Building wall insulation composite board and preparation method thereof

A technology for thermal insulation composite panels and building walls, which is applied in the direction of thermal insulation, building components, adhesive types, etc. It can solve the problems of unsustainable vacuum degree, inconvenient construction operation, and insufficient bonding, so as to increase the overall fire protection Performance, construction operation is convenient and fast, and the effect of good interface enhancement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

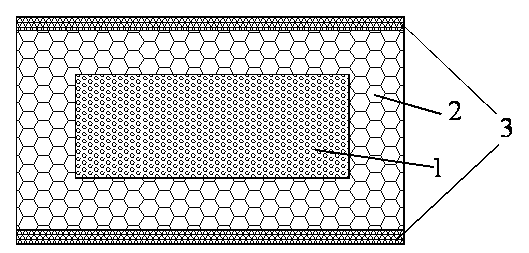

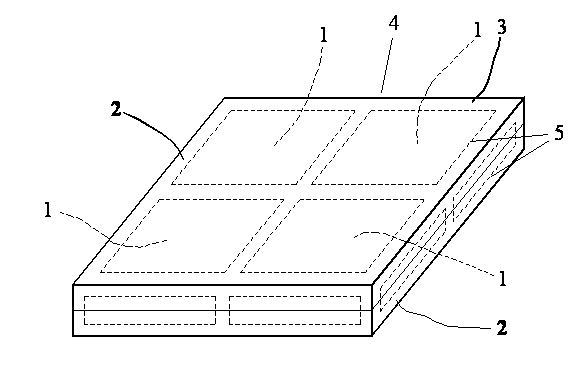

[0058] A reference to thermal insulation composite panels for building walls Figure 1-3 , including four inner cores 1 , a protective layer 2 covering the outer periphery of the inner core 1 , and an interface layer 3 attached to the upper and lower surfaces of the protective layer 2 . The wall thermal insulation composite board has a length of 1200mm, a width of 600mm, and a thickness of 40mm. The four inner cores 1 are all vacuum insulation panels sold on the market, with a length of 450mm, a width of 150mm, and a thickness of 20mm. , belongs to A-level material, which can effectively delay the spread and spread of flame after being applied to the wall, and it has excellent heat preservation and heat insulation performance, and its thermal conductivity is lower than 0.010 W / m·K; the protective layer 2 is the inner core 1. Wrapped and sealed hard foam polyurethane material, with excellent thermal insulation, heat insulation and waterproof performance, thermal conductivity lo...

Embodiment 2

[0075] The difference between this embodiment and embodiment 1 is that

[0076] A method for manufacturing a thermal insulation composite board for a building wall, comprising the following steps:

[0077] Step 1: Prepare flame retardant polymer glue

[0078] 50% of inorganic filler, 15% of flame retardant, 15% of polymer emulsion, 10.0% of auxiliary agent and 10% of water are fully mixed by weight to form flame-retardant polymer glue; the inorganic filler is talc powder 25%, fly ash 25%; the flame retardant is magnesium hydroxide; the polymer emulsion is water-based polyurethane emulsion 10%, binary copolymer emulsion 5%; the auxiliary agent is dispersant 7%, Coalescing aid 0.5%, defoamer 2.5%.

[0079] Step 2: Preparation of interface materials

[0080] The flame-retardant polymer glue prepared above is coated on the substrate through the interface coil production line to produce a flame-retardant interface material for use; the substrate is glass fiber mat.

[0081] The...

Embodiment 3

[0091] The difference between this embodiment and embodiment 1 is that

[0092] A method for manufacturing a thermal insulation composite board for a building wall, comprising the following steps:

[0093] Step 1: Prepare flame retardant polymer glue

[0094] Mix 50% of inorganic filler, 15% of flame retardant, 15% of polymer emulsion, 5% of auxiliary agent and 15% of water in the weight ratio to form a flame-retardant polymer glue; the inorganic filler is mineral powder 25%, silica fume 25%; the flame retardant is magnesium hydroxide 10%, aluminum hydroxide 5%; the polymer emulsion is water-based polyurethane emulsion; the auxiliary agent is dispersant 4%, toner 0.5%, coalescent 0.5%.

[0095] Step 2: Preparation of interface materials

[0096] The flame-retardant polymer glue prepared above is coated on a substrate through an interface coil production line to produce a flame-retardant interface material for use; the substrate is a non-woven fabric.

[0097] The third ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com