Patents

Literature

7517 results about "Composite plate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A composite plate is basically a plate made out of composite materials, i.e. a resin and a fibre. Its mechanical evaluation is more detailed than a normal isotropic plate as it has different material properties in different directions. Composite materials are very light and strong and hence much used in aircraft and spacecraft industries. They are also readily available.

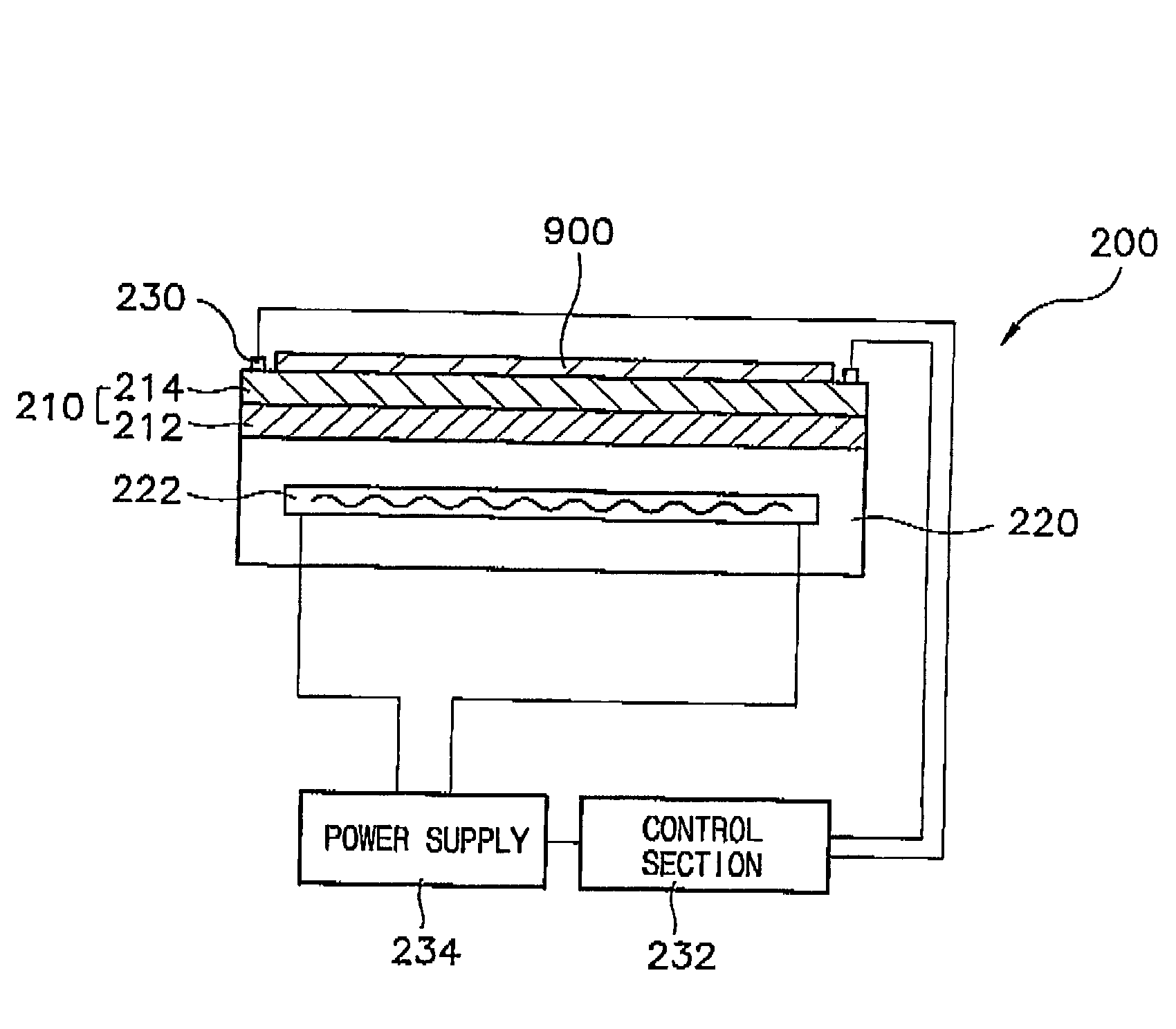

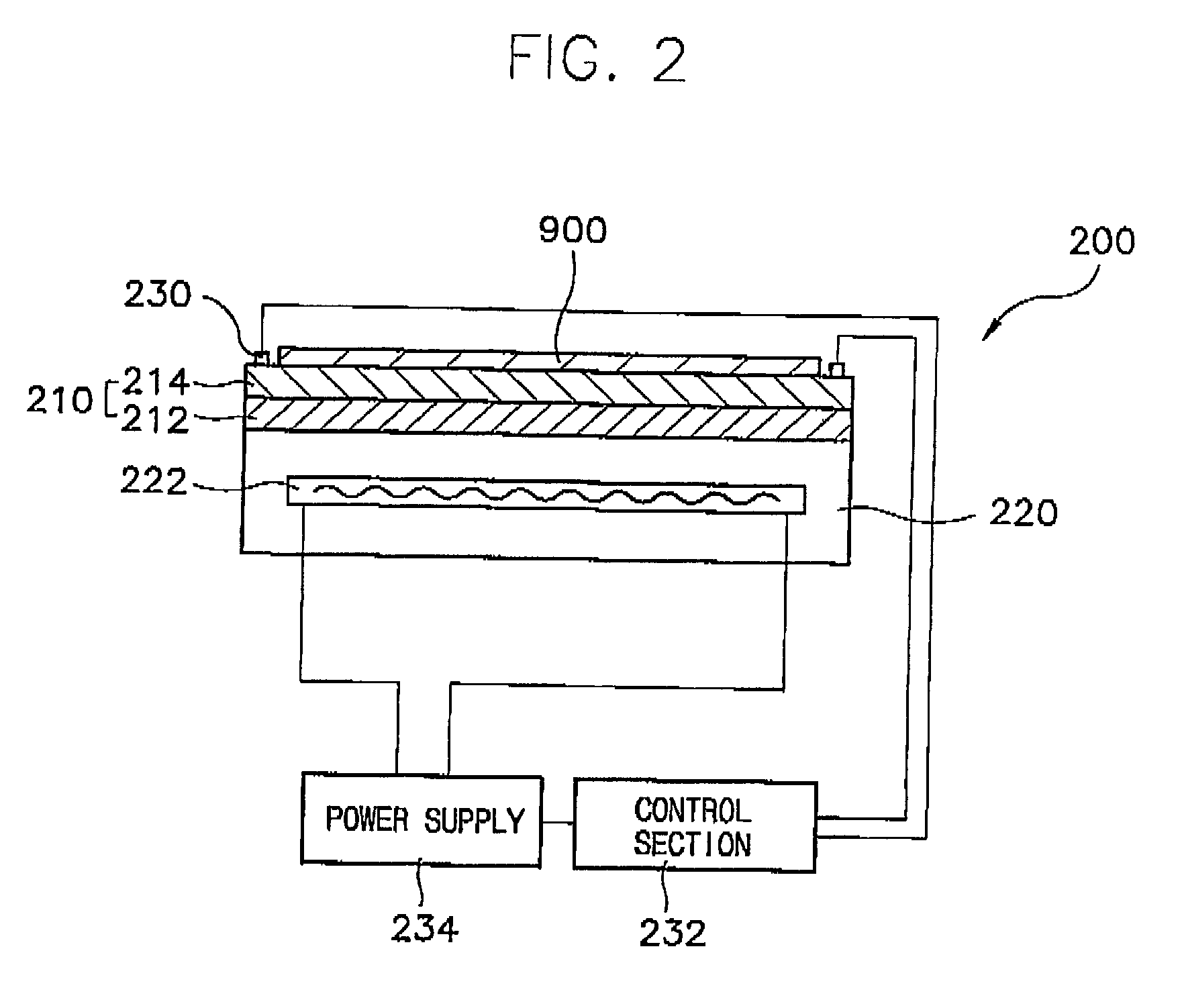

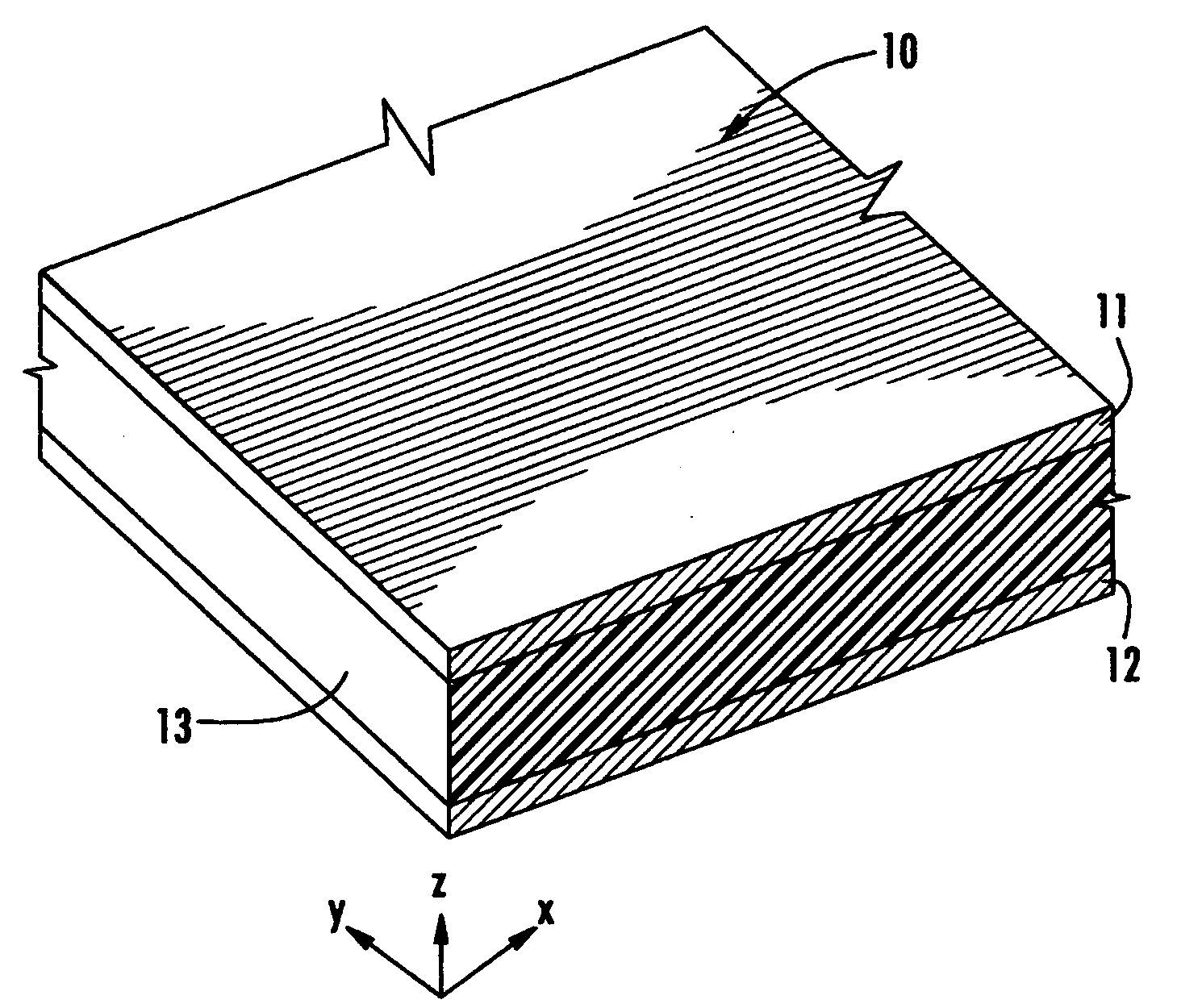

Apparatus for processing a substrate including a heating apparatus

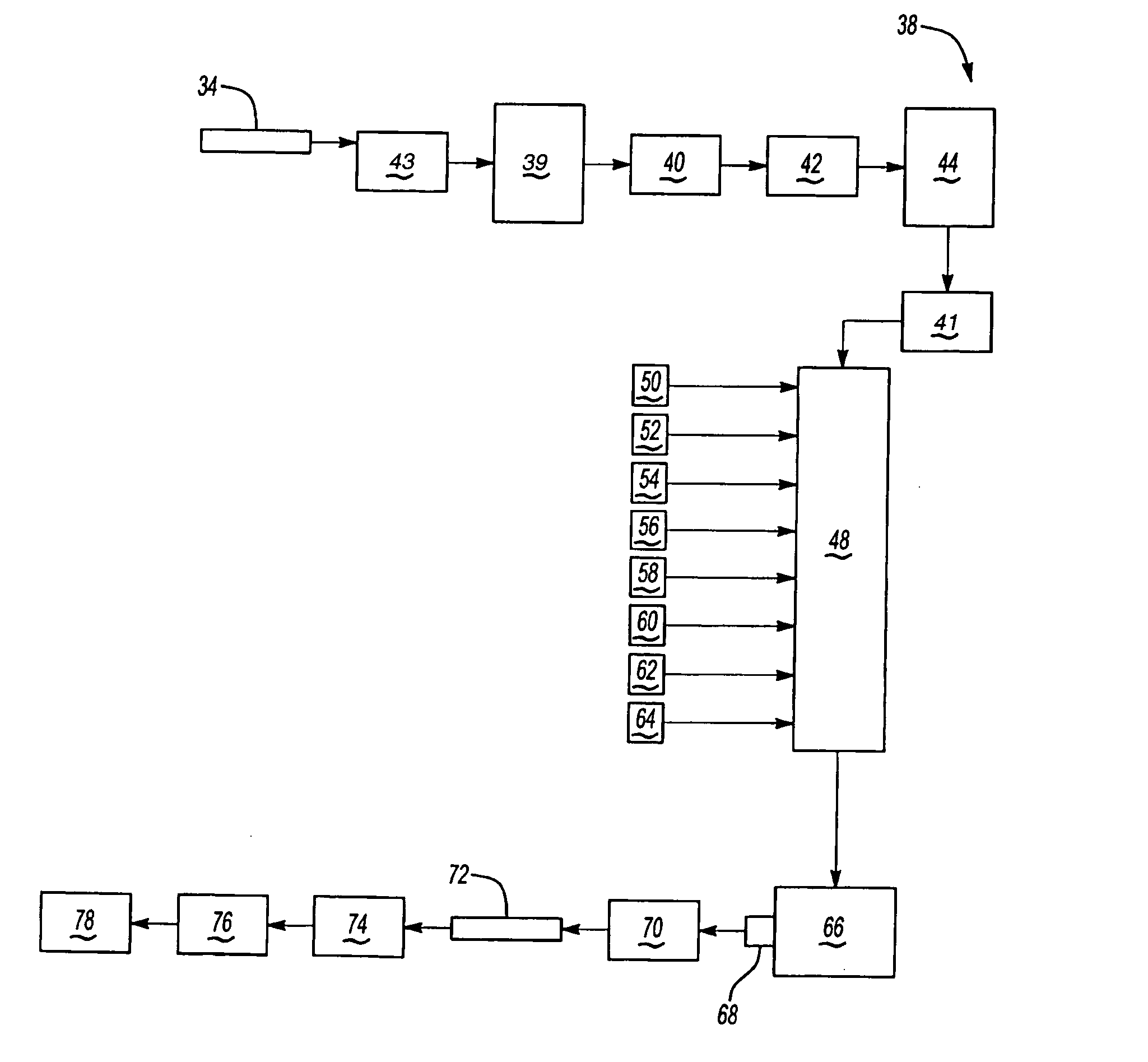

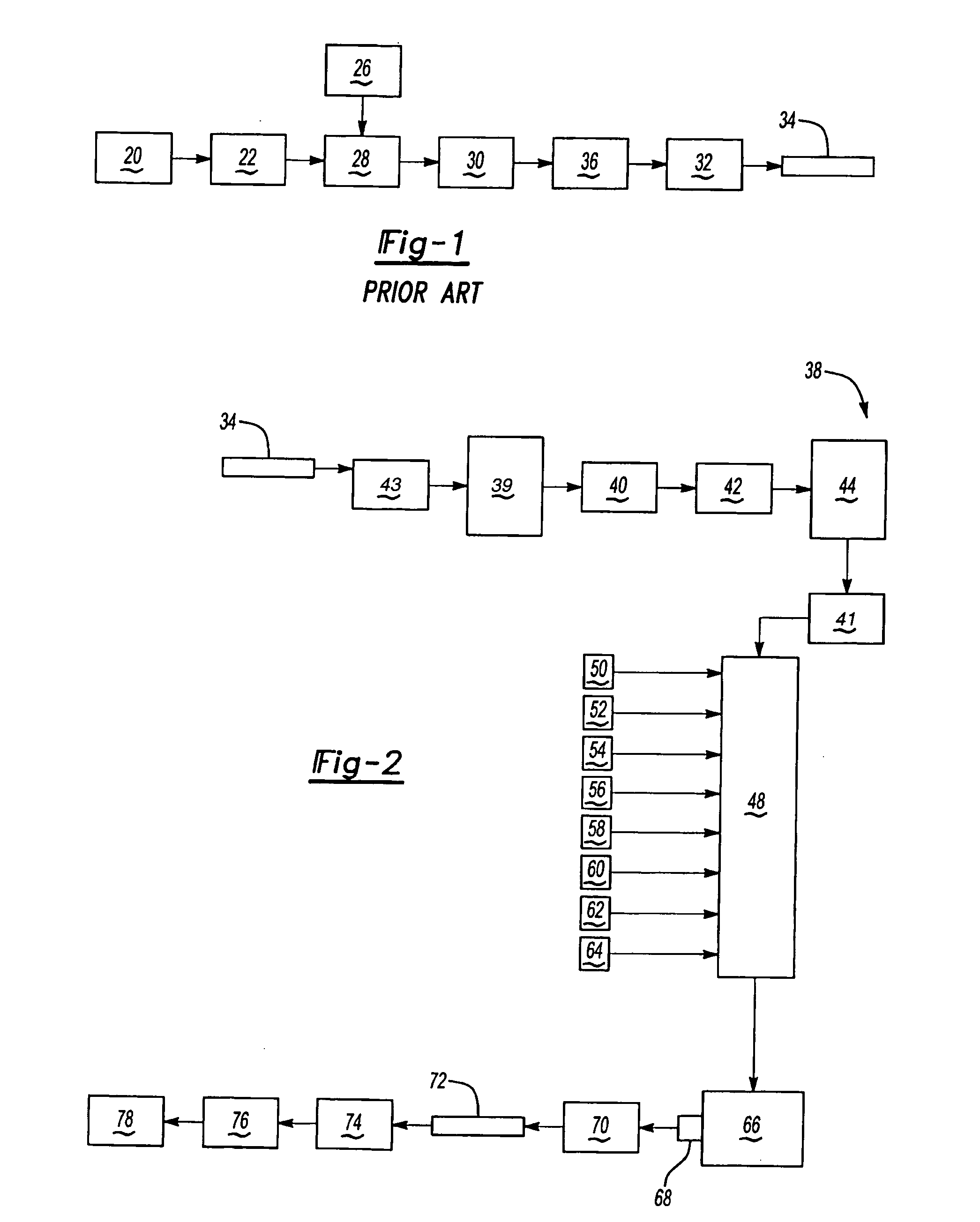

InactiveUS20030066826A1Drying solid materials with heatMuffle furnacesProduction rateDevice material

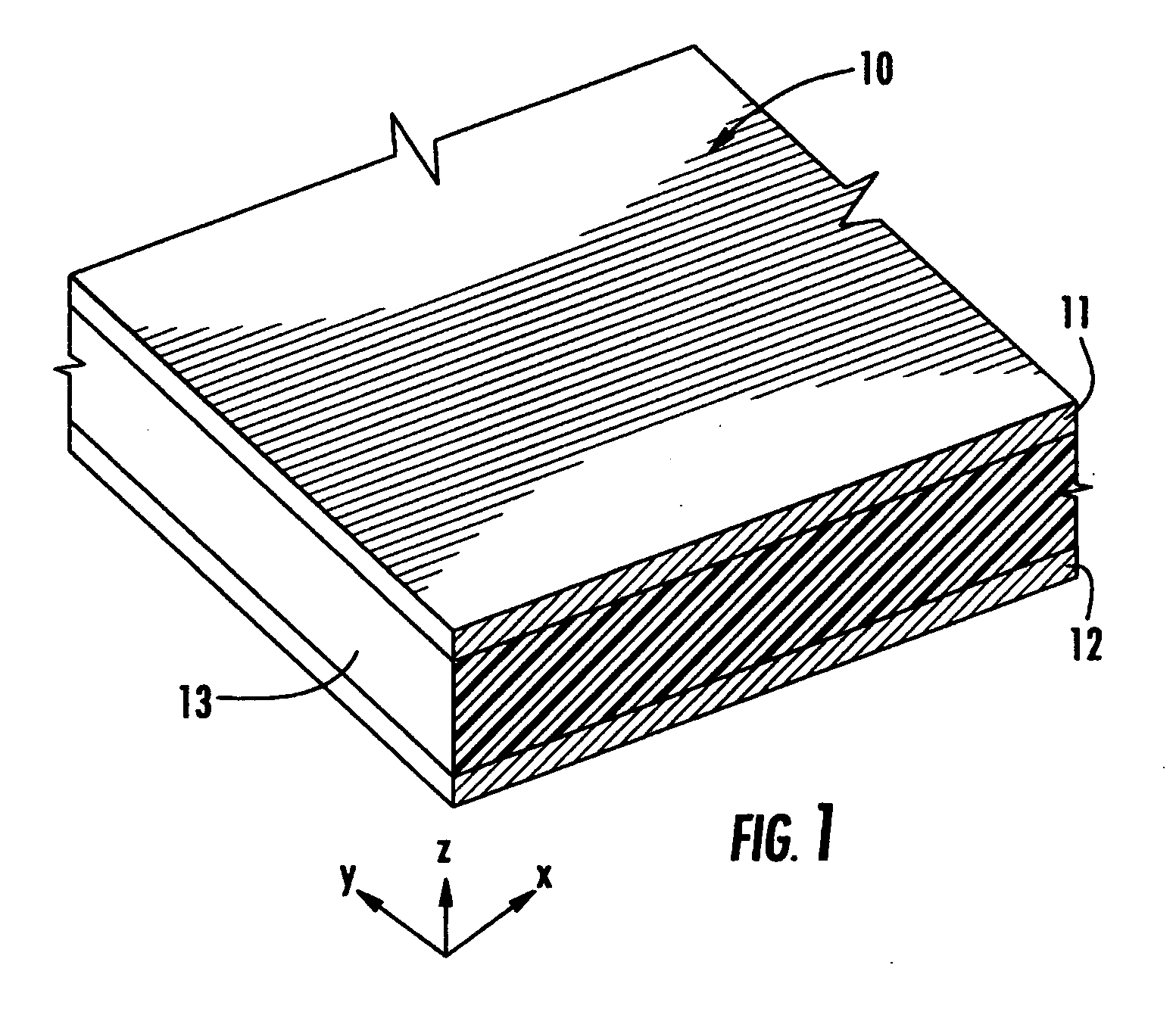

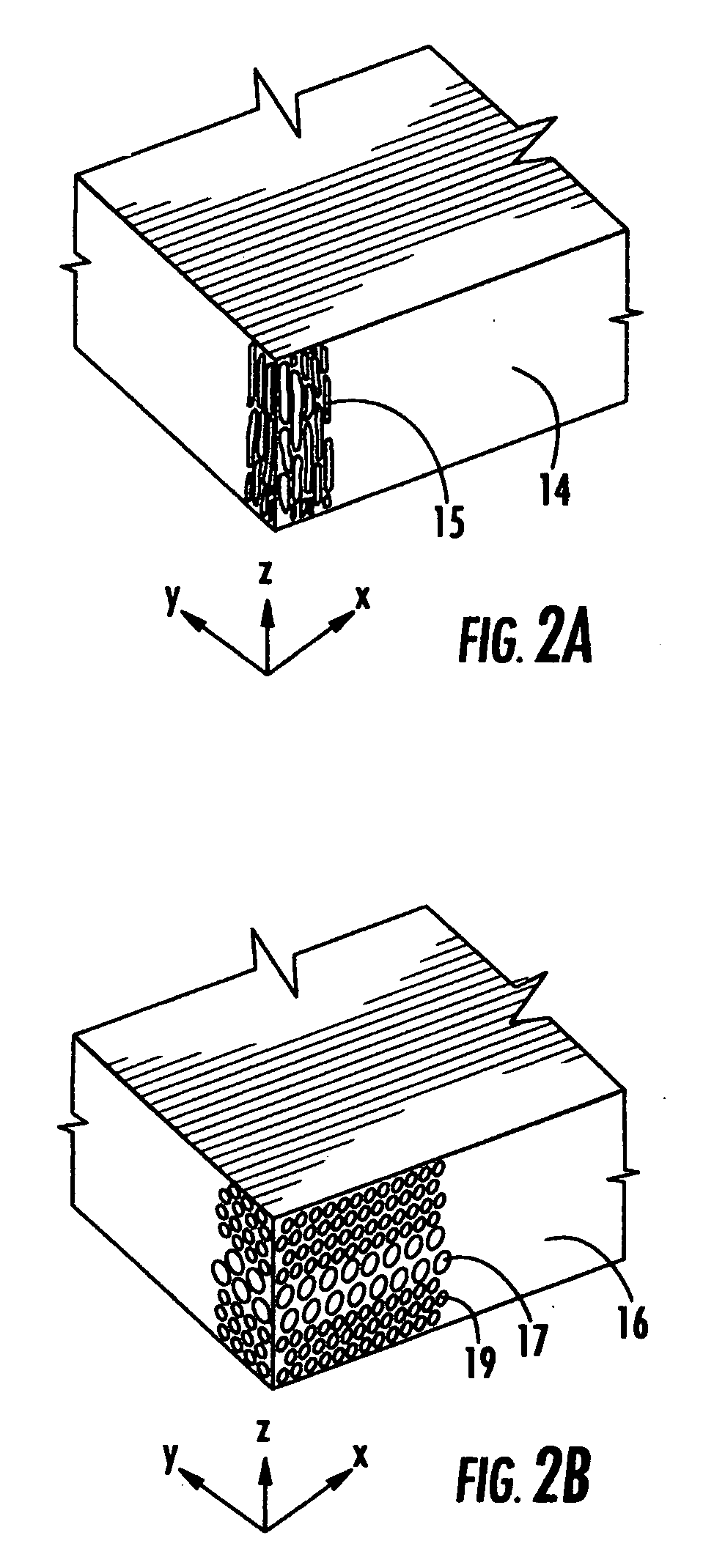

An apparatus for heating a substrate of a semiconductor device includes a hot plate, on which a semiconductor substrate is placed, and a heater for heating the hot plate. The hot plate is preferably a composite plate including a plurality of plates having different thermal conductivities from each other. For example, a first plate adjacent to the heater can be made of aluminum, which has a relatively high thermal conductivity. A second plate, laminated on top of the first plate, can be made of titanium or stainless steel, which both have a thermal conductivity lower than aluminum. A composite hot plate as disclosed herein is better able to maintain a constant temperature and a uniform temperature distribution in order to more uniformly heat a substrate and to reduce an amount of energy required for the heating process. In addition, the reliability and productivity of the semiconductor device manufactured by the apparatus can be improved.

Owner:SAMSUNG ELECTRONICS CO LTD

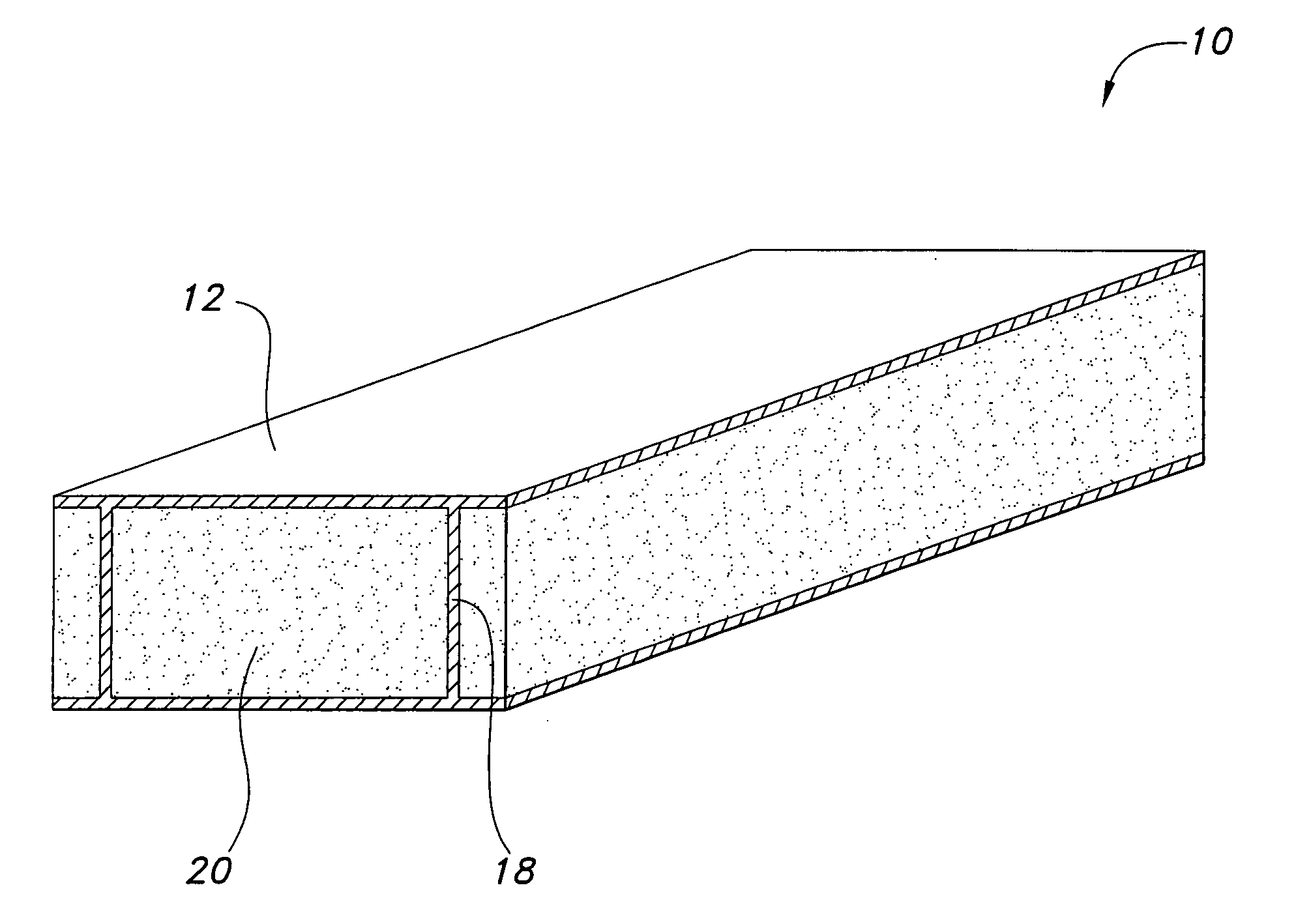

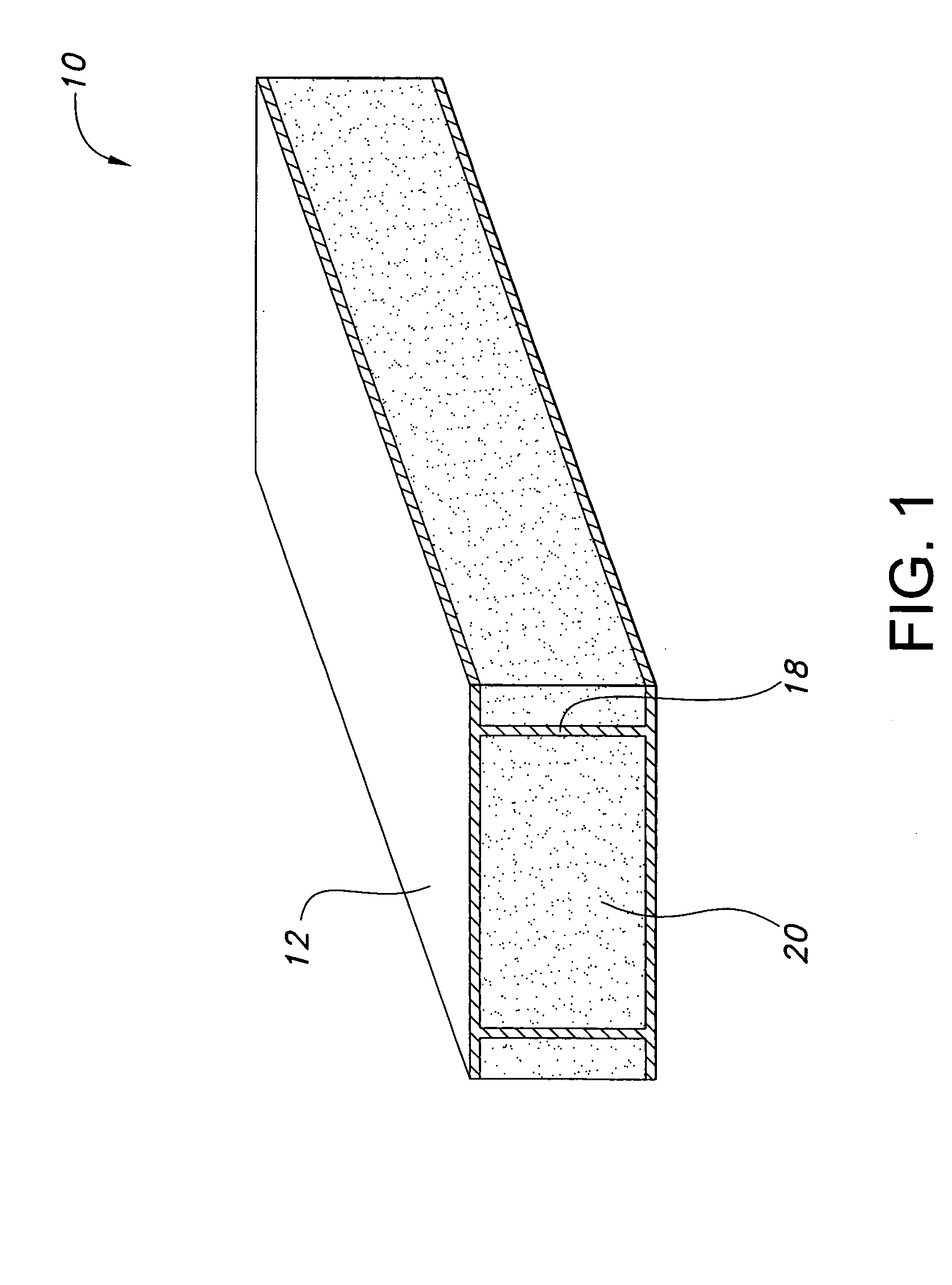

Composite panels

A composite panel consisting of outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic. The composite panel can be made by applying external heat and pressure to melt a skin of thermoplastic composite and an initial thickness of a thermoplastic core which has anisotropic properties causing the skin and core to fuse together followed by cooling the fused structure. The composite panel can be made by applying external heat and pressure to melt layers of a thermoplastic adhesive positioned between the outer skins and an inner core consisting of a foamed polymer, wherein the structure or properties of the inner core are anisotropic, so that the skins are bonded to the core by the melted layers of the thermoplastic adhesive followed by cooling the bonded structure.

Owner:EDWARDS CHRISTOPHER M

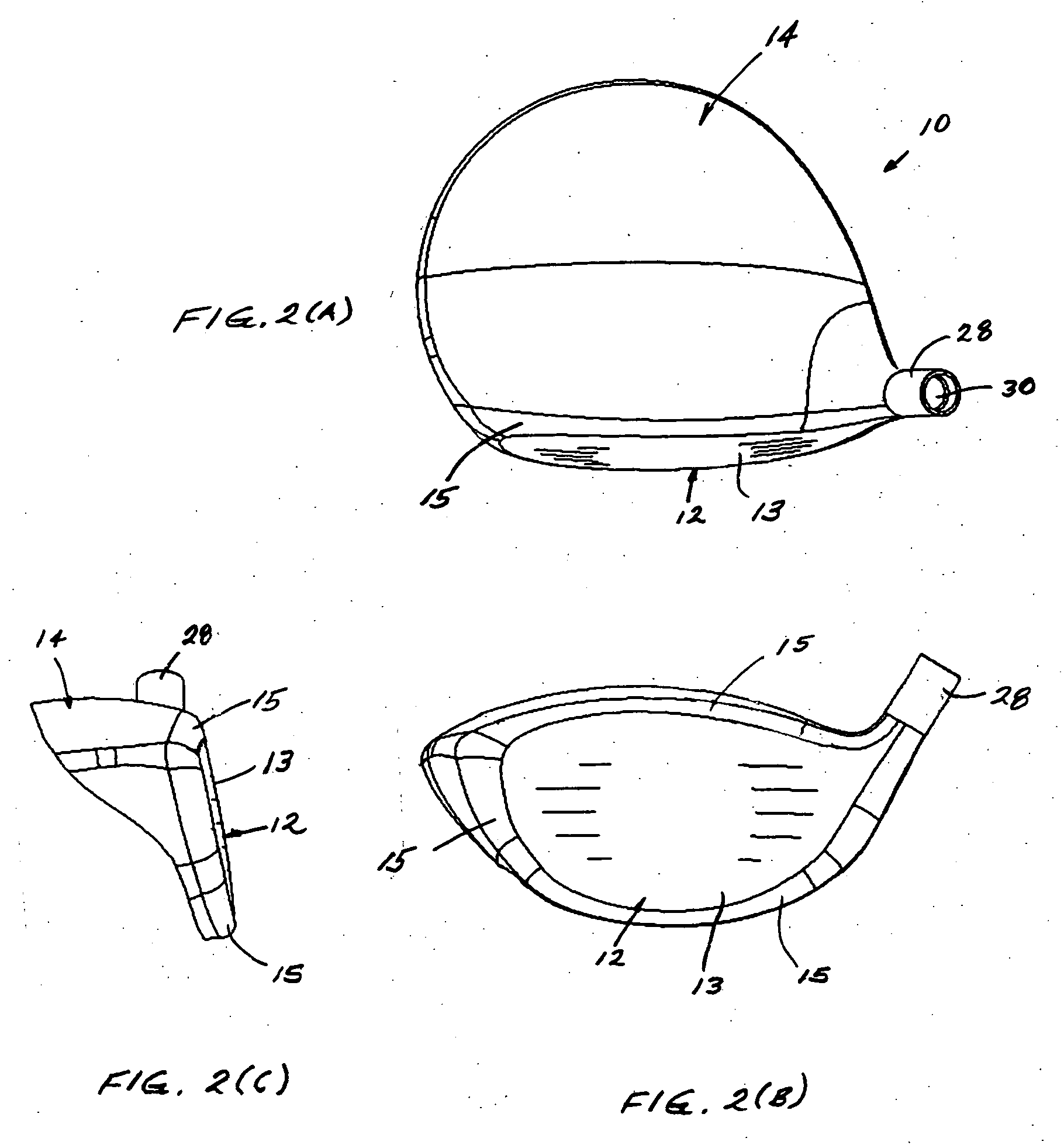

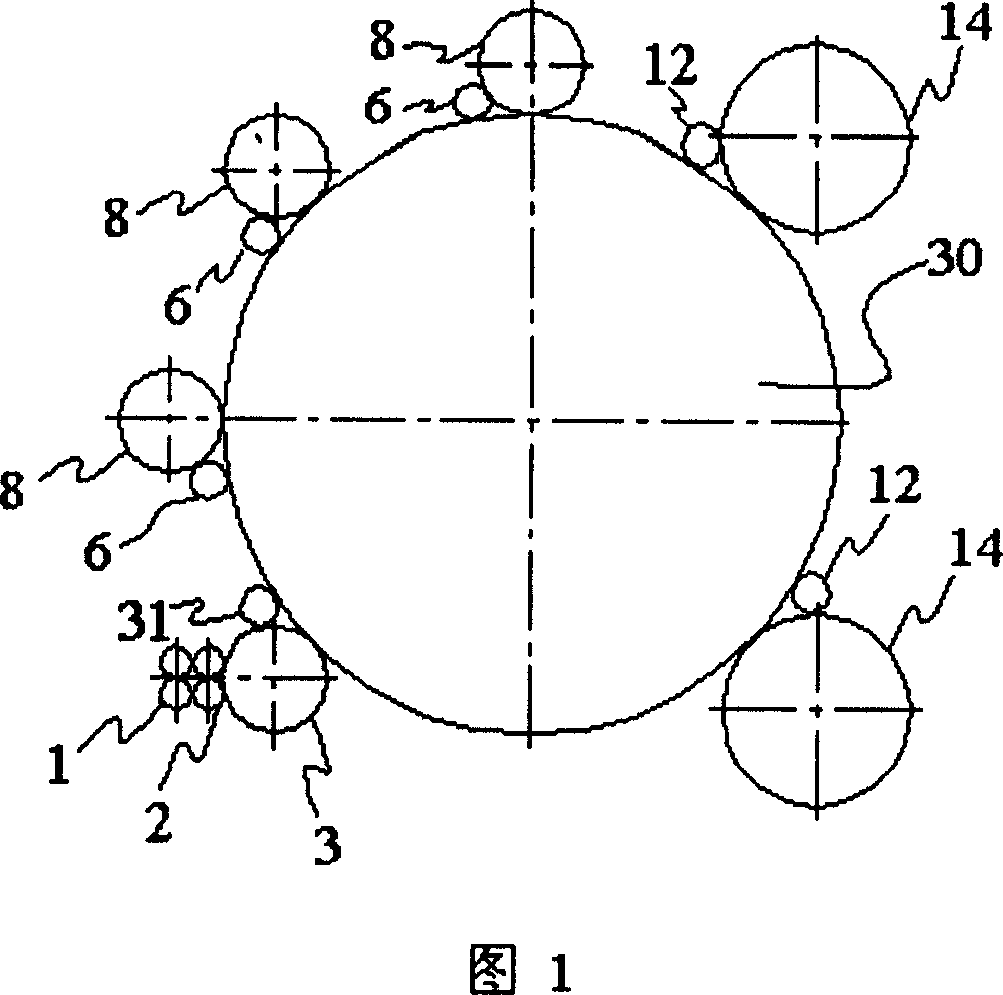

Golf club-heads having a particular relationship of face area to face mass

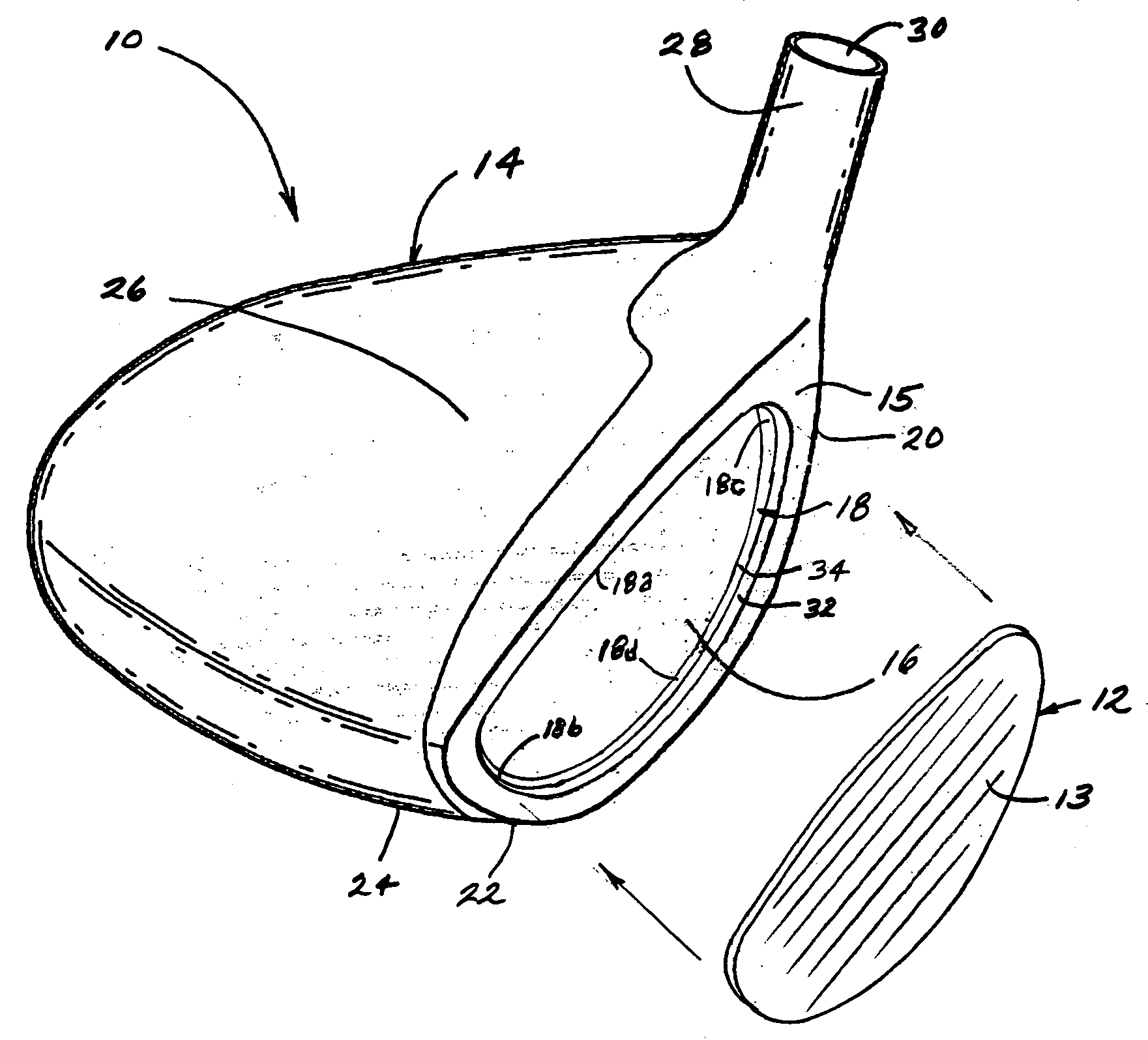

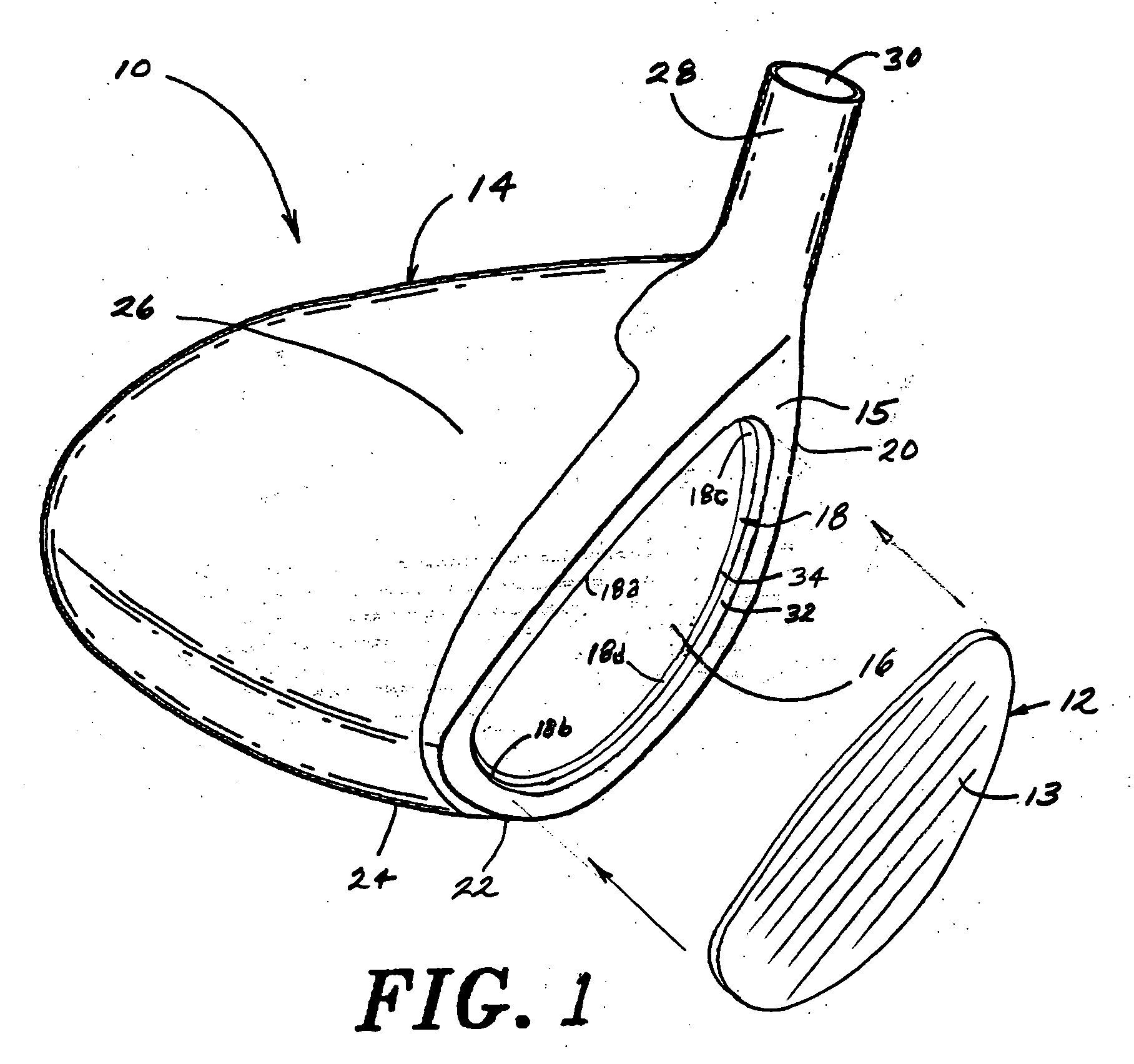

Golf clubs and club-heads for same are disclosed. An exemplary club-head has a hollow body and a face plate. The body defines a front opening and a face support, wherein the face plate is affixed to the face support and covers the front opening. The “face portion” of the club-head has a face area (Af, in mm2) and a face mass (Mf, in grams), wherein Af>5400 mm2, and in a plot of Mf as a function of Af, Mf is below Mf=0.0072(Af)+18. At least a portion of the face plate can be made of composite. E.g., the face plate can include a composite plate made of carbon fiber and cured epoxy resin. The strike face of the face plate can include a composite plate and a cap bonded to the composite plate on the strike face. The cap can be made of a metallic material, such as (but not limited to) titanium alloy or stainless steel.

Owner:TAYLOR MADE GOLF

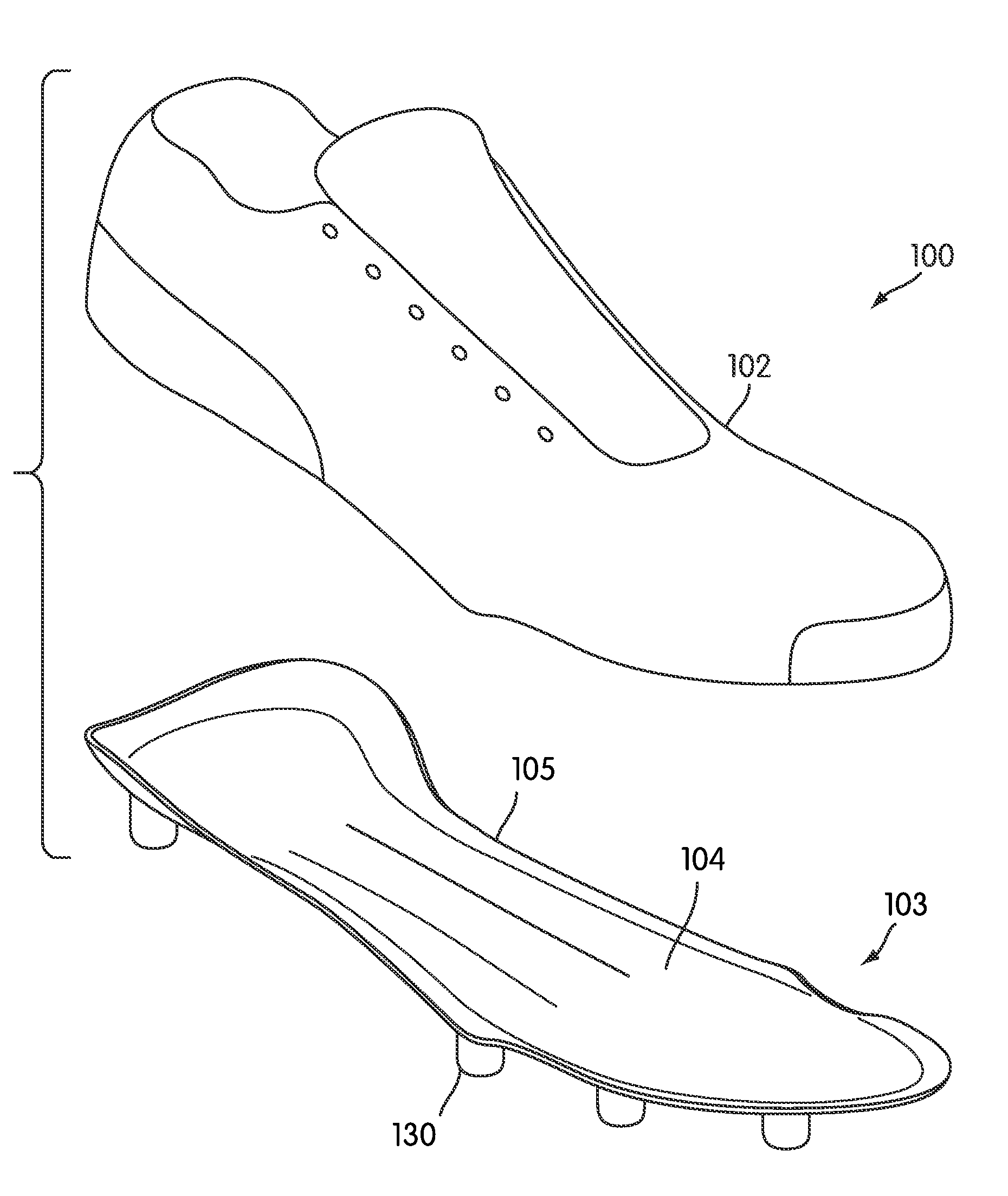

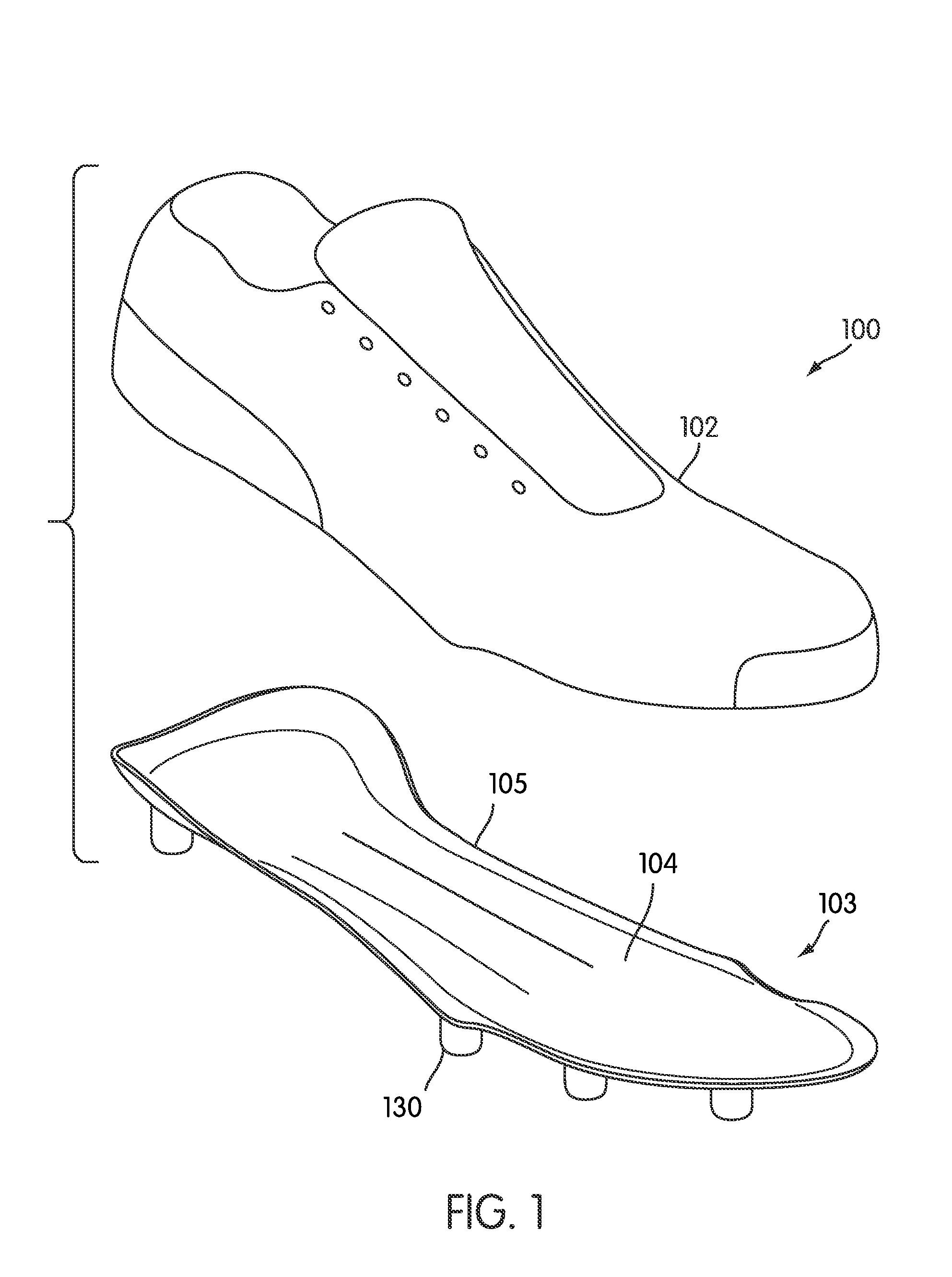

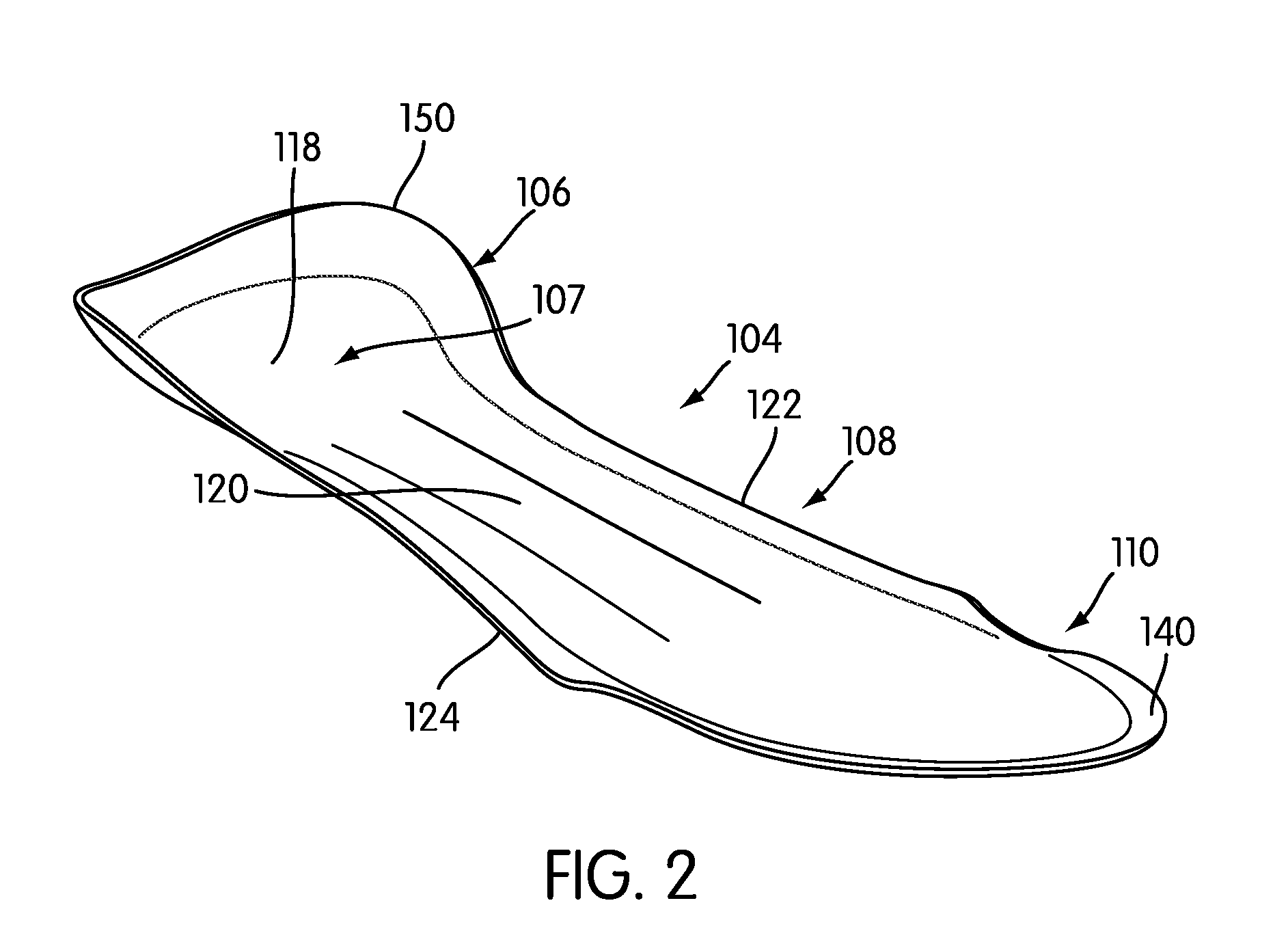

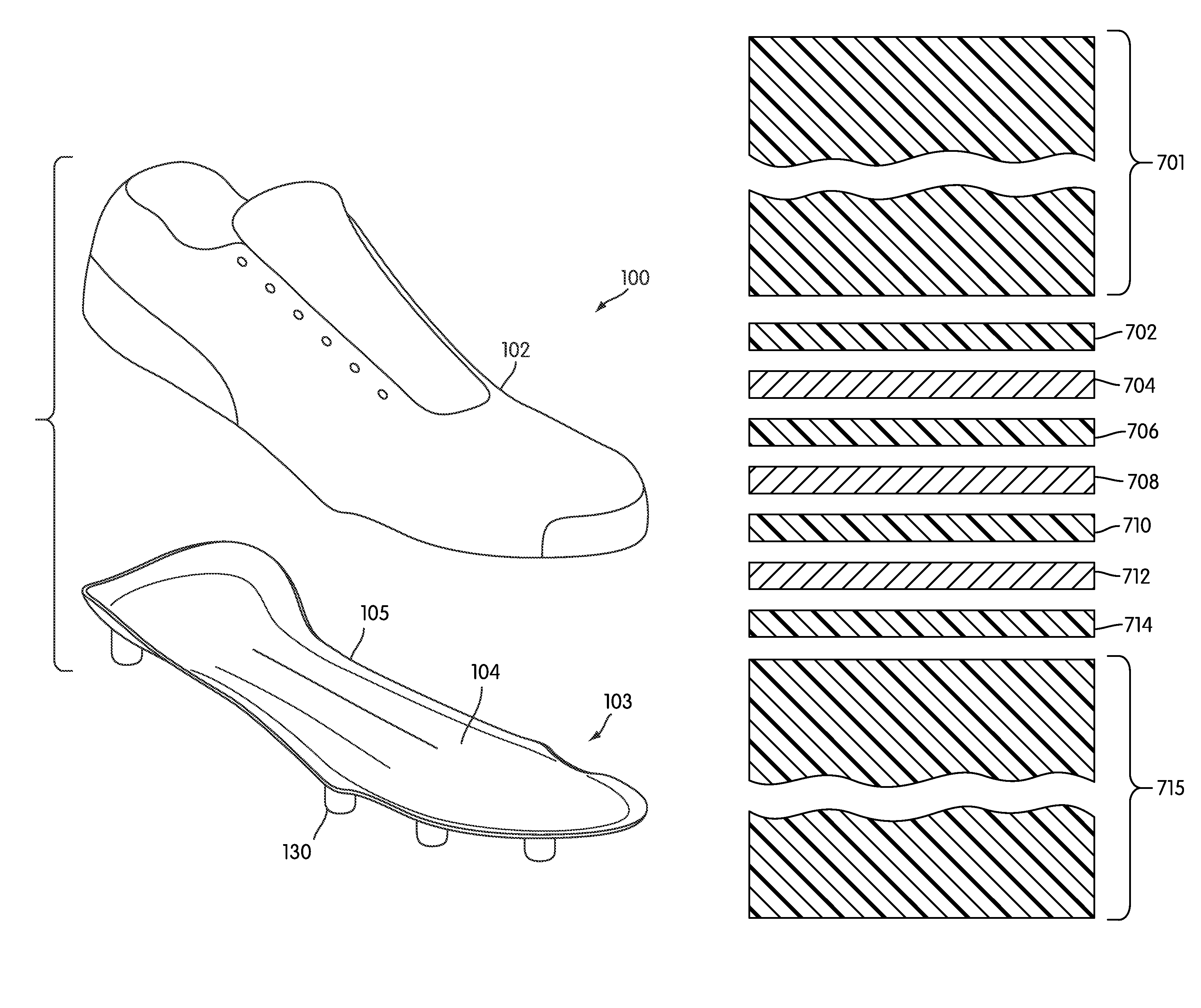

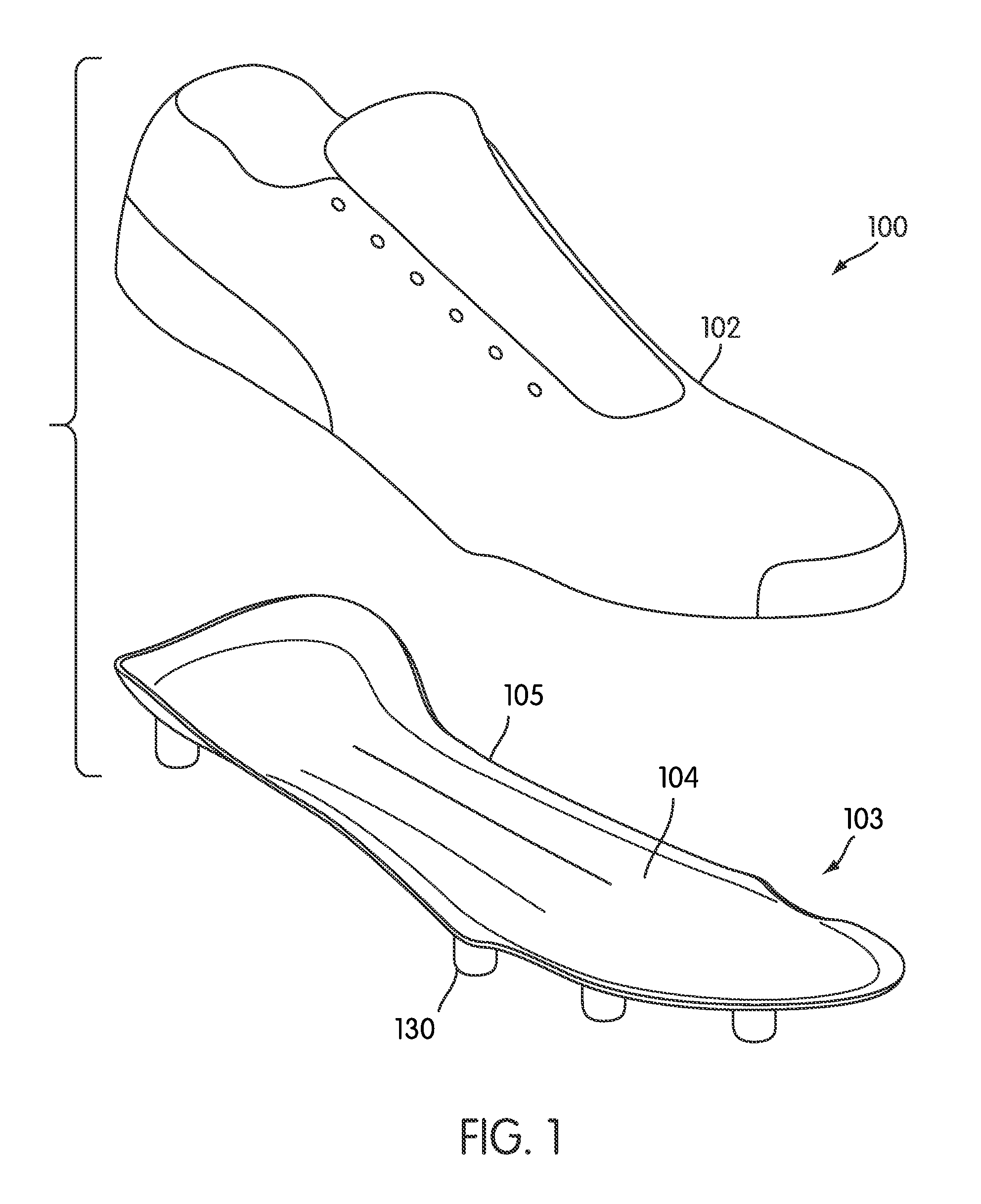

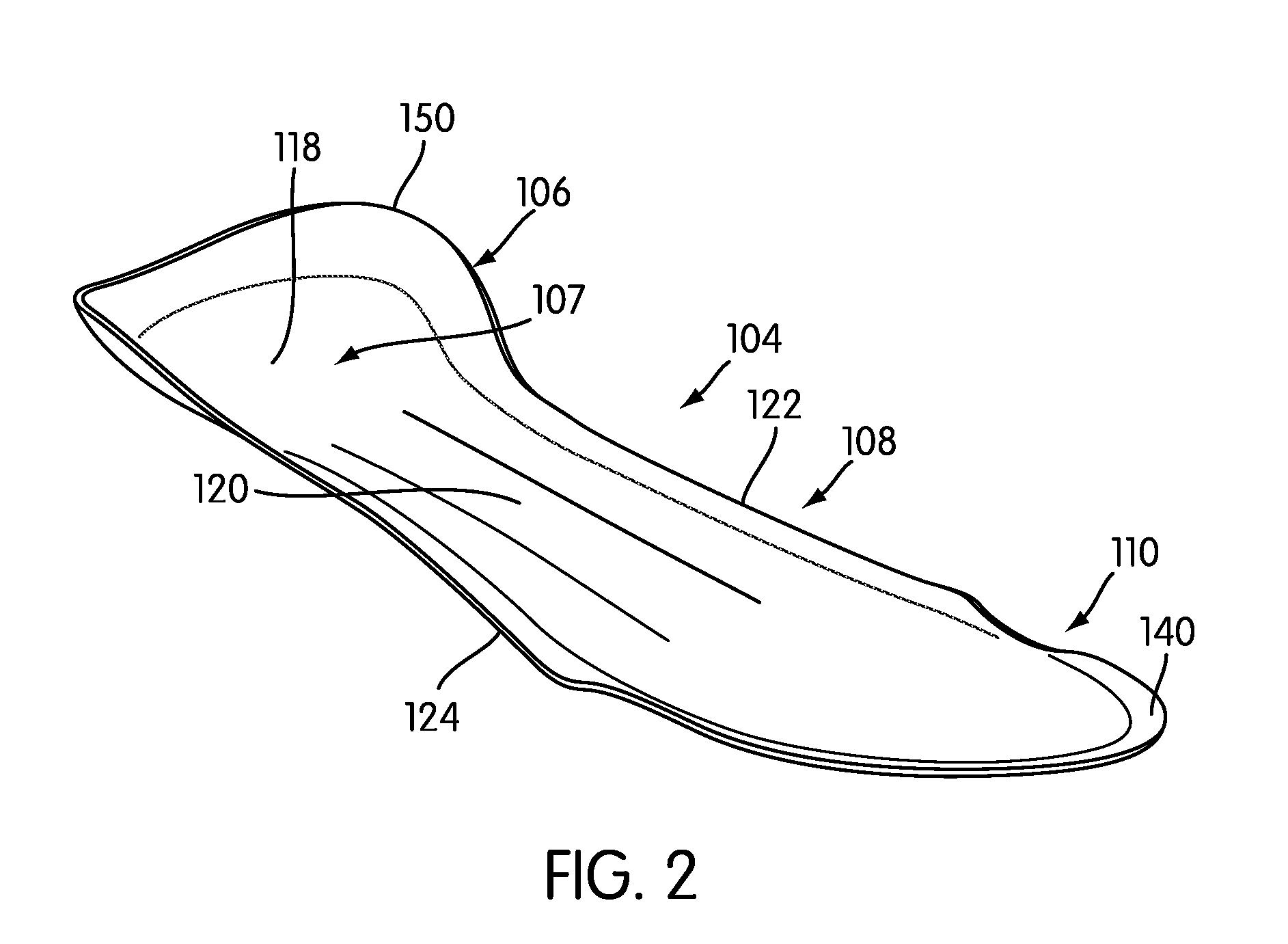

Article of Footwear Including Full Length Composite Plate

A full length composite plate to be used as part of an outsole assembly in an article of footwear is disclosed. The full length composite plate comprises a composite material that has a certain percent elongation. The full length composite plate can include a heel cup for heel stability and improved traction. The full length composite plate also can include two angled portions along an arch region that provide arch support, as well as two flattened edges along the arch region to minimize or eliminate buckling. The forefoot region can be relatively flatter than the arch and heel regions, and notches are preferably included along a portion of the forefoot to increase flexibility.

Owner:NIKE INC

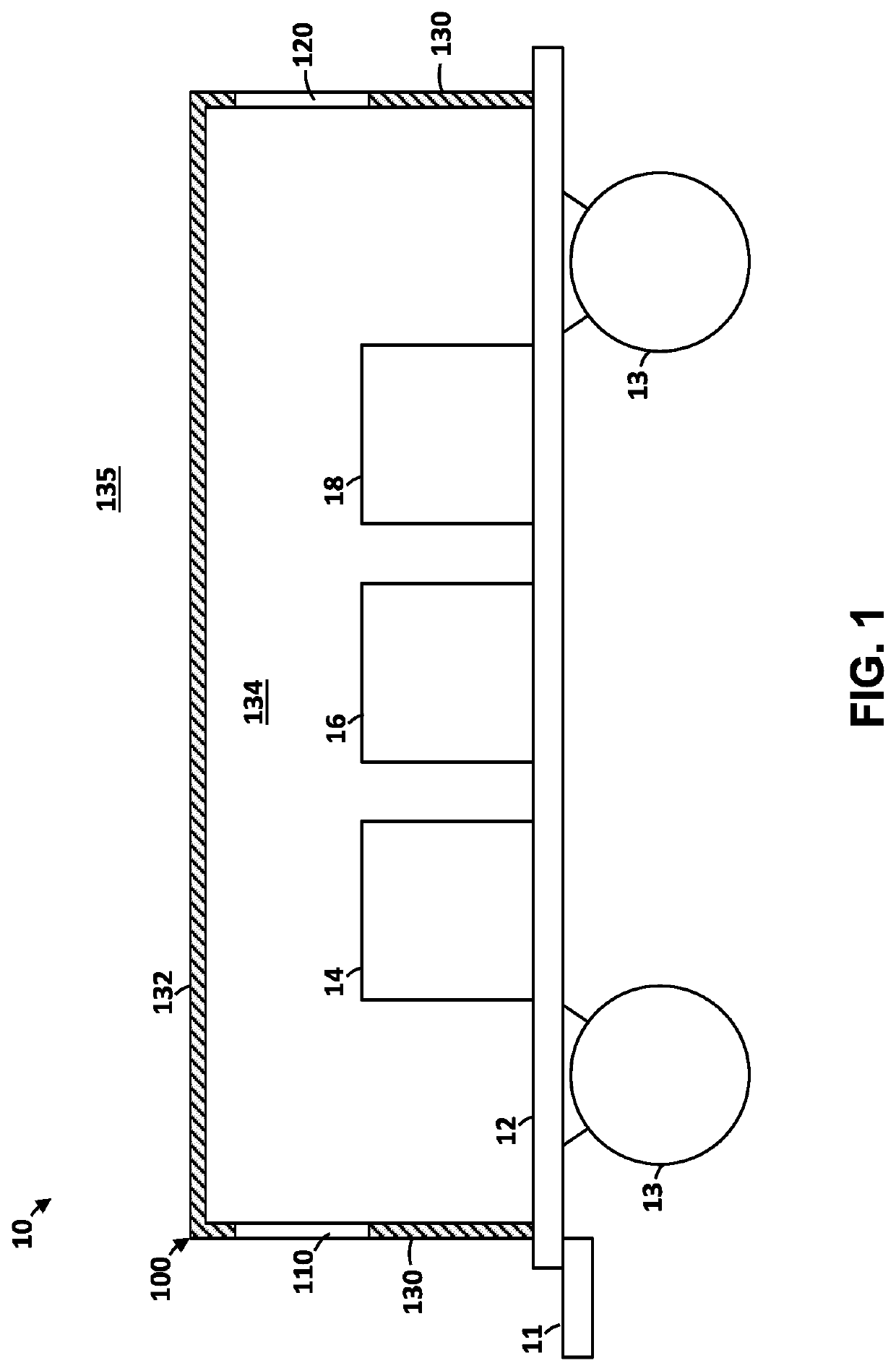

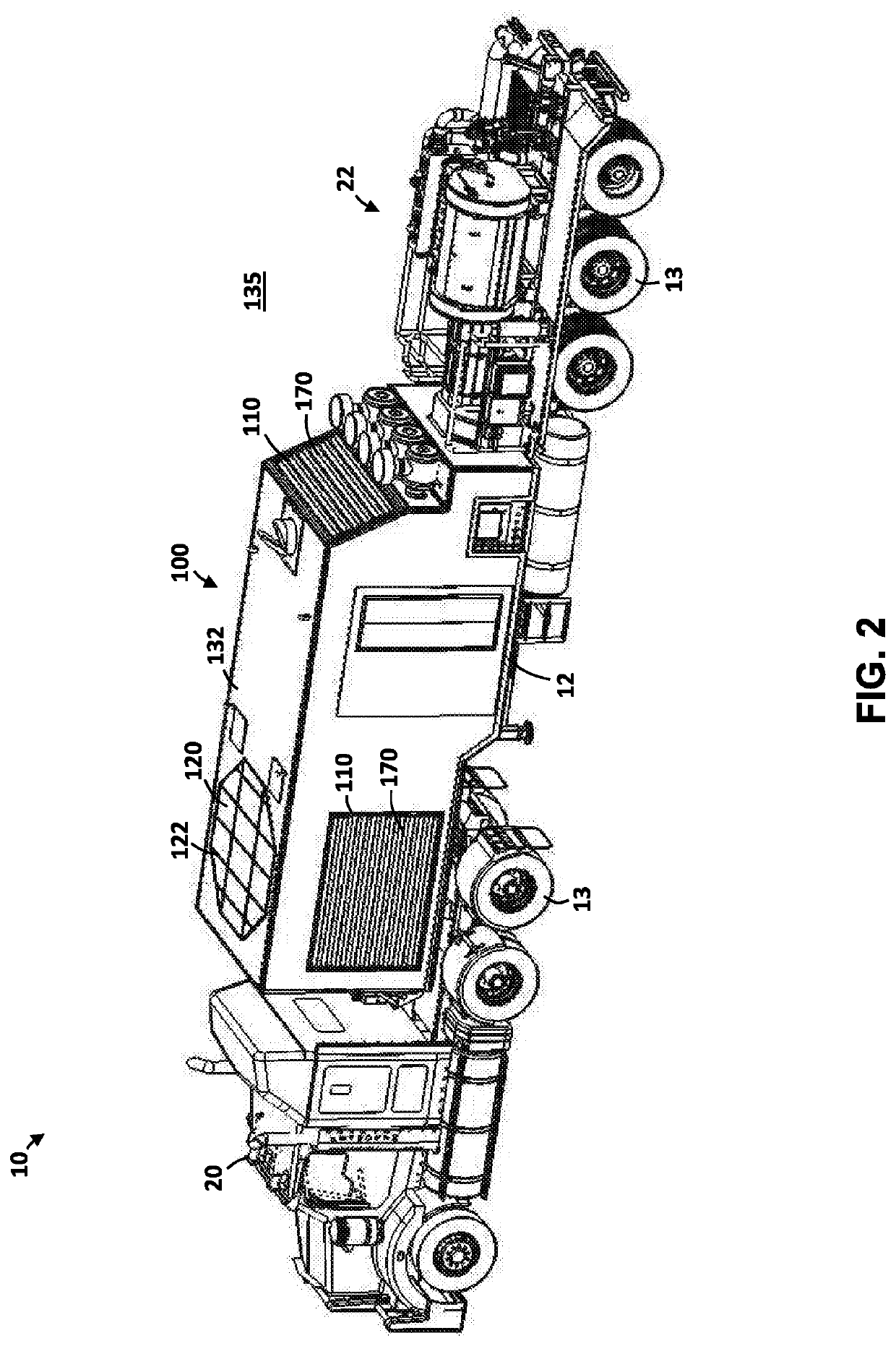

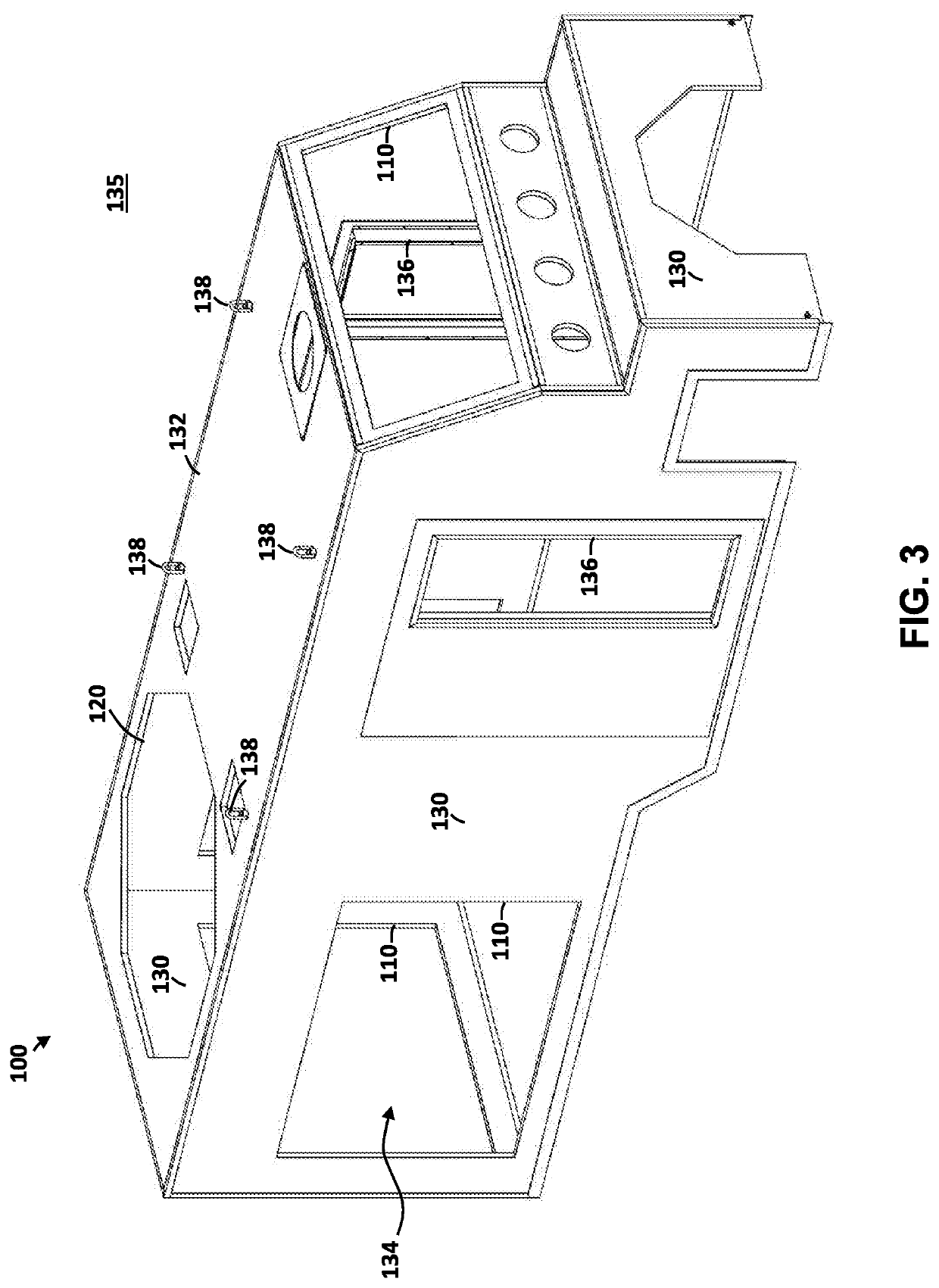

Systems and methods for attenuating sound

ActiveUS20210071654A1Positive displacement pump componentsSound producing devicesInterior spaceComposite plate

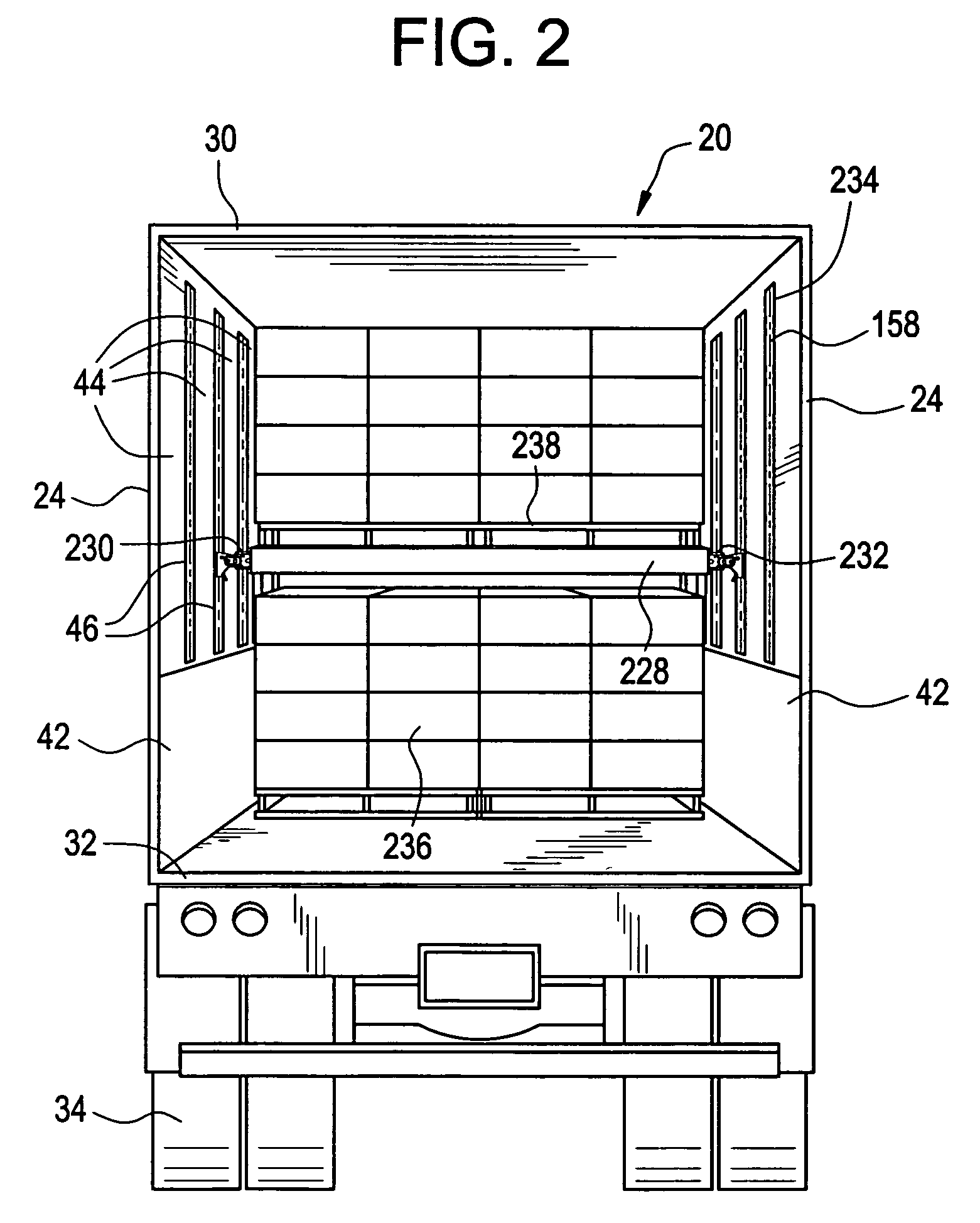

Embodiments disclosed herein include a sound attenuating enclosure defining an interior space, formed by a plurality of composite panels. In some embodiments the composite panels include a frame having a plurality of elongate frame members coupled to one another. The frame defines an inner side facing toward the interior space and an outer side facing away from the interior space. Additionally, some embodiments may include an outer skin secured to the outer side of the frame, an inner skin secured to the inner side of the frame, and a foam layer disposed between the outer skin and the inner skin and between at least a pair of the frame members.

Owner:ENQUEST ENERGY SOLUTIONS LLC

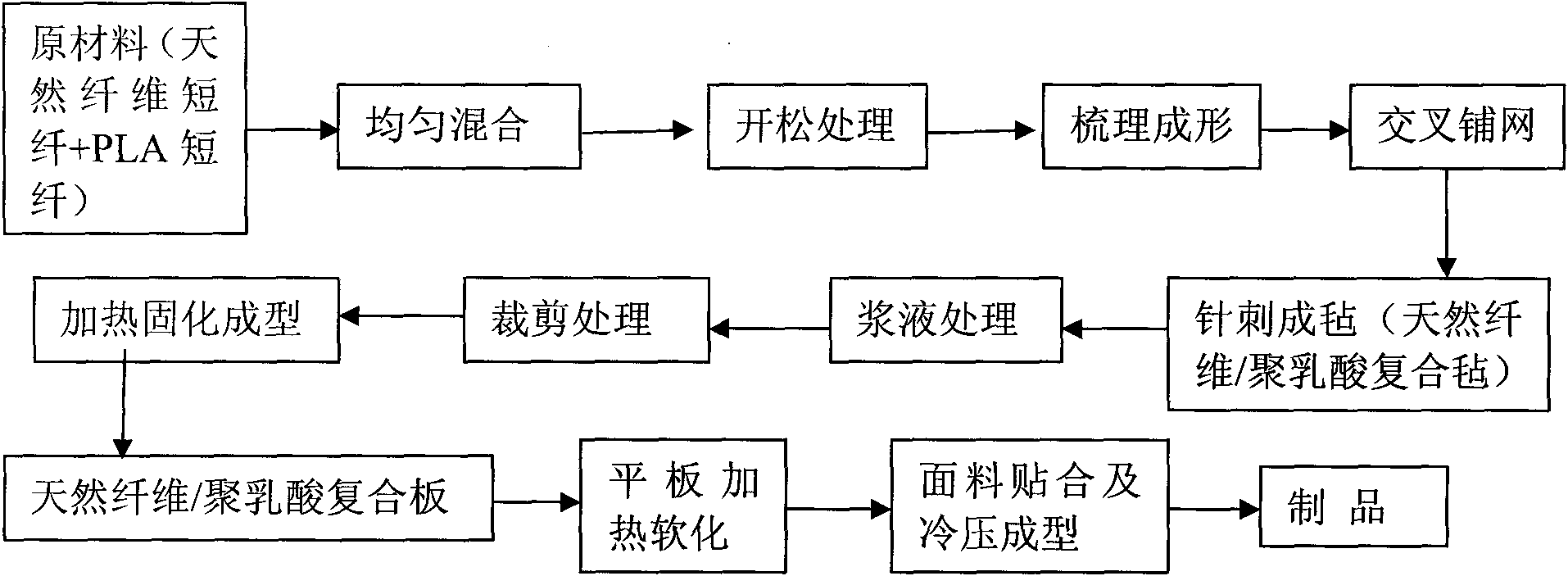

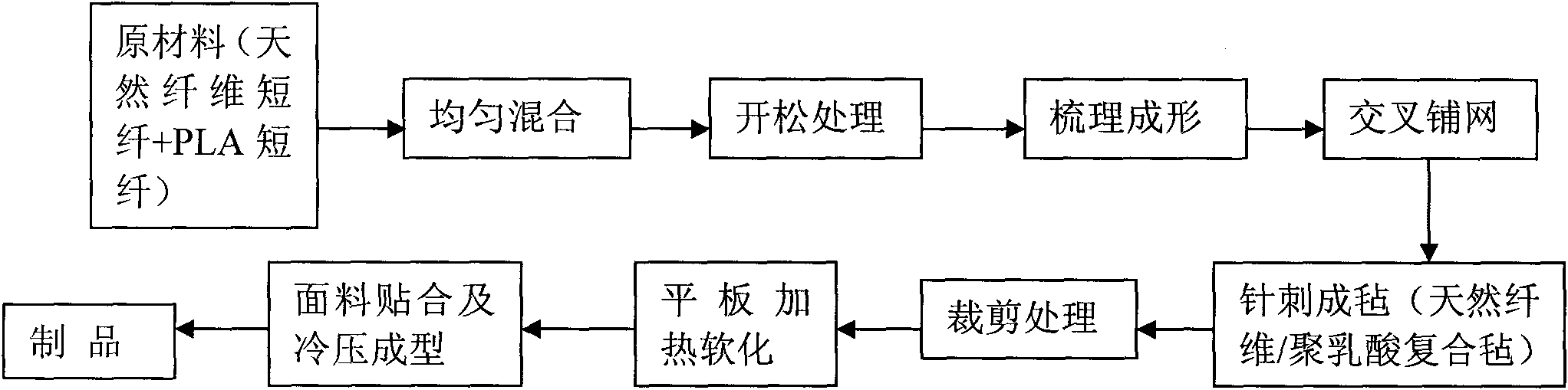

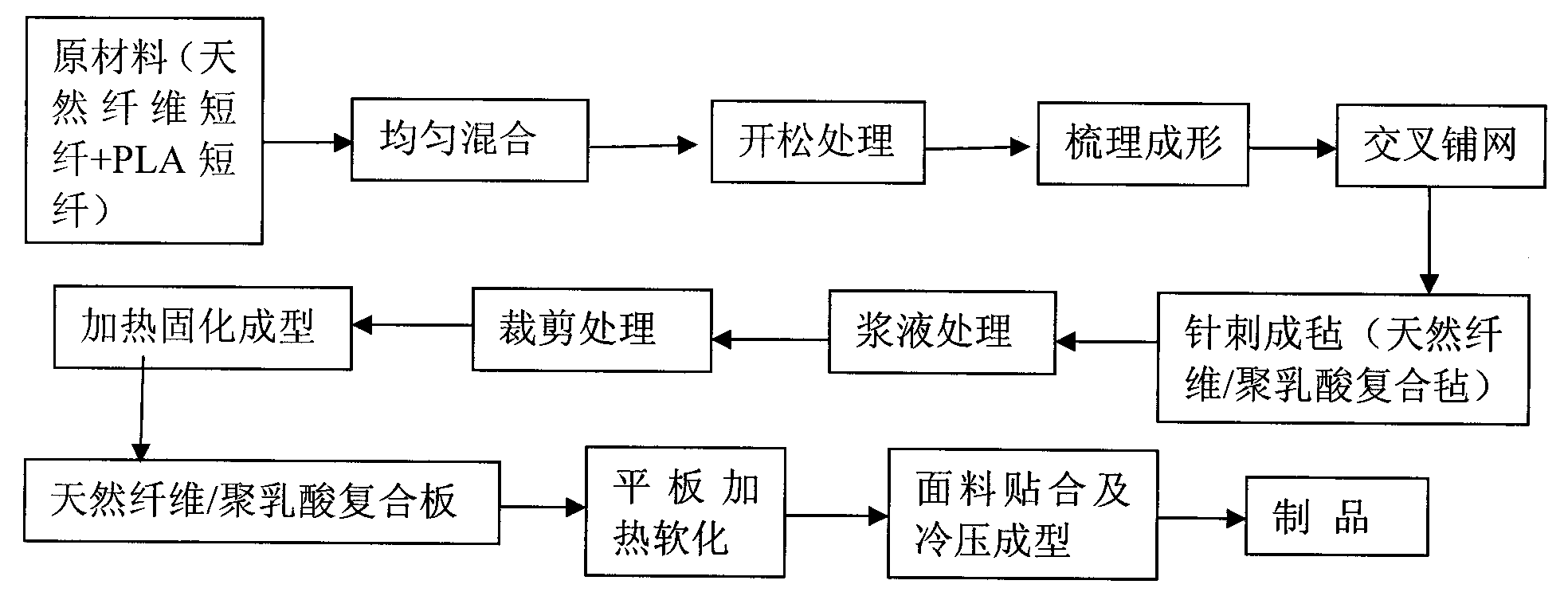

Composite material for automobile interior part and production method thereof

ActiveCN101812773ANo pollution in the processReduce lossVehicle componentsNon-woven fabricsMetallurgySlurry

The invention discloses a formula of a composite material for an automobile interior part. The formula consists of the following materials in percentage by weight: 40 to 60 percent of polylactic acid fiber and 40 to 60 percent of natural fiber. The production method of the invention comprises the following steps: uniformly mixing the raw materials; putting the mixture into an opener for opening, combing and shaping the obtained product, feeding the product into a lapping machine for cross lapping and feeding the cross-lapped product into a needling machine for needling to form a felt; immersing the fiber felt into a processing slurry; drying the immersed coiled material through hot blast and cutting the dried material into pieces of required size; placing the cut material into a mould for curing and shaping by heating; demoulding the material to form a composite plate; and softening the composite plate by flat panel heating, covering the plate with a surface decorative layer and performing cold molding on the plate through a product mould to manufacture the finished product finally; or softening the cut fiber felt by the flat panel heating directly, covering the plate with the surface decorative layer and performing the cold molding to manufacture the finished product finally. The composite material for the automobile interior part of the invention has the advantages of no toxicity, no pollution, simple processing technique, small energy consumption and high environment protection performance.

Owner:CHERY COMML VEHICLE ANHUI

Article of footwear including full length composite plate

A full length composite plate to be used as part of an outsole assembly in an article of footwear is disclosed. The full length composite plate comprises a composite material that has a certain percent elongation. The full length composite plate can include a heel cup for heel stability and improved traction. The full length composite plate also can include two angled portions along an arch region that provide arch support, as well as two flattened edges along the arch region to minimize or eliminate buckling. The forefoot region can be relatively flatter than the arch and heel regions, and notches are preferably included along a portion of the forefoot to increase flexibility.

Owner:NIKE INC

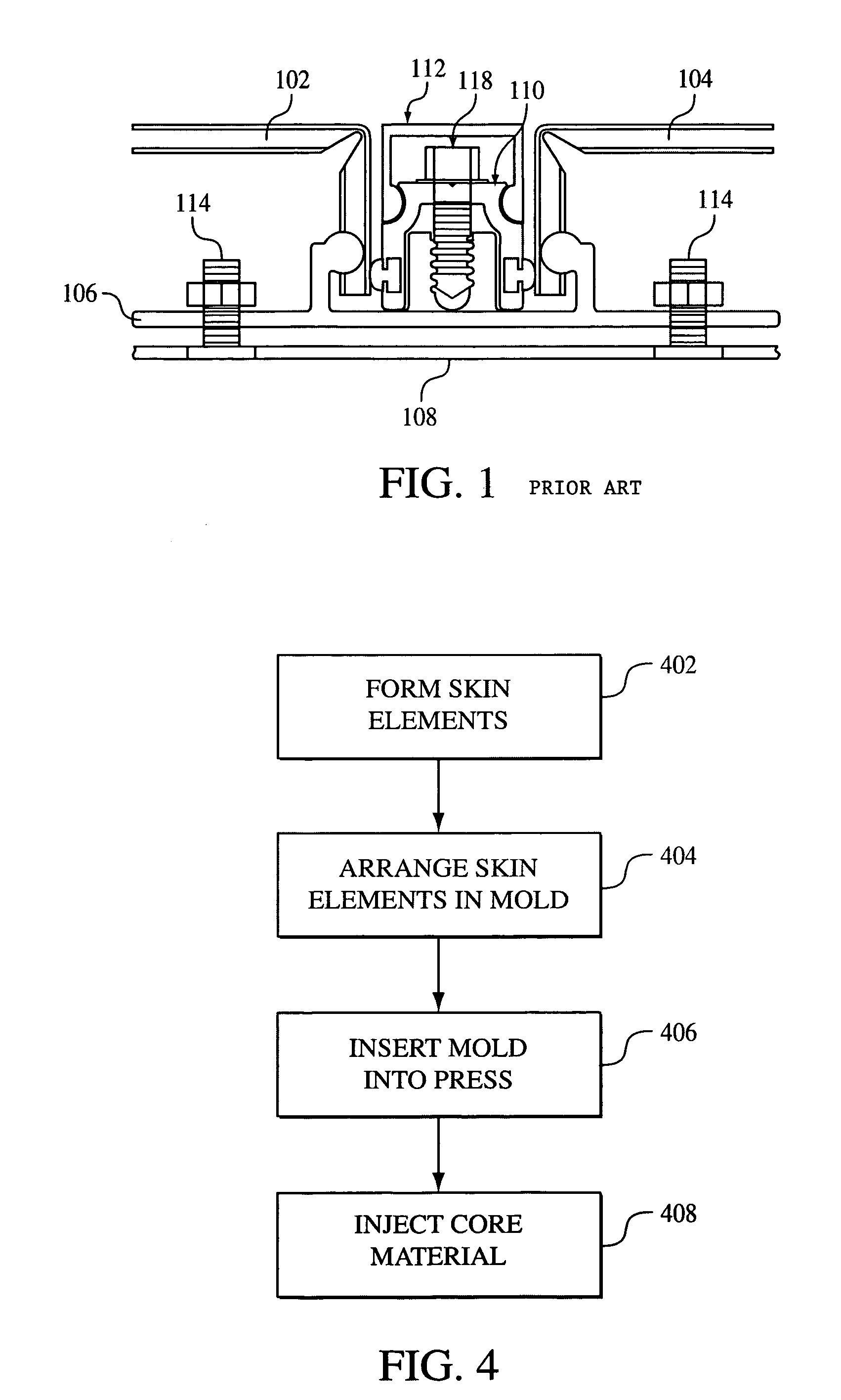

Method of manufacturing composite board

InactiveUS7022756B2Improve flow characteristicsIncreased flexural modulusSynthetic resin layered productsWood working apparatusThermoplasticFiber

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO RETAIL CABINET GROUP

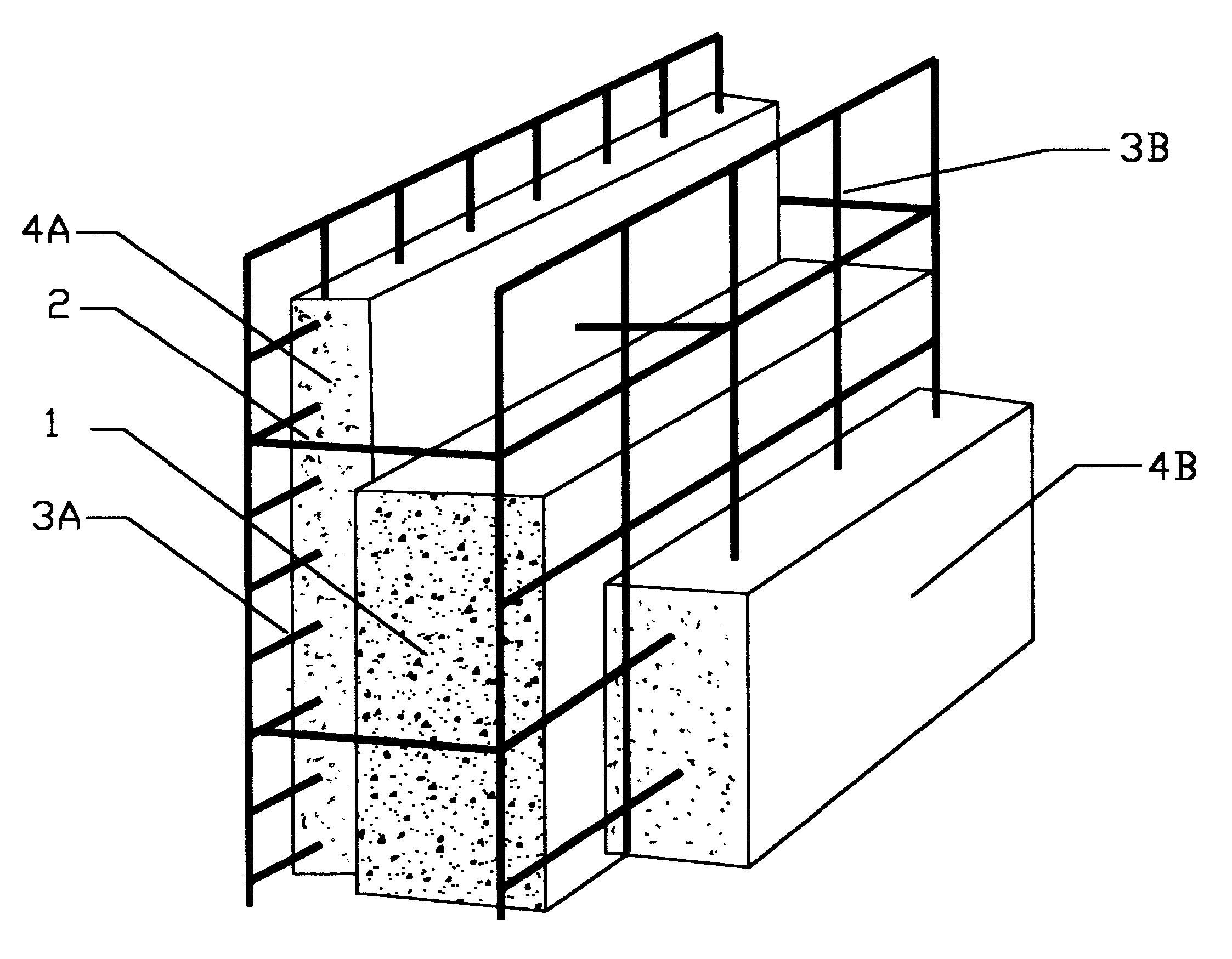

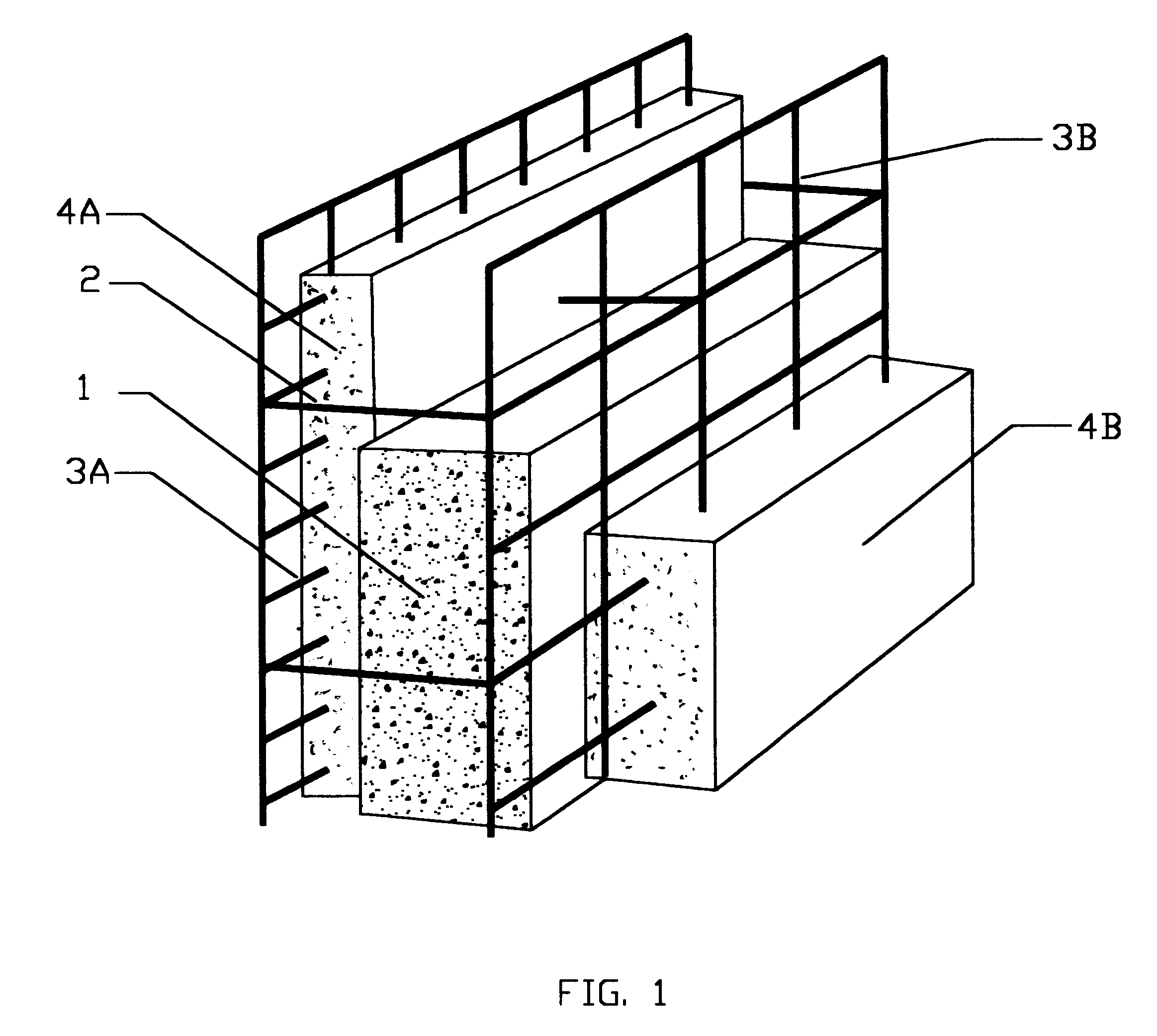

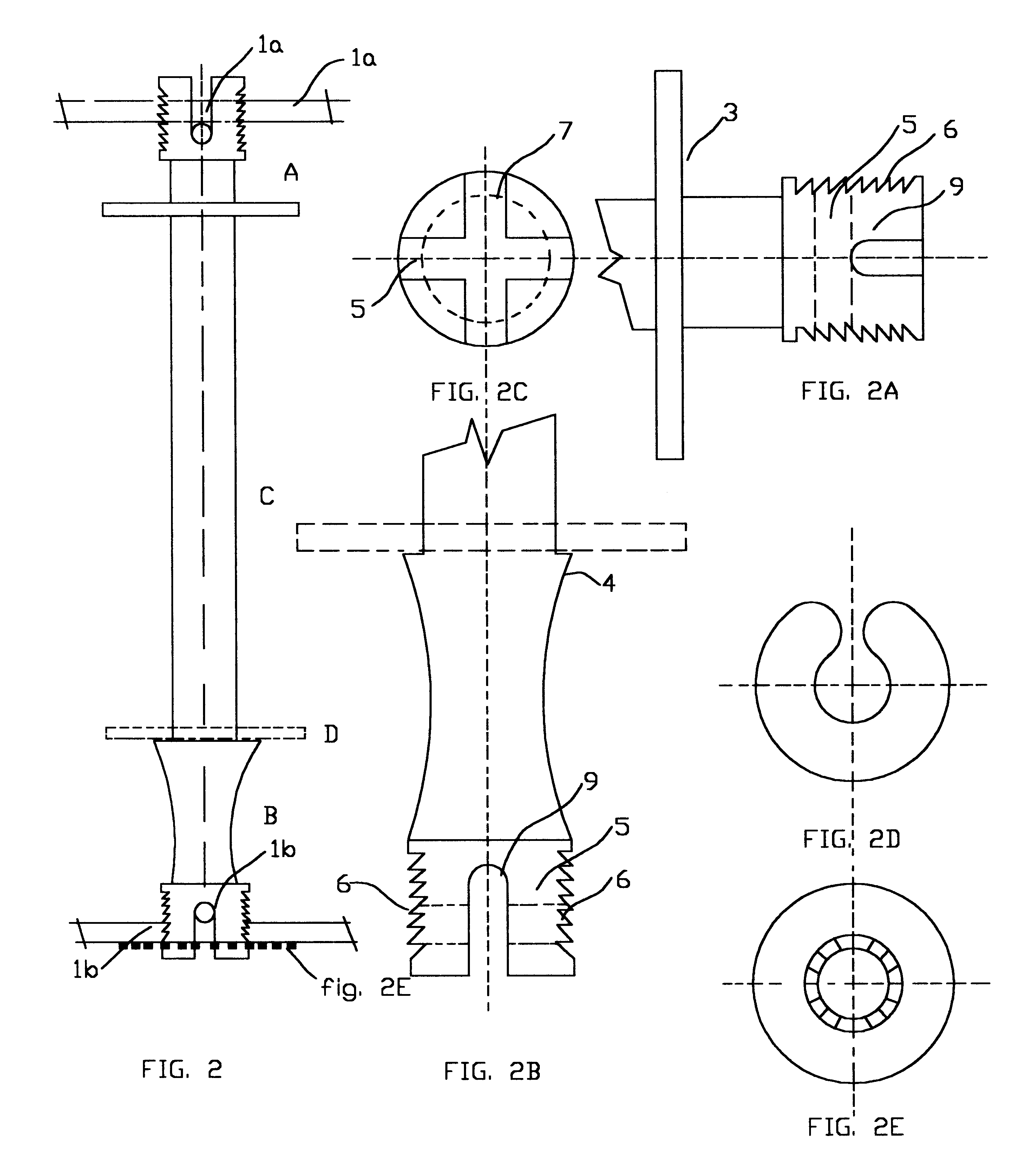

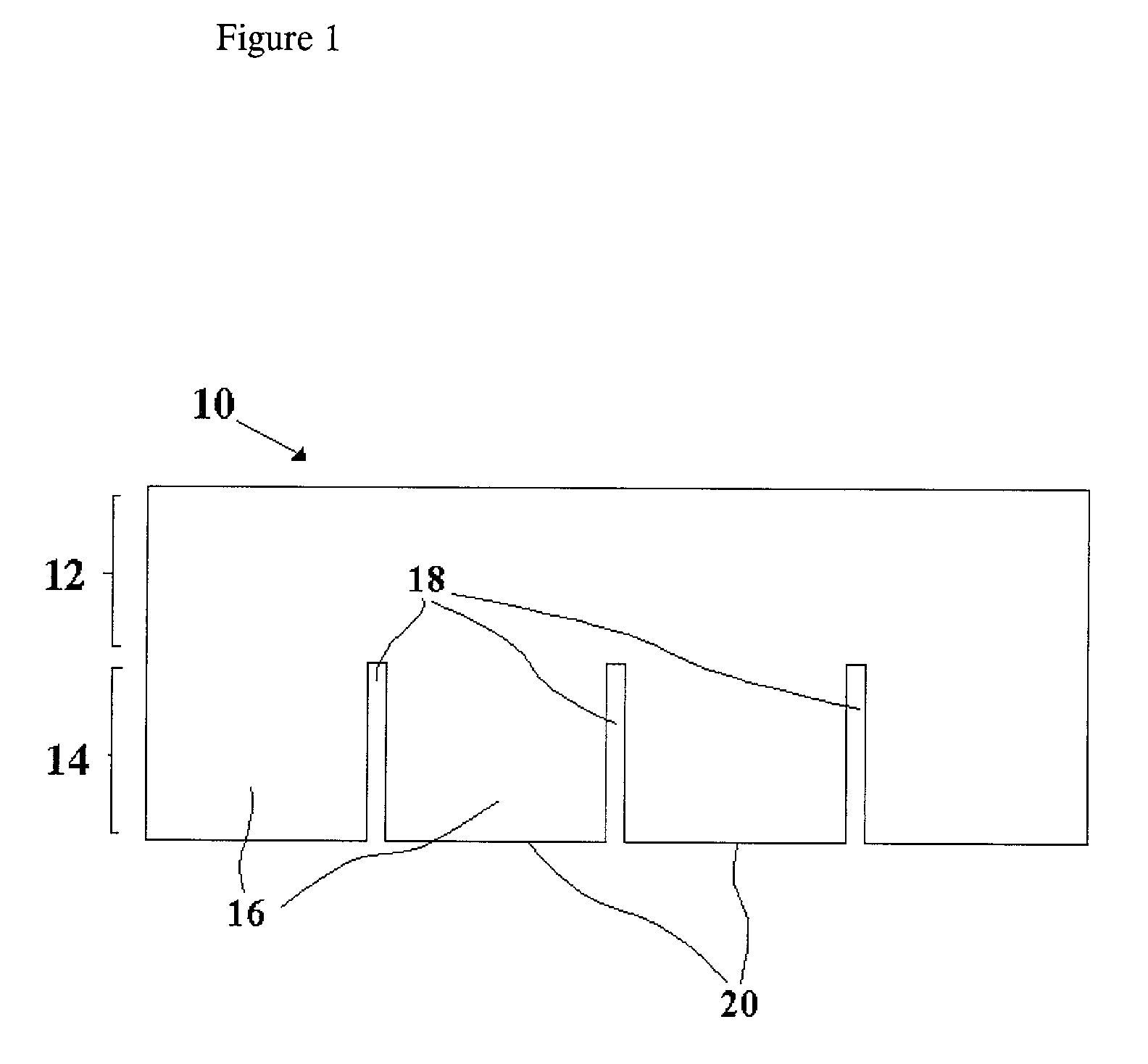

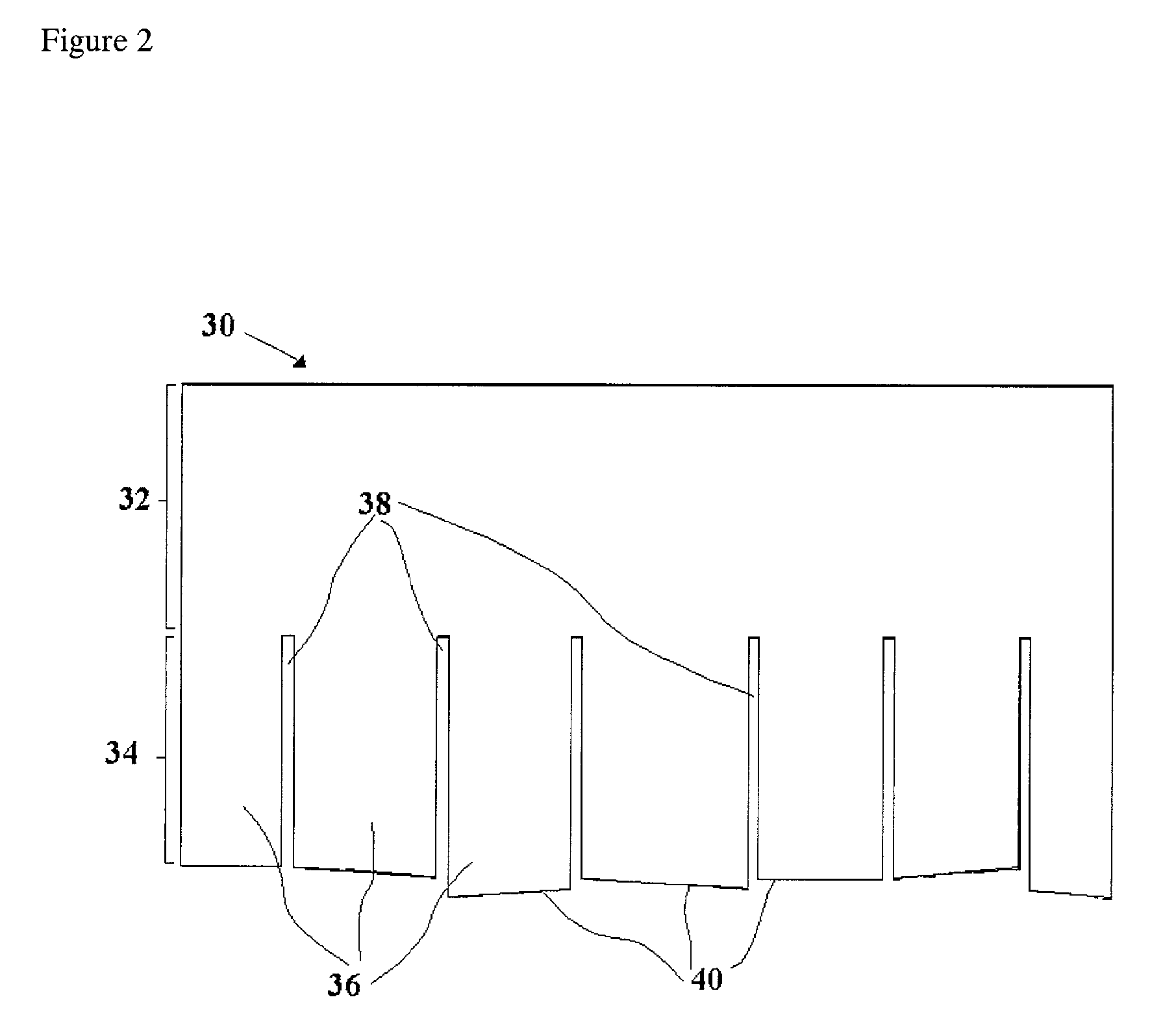

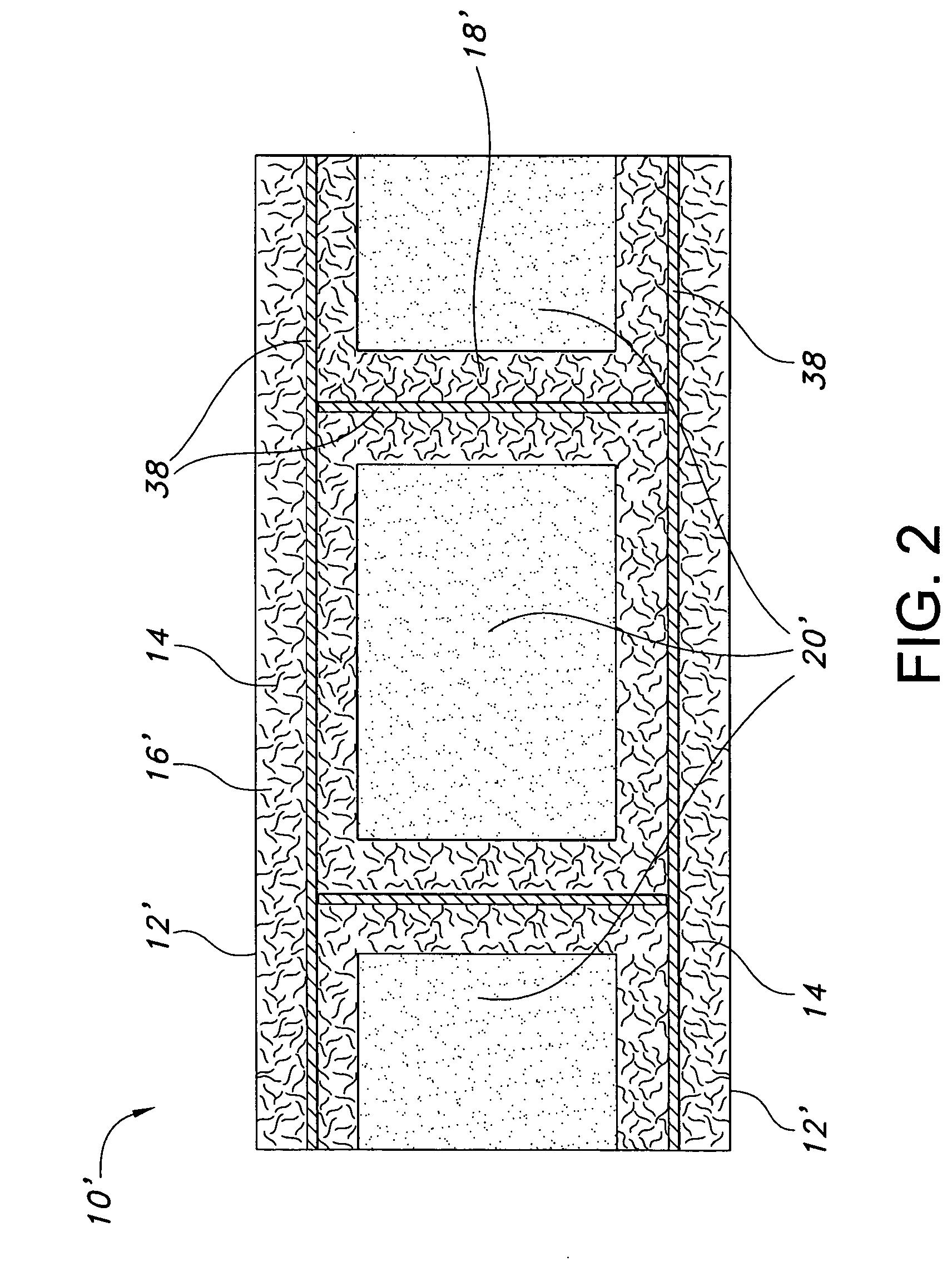

Method for concrete building system using composite panels with highly insulative plastic connector

InactiveUS6202375B1Easy to assembleEasy to transportBuilding roofsConstruction materialFiberShotcrete

The present invention comprises a concrete building system with a method for fabricating composite panels using an improved design plastic connector and assembling them at the construction site to a structure which will be shotcreted on both sides to a concrete building which is highly insulated, is fire and termite proof, hurricane, earthquake and flood resistant and fulfills the requirement for flexible design. The Composite Panels are composed of two concrete layers, enclosing an insulative foam core. The skins are reinforced with wire mesh as structurally required and are connected through the foam core by structural highly insulative plastic connectors using the snap connection on both ends of the connectors so they form a tri-dimentional system and hold the wire mesh in place for the onsite shotcrete application, which includes an application of fiber for shrinkage and cracking. This replaces the welded wire fabric use for secondly reinforcing and let the wire mesh reinforcing only related to the structural strength of the composite panel. The plastic connector guarantees that no thermal bridging occurs like in other systems also the inside layer of the shotcrete panel.

Owner:FCN FOUND FOR THE CONSERVATION OF NATURE

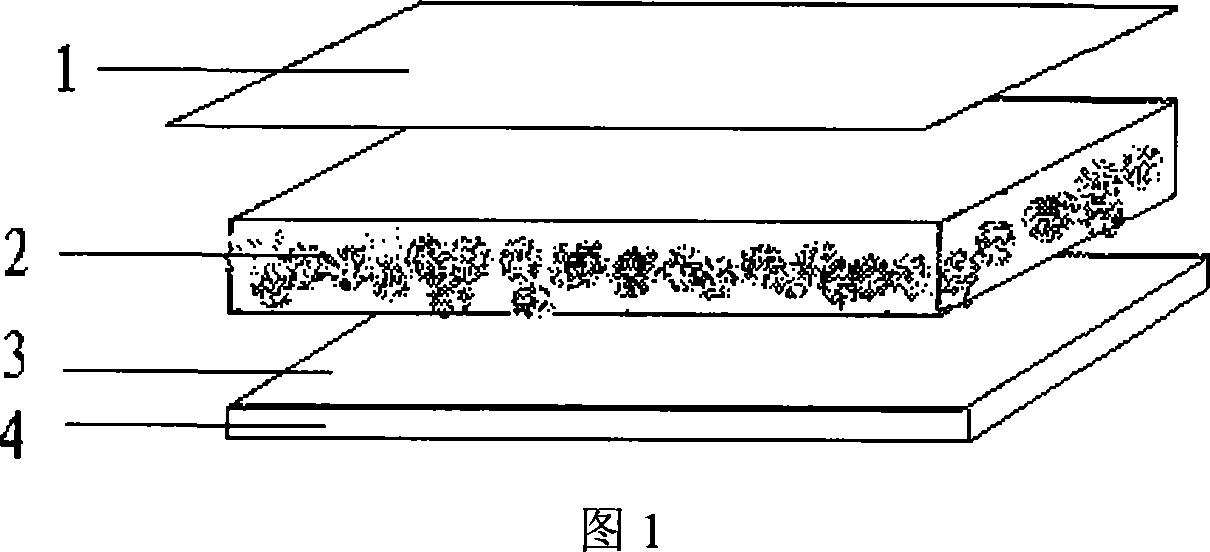

Polyurethane composite thermal insulation board, manufacturing method and application of the same

InactiveCN101220614AImprove thermal insulation performanceImprove fire and flame retardant performanceCovering/liningsLaminationProduction lineAlcohol

The invention provides a polyurethane compound heated board and a manufacturing method and application, which relates to a heated board and supplies a polyurethane compound heated board that has good heat-insulating effect, high fire-fighting and flame-retardant performance, convenient using performance and high constructing efficiency and the manufacturing method and the application. The invention includes a polyurethane rigid foam insulating layer, a bonding layer and an inorganic material composite board; the bonding layer is arranged between the polyurethane rigid foam insulating layer and the inorganic material composite board; the thickness of the polyurethane rigid foam insulating layer is 20-80mm and the thickness of the inorganic material composite plate is 3-10mm. The inorganic material composite board can be continuously produced for further use; an adhesive treatment agent is coated on the inorganic material composite board; polyhydric alcohol combination material and isocyanate combination material are added into the continuous production line for mixed foaming and curing to obtain the polyurethane compound heated board; the mass ratio of the polyhydric alcohol combination material and the isocyanate is 100:95-160.

Owner:厦门高特高新材料有限公司

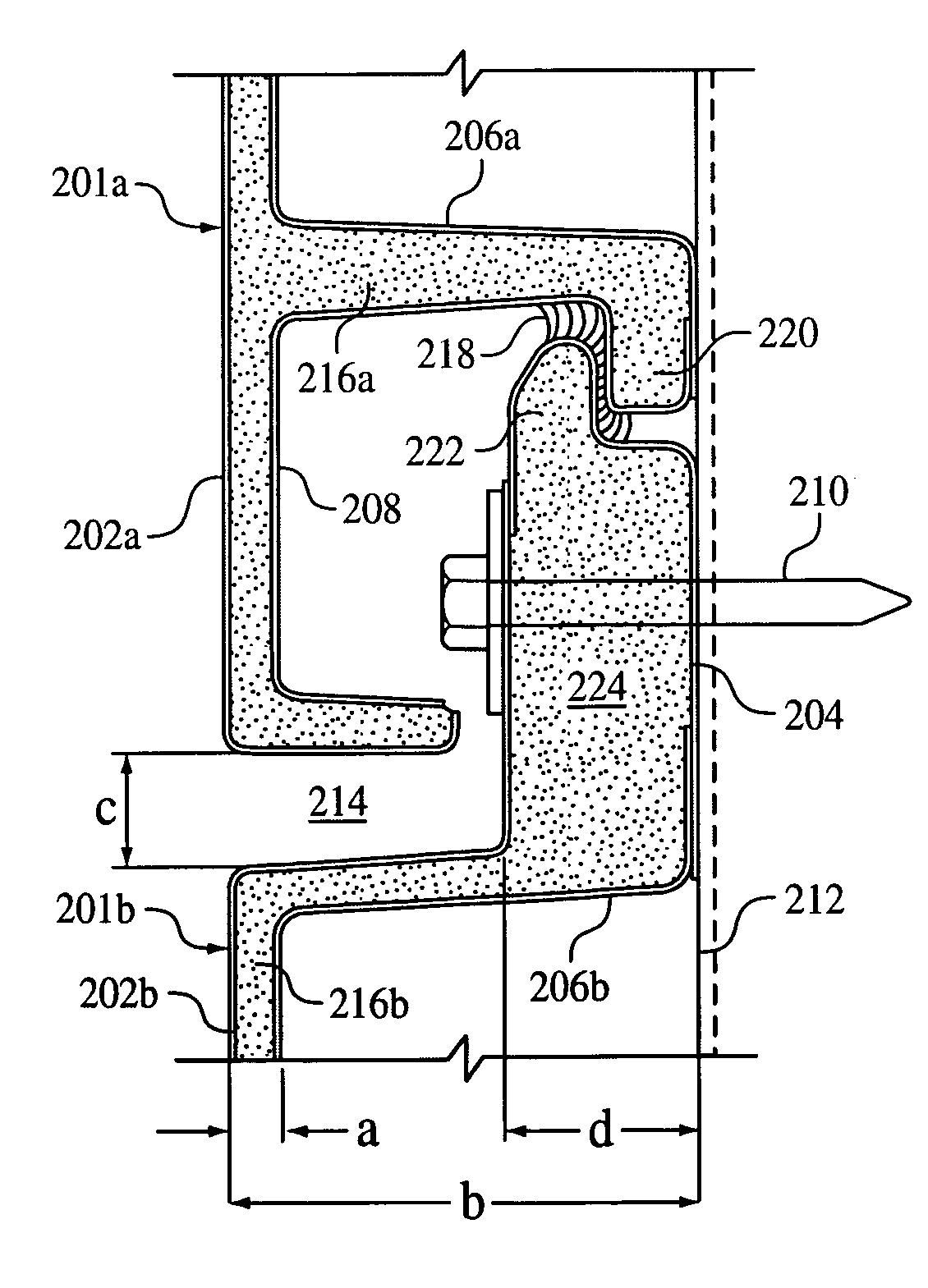

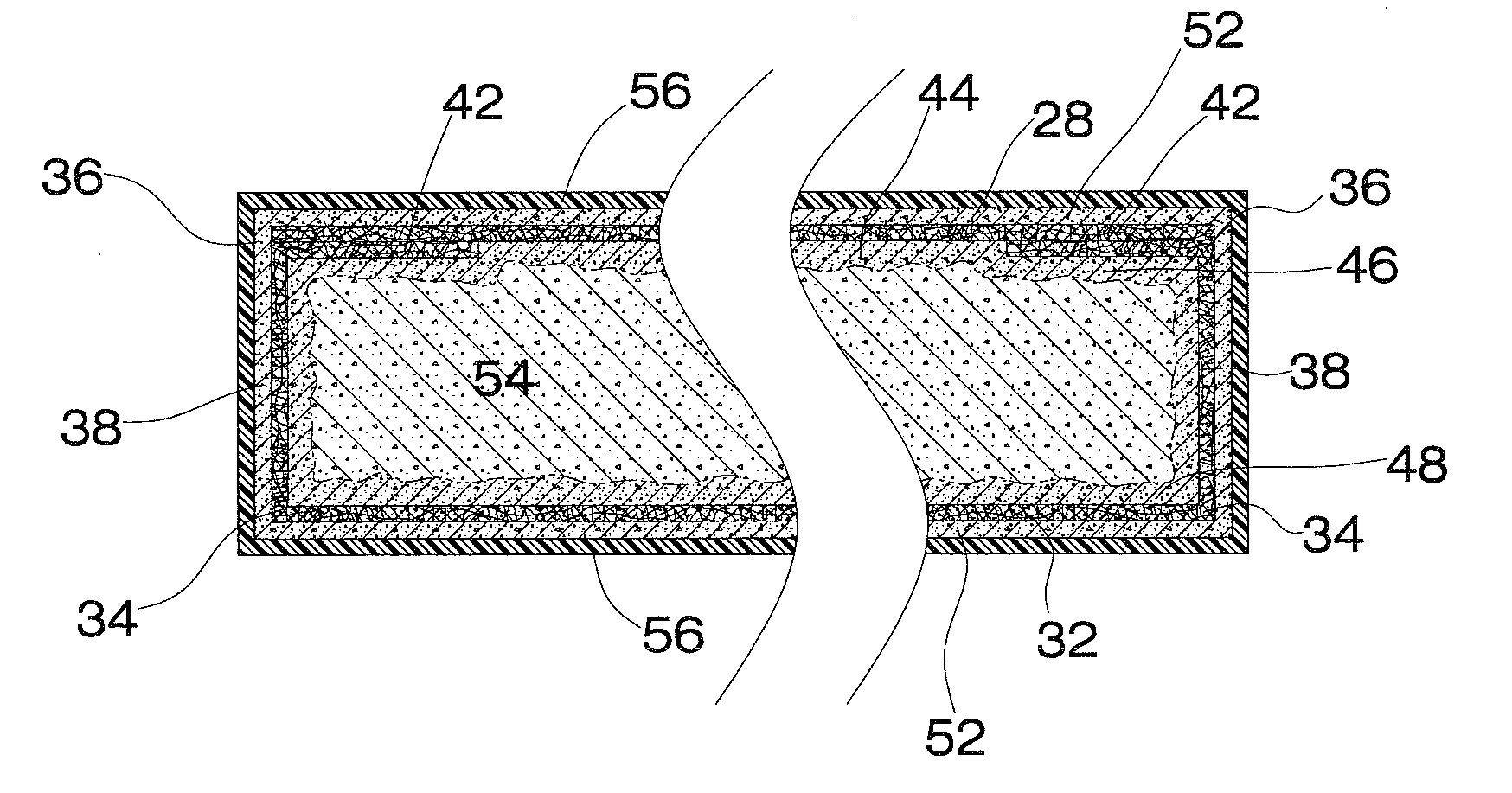

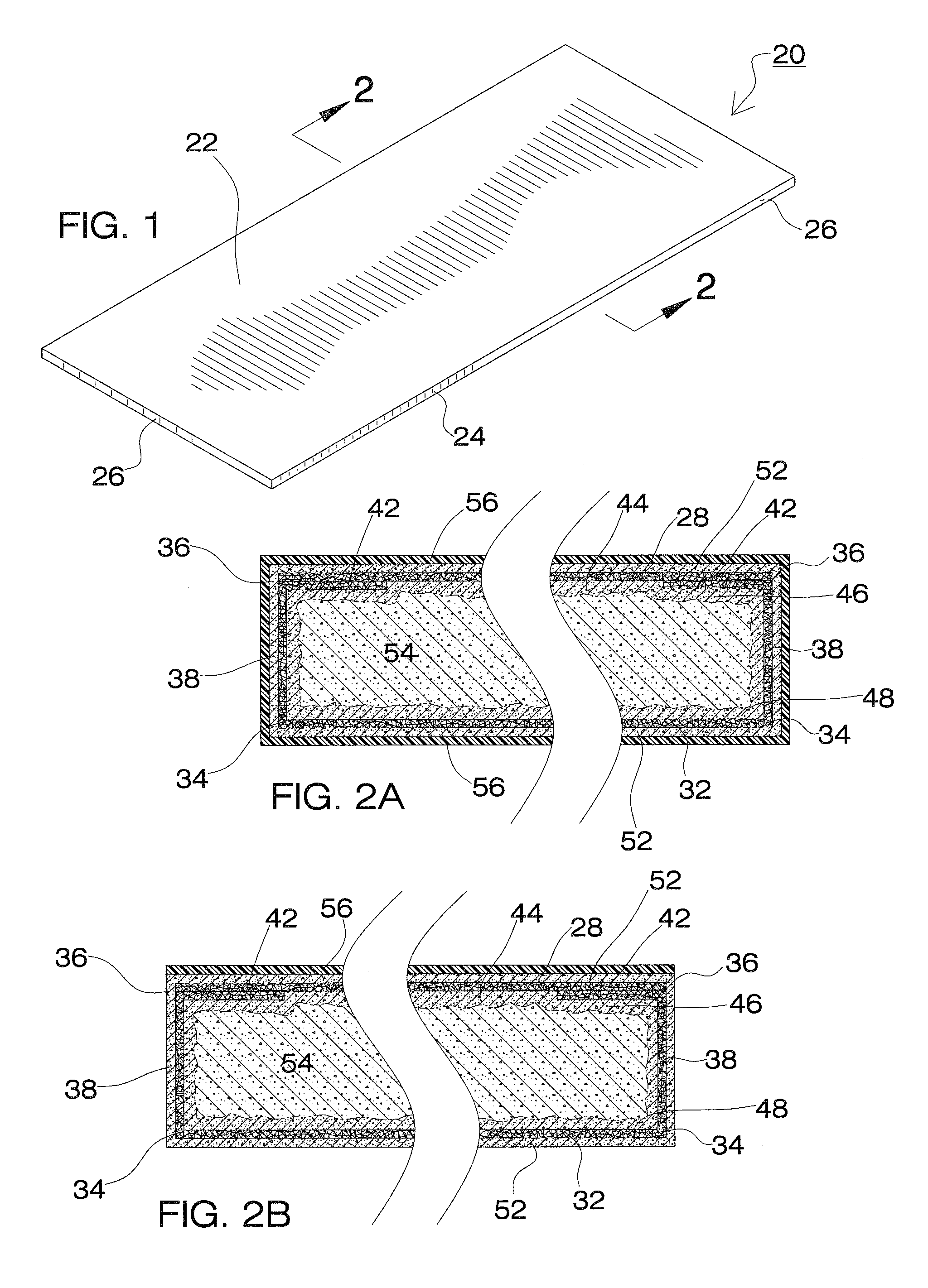

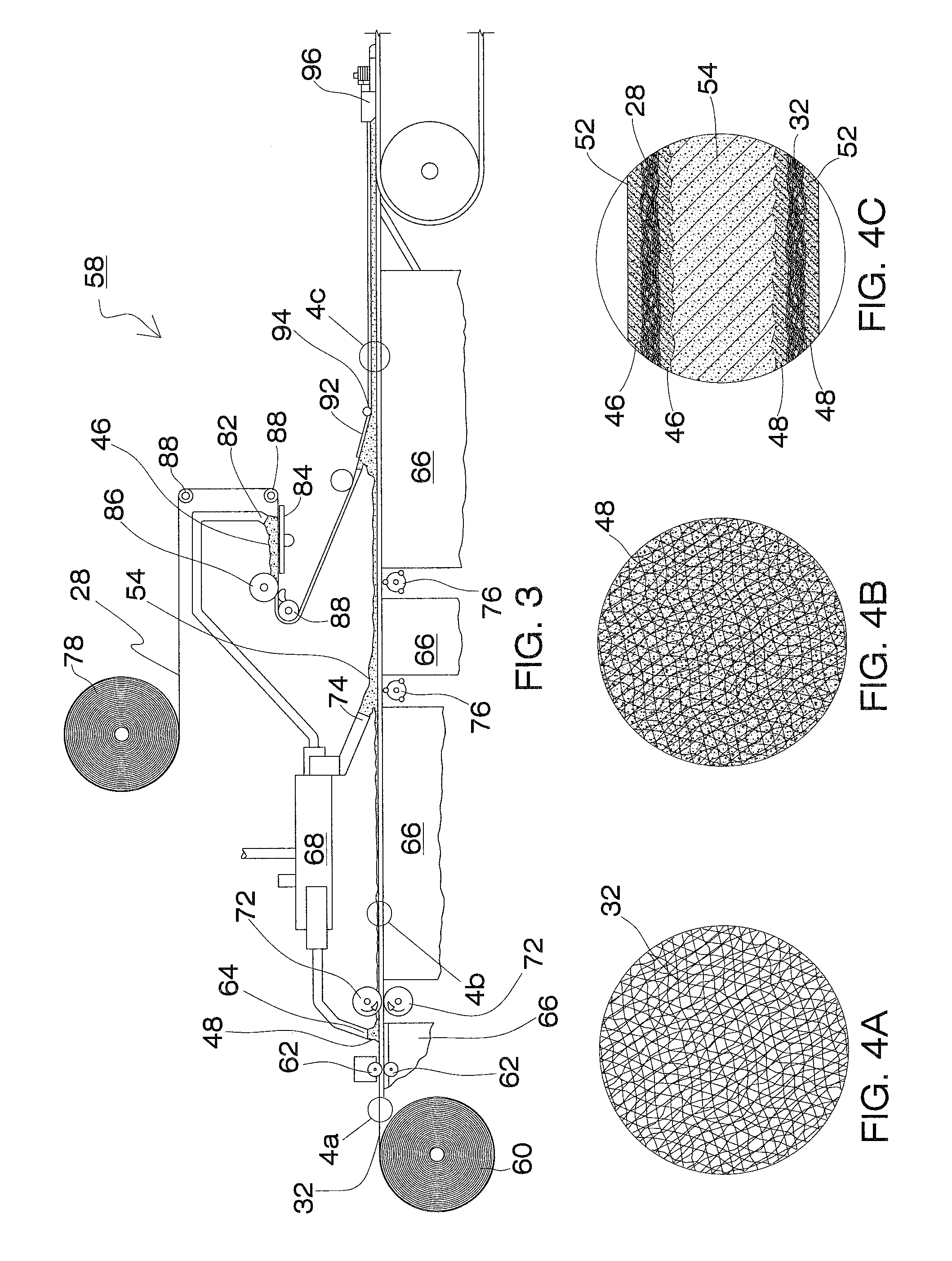

Features for thin composite architectural panels

InactiveUS7007433B2Altering coloringAltering other visual featureCovering/liningsWallsInterconnectionComposite plate

Thin composite panels with interconnection schemes that are unitized with the panels, i.e., formed integrally and substantially simultaneously with the panels. Further contemplated is the application of an injection molding technique, such as reaction injection molding, in establishing a foam or polymeric core between laminates in thin composite panels. Additionally contemplated is the use of interchangeable laminate components in affording the capability of altering the coloring or other visual features of a reveal in a panel or panels.

Owner:CENTRIA

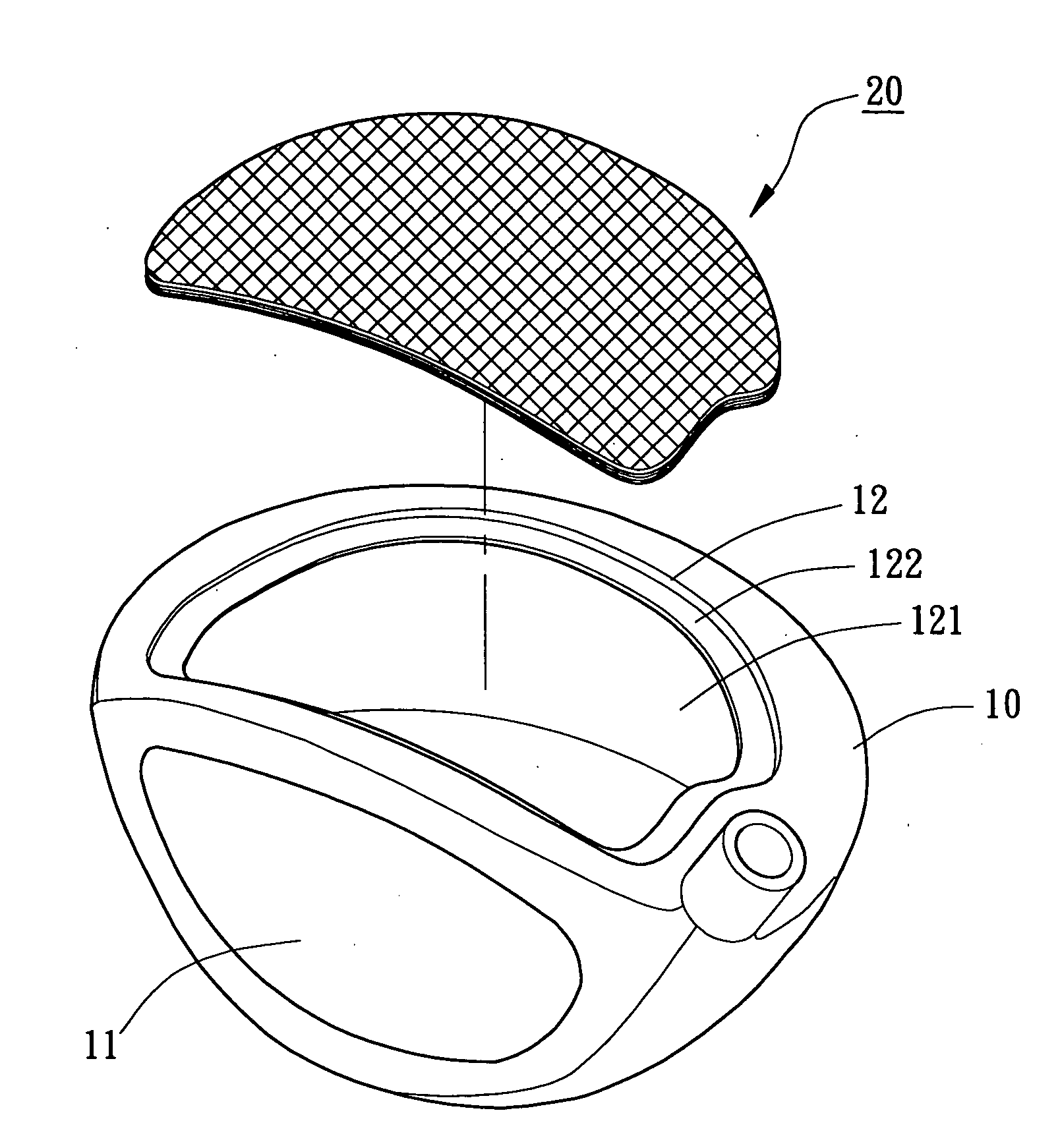

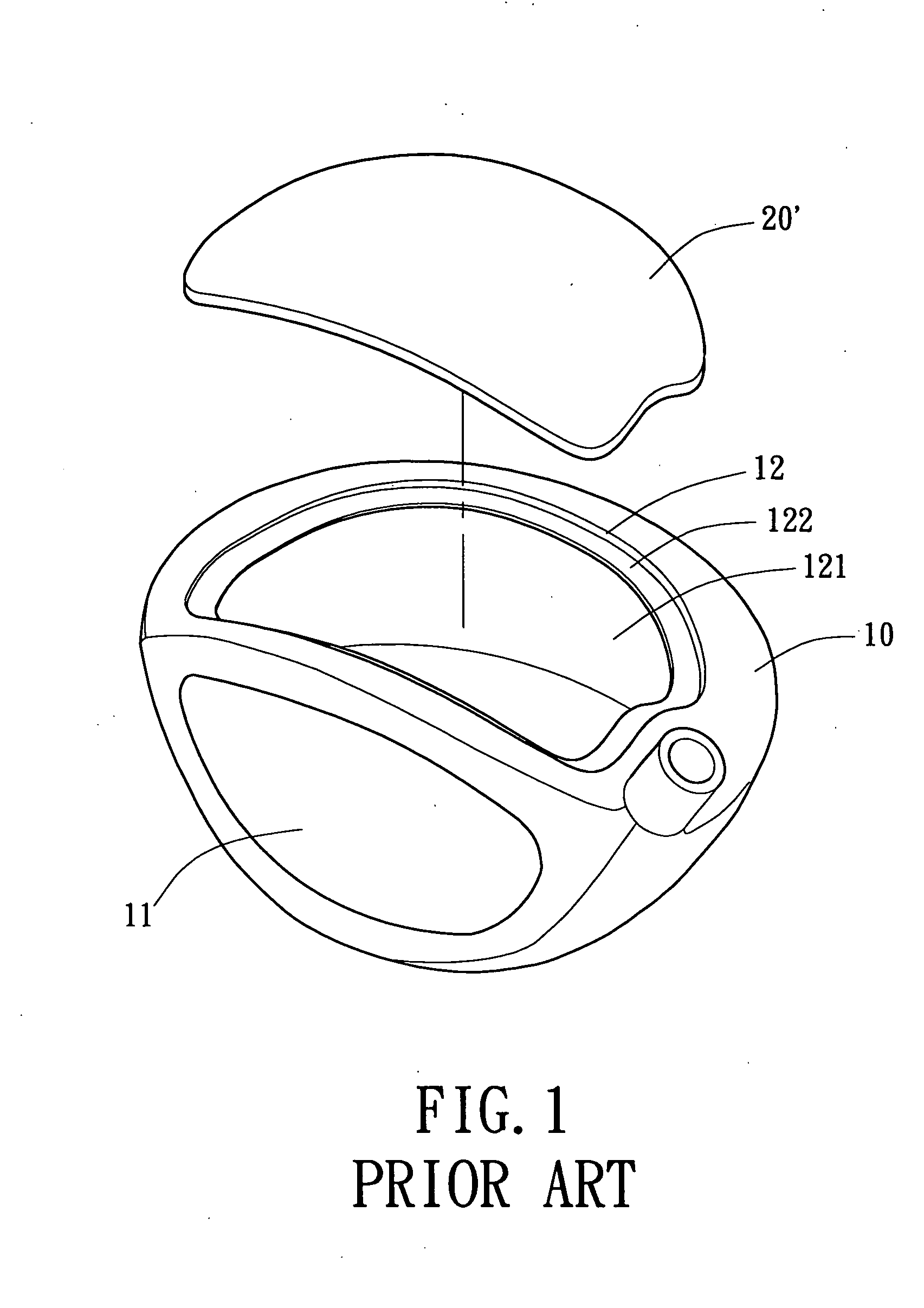

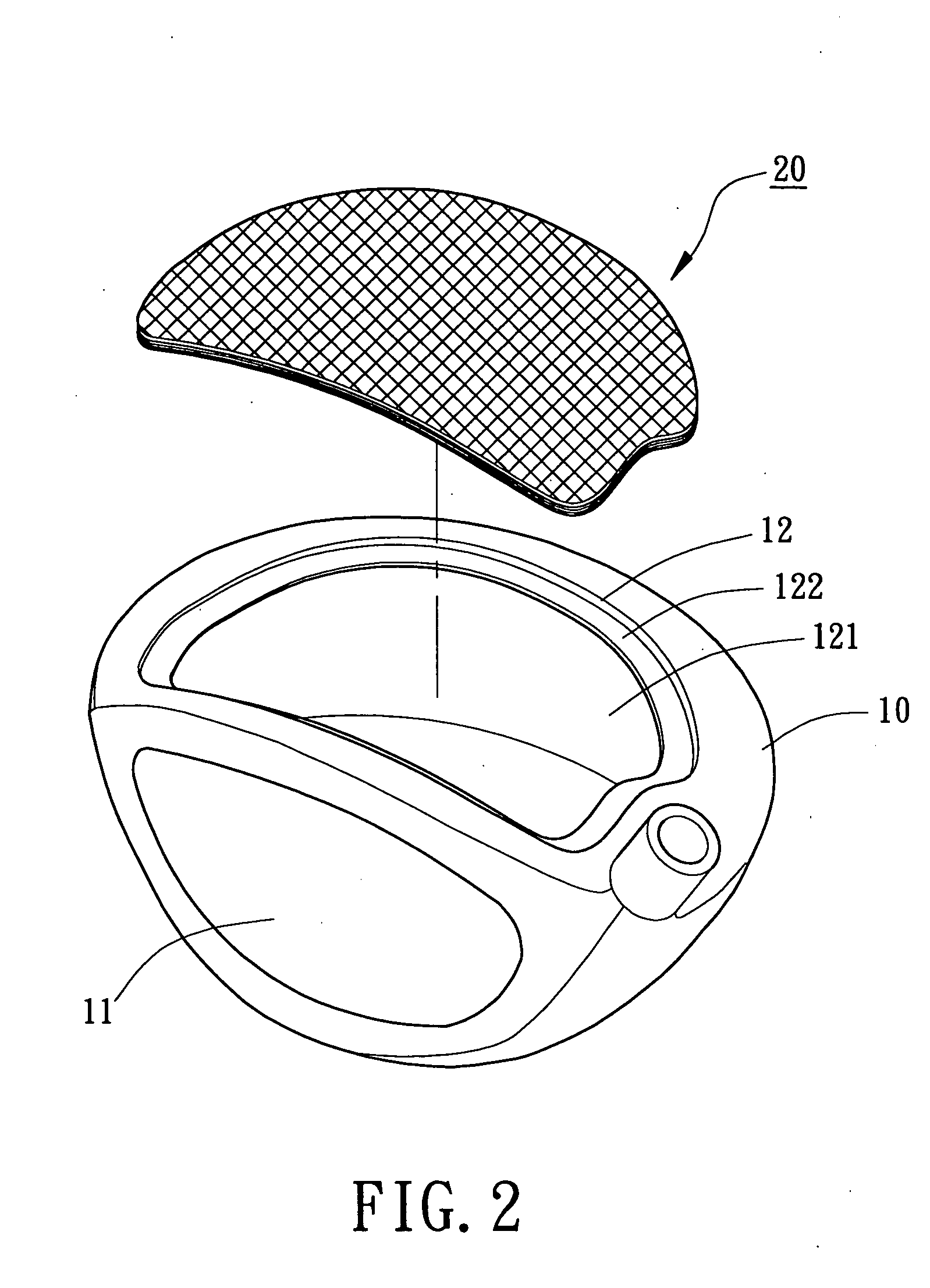

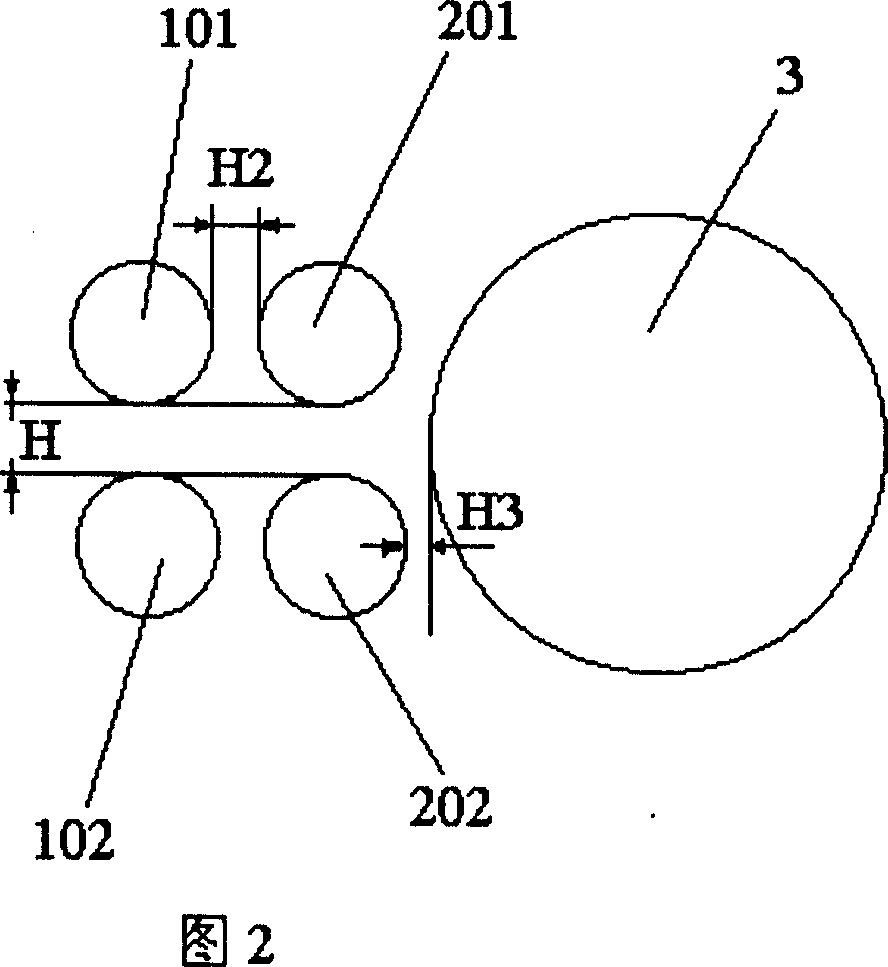

Golf club head and composite plate therefor

InactiveUS20050096154A1Expand the adjustment rangeImprove performanceGolf clubsMetal layered productsEngineeringGolf Ball

A golf club head includes a golf club head body made of metal and having a striking plate, at least one recession defined in the golf club head body, and at least one composite plate engaged in the recession to form a portion of a shell of a golf club head product. The composite plate includes at least one metal layer and at least one non-metal layer that are laminated by pressing. The adjusting ranges of the center of gravity and of the striking sound of the golf club head are increased.

Owner:FUSHENG IND CO LTD

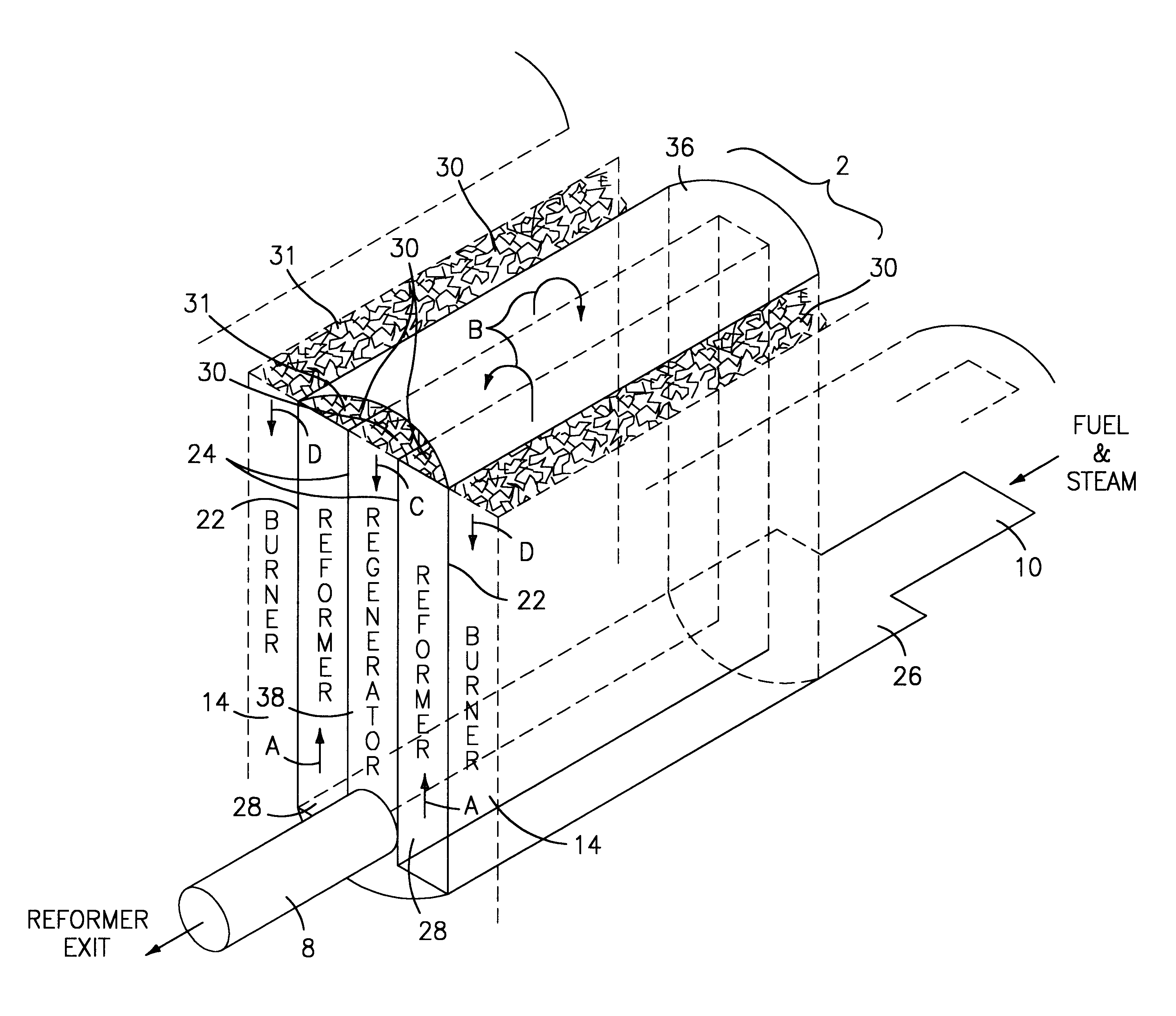

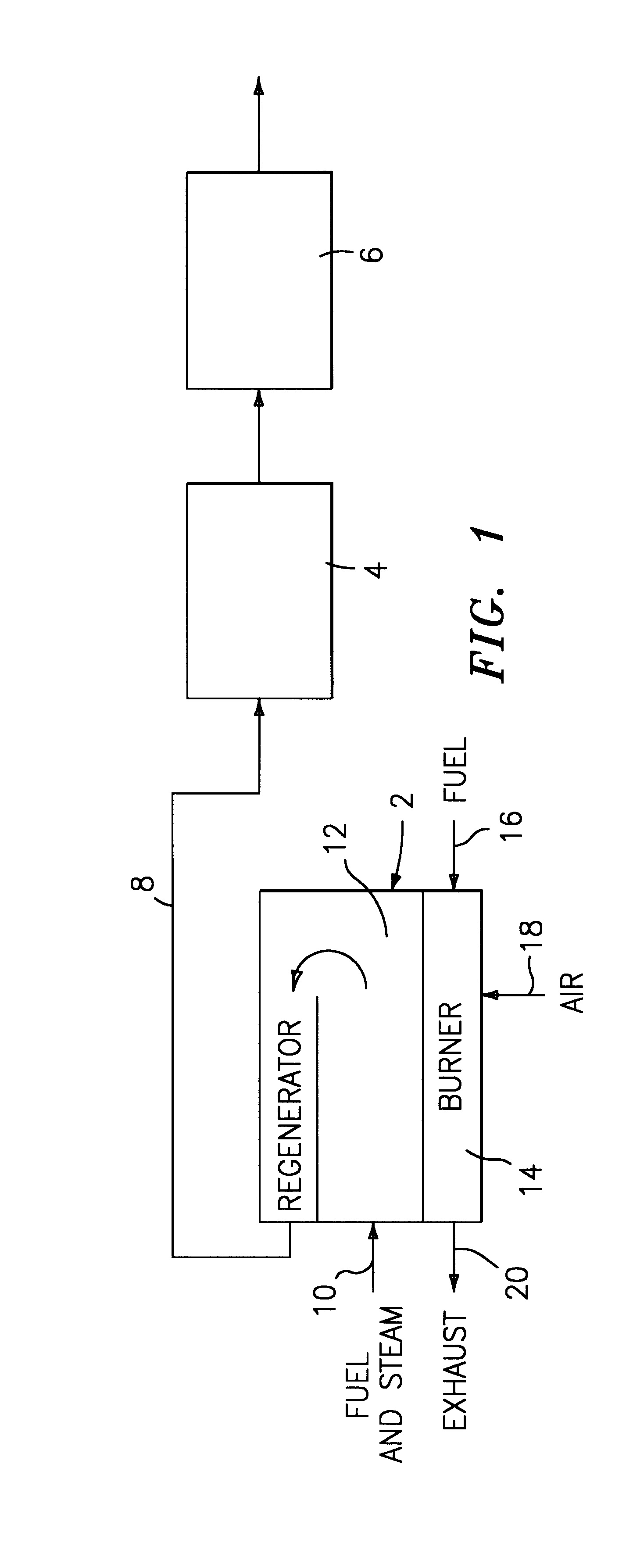

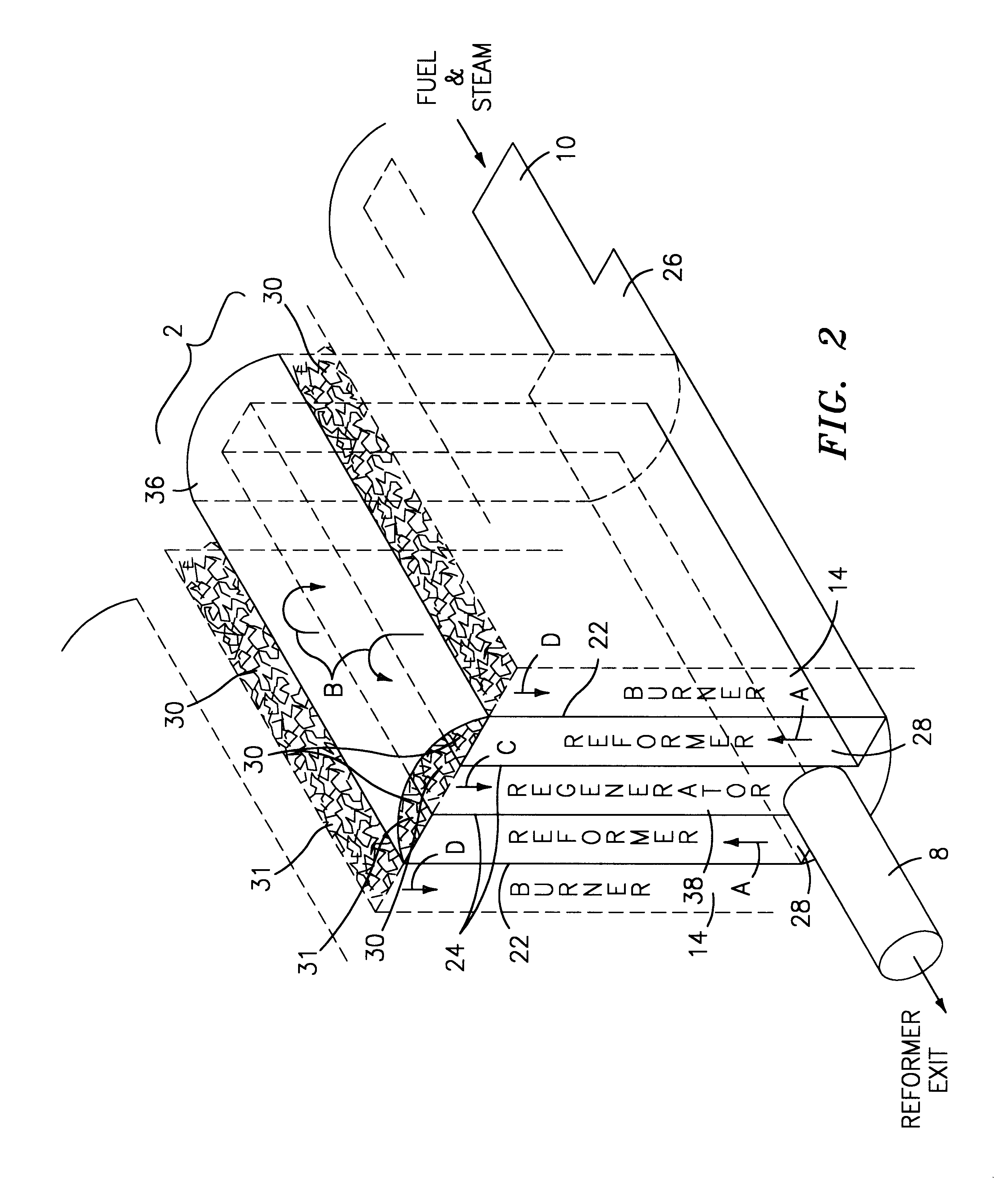

Compact fuel gas reformer assemblage

InactiveUS6203587B1Improve heat transfer performanceReduce the temperatureSemi-permeable membranesHydrogen separation using solid contactFuel cellsForming gas

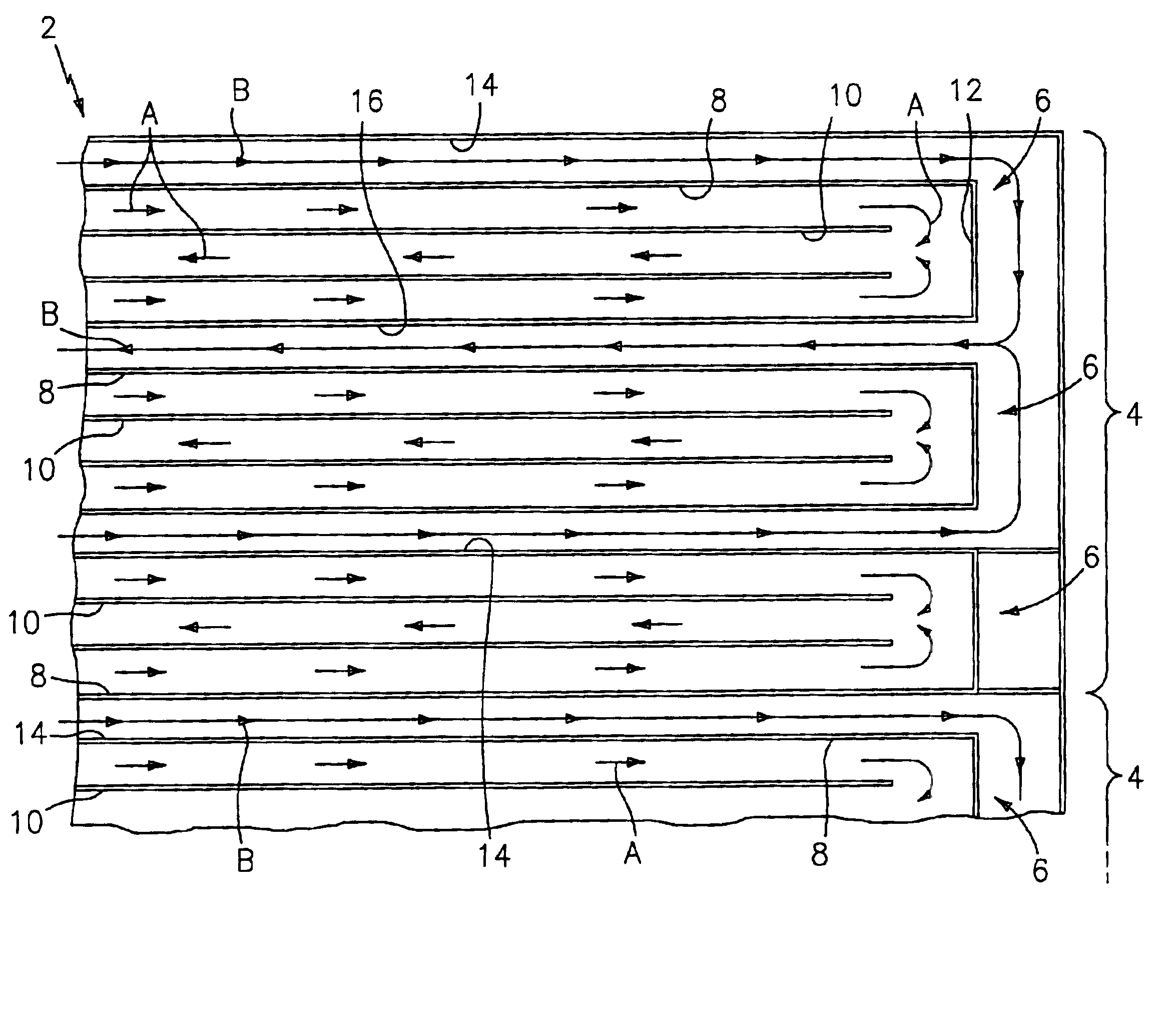

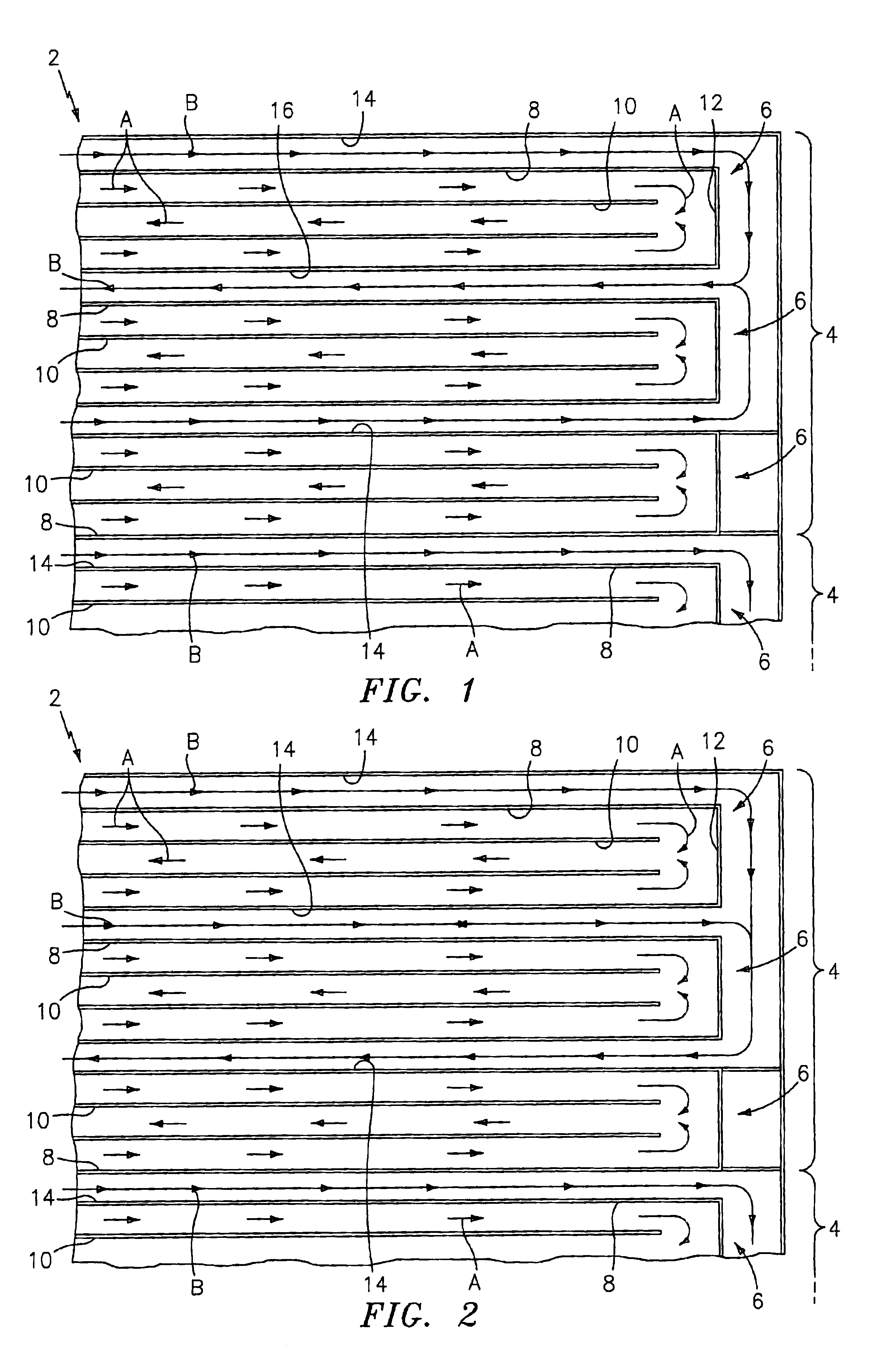

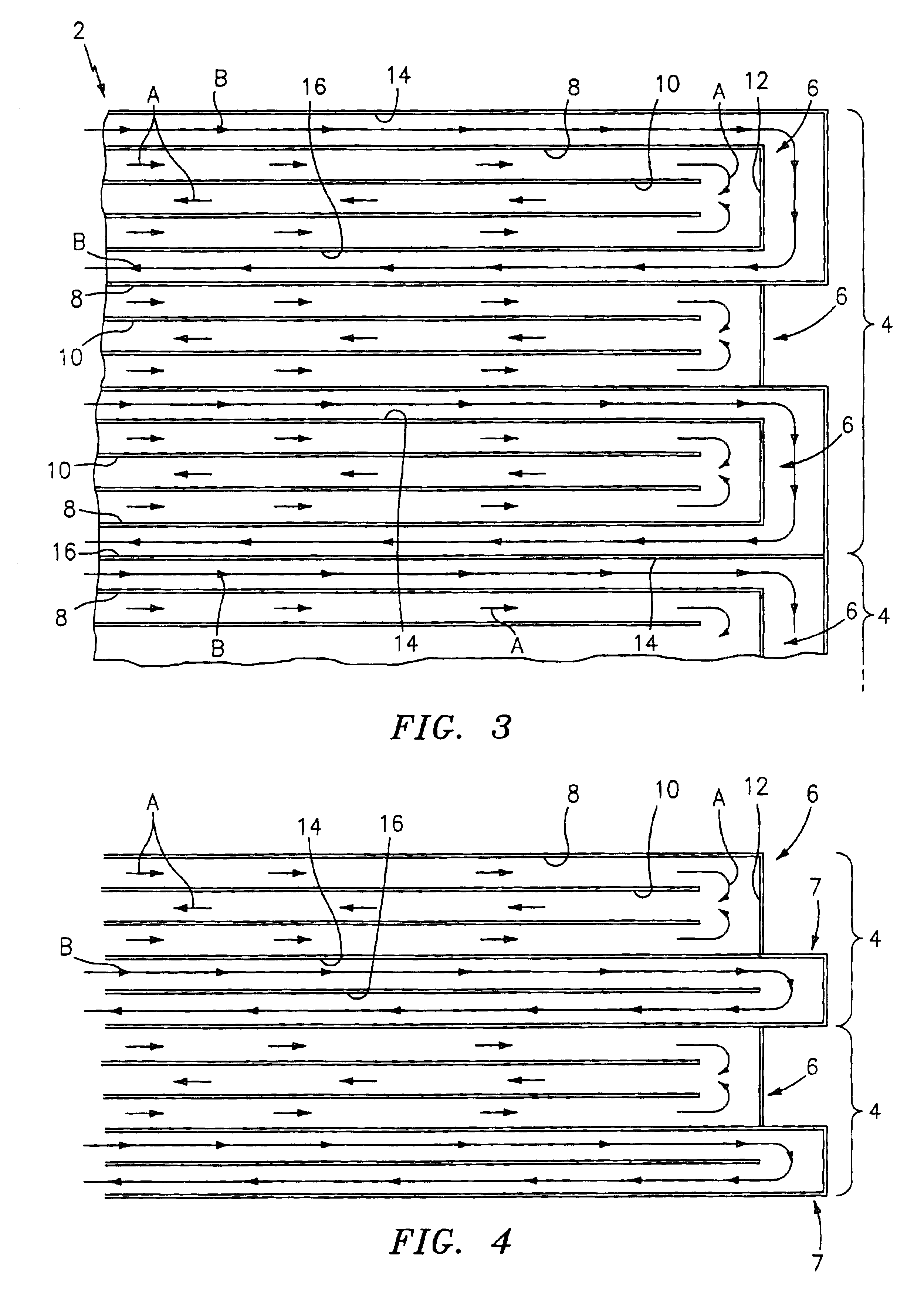

A fuel gas reformer assemblage for use in a fuel cell power plant is formed from a composite plate assembly which includes spaced-apart divider plates with interposed monolithic open cell sponge-like members which form gas passages. The monolithic members have a lattice of internal open cells which are both laterally and longitudinally interconnected so as to provide for a diffuse gas flow. The entire surface area of the monolithic components is wash coated with a porous alumina layer, and selected areas of the wash coat are also catalyzed. The reformer assemblage is constructed from a series of repeating sub-assemblies, each of which includes a core of separate regenerator / heat exchanger gas passages. The core in each sub-assembly is sandwiched between a pair of reformer gas passage skins, which complete the subassembly. Adjacent reformer gas / regenerator / reformer gas passage sub-assemblies in the composite plate assembly are separated from each other by burner gas passages. The regenerator / heat exchanger gas passages and the reformer gas passages in each sub-assembly are connected by gas flow return manifolds which form a part of each sub-assembly. The fuel gases flow in one end of the assemblage, through the reformer gas passages, and then reverse their direction of flow in the return manifolds so as to exit the reformer assemblage through the regenerator gas flow passages. The burner gases flow in one end of the reformer assemblage and out the other end.

Owner:INT FUEL CELLS

Composite roofing panel

InactiveUS20020040557A1Easy to installBetter imitate natural productsRoof covering using tiles/slatesNatural patternsAsphalt shingleNatural fiber

The present invention provides a composite panel for use in construction, and particularly for shingling, which comprises natural fiber and a polymer. Due to its composition and layout the construction panel provides all of the advantages of natural materials and high end roofing materials, particularly an attractive appearance, while at the same time allowing for ease of installation, little or no maintenance requirements, and providing superior impact and fire resistance when compared to other roofing materials. The construction panels can also be installed using conventional equipment and methods similar to the installation of 3-tab asphalt shingles with little or no learning curve.

Owner:COMPOSITECH

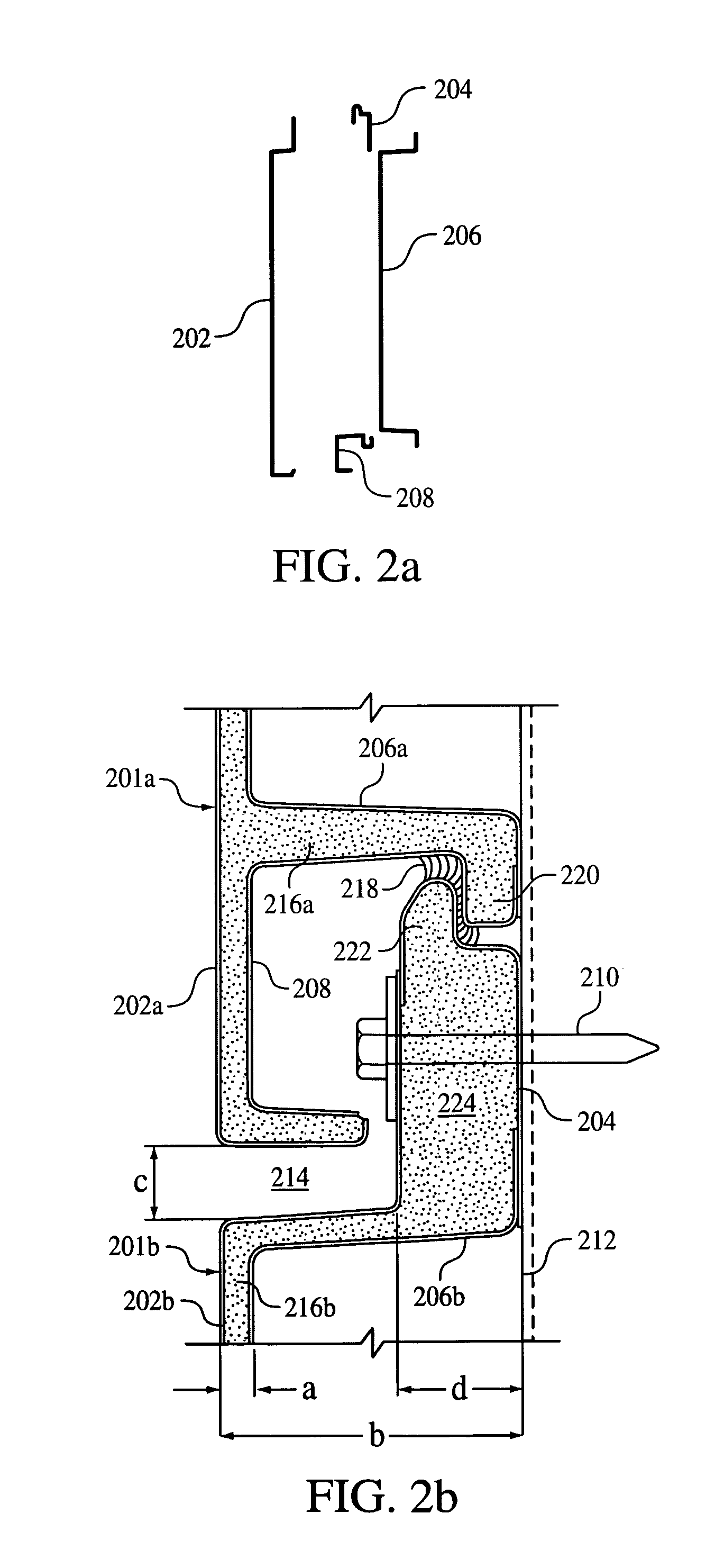

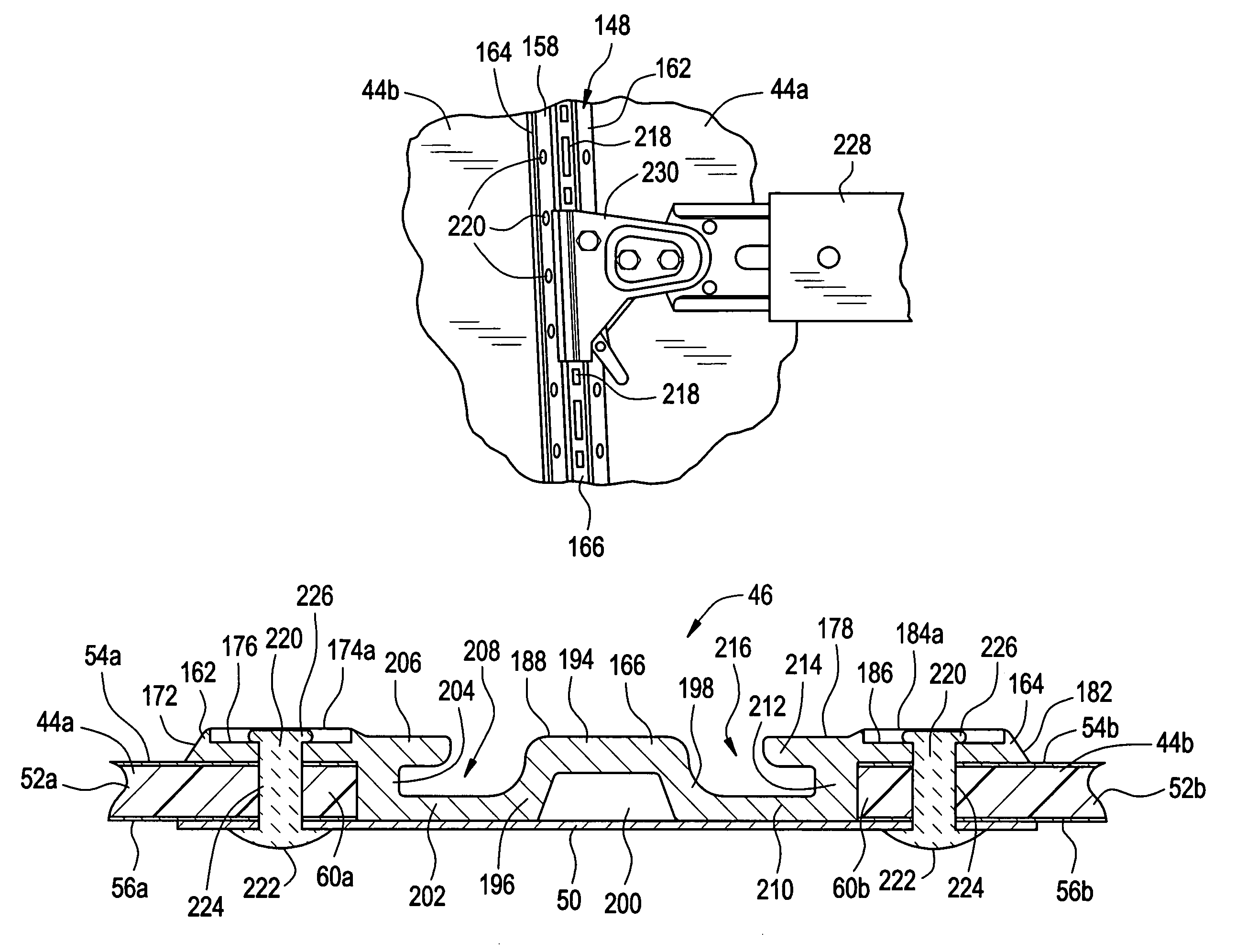

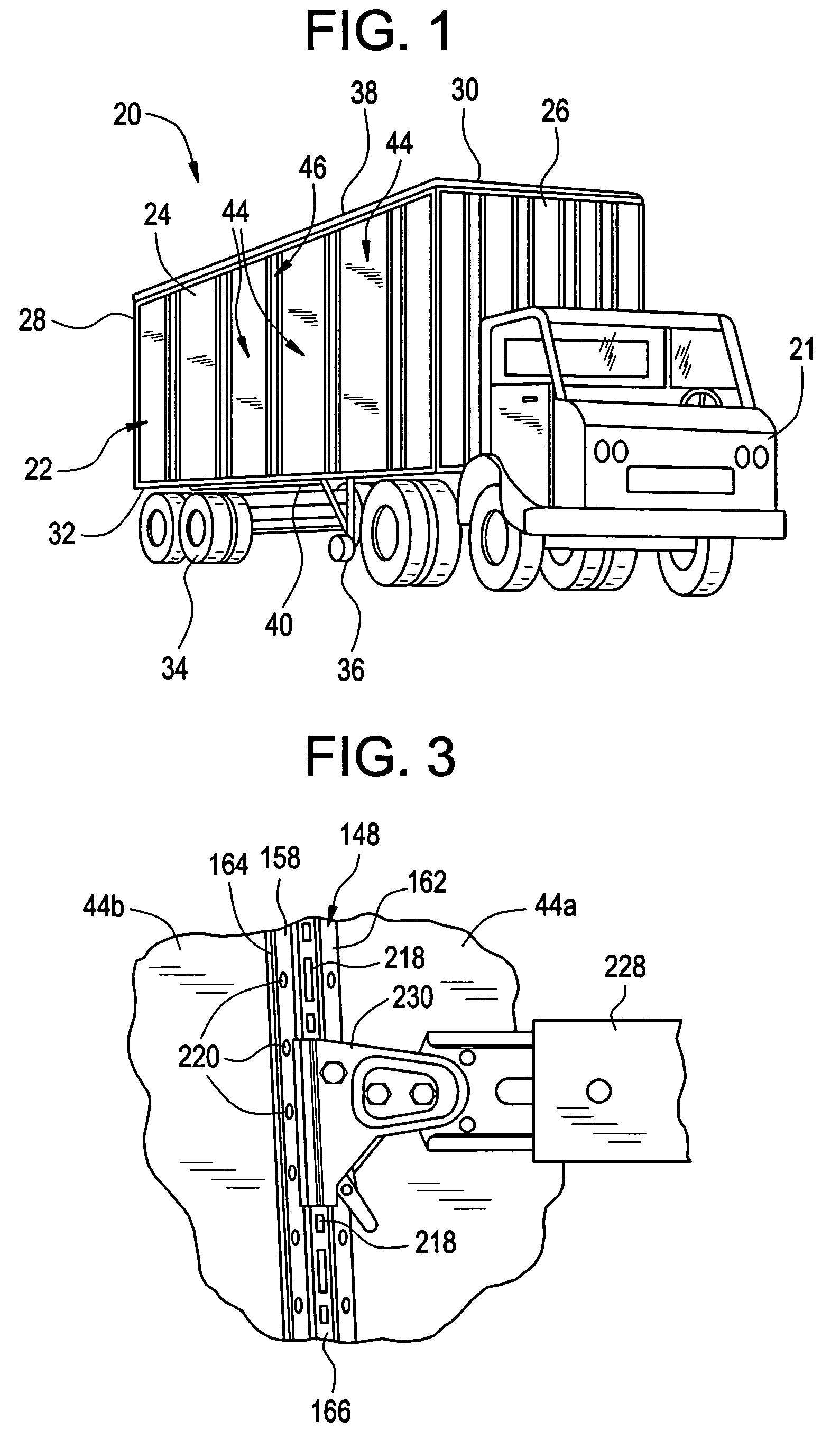

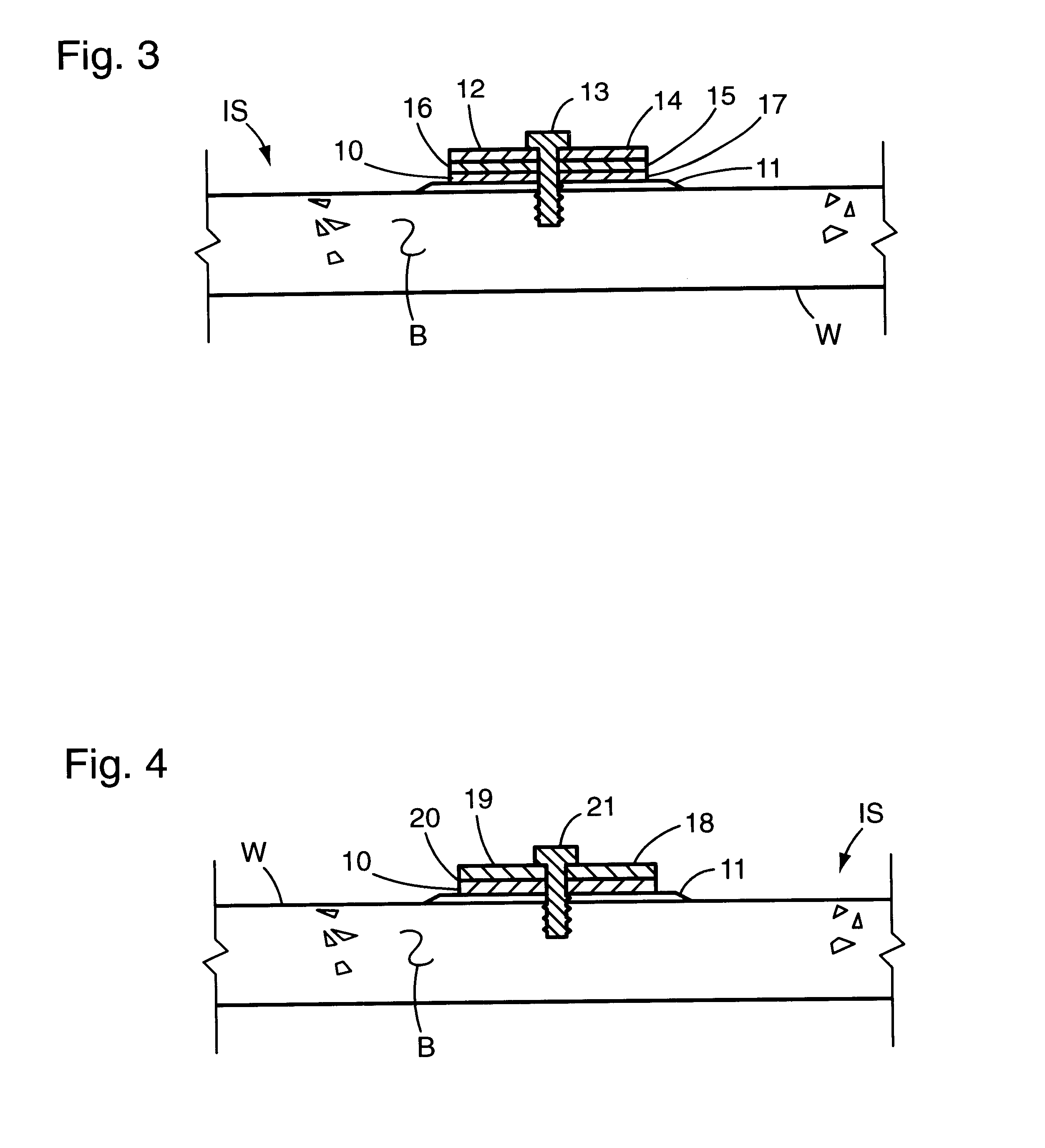

Integrated anchoring system and composite plate for a trailer side wall joint

InactiveUS7134820B2Caused less-damageProvide structural strengthFlexible elementsLoad securingEntire jointMultiple point

The present invention provides a novel joint which includes an anchoring system between composite plate side walls of a trailer body. The anchoring system includes track members which are provided at multiple points on each side wall. Beams extend between the respective track members by attachments and are attached thereto. The beams can be moved up and down along the tracks and support cargo or a removable deck which supports the cargo. The track members can also be removed from the joints without dismantling the entire joint. Splicing members are attached at the joints on the outside of the trailer body.

Owner:WABASH NATIONAL

Compact fuel gas reformer assemblage

InactiveUS6773684B2Speed up heat exchangeSuitable for useHydrogenCarburetting by solid carbonaceous material pyrolysisCombustorFuel cells

Owner:INT FUEL CELLS

Method of manufacturing composite board

InactiveUS20060145384A1Improve flow characteristicsIncreased flexural modulusMouldsFrozen sweetsFiberThermoplastic

A composite board is made from waste medium density fiber (MDF) board or waste particle board that includes solid urea formaldehyde. The waste board is chopped and milled into particles having a size between 20 mesh and 150 mesh, creating a waste flour. After removing moisture from the waste flour, the dried waste flour is mixed with a thermoplastic to bind and encapsulate the waste flour. Internal lubricants are added to improve the flow characteristics of the blended material, and external lubricants are added to present sticking of the mixture to an extruder or mold. Mineral fillers are added to improve the flexural modules of the composite board, and a plasticizer can be added to improve the physical properties or mechanical characteristics of the mixture. An ultraviolet absorber, a biocide, and a pigment can also be added. The blended material is extruded or molded into a desired shape. When cooled, the thermoplastic hardens to form a solid composite board.

Owner:MASCO CABINETRY

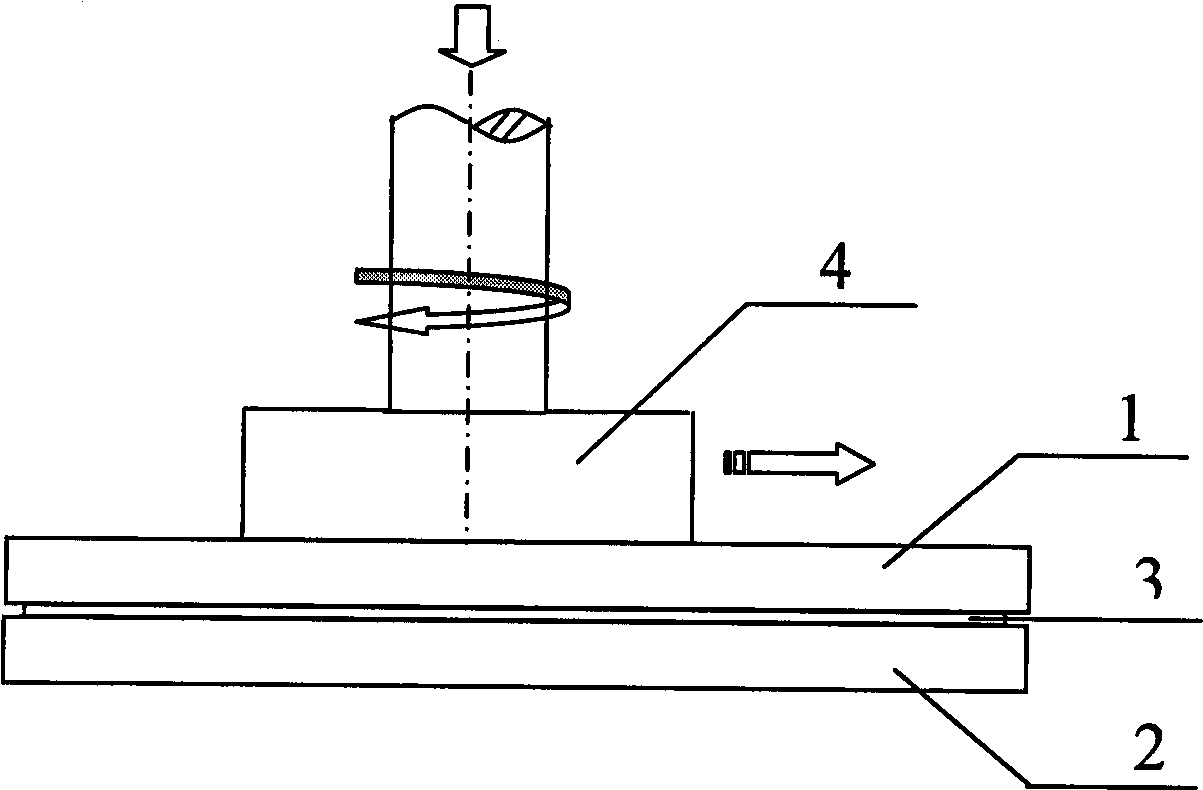

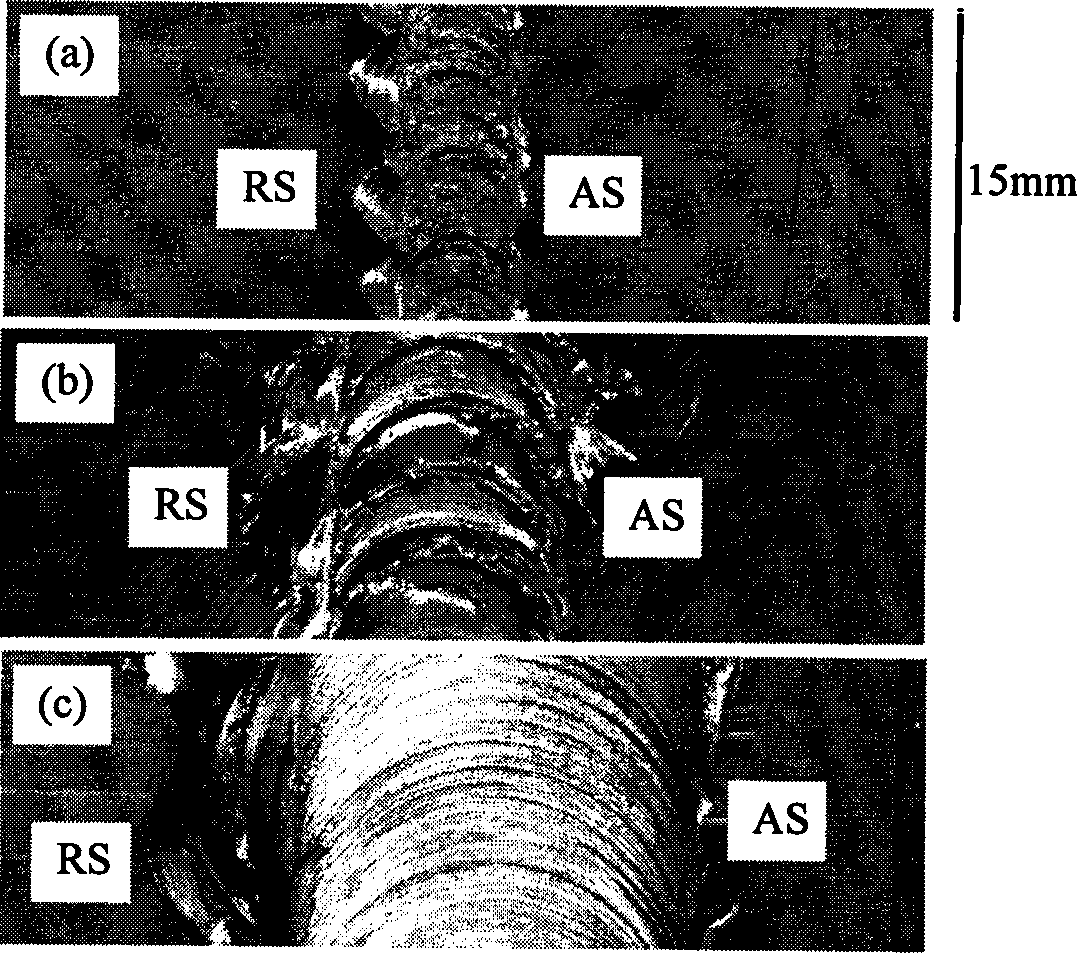

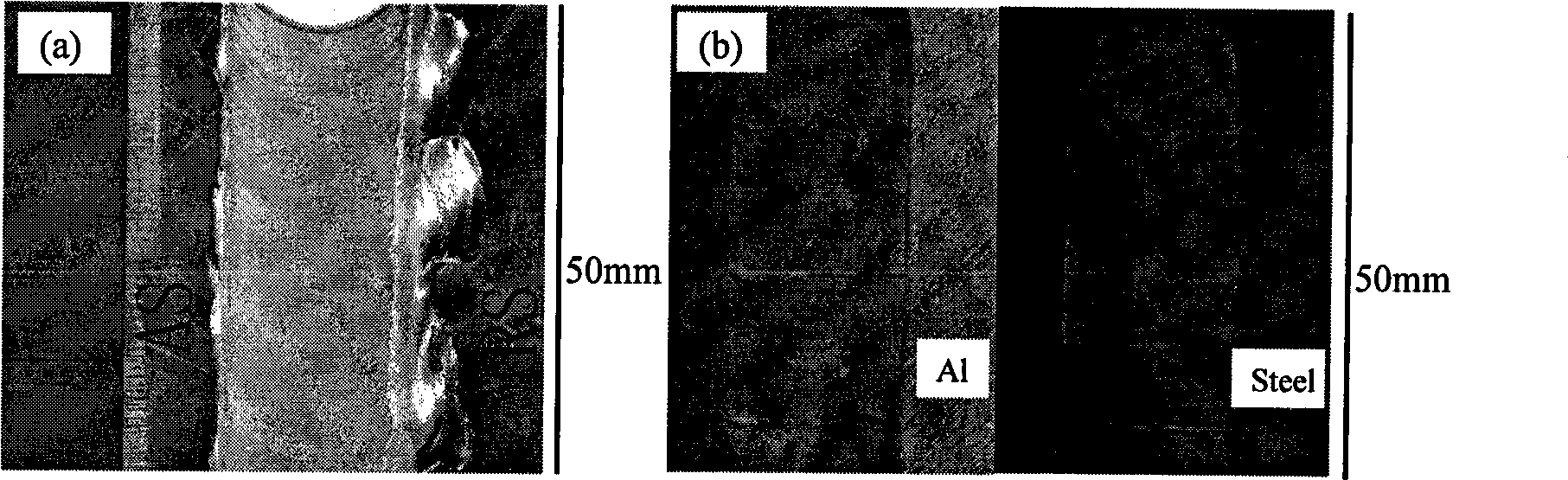

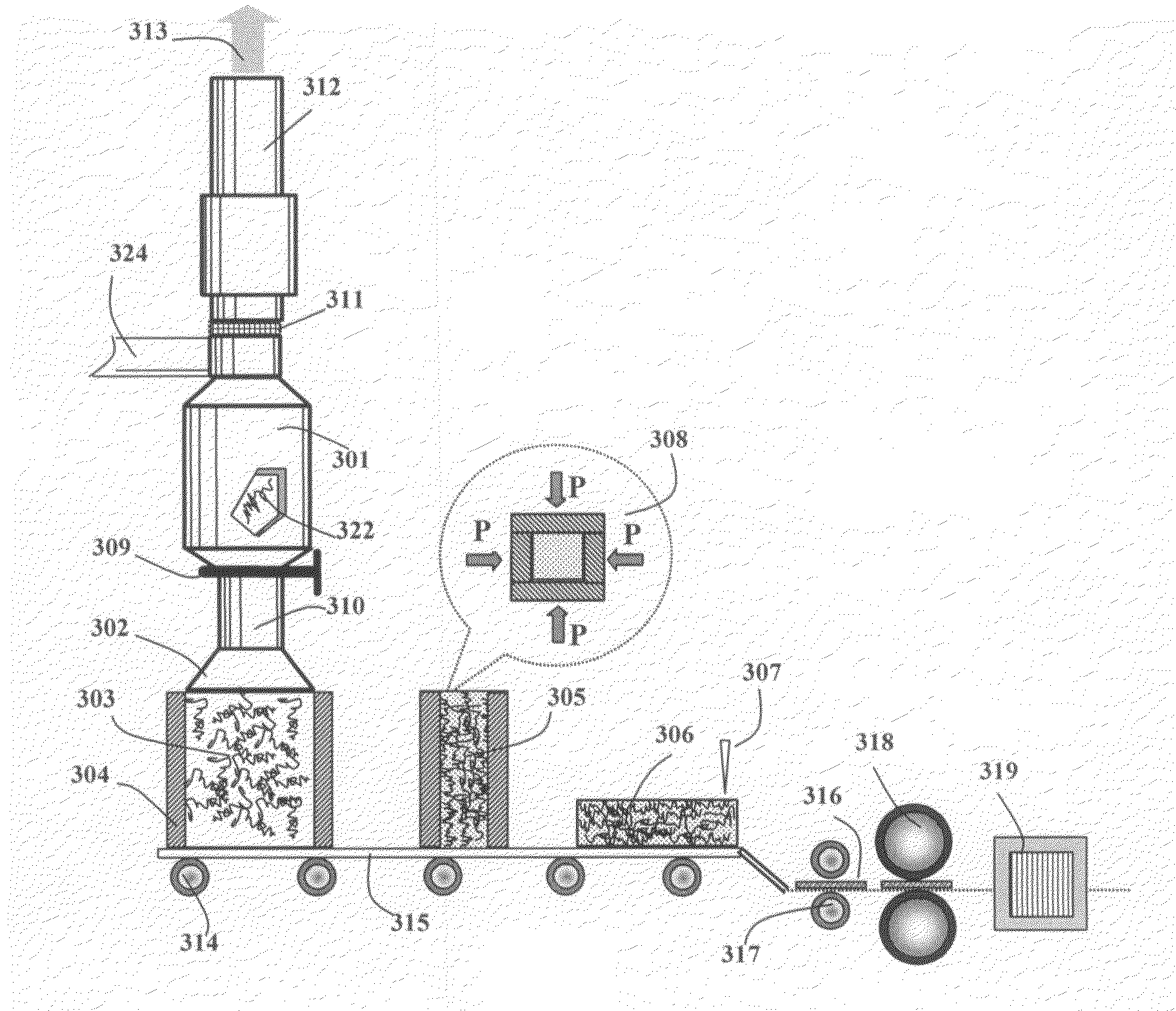

Method for preparing bimetal composite plate by stirring friction braze welding

InactiveCN101530947APrevent thinningAvoid direct contactNon-electric welding apparatusSurface layerShielding gas

The invention discloses a method for preparing a bimetal composite plate by stirring friction braze welding. The method comprises that: a plate with small hardness is used as a covering layer metal plate; a plate with high hardness is used as a base layer metal plate; the covering layer metal plate and the base layer metal plate are horizontally fixed on a working platform surface in a lap joint mode; solders which can generate eutectic reaction with one of the upper / base layer metal plates are preset between the upper / base layer metal plates; a non-needle type cylinder friction device is arranged over the covering layer metal plate; the non-needle type cylindrical friction device is made to rotate and be pressed to be closely contacted with the surface layer of the covering layer metal plate, but not penetrate the covering layer metal plate, and the non-needle type cylindrical friction device rotates in the original position or moves forward along the surface of the covering layer metal plate while rotating; by utilizing frictional heat to melt the solders, the upper / base layer metal plates are both quickly melted in the solders, thereby achieving excellent interface combination; and the excessive solders are squeezed out, and a thin and dense soldering seam is formed, so that the bimetal composite plate is prepared. Compared with the braze welding in a furnace, the method has the advantages of high efficiency, energy conservation, pressure lead-in, unnecessary soldering flux and gas protection and short holding time at a high temperature.

Owner:XI AN JIAOTONG UNIV

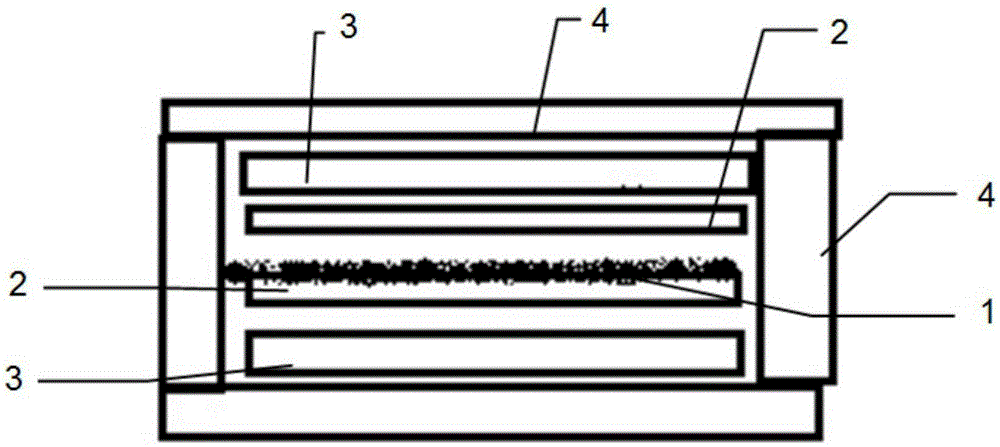

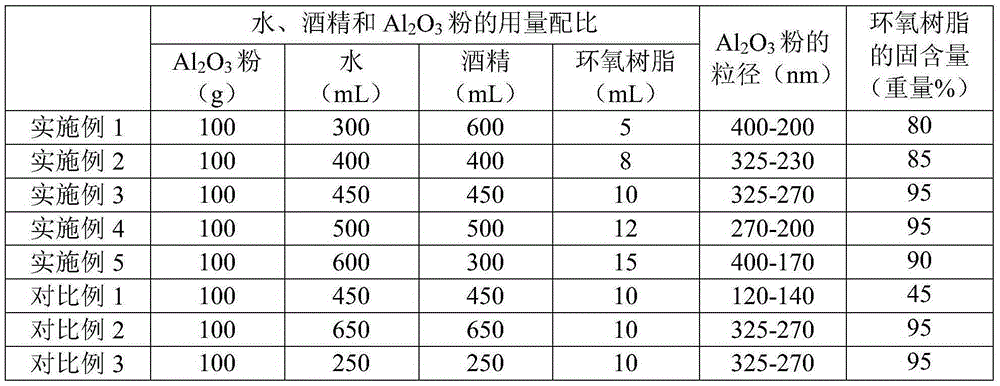

Method for obtaining release agent layer on base plate and composite material containing base plate and release agent layer

ActiveCN105238216AAvoid stickingPlay an isolation roleLayered productsEpoxy resin coatingsTitaniumMaterials science

The invention relates to the field of release agents, in particular to a method for obtaining a release agent layer on a base plate and a composite material containing the base plate and the release agent layer. The method for obtaining the parting agent layer on the base plate comprises coating a release agent on the base plate, and drying to form the parting agent layer on the base plate. The method is characterized in that the release agent comprises water, alcohol, epoxy resin and Al2O3 powder, wherein relative to 100g of Al2O3 powder, the dosage of the water is 300-600mL, the dosage of the alcohol is 300-600mL, and the dosage of the epoxy resin is 5-15mL. The release agent can be online directly sprayed on the surface of a composite titanium board, and can be quickly cured to form a self-drying type coating to achieve a parting effect, so that in a 4-6h constant-temperature process at 800-1000 DEG C and a rolling process of a titanium steel composite board, adhesion and surface roughness increase phenomena of a titanium-titanium interface are avoided, and the yield and the production efficiency for titanium steel composite board processing are improved.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

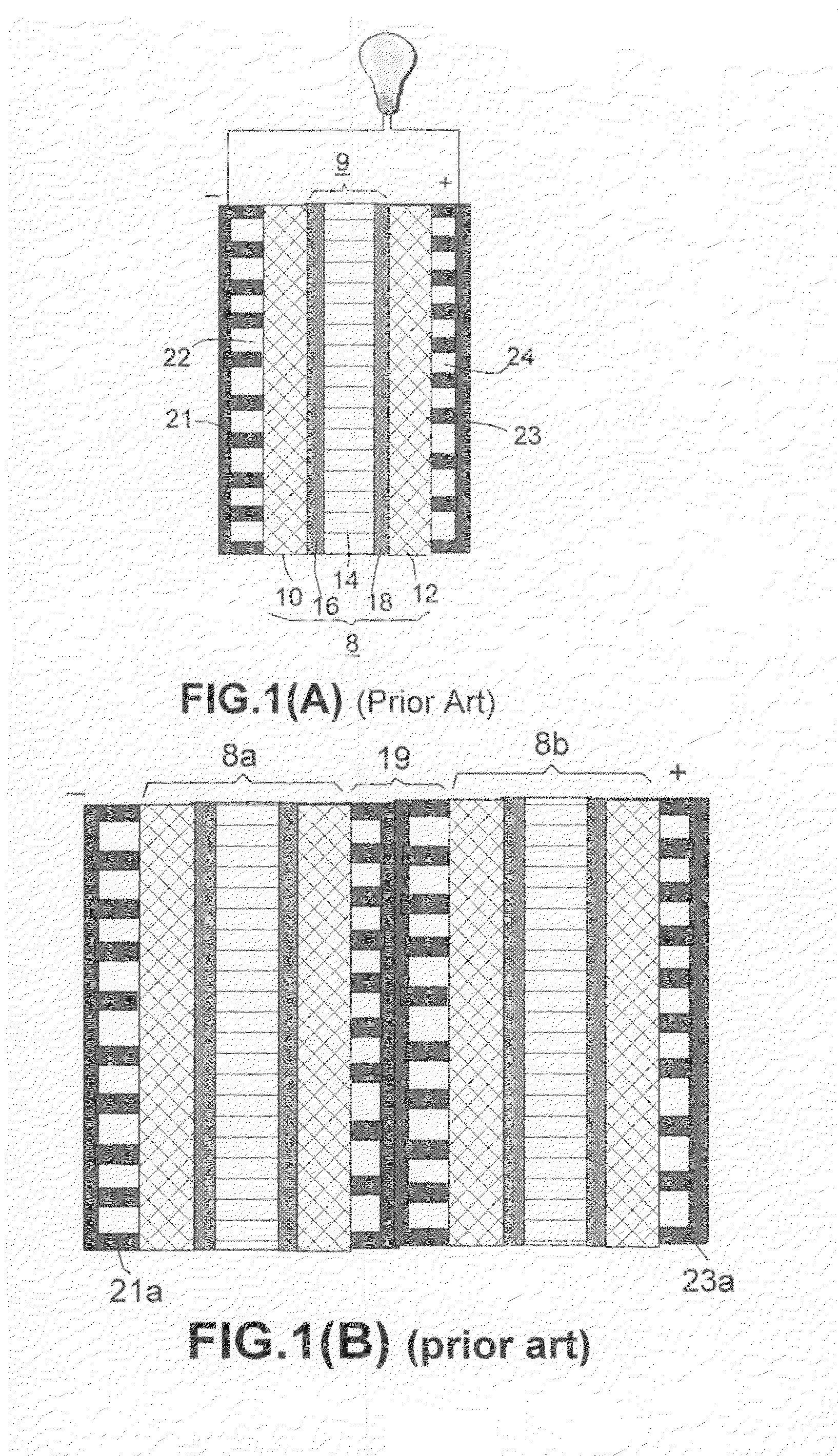

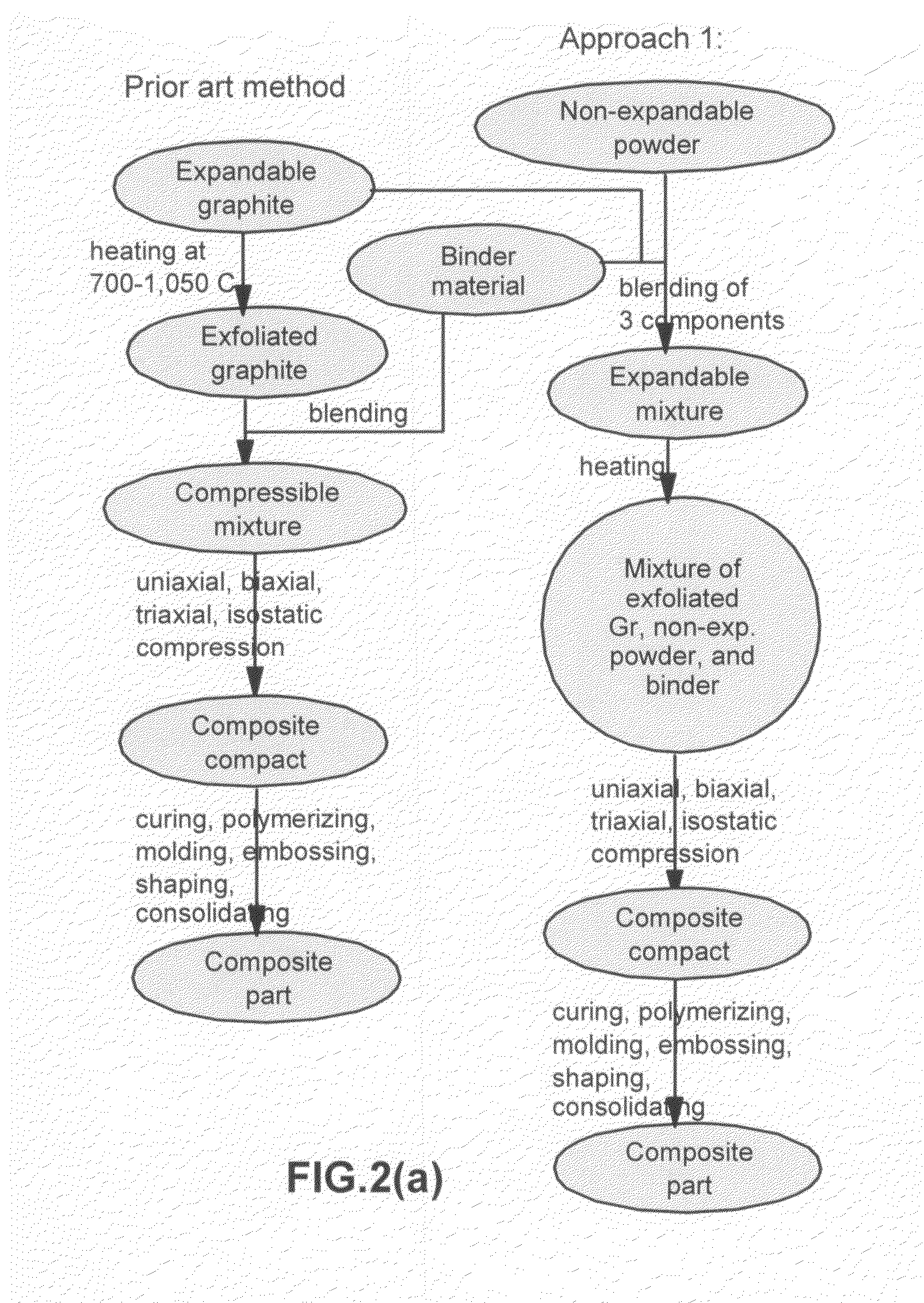

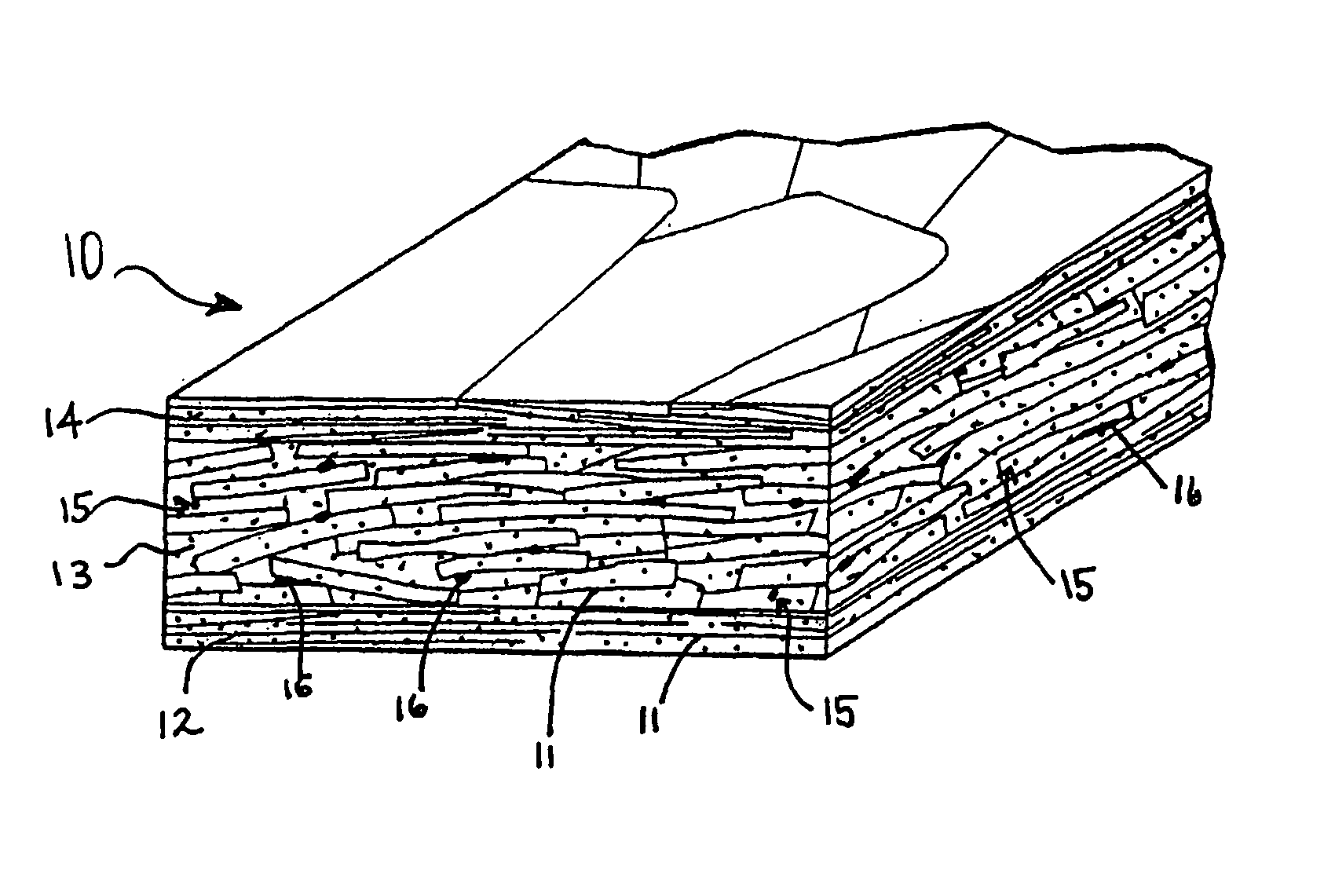

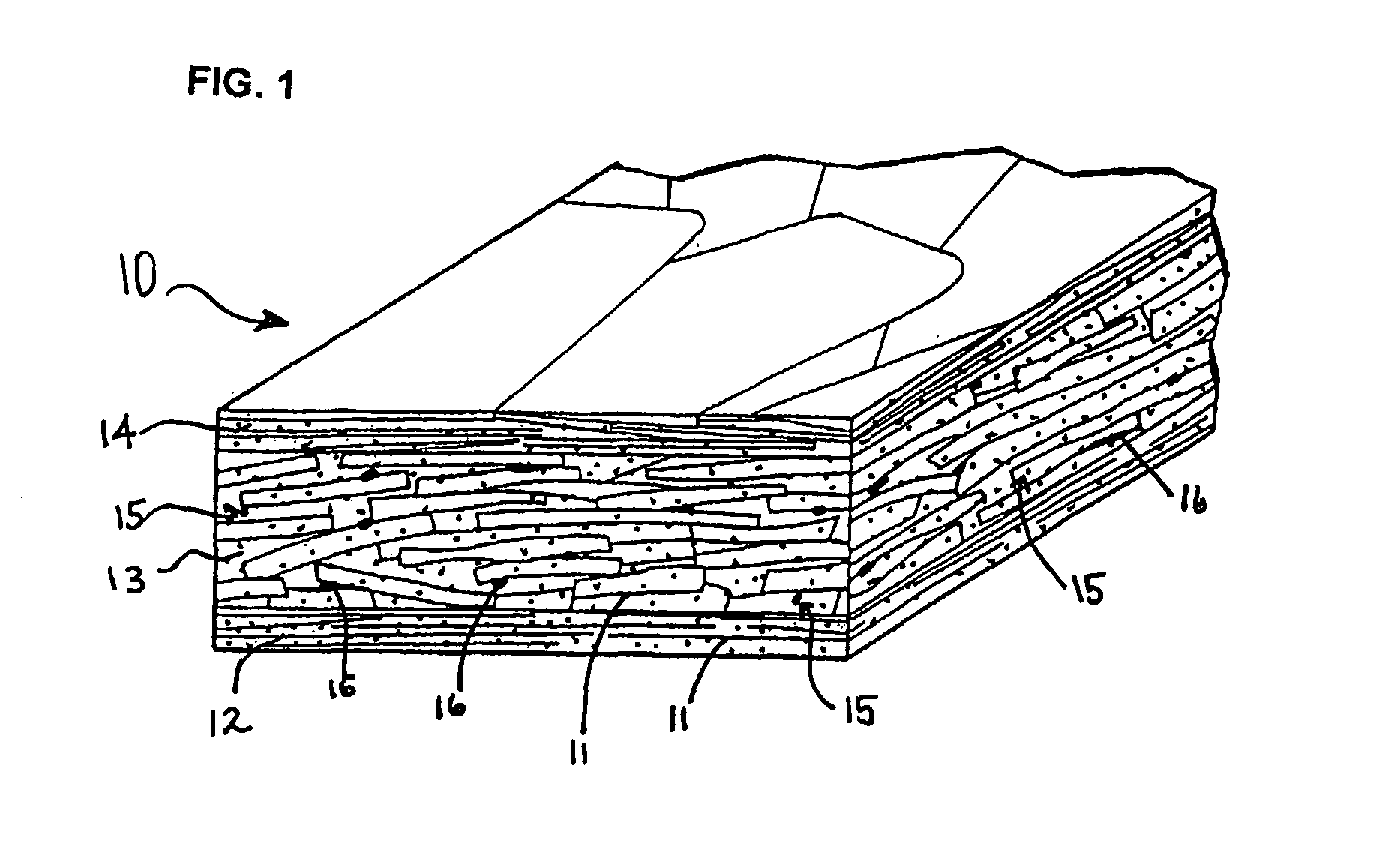

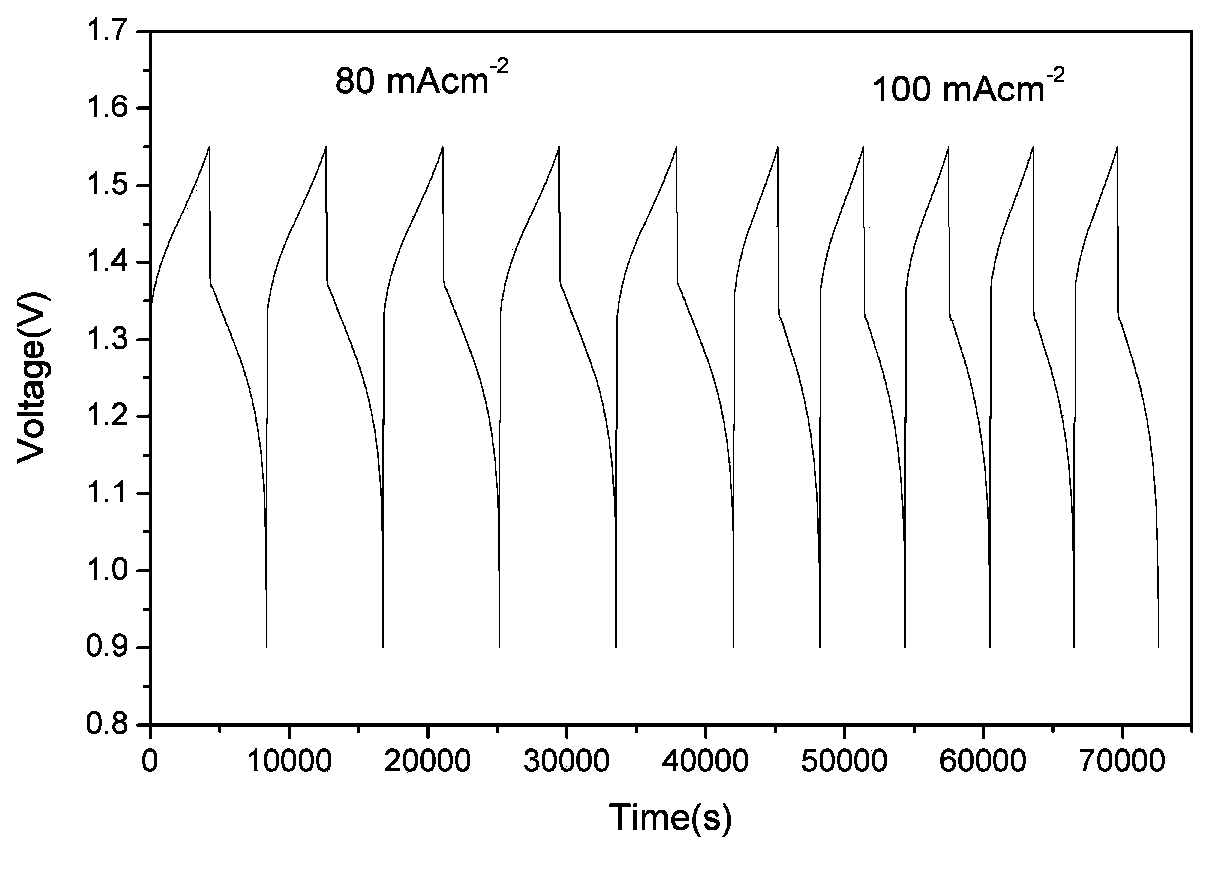

Method of producing exfoliated graphite composite compositions for fuel cell flow field plates

ActiveUS20080279710A1Improve adhesionEliminate or reduce this further anisotropyTransportation and packagingMetal-working apparatusFuel cellsPowder mixture

A method of producing an electrically conductive composite composition, which is particularly useful for fuel cell bipolar plate applications. The method comprises: (a) providing a supply of expandable graphite powder; (b) providing a supply of a non-expandable powder component comprising a binder or matrix material; (c) blending the expandable graphite with the non-expandable powder component to form a powder mixture wherein the non-expandable powder component is in the amount of between 3% and 60% by weight based on the total weight of the powder mixture; (d) exposing the powder mixture to a temperature sufficient for exfoliating the expandable graphite to obtain a compressible mixture comprising expanded graphite worms and the non-expandable component; (e) compressing the compressible mixture at a pressure within the range of from about 5 psi to about 50,000 psi in predetermined directions into predetermined forms of cohered graphite composite compact; and (f) treating the so-formed cohered graphite composite to activate the binder or matrix material thereby promoting adhesion within the compact to produce the desired composite composition. Preferably, the non-expandable powder component further comprises an isotropy-promoting agent such as non-expandable graphite particles. Further preferably, step (e) comprises compressing the mixture in at least two directions. The method leads to composite plates with exceptionally high thickness-direction electrical conductivity.

Owner:NANOTEK INSTR GRP LLC

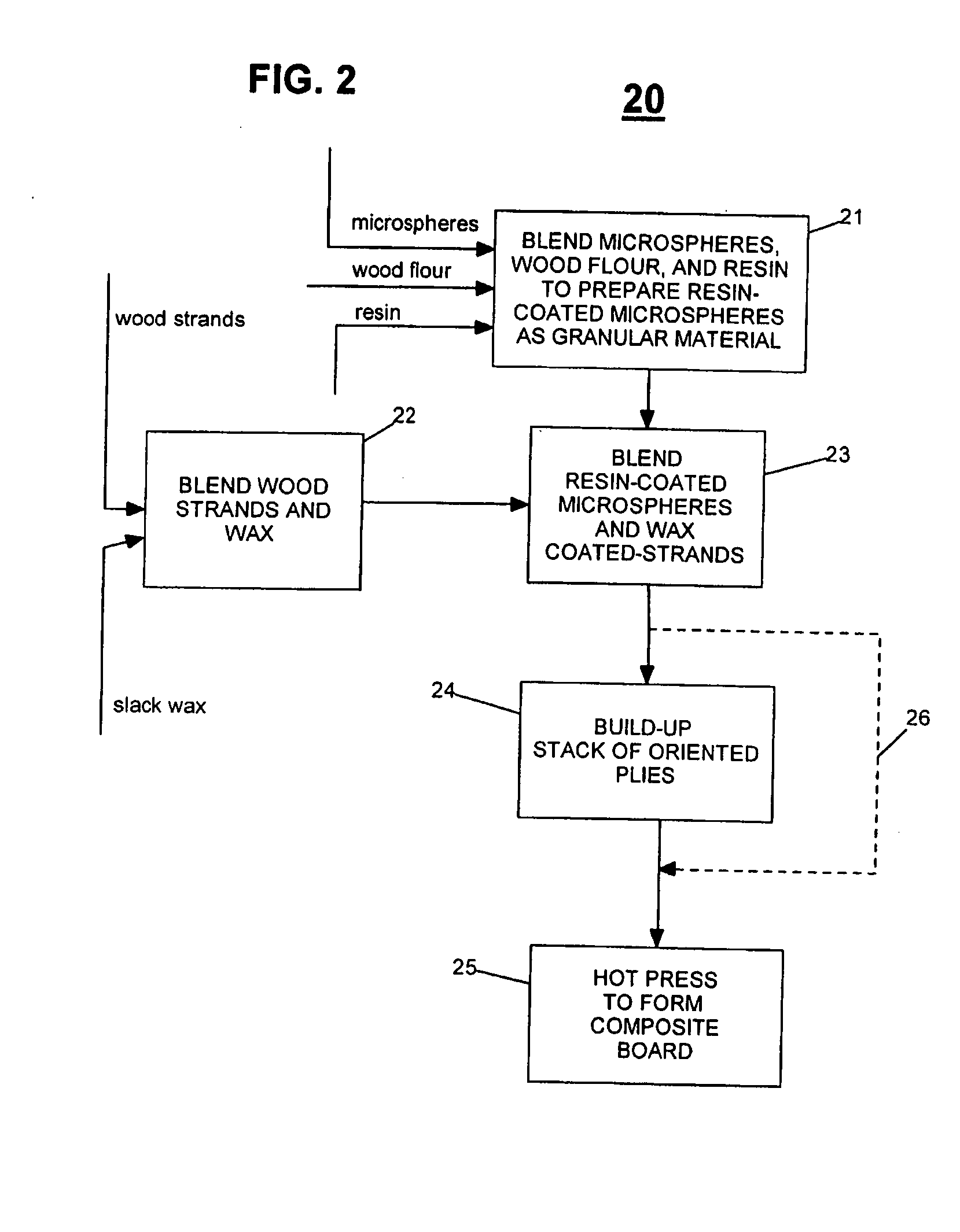

Strength-enhanced, lightweight lignocellulosic composite board materials and methods of their manufacture

InactiveUS20050019548A1Reduced board densityImprove structural strengthSynthetic resin layered productsWood working apparatusCelluloseVolumetric Mass Density

Lighweight lignocellulosic board materials, such as oriented strand board and others, having reduced densities while maintaining suitable mechanical properties, and methods for their manufacture.

Owner:HUBER ENGINEERED WOODS

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

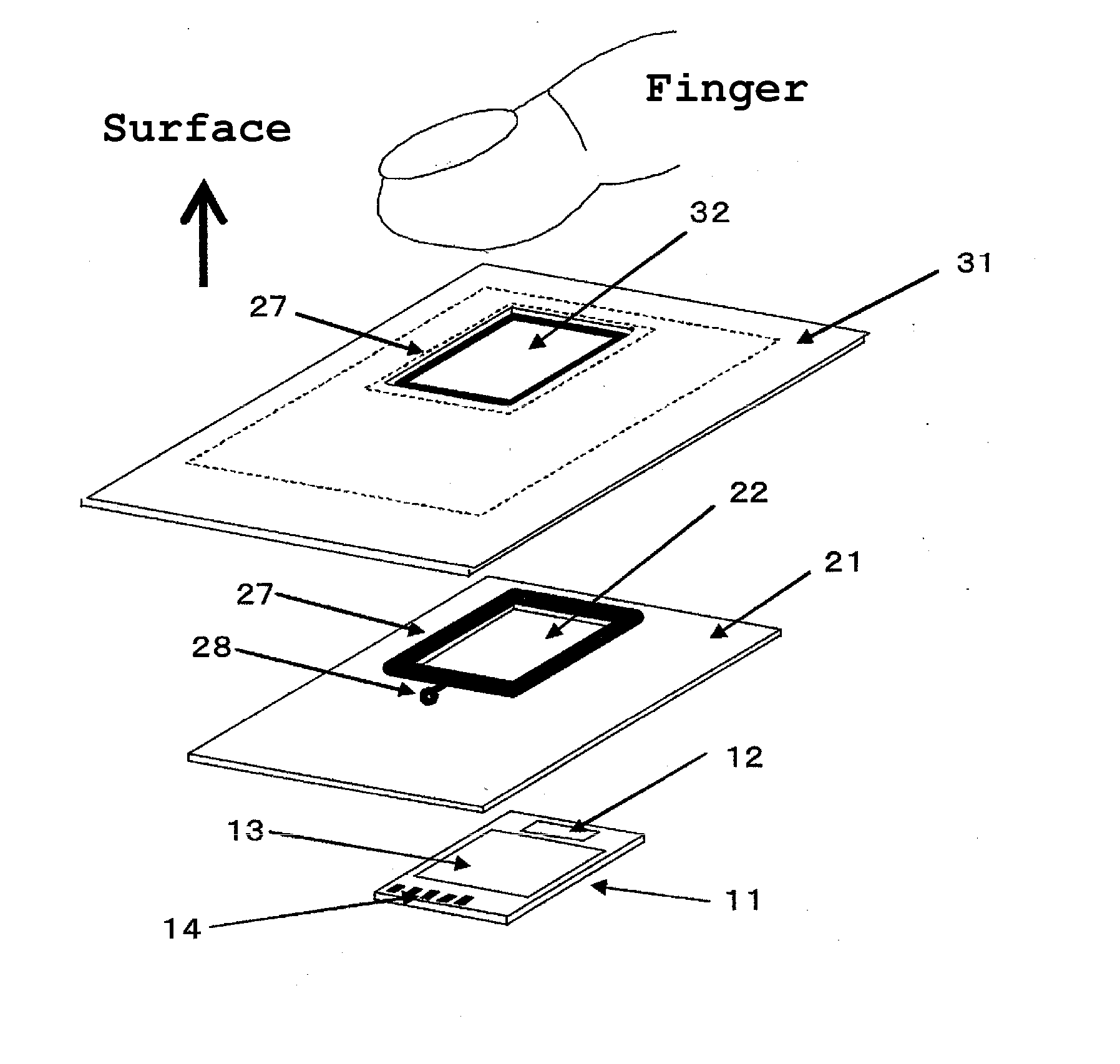

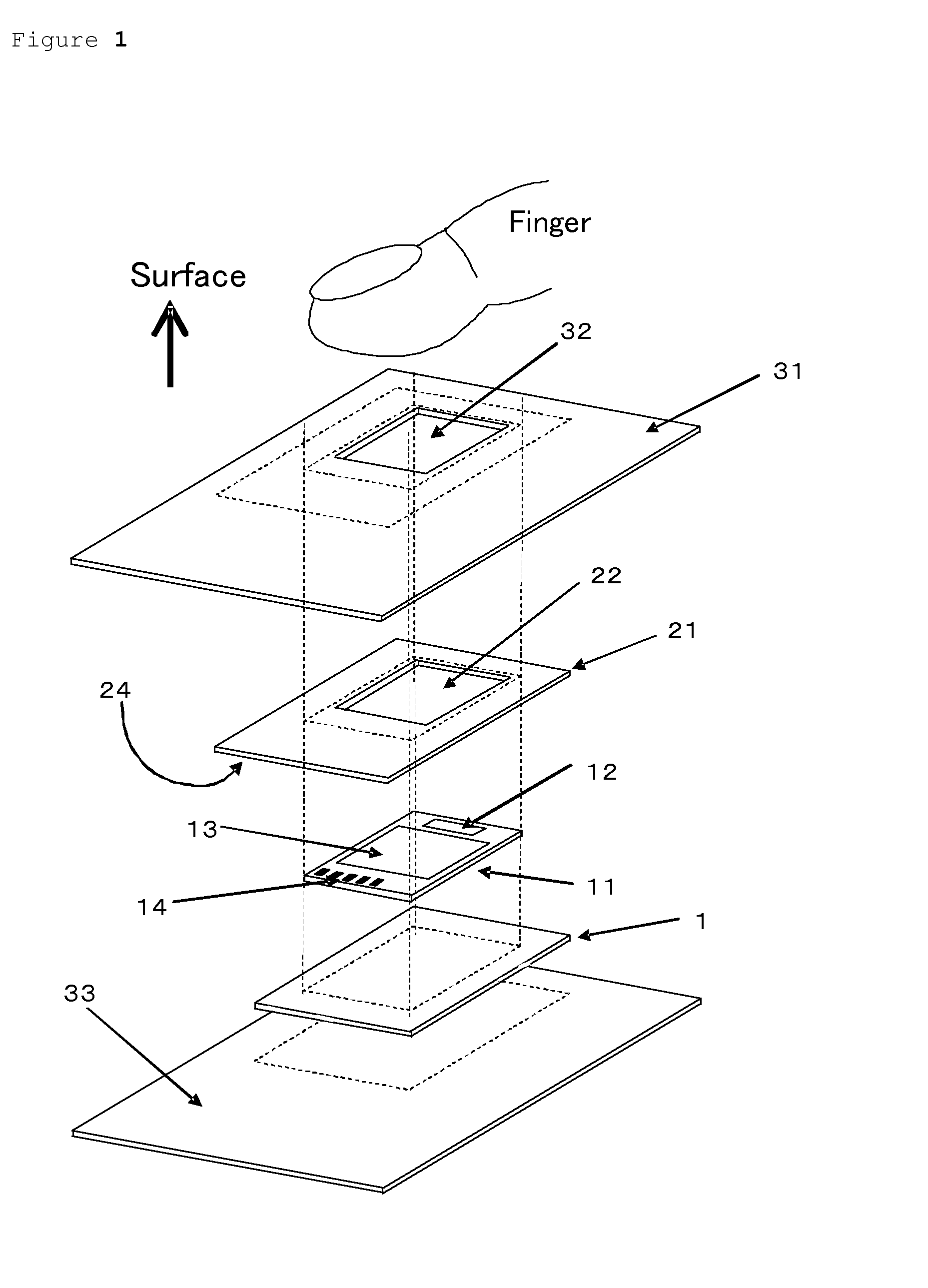

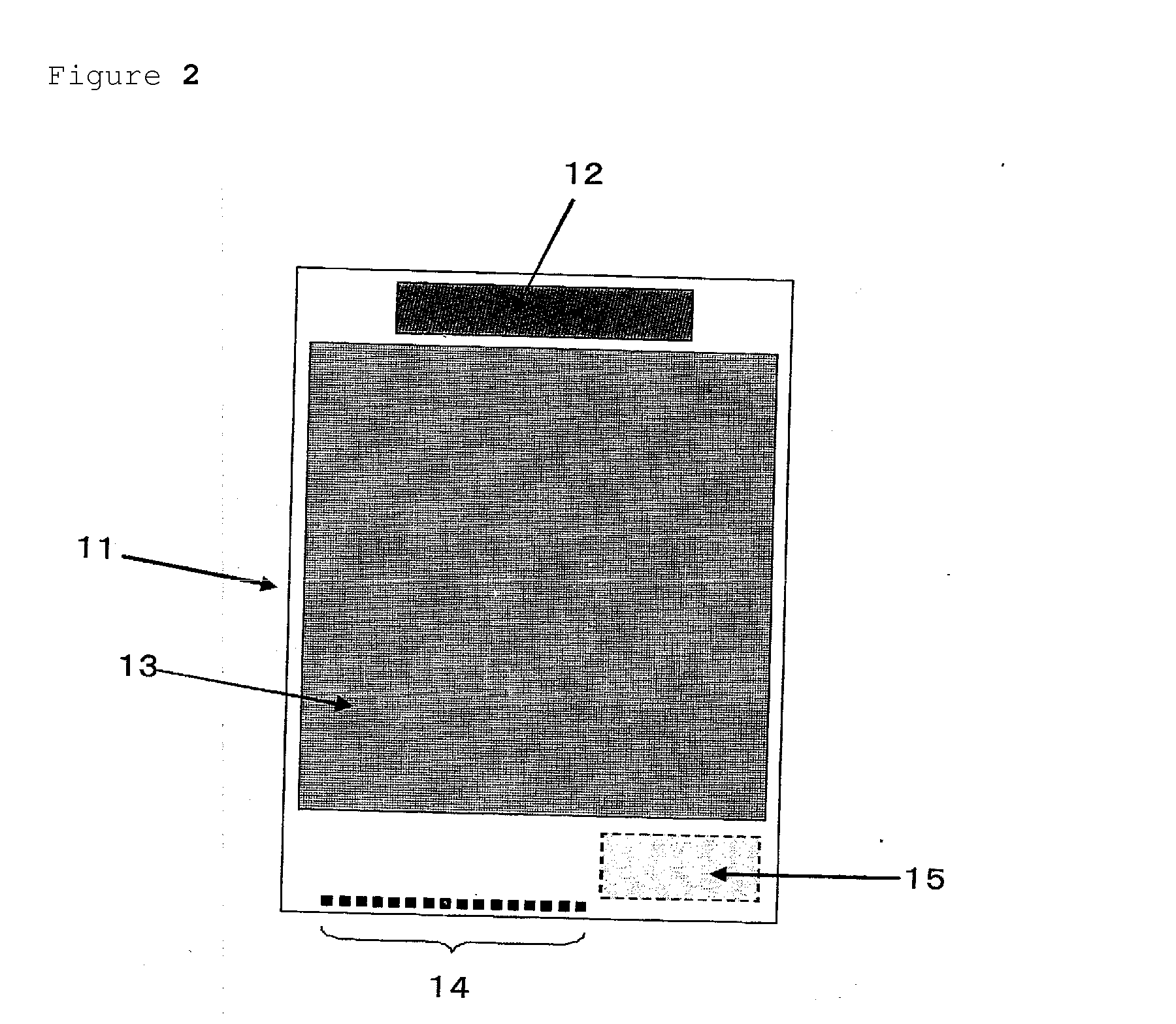

Smartcard integrated with a fingerprint image acquisition sensor and a method for manufacturing the smartcard

InactiveUS20120049309A1High yieldLow production costSolid-state devicesRecord carriers used with machinesThermoplasticInternational standard

The ProblemsTo provide a smartcard that embeds a fingerprint image acquisition sensor, having thickens of 0.76 mm or less compiling with the International Standard organization (ISO).Means for Solving the ProblemA smartcard comprising a core substrate which is configured with a film substrate 21 on which a fingerprint image acquisition sensor IC chip 11, an electric circuit pattern and accompanying electrical, and a reinforcing metal or composite plate 1 which is adhered to the back surface of the fingerprint image acquisition sensor IC chip 11; an over sheets 31 and an under sheet 33, which are made of thermoplastic or paper, sandwiching the core substrate 33, where the over sheet 31 and the under sheet 33 are attached with a thermal adhesive sheet, which functions as a mechanical buffer to protect the electrical components from external stress. The adhesive sheet is made of urethane rubber or similar substance.

Owner:KIYOMOTO SHOICHI +1

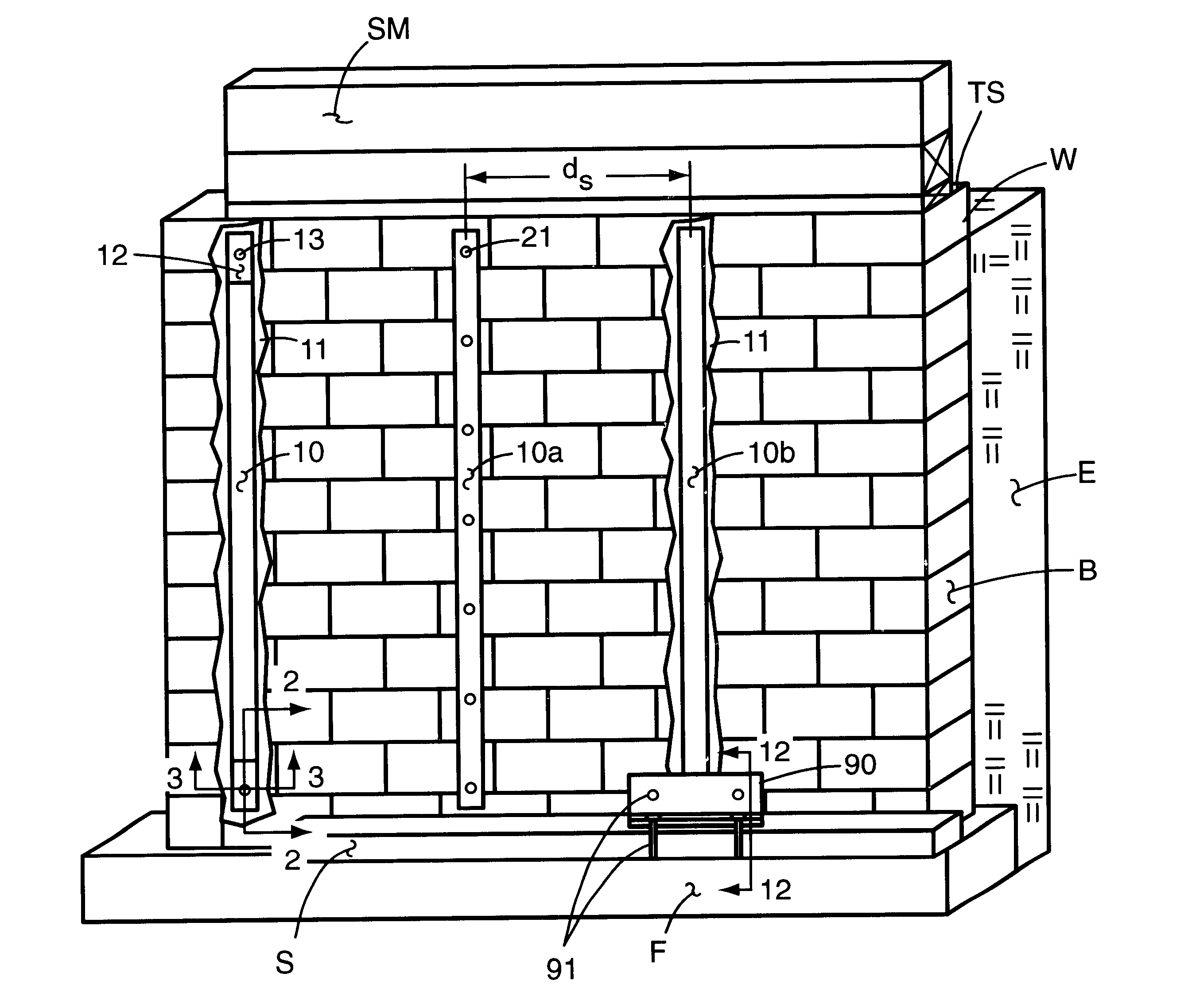

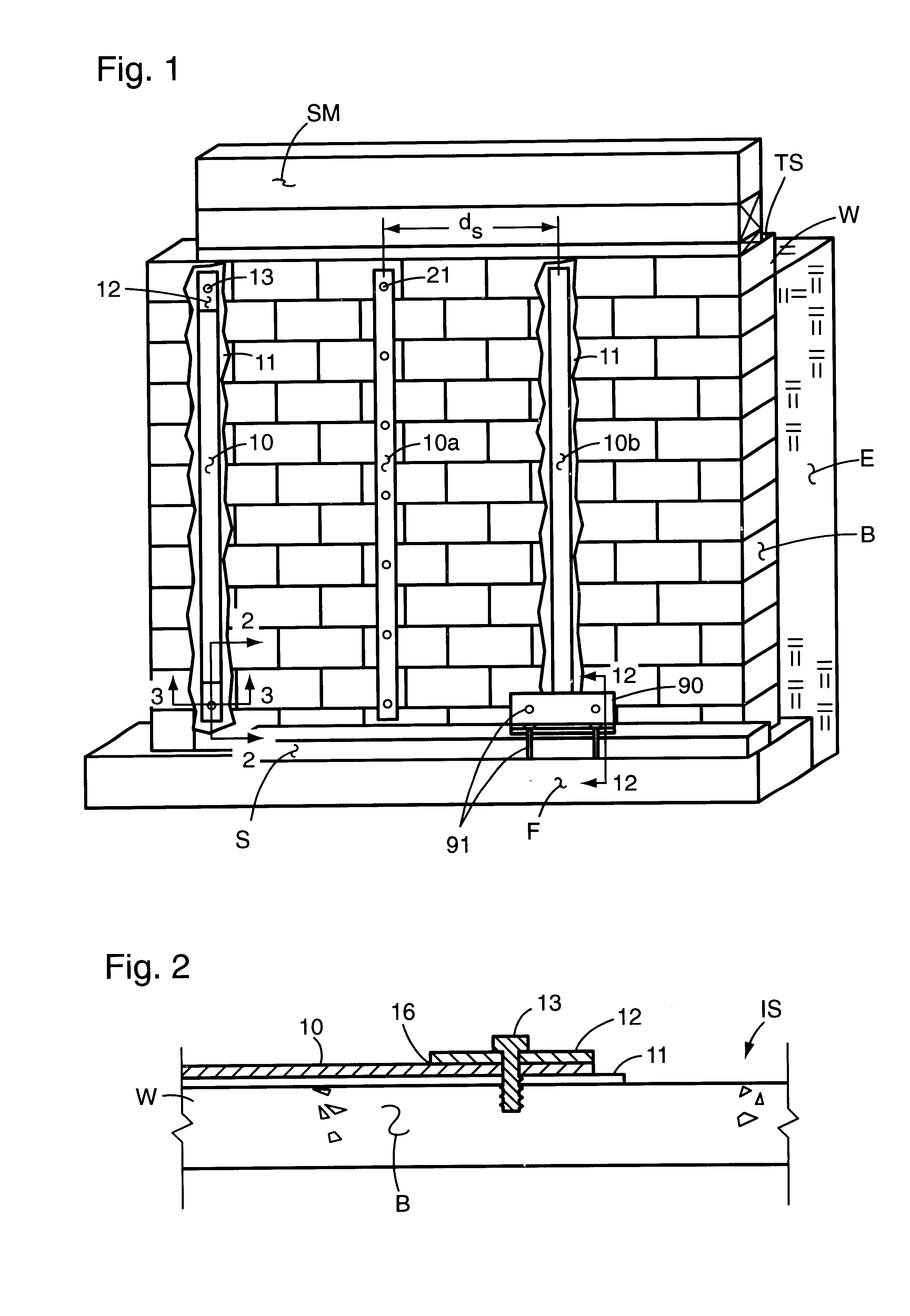

Wall reinforcement apparatus and method using composite materials

A wall reinforcing method including reinforcing members adhered to the wall. The reinforcing members are either pre-cured composite plates or composite members formed in situ, that is, a fabric of reinforcing fibers that is saturated with an adhesive to form the matrix of the composite and to adhere the reinforcement to the wall. The in situ members are either strips of fabric or wide sheets that cover most of the wall. The spacing of the reinforcing members is determined, in one embodiment, by an array of spacing distances. The array, which is preferably in table form, is consulted by the installer who first measures some of the wall parameters and environmental characteristics.

Owner:ENGINEERED COMPOST SYST +1

Composite plate material of foam microcrystalline glass and pure microcrystalline glass and manufacturing method of composite plate material

The invention provides a composite plate material of foam microcrystalline glass and pure microcrystalline glass. The composite plate material comprises a base body and a decoration surface, wherein the base body is made of a foam microcrystalline glass mixed material; the thickness of the base body is 50mm to 500mm; the decoration surface covers the surface of the base body and is made of pure microcrystalline glass granules; the thickness of the decoration surface is 3mm to 30mm. The invention also provides a manufacturing method of the composite plate material. The composite plate material of the foam microcrystalline glass and the pure microcrystalline glass, provided by the invention, can simultaneously replace a building material and a decoration material, and is small in specific gravity, high in strength, fireproof and corrosion-resistant; environment products which are difficultly handled in a natural environment and industrial wastes which are difficultly treated currently can be consumed; the environment stress is reduced.

Owner:北京晶雅石科技有限公司

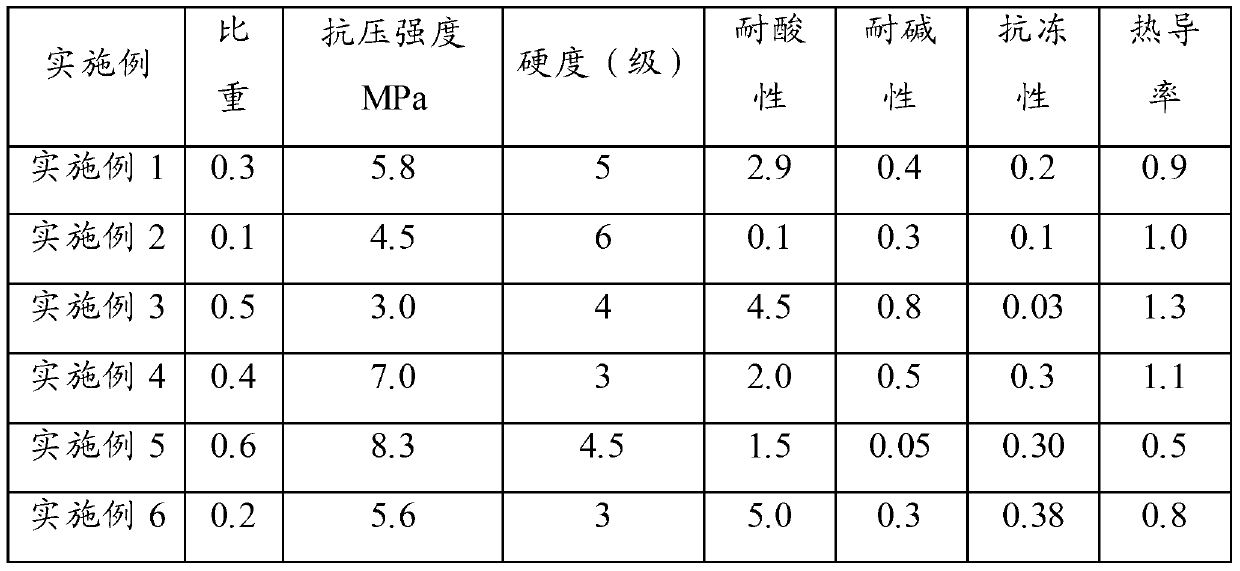

Bipolar plate for liquid flow energy storage battery and preparation method

ActiveCN103633336AEasy to buildReduce contact resistanceCell electrodesElectrical batteryInternal resistance

The invention relates to a bipolar plate for a liquid flow energy storage battery and a preparation method. The bipolar plate employs a carbon plastic composite plate with a thickness of 0.5-5mm as a matrix material. Conducting layers with a thickness of 1-1000 microns are coated on the surface of one side or surfaces of two sides of the matrix. The bipolar plate combines advantages of the carbon plastic composite plate and a graphite plate, decreases the contact resistance between an electrode and the bipolar plate, and finally decreases the Ohm internal resistance of the liquid flow energy storage battery. The bipolar plate raises the energy efficiency and the voltage efficiency of the liquid flow energy storage battery, and therefore the working current density is increased, thus weight, volume and cost of a battery with the same output power are all decreased.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Plastic Coated Composite Building Boards and Method of Making Same

ActiveUS20100055431A1Improve physical propertiesIncrease durability and load carrying capacityGlass/slag layered productsCoatingsCross-linkSlurry

Disclosed are composite building boards and associated manufacturing methods. The composite boards may include, for example, one or more slurry layers with embedded fibrous mats. An exterior plastic coating is mechanically adhered to the underlying slurry layer. The plastic layer chemically bonds and cross-links with polymer additives within the slurry layer. The result is an integrated polymer matrix with greatly improved durability and surface strength.

Owner:CERTAINTEED GYPSUM INC

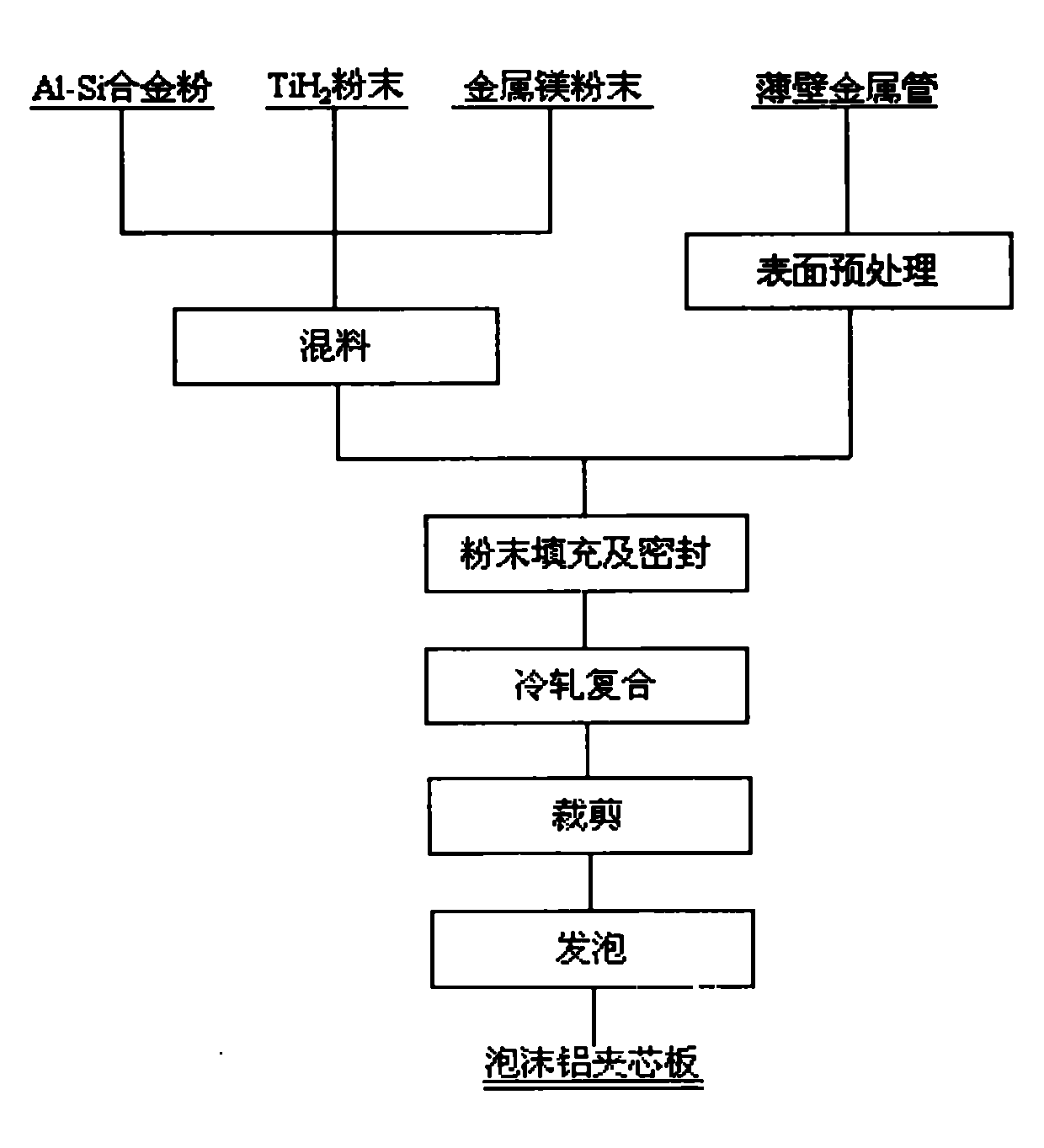

Method for manufacturing foamed aluminum sandwich plate

The invention relates to a method for manufacturing a foamed aluminum sandwich plate, which belongs to the field of porous foam metal and laminar composite materials. The method comprises the following steps of: uniformly mixing aluminum-silicon alloy powder prepared by an atomization method, and foaming agent titanium hydride powder and metal magnesium powder in a certain ratio; filling the powder into a thin-wall steel (or aluminum alloy) tube with one sealed end; sealing the other end of the tube after powder filling and preparing a rolled blank; rolling and compounding at a slow speed on a cold rolling mill; trimming an obtained composite plate and cutting a foamed preformed blank according to the size of a foaming mold; foaming the preformed blank in a steel mold in a limited way; adjusting foaming temperature and foaming time as required; and foaming at a high temperature for a short period of time to obtain a high-quality foamed aluminum sandwich plate with a uniform foam structure in a core layer, good interface bonding, high thickness accuracy and excellent plate profile. The method has the outstanding characteristics of low equipment requirement, high plate profile accuracy of a product, high three-point bending strength and the like and is advantaged technology suitable for mass industrial production of foamed aluminum sandwich structural materials.

Owner:NORTHEASTERN UNIV

Monolithic hurricane resistant structural panels made from low density composites

A three dimensional composite panel structure is provided having a thickness less than about 22.5 cm, overall density less than 0.2 g / cm, and exhibiting a global modulus greater than 1.2 GPa and stiffness greater than 15 kN-m2. The composite panel structure includes at least two fiber-reinforced mats interconnected in a spaced substantially parallel configuration by a skeletal web and a closed cell foam filling the spaces between the panels. The fiber-reinforced mats include a plurality of fibers in a low viscosity cured thermosetting resin matrix.

Owner:UNIVERSITY OF DELAWARE

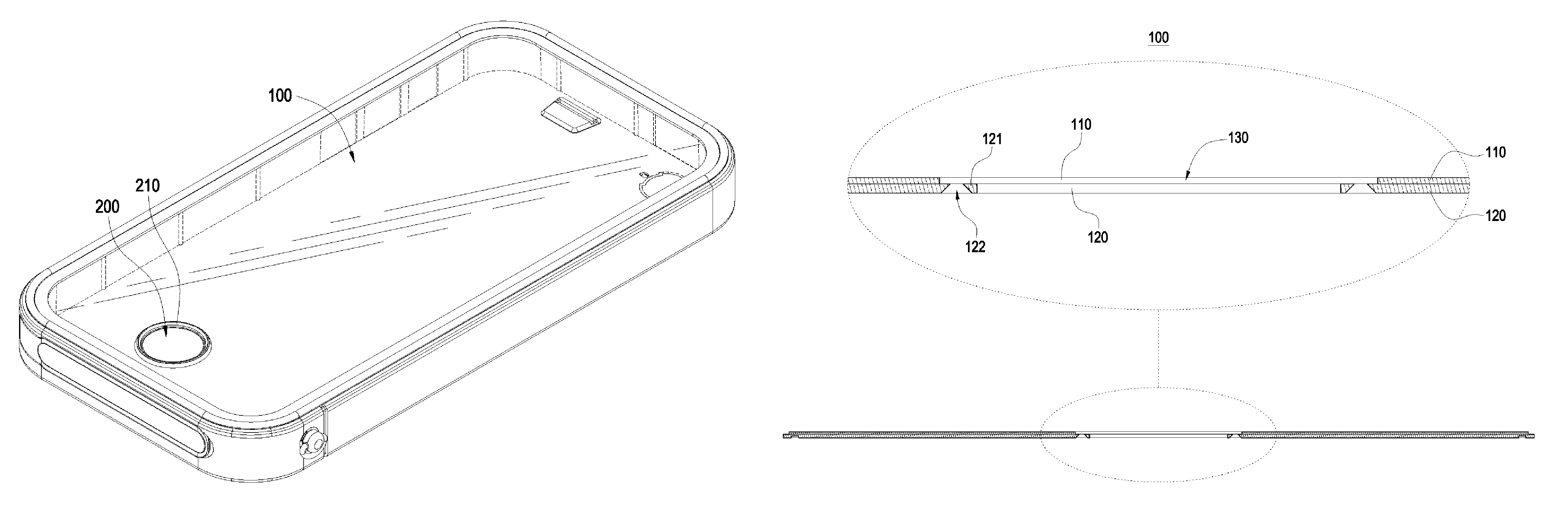

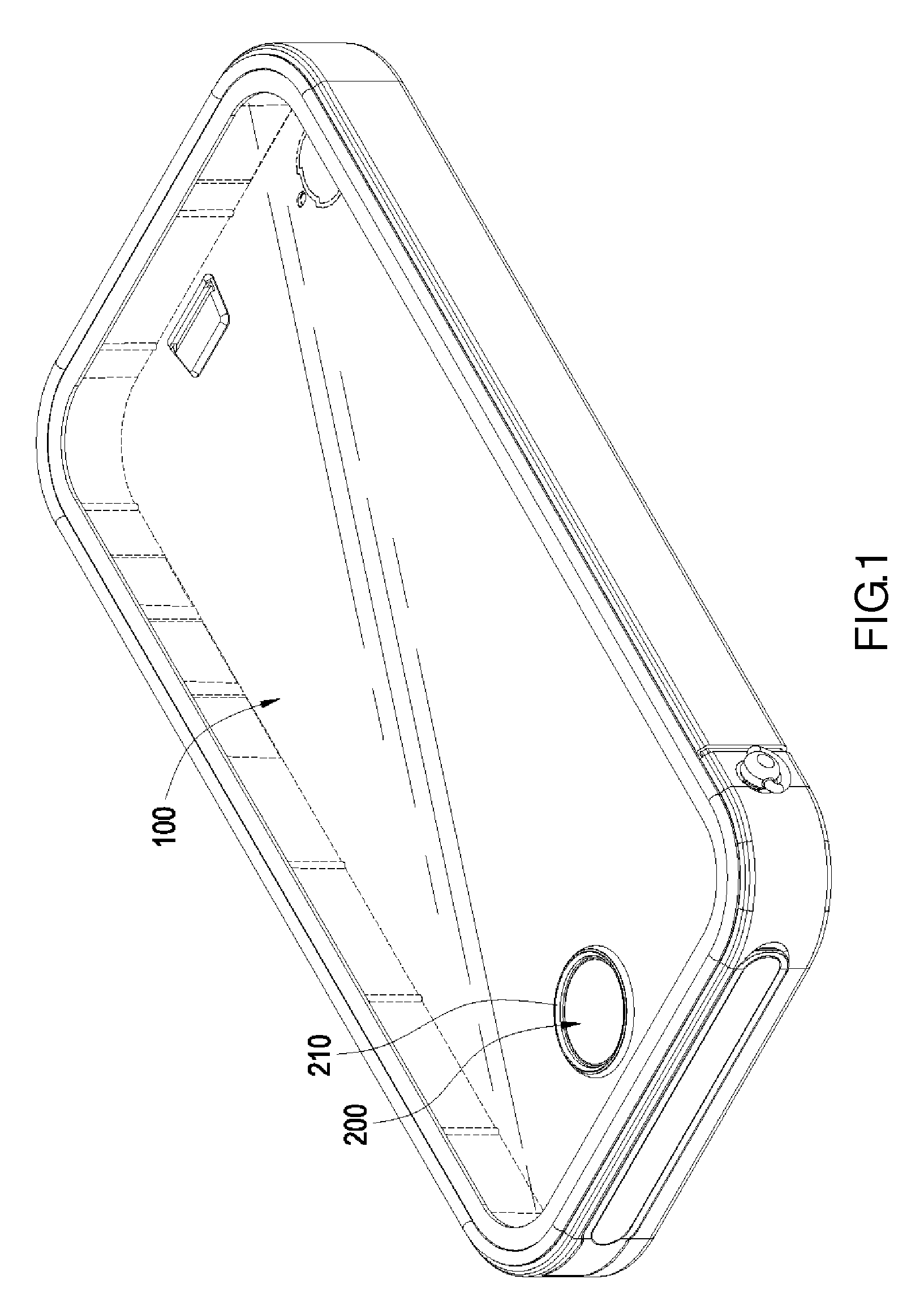

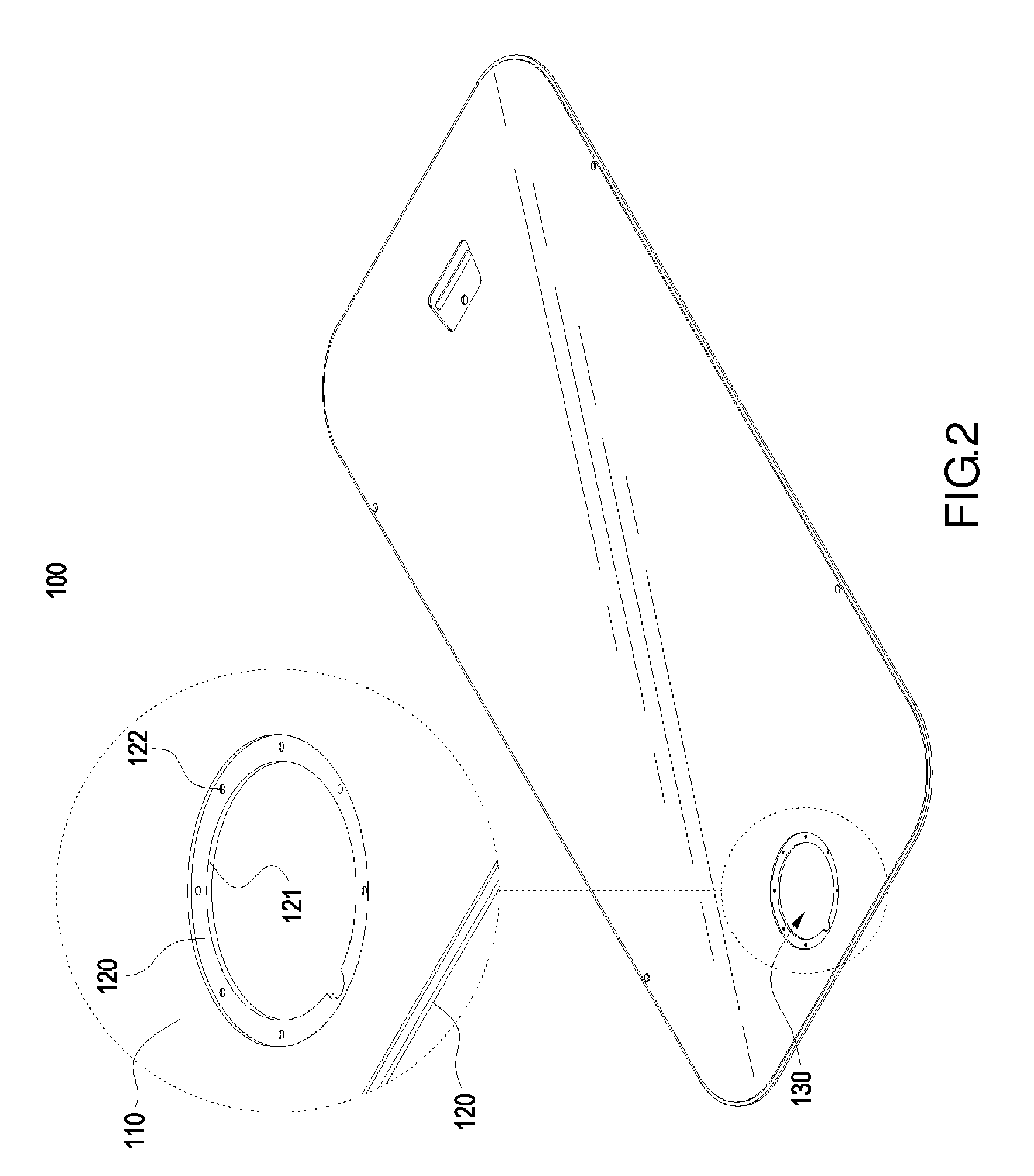

Waterproof box structure

InactiveUS9301414B2Easy to produceEasy to manufactureOther accessoriesDomestic articlesPolymer scienceComposite plate

A waterproof box structure includes a composite plate and a soft film. The composite plate includes a chemical curing layer and a thermoplastic resin layer adhered and coupled to each other. The composite plate has a through hole. The through hole penetrates the chemical curing layer and the thermoplastic resin layer. The thermoplastic resin layer extends from the inner rim of the through hole and toward the center of the through hole to form a flange. The soft film hides the through hole. The outer rim of the soft film encloses the flange and is coupled to the flange.

Owner:GETAC TECH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com