Thin-wall sleeve part processing method

A processing method and thin-wall sleeve technology, applied in the field of parts machining, can solve the problems of increasing the rigidity of the parts, out of tolerance of the outer circle ellipse of the parts, low qualification rate, etc., and achieve the effect of reducing deformation, short production cycle and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0038] The processing steps of an aeroengine steel sleeve using the method of the present invention are as follows:

[0039] (1) Clamp the outer circle of the bar with three jaws on an ordinary lathe for rough turning,

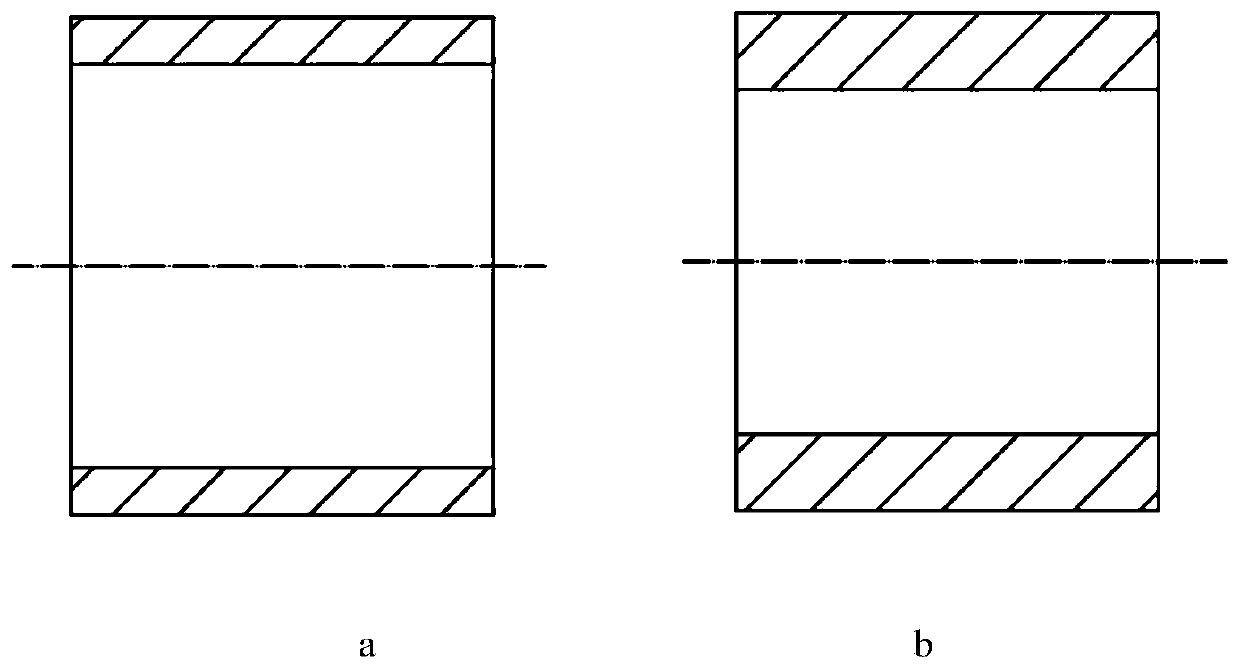

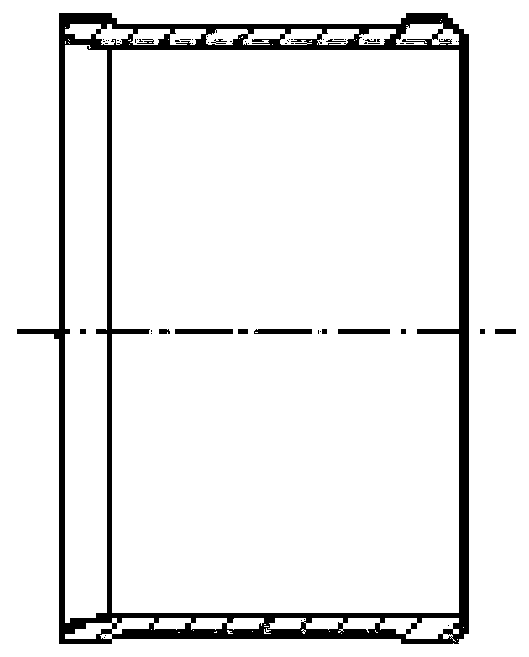

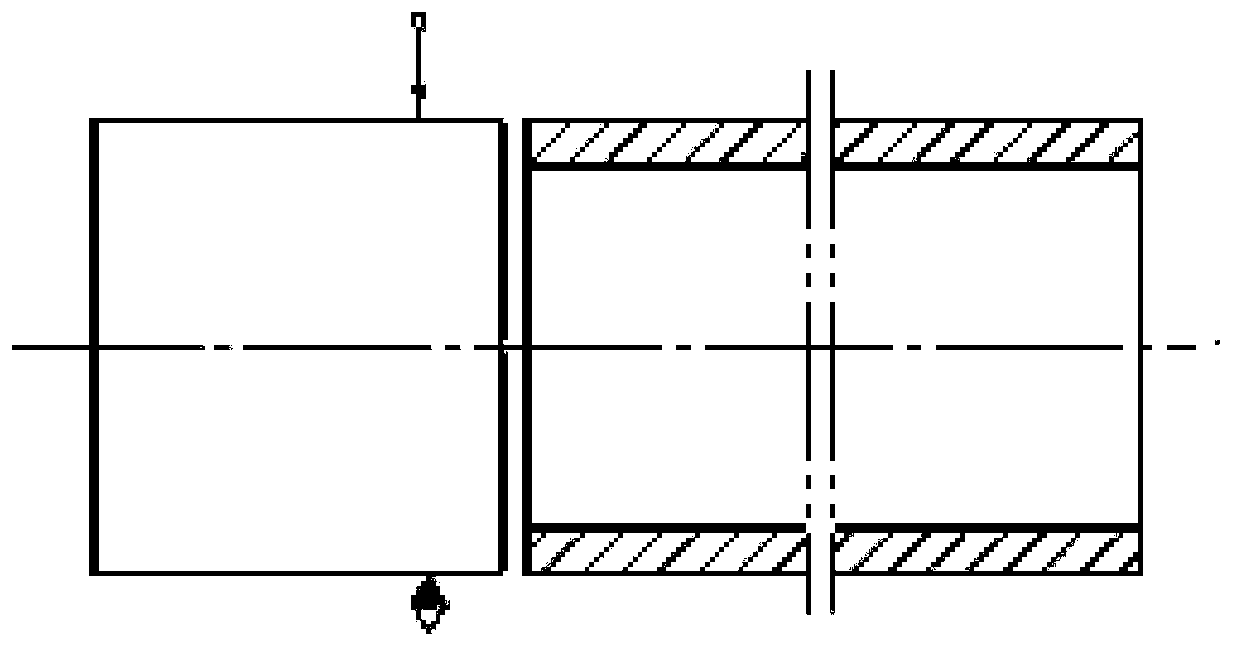

[0040] (11) Turning the end face, rough turning the outer circle, drilling and boring the inner hole, such as image 3 Shown in b; outer circle according to size Inner hole according to size In step (1), the inner hole size is reduced from the original Φ40 to Φ35, such as image 3 a and image 3 As shown in b, in step 1, the semi-finished outer circle can eliminate the deformation of the part caused by the uneven clamping force generated by the three-jaw clamping the outer circle of the wool; the purpose of reducing the size of the rough boring inner hole is to increase the rigidity of the part and reduce The part is deformed.

[0041] (12) Cut the semi-finished parts from the bar stock, the total length of the semi-finished parts is 120±2mm;

[0042] (2) The semi-f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com