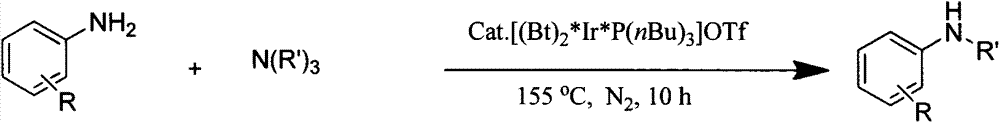

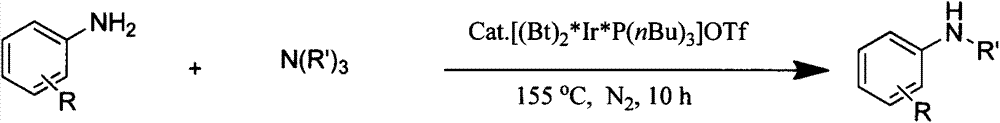

Novel method for preparing secondary amine by reaction of primary amine and tertiary amine

A technology for tertiary amines and secondary amines, applied in chemical instruments and methods, formation/introduction of amino groups, preparation of organic compounds, etc., can solve problems such as difficult demethylation of N-methylamine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: a kind of novel method that obtains secondary amine by reaction of aniline and triethylamine comprises the following process steps:

[0022] Under nitrogen protection, in 50mL Schlenk tube, add aniline (93mg, 1mmol), triethylamine (304mg, 3mmol), [(Bt) 2 *Ir*P(nBu) 3 ]OTf (9.6mg, 0.01mmol, 1.0mol%), add 2.0mL xylene; react the reaction solution at 155°C for 10h, and separate the resulting solution with a 200-300 mesh silica gel column (the eluent is 1:10 ethyl acetate ester / petroleum ether), and the product was obtained after removing the solvent.

[0023] Yield: 95%.

Embodiment 2

[0024] Embodiment two: a kind of novel method that obtains secondary amine by reacting 4-methoxyaniline and triethylamine, comprises the following processing steps:

[0025] Under nitrogen protection, in 50mL Schlenk tube, add 4-methoxyaniline (123mg, 1mmol), triethylamine (304mg, 3mmol), [(Bt) 2 *Ir*P(nBu) 3 ]OTf (9.6mg, 0.01mmol, 1.0mol%), add 2.0mL xylene; react the reaction solution at 155°C for 10h, and separate the resulting solution with a 200-300 mesh silica gel column (the eluent is 1:10 ethyl acetate ester / petroleum ether), and the product was obtained after removing the solvent.

[0026] Yield: 92%.

Embodiment 3

[0027] Embodiment three: a kind of novel method that obtains secondary amine by reacting 4-methylaniline and triethylamine, comprises the following processing steps:

[0028] Under nitrogen protection, in 50mL Schlenk tube, add 4-methylaniline (107mg, 1mmol), triethylamine (304mg, 3mmol), [(Bt) 2 *Ir*P(nBu) 3 ]OTf (9.6mg, 0.01mmol, 1.0mol%), add 2.0mL xylene; react the reaction solution at 155°C for 10h, and separate the resulting solution with a 200-300 mesh silica gel column (the eluent is 1:10 ethyl acetate ester / petroleum ether), and the product was obtained after removing the solvent.

[0029] Yield: 96%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com