Patents

Literature

365results about How to "Reduce cutting resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

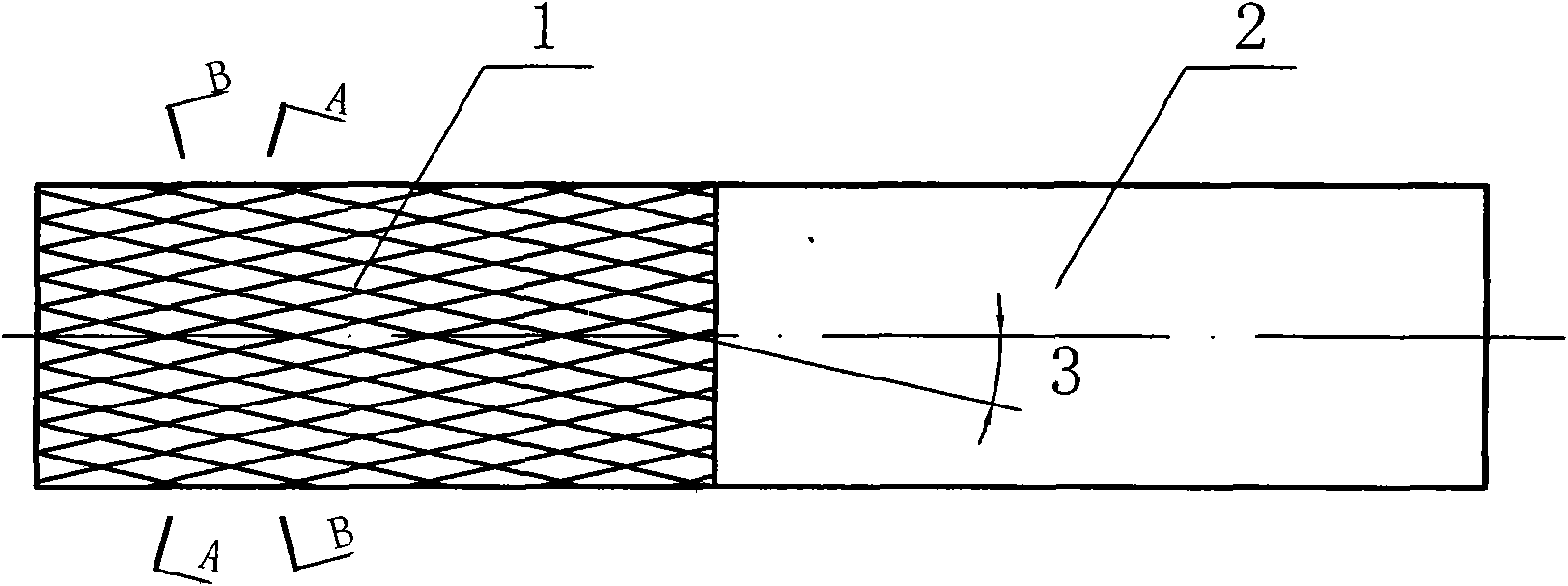

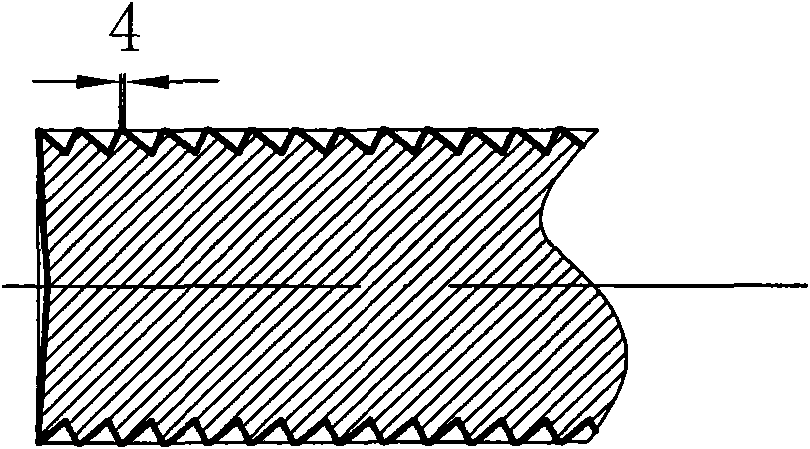

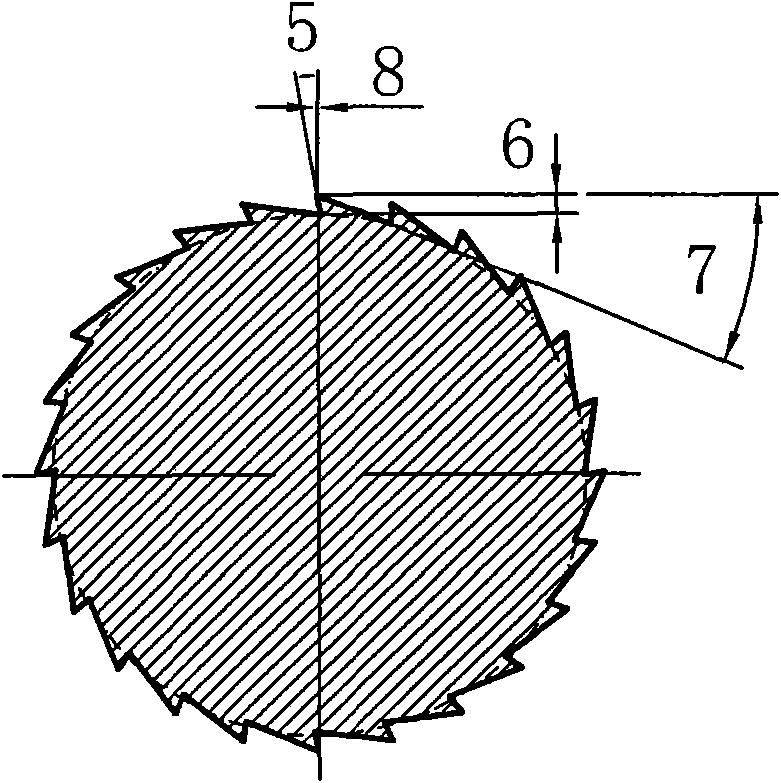

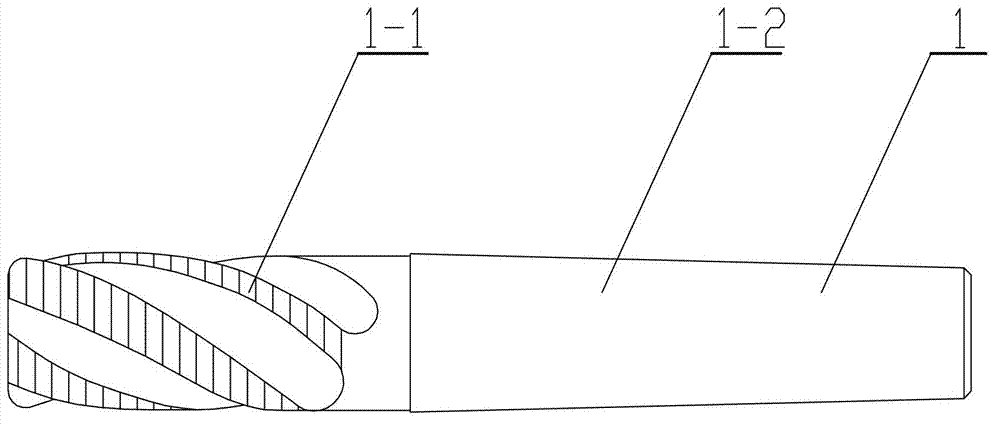

Integral carbide goldfish scale milling cutter

InactiveCN101623778AExtended service lifeImprove processing efficiencyMilling cuttersWorkpiecesGlass fiberFiber

The invention discloses an integral carbide goldfish scale milling cutter used for milling and processing composite materials such as carbon fiber, glass fiber and the like. The milling cutter of the invention comprises a milling cutter blade and a milling handle, wherein the cutting blade on the milling cutter blade is a cutting unit formed by left and right-handed rotation symmetrical staggered spiral grooves, and the number of the left spiral groove is two more than that of the right spiral groove; the length of the cutting blade of each cutting unit is 0.05-0.1mm, and the width of the rear cutter surface of the cutting blade along the cylinder surface is 0-0.01mm; the anterior angle of the cutting blade is 10-15 degrees, the front cutter surface is a straight line on a normal plane; the relief angle of the cutting blade is 20-25 degrees; the depth of the spiral cutter groove is 7-8% of the diameter of the cutter. The invention has the advantages that the cutting blade of the integral carbide goldfish scale milling cutter is composed of a plurality of cutting units and is sharp, which greatly lowers cutting resistance and realizes high speed cutting so as to obtain the effect of using milling for replacing abrading, so that the processing efficiency and the surface quality of the composite materials can be improved, and the service life of the milling cutter can be prolonged.

Owner:SHENYANG AIRCRAFT CORP

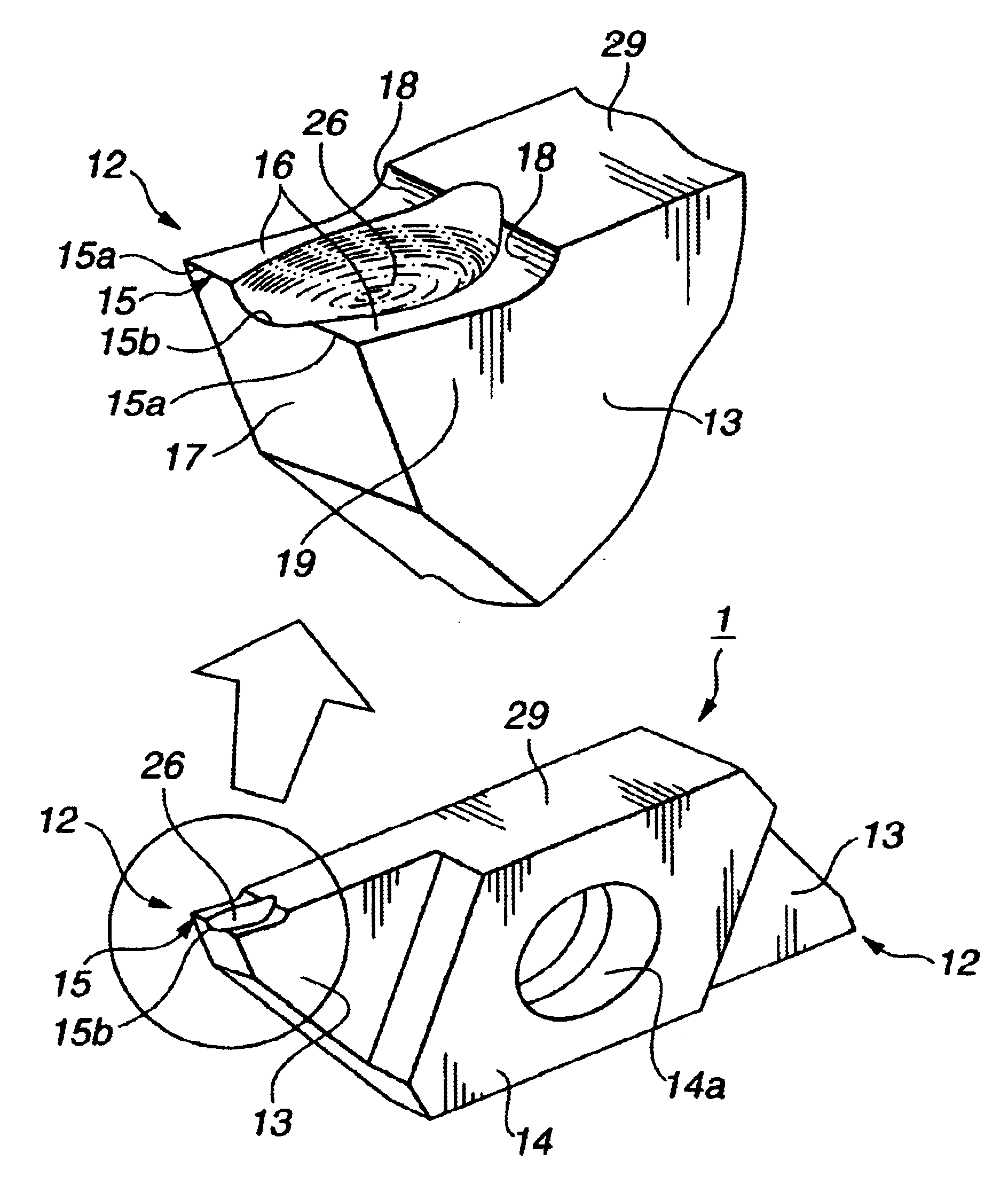

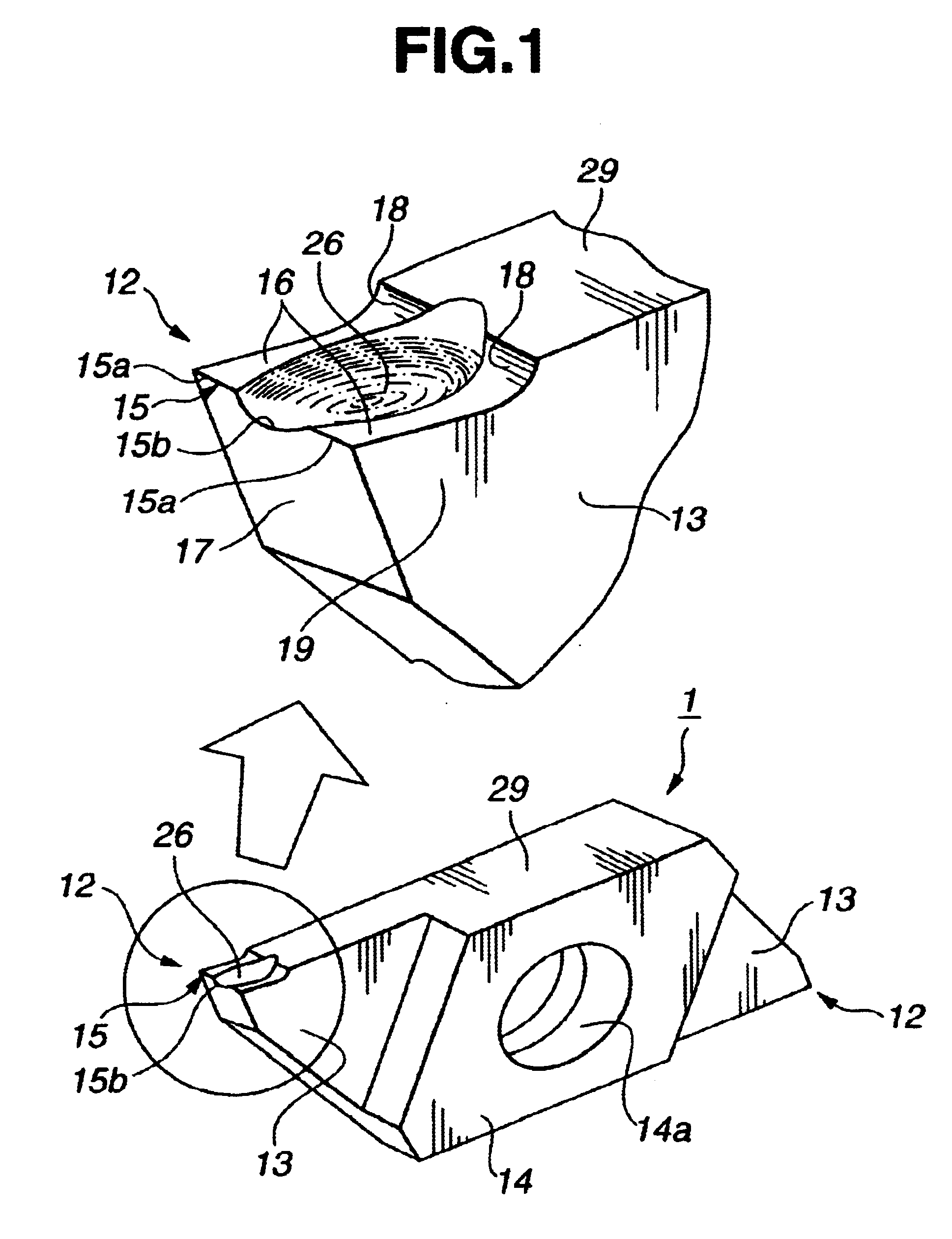

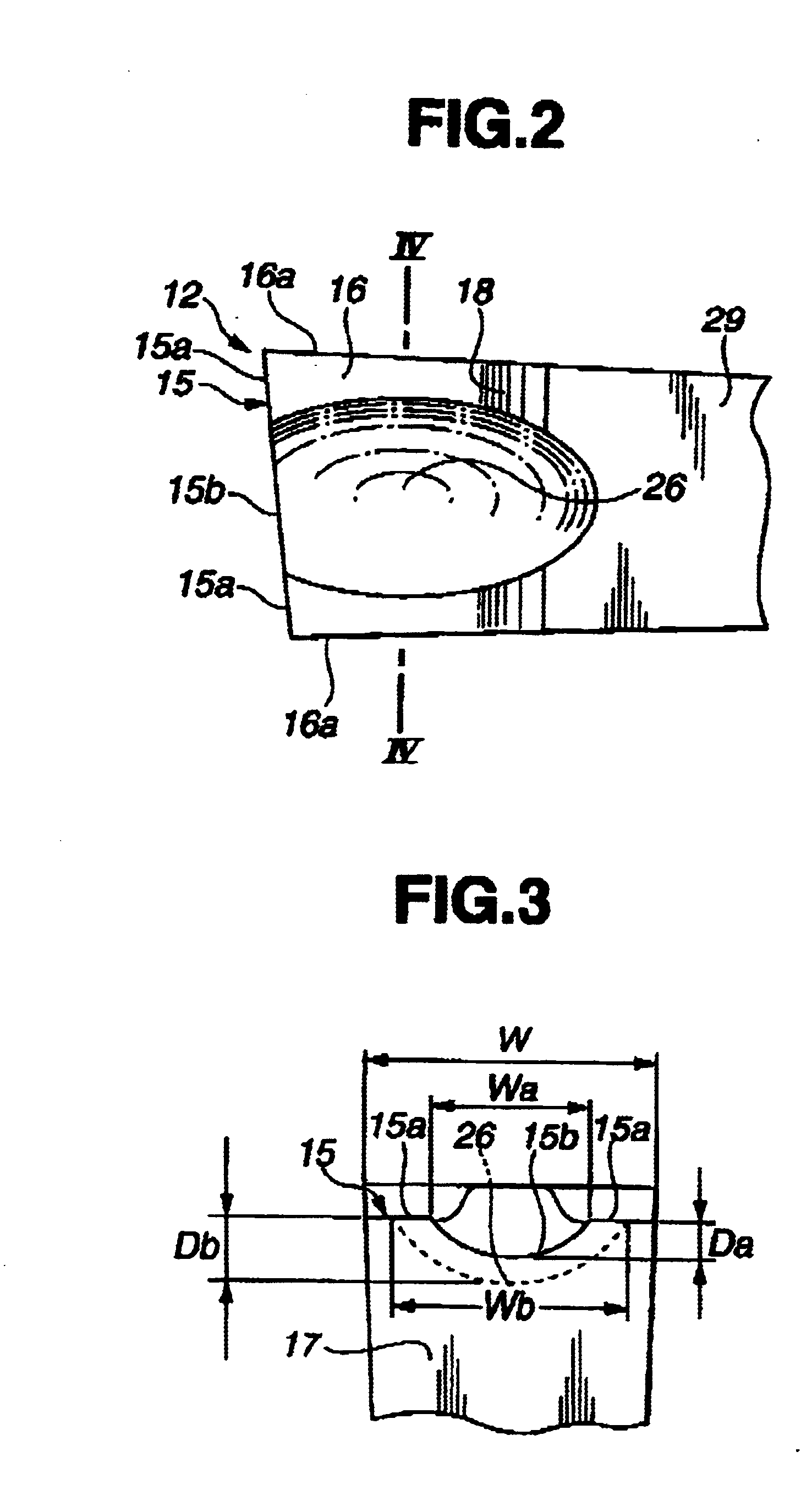

Cutting Insert, Cutting Tool, and Method of Cutting Workpiece Using the Same

ActiveUS20110135407A1Reduce cutting resistanceImprove fracture resistanceTransportation and packagingMilling cuttersEngineeringLower face

A cutting insert of the present invention includes a side face having an upper concave portion which is located between an upper face and a lower face and extends up to the upper face, and a plurality of divided upper cutting edges which are located at the intersection of the upper face and the side face, and are divided by the upper concave portion. Each of these divided upper cutting edges includes a first end and a second end, and is inclined being closer to the lower face from the first end toward the second end. The plurality of divided upper cutting edges include a first divided upper cutting edge and a second divided upper cutting edge adjacent to each other. When viewed from side, the first end of the second divided upper cutting edge is located above the intersection of an extension line of the first divided upper cutting edge, and a line which passes through the first end of the second divided upper cutting edge and is parallel to the central axis of the cutting insert, and is located at the same position as the second end of the first divided upper cutting edge, or located therebelow. A cutting tool including the cutting insert, and a method of cutting a workpiece by using the cutting tool are also provided.

Owner:KYOCERA CORP

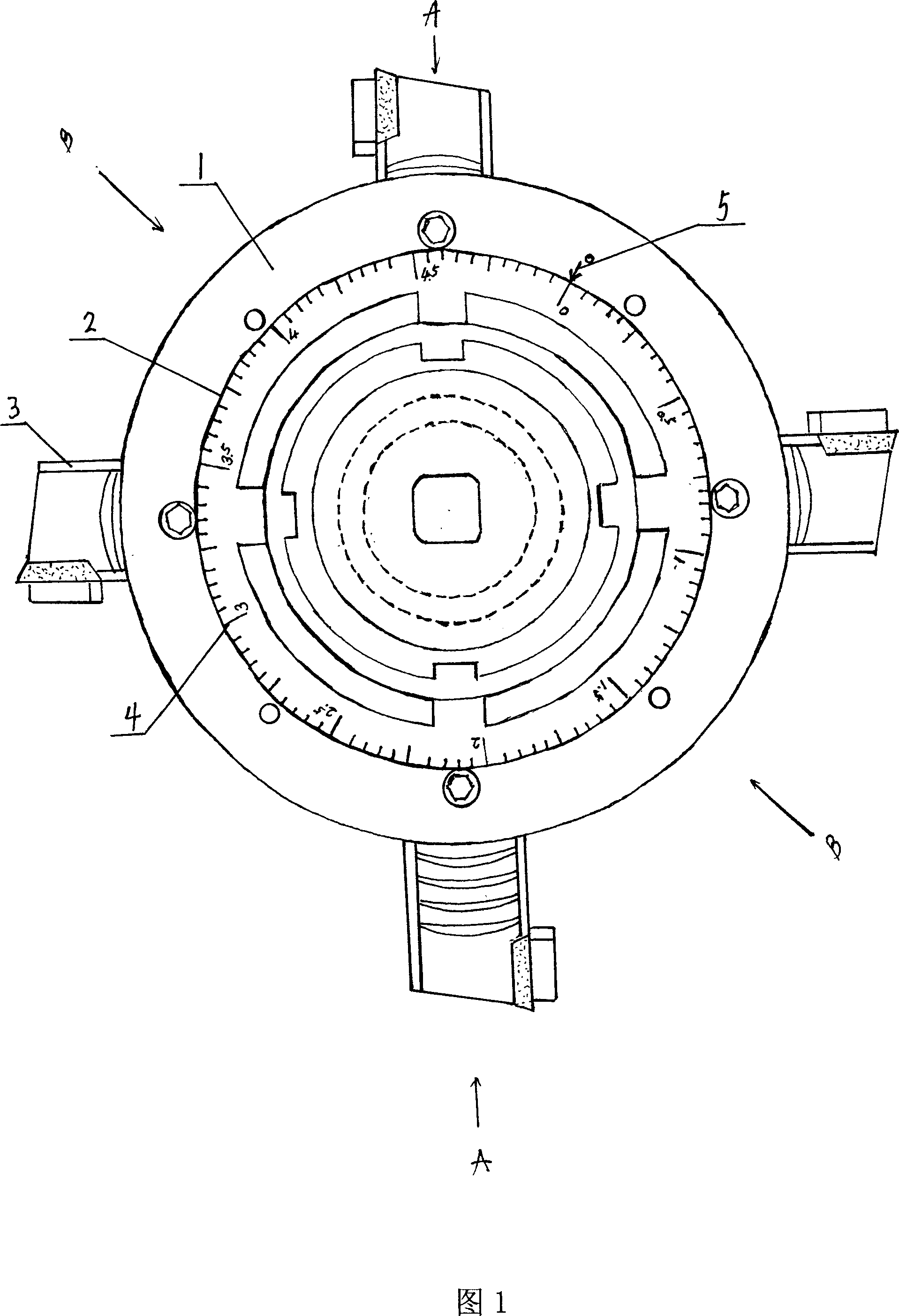

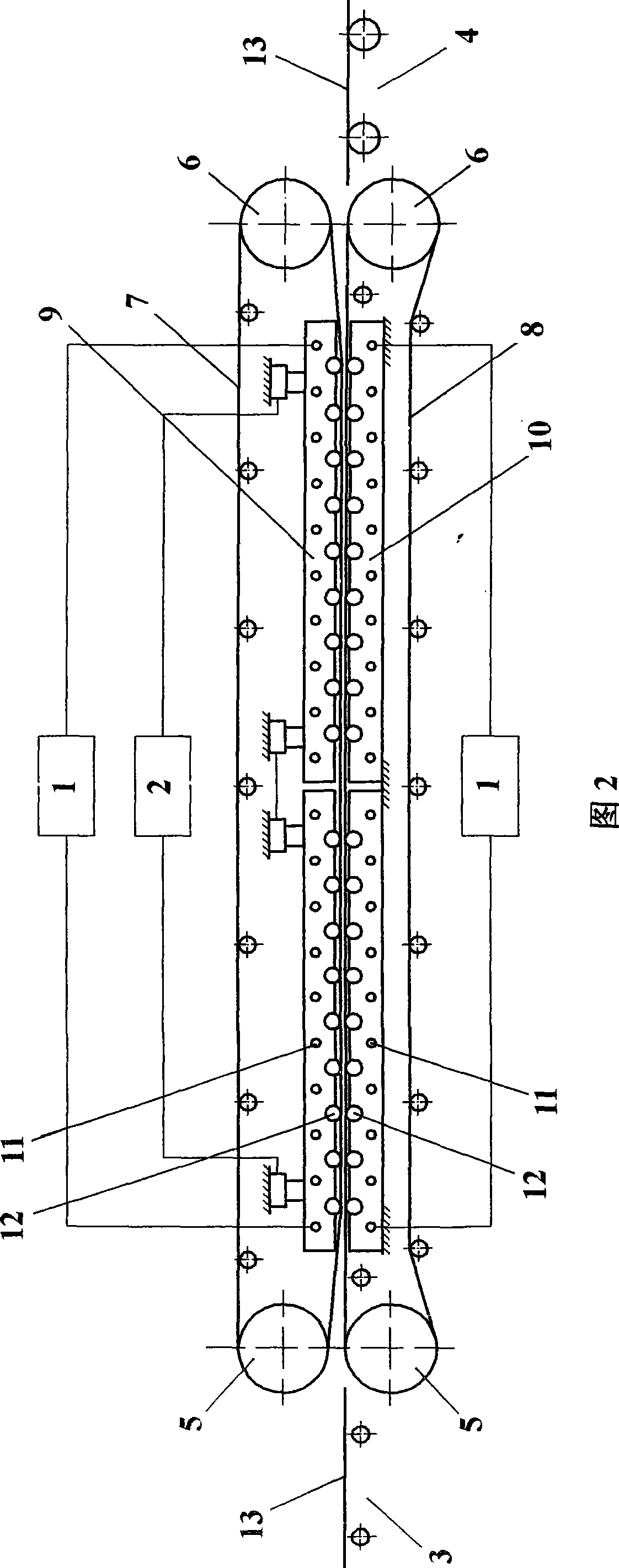

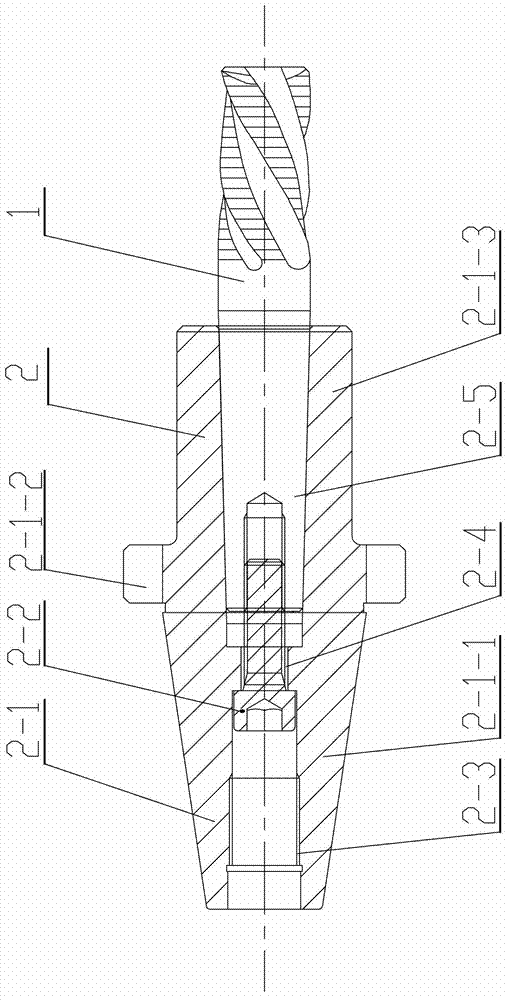

Multifunctional transposable diameter-adjustable multitool machine boring tool

The present invention relates to a multifunctional turnable position adjustable diameter multi-cutter machine-fastened hole-borning cutting-tool. It is characterized by that said invention mainly includes the following several portions: cutting-tool shaft, cutter and cutter support, cutter-regulating disk, turning disk, scale disk, cutter-mounting groove, spring and regulating bolt. Said invention also provides the concrete structure of every above-mentioned portion and the connection mode of all the above-mentioned portions, and also provides its working principle and concrete operation method.

Owner:王诚信

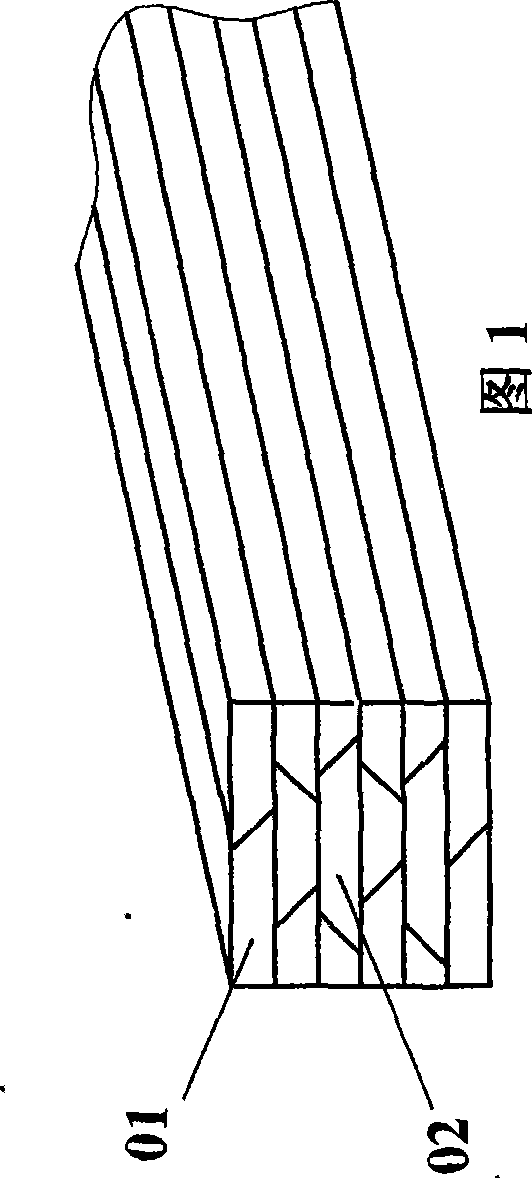

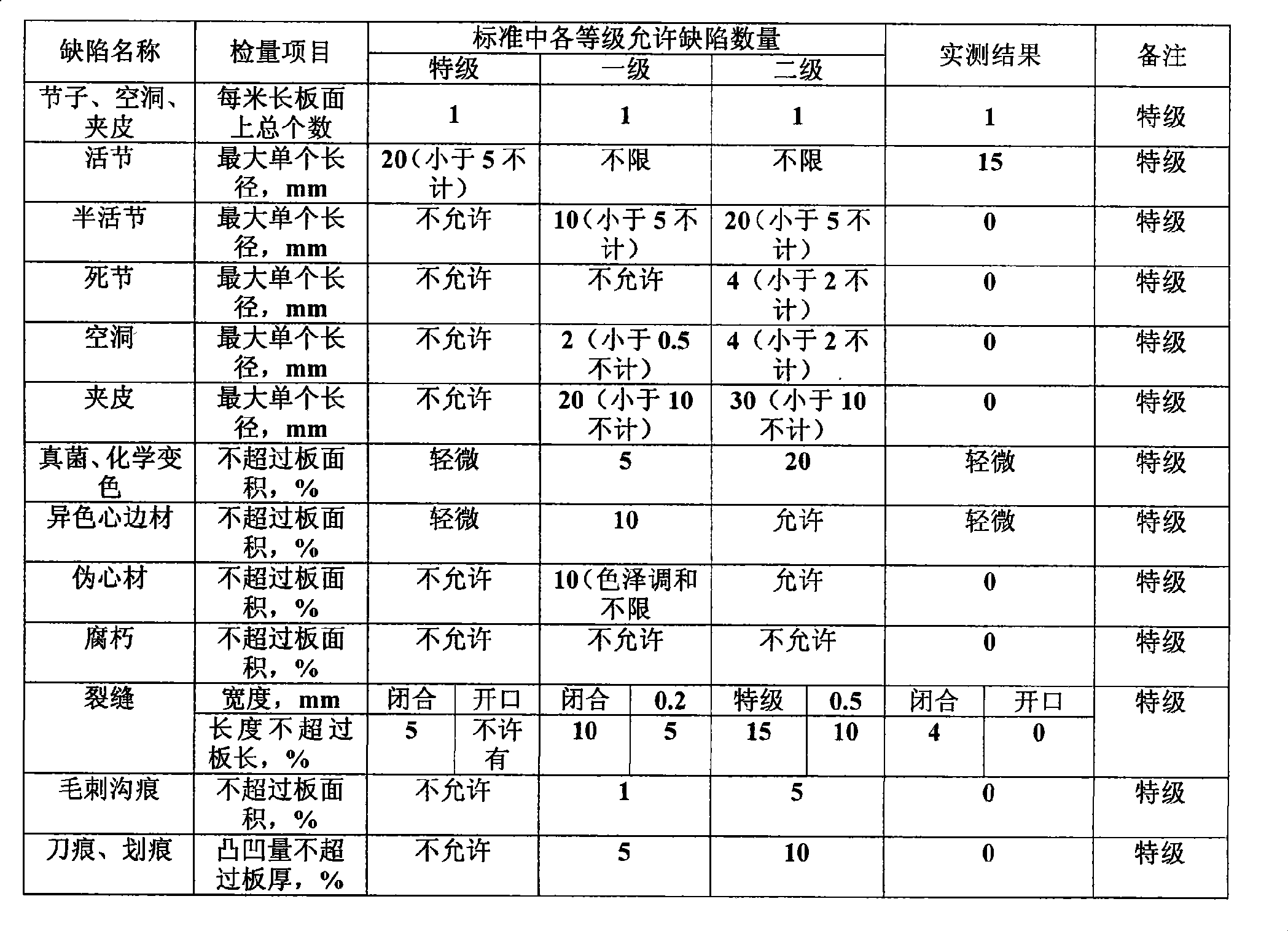

Small wood integrated shaving thin-wood manufacture method and leveling drying device thereof

InactiveCN101417451AHighlight substantiveSignificant technological progressVeneer manufacturePressure impregnationAdhesive cementEconomic benefits

The invention relates to a manufacturing method of small-diameter wood glulam slicing veneers and a leveling drying device. Small-diameter wood, tended wood, inferior wood or cordwood produced in the cutting and manufacturing process, and the like which are not easily efficiently used are softened by a composite agent by being infused with pressure, and then after flitches are integrated by finger joining and obliquely slotting the wood with a moisture-curable type adhesive, the flitches are sliced into wet veneers, and the wet veneers are then sent to a special continuous high-temperature ironing leveling dryer to be leveled and dried into sliced veneers in the clamping of upper and lower steel belts. The invention integrates a series of special technologies and transforms small-diameter wood which is not easily used into sliced veneers which meet requirements of various technical specifications with very wide application ranges. Low-grade wood is fully used, which improves the added value of products and comprehensive utilization efficiency of forest resources. The invention has the advantages of simple and reasonable technique method, low equipment cost, good product quality, broad development prospects and the like. Significant social and economic benefits can be produced after the implementation.

Owner:BEIHUA UNIV

Cutting tool and indexiable insert therefor

InactiveUS6843620B2Improve rigidityStable chip deforming effectCutting insertsTurning toolsEngineering

Owner:NGK SPARK PLUG CO LTD

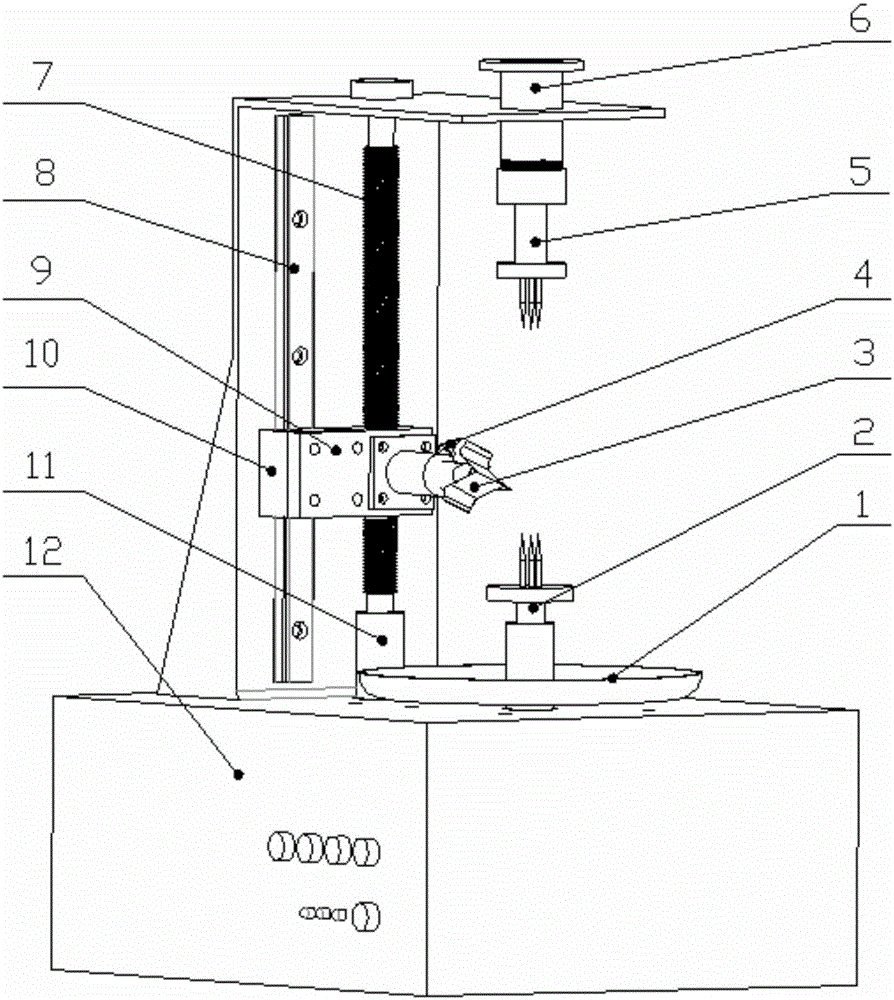

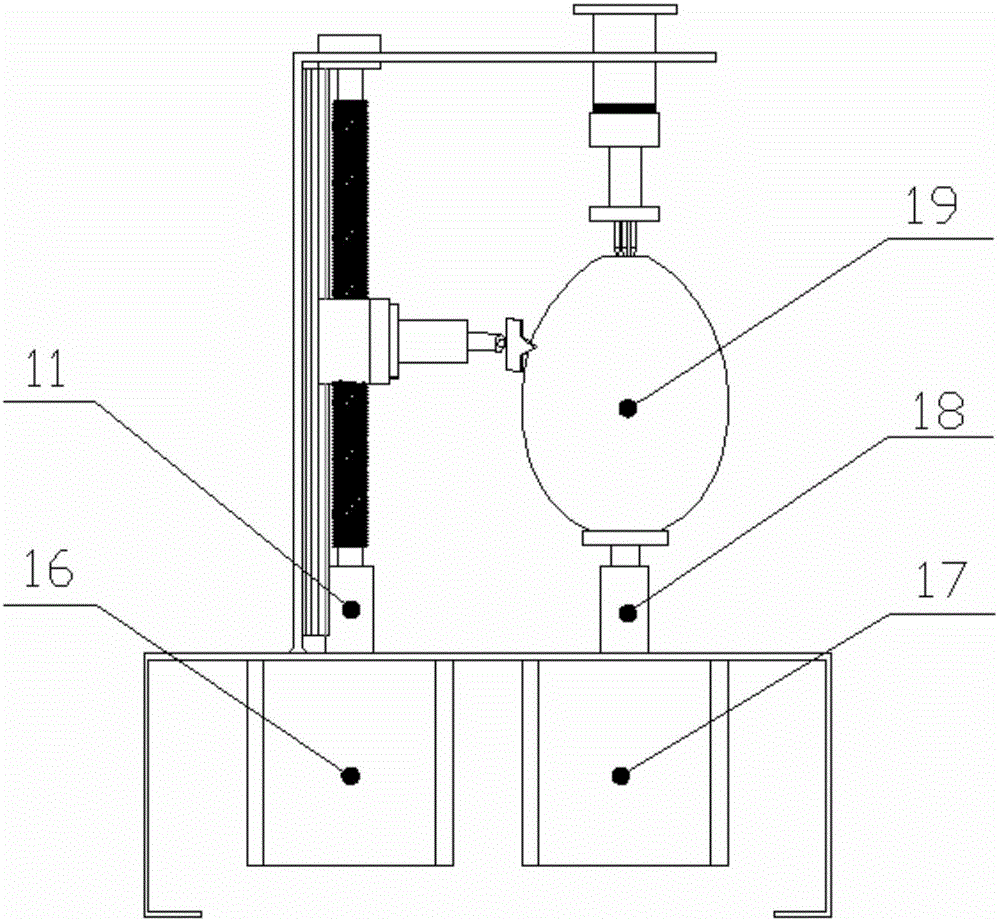

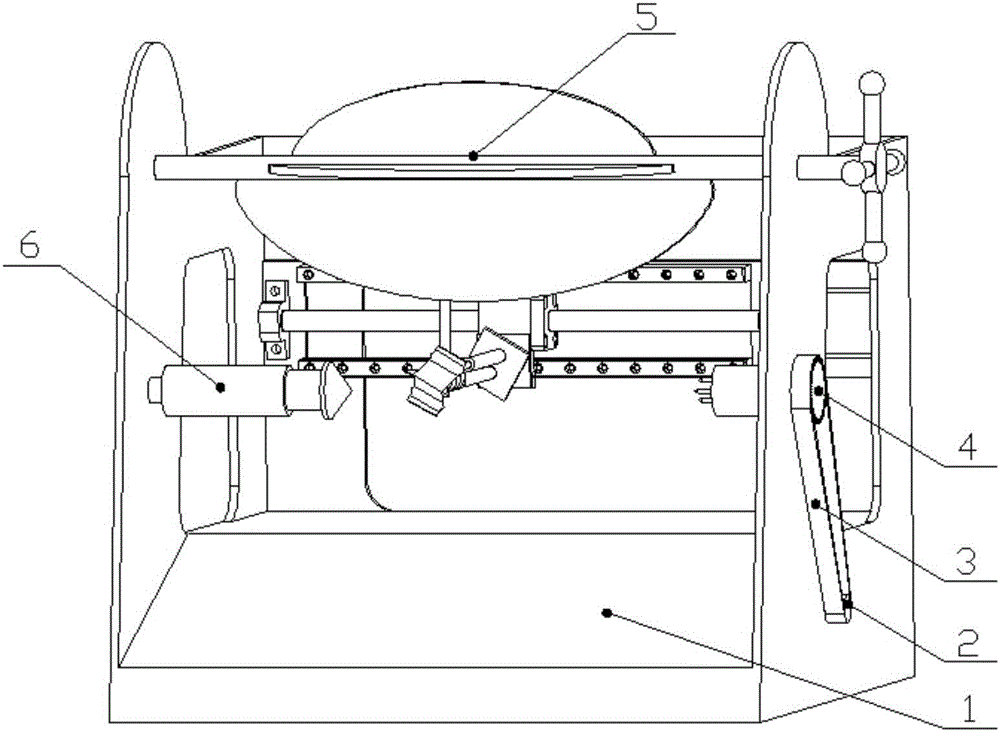

Vertical semiautomatic pineapple peeling machine

A vertical semiautomatic pineapple peeling machine mainly comprises a sliding lead screw, a cutter system, a pineapple rotating mechanism and a machine frame, wherein two motors are mounted inside the machine frame; a lead screw motor is connected with a shaft coupler and the shaft coupler is connected with a lead screw through A-type keys; a lead screw sliding table and the lead screw form a screw pair, and the lead screw sliding table is connected onto a slide block through bolts; the cutter system comprises a cutter holder, a screw, a tubular movable sleeve, a spring, a regulating screw and a cutter; a lower clamping body is connected with the shaft coupler through a wedged key; an upper clamping body and a rotating regulating handle form a threaded pair; a chassis is fixed to the machine frame through bolts; the rotating regulating handle and the top plate of the machine frame form a threaded pair; a pineapple motor is connected with a simple shaft coupler and the simple shaft coupler is connected with the lead screw through B-type keys; a sliding rail is connected with the side plate of the machine frame through a hexagonal bolt. The vertical semiautomatic pineapple peeling machine can meet peeling requirements of pineapples with different sizes.

Owner:GUANGXI UNIV

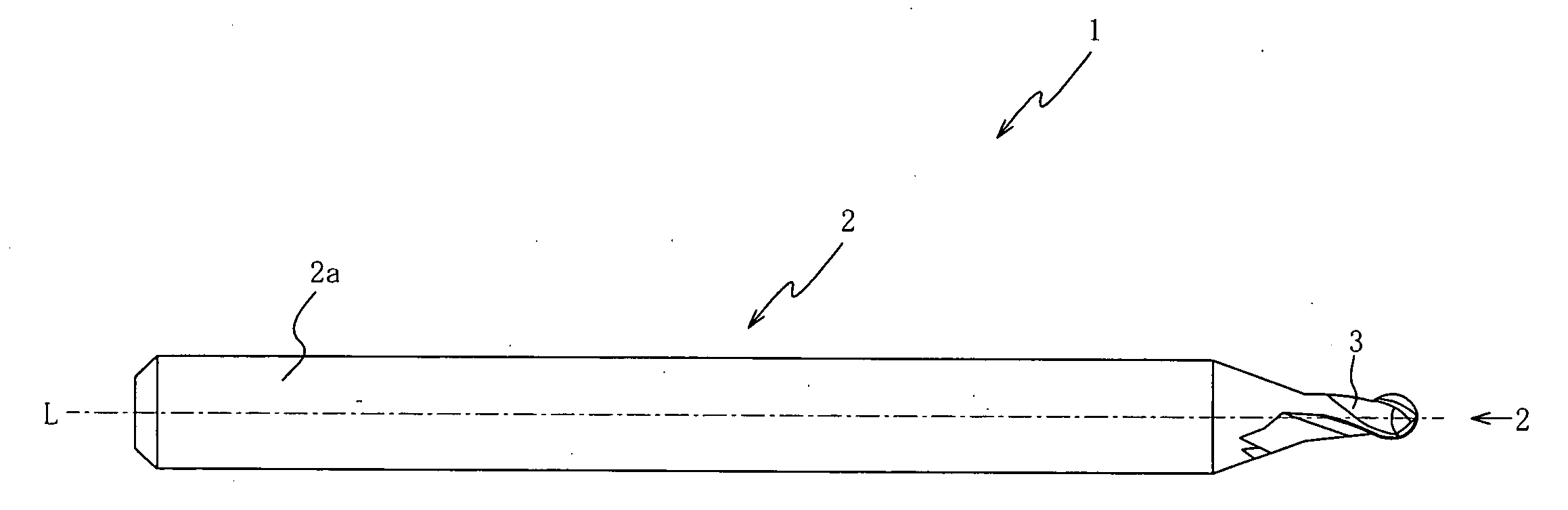

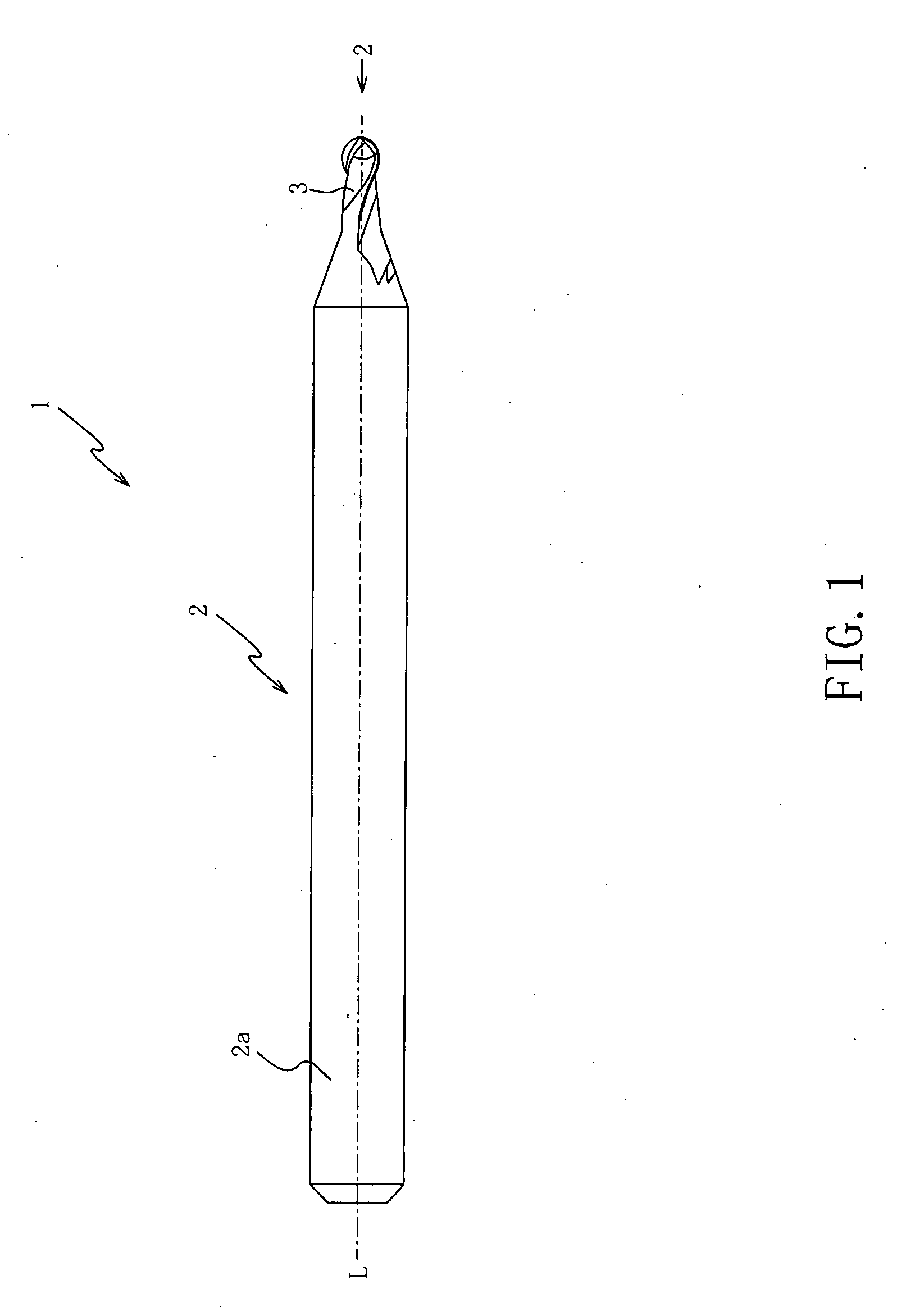

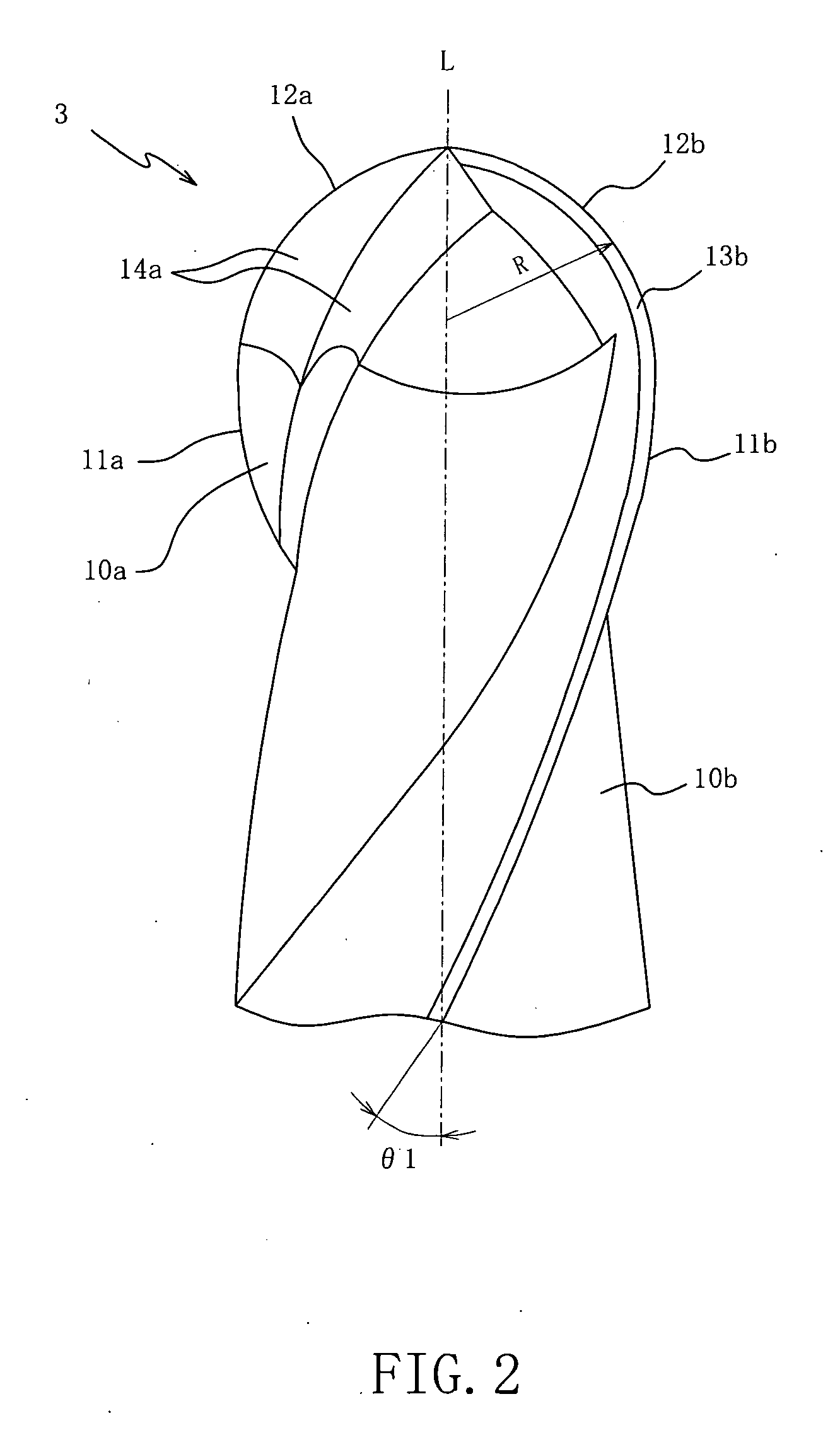

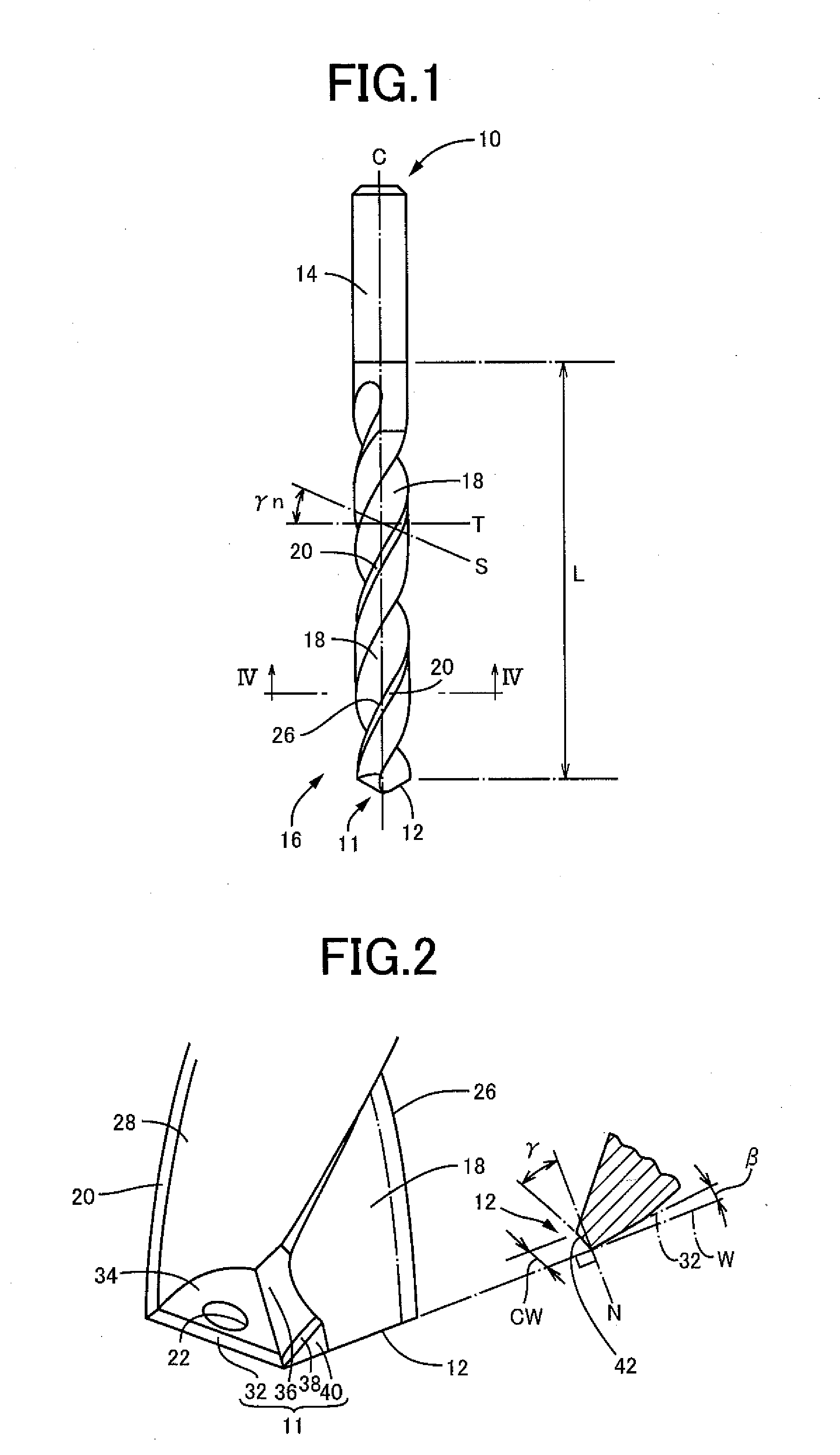

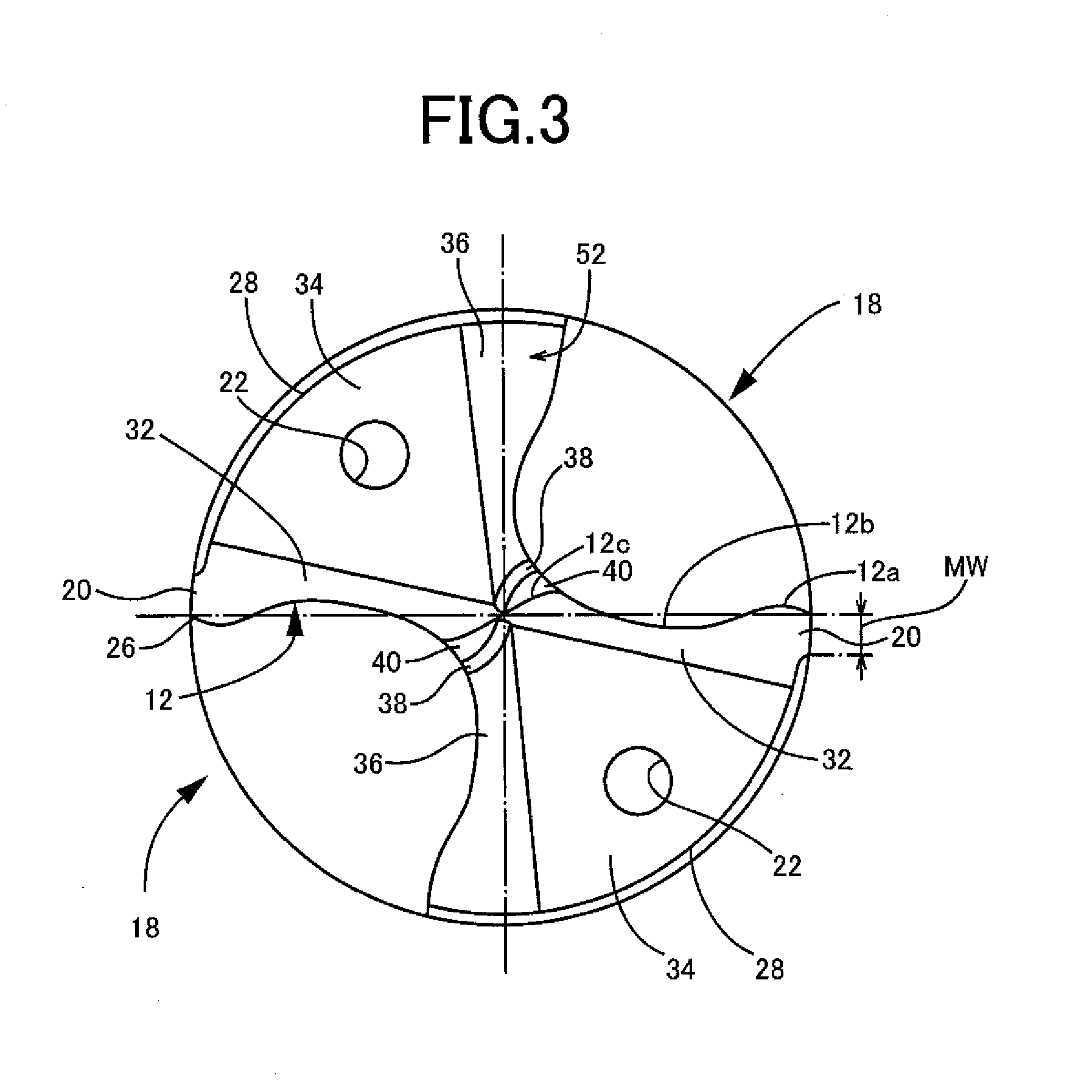

Ball endmill

InactiveUS20070172321A1Increase speedLarge depth of cutMilling cuttersWorkpiecesEngineeringSpherical shaped

A ball endmill includes a cylindrical tool body that is to be rotated about its axis, ball-nosed end cutting edges located in an axially distal end portion of the tool body and describing a semi-spherical-shaped locus during rotation of the tool body, and spiral gashes located in the axially distal end portion of the tool body and defining rake faces of the respective ball-nosed end cutting edges. The tool body is made, at least at its part providing each ball-nosed end cutting edge, of a hard sintered body. Each ball-nosed end cutting edge is inclined with respect to the axis by a helix angle in a range from about 10° to about 30°. The tool body has, in its distal end, a non-gashed central area in which the spiral gashes do not exist. A ratio of a size of the non-gashed central area to a ball nose radius is in a range from about 0.03 to about 0.1.

Owner:OSG +1

Turning method and turning tool

The invention provides a turning method. The method comprises the following step: turning the outer surface of a niobium alloy target material or a niobium alloy target material by adopting a turning tool, wherein the front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees. By selecting the front angle, rear angle, main deflection angle, auxiliary deflection angle and blade inclination angle of the turning tool, cuttings can be discharged from processed surfaces, so that the cuttings are prevented from sticking to the tool, and the cutting difficulty is lowered. The invention further provides a turning tool. The front angle of the turning tool is 20-40 degrees, the rear angle is 4-15 degrees, the main deflection angle is 45-60 degrees, the auxiliary deflection angle is 45-90 degrees, and the blade inclination angle is 10-25 degrees.

Owner:NINGXIA ORIENT TANTALUM IND

Amorphous carbon film, process for producing the same and amorphous carbon film-coated material

InactiveUS20060246290A1High hardnessImprove adhesionVacuum evaporation coatingSputtering coatingSolid carbonVolumetric Mass Density

An amorphous carbon film is provided with a density of 2.8-3.3 g / cm3. It would be preferable for the film to have: a spin density of 1×1018-1×1021 spins / cm3; a carbon concentration of at least 99.5 atomic percentage; a hydrogen concentration of no more than 0.5 atomic percentage; an inert gas element concentration of no more than 0.5 atomic percentage; and a Knoop hardness of 3000-7000. A mixed layer with a thickness of at least 0.5 nm and no more than 10 nm is formed from a parent material and at least material selected from: B, Al, Ti, V, Cr, Zr, Nb, Mo, Hf, Ta, and W. An amorphous carbon film is disposed on the mixed layer or a metallic intermediate layer formed on the mixed layer, thereby increasing adhesion. This amorphous carbon film is formed with solid carbon using sputtering, cathode-arc ion plating, or laser abrasion.

Owner:SUMITOMO ELECTRIC IND LTD

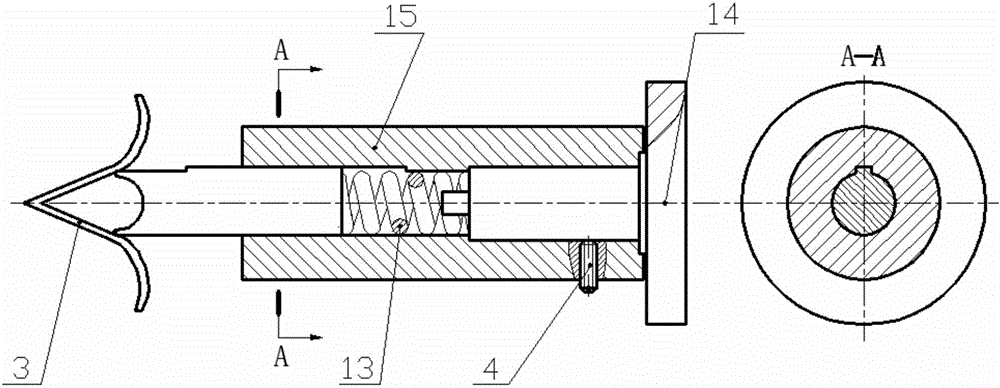

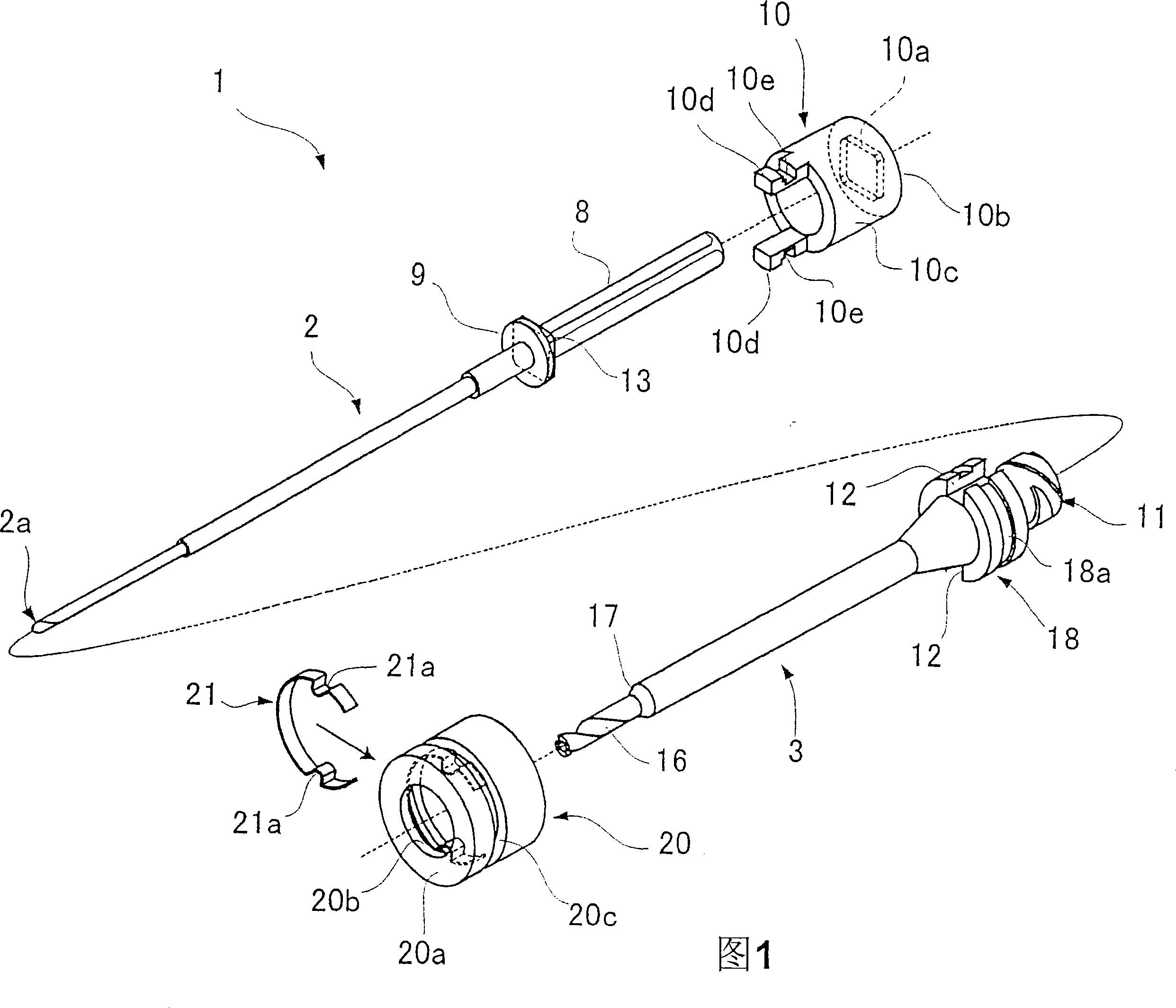

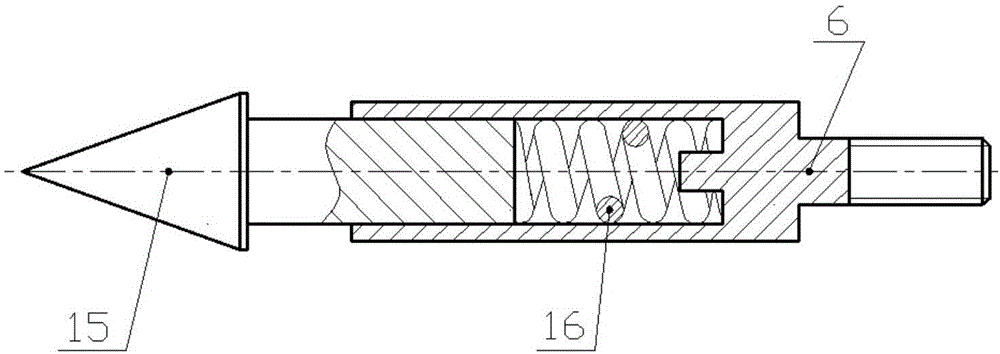

Bone marrow harvesting drill

InactiveCN101229072AImprove acquisitionReduce cutting resistanceVaccination/ovulation diagnosticsBone drill guidesAnatomyBone marrow harvesting

The bone marrow harvesting drill of the invention includes an inner needle having a cutting edge at the tip thereof; a tubular mantle that receives the inner needle thereinto so that the inner needle and the tubular mantle are detachably attached; and a lock mechanism that prevents the axial rotation of the tubular mantle and the inner needle relative to each other; the inner needle having a groove formed at the tip thereof projecting from the tubular mantle for discharging bone scraps produced by the cutting edge at the tip of the inner needle; and the tubular mantle having a cutting edge formed at the tip edge thereof and a helical groove extending from the tip edge to at least part of the peripheral surface of the tubular mantle so as to be flush with the groove of the inner needle.

Owner:JIMRO CO LTD +1

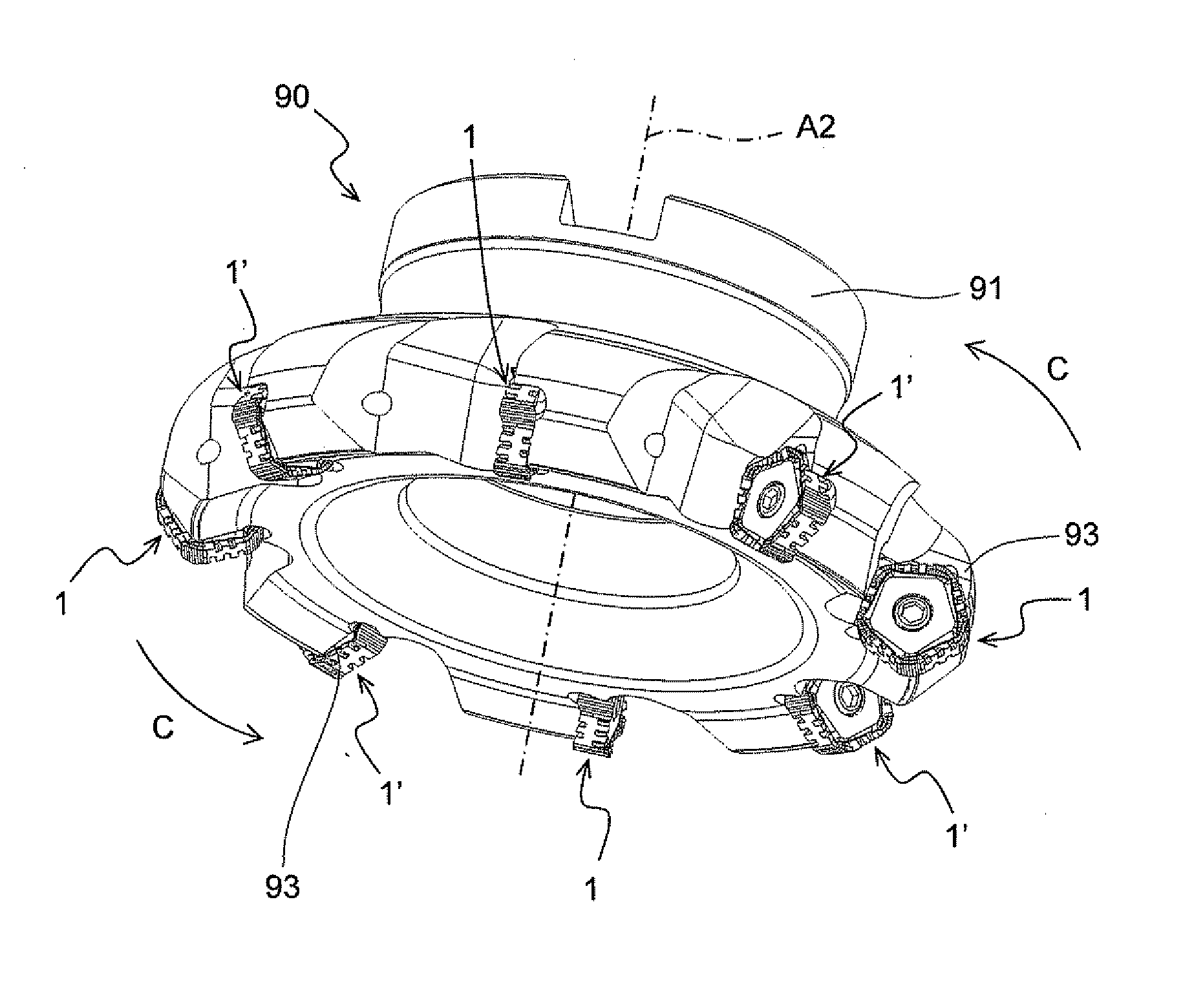

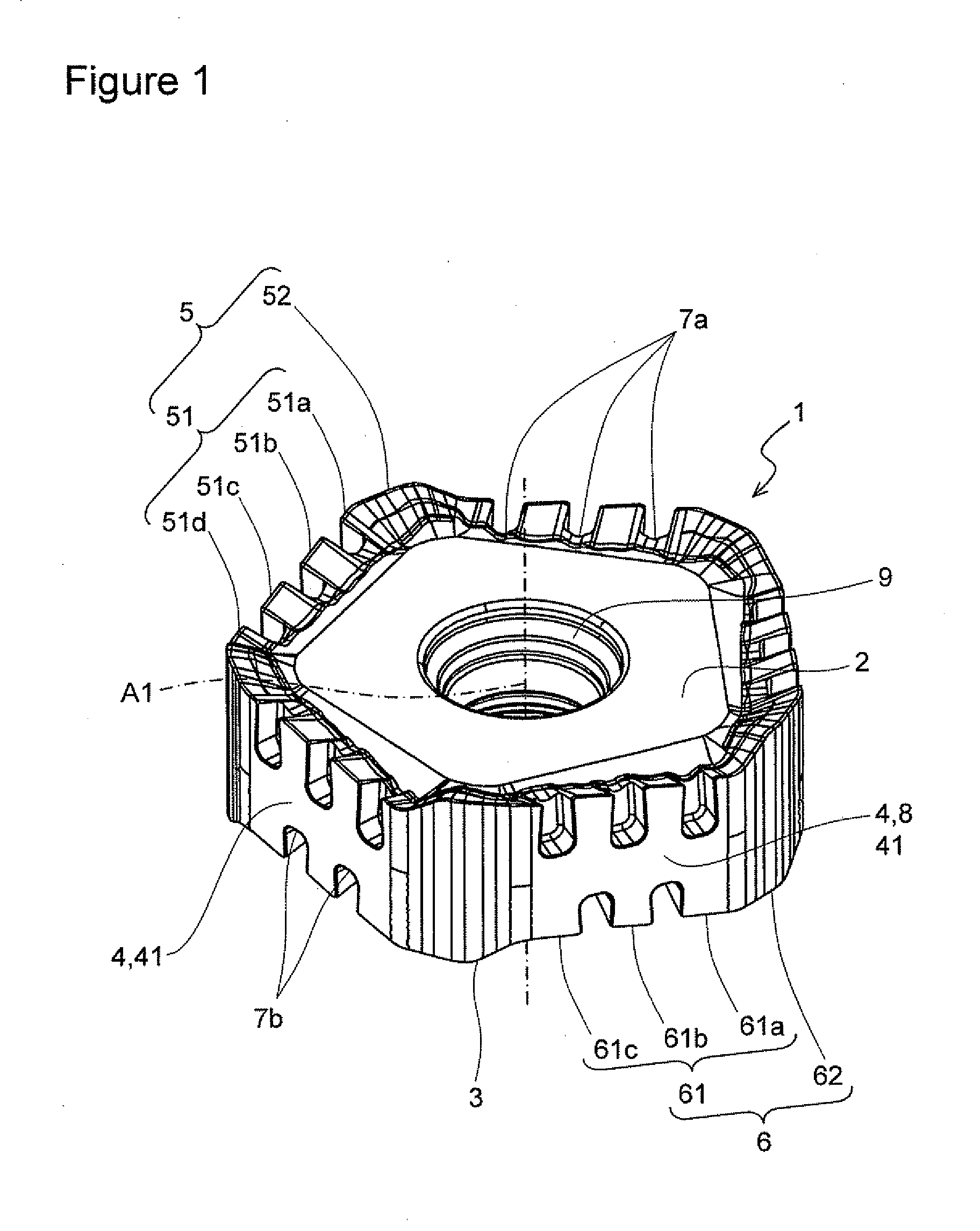

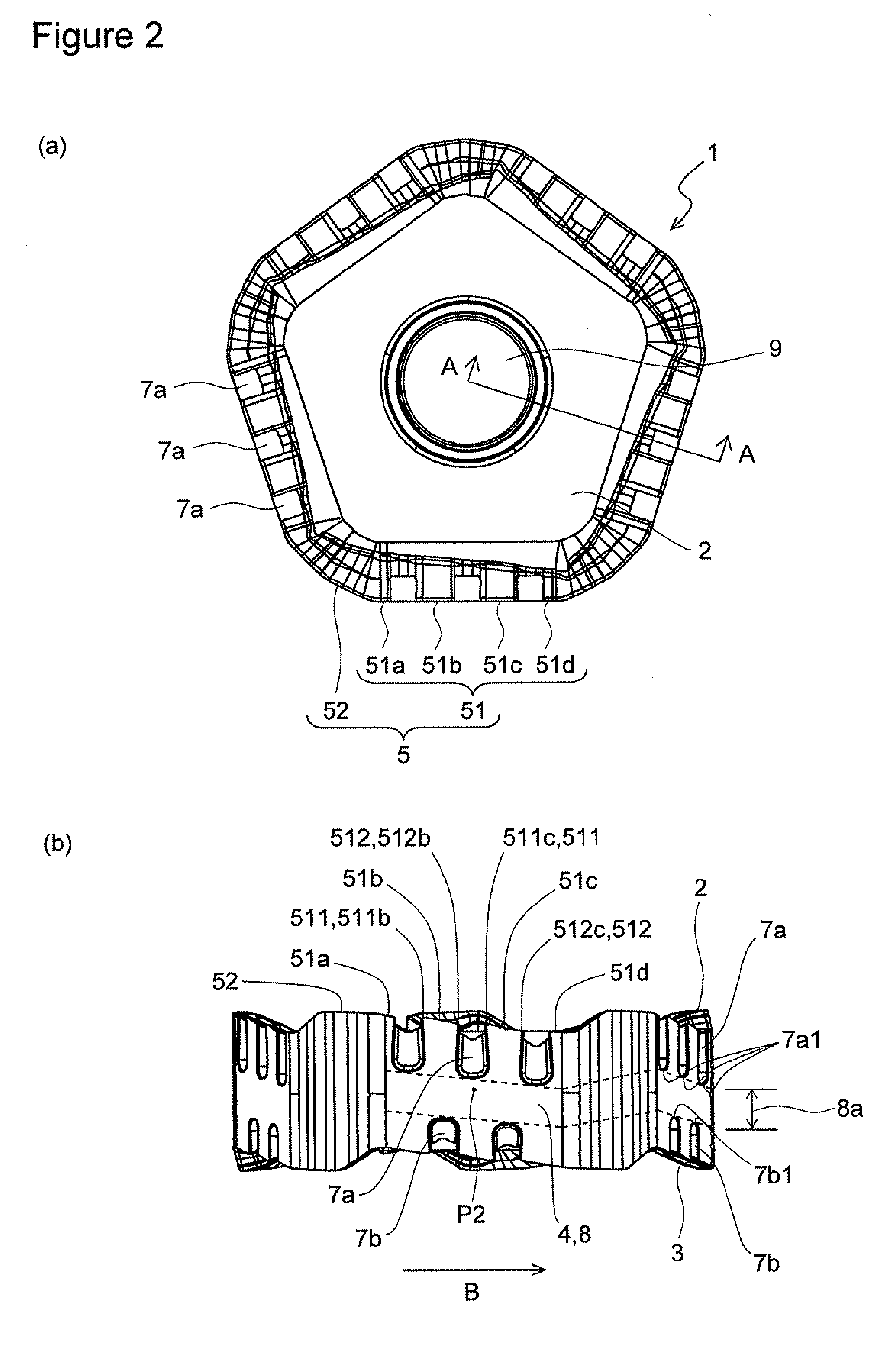

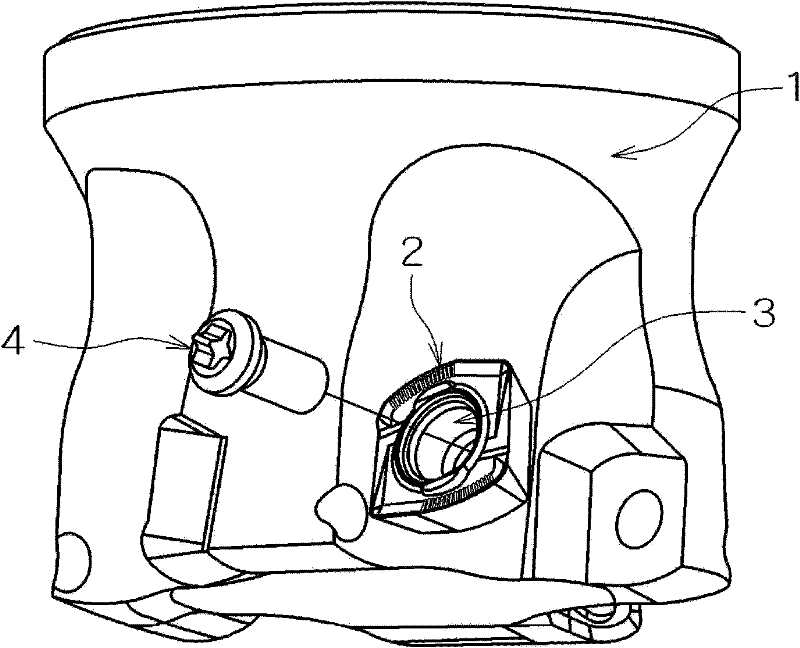

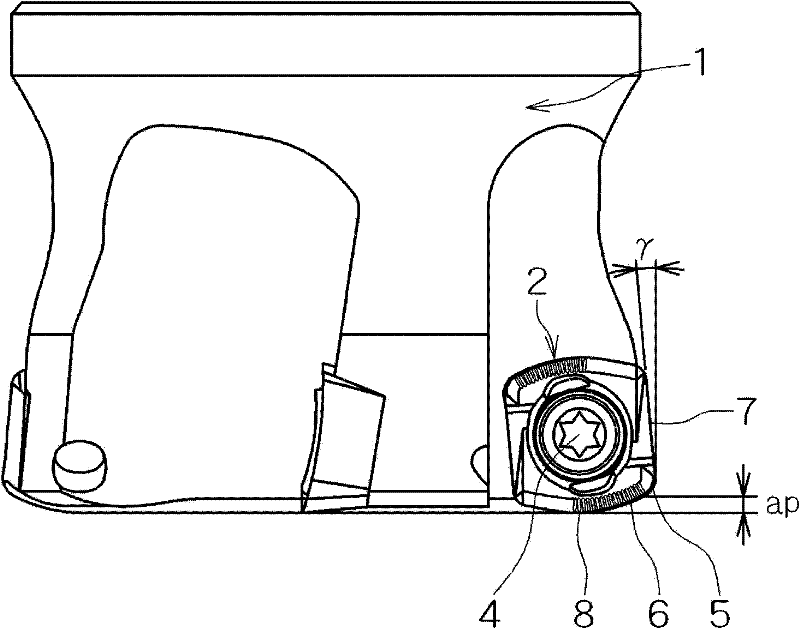

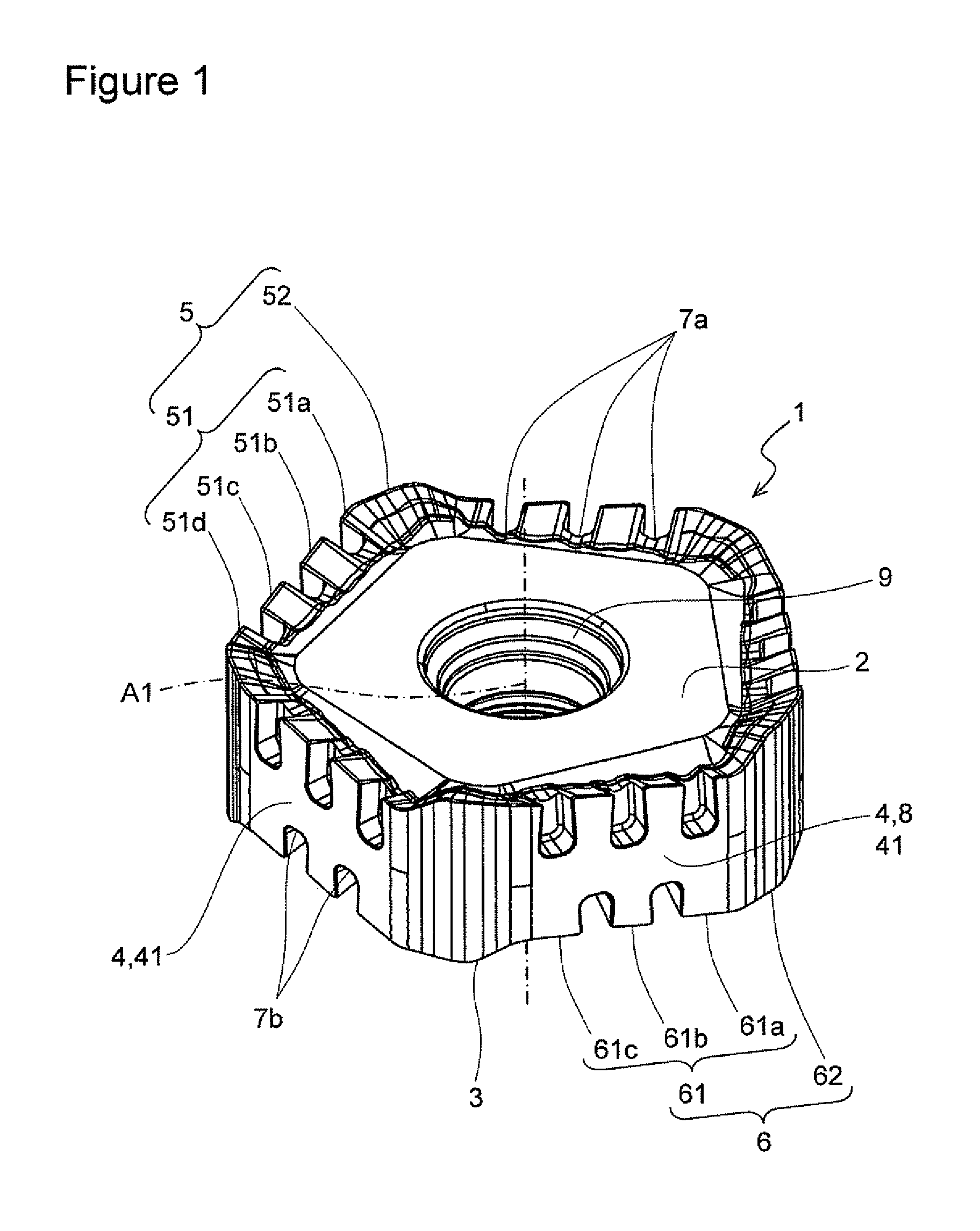

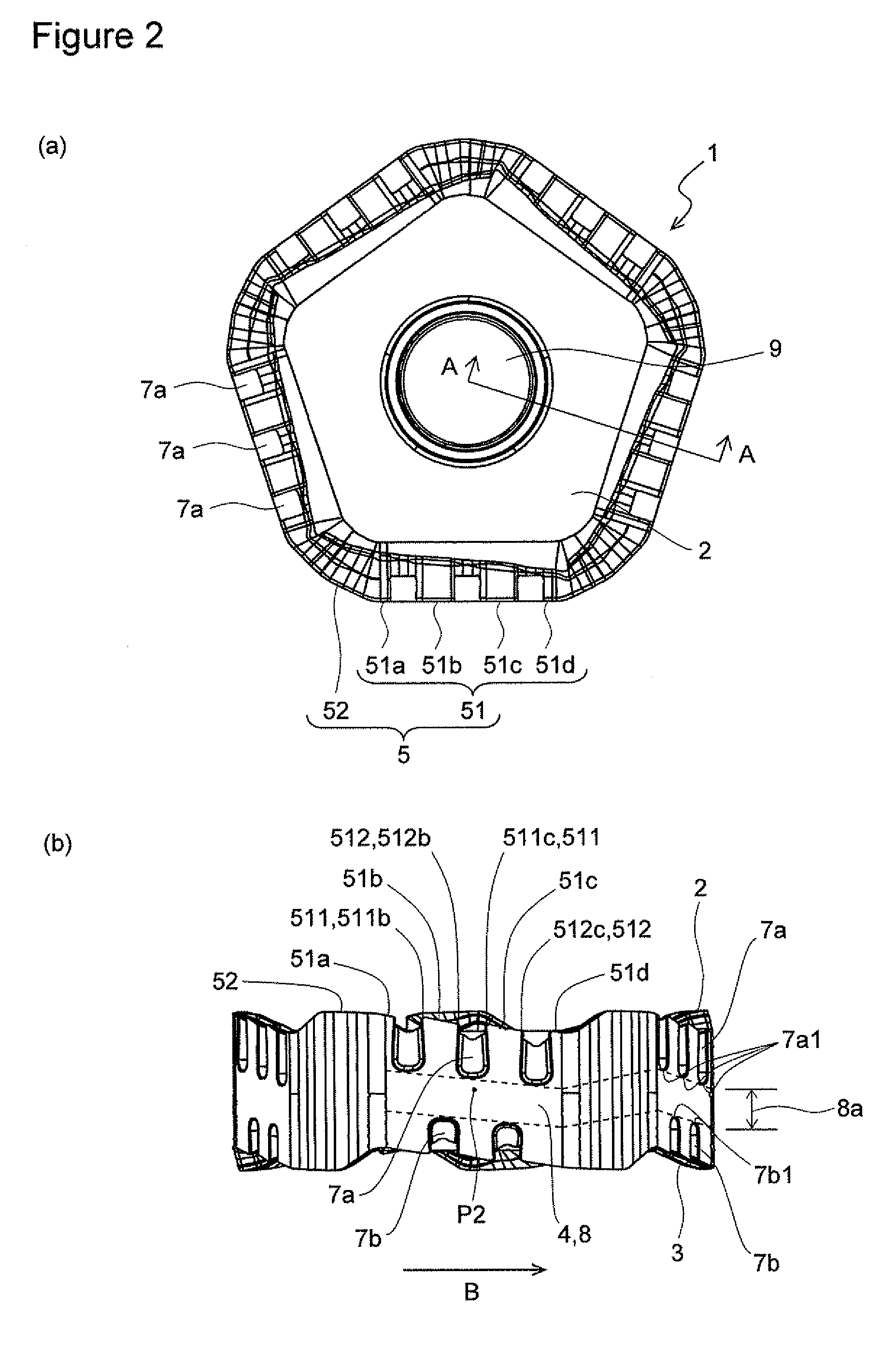

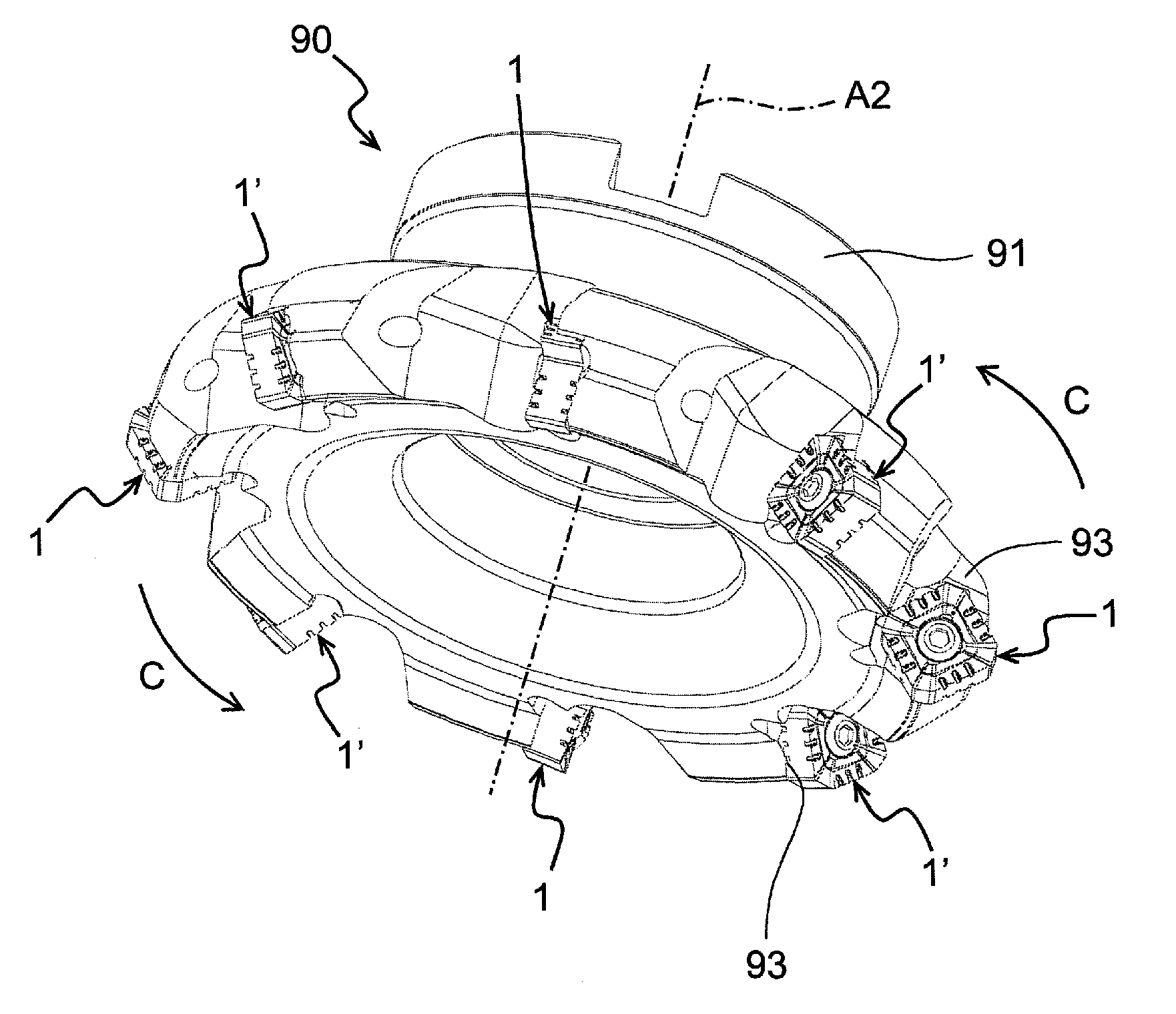

Cutting tip replacement type rotary tool

ActiveCN102317018AReduce cutting resistanceTransportation and packagingMilling cuttersEngineeringMechanical engineering

Owner:HITACHI TOOL ENG LTD

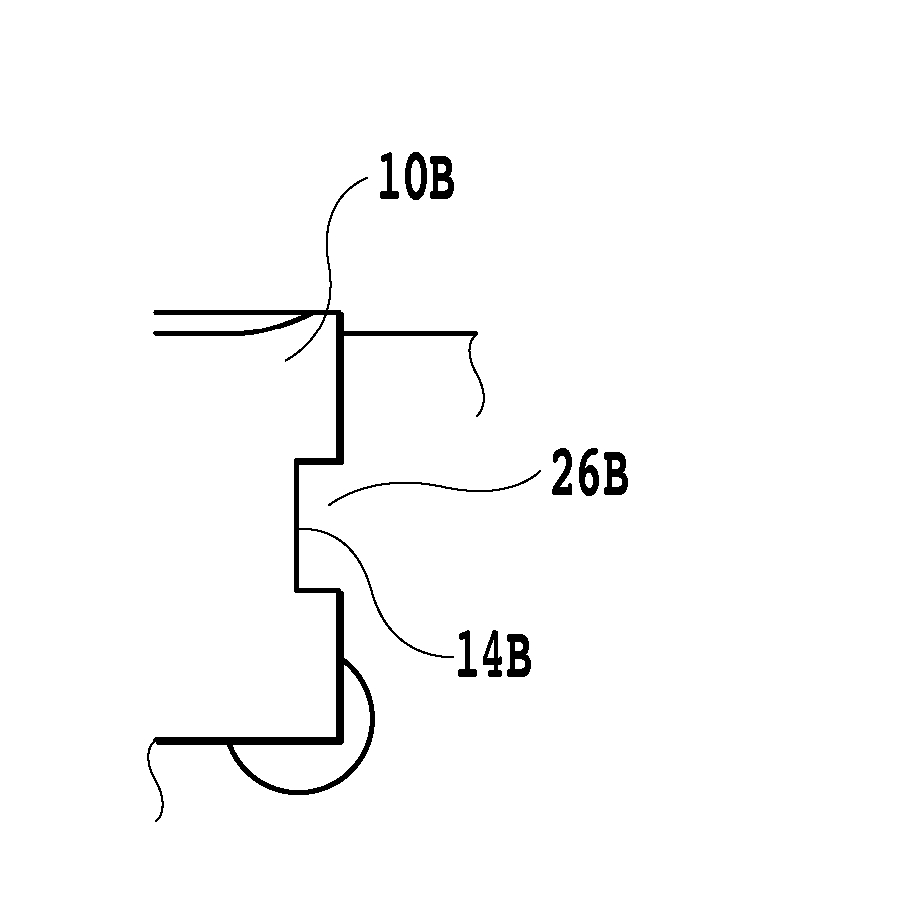

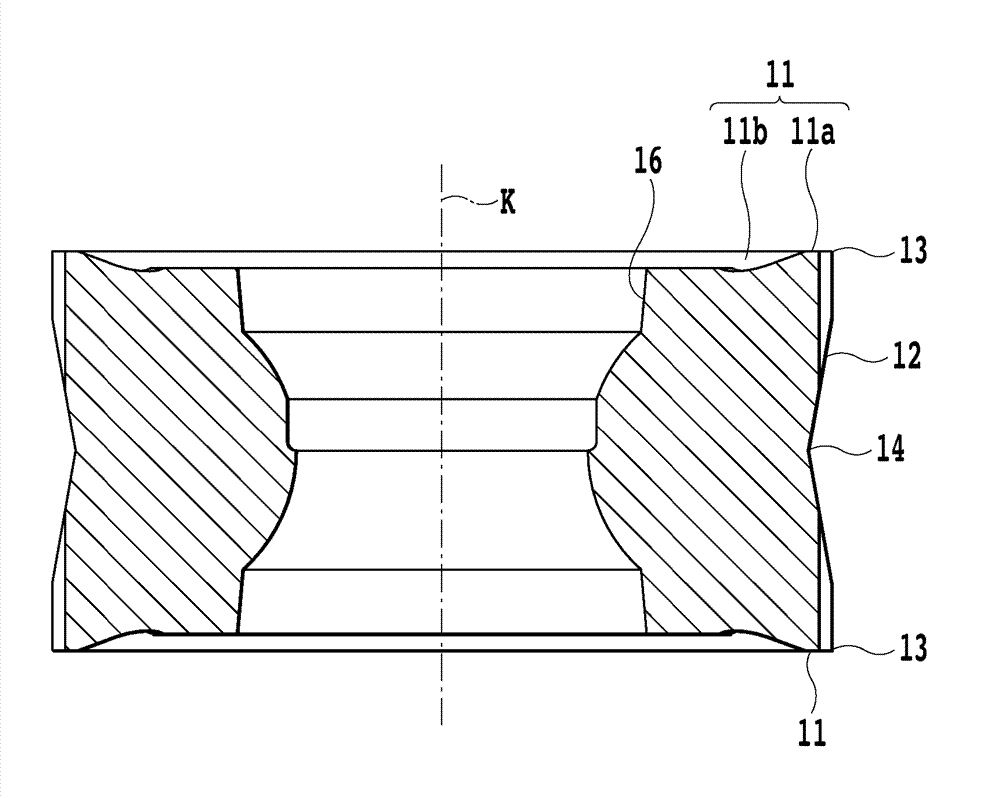

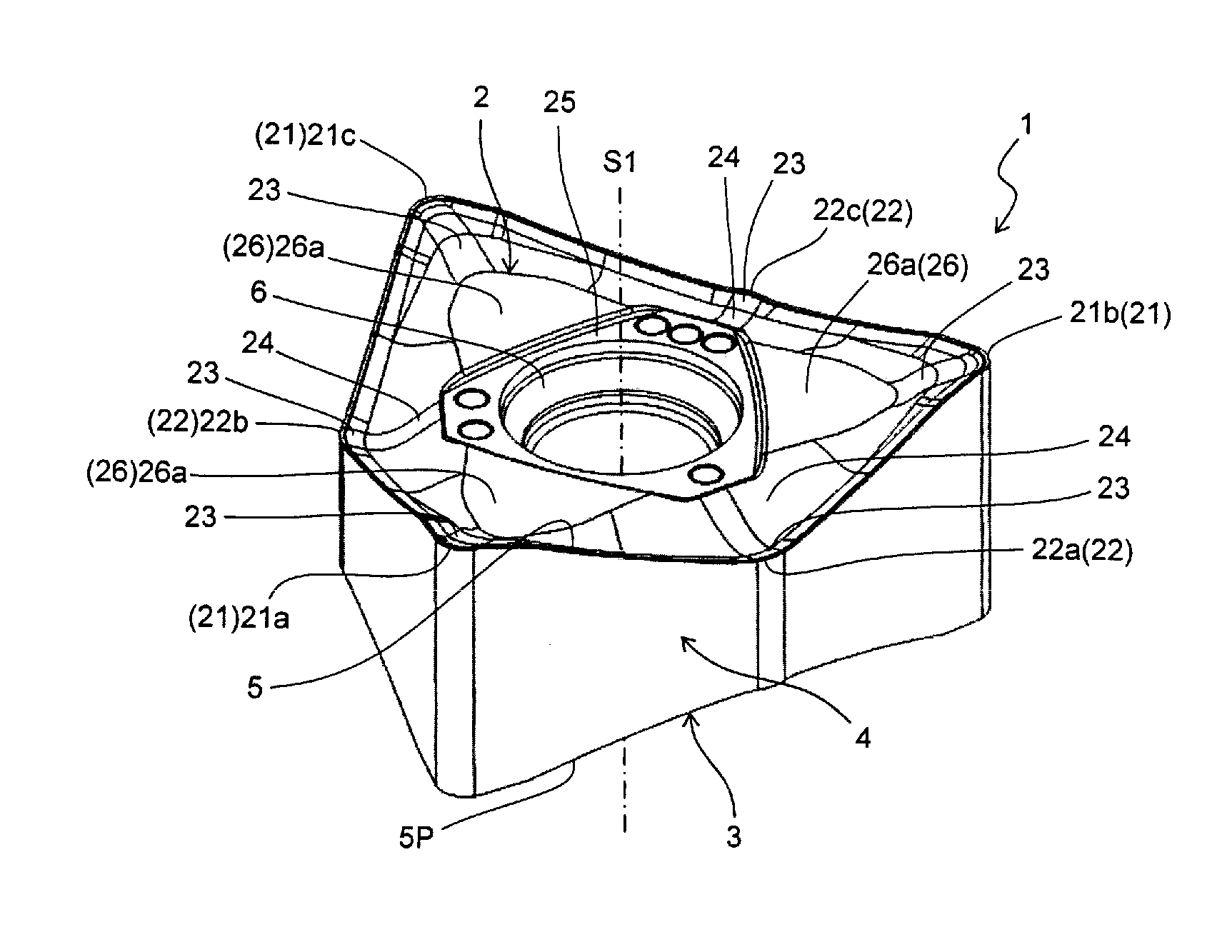

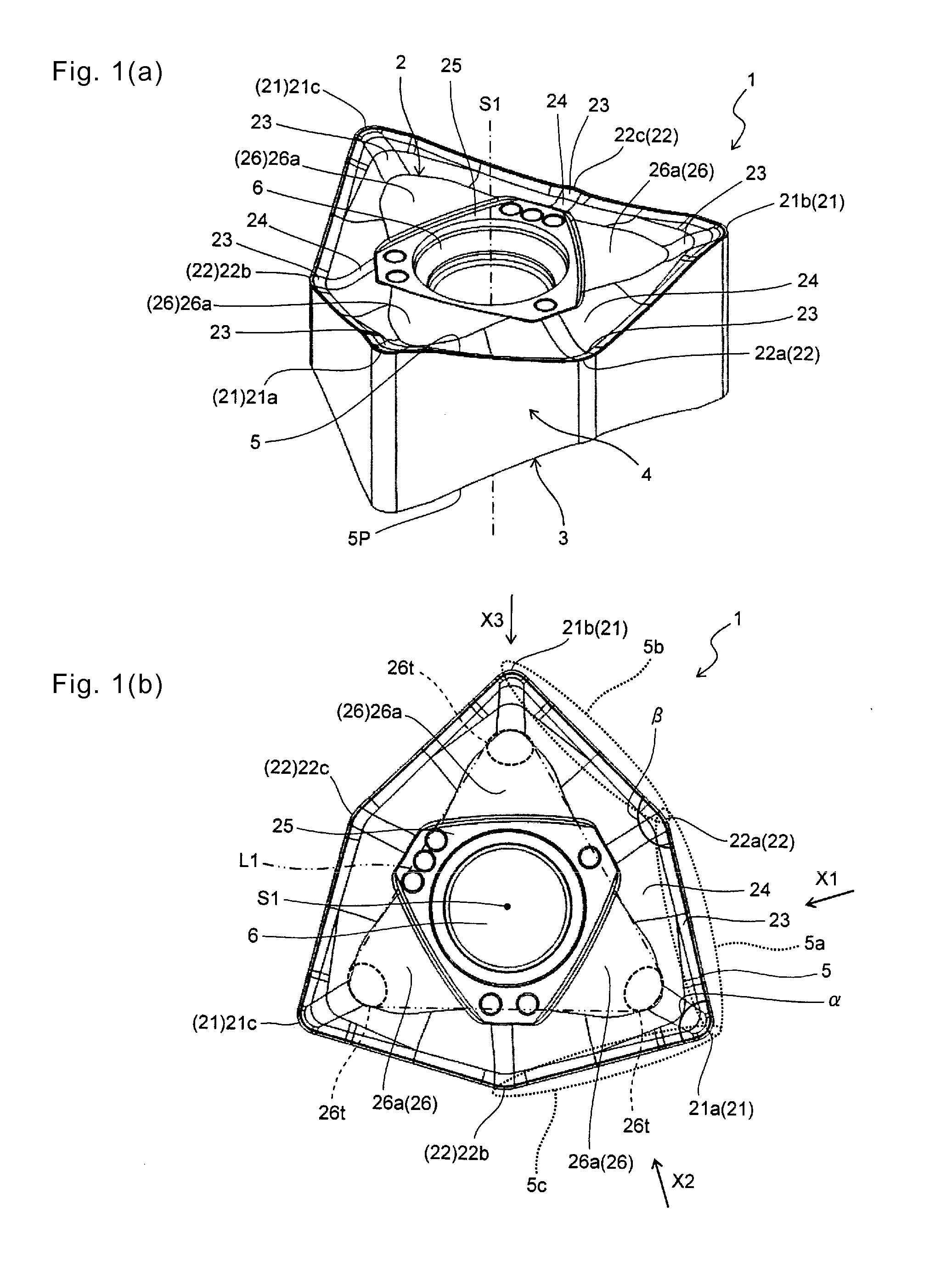

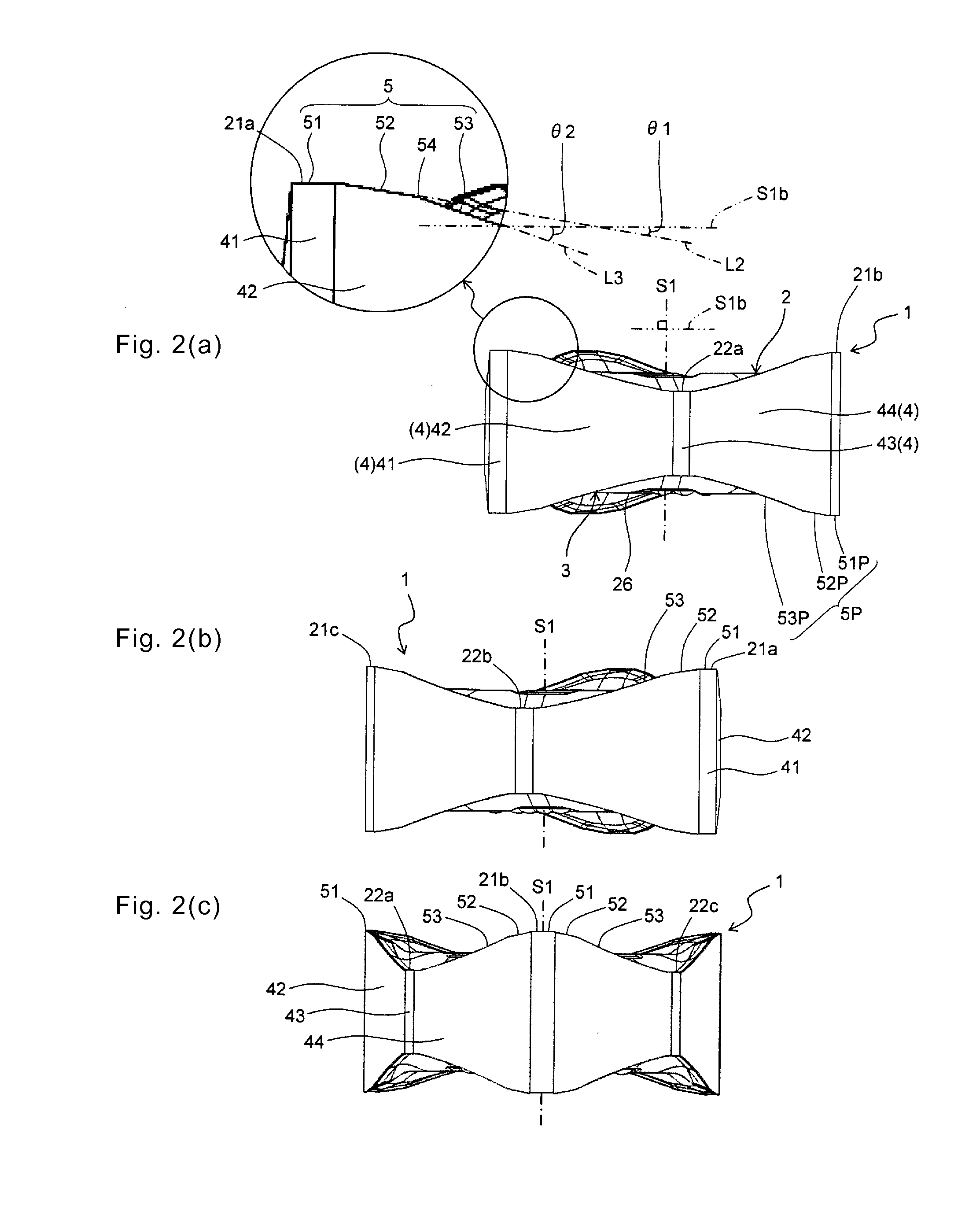

Cutting insert, cutting tool, and method of cutting workpiece using the same

ActiveUS8113746B2Reduce cutting resistanceImprove fracture resistanceTransportation and packagingMilling cuttersEngineeringLower face

A cutting insert of the present invention includes a side face having an upper concave portion which is located between an upper face and a lower face and extends up to the upper face, and a plurality of divided upper cutting edges which are located at the intersection of the upper face and the side face, and are divided by the upper concave portion. Each of these divided upper cutting edges includes a first end and a second end, and is inclined being closer to the lower face from the first end toward the second end. The plurality of divided upper cutting edges include a first divided upper cutting edge and a second divided upper cutting edge adjacent to each other. When viewed from side, the first end of the second divided upper cutting edge is located above the intersection of an extension line of the first divided upper cutting edge, and a line which passes through the first end of the second divided upper cutting edge and is parallel to the central axis of the cutting insert, and is located at the same position as the second end of the first divided upper cutting edge, or located therebelow. A cutting tool including the cutting insert, and a method of cutting a workpiece by using the cutting tool are also provided.

Owner:KYOCERA CORP

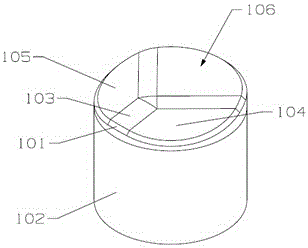

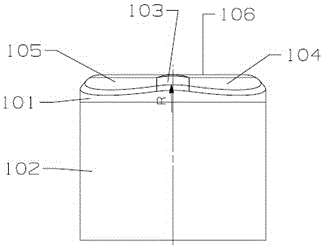

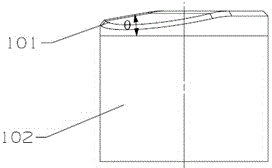

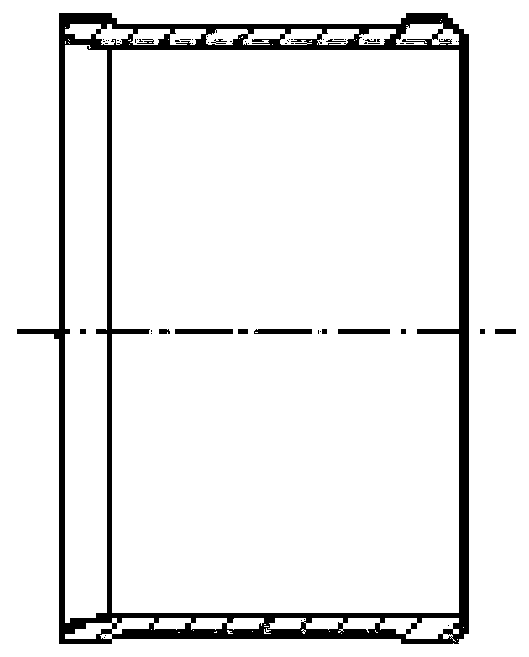

Oil groove milling cutter of hard alloy cold-working mould pressing blank

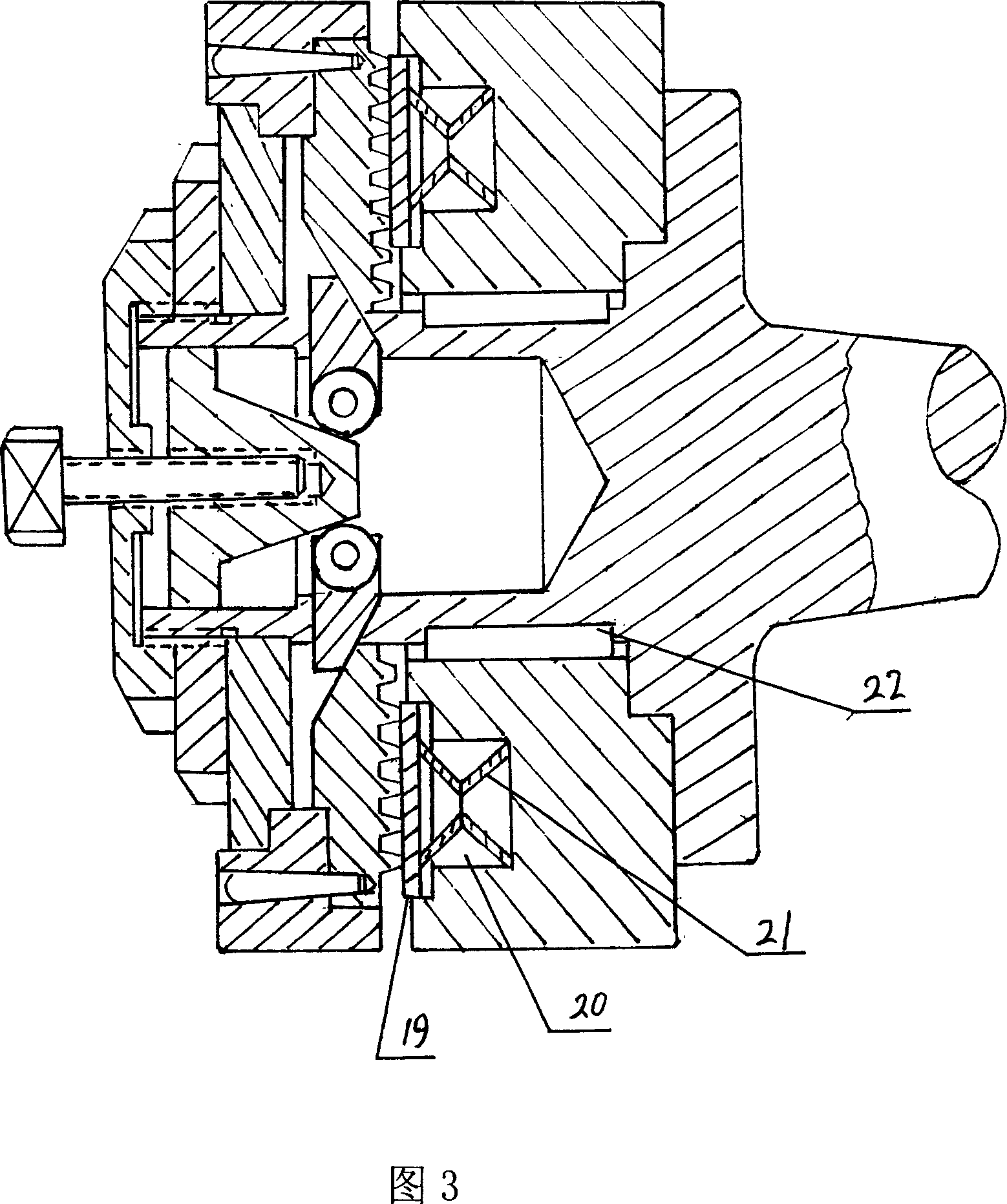

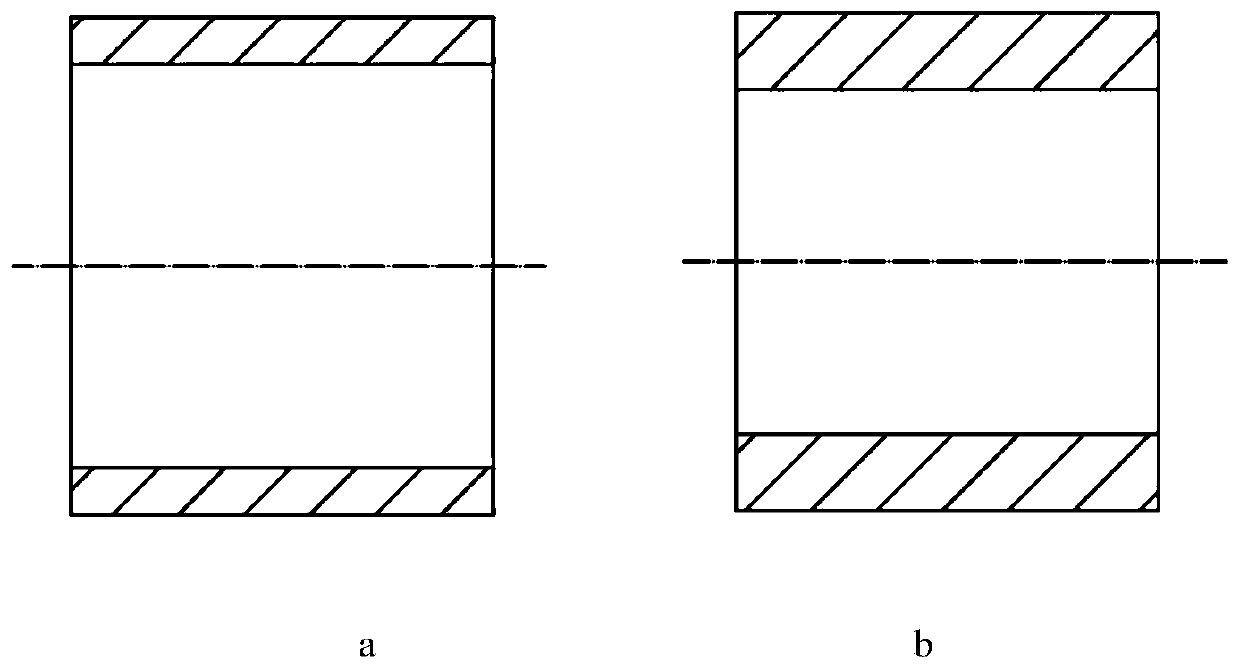

InactiveCN101637829ASolve the discharge problemDischarge in timeMilling cuttersMilling equipment detailsMilling cutterMachined surface

The invention discloses an oil groove milling cutter of a hard alloy cold-working mould pressing blank, which comprises a steel basal body (2) and a PCD blade (1), wherein the steel basal body (2) isprovided with 6-12 saw teeth, the number of PCD blade (1) is the same with the number of saw teeth, the back of the saw teeth of the steel basal body (2) is designed into an inclined flat bottom shape, and the PCD blade (1) is welded on the saw teeth of the steel basal body (2). Aiming at the difficult problems of low integrated intensity, hard grains and easy machined surface collapse in the processing process of a hard alloy pressing blank, the invention concretely limits multiple items of geometric parameters of the milling cutter, particularly a geometric angle. When the milling cutter isused for processing an oil groove of the hard alloy cold-working mould pressing blank, the edge of the oil groove can be kept integrated, and the machined surface roughness is kept to be not more thanRa 0.8, solving the difficult problem that the quality of the machined surface can not be ensured when the existing milling cutter is used for processing the hard alloy pressing blank.

Owner:FUJIAN JINXIN TUNGSTEN

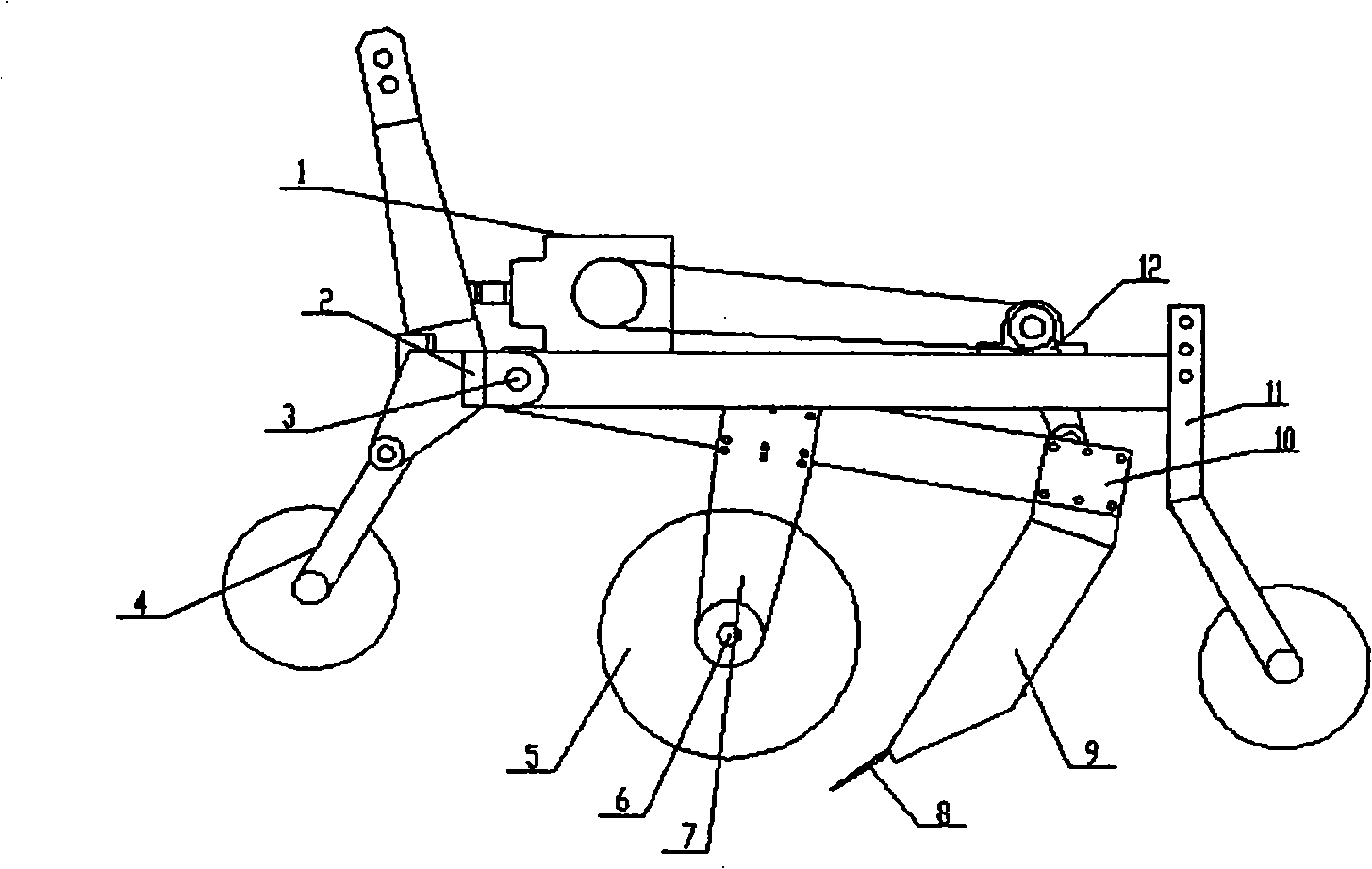

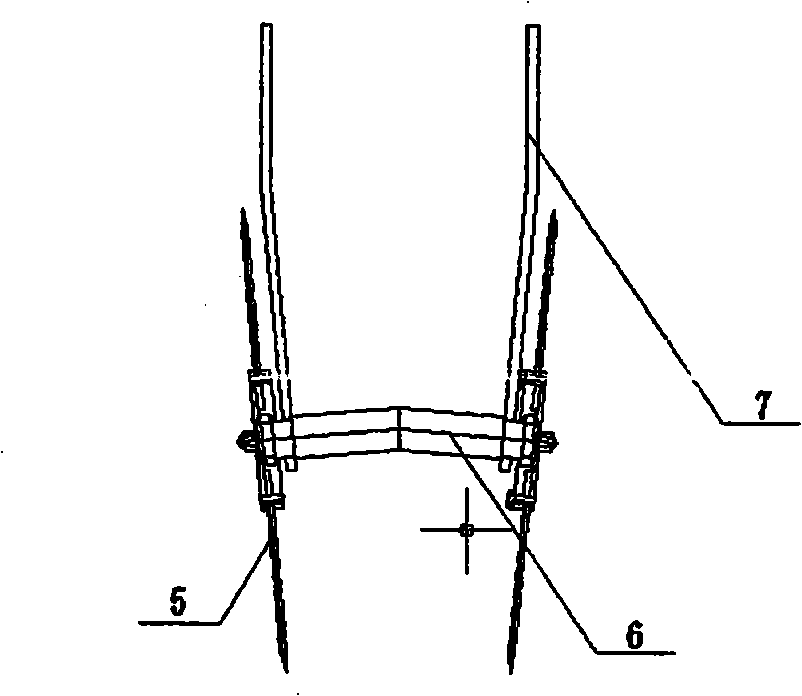

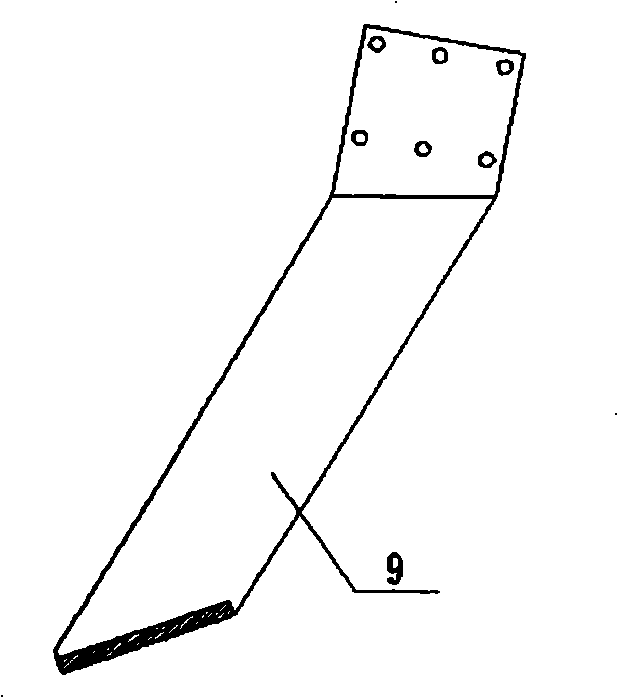

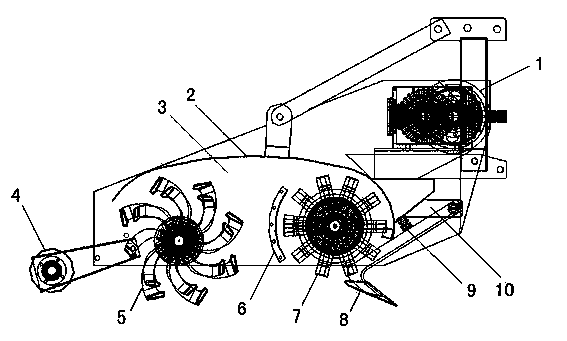

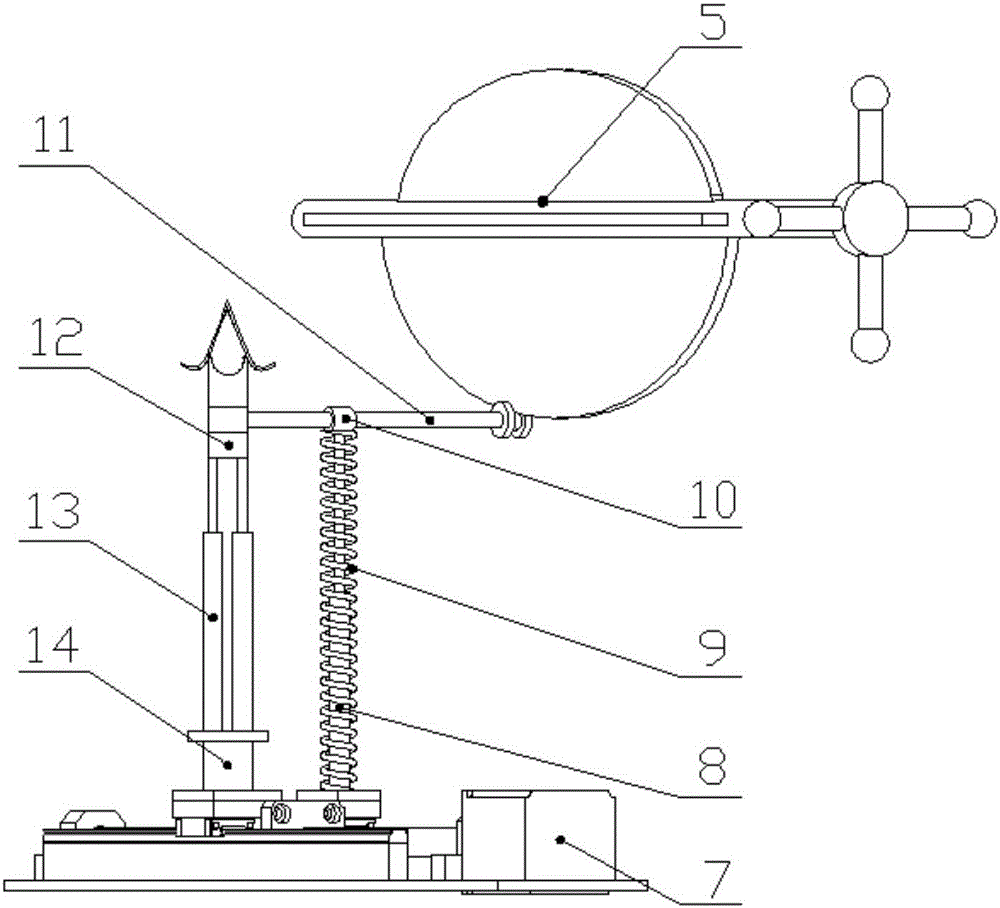

Situ plow-putting vibrating scarifier

ActiveCN101326872AAchieving loose spacingAvoid disturbanceSpadesSoil-working equipmentsCircular discFalsework

The invention belongs to the technical field of agricultural machines, in particular to a soil-dropping vibrating ripper in situ which is used by matching a tractor. A soil-dropping vibrating ripper in situ comprises a gearbox (1) and a stander (2), and is characterized in that the cutting system of a cutting disc (5) and an operational shovel component which comprises an operational shovel (8) are respectively fixed on a falsework (10), and the cutting system is arranged at the front of the operational shovel component; a vibrating system comprises an eccentric shaft connecting rod component (12) fixed on the stander (2); the frond end of the falsework (10) is fixed on the stander (2) by a pin roll (3), and the rear end of the falsework (10) is connected with the eccentric shaft connecting rod component (12); the gearbox (1) is connected with the vibrating system through a main transmission shaft for distributing power to the eccentric shaft connecting rod component (12); a soil-rolling adjusting system comprises a supporting wheel (4) fixed on the stander (2)and a soil-rolling wheel (11).

Owner:CHINA AGRI UNIV

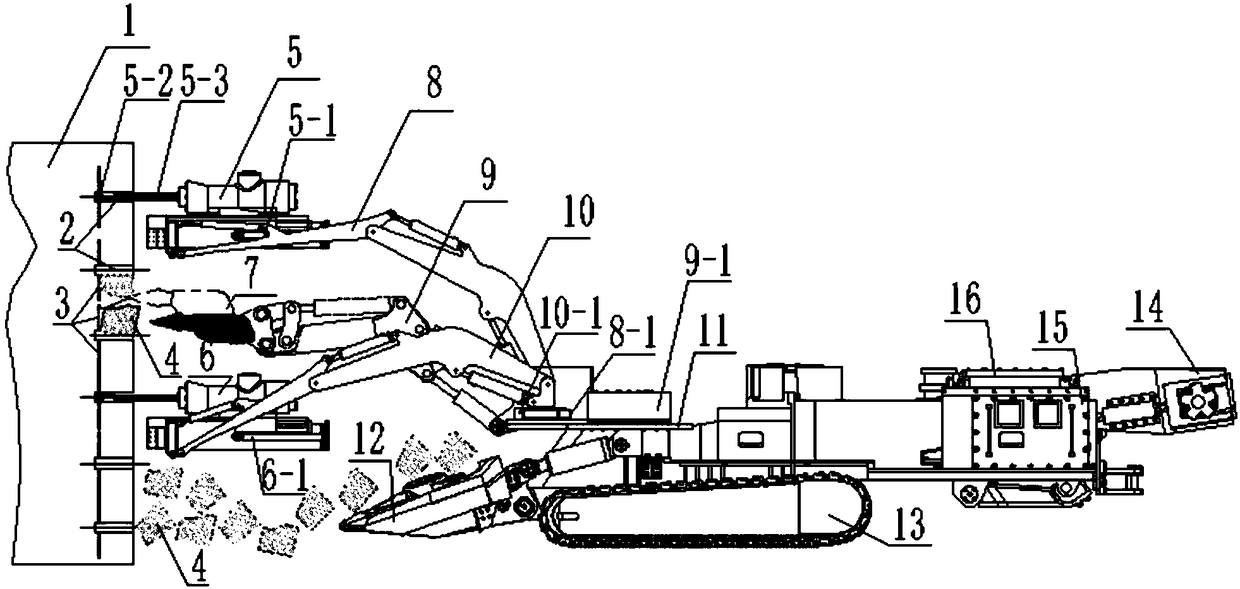

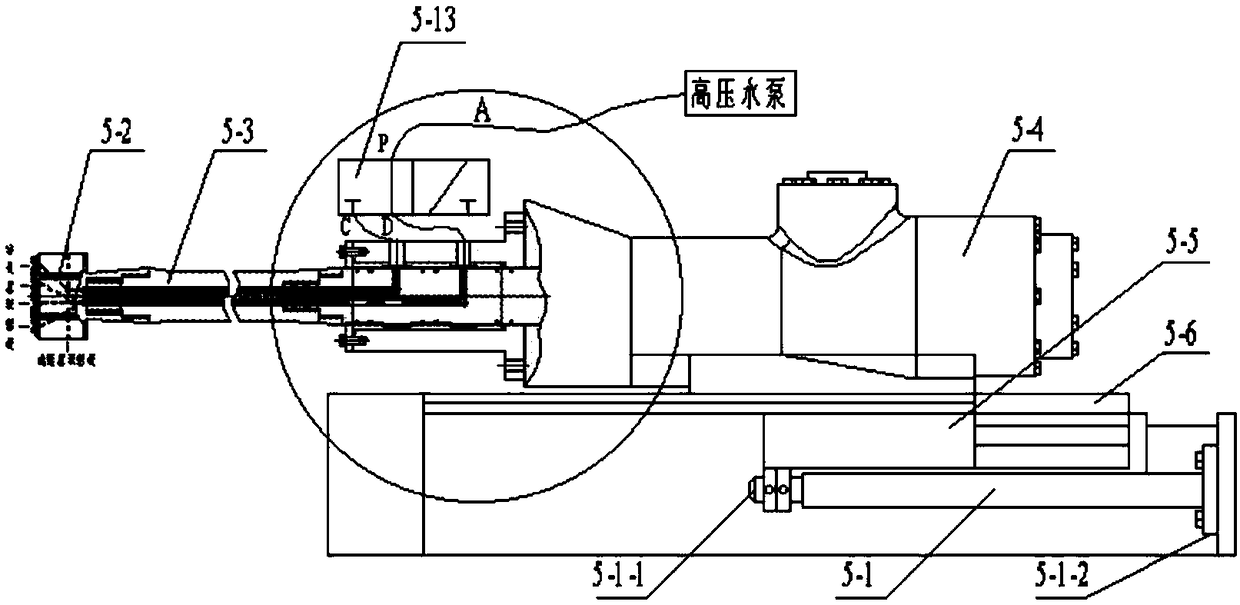

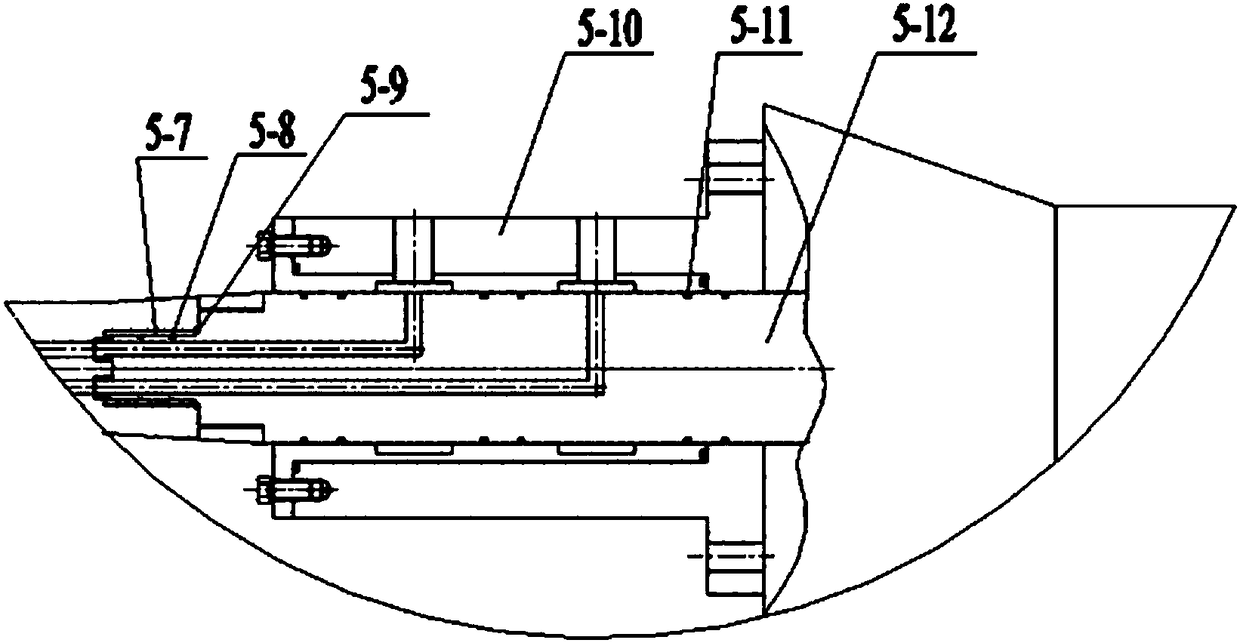

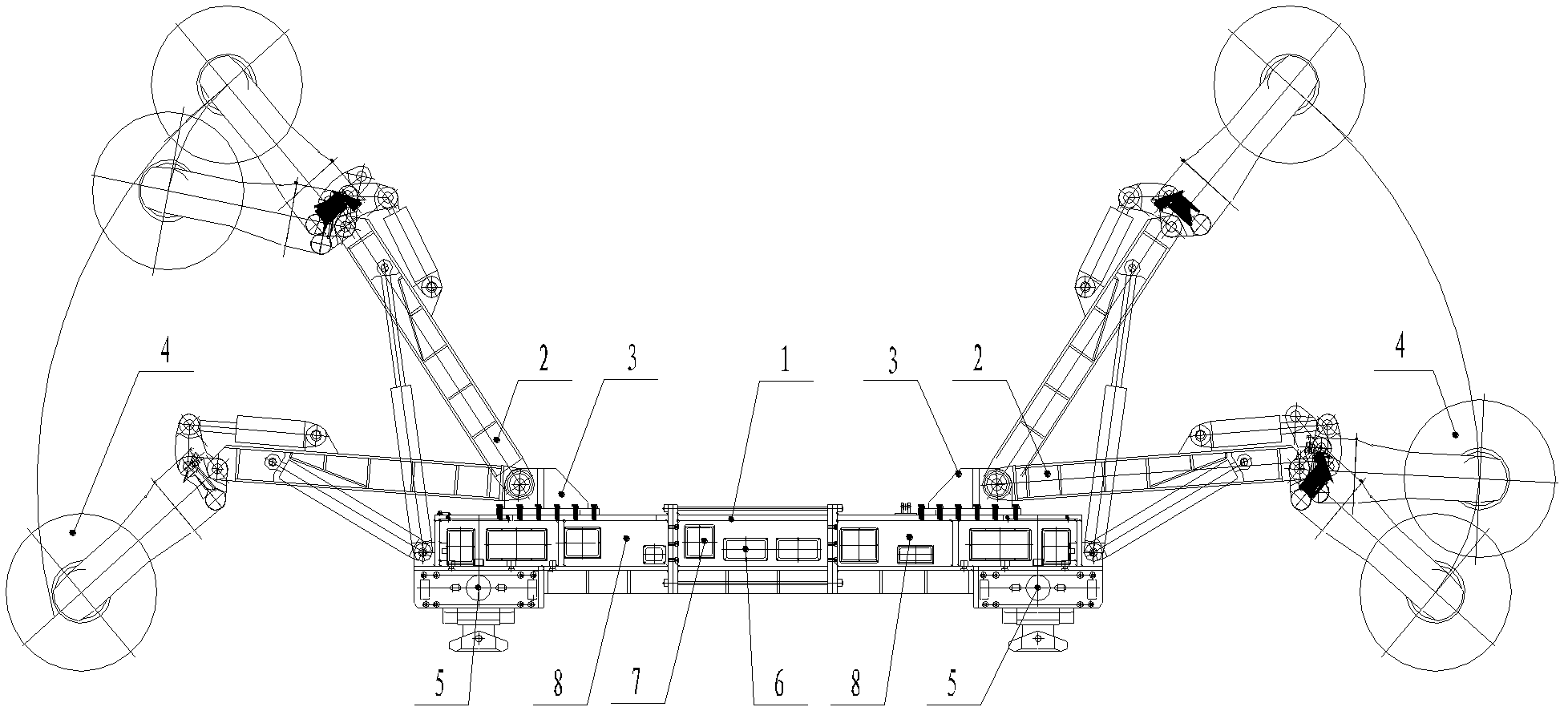

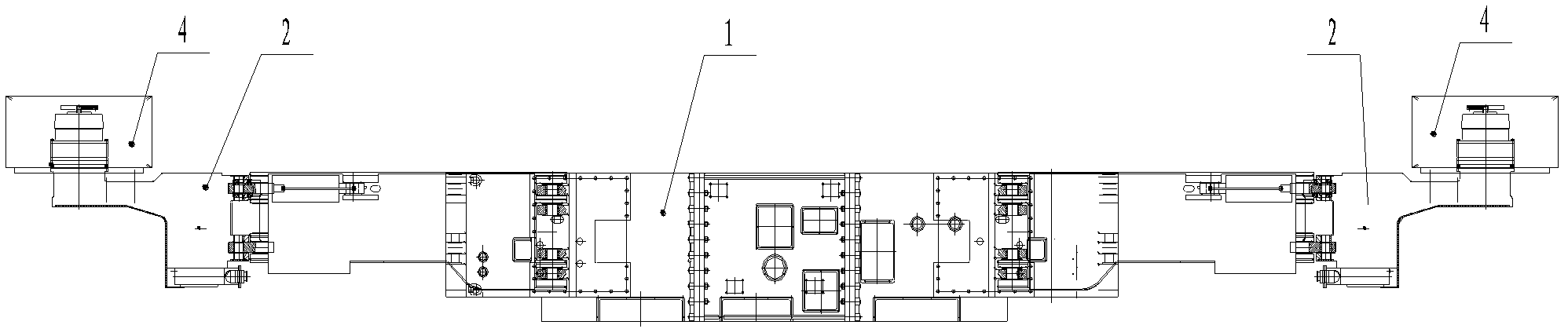

Tunneling device for hard rock body

ActiveCN108086990AReduce cutting resistanceImprove crushing efficiencyDrill bitsDrilling rodsHydraulic pumpMulti degree of freedom

The invention discloses a tunneling device for a hard rock body. The tunneling device comprises a right rock body drilling, fracture generation and abrasive jet mechanism, a left rock body drilling, fracture generation and abrasive jet mechanism, a hydraulic impact hammer, a right multi-degree-of-freedom mechanical arm, a left multi-degree-of-freedom mechanical arm, a middle multi-degree-of-freedom mechanical arm, a main machine frame, a loading mechanism, a crawler walking mechanism, a conveying mechanism, a high-pressure abrasive jet generating system and a hydraulic pump station. The rightrock body drilling, fracture generation and abrasive jet mechanism and the left rock body drilling, fracture generation and abrasive jet mechanism use abrasive jet assisted drilling and high-pressureabrasive jet to conduct rock body fracture generation, the cutting resistance of the hard rock body can be reduced to the largest extent, the difficulty of mechanical cutting teeth in crushing hard rock is reduced, and the crushing efficiency of the hard rock is improved. The crushing difficulty of the hard rock can be reduced, the crushing efficiency of the hard rock is improved, excessive abrasion of a drill bit during work of the mechanism can be avoided, and the tunneling device plays an important role in achieving efficient tunneling of hard rock roadways and tunnels.

Owner:CHINA UNIV OF MINING & TECH

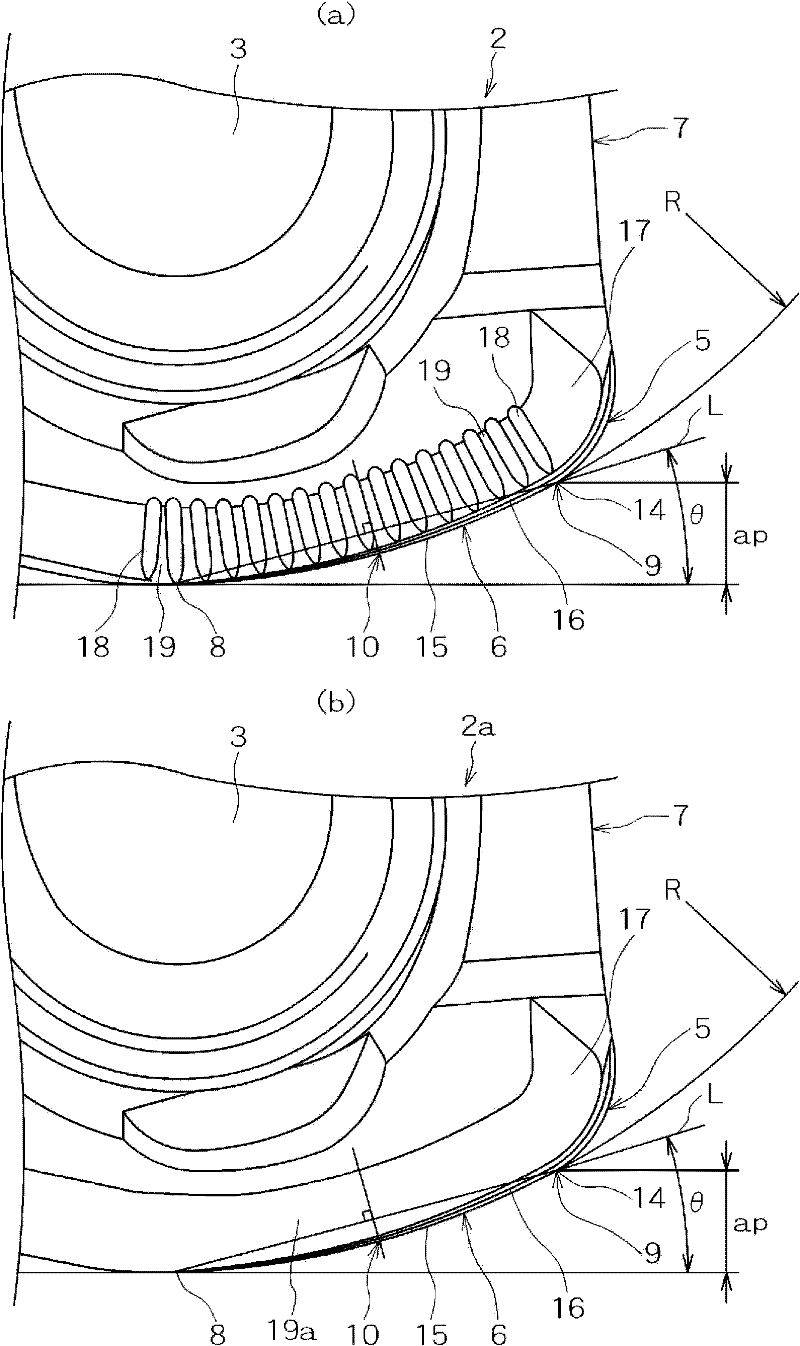

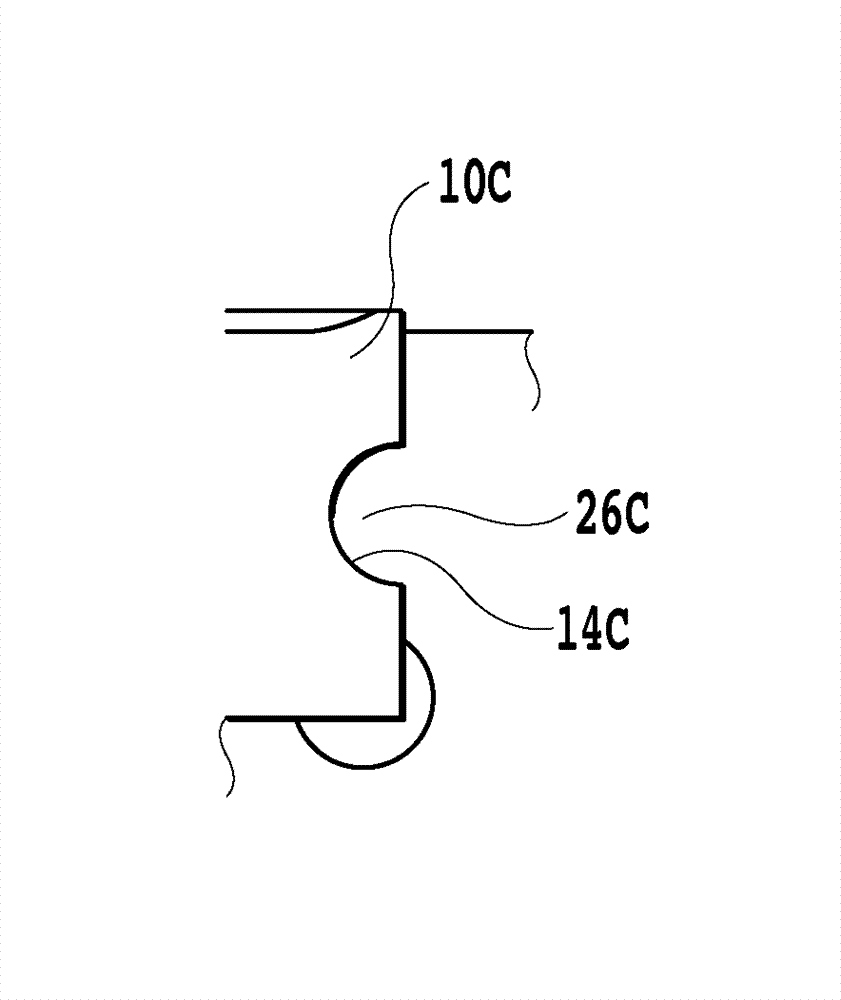

Cutting insert and cutting tool

InactiveCN102781612AImprove processing efficiencyReduce cutting resistanceTransportation and packagingMilling cuttersStructural engineeringKnife blades

Provided is a cutting insert having a cutting edge that can inhibit the cutting resistance applied to a cutting boundary section from increasing with an increase in cutting depth. The cutting insert has one or more rake faces, a flank face, and a cutting edge formed at the intersection of the rake face and the flank face, and is removably attached to an attachment seat of a cutting tool body. The cutting edge has, in at least a portion thereof, a decreased-cutting-angle cutting edge section in which the cutting angle gradually decreases along the direction in which the cutting depth of the cutting edge increases. For example, the rake faces comprise an upper rake face formed on the upper face and a lower rake face formed on the lower face, the flank face is formed on the side face extending between the upper face and the lower face, and the cutting edge is formed at the intersection of the upper rake face and the flank face.

Owner:TUNGALOY CORP

Straw smashing and stubble breaking rotary tillage all-in-one machine

InactiveCN103650676ASmash thoroughlyPrevent moisture from evaporatingSpadesCrop conditionersAgricultural engineeringEnergy consumption

The invention discloses a straw smashing and stubble breaking rotary tillage all-in-one machine, and relates to the technical fields of straw returning machines and rotary tillage. The straw smashing and stubble breaking rotary tillage all-in-one machine comprises a machine frame, a machine case, a power transmission mechanism and a straw smashing device. The machine case is fixed onto the machine frame, the straw smashing device is arranged on the front portion inside the machine case, the straw smashing device rotates counterclockwise, a baffle is arranged behind the straw smashing device, the two ends of the baffle are fixed onto side plates of the machine case, a gap exists between the upper portion of the baffle and the machine case, a stubble breaking rotary tillage device is arranged on the rear portion of the baffle, and the machine case extends to the rear portion of the stubble breaking rotary tillage device. Straw is guided to the position behind the stubble breaking rotary tillage device under the action of the baffle and the machine case. Furthermore, the front side of the machine case is further provided with a straw combing plough. Press wheels are arranged on the rear portion of the machine case. The straw smashing and stubble breaking rotary tillage all-in-one machine has the advantages that straw smashing field returning and stubble breaking rotary tillage are completed at a time, residual straw which is not smashed does not exist under tracks, the efficiency is high, the energy consumption is low and soil moisture conservation is achieved. The development of the straw smashing and stubble breaking rotary tillage all-in-one machine is a breakthrough of agricultural machines.

Owner:董志军

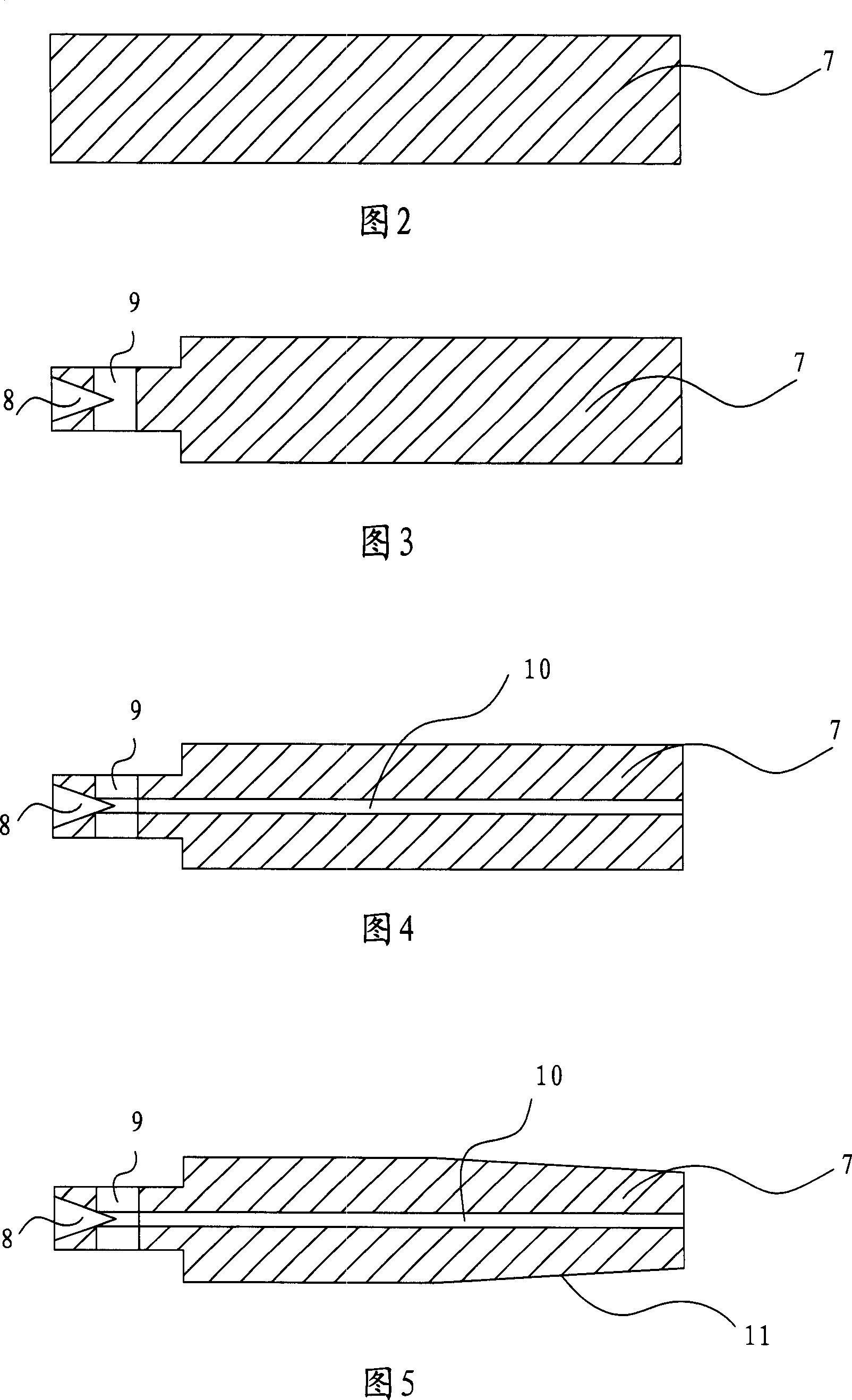

Wave blade-shaped end mill processing method

ActiveCN102848160ASolve the defect of unequal grindingReduce cutting resistanceMilling cutterEngineering

The invention discloses a wave blade-shaped end mill processing method, and relates to an end mill processing method. The invention aims at solving the problem that the currently processed wave blade-shaped end mill is low in working efficiency in the use process caused by the reasons of being excessive in cutting resistance, unsmooth in chip removal, unequal in grinding, prone to damage and short in service life. The method provided by the invention comprises the following steps of: step 1: turning a milling cutter blank; step 2: milling peripheral teeth, widening back of teeth, and accurately milling with a 38-degree helical angle, wherein the cutting parameters are as follows: the rotation speed is 200r / min, and the feeding is 0.15mm / r; step 3: thermal treatment; step 4: external grinding; step 5: grinding the front angle, the wave blade form and the rear angle by a five-axis numerically controlled grinding machine; and step 6: coating treatment. The method provided by the invention is clear in steps and easy to carry out, in comparison with the conventional wave blade-shaped end mill, the working efficiency of the wave blade-shaped end mill processed by the method is doubled and the service life is improved by 20-40%. The method provided by the invention is used for processing the wave blade-shaped end mills.

Owner:HARBIN TURBINE

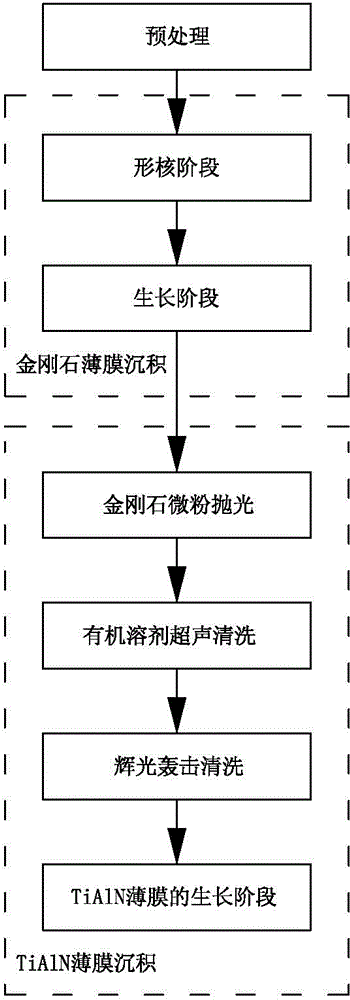

Preparation method of diamond/TiAlN composite coating on surface of hard alloy cutter

ActiveCN105624677AExcellent film-substrate adhesion strengthEnhanced membrane-substrate adhesion strengthVacuum evaporation coatingSputtering coatingOrganic solventAlloy

The invention discloses a preparation method of a diamond / TiAlN composite coating on the surface of a hard alloy cutter. The technical problems that as composite coatings are not flat in surface and prone to peeling off in the prior art, a cutter is easily abraded and the service life is short are solved. The method comprises the steps that the surface of the hard alloy cutter is preprocessed through an acid-alkali two-step method; a diamond film deposits on the preprocessed surface of the hard alloy cutter through a hot filament chemical vapor deposition device, specifically, deposition of the diamond film comprises the nucleation stage and the growth stage; and a TiAlN film deposits through a direct current reactive magnetron sputtering method, specifically, deposition of the TiAlN film sequentially comprises diamond micro-powder polishing, organic solvent ultrasonic washing, glow bombardment washing and the growth stage of the TiAlN film. A composite coating prepared by the invention has the excellent film-matrix adhesion strength, the technical problem that the films are prone to peeling off is avoided, the abrasion resistance and high temperature resistance of the cutter are remarkably improved, and the service life of the cutter is greatly prolonged.

Owner:NANJING ZHONGCHE PUZHEN URBAN RAIL VEHICLE CO LTD

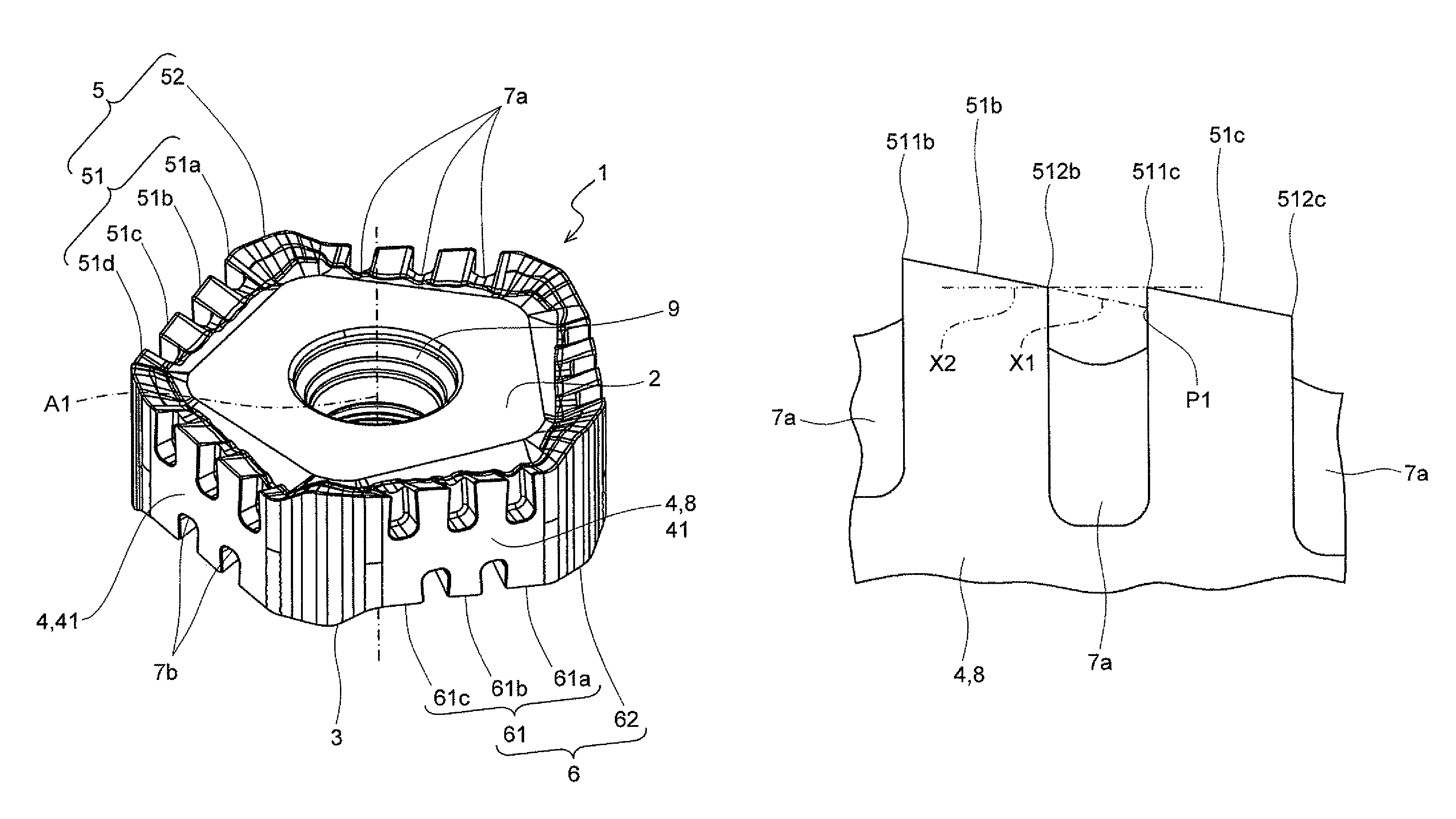

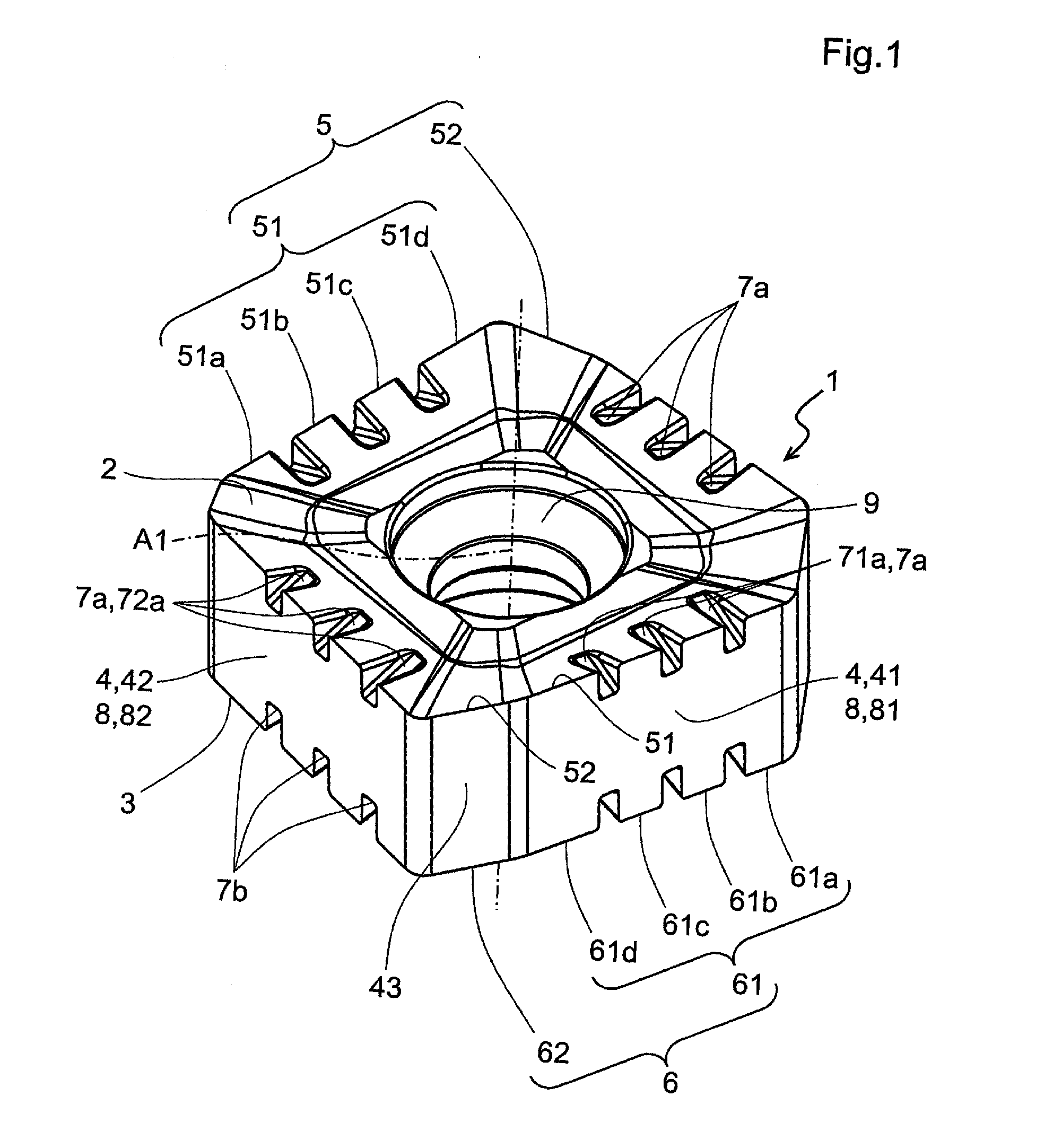

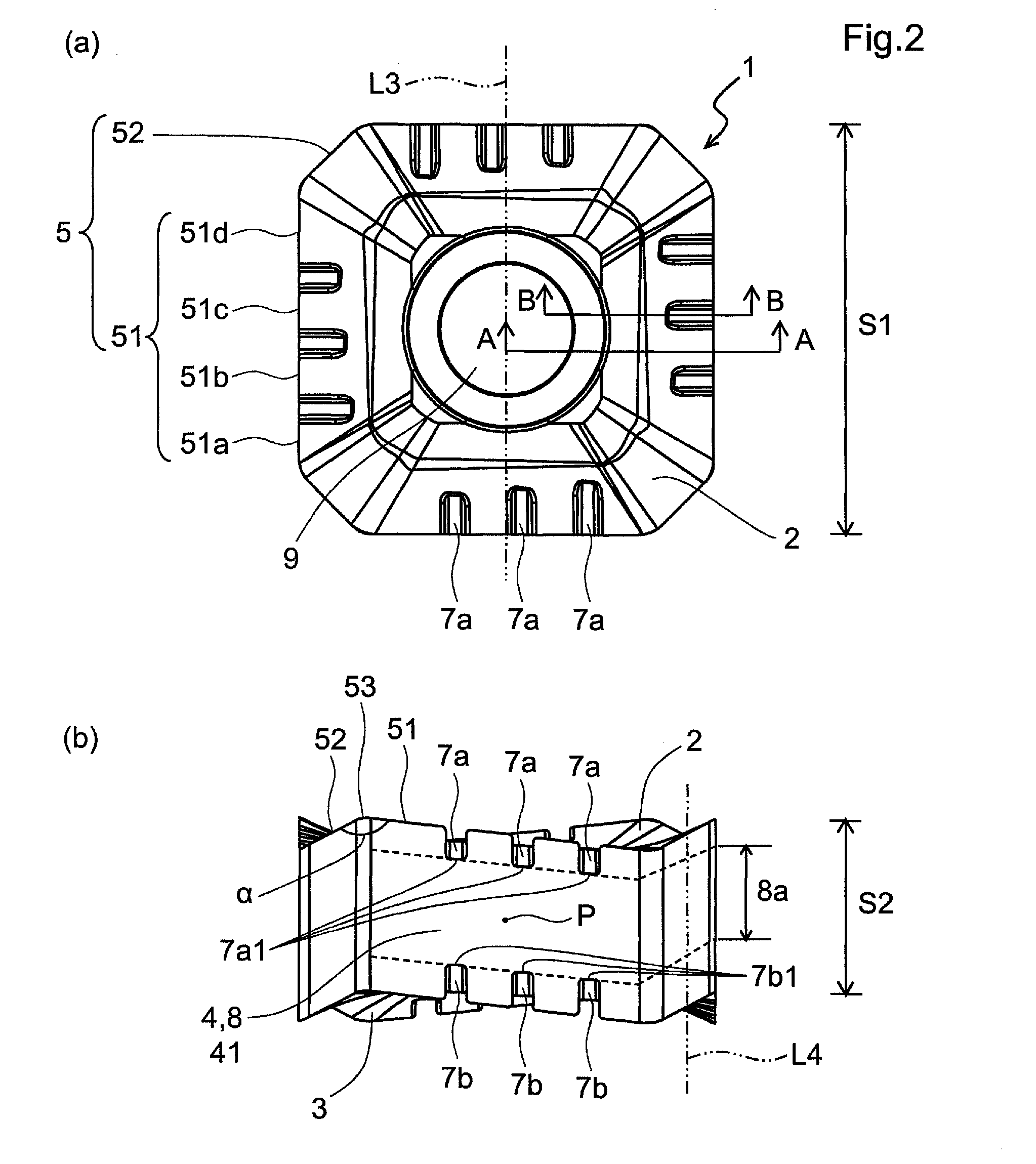

Cutting insert, cutting tool, and method of manufacturing machined product using the same

ActiveUS20140041495A1Reduce cutting resistanceImprove fracture resistanceMilling cuttersTurning toolsEngineeringMechanical engineering

A cutting insert includes: a polygonal shaped upper surface; a lower surface; a side surface connected to each of the upper and lower surfaces; and an upper cutting edge located at the intersection of the upper surface and the side surface. The upper surface alternately includes three major corners and three minor corners. The upper cutting edge includes: a corner cutting edge; a minor cutting edge inclined toward the lower surface as separating from the corner cutting edge at a first inclination angle; and a major cutting edge inclined toward the lower surface as separating from the minor cutting edge at a second inclination angle. The corner cutting edge, the minor cutting edge and the major cutting edge are located sequentially from a first major corner to each of first and second minor corners, both of which are adjacent to the first major corner.

Owner:KYOCERA CORP

Cutting insert, cutting tool, and method of cutting workpiece using the same

ActiveUS20120034041A1Reduce resistanceImprove fracture resistanceTransportation and packagingMilling cuttersEngineeringLower face

A cutting insert of the present invention includes an upper face, a lower face, a side face located between the upper face and the lower face, an upper cutting edge located at the intersection of the upper face and the side face, and a lower cutting edge located at the intersection of the lower face and the side face. The side face includes at least one upper concave part which extends up to the upper face along a thickness direction, and divides the upper cutting edge into a plurality of divided upper cutting edges, and at least one lower concave part which extends up to the lower face along the thickness direction, and divides the lower cutting edge into a plurality of divided lower cutting edges. The aforementioned at least one upper concave part and the aforementioned at least one lower concave part are separated from each other through a thick part being continuous along a width direction of the side face. A cutting tool including the cutting insert, and a method of cutting a workpiece using the cutting tool are also provided.

Owner:KYOCERA CORP

Diamond compact

InactiveCN106089089AStrong plowing actionImprove crushing drilling performanceDrill bitsShock resistanceCemented carbide

The invention relates to a diamond compact which comprises a cemented carbide substrate and a diamond composite layer. The diamond compact is characterized in that a boss and strip-shaped flanges protruding upwards are arranged on the end face of the diamond composite layer, and each strip-shaped flange extends upwards to the edge of the boss in an inclined mode from the edge of the diamond composite layer. According to the diamond compact, multiple strip-shaped flanges are arranged, the cutting face has a high ploughing effect, the crushing and drilling performance of the compact is improved, the drilling cutting resistance is reduced, and the penetration speed of a diamond drill bit is increased; meanwhile, the cutting face composed of the strip-shaped flanges, the lateral inclined plane and the boss has high shock resistance; the effect of guiding downhole debris to be discharged can be achieved, and the penetration speed of the diamond drill bit is increased. The cutting face of the compact is larger, abrasion resistance of the compact is further improved, and the service life of the diamond drill bit is further prolonged.

Owner:KINGDREAM PLC CO +1

Thin-wall sleeve part processing method

The invention discloses a thin-wall sleeve part processing method which comprises the steps of firstly roughly turning an excircle and drilling and boring an inner hole; after roughly turning the excircle and roughly boring the inner hole to the reserved processing allowance, semi-extractive turning an excircle of a thin-wall sleeve part, obtaining a semi-finished product of the thin-wall sleeve part, and cutting off from a bar material; loading the semi-finished product on a digital controlled lathe, precisely turning an incircle and an excircle of the semi-finished product to the set processing allowance, half cutting-off, reserving the set thickness during half cutting-off after chamfering an excircle of a part at the cut-off end, and semi-extractive turning the excircle to the design dimension again; and thoroughly cutting off the processed thin-wall sleeve part from the semi-finished product. The process method provided by the invention is simple and feasible, no working procedureis increased, the deformation in the part processing process is greatly reduced, the excircle dimension tolerance can be ensured to meet the technical requirement of the process design, the product qualification rate is remarkably improved, the method can be completed by adopting a cutting manner, the production period is short, and no auxiliary fixture with high cost is required to be configured.

Owner:AECC AVIATION POWER CO LTD

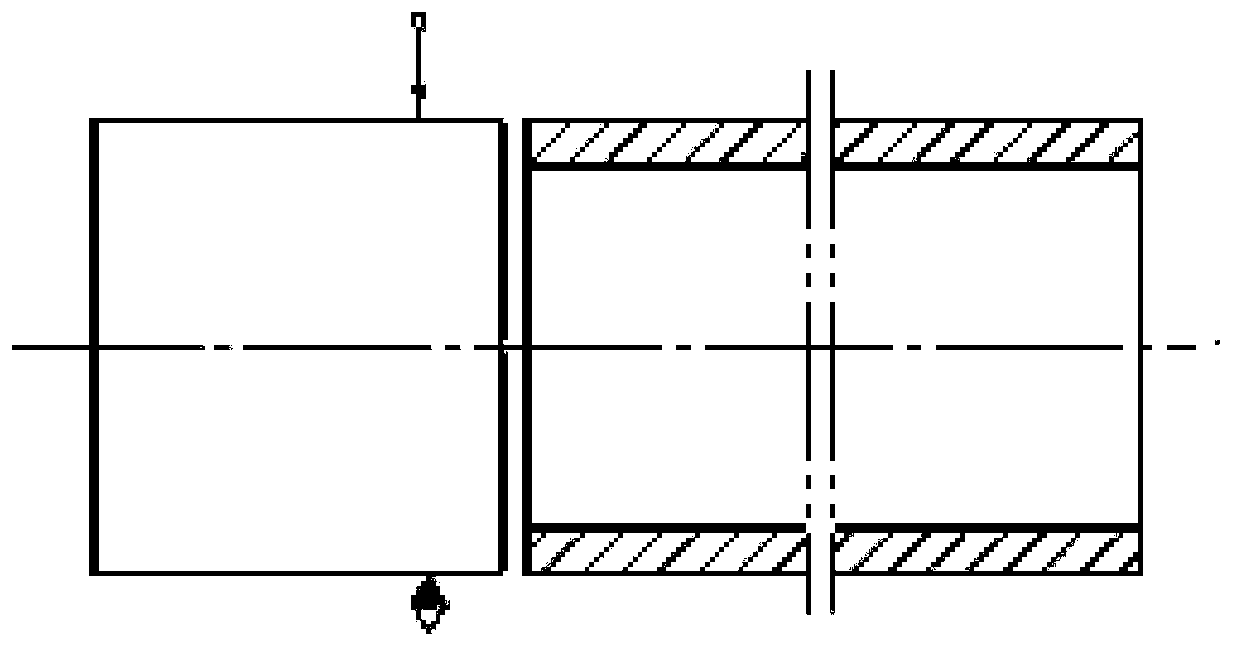

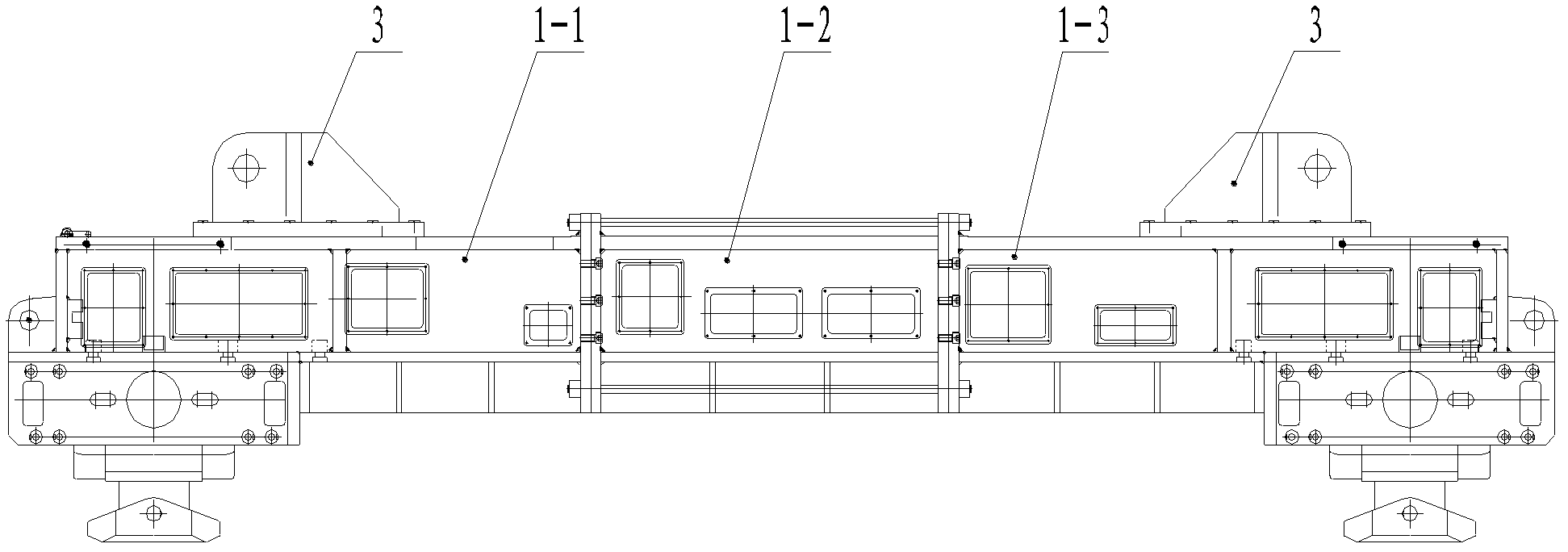

Combined height-adjustable coal cutting machine with small roller and large mining height, as well as coal cutting process of combined height-adjustable coal cutting machine

InactiveCN102536233AReduce energy consumptionReduce cutting resistanceUnderground miningSurface miningElectrical controlCoal

The invention relates to a combined height-adjustable coal cutting machine with a small roller and a large mining height, as well as a coal cutting process of the combined height-adjustable coal cutting machine. The combined height-adjustable coal cutting machine comprises a machine body assembly, coal cutting rollers, a travelling mechanism, an auxiliary device, a hydraulic control system and an electrical control system, and is characterized in that combined height-adjusting devices are symmetrically mounted on two side surfaces of the machine body assembly; and each combined height-adjusting device comprises a main height-adjusting oil cylinder, an auxiliary height-adjusting cutting arm and an auxiliary height-adjusting oil cylinder. The coal cutting process adopts a knife inserting method without notch cutting; the coal cutting roller at the front end of the coal cutting machine cuts residual coal bodies under the action of the oscillation of both the main height-adjusting cutting arm and the auxiliary height-adjusting cutting arm, wherein the moving trace is an arc, and the oscillation angle Alpha is at least 90 DEG; and the coal cutting roller at the rear end of the coal cutting machine cuts coal along a bottom plate, wherein the moving trace is a straight line. The coal cutting machine has the advantages that the structure is compact; the size and the weight are smaller; the suitability is strong; the mounting and the transportation are convenient; and the coal cutting machine is suitable for large, middle or small scale of coal mines with large mining heights.

Owner:闫振东

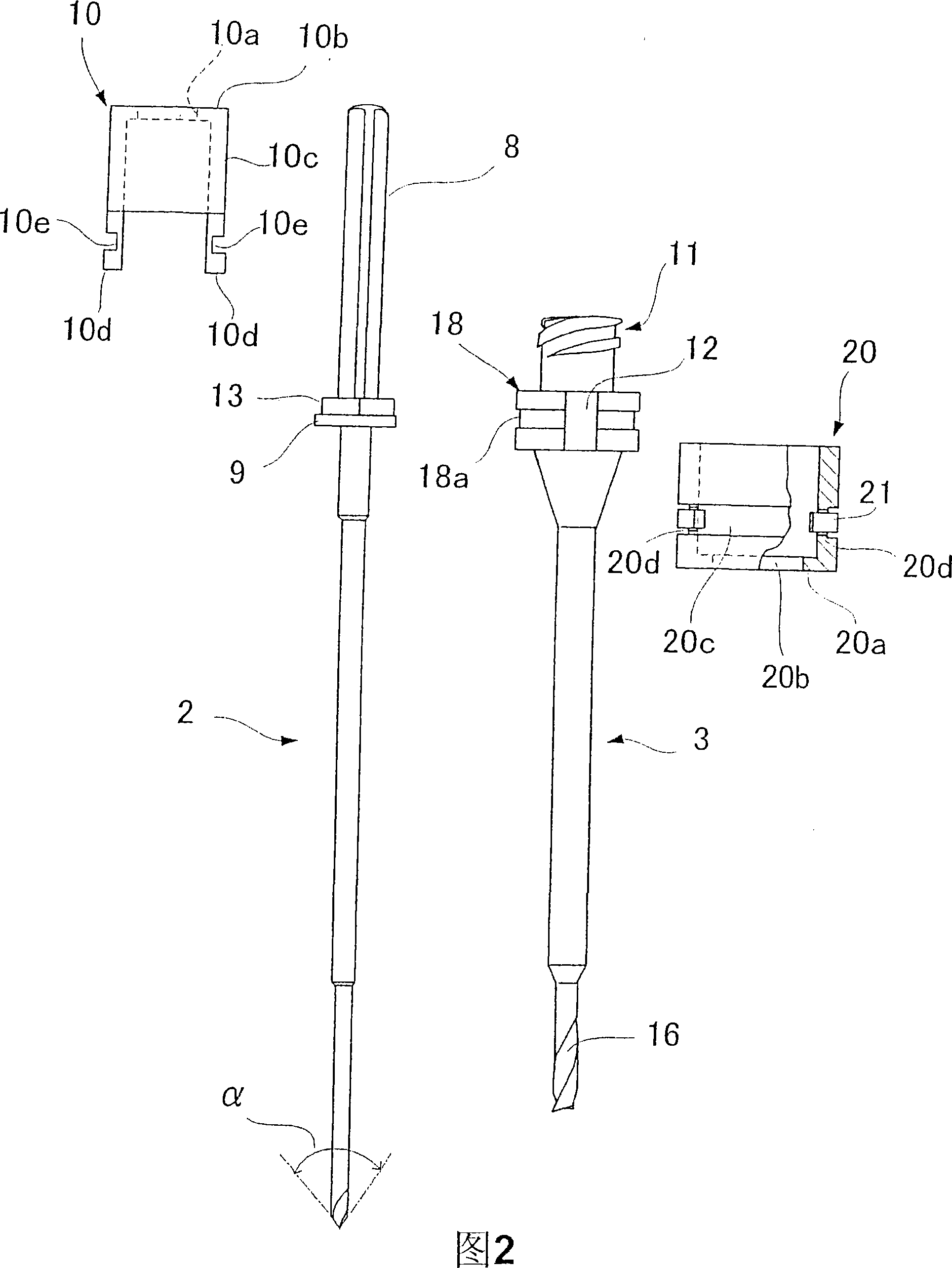

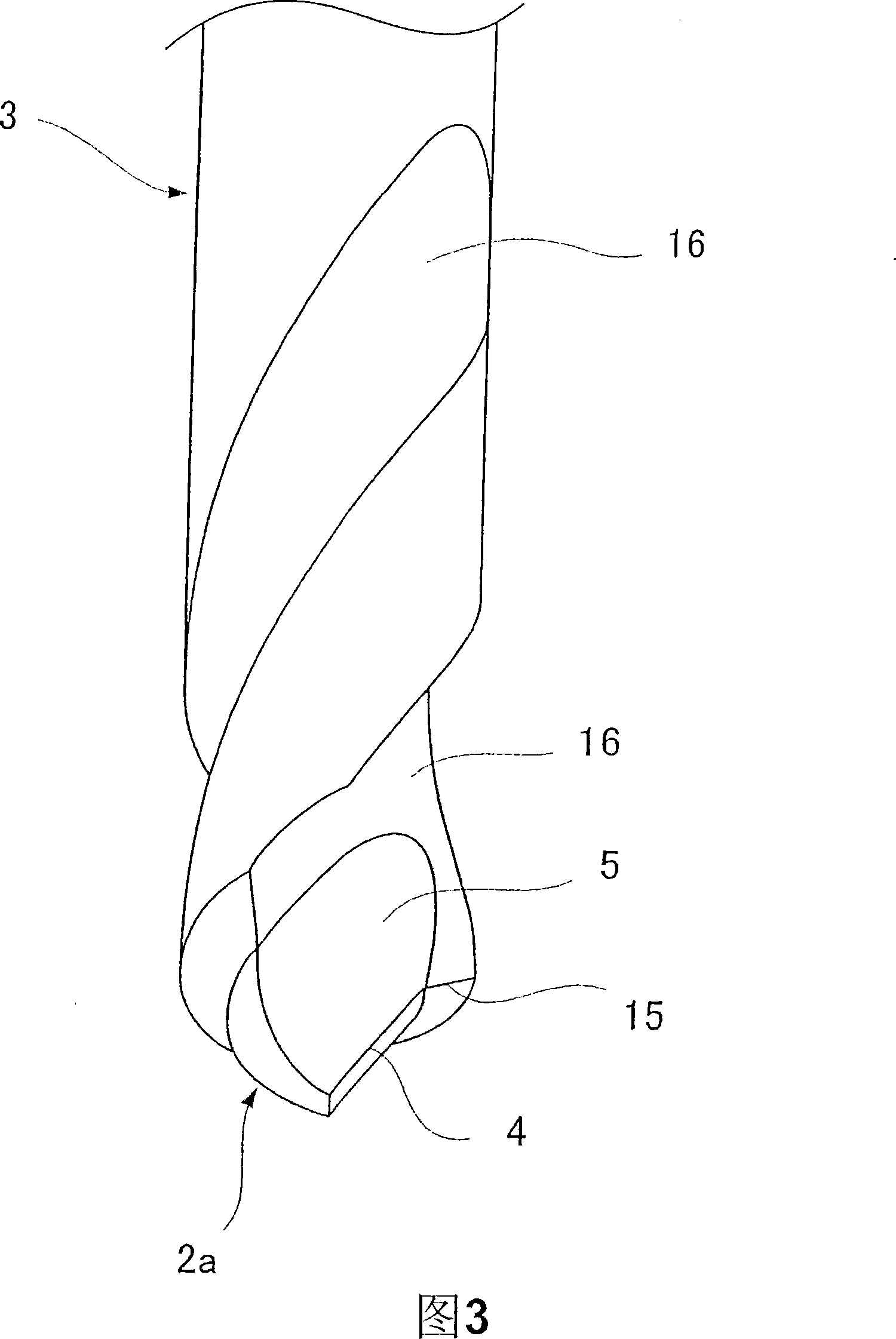

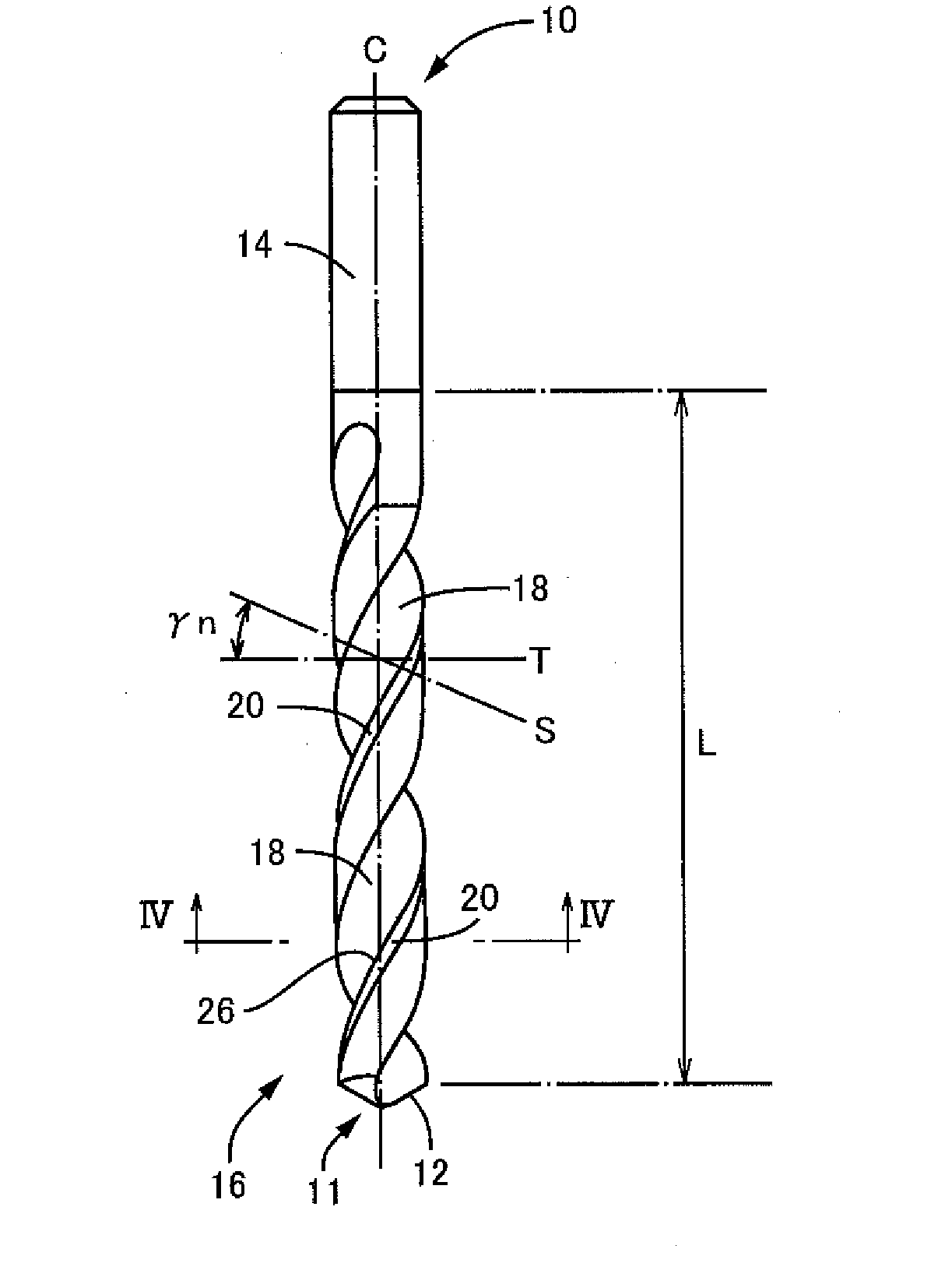

drill

ActiveUS20140294529A1Reduce resistanceAvoid breakingWood turning toolsTransportation and packagingEngineeringDrill bit

A drill including: a chip discharge flute; and a cutting edge, the cutting edge being made up of a concavely-curved cutting edge portion formed on an inner circumferential side and a convexly-curved cutting edge portion formed on an outer circumferential side, the drill further including a cross section orthogonal to an axial center having a first convex curve corresponding to the convexly-curved cutting edge portion and a first concave curve corresponding to the concavely-curved cutting edge portion intersecting with each other, a flank following the cutting edge on the tip surface having an orthogonal clearance angle β formed within an angular range of 9 to 20 degrees, and a ridgeline of the cutting edge having a chamfer formed with a width CW within a range of 0.002D to 0.02D (where D is a drill diameter).

Owner:OSG

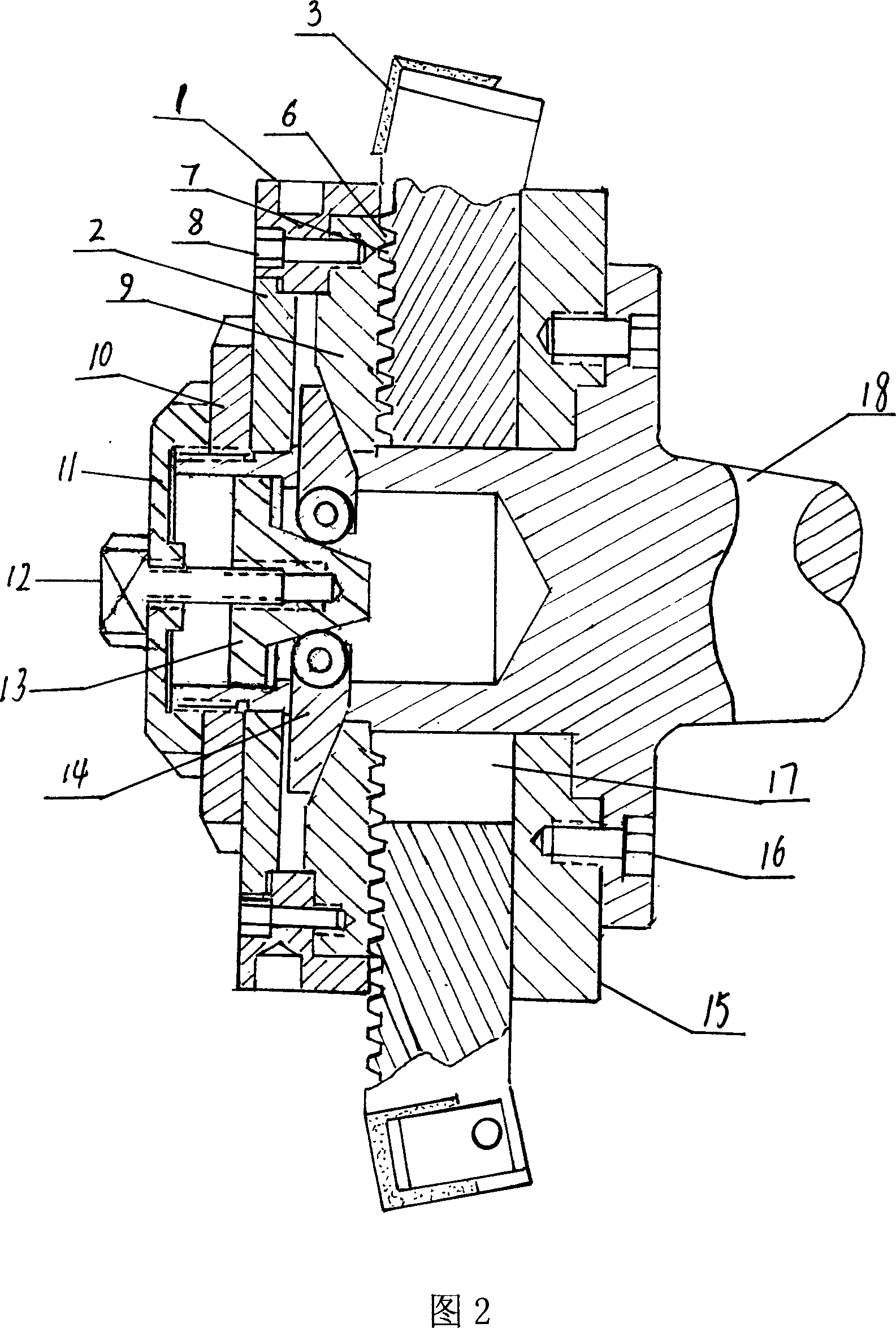

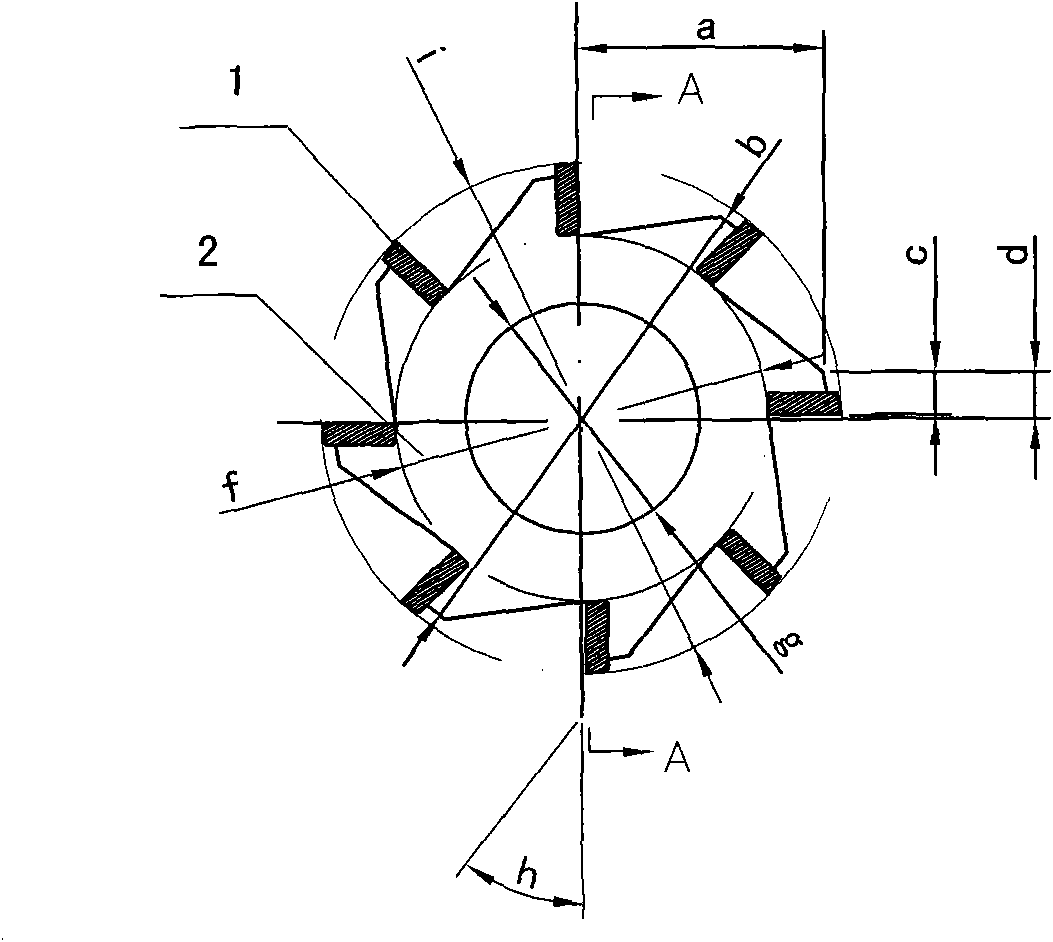

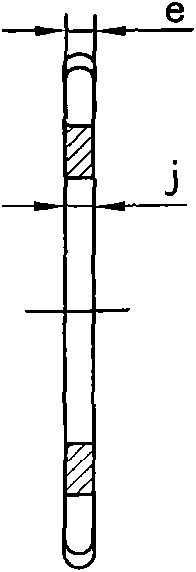

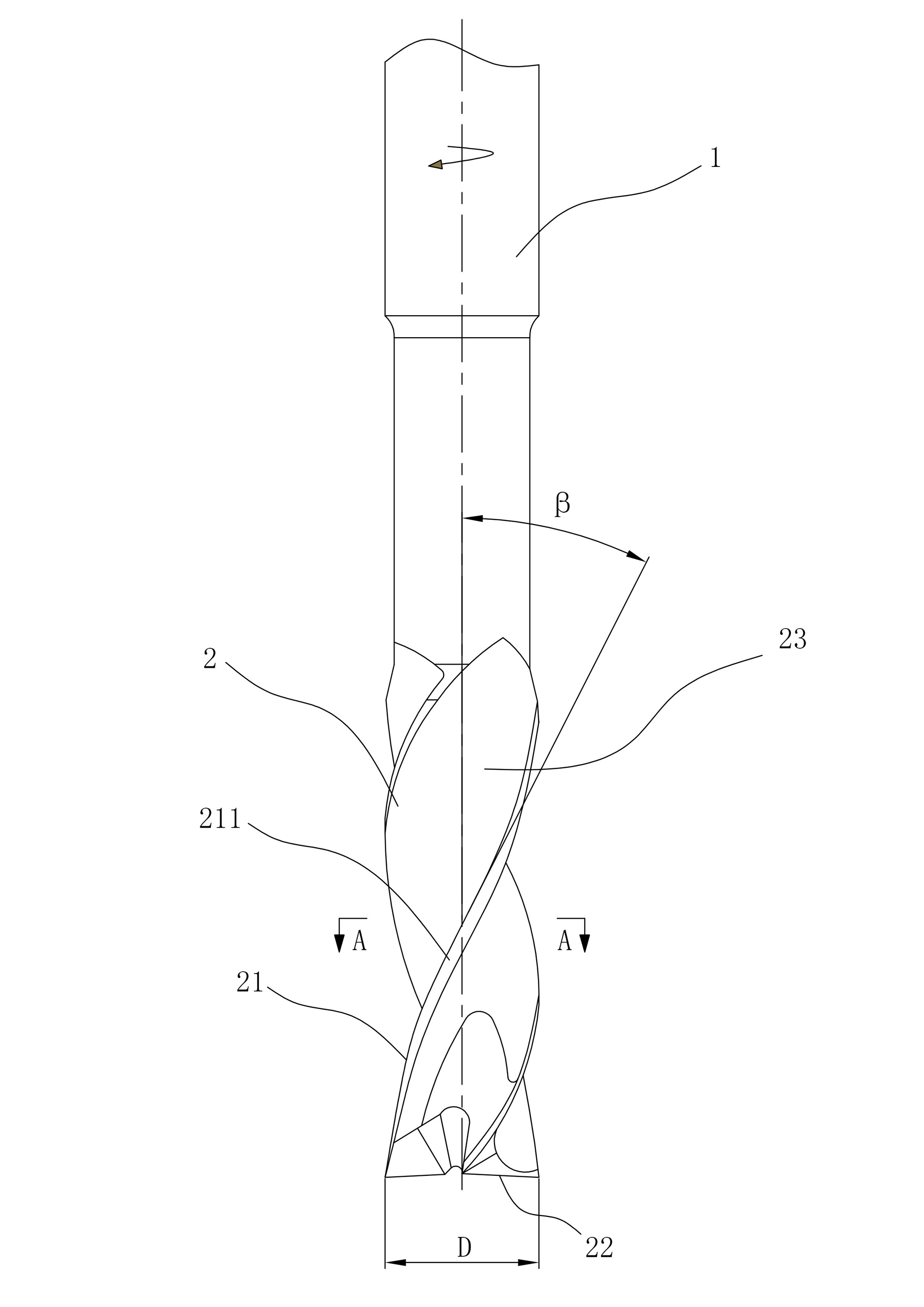

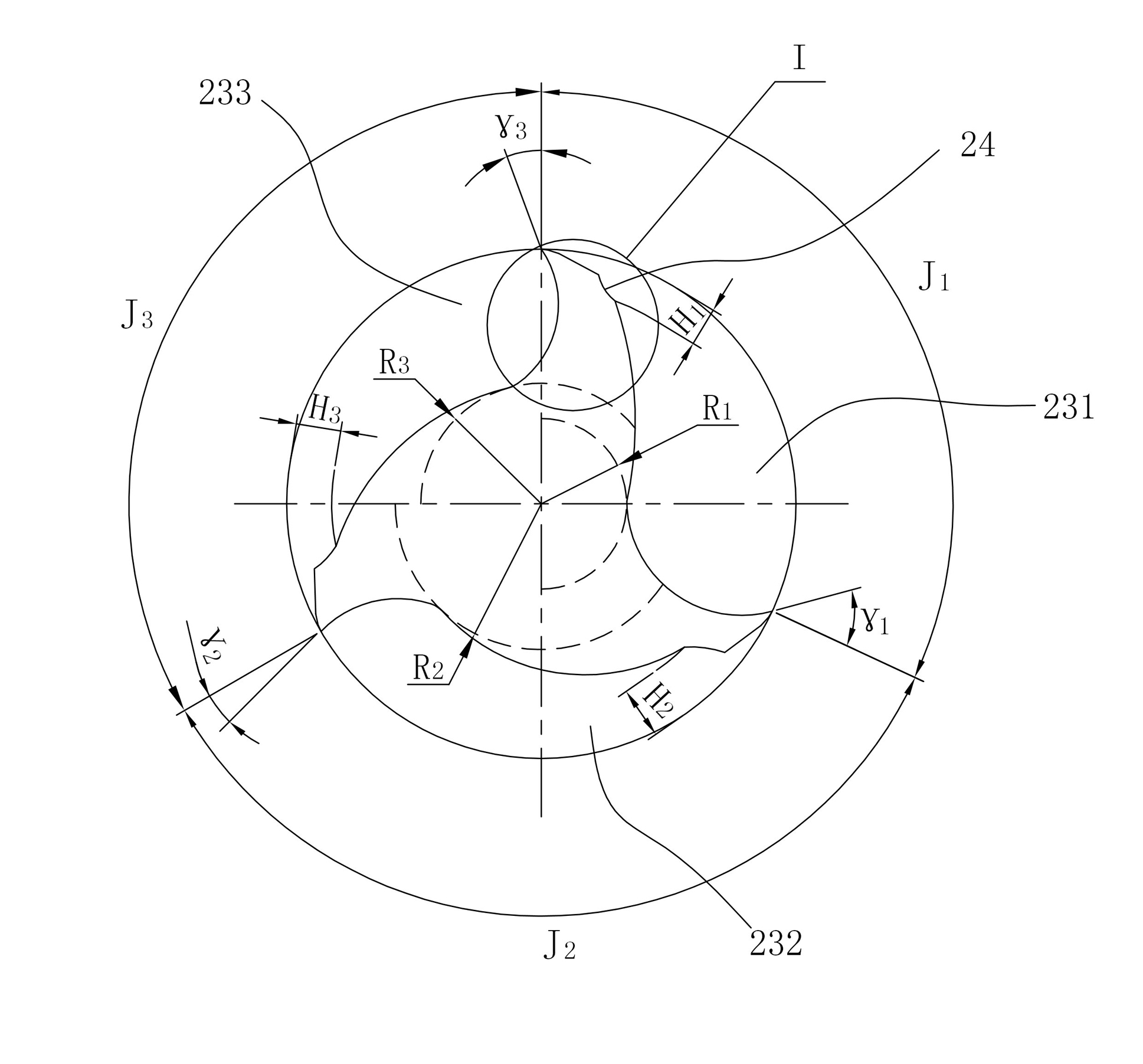

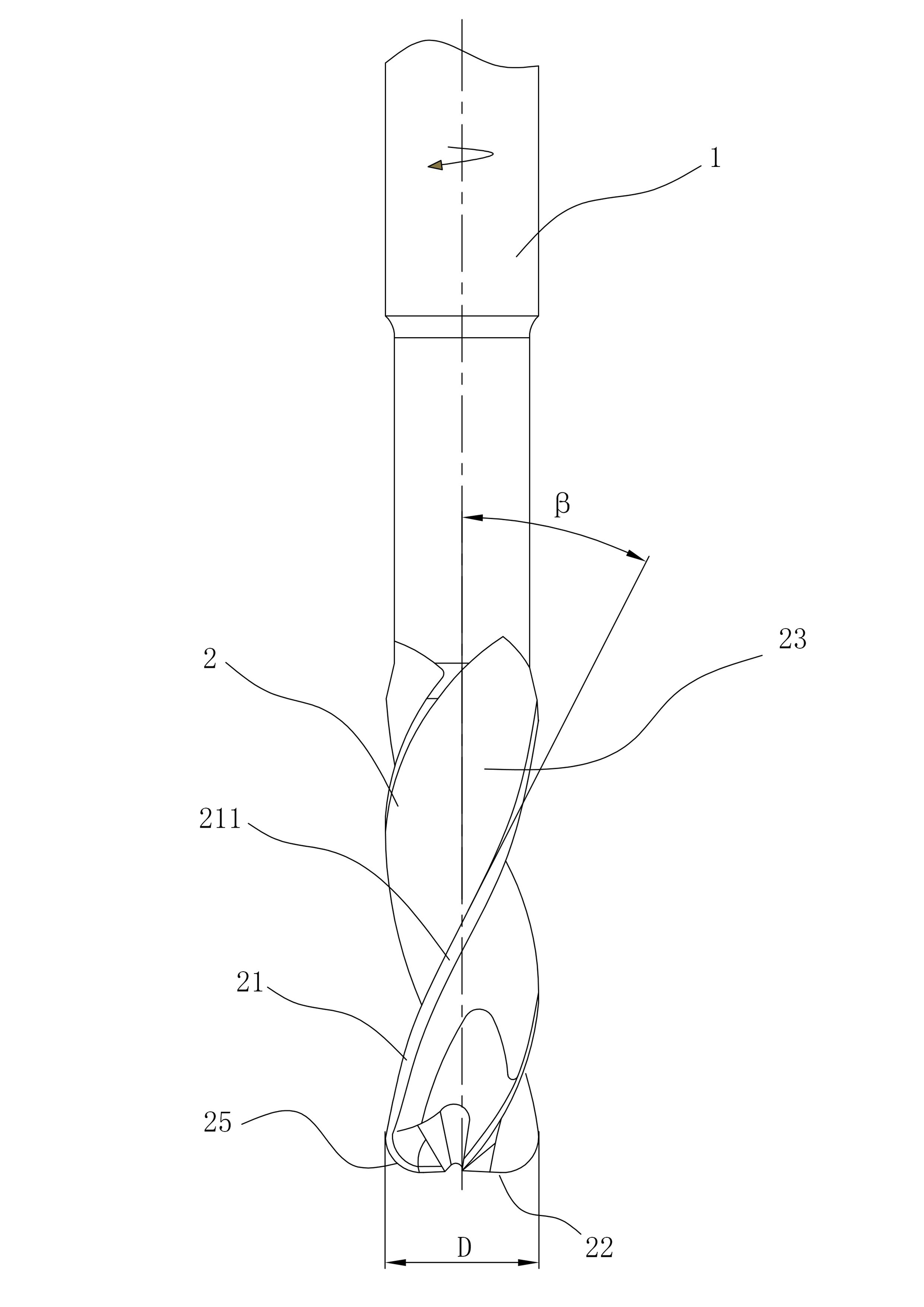

Asymmetric dynamic balance vertical milling cutter

ActiveCN101920354AImprove machining accuracySatisfy the problem of unbalanced mass distributionMilling cuttersFluteMilling cutter

The invention discloses an asymmetric dynamic balance vertical milling cutter which comprises a cutter shank part and a cutting part, wherein the cutting part comprises more than two peripheral cutting edges and chip flutes, wherein each chip flute is arranged between every two adjacent cutting edges, the sizes of two adjacent chip flutes are different, and an unbalance quantity control step which enables the vertical milling cutter to satisfy the dynamic balance requirement is arranged at the tail of each chip flute. The asymmetric dynamic balance vertical milling cutter has the advantages of high metal removal rate and high processing accuracy and satisfies the requirement for dynamic balance.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

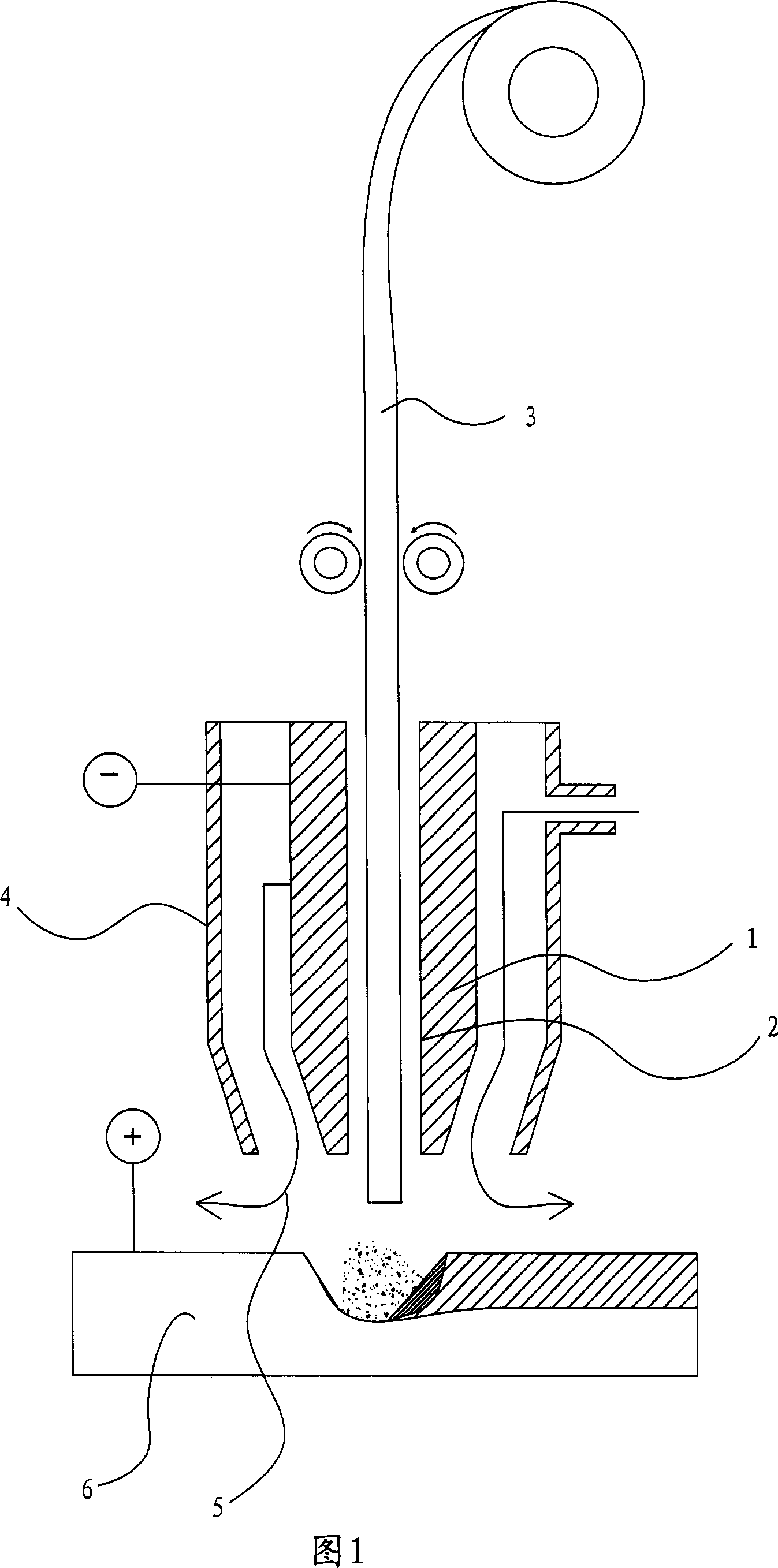

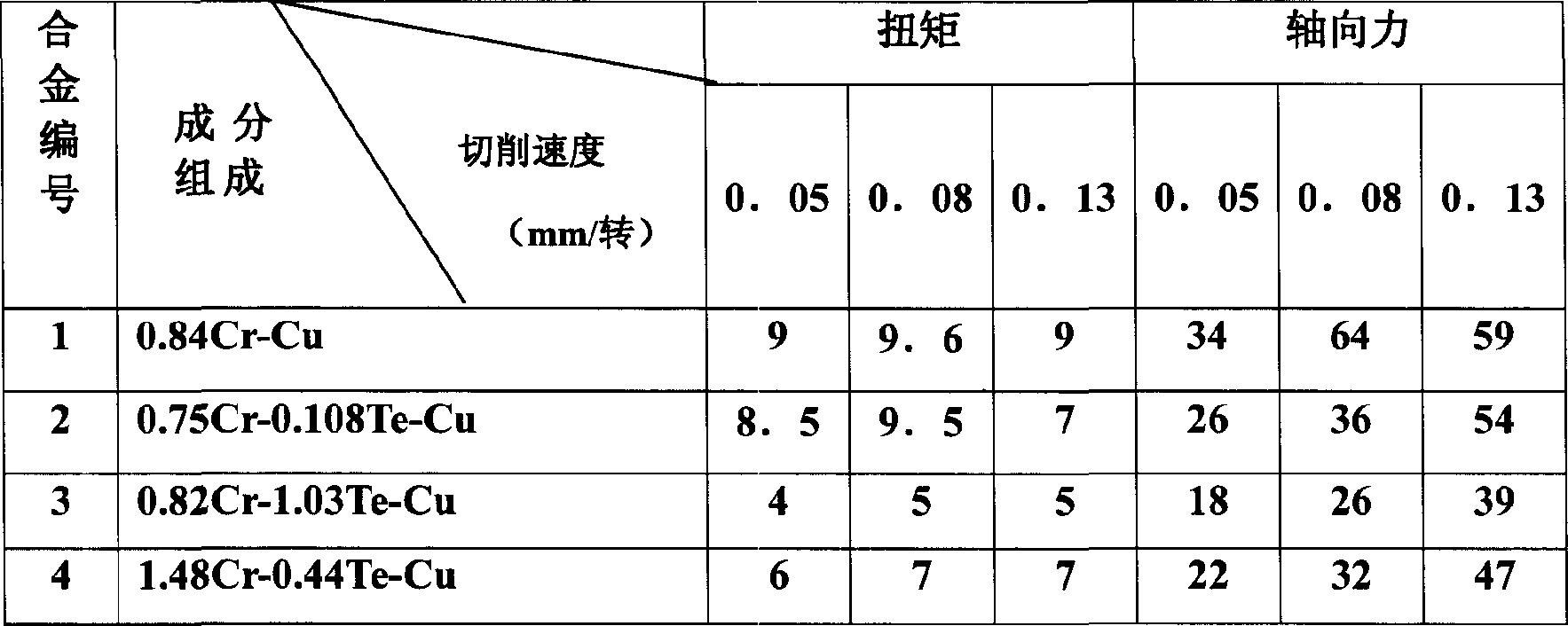

Chrome copper alloy, preparation method and application

InactiveCN101003869AHigh precisionExcellent machinabilityElectrode accessoriesHardnessSolid solution

This invention relates to a method for preparing Cr-Cu alloy and its application as conductive nozzle or electrode head of welding machine. The Cr-Cu alloy comprises: Cr 0.5-2.0 wt. %, Te 0.01-1.0 wt. %, Cu and impurities. The method comprises: performing solid solution treatment at 940-980 deg.C, and aging at 430-470 deg.C. The Cr-Cu alloy has high hardness, high electric conductivity, and good machinability, and can be used to produce conductive nozzle or electrode head with high accuracy and high quality.

Owner:苏州东金机械金属有限公司 +1

Horizontal type automatic profiling pineapple peeling machine

A horizontal type automatic profiling pineapple peeling machine comprises a lead screw drive mechanism, a knife system, a cam mechanism, a synchronous belt drive mechanism, a clamp system and a rack, wherein the lead screw drive mechanism comprises a lead screw motor, a lead screw, a coupler, an A-shaped key, a sliding rail, a sliding block and a fixing block. The knife system comprises a knife, a sleeve, a knife rest, an adjusting screw and a fixing boss. The cam mechanism comprises a profiling cam frame, a cam rod, a supporting rod, a supporting sleeve and a compression spring. The synchronous belt drive mechanism comprises a stepping motor, a small belt wheel, a synchronous belt, a clamp wheel and a B-type key. The clamp system comprises a clamp wheel, a retainer cup, a conical chuck and a telescopic spring. The cam rod of the peeling machine can drive the knife to telescope along an arc line outline of the profiling cam frame, so that the peeling machine can adapt to different shapes of drum-shaped pineapples.

Owner:GUANGXI UNIV

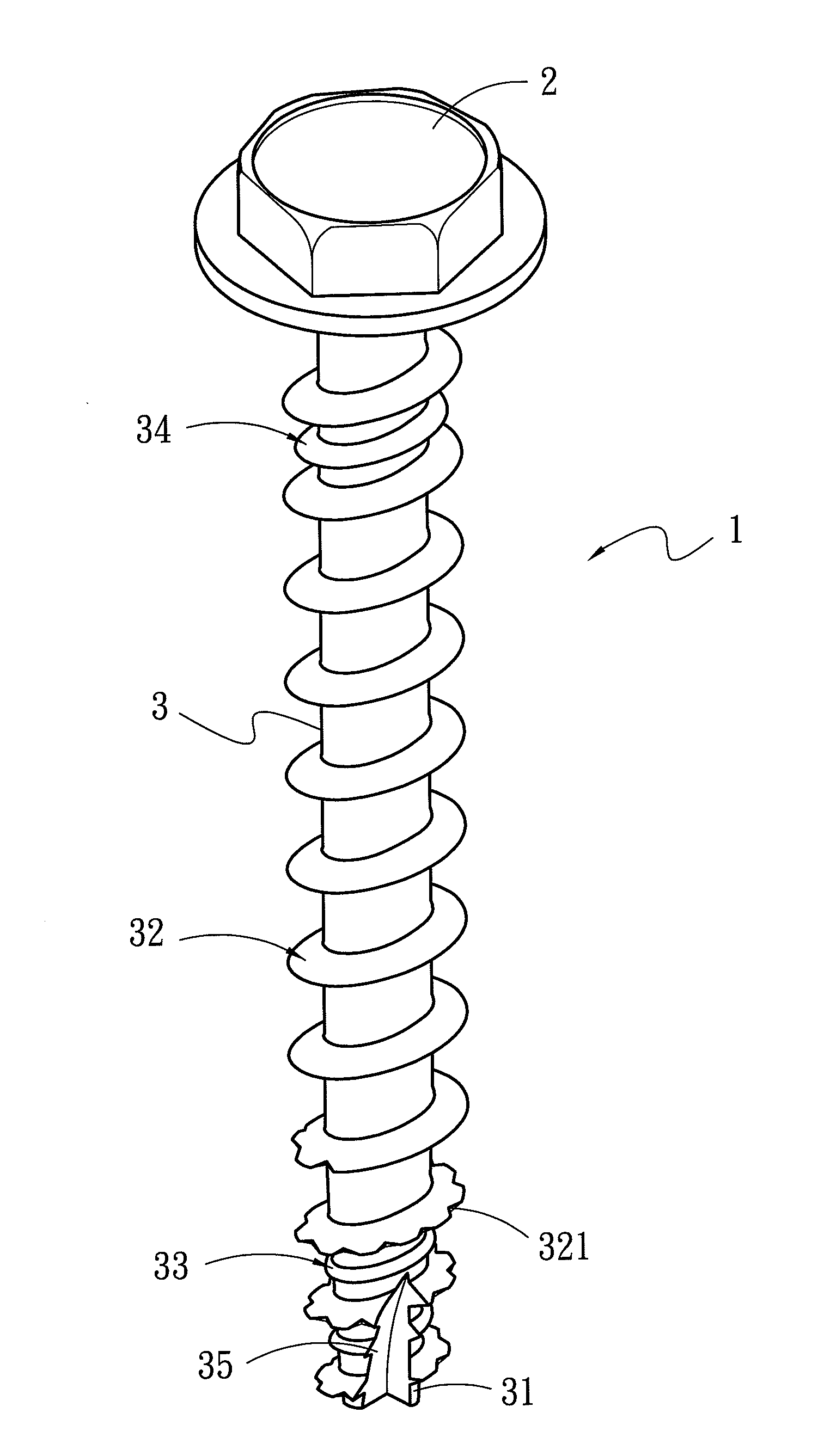

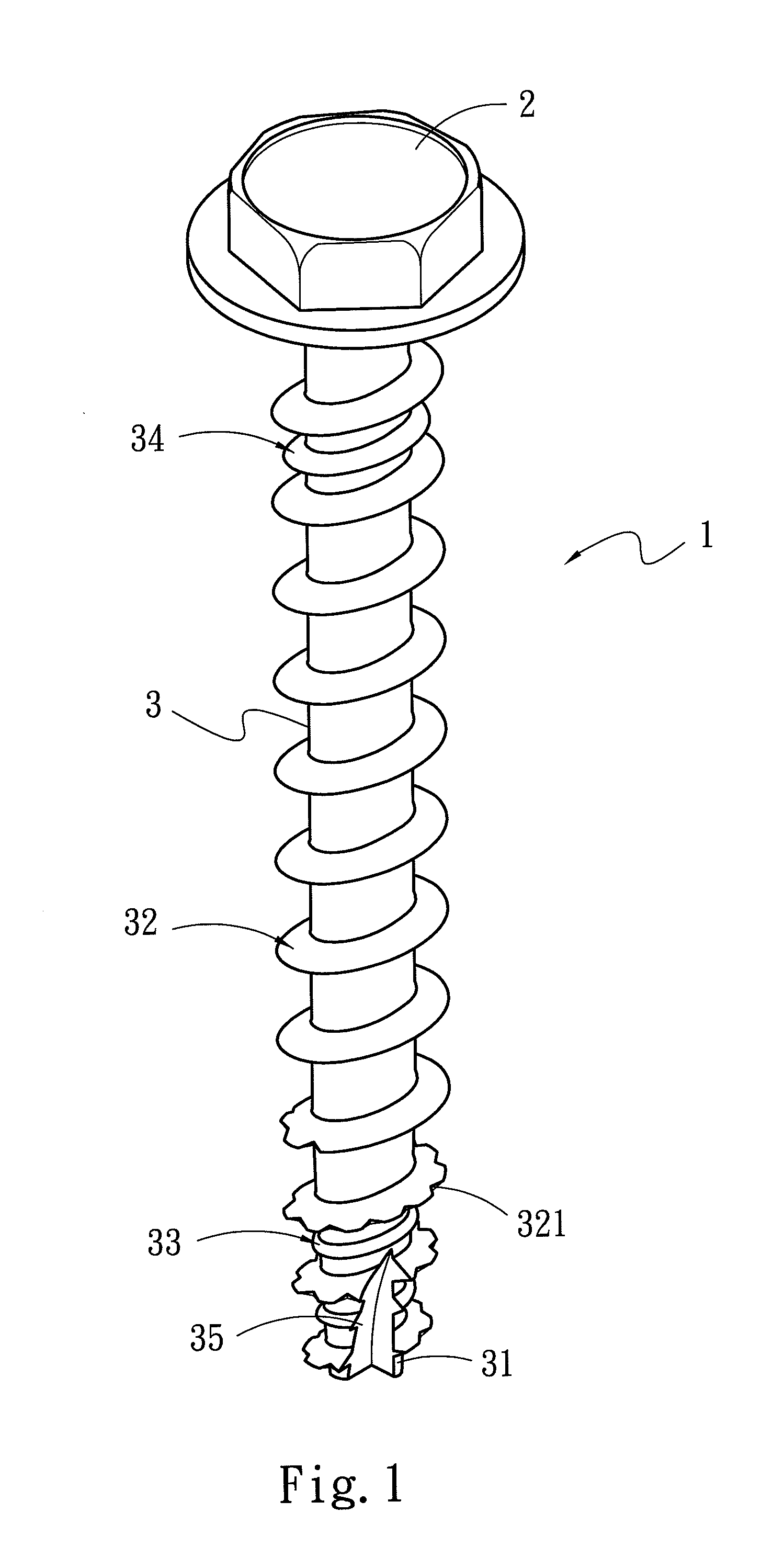

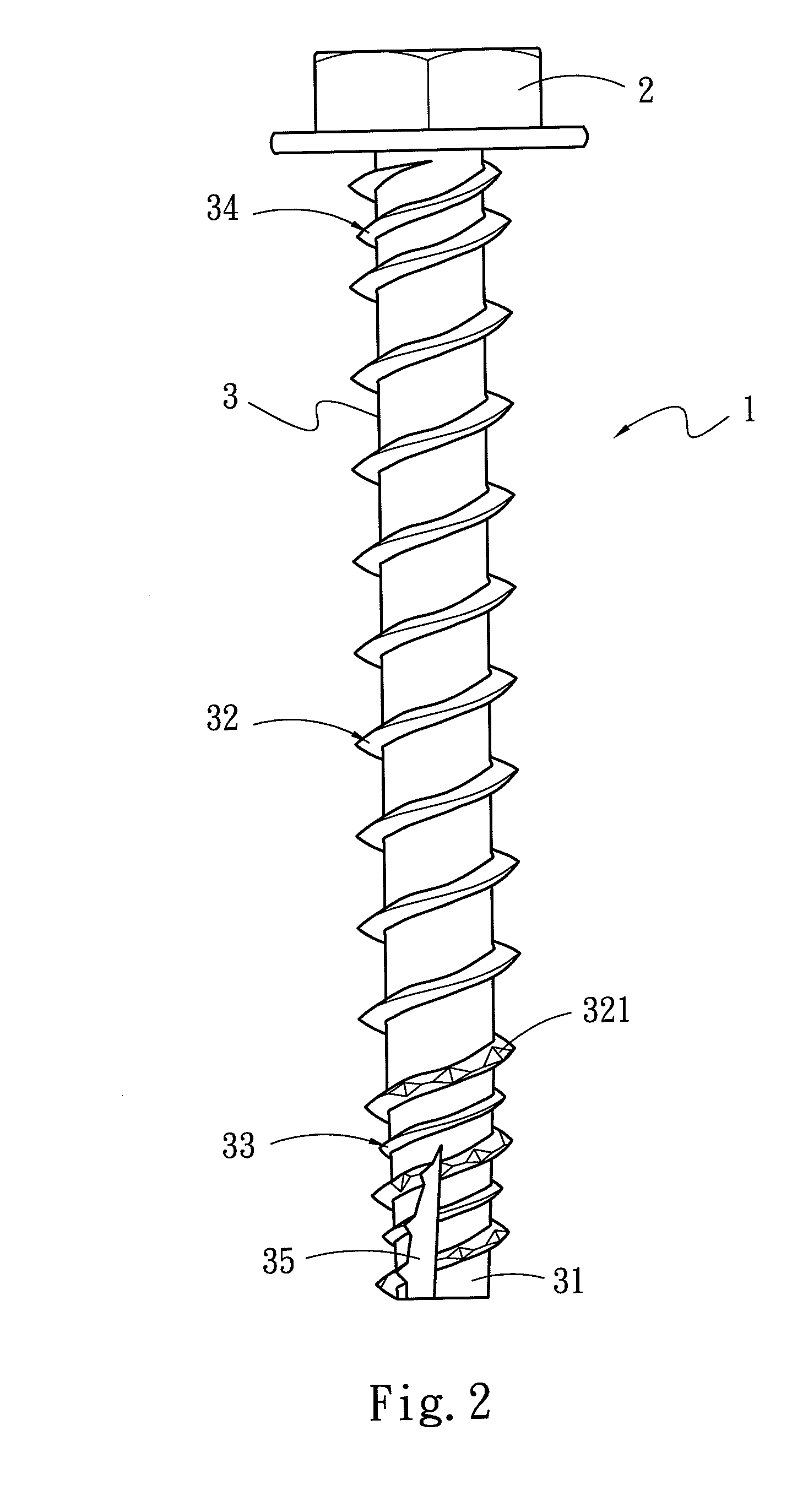

Concrete screw structure

A concrete screw includes a screw head and a rod with a drilling tail section at a distal end thereof. The rod includes a first thread section formed annularly thereon and extended upwards from the drilling tail section, and a second thread section encircling between at least two thread pitches of the first thread section and having an outer diameter smaller than that of the first thread section. The rod further includes a third thread section on an upper end thereof encircling between at least two thread pitches of the first thread section. As the outer edge of the second thread section butts the wall of the screw hole, the first thread section can steadily perform cutting without swaying. Moreover, through the third thread section, compact effect is thereby achieved at a position near the screw head. Hence the concrete screw can provide precise, effort-saving and steady fastening effect.

Owner:BI MIRTH CORP

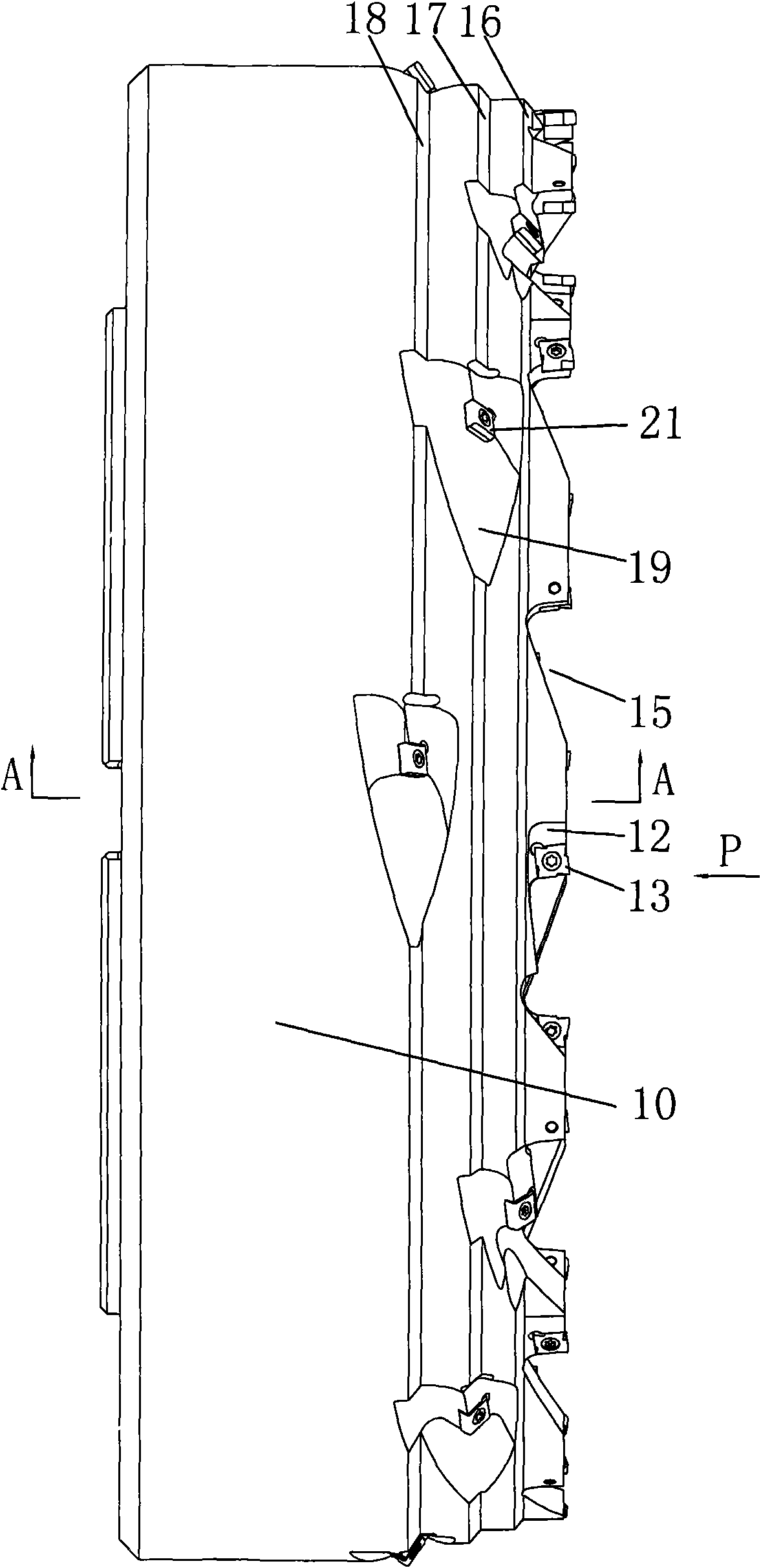

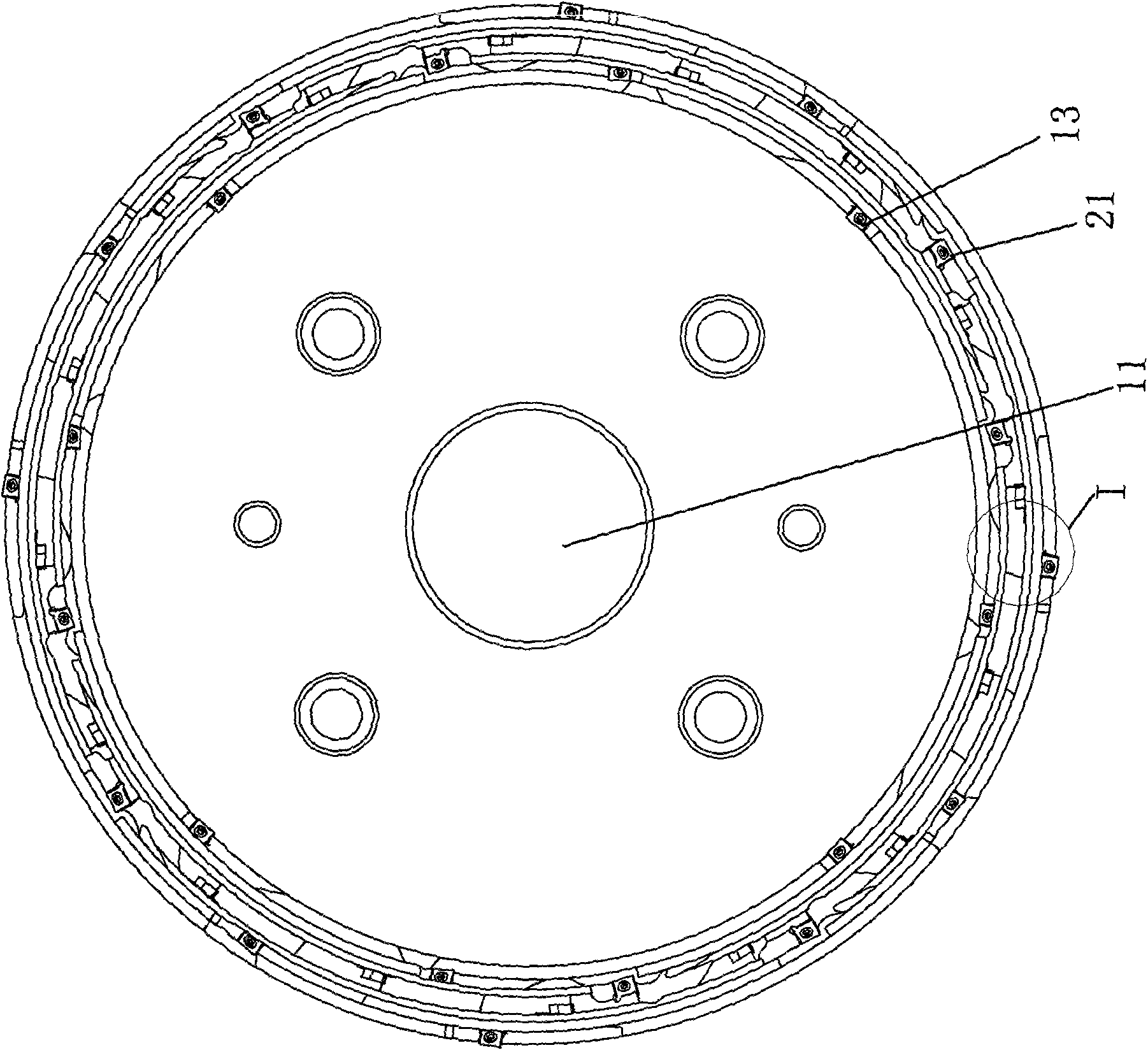

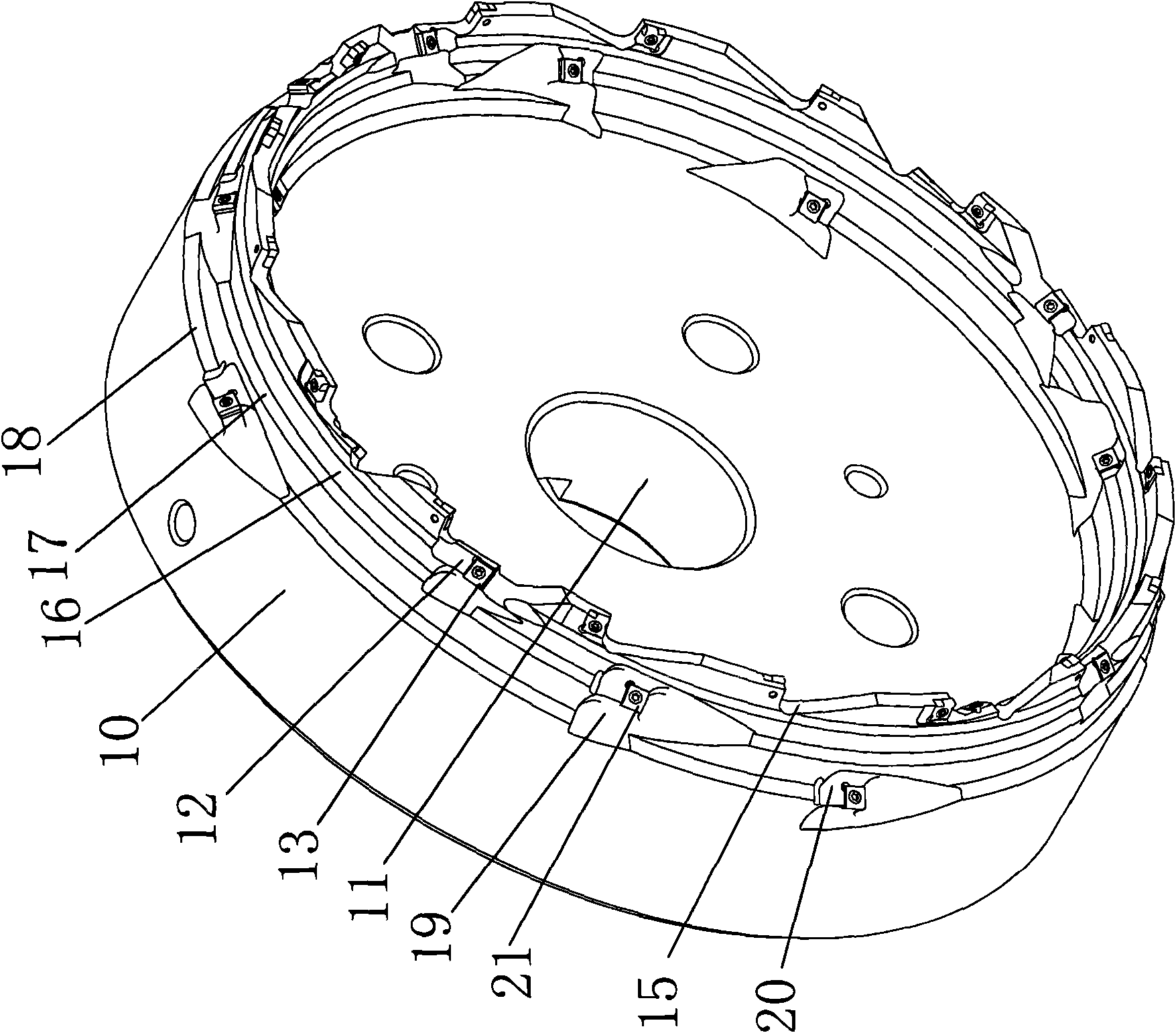

Stream turbine rotor blade root arc groove roughing milling cutter

InactiveCN101628347AExtended service lifeIncrease productivityMilling cuttersMilling cutterEngineering

The invention relates to a stream turbine rotor blade root arc groove roughing milling cutter comprising a cylindrical cutter body, wherein the upper end face of the cutter body in the same circumference is provided a plurality of blade bearings at intervals on which end face cutting blades are arranged; one of the end face cutting blades of any two adjacent blade bearings is arranged on the outer side face of the blade bearing fixed with the end face cutting blade, and the other one of the end face cutting blades is arranged on the inner side face of the blade bearing fixed with the end face cutting blade; the outer periphery and the inner periphery of the cuter body are provided with a plurality with steps symmetrically from top to bottom, wherein the radius of the steps on the outer periphery from top to bottom increases by effect, the periphery of the steps on the inner periphery and the outer periphery is provided with a plurality of cuttings chutes which are sunken towards the wall surface of the cutter body, and the root parts of the cuttings chutes are provided with a tool apron on which a step cutting blade is arranged. The invention has the advantage of high processing efficiency and long service life.

Owner:常州市西夏墅工具研究所有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com