Patents

Literature

5253 results about "Vacuum packing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum packing is a method of packaging that removes air from the package prior to sealing. This method involves (manually or automatically) placing items in a plastic film package, removing air from inside, and sealing the package. Shrink film is sometimes used to have a tight fit to the contents. The intent of vacuum packing is usually to remove oxygen from the container to extend the shelf life of foods and, with flexible package forms, to reduce the volume of the contents and package.

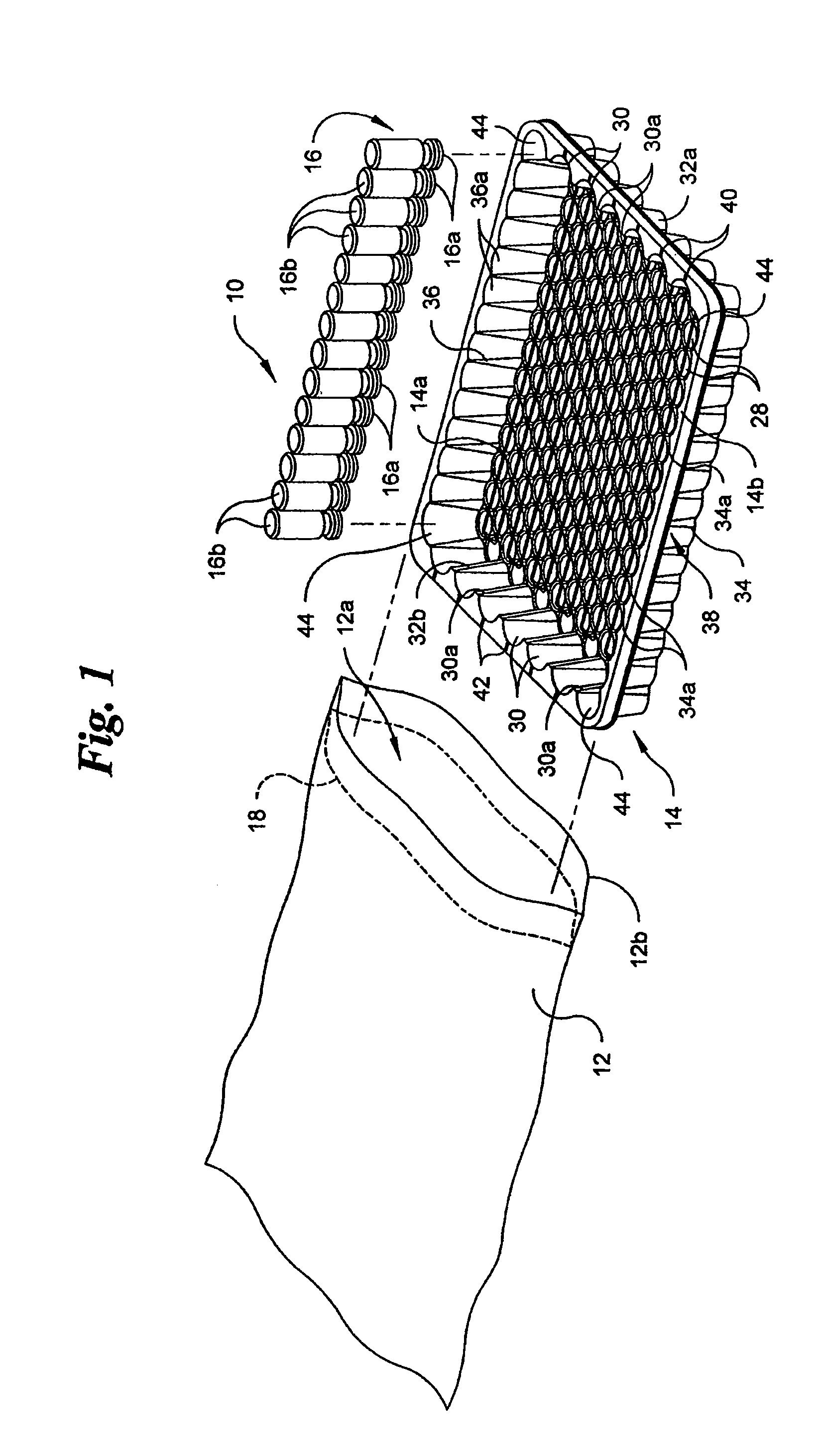

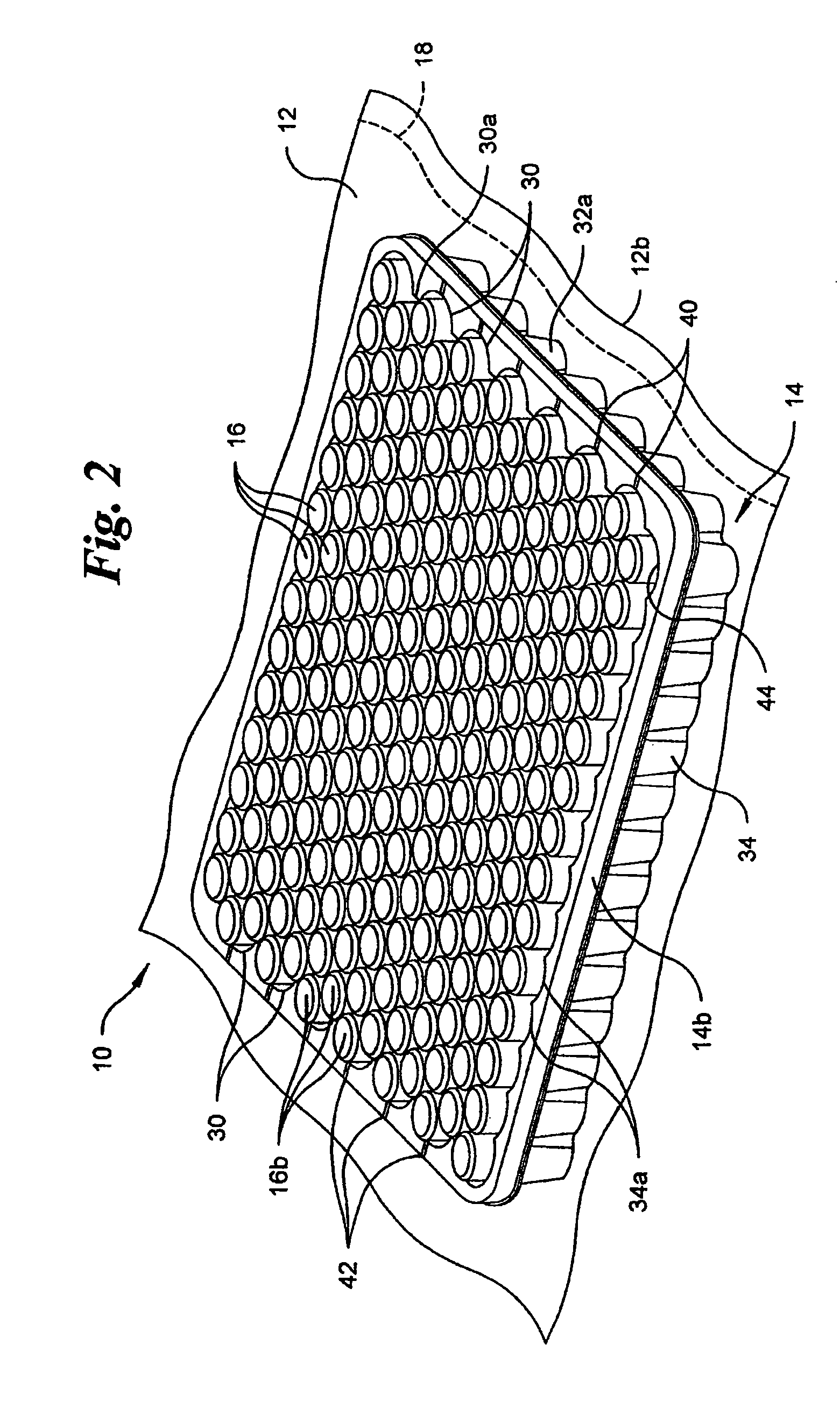

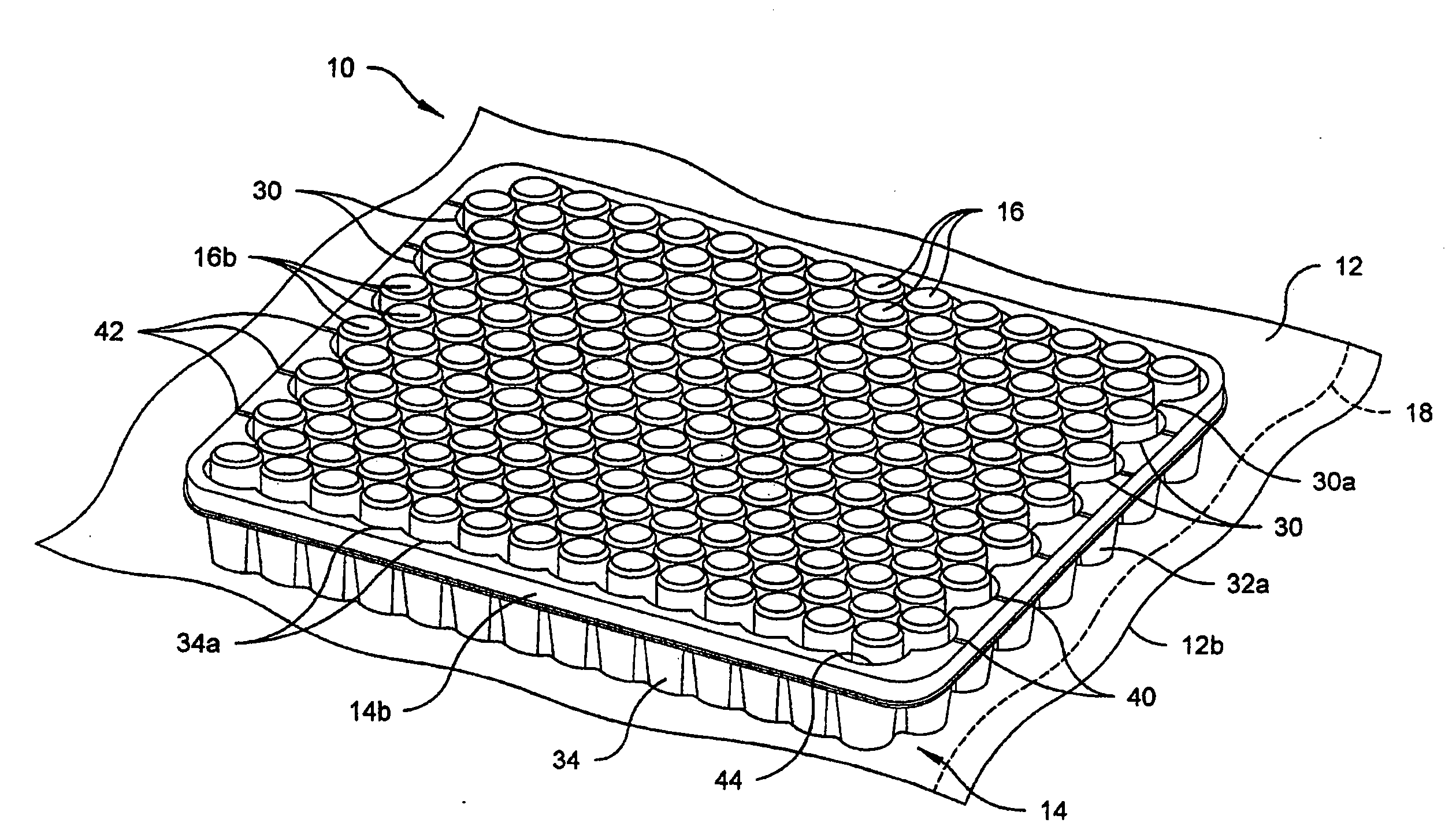

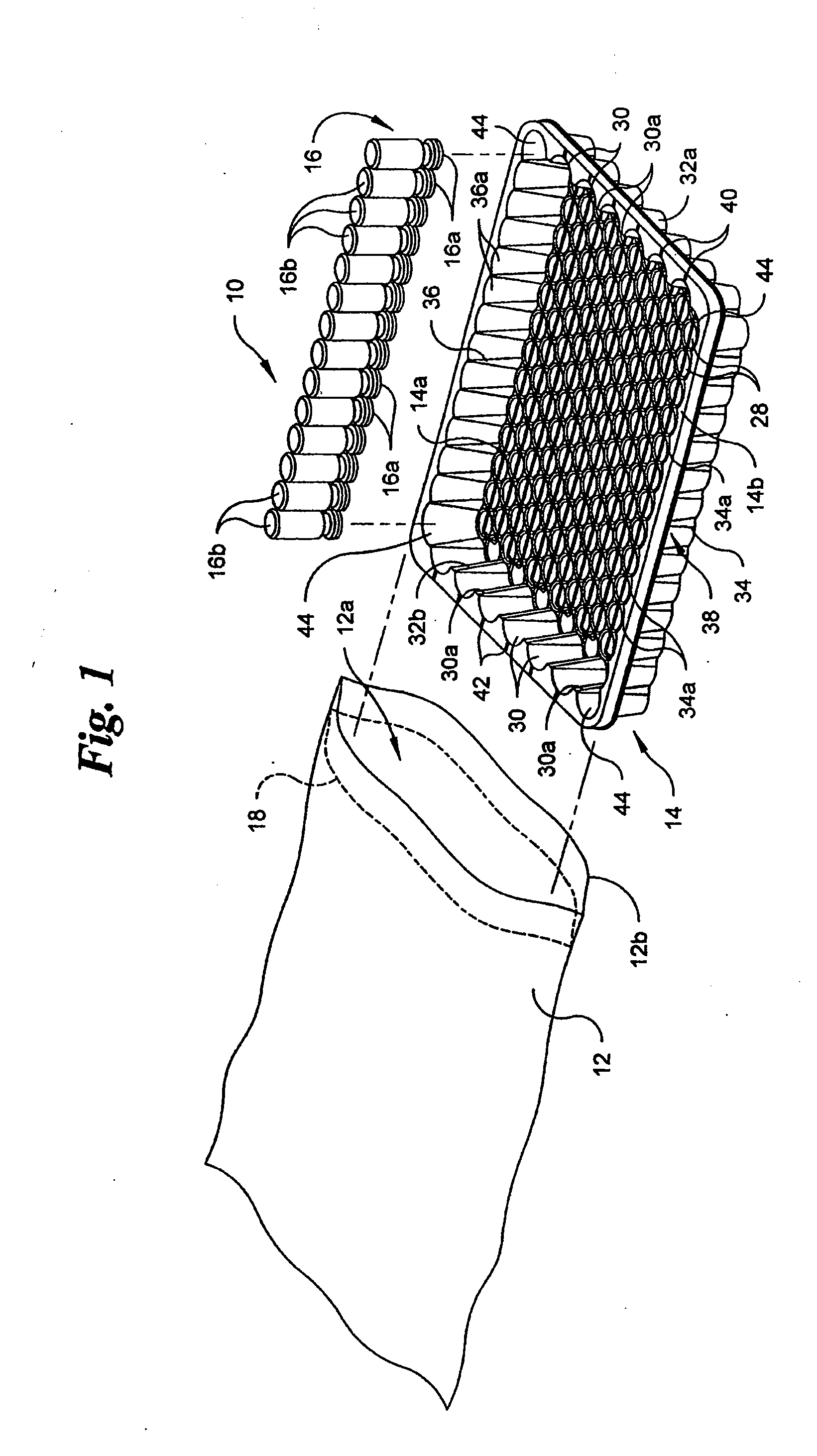

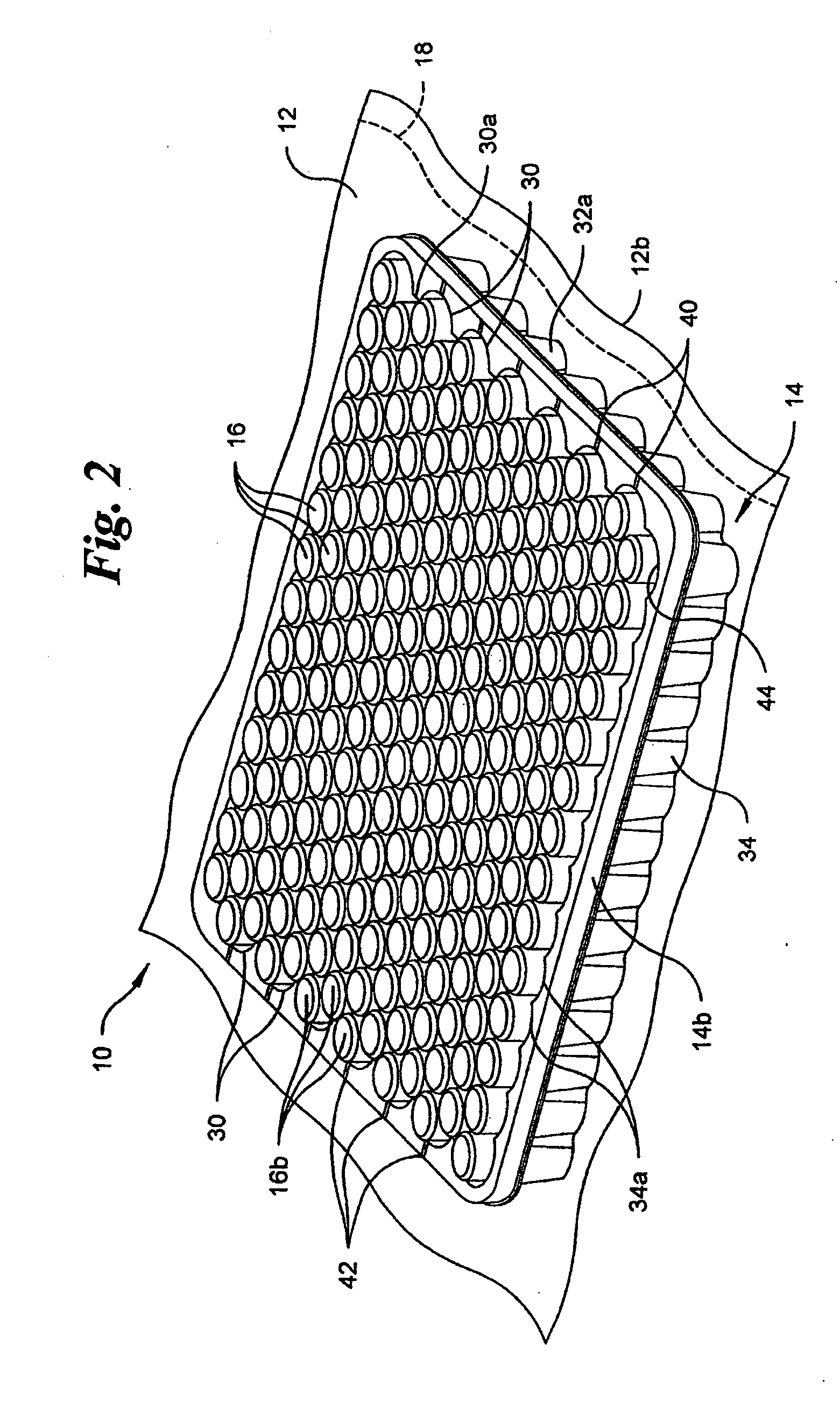

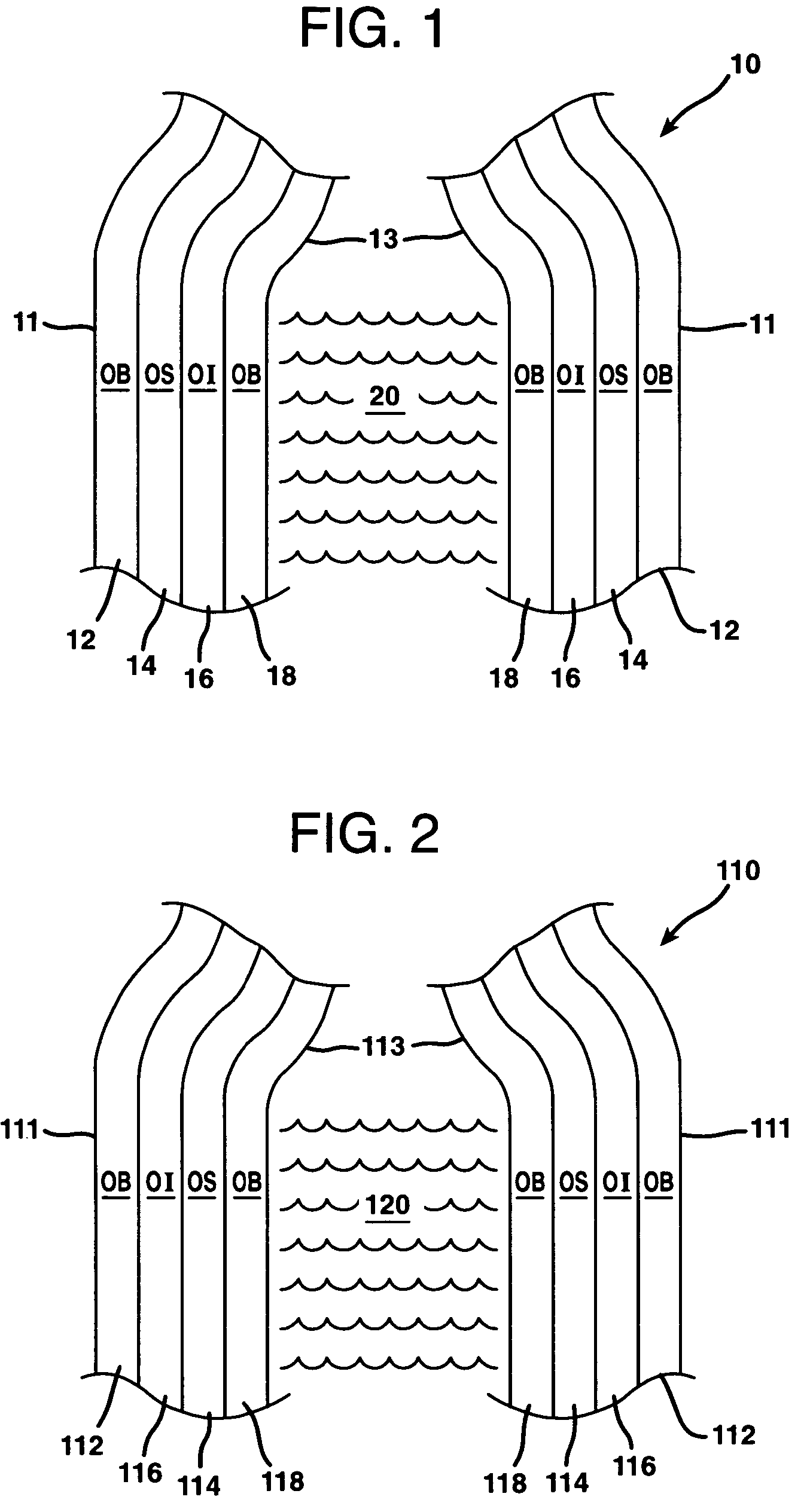

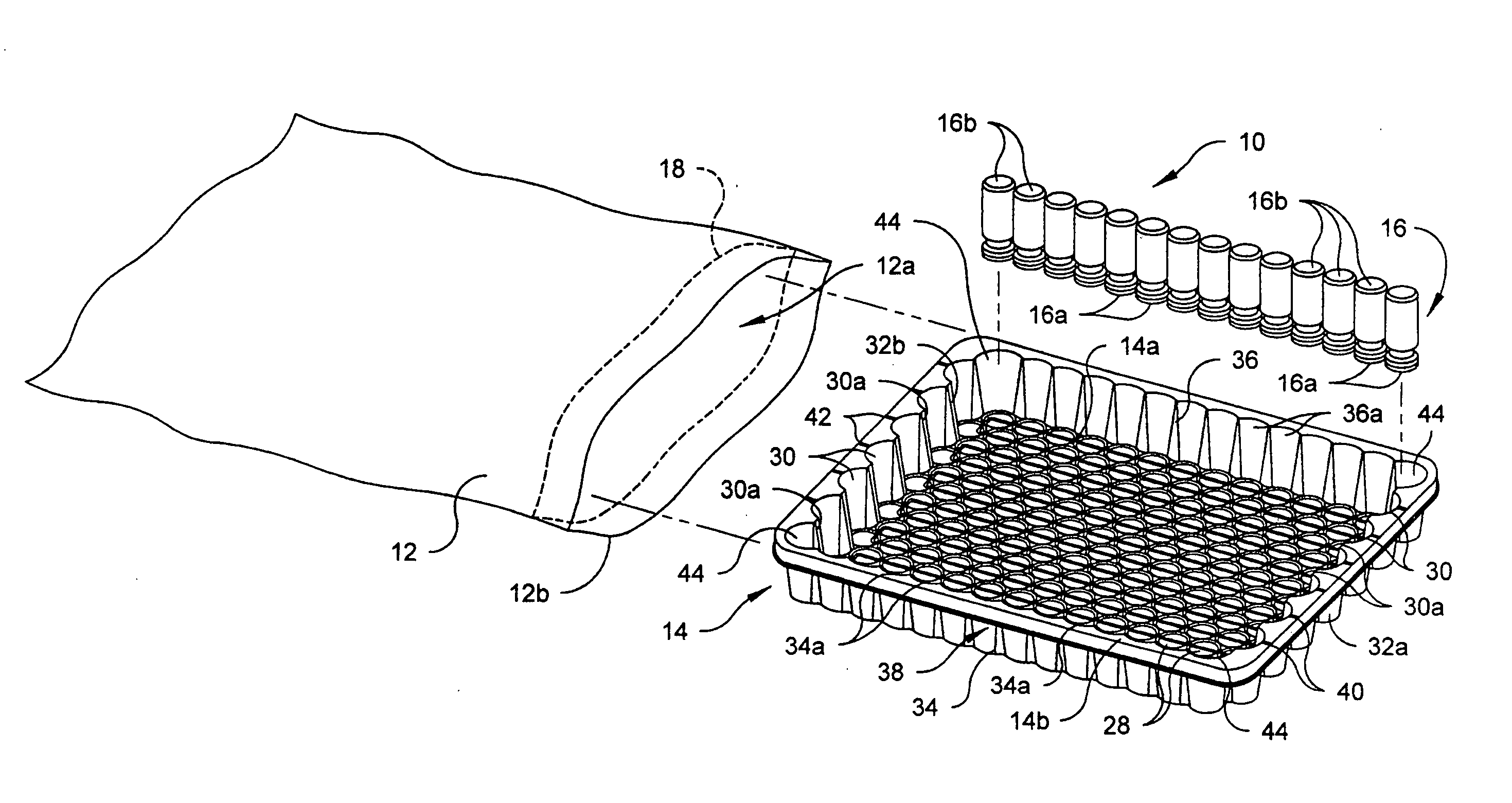

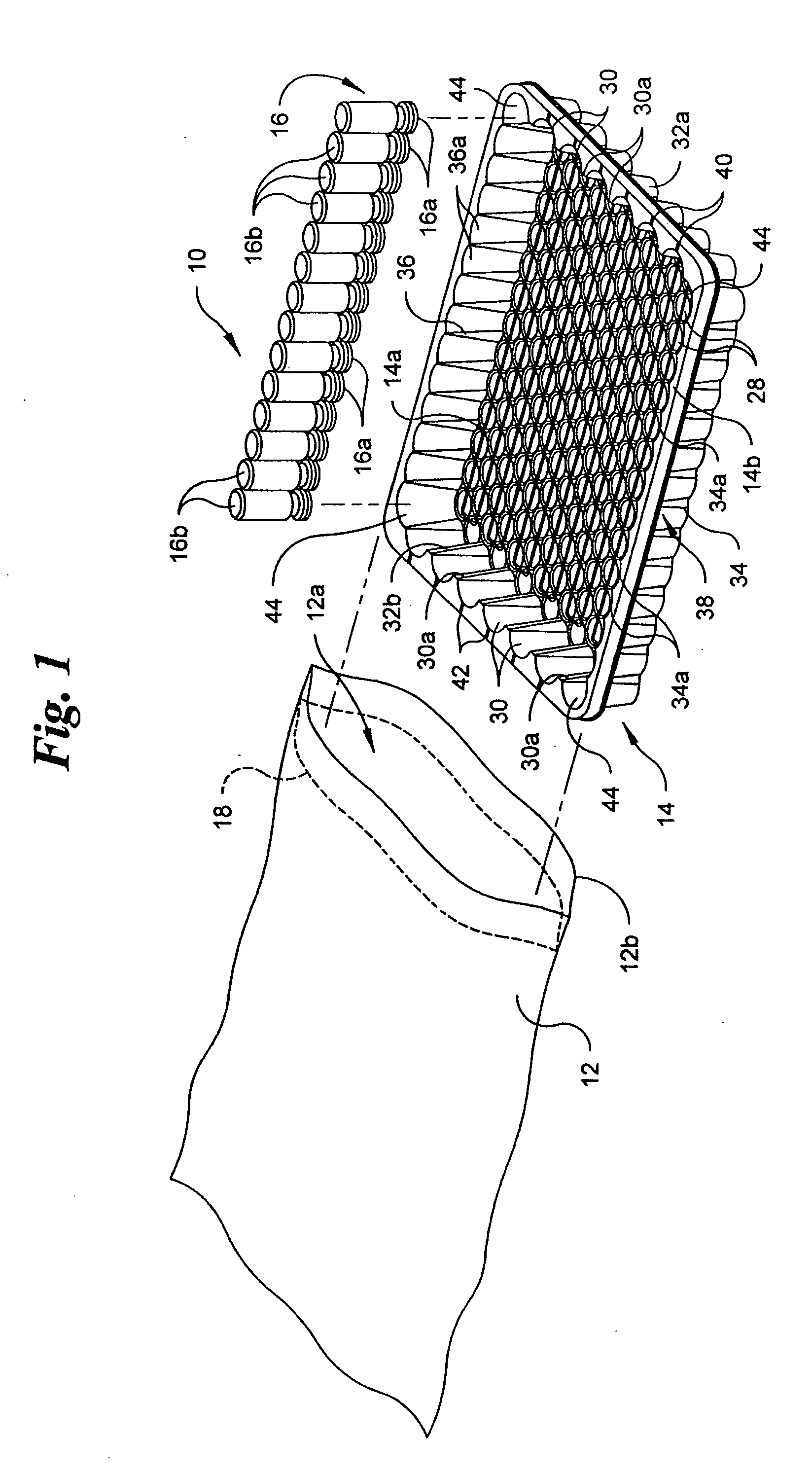

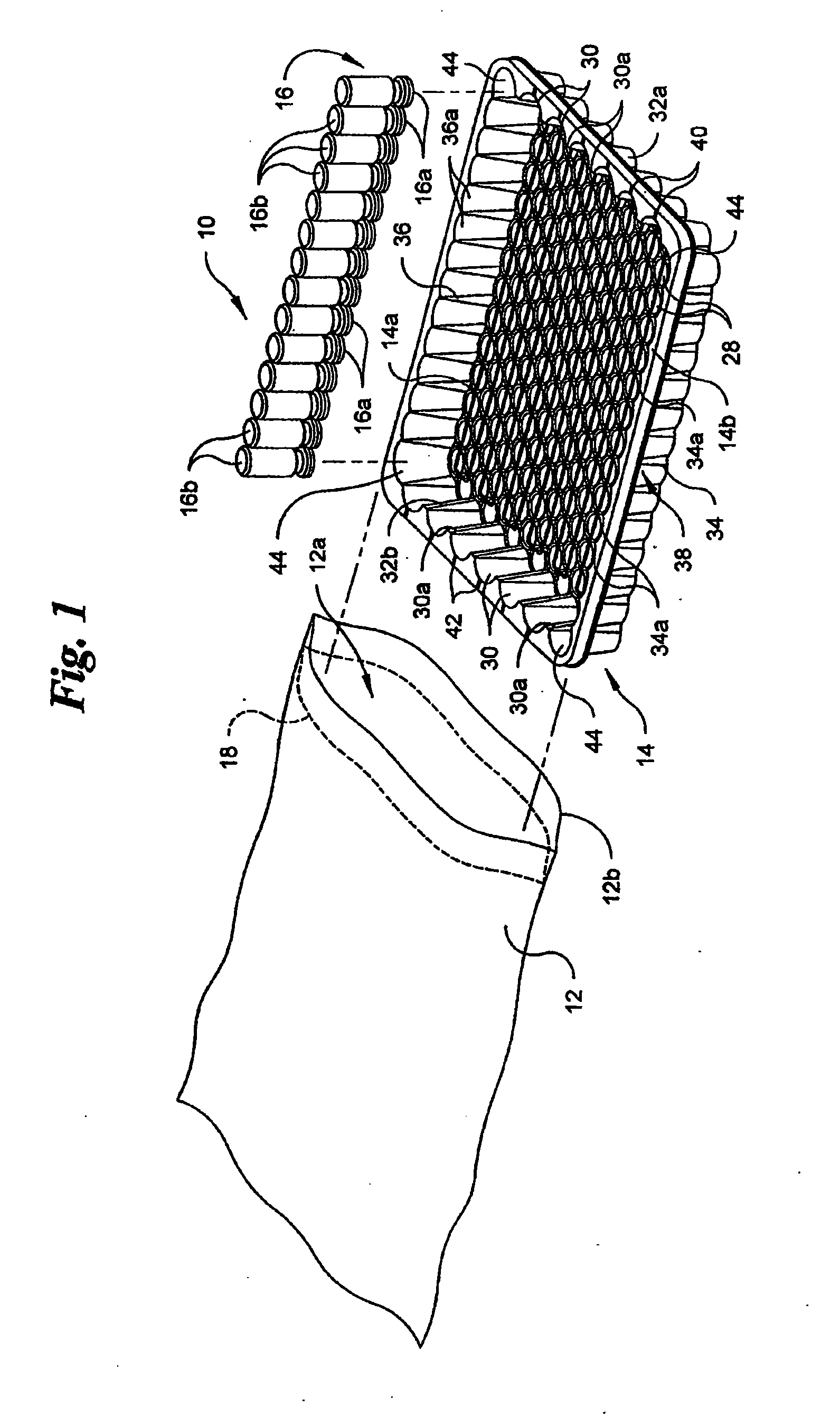

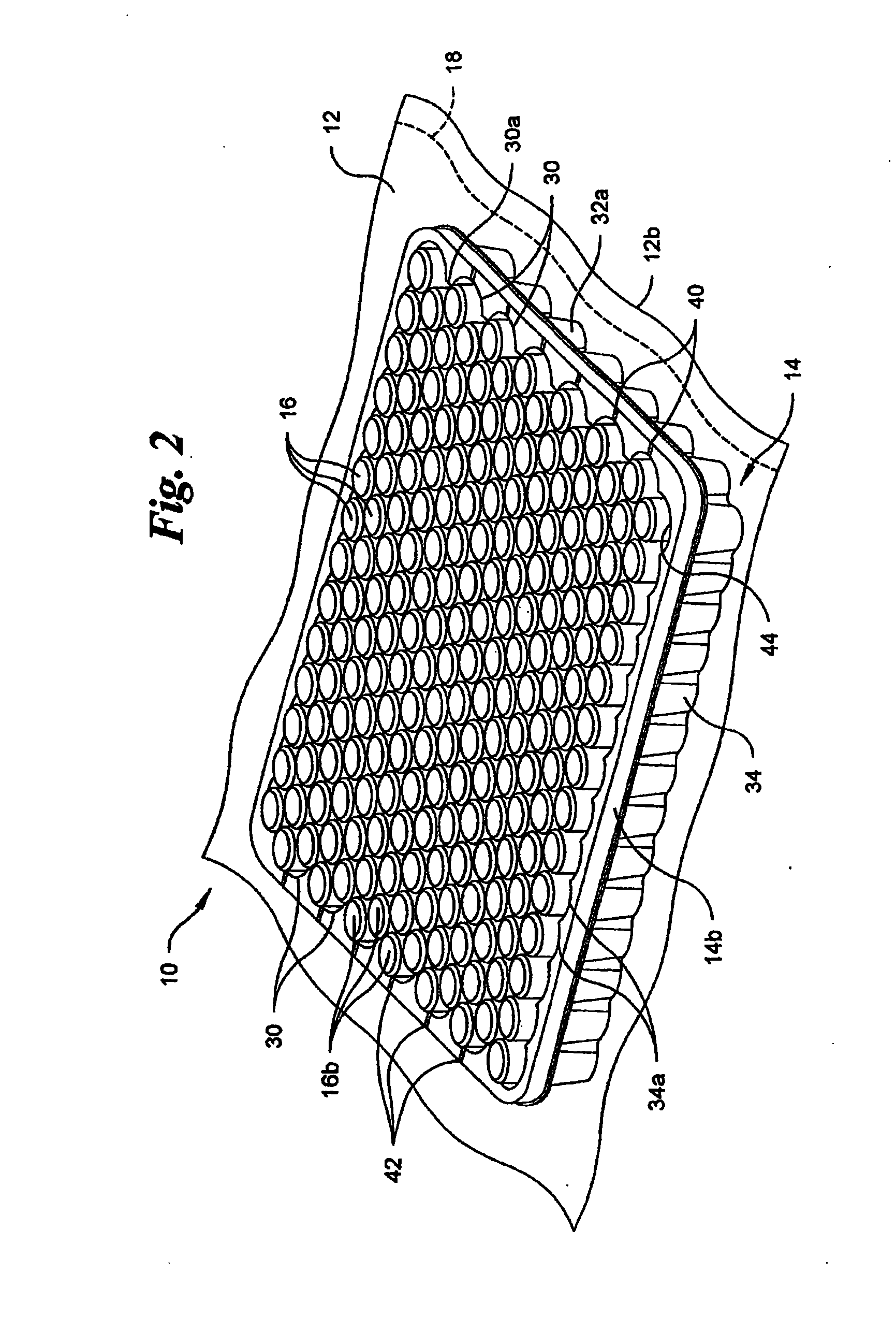

Vacuum package system

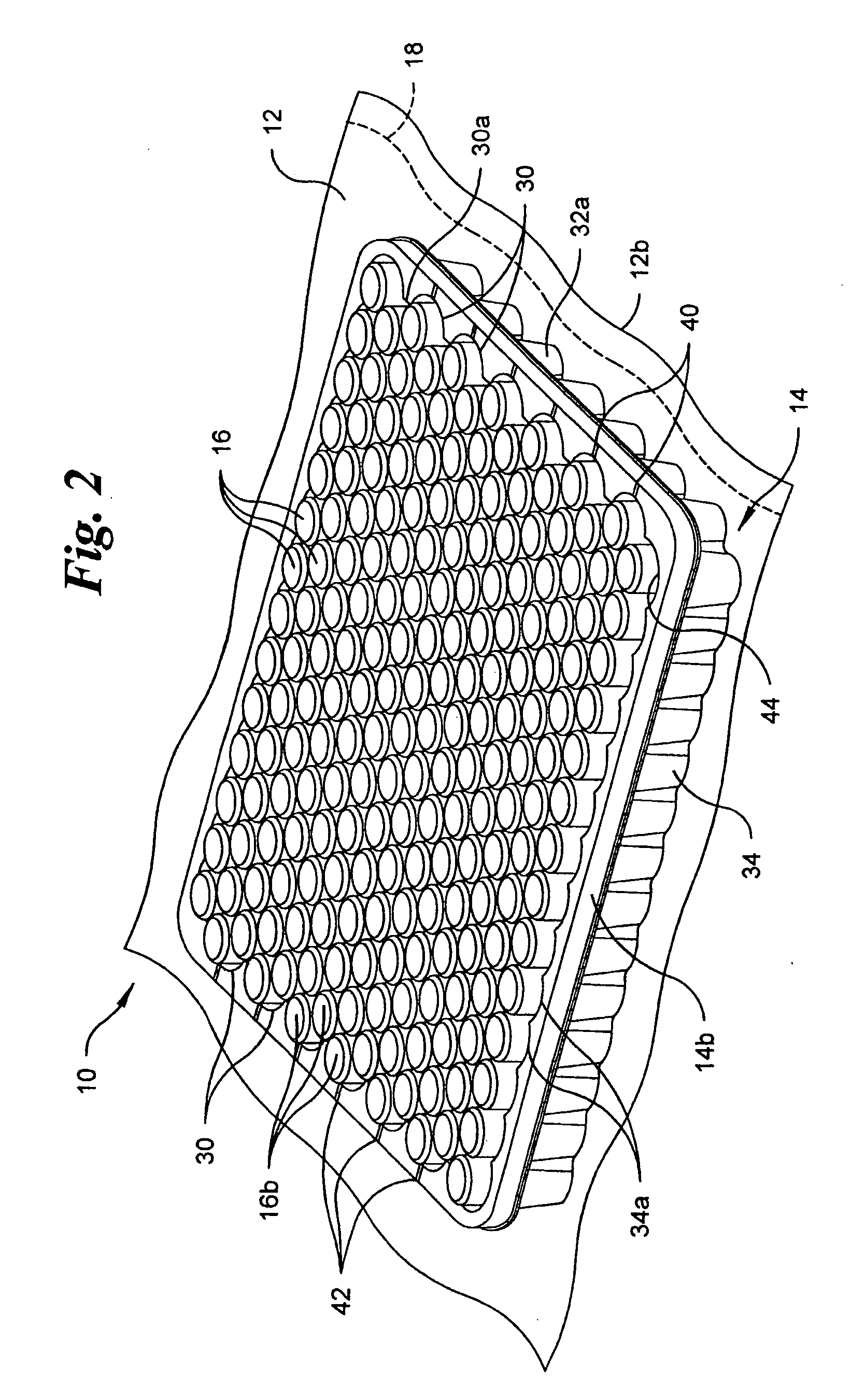

A vacuum packaging system for transporting a plurality of medical containers includes a plurality of medical containers each having a head side and a base side and a tray that receives and supports the medical containers. The tray includes opposing first and second sidewalls, opposing front and rear walls and a bottom floor. The walls extend generally vertically from the floor of the tray. At least one platform generally extends parallel to the floor of the tray. An air impervious flexible film defines an internal cavity. The air impervious flexible film completely surrounds the tray and the medical containers and the internal cavity is evacuated to and maintained at a predetermined vacuum level below atmospheric pressure. One of the head side and the base side of each medical container contacts a top surface of at least one platform when the medical containers are positioned in the tray.

Owner:WEST PHARM SERVICES INC +1

Vacuum package system

A vacuum packaging system for transporting a plurality of medical containers includes a plurality of medical containers each having a head side and a base side and a tray that receives and supports the medical containers. The tray includes opposing first and second sidewalls, opposing front and rear walls and a bottom floor. The walls extend generally vertically from the floor of the tray. At least one platform generally extends parallel to the floor of the tray. An air impervious flexible film defines an internal cavity. The air impervious flexible film completely surrounds the tray and the medical containers and the internal cavity is evacuated to and maintained at a predetermined vacuum level below atmospheric pressure. One of the head side and the base side of each medical container contacts a top surface of at least one platform when the medical containers are positioned in the tray.

Owner:WEST PHARM SERVICES INC +1

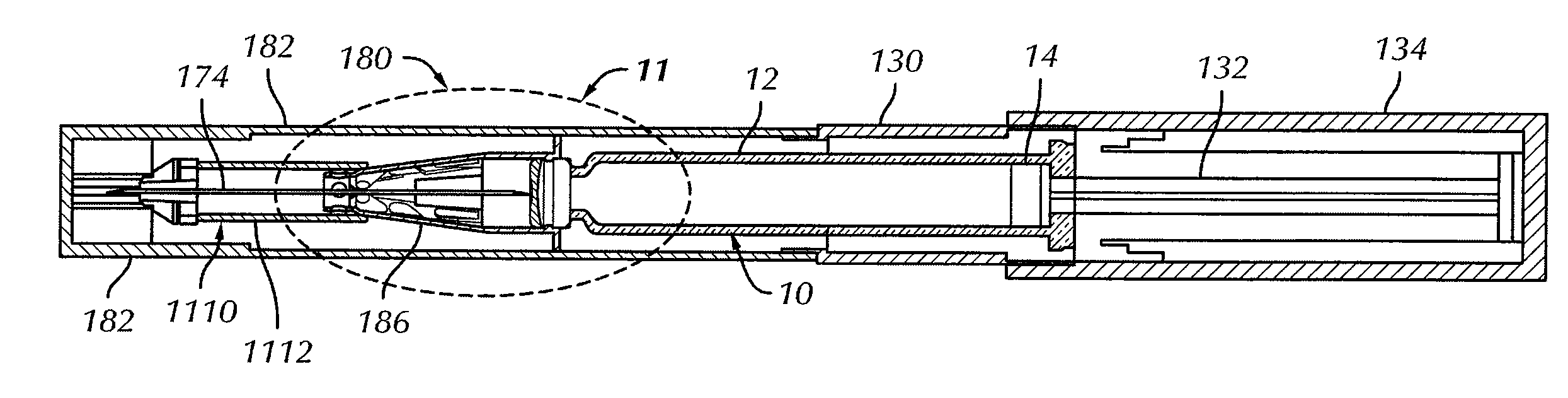

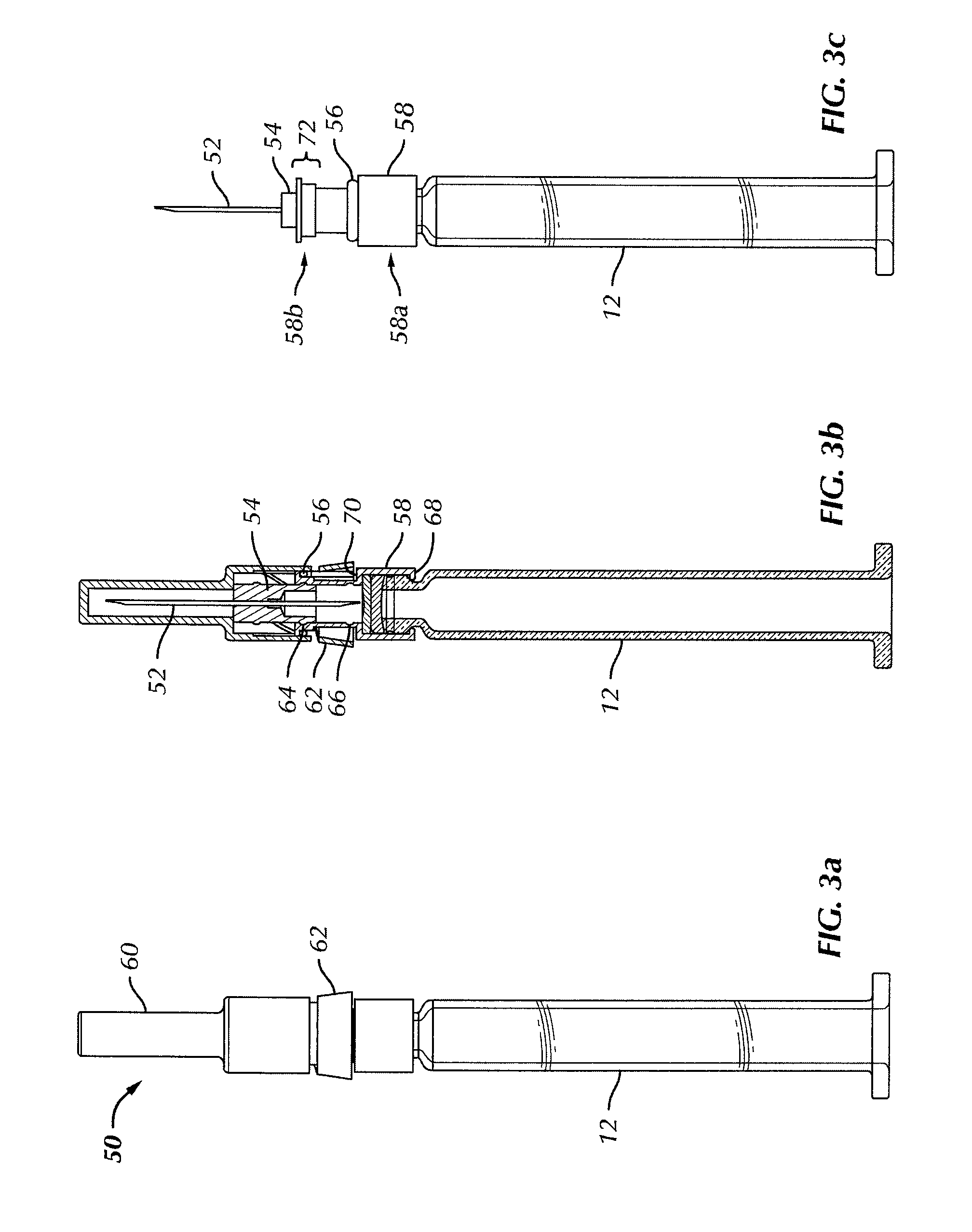

Syringe cartridge system

The present embodiments provide for a syringe cartridge system that can be used in combination with multiple couplings and injection systems. The syringe cartridge system can be provided in a vacuum packaging assembly configuration. Alternatively, the syringe cartridge system can be provided with a coupler attached to a safety device, a hypodermic needle, or a Luer adaptor. The syringe cartridge system can also be used in combination with an automatic injector.

Owner:WEST PHARM SERVICES INC

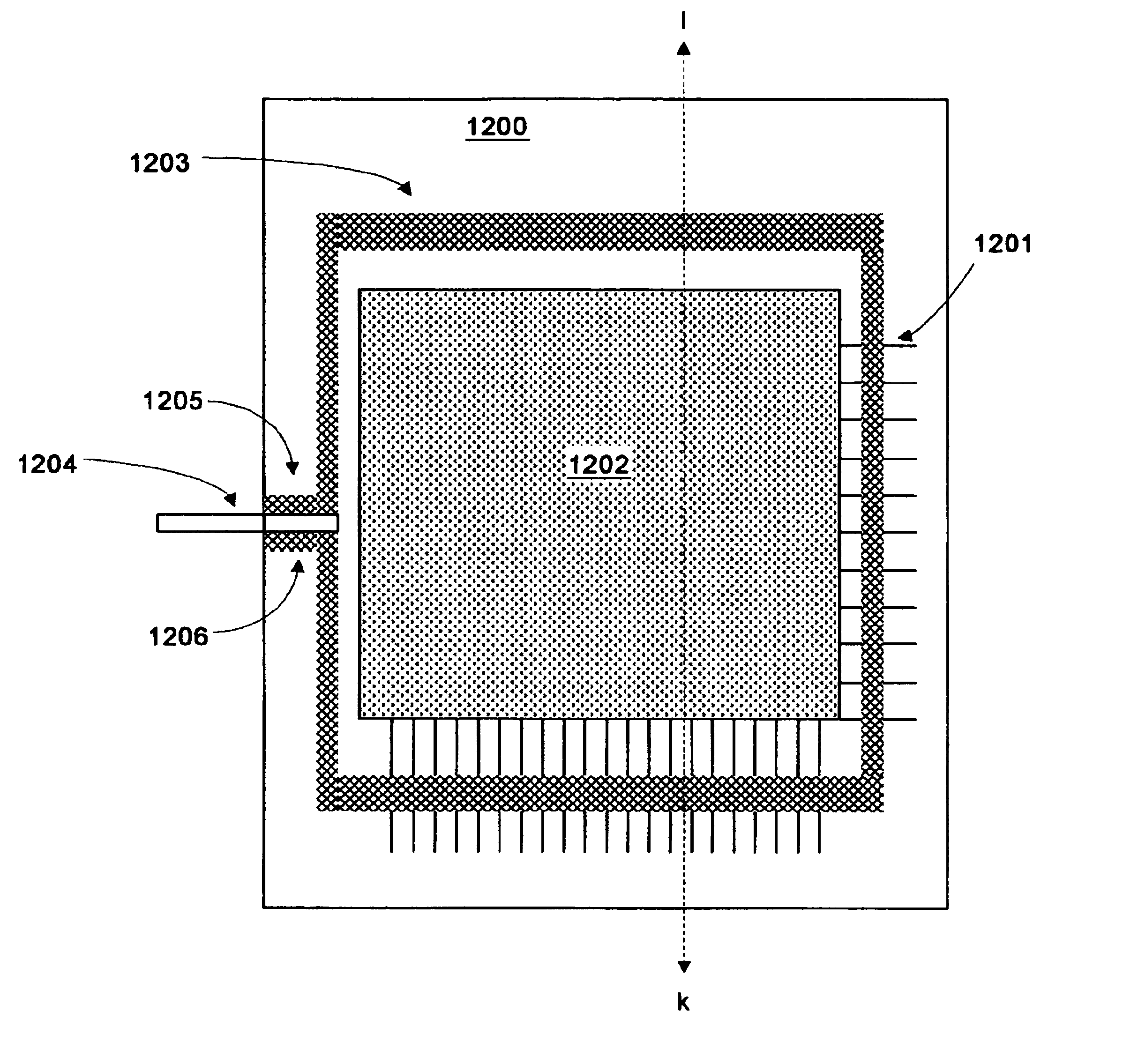

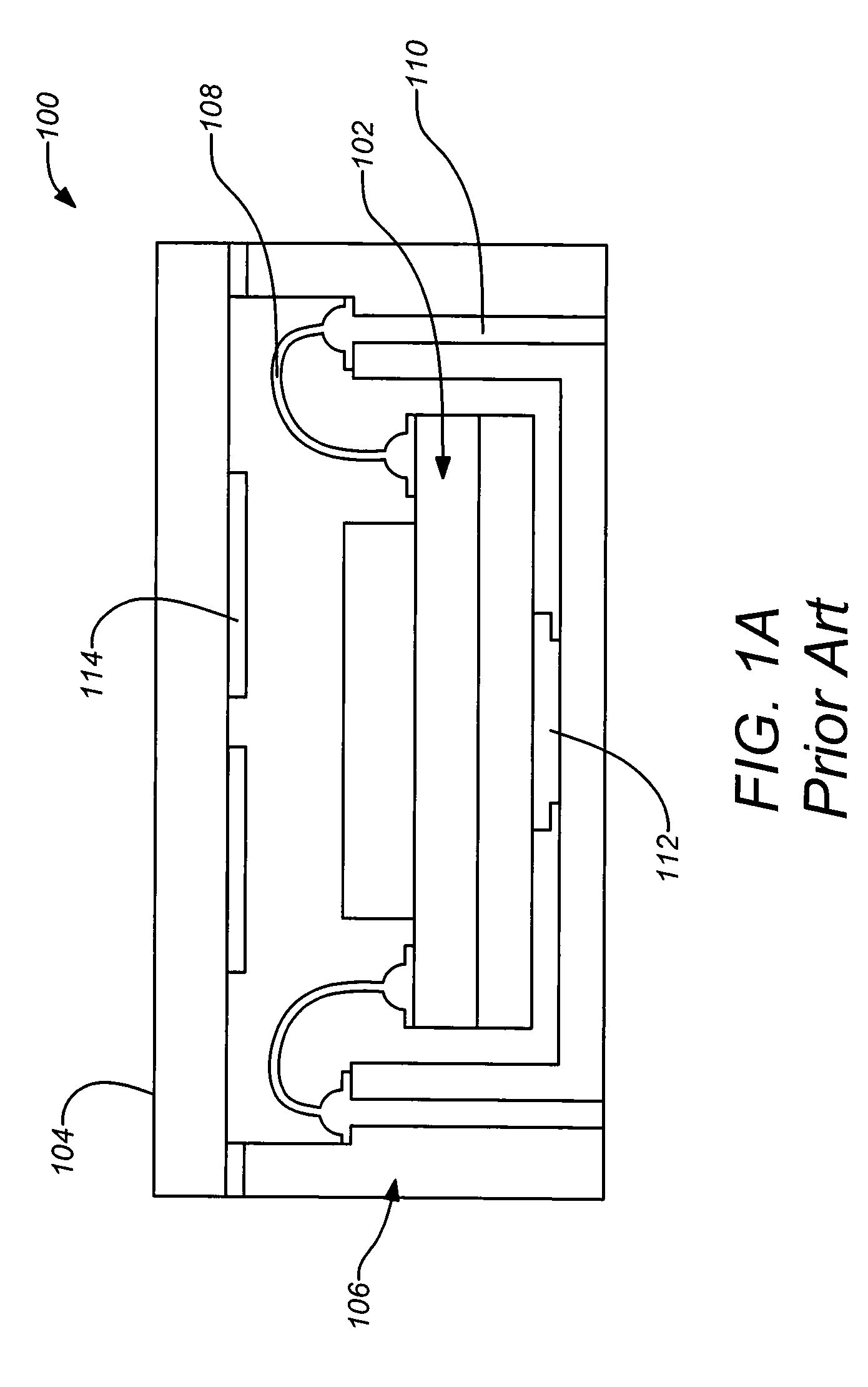

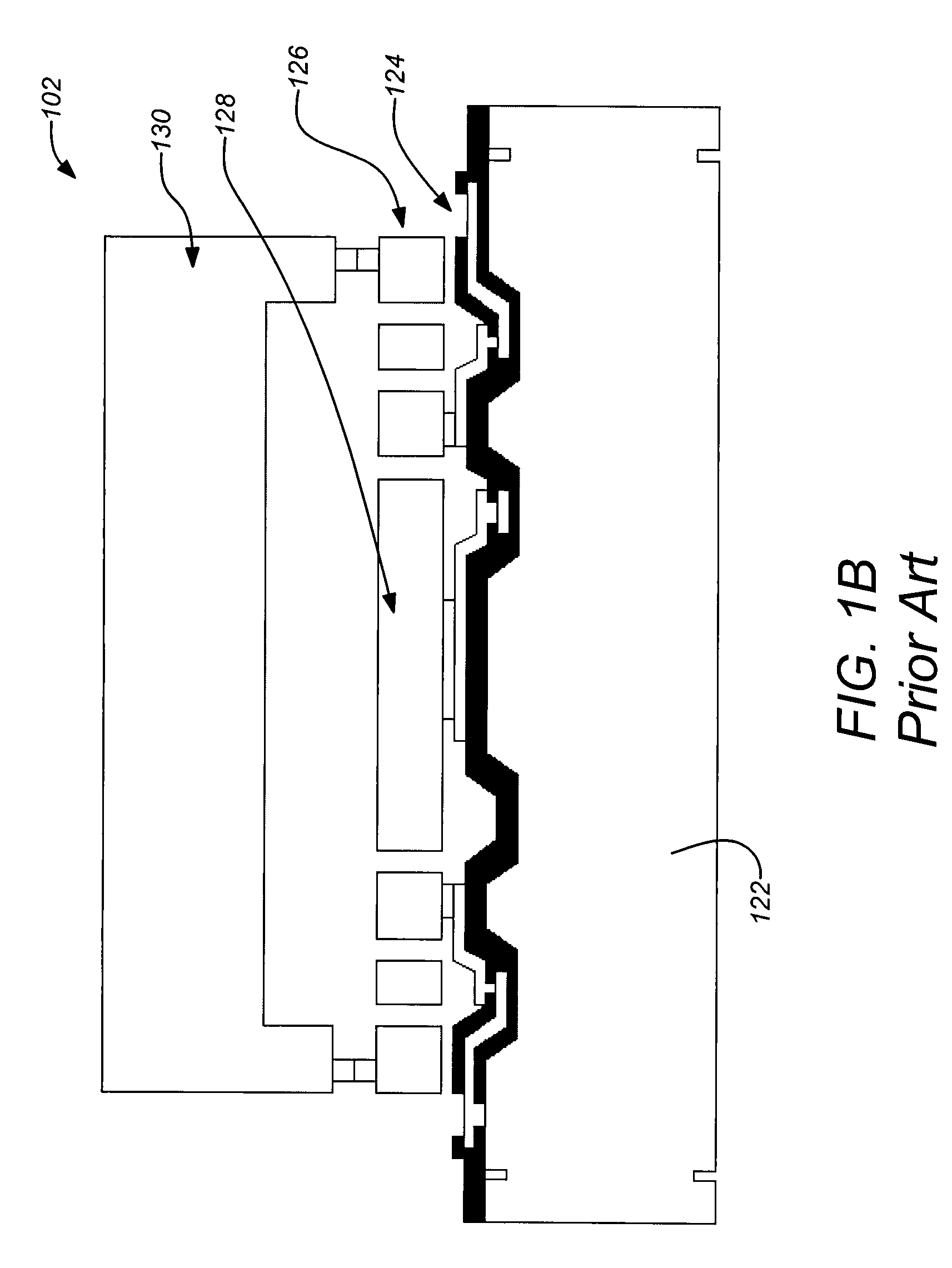

Vacuum packaged micromirror arrays and methods of manufacturing the same

ActiveUS6903860B2Improved dielectric isolationImprove isolationOptical elementsSpatial light modulatorFrit

A vacuum packaged electromechanical micromirror array comprises a 1st packaging substrate, a 2nd packaging substrate, a device substrate with a 1st surface and a 2nd surface, control circuitry on said 1st surface, and micromirrors on said 2nd surface. The device substrate resides on the 1st packaging substrate with electrical connections between them. The electromechanical micromirror array is sealed in a vacuum package formed by the packaging substrates. The vacuum packaged micromirror array may be used as a spatial light modulator (SLM). Methods of fabricating the vacuum packaged array are disclosed. Such methods generally involve providing a device substrate with a 1st surface and a 2nd surface, fabricating control circuitry on the 1st surface, fabricating micromirrors on the 2nd surface, providing a 1st packaging substrate, mounting the device substrate on the 1st packaging substrate by flip-chip assembly, providing a 2nd packaging substrate, and sealing the packaging substrates by glass frit sealing.

Owner:IGNITE INC

Marine product meat sausage and making method thereof

The invention discloses a marine product meat sausage and a making method thereof. The marine product meat sausage is characterized by comprising the following raw materials proportioning by weight: 30-85 portions of marine product, 0-30 portions of edible meat, 10-30 portions of edible water, 1-12 portions of edible vegetable oil, 2-6 portions of soybean protein isolate, 0.5-1.6 portions of saltand 2.0-7.5 portions of starch; the marine product meat sausage is prepared according to the steps of raw material processing, twisting, chopping, stirring, filling, sterilizing and packaging. The invention is prepared by adopting the marine products (scallop muscle, oyster meat, sleeve-fish meat, salmon meat, shrimp meat, trepang, abalone, yellow croaker meat, hairtail meat, fish seeds, ling meat, waste fish meat and the like) or adding the edible meat (chicken, pork, mutton, beef and the like) as the main raw materials, has abundant and balanced nutrition, meets the requirement of a consumeron the marine products and increases the appetite, and the product has strong seafood taste and unique flavor, does not contain nitrite, is beneficial to health, is packaged in vacuum, has unique appearance and is ready to be enjoyed when a bag is opened.

Owner:青岛农博农食品科技有限公司

Vacuum packaging system

InactiveUS20050205455A1Precise positioningAvoid drawingEnvelopes/bags making machineryBag making operationsHand heldFront loading

A system for vacuum packaging foods and other perishable items, including a front loading appliance and a hand held appliance. A multiple stage vacuum and sealing process enhances performance. Low cost vacuum bags are formed using a continuous process. A visible indicator assures consumers that a safe level of vacuum has been reached and maintained.

Owner:HARRISON HOWARD ROBERT

Passiflora coerulea and honey peach complex juice and preparation method thereof

The present invention relates to a passiflora coerulea and honey peach complex juice and a preparation method thereof. The complex juice consists of 20-30% passiflora coerulea juice, 10-15% honey peach juice, 3-5% honey and water and the preparation method of the complex juice is made of the following steps: washing, cleaning and cutting the passiflora coerulea, removing the fruit pulp with seeds to squeeze juice, washing and cleaning honey peaches, peeling honey peaches to squeeze juice, mixing the two juices evenly and heating to a temperature of 20-60 DEG C, adding pectinase and amylase to conduct enzymolysis, filtering the juice and adding water and honey to flavor, removing parts of bacteria with sterilizing filtration membranes; then homogenizing and degassing the sterilized juice, and vacuum packaging and treating the packaged juice with super-high pressure sterilization and enzyme inactivation treatment, thereby obtaining the complex juice. The preparation method of the complex juice can maintain the unique flavor of passiflora coerulea and delicate fragrance of honey peaches, thus the prepared complex juice has authentic taste of the raw juice, natural and lingering flavor, and improved the quality of fruit juice, and meet the pursuit of natural fruit juice of the majority of consumers.

Owner:黄志娟

Oxygen detection system for a rigid container

The present invention relates to the non-invasive use of a luminescent compound to detect and measure concentrations of oxygen dissolved in a rigid container, especially a bottle, a tray, a carton, a lidstock associated with a tray, a stand up pouch, or a paperboard container. The measurement is made independent of the oxygen concentration of the surrounding atmosphere. The invention is especially useful as a quality assurance check to verify oxygen scavenger activation during the assembly of bottled products, and modified atmosphere and vacuum packages. The method according to the invention is faster and less wasteful than previous methods that rely on measuring oxygen concentration within the headspace of an assembled package.

Owner:CRYOVAC INC

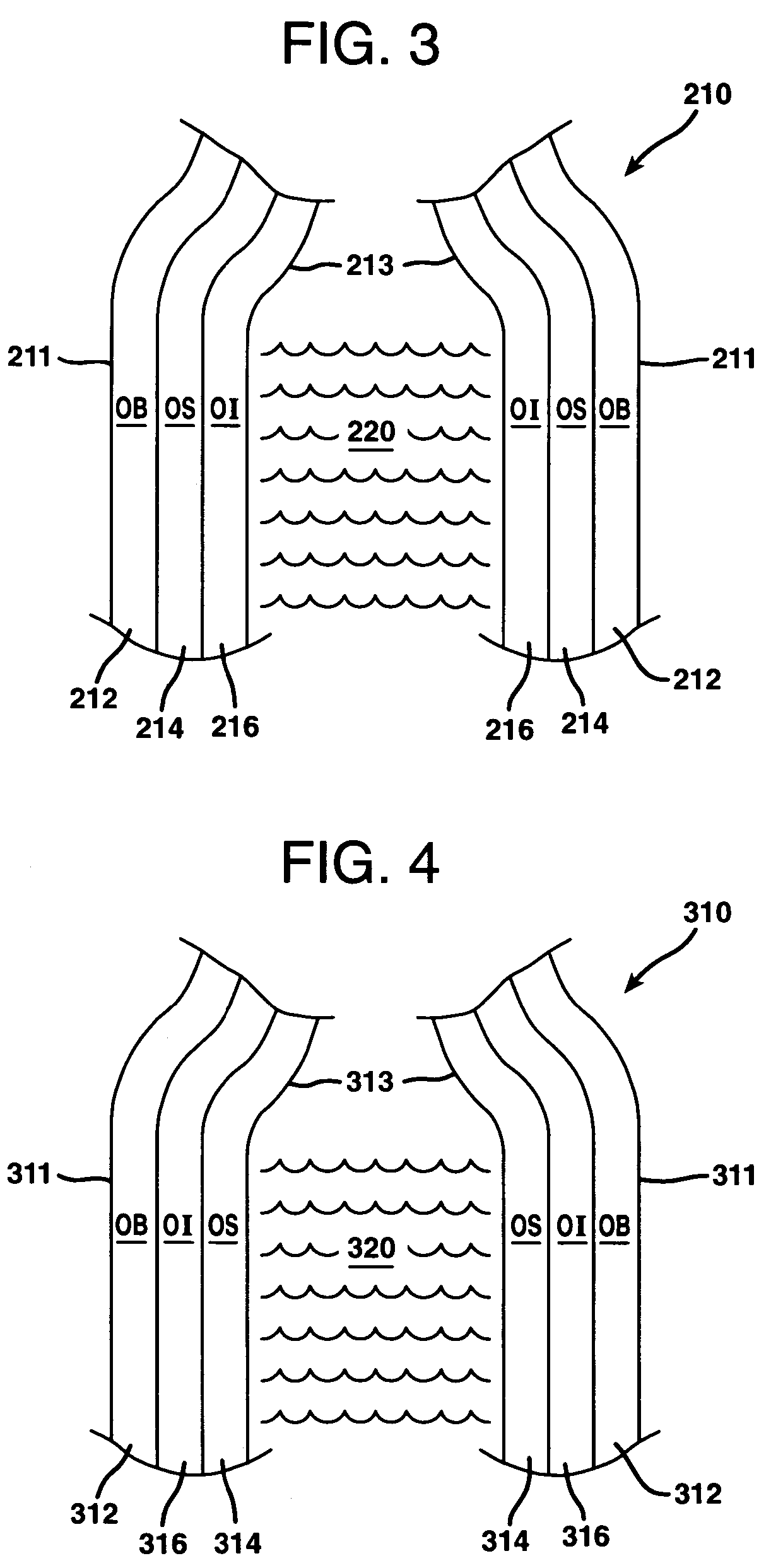

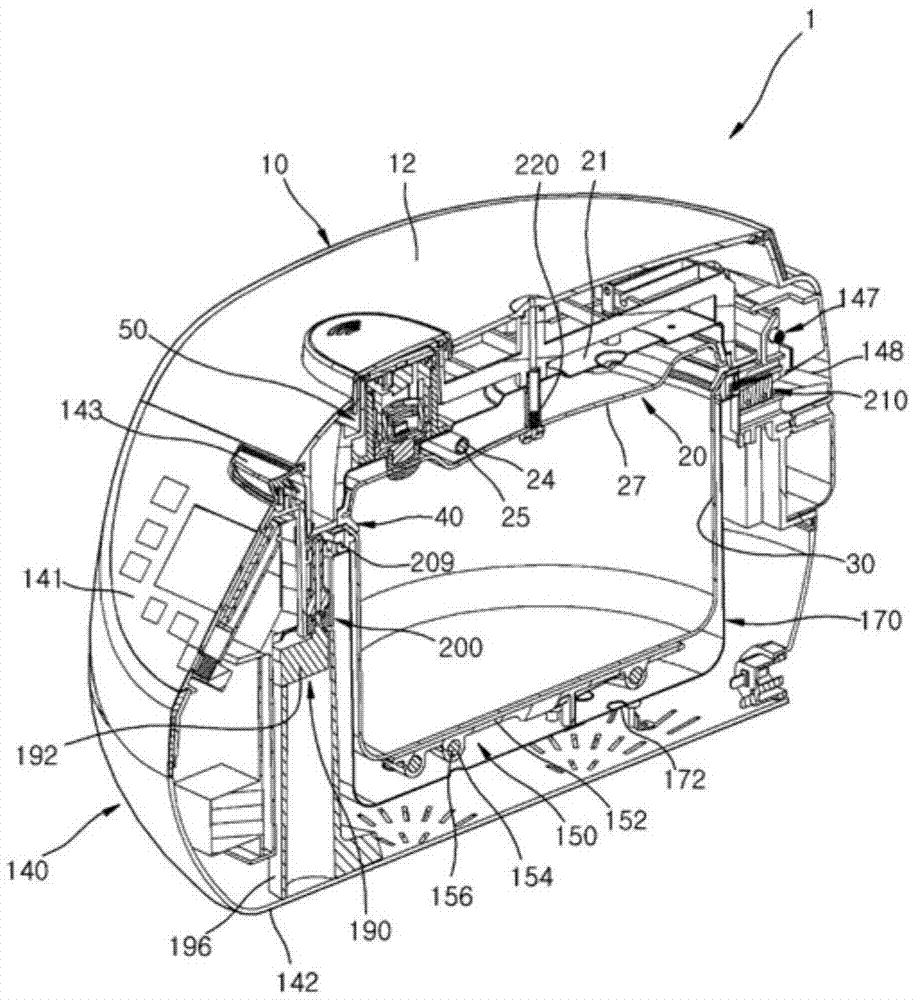

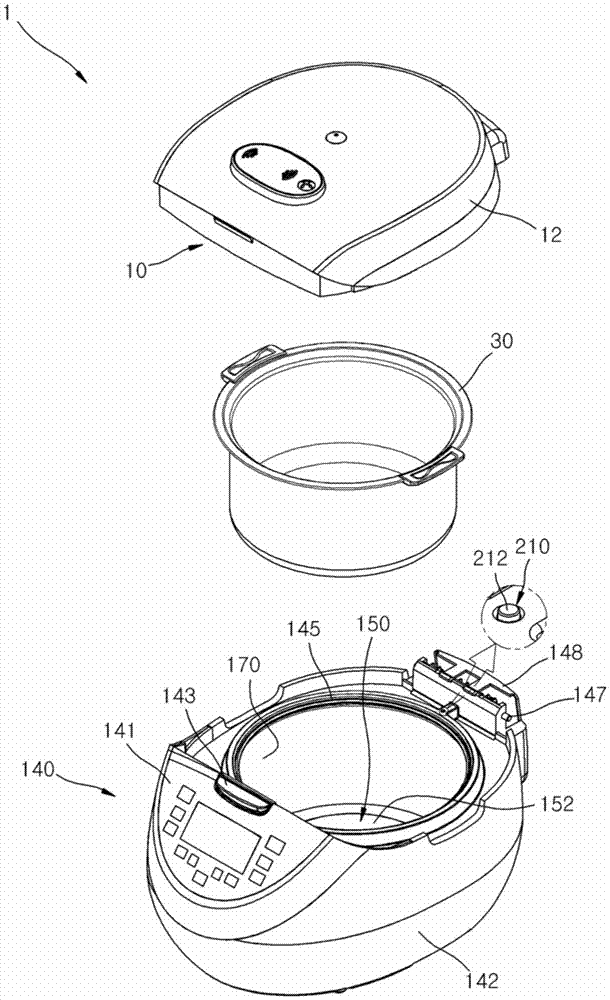

Electric rice cooker

InactiveCN105451610AImprove temperature uniformityPrevent corruptionPressure-cookersVessels with intergral heatingEngineeringCooker

An invention relating to an electric rice cooker is disclosed. The electric rice cooker according to an embodiment of the present invention comprises: an upper case part; an upper heater which is located on the lower side of the upper case part and downwardly emits heat; an inner container located on the lower side of the upper heater and containing an object to be cooked; an upper heat transfer plate located on the lower side of the upper heater while facing the inner container; a body constituting an outer shape of the electric rice cooker and having the inner container installed therein; and a vacuum packing part installed along the boundary of the upper heat transfer plate facing the inner container and blocking the flow of air moving between the upper heat transfer plate and the inner container.

Owner:金且植

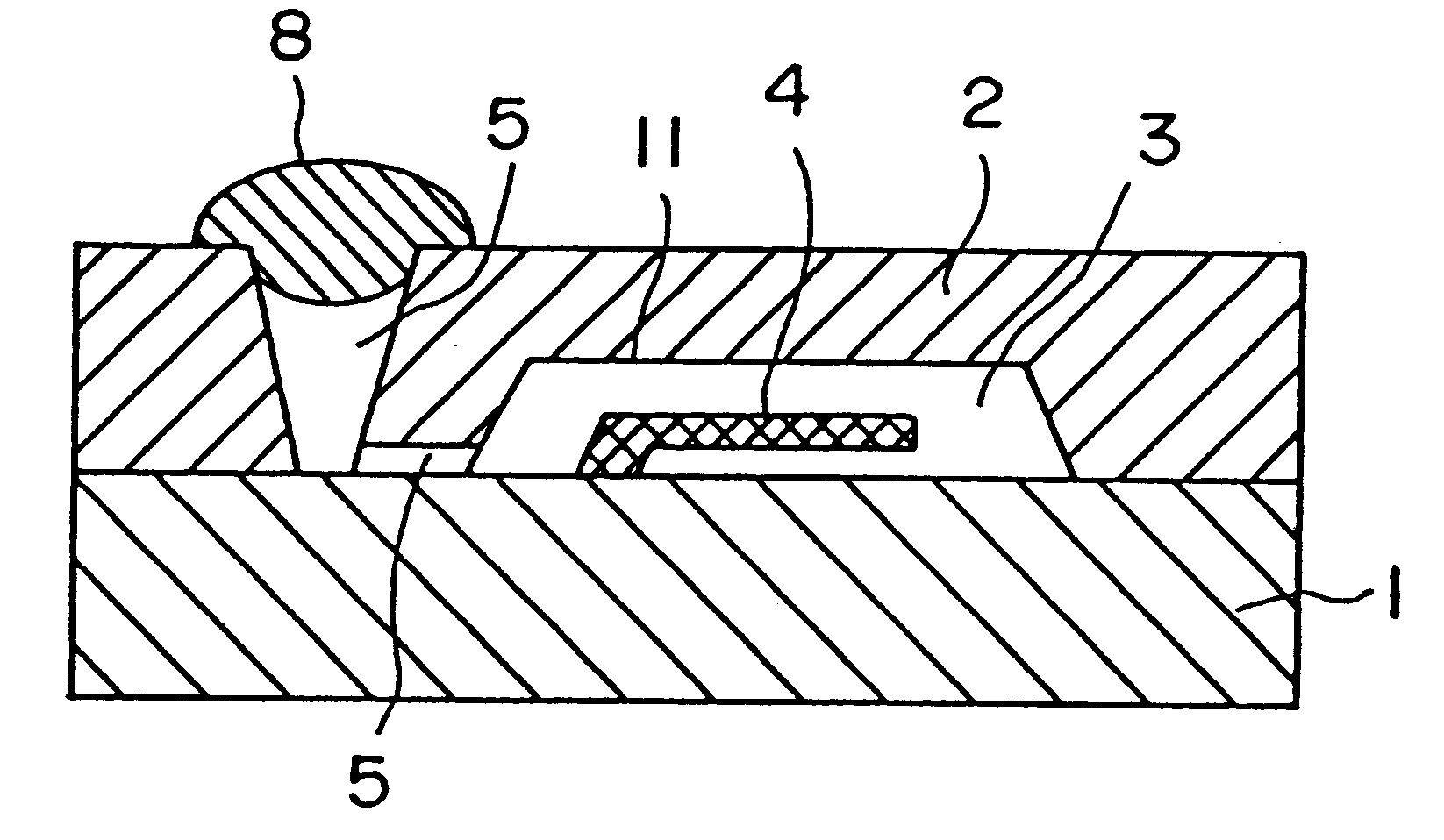

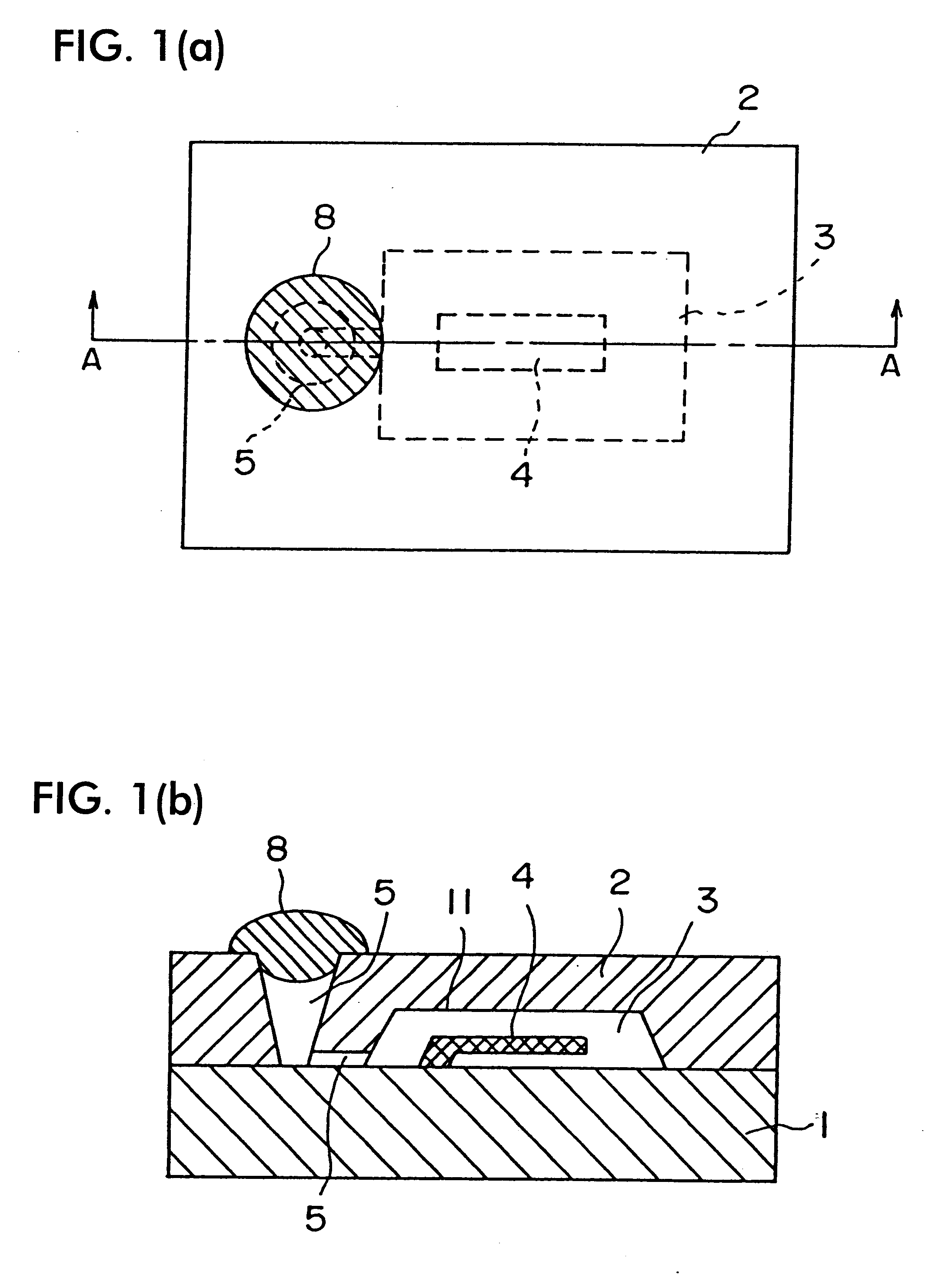

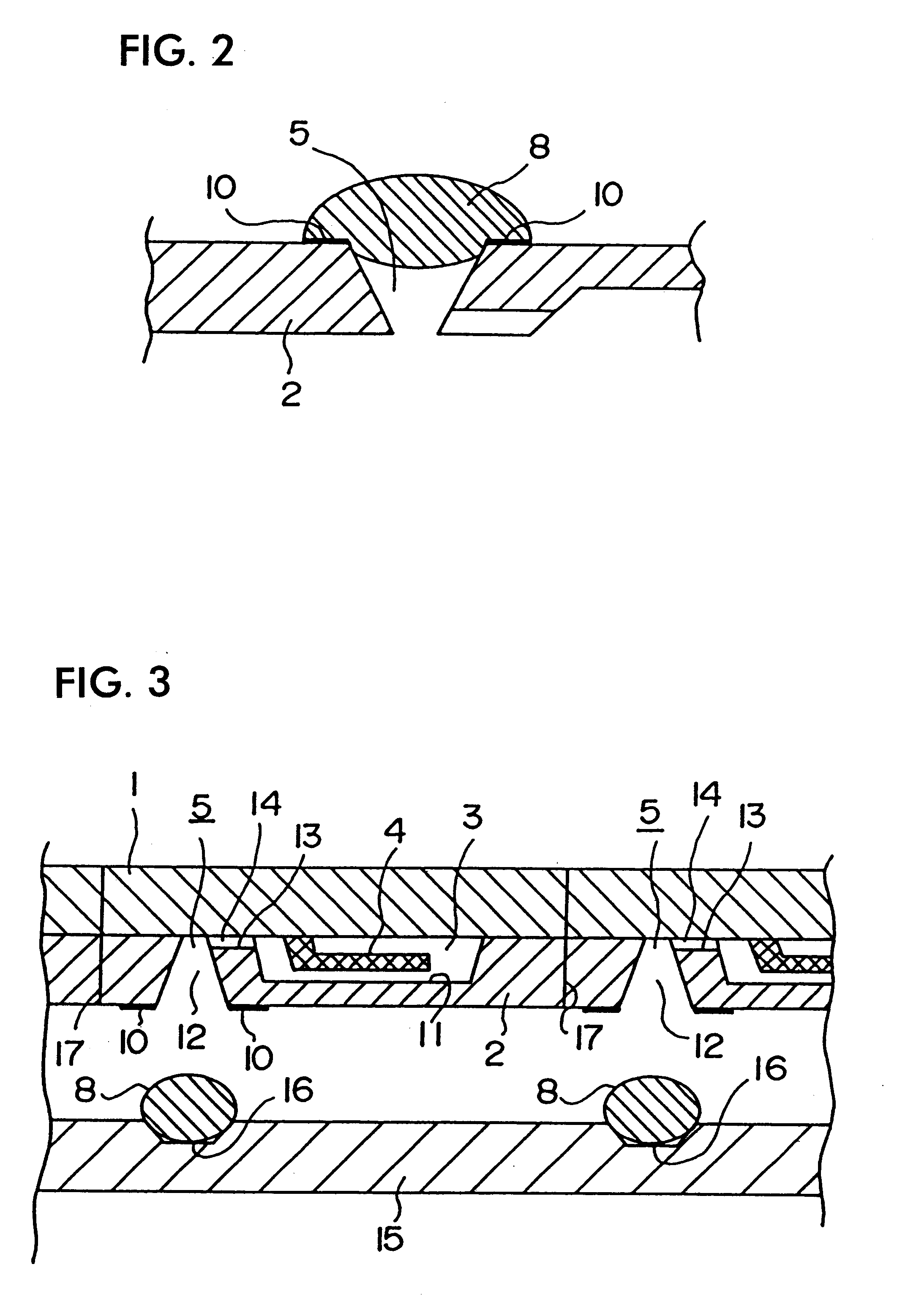

Evacuated package and a method of producing the same

InactiveUS6416831B1Fluid pressure measurement by electric/magnetic elementsSolid-state devicesHot meltMetal

An evacuated package with highly reliable vacuum-sealing and a method for producing an evacuated package with the evacuatable package. A lid portion is joined onto a substrate with an element accommodated in an evacuated space formed by the substrate and the lid portion. A connecting hole in the lid portion extends from the space to the top face of the lid portion. A metal film is formed around the complete peripheral region of the opening of the connecting hole, and a thermo-melting material is joined to the metal film to close the opening of the connecting hole so as to seal the element in the evacuated space. Before closing the opening of the connecting hole with the thermo-melting material, the space is evacuated, and simultaneously, the thermo-melting material is melted by heat and left until completely degassed in a vacuum. The degassed thermo-melting material is then pressed and joined to the metal film around the periphery of the opening of the connecting hole to close the opening with the thermo-melting material and vacuum-seal the space.

Owner:COMPAQ COMP CORP +1

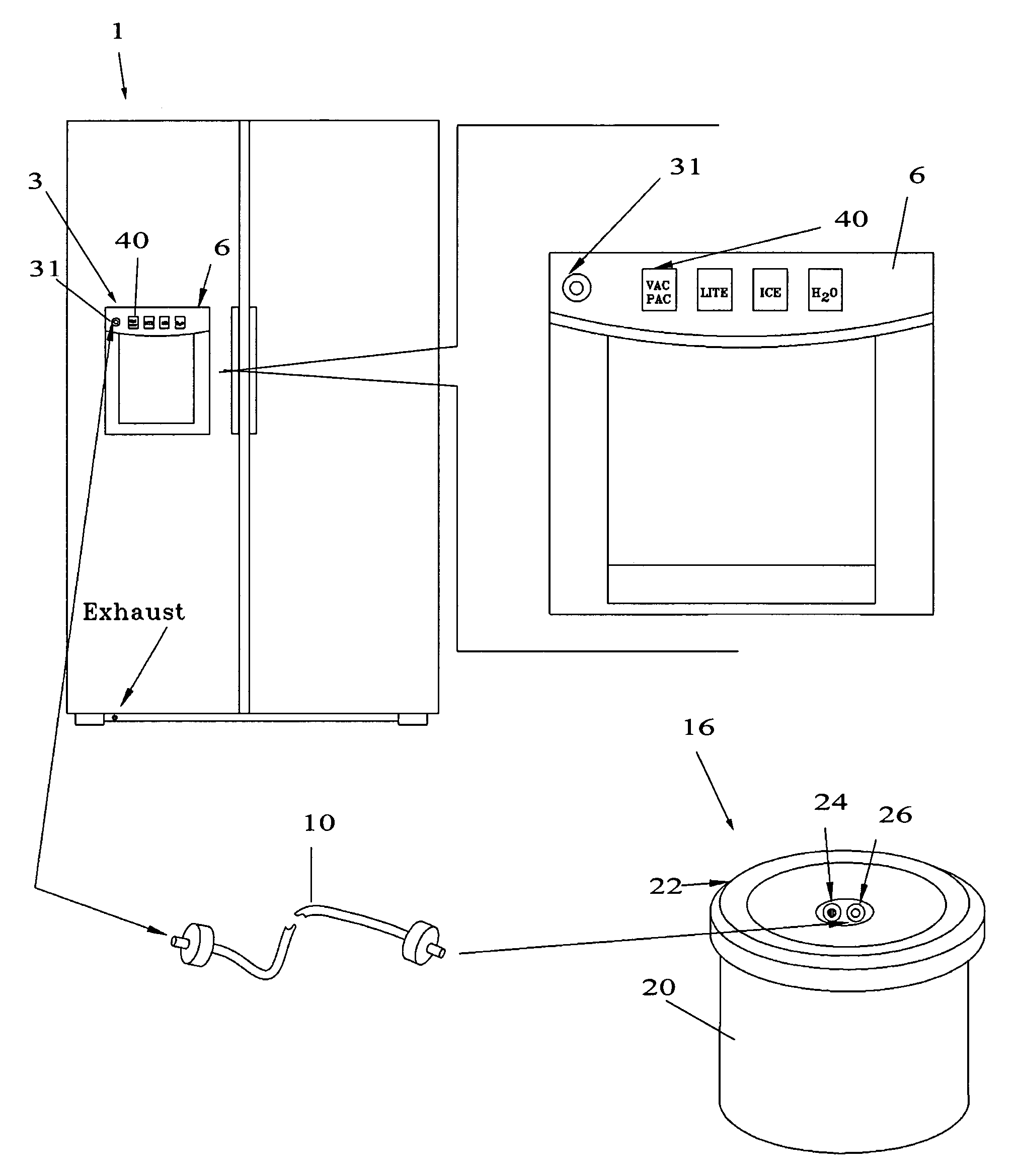

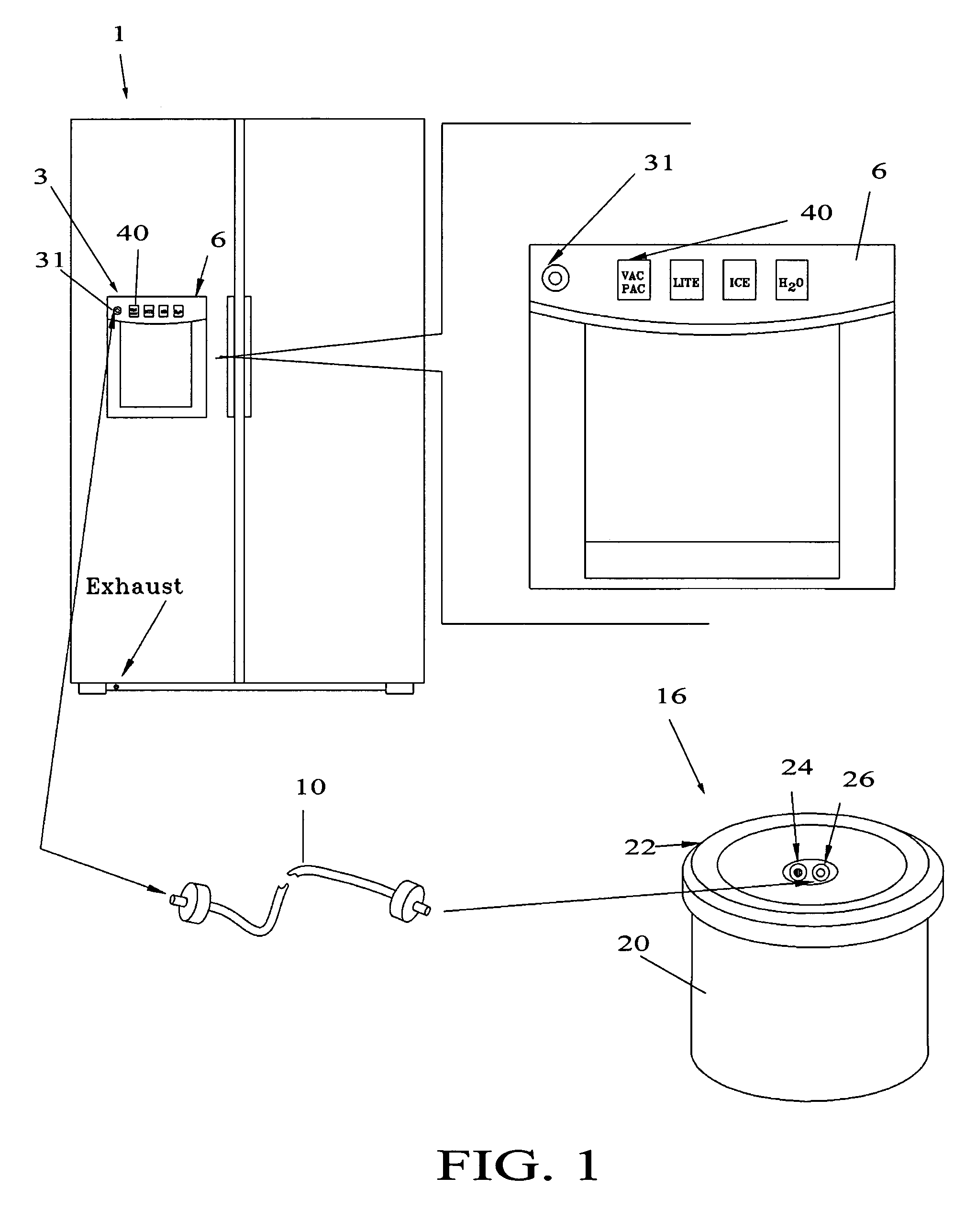

Refrigerator with integral vacuum sealer

InactiveUS7331163B2Easy to useEasy accessLighting and heating apparatusPackaging under vacuum/special atmosphereEngineeringBottle

Owner:HAU JOSEPH A +1

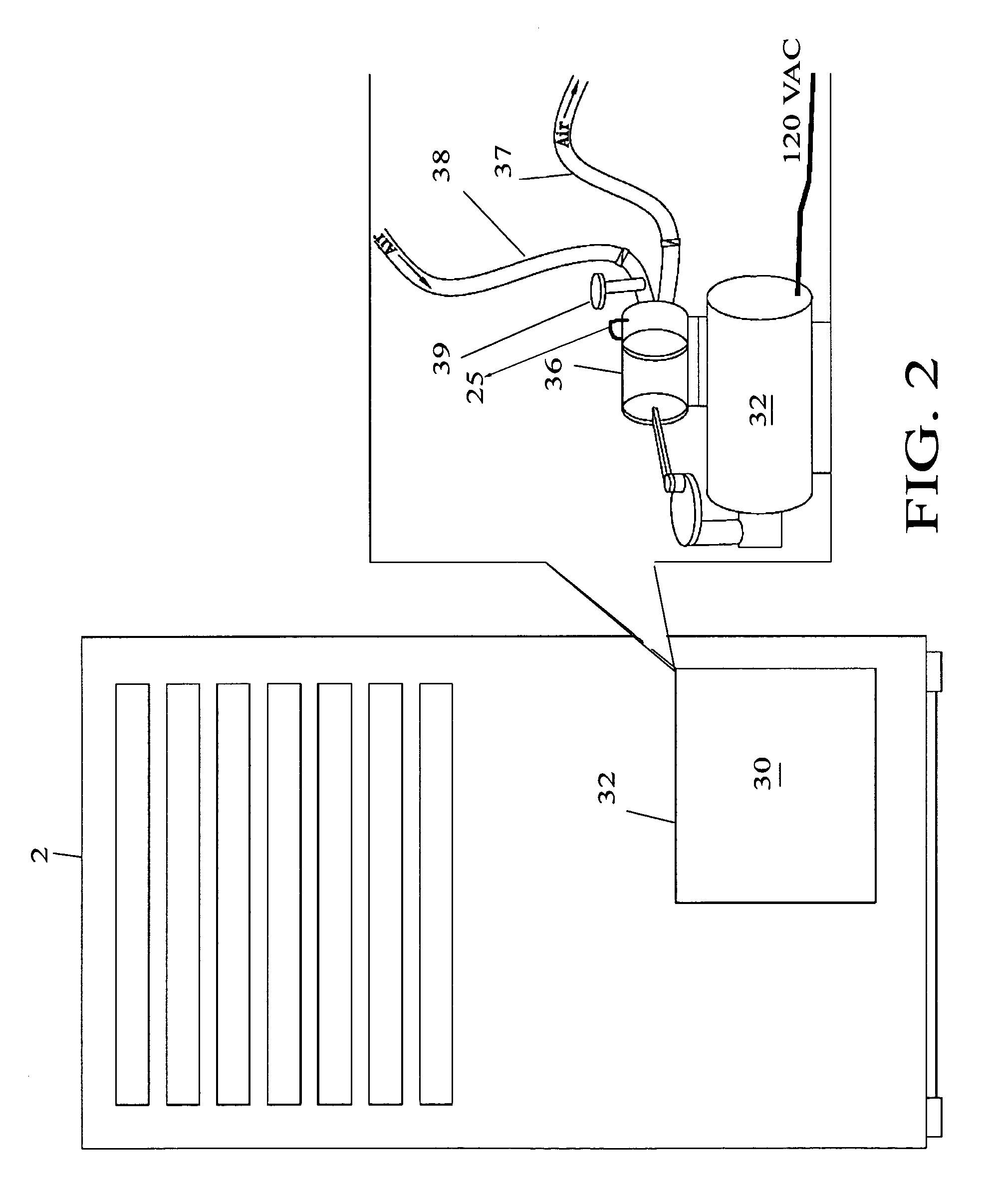

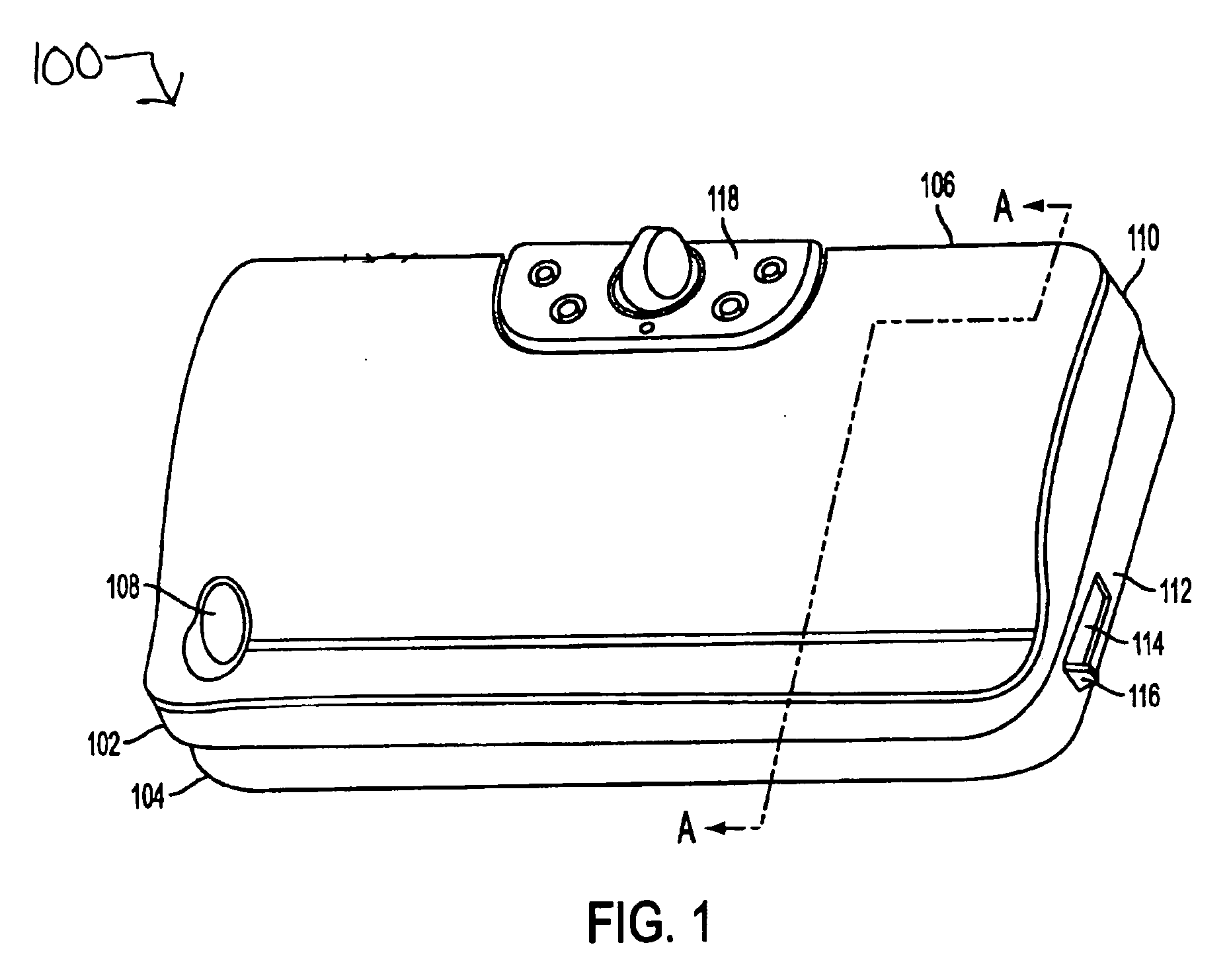

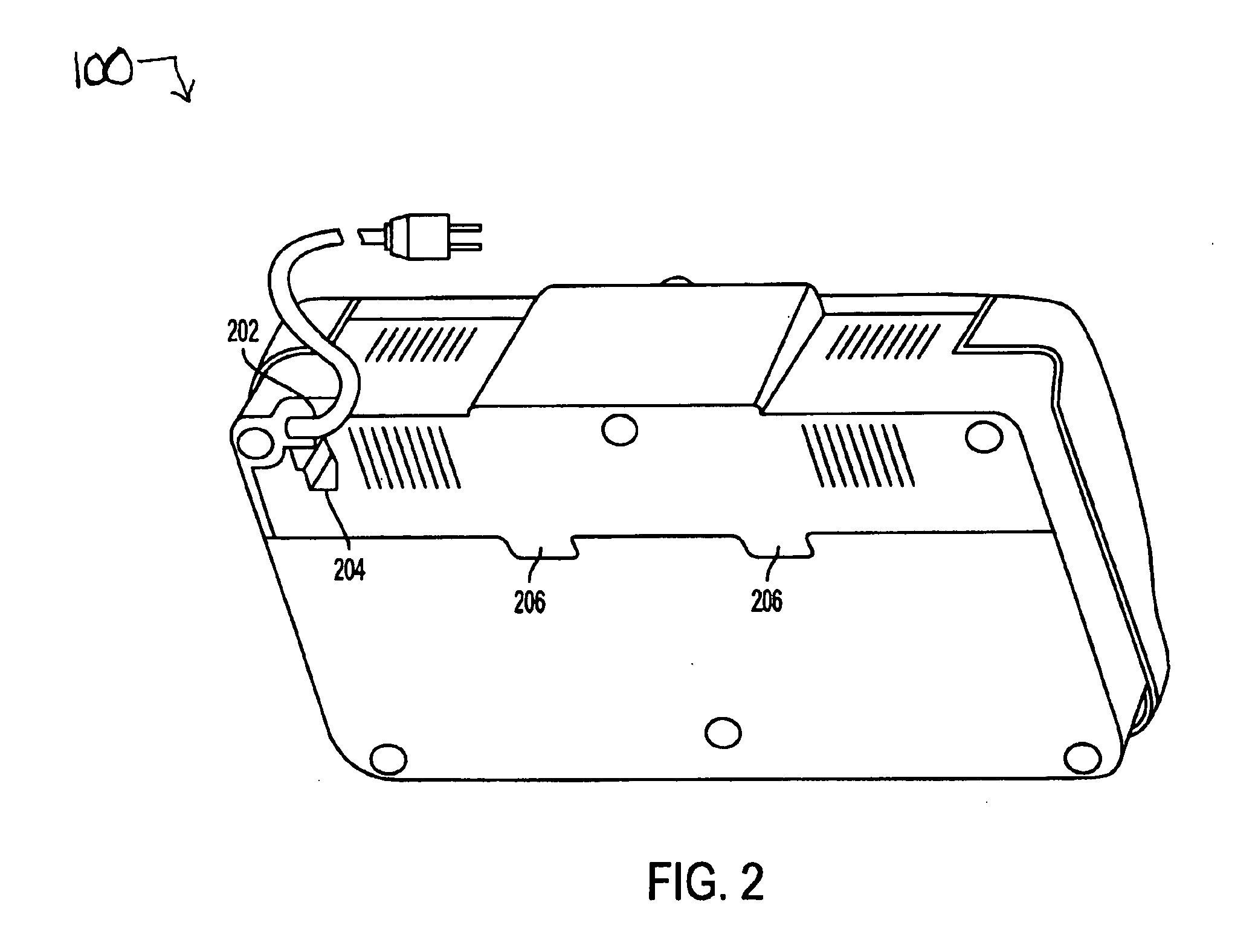

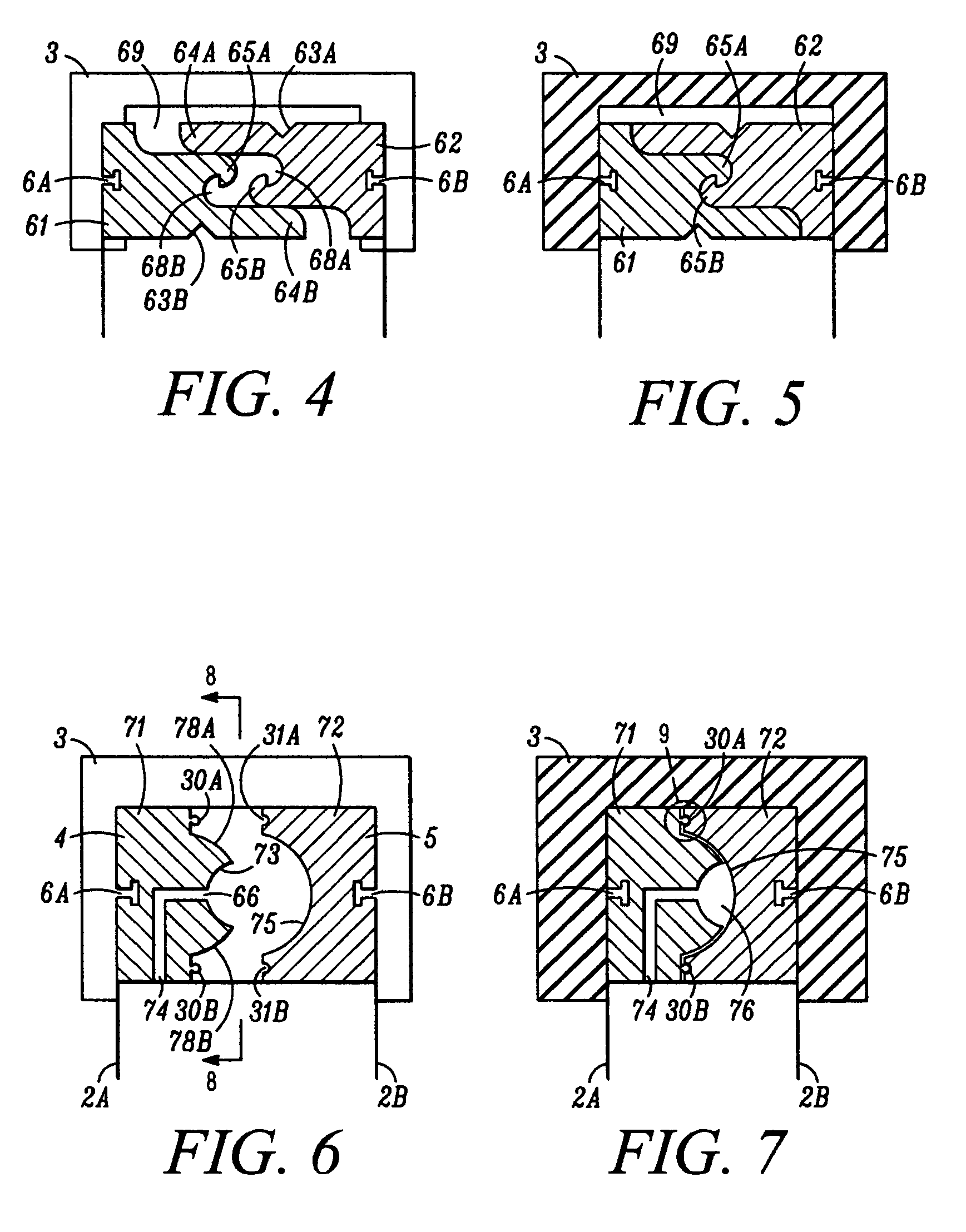

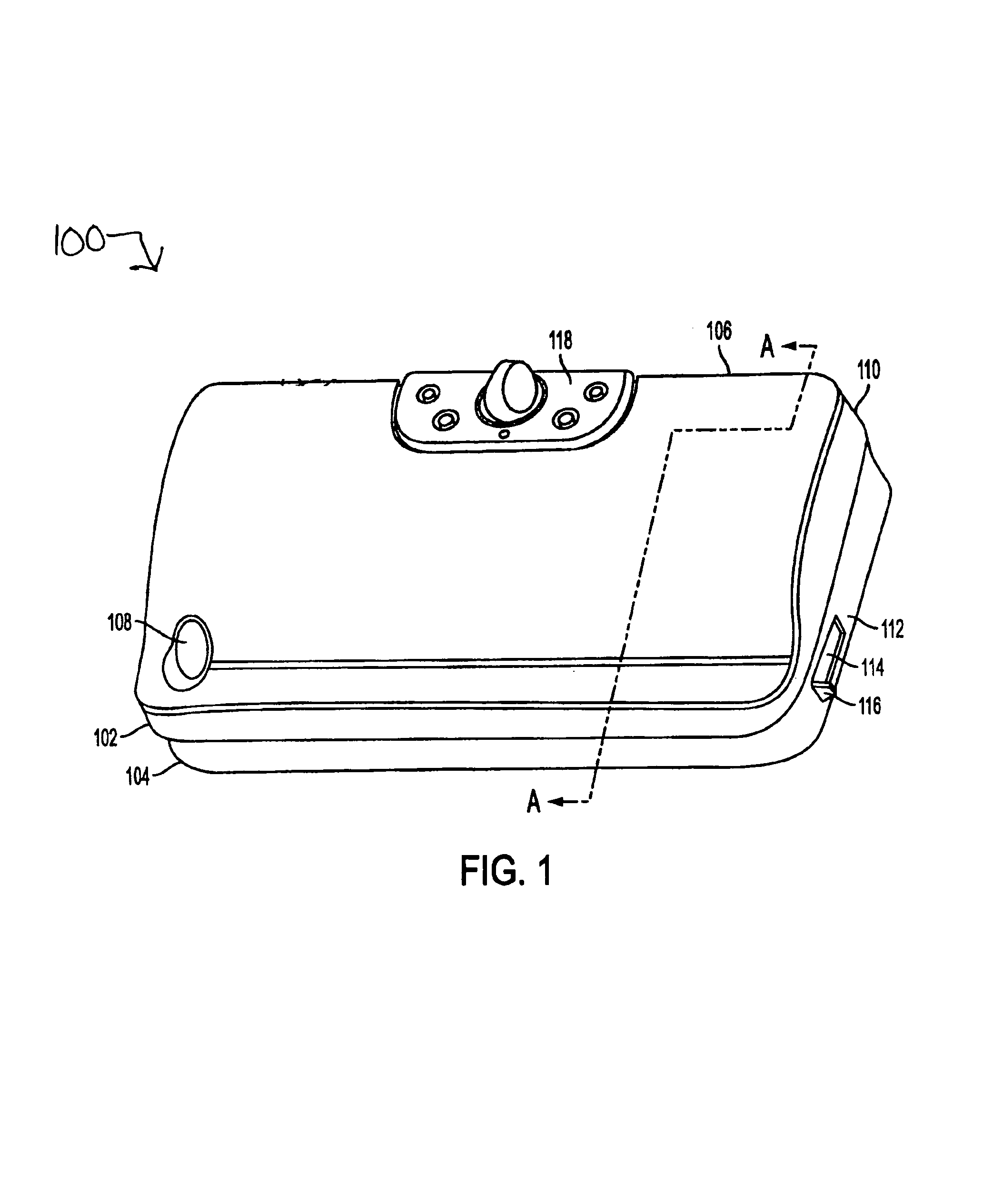

Vacuum packaging appliance with vacuum side channel latches

InactiveUS20050050856A1Wrapper twisting/gatheringPackaging under vacuum/special atmosphereEVACUATED CONTAINEREngineering

A vacuum packaging appliance for forming a hermetically sealed evacuated container. The appliance includes a lid adapted to define a vacuum chamber when moved to a closed position relative to a trough in the lower portion of the appliance. The trough in the lower portion of the appliance is removable from the lower portion of the appliance. In one embodiment, the appliance includes pneumatic latches that are used to hold the lid in a substantially fixed position relative to the lower portion of the appliance. Additionally, a single vacuum source can be used to active the pneumatic latches and the evacuate the vacuum chamber. The appliance is further adapted for connection to vacuum sealing attachments for various containers whereby the containers can be selectively evacuated.

Owner:SUNBEAN PROD INC

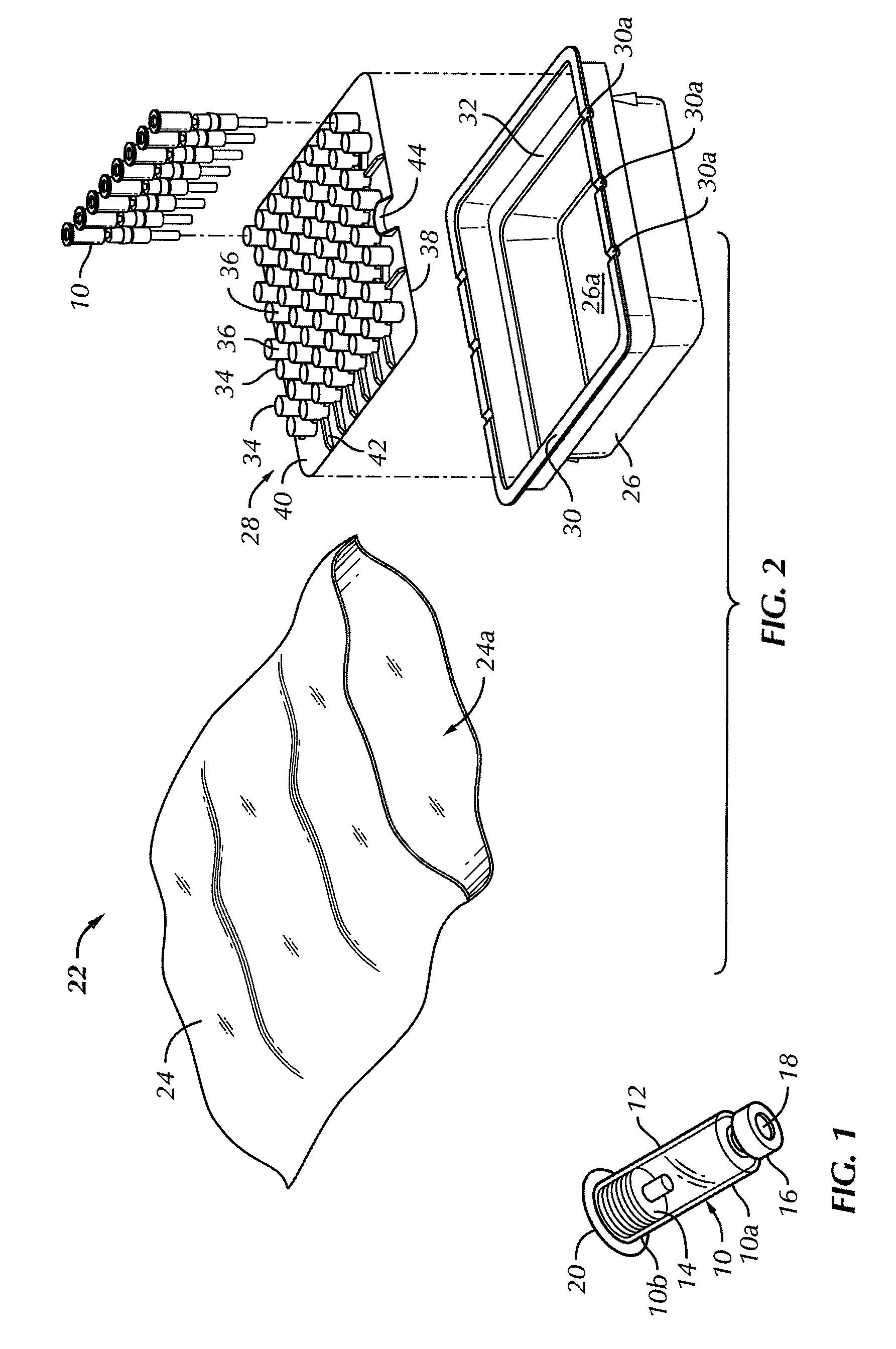

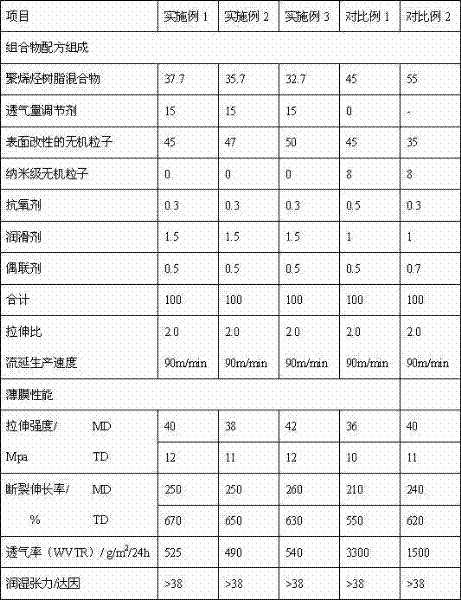

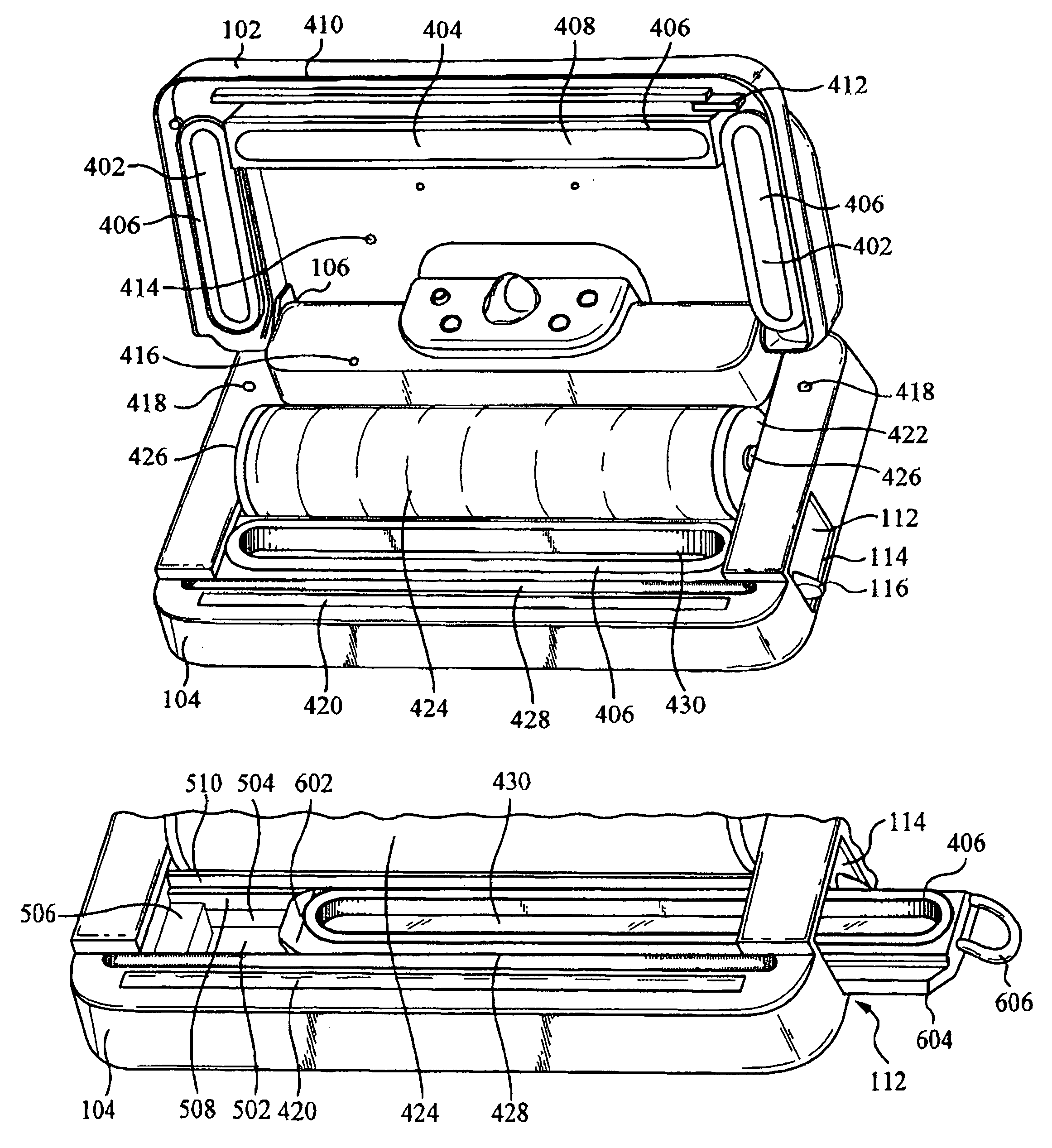

Vacuum package system and method

InactiveUS20060016156A1Medical devicesPackaging by pressurising/gasifyingVacuum pressureThin membrane

A vacuum packaging system for transporting a plurality of medical containers including a tray that supports the medical containers and an air impervious flexible film defining an internal cavity. The air impervious flexible film completely surrounds the tray and the medical containers. The internal cavity is evacuated to a predetermined vacuum level below atmospheric pressure. A method for packaging the plurality of medical containers for transportation in the tray includes inserting the medical containers into the tray, inserting the tray filled with medical containers into the internal cavity, evacuating the internal cavity to a predetermined vacuum pressure and sealing the flexible film such that the predetermined vacuum pressure is generally maintained in the internal cavity.

Owner:WEST PHARM SERVICES INC +1

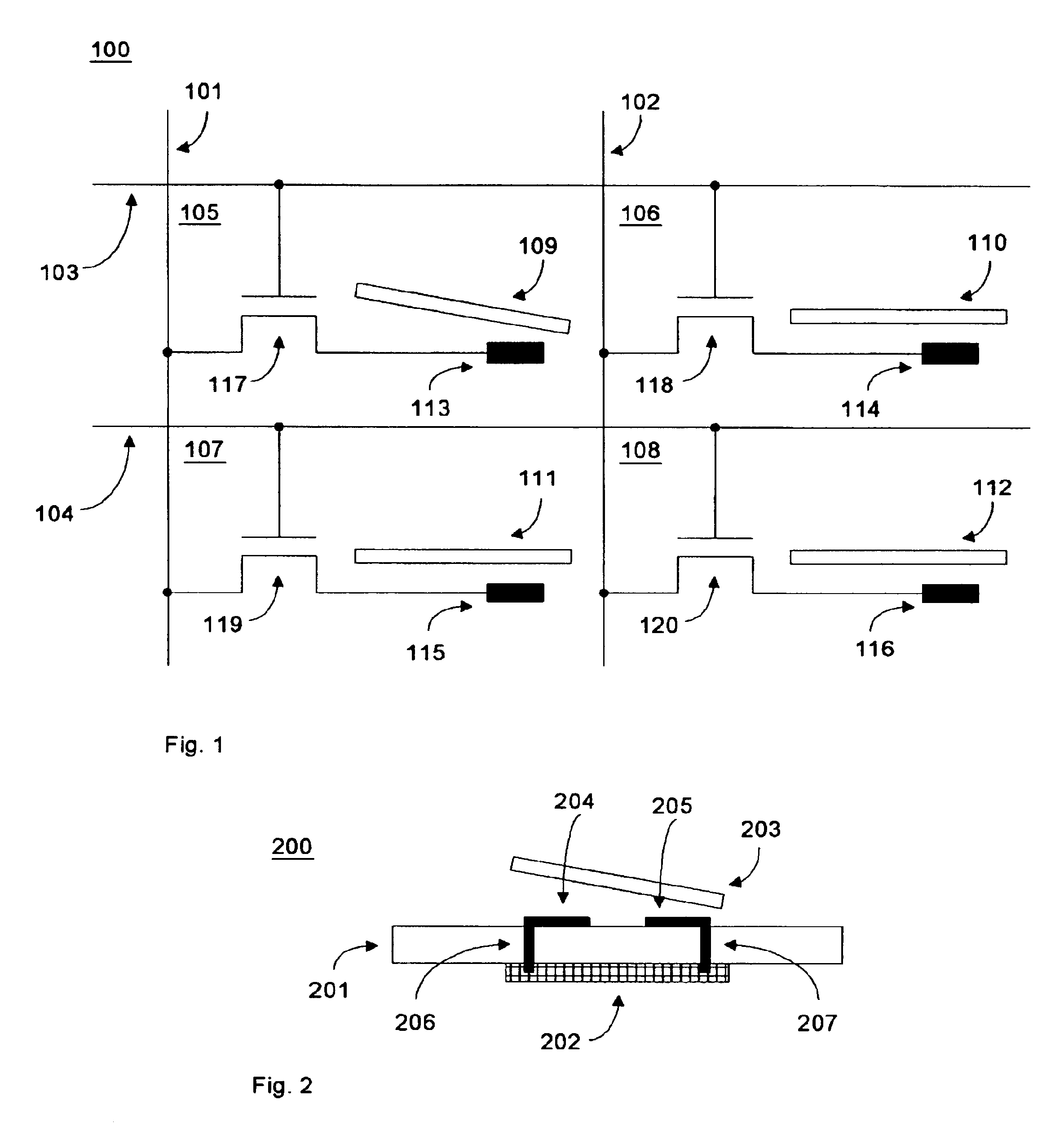

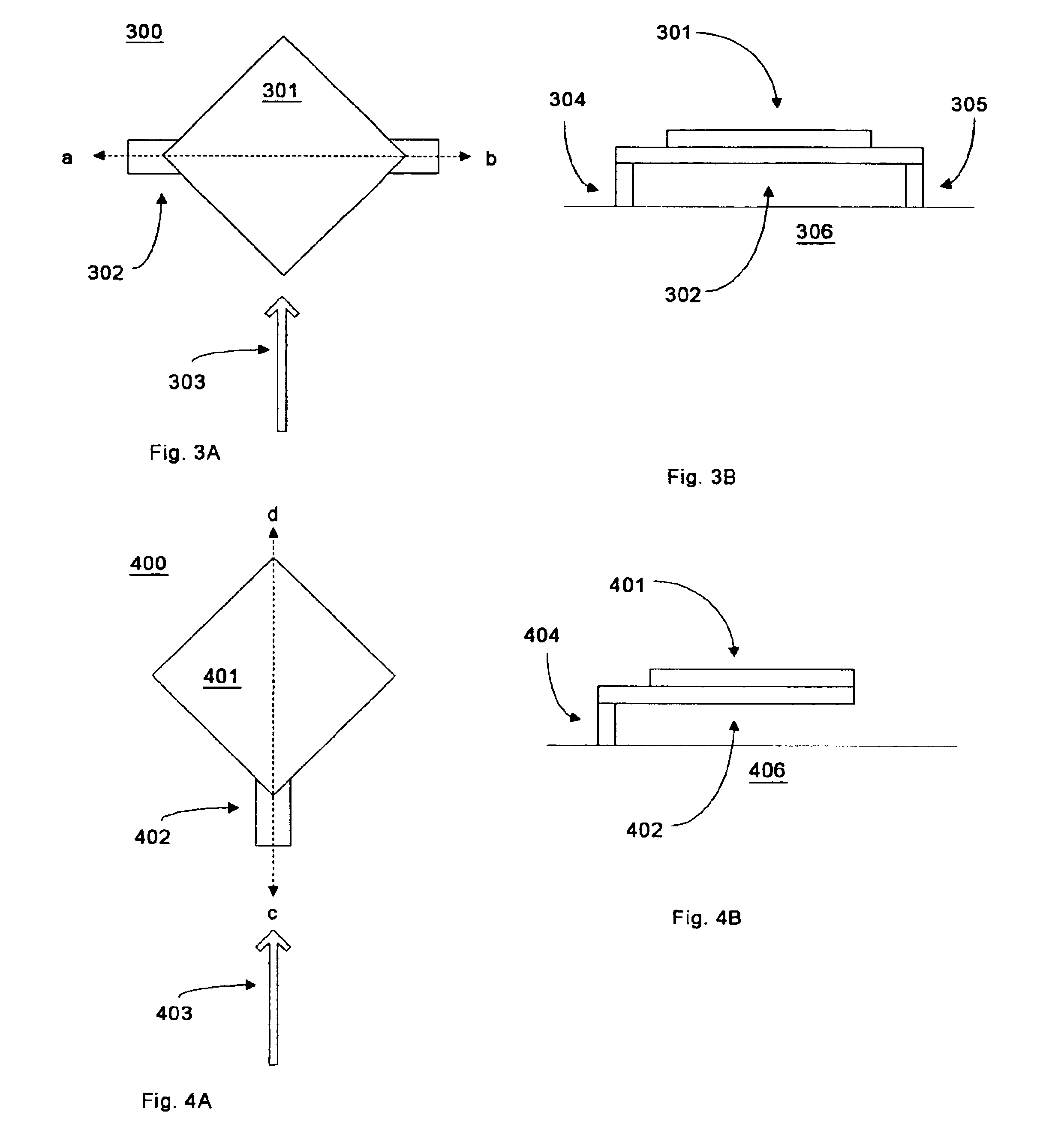

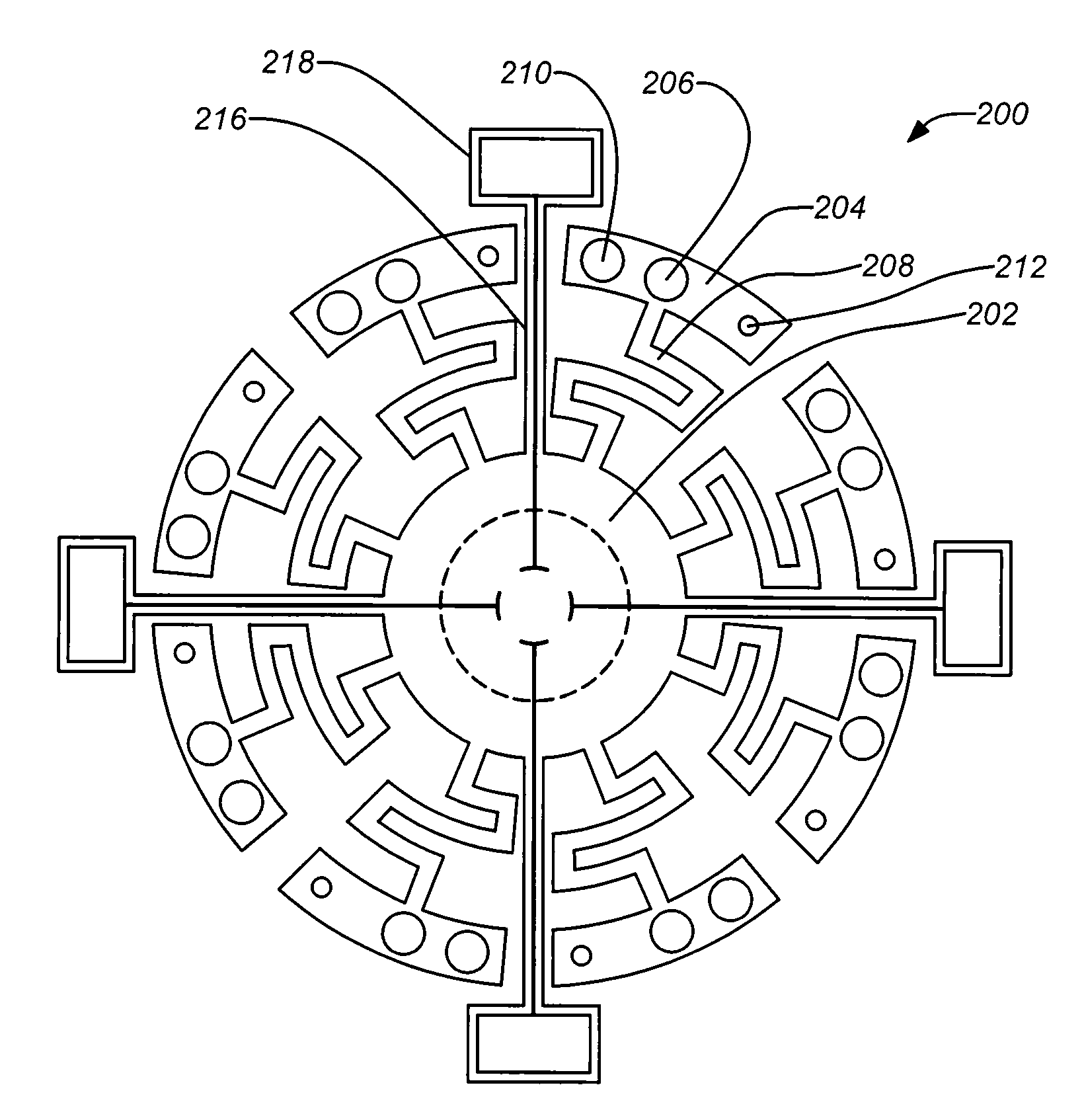

Isolated active temperature regulator for vacuum packaging of a disc resonator gyroscope

ActiveUS20100300201A1Reduce temperature sensitivityReduce mechanical stressAcceleration measurement using interia forcesDecorative surface effectsGyroscopeChip carrier

A micromachined thermal and mechanical isolator for MEMS die that may include two layers, a first layer with an active temperature regulator comprising a built-in heater and temperature sensor and a second layer having mechanical isolation beams supporting the die. The isolator may be inserted between a MEMS die of a disc resonator gyroscope (DRG) chip and the leadless chip carrier (LCC) package to isolate the die from stress and temperature gradients. Thermal and mechanical stress to the DRG can be significantly reduced in addition to mitigating temperature sensitivity of the DRG chip. The small form can drastically reduce cost and power consumption of the MEMS inertial sensor and enable new applications such as smart munitions, compact and integrated space navigation solutions, with significant potential cost savings over the existing inertial systems.

Owner:THE BOEING CO

Nutritional porridge mixture and preparation method thereof

InactiveCN104351659AEasy to changeBalanced NutrientsClimate change adaptationFood preparationFood additiveAdditive ingredient

The invention relates to a nutritional porridge mixture and a preparation method thereof, belonging to the technical field of production and processing of nutritional foods. The food mixture consists of coarse cereals, vegetables, fruits, dried fruits, nuts, seeds, beans, funguses, alga and special foods. According to various characters and different qualities of the foods, the foods are treated by a method and a process of washing, soaking, washing, airing, steaming, boil-drying, air drying and sun drying, then the dried food products are mixed together, milled in a flour mill and sent to a molding machine to be prepared into oatmeal, and finally the products are subjected to vacuum packaging under the illumination of an ultraviolet sterilizing lamp. The nutritional porridge disclosed by the invention is free of any food additives, anti-corrosive agents, sugar, salt and the like, so the original taste and flavor as well as the natural nutritional ingredients and effects of the foods are retained.

Owner:杨征宇

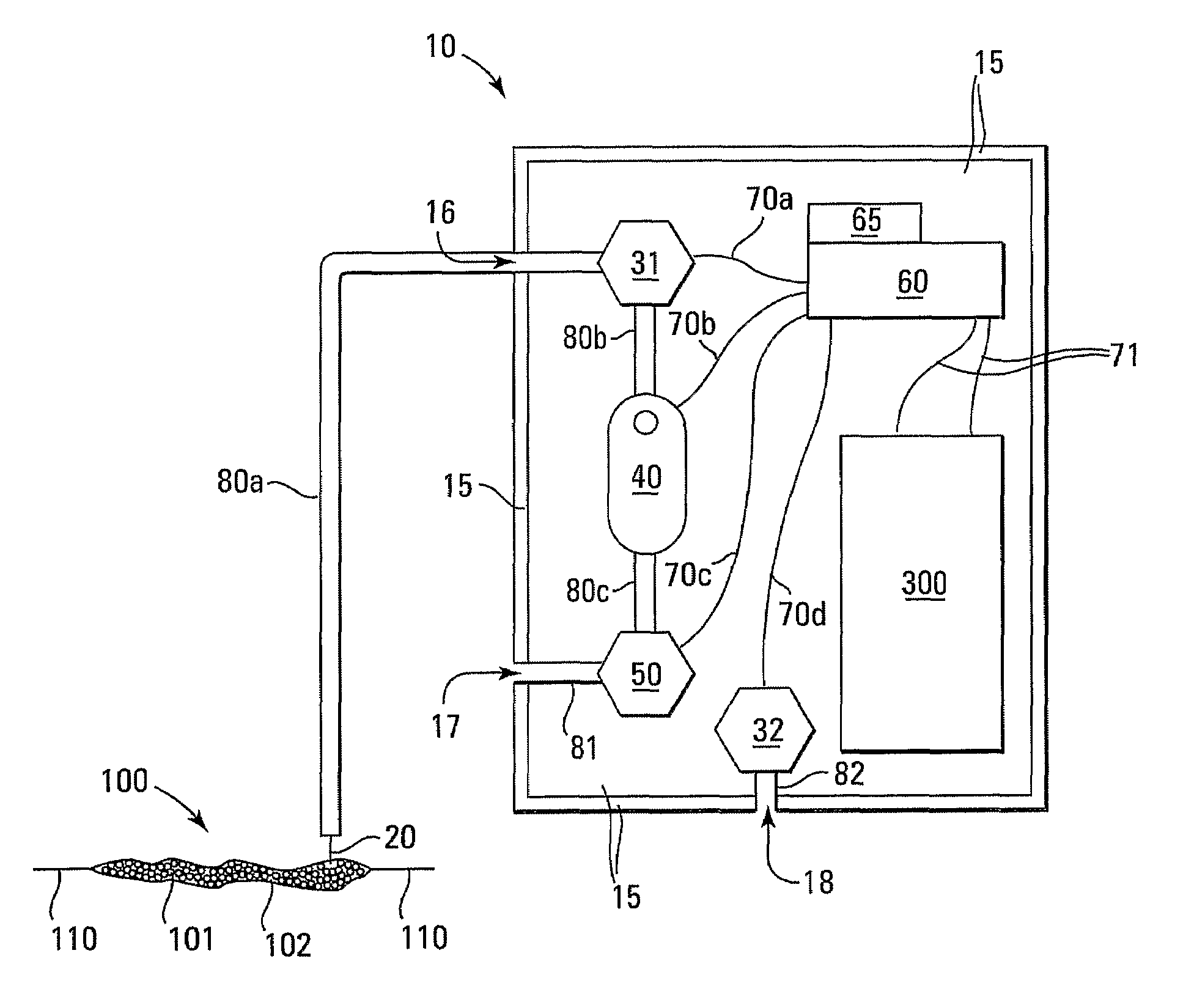

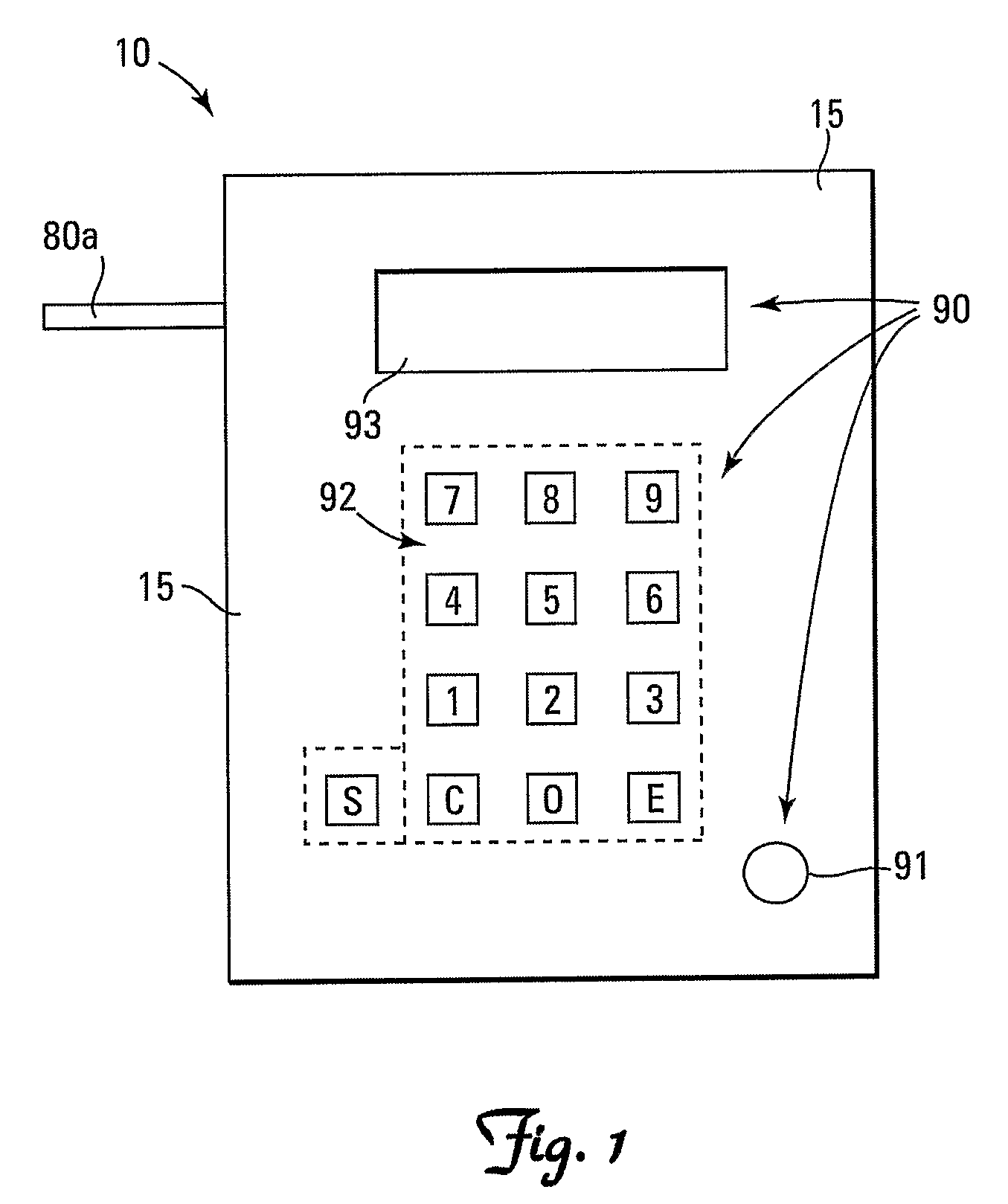

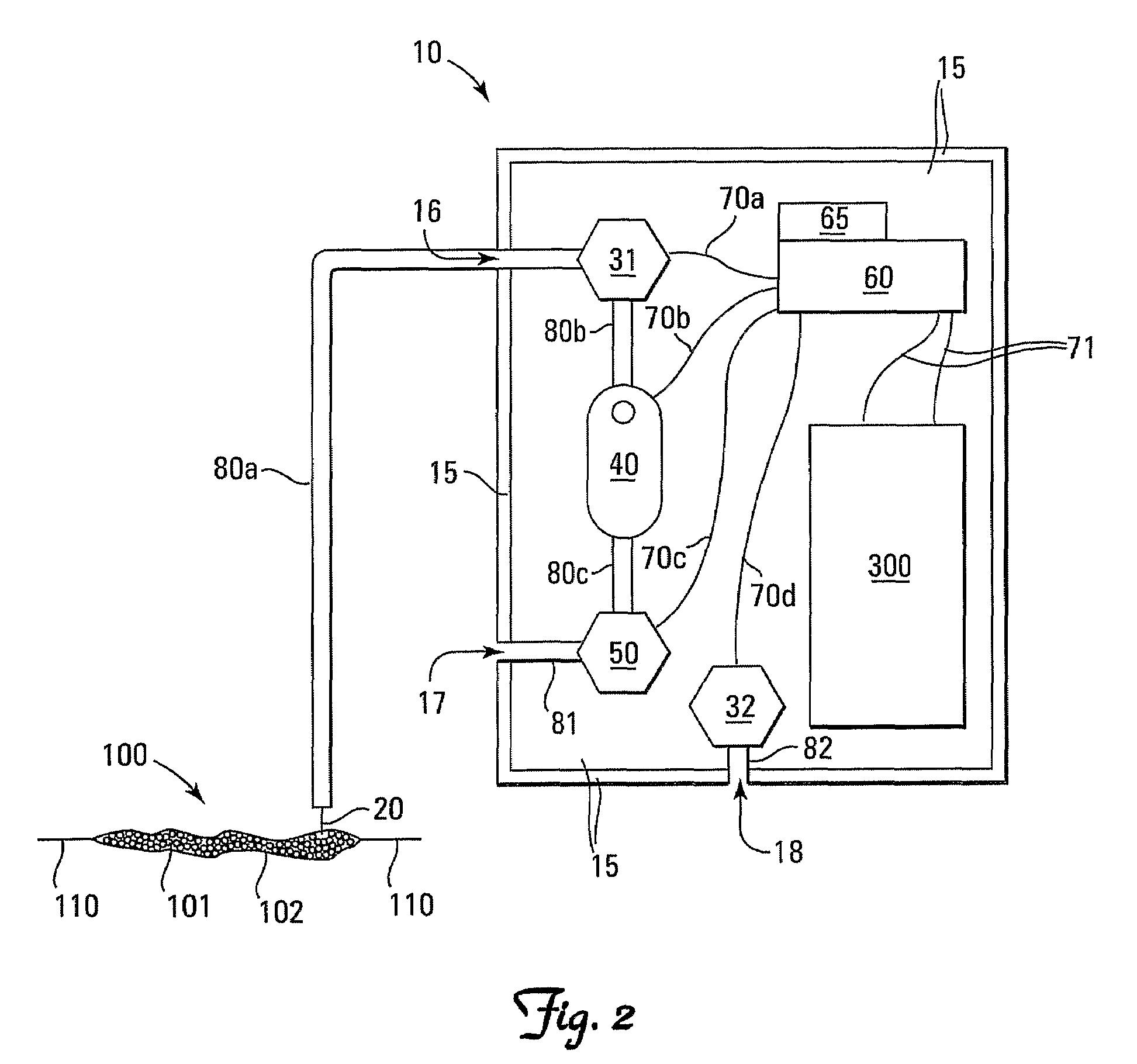

Instrument and method for detecting and reporting the size of leaks in hermetically sealed packaging

An instrument for detecting leaks in a hermetically sealed package. The instrument includes (i) a hollow needle, (ii) a mass flow rate sensor in sealed fluid communication with the lumen defined by the hollow needle, and (iii) a vacuum pump. The vacuum pump is in fluid communication with the lumen defined by the needle for evacuating gas from the hermetically sealed package, and in fluid communication with the mass flow rate sensor for directing mass flow from the evacuated package into operable contact with the mass flow rate sensor so as to permit sensing of any continuing mass flow from the evacuated package. The instrument may further include an oxygen sensor, also in sealed fluid communication with the lumen defined by the hollow needle for analyzing the oxygen concentration of the gas within the hermetically sealed package.

Owner:MODERN CONTROLS

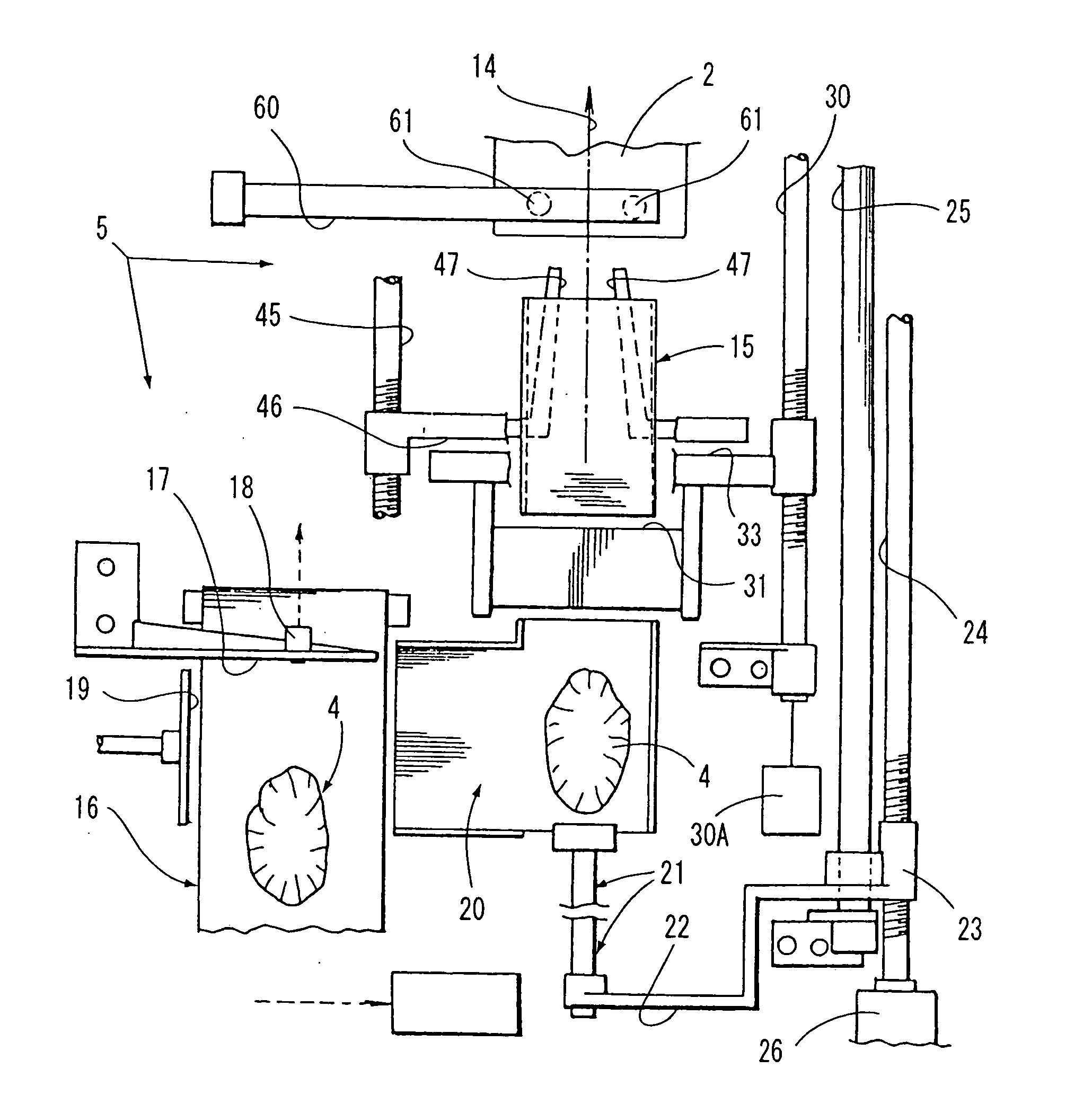

Packaging system

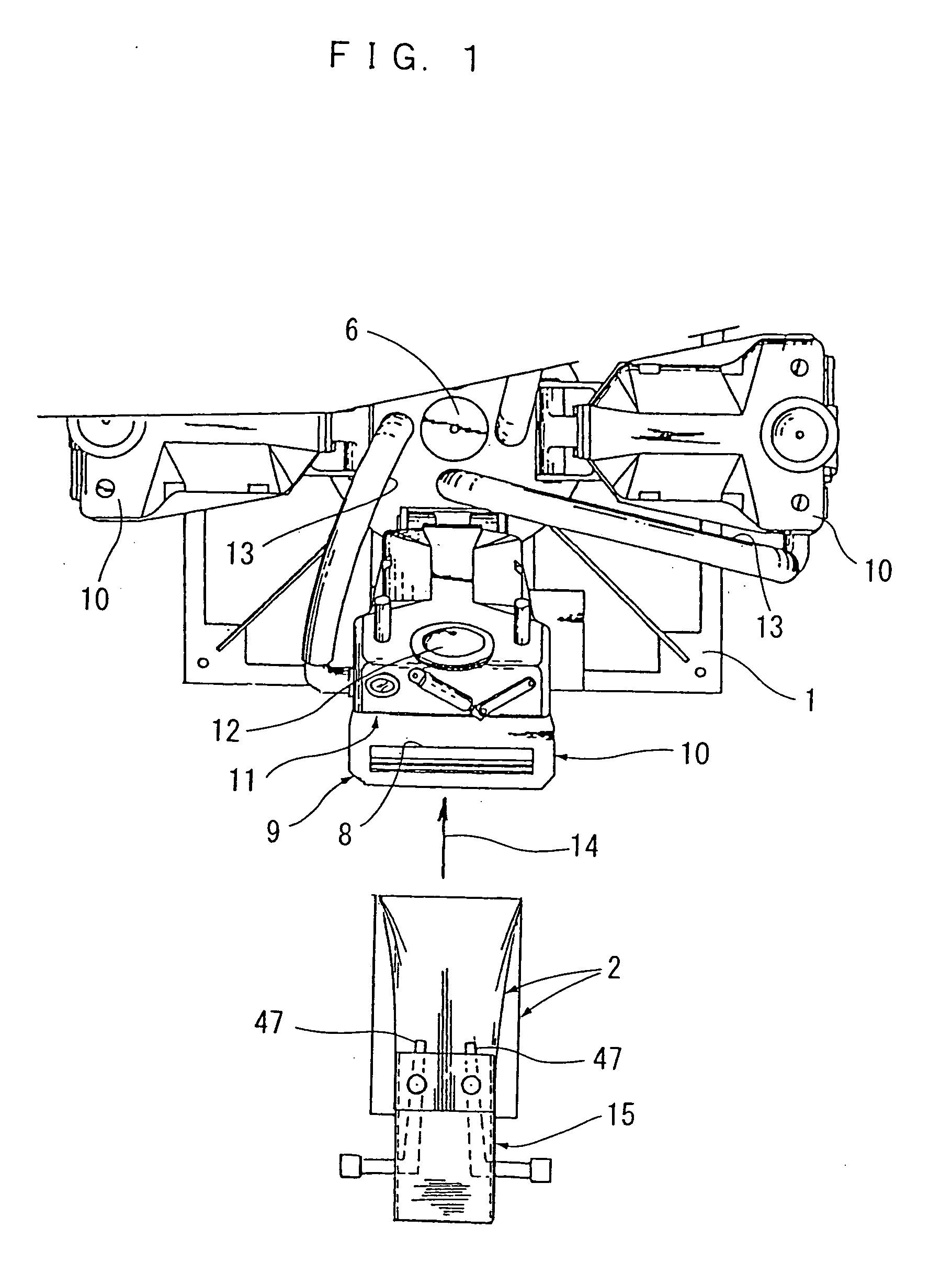

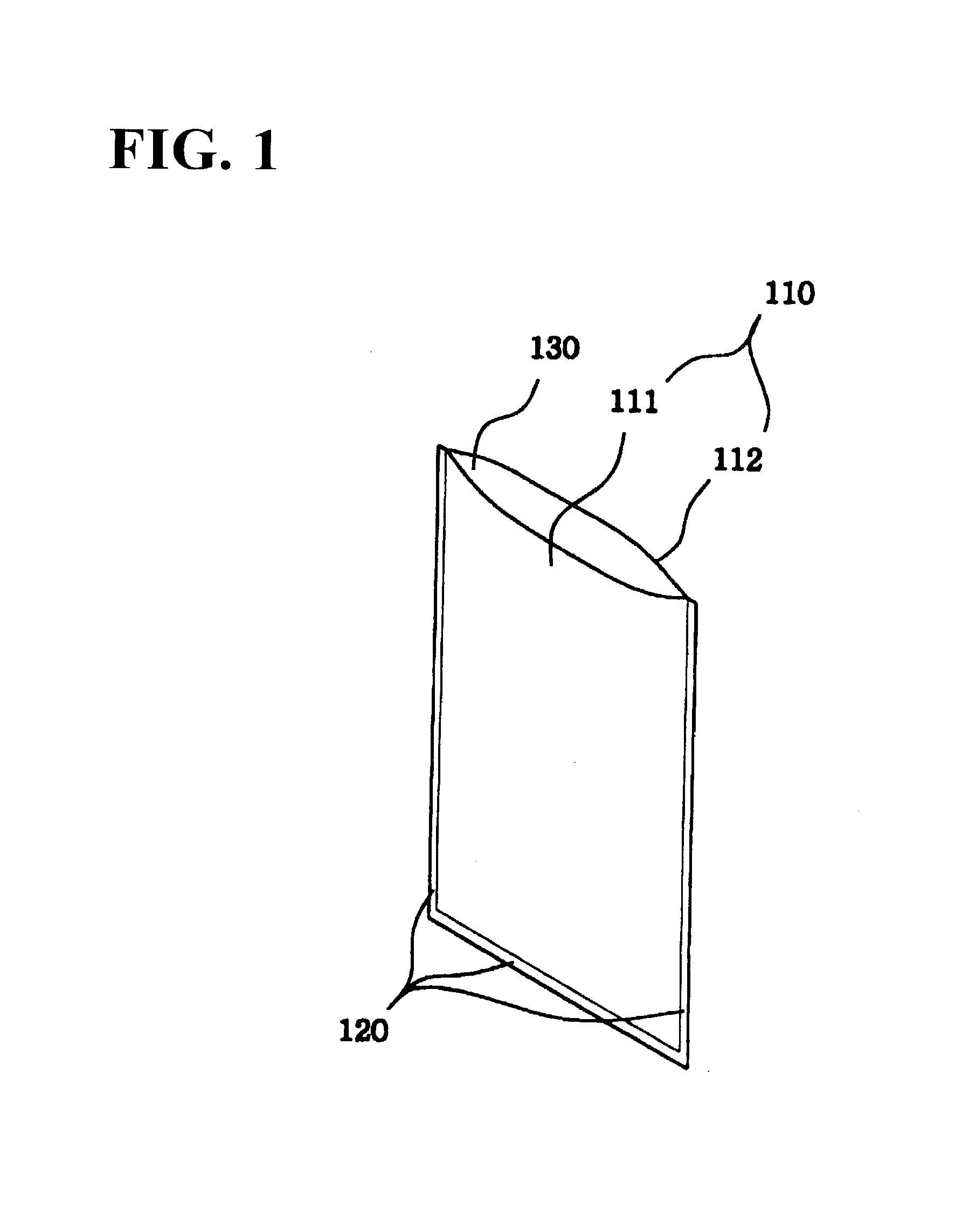

A packaging system is provided which supplies an item to be packaged and a bag covering the item to a pressure resistant chamber, for a heat sealing mechanism which arrives at a certain time interval, in accordance with the circulation timing of each sealing mechanism. The packaging system includes means for causing a beak-shaped hopper and a pair of opening and closing bars, to move back and forth in unison along a main travel path leading to a rotary vacuum packaging device, means for extending and supporting the opening section of an uppermost packaging bag, and conveying same into a pressure resistant chamber of the vacuum packaging device, means for causing a waiting station to move following the conveyance movement of the beak-shaped hopper into a pressure resistant chamber, and means for opening the opening and closing bars towards either side immediately after the bag has been conveyed into the pressure resistant chamber.

Owner:FURUKAWA MFG

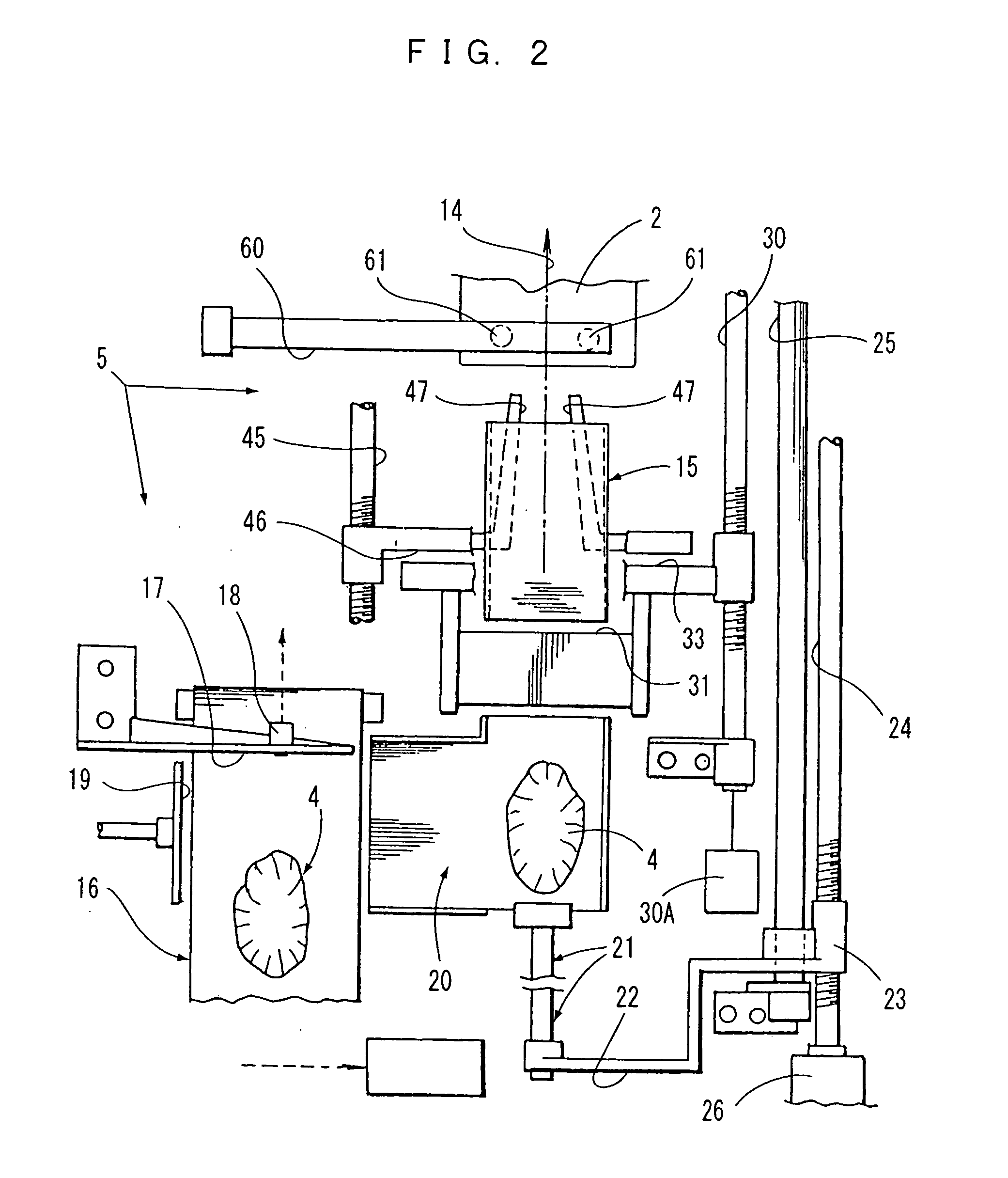

Composition of air-permeable film with low permeation volume and preparation method thereof

InactiveCN102336940AImprove mechanical propertiesGood compatibilityCoatingsPolymer sciencePolyolefin

The invention discloses a composition of an air-permeable film with a low permeation volume. The composition consists of the following components in percentage by weight: 30-60 percent of polyolefin resin mixture, 5-15 percent of permeation volume regulator, 30-55 percent of surface-modified nano-grade organic particles, 0.2-0.5 percent of antioxidant, 0.1-2.0 percent of lubricant and 1-3 percent of coupling agent. A preparation method of the composition comprises the following steps of: mixing a micro-grade inorganic filler with the coupling agent in a high-speed mixer to obtain a pretreated filler; feeding the pretreated filler, polyolefin resin, a modifier, the antioxidant and the lubricant into a double screw extruder by using a feeding system, extruding, cooling, pelletizing, drying, and packaging with an aluminum film bag in vacuum to obtain a finished air-permeable film composition with low permeation volume; and casting the prepared composite by using an extruder with a T-shaped film head, and stretching with a single shaft in two steps, wherein the stretching rate is 0.5-3.5. The invention has the advantages: 1, the nano inorganic filler is added, so that the mechanical property of the air-permeable film can be enhanced; 2, the surface of the inorganic particles is coupled, so that the compatibility with the polyolefin resin can be enhanced; 3, due to the adoption of the T-shaped film head, the drawing efficiency and the flatness can be fully enhanced; and 4, due to the adoption of the permeation volume regulator, the permeation volume of the air-permeable film can be lowered remarkably.

Owner:KINGFA SCI & TECH CO LTD +2

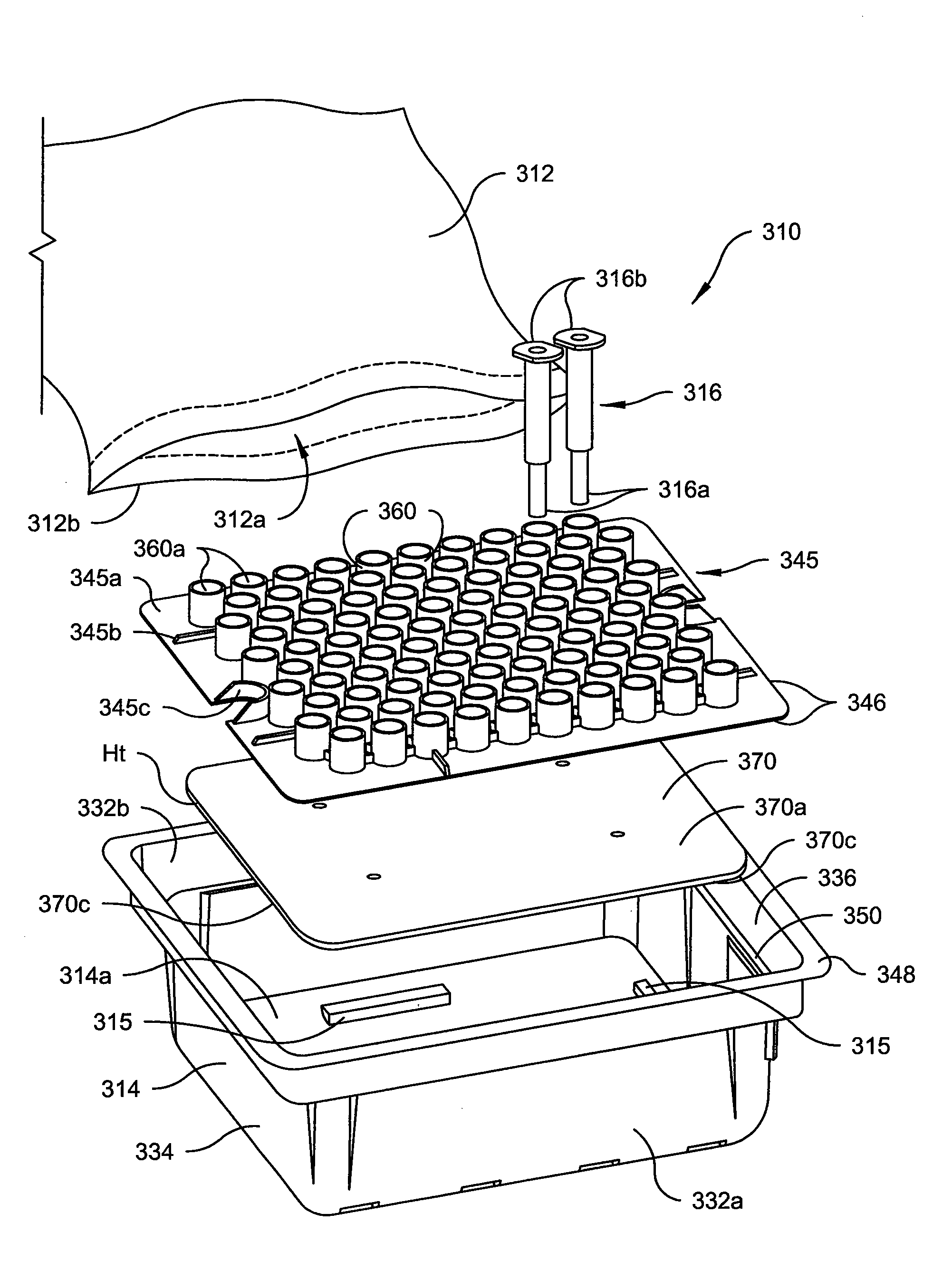

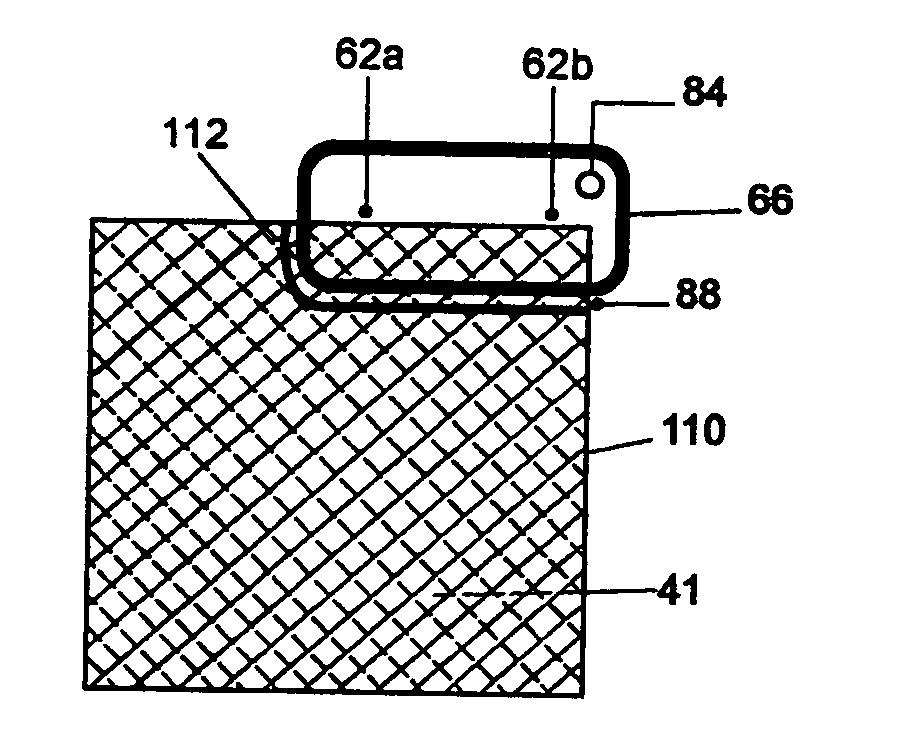

Vacuum Package System

A vacuum packaging system for transporting a plurality of medical containers includes a plurality of medical a tray that receives and supports the medical containers. The tray includes opposing first and second side walls, opposing side and rear walls and a bottom floor. The walls extend generally perpendicularly from the bottom floor of the tray to a top edge thereof. A nesting plate is removably mountable in the tray and includes a plurality of generally cylindrical sleeves each receiving one of the plurality of medical containers. A support surface within the tray generally extends parallel to and spaced a predetermined distance from the bottom floor of the tray and receives and supports the nesting plate. An air impervious flexible film defines an internal cavity and completely surrounds the tray and the medical containers. The internal cavity is evacuated to and maintained at a predetermined vacuum level below atmospheric pressure.

Owner:WEST PHARM SERVICES INC +1

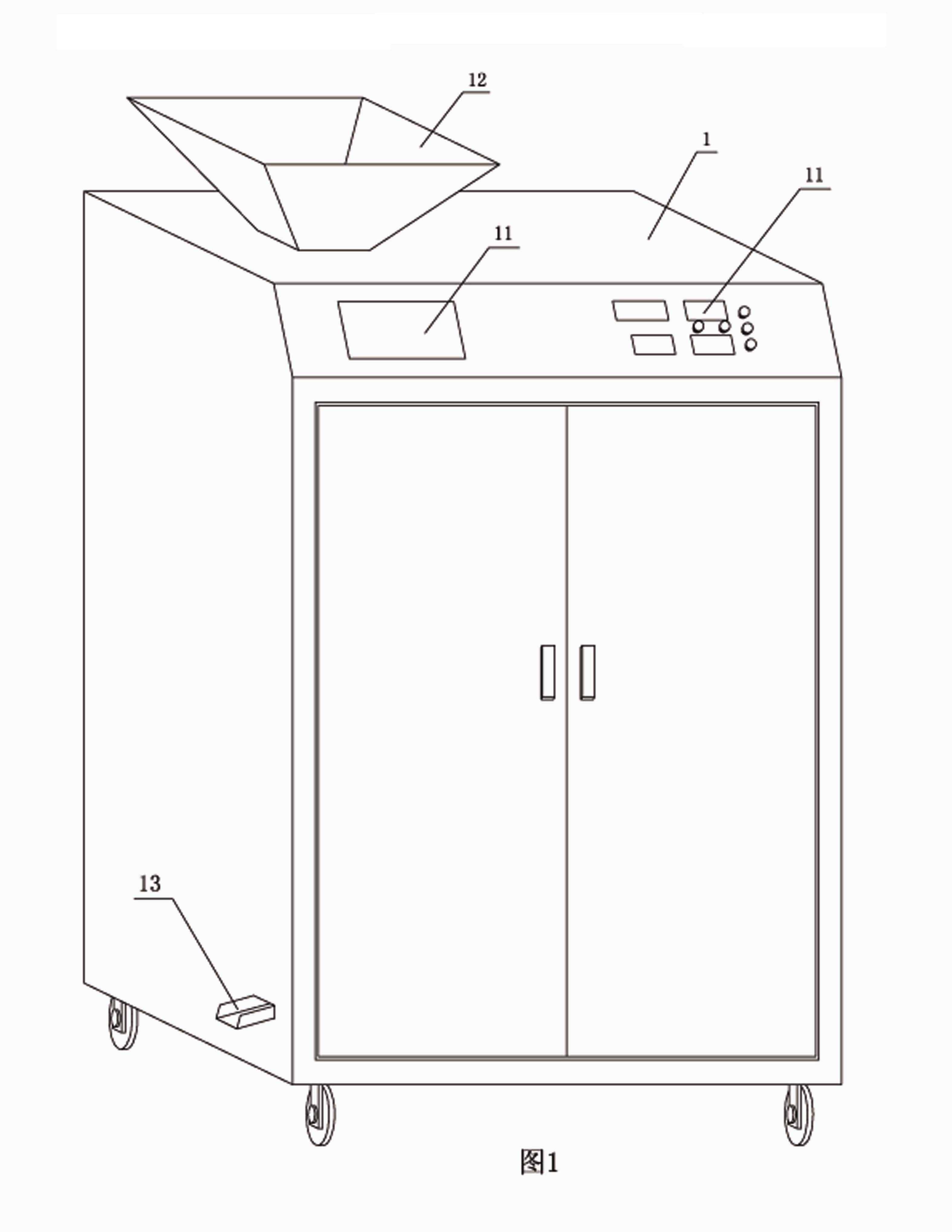

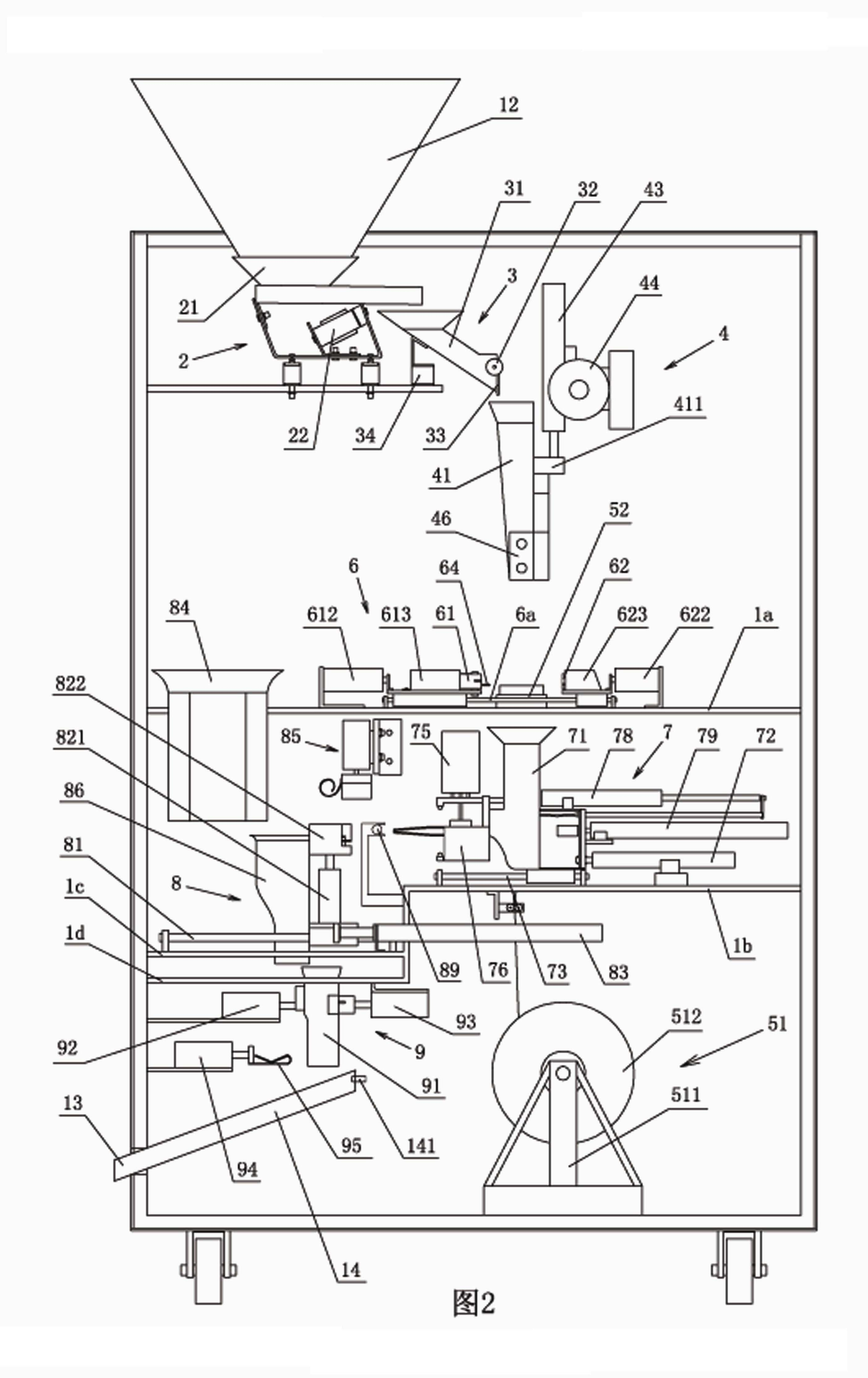

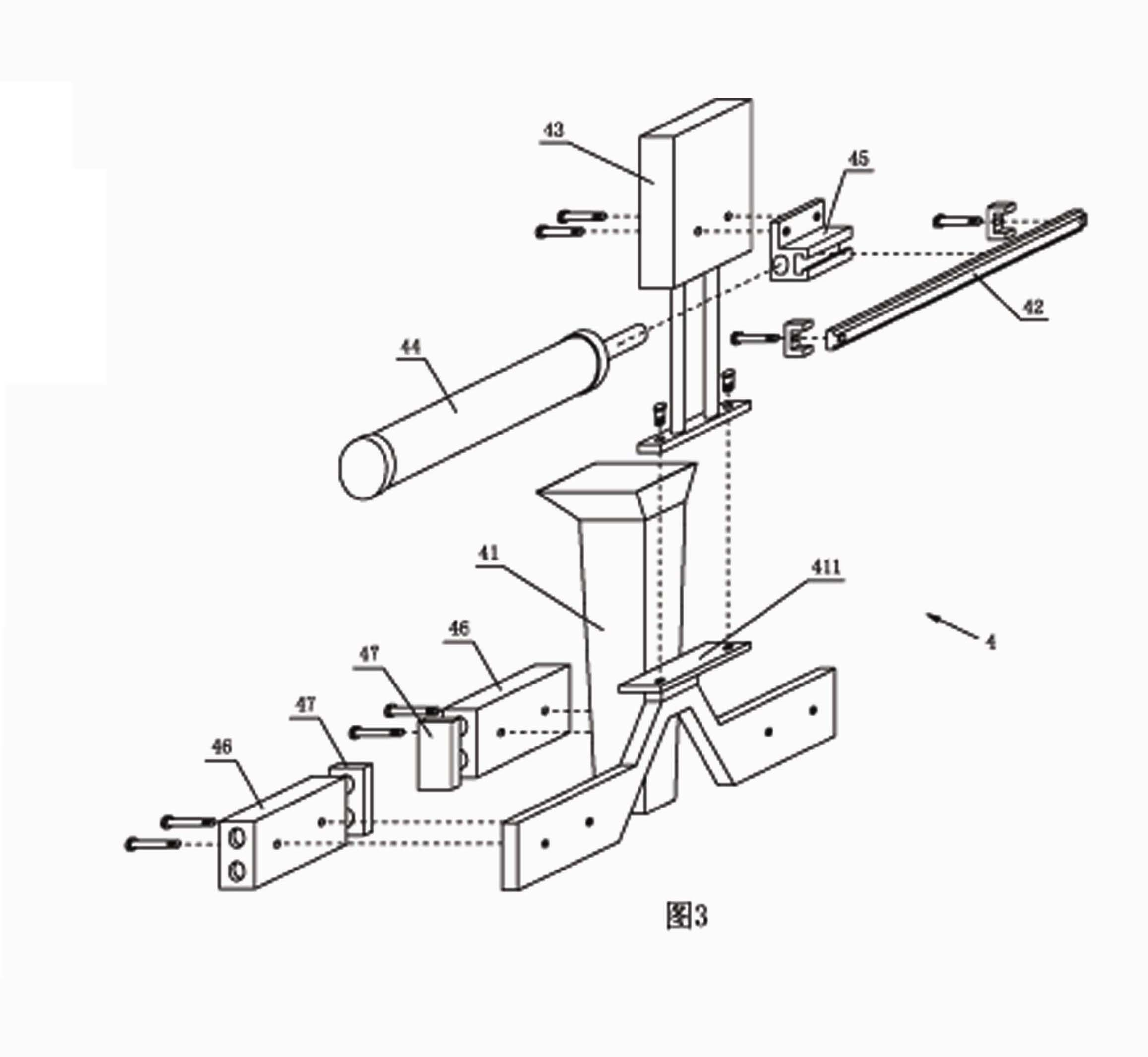

Automatic packaging unit for vacuum packaging of inner bag and outer bag

InactiveCN101837843AHigh degree of automationIncrease productivityPackaging by pressurising/gasifyingPackaging automatic controlThin membraneContinuous operation

The invention relates to an automatic packaging unit for vacuum packaging of an inner bag and an outer bag, which is characterized by comprising a case, a material hopper, a feeding device, a metering device, an inner bag loading device, an outer bag loading device and a vacuum sealing device, wherein the material hopper is fixed on the top of the case; the lower part of the material hopper is provided with the feeding device, the metering device, the inner bag loading device, the outer bag loading device and the vacuum sealing device successively; the unit also comprises an inner bag film supplying device and an inner bag making device which are matched with the inner bag loading device, and an outer bag conveying device which is arranged between the outer bag loading device and the vacuum sealing device; and an outer bag deposited device and an outer bag gaping device are correspondingly arranged on the outer bag conveying device. The automatic packaging unit has reasonable arrangement of the various actuating mechanisms, automatically organic connection of the multiple steps of feeding, metering, bag making, loading of the inner bag and outer bag vacuum sealing and the like and rapid and stable continuous operation, can automatically complete the inner and outer bag vacuum packaging of the flowing solid granule materials such as tealeaf and the like, and greatly improves the automaticity and the production efficiency of the vacuum packaging operation of the inner bag and outer bag.

Owner:李文峰

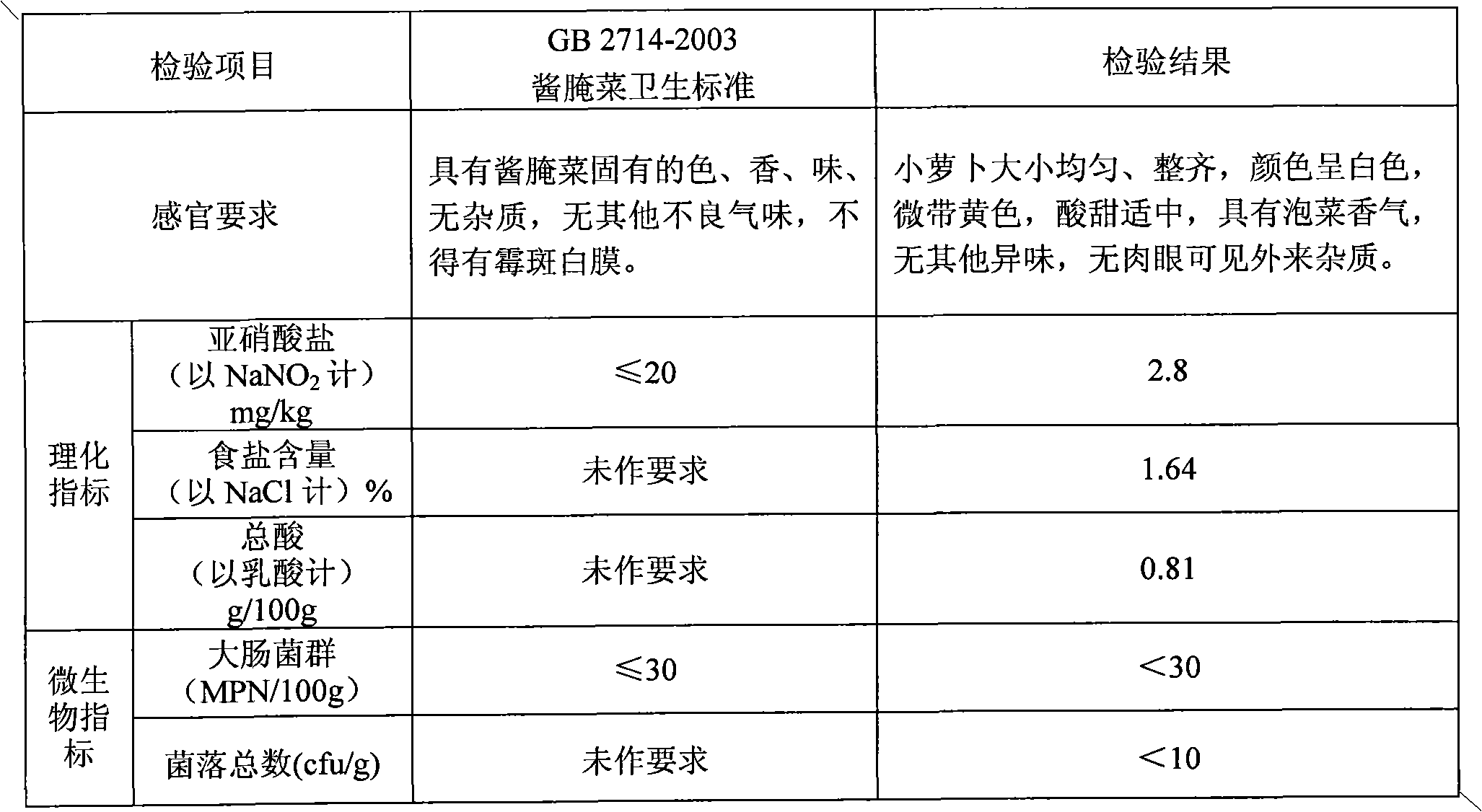

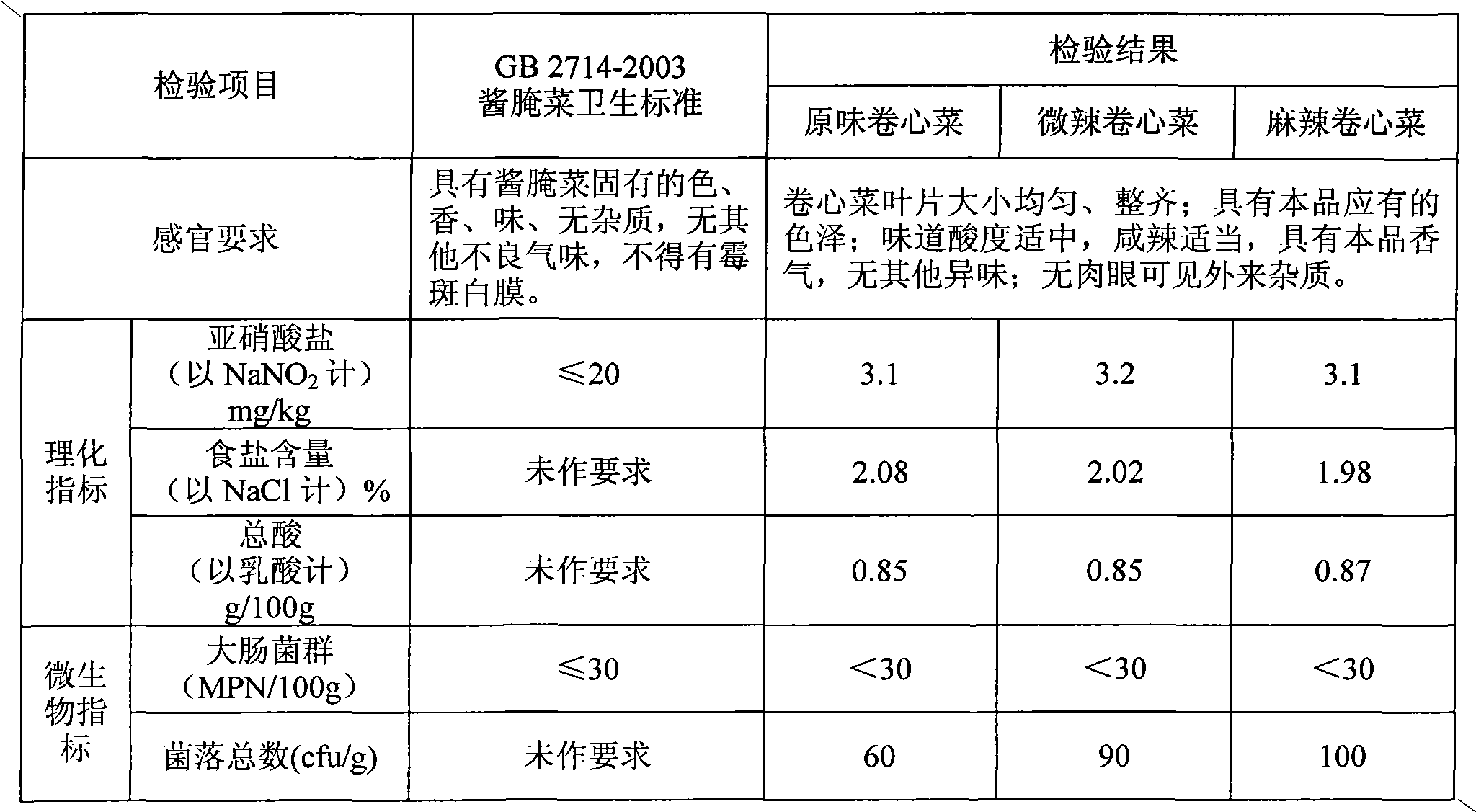

Method for processing and producing pickle products by circularly utilizing bifida ferment lysate

InactiveCN102370147AReduce moisture contentIncrease moisture contentFood preparationAdditive ingredientGlucose polymers

The invention relates to the technical field of deep processing of vegetable products, in particular to a method for processing and producing pickle products by circularly utilizing bifida ferment lysate. The method is characterized by comprising the following steps of: (1) processing fresh vegetable into parts with proper size; (2) drying via hot air to remove partial water; (3) transferring the processed vegetables into ozone water to clean and sterilize and remove resident pesticide; (4) by taking the residual bifida ferment lysate, which has viable bacteria count not less than 10<5> pieces per milliliter and is produced by fermenting pickle, as mother liquor, properly adding water, table salt and glucose to prepare into lactobacillus fermenting water; (5) transferring the primarily sterilized vegetables into a fermenting tank, introducing the lactobacillus fermenting water, and dipping for fermenting; and (6) taking the fermented vegetables; spinning to remove partial water, mixing with ingredients, packing in a vacuum condition, and pasteuring to obtain the finished product of the pickle. The method for processing and producing the pickle products by circularly utilizing the bifida ferment lysate has the advantages that: the time for fermenting the pickle is reduced; the pollution due to miscellaneous bacteria is reduced; the fermenting water can be repeatedly utilized; the inoculating rate is reduced; the fermenting cost is reduced; and resource waste and environment pollution are reduced.

Owner:ZHEJIANG GAOSHAN AGRI DEV

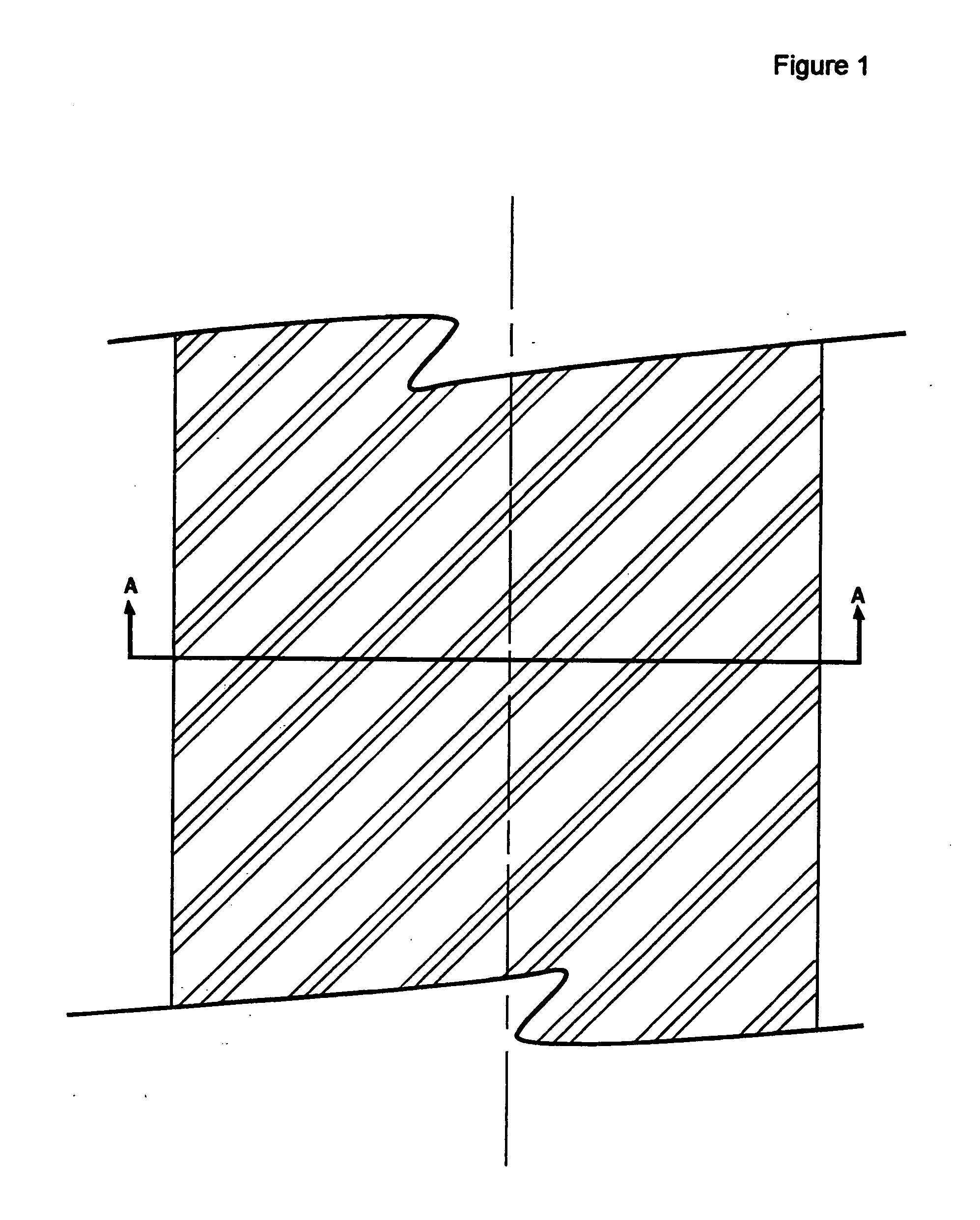

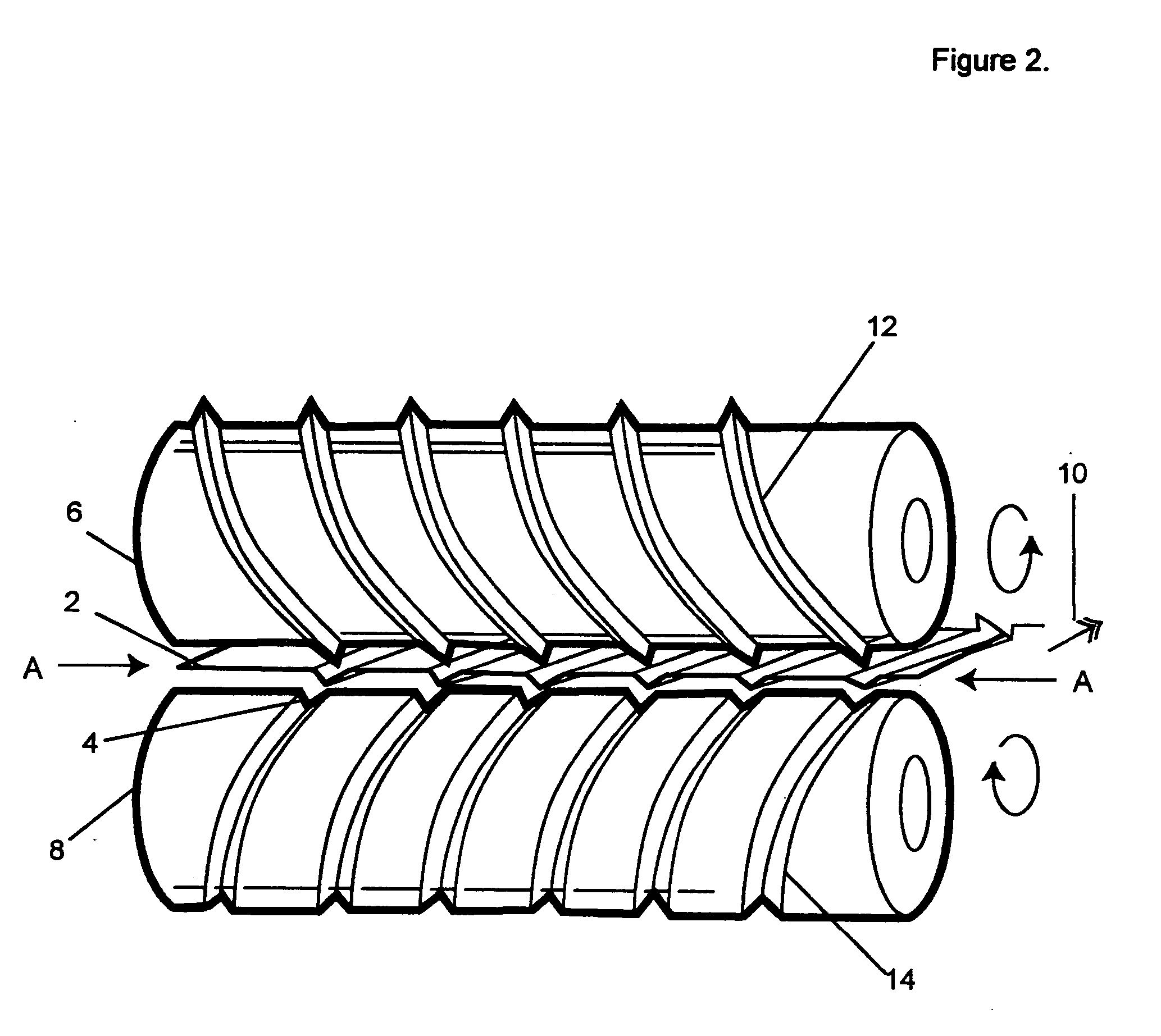

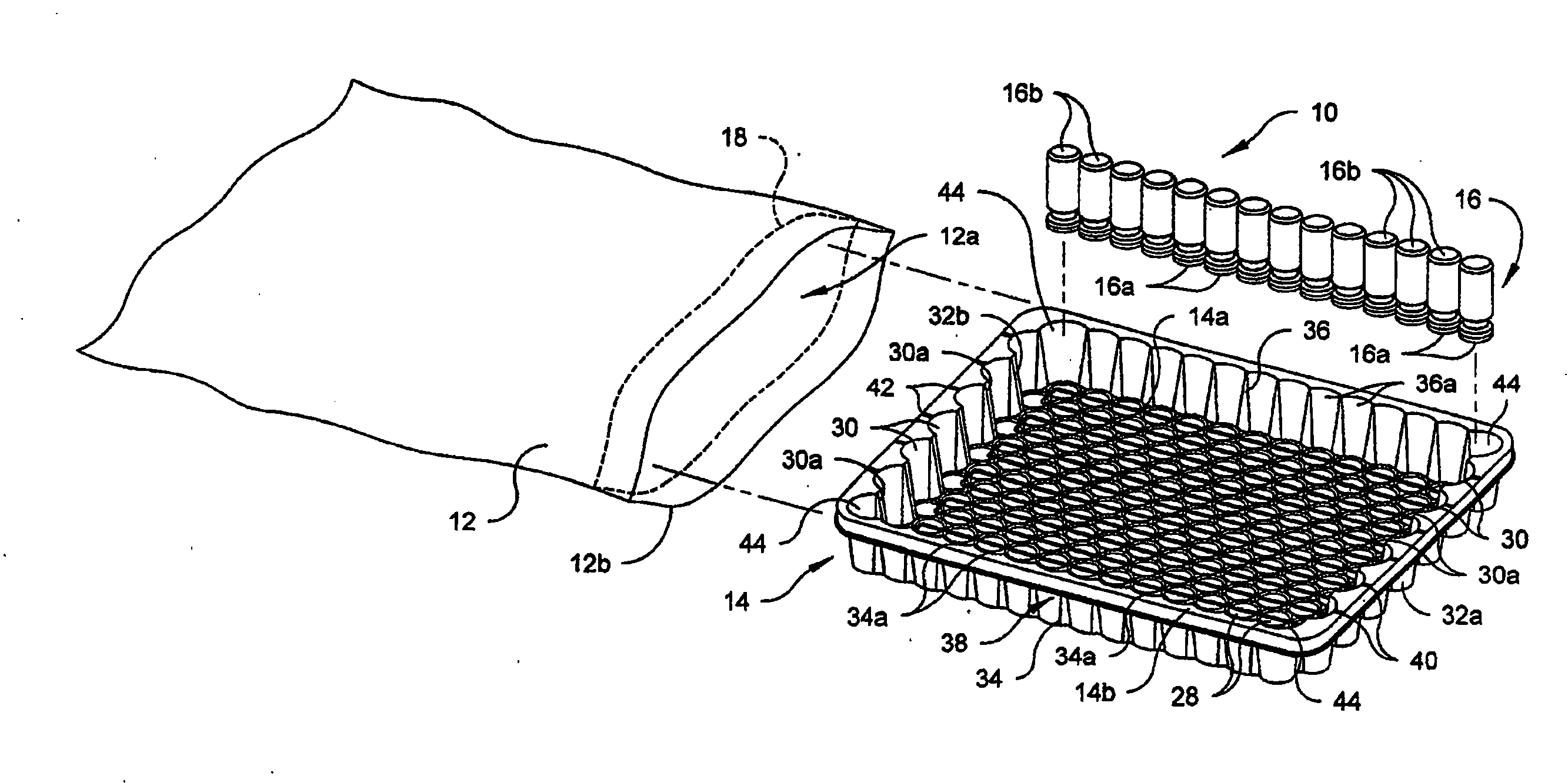

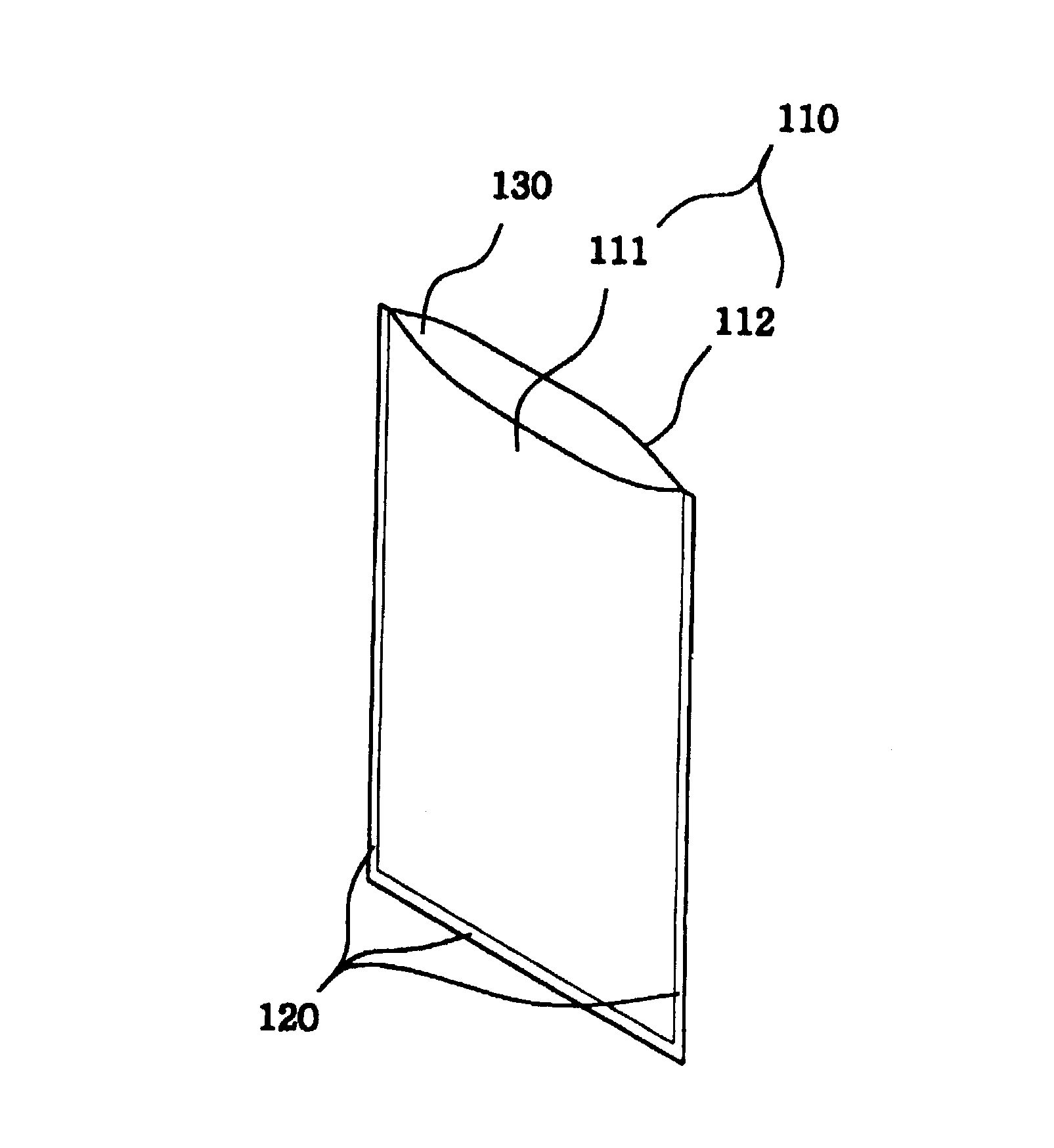

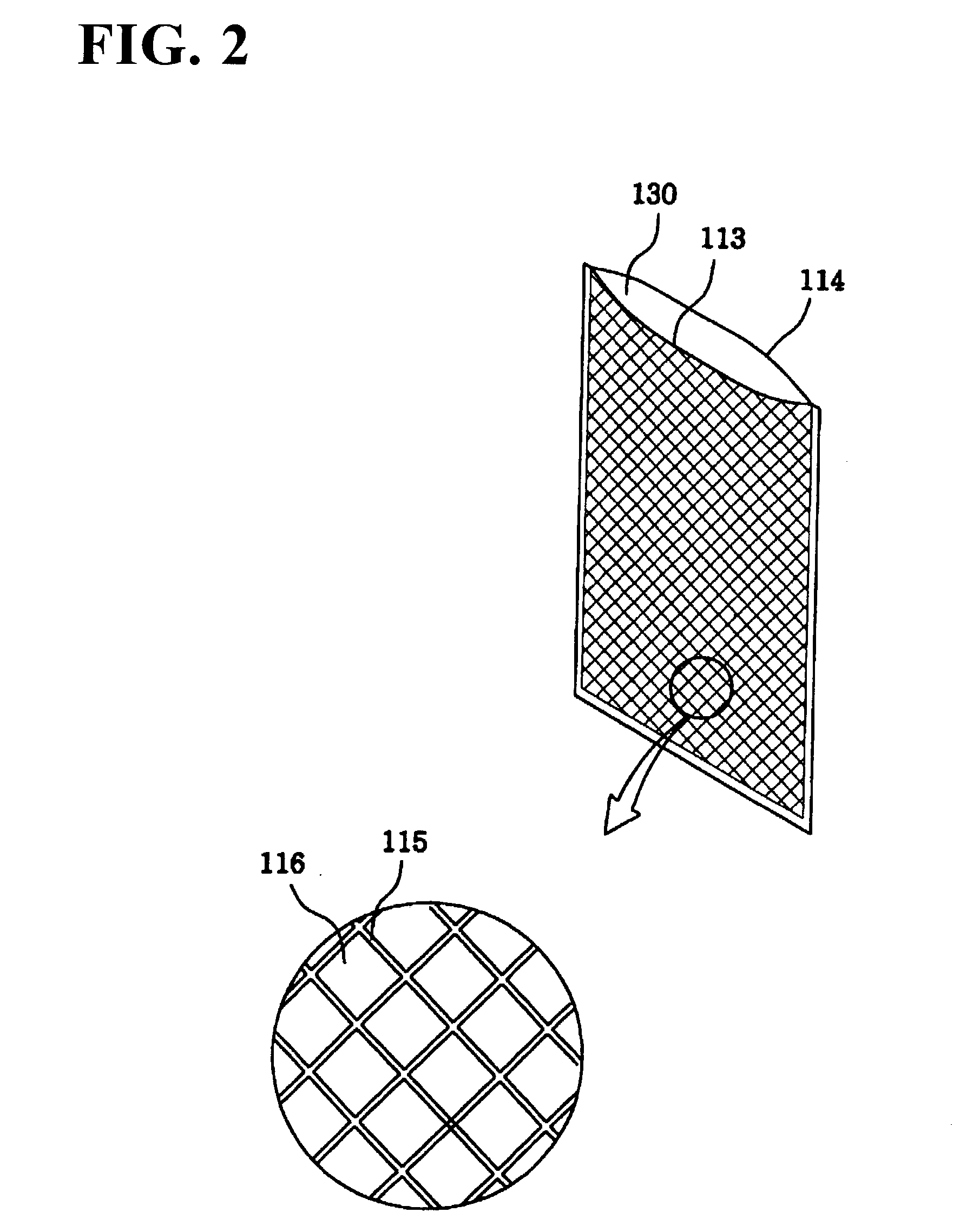

Method for preparing air channel-equipped film for use in vacuum package

InactiveUS20030155269A1Improve abilitiesEffectively prevent pinholes from occurringEnvelopes/bags making machineryWrappersEngineeringMelt extrusion

Disclosed is a method for preparing an air channel-equipped film for use in vacuum packages, which comprises the step of providing a gas-impermeable base, along with a melt-extruded heat-sealable resin, to a laminating unit consisting of a laminating roll and a cooling roll, to form a heat-sealable resin layer on the gas-impermeable base, characterized in that the heat-sealable resin is molded and quenched in such a way that a plurality of protrusions, corresponding to a plurality of grooves formed in a predetermined pattern on the circumferential surface of the cooling roll, are formed on the molded heat-sealable resin layer, defining channels for the evacuation of air therebetween. The method is simple because of its ability to form air channels without the aid of additional embossing techniques, as well as being economically favorable owing to the employment of no embossing molds.

Owner:SUNBEAN PROD INC

Method for processing flavourings instant sea cucumber

The invention discloses a processing method of seasoned instant sea cucumber, comprising the steps of the decontamination of raw sea cucumber, pressure boiling, low temperature fermentation, cutting, seasoning, vacuum packing, super high pressure sterilization, etc. The myofibril of the sea cucumber tissue becomes thinner after the process of fermented preparation, the inter-place between the fiber is large, organization structure is even, the volume of the sea cucumber is large, tenderness is improved and water capacity is enhanced, being conducive to the absorption of nutritional components; the sea cucumber tastes good after being seasoned by two liquid condiment; the super high pressure sterilization comparatively maintains the original favor, shape and nutrition of the instant sea cucumber product and the shelf life is greatly prolonged. The instant sea cucumber processed and produced by the method has no ocean fishy smell, delicious with good taste, proper hardness and softness, easy to carry and instant, basically maintaining the original nutritional components of the sea cucumber. The product can be preserved for a long time with freshness, nutrition, convenience and safety and overcomes the shortages of the coarse texture and the poor taste of the sea cucumber processed by the current technology.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Method for processing leisure seasoning dewatered fruit and vegetable

InactiveCN1554292AIncreased drying costsLittle increase in drying costsFood preservationFood preparationPre treatmentHot blast

The present invention relates to the production process of seasoned dewatered fruit and vegetable as snack, and belongs to the field of fruit and vegetable food producing technology. The production process includes selecting vegetable, meat, edible fungus and other material, peeling, washing, slicing, scalding to kill enzyme, color keeping, hot blast drying to safe water content of 5-7%, re-combining with water inside seasoning liquid for 30-60 min to increase the water content to 20-60%, vacuum drying to water content of 3-7%, and nitrogen-filling or vacuum packing. The product is puffy and tasty and is used as snack.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

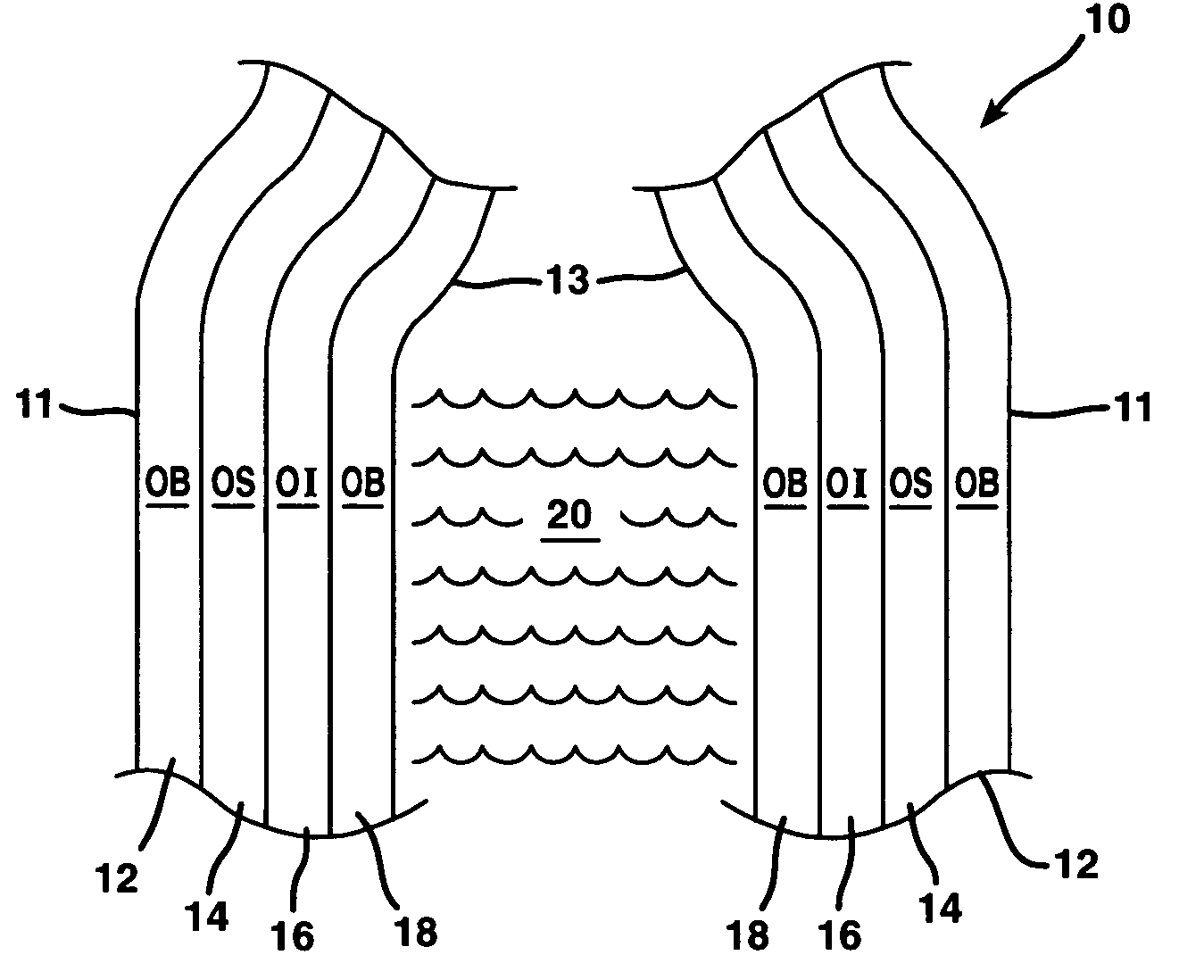

Atmospheric and/or differential pressure closure for an evacuable storage container

An evacuable bag or container for items which benefit from being stored in a vacuum environment by reason that the bag or container is impermeable to air or liquid, with a first opening for entrance or closure purposes, which first opening has a zipper sealing closure adjacent thereto and integral with said bag or container for closing and opening purposes, the sealing integrity of which is aided by atmospheric and / or differential pressures, and a second opening, with an exit-only valve therein, for connection purposes to an external vacuum source, by which means said bag or container can be evacuated of air or liquid. Thus, this invention provides the constituent key to a relatively inexpensive appliance system for home vacuum packaging of perishables and / or items requiring compression packaging due to limited storage space.

Owner:ERKENBRACK KENNETH BERESFORD

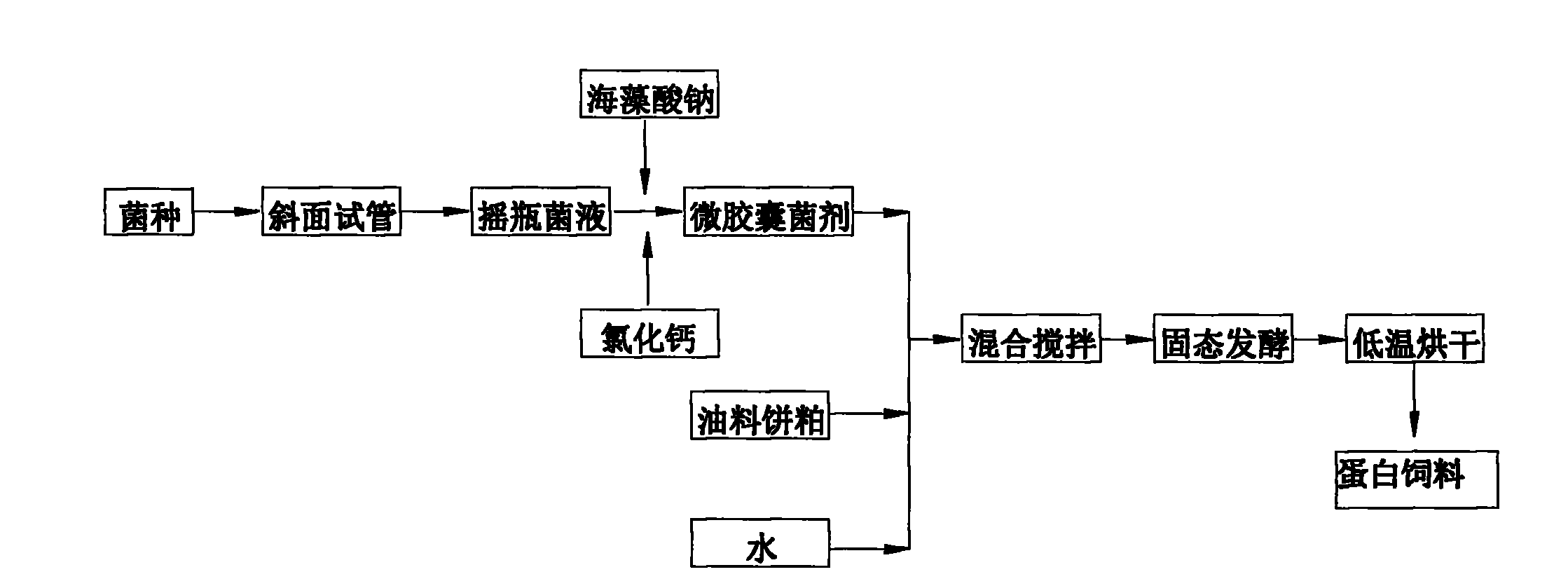

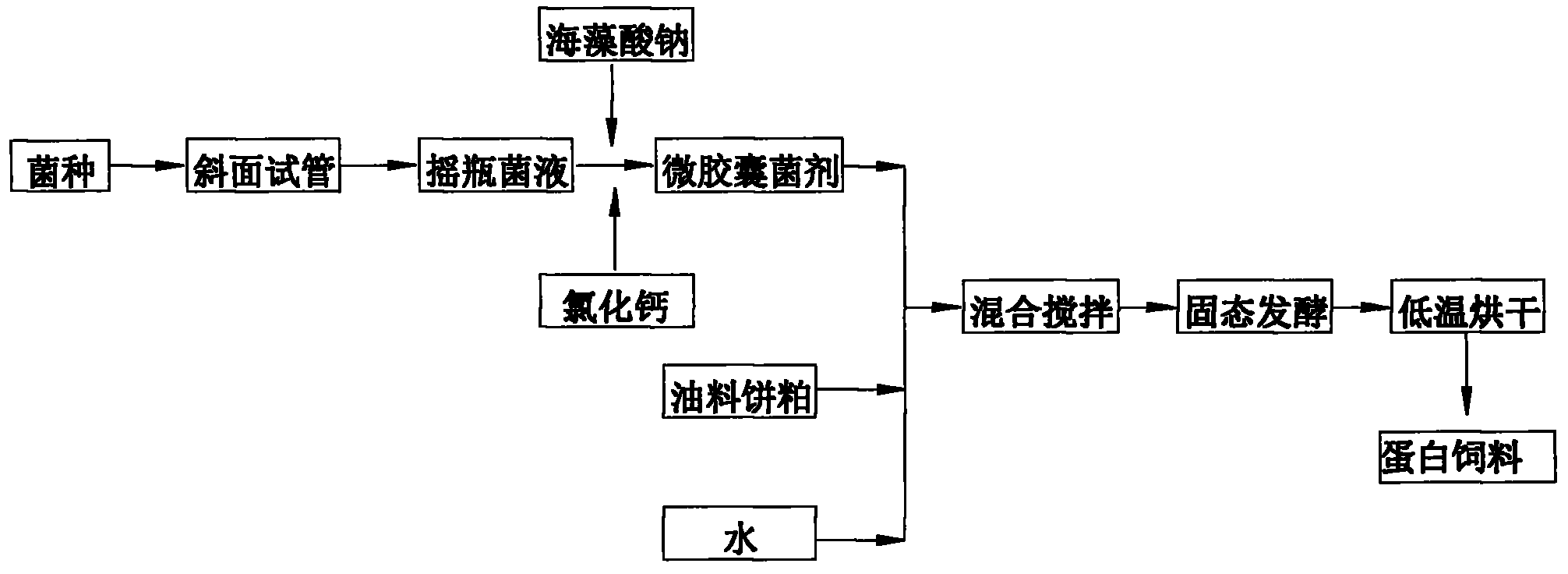

Method for preparing oil cake protein feedstuff through low moisture solid state fermentation

InactiveCN102318732AEasy to prepareLow priceFood processingAnimal feeding stuffMicroorganismRoom temperature

The invention belongs to the technical field of microbial fermentation, specifically relates to a method for preparing an oil cake protein feedstuff through low moisture solid state fermentation. The method for preparing the oil cake protein feedstuff through the low moisture solid state fermentation is characterized in that: the method comprises the following steps: 1) preparing a bacterial inoculum: injecting a mixed solution (comprising a bacterial liquid and a sodium alginate solution) in a CaCl2 solution through an injector, washing three times through sterilized physiological saline after curing to obtain a microcapsule bacterial inoculum, wherein a volume ratio of the sodium alginate solution to the CaCl2 solution is 1:2-1:10; 2) mixing and fermenting cake base materials: uniformly mixing and stirring the microcapsule bacterial inoculum, oil cake and water, carrying out standing fermentation for 24-96 hours at a room temperature to obtain a fermented product; 3) adopting one of the following two methods: (1) carrying out drying, wherein the fermented product is dried after completing the fermentation to obtain the oil cake protein feedstuff; (2) directly carrying out vacuum packaging for the fermented product after completing the fermentation to obtain the oil cake protein feedstuff. The method has characteristics of high survival rate and low production cost.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

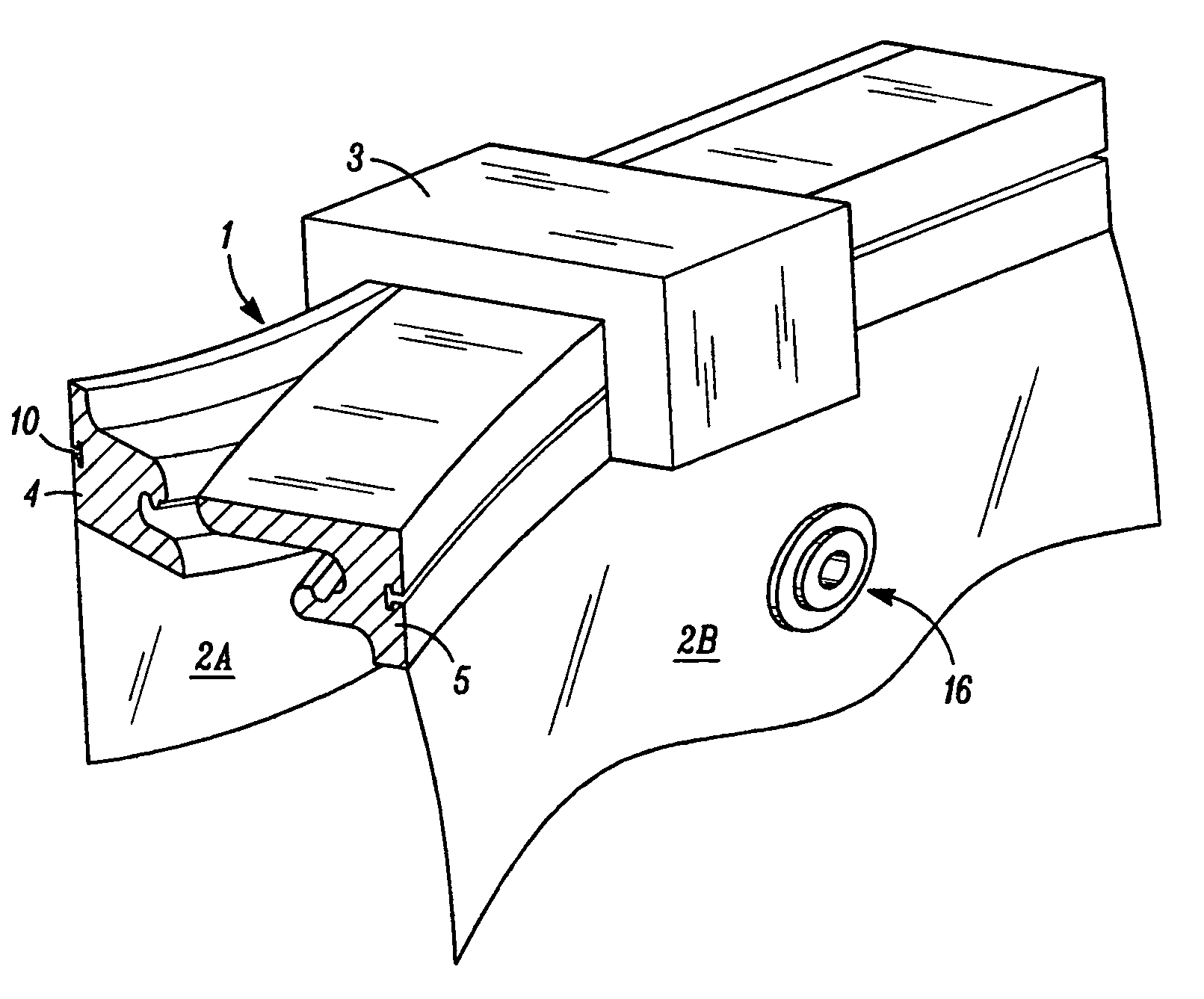

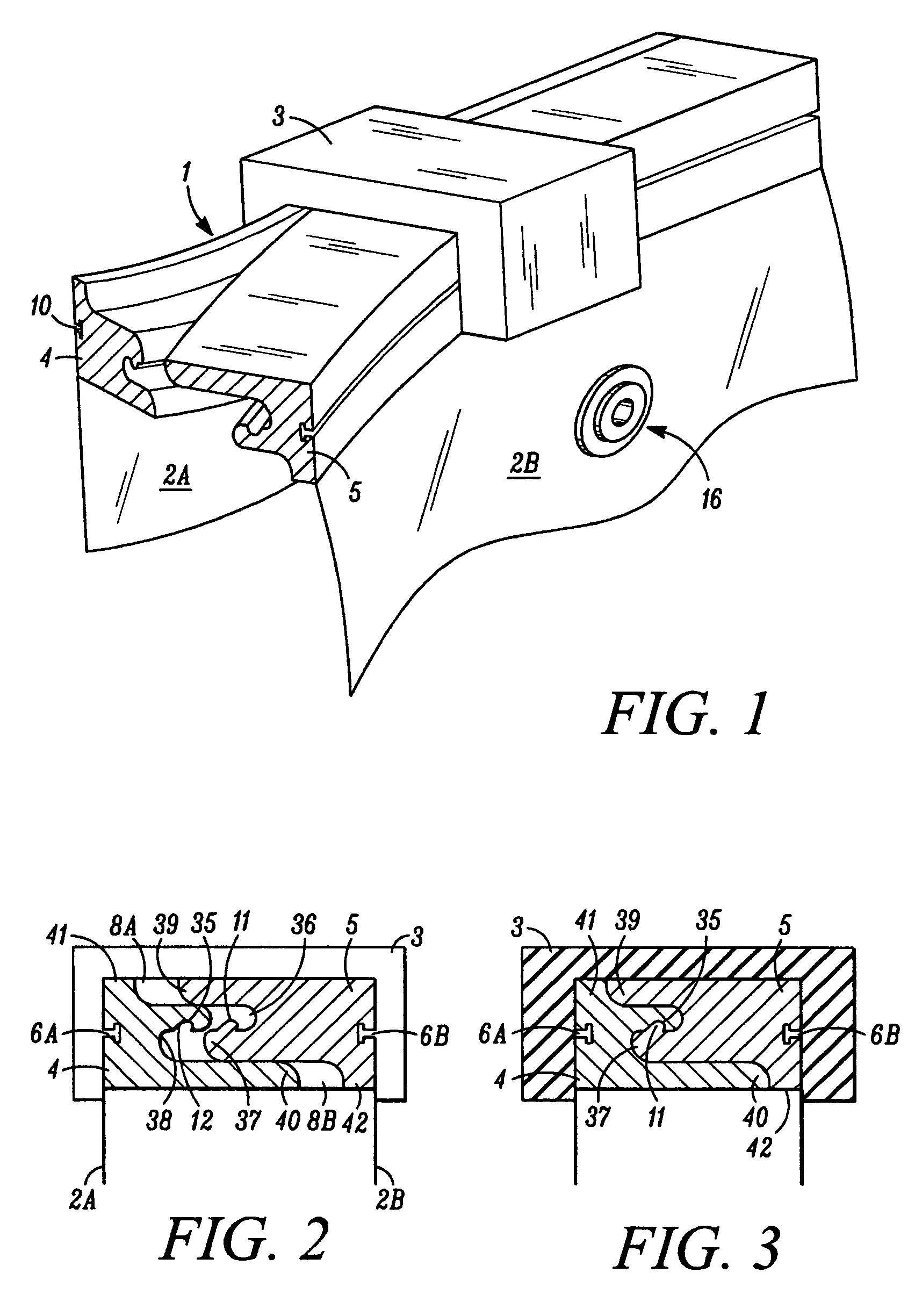

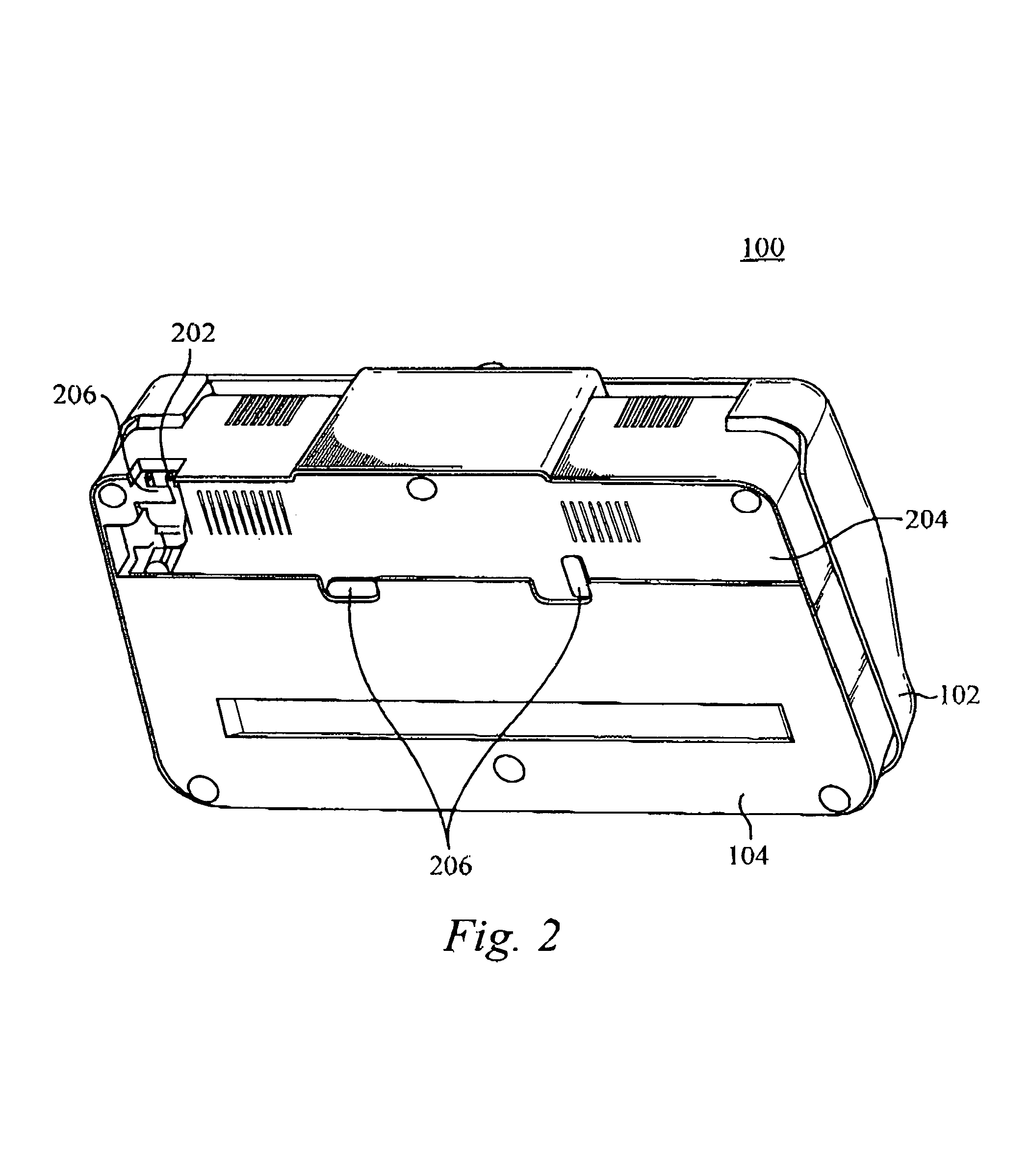

Vacuum packaging appliance with removable trough

An appliance for storing articles within flexible and non-flexible containers under vacuum. The appliance comprises a lid adapted to define a vacuum chamber when it is moved to a closed position relative to a trough in the base of the appliance. The trough is slidably removable from the base of the appliance. The appliance is further adapted for connection to vacuum sealing attachments for various containers whereby the containers can be selectively evacuated. The appliance includes a thermal sealing mechanism for sealing a flexible container as well as a cutting mechanism for cutting the flexible container to a desired size. The appliance includes a control panel for selectively operating the vacuuming and sealing processes.

Owner:ALLTRISTA CORP

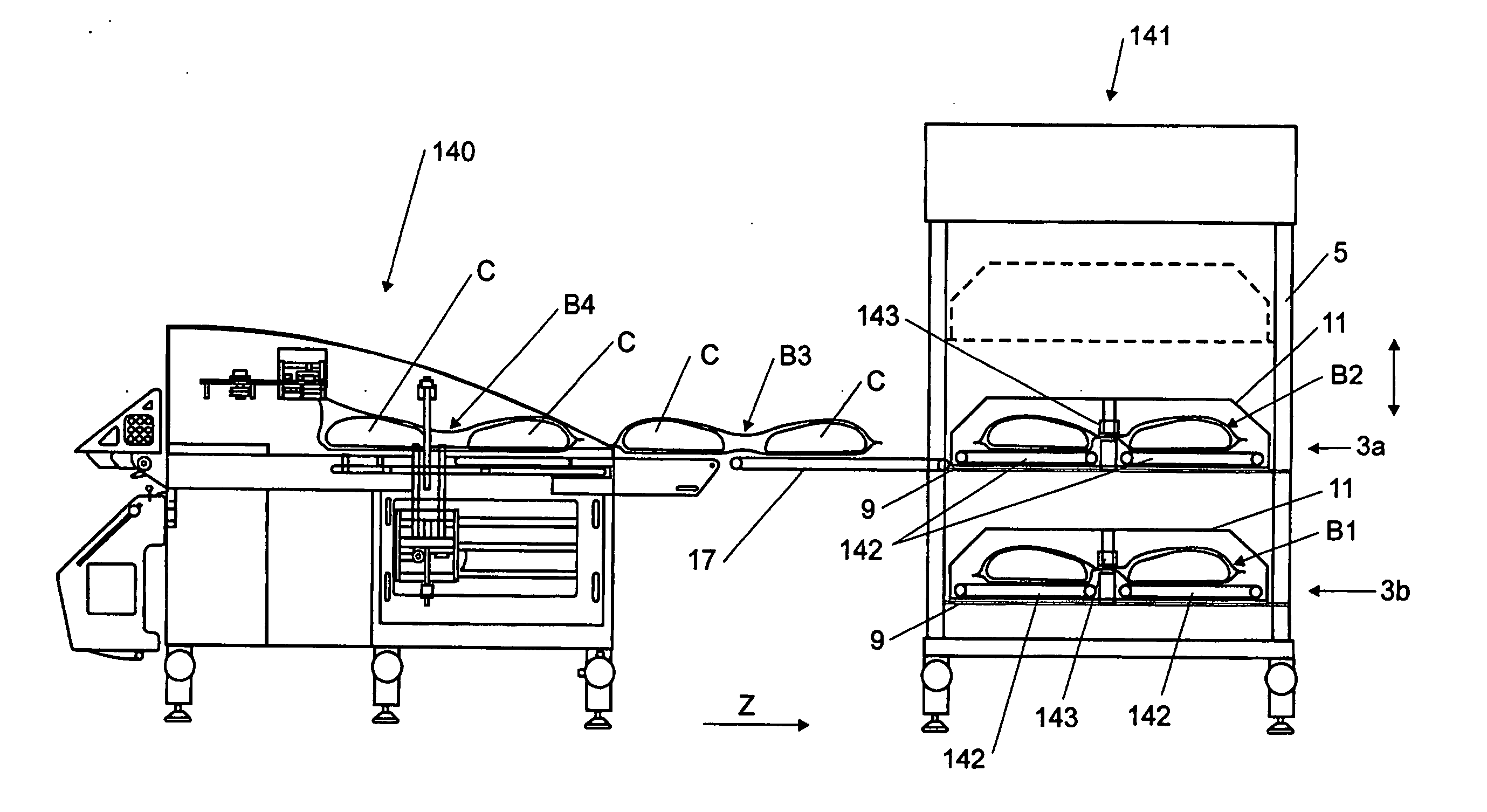

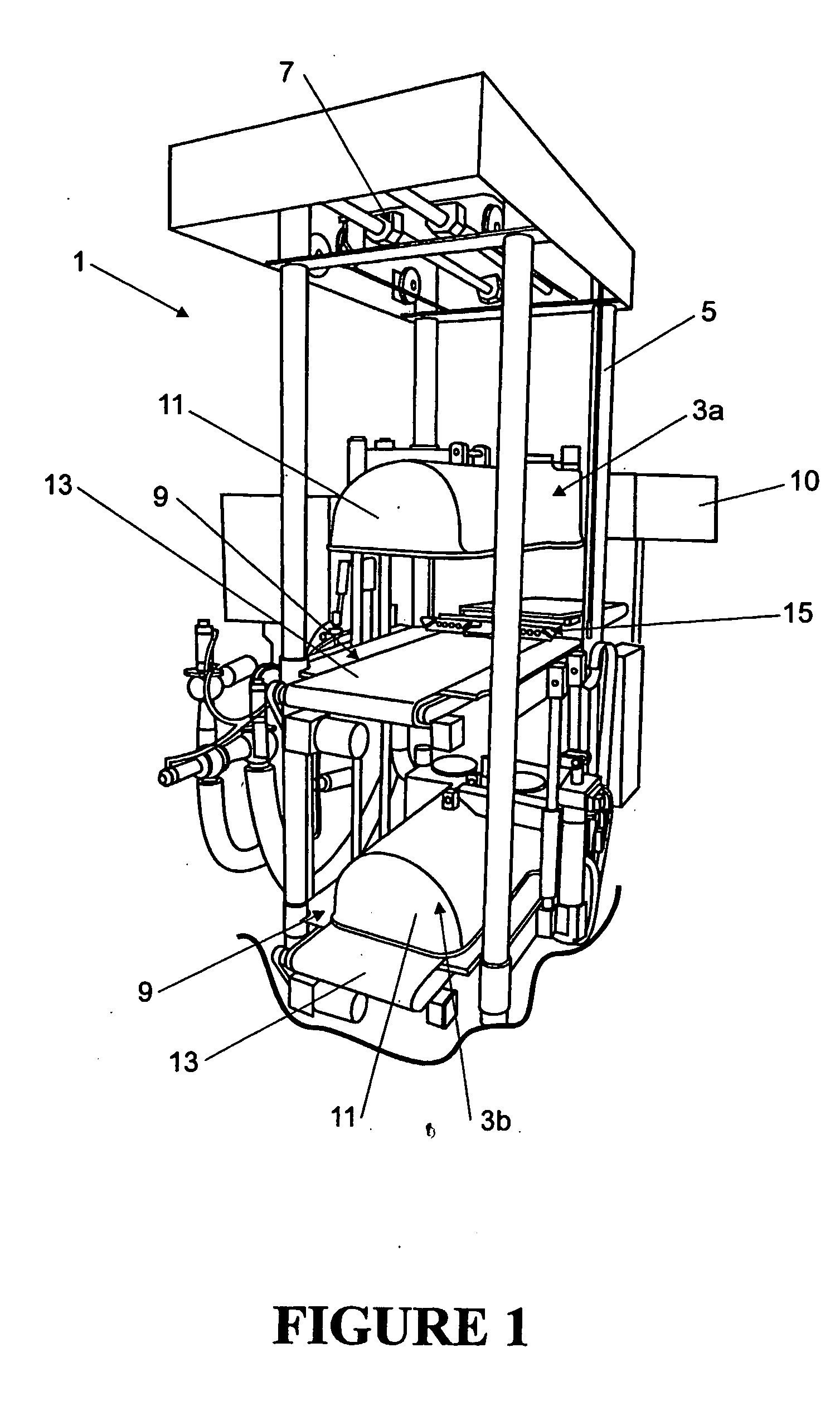

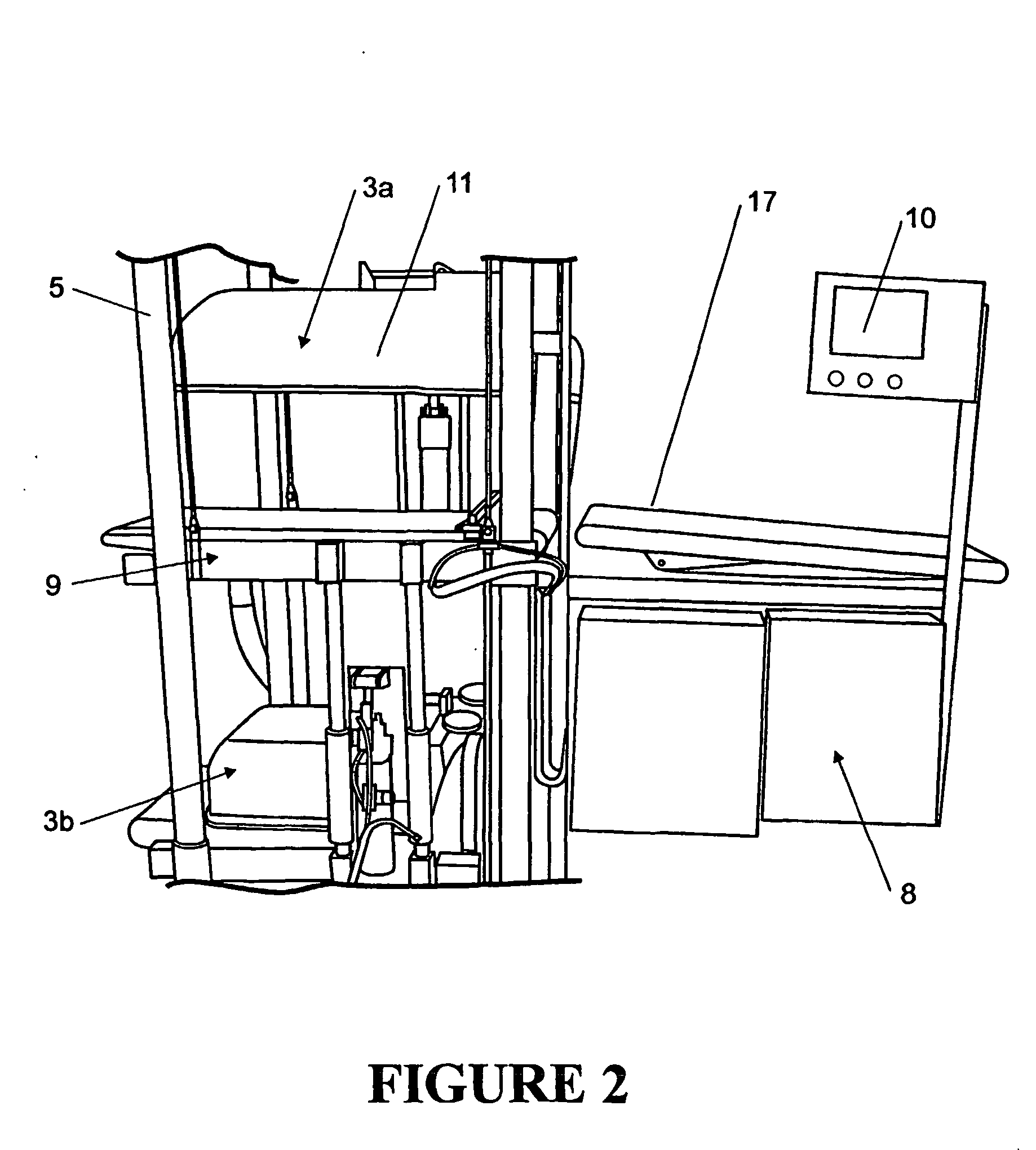

Vacuum packaging machine

InactiveUS20050178090A1Packaging by pressurising/gasifyingPackaging under vacuum/special atmosphereEngineeringVacuum chamber

A vacuum packaging machine includes a plurality of vacuum chambers (3a, 3b) each arranged to receive at least one unsealed product package and operable to perform an independent vacuum sealing operation, each vacuum chamber having a longitudinal direction defined by a direction of travel of the respective product package through the chamber (3a, 3b), each chamber having a heat seal assembly (15) therein which extends transversely to the longitudinal direction. An infeed conveyor (17) can be provided with a telescoping portion (17a) which can extend over the heat seal assembly or a part thereof. Each vacuum chamber can have a respective bed (9) and independently moveable hood (11), and the beds (9) can be synchronously vertically moveable. The vacuum packaging machine can be used in combination with a suitable product bagging or wrapping machine.

Owner:SEALED AIR NEW ZEALAND

Composite vegetable powder products and method for preparing the same

InactiveCN101095493ACompatibility is reasonablePreserve nutritional valueFruits/vegetable preservation by freezing/coolingFood preparationFlavorPre cooling

The invention relates to a kind of compound vegetable powder and the production method. The comprised components and their weight proportion are as follows: cabbage powder 20-85%, west orchid powder 0-50%, and other vegetable powder of cruciferae 0-30%. The method comprises following steps: picking raw material, selecting, pre-cooling, washing, blanching, cooling, cutting to sheet or block, freezing, subliming drying, hydrolyzing drying, grinding, matching, vacuum packing. The product is characterized by reasonable matching, flavor for absorption, health-care effect. The process is reasonable and the nutrition and biological activity in vegetable are retained at maximum degree because of the vacuum freezing technique.

Owner:SHANGHAI RIYI AGRI TECH

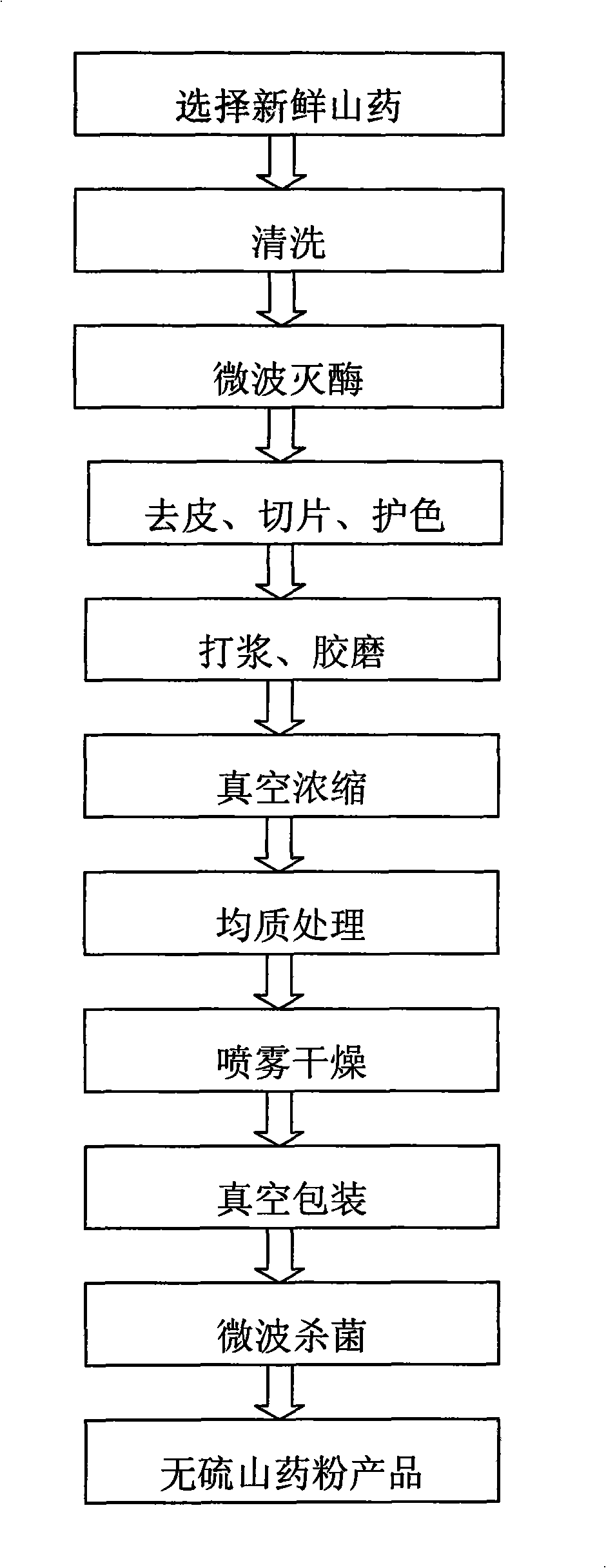

Production method for spray-drying Chinese yam powder without using sulfur to protecting color

InactiveCN101513241AImprove quality and efficiencyIncrease productivityHair cosmeticsDead plant preservationVitamin CAdditive ingredient

The invention relates to a production method for spray-drying Chinese yam powder without using sulfur to protecting color. The Chinese yam is prepared from fresh Chinese yam and is obtained by the steps of microwave enzyme deactivation, shelling, slicing, color protection, pulping, grinding, vacuum condensation, homogenization, spray-drying, vacuum packaging and microwave sterilization. The Chinese yam raw material is deactivated by microwave at temperature of 60 DEG C, cut to slice, and is soaked in sulfur-free color protection liquid containing phytic acid, Ethylenediaminetetraacetic acid disodium, vitamin C and citric acid, the color protection liquid and the Chinese yam slice is pulped together and is milled by a colloid mill, the Chinese yam slurry is concentrated by a vacuum condensation equipment until the content of solid is 15-25% and is homogeneously processed, homogenized liquid material is sprayed and dried by a centrifugal spray-drying machine, the obtained Chinese yam powder is packaged by vacuum and is sterilized by a microwave sterilization equipment to prepare the sulfur-free Chinese yam powder product. The invention has high production efficiency and low cost, the produced Chinese yam product has good color, high safety and complete nutrient composition, and can applied for field such as foodstuff, medicine and cosmetic product.

Owner:袁书林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com