Glass-fiber vacuum insulation panel nano core material and preparation method thereof

A vacuum insulation board, glass fiber technology, applied in the direction of fiber board, synthetic cellulose/non-cellulose material pulp/paper, heat exchange equipment, etc., to achieve the effect of good mechanical strength, long service life and superior physical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

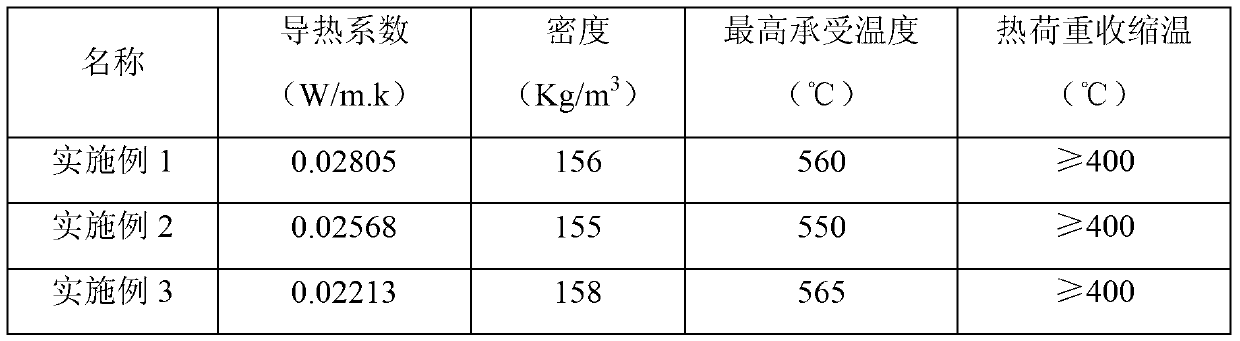

Examples

Embodiment 1

[0020] The preparation method of the glass fiber vacuum insulation panel nano-core material of the present embodiment comprises the following steps:

[0021] Step 1: Take medium-alkali glass balls and heat them to 1700°C to melt them, blow and cut them to produce medium-alkali glass fiber chopped strands with an average diameter of 4um.

[0022] Step 2, select 80 parts of medium-alkali glass fiber chopped strands with an average diameter of 4um and 20 parts of non-alkali glass fiber cotton with a diameter of 1um.

[0023] Step 3: add the above-mentioned raw materials into an aqueous sulfuric acid solution for beating and disperse to obtain a slurry, control the concentration of the slurry to 1.7%, the degree of beating to 9°SR, the pH value to 3.2, and the beating time to 40 minutes.

[0024] Step 4, adding water to the obtained slurry to dilute to a mass concentration of 0.17%, and adjusting the pH value to 2.8;

[0025] Step 5, using a centrifugal deslagging machine to remo...

Embodiment 2

[0029] The preparation method of the glass fiber vacuum insulation panel nano-core material of the present embodiment comprises the following steps:

[0030] Step 1: Take medium-alkali glass balls and heat them to 1600°C to melt them, blow and cut them to produce medium-alkali glass fiber chopped strands with an average diameter of 3um.

[0031] Step 2, choose 50 parts of above-mentioned average diameters and be the medium-alkali glass fiber chopped strands of 3um, 50 parts of diameters be the alkali-free glass fiber cotton of 0.5um,

[0032] Step 3, adding the above-mentioned raw materials into an aqueous sulfuric acid solution for beating and dispersing, controlling the concentration of the slurry to 1.5%, the degree of beating to 8°SR, the pH value to 3, and the beating time to 40 minutes.

[0033] Step 4, add water to the obtained slurry to dilute to a mass concentration of 0.15%, and adjust the pH value to 2.5;

[0034] Step 5, using a centrifugal deslagging machine to r...

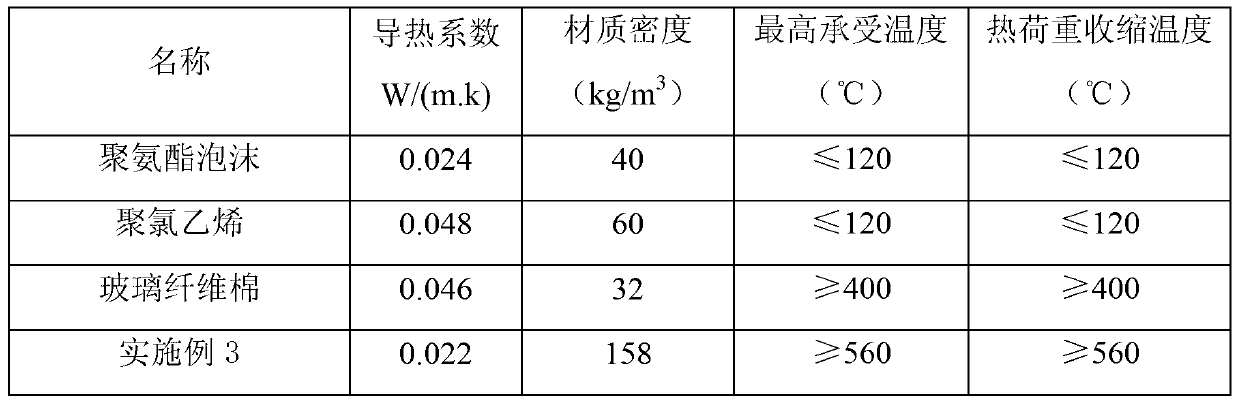

Embodiment 3

[0038] The preparation method of the glass fiber vacuum insulation panel nano-core material of the present embodiment comprises the following steps:

[0039] Step 1: Take medium-alkali glass balls and heat them to 1800°C to melt them, blow and cut them to produce medium-alkali glass fiber chopped strands with an average diameter of 6um.

[0040] Step 2, choose 100 parts of above-mentioned medium-alkali glass fiber chopped strands whose average diameter is 6um,

[0041] Step 3, adding the above-mentioned raw materials into an aqueous solution of sulfuric acid for beating and dispersing, controlling the concentration of the slurry to 2%, the beating degree to 10°SR, the pH value to 3.5, and the beating time to 40 minutes.

[0042] Step 4, add water to the obtained slurry to dilute to a mass concentration of 0.2%, and adjust the pH value to 3;

[0043] Step 5, using a centrifugal deslagging machine to remove slag from the slurry diluted in step 4, and perform wet forming on an i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com