Patents

Literature

2428 results about "Homogeneous catalysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, homogeneous catalysis is catalysis in a solution by a soluble catalyst. Homogeneous catalysis refers to catalytic reactions where the catalyst is in the same phase as the reactants. Homogeneous catalysis applies to reactions in the gas phase and even in solids. Heterogeneous catalysis is the alternative to homogeneous catalysis, where the catalysis occurs at the interface of two phases, typically gas-solid. The term is used almost exclusively to describe solutions and often implies catalysis by organometallic compounds.

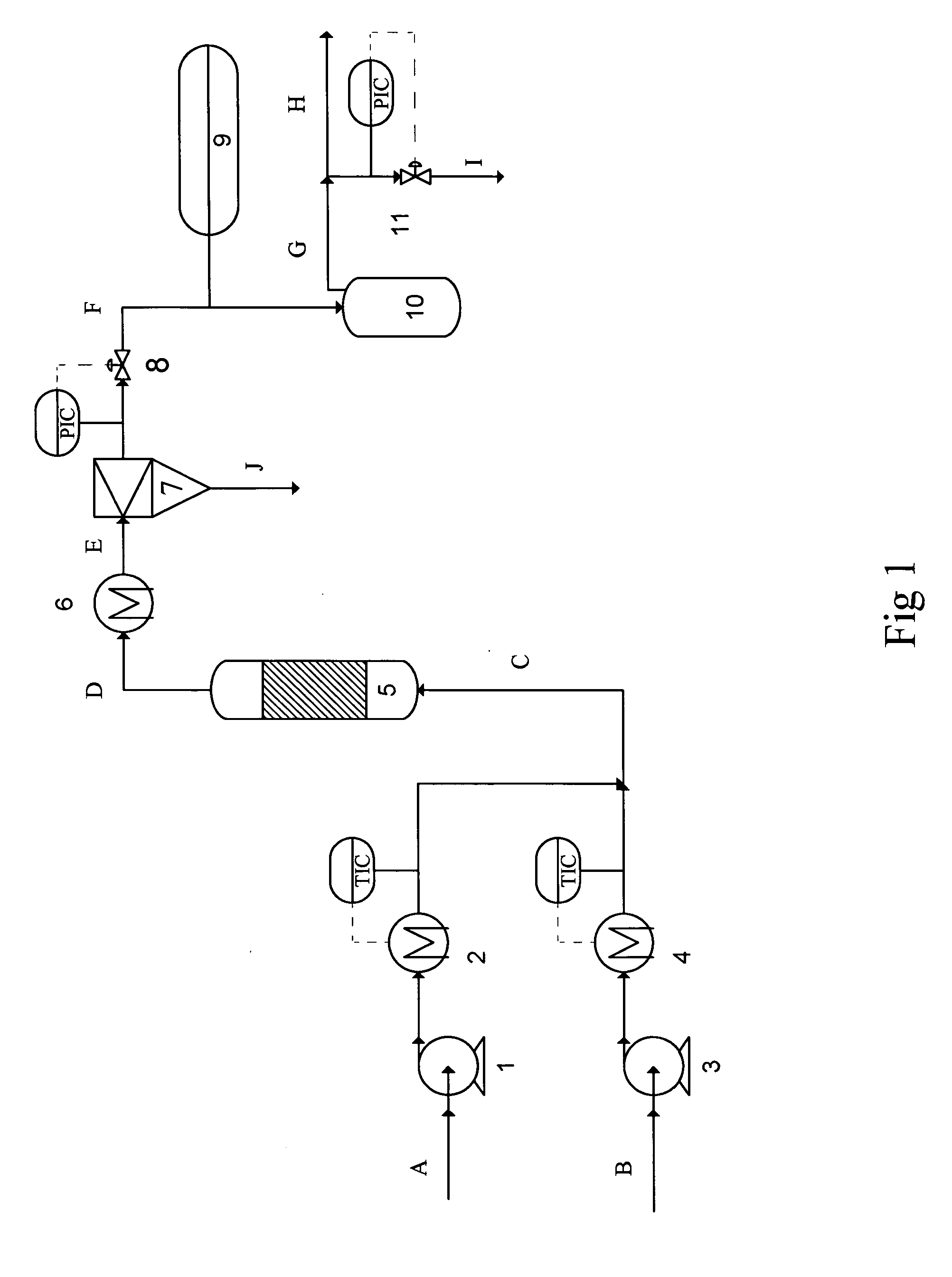

Methods for producing biodiesel

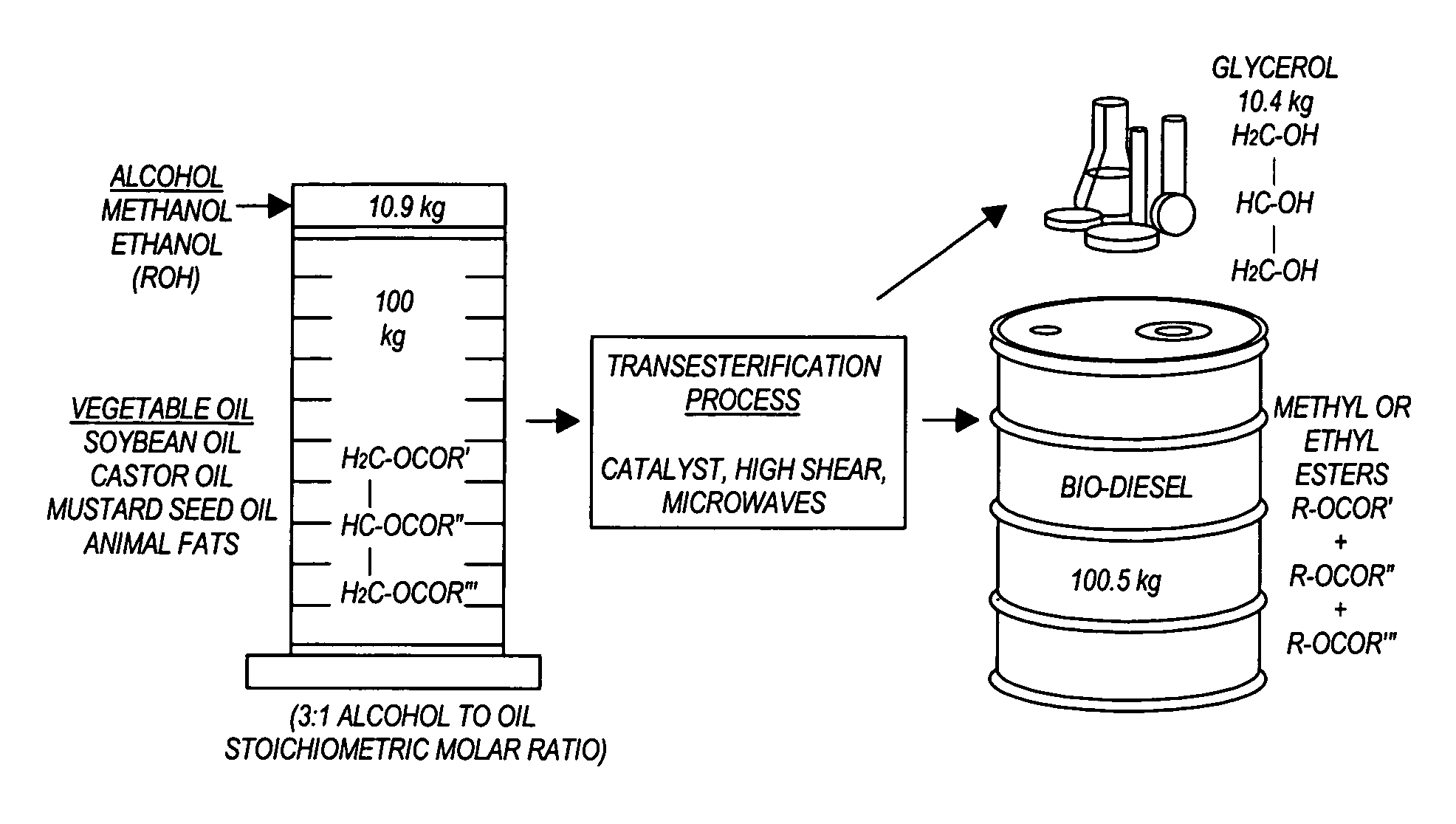

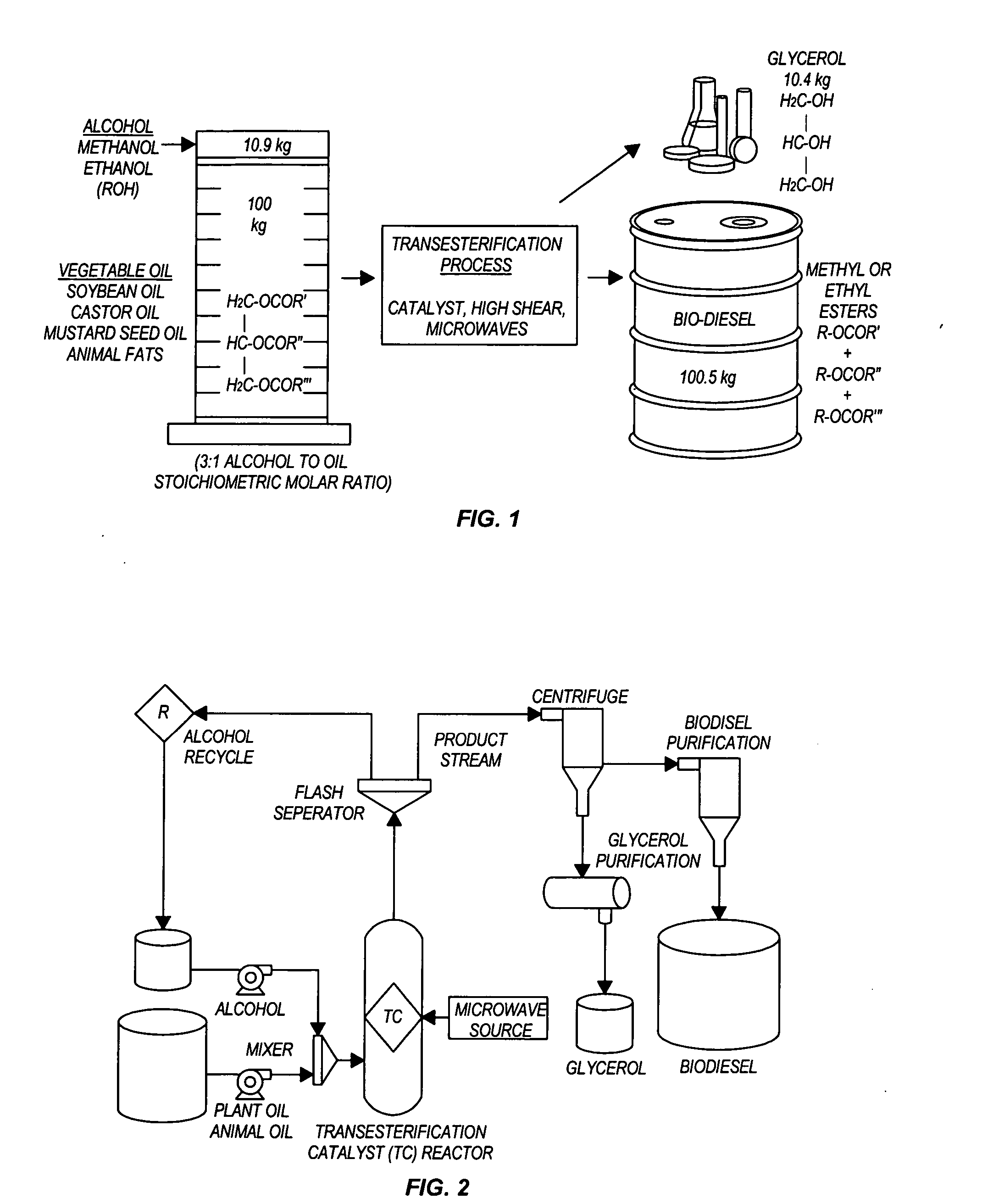

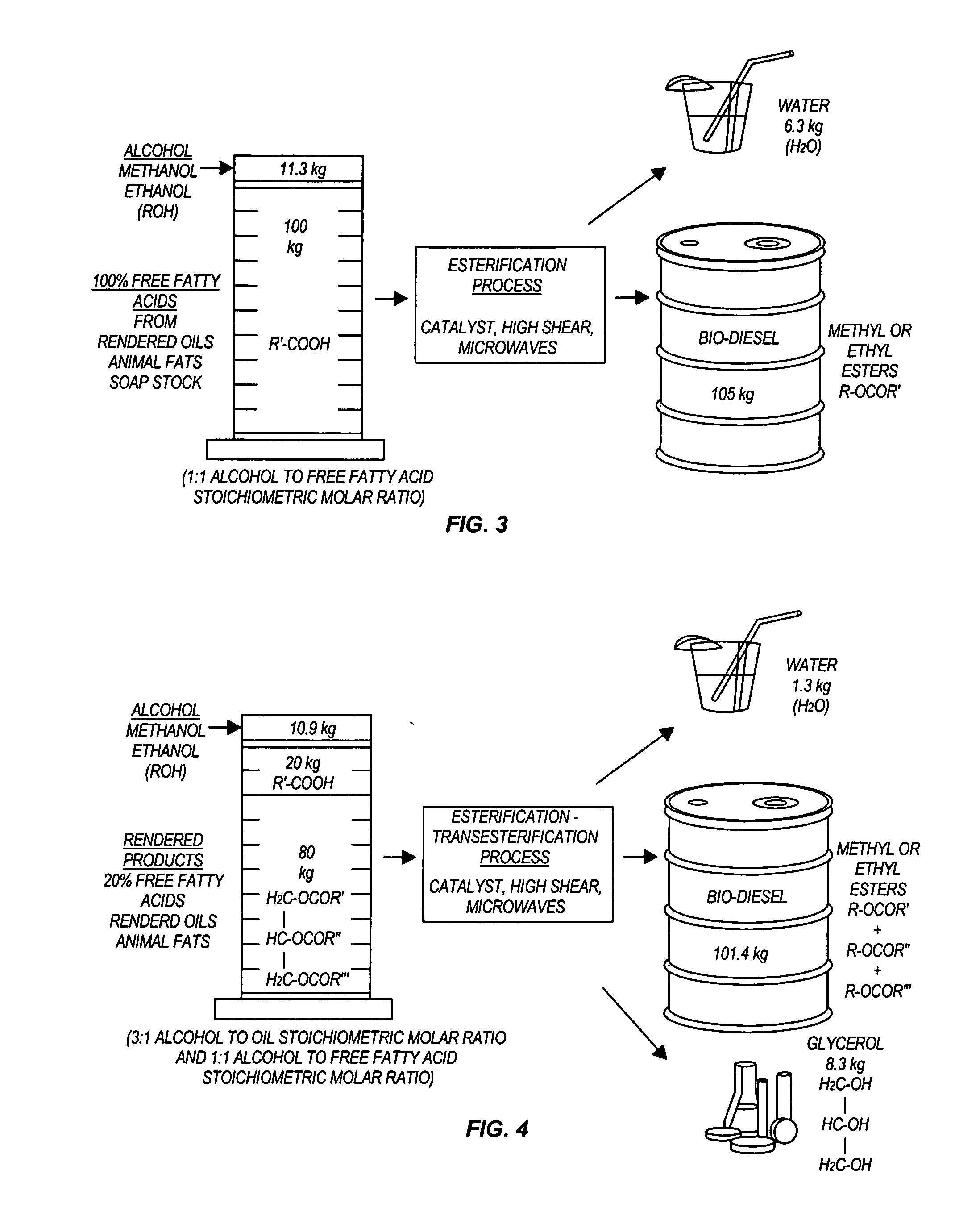

InactiveUS20050274065A1Fatty acid esterificationPreparation by ester-hydroxy reactionMicrowaveTransesterification

Transesterification, esterification, and esterification-transesterification (both one-step and two-step) for producing biofuels. The process may be enhanced by one or more of the following: 1) applying microwave or RF energy; 2) passing reactants over a heterogeneous catalyst at sufficiently high velocity to achieve high shear conditions; 3) emulsifying reactants with a homogeneous catalyst; or 4) maintaining the reaction at a pressure at or above autogeneous pressure. Enhanced processes using one or more of these steps can result in higher process rates, higher conversion levels, or both.

Owner:CARNEGIE MELLON UNIV

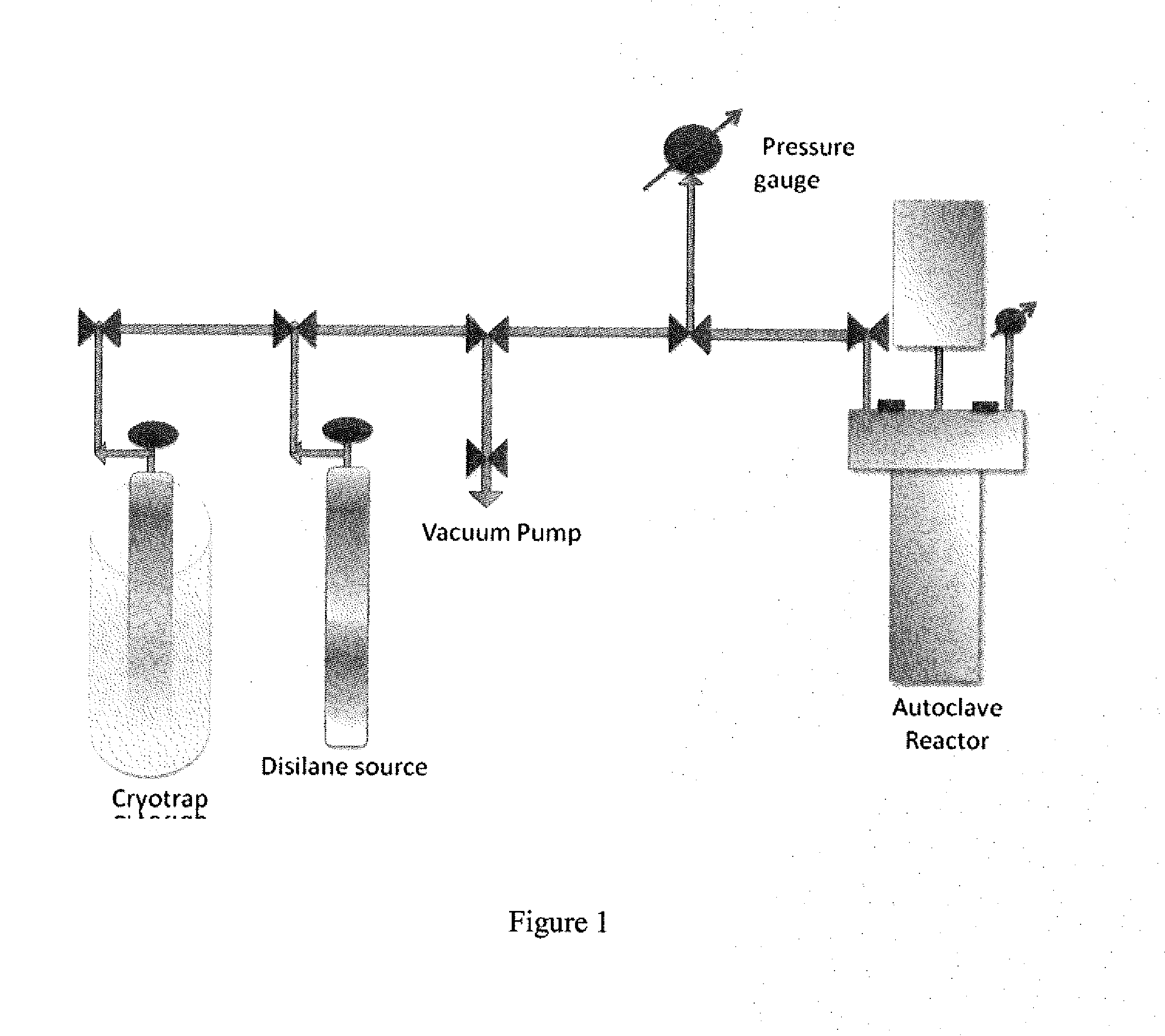

Halogen free syntheses of aminosilanes by catalytic dehydrogenative coupling

ActiveUS20150094470A1Silicon organic compoundsOrganic-compounds/hydrides/coordination-complexes catalystsHydrogenGas phase

Compounds and method of preparation of Si—X and Ge—X compounds (X═N, P, As and Sb) via dehydrogenative coupling between the corresponding unsubstituted silanes and amines (including ammonia) or phosphines catalyzed by metallic catalysts is described. This new approach is based on the catalytic dehydrogenative coupling of a Si—H and a X—H moiety to form a Si—X containing compound and hydrogen gas (X═N, P, As and Sb). The process can be catalyzed by transition metal heterogenous catalysts such as Ru(0) on carbon, Pd(0) on MgO) as well as transition metal organometallic complexes that act as homogeneous catalysts. The —Si—X products produced by dehydrogenative coupling are inherently halogen free. Said compounds can be useful for the deposition of thin films by chemical vapor deposition or atomic layer deposition of Si-containing films.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

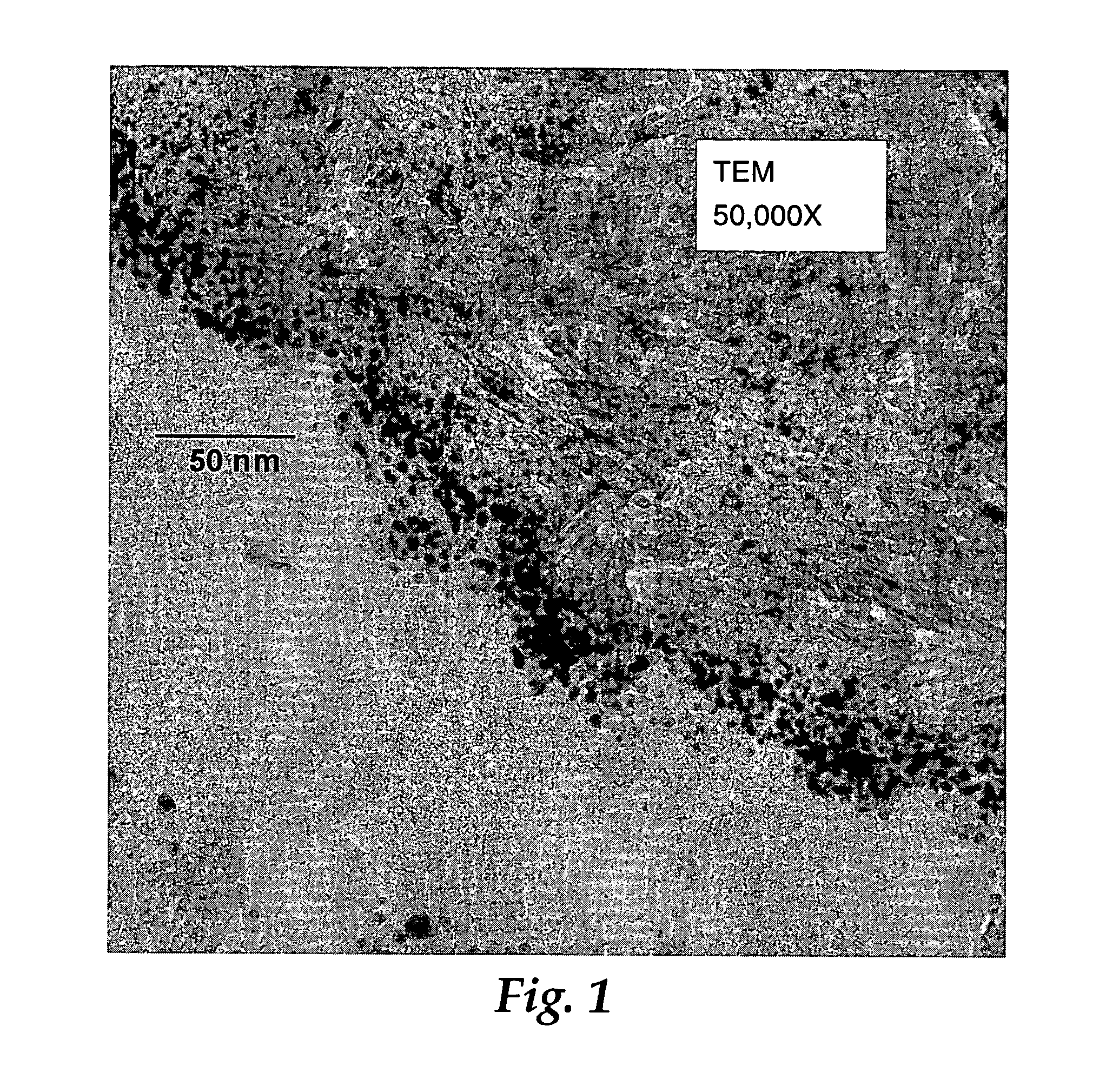

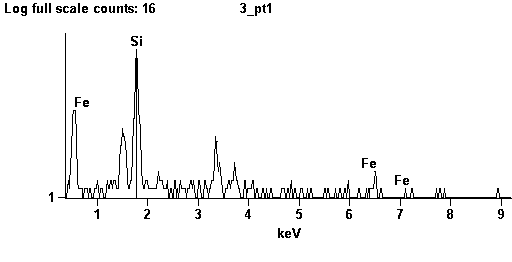

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS20050095189A1Improve performanceEasy to useMaterial nanotechnologyInternal combustion piston enginesGas phaseAdditive ingredient

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

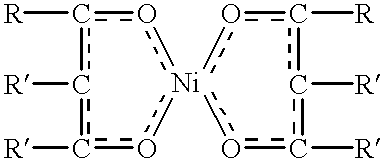

Dimerized alcohol compositions and biodegradible surfactants made therefrom having cold water detergency

InactiveUS6222077B1Good cold water detergencyOrganic detergent compounding agentsOther chemical processesDouble bondCarboxylic acid

There is provided an alcohol composition obtained by dimerizing an olefin feed comprising C6-C10 linear olefins to obtain C12-C20 olefins, followed by conversion to alcohols, such as by hydroformylation. The composition has an average number of branches ranging from 0.9 to 2.0 per molecule. The linear olefin feed preferably comprises at least 85% of C6-C8-olefins. The primary alcohol compositions are then converted to anionic or nonionic surfactants, preferably sulfated or oxyalkylated or both. The sulfated compositions are biodegradable and possess good cold water detergency. The process for making the dimerized primary alcohol comprises dimerizing, in the presence of a homogeneous dimerization catalyst under dimerization conditions, an olefin feed comprising C6-C10 olefins and preferably at least 85 weight % of linear olefins based on the weight of the olefin feed, to obtain a C12-C20; optionally double bond isomerizing said C12-C20 olefins; and converting the C12-C20 olefins to alcohols, preferably through hydroformylation. The process is preferably a one-step dimerization. The homogenous catalyst comprises a mixture of a nickel carboxylate or a nickel chelate, with an alkyl aluminum halide or an alkyl aluminum alkoxide.

Owner:SHELL OIL CO

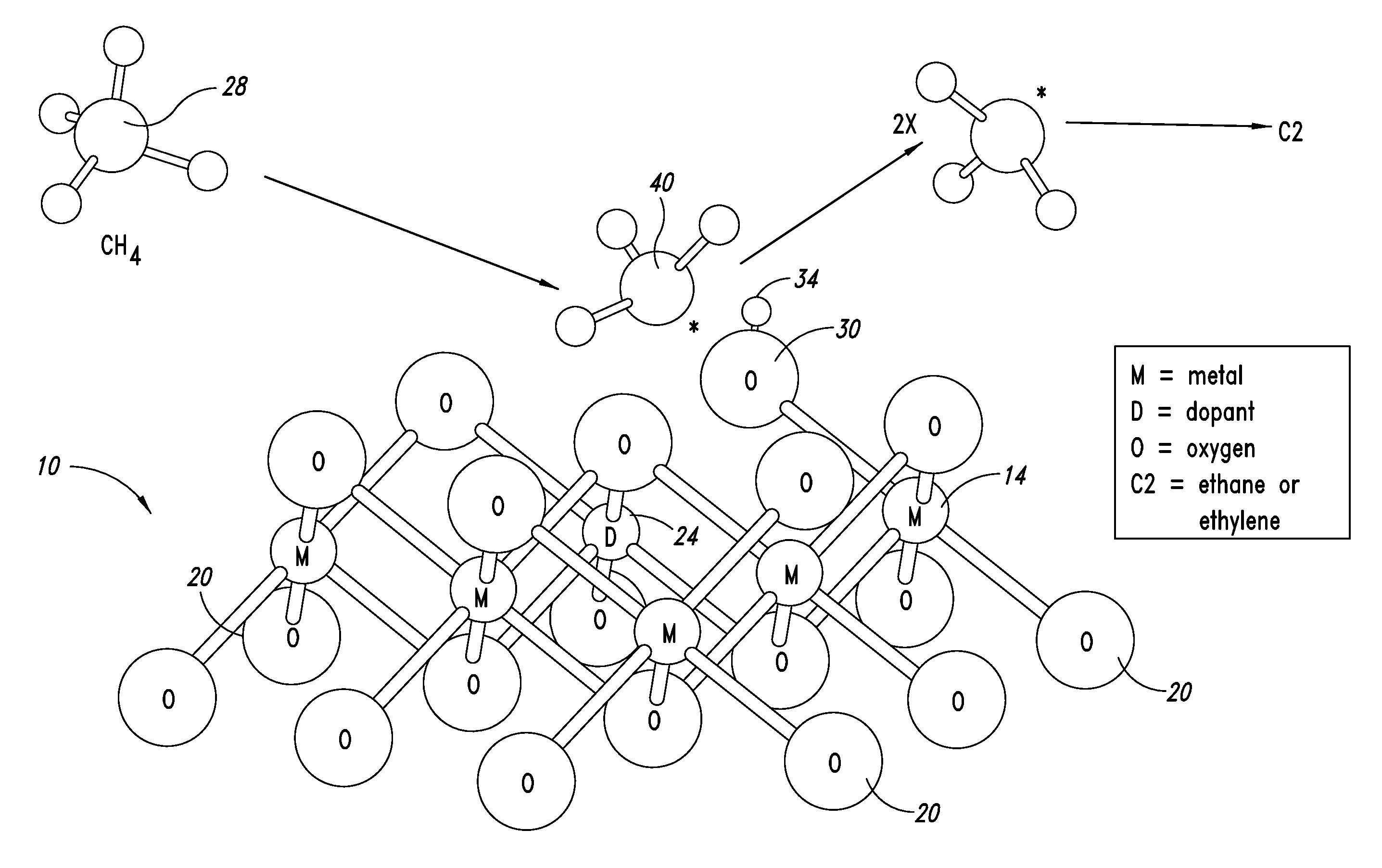

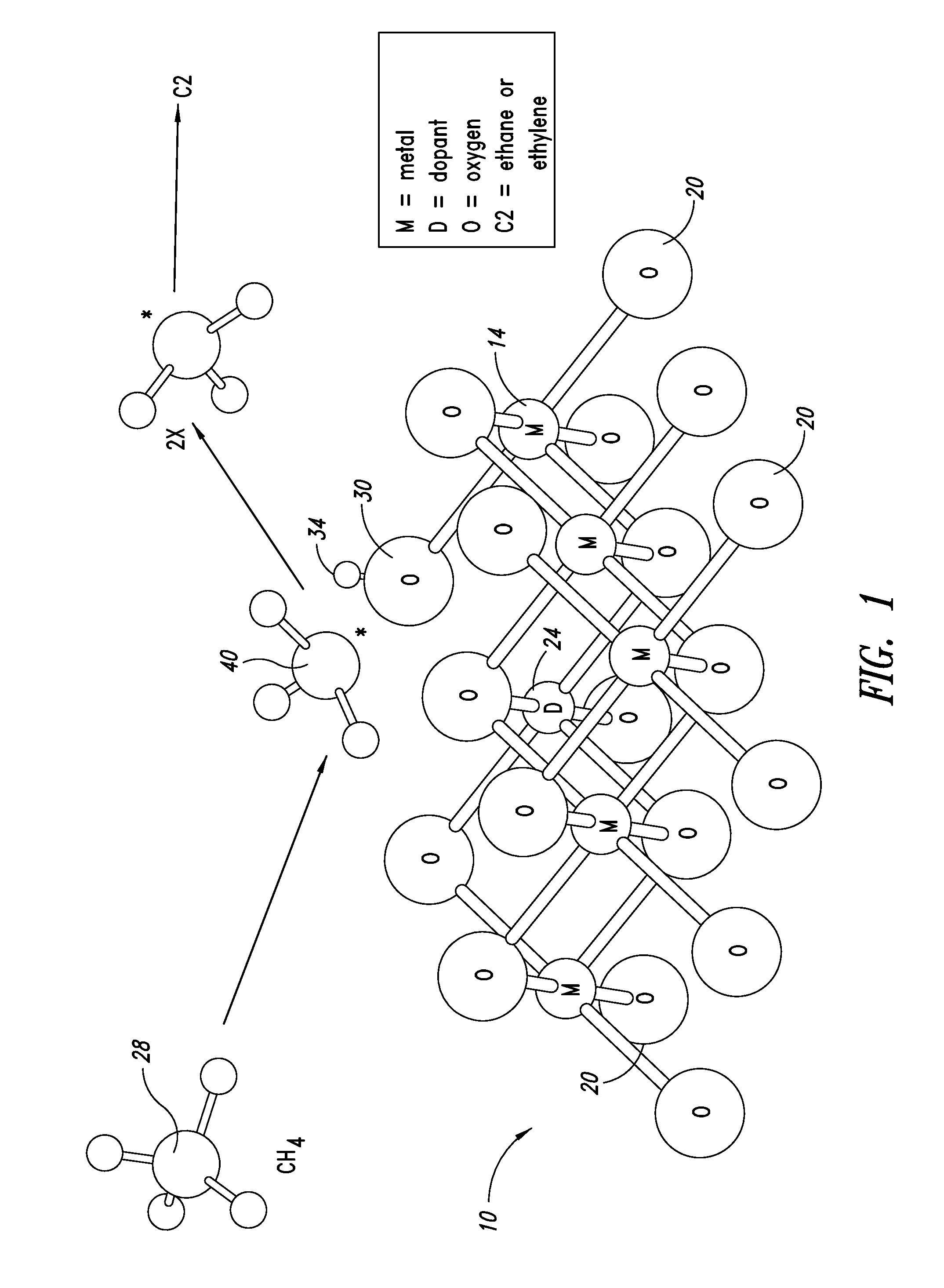

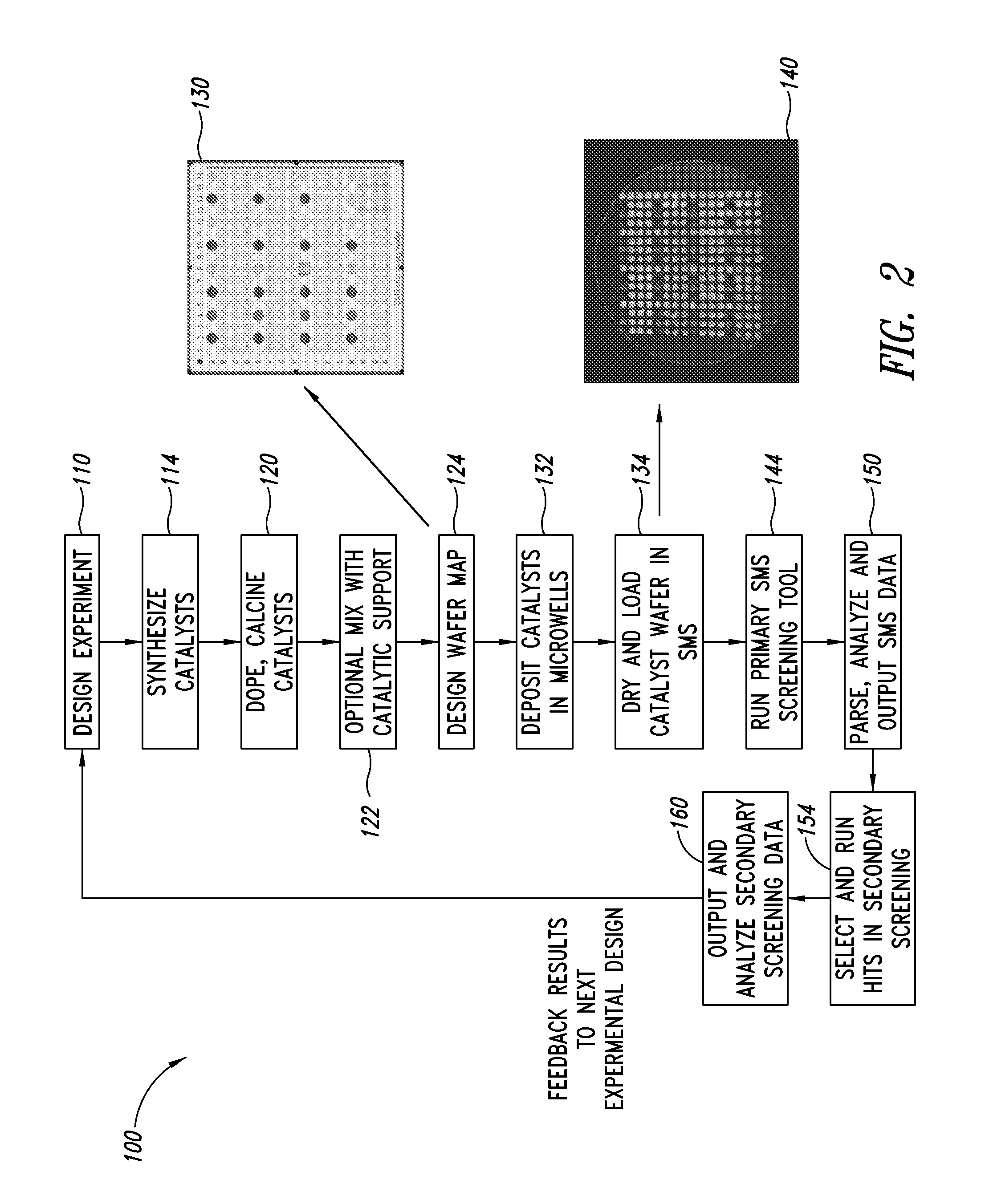

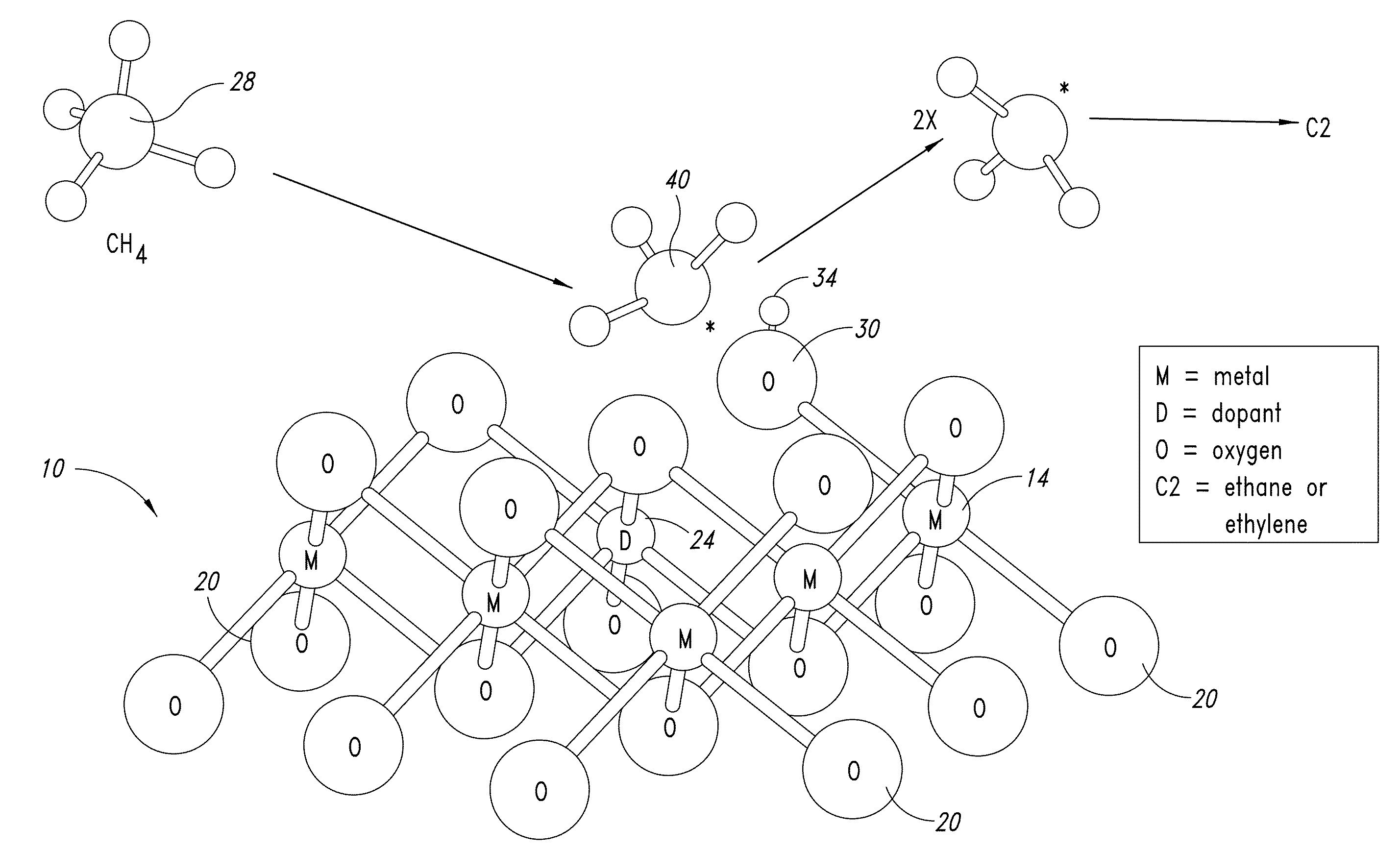

Catalysts for petrochemical catalysis

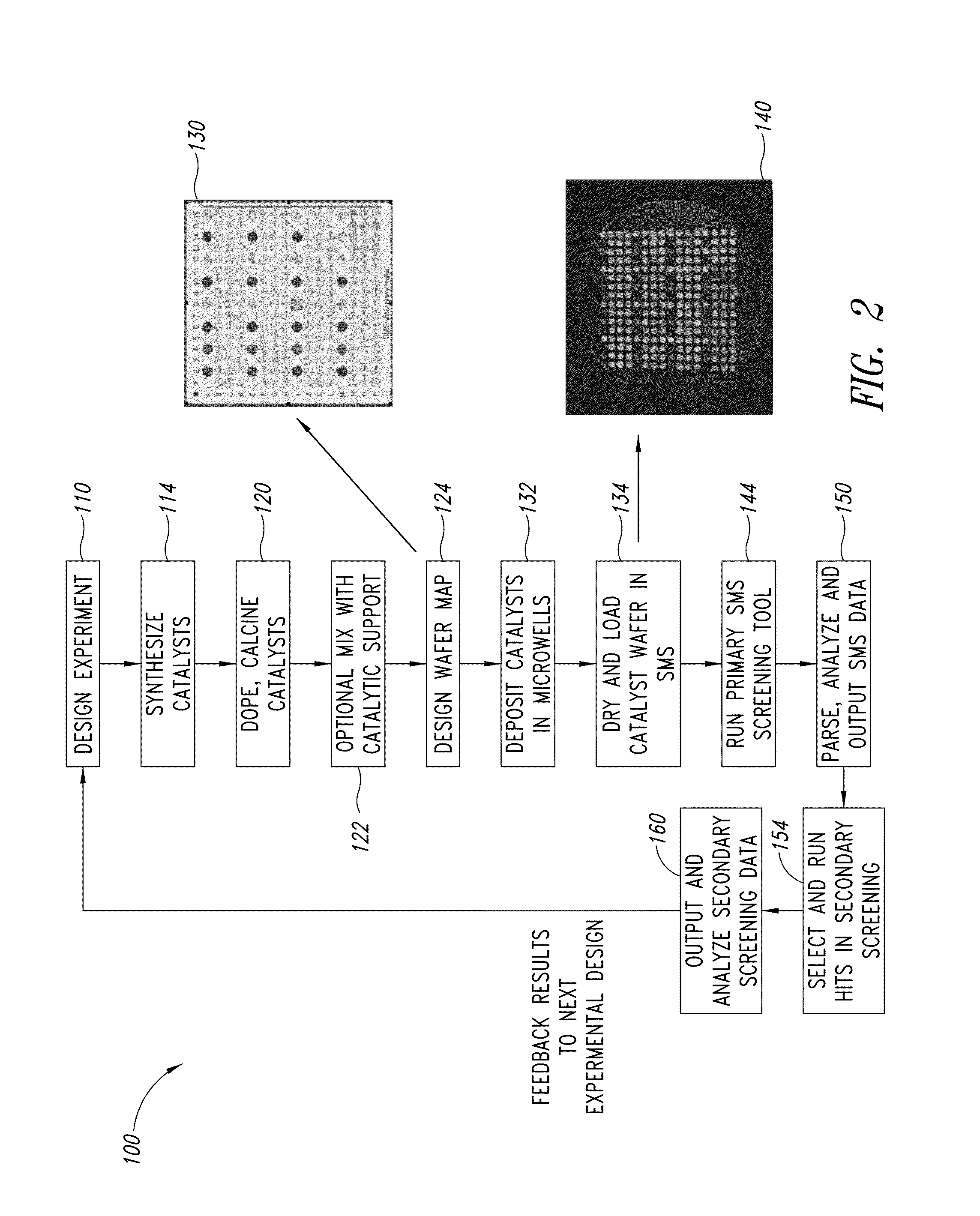

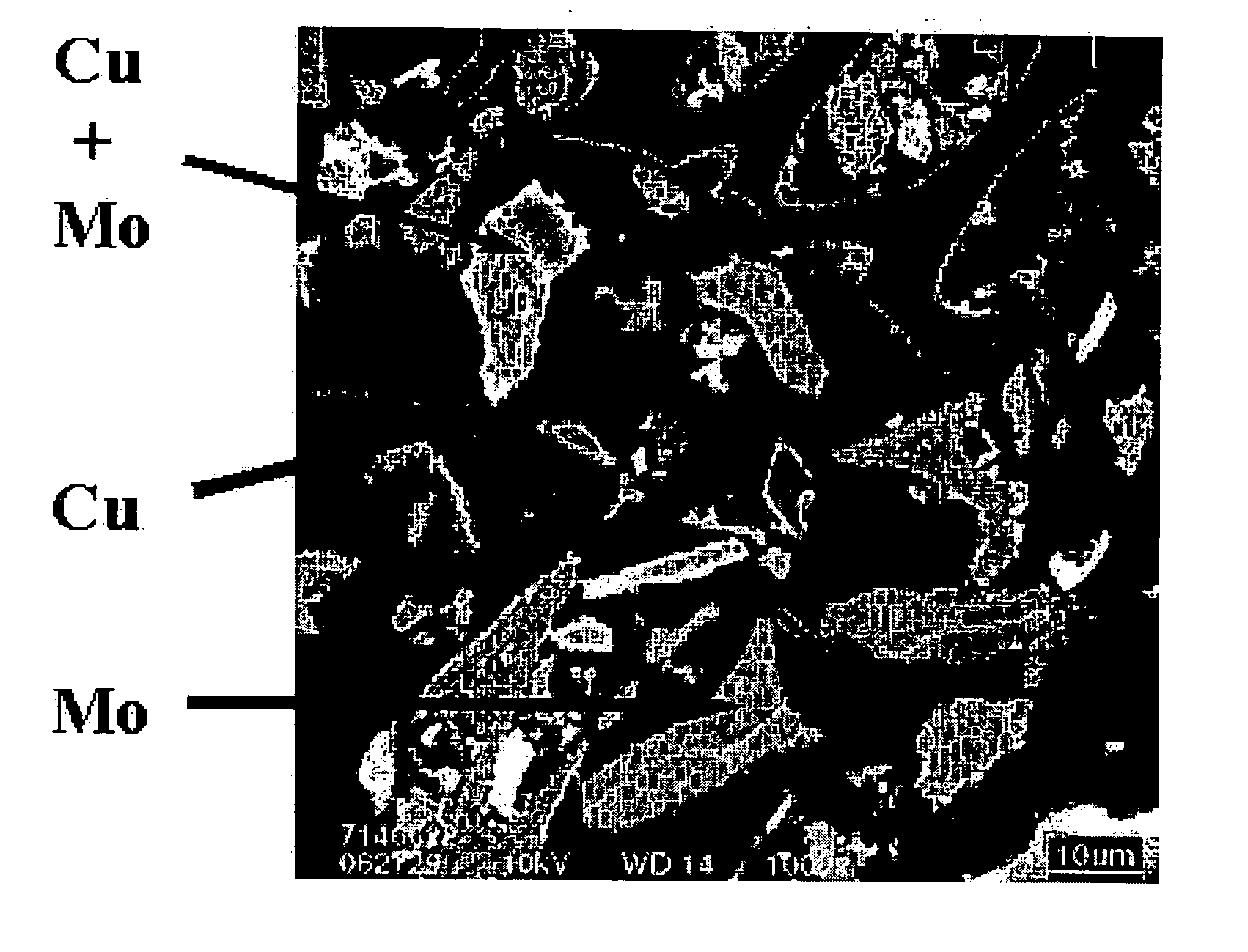

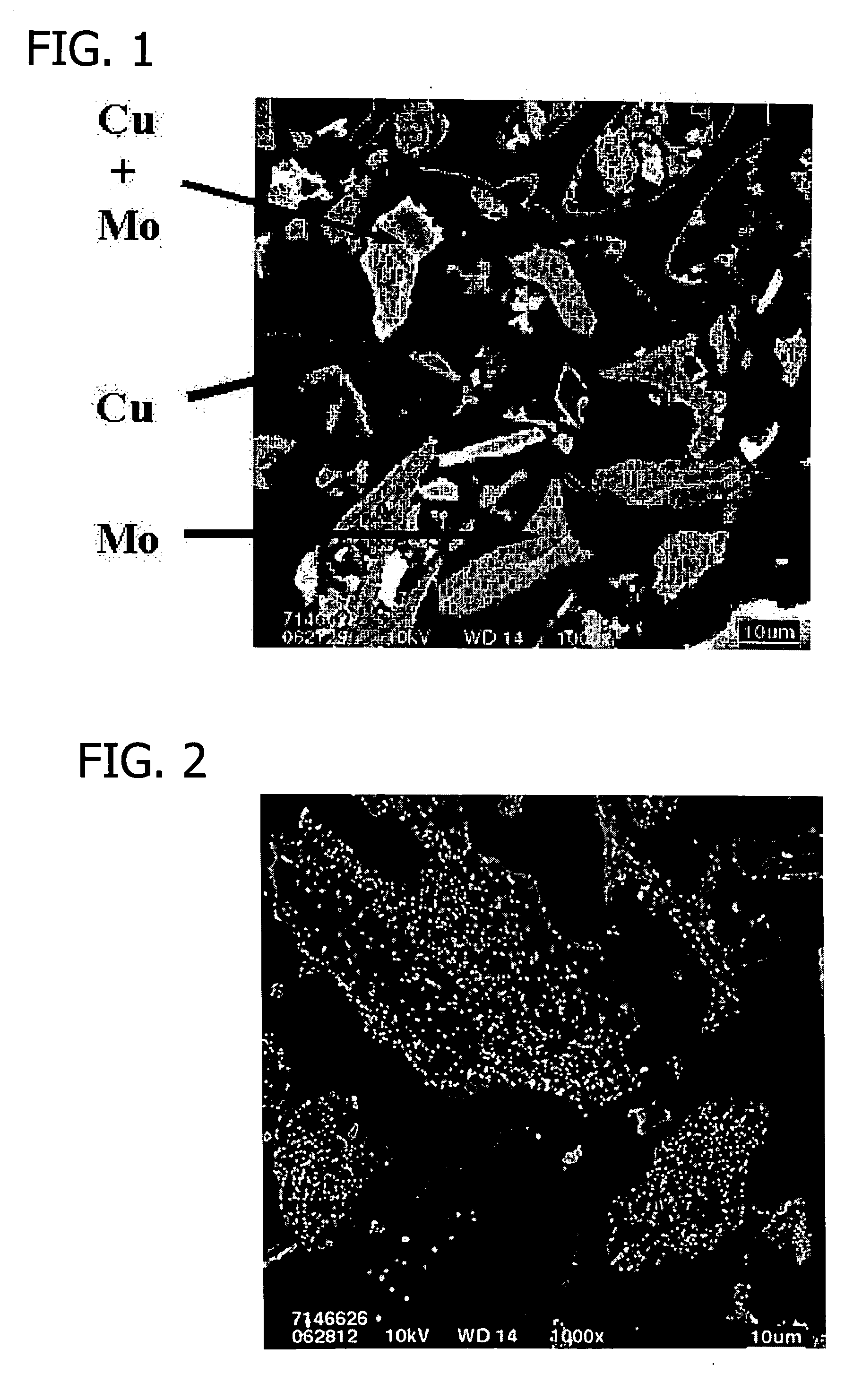

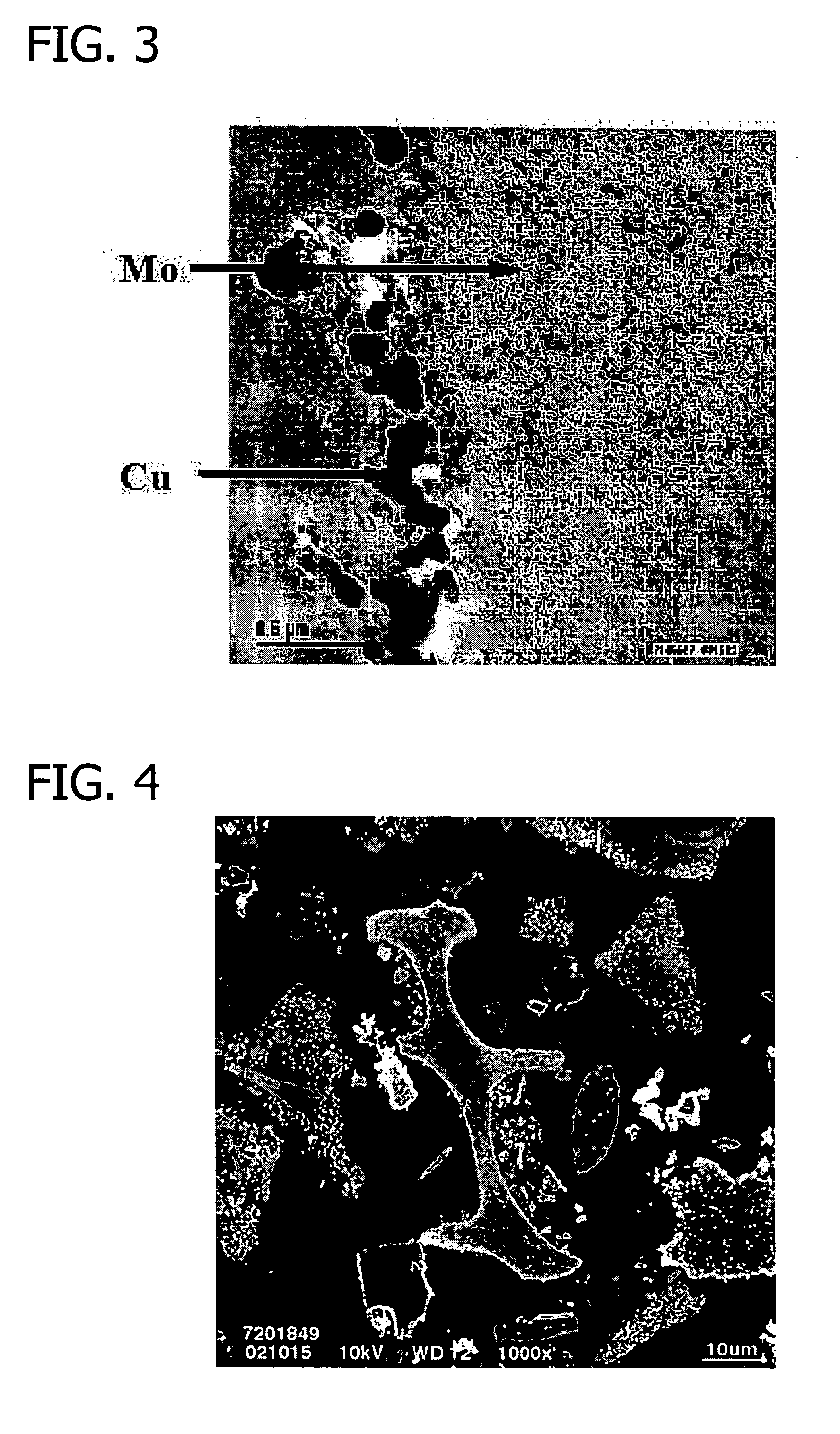

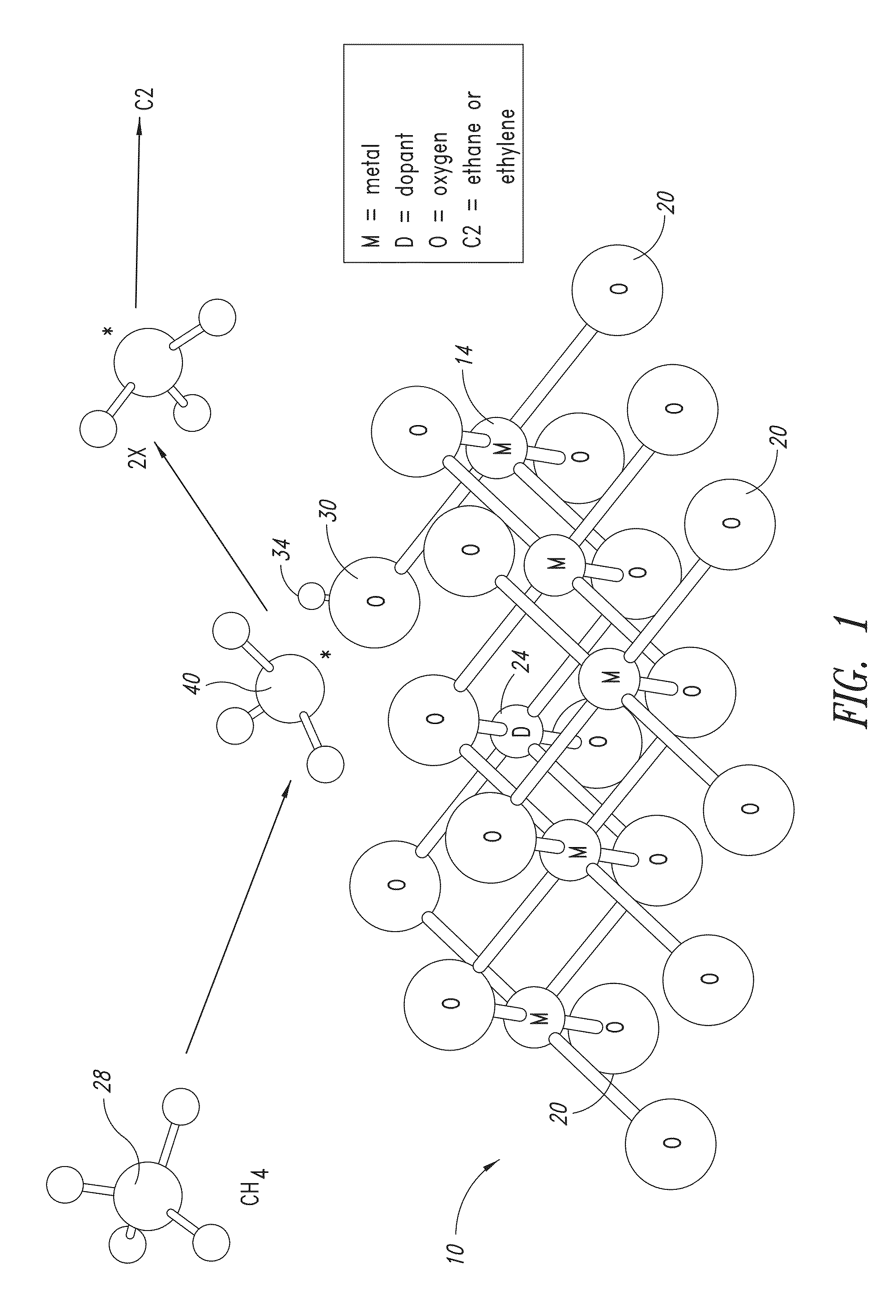

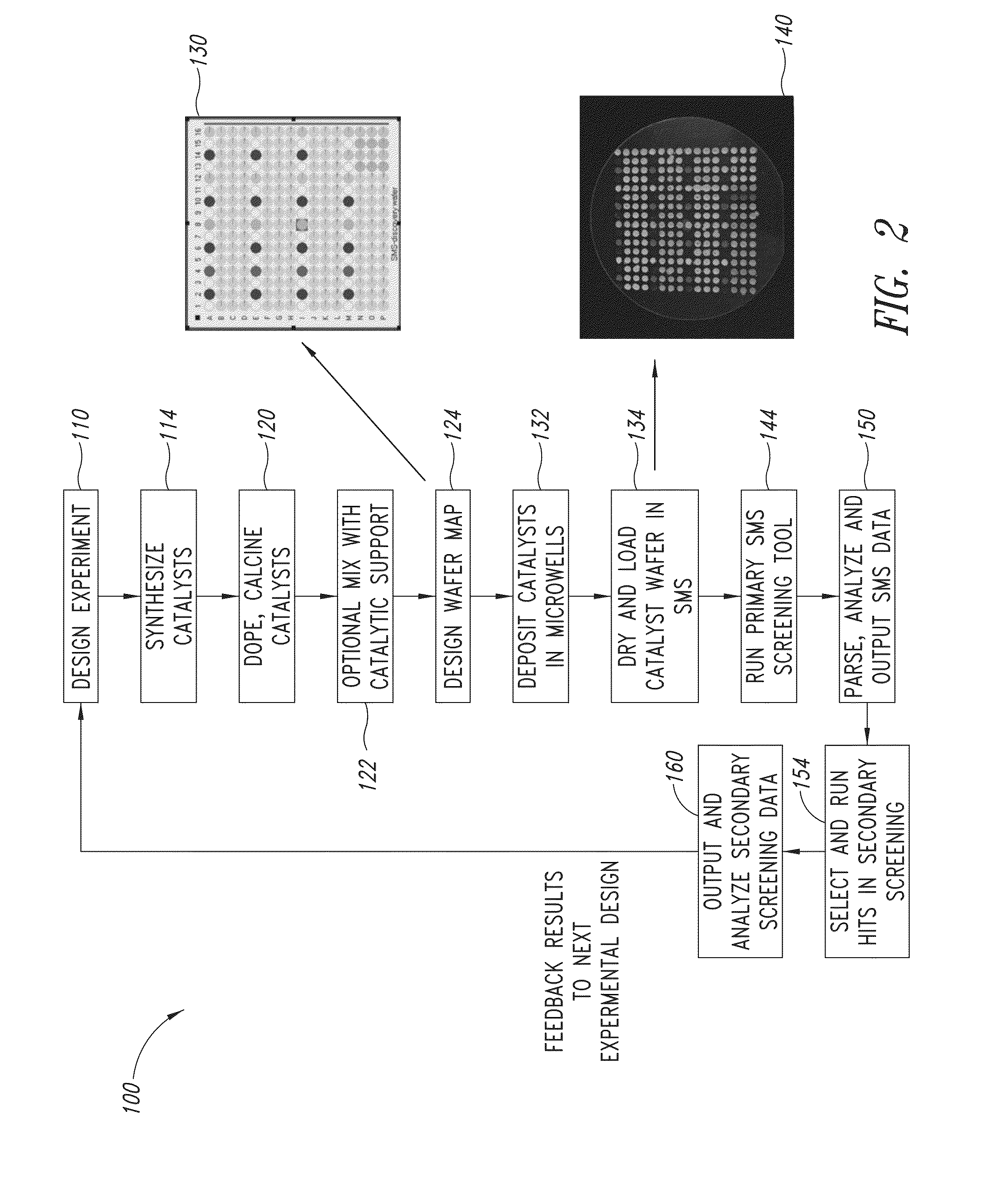

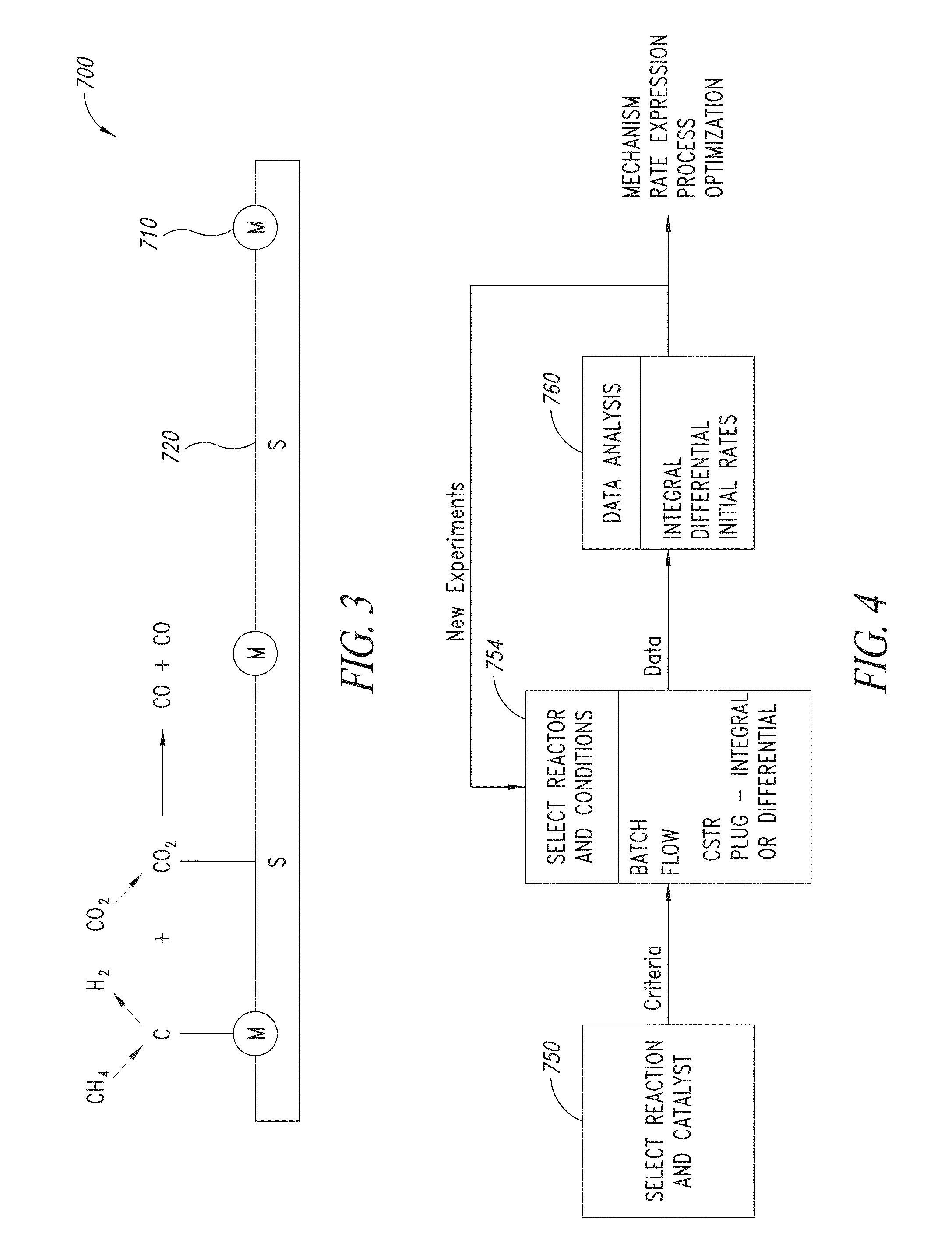

ActiveUS20130023709A1Sequential/parallel process reactionsManganese oxides/hydroxidesDopantPetrochemical

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Multimetal oxide materials

Owner:BASF SE

Catalysts, activating agents, support media, and related methodologies useful for making catalyst systems especially when the catalyst is deposited onto the support media using physical vapor deposition

InactiveUS7727931B2High catalytic activityTendency increaseMaterial nanotechnologyInternal combustion piston enginesGas phasePhysical chemistry

Use of physical vapor deposition methodologies to deposit nanoscale gold on activating support media makes the use of catalytically active gold dramatically easier and opens the door to significant improvements associated with developing, making, and using gold-based, catalytic systems. The present invention, therefore, relates to novel features, ingredients, and formulations of gold-based, heterogeneous catalyst systems generally comprising nanoscale gold deposited onto a nanoporous support.

Owner:3M INNOVATIVE PROPERTIES CO

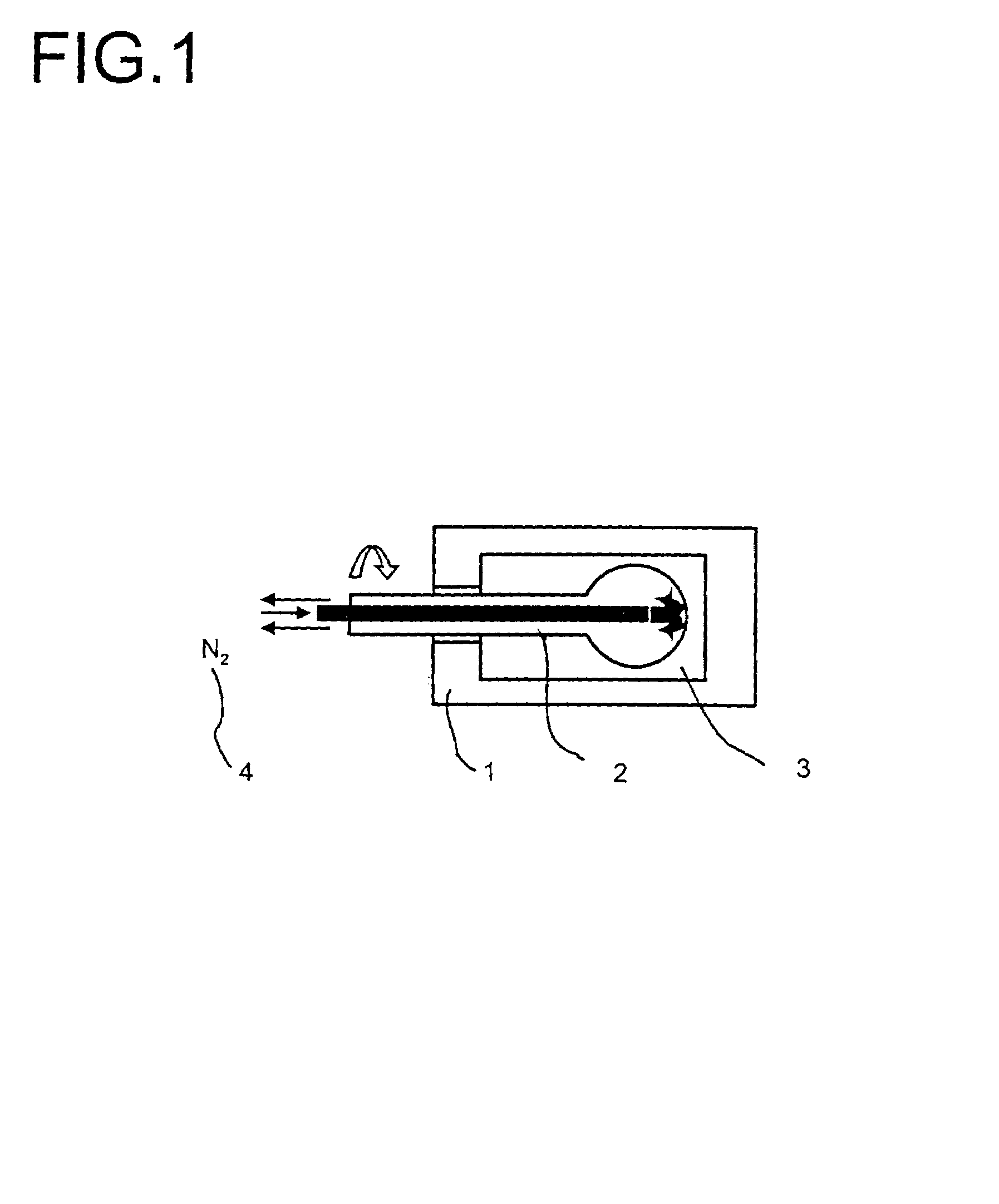

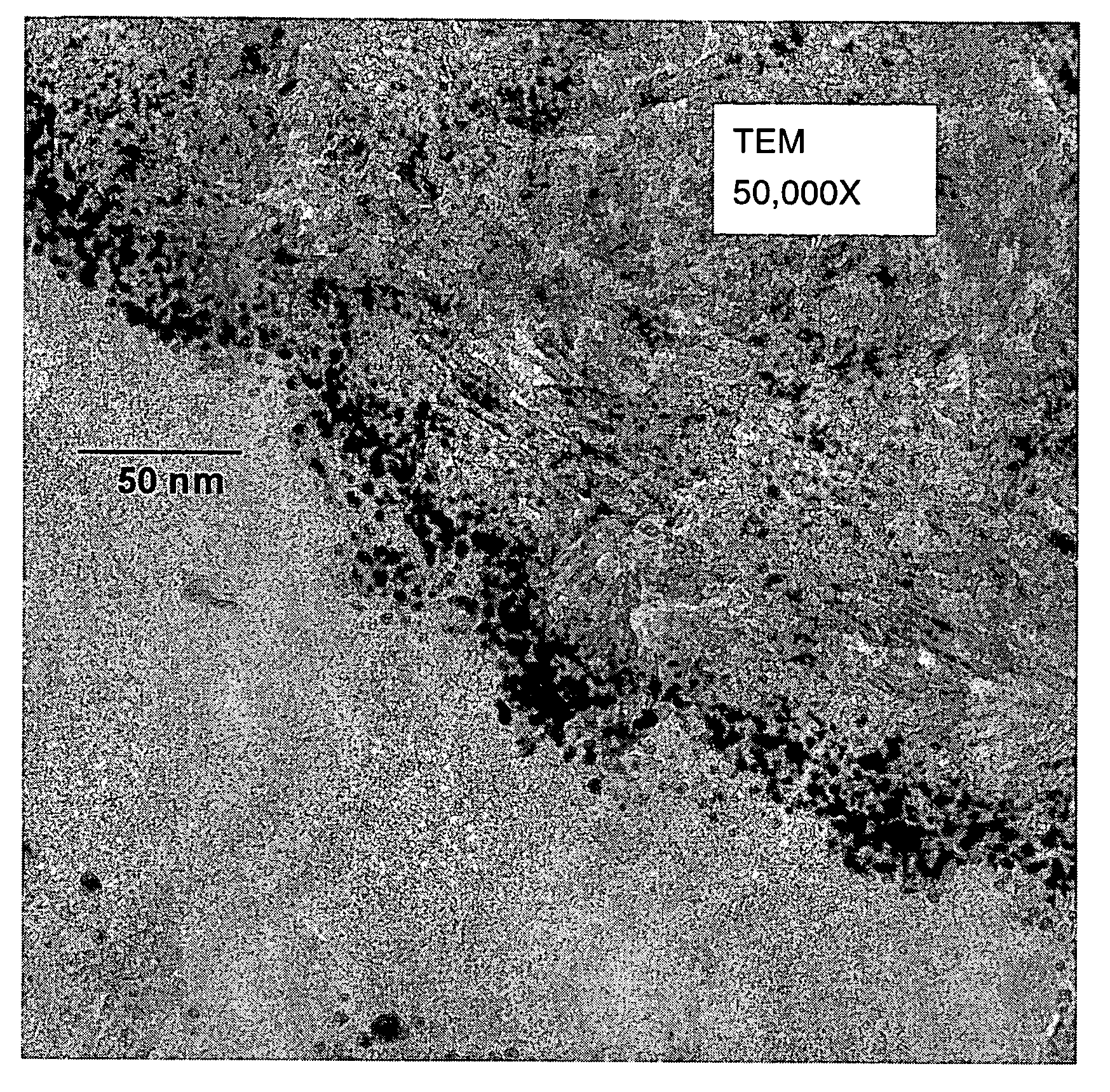

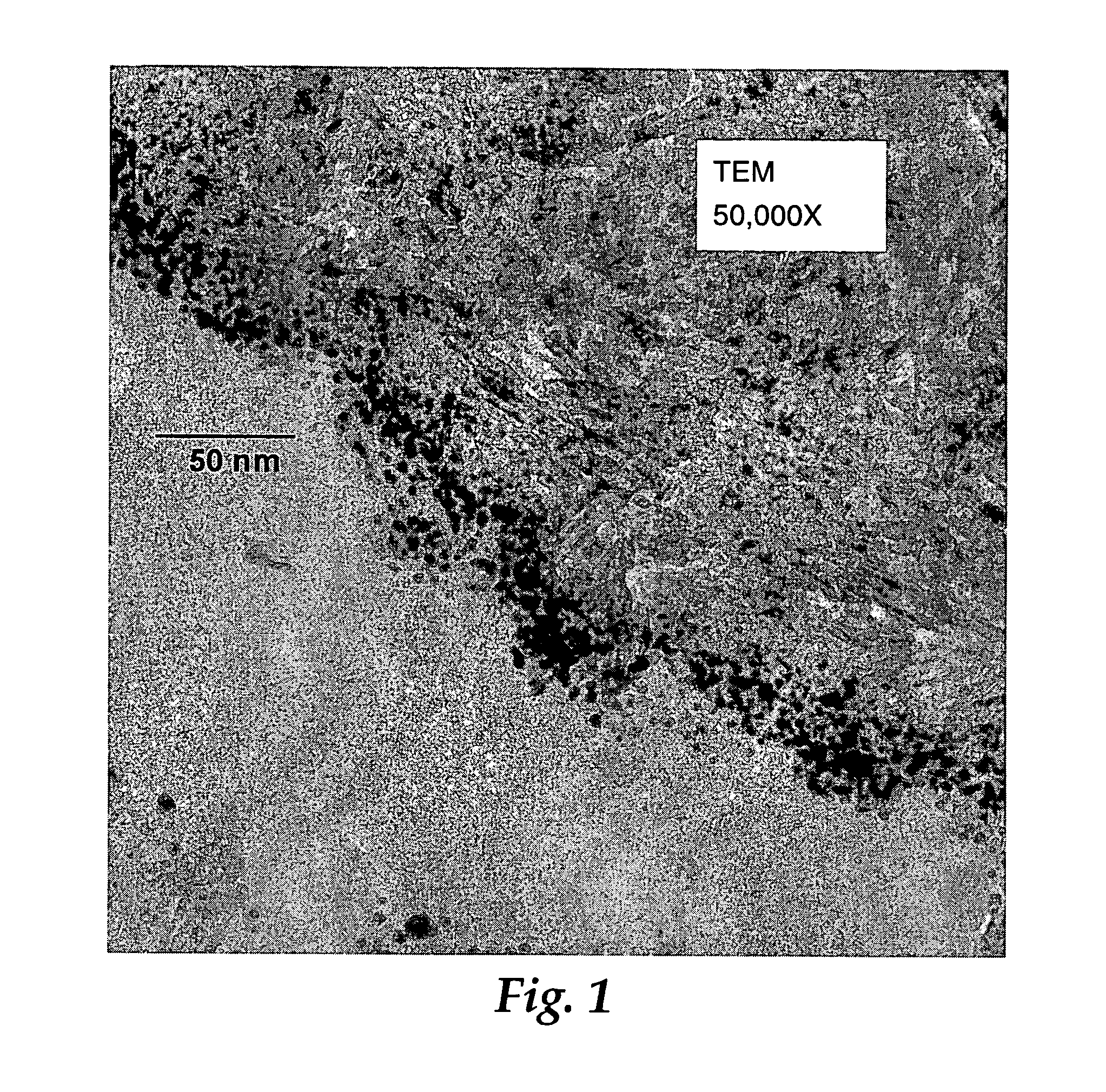

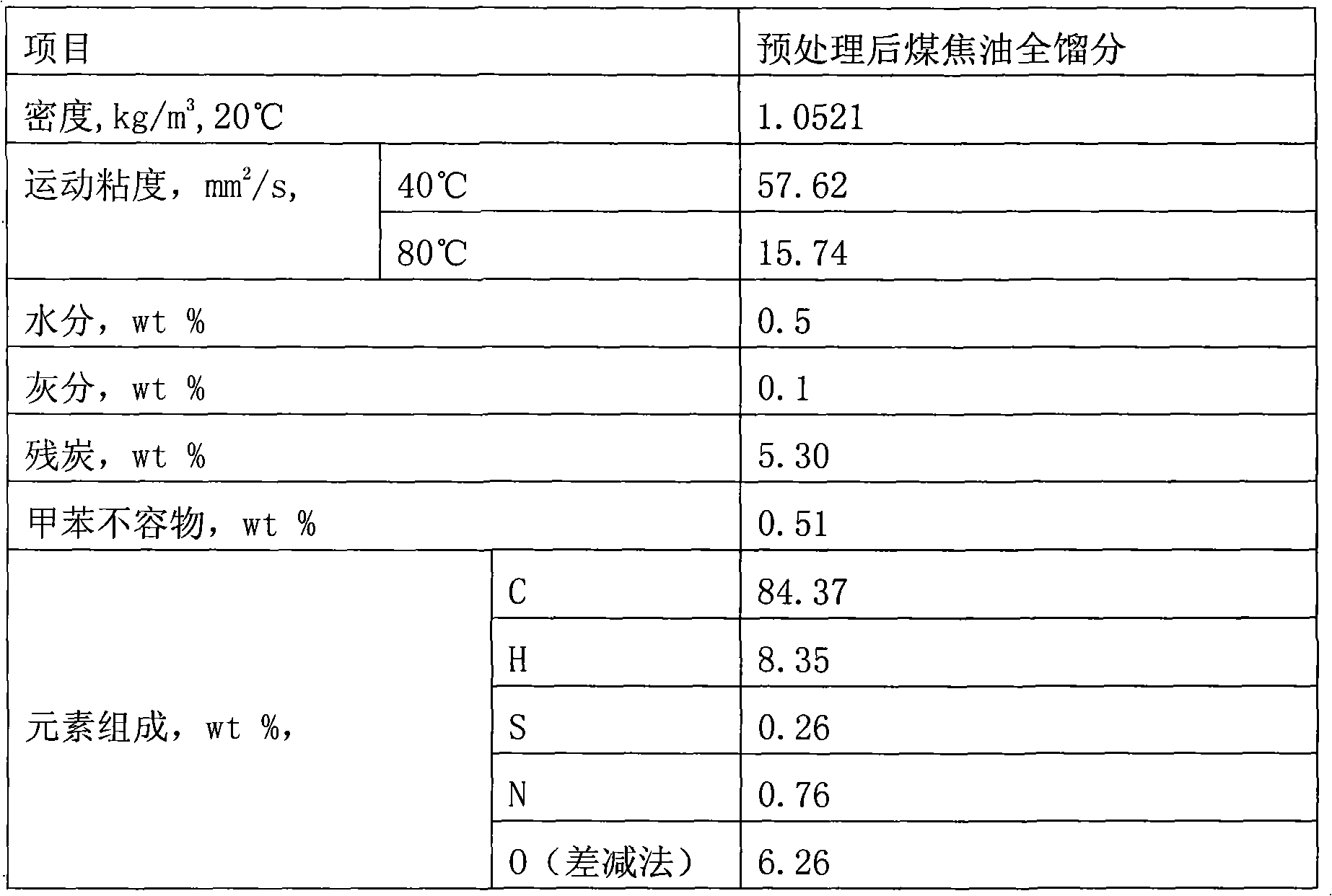

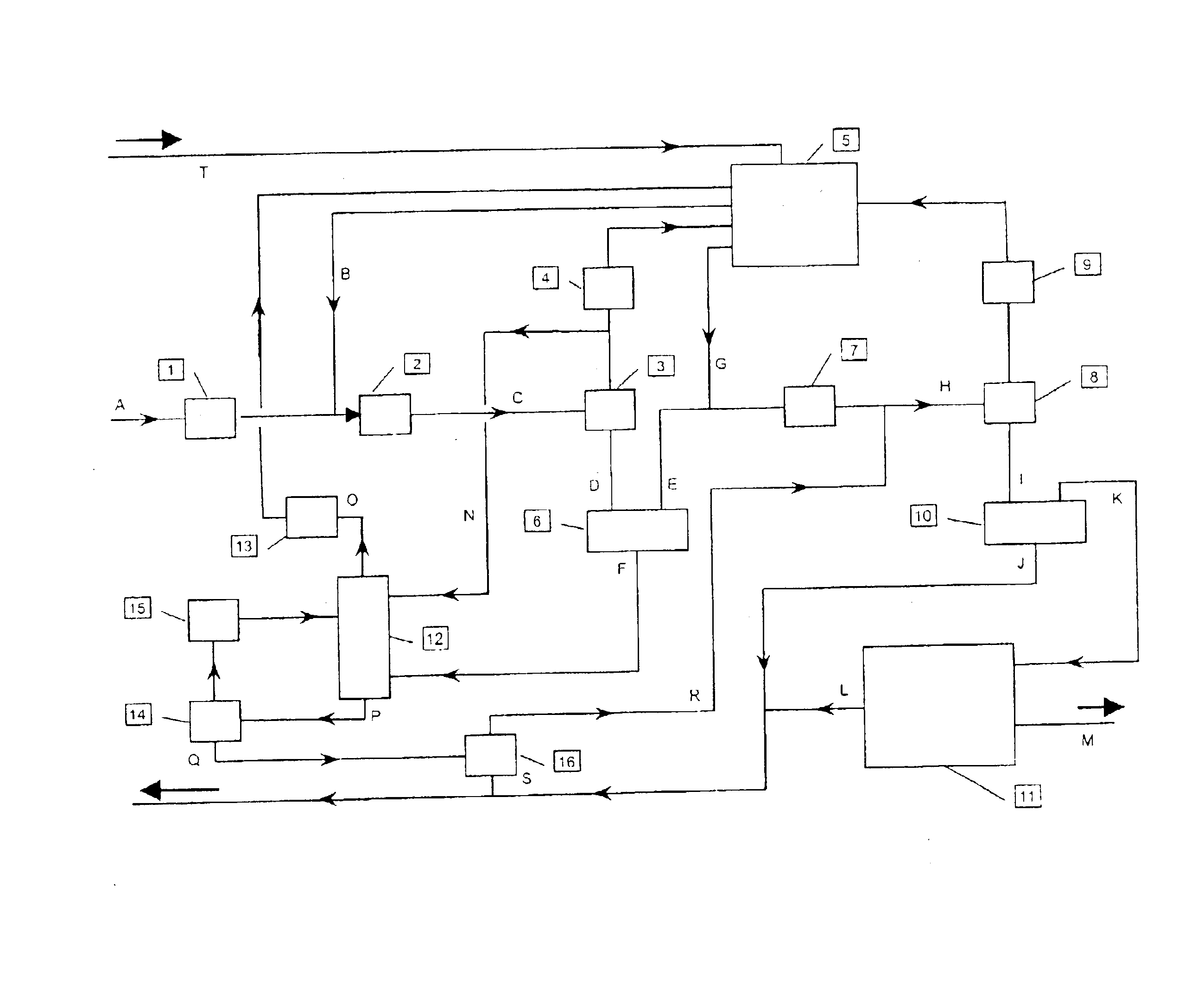

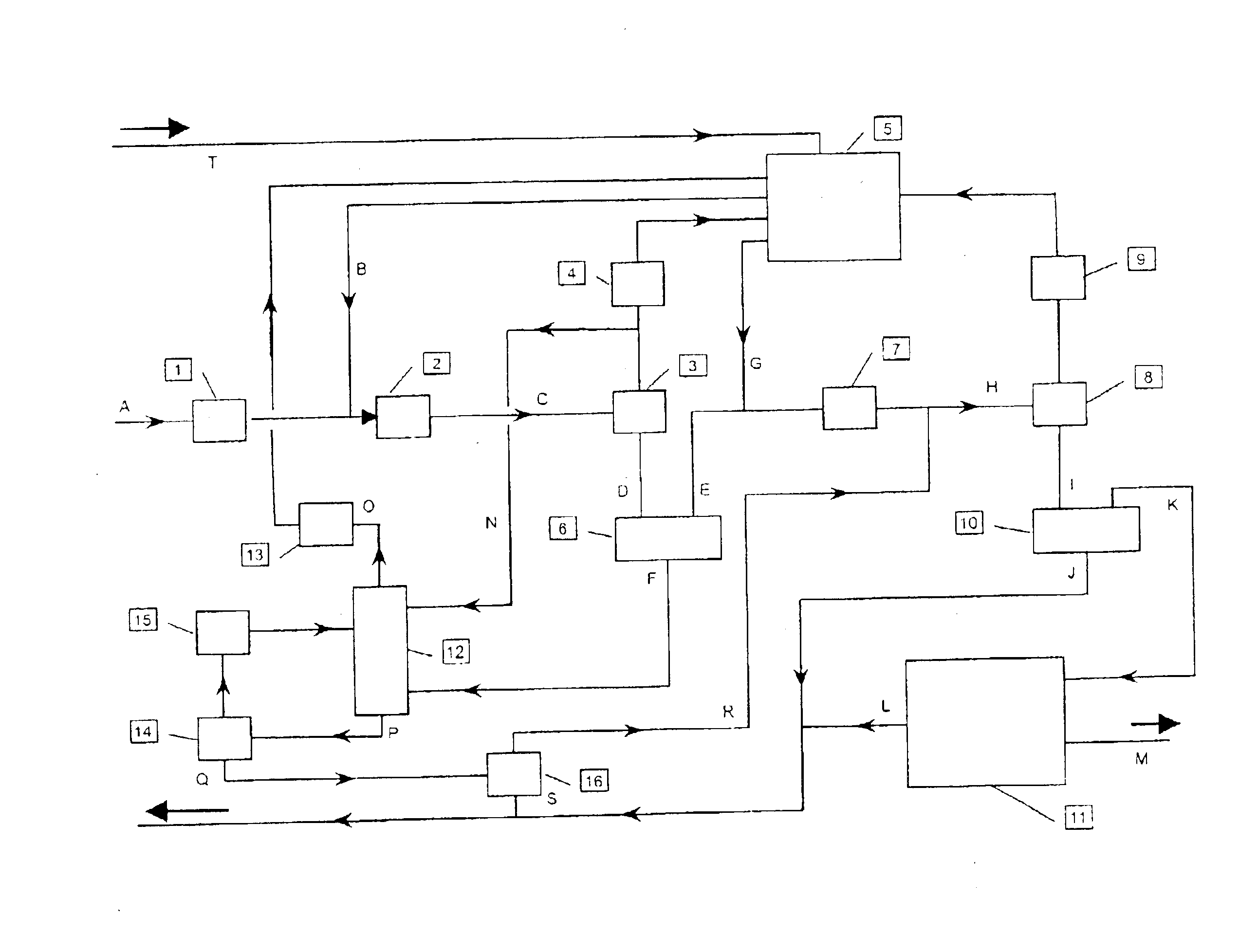

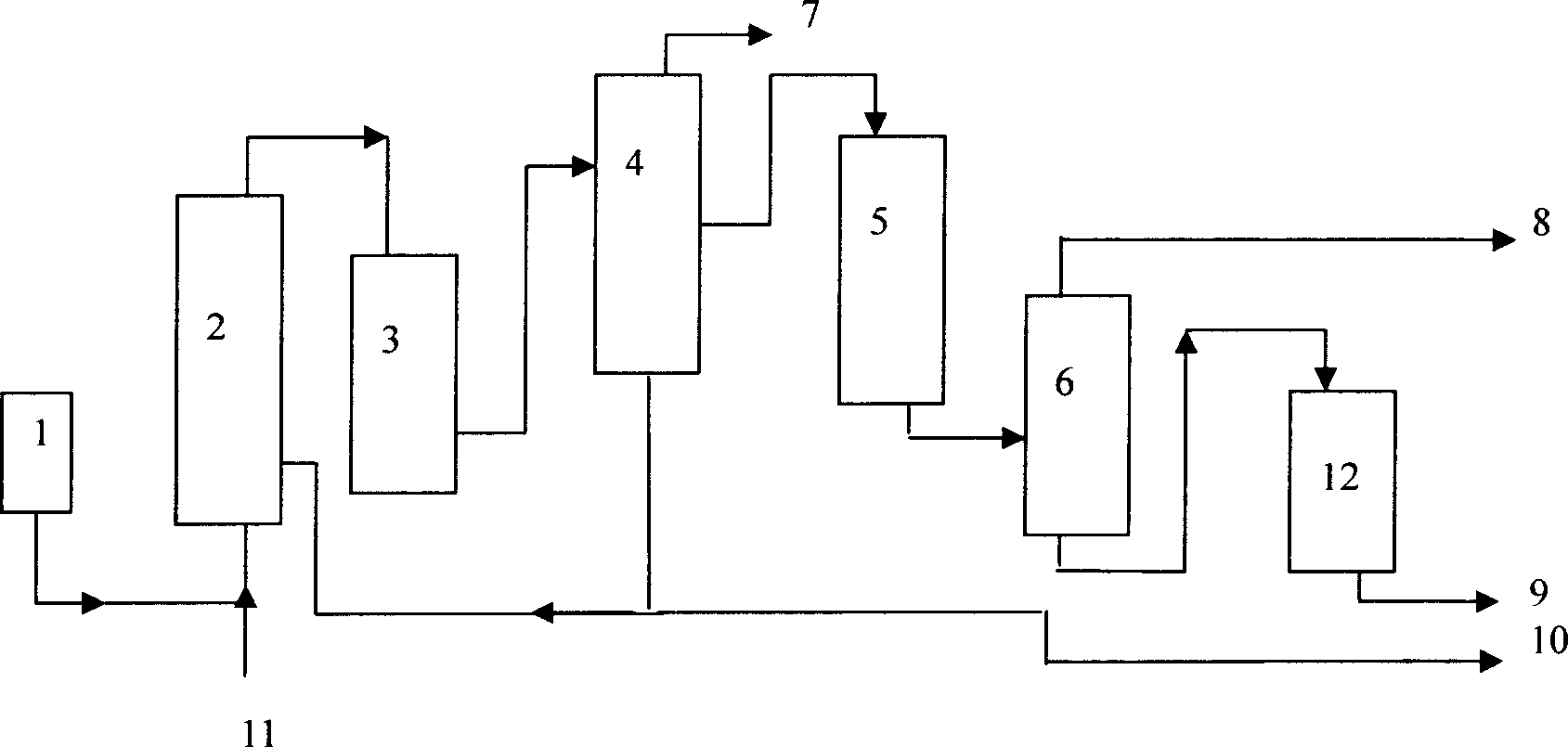

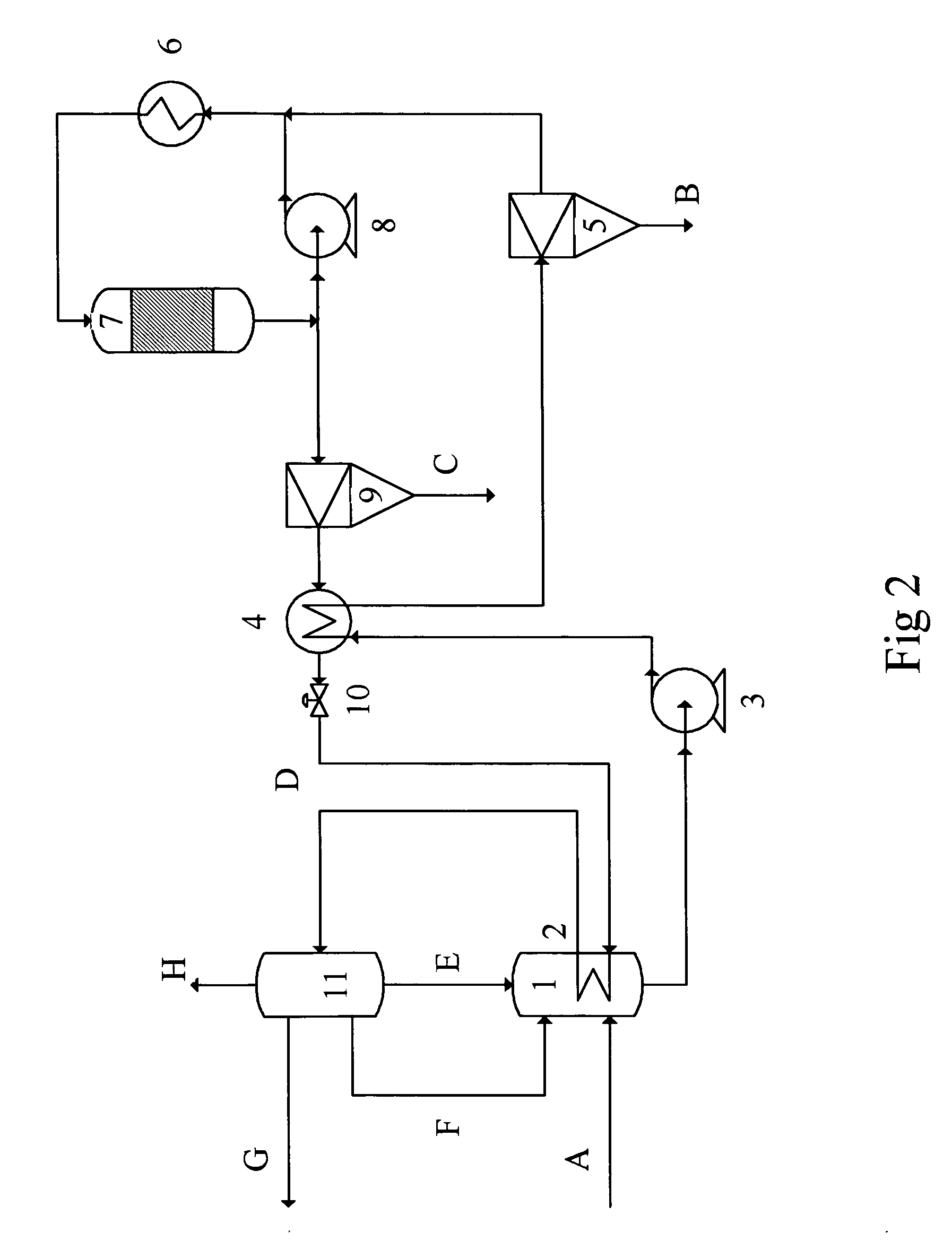

Hydrogenation method for coal tar suspension bed of heterogeneous catalyst

ActiveCN101885982ATo achieve the purpose of recyclingImprove utilization efficiencyTreatment with hydrotreatment processesFuel oilBULK ACTIVE INGREDIENT

The invention relates to a hydrogenation method for a coal tar suspension bed of a heterogeneous catalyst. The method comprises processes of coal tar raw material pretreatment and distillatory separation, coal tar heavy fraction suspension bed hydrogenation cracking and conventional light fraction oil extraction, wherein the suspension bed hydrogenation reaction temperature is between 320 and 480DEG C, the reaction pressure is 8 to 19MPa, the volume air speed is 0.3 to 3.0h<-1>, the hydrogen oil volume ratio is 500 to 2,000, the catalyst is a powdery granular coal tar suspension bed hydrogenation catalyst of a single metal active ingredient containing molybdenum, nickel, cobalt, tungsten or iron or a composite multi-metal active ingredient, the adding amount of the catalyst is based on the ratio of the metal quantity of the active ingredient to the weight of the coal tar raw materials of 0.1: 100-4: 100, most of tail oil containing the catalyst after lightweight oil is separated froma hydrogenation reaction product is directly circulated to a hydrogenation bed reactor, a small part of tail oil is subjected to catalyst removal treatment and then circulated to the hydrogenation bed reactor to be subjected to further lightweight treatment, and the heavy oil is totally or furthest circulated. The method fulfills the purposes of maximum production of the lightweight oil in the coal tar and cyclic utilization of the catalyst, and greatly improves the utilization efficiency of the raw materials and the catalyst.

Owner:CCTEG CHINA COAL RES INST

Process for producing alkyl esters from a vegetable or animal oil and an aliphatic monoalcohol

InactiveUS6878837B2High purityImpact on overall process costFatty oils/acids recovery from wasteFatty acid esterificationAluminateTransesterification

Alkyl esters of fatty acids, and high purity glycerin, are produced using a process comprising a set of transesterification reactions between a vegetable or animal oil and an aliphatic monoalcohol employing a heterogeneous catalyst, for example based on zinc aluminate, the water content in the reaction medium being controlled to a value that is below a given limiting value.

Owner:INST FR DU PETROLE

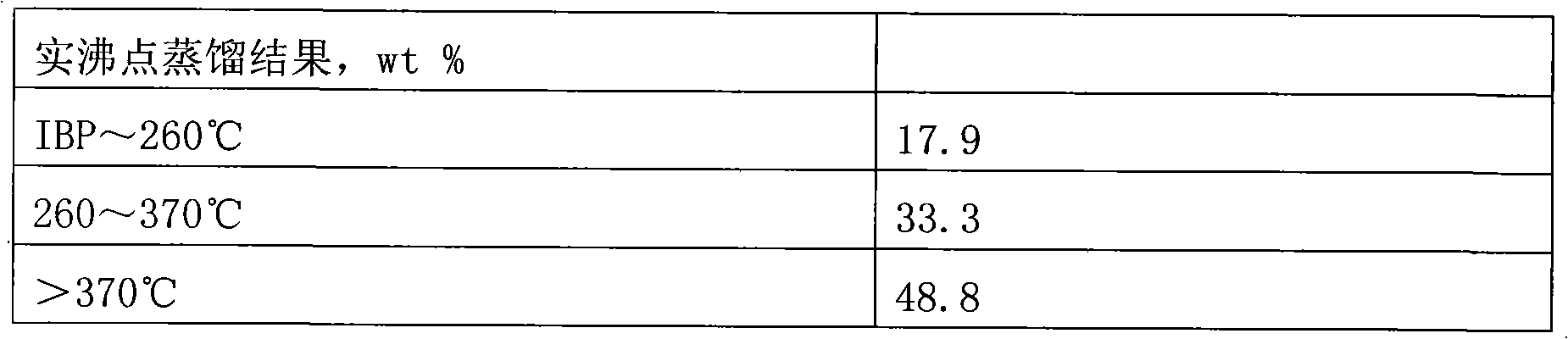

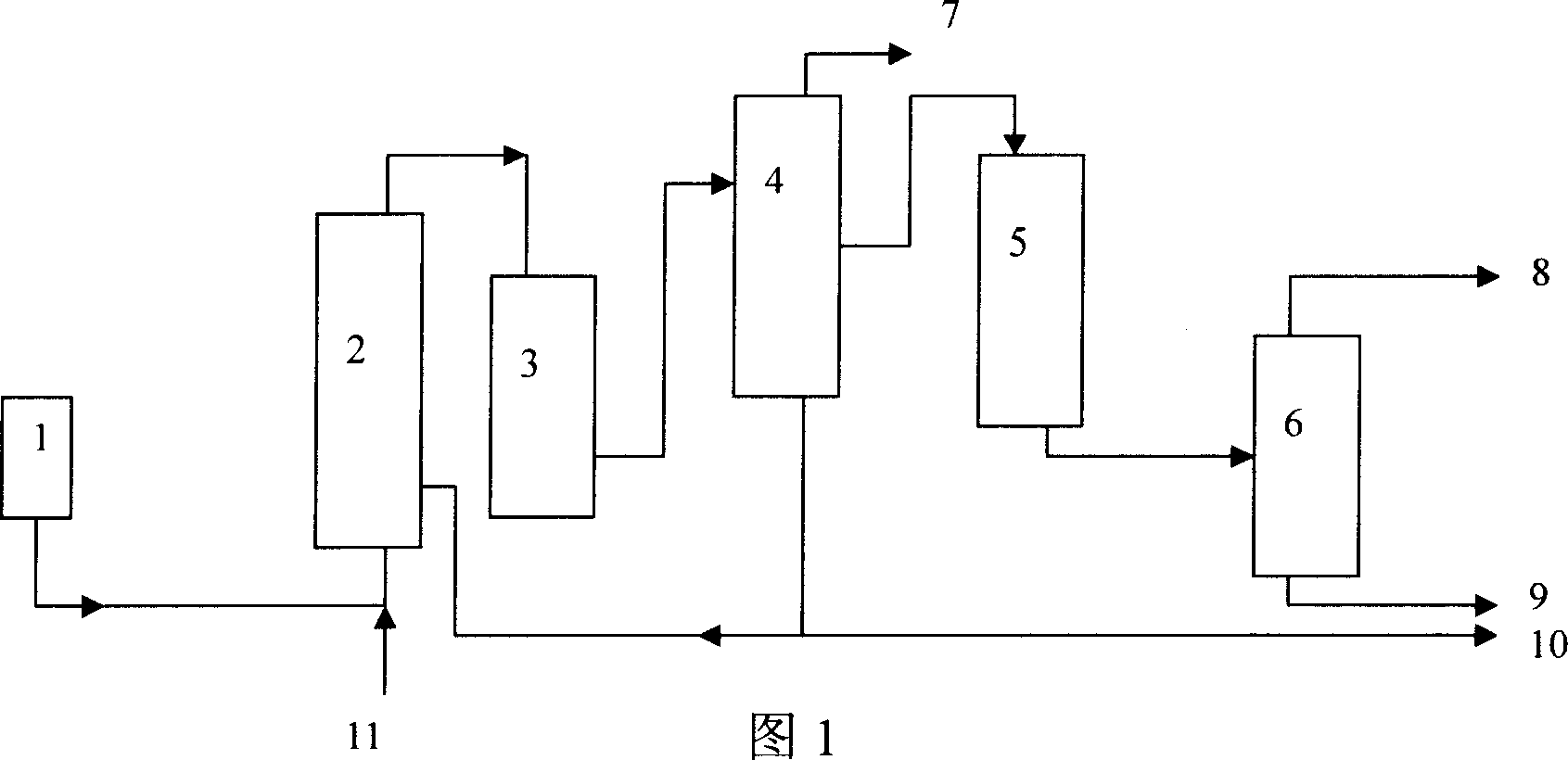

Coal tar whole fraction hydrotreatment process

ActiveCN1766058AImprove operating conditionsSimple processTreatment with hydrotreatment processesFixed bedGasoline

The invention discloses a hydrocracking treatment technique for coal tar total distillate, which comprises: first mixing with homogeneous catalyst, or adding impurity, gum, asphaltene and coal oil total distillate contained much oxygen element directly into suspended-bed hydrogenation device; cutting the stream with distilling plant to discharge water, distillate less than 370Deg that enters fixed bed reactor for hydrorefining reaction to cut gasolene less than 150Deg and diesel oil 150-370Deg, and tail oil less than 370Deg that recycles to said reactor and converts into light oil product. Compared with prior art, this invention is simple, but high conversion rate and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

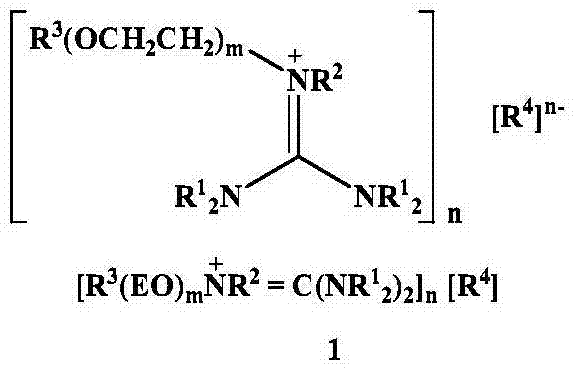

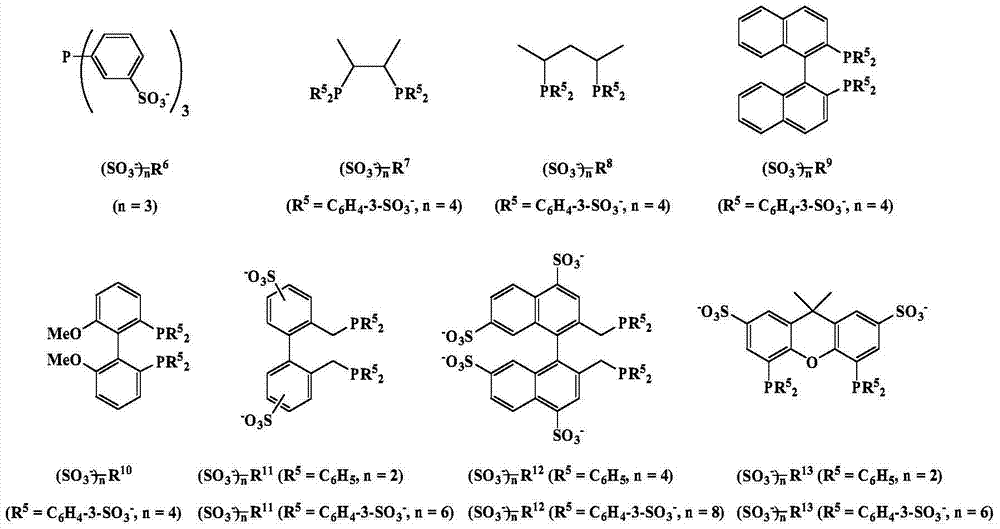

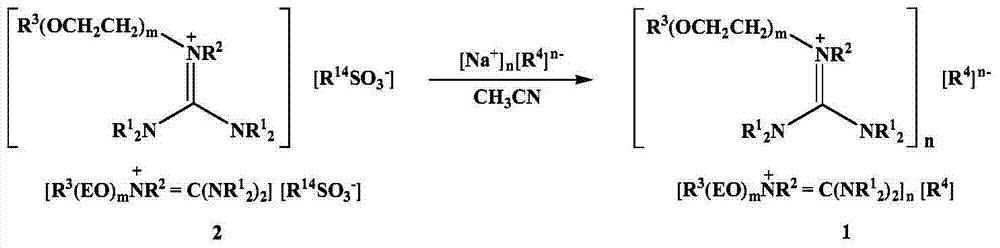

Preparation method of first-class phosphorus functionalized ionic liquid and application of ionic liquid in hydroformylation

ActiveCN103483381AEasy to synthesizeThe synthetic method is matureOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsIon exchangeOrganic reaction

The invention relates to synthesis of first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid, and an application of the first-class phosphorus functionalized polyether alkyl guanidinium ionic liquid in a homogeneous catalytic reaction. The functionalized ionic liquid of such class can be easily prepared by an ion exchange reaction between the polyether alkyl guanidinium ionic liquid and sulfonic acid type water soluble phosphine ligand. The designed phosphorus functionalized ionic liquid can be applied to organic reactions, including hydroformylation, hydroesterification, hydrocarboxylation and catalytic hydrogenation under the catalyzing of a transition metal; the dosage of the ionic liquid used in the catalytic reaction can be decreased; the activity of the catalytic reaction can be improved; a catalyst can be separated and cycled simply and conveniently.

Owner:QINGDAO UNIV OF SCI & TECH

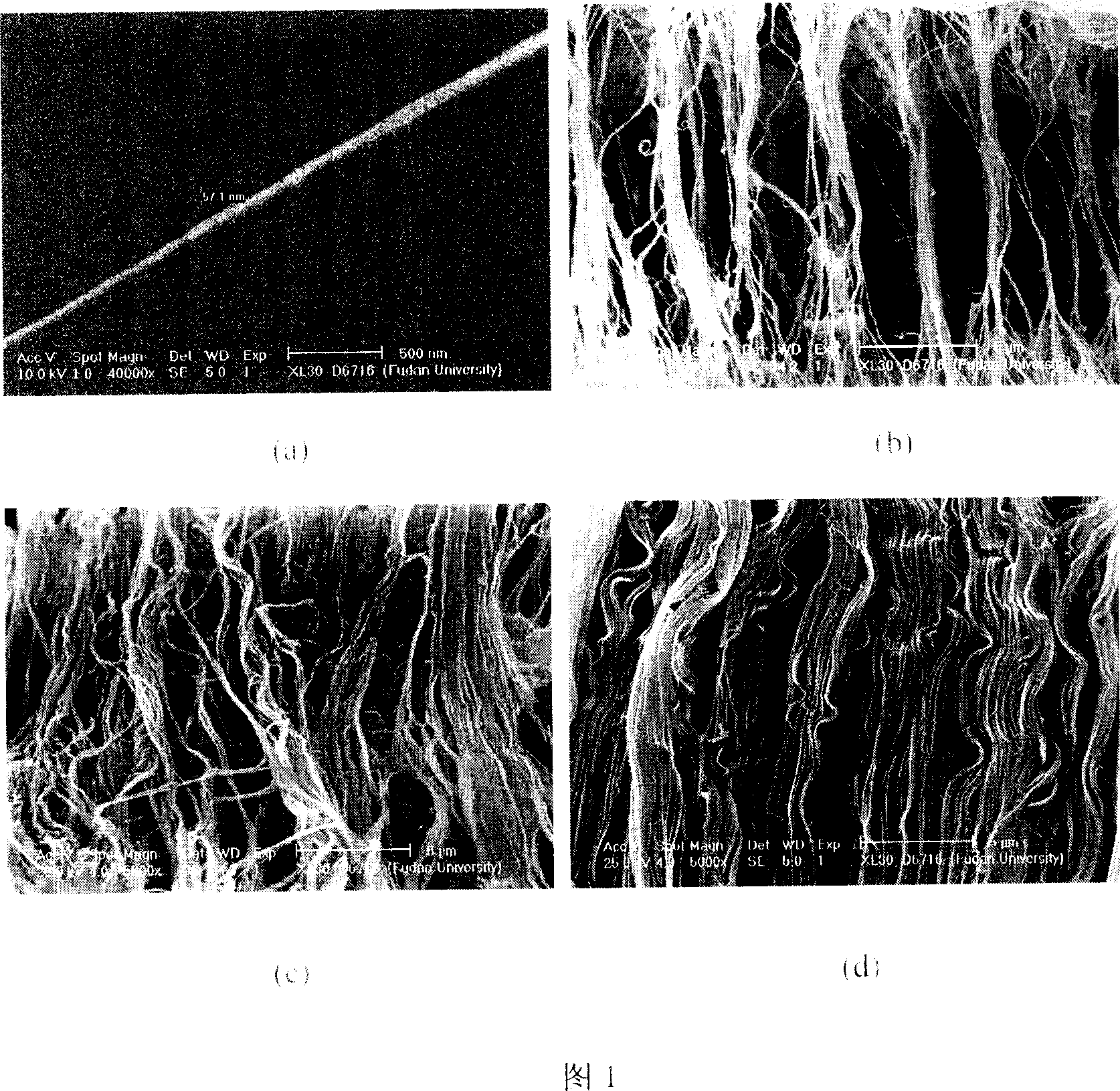

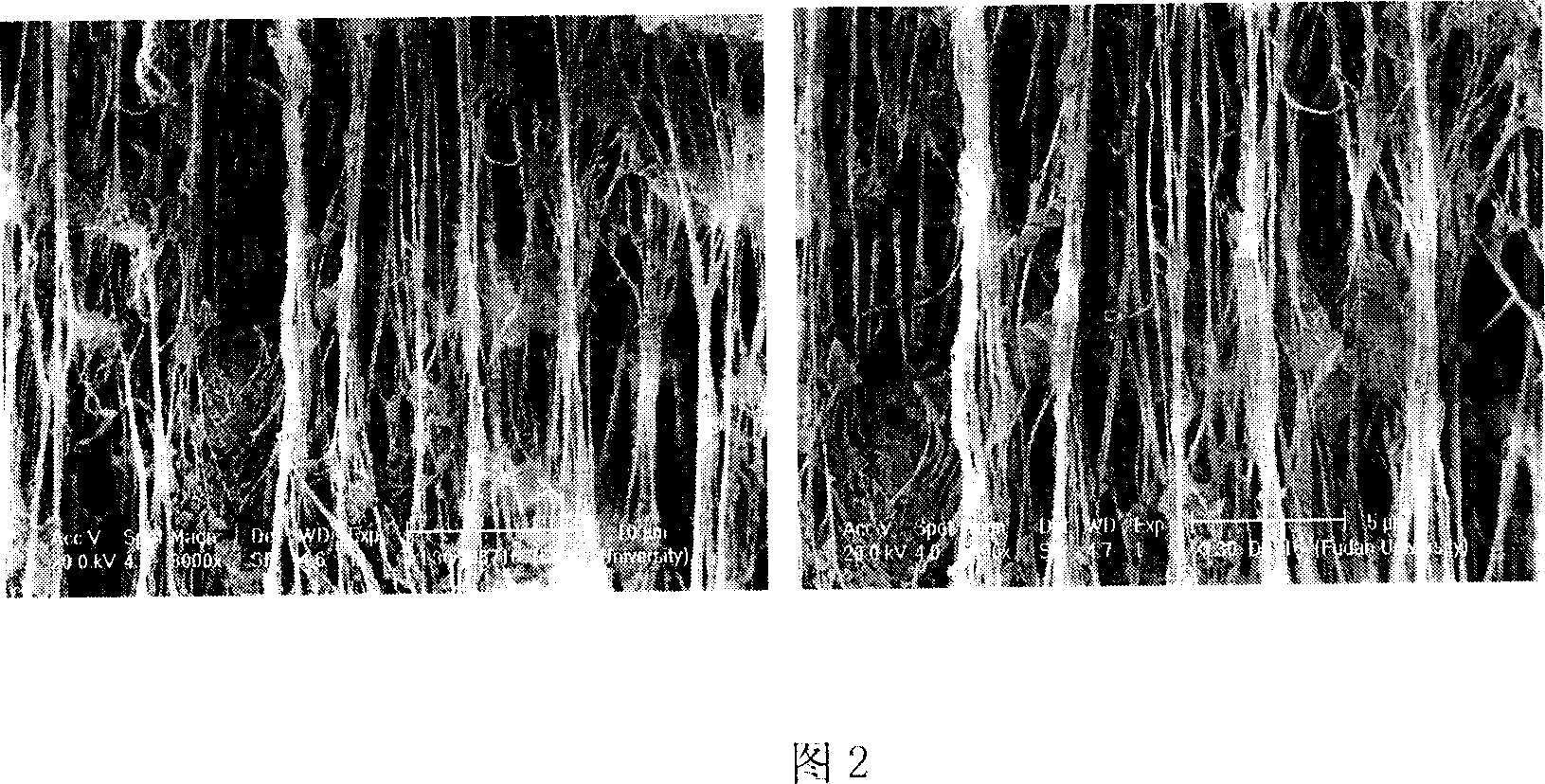

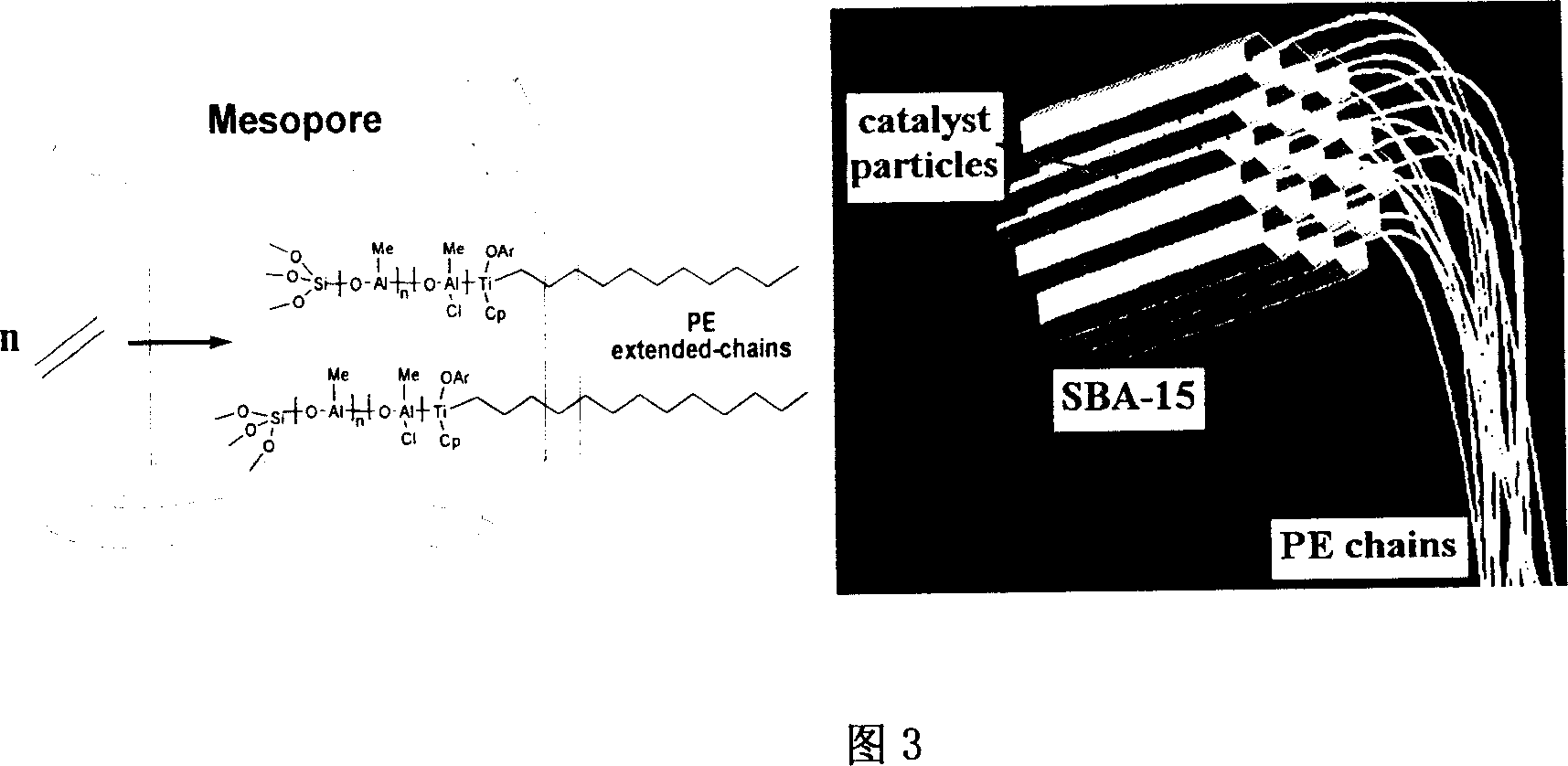

Mesoporous molecular sieve carried olefin polymerization catalyst, preparation method and application thereof

InactiveCN1923862AHigh molecular weightHigh melting pointBulk chemical productionGas phaseHomogeneous catalysis

The invention discloses an olefin polymeric catalyst and preparing method and reacting technology, which is characterized by the following: the expression formula of catalyst is [SiO2-Cat], wherein Cat represents semi-sandwich homogeneous phase catalyst of transient element metallic titanium (IV) or zirconium (IV); SiO2 represents dielectric molecular sieve SBA-15 decorated by methyl alundum alkyl, which can synthesize polyethylene; the catalyst possesses high ethylene polymeric activity, which displays ultrahigh molecule with different patterns.

Owner:FUDAN UNIV

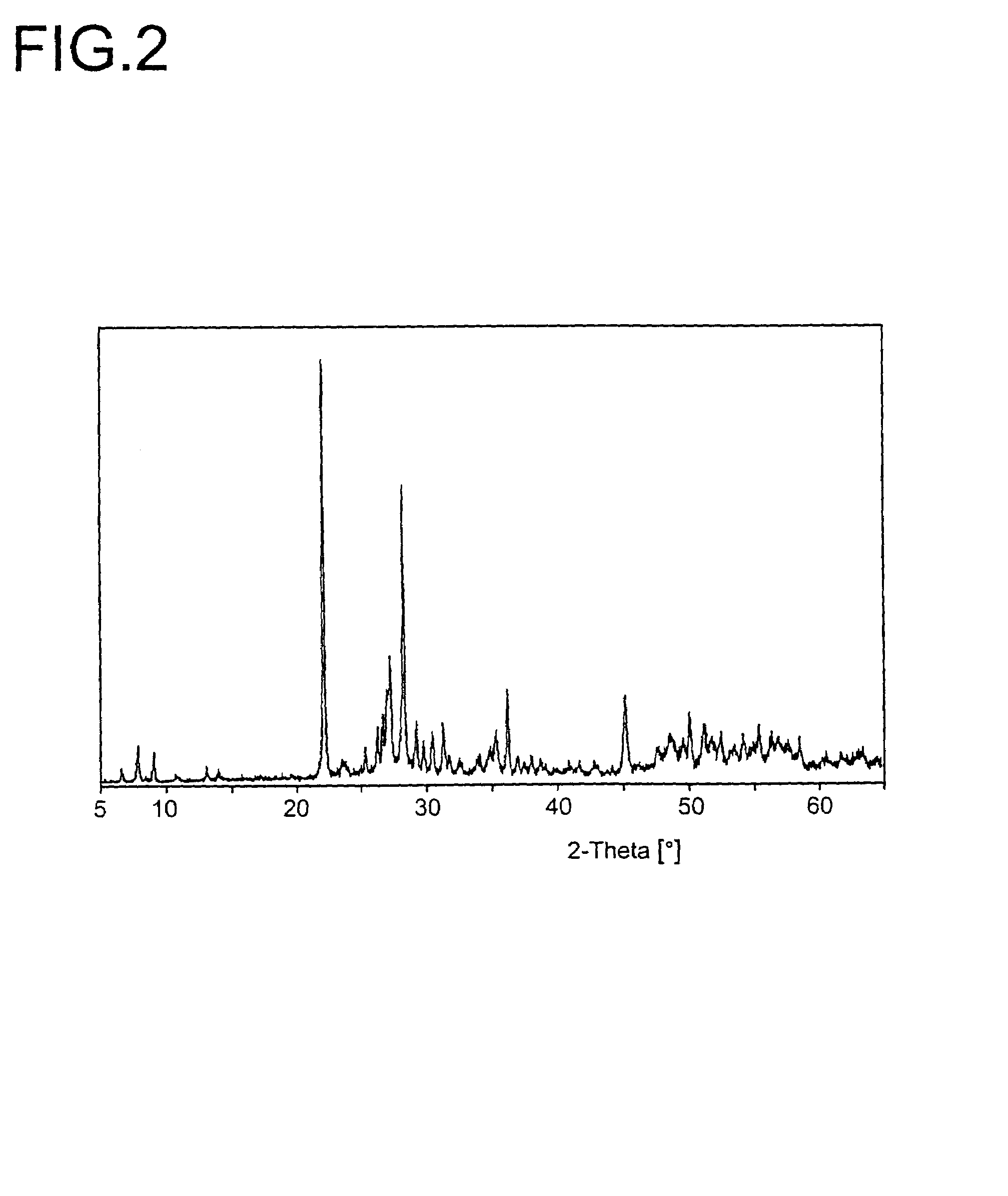

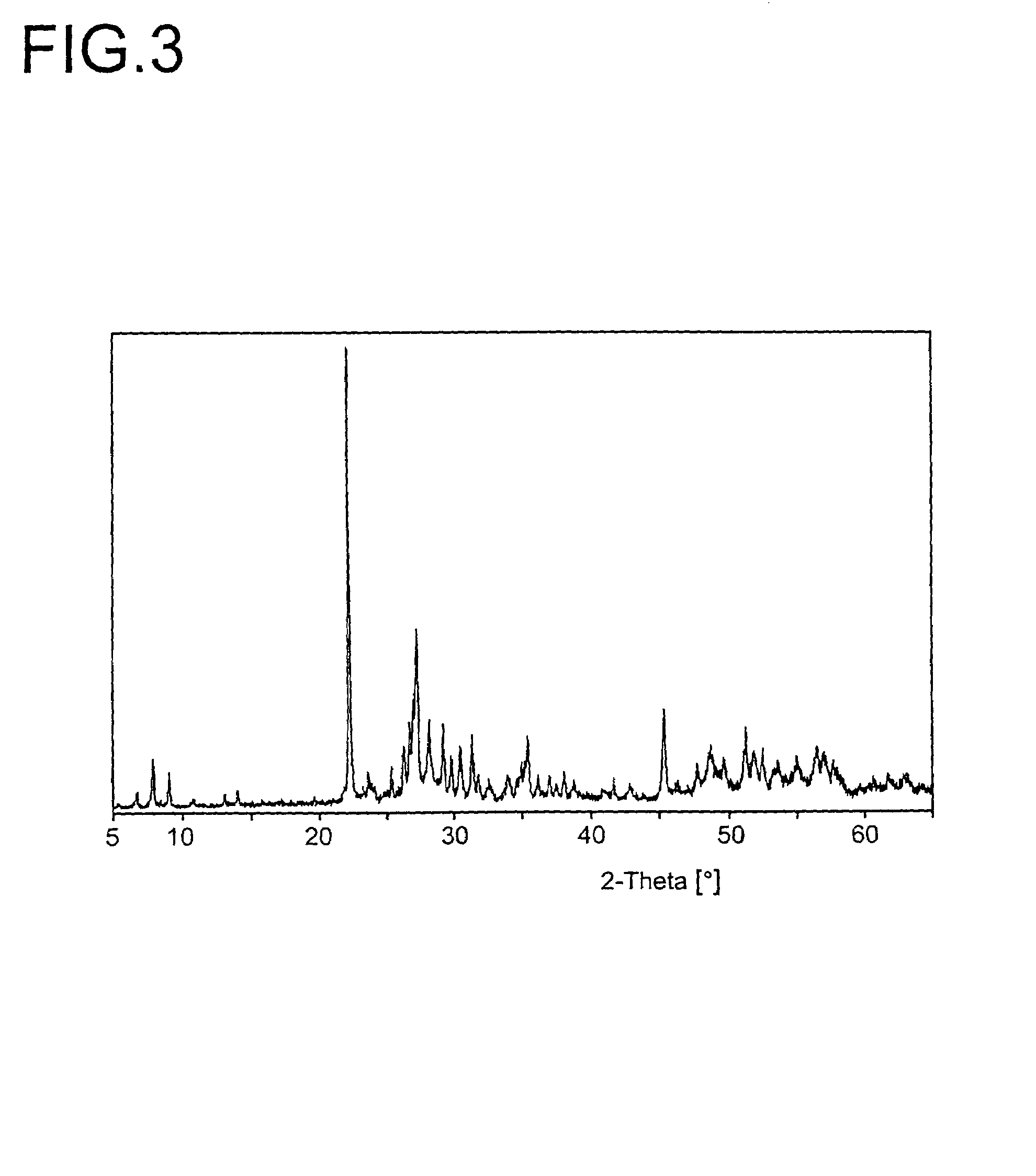

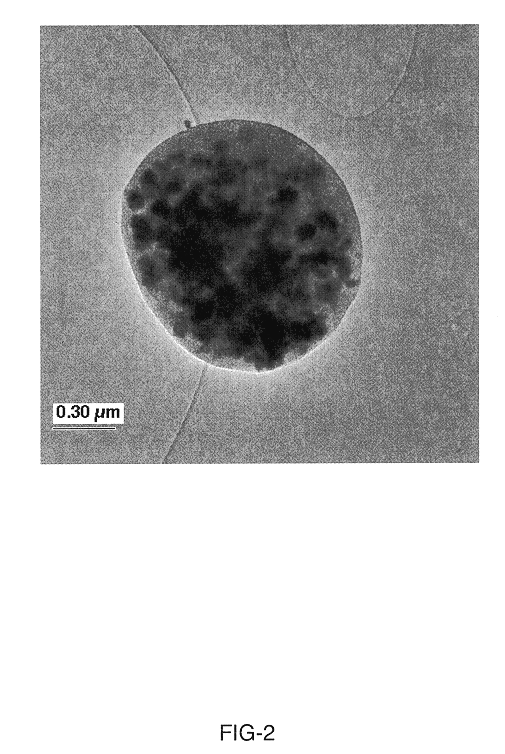

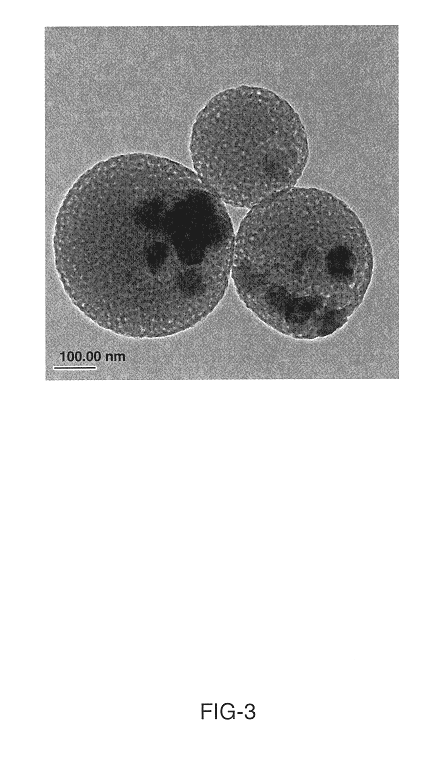

Synthesis of attrition-resistant heterogeneous catalysts using templated mesoporous silica

The present invention relates to catalysts in mesoporous structures. In a preferred embodiment, the invention comprises a method for encapsulating a dispersed insoluble compound in a mesoporous structure comprising combining a soluble oxide precursor, a solvent, and a surfactant to form a mixture; dispersing an insoluble compound in the mixture; spray-drying the mixture to produce dry powder; and calcining the powder to yield a porous structure comprising the dispersed insoluble compound.

Owner:STC UNM +1

Catalysts for petrochemical catalysis

Metal oxide catalysts comprising various dopants are provided. The catalysts are useful as heterogenous catalysts in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2 hydrocarbons such as ethane and ethylene. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

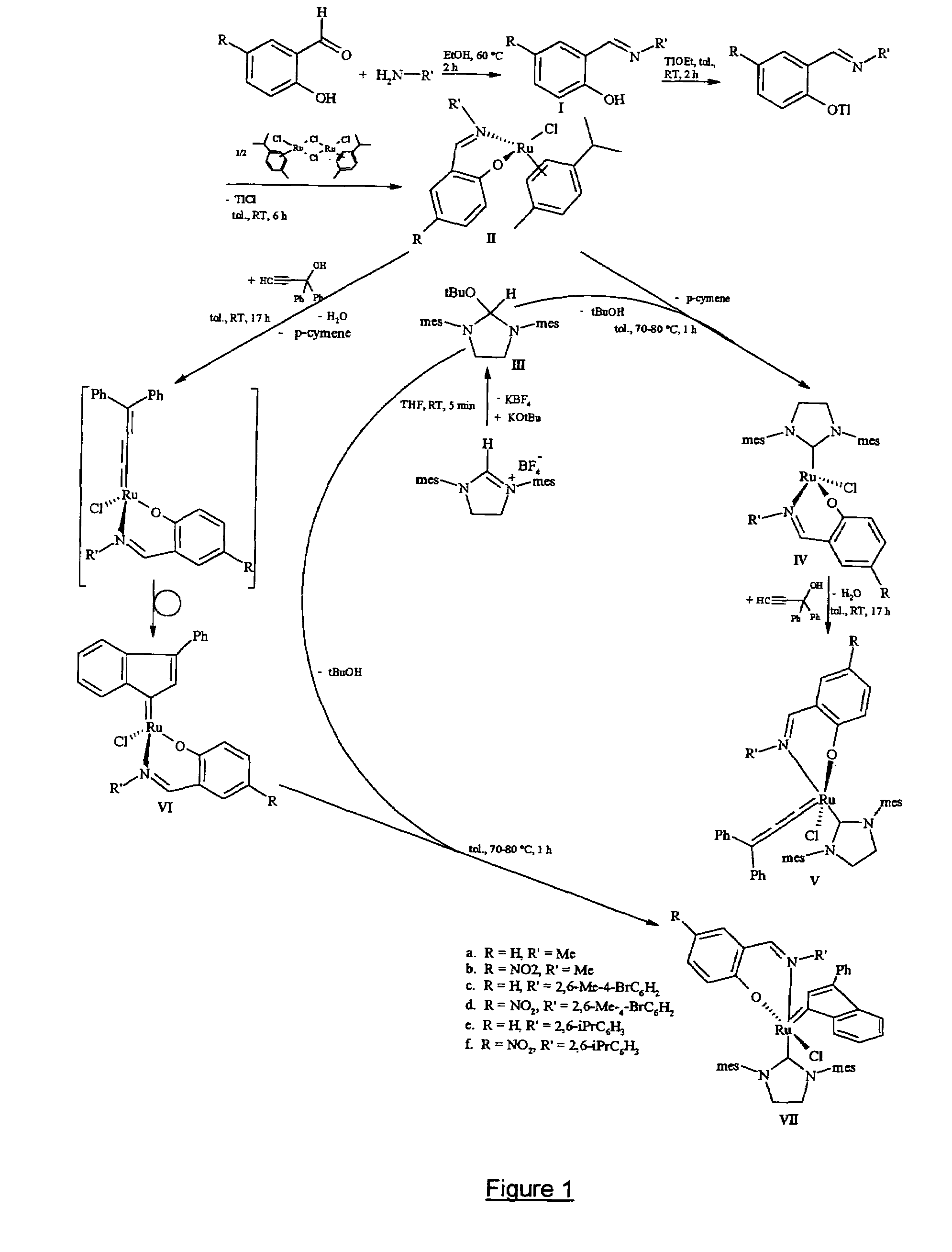

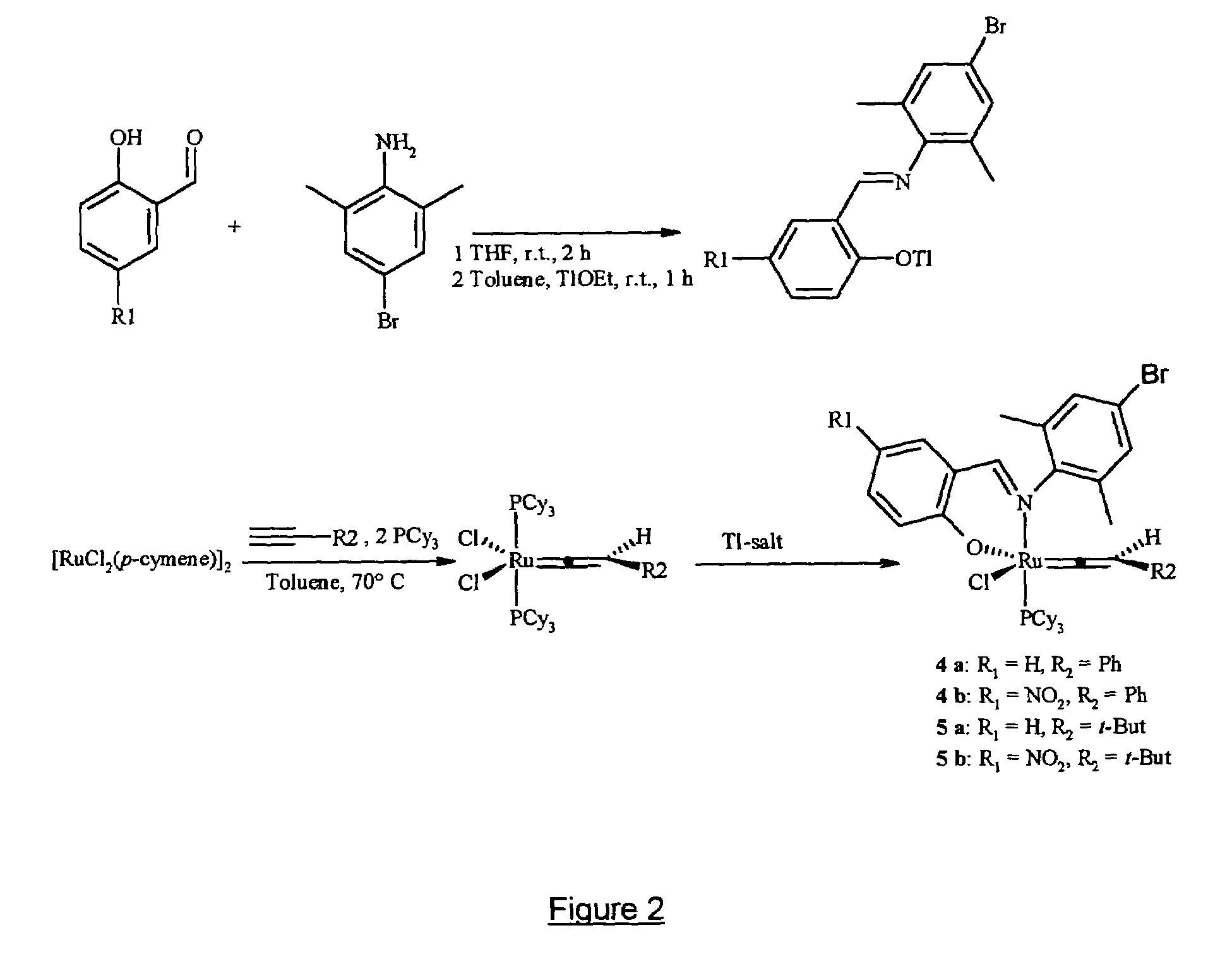

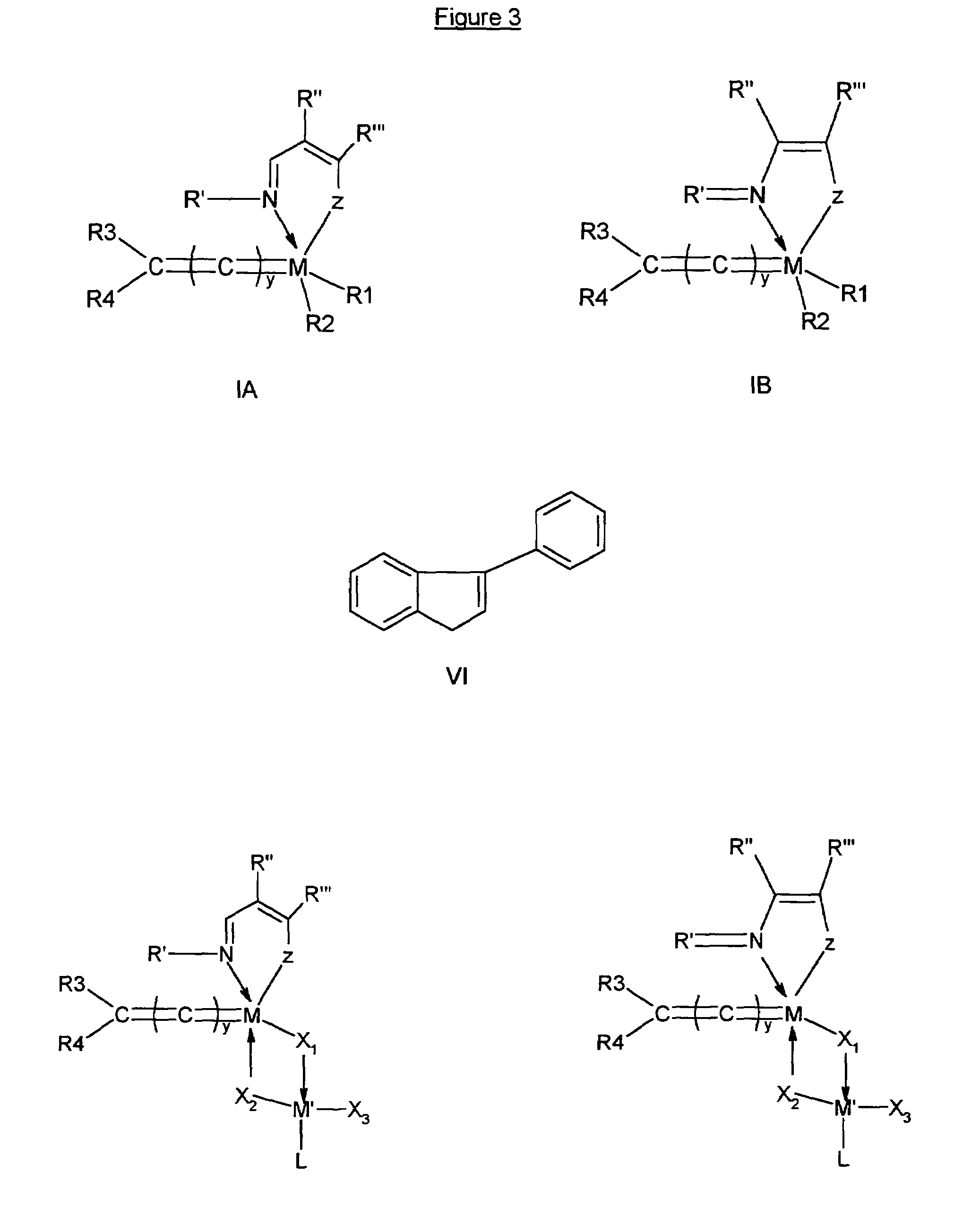

Metal complexes useful in metathesis and other reactions

This invention provides metal complexes being useful as catalyst components in metathesis reactions and in reactions involving the transfer of an atom or group to an ethylenically or acetylenically unsaturated compound or another reactive substrate and, with respect to a sub-class thereof, for the polymerisation of α-olefins and optionally conjugated dienes, with high activity at moderate tempera-tures. It also provides methods for obtaining polymers with very narrow molecular weight distribution by means of a living reaction. It also provides methods for making said metal complexes and novel intermediates involved in such methods. It further provides derivatives of said metal complexes which are suitable for covalent bonding to a carrier, the product of such covalent bonding being useful as a supported catalyst for heterogeneous catalytic reactions. It also provides a direct one-step synthesis of pyrrole, furan and thiophene compounds from diallyl compounds.

Owner:RIMTEC CORP

Transition metal-containing catalysts and processes for their preparation and use as oxidation and dehydrogenation catalysts

ActiveUS20050176989A1Efficient oxidationMaterial nanotechnologyAmino preparation from aminesAlcoholDehydrogenation

This invention relates to the field of heterogeneous catalysis, and more particularly to catalysts including carbon supports having formed thereon compositions which comprise a transition metal in combination with nitrogen and / or carbon. The invention further relates to the fields of catalytic oxidation and dehydrogenation reactions, including the preparation of secondary amines by the catalytic oxidation of tertiary amines and the preparation of carboxylic acids by the catalytic dehydrogenation of alcohols.

Owner:MONSANTO TECH LLC

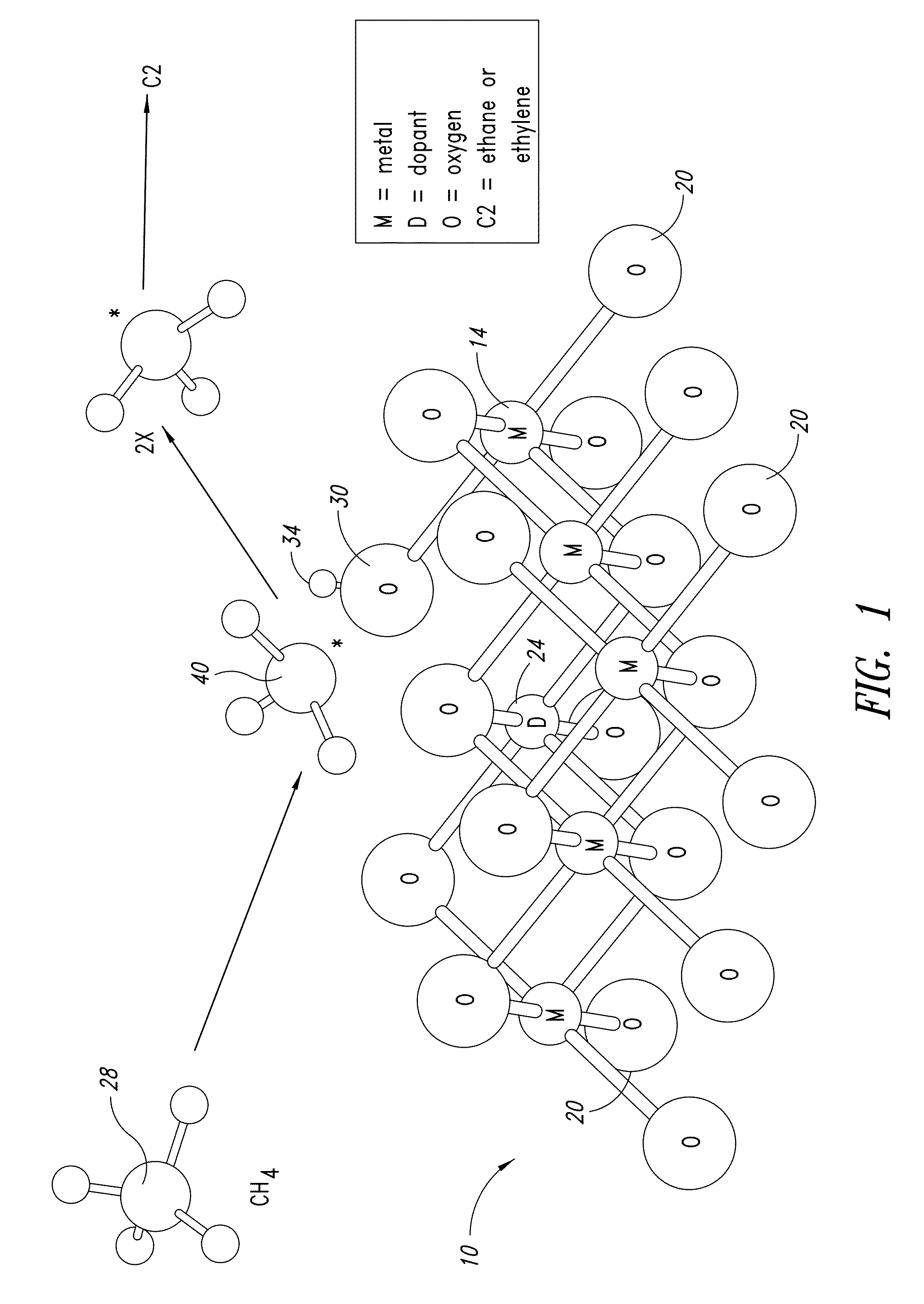

Heterogeneous catalysts

ActiveUS20150314267A1High catalytic activityMolecular sieve catalystCatalystsDopantOxidative coupling of methane

Heterogeneous catalysts with optional dopants are provided. The catalysts are useful in a variety of catalytic reactions, for example, the oxidative coupling of methane to C2+ hydrocarbons. Related methods for use and manufacture of the same are also disclosed.

Owner:SILURIA TECH INC

Biomass magnetic carbon material for degrading organic dye

InactiveCN103480331AHigh catalytic activityPromote degradationOther chemical processesAlkali metal oxides/hydroxidesPtru catalystOrganic dye

The invention relates to a biomass magnetic carbon material for degrading organic dye. The material is prepared by mixing a biological raw material and an iron precursor at a ratio of (2-20kg):1kg. Meanwhile, the invention also discloses a preparation method of the biomass magnetic carbon material. The biomass magnetic carbon material provided by the invention is cheap and efficient and has double effects of adsorption catalysis and degradation; serving as an efficient catalyst in a process of constructing a Fenton-like system for treating high-concentration wastewater, the biomass magnetic carbon material has high catalytic activity in thoroughly oxidizing and degrading organic dye; the degradation effect is better than that of a ferrous ion homogeneous catalysis reaction and a Fenton-like reaction taking ferroferric oxide as a catalyst.

Owner:LANZHOU UNIVERSITY

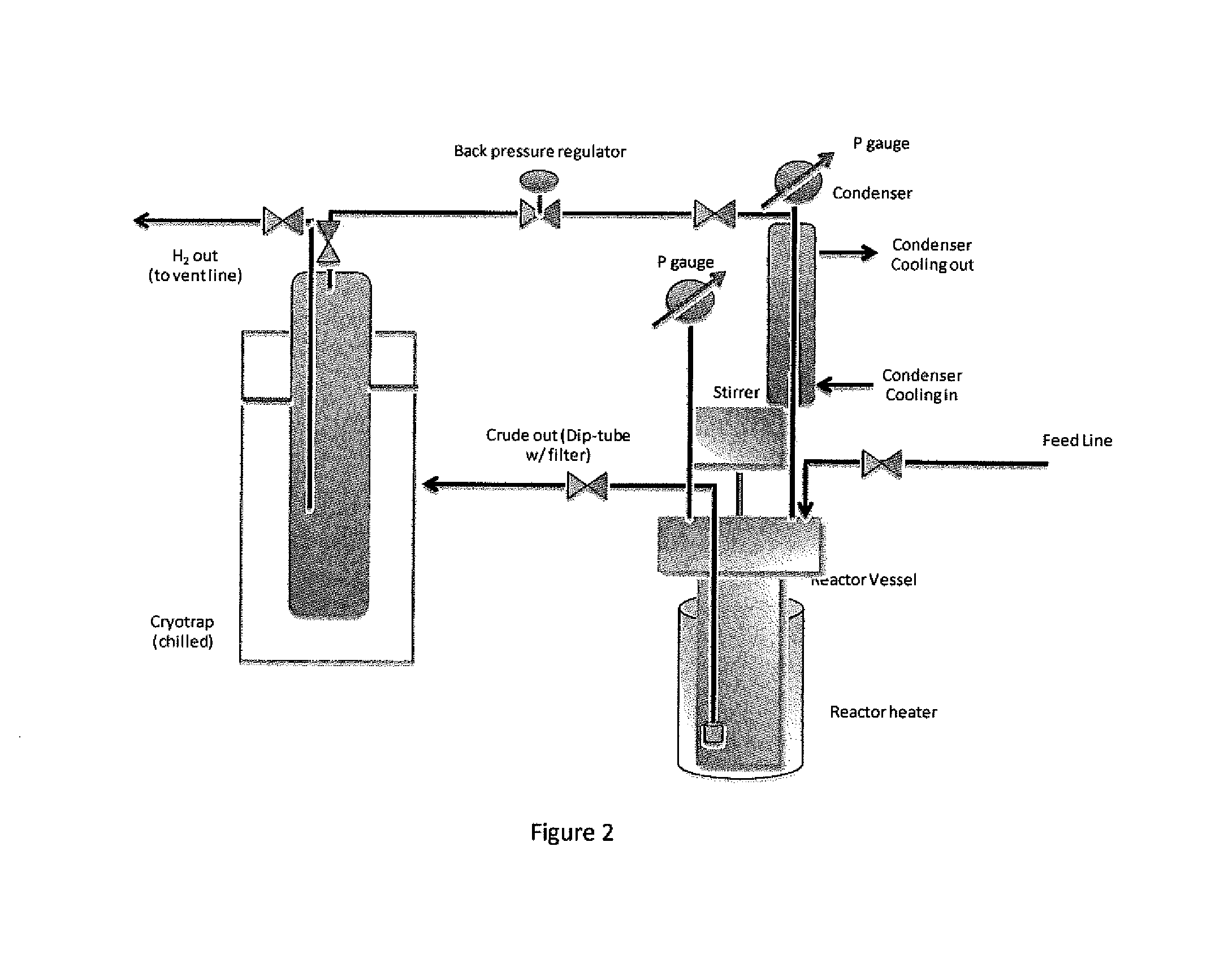

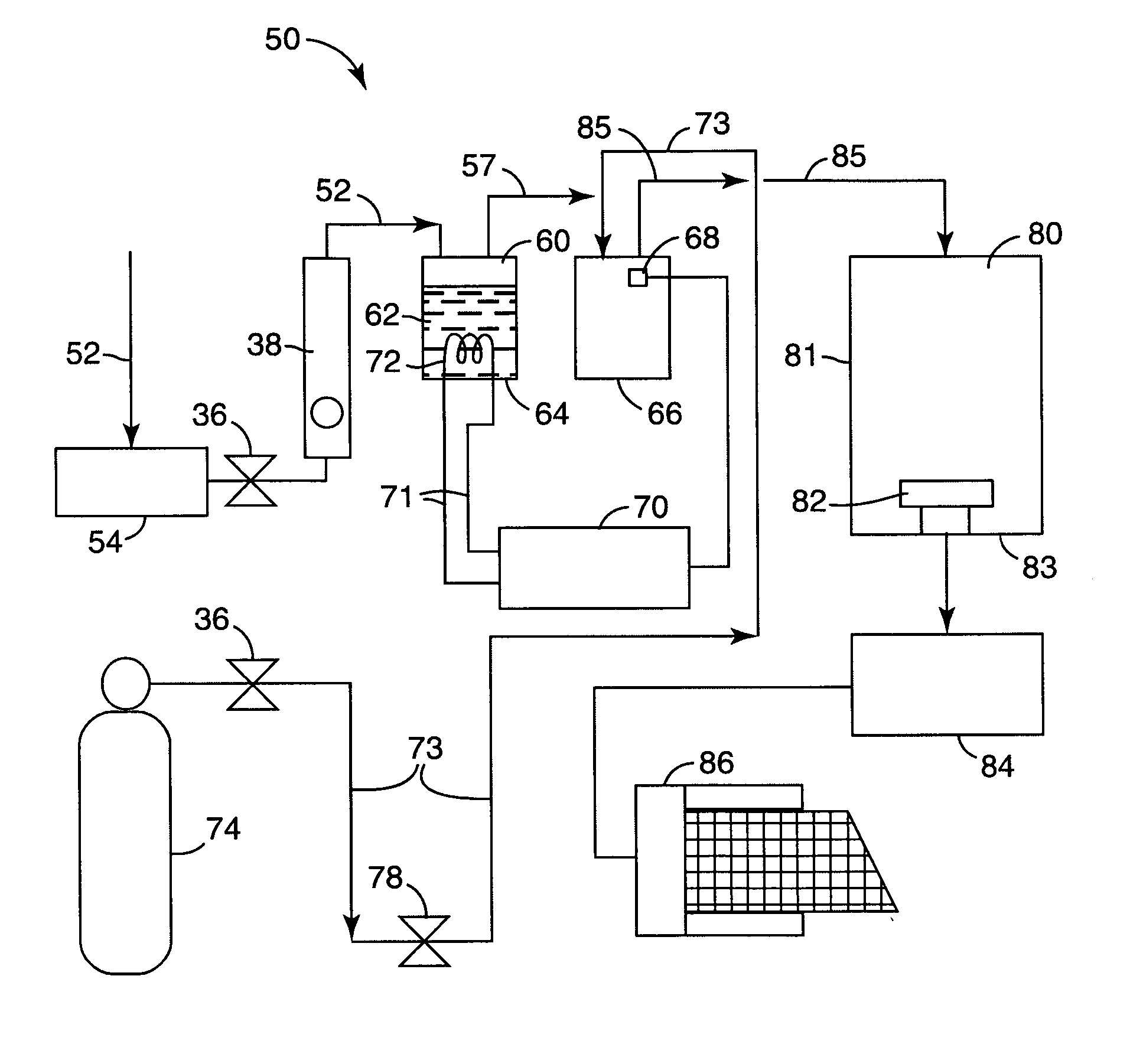

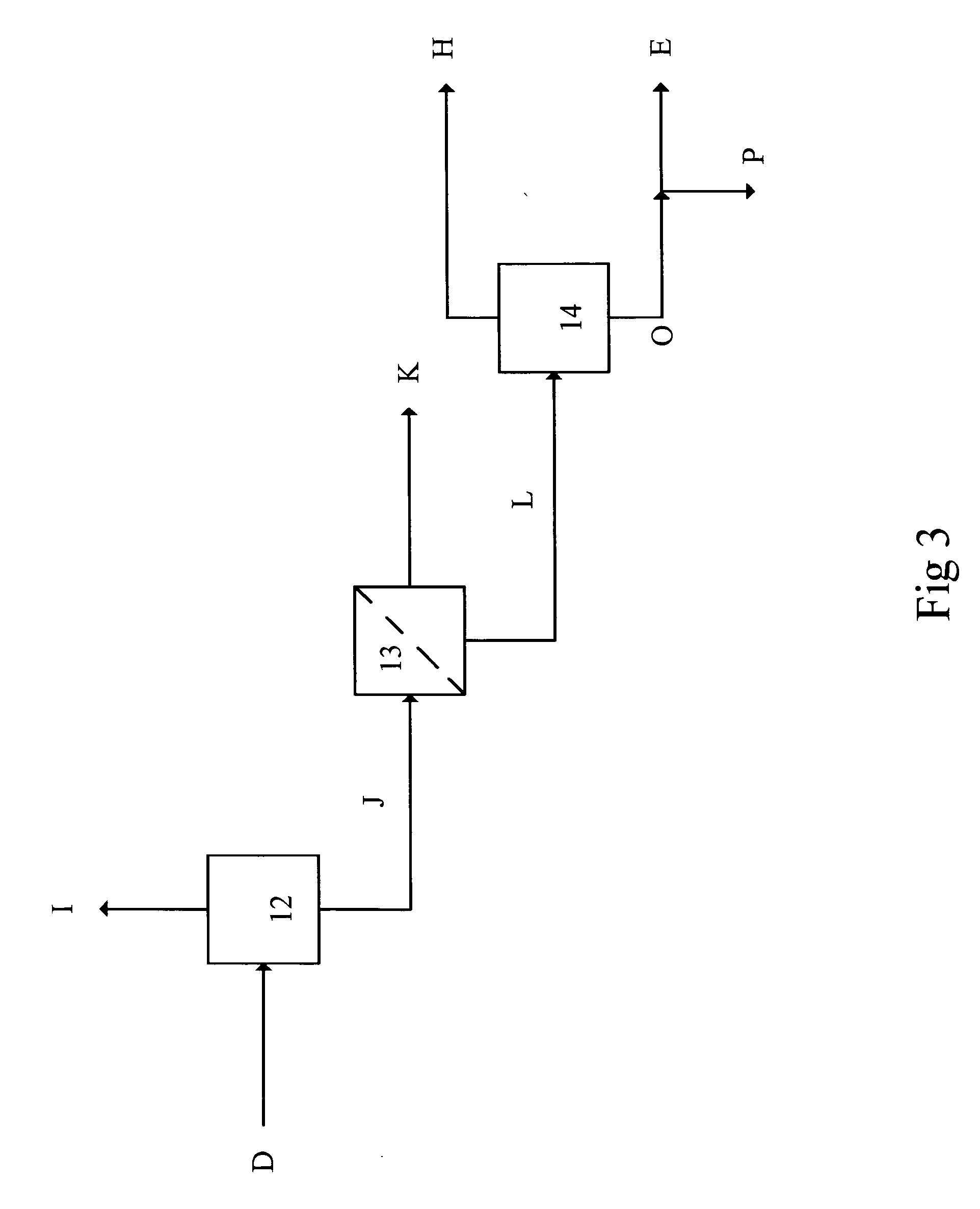

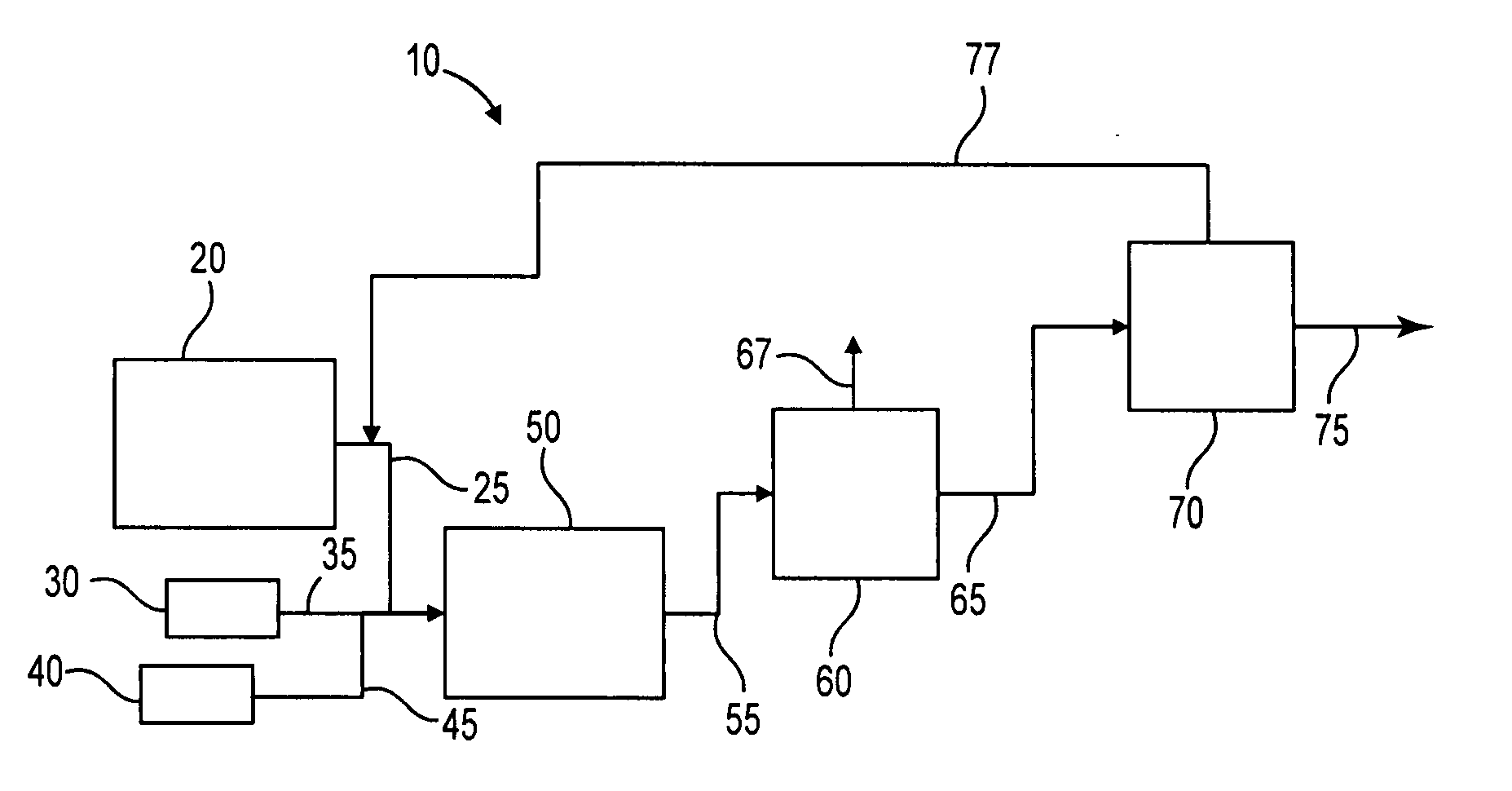

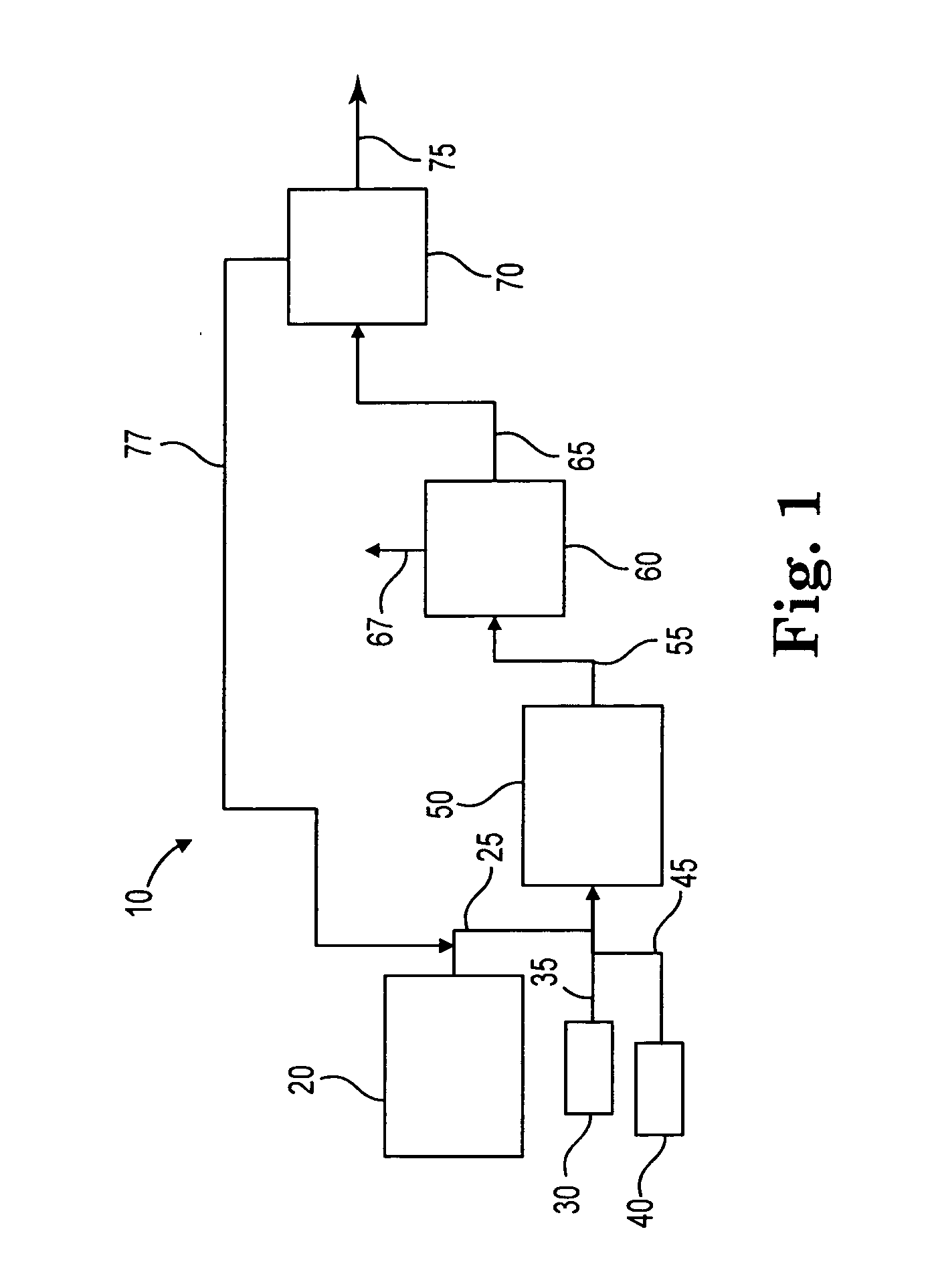

Method and apparatus for converting organic material

ActiveUS20060260186A1Apparatus is enlargedCatalytic crackingByproduct vaporizationHomogeneous catalysisHydrocarbon

Owner:SCF TECH AS

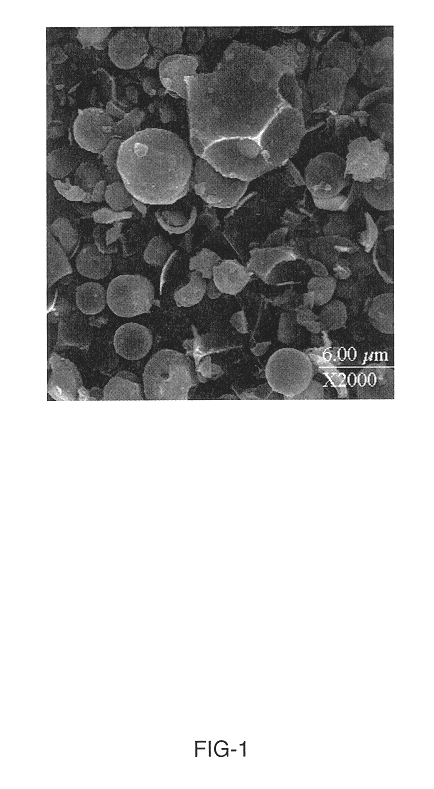

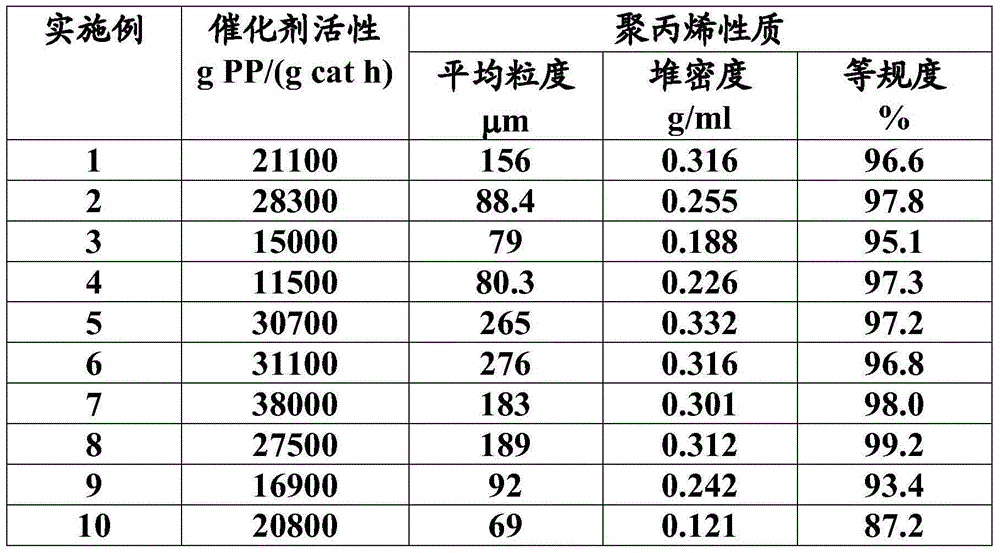

Preparing method and application of catalyst for preparation of high-spherical low-particle-size polyolefin particles

ActiveCN104829762AHigh sphericityHigh sphericity low particle sizeAdditive manufacturing apparatusPolyolefinPolymer science

The invention provides a preparing method of catalyst for preparation of high-spherical low-particle-size polyolefin particles. The catalyst is used for olefinic polymerization, the prepared polyolefin particles are of high sphericalness, small particle size (averagely 50 micrometers to 30 micrometers), narrow particle size distribution and low bulk density (0.1g / mL to 0.4g / mL). By means such as adjusting the forming temperature of a catalyst carrier and forming time of the catalyst and using any added nanoparticle as a third component for accelerating the formation of the catalyst, the catalyst is of small particle size and high sphericalness; according to replication of heterogeneous catalysts, submicron polyolefin spherical particles are prepared.

Owner:INST OF CHEM CHINESE ACAD OF SCI

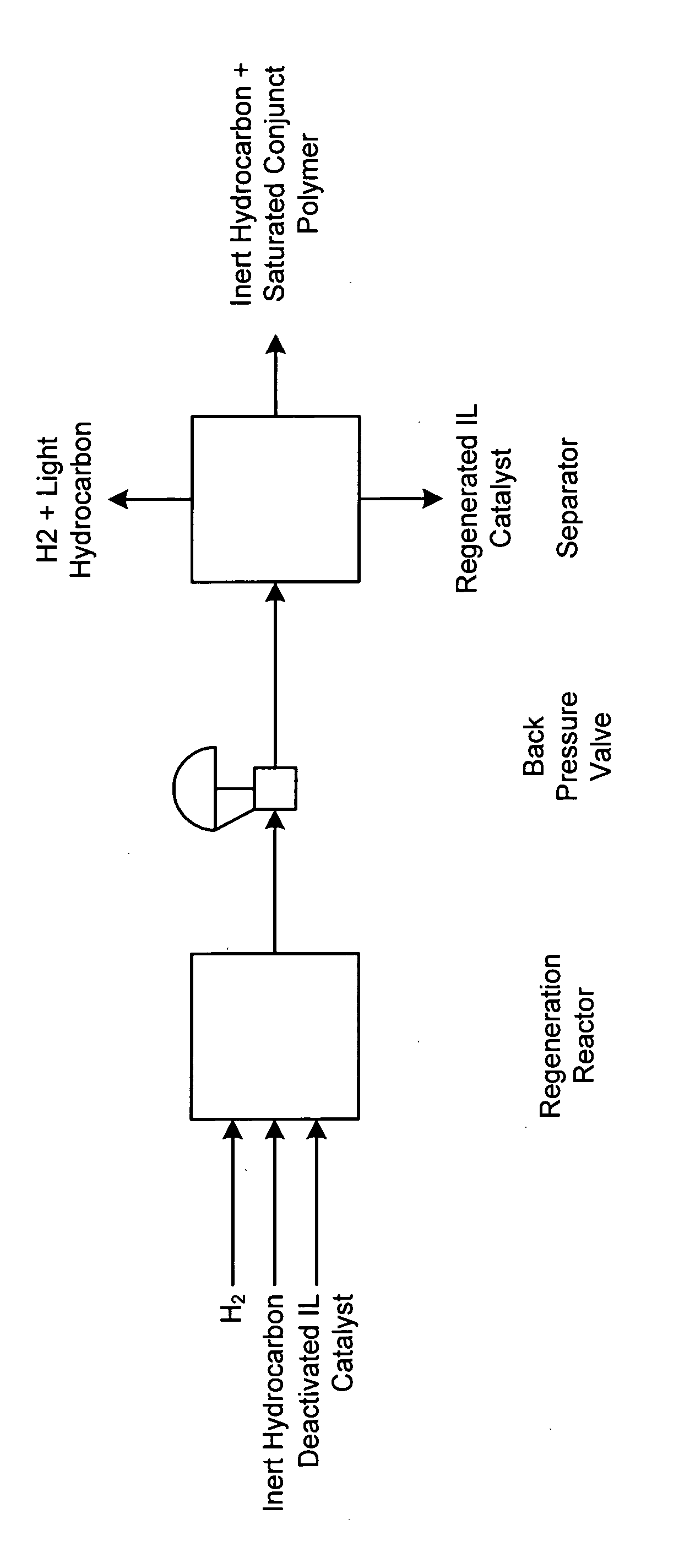

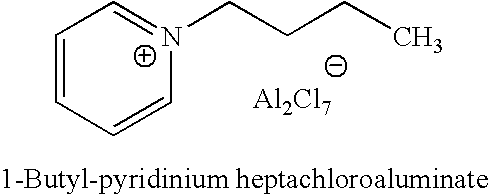

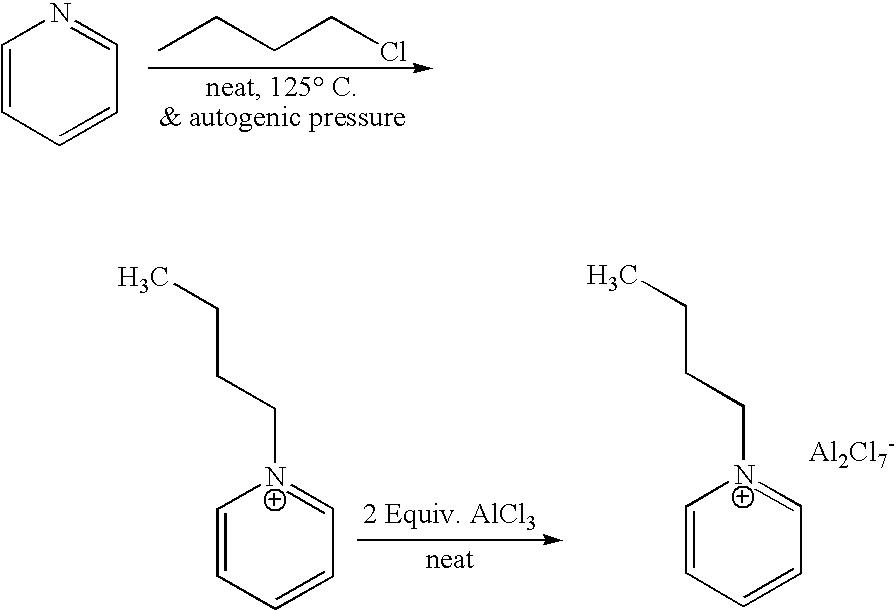

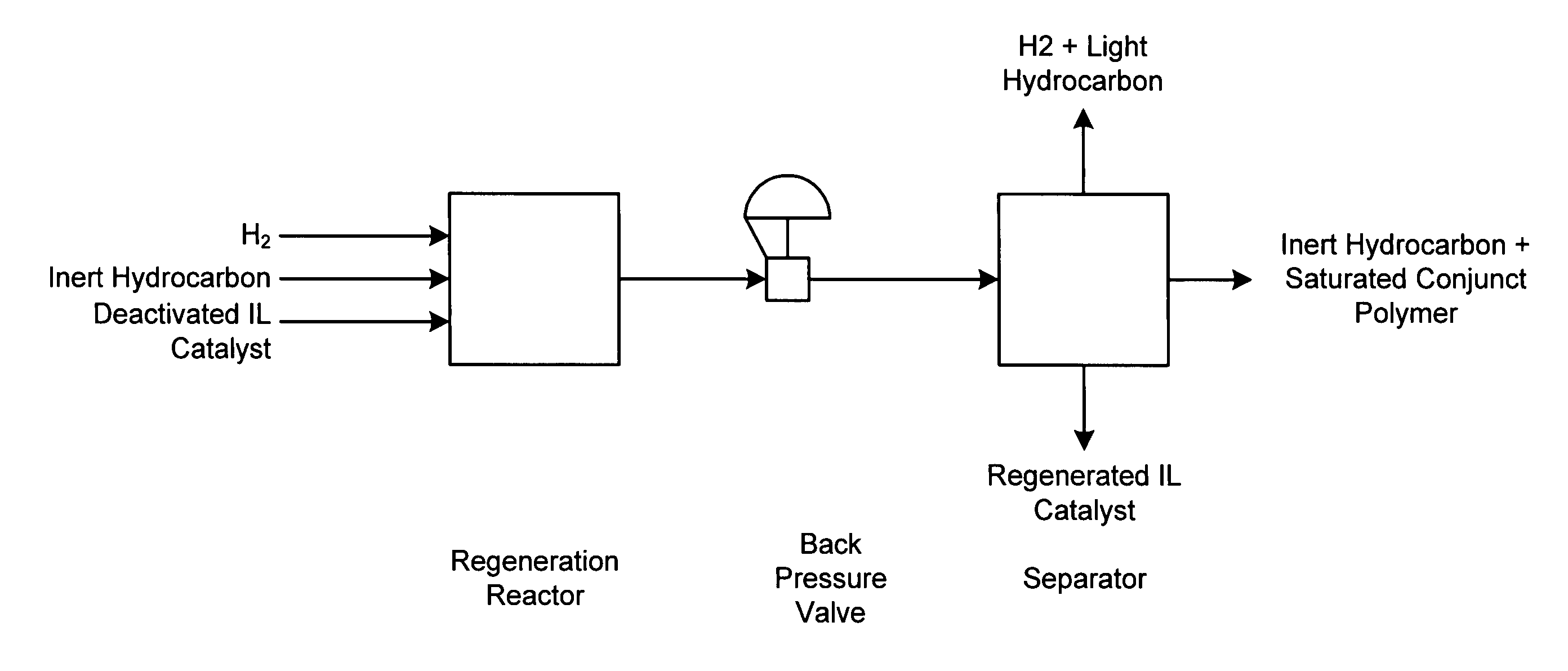

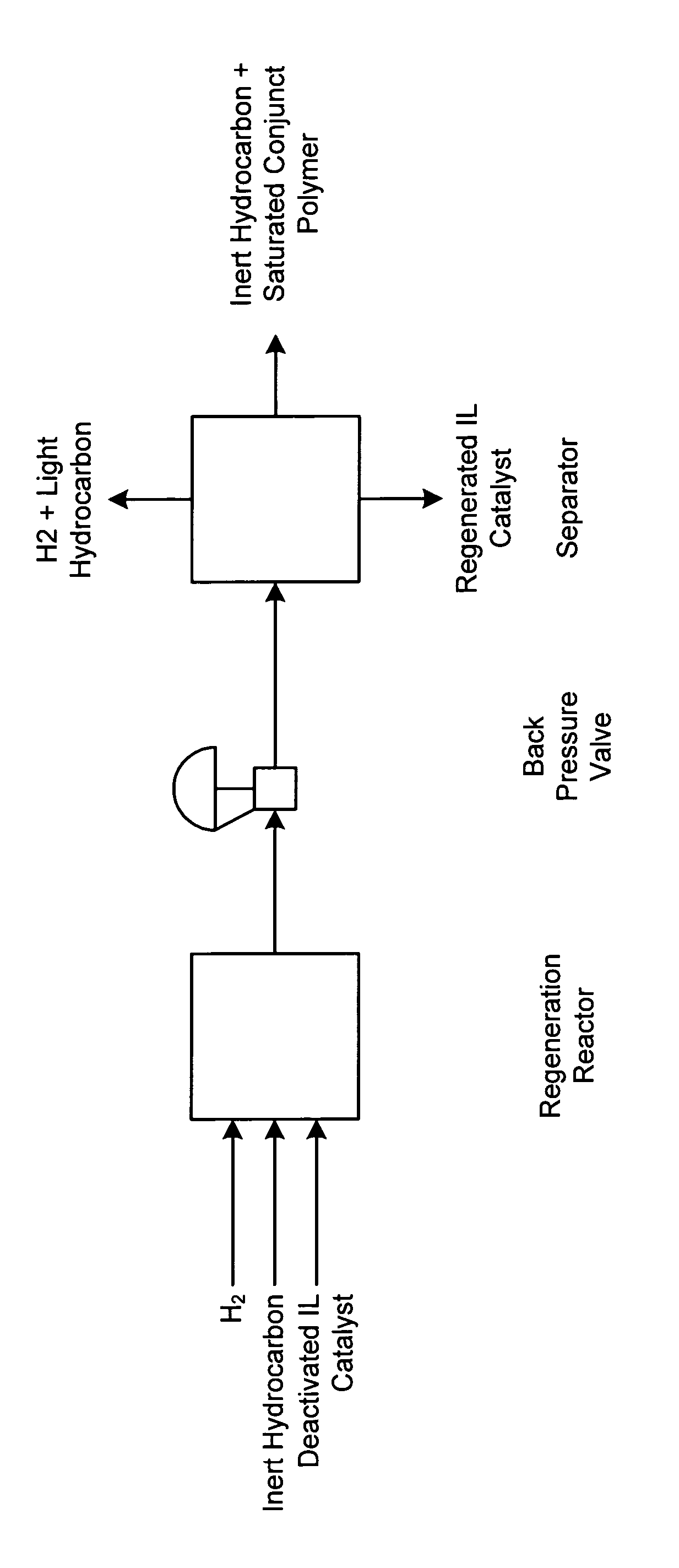

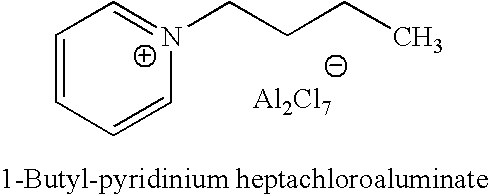

Regeneration of ionic catalyst by hydrogenation using a homogeneous catalyst

A process for regenerating a used acidic ionic liquid catalyst comprising the steps of contacting the used ionic liquid catalyst and hydrogen with a homogeneous hydrogenation catalyst in a reaction zone under hydrogenation conditions for a time sufficient to increase the activity of the used catalyst is disclosed.

Owner:CHEVROU USA INC

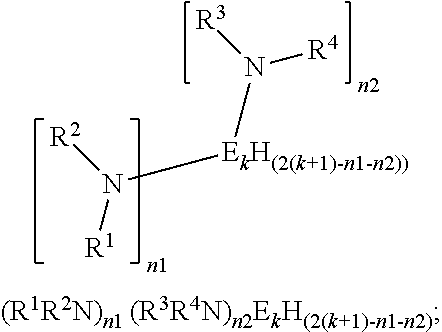

Process to selectively manufacture diethylenetriamine (DETA) or other desirable ethylenamines via continuous transmination of ethylenediamine (EDA), and other ethyleneamines over a heterogeneous catalyst system

ActiveUS20100087683A1Quantity maximizationQuantity minimizationOrganic compound preparationAmino compound preparation by disproportionationEthylenediamineDiethylenetriamine

The present invention reacts ethylenediamine with one or more additional ethyleneamines in the presence of a transamination catalyst to provide a different, preferably more desirable product mix of one or more ethyleneamines.

Owner:UNION CARBIDE CORP

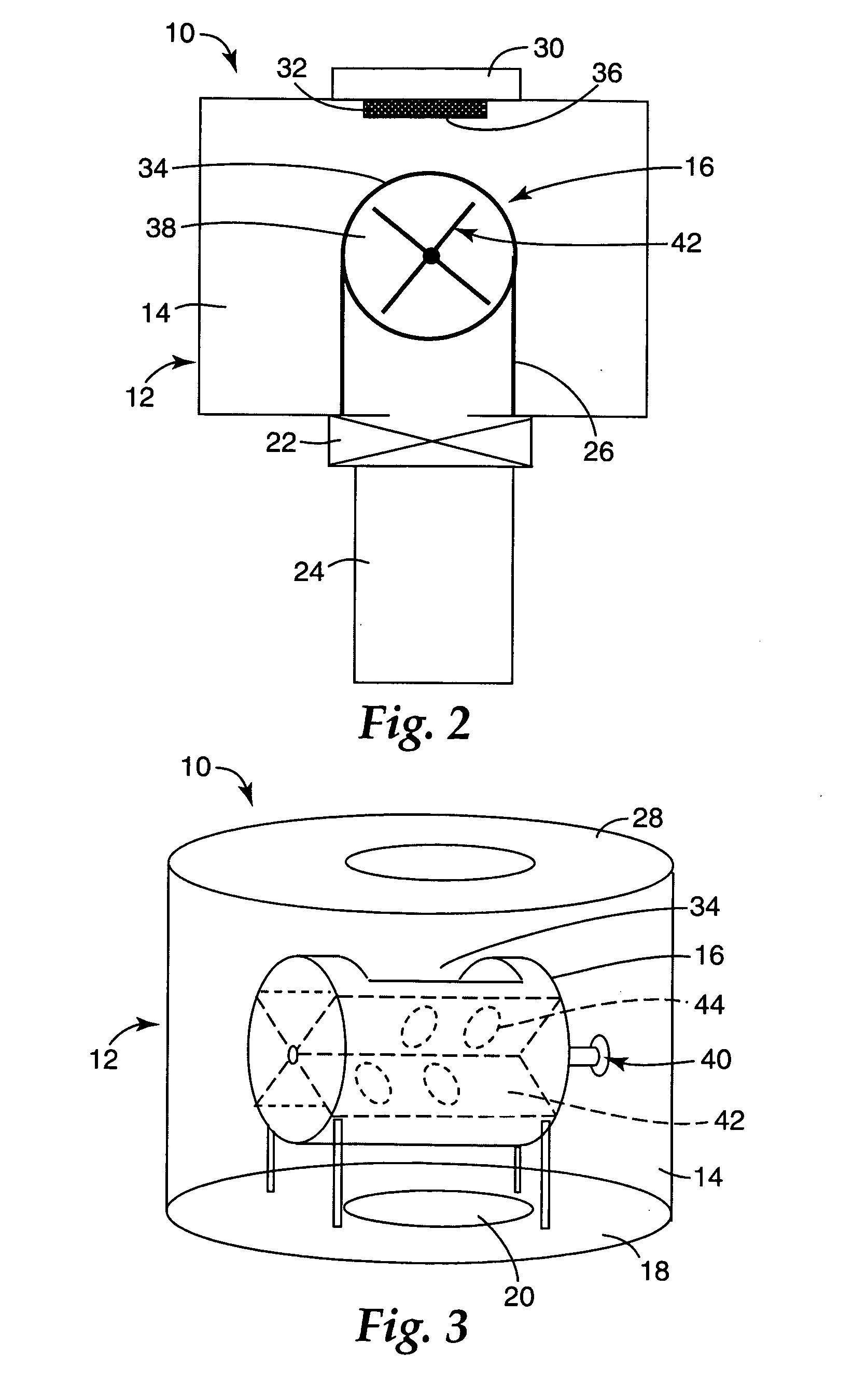

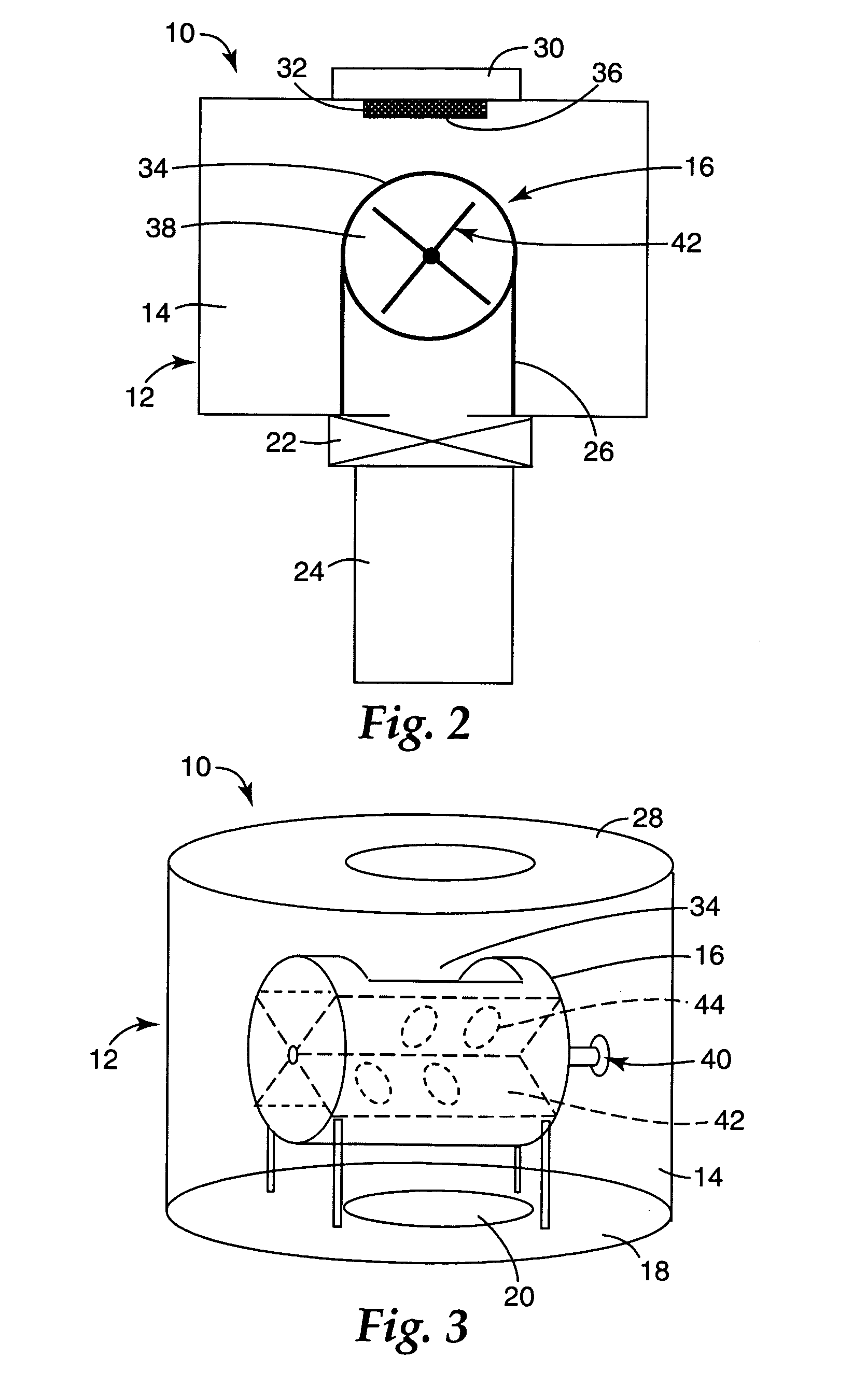

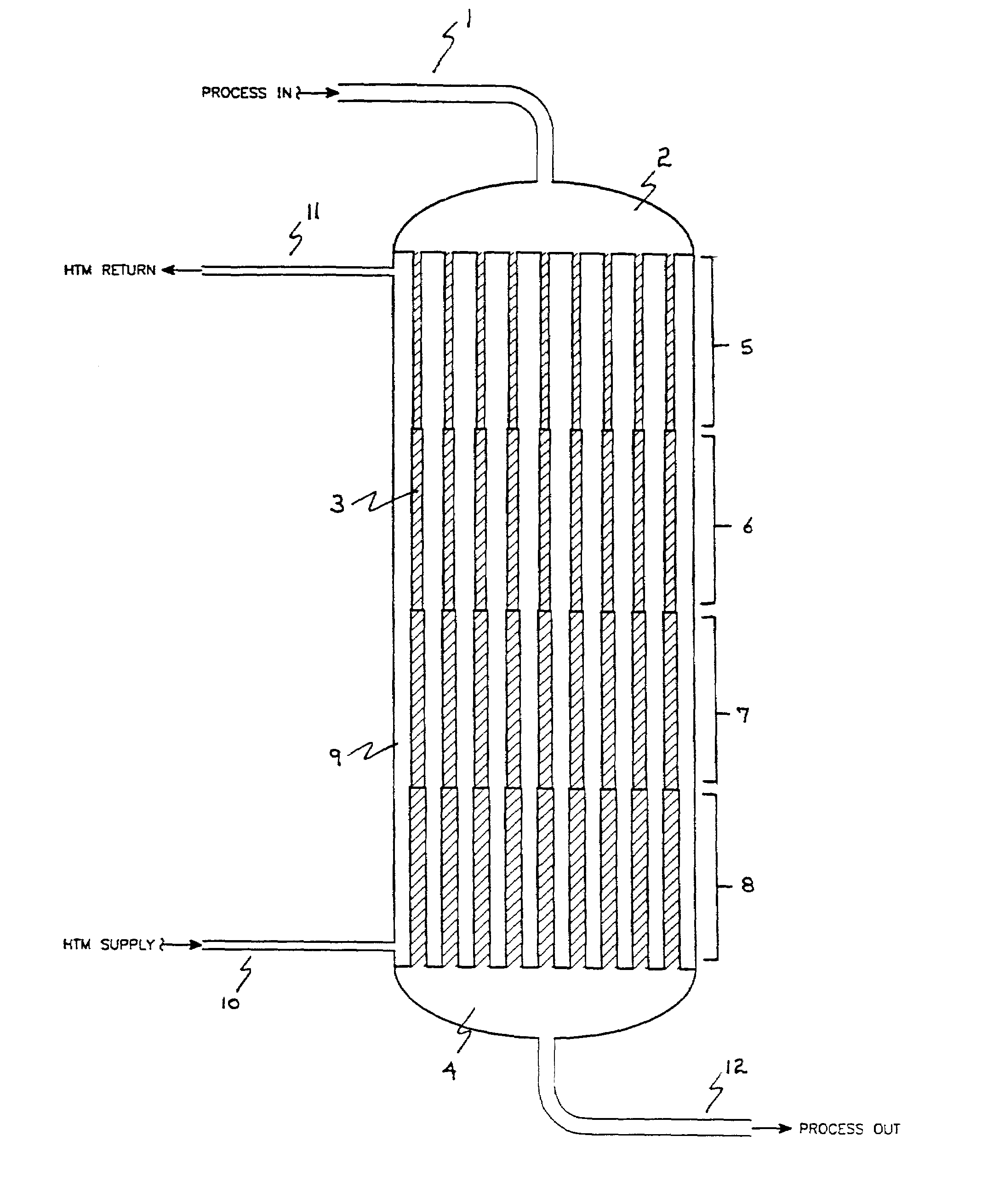

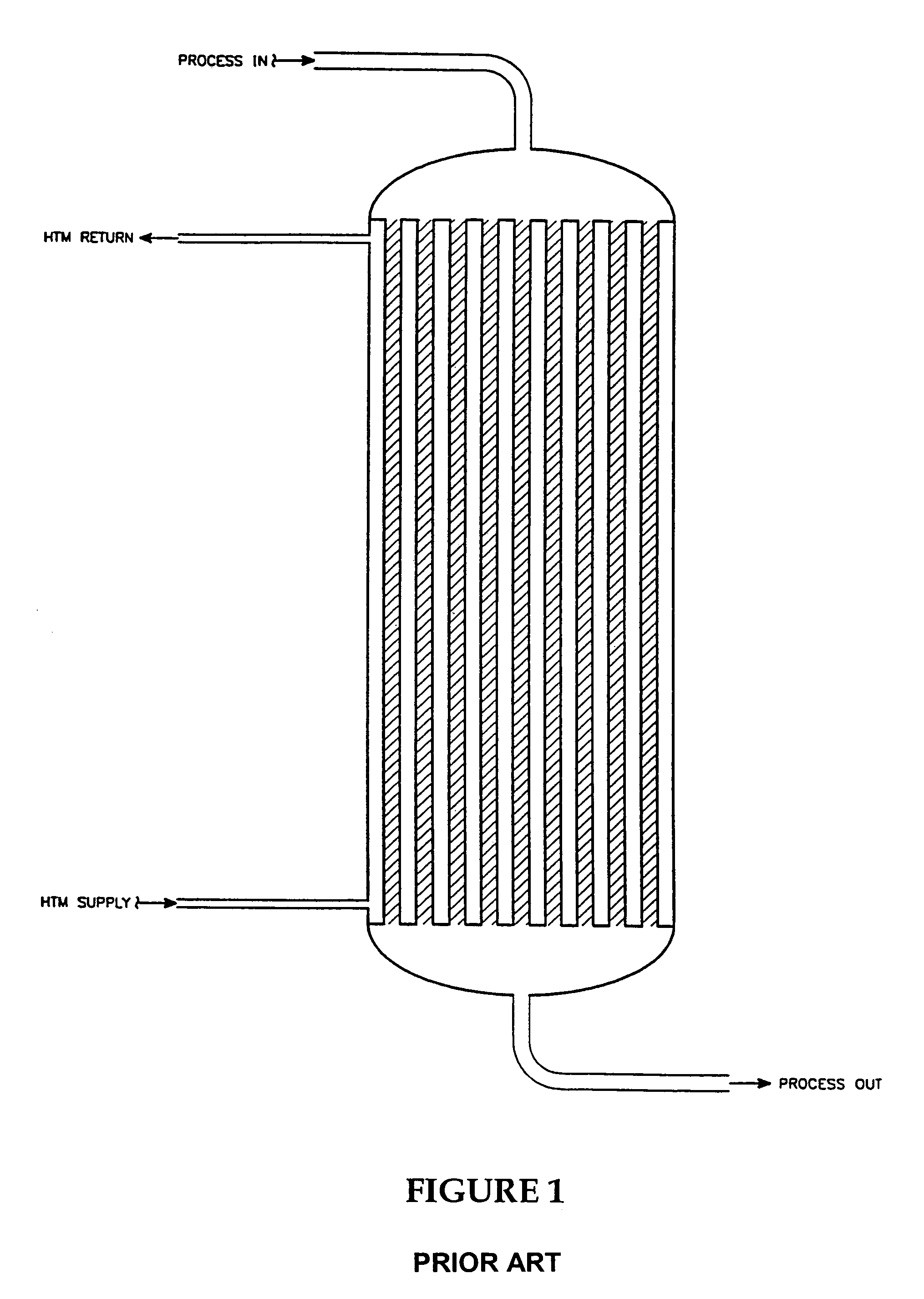

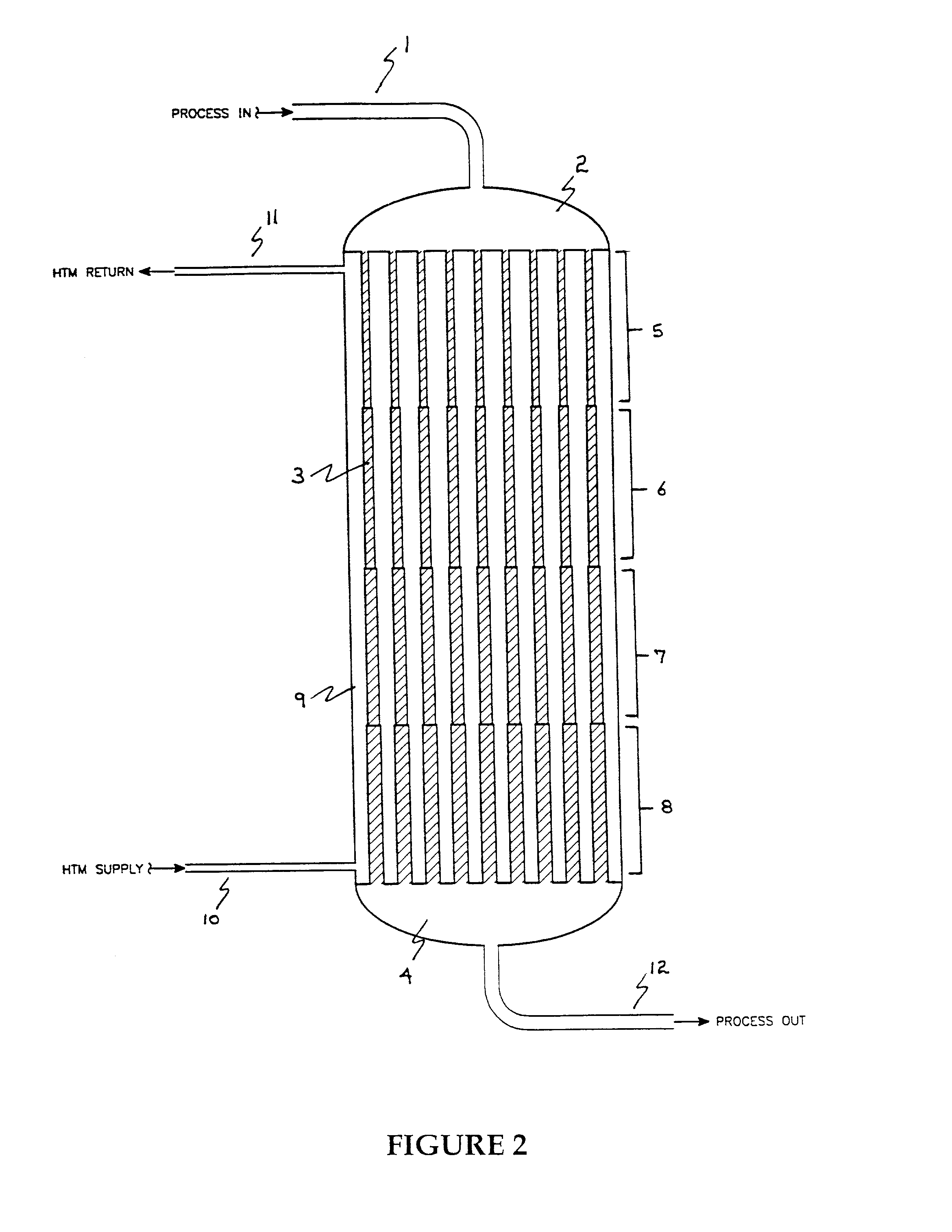

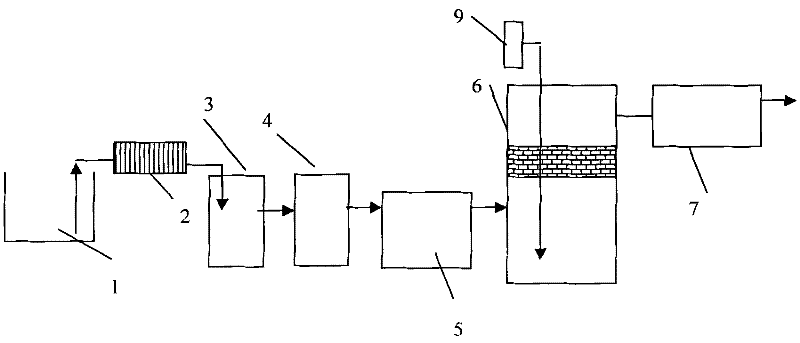

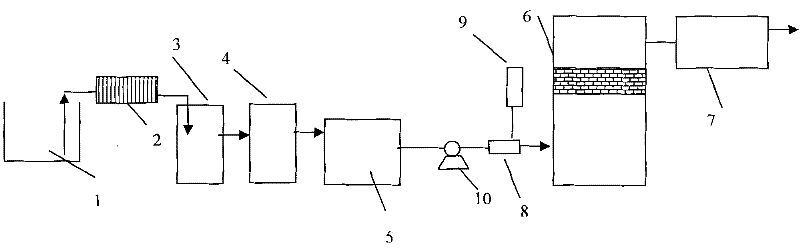

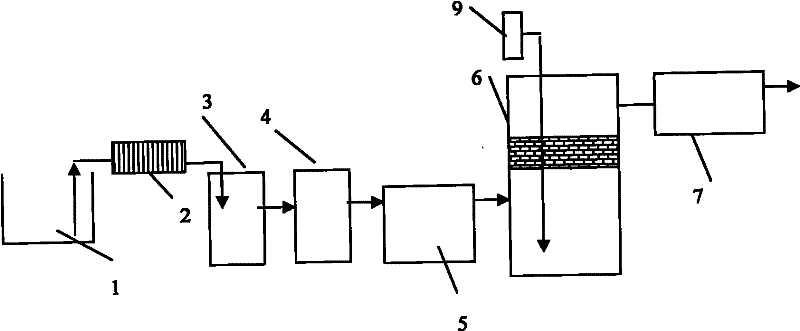

Flow reactors for chemical conversions with heterogeneous catalysts

InactiveUS7316804B2High trafficPhysical/chemical process catalystsOrganic compound preparationProcess systemsProcess engineering

Improved apparatus for use in process systems which include exothermic chemical conversions of organic compounds to value added products is disclosed, more particularly, flow reactors for exothermic chemical conversions using a fixed heterogeneous catalyst with means for control of the exotherm. Flow reactors of the invention comprise a plurality of walled conduits each having an outer surface disposed for contact with a heat-transfer medium, an inlet distribution manifold adapted for flow communication with a downstream manifold through channels formed by heterogeneous catalytic material disposed within each conduit during operation in a sequence of zones for catalyst having the same or different length along the longitudinal coordinate of the conduit and within each zone essentially uniform cross-section of the conduit measured in a plane perpendicular to the longitudinal coordinate thereby defining volume of the zone, and the sequence of zones comprising of at least two zones such that each downstream zone has a larger or smaller cross-section than the contiguous upstream zone. Another aspect of the invention includes processes which use such flow reactors, for example the continuous manufacture of maleic anhydride.

Owner:BP CORP NORTH AMERICA INC

Methods of making alkyl lactates and alkyl levulinates from saccharides

InactiveUS20150045576A1Organic compound preparationPreparation by carbon monoxide or formate reactionLevulinic acidAlcohol

Unique methods have been developed to convert saccharides into value-added products such as alkyl lactates, lactic acid, alkyl levulinates, levulinic acid, and optionally alkyl formate esters and / or hydroxymethylfurfural (HMF). Useful catalysts include Lewis acid catalysts and Brønsted acid catalysts including mineral acids, metal halides, immobilized heterogeneous catalysts functionalized with a Brønsted acid group or a Lewis acid group, or combinations thereof. The saccharides are contacted with the catalyst in the presence of various alcohols.

Owner:BATTELLE MEMORIAL INST

Method for removing organic pollutant in water by catalysis ozonation

InactiveCN101327985APromote decompositionSolve the remaining problemsWater contaminantsWater/sewage treatment by oxidationBromateHuman health

The invention relates to a catalytic ozonation method for removing the organic pollutant, which solves the problems that in the prior art both the residual hydrogen peroxide from the homogeneous catalysis ozonation using hydrogen peroxide as catalyst and the byproduct bromate produced by the heterocatalysis ozonation using metal oxide as catalyst play a bad impact on human health and cause secondary pollution of water. The method of the invention comprises the following steps: a. laying the catalyst in a reactor; b. adding ozone and hydrogen peroxide; c. controlling the contacting time of the ozone and the hydrogen peroxide, that is, finishing the removal of the organic pollutant in water. The method of the invention dissolves the problem of residual hydrogen peroxide, reduces the formation of the bromate without causing the secondary pollution of water and affecting human health, which is suitable to apply in the real water treatment process as a drinking water advanced treatment technology.

Owner:HARBIN INST OF TECH

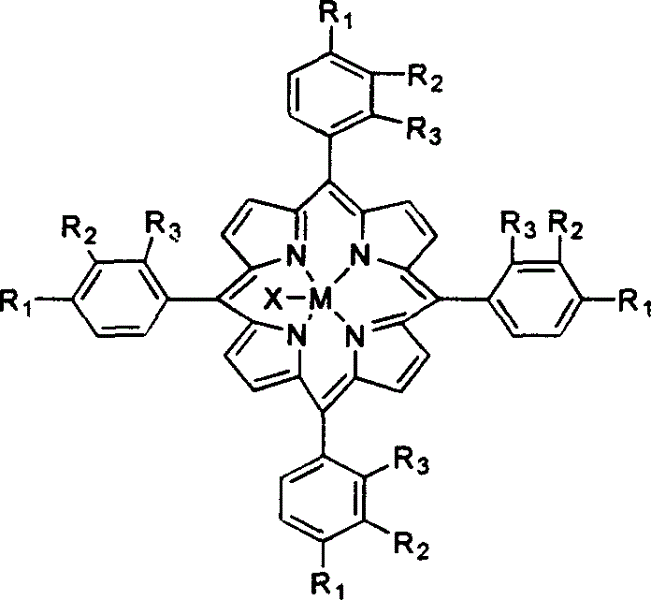

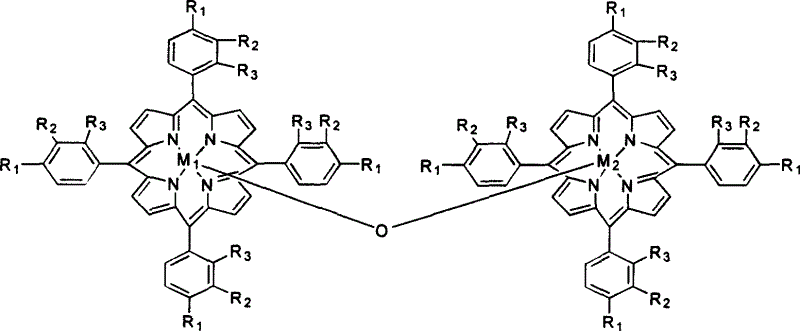

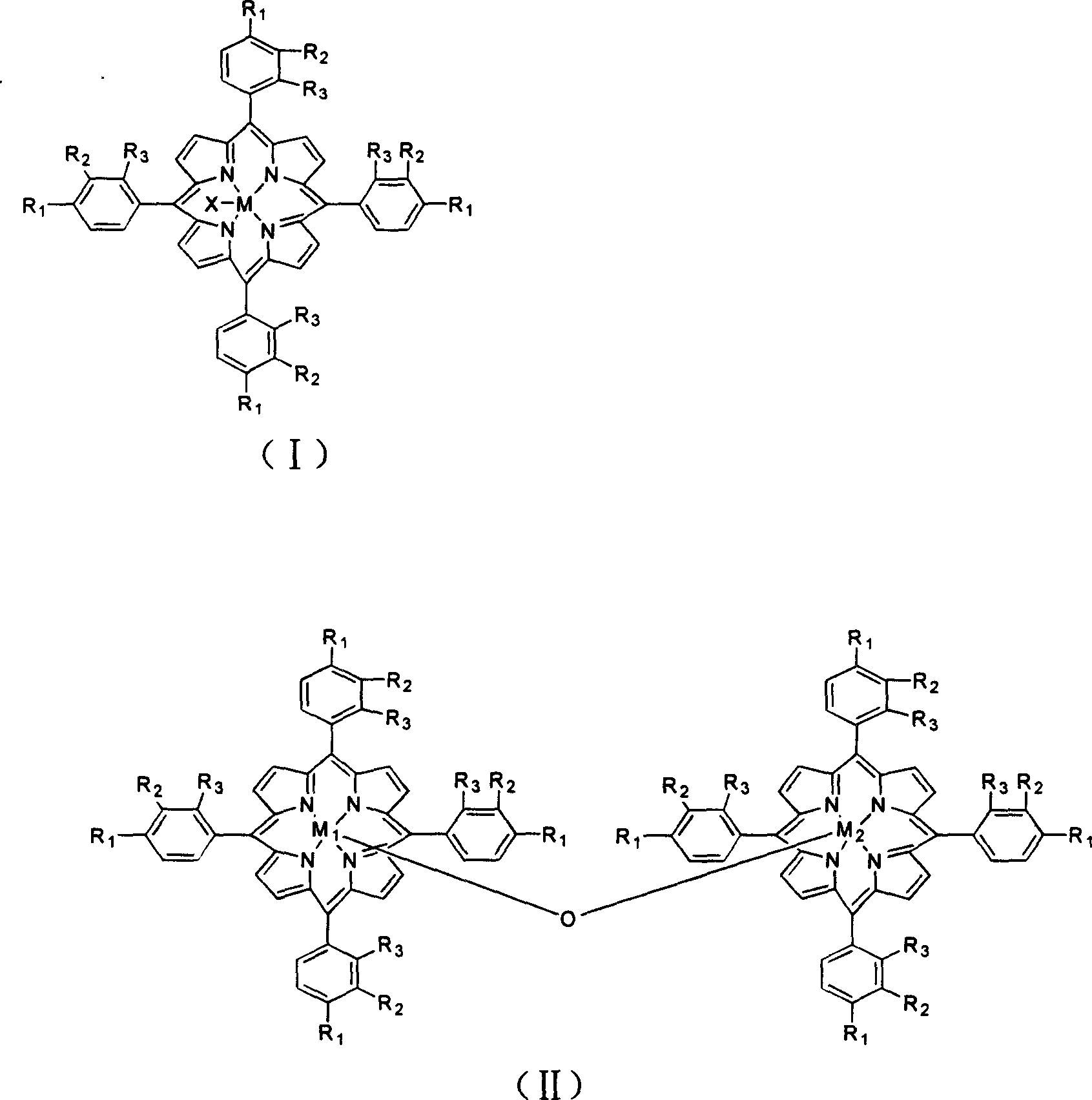

Method for atmospheric catalytic oxidation of cyclohexane by metalloporphyrin

InactiveCN1405131APreparation by oxidation reactionsOxygen compounds preparation by hydrocarbon oxidationCyclohexanoneReaction temperature

The invention relates to a new process in which under the catalytic action of metal porphyrin the cyclohexane can be selectively oxdated by air and made into cyclohexanol and cyclohexanone. Under the condition of 2-10 atm air, reaction temp. is 125-150 deg.C, it selects and uses micro-oxo double metal porphyrin and single metal porphyrin or their solid carrier as main catalyst, and uses transition metal salt or oxide as co-catalyst, the metal porphyrin can high-effectively and high-selectively catalyze oxidation of cyclohexane by using air in the biological concentratino as biological enzyme. The dose of metal porphyrin is small and said metal porphyrin can be repeatedly used, and said catalyst dose also is small, its catalystic effect is good, said catalyst can be used for making homogeneous catalysis, and after it is solid-carried, it also can be used for making heterogeneous catalysis.

Owner:HUNAN UNIV

Method of preparing adipic acid by air-oxidating hexacarbocyclic compound

InactiveCN1535947AReduce dosageHigh catalytic efficiencyOrganic compound preparationCarboxylic compound preparationCyclohexanoneCyclohexene

The present invention relates to a new process for preparing adipic acid by air oxidating cyclohexane, cyclohexanol, cyclohexanone and cyclohexene or mixture of cyclohexanol and cyclohexanone under the catalysis of metal porphyrin. Under the condition of 1-20 atm air and reaction temp. is 50-200 deg.C it can select and use mu-oxidized metal porphyrin and monometal porphyrin or their fixed carrier material as catalyst independently, also can select and use metal porphyrin or their fixed carrier material as main catalyst, and use transition metal salt or oxide as co-catalyst. The metal porphyrin like biological-enzyme can high-effectively and high-selectivity catalyze air under the biologicae concentration to directly oxidate the cyclohexane into adipic acid. Said invented dose of metal porphyrin is less, and its catalytic effect is good, it can make homogeneous catalysis, also can make heterogeneous catalysis after the carrier is fixed.

Owner:HUNAN UNIV

Advanced treatment method for fracturing flow-back fluid

ActiveCN102161536AHigh removal rateSimple processMultistage water/sewage treatmentWater/sewage treatment by oxidationLiquid wasteTreatment effect

The invention discloses an advanced treatment method for fracturing flow-back fluid, belongs to the field of water treatment of the development of oil and gas fields, and particularly relates to an advanced treatment method for the fracturing flow-back fluid generated during the operation of the oil and gas fields. The treatment method for the fracturing flow-back fluid, which has high effect and continuous treatment process, is provided to solve the problems that the treatment effect is lower, the continuous treatment cannot be performed, and the cost is higher existing in the prior art. The method comprises the following steps of: pre-oxidizing waste liquor with the pH value of between 8 and 12, adding a coagulant and performing gel breaking treatment and adding a Fenton reagent and treating, and performing secondary coagulation and oxidization treatment. In the method, through homogeneous and heterogeneous catalysis reactions, the treatment cost is reduced, and the removal rate of organic substances is also high; and chemical oxygen demand (COD) of effluent can meet the national sewage discharge standard.

Owner:四川绿源环保技术开发有限公司

Regeneration of ionic catalyst by hydrogenation using a homogeneous catalyst

A process for regenerating a used acidic ionic liquid catalyst comprising the steps of contacting the used ionic liquid catalyst and hydrogen with a homogeneous hydrogenation catalyst in a reaction zone under hydrogenation conditions for a time sufficient to increase the activity of the used catalyst is disclosed.

Owner:CHEVROU USA INC

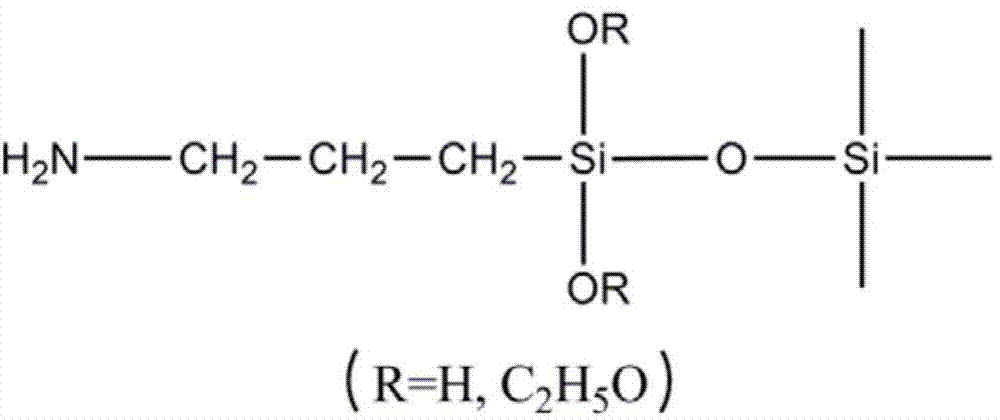

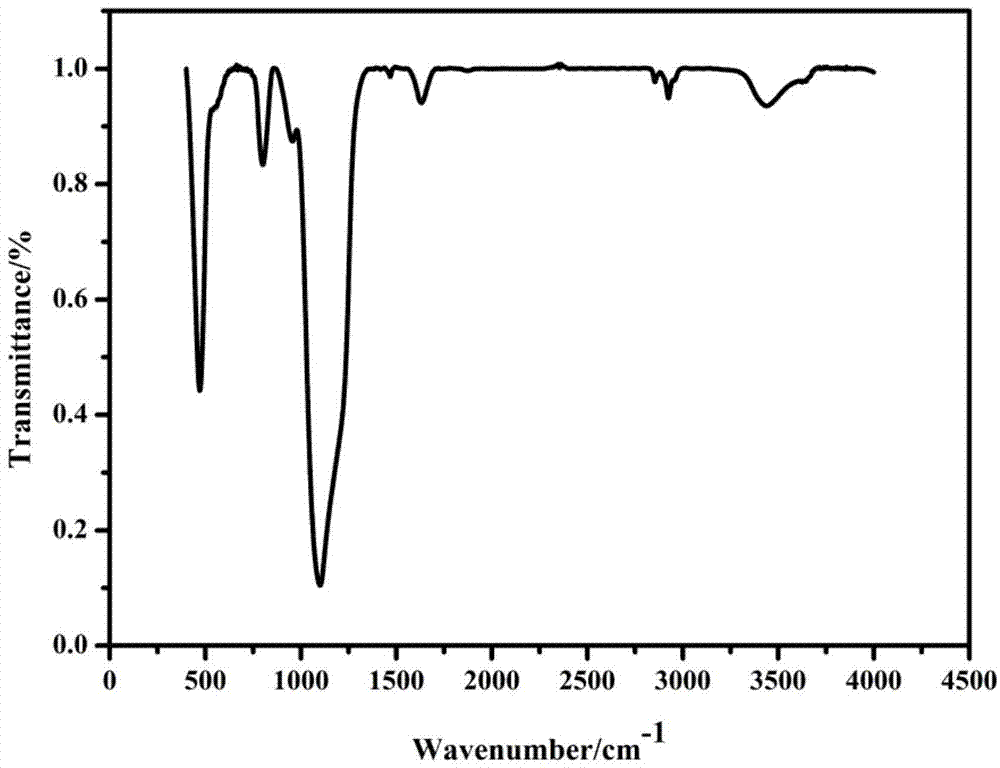

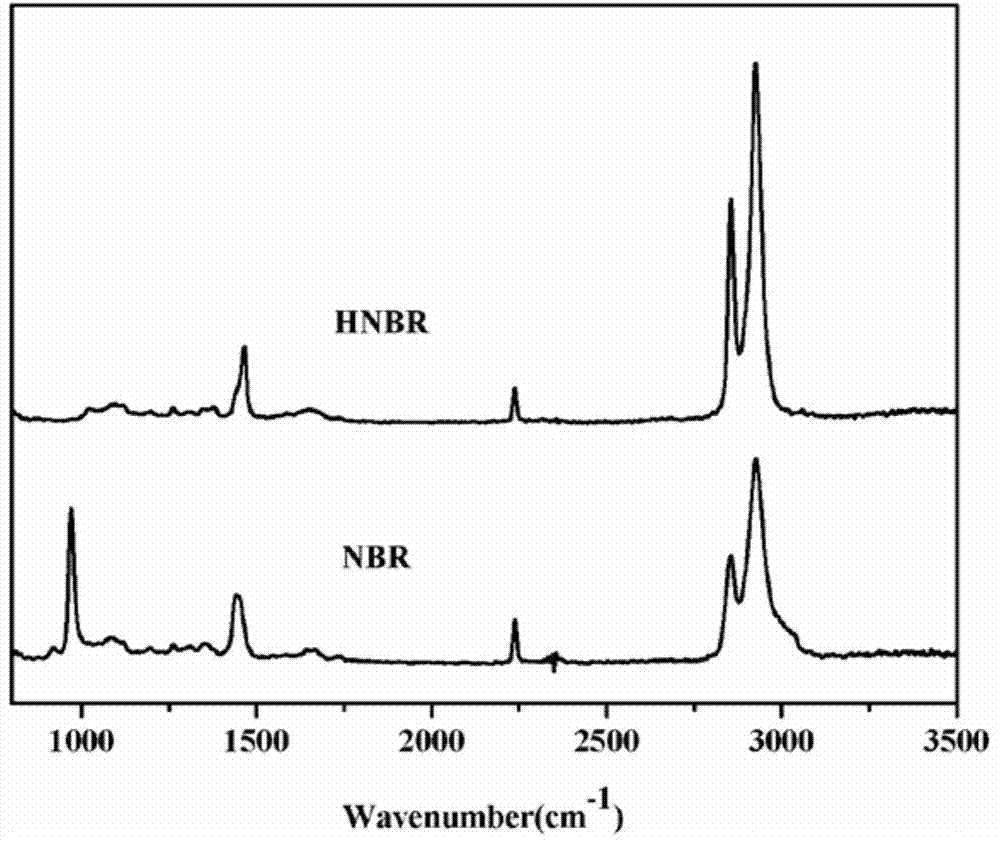

Preparation of silane coupling agent-modified SiO2 loaded rhodium catalyst and selective hydrogenation application of catalyst to butadiene-acrylonitrile rubber

ActiveCN103537304ASimple preparation processGood choiceOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingSilanesAcrylonitrile

The invention discloses preparation of a silane coupling agent-modified SiO2 loaded rhodium catalyst and a selective hydrogenation application of the catalyst to butadiene-acrylonitrile rubber. The method comprises the following steps: (1) carrier modification, namely, modifying SiO2 by utilizing a silane coupling agent with an amino group in an organic solution or water so as to obtain modified SiO2; and (2) loading catalyst preparation, namely, adding the modified SiO2 into a rhodium solution, standing, washing and drying so as to obtain the loaded catalyst APTS (aminopropyltriethoxysilane)-SiO2-Rh. The prepared catalyst is used for nitrile butadiene rubber (NBR) hydrogenation research, and the hydrogenated butadiene-acrylonitrile rubber with the hydrogenation strength being more than 98% can be obtained. The preparation process is simple, and the adopted reaction raw materials are wide in source scope and small in toxicity and are economic and practicable. The NBR hydrogenation research shows that the hydrogenation efficiency is greatly improved, the hydrogenation strength is improved to above 98% from the original 52% under the same condition, and moreover, the recycling performance of the catalyst is also greatly improved after the reaction is ended. The APTS-SiO2-Rh is a high activity recycled NBR hydrogenation heterogeneous catalyst and is beneficial to HNBR (hydrogenated butadiene-acrylonitrile rubber) large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com