Patents

Literature

1192 results about "Vacuum insulated panel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A vacuum insulated panel (VIP) is a form of thermal insulation consisting of a gas-tight enclosure surrounding a rigid core, from which the air has been evacuated. It is used in building construction, refrigeration units, and insulated shipping containers to provide better insulation performance than conventional insulation materials.

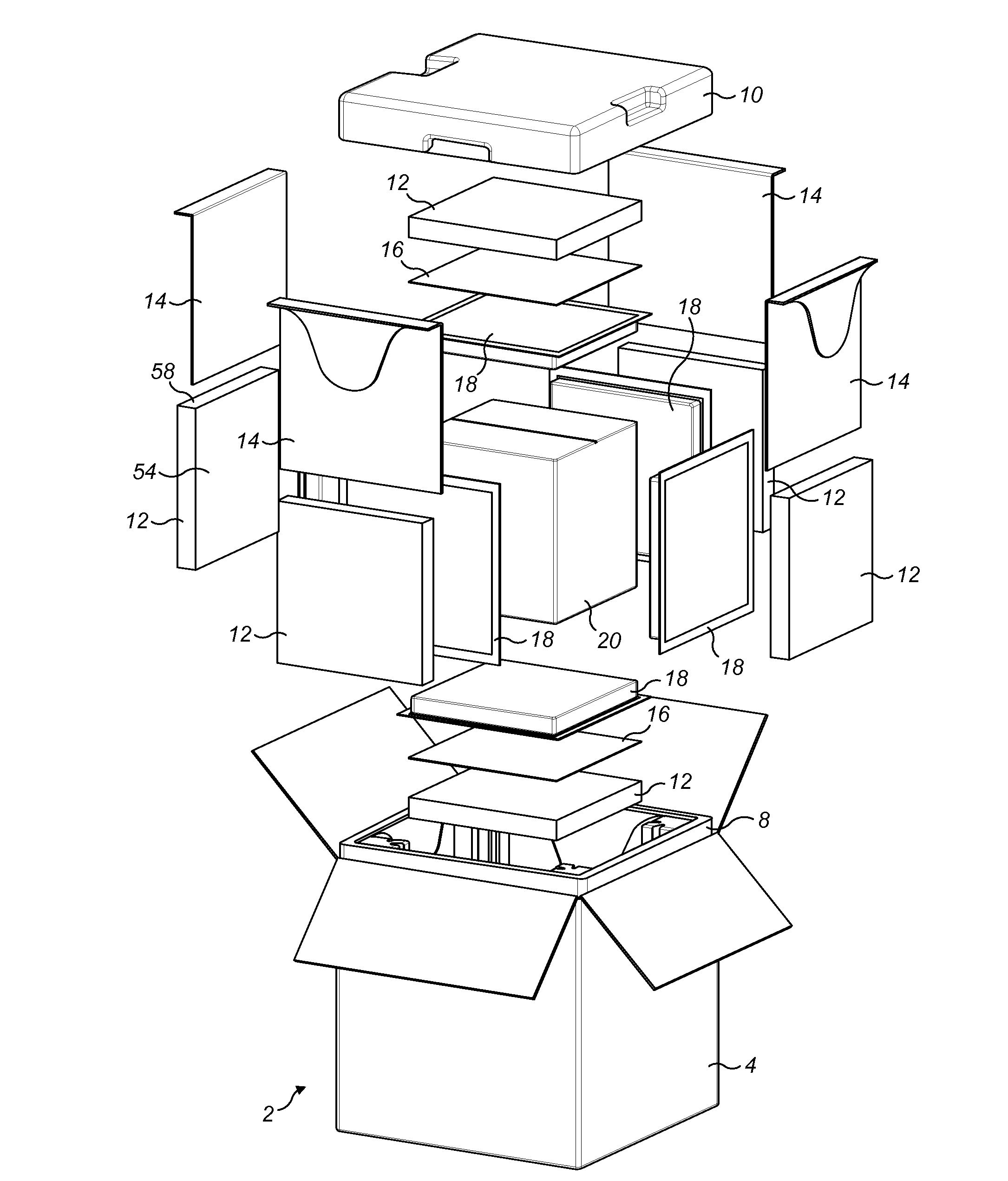

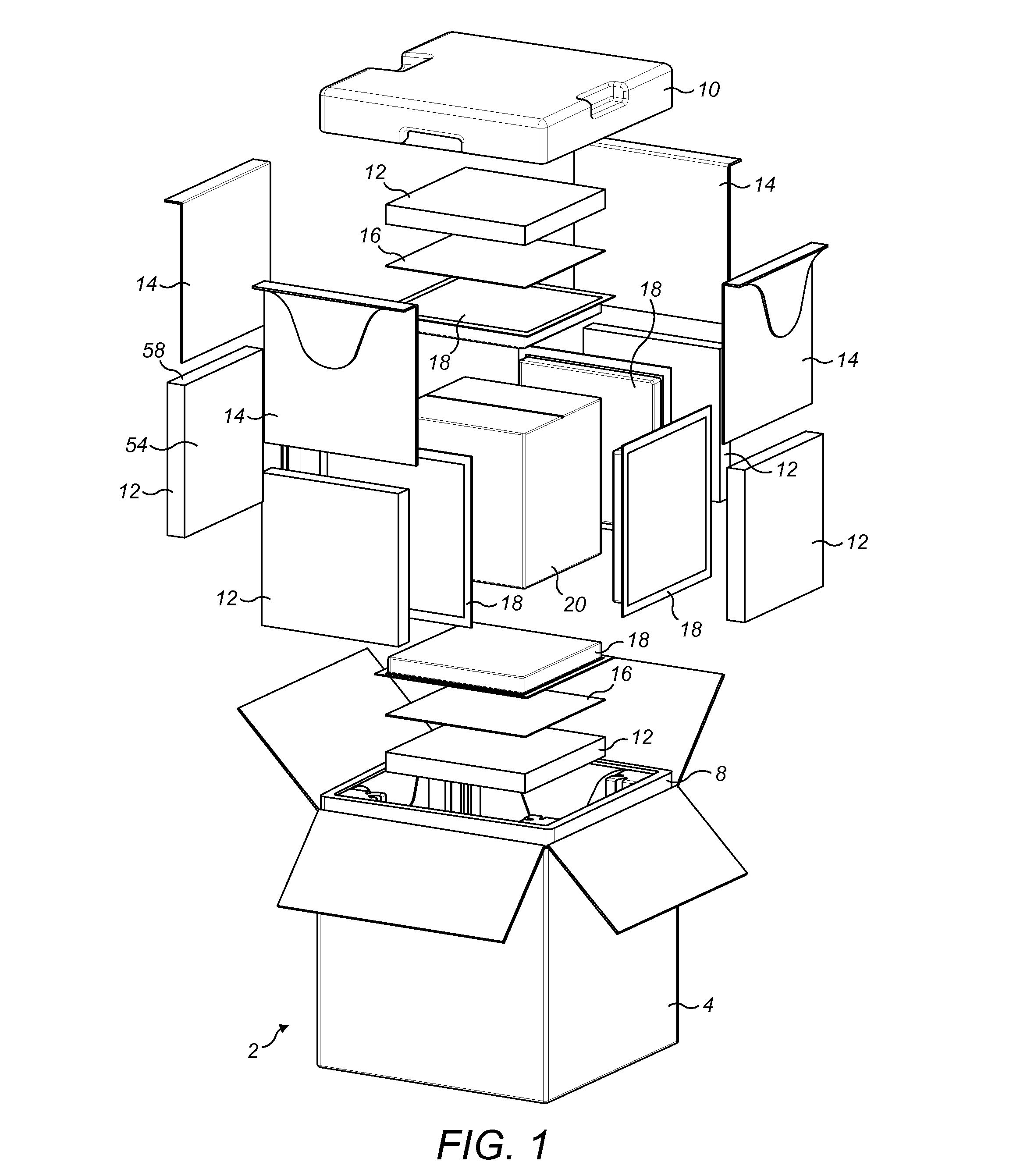

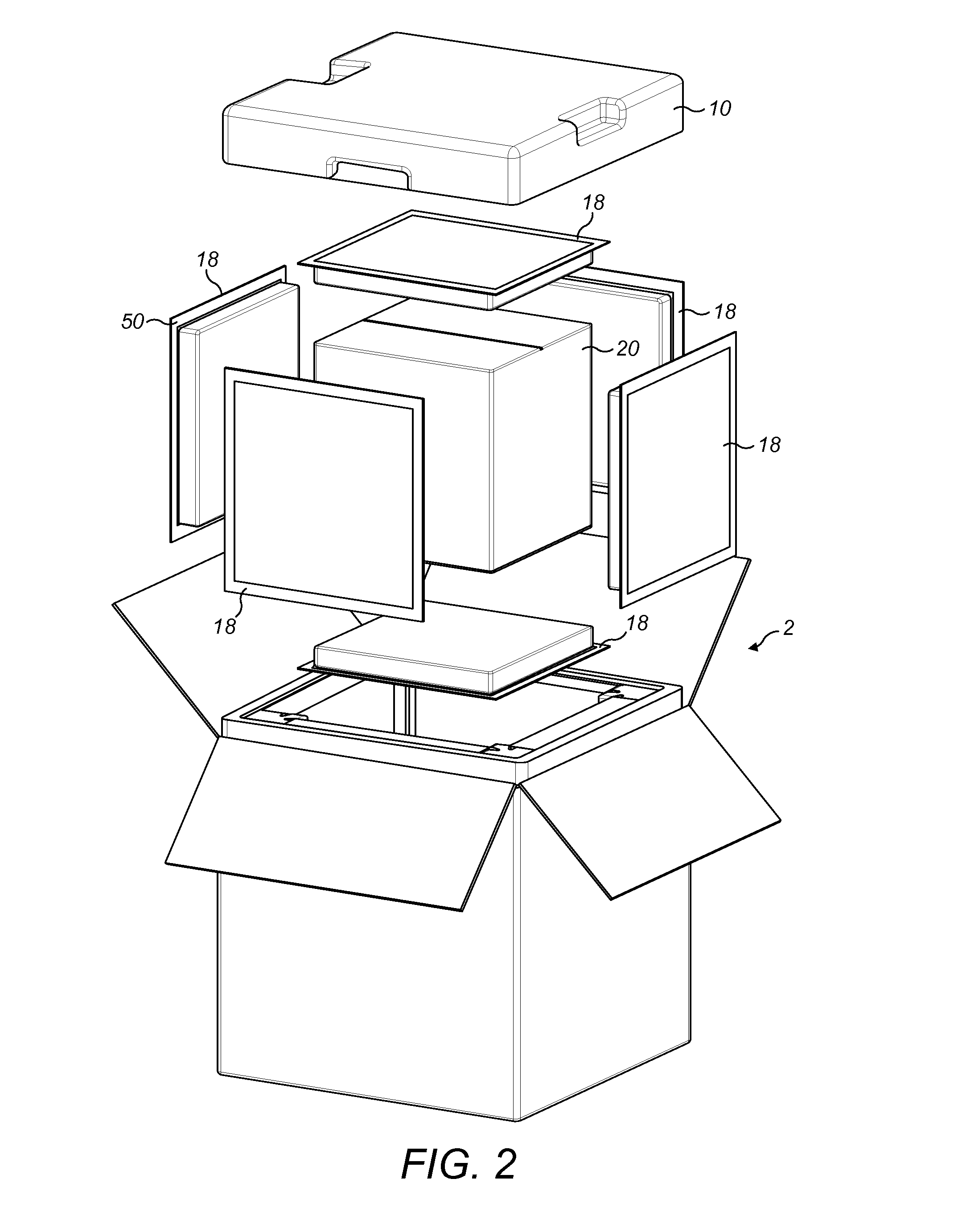

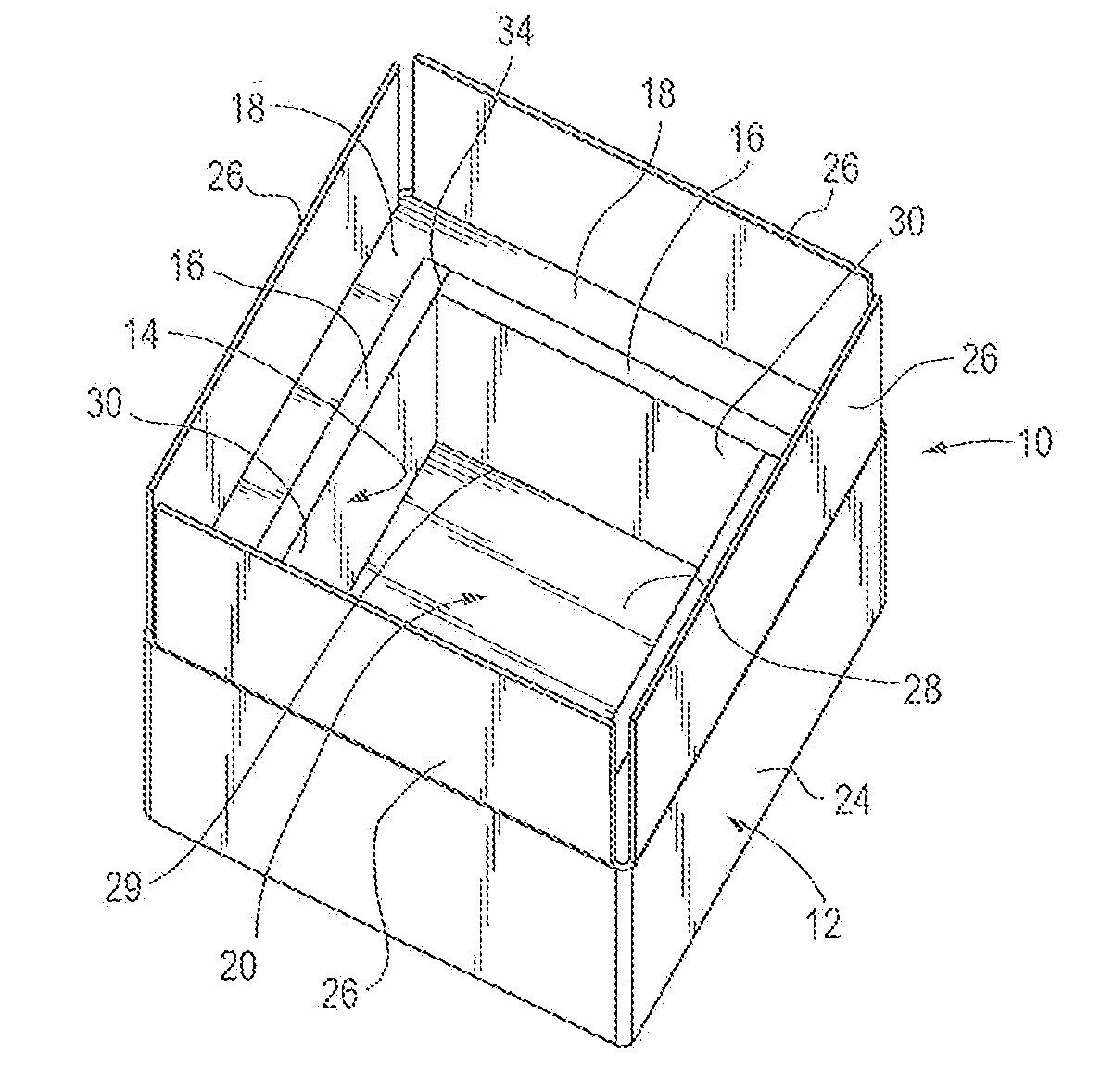

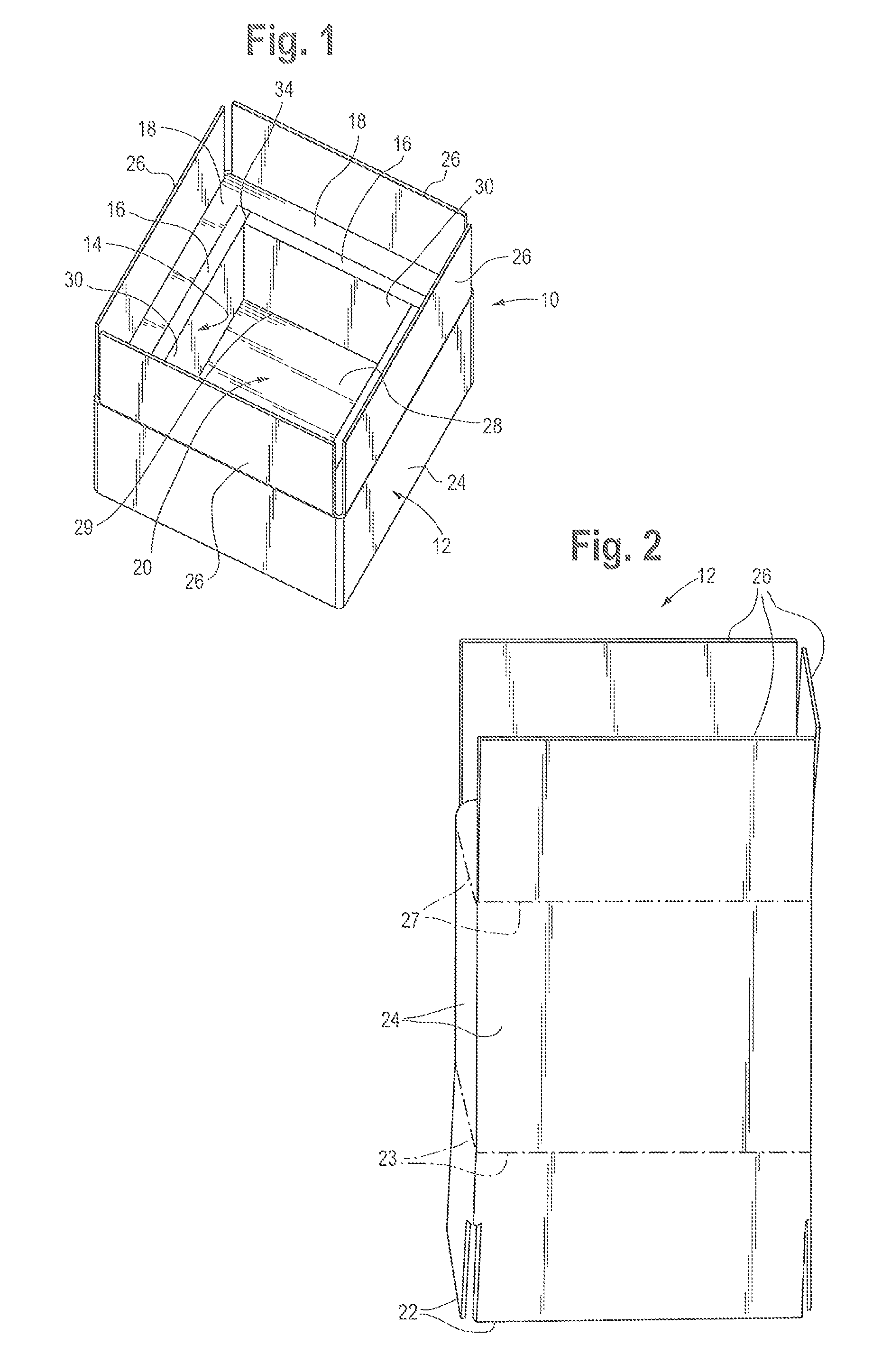

Thermally insulated package

ActiveUS20150166244A1Easy temperature controlLess expensiveLighting and heating apparatusBox making operationsEngineeringPhase-change material

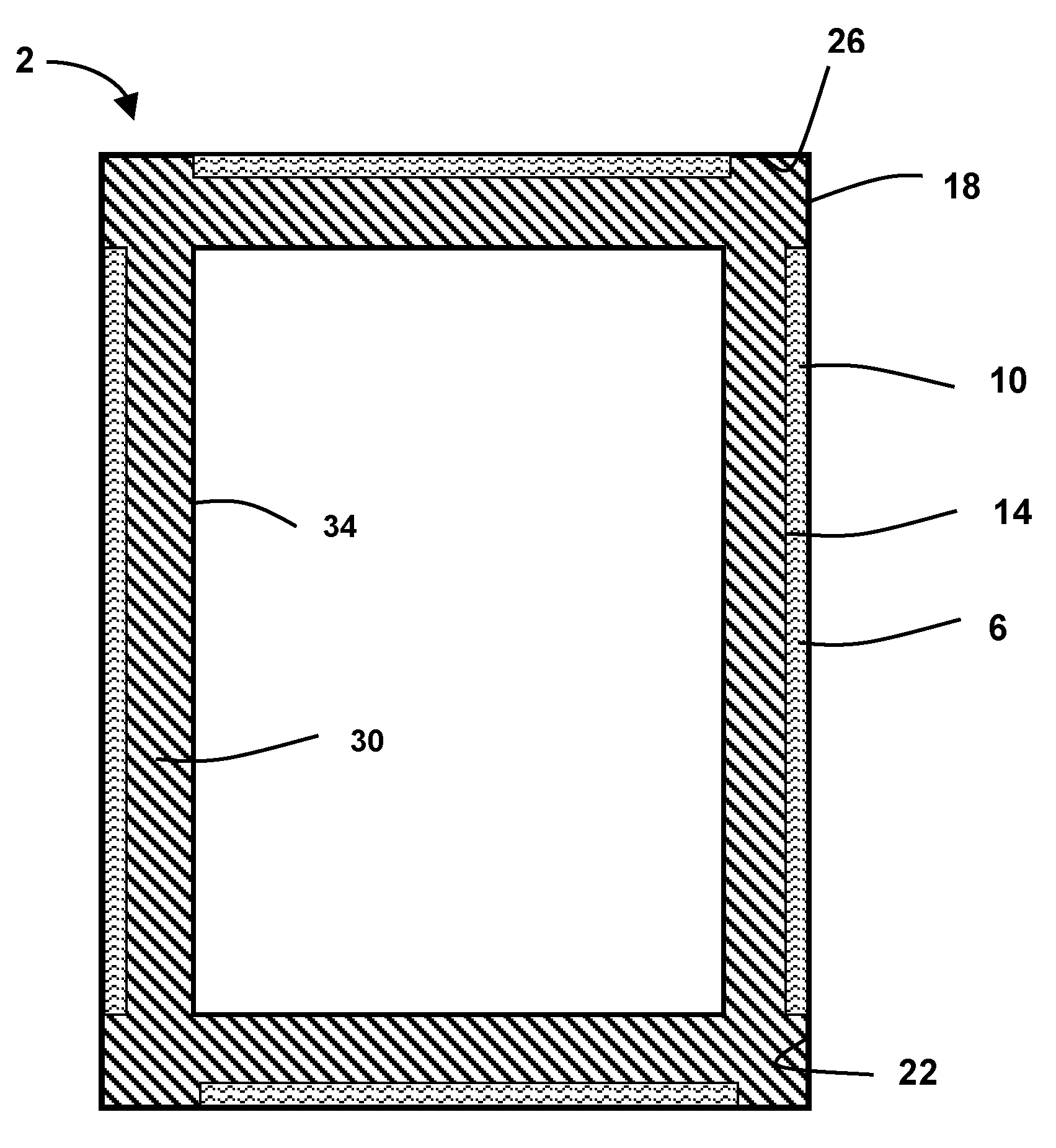

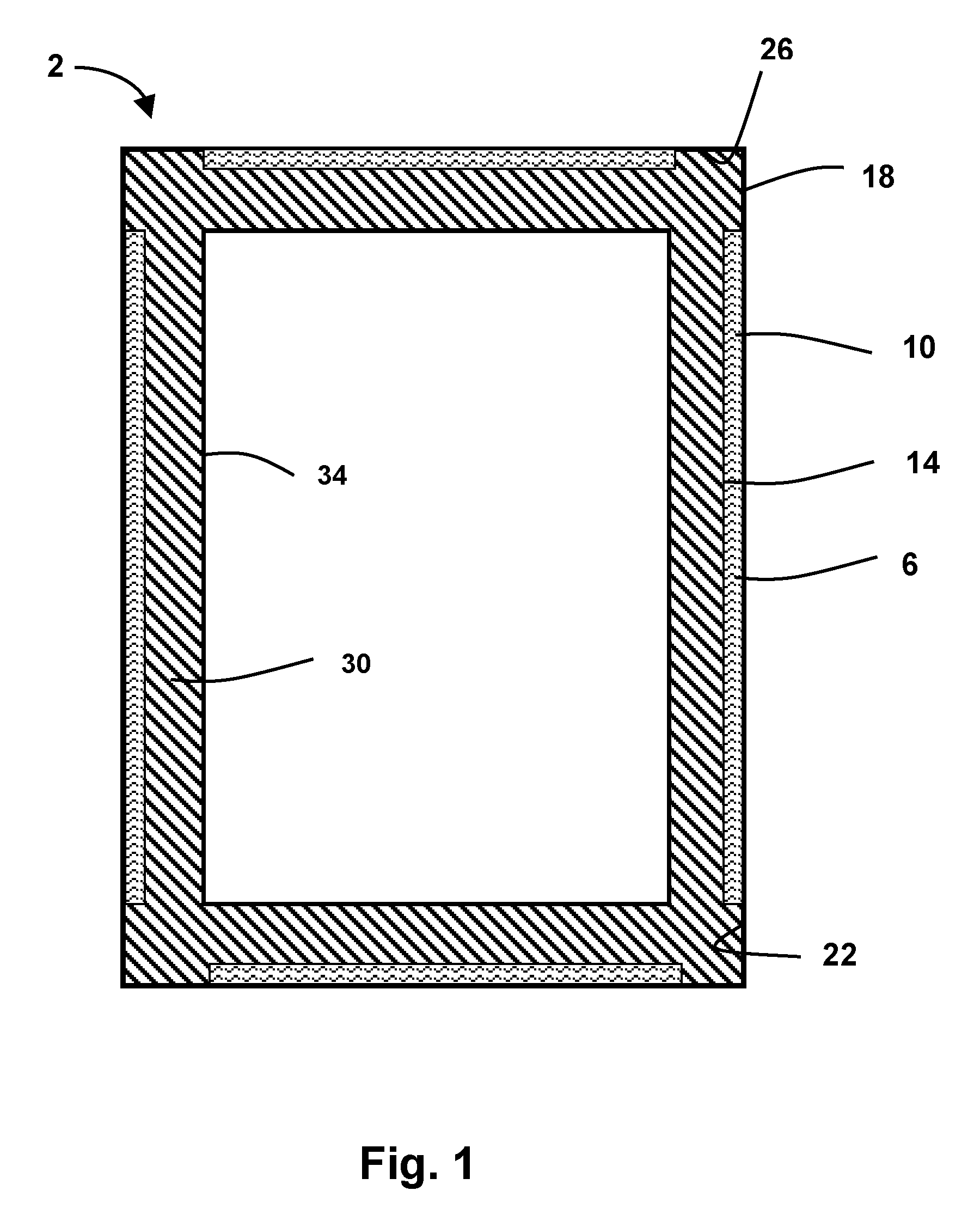

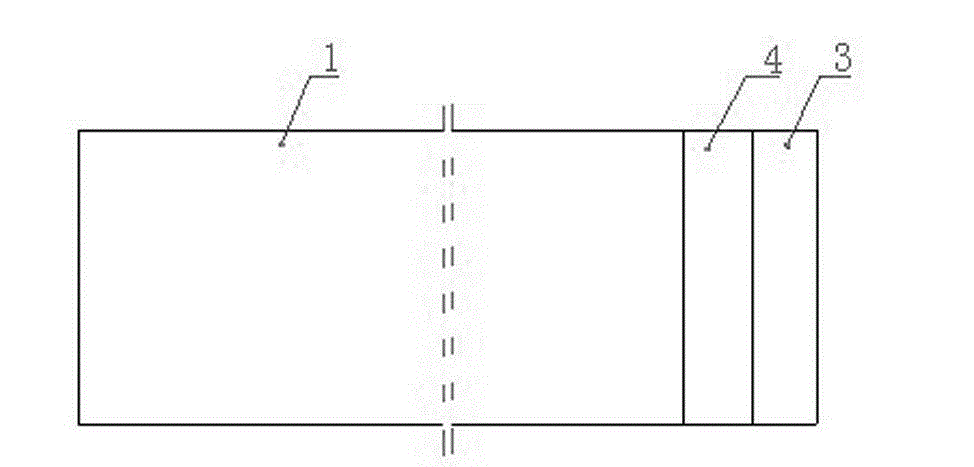

A thermally insulating package comprises an outer shell (6) formed from a foam insulating material, a plurality of vacuum insulated panels (12) removably received on the walls of the outer shell (6) and a plurality of phase change material panels (18) arranged within the vacuum insulated panels (12) to define a payload space.

Owner:PELI BIOTHERMAL LLC (N D GES D STAATES DELAWARE)

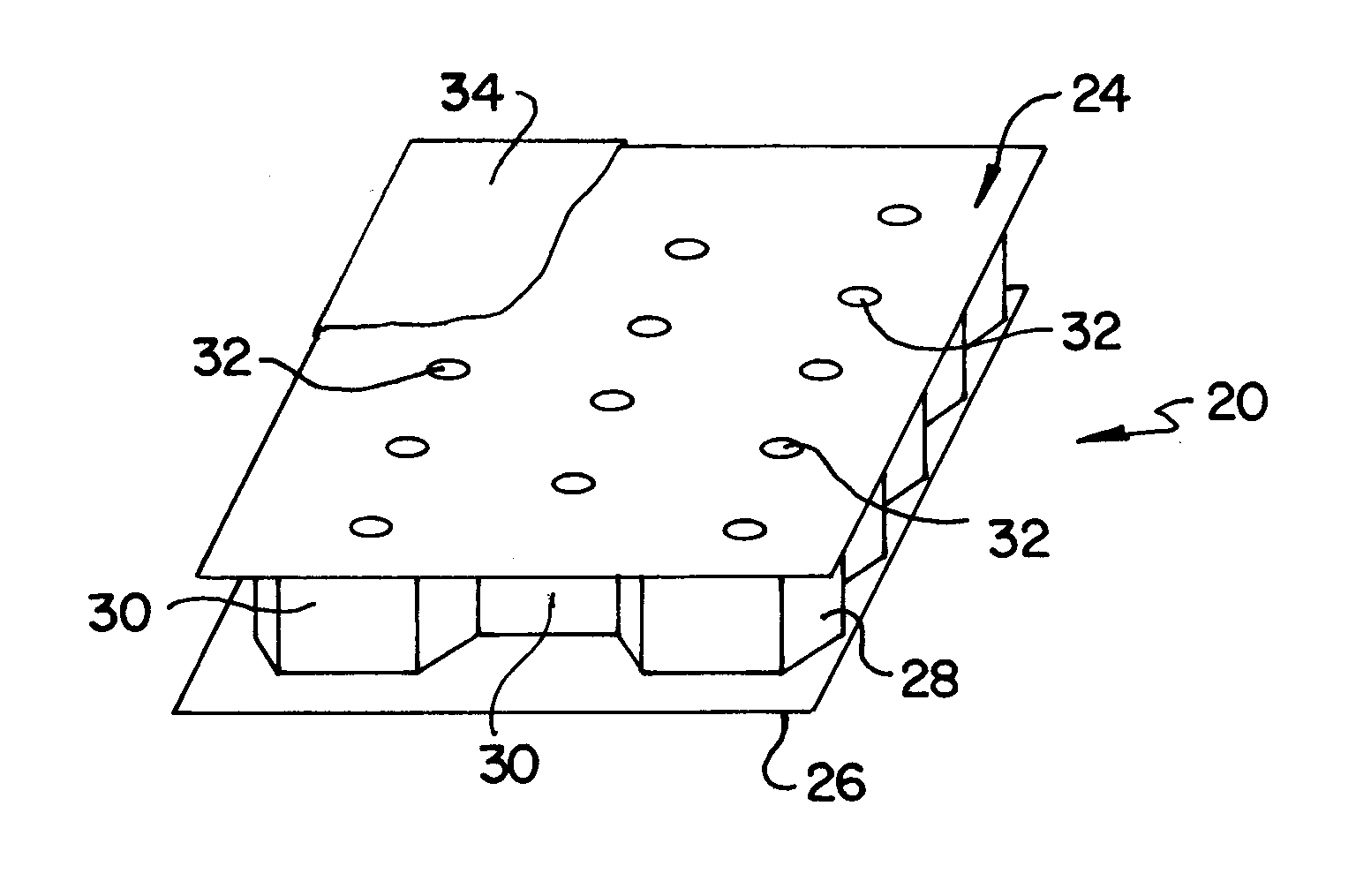

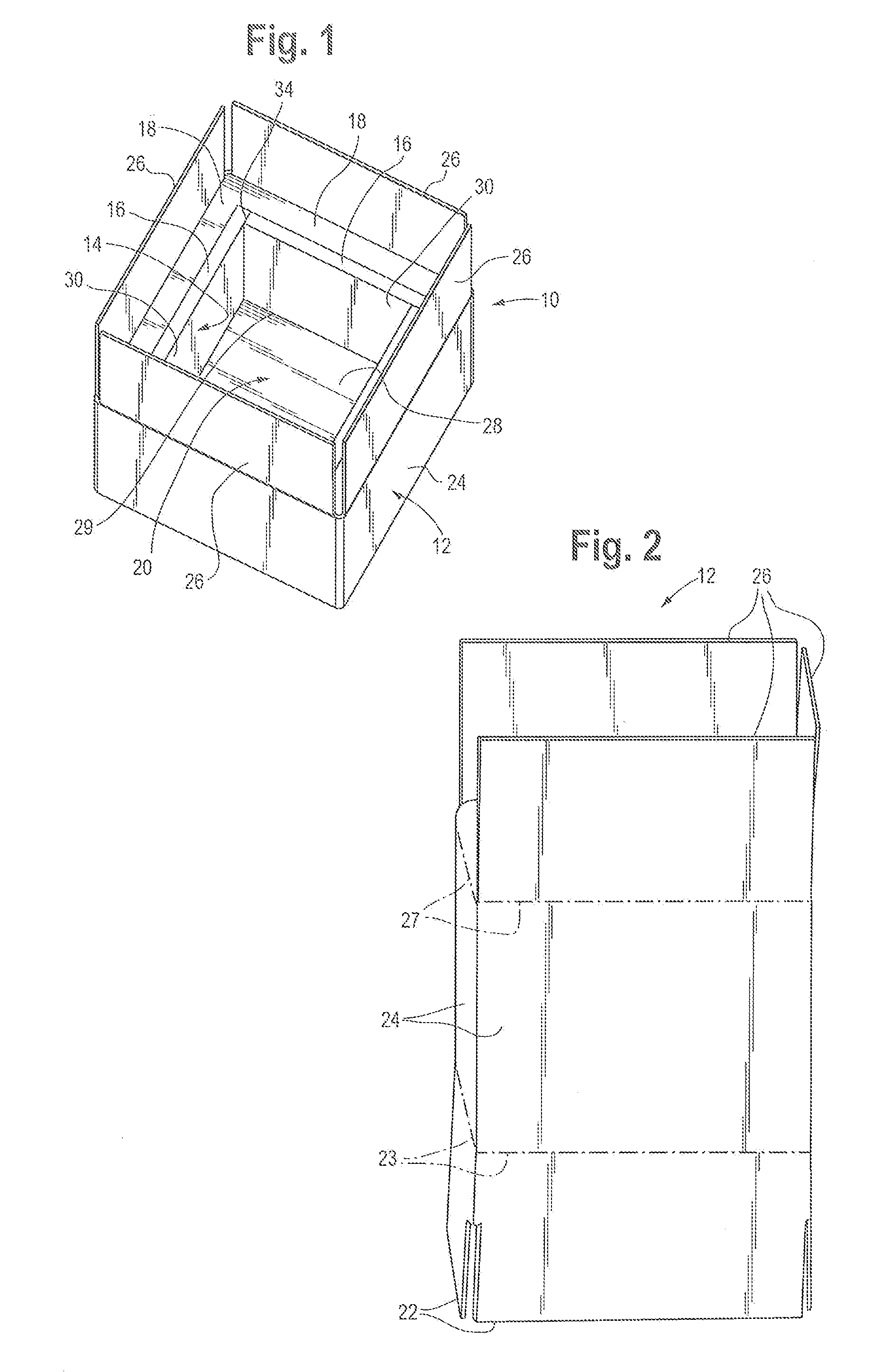

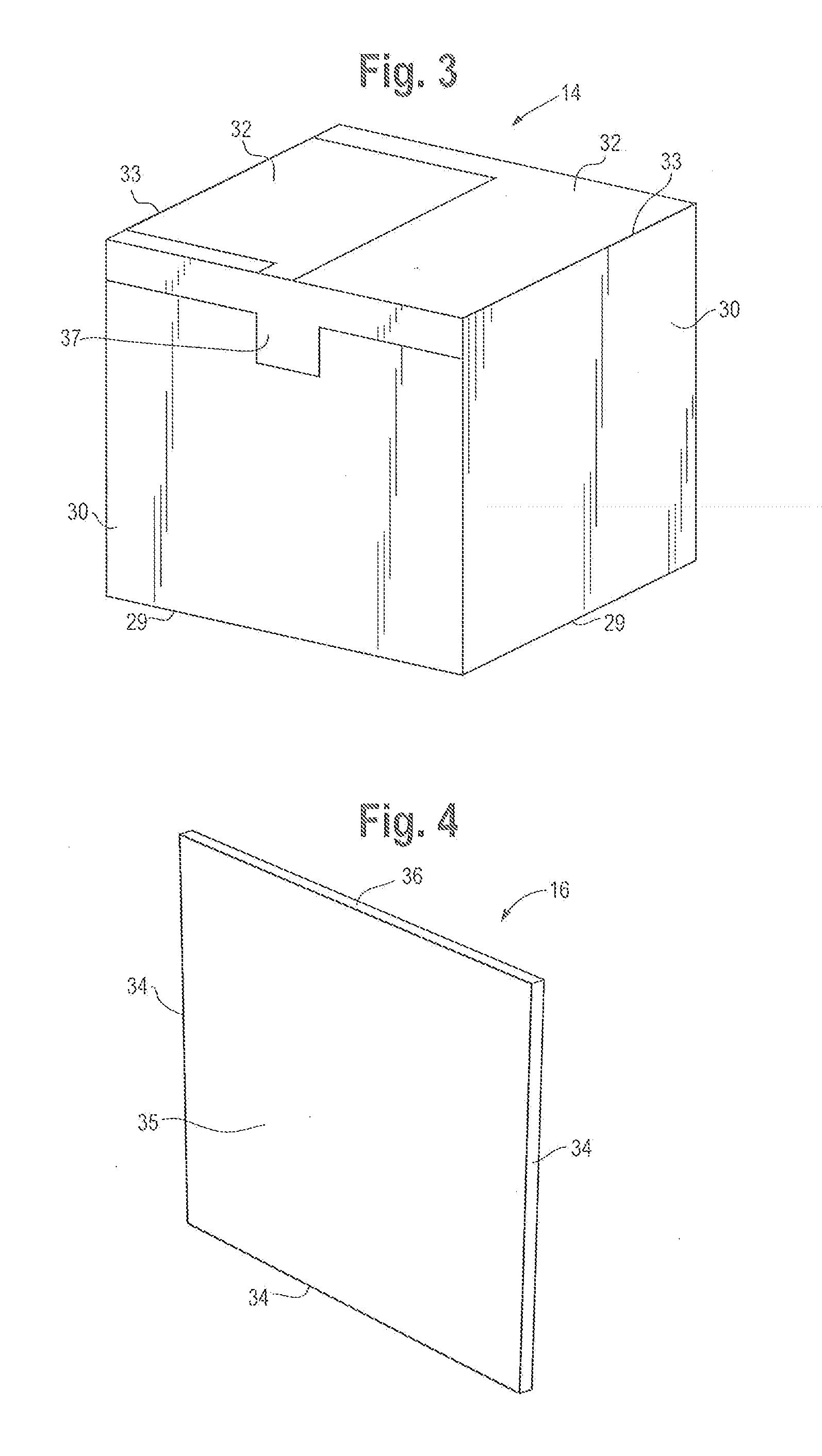

Vacuum insulation panel

InactiveUS20120031957A1Low costDomestic cooling apparatusLighting and heating apparatusEngineeringFace sheet

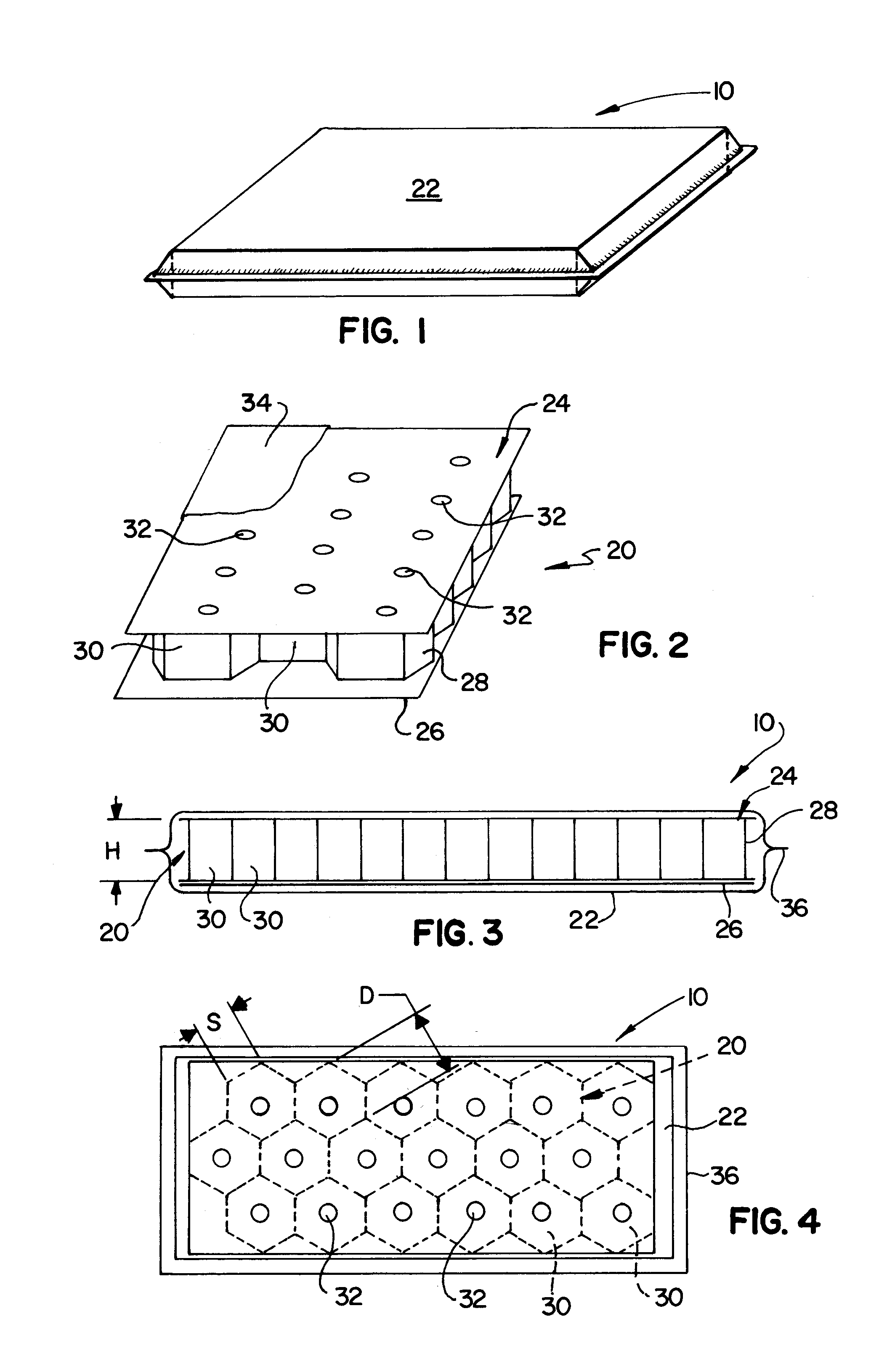

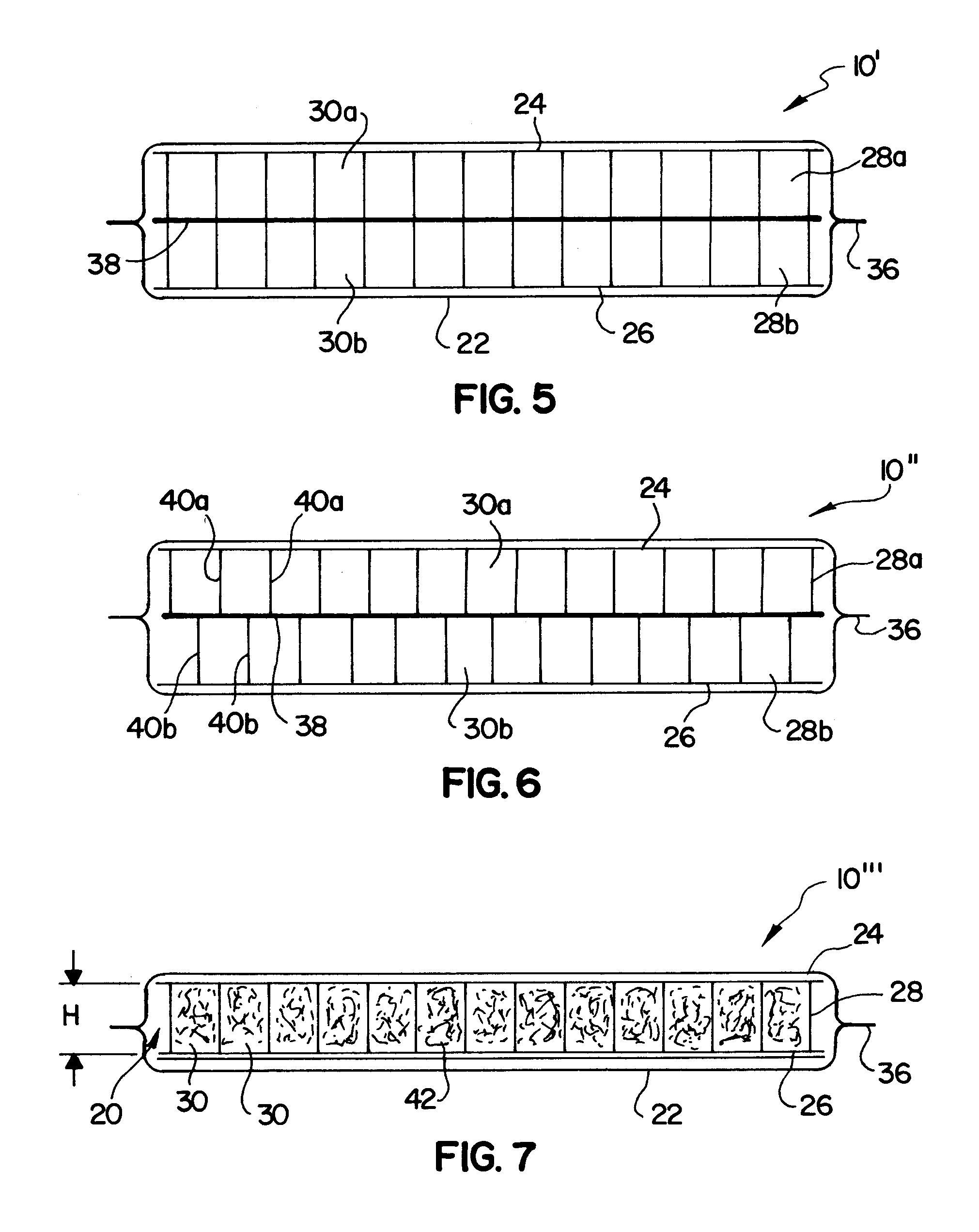

A vacuum insulation panel that includes a paper core made of at least one panel consisting of first and second facing sheets, made of paper, that sandwich a paper honeycomb structure. The honeycomb structure preferably includes a plurality of cells that extend from the first facing sheet to the second facing sheet. The panel also includes an outer shell that surrounds the core, wherein the outer shell is made of a material of low gas permeability and is sealed to form a substantially airtight container around the core. In preferred embodiments, an interior of said outer shell has been evacuated to a pressure of between approximately 1-10 Torr, resulting in an insulating panel that has an R-value of approximately 3.

Owner:PACKAGINGPRICE COM

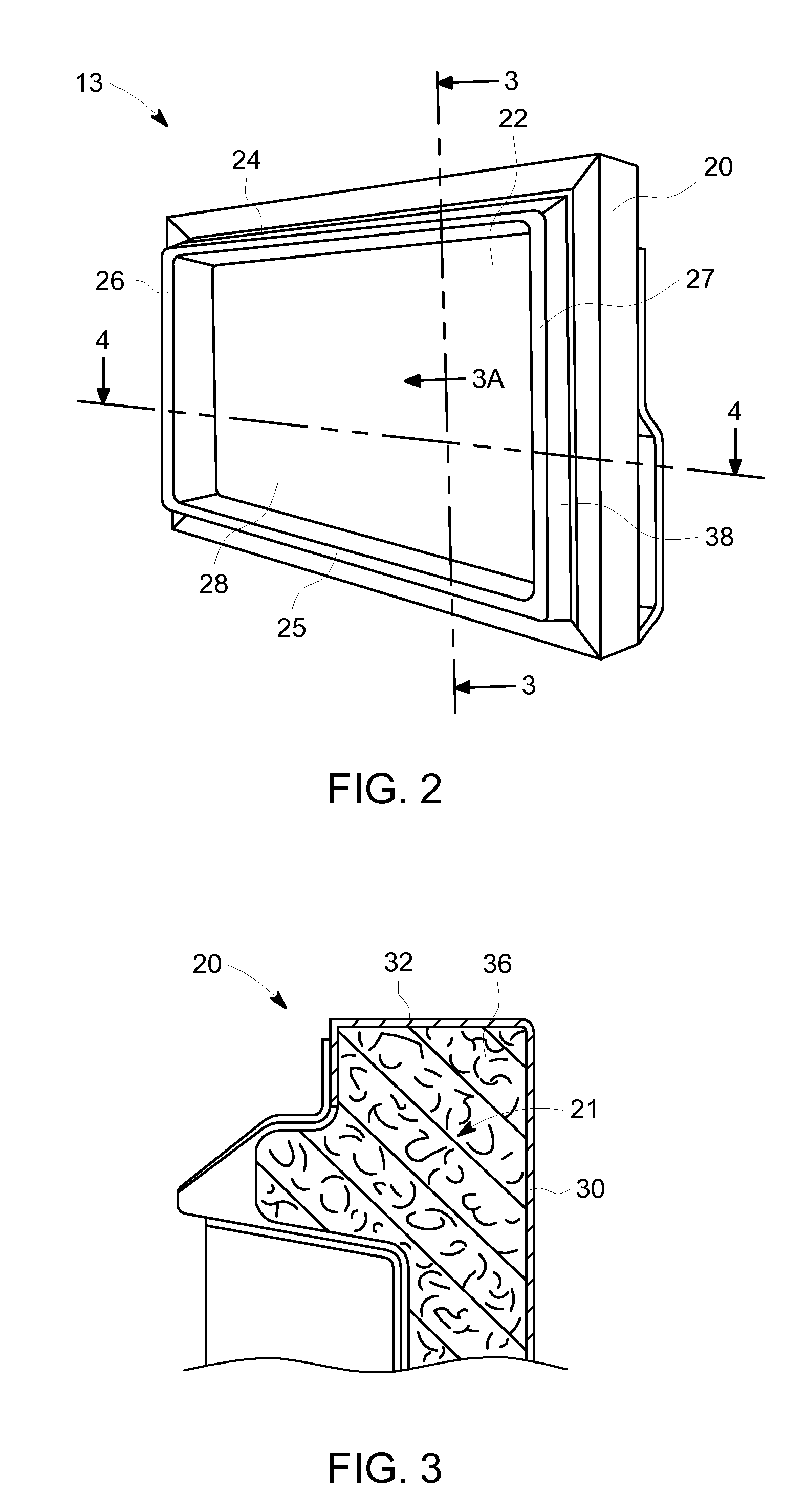

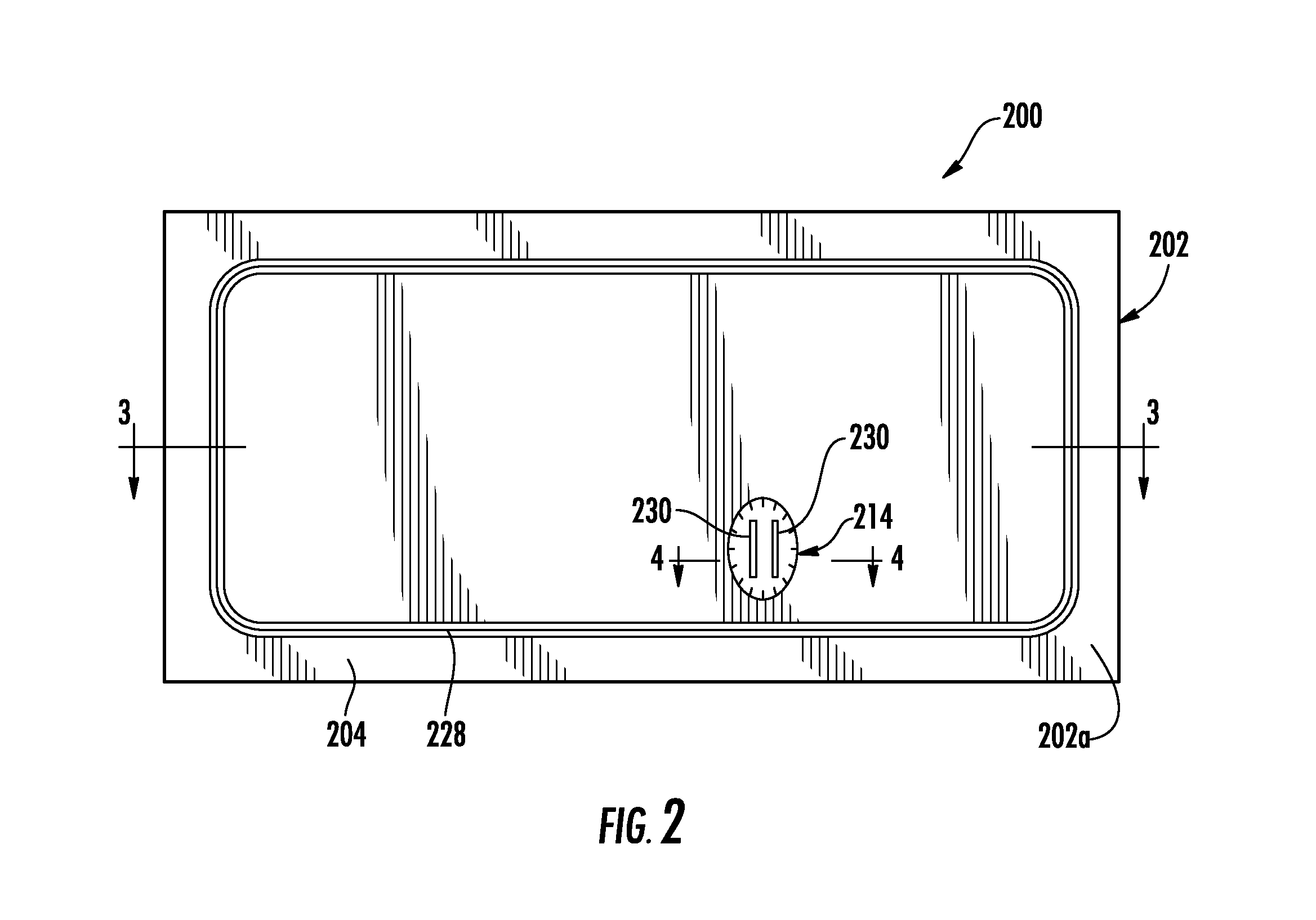

Vacuum insulation panel with smooth surface method for making and applications of same

InactiveUS20090179541A1Reduce roughnessUniform appearanceLighting and heating apparatusHollow inflatable ballsEngineeringRefrigeration

Vacuum insulation panels and methods for making vacuum insulation panels. The panels include first and second spaced-apart sidewalls, where at least one of the sidewalls has a very smooth surface. The panels are particularly useful as insulation in applications where a smooth and aesthetically acceptable surface is required, such as in a refrigeration appliance. A method for making a vacuum insulation panel can include placing an insulative core material and a liner within a barrier envelope defining an enclosure, evacuating the enclosure, and sealing the envelope to form the vacuum insulation panel.

Owner:NANOPORE INC

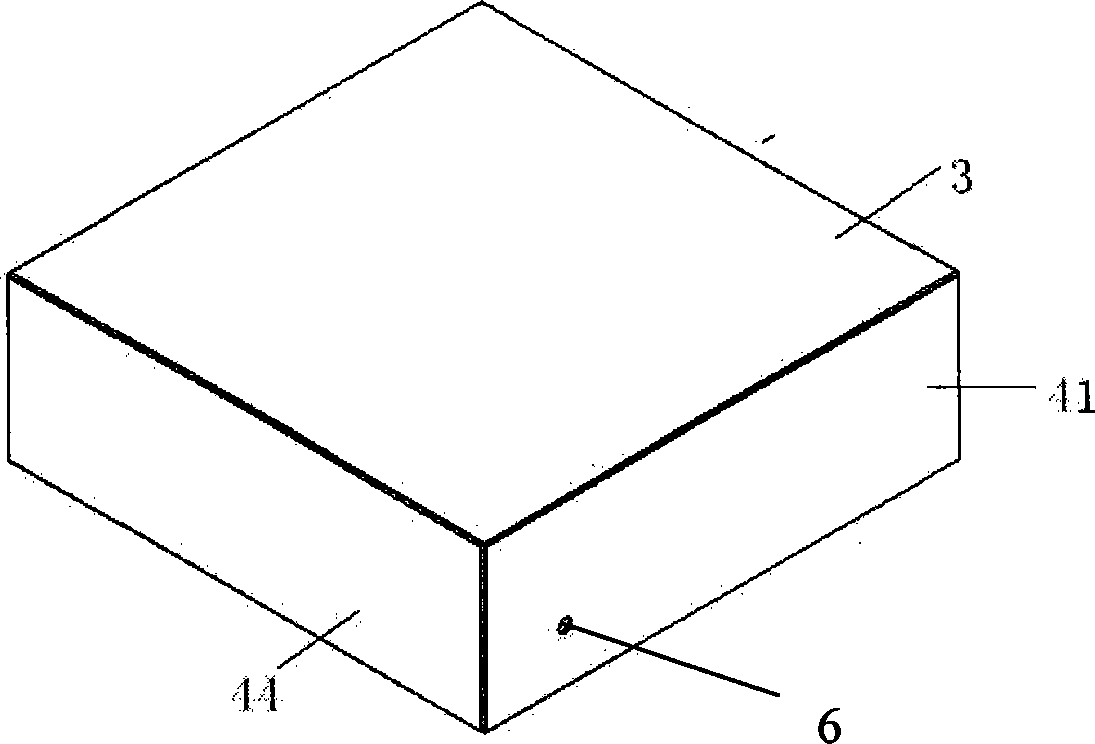

Fixed vacuum insulation panel

InactiveUS6164030ASimple wayReliable anchoringThermal insulationInsulation for cooling apparatusEngineeringOpen cell

An apparatus is described which consists of a rigid plate and a vacuum insulation panel, in which the vacuum insulation panel is fixed to the rigid plate by a polyurethane foam applied as a liquid reaction mixture, wherein the vacuum insulation panel contains open-cell rigid plastics foam and / or open-cell rigid plastics foam recyclate. A refrigerated cabinet element containing said apparatus is additionally described.

Owner:KARL WERNER DIETRICH

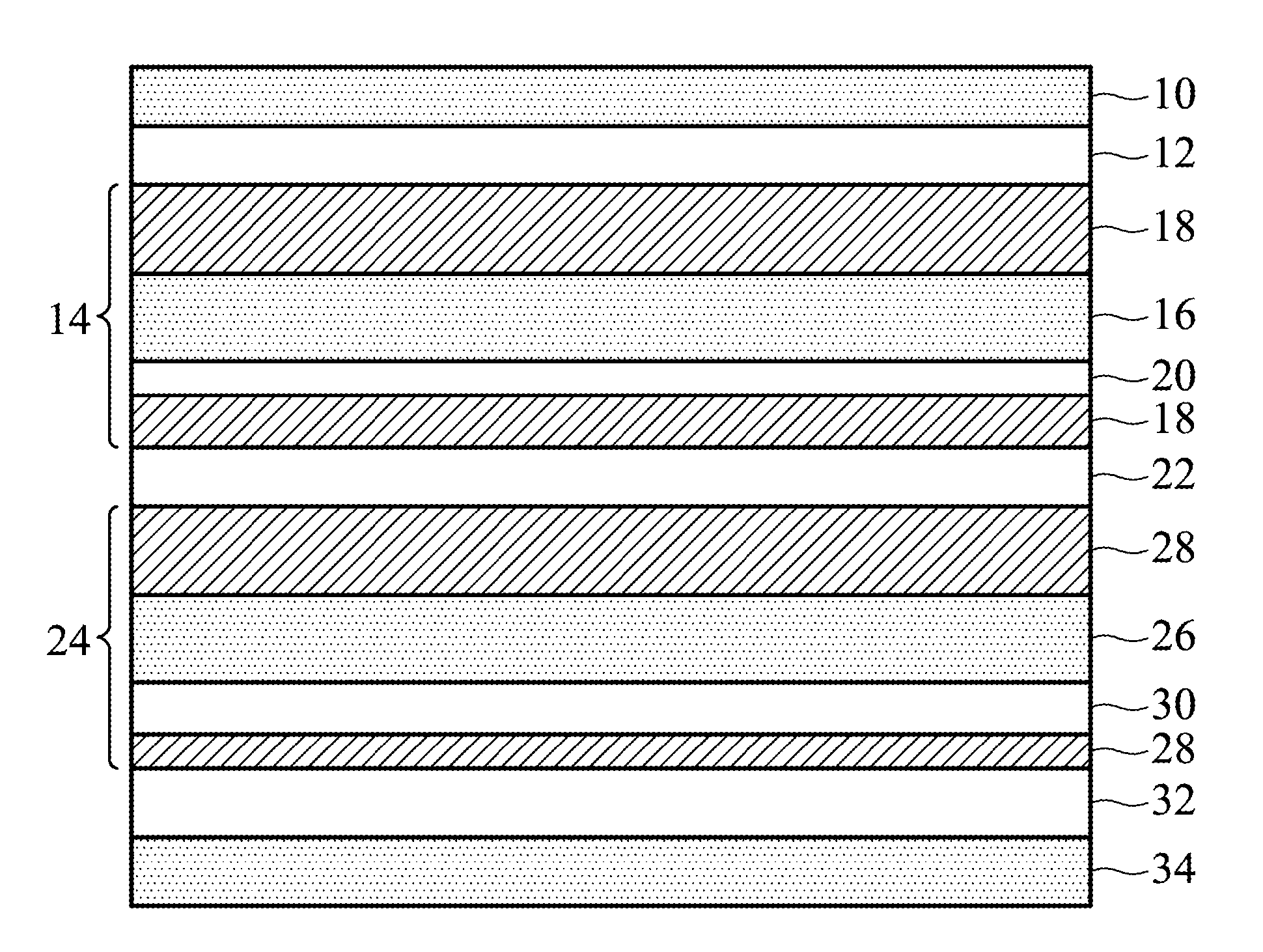

Nanometer multiple-layer composite thermal insulation material and preparation method thereof

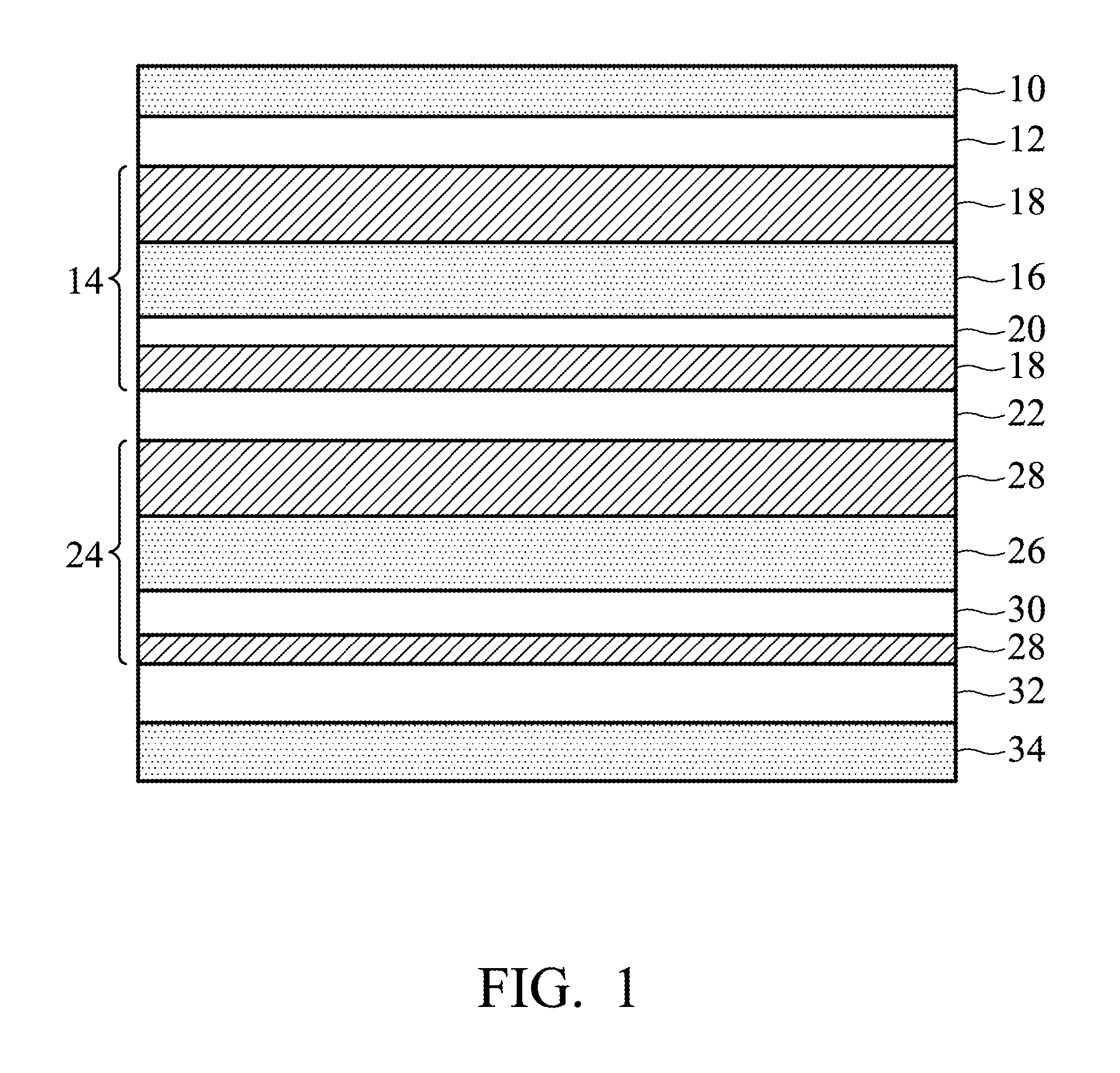

ActiveCN101799099AEasy to useInhibition of high temperature radiative heat transferThermal insulationPipe protection by thermal insulationAdhesiveMetal foil

The invention discloses a nanometer multiple-layer composite thermal insulation material and a preparation method thereof. The nanometer multiple-layer thermal insulation composite material is formed by alternatively overlapping an infrared reflecting screen and a spacer; the ratio of total layer amounts n of the infrared reflecting screens and the spacers to the total thickness of the nanometer multiple-layer composite thermal insulation material is 0.5-4; the infrared reflecting screen is a metal foil or a metal plated foil; the spacer is a thermostability nanometer porous aerogel composite thermal insulation material; the infrared reflecting screen and the spacer are combined by being adhered with thermostability adhesives or in puncturing connection by thermostability sewing threads. The invention also comprises the preparation method of the nanometer multiple-layer composite thermal insulation material. The nanometer multiple-layer composite thermal insulation material of the invention has low density, favorable mechanical property and favorable high-temperature thermal insulation property, lowers requirements on the vacuum degree by a VIP plate when being used as vacuum thermal insulation plate core materials, does not need getter and can satisfy harsh high-efficiency thermal insulation using requirements on materials by aviation, aerospace and civil fields. The method of the invention can prepare thermal insulation material members with large size and complex shape.

Owner:NAT UNIV OF DEFENSE TECH

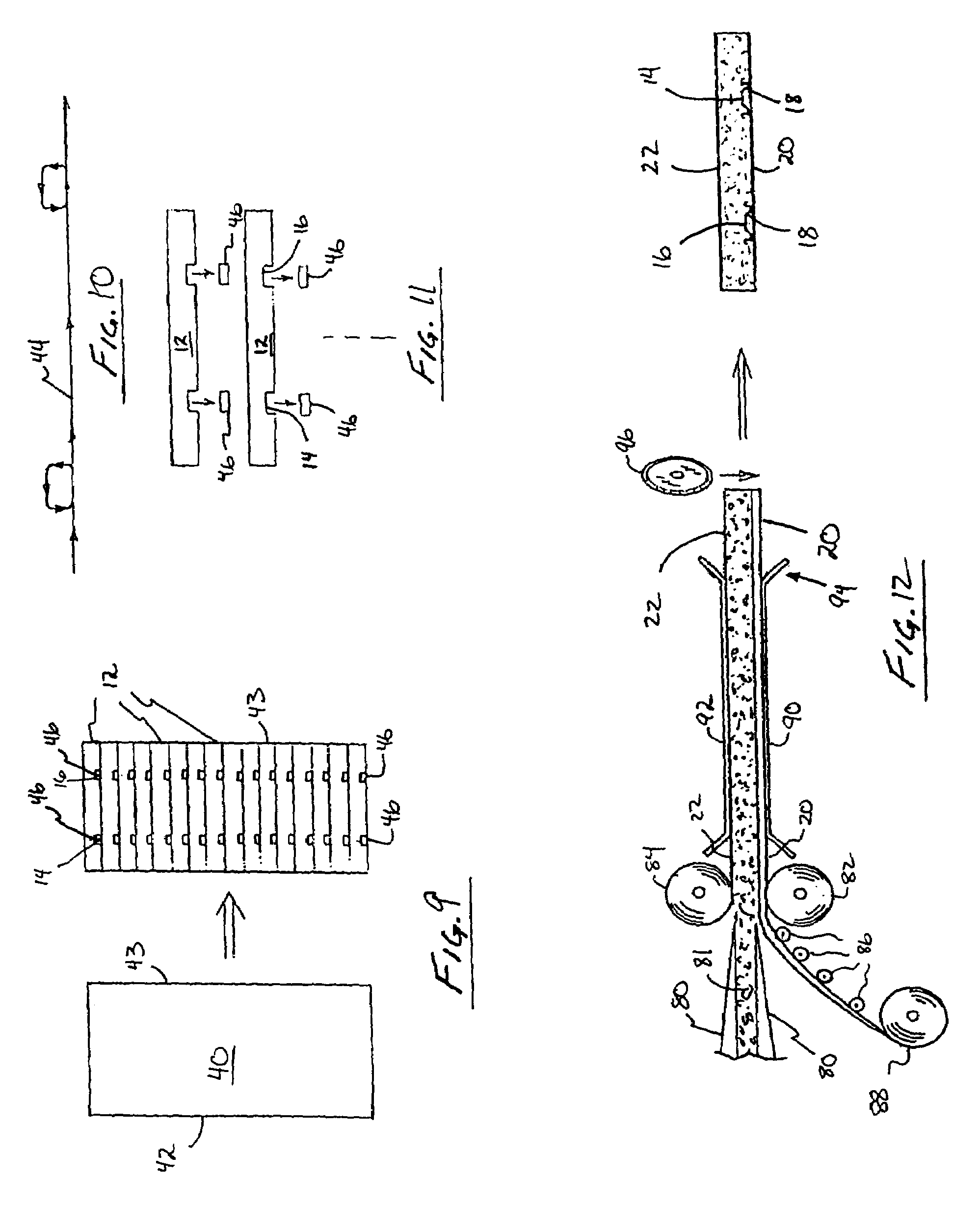

Thermally insulated polyurethane shipper and method of making same

ActiveUS20140367393A1Simple structureAdditional operating advantageDomestic cooling apparatusLighting and heating apparatusTemperature sensitiveVacuum insulated panel

A thermally insulated sandwich polyurethane (PUR) shipper for a temperature sensitive payload is provided. The sandwich PUR shipper comprises an outer corrugated box, an inner corrugated box, vacuum insulated panels (such as VIP panels) and PUR foam. The inner box is nested within the outer box and has a bottom, sides and a top. The inner box defines a payload compartment. The VIP panels are adhered to the outer facing surfaces of the inner box. Preferably the VIP panels are wedged against each other so that a side edge of one VIP panel abuts an adjacent VIP panel. The PUR foam fills the space between the VIP panels and the outer box. The PUR foam may cover the top edges of the VIP panels.

Owner:SONOCO DEV INC

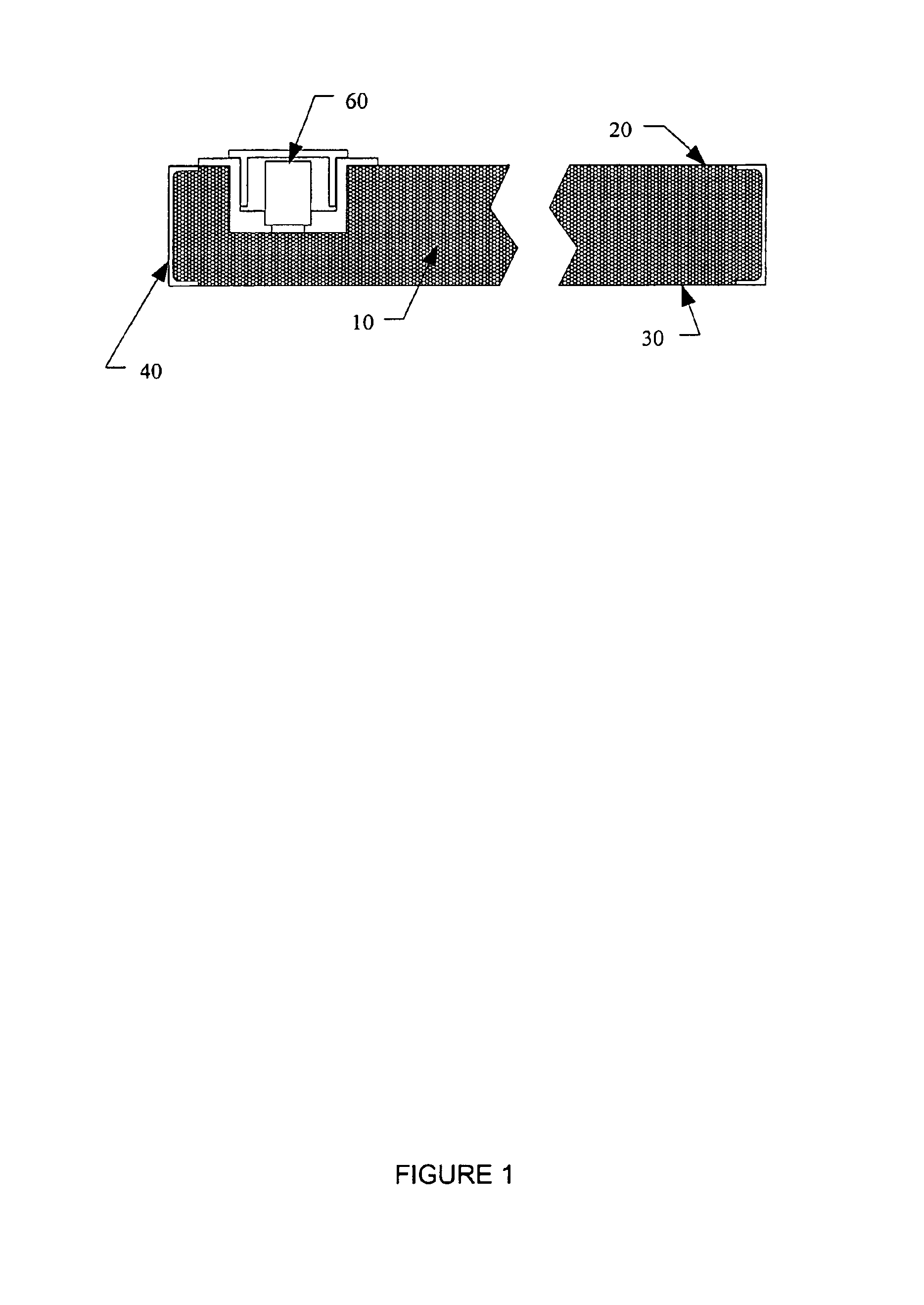

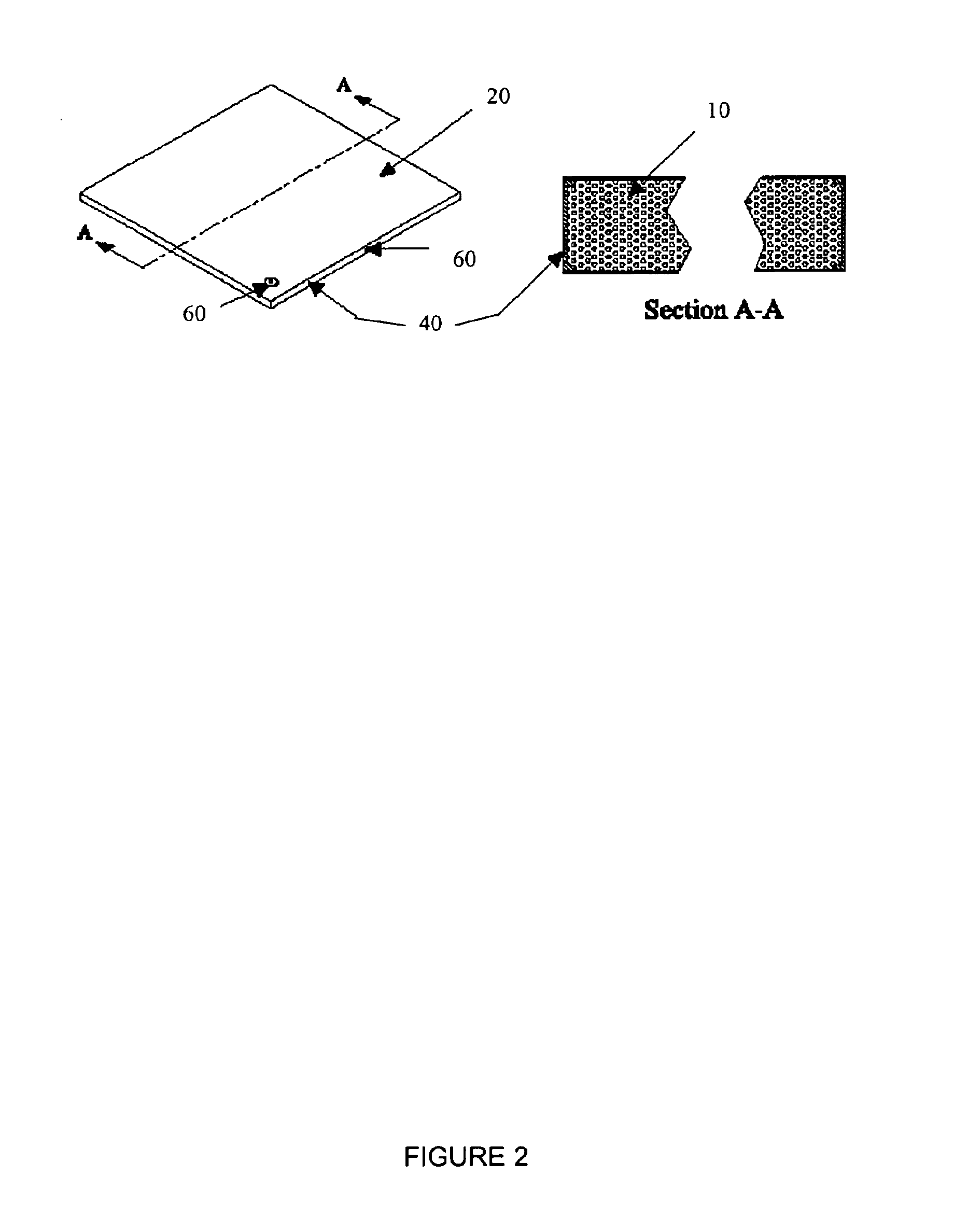

Microsphere insulation systems

InactiveUS6858280B2Reduce the impactIncreases insulation valueLayered productsContainer filling methodsMicrosphereEngineering

A new insulation system is provided that contains microspheres. This insulation system can be used to provide insulated panels and clamshells, and to insulate annular spaces around objects used to transfer, store, or transport cryogens and other temperature-sensitive materials. This insulation system provides better performance with reduced maintenance than current insulation systems.

Owner:TECH APPL

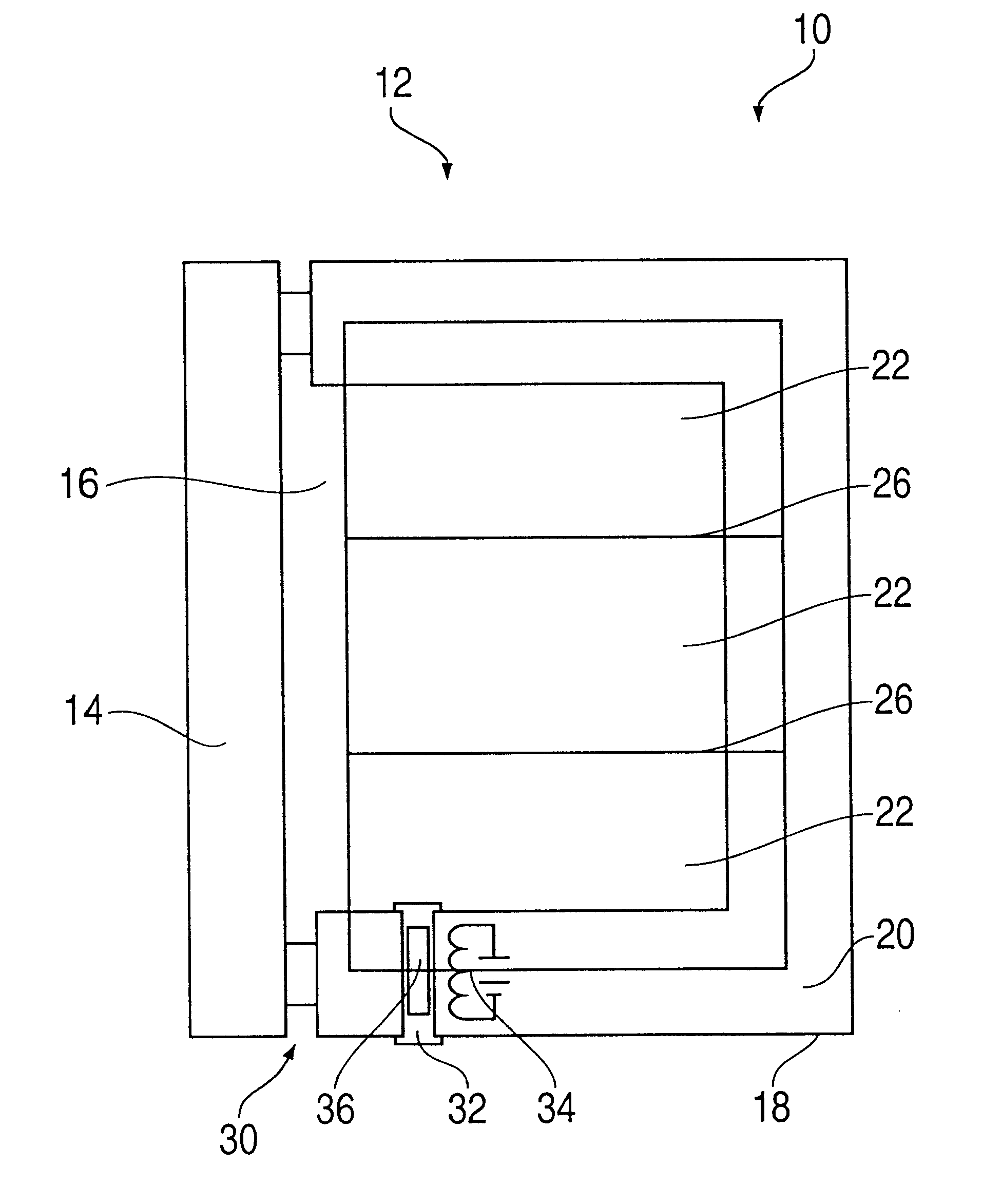

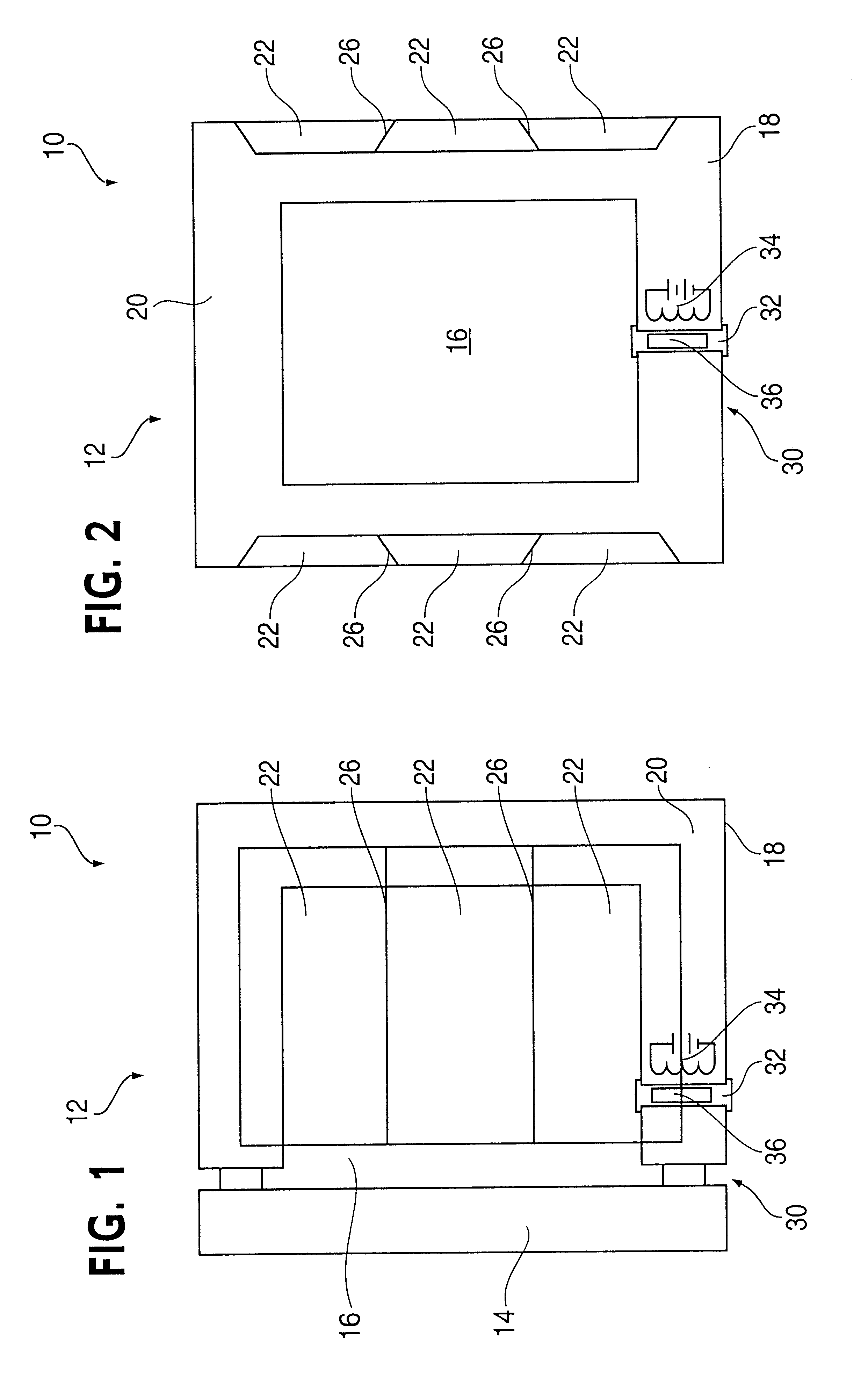

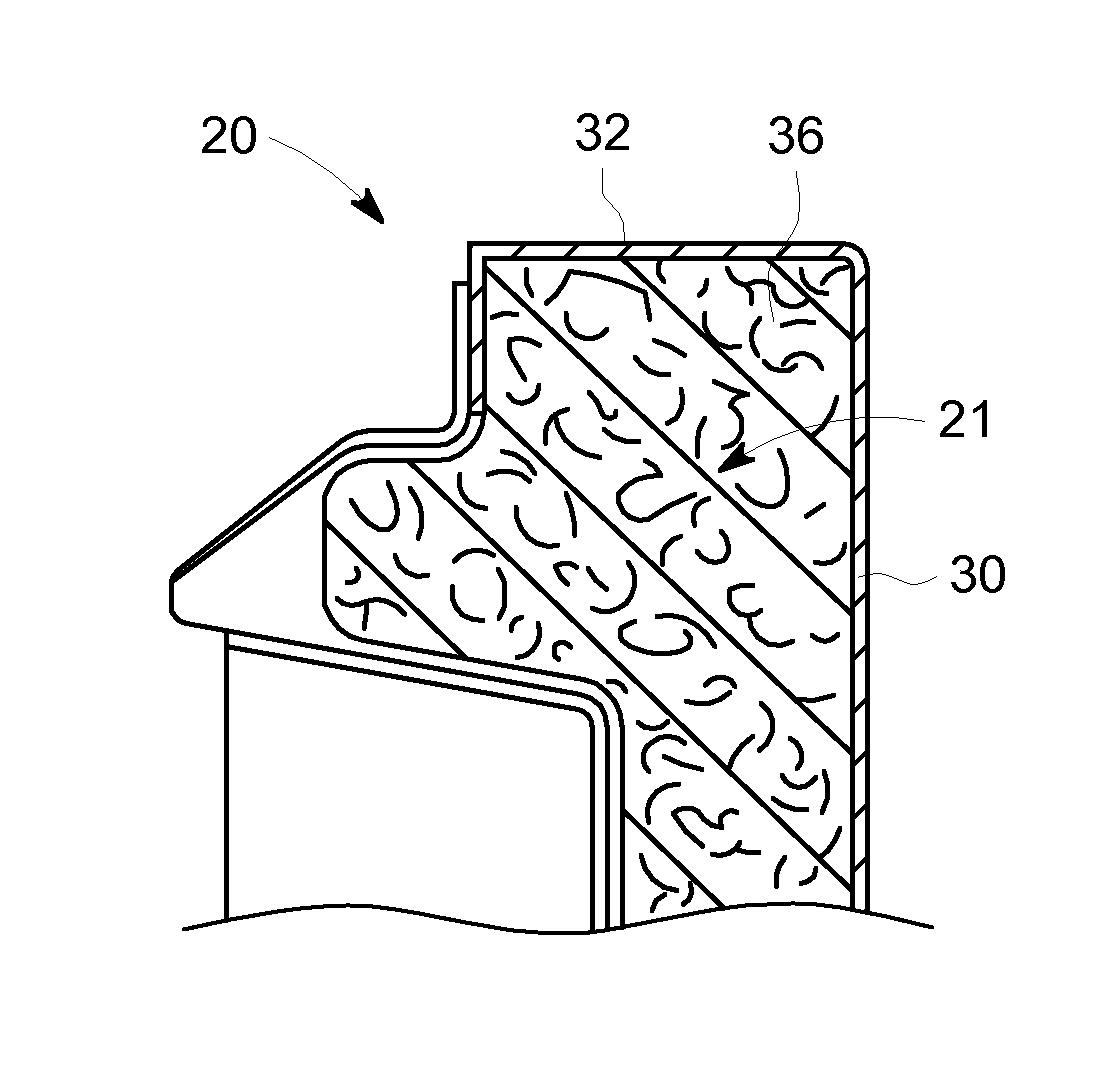

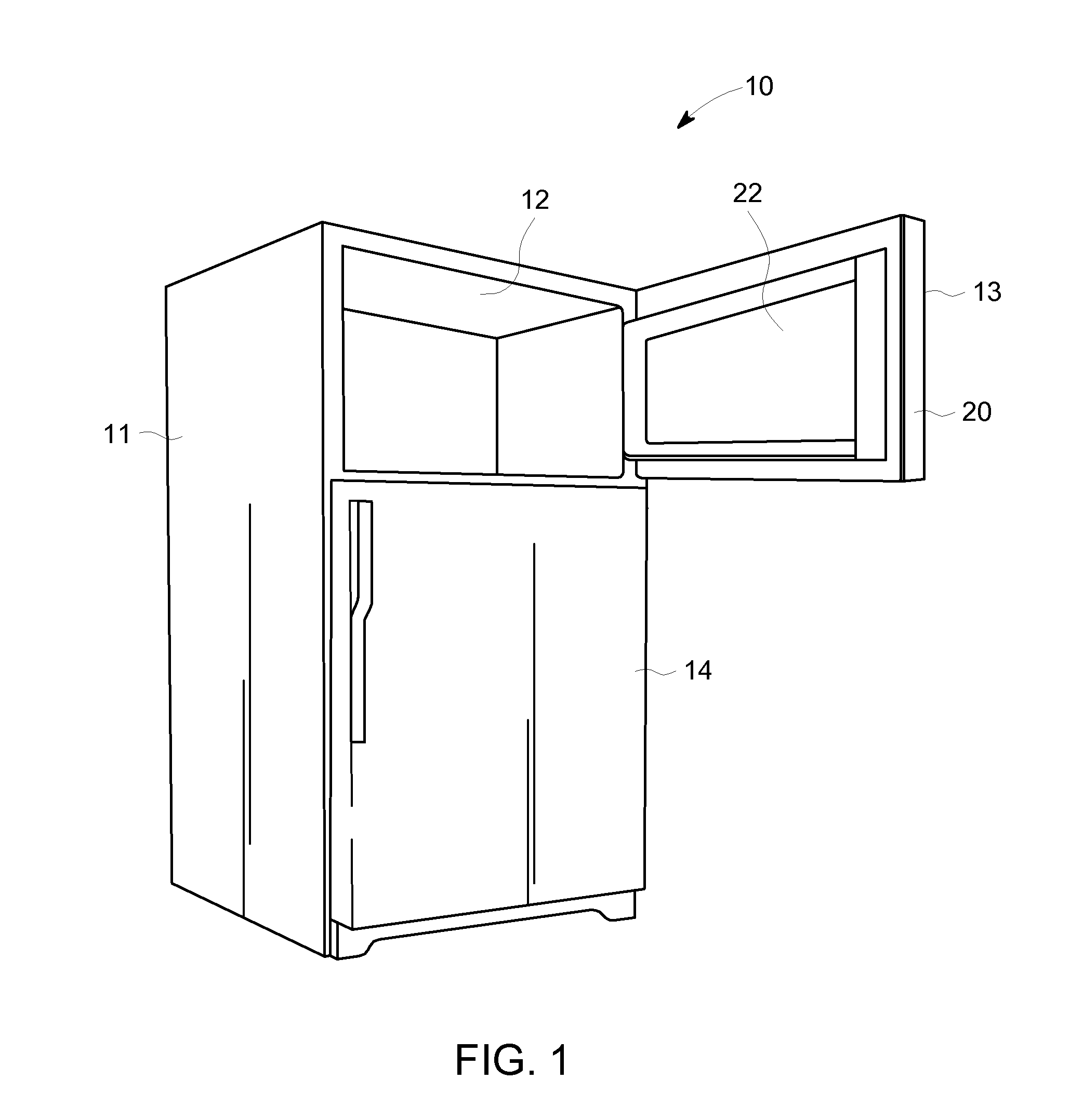

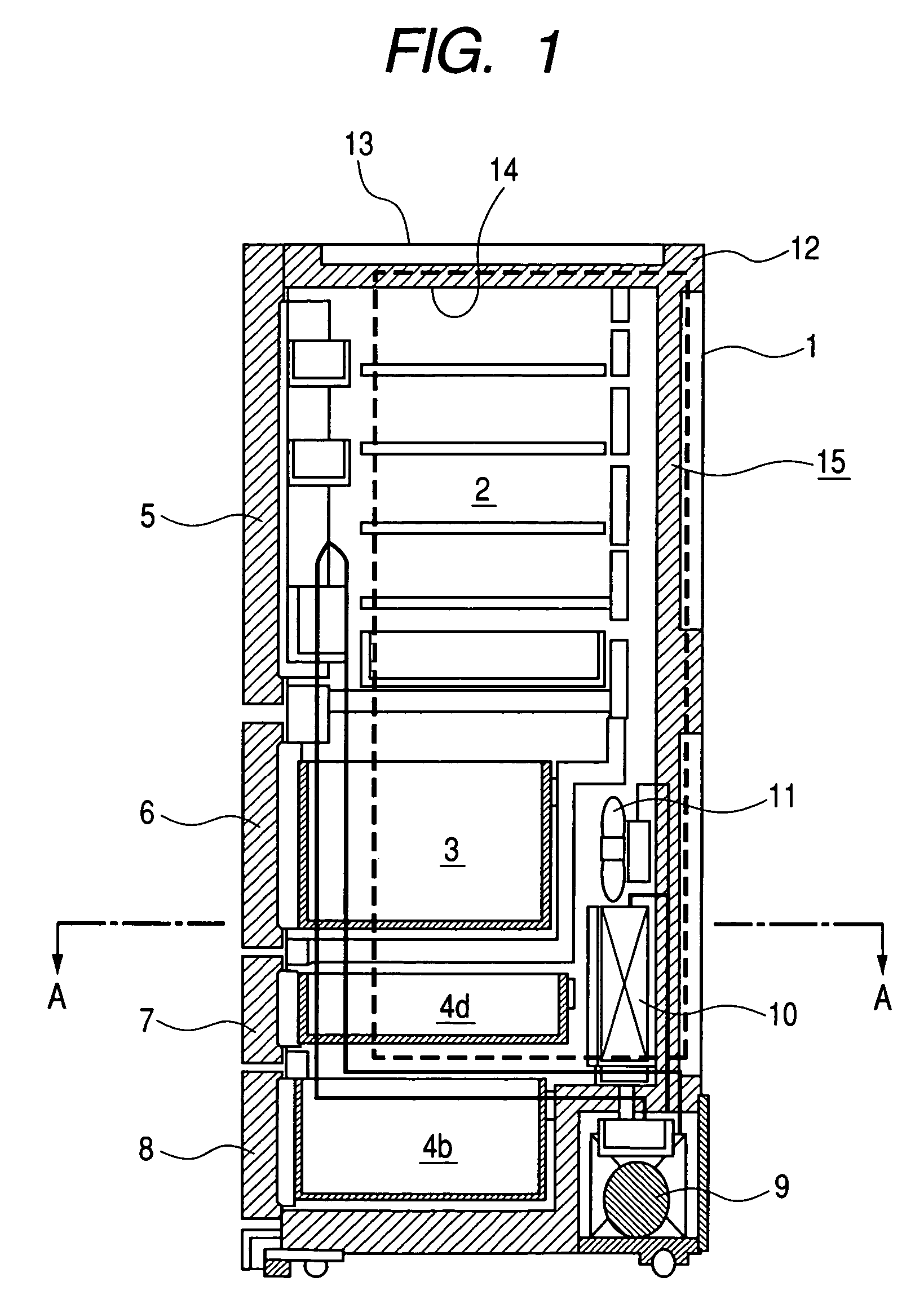

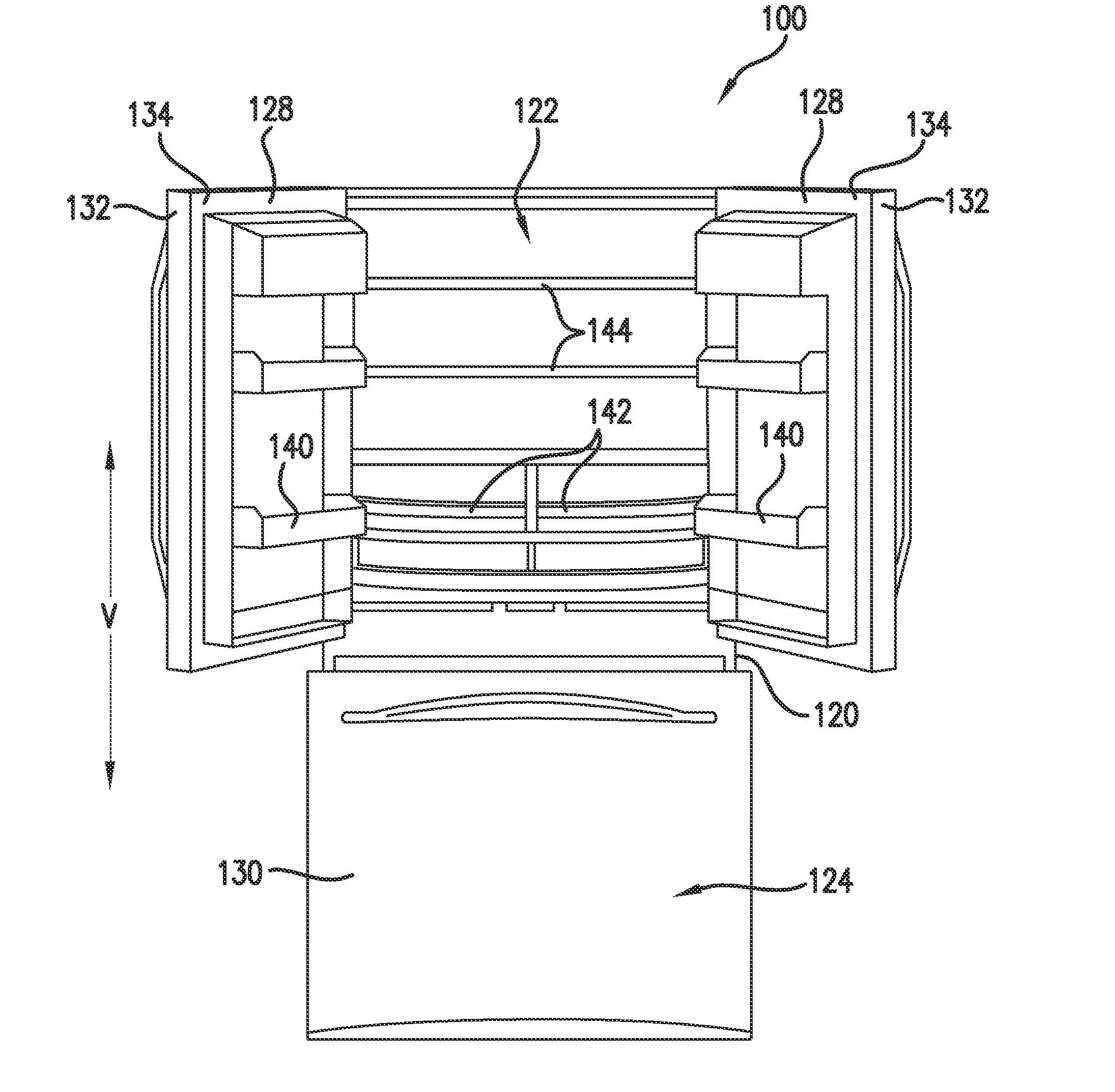

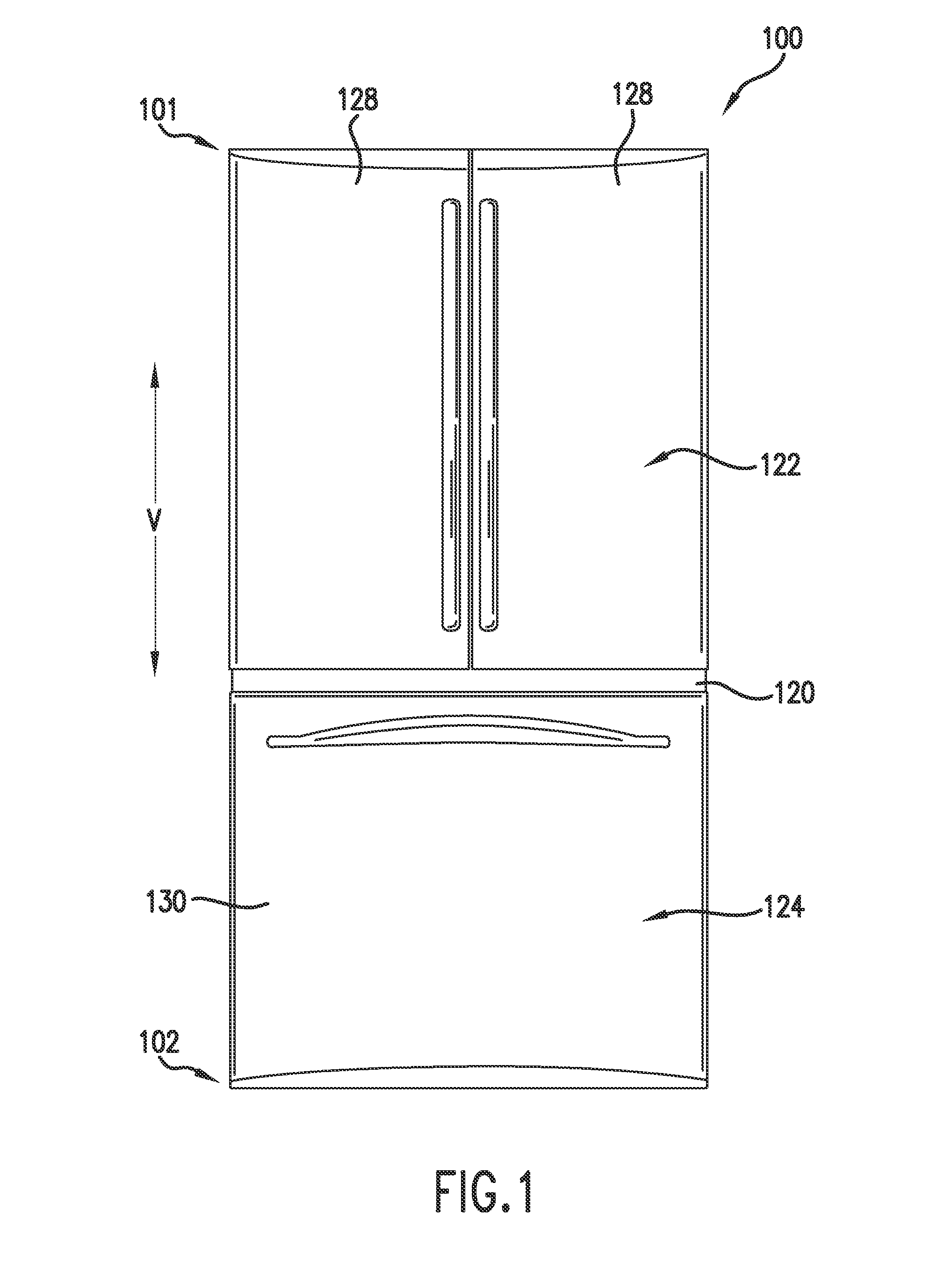

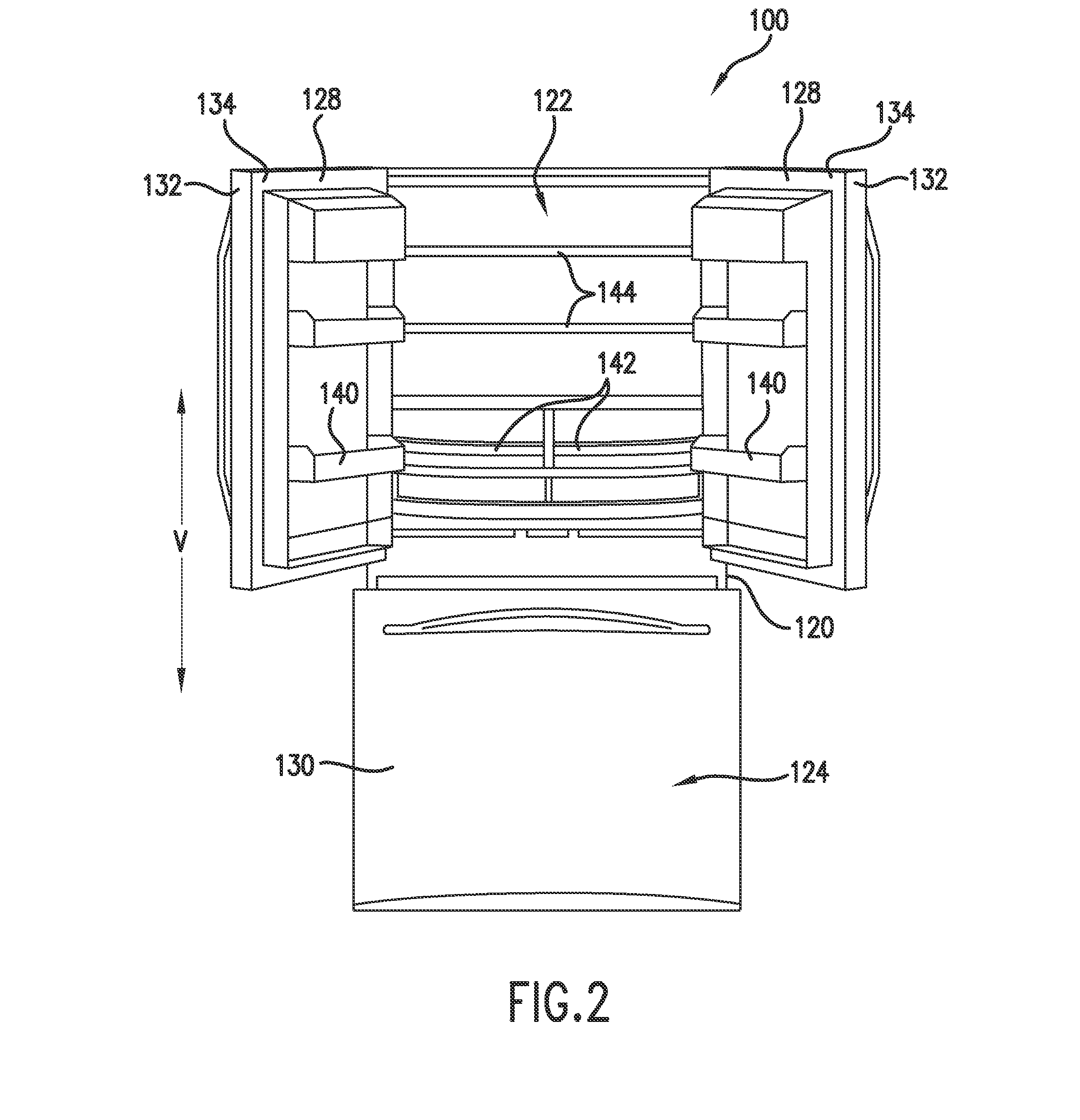

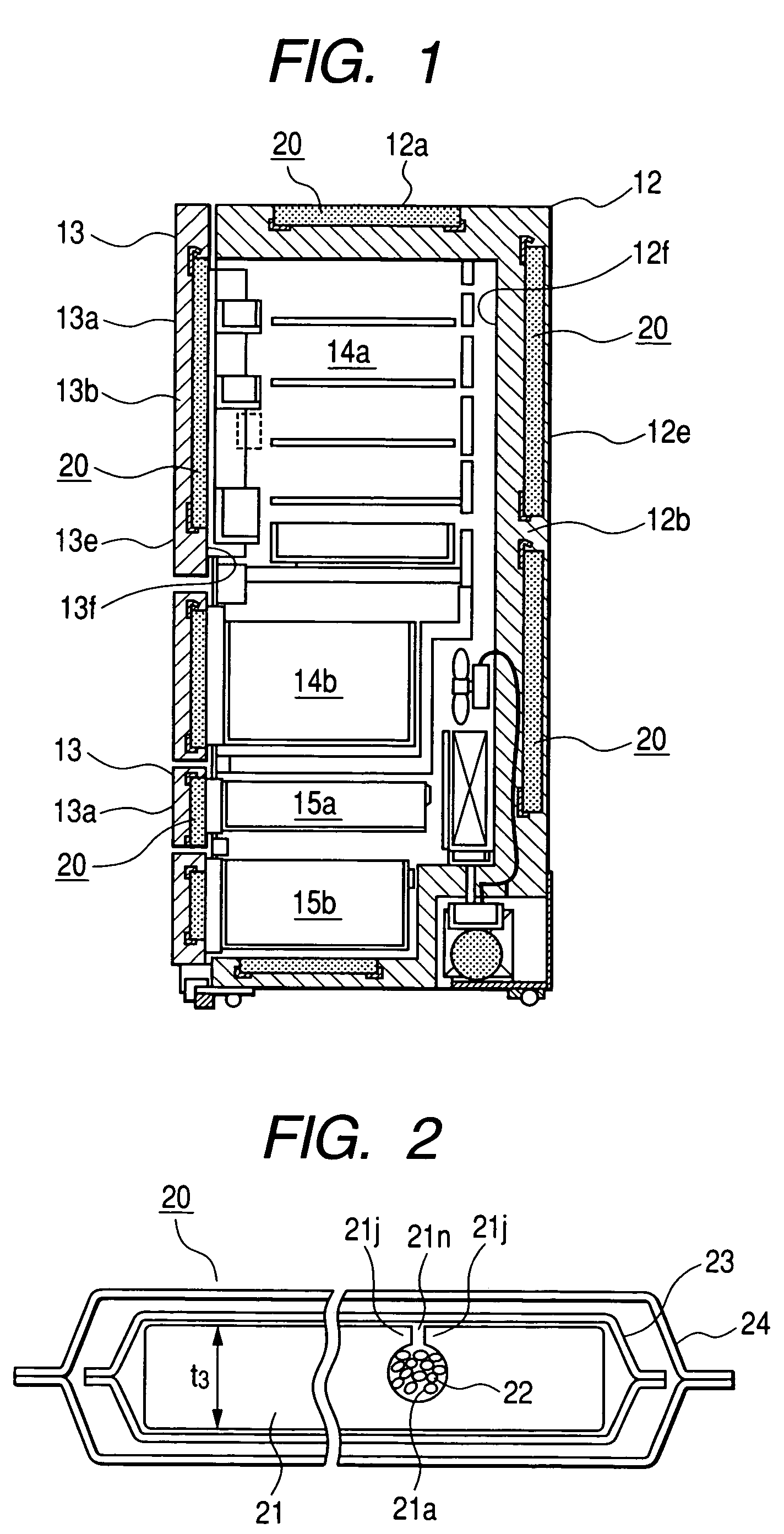

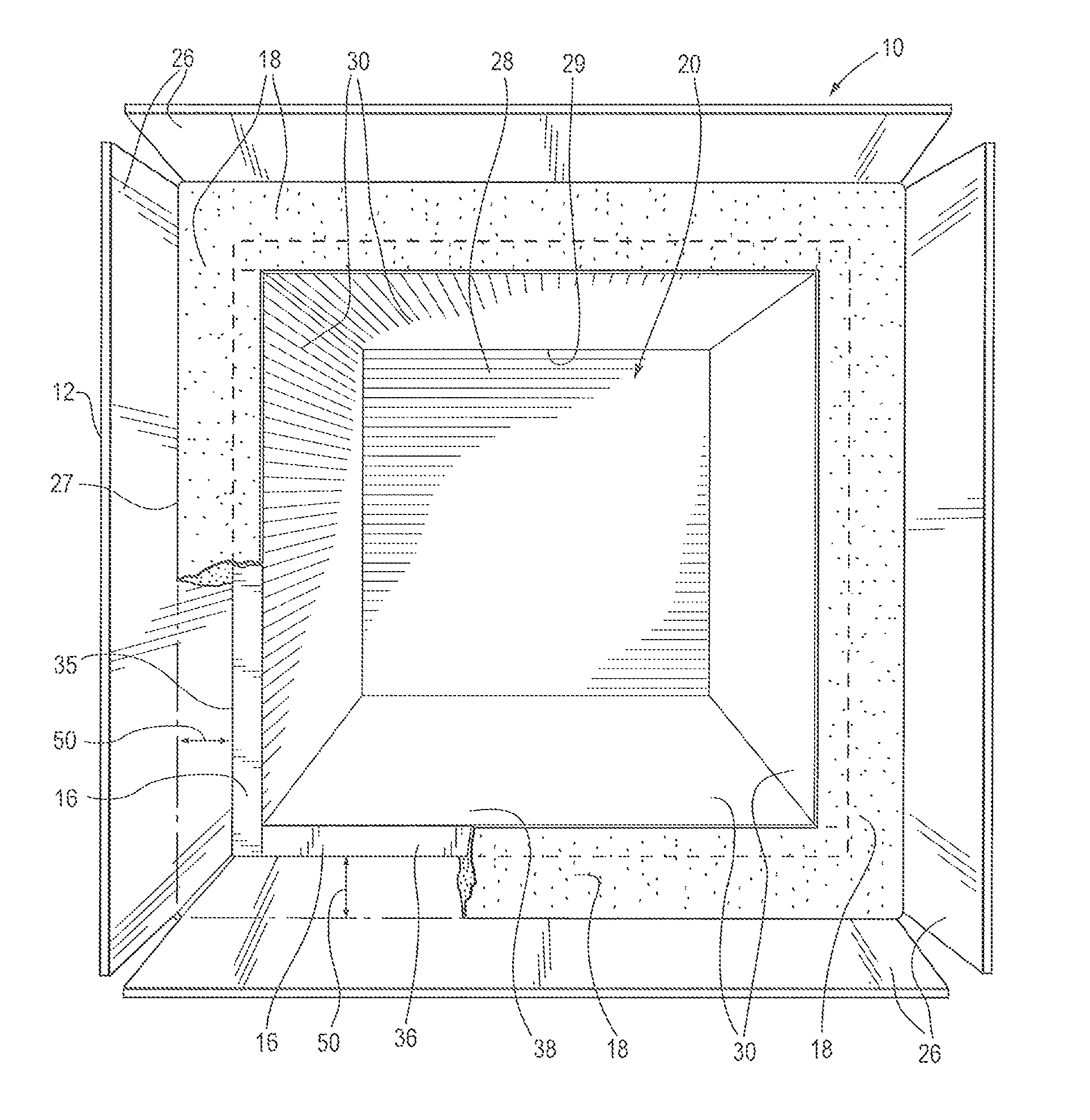

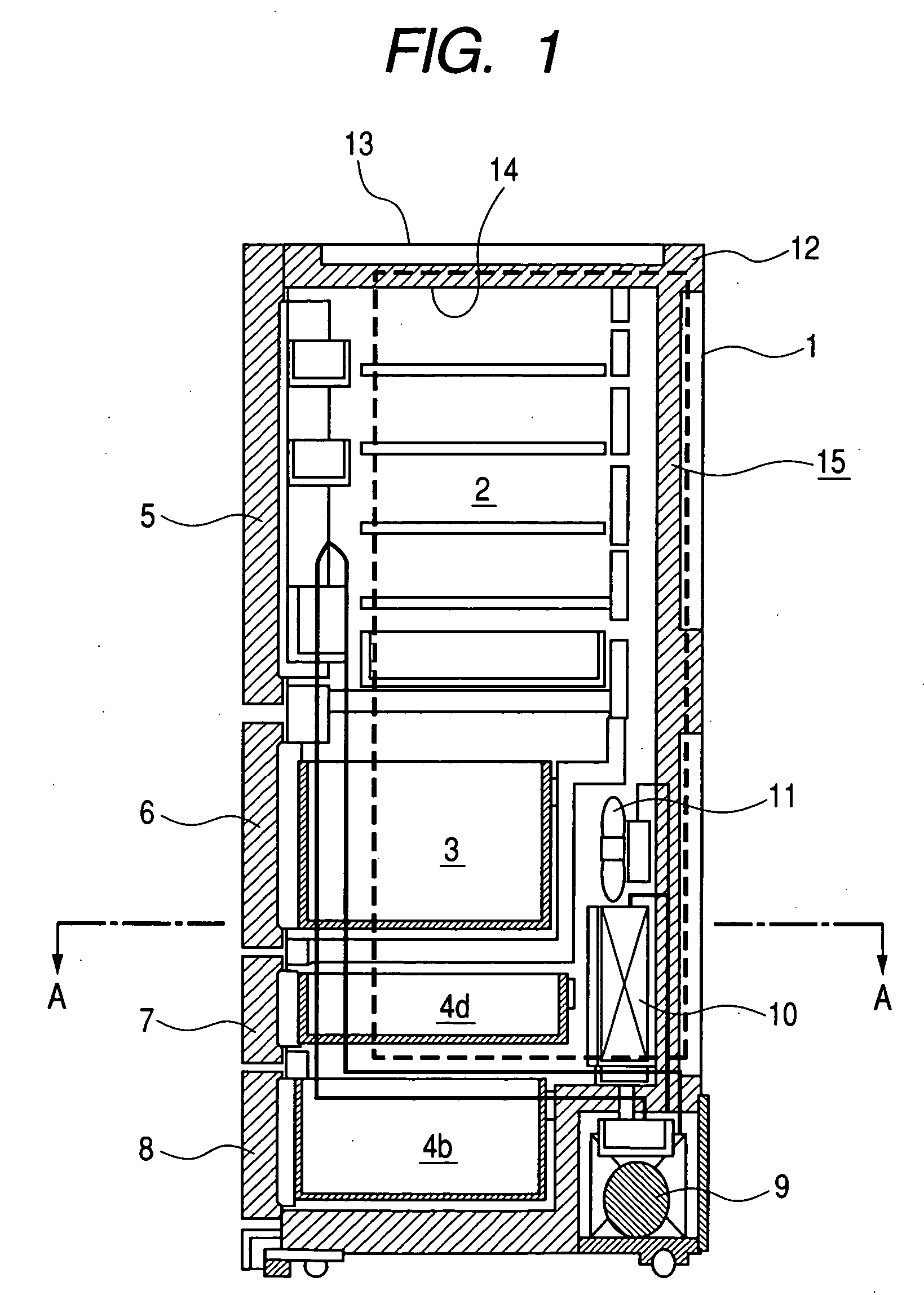

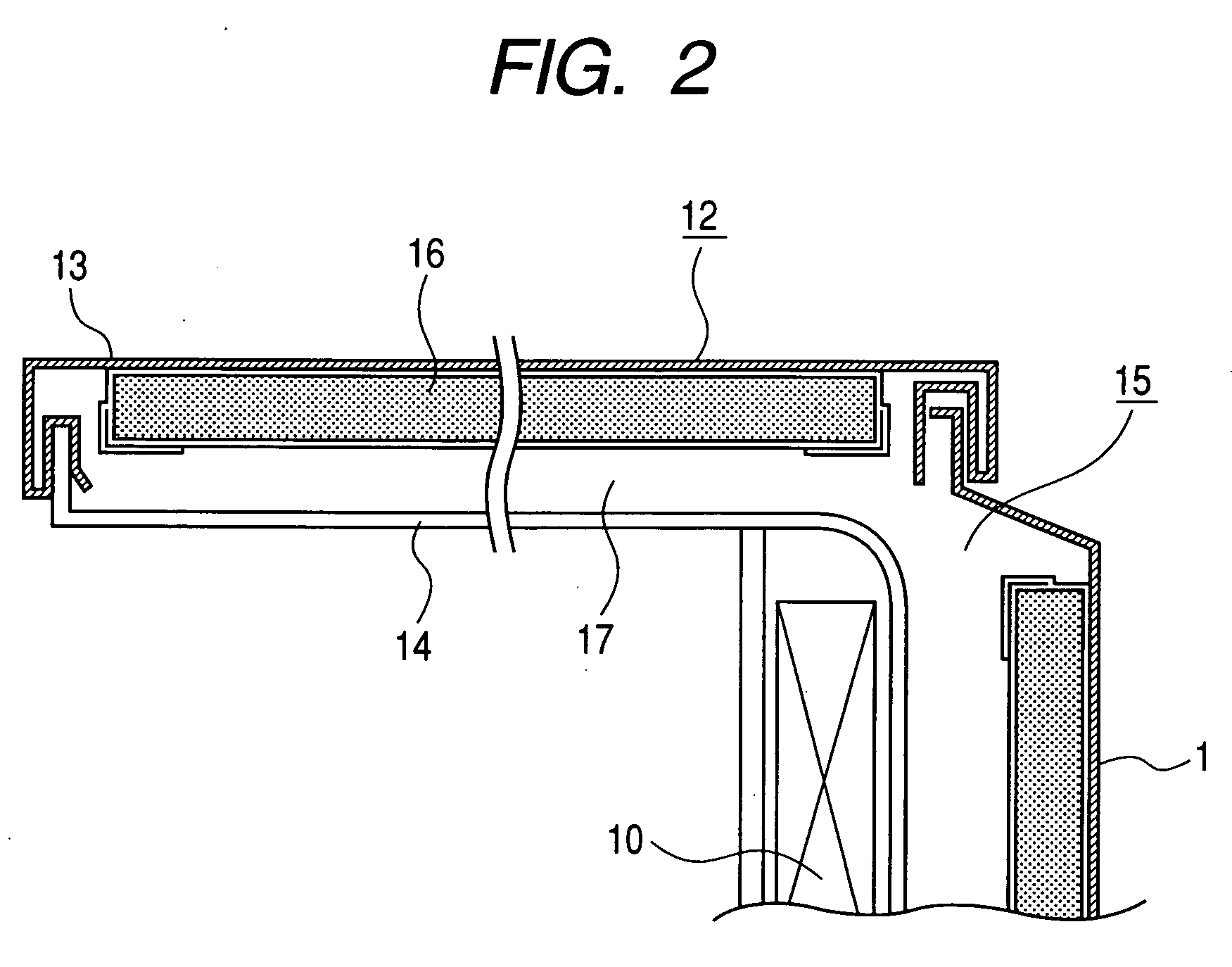

Ultra-low temperature freezer cabinet utilizing vacuum insulated panels

InactiveUS6397620B1Lighting and heating apparatusDomestic refrigeratorsUltra Low Temperature FreezerEngineering

An ultra-low temperature refrigeration system (10) comprising a housing (12) and a door (14) which together define an interior storage compartment (16). The system (10) uses multiple layers (20,22) of varying insulative materials to insulate the housing (12), including conventional foam (20) and vacuum insulation panels (22), to balance cost, size, and capacity considerations. The vacuum insulation panels (22) are provided with beveled edges (26) or otherwise positively interfacing edges so as to overlap adjacent panels and present a more reliably insulative seam. The system (10) further includes a self-defrosting pressure equalization port (30) for automatically equalizing interior and exterior pressures.

Owner:SPX CORP +1

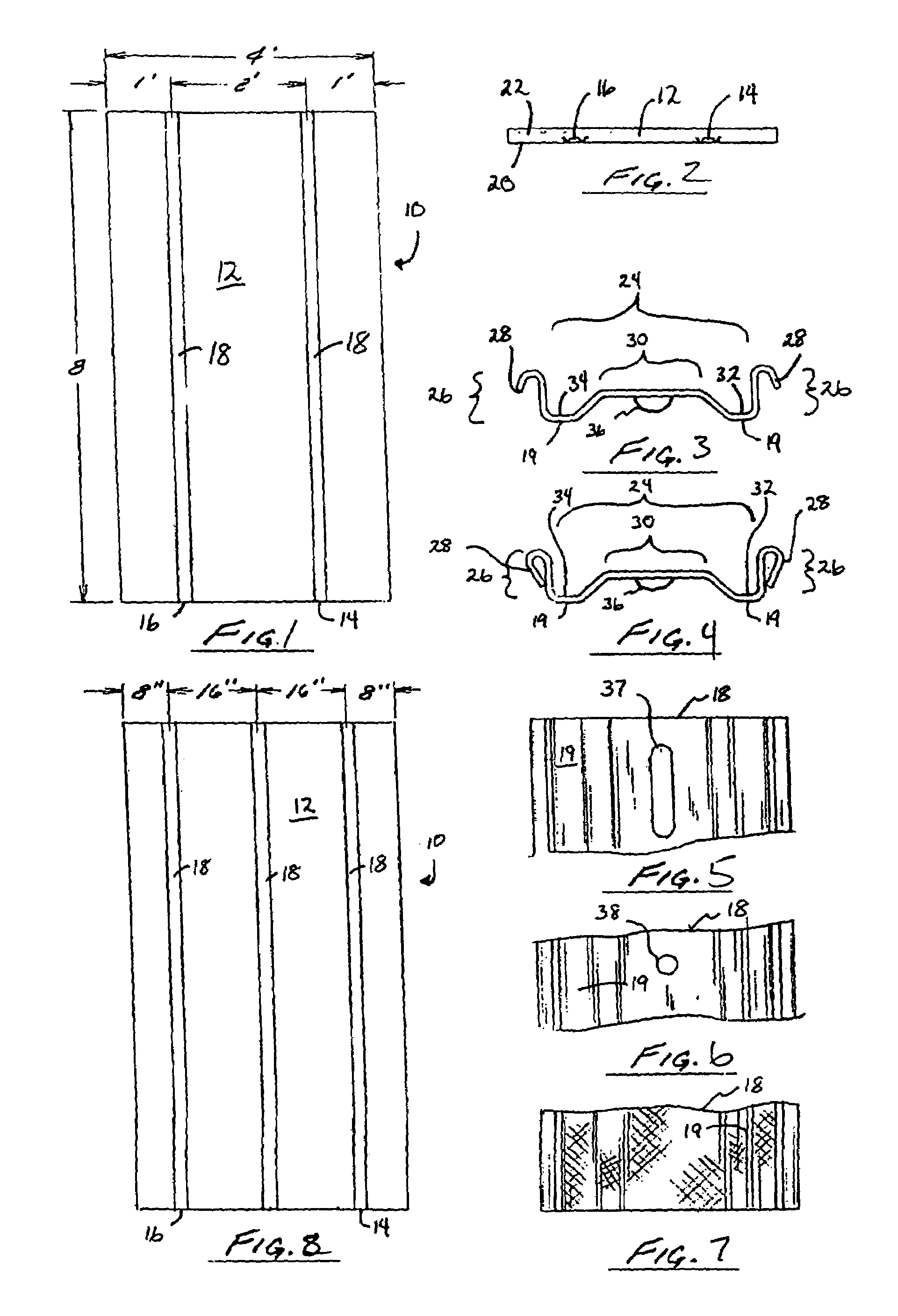

Insulated panel for commercial or residential construction and method for its manufacture

InactiveUS6892507B1Improved gripping surfaceBuilding roofsConstruction materialVapor barrierEngineering

A method and apparatus for making an rigid foam insulating panel is disclosed. The panel includes an rigid foam sheet with a plurality of grooves or recesses in which reinforcing strips are placed. Both sides of the sub-assembly are covered with a reinforcing sheet made of plastic, paper, foil, or a combination thereof. These reinforcing sheets are bonded to the surface of the rigid foam sheet and provide structural support to the sheet, as well as retaining the reinforcing strips in place. They also provide a vapor barrier on both sides of the sheet to prevent the migration of moisture through the sheet toward the wall covering, which will typically be attached to the side of the sheet in which the reinforcing strips are inserted.

Owner:PLYMOUTH FOAM LLC

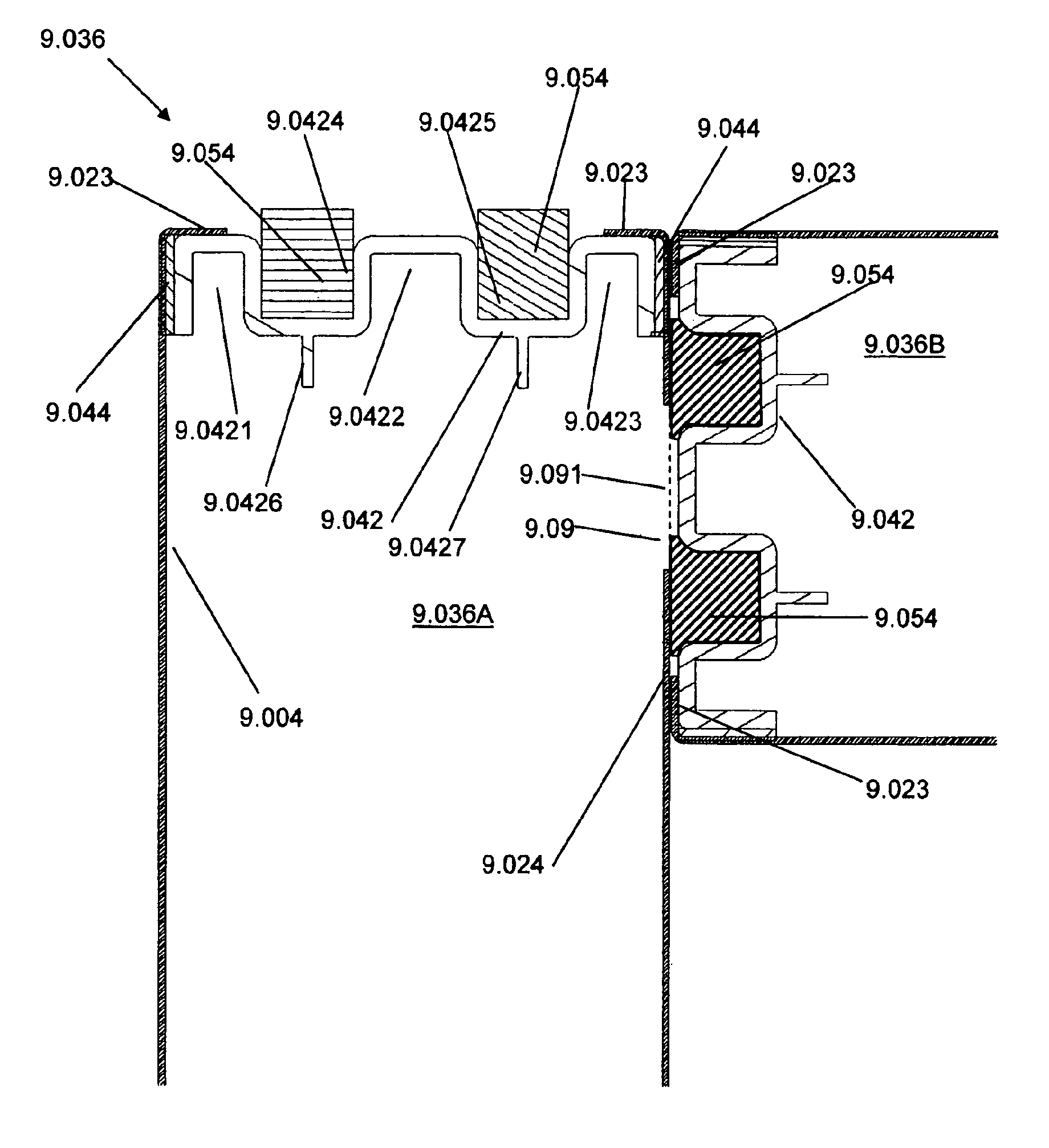

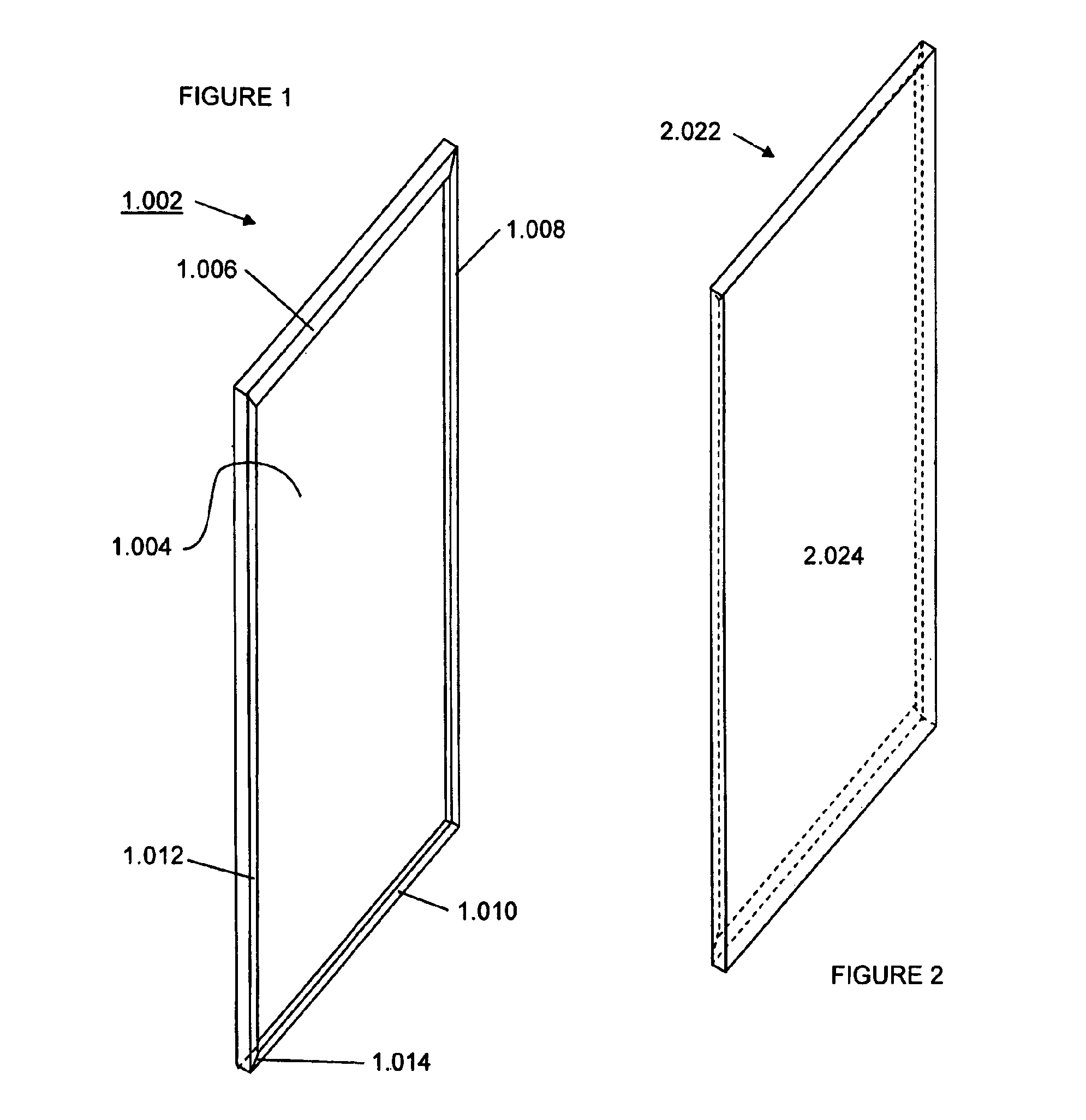

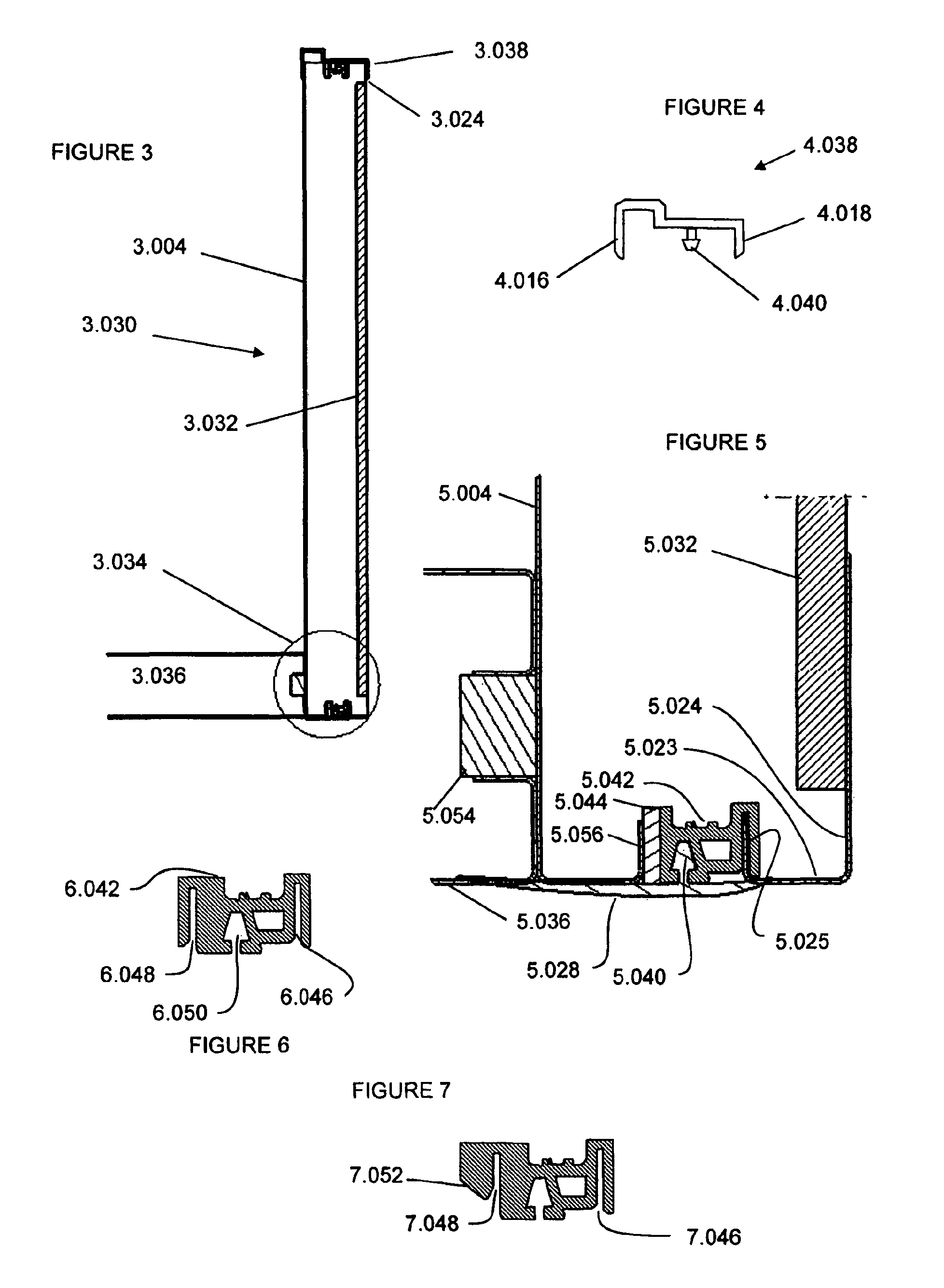

Insulated panel and method of assembly

An insulated panel including first and second walls (5.004, 5.024) spaced apart by a predetermined distance, each wall including an internal peripheral channel formed by first and second bends, the second bend forming an internal peripheral flange (5.025, 5.056), the panel including an intermediate joining member (5.042) adapted to connect to the internal peripheral flanges of the first and second walls. The connection to a first flange can be via a slot (6.046), and the connection to the second flange can be by adhesive (5.044).

Owner:ELECTROLUX HOME PROD PTY LTD

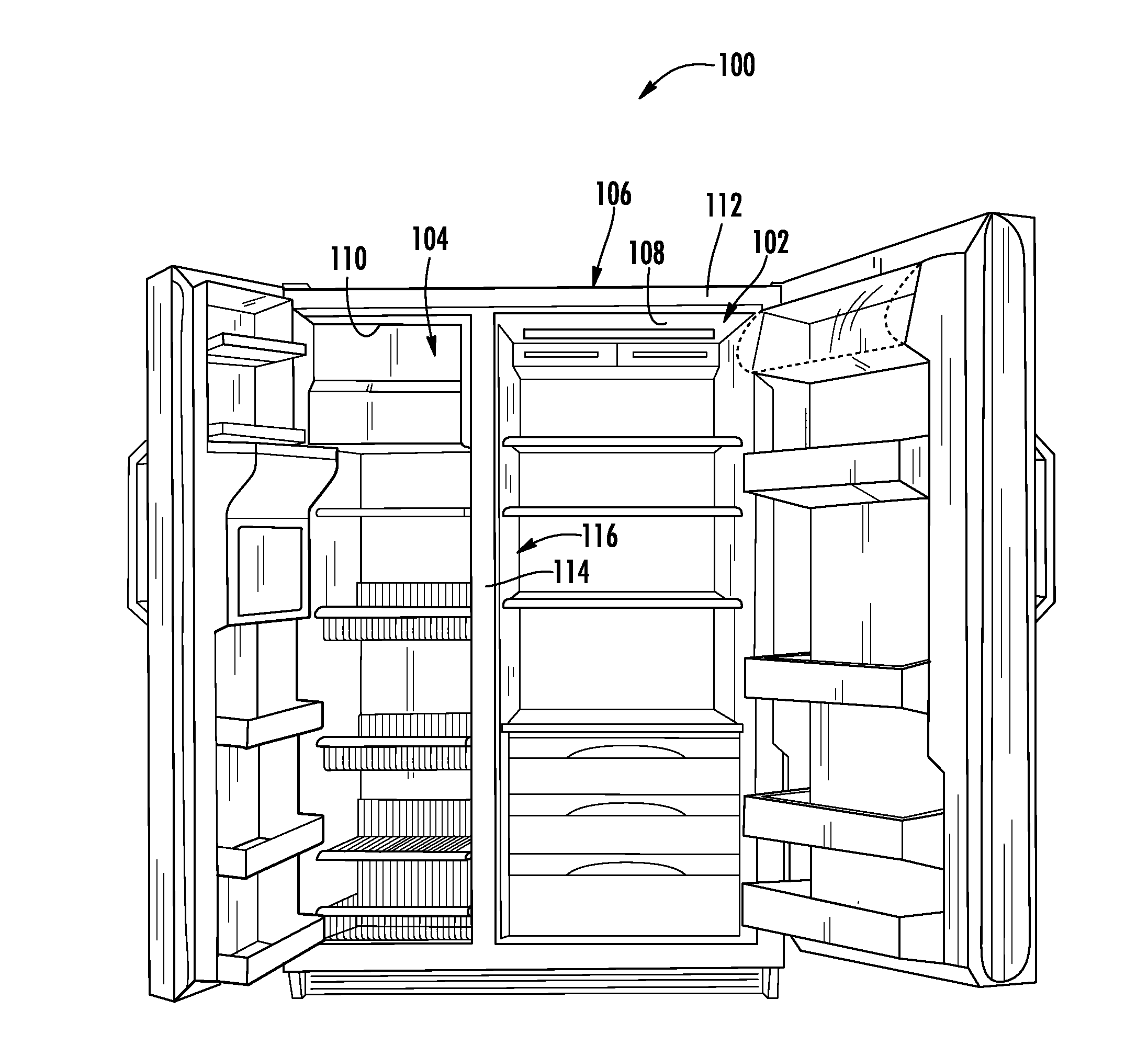

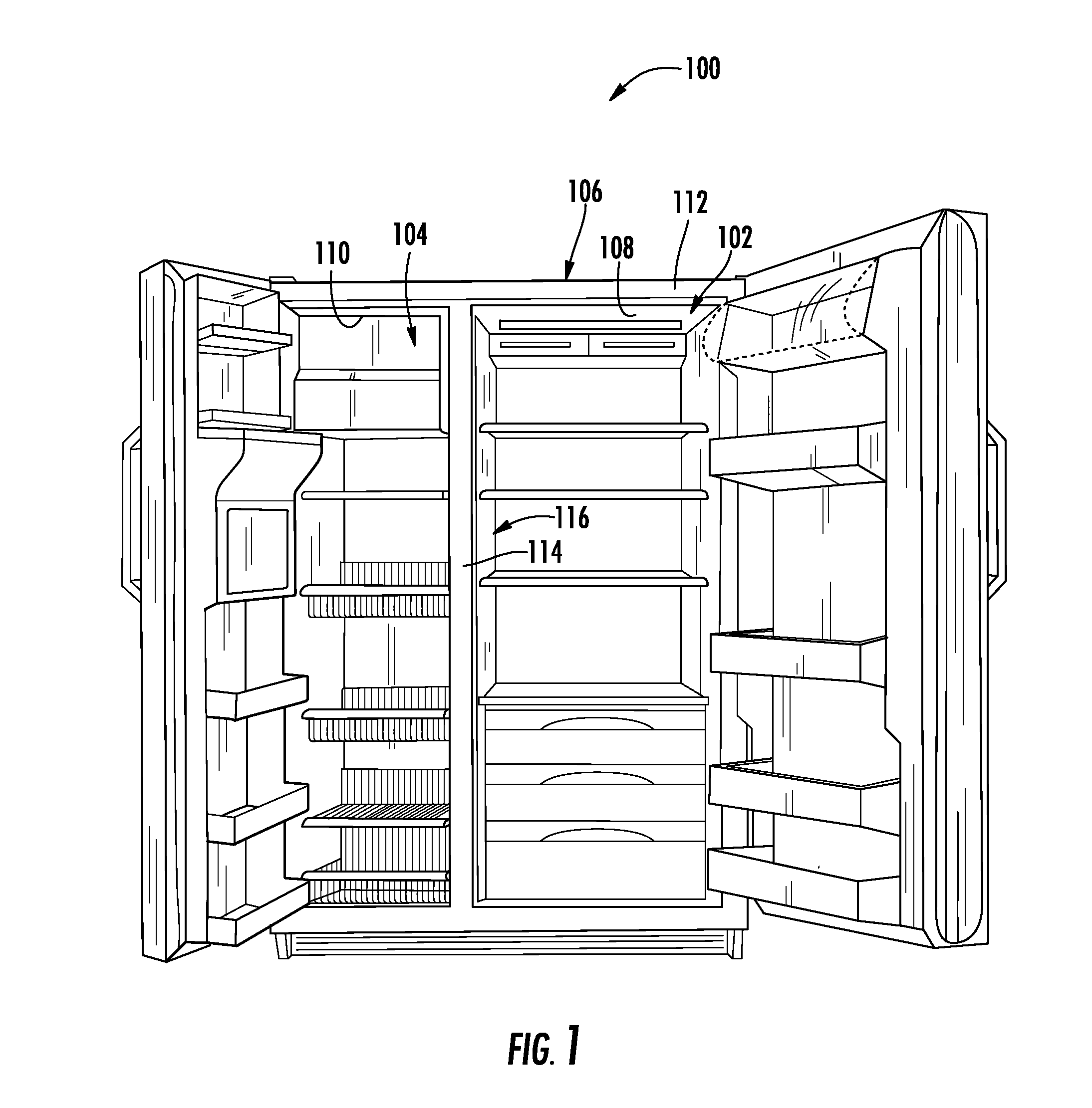

Refrigerator vacuum insulation application

InactiveUS20110095669A1Overcome disadvantagesMetal-working apparatusFurniture partsEngineeringRefrigerated temperature

Owner:GENERAL ELECTRIC CO

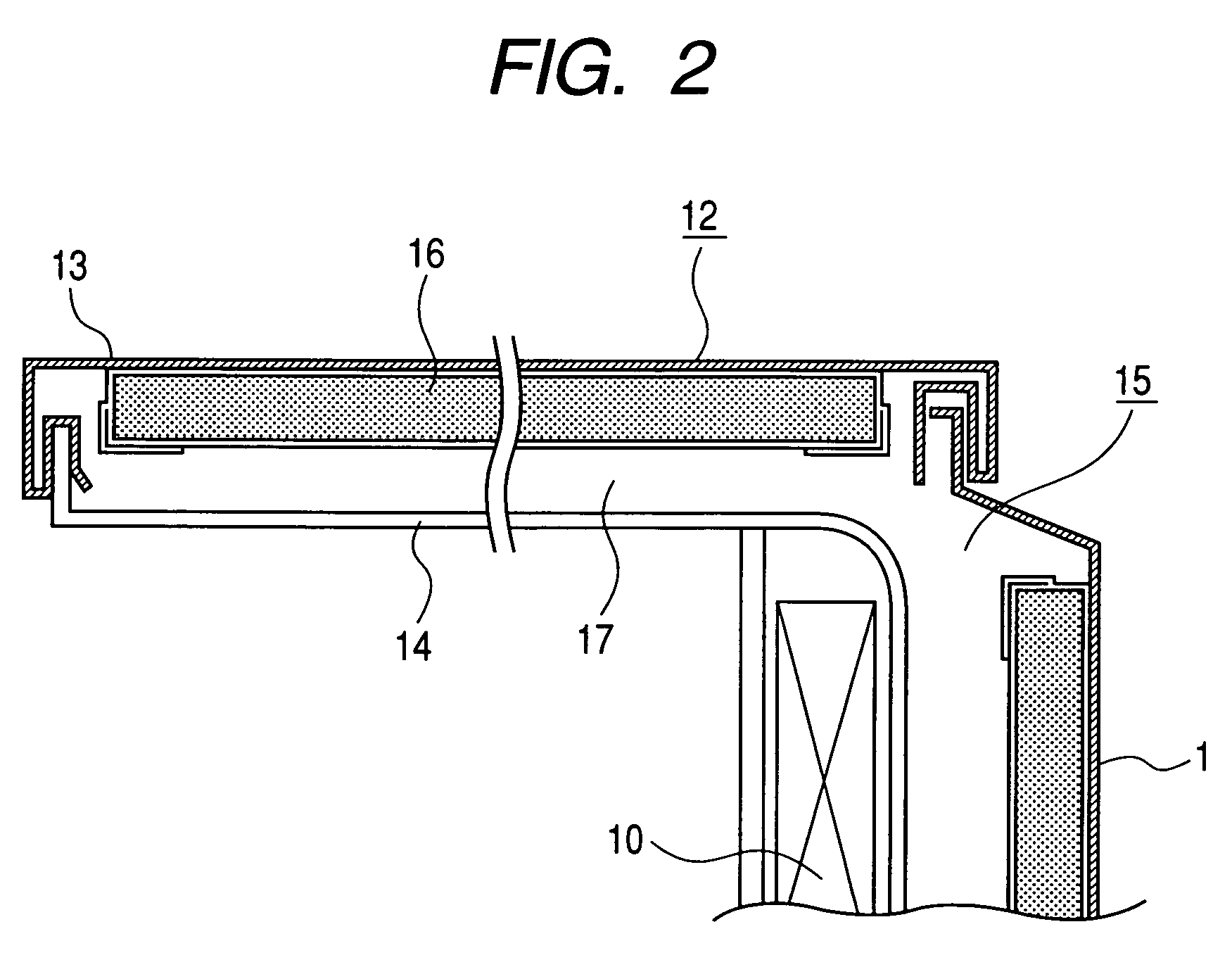

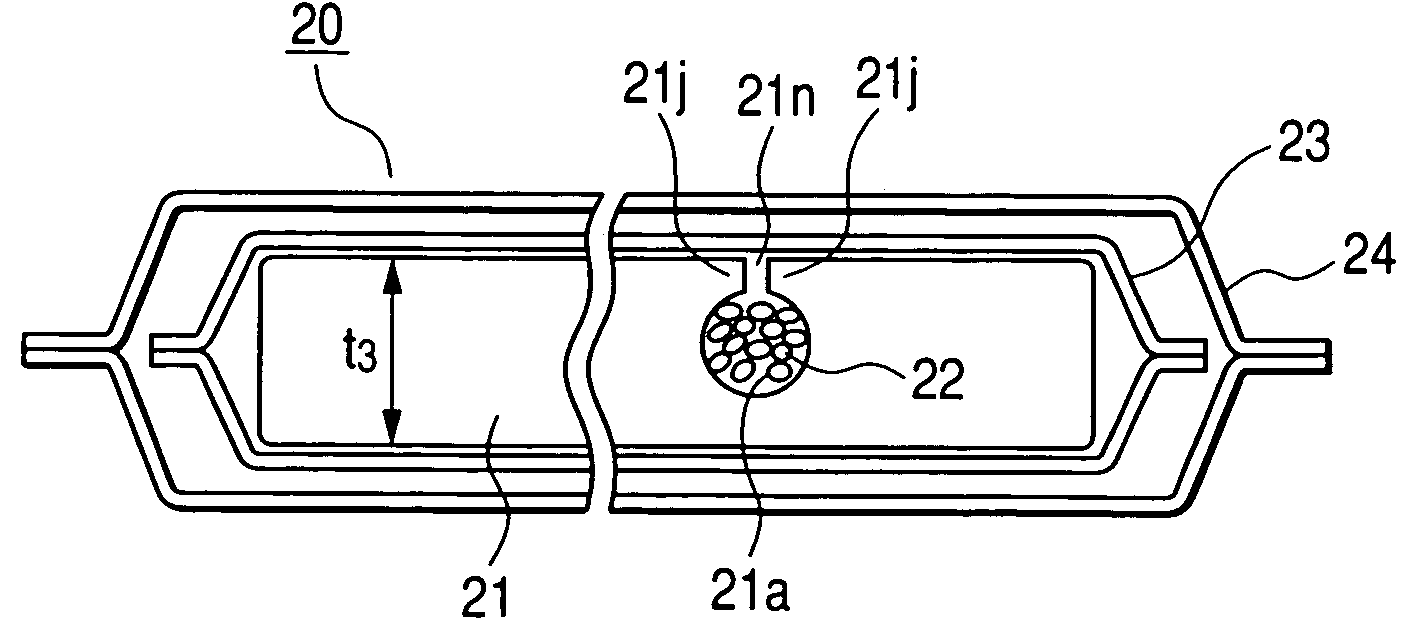

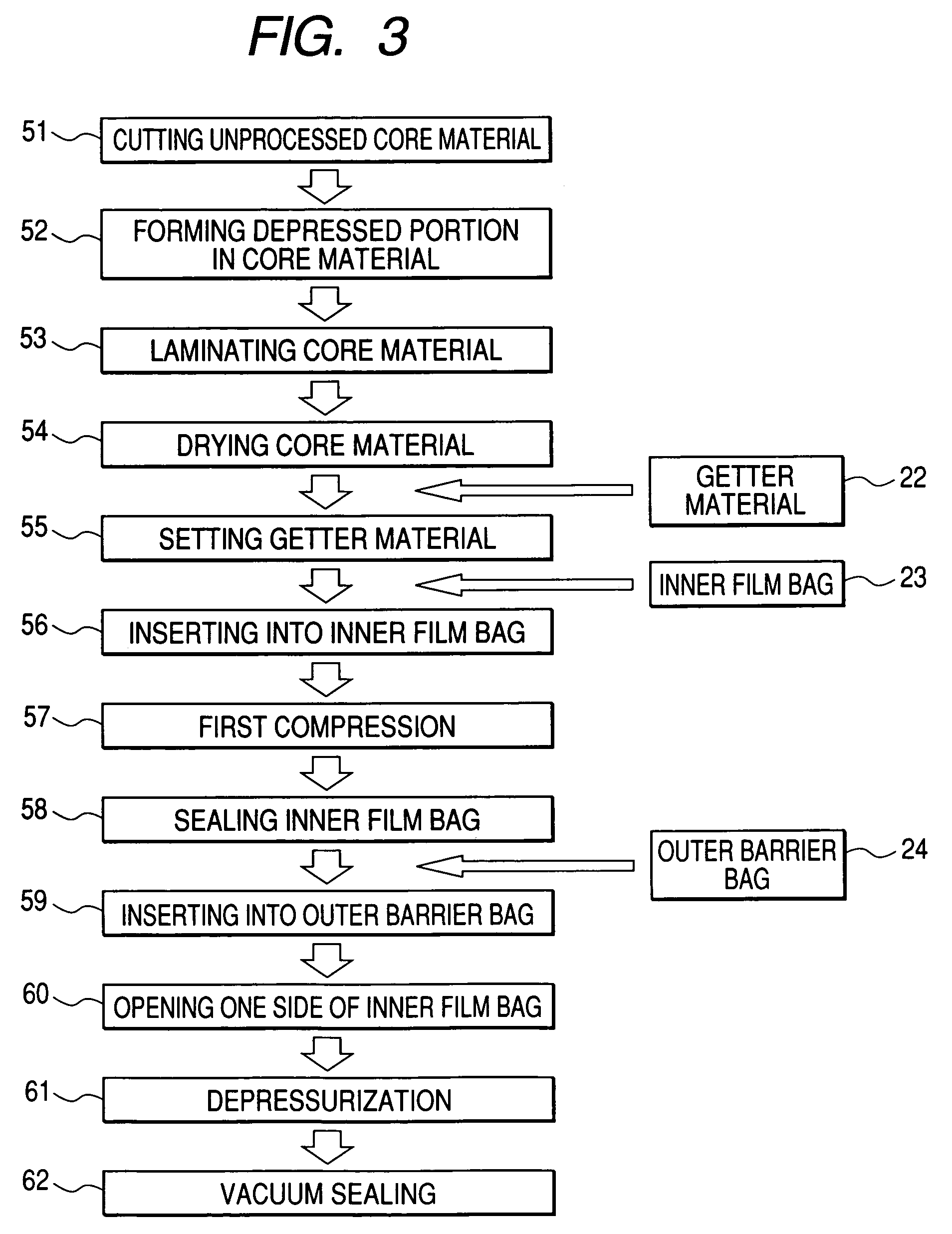

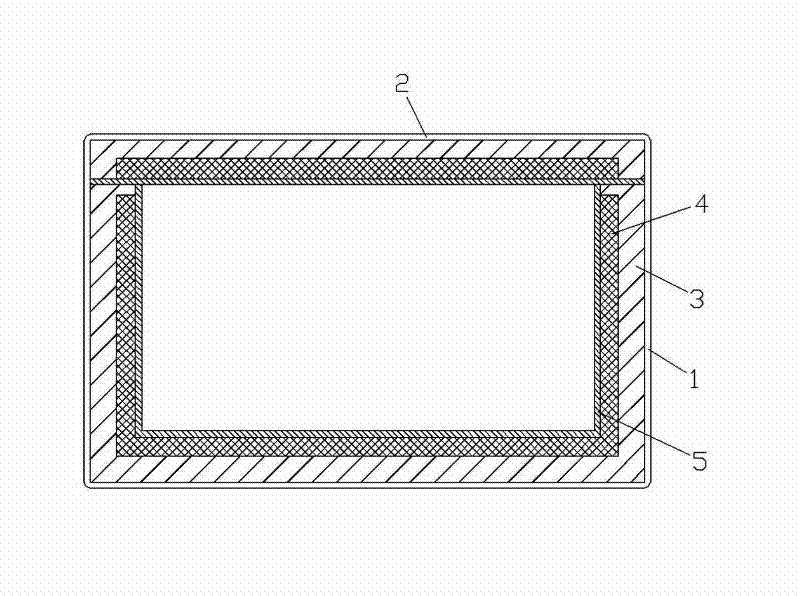

Vacuum insulation panel and refrigerator incorporating the same

InactiveUS7449227B2Reduce heat transferGuaranteed accuracyThermal insulationLayered productsFiberMetallic foil

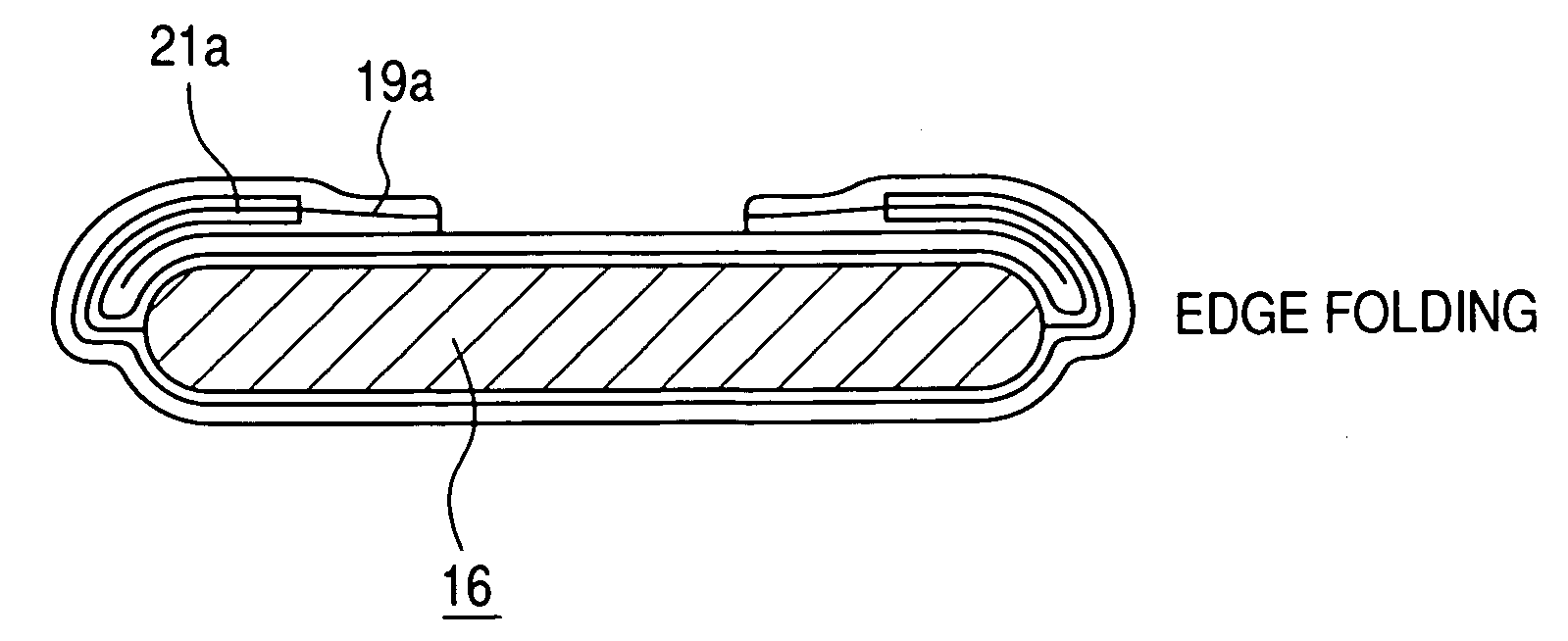

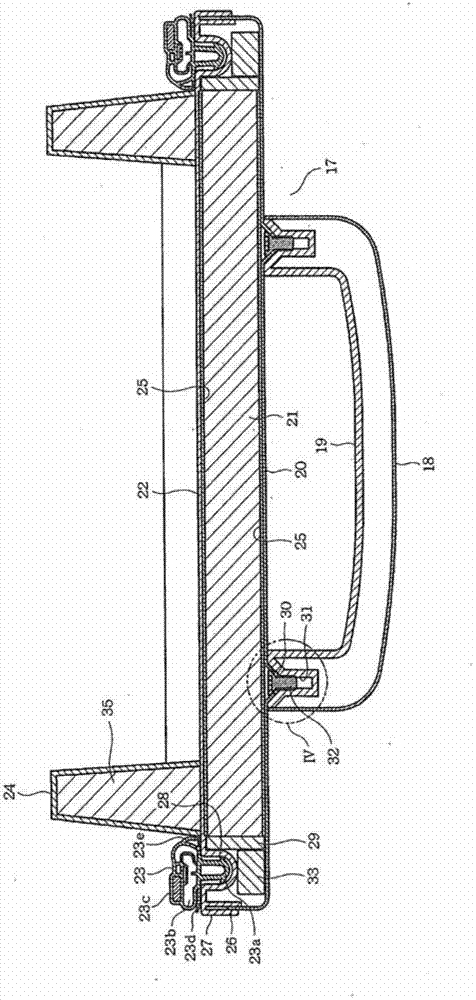

The invention relates to a vacuum insulation panel which can be used as an insulator for a refrigerator requiring heat insulation to be provided and also to a refrigerator incorporating such a vacuum insulation panel. The invention particularly relates to an arrangement for preventing convection spaces from being formed where an edge of the vacuum insulation panel is folded back. The vacuum insulation panel includes a core which has an inner film bag in which a flexible inorganic fiber laminate is accommodated, and an outer barrier bag which is made of gas-impermeable film such as metallic foil laminated film and which accommodates the core. The inner film bag includes a welded portion and a ventilation portion. The outer barrier bag has a depressurized interior and has been sealed by welding. An edge of the inner film bag is placed in an edge of the outer barrier bag.

Owner:HITACHI APPLIANCES INC

Integrated vacuum insulation panel

InactiveUS20120285971A1Insulation for cooling apparatusElectron beam welding apparatusEngineeringRefrigerated temperature

Owner:GENERAL ELECTRIC CO

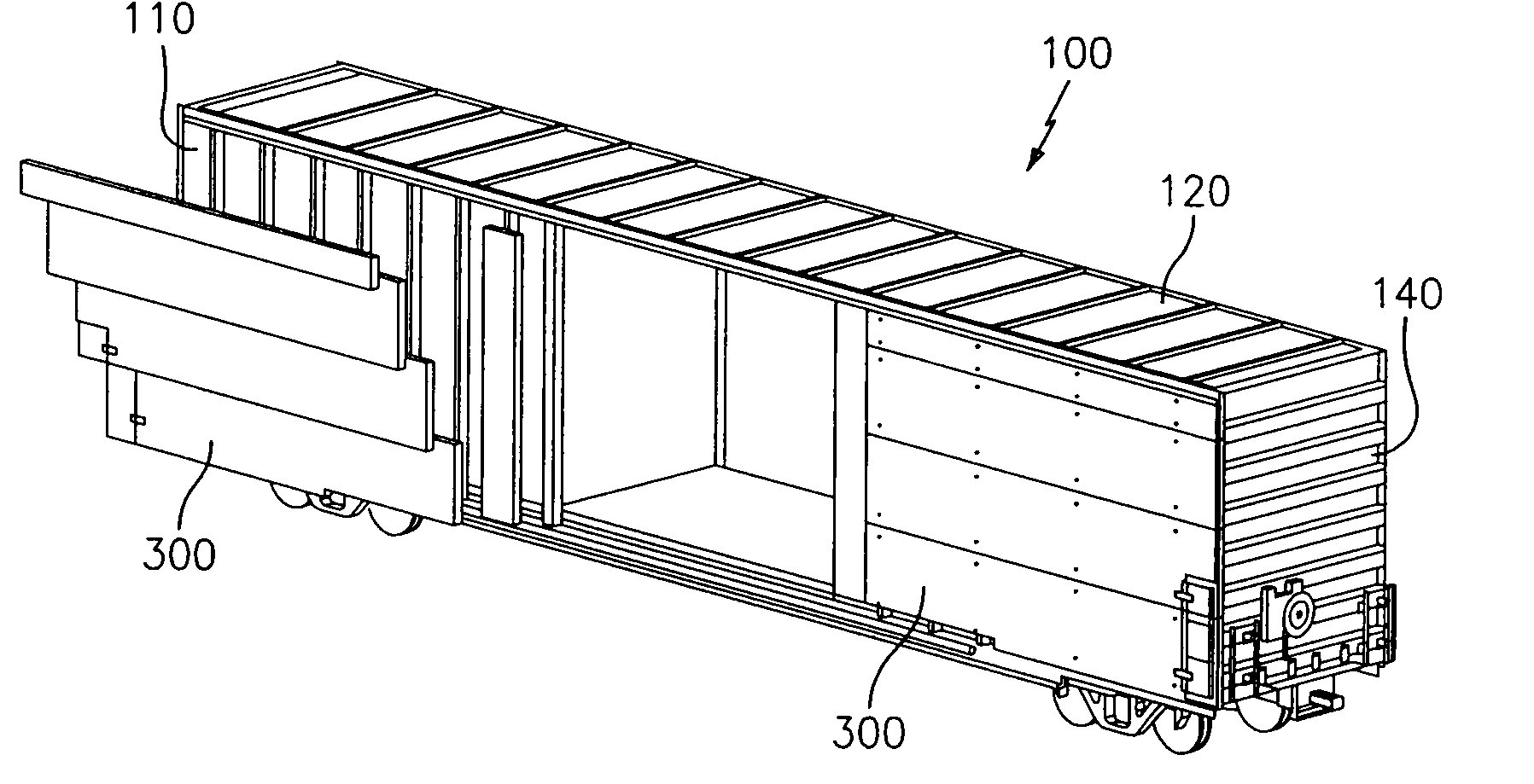

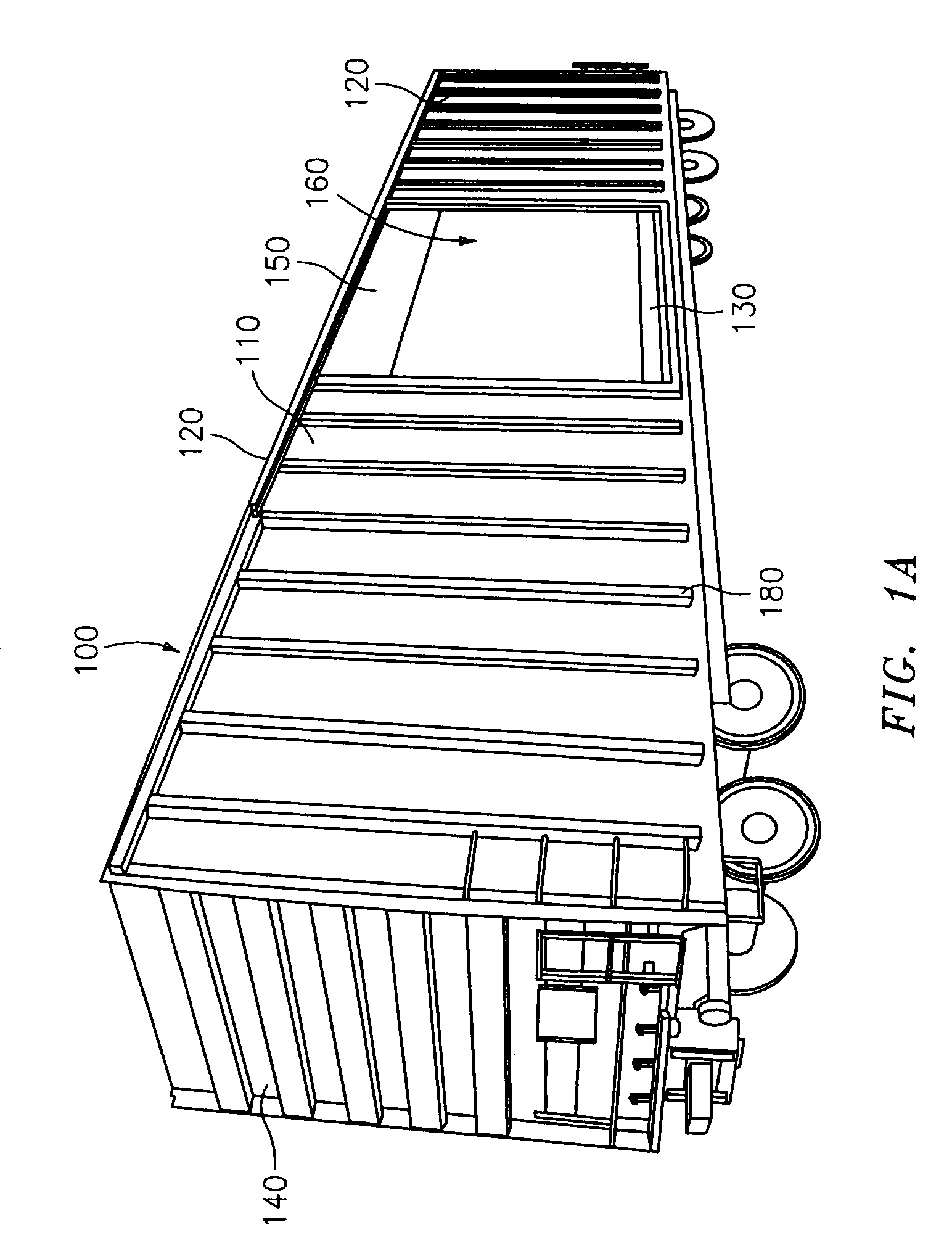

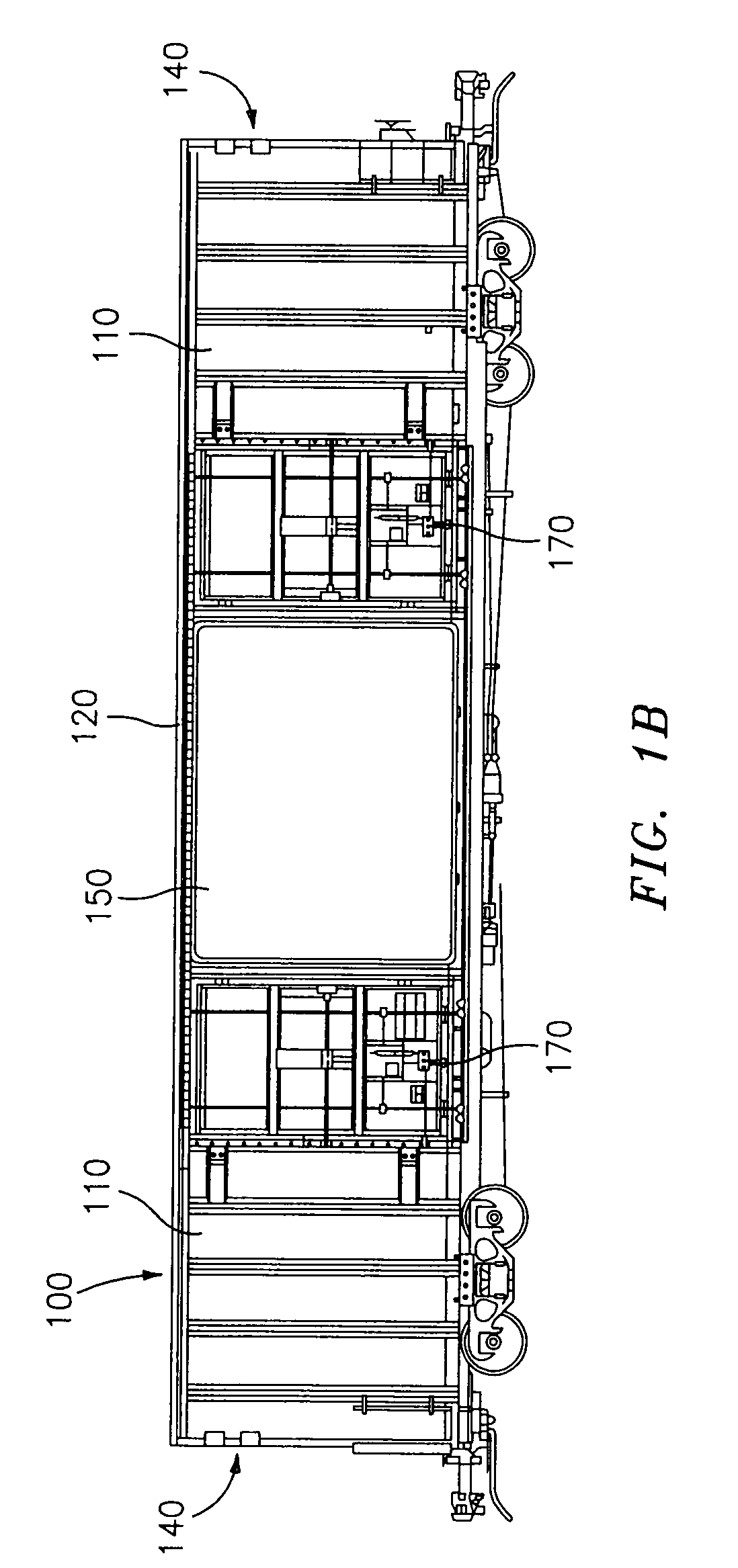

Insulated cargo container and methods for manufacturing same using vacuum insulated panels and foam insulated liners

InactiveUS20090126600A1Domestic cooling apparatusLighting and heating apparatusEngineeringCargo container

An insulated cargo container is composed of an underframe, a floor, a first side wall, a second side wall, a roof, and at least one door being connected together to form an enclosure. At least one insulating liner is mounted to the interior surfaces and exterior surfaces of the enclosure in an amount sufficient to achieve a UA rating of less than about 300 for the cargo container.

Owner:MARTIN MARIETTA MATERIALS

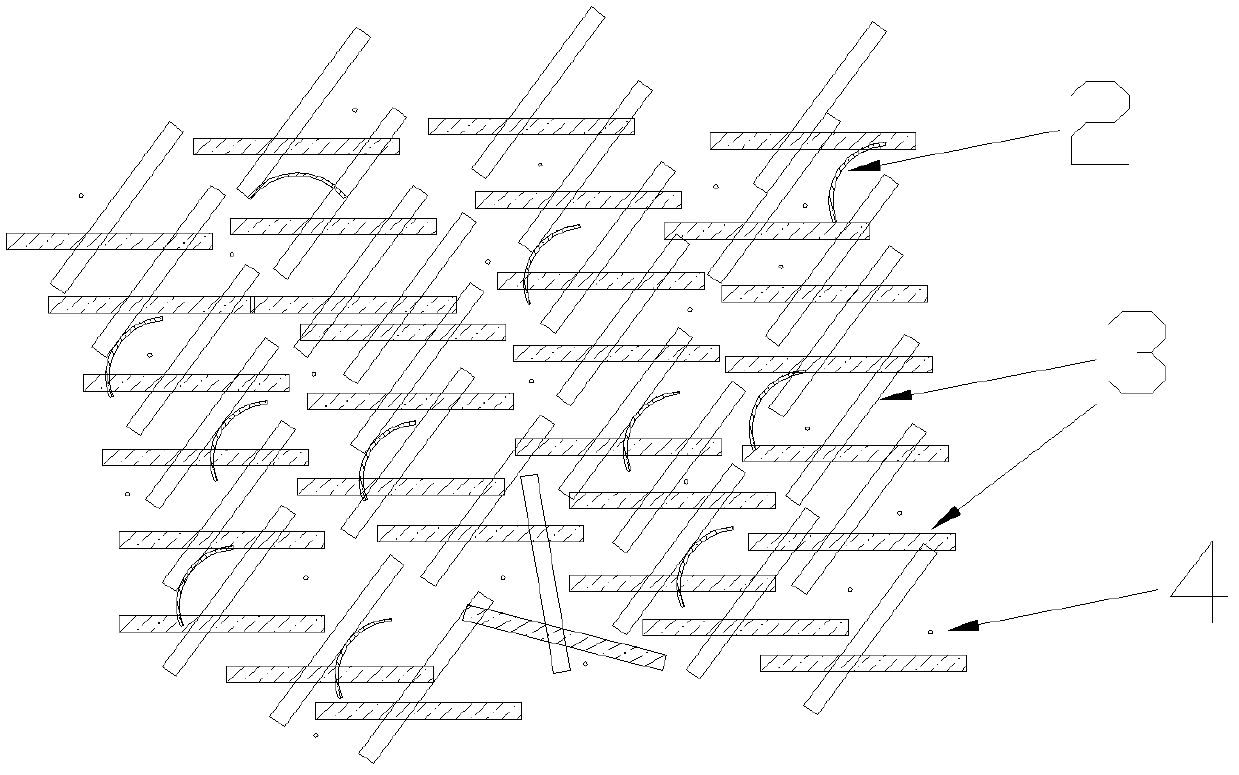

Composite core material vacuum insulation panel and preparation method thereof

ActiveCN101691899AHigh material utilizationReduce processing costsThermal insulationPipe protection by thermal insulationPlastics industryVacuum insulated panel

The invention discloses a composite core material vacuum insulation panel and a preparation method thereof and relates to a vacuum insulation panel. The invention provides the composite core material vacuum insulation panel which utilizes a large number of scraps of rigid foam plastics in the existing rigid phenolic foam plastic industry, the rigid polyurethane foam plastic industry and the like and can significantly improve the comprehensive utilization rate of the rigid foam plastics, improve the environment and promote the recycling of materials, and the preparation method thereof. The composite core material vacuum insulation panel comprises a composite core material, a getter and a closed packaging bag. The composite core material vacuum insulation panel can be prepared by adopting the wet method or the dry method.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Method utilizing expanded perlite to produce vacuum insulated plate

ActiveCN102717578ALow thermal conductivityLow priceLaminationLamination apparatusHigh resistanceFiber

The invention relates to a method utilizing expanded perlite to produce a vacuum insulated plate. The fabrication process of the method comprises the following steps of: burdening: putting the expanded perlite, an auxiliary material, fiber and a vacuum active stabilizing agent into a mixing machine to be fully mixed; drying: drying the uniformly stirred mixture; core material forming: putting the dried materials and a getter into a mould, and putting the mould into a pressing machine for pressure forming; package: taking out a pressure-formed core plate from the mould, packing a layer of non-woven fabric at the periphery of the core plate so as to obtain the core plate of the vacuum insulated plate for buildings; putting the core plate into a high-resistance gas membrane bag, vacuumizing with the vacuum degree of 0.02-20Pa, and then sealing. The method has the advantages that the sound absorption of the expanded perlite is good, and the own coefficient of thermal conductivity of the expanded perlite is low; the mixing of the auxiliary material, the fiber and the perlite can form a high-performance thermal-protective layer among perlite particles, and further the thermal insulation properties and the strength are increased; and the expanded perlite is an inorganic materials and is not easy to burn.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

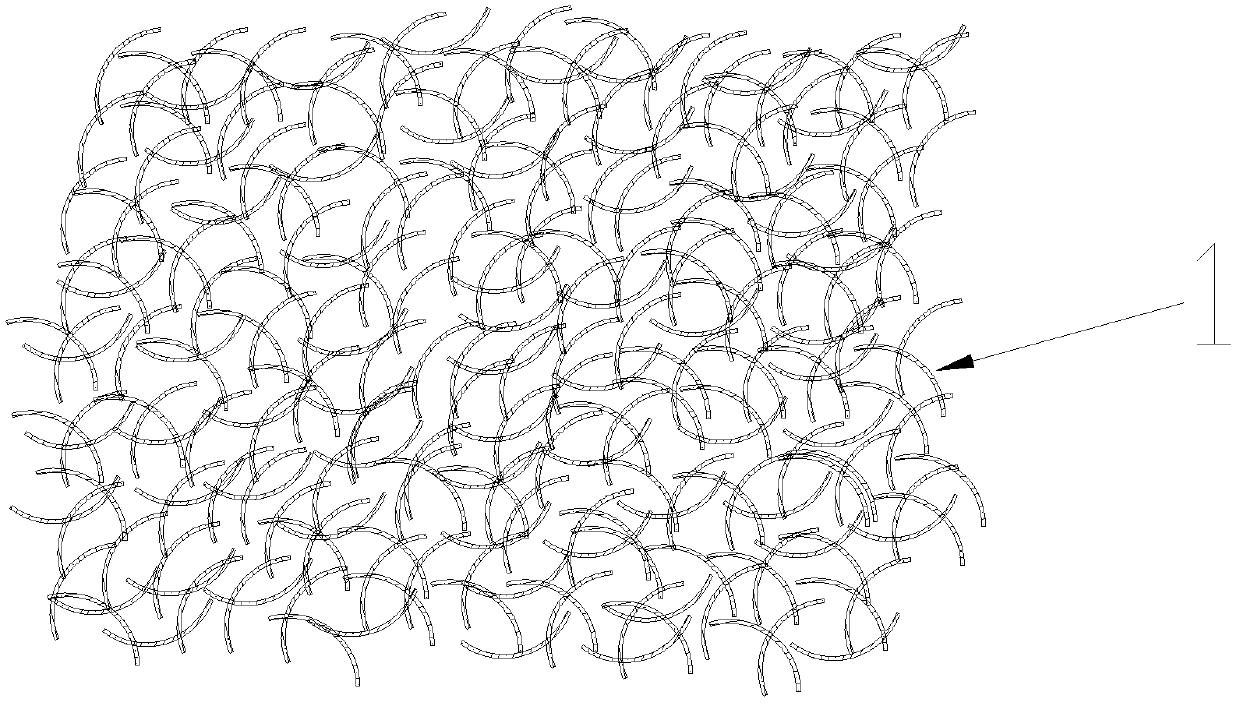

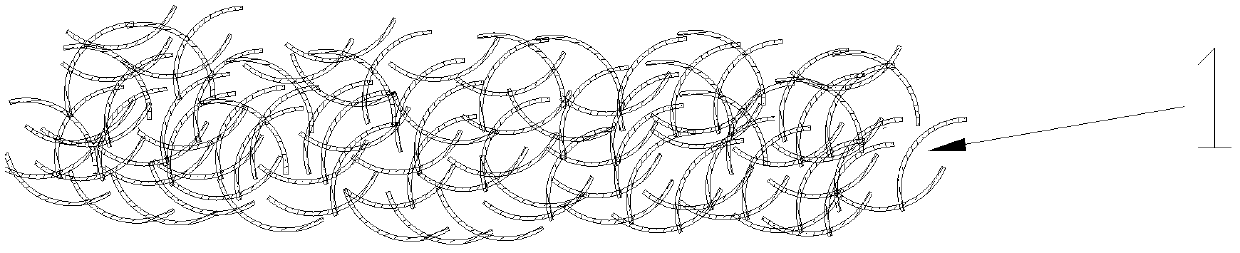

Fiber mat, preparation method and core material for vacuum thermal insulation plate

InactiveCN103306048ALow thermal conductivityHigh strengthFibreboardGlass/slag layered productsGlass fiberPunching

The invention discloses a fiber mat, comprising 50-100 (weight ratio accounting for the dried fiber mat and the same below) glass fiber and chopped strands, and one or more of 0.1-30 inorganic fibers, 0.1-30 natural fibers, 0.1-30 synthetic fibers, 0.1-30 manmade fibers and an anti-radiation material besides the glass fibers and the chopped strands. The fiber mat is prepared by a needle punching method, a spun lacing method, a thermal rolling method, a wet type paper-manufacturing acid process, a wet type paper-manufacturing thickener method, a wet type paper-manufacturing gel method and the like. According to the preparation method for the fiber mat disclosed by the invention, the conductive thermal coefficient of a vacuum thermal insulation plate made of the fiber mat achieves 25-65% under the premise of adopting the same production mode, and a more superexcellent thermal insulation effect is obtained.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

Refrigerator appliance and a door for an appliance

InactiveUS20150241115A1Lighting and heating apparatusLayered productsEngineeringRefrigerated temperature

A door for an appliance is provided. The door of the appliance includes an outer panel with a rear surface. The door also includes a vacuum insulation panel and a barrier layer. The barrier layer is positioned between the rear surface of the outer panel and the vacuum insulation panel within the door.

Owner:GENERAL ELECTRIC CO

Core material used in vacuum insulation board, preparation method thereof, and purpose thereof

InactiveCN103072321AUnbreakableEasy to moveThermal insulationLayered productsRefrigerated temperatureMaterials science

The invention relates to the field of vacuum insulation board, and especially relates to a core material used in a vacuum insulation board, a preparation method thereof, and a purpose thereof. The core material comprises a sealed film bag manufactured by using an air-permeable and powder-impermeable filtering material, and a powder material filled in the film bag. The powder material is a porous material with a particle size smaller than 20mum. The filtering material can at least resist high temperature of 120 DEG C. Compared with a core material obtained with a sandwiching structure and with a sol-gel method in prior art, the vacuum insulation board provided by the invention has the advantages of crushing resistance, easy moving, and simple preparation method. With the vacuum insulation board, the requirements of fields such as refrigerators on vacuum insulation boards can be satisfied, and requirements of the field of construction energy saving and insulation on service lives of 20 years or even 50 years can be satisfied. The vacuum insulation board can be widely applied in the field of construction energy saving and insulation.

Owner:FUJIAN SUPERTECH ADVANCED MATERIAL

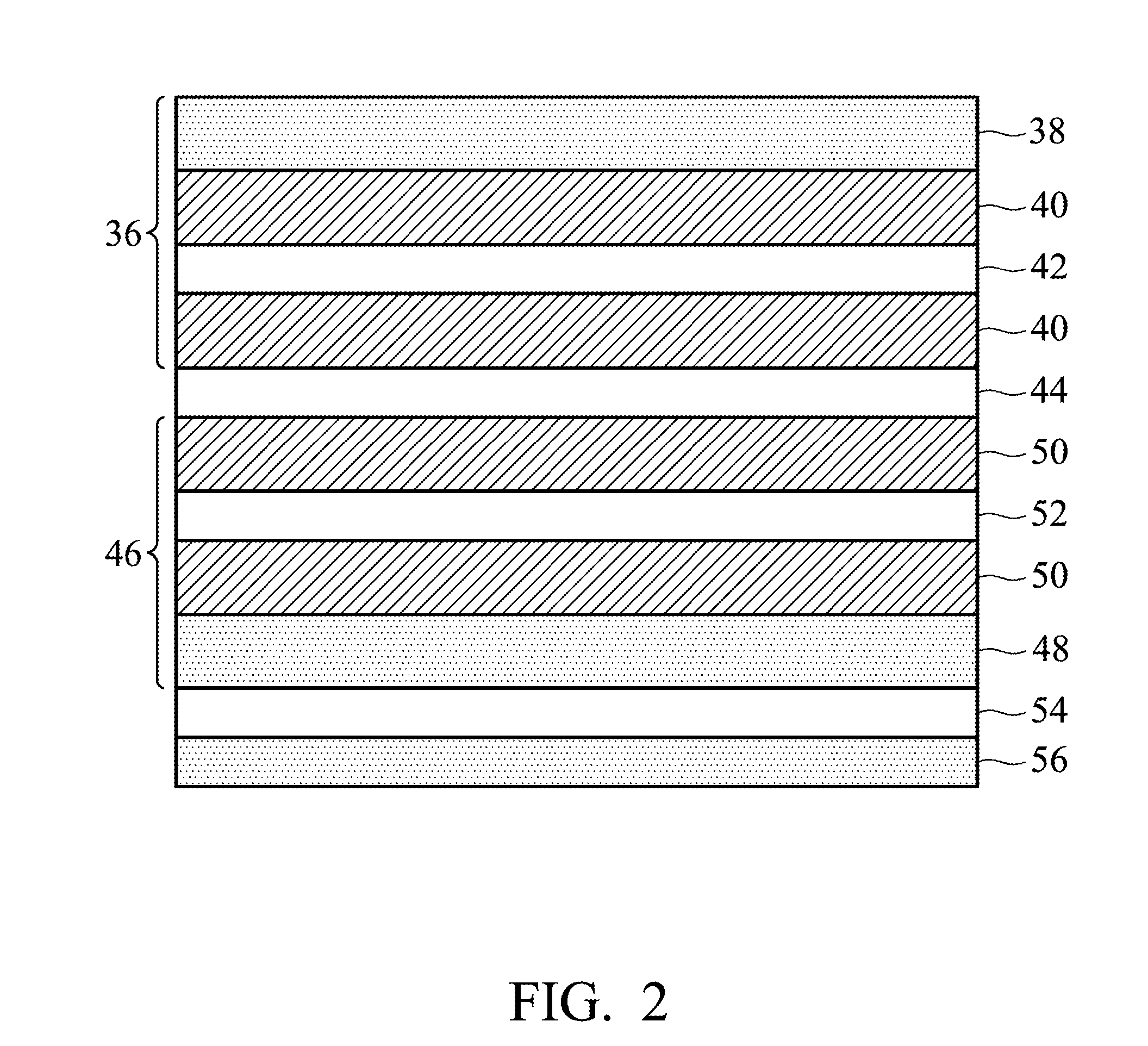

Gas-barrier heat-seal composite films and vacuum insulation panels comprising the same

ActiveUS20120148785A1High gas barrierImprove adhesionSynthetic resin layered productsRecord information storageLow-density polyethyleneLinear low-density polyethylene

A gas-barrier heat-seal composite film is provided. The gas-barrier heat-seal composite film includes a heat-seal layer including very low density polyethylene (VLDPE), low density polyethylene (LDPE), linear low density polyethylene (LLDPE), high density polyethylene (HDPE), metallocene polyethylene (mPE), metallocene linear low density polyethylene (mLLDPE), ethylene vinyl acetate (EVA) copolymer, ethylene-propylene (EP) copolymer or ethylene-propylene-butene (EPB) terpolymer, and a gas-barrier layer formed on the heat-seal layer, wherein the gas-barrier layer includes a plurality of composite layers, each including a polymer substrate and a single layer or multiple layers of metal or oxide thereof which is formed on one side or both sides of the polymer substrate, and the polymer substrate includes uniaxial-stretched or biaxial-stretched polyethylene terephthalate (PET), polybutylene terephthalate (PBT), polyimide (PI), ethylene / vinyl alcohol (EVOH) copolymer or a combination thereof. The invention also provides a vacuum insulation panel including the composite film.

Owner:IND TECH RES INST

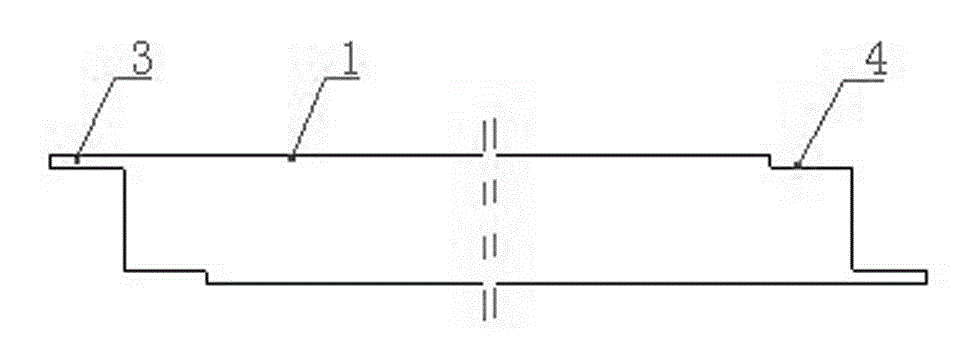

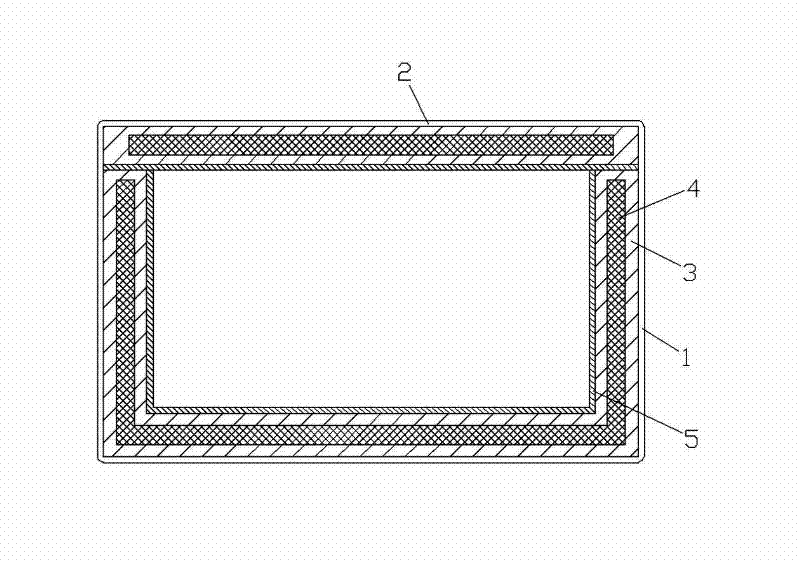

Air insulating structure of vacuum insulation panel and packaging method thereof

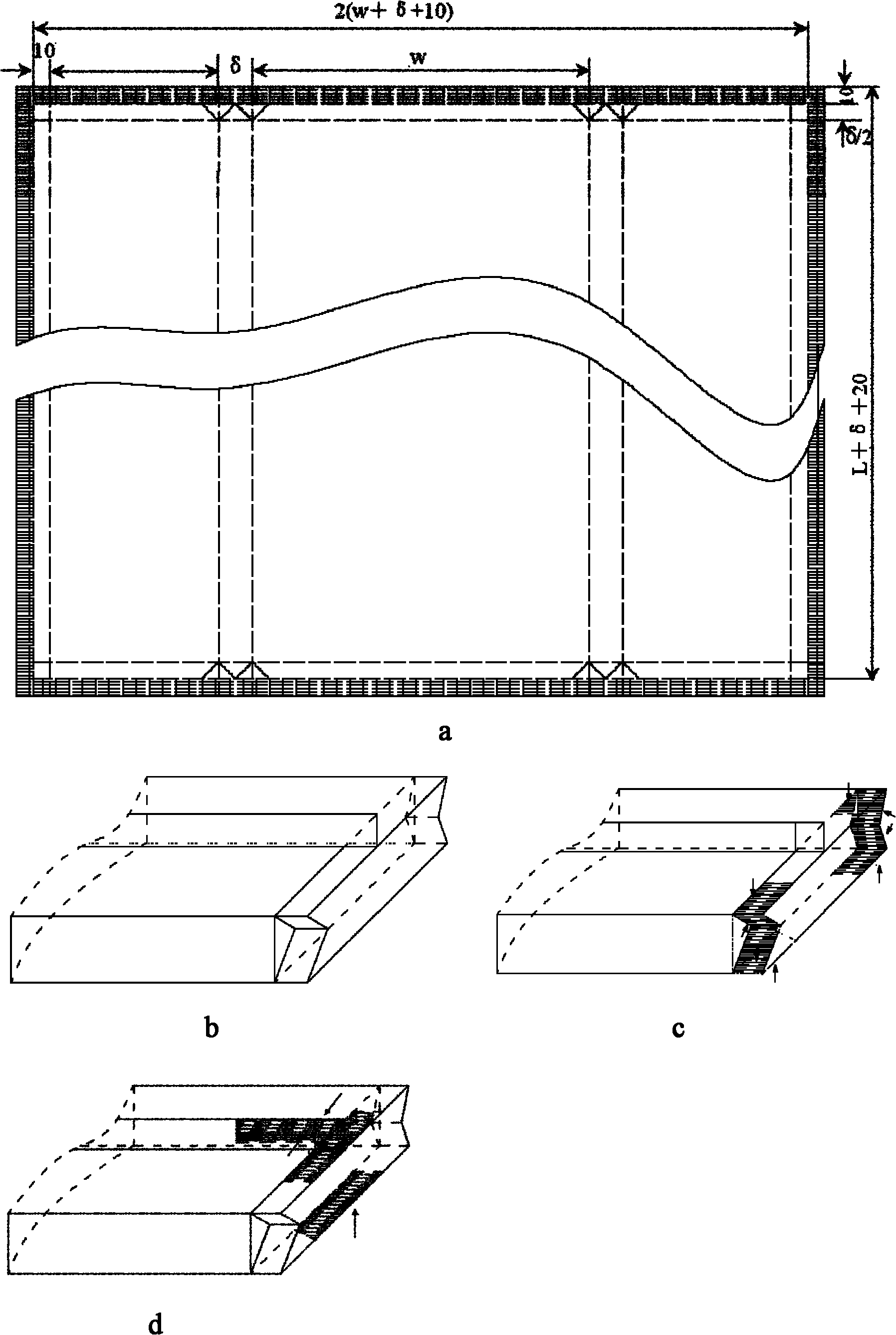

InactiveCN101963267AReduce the number of heat-sealed edgesSave on packaging costsThermal insulationPipe protection by thermal insulationVacuum pumpingThermal bridge

The invention provides an air insulating structure of vacuum insulation panel, which is formed by composite material. The composite material does not contain aluminium foil layer; therefore, the heat bridge effect of seal edge during heat seal is avoided. The packaging method of the air insulating structure comprises the following steps of: folding a single piece of composite material to form a bag shaped air insulating structure having a size consistent with that of adiabatic core material according to the specification of the core material and form three seal edges; sealing part of sealing edges with heat, and keeping an opening for placing the adiabatic core material inside; filling the adiabatic core material in the air insulating structure, performing heat seal on the remained opening and keeping a vacuum pumping opening; and placing the air insulating structure, which is filled with the adiabatic core material and has a vacuum pumping opening, in a vacuum room and pumping to produce vacuum, and performing heat seal on the preserved vacuum pumping opening to form a vacuum thermal insulation panel. The air insulating structure has three seal edges, which are fewer than those of the conventional method; therefore, the integral heat bridge effect is reduced, the operation is simple, the appearance planeness of the vacuum insulation panel is improved, and the fold and air leakage of the air insulating structure in convention manufacturing process are avoided.

Owner:SHANGHAI MARITIME UNIVERSITY

Vacuum insulation panel

InactiveUS7517576B2Shorten the timeIncrease air circulationThermal insulationLayered productsAir cycleProduct gas

The invention provides a vacuum insulation panel to which moisture and gas do not easily adsorb while it is being processed or being in storage in an unfinished state. The vacuum insulation panel includes a core provided with air circulation, a getter material which adsorbs moisture and gas from the core, an inner film bag which accommodates the core and the getter material, and an outer barrier bag which accommodates the inner film bag. The getter material is filled in an incision provided on the surface of the core. To prevent the getter material from getting out of the incision, the opening of the incision is narrowed by evacuating air from the interior of the inner film bag and, concurrently, compressing the inner film bag and the core.

Owner:HITACHI APPLIANCES INC

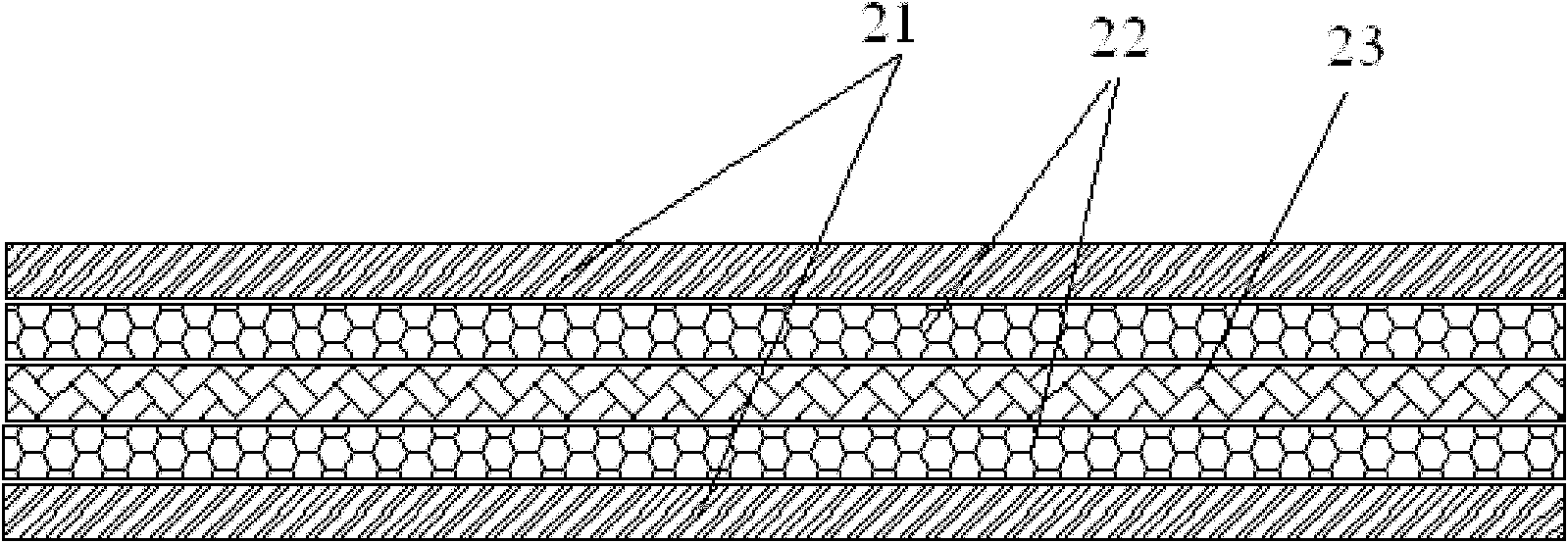

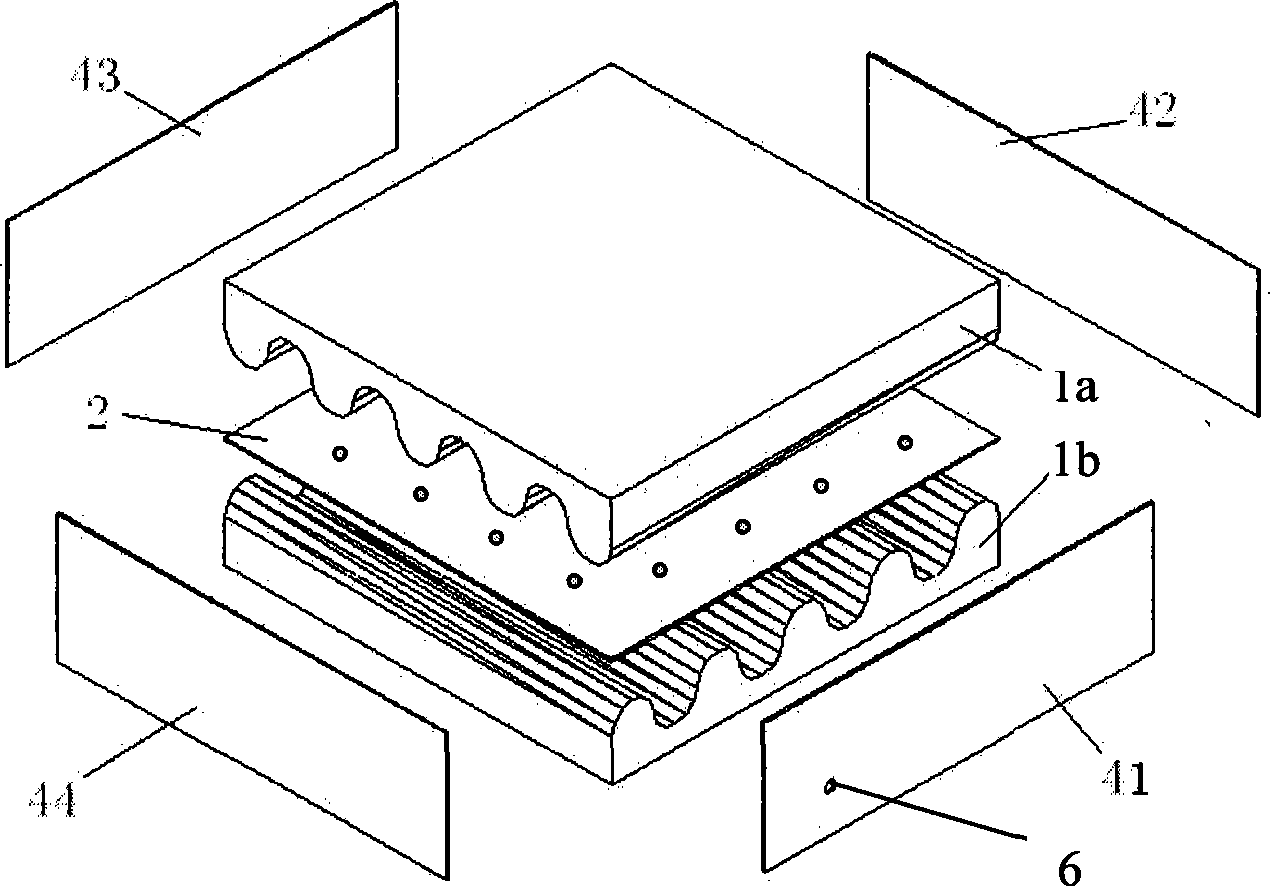

High-strength, flame-proof vacuum insulation plate and manufacture method thereof

The invention discloses a high-strength and flame-resistant vacuum insulating board which comprises core material and a sealing film wrapped outside the core material. The core material comprises an intermediate layer, thermal insulation material layers are respectively superposed above and below the intermediate layer, the sides of the insulation material layers above and below the intermediate layer facing toward the intermediate layer are corrugated surfaces, corrugated depressions of the corrugated surfaces are filled with silicon dioxide aerogel and getter, the sides of the insulation material layers back against the intermediate layer are planes, and the planes are adhered with reflection layers. The vacuum insulating board of the invention has a stable structure, better impact-resistant property, strong flame resistance, good moderated and high temperature resistant performance and long service life, and can be repetitively pumped to use.

Owner:纳诺科技有限公司

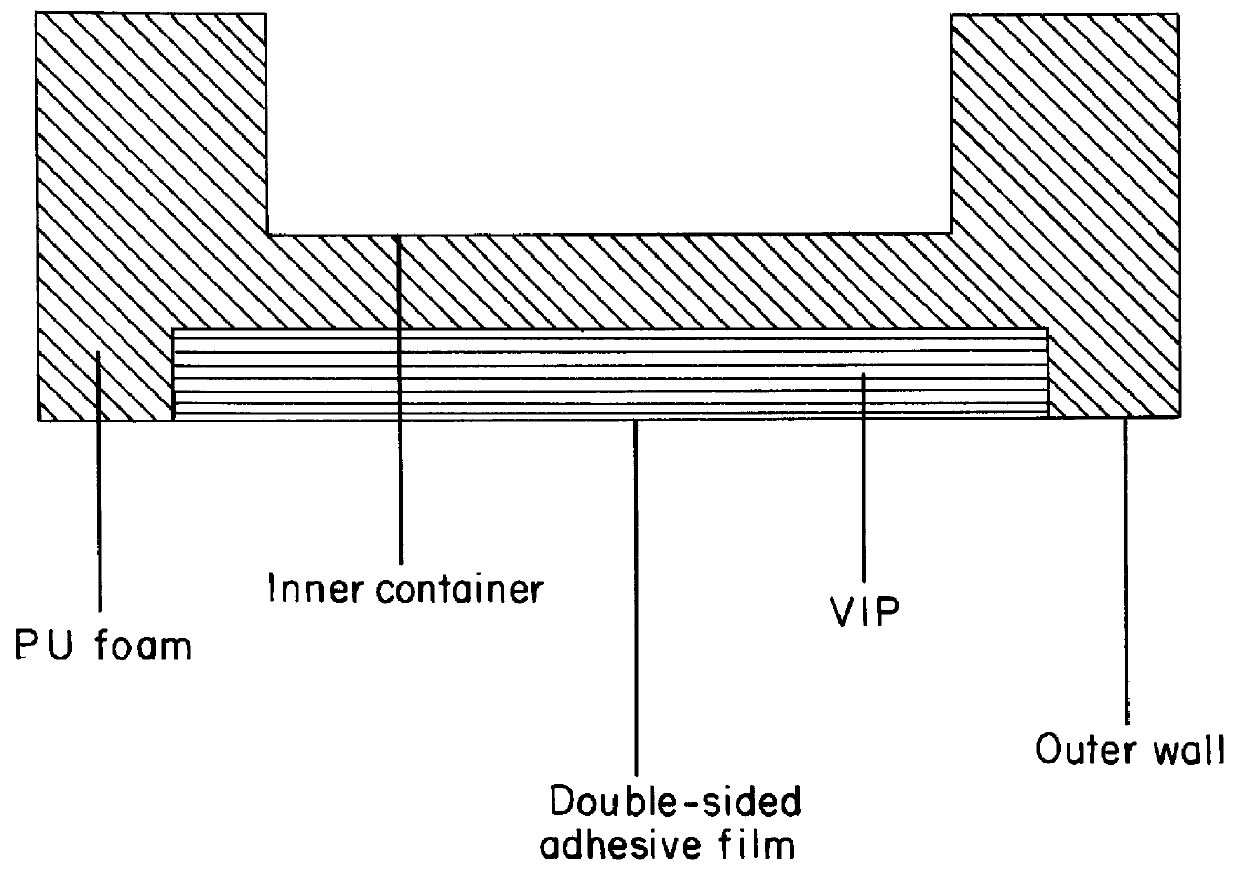

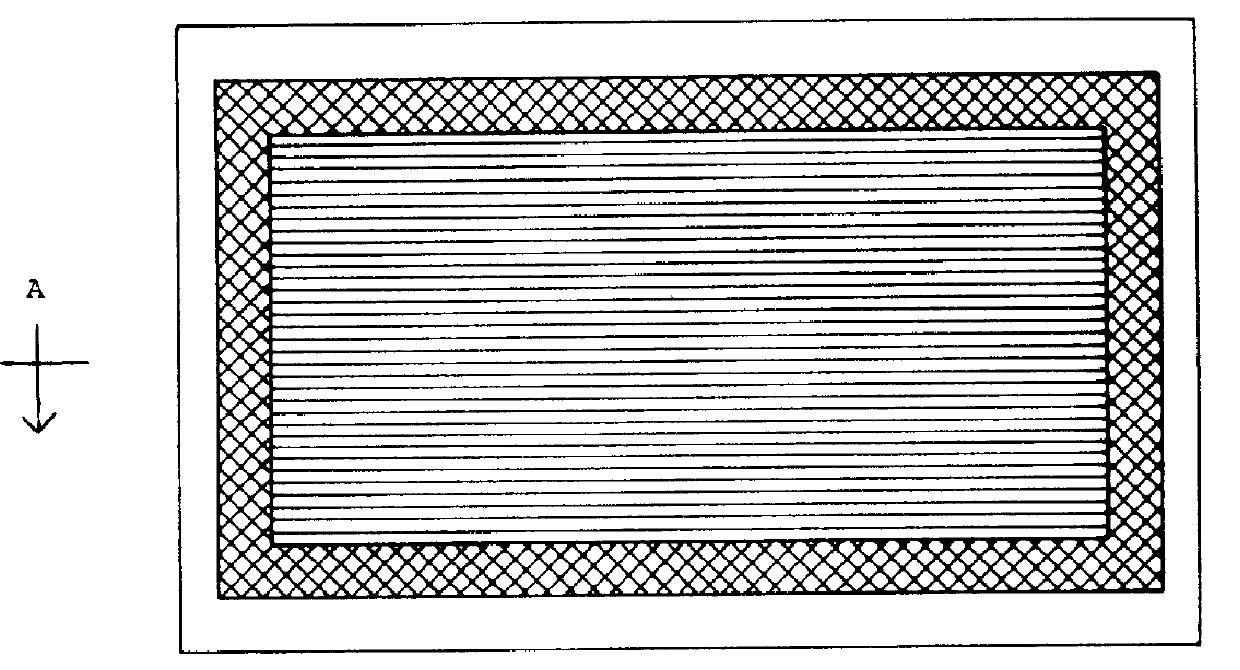

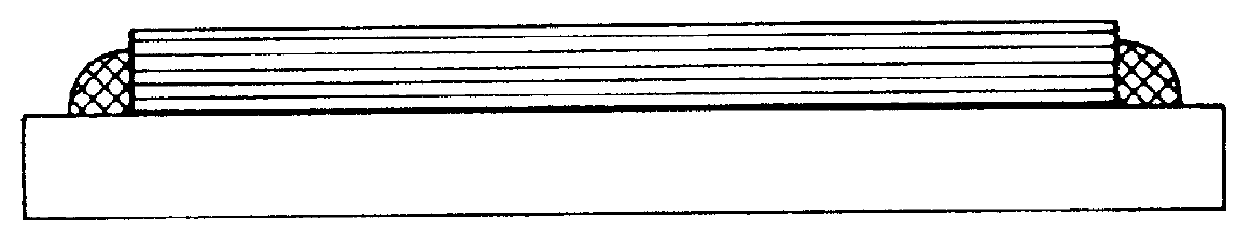

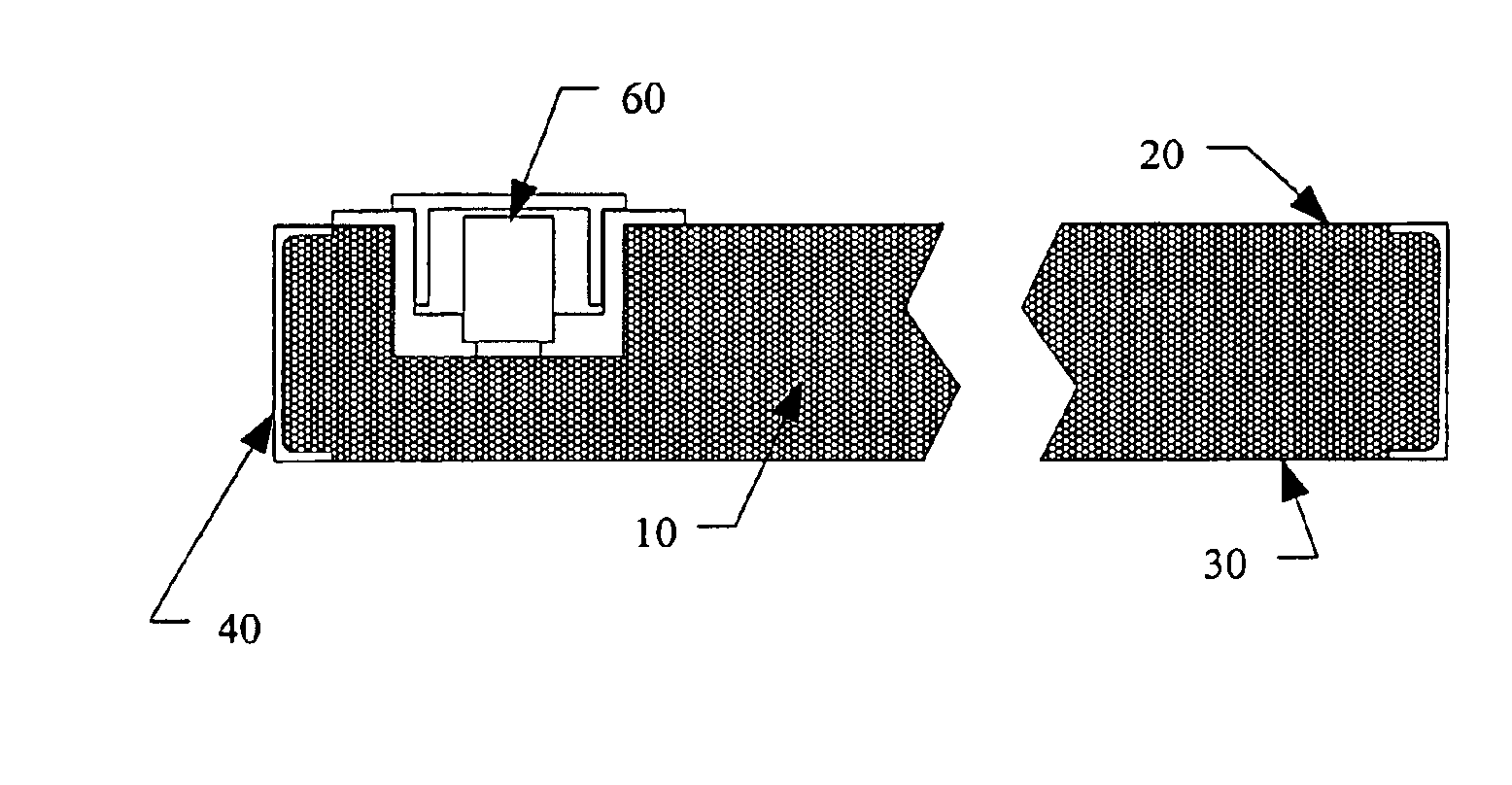

Thermally insulated polyurethane shipper and method of making same

ActiveUS9022249B2Enhanced advantageAvoid disadvantagesDomestic cooling apparatusLighting and heating apparatusVacuum insulated panelTemperature sensitive

A thermally insulated sandwich polyurethane (PUR) shipper for a temperature sensitive payload is provided. The sandwich PUR shipper comprises an outer corrugated box, an inner corrugated box, vacuum insulated panels (such as VIP panels) and PUR foam. The inner box is nested within the outer box and has a bottom, sides and a top. The inner box defines a payload compartment. The VIP panels are adhered to the outer facing surfaces of the inner box. Preferably the VIP panels are wedged against each other so that a side edge of one VIP panel abuts an adjacent VIP panel. The PUR foam fills the space between the VIP panels and the outer box. The PUR foam may cover the top edges of the VIP panels.

Owner:SONOCO DEV INC

Portable refrigeration container

InactiveUS20070175236A1Improves Structural IntegrityPrevent theftContainer filling methodsDomestic refrigeratorsEngineeringRefrigeration

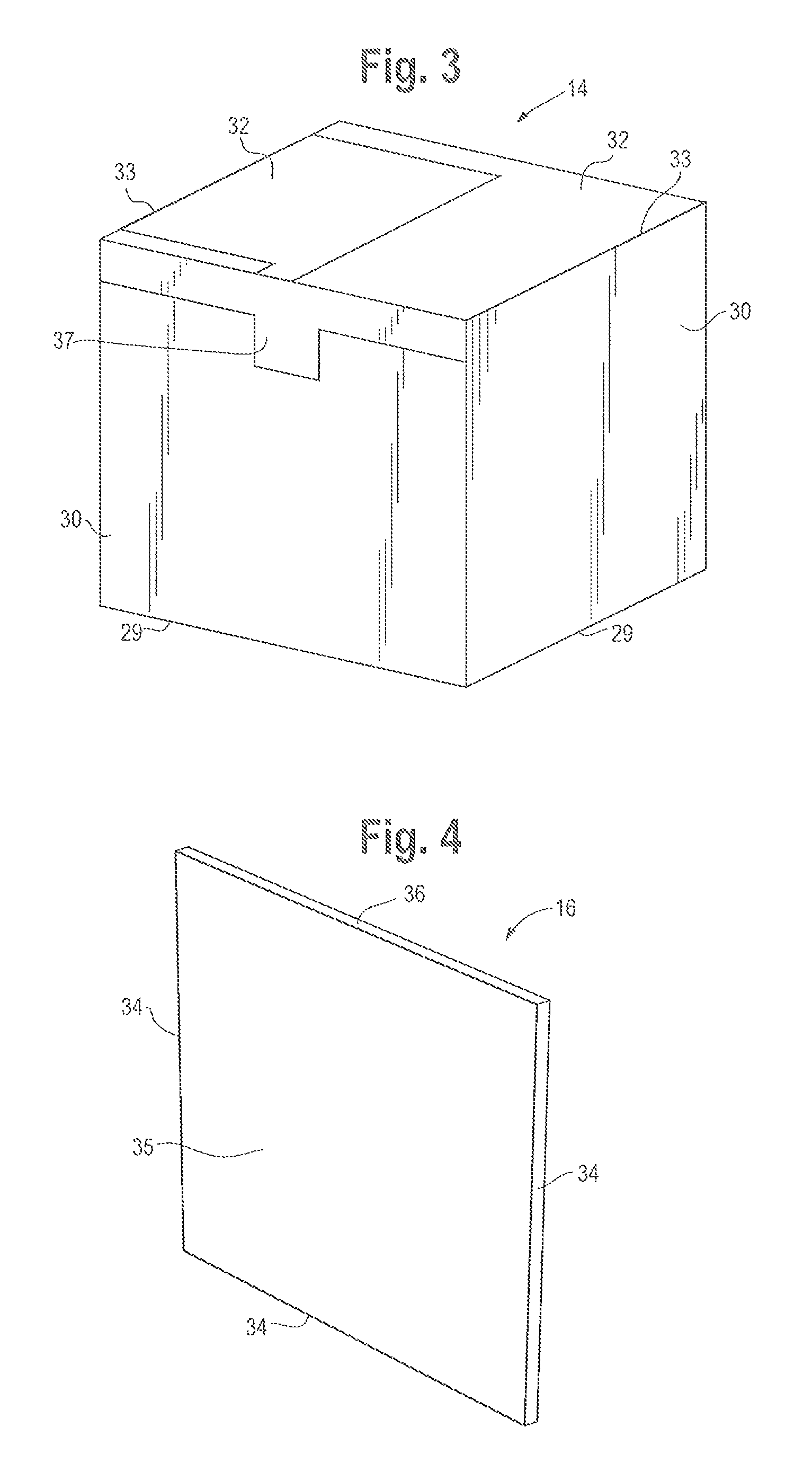

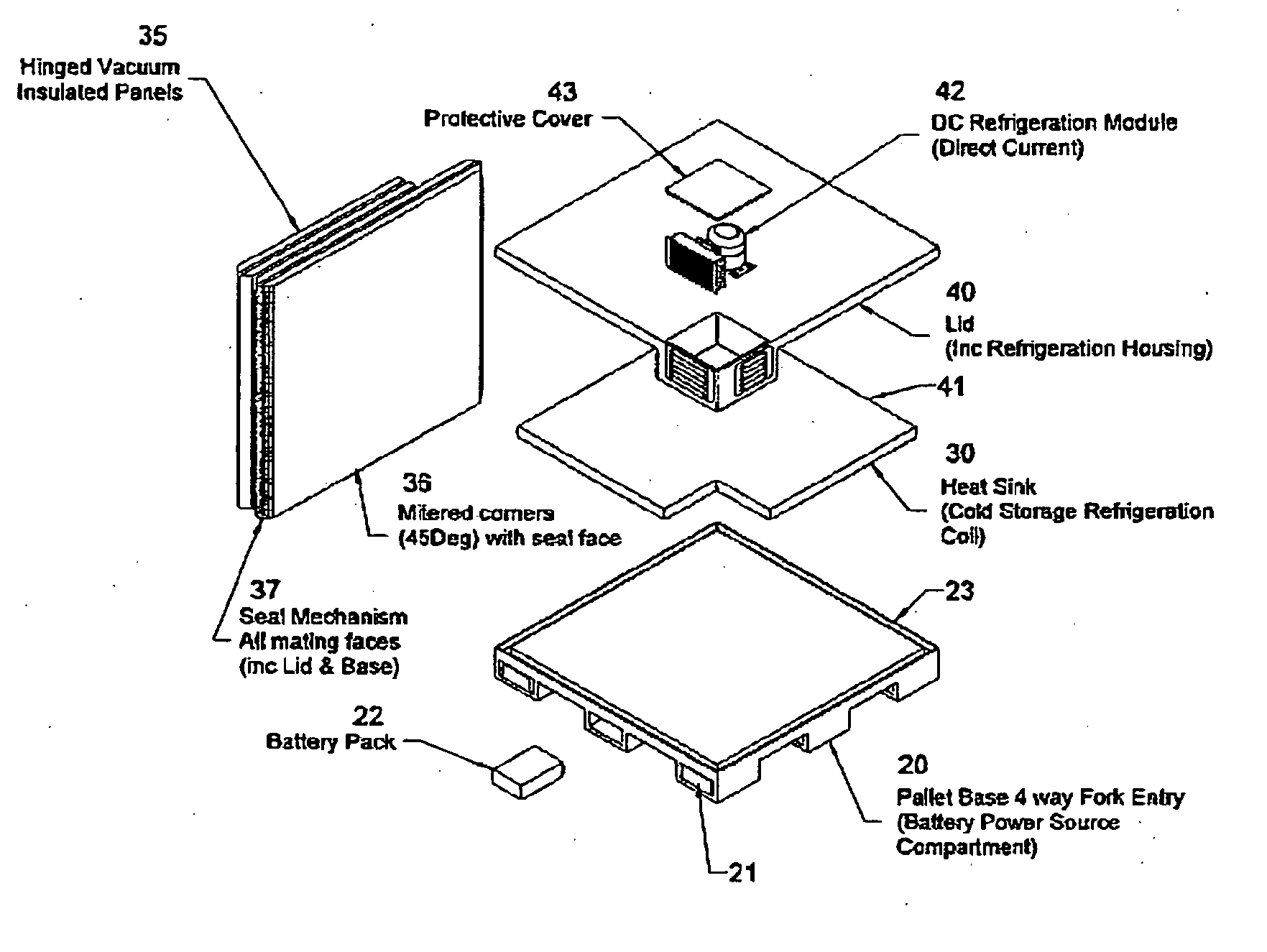

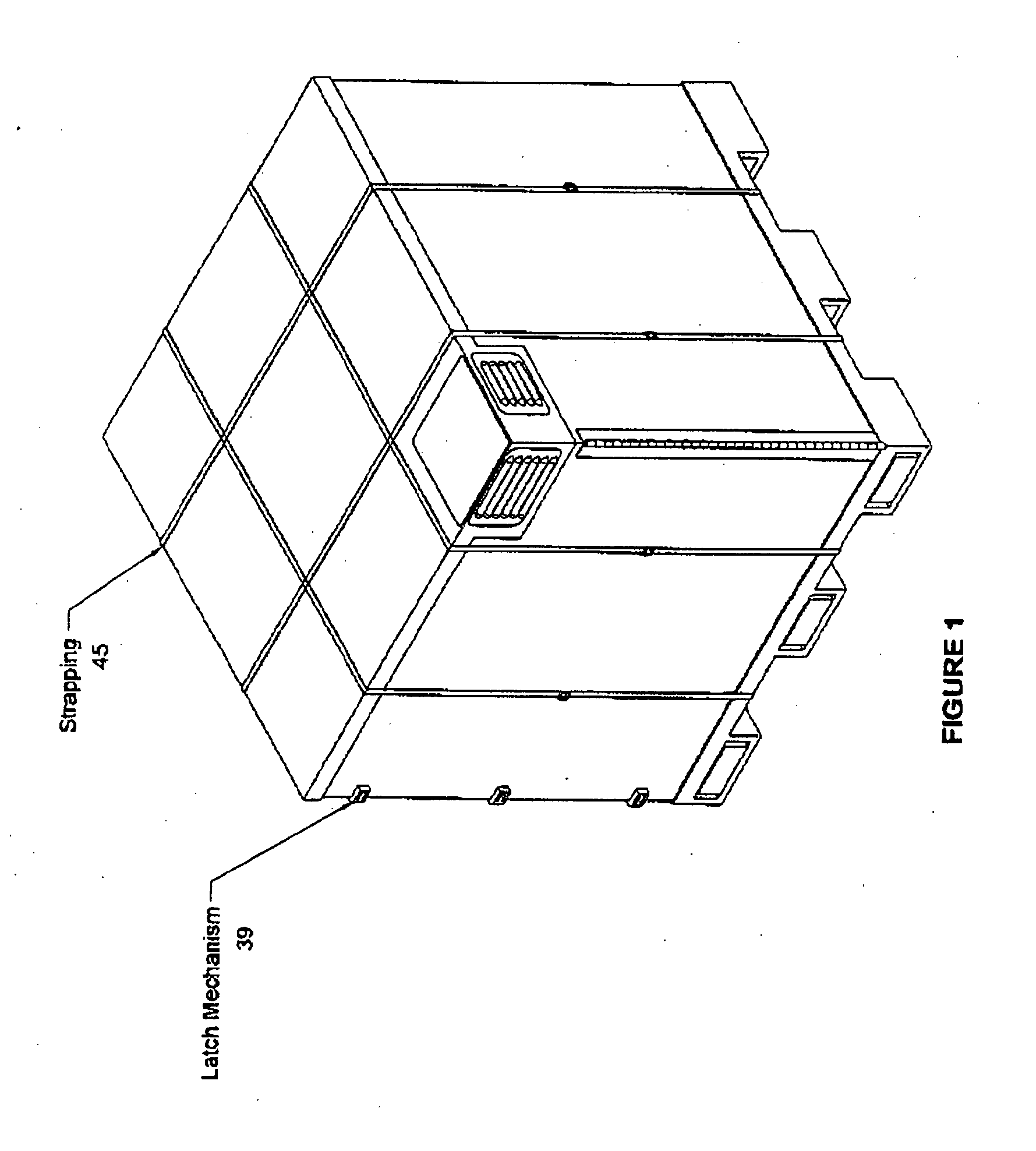

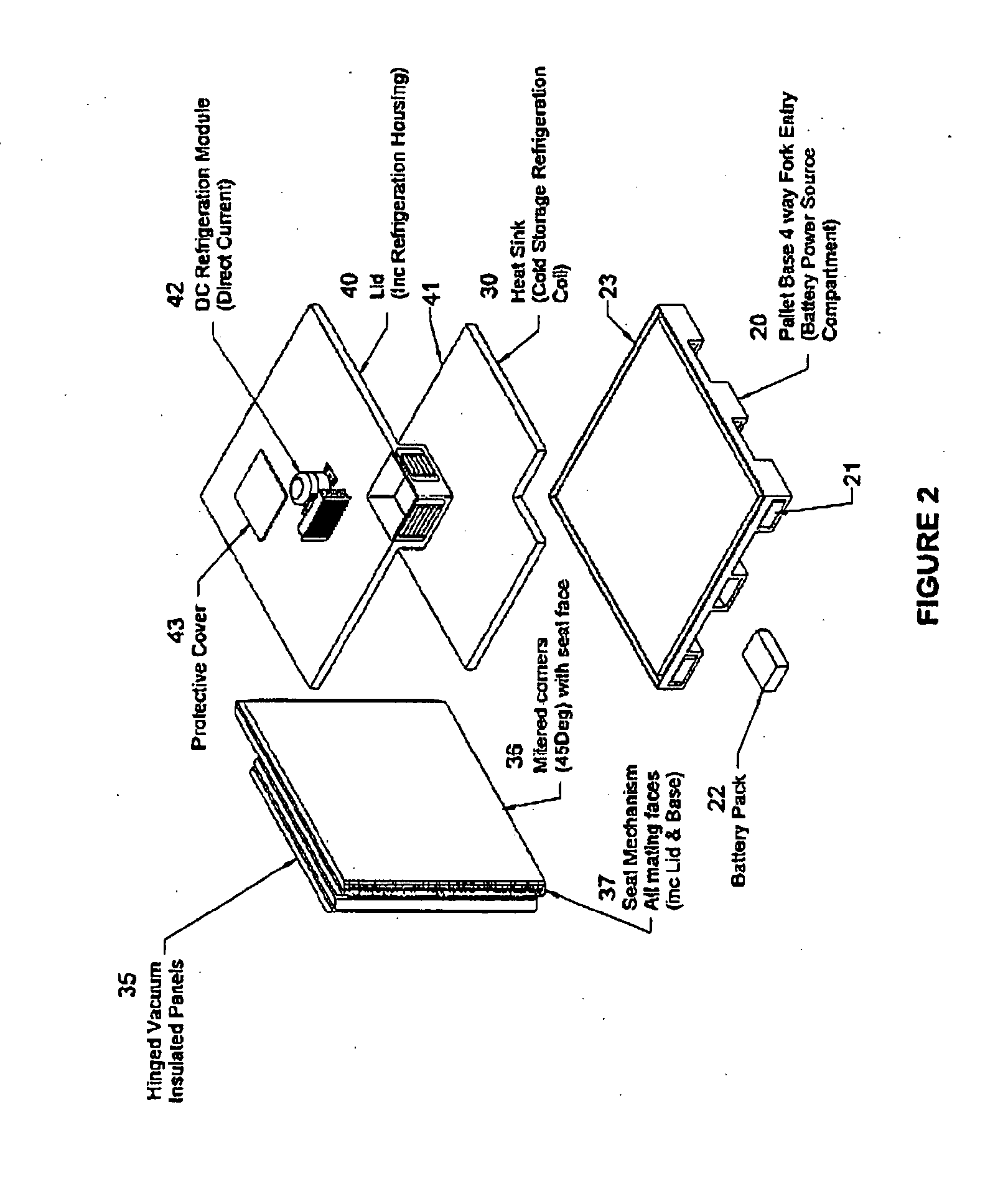

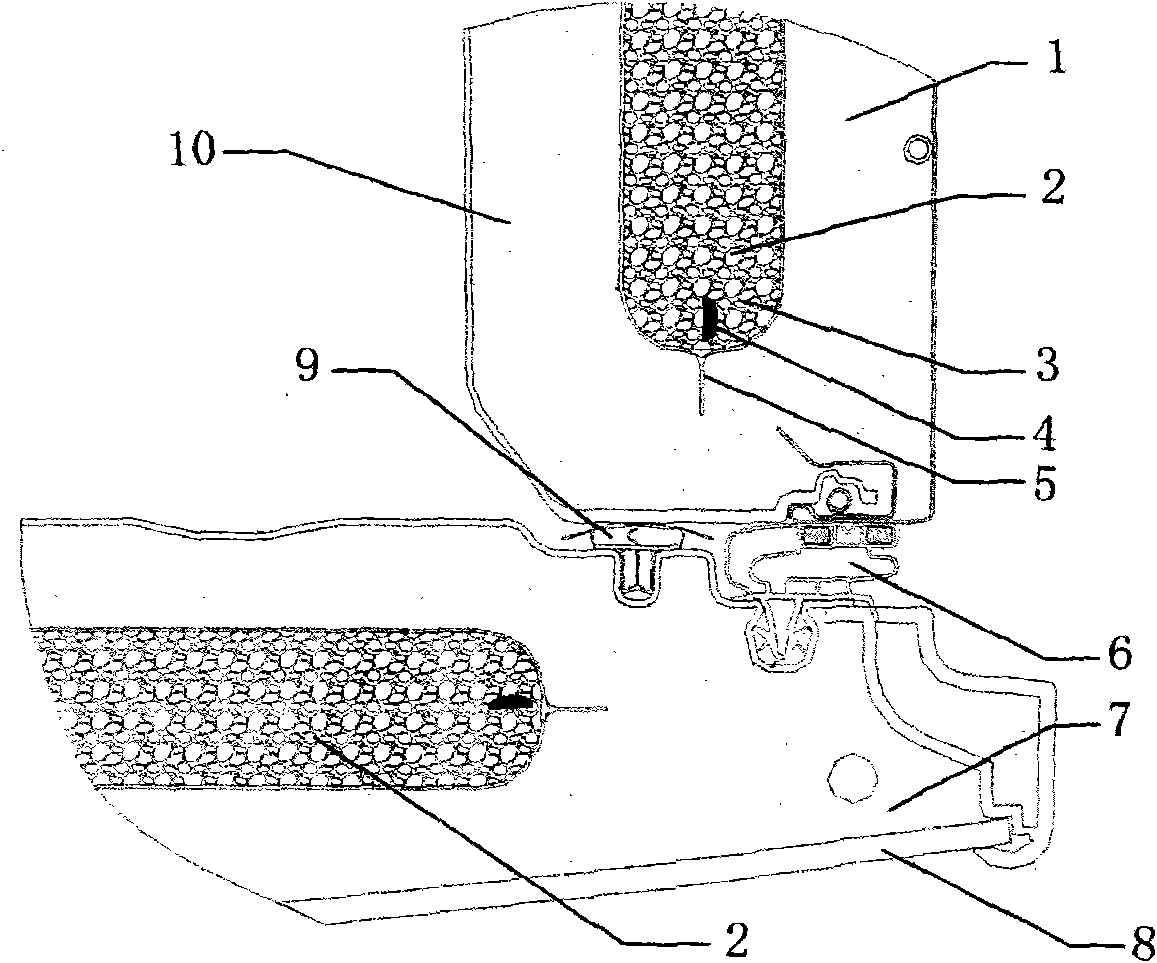

Pallet version of the portable refrigeration container including a palletised thermally insulated base (20) including seal mechanism, forklift fork receiving cavities (21) allowing ready transportability. A dismantlable wail assembly (35) comprising hinged vacuum insulated panels (35) are able to be mounted on the palletised thermally insulated base (20) and engaging with the perimeter channel (23) forming the base sealing mechanism. The thermally insulated hinge type collapsible concertina configuration of side panels (35) have latch mechanism for holding panels in rectangular configuration defining a container volume therein. A thermally insulated lid (40) covers the top of the container volume and includes a seal mechanism for engaging with the wall assembly. The portable refrigeration container includes an integral cooling system, for cooling the container volume, incorporated in one or more of the base, sides or lid.

Owner:DRYZUN NATHAN

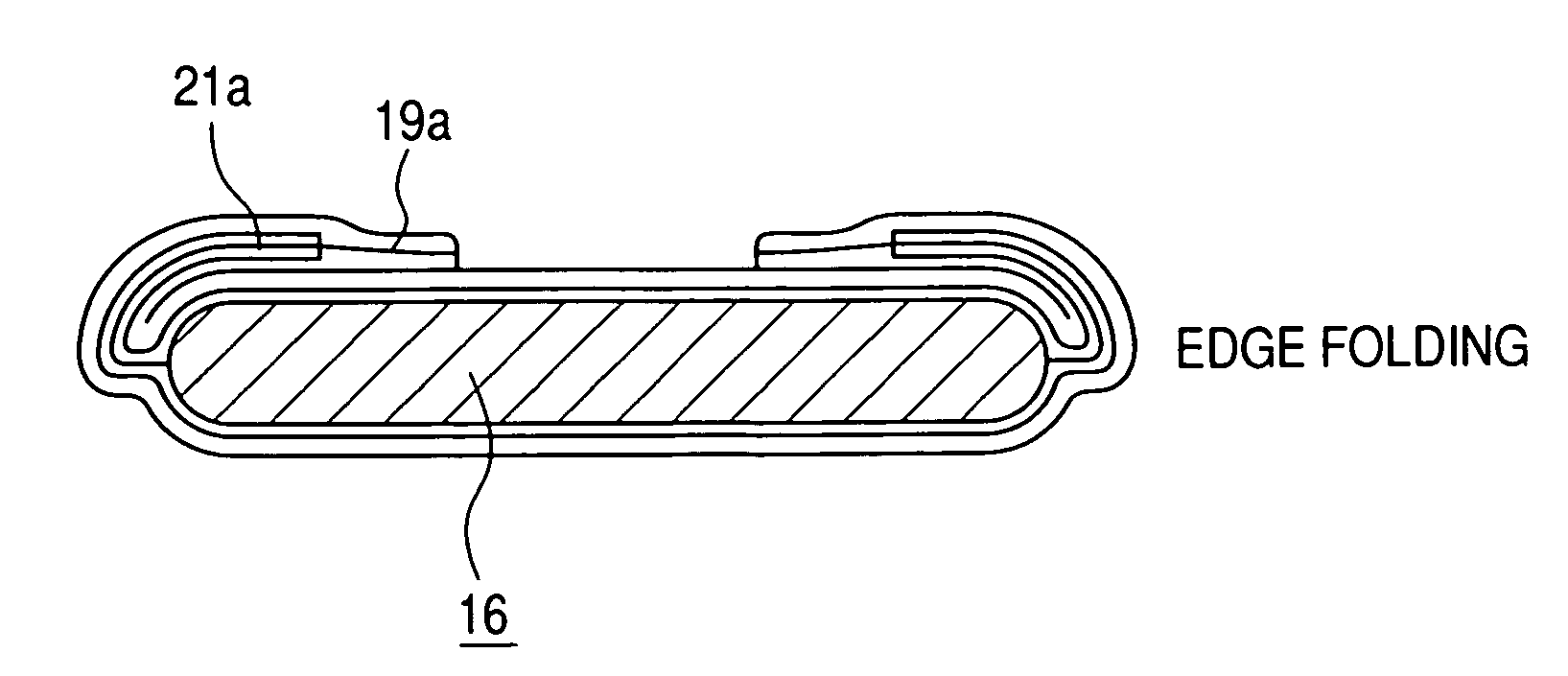

Vacuum insulation panel and refrigerator incorporating the same

InactiveUS20060088685A1Improve reliabilityPrevent heat transferThermal insulationLayered productsFiberMetallic foil

The invention relates to a vacuum insulation panel which can be used as an insulator for a refrigerator requiring heat insulation to be provided and also to a refrigerator incorporating such a vacuum insulation panel. The invention particularly relates to an arrangement for preventing convection spaces from being formed where an edge of the vacuum insulation panel is folded back. The vacuum insulation panel includes a core which has an inner film bag in which a flexible inorganic fiber laminate is accommodated, and an outer barrier bag which is made of gas-impermeable film such as metallic foil laminated film and which accommodates the core. The inner film bag includes a welded portion and a ventilation portion. The outer barrier bag has a depressurized interior and has been sealed by welding. An edge of the inner film bag is placed in an edge of the outer barrier bag.

Owner:HITACHI APPLIANCES INC

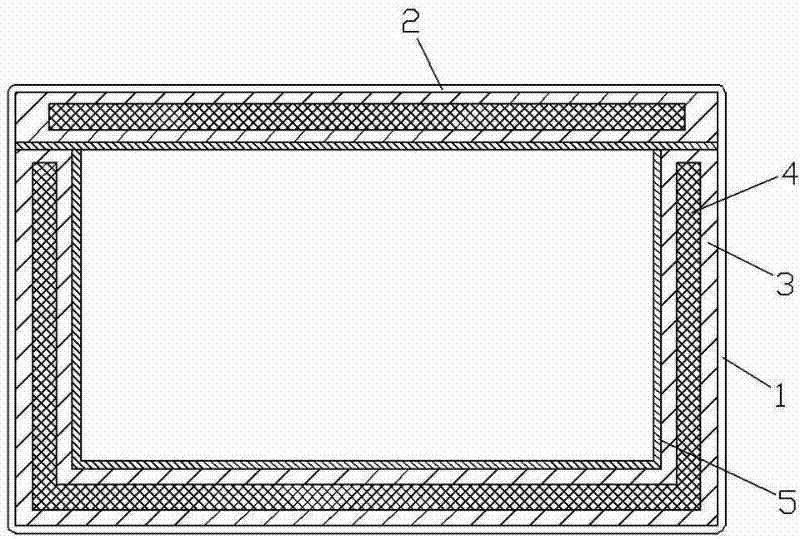

Heat insulation tank

InactiveCN102818421AIncrease the internal volumeFully thinDomestic cooling apparatusLighting and heating apparatusEngineeringRefrigerated temperature

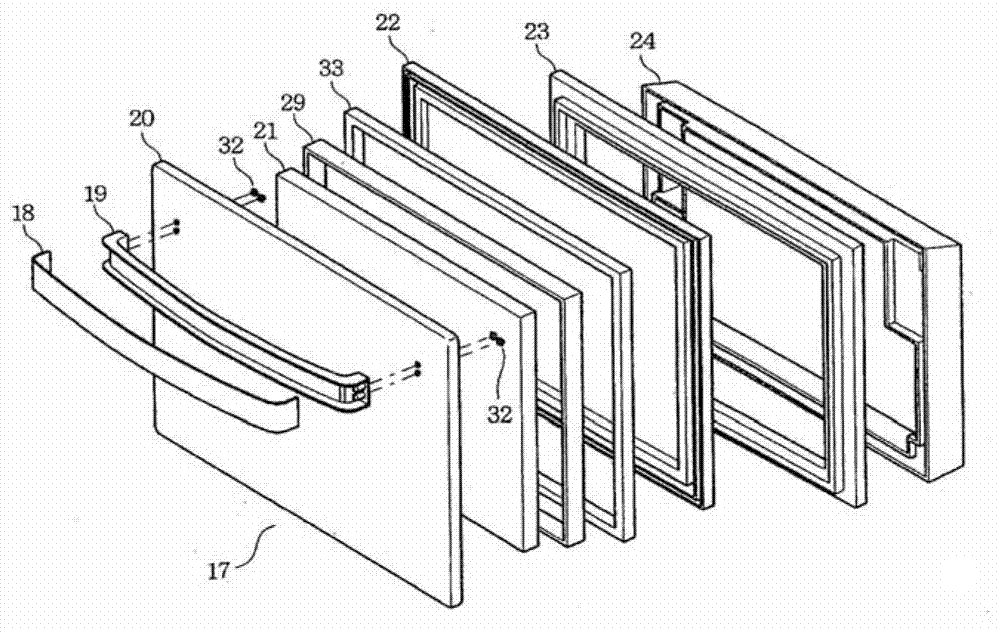

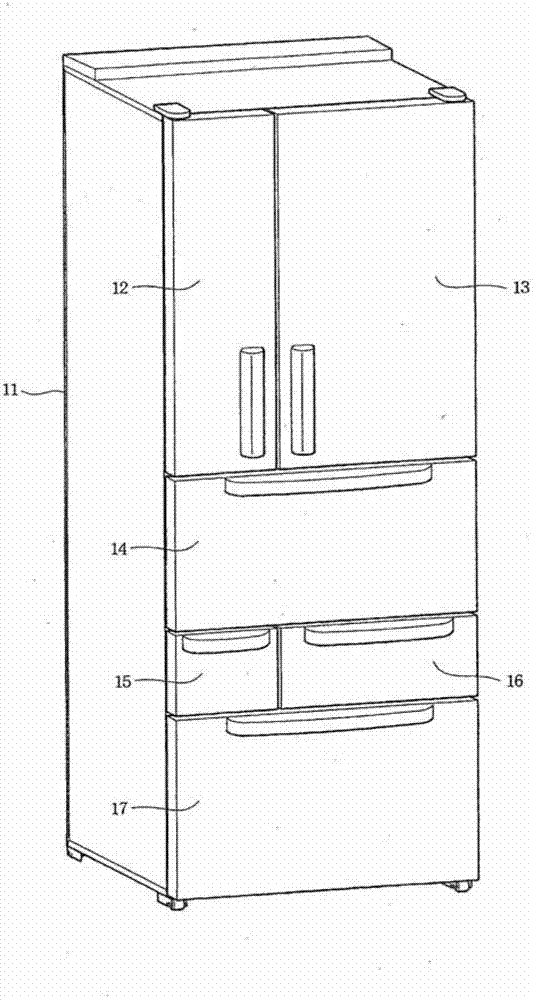

The invention provides a heat insulation tank which can achieve fully thinning doors of refrigerators, etc., thereby enabling the expansion of the inside volume of the tank body. For an outer door plate (20), the outer side surface of a vacuum insulation panel (21) is enabled to abut the rear surface of the outer door plate (20), and the front surface of the inner door plate (22) is enabled to abut the inner side surface of the vacuum insulation panel (21), thereby forming a large refrigerating room door (17) (door) without using foamed polyurethane. According to this structure, the fully thinning of the large refrigerating room door (17) can be achieved, thereby enabling the expansion of the inside volume of the tank body.

Owner:TOSHIBA LIFESTYLE PROD & SERVICES CORP

Energy-saving refrigerator

InactiveCN102003860AAchieve energy savingTo achieve the purpose of reducing consumptionLighting and heating apparatusDomestic refrigeratorsProduct gasRefrigerated temperature

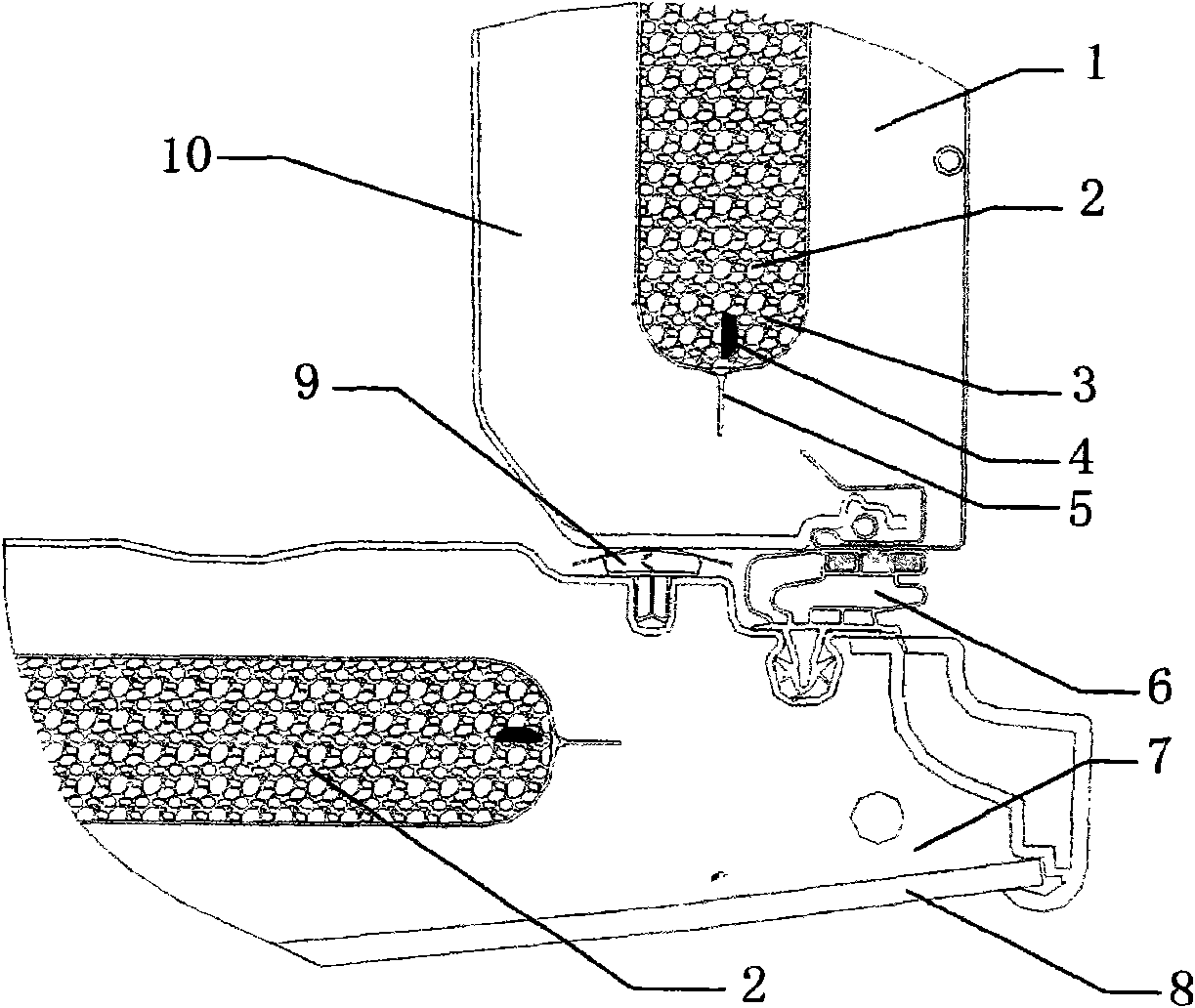

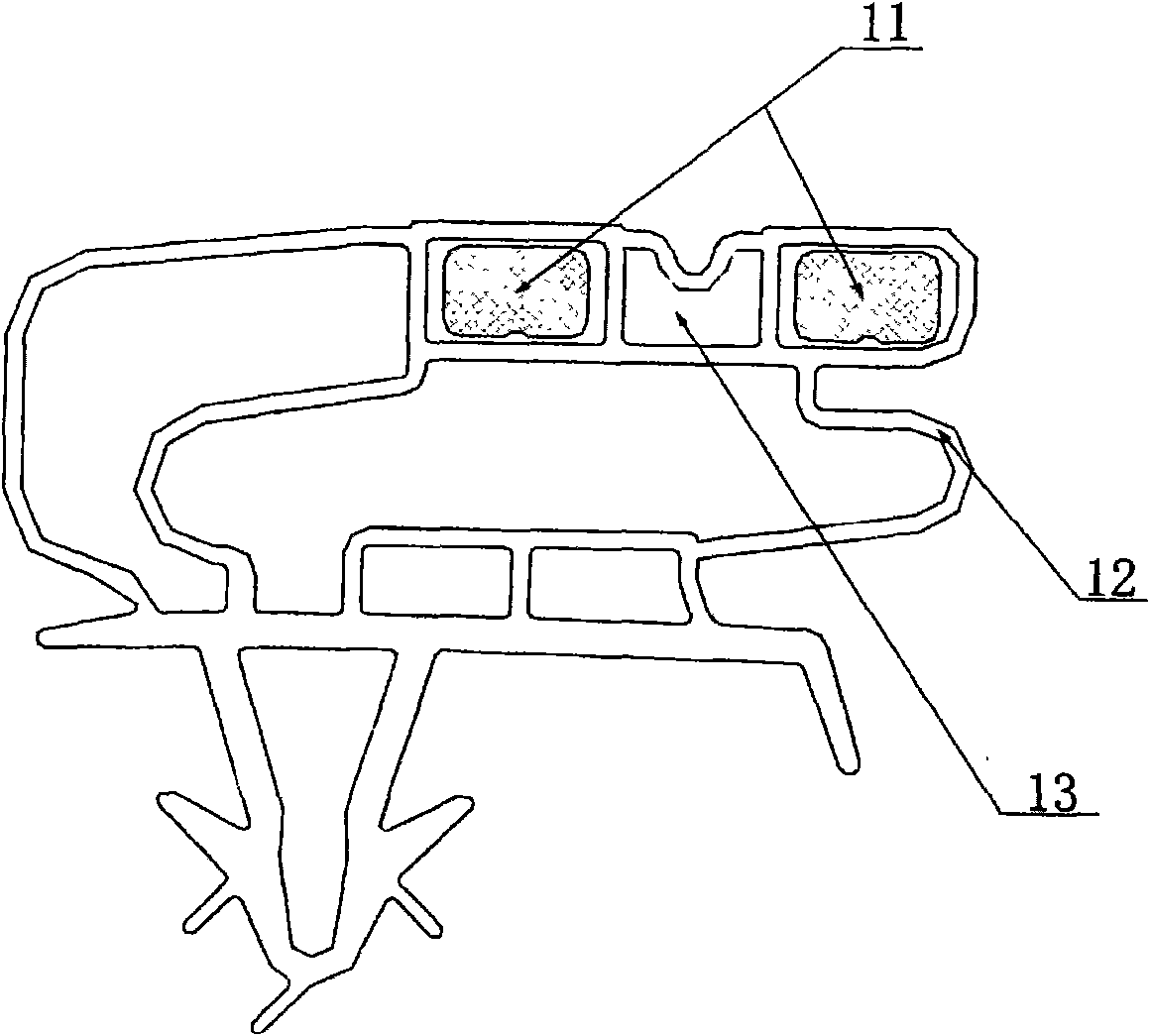

The invention discloses an energy-saving refrigerator and belongs to the technical field of refrigerator energy conservation. Before polyurethane foam is filled in a heat-insulating layer to foam, one or two high-vacuum thermal insulation plates are arranged in the heat-insulating layer. The whole heat-insulating material consists of polyurethane open-cell foam, an air adsorbent and a trapping membrane, wherein the polyurethane open-cell foam serves as a core heat-insulating material; the aperture ratio of the polyurethane foam is more than or equal to 95 percent; and the polyurethane open-cell foam is vacuumized and is sealed by the trapping membrane, so that the heat conductivity is greatly reduced. A double-magnetic stripe door seal is arranged at a connecting place of the cabinet body and a door body; two parallel magnetic stripes of which the length is 4 to 6mm respectively pass through two correspondingly independent air bags; and a small air bag is spaced between the two air bags. The two magnetic stripes realize two door seals and have complementary effect of two sealing surfaces which overcome leakage caused by warping of a single magnetic stripe and guarantee that the seal is more thorough. The aim of energy conservation and consumption reduction is fulfilled by changing the material and structure of the heat-insulating layer and the mounting positions and number of the magnetic stripes of the door seal.

Owner:SHANGHAI DUSHI IND

Modified cement polyphenyl granule composite vacuum insulated panel and preparation method thereof

ActiveCN102979207ASolve the problem of broken air leakageEasy to installClimate change adaptationInsulation improvementUltimate tensile strengthFire retardant

The invention relates to a modified cement polyphenyl granule composite vacuum insulated panel. The modified cement polyphenyl granule composite vacuum insulated panel is characterized by comprising a vacuum heat insulation panel and modified cement polyphenyl granule thermal mortar which covers the periphery of the vacuum heat insulation panel. The vacuum heat insulation panel comprises core materials, high strength air resistance film and interface mortar. The high strength air resistance film covers the periphery of the core materials and is encapsulated between core materials through vacuumpumping. A layer of interface mortar is coated on the periphery of the high strength air resistance film. The thickness of the interface mortar is 2 millimeters to 3 millimeters. The modified cement polyphenyl granule composite vacuum insulated panel has the advantages that problem of damage and air leakage of the vacuum heat insulation plate in a work process is solved, construction and installation are convenient to achieve, heat retaining property, water resisting property, durability and freezing resistance are good, flame class is non-ignitable or fire-retardant and fireproof performance is good.

Owner:ANHUI KERUIKE INSULATION MATERIAL

A cold storage transport incubator

InactiveCN102285495AIncrease effective volumeReduce weightDomestic cooling apparatusLighting and heating apparatusPolymer scienceProtection layer

The invention discloses a cold-storage transport incubator, which comprises a box body and a box cover matched with the box body, the inner walls of the box body and the box cover are provided with a polyurethane foam plastic layer, and the polyurethane foam plastic layer There is a layer of vacuum heat insulation board inside the layer, and the polyurethane foam plastic layer and the vacuum heat insulation board form a composite heat insulation structure. The thickness of the polyurethane foam plastic layer is 6-30 mm, and the thickness of the vacuum insulation panel is 5-10 mm. The surface of the polyurethane foam layer or the vacuum insulation board located on the inner wall of the incubator is covered with a protective layer. Adopting the cold storage type transportation incubator of the present invention, since the vacuum insulation board with excellent heat insulation effect is provided in the polyurethane foam plastic layer, the thickness of the polyurethane foam plastic layer can be greatly reduced, so that the heat preservation box with the same shape can The effective volume of the box is greatly improved, the weight of the incubator is also reduced to a certain extent, and the heat preservation effect is also better.

Owner:BEIJING ACADEMY OF AGRICULTURE & FORESTRY SCIENCES +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com