Patents

Literature

478results about "Conductive material mechanical removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

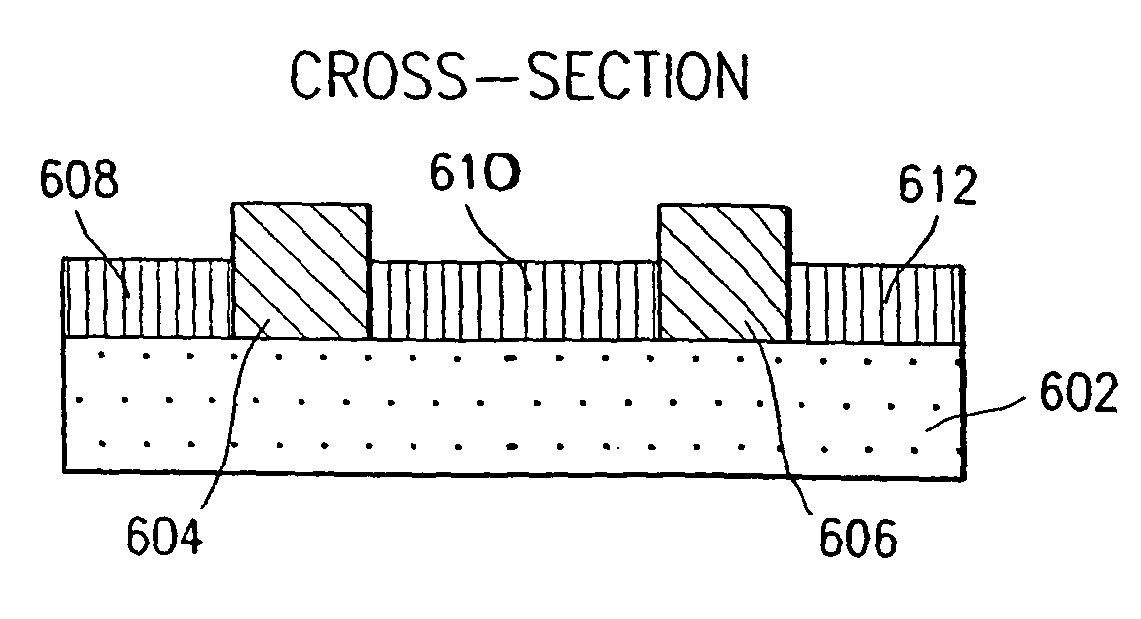

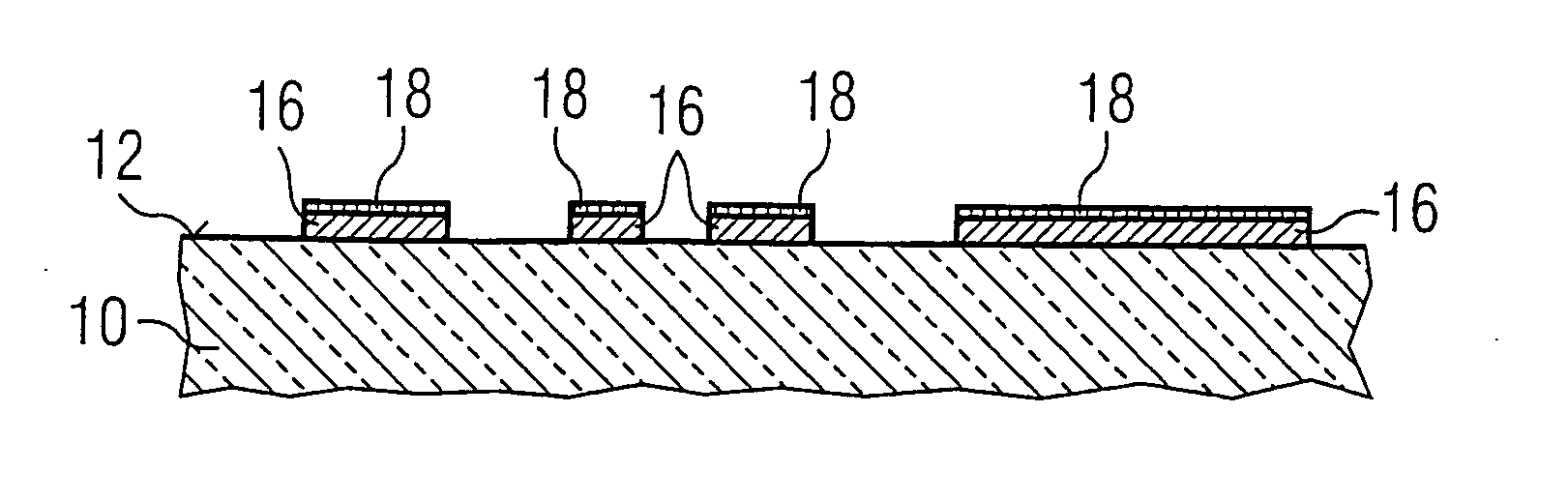

High reliability multlayer circuit substrates and methods for their formation

InactiveUS20040061234A1Semiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorOptoelectronics

A multilayer circuit substrate for multi-chip modules or hybrid circuits includes a dielectric base substrate, conductors formed on the base substrate and a vacuum deposited dielectric thin film formed over the conductors and the base substrate. The vacuum deposited dielectric thin film is patterned using sacrificial structures formed by shadow mask techniques. Substrates formed in this manner enable significant increases in interconnect density and significant reduction of over-all substrate thickness.

Owner:MEDTRONIC MIMIMED INC

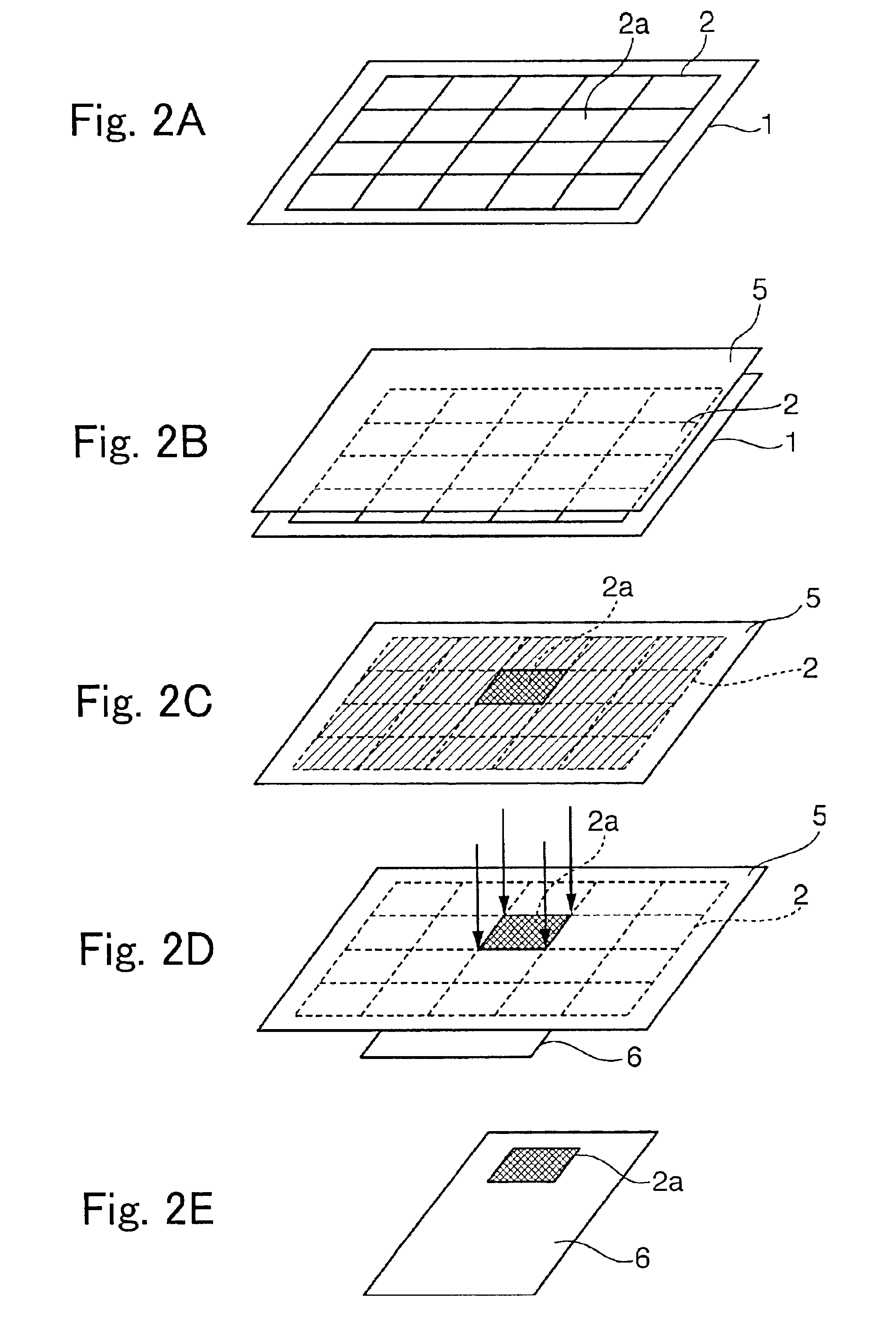

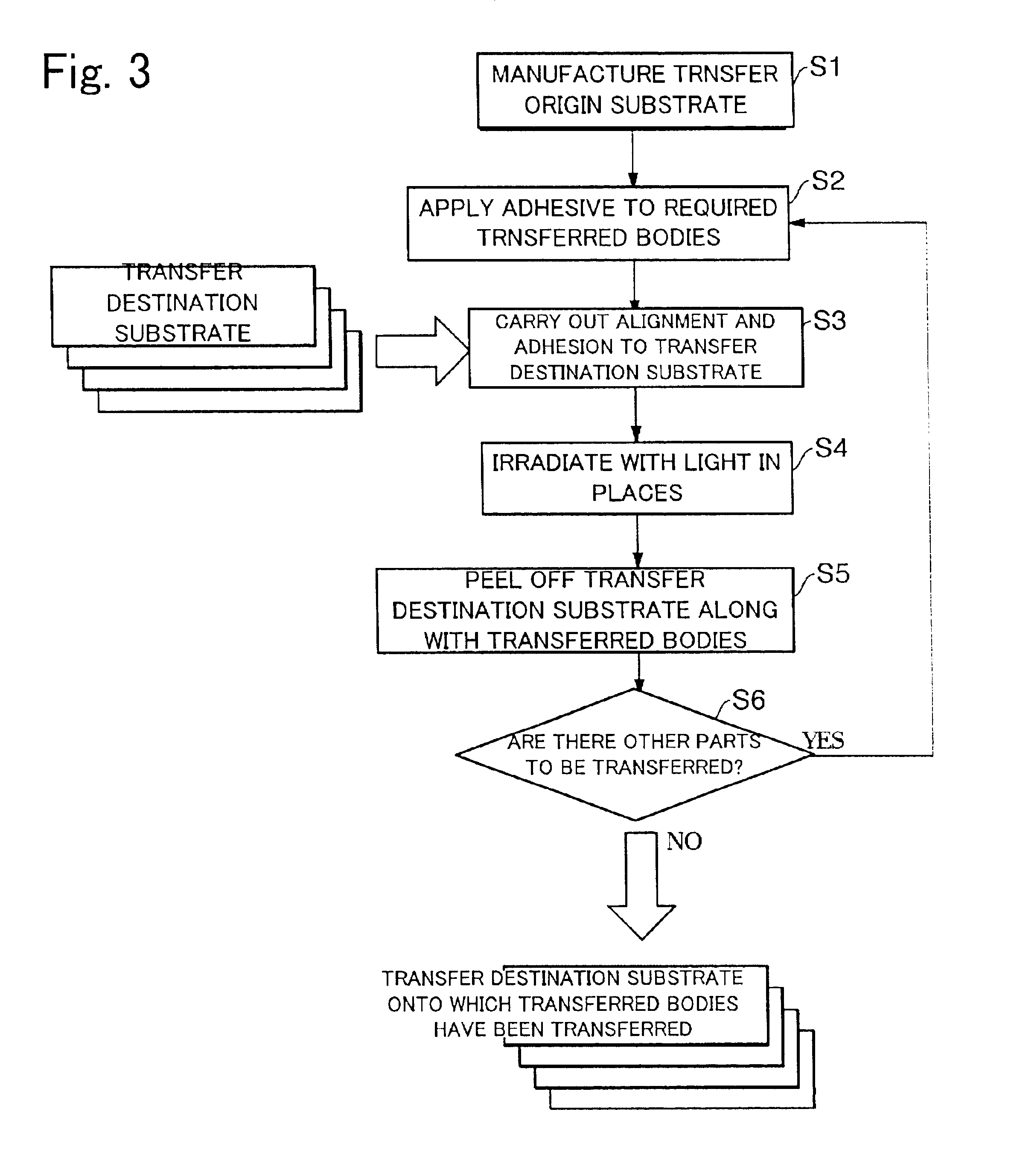

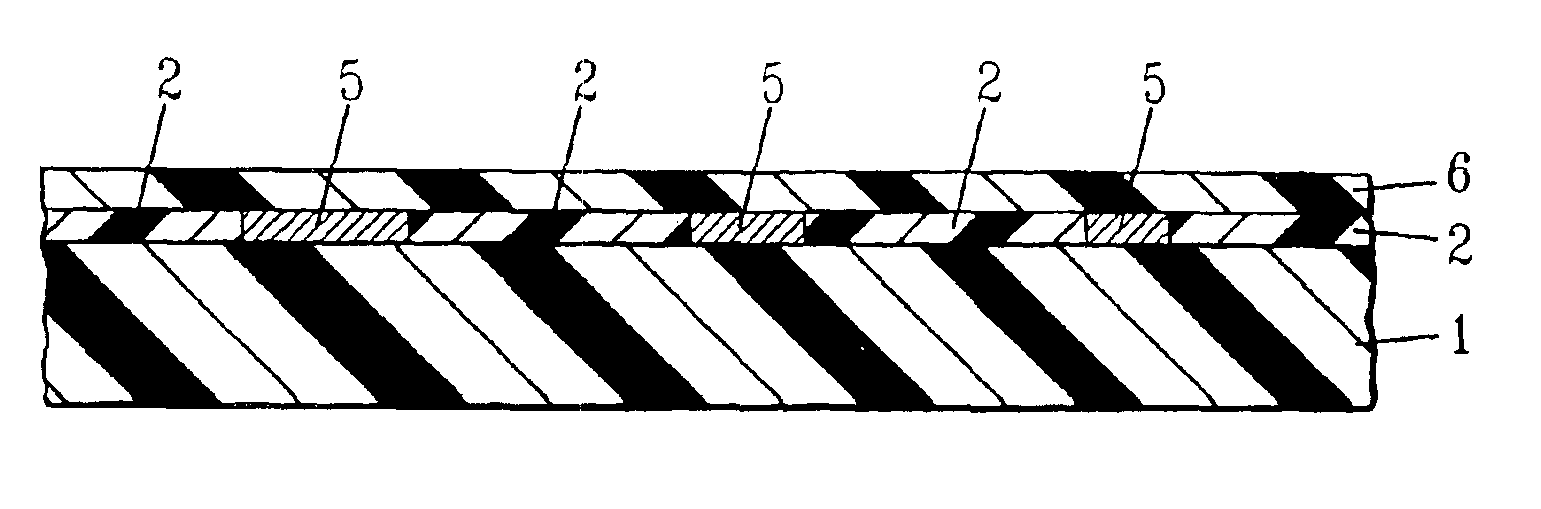

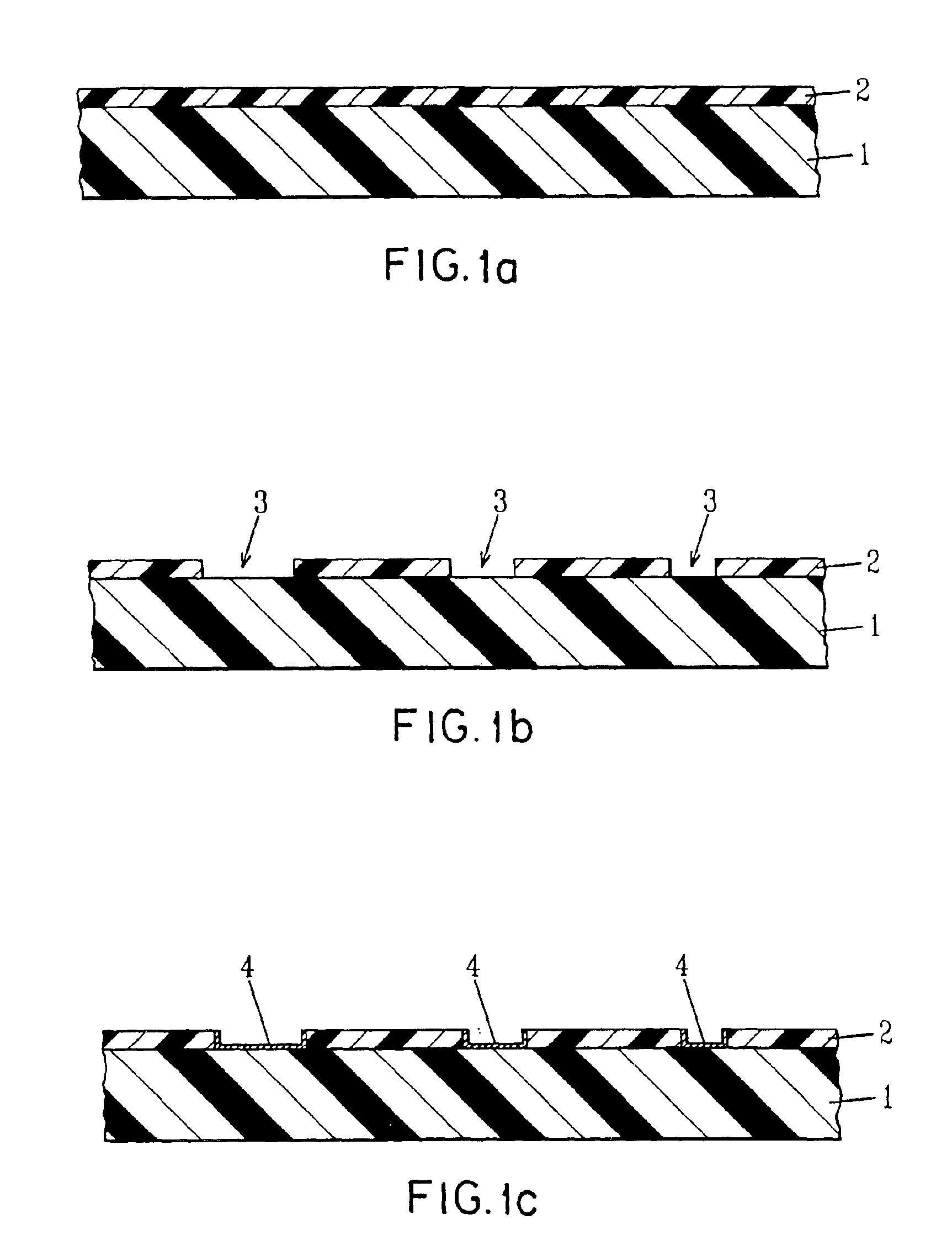

Transfer method, method of manufacturing thin film devices, method of manufacturing integrated circuits, circuit board and manufacturing method thereof, electro-optical apparatus and manufacturing method thereof, IC card, and electronic appliance

InactiveUS6887650B2Reduce material usageImprove area efficiencyMaterial nanotechnologyElectric discharge heatingIntegrated circuitElectronic equipment

Owner:SAMSUNG ELECTRONICS CO LTD

Structure having laser ablated features and method of fabricating

InactiveUS6919514B2Dense configurationInsulating substrate metal adhesion improvementPrinted circuit secondary treatmentOptoelectronicsMetal

Embedded flush circuitry features are provided by providing a conductive seed layer on the sidewalls and bottom of laser ablated trench features plating a layer of conductive metal onto the seed layer and depositing a layer of dielectric material.

Owner:META PLATFORMS INC

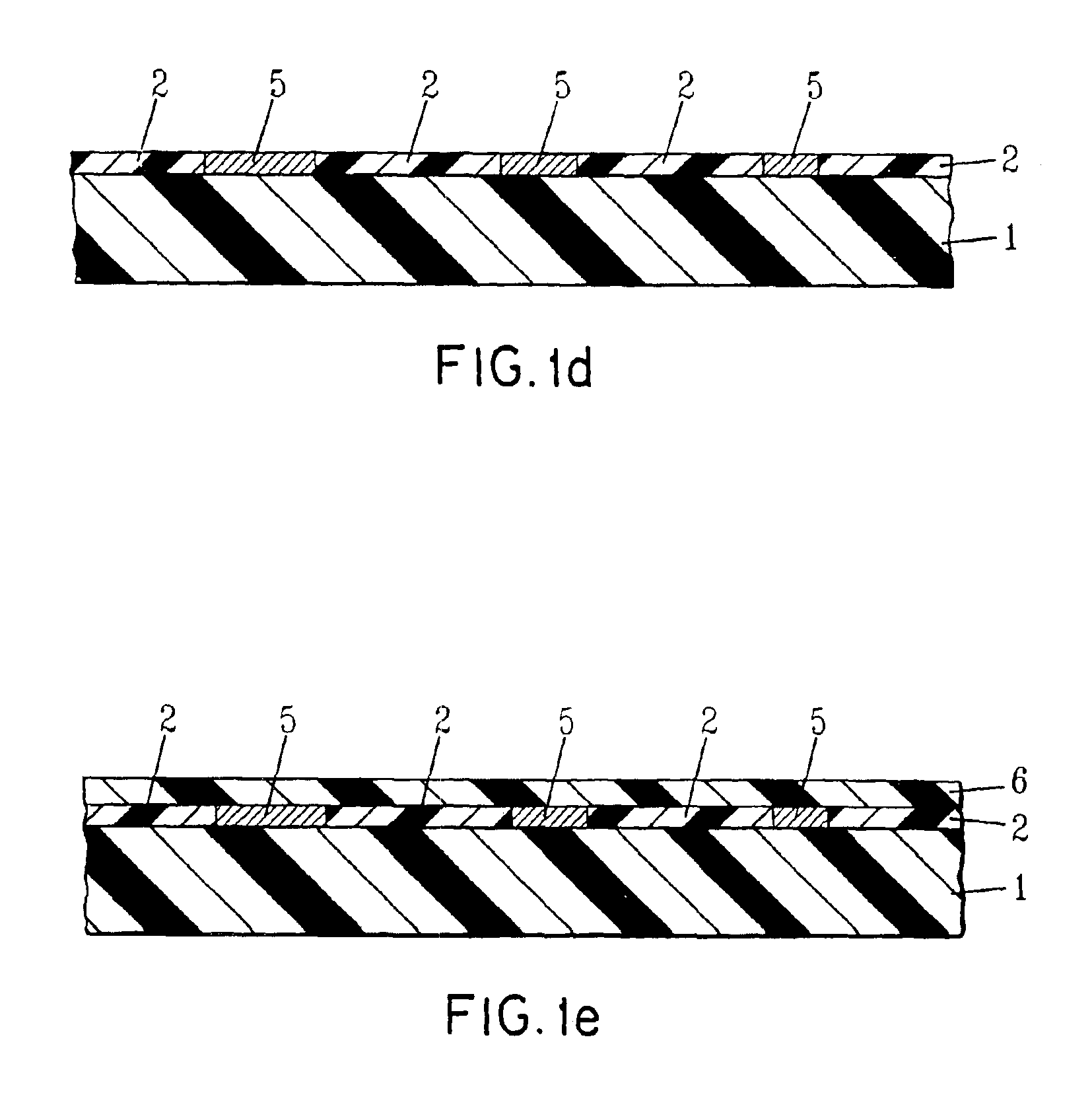

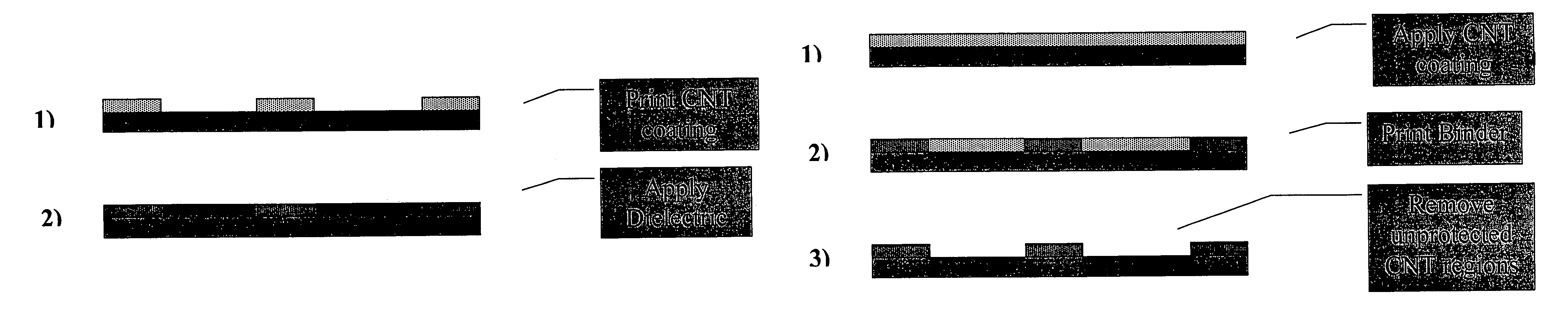

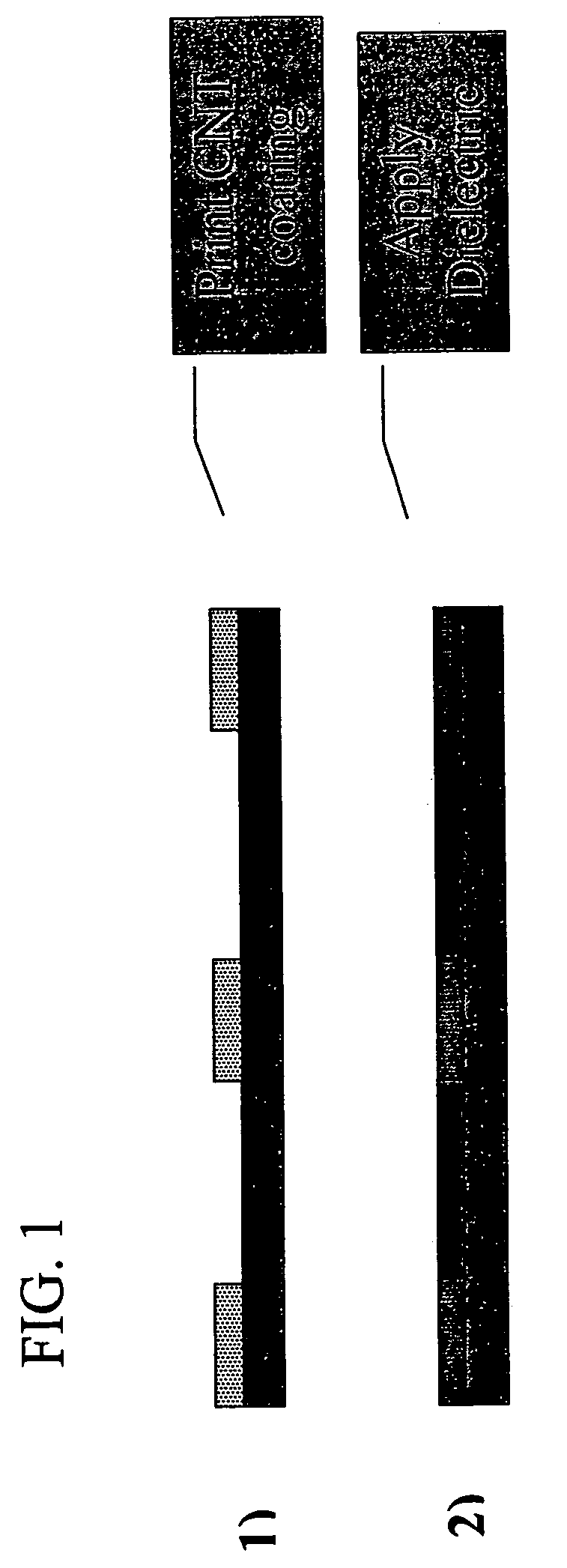

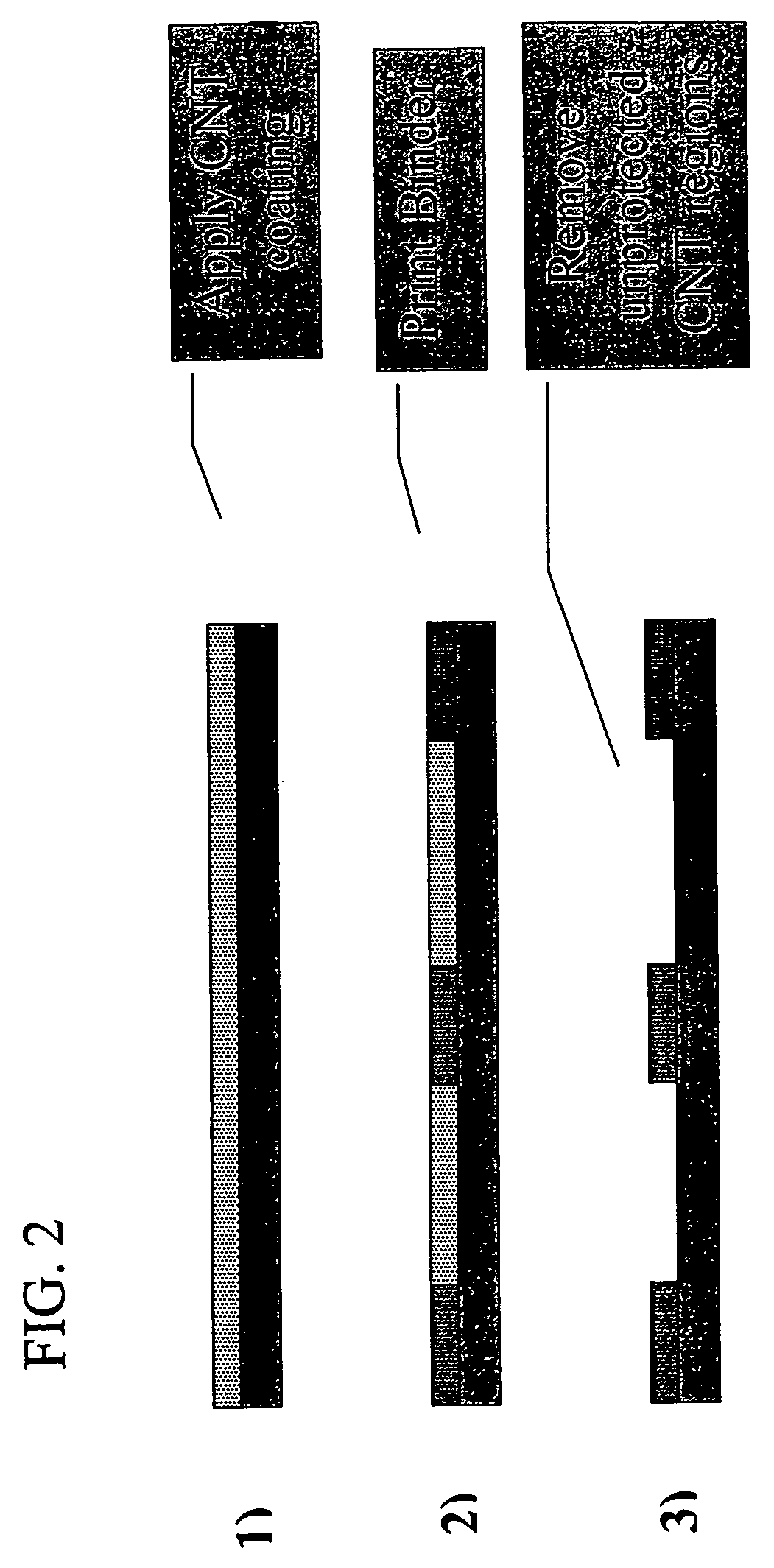

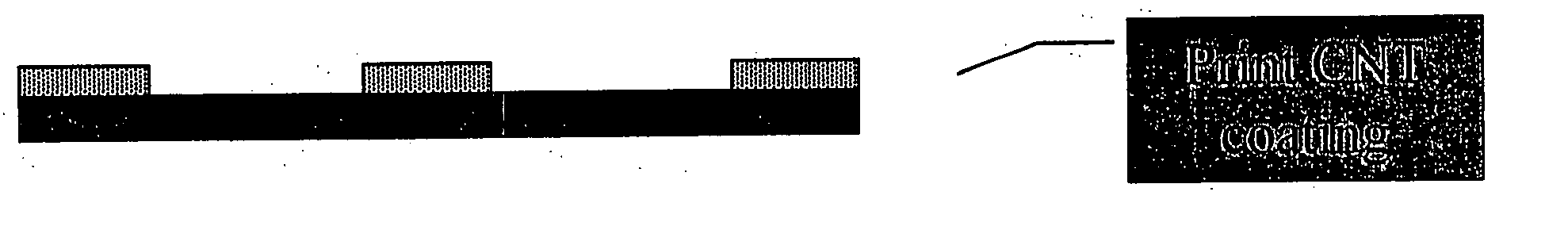

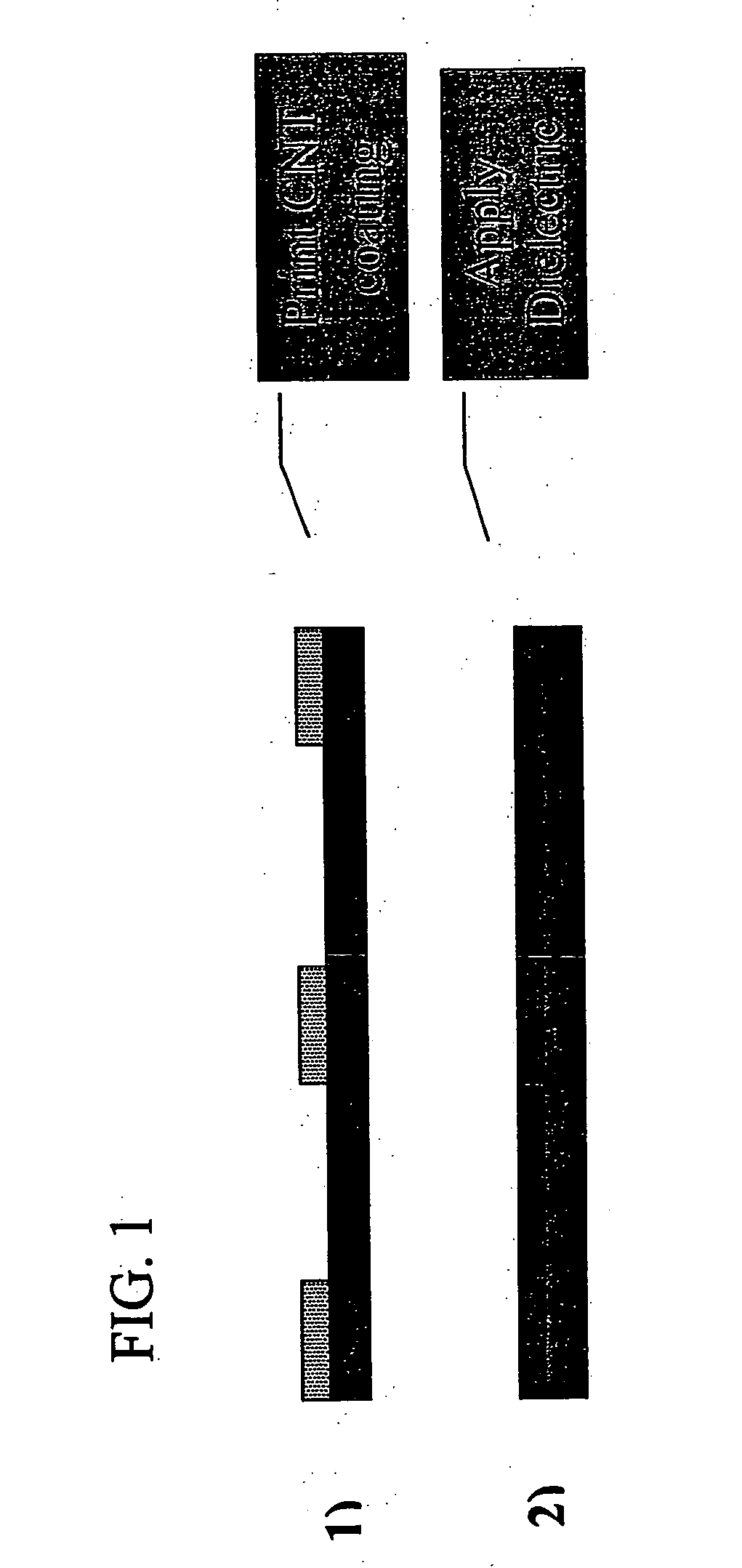

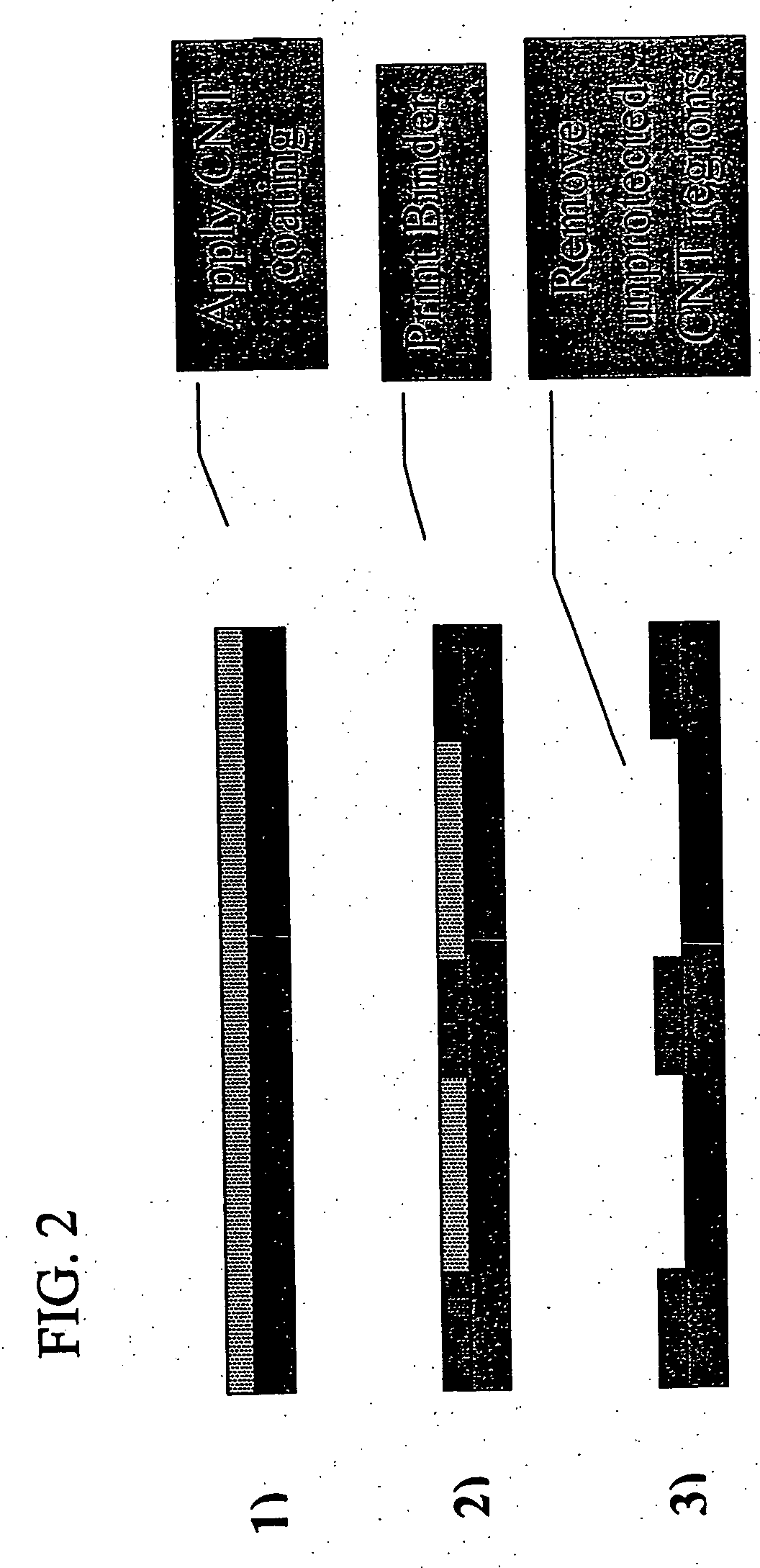

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:EIKOS

Method for the fabrication of conductive electronic features

InactiveUS20100112195A1Reduce settlementGood dispersionPretreated surfacesSemiconductor/solid-state device manufacturingElectronMaterials science

Owner:CABOT CORP

System and method for manufacturing embedded conformal electronics

ActiveUS20050029236A1Increase power generationMolten spray coatingThermoelectric device with peltier/seeback effectThermal sprayingEngineering

A method for fabricating an electronic device comprises providing a substrate (501), direct writing a functional material by a thermal spray on the substrate (502) and removing a portion of the function material to form the electronic or sensory device (503).

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

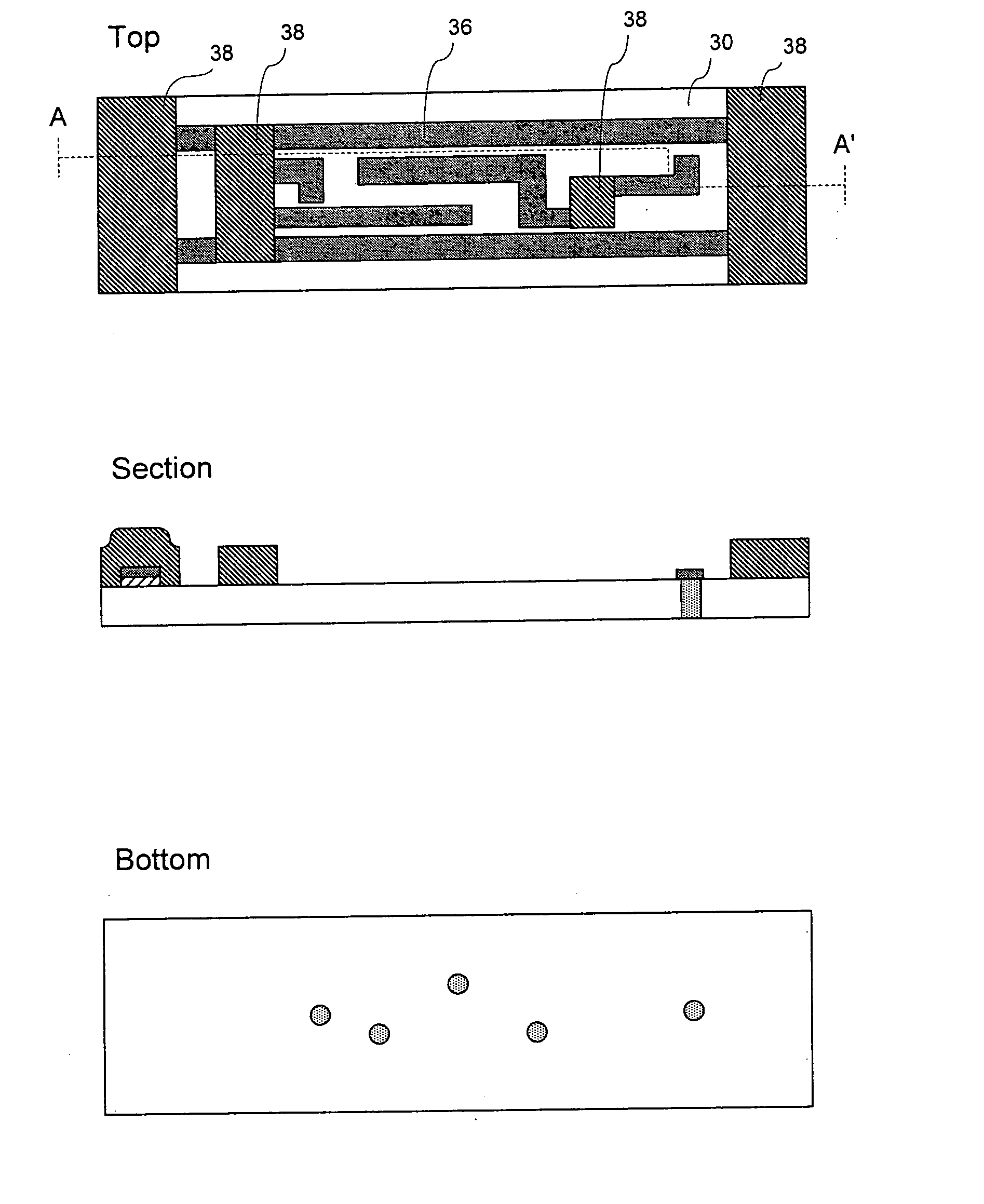

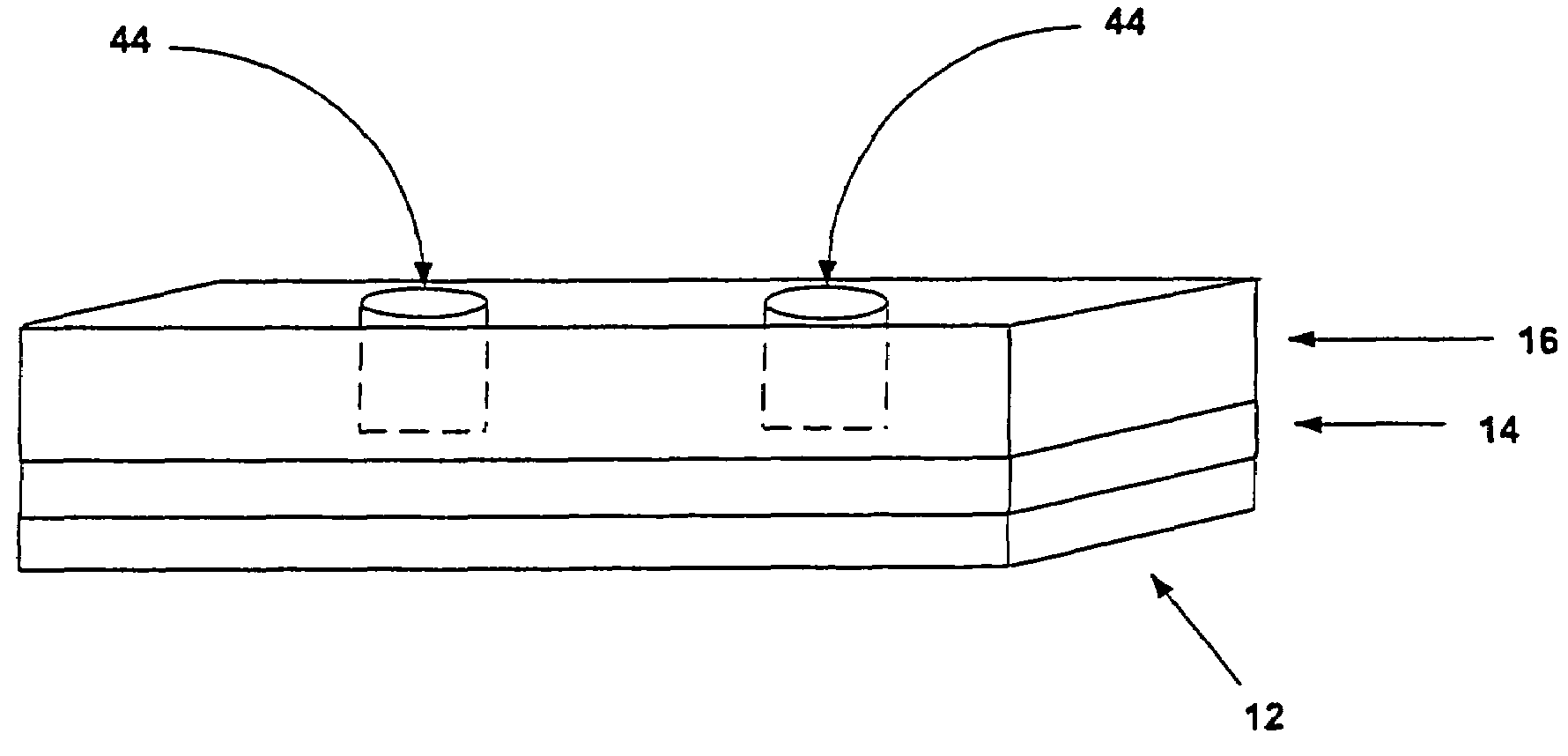

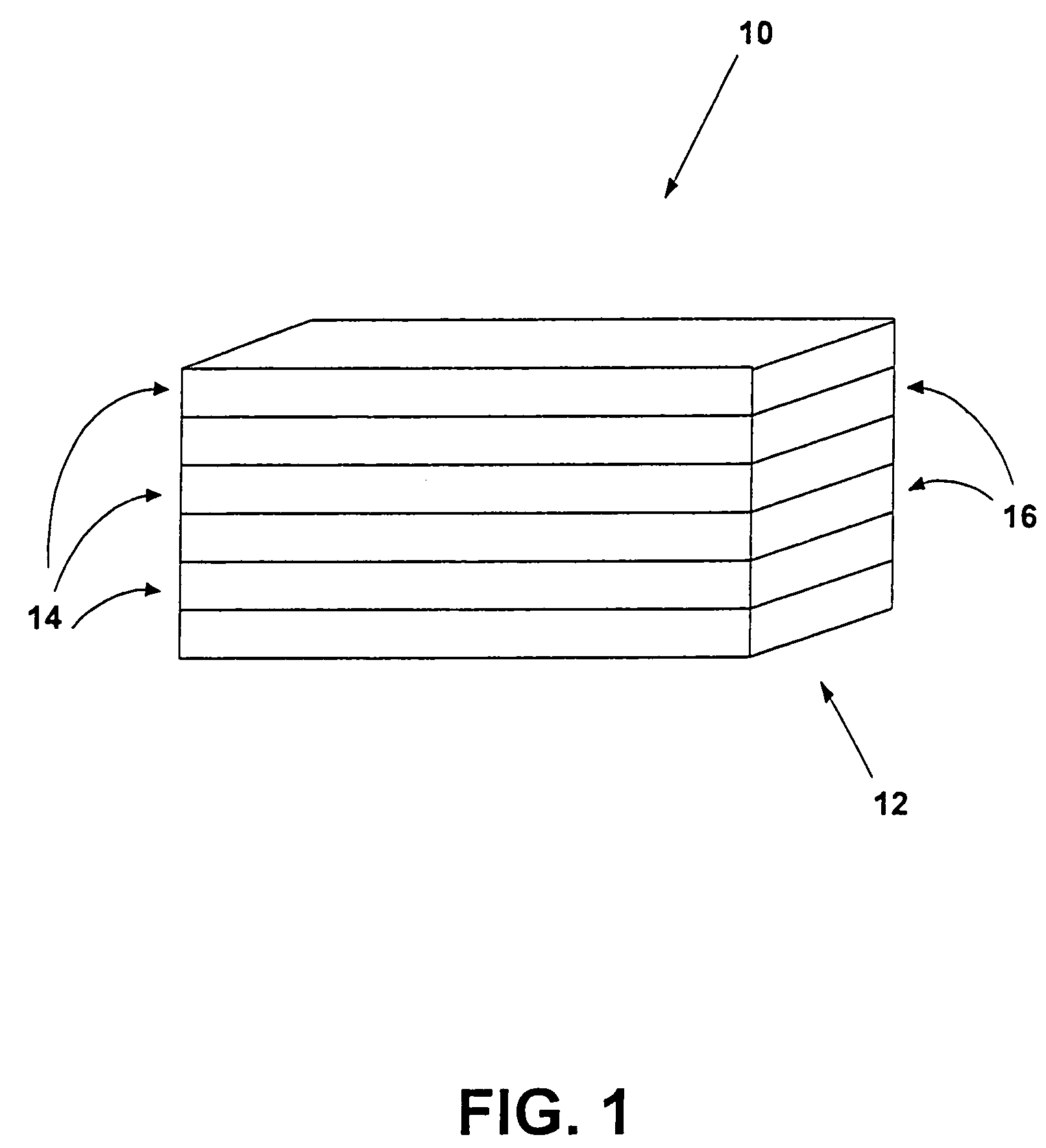

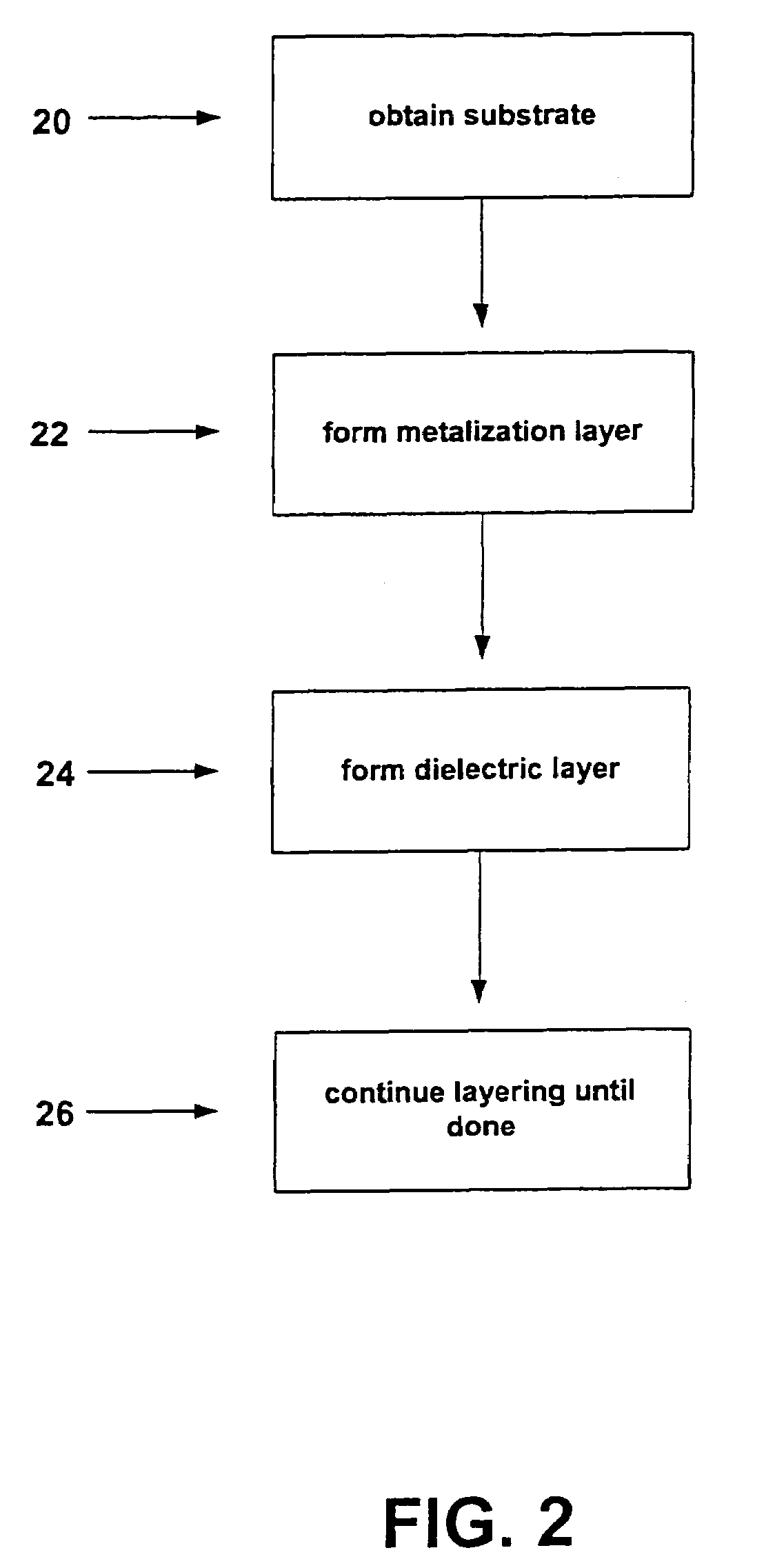

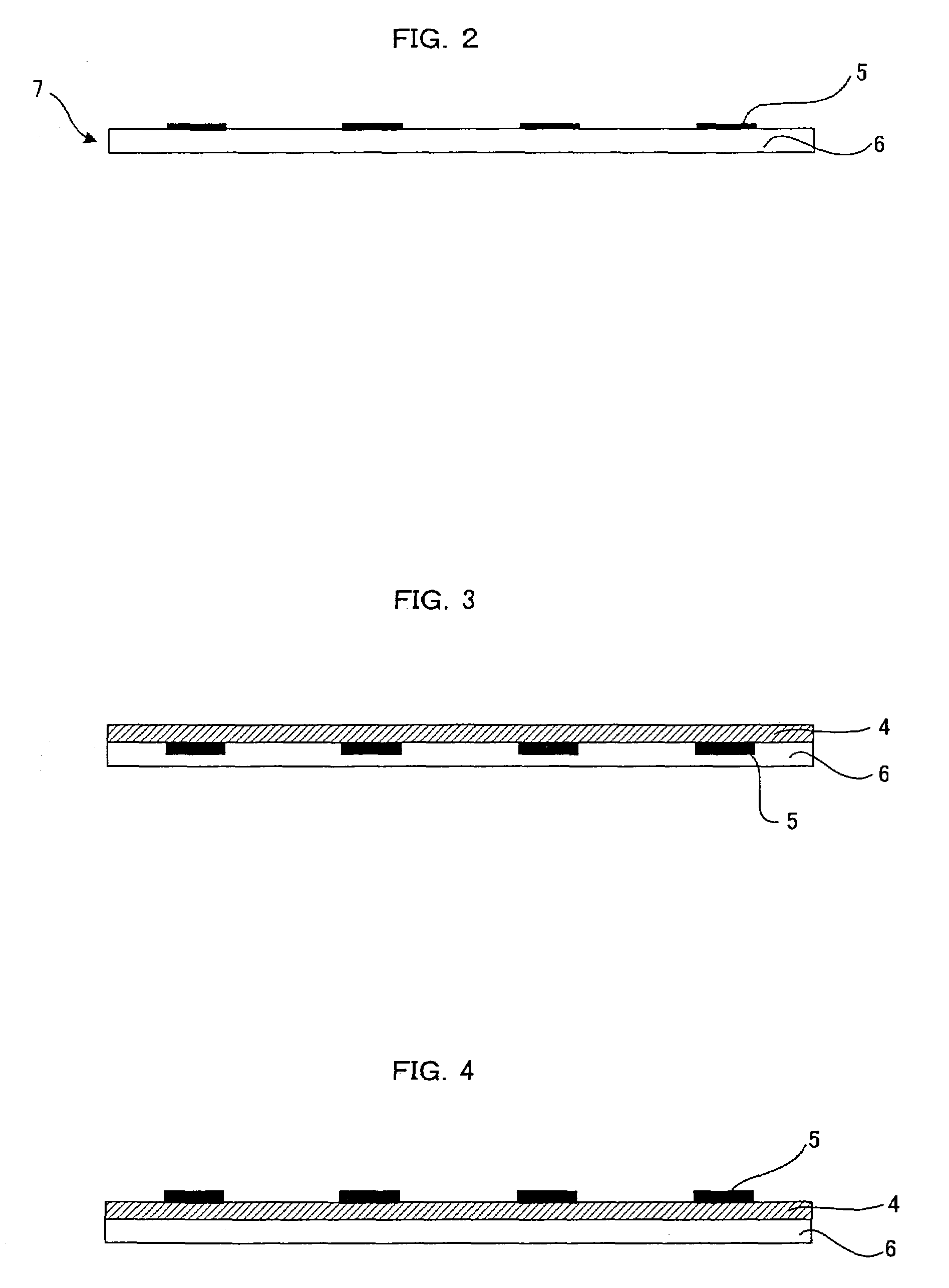

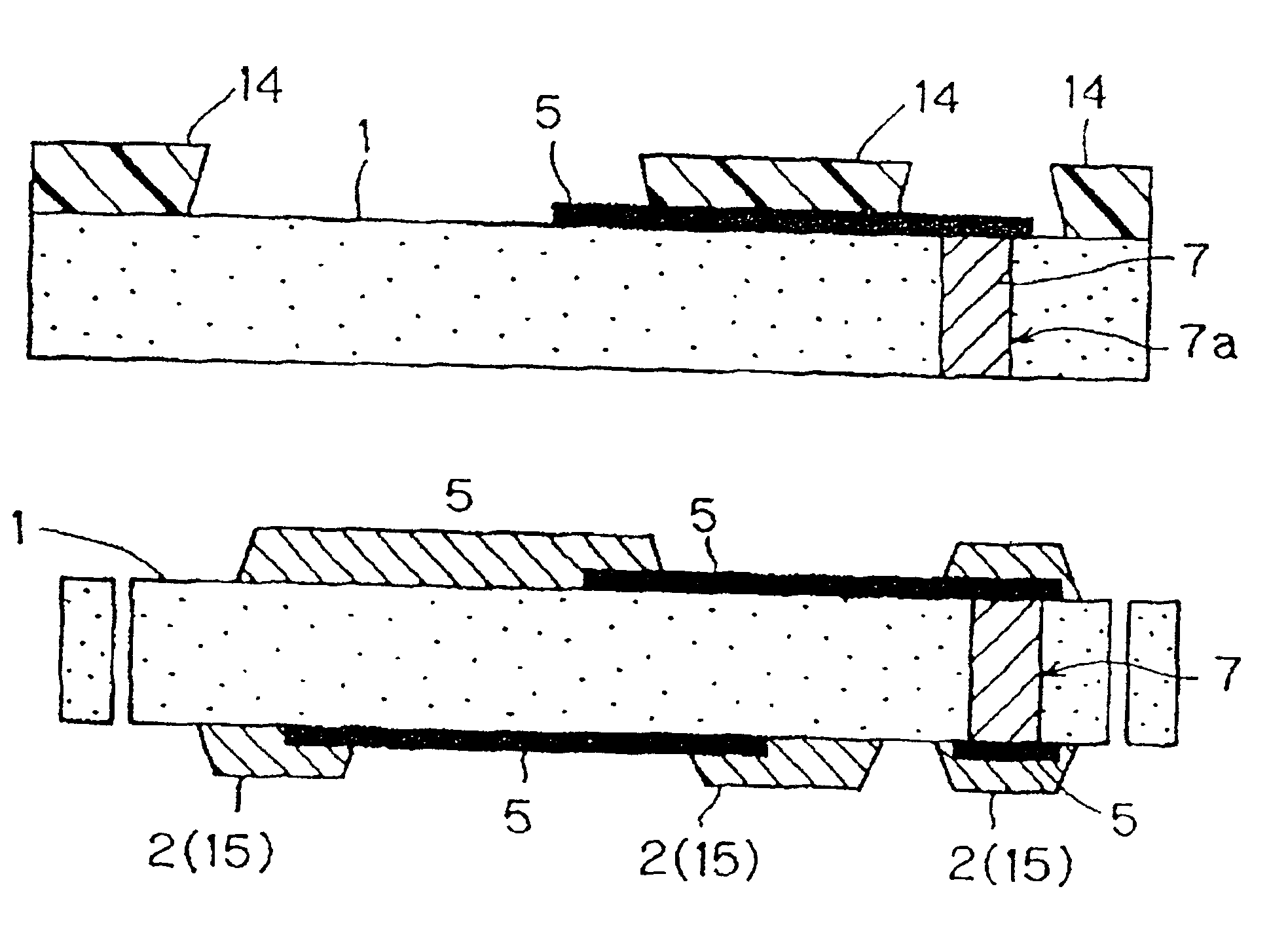

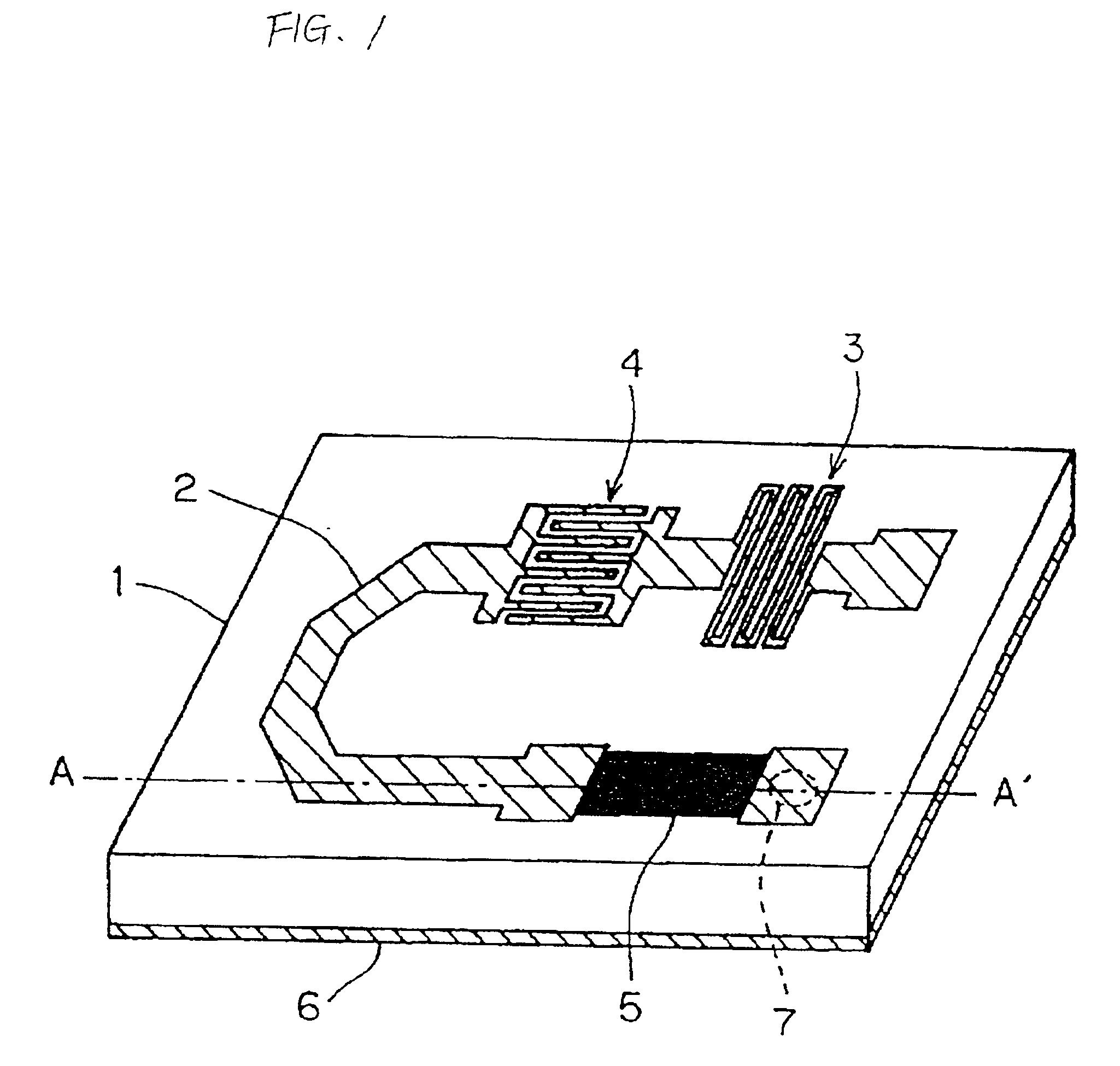

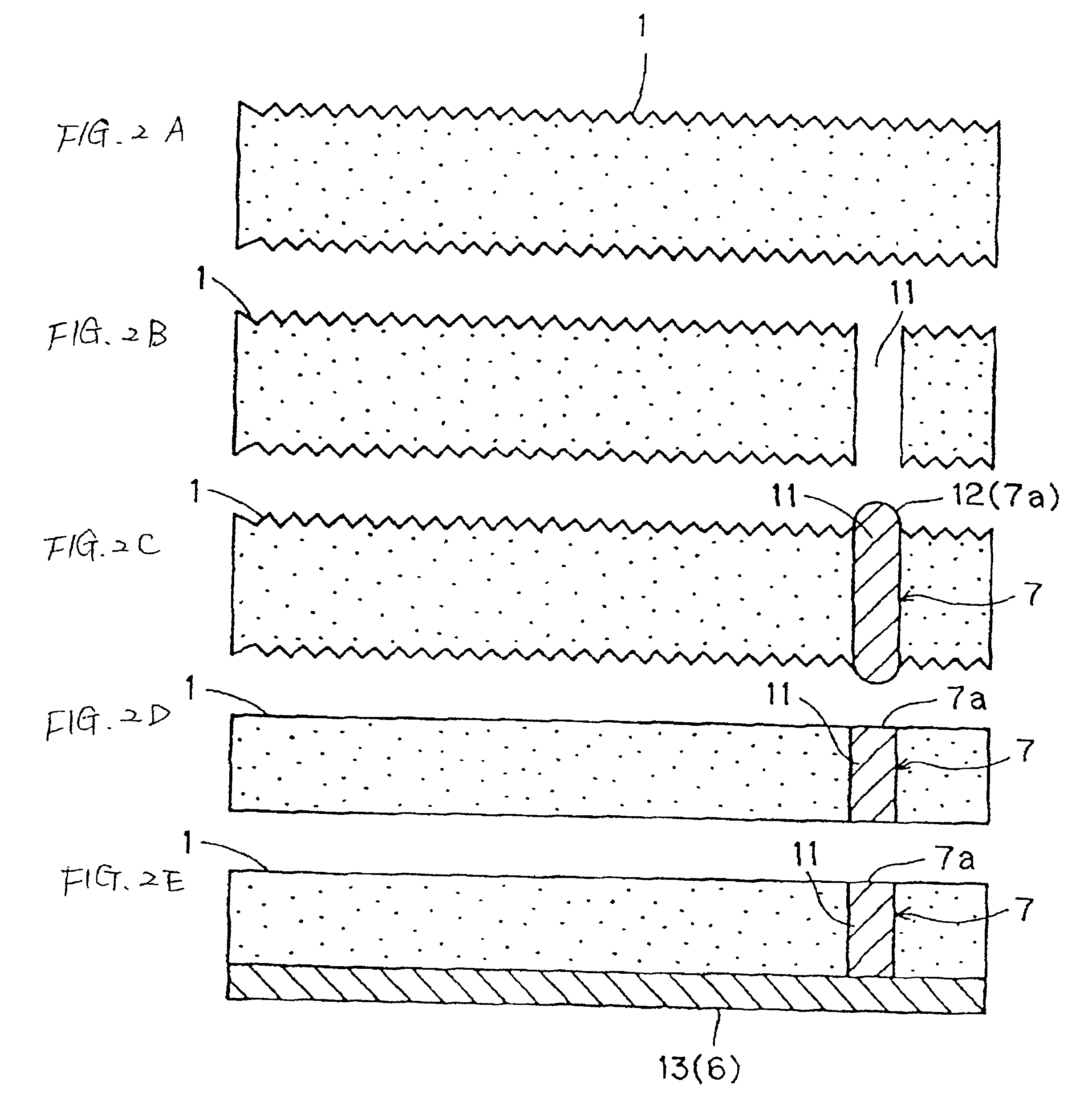

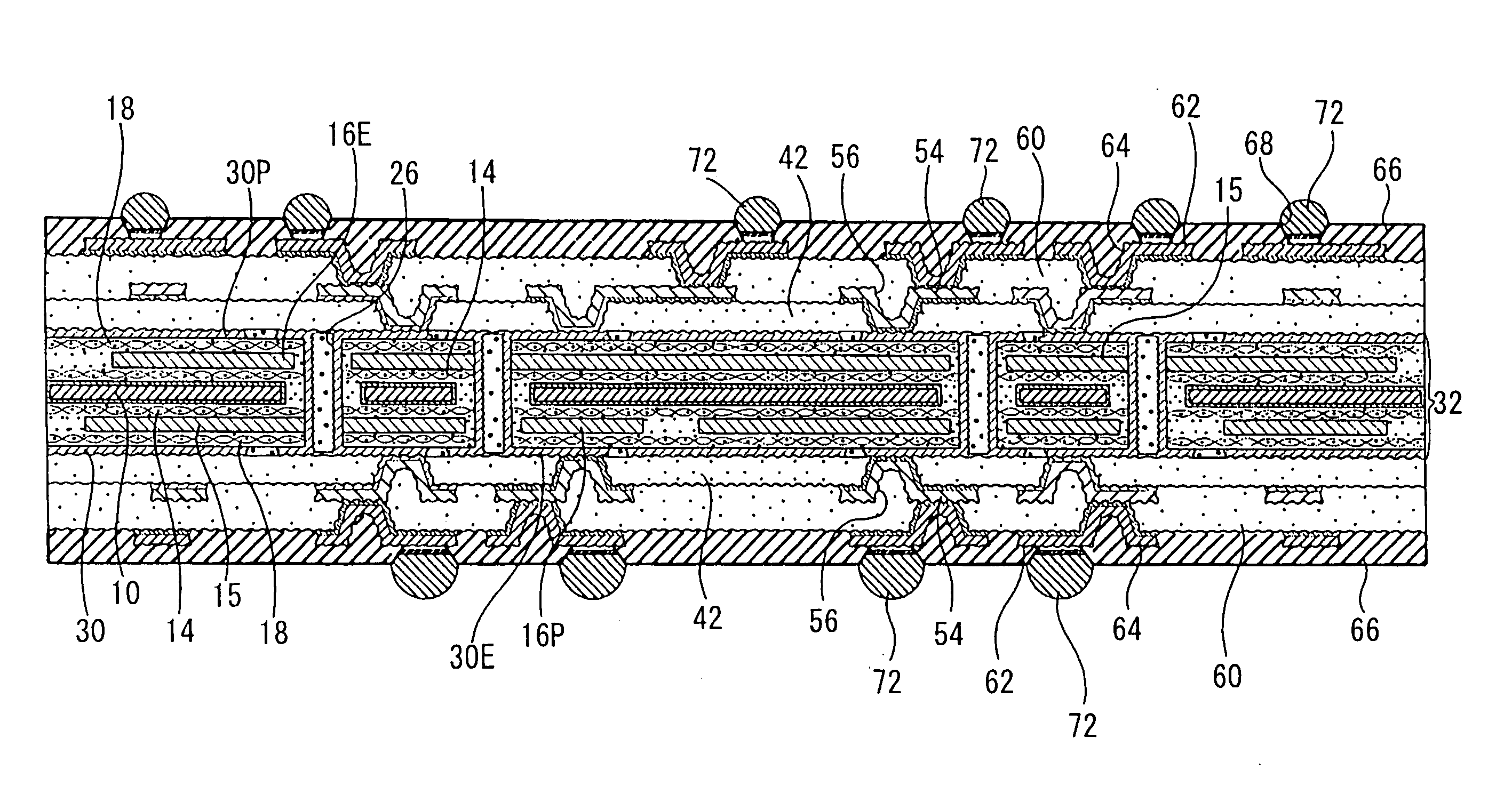

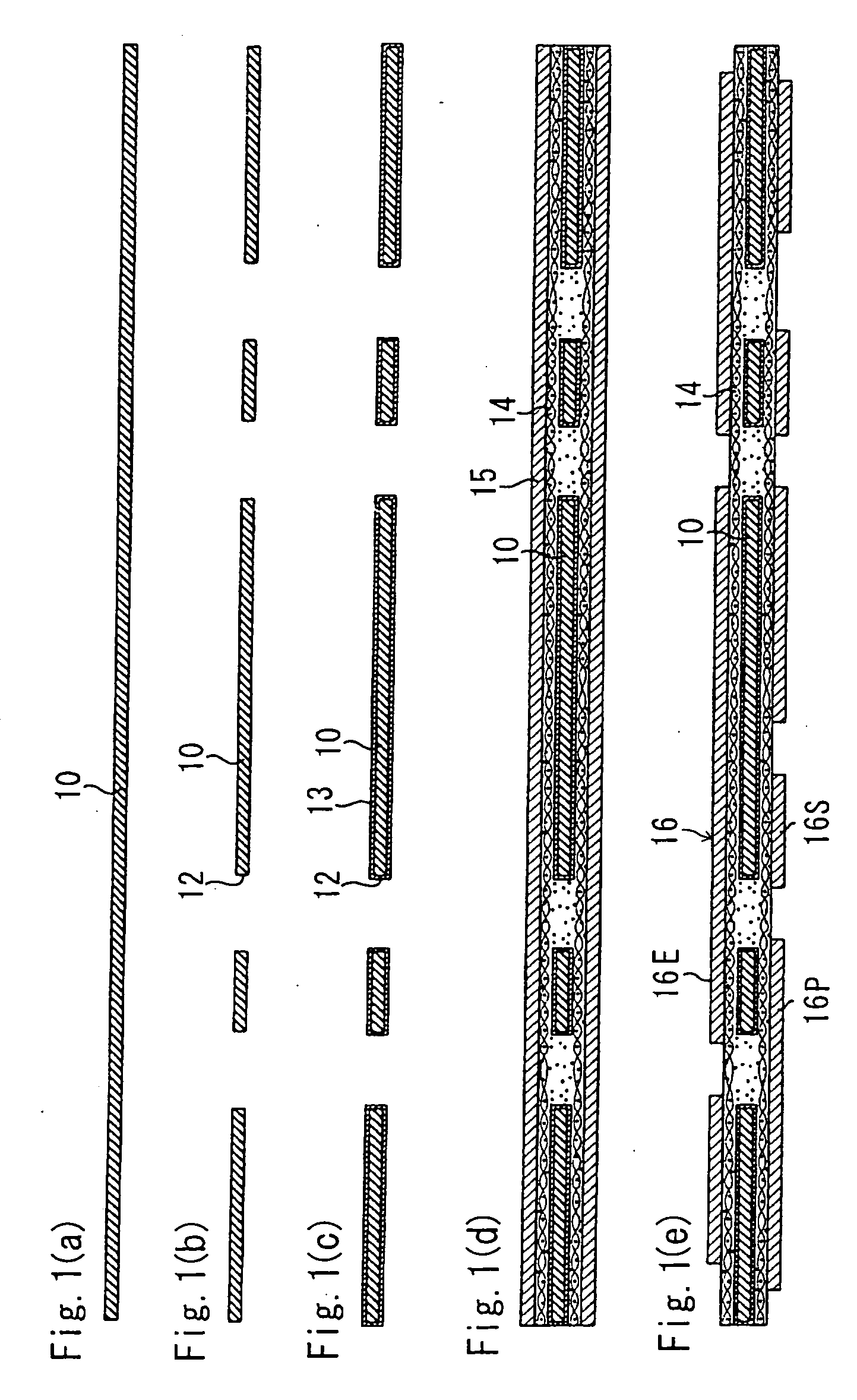

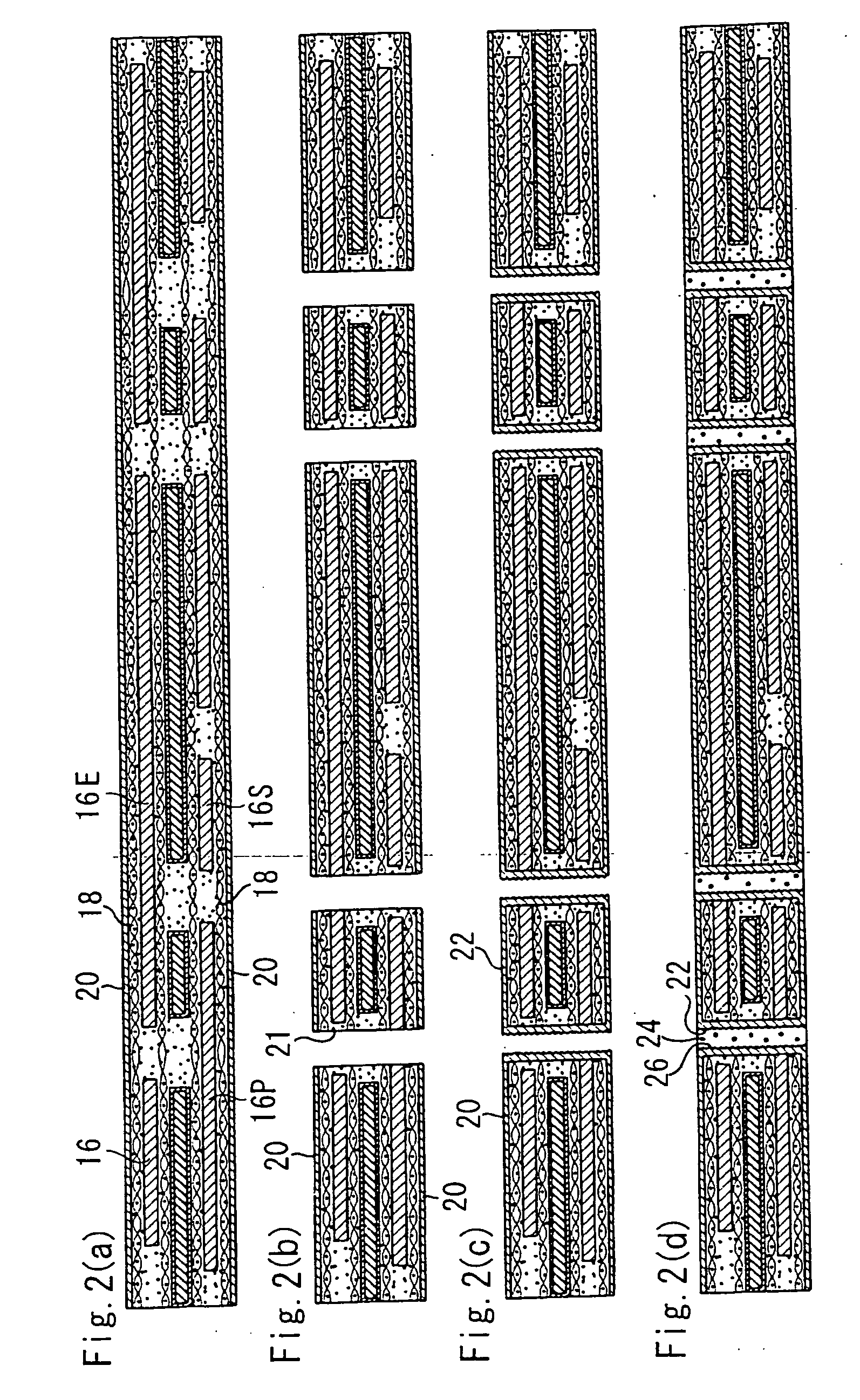

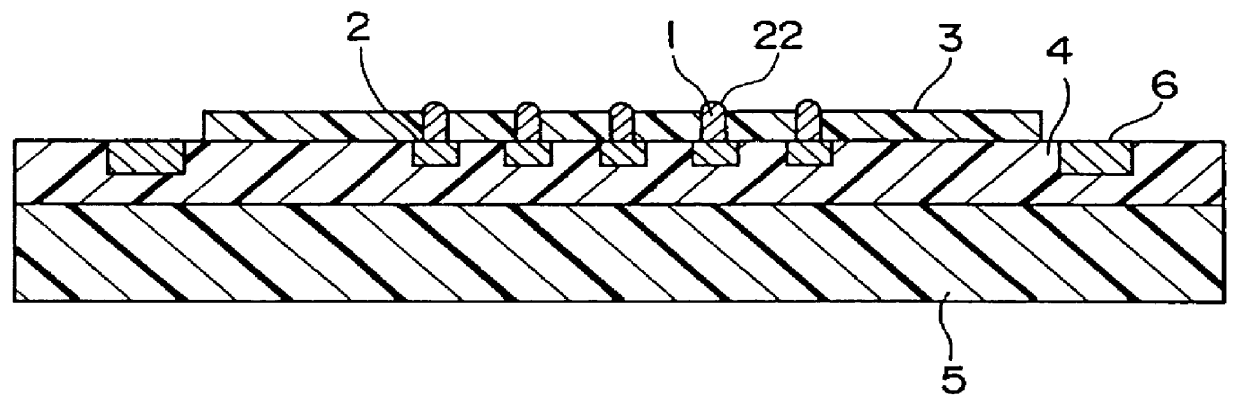

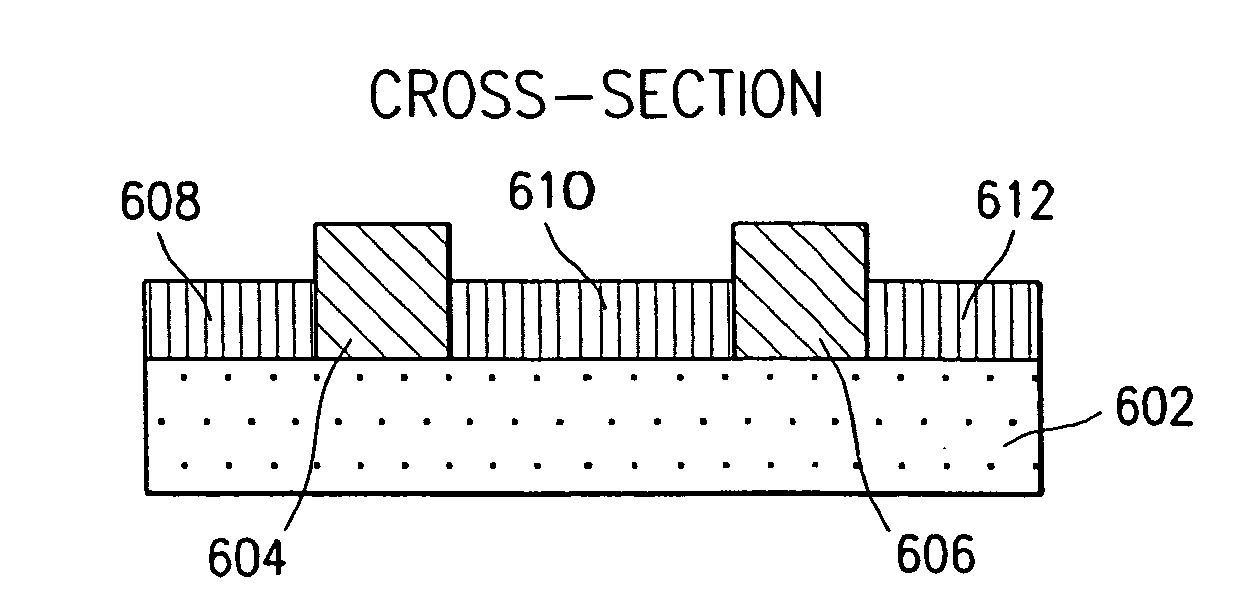

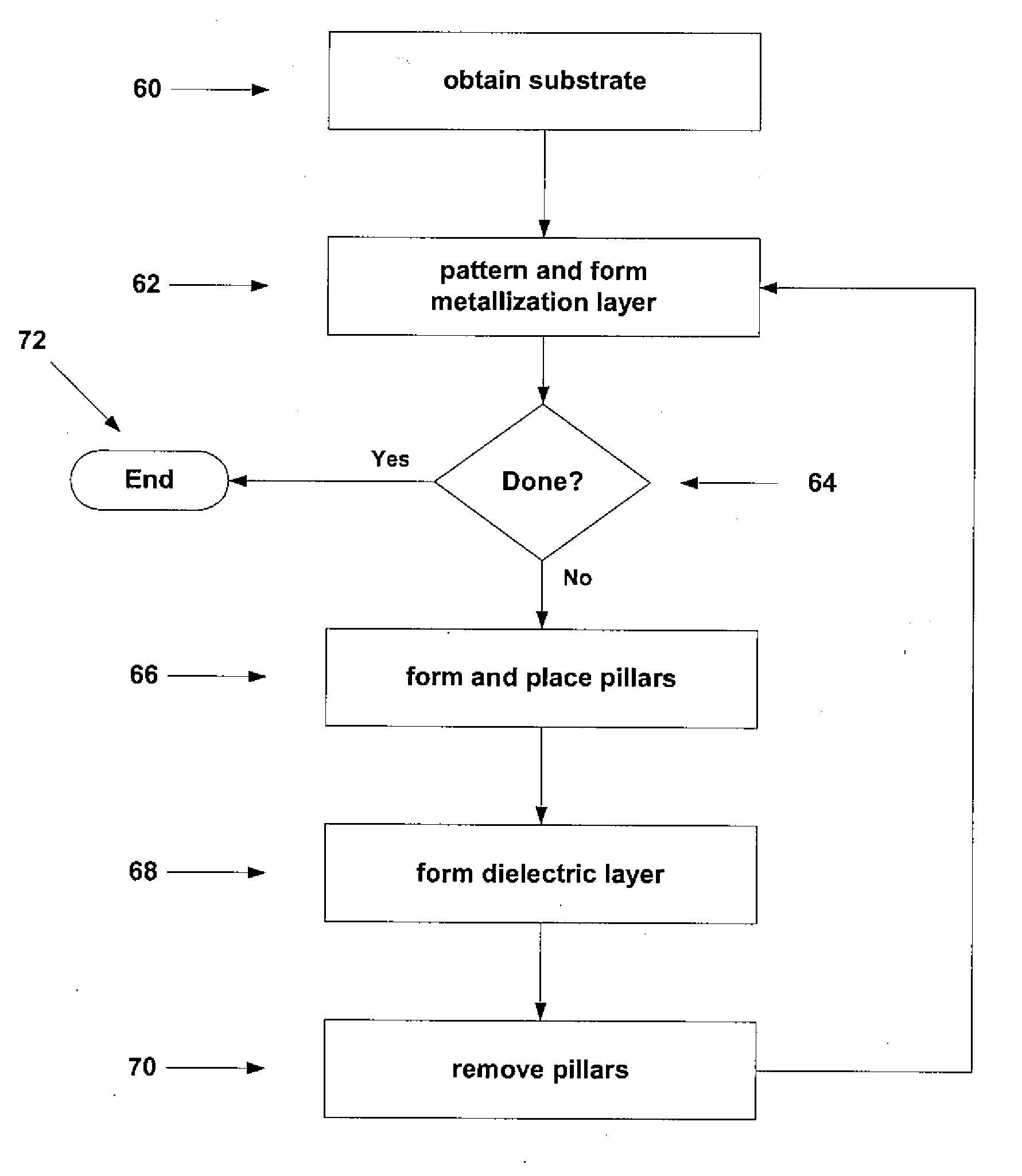

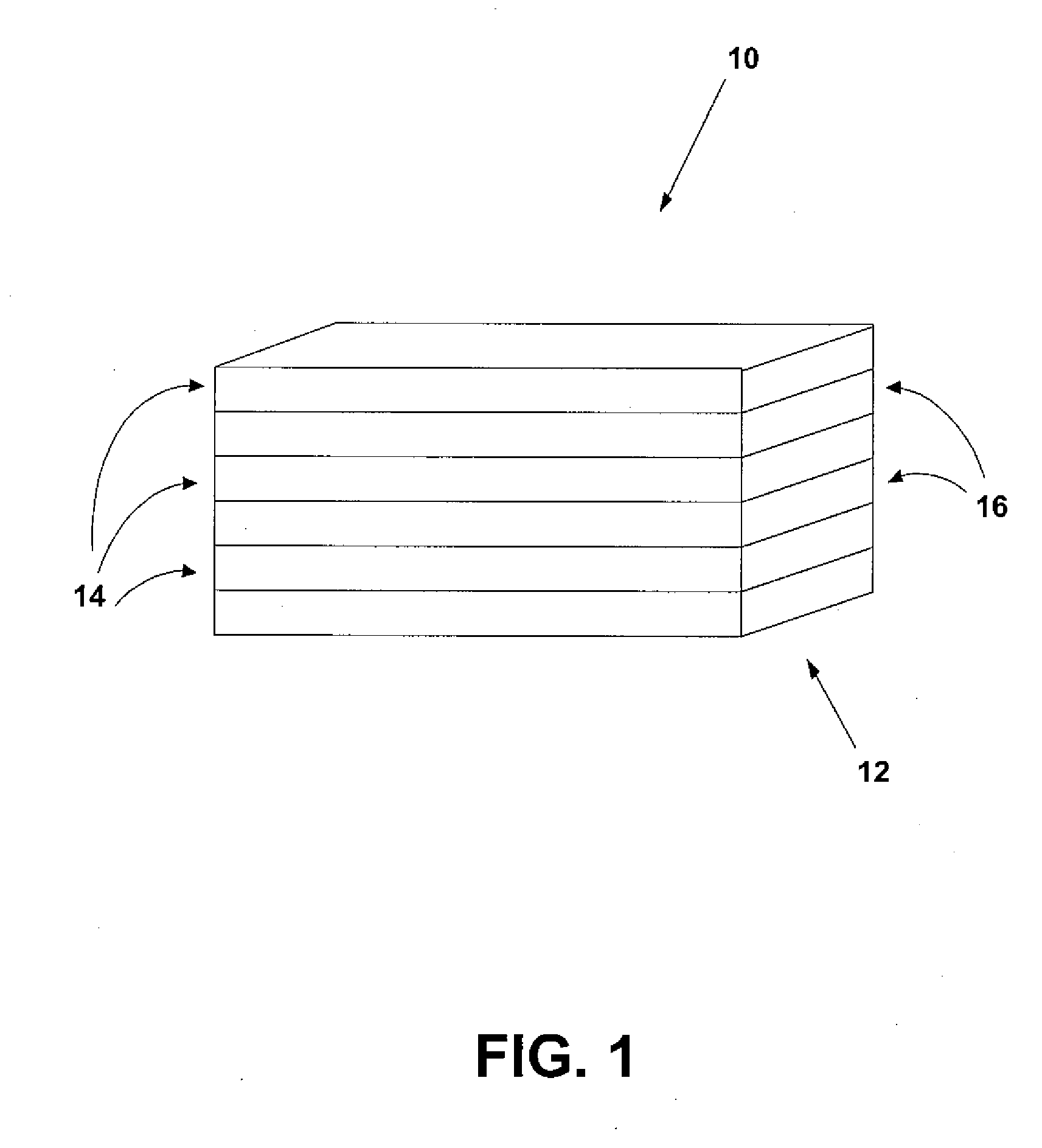

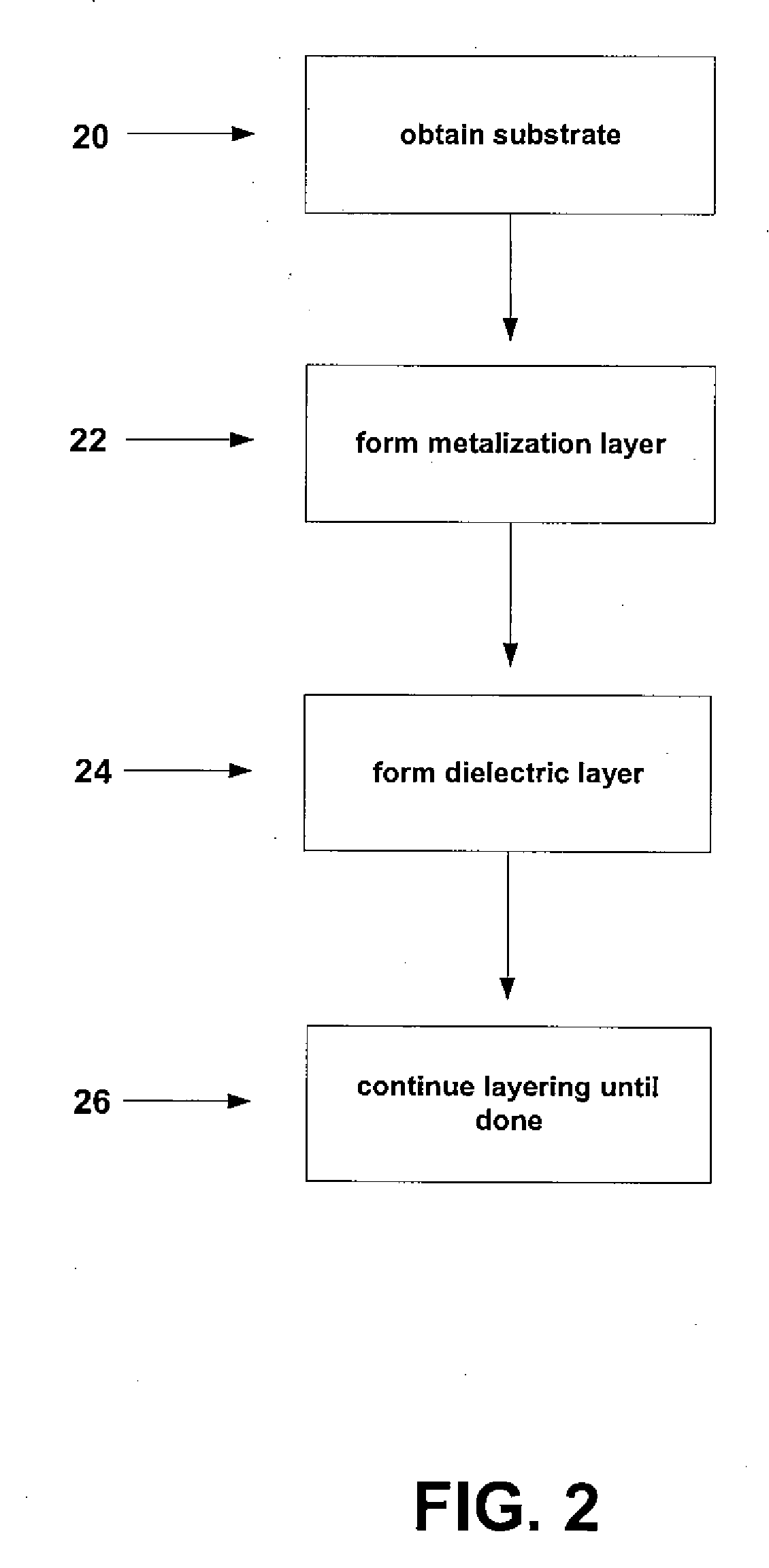

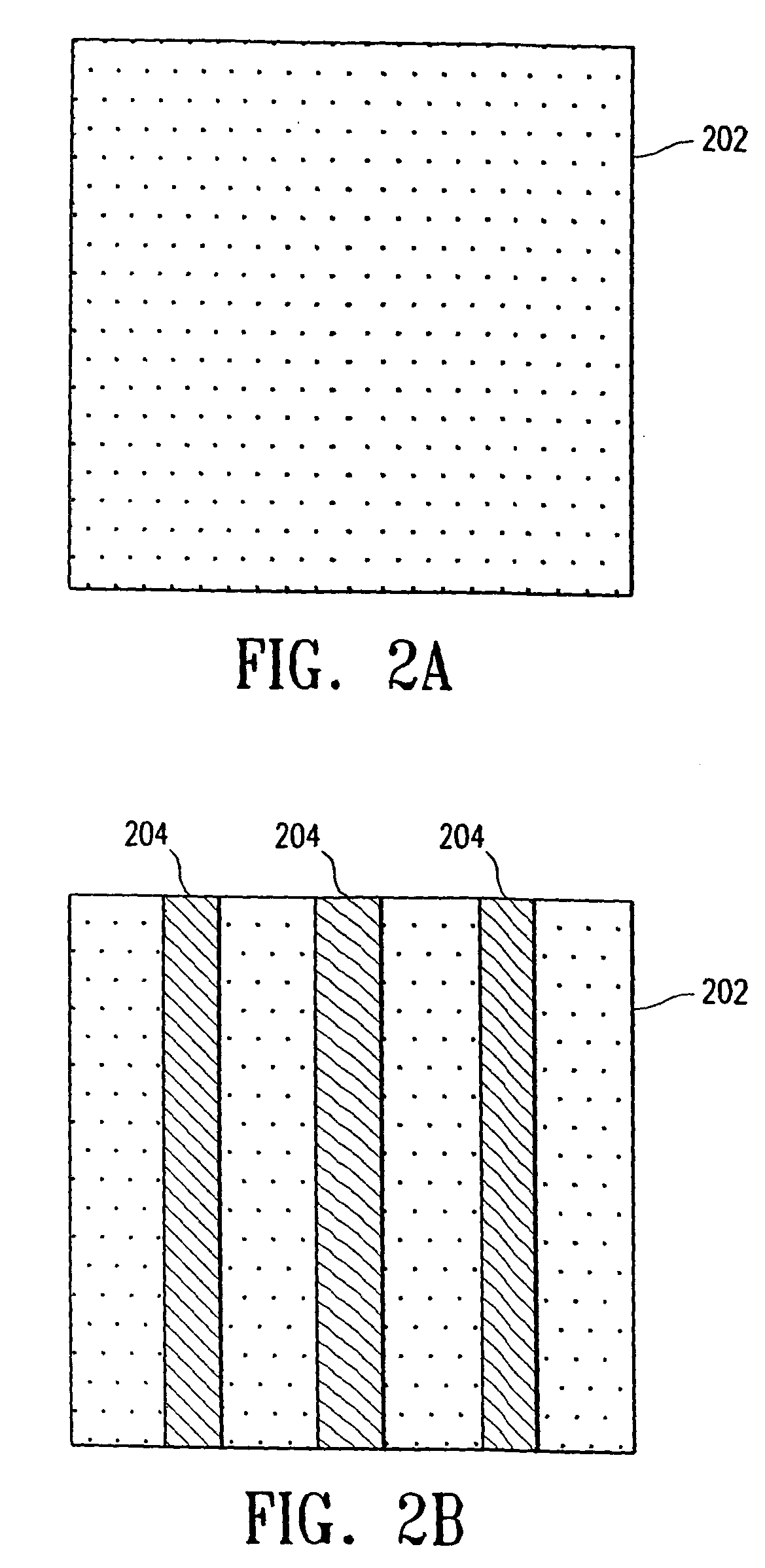

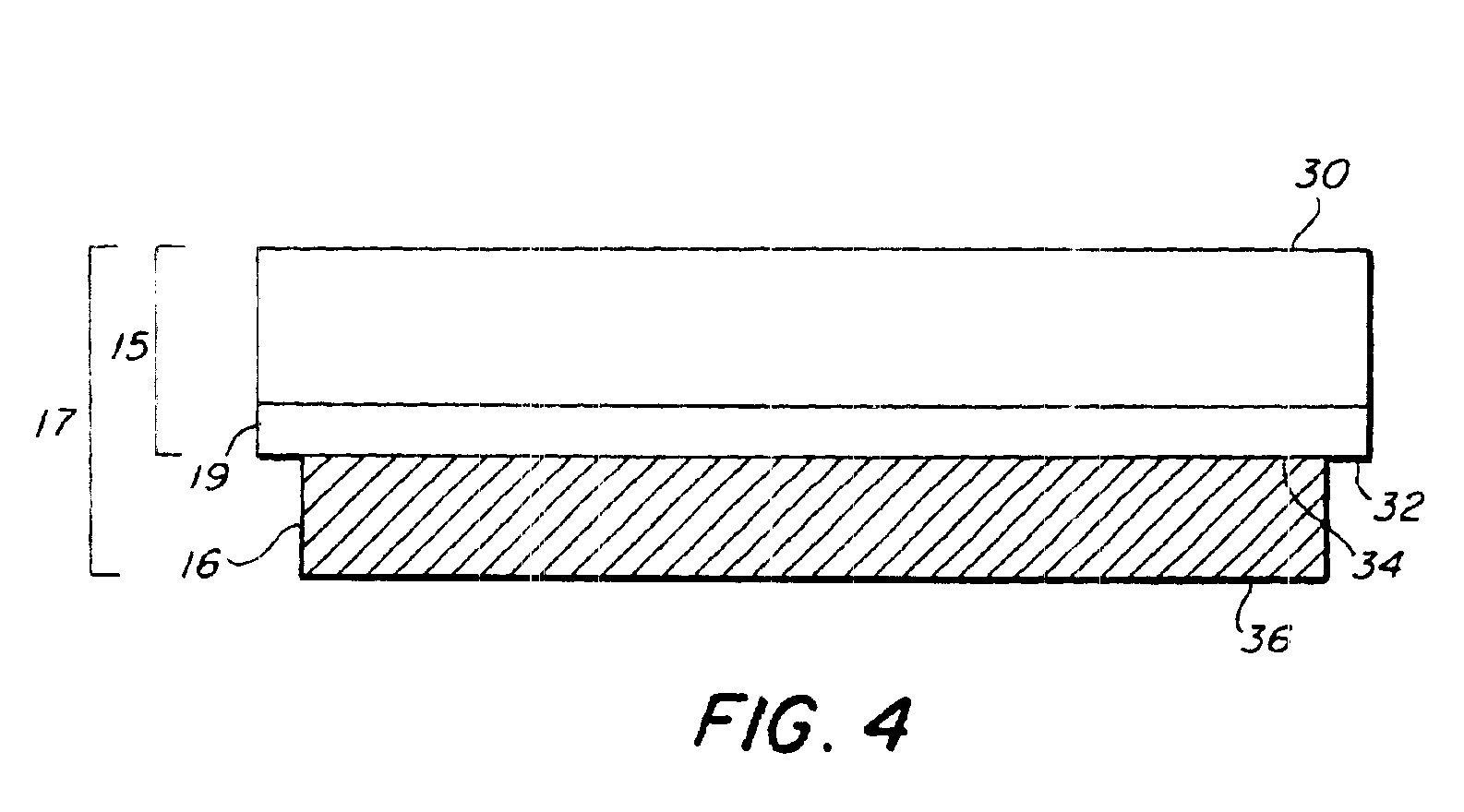

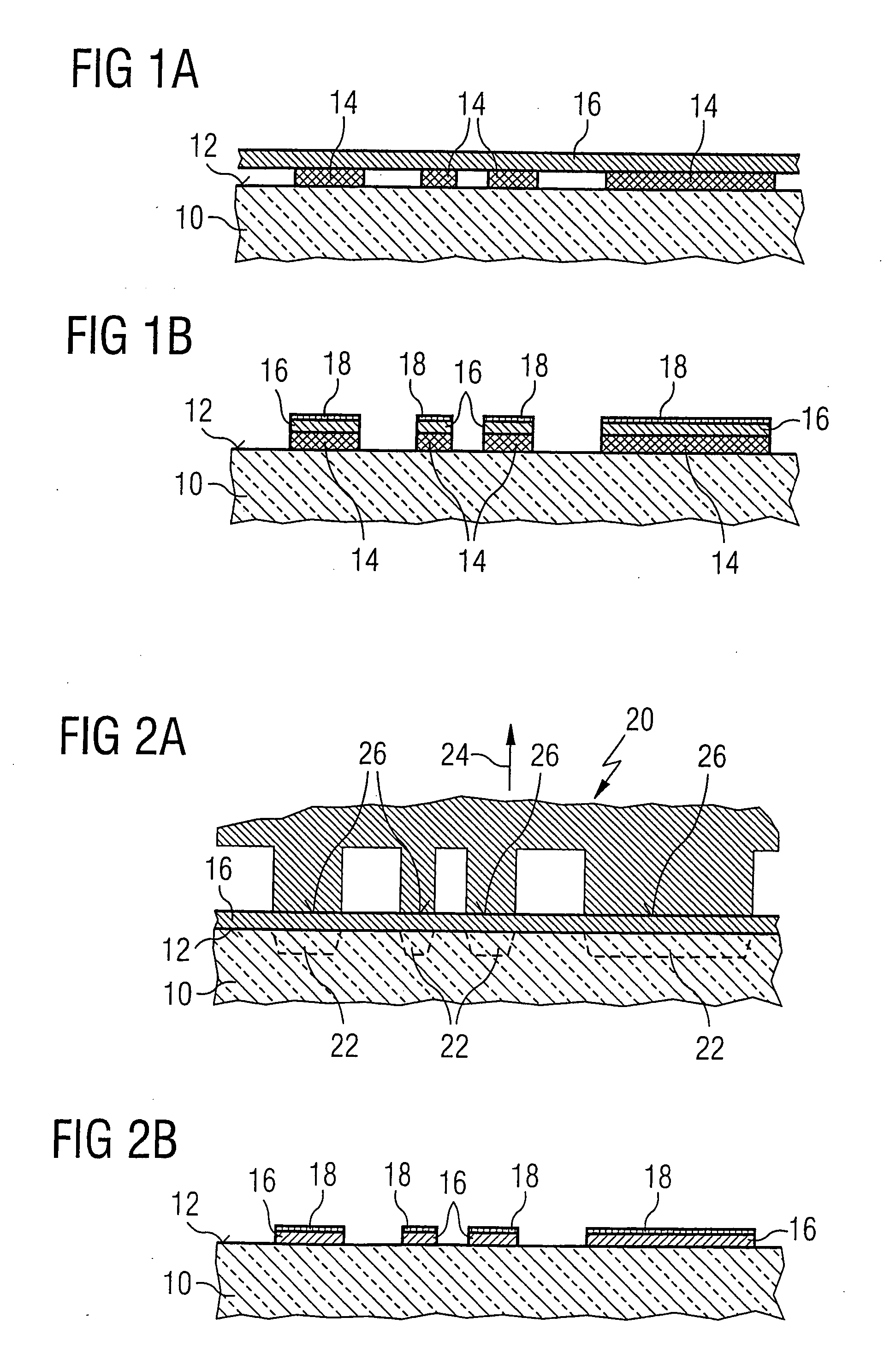

Multilayer substrate

InactiveUS7297627B2Easy to controlDimension shrinkage is keptPrinted electric component incorporationSemiconductor/solid-state device detailsDevice formDielectric layer

A multilayer substrate device formed from a base substrate and alternating metalization layers and dielectric layers. Each layer is formed without firing. Vias may extend through one of the dielectric layers such that two metalization layers surrounding the dielectric layers make. contact with each other. The vias may be formed by placing pillars on top of a metalization layer, forming a dielectric layer on top of the metalization layer and surrounding the pillars, and removing the pillars. Dielectric layers may be followed by other dielectric layers and metalization layers may be followed by other metalization layers. Vias in the substrate may be filled by forming an assembly around the substrate, the assembly including printing sheets containing a conductive ink and pressure plates for applying pressure. A vacuum may be applied to remove air in the ink. Pressure may then be applied to the printing sheets through the pressure plates. The conductive ink in the printing sheets is pushed through the vias when pressure is applied by the pressure plates.

Owner:MEDTRONIC MIMIMED INC

Transfer method, method of manufacturing thin film devices, method of maufacturing integrated circuits, circuit board and manufacturing method thereof, electro-optical apparatus and manufacturing method thereof, IC card, and electronic appliance

InactiveUS20050106839A1Reduce material usageImprove area efficiencyMaterial nanotechnologySemiconductor/solid-state device detailsEngineeringIntegrated circuit

Owner:SEIKO EPSON CORP

Tape compositions for the deposition of electronic features

InactiveUS20070178232A1Reduce settlementGood dispersionAdditive manufacturing apparatusSynthetic resin layered productsElectronMaterials science

Owner:CABOT CORP

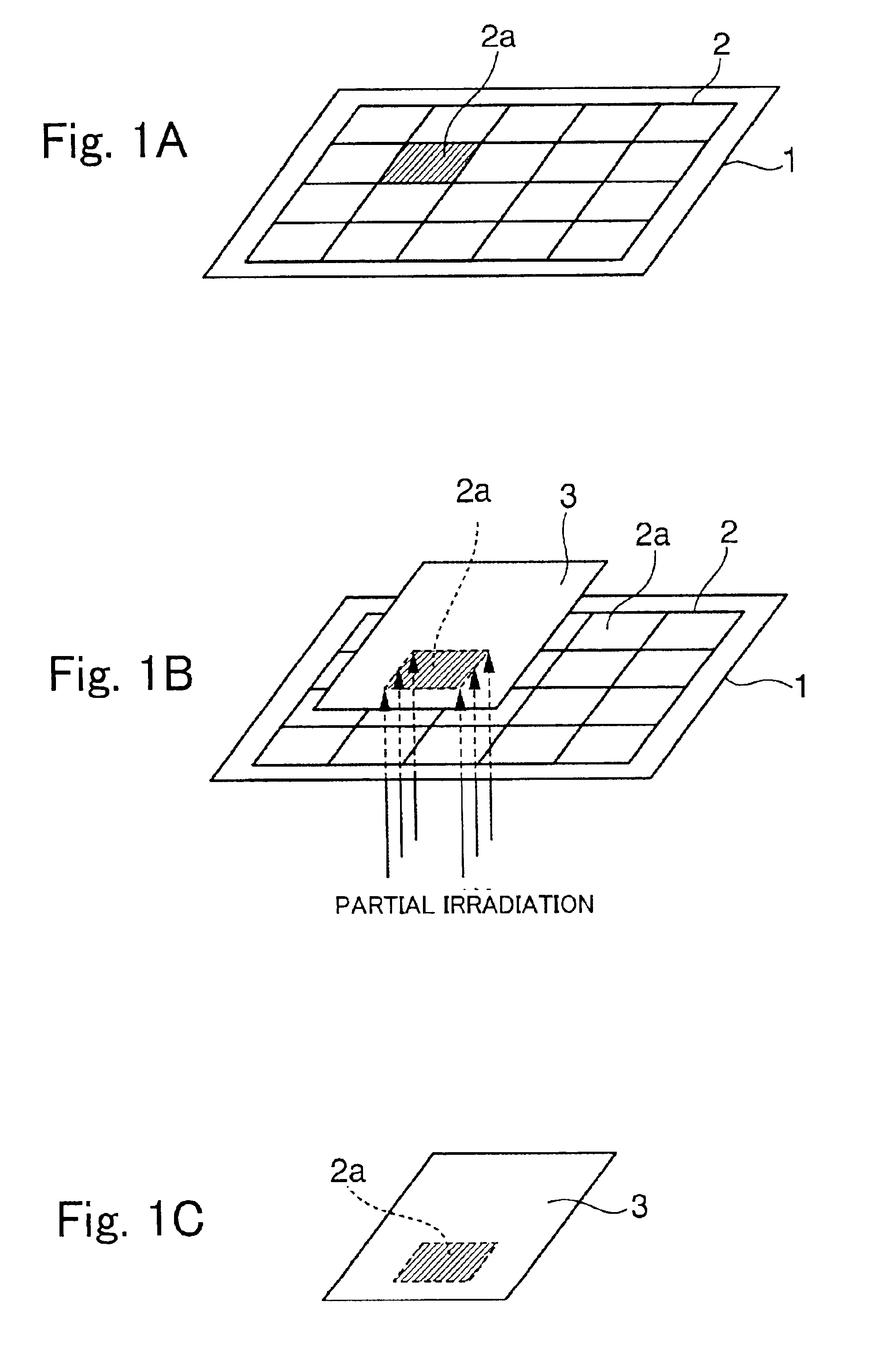

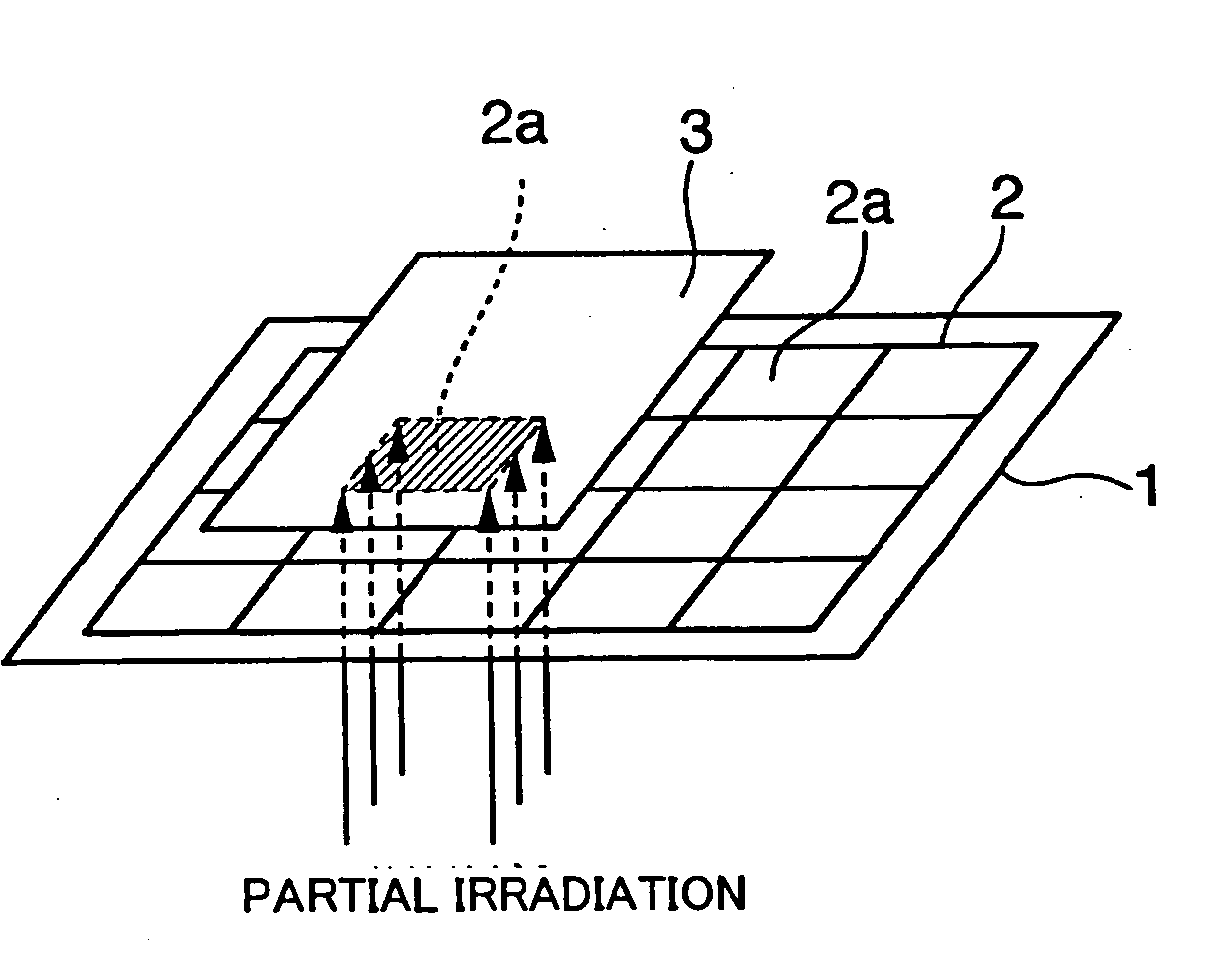

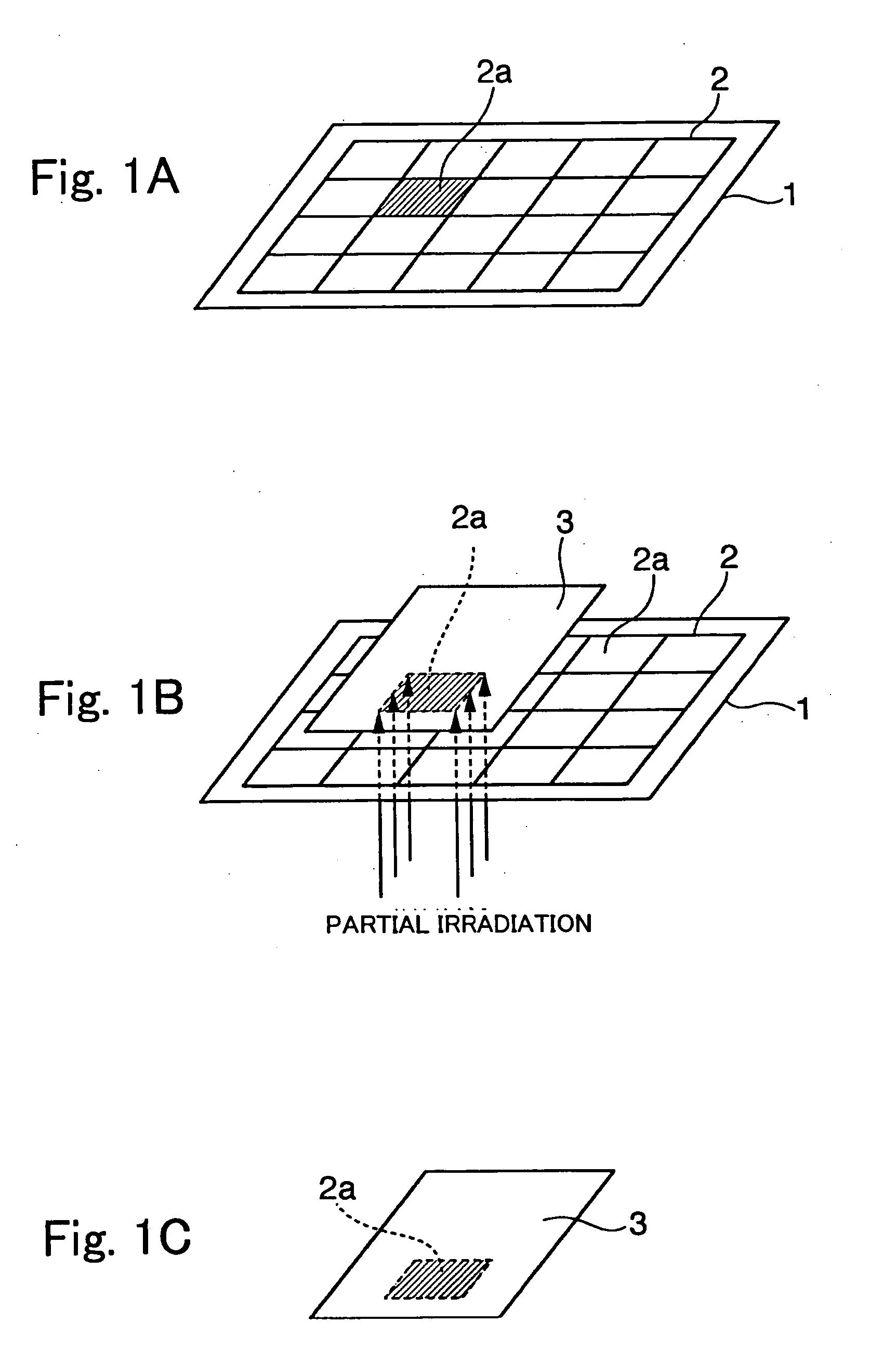

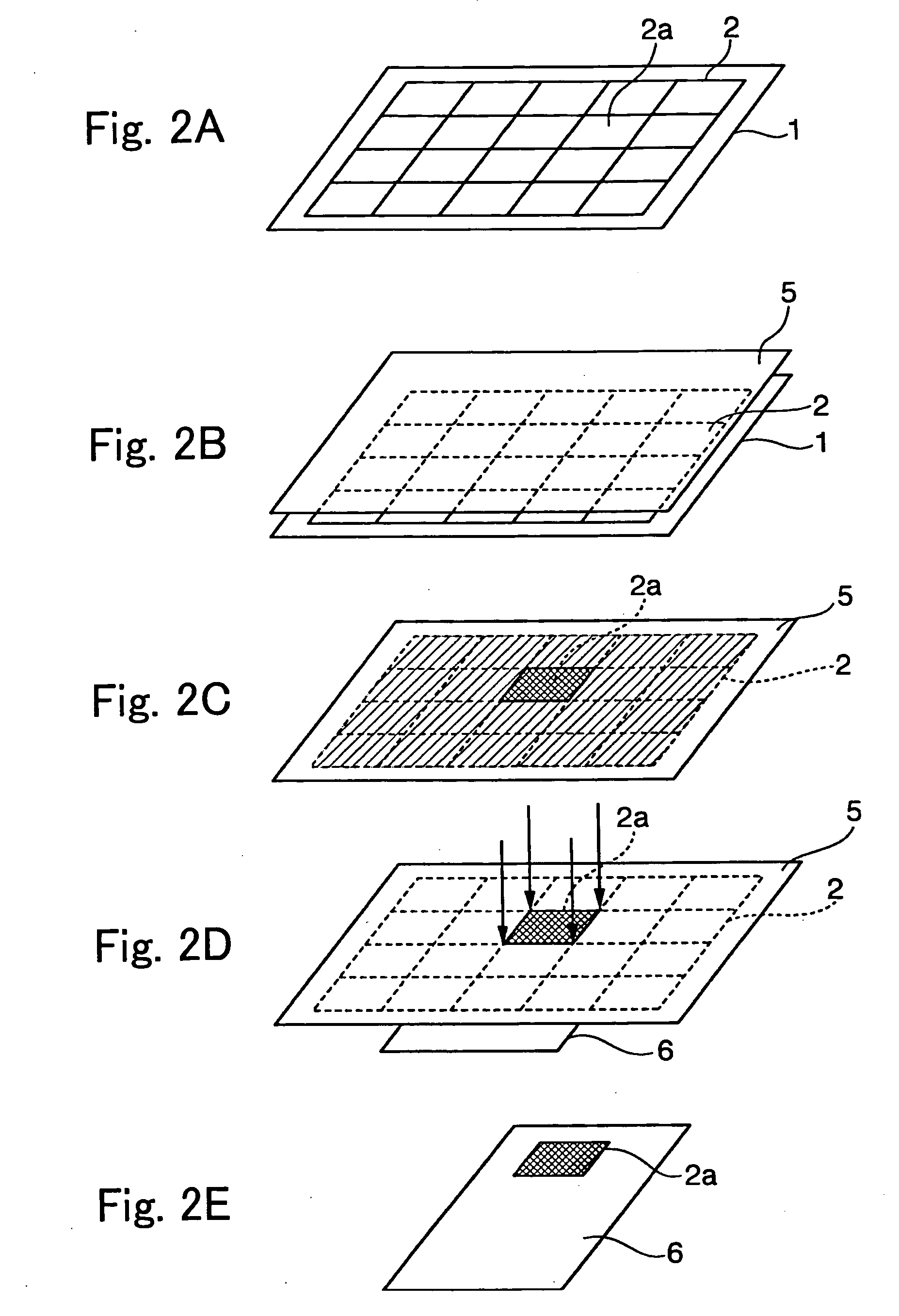

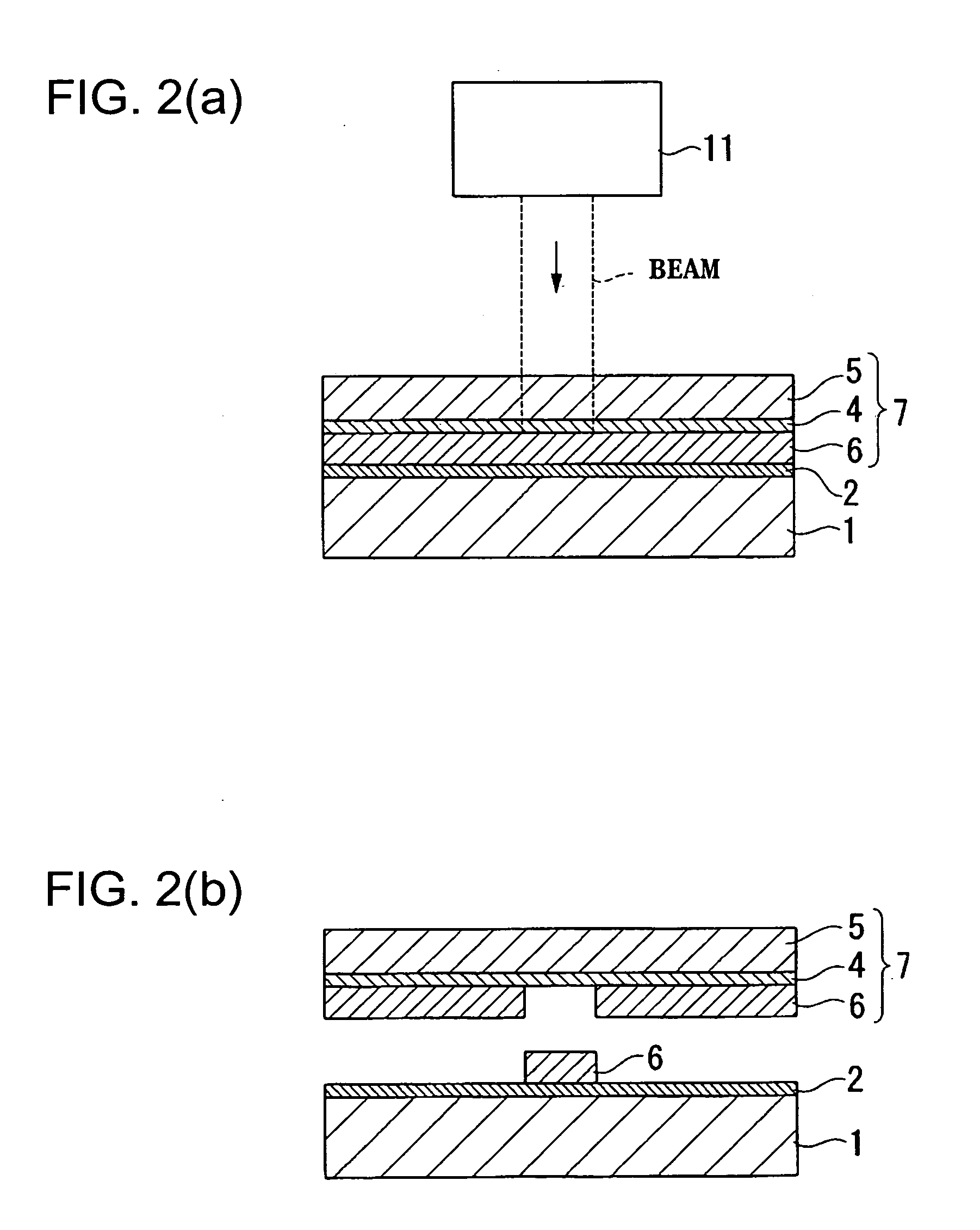

Methods for producing pattern-forming body

InactiveUS7252923B2Improve accuracyEffect can be problematicMaterial nanotechnologyPhotosensitive materialsEngineeringPost exposure

A method of producing a pattern-forming body with high accuracy with no need for a post-exposure treatment and without allowing any photocatalyst to remain in the resultant pattern-forming body and whereby any problematic effect of the photocatalyst in the pattern-forming body is eliminated. The method includes providing a photocatalyst-containing layer-sided substrate and a pattern-forming body substrate having a characteristic-changeable layer, which is changed by the effect of the photocatalyst in the photocatalyst-containing layer, and a light-shading part formed as a pattern in such a manner that the photocatalyst-containing layer and the characteristic-changeable layer are brought into contact with each other, followed by exposure on the side of the pattern-forming body substrate to change the characteristics of the characteristic-changeable layer of the exposed part, followed by removing the photocatalyst-containing layer-sided substrate.

Owner:DAI NIPPON PRINTING CO LTD

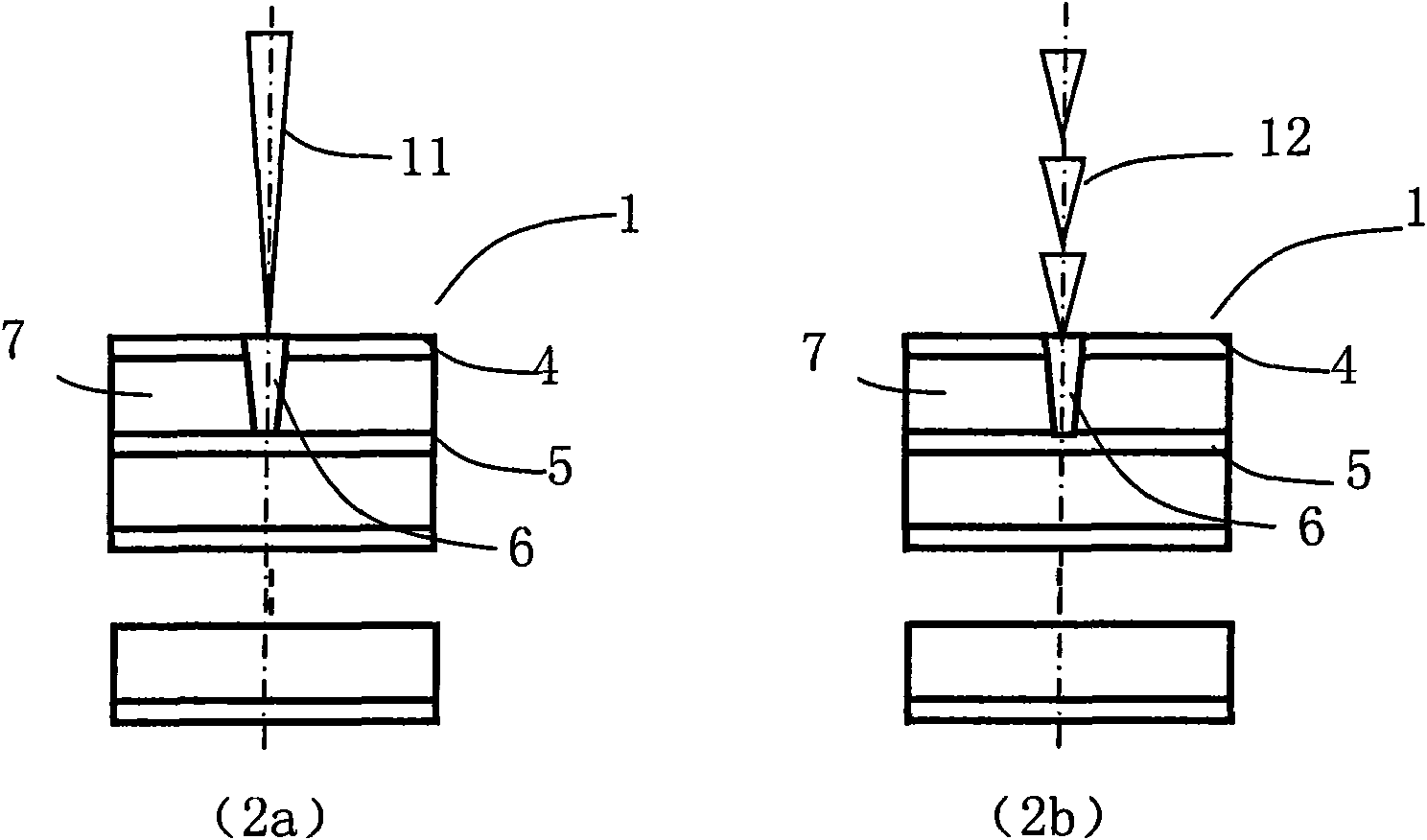

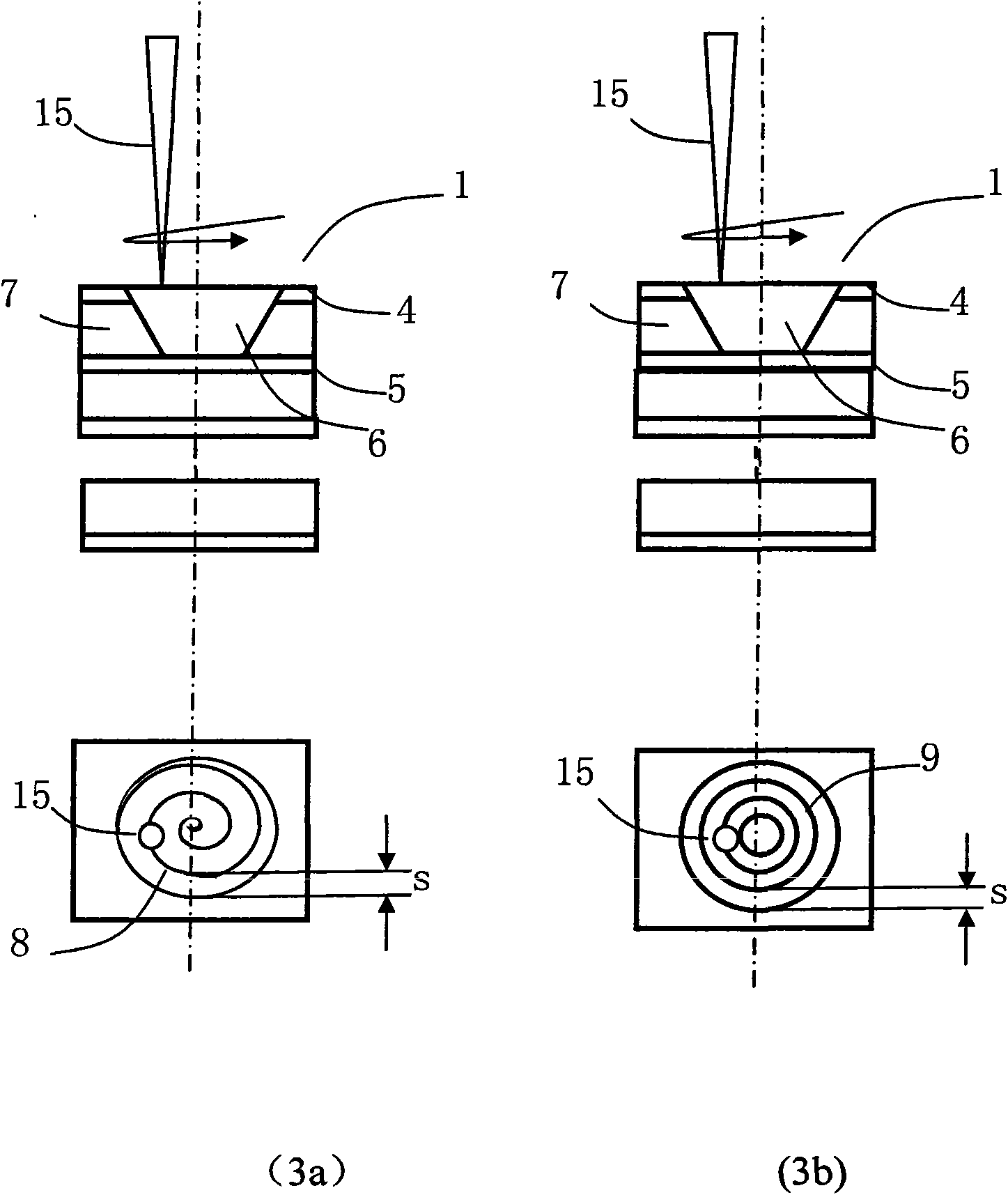

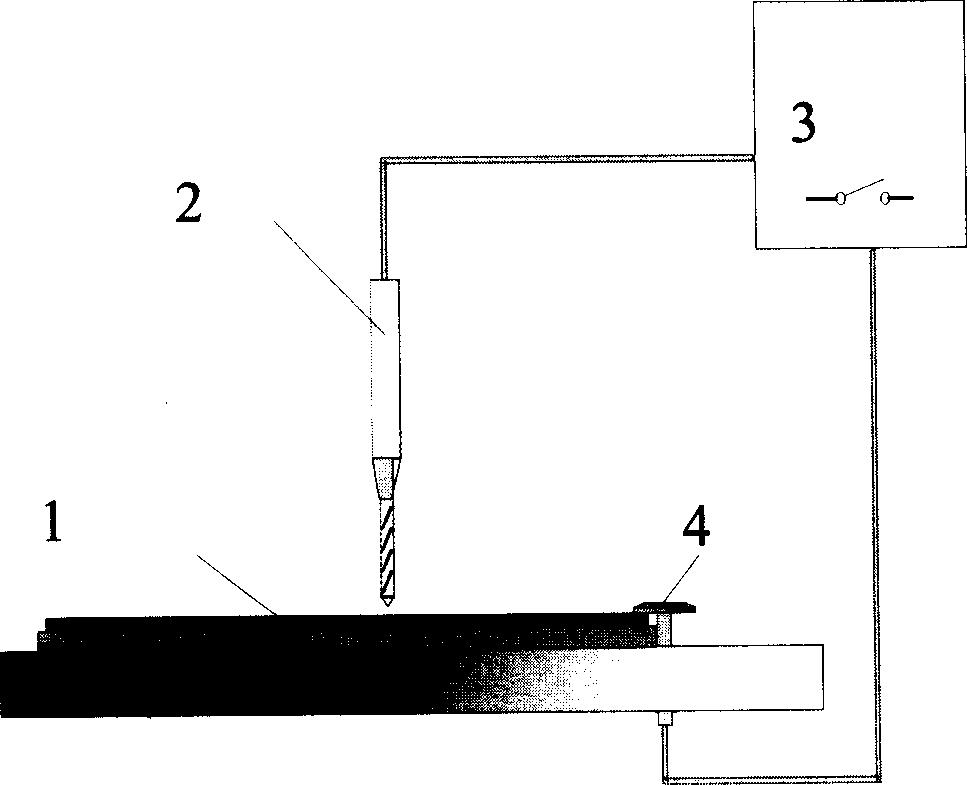

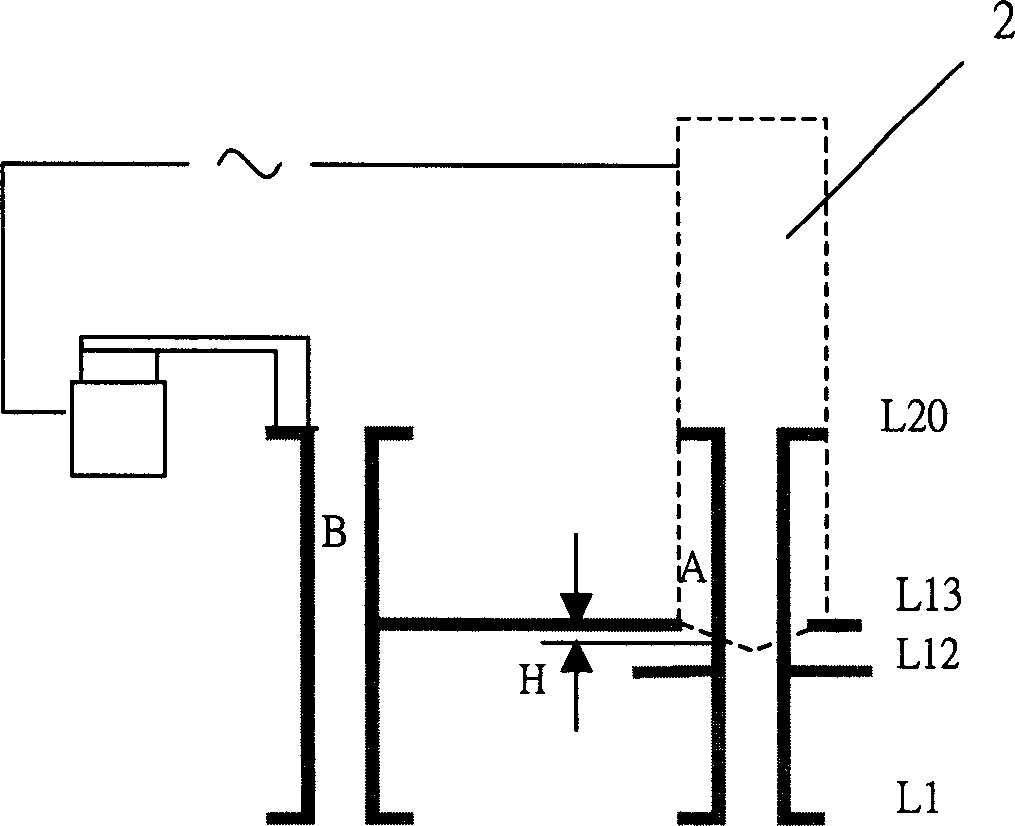

Method for processing blind hole by laser

InactiveCN101610643AAvoid Scanning RequirementsRemove distortionConductive material mechanical removalLaser beam welding apparatusUv laserLaser processing

The invention discloses a method for processing a blind hole by laser. The method combines fixed point UV laser impulse and UV laser spiral line or concentric circle scanning and is used for one-step blind hole processing or multi-step blind hole processing on multilayer circuit board. The method divides the UV laser blind hole drilling process into two parts, namely a part with an area near the circle center of the blind hole not more than UV laser spot diameter and a part with an area more than the UV laser spot diameter. Fixed point UV laser impulse is adopted to drill the blind hole, so as to remove material in the region with an area near the circle center not more than UV laser spot diameter; then UV laser spiral line or centric circle scanning method is adopted to move outside, so as to remove the material in the region with an area near the circle center more than UV laser spot diameter until meeting set blind hole size; and one-step blind hole or multi-step blind hole processing is drilled by UV laser through two steps or more steps. The method can ensure processing quality consistency of each blind hole, can greatly reduce bottom unevenness of the blind hole, and also can improve margin quality of blind hole processing.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for patterning carbon nanotube coating and carbon nanotube wiring

A method for making a nanocomposite electrode or circuit pattern includes forming a continuous carbon nanotube layer impregnated with a binder and patterning the binder resin using various printing or photo imaging techniques. An alternative method includes patterning the carbon nanotube layer using various printing or imaging techniques and subsequently applying a continuous coating of binder resin to the patterned carbon nanotube layer. Articles made from these patterned nanocomposite coatings include transparent electrodes and circuits for flat panel displays, photovoltaics, touch screens, electroluminescent lamps, and EMI shielding.

Owner:ARTHUR DAVID J +1

High frequency circuit chip and method of producing the same

InactiveUS6838377B2Small sizeEfficient productionSemiconductor/solid-state device detailsPrinted circuit aspectsMaterial PerforationElectrical and Electronics engineering

In the production of a high frequency circuit chip in which a wiring pattern is disposed on a substrate having a through-hole, a connecting electrode of the through-hole is formed by filling electrically conductive paste into a perforation and firing it, and the wiring pattern is formed by a lift-off method. Moreover, at least the surface of the substrate for the wiring pattern to be formed thereon is mirror-polished, and thereafter, the wiring pattern is formed on the mirror-polished surface by the lift-off method.

Owner:MURATA MFG CO LTD

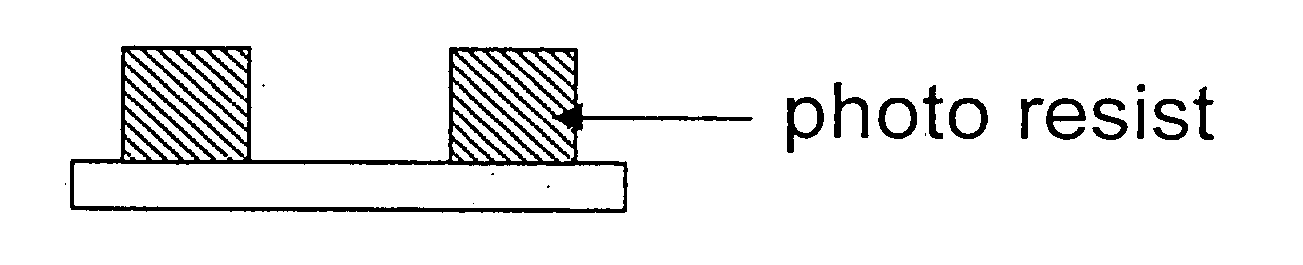

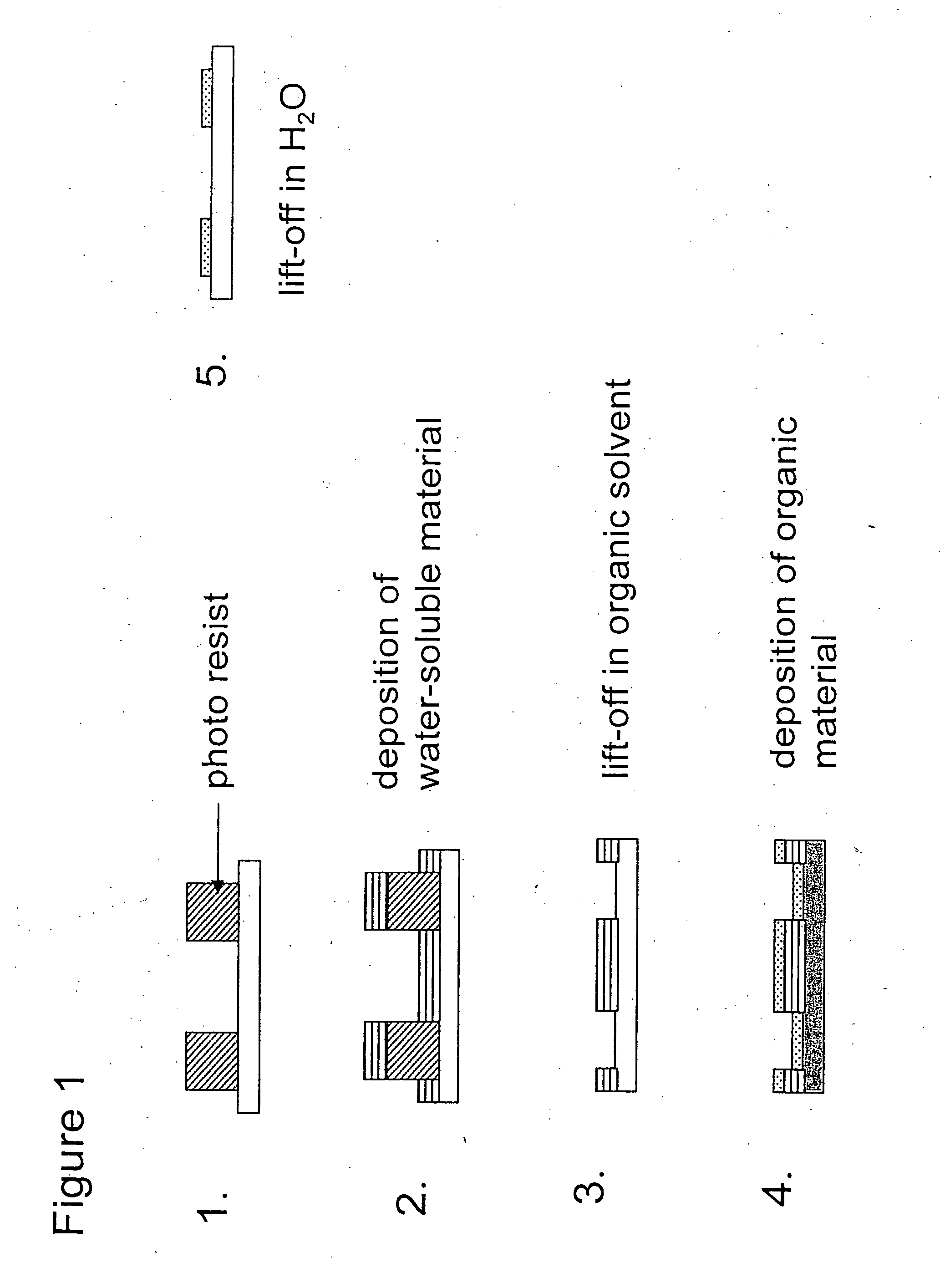

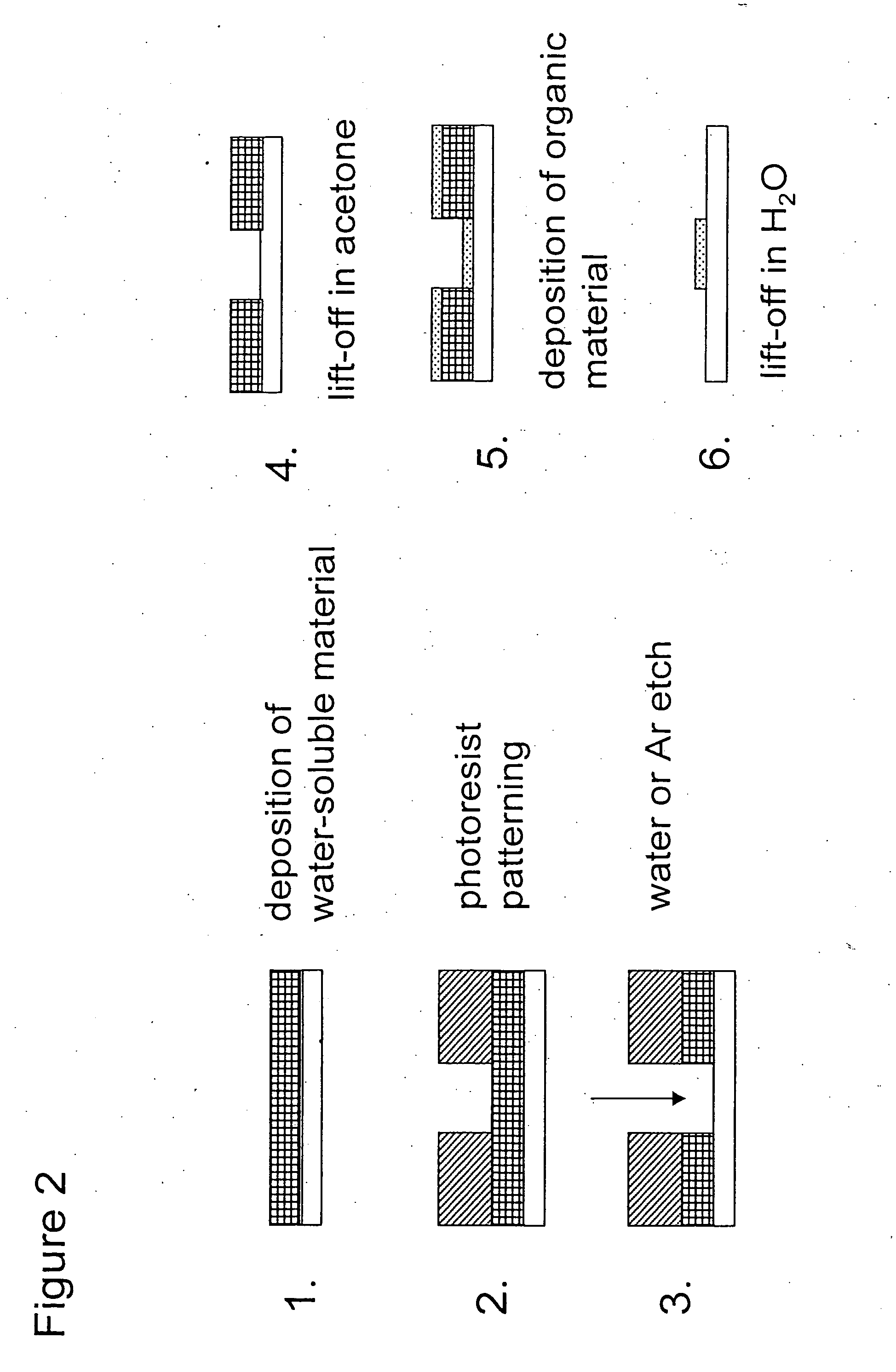

Method for patterning organic materials or combinations of organic and inorganic materials

The present application refers to a method of patterning organic materials or organic / inorganic materials onto a substrate, comprising the following steps: (1) patterning of a water-soluble material “A” onto a surface of the substrate, thereby forming a substrate / material “A” surface; (2) depositing organic or organic / inorganic material “B” onto the substrate / material “A” surface; (3) lifting-off material “A” in aqueous solution; wherein, step (1) comprises the following steps: (1a) patterning of a photoresist material onto the substrate surface, thereby forming a substrate / photoresist material surface; (1b) depositing the water soluble material “A” onto the substrate / photoresist material surface; (1c) lifting-off the photoresist material in an organic solvent; or, alternatively, step (1) comprises the following steps: (1a′) depositing the water-soluble material “A” onto the substrate surface, thereby forming a substrate / material “A” surface; (1b′) patterning the photoresist material onto the substrate / material “A” surface; (1c′) etching the unmasked material “A” in aqueous solution; (1d′) lifting-off the photoresist material in an organic solvent. The present application also refers to the use of said method, to a pattern of organic materials or organic / inorganic materials prepared by said method, and to a substrate carrying such patterns. The application also refers to the use of a patterned nanoparticle film.

Owner:SONY DEUT GMBH

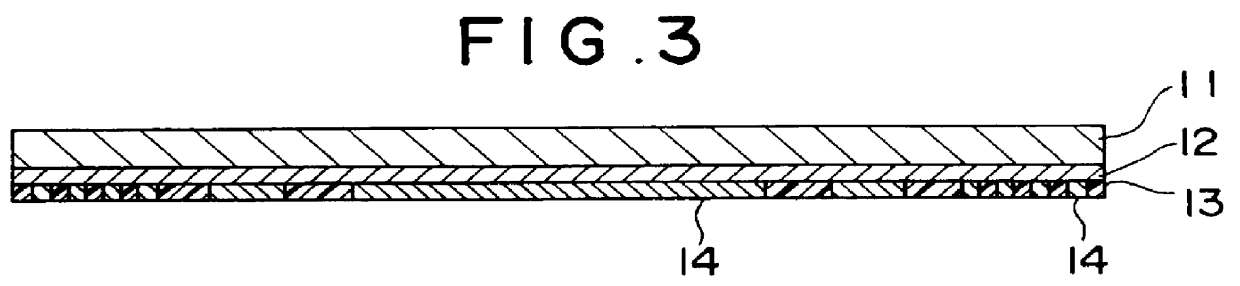

Interlayer insulating layer for printed wiring board, printed wiring board and method for manufacturing same

InactiveUS20070013049A1Small in expansibilitySmall in contractilityLayered productsSemiconductor/solid-state device detailsEtchingHeat resistance

A printed wiring board is provided which includes an interlayer dielectric layer formed on a substrate from a curable resin having flaky particles dispersed therein. The printed wiring board is excellent in cooling / heating cycle resistance and packaging reliability while maintaining a satisfactory heat resistance, electrical insulation, heat liberation, connection reliability and chemical stability. Also a method of producing a printed wiring board is proposed in which an imprint method using a mold having formed thereon convexities corresponding to wiring patterns and viaholes to be formed being buried in an interlayer dielectric layer is used to form the wiring patterns and viaholes by transcribing the concavities of the mold to the interlayer dielectric layer. The imprint method permits to form the wiring patterns and viaholes but assures an easy and accurate transcription without any optical transcription or complicated etching. Thus, a multilayer printed wiring board excellent in insulation reliability and interlayer connection and having fine wiring patterns formed therein can be mass-produced extremely easily and inexpensively.

Owner:IBIDEN CO LTD

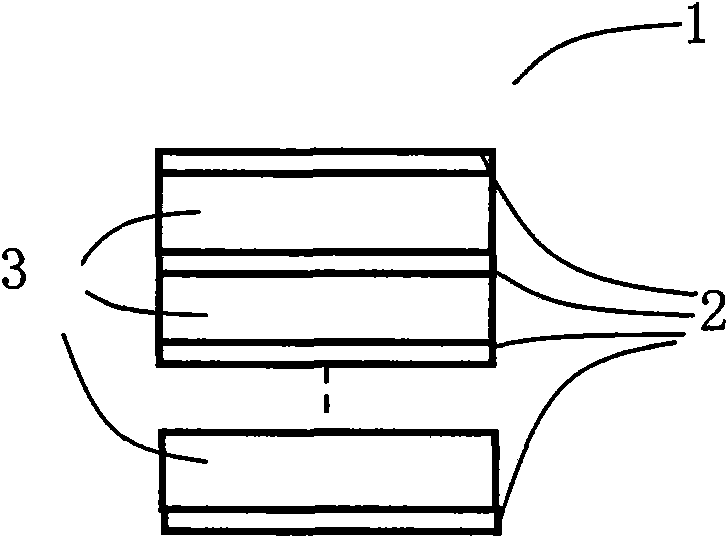

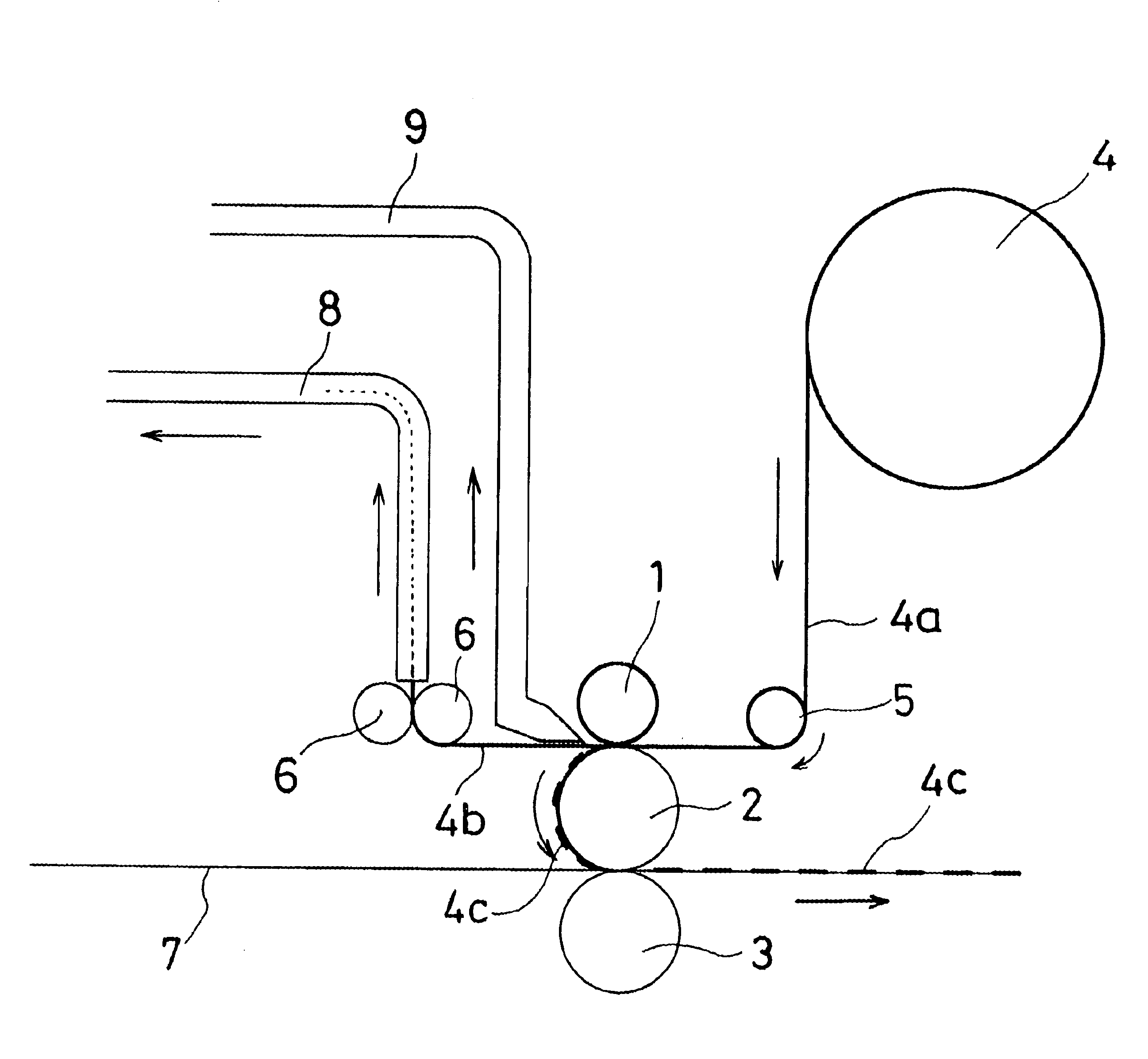

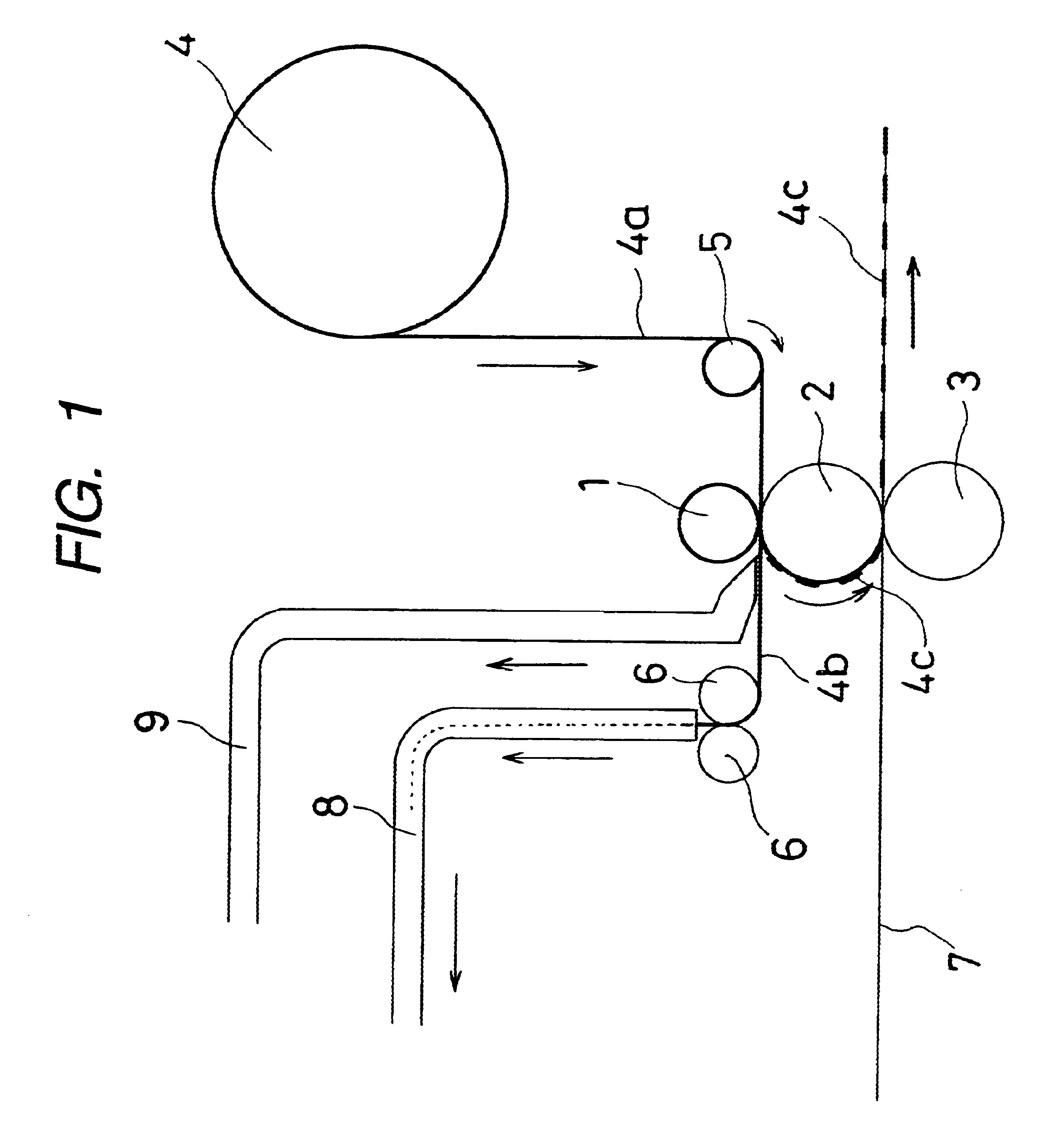

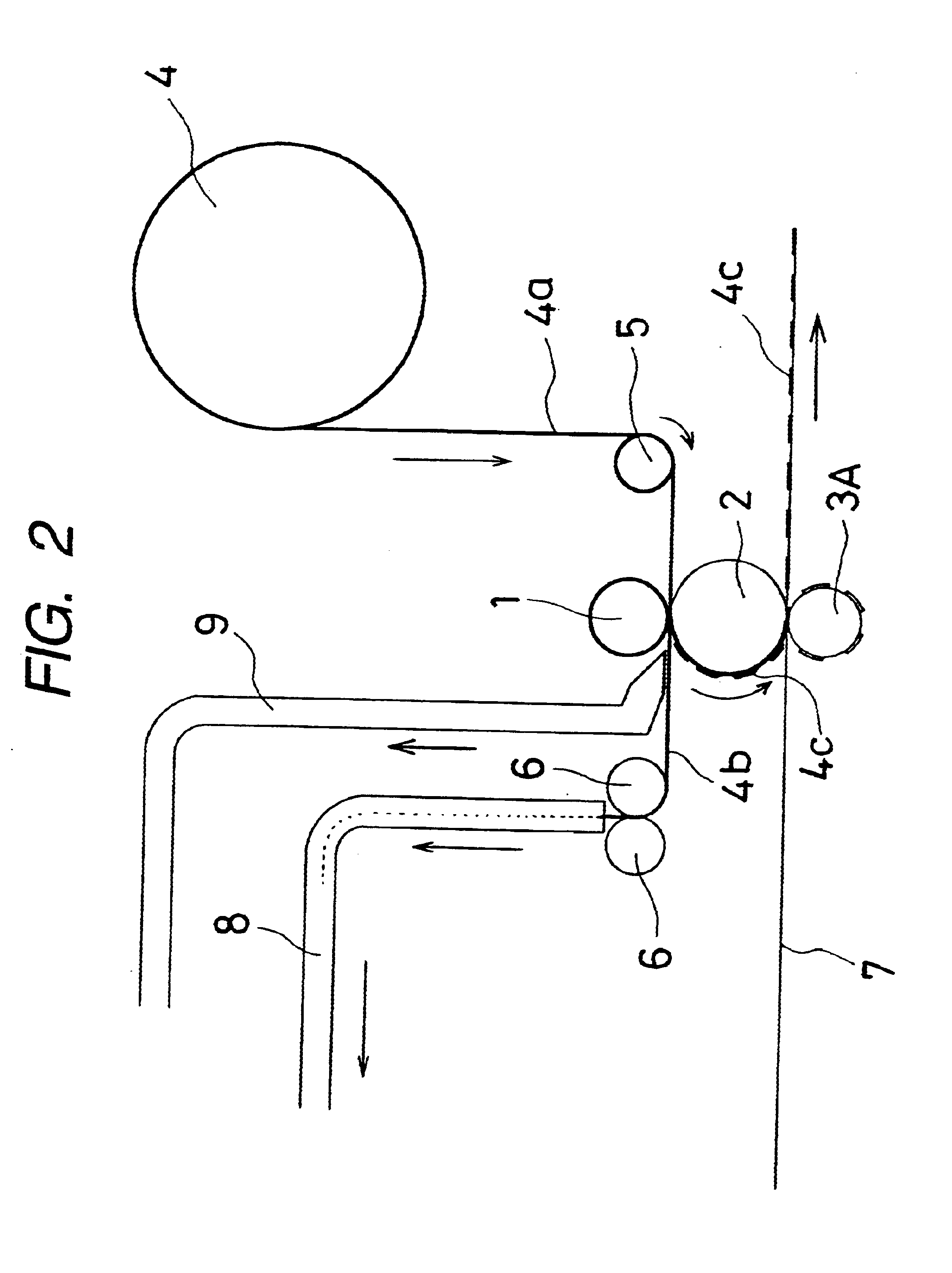

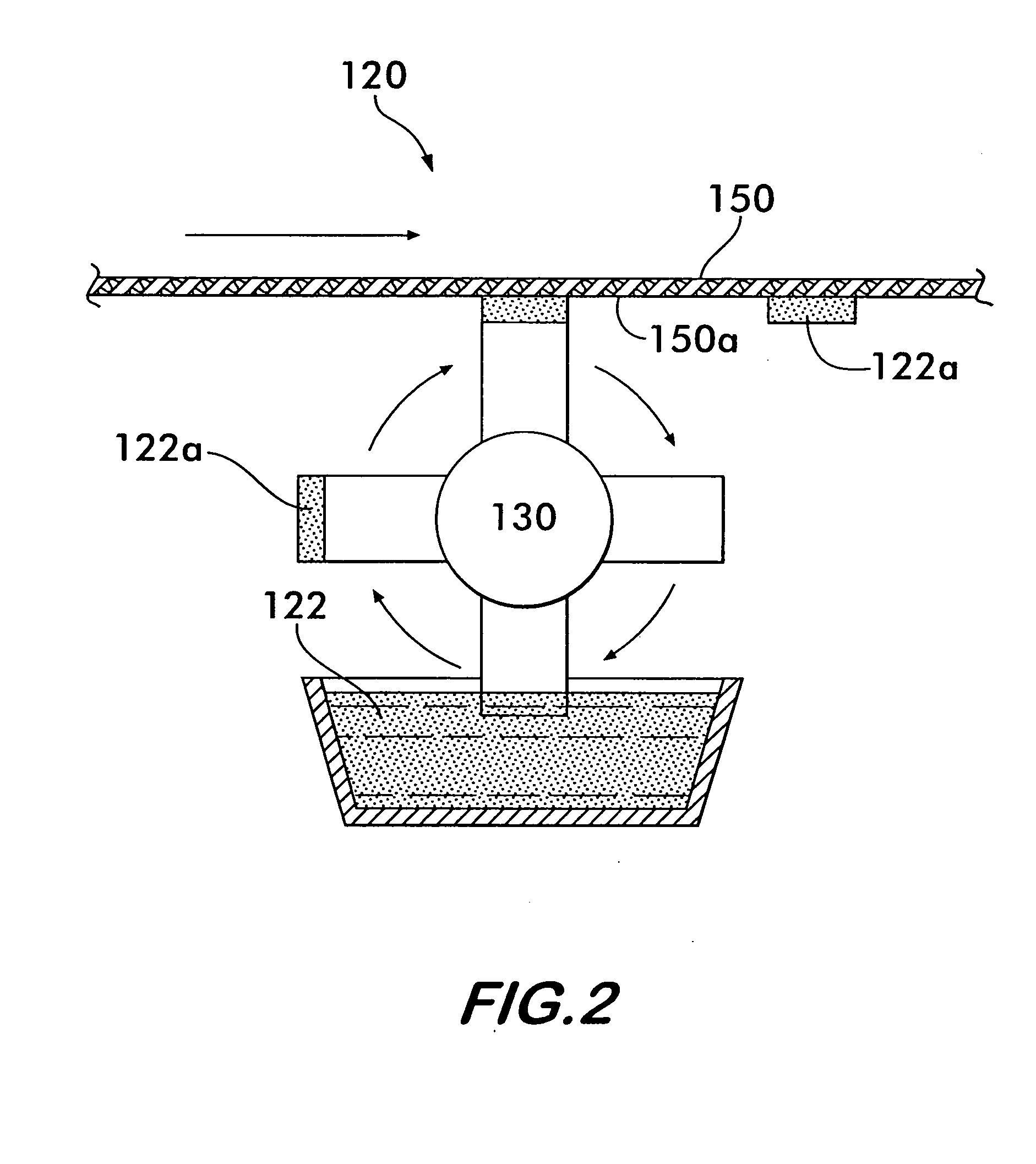

Process for producing resonant tag

InactiveUS6618939B2Easy to manufactureStable resonant characteristicWave amplification devicesElectrical connection printed elementsMetal foilAdhesive

A process for producing a resonant tag, wherein a metal foil having a thermal adhesion adhesive applied to at least one face thereof is stamped out into a circuit-like shape and is adhered to a base sheet, the process comprising: stamping out the metal foil into a predetermined shaped metal foil portion (4c) while being passed through a die roll (1) having thereon a stamping blade with a predetermined shape and a transfer roll (2) in contact with the die roll (1) which functions also as a die back-up roll; holding this metal foil portion obtained by the stamping-out operation onto the surface of the transfer roll by suction holes formed in the transfer roll; and thermally adhering the stamped metal foil portion to the base sheet (7) in contact with the transfer roll (2) at its another face by an adhesive roll (3) in contact with the transfer roll through the base sheet. The present invention has such advantages as no damage to the base sheet since the stamping-out operation for the metal foil and the thermal adhesion operation thereof to the base sheet are carried out in separate positions, and no requirement of carrier sheet because the resultant metal foil portion obtained by the stamping-out operation is sucked and held onto the surface of the transfer roll.

Owner:NOVATRON ELECTRONICS HANGZHOU

Wiring board for electrical tests with bumps having polymeric coating

InactiveUS6133534AElectrical measurement instrument detailsPrinted electric component incorporationElectrical testingEngineering

A wiring board for electrical tests; having an insulating substrate, wiring of predetermined pattern which is embedded in the insulating substrate, and bump electrodes which are formed on the wiring and which are respectively brought into contact with corresponding electrodes of an article to-be-tested. Thus, even when the electrode pitch of the article to-be-tested such as a semiconductor device has become smaller(for example, less than 0.1 [mm]), the electrodes can be formed so as to cope with the electrical tests of the article.

Owner:HITACHI CHEM CO LTD

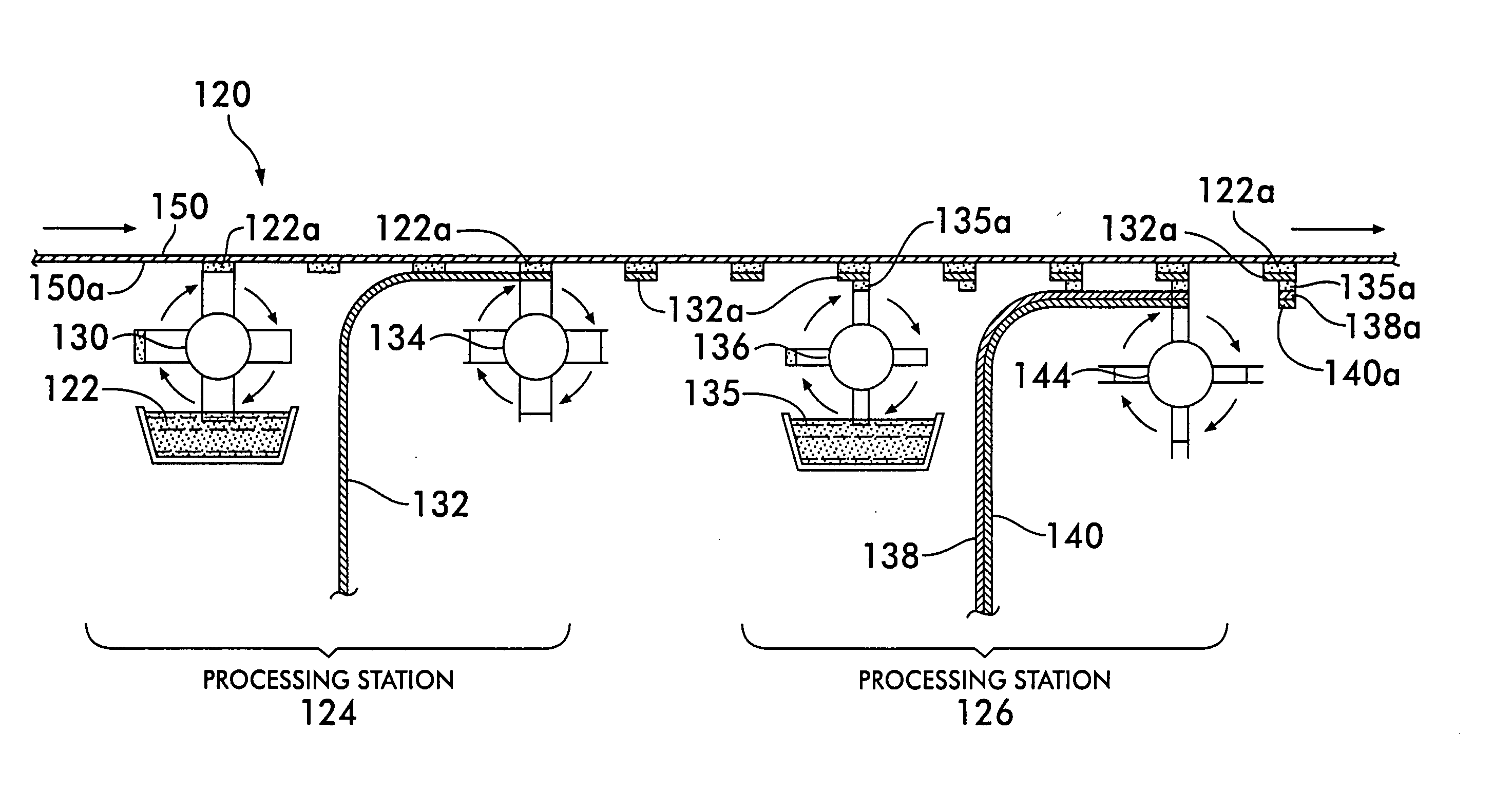

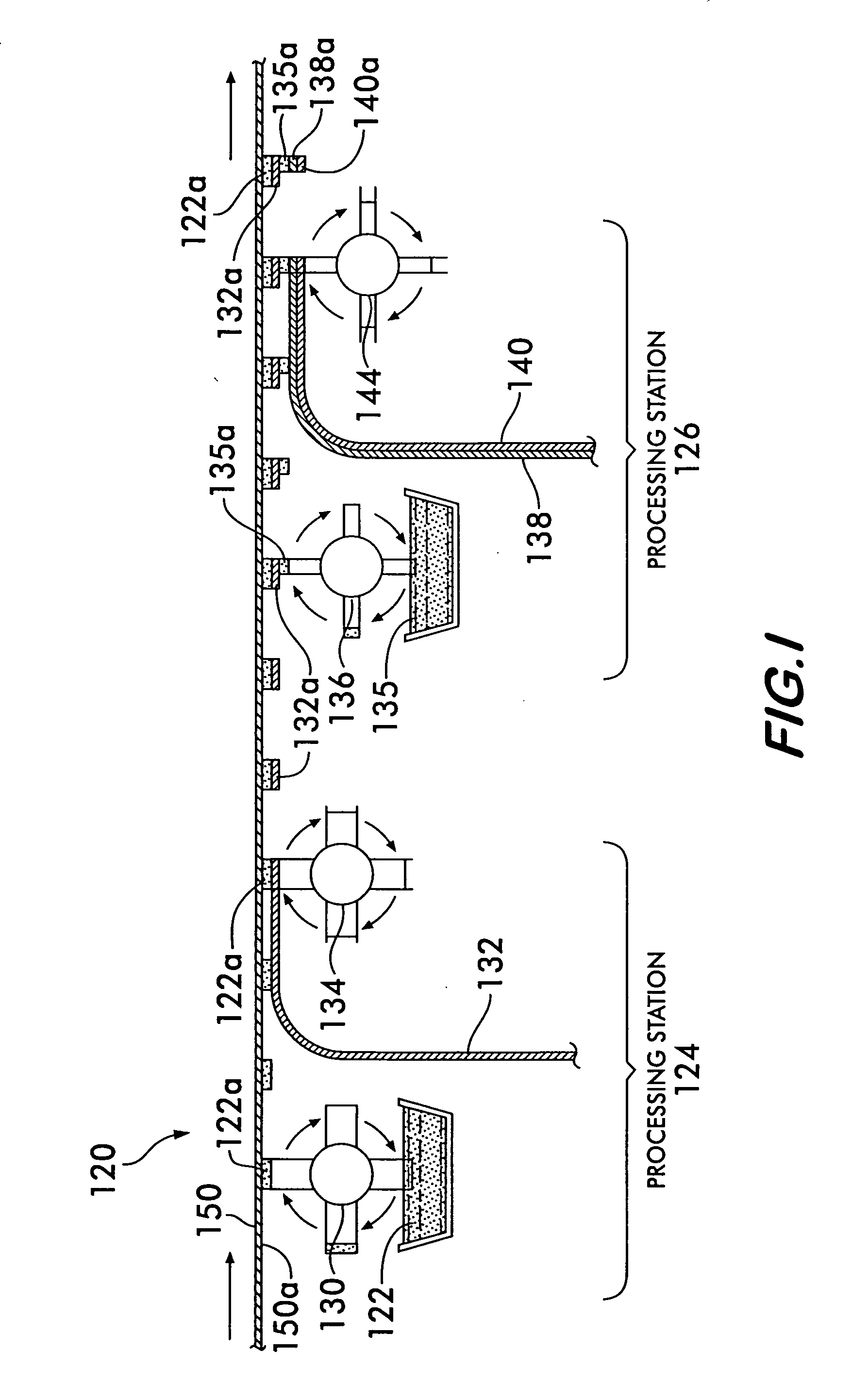

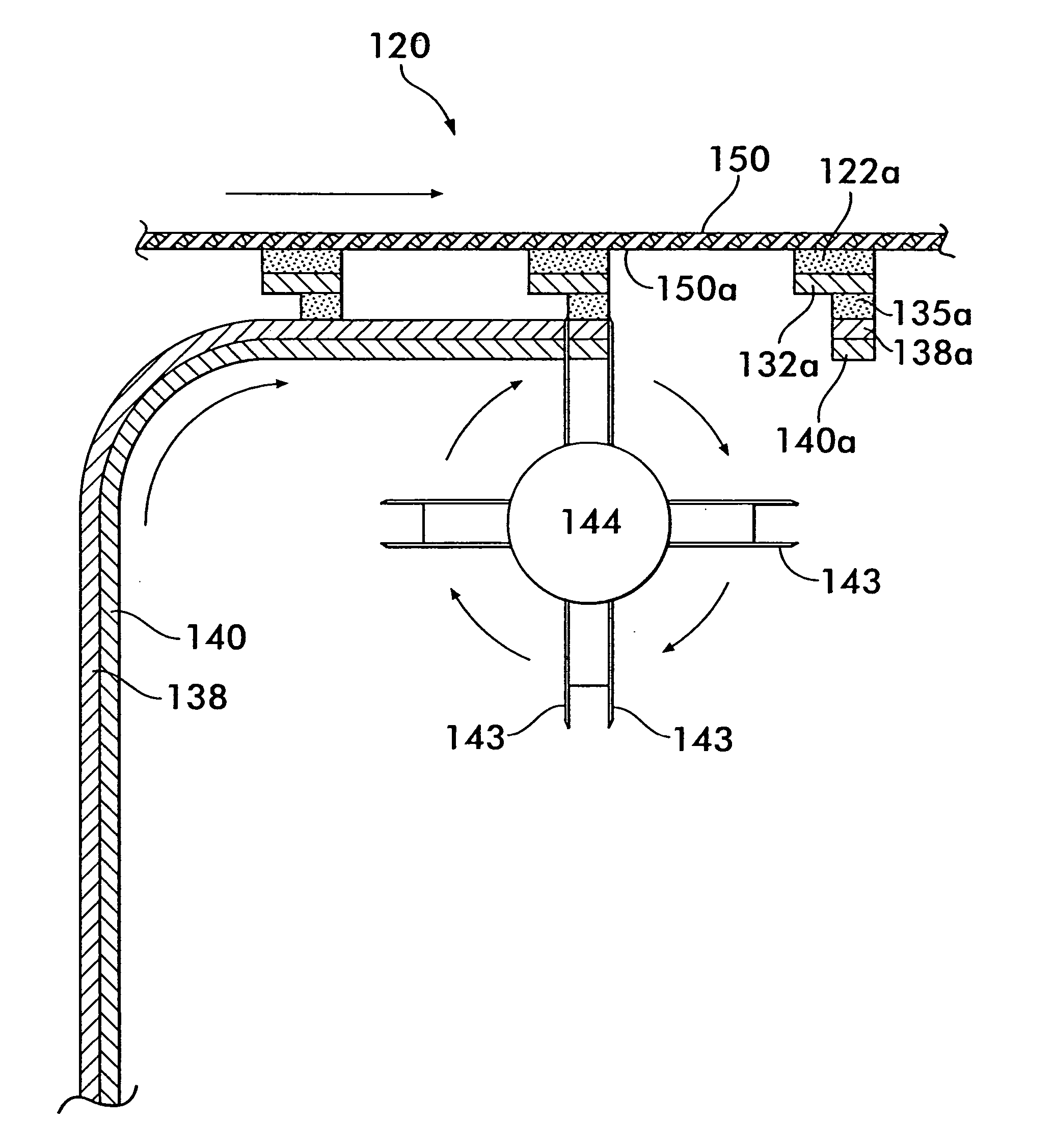

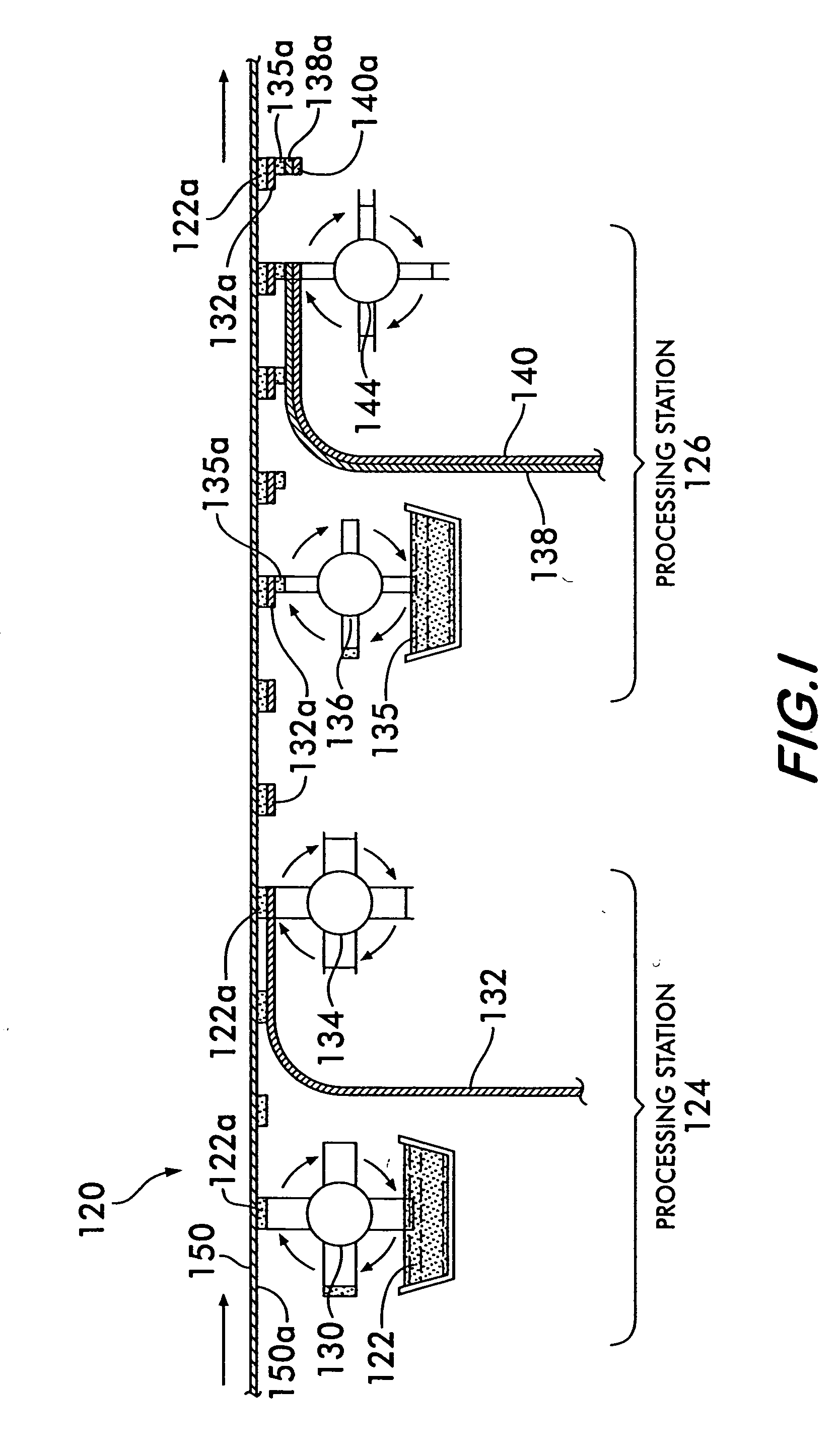

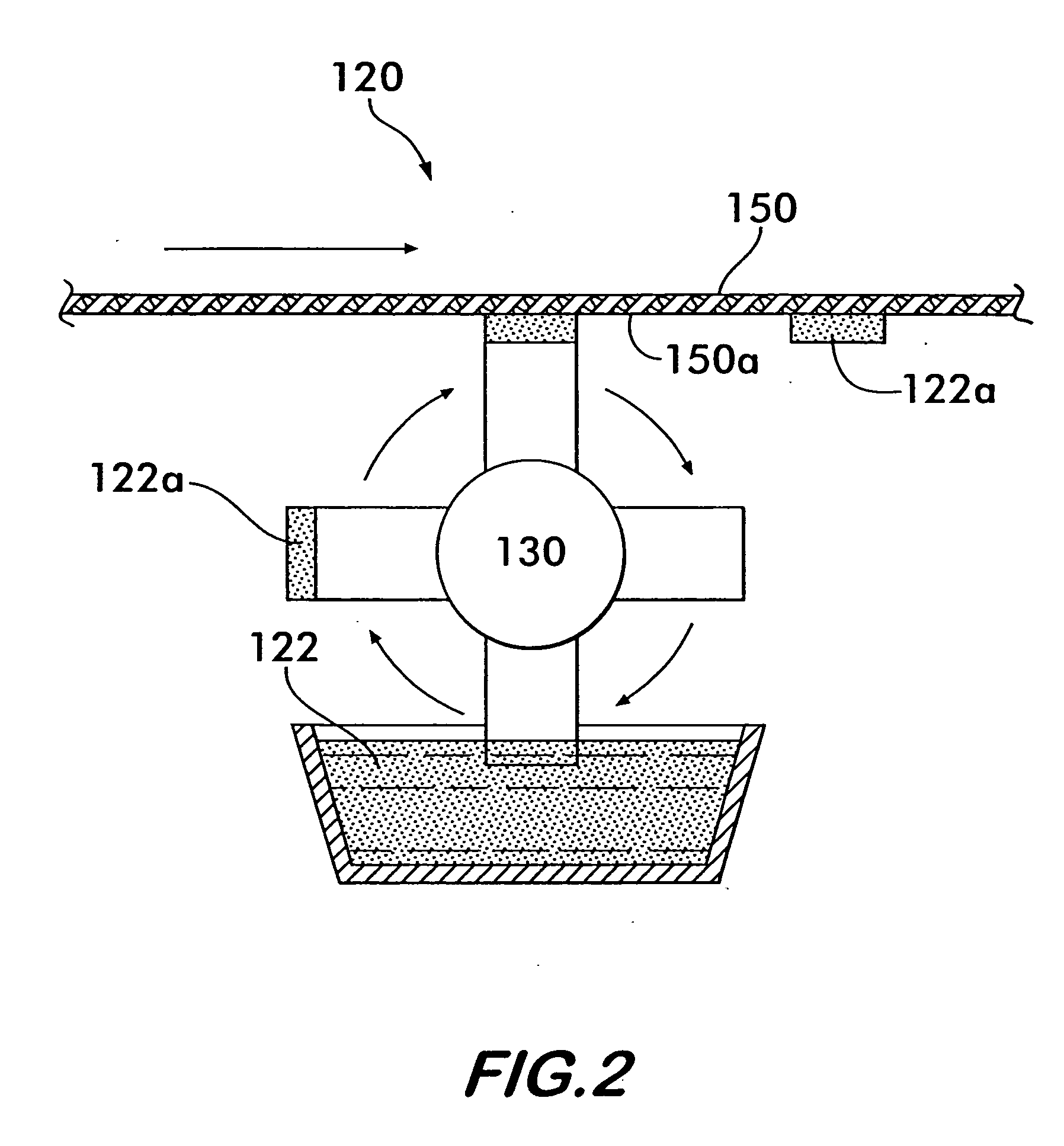

Security tag system for fabricating a tag including an integrated surface processing system

A method of fabricating a tag includes the steps of applying a first patterned adhesive to the surface of the substrate and applying a first electrically conductive foil to the first patterned adhesive. A portion of the first electrically conductive foil not adhered to the first patterned adhesive is removed and a second patterned adhesive is applied to a portion of a surface area of the tag. A preformed second electrically conductive foil is applied to the second patterned adhesive to adhere the second electrically conductive foil to the surface of the substrate and portions of the first and second electrically conductive foils are electrically coupled to each other to form a tag circuit. A second patterned adhesive can be disposed between the first and second electrically conductive foils.

Owner:CHECKPOINT SYST INC

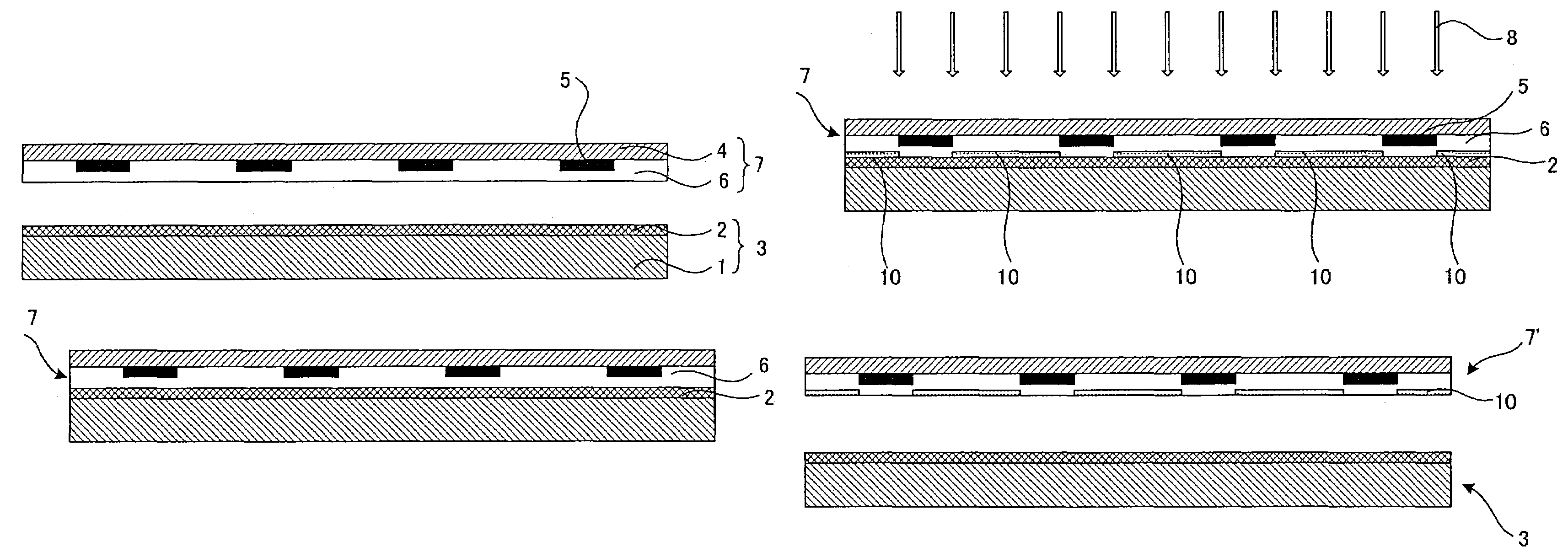

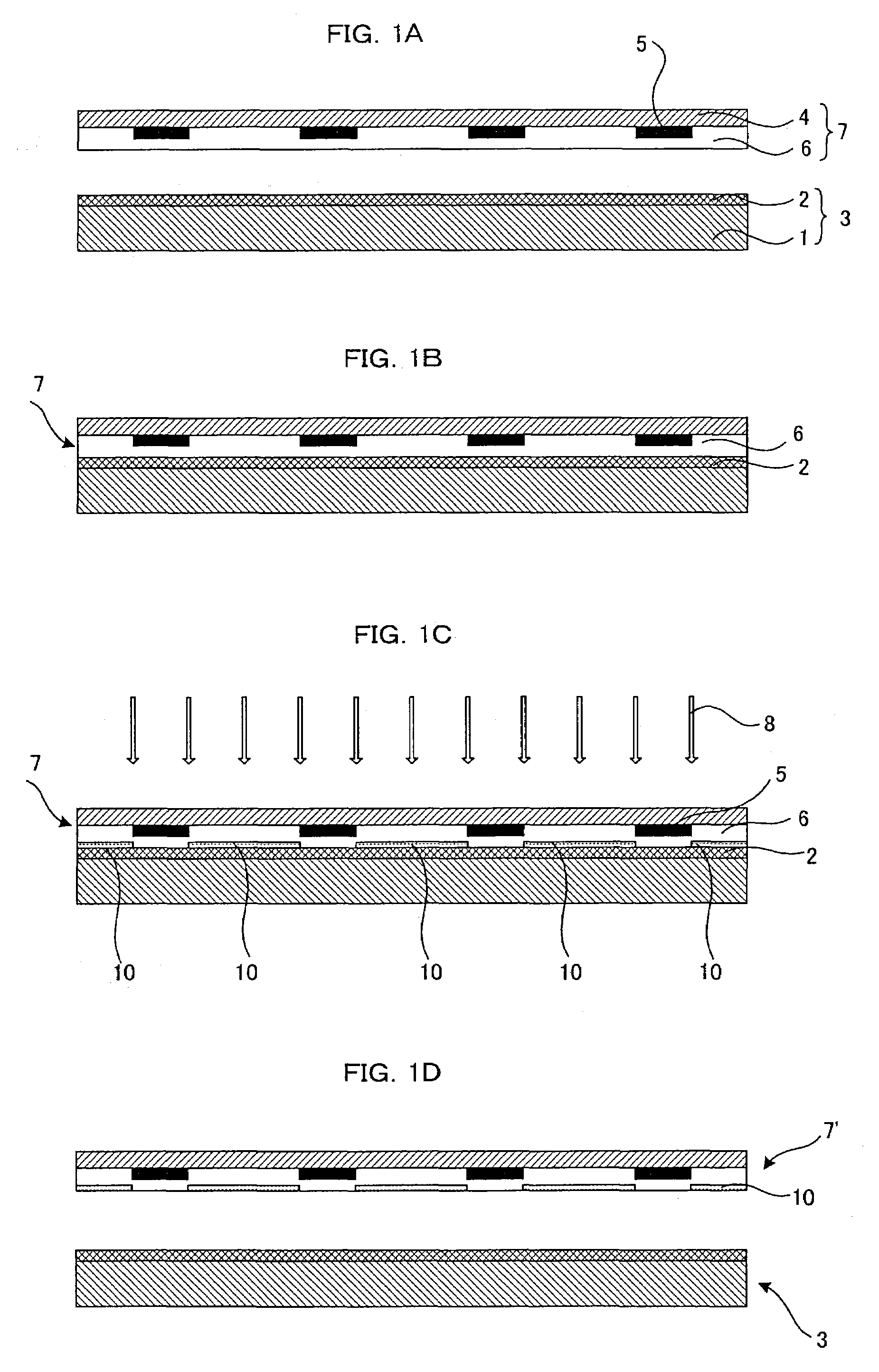

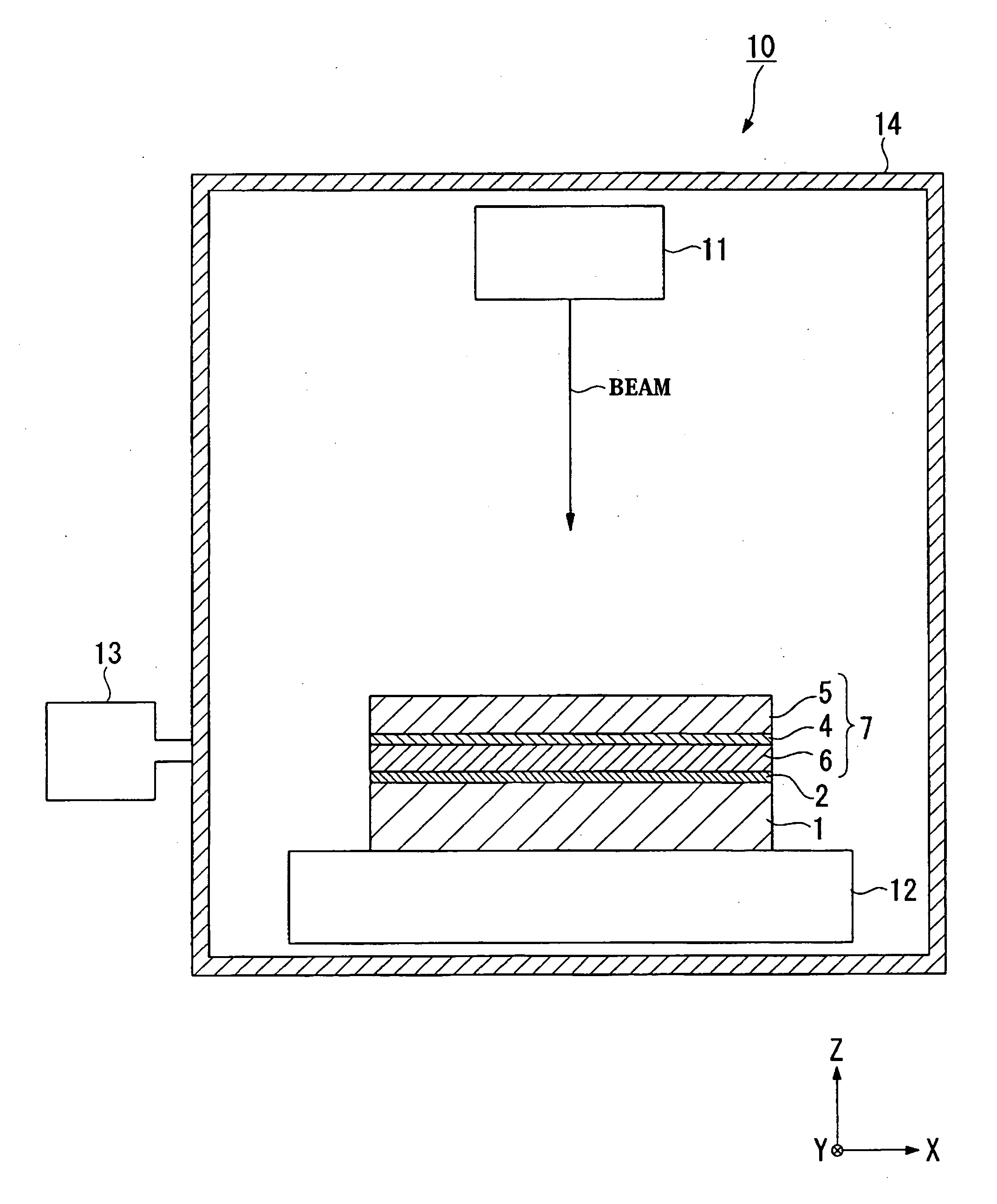

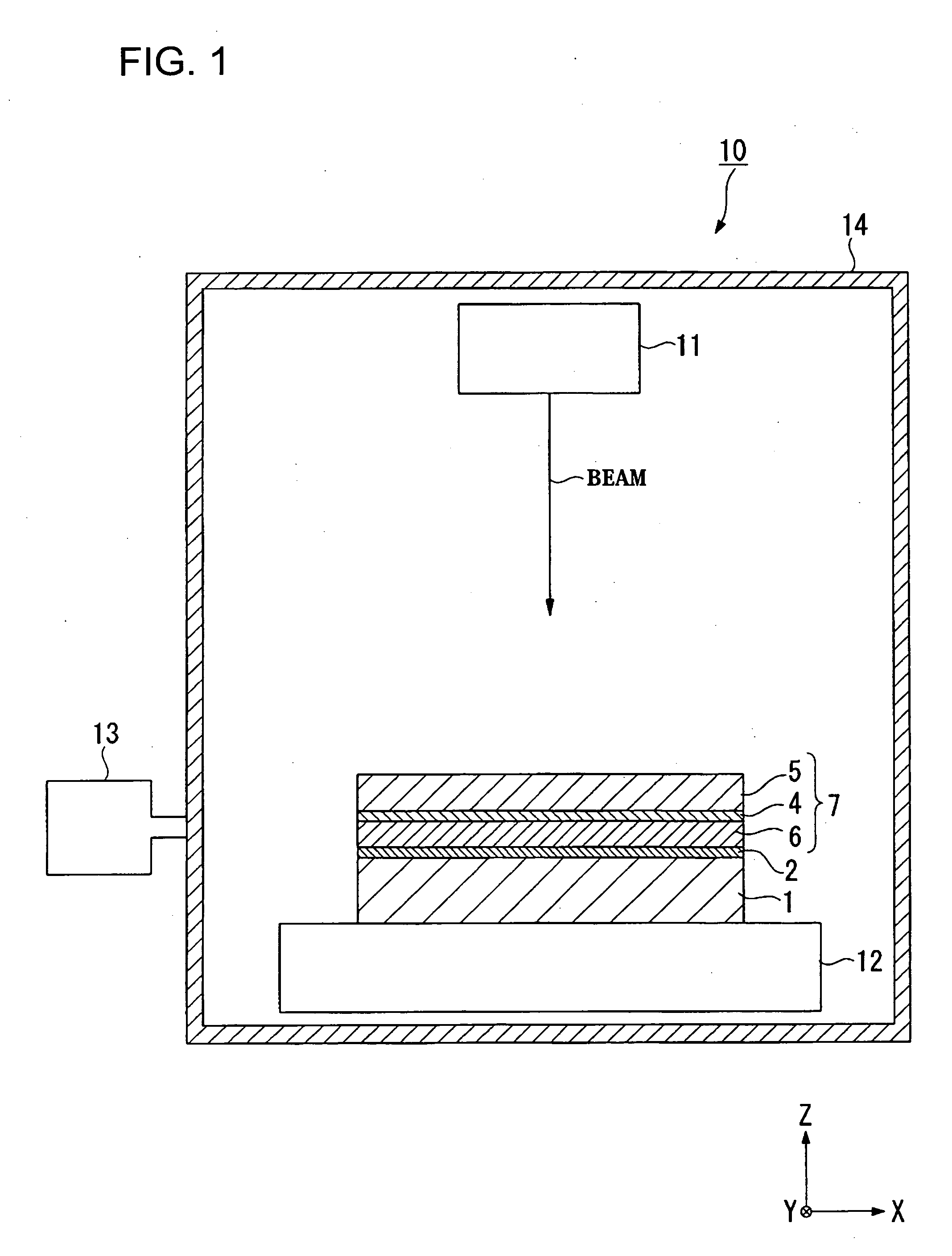

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

ActiveUS20050087289A1Efficiently converted into thermal energySmall diameterElectric lighting sourcesSolid-state devicesDevice materialEngineering

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

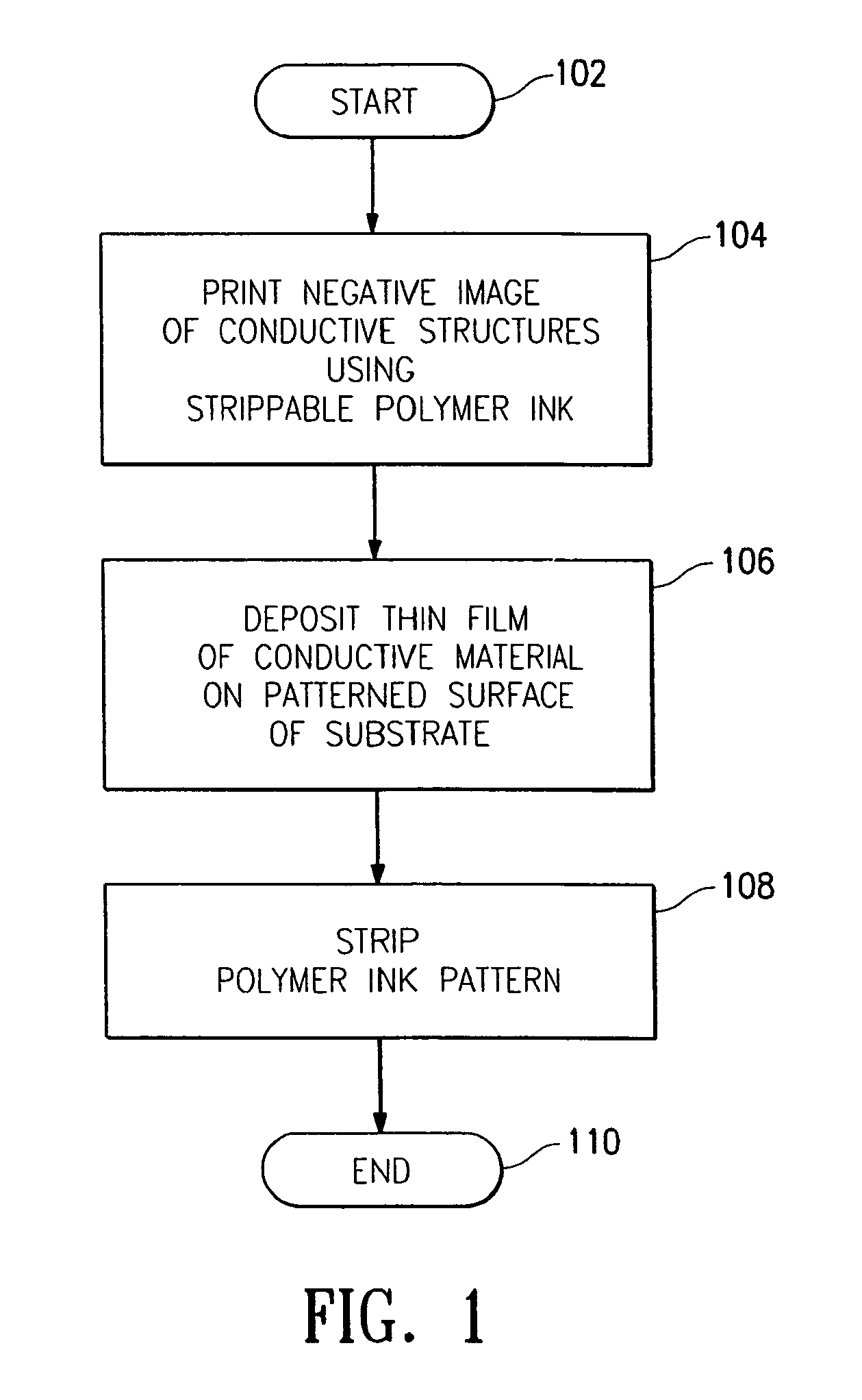

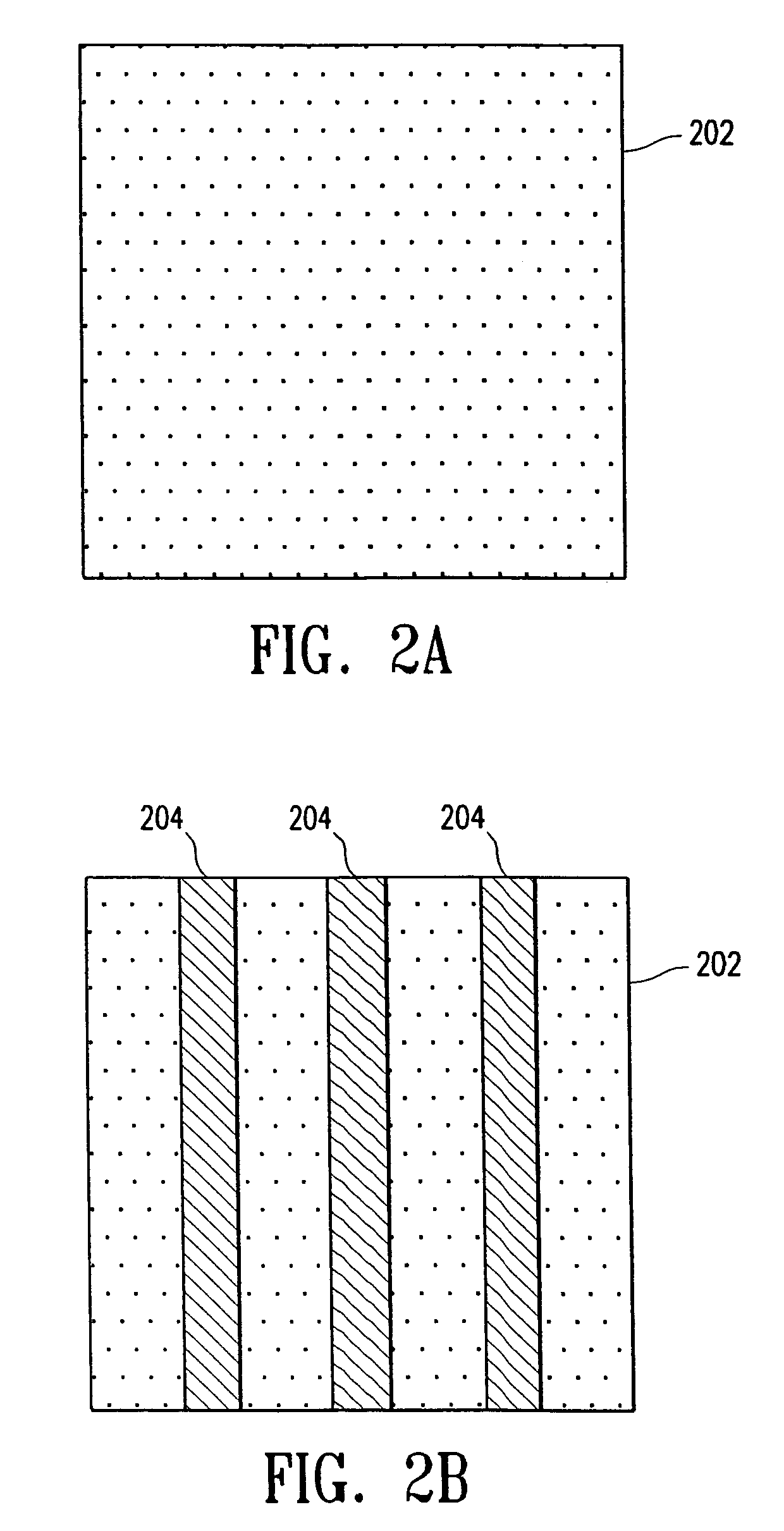

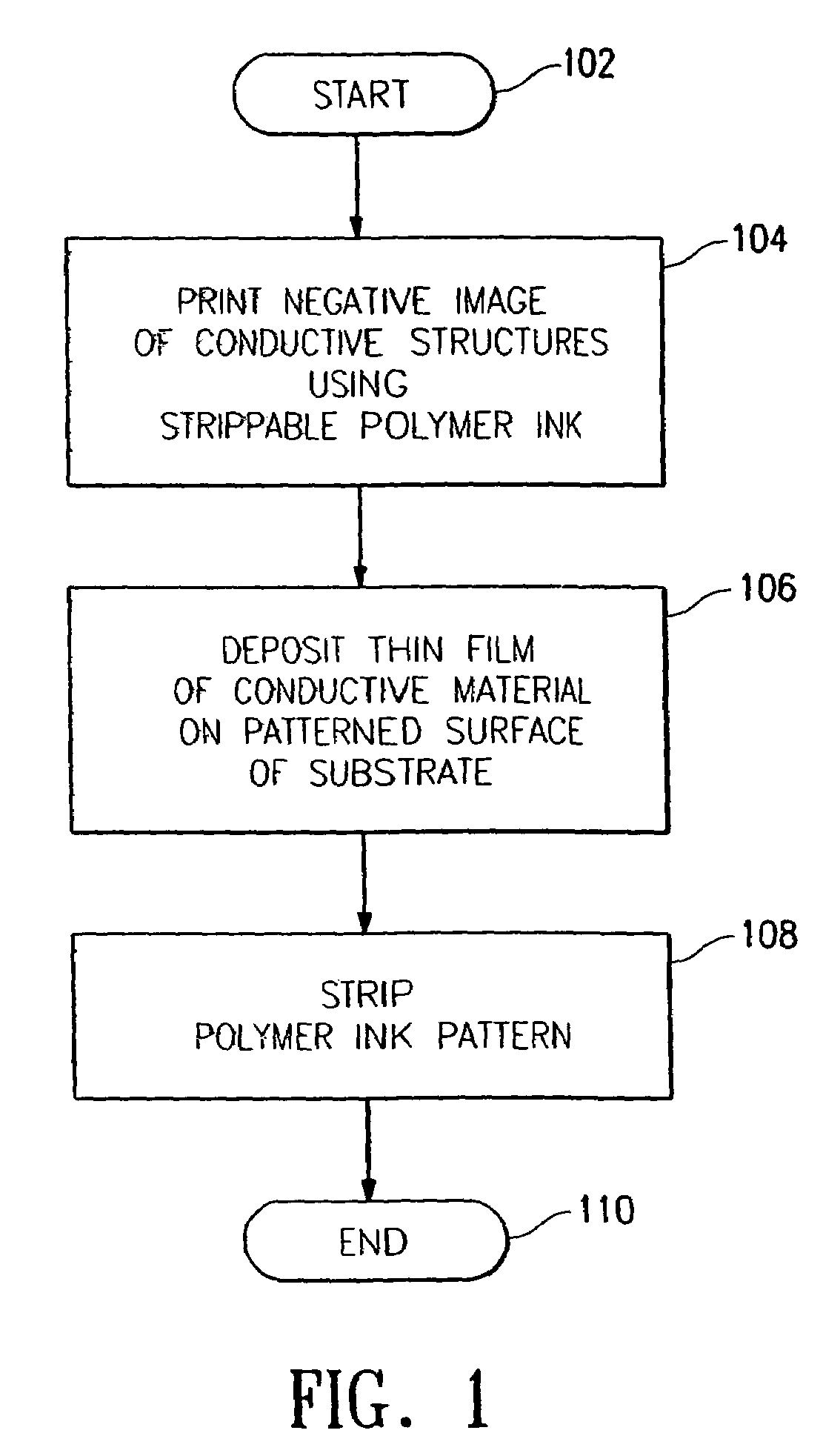

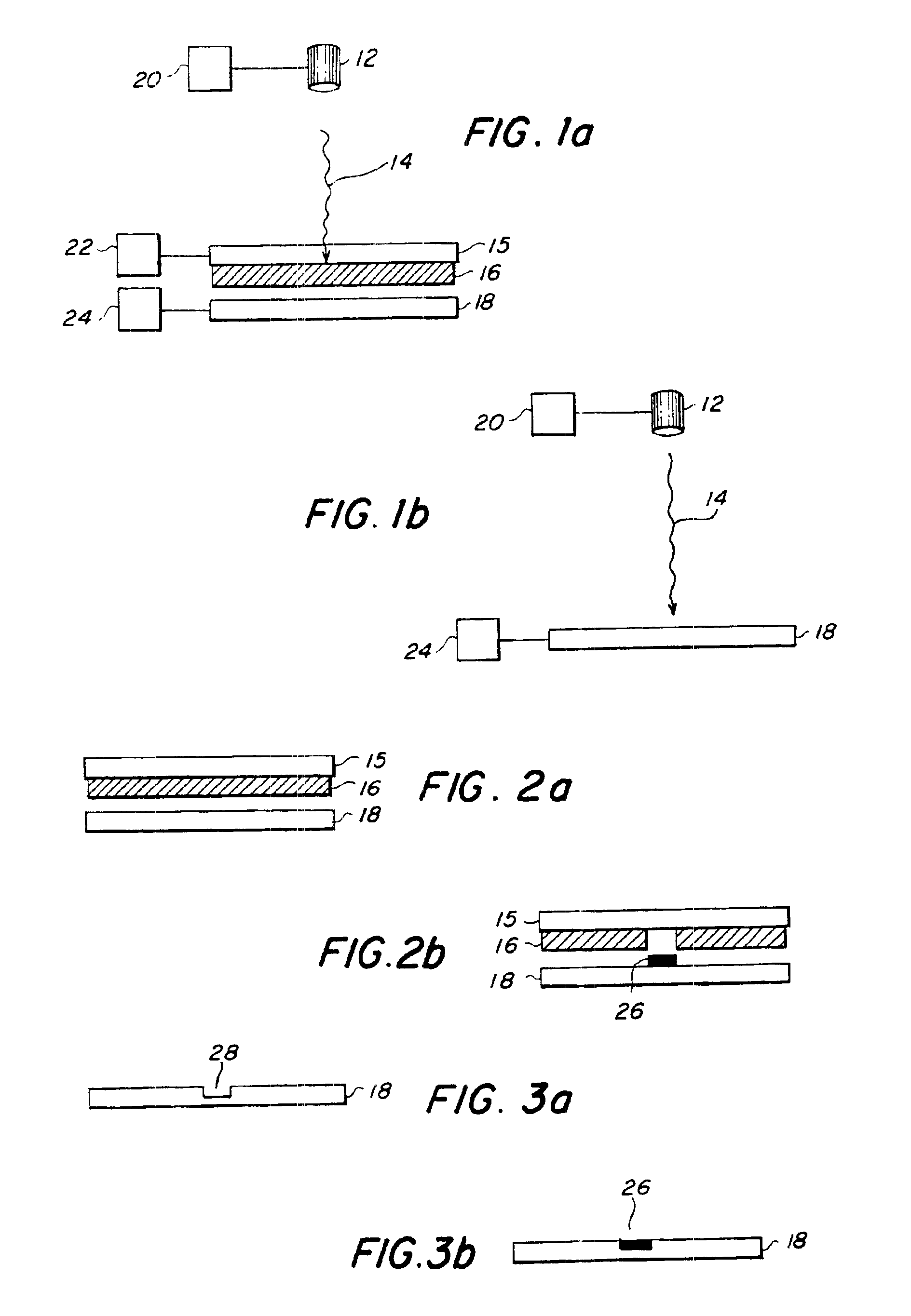

Process for forming a patterned thin film structure on a substrate

InactiveUS7261920B2Pretreated surfacesSemiconductor/solid-state device manufacturingOptoelectronicsPatterned substrate

A process for forming a patterned thin film structure on a substrate is disclosed. A pattern is printed with a material, such as a masking coating or an ink, on the substrate, the pattern being such that, in one embodiment, the desired thin film structures will be formed in the areas where the printed material is not present, i.e., a negative image of thin film structure to be formed is printed. In another embodiment, the pattern is printed with a material that is difficult to strip from the substrate, and the desired thin film structures will be formed in the areas where the printed material is present, i.e., a positive image of the thin film structure is printed. The thin film material is deposited on the patterned substrate, and the undesired area is stripped, leaving behind the patterned thin film structures.

Owner:E INK CALIFORNIA

Multilayer substrate

InactiveUS20080026592A1Easy to controlDimension shrinkage is keptPrinted electric component incorporationPrinted circuit aspectsDevice formDielectric layer

A multilayer substrate device formed from a base substrate and alternating metalization layers and dielectric layers. Each layer is formed without firing. Vias may extend through one of the dielectric layers such that two metalization layers surrounding the dielectric layers make contact with each other. The vias may be formed by placing pillars on top of a metalization layer, forming a dielectric layer on top of the metalization layer and surrounding the pillars, and removing the pillars. Dielectric layers may be followed by other dielectric layers and metalization layers may be followed by other metalization layers. Vias in the substrate may be filled by forming an assembly around the substrate, the assembly including printing sheets containing a conductive ink and pressure plates for applying pressure. A vacuum may be applied to remove air in the ink. Pressure may then be applied to the printing sheets through the pressure plates. The conductive ink in the printing sheets is pushed through the vias when pressure is applied by the pressure plates.

Owner:MEDTRONIC MIMIMED INC

Process for forming a patterned thin film structure for in-mold decoration

A process for forming a patterned thin film structure on a substrate or in-mold decoration film is disclosed. A pattern is printed with a material, such as a masking coating or ink, on the substrate, the pattern being such that, in one embodiment, the desired structures will be formed in the areas where the printed material is not present, i.e., a negative image of thin film structure to be formed is printed. In another embodiment, the pattern is printed with a material that is difficult to strip from the substrate, and the desired thin film structures will be formed in the areas where the printed material is present, i.e., a positive image of the thin film structure is printed. The thin film material is deposited on the patterned substrate, and the undesired area is stripped, leaving behind the patterned thin film structure.

Owner:SIPIX CHEM

Method for drilling deep hole and PCB product obtained by same method

InactiveCN1787726AControl drilling depthReduce the impactConductive material mechanical removalEngineeringControl software

This invention discloses a new method for deep drilling and PCB products got from it, which sets the platform control loop on the POWER layer in the board and begins computing the designed depth from the place contacting the POWER by the drilling pin or drills the test holes of Z1,Z2 and Z3 on the necessary drilled regions of the upper surface, the upper target layer and the lower target layer then adds G87, G88 and G89 functional instructions on the control software of the platform to detect the depth values of Z1 and Z2 and judges the drilled depth value based on their positions, finally the platform adds a compensation value of a drill point to the depth of (Z2+Z3) / 2 to drill.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

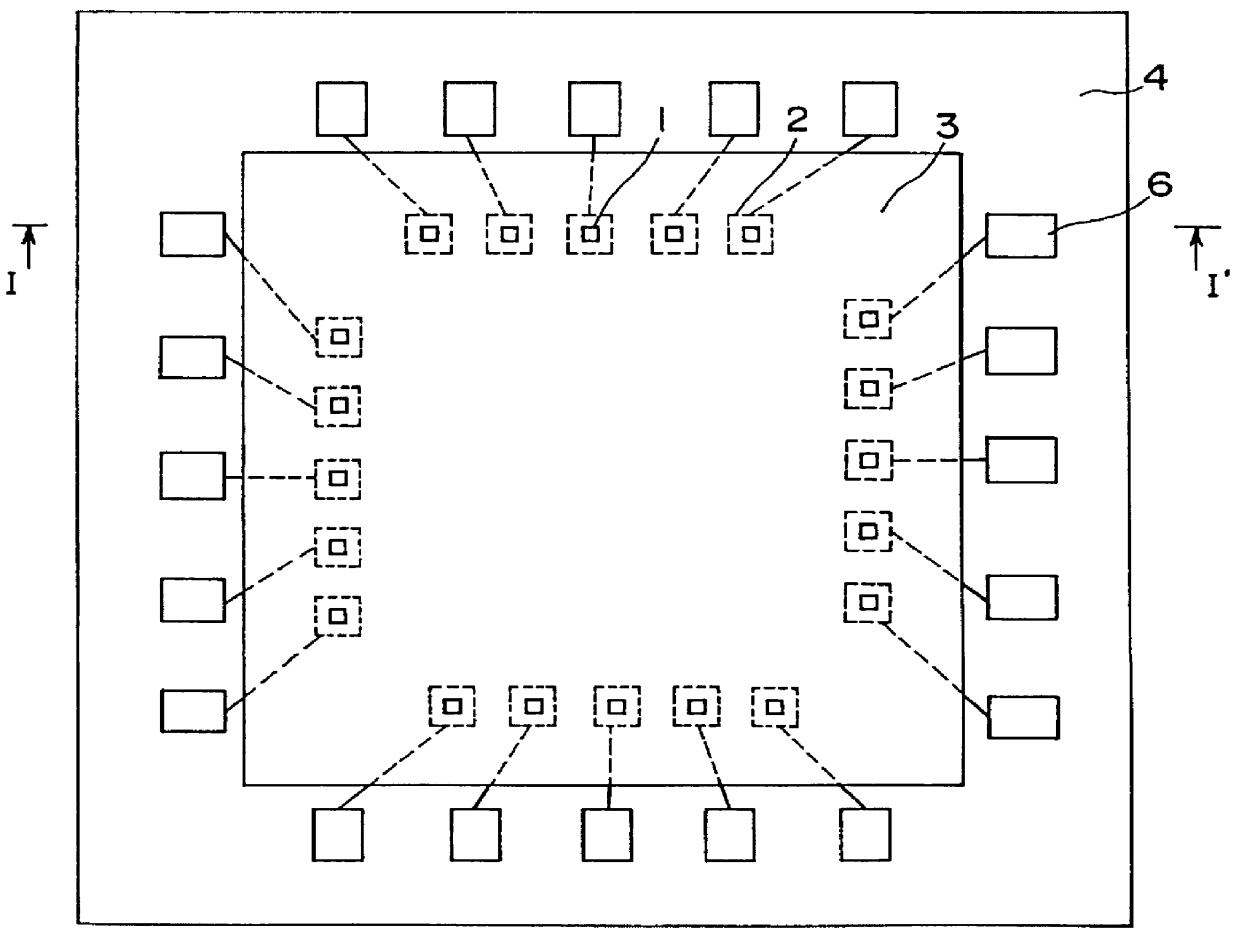

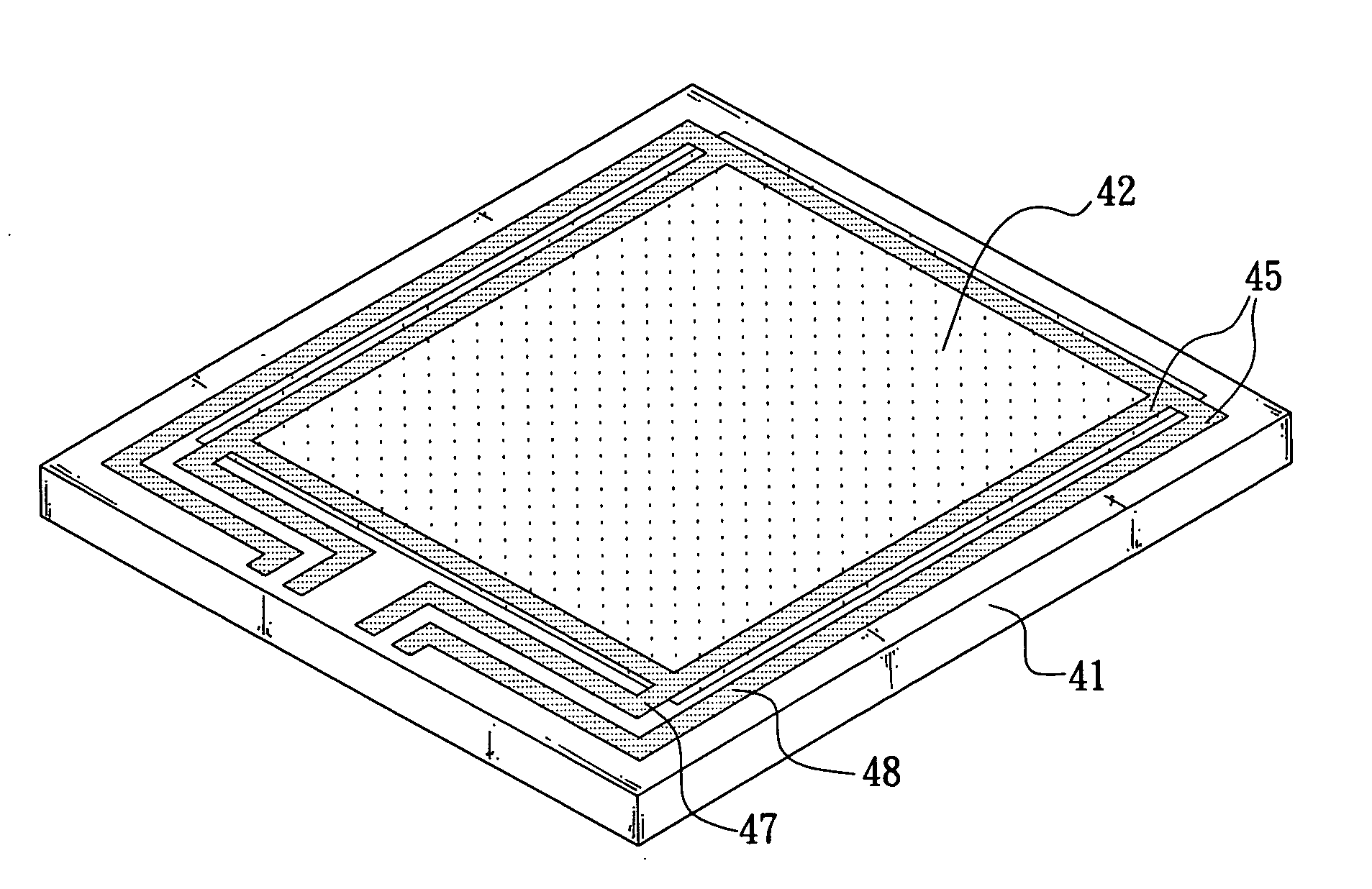

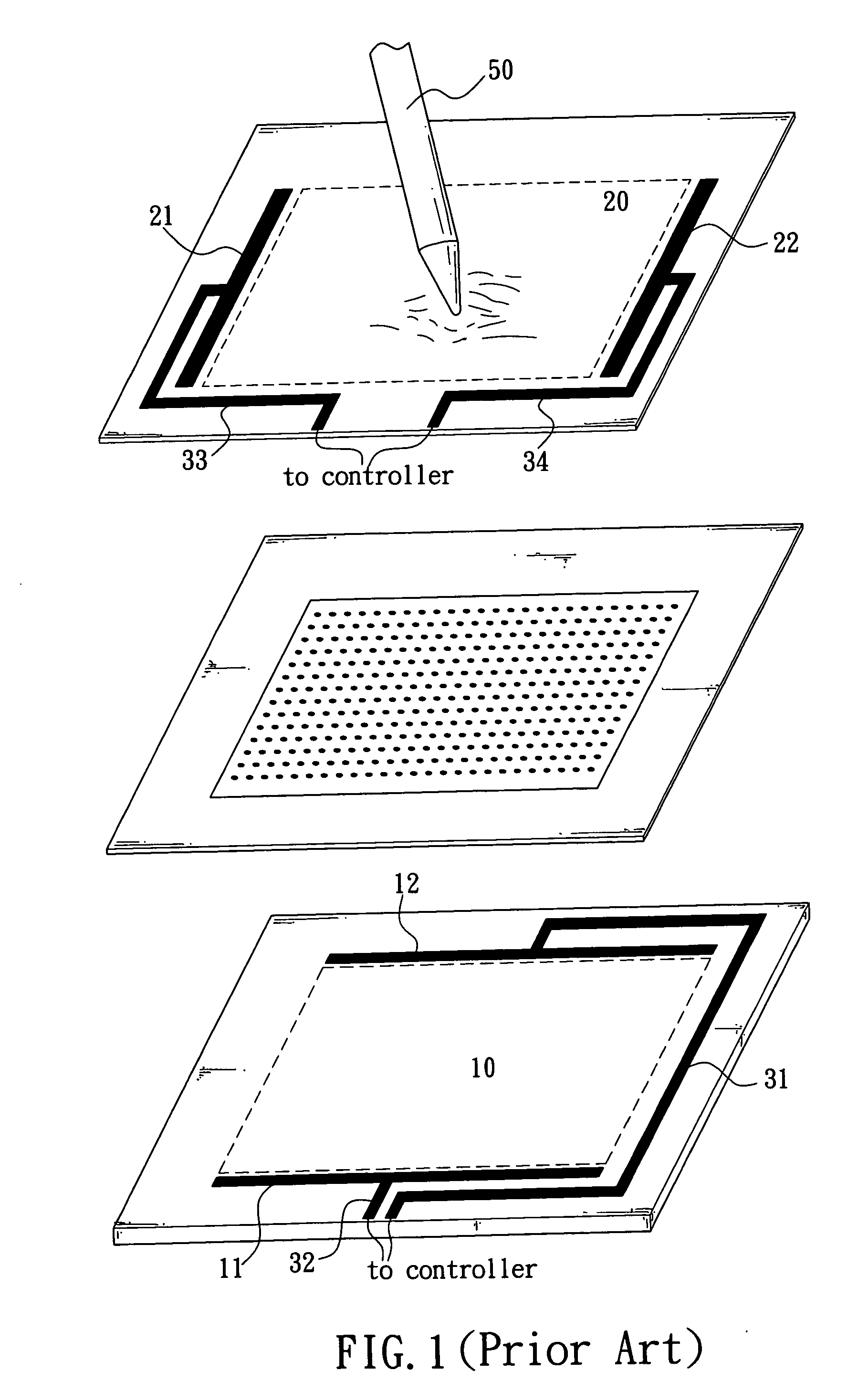

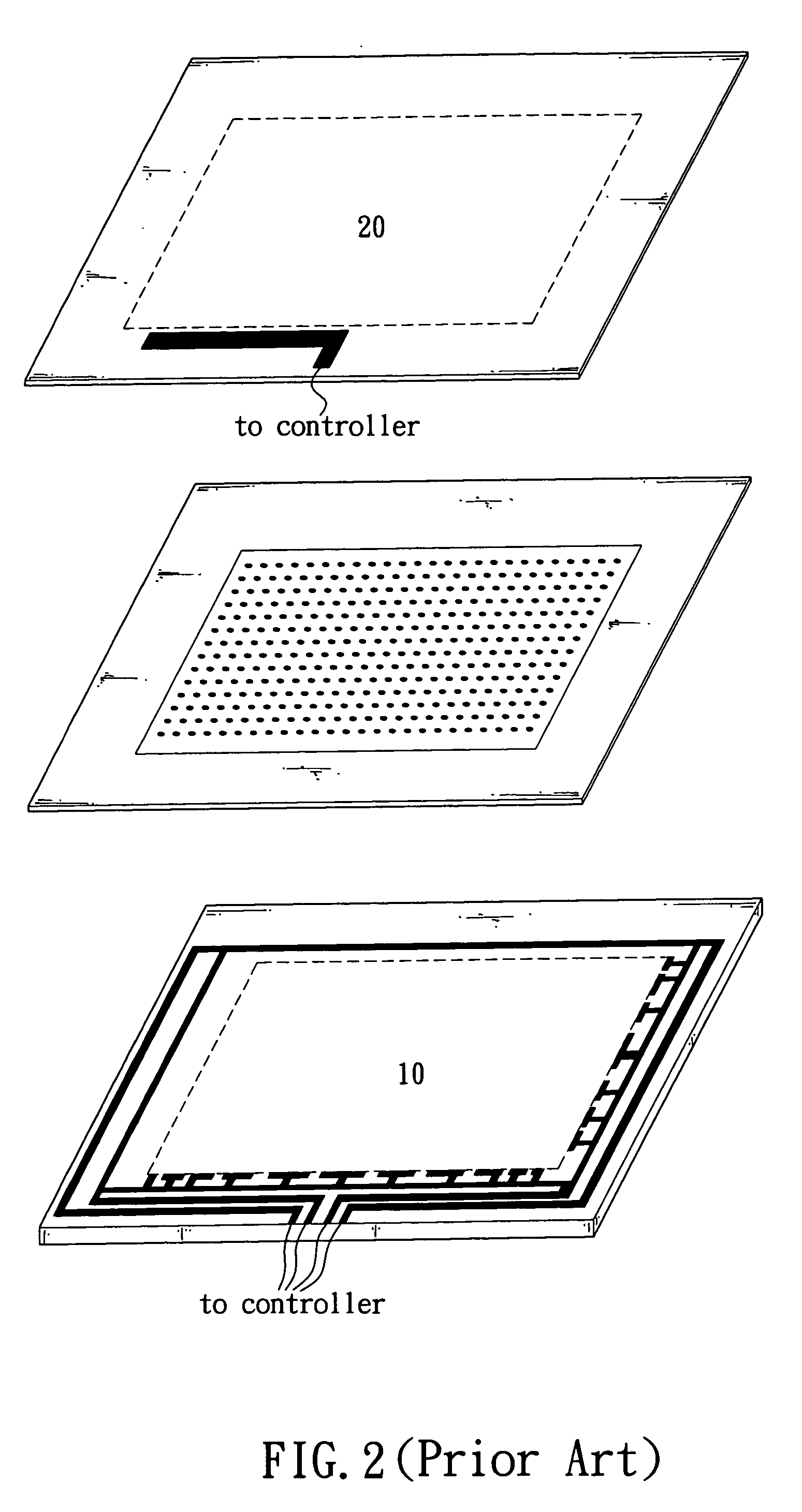

Method for aligning capacitor plates in a security tag and a capacitor formed thereby

InactiveUS20050183264A1Radiating elements structural formsPrinted capacitor incorporationCapacitanceEngineering

A circuit element the presence of the circuit element includes first and second capacitor plates disposed over the surface of the substrate in an aligned relationship with each other. The aligned relationship has manufacturing variations in the relative positioning of the first and second capacitor plates and a dielectric layer disposed between the first and second capacitor plates. At least one of the first and second capacitor plates is formed substantially smaller relative to the other of the first and second capacitor plates. The at least one of the capacitor plates is disposed at a predetermined offset in at least one planar direction from an edge of the other of the first and second capacitor plates. The predetermined offset is selected according to the manufacturing variations to prevent variations in the value of capacitance of the capacitor due to the manufacturing variations.

Owner:CHECKPOINT SYST INC

Method of manufacturing circuit layout on touch panel by utilizing metal plating technology

InactiveUS20050260338A1Uniform thicknessImprove adhesionPrinted circuit aspectsLiquid/solution decomposition chemical coatingSolderabilityEngineering

The present invention is to provide a method of manufacturing a circuit layout on a touch panel by utilizing metal plating technology, comprising uniformly coating a conductive metal or conductive oxidized metal on predetermined areas proximate edges of a transparent conductive layer on a transparent glass substrate for forming a circuit by utilizing metal plating technology, which has the advantages of uniform thickness of circuit, higher hardness, better adhesion of the plated material to the underlying substrate, whether it is a resistive film or bare glass, improved weathering and chemical properties, and solderability.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

Method for forming film, method for forming wiring pattern, method for manufacturing semiconductor device, electro-optical device, and electronic device

ActiveUS7217334B2Enhance and improve adhesionHigh quality transmissionElectric lighting sourcesSolid-state devicesEngineeringSemiconductor

Exemplary embodiments of the invention to provide an efficient and productive method to form a reliable film. A method to form a film according to exemplary embodiments of the present invention, in which a transferring layer formed on a substrate is transferred to a workpiece to form a predetermined film on the workpiece, includes treating a surface of the workpiece to enhance or improve the adhesion between the transferring layer and the workpiece by chemical interaction.

Owner:INTELLECTUAL KEYSTONE TECH LLC

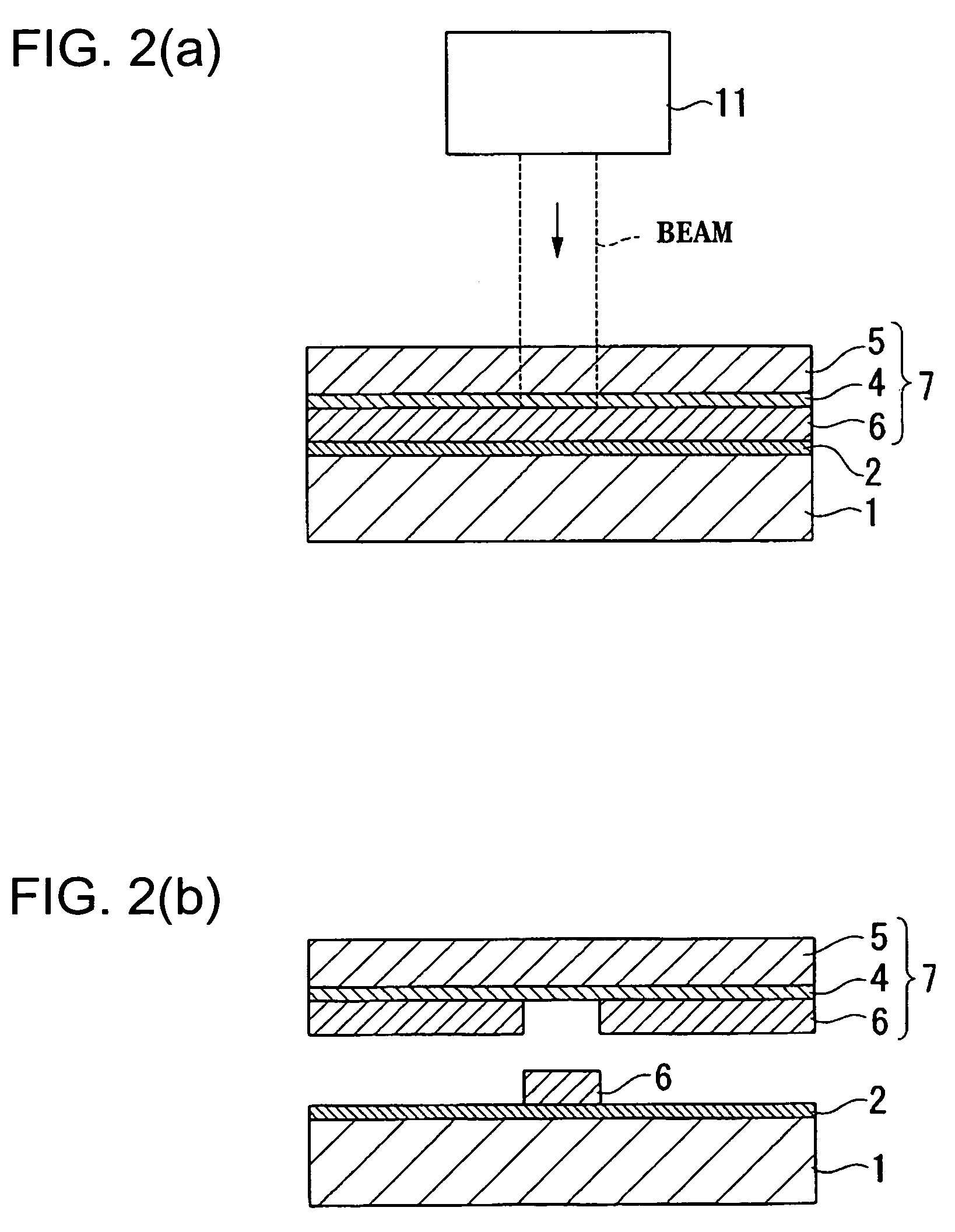

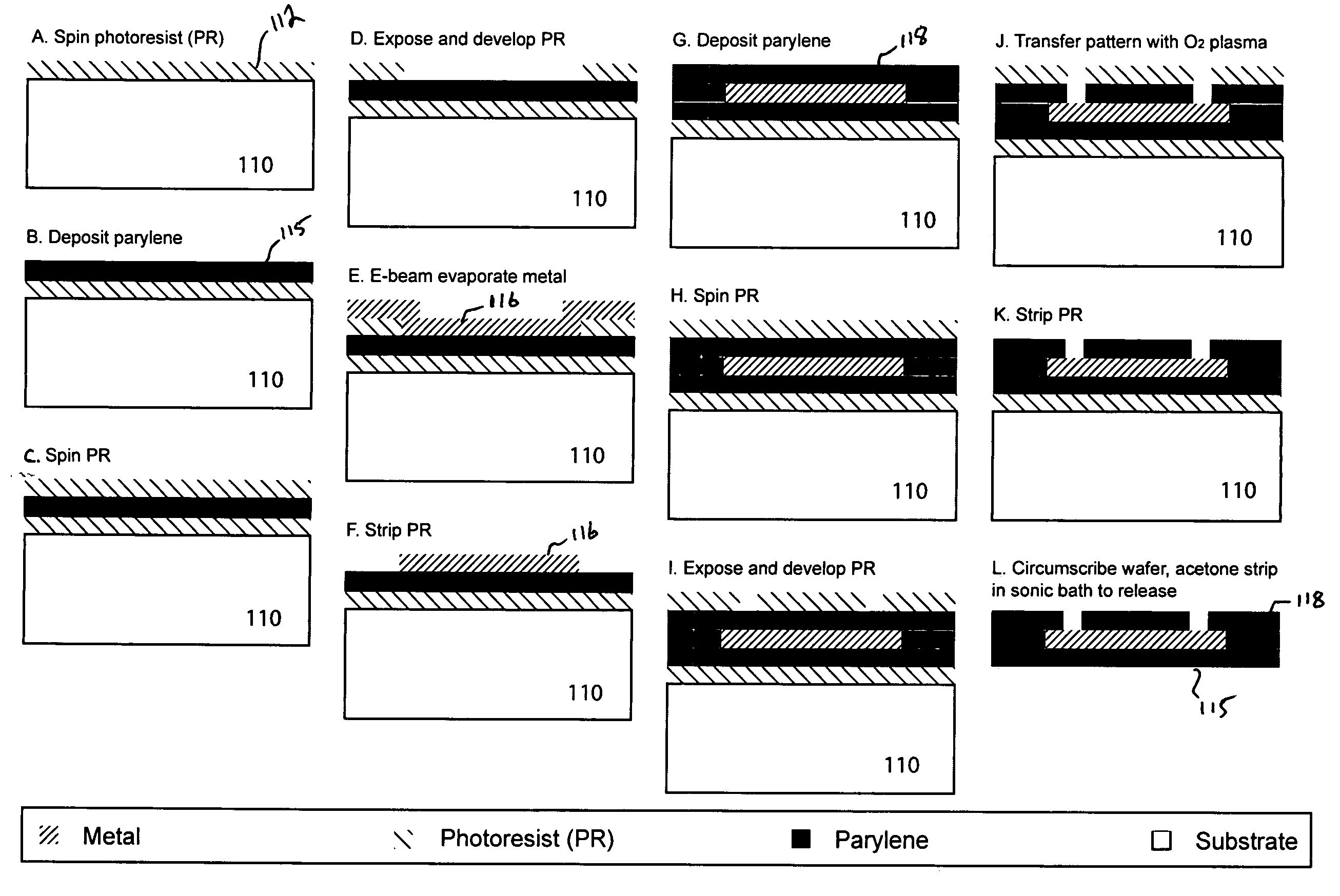

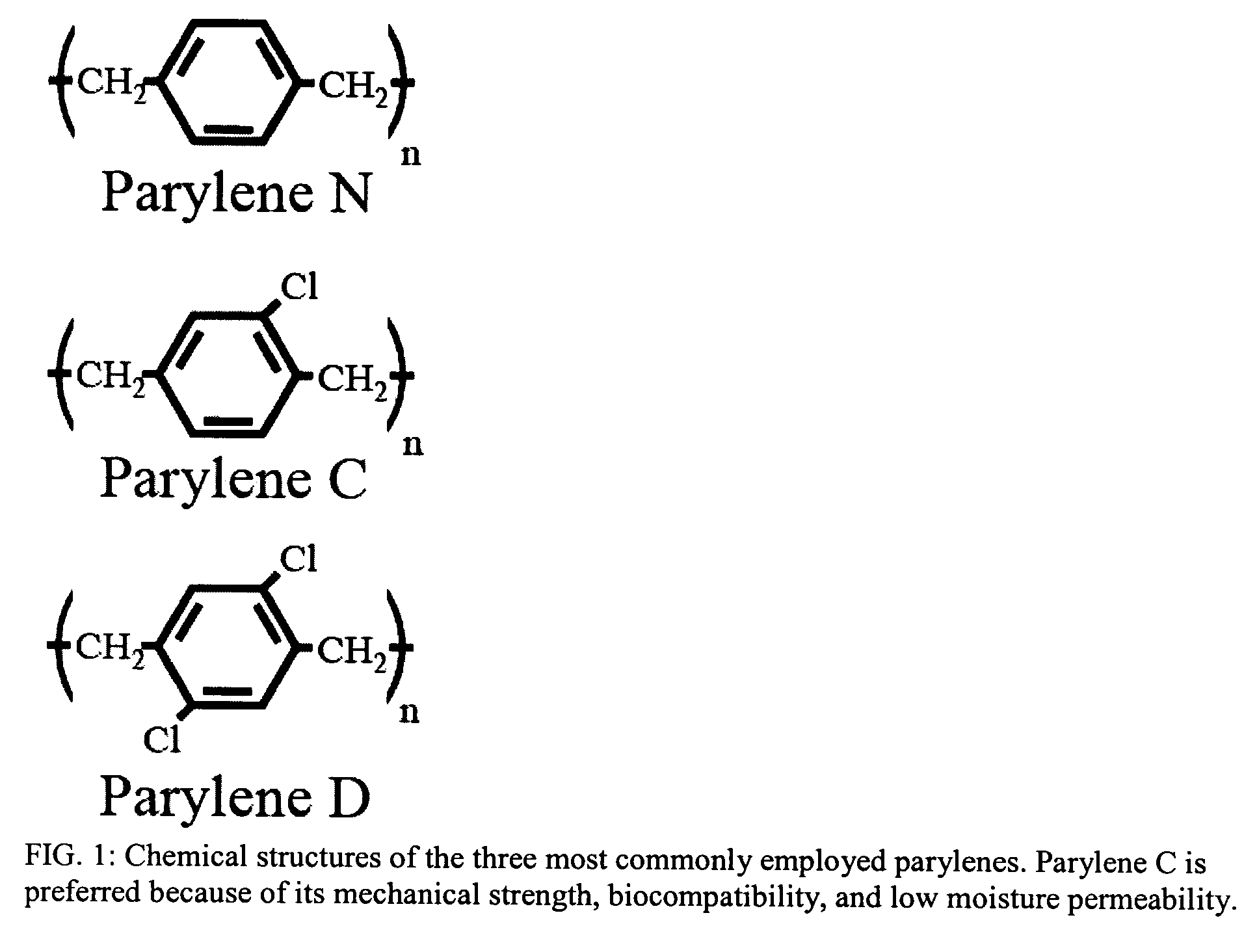

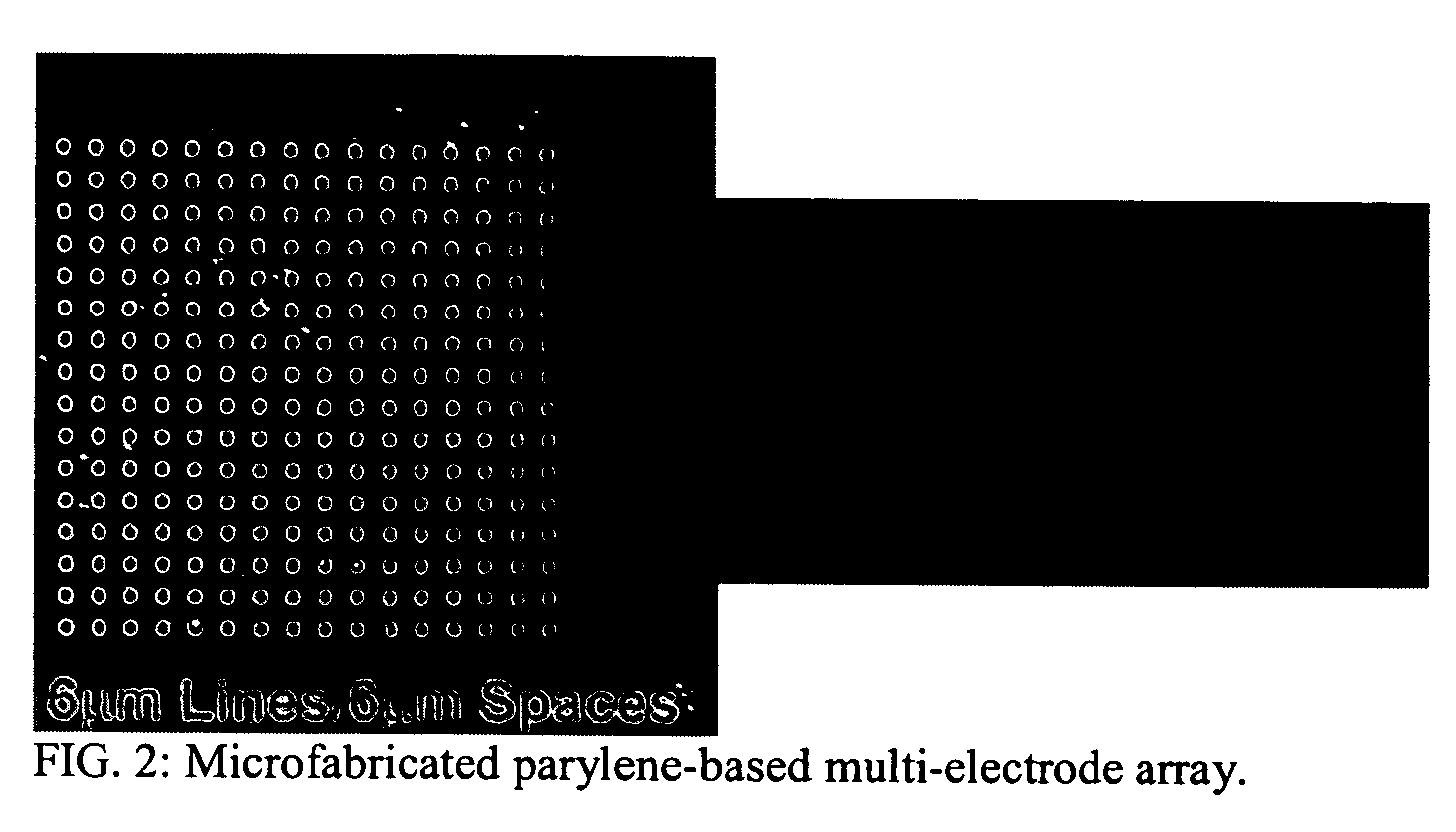

Parylene-based flexible multi-electrode arrays for neuronal stimulation and recording and methods for manufacturing the same

ActiveUS7326649B2Environment can be compatibleSemiconductor/solid-state device detailsSolid-state devicesNeuronal stimulationParylene

Method for manufacturing a parylene-based electrode array that includes an underlying parylene layer, one or more patterned electrode layers comprising a conductive material such as a metal, and one or more overlying parylene layers. The overlying parylene is etched away or otherwise processed to expose the electrodes where stimulation or recording is to occur. All other conductive material in the device is occluded from the environment by the two layers of parylene surrounding it.

Owner:UNIV OF SOUTHERN CALIFORNIA +1

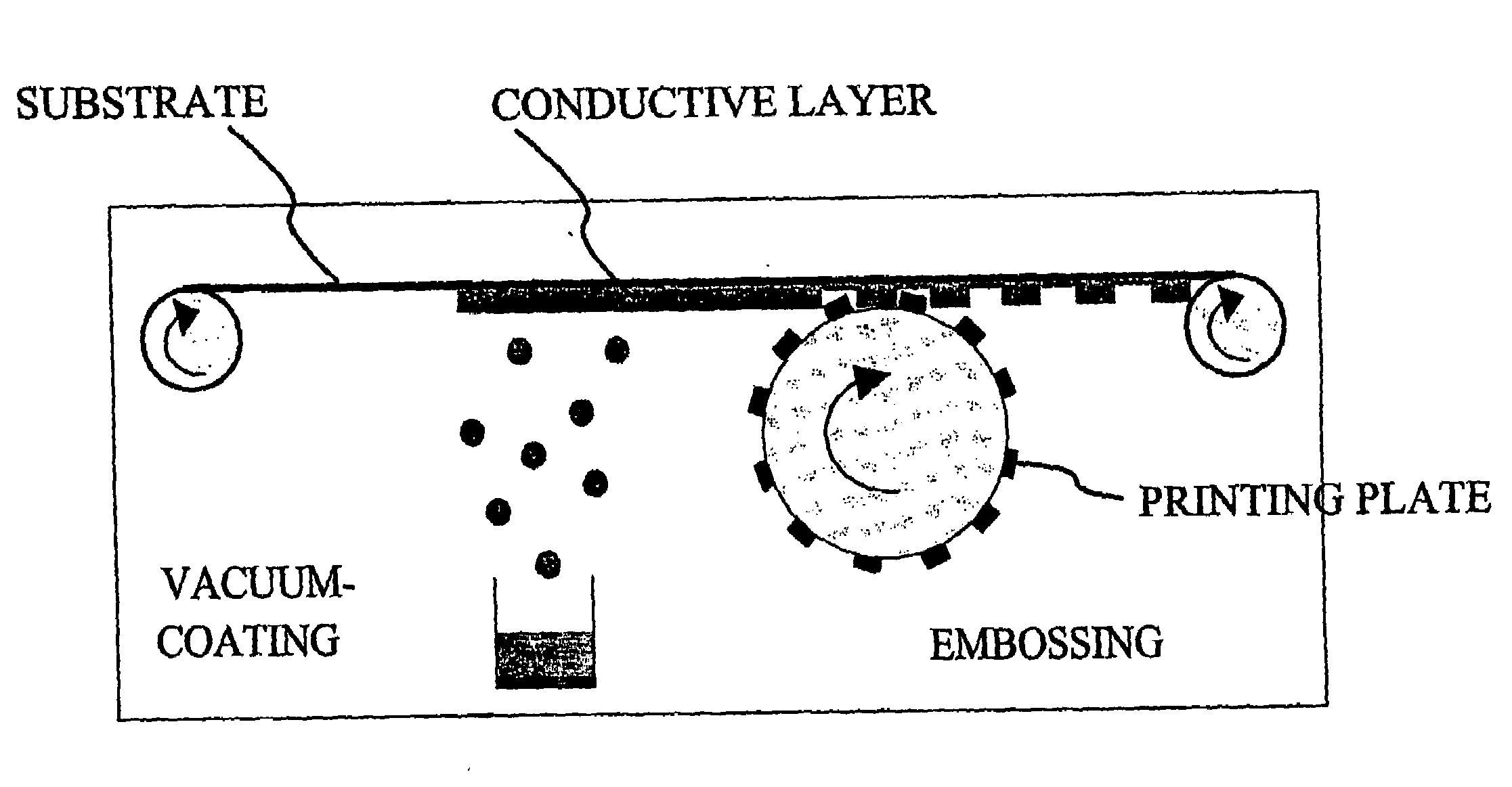

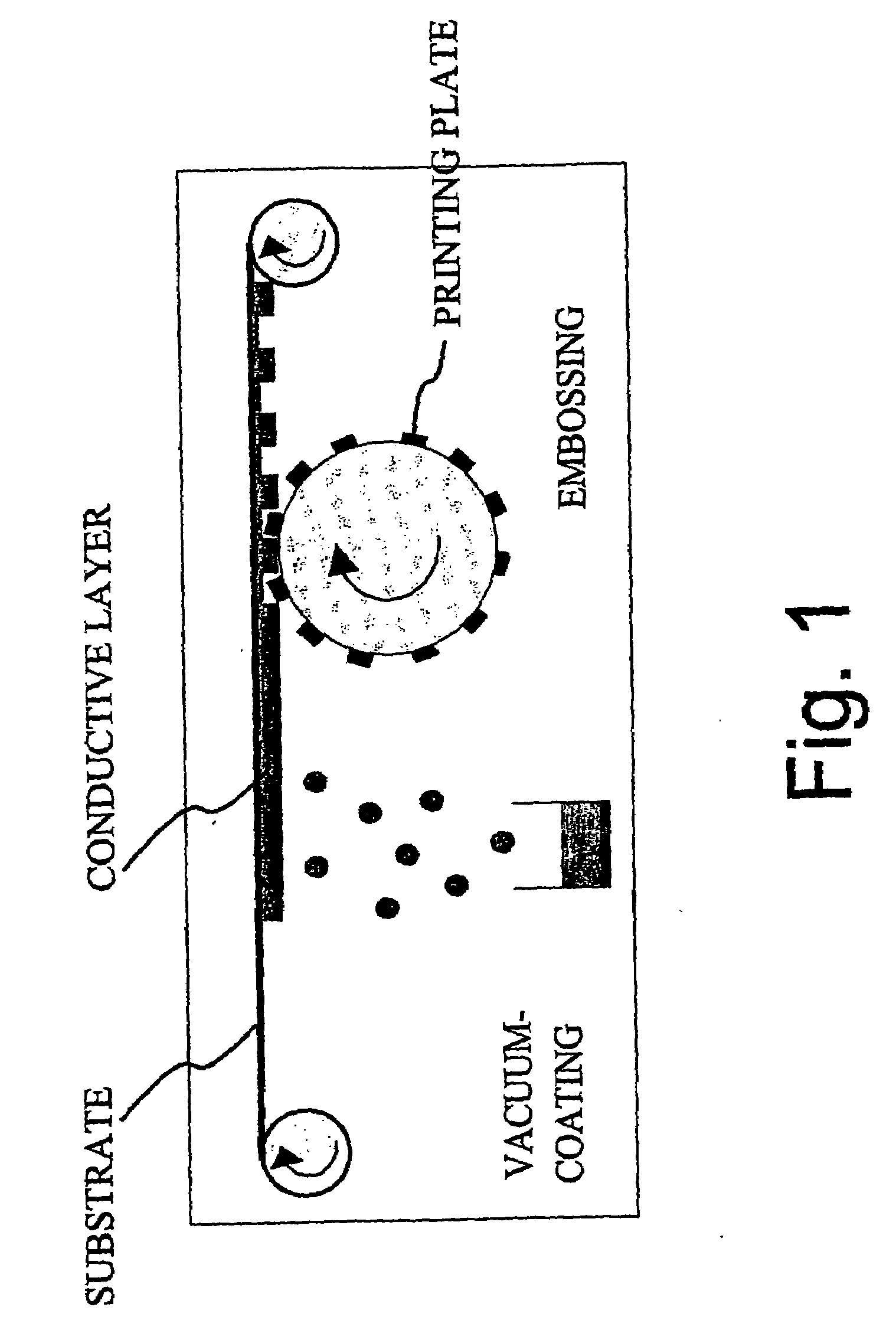

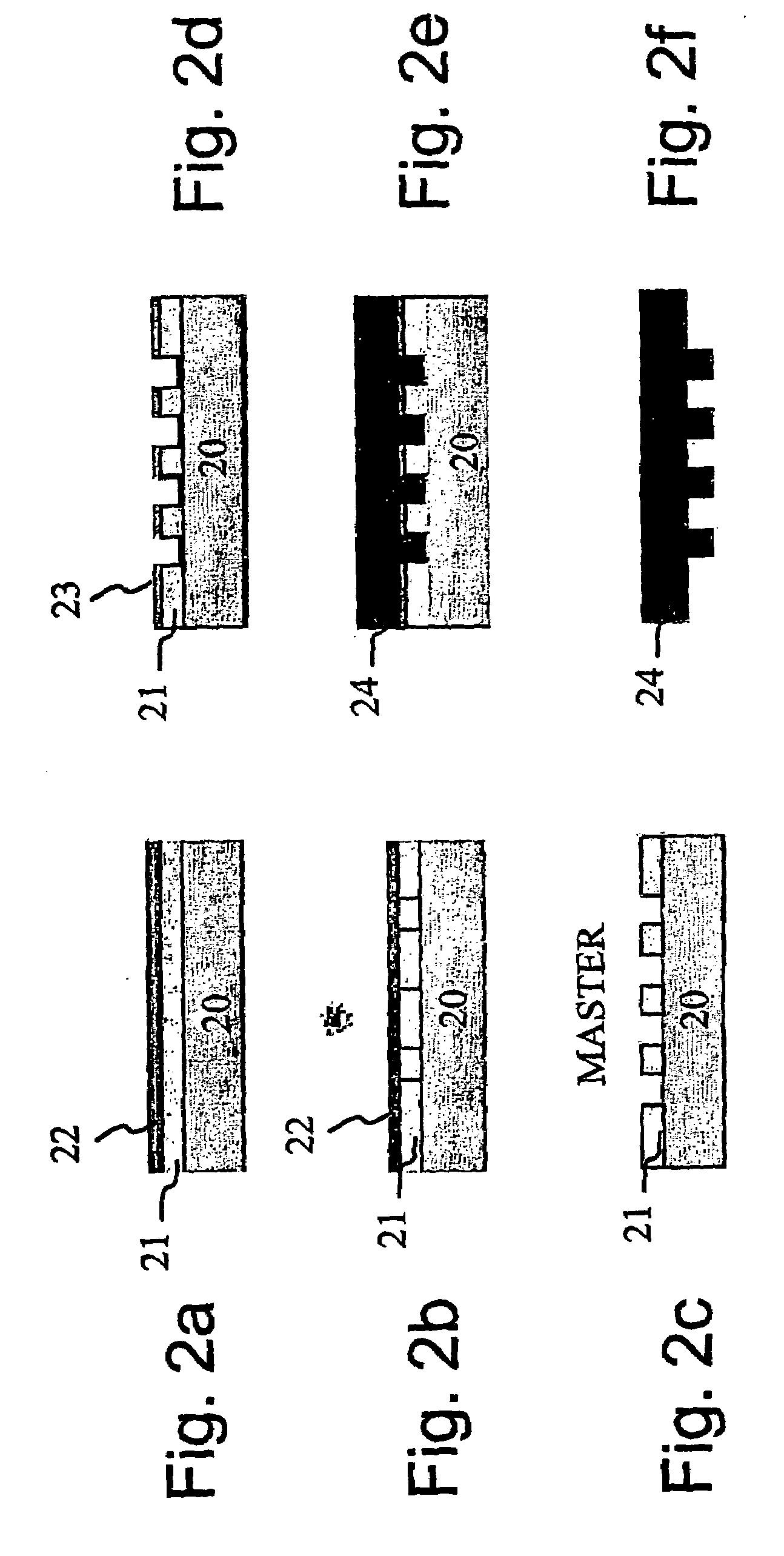

Method and an Apparatus for Manufacturing an Electronic Thin-Film Component and an Electronic Thin-Film Component

InactiveUS20080012151A1Increase contactSurface area of efficientlyLiquid surface applicatorsFinal product manufactureDielectric substrateConductive materials

A method for manufacturing an electronic thin-film component, an apparatus implementing the method, and an electronic thin-film component manufactured according to the method. A lowermost, galvanically uniform conductive layer of electrically conductive material is first formed on a substantially dielectric substrate, from which lowermost conductive layer conductive areas are galvanically separated from each other to form an electrode pattern. On top of the electrode pattern it is then possible to form one or several upper passive or active layers required in the thin-film component. The separation of the lowermost conductive layer into an electrode pattern takes place by exerting on the lowermost conductive layer a machining operation based on die-cut embossing, i.e. embossing, wherein the relief of the machining member used in the machining operation causes a permanent deformation on the substrate and at the same time embosses areas from the conductive layer into conductive areas galvanically separated from each other. The method and apparatus are suitable for manufacturing thin-film components in a roll-to-roll process.

Owner:AVANTONE OY

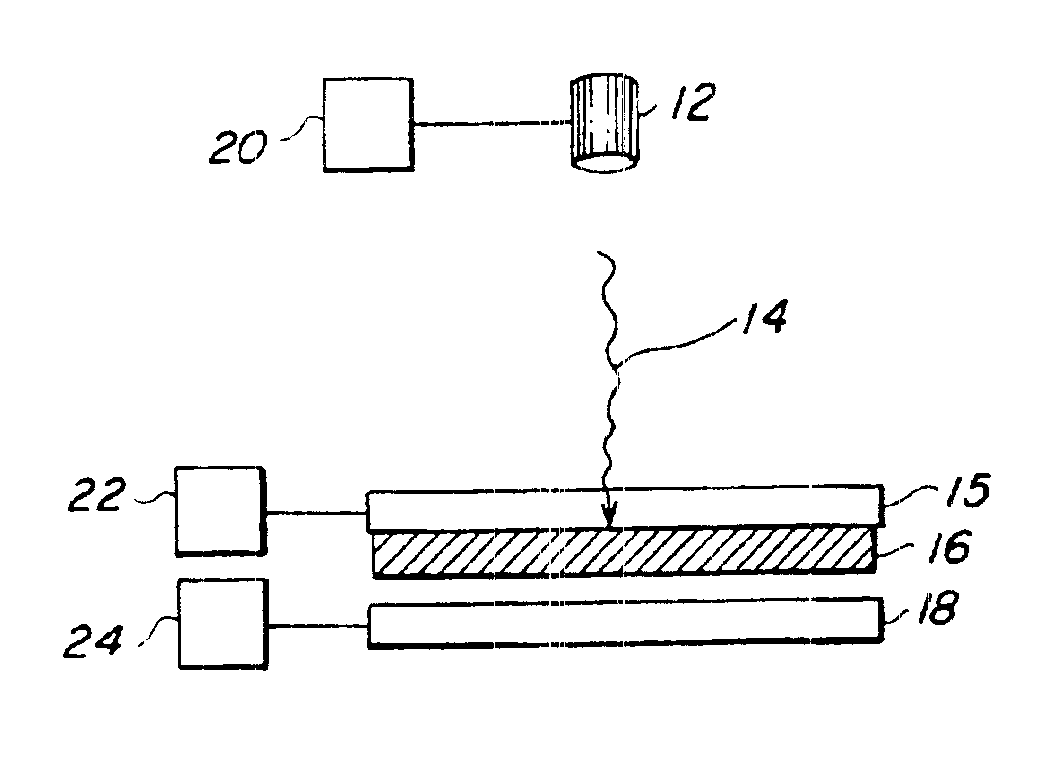

Generation of viable cell active biomaterial patterns by laser transfer

InactiveUS6905738B2Excessive transferMaterial nanotechnologySequential/parallel process reactionsOptoelectronicsBiological materials

A method for depositing a transfer material onto a receiving substrate uses a source of laser energy, a receiving substrate, and a target substrate. The target substrate comprises a laser-transparent support having a laser-facing surface and a support surface. The target substrate also comprises a composite material having a back surface in contact with the support surface and a front surface. The composite material comprises a mixture of the transfer material to be deposited and a matrix material. The matrix material is a material that has the property that, when it is exposed to laser energy, it desorbs from the laser-transparent support. The source of laser energy is positioned in relation to the target substrate so that laser energy is directed through the laser-facing surface of the target substrate and through the laser-transparent support to strike the composite material at a defined target location. The receiving substrate is positioned in a spaced relation to the target substrate. The source of laser energy has sufficient energy to desorb the composite material at the defined target location, causing the composite material to desorb from the defined target location and be lifted from the support surface of the laser-transparent support. The composite material is deposited at a defined receiving location on the receiving substrate. The method is useful for creating a pattern of biomaterial on the receiving substrate.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

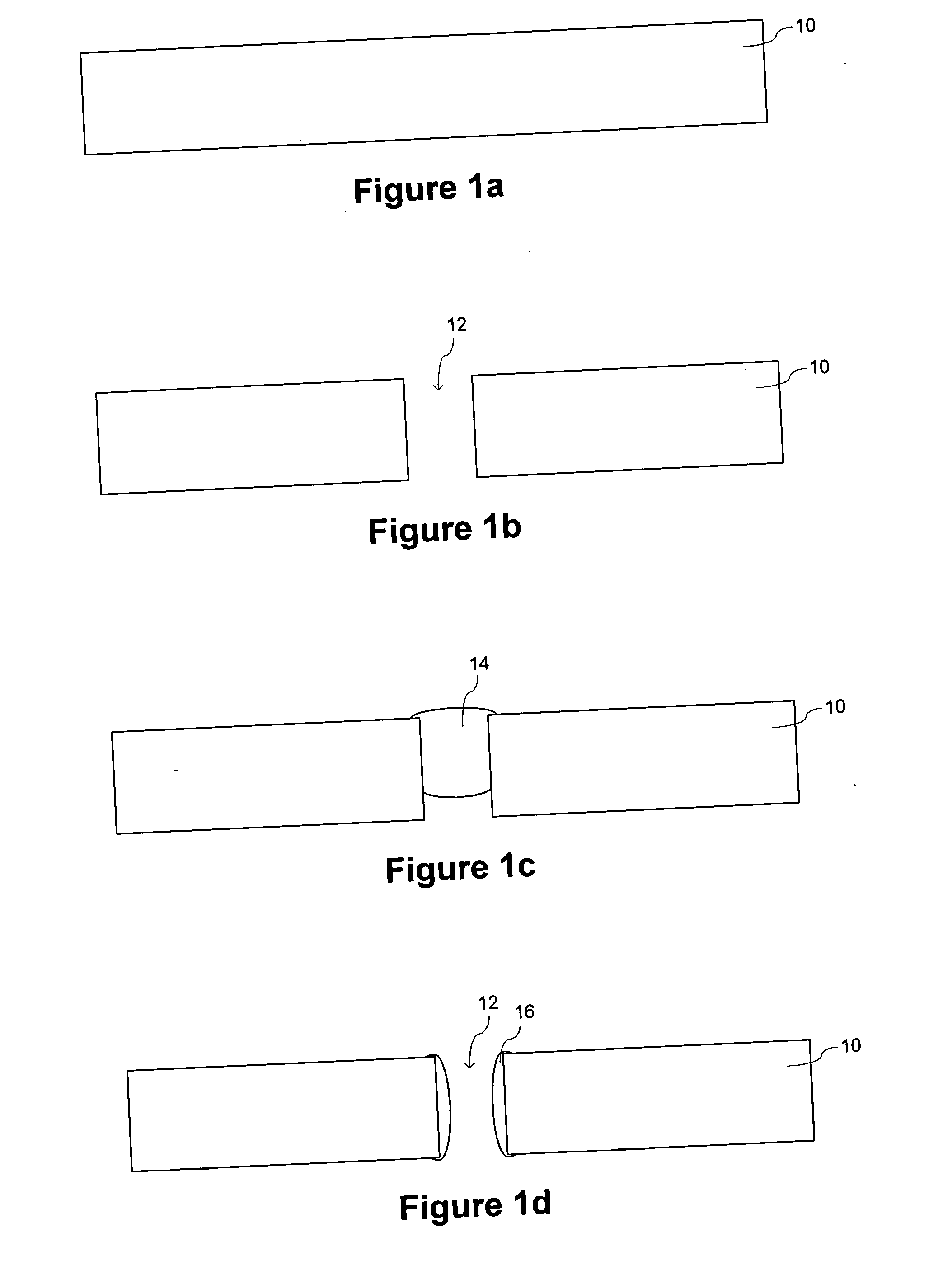

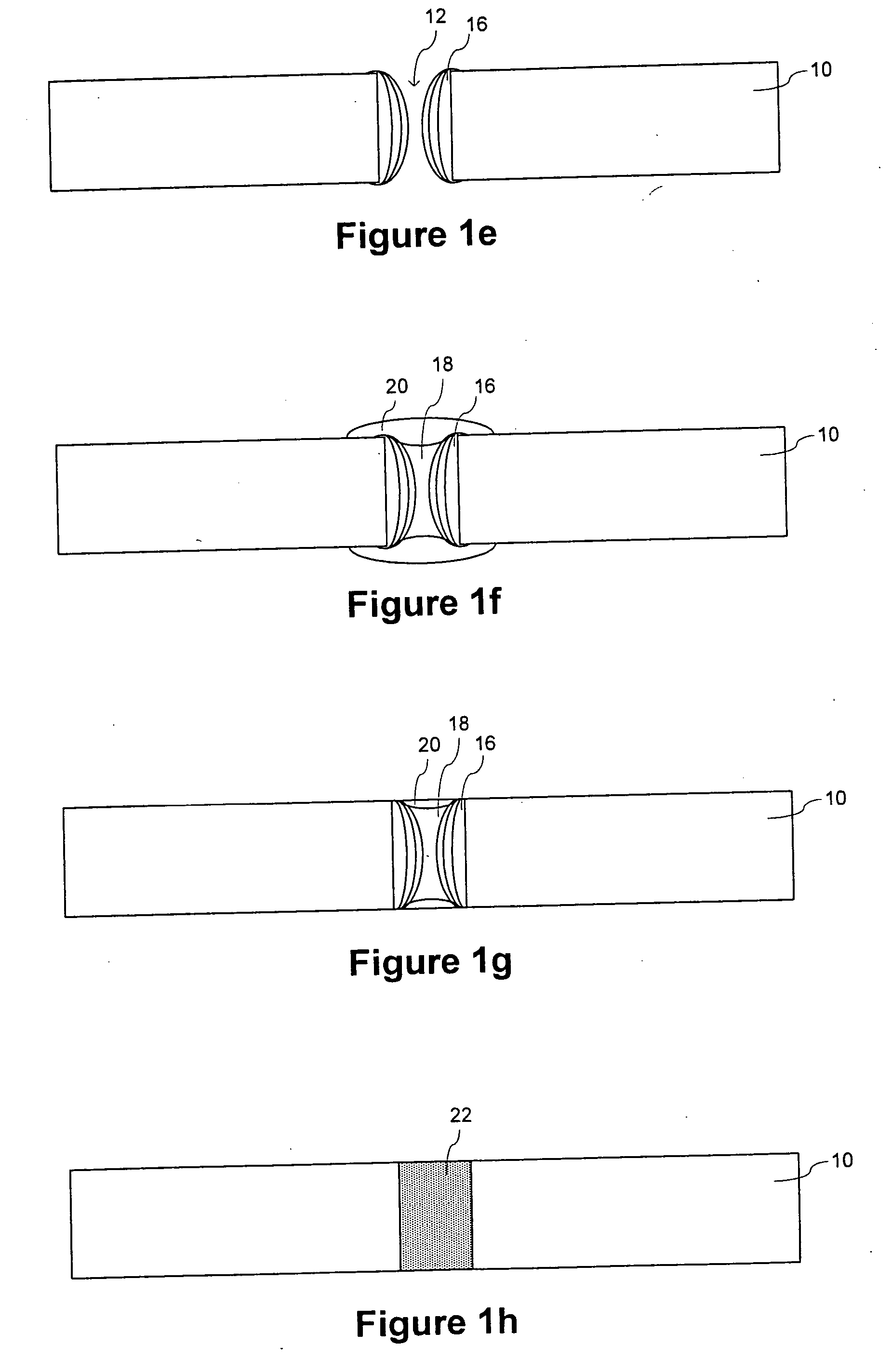

Process for producing a structured metal layer on a substrate body, and substrate body having a structured metal layer

InactiveUS20050034995A1Simple and time-savingLow costConductive pattern formationConductive material mechanical removalMetallurgyAdhesive

Process for producing a structured metal layer on a substrate body, in which either a structured bonding layer is applied to the substrate body, in order for a metal foil or a metal powder to be fixed on this bonding layer, or in which a metal foil or a metal layer is applied to the entire surface of a substrate body made from a plastics material and is pressed onto the substrate body with the aid of a structured, heated ram and fixed by a subsequent setting of the substrate body. The metal layer is structured by mechanical removal of those regions of the metal foil or of the metal powder which are not joined to the adhesive or to the substrate body.

Owner:INFINEON TECH AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com