Patents

Literature

117results about How to "The process method is simple" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polylactic acid alloy membrane and application thereof

ActiveCN103319865AImproved oxygen barrier propertiesThe process method is simpleCoatingsEnvironmentally friendlyPolylactic acid

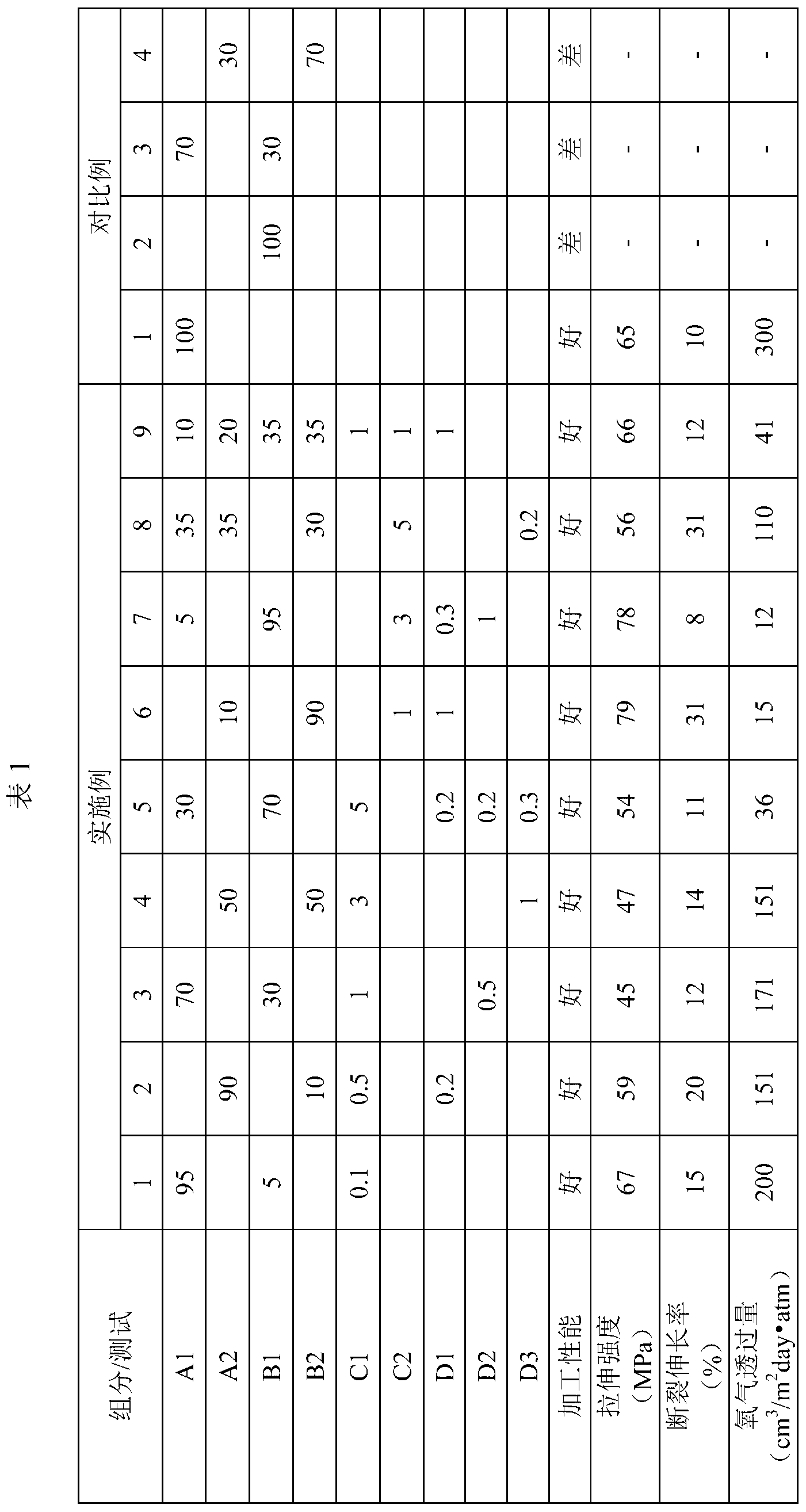

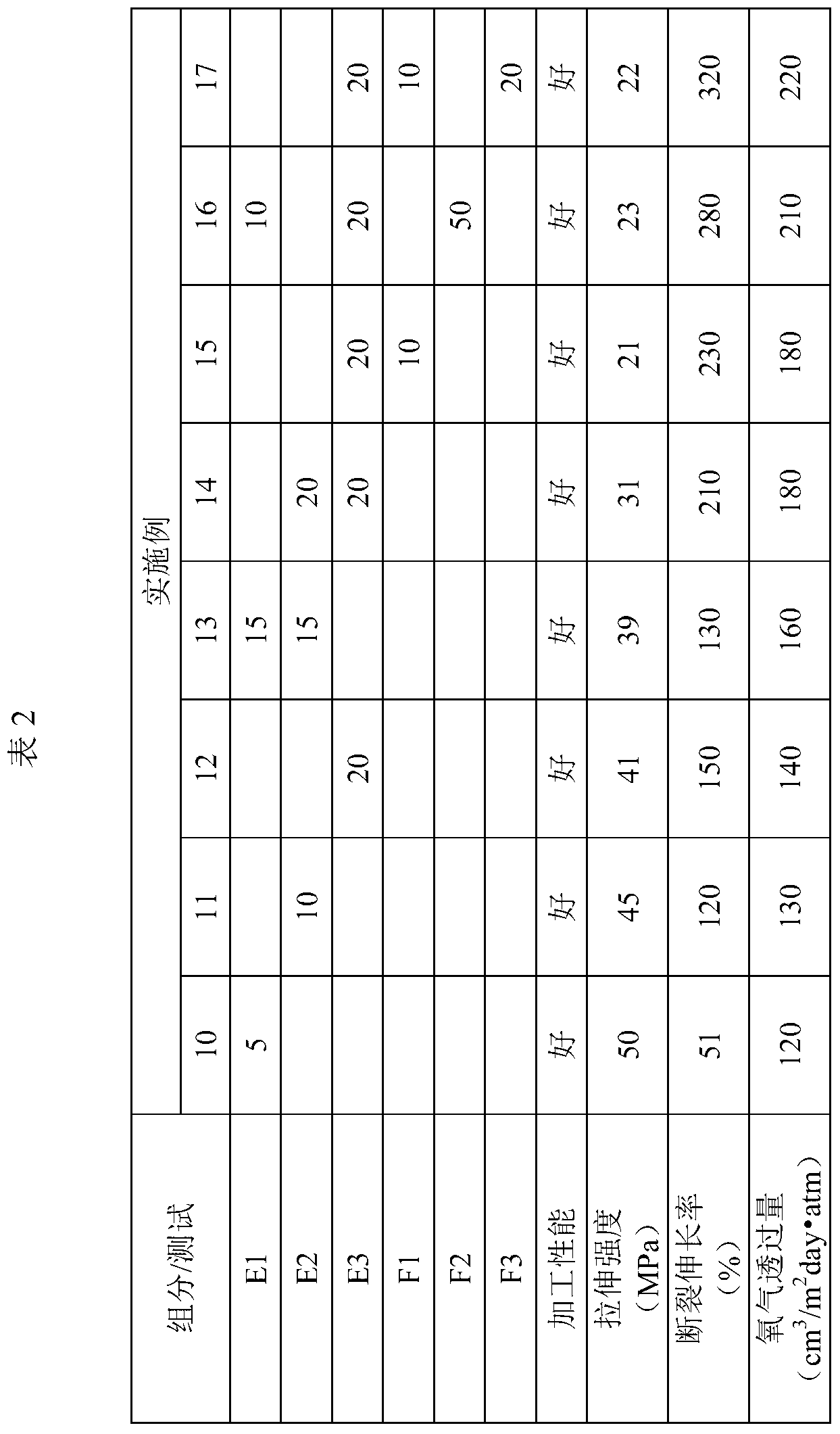

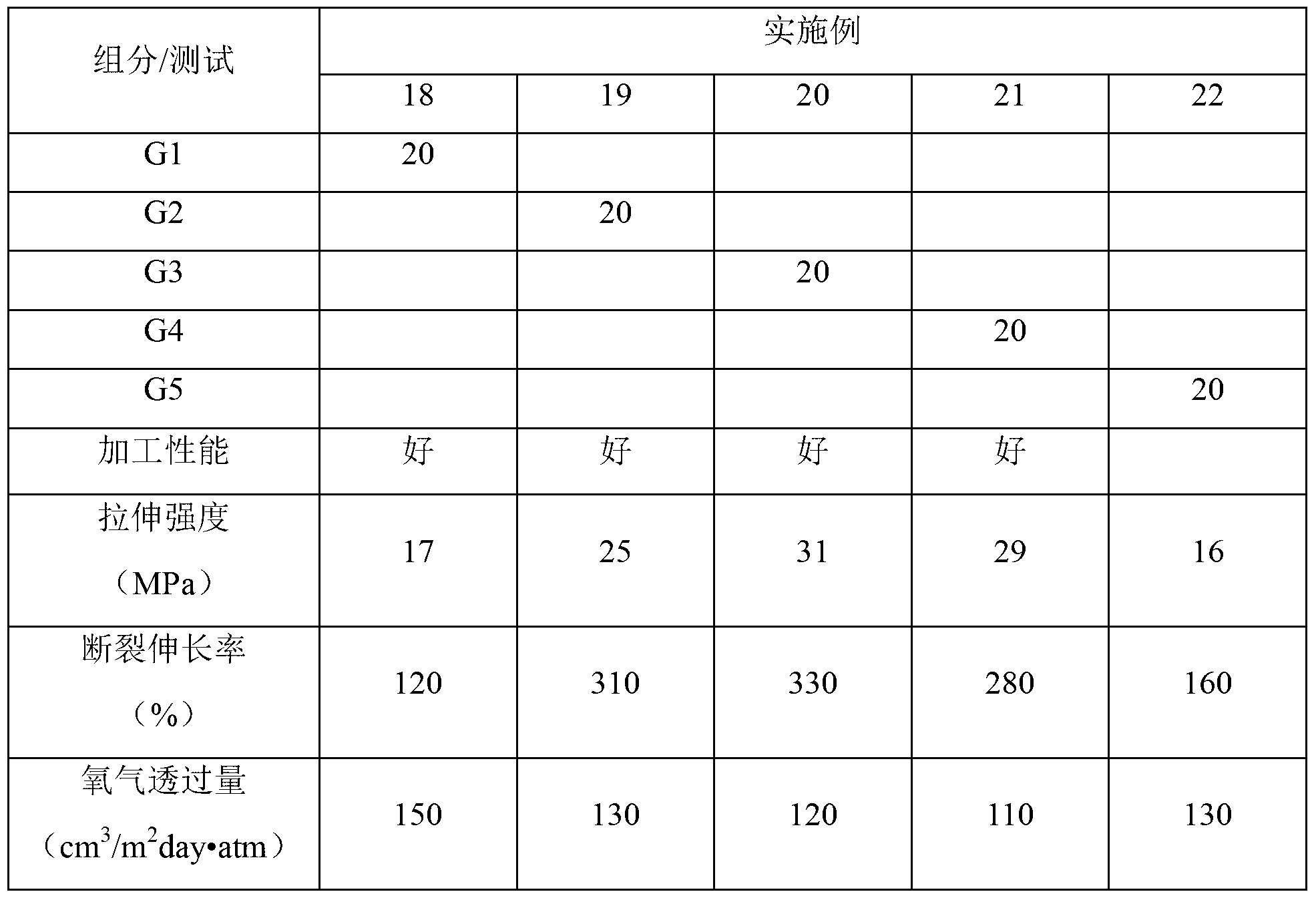

The present invention discloses a polylactic acid alloy membrane, which comprises polylactic resin, polyvinyl alcohol resin and a bulking agent, wherein the three are in parts by weight of 1to 99 parts, 1 to 99 parts and 0.05to 5 parts respectively, with the total account of polylactic resin and polyvinyl alcohol resin in parts by weight of 100 parts. By the invention, the oxygen barrier property of the polylactic acid alloy membrane is effectively improved under the premise of keeping the membrane completely biodegradable and providing the membrane high mechanical strength. The technology method provided by the invention is easy with low cost, and is able to effectively promote widespread use of the environmentally friendly polylactic acid products.

Owner:常州博疆新材料科技有限公司

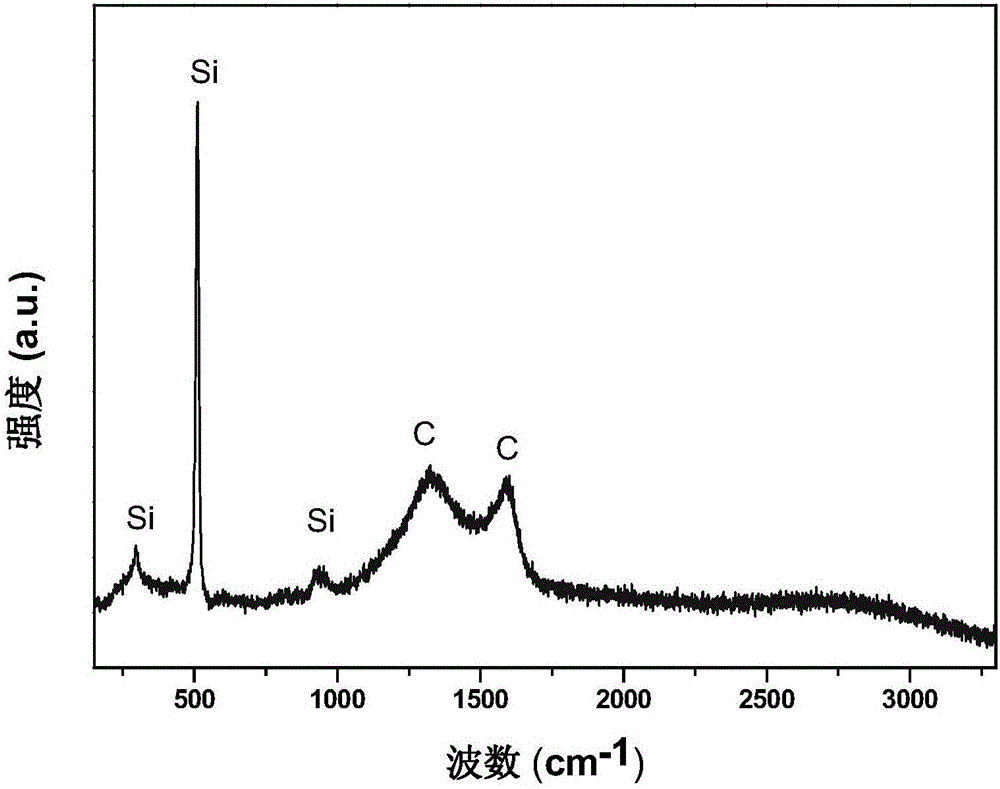

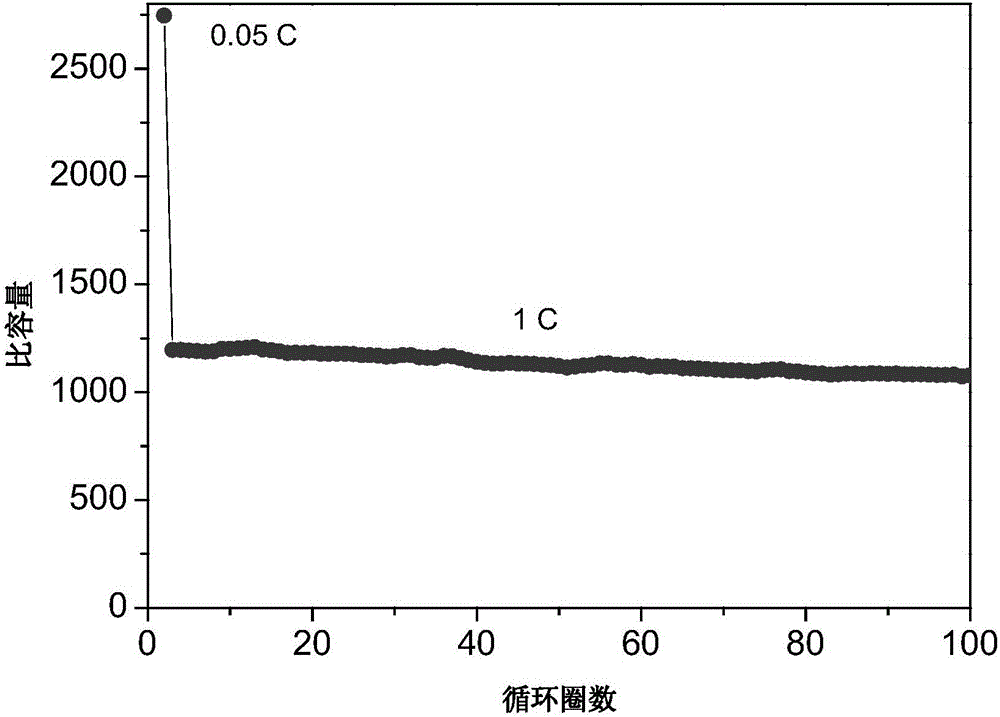

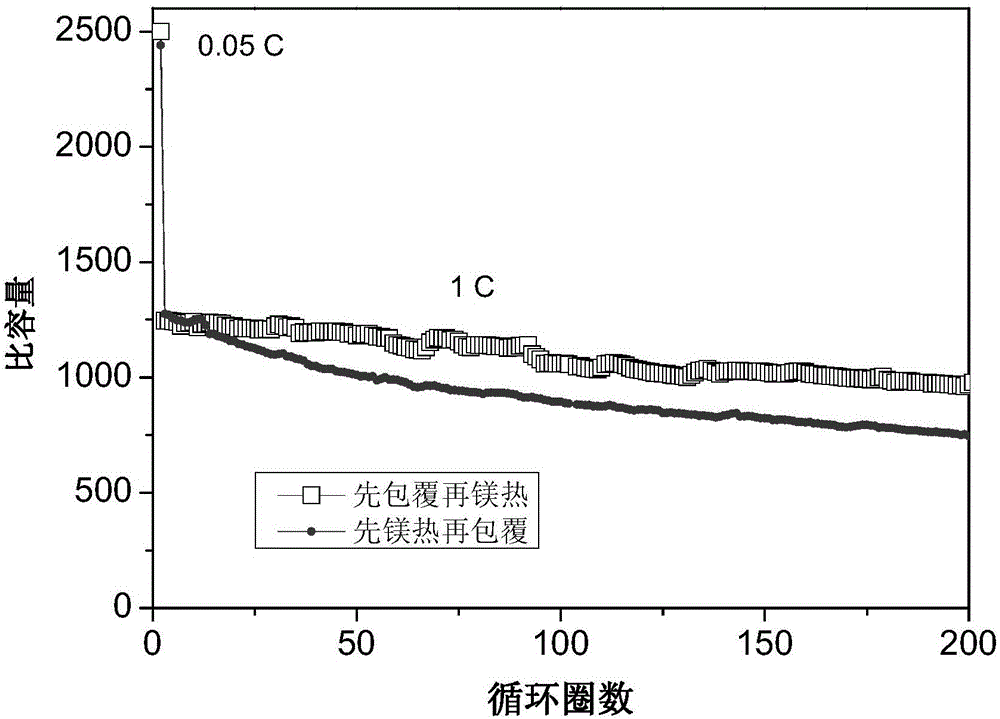

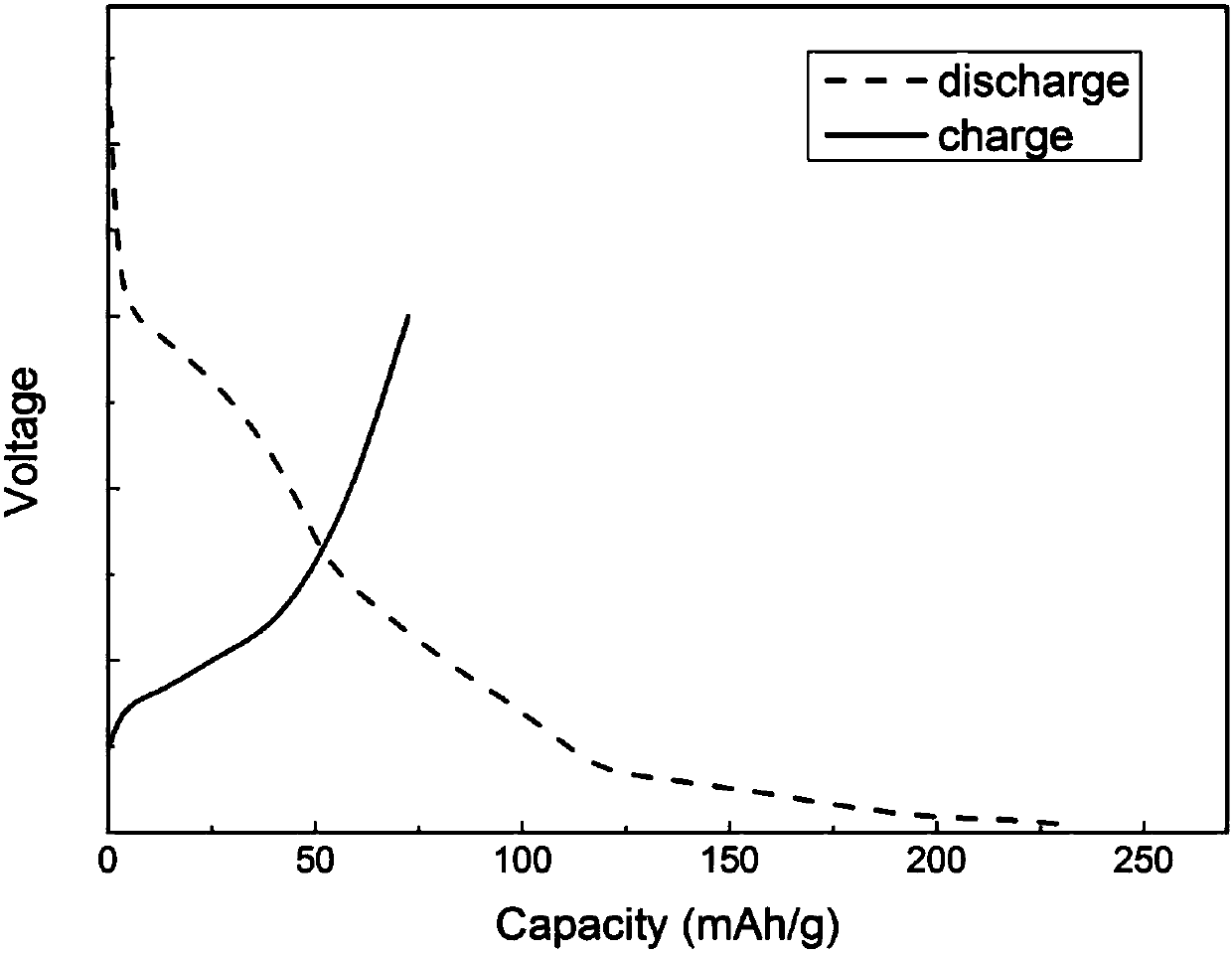

Method for preparing silicon/carbon composite material with magnesiothermic reduction process

InactiveCN106374088AThe process method is simpleLow costCell electrodesSecondary cellsSolventPorous composite

The invention discloses a method for preparing a silicon / carbon composite material with a magnesiothermic reduction process, and belongs to the technical field of composite material preparation. The method comprises the following steps: (1) mixing a silicon dioxide source, an organic carbon source and a solvent, carrying out ball-milling to prepare a uniformly pulpous mixture, and obtaining a silicon dioxide-carbon precursor composite material through drying; (2) mixing the silicon dioxide-carbon precursor composite material with magnesium powder to carry out a magnesiothermic reduction reaction, collecting products and carrying out acid pickling and washing, and drying to obtain the silicon / carbon composite material. According to the method, silicon dioxide reduction and high temperature carbonization are completed by using a one-step process, and the method has the advantages of simple technical process, low cost and large-scale production; the prepared composite material effectively maintains the appearance of porous silicon, so that the composite material has preferable capability for bearing volumetric strain; the porous composite material is applied to a lithium battery, so that the lithium-ion de-intercalation depth is small, the ion diffusion path is short, the reversible capacity and coulombic efficiency of the lithium battery are effectively improved, and the cycle life is prolonged.

Owner:TIANNENG SAFT ENERGY JOINT CO

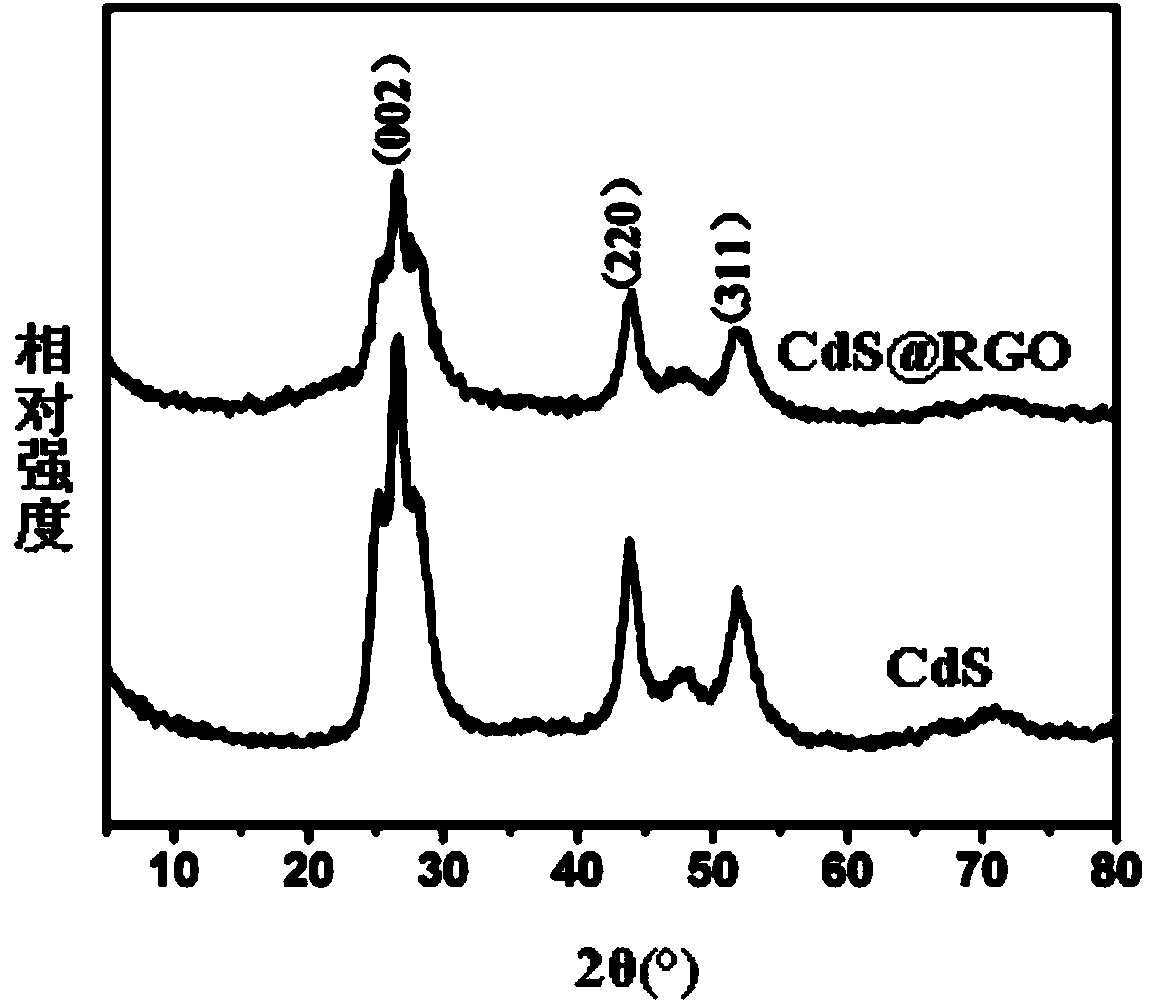

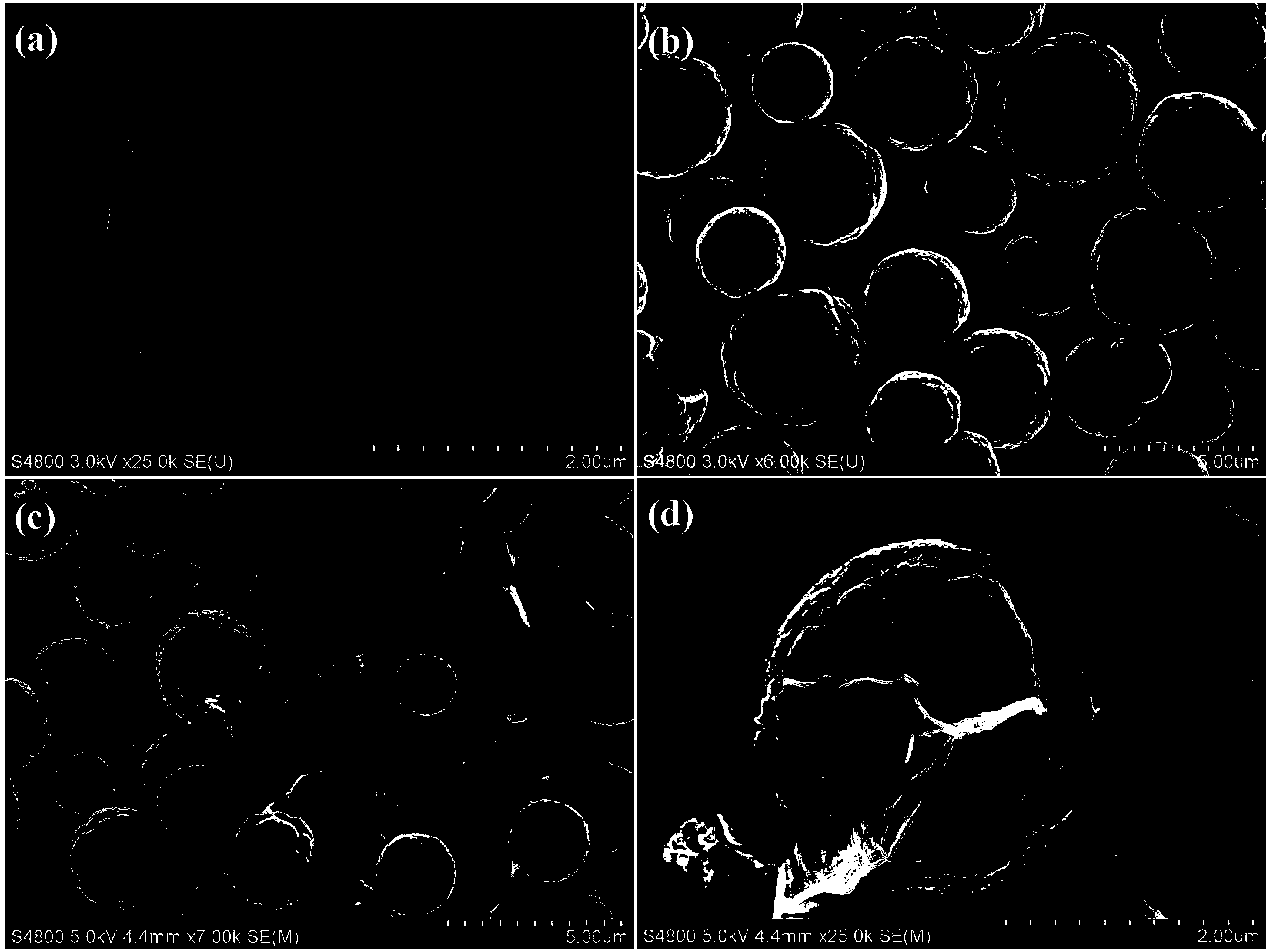

Method for preparing photocatalytic material with graphene-covered cadmium sulfide nuclear shell structure

InactiveCN103769167AThe process method is simpleUniform sizePhysical/chemical process catalystsPhotocatalytic degradationCvd graphene

The invention discloses a method for preparing a photocatalytic material with a graphene-covered cadmium sulfide nuclear shell structure. The photocatalytic material with the nuclear shell structure is high in monodispersity and controllable in particle size; furthermore, the photocatalytic material is extremely high in photocatalytic degradation efficiency to a simulated organic pollutant rhodamine B in a water body. A cadmium sulfide microsphere is prepared by a hydrothermal technology, and then the surface of the cadmium sulfide microsphere is coated with a layer of graphene, so that the nitrogen- and cerium-doped titanium dioxide photocatalytic material is finally prepared. The photocatalytic material with the graphene-covered cadmium sulfide nuclear shell structure, which is prepared by the method disclosed by the invention, is high in monodispersity; furthermore, the size of the product can be controlled according to a reaction condition, and the specific area is large; the photocatalytic material is higher in photocatalytic reaction efficiency and has a wide application prospect. The preparation method and the technology are simple and environment-friendly; the raw materials and equipment are cheap and readily available and are low in cost; the synthesis time is short, and the efficiency is high; the method has an extremely wide industrial production prospect.

Owner:SHAANXI UNIV OF SCI & TECH

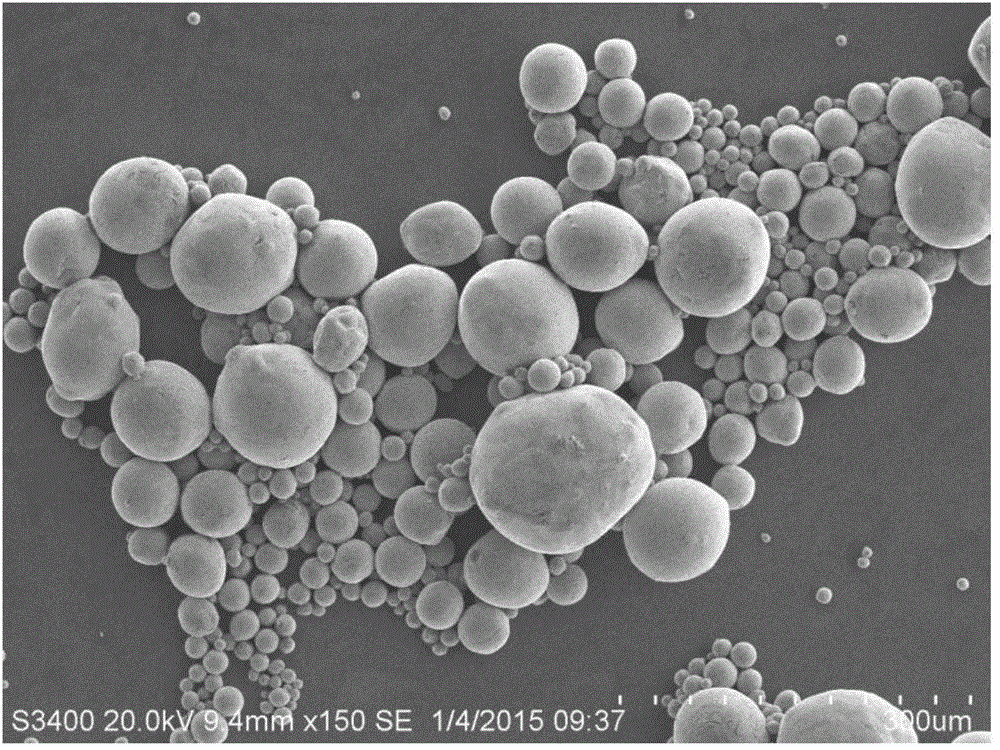

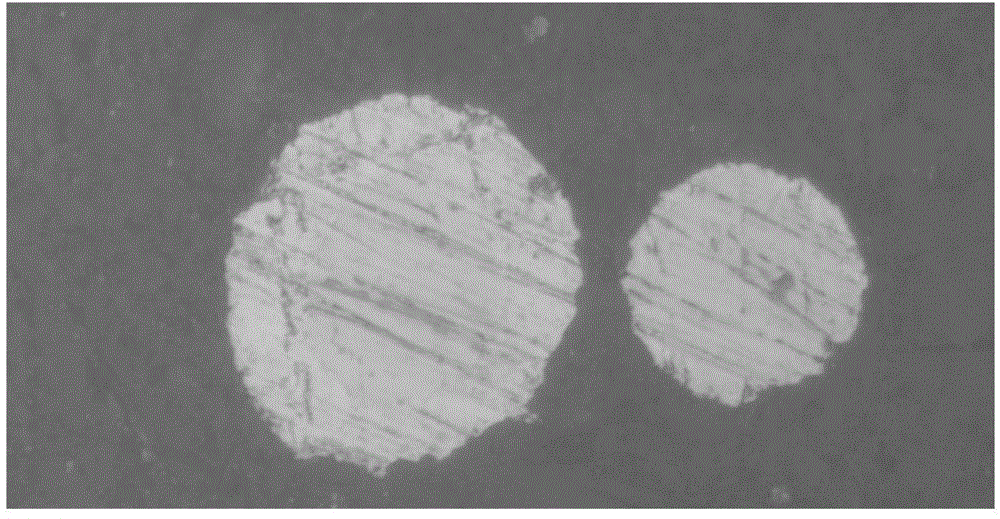

Manufacturing method of micrometer and nanometer composite spherical metal powder of core-shell structure

ActiveCN104625046AClear principleThe process method is simpleMaterial nanotechnologyPowder metallurgyMicrometer

The invention provides a manufacturing method of micrometer and nanometer composite spherical metal powder of a core-shell structure. The manufacturing method comprises the steps that 1, a composite metal powder precursor is prepared; 2, the prepared composite metal powder precursor is evenly mixed with carbon material powder or ceramic material powder; 3, one or more kinds of metal in the composite metal precursor is molten through high-temperature treatment, after solidification, composite metal spheres of a core-shell structure are formed, wherein the temperature of high-temperature treatment at least reaches the melting temperature of one kind of metal in the composite metal precursor, and particularly the temperature is 400-1000 DEG C higher than the melting point of the kind of metal; 4, the carbon material powder or the ceramic material powder are removed, so that the micrometer and nanometer composite spherical metal powder of the core-shell structure is formed. The size of the composite metal powder precursor is smaller than 10 mm, and the optimal size of the composite metal powder precursor ranges from 50 nm to 1 mm. The degree of sphericity of composite metal spheres of the core-shell structure is high, and the composite metal spheres of the core-shell structure can be widely applied to powder metallurgy and conductive slurry.

Owner:NANJING UNIV

Method for preparing titanium-rich material from titanium-containing slag

InactiveCN101768673AReduce the amount of exhaust gasThe process method is simpleProcess efficiency improvementSlagBall mill

The invention relates to a method for preparing titanium-rich material from titanium-containing slag, comprising the following steps: 1. carrying out ball-milling on titanium-containing slag, then adding Na2CO3 or NaOH and mixing evenly; 2. carrying out calcination on the mixture obtained in step 1, then adding HC1 solution for leaching; 3. filtering the leached solution, concentrating and then recycling the filtrate; 4. calcining the filter residue to obtain titanium-rich material with grade of TiO2 being more than 90%.In the invention, Na2CO3, NaHCO3 or NaOH are added into the titanium-containing slag, then SiO2, Al203 in the slag are converted into NaSiO3 and NaAlO2 which are later leached by HC1 solution, so that SiO2, Al2O3 and MgO which are not converted are leached into the solution and grade of TiO2 in leached slag is improved by a big margin. The technique of the invention features simple method, convenient operation, environmental-friendliness, good economic benefits, high level of resource utilization and adaptability to industrialized production; in addition, the technique is especially suitable for recovering titanium in titanium-containing slag produced by the direct iron process.

Owner:CENT SOUTH UNIV

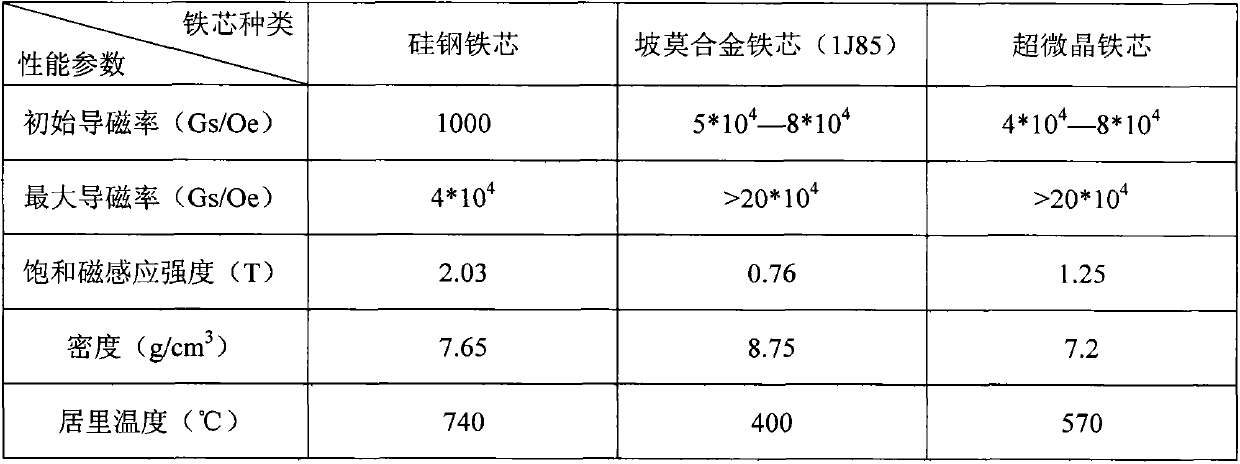

Production process of ultra-crystallite cutting iron core for split mutual inductor

ActiveCN103390492AThe process method is simpleLow costInductances/transformers/magnets manufactureCrystalliteInductor

The invention discloses a production process of an ultra-crystallite cutting iron core for a split mutual inductor. The production process comprises the following steps: a, placing an ultra-crystallite belt material iron core on a winding machine for winding into an iron core, and fixing by spot welding; b, thermally heating the iron core in a gradual temperature rising way, namely, heating to 380 DEG C and preserving heat for 10-50 minutes, heating to 450 DEG C and preserving heat for 10-50 minutes, and heating to 560-600 DEG C and preserving heat for 30-60 minutes; c, rapidly cooling by adopting air cooling till the temperature of the iron core is lowered to 300 DEG C, and controlling the time period from the end of the heat preservation to a moment when the temperature of the iron core falls below 300 DEG C to be within 45 minutes; d, reshaping the iron core, loading into a mold, putting into prepared paint together for soaking in vacuum, and hardening; e, cutting the cured iron core along a symmetrical center line, ensuring the flatness and smoothness of a notch, and eliminating scattering and burrs of the iron core; and f, testing and encapsulating. The process disclosed by the invention has the advantages that the method is simple, a thermal treatment process is improved, a paint soaking step is added, a low-cost and high-performance iron core can be realized, and a very remarkable effect is achieved.

Owner:河北申科电力股份有限公司 +5

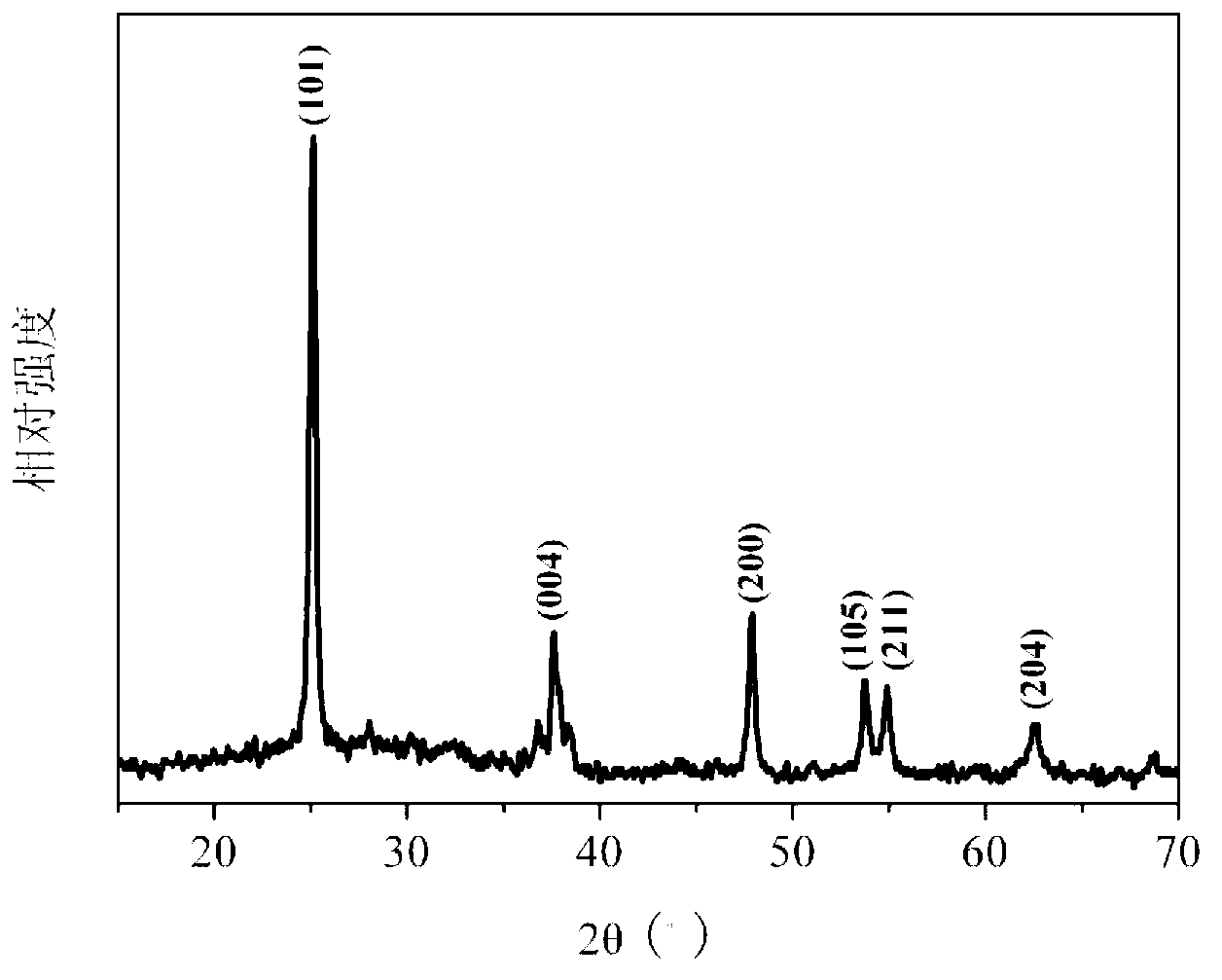

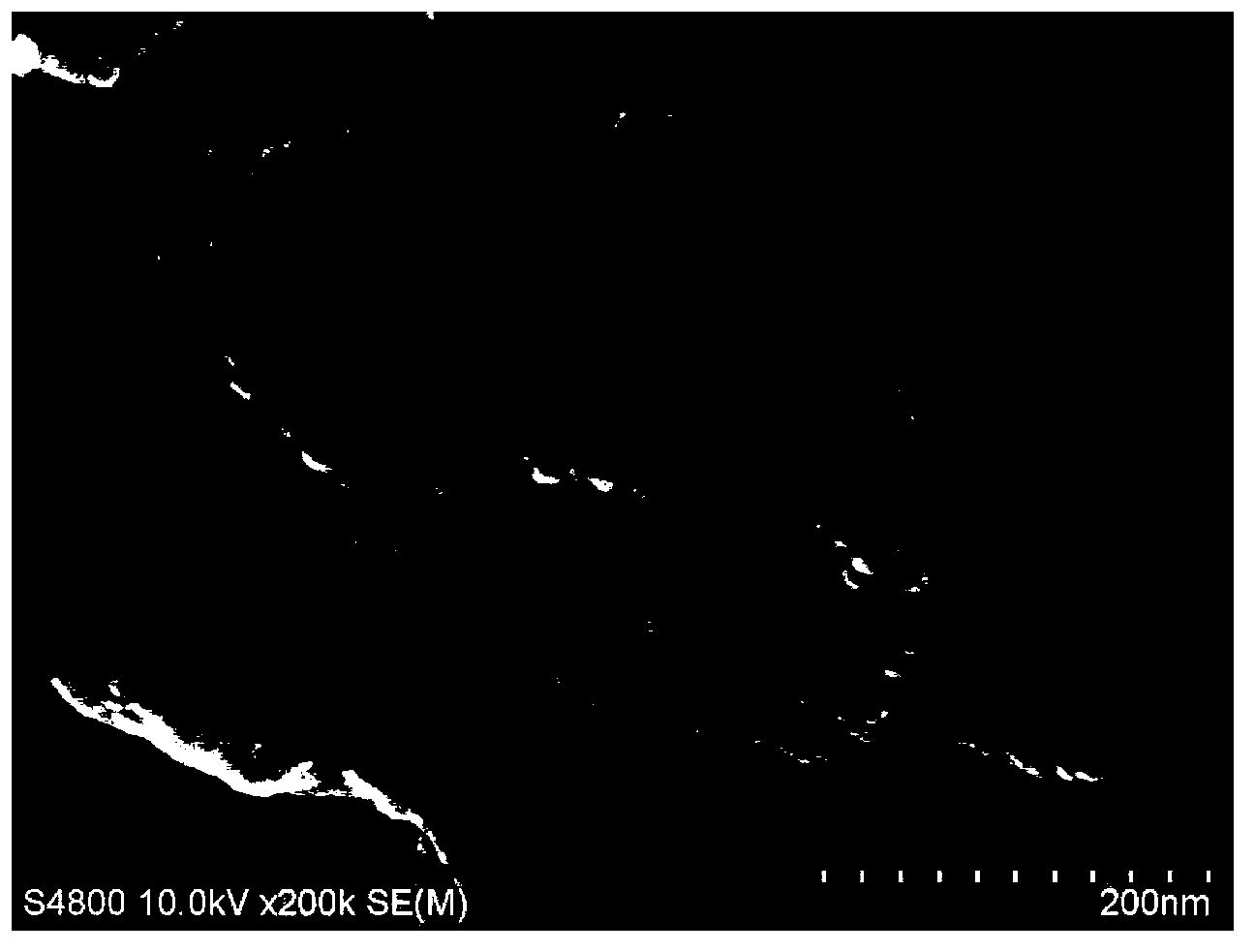

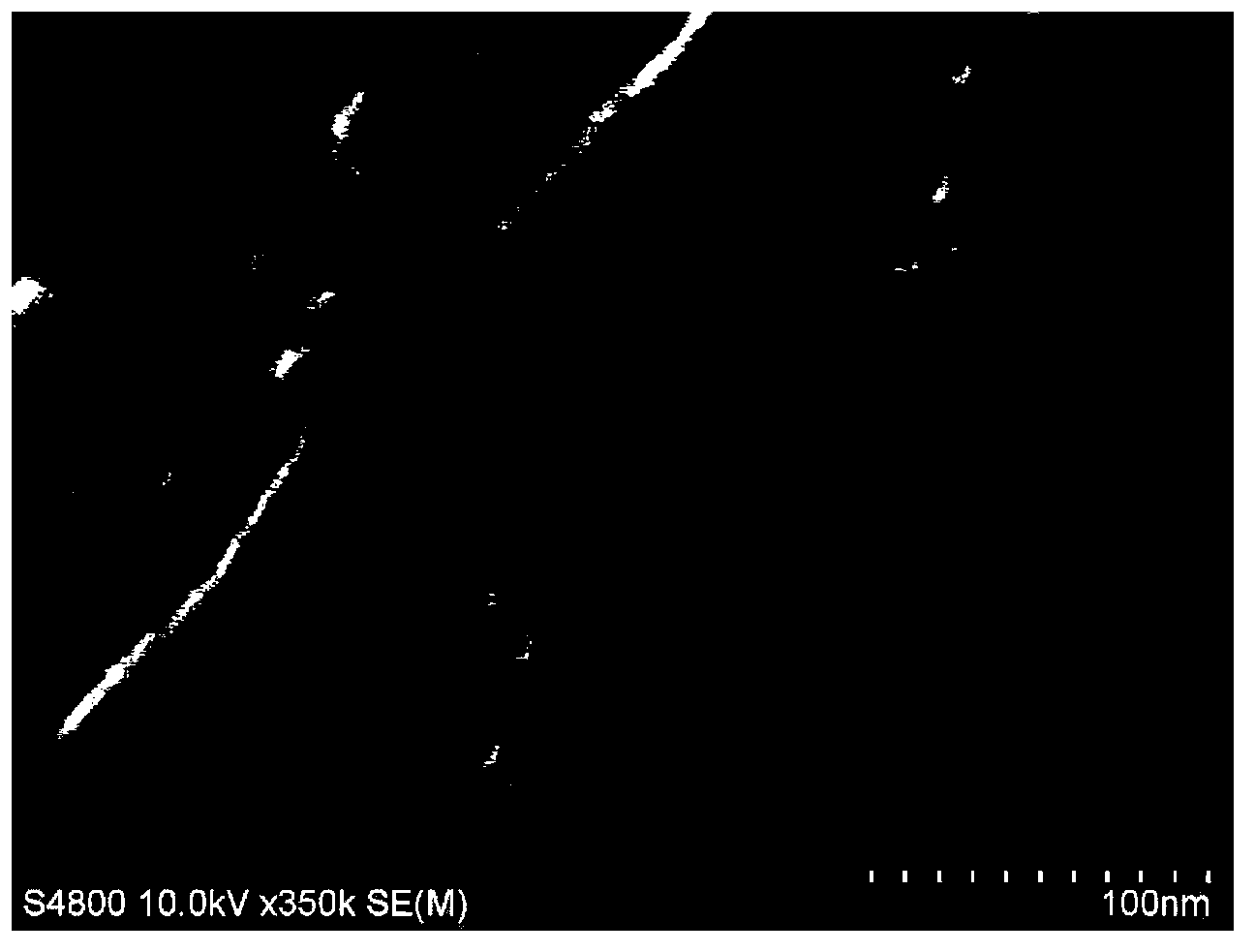

Method for preparing grapheme-titanium dioxide composite electrochemical biosensor

InactiveCN103308573AThe process method is simpleRaw materials are easy to getMaterial electrochemical variablesCvd grapheneBiocompatibility Testing

The invention discloses a method for preparing a grapheme-titanium dioxide composite electrochemical biosensor. The preparation method is orderly carried out according to the following steps of: preparing a grapheme oxide; preparing a graphene load titanium dioxide composite material; preparing a glassy carbon electrode; preparing a decorative glassy carbon electrode. The method for preparing the grapheme-titanium dioxide composite electrochemical biosensor is simple in technique, available in material and free of pollution. The product prepared by the preparation method achieves direct electron transfer of horseradish peroxidase and electrodes, and has the advantages of low detection limit, short response time, good biocompatibility, high sensitivity, good stability and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of fiber fabric with shaping and toughening double functions

The invention belongs to the technical field of manufacturing of a liquid-state forming composite material, and relates to a preparation method of a fiber fabric with shaping and toughening double functions. When the double-function fabric is prepared, a thermoplastic resin toughening agent and a benzoxazine resin auxiliary adhesive are attached to one surface by using an atomizing spraying process, and a benzoxazine resin prepolymer powder shaping agent is attached to the other surface in a mechanical spreading mode. The process is simple and easy to implement; and the toughening agent, the auxiliary adhesive and the shaping agent are uniformly distributed on the surfaces of the fiber fabric without entering the interior of tows, so that the fiber fabric keeps good wettability to a resin matrix.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS +1

A method for recycling waste plastics

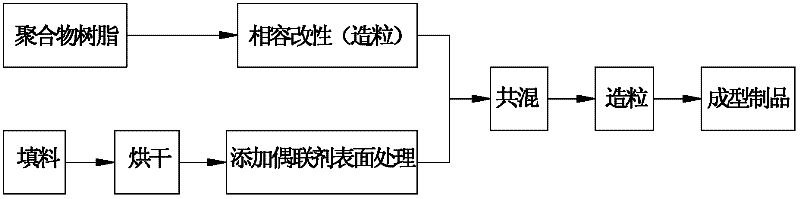

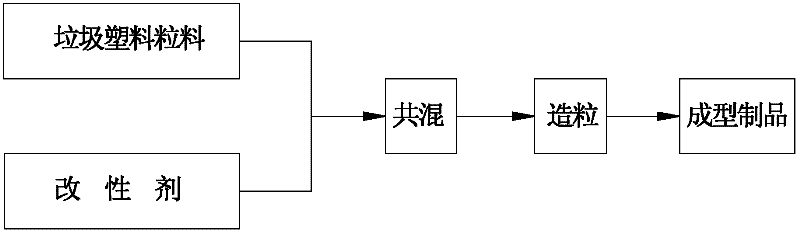

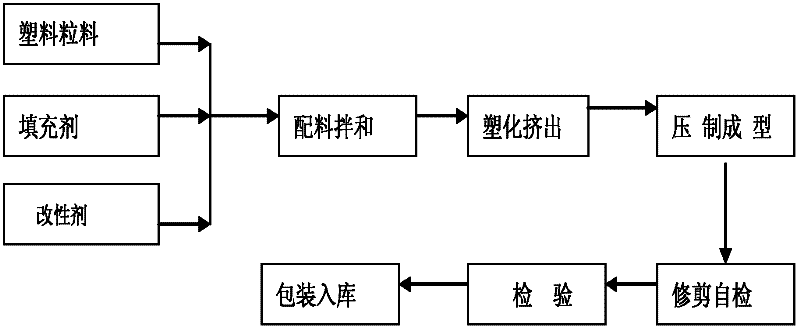

InactiveCN102268190AThe process method is simpleReduce environmental pollutionClimate change adaptationHeat proofingPelletizingReinforced concrete

The invention relates to a recycling method of garbage plastic, and mainly solves the technical problems of high cost and large environmental pollution existing in the traditional technology methods. The technical schemes comprises the following steps: firstly directly granulating the recycled garbage plastic, then adding a modifier with compatibility and coupling performance and filler and mixing, then carrying out alloy modification, and then processing into plastic pellets to produce buried drainage combined pipelines for municipal building, combined core molds or mold shells for building structures, or wall heat-insulation inner molds. Through the recycling method provided by the invention, garbage plastic can be recycled, and the process method is relatively simple and generates little environmental pollution. The treated recycled plastic including garbage plastic can be used to manufacture in-situ cast reinforced concrete core molds or manufacture industrial and building articles, daily necessities and the like, and can also be used to manufacture production raw materials such as granulation materials.

Owner:阳文皇

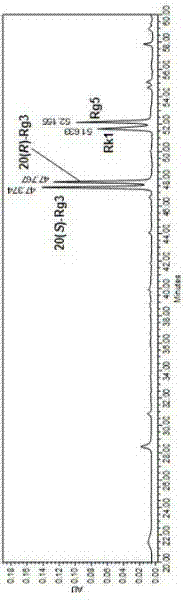

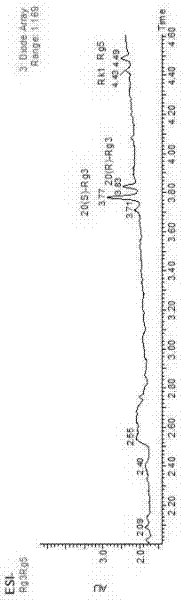

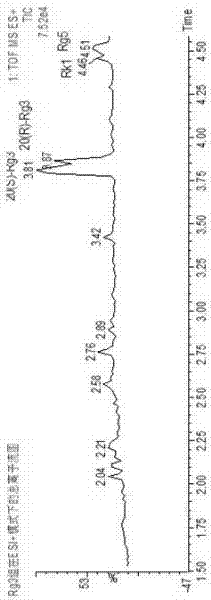

Method for preparing red ginseng saponins Rg3 group and Rh2 group mixed saponins

The invention discloses a method for preparing red ginseng saponins Rg3 group and Rh2 group mixed saponins. The method comprises the following steps: gen-seng-containing saponins enzyme without containing saponins and extract products of other water-soluble substance are mixed with protopanaxadiol saponins Rb1, Rb2, Rc or Rd monomer or mixed saponins, preparing the Rg3 group saponins composed of 20(S)-Rg3, 20(R)-Rg3, Rk1 and Rg5 red ginseng saponins; reacting with ginsenoside F2, preparing the Rh2 group saponins composed of 20(S)-Rh2, 20(R)-Rh2, Rk2 and Rh3 red ginseng saponins. The red ginseng saponins mixed by Rg3 group and Rh2 group has more safety to human body and higher activity than monomer saponins such as Rg3 and Rh2, and can be used for the exploitation of gen-seng products, health products, cosmetics and other medicines.

Owner:SUNFLOWER PHARM GRP (TIANJIN) DRUG RES INST CO LTD

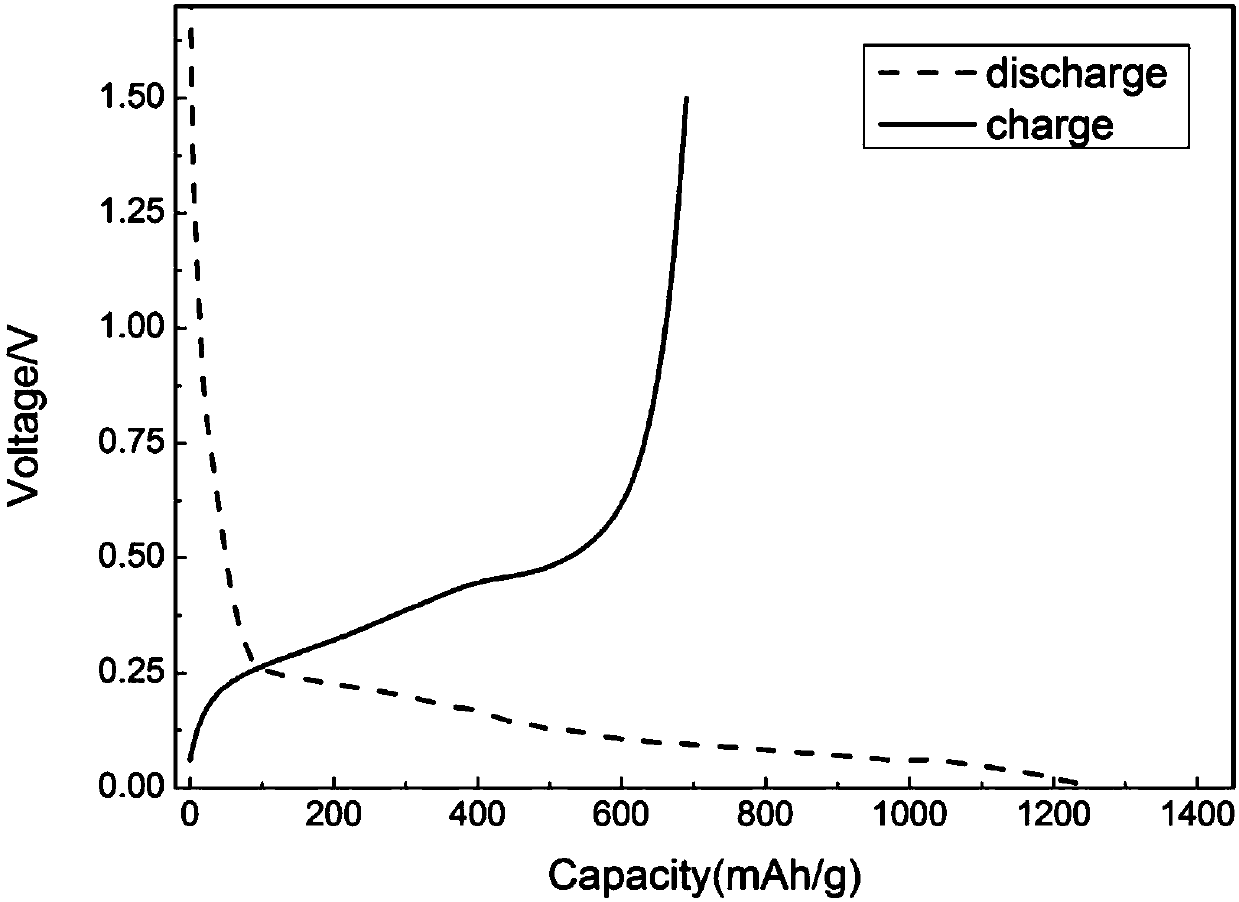

Method for preparing lithium ion battery negative electrode material from photovoltaic industry wastes

InactiveCN107732200AReduce manufacturing costEfficient Development StrategyCell electrodesPhotovoltaic industrySolvent

The invention discloses a method for preparing a lithium ion battery negative electrode material from photovoltaic industry wastes. The method comprises 1) pretreating photovoltaic industry wastes toobtain silicon powder, and 2) preparing a lithium ion battery negative electrode material through 2.1), adding the prepared silicon powder and a dispersant into a solvent according to a mass ratio of4 to 1 and carrying out dispersion to obtain uniformly dispersed nano-silicon particles, 2.2), adding an initiator ammonium persulfate into the solution obtained by the step 2.1) and carrying out ultrasonic dispersion, 2.3), acidifying the solution and adjusting the pH of the solution to 1-3, 2.4), then dropwisely adding monomers into the silicon particles for coating and stirring the mixture fora reaction in an ice bath for 8-12h, and 2.5) after the reaction, centrifuging the liquid, washing the liquid to pH of 7, then carrying out vacuum drying and carrying out grinding to obtain the lithium ion battery negative electrode material. Through treatment on photovoltaic industry wastes, the silicon raw material is modified through the simple and easy industrial use method and the commercialapplication of the silicon negative electrode is promoted.

Owner:XI AN JIAOTONG UNIV

Textile finishing agent modified from Nano material and preparation method

InactiveCN1539860AConvenient sourceThe process method is simpleFibre treatmentChemistryIsooctyl acrylate

A nano material modified finishing agent for fabric is prepared through synthesizing the fluoric monomer by electrolysis, and copolymerization between 2-perfluoro octylamido ethyl acrylate, isooctyl acrylate, hydroxyethyl acrylate and metadichloroethylene. Its advantages are high antibacterial, hydrophobic and oleophobic power.

Owner:吉林省长吉图教育发展有限公司

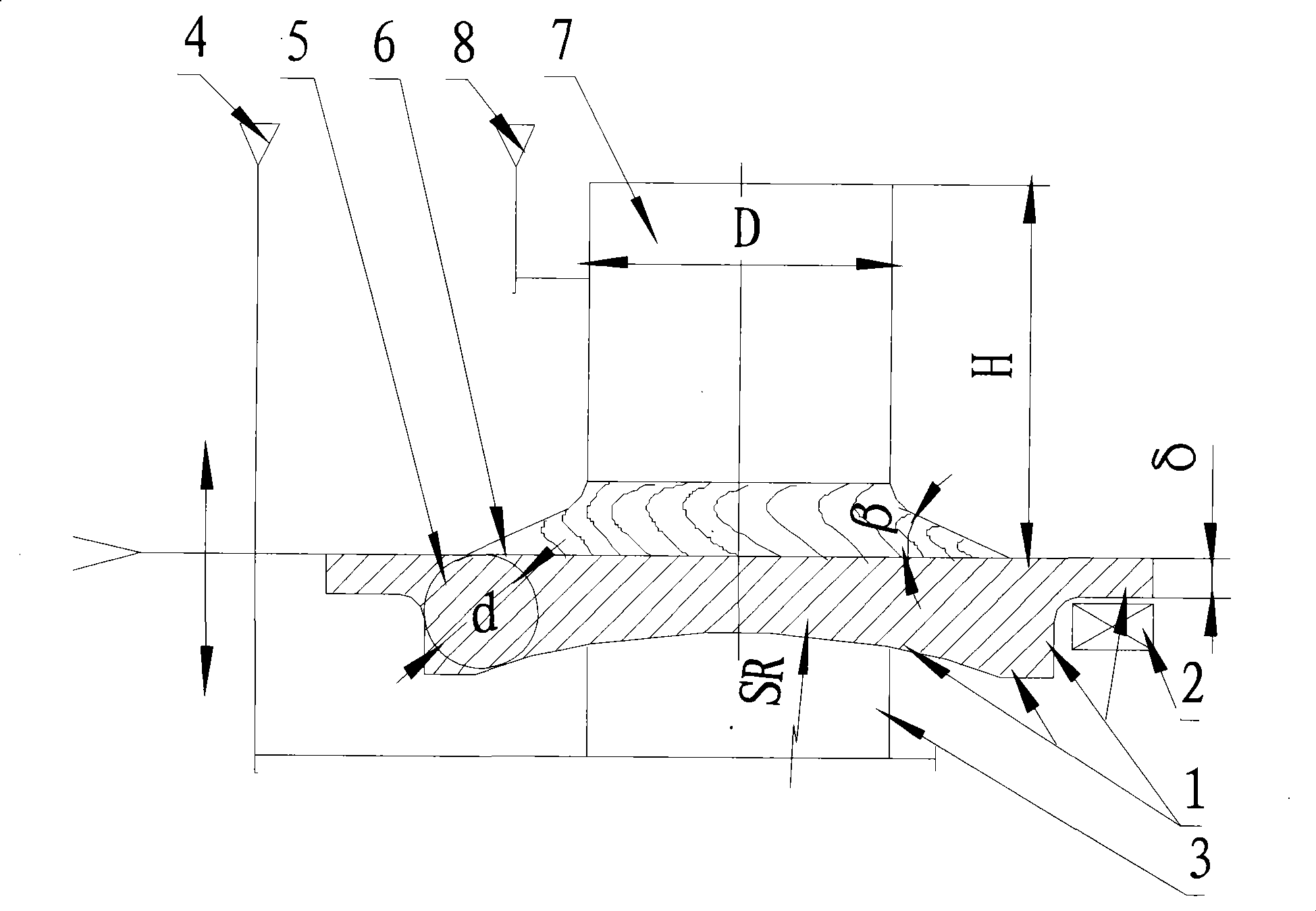

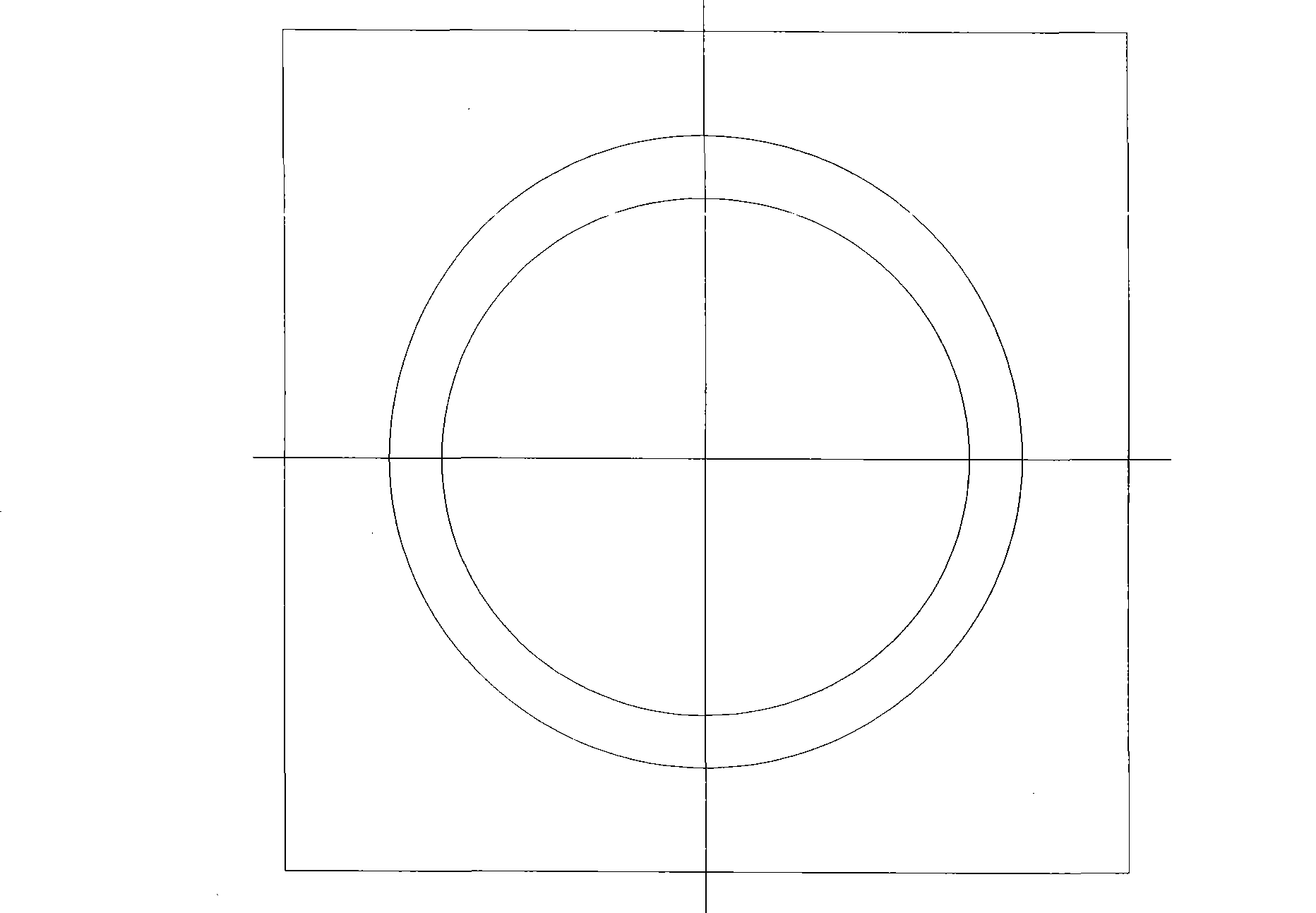

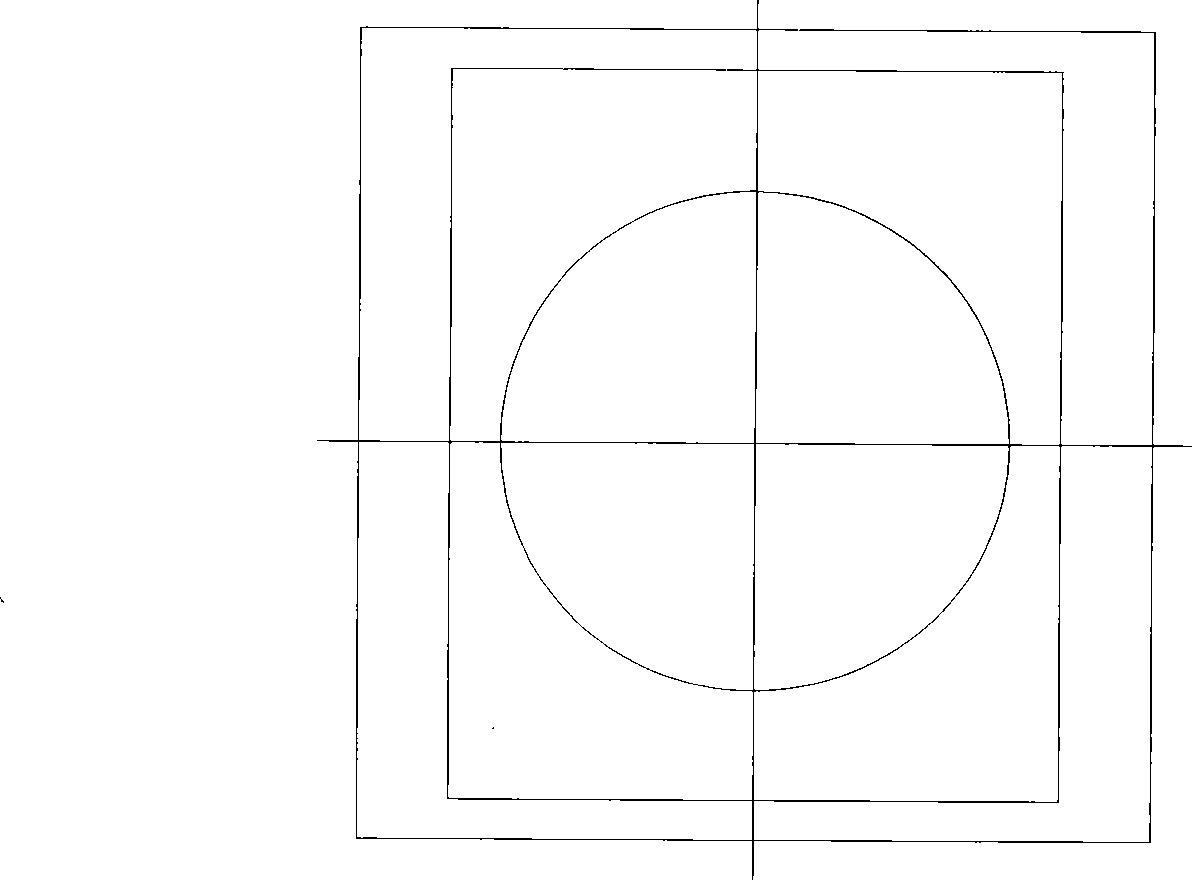

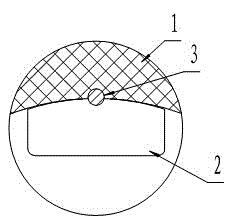

Foundry technique method of lower support board of ball type support

InactiveCN101462149AAdverse effects of changing the pouring position to a large planeReduce trachomaFoundry mouldsFoundry coresFoundryBall type

The invention discloses a technological method for casting a lower support plate of a ball shaped support. The technological method comprises the following steps: according to the structural shape of the lower support plate of the ball shaped support, namely, a square plate, manufacturing a sand mold, adopting a shape of a water glass quartz sand pit, using an upward large plane of the lower support plate as a parting surface, and horizontally pouring the parting surface; scraping a lower middle circular lug boss and a concave spherical surface on the other side by a scraper (1), pounding the rest parts by natural patterns, and providing outer chill blocks (2) at four cast corners thereof; providing a pouring head outside the sand mold, and adopting a reverse-bottom pouring head in an inner pouring channel (3); and pounding an upper mold by a sand box, and providing a shrink head table and a shrink head horizontal reinforce (6) in the center part. The technological method reduces the defects such as planar sand holes, sand marks, and the like on the cast, meets the feeding requirement of the cast, ensures compactness inside the cast, improves quality of the cast, and reduces production cost.

Owner:LUOYANG XINGRONG IND

Cleaning and tinning process for steel shell

InactiveCN105695913AThe process method is simpleSimple processHot-dipping/immersion processesAmmonium chloride mixtureOxide

The invention discloses a cleaning and tinning process for a steel shell. The process comprises the following steps: 1) cleaning the steel shell and removing grease; 2) examining and correcting the steel shell; 3) removing oil stains again; and 4) carrying out tinning: (1) preparation before tinning: a, dissolving a mixture of zinc chloride and ammonium chloride mixed according to ratio of 2: 1 in hot water with a temperature of 60 to 70 DEG C so as to prepare a saturated solution, and b, preparing a saturated solution from 32% of zinc chloride, 2.5% of ammonium chloride, 4% of tin chloride and water being the balance; (2) heating of a tinning pot, wherein the steel shell should be preheated at a temperature of 270 to 300 DEG C before tinning, and if preheating temperature is too high, an oxide layer occurs on the surface of the steel shell, bonding is hard to realize during tinning, and even though bonding is barely succeeded, the bonding is not firm; and (3) tinning. The process provided by the invention is simple, omits a great number of repeated procedures and has improved work efficiency.

Owner:CHONGQING CITY BANAN DISTRICT YONGXING MACHINERY FACTORY

Chemical method for activating aramid fiber surface

InactiveCN101798752ALow priceThe process method is simpleFibre typesSide chainFriedel–Crafts reaction

The invention relates to a chemical method for activating aramid fiber surface and the method adopts aramid fiber as activated object. The method comprises the following steps: using a large amount of benzene rings in the molecular chains of aramid fiber to perform Friedel-Crafts reaction with epichlorohydrin, grafting epichlorohydrin to aramid fiber surface to form o-chlorohydrin side chains, and then using alkaline solution to perform epoxidation and obtain active side chains. The specific steps are as follows: firstly drying aramid fiber, epichlorohydrin and anhydrous aluminium chloride, performing a grafting reaction, using acetone to soak, secondly performing epoxidation reaction, washing with distilled water, and finally drying aramid fiber to obtain aramid fiber with activated surface. The chemical method can increase the surface activity of aramid fiber under the premise of not damaging the entity structure, have the advantages that the cost is low, the process operability is strong, the surface activation effect is good, the activation does not have degradation effect and the social benefit is good, and be applicable to batch industrial production.

Owner:XI AN JIAOTONG UNIV

Method for producing energy-saving ornament composite board

InactiveCN101177056AThe process method is simpleReasonable selection of materialsLaminationLamination apparatusBuilding materialAdhesive

The invention relates to a production method for the construction materials, in particular to an energy-saving decoration composite panel, which comprises two steps; wherein, the first step is the pretreatment: a panel is pretreated depending on the material of the panel; a decoration protective layer is coated on the surface of the panel; the second step is compound: the adhesive is coated on the two surfaces of a heat insulation plate of the first layer; then one surface is compounded with the panel and the other surface is compounded with one surface of a metal reinforced layer; the other surface of the reinforced layer is compounded with a heat insulation plate of the second layer coated with adhesive on one surface, finally the panel is compressed tightly and shaped with a board pressing machine. The invention has the advantages of simple technology method, industrial production, combination of the panel, the heat insulation plate and the metal reinforcing plate, coated protective layer for the panel paint film depending on the material and the decorative patterns, rational material choosing for the decoration protective layer, excellent decorative property, good weatherability, high self-cleaning performance, good product quality of industrial production, good performance, and high productivity.

Owner:李晶

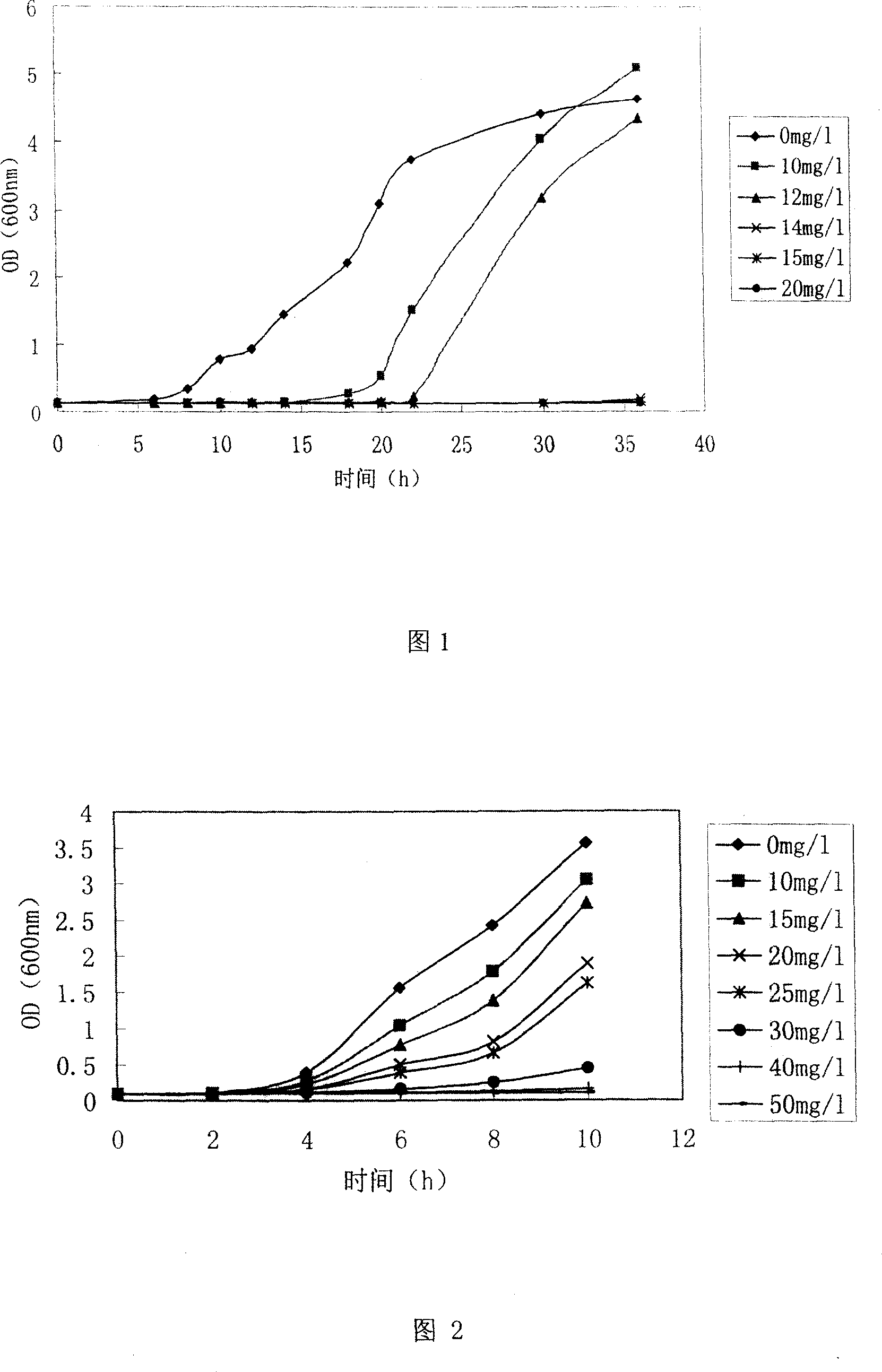

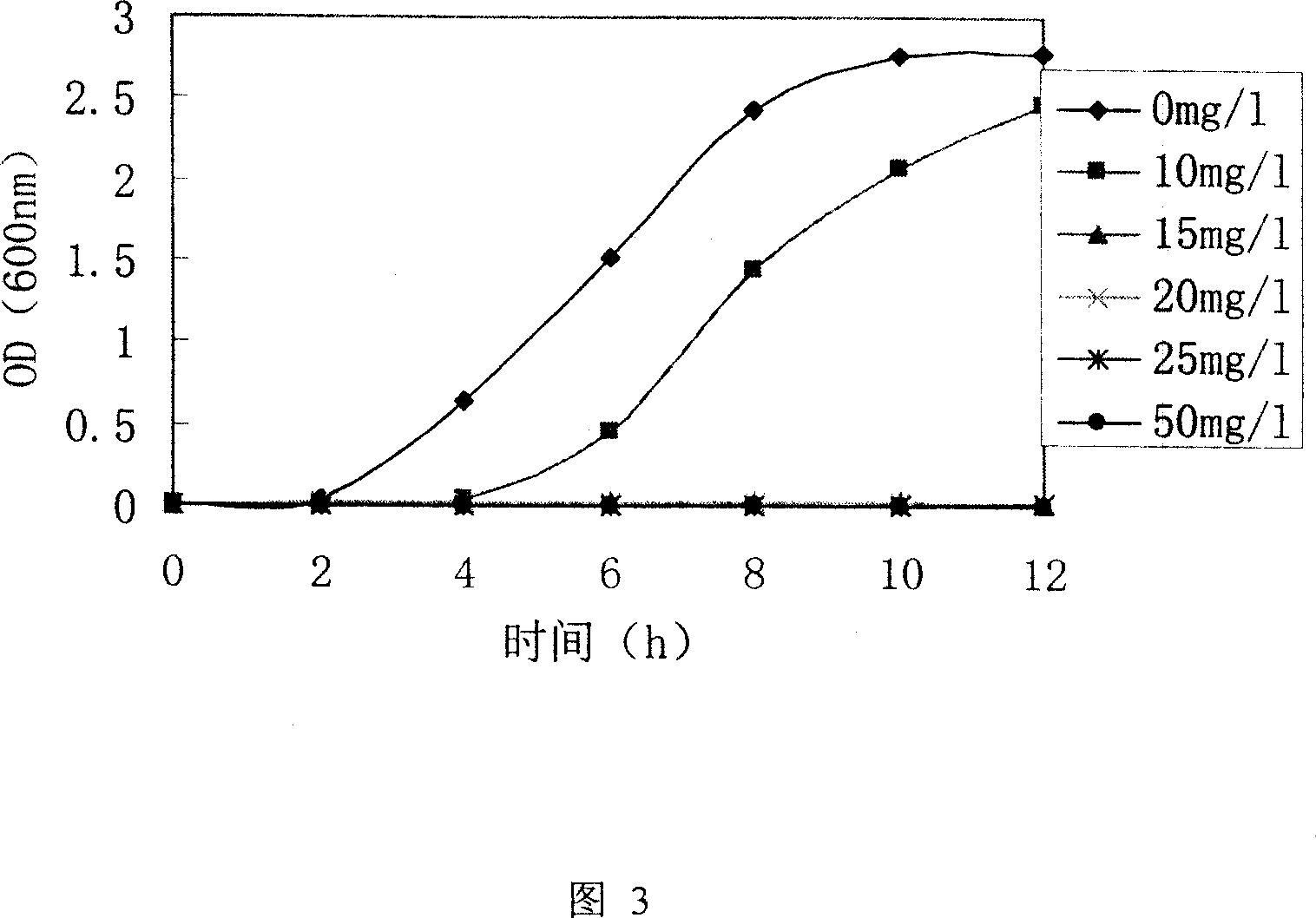

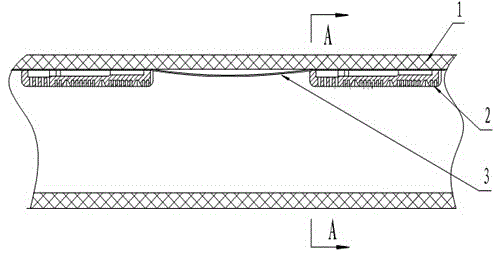

Application of sophorolipid in preparing antibiotic medicine

InactiveCN101019875AThe process method is simpleLow costAntibacterial agentsOrganic active ingredientsDrugGram-positive bacterium

The present invention discloses the application of sophorolipid or composition with sophorolipid as effective component in preparing antibiotic, especially in preparing antibiotic medicine for inhibiting cadida albicans and gram positive bacteria. The present invention prepares sophorolipid through fermentation, and the preparation process has the features of simplicity, low cost and high product purity. The sophorolipid and the composition with sophorolipid as effective component have high bacteriostasis effect and no toxic side effect.

Owner:SHANDONG UNIV

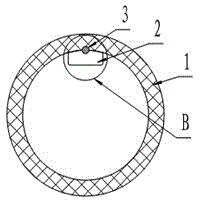

Anti-blocking drip irrigation pipe and manufacturing method

InactiveCN104126485AInhibits plant root growthThe process method is simpleClimate change adaptationWatering devicesRoot systemCopper wire

An anti-blocking drip irrigation pipe and a manufacturing method are used for solving the problem that water outlet holes of a drip irrigation pipe are blocked by root systems of plants. The anti-blocking drip irrigation pipe comprises a plastic hose and drippers evenly welded to the inner wall of the plastic hose. The anti-blocking drip irrigation pipe is characterized in that copper wires are arranged in the plastic hose and are located between the inner wall of the plastic hose and the drippers, the drippers, the plastic hose and the copper wires are bonded and fixed on the portions, corresponding to the drippers, of the cupper wires, and the copper wires between the adjacent drippers are in a suspension state. The anti-blocking drip irrigation pipe is based on copper oxide and has the function of inhabiting the growth of the root systems of the plants, and the root systems of the plants can be prevented from blocking flow channels of the drippers. The anti-blocking drip irrigation pipe has the advantage of being good in manufacturability. According to the manufacturing method, mass production can be conducted simply by locally improving original dripper pipe manufacturing device production equipment, the long-term troubling problem of dripper blocking is solved with small cost investment, the maneuverability is high, and application and popularization prospects are highly achieved.

Owner:武志生

Method for hobbing disc cylindrical gear type spiral involute gear

The invention discloses a method for hobbing a disc cylindrical gear type spiral involute gear. The disc cylindrical gear type spiral involute gear can be directly hobbed by adjusting the parameters of a general hobbing cutter on a numerical control hobbing machine or a modified common hobbing machine to make the parameters accord with relationships shown in the specifications. The method has the advantages of simple process, high processing efficiency and low cost.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of self-assembled sulfonic acid group silane-titanium dioxide composite film on monocrystalline silicon substrate surface

InactiveCN101555629AThe process method is simpleLow costPolycrystalline material growthAfter-treatment detailsChemistryNitrogen gas

The invention relates to a preparation method of self-assembled sulfonic acid group silane-titanium dioxide composite film on monocrystalline silicon substrate surface. The invention is characterized in that the monocrystalline silicon piece is treated in advance and is immersed in prepared hydrosulphonyl silane solution, after holding for 8 hours, the monocrystalline silicon piece is taken out and washed by acetone, chloroform and deionized water, and the nitrogen is used for drying the monocrystalline silicon piece, after being dried, the monocrystalline silicon piece is put into the nitric acid with finite concentration for 2 hours under 80 DEG C, and then the sulfonic acid group silane-titanium dioxide self-assembled nano film is obtained. The preparation method has the advantages of simple process, low cost and no environment pollution and the obtained titanium dioxide nano film is well-distributed and compactly with evident antifriction effect. Furthermore the titanium dioxide self-assembled nano film has the advantage of good abrasion resistance property.

Owner:SHANGHAI SECOND POLYTECHNIC UNIVERSITY

Anti-ultraviolet nylon fiber spinning process

InactiveCN102766962AThe process method is simpleLong-lasting and effective UV protectionFilament/thread formingArtifical filament manufactureEngineeringUv absorber

The invention relates to an anti-ultraviolet nylon fiber spinning process. The anti-ultraviolet nylon fiber spinning process includes steps of using nylon chips and additives as raw materials on high-speed spinning equipment and adopting a process route of a screw extruder, a pre-filter, a static mixer, a metering pump, a spinning component, trickling, side blowing, oiling, a passage, a first fiber guide roll, a second fiber guide roll, a third fiber guide roll and winding. The process method is simple and feasible, an ultraviolet screening agent and an ultraviolet absorbing agent are added into prepared nylon fibers, and the microcapsulary is further adopted to enable lasting effectiveness of the anti-ultraviolet performance of the fibers. In addition, the process is applicable to preparation of 20D-70D nylon filaments, and corresponding dull or semi-dull products can be obtained by adding delustrant for preparation.

Owner:WUJIANG YATAI CHEM TEXTILE

Recovery method of zircon-based amorphous alloy

InactiveCN105132687AReduce oxygen contentThe process method is simpleProcess efficiency improvementCeramicAmorphous metal

The invention discloses a recovery method of zircon-based amorphous alloy. The method comprises the following steps: crushing; pickling; performing alkaline cleaning; adding oxophile elements to smelt; filtering through foamed ceramics. With the adoption of the recovery method, the content of oxygen elements in the recovered zircon-based amorphous alloy can be greatly reduced, and moreover, inclusions in the alloy can be effectively removed, so that the recovered zircon-based amorphous alloy can reach the purity for recycling. Meanwhile, the method is simple, practical, easy to operate, and suitable for popularization and application.

Owner:宋佳

Method for producing snail chitin

A process for preparing snail chitin from snail shell includes immersing snail shell in hydrochloric acid solution in vacuum reactor for decalcifying it, and immersing in the solution of sodium hydroxide or potassium oxide in vacuum reactor at 90-95 deg.C for 3-4 hrs under 756-758 mmHg for defatting. Its product has high purity (98% or more).

Owner:陈玉柱

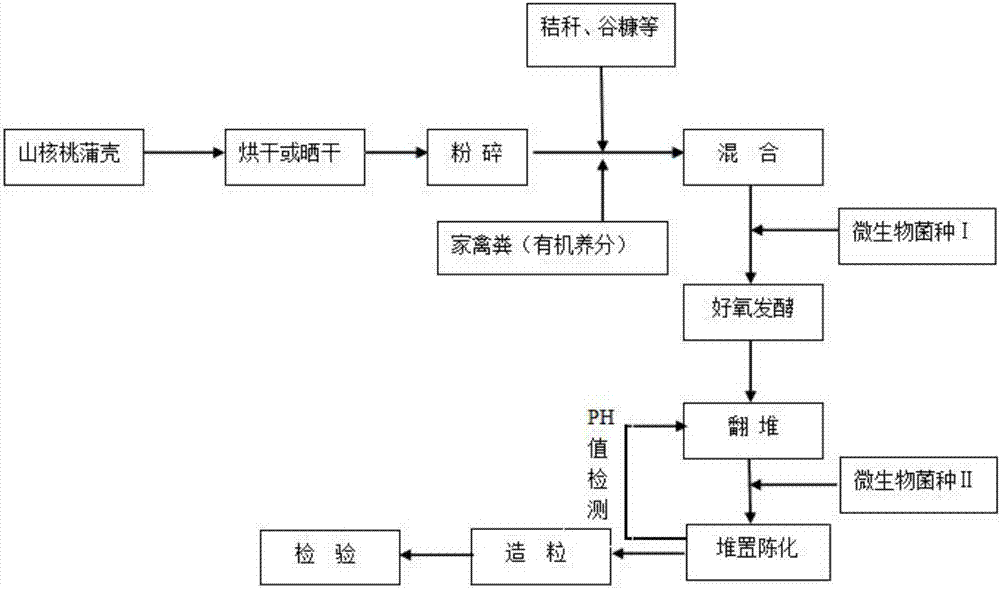

Biological organic fertilizer prepared by utilizing hickory hull and preparation method thereof

InactiveCN107151152AIncrease profitImprove disease resistanceClimate change adaptationExcrement fertilisersMicrobial agentOxygen

The invention discloses a preparation method of biological organic fertilizer prepared by utilizing hickory hull. The preparation method includes following steps: S1, preparing a main raw material: picking the hickory hull for drying or sun-drying, and smashing the same into hickory hull powder; S2, mixing materials: well mixing the hickory hull powder, organic nutrient and phosphor-containing additive, and adding water to adjust water content of a mixture; S3, performing aerobic fermentation: adding a microbial agent I for sufficiently curing the hickory hull powder into the mixture, and performing primary fermentation in a gap turning heap condition, wherein the microbial agent I at least contains aspergillus niger, thermophilic sporotrichum and thermoactinomyces; S4, heaping and aging: adding a material obtained after aerobic fermentation is finished to degrade lignin in the hickory hull and form a microbial agent II of humic acid, turning a heap, heaping, and aging, wherein the microbial agent II is trametes gallica; S5, detecting PH value: detecting the PH value of a material obtained after heaping and aging for a certain time, and repeating the S4 when the PH values of the material in different areas are highly different.

Owner:杭州珍鑫源食品股份有限公司

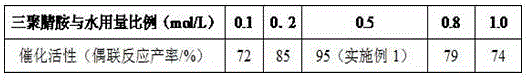

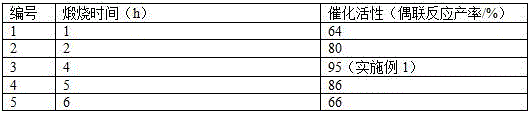

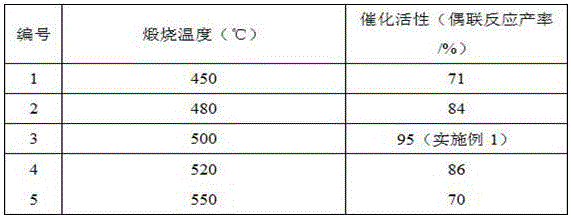

Synthesis method of carbon nitride loaded copper catalyst

ActiveCN106423245AThe process method is simpleRaw materials are easy to getPhysical/chemical process catalystsOrganic chemistryCopper nitrateHomogeneous catalysis

The invention provides a synthesis method of a carbon nitride loaded copper catalyst and relates to the technical field of synthesis of catalysts. The carbon nitride loaded copper catalyst is synthesized from melamine and copper nitrate. The technological method is simple, the raw materials are easy to obtain, and high practical application value is achieved. The catalyst can catalyze halohydrocarbon to be coupled with amine, different from traditional heterogeneous catalysts, in the catalyst, a carrier nitrogen and copper have a coordination effect, and the activity of the catalyst can be improved. In addition, the catalyst can be recycled. Thus, the catalyst has the stability of the inorganic heterogeneous catalysts and the variability of the organic heterogeneous catalysts at the same time, and wide application prospects are achieved.

Owner:YANGZHOU UNIV

Epoxy anti-rust paint capable of thick-film coating and saitable for construction in winter and preparing method

InactiveCN101070447AGood chemical resistanceImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsFirming agentFilm-coated tablet

This invention relates to one kind of epoxy antirust paints, discloses one kind of epoxy antirust paints and its making method that can spray by using the thick film and construct under the winter environment. This invention begins with ameliorating the model material, selects the modified amines firming agent and the epoxy group to response, and add preventing flowing hang-aid material, when using the epoxy antirust paint of this invention to paint, not being restricted because the temperature is lower than 5 degree C. In addition, it can do a construction of one-time thick film spray, the wet film thickness can achieve 600 mu m, after uniformly mixing the Group A and B, it has excellent film-forming character and good storage stability under the normal or low temperature (above -10 degree ).

Owner:上海华谊精细化工有限公司上海开林造漆厂

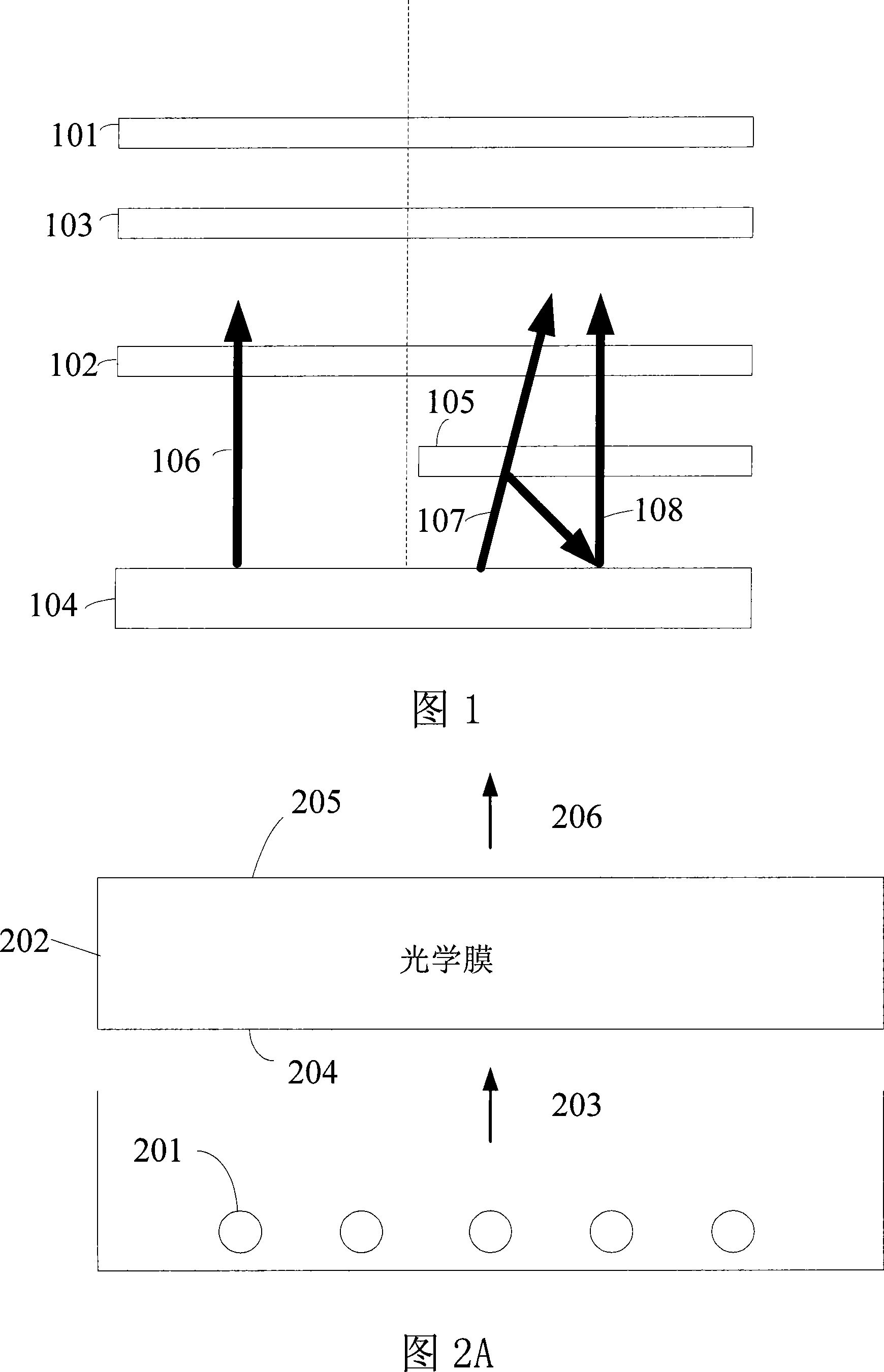

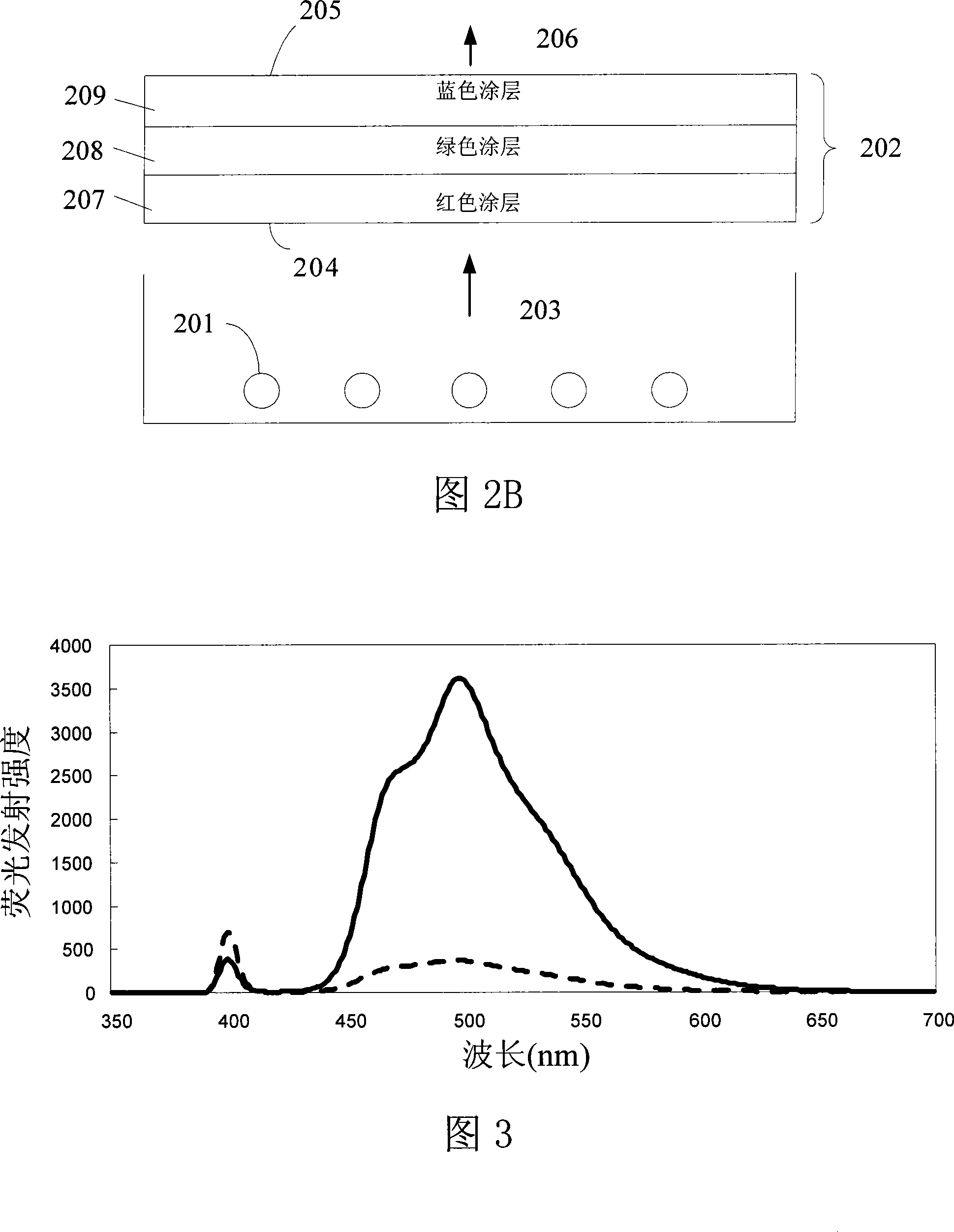

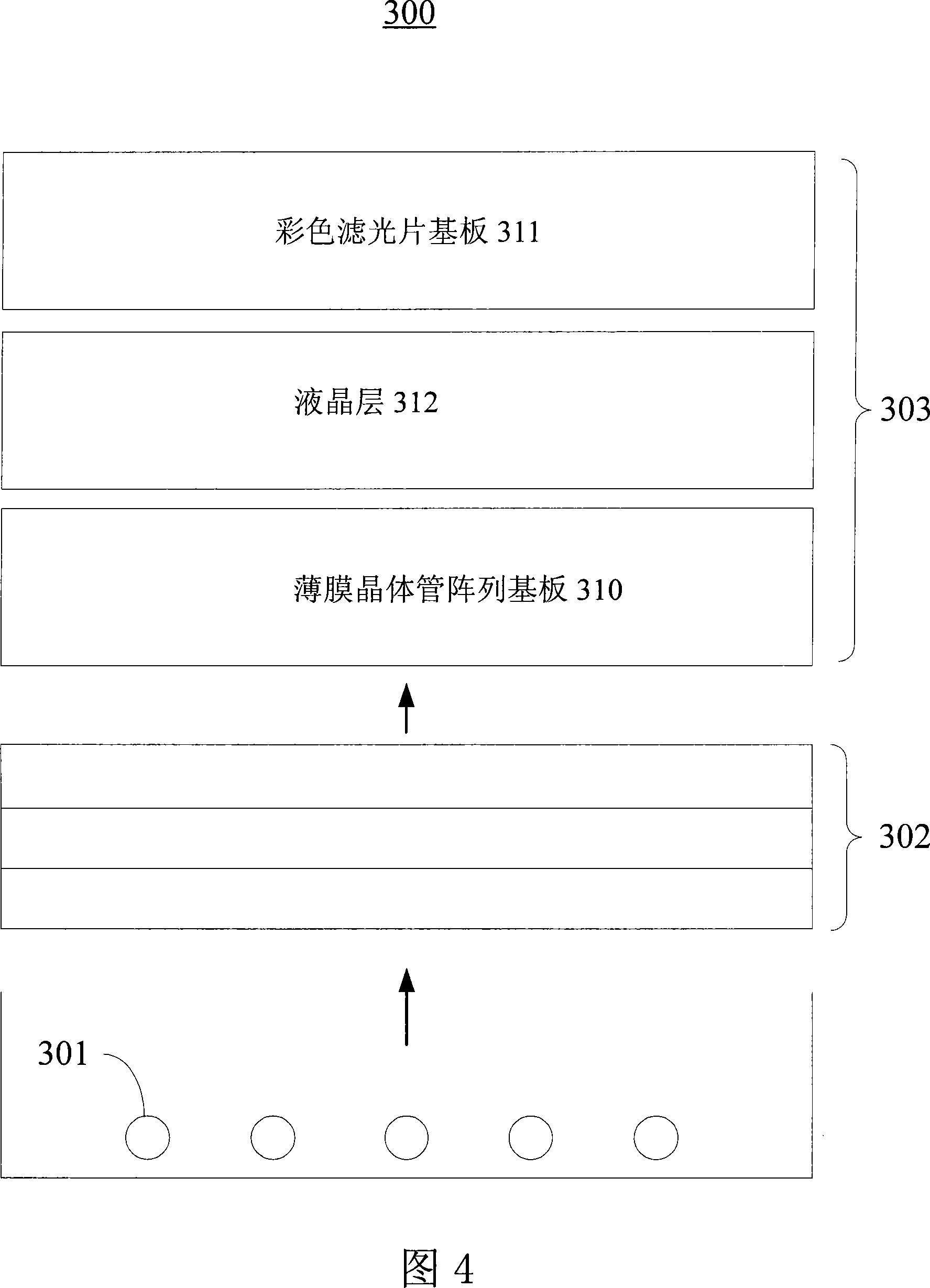

Display apparatus and its optical film preparation method

InactiveCN101216634AImprove thickness too thickThe process method is simpleNon-linear opticsIdentification meansLight sourceDisplay device

The invention provides a display device and a manufacture method of the optical film of the display device. The display device at least comprises a light source and an optical film, wherein the light source is used for providing a first light beam to the optical film, and the optical film contains at least one coating. The coating includes a first surface and a second surface opposite to the first one, and is used for absorbing the first light beam through the first surface and emitting a second light beam under excitation to the outside through the second surface, wherein the intensity of the second light beam is larger than the intensity of the first light beam. The invention can overcome the disadvantage of overlarge thickness of a brightness enhancement film of the display panel in prior art, simplify the complex process of prior art, assist the backlight source in improving light emission intensity and improve the light utilization rate of the display device.

Owner:AU OPTRONICS CORP

Method for manufacturing green solid fuel by using biomass mixed material

InactiveCN102517113AAvoid pollutantsThe process method is simpleBiofuelsSolid fuelsContinuous useSodium carboxymethylcellulose

The invention discloses a method for manufacturing a green solid fuel by using a biomass mixed material, and belongs to the technical field of solid fuels manufactured by using biomass. The method comprises the following steps of: crushing, adding, heating, cooling and extruding, namely crushing the biomass mixed material into granules of which average diameter is 10 to 30 millimeters, adding 5 to 20 mass percent of water, 5 to 30 mass percent of pulverized coal, 1 to 3 mass percent of calcined lime and 5 to 10 mass percent of sodium carboxymethylcellulose into the granules, heating for 1 to 3 hours with stirring at the temperature of between 150 and 250 DEG C, cooling the mixture at the cooling rate of 20 to 30 DEG C per minute, and finally extruding the mixture into the solid fuel. The method has the advantages that: many mixtures such as straw biomass, waste plastic, urban organic solid wastes and the like are used as raw materials for low heat treatment, and the green solid fuel with high specific weight, high density and high calorific value is finally manufactured by synergy of the substances; and the green solid fuel is convenient to store, transport and continuously use.

Owner:JIANGSU SIFANG BOILER

Production technology of nuts

The invention discloses a production technology of nuts. The technology comprises the steps of A raw material selection; B, annealing; C, pickling and phosphatizing; D, drawing; E, cold heading forming; F, tapping; G, surface finishing: a finished product nut is placed into a cleaning pond which contains a cleaning solution to be cleaned and remove rust, and then drying and spraying process are conducted on the finished product nut; H, packaging and outbound delivery. The technology has the advantages that the method is simple and reasonable, the production speed is fast, the production efficiency is effectively improved, the production cost is reduced, the processing sequences of the nut is simplified by adopting the cold heating forming method, the processing cost is reduced, and the processing speed and accuracy are improved.

Owner:嘉兴市兆丰五金科技股份有限公司

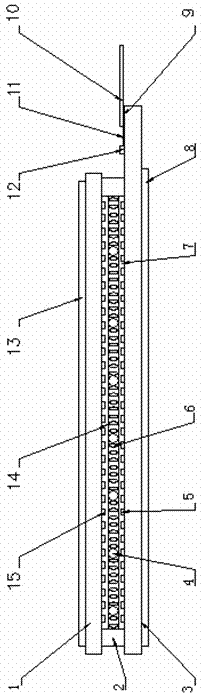

LCD module and method for improving interference resistance of LCD

InactiveCN104238166AThe process method is simpleIncrease productivityStatic indicating devicesNon-linear opticsPhysicsIntegrated circuit

The invention discloses an LCD module and a method for improving the interference resistance of an LCD. According to the LCD module and the method for improving the interference resistance of the LCD through an ITO graph planar inductor, the LCD module which is manufactured by designing a spiral type ITO planer inductor between an integrated circuit controller IC on ITO glass and a flexible printed circuit board FPC structurally comprises a piece of upper ITO glass, frame rubber, a piece of lower ITO glass, a liner, a lower ITO layer, super twist nematic liquid crystal, a lower liquid crystal alignment film, a lower transmission film polaroid, an upper elliptic single-compensation film polaroid, an upper liquid crystal alignment film, an upper ITO layer, the ITO graph planar inductor, the integrated circuit controller IC, a piece of anisotropic conductive adhesive tape ACF and the flexible printed circuit board FPC. The LCD module and the method have the advantages that the LCD module and the method are suitable for a display screen of a COG+FPC structure, similar circuits are prevented from being added to the periphery of the LCD, reliability is high, the process method is simple, and production cost and material cost are low.

Owner:南京华日触控显示科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com