Display apparatus and its optical film preparation method

A display device and optical film technology, applied in optics, identification devices, nonlinear optics, etc., can solve the problems that do not conform to the development trend of increasingly thin and light liquid crystal display devices, and the structure and process are complicated, and achieve auxiliary luminous intensity, enhance light Use rate, improve the effect of excessive thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

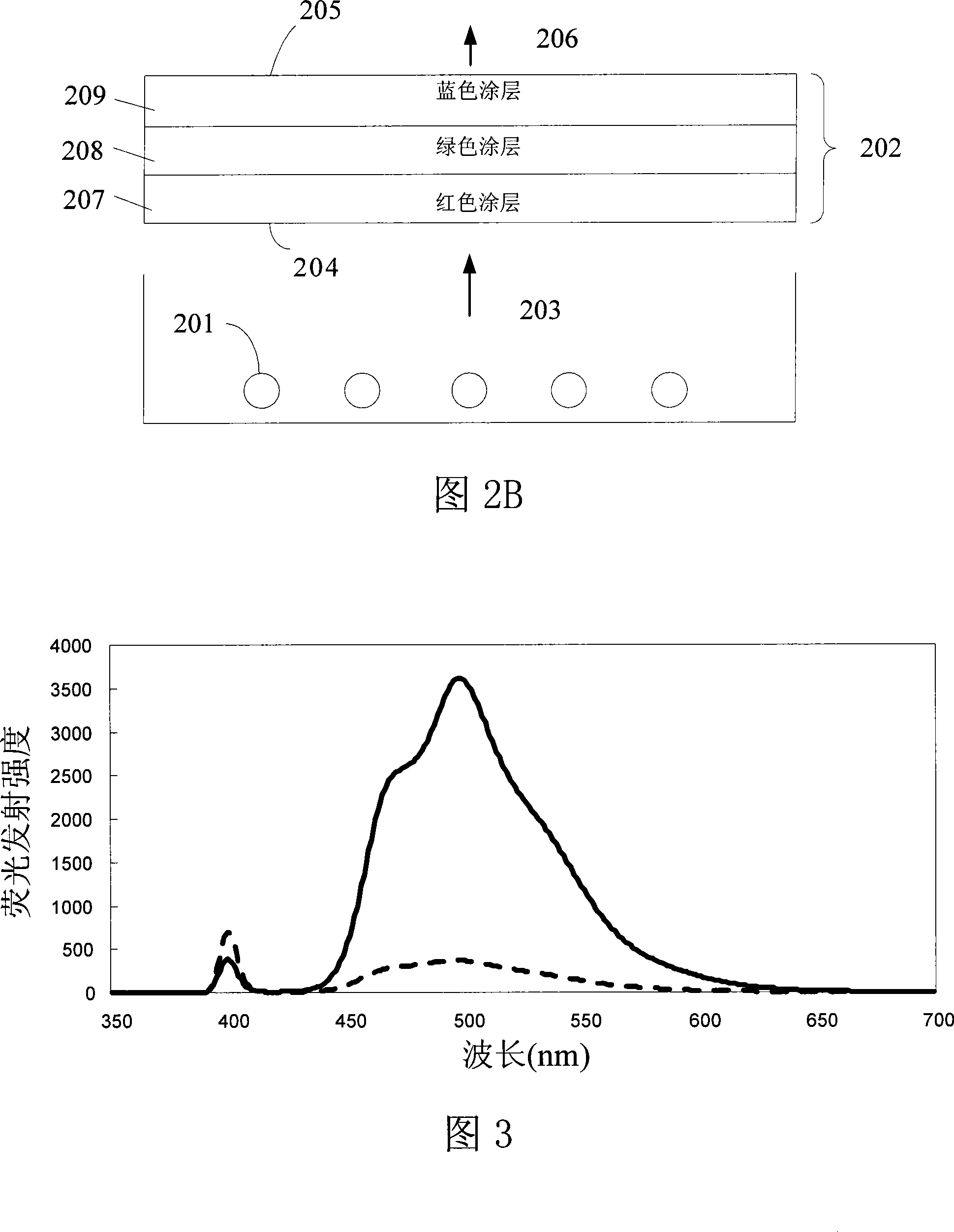

[0033] FIG. 2A depicts a first embodiment of the present invention, which is an optical film 202 and a backlight module for a display device. The display device includes a light source 201 and an optical film 202 in a backlight module. The light source 201 provides a first light 203 to the optical film 202 . The light source of the backlight module can be a direct light source, as shown in FIG. 2A , or an edge light source with a light guide plate. The structure of the optical film 202 includes at least one coating layer having a first surface 204 and a second surface 205 opposite to the first surface. One of the features of the present invention is that the coating of the optical film 202 is adapted to absorb the first light 203 emitted from the light source 201 from the first surface 204 , and stimulate a second light 206 to emit from the second surface 205 . In particular, the intensity of the second light 206 is greater than that of the first light 203 to assist the back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com