Patents

Literature

796results about "Sheets/panels" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermoplastic light-duty composite plate and preparing method thereof

The invention discloses a thermoplastic light compound plate and the manufacturing method, characterized in that it comprises acupuncture fiber carpet dipped in double faced foam of thermoplastic glue liquid and thermoplastic glue liquid layer coated on the surface, the density of compound plate is 0.35-0.90g / cm3, the weight of fiber scattered in bunchiness is 15-45% of acupuncture fiber carpet. The merit of invention is very remarkable. Special super long fiber and bunchiness fiber with certain proportion are maintained in the material so that the mechanical performance of material can be improved. In addition, the material is provided with foam structure, very good effect of heat and sound insulation. The invention is also provided with environmental protection and recovery.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

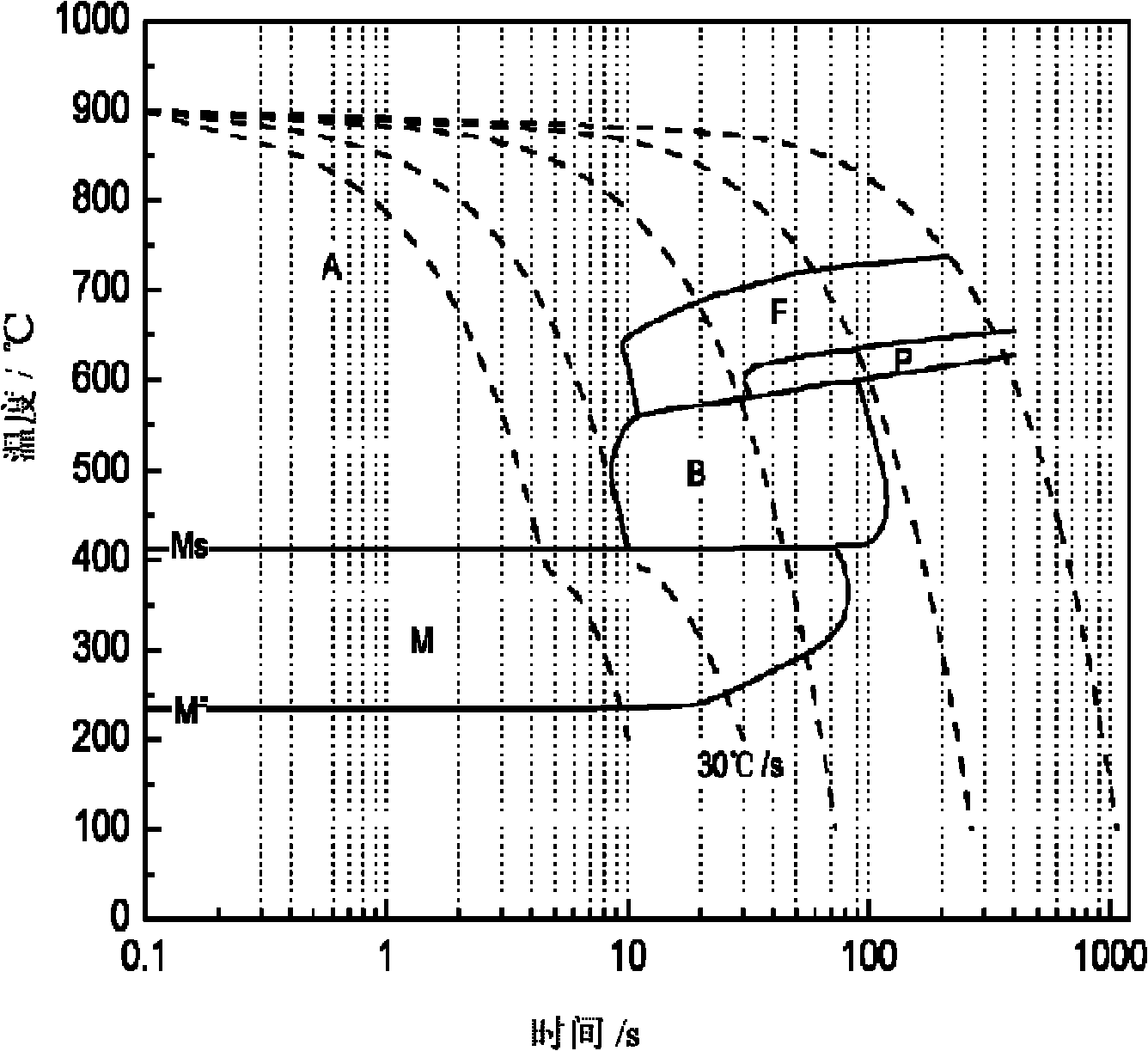

Ultrahigh-strength steel laser tailor welded blank and forming process thereof

InactiveCN102162574AGood formabilityReduce weightSheets/panelsLaser beam welding apparatusHot stampingRoom temperature

The invention relates to an ultrahigh-strength steel laser tailor welded blank and a forming process thereof. The forming process provided by the invention comprises the following steps: carrying out the laser tailor welding on ultrahigh-strength steel and high-strength steel according to the needed shape; then, delivering the obtained welded blank to a furnace filled with a protective gas and heating to 920-940 DEG C to be continued for at least 5 minutes; fully austenitizing; transferring the austenitized welded blank to a press machine to be rapidly molded and formed; cooling to 100-150 DEG C through pressurization quenching; and cooling along room temperature to obtain the needed parts. The hot stamping process of the laser tailor welded blank provided by the invention has the double advantages of the forming and hot stamping forming of the laser tailor welded blank and simultaneously solves the problems that the ultrahigh-strength steel is difficultly applied to the production ofautomobile structural components / framework components in a laser tailor welded blank mode.

Owner:SHANDONG JIANZHU UNIV

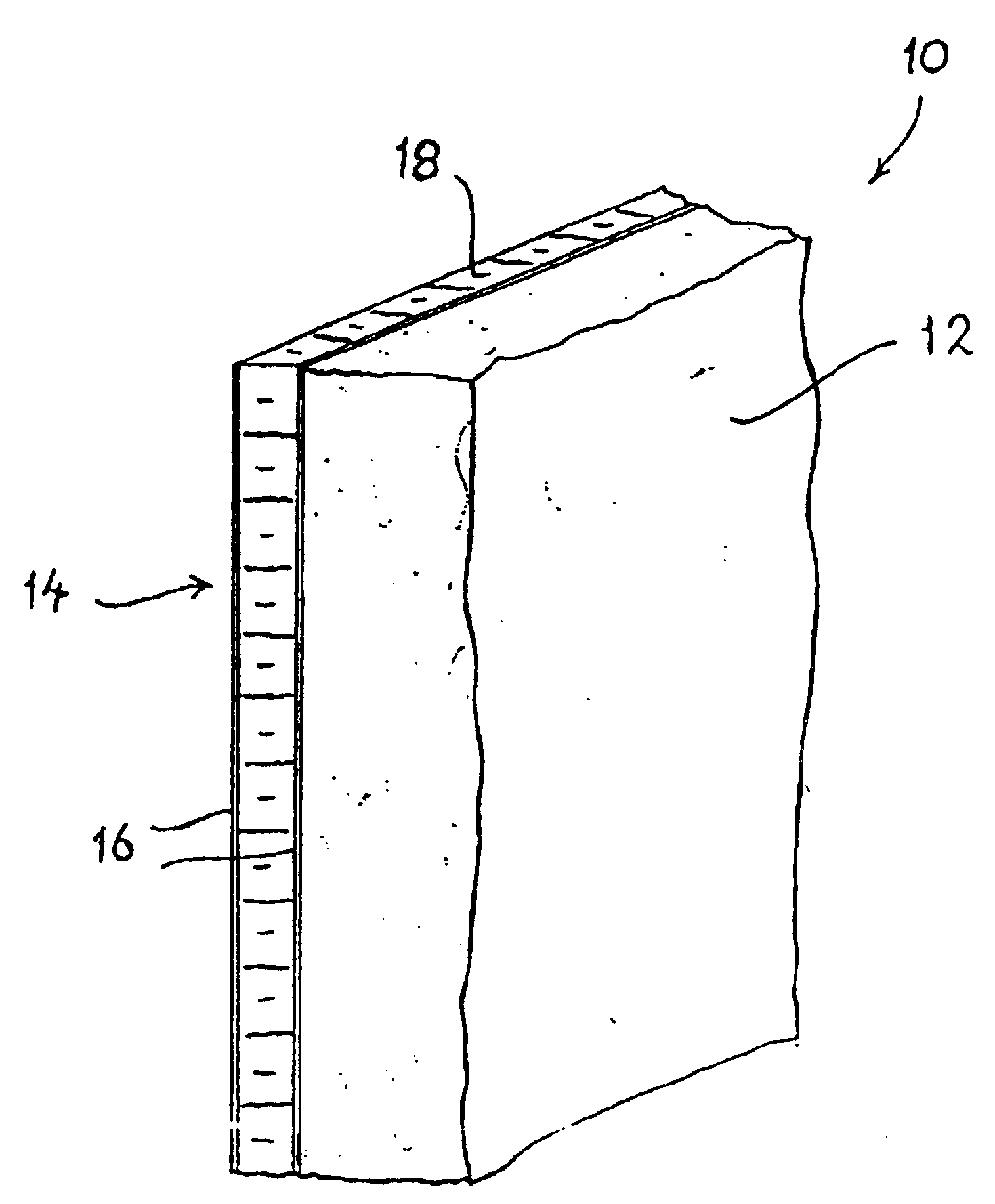

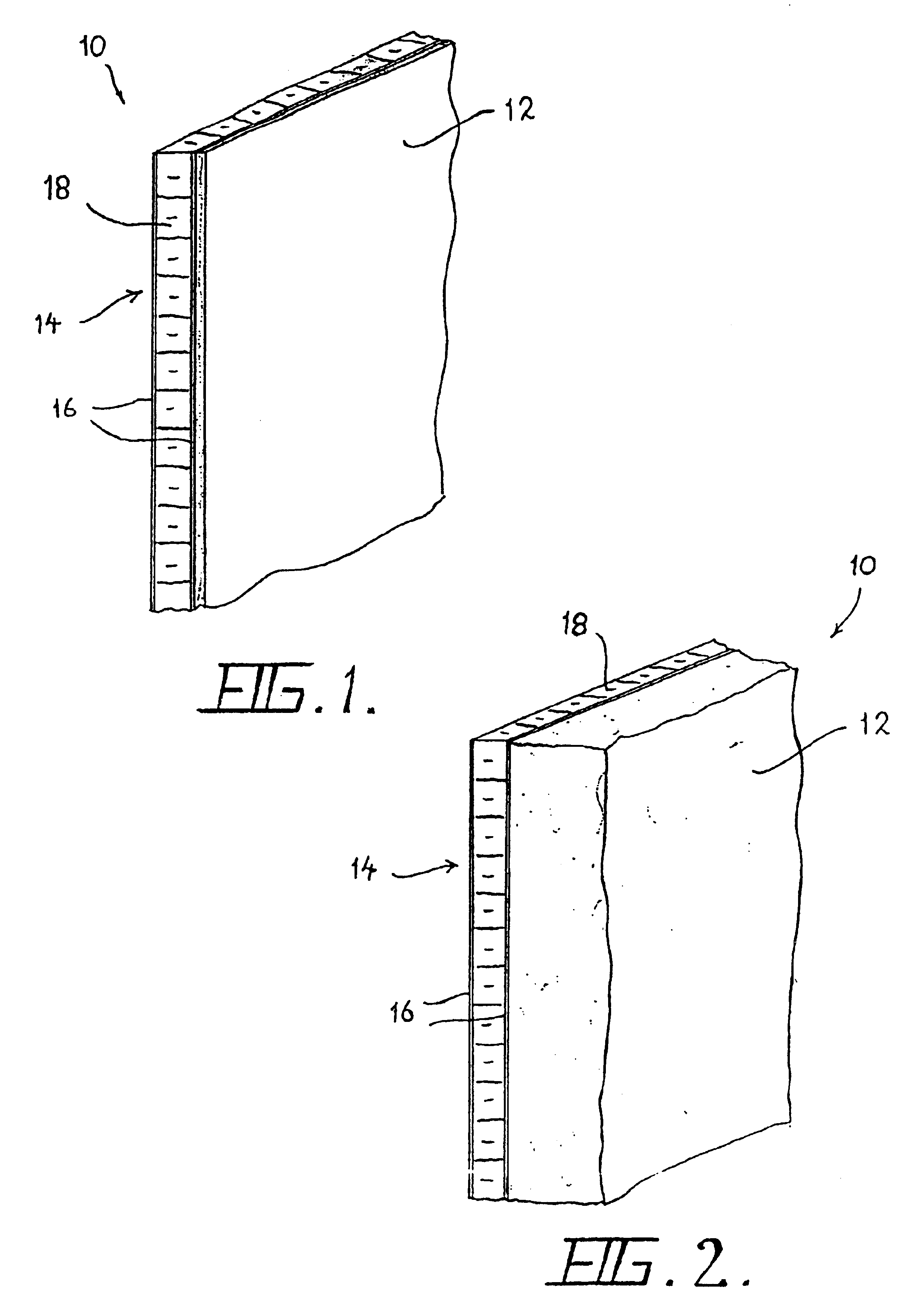

Fire barrier panel

A fire barrier panel of the kind suitable for lining car decks and engine rooms of high speed aluminum ferries is described. The panel (10) includes a relatively thin layer of inorganic insulating material (12) adhered to a lightweight support structure (14). The layer of inorganic insulating material may be an intumescent material made from mineral fibers. The decribed lightweight support structure (14) is a honeycomb panel having a honeycomb core (18) of non-combustible aluminum foil provided with two face skins made of glass reinforced plastics resin material (16). This construction of the honeycomb panel (14) is lightweight and has high stiffness and rigidity suitable for stiffening and supporting the insulating material into a rigid panel. The layer of intumescent material (12) supported on the panel expands when exposed to high temperatures to form a thick fire insulating barrier panel. Because the panels are self-supporting, and therefore support structures, installation costs are much lower than for prior art fire insulation systems.

Owner:ASHMERE HLDG

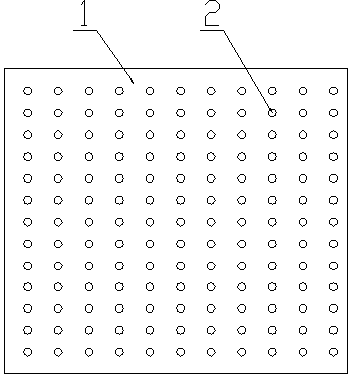

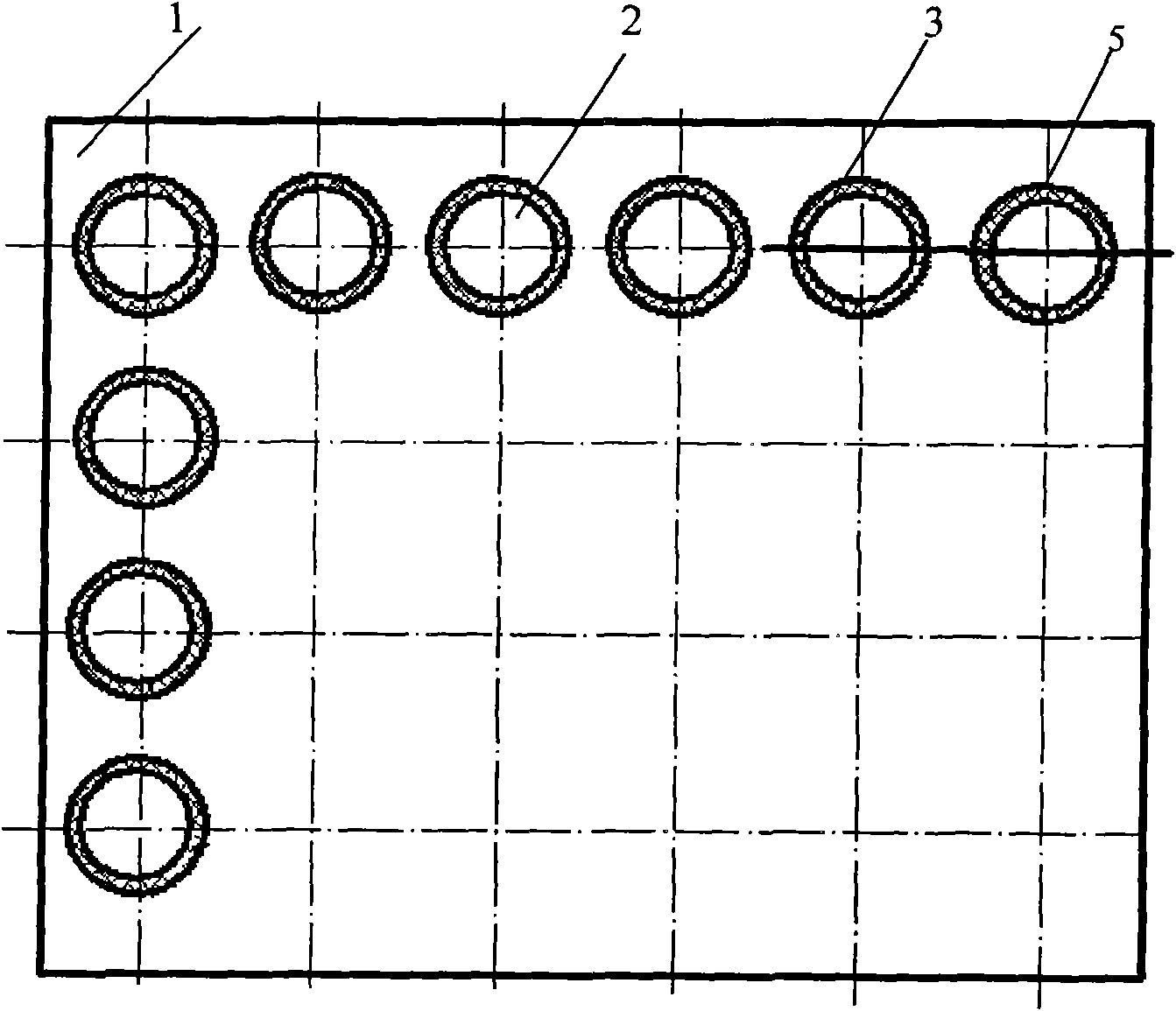

Porous glass

InactiveCN104344202AImprove breathabilityImprove sound absorptionSheets/panelsFlat glassOptoelectronics

The invention relates to porous glass which comprises a glass body (1), wherein a plurality of air holes (2) are formed in the glass body (1), are distributed in a rectangular array manner, penetrate through the whole glass body (1) in the thickness direction and are round, square or hexagonal. According to the porous glass, the plurality of air holes are formed in the plate glass of the porous glass in the rectangular array manner, so that the porous glass has good air permeability and sound absorption performance.

Owner:张玉芬

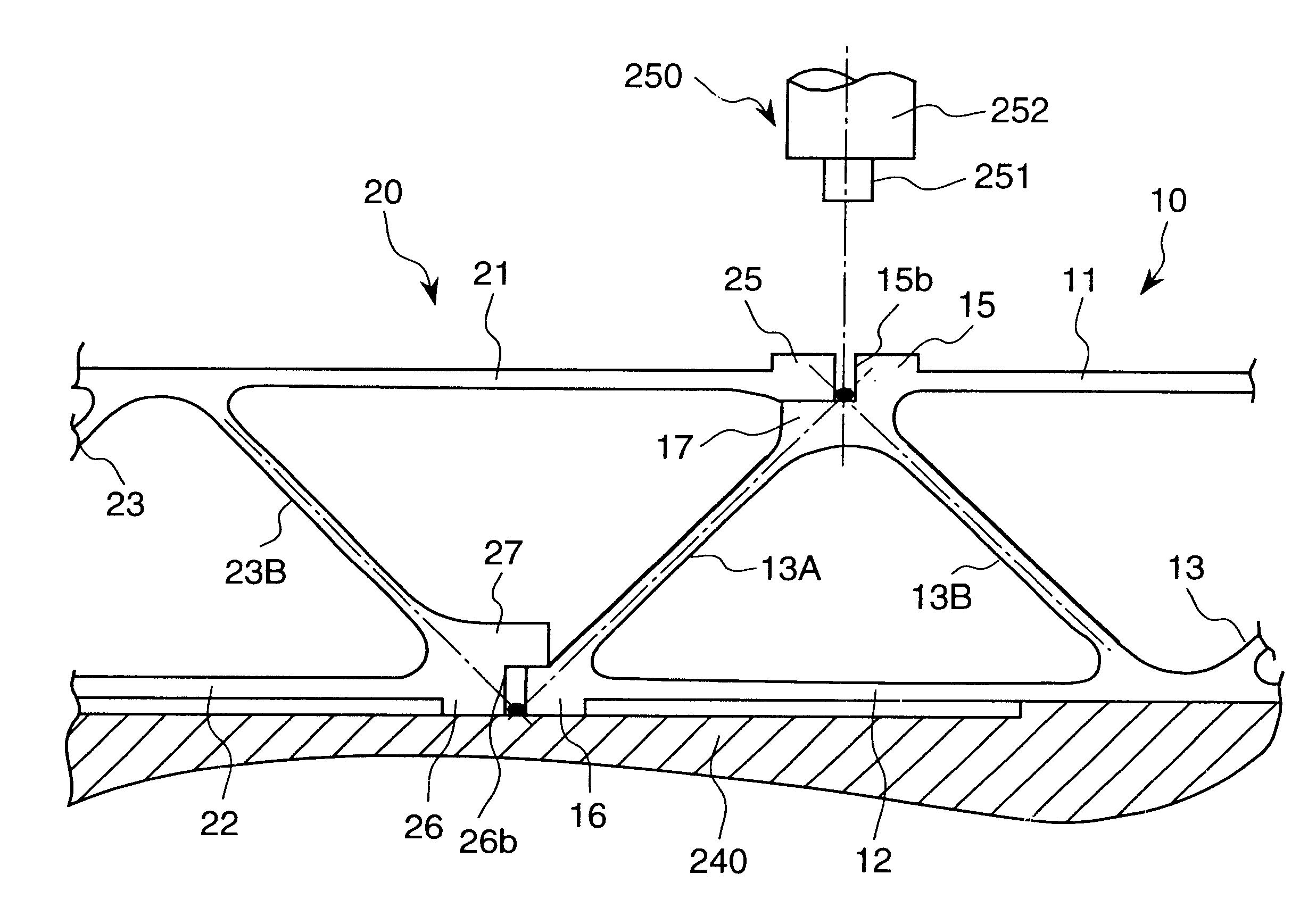

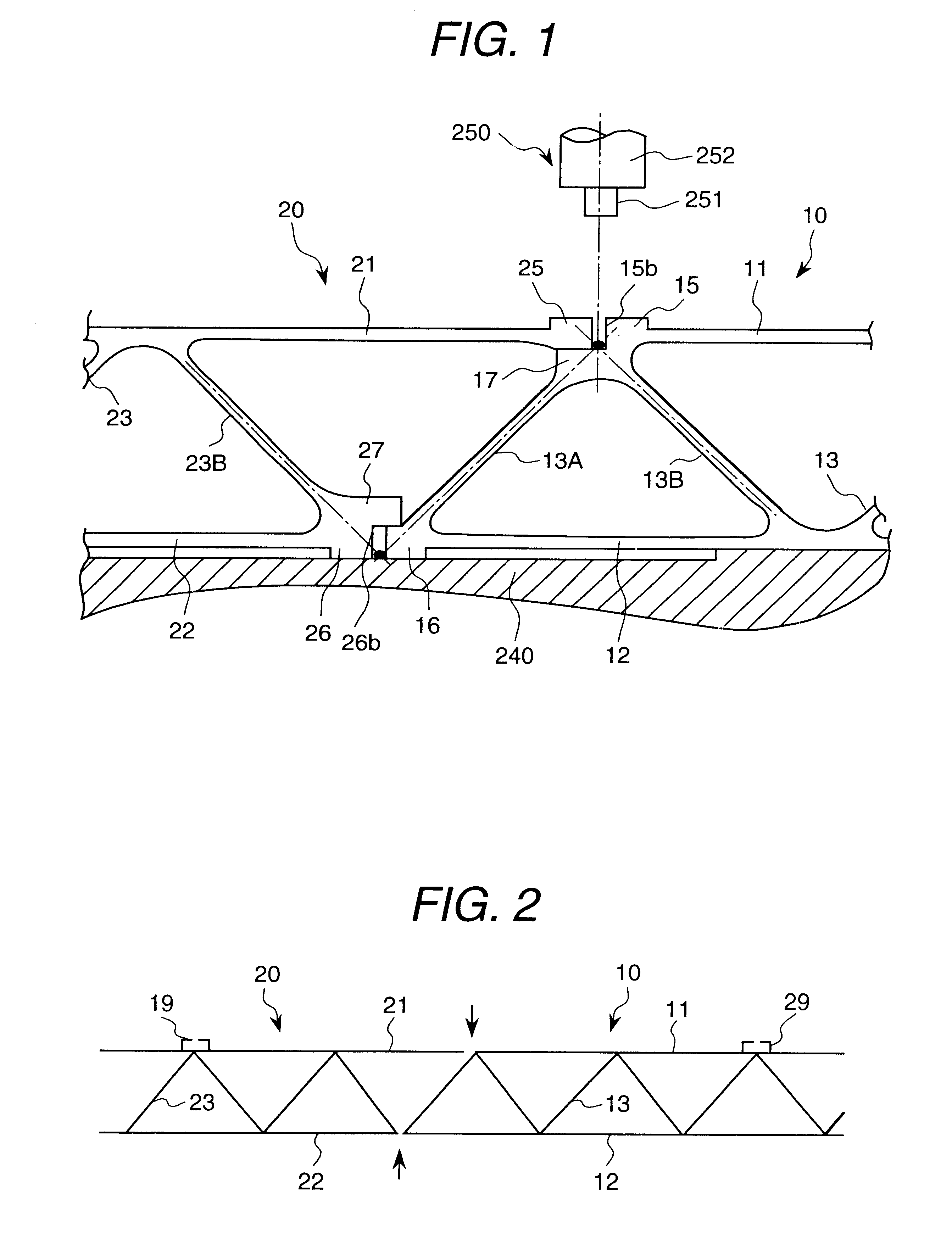

Structure body and a manufacturing method of a structure body

InactiveUS6413610B1Light structureImprove rigidityLayered productsSheets/panelsEngineeringSurface plate

Owner:HITACHI LTD

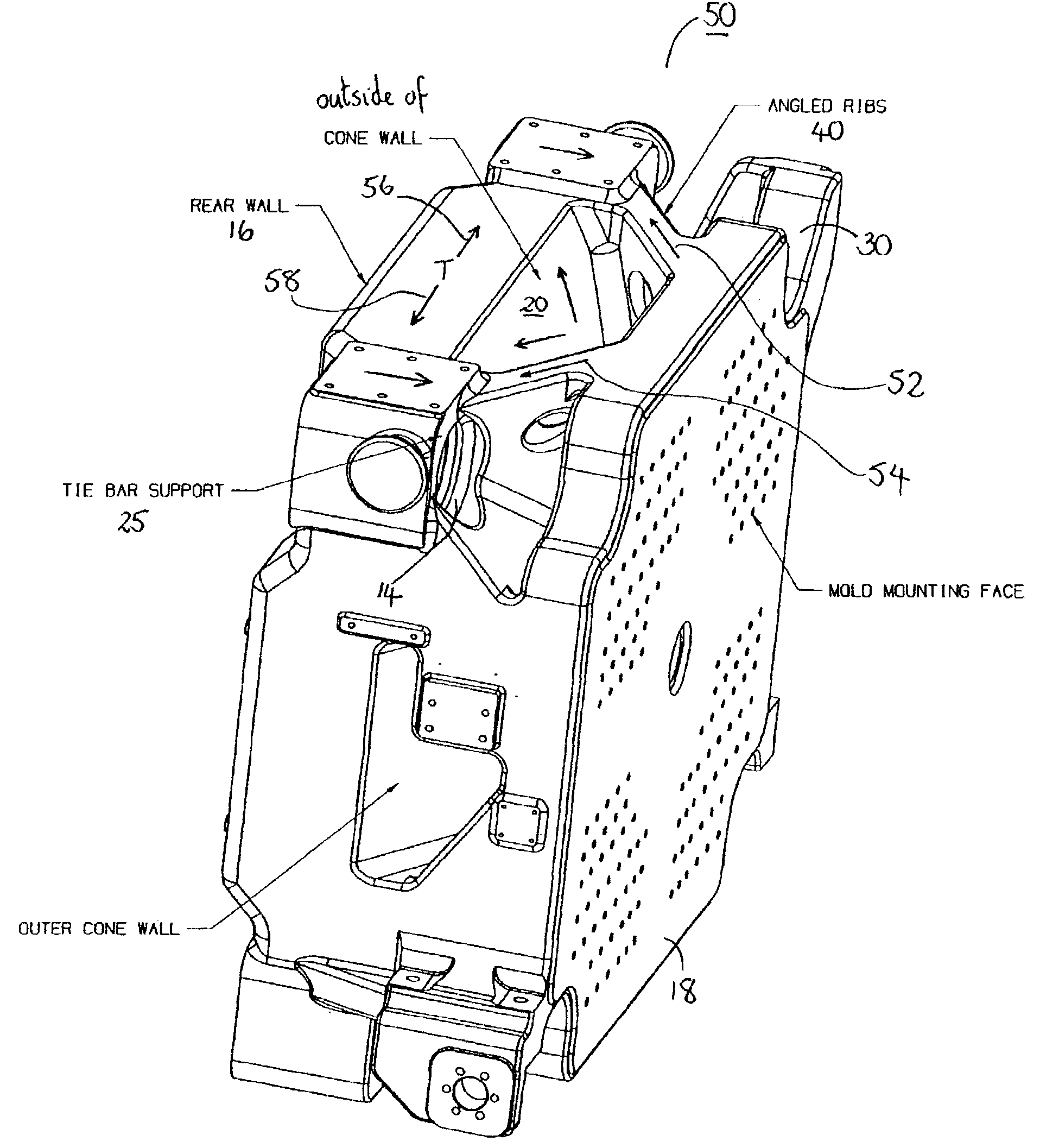

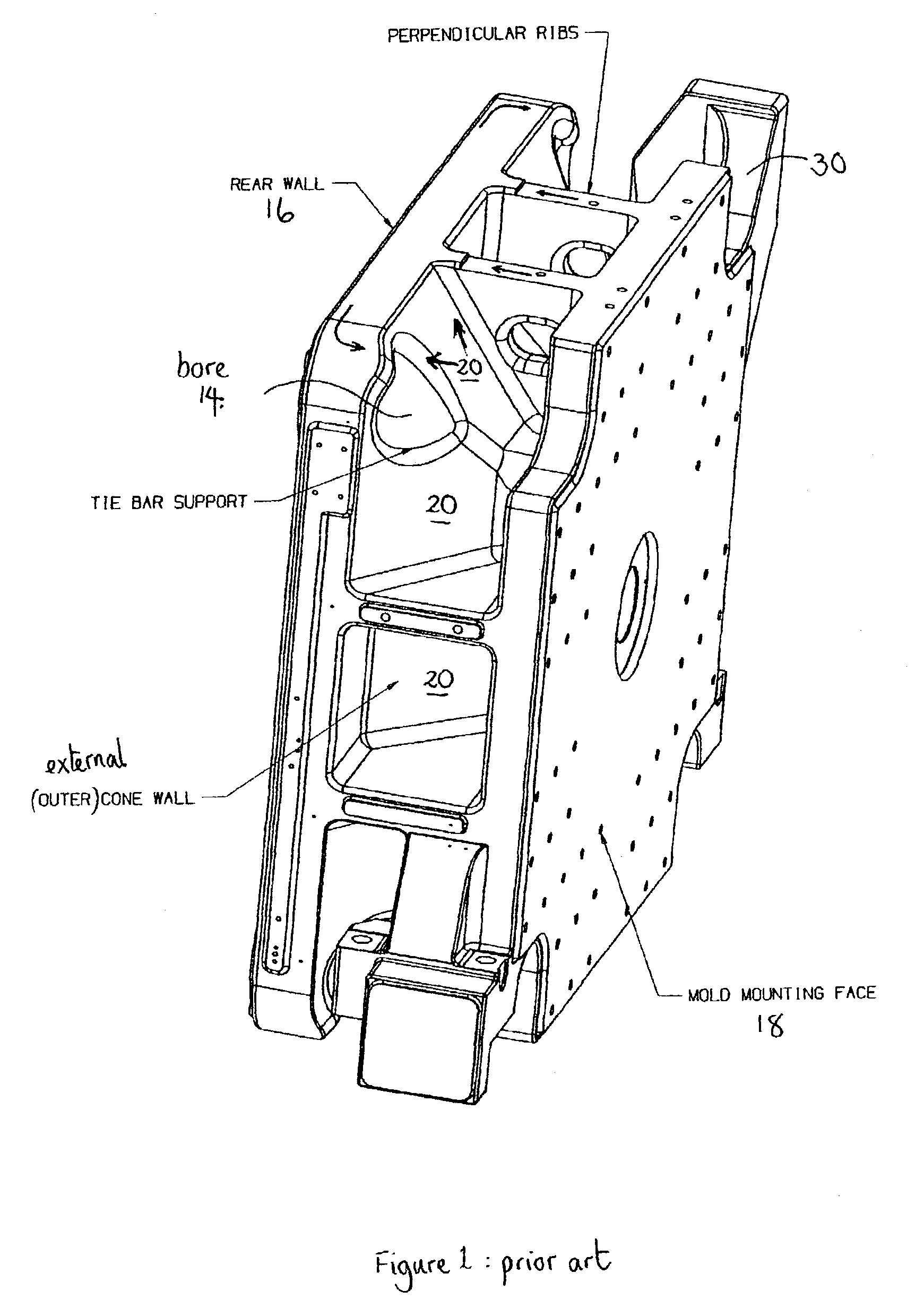

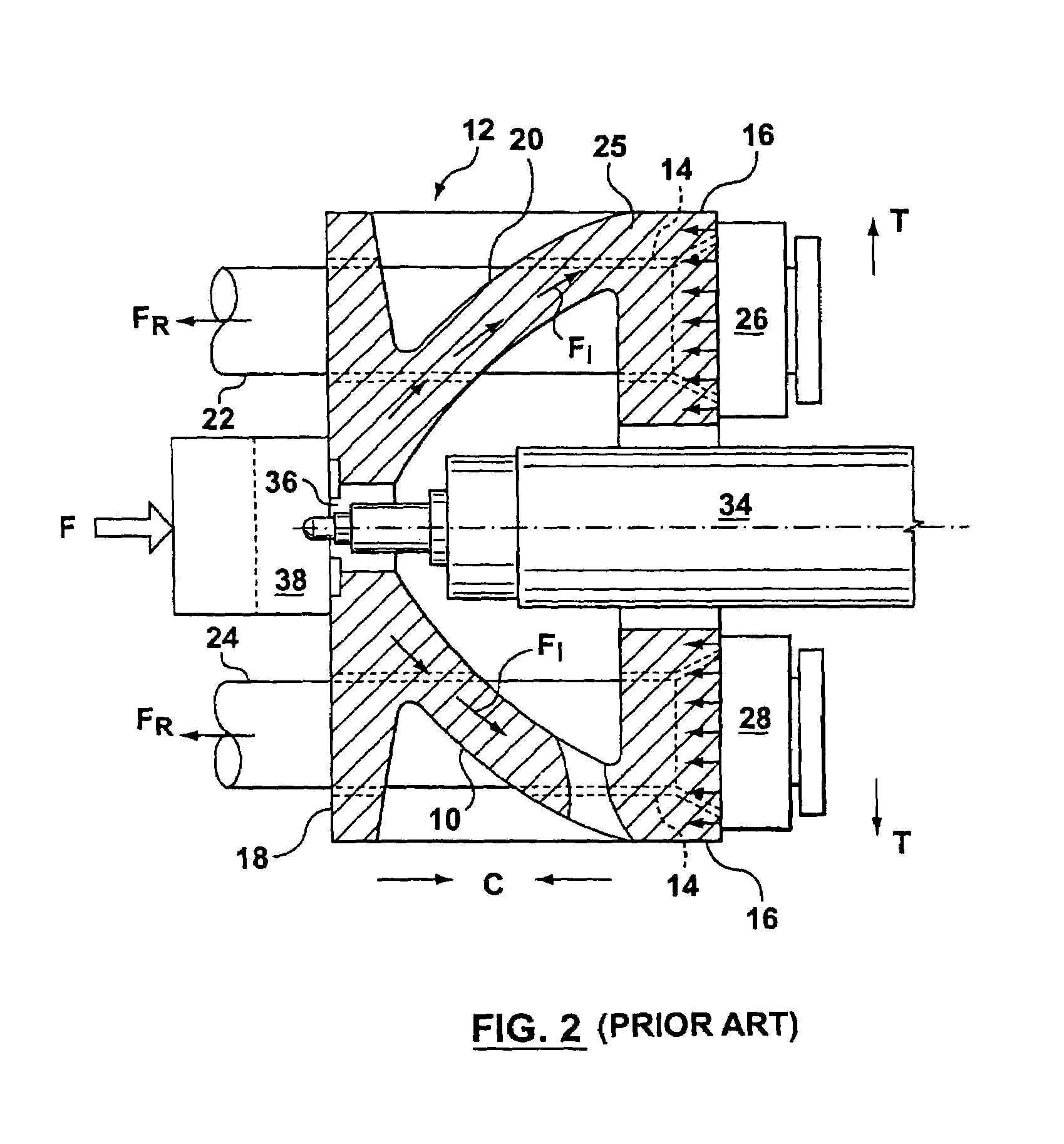

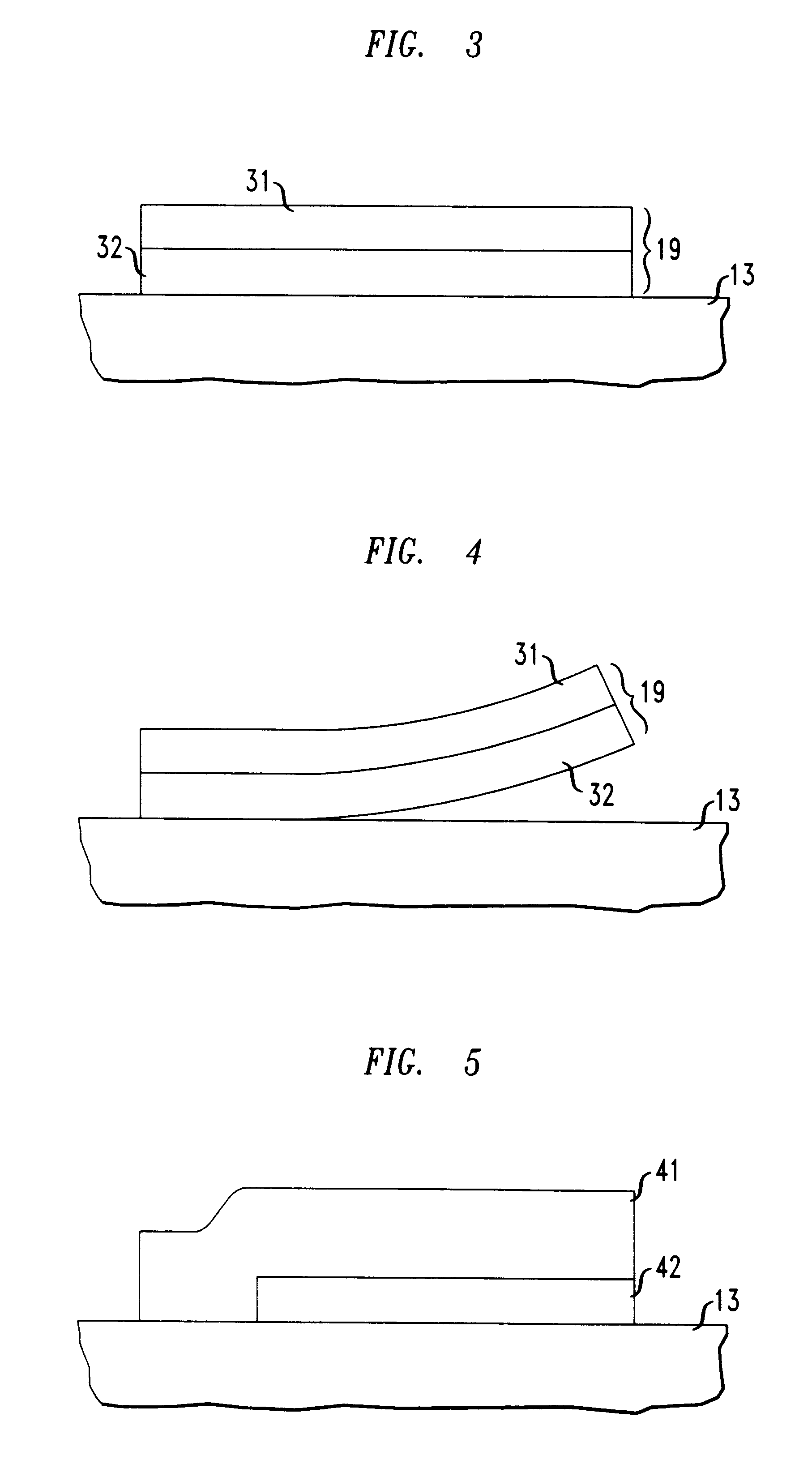

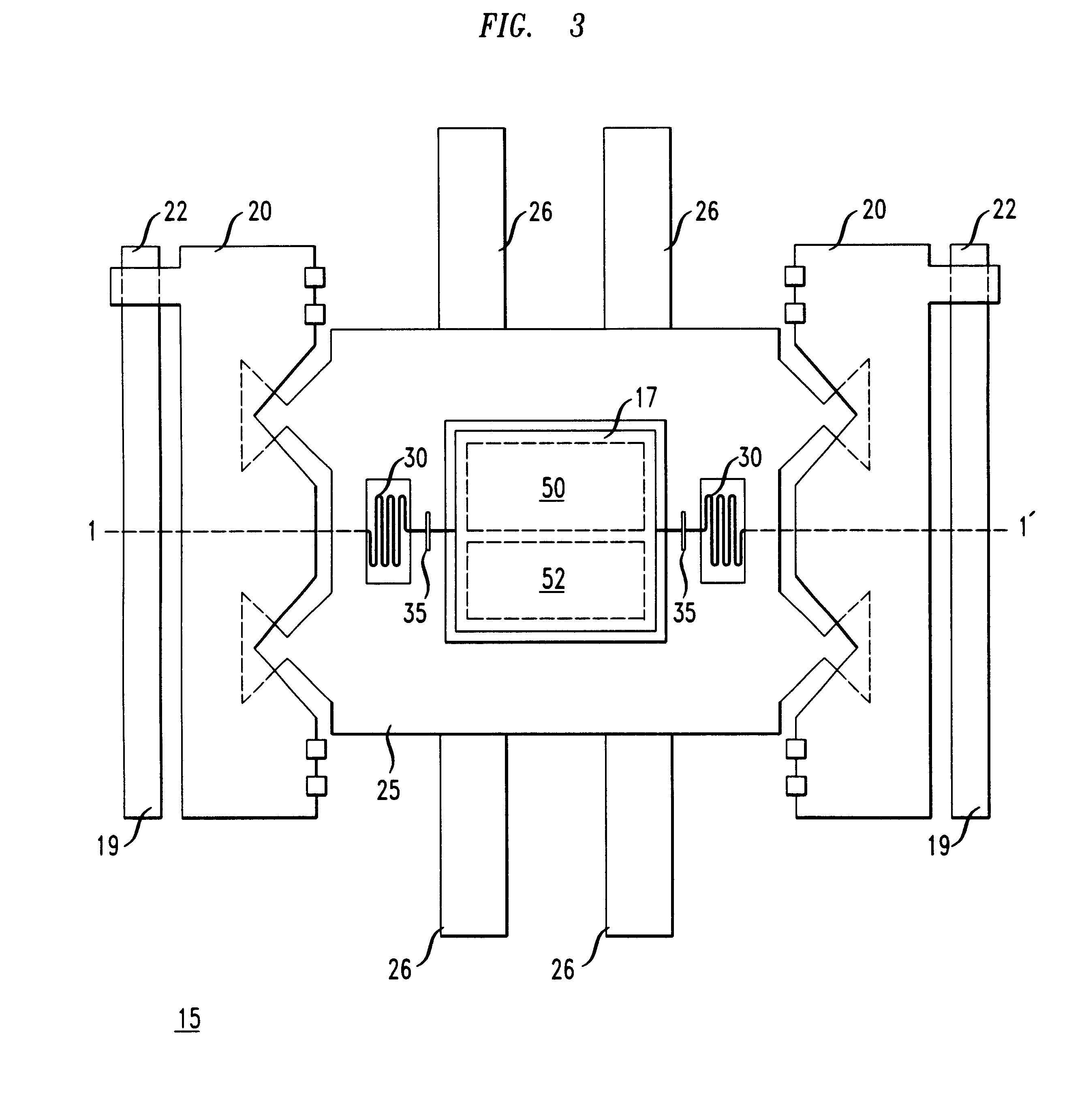

Platen

ActiveUS7080978B2Efficient couplingMaintenance of the flatness of the arrangementWelding/cutting auxillary devicesLaminationMolding machineCoupling

A platen (50) for a molding machine includes an intermediate support structure (20) between two planar walls (16, 18) having ribs (40) arranged at a non-normal angle β to a first wall (18). The ribs (40) couple forces from the first wall (18) to the second wall (16) in such a way that bending of the second wall (16) is resisted. This adds to the rigidity of the second wall (16) and hence the platen (50), adding to flatness of the arrangement. Gussets (42) may be provided extending between the ribs (40) and the intermediate support structure (20). This has the effect of surrounding and supporting an injection bore (14) and further adding to the coupling of forces to the edge portions of the second wall (16) to resist forces acting to bend the wall.

Owner:HUSKY INJECTION MOLDING SYST LTD

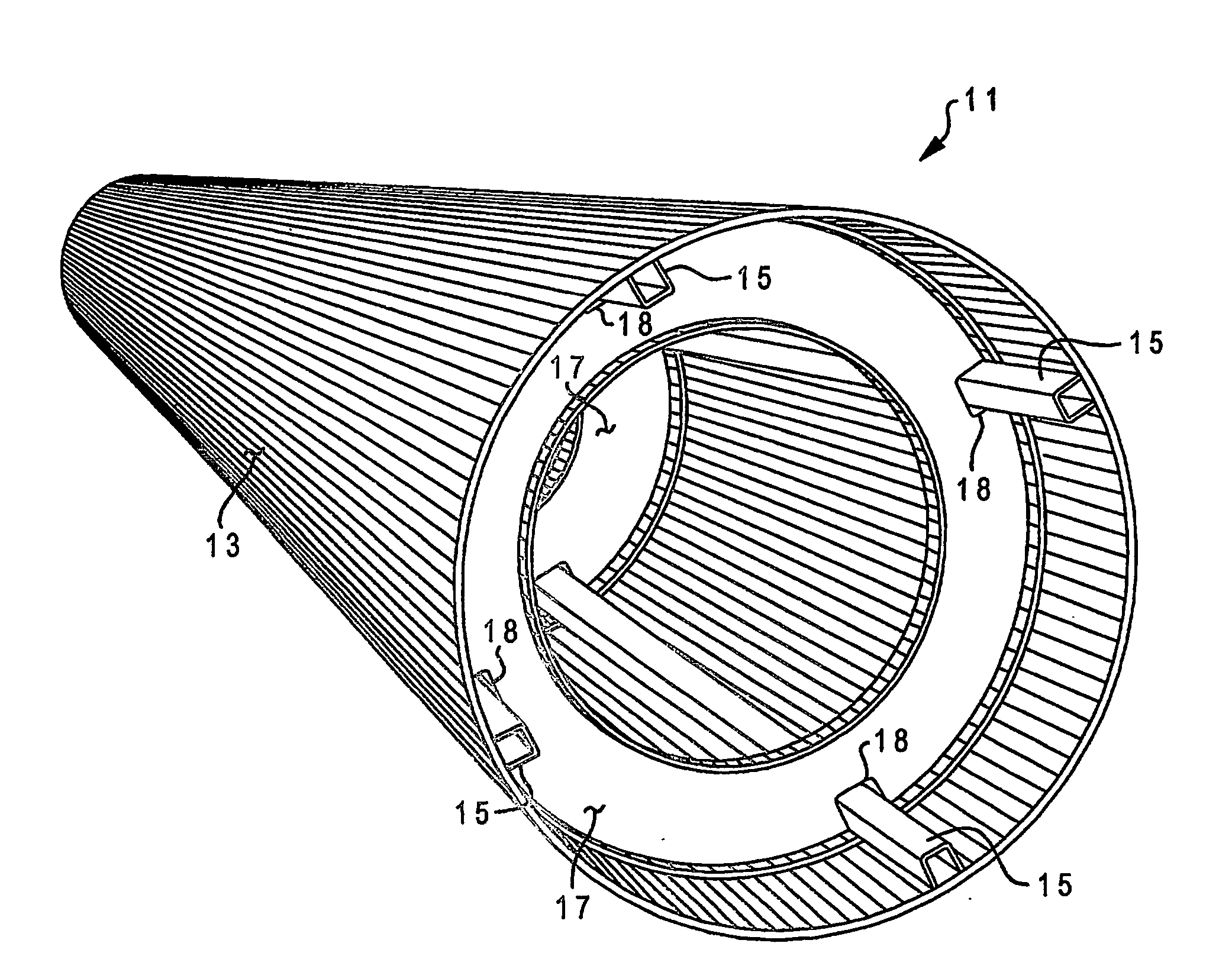

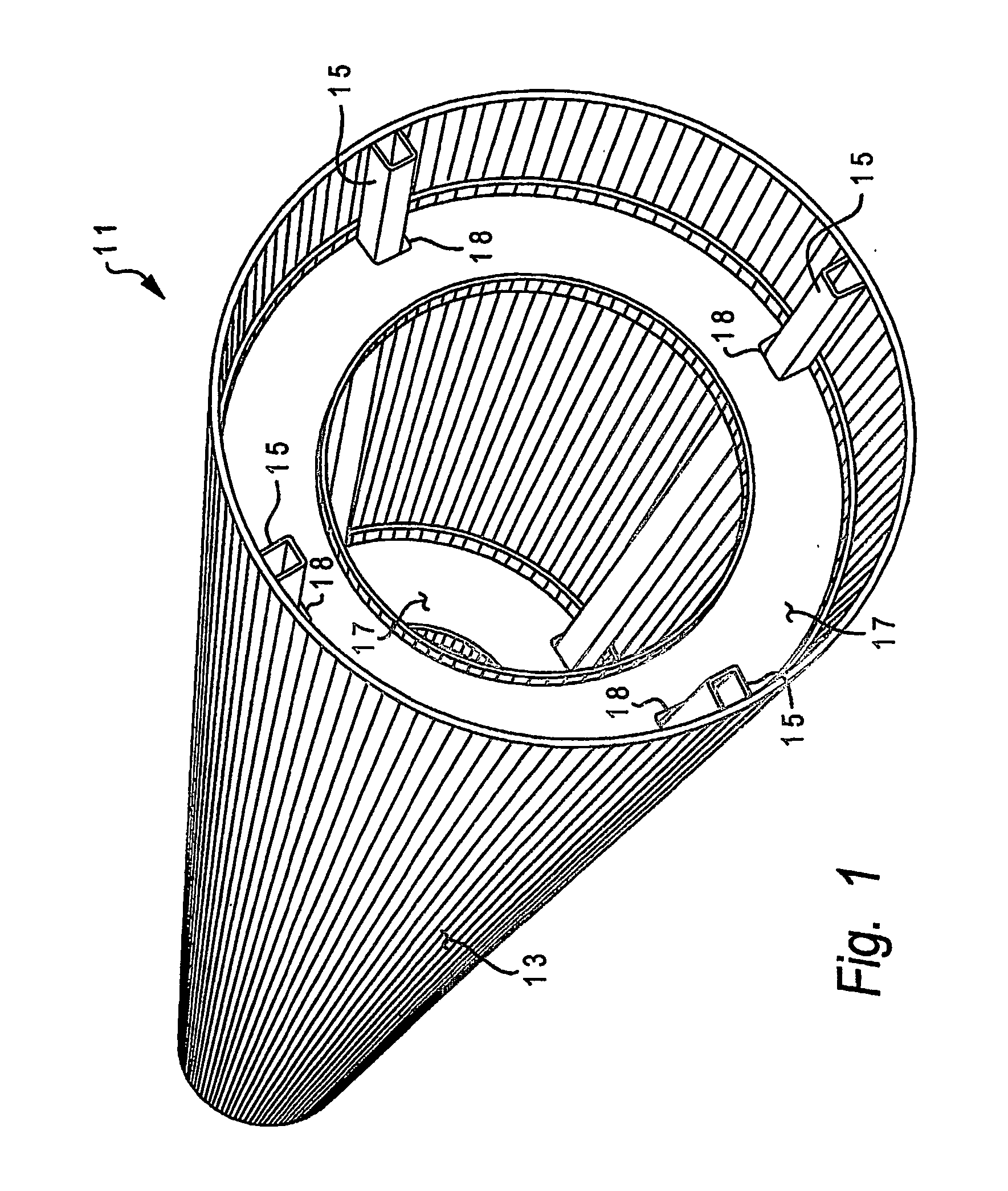

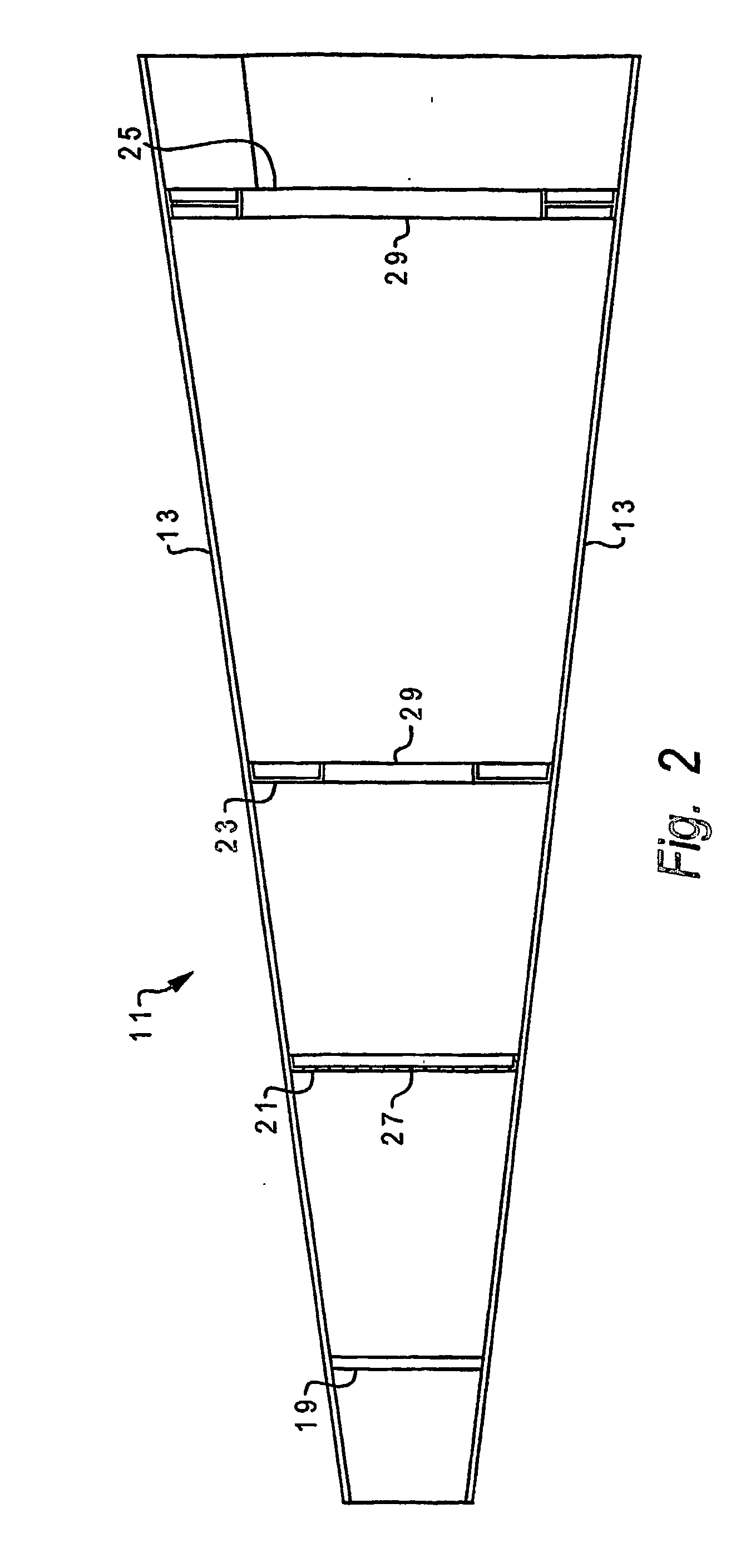

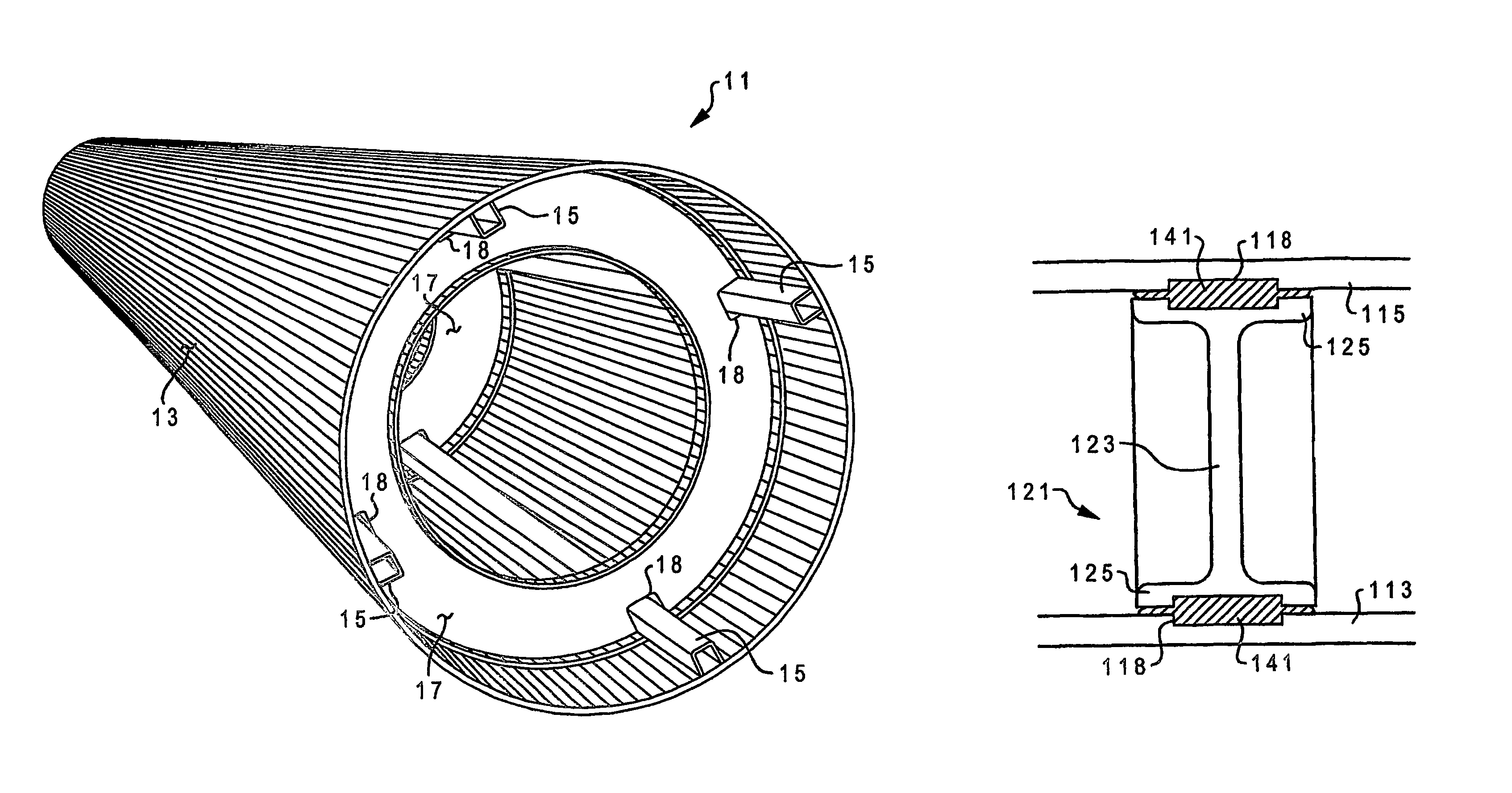

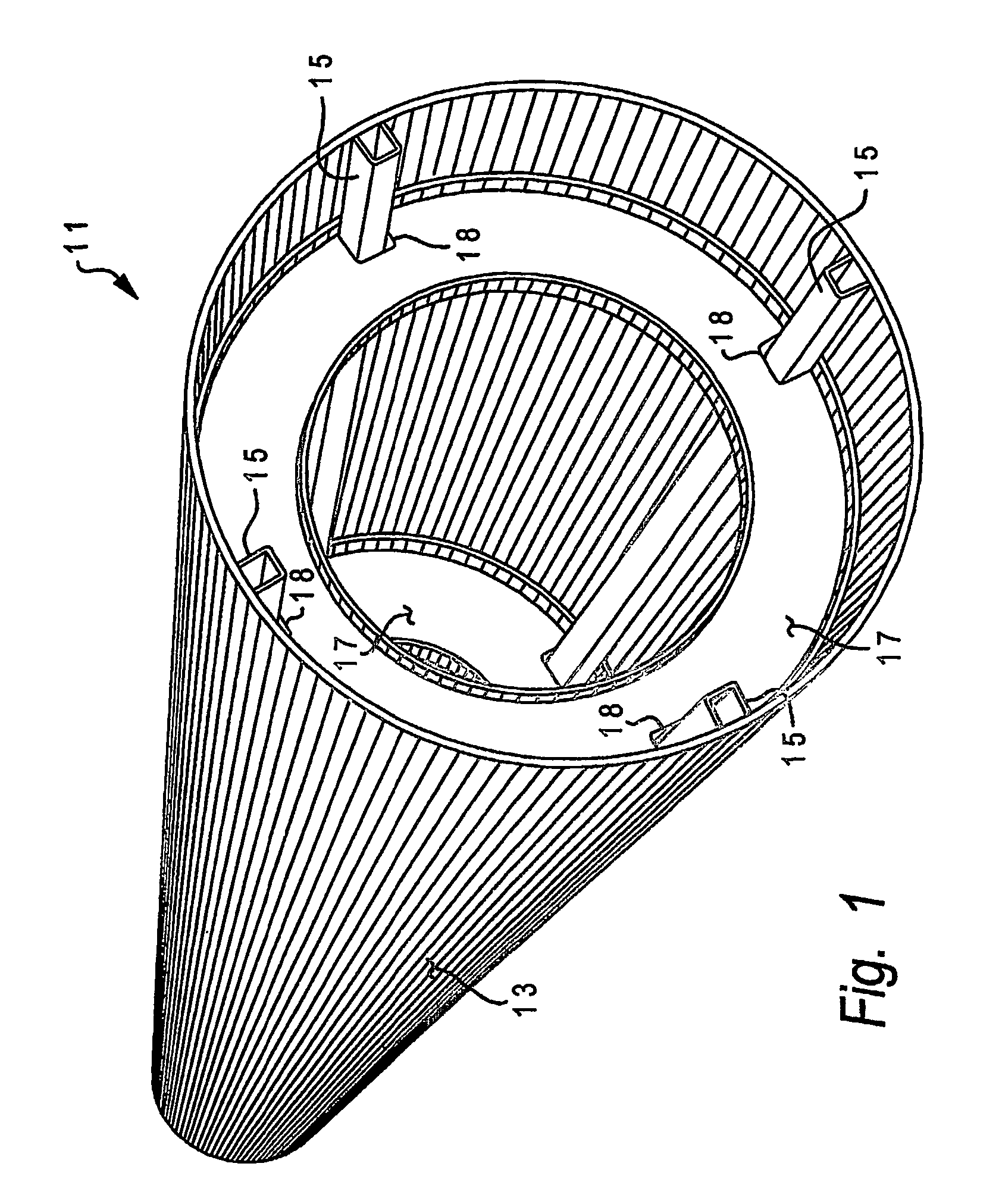

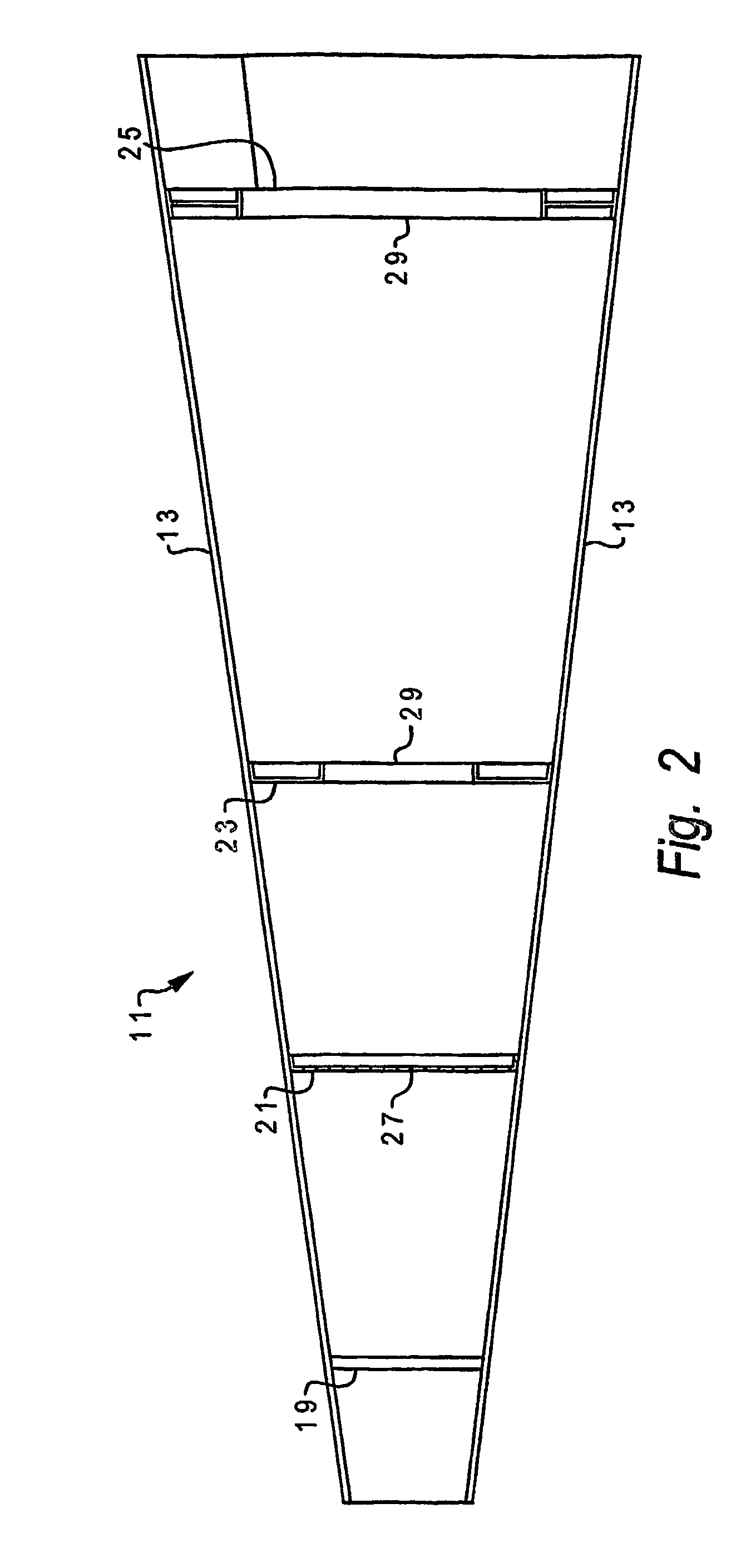

Contact stiffeners for structural skins

ActiveUS20070011970A1Reduce manufacturing costBulky assemblyAircraft stabilisationSpars/stringersAdhesiveFilling materials

An internal stiffening member of varying configurations in which the stiffening elements support the skin using a compression-only load path is dislcosed. In the preferred embodiment, the stiffening element has a peripheral edge that is adapted to be press fit into contact with the skin. The stiffening member may be held in place by various retention devices. Another configuration is a slip-in rib having a flange with a peripheral channel in which a filler material is disposed. The rib is inserted into an assembled structural box beam, and the filler material is used to fill any gaps between the slip-in rib and the interior surface of the structural box beam. The filler material is preferably an expandable material, such as an expandable foam-type material. However, in situations where a slip-in rib forms a primary structural rib, the filler material is preferably a structural adhesive or liquid shim material. A solid adhesive or filler would not crush under the clamping forces from fasteners or bolts at localized fitting attachments.

Owner:BELL HELICOPTER TEXTRON INC

Contact stiffeners for structural skins

ActiveUS8156711B2Reduce manufacturing costBulky assemblyAircraft stabilisationSpars/stringersAdhesiveFilling materials

An internal stiffening member of varying configurations in which the stiffening elements support the skin using a compression-only load path is disclosed. In the preferred embodiment, the stiffening element has a peripheral edge that is adapted to be press fit into contact with the skin. The stiffening member may be held in place by various retention devices. Another configuration is a slip-in rib having a flange with a peripheral channel in which a filler material is disposed. The rib is inserted into an assembled structural box beam, and the filler material is used to fill any gaps between the slip-in rib and the interior surface of the structural box beam. The filler material is preferably an expandable material, such as an expandable foam-type material. However, in situations where a slip-in rib forms a primary structural rib, the filler material is preferably a structural adhesive or liquid shim material. A solid adhesive or filler would not crush under the clamping forces from fasteners or bolts at localized fitting attachments.

Owner:BELL HELICOPTER TEXTRON INC

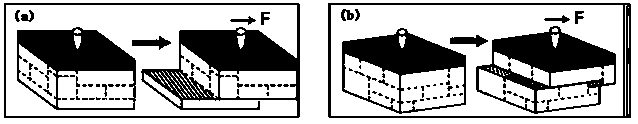

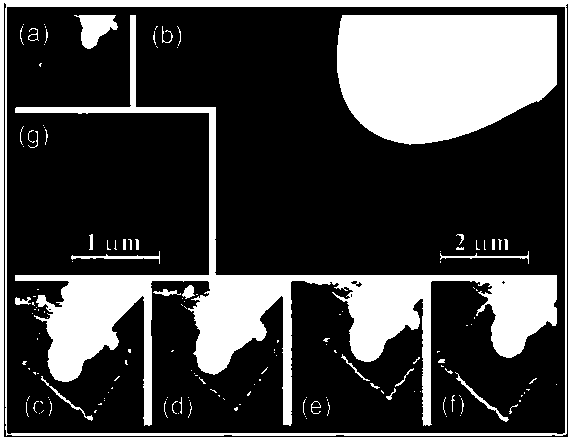

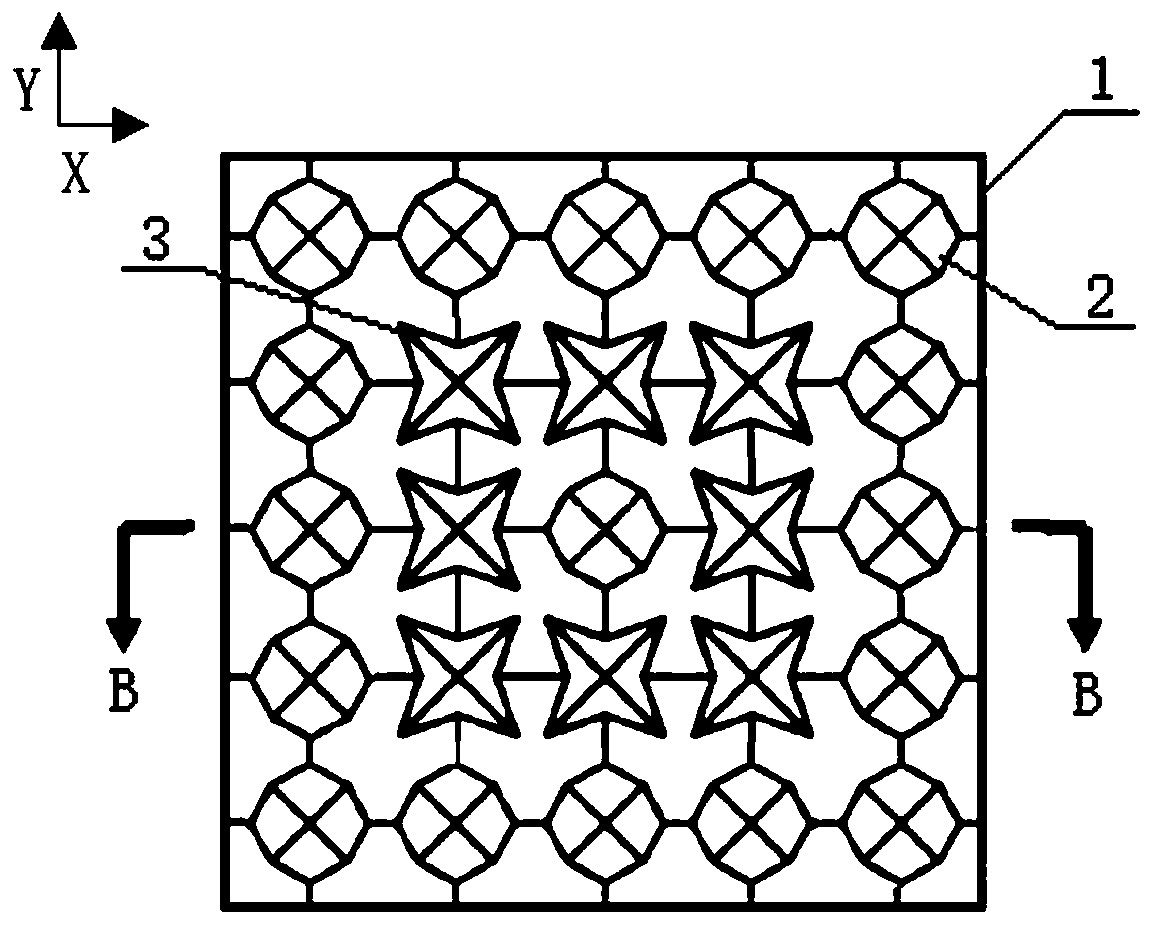

Super-lubricity basic structure, multi-stage super-lubricity structure, component with super-lubricity basic structure or with multi-stage super-lubricity structure and forming method of super-lubricity basic structure

ActiveCN103438348ASuper smooth reachSheets/panelsChemical vapor deposition coatingEngineeringLubricity

The invention provides a super-lubricity basic structure, a multi-stage super-lubricity structure, a component with the super-lubricity basic structure or with the multi-stage super-lubricity structure and a forming method of the super-lubricity basic structure, and belongs to the field of structural super lubricity. The super-lubricity basic structure comprises a substrate and a plurality of island structures on the substrate, wherein each island structure is provided with at least one super-lubricity shearing face, and the upper contact face and the lower contact face of the super-lubricity shearing face are in an incommensurate contact state. The invention further discloses the multi-stage super-lubricity structure which comprises multiple super-lubricity basic structures, wherein the multiple super-lubricity basic structures form the multi-stage super-lubricity structure in a side-by-side extension mode, an independent stacking mode, a sharing-type stacking mode or other combination modes. The invention further discloses the forming method of the super-lubricity basic structure. According to the super-lubricity basic structure, the multi-stage super-lubricity structure, the component and the forming method of the super-lubricity basic structure, the limit that the super-lubricity phenomenon only exists in a microcosmic scope is broken through, and large-scale and large-slippage-stroke super-lubricity can be achieved.

Owner:SHENZHEN TSIMEC CO LTD

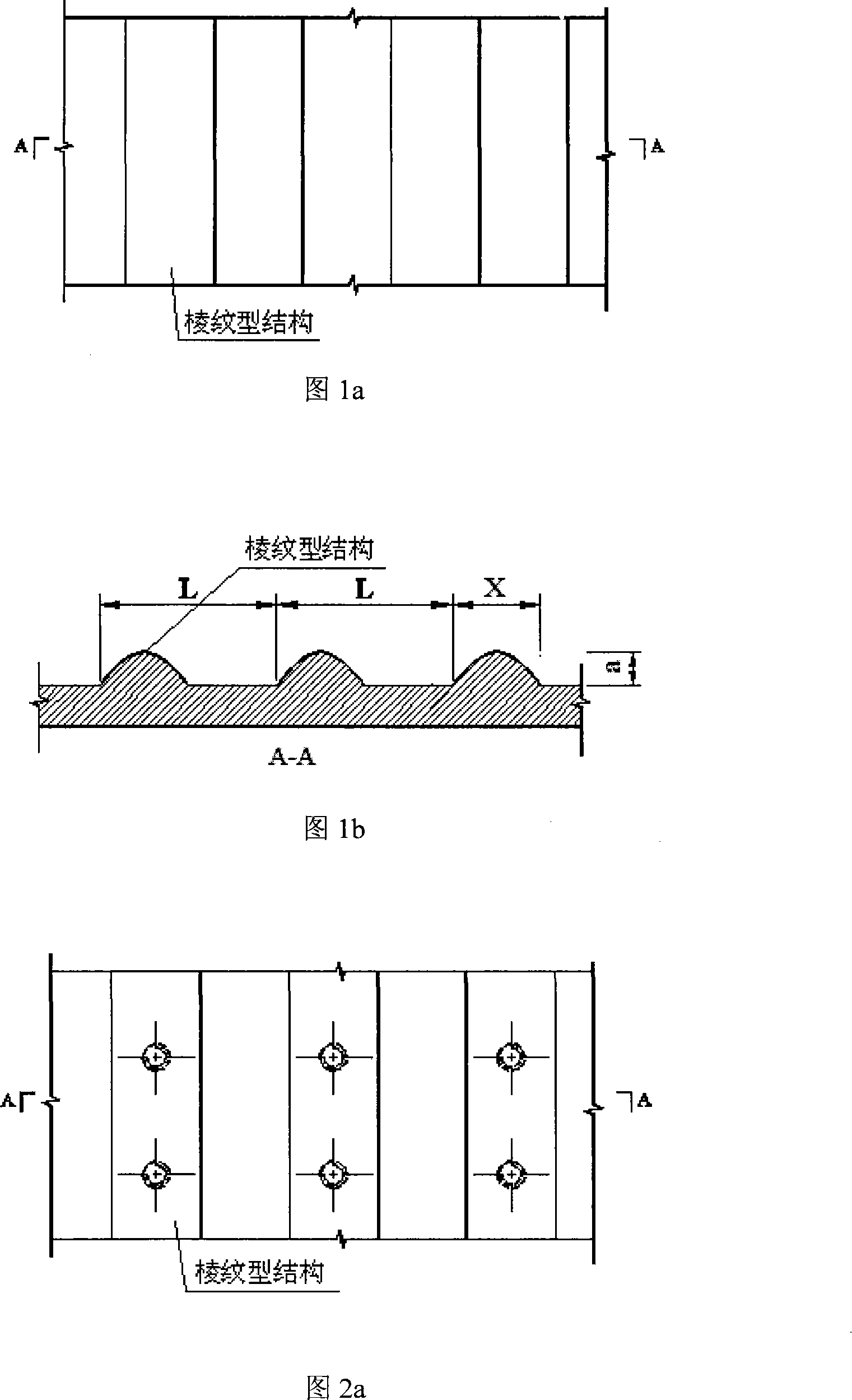

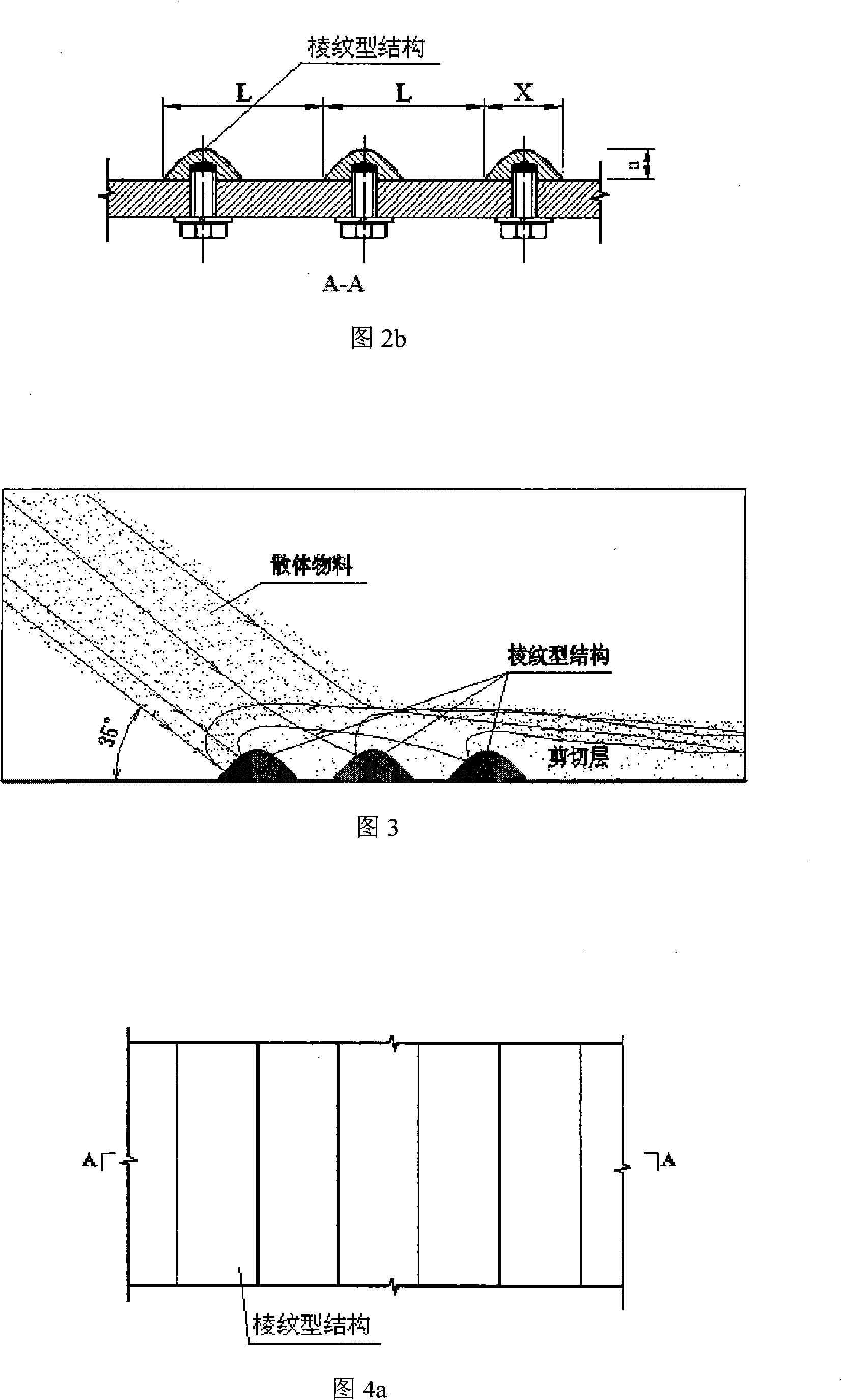

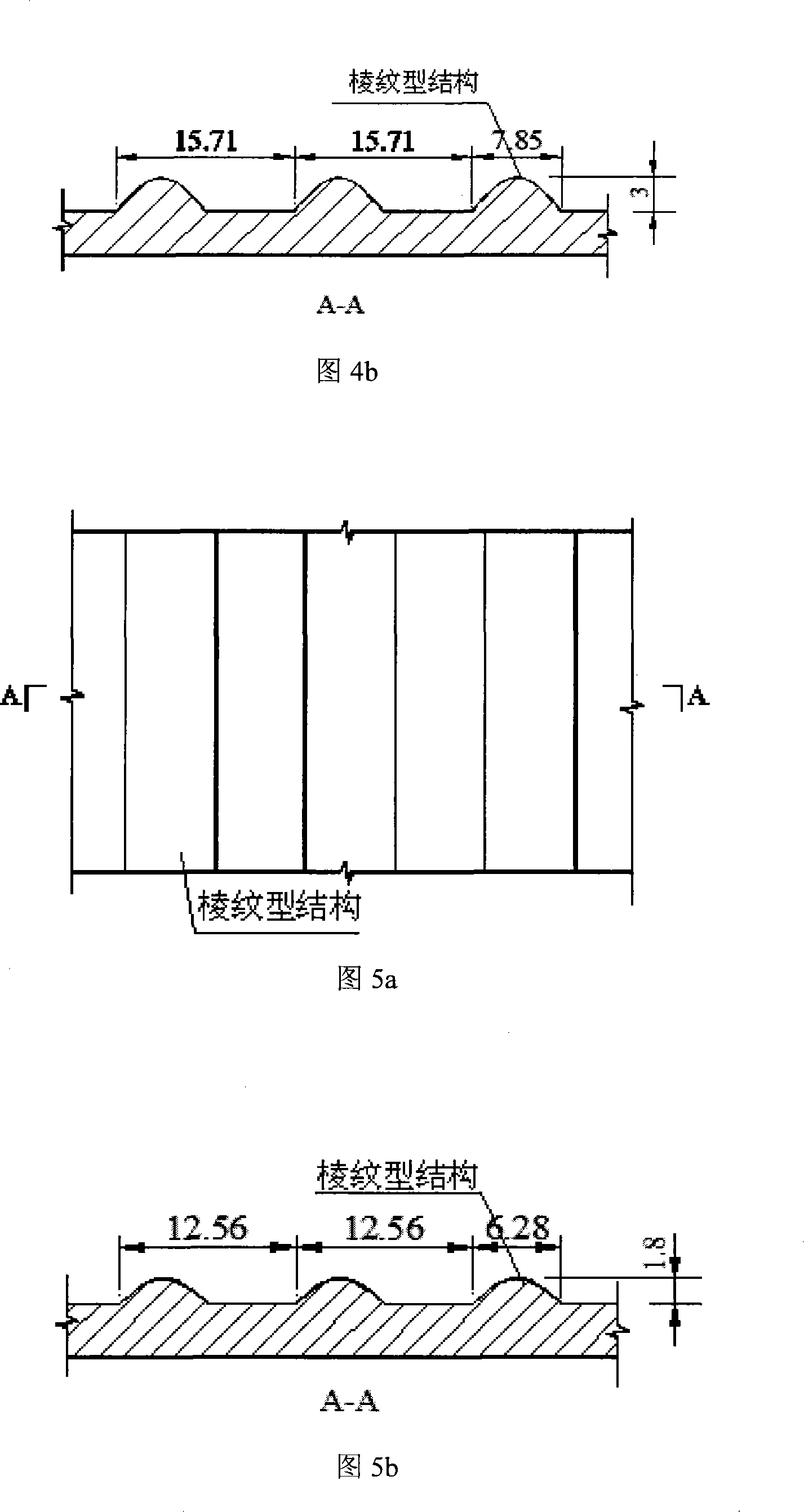

Rib type bionic abrasion-proof structure surface

The invention relates to a surface of bionic wear-resistant structure, in particular to a surface of ribbing bionic wear-resistant geometry structure; the surface of bionic wear-resistant structure is based on the squama surface of the soil and cave animal pangolin and has geometry structural characteristics of soil resistant grinding medium. The surface of bionic wear-resistant structure aims at solving the abrasion problem of the prior particulate material contact parts. The surface of bionic wear-resistant structure is characterized in that: the structure of original equipment or element and the surface of the contact material is changed; and the surface is newly provided with a series of ribbing structure which has a certain geometric parameters and space. The shape of the bionic wear-resistant structure is y=asin(bx+c), wherein a is amplitude, b is frequency and c is initial phase, and 0 F16S 5 / 00 F16S 1 / 00 A01B 15 / 00 A01B 33 / 10 A01C 5 / 00 A01D 13 / 00 B65G 15 / 30 B67C 11 / 00 B65D 90 / 02 E02F 9 / 00 F16L 57 / 06 4 3 1 2008 / 1 / 30 101225919 2008 / 7 / 23 000000000 Jilin University 130012 Tong Jin Rong Baojun Ma Yunhai Chen Donghui Sun Jiyu Zhou Jiang Yan Jiulin Chang Zhiyong Zhang Jinbo zhushi lin 22201 The Patent Agency of Jilin University No.83 Liberation Main Street, the City of Changchun, Jilin Province 130023

Owner:JILIN UNIV

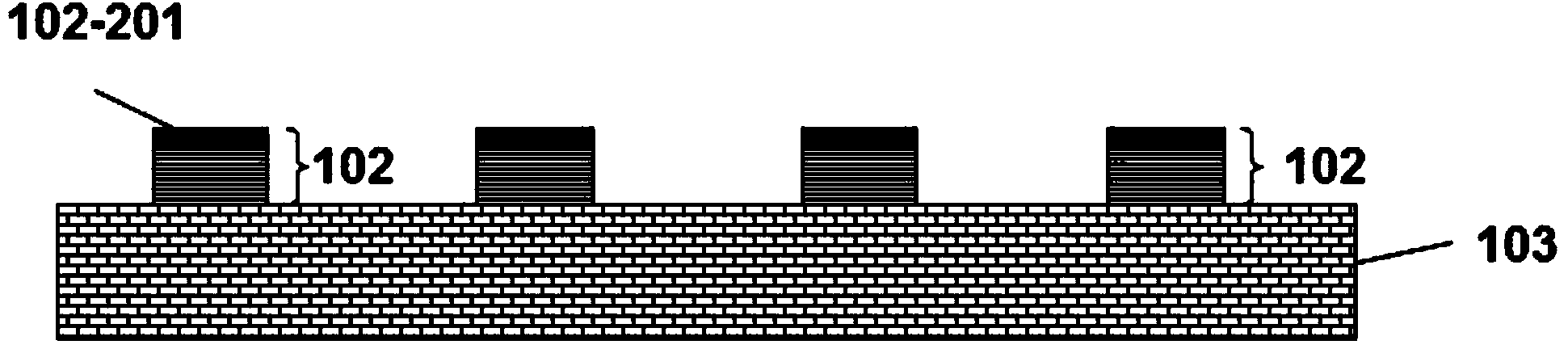

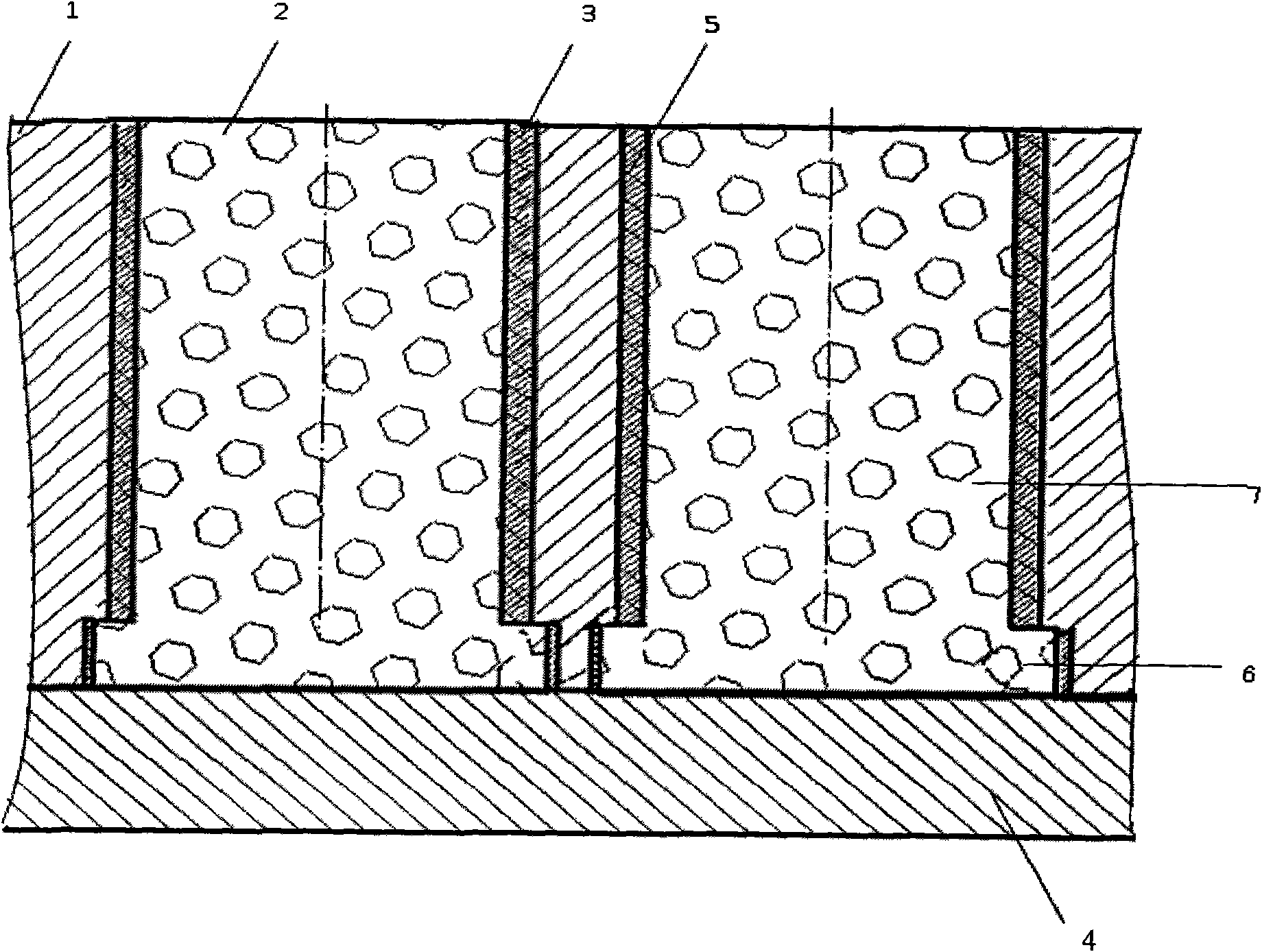

Abrasion resistant material featuring ceramic embedded in metal and preparation method thereof

InactiveCN101598261ANot easy to fall offImprove reliabilityShrinkage connectionsSheets/panelsAdhesiveMetallurgy

The invention discloses an abrasion resistant material featuring ceramic embedded in metal and a preparation method thereof. The abrasion resistant material comprises an abrasion resistant ceramic block, a base plate and a substrate with a through hole; the abrasion resistant ceramic block is embedded in the through hole of the substrate, the substrate is mounted on the base plate, the abrasion resistant ceramic block comprises a working section and a positioning section with identical cross section shape and the cross section area of the positioning section is larger than that of the working section, the abrasion resistant ceramic block is connected with the substrate by the positioning section, the through hole of the substrate is matched with the working section and the positioning section of the abrasion resistant ceramic block, or the through hole of the substrate is only matched with the working section of the abrasion resistant ceramic block. The material adopts the abrasion resistant ceramic block designed with a variable cross section structure, overcomes the defect of easy peeling off as the original metal ceramic abrasion composite material is only fixed by adhesive; at the same time, the abrasion resistant ceramic block is embedded in the metal through hole by the hot mounting method, thus overcoming easy ageing of the adhesive and easy peeling off of the abrasion resistant ceramic block caused by using adhesive.

Owner:SHANDONG UNIV

Steel-aluminum composite board and preparation method thereof

InactiveCN102734625AReduce in quantityHigh binding densitySheets/panelsMetal rolling arrangementsCompound aPerformance index

The invention relates to a steel-aluminum composite board which is formed by compounding a steel belt and an aluminum alloy belt, wherein the steel belt comprises the following components in percentage by weight: less than or equal to 0.012% of C, less than or equal to 0.025% of Si, 0.10-0.30% of Mn, less than or equal to 0.018% of P and less than or equal to 0.010% of S; and the aluminum alloy belt comprises the following components in percentage by weight: 0.75-0.85% of Si, 0.36-0.45% of Fe, less than 0.05% of Cu and less than or equal to 0.03% of Mn. The preparation method comprises the following steps of: a, pretreatment; b, compounding rolling; and c, recrystallizing and annealing. Through the invention, the prepared steel-aluminum composite board has excellent mechanical performance index, and the bonding strength between the steel belt and the aluminum alloy is guaranteed after the brazing of a cooler fin.

Owner:JIANGSU LONGYUAN METAL TECH

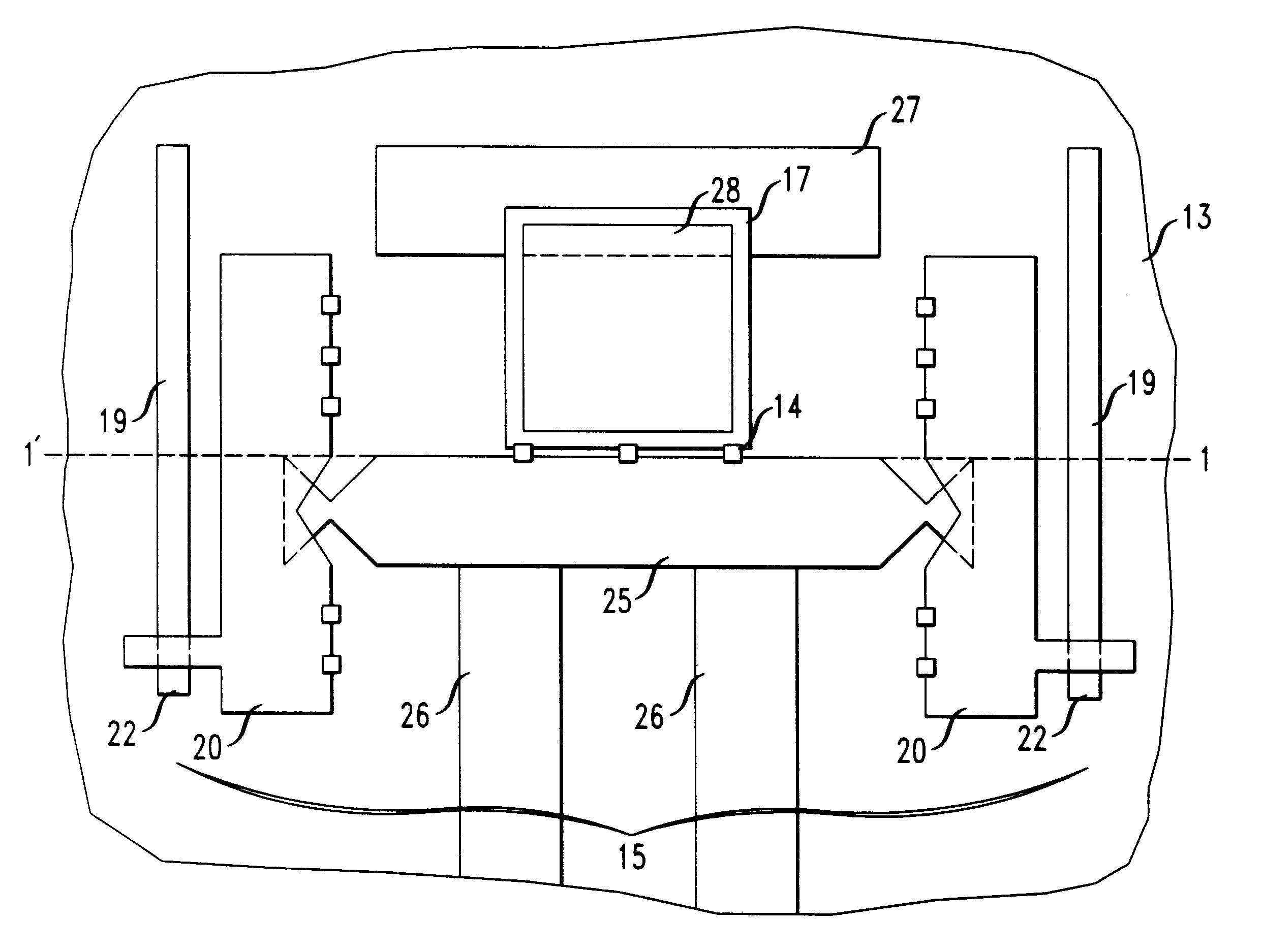

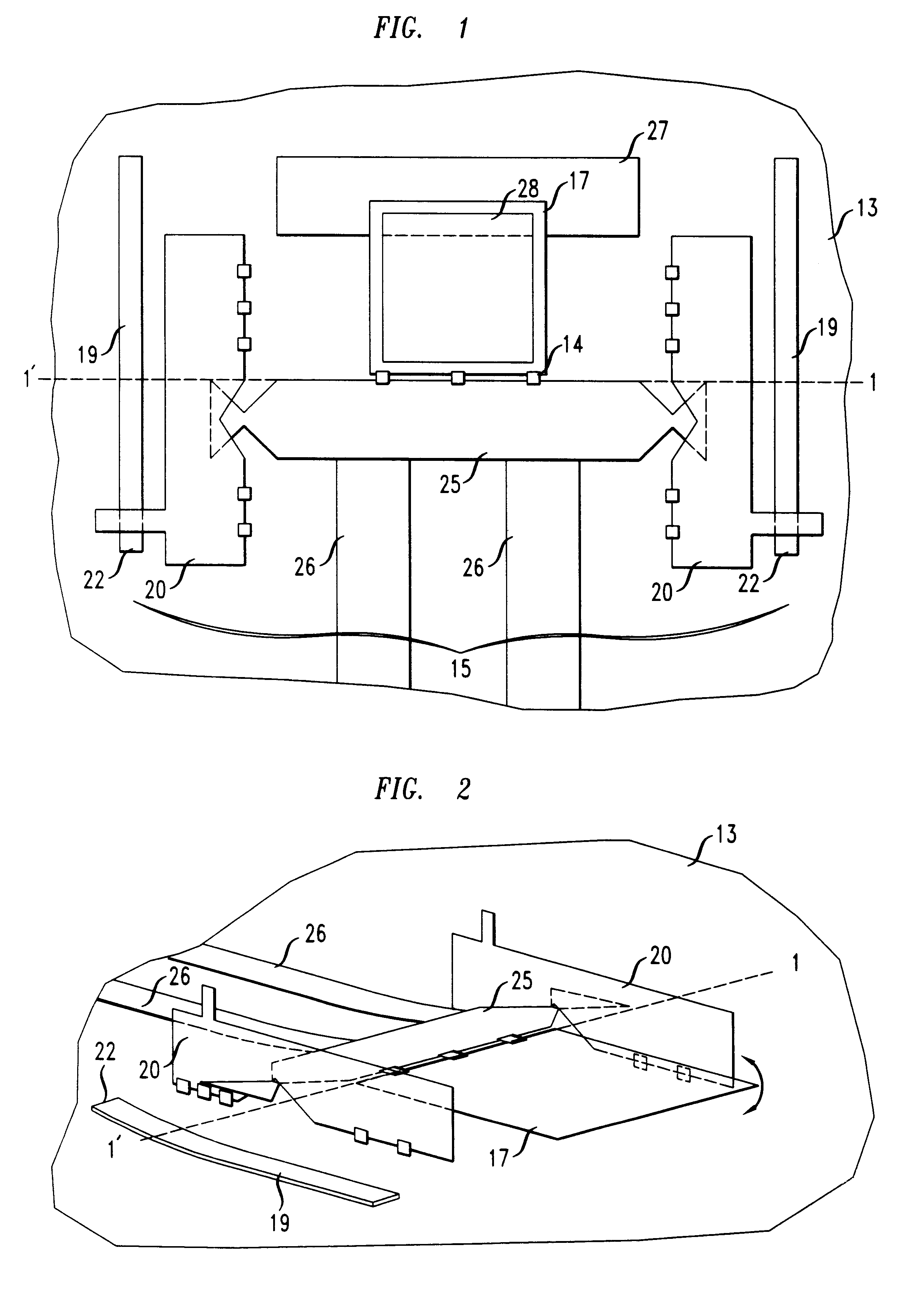

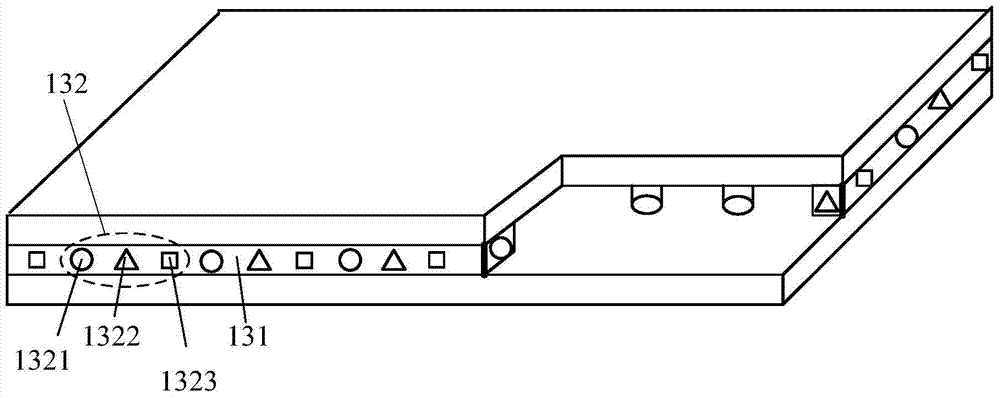

Method and equipment for hot rolled plate colored forming continuous production

ActiveCN101249606AIncrease productivityReduce wastePretreated surfacesSheets/panelsSheet steelSteel belt

The invention provides a method for the continuous production of the color-coated forming of hot-rolled plates and a device thereof. The method is characterized in that all processes are continuously completed on line. The method comprises the following steps: the head and tail of a hot-rolled steel band are welded together; the steel band enters a pickling tank to remove the oxide of the steel band surface and then the steel band enters a hot air drying segment to remove the moisture of the steel band surface; the steel band enters a roll coater 11 to coat the band surface, and then transmitted into a paint curing furnace 12 to cure and dry the band after coating, and the steel band with a certain temperature is blown by cold wind 14 to reduce the temperature of the steel band; the steel band enters the roller forming stage, so the steel band is transmitted into the roller 19 to carry out the roller forming; the steel band is allowed to has a certain waveform; the waveform steel band after the roller forming is transmitted into a flying shear 22 for definite distance cutting, in order to cut the steel plate according to the requirement; finally, the steel band is transmitted into a dual stacking to perform the stacking according to the height. The method improves the efficiency of production and saves the cost.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

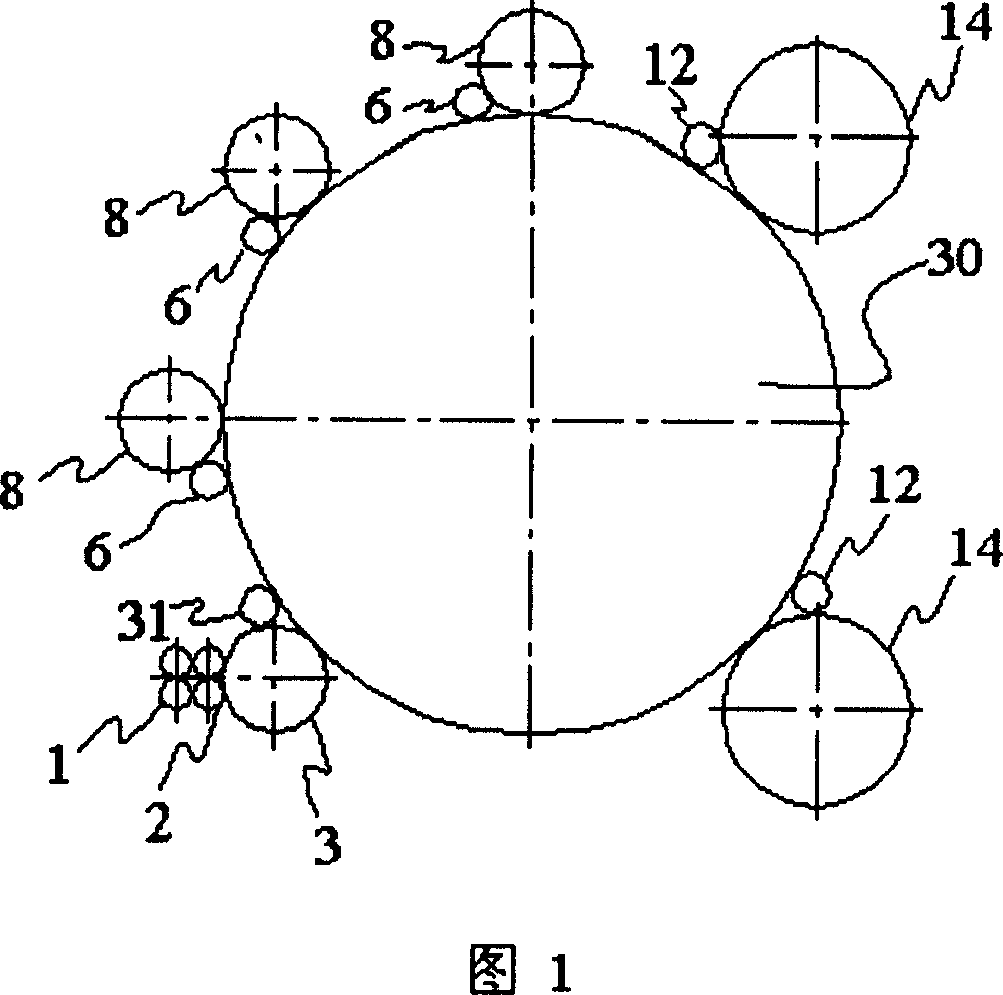

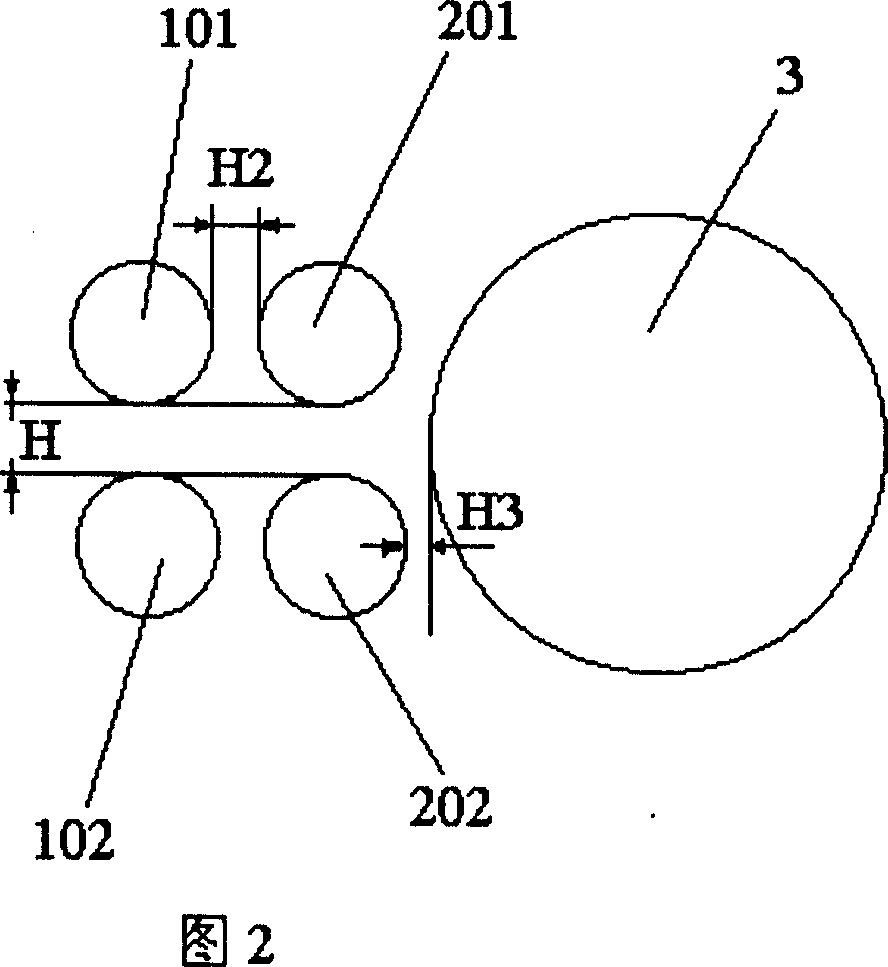

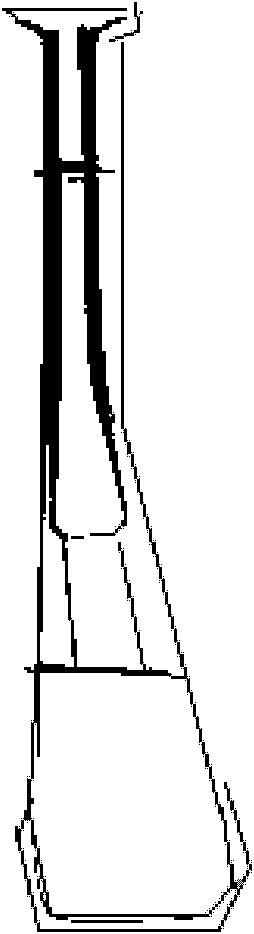

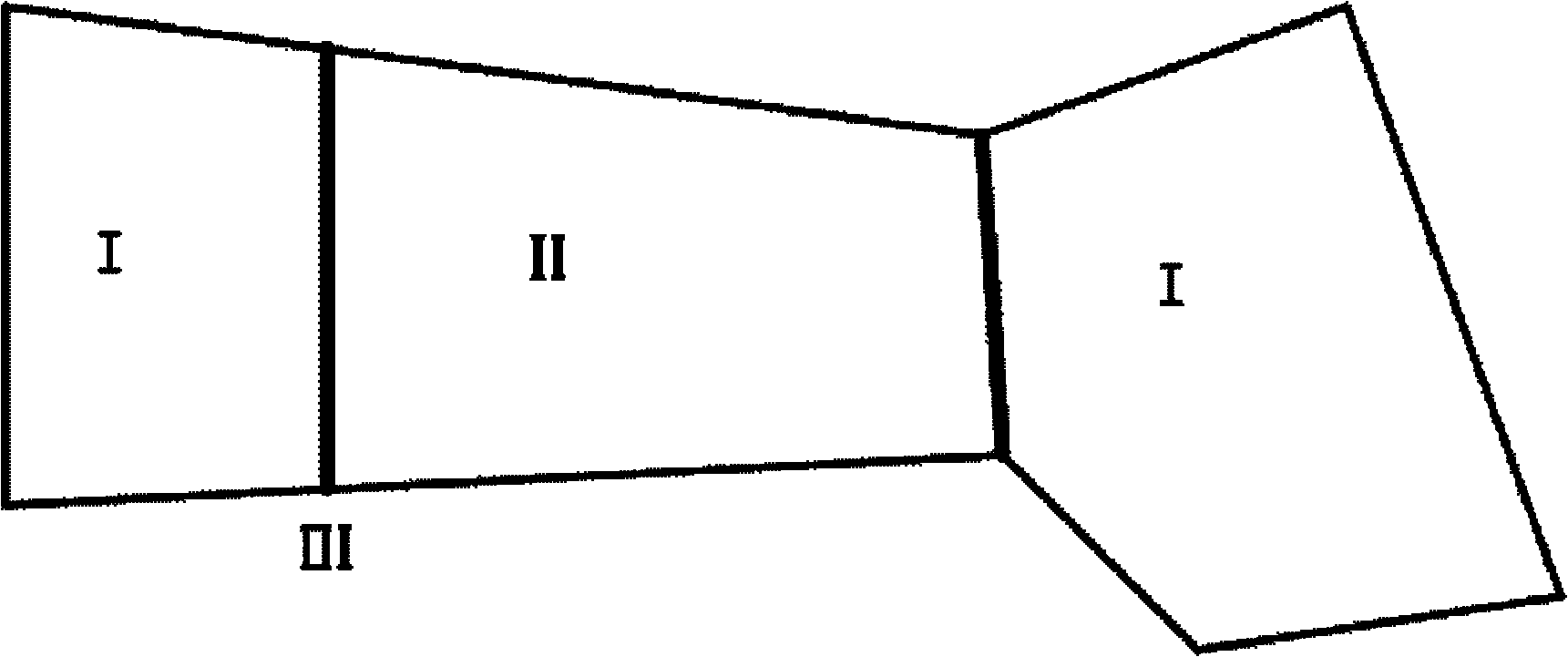

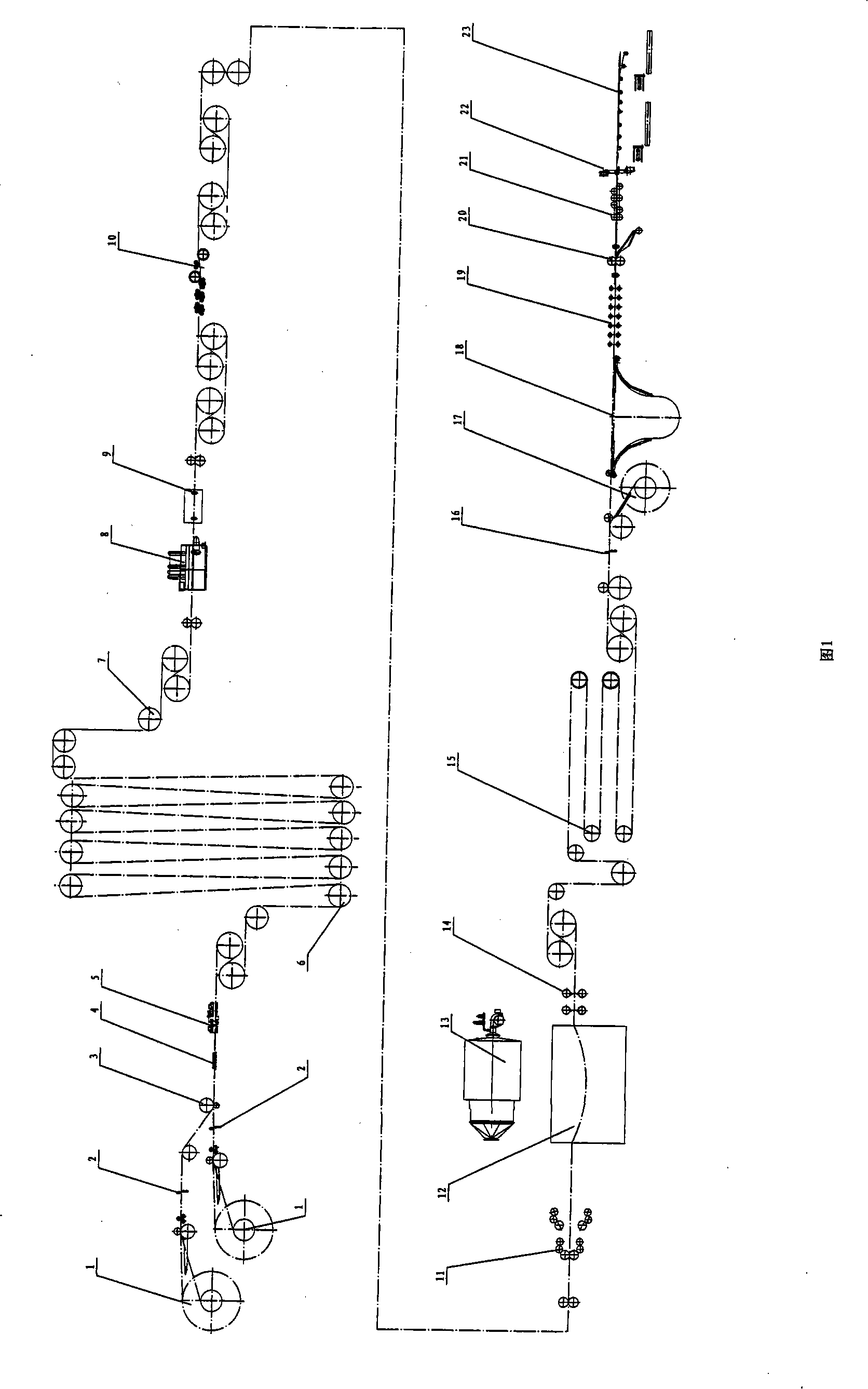

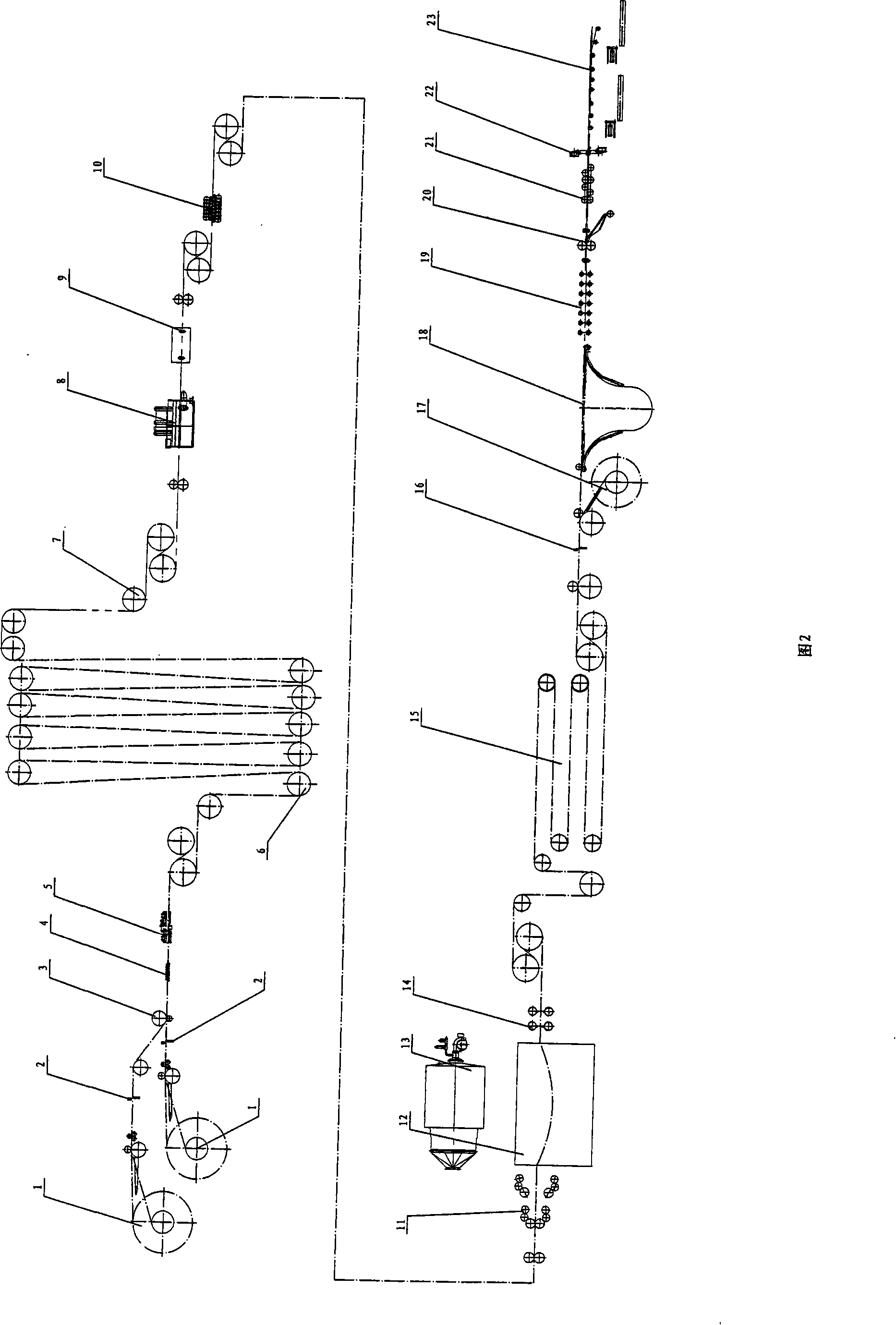

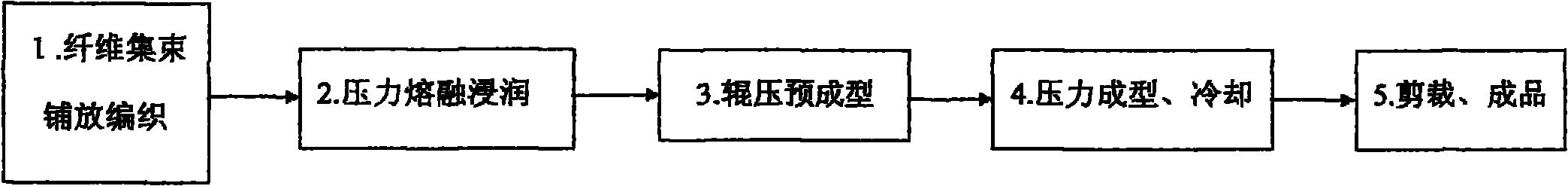

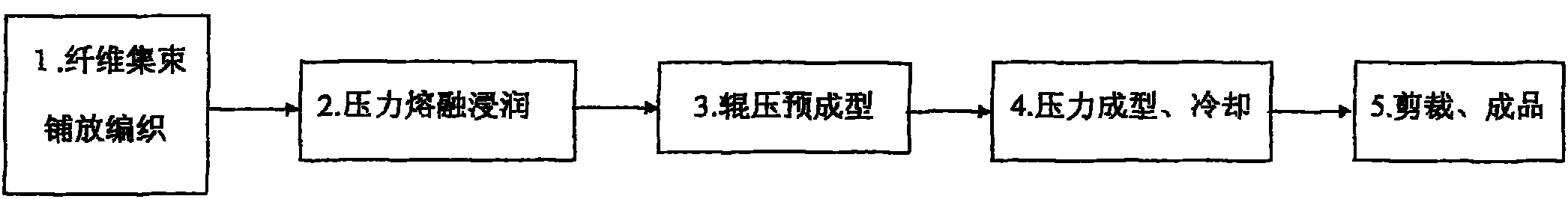

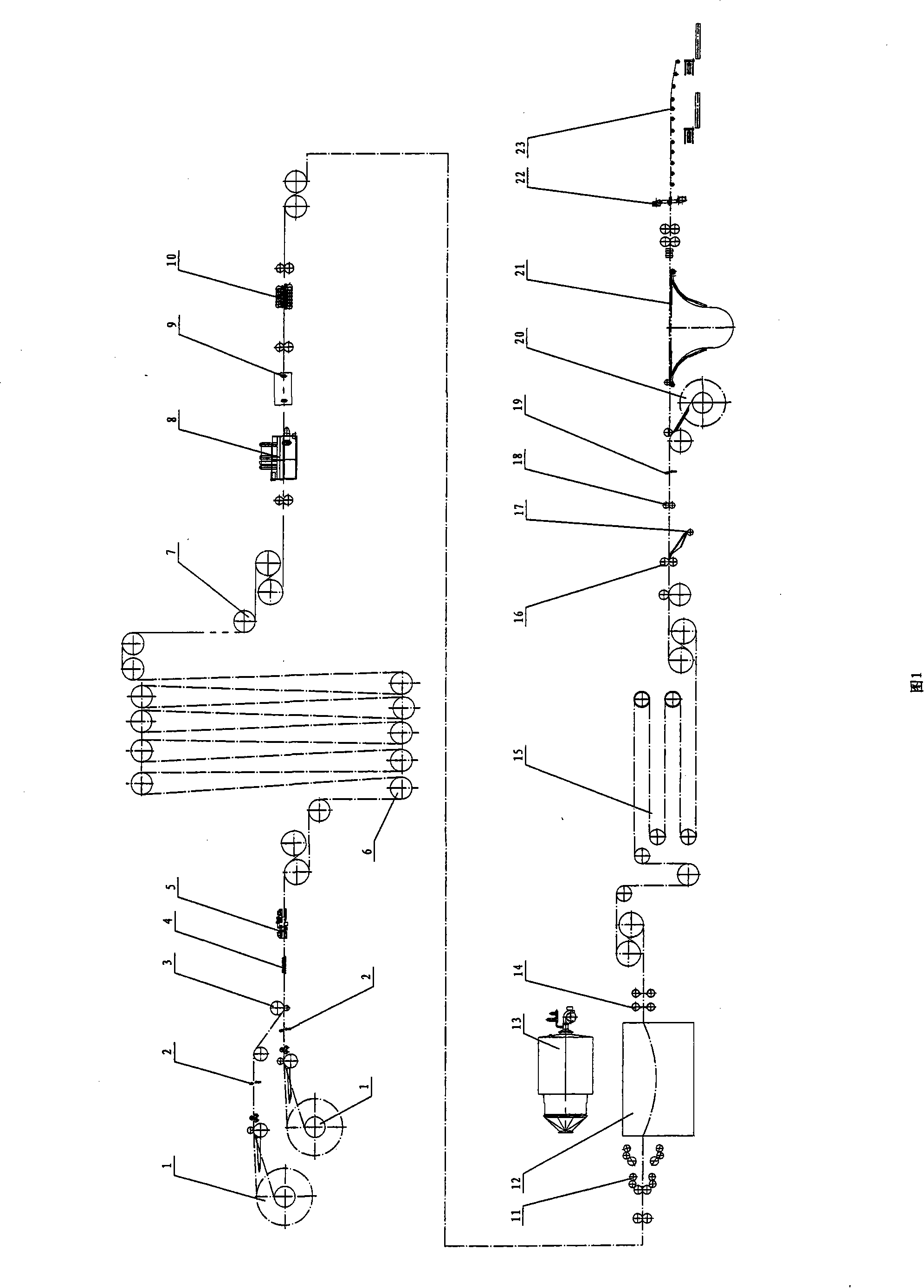

Fiber reinforced thermoplastics composite material section bar and molding technology

The invention discloses a fiber reinforced thermoplastics composite material section bar relating to a new molding technology for producing continuous fiber thermoplastics composite material section bar. Glass fiber yarn, fiber glass cloth and a glass fiber mat form a fiber preimpregnating board in a fiber laying and weaving area (1) by a beam concentration weaving device. The fiber preimpregnating board which is in beam concentration weaving forms a composite blank board after fully rolled and infiltrated by a material pressing roller in a constant-temperature gum dipping slot. The compositeblank plate is successively subject to pressure preforming (3) and pressure forming (4), is cooled by a cooling device to form continuous finished product section bar and is cut into required finished product section bar by a board shearing device. The product of the invention can automatically determine material and proportioning according to different requirements of the product, and burdening degree of freedom is high; in the molding process, the product of the invention has extra low abrasion degree on fiber, and all glass fiber in the product is continuous filament; according to different using requirements, the fiber is laid to be designed and adjusted to ensure that the final finished product has excellent mechanical property and appearance; and the product has smaller abrasion on molding equipment and is easier to recycle and reuse the recycled scrap.

Owner:SHANDONG GRAD GROUP

Method for continuous producing rust-inhibiting primer coating steel plate

ActiveCN101249605AIncrease productivityReduce wastePretreated surfacesSheets/panelsCircular discSheet steel

The invention provides a method for continuously producing rust-proof primer coated steel plate applied to the coating production field in the metallurgical industry. The method is characterized in that the defect of discontinuous former production is overcome and all processes are continuously completed on line. The method comprises the following steps: the head and tail of a hot-rolled steel band are welded together; the steel band enters a pickling tank to remove the oxide of the surface, and enters a hot air drying segment to remove the moisture of the surface; the steel band enters a roll coater 11 to coat the surface of the steel band and is then transmitted to a paint curing furnace 12 to cure and dry the band; the steel band with a certain temperature is blown by cold wind 14 to reduce the temperature; the steel band enters a horizontal type loop 15, is corrected an error through a loop 21, and then enters a flying shear 22 for definite distance cutting in order to be cut into the required plate according to the requirement; and then the steel band enters a dual stacking 23 to be stacked into a sheet bar with the defined height. When coiled materials are required, the steel band is longitudinally sheared into strip by a disc shear, then is coiled separately by a dividing shear, and enters a rolling machine 20 to form a coiled steel band.

Owner:BEIJING STAR RIVER INTEGRATED EQUIP TECH

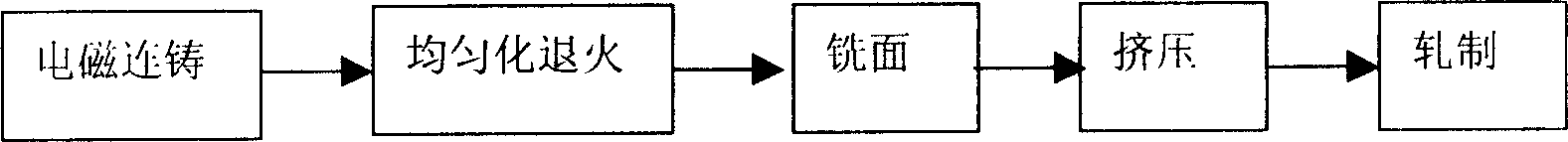

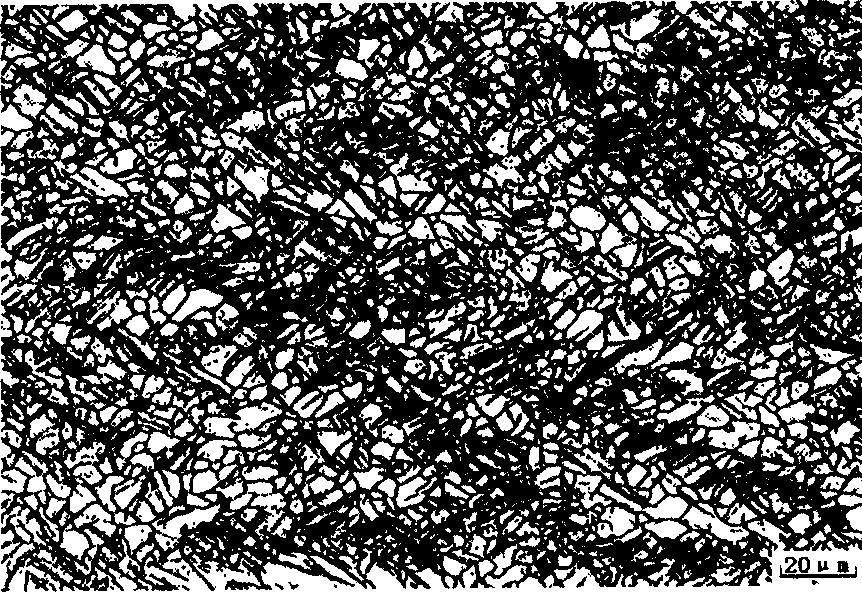

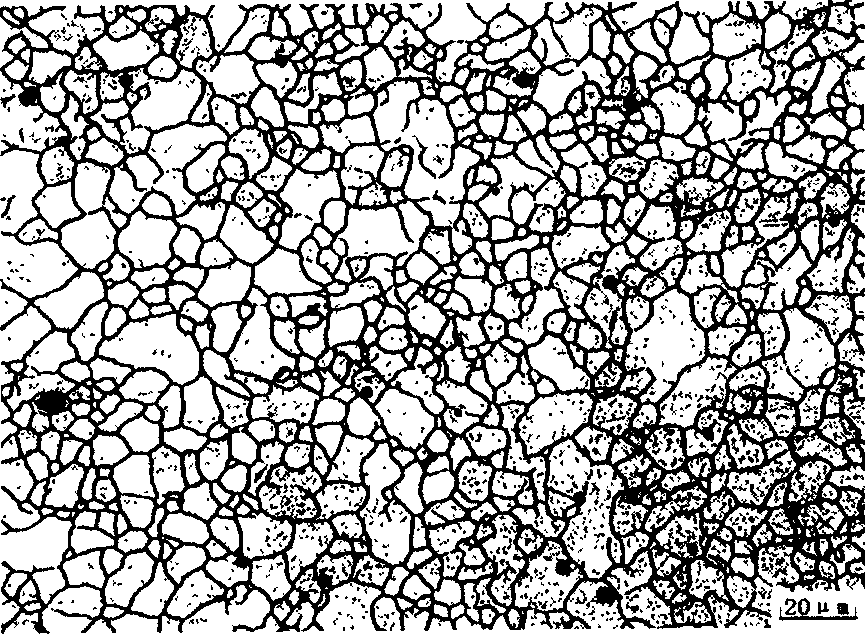

Method for preparing 300MPa grade and isotropous AZ31 magnesium alloy sheet

InactiveCN1884896AHigh precisionImprove performanceTemperature control deviceSheets/panelsHigh intensityThin sheet

The invention relates to a method for producing AZ31 magnesium alloy sheet, at 300MPa level and isotropic property, wherein the invention uses magnesium alloy electromagnetic low-temperature semi-casting method to produce blank to be uniformly annealed, milled and compressed at 200-400Deg. C into sheet band, while the compress ratio is 8-15 and the thickness of compressed sheet is 5-20mm; then cutting the compressed sheet into the sheets whose width is 10-30mm, to be heated to 300-400Deg. C; then preheating the roller of rolling machine, vertically to the former extrusion direction, to obtain the sheet whose width is not higher than 500mm and thickness is 0.3-1.0mm; via combining the extruding temperature and rolling temperature, obtaining the sheet with high plasticity or high strength; then cutting edge, coating protective film and packing. The invention has simple process, low cost, and high property, while the anti-drawing strength is 300MPa level.

Owner:NORTHEASTERN UNIV

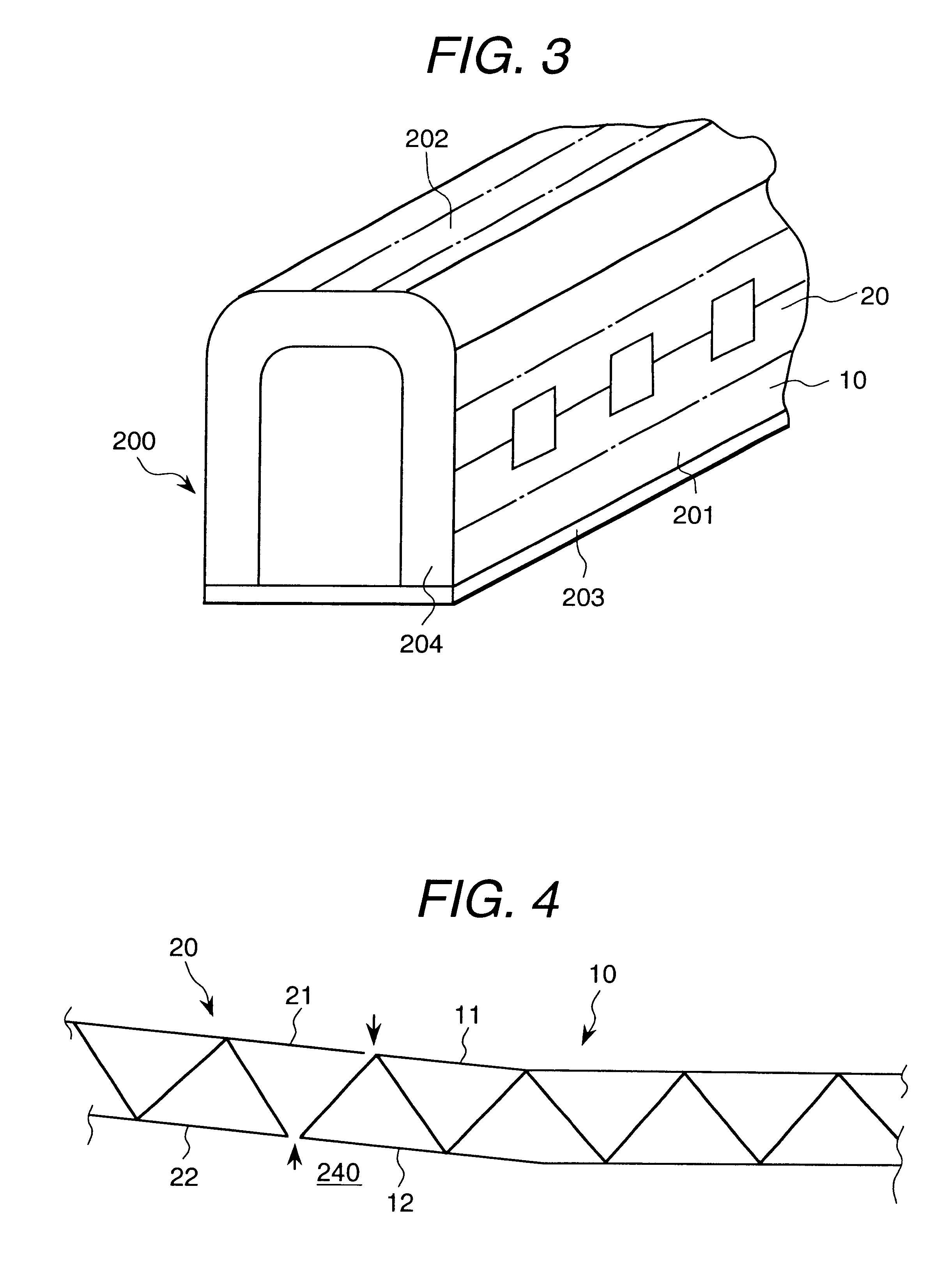

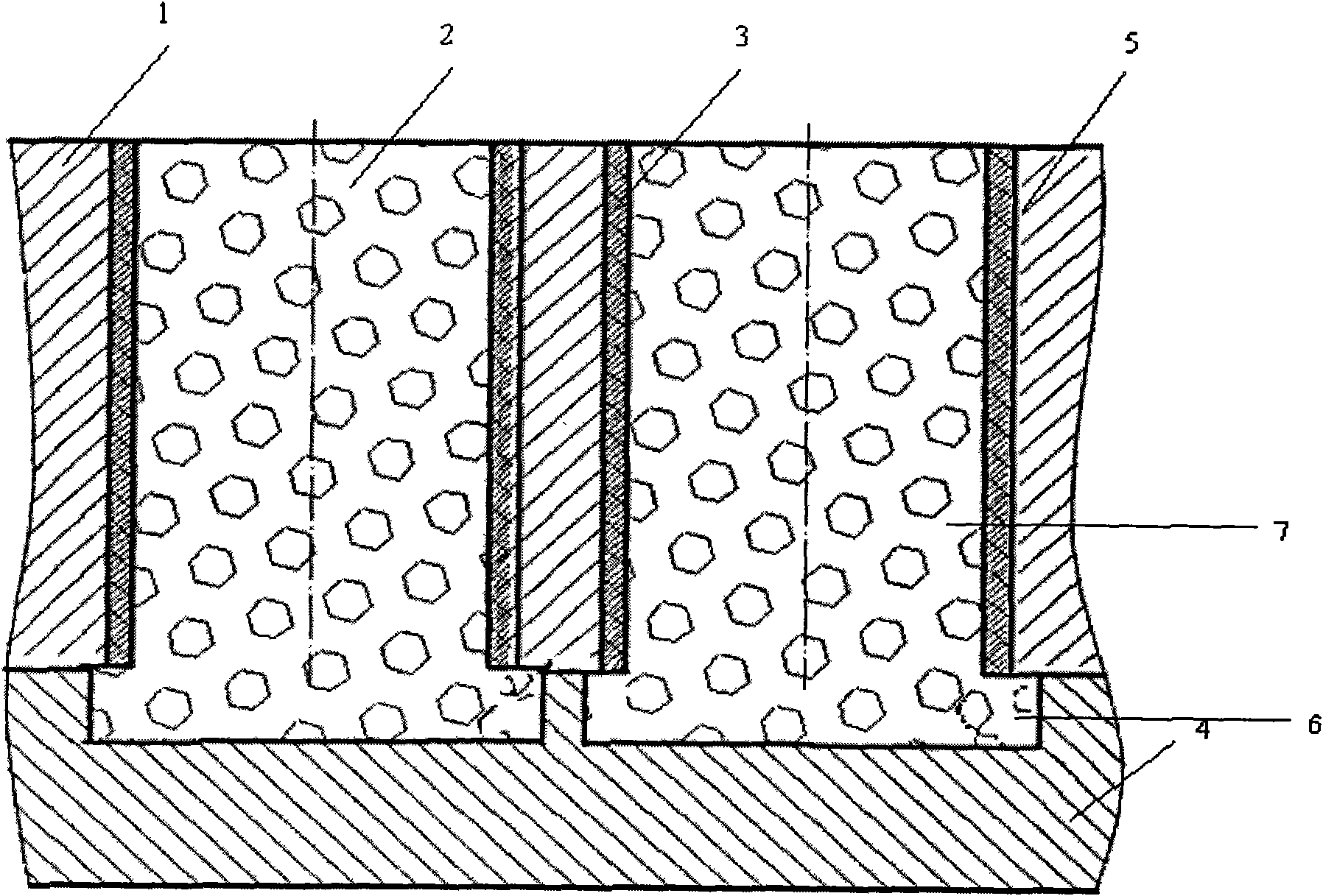

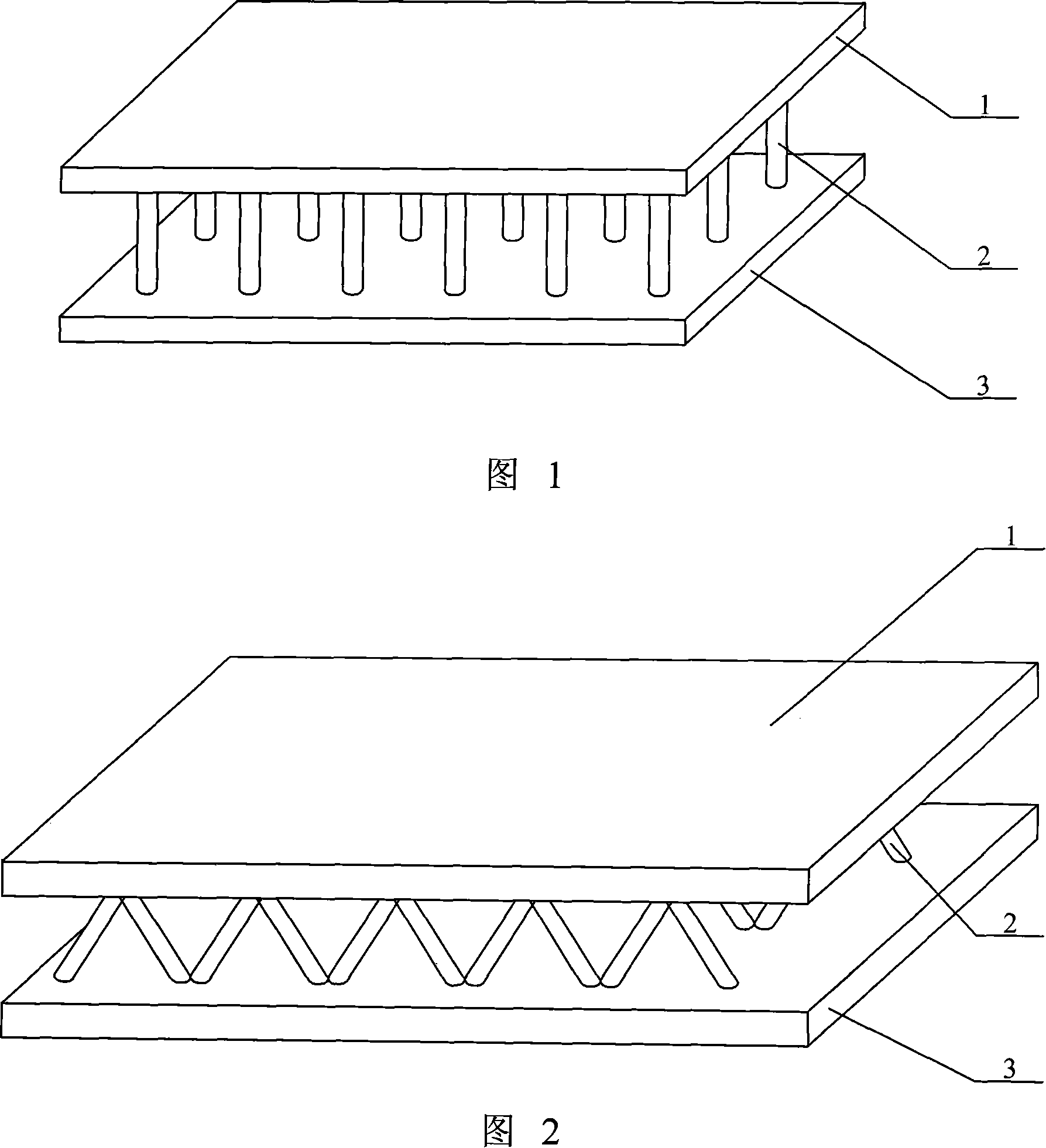

Fibre-reinforced composite lattice sandwich plate and its preparing process

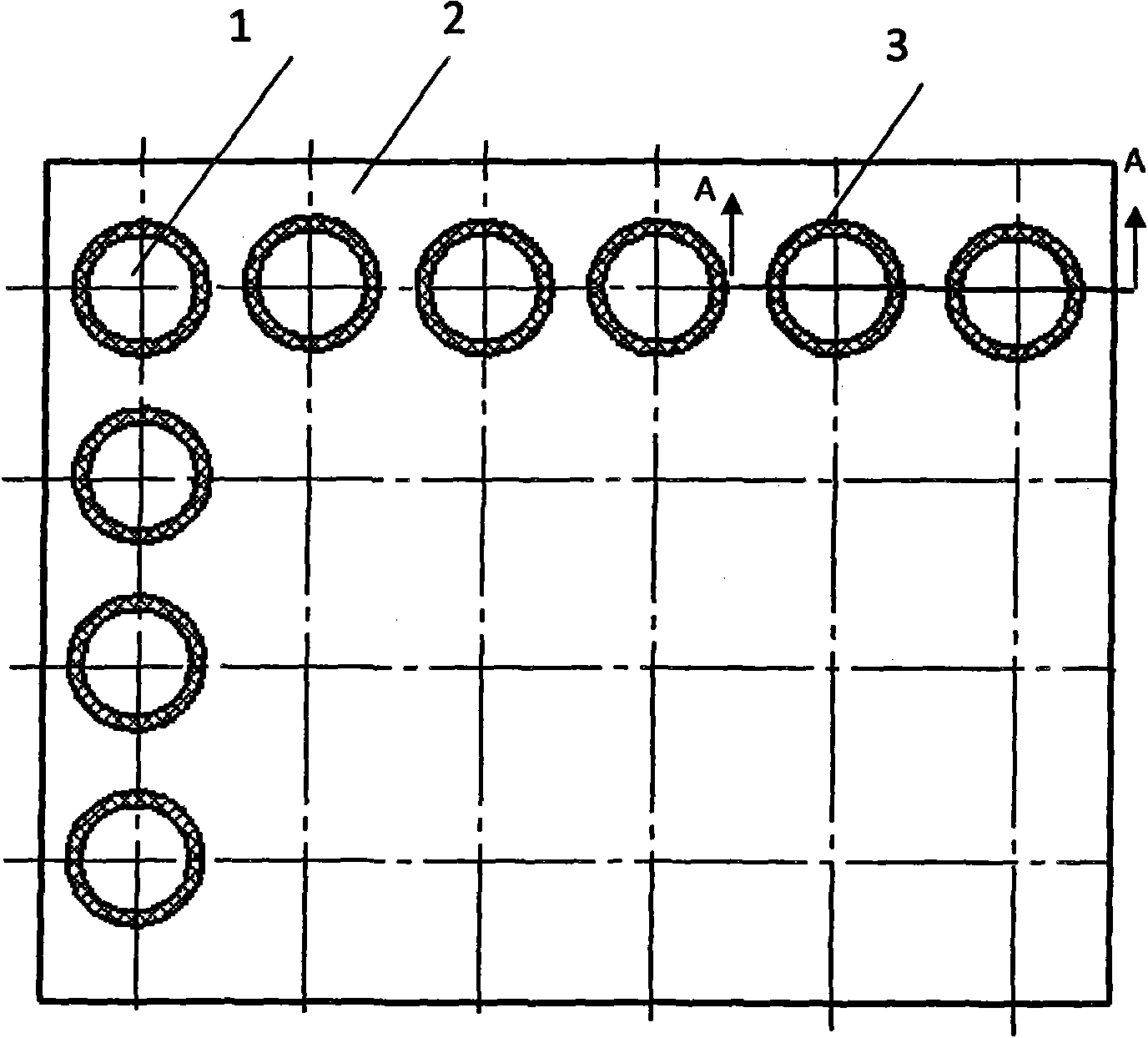

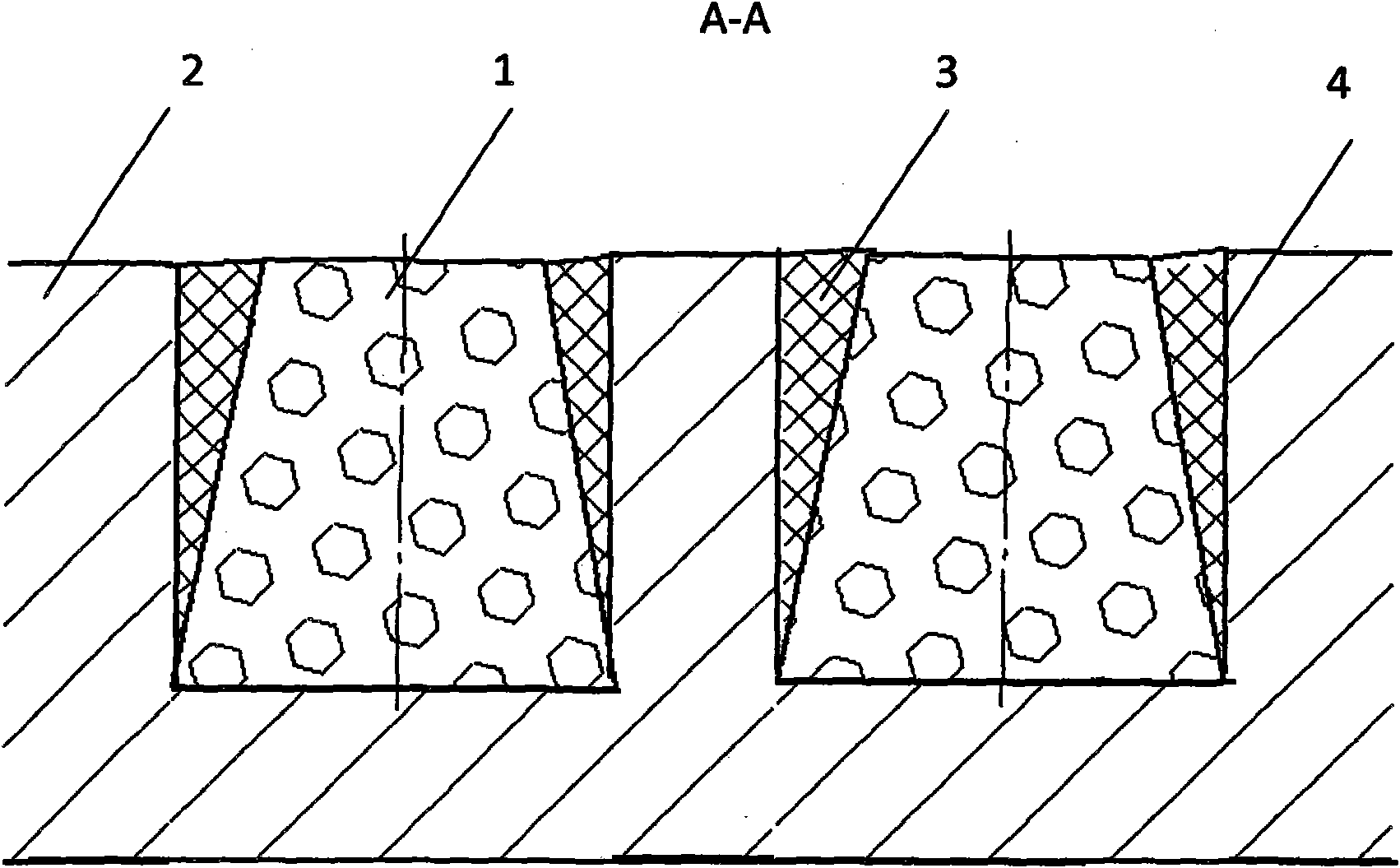

The invention is a lattice sandwich plate made of reinforced composite fiber material and a manufacture method of the sandwich plate, and relates to a lattice sandwich plate and a manufacture method of the sandwich plate. The invention settles the problem that a prior lattice sandwich plate is difficult to be molded and materials used are limited to metal materials. A lattice of the invention is arranged between an upper fiber composite panel (1) and a lower fiber composite panel (3), and consists of a plurality of fiber composite columns (2). The upper ends of the fiber composite columns (2) are connected with the upper fiber composite panel (1) in a fixing way, while the lower ends of the fiber composite columns (2) is connected with the lower fiber composite panel (3) in a fixing way. The manufacture method is as follows: 1. a cleaning mould is designed and a demoulding agent is applied on the mould; 2. a pre-immersed material is cut into the designed size and filed into a pole, which is put into a mould hole; 3. the upper panel and the lower panel are laid; (4) solidification by heating and pressurizing is done, and the reinforced composite fiber material lattice sandwich plate is made. Compared with a traditional metal lattice sandwich plate, the reinforced composite fiber material lattice sandwich plate of the invention is provided with the higher intensity and rigidity, and can be designed easily.

Owner:HARBIN INST OF TECH

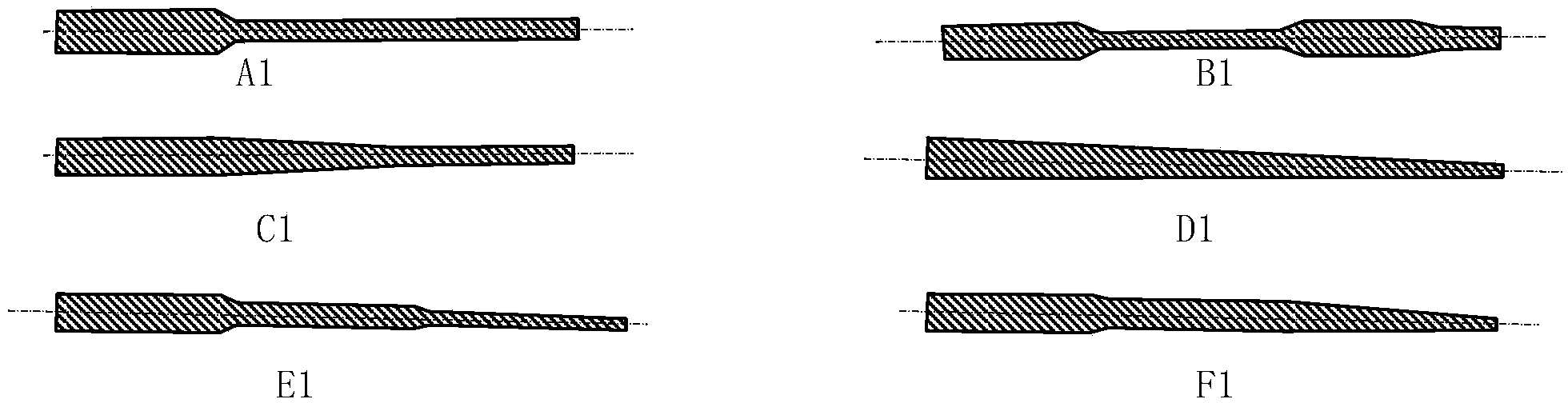

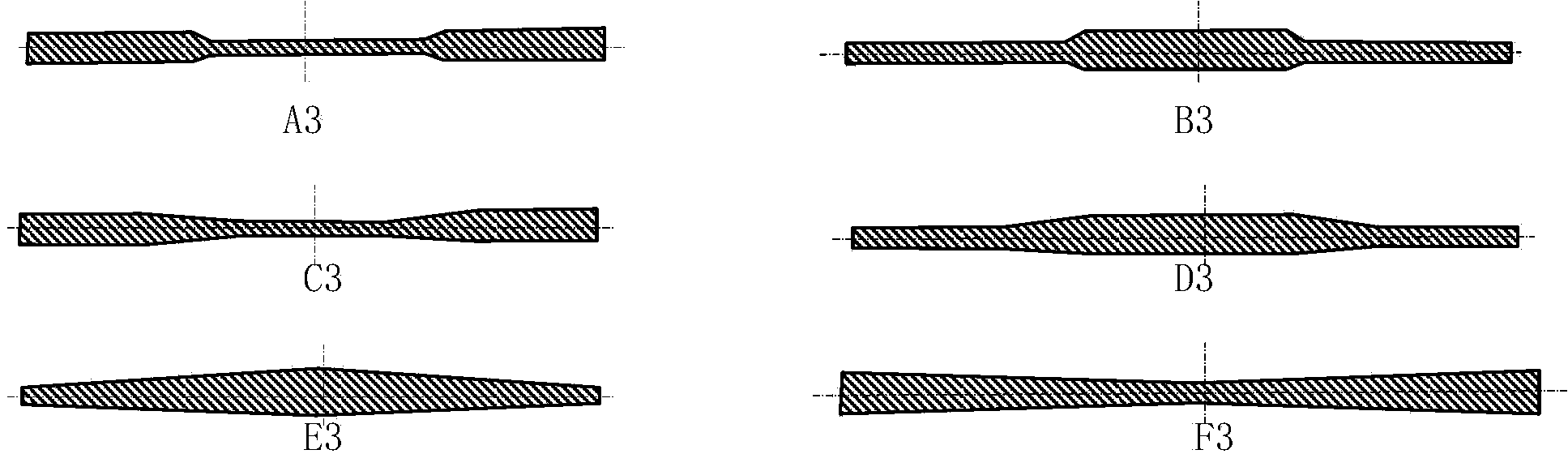

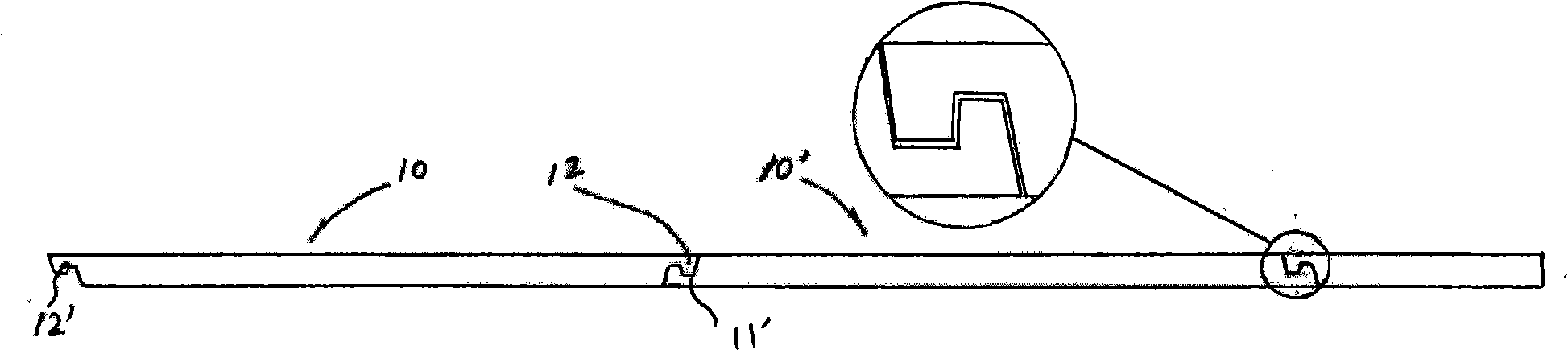

Crosswise thickness-variable strip and preparation method thereof

ActiveCN103822081ASave materialReduce structural weightSheets/panelsMetal rolling arrangementsWork rollMetallic materials

The invention relates to a crosswise thickness-variable strip and a preparation method thereof. The crosswise thickness-variable strip is composed of at least two equal thickness areas and at least one transition area, at least one equal thickness area and at least one wedge-shaped area, one or more than two wedge-shaped areas, or more than two curved thickness-variable areas. The preparation method comprises the following steps: (1) performing transition rolling, wherein at least one bulge and at least one groove are arranged on both of the two working rolls of a rolling machine or at least one bulge and at least one groove are respectively arranged on the two working rolls of the rolling machine; 2) performing forming rolling. According to the preparation method provided by the invention, the purposes of saving metal materials and reducing structure weight are achieved. According to the method for producing the crosswise thickness-variable strip by utilizing a rolling method, the defects of low production efficiency, higher production cost, and the like, of the production of the crosswise thickness-variable strip according to a welding method are avoided.

Owner:NORTHEASTERN UNIV

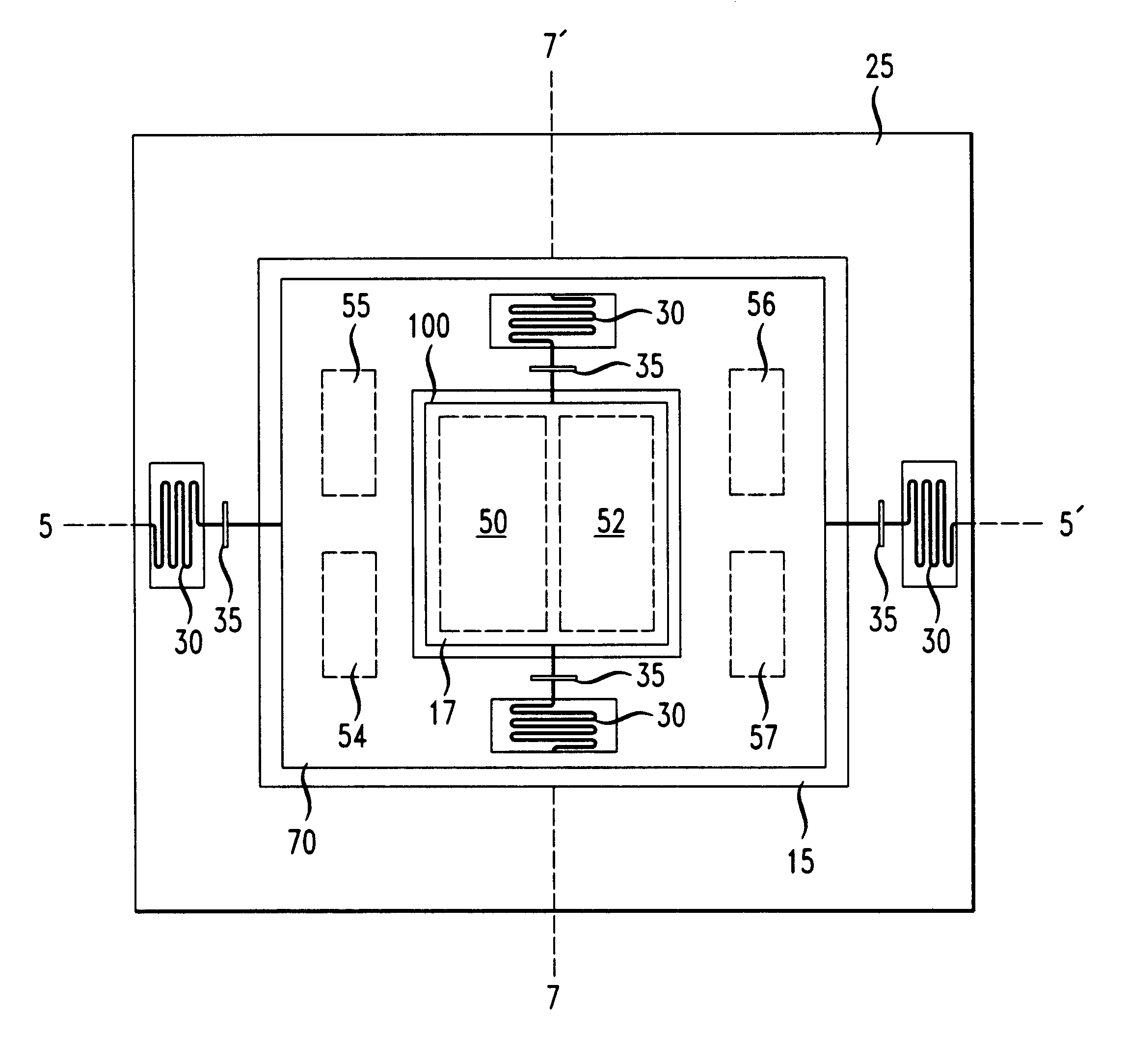

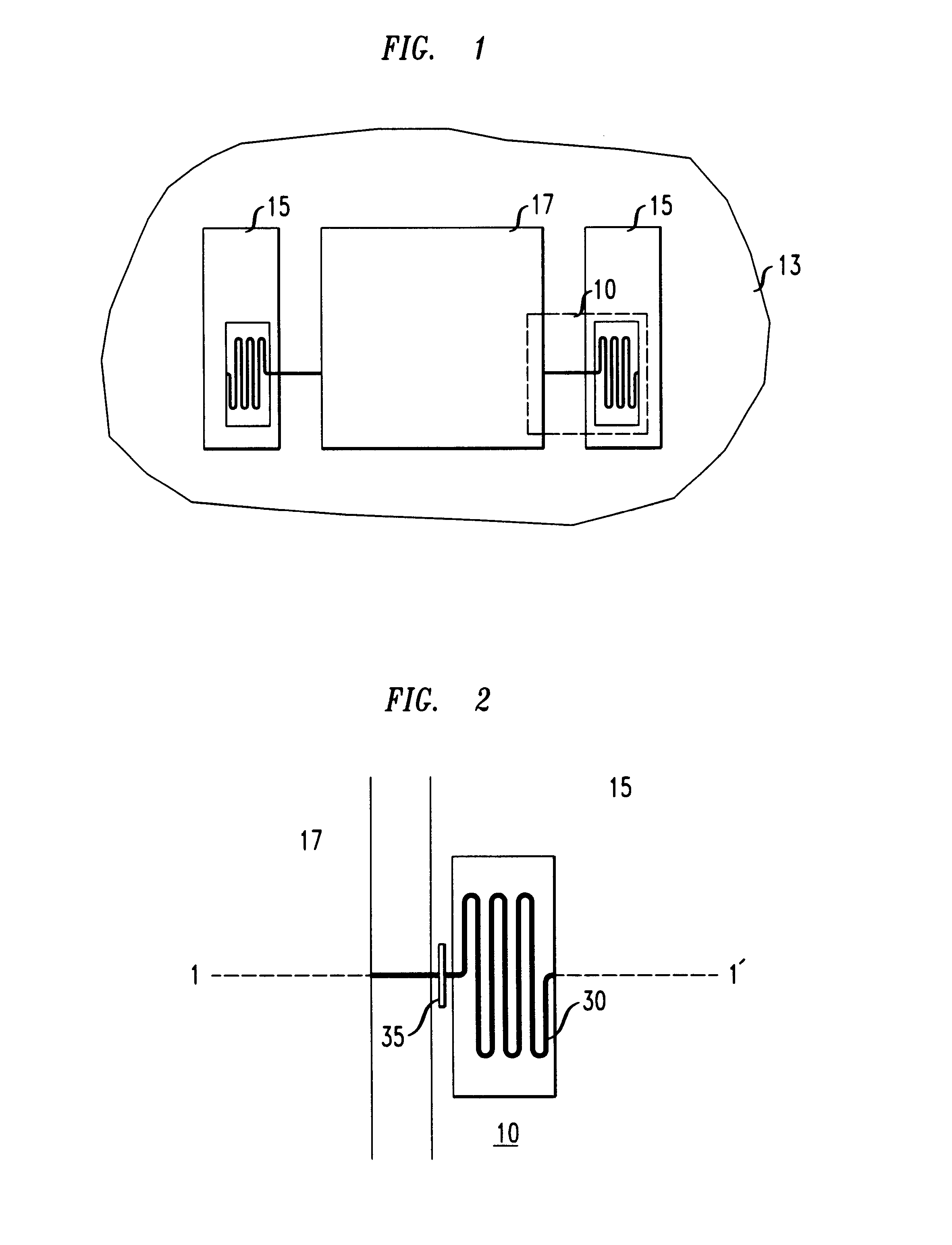

Micro-electro-mechanical optical device

InactiveUS6392221B1Piezoelectric/electrostriction/magnetostriction machinesSolid-state devicesElectricityOptoelectronics

A micro-electro-mechanical optical device is disclosed. The micro-electro-mechanical optical device includes a micro-electro-mechanical structure coupled with an optical device. Both the micro-electro-mechanical structure and the optical device are disposed on a substrate surface. The micro-electro-mechanical structure lifts the optical device a predetermined distance above the plane of the substrate surface. Thereafter, the lifted optical device is moveable relative to the plane of the substrate surface in response to an electrostatic field generated between the optical device and the substrate.

Owner:LUCENT TECH INC +1

Artificial board with added tea dust and tea polyphenol and manufacturing method thereof

InactiveCN103133851AAvoid pollutionPlay the role of purifying the airWood working apparatusSheets/panelsPhenolic content in teaProcess engineering

The invention discloses an artificial board with added tea dust and tea polyphenol and a manufacturing method thereof. The artificial board with the added tea dust and the tea polyphenol is composed of wood raw materials, the tea dust, the tea polyphenol, adhesive, fire retardant and antiseptic agents. Preferentially, the artificial board with the added tea dust and the tea polyphenol is composed of the wood raw materials 1 m3, the tea dust 0.05-0.3 m3, the tea polyphenol 0.5-3Kg, the adhesive 5-20 Kg, the fire retardant 0-3 Kg and the antiseptic agents 0-3 Kg. The manufacturing method of the artificial board with the added tea dust and the tea polyphenol comprises the steps of processing the wood raw materials, pre-steaming, drying, mixing the materials, and forming of the artificial board. The artificial board manufactured with the method can not only kill bacteria of the artificial board and bacteria produced in a manufacturing process, but also can inhibit and kill indoor bacteria when the artificial board is applied to interior trim and furniture, and meanwhile, the artificial board with the added tea dust and the tea polyphenol can play a role in purifying air due to the fact that the artificial board can clear methanal in wood and in a room.

Owner:河北百年巧匠文化传播股份有限公司

Metal ceramic composite wear-resistant material and preparation method thereof

InactiveCN101566271AHigh bonding strengthOvercome the disadvantages of easy agingArc welding apparatusSheets/panelsAdhesiveWear resistant

The invention discloses a metal ceramic composite wear-resistant material and a preparation method thereof. The method solves the problems that in the prior metal ceramic composite wear-resistant material, the bonding strength of metal and ceramic is low, an adhesive is easy to age, and a wear-resistant ceramic is easy to fall off and is not suitable for high temperature operating conditions. Themethod has the advantages that the metal and the ceramic are welded firmly to improve the wear resistance of the composite material, reduce the use cost, meet production requirements and the like. Thestructure of the metal ceramic composite wear-resistant material comprises a substrate which is provided with a plurality of blind holes, and wear-resistant ceramic blocks matched with the blind holes are arranged in the blind holes and are connected with the blind holes by welding.

Owner:SHANDONG UNIV

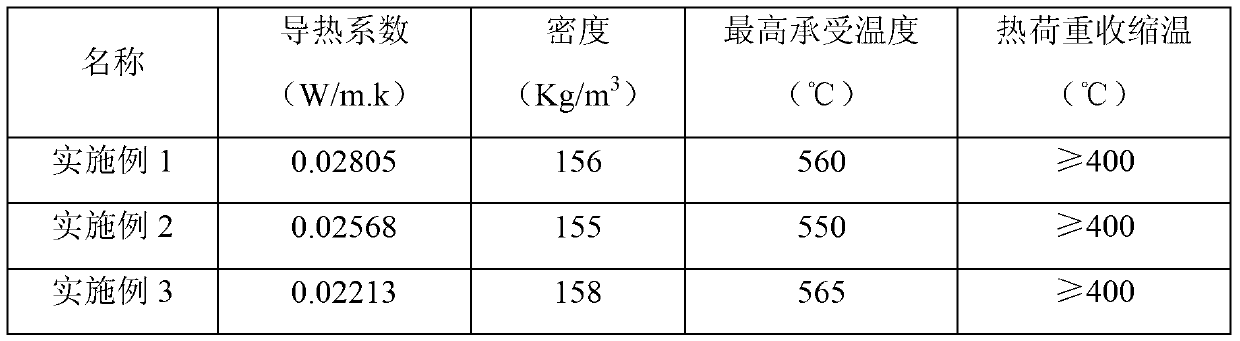

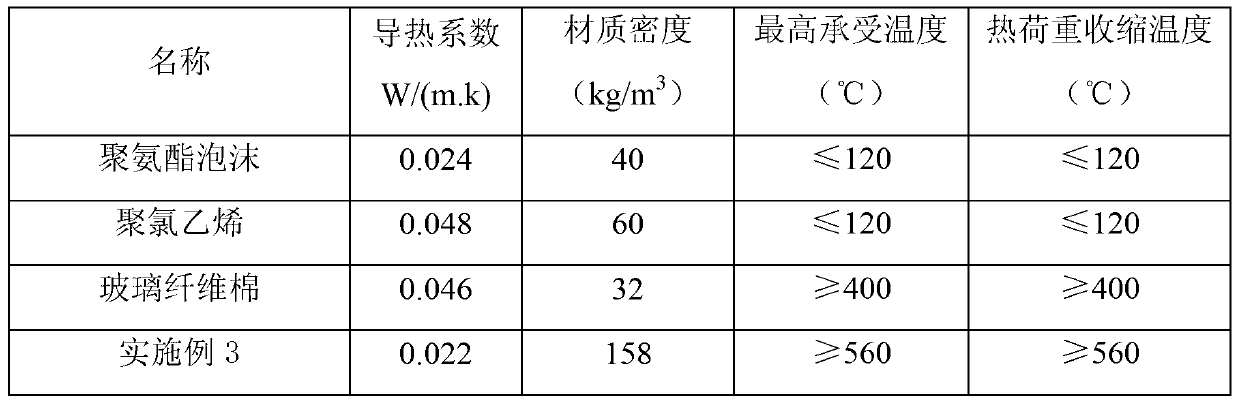

Glass-fiber vacuum insulation panel nano core material and preparation method thereof

ActiveCN103277631AUniform diameterPrevent collapseFibreboardThermal insulationGlass fiberAlkali free

The invention discloses a glass-fiber vacuum insulation panel nano core material. The core material is made of, in percentage by mass, 50-100% of medium-alkali glass fiber chopped strands with diameters of 3-6um and 0-50% of alkali-free glass fiber cotton with diameter of 0.5-1.5um. The invention further discloses a preparation method for the glass-fiber vacuum insulation panel nano core material. The preparation method includes the following steps: 1), selecting raw materials according to the matching proportion, 2), pulping to scatter the raw materials to obtain sizing agent, 3), diluting the obtained sizing agent, 4), performing deslagging treatment on the diluted sizing agent and obtaining glass fiber wet paper through wet-process forming, 5), performing dehydration treatment on the obtained wet paper to make the moisture percentage less than 20%, and 6), drying the dehydrated wet paper. The vacuum insulation panel nano core material is good in heat-insulating effect, high in mechanical strength, and long in service life; and with the preparation method, the above effects of the vacuum insulation panel nano core material can be further guaranteed.

Owner:CHONGQING ZAISHENG TECH CORP

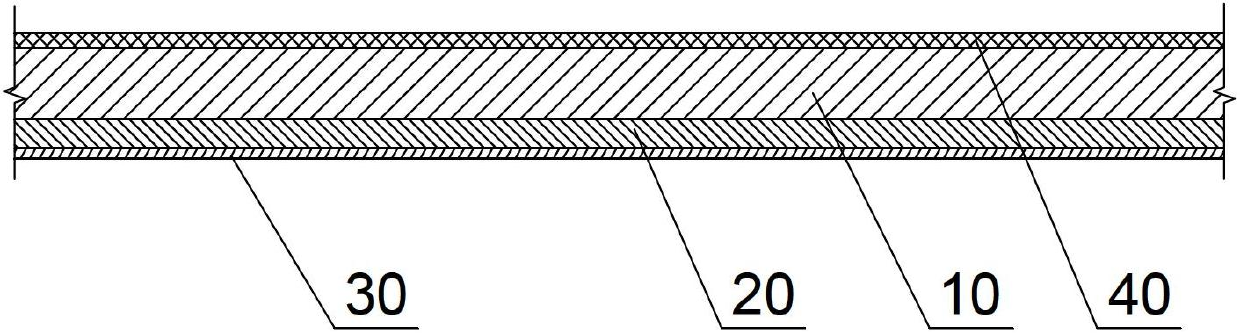

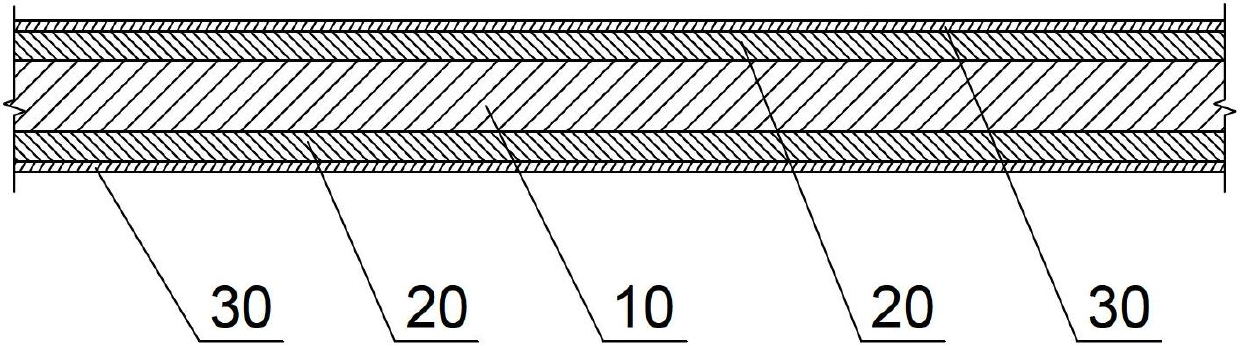

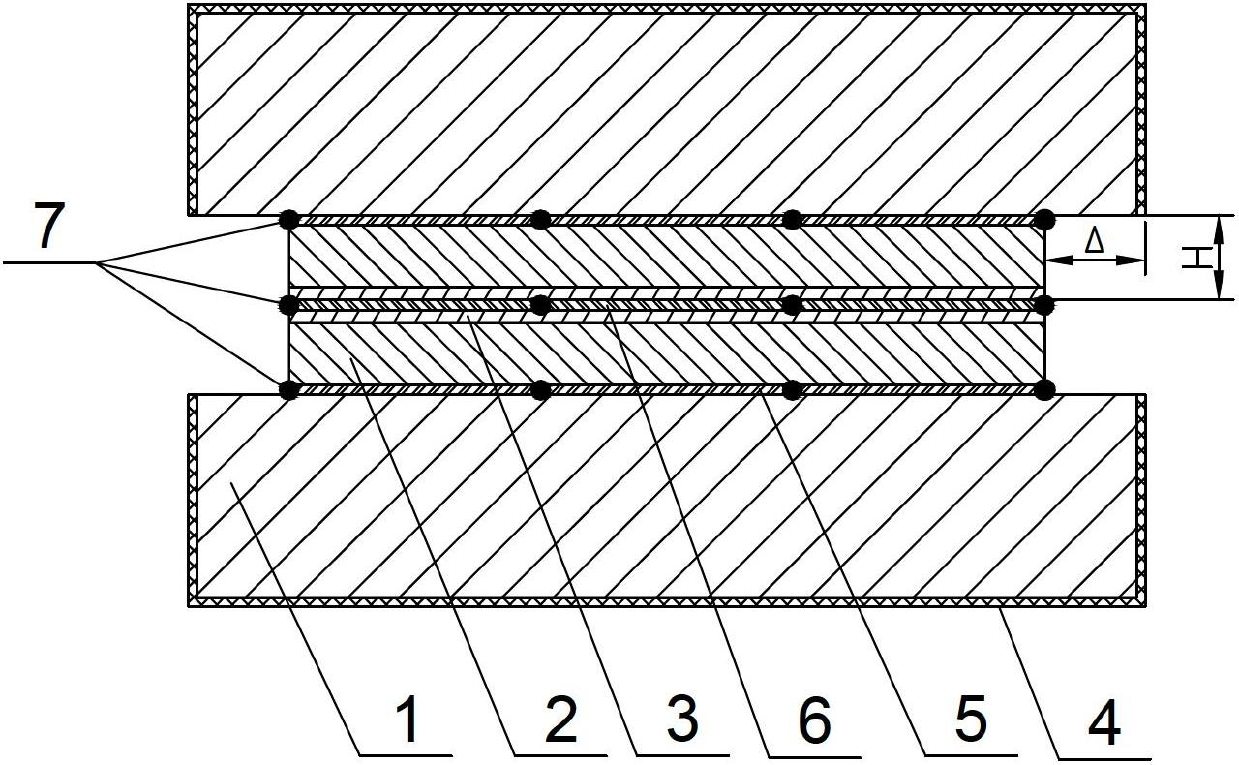

Titanium steel composite slab and manufacturing method thereof

ActiveCN102679134AImprove structural strengthAccelerated corrosionSheets/panelsAuxillary arrangementsSteel platesSheet steel

The invention discloses a titanium steel composite slab and a manufacturing method thereof. The titanium steel composite slab comprises a weather-resistant steel bottom plate layer (10) and a titanium compound layer (20), wherein the titanium compound layer (20) is compounded on one side or two sides of the weather-resistant steel bottom plate layer (10); an exposed surface of the titanium compound layer (20) is an oxidization layer (30) of titanium; the titanium compound layer (20) and the weather-resistant steel bottom plate layer (10) are compounded integrally through a heat-state rolling process; and a compounded interface between the titanium compound layer (20) and the weather-resistant steel bottom plate layer (10) is formed by combining of a metallic bond. The manufacturing method comprises the following steps of: performing surface activating treatment on plate surfaces to be combined of a weather-resistant steel plate (1) and a titanium plate (2); removing an oxidization layer to ensure that the plate surfaces to be combined lean against each other and non-combined plate surfaces of the titanium plate (2) lean against each other to form a symmetric laminated state that the weather-resistant steel plate (1) is positioned between the adjacent outmost weather-resistant steel plates (1) for clamping multiple layers of plate materials of two layers of titanium plates (2); and multiple times of hot-rolling at high temperature are carried out; diffusing, cooling, annealing and refining to form a plurality of compound titanium steel composite slabs. The titanium steel composite slab can be used for the field of titanium steel composite slabs.

Owner:韩静涛

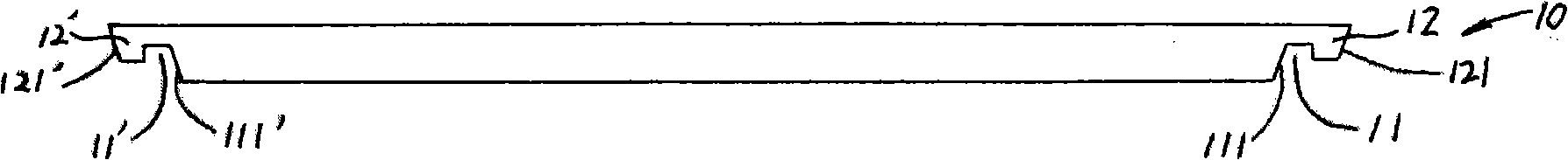

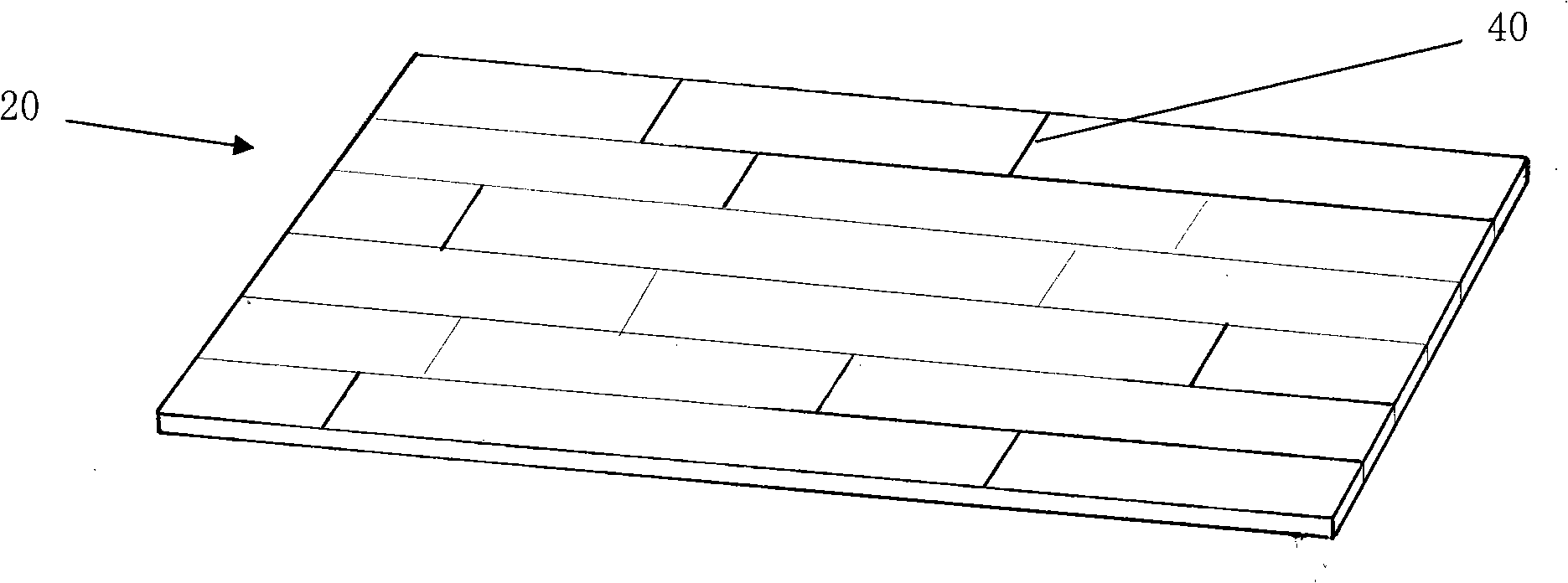

Seamless long bamboo sectional material

InactiveCN101294653ANovel structureWith horizontal pulling effectElongated constructional elementsWood treatment detailsEngineeringStructural engineering

Owner:SHANGHAI YUNSHENG BAMBOO & WOOD PROD

Micro-electro-mechanical optical device

InactiveUS6265239B1Piezoelectric/electrostriction/magnetostriction machinesSolid-state devicesElectricity

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE +1

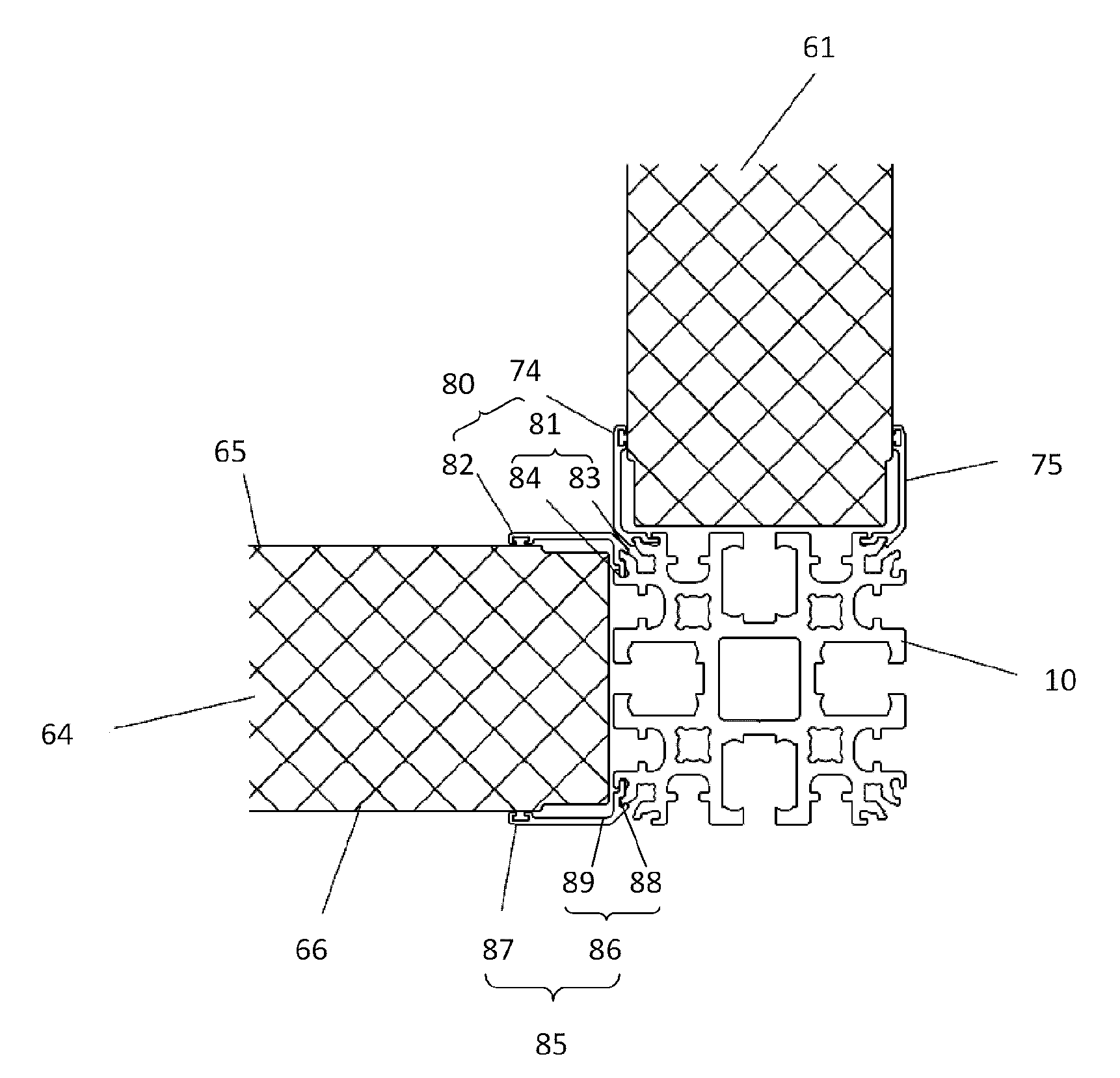

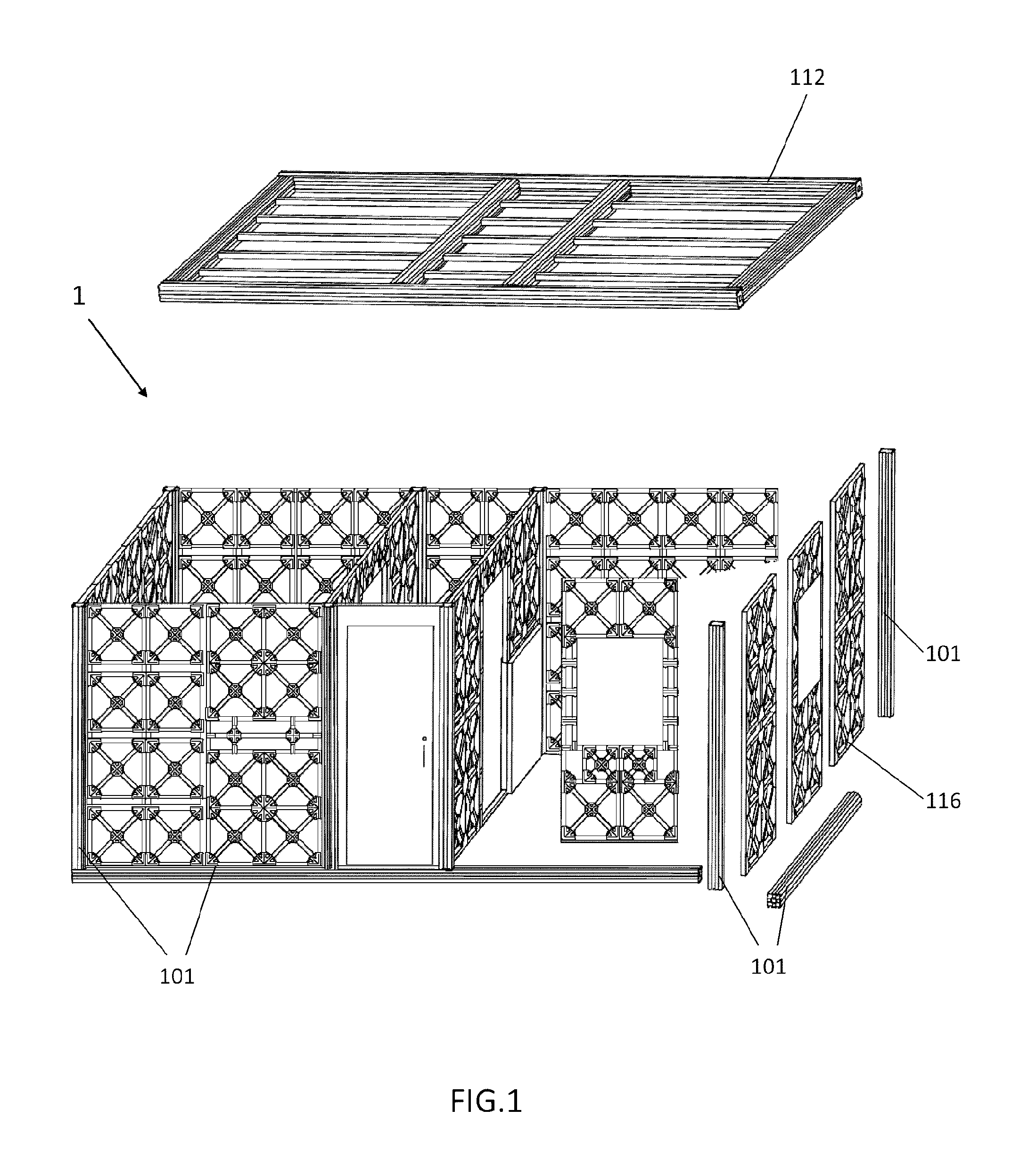

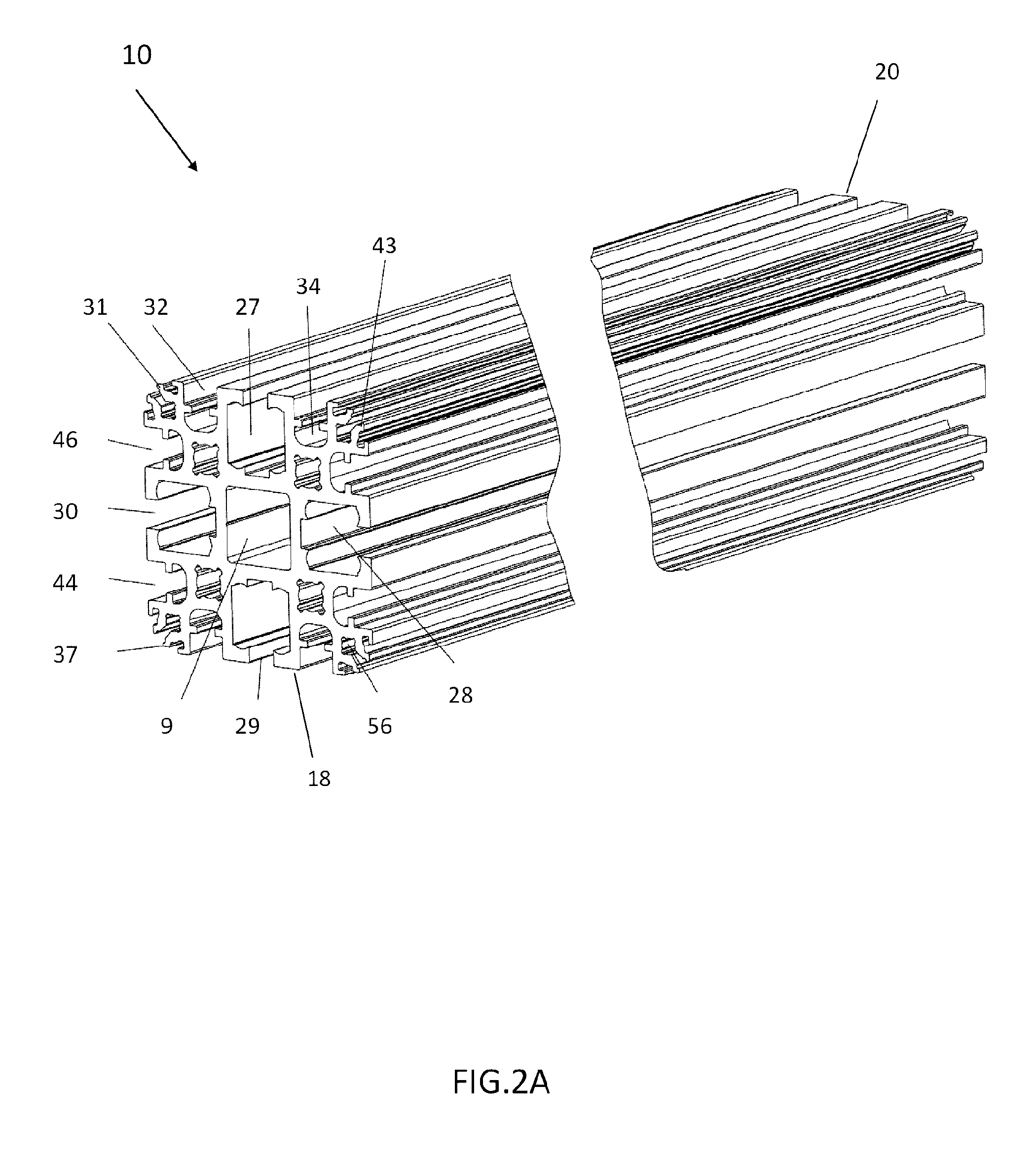

Quick connect structural system

A kit for an easy quick connect structural system for constructing framework structures comprising a plurality of elongate rectangular prism frame members is provided. The frame members incorporate custom design features which provide structural strength, facilitate assembly and expansion of the framework structure and allow ease of attachment and securing of accessories. These design features include a corner groove, a central hollow longitudinal chamber, at least one sub-trade chamber, at least one outer main channel, stub-nosed channels, and claw assembles flanking each corner groove. There is provided a plurality of snap-in connectors designed and configured to mate with the frame members such that the frame members can be secured in various arrangements with respect to each other. There is further provided custom reinforcement brackets designed and configured to securely bind together a selection of the plurality of the frame members.

Owner:E6 XTRUSION STRUCTURES

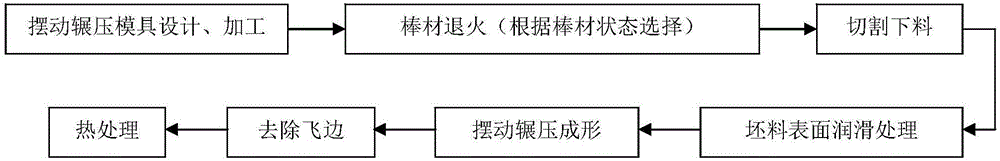

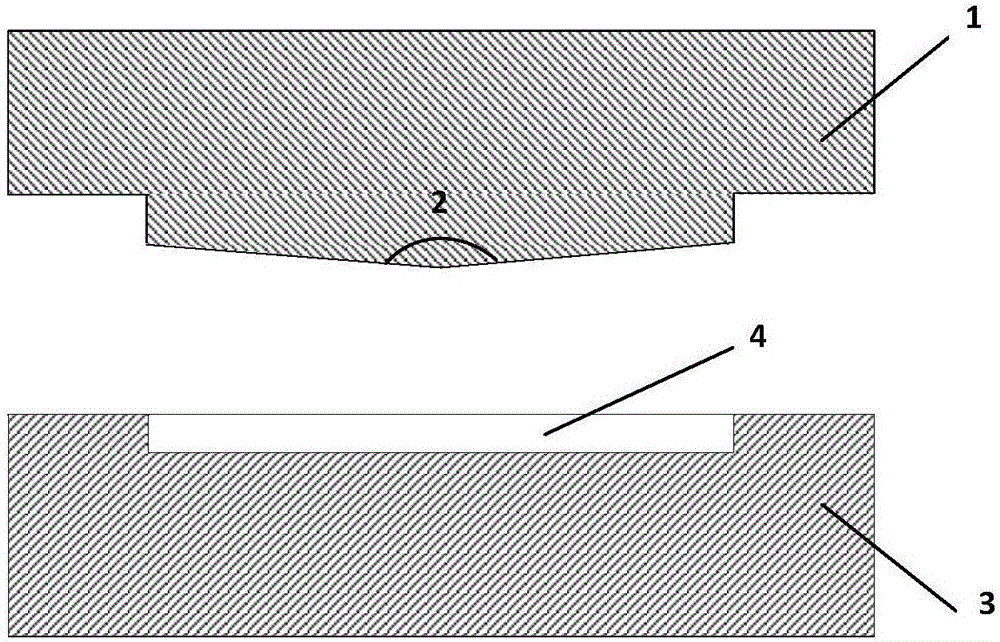

Rotary forging forming method for metal circular plate

The invention belongs to the technical field of metal plastic deformation and particularly relates to a rotary forging forming method for a metal circular plate. The method comprises the steps of rod annealing, cutting and blanking, blank surface lubricating, rotary forging forming, trimming removal, thermal treatment, obtaining of the finished circular plate and the like. According to the rotary forging forming method for the metal circular plate, large deformation machining of the metal circular plate can be conducted through a small-tongue rotary forging machine, the manufactured metal circular plate has the excellent structure property, the blank deformation is uniform, the metal streamline is complete and radial, the aeolotropism of the rolled plate is avoided, generation of a great amount of leftover materials is avoided, the material utilization rate is high, small or zero cutting machining can be achieved, metal materials are saved, the production efficiency is high, the production process is easy to operate, and the rotary forging forming method is suitable for batch production.

Owner:GRIMAT ENG INST CO LTD

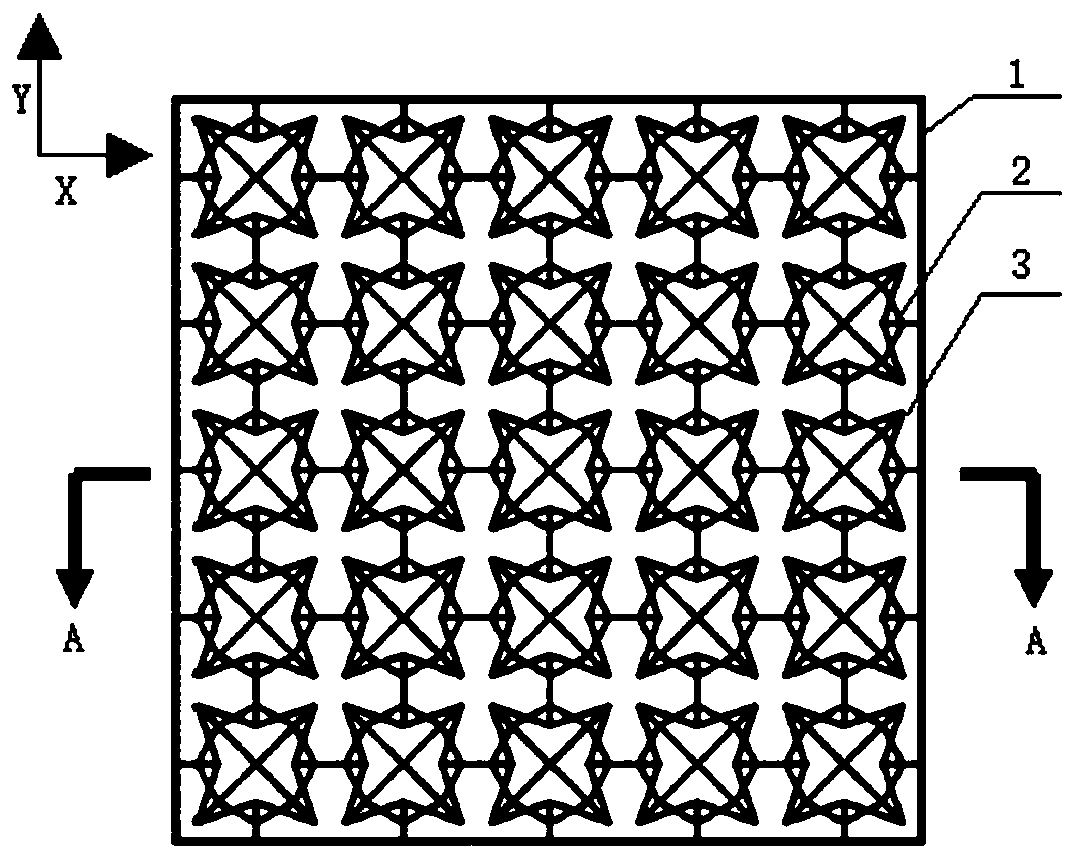

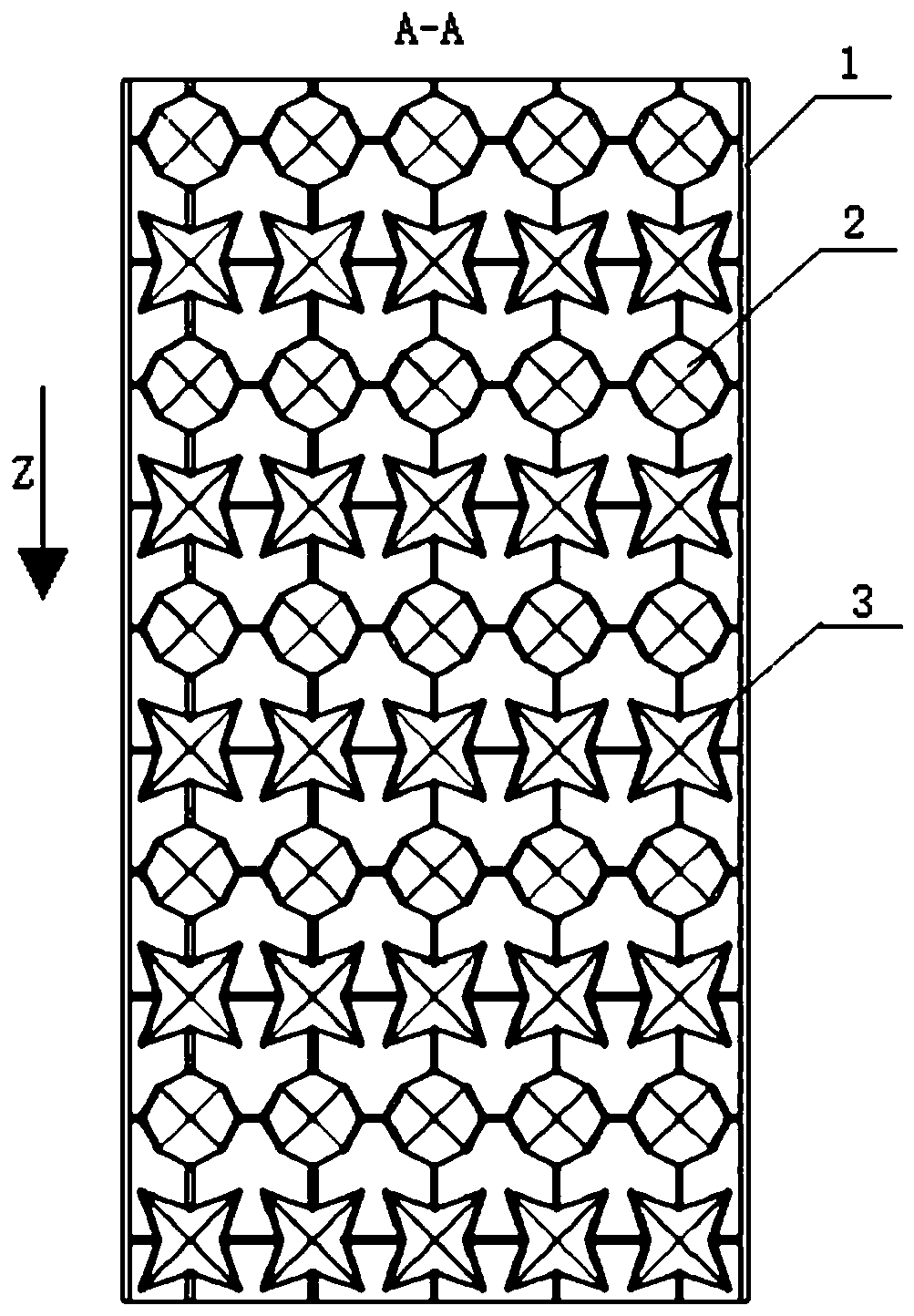

Energy absorbing structure

PendingCN109707985ARich mechanical behaviorThe deformation mode is complex and diverseSheets/panelsElastic dampersEnergy absorptionEngineering

The invention relates to the technical field of energy absorbing, in particular to an energy absorbing structure. The energy absorbing structure comprises a shell and a composite filler core. The shell is provided with a cavity. The composite filler core fills the cavity and is connected with the shell, and the composite filler core comprises a plurality of connected unit cell structures. At leasttwo of the multiple unit cell structures are different in Poisson's ratio. According to the energy absorbing structure, the unit cell structures with the different Poisson's ratios are combined intothe composite filler core, then the composite filler core fills the cavity of the shell, thus, deformation coupling between the unit cell structures with the different Poisson's ratios as well as deformation coupling between the composite filler core and the shell exists when the energy absorbing structure is subjected to impact or a compression load, that is, at this moment, the energy absorbingstructure can have a double coupling effect, the mechanical behavior of the energy absorbing structure is enriched under the double coupling effect, accordingly, the deformation patterns of the energyabsorbing structure are complex and varied, and therefore, the energy absorption capacity of the energy absorbing structure can be improved.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

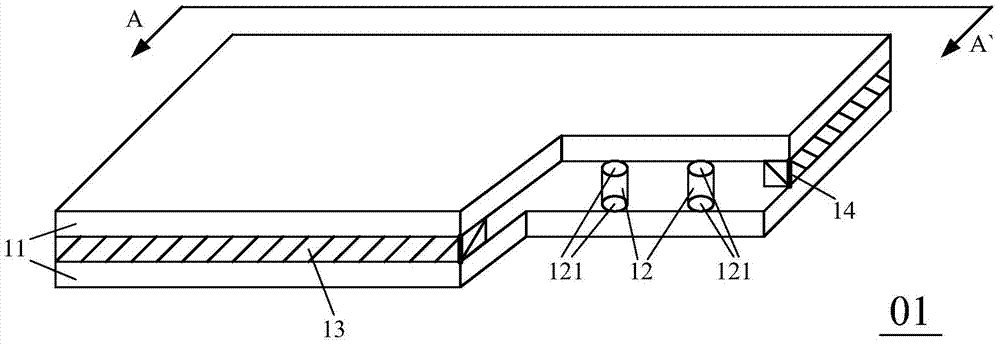

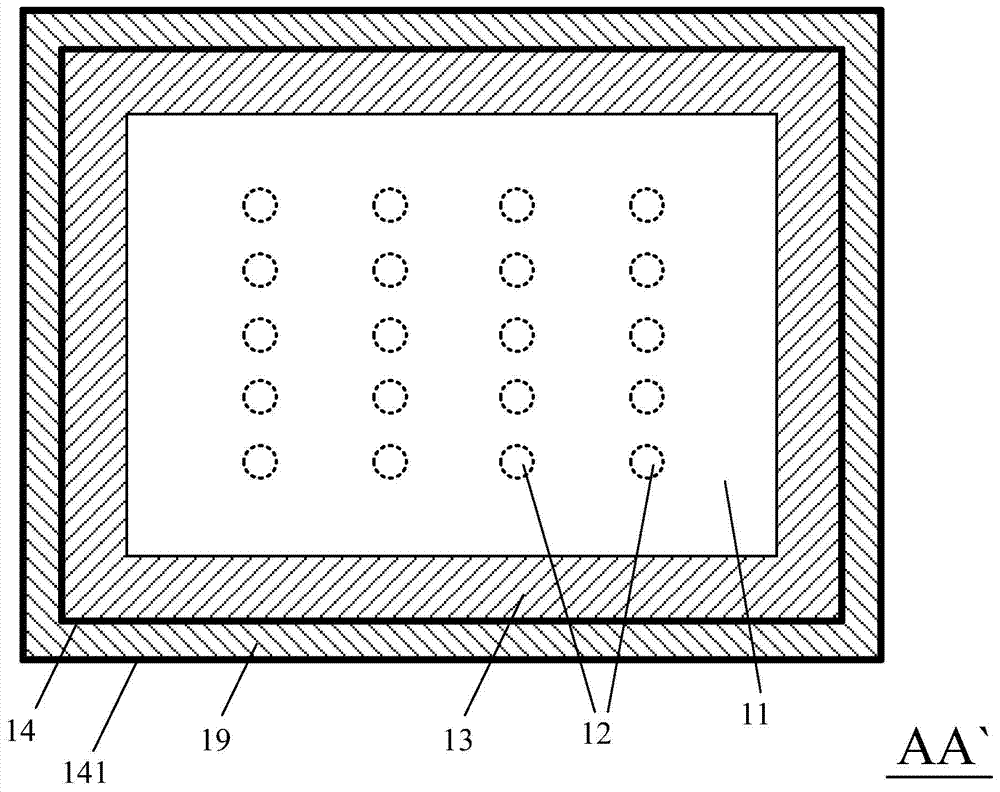

Vacuum board and manufacturing method thereof

ActiveCN104329558APlay a supporting roleReduce security risksSheets/panelsBuilding componentsElectrical and Electronics engineering

The invention provides a vacuum board and a manufacturing method thereof. The vacuum board provided by the invention comprises at least two layers of boards, a plurality of support structures different in height and an organic membrane, wherein the boards on adjacent layers are separated by the support structures different in height; the edges of the at least two layers of boards are connected and closed by a sealing mixture; the organic membrane covers the edges of the at least two layers of boards and the outer side of the sealing mixture. According to the rugged surface of the board provided by the invention, the support structure with the corresponding height is arranged at the corresponding position between the board layers; moreover, the height of each support is matched with the clearance height of the corresponding part of the interior of the vacuum board, so that each support structure can be clamped by the upper and lower two layers of boards, and therefore the support effect is effectively exerted, and the potential safety hazard brought by the structural damage of the vacuum board is reduced.

Owner:ICESUN VACUUM GLASS

Production method of 5052-H32 aluminum alloy plate-strip

ActiveCN103008342AComplete annealingEliminate intermediate annealing processElongated constructional elementsTemperature control deviceIngotMachining

The invention discloses a production method of a 5052-H32 aluminum alloy plate-strip. The production method mainly comprises the following steps: casting, saw-cutting, face-milling, heating, hot rolling, cold rolling, stable annealing and finishing, wherein in the hot rolling step, the finish rolling temperature of hot rough rolling is controlled at 370-450 DEG C, the finish rolling temperature of hot fine rolling is 320-350 DEG C, and the thickness of a hot rolling ingot can be determined according to the requirement on the thickness of a finished product; and in the cold rolling step, the thickness of the finished product can be achieved by performing cold rolling once, and the total machining rate is 20-45%. According to the production method disclosed by the invention, for a finished 5052-H32 product with the thickness of not less than 1.1mm, full annealing and intermediate annealing process steps of the hot rolling ingot can be eliminated, the production cycle can be shortened and the production cost can be reduced.

Owner:ALUHOUSE TECHGD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com