Patents

Literature

50results about How to "Solve the problem of environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

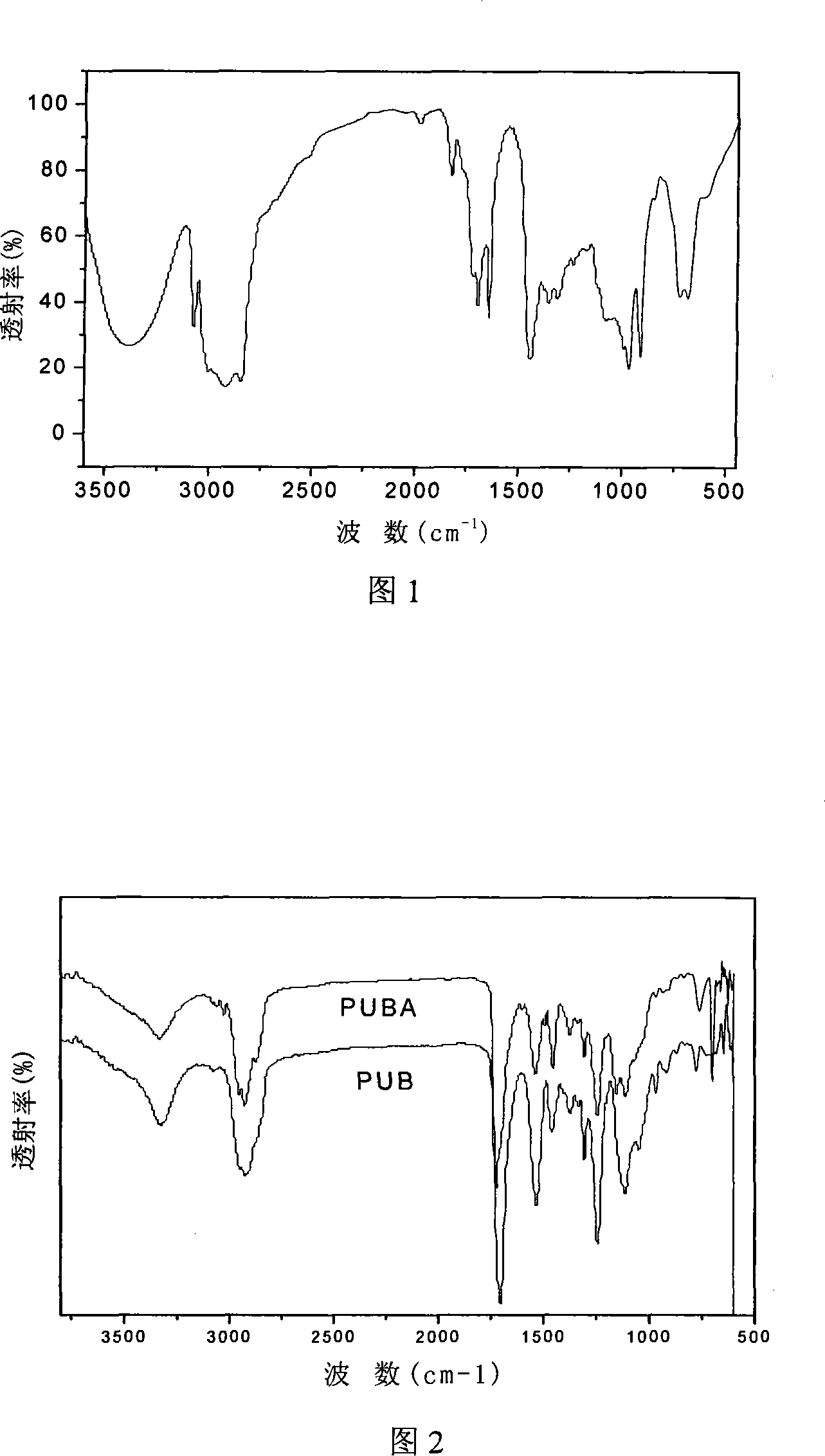

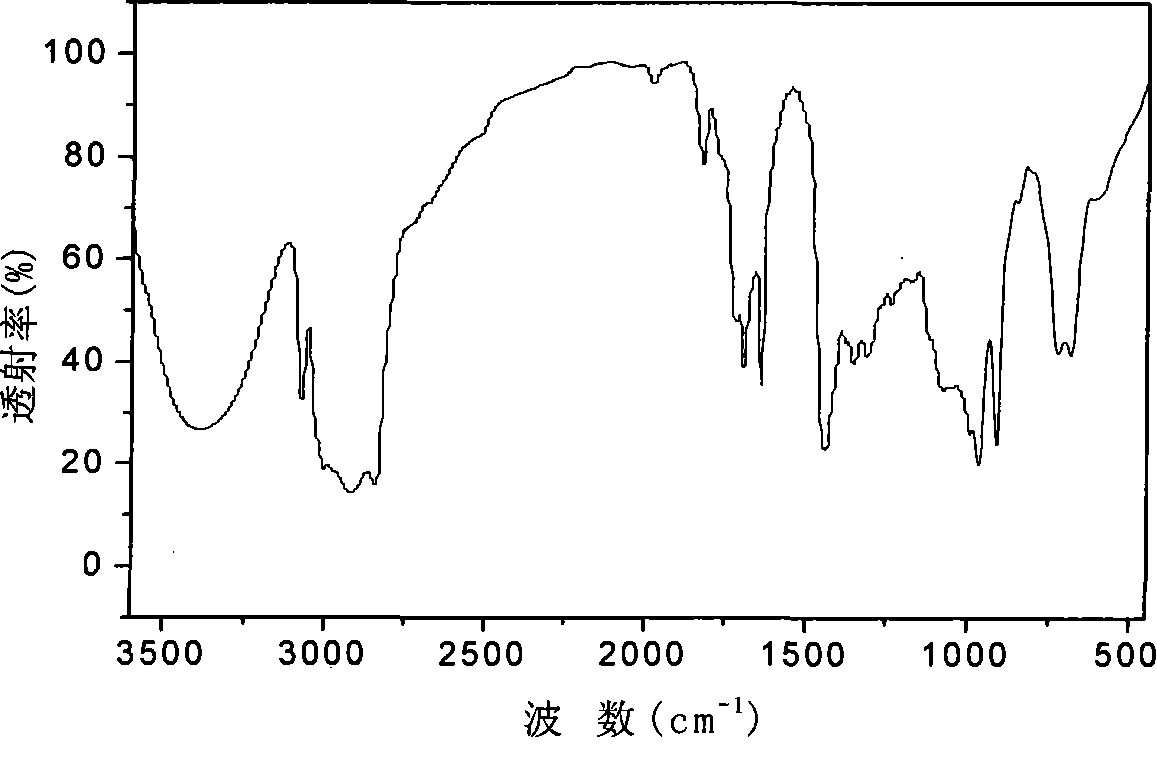

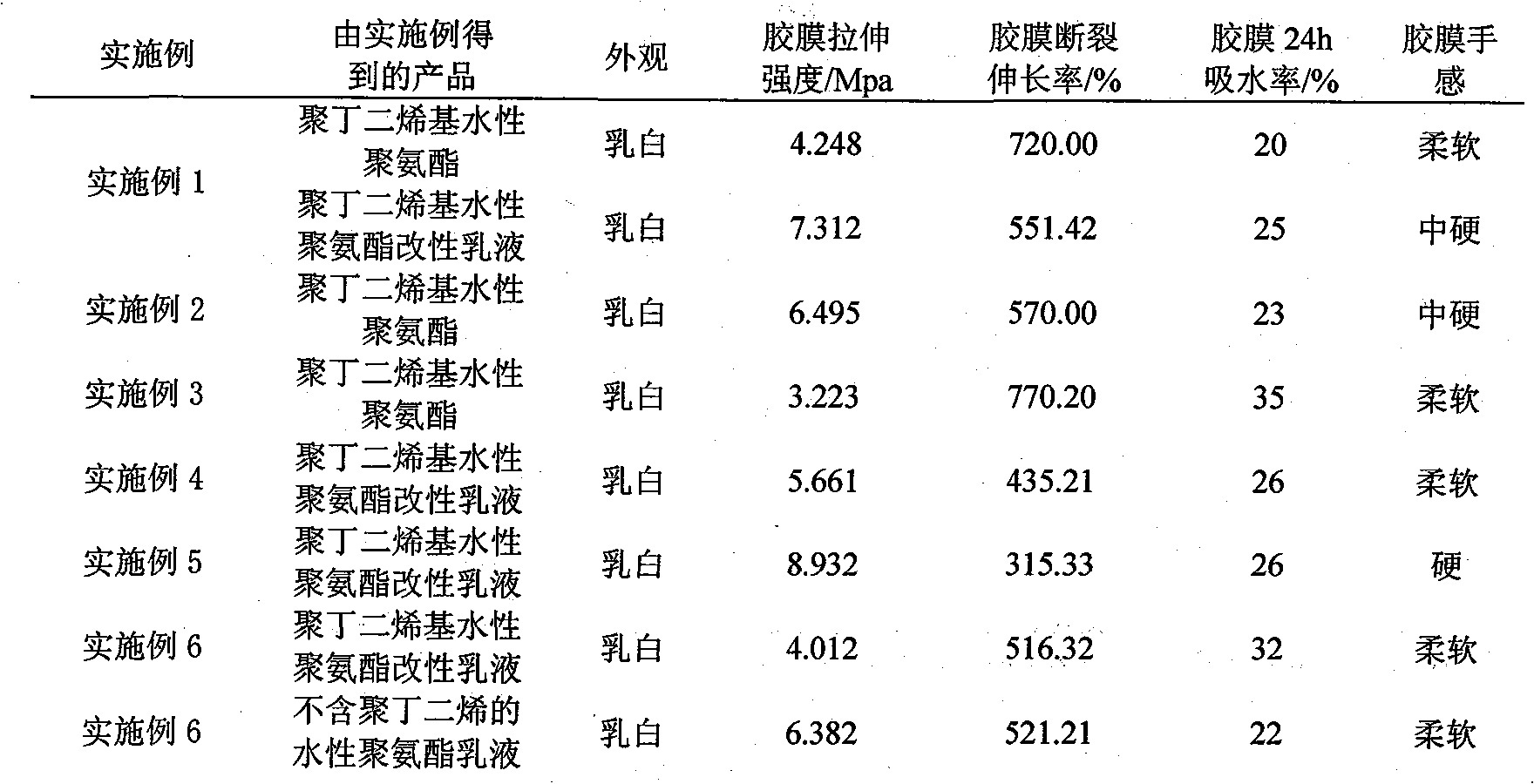

Method for preparing polybutadiene-base water polyurethane and modified emulsion thereof

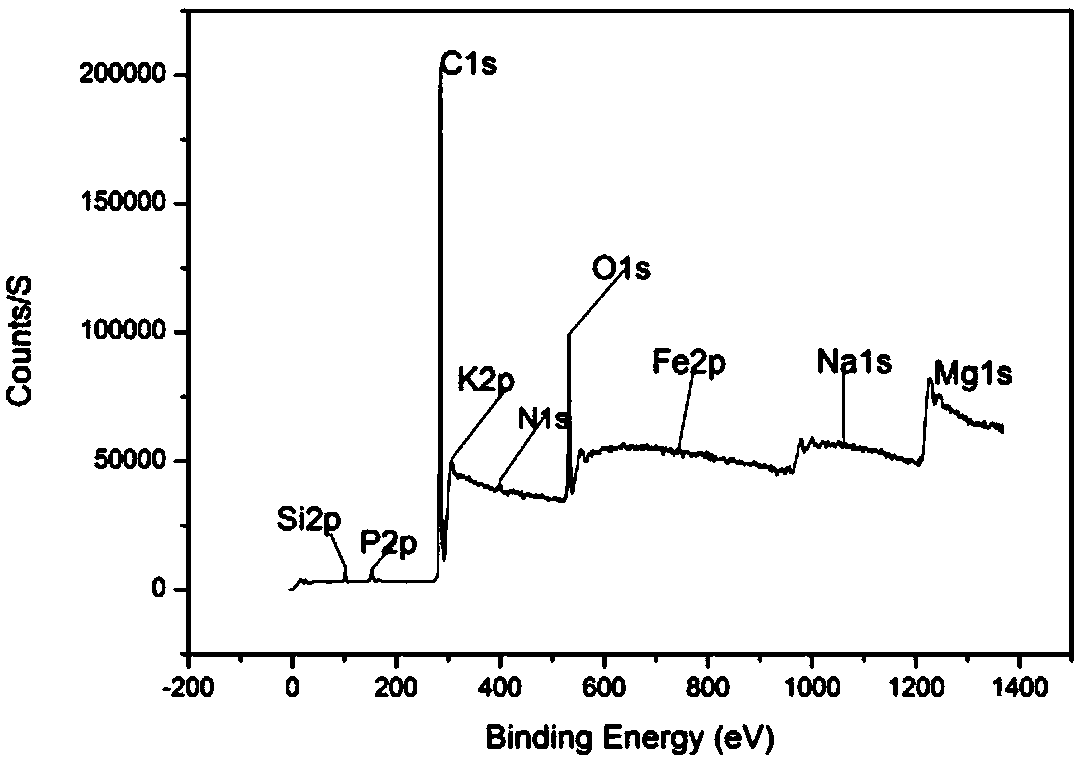

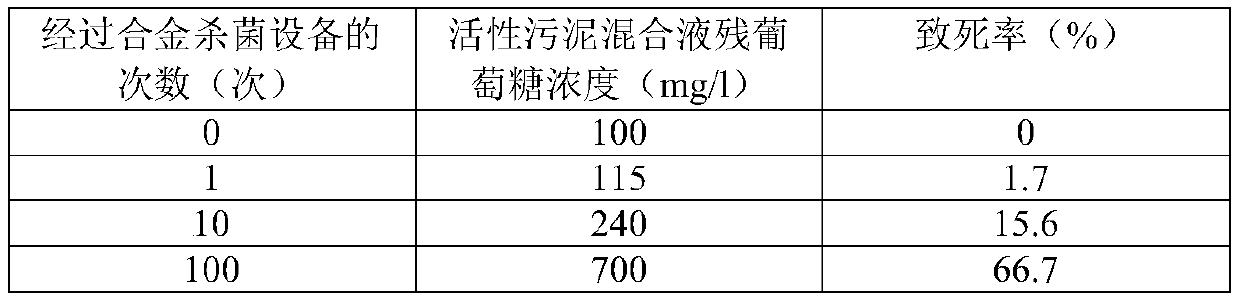

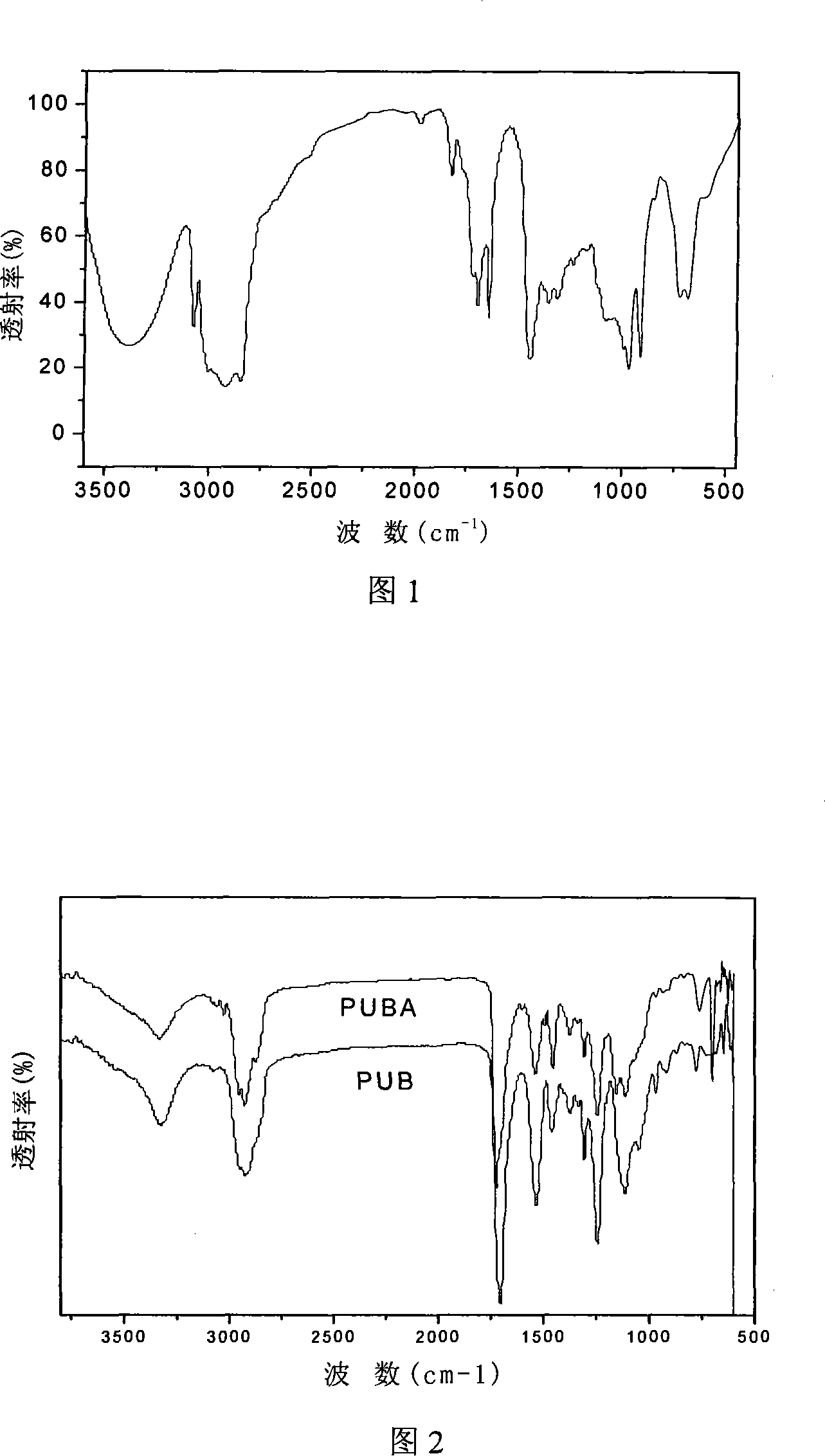

InactiveCN101235129ASolve the problem of environmental protectionGood compatibilityPolymer scienceAlcohol

The invention discloses a polybutadiene aqueous polyurethane and a preparation method of relative modified emulsion, which is characterized by reacting low polymer polyatomic alcohol and hydroxy-terminated butadiene rubber and isocyanate, adding hydrophilic chain extender and catalyst to be reacted, cooling and emulsifying to obtain polybutadiene aqueous polyurethane, mixing polybutadiene aqueous polyurethane, emulsifier, water and inducer uniformly, adding ethenyl monomer to carry out emulsion polymerization to obtain polybutadiene aqueous polyurethane modified emulsion. The invention uses hydroxy-terminated butadiene rubber to synthesize aqueous polyurethane which can be modified by ethenyl to obtain environment-friendly, stable and low temperature resistant aqueous resin with better mechanical property. The resin can be used in weaving, leather processing, paint and adhesive or the like.

Owner:ANHUI UNIVERSITY

Method for innocent treatment of antibiotic gruffs by utilizing biological technology

The invention belongs to a method for treating the dregs of antibiotics decoction, which can utilize the biological technique to innocently treatment the dregs of antibiotics decoction. The invention comprises: preparing the cultivate medium, seeding and ferment. The invention can solve the environmental treatment of dregs of antibiotics decoction, while it has the advantages of easy storage, high inner nutrition quality of treated dregs of antibiotics decoction, significant treating effect, and easy operation. The invention belongs to the environmental protection project.

Owner:雷增学

Nano shell powder ecological functional flatly painted coating

The invention relates to environmental protection paint, in particular to nano shell powder ecological functional flatly painted coating. The coating is prepared from shell powder (calcined), ash-calcium, kaolin, heavy calcium carbonate, hydrated magnesium silicate, titanium dioxide, vinyl acetate, hydroxyethyl cellulose, polyving akohol, polydimethylsiloxane, a water reducer and a defoamer. The coating solves the problem that indoor ornament or decoration paint is not environment-friendly. The coating has the characteristics that the coating is antifungal, purifies the air, prevents mildew, adopts a spiral pore structure, is 3.0mm in press coating thickness and high in glossiness, does not has obvious color aberration, is resistant to shock, abrasion, water, high and low temperature weather and aging, and ensures that the service life of a product reaches more than 20 years.

Owner:通化市星赛尔生物科技有限公司

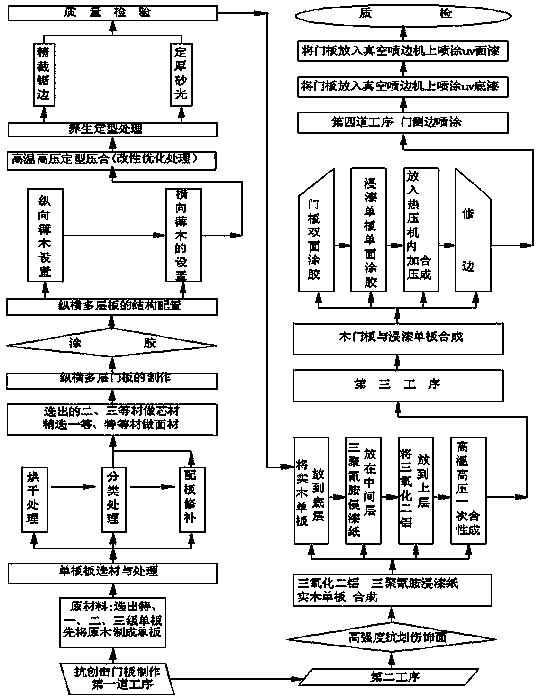

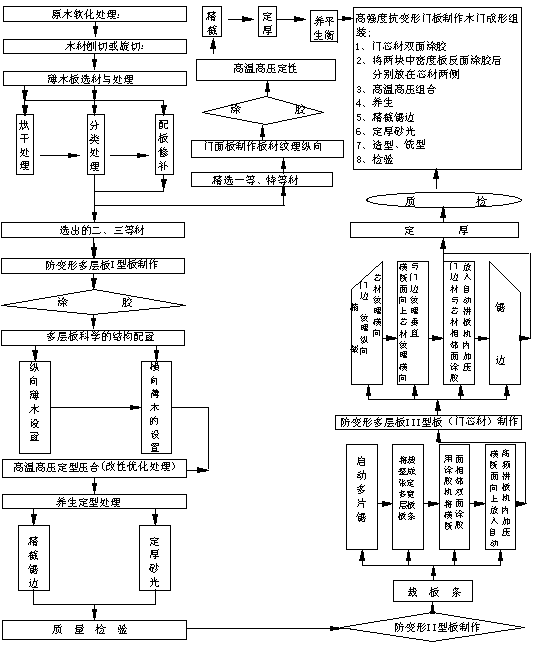

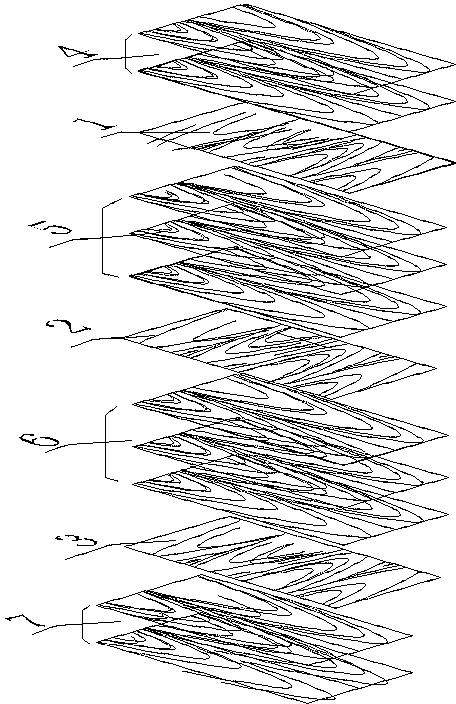

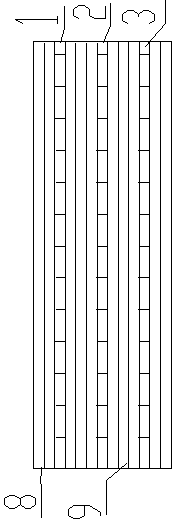

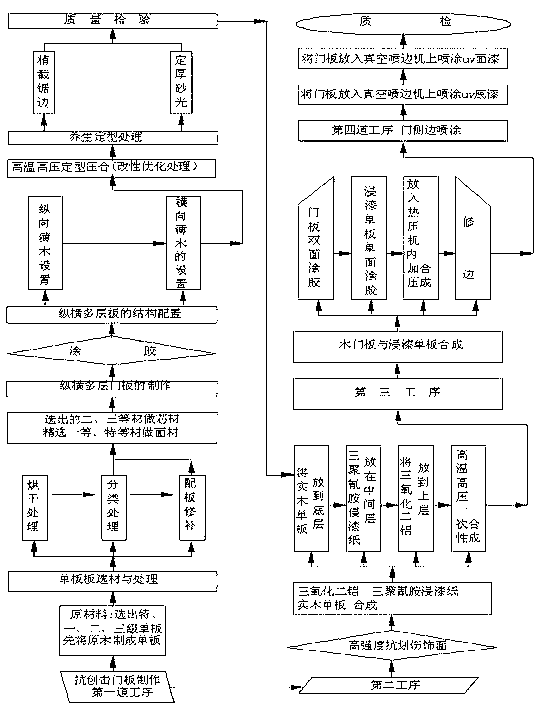

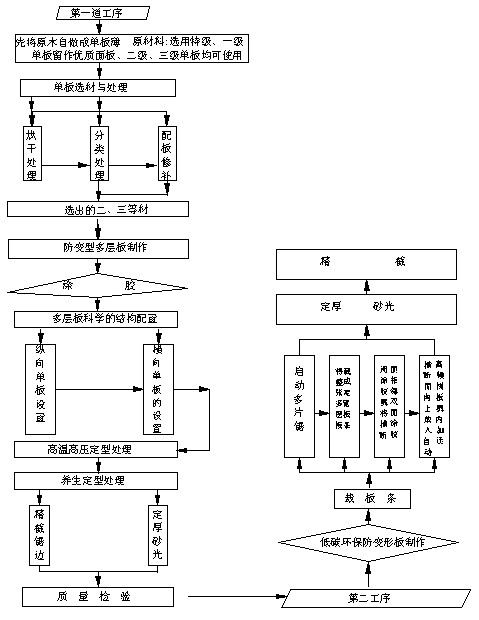

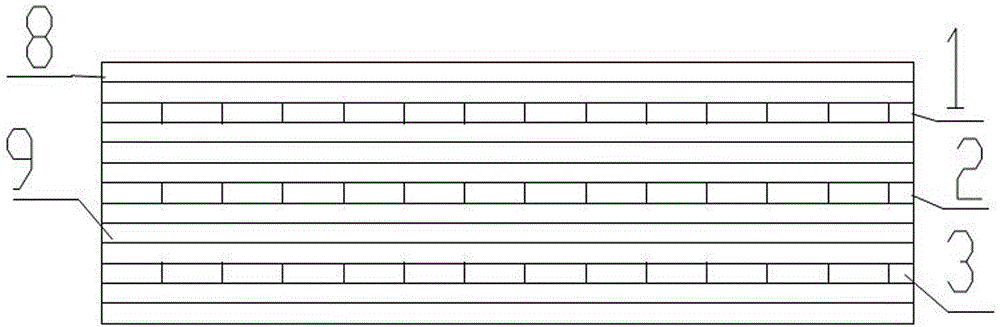

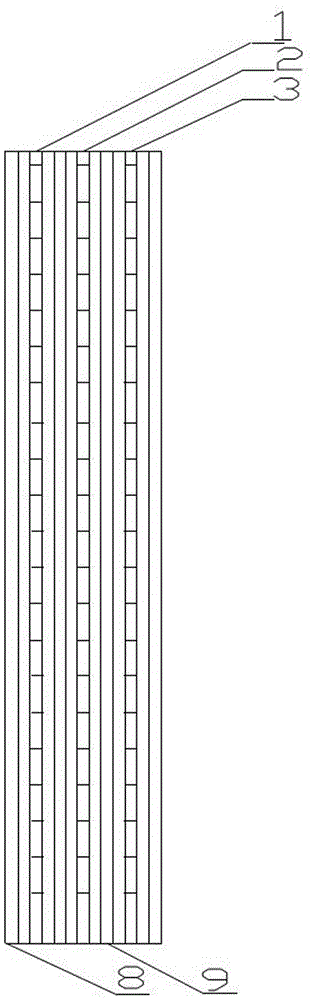

Method for manufacturing environment-friendly high-strength anti-deformation solid wood composite door

InactiveCN103128823AReduce moisture contentOvercoming high moisture content and poor flatnessWood veneer joiningAdhesive application devicesSanderSolid wood

The invention discloses a method for manufacturing an environment-friendly high-strength anti-deformation solid wood composite door. The method includes steps of softening and miniaturizing log to obtain wood sheets; classifying the wood sheets into a panel and core materials and drying the panel and core materials; splicing the thin sheets into integral plates, classifying the integral plates into a panel and core materials, selecting integral plates with transverse textures in the core materials to be used as balance tension plates, arranging the balance tension plates into multiple layers and gluing the multiple layers of balance tension plates; performing press fit for the multiple layers of glued balance tension plates into a multilayer plate by the aid of a hot press, preserving the multilayer plate, cutting off four edges of the multilayer plate and sanding the multilayer plate by a sander so as to set the thickness of the multilayer plate; cutting the multilayer plate into fixed-width battens, manufacturing an anti-deformation core material, and setting the thickness of the anti-deformation core material; and manufacturing a medium-density plate and the anti-deformation core material into a structural plate, preserving the structural plate, cutting four edges of the structural plate, sanding the structural plate to set the thickness of the structural plate, carving the structural plate, milling the profile of the structural plate, milling lines of the structural plate and finishing the structural plate to obtain the high-strength anti-deformation solid wood composite door. The method has the advantages that common wood resources are sufficiently utilized to replace valuable wood resources, accordingly, materials are saved, waste materials are recycled, forest resources are powerfully protected, the cost is lowered, composite materials are replaced, and the method has an excellent application prospect.

Owner:HARBIN SHENGSHI HUALIN TECH

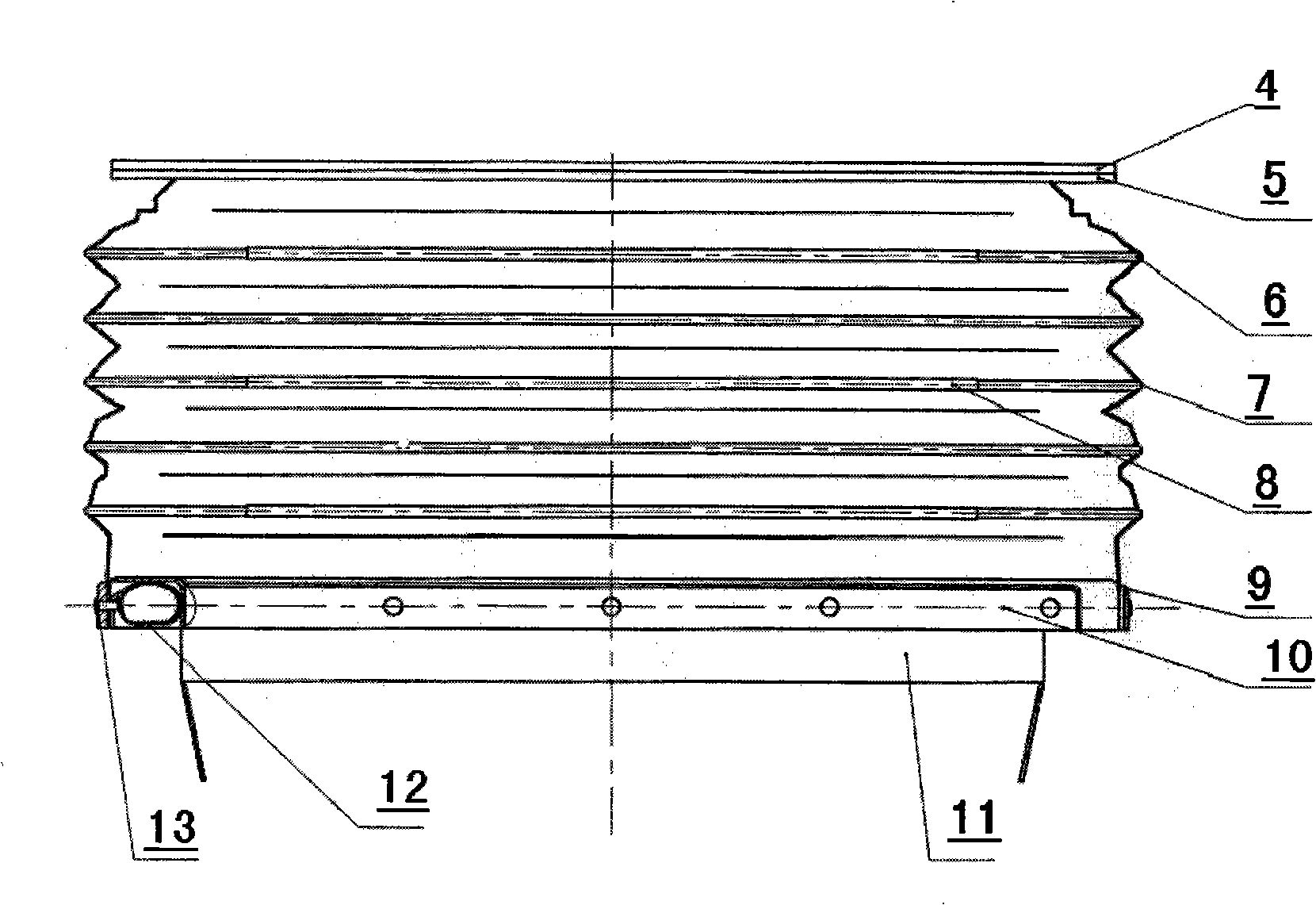

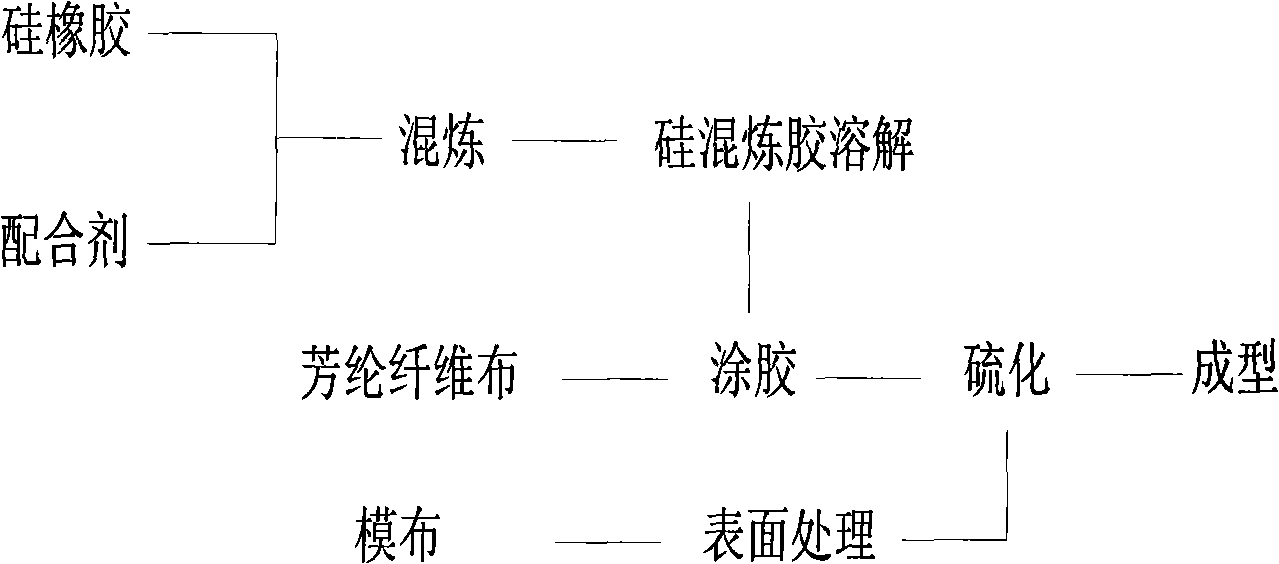

Aramid fiber fibre-silastic fabric, production method thereof and use in soft pipeline

InactiveCN101328650AEnables direct bondingImprove adhesionFibre typesLiquid/gas/vapor textile treatmentRubber materialPolymer science

The invention relates to an aromatic polyamide fiber-silicone rubber cloth, a method for producing the same and an application thereof in the aspect of manufacturing a hose. The production method comprises the following steps that: silicone rubber virgin rubber is added with an auxiliary agent to be mixed into silicone gross rubber through a rubber refining machine; the silicone gross rubber is added with the auxiliary agent and a coupling agent to be stirred and prepared into silicone gross rubber paste; the silicone gross rubber paste is applied on the surface of an aromatic polyamide fiber cloth; sulfur treatment is performed; etc. The production method realizes direct adherence of the rubber and the surface of the aromatic polyamide fiber cloth by adoption of the method of adding the coupling agent in the silicone gross rubber. The product of the aromatic polyamide fiber-silicone rubber cloth produced by the method can meet the following performance indexes: the tensile strength of rubber materials is more than or equal to 6 MPa; the tear strength of the rubber materials is more than or equal to 30 N.mm<-1>; the adhesive strength between Ib rubber with flame-retardant property and a base-cloth layer is more than or equal to 3 N.mm<-1>; the service temperature is between 60 DEG C below zero and 200 DEG C; and the folding fatigue resistant time is more than or equal to 2 million times. The aromatic polyamide fiber-silicone rubber cloth is used for manufacturing various flexibly connected pipes and is a superior cloth for manufacturing a transition air channel hose of a pulling motor of a locomotive.

Owner:株洲市华丰复合材料有限公司

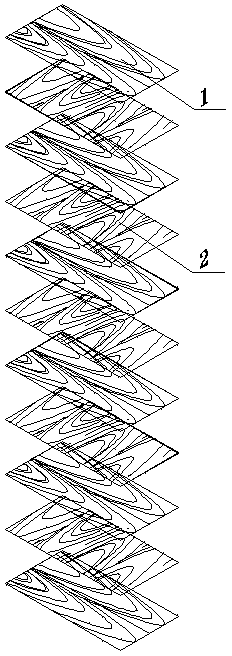

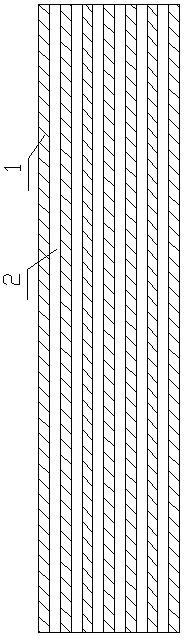

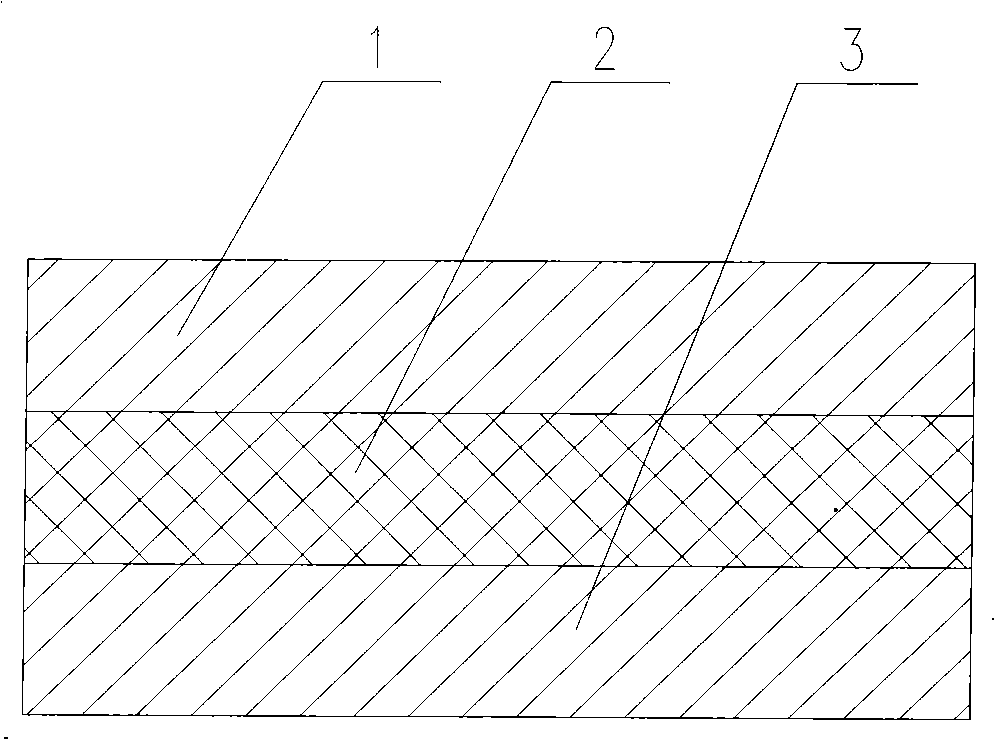

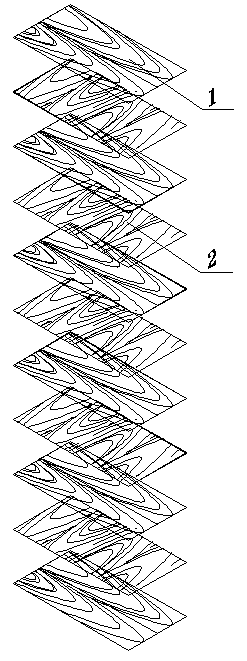

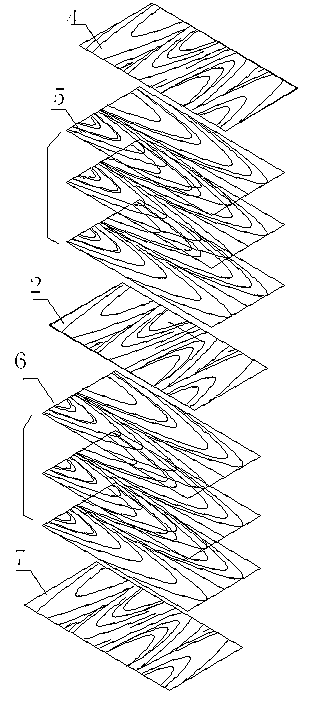

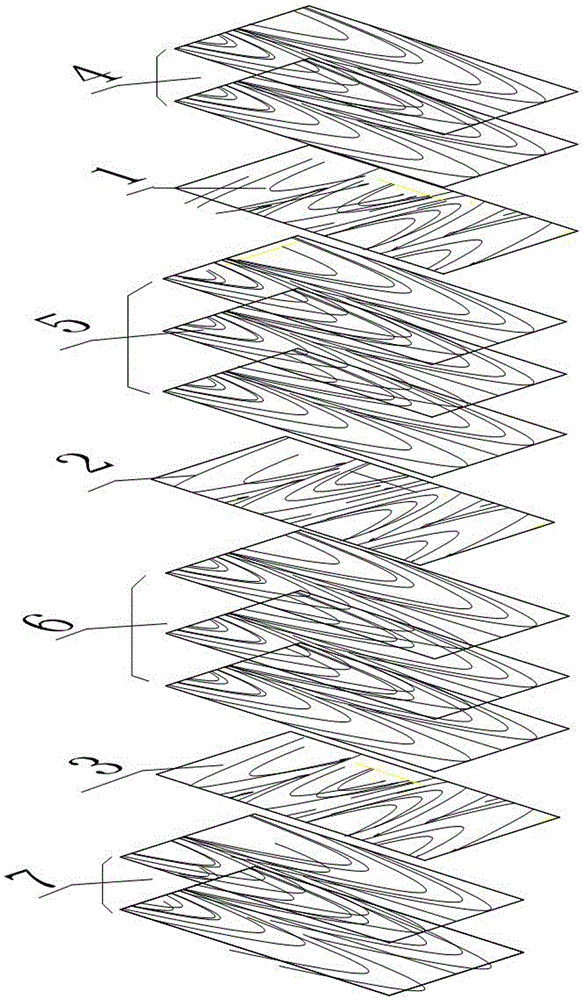

Door manufactured by environment-friendly, energy-saving and fireproof composite board and manufacture method of composite board

InactiveCN103174371ASolve the problem of environmental protectionSolve the problem of not being waterproofFireproof doorsWood veneer joiningSolid woodSingle plate

The invention discloses a door manufactured by an environment-friendly, energy-saving and fireproof composite board and a manufacture method of the composite board. At present, fireproof doors on the market include two kinds including steel fireproof doors and wood fireproof doors, wherein the steel fireproof doors are manufactured by steel plates outside, and the interiors of the steel fireproof doors are filled with rock wool or expanded perlite. The manufacture method of the composite board comprises the following two steps. Firstly, pure solid wood is adopted to manufacture inflaming retarding veneers. Secondly, the inflaming retarding veneers are manufactured to be the fireproof composite board according to a manner that one layer of longitudinal texture veneers and one layer of transverse texture veneers are stacked in an intersected mode. The manufacture method is used for manufacturing the environment-friendly, energy-saving and fireproof composite board.

Owner:HEILONGJIANG HUAXIN FURNITURE

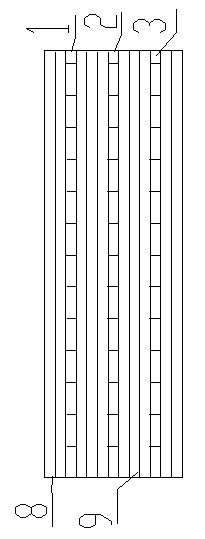

Production method of low-carbon environment-friendly anti-deformation solid wood composite plate

InactiveCN103128811ASolve the problem of environmental protectionImprove sound insulationWood veneer joiningSolid woodPaulownia

The invention discloses a production method of a low-carbon environment-friendly anti-deformation solid wood composite plate. Poplars on roadside and phoenix trees and Paulownia trees in front and rear of the village are available now, but people use the trees for low-level purposes. The production method includes the steps of rotary-cutting log into 2mm veneers, selecting primary, secondary and tertiary veneers, and drying; gluing the plates with 70% glue of environment protection level E, press-fitting the plates with a press, cutting to obtain equal-specification slabs; gluing the surface slabs and the middle slabs, selecting three layers of transverse texture slabs as balance tension plates to make multi-layer plate stock, and cutting the multi-layer plate into wide battens; gluing the wide battens, splicing the wide battens once by an automatic splicer to form a multi-layer plate, sanding the multi-layer plate, fixing the thickness and adding decorative surfaces. Common wood resource is fully utilized to replace valuable wood resources, so that resources are saved, waste is turned into wealth, forest resources are protected forcibly and cost is lowered.

Owner:HARBIN SHENGSHI HUALIN TECH

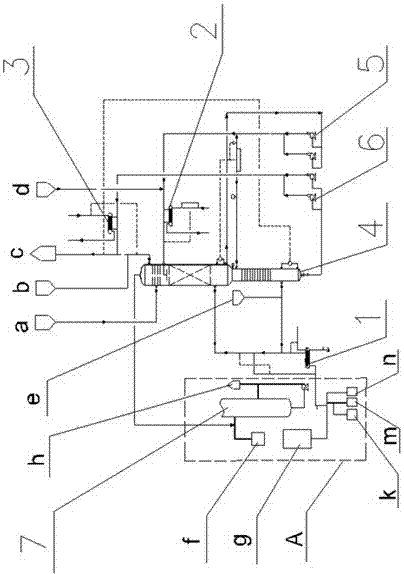

Reduction purification technology for nitric acid in production of coal produced glycol

InactiveCN106904714AEmission reductionLess recyclingWater contaminantsWater/sewage treatmentGas phaseHydrogenation reaction

The invention relates to a reduction purification technology of nitric acid in production of coal produced glycol. A coal produced glycol technology mainly comprises coal gasification, purification and separation, coupling reaction, regeneration reaction and hydrogenation reaction. According to the technology, a nitric acid purification system is arranged in rear of a regeneration technology of an original system (A); in the original system (A), after a gas phase material (g) from the top of a DMO removal tower is treated through the nitric acid purification system, the content of nitric acid in discharge liquor is smaller than 0.5 percent. The technology solves the problems in the prior art, and provides a nitric acid reduction purification technology which fundamentally solves the problem of reduction purification of nitric acid in production of coal produced glycol, reduces the nitrogen source loss and nitric acid consumption in coupling reaction, solves the problems, such as wastewater treatment, in a coal produced glycol project, and is good in equipment treatment capacity and energy-saving effect in the same operation condition and technical condition control, high in device reliability, convenient to operate, safe and reliable, and easy to maintain.

Owner:XINJIANG TIANZHI CHENYE CHEM +1

Manufacturing method of environment-friendly high-strength anti-deformation solid wood composite door

InactiveCN104552538AEliminate internal stressPrevent lateral bending deformationWood veneer joiningProcess engineeringSolid wood

The invention discloses a manufacturing method of an environment-friendly high-strength anti-deformation solid wood composite door. The manufacturing method comprises the following steps of carrying out softening and miniaturization treatment on raw wood materials to form thin wood plates; dividing the thin wood plates into panels and core materials, and drying the thin wood plates; splicing the thin wood plates into integrated plates, separating the panels from the core materials, selecting integrated transverse-grain plates from the core materials to be used as balance tension plates, arranging the balance tension plates into multiple layers and gluing; pressing the balance tension plates into multi-layer plates by using a hot press, conditioning, cutting off four edges, and sanding into fixed thickness by using a sanding machine; cutting the multi-layer plates into wide wood strips, manufacturing the wide wood strips into anti-deformation core materials, and setting the fixed thickness; manufacturing middle-density plates and the anti-deformation core materials into structure plates, conditioning, cutting off four edges, sanding into fixed thickness, and then carving, milling the shape, milling the wire and decorating the surface to form a high-strength anti-deformation solid wood composite door plate. According to the manufacturing method, common wood resources are fully utilized for replacing valuable wood resources, thus the resources are saved, the situation of changing waste into wealth is realized, the forest resources are powerfully protected, the cost is reduced, meanwhile, composite materials are replaced, and a good application prospect is obtained.

Owner:HEILONGJIANG HUAXIN FURNITURE

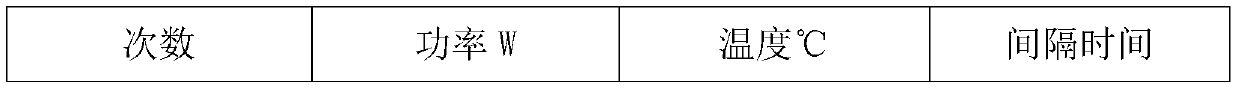

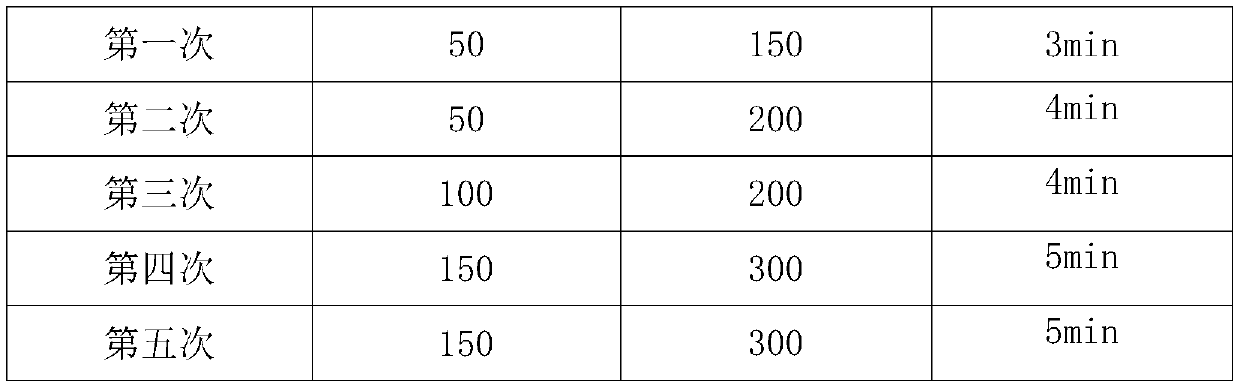

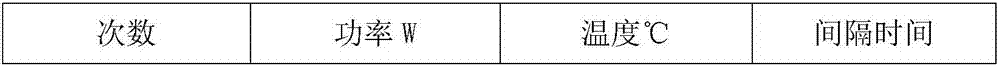

Preparation method of toughened aluminum oxide ceramic

The invention belongs to the technical field of preparation of ceramic materials, and particularly relates to a preparation method of toughened aluminum oxide ceramic. The preparation method comprisesthe following steps: by taking sludge of an aluminum profile factory as an aluminum source and taking an impurity in the sludge as a first additive, performing acid and alkali treatment and then suction filtration, thus obtaining additive impurity-containing aluminum sediments, adding the aluminum sediments into an ethyl alcohol aqueous solution, adding nano aluminum powder serving as a second additive, and performing aeration reaction and reduced pressure distillation, thus obtaining slurry; finally, performing grouting solidification in a microwave reaction manner, and after solidification,performing sintering, thus obtaining the toughened aluminum oxide ceramic. According to the preparation method, the sludge of the aluminum profile factory is used as the aluminum source, and the impurity in the sludge is used as a toughening additive and a stabilizer, so that the problem on environmental protection treatment of the sludge of the aluminum profile factory is solved, and the production cost of the aluminum oxide ceramic is also reduced.

Owner:无锡特科精细陶瓷有限公司

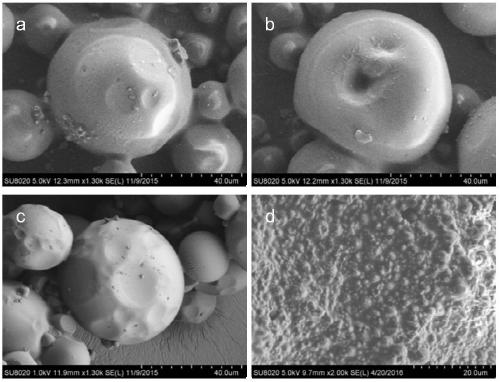

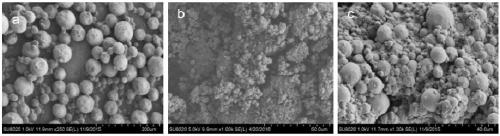

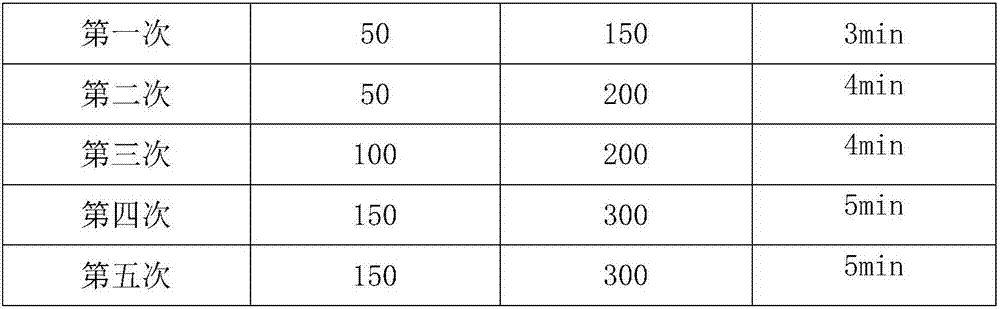

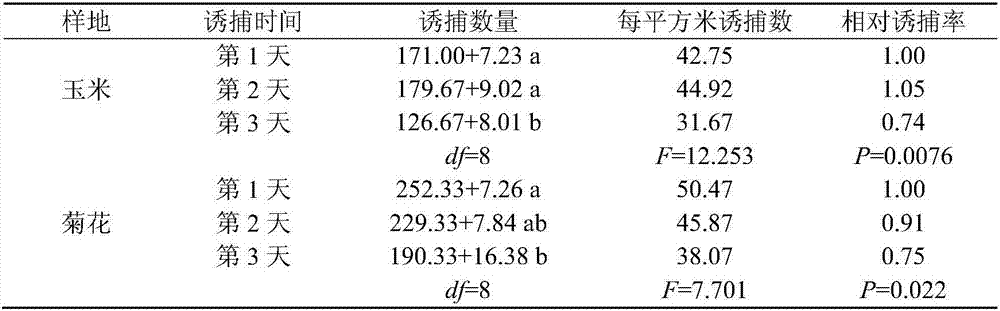

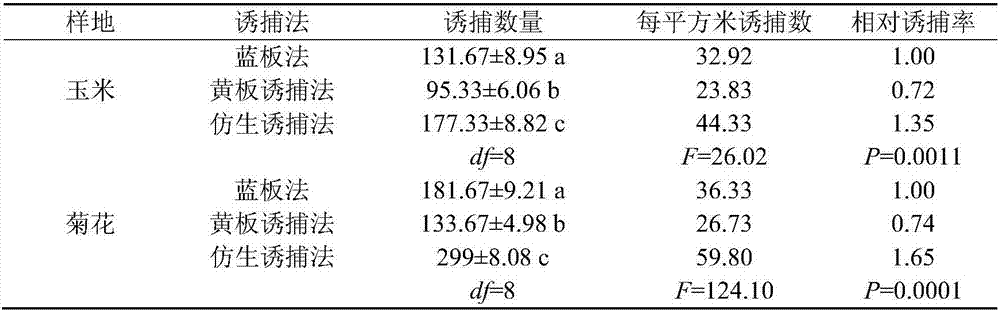

Bionic trapping device and trapping method for living frankliniella occidentalis

The invention relates to a bionic trapping device for living frankliniella occidentalis. The device comprises a trapping cover (1), a trapping base (2) connected with the trapping cover (1) in a cooperative mode, a peripheral gauze screen (3) fixedly arranged on an opening of the trapping cover (1) and a central gauze screen (4) arranged in the center of the peripheral gauze screen (3); the exterior of the peripheral gauze screen (3) is provided with brackets (5) supporting the screens; the corresponding end of the opening of the trapping cover (1) is fixedly provided with a sleeve ring (6) connected with the trapping base (2) in a cooperative mode; the upper portion of the trapping base (2) is provided with a filament-imitated structure (7) with inverted hooks. The bionic trapping device is simple in structure, convenient to use, low in cost and high in flexibility, the labor efficiency can be significantly improved, the labor intensity is reduced, and the quantity of living frankliniella occidentalis trapped in the wild field is increased. A trapping method for living frankliniella occidentalis ensures the efficiency of agricultural production to the maximum degree with the purposes of achieving minimal resource consumption, most environment-friendly and fastest trapping and highest trapping number.

Owner:YUNNAN AGRICULTURAL UNIVERSITY

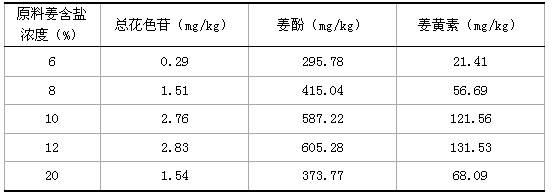

Method for producing ultra-micro ginger powder from ginger processing by-products

InactiveCN102599517AReduce lossIncrease profitClimate change adaptationFood preparationSlagBULK ACTIVE INGREDIENT

The invention particularly relates to a method for producing ultra-micro ginger powder from ginger processing by-products, belonging to the agricultural product processing field. The method comprises the following steps: the ginger processing by-products are washed, desalted and deacidified by clear water, and are dried in the sun or dried at the temperature of 40-60 DEG C till the moisture content of the by-products is less than 8% to obtain dry ginger slag blocks, dry ginger slag blocks are then crushed to 100+ / -20 mesh coarse ginger slag powder, and coarse ginger slag powder is crushed superfinely at the temperature of 0-5 DEG C to form 500-800-mesh fine powder, so as to obtain the ultra-micro ginger powder. The ultra-micro ginger powder prepared by the method can replace part of fresh ginger powder and is directly used for preparing ginger powder seasoning, ginger beverage, nutritional supplement, Chinese patent drug and the like. On the premise that active ingredients are not reduced, the cost of the raw material of the fresh ginger powder is greatly lowered, and the problem of environmental protection treatment for the discharge of leftovers during ginger processing is completely solved.

Owner:INST OF AGRI ENG TECH FUJIAN ACAD OF AGRI SCI

Phosphorus-free corrosion-retarding scale inhibitor used for industrial circulating cooling water

InactiveCN102491543AGood corrosion inhibitionReduce deposition rateScale removal and water softeningTungstatePotassium

The invention relates to a practical and environment-friendly phosphorus-free corrosion-retarding scale inhibitor used for industrial circulating cooling water. The scale inhibitor is characterized in that the scale inhibitor comprises components of, by weight: 10-40% of N-alkyl-N-fat phthalein amino fatty acid salt, 5-25% of hydroxyl carboxylate, 5-20% of a carboxylic acid copolymer, 1-4% of metal salt, and balance of water. The mass percentage concentration of the N-alkyl-N-fat phthalein amino fatty acid salt is 12-38%, the N-alkyl-N-fat phthalein amino fatty acid salt is selected from sodium salt or potassium salt. The polyhydroxyl carboxylate is selected from sodium gluconate, sodium lactobionate, and sodium malate. The mass percentage concentration of the polyhydroxyl carboxylate is 8-22%. The carboxylic acid copolymer is selected from acrylic acid-AMPS-methylacrylsulfonate copolymer, polymaleic acid, polyaspartic acid, and polyaminosuccinic acid. The mass percentage concentration of the carboxylic acid copolymer is 8-22%. The metal salt is selected from zinc salt, chromate, silicate, molybdenate, and tungstate. The mass percentage concentration of the metal salt is 1-5%.

Owner:天津通悦科技有限公司

Green and environment-friendly antique floor tile

InactiveCN105777067ALow absorption rateHigh strengthCeramic materials productionClaywaresChemistryClay soil

The invention belongs to the field of preparation of floor tiles, and in particular relates to an antique floor tile. The antique floor tile is prepared from the following raw materials in percentage by weight: 10% to 20% of kaolin, 4% to 8% of waste stone sheets of a stone factory, 6% to 10% of weathered sand, 12% to 17% of potash feldspar, 5% to 9% of ball clay, 1% to 3% of magnesium mud, 6% to 10% of black clay, 6% to 10% of pyrophyllite, 1% to 2% of wollastonite, and 25% to 35% of clay, wherein the sum of percentages by weight of the above raw materials is 100%. The antique floor tile has the advantages that the water absorbing rate is low, the strength is high, and the quality is higher than the quality of a high-grade wall tile which is produced by domestic manufacturers.

Owner:FUJIAN DESHENG NEW BUILDING MATERIAL CO LTD

Production method for recovering regenerated chemical filaments from industrial blankets

InactiveCN105386143AEnvironmental recyclingEasy to useArtificial thread manufacturing machinesMelt spinning methodsFiberUltimate tensile strength

The invention discloses a production method for recovering regenerated chemical filaments from industrial blankets. The production method comprises the following steps of firstly, classifying the waste blankets; secondly, smashing the waste blankets; thirdly, cleaning the surfaces of the blankets; fourthly, grinding the blankets into powder; fifthly, performing cleaning through hot water; sixthly, drying the powder blankets cleaned in the fifth step and storing the powder blankets in the dry environment; seventhly, performing high-temperature melting and filtering on the powder materials; eighthly, enabling melting to pass through a spinneret plate to form multiple columnar fibers; ninthly, performing high-temperature shaping on filament fibers which are stretched to meet the strength requirement so that the filament fibers can meet the requirement for straightness, and feeding the shaped filament fibers into winding equipment for winding and packaging into finished products so as to obtain the regenerated chemical filaments. The production method for recovering regenerated chemical filaments from industrial blankets is capable of recovering the waste industrial blankets in a more environment-friendly mode, wider in application range and better in use effect, reduces waste of resources and is more environmentally friendly.

Owner:WUJIANG SHUANGJIE GLASS STEEL EQUIP CO LTD

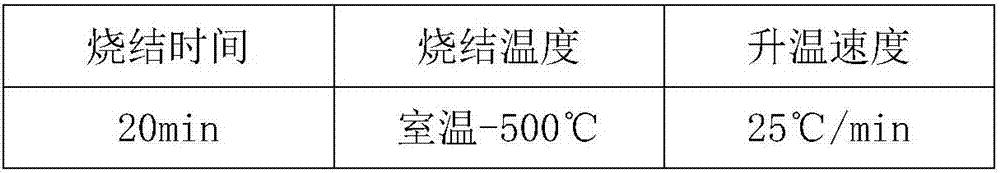

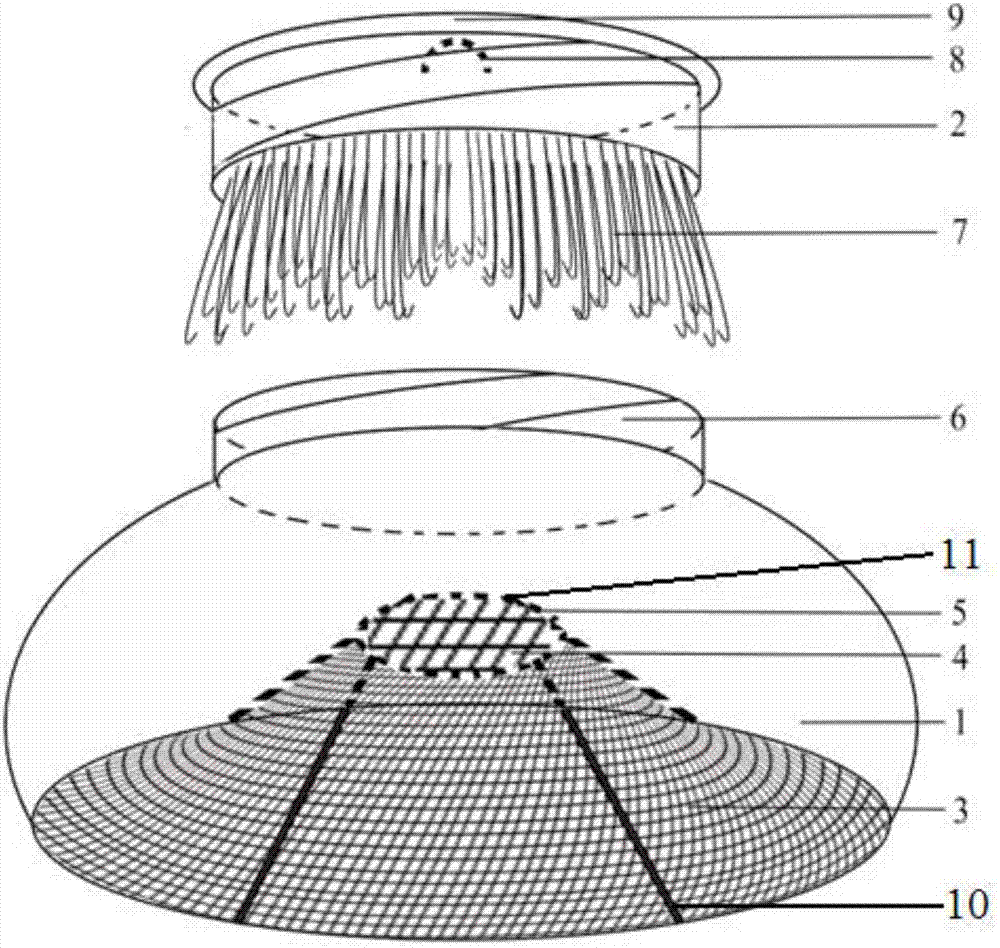

Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound

ActiveCN111100085ASolve the problem of environmental protectionSynthetic method is cheapOrganic chemistryM-aminophenolKetonic acids

The invention discloses a preparation method of a 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound, which comprises the following steps: carrying out magnetic stirring on a reaction substrate 2-aminophenol compound and a ketonic acid compound in an oil bath pot by using a deep eutectic solvent as a reaction solvent, and carrying out after-treatment after the reaction is finished, thereby obtaining the 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound. The deep eutectic solvent is formed by uniformly mixing choline chloride and urea according to a molar ratio of 1: 2, and then heating the mixed solution to a uniform and transparent liquid at 80 DEG C. The method is simple in operation process, mild in reaction condition, low in cost and environmentally friendly, and hasapplication and popularization value.

Owner:EAST CHINA UNIV OF TECH

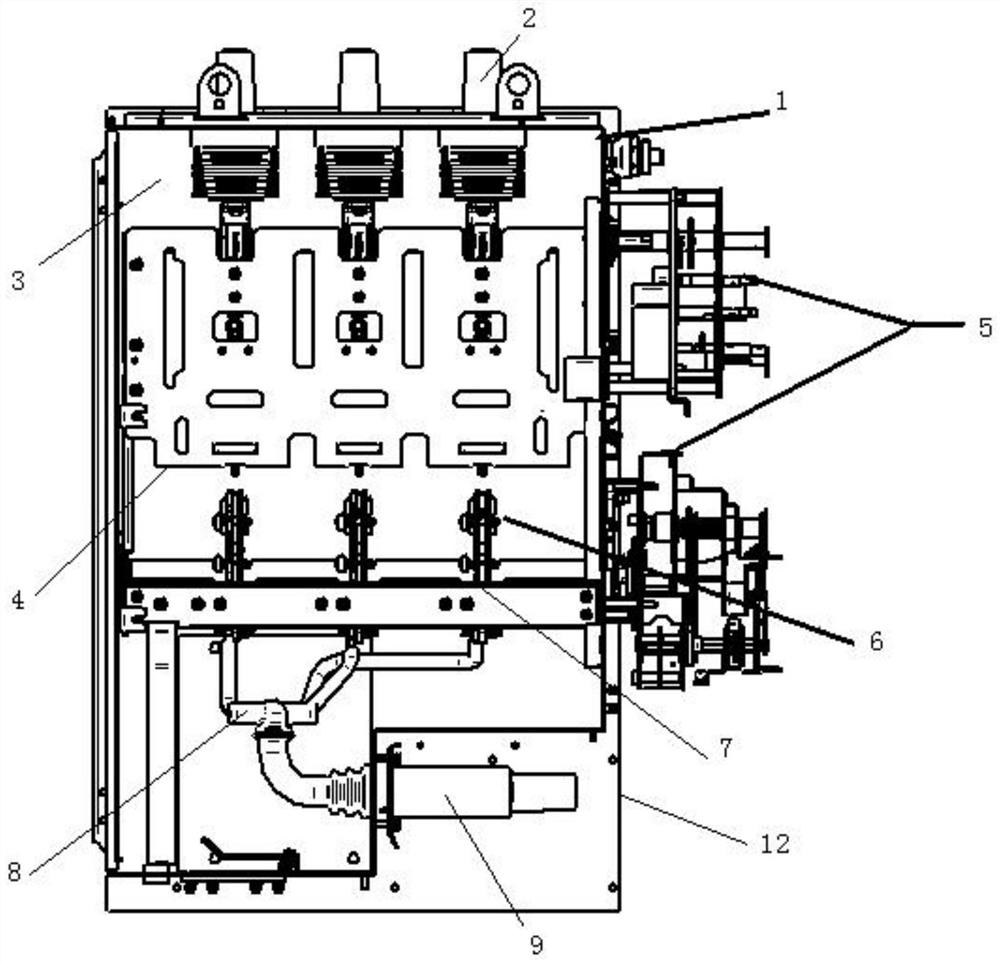

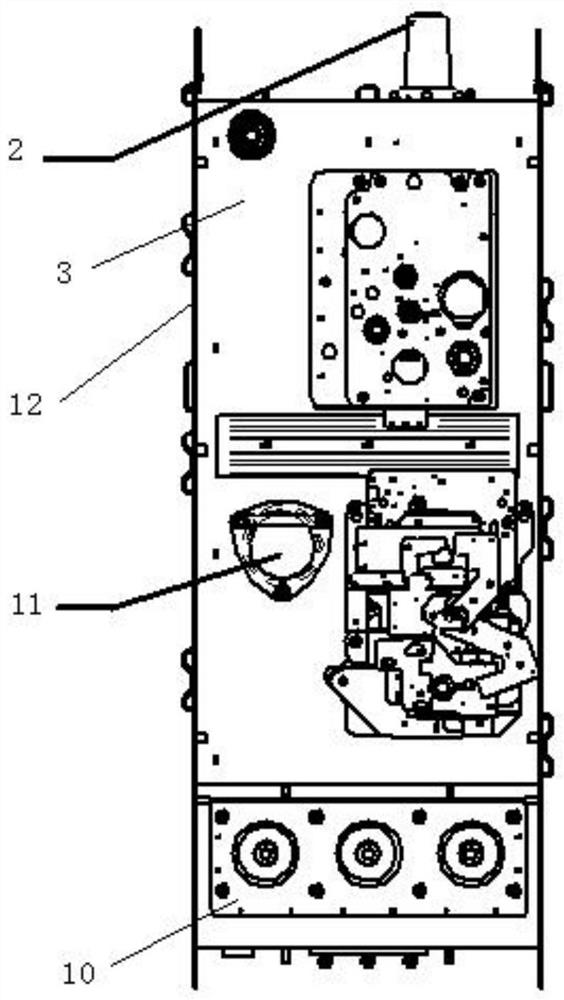

Environment-friendly insulating ring main unit

InactiveCN111817198ASolve the problem of environmental protectionSwitchgear arrangementsStructural engineeringSmall footprint

The invention discloses an environment-friendly insulating ring main unit, which comprises a gas tank, an ejection sleeve, an arc extinguishing chamber, an isolation static contact, an operating mechanism, an isolation-grounding switch, a grounding static contact, a lower branch bus, a lower ejection sleeve, a lower ejection sleeve pressing plate and an outer shell, wherein the gas tank is arranged in the outer shell; the gas tank is filled with a heptafluoroisobutyronitrile-air mixed gas; the ejection sleeve penetrates through the upper plane of the gas box and then is connected with the arcextinguishing chamber, and the arc extinguishing chamber is arranged in the gas box; the isolation static contact is connected with the operating mechanism; one end of the isolation-grounding switch is connected with the isolation static contact, and the other end of the isolation-grounding switch is connected with the grounding static contact; and the lower branch bus and the lower ejection sleeve are arranged in the lower ejection sleeve pressing plate, and the operating mechanism is connected with the lower branch bus. According to the environment-friendly insulating ring main unit providedby the invention, the heptafluoroisobutyronitrile-air mixed gas is used as an insulating medium, so that an environment-friendly effect is achieved, and the environment-friendly insulating ring mainunit is small in occupied area.

Owner:云南电网有限责任公司丽江供电局 +2

Leather printing product and preparation method thereof

InactiveCN113249988ASolve the problem of intolerance to wet and dry rubbingSolve the problem of environmental protectionPolyurea/polyurethane coatingsDyeing processTextile printerSheep skin

The invention relates to a leather printing product and a preparation method thereof. The preparation method comprises the following steps of (1) selecting finished leather (cowhide, sheepskin, pigskin or horse skin) for surface pretreatment to obtain pretreated leather; (2) preparing water-based color paste, and printing the water-based color paste on the surface of the pretreated leather to obtain printed leather; and (3) enabling the printed leather to be dried and then subjected to color fixation treatment, and obtaining the leather printed product after color fixation treatment is completed. The preparation method solves the existing problems that leather printing fades and is not resistant to dry and wet rubbing, a printing material is not environmentally friendly, a printed finished product is poor in hand feeling, the breathability of leather is affected, the printing material is high in cost, and printing paste is likely to crack due to long-time use. And the quality of the leather printed leather finished product can be effectively improved, so that the leather product is more colorful and has fashionable design.

Owner:段永进

Method for preparing polybutadiene-base water polyurethane and modified emulsion thereof

InactiveCN101235129BSolve the problem of environmental protectionGood compatibilityPolymer scienceAlcohol

The invention discloses a polybutadiene aqueous polyurethane and a preparation method of relative modified emulsion, which is characterized by reacting low polymer polyatomic alcohol and hydroxy-terminated butadiene rubber and isocyanate, adding hydrophilic chain extender and catalyst to be reacted, cooling and emulsifying to obtain polybutadiene aqueous polyurethane, mixing polybutadiene aqueouspolyurethane, emulsifier, water and inducer uniformly, adding ethenyl monomer to carry out emulsion polymerization to obtain polybutadiene aqueous polyurethane modified emulsion. The invention uses hydroxy-terminated butadiene rubber to synthesize aqueous polyurethane which can be modified by ethenyl to obtain environment-friendly, stable and low temperature resistant aqueous resin with better mechanical property. The resin can be used in weaving, leather processing, paint and adhesive or the like.

Owner:ANHUI UNIVERSITY

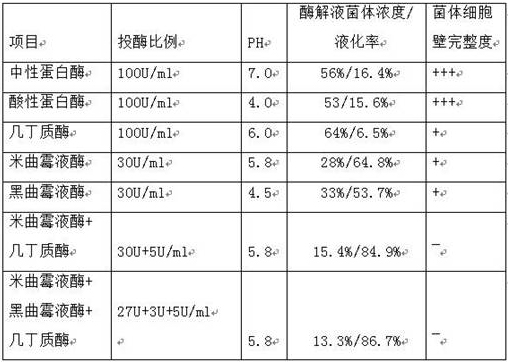

Utilization method of 7-aminocephalosporanic acid production waste

PendingCN114230380ARapid destruction of integrityReduce physical sizeNitrogenous fertilisersOrganic fertilisersFiberHydrolysate

The invention discloses a utilization method of 7-aminocephalosporanic acid production waste, which comprises the following steps: (1) adjusting the pH value of fresh cephalosporin C wet mushroom dregs to 5.5-6.0 by using alkali, adding a complex enzyme preparation in a certain proportion, and carrying out enzymolysis at 55-60 DEG C for 48-72 hours; (2) separating the enzymatic hydrolysate by using a settling centrifuge to remove calcium oxalate salt and part of fibers, wherein the calcium oxalate salt and part of fibers can be used as organic fertilizer raw materials; (3) the centrifugate is treated with ceramic membrane ultrafiltration equipment, filtrate and filter residues are collected respectively, one part of the ultrafilter residues serve as a fermentation preparation culture medium of aspergillus oryzae or aspergillus niger liquid enzyme, and the other part of the ultrafilter residues are added into the next batch of cephalosporin fresh fungus residues for secondary enzymolysis; (4) carrying out nanofiltration concentration on the ultrafiltrate; and (5) alpha-aminoadipic acid is added into the nanofiltration concentrated solution in the step (4) for blending, the amino acid liquid fertilizer or a production raw material thereof is obtained, and the alpha-aminoadipic acid is derived from 7-ACA extraction mother liquor.

Owner:HEZE RUIZHI TECH DEV

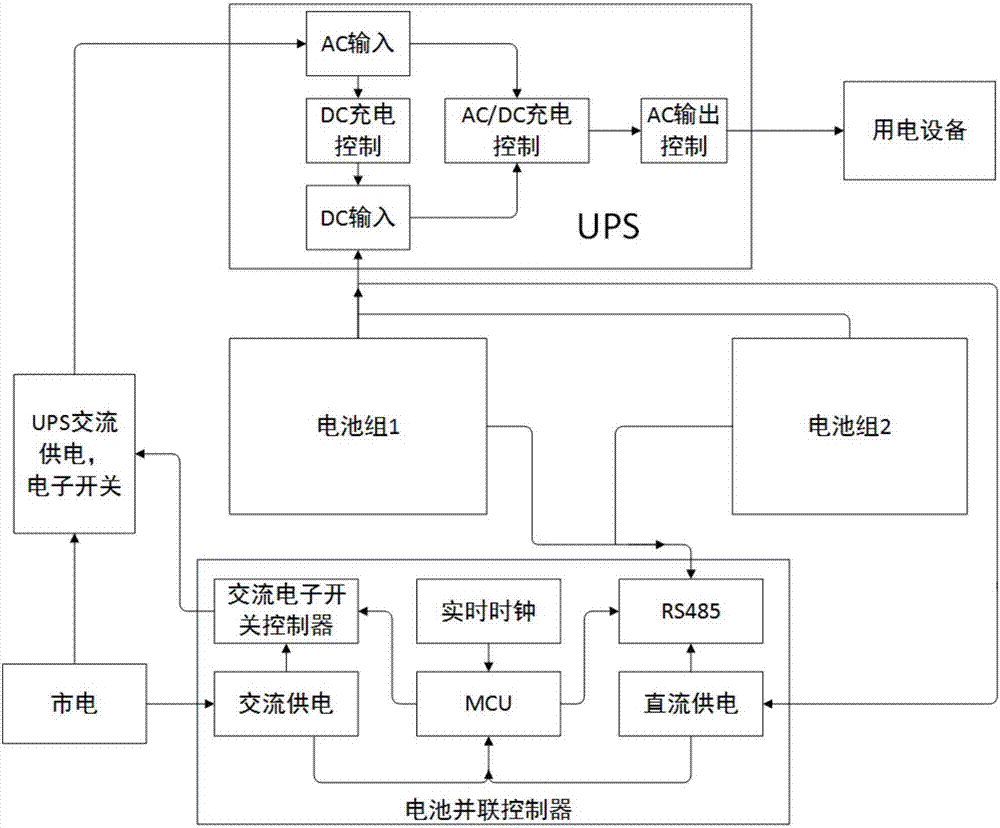

Lithium storage battery

PendingCN107154672AAddressing Adaptive IssuesSolve the problem of longevityEmergency power supply arrangementsFloating chargeElectrical battery

The invention discloses a lithium storage battery comprising at least one battery pack, an electronic switch module, a mains supply input interface connected to the electronic switch module, a UPS module connected with the at least one battery pack, the electronic switch module and electrical equipment, and a battery parallel connection controller connected with the at least one battery pack, the mains supply input interface, the electronic switch module and the UPS module. By using the novel lithium storage battery of the invention, the problem of long-time storage and long-time floating charge is solved. Thus, a cheap material with high capacity density can be selected, and the cost is reduced greatly.

Owner:ZHUHAI XUNDA TECH CO LTD

Antibacterial kitchen detergent

InactiveCN112481046AImprove the bactericidal effectReduce dosageInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsBiotechnologyTriclosan

The invention discloses an antibacterial kitchen detergent, which comprises the following raw materials: sodium linear alkylbenzene sulfonate (LAS), sodium alcohol ether sulphate (AES), cocoanut fattyacid diethanolamide (6501), triclosan, ethanol, sodium chloride, sodium dihydrogen phosphate, sodium thiosulfate, sodium citrate, deionized water, a deodorant and essence. According to the invention,triclosan is supplemented by components such as sodium linear alkylbenzene sulfonate (LAS), sodium alcohol ether sulphate (AES), cocoanut fatty acid diethanolamide (6501), ethanol and the like to design the antibacterial kitchen detergent with dual effects of hard surface washing and antibiosis, and the antibacterial kitchen detergent has the advantages of high detergency, good stability, good antibacterial effect and great safety and efficiency. The detergent has broad-spectrum antibacterial property, solves the problem that the traditional kitchen detergent formula is not environment-friendly, has dual effects of washing and resisting bacteria, and effectively solves the problem of single function of the kitchen detergent product.

Owner:COSBE LAB INC

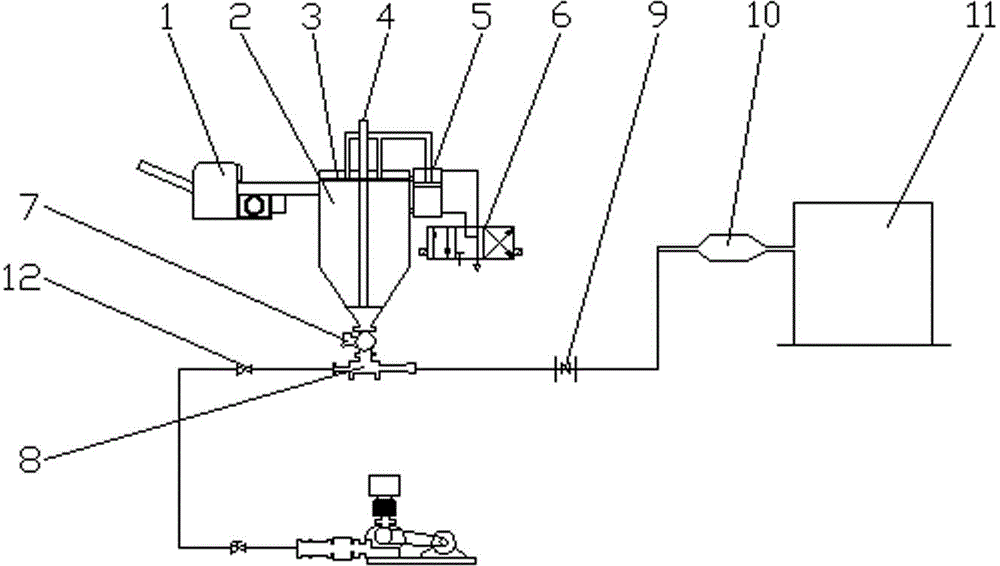

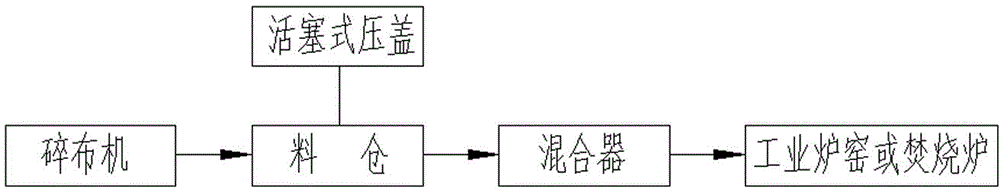

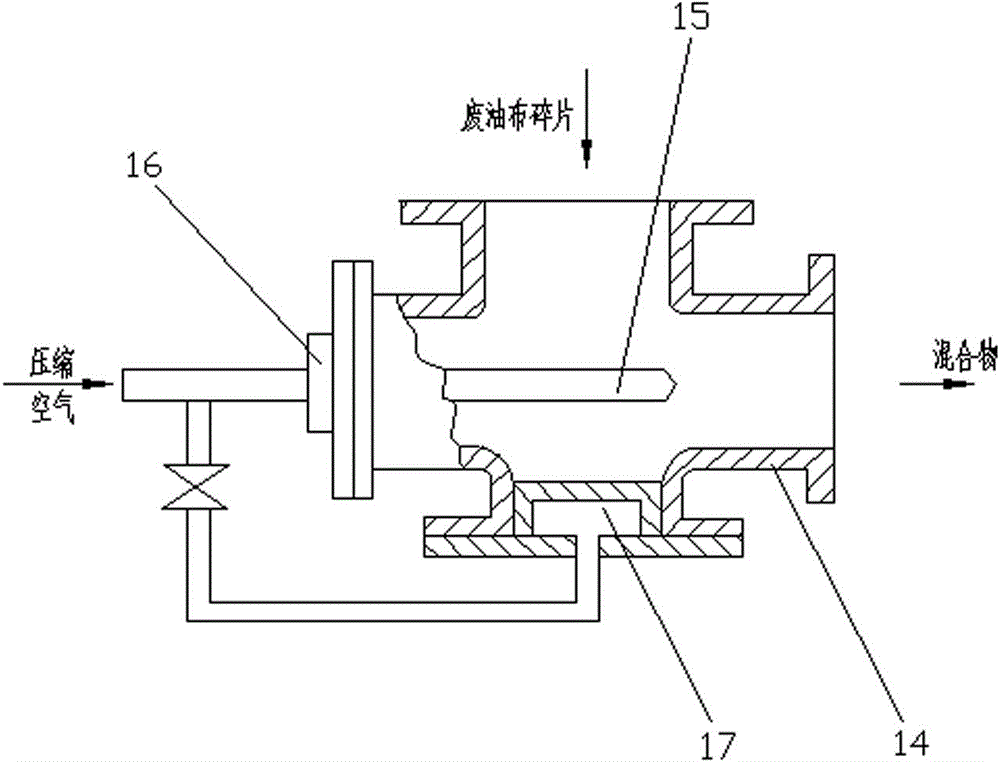

Waste oil cloth injection burning environmental protection treatment technology

ActiveCN104791810ASolve the problem of environmental protectionEnsure benefitsIncinerator apparatusProcess engineeringEnvironmental engineering

The invention relates to a waste oil cloth injection burning environmental protection treatment technology. The waste oil cloth injection burning environmental protection treatment technology comprises the steps that firstly a cloth tearing machine is adopted for extruding and cutting up waste oil cloth, wherein the purpose of extrusion is to extrude most waste oil in the waste oil cloth and collect the waste oil cloth for recycling, and broken pieces are prevented from bonding to a ball; then the waste oil cloth after being cut up and extruded is conveyed in a stock bin, since the waste oil cloth is light, feeding in the stock bin can not be achieved through the self weight of the waste oil cloth, so a piston-type press cover is arranged on the stock bin, the piston-type press cover is driven by a lifting air cylinder, and the conveying of the broken pieces of the waste oil cloth in the stock bin is achieved through the pre-pressing of the piston-type press cover; finally the waste oil cloth enters a mixer through the stock bin and a blanking control valve, and the waste oil cloth is conveyed into an industrial furnace or an incinerator to be burned in an environmental protection mode through an injection tube after blown by compressed air in the mixer. The environmental protection treatment problem of the waste oil cloth generated by working condition enterprise daily work is solved, and the achievement of economic benefits and social environmental protection benefits of enterprises is guaranteed.

Owner:SGIS SONGSHAN CO LTD

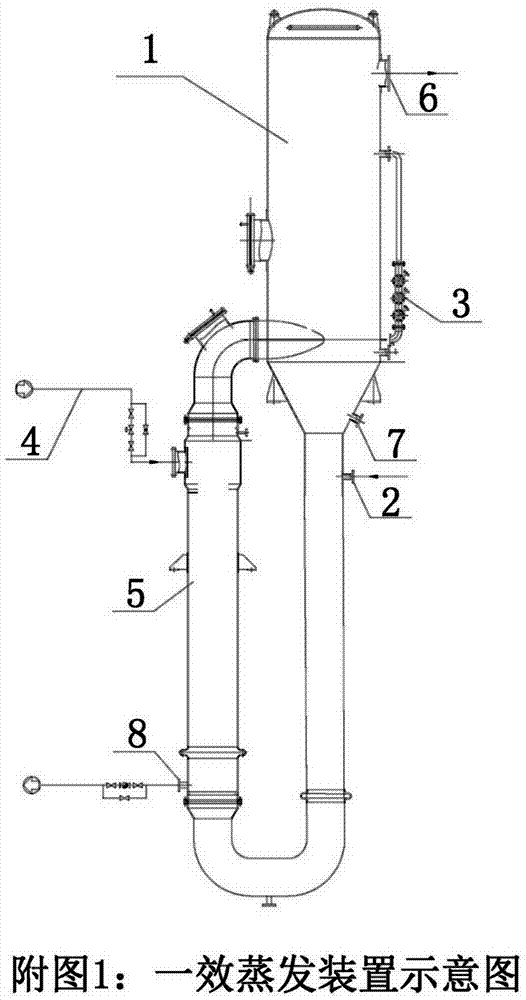

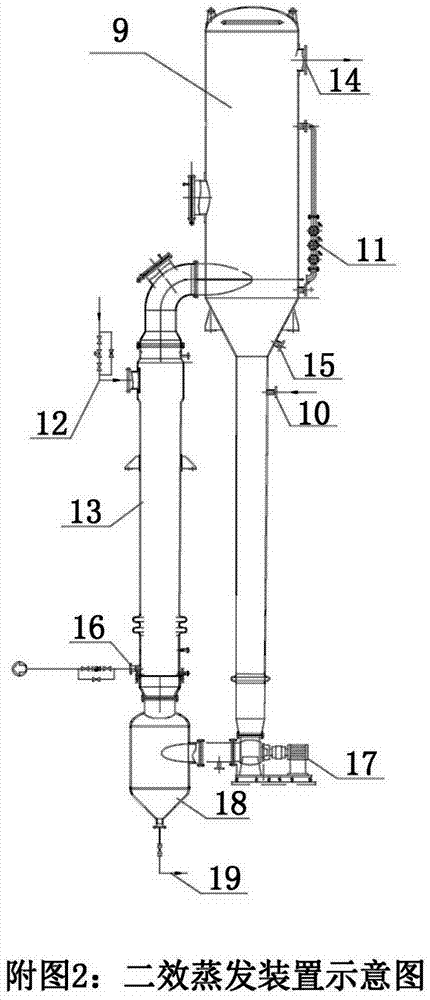

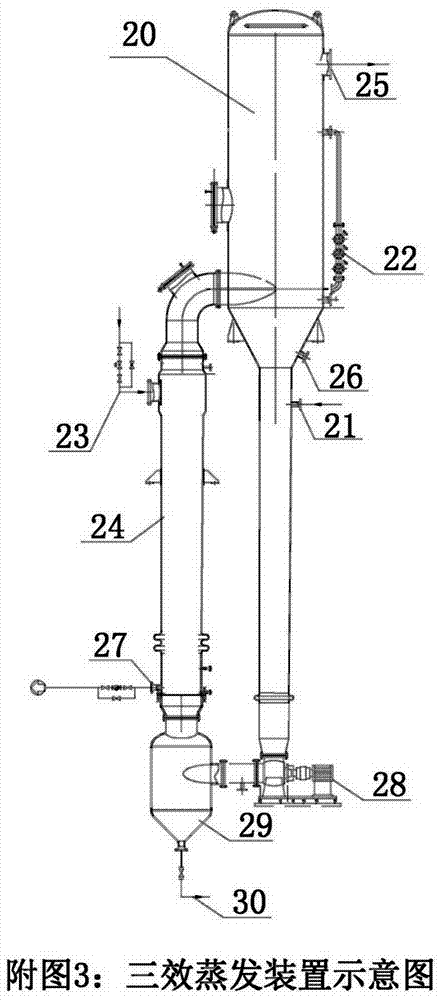

Technique for evaporating and recycling wastewater generated in hydroxypropyl methyl cellulose production

ActiveCN103359864BSolve the problem of environmental protectionSolve the problem of needing a large amount of hot water without hardnessMultistage water/sewage treatmentNature of treatment waterCelluloseLiquid waste

The invention discloses a technology for evaporating waste water from hydroxypropyl methylcellulose production, which has a first-effect evaporation device, a second-effect evaporation device, a three-effect evaporation device, a second-effect separation device and a three-effect separation device, and is characterized in that: The wastewater from the first-effect evaporator is evaporated by primary steam heating; the steam generated from the wastewater from the first-effect evaporator is used as the heat source of the second-effect evaporator to further evaporate the wastewater from the second-effect evaporator; the steam generated from the wastewater from the second-effect evaporator is used as the third-effect evaporation The heat source of the device; under the condition of negative pressure extraction, the wastewater in the three-effect evaporation device is vaporized at about 80°C, and after condensation, it enters the biochemical treatment system for further treatment. The second-effect evaporator and the third-effect evaporator are equipped with separation devices, and the waste water containing crystalline salt is separated from solid and liquid by the second-effect separation device and the third-effect separation device at any time, the solid salt is recovered and treated, and the liquid waste water is returned to the third-effect evaporator for recrystallization . The recovered hot water is reused for production through three-effect evaporation.

Owner:山东光大赛路新材料科技有限公司

Door made of environmental-protection and energy-saving fireproof composite plates and production method

InactiveCN104533252ASolve the problem of environmental protectionSolve the problem of not being waterproofFireproof doorsWood veneer joiningSolid woodSingle plate

Provided are a door made of environmental-protection and energy-saving fireproof composite plates and a production method. Fireproof doors at the market are steel fireproof doors and wood fireproof doors, wherein the steel fireproof doors are usually made of steel plates with rock wool or expanded perlite filled inside. The production method of environmental-protection and energy-saving fireproof composite plates includes the following two steps: producing flame retardant single plates by aid of pure solid wood; arraying the flame retardant single plates in a way of placing one layer of longitudinal texture single plates and then placing one layer of transverse texture single plates crossly. The production method is used for producing the door made of the environmental-protection and energy-saving fireproof composite plates.

Owner:HEILONGJIANG HUAXIN FURNITURE

A kind of preparation method of toughened alumina ceramics

ActiveCN107540353BSolve the problem of environmental protectionReduce manufacturing costSludgeFiltration

The invention belongs to the technical field of preparation of ceramic materials, and particularly relates to a preparation method of toughened aluminum oxide ceramic. The preparation method comprisesthe following steps: by taking sludge of an aluminum profile factory as an aluminum source and taking an impurity in the sludge as a first additive, performing acid and alkali treatment and then suction filtration, thus obtaining additive impurity-containing aluminum sediments, adding the aluminum sediments into an ethyl alcohol aqueous solution, adding nano aluminum powder serving as a second additive, and performing aeration reaction and reduced pressure distillation, thus obtaining slurry; finally, performing grouting solidification in a microwave reaction manner, and after solidification,performing sintering, thus obtaining the toughened aluminum oxide ceramic. According to the preparation method, the sludge of the aluminum profile factory is used as the aluminum source, and the impurity in the sludge is used as a toughening additive and a stabilizer, so that the problem on environmental protection treatment of the sludge of the aluminum profile factory is solved, and the production cost of the aluminum oxide ceramic is also reduced.

Owner:无锡特科精细陶瓷有限公司

A kind of preparation method of photocurable polyurethane modified wood paint

ActiveCN103160204BSolve the environmental problems caused by long volatilization cycleSolve the problem of continuous operationPolyurea/polyurethane coatingsLacquerAbnormal shaped

The invention provides a preparation method of light-curing polyurethane modified carpentry paint. The light-curing polyurethane modified carpentry paint prepared according to the method solves the problems that common polyurethane carpentry paint is not environment-friendly due to long volatilization cycle, and consecutive operation can not be conducted when the common polyurethane carpentry paint is painted on abnormal-shaped parts. The light-curing polyurethane modified carpentry paint is high in priming paint solid content and thick in paint coating film, and effectively reduces painting times, and can be instantly solidified after painted for multi-layers and irradiated by light. A workpiece leaving after painted can enter next procedure instantly, and therefore consecutive operation is realized, and construction efficiency is remarkably improved, and high environment protection performance is achieved. The light-curing polyurethane modified carpentry paint is good in scratch resistance due to the fact that adhering density is larger than that of polyurethane paint when finish paint is solidified.

Owner:BBMG TIANTAN FURNITURE CO LTD

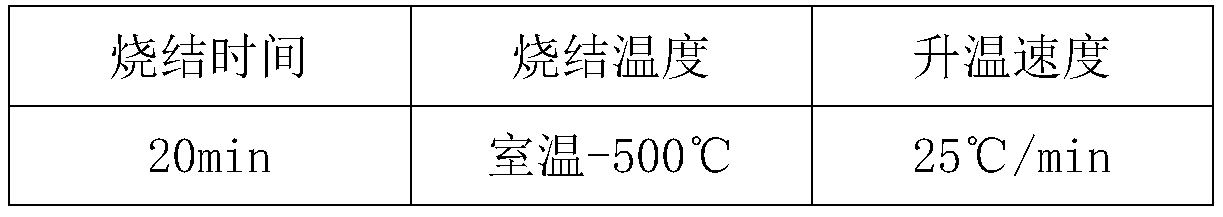

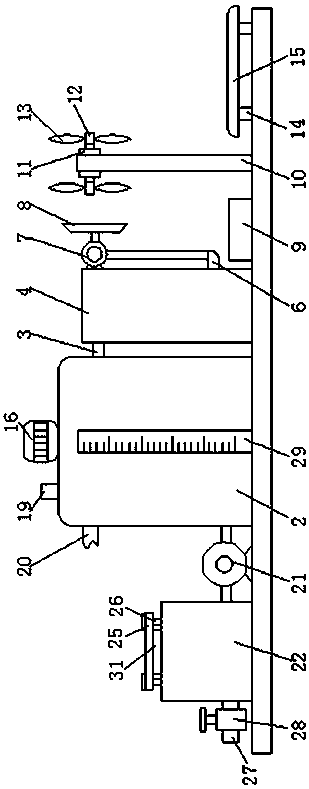

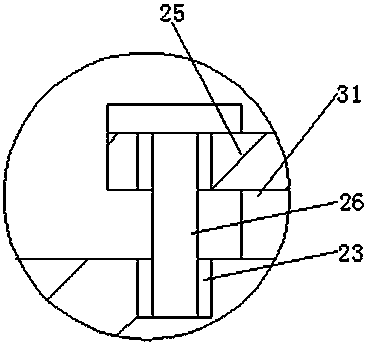

Environment-friendly wastewater treatment device

InactiveCN109279732ASolve the problem of environmental protectionEnvironmentally friendlyWater/sewage treatment by irradiationTreatment involving filtrationElectricityEngineering

The invention discloses an environment-friendly wastewater treatment device. The device comprises a bottom plate, wherein the top of the bottom plate is fixedly connected with a first box body, the right side of the first box body communicates with a first through pipe, the right end of the first through pipe communicates with a second box body, the bottom of the second box body is fixedly connected with the top of the bottom plate, a filter net is arranged in the inner cavity of the second box body, the bottom of the right side of the second box body communicates with a second through pipe, and the bottom of the right side of the second box body is fixedly connected with an air suction machine. The second box body, the filter net, the second through pipe, the air suction machine, an air cover, an electricity storage box, a supporting rod, a generator, a rotating rod and fan blades are matched and used, so that the problem that existing wastewater treatment devices are not environmentally friendly is solved. The environment-friendly wastewater treatment device has the advantages of environment protection, resources are saved, cost is reduced, practicability is improved, waste gas is purified, working efficiency is high, and use of people is facilitated, so that the device is worthy of popularization.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

A water-resistant and degradable plant nutrient slow-release material and its preparation method

ActiveCN106220325BEasy to degradeLow costOrganic fertilisersFertilizer mixturesPlant nutritionCorn flour

The invention discloses a waterproof degradable plant-nutrient slow-release material and a preparing method thereof. The waterproof degradable plant-nutrient slow-release material is prepared from modified corn flour, a PVA solution, a chitosan acetic acid solution, a zinc-humic acid compound fertilizer, oil-phase emulsion, a crosslinking agent glutaraldehyde and waste straw. The nutrient slow-release material has the waterproof function, the degradable function, the slow-release function and the like, is free of pollution, low in cost, simple in production technology, convenient to operate, small in equipment investment, capable of bringing convenience to industrial large-scale production and broad in market prospect.

Owner:HEFEI UNIV OF TECH

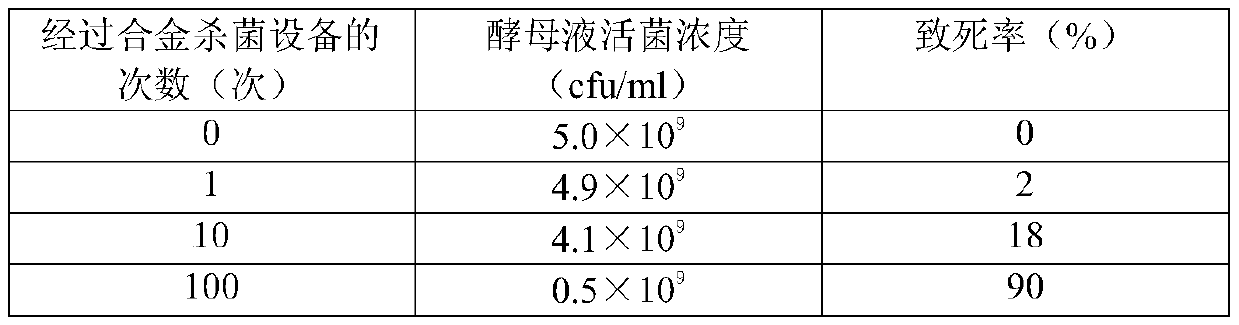

Formula of multiple oxidation-reduction alloy material with inactivated microorganisms

PendingCN110342617AImprove mechanical propertiesEasy to processWater/sewage treatment using germicide/oligodynamic-processActivated sludgeMicroorganism

The invention discloses a formula of a multiple oxidation-reduction alloy material with inactivated microorganisms. According to the formula, the multiple oxidation-reduction alloy material is prepared from the following elements in percentage by weight: 28%-35% of zinc; 4%-7% of tin; 19%-26% of nickel; 1.5%-3.5% of rare earth; and the balance of copper. Alloy prepared by the multiple oxidation-reduction alloy material formula has wide adaptability to microbial flora, can selectively and effectively inactivate the microorganisms proliferating in the field of biochemical sewage treatment, realize the in-situ reduction of residual activated sludge, solve the environmental outlet problem of traditional residual activated sludge, and is superior to traditional KDF alloy in terms of machinability and thermoforming.

Owner:苏州格致天工节能环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound](https://images-eureka.patsnap.com/patent_img/15fd3ecf-e920-4a57-956c-9d95d30d7066/FDA0002350751770000011.png)

![Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound](https://images-eureka.patsnap.com/patent_img/15fd3ecf-e920-4a57-956c-9d95d30d7066/FDA0002350751770000012.png)

![Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound Preparation method of 3-aryl-2H-benzo [beta] [1, 4] benzoxazine-2-ketone compound](https://images-eureka.patsnap.com/patent_img/15fd3ecf-e920-4a57-956c-9d95d30d7066/BDA0002350751780000021.png)