Automatic feed multi-station progressive die

A multi-station progressive die, automatic feeding technology, applied in the direction of perforation tools, forming tools, feeding devices, etc., can solve the problems affecting the economic benefits of enterprises, backward manufacturing methods, poor reliability, etc., and achieve reliable performance and stable quality. , Improve the effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

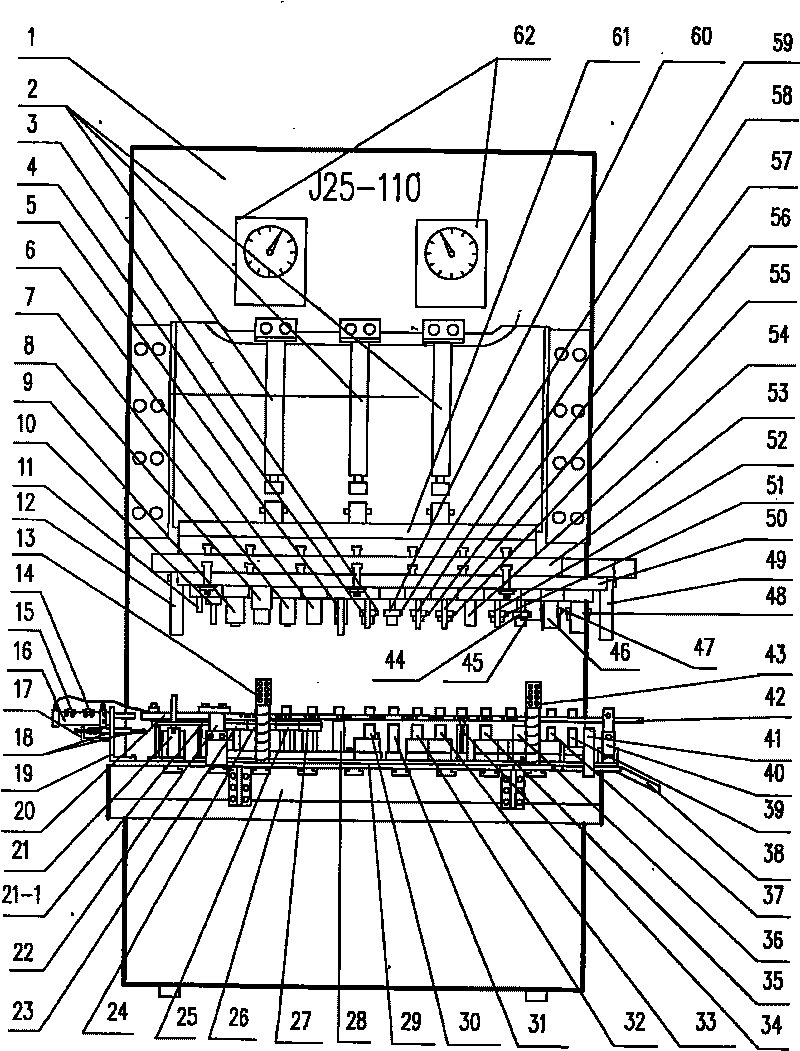

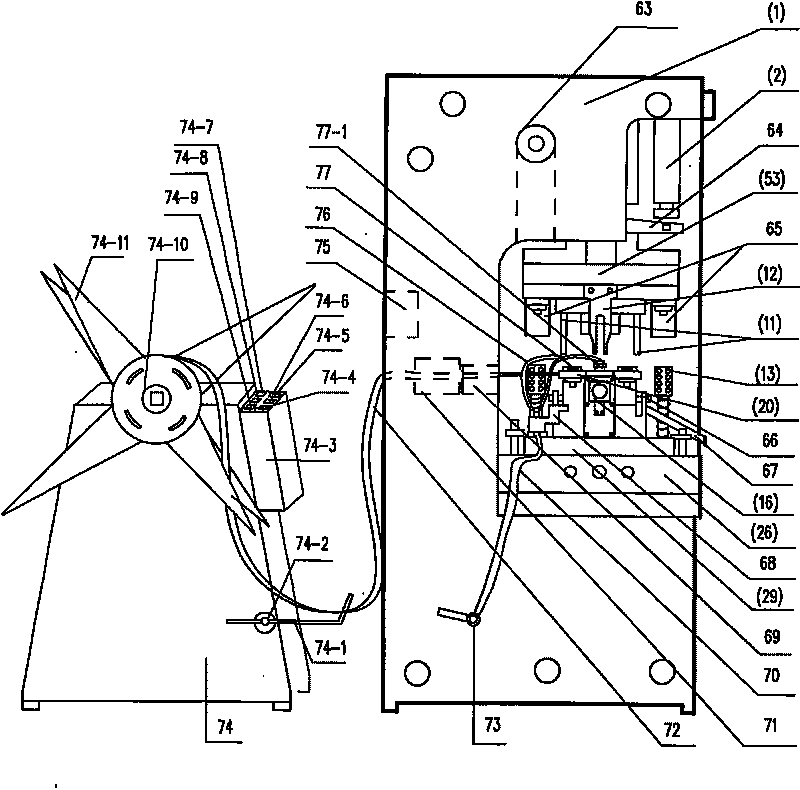

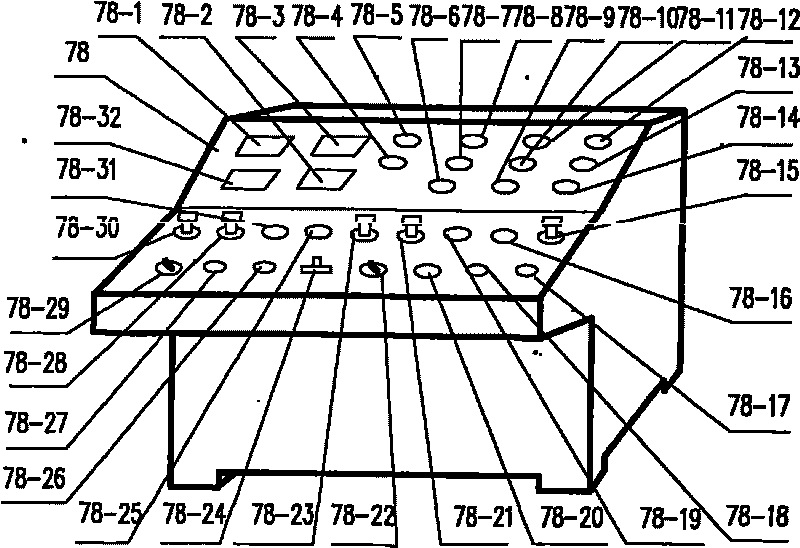

[0020]An automatic feeding multi-station progressive die, equipped with a press 1, a guide column 11, a cylinder 16, a cylinder support 19, a hydraulic buffer 18, a buffer support 17, a feeding pallet 20, a feeding slider A21, and a push rod 21-1. Feeding slice upper die 10, feed slice lower die 22, deep drawing upper die A9, deep drawing lower die A23, deep drawing upper die B8, deep drawing lower die B24, deep drawing upper die C7, deep drawing lower die C25, shaping upper die A6, convex round shaping lower die 27, punching hole upper die 5, punching hole lower die 28, pressing upper die A4, side four-hole punching die 30, pressing upper die B60, rotary die with holes 31, Pressing upper die C58, side process hole punching die 32, pressing upper die D56, side U-shaped hole punching die 33, shaping upper die B54, shaping lower die 34, pressing upper die E52,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com