Polydimethylsiloxane with initiator on surface and its preparation method and use

A technology of polydimethylsiloxane and dimethylmethylvinylsiloxane, which is applied in the field of materials, and achieves the effect of simple method and wide application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1, prepare the iPDMS of 1% initiator density

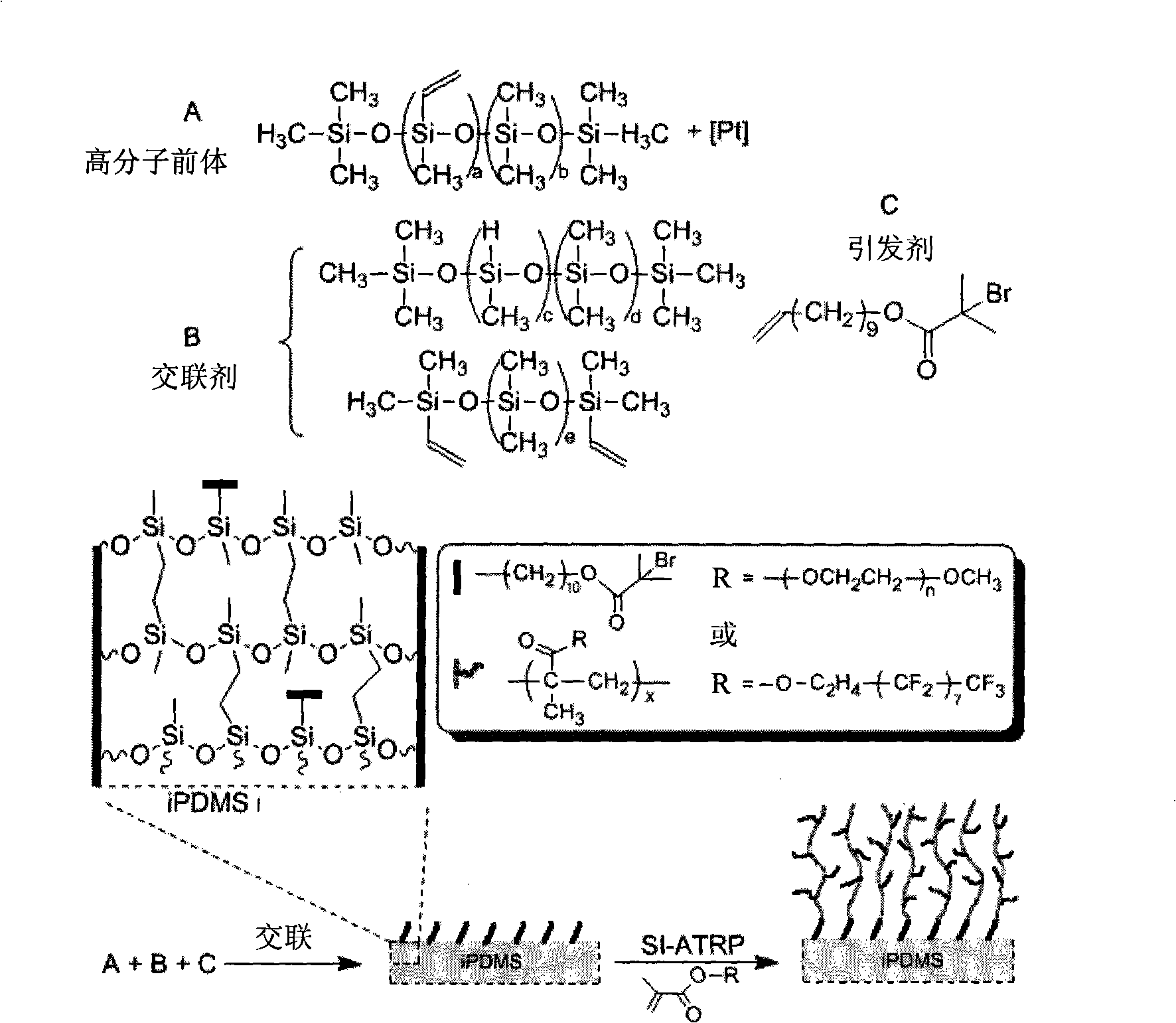

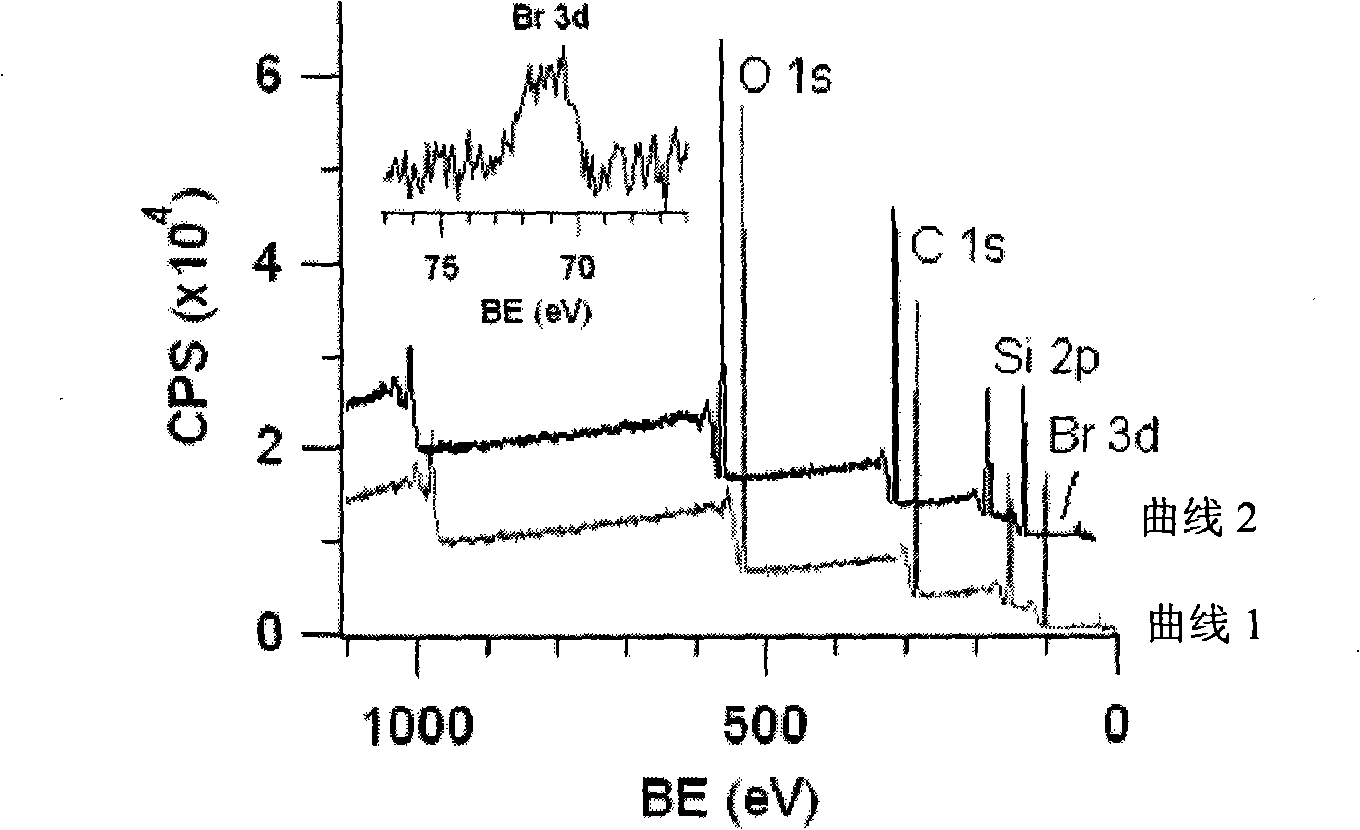

[0022] according to figure 1 In the method shown, the polymer precursor A poly(dimethyl-methylvinylsiloxane) poly(dimethyl-methylvinylsiloxane), the cross-linking agent B poly(dimethyl-methylvinylsiloxane) with olefin end Alkane) vinyl-endcapped poly(dimethyl-methylvinylsiloxane), initiator C2-bromo-2-methylpropionate 10-undecenyl ester (10-undecenyl 2-bromo-2-methylpropionate) by weight ratio 10: 1: 4 mixed and left for 24 hours to form an elastomer (elastomer), that is, to obtain the polydimethylsiloxane iPDMS with an initiator on the surface of the present invention, through a surface chemical analyzer (X-ray photoelectronspectroscopy, XPS) Determination, such as figure 2 As shown, the iPDMS surface contains 10-undecenyl 2-bromo-2-methylpropionate immobilized by covalent bonds at a density of 1% at an atomic concentration (At%). Compared with ordinary PDMS, the initiators of the present invention are distrib...

Embodiment 2

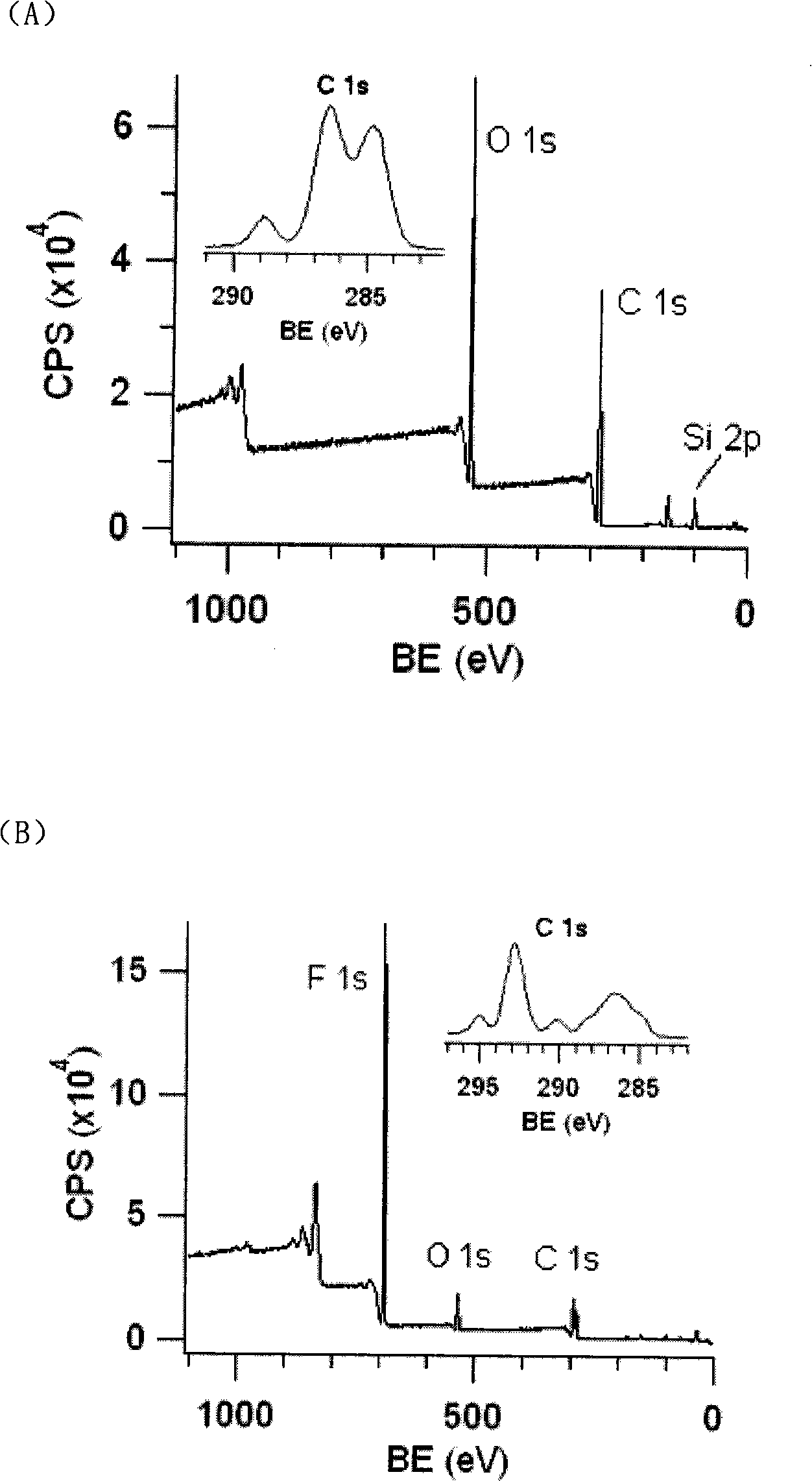

[0023] Example 2, using the iPDMS prepared in Example 1 to prepare oligoethylene glycol methacrylate film

[0024] Application of SI-ATRP to iPDMS for controllable surface modification. Put iPDMS in a 100mL glass bottle for anaerobic treatment (vacuumize and fill with nitrogen). At the same time, the reaction liquid containing the reaction liquid, the monomer, and the catalyst containing the catalytic amount is prepared. The reaction solution was configured according to the following ratio: a mixture of water and methanol (15mL, the volume ratio of water and methanol was 1:2), and monomer oligoethylene glycol methacrylate ((CH 2 =CH)CH 3 COO(CH 2 CH 2 O) 12 CH 2 COOH) (8mmol, 0.35M), adding catalyst, CuBr (36mg, 0.25mmol) and bipyridyl (78mg, 0.5mmol) configuration, it was a dark red liquid, stored in an inert gas.

[0025] The reaction solution was transferred to a glass bottle containing iPDMS under the protection of an inert gas. The reaction was started and carried ...

Embodiment 3

[0026] Example 3, using the iPDMS prepared in Example 1 to prepare 1H, 1H, 2H, 2H-perfluorodecyl methacrylate (FMA) membrane

[0027] Application of SI-ATRP to iPDMS for controllable surface modification. Put iPDMS in a 100mL glass bottle for anaerobic treatment (vacuumize and fill with nitrogen). At the same time, the reaction liquid containing the reaction liquid, the monomer, and the catalyst containing the catalytic amount is prepared. The reaction solution is dichloromethane, and monomer 1H, 1H, 2H, 2H-perfluorodecyl methacrylate (FMA) (8mmol, 0.35M), adding catalyst, CuBr (36mg, 0.25mmol) and bipyridine (78mg, 0.5mmol) configuration Formed as a dark red liquid, stored in an inert gas.

[0028] The reaction solution was transferred to a glass bottle containing iPDMS under the protection of an inert gas. The reaction was started and carried out at 20°C for 24 hours; the iPDMS was taken out, washed with methanol and deionized water, and dried under nitrogen flow to obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com