Method for drilling deep hole and PCB product obtained by same method

A new method and deep technology, which is applied in the direction of mechanically removing conductive materials, electrical components, printed circuits, etc., can solve problems such as poor depth drilling accuracy, and achieve the effect of improving depth accuracy and improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

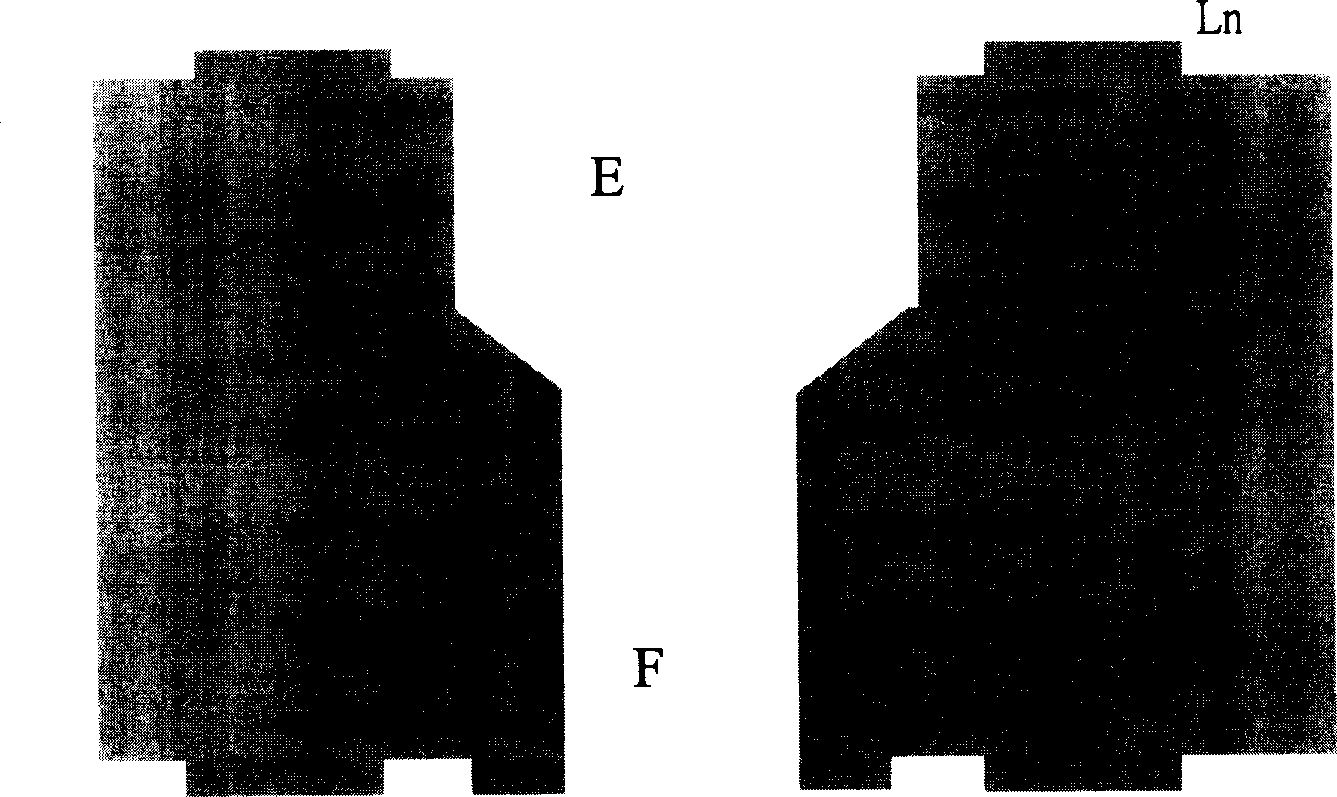

[0033] According to the customer's requirement to control the drilling depth between L12-L13, the present invention performs deep drilling operations on the production plate through the following methods:

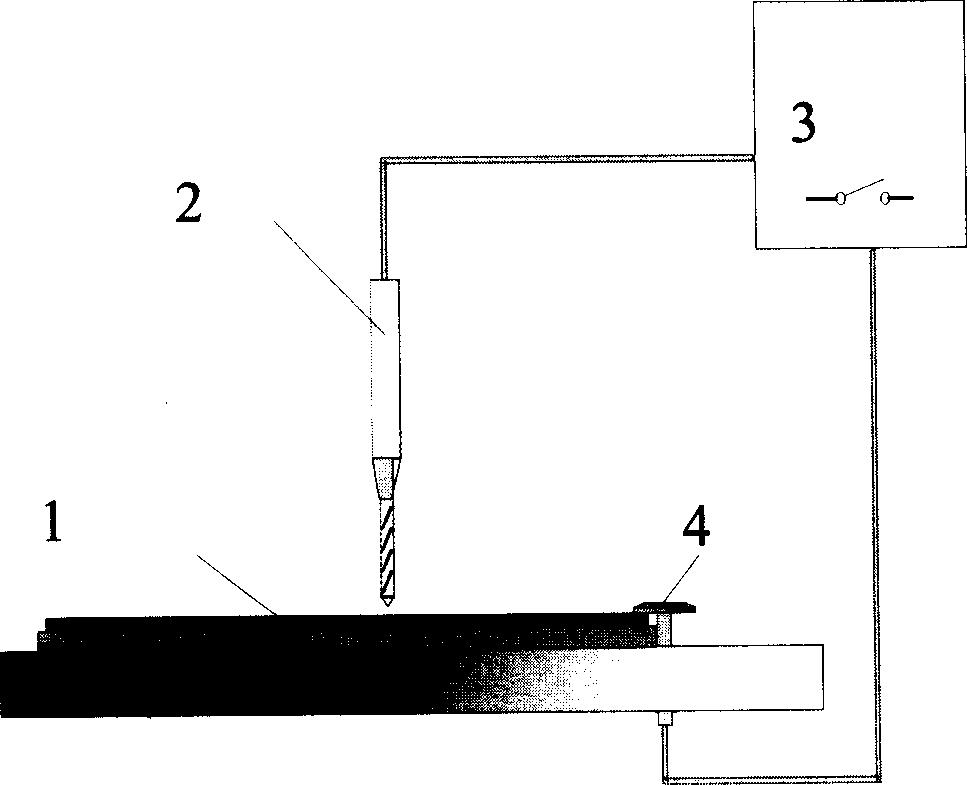

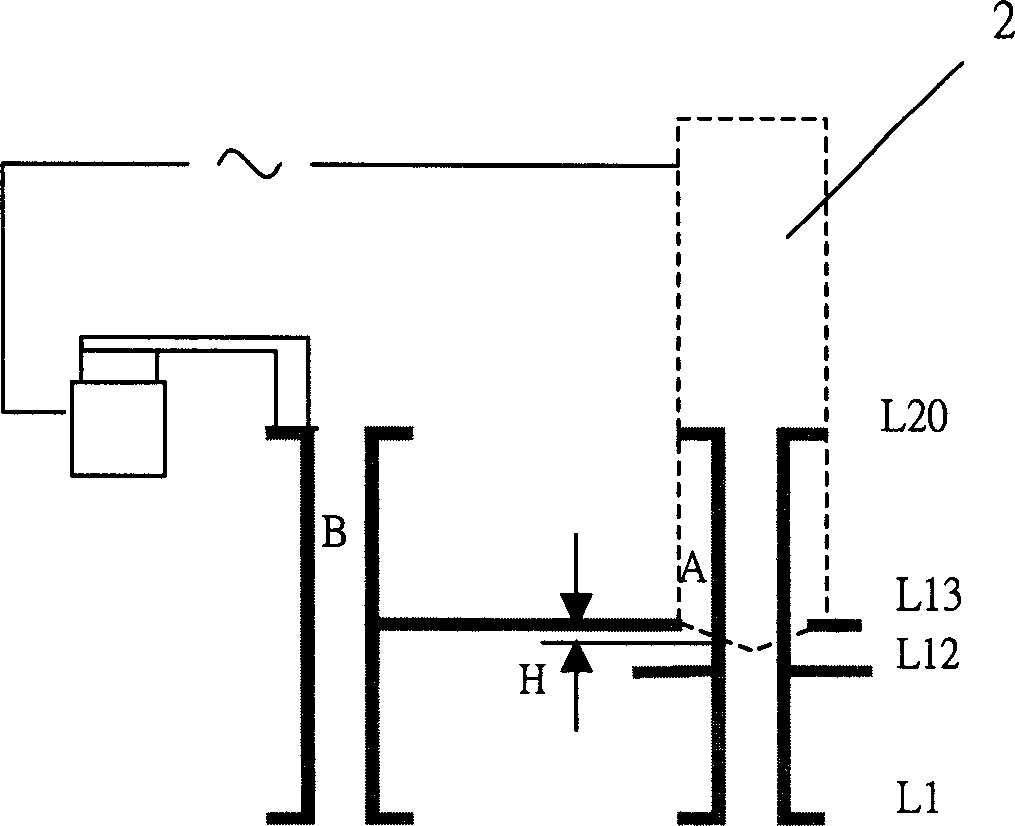

[0034] like image 3 As shown, find the POWER layer closest to L12 between the L20-L13 layers (assuming that the POWER layer is the L13 layer), and set a via hole B on the outside of the board to connect with the POWER layer; increase the diameter of the drill needle 2 as shown in the figure Then start drilling, and when the drill is drilled down, it will be connected to the POWER layer (L13) for conduction, resulting in the formation of the machine control circuit; point A in the figure is regarded as the zero point, and the H value is regarded as the depth that needs to be controlled when drilling down. Doing so can avoid the impact of uneven plate thickness on depth control, and can greatly improve the control accuracy of drilling.

Embodiment 2

[0036] According to the customer's requirement to control the drilling depth between L12-L13, the present invention performs deep drilling operations through the following methods:

[0037] like Figure 4 As shown, some depth test holes Z1 are drilled on the upper surface of the production board, that is, the area requiring deep drilling on the aluminum cover plate 1, and depth test holes Z2 are drilled on the edge of the upper target layer L13, and depth test holes Z2 are drilled on the edge of the lower target layer. Drill depth test hole Z3 on the edge of the L12 board;

[0038] Add G87, G88, G89 and other functional commands to the machine control software, so that the machine can detect the depth values of Z1 and Z2, and make a judgment on the drilling depth value based on the positions of Z1 and Z2;

[0039] G87, G88, and G89 are written in the program. When the G87 command is executed, the machine detects the position of the upper surface of the production board, whi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com