Anti-blocking drip irrigation pipe and manufacturing method

A drip irrigation pipe, anti-clogging technology, applied in the fields of botany equipment and methods, climate change adaptation, horticulture, etc., can solve problems such as failure to be implemented, achieve the problem of dripper clogging, low cost investment, and strong operability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

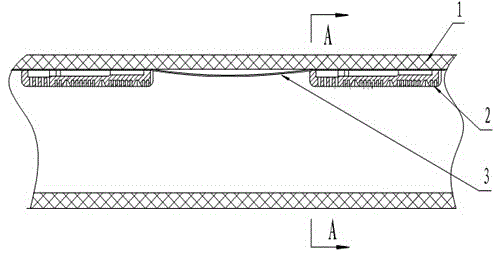

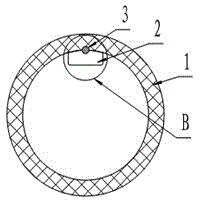

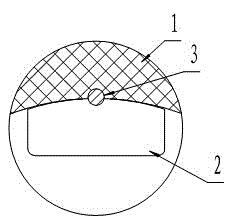

[0017] See Figure 1-3 The anti-clogging drip irrigation pipe of the present invention includes a plastic hose 1 and a dripper 2 uniformly welded on the inner wall of the plastic hose. The dripper is provided with a water flow channel, and the terminal of the water flow channel and a water outlet hole provided on the plastic hose Interlinked. There is a copper wire 3 in the plastic hose. The copper wire is arranged between the inner wall of the plastic hose and each dripper. The dripper, plastic hose and copper wire are bonded and fixed at the corresponding part of the copper wire and each dripper. , The copper wire is suspended between adjacent drippers to prevent the copper wire from breaking due to tensile force during the winding or use of the drip irrigation pipe. The diameter of the copper wire is preferably 0.1-0.2 mm. The diameter of the copper wire is too thick, which will increase the cost of the drip irrigation pipe; on the one hand, the diameter of the copper wire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com