Vacuum packaging system

a vacuum packaging and vacuum technology, applied in the field of vacuum packaging system, can solve the problems of not allowing a sufficient vacuum to be drawn, high production cost, and substantially higher retail price, and achieve the effect of facilitating vacuum sealing and preventing the drawing of fluids

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the invention are described by way of example with reference to the drawings in which:

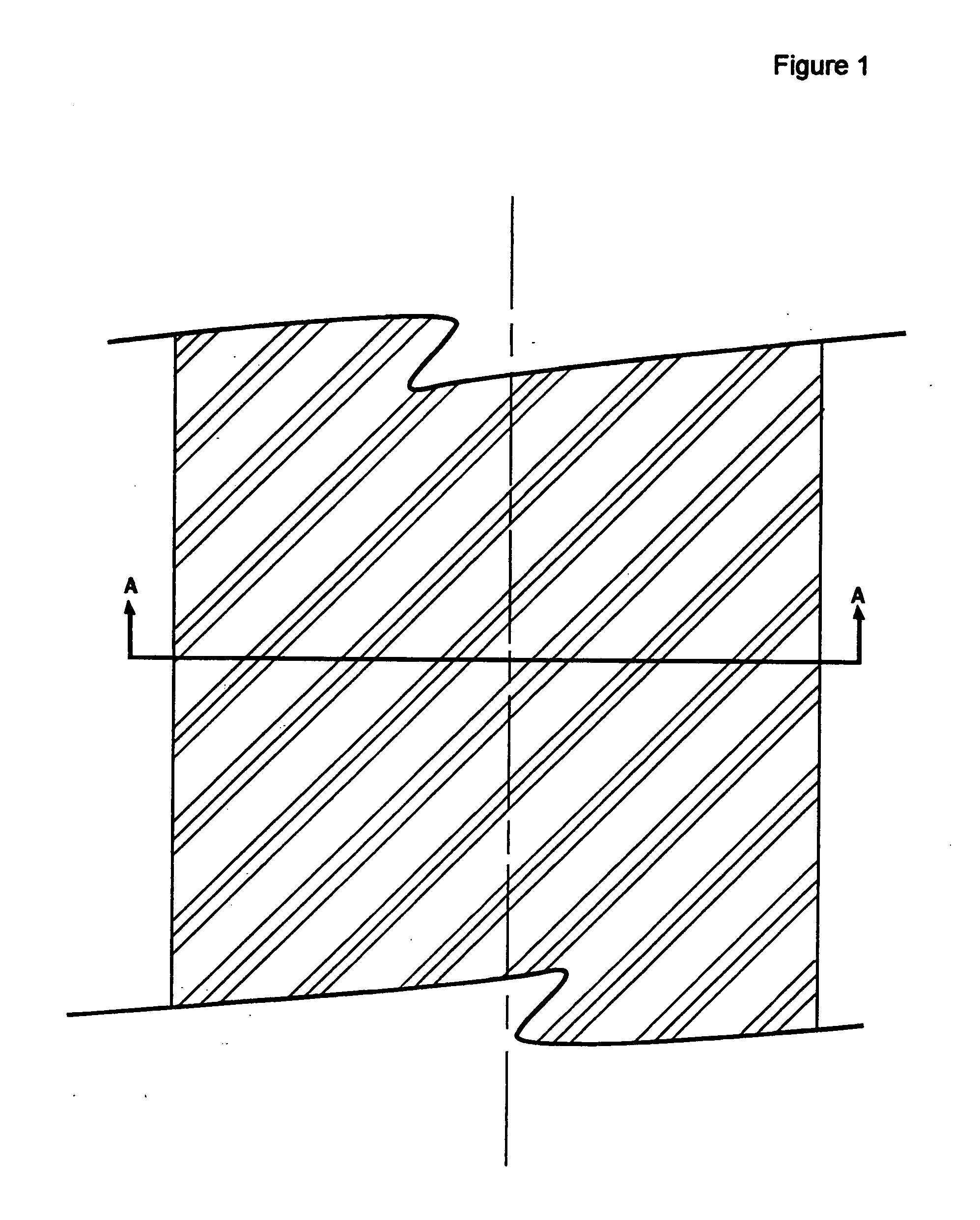

[0018]FIG. 1 illustrates a formed plastic sheet prior to forming a roll or bag,

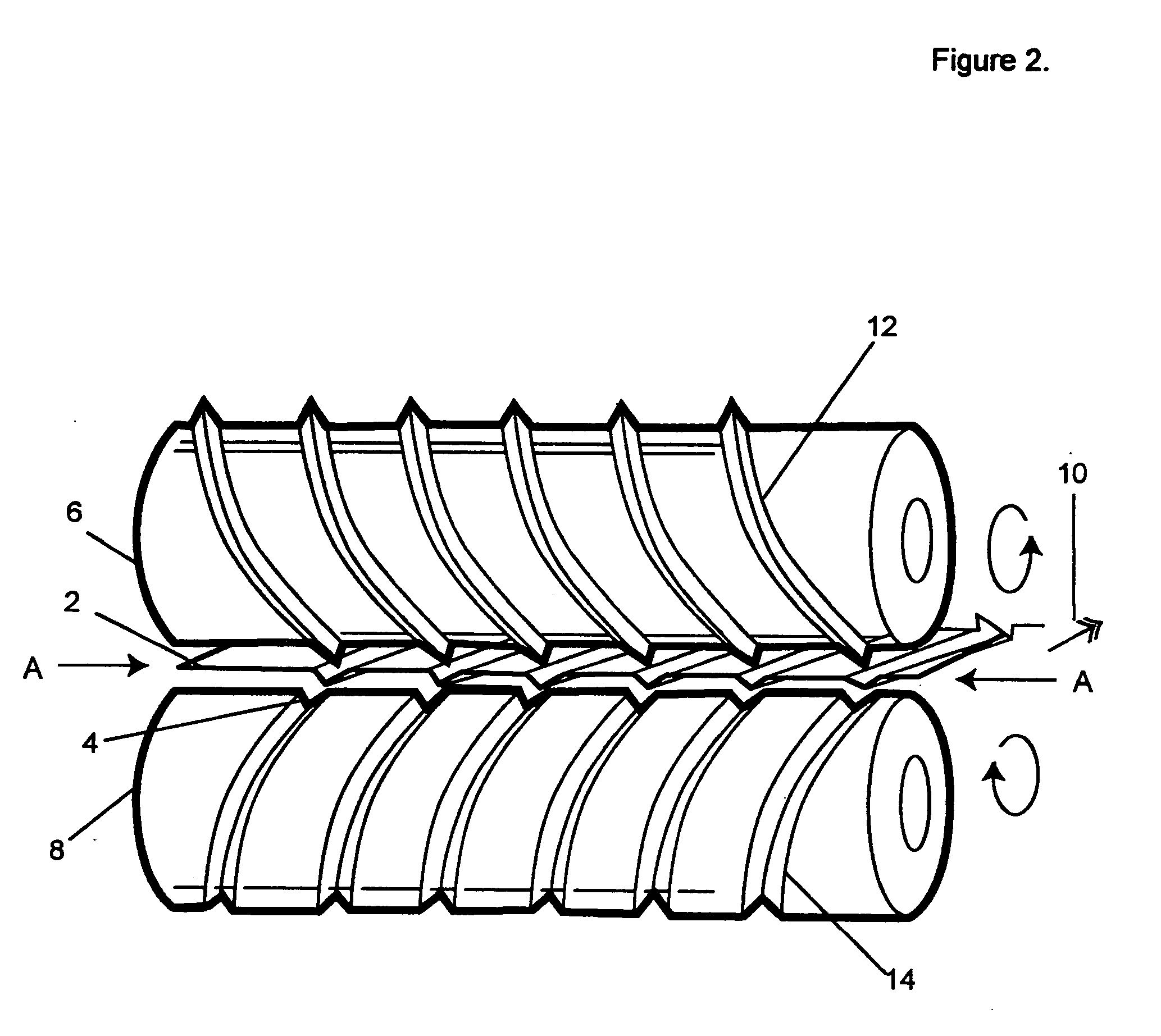

[0019]FIG. 2 provides a sectional view of a formed plastic sheet and illustrates a process for forming the oblique channels,

[0020]FIG. 3 illustrates folding of a formed plastic sheet,

[0021]FIG. 4 provides a sectional view of a folded plastic sheet,

[0022]FIG. 5 provides an alternative sectional view of a folded plastic sheet,

[0023]FIG. 6 illustrates a vacuum bag in roll format,

[0024]FIG. 7 illustrates a vacuum bag in bag format,

[0025]FIG. 8 provides a side view of the hand-held vacuum storage appliance,

[0026]FIG. 9 provides an internal view of the hand-held vacuum storage appliance,

[0027]FIG. 10 provides further detail regarding the heat sealing strip,

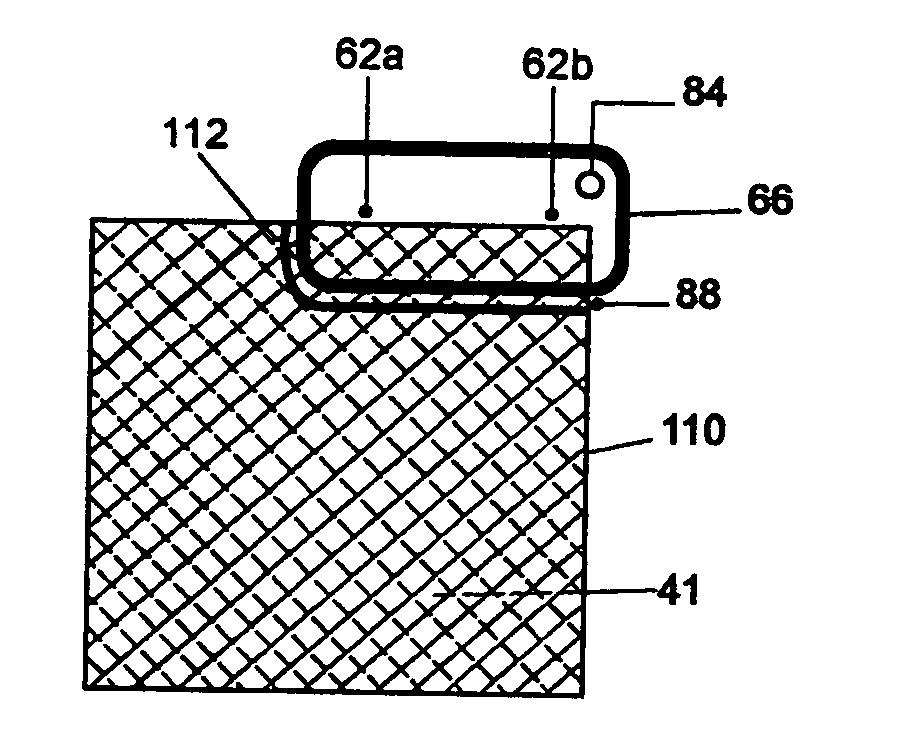

[0028]FIG. 11 illustrates a two step process for sealing a larger vacuum storage bag,

[0029]FIG. 12 illustrates the effectiveness of an “L” ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com