Door made of environmental-protection and energy-saving fireproof composite plates and production method

A production method, environmental protection and energy-saving technology, applied in the direction of fire doors, wooden veneer joints, manufacturing tools, etc., can solve the problems of poor fireproof performance of wooden fire doors, monotonous and disharmonious colors, peeling of wooden boards, etc., and achieve saving Effects of raw materials, extended service life, and improved fire performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

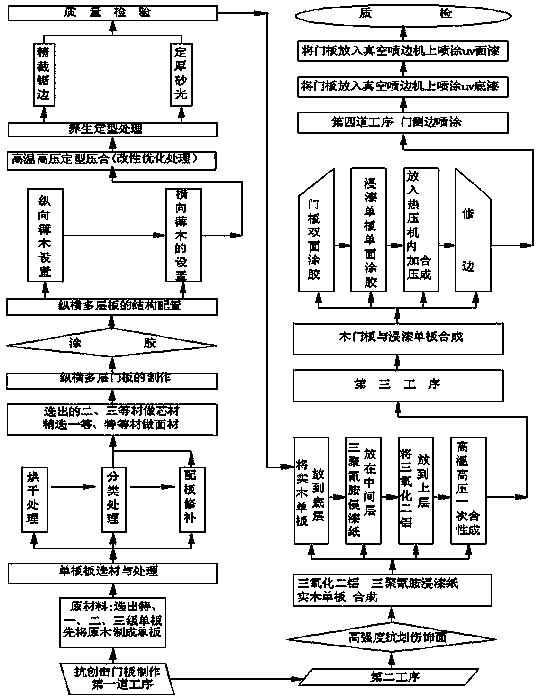

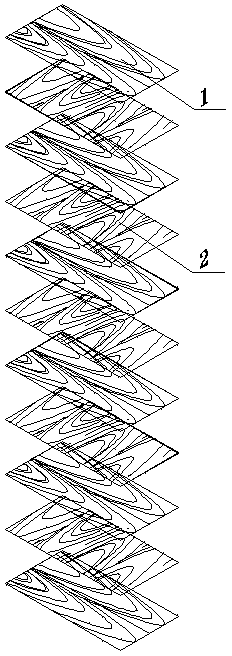

[0051] A method for making an environmentally friendly, energy-saving and fireproof multi-layer board, as attached figure 1 As shown, the method includes the following steps: the method includes two steps, the first step is to use pure solid wood to make the flame-retardant veneer, and the second step is to make the flame-retardant veneer cross one layer of vertical grain veneer and one layer of transverse grain veneer Arranged in a superimposed manner to make a fireproof multi-layer board.

Embodiment 2

[0053] The manufacturing method of the environment-friendly, energy-saving and fireproof multi-layer board described in Embodiment 1, as attached Figure 2-6 As shown, the first step is to use pure solid wood to make flame-retardant veneer. The first process is to soften the log. When the log is stored at an outdoor temperature below 0°C, first soak the log in water at 25-35°C for 6-10 hours. hours, and then steam the water with steam at 1.5 to 3 atmospheres;

[0054] The second process is to make the veneer, slice or peel the log into the veneer, first put the log on the planer or rotary cutter, adjust the speed, adjust the thickness to 2mm, and cut the log into the veneer of 1.8-2mm ;

[0055] The third process is to perform flame-retardant treatment on the veneer. ①Put the veneer with a moisture content of 70% into the flame-retardant mixture a for 48 hours, take it out, dry it, and dry it naturally until the moisture content is below 40%; Put 22 parts of triammonium phos...

Embodiment 3

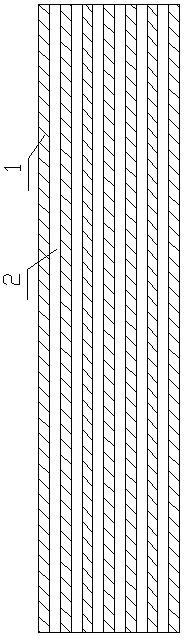

[0063] The manufacturing method of the environment-friendly, energy-saving and fireproof multi-layer board described in Embodiment 1, as attached Figure 2-6 As shown, in the second step, the flame-retardant veneers are arranged in a cross-overlay manner of one layer of longitudinal grain veneer 1 and one layer of transverse grain veneer 2 to make a fireproof multi-layer board, and the total number of layers is an odd number; the first The upper layer flame retardant panel, the middle layer flame retardant veneer and the lower layer flame retardant panel that have been coated with glue are pressed into shape at one time under high temperature and high pressure; Arrange according to the structure of one layer of vertical grain veneer and one layer of transverse grain veneer, put it into the hot press, and adjust the pressure to 15kg / cm 2 , the relatively high-quality veneer pressure is adjusted to 4 kg / cm 2 ;Adjust the compression ratio to 90%, heat pressing time is 15 minutes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com