Patents

Literature

6483results about How to "Simple processing method" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

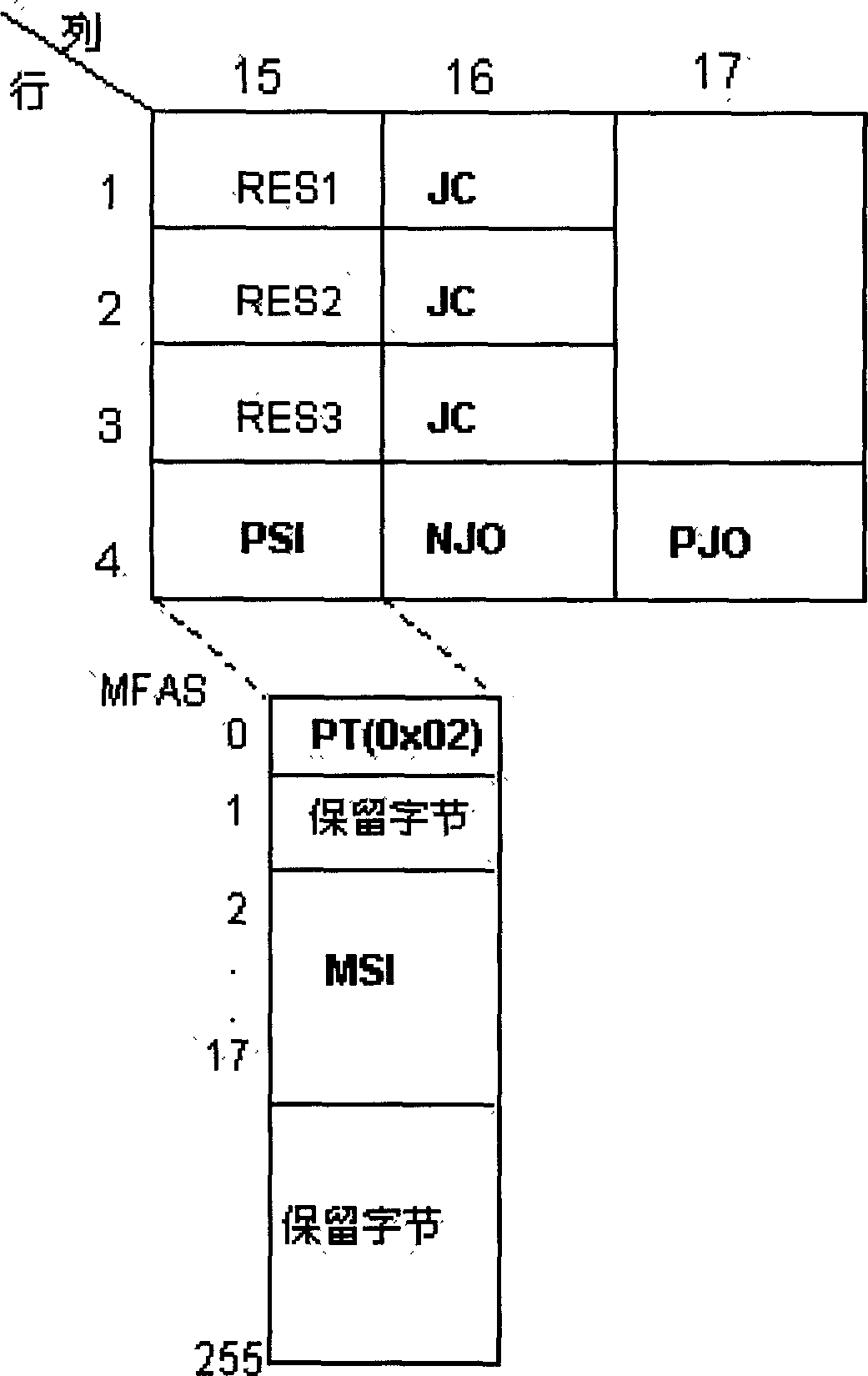

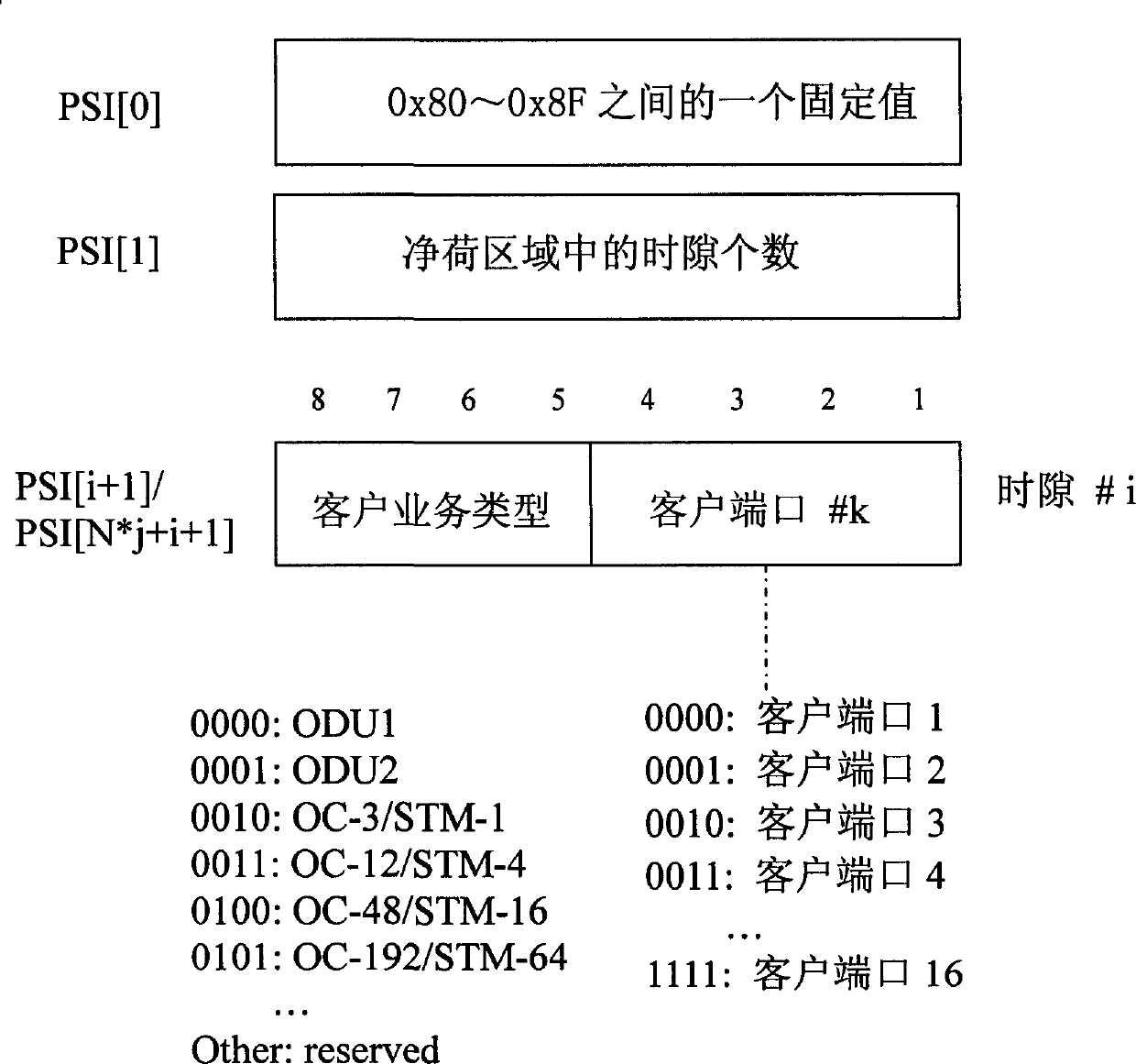

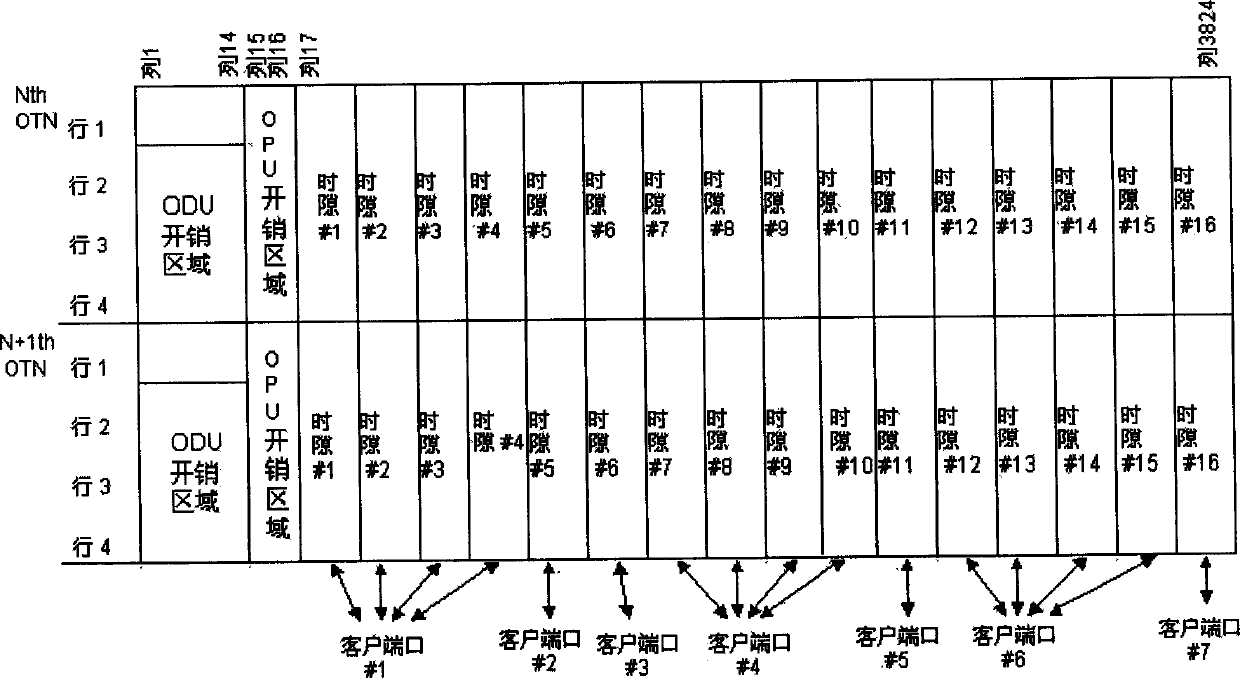

Spending processing method for service integration in OTN network

InactiveCN1770673ASimple meansSimple processing methodOptical multiplexLow speedInformation transmission

This invention relates to digital information transmission OTN network business compound expenditure process method, which comprises the following steps: a, dividing the OTN frame OPU net load area in low speed business signal mapping and compound OTN; b, indicating OPU net load area division, dispatching and relative customer business type and the OPU net load area is divided into several same time gaps and adopting alliance sequence MFAS relative net load structure to indicate FSI each time gap to relative customer terminal and relative customer business type information; dividing the OPU customer terminal and relative customer business type and using the OPU expenditure to express relative customer business sub-block position information.

Owner:HUAWEI TECH CO LTD

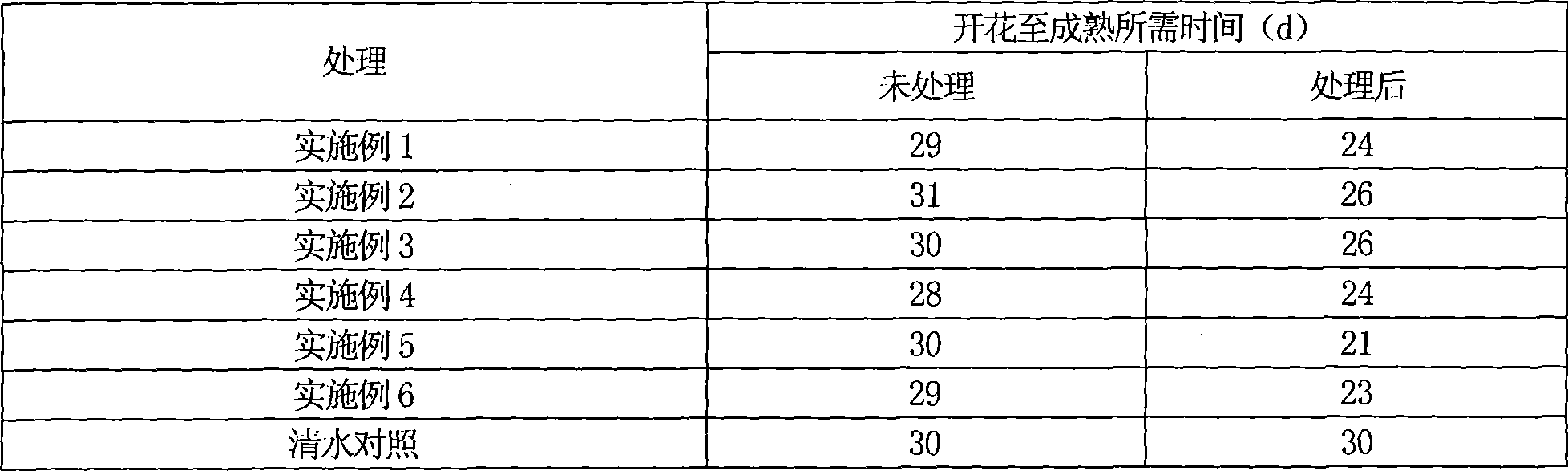

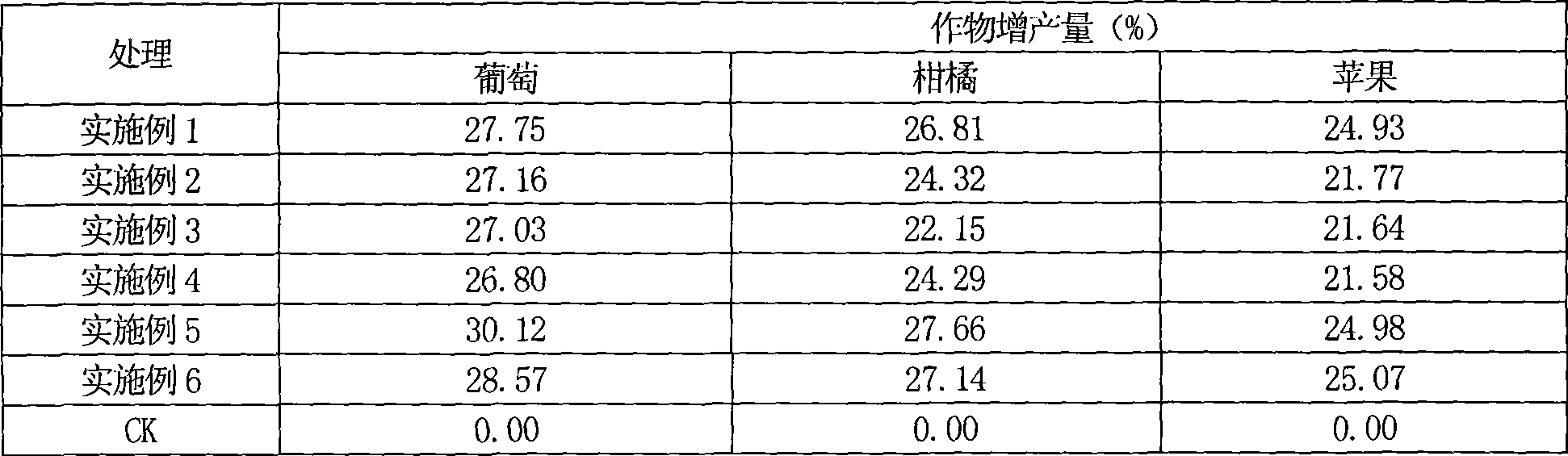

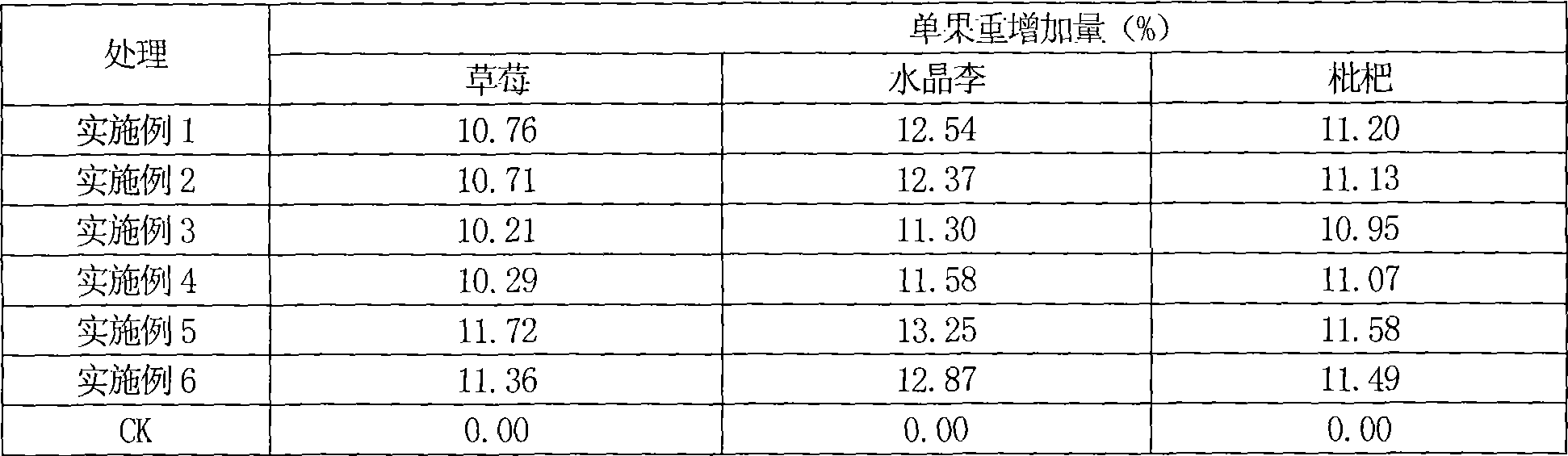

Fertilizer containing plant charcoals and preparation thereof

ActiveCN101434500AStructural improvementInhibit growth and reproductionOrganic fertilisersFertilizer mixturesFertilizerNutrient

The invention relates to a fertilizer containing plant-charcoal, and a preparation method thereof, belonging to the technological field of fertilizers. The invention is characterized in that the fertilizer contains the components with the following weight percentages: plant carbon powder accounting for 45% to 70%, major elements accounting for 10% to 40%, medium elements accounting for 0.5% to 5%, trace elements accounting for 4% to 20%, plant growth regulators accounting for 4% to 18%, surfactant accounting for 0.2% to 1.5% and planting vinegar liquid accounting for 1% to 12%. The fertilizer use bamboo, wood and grass peat which are purely natural and can regulate plant growth as main ingredients, and the fertilizers also contains medium and trace elements, such as calcium, magnesium, sulfur, iron, boron, molybdenum, copper and cobalt, and the like, besides the three nutritive elements, i.e., nitrogen, phosphorus and potassium, which are necessary for crops. The fertilizer is reliable in nutrient proportion and good in manurial effects, improves soil texture, improves soil organic matter content, reduces sealing of soil, gives more perfect nutrition to crops, and leads to vigour crops, full particles and greatly increased output.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Non-chromium deactivation liquid for processing aluminium alloy and method of use thereof

InactiveCN101161861AReduce pollutionMeet WEESMetallic material coating processesTitanium zirconiumPhosphoric acid

The present invention relates to a chrome-free passivating liquid for treating aluminum alloy and a method for using the same; the components of the passivating liquid and the weight concentration of the elements thereof consist of fluorin titanate comprising Ti (IV) between 0.05 wt percent and 0.15 wt percent, fluorin zirconate comprising Zr (IV) 0.01 wt percent and 0.05 wt percent and organic phosphate compound comprising 0.02 wt percent to saturated concentration. The use method of the passivating liquid of the invention has the following procedures: after grease on the surface of the aluminum alloy is removed, the aluminum alloy is treated by alkali cleaning, deoxidation and activation; when the temperature is between 25 DEG C and 60 DEG C and the PH value is between 3 and 3.5, the aluminum alloy is treated by impregnating or spraying for 2 min to 5 min. In the passivating liquid of the invention, organic phosphoric acid is directly added to a titanium zirconium system; the formed zirconium phosphate composite structure can obviously improve the corrosion resisting property of a passivating film and the adhesive capactiy of polymer coating (primer) on the surface of aluminum alloy.

Owner:NORTHEASTERN UNIV

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

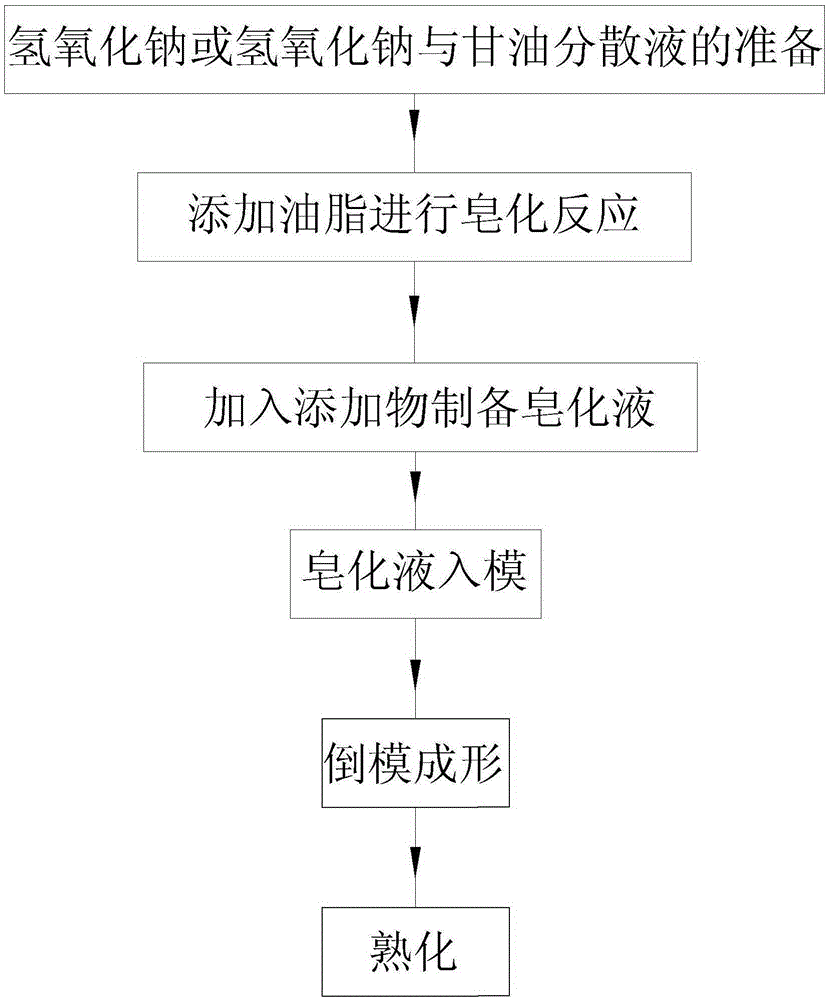

Preparation method of cold-formed soap

ActiveCN105400617AAvoid contact reactionsGive full play to effective functionsShaping soapAlkali/ammonium soap compositionsCold formedReaction rate

The invention relates to a preparation method of a cold-formed soap. The method has simple process steps, and substitutes traditional aqueous solution of sodium hydroxide with sodium hydroxide or a dispersion of sodium hydroxide and glycerol; sodium hydroxide is completely soluble in glycerol but disperses in glycerol, so as to avoid fast reaction after mixing of sodium hydroxide solution with oil too, reduce the initial reaction rate of saponification, and effectively control saponification reaction rate; along with the saponification reaction, the reaction product of glycerol continuously increases to help more fully dispersion of sodium hydroxide, accelerate the reaction rate of sodium hydroxide and the remaining oil. Since the method employs an anhydrous formula, water evaporation process is not needed after soap formation by liquid soap, and the production cycle is significantly shortened; and the nutrition substances are added in solid form powder to effectively prevent the contact reaction of non-alkali-resistant nutrients and alkali hydroxide molecules, so as to retain the active nutrient ingredients in the soap and give full play to the role of skin care of the nutrients.

Owner:NINGBO UNIVERSITY OF TECHNOLOGY

Diamond wire saw production method of surface modified diamond

InactiveCN101812710AAchieve electroplating depositionEasy to operateElectrophoretic coatingsElectrophoresisDiamond wire saw

The invention relates to a diamond wire saw production method of a surface modified diamond, which comprises the following steps: 1. removing surface grease and surface metal oxides on the surface of the diamond; 2. placing diamond micropowder into a cationic surfactant solution, applying positive potential and forming a layer of positive charge film on the surface of the diamond under the electrophoretic action by action of a cationic surfactant; and 3. carrying out composite electroplating of a diamond wire saw. In the invention, conductive processing is carried out on the diamond, so that diamond grains can orderly move in a plating solution under the action of an electric field to realize the electroplating deposition on the surface of a metal wire without the influence of the size of the diamond grains; the surfactant is adsorbed on the surface of the diamond, so that a plating layer and the diamond present an infiltrative type interface, and a Ni plating layer has strong holding capability on the diamond; and the diamond micropowder has high utilization ratio. The invention has simple process method and convenient operation, the diamond grains have rapid deposition speed, good deposition uniformity and high deposition density on the metal wire, an electroplating layer has high holding force on the diamond grains, and the diamond micropowder has high utilization ratio. The invention can realize industrialized production and provides a method for efficiently and rapidly producing the diamond wire saw.

Owner:CHANGSHA DIAT NEW MATERIAL SCI & TECH

Method for synthesizing 2,5-furandicarboxylic acid

InactiveCN101891719ASimple processing methodHigh yieldOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsFuranMass ratio

The invention discloses a method for synthesizing 2,5-furandicarboxylic acid, which comprises the following steps of: mixing furans and alkaline solution in a mass ratio of 1:5-50, adding a noble metal catalyst in an amount of 1 to 5 percent of the molar weight of the furans, continuously introducing oxygen at normal temperature, and reacting for 10 to 30 hours, wherein based on each gram of the furans, the oxygen introducing rate is 5 to 20ml / min; and adjusting the pH of the reaction liquid to less than 3 with concentrated acid, and precipitating the 2,5-furandicarboxylic acid, wherein the noble metal catalyst is Pt / C, Au / C, Pd / C, Pt / C / CuO-Ag2O, Au / C / CuO-Ag2O or Pd / C / CuO-Ag2O, and the concentrated acid is concentrated hydrochloric acid or concentrated sulfuric acid. The process method for synthesizing the 2,5-furandicarboxylic acid has the advantages of simple and direct route, energy conservation, environmental protection, high quality and low cost of the obtained product, and good application prospect.

Owner:SOUTH CHINA UNIV OF TECH

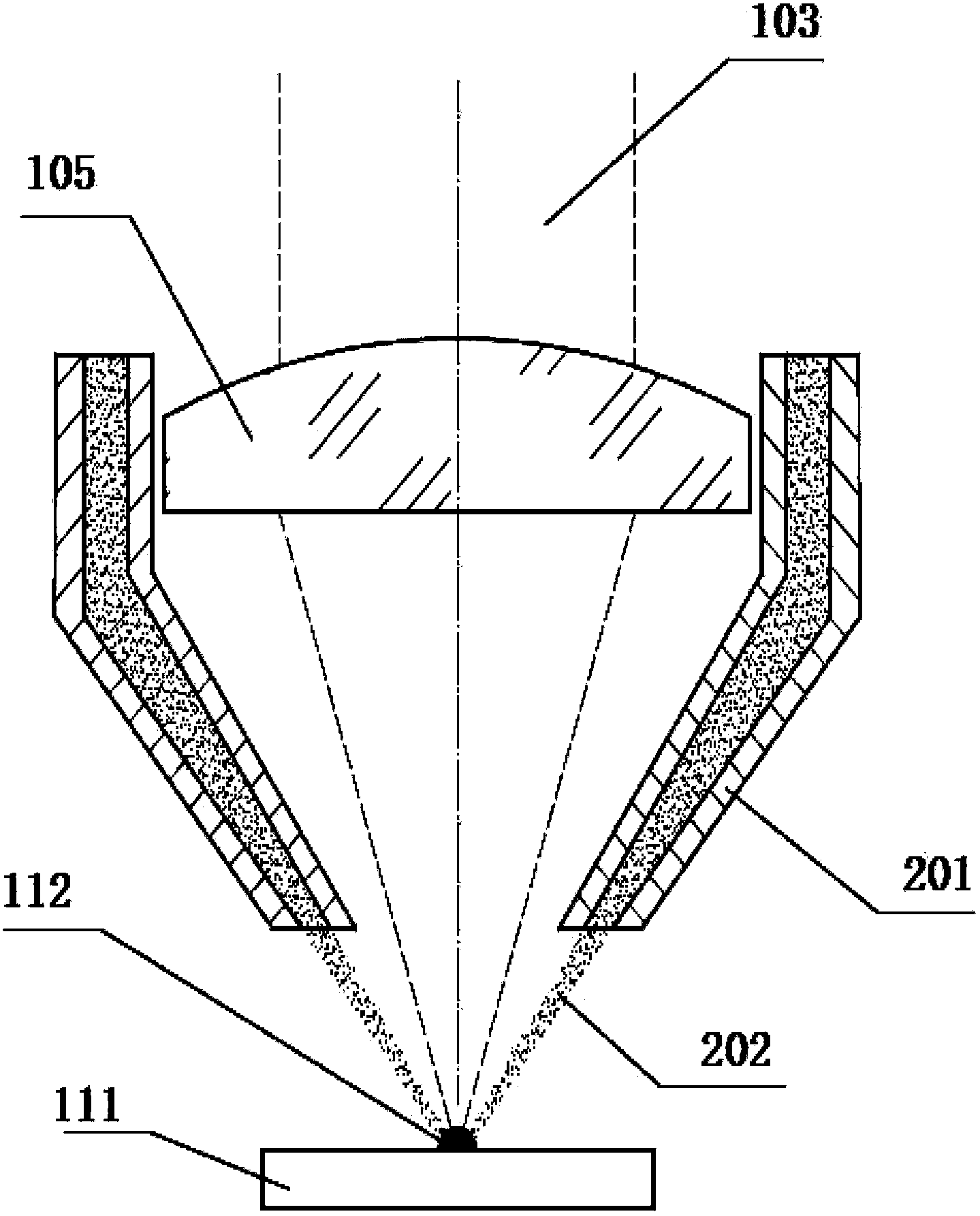

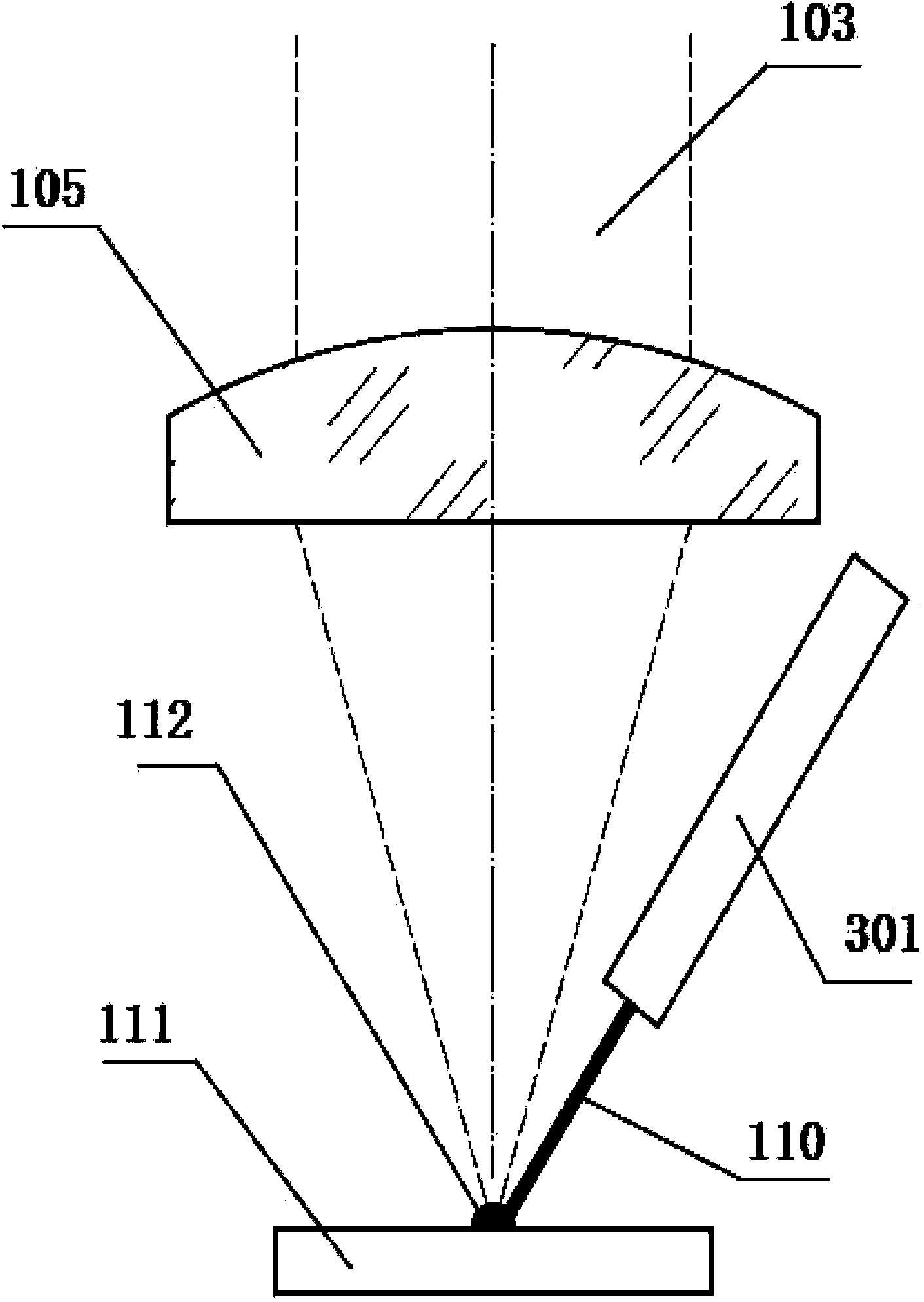

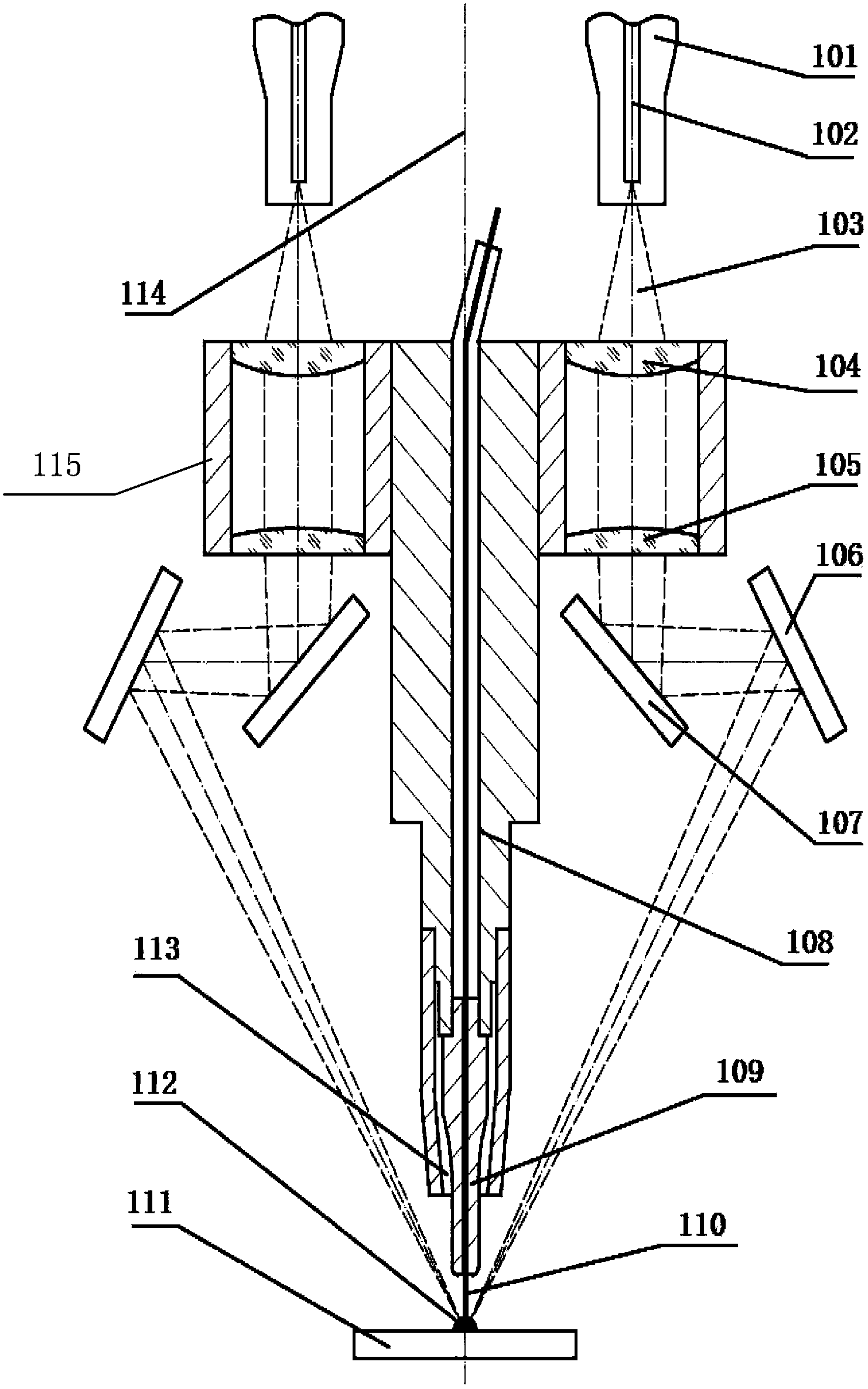

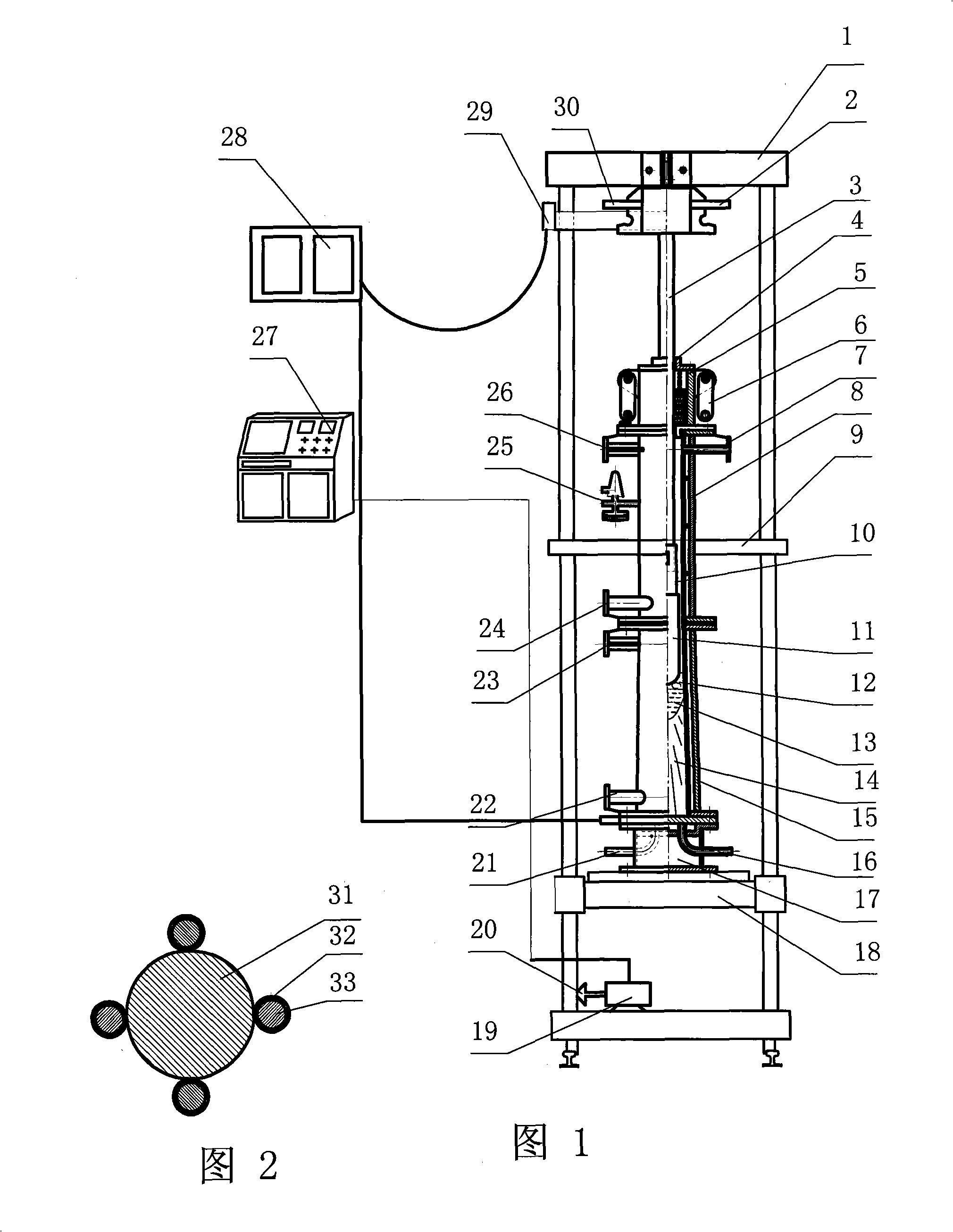

Multi-beam center wire feeding laser processing head and processing method thereof

InactiveCN104289811AEnsure consistencyEvenly heatedLaser beam welding apparatusOptical ModuleLaser processing

The invention belongs to the field of laser processing, in particular to a multi-beam center wire feeding laser processing head and a processing method of the multi-beam center wire feeding laser processing head. The laser processing head comprises a wire feeding tube, a wire feeding nozzle and a plurality of identical optical modules, wherein the wire feeding tube and the wire feeding nozzle are located on the center axis of the laser processing head, the optical modules are rotationally and symmetrically distributed around the center axis, each optical module comprises a collimating lens set, a focusing lens set and a reflecting mirror set, lasers are transmitted to the processing head through a plurality of paths of optical fibers, a plurality of laser beams are focused on one point of the surface of a workpiece to form a molten pool after being collimated, focused and reflected by the optical modules, a metal wire is perpendicularly fed into the molten pool on the surface of the workpiece through the fire feeding nozzle, and the laser processing head moves on the surface of the workpiece according to a certain track so that the center wire feeding laser processing process can be achieved. Through the multi-beam center wire feeding laser processing head, center wire feeding in laser focusing light spots in circular symmetry distribution is achieved, and the processing quality consistency is guaranteed when the laser processing head moves in different directions.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

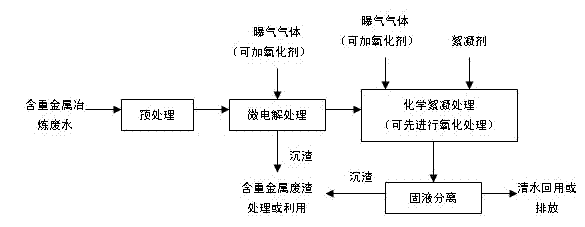

Method for treating smelting wastewater containing heavy metals

InactiveCN102381789AEasy to handleSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentChemical treatmentElectrolysis

The invention discloses a method for treating smelting wastewater containing heavy metals. The method comprises the following steps: 1, the smelting wastewater containing heavy metals is pretreated to remove particulate impurities in the wastewater and adjust the wastewater to be acidic; 2, the wastewater is transferred to an iron-carbon micro-electrolytic reactor to be subjected to single-stage or multi-stage micro-electrolytic electrochemical treatment under acidic conditions to remove most heavy metal ions in the wastewater, the wastewater is adjusted to be weakly alkaline or alkaline, is subjected to single-stage or multi-stage chemical flocculation treatment to further remove other heavy metal ions, and pollutants of arsenic, fluorine, chlorine and the like in the wastewater; and 3, solid-liquid separation is carried out to obtain production water which can be recycled. The method comprises steps of wastewater pretreatment, iron-carbon micro-electrolysis, chemical flocculation and solid-liquid separation which are organically coupled in series. The method which organically combines the micro-electrolysis with the chemical flocculation and allows them to mutually cooperate with each other and co-perform effects has the advantages of simple treating process and technology, low treatment cost, high treatment efficiency, and standard-reached discharge and recovery of the treated wastewater.

Owner:KUNMING UNIV OF SCI & TECH

Method for manufacturing dendrobium officinale fresh juice stock solution

InactiveCN102008654ANot easy to clarifyNot easy to filterMetabolism disorderAlcoholic beverage preparationFlavorAdditive ingredient

The invention discloses a manufacturing method for extracting and processing fresh juice stock solution by using dendrobium officinale as a raw material. The method furthest protect the color, flavor, nutrition and effective ingredients of dendrobium officinale fresh juice by surface sterilization of the collected fresh dendrobium officinale and technology of juicing, enzymolysis, vacuum degasification, micro-filtration, ultra-filtration, sterile filling, high-temperature instantaneous sterilization and the like, and meanwhile, the product is favorable for storing and realizing industrialized production. The dendrobium officinale is processed into the dendrobium officinale fresh juice stock solution which is easy to store, convenient to carry, simple to administrate, good in mouthfeel and easy to absorb and has health-care nutritional components and medicinal functions; the fresh juice stock solution does not contain any additive; and the content of the fresh juice stock solution reaches over 99 percent. The dendrobium officinale fresh juice stock solution can be administrated separately, also can be added into mineral water to form health-care beverage, also can be dissolved into wine to form nourishing health-care wine, and can be added into high-grade dishes to form nourishing dishes for eating.

Owner:杨军

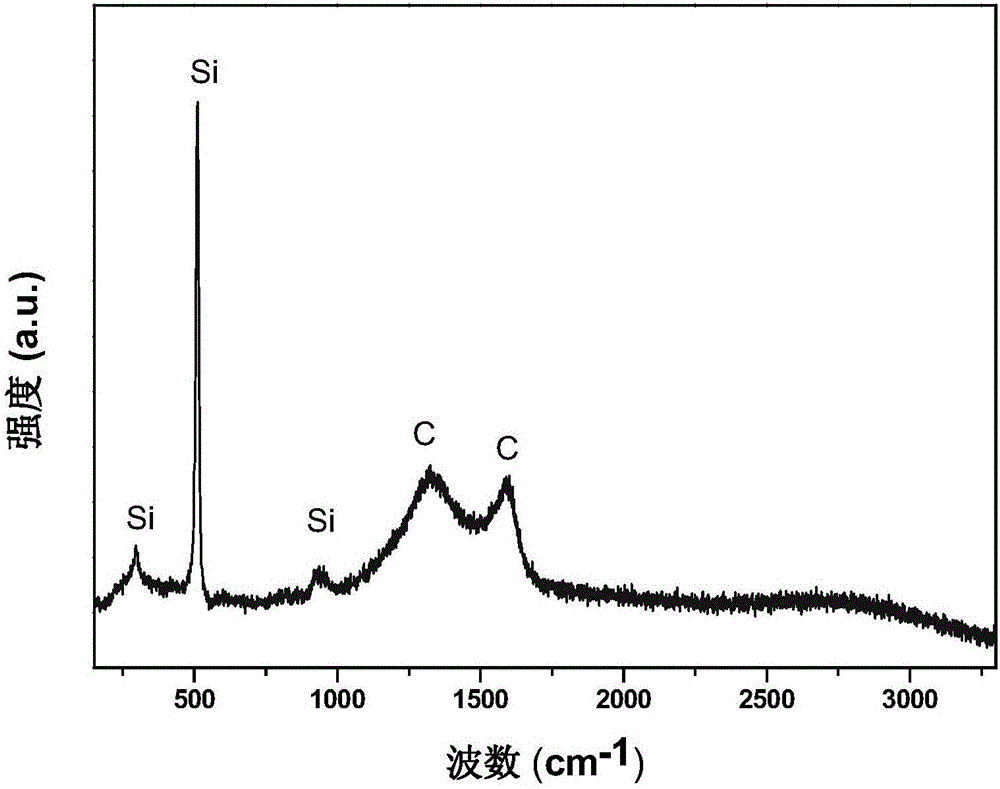

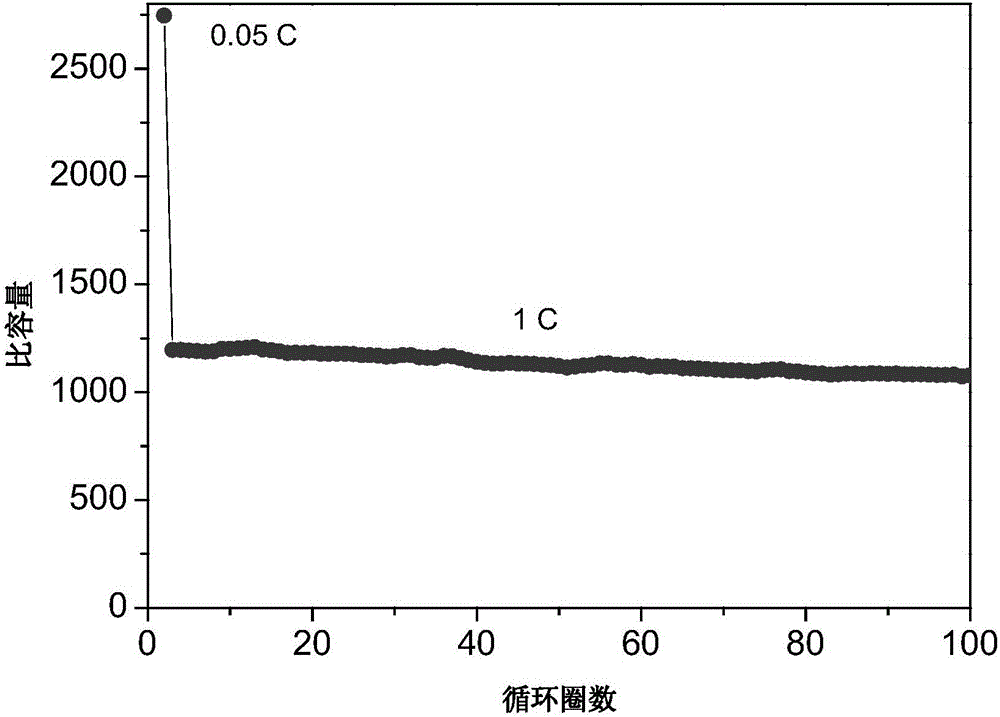

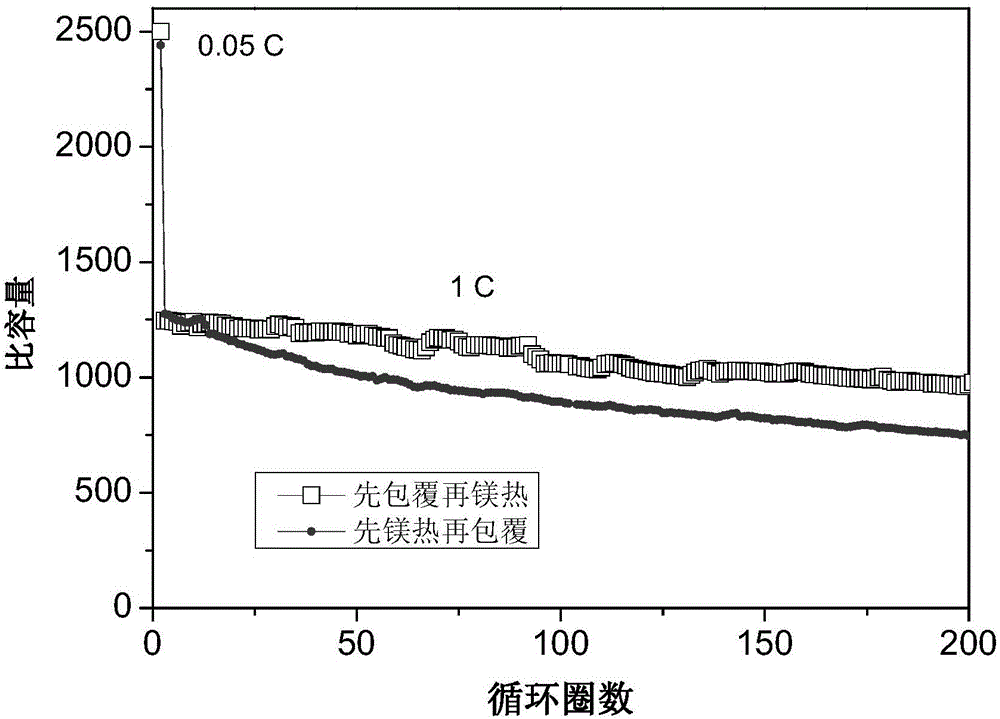

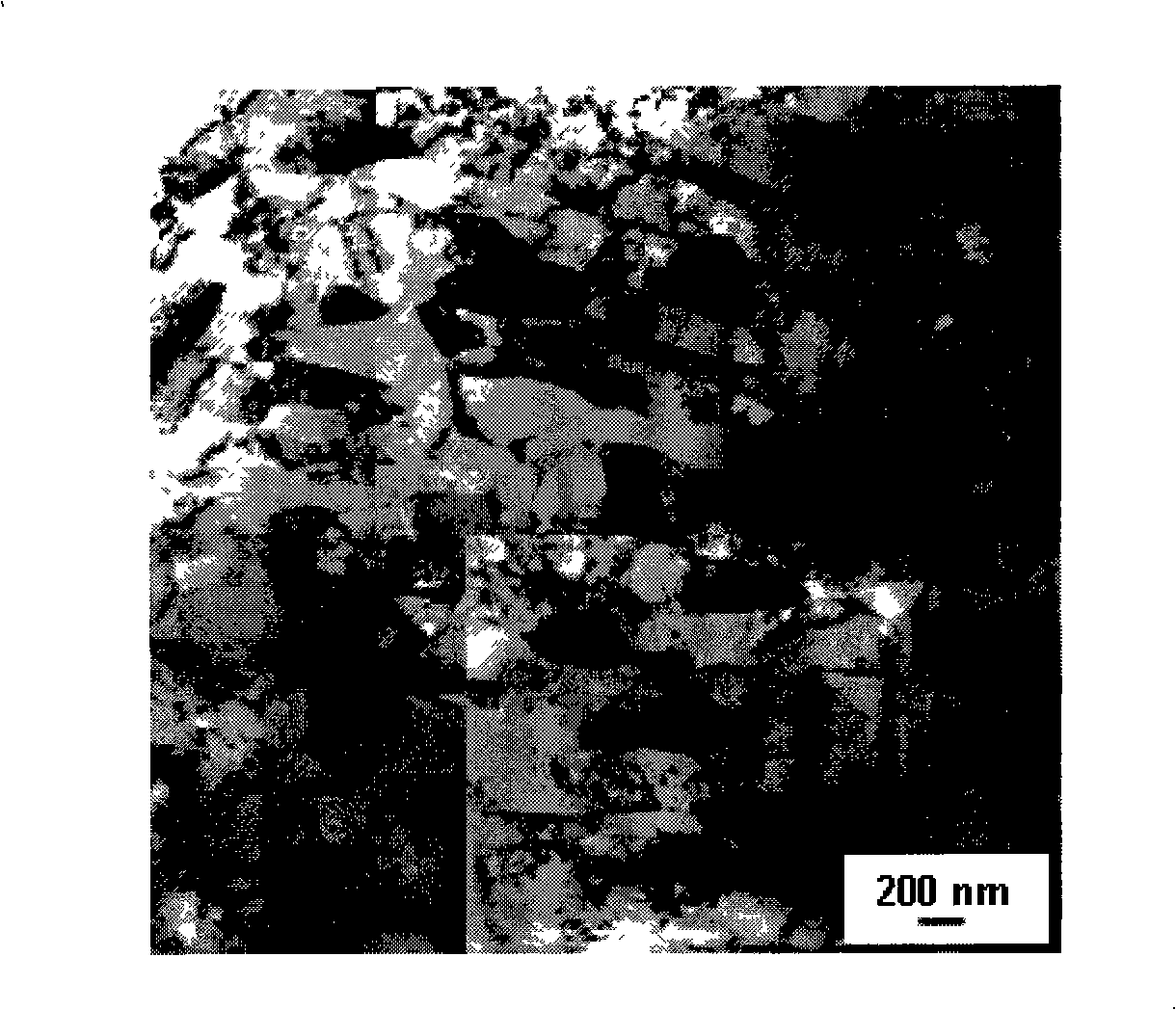

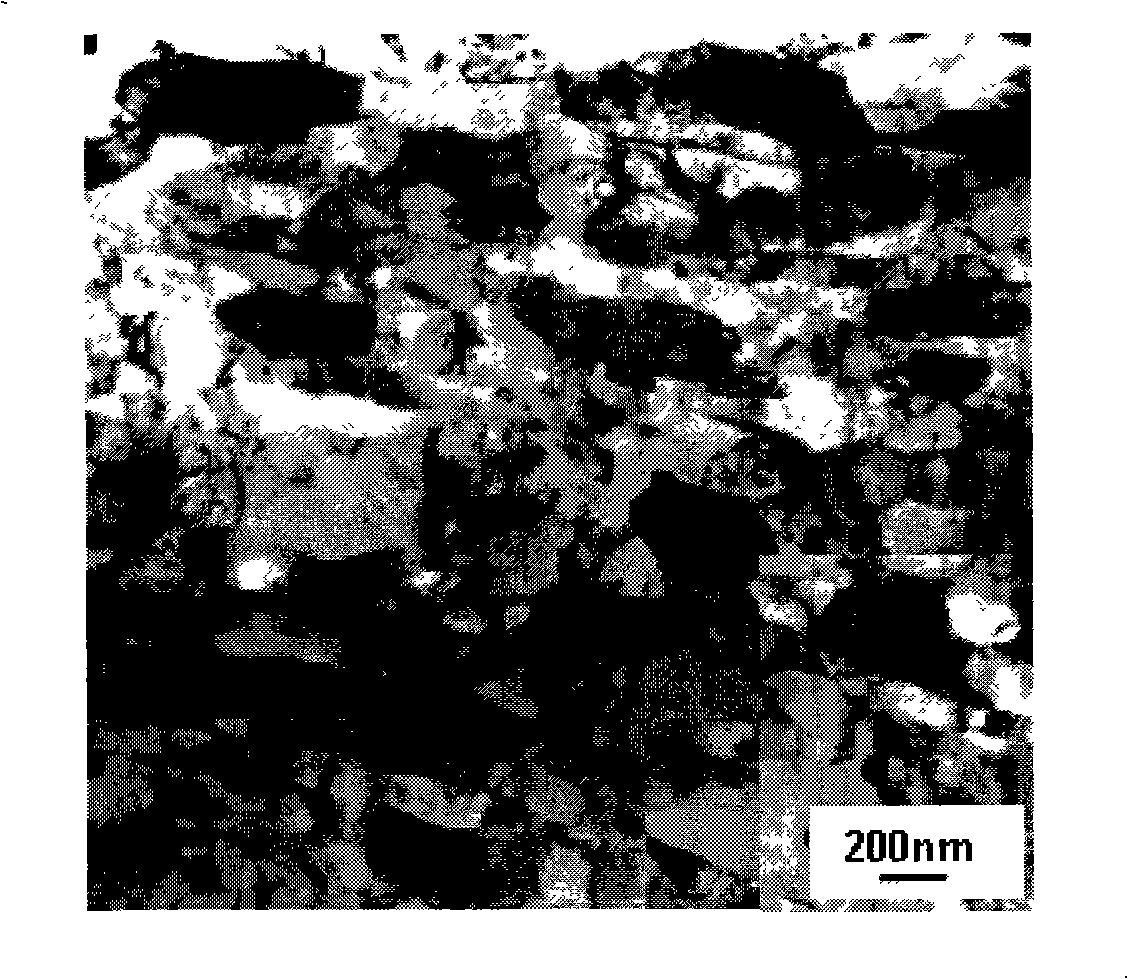

Method for preparing silicon/carbon composite material with magnesiothermic reduction process

InactiveCN106374088AThe process method is simpleLow costCell electrodesSecondary cellsSolventPorous composite

The invention discloses a method for preparing a silicon / carbon composite material with a magnesiothermic reduction process, and belongs to the technical field of composite material preparation. The method comprises the following steps: (1) mixing a silicon dioxide source, an organic carbon source and a solvent, carrying out ball-milling to prepare a uniformly pulpous mixture, and obtaining a silicon dioxide-carbon precursor composite material through drying; (2) mixing the silicon dioxide-carbon precursor composite material with magnesium powder to carry out a magnesiothermic reduction reaction, collecting products and carrying out acid pickling and washing, and drying to obtain the silicon / carbon composite material. According to the method, silicon dioxide reduction and high temperature carbonization are completed by using a one-step process, and the method has the advantages of simple technical process, low cost and large-scale production; the prepared composite material effectively maintains the appearance of porous silicon, so that the composite material has preferable capability for bearing volumetric strain; the porous composite material is applied to a lithium battery, so that the lithium-ion de-intercalation depth is small, the ion diffusion path is short, the reversible capacity and coulombic efficiency of the lithium battery are effectively improved, and the cycle life is prolonged.

Owner:TIANNENG SAFT ENERGY JOINT CO

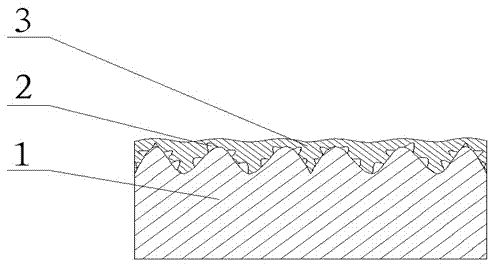

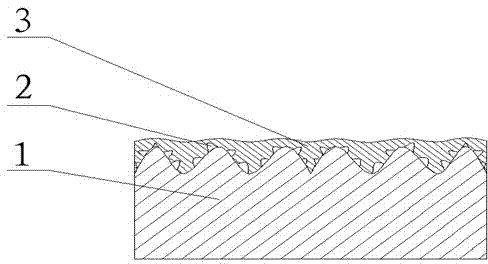

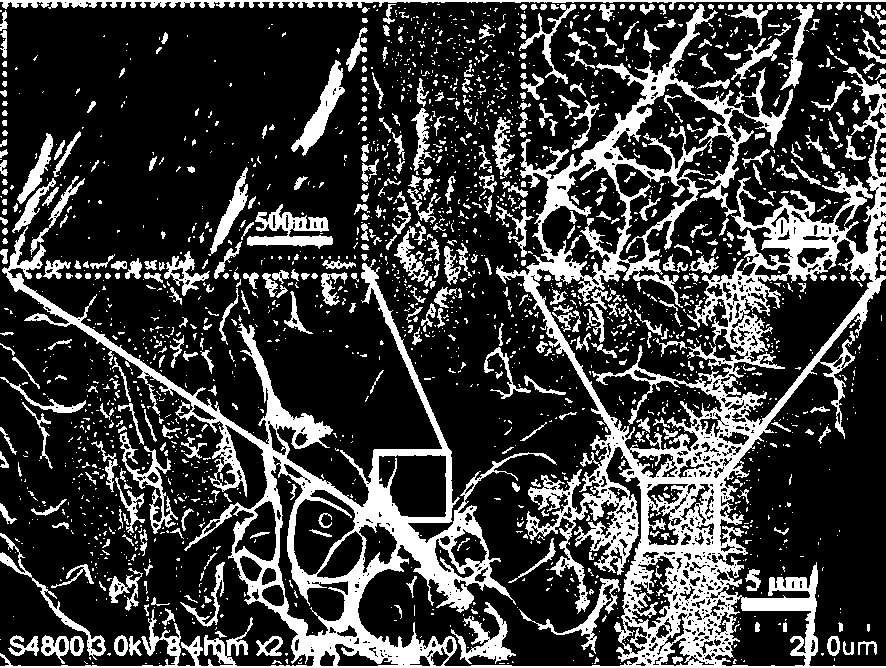

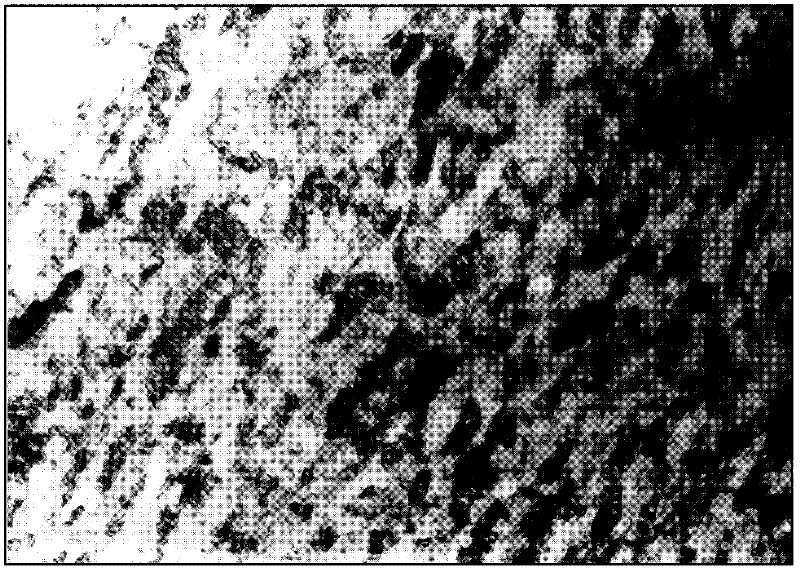

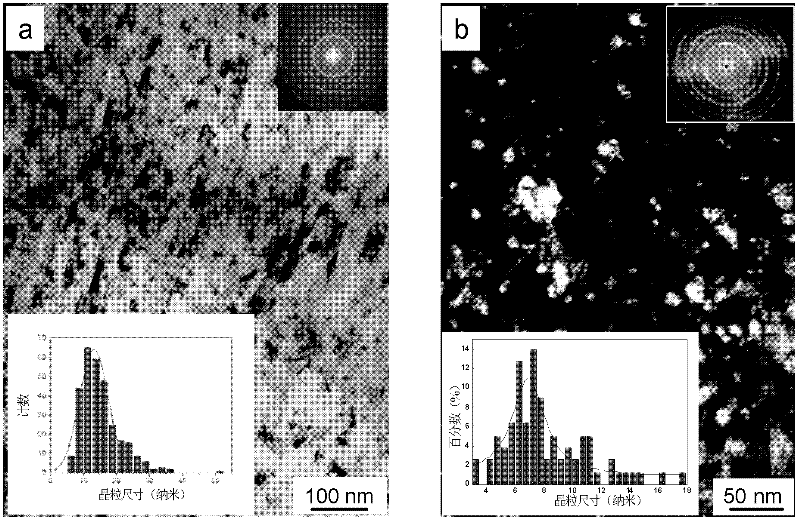

High speed processing method for realizing superfine crystal grain structure on metallic material surface

The invention relates to a method for processing the high-speed deformation on the surface of metallic material with nano structure, and particularly provides a method for realizing high-speed processing of the organization structure of ultra-fine grains. On the condition of room temperature or low temperature, by adopting a mechanical treatment method with high-speed plastic deformation, the nanoscale bulky crystalline grain structure on the surface layer of the metallic material is refined as equiaxial submicron crystalline grain or nano crystalline grain to form an ultra-fine organization structure of the crystalline grain on the surface layer of the metallic material. With the increase of the depth to the processing surface, the size of microstructure has the change of gradient, increasing from nanoscale and submicron size to micron size. Compared with the existing processing method for forming a surface ultra-fine crystalline grain structure, the high-speed processing method of the invention greatly reduces the roughness of the surface of the processed metallic material and increases the thickness of a deformation layer, and has simple processing method and high working efficiency.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Nonstick cookware and manufacturing method thereof

The invention discloses nonstick cookware and a manufacturing method thereof, wherein the inner surface of the pot body of the nonstick cookware is provided with an uneven raised structure; a grain structure is distributed on the raised structure; and a nonstick coating covers outside the raised structure and the grain structure. The manufacturing method of the cookware comprises the following steps of: (1) forming the pot body of the cookware; (2) carrying out inner surface treatment on the pot body of the cookware to ensure that the uneven raised structure is formed at the inner surface of the pot body of the cookware; (3) carrying out meltallizing treatment on the cookware blank after being subjected to the roughening treatment to ensure that nanoscale hard metal-based or nonmetal-based grain structure is distributed on the raised structure of the pot body of the cookware; (4) spraying nonstick coatings on the inner surface of the pot body of the cookware after being subjected to the meltallizing treatment to ensure that the nonstick coating covers outside the raised structure and the grain structure; and (5) putting in a sintering channel at a temperature of 350-440 DEG C after the spraying to sinter for 5-20 minutes so as to obtain a finished product. The nonstick cookware disclosed by the invention is good in nonstick effect and abrasive resistance, simple in manufacturing process and suitable for large scale production.

Owner:谛卓(北京)咨询顾问有限公司

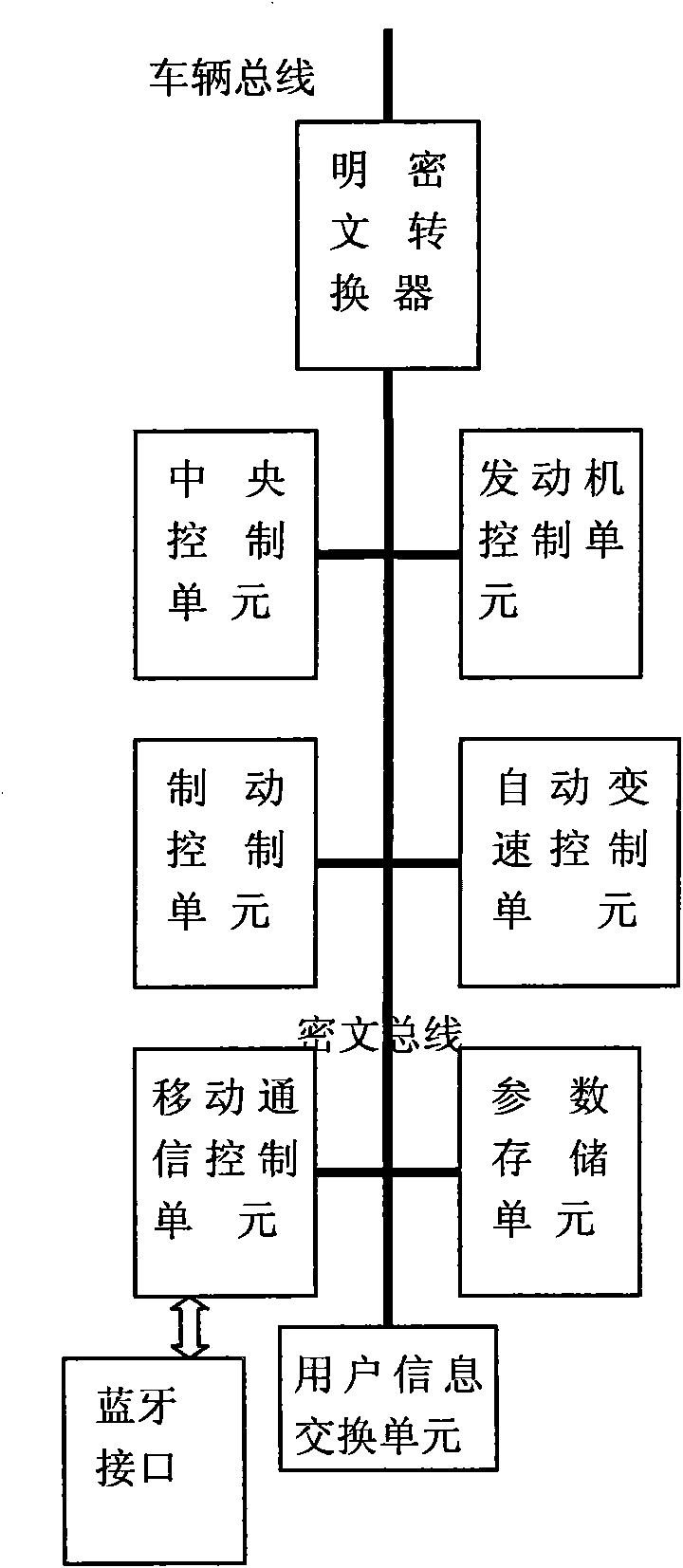

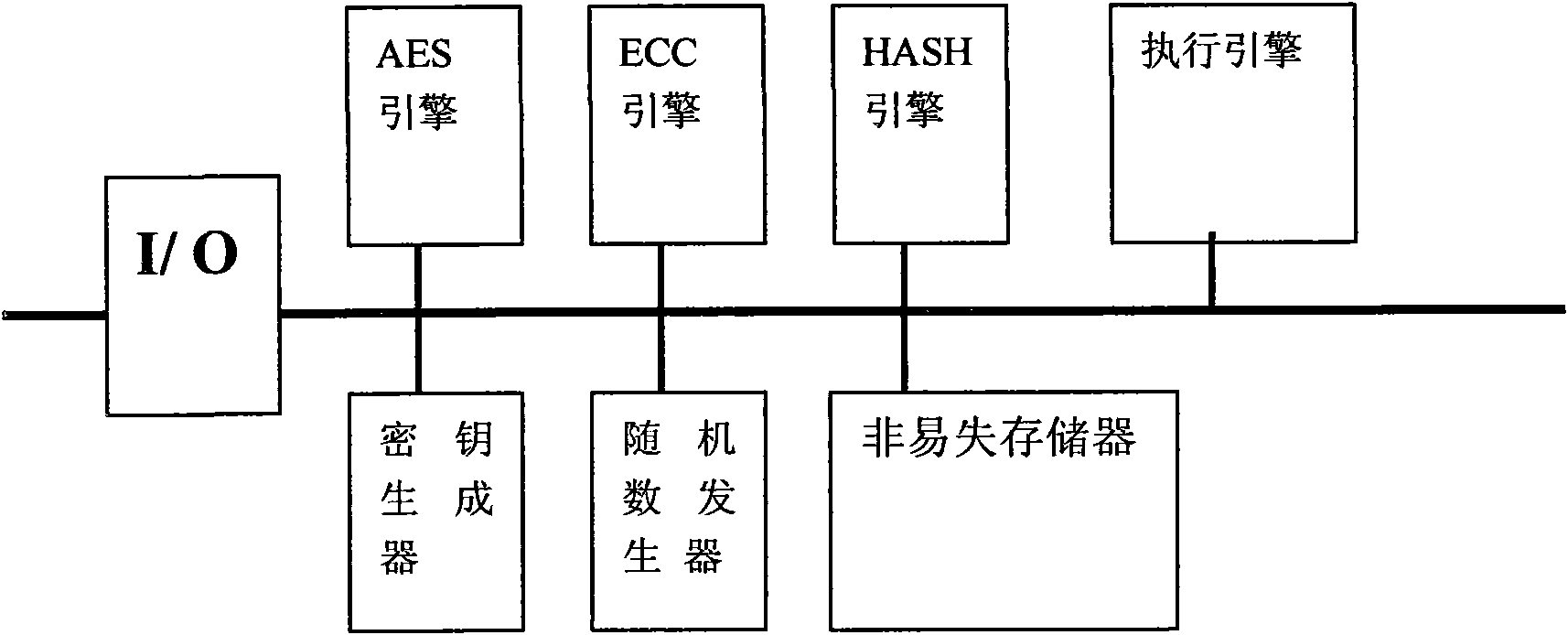

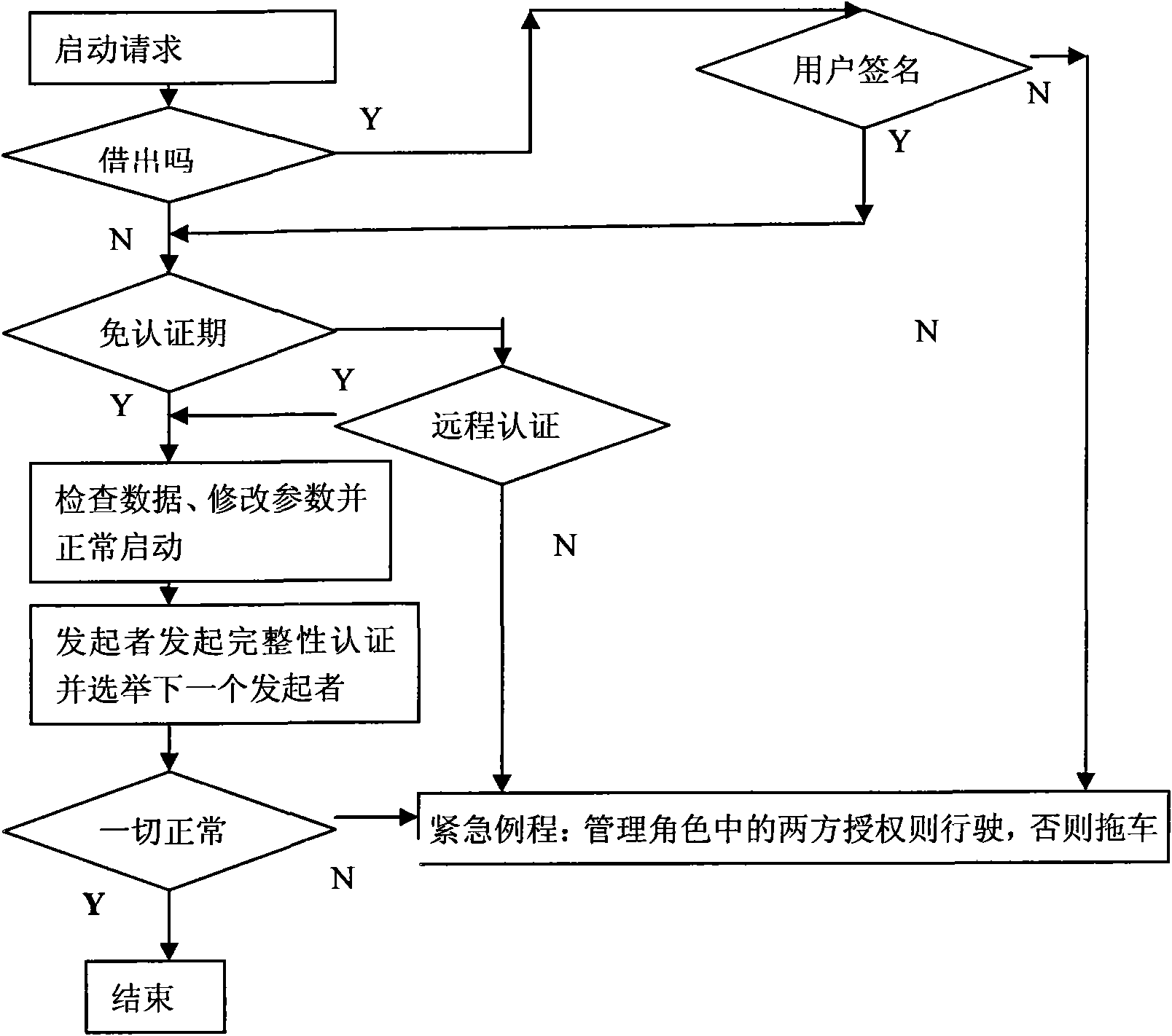

Vehicle control system for preventing stealing and robbery and implementation method thereof

InactiveCN101559745AMileage limitStart limitPublic key for secure communicationAnti-theft devicesPlaintextConfidentiality

The invention discloses a vehicle control system for preventing stealing and robbery, comprising a central control unit, an engine control unit, an automatic variable speed control unit, a brake control unit, a mobile communication control unit, a parameter storage unit, a user information exchange unit and a vehicle owner key, which are all provided with an encode processing module; besides, the vehicle control system also comprises a plaintext and ciphertext converter, a ciphertext bus, an ordinary vehicle key and a vehicle owner key; and the invention has another purpose of providing a method for implementing the vehicle control system, and the method includes the steps of (1) initialization; (2) start-up process; and (3) emergent verification. By adopting the technologies of confidentiality, verification and threshold, the invention effectively improves the safety of vehicles, prevents other people from illegally driving the vehicle and illegally changing elements on the ciphertext bus, and the method for handling the case of loss of an ordinary vehicle key is simple.

Owner:SOUTH CHINA UNIV OF TECH

Method for processing isolated stone groups in shield excavation karren section

ActiveCN102518442AImprove detection accuracySimple processBlastingTunnelsHigh densityGeological survey

The invention relates to a technology for detecting and processing isolated stone groups in the shield excavation karren section, in particular to a method for processing isolated stone groups in the shield excavation karren section, aiming to solve the problems that the isolated stone groups can not be detected accurately and processed rapidly by using the traditional method. The method comprises the following steps: finding out the section probably having the isolated stone groups according to a geological survey report; arranging testing holes along the longitudinal direction of a tunnel in the section having the isolated stone groups, putting PVC (polyvinyl chloride) pipes in the testing holes, disposing dense small holes on the walls of the PVC pipes, sealing the bottom ends of the PVC pipes, filling the testing holes with water, arranging electrodes in the PVC pipes in the adjacent two holes, detecting by crossing holes and collecting data by using a high-density resistivity instrument, and determining the position of the isolated stone; optimizing a blasting design, positioning blasting charges accurately by using a counter weight, blasting the holes at the periphery of the isolated stone first to squeeze to generate a space, and then blasting the holes row by row. The method is used for detecting the isolate stone accurately, adopts a simple process, uses the blasting technology to ensure that the biggest blasted isolated stone is less than 25cm, avoids the secondary blasting and has high isolated stone processing efficiency.

Owner:2ND ENG CO LTD OF CHINA RAILWAY 12TH BUREAU GRP +1

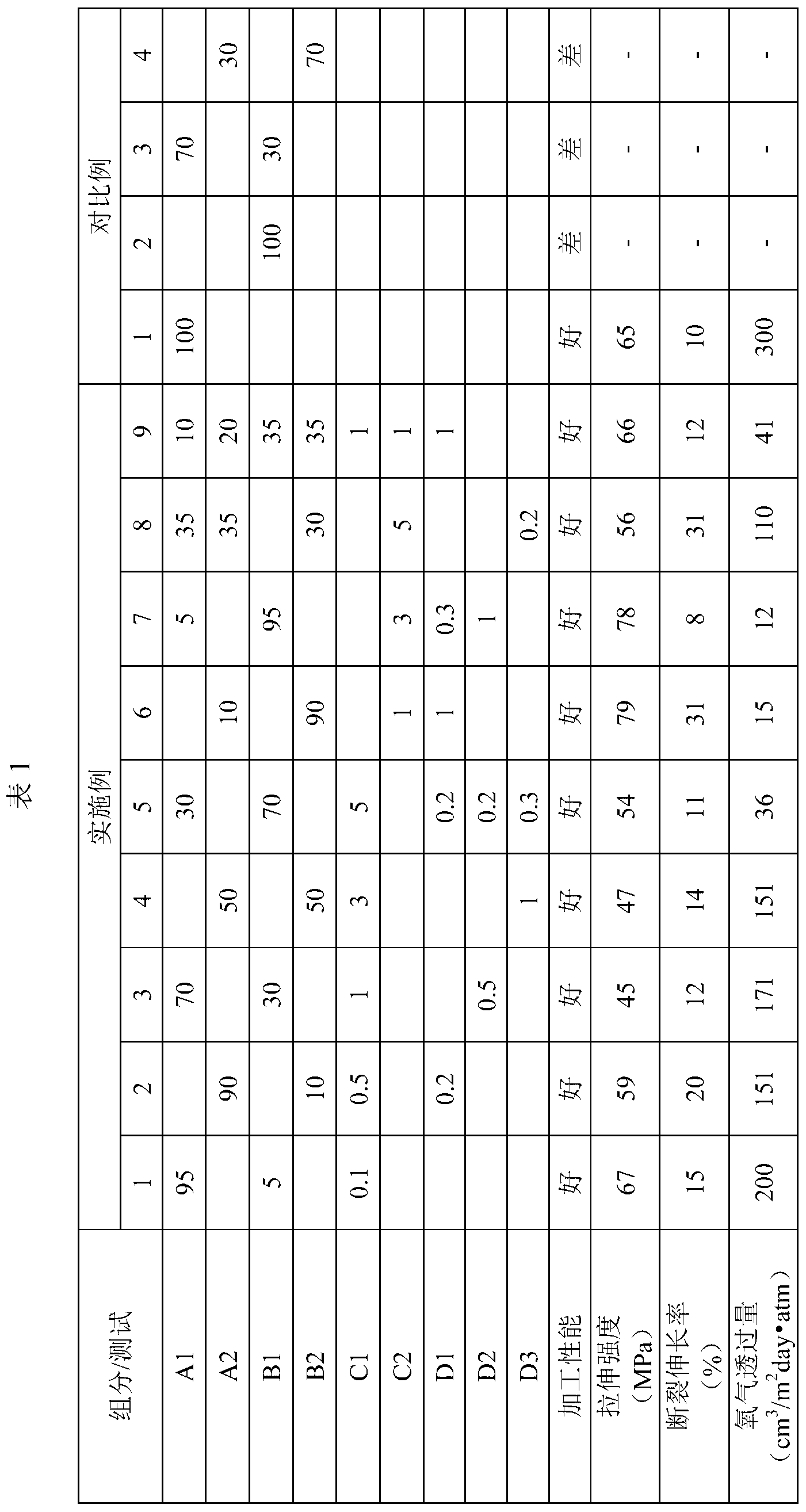

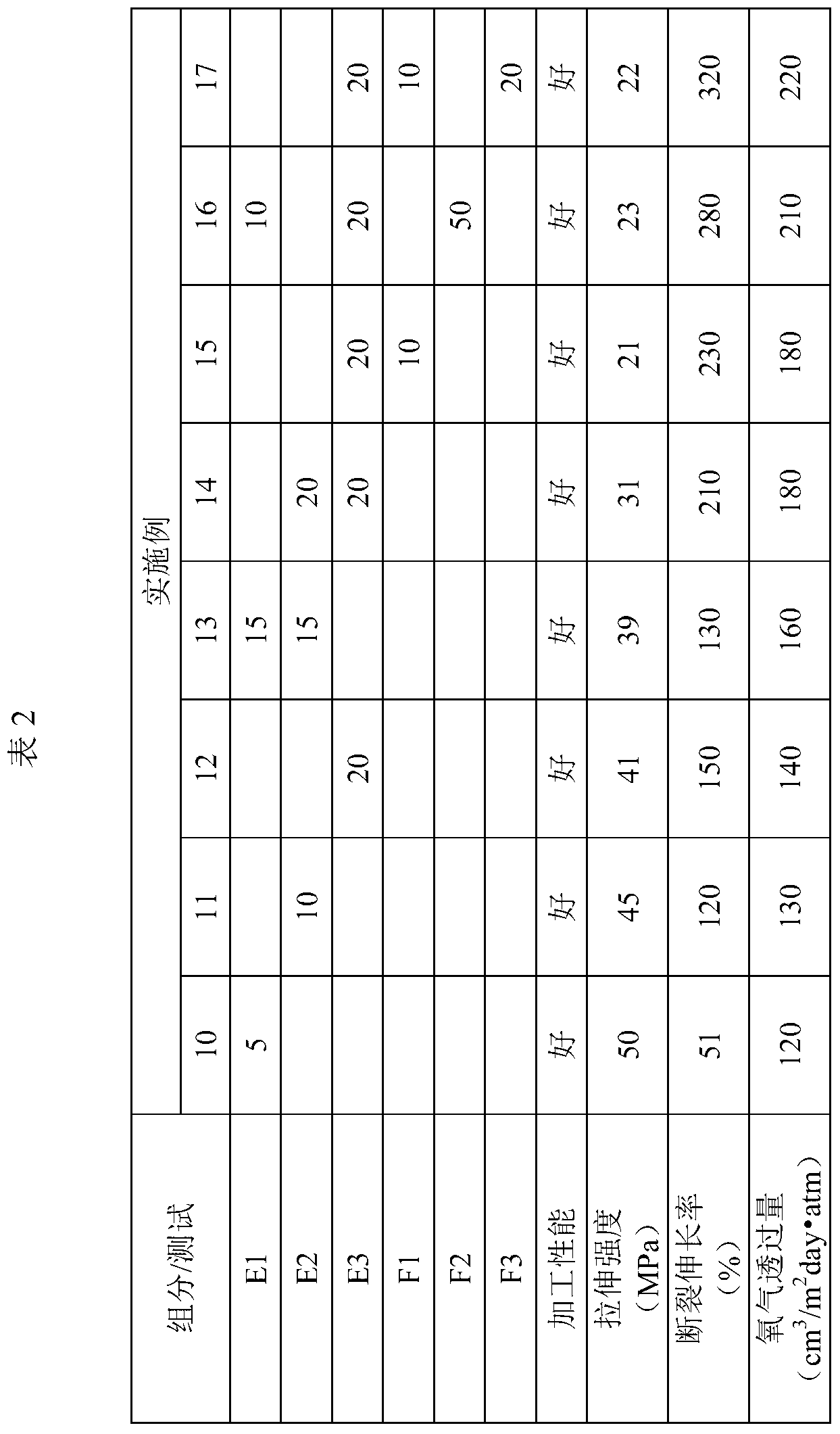

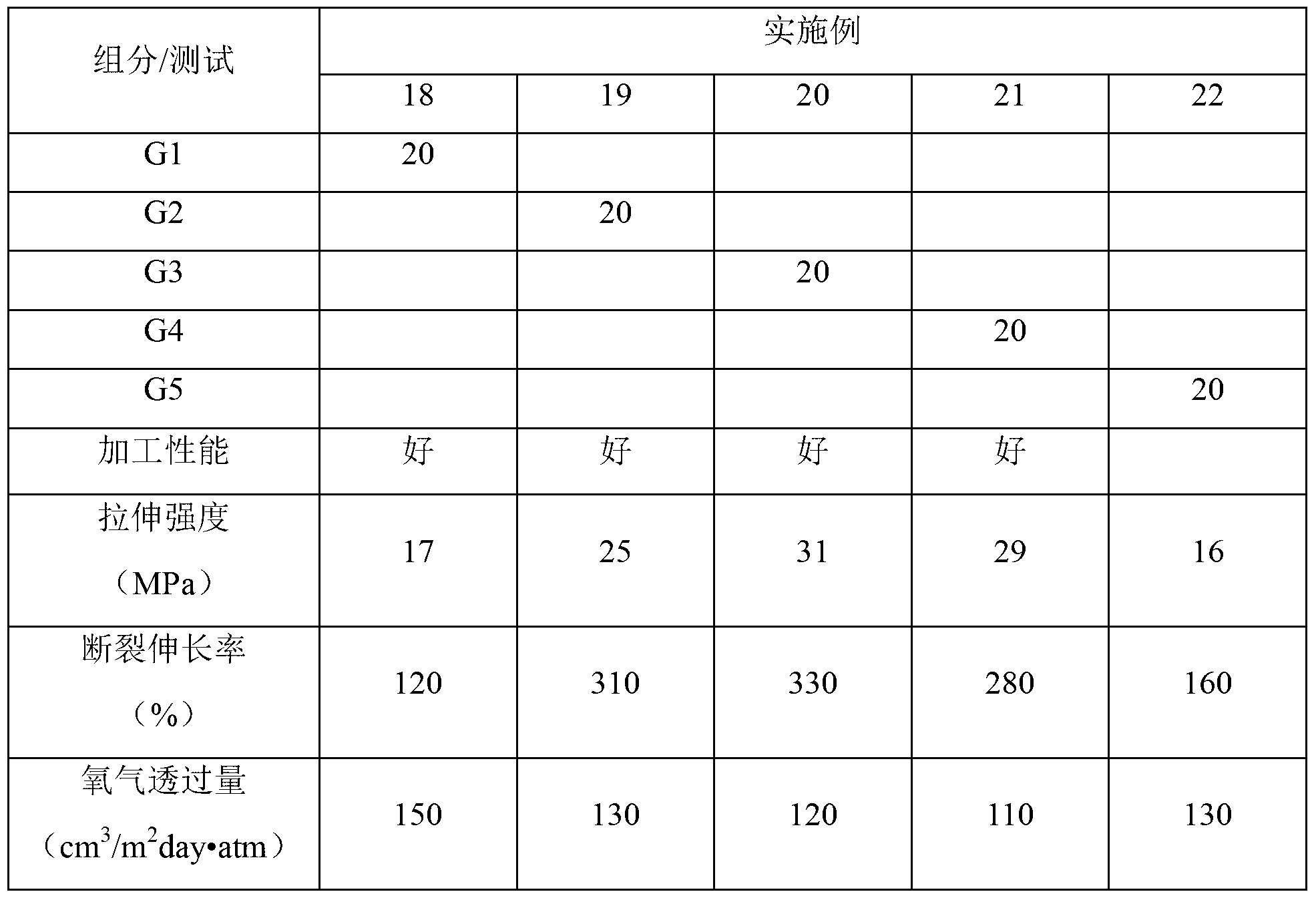

Polylactic acid alloy membrane and application thereof

ActiveCN103319865AImproved oxygen barrier propertiesThe process method is simpleCoatingsEnvironmentally friendlyPolylactic acid

The present invention discloses a polylactic acid alloy membrane, which comprises polylactic resin, polyvinyl alcohol resin and a bulking agent, wherein the three are in parts by weight of 1to 99 parts, 1 to 99 parts and 0.05to 5 parts respectively, with the total account of polylactic resin and polyvinyl alcohol resin in parts by weight of 100 parts. By the invention, the oxygen barrier property of the polylactic acid alloy membrane is effectively improved under the premise of keeping the membrane completely biodegradable and providing the membrane high mechanical strength. The technology method provided by the invention is easy with low cost, and is able to effectively promote widespread use of the environmentally friendly polylactic acid products.

Owner:常州博疆新材料科技有限公司

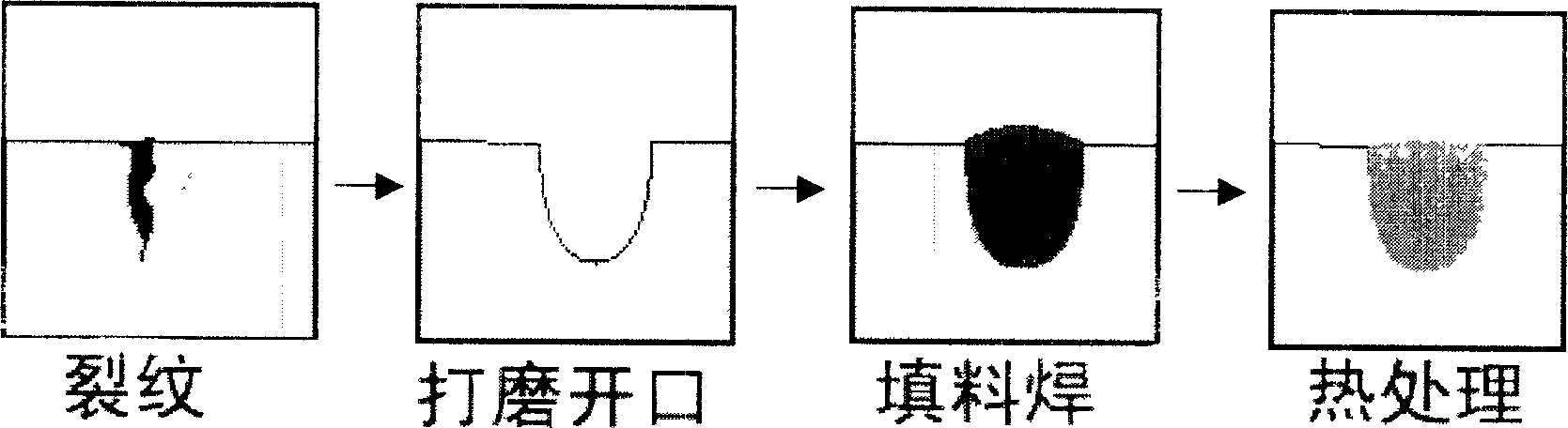

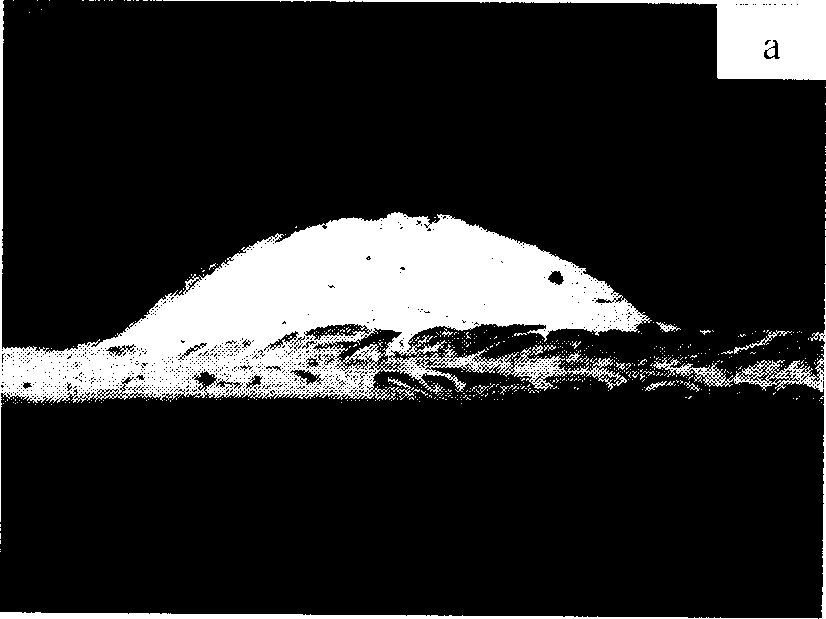

Crack repair process for high-pressure turbine blade tip in gas turbine

The present invention belongs to the metal surface crack repairing method, meaning the tip crack repairing method of a gas-turbine engine high-pressure turbine blade. The method comprises polishing apertures for complete crack removal based on the crack conditions of the gas-turbine engine high-pressure turbine blade tip, carrying out surfacing welding in the repair welding zone using low-heat input welding technology and implementing heat treatment process to the repaired blade. The present invention has the virtues of simple process, needing no vacuum or preheating, small damage to blade base materials, realizing loss-free repair to the high-pressure turbine blade tip cracks and reducing repair cost. The invention can be used to repair both the gas-turbine engine high-pressure turbine blade tip cracks and steam turbine, smoke turbine and other turbine mechanisms high-pressure or low-pressure blade tip cracks. And the aircraft engine high-pressure turbine blade repaired with the method has passes 368h long-term bench trial check.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

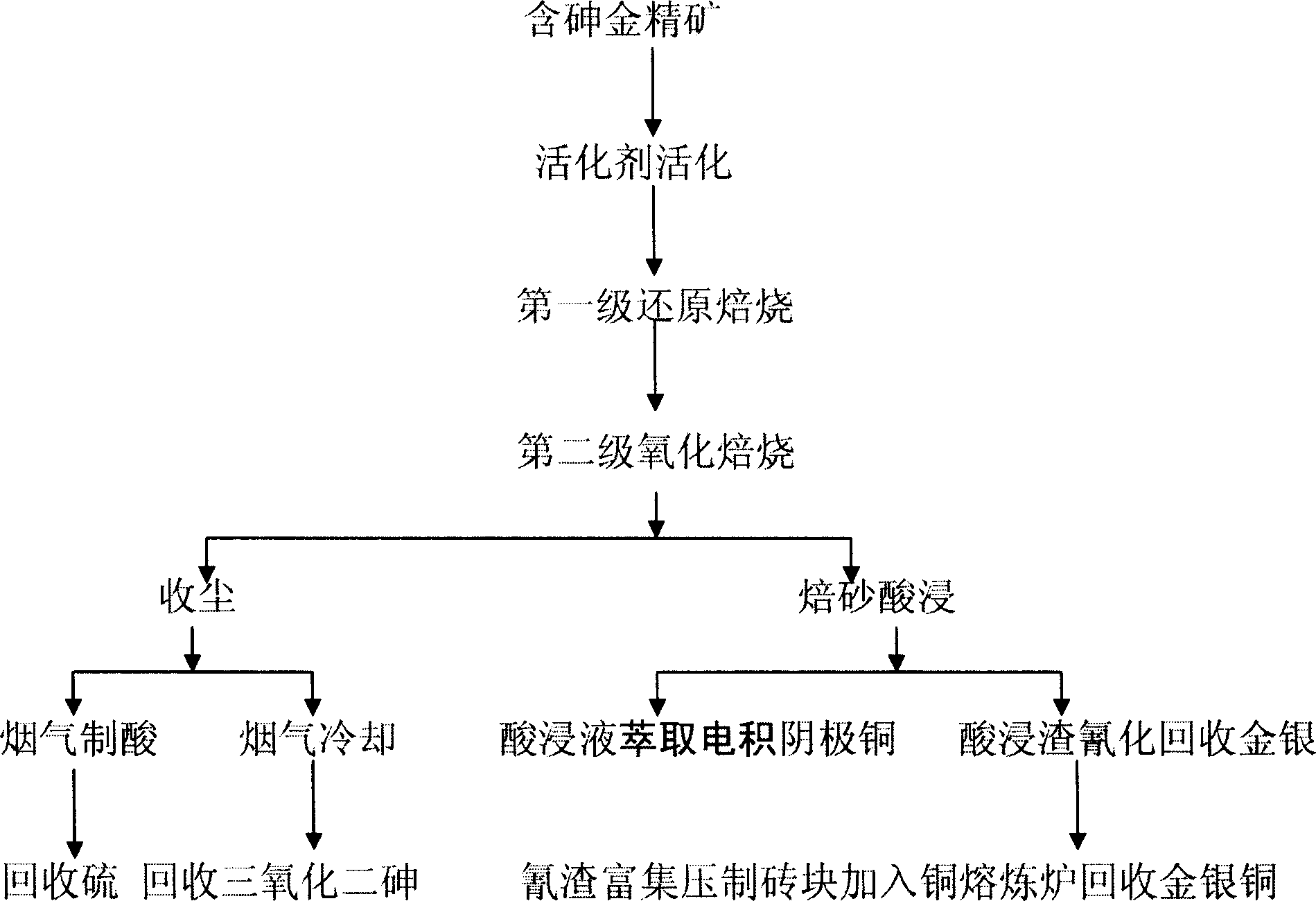

Method of extracting gold and silver from arsenic containing aurin ore

InactiveCN1904094ALow impurity contentAvoiding the problem of chemical synthesis of iron arsenatePhotography auxillary processesProcess efficiency improvementSulfurCopper

The present invention relates to a method for extracting gold and silver from arsenical gold headings. It is characterized by that said method includes the following steps: (1), using activating agent to make activation; (2), first-stage reduction and calcinations; (3), second-stage oxidation and calcinations; (4), acid-pickling, using acid-pickling liquor to make extraction and electrodepositing cathode copper; (5), cyaniding acid-pickling dregs and recovering gold and silver; and (6), calcining smoke gas, making trentment and recovering arsenic and recovering sulfur.

Owner:SHANDONG GUODA GOLD

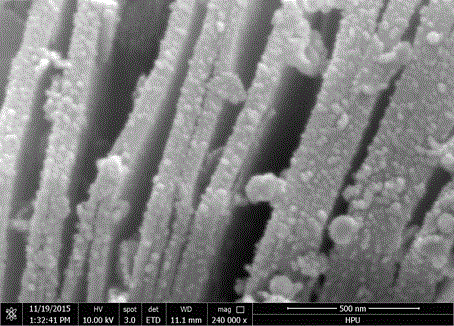

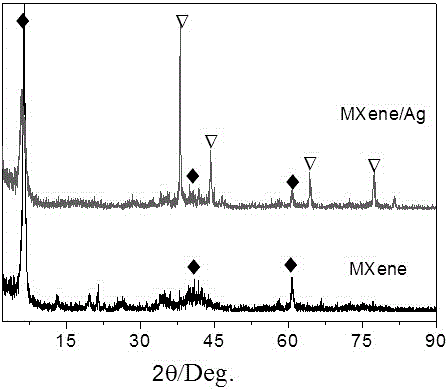

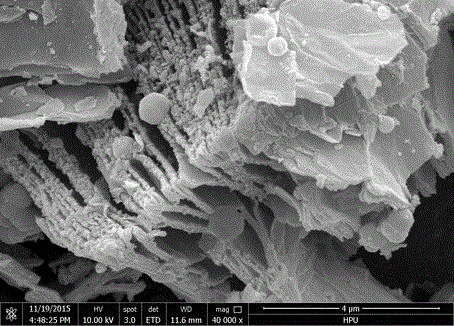

Two-dimension carbide loaded metal simple substance nano-powder, and preparation method and application thereof

InactiveCN105854913AAvoid uneven loadThe load is easy to controlPhysical/chemical process catalystsWater/sewage treatment by irradiationReducing agentLithium fluoride

The invention relates to two-dimension carbide loaded metal simple substance nano-powder, and a preparation method and an application thereof. The preparation method comprises the following steps: (1) soaking MAX phase ceramic powder in a hydrochloric acid solution in which lithium fluoride is dissolved, stirring, centrifugally separating, washing with deionized water and ethyl alcohol, drying and then acquiring solid powder, namely, two-dimension carbide; (2) dissolving the two-dimension carbide in a metal saline solution and preparing into a mixing solution; (3) adding a reducing agent aqueous solution into the mixing solution while stirring, reacting for 0.5-2h at room temperature, and washing and drying the solid precipitate acquired by centrifuging the turbid liquid after ending the reaction, thereby acquiring the two-dimension carbide loaded metal simple substance nano-powder. According to the invention, the uniform loading of metal simple substance nano-particles on the surface of the two-dimension carbide and between the layers is realized; according to the method, various metal simple substance nano-particles are loaded onto the two-dimension carbide; the prepared two-dimension carbide loaded metal simple substance nano-powder as a photocatalyst has excellent application prospect in the field of treating organic pollutants in sewage.

Owner:HENAN POLYTECHNIC UNIV

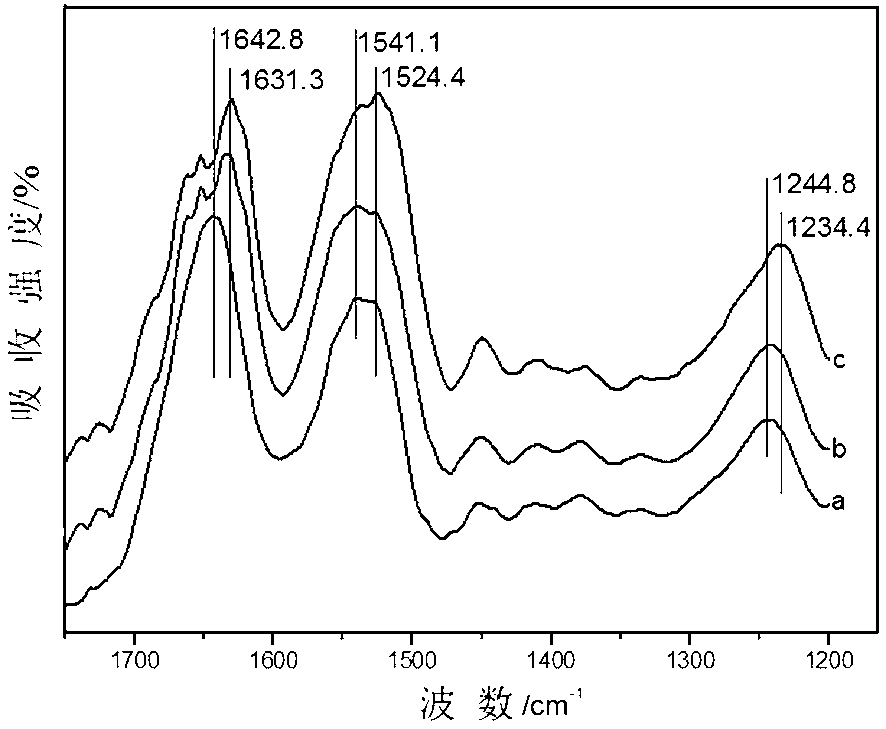

Raw material prescription for xylogen-inorganic nano composite material producing process thereof

The invention provides a raw material prescription of lignin-inorganic nanometer composite material and the preparation method thereof. The composite material comprises lignin or derivate, inorganic nm material, water soluble lignin surface finishing agent and other types of surface finishing agent. The preparation method comprises the steps as follows: the inorganic nanometer material is pretreated with the water soluble lignin surface finishing agent, the other types of the surface finishing agent are added to finish pretreatment; the inorganic nanometer material is added into the lignin or the derivate, acid is added for sediment, and is filtered and dried to acquire the lignin-inorganic nm composite material. The invention has simple raw materials prescription, easily-available sources, low cost and simple technique, is favorable for the recirculation and the reuse of biographic resources, and has good product performance, brilliant economical benefit and wide application prospect without pollution.

Owner:FUZHOU UNIV

Method for processing reverse osmosis concentrated water

ActiveCN101723485ALow investment costReduce dosageWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by flocculation/precipitationReverse osmosisWastewater

The invention relates to a method for processing reverse osmosis concentrated water, which comprises the steps of: adding oxidant into reverse osmosis concentrated water to be processed to perform an oxidizing reaction to oxidize organic matters in the concentrated water into carbon dioxide and water, and directly. discharging wastewater after oxidation Compared with the prior art, the method is simple in processing, easy to implement, low in investment and cost of processing facilities, lower in raw water COD, small in dosage of the oxidant and low in processing cost; and in addition, the method is green and environmentally-friendly and does not cause secondary pollution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Silk fibroin membrane and preparation method thereof

ActiveCN103341214AImprove stabilityStable and controllable structureSurgeryCatheterInorganic saltsPolymer science

The invention discloses a silk fibroin membrane and a preparation method of the silk fibroin membrane. The preparation method comprises the following specific steps of: dissolving natural silk taken as a main raw material in an acid inorganic salt solution, forming a membrane, desalting, and carrying out vacuum drying to prepare the silk fibroin membrane which is insoluble in water and has high mechanical property. The silk fibroin membrane has the breaking strength of greater than 50Mpa at dry state, the breaking elongation of greater than 5% at dry state, the breaking strength of greater than 10Mpa at wet state and the breaking elongation of greater than 150% at wet state. In addition, the silk fibroin membrane prepared by the method is stable and controllable in structure, has good biocompatibility and can serve as a medicinal biological material. The preparation method disclosed by the invention is simple and short in flow path, has high film formation efficiency and is suitable for industrialization large-scale production.

Owner:苏州盛泽科技创业园发展有限公司

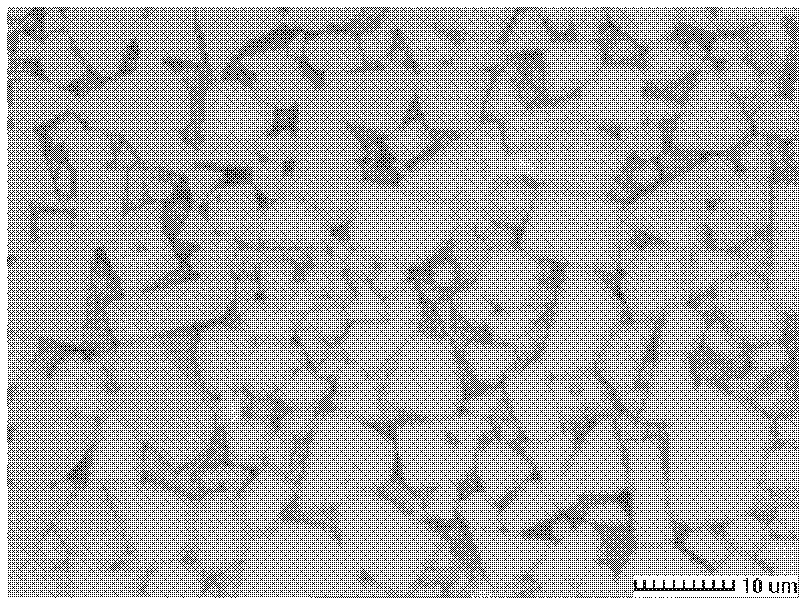

Method for forming nanometer gradient structure on surface layer of shaft metallic material

The invention relates to a surface treatment method for forming a nanometer gradient structure on a surface layer of a shaft metallic material. The invention aims to solve the problems that the surface roughness of the material to be treated is higher, the surface smoothness is not high and a nanometer crystal structure is difficult to form on the surface of a workpiece in the prior art. A spherical treatment tool is adopted to roll on the surface of the rotary shaft metallic material, and meanwhile, the spherical treatment tool moves along the axial direction of the workpiece, and plastic deformation is generated on the surface layer of the material, so that grains on the surface layer of a workpiece material are refined to form the nanometer gradient structure, wherein the depth of the deformation layer of the nanometer gradient structure reaches 100-300 micrometers; and the grains on the surface layer of the workpiece material are nanometer grains, submicron grains, deformation grains and initial grains in sequence in size from the surface to the inside. According to the processing method provided by the invention, the integral mechanical property of the material is improved through improving the microstructure of the surface layer, thereby, the service life of the material is prolonged. The processing method provided by the invention is small in investment and is simple and convenient in operation.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

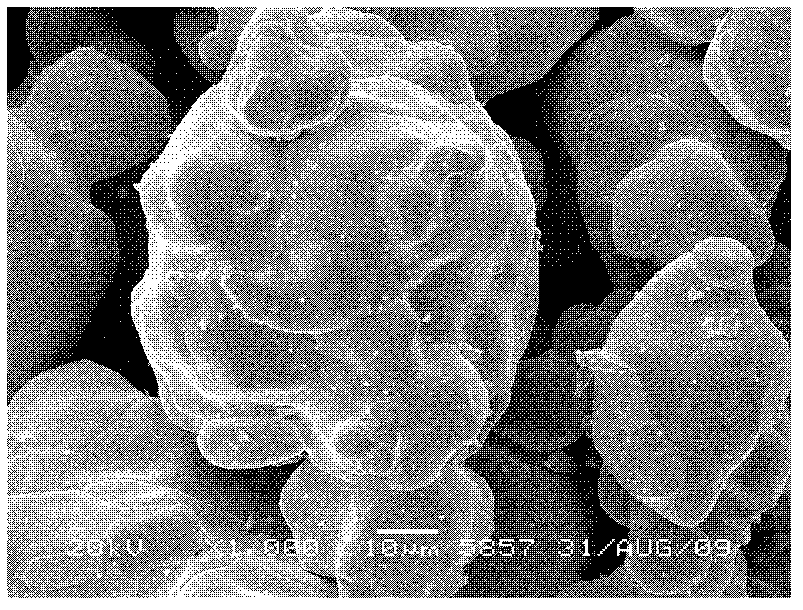

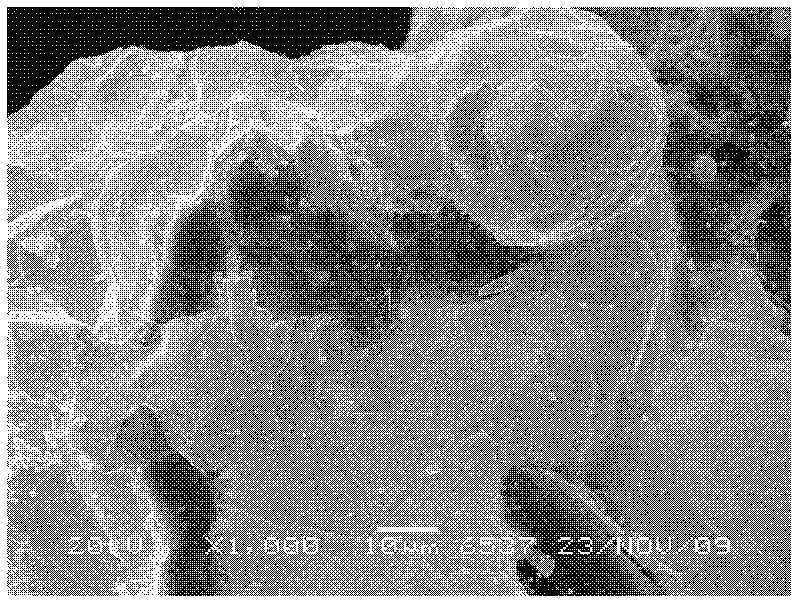

Extra coarse grain WC-Co hard alloy and preparation process thereof

ActiveCN102534344APromote grain growthIncrease the carbon content of tungsten carbideCemented carbideGrain distribution

The invention relates to an extra coarse grain WC-Co hard alloy. The hard alloy comprises 5 to 15 weight percent of Co and the balance of WC, wherein the average grain size of the WC is 6 to 10mu m. A preparation process for the hard alloy comprises the following steps of: pre-ball-milling coarse and fine tungsten carbide to prepare mixed tungsten carbide powder, preparing mixed tungsten carbide powder-cobalt-former mixed powder, pressing, and sintering, wherein the sintering step is divided into a former removing part and a high-temperature sintering part. The average grain size of a metallographic structure of the WC-Co hard alloy prepared by the process is 6mu m or more than 6mu m, the process method is simple and convenient to operate, the prepared hard alloy has a large average grainsize, a narrow grain distribution range, a low thermal expansion coefficient and high heat conductivity, high-temperature wear resistance, transverse rupture strength and rupture toughness, and is suitable for a mining tool and an excavating tool, and the thermal fatigue crack resistance of the alloy is effectively improved.

Owner:HUNAN BOYUN DONGFANG POWDER METALLURGY

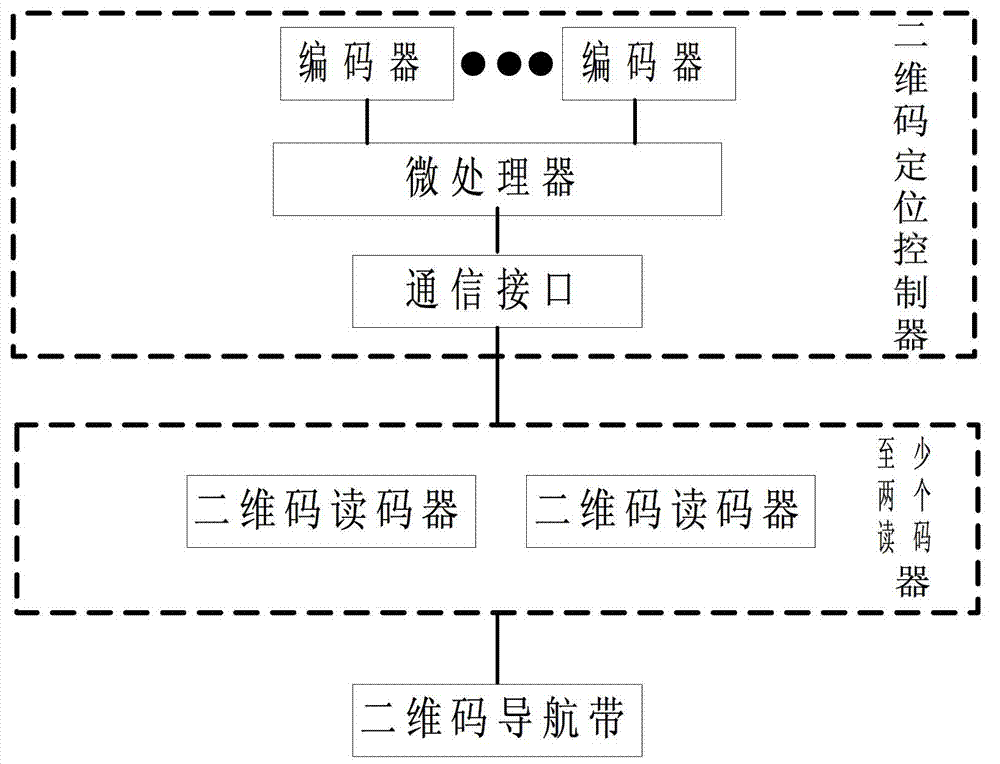

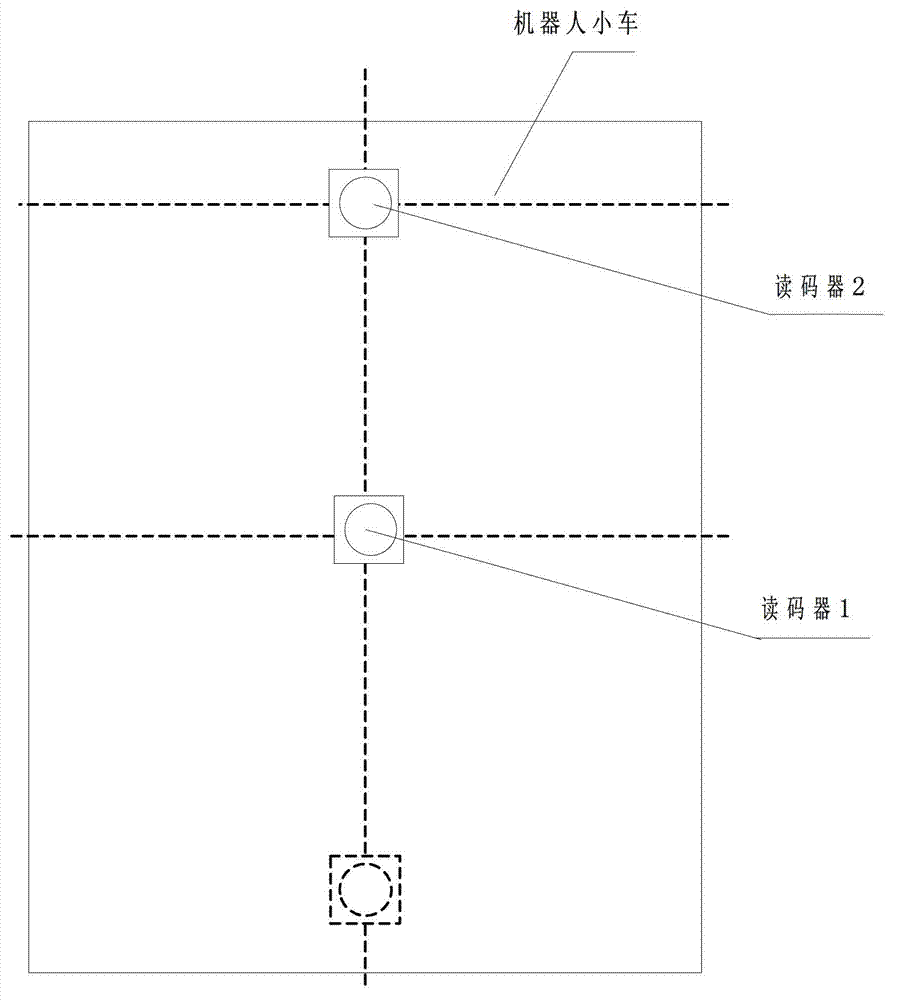

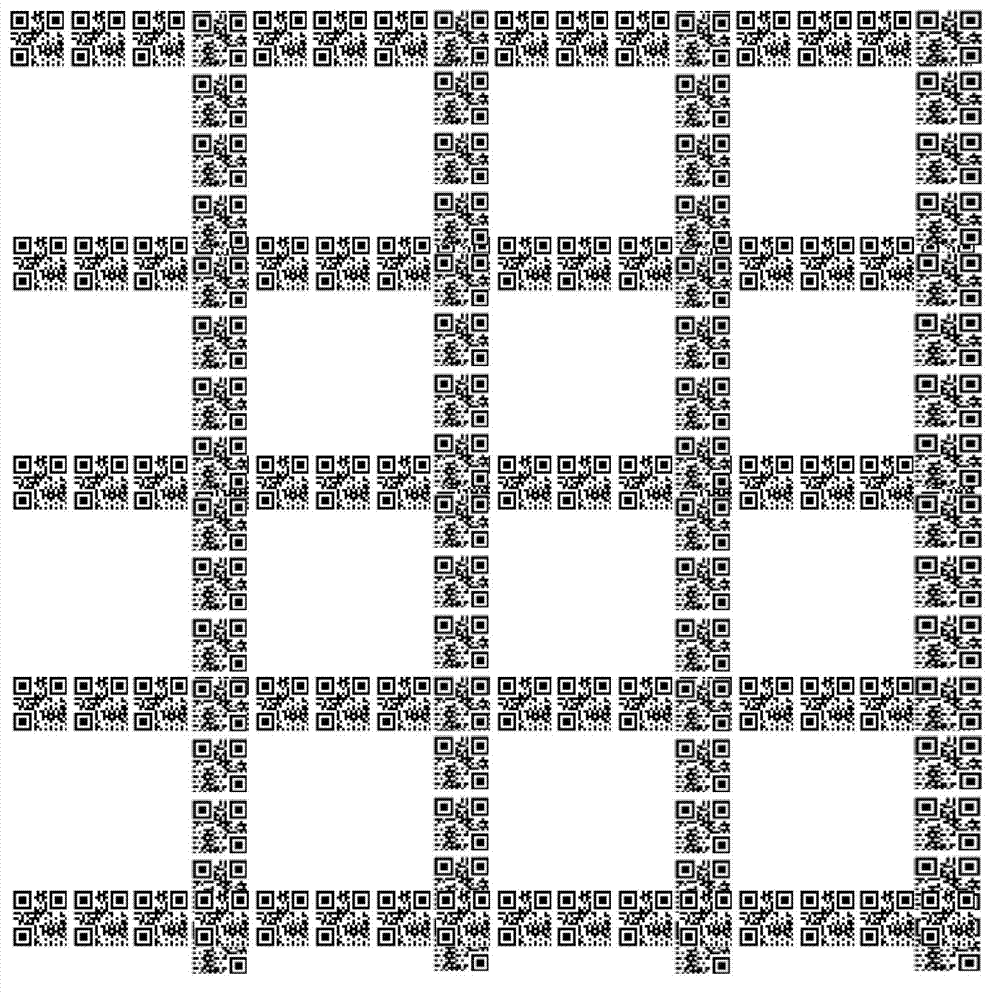

Mobile robot positioning system based on two-dimension code navigation band

ActiveCN103324194ARun fastImprove efficiencyPosition/course control in two dimensionsImaging processingComputer science

The invention relates to a mobile robot positioning system based on a two-dimension code navigation band. The mobile robot positioning system based on the two-dimension code navigation band is mainly and technically characterized by comprising a two-dimension code positioning controller, at least two two-dimension code readers and a two-dimension code navigation band, wherein the two-dimension code positioning controller and the two-dimension code readers are installed on a mobile robot dolly, and the two-dimension code navigation band is laid on the ground. The two-dimension code navigation band is formed by a plurality of two-dimension codes arranged in sequence and adjacently. The two-dimension code positioning controller is connected with the two-dimension code readers to be used for collecting two-dimension code navigation information and achieving the accuracy positioning function of a mobile robot. The mobile robot positioning system based on the two-dimension code navigation band is reasonable in design, skillfully avoids the complex character of vision image processing by the adoption of the method of the two-dimension code navigation band, enables the real-time performance of image collection not to be restricted by software conditions and hardware conditions, fundamentally solves the real-time image collection problem which is difficult to solve by technical staffs in the field for a long time, effectively improves operating speed of the mobile robot, and ensures the high efficiency of the mobile robot positioning system.

Owner:爱泊科技(海南)有限公司

Four-step phase shifting method based on absolute phase recovery

InactiveCN102155924AReduce the numberIncrease contrastOptical measurementsUsing optical meansGratingThree dimensional measurement

The invention discloses a four-step phase shifting method based on n absolute phase recovery, and belongs to the technical field of three-dimensional measurement. The method comprises the following steps of: generating a grating coding stripe image implied with absolute phase identifiers through a computer; projecting coding stripe patterns and acquiring a detected object image; distinguishing the absolute phase identifiers according to the modulation degree information; and solving the phases by using different phase solving methods inside and outside an identifier region respectively. Compared with other phase solving methods, the solution of the phases does not need to individually project additional absolute phase identifier images in the methods, and the number of the required images is few; the phase solving methods are not strict with the boundary requirements of the absolute phase identifier region, and have good stability of acquiring accurate absolute phases; and the implied absolute phase identifier characteristics are obvious, the contrast is strong, the extraction is convenient, the form is not limited, and different application requirements are met.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

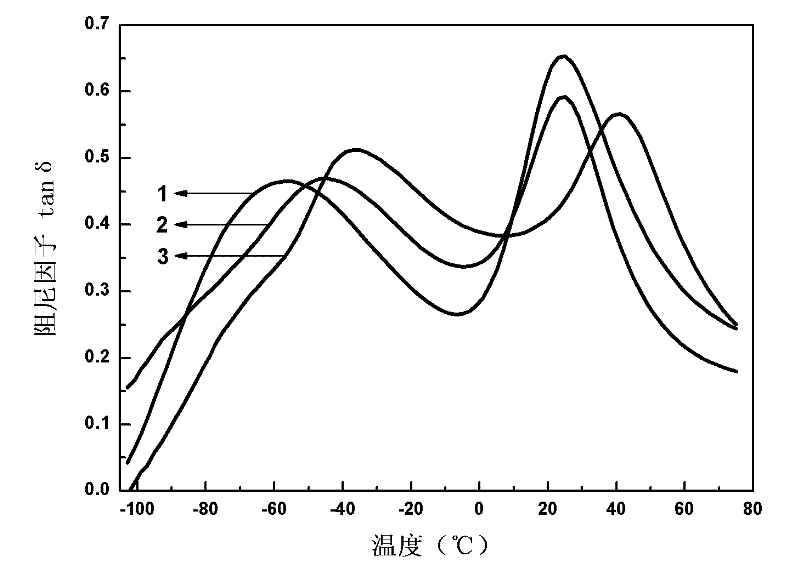

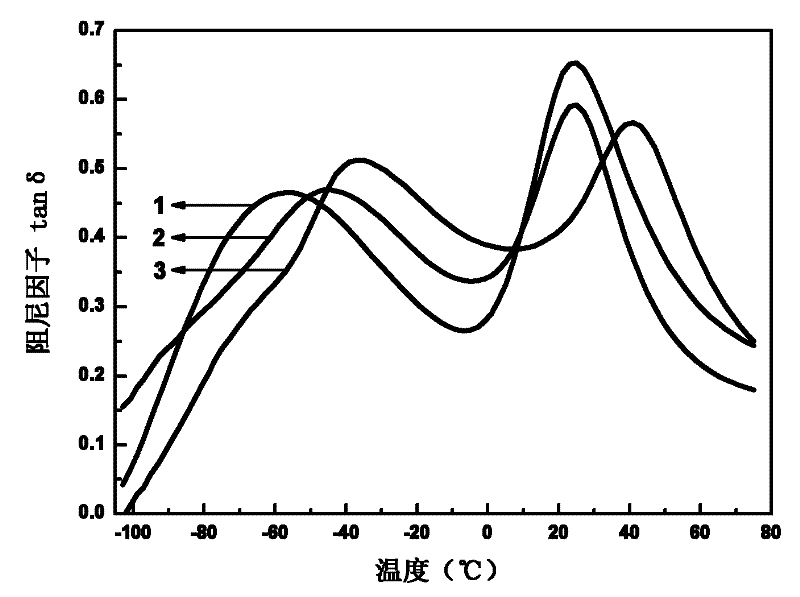

Ternary rubber composite with wide temperature range and high damping property and preparation method thereof

InactiveCN102229724ACommercially availableSimple processing methodComposite materialPolymer chemistry

The invention discloses a ternary rubber composite with a wide temperature range and high damping property and a preparation method thereof. The preparation method of the ternary rubber composite comprises the following steps of: firstly plasticating 100 parts by weight of butyl rubber, 10-40 parts of butyronitrile rubber and 160 parts of chloroprene rubber separately at 40-100 DEG C for 1-20 minutes and blending to obtain a blend; then, adding 2-32 parts by weight of vulcanizer, 7-17 parts by weight of vulcanization accelerating agent and 5-100 parts of filler the blend of the butyl rubber, the butyronitrile rubber and the chloroprene rubber to obtain a gross rubber; and finally standing the gross rubber for 8-24 hours, and vulcanizing at 100-200 DEG C and 5-20 MPa for 1-60 minutes to finally obtain the required ternary rubber composite. According to the invention, the preparation method is simple, the prepared vulcanized rubber has excellent damping property in a wider temperature range larger than 110 DEG C as well as excellent physical and mechanical properties; as a damping material, the ternary rubber composite can be widely used in damping and noise reduction aspects.

Owner:SOUTH CHINA UNIV OF TECH

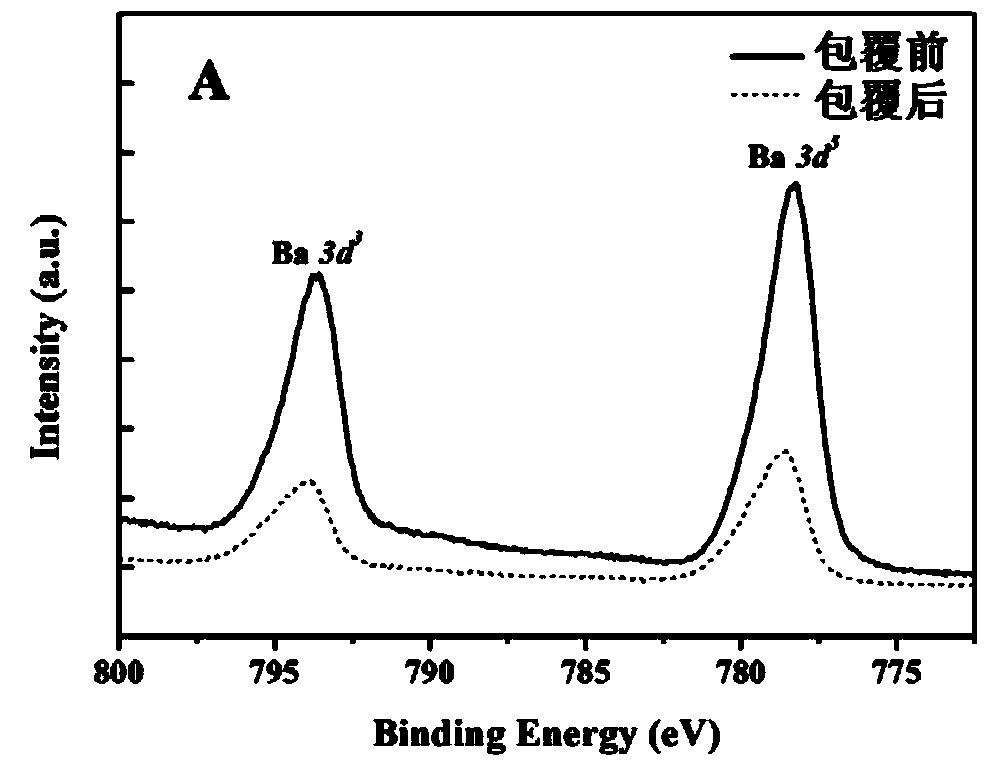

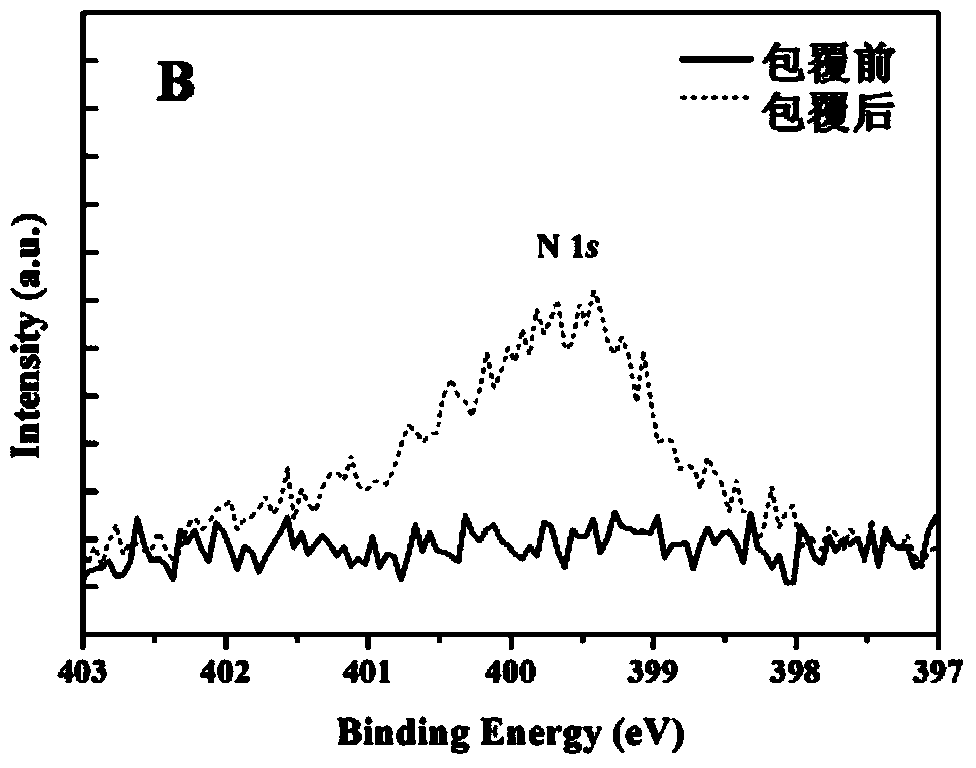

Piezoelectric active bone repair composite material and preparation method thereof

The invention relates to a piezoelectric active bone repair composite material and a preparation method thereof, aiming at solving the problems that the existing material does not have biocompatibility and is poor in piezoelectric property. The piezoelectric active bone repair composite material comprises ceramic particle filler with a core-shell structure, and polymer matrix, wherein the ceramic particle filler with the core-shell structure is evenly dispersed in the polymer matrix; the core body of the ceramic particle filler with the core-shell structure is formed by ceramic particles, and the surfaces of the ceramic particles are covered by organic matter coating layers. The invention also provides the preparation method of the piezoelectric active bone repair composite material. The preparation method can be widely applied to the field of preparation of the bone repair composite material.

Owner:PEKING UNIV SCHOOL OF STOMATOLOGY

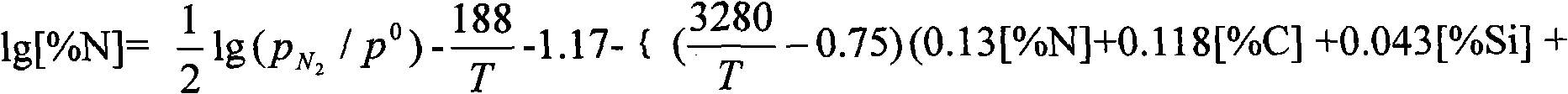

Method for smelting high-nitrogen steel by compression electroslag furnace

InactiveCN101260478ASolve the problem of uneven distribution of nitrogen contentAvoid secondary remeltingCurrent rangeSlag

The invention relates to a method for smelting the high-nitrogen steel by pressurizing an electroslag furnace. The method comprises the following steps that: the content and the weight percentage of each raw material of a self-consuming combined electrode parent metal are determined; the self-consuming electrode parent metal is smelted, an alloy pipe after charged with nitro-alloy particles and a deoxidizing agent is welded on the parent metal to produce the self-consuming combined electrode which is welded on a fake electrode and is clamped on the electrode; an arc starting agent is placed into a bottom water tank below the self-consuming electrode; the slag is dried for three to ten hours and is poured into a crystal device, a smelting chamber is sealed; under the condition of nitrogen, the slag is melted with a current ranging from 1000 to 2000A; afterwards, the pressure of the smelting chamber and the cooling water are increased to be 3 to 10 MPa, the smelting is performed with a current ranging from 2000 to 6000A; when the smelting current is reduced to 1000 A, the smelting is over. The method has the advantages that the solid state arc starting slagging way and the self-consuming combined electrode are adopted to perform the smelting in an over-normal pressure sealing smelting chamber, and the problem of the prior art of uneven distribution of nitrogen in the process of preparing high-nitrogen steel is solved, thereby avoiding the remelting and saving the production cost; moreover, the technique method is simple and the smelting effect is good.

Owner:NORTHEASTERN UNIV

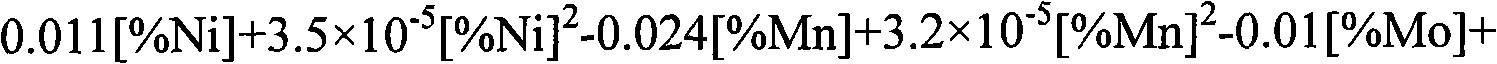

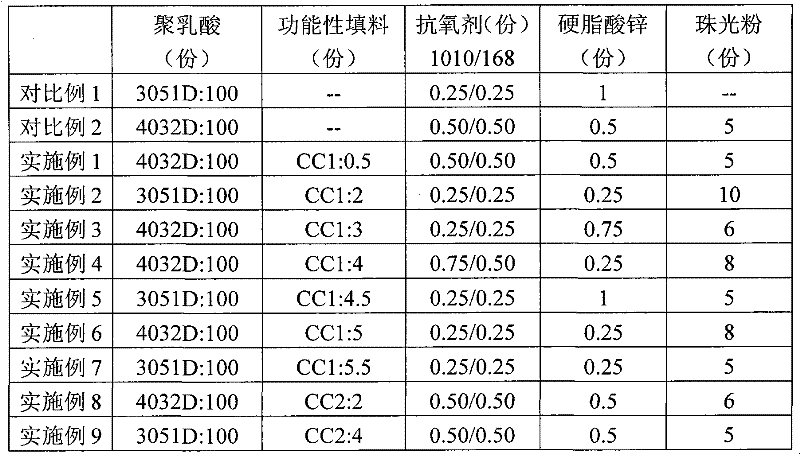

Polylactic resin composition film and preparation method thereof

The invention provides a polylactic resin composition film and a preparation method thereof, and relates to the field of plastic processing. The polylactic resin composition film comprises the following components: 100 weight parts of polylactic resin and 0.5 to 5.5 weight parts of functional filler which are blended, wherein the polylactic resin has the weight-average molecular weight of 80,000-300,000 and the molecular weight dispersibility of 1.5-2.2; and the functional filler is at least one of the following inorganic fillers: calcium carbonate, clay, silica, alumina, barium sulfate, calcium sulfate, talc, magnesium sulfate, titanium dioxide, zeolite, aluminum sulfate, kieselguhr, kaolin, calcium oxide and magnesium oxide. The preparation method comprises the following steps of: melting, blending and granulating the components in the proportion, casting and pressing, and biaxially tensioning to obtain the polylactic resin composition film. The film is completely biodegradable, has balanced rigidity and toughness, maintains the tensile strength, has the elongation at break improved by 3 to 7 times compared with the original elongation at break, and has uniform texture, high decorative property, high printing property and unidirectional tearing property.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com