Method for processing and producing pickle products by circularly utilizing bifida ferment lysate

A lactic acid bacteria fermentation liquid and lactic acid bacteria fermentation technology, which are applied in the fields of application, food preparation, food science, etc., can solve the problems of high salt content and nitrite content, unstable product quality, and low environmental pollution, so as to reduce environmental pollution. , The effect of solving the harsh storage conditions and reducing the production cost of enterprises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

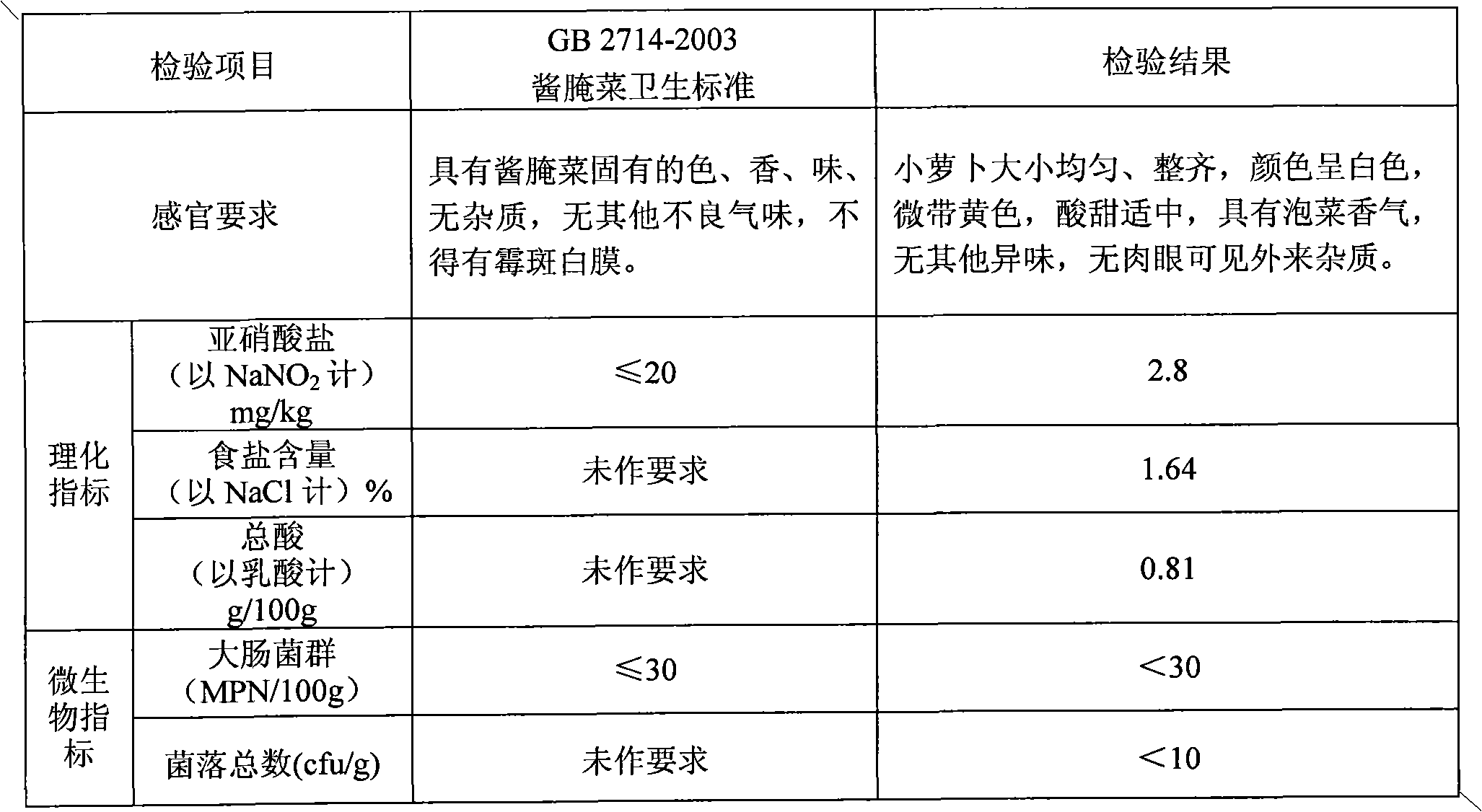

[0021] Embodiment 1: the method for recycling lactic acid bacteria fermented liquid to process and produce radish kimchi.

[0022] 1. Spread 500kg of cleaned and trimmed radishes on the tray of the hot air dehydration oven, set the temperature at 60°C, and take 1.5 to 2.5 hours until the moisture on the surface of the radishes disappears and the vegetables become soft. Radishes lose 20-25% of their moisture.

[0023] 2. Put the dehydrated radishes in a covered sink to ensure that the radishes are submerged under the water, turn on the ozone generator, and inject ozone gas into the water for 5 to 10 minutes.

[0024] 3. Prepare lactic acid bacteria fermented water. When carrying out kimchi processing for the first time, the preparation of lactic acid bacteria fermented water is carried out, and its preparation process is as follows:

[0025] (1) Mix the freeze-dried pure Lactobacillus plantarum, Acetobacter and Saccharomyces cerevisiae powders evenly according to the ratio of...

example 2

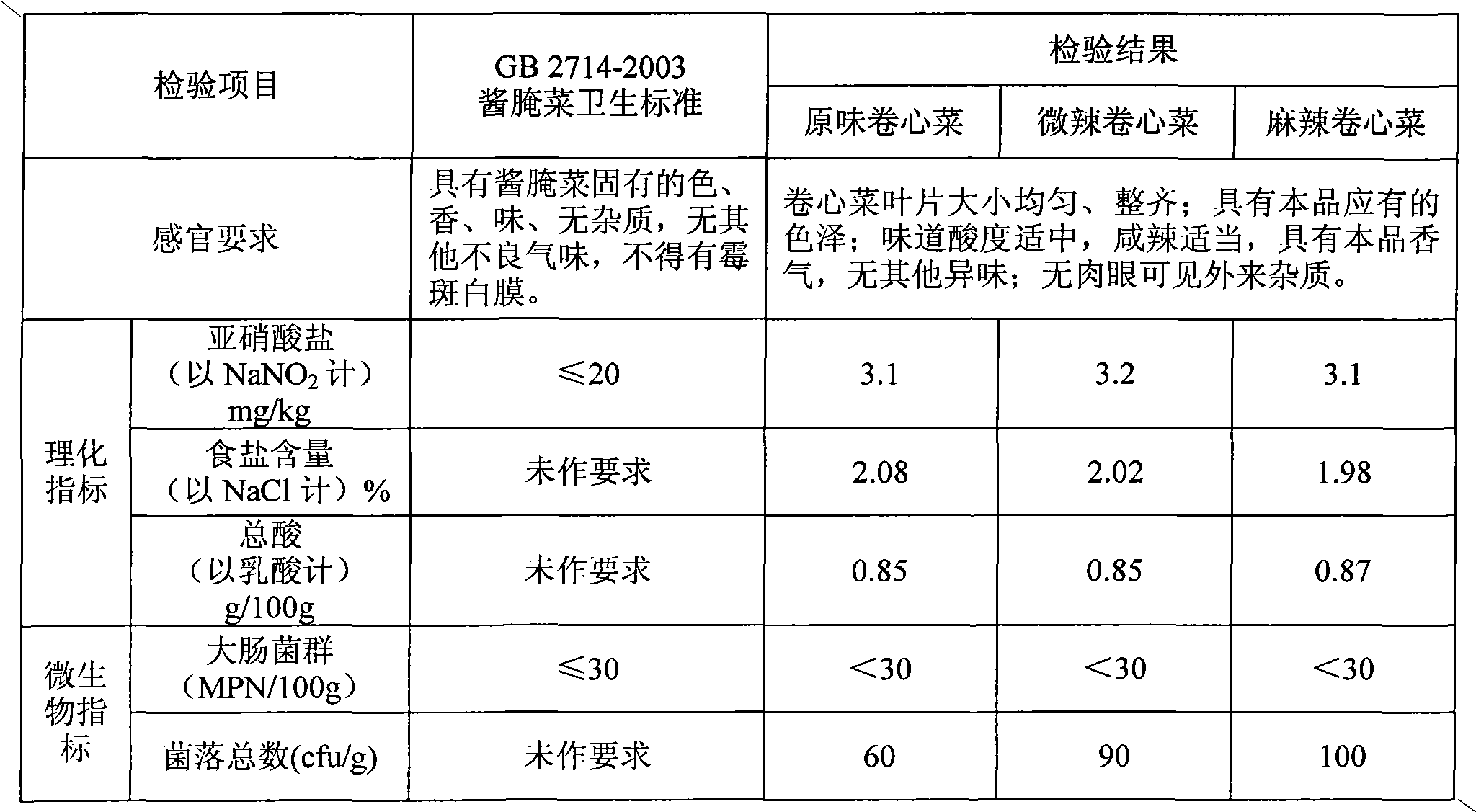

[0033] Example 2: The method of recycling lactic acid bacteria fermentation broth to process and produce cabbage kimchi.

[0034] 1. Fully sterilize the fermentation water, fermentation tanks, blending tanks and water pipelines. The number of live bacteria should not be less than 10 5 The leftover liquid of lactic acid bacteria fermentation of each / ml is used as mother liquor, adds water, salt and glucose, detects and adjusts the acidity of fermented water to be pH=5.8~6.8, and salt content is 1%~3% (weight), and sugar content is 0.5~2% ( weight), as the lactic acid bacteria fermented water processed by this batch of dishes.

[0035] 2. Spread 500kg of cleaned and cut cabbage on the tray of the hot air dehydration oven, set the temperature at 60°C, and take 1.5 to 2.5 hours until the surface moisture of the cabbage disappears and the cabbage becomes soft. During this period, the cabbage Lose 20% to 25% of moisture.

[0036] 3. Put the dehydrated cabbage in the water tank wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com