Patents

Literature

821 results about "Process quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process Quality. Process Quality is defined as all the steps used in the manufacturing the final product. Its focus are on all activities and steps used to achieve a maximum acceptance regardless of its final product.

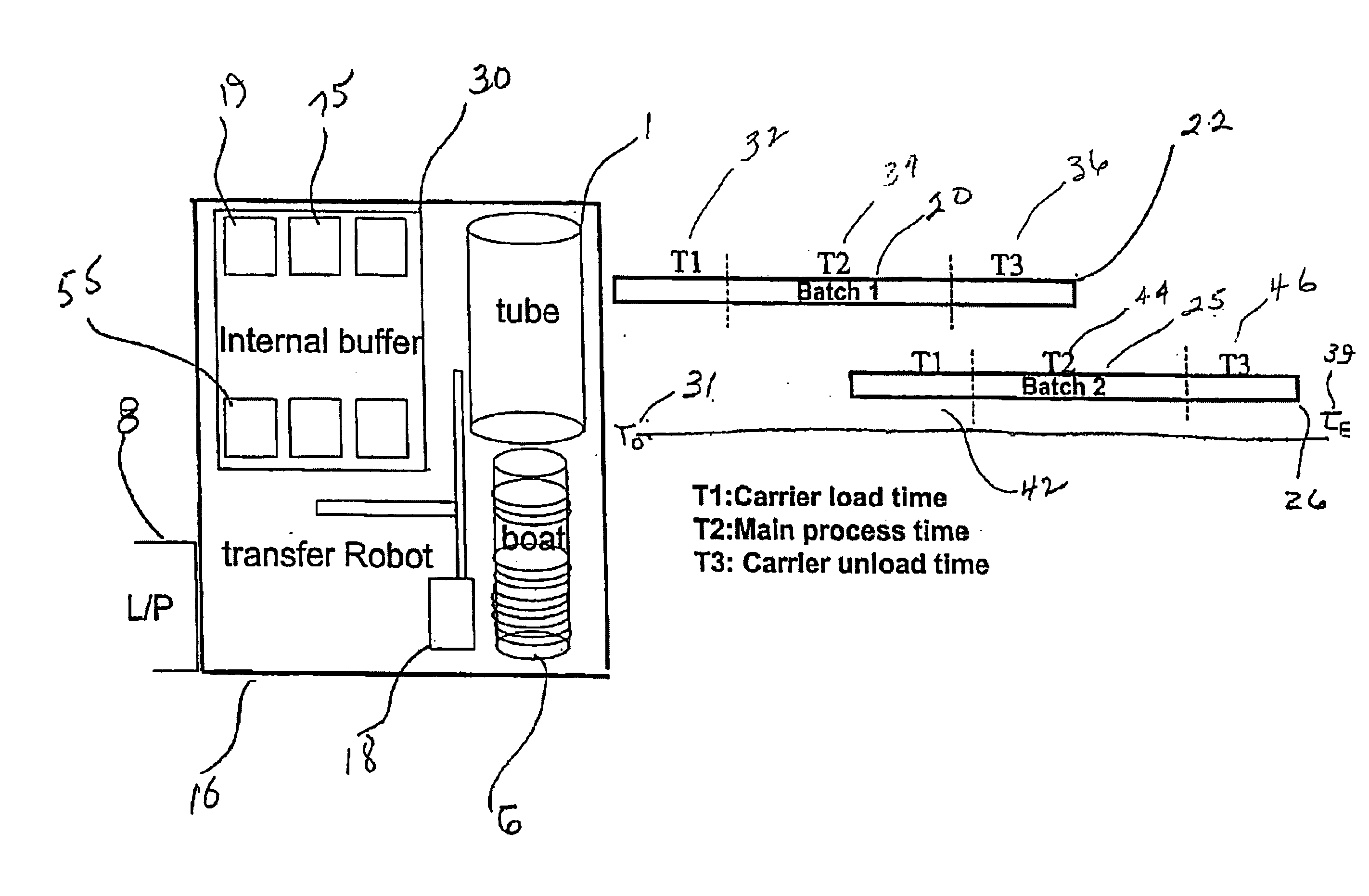

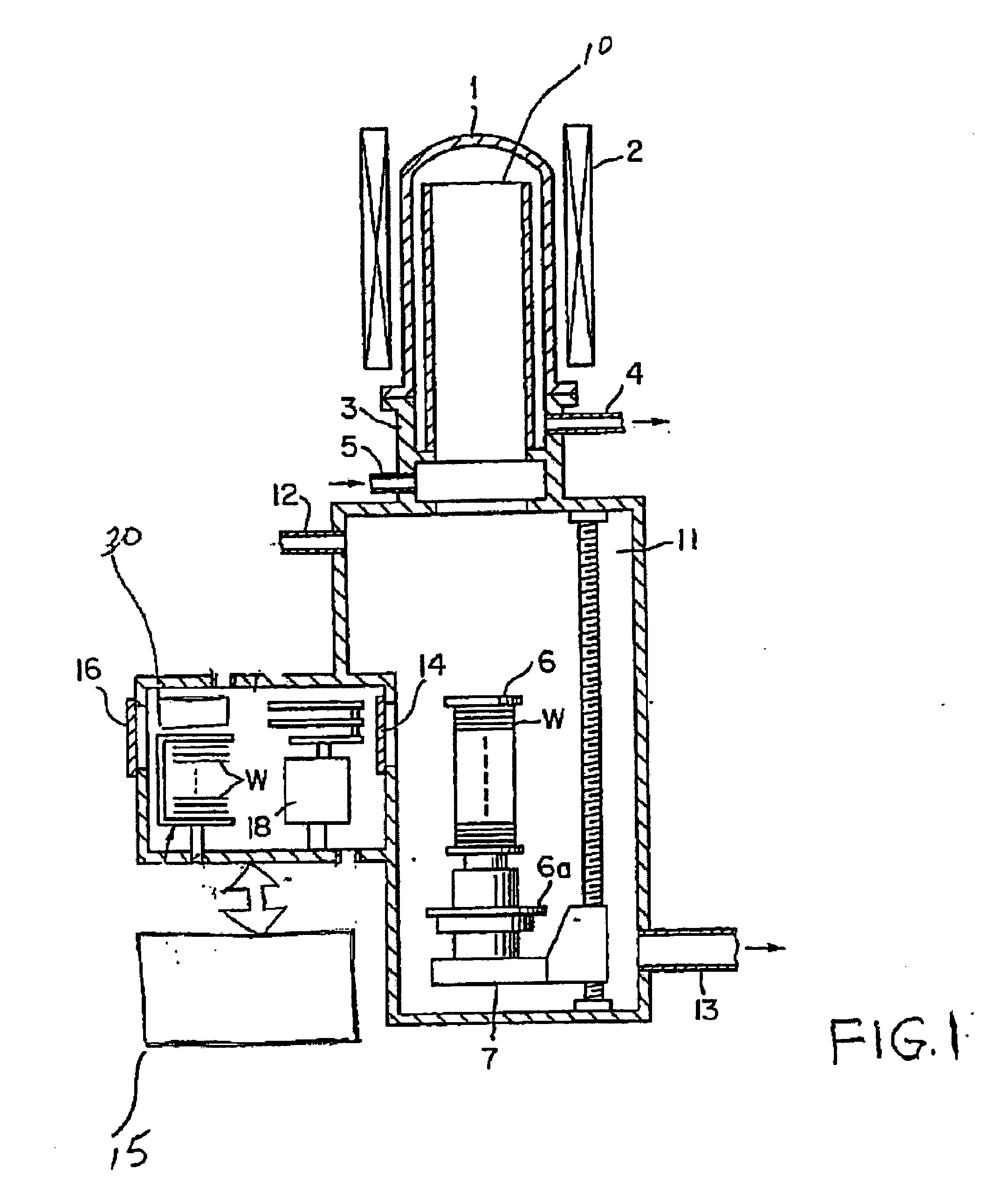

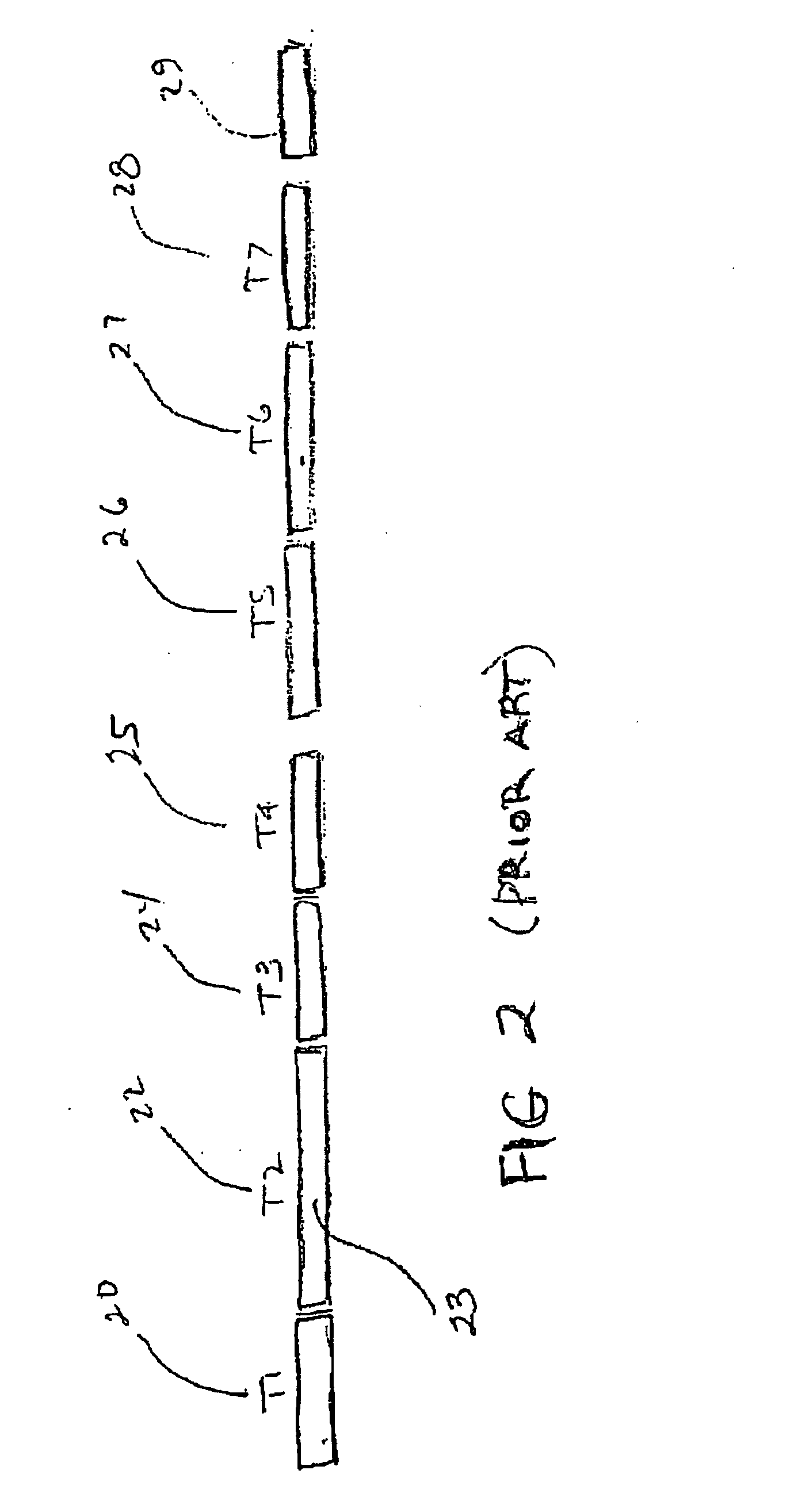

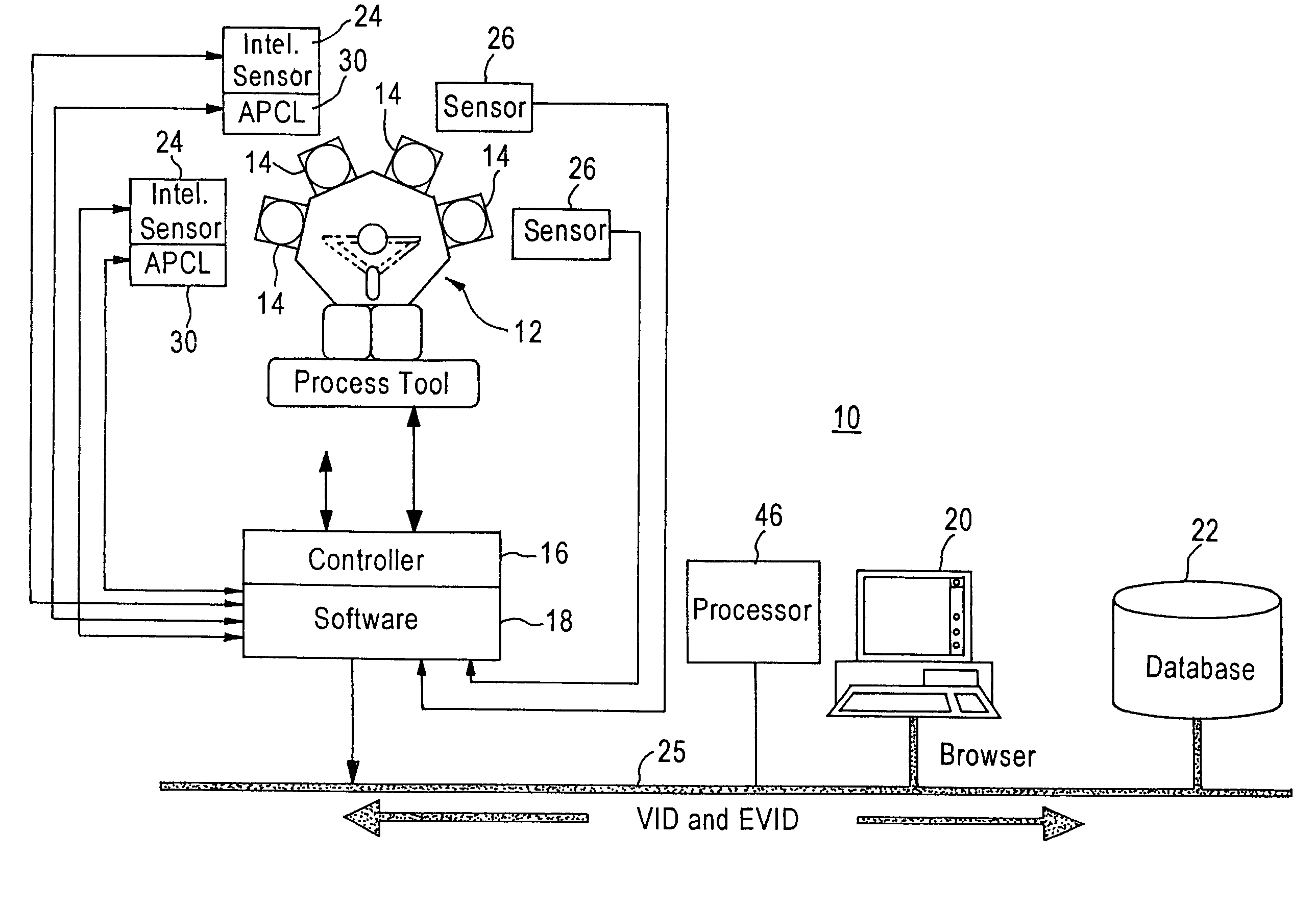

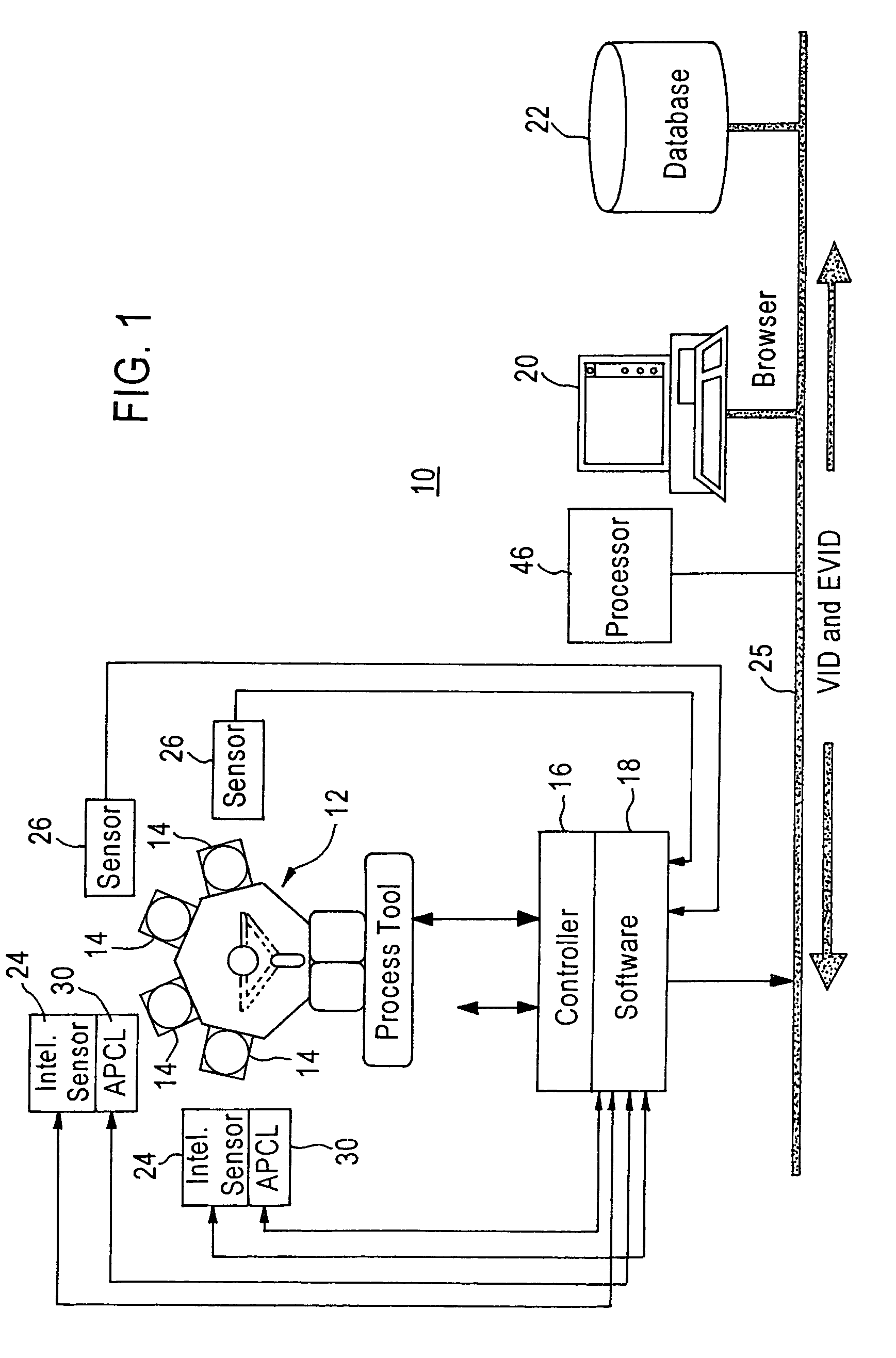

Intelligent full automation controlled flow for a semiconductor furnace tool

InactiveUS20050187647A1Reduce idle timeSemiconductor/solid-state device manufacturingSpecial data processing applicationsControl flowAutomatic control

The present invention relates to an apparatus and method for processing the flow of semiconductor wafers through a furnace tool having a front-opening unified pod (FOUP) material handling system. The invention provides for an automated control flow to realize greater efficiency and assure process quality. In one aspect of the invention the wafer batch completing its operation is discharged simultaneous with the charging of the next batch. Essentially the operation takes place by overlapping processing operations. An embodiment of the invention includes a process comprising the steps of: providing a first batch of semiconductor material, and loading the first batch into a carrier which transports the first batch into a semiconductor manufacturing process, and while the first batch undergoes the process, forming a second batch of semiconductor material, and pausing a second batch process operation until the first batch completes processing, to reduce the idle time of said process.

Owner:TAIWAN SEMICON MFG CO LTD

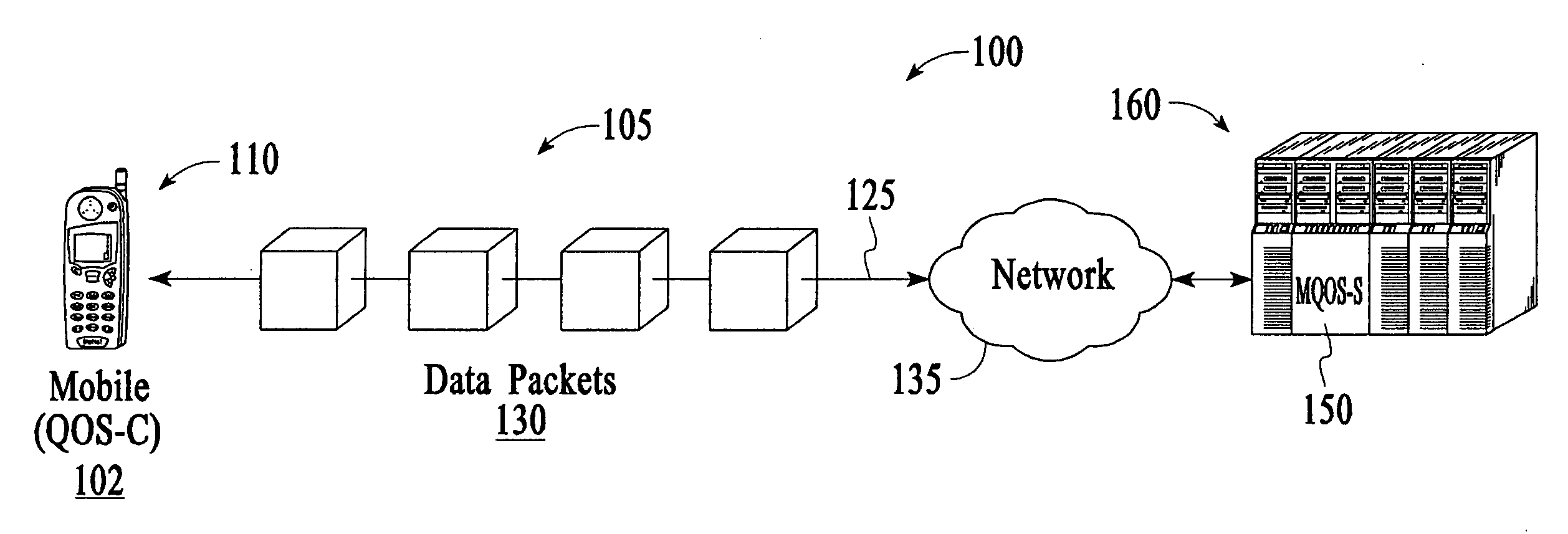

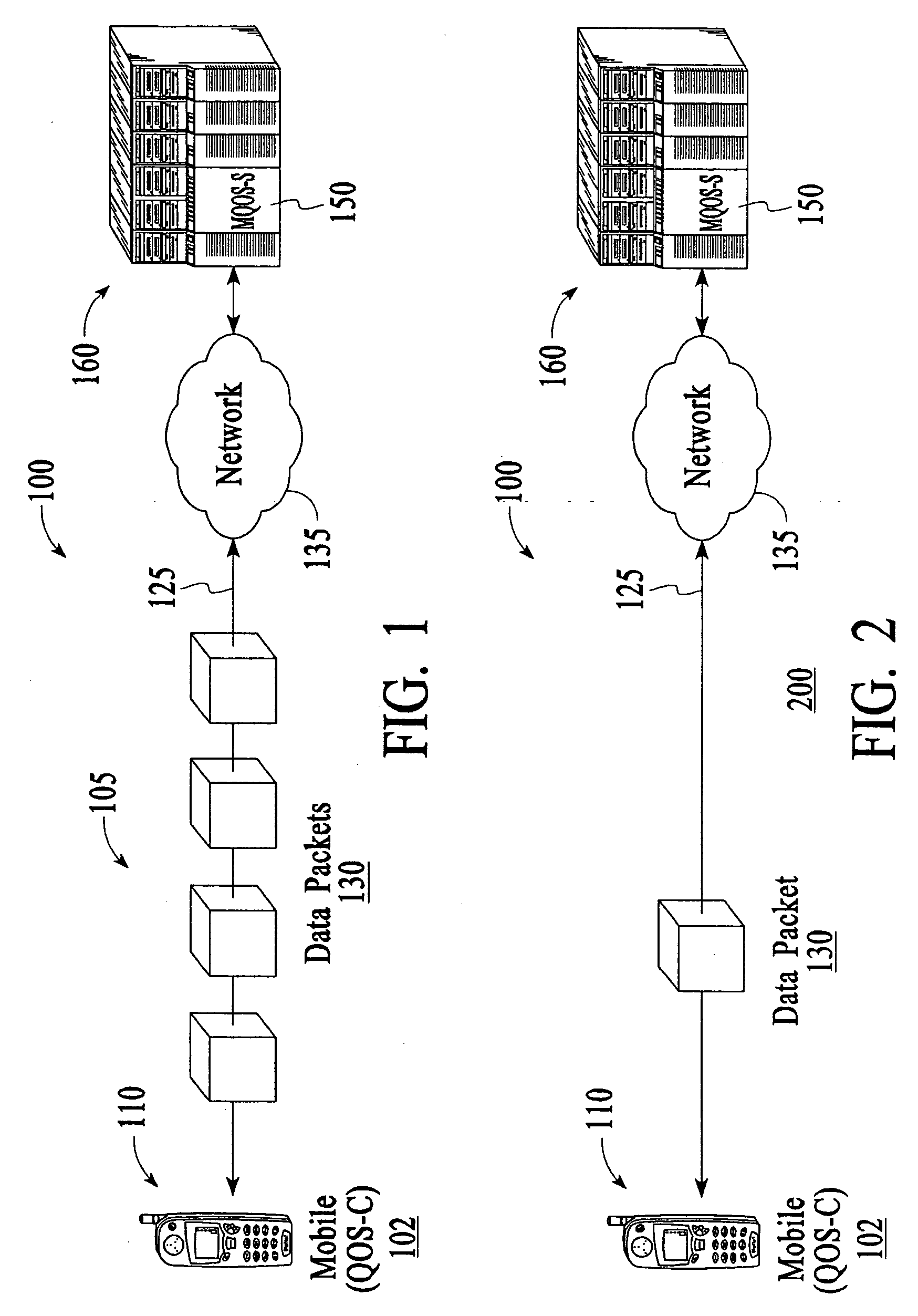

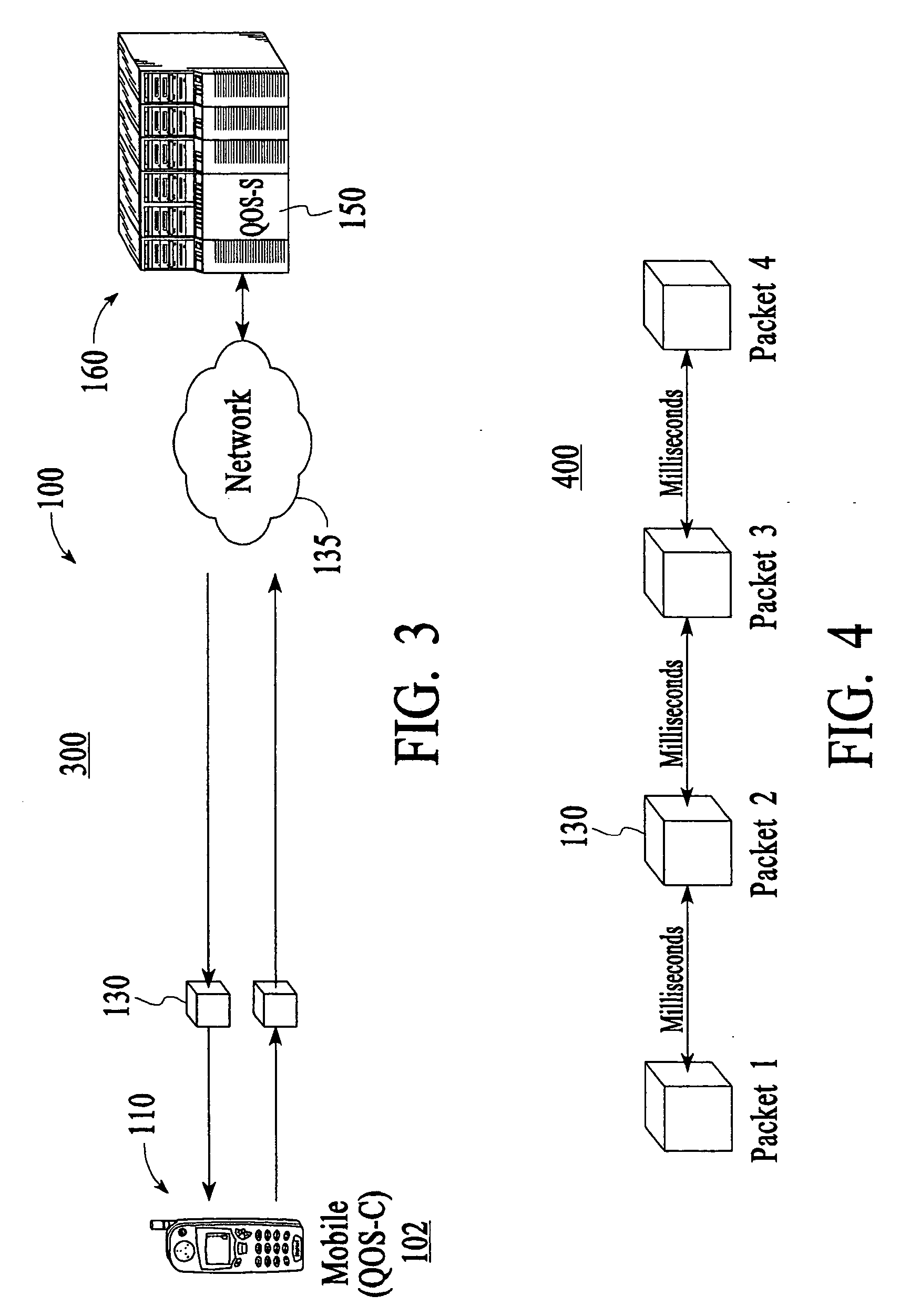

Method and system for processing quality of service (QOS) performance levels for wireless devices

InactiveUS20050163047A1Monitoring quality of serviceReceivers monitoringError preventionQuality of serviceThird party

A method and apparatus to monitor quality of service (QoS) of wireless mobile devices is described. In one embodiment, the present invention provides a method to monitor QoS performance of one or more services provided to a mobile user. The method includes comparing the performance of at least one service provided to the mobile user against at least one QoS threshold value. In one aspect, the present invention detects and determines responses to services having performance levels that cross at least one associated QoS threshold value. In one aspect, QoS thresholds may be associated with QoS between a mobile device and network. In another aspect, QoS thresholds may be associated with the performance level of mobile device operation services such as hardware and software operations. In one embodiment, when a performance level of a service associated with a mobile device crosses at least one QoS threshold, the affected mobile device process data associated with such service performance. Such processed data may then be provided to a user, network personnel, and third parties, etc. for processing thereof.

Owner:CHRISTOPHER M MCGREGOR

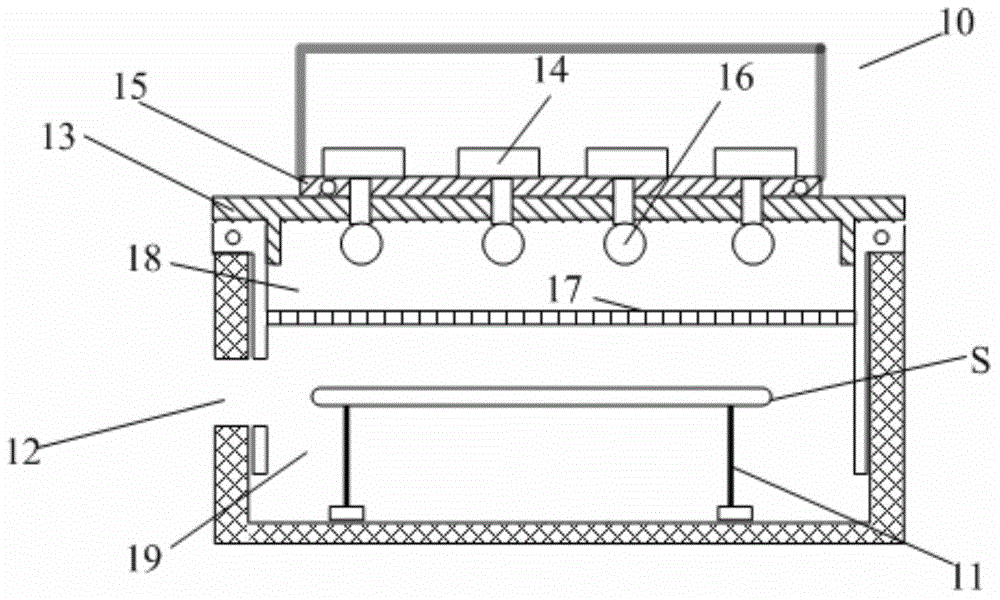

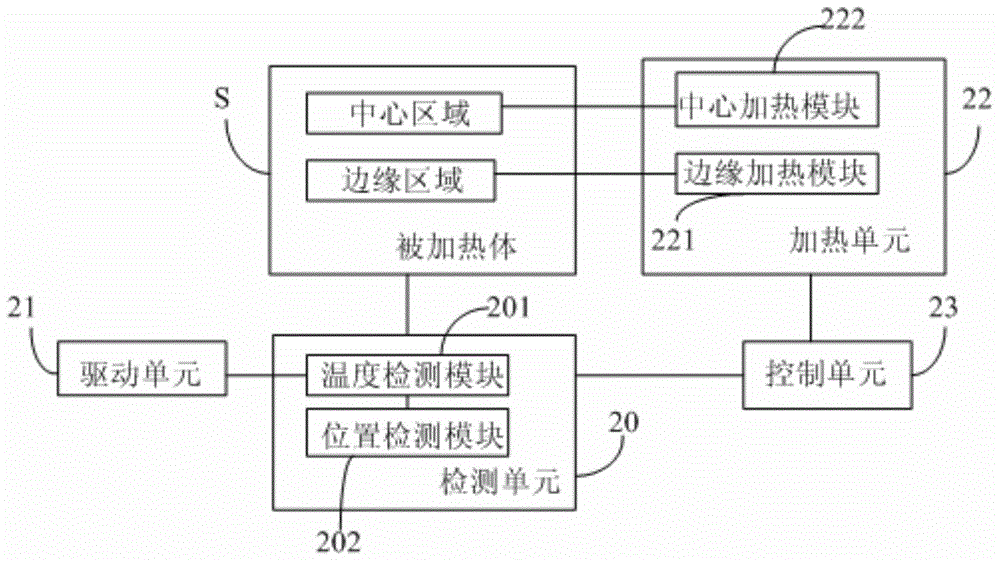

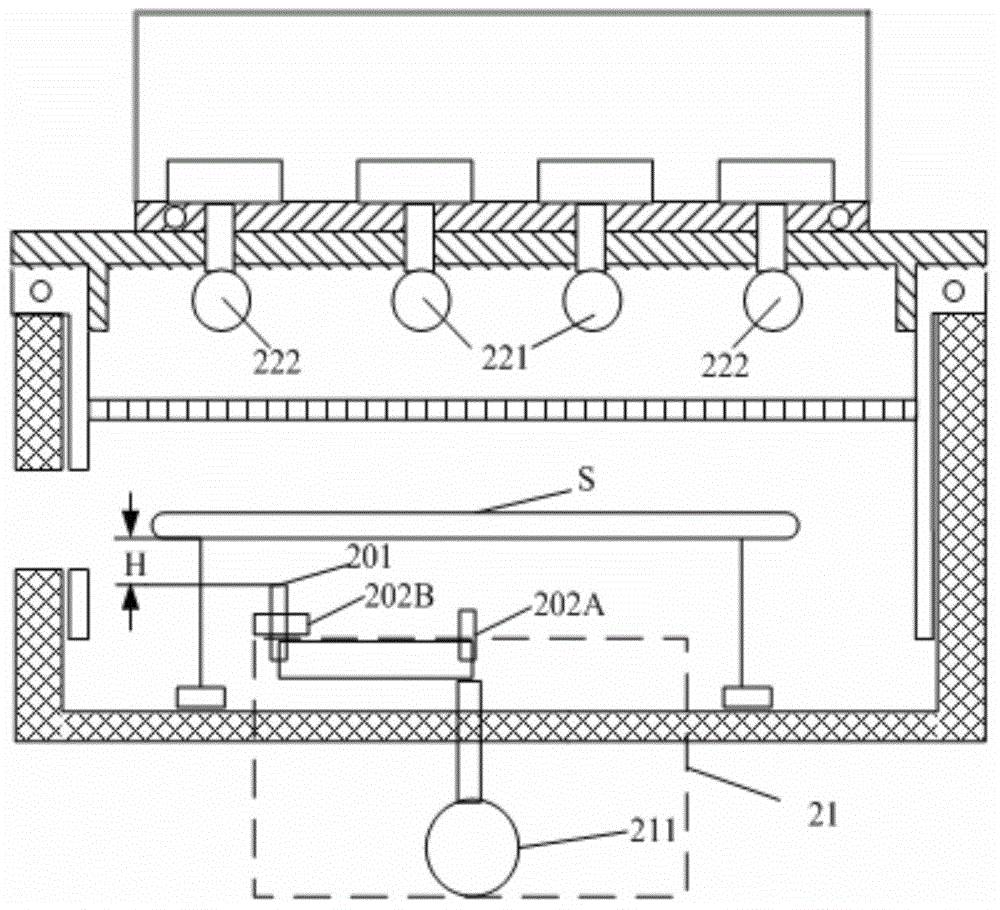

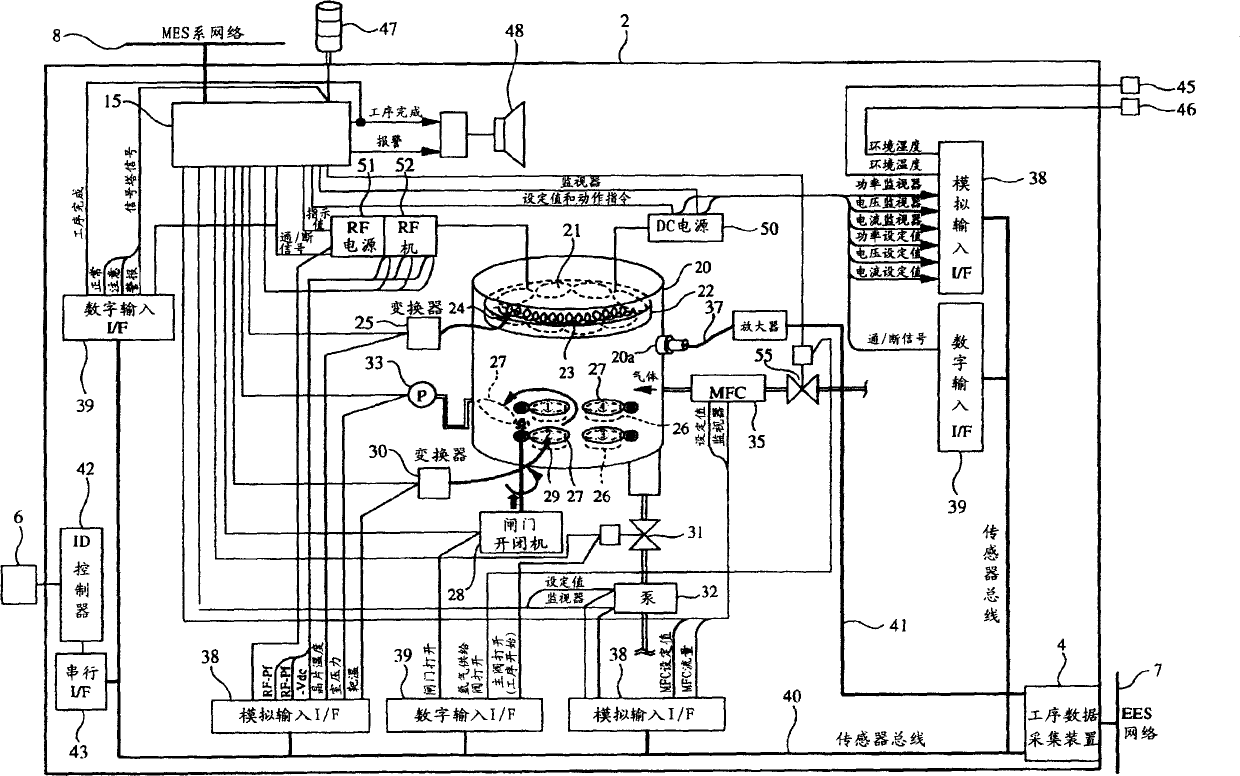

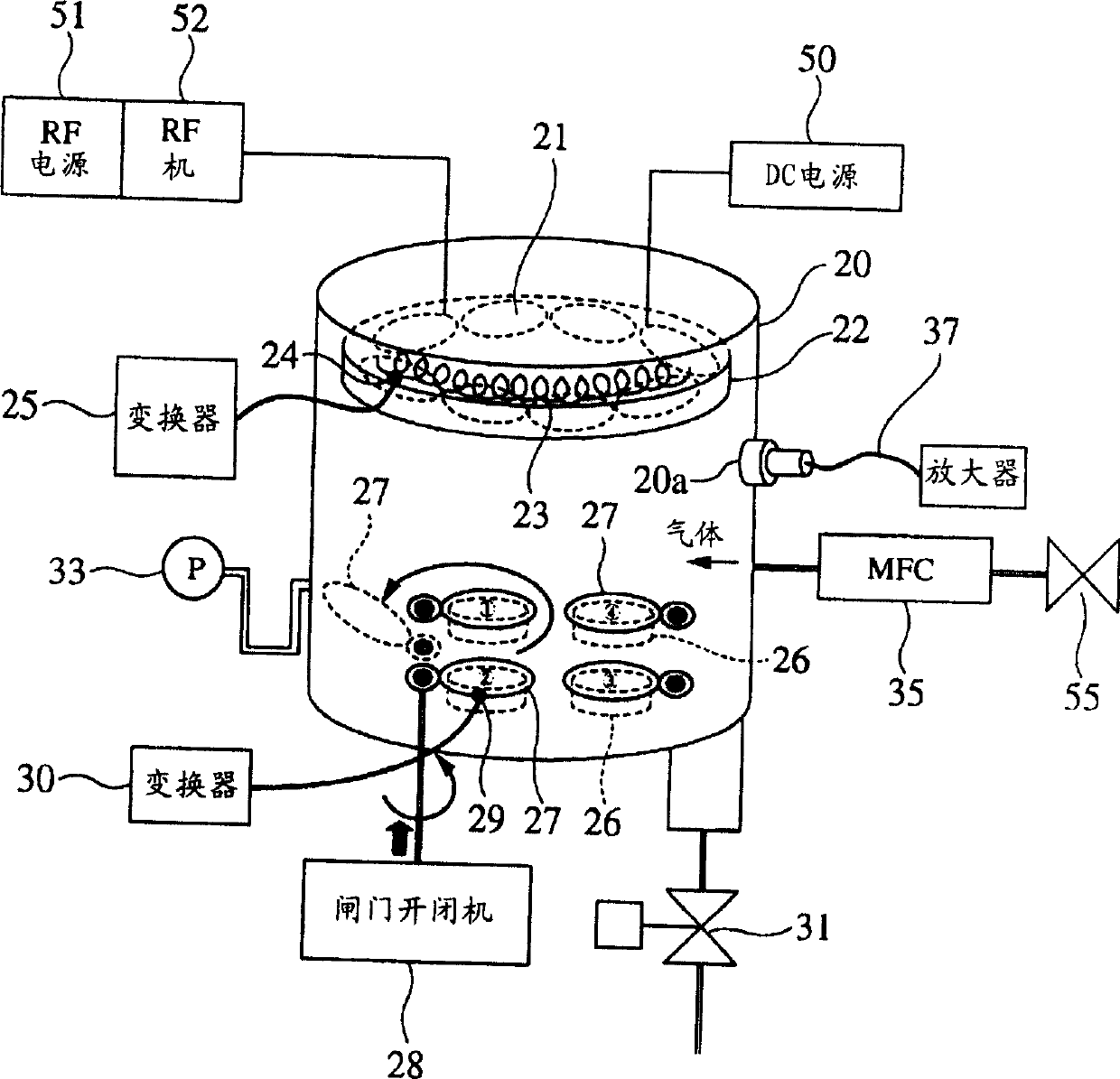

Temperature monitoring device and plasma processing apparatus

ActiveCN104630735AImprove heating uniformityImprove the quality of workmanshipVacuum evaporation coatingSputtering coatingProcess qualityTemperature monitoring

The invention provides a temperature monitoring device and a plasma processing apparatus. In the temperature monitoring device, a drive unit driving temperature detection module moves in a reaction chamber to make the temperature detection module detect the temperatures of different areas of a heated body in the movement process and send the detected temperatures to a control unit; and the control unit compares the temperatures sent by the temperature detection module with a preset standard temperature, and a calibration heating unit outputs power to the detected areas corresponding to the temperatures sent by the temperature detection module when a deviation exists between the temperatures and the preset standard temperature. The temperature monitoring device provided by the invention can improve the heating uniformity of the heated body in order to improve the process quality, and can simplify the operation process in order to improve the work efficiency.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

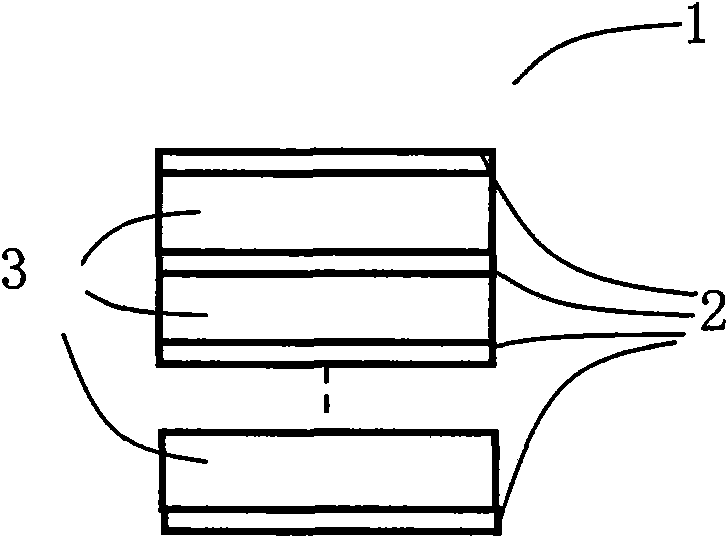

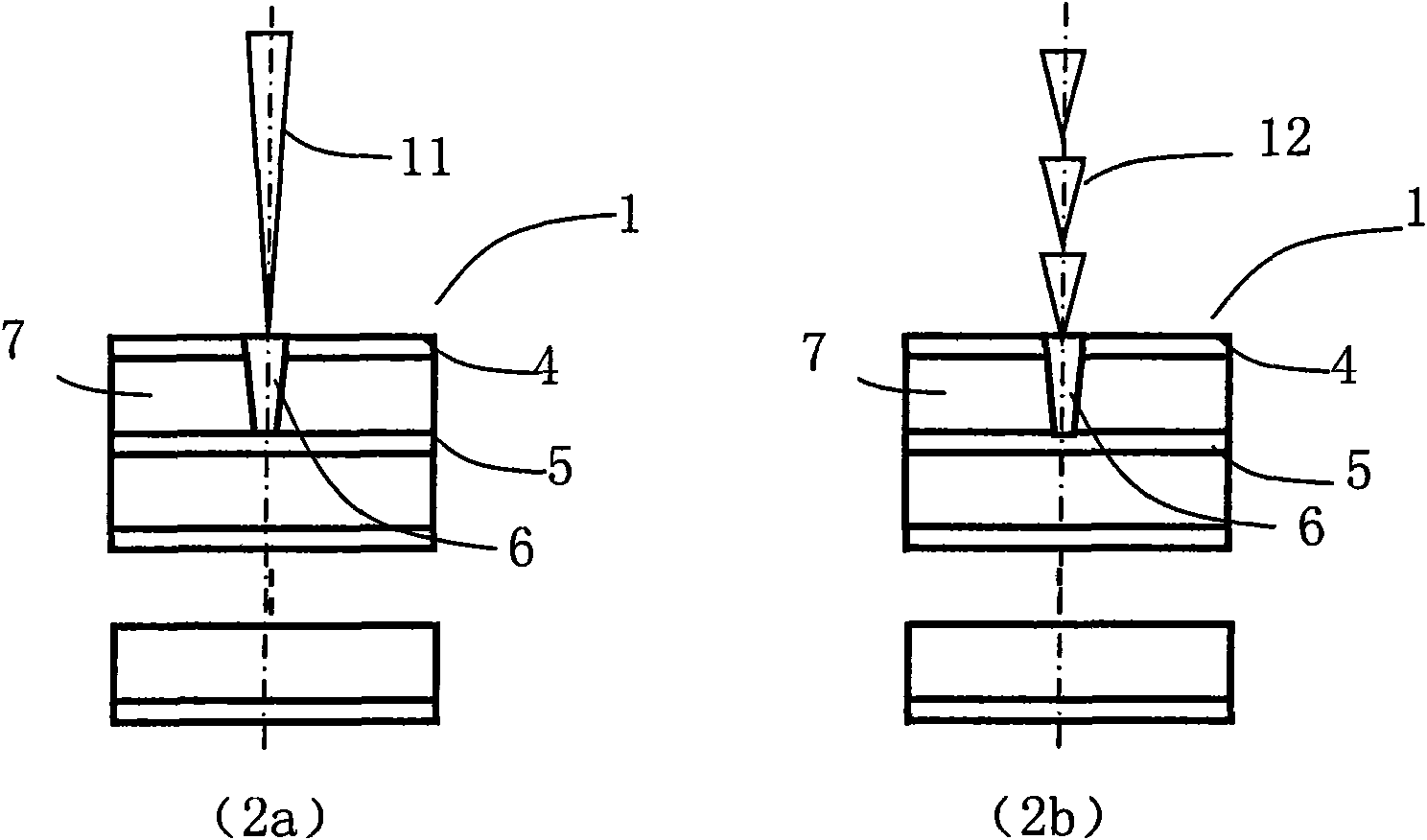

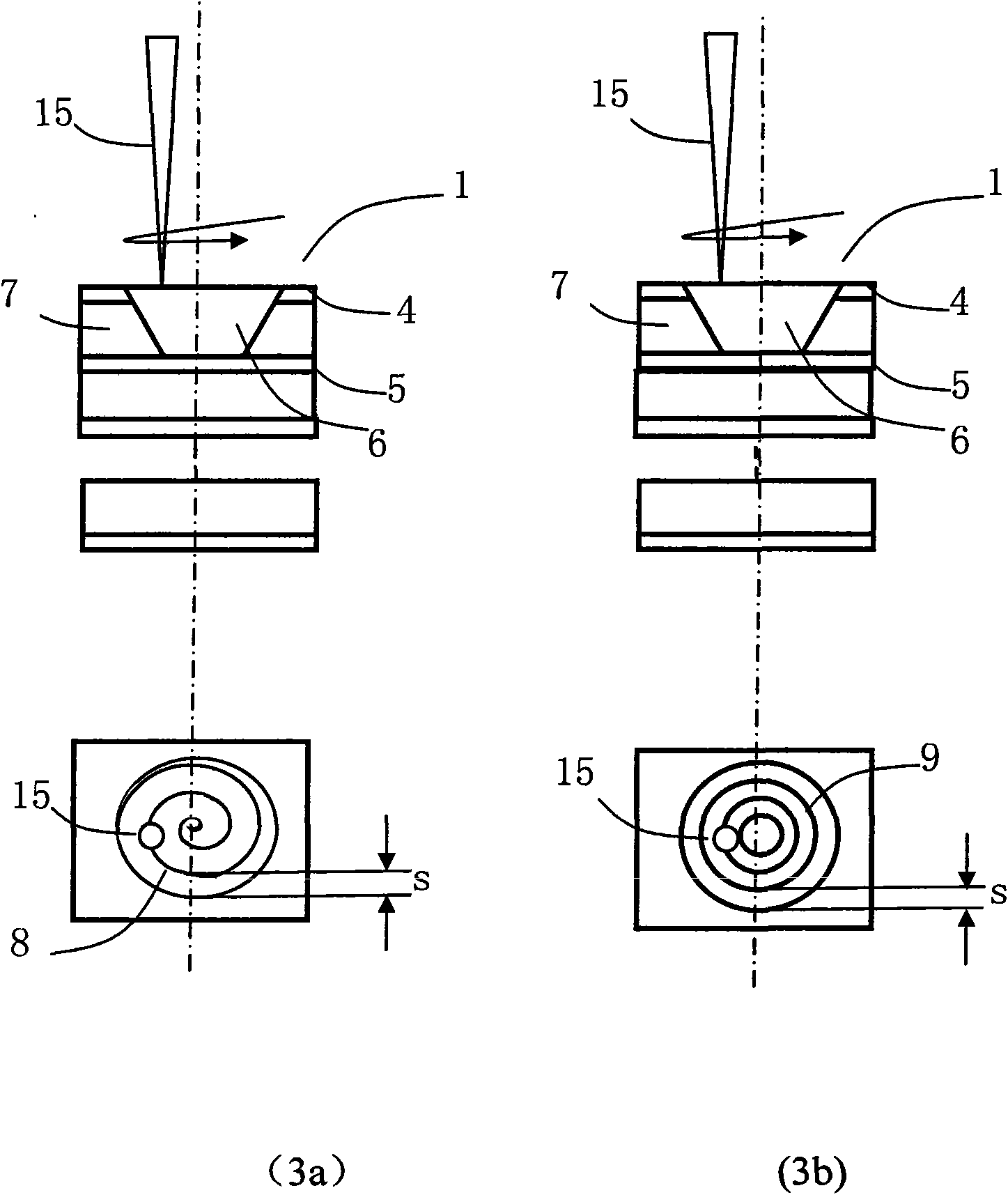

Method for processing blind hole by laser

InactiveCN101610643AAvoid Scanning RequirementsRemove distortionConductive material mechanical removalLaser beam welding apparatusUv laserLaser processing

The invention discloses a method for processing a blind hole by laser. The method combines fixed point UV laser impulse and UV laser spiral line or concentric circle scanning and is used for one-step blind hole processing or multi-step blind hole processing on multilayer circuit board. The method divides the UV laser blind hole drilling process into two parts, namely a part with an area near the circle center of the blind hole not more than UV laser spot diameter and a part with an area more than the UV laser spot diameter. Fixed point UV laser impulse is adopted to drill the blind hole, so as to remove material in the region with an area near the circle center not more than UV laser spot diameter; then UV laser spiral line or centric circle scanning method is adopted to move outside, so as to remove the material in the region with an area near the circle center more than UV laser spot diameter until meeting set blind hole size; and one-step blind hole or multi-step blind hole processing is drilled by UV laser through two steps or more steps. The method can ensure processing quality consistency of each blind hole, can greatly reduce bottom unevenness of the blind hole, and also can improve margin quality of blind hole processing.

Owner:HUAZHONG UNIV OF SCI & TECH

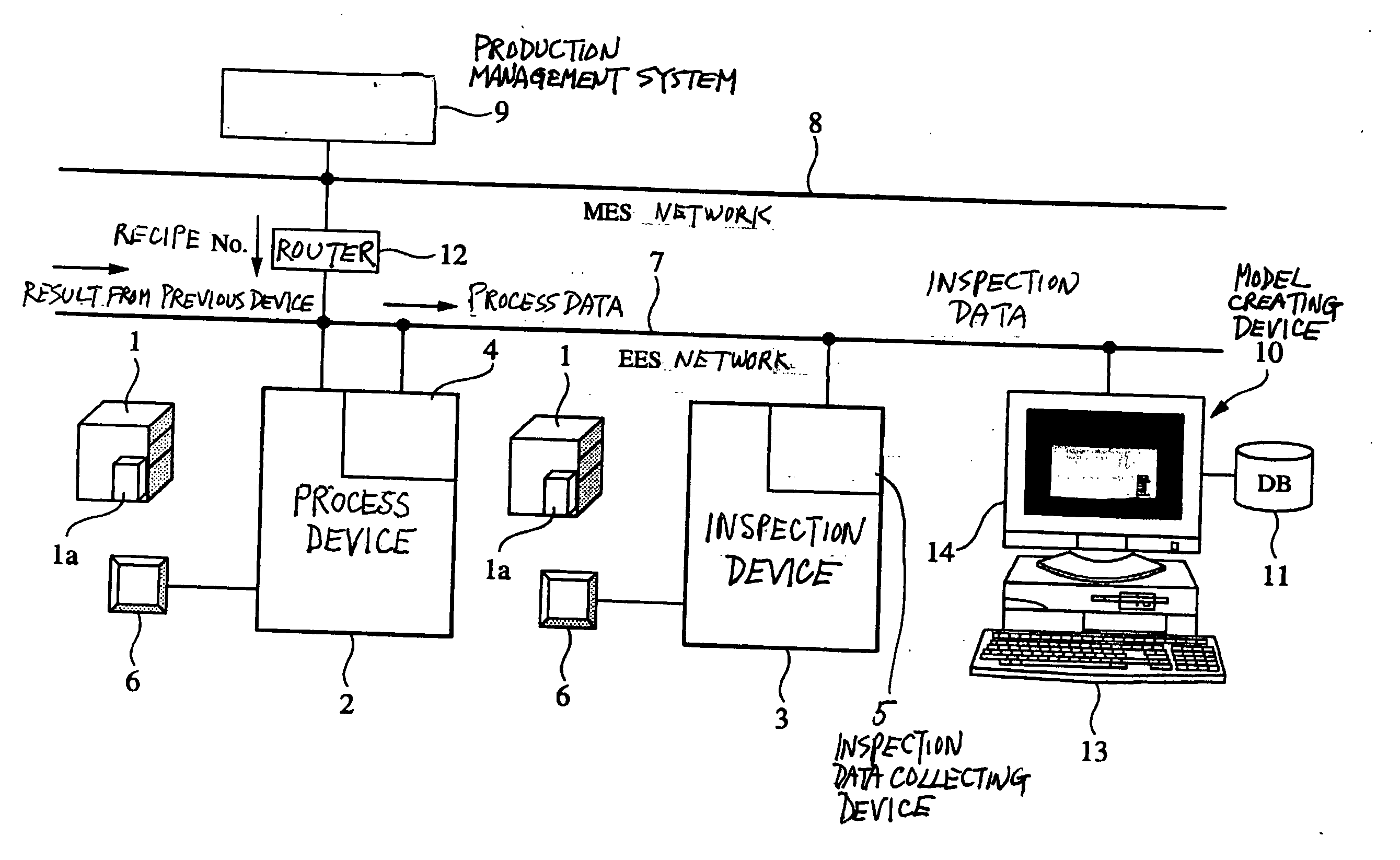

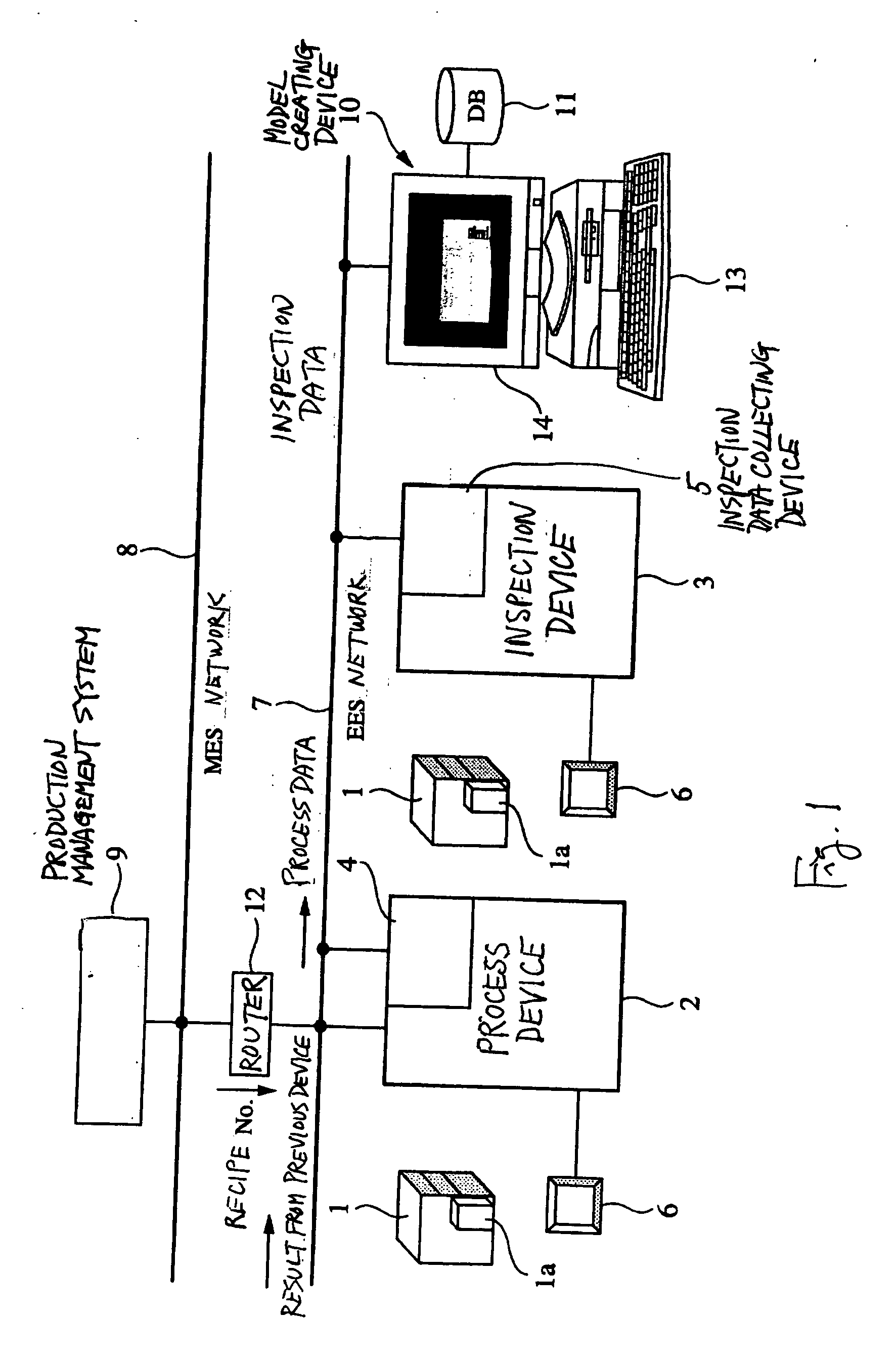

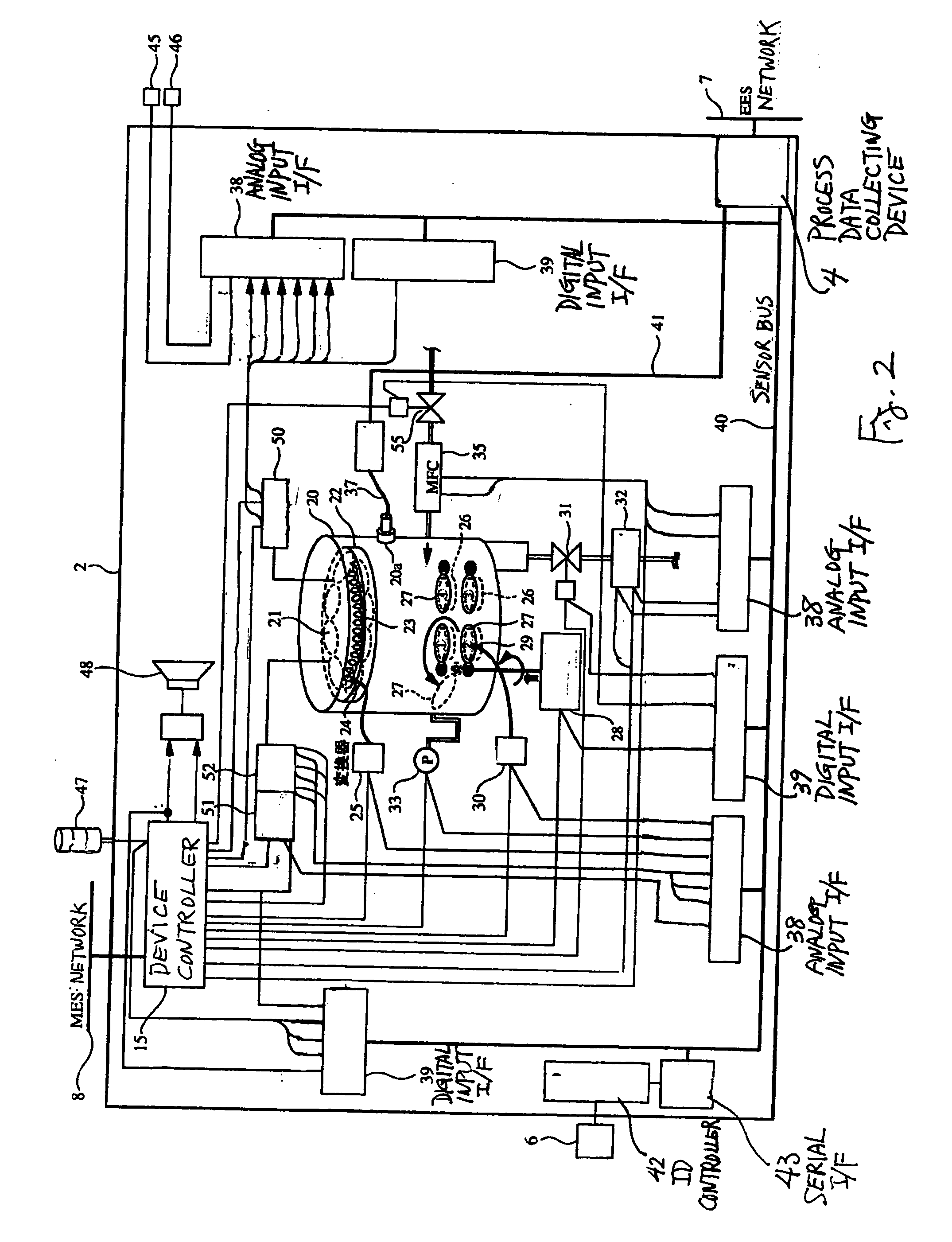

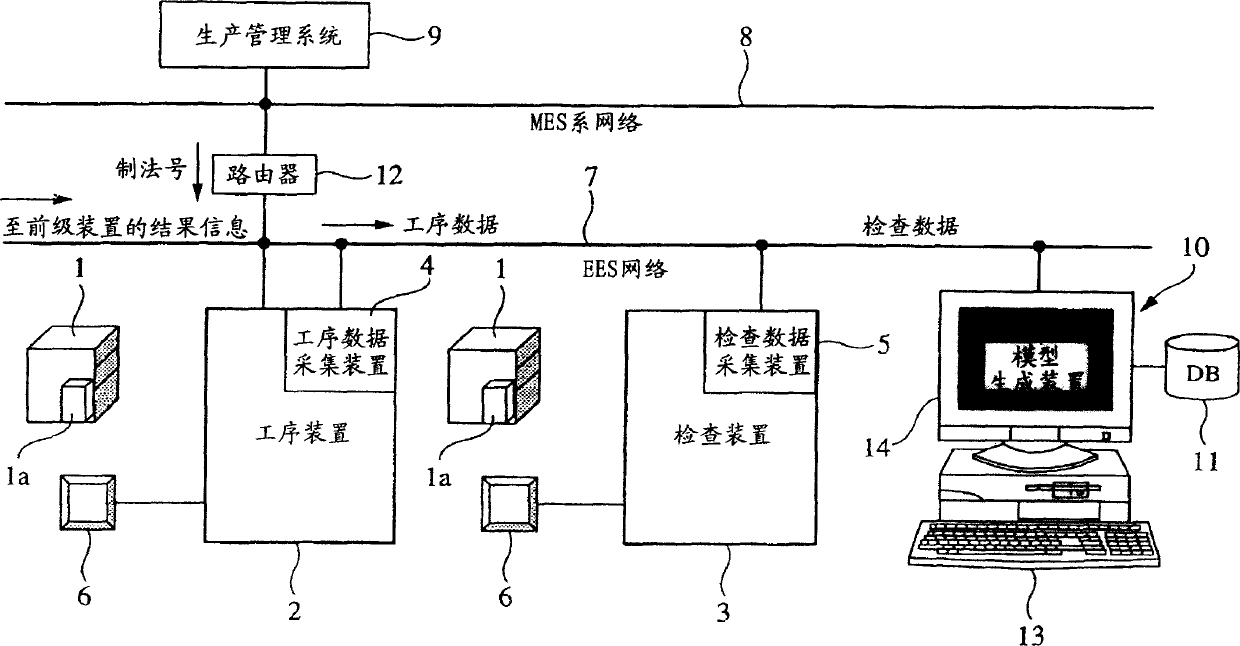

Device for and method of creating a model for determining relationship between process and quality

InactiveUS20050159835A1Sufficient quantitySemiconductor/solid-state device testing/measurementVacuum evaporation coatingProcess qualityState dependent

A model creating device inputs process status data that are obtained in time series during a period during which each of process steps of a process is carried out and are related to status of this process, as well as inspection result data related to object articles that were processed by said process. An extracting part extracts a characteristic quantity from the process status data for every unit object article and for every process step. An analyzing part carries out an analysis by data mining by using the characteristic quantities and inspection result data in correlation with the unit object articles and creates a process-quality model that shows a relationship between the correlated characteristic quantities and inspection result data.

Owner:CANON SYST SOLUTIONS +1

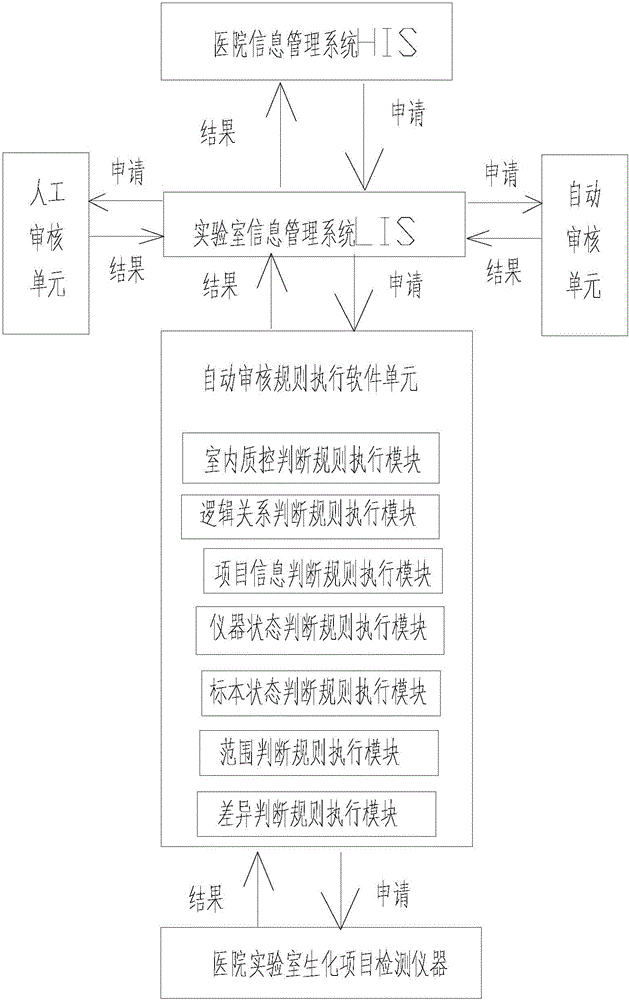

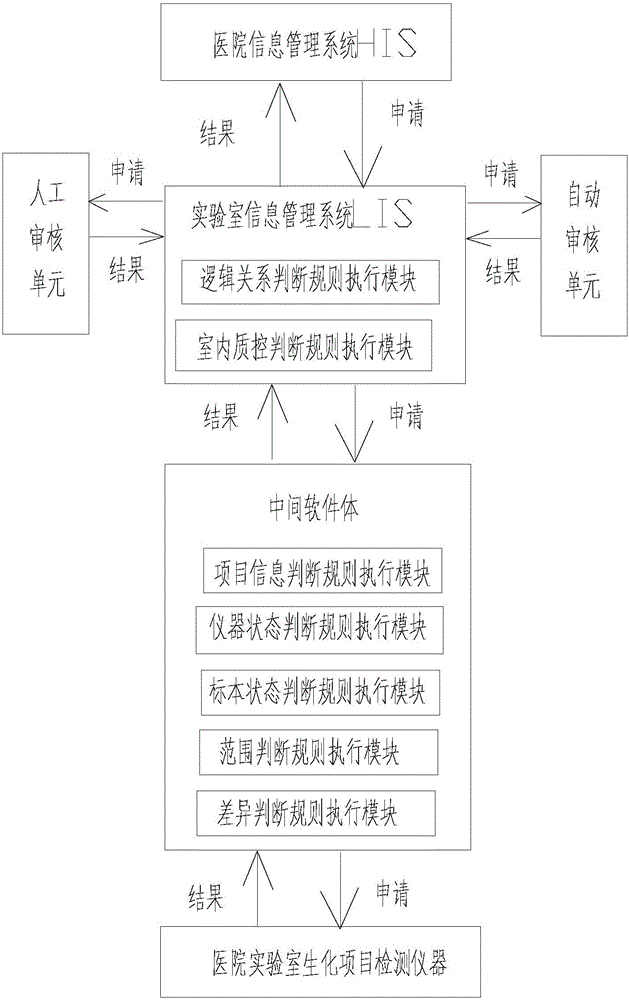

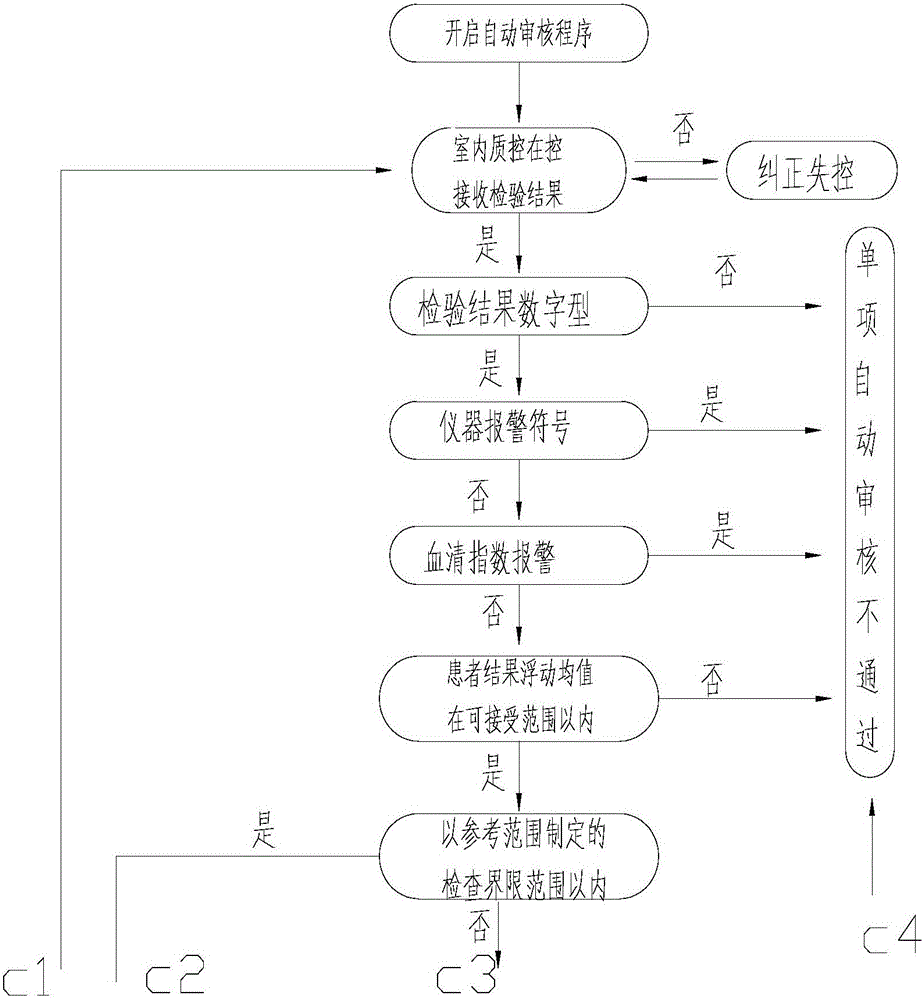

A medical laboratory clinical biochemical detection automatic checking method and system

ActiveCN106126958AImprove pass rateImprove accuracyMedical automated diagnosisMedical equipmentMedical laboratoryProcess quality

The invention provides a medical laboratory clinical biochemical detection automatic checking method and system. The method employs a computer software and hardware system and programs multiple checking rules to form a multiple checking rule execution module to automatically check the detection results of various biochemical immunity detection items. The detection results of the various biochemical immunity detection items cannot be sent to an automatic checking unit for automatic checking until they pass the multiple checking rules; if the detection results of the various biochemical immunity detection items cannot pass the above-mentioned checking rules, the detection results are transferred to a manual checking unit for checking; only after the detection results are checked by the manual checking unit or checked again after automatic treatment of dilution, reexamination, test item adding, unqualified sample return and the like by an assembly line can a detection report be issued; the multiple checking rules mainly include a clinical information judging rule, a sample state judging rule, an indoor quality control judging rule, an instrument state judging rule, a range judging rule, a difference judging rule, and a logical relationship judging rule. The checking rules are reasonable in design and cover the pre-analysis, analysis and post-analysis processes, thereby realizing whole-process quality control on a detection analysis process and guaranteeing the accuracy of detection results.

Owner:温冬梅

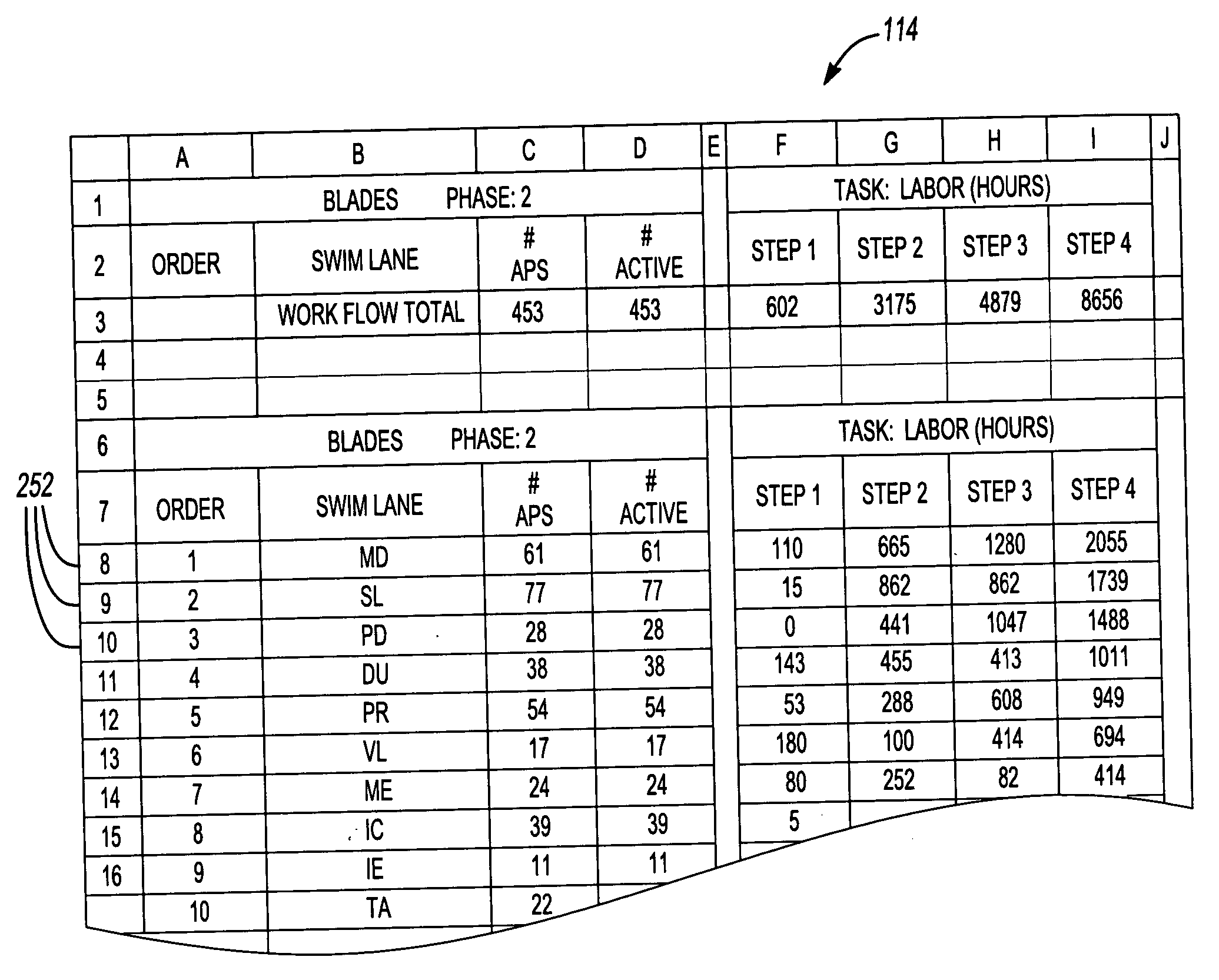

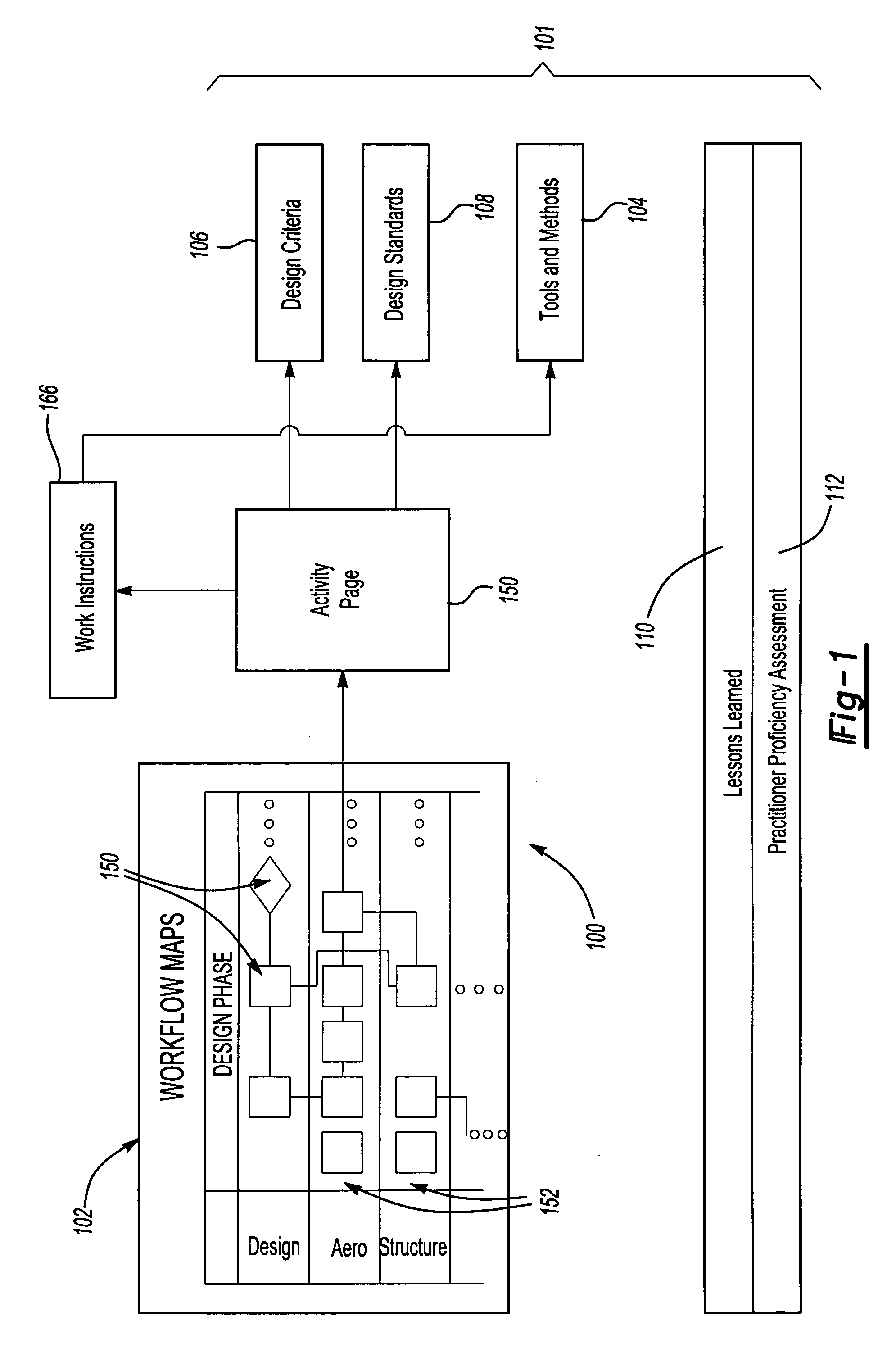

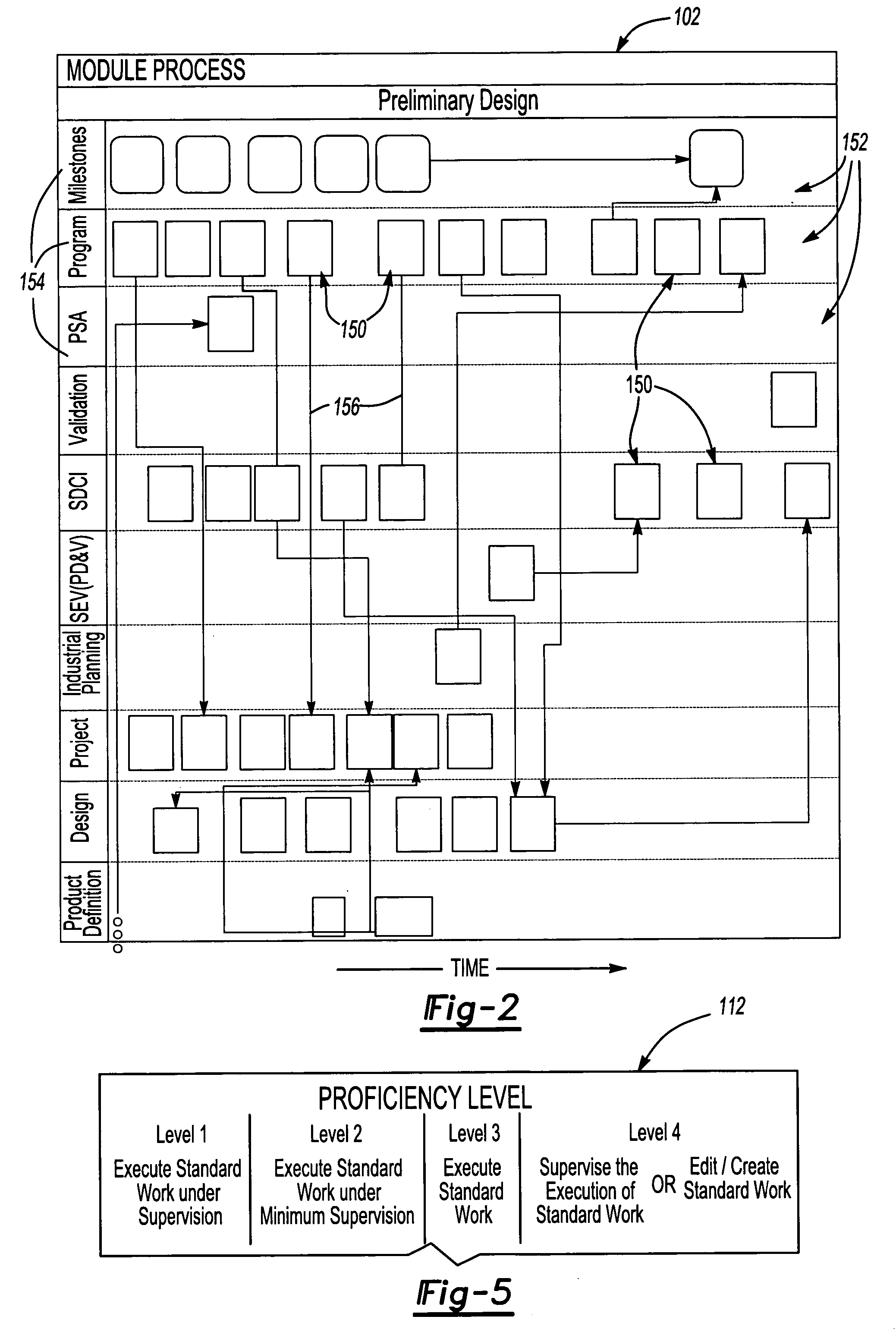

Engineering standard work framework method and system

InactiveUS20060005157A1Firmly connectedReduce the possibilityOffice automationSpecific program execution arrangementsProcess qualitySoftware engineering

A method and system for managing complex projects uses a framework having workflow maps containing activity blocks that provide detailed, easily accessible information within the framework about the project. The framework links functional groups, their associated activities, and the dependences between activities. The detailed, prescriptive instructions provided at each stage in the process creates in-process quality control, reducing the likelihood of costly mistakes and turnbacks. Implementing the framework as a web-based application allows easy access to the framework as well as data entered into the framework for future analysis, making it easy to identify improvement opportunities in the framework.

Owner:UNITED TECH CORP

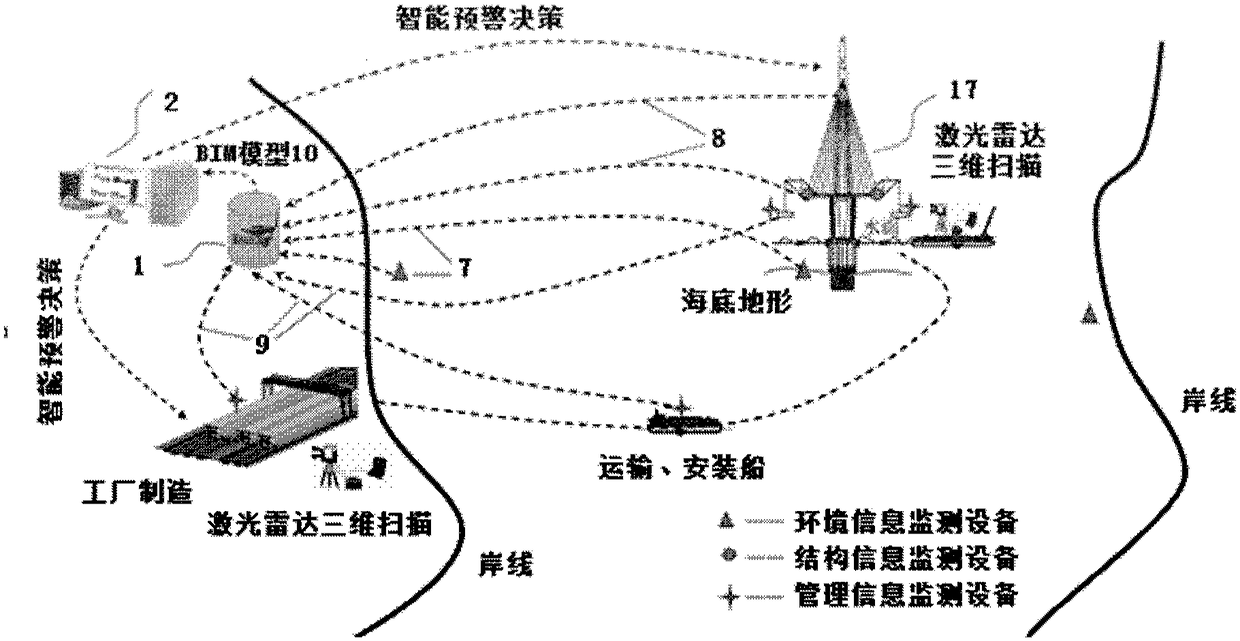

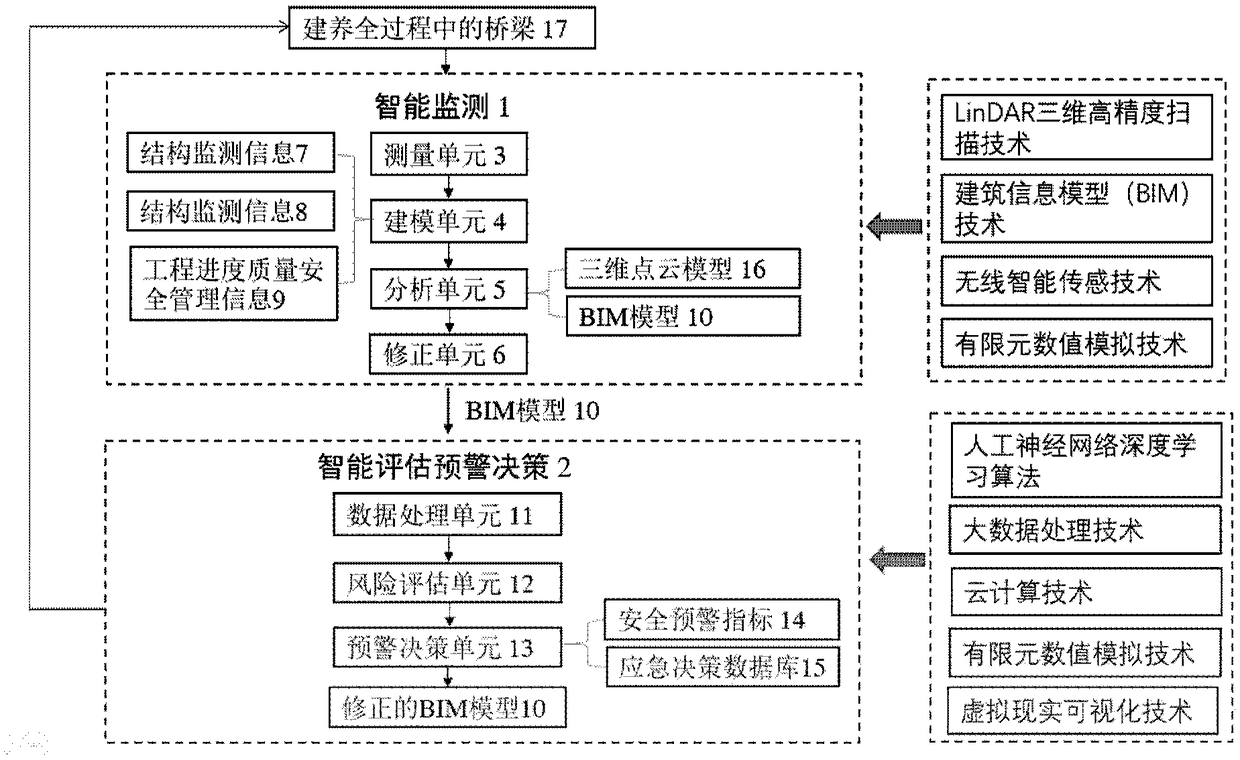

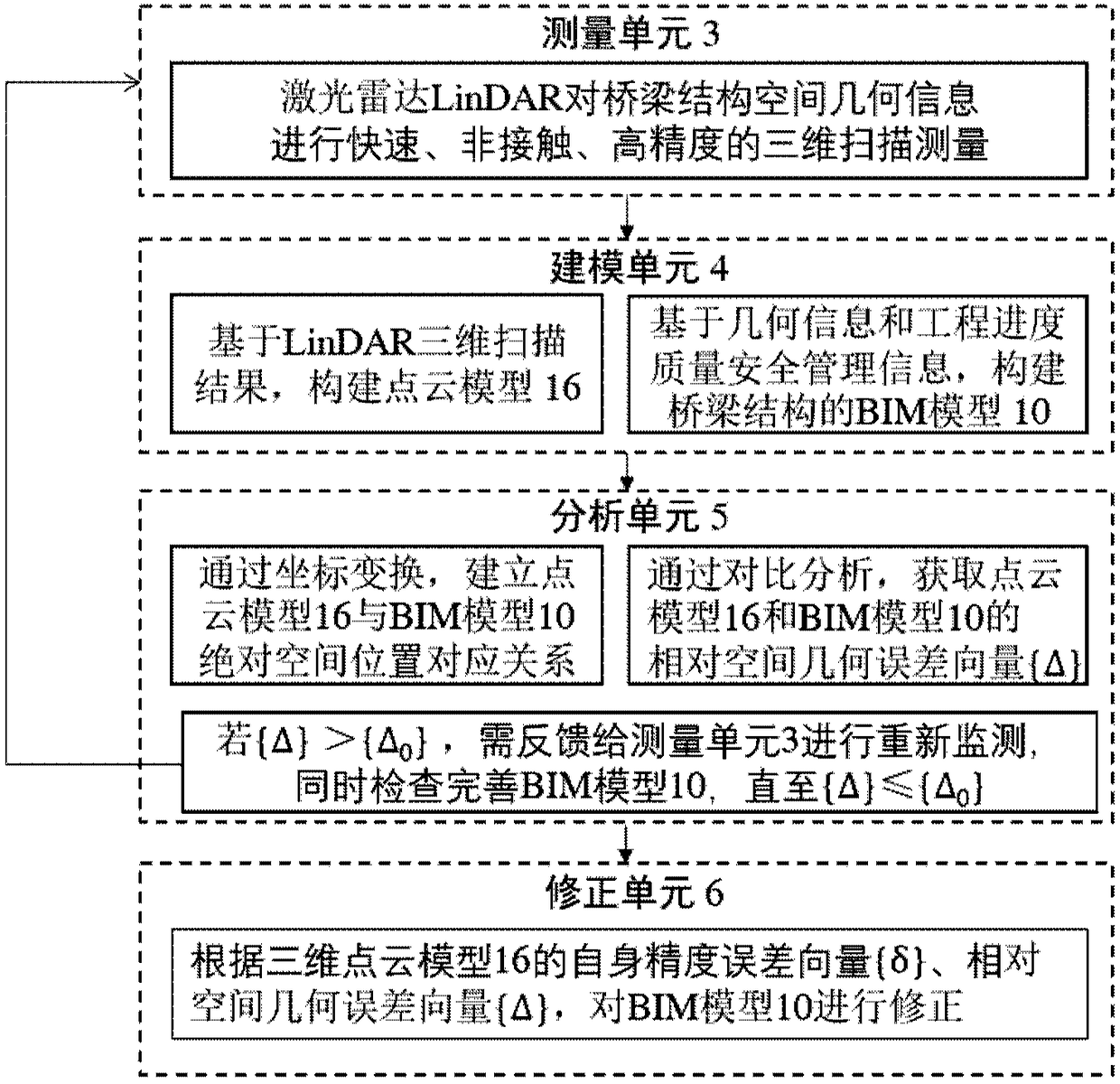

Bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system and method

PendingCN108460231ARealize online real-timeHigh precisionGeometric CADInput/output for user-computer interactionStructural monitoringProcess quality

Disclosed is a bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system and method. The bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system is composed of an intelligent collecting module and an intelligent assessment, alarming and decision-making module, wherein the intelligent collecting module integrates laser radar three-dimensional high-precision scanning technology, building information model technology and wireless intelligent sensing technology and intelligently collects multi-source heterogeneous multi-dimensional high-precision information during a bridge construction and maintenance whole process such as environment monitoring information, structure monitoring information and project process quality safety management information; the intelligent assessment, alarming and decision-making module integrates big data processing technology, cloud computing technology, artificial neural network algorithms and virtual reality technology and structures multi-stage safety alarming indexes and emergency decision-making database to perform online, real-time, high-precision, visual and intelligent assessment analysis, alarming and decision-making on structure and traffic safety performance of the bridge construction and maintenance whole process.The bridge construction and maintenance whole-process intelligent monitoring, assessment, alarming and decision-making system covers the bridge construction and maintenance whole process and has the advantages of being high in efficiency and precision, visualized, intelligent and the like.

Owner:CCCC HIGHWAY BRIDNAT ENG RES CENT

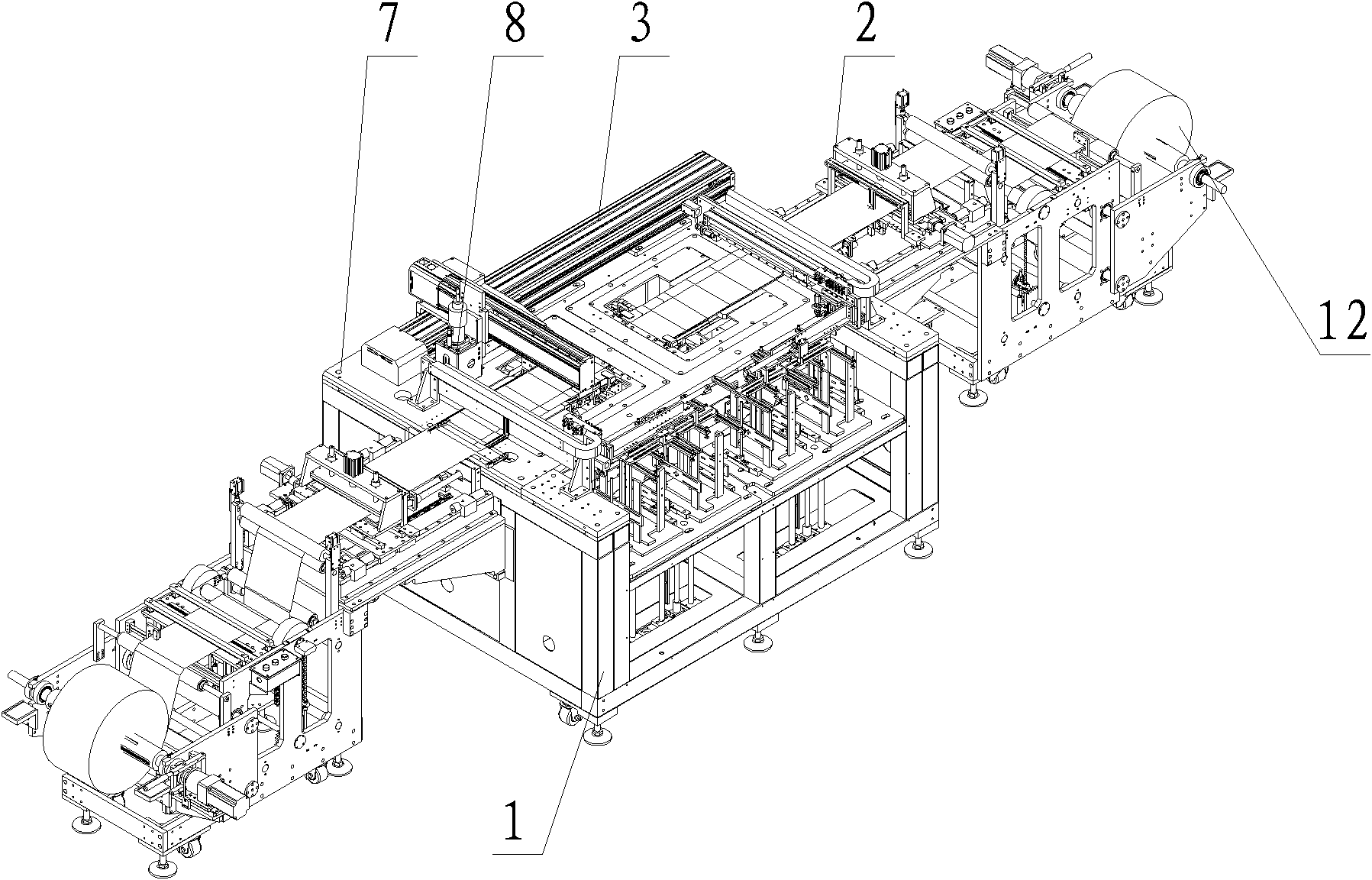

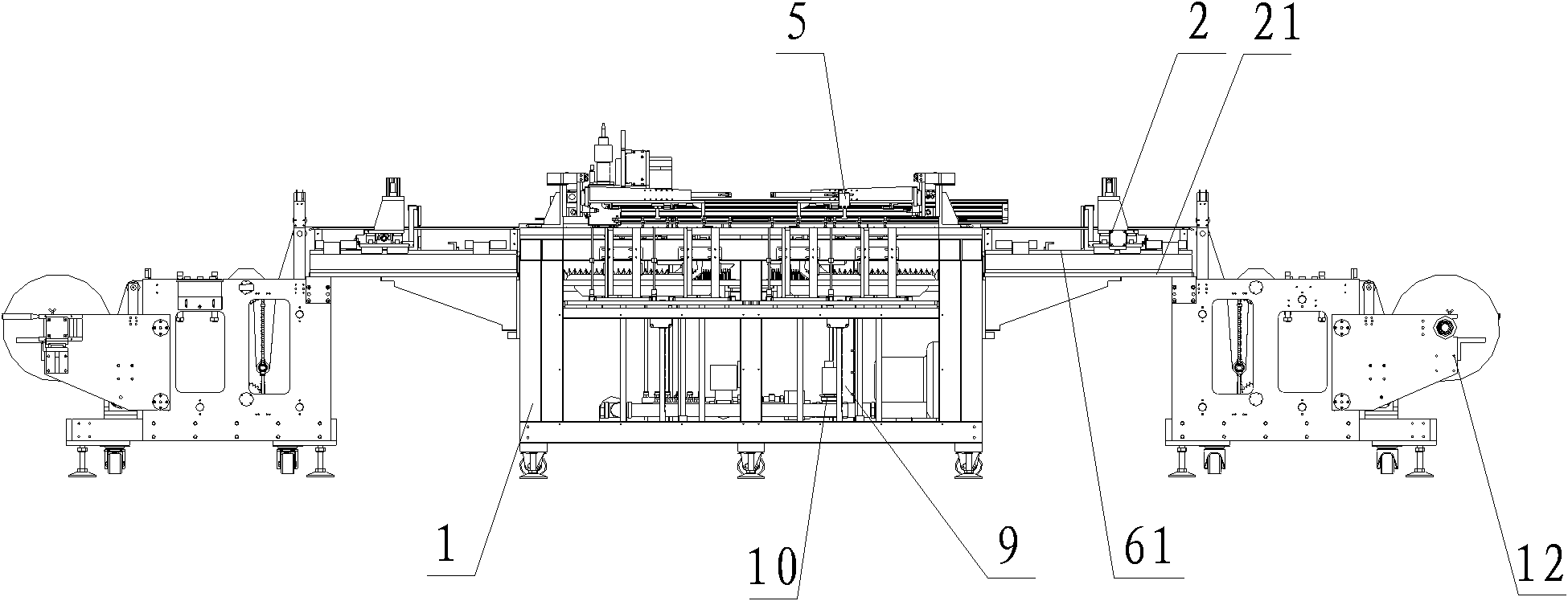

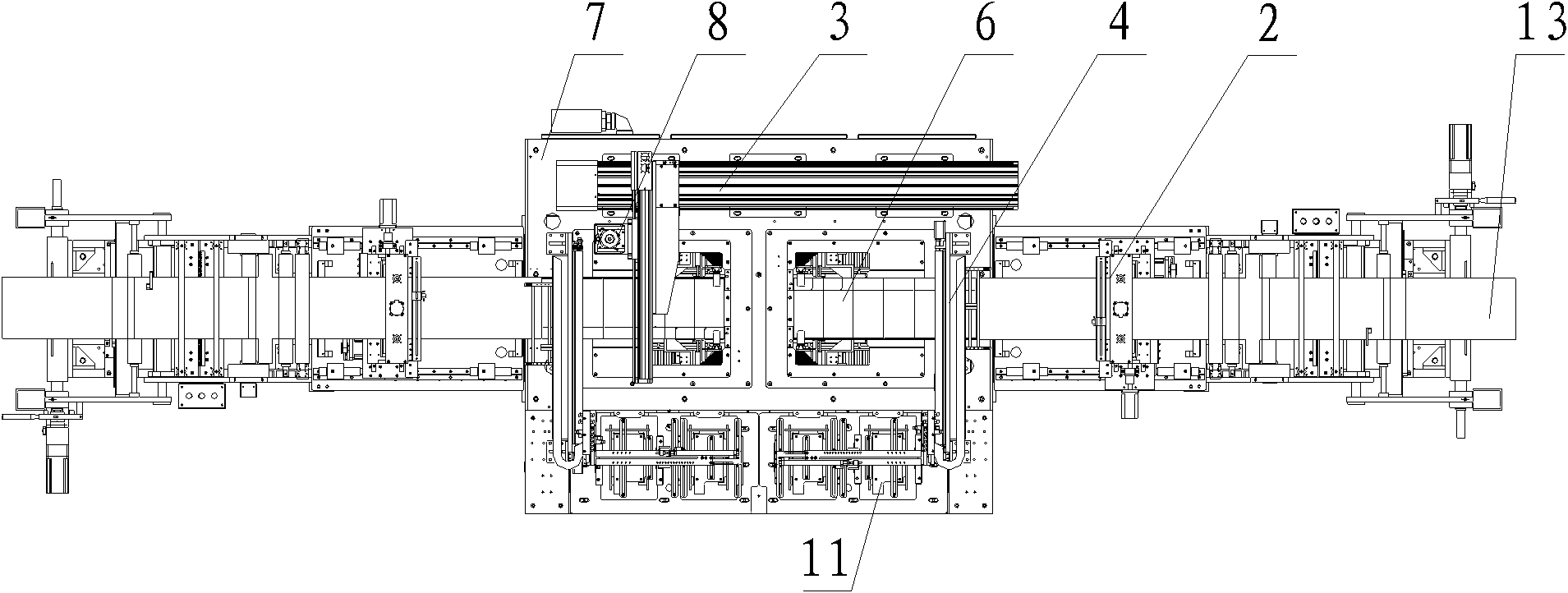

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

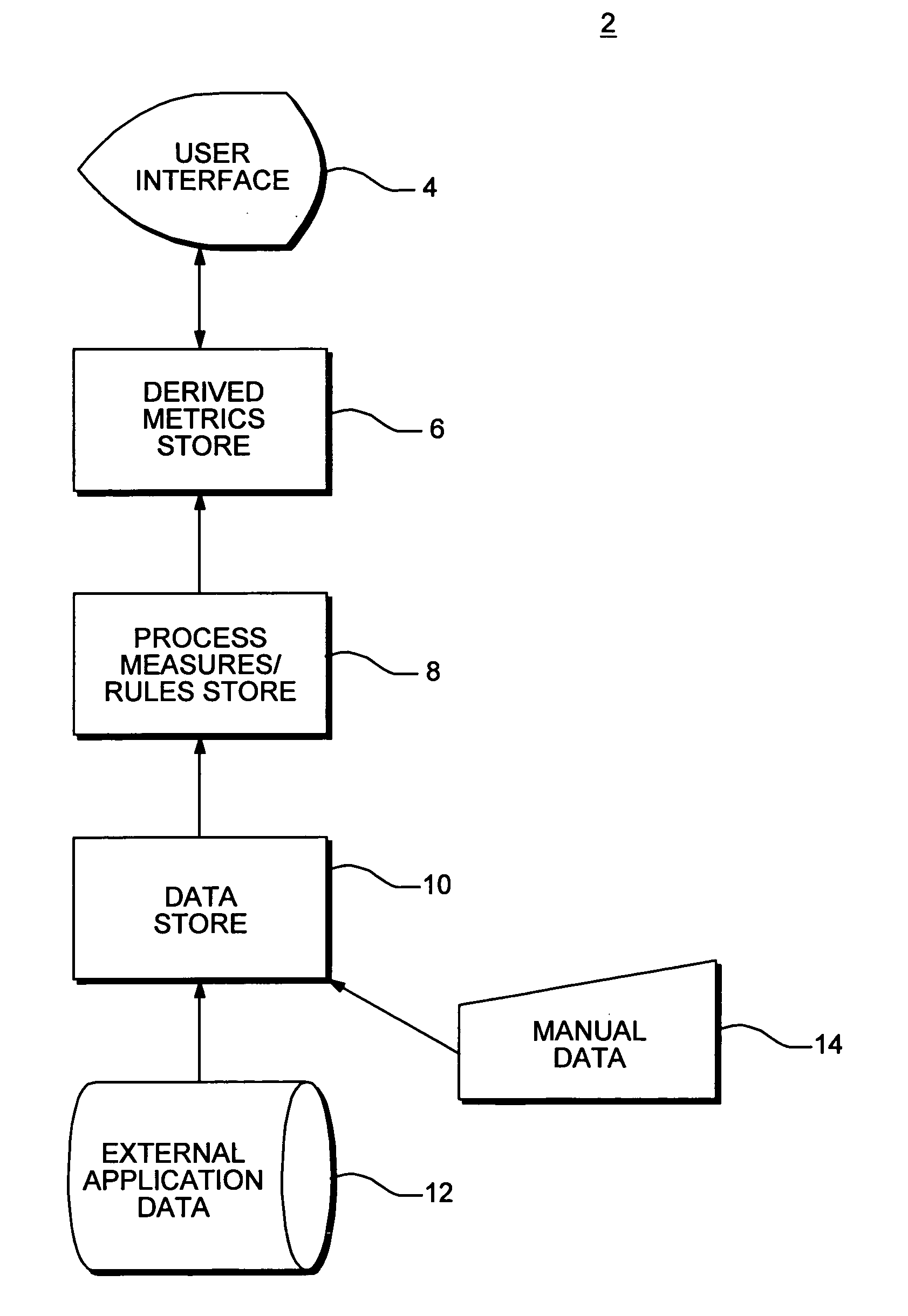

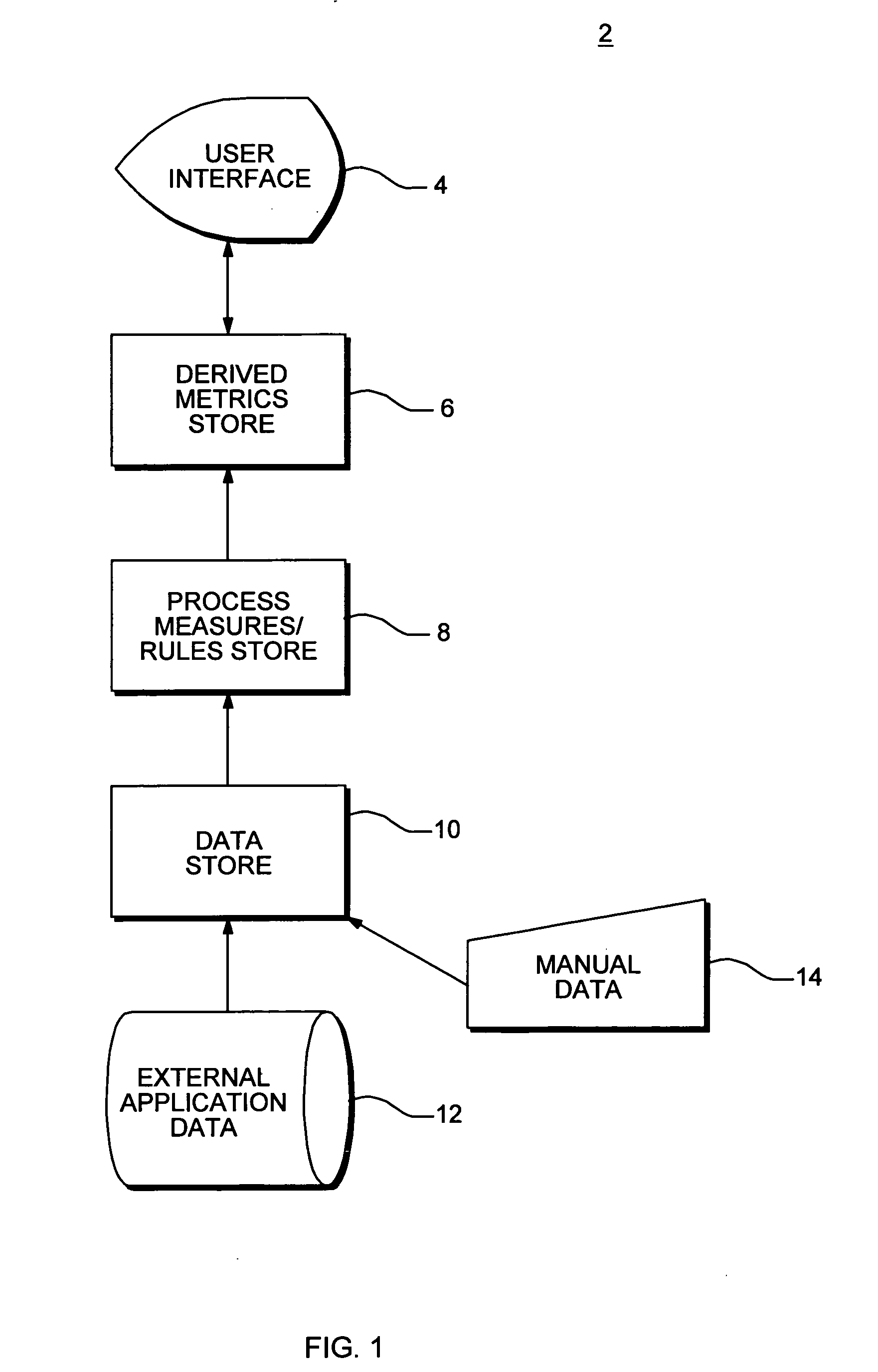

System and method for monitoring and measuring quality performance of health care delivery and service

InactiveUS20120303378A1Avoid disadvantagesFinanceOffice automationProcess qualityQuality performance

A software driven health care quality management system is disclosed. This system is user friendly, allowing easy navigation through various screens that enable the user to identify drivers of Star Rating System performance. The present invention offers easy drill-down functionality from a plan level, to a provider group, individual provider, and member level to provide actionable data that can improve the quality of care and ultimately a plan's star ratings. This system addresses each of the drivers that influence overall plan revenue, by providing an enterprise business intelligence system, designed to maximize process quality measures, promote value-based purchasing, and maximize risk-adjusted revenue for such health plans and health provider organizations.

Owner:ESSENTIALSTARS

Method for implementing software assembly line platform

InactiveCN101174208APrecise structureReduce useless laborSpecific program execution arrangementsProcess qualityFull life cycle

The invention provides a method for building a software production line platform based on Test Director, Harvest or Subversion, which is characterized in that: by combing the information standards, information flow and information dependency relationship during the process of software research and development; then general defects, modification and configuration management rules (such as flows, tables, fields, roles, authority and protocols) are formulated; unified bases for quality measurement and statistical analysis are established, and a set of measurement models for product quality and process quality is formed. Furthermore, an assistant software research and development synergic management system is also provided for fulfilling support; the operations of service linkage connection, rule mapping and information synchronization are performed for Test Director, Harvest or Subversion. Therefore, the invention has the advantages that: the multi-dimensional data acquisition for demand management, configuration management, alteration management, release management, project management and defect management can be completed, and a software enterprise asset library with a full life cycle is thus formed.

Owner:INSPUR SOFTWARE CO LTD

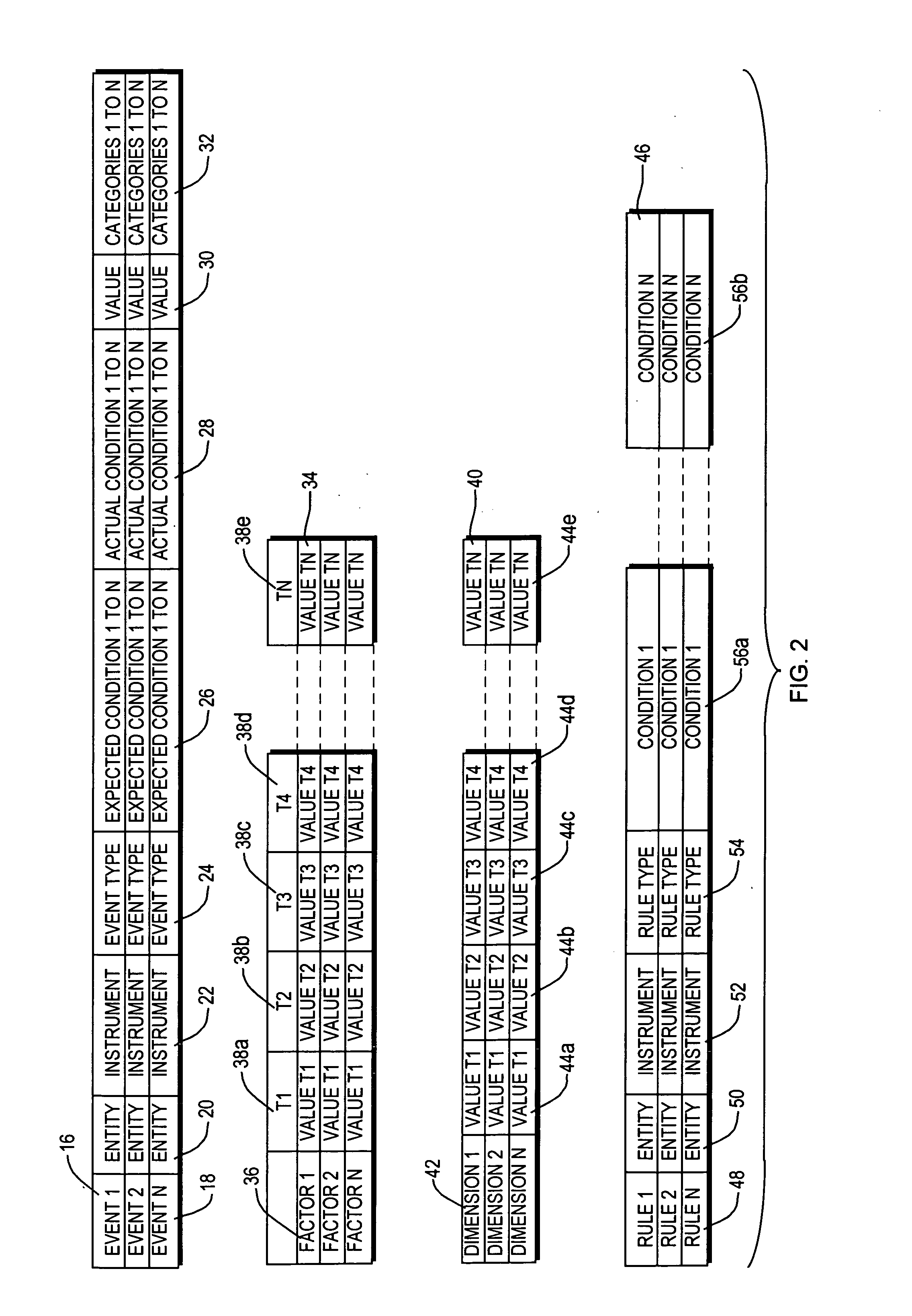

Methods and apparatus for assessing operational process quality and risk

InactiveUS20080015920A1Sufficient rapidityIdeal overall performanceFinanceMultiprogramming arrangementsProcess qualityHuman decision

Methods and apparatus for assessing operational process quality and risk of an entity or a group of entities. The present invention enables a user to effectively compare one or more events, representing what actually happened, with a reference, which represents ideal performance in terms of operational process quality and risk, and express the corresponding results in quantitative terms. The present invention is capable of presenting results in a form and with sufficient rapidity that a human decision-maker is able to timely observe conditions which represent unacceptable quality or excessive risk and respond appropriately.

Owner:FAWLS ROBERT A +1

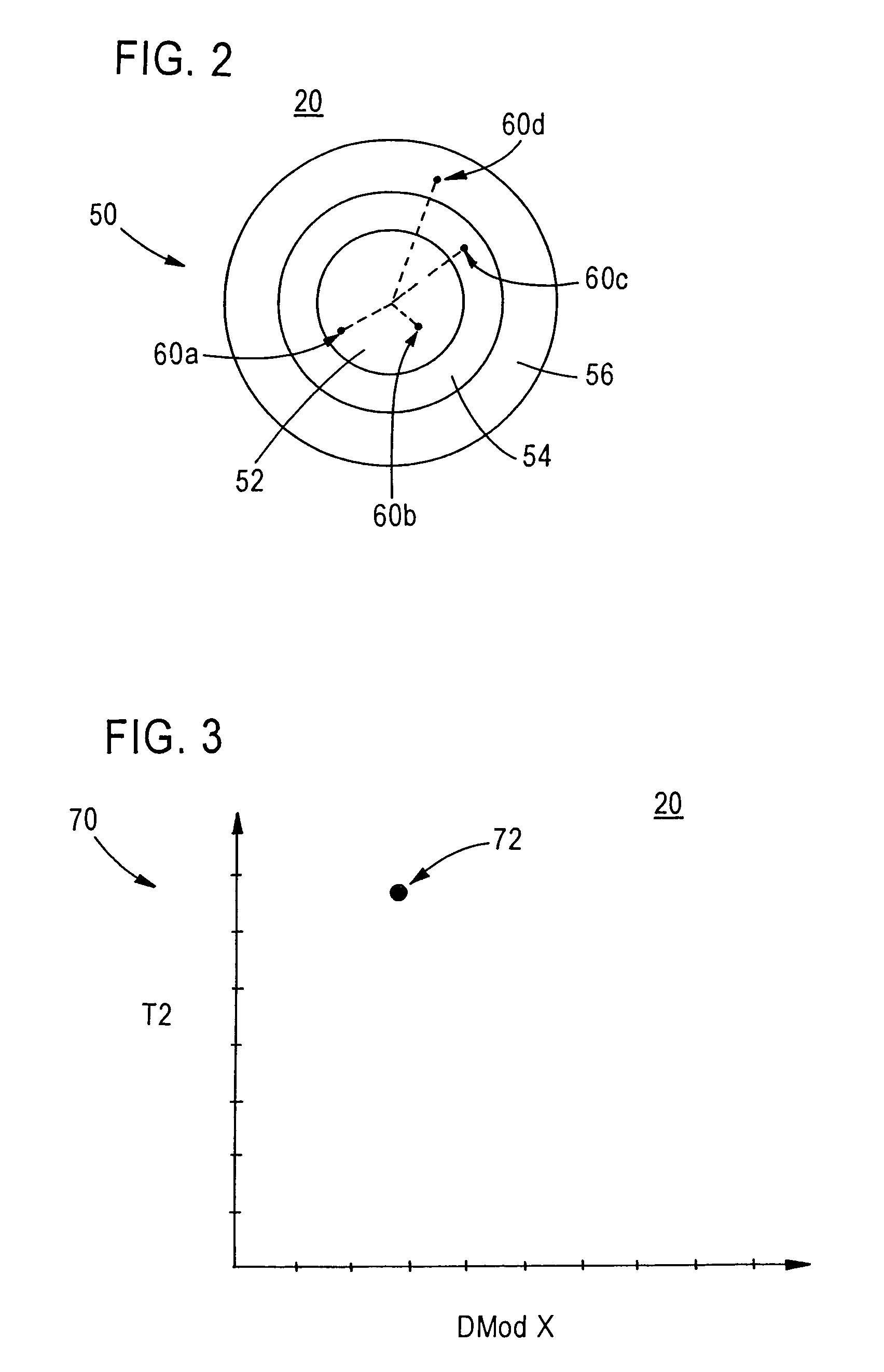

Graphical user interface with process quality indicator

A graphical user interface for enabling a user to graphically observe on a displaying mechanism a statistical measure of the process quality of a manufacturing process provides for the display of an icon representing a workpiece. The location and color of the icon on the displaying mechanism indicates the process quality of the manufacturing process for the represented workpiece.

Owner:MKS INSTR INC

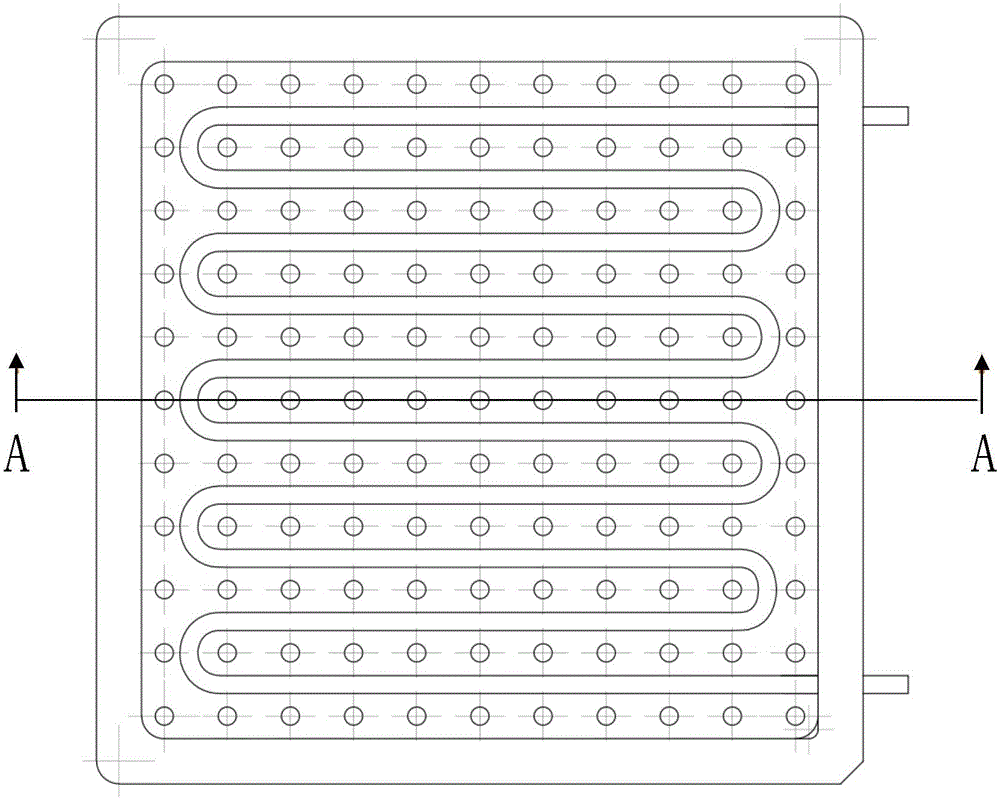

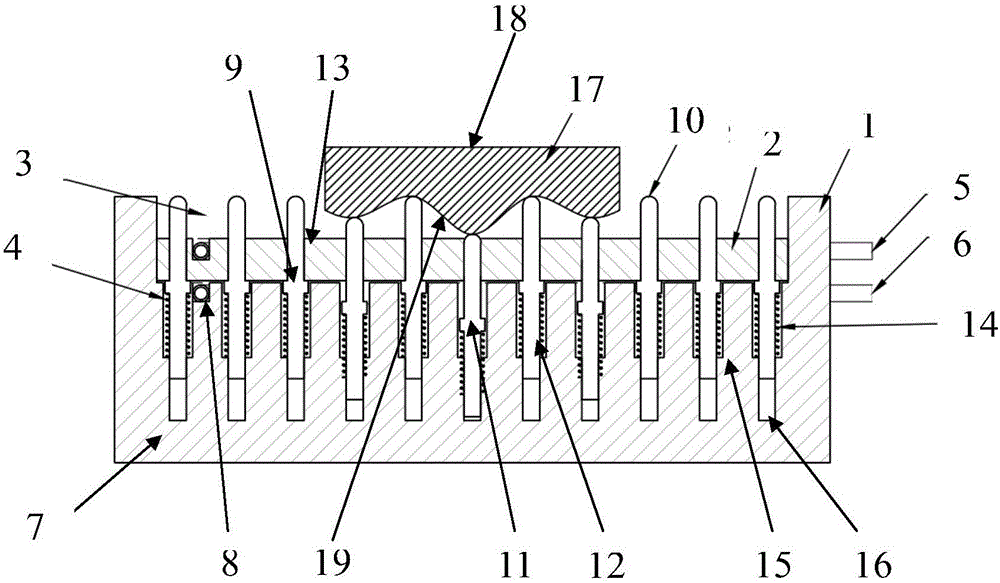

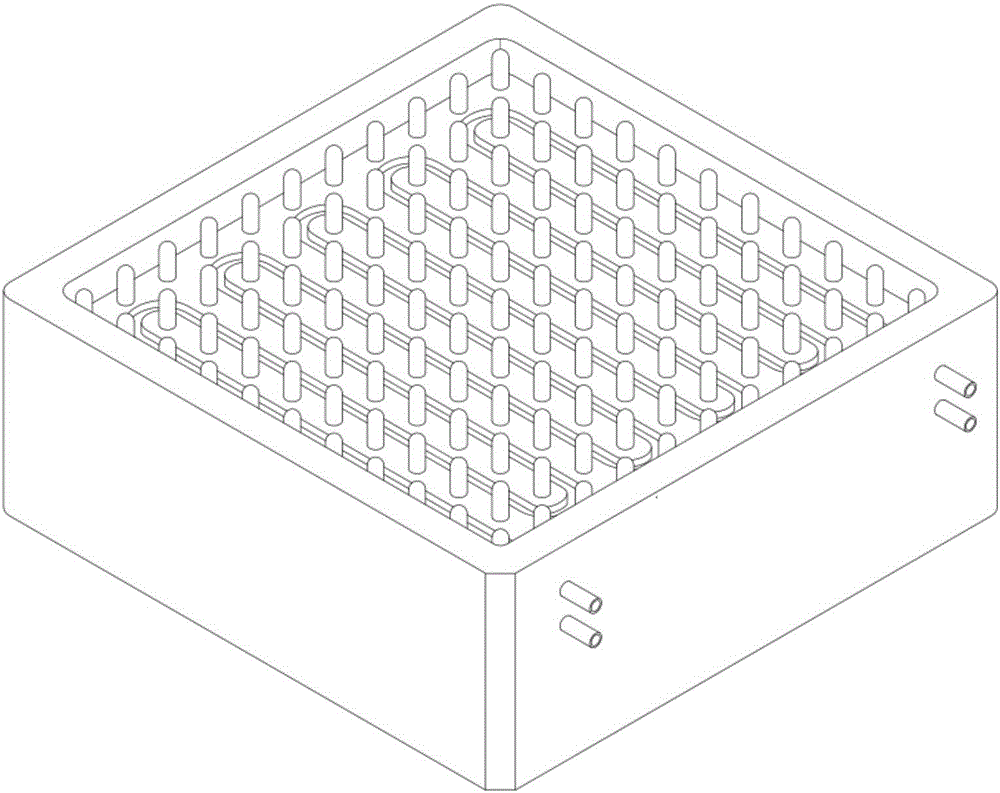

Shape Adjusting Tool

InactiveCN106334961ASimple designHigh speedPositioning apparatusMetal-working holdersNumerical controlProcess quality

The invention discloses a profile-followed adjustment frock, including main box, demarcation strip, upper cabin, lower cabin, upper-deck cabin cooling tube, lower cabin cooling tube, freezing liquid, cold-producing medium, floating thimble, centrehole, thimble spring, spring groove, pin bottom outlet, wherein floating thimble is each independently arranged, and each floating thimble can fluctuate under thimble spring and workpiece effect; Demarcation strip is divided into upper and lower two-layer main body case, upper and lower cabin cooling tube is respectively equipped with two sheaf spaces, it is filled with freezing liquid water, take arbitrary shape workpiece to be put in frock, be pressed downward floating thimble, profiling is formed by compression in workpiece shapes syringe needle with the shape, cooling tube is passed through cold-producing medium, sheaf space freezes up and down, and floating thimble positioning, workpiece are wrapped fixing positioning; Coordinate with Digit Control Machine Tool, gun turret milling machine, grinding machine, drilling machine, unstressed clamping and fast clamp are done to abnormal shape, yielding thin-walled, easy spring angle workpiece and minor items, it is ensured that work pieces process quality, precision and working (machining) efficiency.

Owner:NEUTRON SHANGHAI

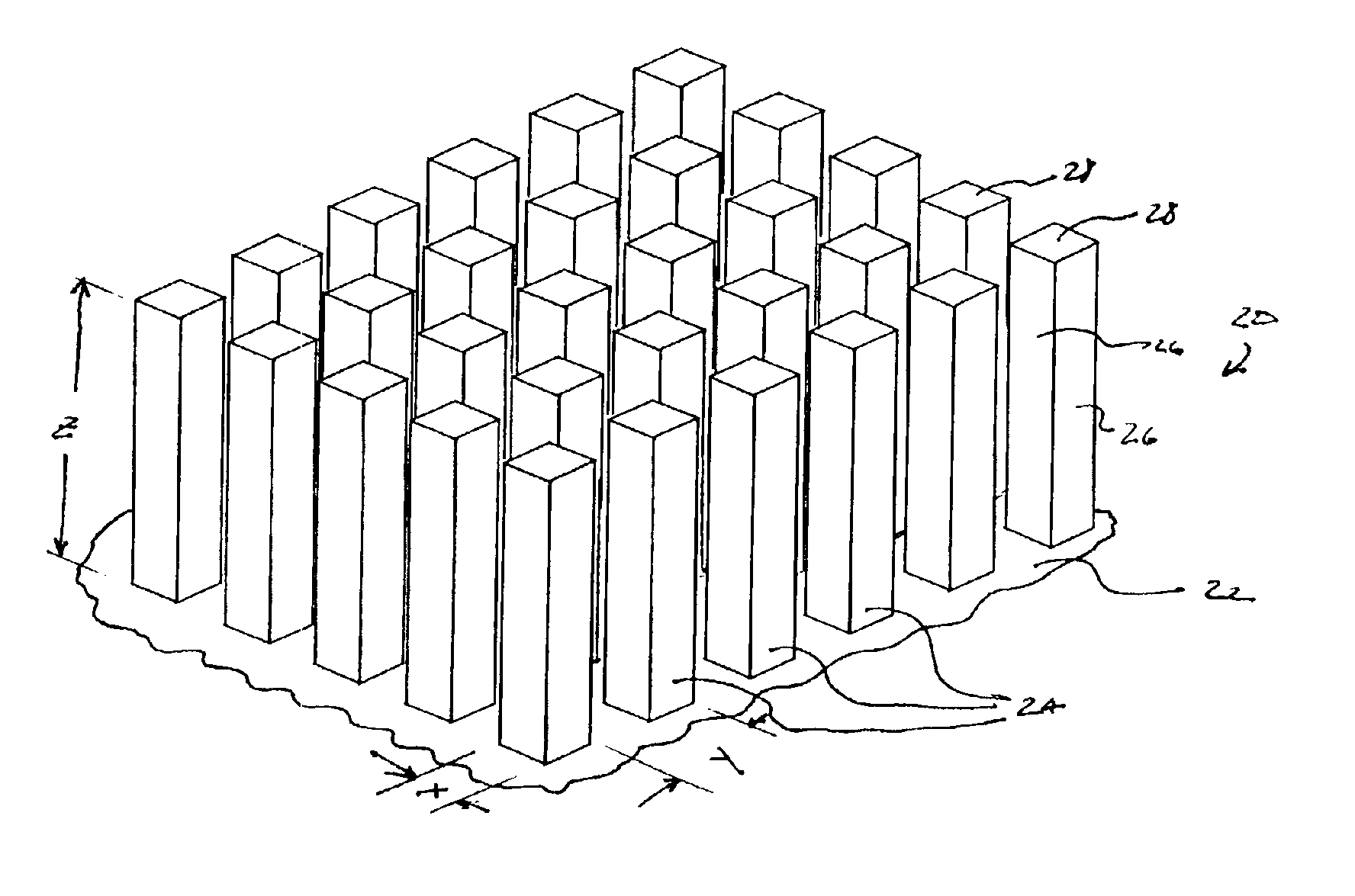

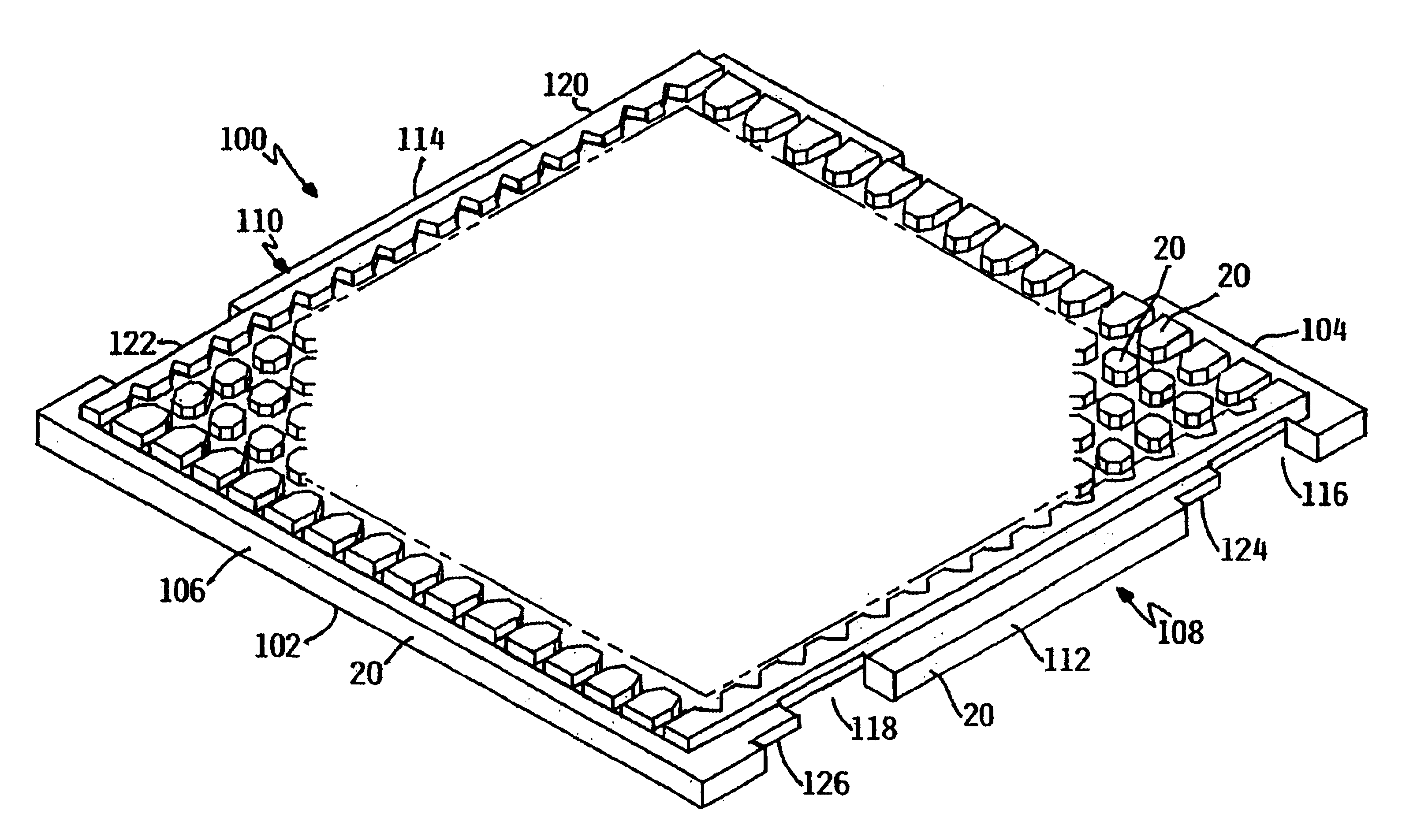

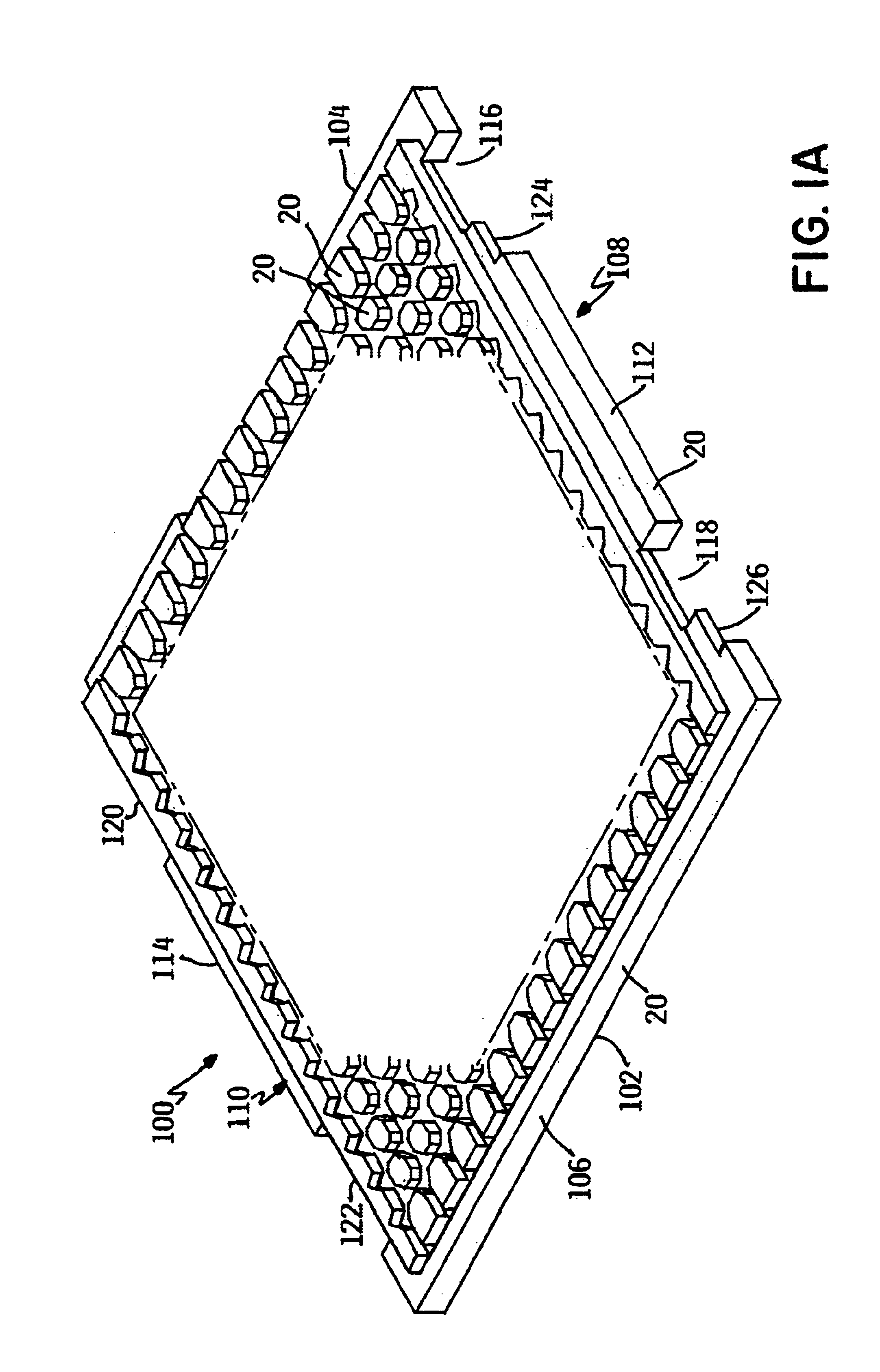

Wafer carrier with ultraphobic surfaces

InactiveUS6976585B2Easy to cleanThe process is convenient and fastMaterial nanotechnologySemiconductor/solid-state device manufacturingProcess qualityEngineering

A carrier with ultraphobic surfaces for promoting more effective cleaning and drying of the carrier. In the invention, entire surfaces or portions of surfaces of a carrier are made ultraphobic. The ultraphobic surfaces of the carrier cause liquids that may come in contact with the surface, such as may be used in cleaning, to quickly and easily “roll off” without leaving a liquid film or substantial number of liquid droplets. As a result, less time and energy is expended in drying the surfaces, and redeposited residue is minimized, thereby improving overall process quality. In addition, the ultraphobic surfaces may be resistant to initial deposition of contaminants, where the contaminants may be in liquid or vapor form.

Owner:ENTEGRIS INC

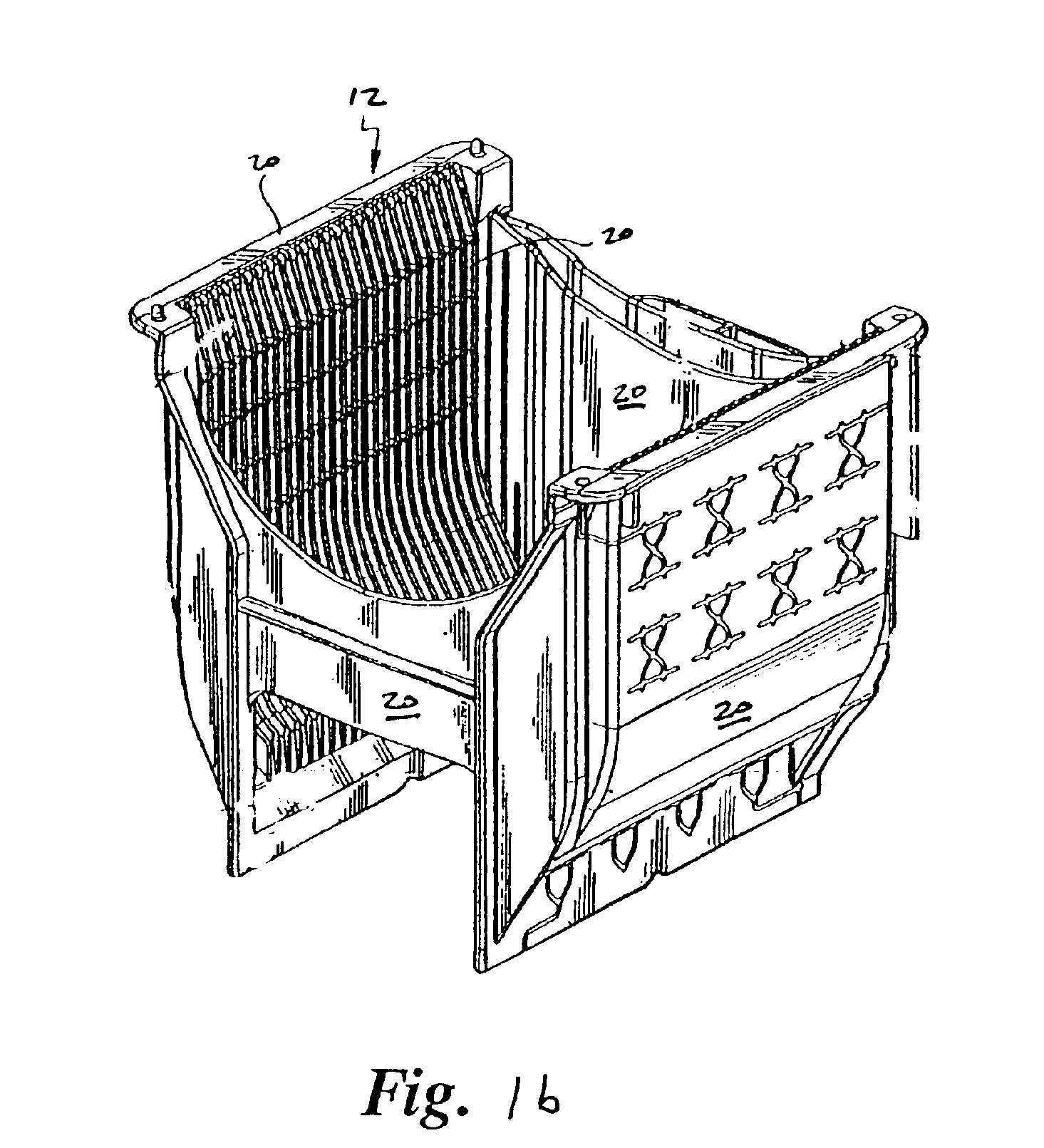

Product production control system and control method

ActiveCN105182935ARealize information production managementAchieve effectivenessProgramme total factory controlInformatizationProduct type

The invention discloses a product production control system which comprises a server. The server is connected with an order entry device for inputting product type information and quantity information, a label generator for generating corresponding product labels according to the product type information and quantity information, a product label scanner for scanning label information and reading the product process of the server according to the label information, a plurality of process flow displayers arranged at each process and used for displaying the corresponding process production, a plurality of process quality detection devices arranged at each process and used for detecting the quality of each process product, a warehousing scanner used for reading quality statistics information of each process of the server after all processes are finished so as to judge whether the finished products are qualified to be boxed, and a camera device for recording the appearance of the finished products and integrity of accessories before boxing. The steps of order placing, production processes in a workshop and cargo shooting and recording before boxing and the like are combined through the server, and thus informationized production management of the products is realized.

Owner:ZHONGSHAN WANJIN INTELLIGENT SCI & TECHCO LTD

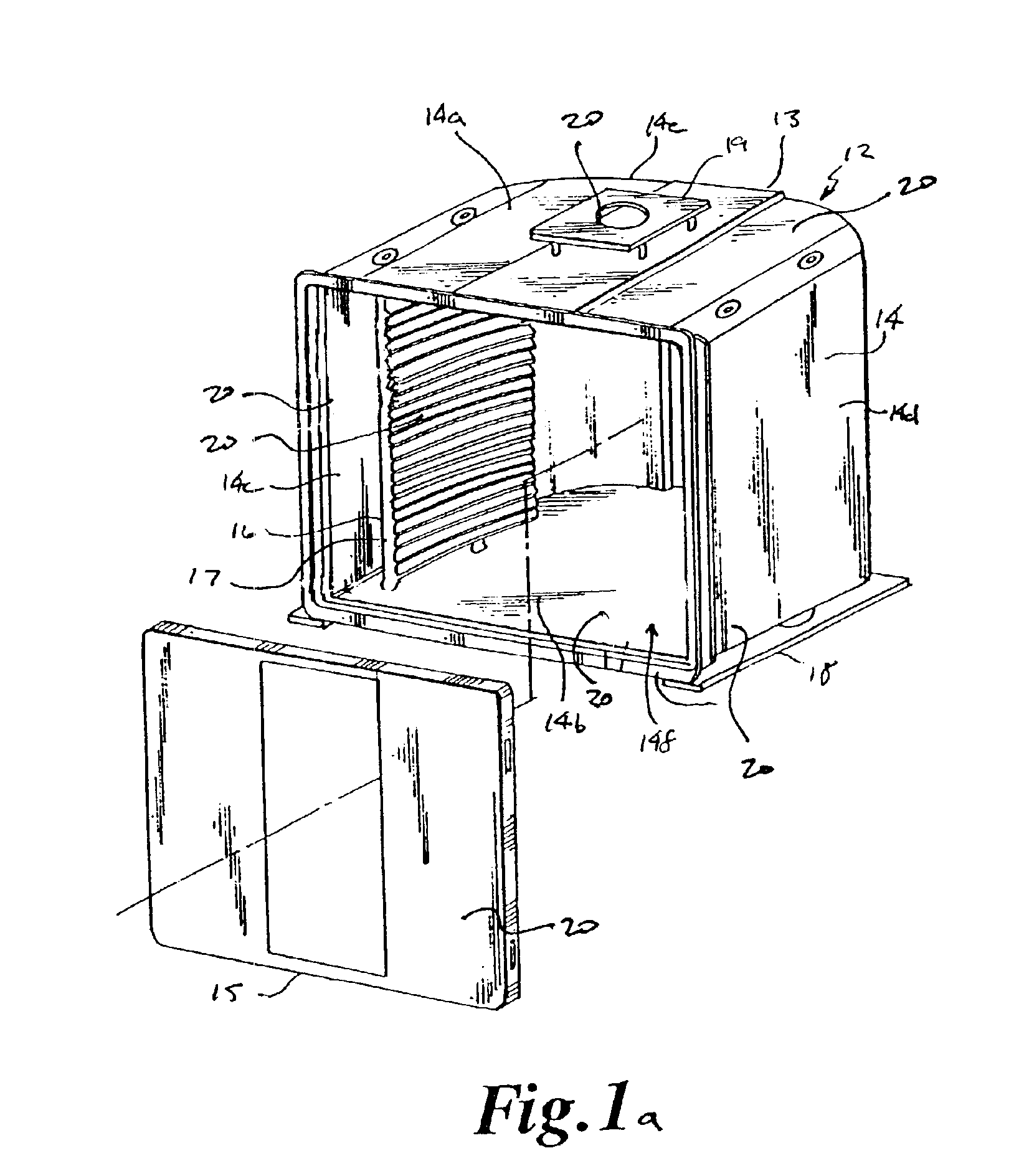

Tray carrier with ultraphobic surfaces

InactiveUS6938774B2Easy to cleanThe process is convenient and fastMaterial nanotechnologySemiconductor/solid-state device manufacturingProcess qualityBiomedical engineering

A tray carrier with ultraphobic surfaces for promoting more effective cleaning and drying of the tray carrier. In the invention, entire surfaces or portions of surfaces of a tray carrier are made ultraphobic. The ultraphobic surfaces of the tray carrier cause liquids that may come in contact with the surface, such as may be used in cleaning, to quickly and easily “roll off” without leaving a liquid film or substantial quantity of liquid droplets. As a result, less time and energy is expended in drying the surfaces, and redeposited residue is minimized, thereby improving overall process quality and facilitating economical reuse of the tray carrier. In addition, the ultraphobic surfaces may be resistant to initial deposition of contaminants, where the contaminants may be in liquid or vapor form.

Owner:ENTEGRIS INC

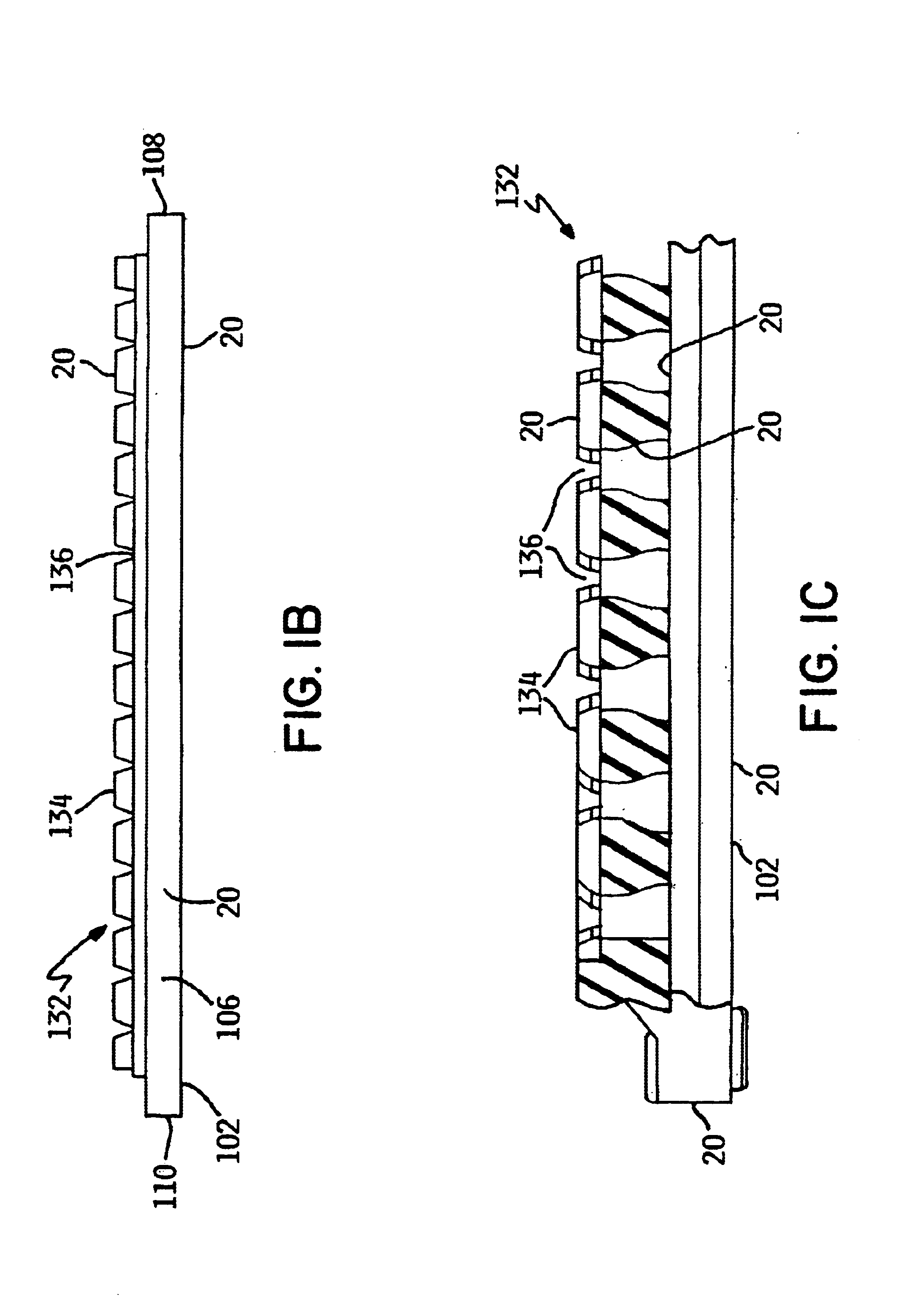

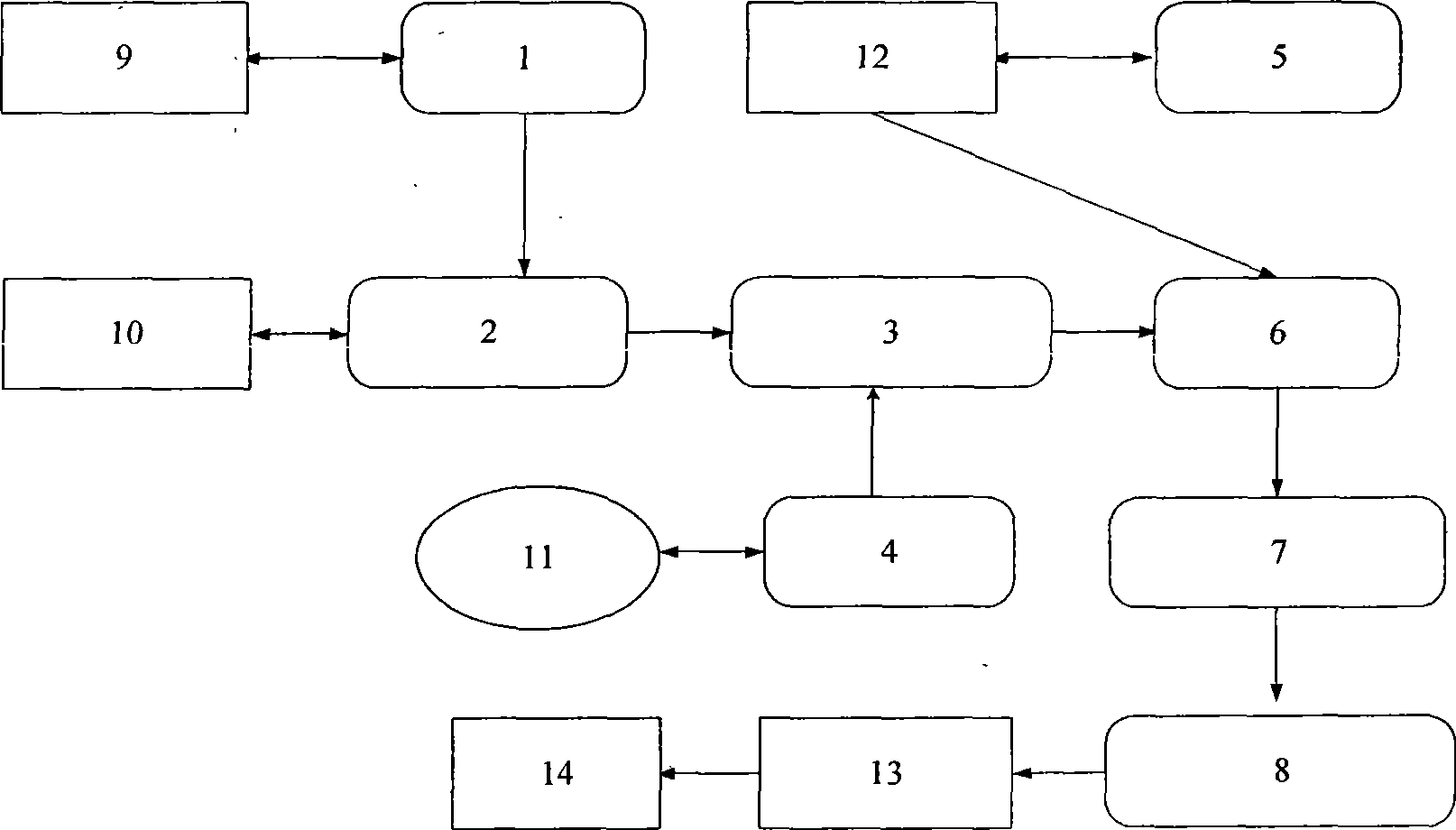

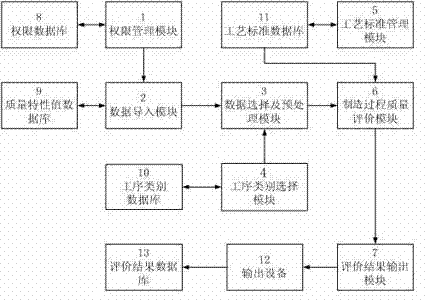

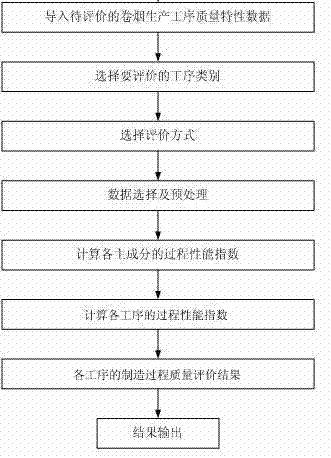

Cigarette working procedure quality overall evaluation system and method based on gray correlation analysis

ActiveCN101414183ASolve the ambiguous situation of process capability evaluationFunctional job improvementTotal factory controlProgramme total factory controlGrey correlation analysisProcess quality

The invention discloses a comprehensive cigarette process quality evaluation system based on grey correlation analysis and a method thereof, aims at overcoming the disadvantage that the existing single process evaluation method can not comprehensively evaluate the overall process quality of the cigarette process, and changing the situation of fuzzy process capability evaluation of a whole line at present. The evaluation system and the method thereof help comprehensively evaluates the quality of a plurality of processes, and can effectively grasp comprehensive situation of the process quality so as to provide basis for the continuous improvement in the process quality, and provide assurance for quality improvement of cigarette products. The system and the method combine the single-process quality evaluation method and the grey correlation analysis method. The method comprises the following steps: firstly, computing process capability indexes of various process parameters; then, comprehensively evaluating a Cpk value by the grey correlation method; finally, obtaining a comprehensive evaluation result which is taken as a process quality rank of various evaluated objects. Production practice can be effectively directed by analyzing the Cpk and the process quality ranking result.

Owner:CHINA TOBACCO SHANDONG IND +1

Processing technique of 9Cr18 stainless steel capable of being improved to G3 level

InactiveCN101186005AOptimize processing parametersSpherical surface grinding machinesMetal working apparatusCold treatmentProcess quality

The invention relates to a 9Cr18 stainless steel ball processing technique which can be raised to G3 grade. The processing technique sequentially includes raw material inspection, ball-forging, stress-relief and anneal, hot-acid pickling, polishing, quenching plus cold treatment plus backfire, hard milling, a first-time stabilizing treatment, fine milling, a second-time stabilizing treatment, fine grinding, washing, fine appearance-forming and lubricating and packing. On a basis of making a full use of the existing steel ball processing technology, machine-tool equipments and testing equipments, the technique of the invention adopts a reinforced steel ball manufacturing equipment, industrial preparations, and a novel abrasive to optimize various machining process parameters in the steel ball processing technique and to strengthen a process quality testing and has a proper washing, packing and conserving proposals, etc. process technology. The invention can raise the precision grade of the stainless steel ball to G3 grade and solves the processing technology, testing control and finished-product washing of the 9Cr18 stainless steel ball, and then a batch manufacture is realized finally.

Owner:LUOYANG BEARING SCI & TECH CO LTD

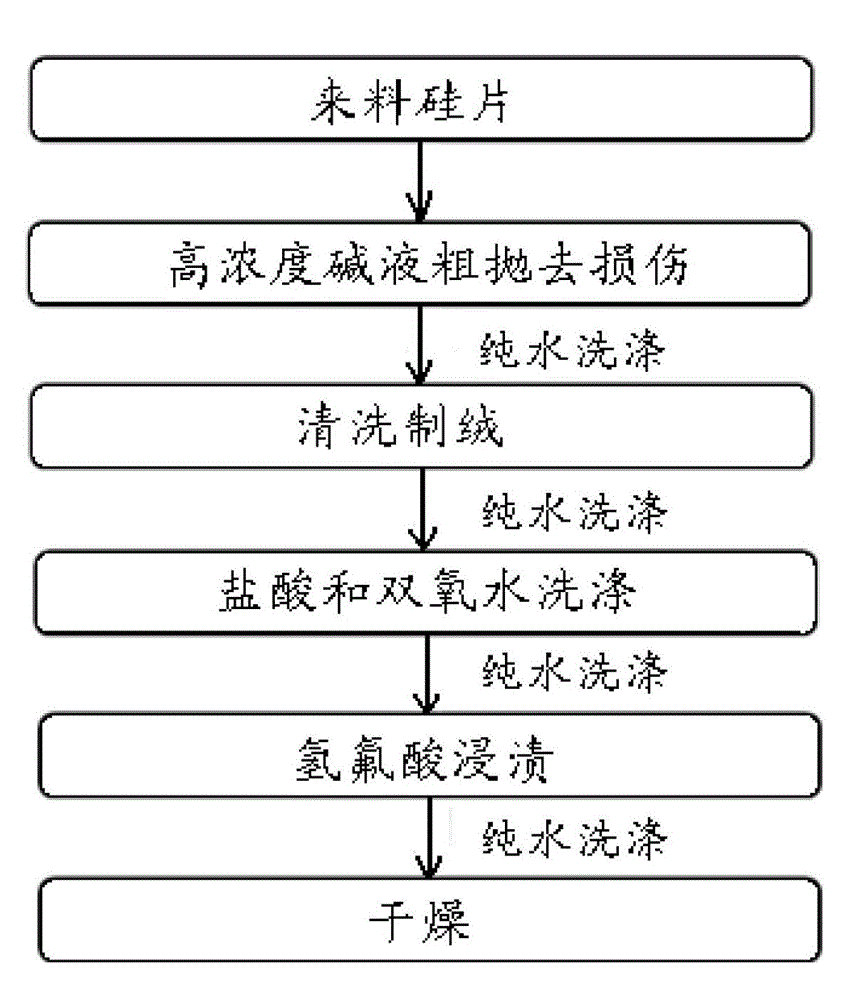

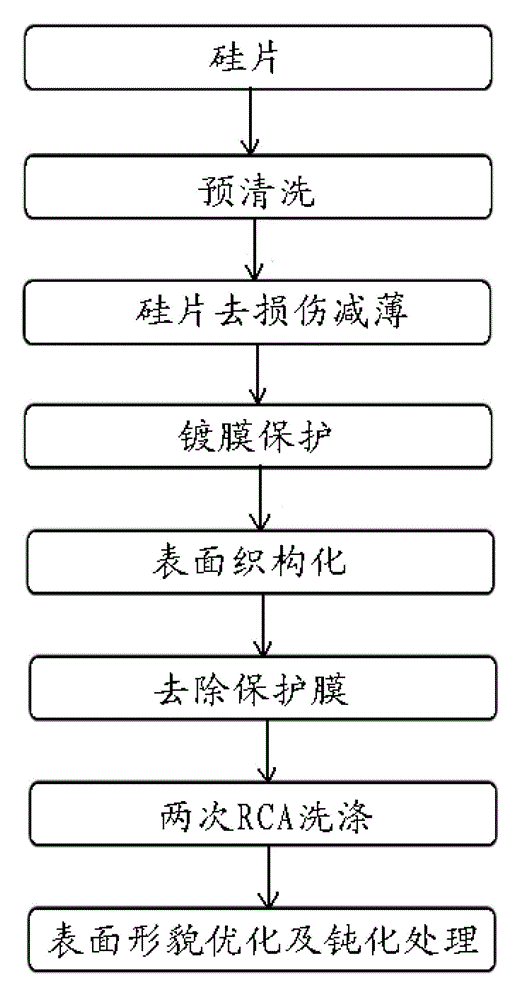

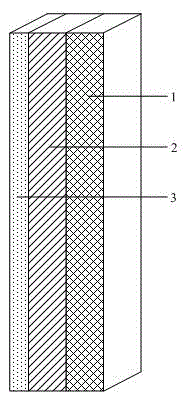

Wet surface processing technique used for manufacturing high efficiency crystalline silicon solar cells

ActiveCN102751377AMeet the requirements of one-side cleaning and making woolImprove the quality of surface chemical passivationAfter-treatment detailsFinal product manufactureTectorial membraneProcess quality

The invention relates to a wet surface processing technique used for manufacturing high efficiency crystalline silicon solar cells. The surface wet processing technique comprises the following steps of (1) pre-washing a silicon chip; (2) removing damage and thinning the silicon chip, wherein the upper and lower surfaces of the silicon chip are in a polishing shape; (3) coating protection: depositing a protective film on a single surface of the silicon chip; (4) surface structuralizing: obtaining a pyramid suede structure with a depth of 4-10 microns for the surface of the silicon chip which has no protective film, and meanwhile keeping a plane state for the surface of the other side of the silicon chip which has the protective film; (5) removing the protective film; (6) performing RCA washing, and (7) enhancing and optimizing for the surface appearance and forming a wet passivated surface. With the adoption of the wet surface processing method provided by the invention, the requirement on single-sided cleaning and texturing of the substrate of the thin silicon chip in the manufacturing process of high efficiency solar cells can be simply satisfied; the cleaning process quality and the battery efficiency and yield can be effectively improved; and moreover, no additional relevant cleaning equipment is required, and thus, the process cost is saved.

Owner:TRINASOLAR CO LTD

Method for identifying positive cells and negative cells of immunologic tissue

ActiveCN103020585AThe overall calculation is smallImprove adaptabilityCharacter and pattern recognitionProcess qualityPrior information

The invention discloses a method for identifying positive cells and negative cells of an immunologic tissue. The method provided by the invention can be used for determining a corresponding threshold value without using a certain threshold in a self-adaptive manner according to an own maximum between-cluster variance method of immunohistochemical image data to be processed, and can be adapted to deviations of an image on the color and the light intensity, so that the method is more stable when being compared with the conventional method; when nucleuses are judged to be positive or negative, dyeing processing information of the immunohistochemical image is used as prior information without manual marking, so that the intervene of subjective factors can be avoided, the full-automatic processing can be realized, and the stability of analysis efficiency and process quality can be improved.

Owner:上海启肽智能科技有限公司

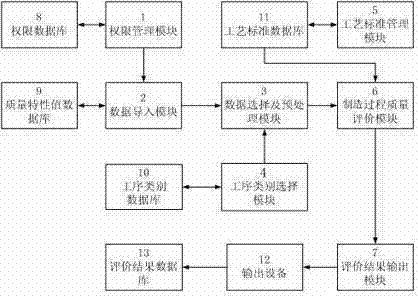

Method and system for evaluating quality in process of manufacturing cigarette

InactiveCN102509243AReflect the processing quality statusImprove quality controlData processing applicationsManufacturing computing systemsProcess qualityPrincipal component analysis

The invention discloses a method and system for evaluating quality in the process of manufacturing batch cigarette products. The method and system are characterized in that on the basis of evaluating the process quality of certain procedure single quality characteristic value, process performance indexes of a multivariable procedure are calculated by a principal component analysis method to obtain the weights of all principal components according to the respective characteristics of the procedures of shredding, wrapping, molding and the like, and the process performance indexes of the procedure are acquired through arithmetic weighted average, so that the quality in the process of manufacturing the cigarette is evaluated. Compared with other evaluation methods, the evaluation method disclosed by the invention has the advantages that: the selection of evaluation indexes more conforms to actual production demands, and the actual application range is wider; the establishment of evaluation standards fully refers to the conventional research results and is more scientific and objective; the quality control conditions of all production procedures of the cigarette can be better known through the evaluation; and more adequate data support is provided for continuously improving the quality in the process of manufacturing the cigarette and the final quality.

Owner:CHINA TOBACCO HEBEI INDUSTRIAL CO LTD

Special formulation fertilizer for rice

ActiveCN101054326APromote growthIn line with the law of absorptionSuperphosphatesUrea compound fertilisersFiberProcess quality

The invention belongs to fertilizer technical field, more particularly relates to a rice special formula fertilizer, which is characterized in that effective elements of the fertilizer are calculated by weight percent of pure nutrient are nitrogen 25-15, phosphorus pentoxide 15-9, potassium oxide 20-12, silicon dioxide 5-0, calcium 8-0, sulphur 5-1 and zinc 2-1. Compared with the present technique, the rice special formula fertilizer of the invention has reasonable match, accords with the nutrient absorption law of rice, can promote rice growth obviously and raise rough rice output, increase economic benefits and improve rice nutriment quality. In application test, the rice special formula fertilizer of the invention increases the rice yield by 660-820 kg per hectare, increases income 756-146 RMB, increases crude protein, raw fat, crude fiber, nitrogenfree extract and crude ash by 4.1-8.6, 0.14-0.80, 0.4-0.8, 0.1-3.0, 0.4-1.0 percentage points respectively, increases brown rice rate, integral white rice rate, white rice rate of rice processed quality by 1.4%, 1.7% and 1.8% respectively, reduces chalkiness granule rate, chalkiness by 3.2% and 1.9% respectively, reduces content of amylose by 1.0%. In the meanwhile, the fertilizer utilization efficiency is raised by 5.1%-13.8%.

Owner:HUBEI YISHIZHUANG AGRI TECH

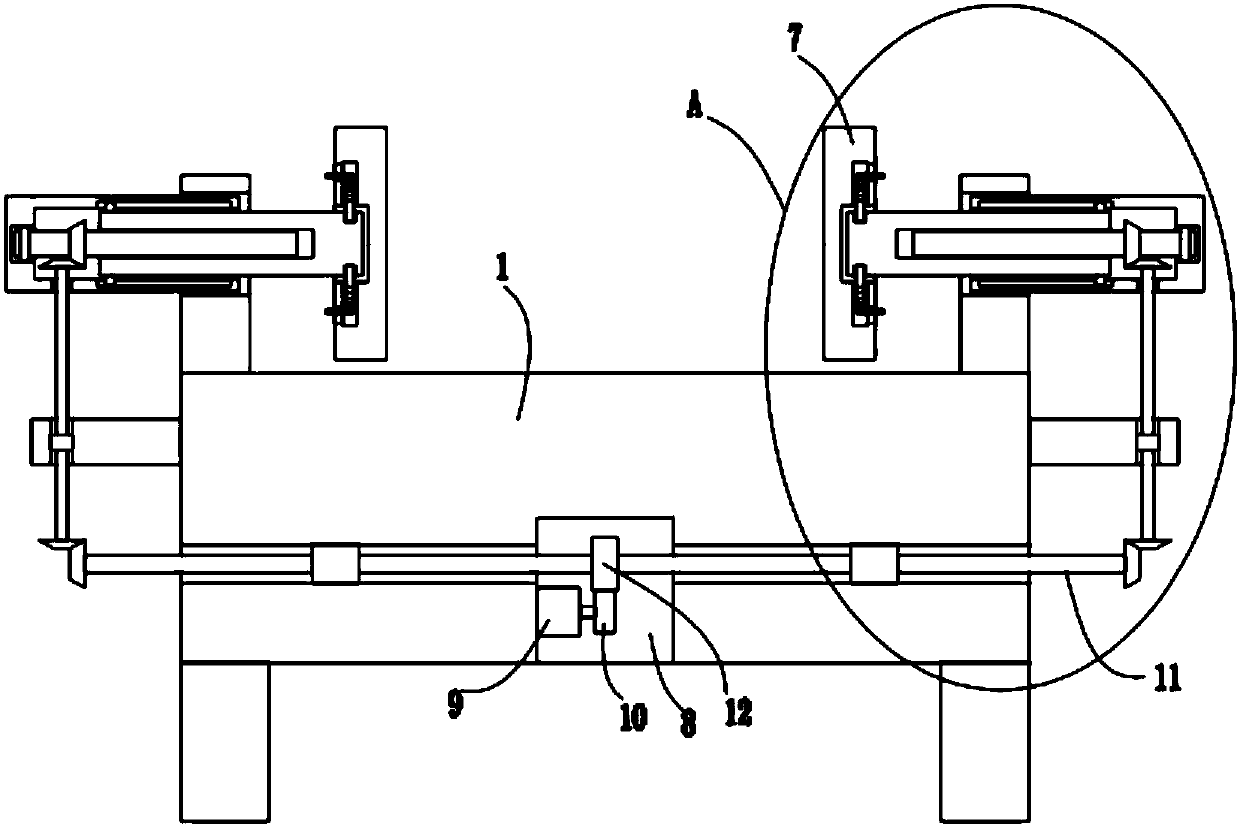

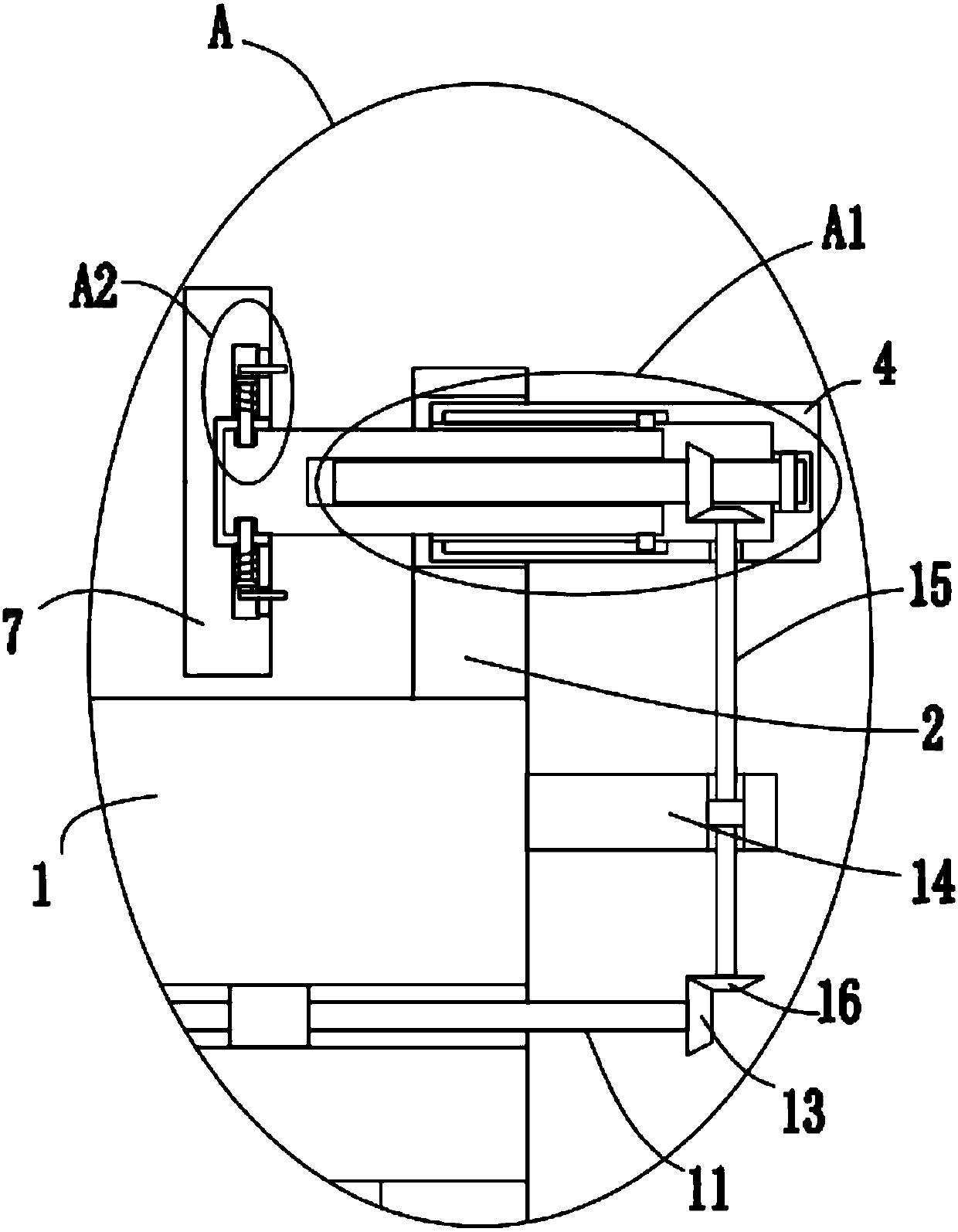

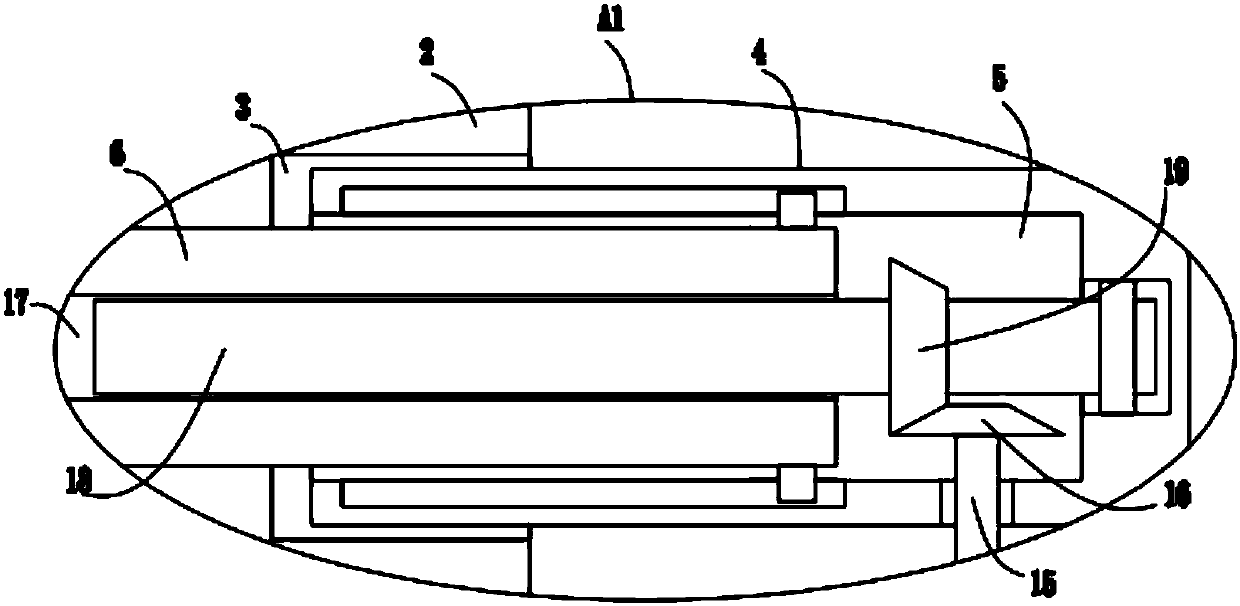

Processing table for automobile part

The invention discloses a processing table for an automobile part. The processing table comprises a processing table body, and two fixed seats are symmetrically and fixedly mounted at the top of the processing table body; first through holes are formed in the sides, close to each other, of the two fixed seats; fixed rods are fixedly mounted in the first through holes; the ends, away from each other, of the two fixed rods separately extend to the outer parts of the two first through holes; first grooves are formed in the ends, close to each other, of the two fixed rods; movable rods are mountedin the first grooves in a sliding manner; and a driving assembly used for controlling the movable rods to move is arranged between the processing table body and the fixed seats. According to the processing table, the automobile part can be conveniently and quickly clamped between two clamping blocks, processing quality of the automobile part is guaranteed, besides, the different clamping blocks can be conveniently changed to clamp the automobile parts of different shapes and specifications, and the processing table has relatively high practicability.

Owner:柳州市钜嘉机械有限公司

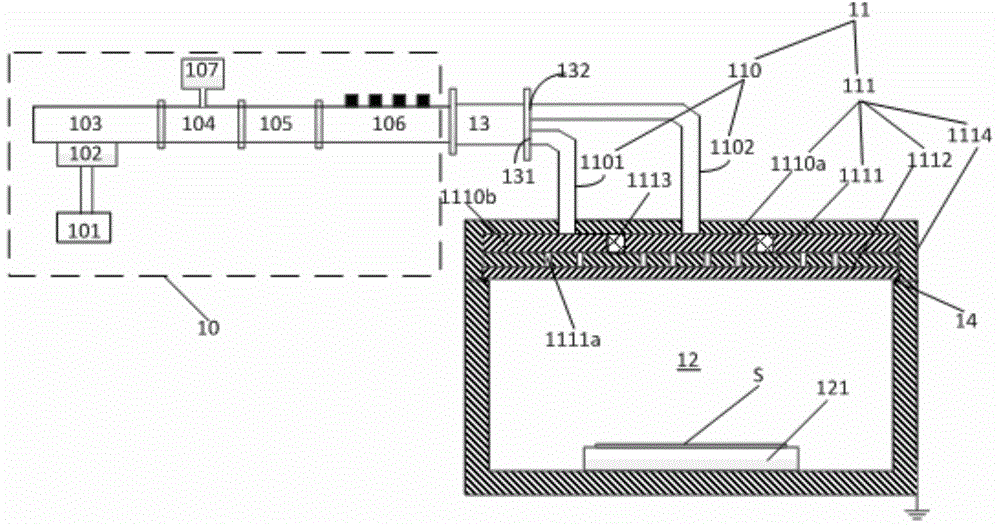

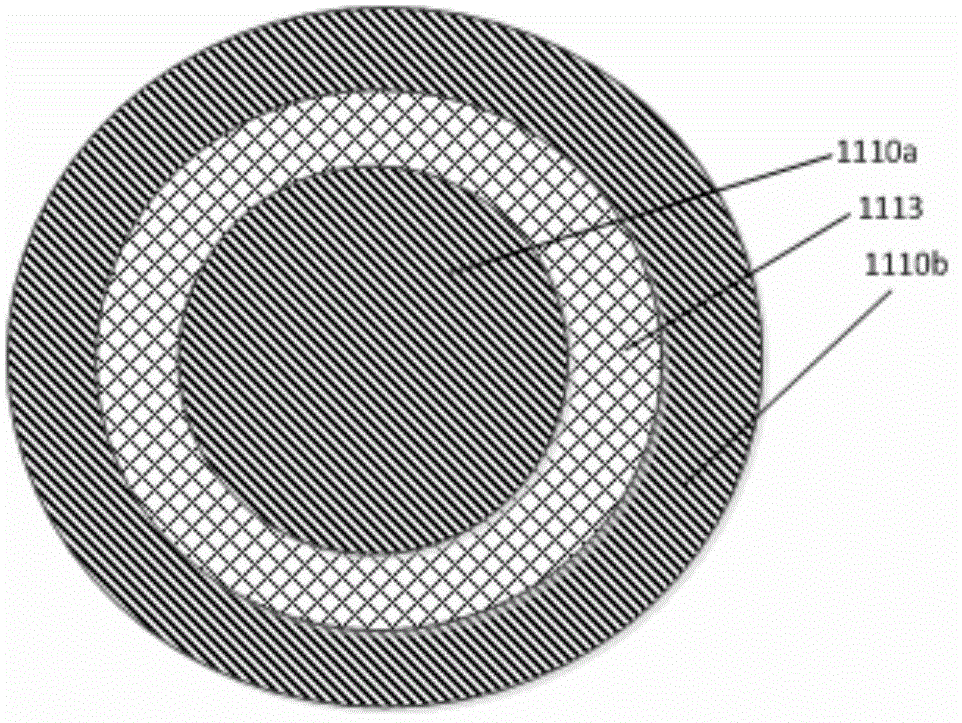

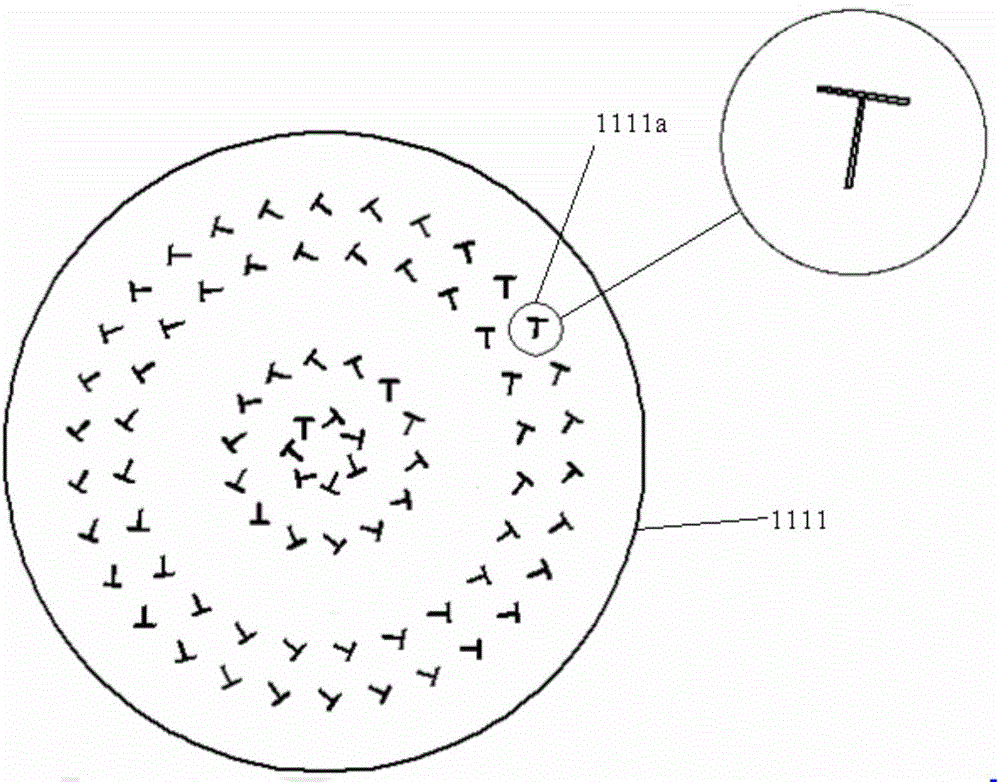

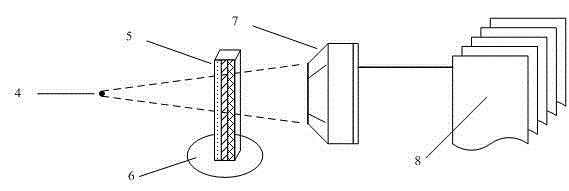

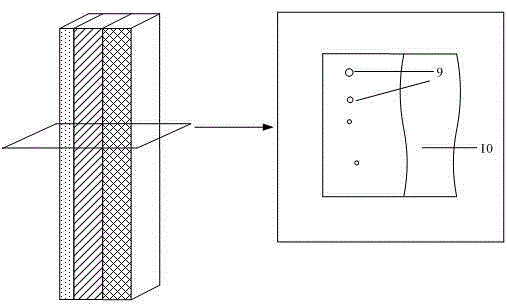

Surface-wave plasma equipment

InactiveCN105430862AImprove the quality of workmanshipPlasma techniqueProcess qualityProcess conditions

The invention provides surface wave plasma equipment. The surface wave plasma equipment comprises a microwave generation device, a microwave transmission device and a reaction cavity which are successively connected; the microwave generation device is used to generate a microwave forming a surface-wave plasma; the microwave transmission device comprises wave guides and a microwave antenna, the microwave antenna is divided into a plurality of sub antennas, the sub antennas correspond to different areas of the reaction cavity, the number of the wave guides is equal to the number of the sub antennas, the wave guides are correspondingly connected with the sub antennas one by one, and the microwave generated by the microwave generation device is coupled to the different areas of the reaction cavity via the wave guides and the sub antennas corresponding to the wave guides; and, through respective adjustments of power of the microwave coupled to the different areas of the reaction cavity, uniform and large-area surface-wave plasmas are formed over a substrate in the reaction cavity. According to the surface-wave plasma equipment provided by the invention, the uniform and large-area surface-wave plasmas can be formed over the substrate under different process conditions, and then process quality can be improved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Method for three-dimensional representation of stratified structure micrometer CT imaging of turbine blade heat barrier coating

InactiveCN104897698AImprove reconstructed image qualityRealize 3D structural analysisMaterial analysis by transmitting radiationPorosityProcess quality

The invention discloses a method for three-dimensional representation of stratified structure micrometer CT imaging of a turbine blade heat barrier coating. The method comprises the following steps: preparing a double-layer-structure heat barrier coating micrometer CT scanning sample; firstly, carrying out micrometer CT scanning on the heat barrier coating sample, carrying out ring artifact and beam hardening correction on projection data, then carrying out three-dimensional reconstruction to obtain three-dimensional stratified structure information, establishing a three-dimensional structure analysis model, and carrying out characteristic segmentation and extraction on three components, namely a ceramic heat insulating layer, a bonding layer and matrix alloy; then, analyzing the thickness of the coating, extracting the distribution of holes in the coating, calculating the porosity, extracting the interface topography of the coating, and analyzing structure characteristics such as internal defects; and finally, estimating the preparation process quality of the heat barrier coating by integrating the composition, thickness, porosity distribution, interface topography and the like. The method for three-dimensional representation of the stratified structure of the heat barrier coating provided by the invention is suitable for estimation and optimization of the spraying process quality of the heat barrier coating, so that the quality of the heat barrier coating can be well controlled.

Owner:NANCHANG HANGKONG UNIVERSITY

Degumming method of fabric

The invention relates to a degumming method for hemp fiber, in particular to a method for combined application of chemical with super critical CO2 fluid degumming. Wherein, before carrying out super critical CO2 fluid degumming, the hemp fiber first goes through chemical treatment, then super critical degumming is carried out under low and hi pressure respectively. The invention can obviously reduce the non-cellulose composition for example lignin, etc. in hemp fiber, is of an ideal degumming effect, with obviously improved cellulose ratio, very good softening effect of fiber, hence improved process quality of hemp fiber; the invention additionally overcomes the shortcoming associated with prior degumming way such as high pollution, etc., and is of high economic efficiency.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

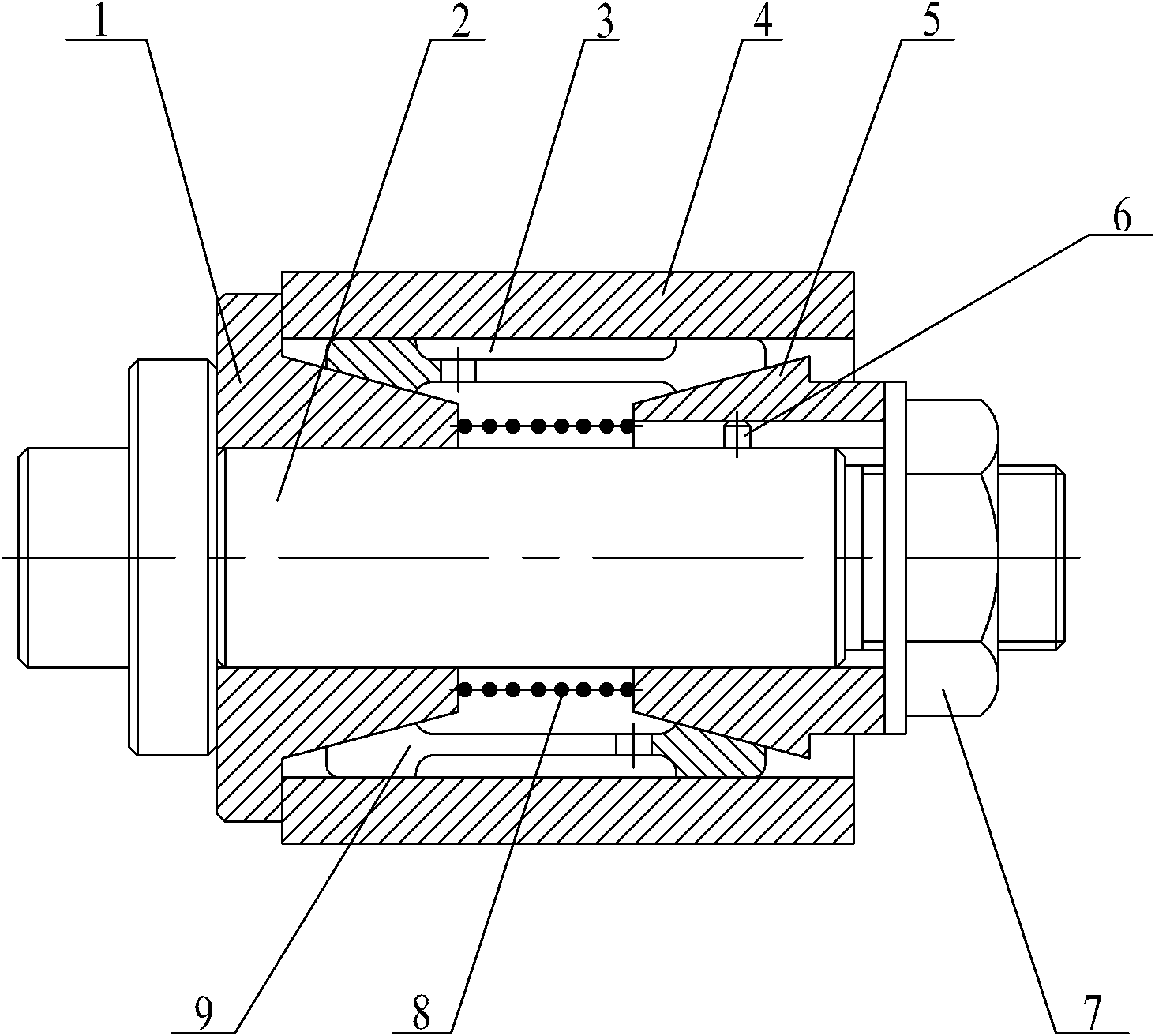

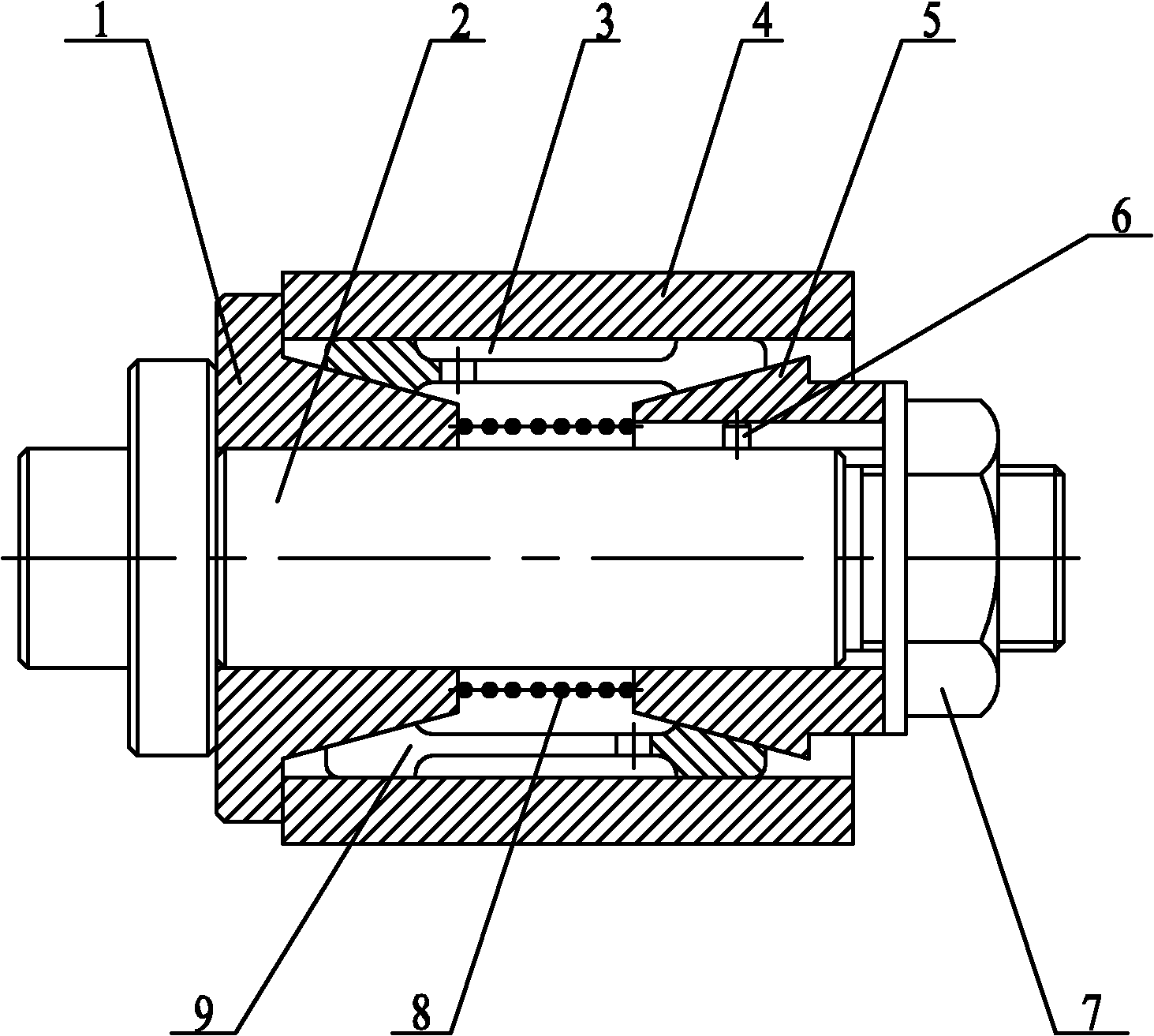

Device capable of elastically clamping two ends of long hole

InactiveCN102069207AEasy to removeRemove effectiveExpansion mandrelsProcess qualityMechanical engineering

The invention relates to a device capable of elastically clamping two ends of a long hole. The device comprises a central spindle, wherein a left taper sleeve is arranged at one end of the central spindle, and a right taper sleeve is arranged at the other end; elastic clamping heads are arranged at correspondingly connected ends of the left taper sleeve and the right taper sleeve; a plurality of flexible open slots are evenly distributed on peripheral surfaces of the elastic clamping heads; and the ends of the left and right taper sleeves connected with the elastic clamping heads are both extended into the elastic clamping heads. The elastic clamping device provided by the invention is simple in structure and low in manufacturing cost and has the following advantages: when a locknut is screwed, the right taper sleeve can be pushed to move to cause the elastic clamping heads to extend outwardly, thus achieving the purpose of fastening and installing a workpiece; in addition, when the locknut is loosened, the elastic clamping heads shrink and the processed workpiece is convenient to remove; the workpiece is fixed effectively and reliably, and the stability of process quality is improved greatly; since the elastic clamping heads have low requirements on hole tolerance of a blank to be processed, the manufacturing cost is reduced; since the elastic clamping device provided by the invention is convenient to clamp, the work efficiency is improved greatly; and the elastic clamping device provided by the invention has a wide application scope and longer service life because of no sliding friction.

Owner:WUXI YINLIAN GEAR MACHINERY CO LTD

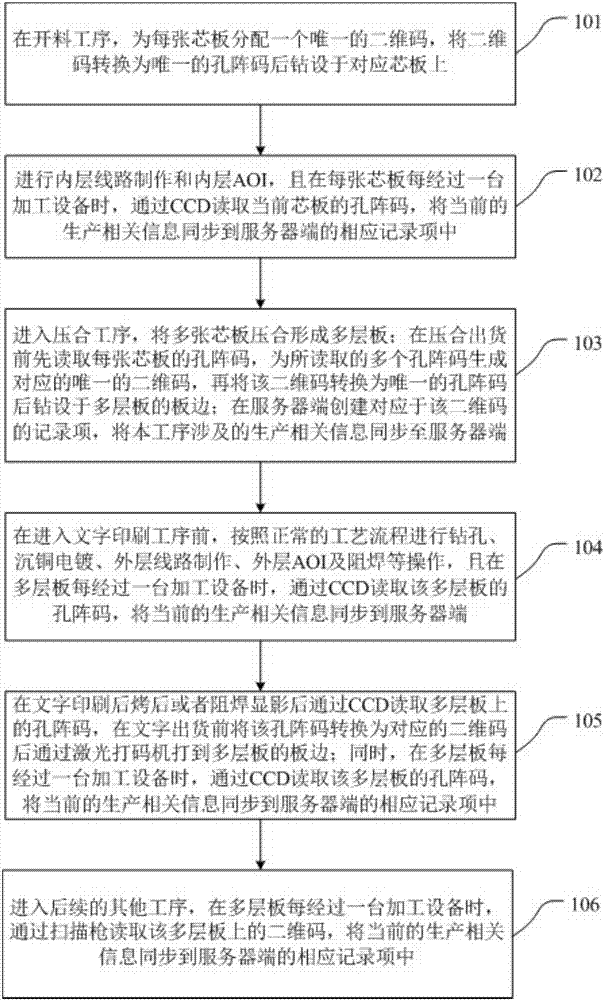

Quality tracing method for multi-layer PCB

ActiveCN108012426AAccurate identificationRealize quality controlPrinted circuit aspectsInspection/indentification of circuitsProcess qualityParallel computing

The invention relates to the field of PCBs, and discloses a quality tracing method for a multi-layer PCB. The quality tracing method comprises the steps of distributing a unique two-dimensional code for each core board in a board cutting procedure, converting each two-dimensional code into a unique hole array code and then drilling the unique array code on the corresponding core board; reading thehole array code on each core board in a laminating procedure, combining all of the read hole array codes into a corresponding unique two-dimensional code, then converting the two-dimensional code into a unique hole array code, and drilling the unique hole array code on a laminated multi-layer board; and reading the hole array code on the multi-layer board after a resistance welding procedure, converting the hole array code into a corresponding two-dimensional code, and marking the two-dimensional code on the multi-layer board. The embodiment of the invention can ensure accurate recognition ofa tracing identifier in each procedure in the manufacturing process of the multi-layer PCB, thereby laying a foundation for realizing whole-process quality monitoring for products; and the transfer of information from an inner layer to an outer layer is realized in the laminating procedure, thereby preventing the loss of the information in the inner layer, and being capable of realizing whole-life-cycle tracing for the products.

Owner:GUANGDONG ZHENGYE TECH

Device for and method of creating a model for determining relationship between process and quality

InactiveCN1655325ASemiconductor/solid-state device testing/measurementVacuum evaporation coatingState dependentProcess quality

A model creating device inputs process status data that are obtained in time series during a period during which each of process steps of a process is carried out and are related to status of this process, as well as inspection result data related to object articles that were processed by said process. An extracting part extracts a characteristic quantity from the process status data for every unit object article and for every process step. An analyzing part carries out an analysis by data mining by using the characteristic quantities and inspection result data in correlation with the unit object articles and creates a process-quality model that shows a relationship between the correlated characteristic quantities and inspection result data.

Owner:CANON SYST SOLUTIONS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com