Patents

Literature

34results about "Amino compound preparation by disproportionation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

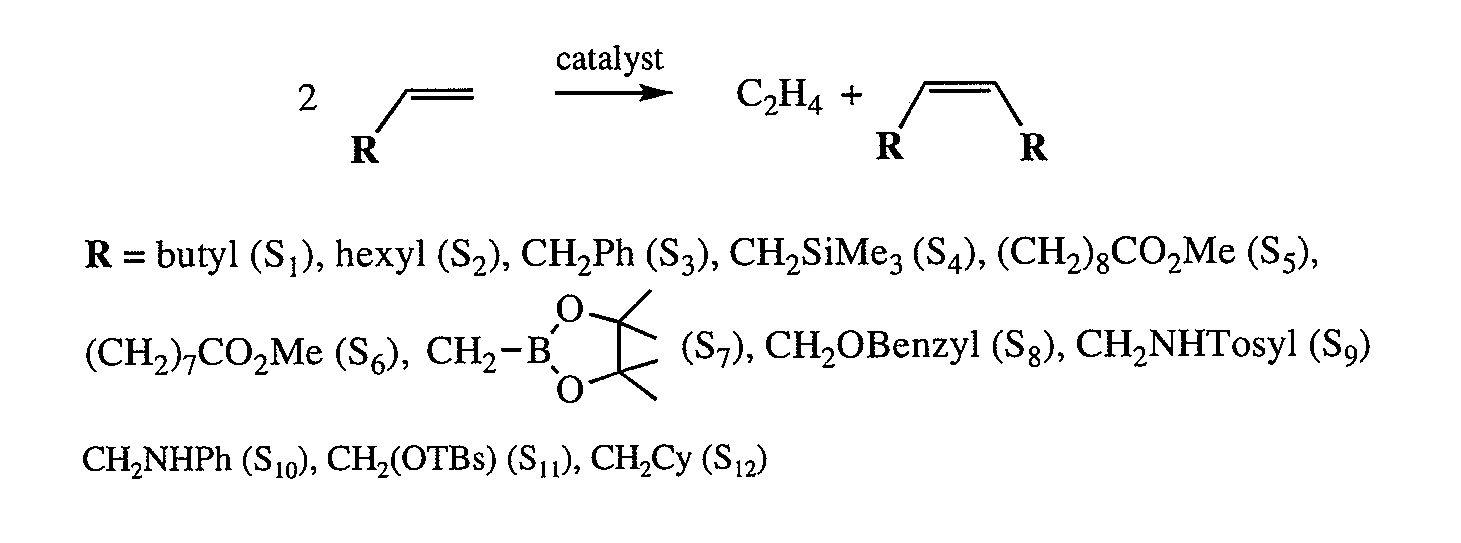

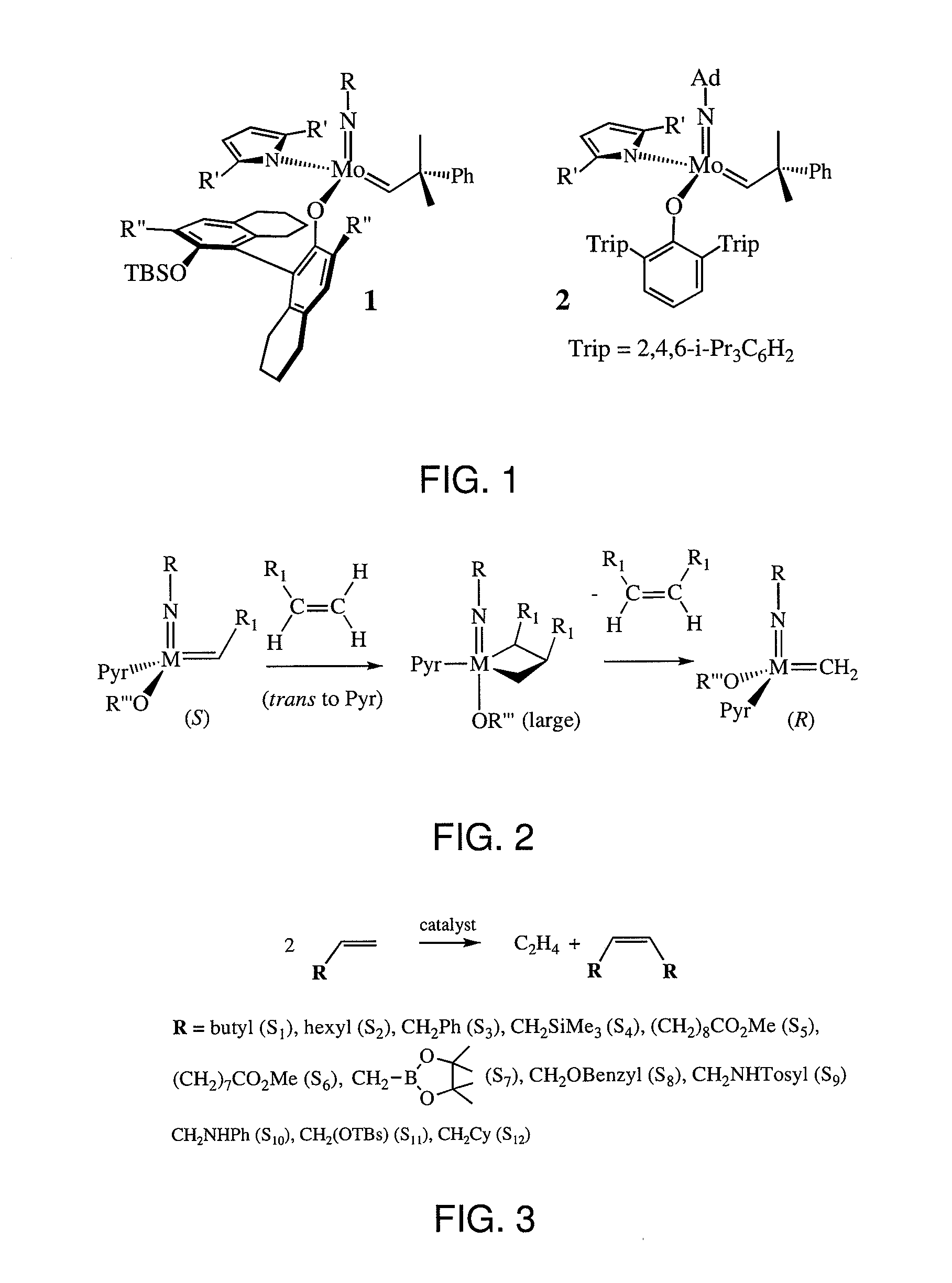

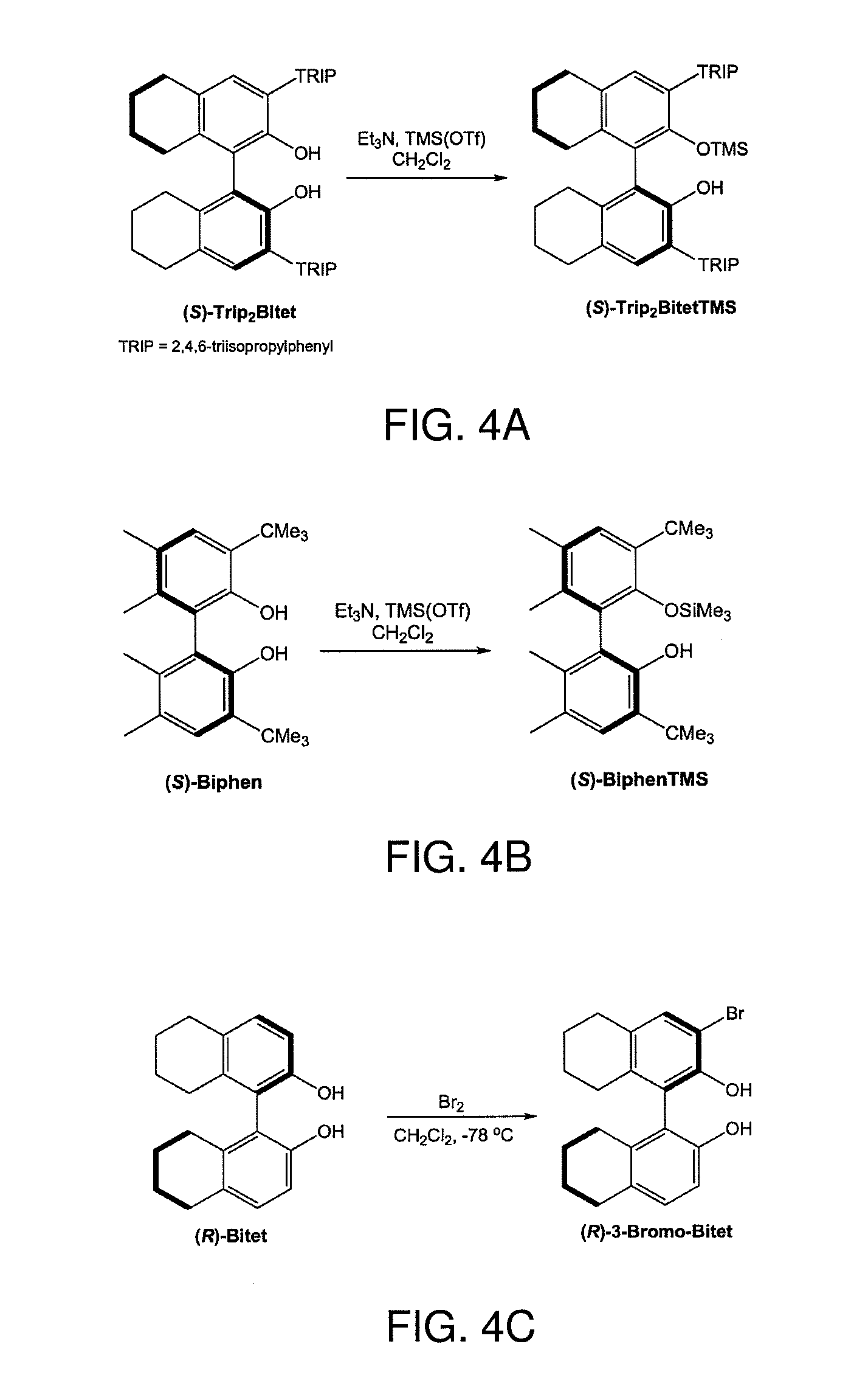

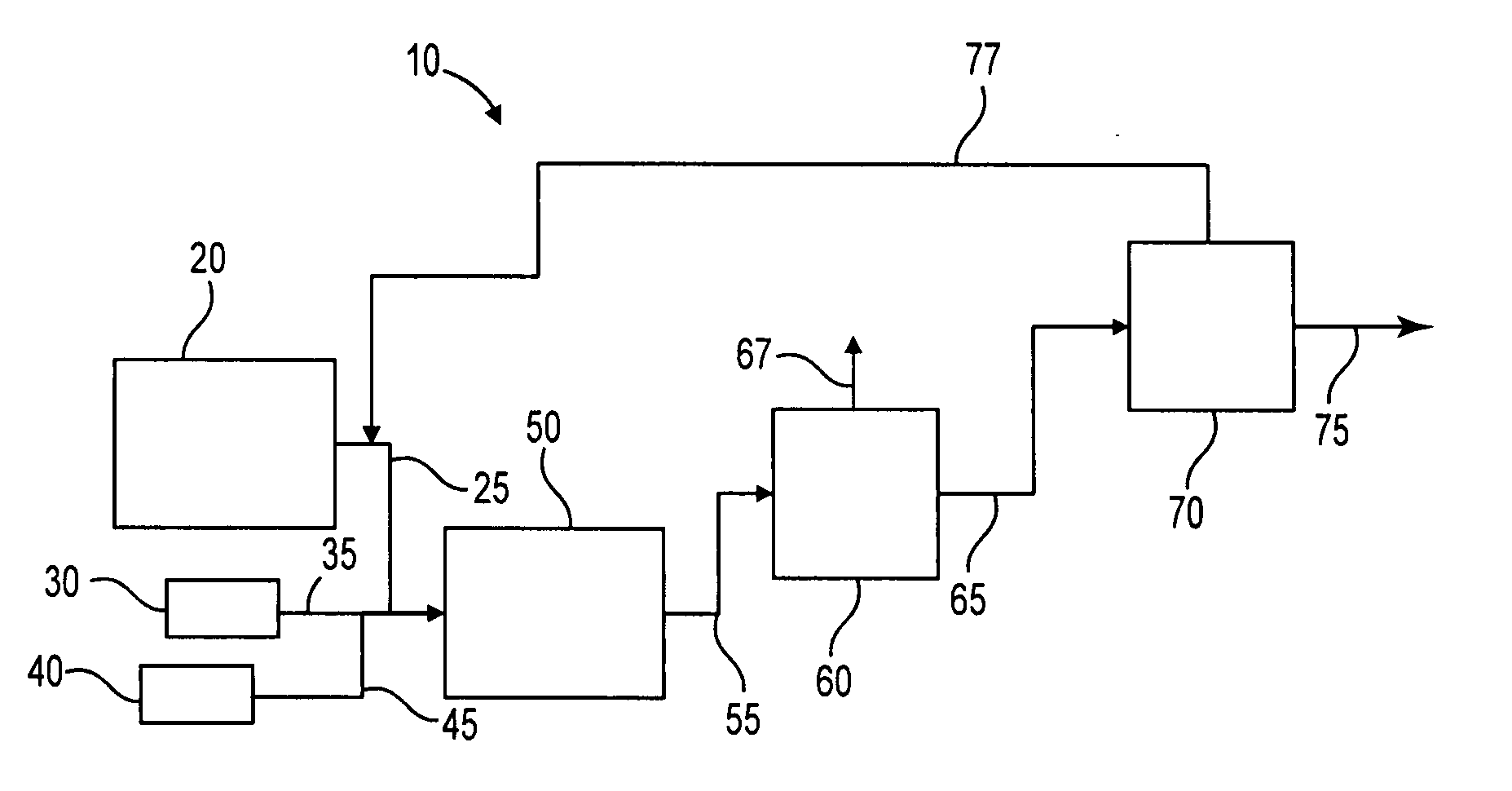

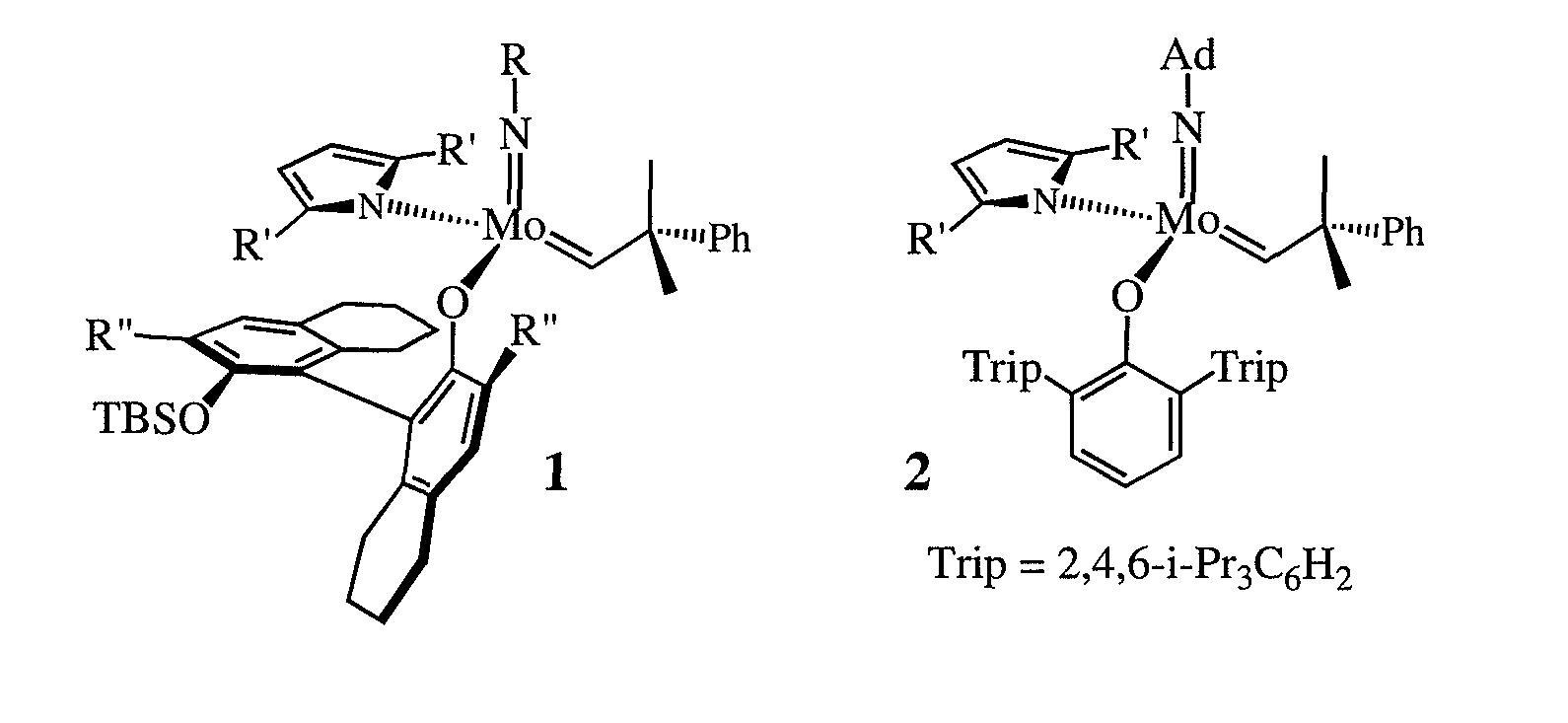

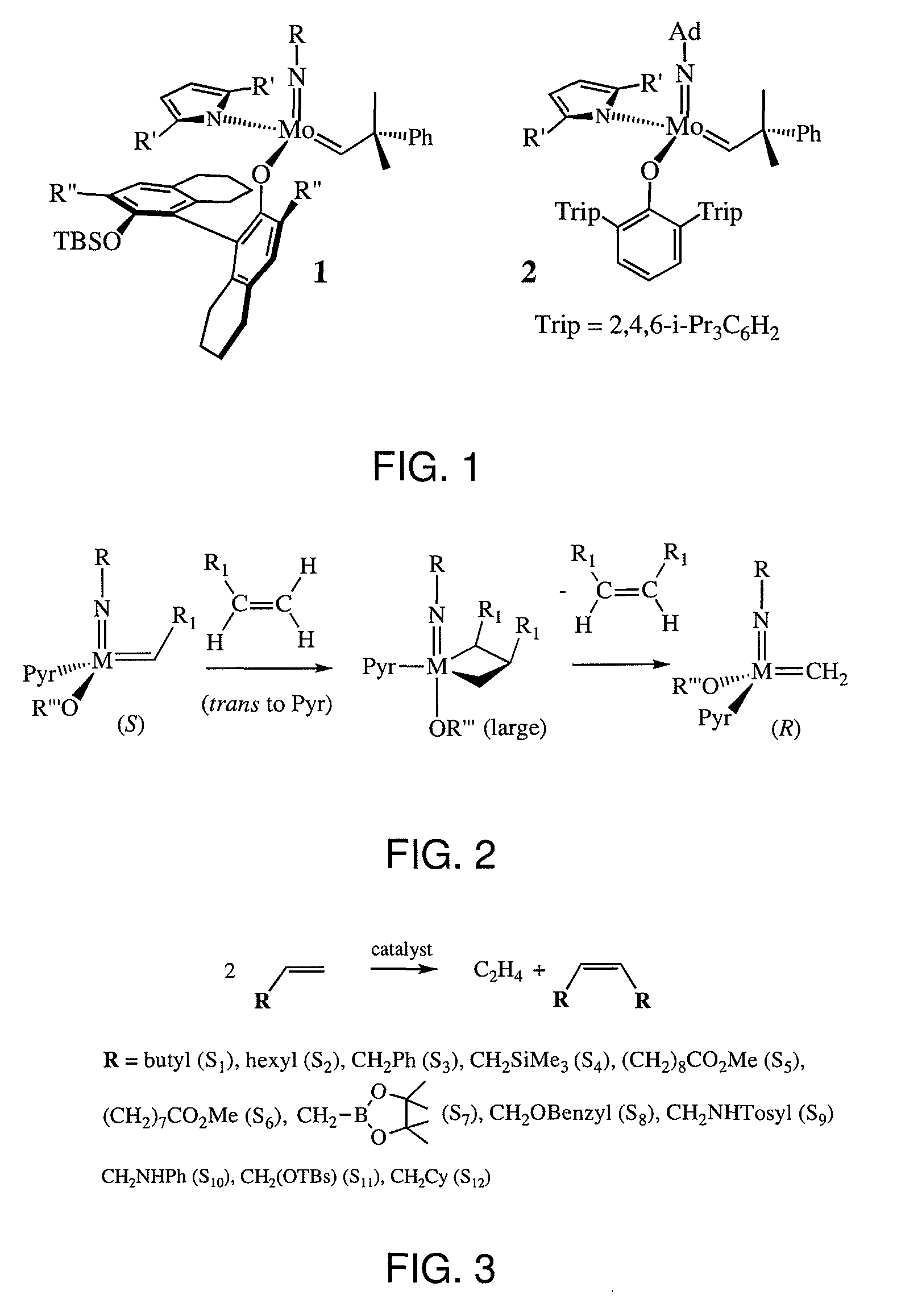

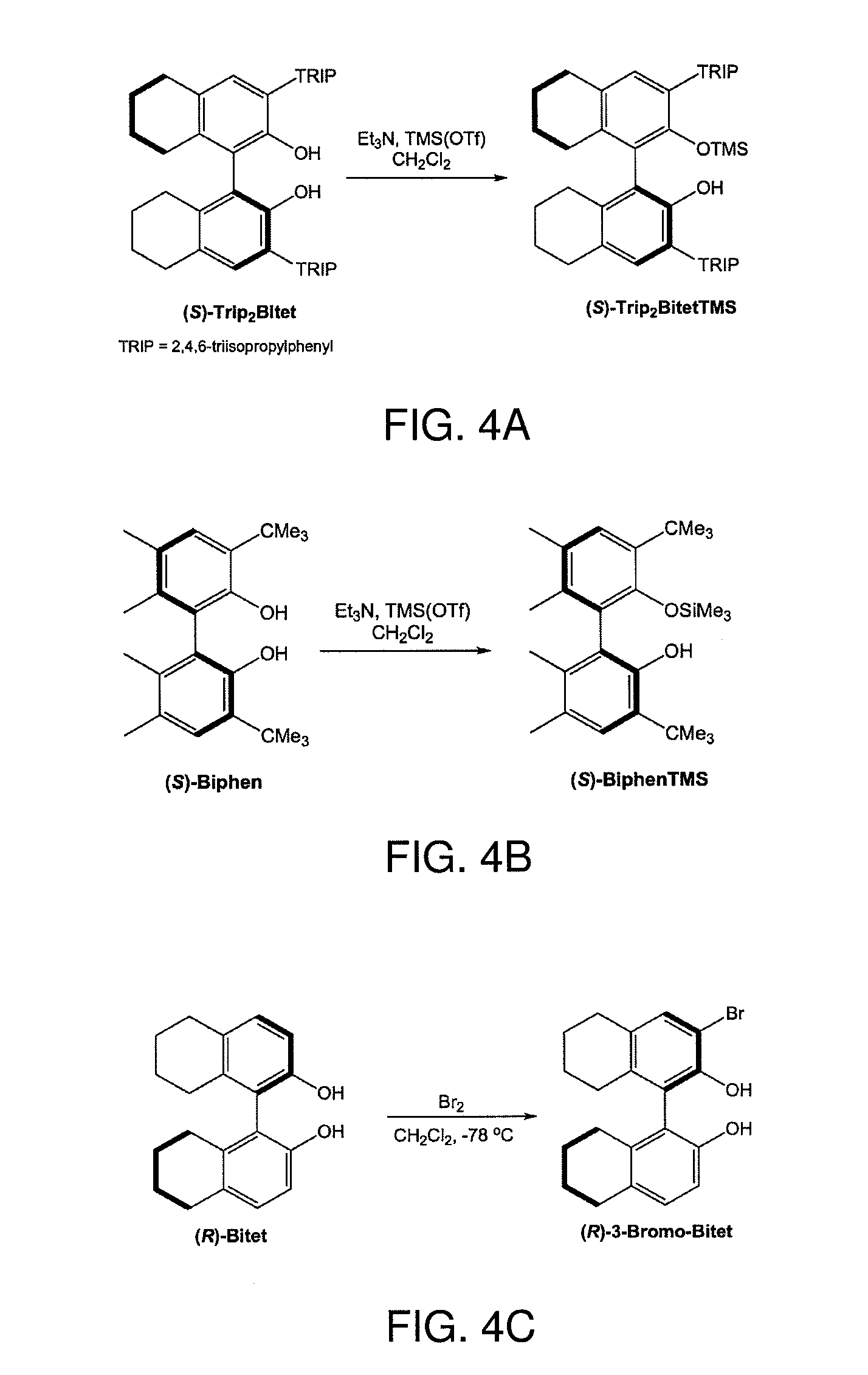

Highly z-selective olefins metathesis

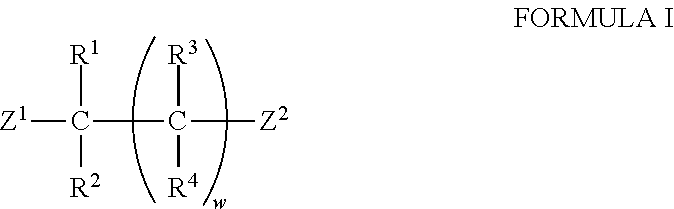

ActiveUS20110077421A1Organic chemistry methodsCarboxylic acid esters preparationOrganic chemistryOlefin metathesis

Owner:MASSACHUSETTS INST OF TECH +1

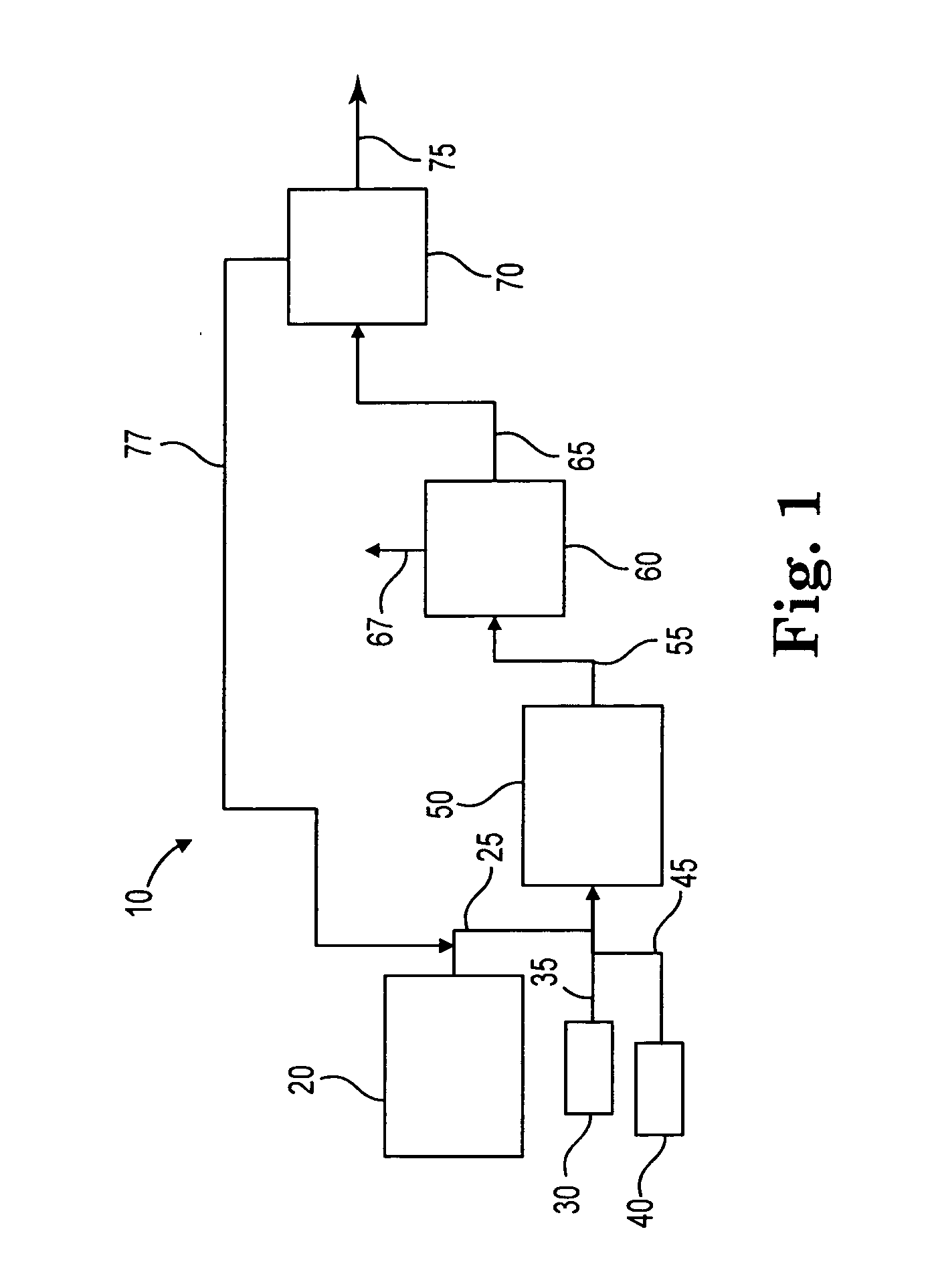

Process to selectively manufacture diethylenetriamine (DETA) or other desirable ethylenamines via continuous transmination of ethylenediamine (EDA), and other ethyleneamines over a heterogeneous catalyst system

ActiveUS20100087683A1Quantity maximizationQuantity minimizationOrganic compound preparationAmino compound preparation by disproportionationEthylenediamineDiethylenetriamine

The present invention reacts ethylenediamine with one or more additional ethyleneamines in the presence of a transamination catalyst to provide a different, preferably more desirable product mix of one or more ethyleneamines.

Owner:UNION CARBIDE CORP

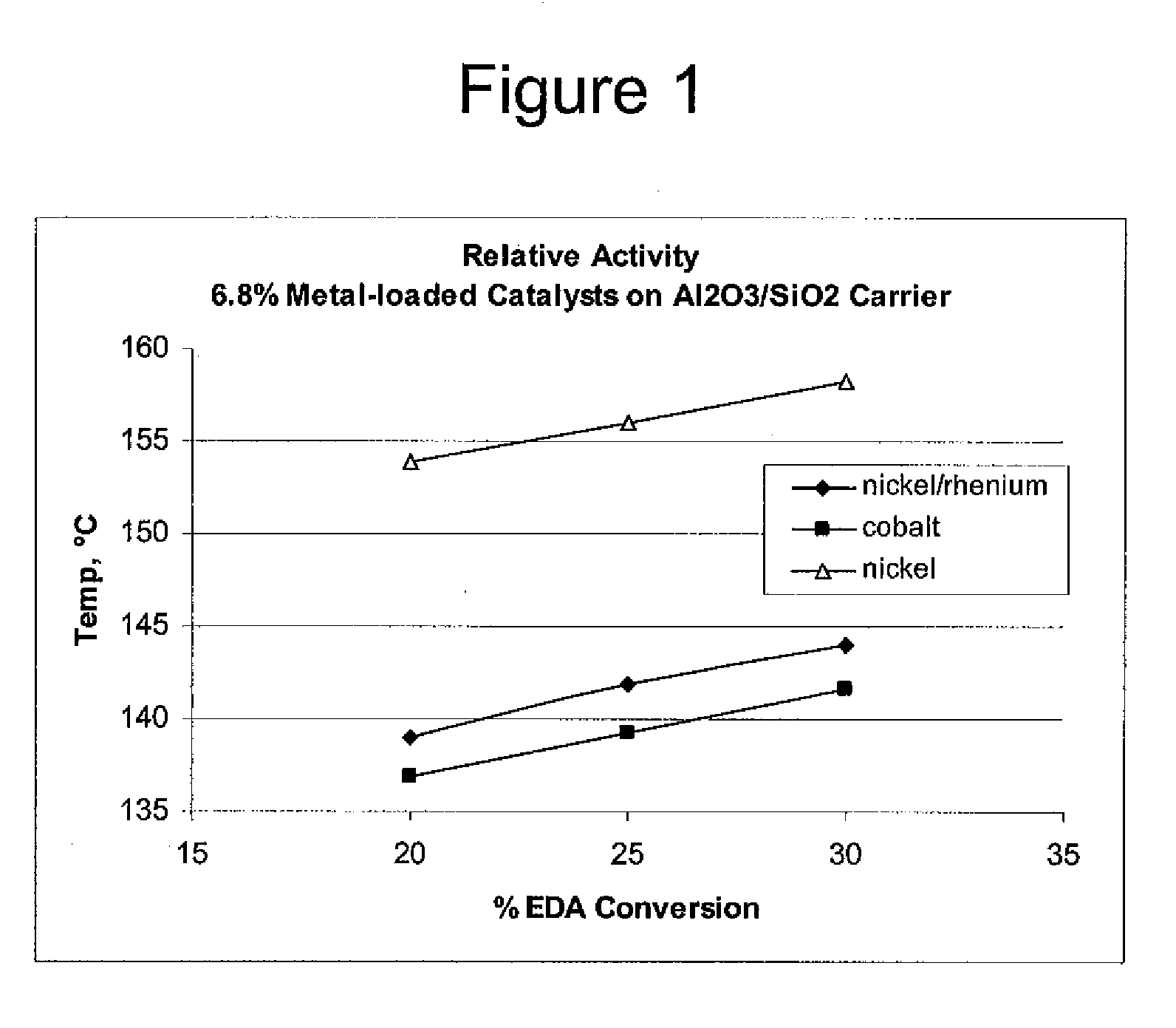

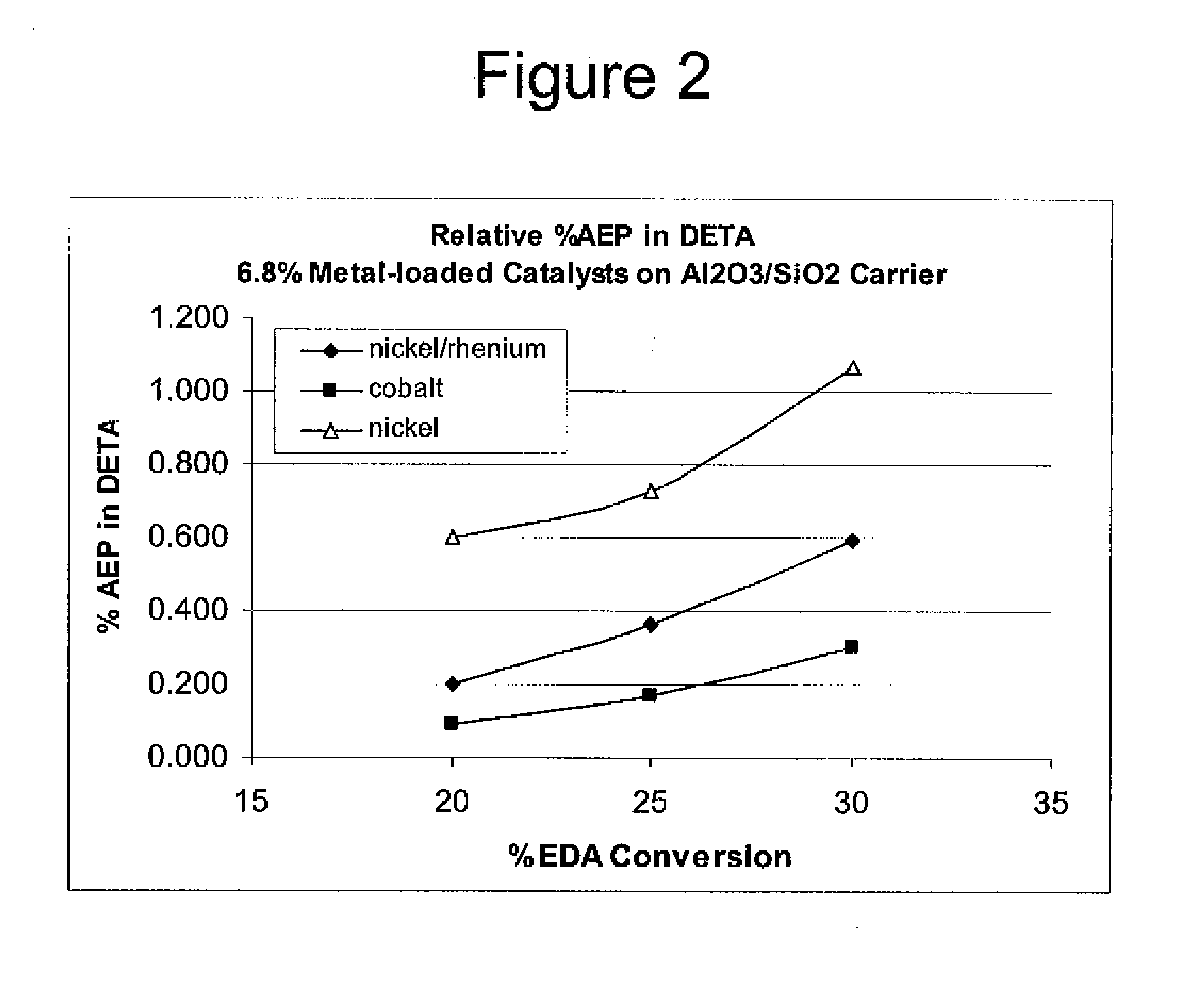

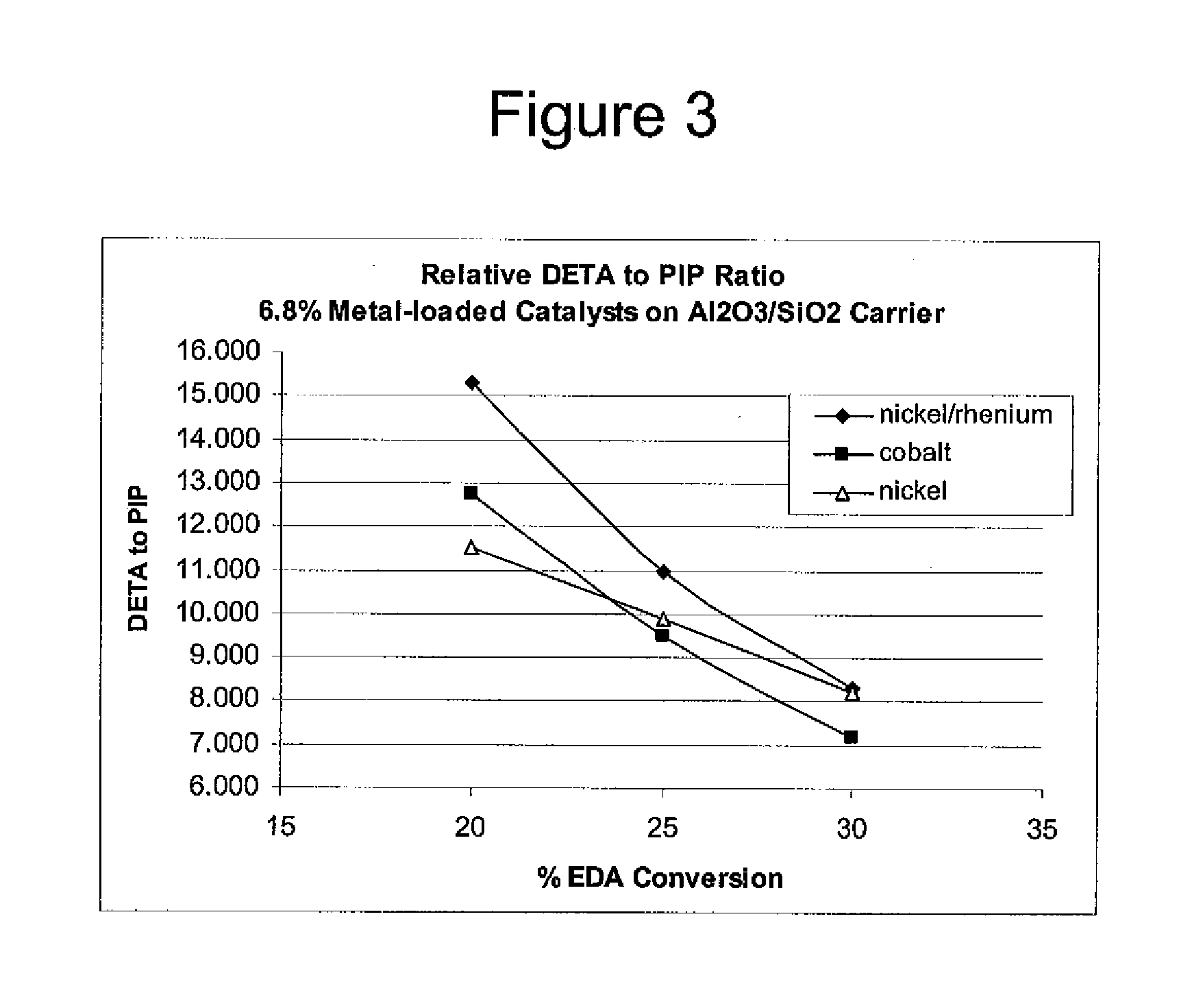

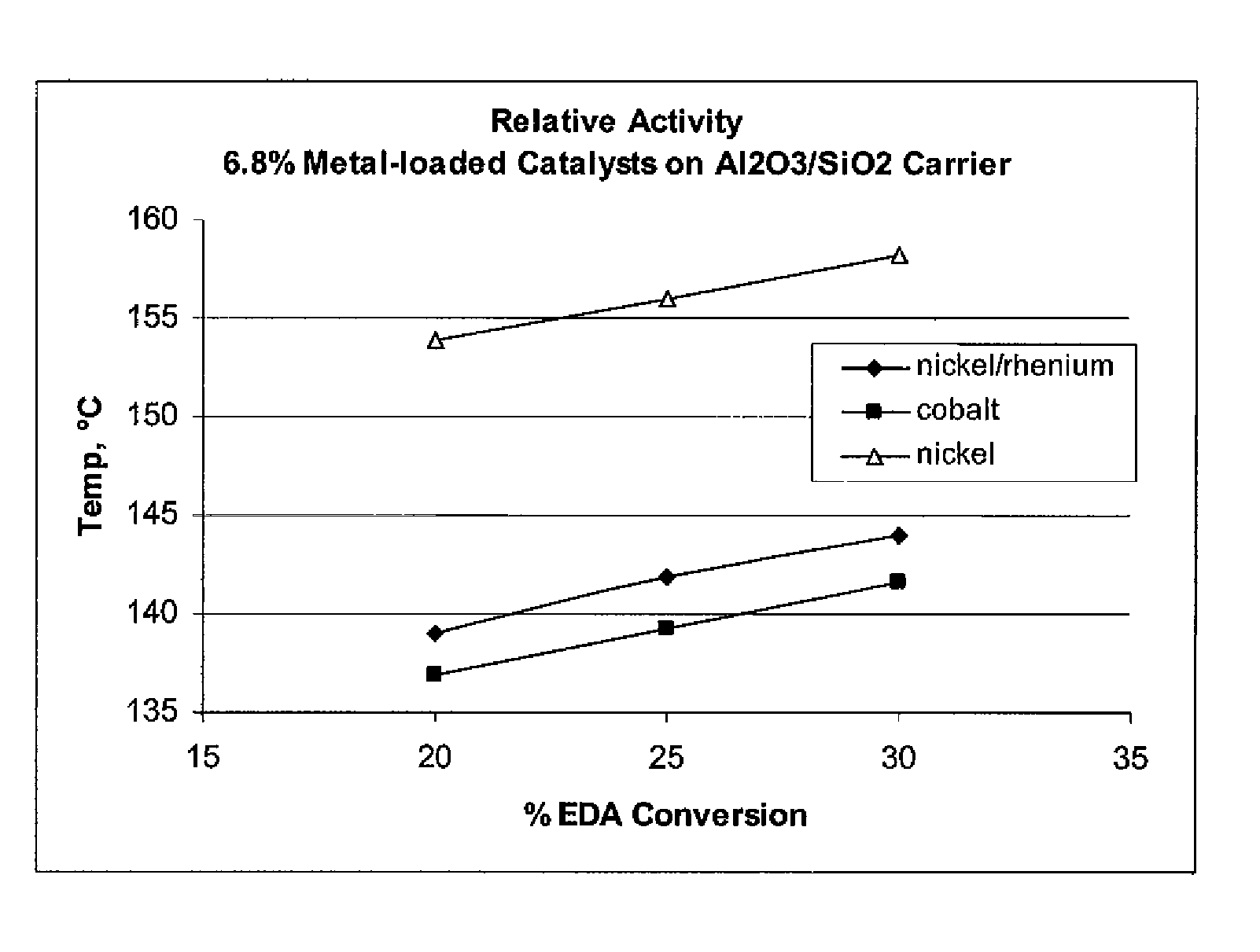

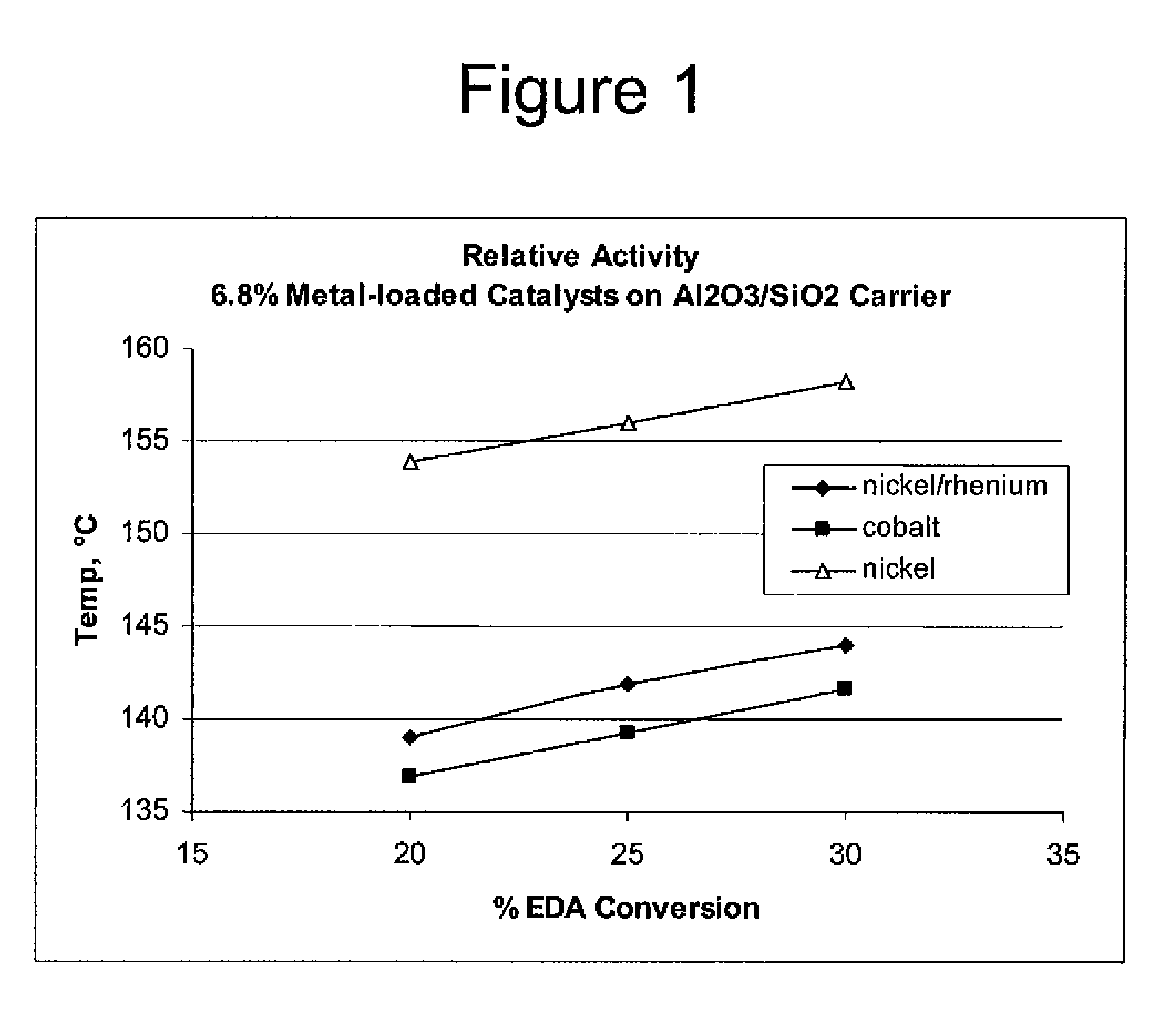

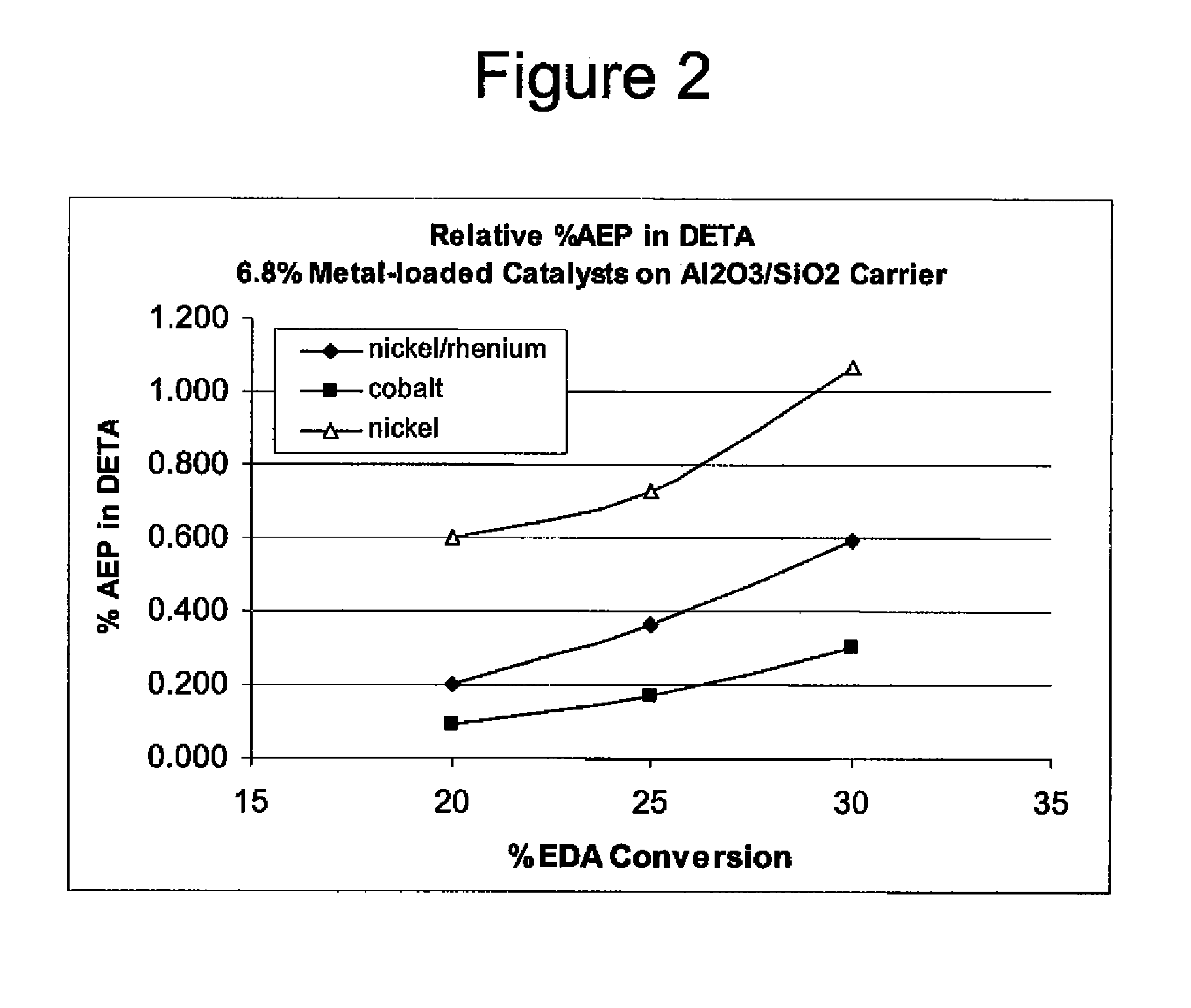

Low metal loaded, alumina supported, catalyst compositions and amination process

ActiveUS20100137642A1Good choiceMinimizingOther chemical processesOrganic compound preparationRheniumAmination

The present invention provides catalyst compositions useful for transamination reactions. The catalyst compositions have a catalyst support that includes transitional alumina, use a low metal loading (for example, less than 25 wt. %), and do not require the presence of rhenium. The catalyst compositions are able to advantageously promote transamination of a reactant product (such as the transamination of EDA to DETA) with excellent activity and selectivity, and similar to transaminations promoted using a precious metal-containing catalyst.

Owner:UNION CARBIDE CORP

Low metal loaded, alumina supported, catalyst compositions and amination process

ActiveUS8293676B2Reduce metal contentRemarkable activityOrganic compound preparationOther chemical processesRheniumAmination

The present invention provides catalyst compositions useful for transamination reactions. The catalyst compositions have a catalyst support that includes transitional alumina, use a low metal loading (for example, less than 25 wt. %), and do not require the presence of rhenium. The catalyst compositions are able to advantageously promote transamination of a reactant product (such as the transamination of EDA to DETA) with excellent activity and selectivity, and similar to transaminations promoted using a precious metal-containing catalyst.

Owner:UNION CARBIDE CORP

Highly Z-selective olefins metathesis

ActiveUS8362311B2Organic chemistry methodsCarboxylic acid esters preparationOrganic chemistryOlefin metathesis

Owner:MASSACHUSETTS INST OF TECH +1

Process to selectively manufacture diethylenetriamine (DETA) or other desirable ethyleneamines via continuous transamination of ethylenediamine (EDA), and other ethyleneamines over a heterogeneous catalyst system

ActiveUS8383860B2Quantity maximizationQuantity minimizationOrganic compound preparationAmino compound preparation by disproportionationEthylenediamineHomogeneous catalysis

The present invention reacts ethylenediamine with one or more additional ethyleneamines in the presence of a transamination catalyst to provide a different, preferably more desirable product mix of one or more ethyleneamines.

Owner:UNION CARBIDE CORP

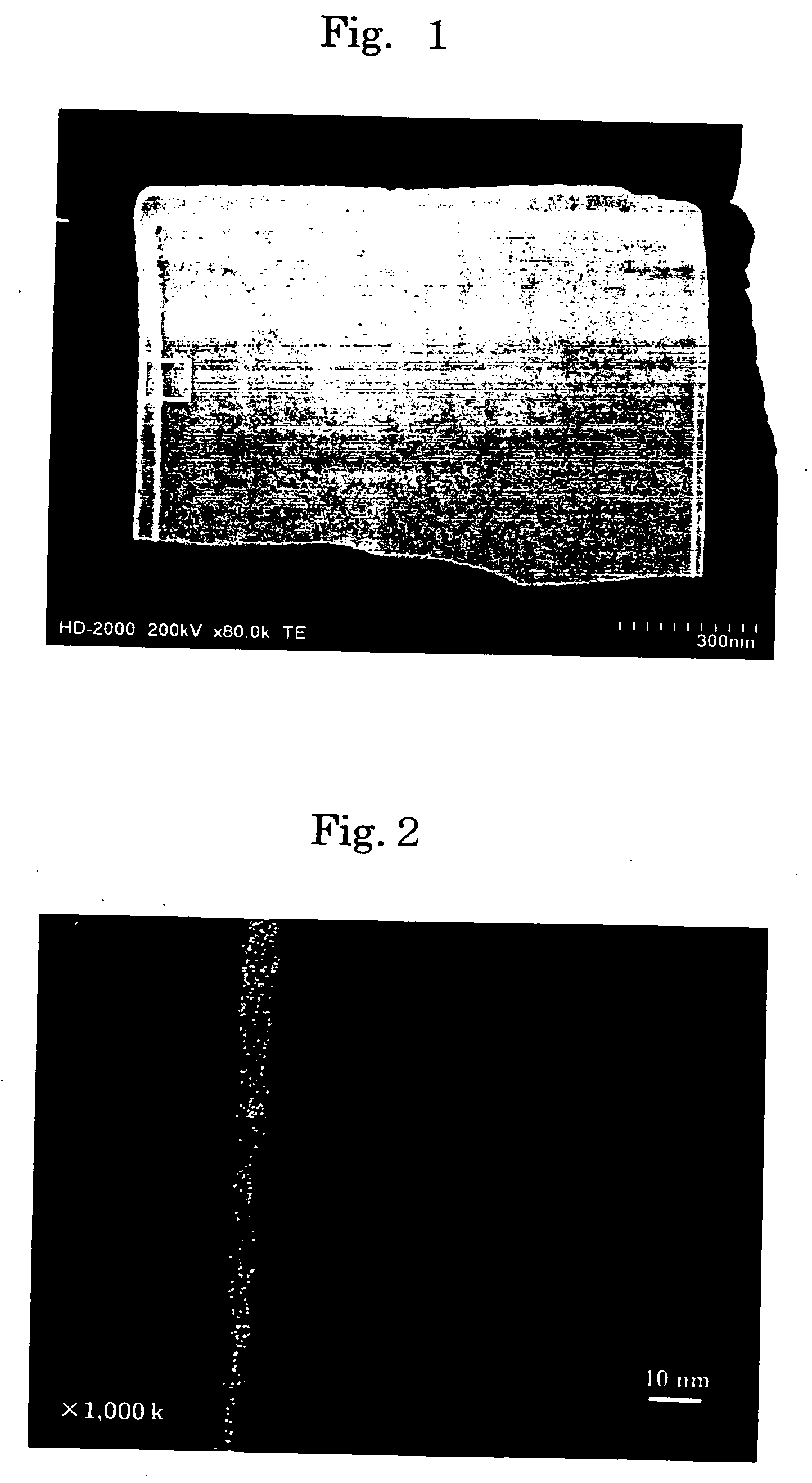

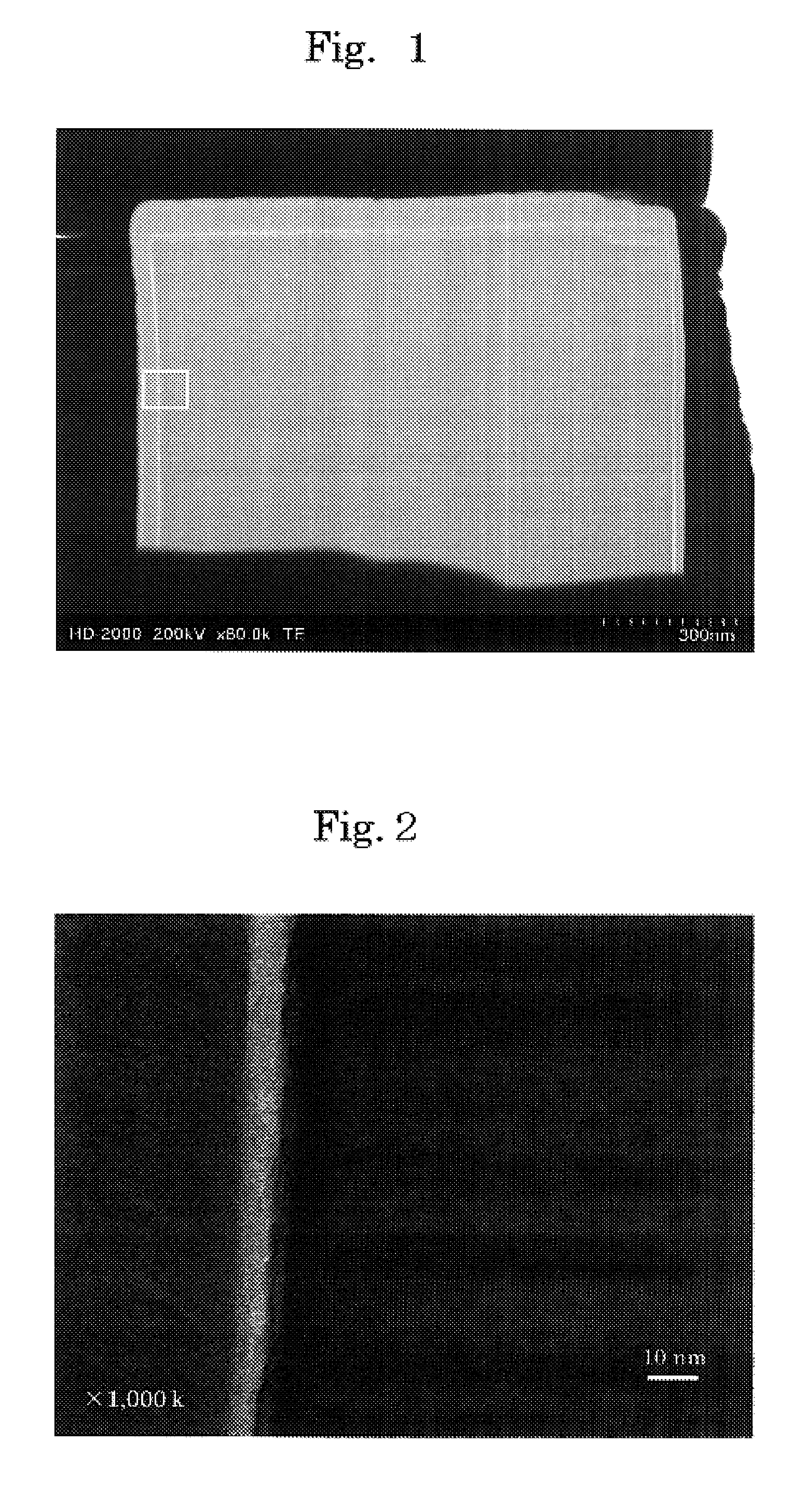

Crystalline silicoaluminophosphate salt molecular sieve having octaoxygen-membered ring pore, process for producing the same and process for producing methylamine with the molecular sieve as catalyst

InactiveUS20050249661A1High activity selectivityStable in dimethylamine selectivityAluminium compoundsPhosphatesPresent methodOxygen

Problems on catalyst production and catalyst performance with respect to conventional 8-oxygen-membered ring micropore-containing crystalline silicoaluminophosphate molecular sieves as non-equilibrium methylamine synthesis catalysts, are resolved. A chabazite type crystalline silicoaluminophosphate molecular sieve having high purity and high crystallinity and having, on a crystal grain surface, an amorphous oxide layer whose Si / Al atomic ratio is greater than that of the whole crystal grain can be stably produced with high yield with the use of a small amount of structure directing agents by the present method characterized in that hydrothermal treatment conducted in the production of 8-oxygen-membered ring micropore-containing crystalline silicoaluminophosphate sieves is controlled under specified treating conditions. The thickness and composition of the amorphous oxide layer, which exert marked influence on the yield of dimethylamine synthesis, can be easily controlled and reproduced under the conditions of catalyst synthesis according to the invention. Thus, the catalyst of high performance can be stably supplied by the present invention at a low cost with reduced output of waste.

Owner:MITSUBISHI GAS CHEM CO INC

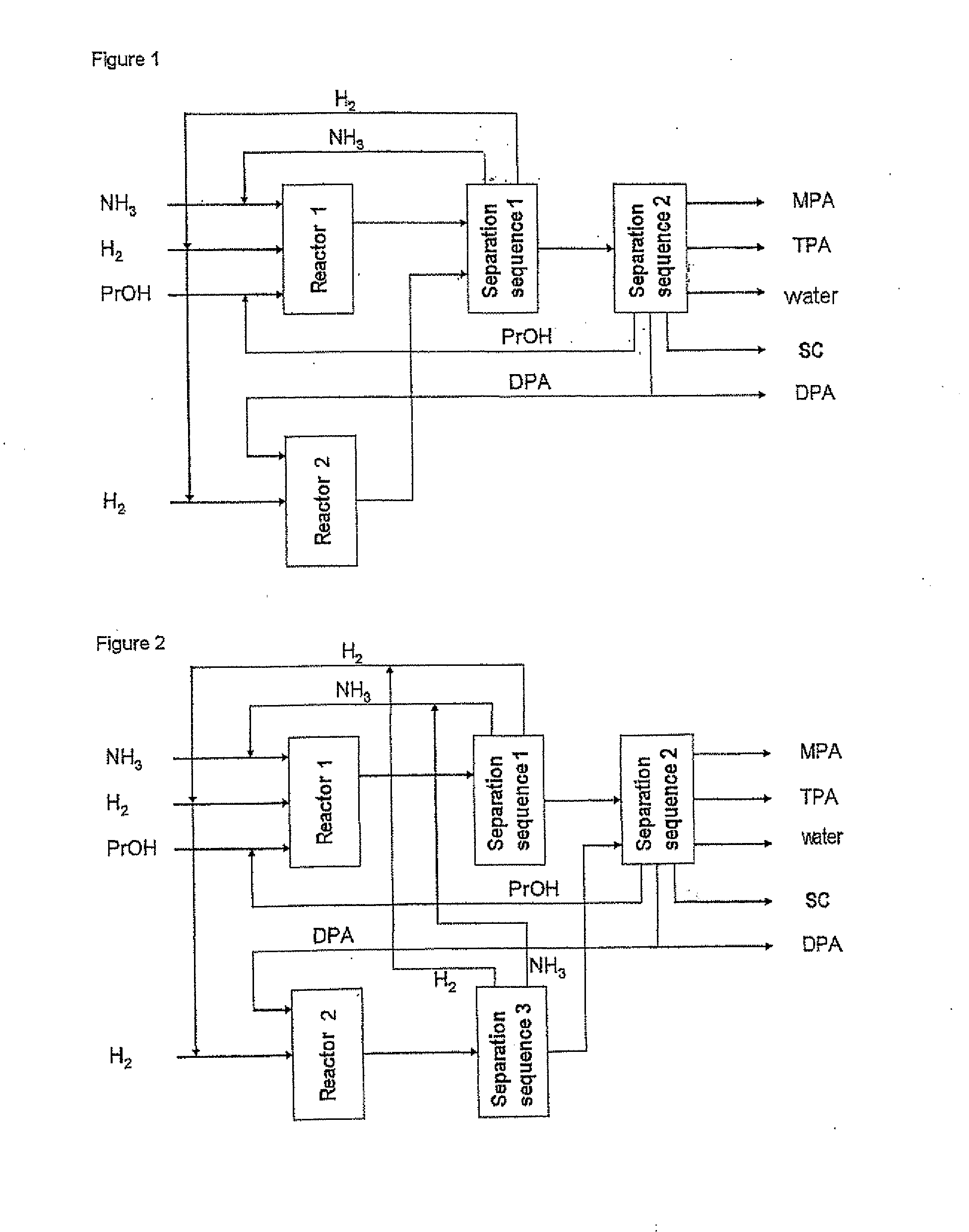

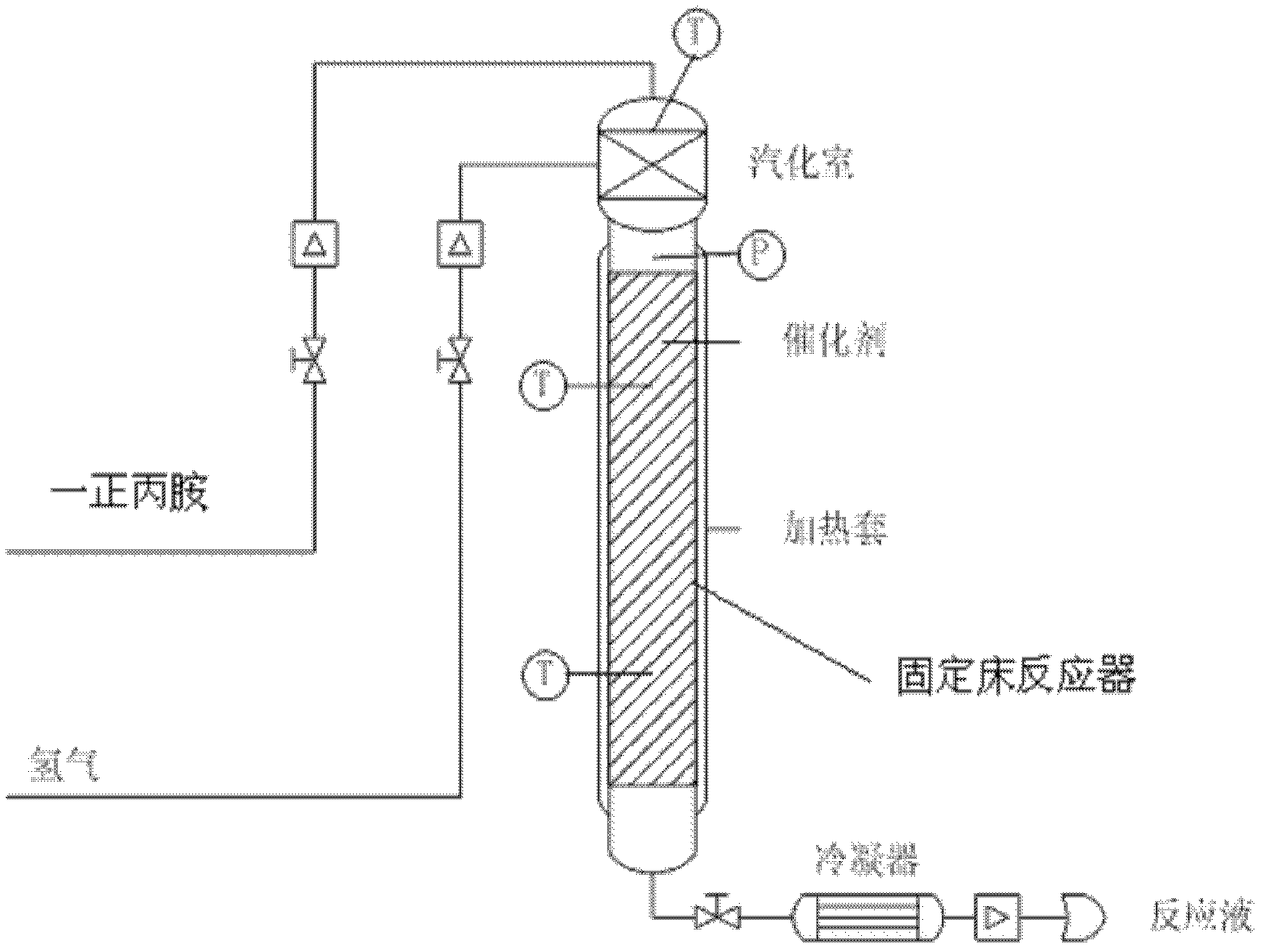

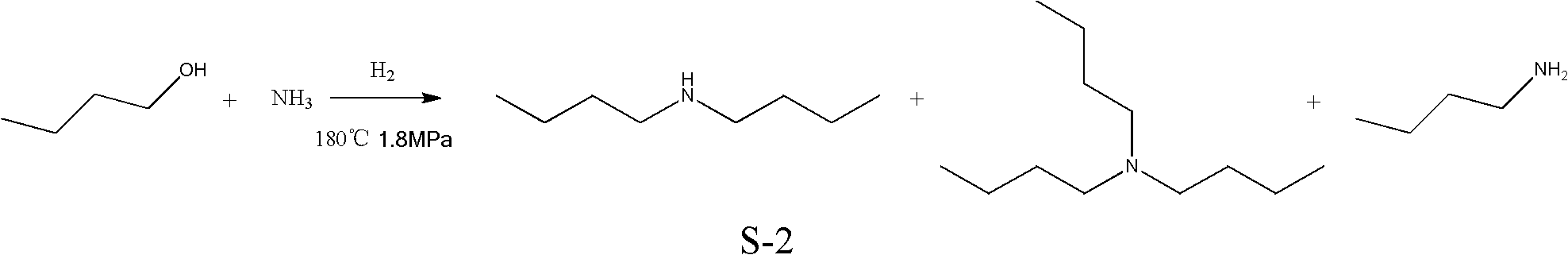

Process for preparing tri-n-propylamine (TPA)

InactiveUS20120004464A1Improve economyHigh selectivityOrganic compound preparationChemical industryPropanolHydrogen

Process for preparing tri-n-propylamine (TPA), wherein di-n-propylamine (DPA) is reacted in the presence of hydrogen and a copper-comprising heterogeneous catalyst.An integrated process for preparing TPA, which comprises the following operations:I) reaction of n-propanol with ammonia in a reactor in the presence of an amination catalyst and optionally hydrogen to form a mixture of mono-n-propylamine, DPA and TPA,II) separation of unreacted ammonia, unreacted n-propanol and possibly hydrogen from the reaction product mixture and recirculation of at least the ammonia and propanol to the reactor in I) and also separation of the n-propylamine mixture by distillation and isolation of the TPA,III) reaction of the DPA obtained in the separation by distillation in II) in a reactor in the presence of hydrogen and a copper-comprising heterogeneous catalyst to form TPA andIV) feeding of the reactor output from III) to operation II).

Owner:BASF AG

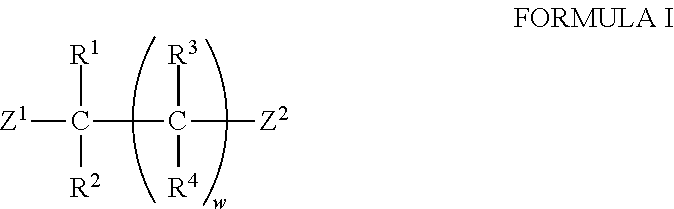

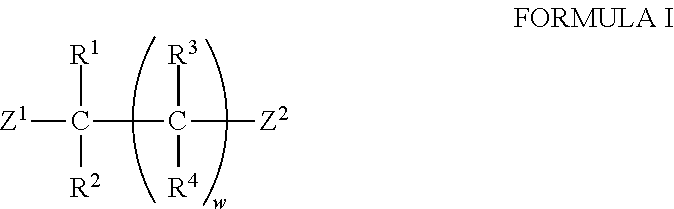

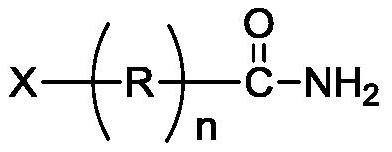

Transamination of nitrogen-containing compounds to high molecular weight polyalkyleneamines

ActiveUS9000217B2Easy to customizeHigh molecular weightOrganic compound preparationAmino compound preparation by disproportionationDehydrogenationAlkyl amine

A process for preparing high molecular weight acyclic polyamines comprising providing a reaction mixture that includes at least a first component comprising a first organic, nitrogen-containing compound that contains at least two non-tertiary amine groups separated from one another by a ternary or higher carbon atom spacing that can be transaminated in the presence of a hydrogenation / dehydrogenation catalyst to form a mixture of higher molecular weight, acyclic polyamines while minimizing the formation of cyclic polyamines.

Owner:DOW GLOBAL TECH LLC

Crystalline silicoaluminophosphate salt molecular sieve having octaoxygen-membered ring pore, process for producing the same and process for producing methylamine with the molecular sieve as catalyst

Problems on catalyst production and catalyst performance with respect to conventional 8-oxygen-membered ring micropore-containing crystalline silicoaluminophosphate molecular sieves as non-equilibrium methylamine synthesis catalysts, are resolved. A chabazite type crystalline silicoaluminophosphate molecular sieve having high purity and high crystallinity and having, on a crystal grain surface, an amorphous oxide layer whose Si / Al atomic ratio is greater than that of the whole crystal grain can be stably produced with high yield with the use of a small amount of structure directing agents by the present method characterized in that hydrothermal treatment conducted in the production of 8-oxygen-membered ring micropore-containing crystalline silicoaluminophosphate sieves is controlled under specified treating conditions. The thickness and composition of the amorphous oxide layer, which exert marked influence on the yield of dimethylamine synthesis, can be easily controlled and reproduced under the conditions of catalyst synthesis according to the invention. Thus, the catalyst of high performance can be stably supplied by the present invention at a low cost with reduced output of waste.

Owner:MITSUBISHI GAS CHEM CO INC

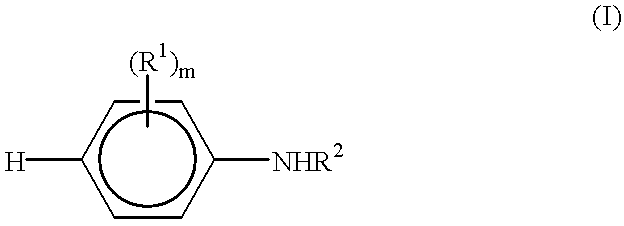

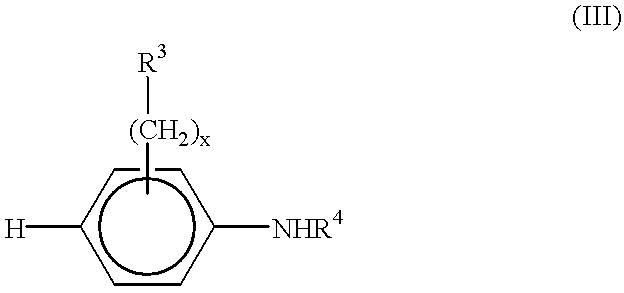

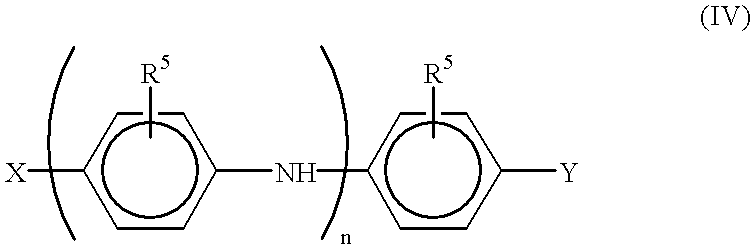

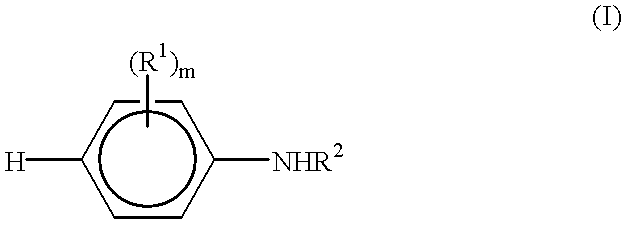

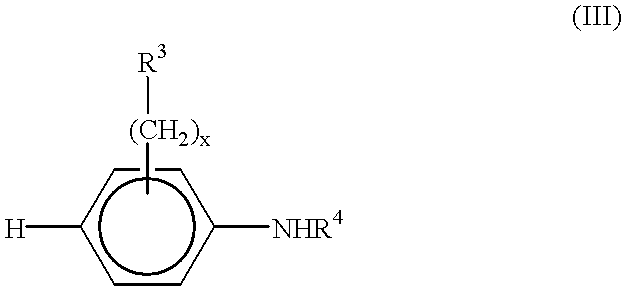

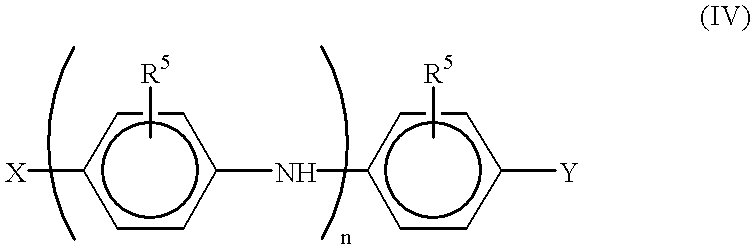

End-functionalized aniline-based oligomers, corrosion-resistant copolymers and methods of making the same

InactiveUS6518394B2Improve solubilityEasy to processElectrolysis componentsOrganic compound preparationOligomerAniline

Owner:DREXEL UNIV

Transamination of nitrogen-containing compounds to high molecular weight polyalkyleneamines

ActiveUS20130225864A1High molecular weightEasy to customizeOrganic compound preparationAmino compound preparation by disproportionationHigh carbonNitrogen

A process for preparing high molecular weight acyclic polyamines comprising providing a reaction mixture that includes at least a first component comprising a first organic, nitrogen-containing compound that contains at least two non-tertiary amine groups separated from one another by a ternary or higher carbon atom spacing that can be transaminated in the presence of a hydrogenation / dehydrogenation catalyst to form a mixture of higher molecular weight, acyclic polyamines while minimizing the formation of cyclic polyamines.

Owner:DOW GLOBAL TECH LLC

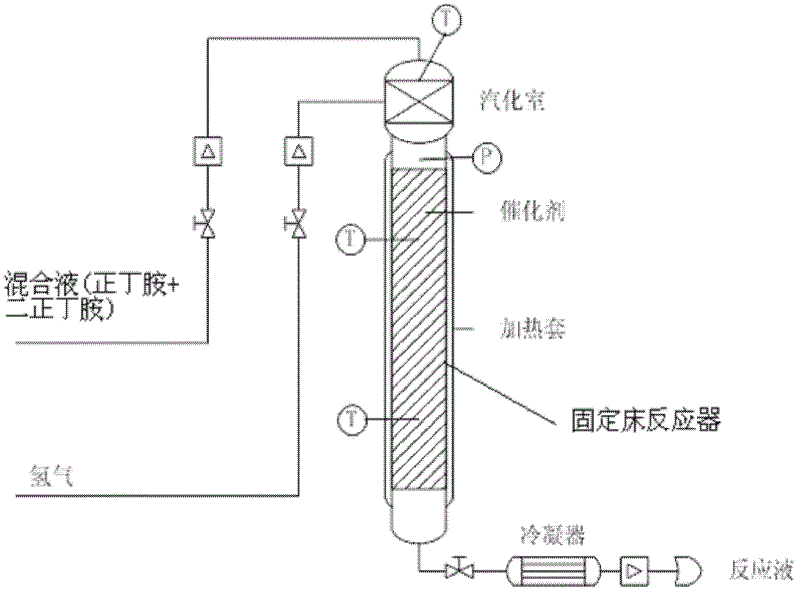

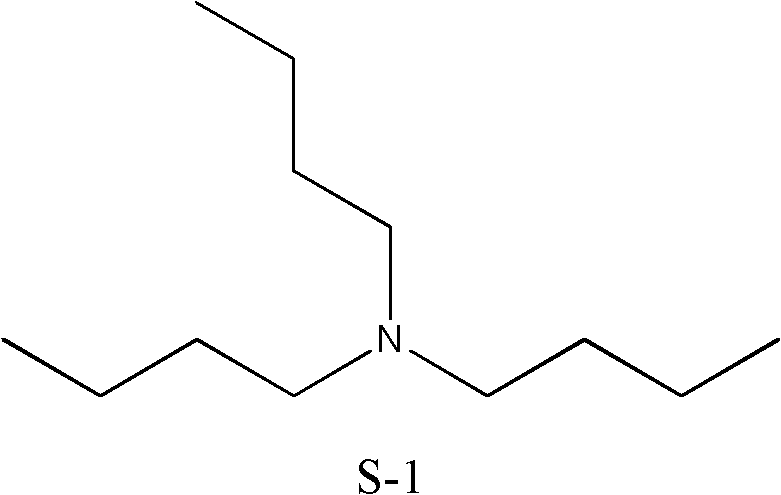

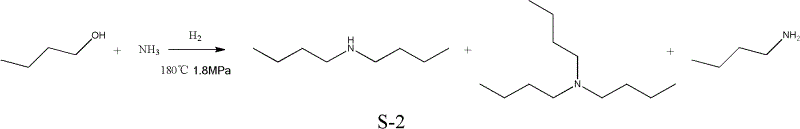

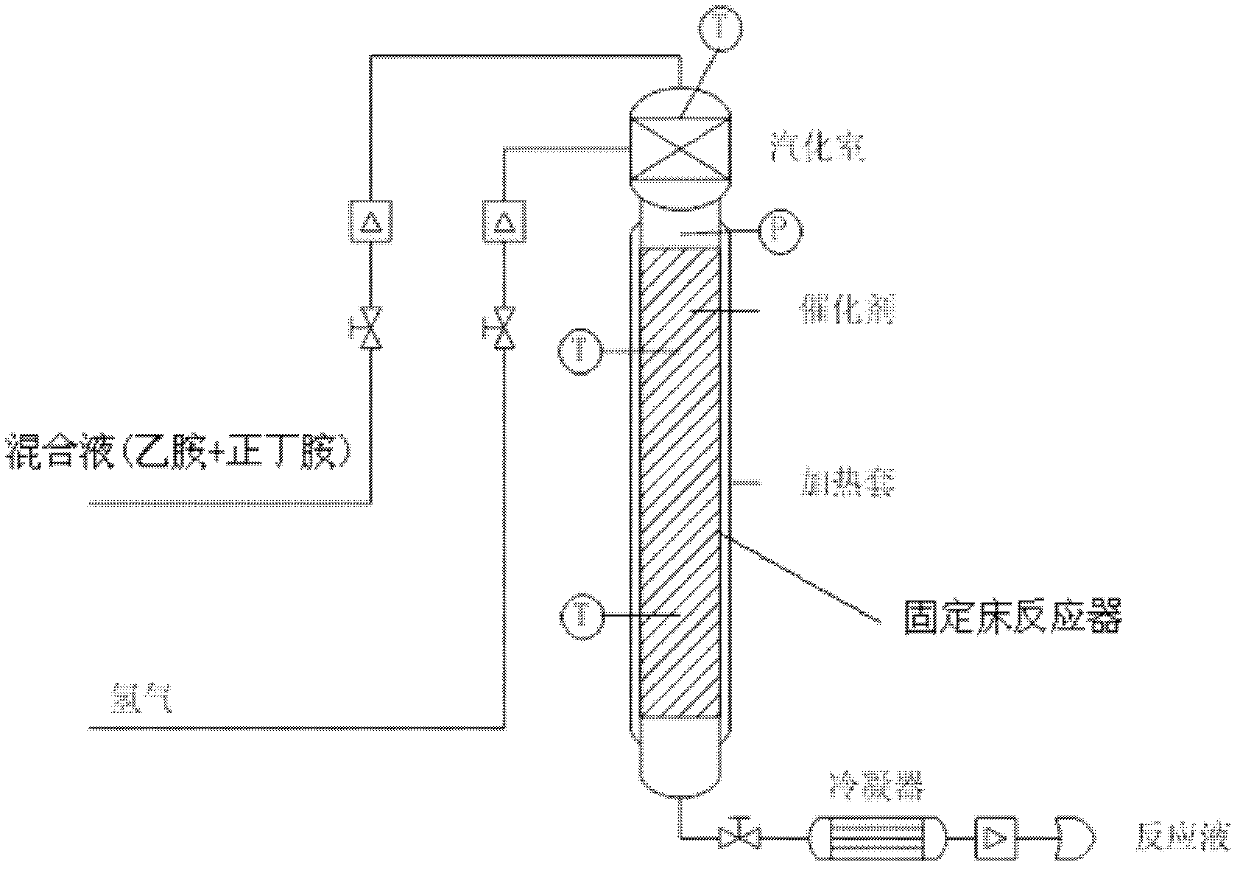

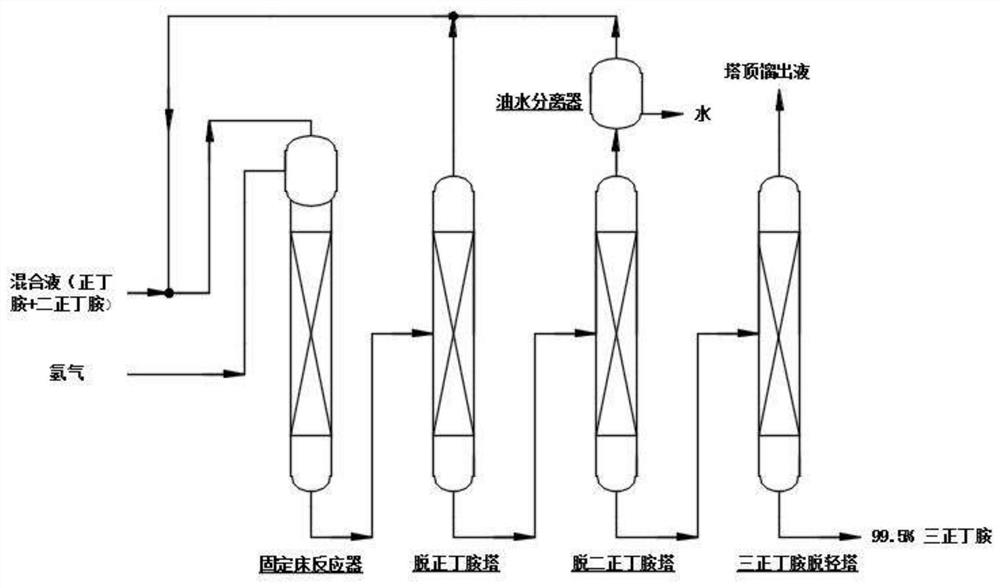

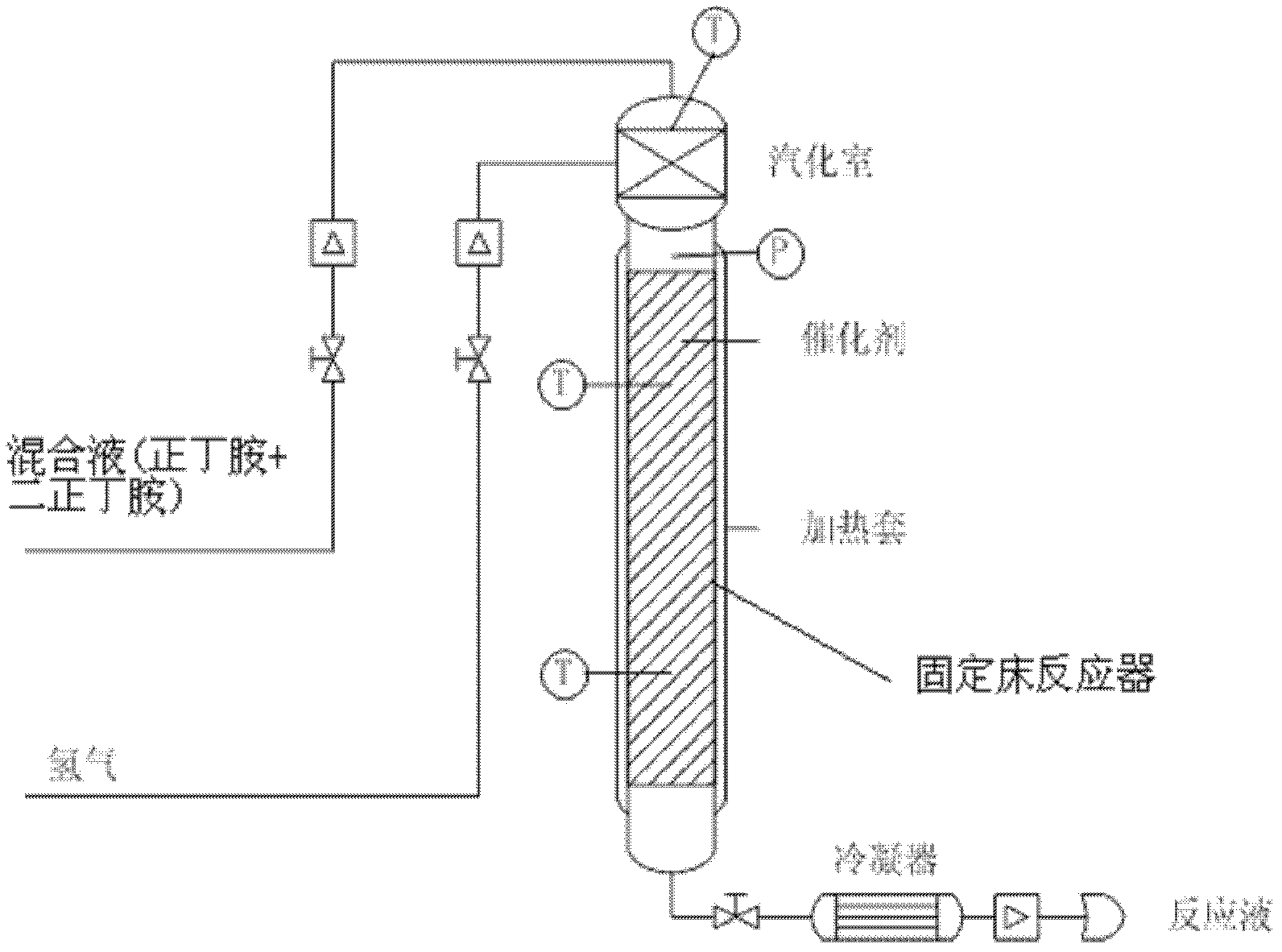

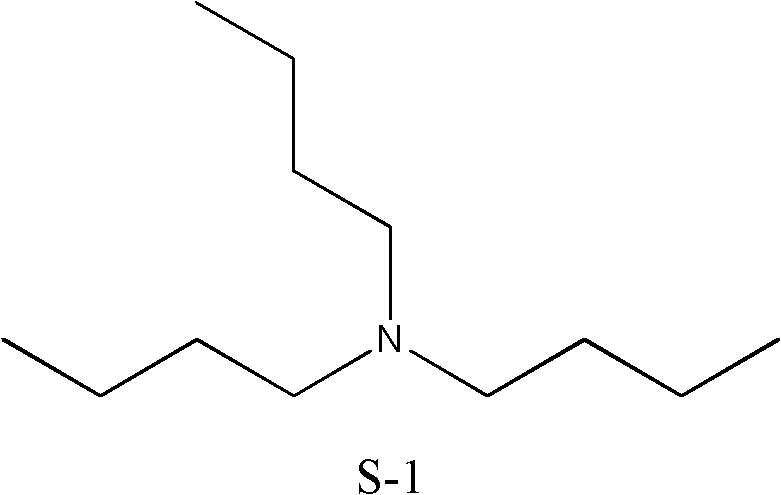

Method for combining tributylamine and used catalyst

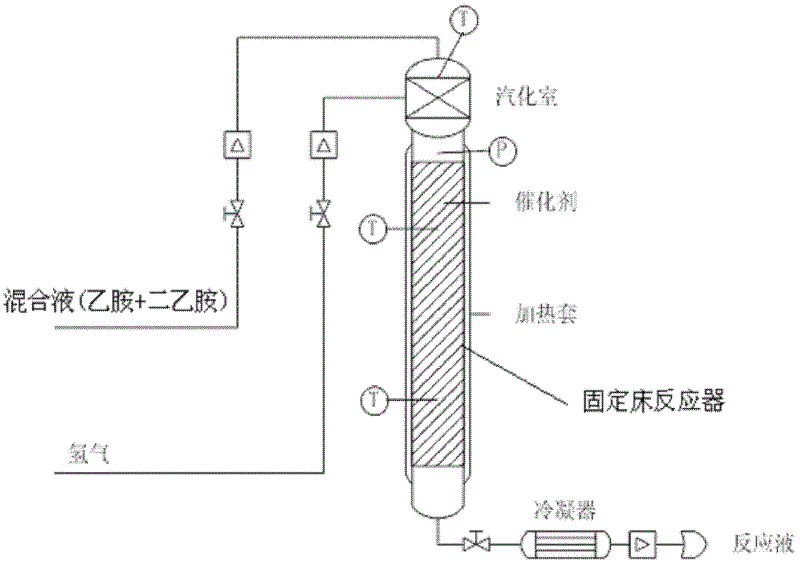

ActiveCN102614893AModerate reaction conditionsHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationPlatinumHydrogen

The invention discloses a load type catalyst, which utilizes roasted gama-alumina as a carrier. An active component is loaded on the carrier to obtain the load type catalyst. The active component is composed of nickel, copper, iron and platinum. The weight sum of the nickel, the copper, the iron, the platinum and the roasted gama-alumina is the total weight. The nickel occupies 15% to 25% of the total weight, the copper occupies 5% to 12% of the total weight, the iron occupies 0.5% to 1% of the total weight, and the platinum occupies 0.5% to 1% of the total weight. A preparation method of the load type catalyst and a method for preparing tributylamine by using the load type catalyst are further disclosed. Butylamine and dibutylamine are mixed in a mixed cylinder to obtain mixed liquid, the mixed liquid is gasified and then passes through a fixed bed reactor containing an activated load type catalyst, catalyst reaction is conducted under the hydrogen condition, and a product is collected after condensation to obtain the tributylamine.

Owner:ZHEJIANG JIANYE CHEM

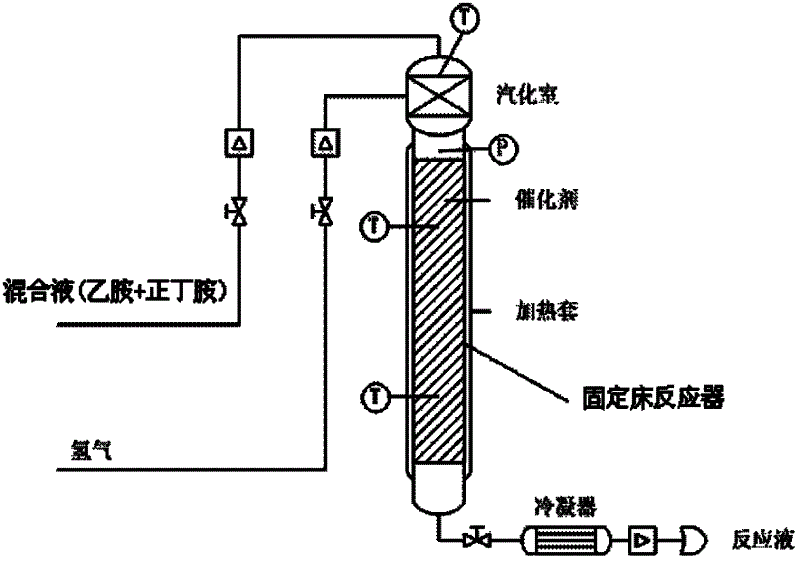

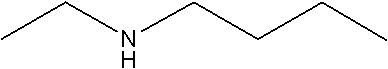

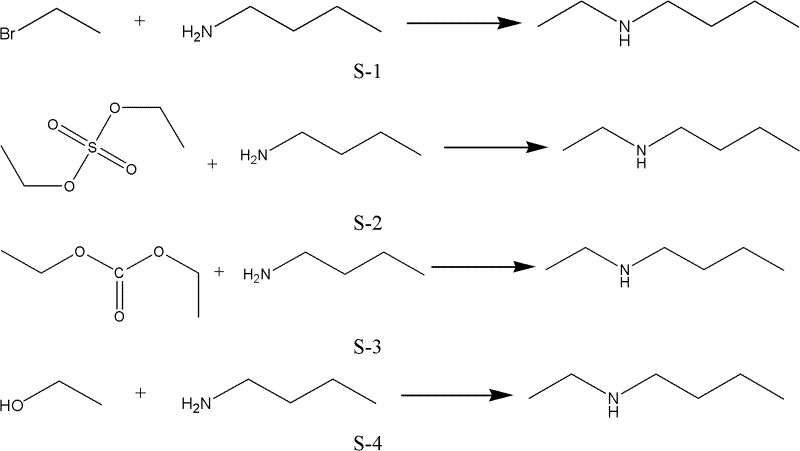

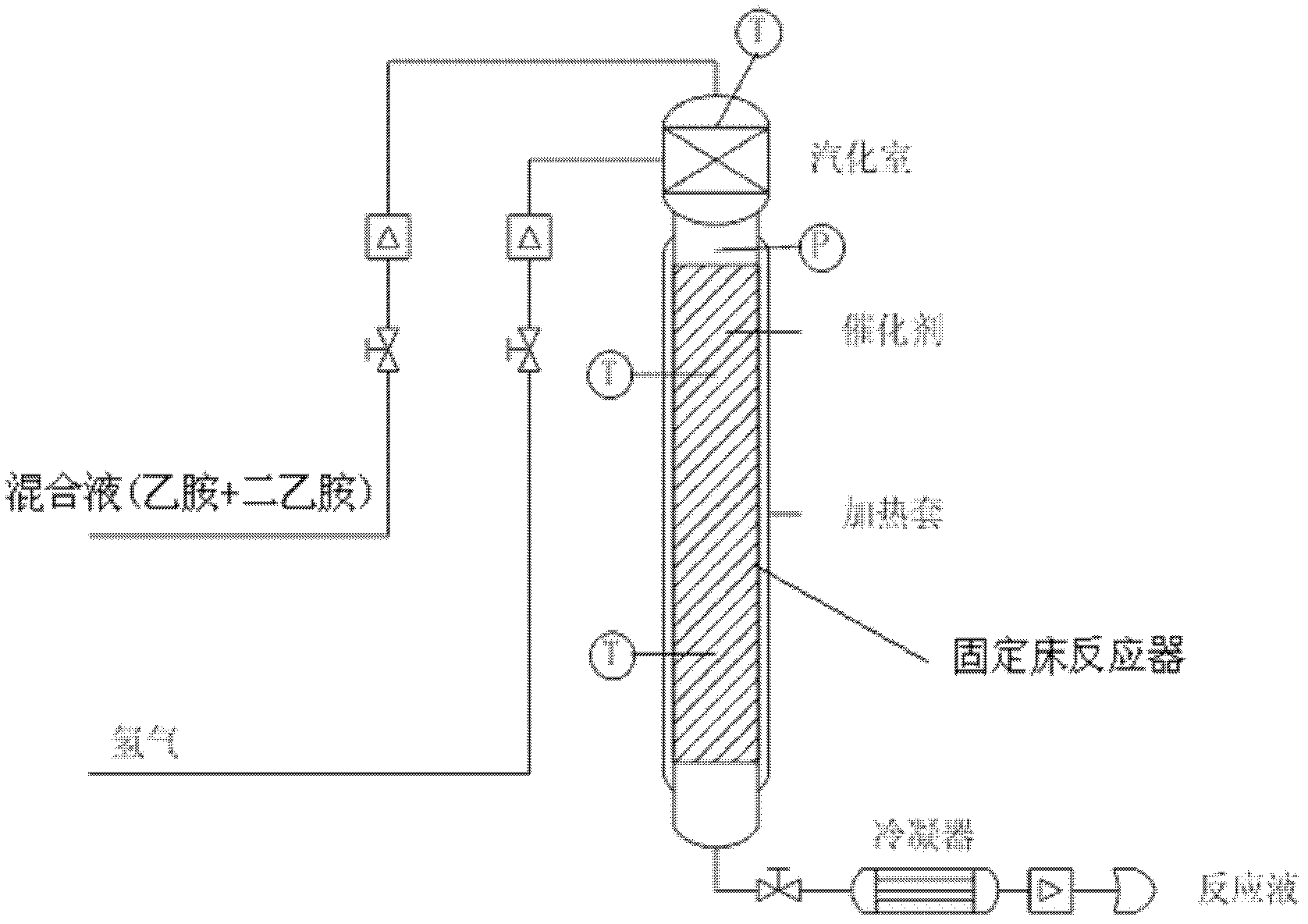

Method and used catalytic agent for synthesizing N-butylethylamine

ActiveCN102614881AAvoid generatingAvoid compositionMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationActive componentFixed bed

The invention discloses a loading-type catalytic agent for synthesizing N-butylethylamine. Gamma-alumina after roasting serves as a carrier, active components composed of Cu and Ni are loaded on the carrier, sum of weight of the Cu, the Ni and the gamma-AI2O3 after roasting is total weight, sum of weight of the Cu and the Ni occupies 25%-38% of the total weight, and ratio of amount of substance of the Cu and the Ni is 0.9-1.5 / 1. The invention further provides a preparation method of the loading-type catalytic agent. A method for synthesizing the N-butylethylamine by using the loading-type catalytic agent is further provided, ethylamine and the n-butylamine are mixed in a mixing tank to obtain mixed liquor which passes through a fixed bed reactor containing activated loading-type catalyticagent after being vaporized, an amine disproportionated reaction is carried out in a hydrogenation condition, products are collected after condensation, and rectification is carried out to obtain theN-butylethylamine.

Owner:ZHEJIANG JIANYE CHEM

Synthesis method of triethylamine and catalyst used in method

ActiveCN102614892AWide variety of sourcesLow priceMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationSynthesis methodsActive component

The invention discloses a load type catalyst for synthesis of triethylamine. The catalyst comprises the components of the calcined gamma-aluminum oxide (Al2O3) serving as a carrier and active components loaded on the carrier; the active components consist of nickel, copper and palladium; the nickel accounts for 15 to 25 percent of the total weight of the nickel, the copper, the palladium and the calcined gamma-Al2O3; the copper accounts for 5 to 12 percent of the total weight of the nickel, the copper, the palladium and the calcined gamma-Al2O3; and the palladium accounts for 1 to 3 percent of the total weight of the nickel, the copper, the palladium and the calcined gamma-Al2O3. The invention further discloses a preparation method for the load type catalyst. The invention further discloses a method for synthesizing the triethylamine by utilizing the load type catalyst. The method comprises the following steps of mixing ethylamine and diethylamine in a mixed tank to obtain mixed liquid; vaporizing the mixed liquid; performing disproportionated reaction by using a fixed bed reactor containing the activated load type catalyst under the hydrogenation condition; condensing after the reaction is finished; collecting condensation products; and rectifying to obtain the triethylamine.

Owner:ZHEJIANG JIANYE CHEM

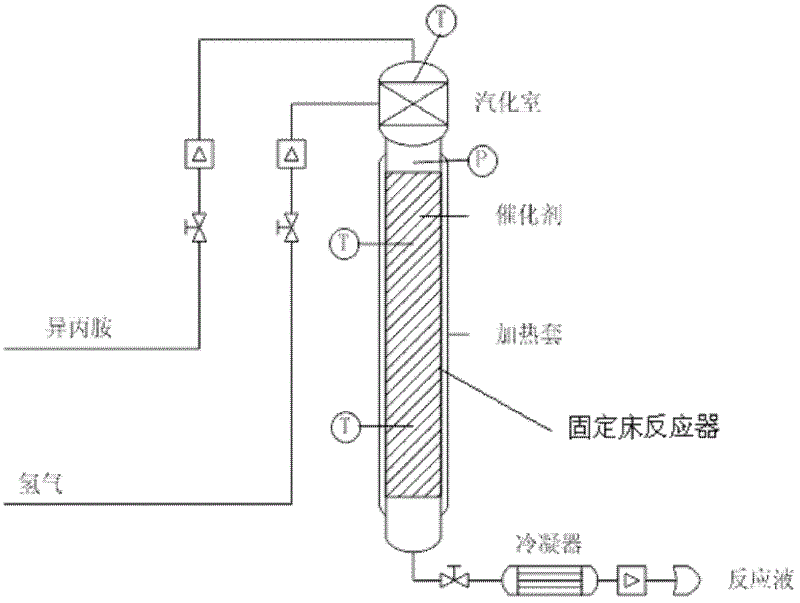

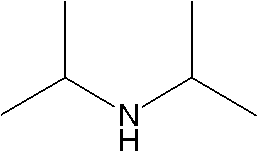

Supported catalyst used for synthesis of diisopropylamine from isopropylamine and preparation method as well as application of supported catalyst

ActiveCN102614894AAvoid generatingAvoidance of azeotropic compositionsMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationPlatinumDiisopropylamine

The invention discloses a supported catalyst used for synthesis of diisopropylamine from isopropylamine. Roasted gamma-alumina is used as a supporter, and active ingredients are supported on the supporter to obtain the supported catalyst, wherein the active ingredients consist of nickel, copper and platinum; the sum of weight of the nickel, the copper, the platinum and the roasted gamma-Al2O3 is referred to as total weight; the nickel accounts for 15-25 percent of the total weight; the copper accounts for 5-12 percent of the total weight; and the platinum accounts for 0.5-1 percent of the total weight. The invention also provides a preparation method of the supported catalyst. The invention also provides application of the supported catalyst, i.e., the supported catalyst is used for synthesizing the diisopropylamine from the isopropylamine. The supported catalyst provided by the invention is used in a process of disproportionation reaction of the isopropylamine for synthesizing the diisopropylamine. The supported catalyst has the characteristics of environmental friendliness, low toxicity, greatly reduced cost compared with other processes, suitability for industrial production and the like.

Owner:ZHEJIANG JIANYE CHEM

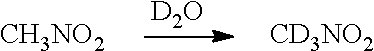

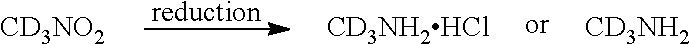

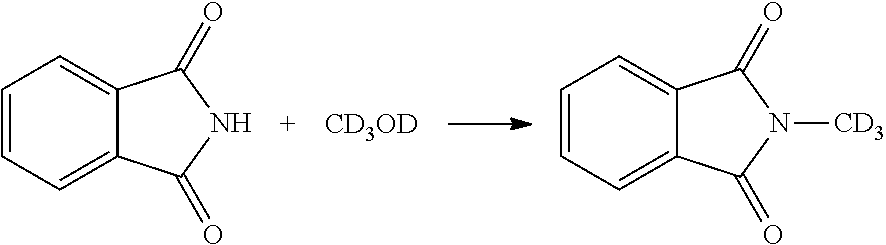

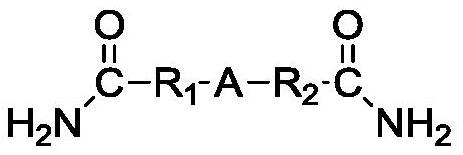

Preparation methods of methyl-D3-amine and salts thereof

ActiveUS8748666B2Simple, highly efficient and/or low costIsotope introduction to heterocyclic compoundsOrganic compound preparationPresent methodNitromethane

Preparation methods of methyl-d3-amine and salts thereof are provided, which contain the following steps: (i) nitromethane is subjected to react with deuterium oxide in the present of bases and phase-transfer catalysts to form nitromethane-d3, which is subsequently subjected to reduction in an inert solvent to form methyl-d3-amine, and optionally, methyl-d3-amine reacts subsequently with acids to form salts of methyl-d3-amine; or (ii) N-(1,1,1-trideuteriomethyl)phthalimide is subjected to react with acids to form salts of methyl-d3-amine. The present methods are easy, high efficient, and low cost.

Owner:SUZHOU ZELGEN BIOPHARML

End-functionalized aniline-based oligomers, corrosion-resistant copolymers and methods of making the same

InactiveUS20010037947A1Improve solubilityEasy to processOrganic compounds purification/separation/stabilisationElectrolysis componentsPolymer scienceOligomer

Methods of forming low molecular weight oligomers of aniline-based compounds are provided as well as methods of forming varied molecular weight oligomers and polymers that are aniline-based which are end-functionalized and capable of being reacted with other monomeric species to form a variety of copolymers. The oligomers, end-functionalized oligomers and copolymers exhibit corrosion-resistant properties and provide corrosion-resistant compounds for use on various substrates.

Owner:DREXEL UNIV

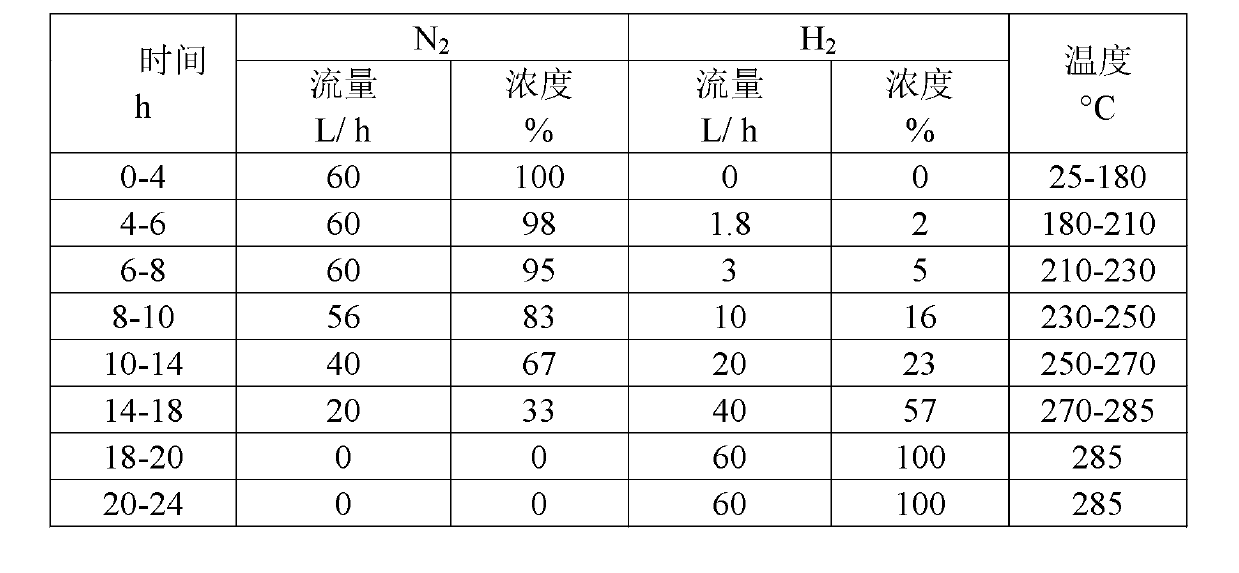

Catalyst for reaction for producing diethylenetriamine by means of hydrogenation of ethylenediamine, and preparation method of catalyst

ActiveCN108772074AHigh reactivityObvious advantagesHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementEthylenediamine

The invention relates to a catalyst for a reaction for producing diethylenetriamine by means of hydrogenation of ethylenediamine, and a preparation method of the catalyst, aiming at solving the problems that the existing catalyst is low in activity and selectivity. The catalyst takes alumina as a carrier, and contains 0.1-3wt% of one or two or more of rare earth elements, 5-30wt% of one or two ormore of nickel, copper, iron, cobalt, zinc or tin, and 0.1-5wt% of palladium based on the total weight of the catalyst. The catalyst is prepared by firstly coating the carrier with the palladium element and the rare earth elements, and then coating the carrier with the other elements. The catalyst provided by the invention is used for catalyzing the reaction for producing the diethylenetriamine bymeans of the hydrogenation of the ethylenediamine, can obviously improve reaction activity and product selectivity, and has a very high industrial application value.

Owner:XIAN MODERN CHEM RES INST

Method for producing catalyst for use in production of methylamine compound, and method for producing methylamine compound

ActiveUS9180444B2High activityHigh selectivityMolecular sieve catalystsOrganic compound preparationMolecular sieveCompound (substance)

According to the present invention, a method for producing a catalyst for use in the production of a methylamine compound can be provided, wherein the catalyst comprises a modified crystalline silicoaluminophosphate salt molecular sieve. The method comprises: a moisture control step of adsorbing moisture onto a crystalline silicoaluminophosphate salt molecular sieve in an amount of 5 to 30 wt % of the crystalline silicoaluminophosphate salt molecular sieve; and a step of heating the crystalline silicoaluminophosphate salt molecular sieve having moisture adsorbed thereon under a pressure of 0.1 MPa or more and at a temperature of 130 to 350° C. for 5 to 40 hours.

Owner:MITSUBISHI GAS CHEM CO INC

Method for producing ethylene amines

ActiveUS7615665B2Improve economyHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationEthylenediamineHydrogen

Processes comprising: providing a starting material comprising ethylenediamine; and reacting the starting material in the presence of a heterogeneous transition metal catalyst to form one or more ethylene amines; wherein the catalyst comprises a catalytically active composition, which prior to treatment with hydrogen, comprises a mixture of oxygen-containing compounds of aluminum, copper, nickel and cobalt; and wherein the catalyst is present as one or more shaped catalyst particles selected from spheres, extrudates, pellets and other geometries, wherein the sphere or extrudate has a diameter of <3 mm, the pellet has a height of <3 mm, and the other geometries have an equivalent diameter L=1 / a′ of <0.70 mm, where a′ is the external surface area per unit volume (mms2 / mmp3), as defined bya′=ApVpwhere Ap is the external surface area of the catalyst particle (mms2) and Vp is the volume of the catalyst particle (mmp3).

Owner:BASF AG

Method for producing catalyst for use in production of methylamine compound, and method for producing methylamine compound

ActiveUS20150258538A1High activityHigh selectivityAluminium compoundsMolecular sieve catalystsMolecular sieveCompound (substance)

According to the present invention, a method for producing a catalyst for use in the production of a methylamine compound can be provided, wherein the catalyst comprises a modified crystalline silicoaluminophosphate salt molecular sieve. The method comprises: a moisture control step of adsorbing moisture onto a crystalline silicoaluminophosphate salt molecular sieve in an amount of 5 to 30 wt % of the crystalline silicoaluminophosphate salt molecular sieve; and a step of heating the crystalline silicoaluminophosphate salt molecular sieve having moisture adsorbed thereon under a pressure of 0.1 MPa or more and at a temperature of 130 to 350° C. for 5 to 40 hours.

Owner:MITSUBISHI GAS CHEM CO INC

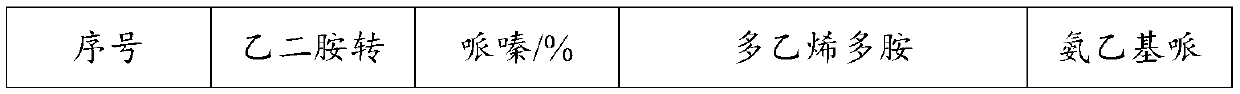

Catalyst for producing polyethylene polyamine, application of catalyst and preparation method of polyethylene polyamine

InactiveCN109569614ALow content of active ingredientsImprove performanceHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive componentBoron oxide

The invention provides a catalyst for producing polyethylene polyamine, an application of the catalyst and a preparation method of the polyethylene polyamine, and relates to the field of polyethylenepolyamine preparation. The catalyst takes Cu and / or Ni as active components and takes boron and / or at least one of transition metal elements as catalysis promoting components, CuO and / or NiO account for 10-60% of the weight of the catalyst, and boron oxide and / or transition metal oxide account for 5-15% of the weight of the catalyst. The catalyst is used for preparing the polyethylene polyamine, the problem of low selectivity of polyethylene polyamine in an existing production method can be relieved, and the selectivity of the polyethylene polyamine can be improved.

Owner:SHANDONG YUHUANG CHEM CO LTD

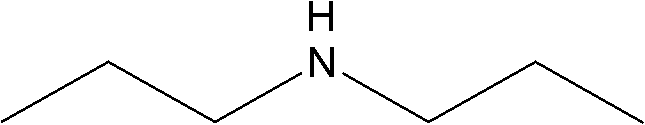

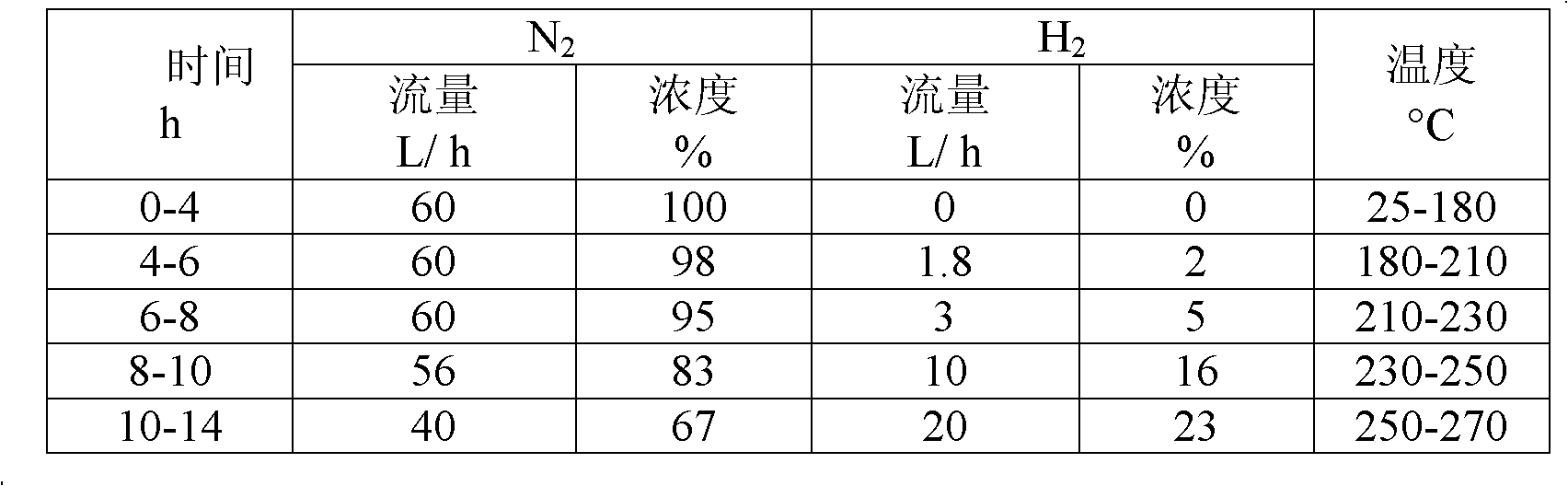

Method for combining di-n-propylamine through n-propylamine disproportionated reaction and used catalyst

ActiveCN102614895BReact cleanReduce pollutionMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationHydrogenActive component

Owner:ZHEJIANG JIANYE CHEM

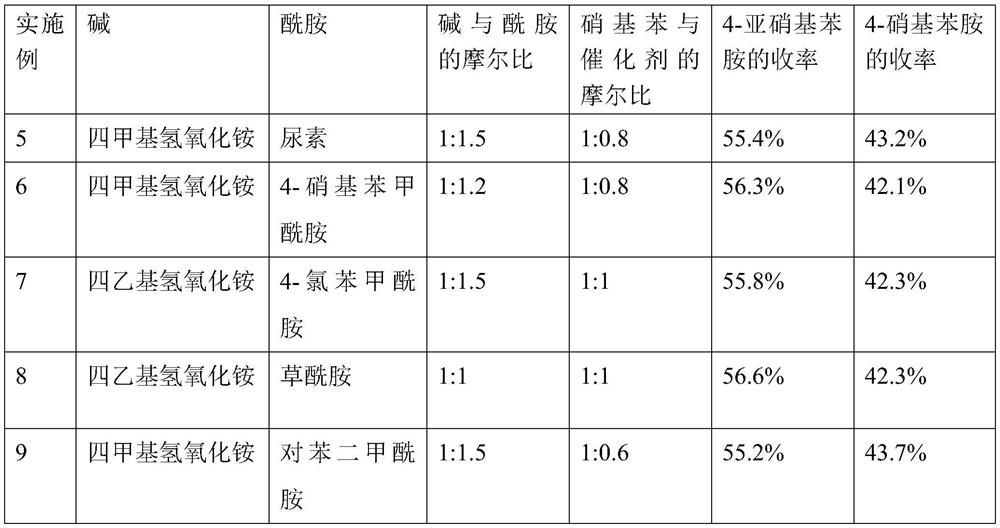

Method for preparing 4-nitrosoaniline and 4-nitroaniline

PendingCN112194584AReduce pollutionHigh selectivityAmino preparation by hydrogen substitutionAmino compound preparation by disproportionationNitrosoPtru catalyst

The invention discloses a method for preparing 4-nitrosoaniline and 4-nitroaniline by reacting nitrobenzene with ammonia under the action of a catalyst. The method is high in conversion rate, good inselectivity and environment-friendly. In addition, the invention further provides a method for preparing p-phenylenediamine by reducing 4-nitrosoaniline and 4-nitroaniline, the yield is high, and separation and purification are not needed.

Owner:江苏方圆芳纶研究院有限公司

Method and used catalytic agent for synthesizing N-butylethylamine

ActiveCN102614881BAvoid generatingAvoid compositionMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationPtru catalystFixed bed

The invention discloses a loading-type catalytic agent for synthesizing N-butylethylamine. Gamma-alumina after roasting serves as a carrier, active components composed of Cu and Ni are loaded on the carrier, sum of weight of the Cu, the Ni and the gamma-AI2O3 after roasting is total weight, sum of weight of the Cu and the Ni occupies 25%-38% of the total weight, and ratio of amount of substance of the Cu and the Ni is 0.9-1.5 / 1. The invention further provides a preparation method of the loading-type catalytic agent. A method for synthesizing the N-butylethylamine by using the loading-type catalytic agent is further provided, ethylamine and the n-butylamine are mixed in a mixing tank to obtain mixed liquor which passes through a fixed bed reactor containing activated loading-type catalyticagent after being vaporized, an amine disproportionated reaction is carried out in a hydrogenation condition, products are collected after condensation, and rectification is carried out to obtain theN-butylethylamine.

Owner:ZHEJIANG JIANYE CHEM

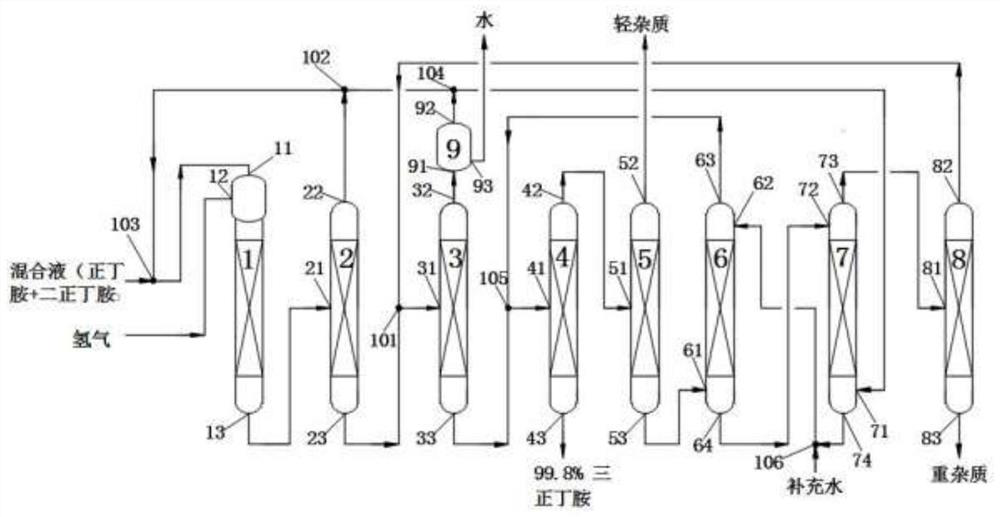

High-purity tri-n-butylamine production method and device used

ActiveCN110526823BIncrease concentrationGuaranteed purityAmino compound purification/separationChemical industryButyramideProcess engineering

The invention discloses a high-purity tri-n-butylamine production device. Regenerating tower and oil-water separator; removing n-butylamine tower, removing di-n-butylamine tower, removing light tower and extracting agent regeneration tower are all rectifying towers, all of which are equipped with feed inlet, tower top distillate outlet and tower The kettle liquid outlet; the extraction tower and the back-extraction tower are both extraction towers, the top is provided with a light phase outlet and a heavy phase inlet, and the bottom is provided with a light phase inlet and a heavy phase outlet. The present invention also provides a method for producing tri-n-butylamine by utilizing the device. The present invention utilizes the process of water extraction+di-n-butylamine back-extraction+rectification to regenerate the extraction agent, and the heavy impurity N-butylbutanamide in the tri-n-butylamine production system is discharged from the production system, thereby ensuring the high quality of the tri-n-butylamine product. purity.

Owner:ZHEJIANG JIANYE CHEM

Synthesis method of triethylamine and catalyst used in method

ActiveCN102614892BWide variety of sourcesLow priceMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationSynthesis methodsActive component

Owner:ZHEJIANG JIANYE CHEM

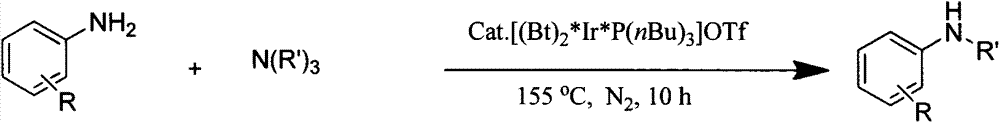

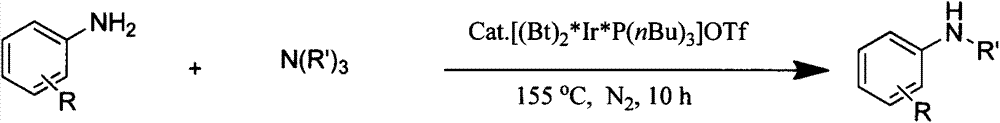

Novel method for preparing secondary amine by reaction of primary amine and tertiary amine

ActiveCN104710257AOrganic compound preparationAmino group formation/introductionOrganic solventElution

The invention discloses a novel method for preparing secondary amine by a reaction of primary amine and tertiary amine. The method comprises the following steps of 1, adding primary amine and tertiary amine into a reaction container according to a mole ratio of primary amine to tertiary amine of 1: 3, adding [(Bt)2*Ir*P(nBu)3]OTf as a catalyst (wherein Bt represents phenylbenzothiazole) into the reaction container, adding an organic solvent into the reaction container, and carrying out a reaction process at a temperature of 120-160 DEG C for 6-12h, wherein a mole ratio of primary amine, tertiary amine to catalyst is 1: 3: 0.01, and 2, carrying out purification by a silica gel column of 200-300 meshes, pre-leaching the silica gel column by 20-50mL of petroleum ether, carrying out elution on the leacheate at a leacheate flowing rate of 1-2mL / min for 3-6h so that the solvent is removed and the corresponding secondary amine product is obtained. A research result shows that the novel method for producing secondary amine by a reaction of primary amine and tertiary amine has the characteristics of mild conditions, high conversion rate and no pollutant. The method solves the problems of the existing secondary amine synthesis method and improves secondary amine synthesis.

Owner:JIANGNAN UNIV

Method for combining tributylamine and used catalyst

ActiveCN102614893BModerate reaction conditionsHigh selectivityMetal/metal-oxides/metal-hydroxide catalystsAmino compound preparation by disproportionationPtru catalystFixed bed

The invention discloses a load type catalyst, which utilizes roasted gama-alumina as a carrier. An active component is loaded on the carrier to obtain the load type catalyst. The active component is composed of nickel, copper, iron and platinum. The weight sum of the nickel, the copper, the iron, the platinum and the roasted gama-alumina is the total weight. The nickel occupies 15% to 25% of the total weight, the copper occupies 5% to 12% of the total weight, the iron occupies 0.5% to 1% of the total weight, and the platinum occupies 0.5% to 1% of the total weight. A preparation method of the load type catalyst and a method for preparing tributylamine by using the load type catalyst are further disclosed. Butylamine and dibutylamine are mixed in a mixed cylinder to obtain mixed liquid, the mixed liquid is gasified and then passes through a fixed bed reactor containing an activated load type catalyst, catalyst reaction is conducted under the hydrogen condition, and a product is collected after condensation to obtain the tributylamine.

Owner:ZHEJIANG JIANYE CHEM

Popular searches

Hydrocarbon by metathesis reaction Sulfonic acid amide preparation Group 3/13 element organic compounds Phosphorus organic compounds Group 6/16 organic compounds without C-metal linkages Silicon organic compounds Amino preparation from amines Organic-compounds/hydrides/coordination-complexes catalysts Catalysts Hydrocarbon preparation catalysts

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com