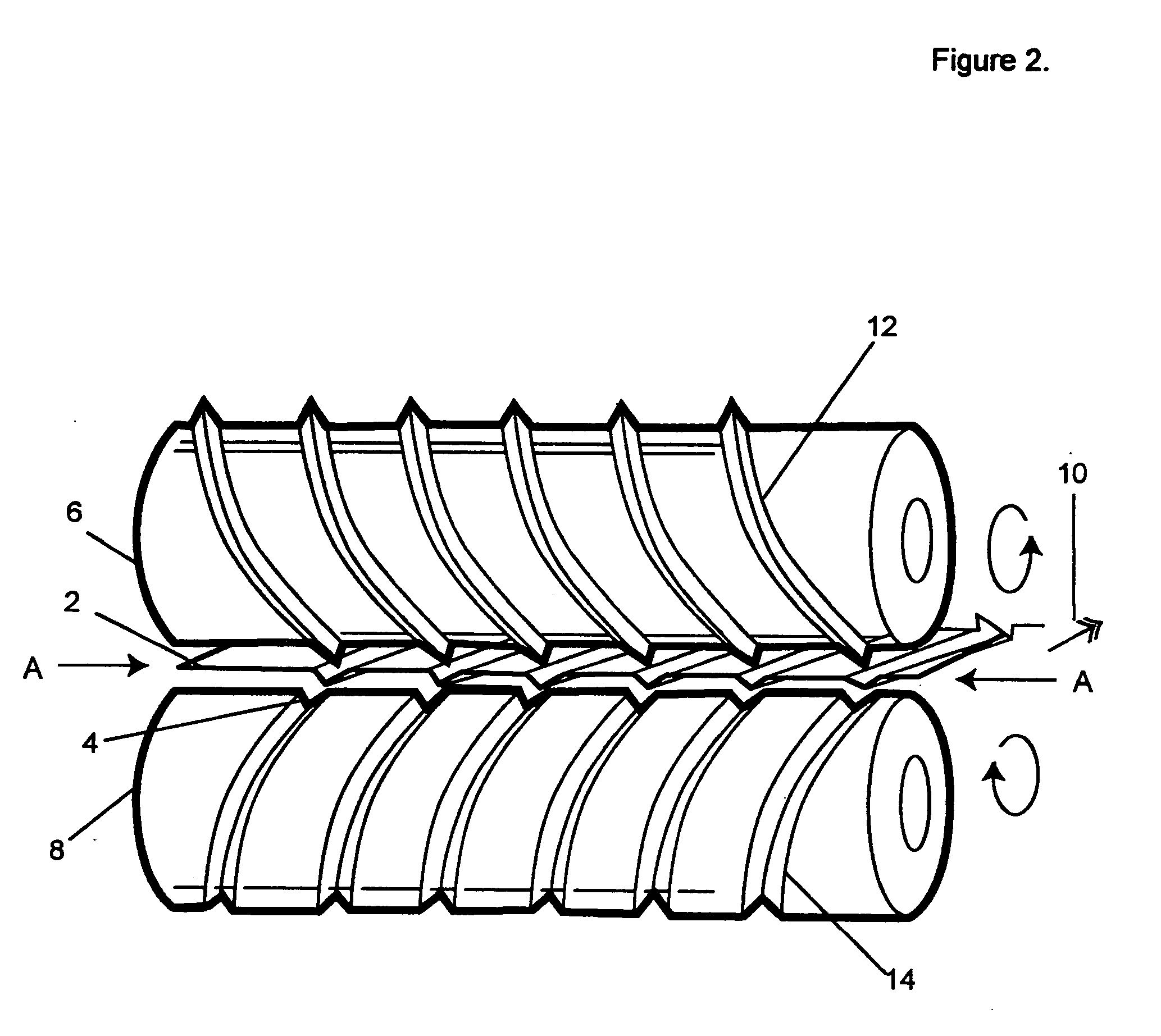

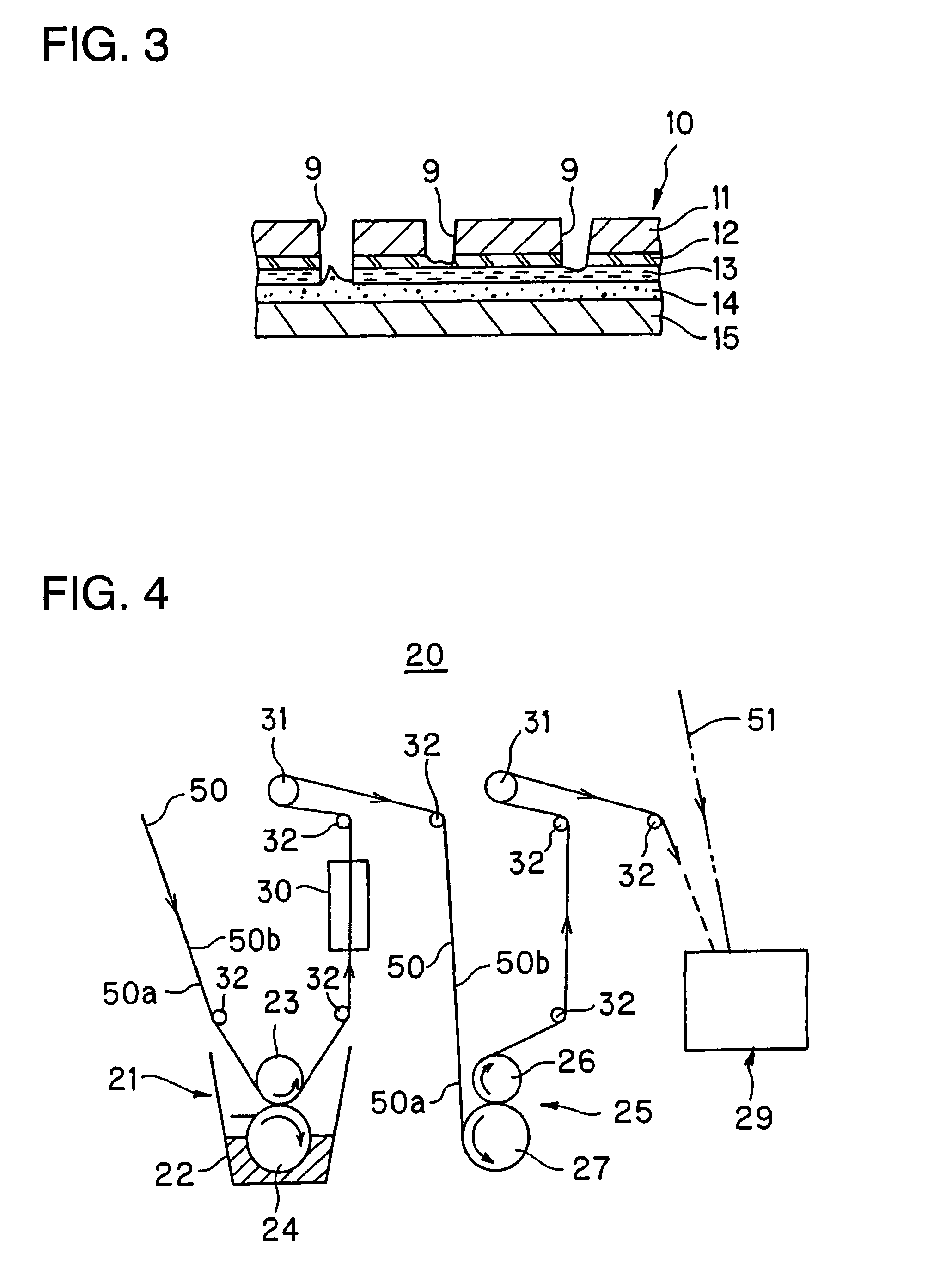

Air-evacuable bag with double-layered valve film and method for manufacturing same

InactiveUS6729473B2Envelopes/bags making machineryBag making operationsEngineeringMechanical engineering

An air-evacuable bag has a one-way valve therein having two layers of valve film, neither of which is the sidewall of the bag. By forming the one-way valve of smooth, double-layered valve film, unwanted air gaps caused by textured surfaces in the sidewalls of the bag are avoided, thereby minimizing air leakage back into an evacuated bag. A method for the manufacture of such air-evacuable bags incorporates a roll supplying a first valve film layer, a roll supplying a first sidewall layer, a roll supplying a second valve film layer, and a roll supplying a second sidewall layer. As the film coming off the first valve film layer roll passes the roll supplying the first sidewall layer, both the sidewall layer and first valve film layer move in close proximity to one another until the valve film is tacked to the first sidewall layer. The second film and second sidewall layer are processed simultaneously in a like manner, and all four layers are joined at a sealing station.

Owner:YUNHONG CTI LTD

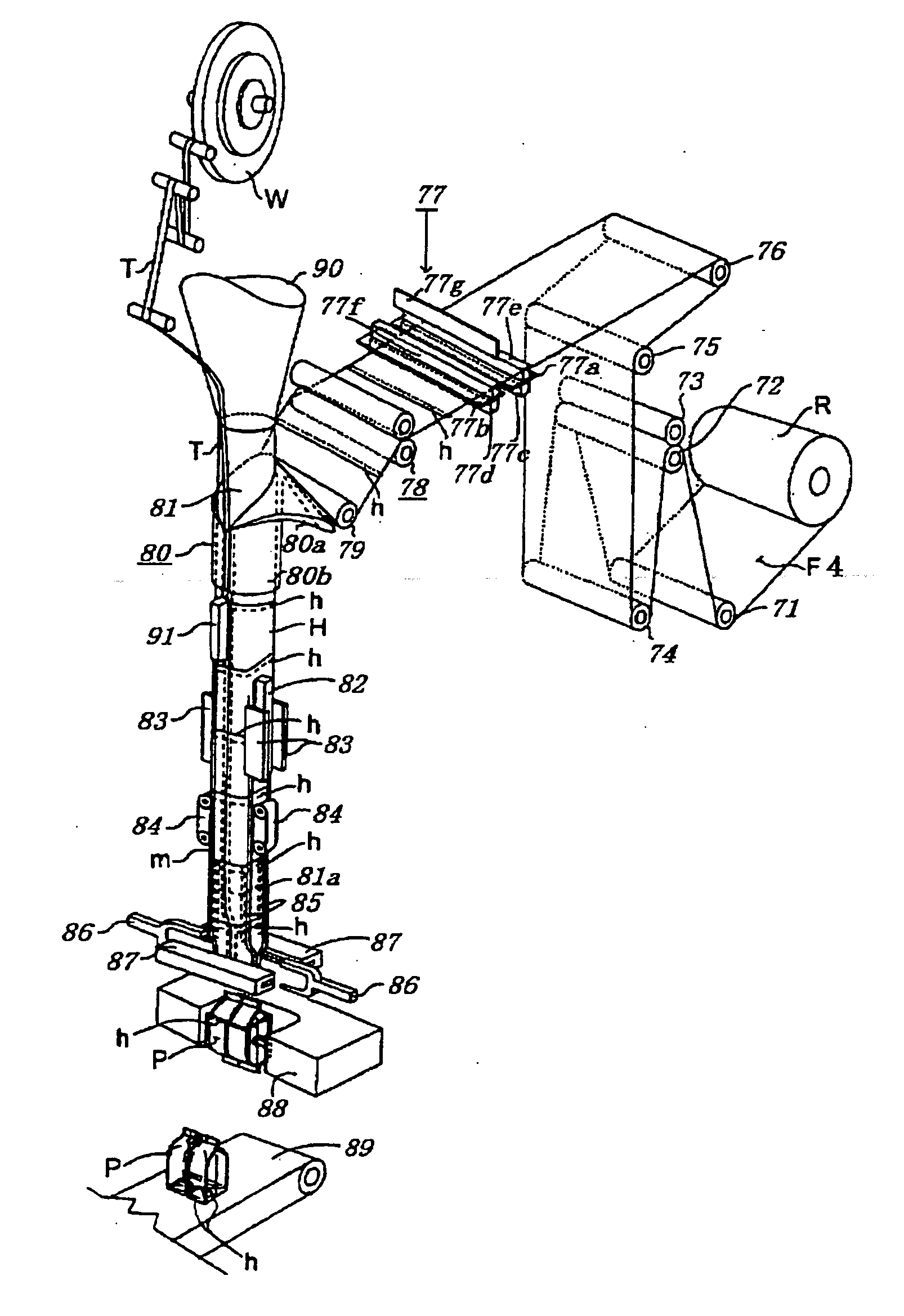

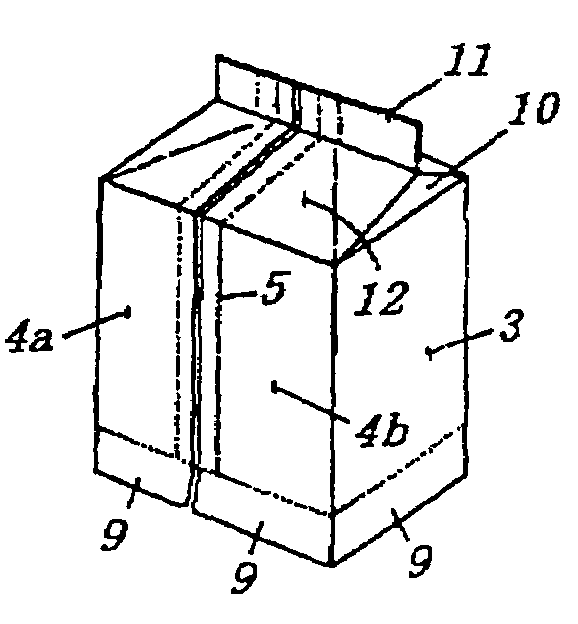

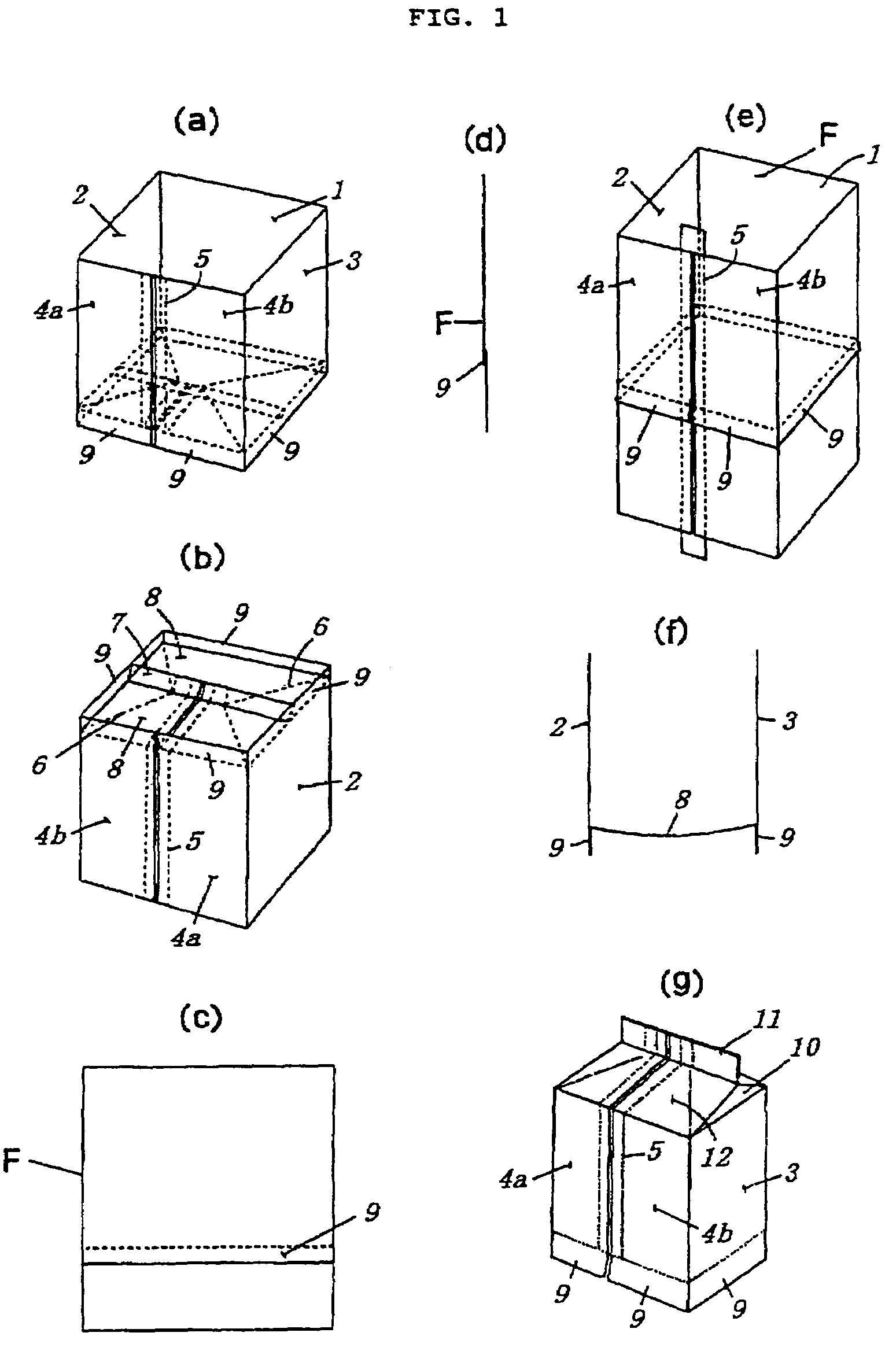

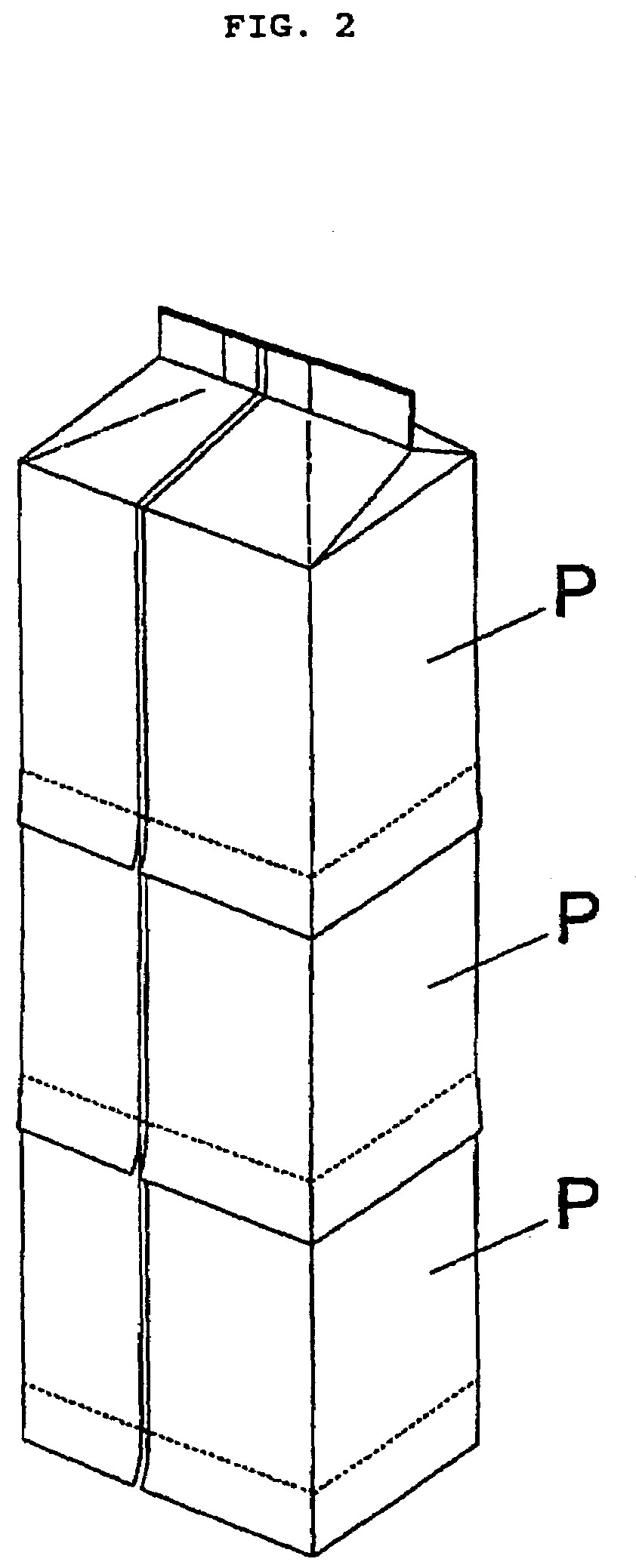

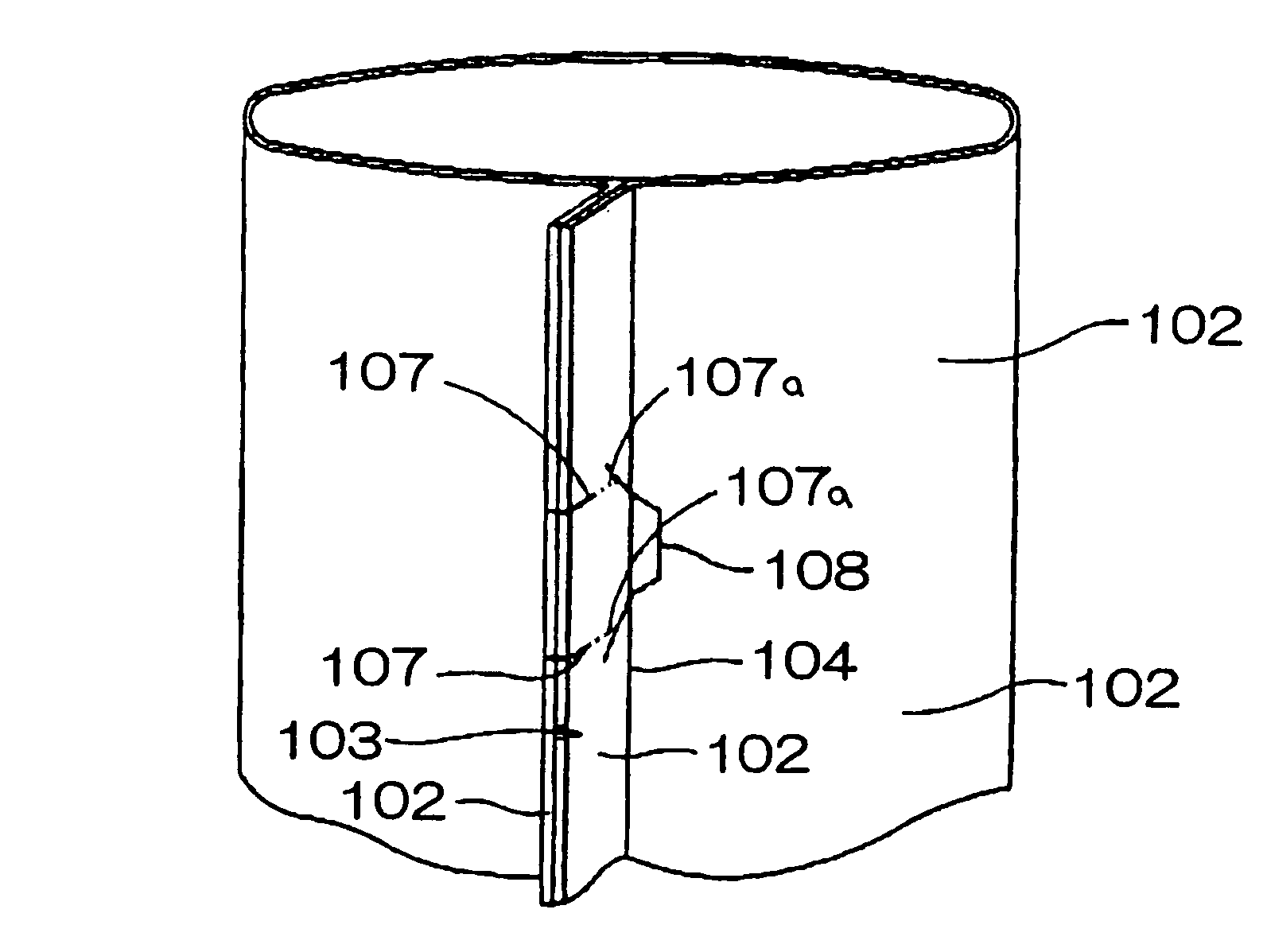

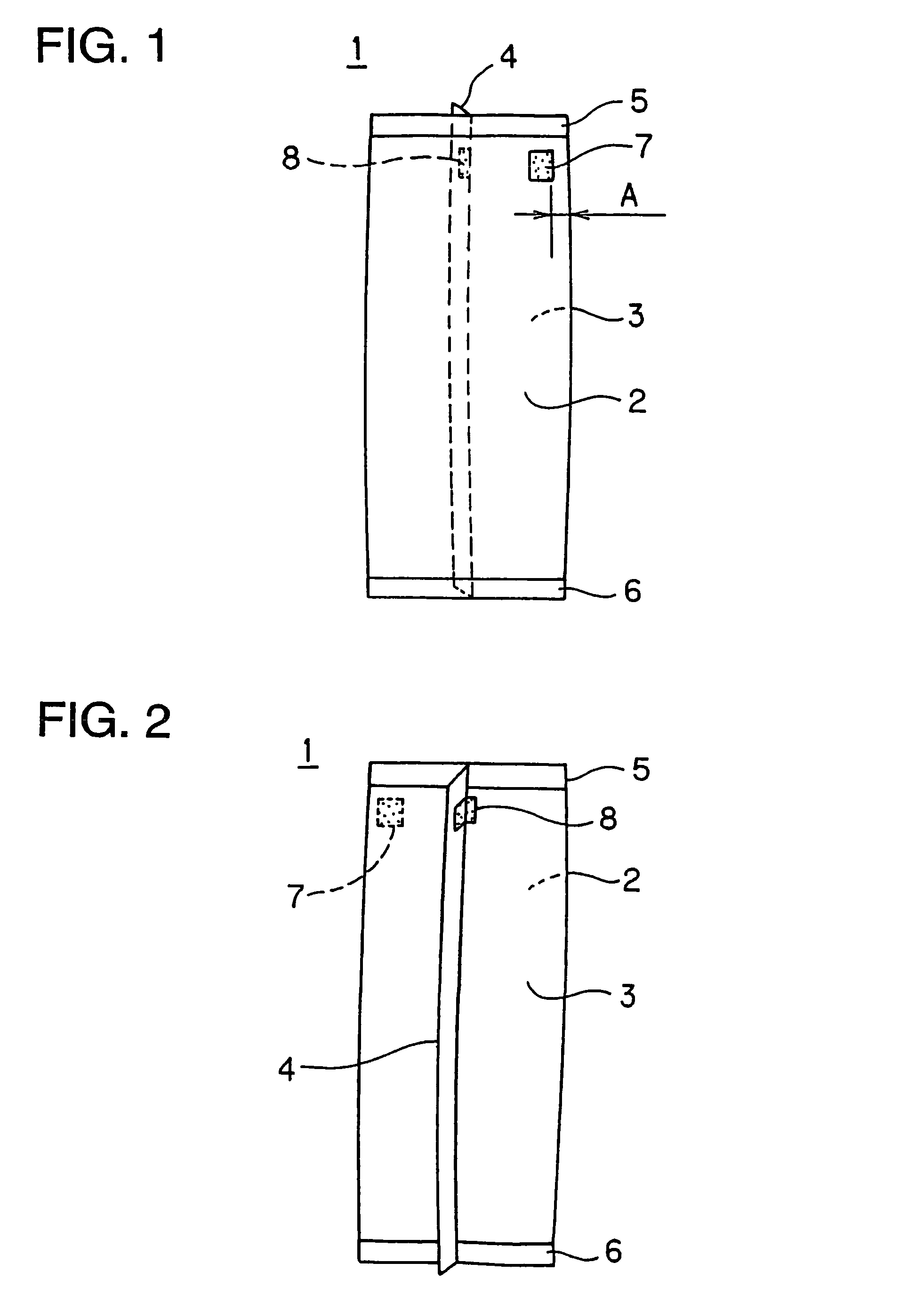

Self-standing packaging bag, packaging body, web roll, and manufacturing method therefor

InactiveUS20050069230A1Quality improvementStably stand upEnvelopes/bags making machineryBag making operationsEngineeringPack material

A stand-up packaging pouch manufactured in three-dimensional form or flattened form and provided with at least front face portion and rear face portion sides formed from packaging material having a pleat which is formed by folding a part of the packaging material in a three-fold strip form and adhering the inner faces of this folded part is constituted such that when the pouch is opened out into three dimensions, the pleat, formed in the same plane as the peripheral face portion, is positioned at a substantial right angle to a bottom face portion, thereby concealing the bottom face portion.

Owner:CHOKOKU PLAST CORP

Composite film bag for packaging bulk products

InactiveUS20070140600A1Efficient preparationGood printabilityWrappersBag making operationsManufacturing technologyComposite film

Owner:COATING EXCELLENCE INT

Flexible containers having improved seam and methods of making the same

ActiveUS20150036950A1Less-expensiveImprove the decorative effectDispensing apparatusBag making operationsThin membraneMechanical engineering

Owner:THE PROCTER & GAMBLE COMPANY

Reclosable food package with improved shelf life

InactiveUS20100002963A1Extended shelf lifeSufficient protectionEnvelopes/bags making machineryFlexible coversEngineeringFood packaging

A resealable container having an easily accessed yet airtight seal via the use of a tamper evident rupture strip which provides the container or package with improved shelf life for the product contained therein.

Owner:AVERY DENNISON CORP

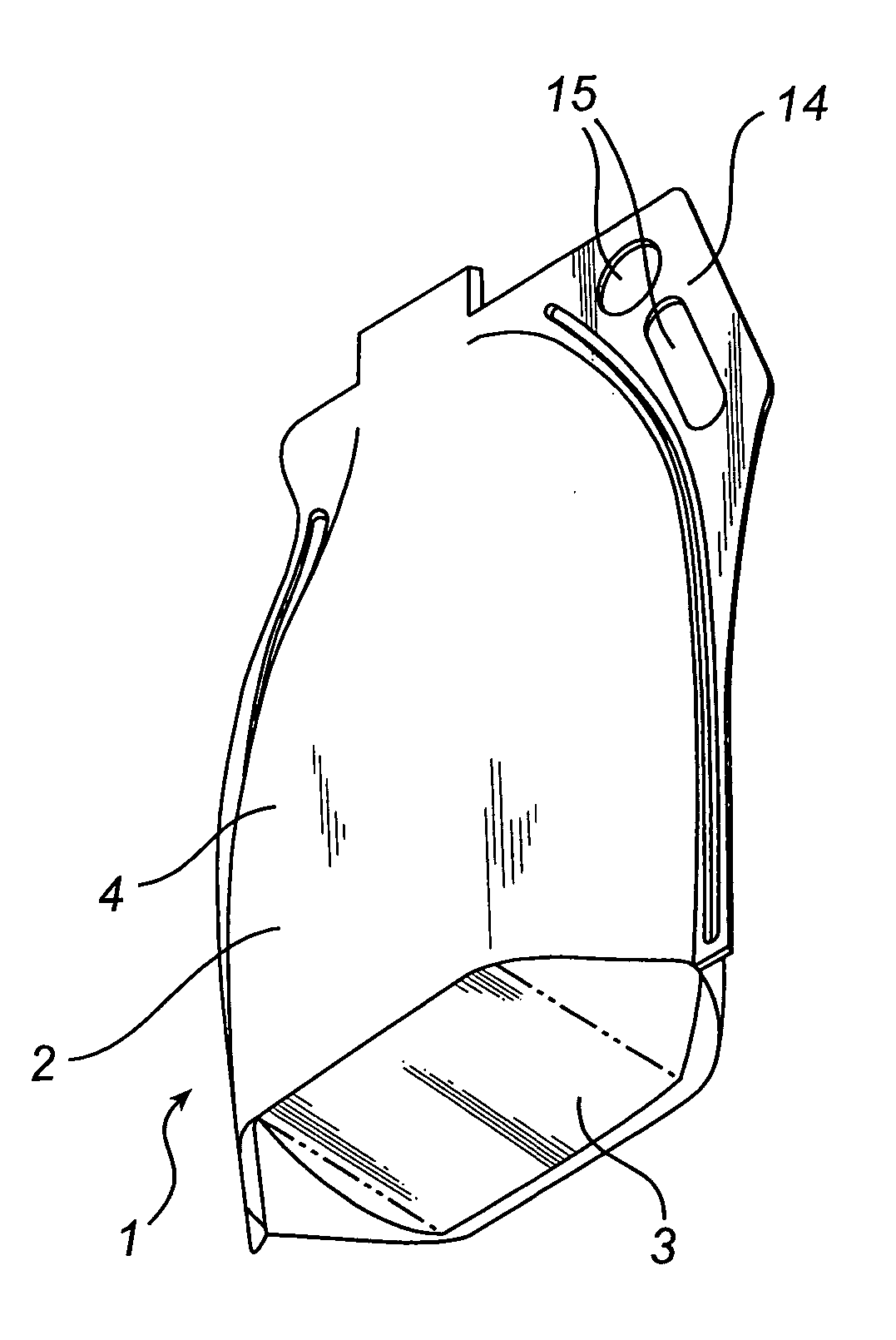

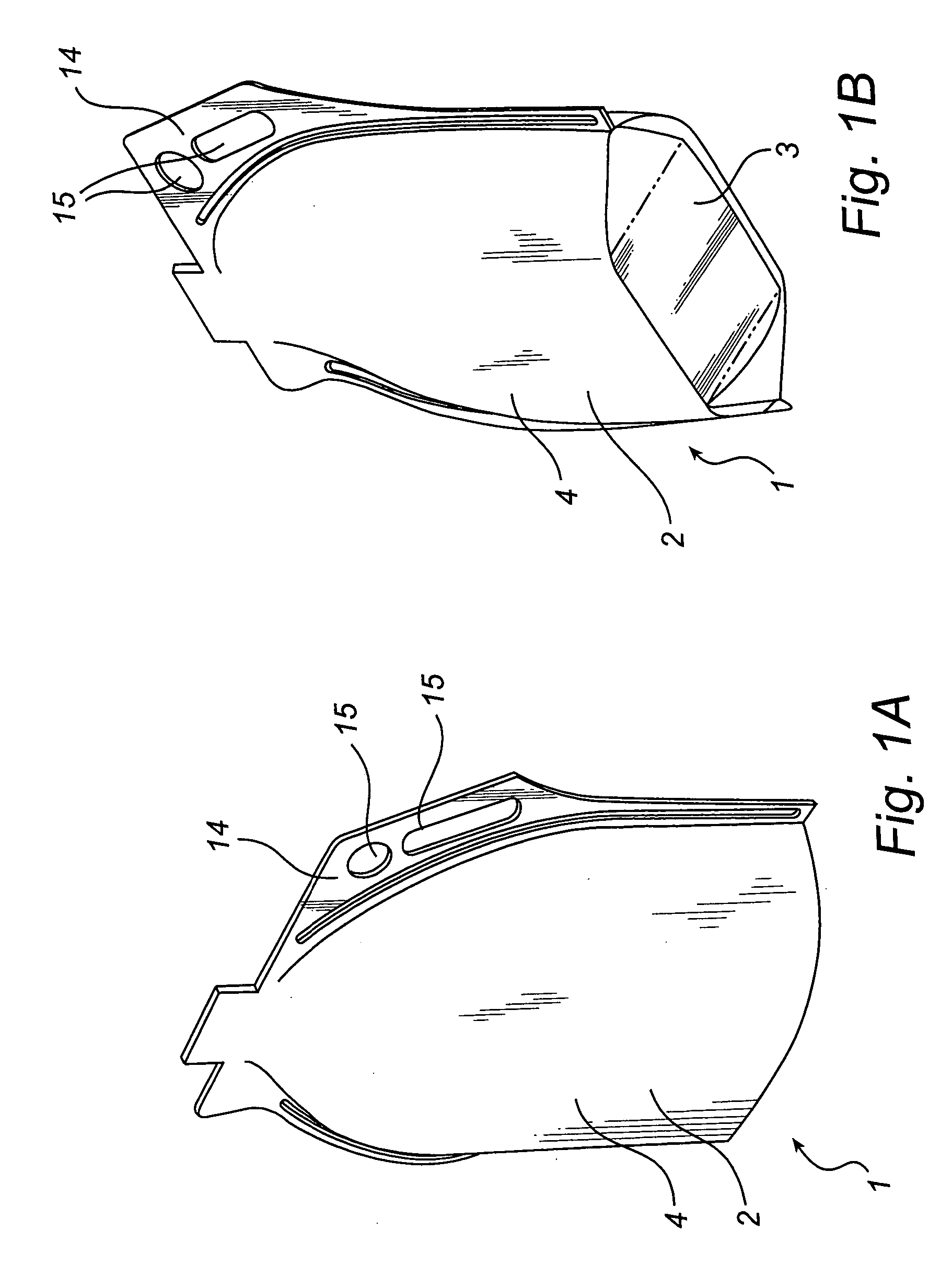

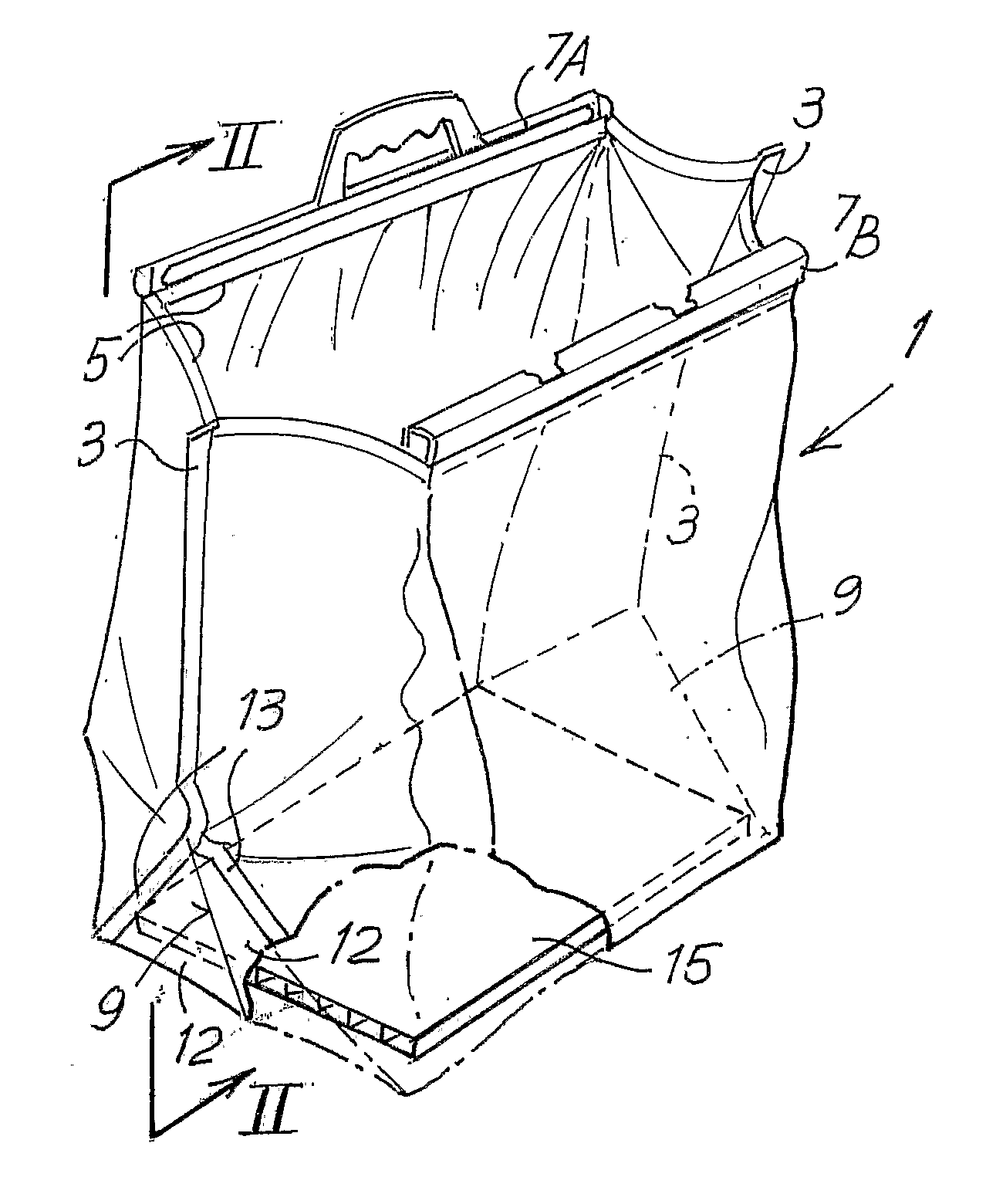

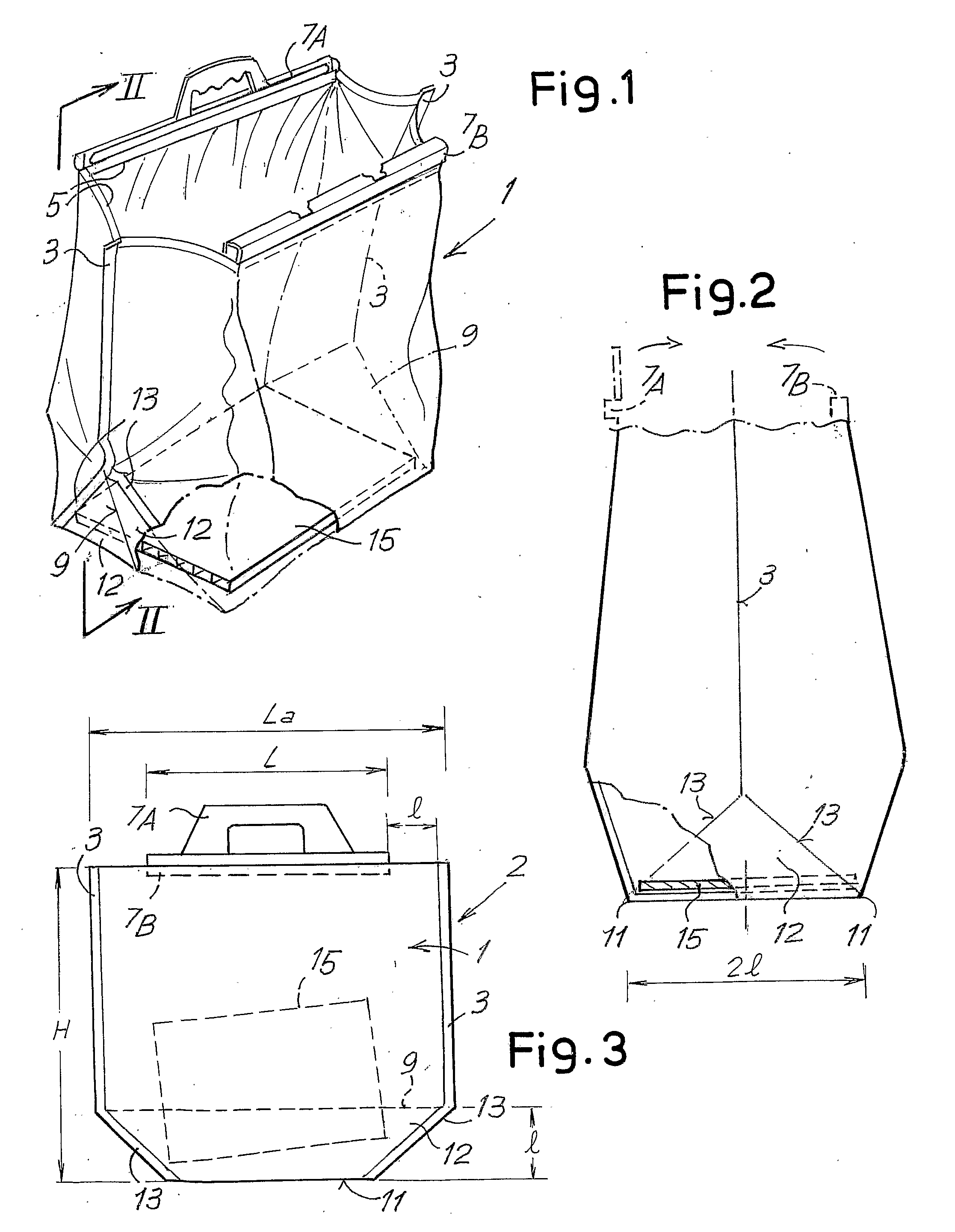

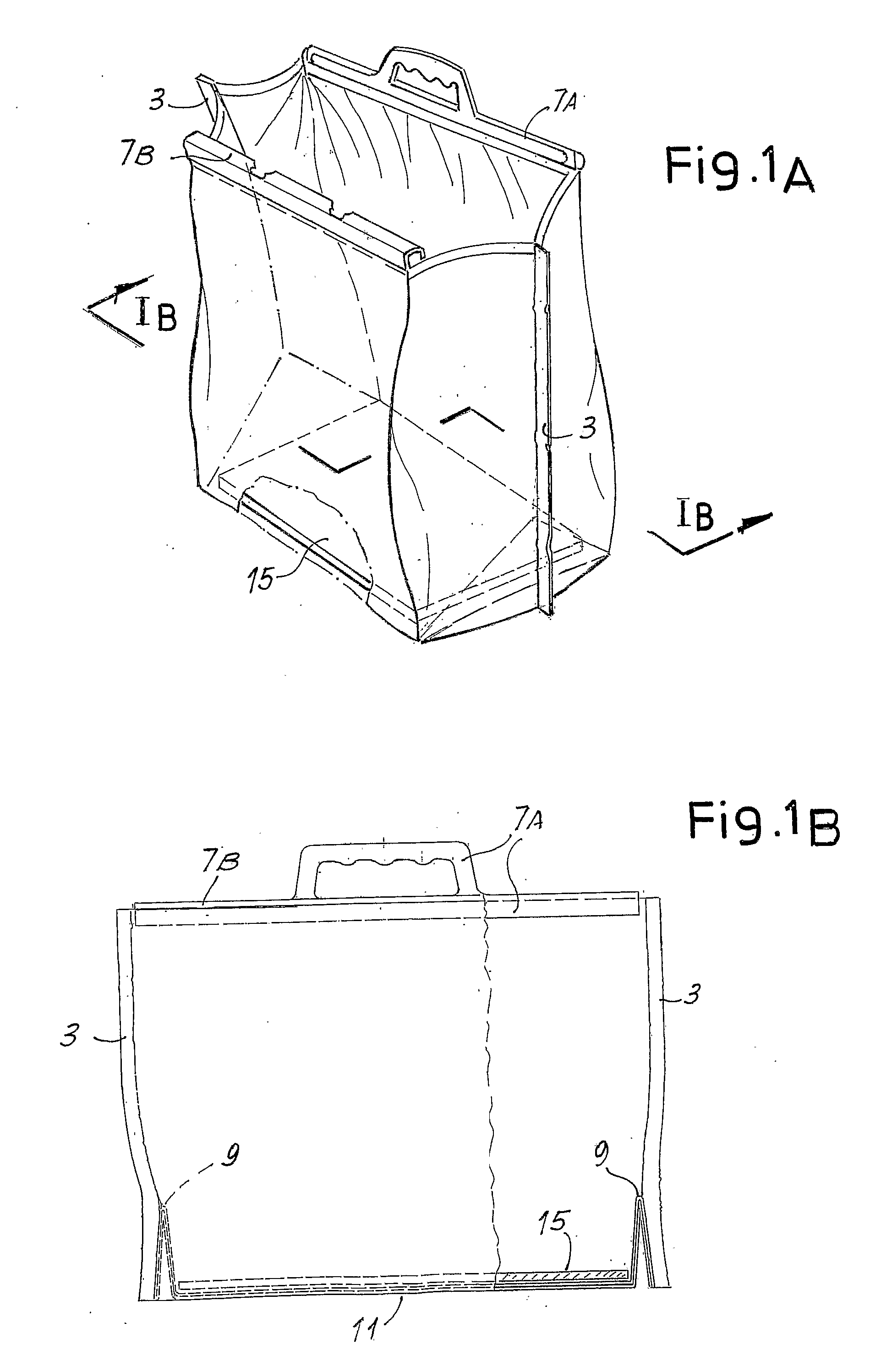

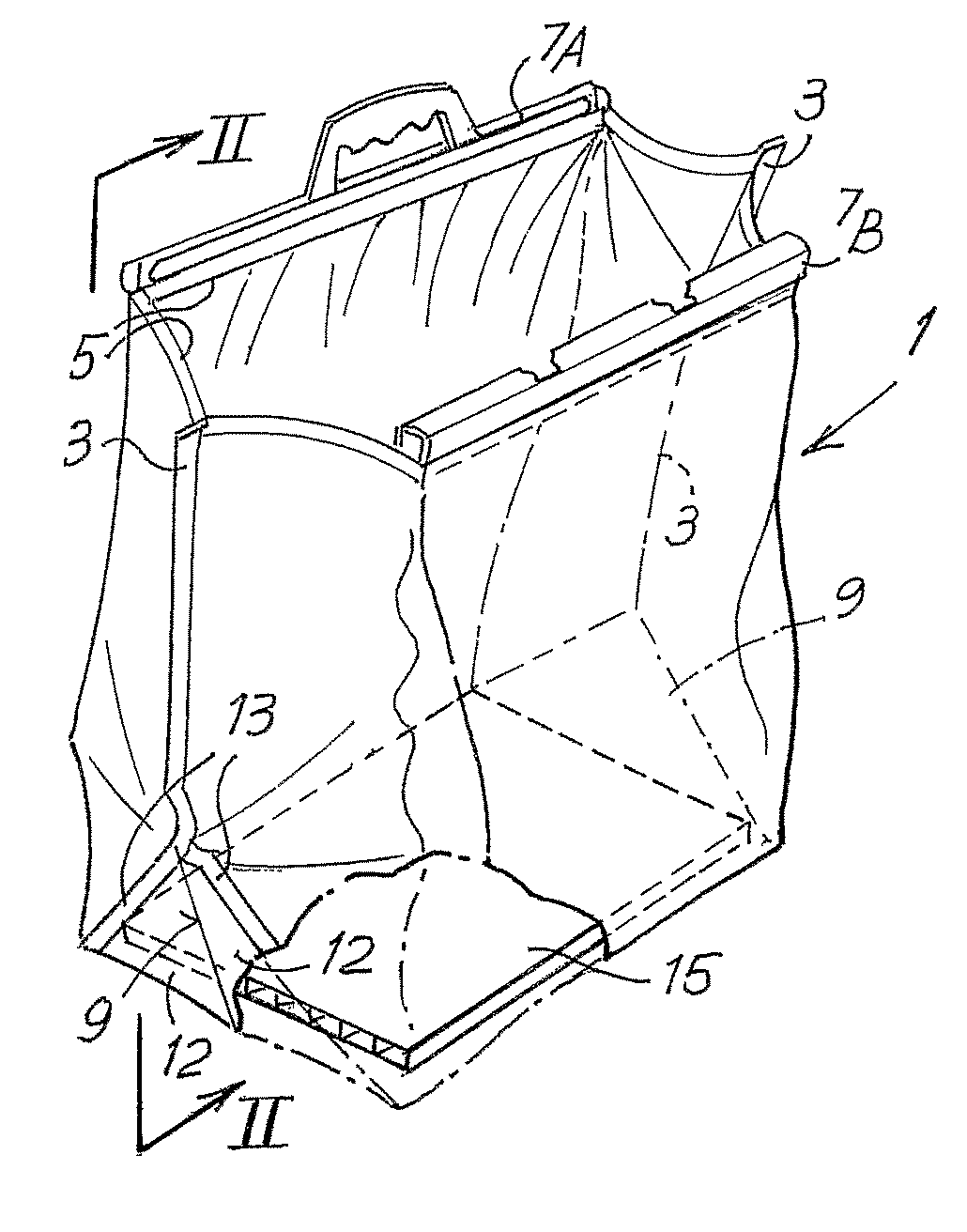

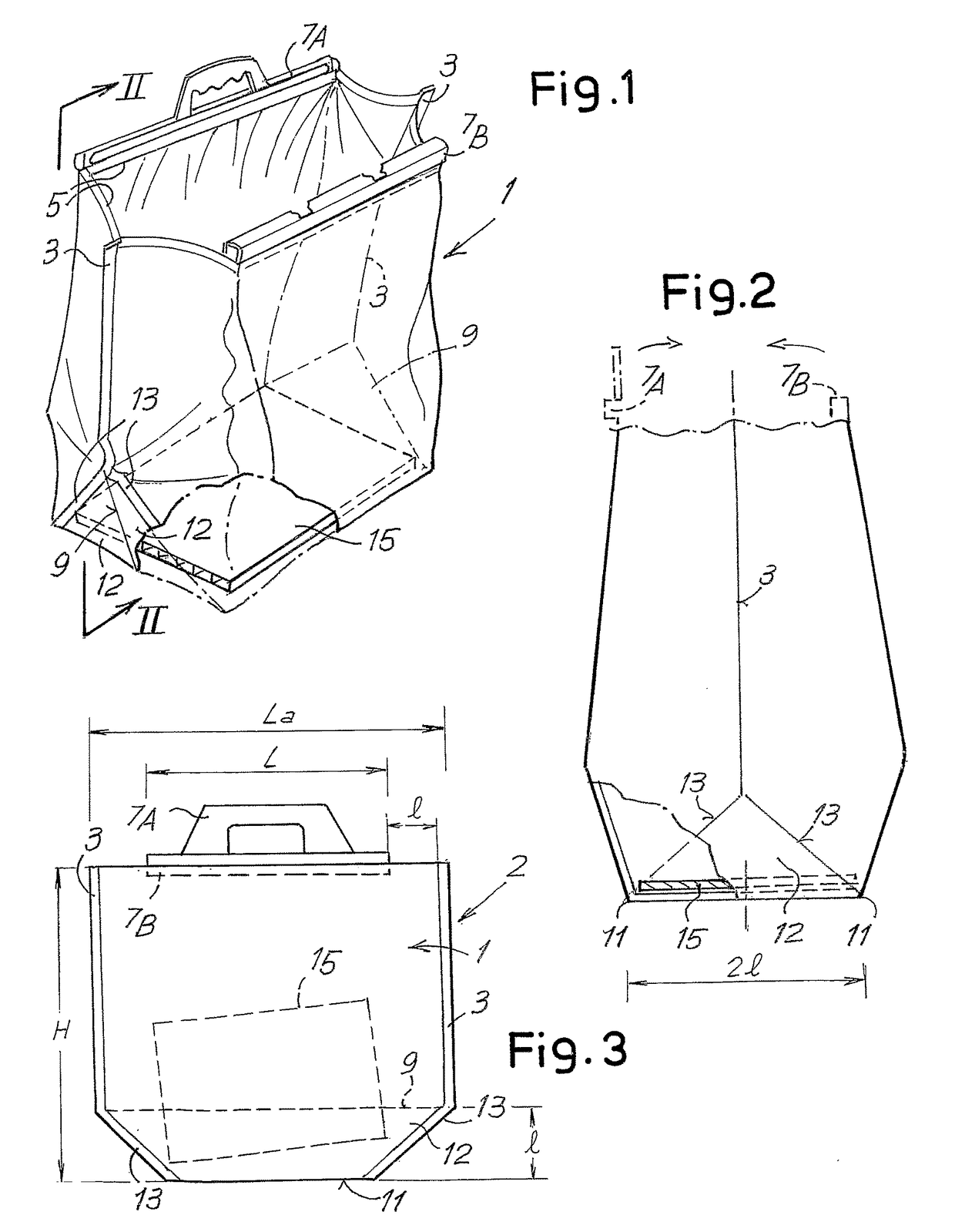

Thermal bag for foods and the like

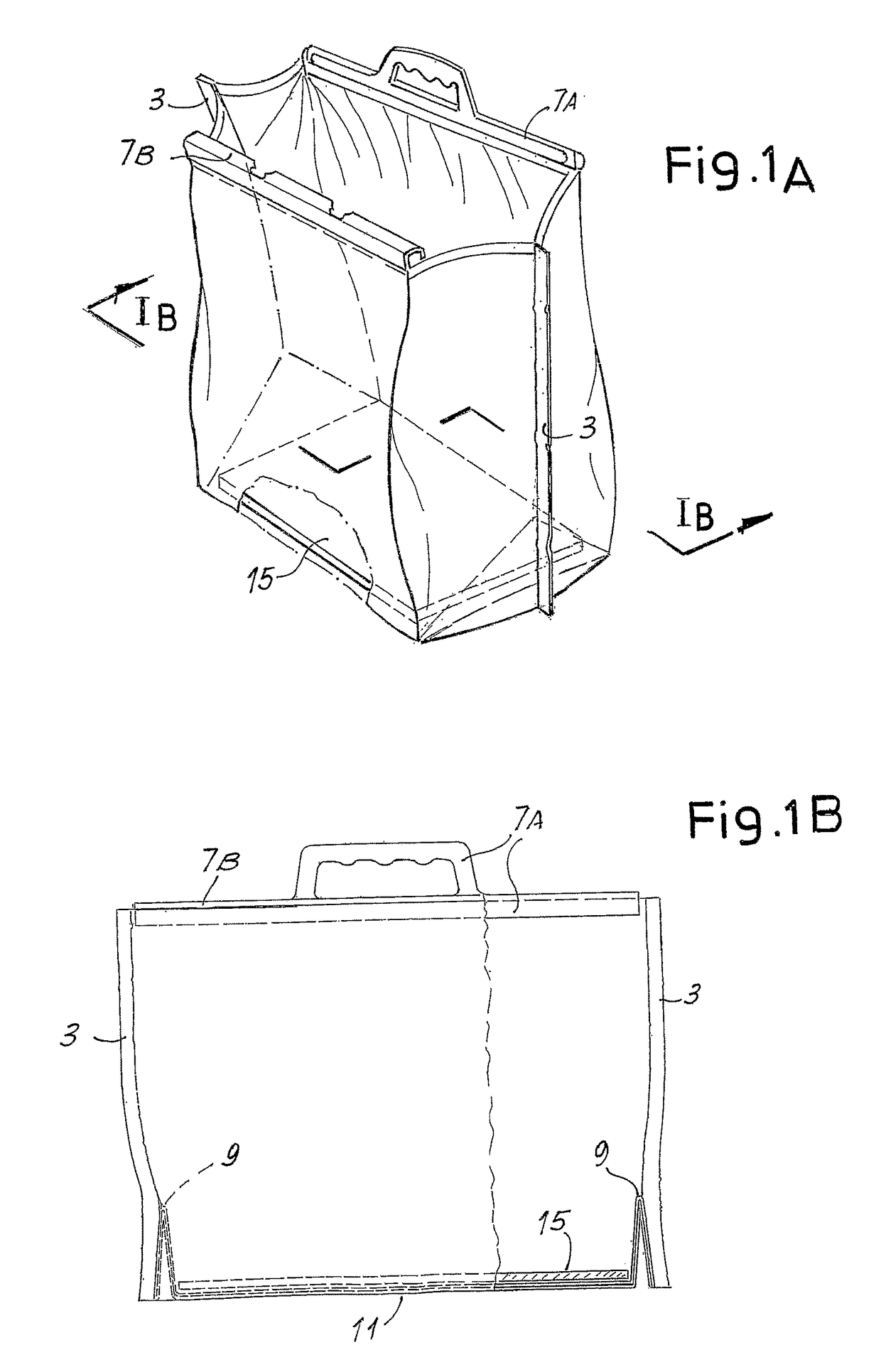

ActiveUS20090034883A1Increase capacityPractical to useEnvelopes/bags making machineryBag making operationsEngineeringMechanical engineering

The thermal bag (2) is made of thermally insulating composite material folded to form a bottom and welded along lateral borders (3) to form a body (1) of the bag with a mouth (5) at the level of which a handle (7A, 7B) is applied. The composite material defines a bottom folded in an accordion-like fashion opposite the mouth of the bag, and a laminar stiffening element (15) of the accordion-like bottom is disposed inside the bag.

Owner:IMBALL CENT

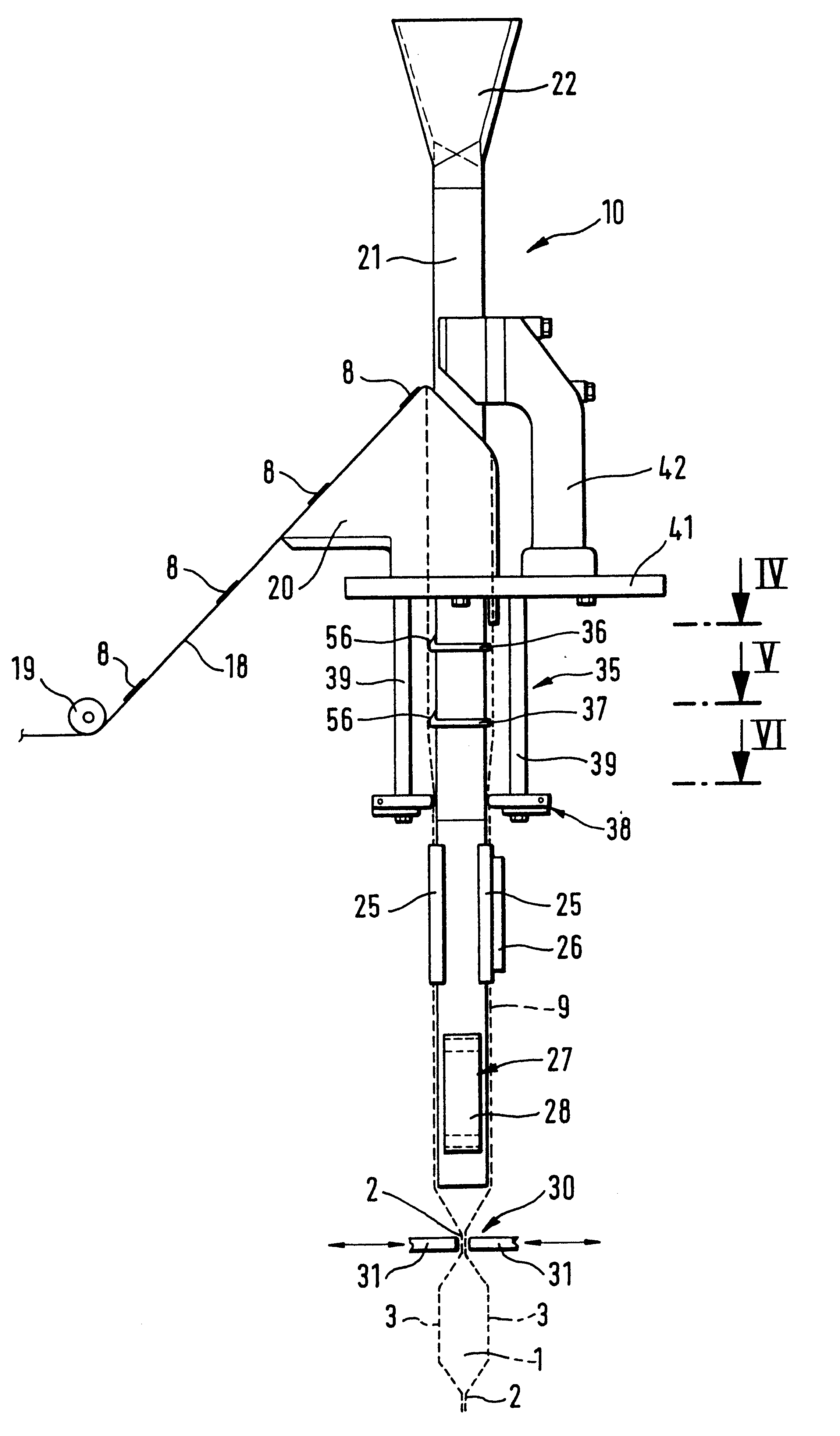

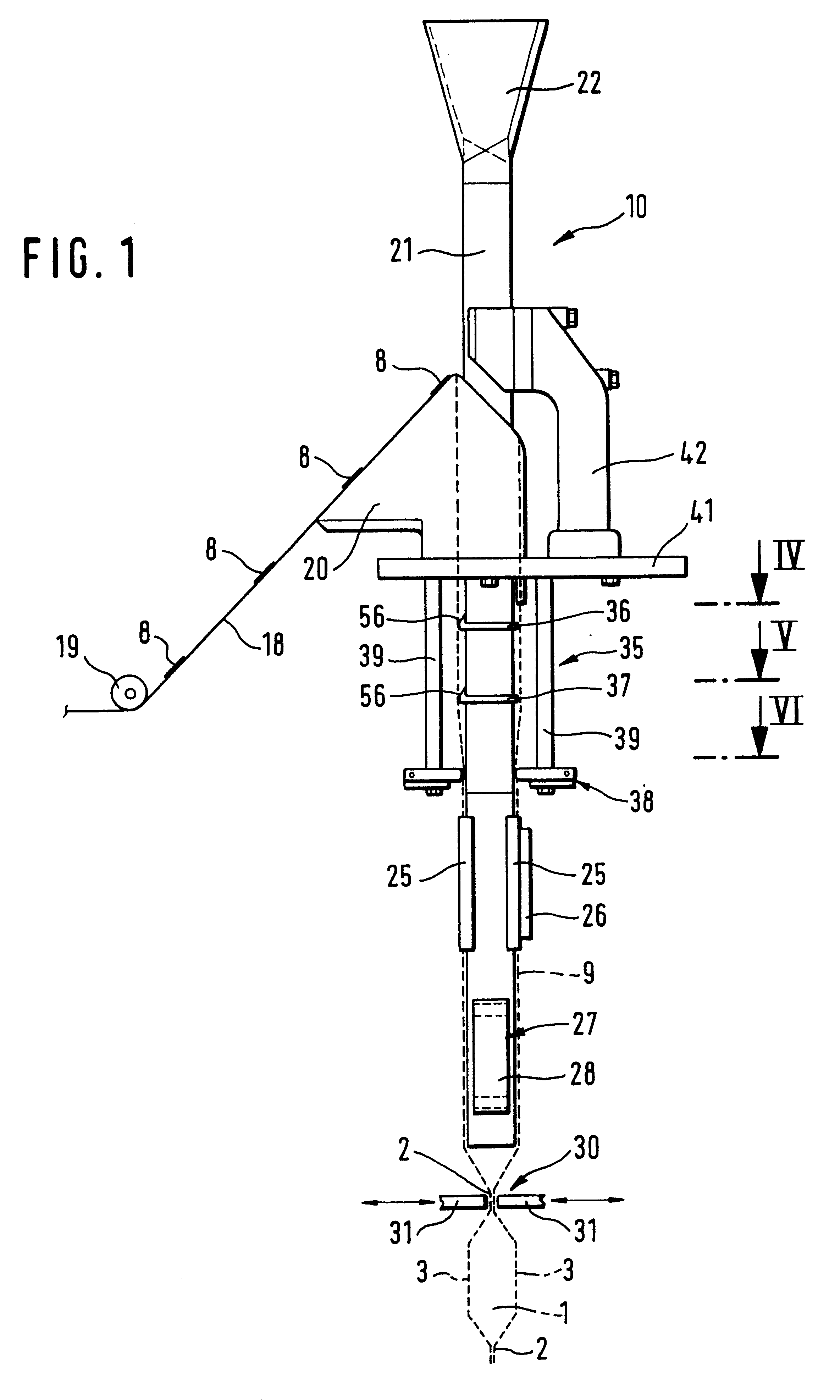

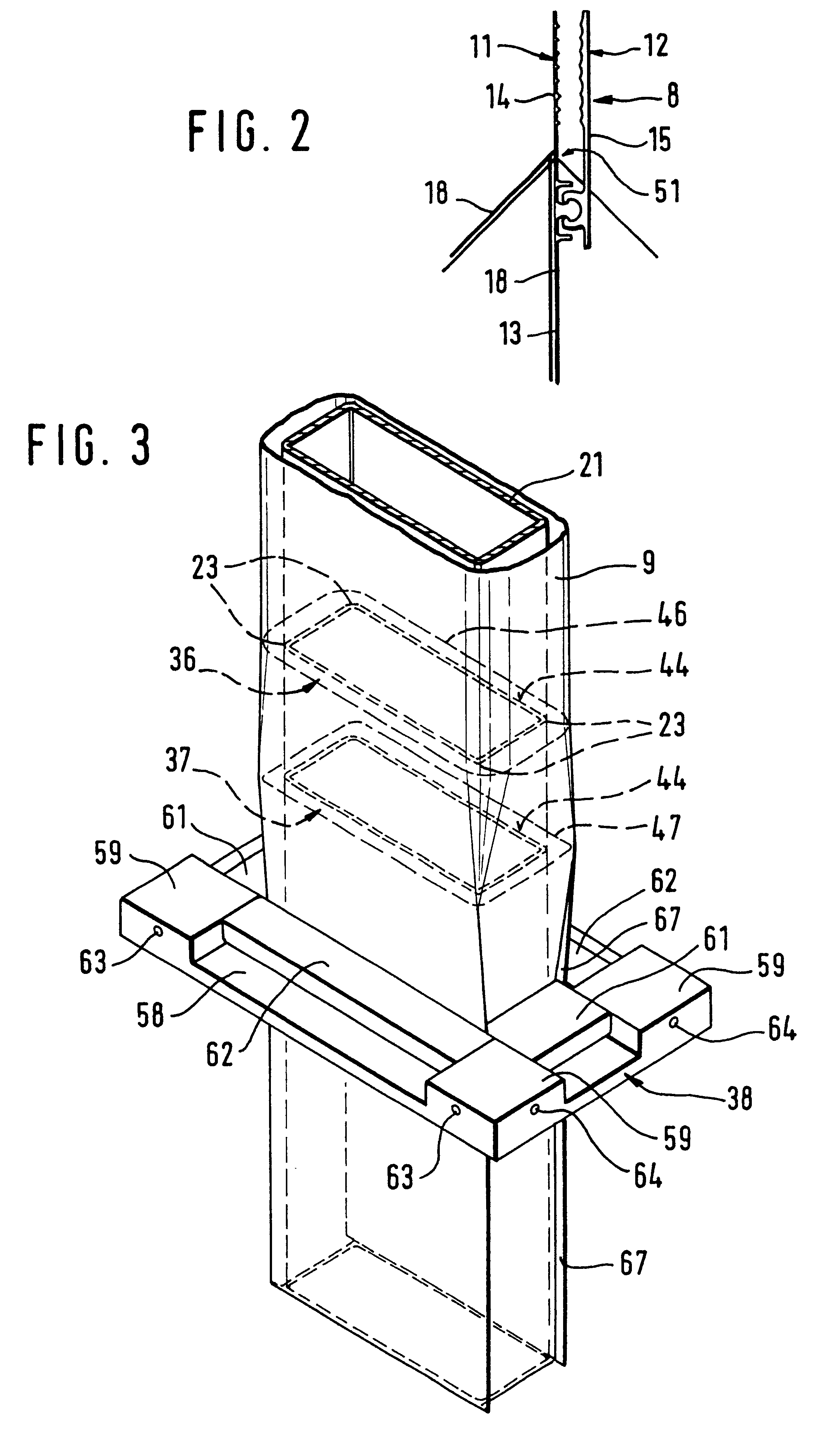

Device for manufacturing tubular bag packages

InactiveUS6513308B1Reduce strainSimple designEnvelopes/bags making machineryMechanical working/deformationBiomedical engineering

A device for manufacturing tubular bag packages has a forming tube with a rectangular cross section. In order to produce reinforcing seams in a projection of the broad side walls of the tubular bag package, the device has a forming and folding device. The forming and folding device has two forming plates attached to the forming tube and a folding frame with folding plates. The relatively simply embodied device according to the invention makes it possible to form the reinforcing seams with less stress on the packaging material.

Owner:ROBERT BOSCH GMBH

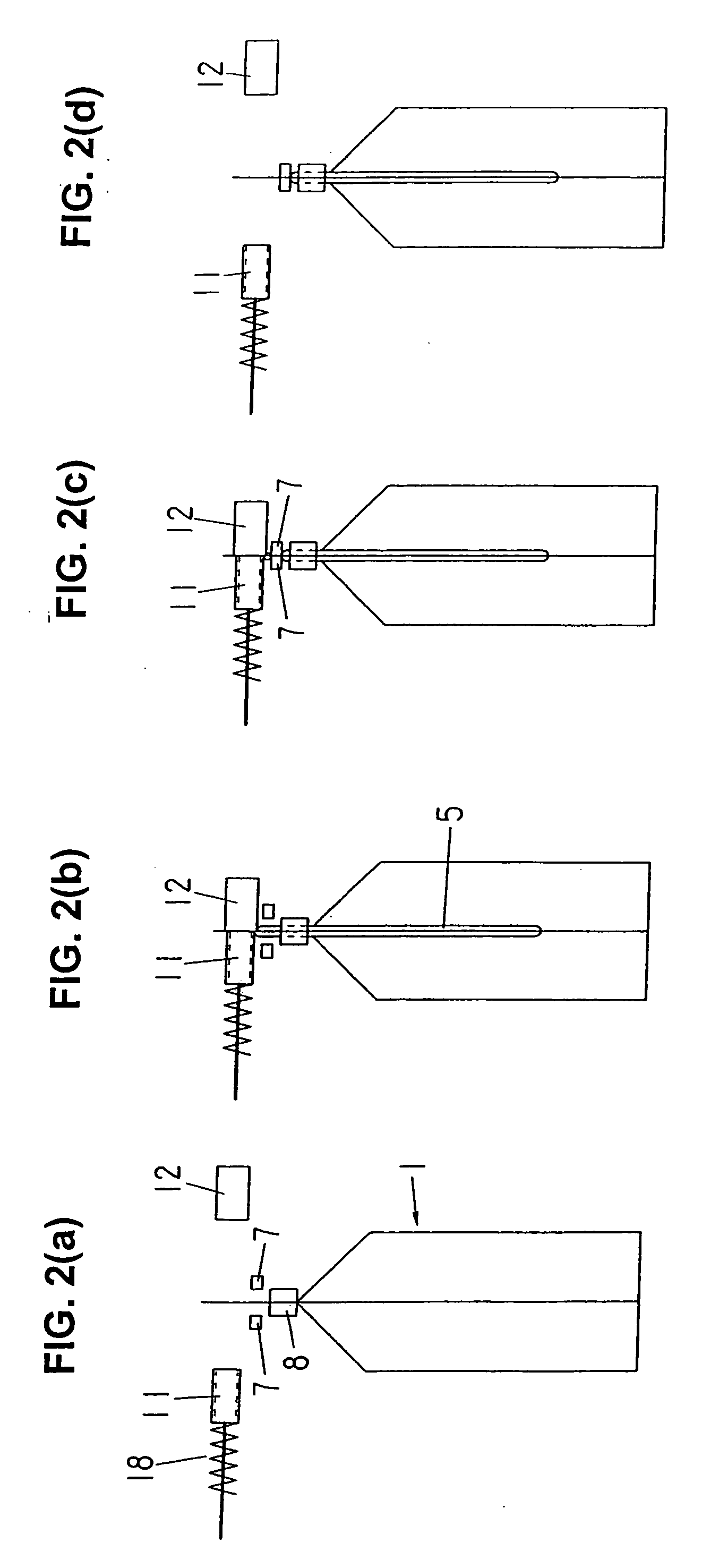

Gas seal-in method for a bag with a gas filling compartment and packaging method for a bag with a gas filling compartment

ActiveUS20070089377A1Automate processingEasy to operateCapsBag making operationsEngineeringPacking method

A method for sealing-in a gas in a gas filling compartment 5 of a bag having a cut-in 6 formed near the upper edge of the gas filling compartment. In the method, two edges of the bag with the contents inserted therein are gripped by grippers and suspended, the blow-in port of a gas (air) blow-in nozzle is brought to contact the cut-in, the back surface side of the bag is supported by a backing member, gas (air) is blown into the gas filling compartment, and the position below the cut-in is held from both sides of the bag by a gas cut-off grippers while the gas blow-in continues, so that the gas inside the gas filling compartment is not allowed to escape from the cut-in, and then the entire bag mouth, including the cut-in, is sealed.

Owner:TOYO JIDOKI CO LTD

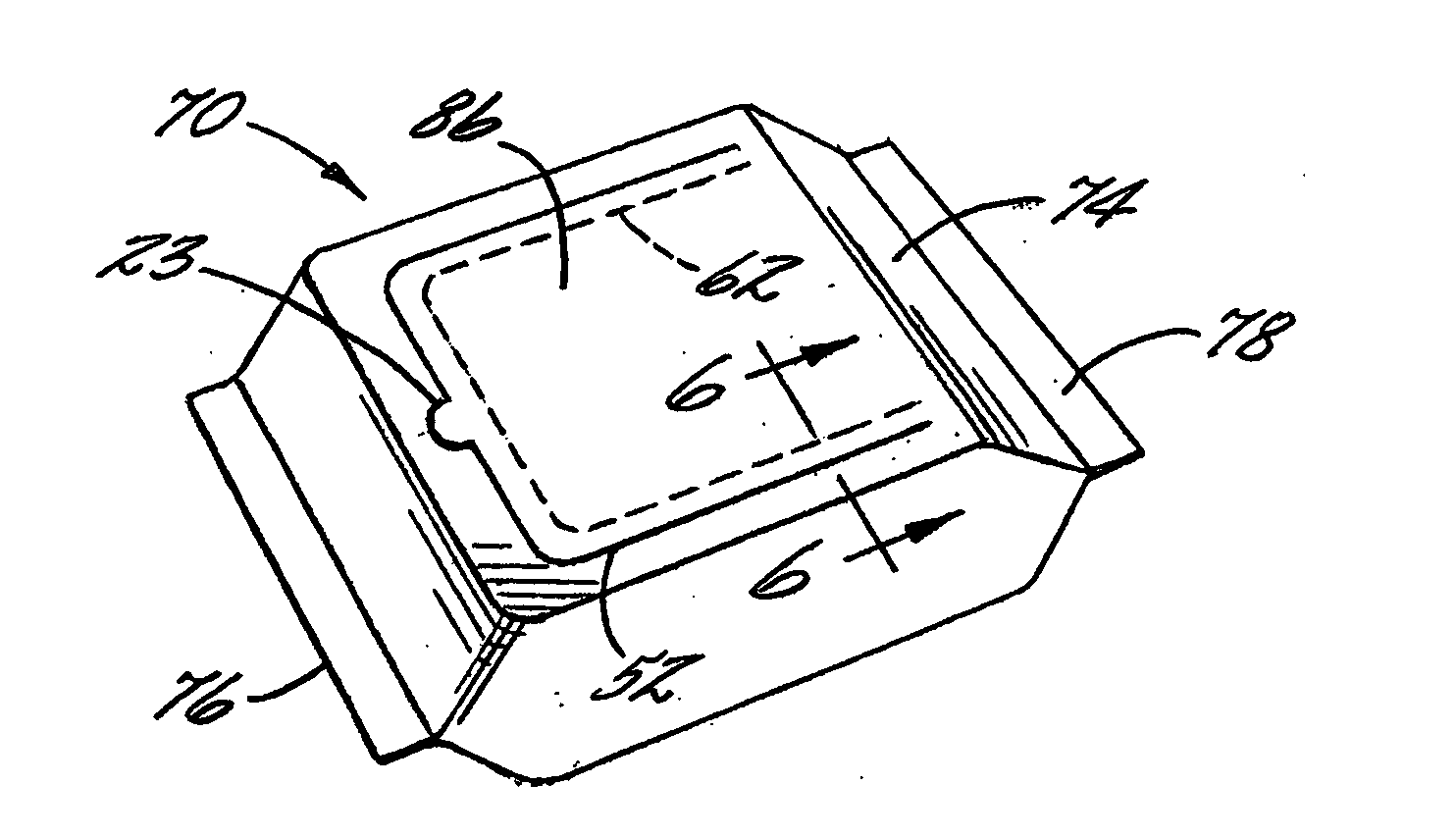

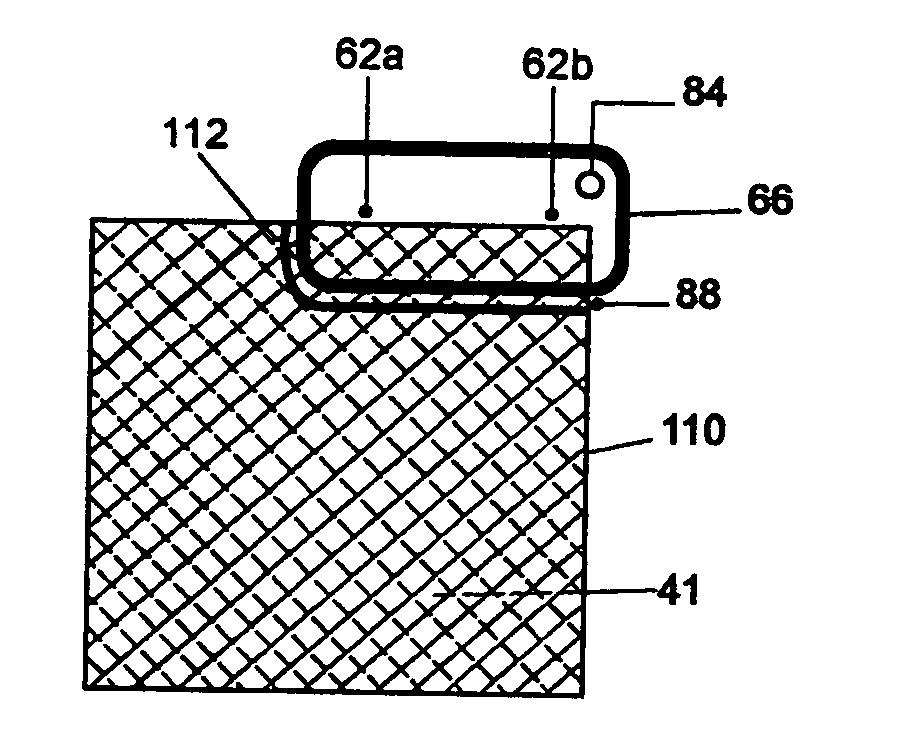

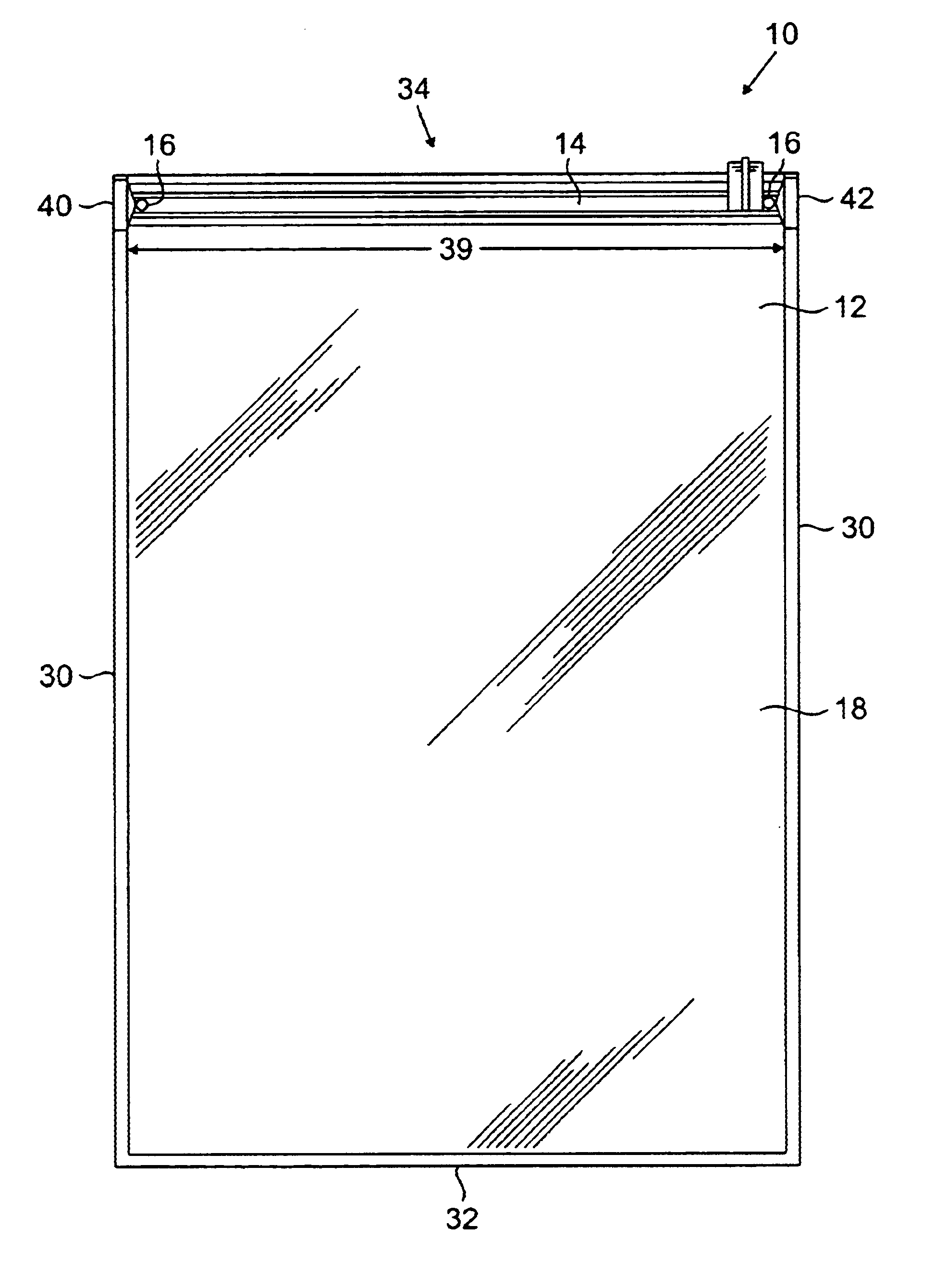

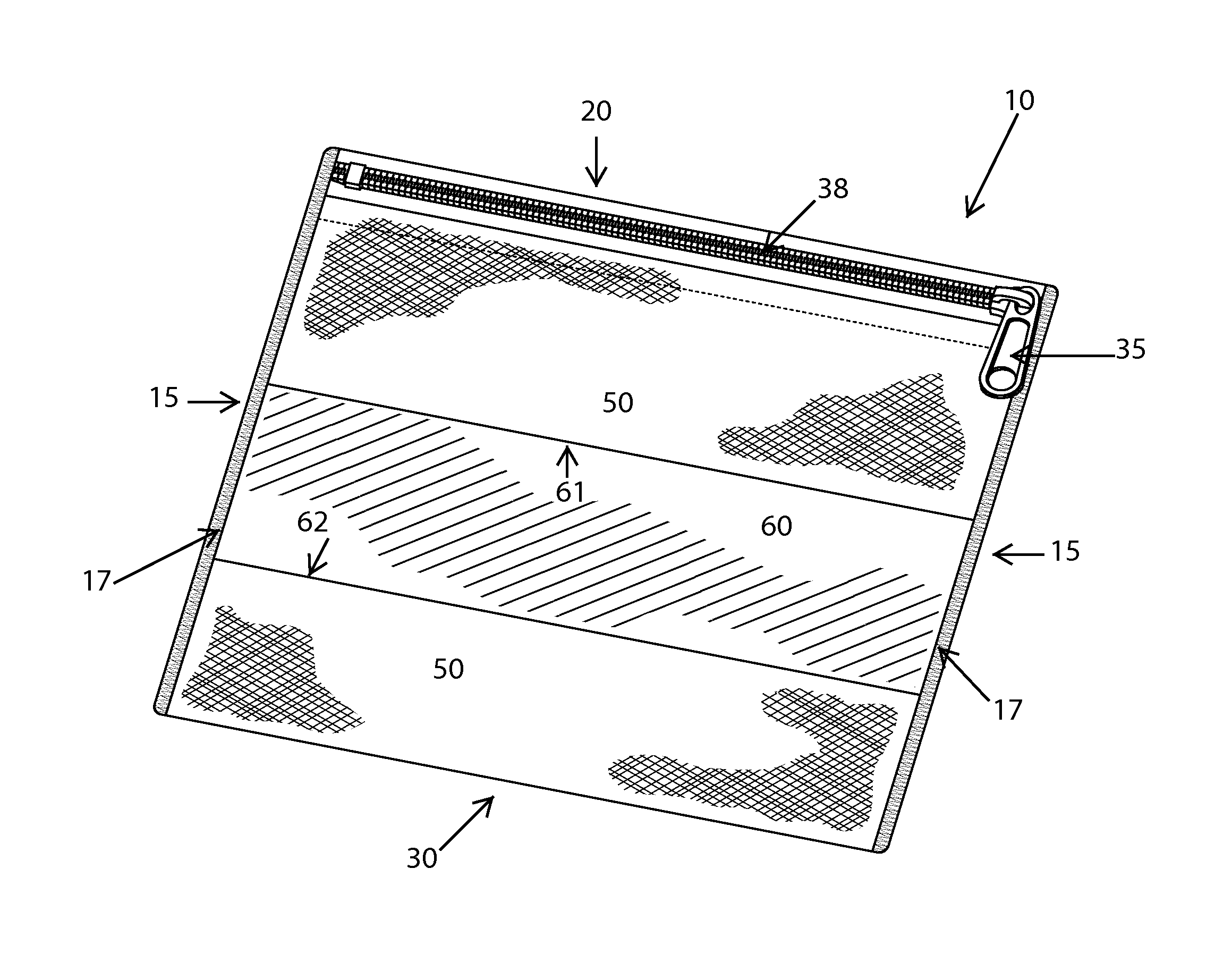

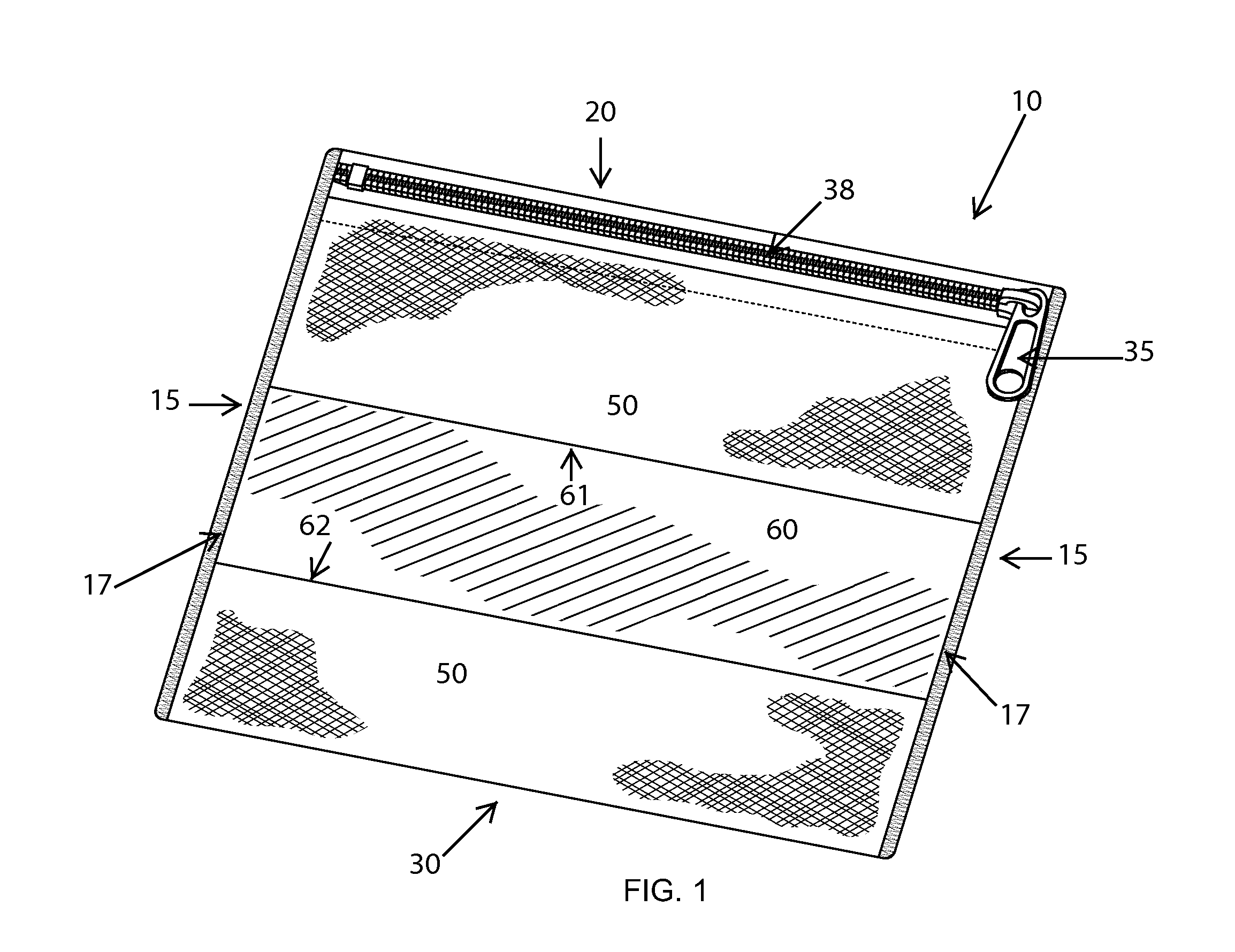

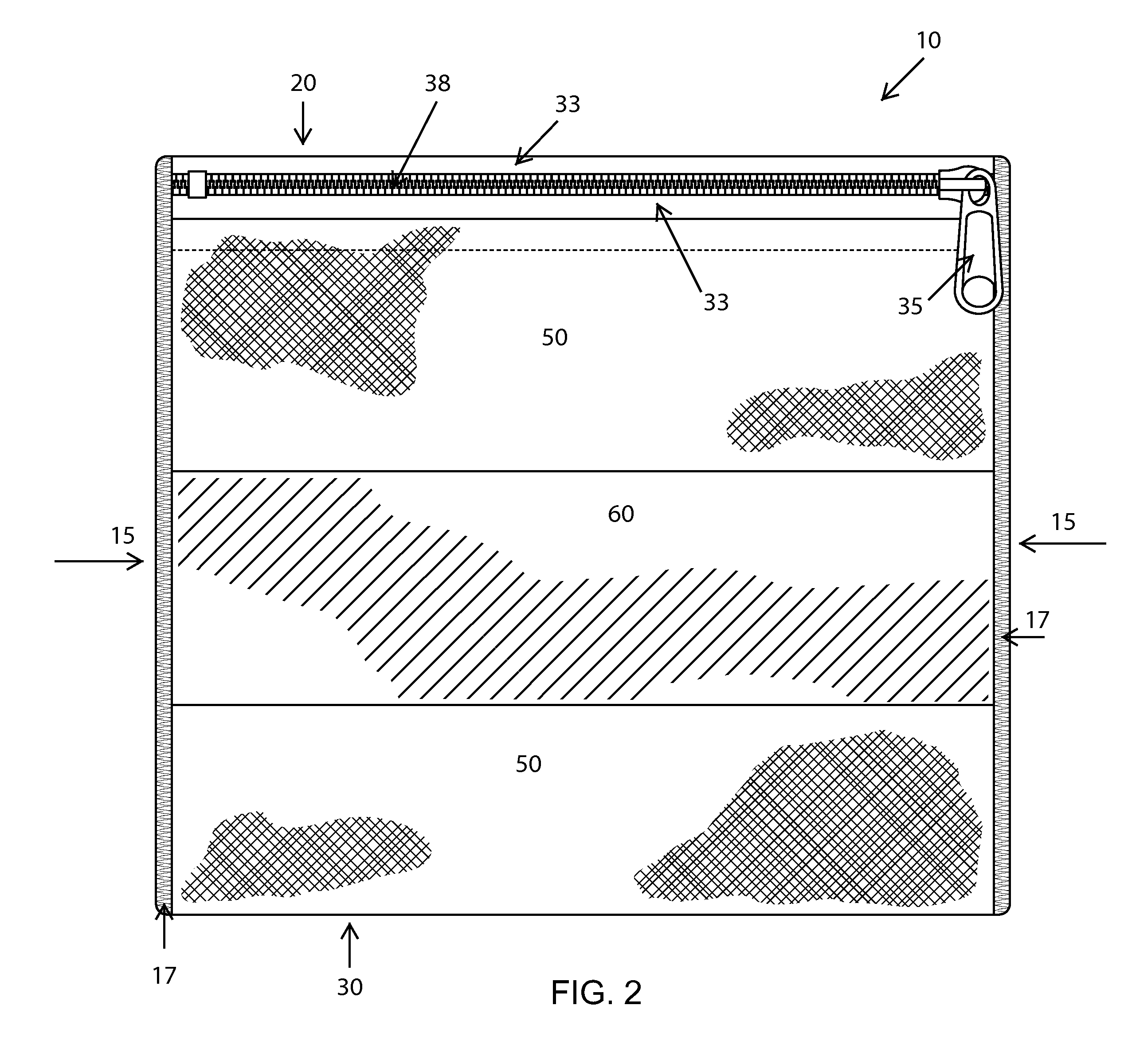

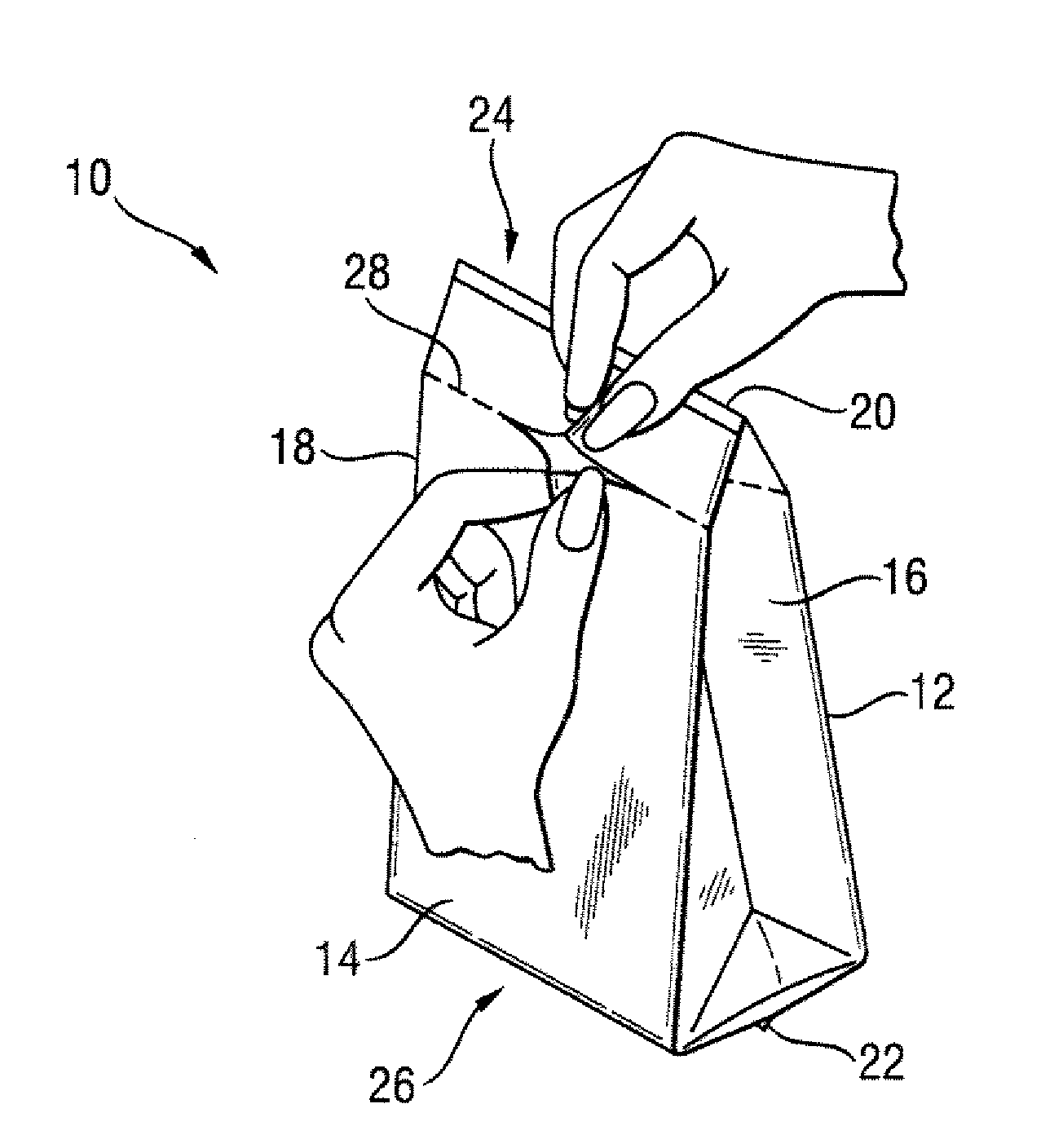

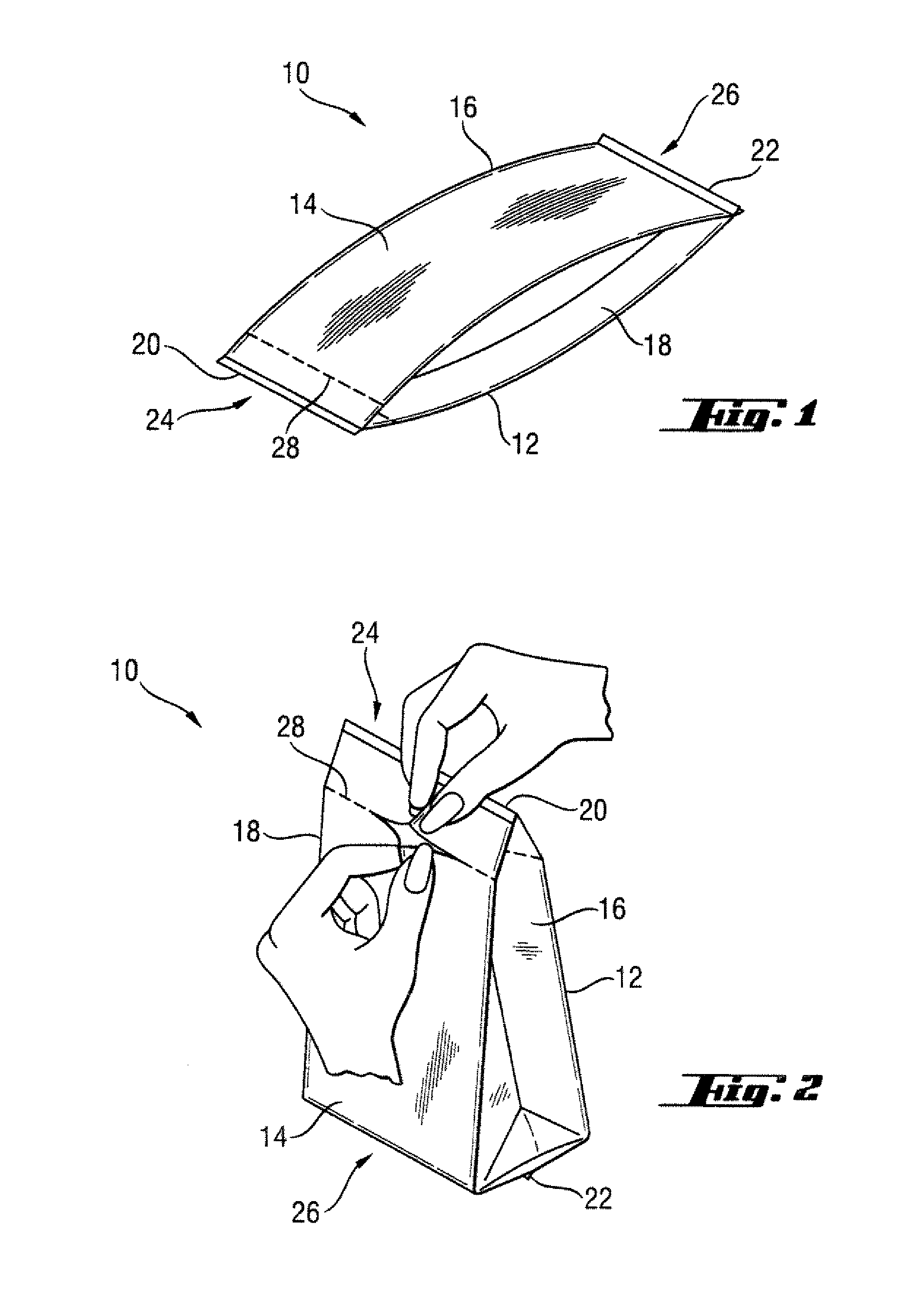

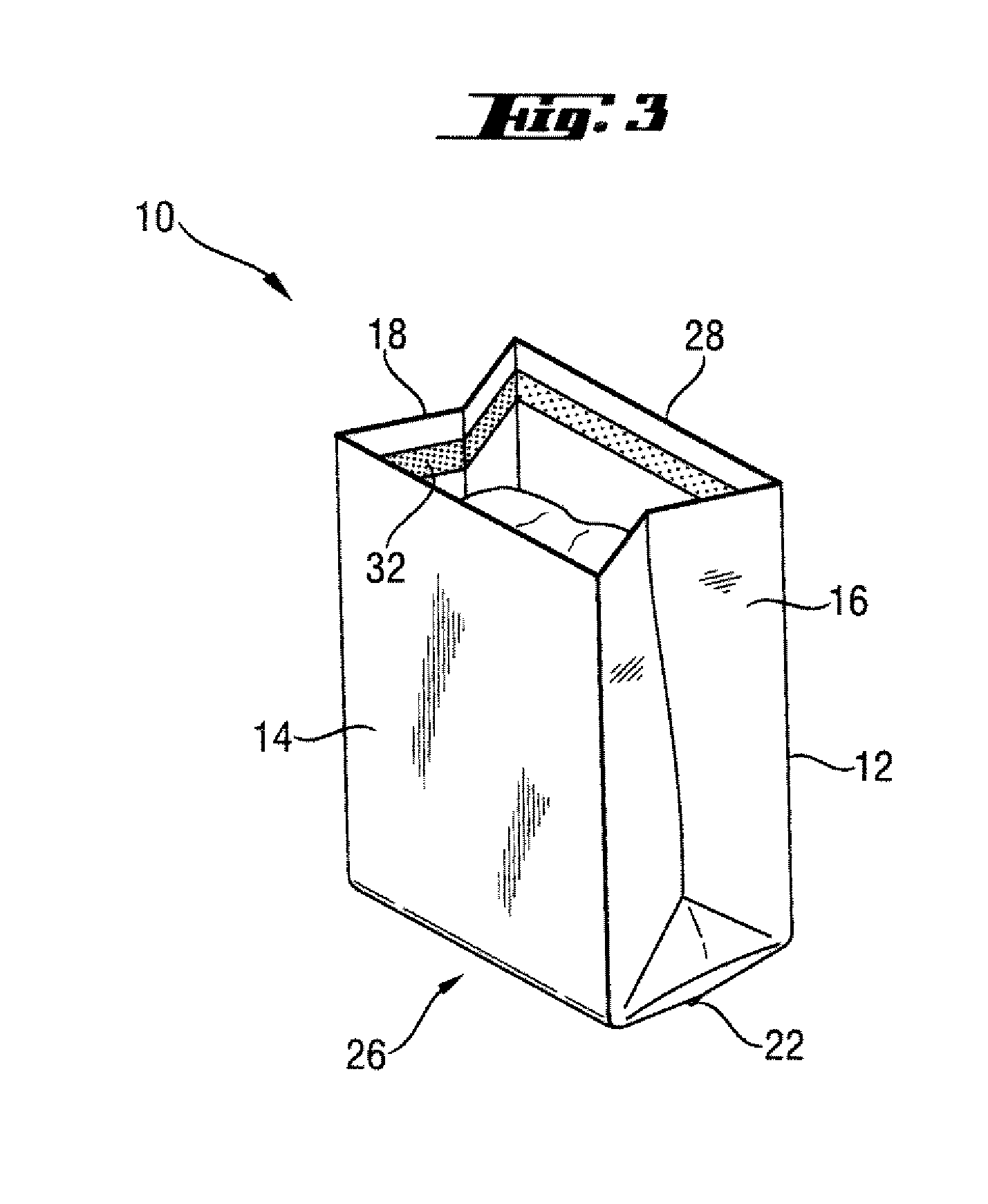

Flexible package with a transverse access panel device

ActiveUS7040810B2Reducing available material holding capacityReduce materialEnvelopes/bags making machineryFlexible coversAdhesiveEngineering

A flexible package generally including a front panel portion, a back panel portion, a first side panel portion, and at least one access device. The flexible package can further include a second side panel portion, a bottom panel portion, and a top panel portion. Additionally, one or more of the portions can be shaped and / or manufactured substantially as a gusset. Each of the panel portions comprise two longitudinal sides or edges. The access-device can be attached to at least one surface of at least one of the side panel portions such that the device is in transverse orientation to the longitudinal sides. The device can be manually attached to the side portions, or attached with existing and / or specially designed manufacturing machinery. Attachment of the access device to a side portion of the package is achieved using heat bonding techniques, adhesives, and the like.

Owner:STEELE MARK

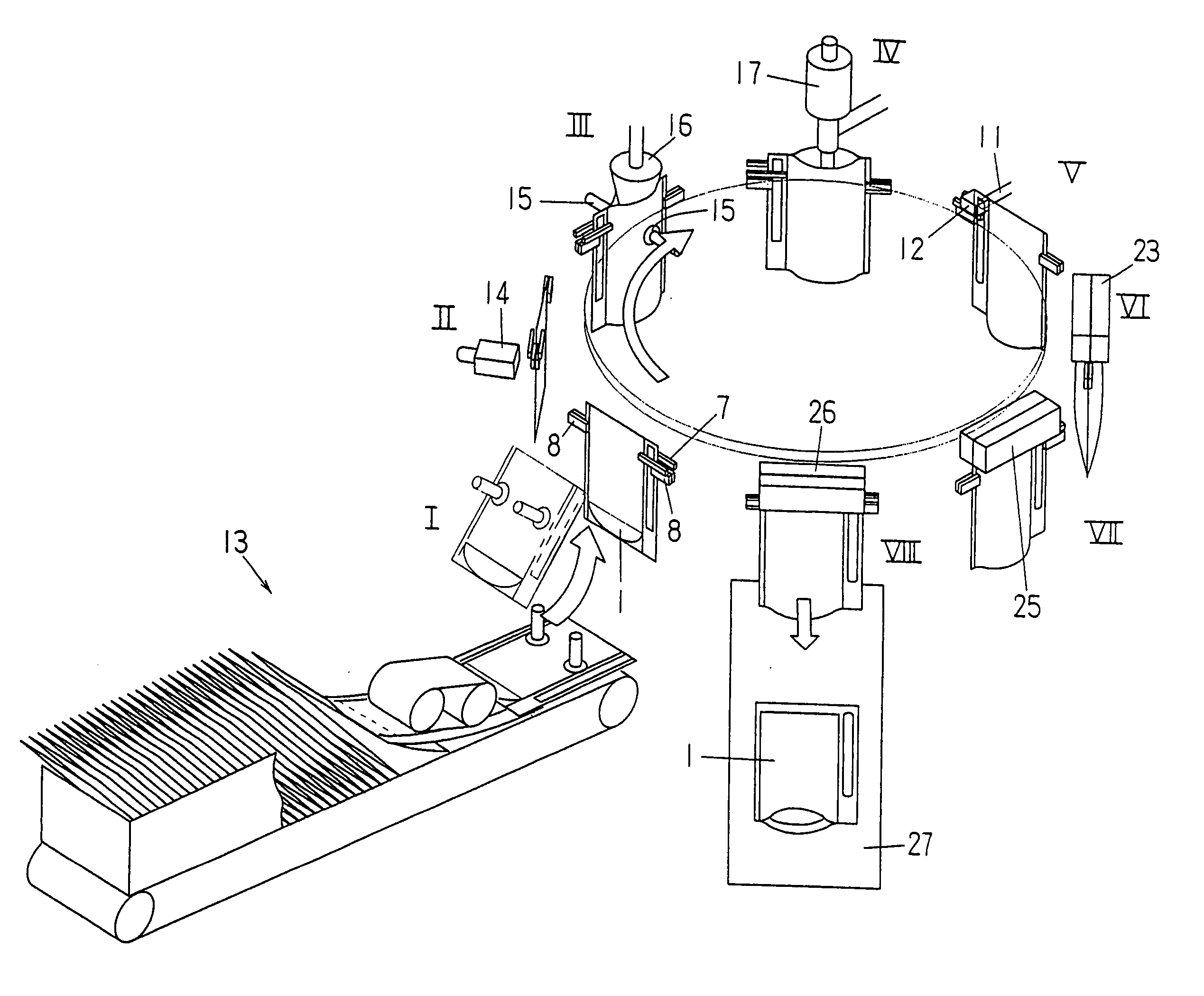

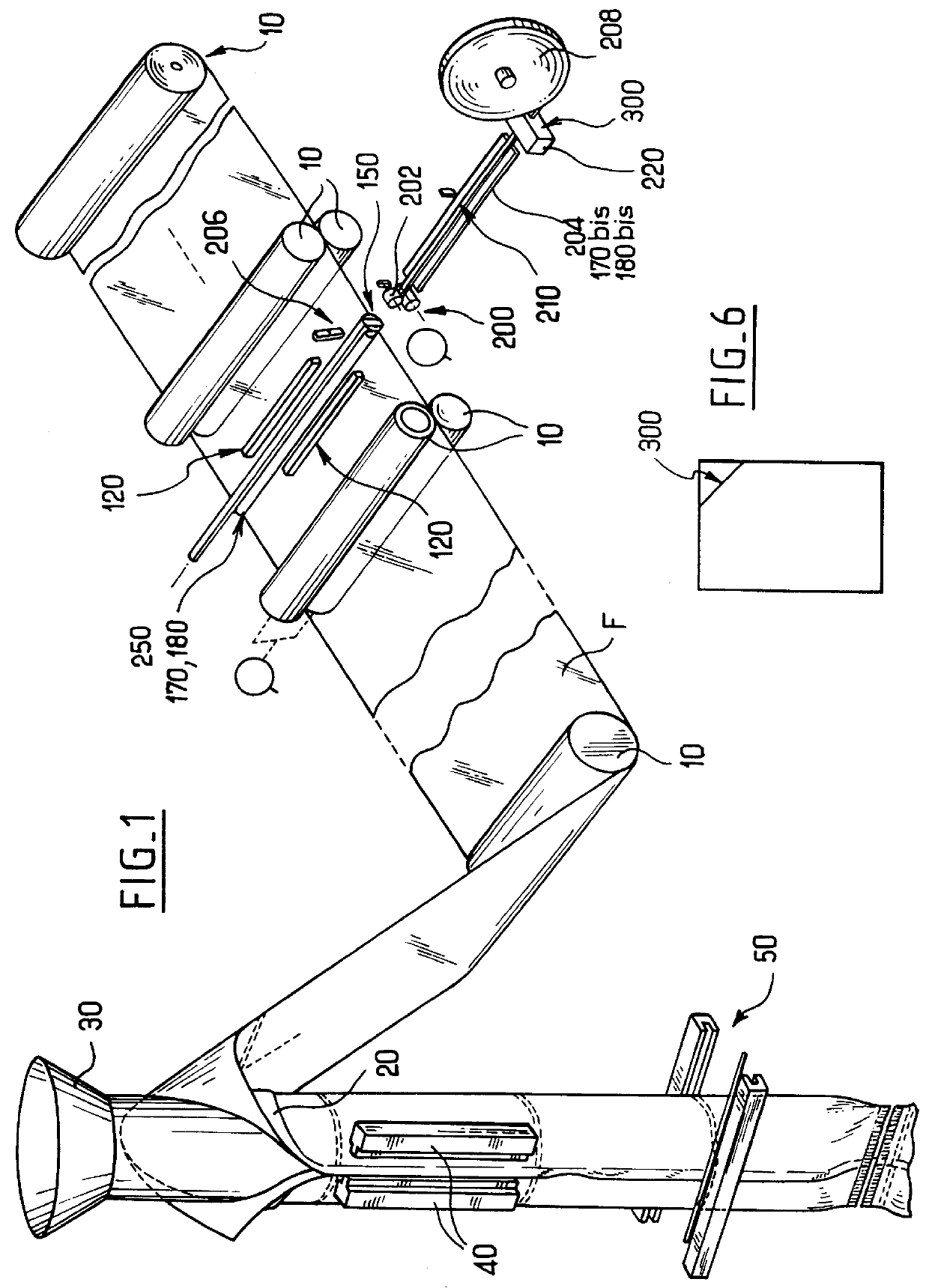

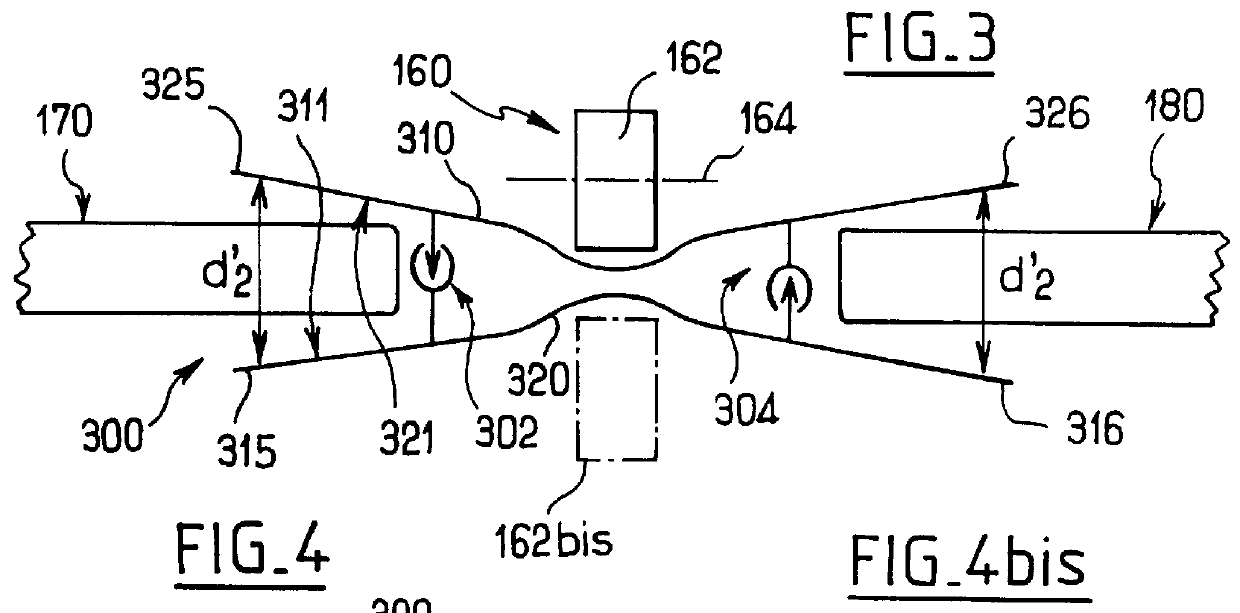

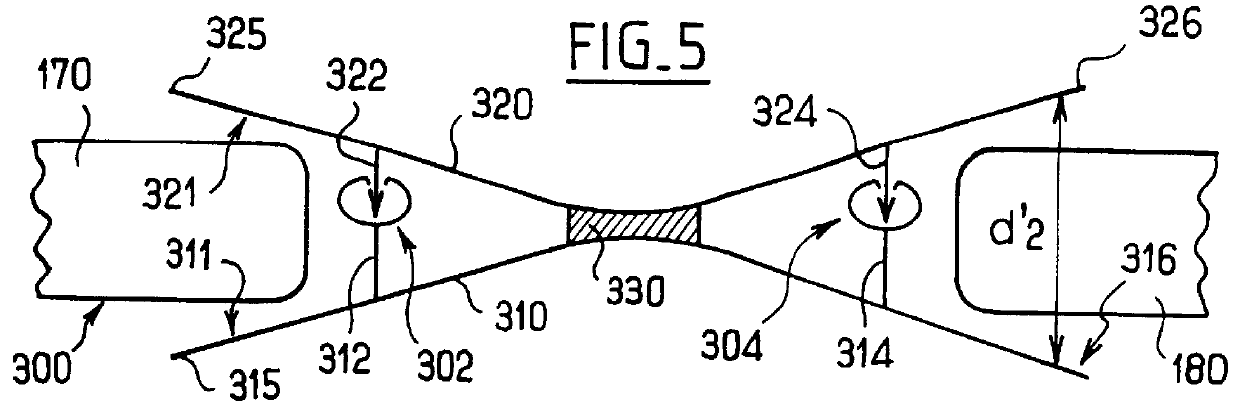

Automatic machine for forming, filling, and sealing bags having transverse closure strips, and bags obtained thereby

InactiveUS6032437AIncrease the gapEnvelopes/bags making machineryBag making operationsThin membraneEngineering

The present invention relates to a machine for forming packaging on the basis of film that includes complementary closure strips, the machine comprising: feeder means for feeding onto the film a closure means comprising two support webs provided with at least a first longitudinal assembly constituted by two complementary strips and with a second longitudinal assembly disposed at a distance from the first, urging means for urging the support webs towards each other between the two longitudinal assemblies, and two rectilinear guides suitable for penetrating respectively into the gaps between each pair of lateral edges of the support webs. The present invention also provides a method, the resulting packages, and closure means for this purpose.

Owner:FLEXICO FRANCE

Stand-up packaging pouch, package body and feed roll, and manufacturing methods therefor

InactiveUS7156556B2Stably stand upQuality improvementEnvelopes/bags making machineryBag making operationsEngineeringMechanical engineering

A stand-up packaging pouch manufactured in three-dimensional form or flattened form and provided with at least front face portion and rear face portion sides formed from packaging material having a pleat which is formed by folding a part of the packaging material in a three-fold strip form and adhering the inner faces of this folded part is constituted such that when the pouch is opened out into three dimensions, the pleat, formed in the same plane as the peripheral face portion, is positioned at a substantial right angle to a bottom face portion, thereby concealing the bottom face portion.

Owner:CHOKOKU PLAST CORP

Method And Apparatus For Inflating And Sealing Packing Cushions Employing Film Recognition Controller

An apparatus for inflating and sealing packing cushions utilizes a controller adapted for acquiring information from preconfigured film material and automatically setting one or more operation parameters suitable for inflating and sealing the film. The controller can avoid or limit the need for user input, thus simplifying use of the apparatus.

Owner:PREGIS INNOVATIVE PACKAGING

Thermal bag for foods and the like

ActiveUS9834366B2Increase capacityPractical to useLighting and heating apparatusBag making operationsLateral borderMechanical engineering

The thermal bag (2) is made of thermally insulating composite material folded to form a bottom and welded along lateral borders (3) to form a body (1) of the bag with a mouth (5) at the level of which a handle (7A, 7B) is applied. The composite material defines a bottom folded in an accordion-like fashion opposite the mouth of the bag, and a laminar stiffening element (15) of the accordion-like bottom is disposed inside the bag.

Owner:IMBALL CENT

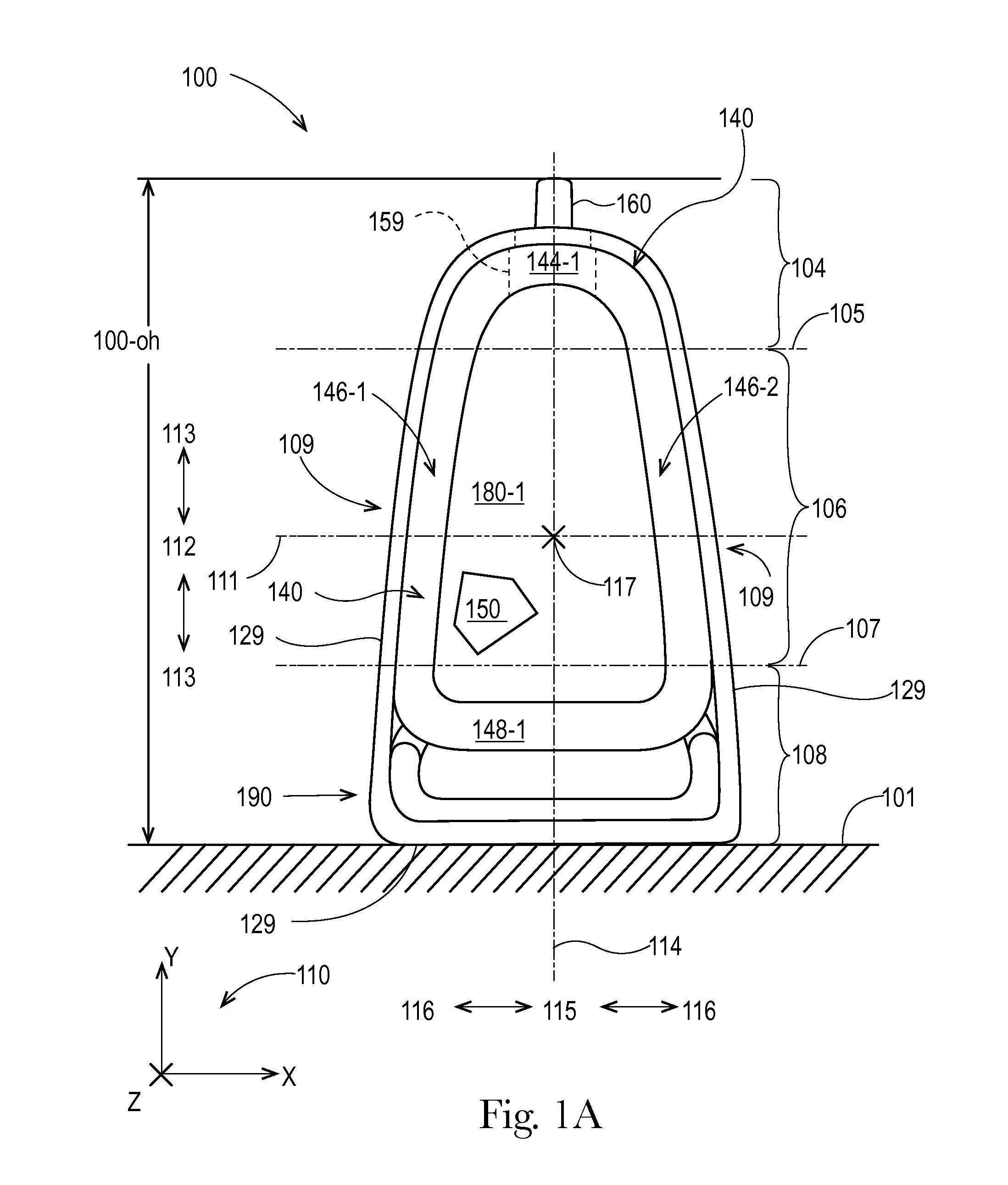

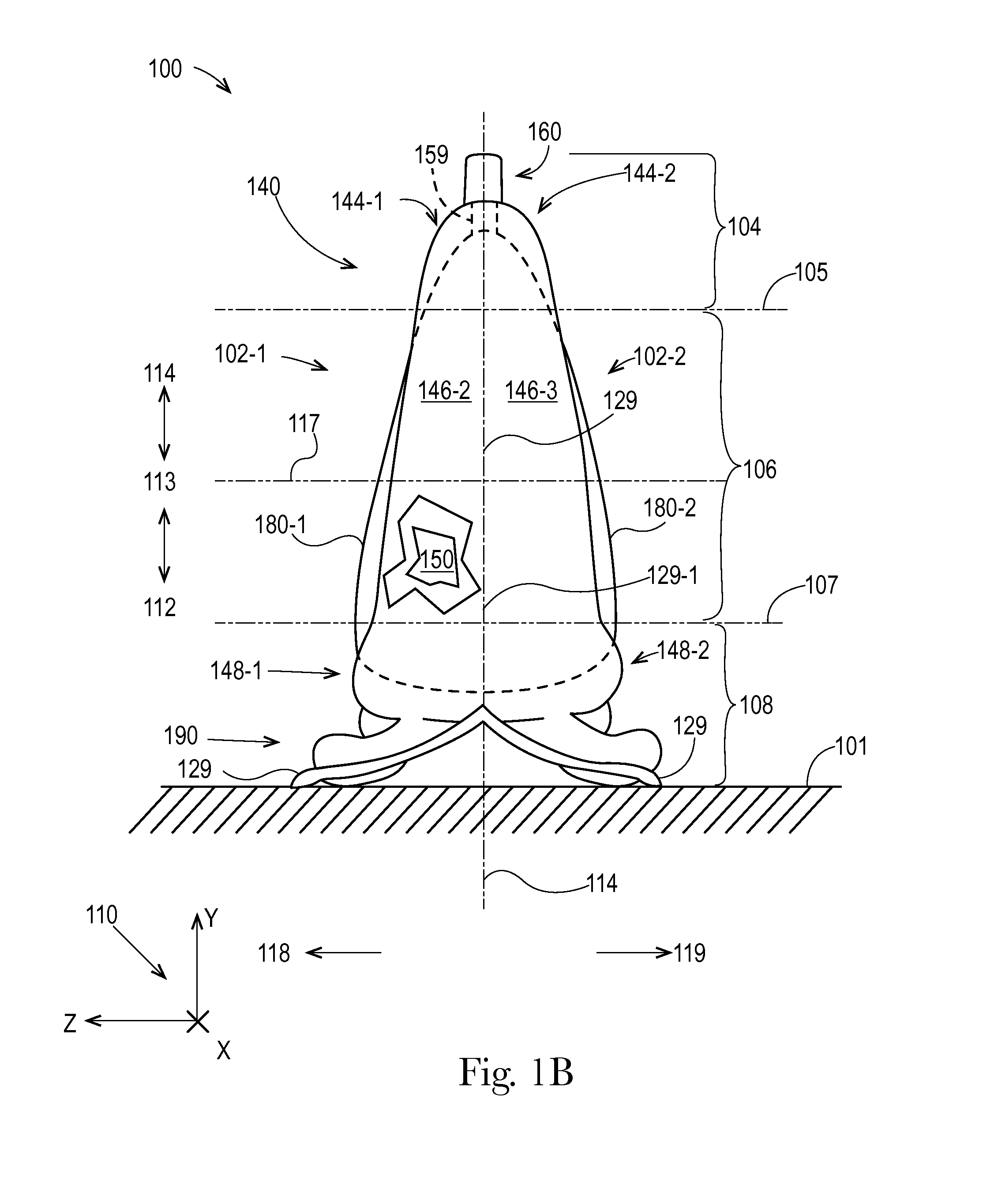

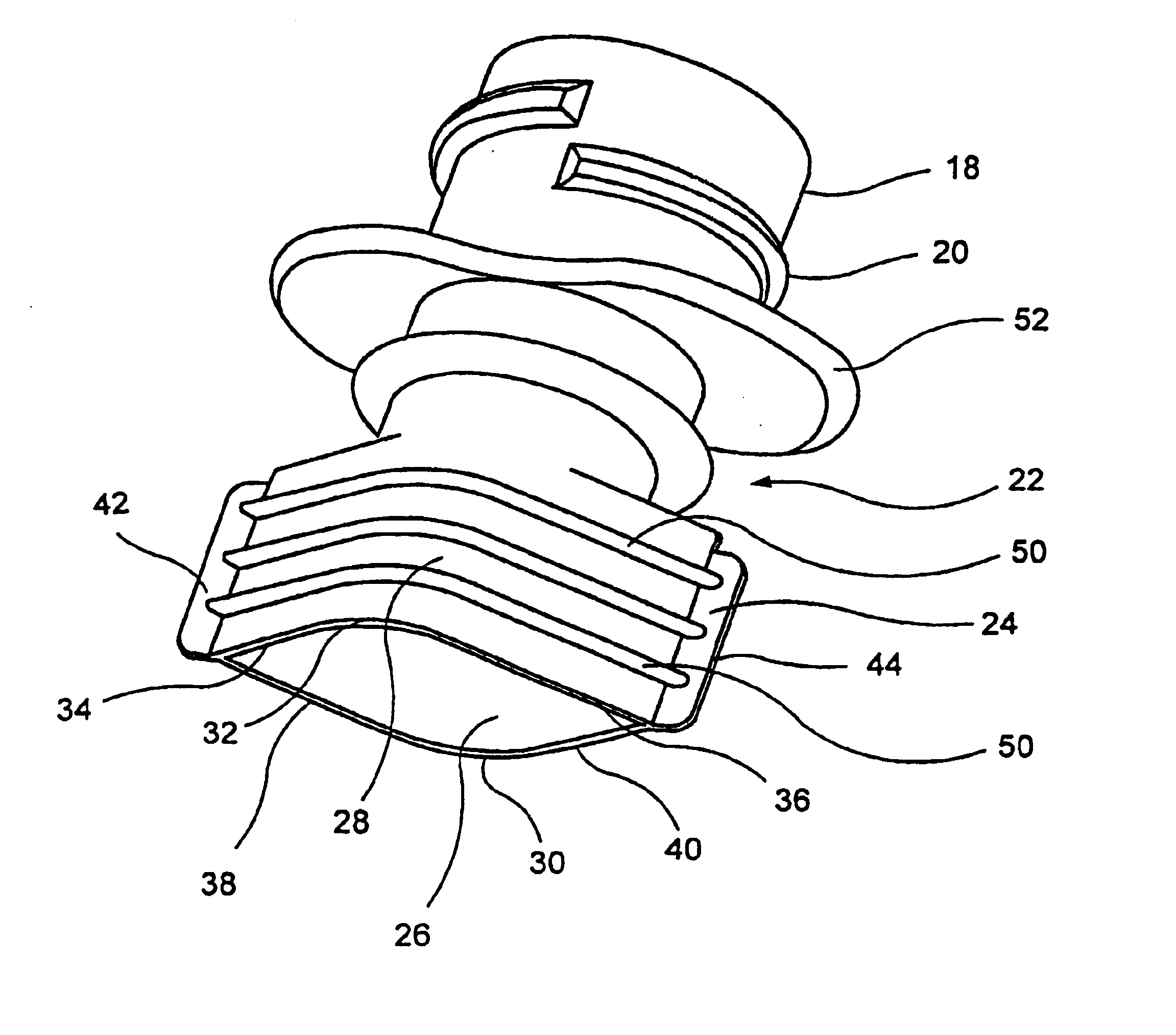

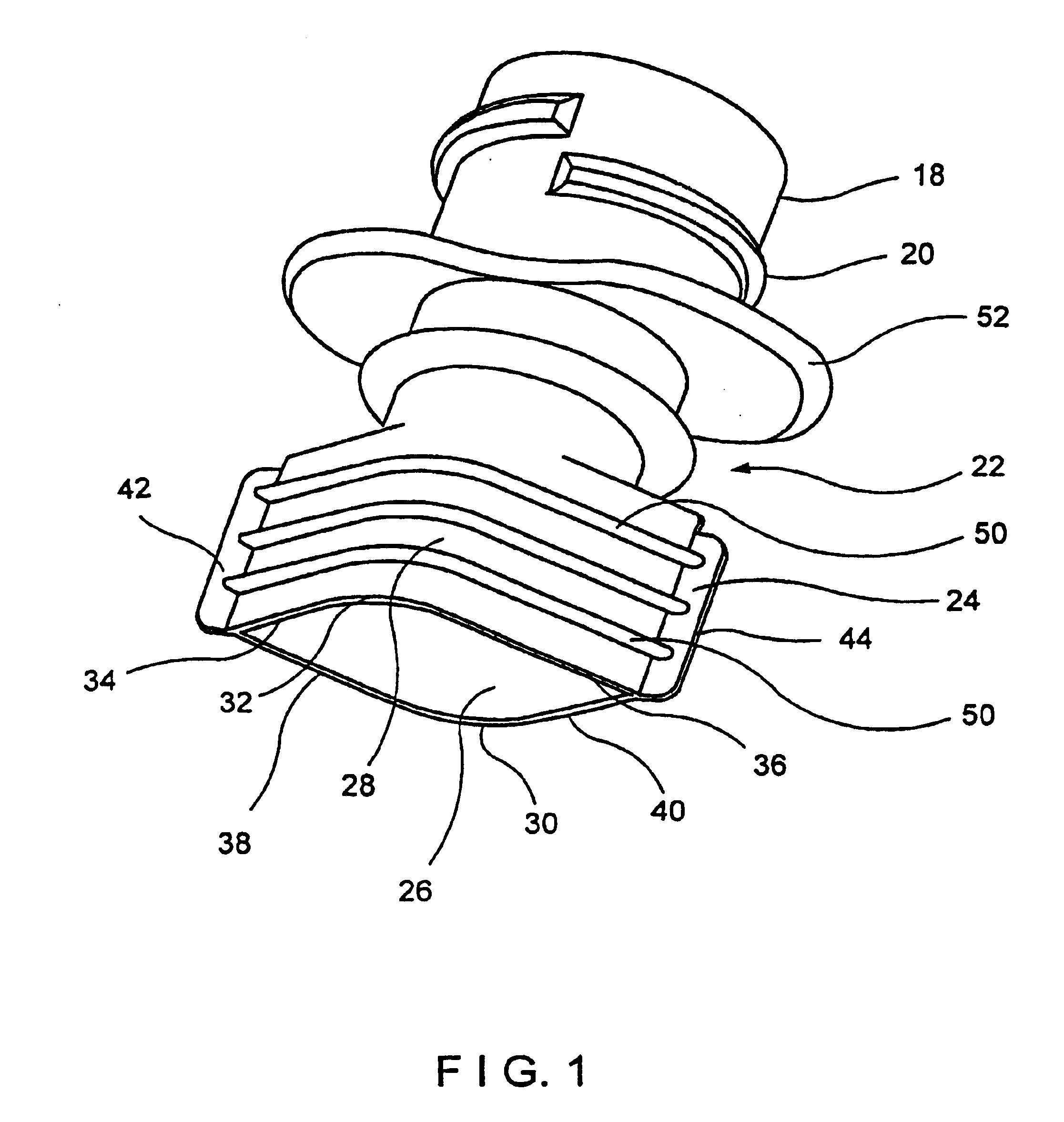

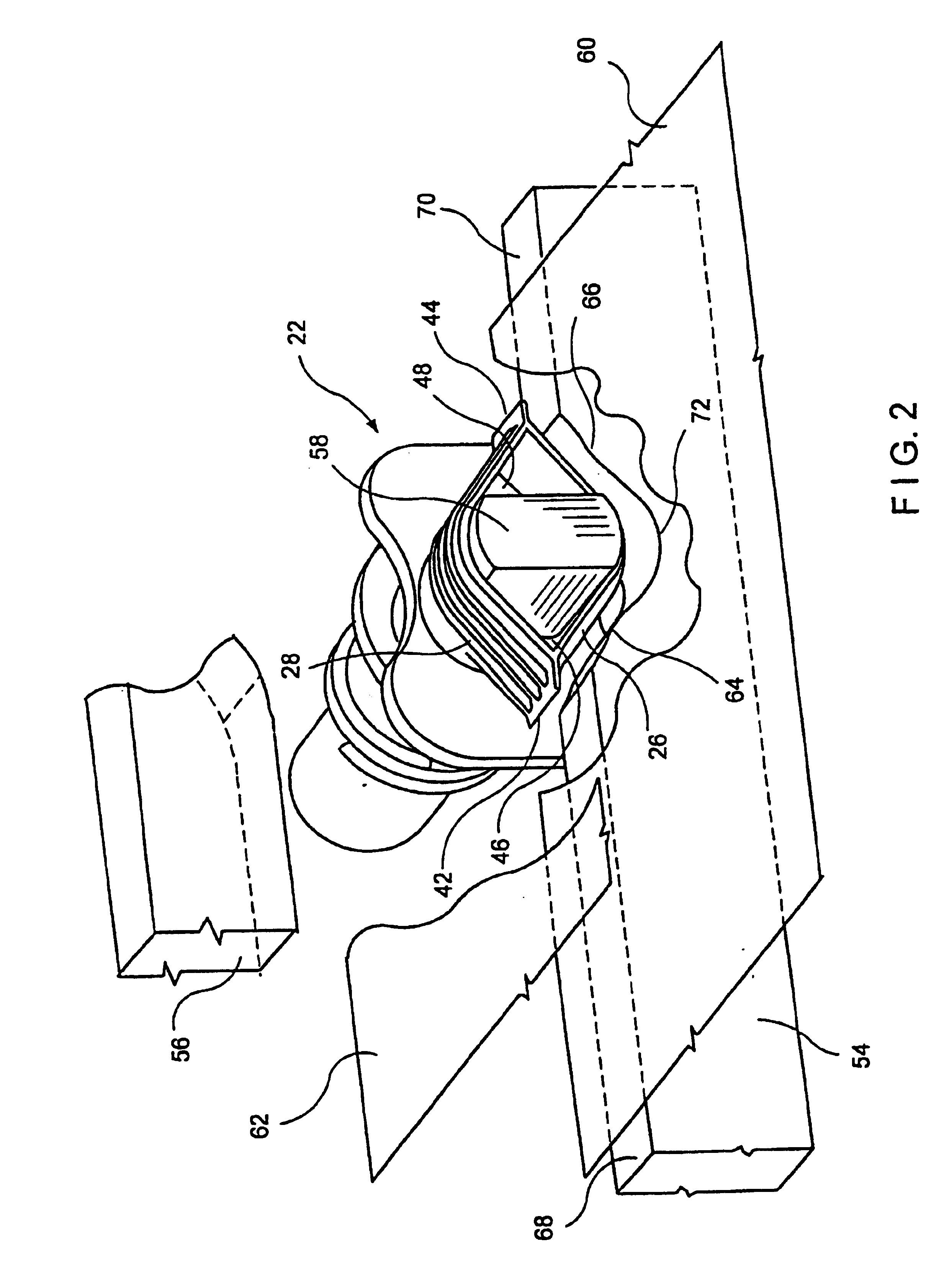

Flexible pouch fitment structure

InactiveUS6860406B2Increase speedFacilitate and enhance sealingEnvelopes/bags making machineryBag making operationsEngineeringStraight segment

A flexible plastic fitment for providing spouts for pouches formed of sheet material. The fitment includes a pair of opposed side walls each having a center portion formed from diametrically opposed segments of a common cylinder and straight segments that blend respectively into the cylindrical segments on opposite sides of the common cylinder. The side walls are joined together at both ends thereof to form a canoe shape. A cover, which provides the only support for the side walls joins the top edges of the canoe shape and extends at both ends of the canoe shape between the cylindrical segments and the joined ends. A thin fin extends from each end of the joined side walls. A method of and apparatus for attaching the fitment by distending the side walls outwardly while urging the sheet material toward the side walls is also disclosed.

Owner:ILLINOIS TOOL WORKS INC

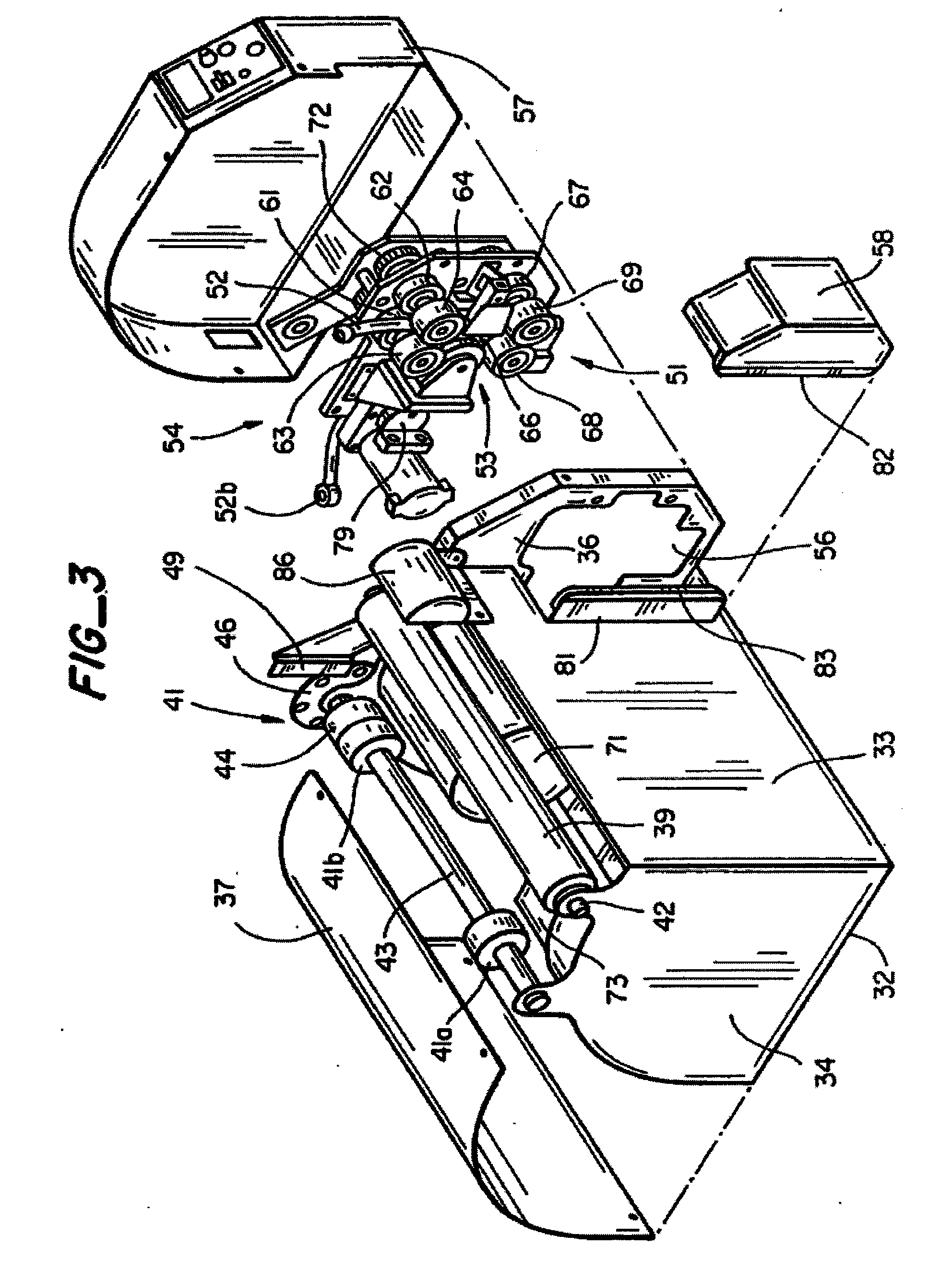

Vacuum packaging system

InactiveUS20050205455A1Precise positioningAvoid drawingEnvelopes/bags making machineryBag making operationsHand heldFront loading

A system for vacuum packaging foods and other perishable items, including a front loading appliance and a hand held appliance. A multiple stage vacuum and sealing process enhances performance. Low cost vacuum bags are formed using a continuous process. A visible indicator assures consumers that a safe level of vacuum has been reached and maintained.

Owner:HARRISON HOWARD ROBERT

Glue drop end stops for zippered bag

Owner:GLUE DOT COM LLP

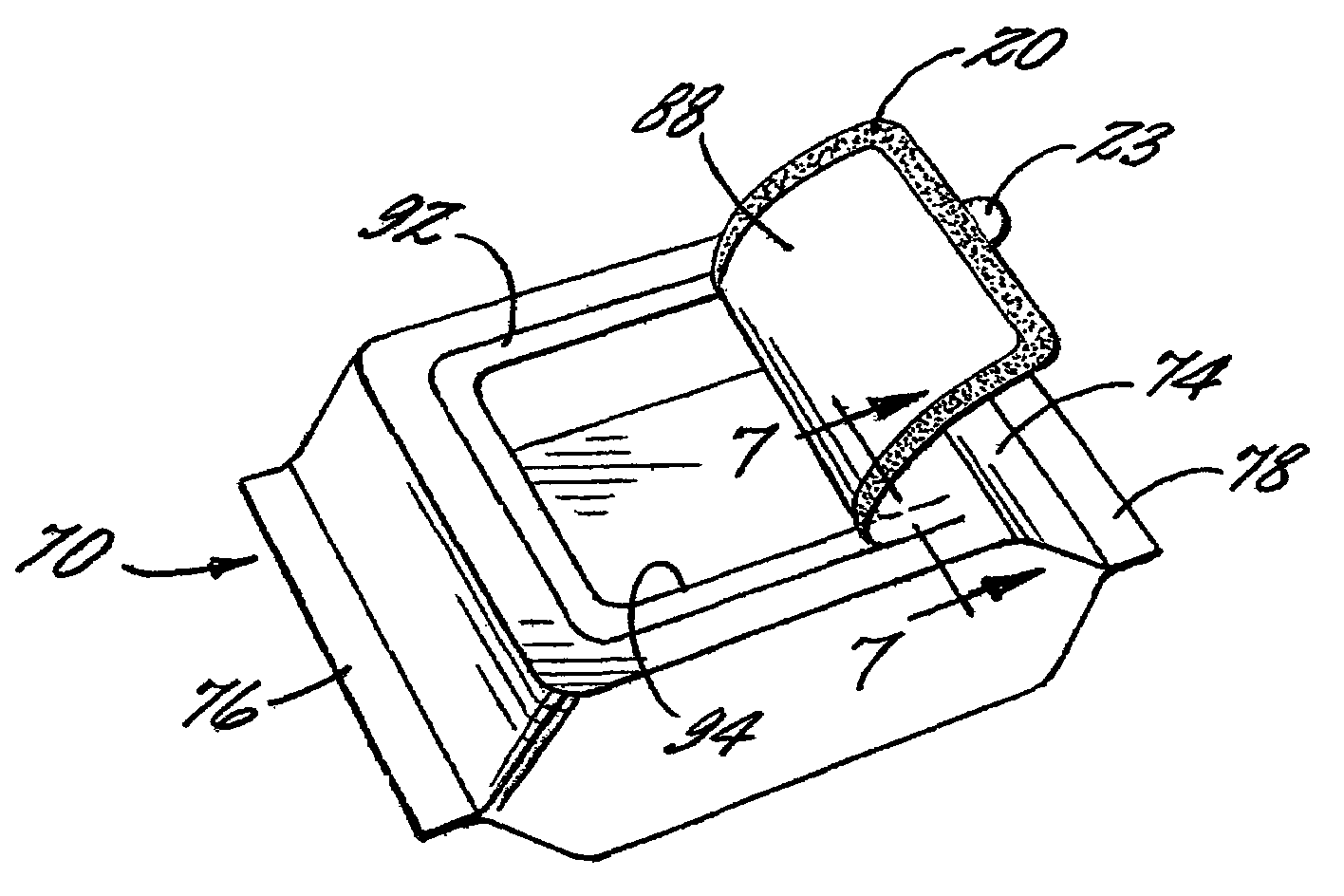

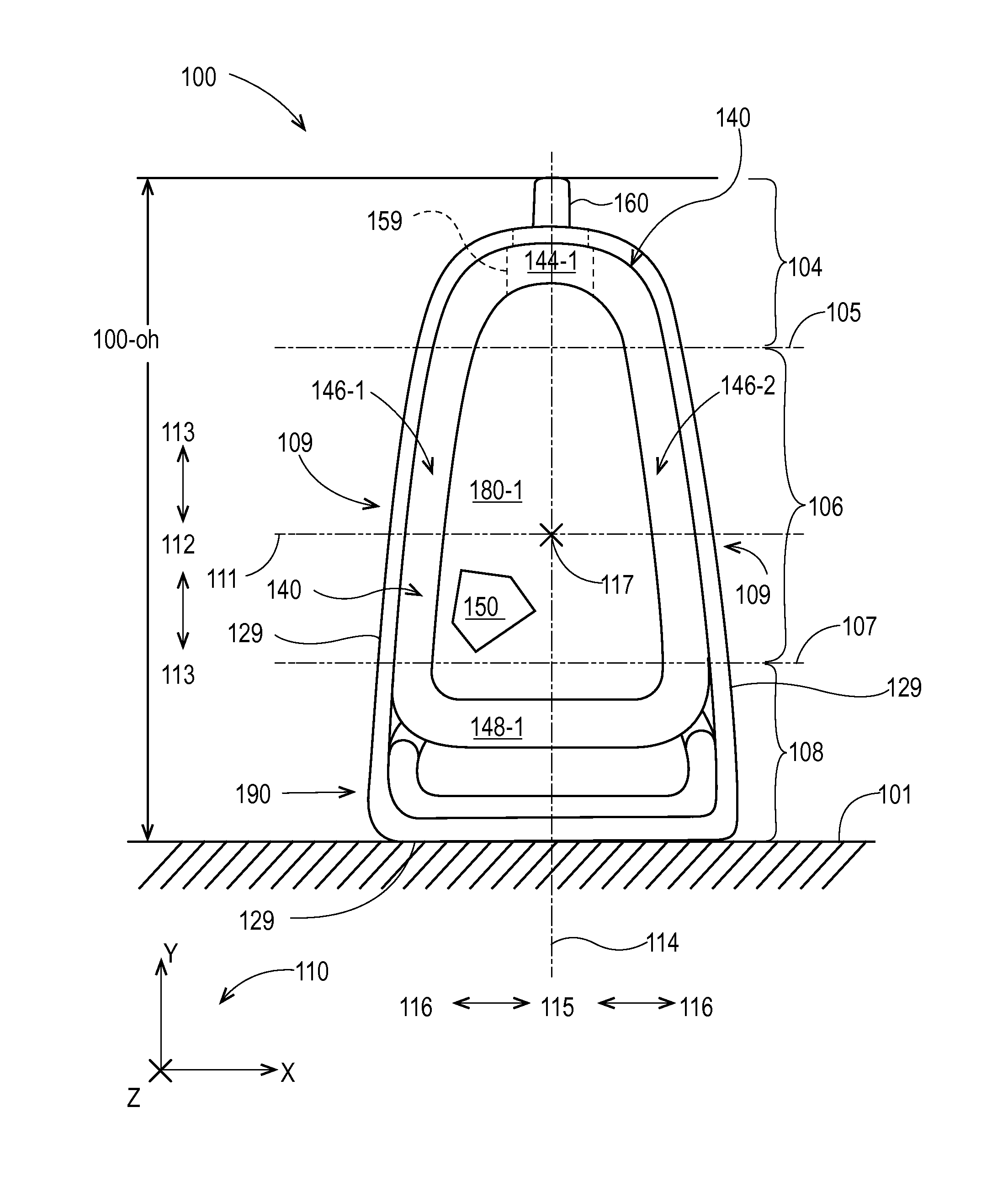

Packages having bubble-shaped closures

ActiveUS8613547B2Repeatable sealing performanceEnvelopes/bags making machineryBag making operationsEngineeringHermetic packaging

Owner:STEELE MARK

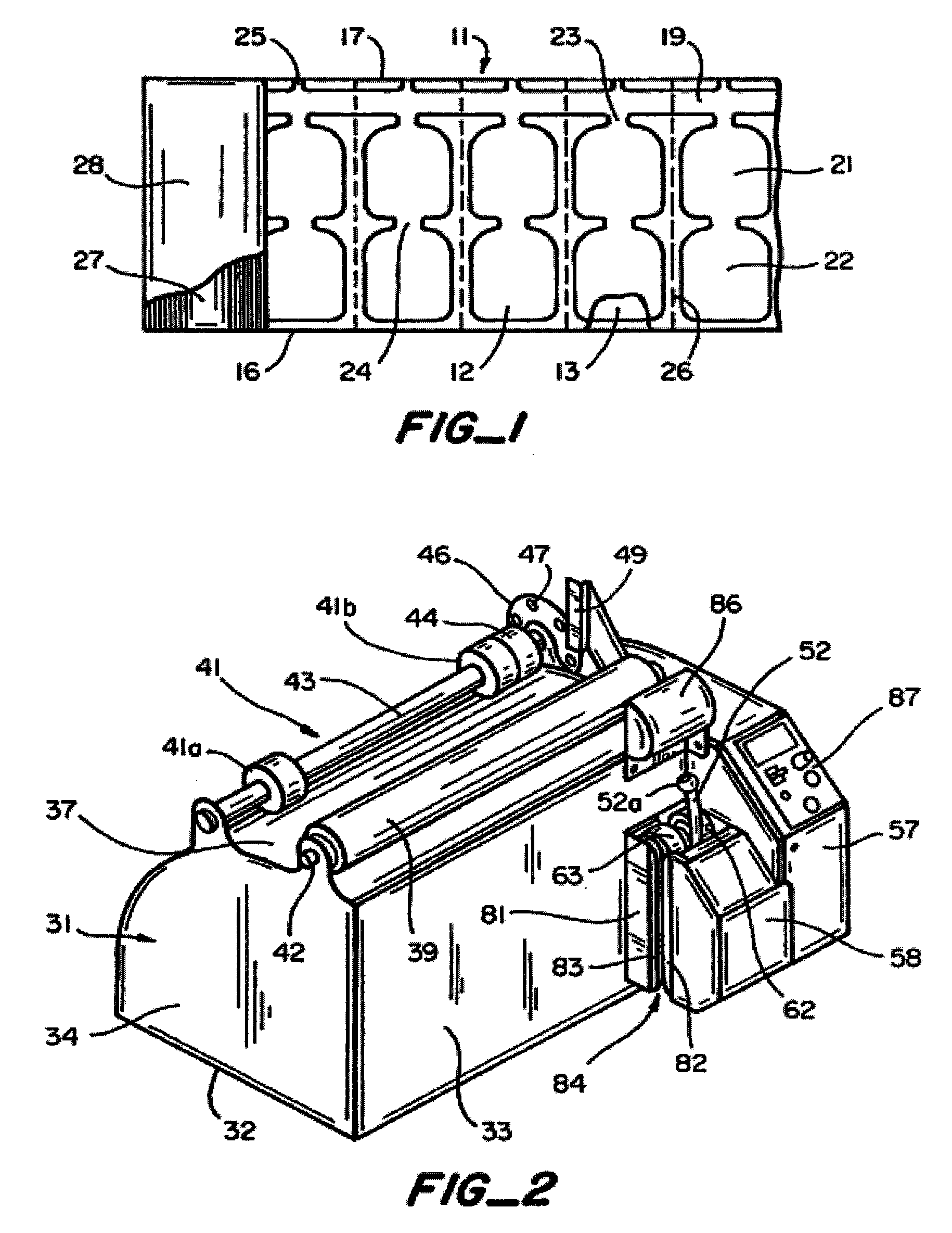

Process for making pouches

The present invention relates to a continuous, horizontal process for making water-reactive pouches, involving the steps of:a) continuously feeding a first water-soluble film onto a horizontal portion of an continuously and rotatably moving endless surface, which comprises a plurality of moulds, or onto a non-horizontal portion thereof and continuously moving the film to said horizontal portion;b) forming from the film on the horizontal portion of the continuously moving surface, and in the moulds on the surface, a continuously moving, horizontally positioned web of open pouches;c) filling the continuously moving, horizontally positioned web of open pouches with a product, to obtain a horizontally positioned web of open, filled pouches;d) closing the web of open pouches, to obtain closed pouches, preferably by feeding a closing material onto the horizontally positioned web of open, filed pouches, to obtain closed pouches; andpreferably sealing the closed pouches and whereby step d) and preferably step e) is also done in a continuous manner, preferably while the web of pouches is in horizontal position and continuously moving.The products introduced in the pouch are preferably cleaning compositions or fabric care compositions, in particular laundry or dish washing compositions.

Owner:THE PROCTER & GAMBLE COMPANY

Food bag release valve

ActiveUS20060030472A1Decrease freezer burnComplicated processEnvelopes/bags making machineryBag making operationsIngested foodVALVE PORT

Owner:CCL LABEL INC

Reusable food storage bag and process for making a reusable storage bag

InactiveUS20140270590A1Easy to cleanTighter closurePackage recyclingBag making operationsEngineeringFood storage

The present invention is a washable and reusable storage bag comprising a plastic coated canvas made from cotton and polyethylene. The storage bag comprises a front panel having a zipper and a back panel, a bottom edge and a top edge, and two side edges. The bag further comprises a rectangular transparent polyurethane window in the front panel, preferably in the shape of a rectangle. Two opposing sides of the transparent polyurethane window are heat sealed to the plastic coated canvas to create a liquid tight seal between the transparent polyurethane window and the plastic coated canvas. The outside of the storage bag can be customized with, e.g., designs, branding, and / or advertising. The storage bags can be hand washed, put in the dishwasher or put in the washing machine and clothes dryer.

Owner:OSTROY LEE RACHEL

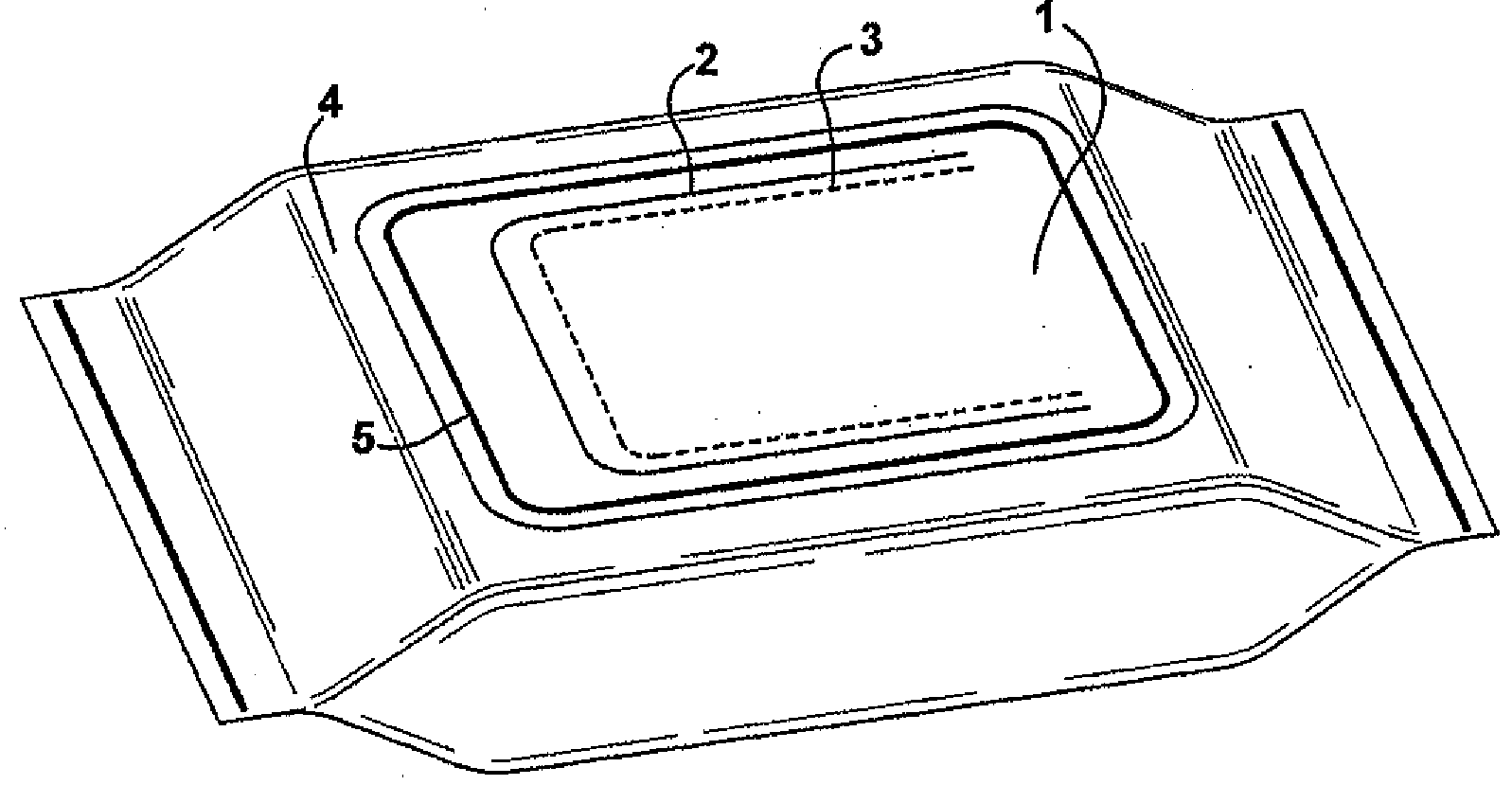

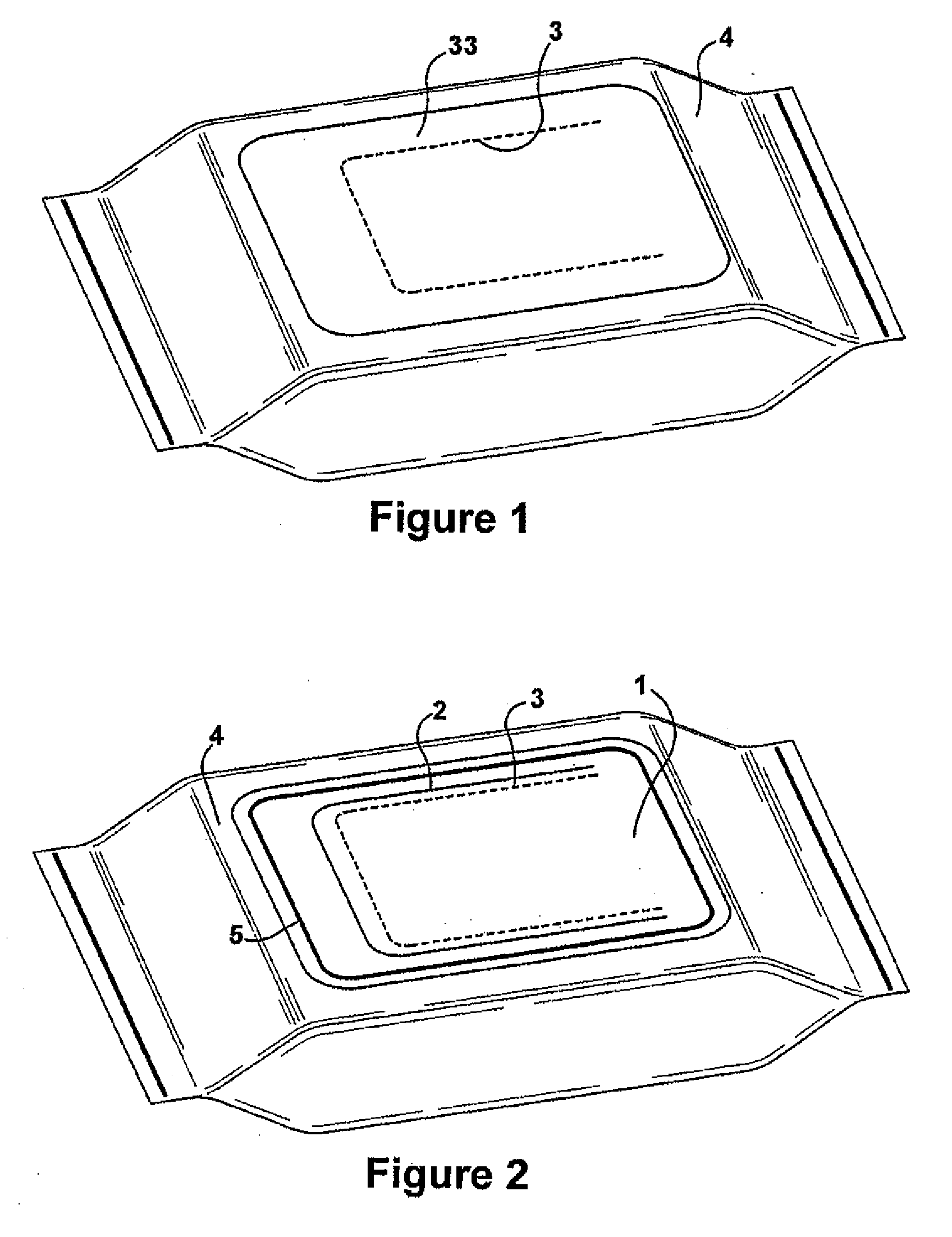

Packaging member with easy-opening means

InactiveUS7470062B2Prevented from being openedEasy to openEnvelopes/bags making machineryFlexible coversBiomedical engineering

Owner:HOSOKAWA YOKO CO LTD

Food bag release valve

ActiveUS7244223B2Sufficient protectionNot compromise current (and quick) bag-making speedEnvelopes/bags making machineryBag making operationsBiomedical engineering

Owner:CCL LABEL INC

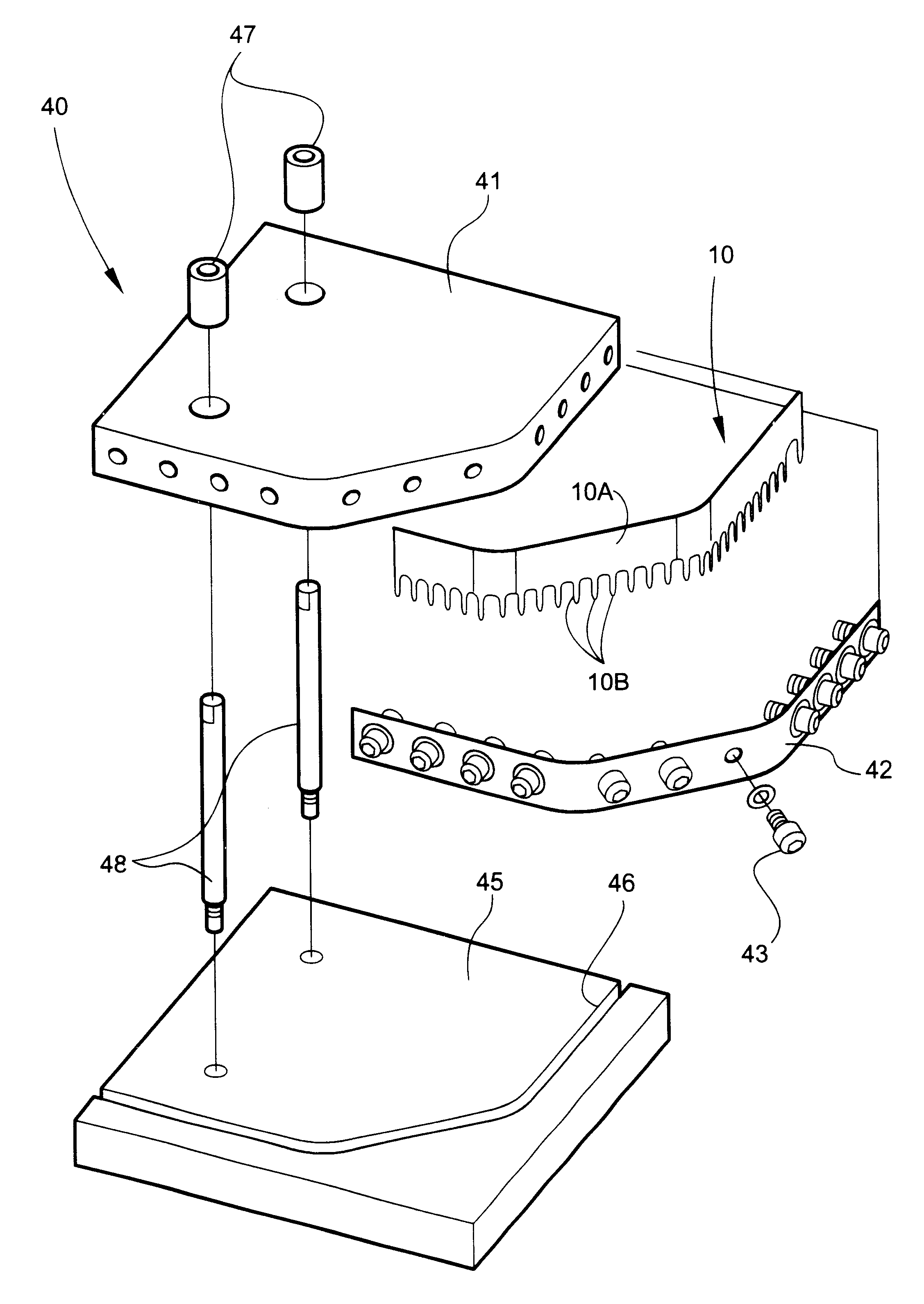

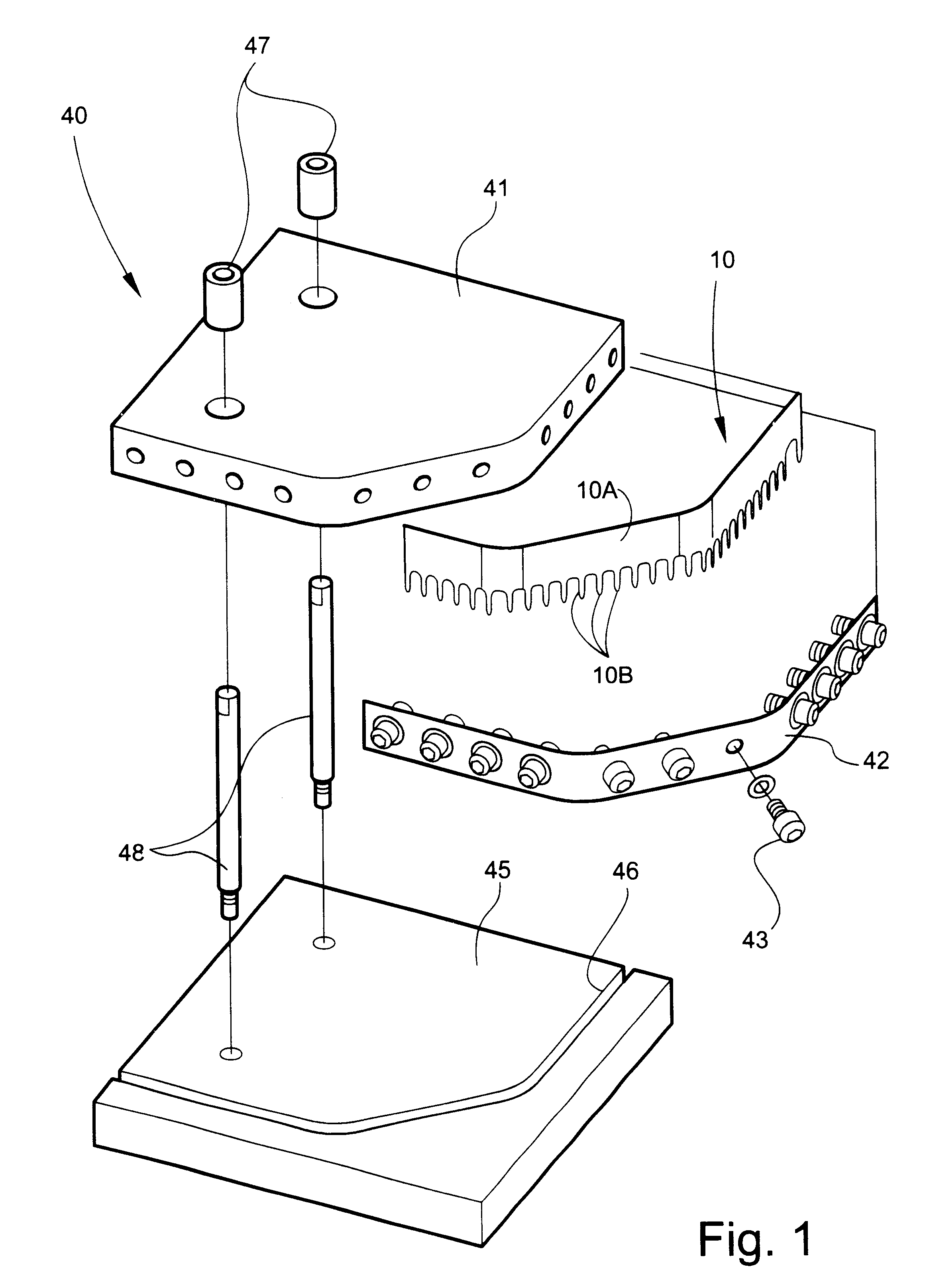

Perforation blade for forming a burst-resistant easy-open corner in a heavy duty bag

InactiveUS6609999B2Improved perforation bladeGuaranteed safe sealMetal sawing devicesEnvelopes/bags making machineryEngineeringHeavy duty

A perforation blade is used for cutting a perforated tear line in a bag to form an easy-open corner portion. The perforation blade includes a base formed to span the corner portion of the bag. The base has a first end adapted to extend to the end edge of the bag proximate a seal line, and a second end adapted to extend to one side edge of the bag. A series of closely spaced perforation teeth are formed with the base, and are adapted to penetrate the first and second walls of the bag to form a corresponding series of perforations at the corner portion of the bag. A starter tooth is formed at the first end of the base, and is adapted to cut a starter nick in a skirt of the bag between the end edge and the proximate seal line. A burst protection gap is formed between the starter tooth and a first of the series of perforation teeth. The burst protection gap is adapted for safely receiving the seal line of the bag to prevent severing the seal line when cutting the perforations.

Owner:EXOPACK TECH

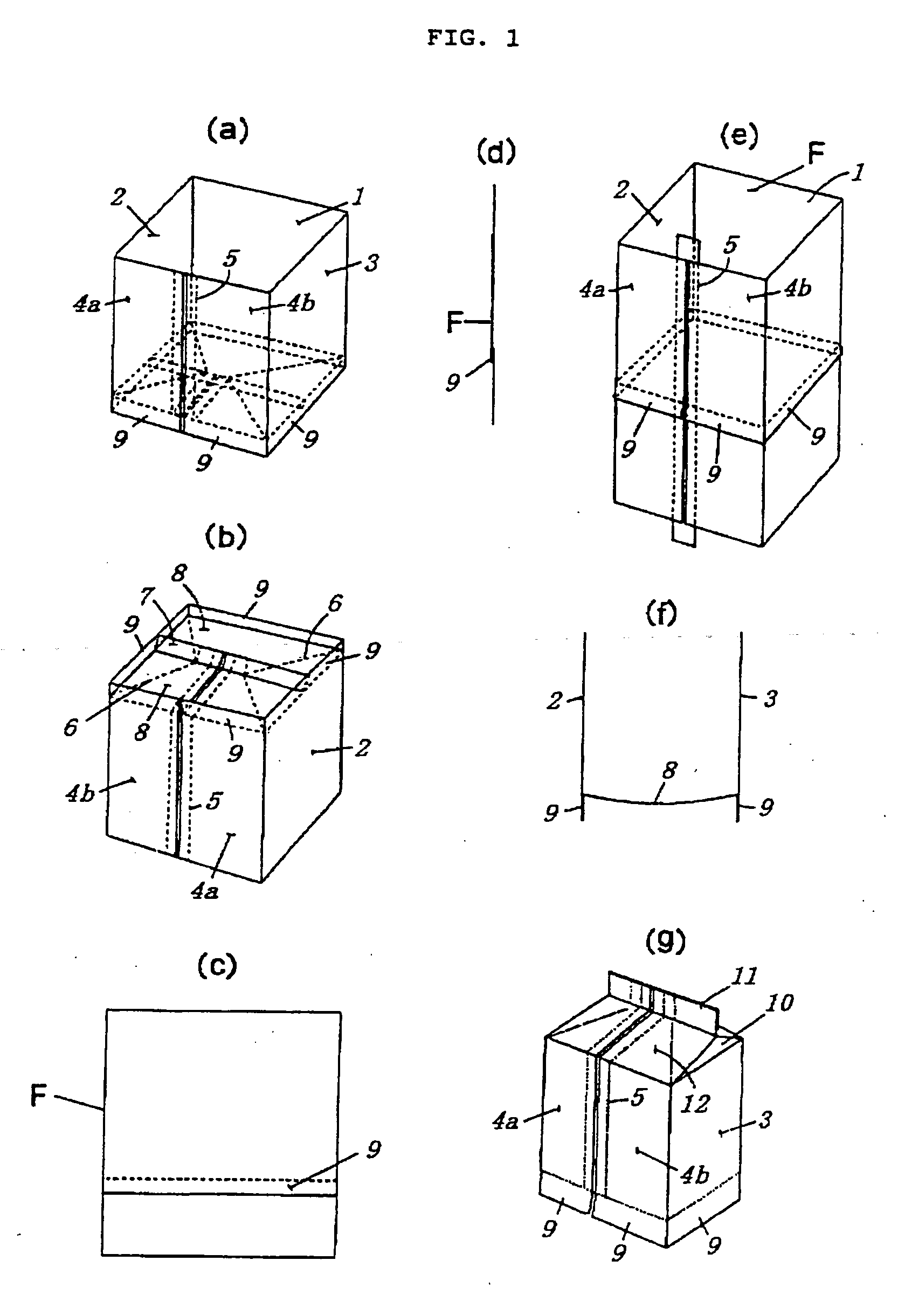

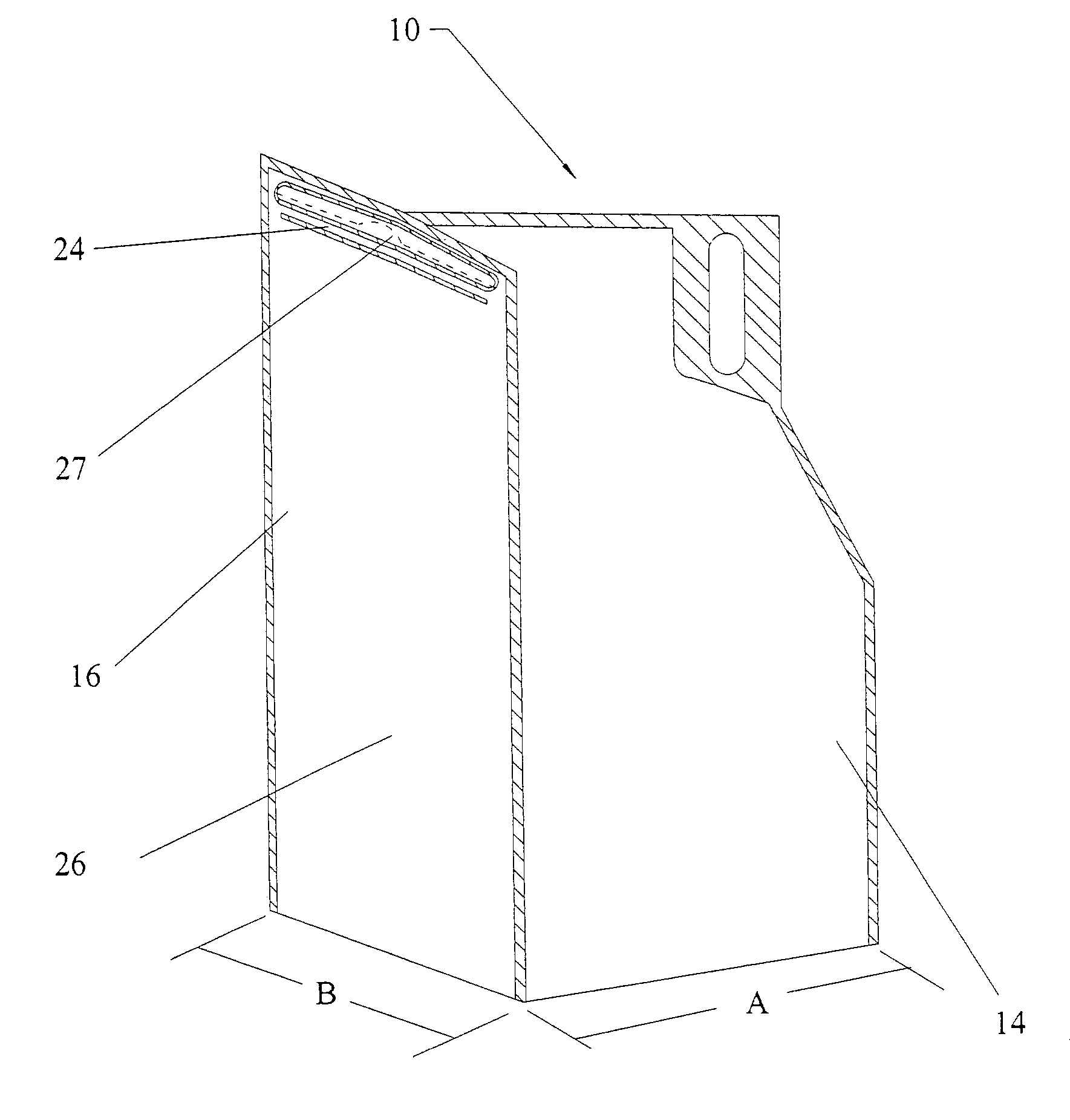

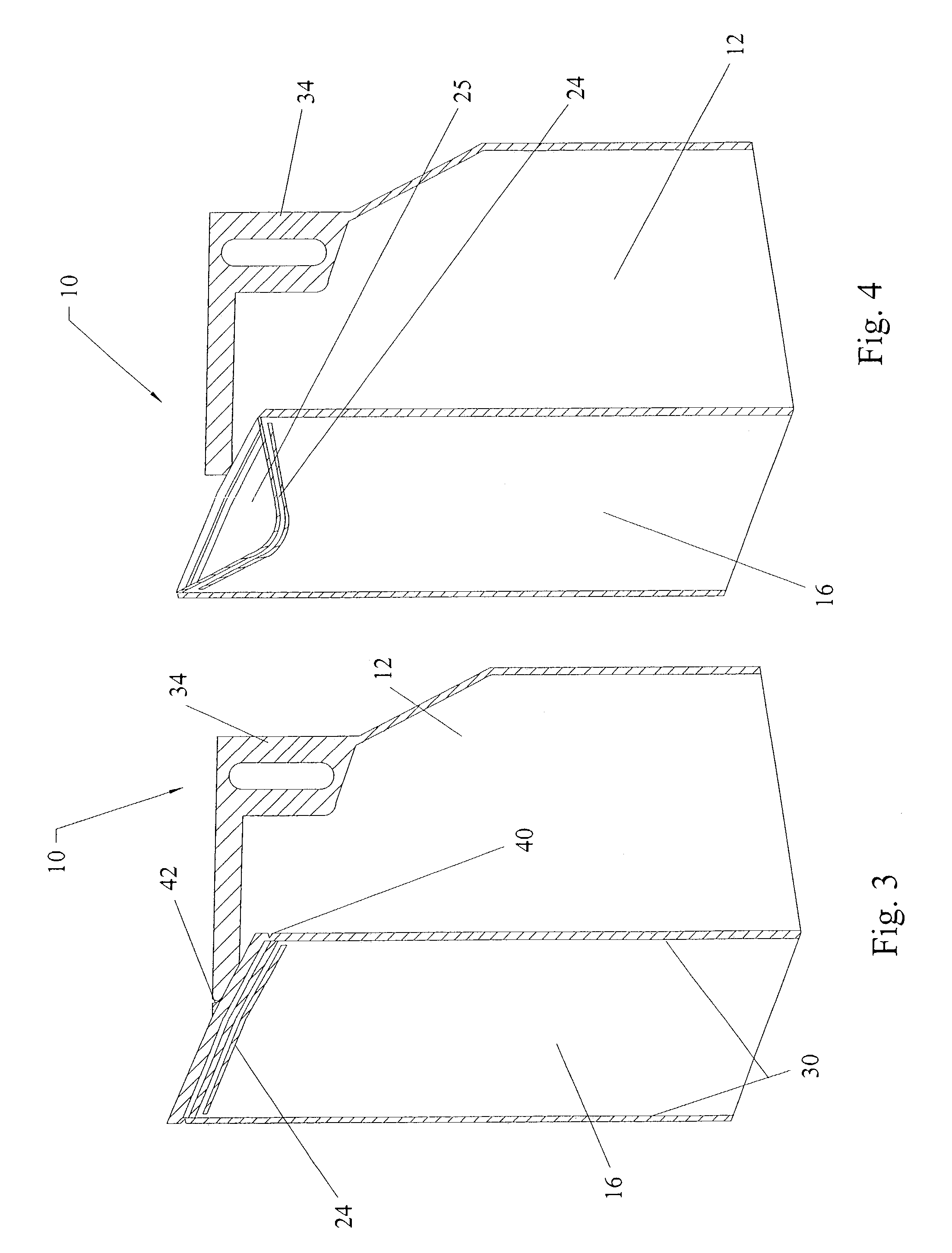

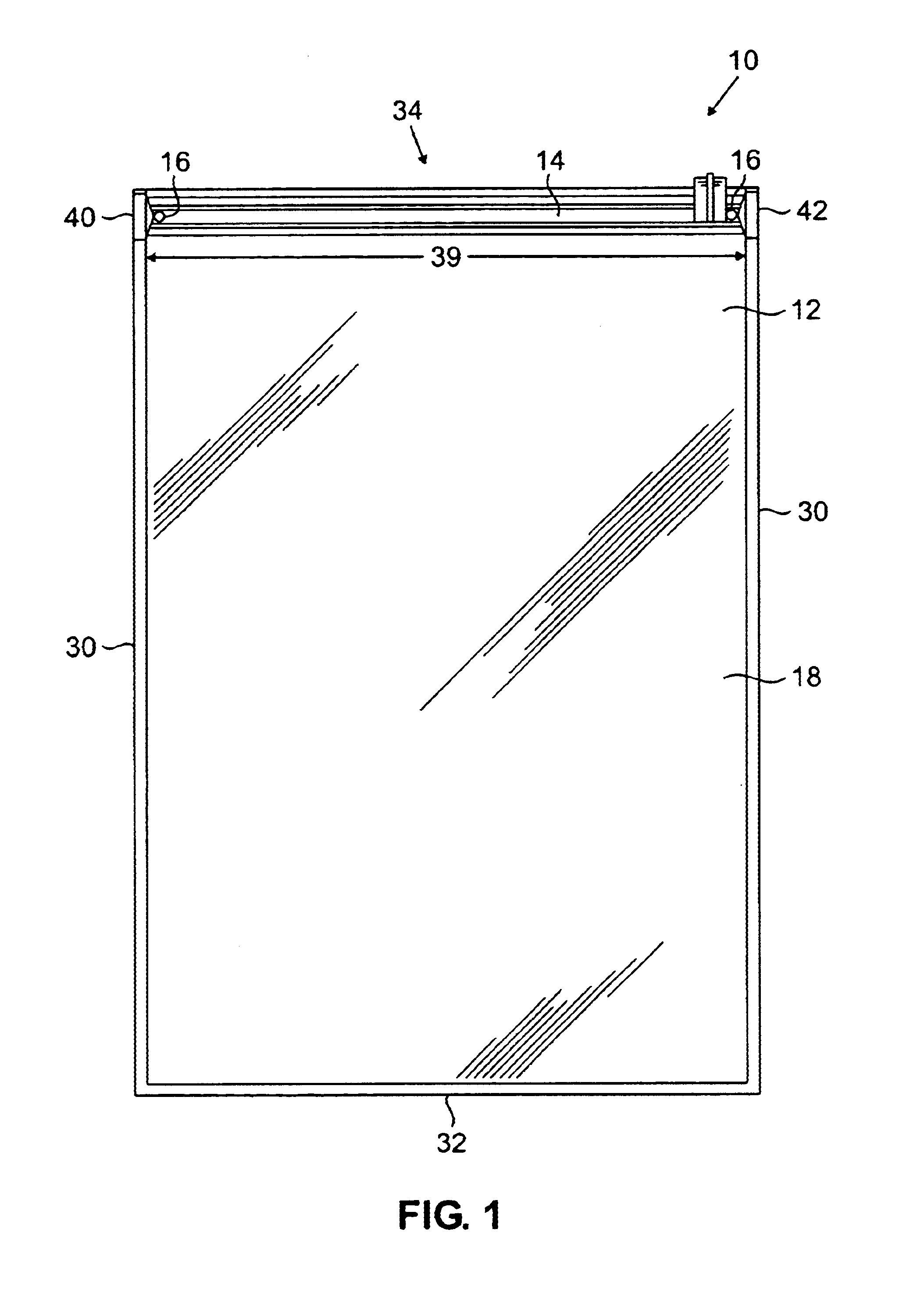

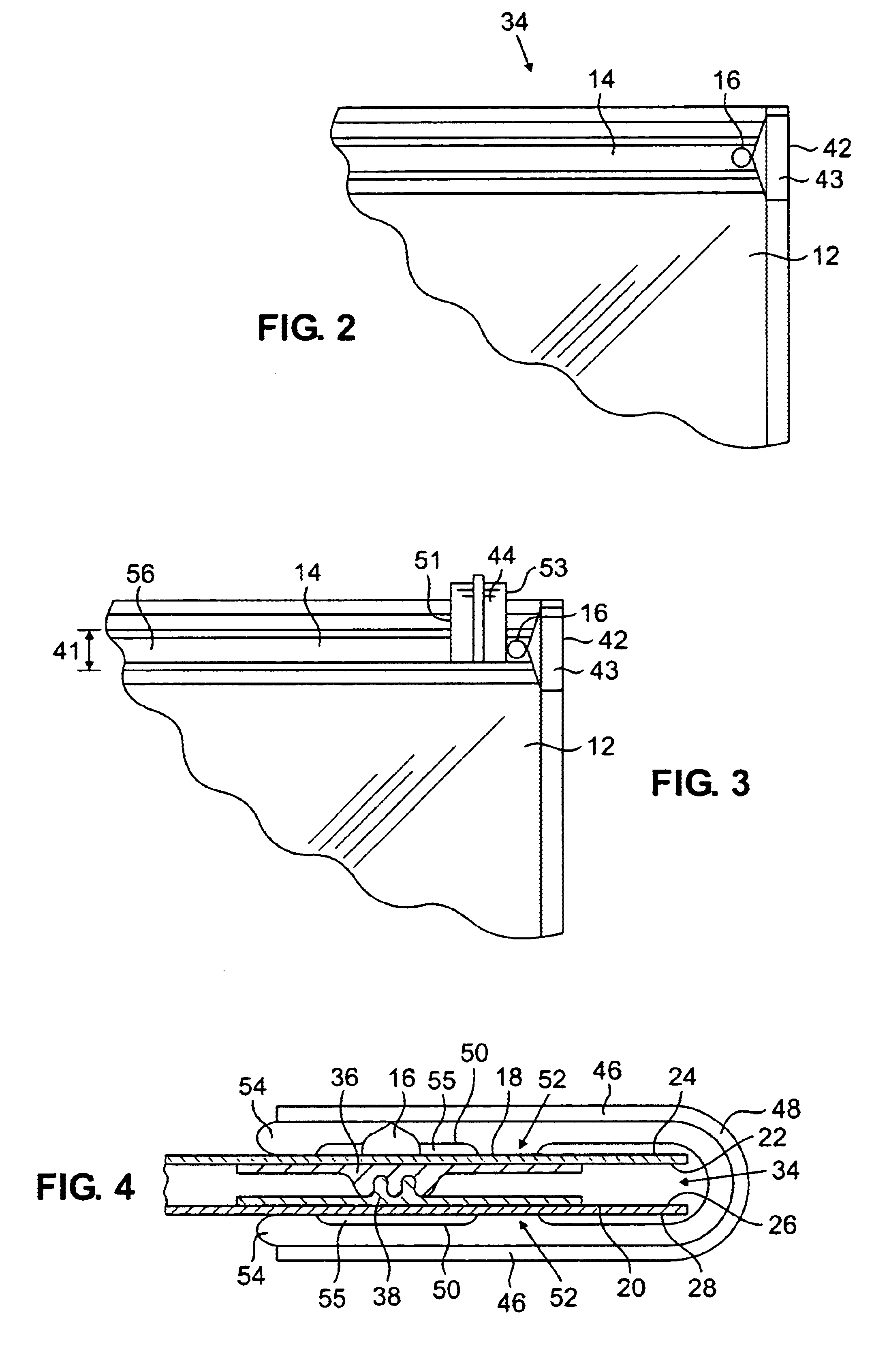

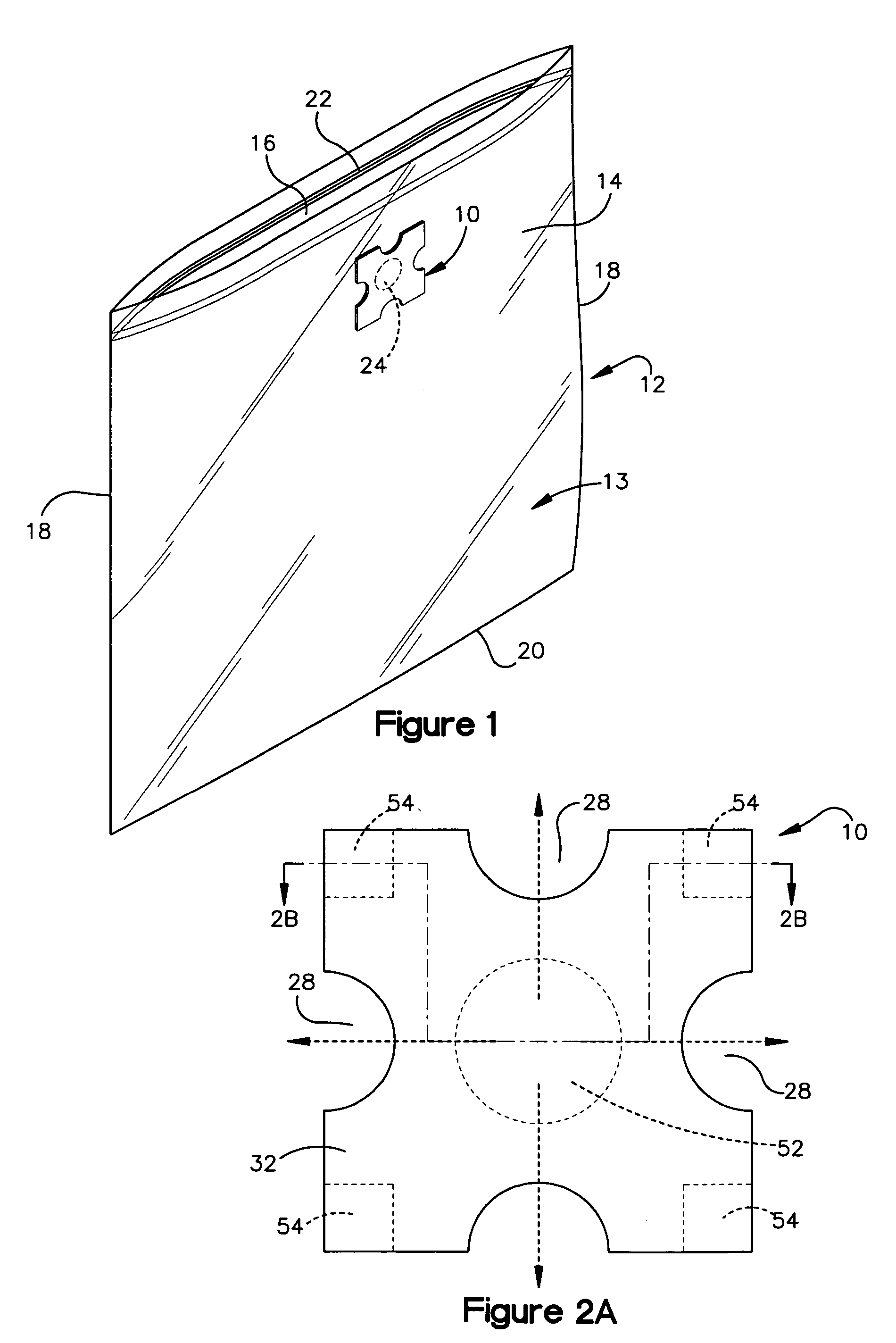

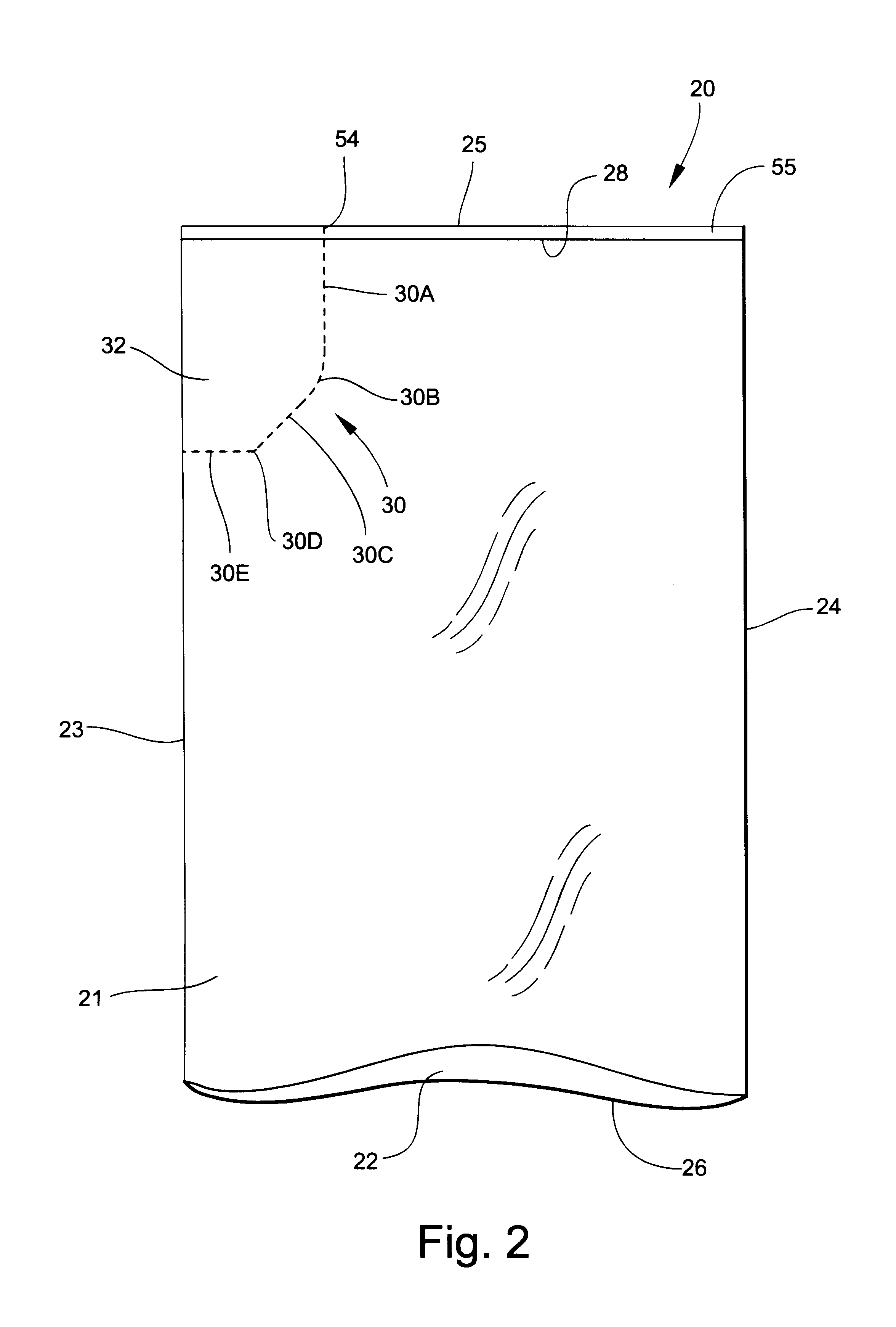

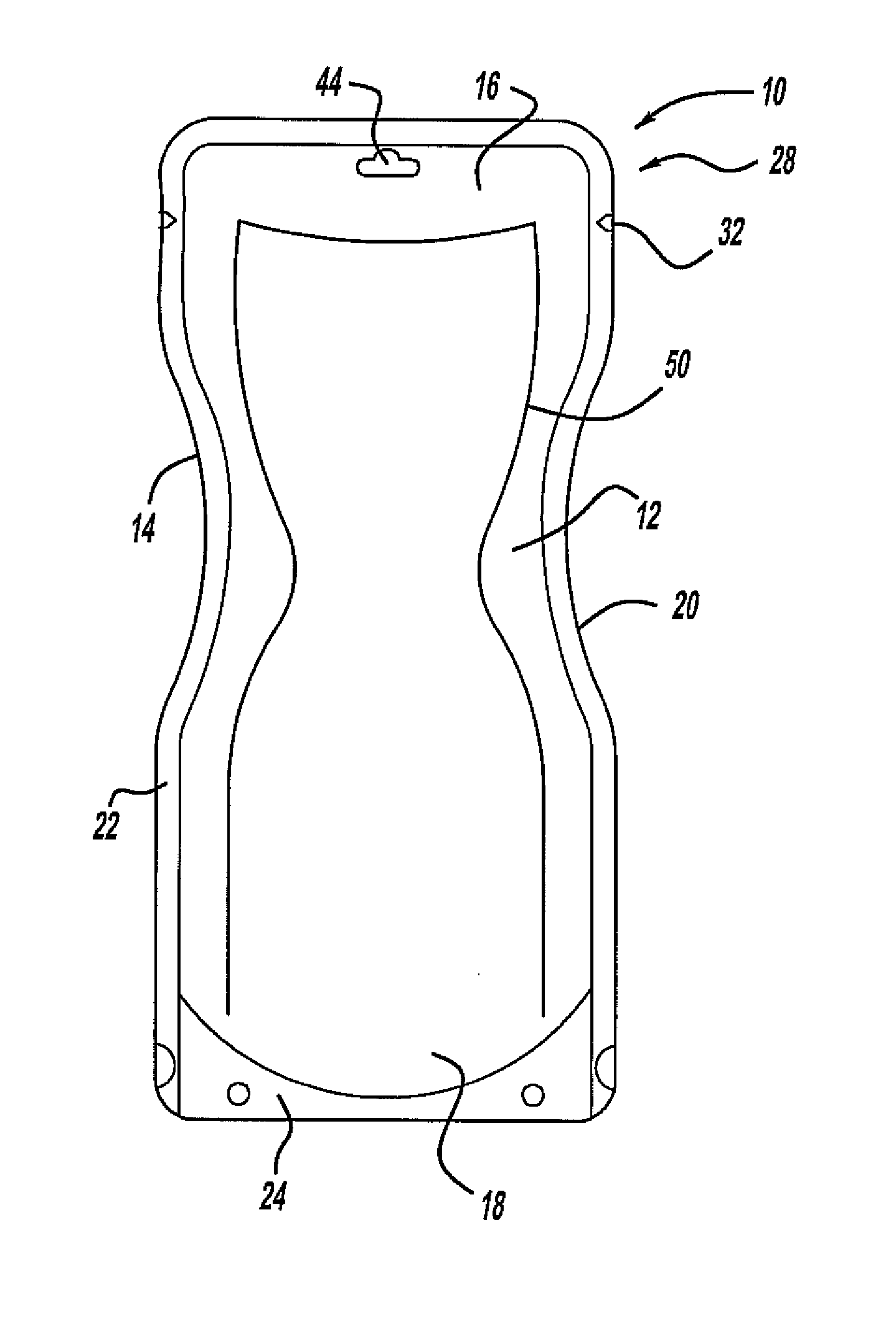

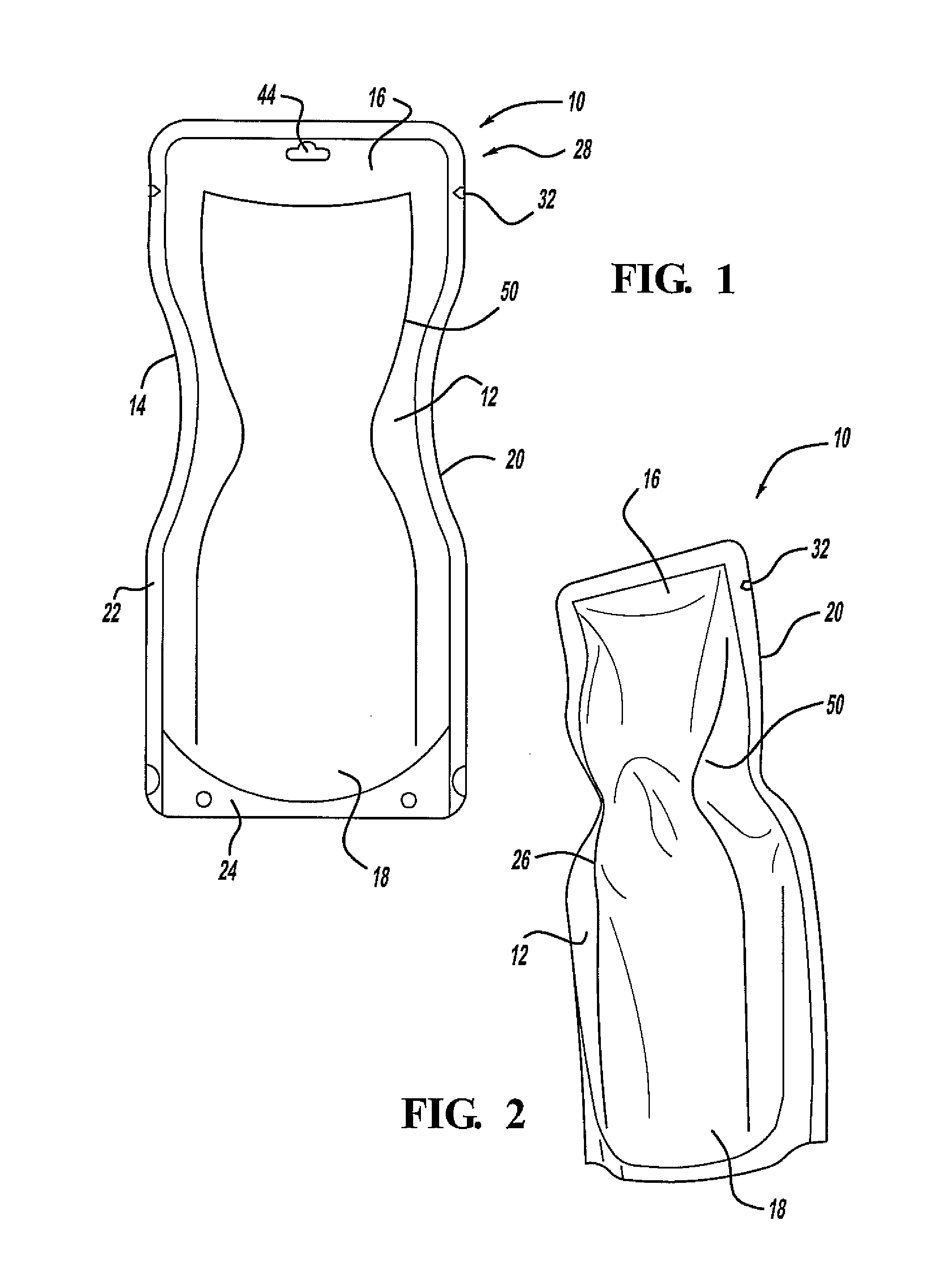

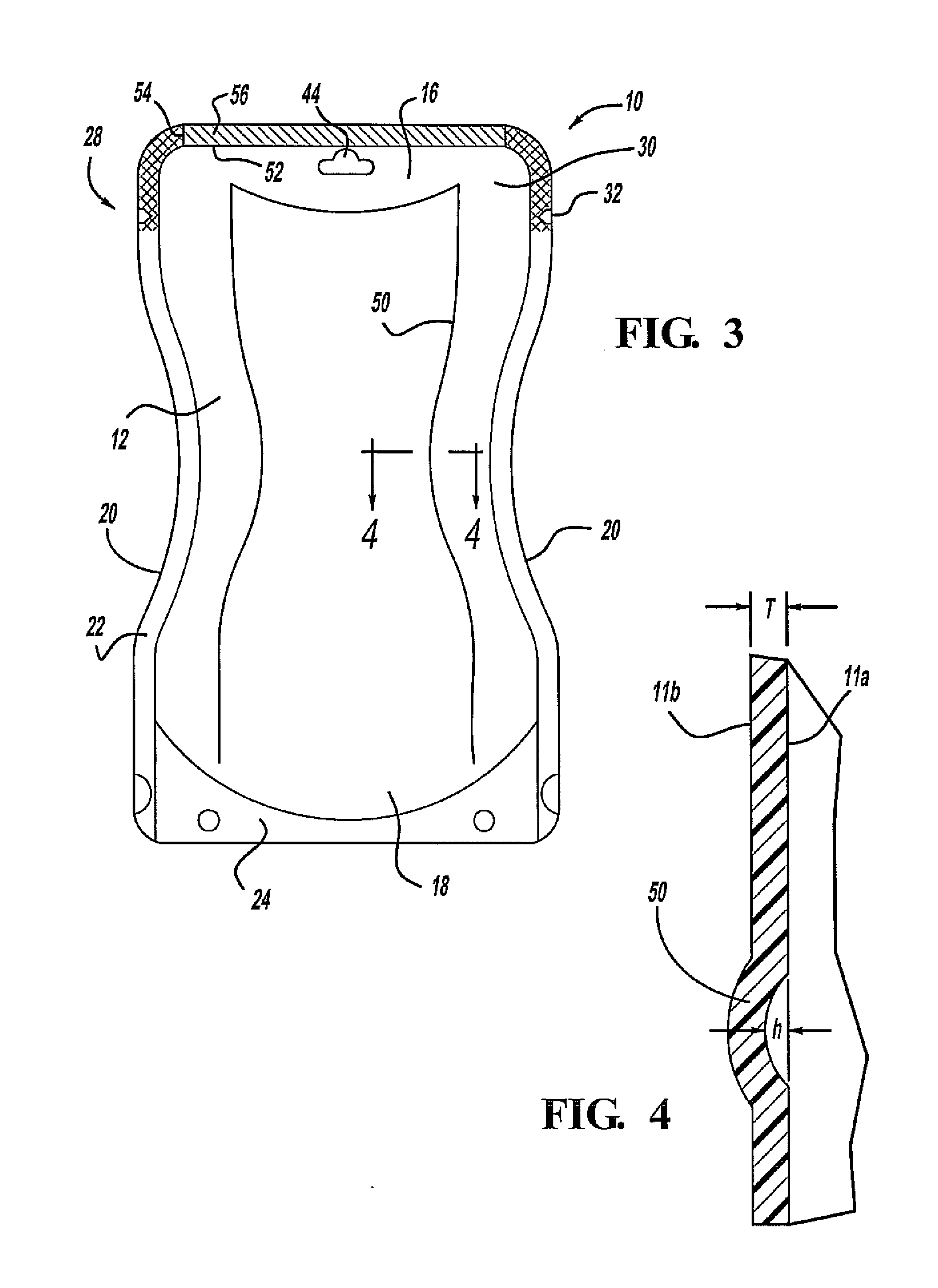

Recloseable bag

The invention relates to bag (10) comprising a line of weakness (28) for ease of opening, and a reclosing means (32), wherein the bag (10) comprises a front panel (12), back panel (14) and opposing side panels (16, 18), the panels being sealed together to provide a top section (24) and a bottom section (26), and wherein the line of weakness (28) extends around all of the front (12), back (14) and side (16, 18) panels so that the top section (24) is completely removable from the rest of the bag, and wherein the reclosing means (32) is attached to the front (12), back (14) and side (16, 18) panels adjacent to the line of weakness (28).The invention also relates to process for forming bags (10) from a web of film (30), wherein the web of film (30) is transported along one or more machines, the process comprising the steps of:(a) providing a line of weakness (28) across substantially the whole width of the film substantially in the cross-machine direction,(b) affixing reclosing means (32) adjacent to the line of weakness;(c) cutting and sealing the film to form a bag (10) comprising the line of weakness (28) and the reclosing means (32).

Owner:THE PROCTER & GAMBLE COMPANY

Stand-up flexible pouch and method of forming

InactiveUS20120008884A1Provide rigidityEnvelopes/bags making machineryWrappers shrinkageEngineeringStructural rigidity

A stand-up flexible pouch for packaging a product and a method of forming and filling the pouch is provided. The pouch includes a panel forming a body of the pouch using a flexible material having an inner surface and an outer surface. A rib is integrally formed in the pouch body, and the rib is spaced a predetermined distance from an edge of the pouch body. The ribs provide structural rigidity to the pouch when filled, allowing the pouch to retain the filled shape and stand upright unassisted as the product is removed from the pouch.

Owner:POUCH PAK INNOVATIONS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com