Patents

Literature

996results about "Insulation improvement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

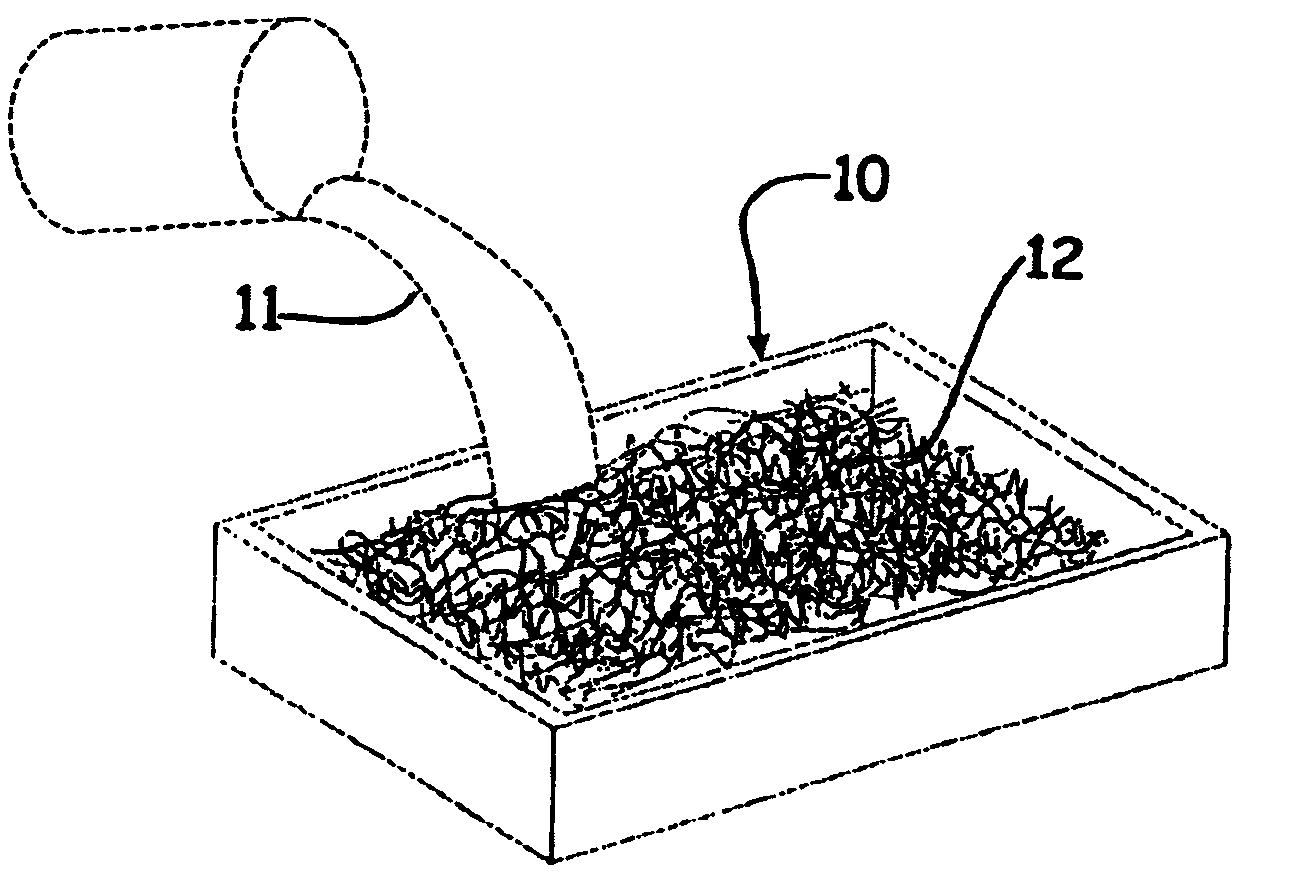

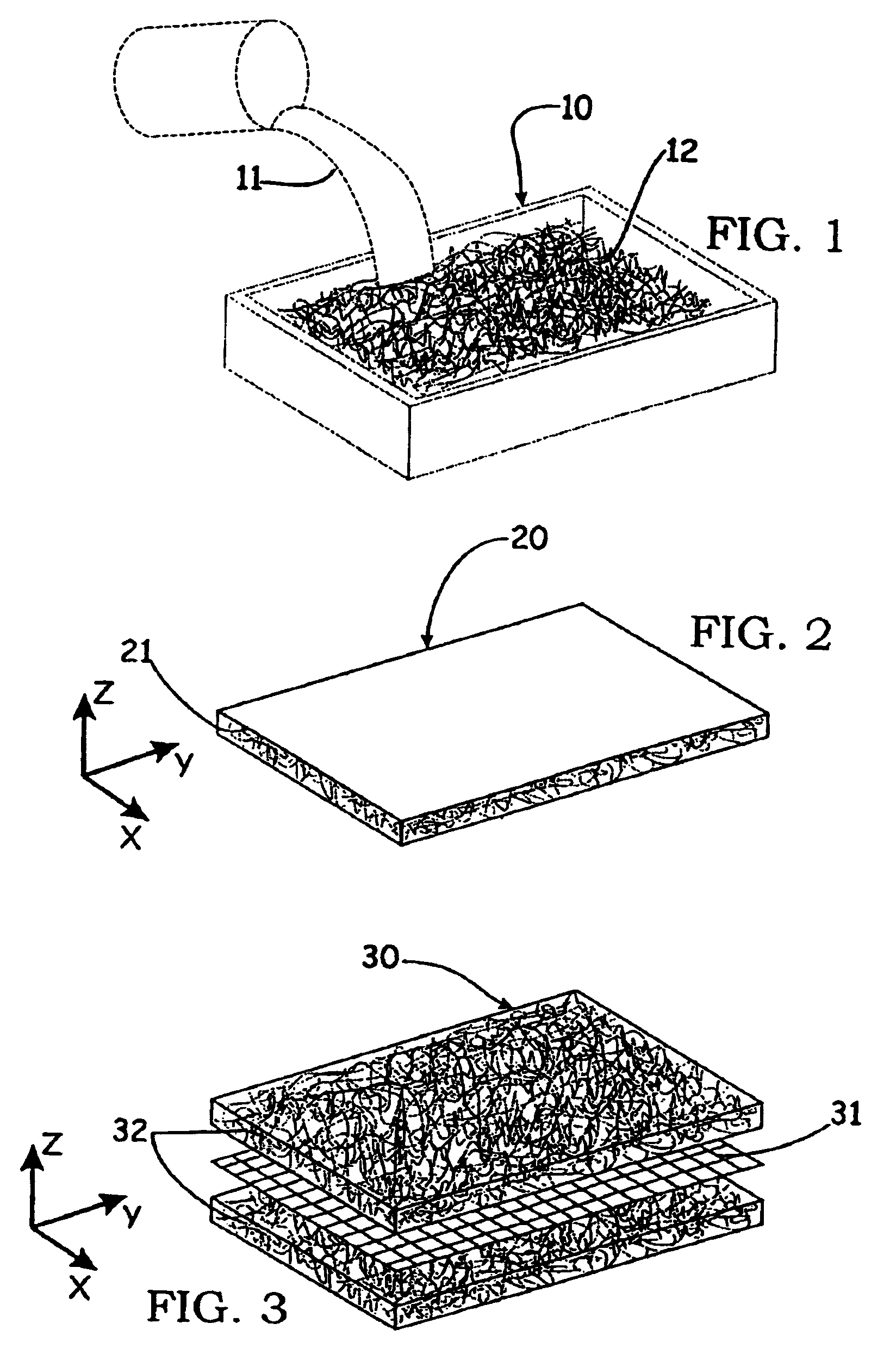

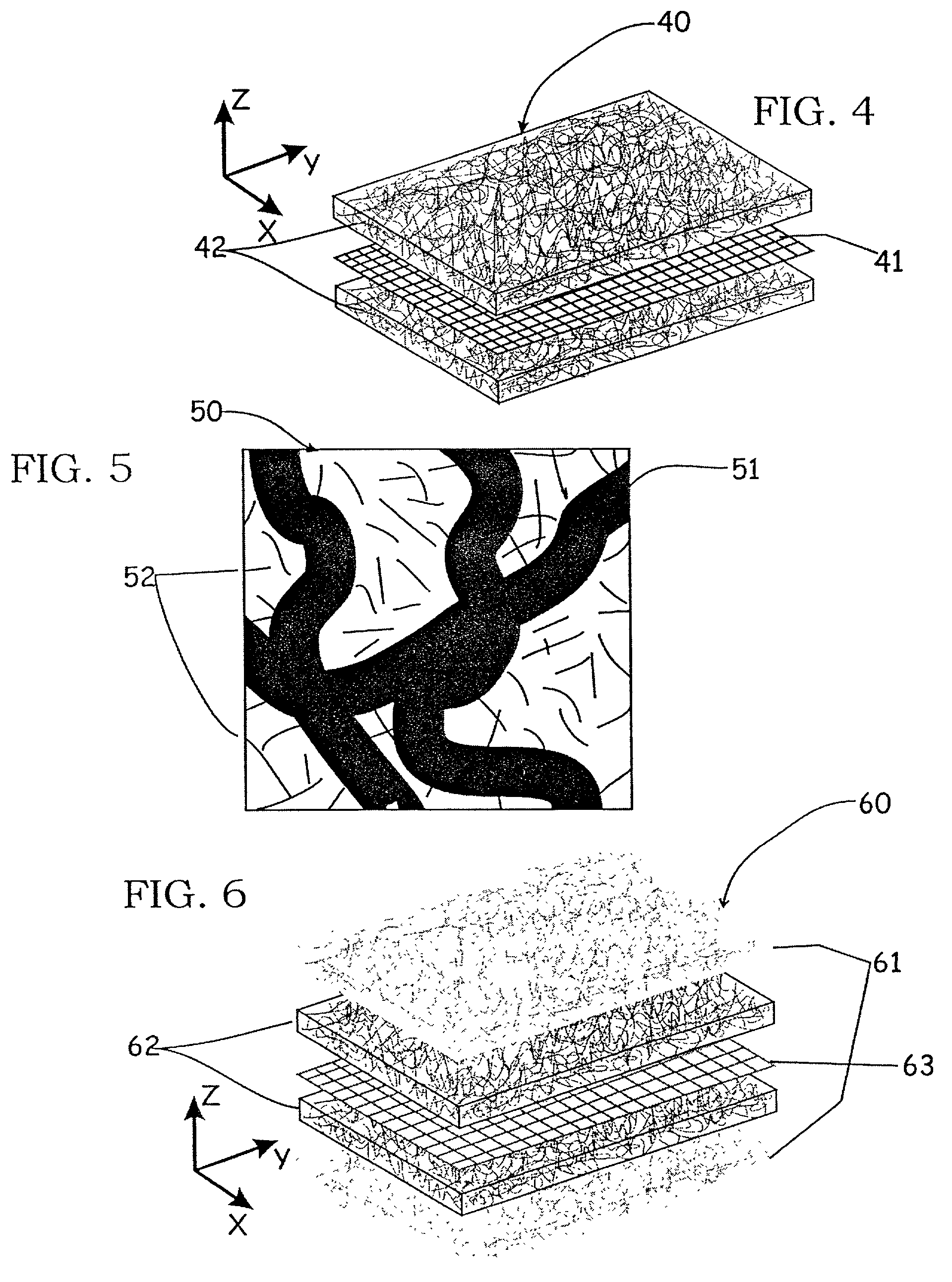

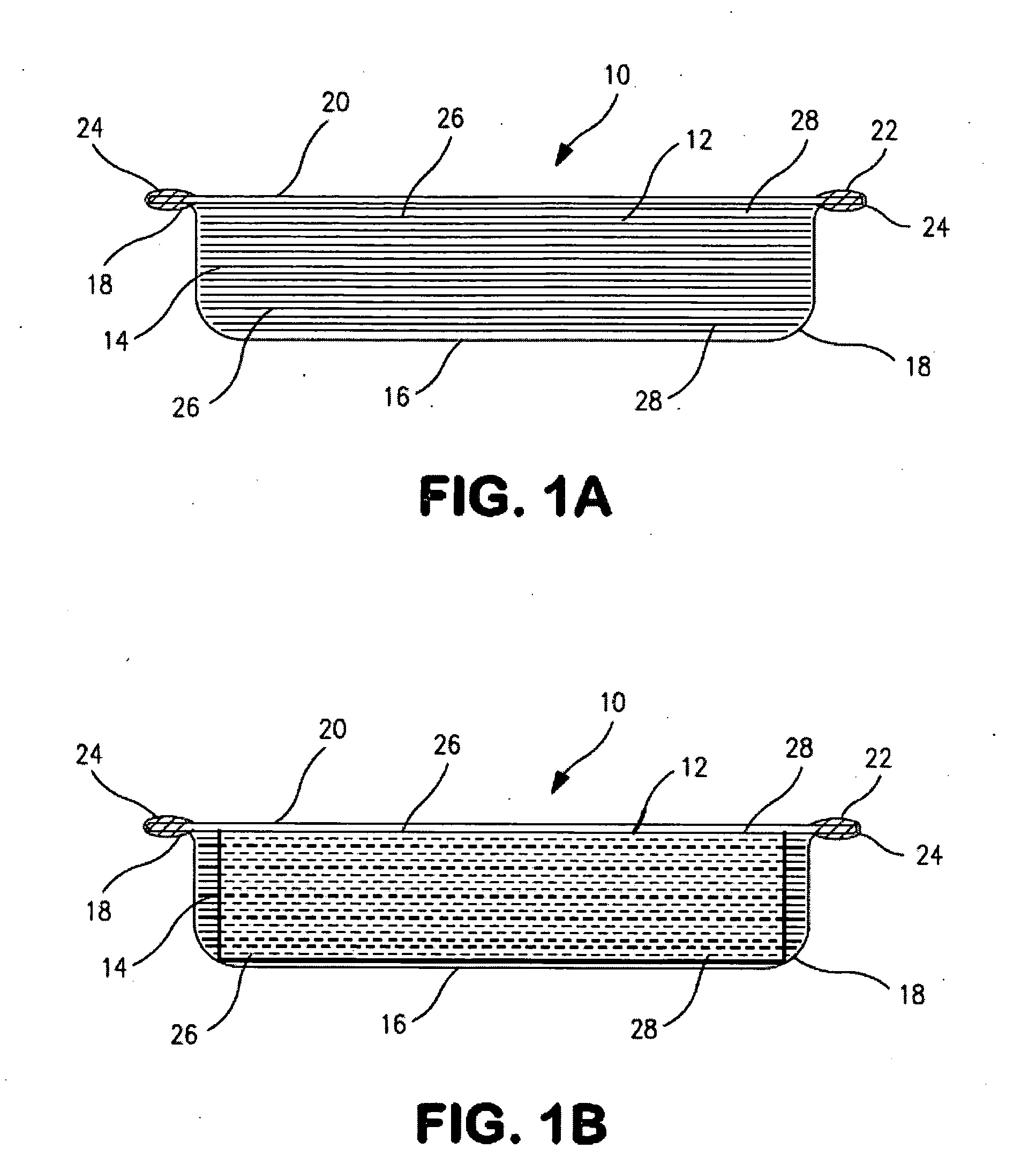

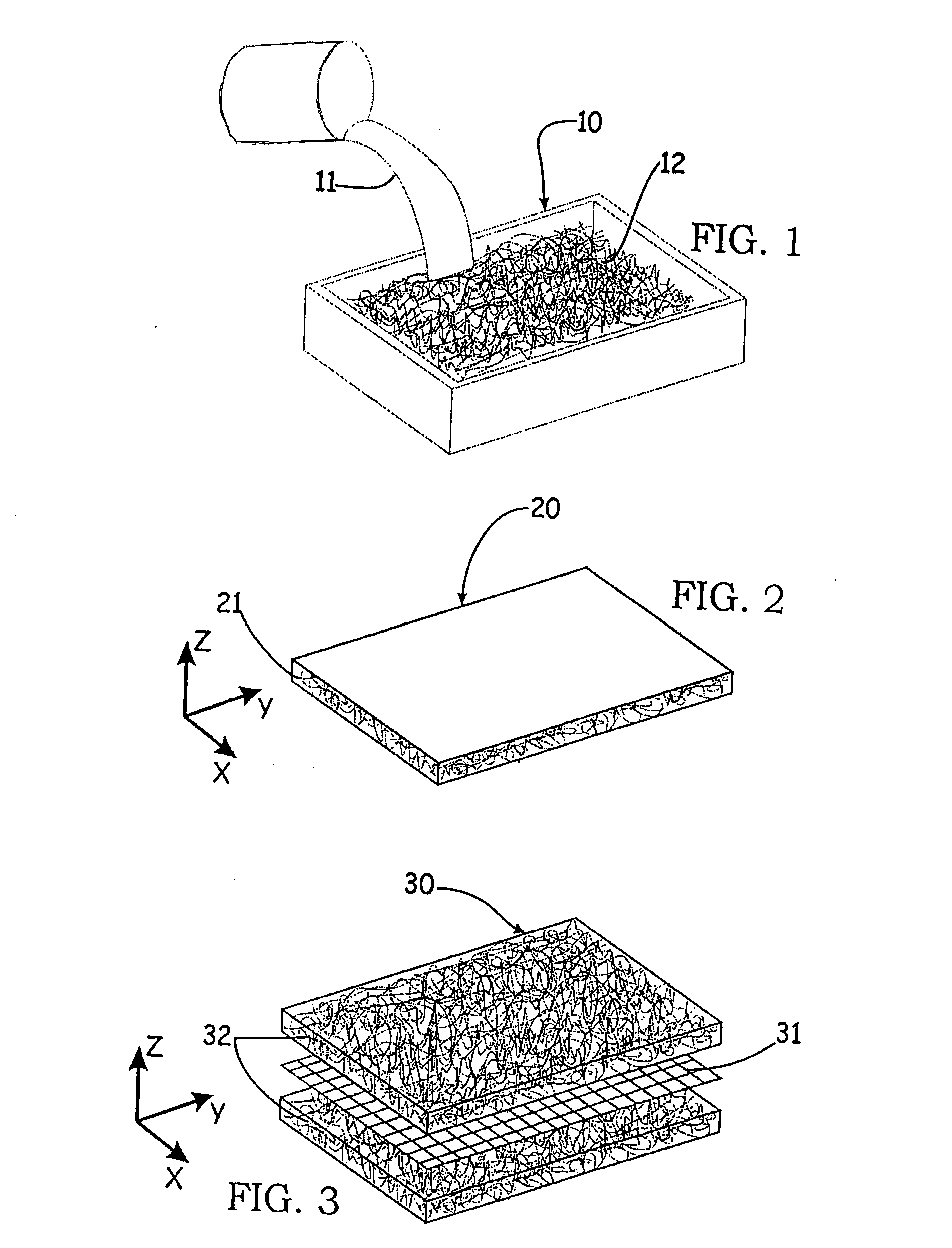

Aerogel composite with fibrous batting

InactiveUS7078359B2Improve thermal efficiencyMinimized volumeShielding materialsCeilingsUltrasound attenuationPliability

Aerogel composite materials having a lofty fibrous batting reinforcement preferably in combination with one or both of individual short randomly oriented microfibers and conductive layers exhibit improved performance in one or all of flexibility, drape, durability, resistance to sintering, x-y thermal conductivity, x-y electrical conductivity, RFI-EMI attenuation, and / or burn-through resistance.

Owner:ASPEN AEROGELS INC

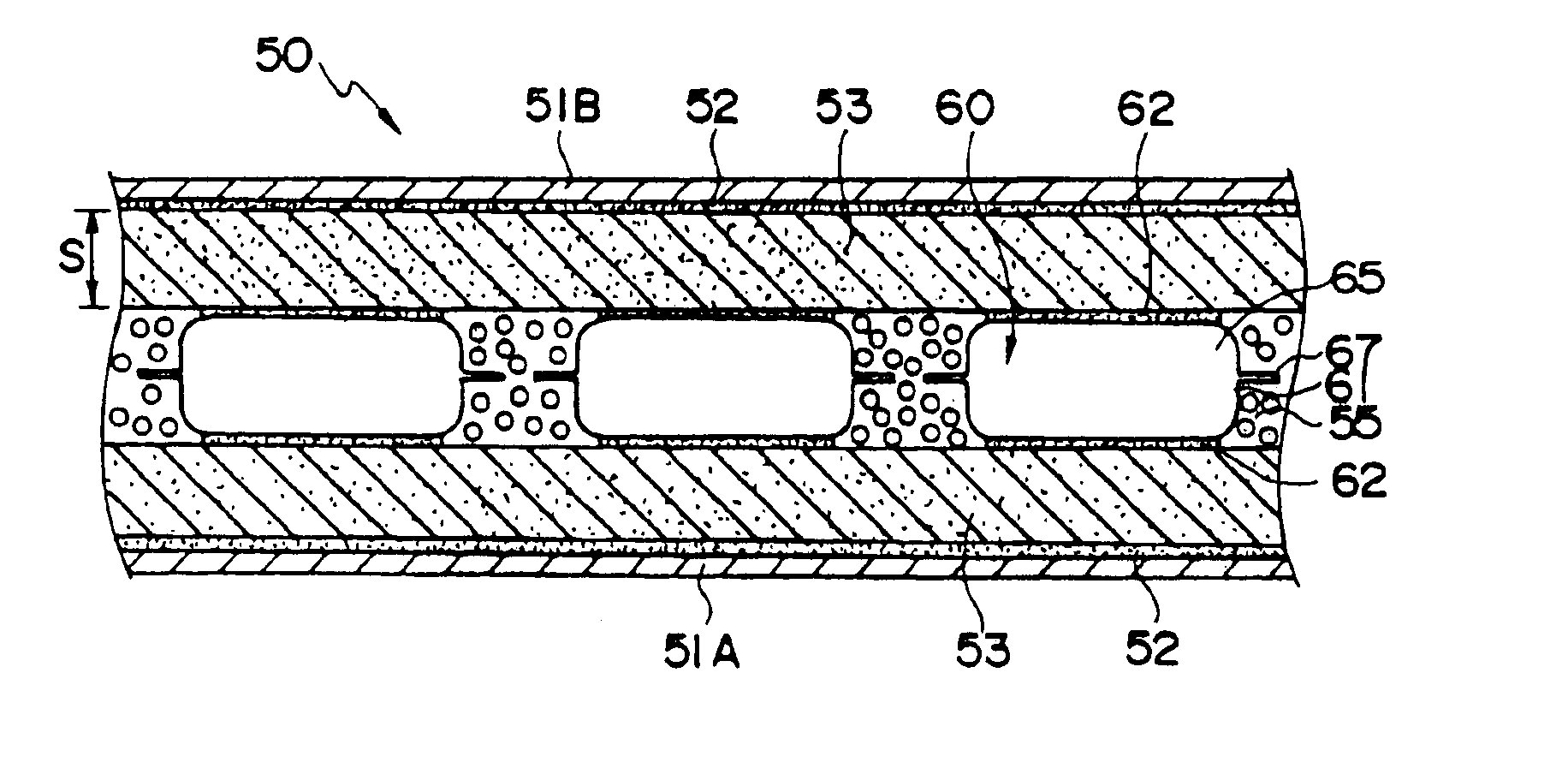

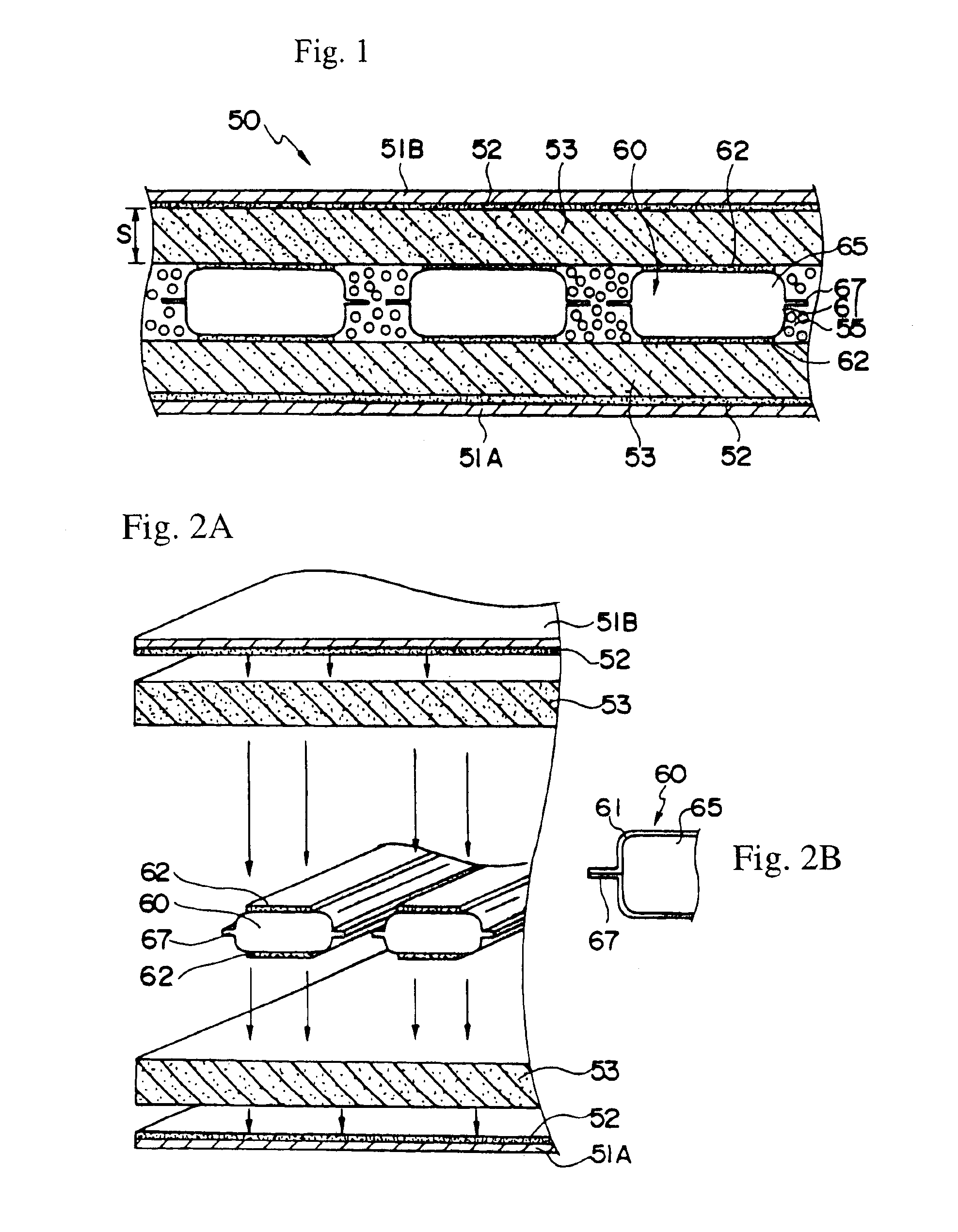

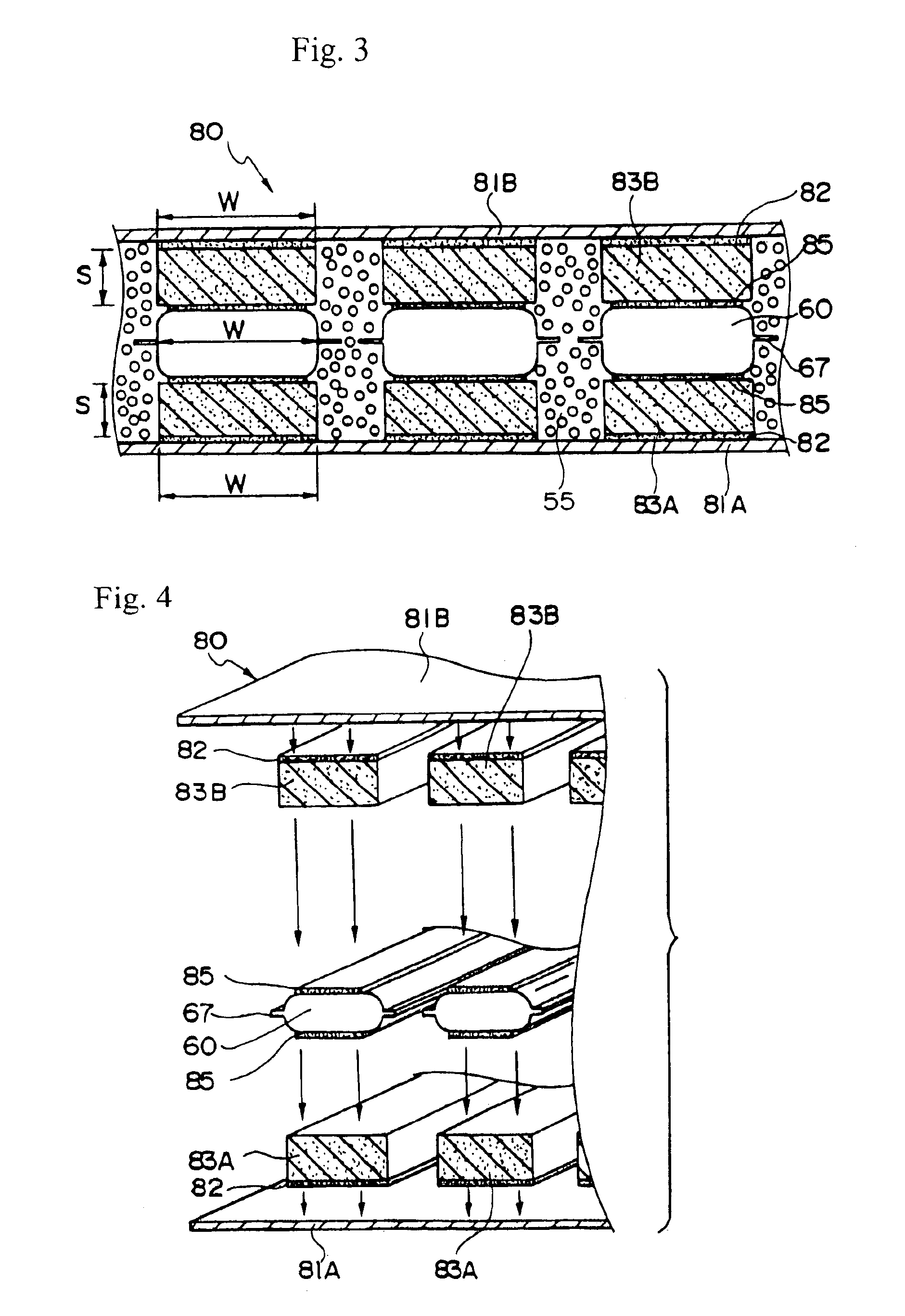

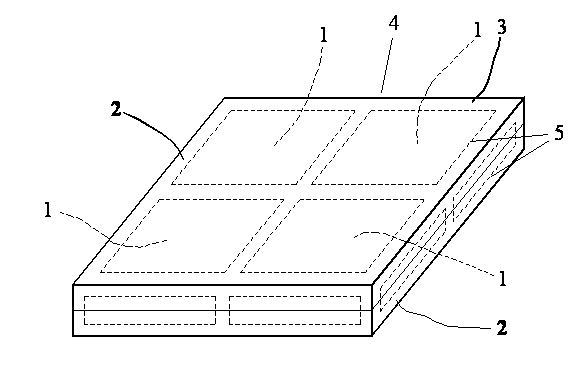

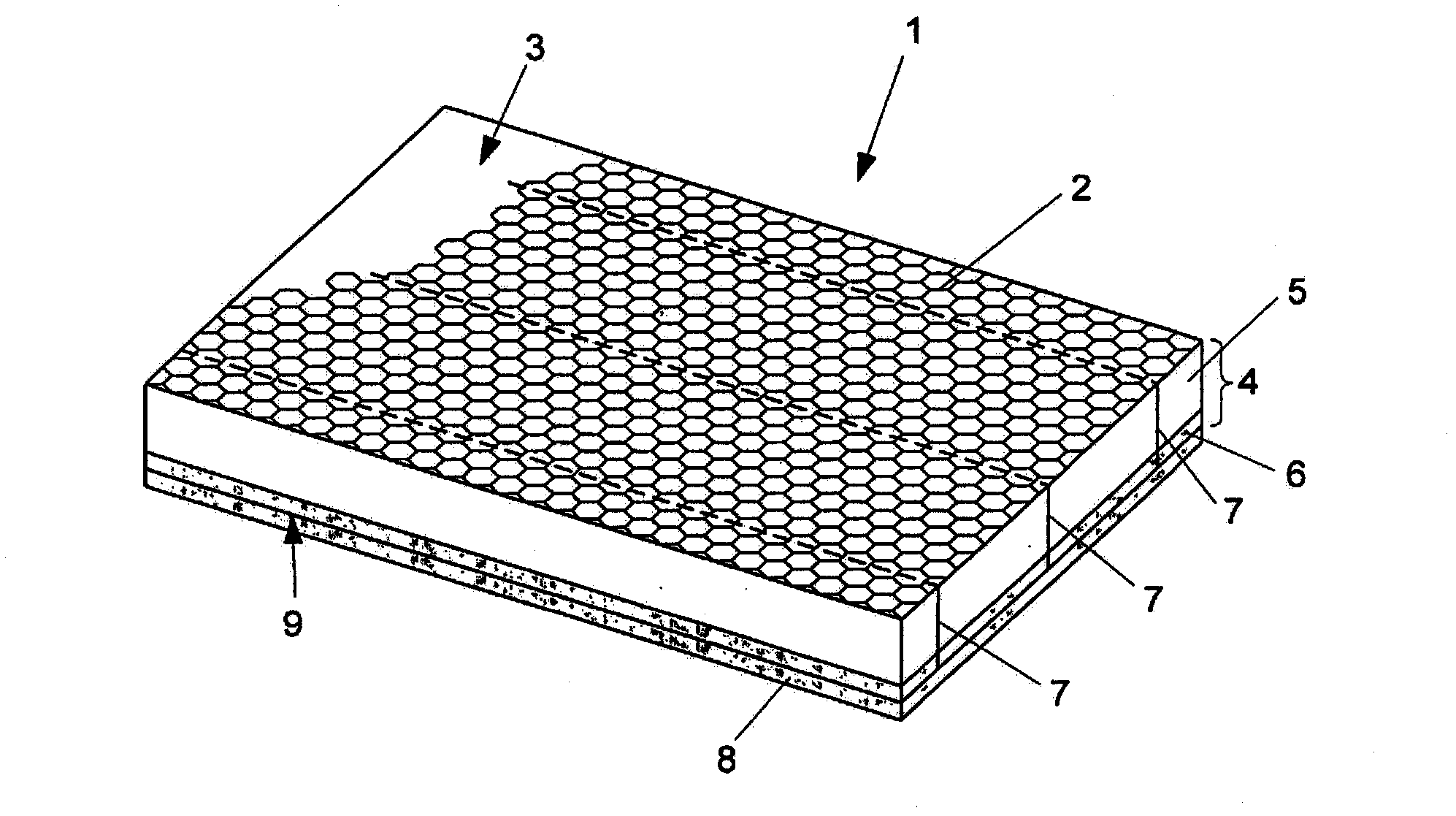

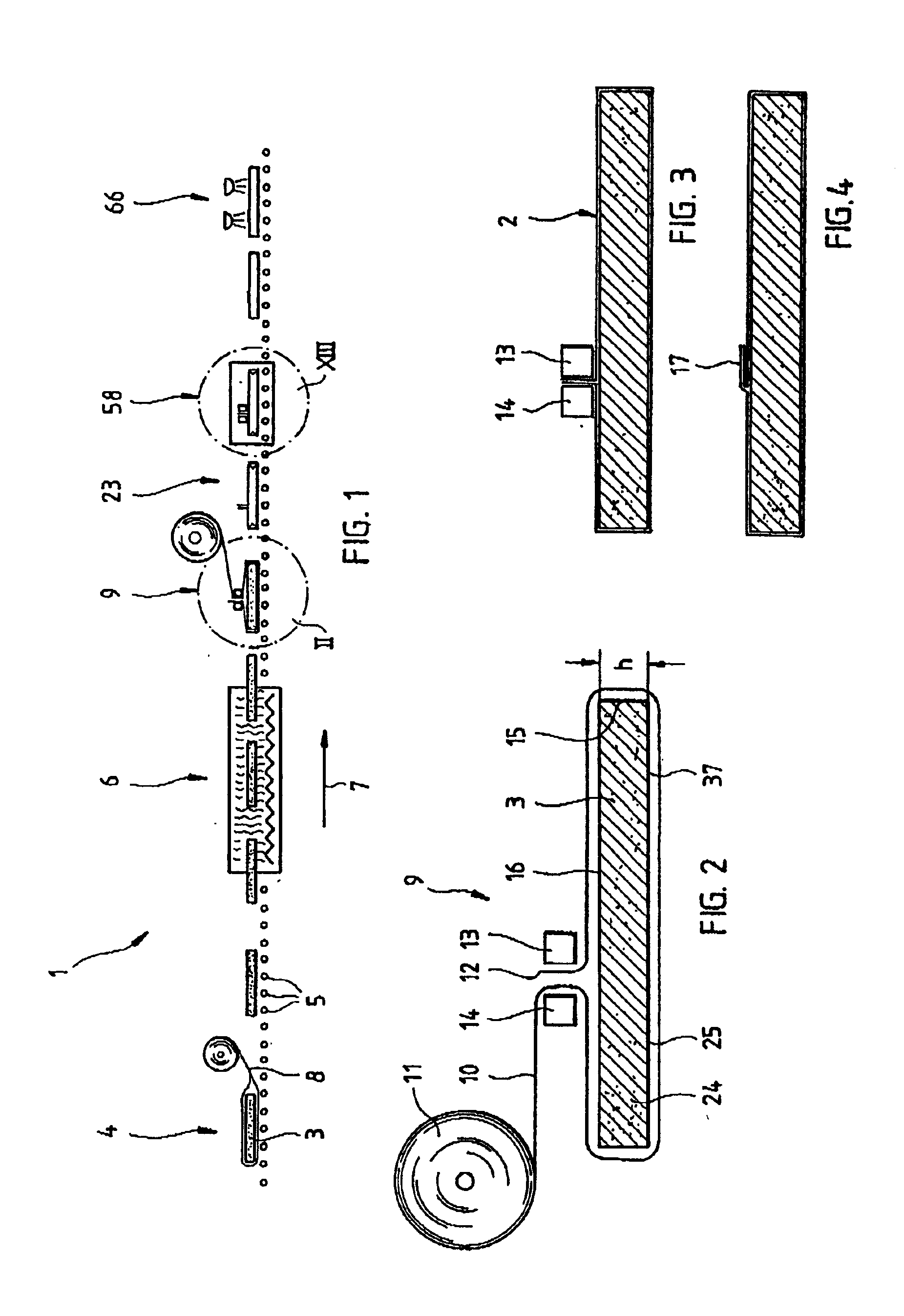

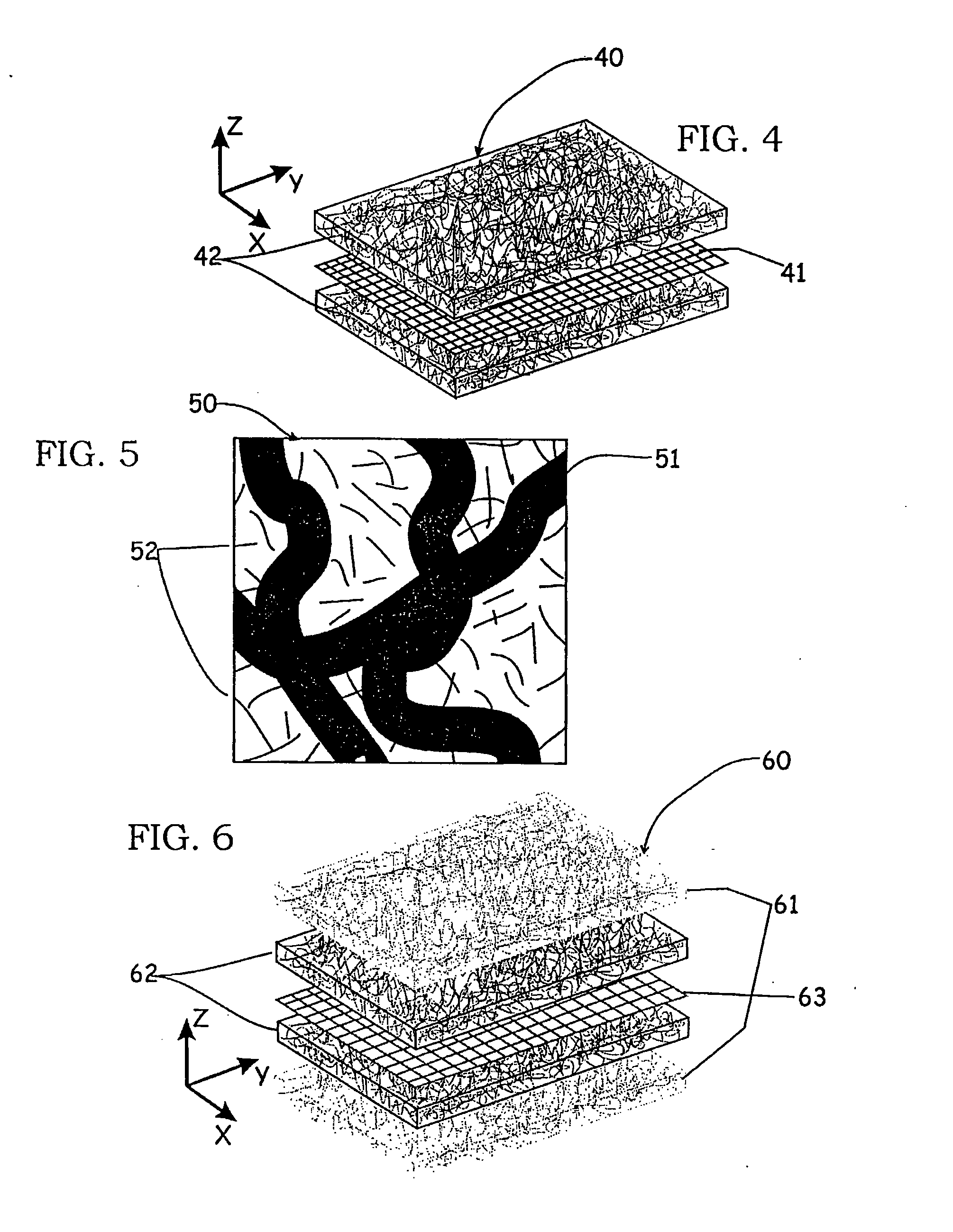

Heat insulating wall member, and method of manufacturing the same

InactiveUS6860082B1Improve insulation performanceLighting and heating apparatusRefrigerated goods vehicleEngineeringPlastic foam

A heat insulating wall, and a method of manufacturing the same. A laminated body includes a first panel, a first plate-shaped insulating member made of plastic foam and having a predetermined thickness, a vacuum insulation member mounted on the insulating member, a second plate-shaped insulating member made of plastic foam, and a second panel. The area between the first and second panels surrounded by the first plate-shaped insulating member, the vacuum insulation member, and the second plate-shaped insulating member is filled with expanded plastic foam. The thickness of the first and second plate-shaped insulating members is set to a predetermined thickness S.

Owner:ISUZU MOTORS LTD

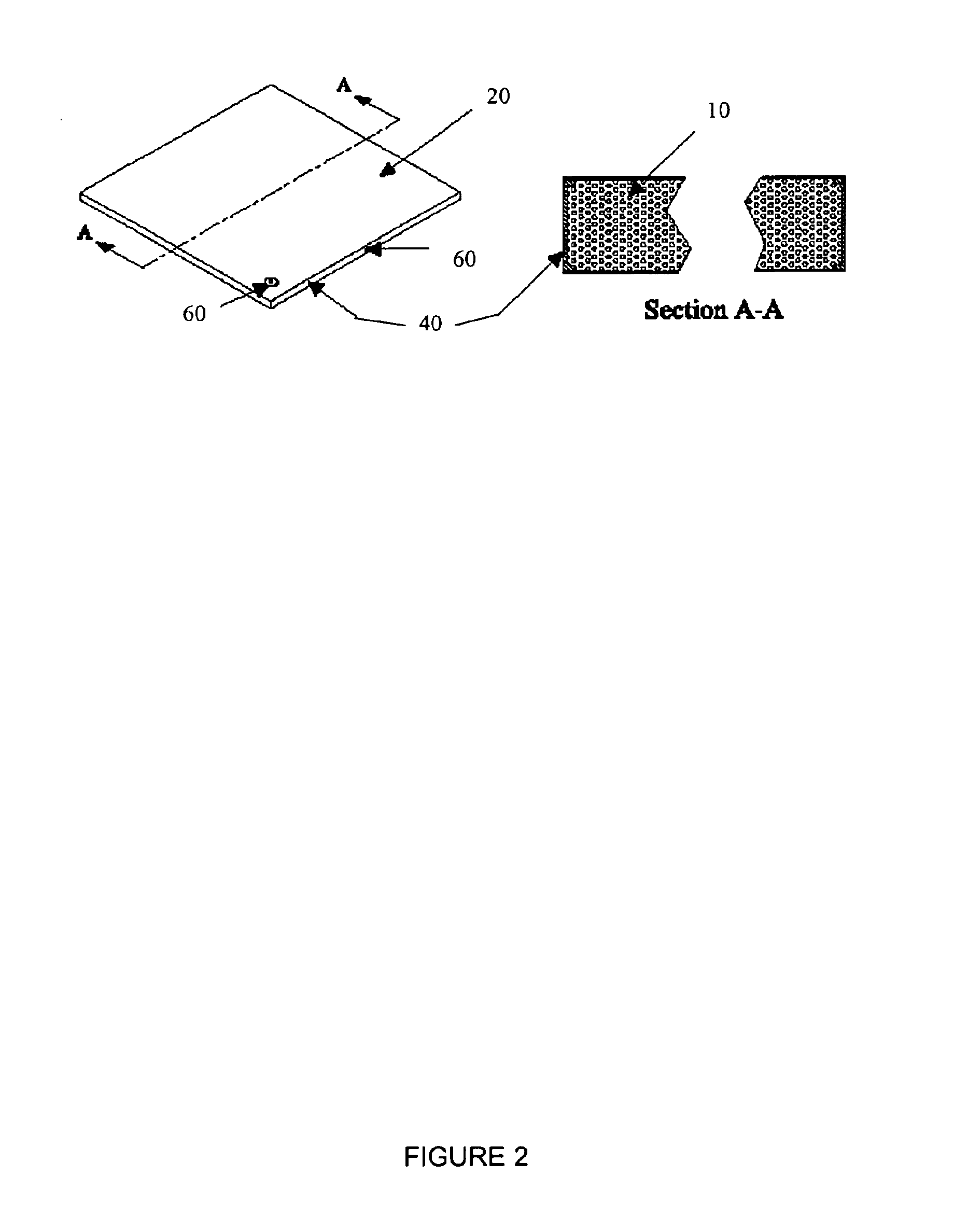

Aerogel containing blanket

ActiveUS20060125158A1Low thermal conductivityEvenly distributedNon-fibrous pulp additionNatural cellulose pulp/paperFiberSlurry

A process of producing a blanket is described and can involve forming an aqueous slurry of hydrophobic aerogels, fibers, and at least one wetting agent, drying the aqueous slurry to form a substantially dried product, and calendaring the substantially dried product to form the blanket. The blanket can be used in a variety of applications, including windows.

Owner:CABOT CORP

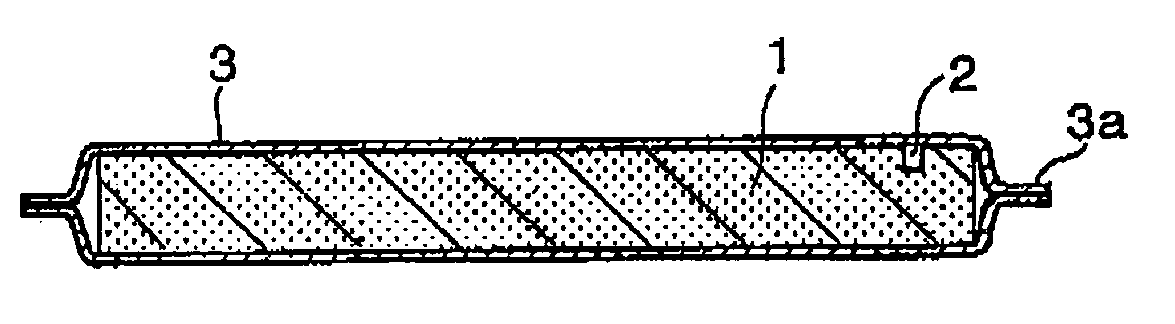

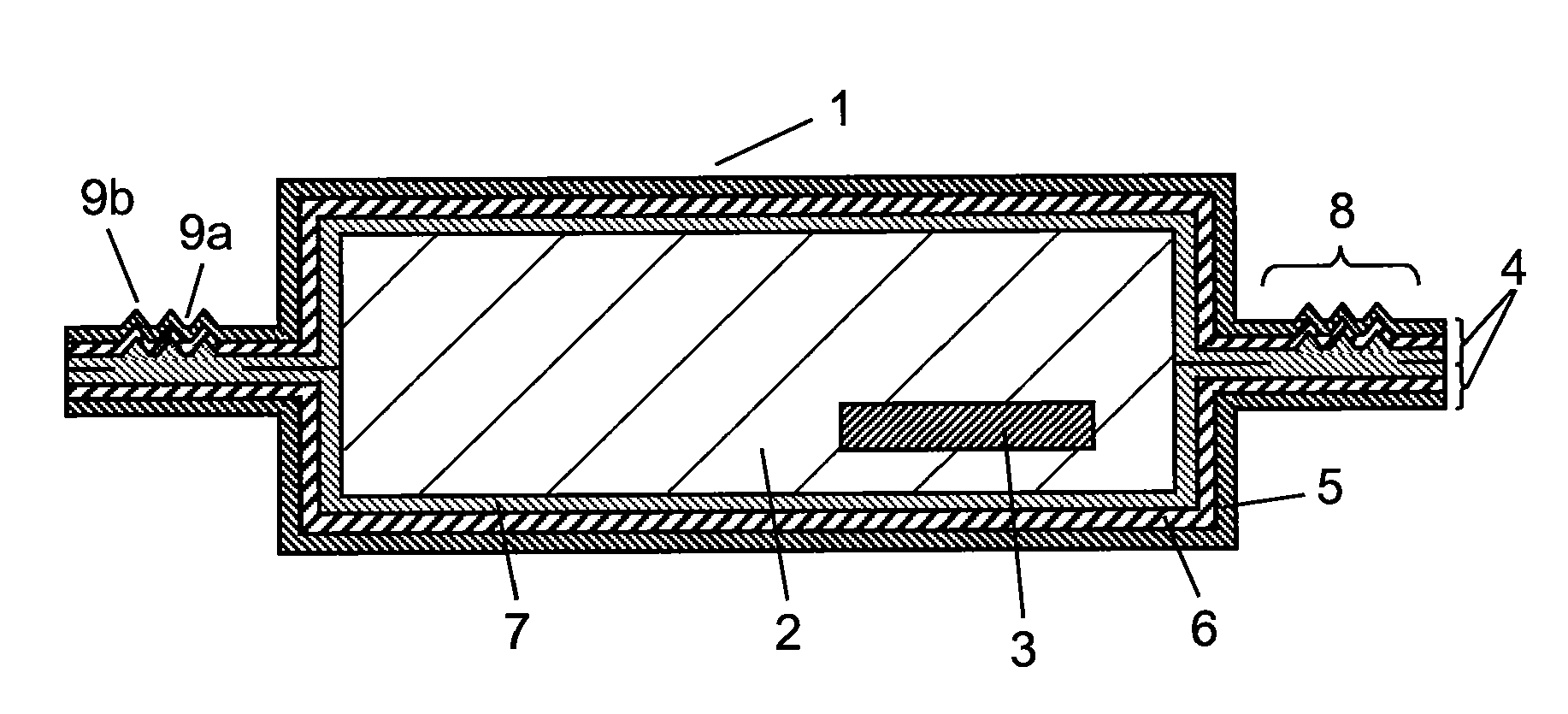

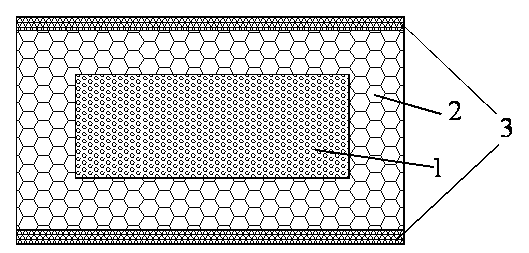

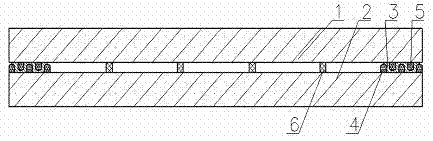

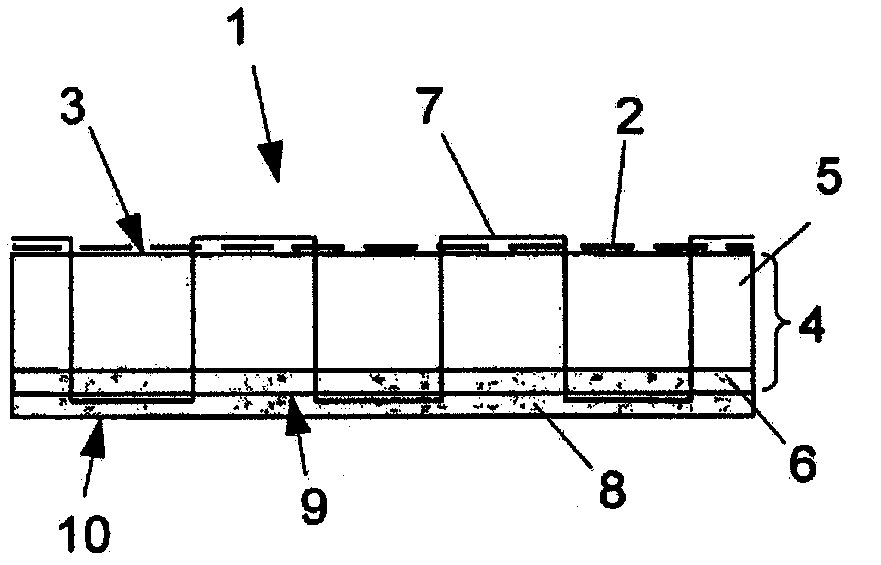

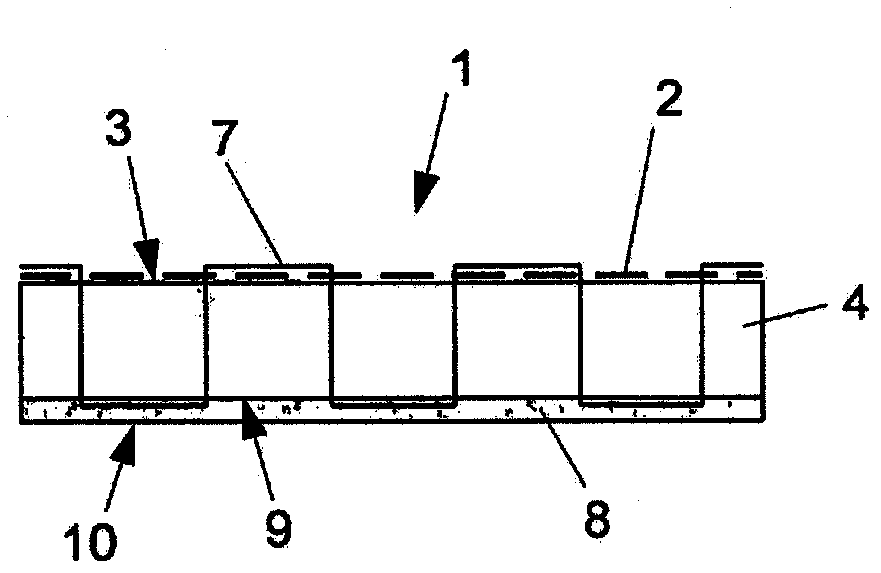

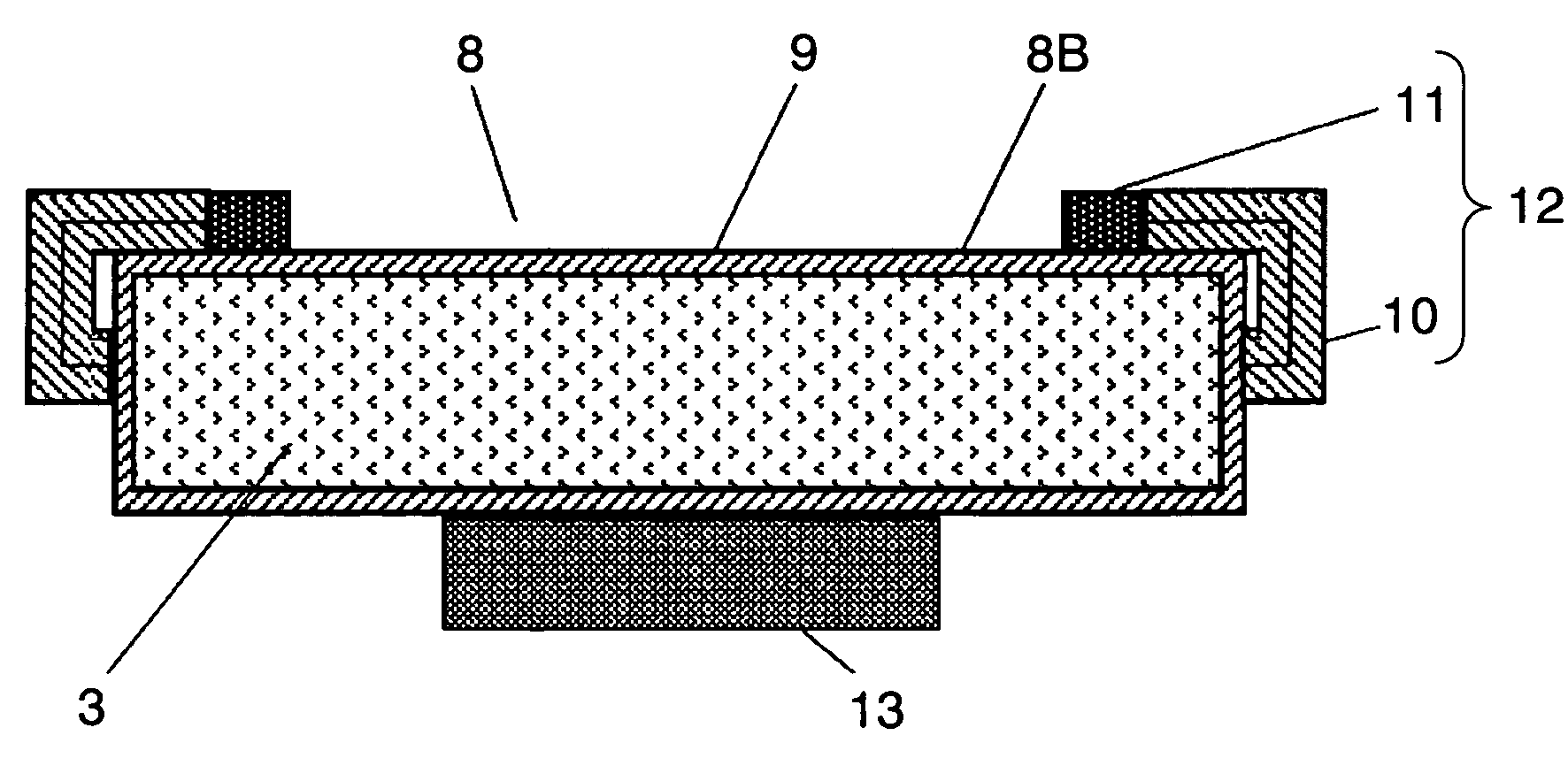

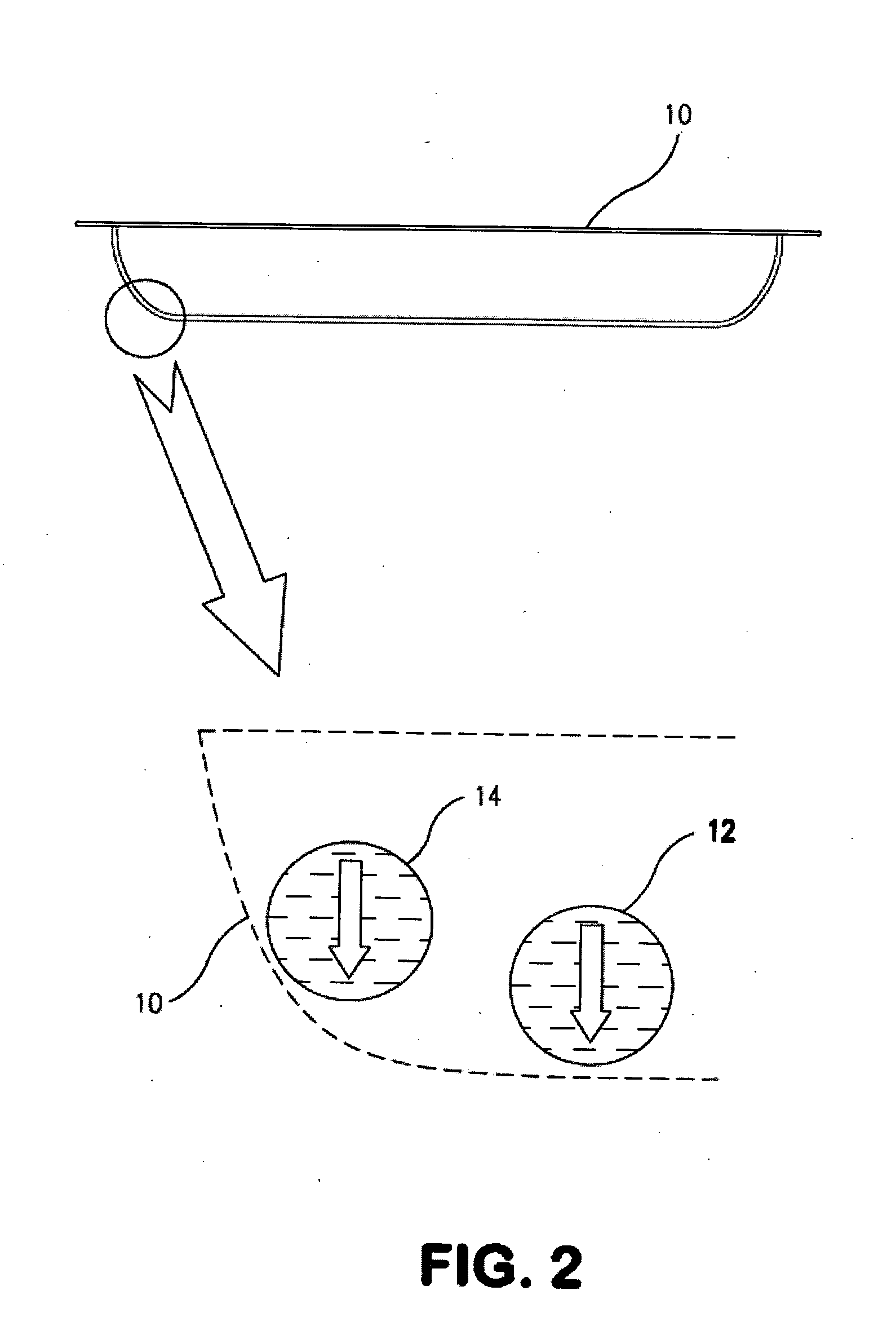

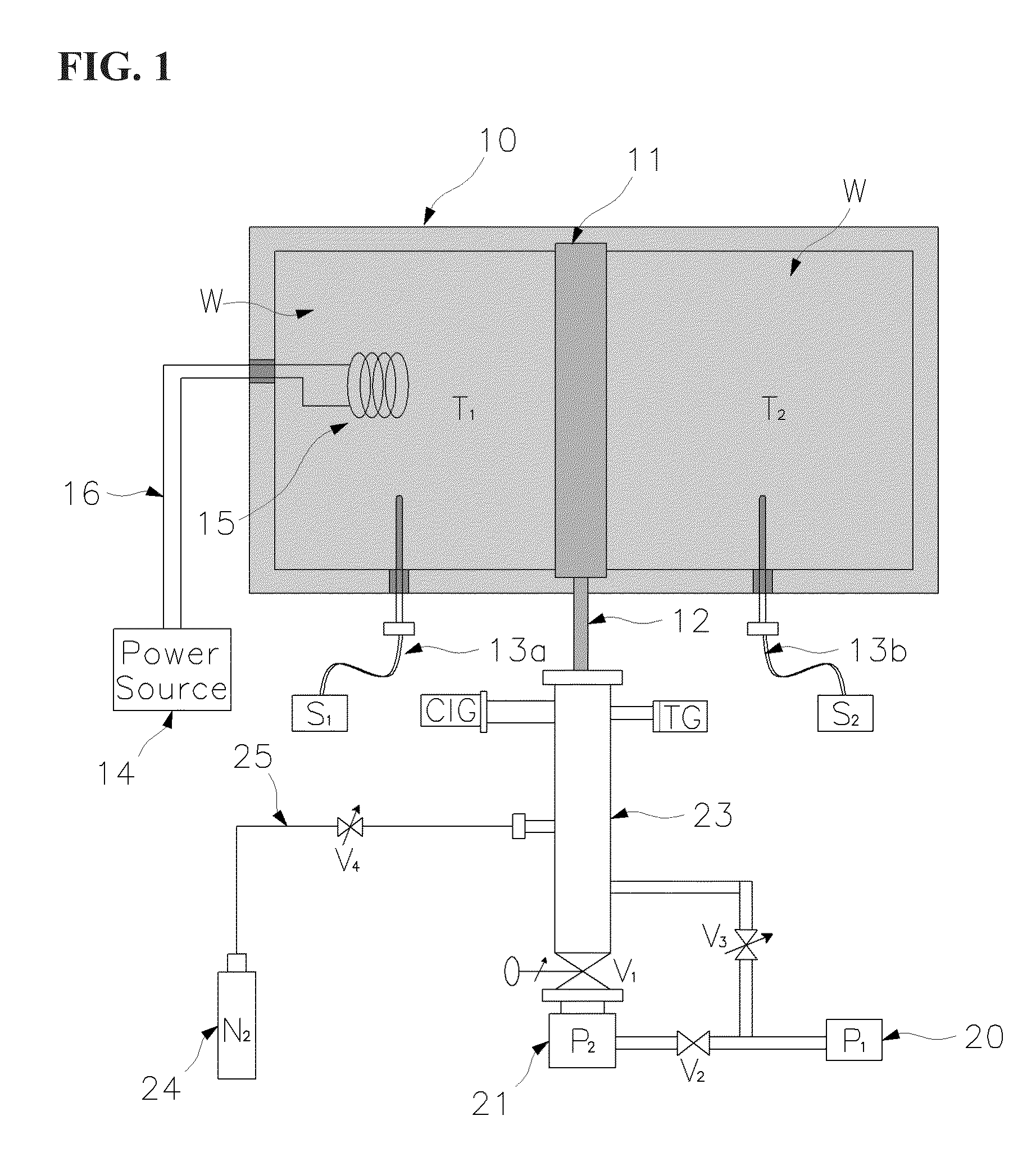

Vacuum heat insulating material and manufacturing method therefor

InactiveUS20040253406A1Improve performanceLow thermal conductivityThermal insulationDomestic cooling apparatusSorbentDecreased pressure

Provided is a vacuum heat insulating material, using inorganic fibers as a core material, high in heat insulating performance (low in thermal conductivity), capable of maintaining the heat insulating performance for a long period, free of defects such as projections and depressions on a large scale on a surface thereof, short in manufacturing time and advantageous in terms of cost; and a manufacturing method therefor. A vacuum heat insulating material of the present invention is of a construction in which a core material 1 and a gas adsorbent 2 are housed in a bag 3 made from a gas barrier film and the interior thereof is reduced in internal pressure thereof and air-tightly sealed, wherein the core material 1 is a molded product obtained by coating a binder B on inorganic fibers having an average fiber diameter in the range of from 3 to 5 mum at a coating amount in the range of from 0.5 to 1.5 wt % relative to the fibers and heat pressing the inorganic fibers, or a laminate fabricated by stacking two or more sheets of the molded product.

Owner:ASAHI FIBER GLASS CO LTD

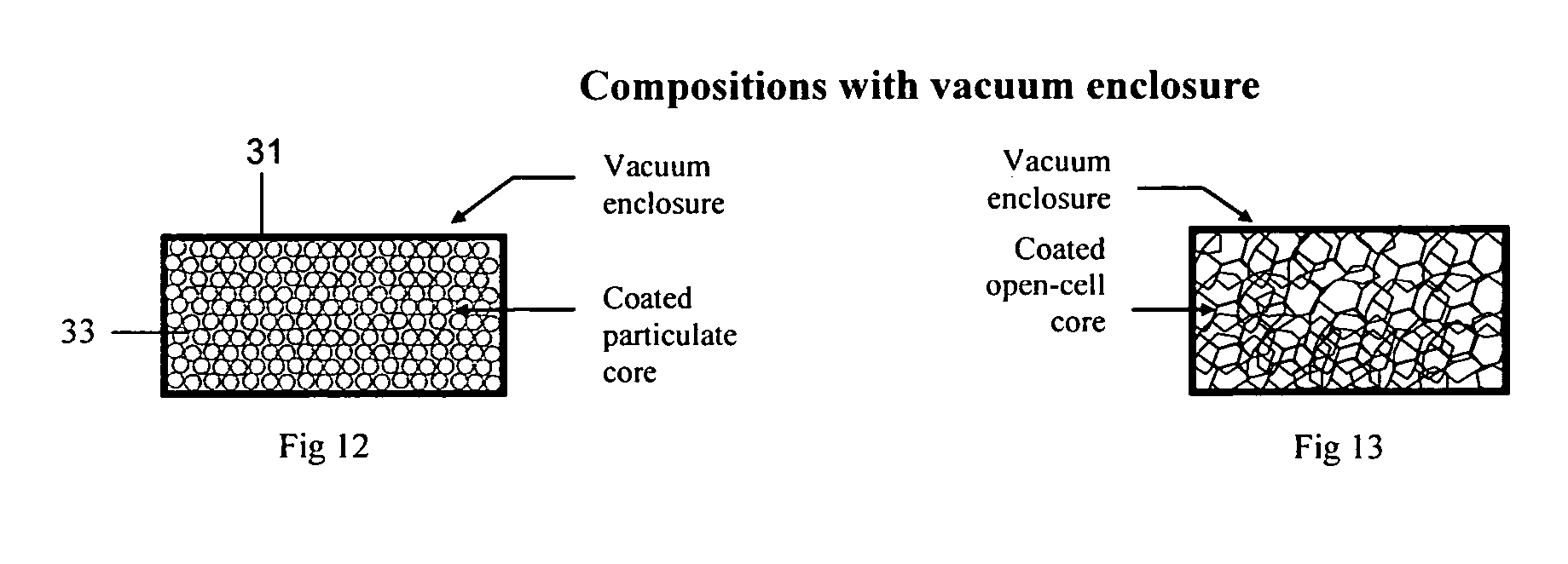

Microsphere insulation systems

InactiveUS6858280B2Reduce the impactIncreases insulation valueLayered productsContainer filling methodsMicrosphereEngineering

A new insulation system is provided that contains microspheres. This insulation system can be used to provide insulated panels and clamshells, and to insulate annular spaces around objects used to transfer, store, or transport cryogens and other temperature-sensitive materials. This insulation system provides better performance with reduced maintenance than current insulation systems.

Owner:TECH APPL

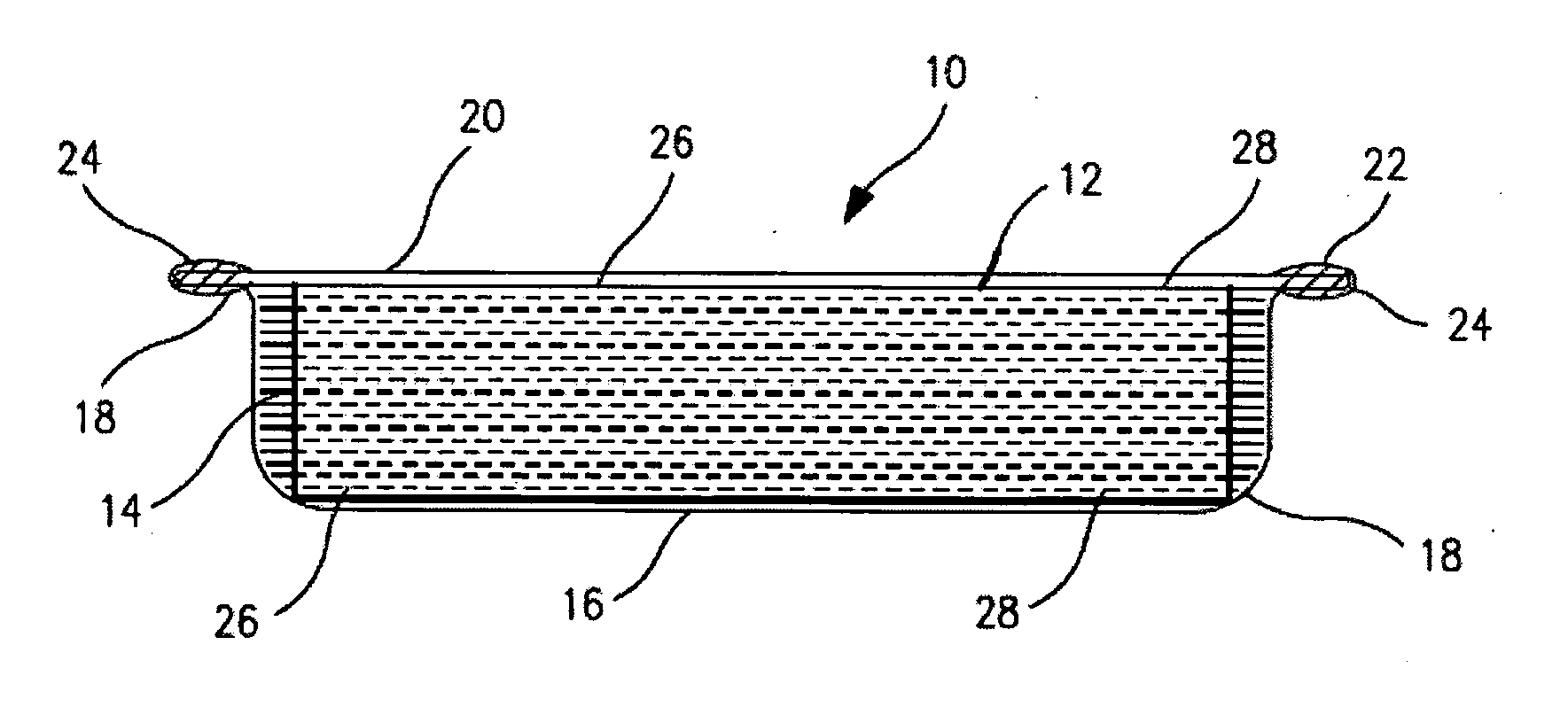

Evacuated Thermal Insulation Panel

InactiveUS20090031659A1Easy accessMaterial nanotechnologyFunctional valve typesThermal insulationWater vapor

A sealed vacuum thermal insulation panel having a thermal barrier that comprises a core made of thermal insulation material and two panel walls made of a barrier material substantially impermeable to atmospheric gases and water vapors. The two panel walls covers opposite sides of the core. The sealed panel further comprises at least one lateral strip of substantially impermeable to atmospheric gases and water vapor. The lateral strip is adapted to sealably enfold the edges of the obverse side of the two panel walls. Additionally, the sealed panel further comprises at least one sealing strip, each comprising sealing material. The sealing strip is adapted to sealably join the edges to the inner side of the lateral strip.

Owner:THERMOVAC LTD

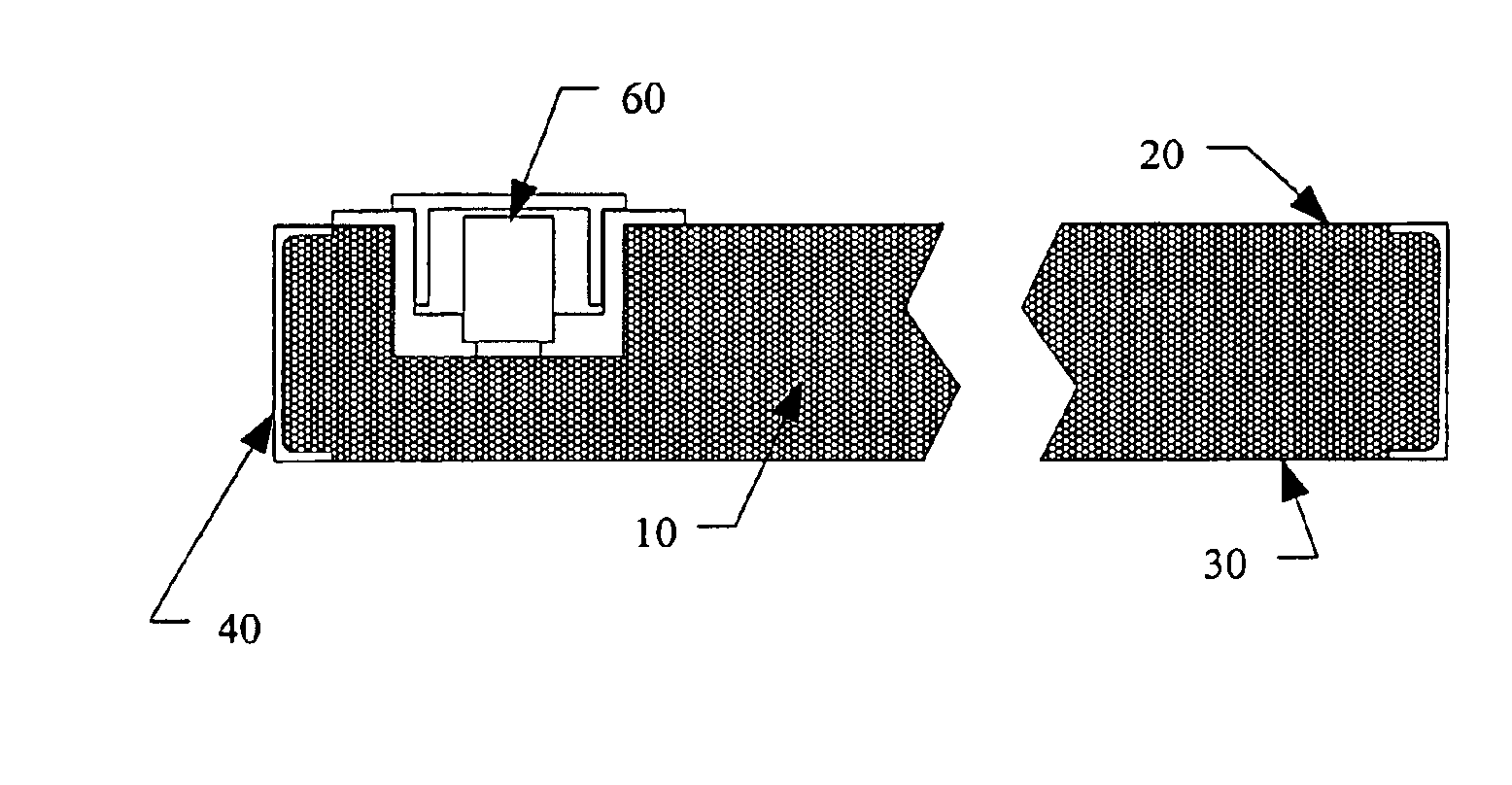

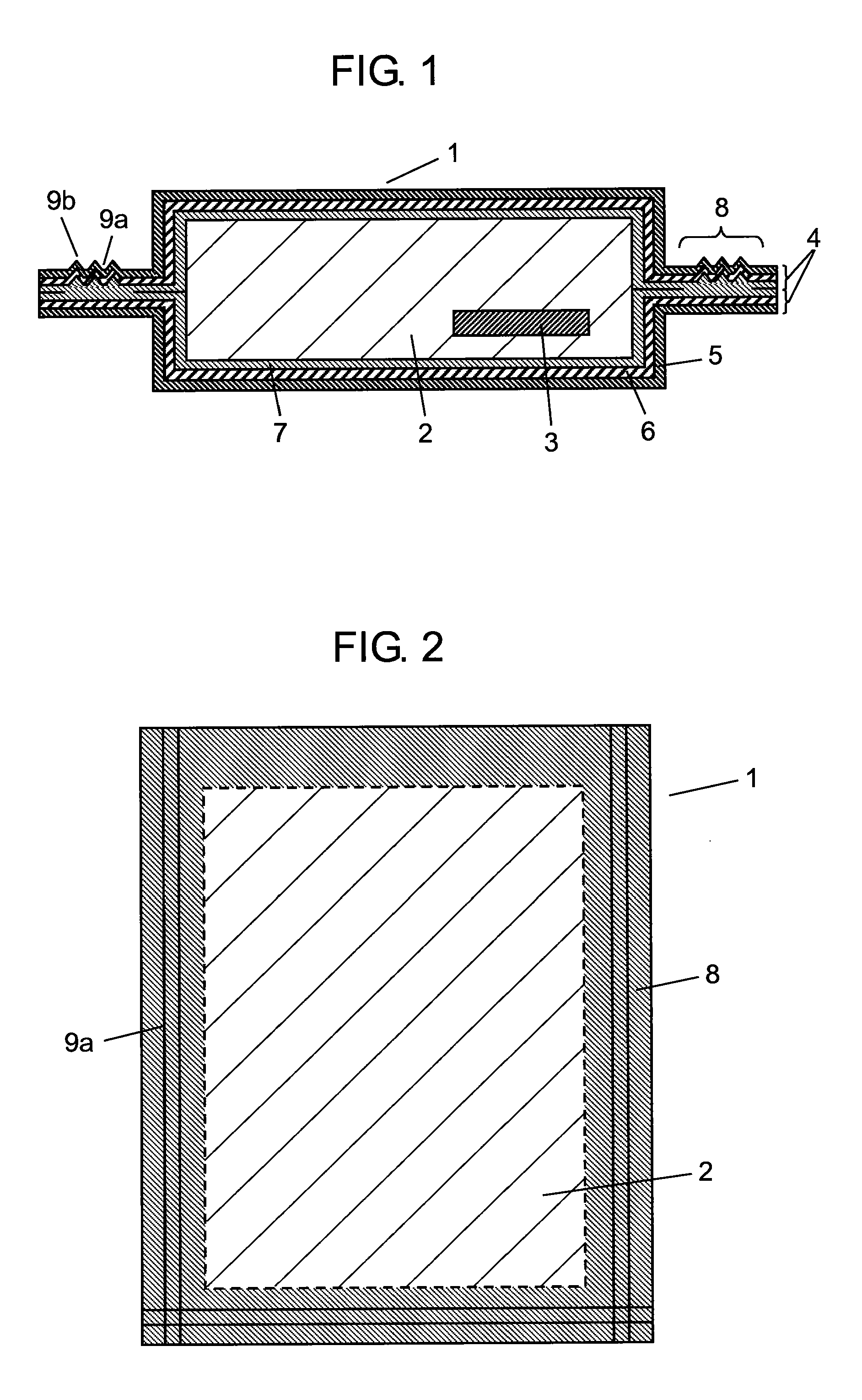

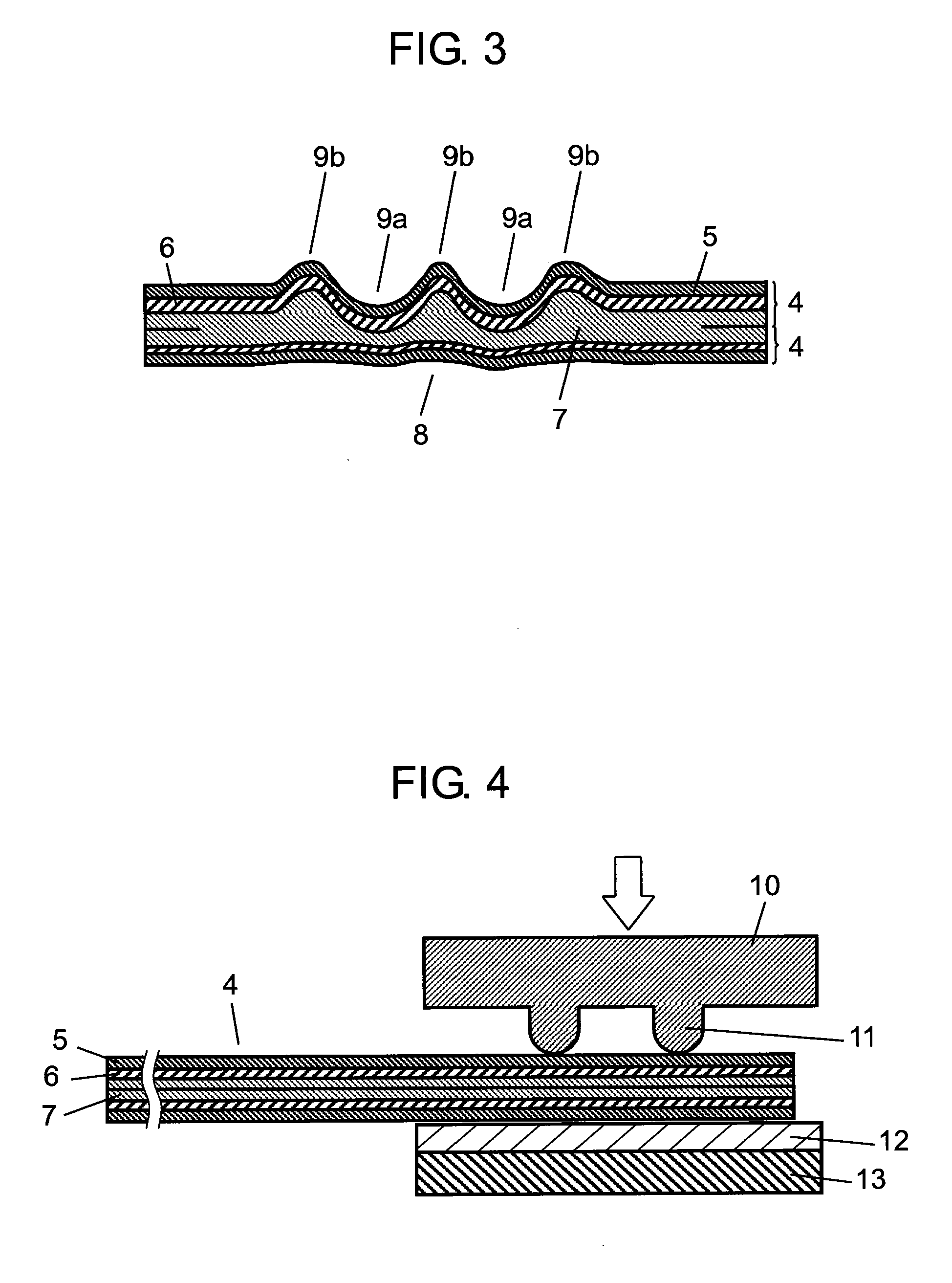

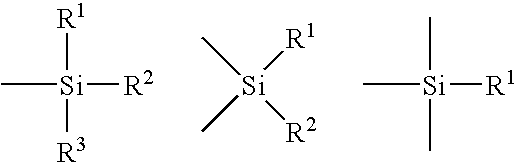

Vacuum heat insulation material and manufacturing method therefor

ActiveUS20110165367A1Avoid it happening againLimited amountThermal insulationClimate change adaptationThick wallEngineering

A plurality of thin-wall parts (9a) of a sealant layer (7) are formed in a portion continuously changed in the interval of one sealing part (8) and a gas barrier layer (6) of other laminate film (4). At the inner circumferential side between the adjacent thin-wall parts (9a) and the thin-wall part (9a) at the innermost circumferential side and at the outer circumferential side of the thin-wall part (9a) of the outermost circumferential side, a thick-wall part (9b) of the sealant layer (7) is formed. All of the opposing sealant layers (7) between the two adjacent thin-wall parts (9a) are mutually heated and fused, so that an excellent adiabatic performance is maintained for a long period.

Owner:PANASONIC CORP

Aerogel containing blanket

ActiveUS7635411B2Low thermal conductivityNon-fibrous pulp additionNatural cellulose pulp/paperFiberSlurry

A process of producing a blanket is described and can involve forming an aqueous slurry of hydrophobic aerogels, fibers, and at least one wetting agent, drying the aqueous slurry to form a substantially dried product, and calendaring the substantially dried product to form the blanket. The blanket can be used in a variety of applications, including windows.

Owner:CABOT CORP

Production method of vacuum insulation wall thermal insulation board by using expanded vitrified microspheres

ActiveCN102296714ALow thermal conductivityImprove insulation effectMixing operation control apparatusClimate change adaptationThermal insulationMetallurgy

The invention discloses a production method for producing a heat insulation board for a vacuum heat insulation wall body by utilizing small expanded and vitrified balls, and the method comprises the following steps: putting the small expanded and vitrified balls, glass fiber, silica fume, bentonite and a getter into a stirring kettle, adding a wetting agent and a bonding agent, and stirring for forming a paste-like material; uniformly spreading the well stirred paste-like material on a micro-wave baking line according to the required thickness for baking, and further cutting into blocks when the water content in the board is below 1%; further placing the board which is cut into the blocks on a vacuum machine assembly line and vacuum pumping till the vacuum degree is below 200Pa; and cutting and packaging the heat insulation board for the vacuum heat insulation wall body. By applying the method provided by the invention for production, the process is simple, the emission of three wastes can be avoided, the produced heat insulation board for the vacuum heat insulation wall body is easy to construct, the fireproof property can be realized, the heat insulation board for the vacuum heat insulation wall body can play great roles in heat preservation and heat insulation, the combustion performance is grade A, the weight is light, the weather-resistant time is long, and the service life can be above 30 years.

Owner:潍坊三强集团有限公司

Foaming cement composite vacuum heat insulation plate and preparation method thereof

ActiveCN102979205ASolve the problem of broken air leakageEasy to installClimate change adaptationInsulation improvementCement compositesHigh intensity

The invention relates to a foaming cement composite vacuum heat insulation plate comprising a vacuum heat insulation plate and foaming cement which covers the periphery of the vacuum heat insulation plate. The vacuum heat insulation plate comprises core materials, high strength air resistance film and interface mortar. The high strength air resistance film covers the periphery of the core materials and is encapsulated between core materials through vacuumpumping. A layer of interface mortar covers the periphery of the high strength air resistance film. The thickness of the interface mortar is 2 millimeters to 3 millimeters. The foaming cement composite vacuum heat insulation plate and a preparation method of the foaming cement composite vacuum heat insulation plate have the advantages that problem of damage and air leakage of the vacuum heat insulation plate in a work process is solved, construction and installation are convenient to achieve, heat retaining property, water resisting property, durability and freezing resistance are good, flame class is non-ignitable or fire-retardant and good fireproof performance is achieved.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

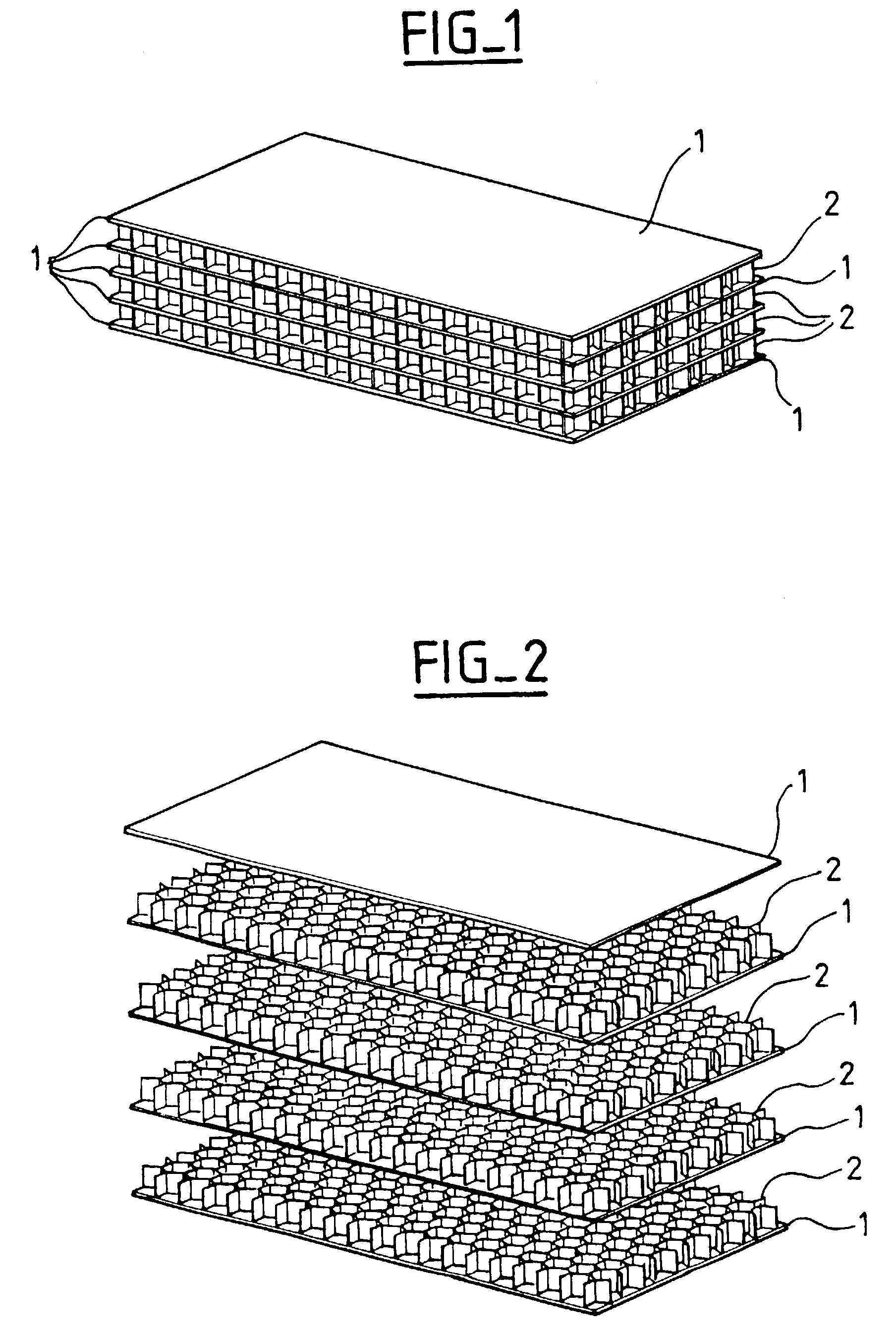

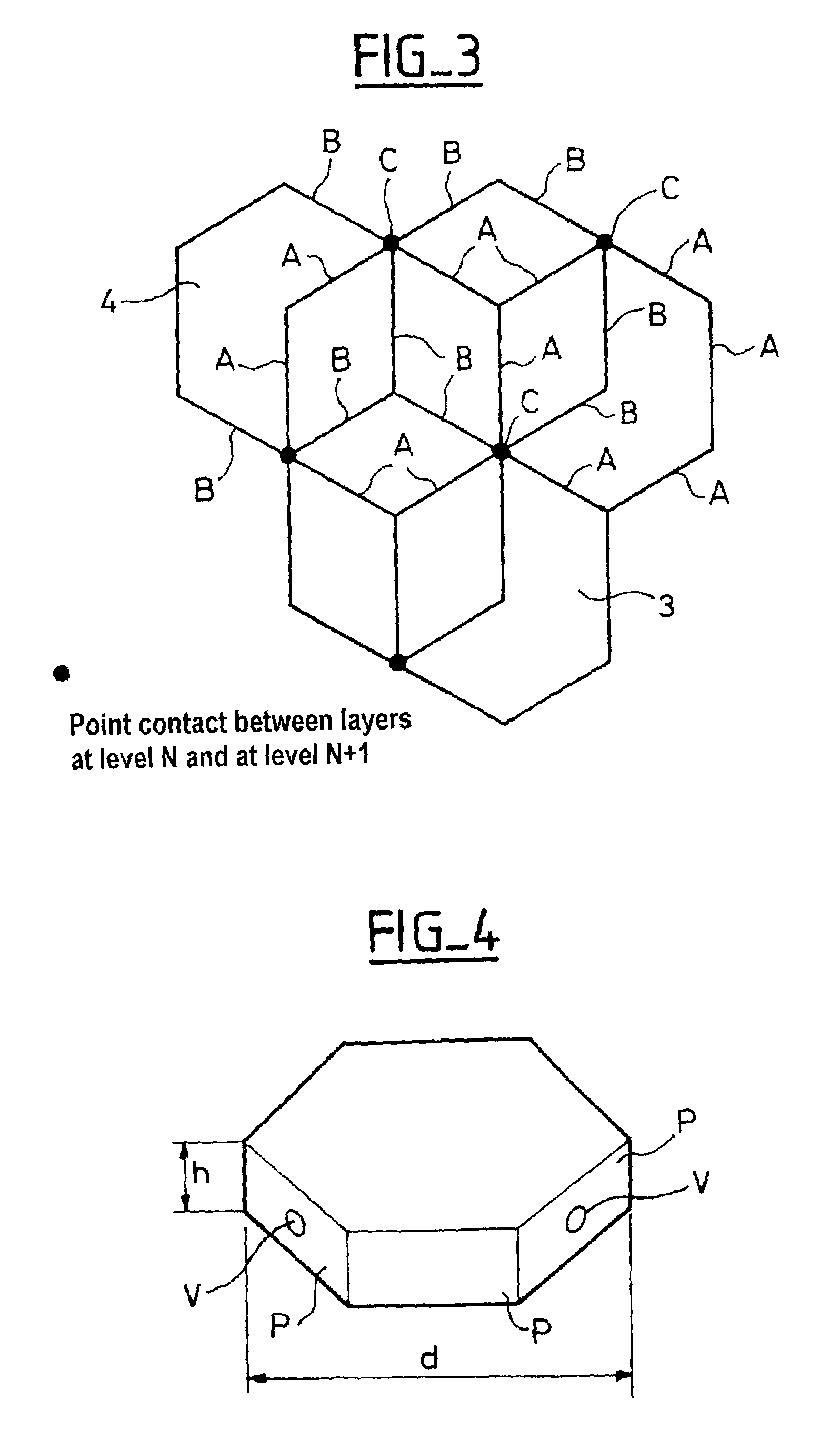

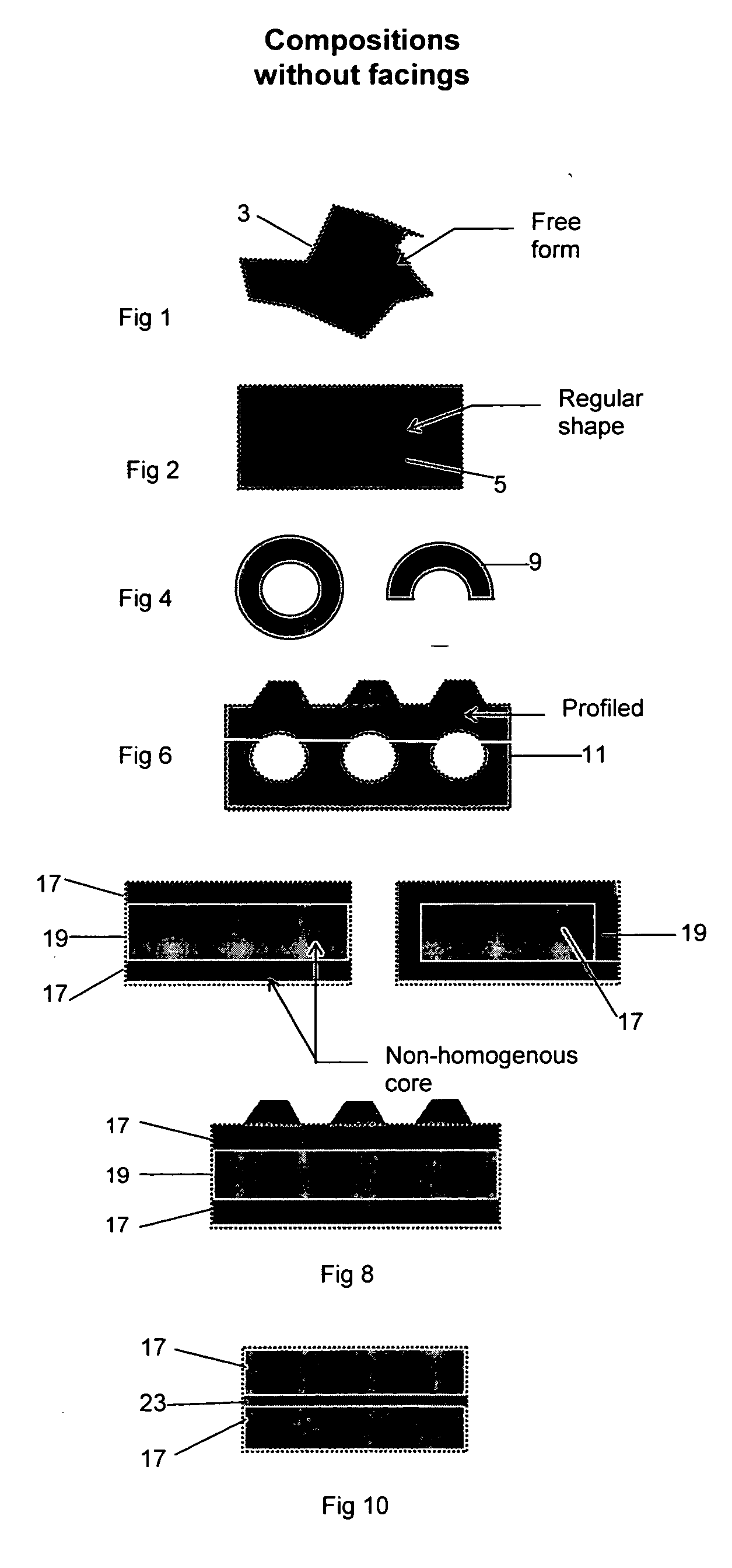

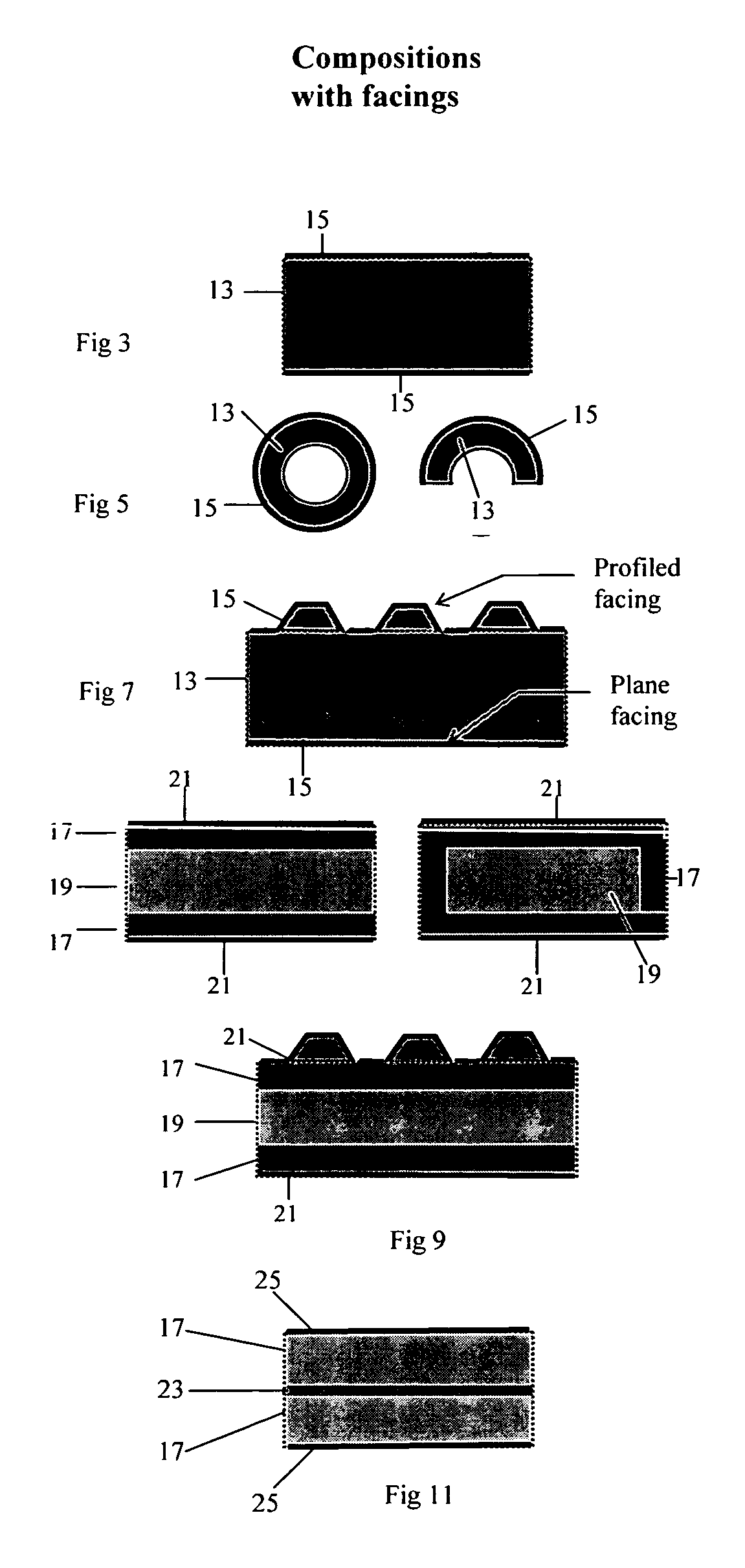

Rigid multilayer material for thermal insulation

InactiveUS7001656B2Mitigate such drawbackLamination ancillary operationsManual label dispensersLow emissivityThermal insulation

Owner:ALCATEL LUCENT SAS

Building wall insulation composite board and preparation method thereof

ActiveCN103104046AReasonable structural designImprove fire performanceClimate change adaptationPolyureas/polyurethane adhesivesBuilding energyThermal insulation

The invention relates to a building wall insulation composite board and a preparation method of the building wall insulation composite board, and belongs to the technical field of building energy-saving insulation materials and preparation methods. A wall insulation hard foam polyurethane composite board comprises inner cores, protective layers coated on the peripheries of the inner cores and interface layers coated on the upper surfaces and the lower surfaces of the protective layers in an attached mode. The inner cores are vacuum insulation boards. The preparation method of the wall insulation hard foam polyurethane composite board comprises preparation of interface coiled materials: coating prepared flame-retarded polymer mucilage on base materials to produce the interface coiled materials, and manufacturing of the protective layers and the wall insulation hard foam polyurethane composite board. The insulation composite board has good thermal insulation performance, waterproof performance and heat insulation performance, can satisfy 65% requirements of building energy efficiency very well, is high in bonding strength and convenient to construct and operate, greatly increases overall fireproof performance of the whole wall heat-insulation system after being arranged on a wall, and can be widely applied to the inner portions of walls, outer walls, and roof covering thermal insulation systems, heat insulation systems and waterproof systems.

Owner:WANHUA ENERGY-SAVING TECH GRP CO LTD

Composite materials comprising a polymer matrix and granules embedded therein

The present invention provides composite materials comprising a polymer matrix comprising one or more polymers and, embedded into the polymer matrix, granules which preferably after embedding have at least one cavity which is closed off relative to the ambient environment and in which there is an underpressure relative to the standard pressure of 1 bar (100 kPa), a method for producing such composite materials, and use as insulating material.

Owner:EVONIK DEGUSSA GMBH

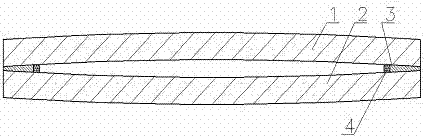

Convex-sided vacuum heat-insulating board, flattened vacuum heat-insulating board and preparation methods thereof

InactiveCN102953441AHigh compressive strengthSimple manufacturing processClimate change adaptationInsulation improvementConvex sideEngineering

The invention provides a vacuum heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed vacuum layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the vacuum heat-insulating board provided by the invention is simple in process, and the prepared vacuum heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a vacuum layer of the vacuum heat-insulating board can be effectively guaranteed, the service life of the vacuum heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the vacuum heat-insulating board can be increased.

Owner:戴长虹

Production method for producing vacuum-insulation wall insulation board by utilizing expanded and vitrified small balls

InactiveCN102720277ASimple processNo waste dischargeClimate change adaptationInsulation improvementGlass fiberCooking & baking

The invention relates to a production method for an insulation board. The method comprises the following steps of: a, adding 50-70 parts by weight of expanded and vitrified small balls, 5-10 parts by weight of fibre glass, 5-20 parts by weight of silicon ash, 5-10 parts by weight of bentonite and 1-5 parts by weight of getter into a stirring kettle, then adding 2-5 parts by weight of wetting agent and 15-20 parts by weight of binding agent, and stirring the ingredients to obtain a pasty material; b, spreading out the well stirred pasty material on a microwave baking line, baking the pasty material until the water content of the board is less than 1% and then cutting the board into blocks; c, vacuumizing the board which is cut into blocks, wherein the degree of vacuum is below 200Pa; and d, cutting and packing the obtained insulation board. By utilizing the production method provided by the invention to produce the insulation board, the process is simple, no three wastes are discharged, and the produced insulation board can well achieve the effects of heat preservation and heat insulation, and has the combustion performance of grade A and the insulation thickness of 10-15mm; and the produced insulation board is light in weight and long in weather-proof time and has service life of more than 30 years.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

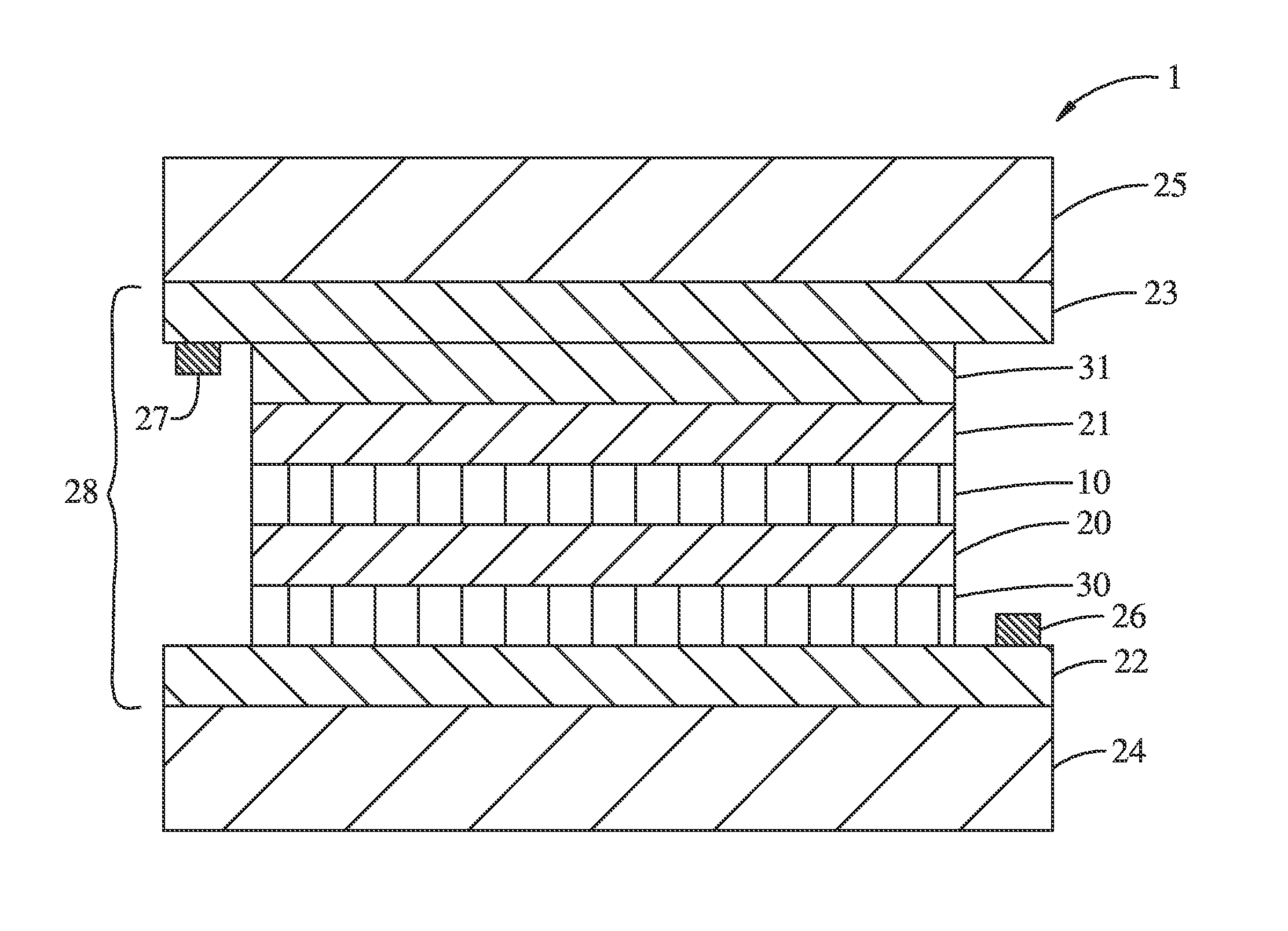

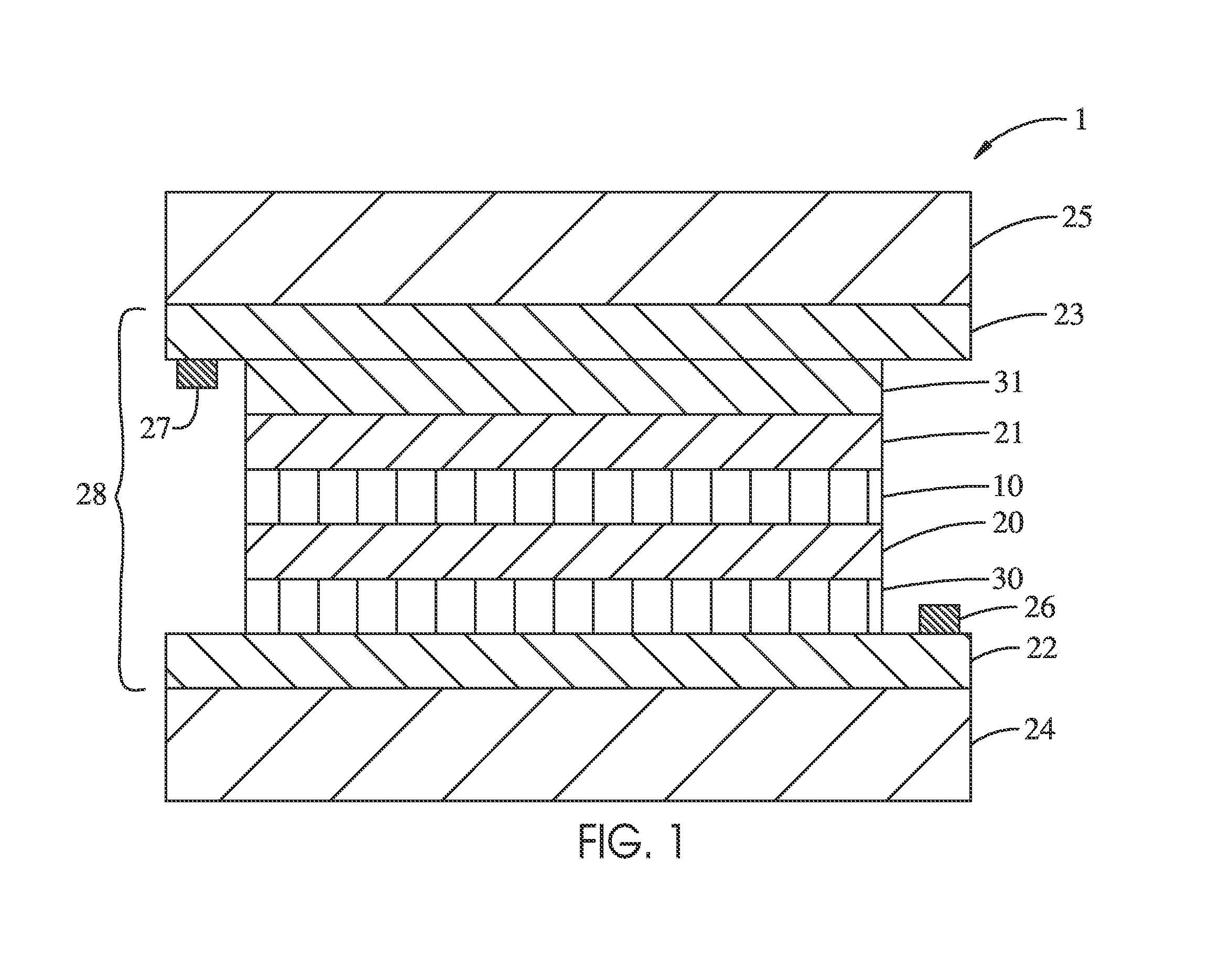

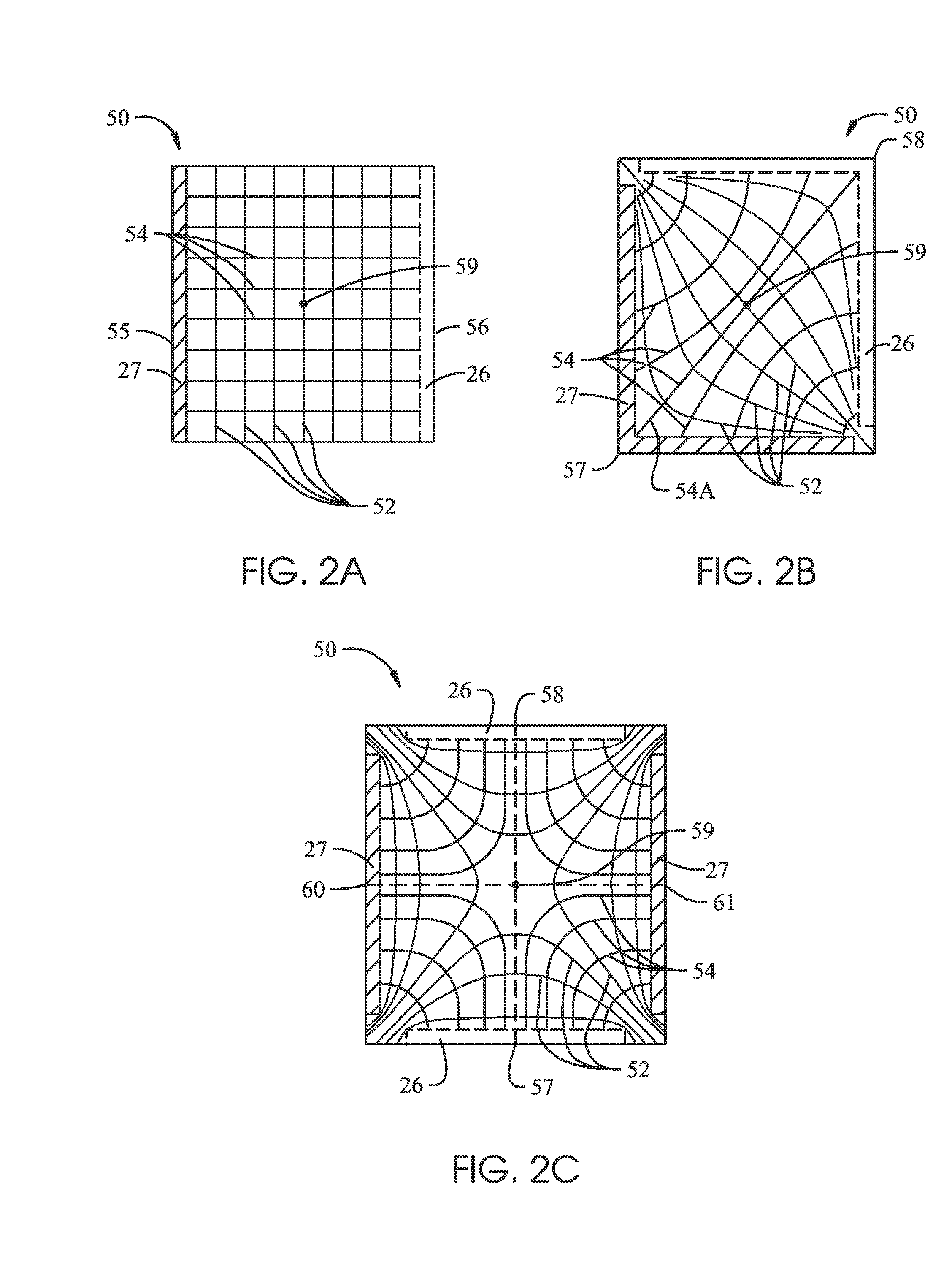

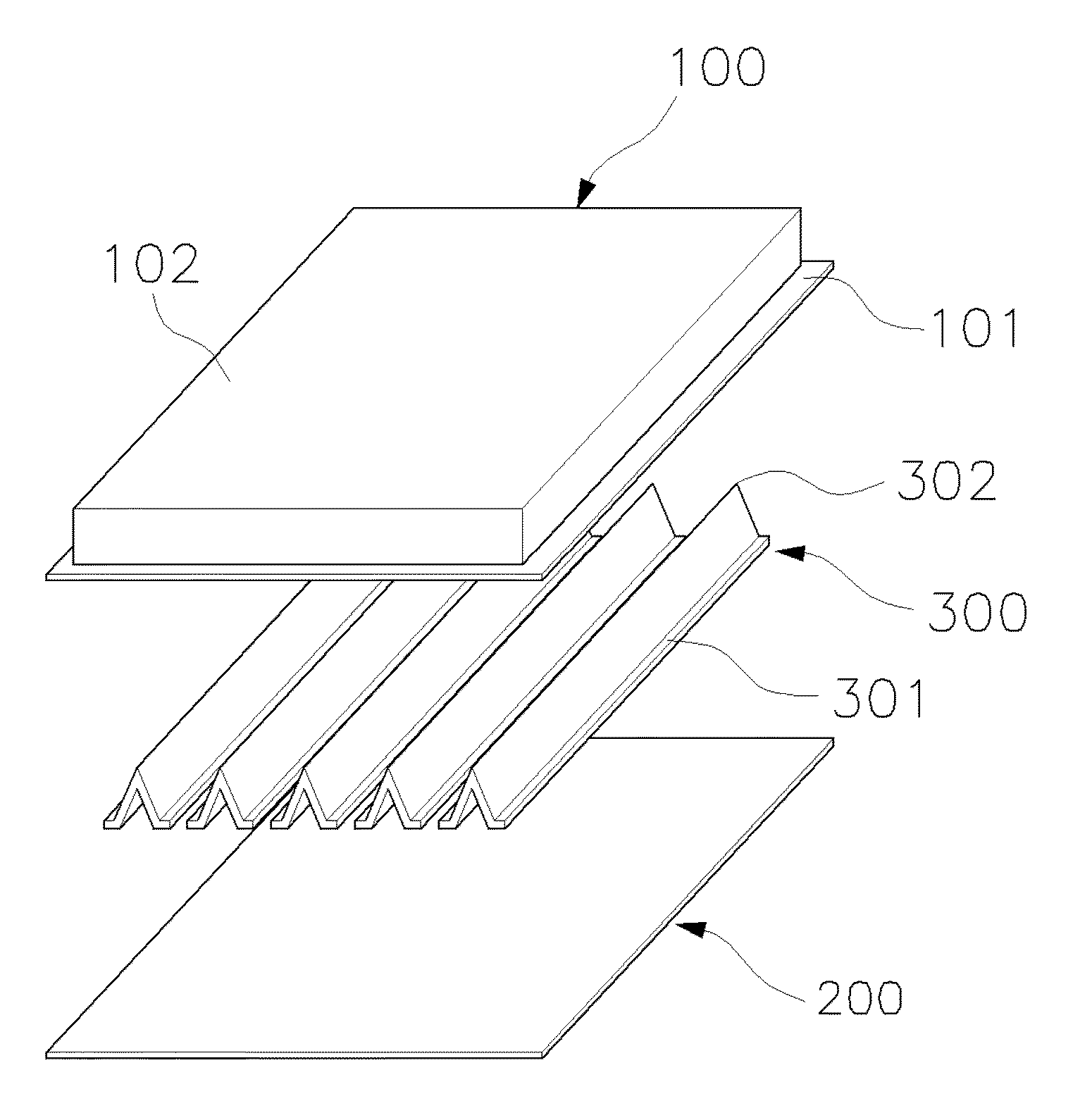

Electrochromic multi-layer devices with current modulating structure

ActiveUS20140043668A1Easy to manufactureClimate change adaptationInsulation improvementElectrical resistance and conductancePower flow

A multi-layer device comprising a first substrate, a first electrically conductive layer on a surface thereof, and a first current modulating layer, the first electrically conductive layer having a sheet resistance to the flow of electrical current through the first electrically conductive layer that varies as a function of position.

Owner:KINESTRAL TECH

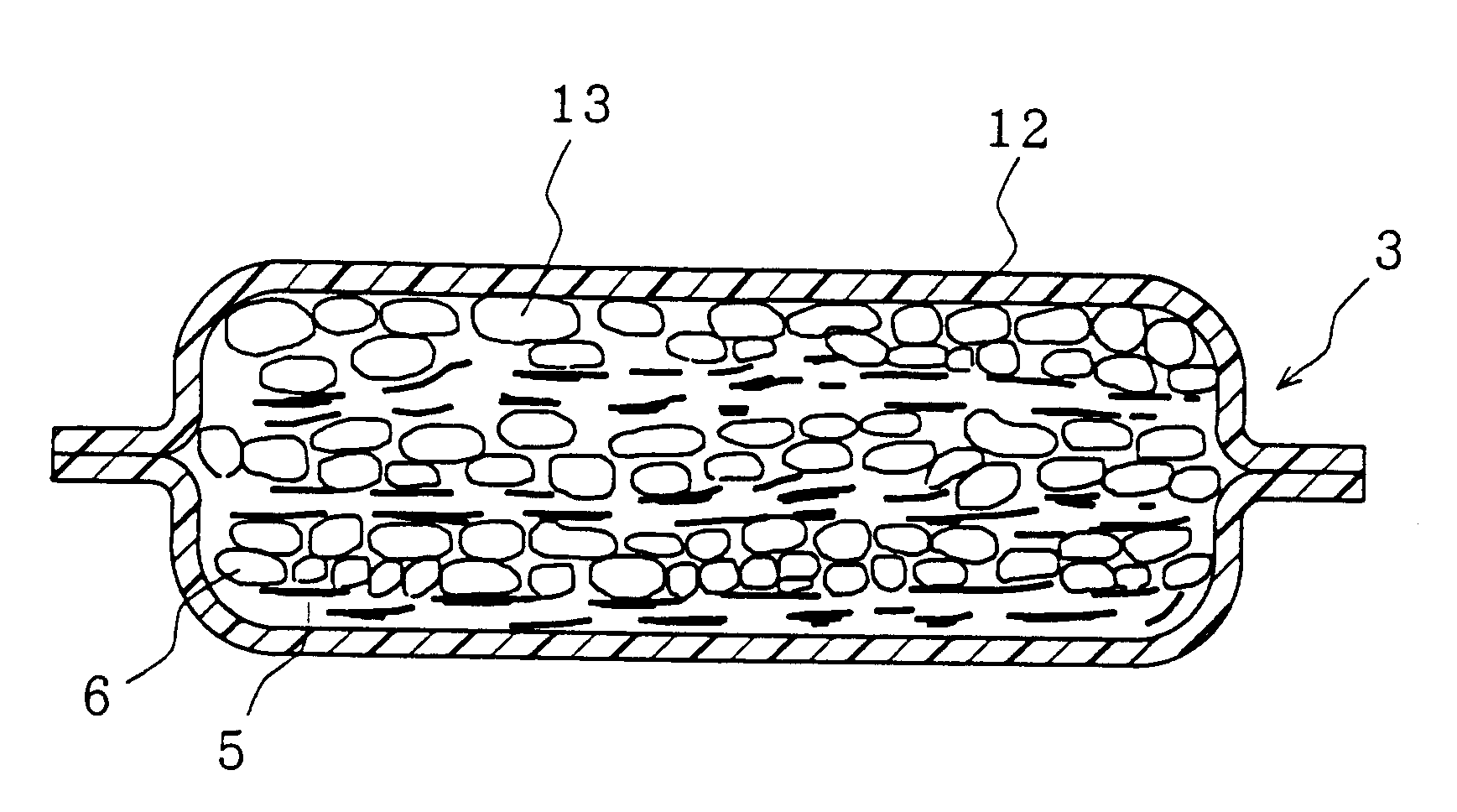

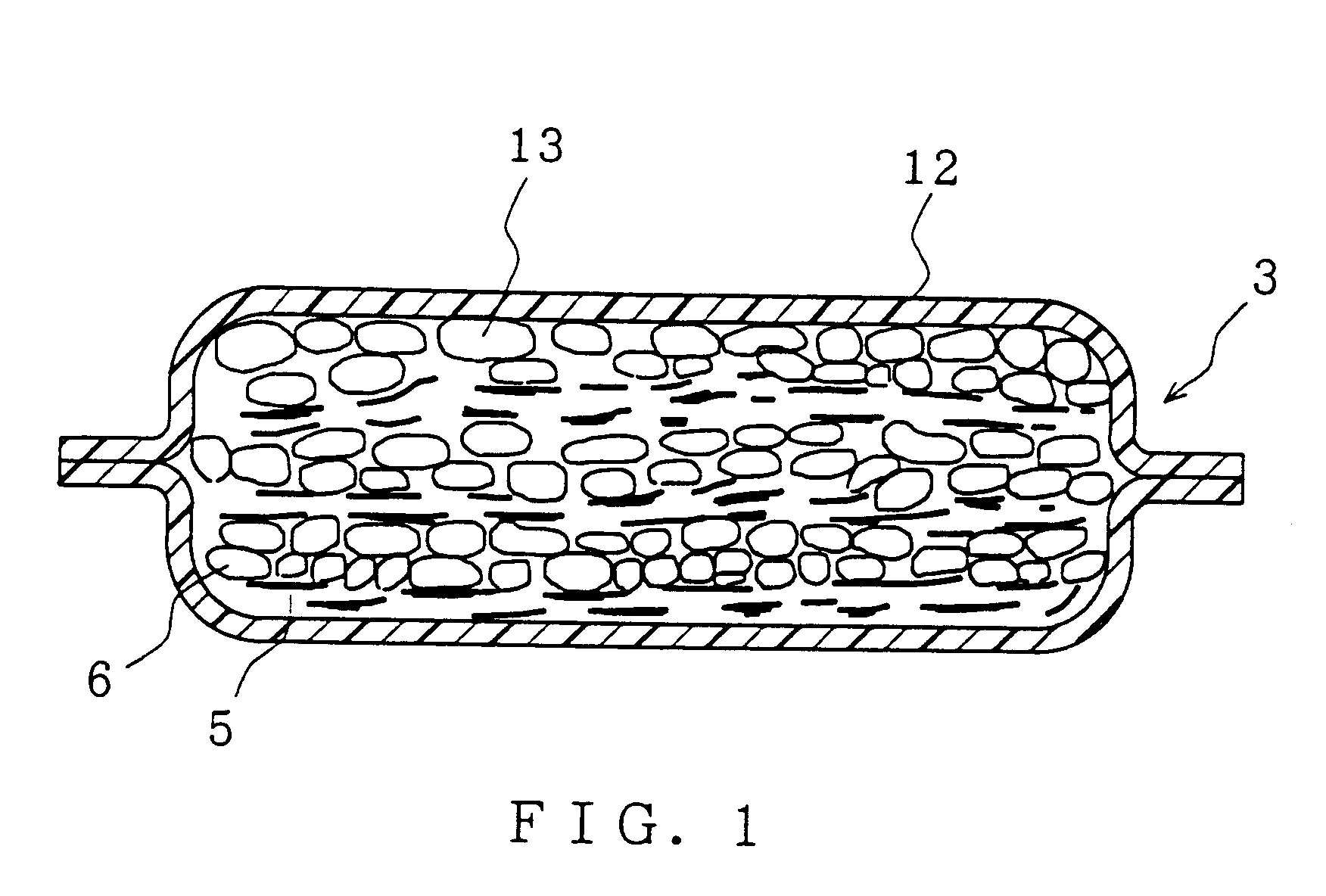

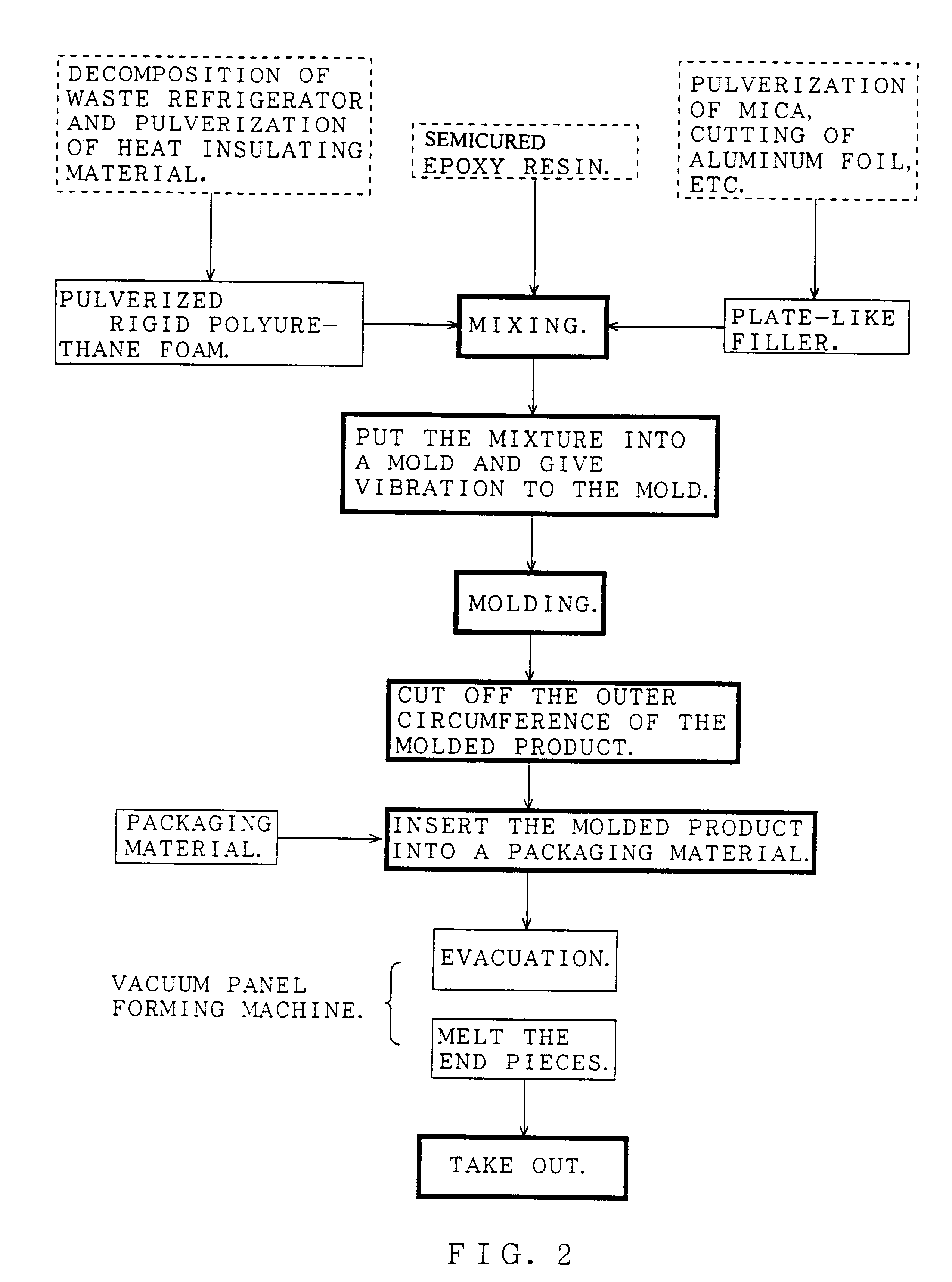

Vacuum heat-insulating panel and method for producing the same

A vacuum heat-insulating panel includes a porous core material formed from a mixture containing plastic foam powder and a filler in the form of flakes or a porous core material formed from a mixture containing plastic foam powder and thermoplastic resin powder; and a packaging material for packaging the core material, the inside of the package material being kept in a vacuum, the core material holding its shape. Rigid polyurethane foam may be used as the plastic foam. Mica flakes, plastic films each coated with thin metal film, metal foil or the like may be used as the filler. Styrene resin may be used as the thermoplastic resin.

Owner:MITSUBISHI ELECTRIC CORP

Insulating product

Owner:ROCKWOOL AS

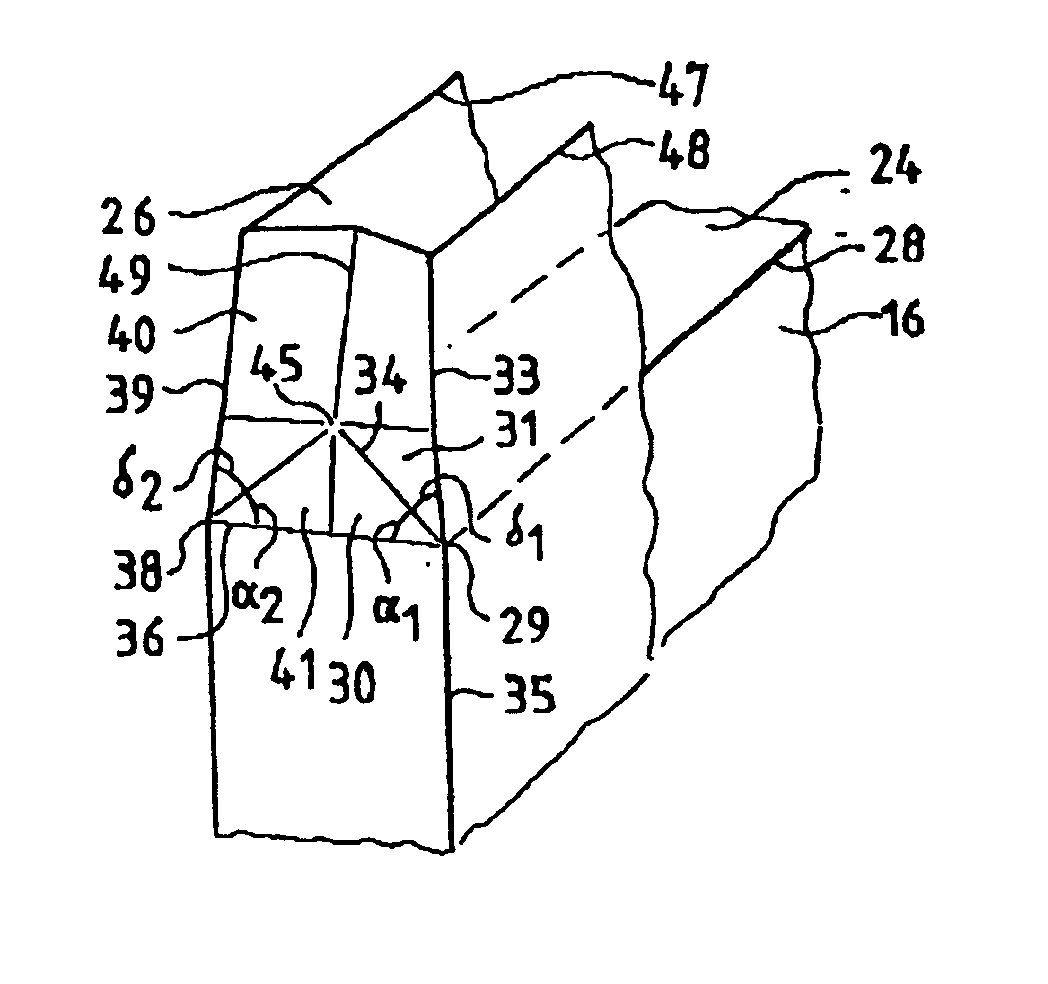

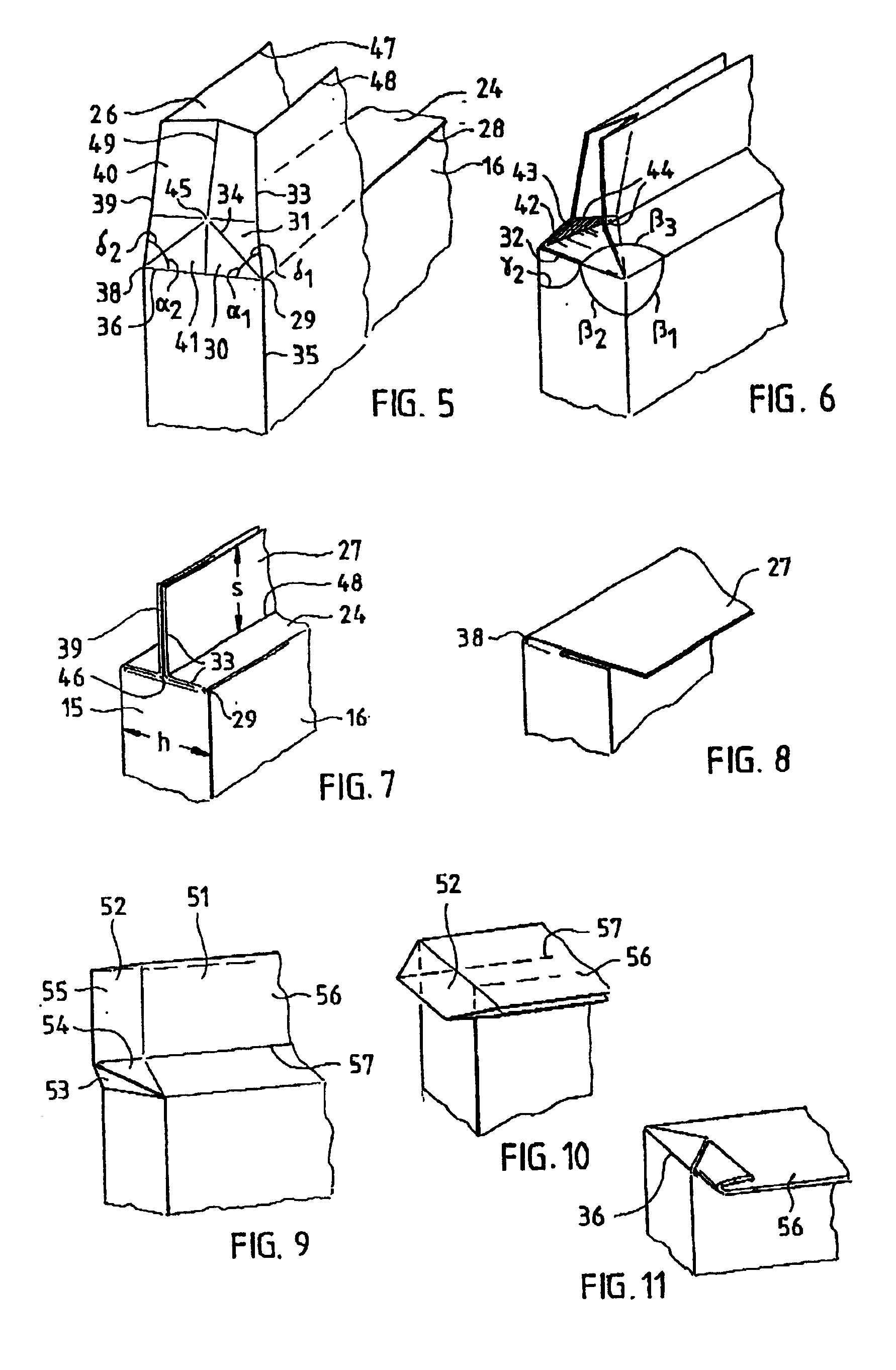

Foil-enveloped evacuated thermal insulation elements

The invention relates, on the one hand, to a prismatic, especially panel-formed thermal insulation element which is enveloped in a gas-tight foil and evacuated, whereby a stable core pre-formed from a porous material is completely enveloped in a single cut sheet of the gas-tight foil; as well as a manufacturing process for same comprising the following steps:a) Manufacture of a prismatic core corresponding to the desired form of the thermal insulation element from a porous material;b) Enveloping of the principal faces of this core with a single sheet of the gas-tight foil;c) At least partial welding together of the foil which is drawn tight around the core along the face of the core;d) Folding-in of the welded seam area of the foil against the face of the core;e) Stress-free folding-together of the areas of the cut sheet of gas-tight foil projecting beyond the core, covering and in flat contact with the end surface(s) of the core;f) Welding together of the folded-together areas of foil on at least one end face of the core;g) Evacuation of the enveloped core;h) Complete welding closed of all remaining openings in the foil under vacuum.

Owner:VA Q TEC AG

Vacuum heat insulator and apparatuses using the same

InactiveUS7537817B2Prevent degradationHigh melting pointThermal insulationClimate change adaptationAtmosphereHigh heat

In a vacuum heat insulator, a heat seal layer of its enveloping member of a laminated structure is made of a film having a melting point of at least 200° C. Alternatively, the heat seal layer is made of a film having a melting point above 100° C. and below 200° C., and fins are bent on a low-temperature side. Either of these structures can inhibit a decrease in gas barrier property even in a high-temperature atmosphere of approx. 150° C. Thus, the heat-insulating property of the vacuum heat insulator is maintained for a long period of time. This vacuum heat insulator is preferable for an apparatus that has a heat source or a portion to be kept warm exceeding a temperature of 100° C.

Owner:PANASONIC CORP

Fire resistant insulation material

InactiveUS20050176833A1Improve fire resistanceEnhance layeringSolid waste managementThermal insulationRefractory

Owner:TAY CHONG HAK

Low-alkaline adhesive mortar compote vacuum heat insulation board and preparation method thereof

ActiveCN102979204AAvoid damageEasy constructionClimate change adaptationInsulation improvementAdhesiveHigh intensity

The invention relates to a low-alkaline adhesive mortar compote vacuum heat insulation board which comprises a vacuum heat insulation board and low-alkaline adhesive mortar which is coated on the periphery of the vacuum heat insulation board. The vacuum heat insulation board consists of core materials, a high-strength gas-blocking membrane and interface mortar, the high-strength gas-blocking membrane is coated on the periphery of the core materials and packed with the core materials in a vacuumizing mode, a layer of the interface mortar is coated on the periphery of the high-strength gas-blocking membrane, and the thickness of the interface mortar is 0.1-3 mm. The low-alkaline adhesive mortar compote vacuum heat insulation board has the advantages of overcoming a phenomenon that damage on traditional vacuum heat insulation materials occurs in the process of construction. The low-alkaline adhesive mortar compote vacuum heat insulation board is convenient to construct, good in heat insulation effect, and fireproof in class A.

Owner:ANHUI KERUIKE INSULATION MATERIAL

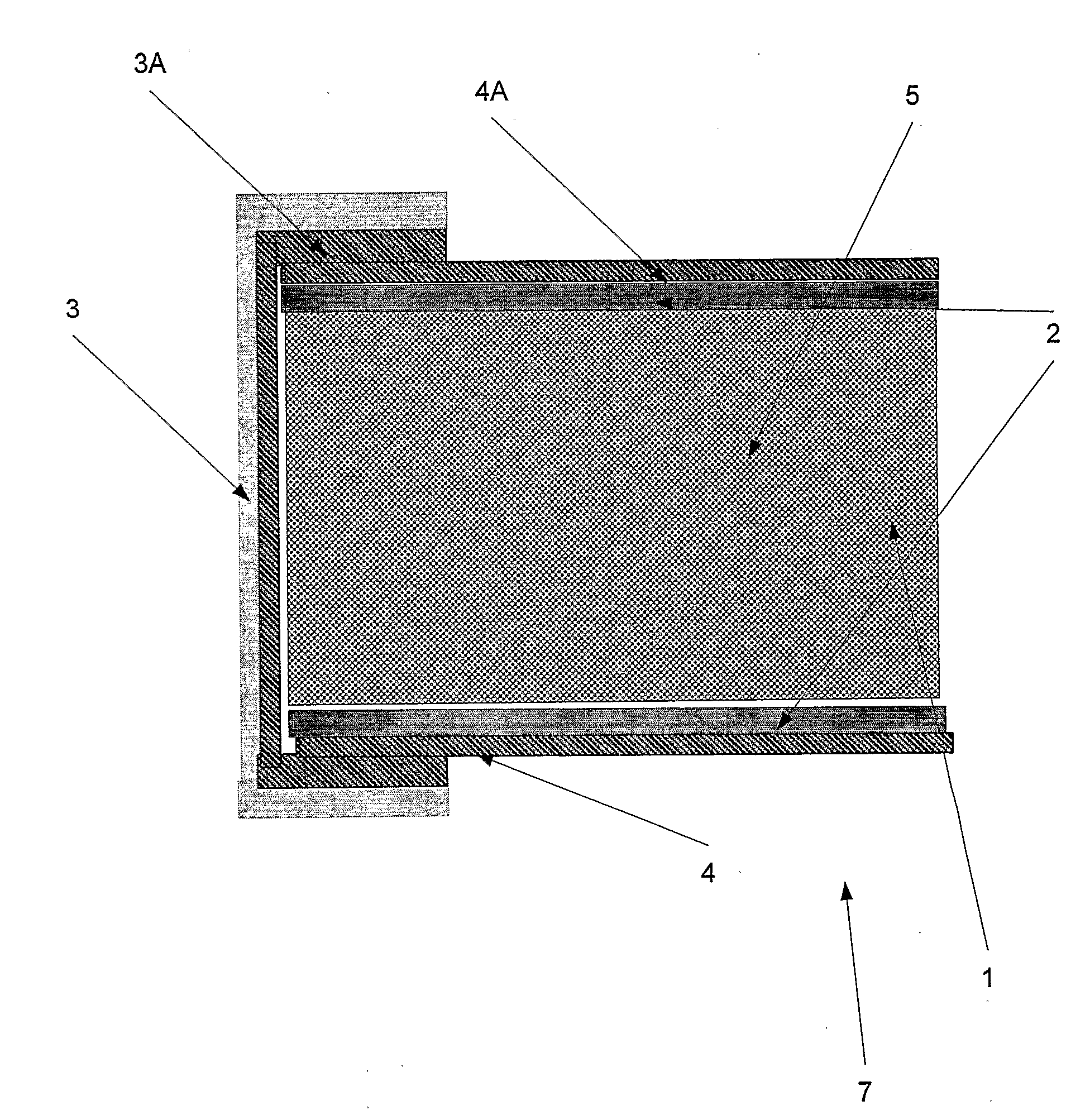

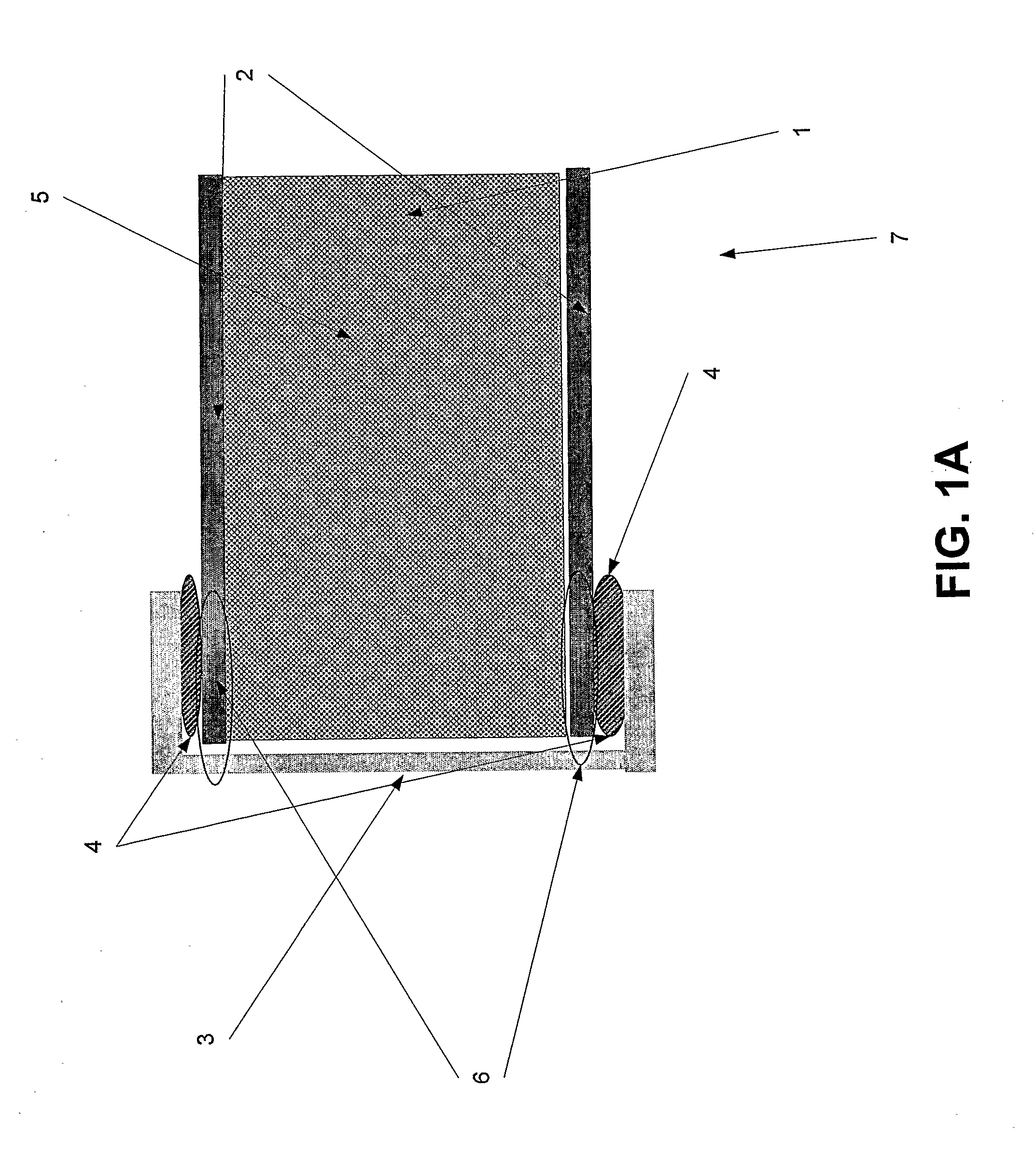

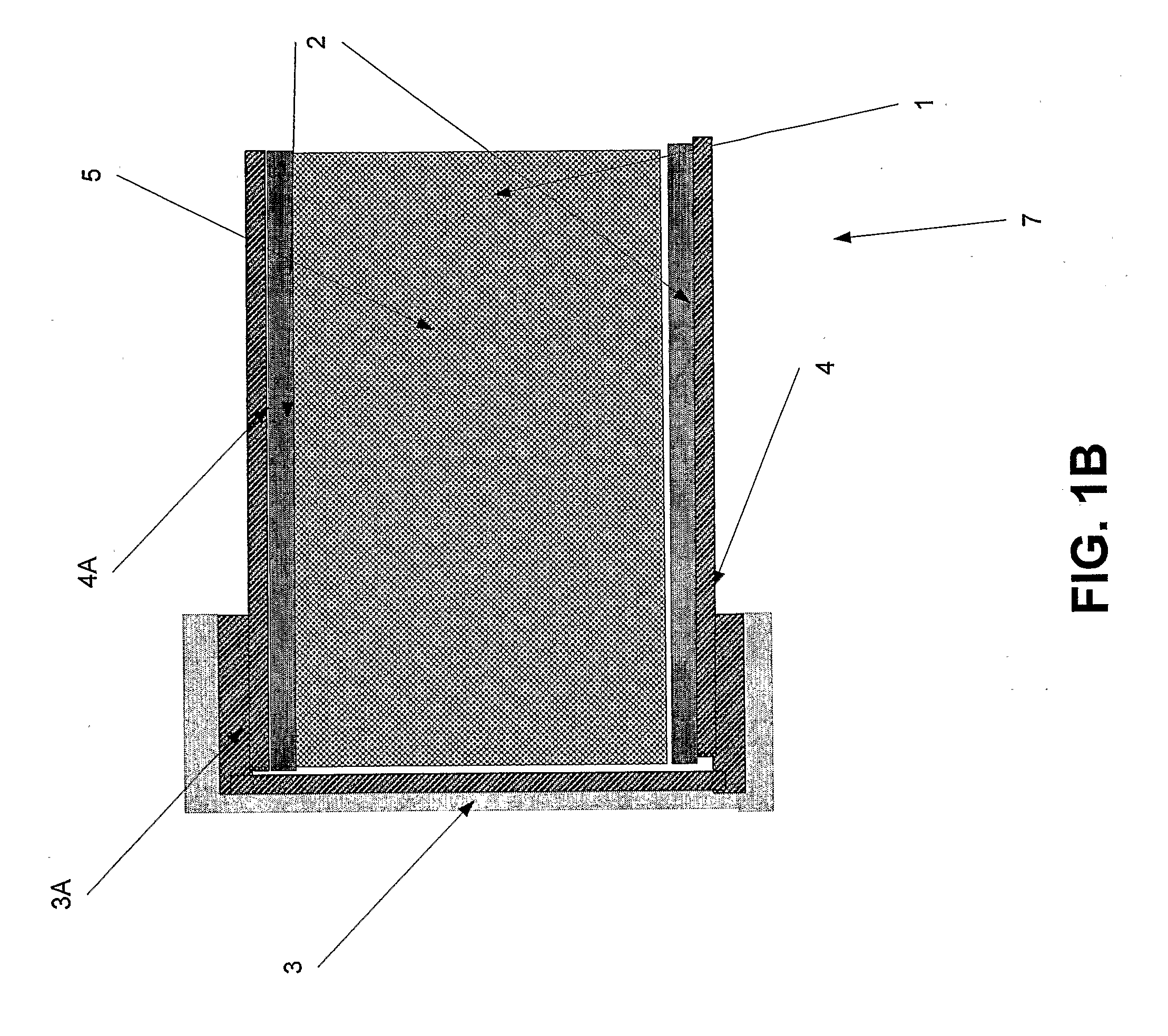

Vacuum Insulation Panel, Insulated Masonry Structure Comprising Same, And Method Of Construction

InactiveUS20120009376A1Easy to controlLevel of vacuum can be reducedClimate change adaptationInsulation improvementGlass fiberFilling materials

Owner:RUSEK JR STANLEY J

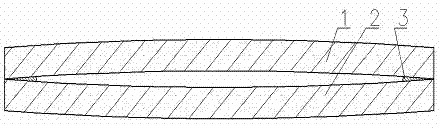

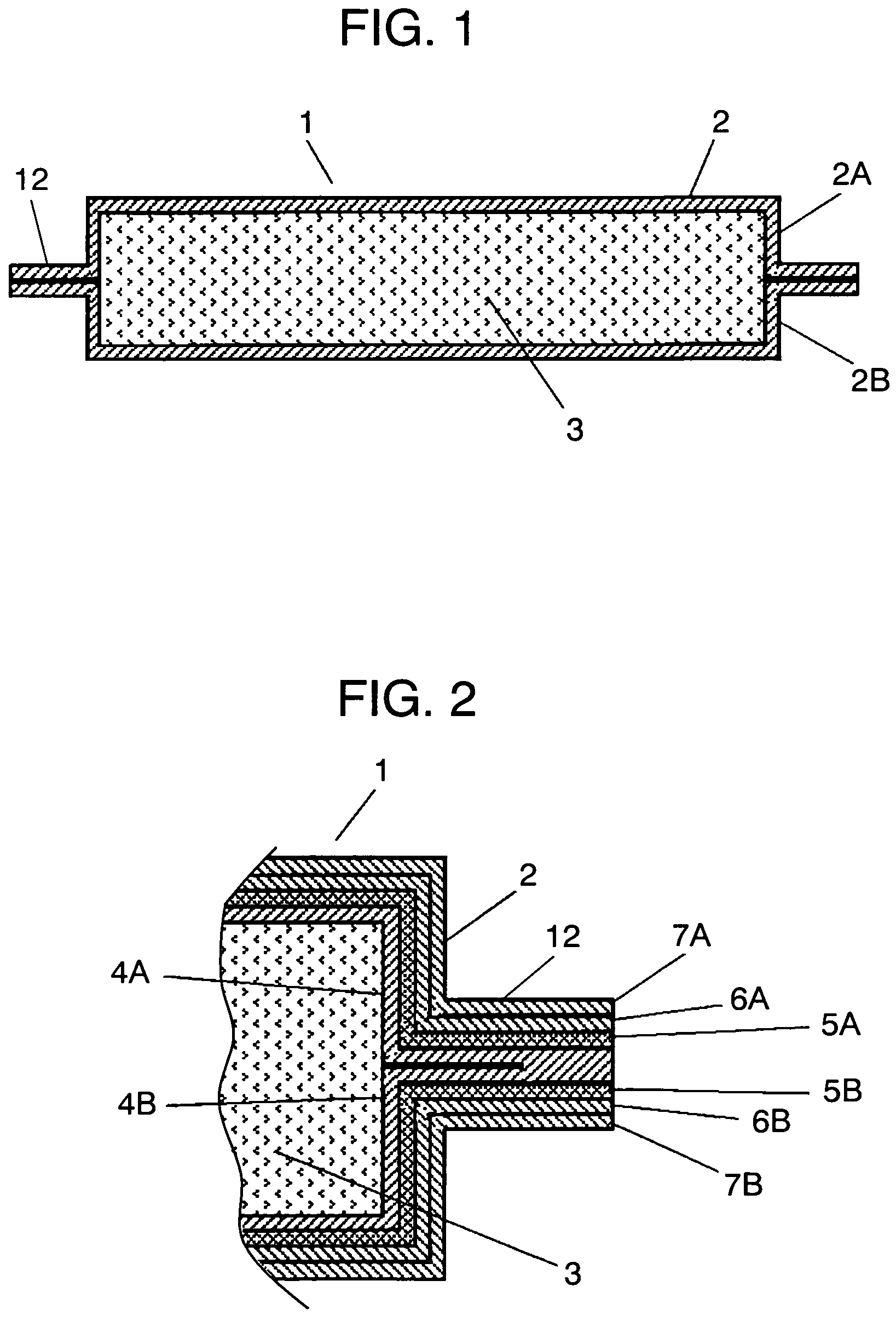

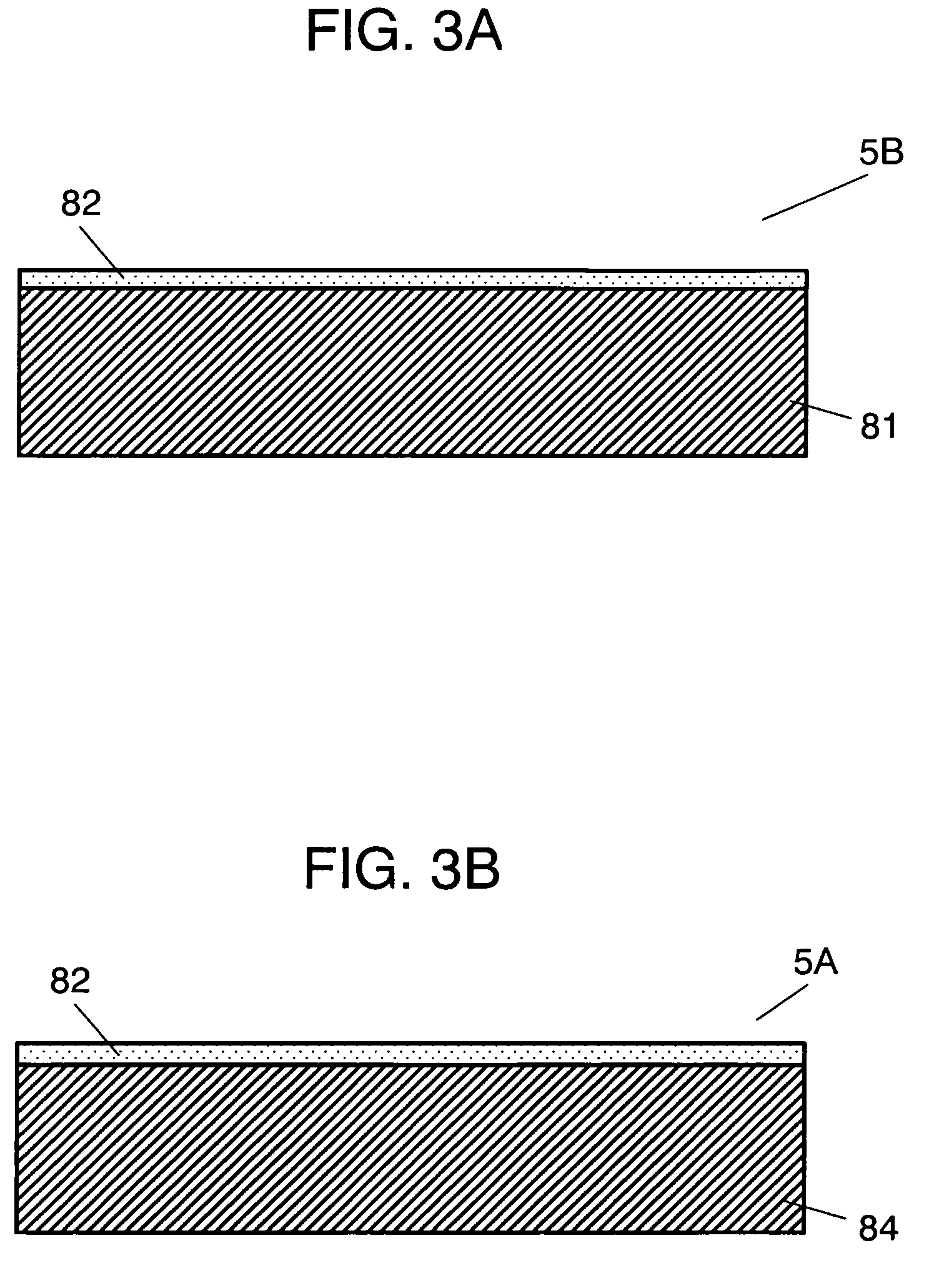

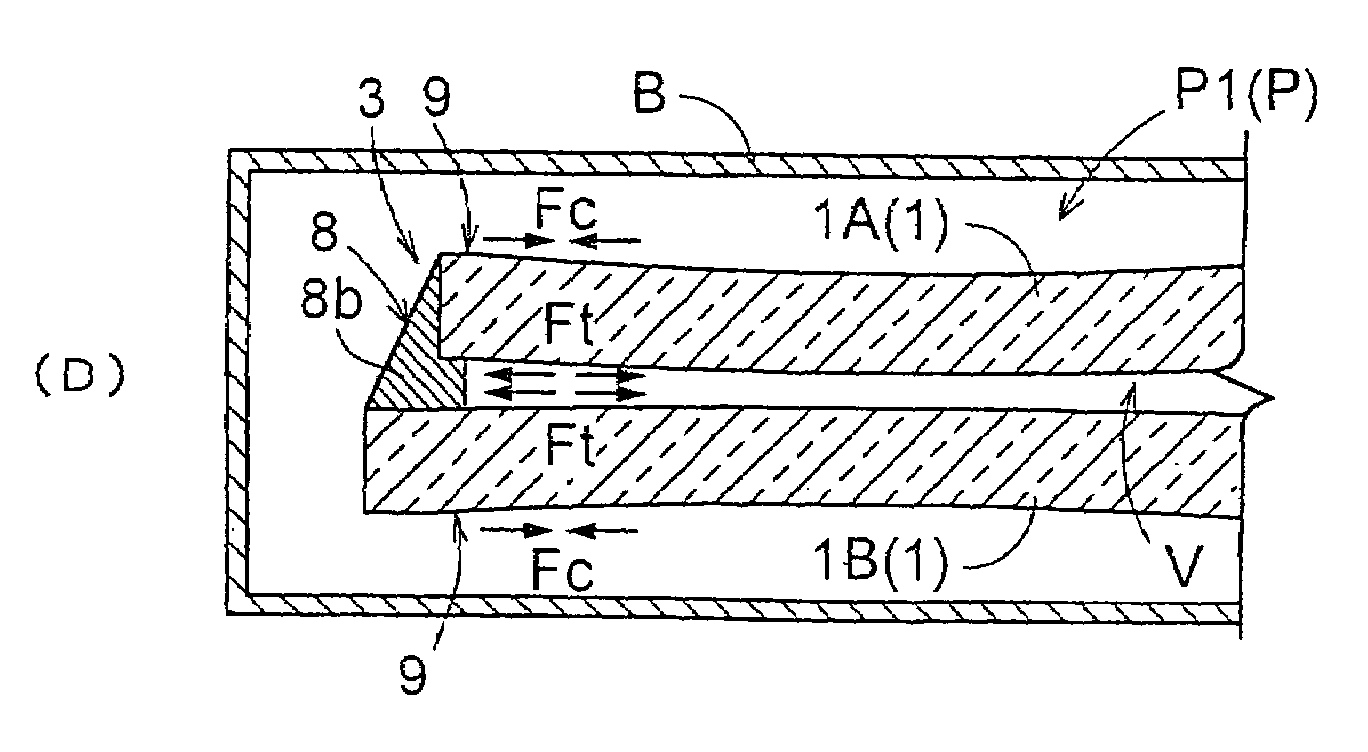

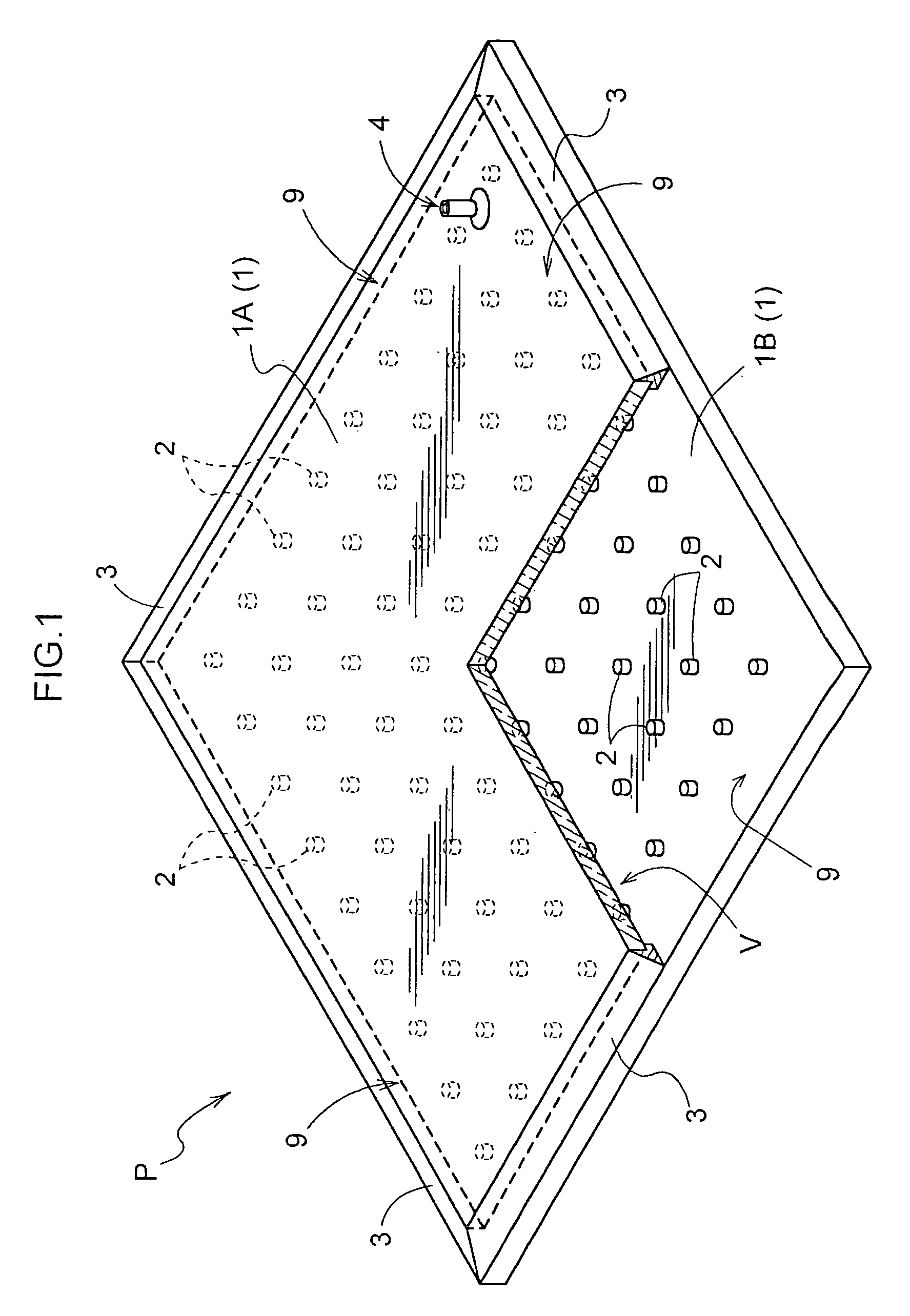

Glass panel

InactiveUS7141130B2Avoid crackingCut surfaceClimate change adaptationInsulation improvementAtmospheric pressureGlass sheet

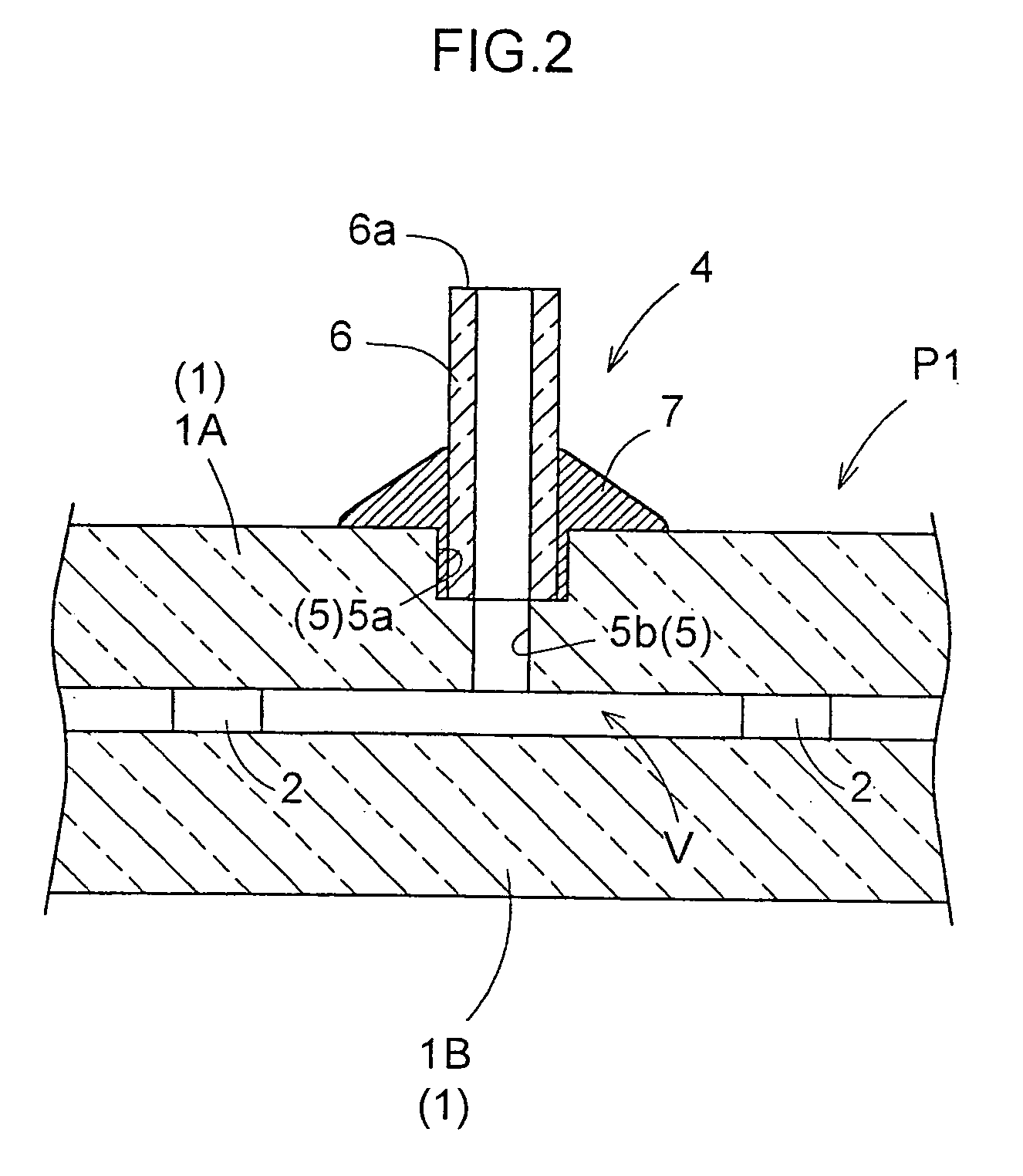

A glass panel (P) comprising a pair of glass plates (1A, 1B) opposed to each other, spacers (2) disposed between the pair of glass plates for maintaining a gap therebetween, and a sealing member (3) having a lower melting point than the glass plates (1) for sealing the pair of glass plates (1A, 1B) at outer peripheries (9) thereof to form a decompression void (V) between the pair of glass plates (1A, 1B), wherein a compressive force Fc is allowed to remain at outer surfaces of the outer peripheries (9) of the glass plates (1), with the decompression void (V) being in atmospheric pressure condition.

Owner:NIPPON SHEET GLASS CO LTD

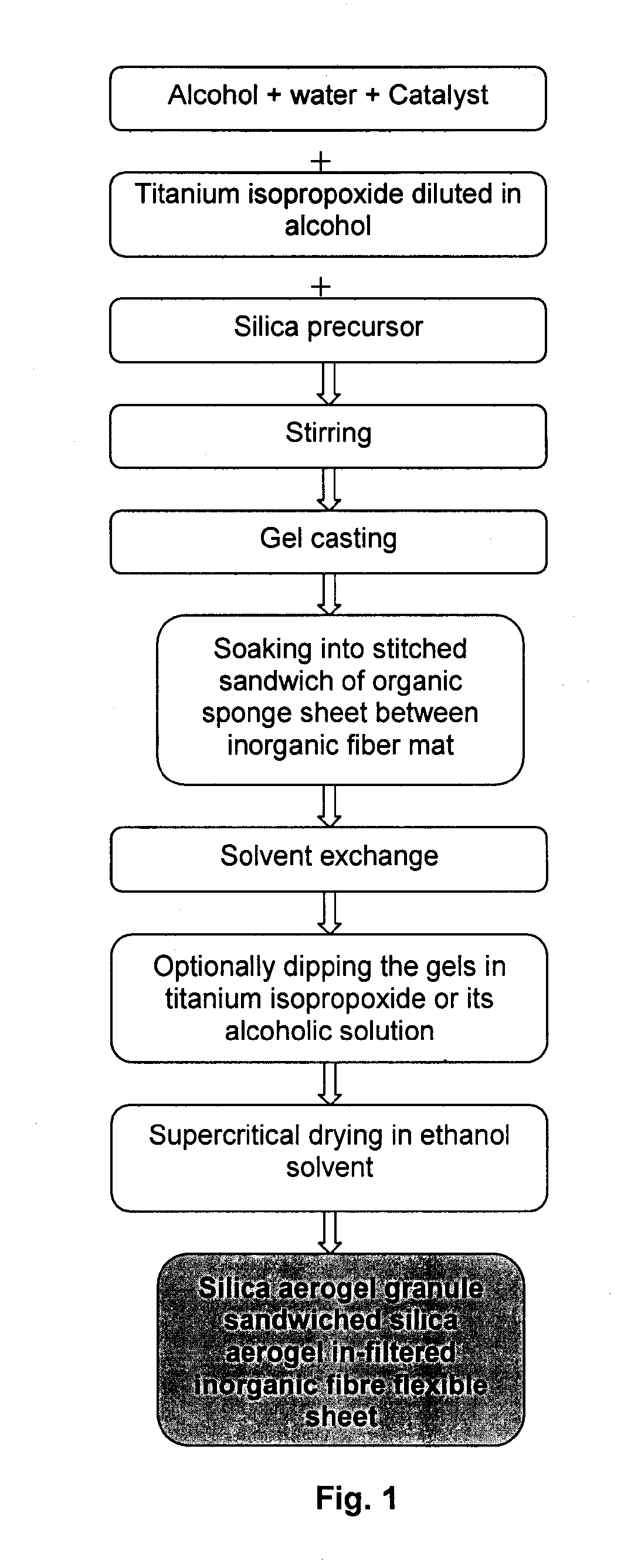

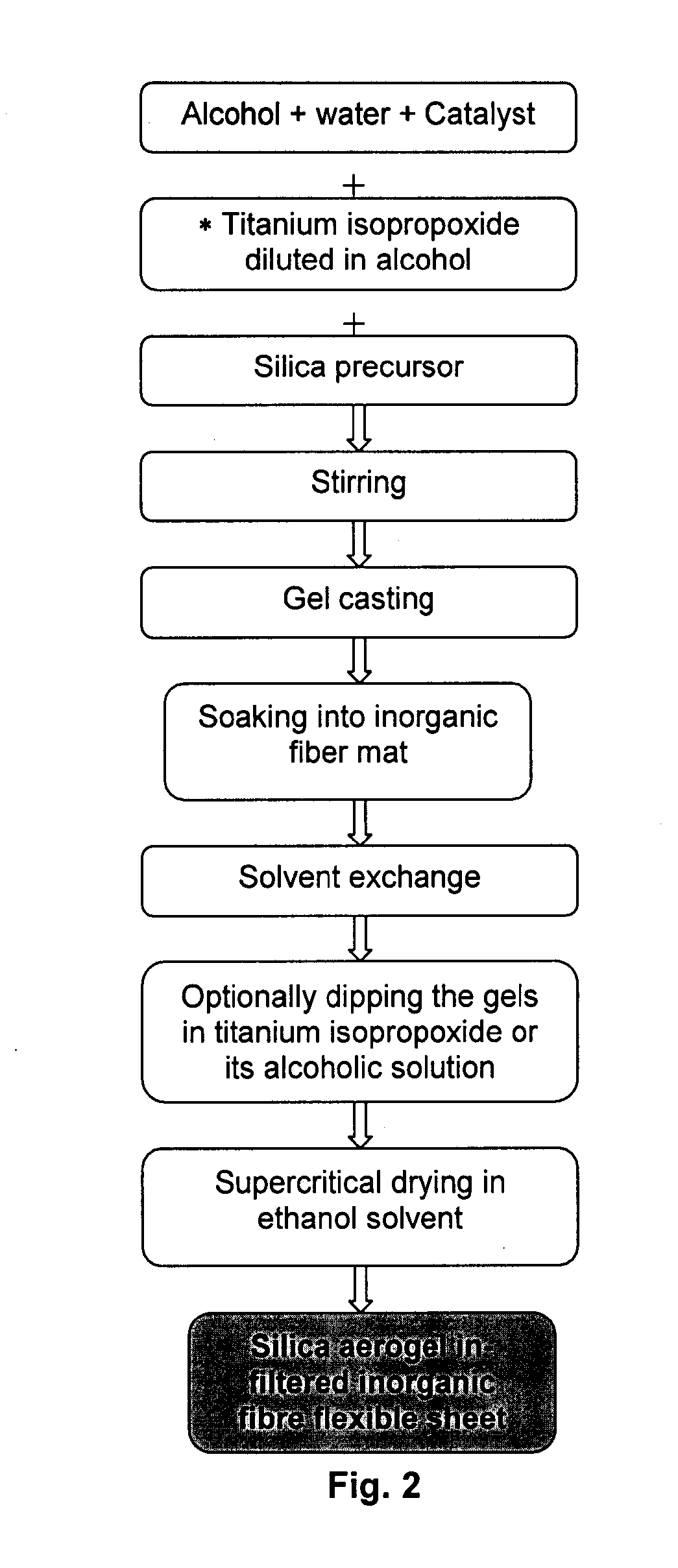

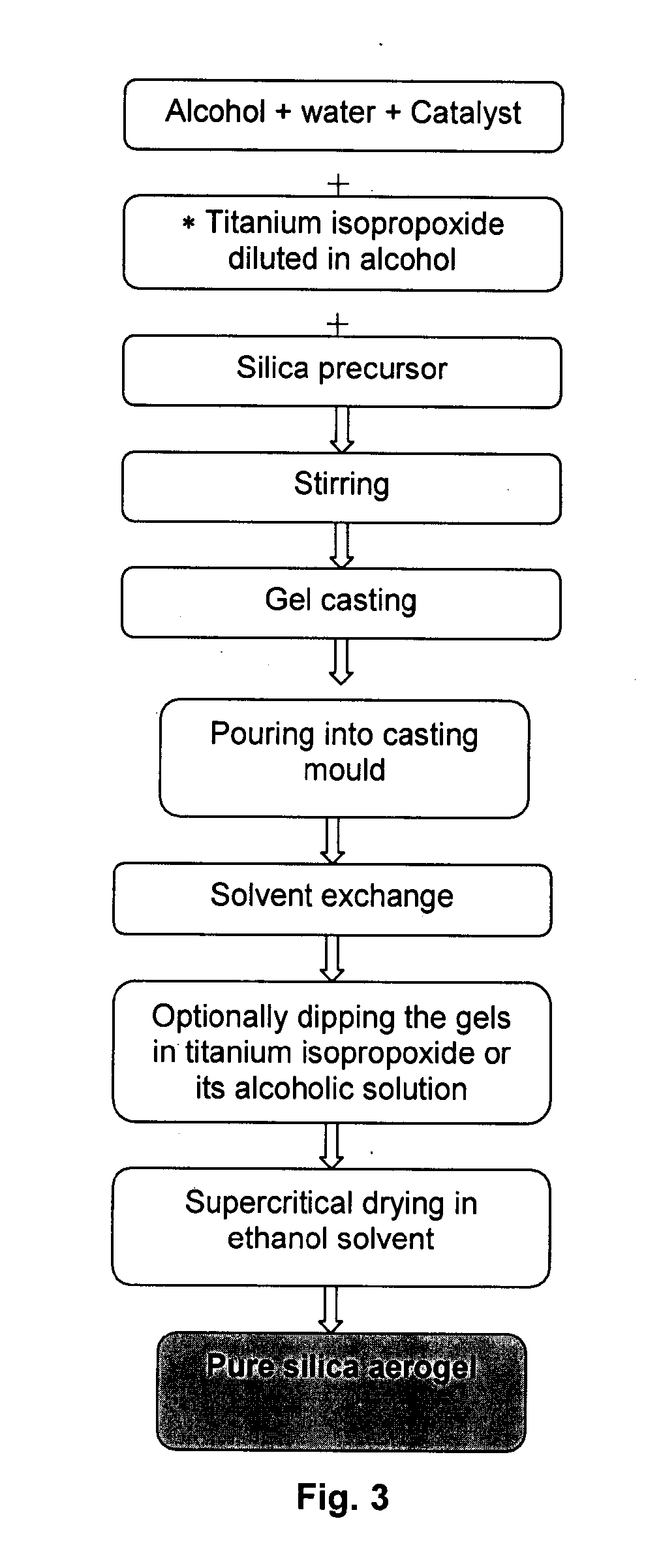

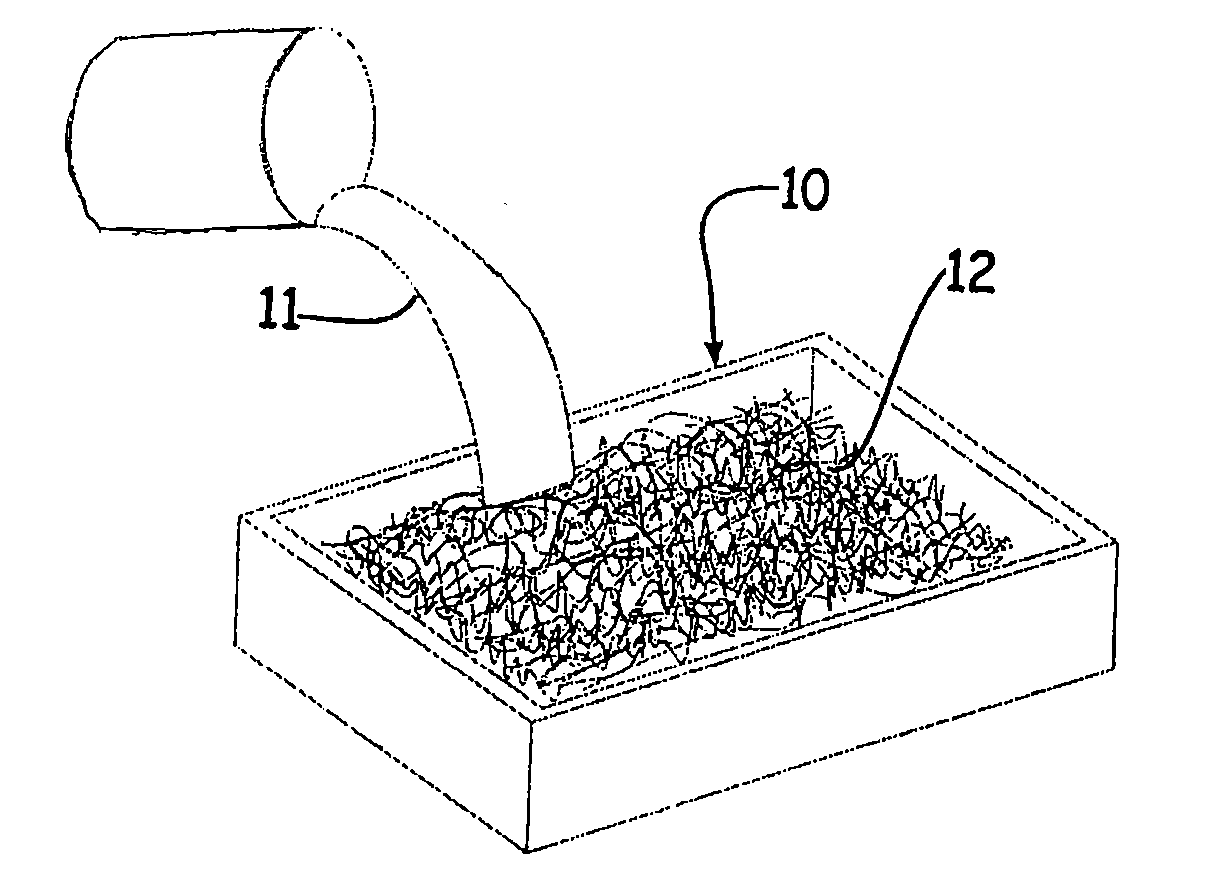

An improved process for producing silica aerogel thermal insulation product with increased efficiency

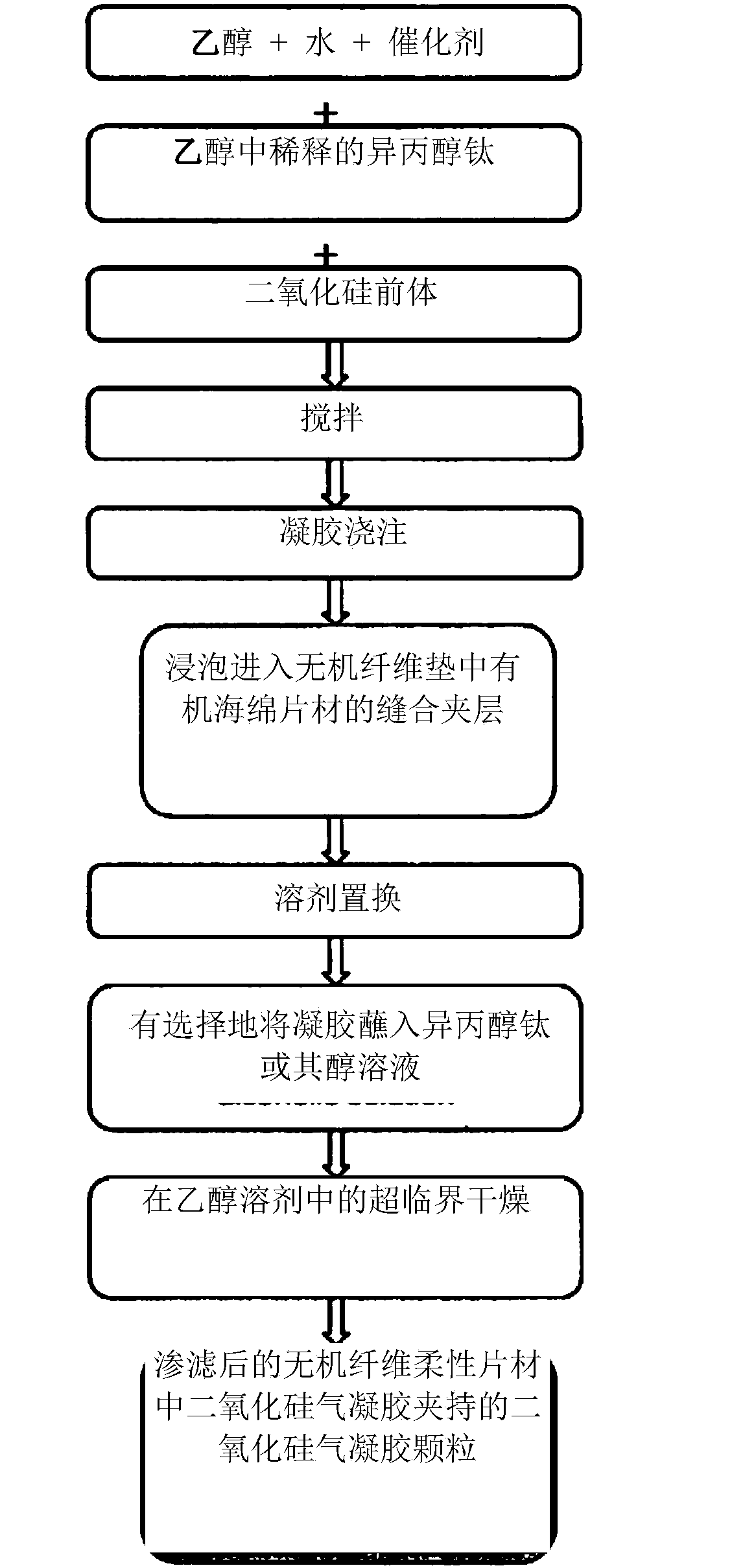

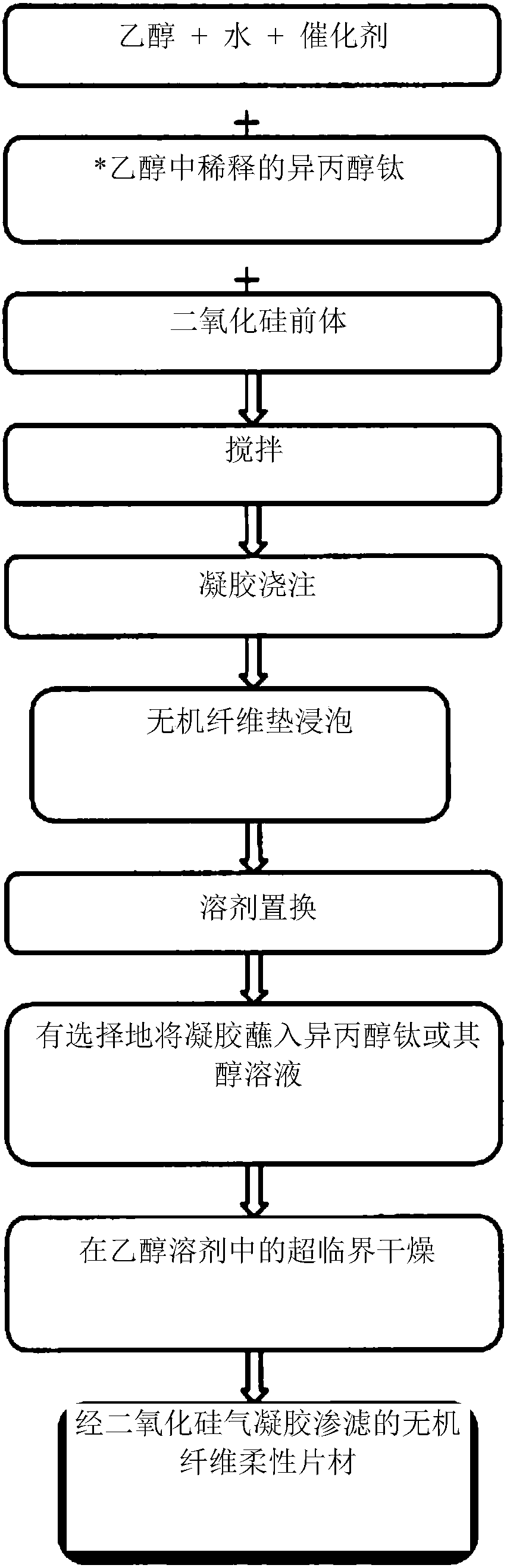

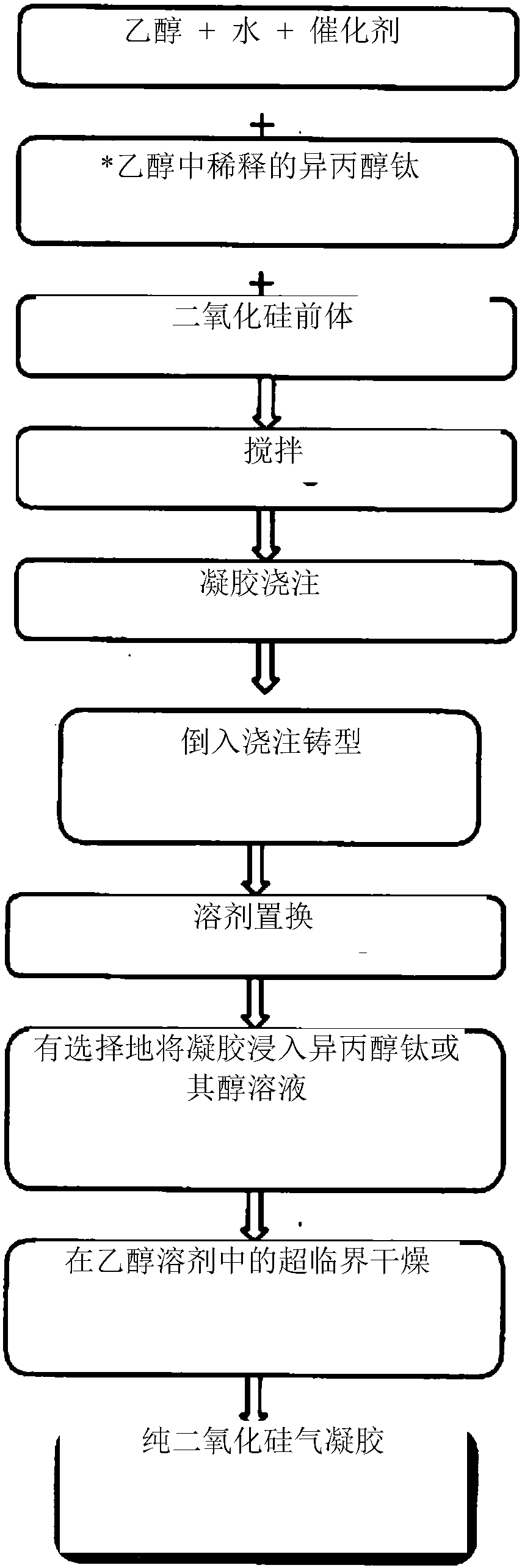

The invention relates to an improved method for producing silica aerogel in pure and flexible sheet form having effective suppression of radiative heat transport at high temperatures and increased thermal insulation property. The suppression of radiative heat transport was achieved by in-situ production of titanium dioxide nanoparticles in very minor concentrations during gelation of silica precursor, with nanoporous surface area more than 300 m<2> / g and acts as an infra red reflecting agent. When aerogel is subjected to heat during hot object insulation, it automatically turns into infra redreflecting material. Said silica aerogel can be incorporated into the inorganic fibre mat matrix individually or into two or more layers with organic sponge sheet placed in between and stitched together to form a sandwich sheet to form highly insulating flexible sheet.

Owner:M S INT ADVANCED RES CENT FOR POWDER METALLURGY & NEW METERIALS ARCI

Improved process for producing silica aerogel thermal insulation product with increased efficiency

InactiveUS20190002356A1Easy to solveImprove insulation effectThermal insulationLayered productsFiberThermal insulation

The invention relates to an improved method for producing silica aerogel in pure and flexible sheet form having effective suppression of radiative heat transport at high temperatures and increased thermal insulation property. The suppression of radiative heat transport was achieved by in-situ production of titanium dioxide nanoparticles in very minor concentrations during gelation of silica precursor, with nanoporous surface area more than 300 m2 / g and acts as an infra red reflecting agent. When aerogel is subjected to heat during hot object insulation, it automatically turn into infra red reflecting material. Said silica aerogel can be incorporated into the inorganic fibre mat matrix individually or into two or more layers with organic sponge sheet placed in between and stitched together to form a sandwich sheet to form highly insulating flexible sheet.

Owner:M S INT ADVANCED RES CENT FOR POWDER METALLURGY & NEW METERIALS ARCI

Modified cement polyphenyl granule composite vacuum insulated panel and preparation method thereof

ActiveCN102979207ASolve the problem of broken air leakageEasy to installClimate change adaptationInsulation improvementUltimate tensile strengthFire retardant

The invention relates to a modified cement polyphenyl granule composite vacuum insulated panel. The modified cement polyphenyl granule composite vacuum insulated panel is characterized by comprising a vacuum heat insulation panel and modified cement polyphenyl granule thermal mortar which covers the periphery of the vacuum heat insulation panel. The vacuum heat insulation panel comprises core materials, high strength air resistance film and interface mortar. The high strength air resistance film covers the periphery of the core materials and is encapsulated between core materials through vacuumpumping. A layer of interface mortar is coated on the periphery of the high strength air resistance film. The thickness of the interface mortar is 2 millimeters to 3 millimeters. The modified cement polyphenyl granule composite vacuum insulated panel has the advantages that problem of damage and air leakage of the vacuum heat insulation plate in a work process is solved, construction and installation are convenient to achieve, heat retaining property, water resisting property, durability and freezing resistance are good, flame class is non-ignitable or fire-retardant and fireproof performance is good.

Owner:ANHUI KERUIKE INSULATION MATERIAL

Heat insulation core board for walls and method for processing heat insulation core board for walls

ActiveCN102718450ASimple processEasy constructionClimate change adaptationInsulation improvementNonwoven fabricSilicon dioxide

The invention relates to a heat insulation core board and a preparation method thereof. The heat insulation core board is made of 40-90wt% of superfine silicon dioxide power, 0-45wt% of filler, 0-20wt% of inorganic core materials, 1-18wt% of inorganic fibers, 0-3wt% of getter and 0-3wt% of vacuum stabilizer. The preparation method of the heat insulation core board includes steps of (1) burdening, (2) drying, (3) bag making by nonwoven fabrics, (4) core material filling, (5) bag material spreading, (4) compression forming and the like.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Aerogel composite with fibrous batting

InactiveUS20060199455A1Improve thermal efficiencyMinimized volumeShielding materialsNatural cellulose pulp/paperElectrical resistance and conductanceUltrasound attenuation

Owner:ASPEN AEROGELS INC

Vacuum insulation panel

InactiveUS20130029082A1Avoid deformationImprove energy efficiencyThermal insulationLayered productsEngineeringAtmospheric pressure

The present invention relates to a vacuum insulation panel to be used as an insulation material, which panel has an improved structure to improve insulation properties over conventional vacuum insulation panels filed with fillers within outer plates. The present panel includes a spacer within vacuumed space, thereby supporting the structure of outer plate against atmospheric pressure and minimizing conductive thermal transfer.

Owner:XL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com